Page 1

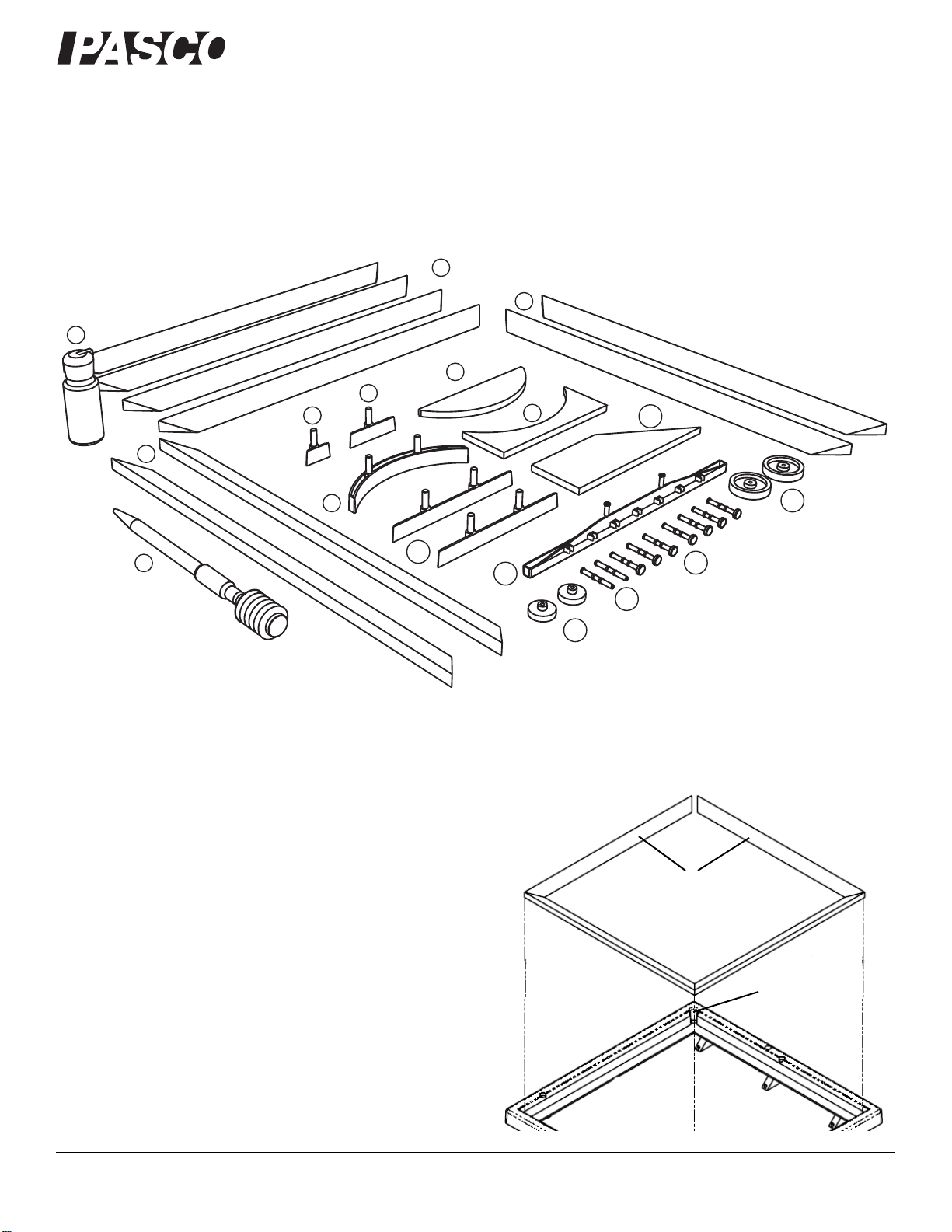

Instruction Sheet

®

1

4

3

2

3

5

6

7

8

9

10

11

12

13

14

15

16

Short foam beaches

Drain hole

Ripple Tank Replacement Set

WA-9898

012-09975B

Introduction

PASCO model WA-9898 consists of replacement parts for the

WA-9897 Ripple Tank and the WA -9896 Ripple Generator and

Light Source. The list of parts is on the next page.

Note that the short foam beaches are mounted on the sides adjacent to the drain hole.

The parts include barriers and refractors, foam rubber beaches, a

pipette, and a plastic bottle for use with the Ripple Tank, and dippers, adapters, actuators, and a plane wave dipper for use with the

Ripple Generator.

Instructions

The foam rubber beaches on the WA-9897 Ripple Tank are

attached to the glass plate of the tank with double-sided sticky

tape. The foam beaches in this replacement set have the same

type of tape. After you remove the foam beach from the glass

plate, scrape off any remaining foam and tape if possible before

putting on the replacement foam beach.

800-772-8700 www.pasco.com

Page 2

®

Model No. WA-9898 Items

Items

Description Part Number

1. Bottle, 1 ounce, (for tergitol surfactant

1

)

650-072

2. Short foam beach (4 pieces) 648-09708

3. Long foam beach (4 pieces) 648-09707

4. Pipette, 5 mL 699-154

5. Mini barrier 648-09717

6. Short barrier 648-09719

7. Convex refractor 648-09721

8. Curved reflector 648-09820

9. Concave refractor 648-09720

10.Long barrier (2 pieces) 648-09718

11.Trapezoidal refractor 648-09714

12.Ripple generator plane dipper 003-09737

13.Small actuator (2 pieces) 648-05470

14.Dipper adapter (2 pieces) 648-09711

15.Standard dipper (7 pieces) 648-09712

16.Large actuator (2 pieces) 648-05471

1

Note: The tergitol L-62 surfactant is part num ber 699-023.

Technical Support

For assistance with any PASCO product, contact PASCO at:

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: 916-786-3800 (worldwide)

800-772-8700 (U.S.)

Fax: (916) 786-7565

Web: www.pasco.com

Email: support@pasco.com

Limited Warranty

For a description of the product warranty, see the PASCO catalog.

Copyright

The PASCO scientific 012-09975B Ripple Tank Replacement Set Instruction Sheet is copyrighted with all rights reserved. Permission is granted to

non-profit educational institutions for reproduction of any part of this manual, providing the reproductions are used only in their laboratories and

classrooms, and are not sold for profit. Reproduction under any other circumstances, without the written consent of PASCO scientific, is prohibited.

Trademarks

PASCO and PASCO scientific are trademarks or registered trademarks of

PASCO scientific, in the United States and/or in other countries. All other

brands, products, or service names are or may be trademarks or service

marks of, and are used to identify, products or services of, their respective

owners. For more information visit www.pasco.com/legal.

2

Page 3

Product Name: TERGITOL(TM) L-62 Issue Date: 01/26/2006

The Dow Chemical Company

as there is important information throughout the document. We expect you to follow the precautions

identified in this document unless your use conditions would necessitate other appropriate methods or

actions.

encourages and expects you to read and understand the entire (M)SDS,

Material Safety Data Sheet

The Dow Chemical Company

Print Date: 15 Aug 2007

1. Product and Company Identification

Product Name

TERGITOL(TM) L-62

COMPANY IDENTIFICATION

The Dow Chemical Company

2030 Willard H. Dow Center

Midland, MI 48674

USA

Customer Information Number: 800-258-2436

EMERGENCY TELEPHONE NUMBER

24-Hour Emergency Contact: 989-636-4400

Local Emergency Contact:

989-636-4400

2. Hazards Identification

Emergency Overview

Color: Clear

Physical St at e: Liquid

Odor: Mild

Hazards of product:

No significant immediate hazards for emergency response are known.

OSHA Hazard Communication Standard

This product is a "Hazardous Chemical" as defined by the OSHA Hazard Communication Standard, 29

CFR 1910.1200.

Potential Health Effects

Eye Contact:

Skin Contact: Prolonged exposure not likely to cause significant skin irritation. Material may be

handled at elevated temperatures; contact with heated material may cause thermal burns.

Skin Absorption: Prolonged skin contact is unlikely to result in absorption of harmful amounts.

Inhalation: At room temperature, exposure to vapor is minimal due to low volatility; single exposure is

not likely to be hazardous. Vapor from heated material or mist may cause respiratory irritation.

May cause slight temporary eye irritation. Corneal injury is unlikely.

* Indicates a Trademark

Page 1 of 7

Page 4

Product Name: TERGITOL(TM) L-62 Issue Date: 01/26/2006

Ingestion: Low toxicity if swallowed. Small amounts swallowed incidentally as a result of normal

handling operations are not likely to cause injury; however, swallowing larger amounts may cause

injury.

Effects of Repeated Exposure: For similar mater ial(s): In ani mals, effects have been reported on the

following organs after exposure to aerosols: Lung.

3. Composition Information

Component CAS # Amount

Polyalkylene glycol 9003-11-6 <= 99.0 %

4. First-aid measures

Eye Contact: Flush eyes thoroughly with water for several minutes. Remove contact lenses after the

initial 1-2 minutes and continue flushing for several additional minutes. If effects occur, consult a

physician, preferably an ophthalmologist.

Skin Contact: Wash skin with plenty of water.

Inhalation: Move person to fresh air; if effects occur, consult a physician.

Ingestion: If swallowed, seek medical attention. Do not induce vomiting unless directed to do so by

medical personnel.

Notes to Physician: If burn is present , treat as any thermal burn, after decontamination. No specific

antidote. Treatment of exposure should be directed at the control of symptoms and the clinical

condition of the patient.

5. Fire Fighting Measures

Extinguishing Media: Water fog or fine spray. Dry chemical fire extinguishers. Carbon dioxide fire

extinguishers. Foam. Do not use direct water stream. May spread fire. Alcohol resistant foams (ATC

type) are preferred. General purpose synthetic foams (including AFFF) or protein foams may function,

but will be less effective.

Fire Fighting Procedures: Keep people away. Isolate fire and deny unnecessary entry. Use water

spray to cool fire exposed containers and fire affected zone until fire is out and danger of reignition has

passed. Fight fire from protected location or safe distance. Consider the use of unmanned hose

holders or monitor nozzles. Immediately withdraw all personnel from the area in case of rising sound

from venting safety device or discoloration of the container. Do not use direct water stream. May

spread fire. Move container from fire area if this is possible without hazard. Burning liquids may be

moved by flushing with water to protect personnel and minimize property damage.

Special Protective Equipment for Firefighters: Wear positive-pressure self-contained breathing

apparatus (SCBA) and protective fire fighting clothing (includes fire fighting helmet, coat, trousers,

boots, and gloves). If protective equipment is not available or not used, fight fire from a protected

location or safe distance.

Unusual Fire and Explosion Hazards: Container may rupture from gas generation in a fire situation.

Violent steam generation or eruption may occur upon application of direct water stream to hot liquids.

Hazardous Combustion Products: During a fire, smoke may contain the original material in addition

to combustion products of varying composition which may be toxic and/or irritating. Combustion

products may include and are not limited to: Carbon monoxide. Carbon dioxide.

6. Accidental Release Measures

Steps to be Taken if Material is Released or Spilled: Contain spilled material if possible. Absorb

with materials such as: Sand. Dirt. Collect in suitable and properly labeled containers. See Section

13, Disposal Considerations, for additional information.

Page 2 of 7

Page 5

Product Name: TERGITOL(TM) L-62 Issue Date: 01/26/2006

Personal Precautions: Keep unnecessary and unprotected personnel from entering the area. Spilled

material may cause a slipping hazard. Use appropriate safety equipment. For additional information,

refer to Section 8, Exposure Controls and Personal Protection.

Environmental Precautions: Prevent from entering into soil, ditches, sewers, waterways and/or

groundwater. See Section 12, Ecological Information.

7. Handling and Storage

Handling

General Handling: Spills of these organic materials on hot fibrous insulations may lead to lowering of

the autoignition temperatures possibly resulting in spontaneous combustion. Product on surfaces can

cause slippery conditions. Product shipped/handled hot can cause thermal burns. Product handled

hot may require additional ventilation or local exhaust.

Storage

Keep container tightly closed when not in use. Store in the following material(s): Stainless steel.

Polypropylene. Polyethylene-lined container. Teflon. Glass-lined container. Aluminum. Plasite 3066

lined container. Plasite 3070 lined container. 316 stainless steel.

Shelf life: Use within Storage temperature:

24 Months 15 - 35 °C

8. Exposure Controls / Personal Protection

Exposure Limits

None established

Personal Protection

Eye/Face Protection: Use safety glasses.

Skin Protection: No precautions other than clean body-covering clothing should be needed. When

handling hot material, protect skin from thermal burns. Selection of specific items will depend on the

operation.

Hand protection: Use gloves with insulation for thermal protection, when needed.

Respiratory Protection: For most conditions , no re s p i ra t o ry p rotection sho ul d be needed; however, if

material is heated or sprayed, use an approved air-purifying respirator. The following should be

effective types of air-purifying respirators: Organic vapor cartridge with a particulate pre-filter.

Ingestion: Use good personal hygiene. Do not consume or store food in the work area. Wash hands

before smoking or eating.

Engineering Controls

Ventilation: Good general ventilation should be sufficient for most conditions. Local exhaust

ventilation may be necessary for some operations.

9. Physical and Chemical Properties

Physical St at e

Color

Odor

Flash Point - Closed Cup

Flammable Limits In Air Lower: No test data available

Autoignition Temperature

Vapor Pressure

Boiling Point (760 mmHg)

Liquid

Clear

Mild

216 °C (421 °F)

Upper: No test data available

No test data available

No test data available

Not applicable decomposes before boiling.

ASTM D93

Page 3 of 7

Page 6

Product Name: TERGITOL(TM) L-62 Issue Date: 01/26/2006

Vapor Density (air = 1)

Specific Gravity (H2O = 1)

Freezing Point

Melting Point

Solubility in Water (by

weight)

pH

Molecular Weight

Kinematic Viscosity

Cloud point

Pour point

>1 Literature

1.011 Calculated

See Pour Point

not applicable to liquids

readily soluble

6.5 Calculated (3% aq.sol)

2500 g/mol Calculated

231 cSt @ 38 °C

30 °C Calculated

-2 °C (28 °F)

Calculated

Calculated

(1% aqueous solution)

10. Stability and Reactivity

Stability/Instability

Thermally stable at typical use temperatures.

Conditions to Avoid: Exposure to elevated temperatures can cause product to decompose.

Generation of gas during decomposition can cause pressure in closed systems.

Incompatib le Materials: Avoid contact with: Strong acids. Strong bases. Strong oxidizers.

Hazardous Polymerization

Will not occur.

Thermal Decomposition

Decomposition products depend upon temperature, air supply and the presence of other materials.

Decomposition products can include and are not limited to: Aldehydes. Alcohols. Ethers.

Hydrocarbons. Ketones. Organic acids. Polymer fragments.

11. Toxicological Information

Acute Toxicity

Ingestion

Typical for this family of materials. Estimated LD50, Rat

Skin Absorption

Typical for this family of materials. LD50, Rabbit

> 10,000 mg/kg

> 4,000 mg/kg

Repeated Dose Toxicity

For similar material(s): In animals, effects have been reported on the following organs after exposure

to aerosols: Lung.

12. Ecological Information

CHEMICAL FATE

Persistence and Degradability

For this family of materials: Material is readily biodegradable. Passes OECD test(s) for ready

biodegradability.

OECD Biodegradation Tests:

Biodegradation Exposure Time Method

> 60 % 28 d OECD 301F Test

Page 4 of 7

Page 7

Product Name: TERGITOL(TM) L-62 Issue Date: 01/26/2006

ECOTOXICITY

For this family of materials: Material is practically non-toxic to aquatic organisms on an acute basis

(LC50/EC50 >100 mg/L in the most sensitive species tested).

13. Disposal Considerations

DO NOT DUMP INTO ANY SEWERS, ON THE GROUND, OR INTO ANY BODY OF WATER. All

disposal practices must be in compliance with all Federal, State/Provincial and local laws and

regulations. Regulations may vary in different locations. Waste characterizations and compliance with

applicable laws are the responsibility solely of the waste generator. DOW HAS NO CONTROL OVER

THE MANAGEMENT PRACTICES OR MANUFACTURING PROCESSES OF PARTIES HANDLING

OR USING THIS MATERIAL. THE INFORMATION PRESENTED HERE PERTAINS ONLY TO THE

PRODUCT AS SHIPPED IN ITS INTENDED CONDITION AS DESCRIBED IN MSDS SECTION:

Composition Information. FOR UNUSED & UNCONTAMINATED PRODUCT, the preferred options

include sending to a licensed, permitted: Recycler. Reclaimer. Incinerator or other thermal

destruction device. As a service to its customers, Dow can provide names of information resources to

help identify waste management companies and other facilities which recycle, reprocess or manage

chemicals or plastics, and that manage used drums. Telephone Dow's Customer Information Group at

1-800-258-2436 or 1-989-832-1556 (U.S.), or 1-800-331-6451 (Canada) for further details.

14. Transport Information

DOT Non-Bulk

NOT REGULATED

DOT Bulk

NOT REGULATED

IMDG

NOT REGULATED

ICAO/IATA

NOT REGULATED

This information is not intended to convey all specific regulatory or operational

requirements/information relating to this product. Additional transportation system information can be

obtained through an authorized sales or customer service representative. It is the responsibility of the

transporting organization to follow all applicable laws, regulations and rules relating to the

transportation of the material.

15. Regulatory Information

OSHA Hazard Communication Standard

This product is a "Hazardous Chemical" as defined by the OSHA Hazard Communication Standard, 29

CFR 1910.1200.

Superfund Amendments and Reauthorization Act of 1986 Title III (Emergency Planning

and Community Right-to-Know Act of 1986) Sections 311 and 312

Immediate ( Acute) Health Hazard

Delayed (Chronic) Health Hazard

Fire Hazard

Reactive Hazard

Sudden Release of Pressure Hazard

No

Yes

No

No

No

Page 5 of 7

Page 8

Product Name: TERGITOL(TM) L-62 Issue Date: 01/26/2006

Superfund Amendments and Reauthorization Act of 1986 Title III (Emergency Planning and

Community Right-to-Know Act of 1986) Section 313

To the best of our knowledge, this product does not contain chemicals at levels which require reporting

under this statute.

Pennsylvania (Worker and Community Right-To-Know Act): Pennsylvania Hazardous

Substances List and/or Pennsylvania Environmental Hazardous Substance List:

To the best of our knowledge, this product does not contain chemicals at levels which require reporting

under this statute.

Pennsylvania (Worker and Community Right-To-Know Act): Pennsylvania Special Hazardous

Substances List:

To the best of our knowledge, this product does not contain chemicals at levels which require reporting

under this statute.

Comprehensive Environmental Response, Compensation, and Liability Act of 1980 (CERCLA)

Section 103

This product contains the following substances which are subject to CERCLA Section 103 reporting

requirements and which are listed in 40 CFR 302.4.

Component CAS # Amount

Ethylene oxid e 75-21-8 <= 10.0 PPM

Propylene oxide 75-56-9 <= 10.0 PPM

1,4-Dioxane 123-91-1 <= 5.0

Acetaldehyde 75-07-0 <= 5.0

Formaldehyde 50-00-0 <= 5.0

PPM

PPM

PPM

California Proposition 65 (Safe Drinking Water and Toxic Enforcement Act of 1986)

WARNING: This product contains a chemical(s) known to the State of California to cause cancer.

Component CAS # Amount

Ethylene oxid e 75-21-8 <= 10.0 PPM

Propylene oxide 75-56-9 <= 10.0 PPM

1,4-Dioxane 123-91-1 <= 5.0

Acetaldehyde 75-07-0 <= 5.0

Formaldehyde 50-00-0 <= 5.0

PPM

PPM

PPM

California Proposition 65 (Safe Drinking Water and Toxic Enforcement Act of 1986)

WARNING: This product contains a chemical(s) known to the State of California to cause birth defects

or other reproductive harm.

Component CAS # Amount

Ethylene oxid e 75-21-8 <= 10.0 PPM

US. Toxic Substances Control Act

All components of this product are on the TSCA Inventory or are exempt from TSCA Inventory

requirements under 40 CFR 720.30

CEPA - Domestic Substances List (DSL)

All substances contained in this product are listed on the Canadian Domestic Substances List (DSL) or

are not required to be listed.

European Inventory of Existing Commercial Chemical Substances (EINECS)

The components of this product are on the EINECS inventory or are exempt from inventory

requirements.

16. Other Information

Product Literature

Page 6 of 7

Page 9

Product Name: TERGITOL(TM) L-62 Issue Date: 01/26/2006

Additional information on this and other Dow products may be obtained by visiting our web page at

www.dow.com. Additional information on this product may be obtained by calling your Dow Chemical

Company sales or customer service contact. Ask for a product brochure.

Hazard Rating System

NFPA Health Fire Reactivity

1 1 1

Recommended Uses and Restrictions

Multi-purpose surfactant.

Revision

Identification Number: 80110 / 1001 / Issue Date 01/26/2006 / Version: 2.1

Most recent revision(s) are noted by the bold, double bars in left-hand margin throughout this

document.

Legend

N/A Not available

W/W Weight/Weight

OEL Occupational Exposure Limit

STEL Short Term Exposure Limit

TWA Time Weighted Average

ACGIH American Conference of Governmental Industrial Hygienists, Inc.

DOW IHG Dow Industria l Hygiene Guideline

WEEL Workplace Environmental Exposure Level

HAZ_DES Hazard Designation

The Dow Chemical Company

consult appropriate expertise, as necessary or appropriate, to become aware of and understand the

data contained in this (M)SDS and any hazards associated with the product. The information herein is

provided in good faith and believed to be accurate as of the effective date shown above. However, no

warranty, express or impl ied, is given.

between various locations. It is the buyer's/user's responsibility to ensure that its activities comply with

all federal, state, provincial or local laws. The information presented here pertains only to the product

as shipped. Since conditions for use of the product are not under the control of the manufacturer, it is

the buyer's/user's duty to determine the conditions necessary for the safe use of this product.

the proliferation of sources for information such as manufacturer-specific (M)SDSs, we are not and

cannot be responsible for (M)SDSs obtained from any source other than ourselves. If you have

obtained an (M)SDS from another source or if you are not sure that the (M)SDS you have is current,

please contact us for the most current version.

urges each customer or recipient of this (M)SDS to study it carefully and

Regulatory requirements are subject to change and may differ

Due to

Page 7 of 7

Loading...

Loading...