Page 1

Includes

Teacher's Notes

and

Typical

Experiment Results

Instruction Manual and

Experiment Guide for

the PASCO scientific

Model WA-9611, and 9613

SONOMETER

012-03489E

5/95

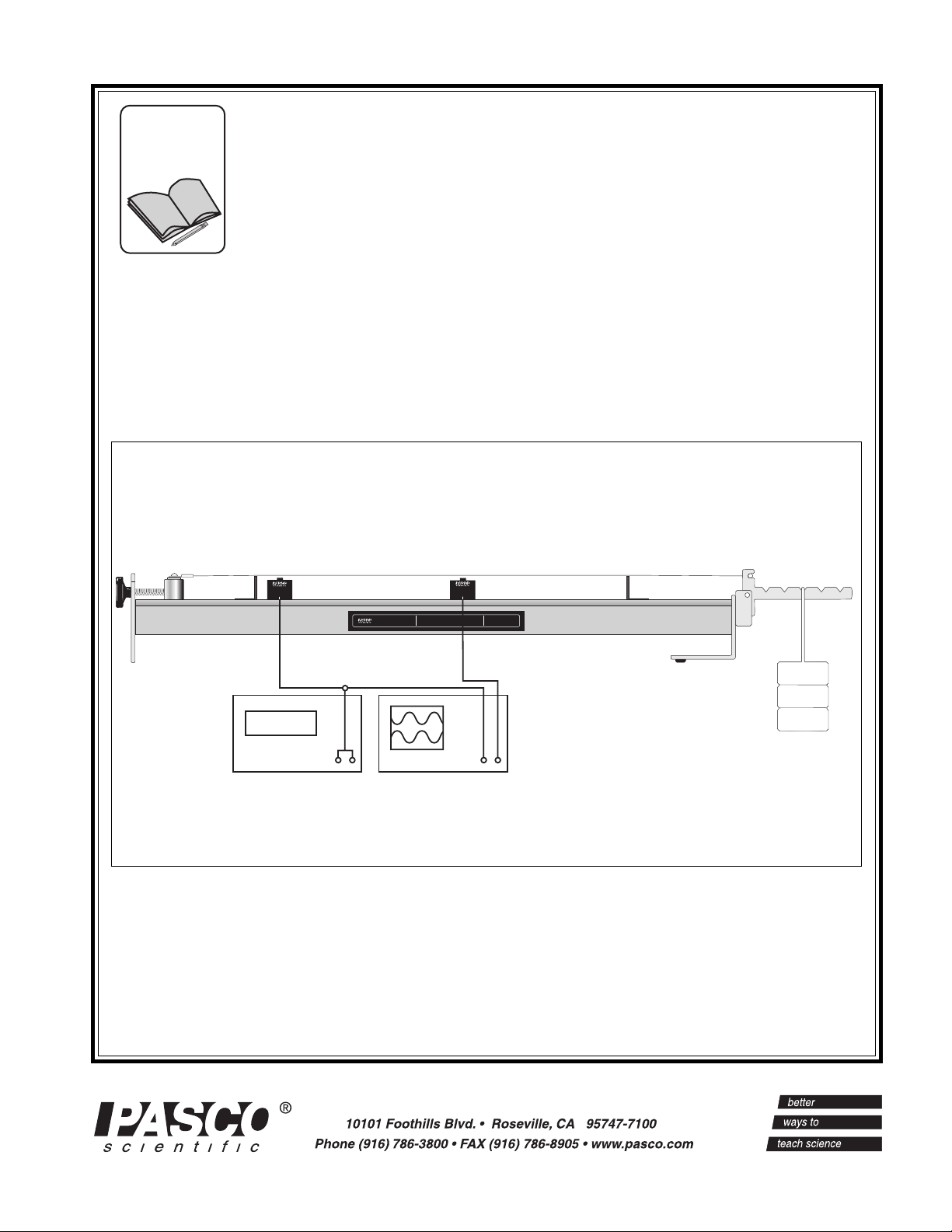

WA-9613

DRIVER

WA-9611

SONOMETER

WA-9613

DETECTOR

KEEP WEIGHTS AS NEAR TO FLOOR

AS POSSIBLE IN THE EVENT THE

SONOMETER WIRE SHOULD BREAK

CAUTION!

1.75 kg MAXIMUM

LOAD ON LEVER

100.5 Hz

© 1988 PASCO scientific $5.00

Page 2

Page 3

012-03489E Sonometer

T able of Contents

Section Page

Copyright, Warranty and Equipment Return......................................................ii

Introduction ......................................................................................................1

Equipment ........................................................................................................1

Setup and Operation..........................................................................................2

Using the Sonometer and the WA-9613 Driver/Detector Coils:

Sonometer w/WA-9613, Driver/Detector Coils ...........................................3

Sonometer and Driver/Detector w/PASCO Computer Interface ...................4

Power Amplifier w/Series 6500 Computer Interface .................................... 4

Power Amplifier w/CI-6550 or CI-6565 Computer Interface .......................4

Function Generator w/Series 6500 Computer Interface ................................ 5

Function Generator w/CI-6550 or CI-6565 Computer Interface ...................6

Replacing Sonometer Strings ............................................................................7

Theory of Waves on a Stretched String..............................................................8

Experiments:

Experiment 1: Resonance Modes of a Stretched String ........................ 11

Experiment 2: Velocity of Wave Propagation ......................................13

Suggested Research Topics ..............................................................................16

Teacher’s Guide...............................................................................................17

Technical Support ....................................................................Inside Back Cover

i

Page 4

Sonometer 012-03489E

Copyright, Warranty and Equipment Return

Please—Feel free to duplicate this manual

subject to the copyright restrictions below.

Copyright Notice

The PASCO scientific Model WA-9611 Sonometer

manual is copyrighted and all rights reserved. However,

permission is granted to non-profit educational institutions for reproduction of any part of this manual providing the reproductions are used only for their laboratories

and are not sold for profit. Reproduction under any other

circumstances, without the written consent of PASCO

scientific, is prohibited.

Limited Warranty

PASCO scientific warrants this product to be free from

defects in materials and workmanship for a period of one

year from the date of shipment to the customer. PASCO

will repair or replace, at its option, any part of the product

which is deemed to be defective in material or workmanship. This warranty does not cover damage to the product

caused by abuse or improper use. Determination of

whether a product failure is the result of a manufacturing

defect or improper use by the customer shall be made

solely by PASCO scientific. Responsibility for the return

of equipment for warranty repair belongs to the customer.

Equipment must be properly packed to prevent damage

and shipped postage or freight prepaid. (Damage caused

by improper packing of the equipment for return shipment will not be covered by the warranty.) Shipping

costs for returning the equipment, after repair, will be

paid by PASCO scientific.

Equipment Return

Should the product have to be returned to PASCO

scientific for any reason, notify PASCO scientific by

letter, phone, or fax BEFORE returning the product.

Upon notification, the return authorization and

shipping instructions will be promptly issued.

ä

NOTE: NO EQUIPMENT WILL BE

ACCEPTED FOR RETURN WITHOUT AN

AUTHORIZATION FROM PASCO.

When returning equipment for repair, the units

must be packed properly. Carriers will not accept

responsibility for damage caused by improper

packing. To be certain the unit will not be

damaged in shipment, observe the following rules:

➀ The packing carton must be strong enough for the

item shipped.

➁ Make certain there are at least two inches of

packing material between any point on the

apparatus and the inside walls of the carton.

➂ Make certain that the packing material cannot shift

in the box or become compressed, allowing the

instrument come in contact with the packing

carton.

Credits

This manual authored by: Clarence Bakken

This manual edited by: Dave Griffith

Teacher’s guide written by: Eric Ayars

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: (916) 786-3800

FAX: (916) 786-3292

email: techsupp@pasco.com

web: www.pasco.com

ii

Page 5

012-03489E Sonometer

Introduction

Introduction

The PASCO scientific Model WA-9611 Sonometer is an

enhanced version of the classic sonometer. You can perform the standard, qualitative sonometer experiments,

varying the tension, length, and linear density of the string

and observing the effects on the pitch of the plucked string.

Also, you can perform quantitative experiments, verifying

the equations for wave motion on a string by adding the

WA-9613 Driver/Detector Coils, a function generator capable of delivering 0.5 A of current, and an oscilloscope (or

a computer interface and power amplifier) where,

l = wavelength

L = length of string

Equipment

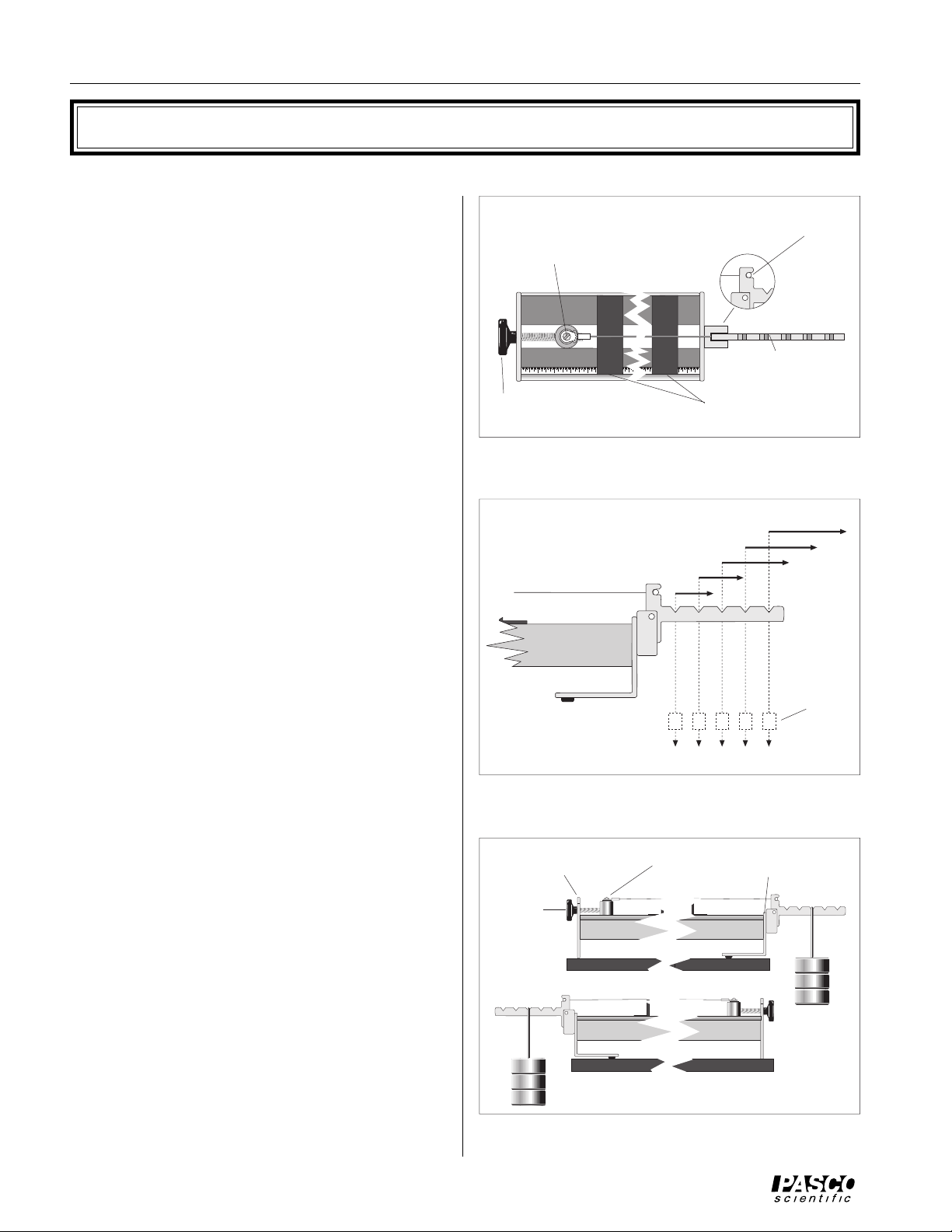

The WA-9611 Sonometer comes with the following

equipment (see Figure 1):

• Sonometer base with tensioning lever

• Two bridges

• 10 wires (guitar strings), 2 each of the following diameters (linear densities):

— 0.010" (0.39 gm/m)

— 0.014" (0.78 gm/m)

— 0.017" (1.12 gm/m)

— 0.020" (1.50 gm/m)

— 0.022" (1.84 gm/m)

Additional Equipment

To perform qualitative experiments, you will also need a

mass hanger and no more than 1.75 kg of mass to hang

from the tensioning lever.

Bridge

WA-9613

DRIVER

String

WA-9611

SONOMETER

WA-9613

DETECTOR

KEEP WEIGHTS AS NEAR TO FLOOR

AS POSSIBLE IN THE EVENT THE

SONOMETER WIRE SHOULD BREAK

n = number of antinodes

V = velocity of wave propagation

T = string tension

m = linear density of string

n = frequency of wave

The driver and detector coil can be placed anywhere along

the string. The driver coil drives string vibrations at any

frequency your function generator (or computer-compatible power amplifier) will produce. The detector coil allows

you to view the vibration of the string on your oscilloscope

or computer interface. With a dual trace oscilloscope or a

computer interface, you can examine phase differences between the driving frequency and the string vibrations.

Recommended Equipment

If you wish to accurately measure the frequency and

wavelength of the string vibrations, you will also need:

• WA-9613 Driver/Detector coils

• CI-6550 or CI-6565 Computer Interface and a

Power Amplifier (CI-6552)

OR

• Series 6500 Computer Interface, CI-6508 Input

Adapter Box, and a function generator capable of

producing 0.5 A

OR

• dual trace oscilloscope and a function generator

capable of producing 0.5 A

Optional Equipment (for use with function

generator)

• banana plug patch cords and BNC-to-banana

adapter (for connecting the function generator to

the BNC connector on an oscilloscope)

Tensioning

lever

CAUTION!

1.75 kg MAXIMUM

LOAD ON LEVER

Sonometer base

Figure 1 The Sonometer and Suggested Accessories

1

Page 6

Sonometer 012-03489E

Setup and Operation

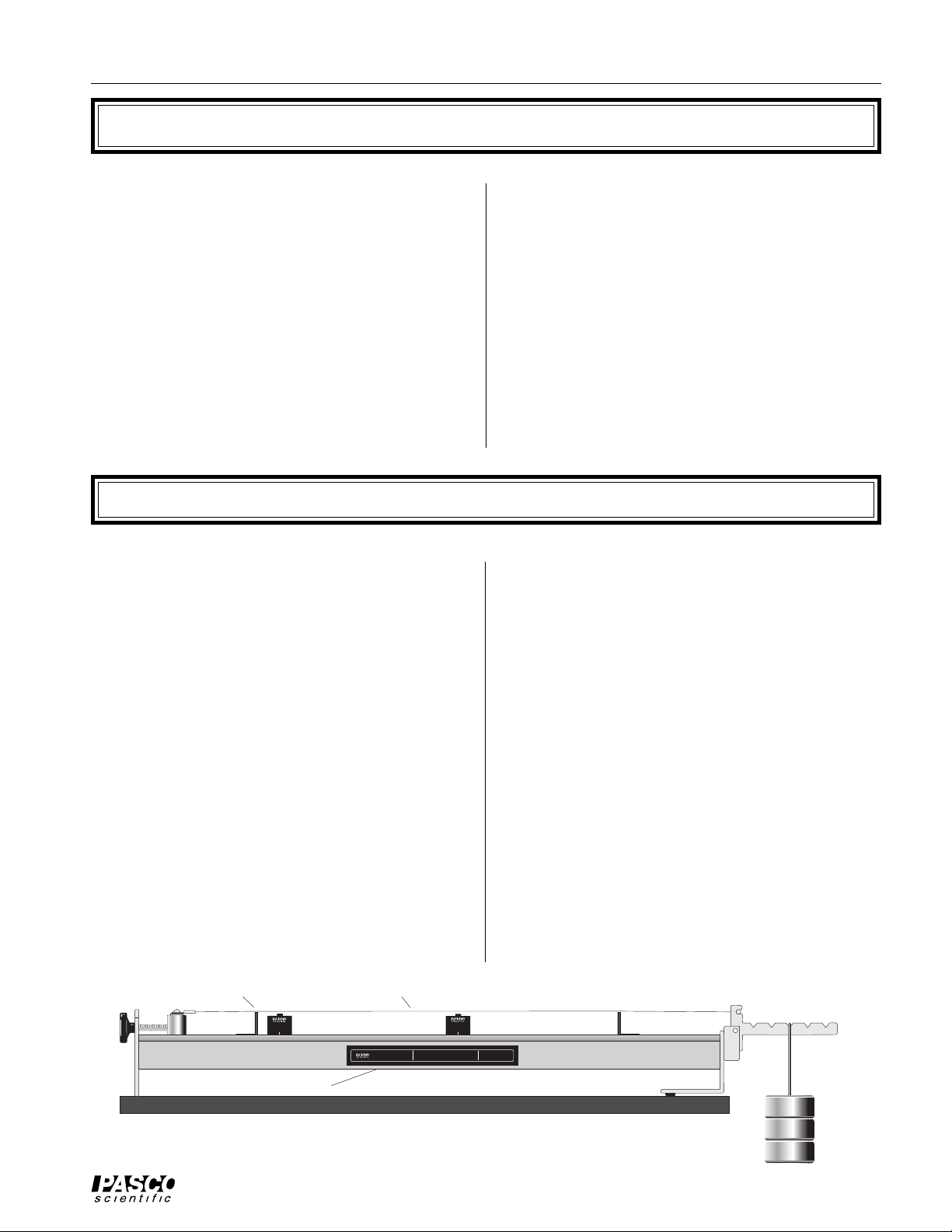

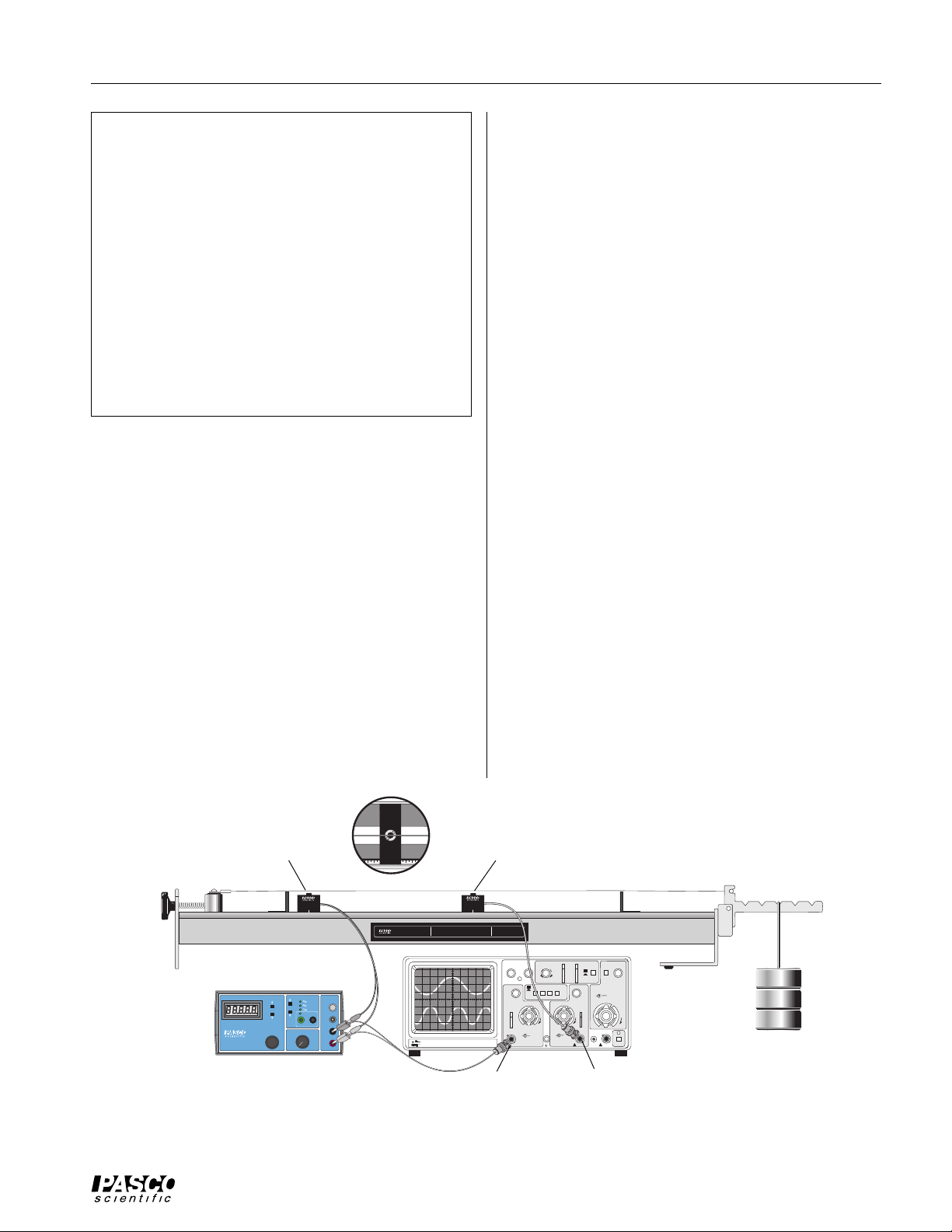

To setup the sonometer (see Figure 2):

➀ Choose one of the ten strings and place the brass

string retainer into the slot on the tensioning lever.

➁ Loosen the string adjustment screw and place the

crimped lug that is attached to the other end of the

string over the screw head, as shown.

Crimped lug

Brass string retainer

➂ Tighten the string adjustment screw until the

tensioning lever hangs level.

➃ Place the bridges in any locations you wish, to deter-

mine the length of the string.

➄ Hang a mass (approximately 1 kg) from the tensioning

lever to produce the desired tension, then adjust the

string adjustment screw as needed so that the

tensioning lever is level. See Figure 3. (The lever must

be level to accurately determine the string tension

from the hanging mass.)

String tension is determined as shown in Figure 3. If

you hang a mass “M” from slot one of the lever, the

tension of the string is equal to Mg, where g is the

gravitational constant (9.8 m/s

2

). If you hang the mass

from slot two, the tension equals 2Mg; if you hang it

from slot three, the tension is 3 Mg, etc.

➅ You can now:

- Vary the tension of the string by hanging the mass

from different slots in the tensioning lever. (Always

adjust the string adjustment screw so the lever remains

level.)

String adjustment screw

Figure 2 Sonometer Setup

String tension (T)

Slot 1 2 3 4 5

Figure 3 Setting the Tension

Tensioning lever

Bridges

5Mg

4Mg

3Mg

2Mg

1Mg

Hanging

Mass

(mass = M)

(weight = Mg)

- Vary the length of the string by adjusting the distance

between the bridges.

- Vary the linear density of the string by changing

strings.

- Pluck the string to observe how each of these variables effects the resonant frequency.

2

End plate

String

Adjustment

screw

Aluminum Cylinder

Figure 4 Reversing the End Plates

End plate

Page 7

012-03489E Sonometer

➤NOTE: At some lab stations, you may want the

tensioning lever to hang over the left end of the

table instead of the right (see Figure 4). In this case,

you can switch the end plates so that, when performing the experiment, the metric scale will still

be right side up. To switch the endplates:

➀ Loosen the string adjustment screw and remove

the string.

➁ Unscrew the two screws that hold each end plate

onto the sonometer and remove the end plates.

➂ Slide the aluminum cylinder out of the slot.

➃ Slide the cylinder into the slot on the other end

of the sonometer, then switch the end plates.

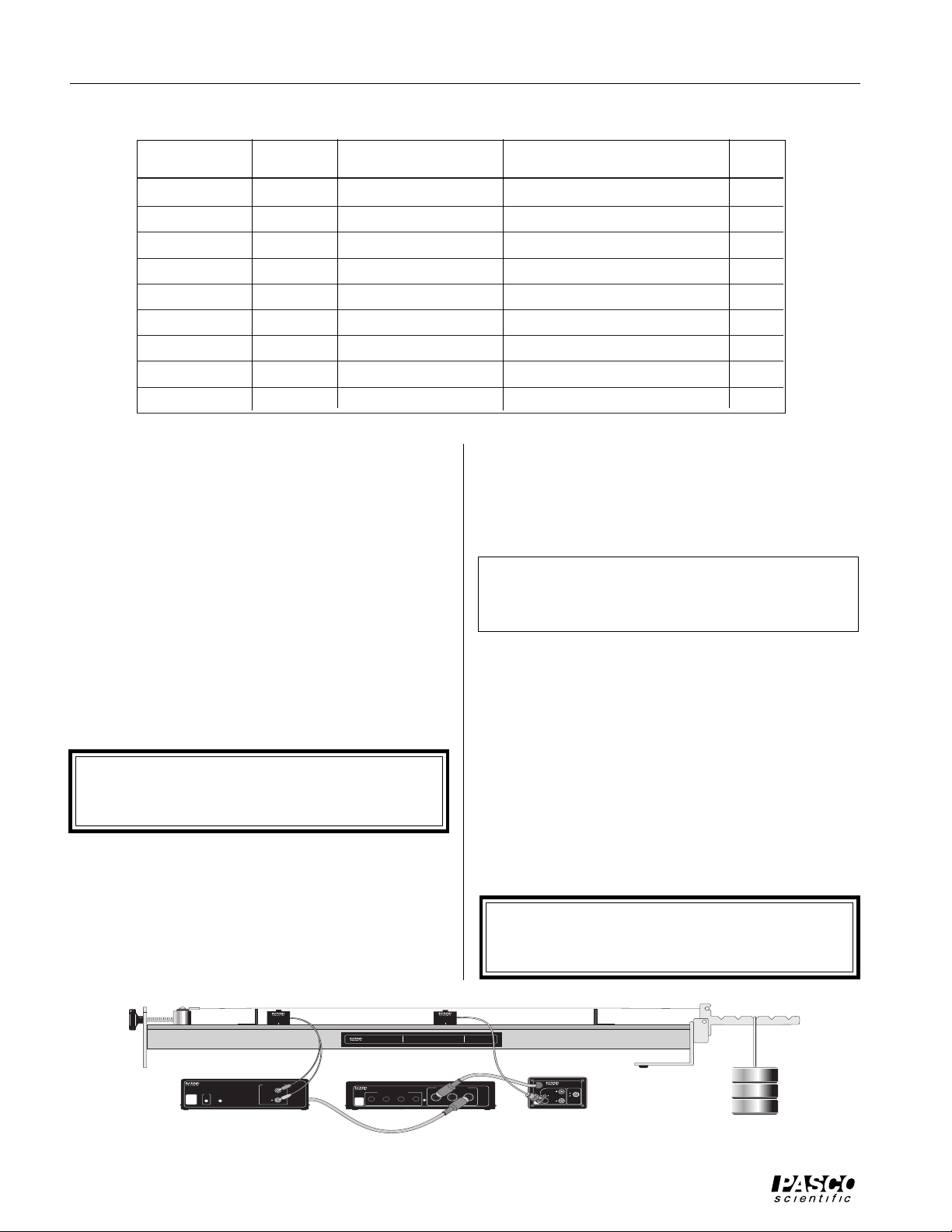

Using the Sonometer and the WA-9613

Driver/Detector Coils:

Sonometer and Driver/Detector Coils with a function

generator and oscilloscope:

➀ Connect the Driver and Detector Coils to the function

generator and oscilloscope as shown in the diagram.

Connect the driver coil directly to the output of the

PASCO PI-9587B Digital Function Generator. Connect the detector coil directly to channel two of an oscilloscope that has a BNC connector. You can use banana plug patch cords and a BNC-to-banana plug

adapter to connect the output of the function generator

to channel one of an oscilloscope that has a BNC connector. (If you are using a single trace oscilloscope,

connect only the detector coil to the oscilloscope.)

➁ Position the driver coil approximately 5 cm from one

of the bridges.

Depending on the wave pattern you are trying to pro-

duce, you might want to place the driver at some other

position. It will drive the string best if it is placed at an

antinode of the wave pattern. However, if you place it

near one of the bridges, it will work reasonably well

for most frequencies.

➂ Position the detector midway between the bridges ini-

tially, though for some patterns you may want to reposition it to best pick up the signal. As with the driver

coil, it works best when positioned near an antinode of

the wave pattern.

➃ Set the gain on channel-one of the oscilloscope to 5

mV/cm. Adjust the oscilloscope so it triggers on the

signal from the function generator.

➄ Set the function generator to produce a sine wave. Set

the frequency to a value between 100 and 200 Hz. Adjust the amplitude to about 5 V (approximately half of

maximum). Slowly vary the frequency of the function

generator output. When you reach a resonant frequency, you should see the motion of the string and

the sound produced by the vibrating string should be a

maximum. The wave pattern shown on the oscilloscope should become a clean sine wave. If you can’t

see or hear the string, raise the amplitude of the function generator output slightly and try again.

Driver coil Detector coil

WA-9613

DRIVER

FREQUEN

CY

HE

RTZ

PI-9587B

DIGITAL FUNCTION

GENERATOR AMPLIFIER

WAVEFO

RA

NGE

RM

EXTERN

AL

INPUTG

ND

AMPLITU

ADJU

ST

DE

M

MI

AX

N

Function generator

WA-9611

SONOMETER

OUTP

UT

TT

L

HI

Ω

G

ND

LO

Ω

WA-9613

DETECTOR

KEEP WEIGHTS AS NEAR TO FLOOR

AS POSSIBLE IN THE EVENT THE

SONOMETER WIRE SHOULD BREAK

200 Mhz OSCILLISCOPE

BK PRECISION

Channel 1 (trigger) Channel 2

Figure 5 Using the Driver and Detector Coils

CAUTION!

1.75 kg MAXIMUM

LOAD ON LEVER

INTENSITY

TRACE NOTATION

POS

AC

DC

CH 1

∞

400V

MODEL

MAX

2120

Oscilloscope

3

FOCUS

TRIG LEVEL

-

MANUAL AUTO

NORM

CH1

EXT

EXT

CH2

VERTICAL MODE

CH 1

VOLTZ/DIV

CAL

V

mV

VAR VAR

PULL XS PULL XS

+

T XY

T XY

LINE

CH1

CH2

CH 2

VOLTZ/DIV

V

COUPLE SOURCE

AC

mV

CH1

X-POS

λ - Y

SLOPE

+

CH2

-

ALT

EXT

POSNORM

TIME/DI

V

VAR SWEEP

AC

CAL

DC

CAL

CH4

CAL EXT

CH 2

∞

200V

POWER

400V

MAX

MAX

Page 8

Sonometer 012-03489E

Table 1

Computer Interface Device to drive coil Software FFT?

Apple II AI-6501 Power Amplifier Power Amplifier (Apple II) no

Apple II AI-6501 function generator Data Monitor (Apple II) no

DOS - PC CI-6500 Power Amplifier Power Amplifier (MS-DOS) no

DOS - PC CI-6500 function generator Data Monitor (MS-DOS) yes

Macintosh CI-6550 Power Amplifier Science Workshop (Mac) yes

Macintosh CI-6550 function generator Science Workshop (Mac) yes

Windows - PC CI-6565 Power Amplifier Science Workshop (Windows) yes

Windows - PC CI-6565 function generator Science Workshop (Windows) yes

Windows - PC CI-6500 function generator Data Monitor (Windows) yes

Sonometer and Driver/Detector Coils with a PASCO

Computer Interface

There are several ways to use a PASCO Computer Interface with the sonometer. The method you use depends on

the kind of computer, the interface (e.g., CI-6500, CI6550, etc.), the device to control the coil, and whether you

wish to do frequency analysis (Fast Fourier Transform or

FFT) of the standing waves. See Table 1.

Using the Power Amplifier with a Series 6500

Computer Interface:

➀ Connect the Power Amplifier DIN plug to channel C

of the interface. Connect the Sonometer Driver Coil to

the output of the Power Amplifier.

➤ CAUTION: Do not turn on the power amplifier

until you have set the output amplitude from within

the program.

➁ Connect the BNC plug on the Sonometer Detector

Coil to the BNC jack on the CI-6508 Input Adapter

Box, and the DIN plug on the Adapter Box to channel

A of the interface. Turn the amplification select switch

on the CI-6508 to 100X. (See Figure 5.1.)

➂ Start the Power Amplifier program and set the output

to a 3-5 V sine wave; then turn on the power amplifier. Show channel A and channel C on the screen, so

you can see both the driving force and the resultant

motion of the wire.

➤ NOTE: The Power Amplifier program does not

have a frequency analysis feature (Fast Fourier

Transform or FFT).

Using the Power Amplifier with a CI-6550 or CI-6565

Computer Interface:

The Science Workshop program that comes with the CI-

6550 or CI-6565 interface allows you to do frequency

analysis (Fast Fourier Transform, or FFT) of the standing

waves. This can be used for an in-depth analysis of the

harmonics present in a standing wave, analysis of noise,

or observation of multiple simultaneous resonances.

➀ Connect the Power Amplifier DIN plug to channel C

of the interface. Connect the Sonometer Driver Coil to

the output of the Power Amplifier.

➤ CAUTION: Do not turn on the power amplifier

until you have set the output amplitude from within

the program.

CI-6502

POWER AMPLIFIER

FOR USE WITH PASCO SERIES 6500 INTERFACES

ON

CAUTION!

PASCO

SERIES

WHEN LIGHT IS ON

WAVEFORM IS DISTORTED.

6500

INTERFACE

DECREASE AMPLITUDE!

SYSTEM

Power Amplifier

KEEP WEIGHTS AS NEAR TO FLOOR

AS POSSIBLE IN THE EVENT THE

SONOMETER WIRE SHOULD BREAK

Interface

A ▲

ON

GAIN = 1,10,100

ISOLATED

WA-9613

DETECTOR

ANALOG CHANNELS

B ■ C ●

=

GAIN

1

ISOLATED

GAIN = 1

REF TO GND

CAUTION!

1.75 kg MAXIMUM

LOAD ON LEVER

ANALOG INPUT

PASCO

SERIES

6500

INTERFACE

SYSTEM

INPUT ADAPTOR

FOR USE WITH PASCO SERIES 6500 INTERFACES

(±10V MAX)

Model CI-6508

GAIN SELECT

X 100

X 10

X 1

NOTE: SWITCH

FUNTIONS ONLY WHEN

ADAPTOR IS

CONNECTED TO INPUT

MARKED ▲ ON THE

SIGNAL INTERFACE

SIGNAL OUTPUT

0 to ±10 V

1 A MAX

WA-9613

DRIVER

WA-9611

SONOMETER

CI-6510

SIGNAL INTERFACE

+

FOR USE WITH PASCO SERIES 6500 SENSORS

DIGITAL CHANNELS

1234

PASCO

SERIES

6500

INTERFACE

SYSTEM

Adapter Box

Figure 5.1 Using the Power Amplifier and Series 6500 Interface

4

Page 9

012-03489E Sonometer

➁ Connect the BNC plug on the Sonometer Detector

Coil to the BNC adapter that is included with the

Driver/Detector Coils. Connect the banana plugs of a

CI-6503 Voltage Sensor to the BNC adapter. Connect

the DIN plug of the Voltage Sensor to channel A of

the interface.

➂ Start the Science Workshop program. In the Experi-

ment Setup window, click-and-drag the analog sensor

plug icon to channel C. Select “Power Amplifier”

from the list of sensors. Set the Signal Generator output to a 3-5 V sine wave. Click on “Auto ON/OFF”

(so the output signal will begin when you start your

measurements) and switch on the power amplifier.

➄ In the Scope, use the input menu for the second chan-

nel to select “Analog A” so the Scope will show both

the driving signal and the detected motion of the wire.

Set the sensitivity for the Analog A channel to about

0.005 v/div.

For frequency analysis, select “New FFT” from the Display

menu. Click on “MON” in the Setup window (or commandM on the keyboard) when you are ready to begin.

➃ In the Experiment Setup window, click-and-drag the

analog sensor plug icon to channel A. Select “Sound

Sensor” from the list of sensors. Click-and-drag a

Scope display to the Output channel icon in the Setup

window.

WA-9613

DRIVER

WA-9611

SONOMETER

WAVEFO

FREQUEN

RA

NGE

CY

HE

RTZ

ADJU

PI-9587B

DIGITAL FUNCTION

GENERATOR AMPLIFIER

ST

PI-4587C Function Generator

OUTP

RM

UT

TT

L

EXTERN

AL

HI

Ω

INPUTG

ND

G

AMPLITU

ND

DE

LO

Ω

M

MI

AX

N

CI-6510

FOR USE WITH PASCO SERIES 6500 SENSORS

DIGITAL CHANNELS

1234

PASCO

SERIES

6500

INTERFACE

SYSTEM

SIGNAL INTERFACE

Figure 5.2 Using a Function Generator and the Series 6500

WA-9613

DETECTOR

KEEP WEIGHTS AS NEAR TO FLOOR

AS POSSIBLE IN THE EVENT THE

SONOMETER WIRE SHOULD BREAK

CI-6500

A ▲

ON

GAIN = 1,10,100

ISOLATED

Using a Function Generator with the Series 6500

Computer Interface:

The MS-DOS and Windows™ versions of the Data

Monitor program allow you to do frequency analysis

(Fast Fourier Transform or FFT) of the standing waves.

This can be used for an in-depth analysis of the harmonics present in a standing wave, analysis of noise, or observation of multiple simultaneous resonances.

➀ Connect the BNC plug on the Sonometer Detector

Coil to the BNC jack on the CI-6508 Input Adapter

Box, and the DIN plug on the Adapter Box to channel

A of the Series-6500. Turn the amplification select

switch on the CI-6508 to 100X.

➁ If you have a CI-6503 Voltage Sensor, use it to link

the function generator to channel B of the CI-6500

interface. (This step is optional; it allows you to use

the function generator for triggering, with slightly improved results.) See Figure 5.2.

CAUTION!

1.75 kg MAXIMUM

LOAD ON LEVER

Model CI-6508

INPUT ADAPTOR

ANALOG CHANNELS

B ■ C ●

=

GAIN

1

ISOLATED

GAIN = 1

REF TO GND

FOR USE WITH PASCO SERIES 6500 INTERFACES

ANALOG INPUT

(±10V MAX)

PASCO

SERIES

6500

INTERFACE

SYSTEM

CI-6508

GAIN SELECT

X 100

X 10

X 1

NOTE: SWITCH

FUNTIONS ONLY WHEN

ADAPTOR IS

CONNECTED TO INPUT

MARKED ▲ ON THE

SIGNAL INTERFACE

5

Page 10

Sonometer 012-03489E

➂ Set the function generator to produce a sine wave. Set

the frequency to a value between 100 and 200 Hz. Adjust the amplitude to about 5 V (approximately half of

maximum). Slowly vary the frequency of the function

generator output. When you reach a resonant frequency,

you should see the motion of the string and the sound

produced by the vibrating string should be a maximum.

For the Data Monitor (MS-DOS) Program:

Start the program. Select “Oscilloscope” from the Main

Menu. Set triggering to automatic on channel B. Show

channels A and B on the screen, and find the resonances

you are interested in. If you wish, turn on the frequency

analysis option (FFT) and observe the frequencies that are

contributing to the standing wave.

For the Data Monitor (Windows™) Program:

Start the program. Choose “Select Channels” from the

Experiment menu and turn off channel C. Select “Replace

Window” from the Window menu, and change the Plotter/Graph window to an Oscilloscope window. Repeat the

process to change the Data Table window to the FFT window. Click on “Trigger” to set the triggering for channel B.

Using a Function Generator with a CI-6550 or CI6565 Computer Interface:

The Science Workshop program that comes with the CI-

6550 or CI-6565 interface allows you to do frequency

analysis (Fast Fourier Transform, or FFT) of the standing

waves. This can be used for an in-depth analysis of the

harmonics present in a standing wave, analysis of noise,

or observation of multiple simultaneous resonances.

➀ Connect the BNC plug on the Sonometer Detector

Coil to the BNC adapter that is included with the

Driver/Detector Coils. Connect the banana plugs of a

CI-6503 Voltage Sensor to the BNC adapter. Connect

the DIN plug of the Voltage Sensor to channel A of

the interface.

If you have another CI-6503 Voltage Sensor, use it to

link the function generator to channel B of the computer interface. (This step is optional; it allows you to

use the function generator for triggering, with slightly

improved results.)

➁ Start the Science Workshop program. In the Experi-

ment Setup window, click-and-drag the analog sensor

plug icon to channel A. Select “Sound Sensor” from

the list of sensors. If you have connected a Voltage

Sensor from the function generator to channel B,

click-and-drag the analog sensor plug icon to channel

B and select “Voltage Sensor” from the list of sensors.

➂ To view the data, click-and-drag a Scope display to

the Sound Sensor icon. (If you have connected a Voltage Sensor from the function generator to channel B,

use the input menu of the first channel on the Scope to

switch the input to “Analog B”. Use the input menu of

the second channel on the Scope to select “Analog A”.

This will allow you to use the function generator for

triggering.) Set the sensitivity for the Analog A channel to about 0.005 v/div. Click on “MON” to begin

measuring data.

➃ Set the function generator to produce a sine wave. Set

the frequency to a value between 100 and 200 Hz. Adjust the amplitude to about 5 V (approximately half of

maximum). Slowly vary the frequency of the function

generator output. When you reach a resonant frequency, you should see the motion of the string and

the sound produced by the vibrating string should be a

maximum.

6

Page 11

012-03489E Sonometer

➤NOTES:

➀ The frequency observed on the wire may not be

the frequency of the driver. Usually it is twice the

driver frequency, since the driver electromagnet

exerts a force on the wire twice during each cycle.

It is theoretically possible for the wire to form

standing waves at the driver frequency, and at any

even integer multiple of the driver frequency; although the highest multiple observed on this equipment so far has been six.

➁ If the detector is placed too close to the driver, it

will pick up some interference. You can check for

this interference by observing the waveform from

the detector on an oscilloscope; when they are too

close, the trace will change shape. For best results,

keep the detector at least 10 cm from the driver.

➂ You will occasionally see higher and lower fre-

quencies superimposed on the primary waveform. It

is possible for multiple standing waves to form. For

example, the wire may vibrate at the driver frequency

and twice the driver frequency at the same time, thus

causing two sets of “nodes” (see figure below).

At the points where only one wave has a node, instead of complete extinction you will see the waveform change from a combined wave to a single

wave of the lower frequency. Complete extinction

will occur only at the nodal points for both waves.

This does somewhat complicate things; if you wish

to avoid this problem, you may do so by using

higher frequencies whenever possible. (Since

higher frequencies damp faster, the doubled-frequency standing wave will not have a significant

amplitude—compared to the normal wave—at high

frequencies.) A full analysis of this effect would

make an excellent experiment for sophomore- or

junior-level physics or engineering students.

Replacing Sonometer Strings

You can use standard steel or electric guitar strings to

replace lost or broken strings. However, you will need to

attach a spade lug to the end of the wire to mount it on the

Sonometer. To ensure that the connection between the

wire and the lug is secure, wrap the wire around the spade

lug, then crimp and/or solder the wire into the lug

(see Figure 7).

Nodes for higher frequency, but not lower.

Nodes for both frequencies.

Wrap wire around lug, then

crimp and/or solder.

Standard steel or

Spade lug

Figure 7 Adapting Guitar Strings for the

Sonometer

electric guitar string

7

Page 12

Sonometer 012-03489E

Theory of Waves on a Stretched String

Standing Waves

A simple sine wave traveling along a taut string can be

described by the equation y1 = ym sin 2π (x/λ - t/n). If the

string is fixed at one end, the wave will be reflected back

when it strikes that end. The reflected wave will then interfere with the original wave. The reflected wave can be

described by the equation y2 = ym sin 2π (x/λ + t/n). Assuming the amplitudes of these waves are small enough

so that the elastic limit of the string is not exceeded, the

resultant waveform will be just the sum of the two waves:

y = y

+ y2 = ym sin 2π (x/λ - t/λ) + ym sin 2π (x/λ + t/λ).

1

Using the trigonometric identity:

sin A + sin B = 2 sin1/2(A + B) cos1/2(B - A),

this equation becomes:

y = 2y

This equation has some interesting characteristics. At a

fixed time, t

, the shape of the string is a sine wave with a

0

maximum amplitude of 2ym cos (2πt0/λ). At a fixed position on the string, x0, the string is undergoing simple harmonic motion, with an amplitude of 2ym sin (2πx0/λ).

Therefore, at points of the string where x0 = l/4, 3l/4, 5l/4,

7l/4, etc., the amplitude of the oscillations will be a maximum. At points of the string where x0 = l/2, l, 3l/2, 2l,

etc., the amplitude of the oscillations will be zero.

This waveform is called a standing wave because there is

no propagation of the waveform along the string. A time

exposure of the standing wave would show a pattern

something like the one in Figure 8. This pattern is called

the envelope of the standing wave. Each point of the

string oscillates up and down with its amplitude determined by the envelope. The points of maximum amplitude are called antinodes. The points of zero amplitude

are called nodes.

Antinode

Node

Figure 8 The Envelope of a Standing Wave Pattern

sin (2πx/λ) cos (2πt/λ).

m

Antinode

Node

Node

Antinode

Node

Antinode

Node

Resonance

The analysis above assumes that the standing wave is

formed by the superposition of an original wave and one

reflected wave. In fact, if the string is fixed at both ends,

each wave will be reflected every time it reaches either

end of the string. In general, the multiply reflected waves

will not all be in phase, and the amplitude of the wave

pattern will be small. However, at certain frequencies of

oscillation, all the reflected waves are in phase, resulting

in a very high amplitude standing wave. These frequencies are called resonant frequencies.

In Experiment 1, the relationship between the length of

the string and the frequencies at which resonance occurs

is investigated. It is shown that the conditions for resonance are more easily understood in terms of the wavelength of the wave pattern, rather than in terms of the frequency. In general, resonance occurs when the wavelength (λ) satisfies the condition:

λ = 2L/n; n = 1, 2, 3, 4,…

Another way of stating this same relationship is to say

that the length of the string is equal to an integral number

of half wavelengths. This means that the standing wave is

such that a node of the wave pattern exists naturally at

each fixed end of the string.

Velocity of Wave Propagation

Assuming a perfectly flexible, perfectly elastic string, the

velocity of wave propagation (V) on a stretched string

depends on two variables: the mass per unit length or linear density of the string (m) and the tension of the string

(T). The relationship is given by the equation:

V =

Without going into the derivation of this equation, its basic form can be appreciated. The equation is analogous to

Newton’s Second law, providing a relationship between a

measure of force, a measure of inertia, and a quantity of

motion. With this analogy in mind, it makes sense that the

velocity should depend on the tension and linear density

of the string. That the form of the two equations is not exactly the same is to be expected. The motion of the string is

considerably different than the motion of a simple rigid

body acted on by a single force. (It could be asked whether

velocity, rather than acceleration, is the right measure of

motion to focus on. Since the waves on the string do not

accelerate, this is at least a reasonable assumption.)

T

µ

8

Page 13

012-03489E Sonometer

If the analogy with Newton’s Law is accepted, and it is

assumed that the wave velocity depends only on tension

and linear density, dimensional analysis shows that the

form of the equation must be as it is. There is no other

way to combine tension (with units of MLT -2) with linear

density (ML-1) to get velocity (LT -1).

Of course, the equation must be verified experimentally.

This is done in Experiment 2, in which the linear density

of the string is varied by using different strings. The tension is varied using hanging weights on a lever arm. The

wavelength is then measured by adjusting the frequency

until a resonance pattern develops. The velocity can then

be calculated using the relationship

V = λν, and the effects of tension and linear density on

velocity can be determined.

Experiments

The two experiments are:

• Resonance Modes of a Stretched String

• Velocity of Wave Propagation

Both can be done with a function generator and dual-trace

oscilloscope OR with a computer interface (such as the

CI-6550) and power amplifier.

9

Page 14

Sonometer 012-03489E

Notes:

10

Page 15

012-03489E Sonometer

Experiment 1: Resonance Modes of a Stretched String

EQUIPMENT NEEDED:

– WA-9611 Sonometer – Mass and mass hanger

– WA-9613 Driver/Detector Coils – Dual trace oscilloscope

– Function generator capable of delivering 0.5 amp

Procedure

➀ Set up the Sonometer as shown in Figure 1.1.

Start with the bridges 60 cm apart. Use any of the included strings and hang a mass of approximately 1 kg from the tensioning lever. Adjust the string adjustment knob so that the tensioning

lever is horizontal. Position the driver coil approximately 5 cm from one of the bridges and position the detector near the center of the wire. Record the length, tension (mg), and linear density

of the string in Table 1.1.

String

adjustment

knob

FREQUEN

CY

HE

RTZ

PI-9587B

DIGITAL FUNCTION

GENERATOR AMPLIFIER

Frequency generator

Driver coil

RA

NGE

ADJU

ST

Detector coil

60 cm

KEEP WEIGHTS AS NEAR TO FLOOR

AS POSSIBLE IN THE EVENT THE

SONOMETER WIRE SHOULD BREAK

BK PRECISION

WA-9613

DETECTOR

MODEL

200 Mhz OSCILLISCOPE

2120

Oscilloscope

CAUTION!

1.75 kg MAXIMUM

LOAD ON LEVER

INTENSITY FOCUS

TRACE NOTATI ON

AC

DC

CH 1

MANUAL AUTO

POS POSNORM

CH 1

VOLTZ/DIV

V

∞

400V

PULL XS PULL XS

MAX

COUPLE SOURCE

AC CH1

TRIG LEVEL

T X-

-++Y

T XY

LINE

CH1

NORM

CH1

EXT

CH2

EXT

CH2

VERTICAL MODE

CH 2

VOLTZ/DIV

CAL

mV

VAR VAR

X-POS

SLOPE - Y

CH2

ALT

EXT

TIME/DI

V

VAR SWEEP

AC

CAL

mVV

CAL

DC

∞

CH 2

CAL EXT CH4

200V

400V

MAX

MAX

POWER

Channel 2 (detector coil)

Channel 1 (driver coil)

WA-9613

DRIVER

WA-9611

SONOMETER

OUTP

WAVEFO

UT

RM

TT

L

HI

EXTERN

INPUTG

Ω

ND

AL

G

ND

AMPLITU

DE

LO

Ω

MI

M

N

AX

Figure 1.1 Equipment Setup

➁ Set the signal generator to produce a sine wave and set the gain of the oscilloscope to approxi-

mately 5 mV/cm.

➂ Slowly increase the frequency of the signal to the driver coil, starting at approximately 25 Hz.

Listen for an increase in the volume of the sound from the sonometer and/or an increase in the size

of the detector signal on the oscilloscope screen. Frequencies that result in maximum string vibration are resonant frequencies. Determine the lowest frequency at which resonance occurs. This is

resonance in the first, or fundamental, mode. Measure this frequency and record it in Table 1.1.

Tensioning

lever

1 kg

➃ Start with the detector as close as you can get it to one of the bridges. Watch the oscilloscope as

you slide the detector slowly along the string. Locate and record the locations of each node and

antinode. Record your results in Table 1.1.

➄ Continue increasing the frequency to find successive resonant frequencies (at least five or six).

Record the resonance frequency for each mode, and the locations of nodes and antinodes in

Table 1.1.

11

Page 16

Sonometer 012-03489E

Vibrating

Waveform

Driving

Waveform

Oscilliscope Screen

➤ NOTE: The driving frequency of the signal generator may not be

the frequency at which the wire is vibrating. By using a dual trace

oscilloscope, you can determine if the two frequencies are the same,

or if the vibrating frequency is a multiple of the driving frequency,

as shown in Figure 1.2.

➅ From your results, determine and record the wavelength of each

resonance pattern you discovered. (➤ Note that adjacent nodes are

one half wavelength apart.)

➆ Change the string length by moving one or both of the bridges.

Construct a new data table and repeat your measurements for at least

Figure 1.2 String Vibrations at a

Multiple of the Driving Frequency

three different string lengths.

Analysis

Using your data, determine the shape of the successive resonance waveforms as the frequency is

increased. How do the wave shapes depend on the length of the string? Sketch the resonance

waveforms for an arbitrary string length. What relationship holds between the wavelength of the

wave and the string length when resonance occurs? Can you state this relationship mathematically?

For each string length, inspect the frequencies at which resonance occurred. Determine a mathematical relationship between the lowest resonant frequency (the fundamental frequency) and the

higher frequencies (overtones) at which resonance occurred.

Optional

➀ Change the string tension by hanging the weight from a different notch. Experiment as needed to

answer the following questions. Do the frequencies at which resonance occurs depend on the

tension of the wire? Do the shapes of the resonance patterns (locations of nodes and antinodes)

depend on the tension of the wire?

➁ Change the linear density of the string by changing strings. Do the frequencies at which resonance

occurs depend on the linear density of the wire? Do the shapes of the resonance patterns (locations of nodes and antinodes) depend on the linear density of the wire?

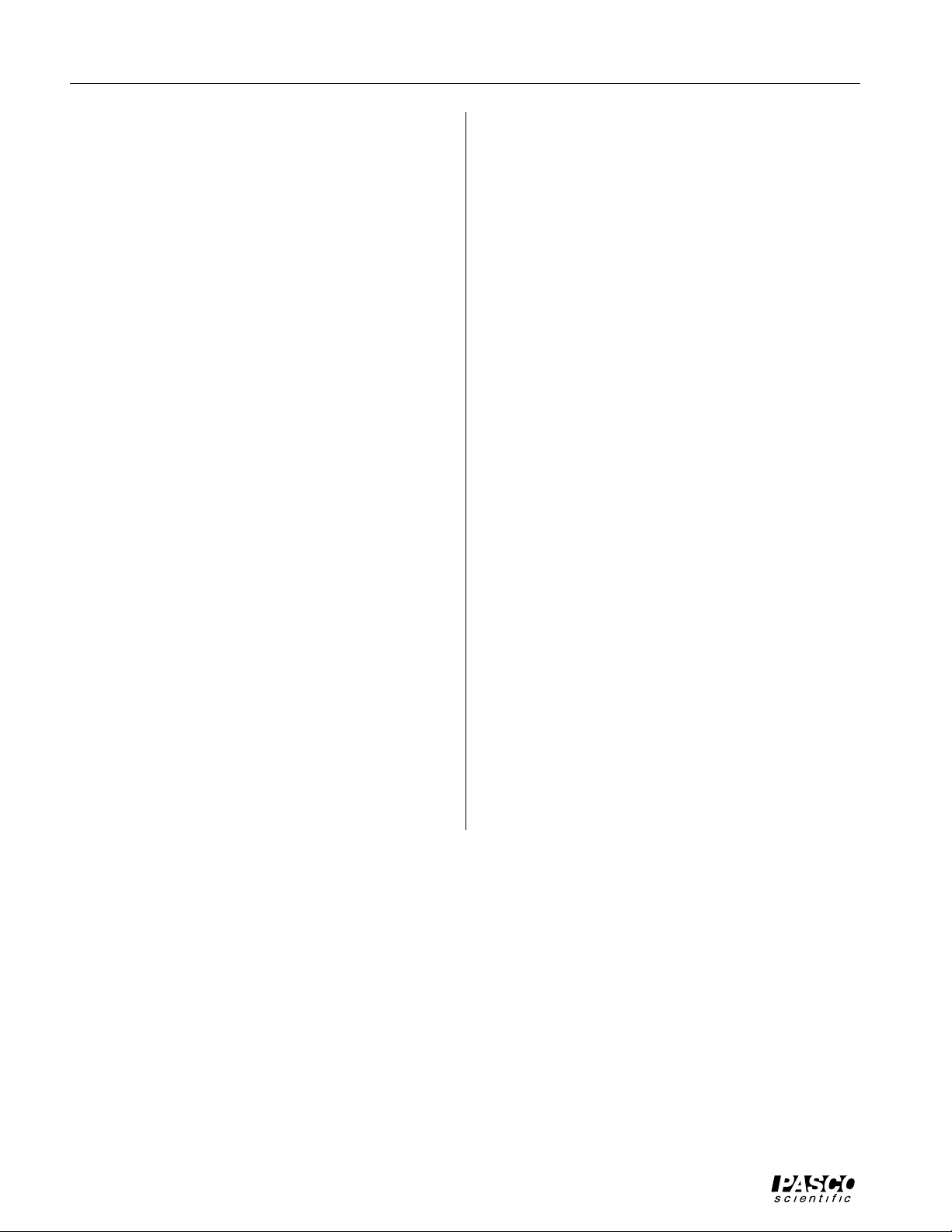

Table 1.1

String length:________________ String tension:_______________ Wire diameter:_______________

Resonant Amplitude Maxima Amplitude Minima

Mode Frequencies (Antinodes) (Nodes)

12

Page 17

012-03489E Sonometer

Experiment 2: Velocity of Wave Propagation

EQUIPMENT NEEDED:

– WA-9611 Sonometer – WA-9613 Driver/Detector Coils

– Function generator capable of delivering 0.5 amp – Dual trace oscilloscope

– Mass and mass hanger

Procedure

➀ Set up the Sonometer as shown in Figure 2.1.

Set the bridges 60 cm apart. Use any of the included strings and hang a mass of approximately 1

kg from the tensioning lever. Adjust the string adjustment knob so that the tensioning lever is

horizontal. Position the driver coil approximately 5 cm from one of the bridges and position the

detector near the center of the wire.

➁ Set the signal generator to produce a sine wave and set the gain of the oscilloscope to approxi-

mately 5 mV/cm.

➂ Slowly increase the frequency of the signal driving the driver coil, starting with a frequency of

around 1 Hz. Determine the lowest frequency at which resonance occurs. Record this value in

Table 2.1.

WA-9613

DETECTOR

KEEP WEIGHTS AS NEAR TO FLOOR

AS POSSIBLE IN THE EVENT THE

SONOMETER WIRE SHOULD BREAK

200 Mhz OSCILLISCOPE

MODEL

2120

CAUTION!

1.75 kg MAXIMUM

LOAD ON LEVER

INTENSITY

AC

DC

CH 1

400V

MAX

FOCUS

TRACE NOTATION

POS

CH 1

VOLTZ/DIV

V

∞

VAR VAR

PULL XS PULL XS

TRIG LEVEL

-

MANUAL AUTO

CH1

EXT

CH2

VERTICAL MODE

CAL

mV

NORM

EXT

+

CH 2

VOLTZ/DIV

COUPLE SOURCE

AC

T XY

T XY

LINE

CH1

CH2

V

CH1

CH2

ALT

EXT

CAL

mV

X-POS

λ - Y

SLOPE

+

-

POSNORM

TIME/DI

V

VAR SWEEP

AC

DC

CAL

CH4

CAL EXT

∞

CH 2

200V

POWER

400V

MAX

MAX

FREQUEN

CY

HE

RTZ

PI-9587B

DIGITAL FUNCTION

GENERATOR AMPLIFIER

WA-9613

DRIVER

WA-9611

SONOMETER

WAVEFO

RA

NGE

ADJU

ST

OUTP

RM

UT

TT

L

EXTERN

AL

HI

Ω

INPUTG

ND

G

AMPLITU

ND

DE

LO

Ω

M

MI

AX

N

BK PRECISION

Figure 2.1 Equipment Setup

➤ NOTE: To be sure you have found the lowest resonant frequency, slide the detector coil the

length of the string. The wave pattern should have just a single antinode located midway between the two bridges.

13

Page 18

Sonometer 012-03489E

➃ In Table 2.1, record the string tension (T) and the linear

density of the string (µ).

The tension is determined as shown in Figure 2.2. Just

multiply the weight of the hanging mass by one, two,

three, four, or five, depending on which notch of the

tensioning lever the mass is hanging from. The linear

density of the strings are given in the front of this

manual (see your teacher, if necessary).

➄ Change the string tension by hanging the mass from a

different notch. Repeat steps 3 and 4 for five different

values of the string tension.

➅ Set the string tension to a midrange value. Then repeat

your measurements of steps 3 and 4 using each of the

five different strings.

Table 2.1 Data and Calculations

Tension Linear Density Fundamental Wave

(T) (µ) Frequency Velocity

String tension

(T)

2Mg

1Mg

15234Slot

5Mg

4Mg

3Mg

(mass = M)

(weight = Mg)

Figure 2.2 Setting the Tension

Hanging

Mass

14

Page 19

012-03489E Sonometer

Analysis

➀ Use your measured string length, the fundamental frequency, and the equation V = λν to determine the velocity

of the wave on the string for each value of tension and linear density that you used.

➁ Determine the functional relationship between the speed of the wave (V) and the wire tension (T). This can be

accomplished using either of the following three methods. If you are not familiar with these procedures, you

might want to try all three.

➤ NOTE: Options A and B are easily performed using a computer with graphical analysis

software.

A. Plot a graph of V versus T, with V on the y-axis. If the graph is not a straight line, try plotting V versus some

2

power of T (such as T

B. Assume that the functional relationship is of the form V = kT

1/2

, T

, etc.), until you get a straight line.

p

. Then ln V = p ln T + ln k, where p and k are

unknown constants. Then, if lnV is plotted against the independent variable lnT, a straight line will be obtained having a slope p, where p is lnV/ lnT and ln k is the y-intercept.

C. Many calculators have the ability to do power regressions or linear regressions on the logarithms of V and T.

This will accomplish essentially what the graph of method B did.

➂ Using one of the methods above, determine the functional relationship of the speed of the wave (V) to the linear

density of the string (µ).

Conclusions

Characterize the resonant modes of a vibrating wire. That is:

➀ Determine a mathematical relationship that describes the wavelengths of the waves that form standing wave

patterns in a wire of length L (see Experiment 1).

➁ Use your answer to question 1, and the expression V = λν, to determine the resonant frequencies of a wire of

length L.

➂ Use your experimental results to write an expression for the resonant frequencies of a vibrating wire in terms of

T, µ, and L.

15

Page 20

Sonometer 012-03489E

Suggested Research T opics

The following are a few suggestions for further experimentation with the Sonometer.

➀ Obtain two wires of the same linear density (mass per unit length), one that is wound and one that

is not wound (a plain wire). Investigate the effects of the winding on the mathematical relationships of wave propagation.

➁ Use a harmonic analyzer to analyze the effects of placing the Driver Coil at different places along

the wire. Also investigate the effects of placing the Detector Coil at different places along the

wire. You can also investigate the effects of plucking, strumming, and bowing the string.

➂ By devising a method to measure string stretch, you can use this apparatus to investigate the

Hooke's Law relationship for a wire placed under tension. Possible investigations include:

a. Strain versus Stress (Stretch versus Applied Load)

b. Strain versus Diameter of Wire (Constant Stress)

c. Strain versus Type of Wire (Constant Diameter)

➃ Obtain wires made of different materials, but with the same linear density. Investigate the speed

of wave propagation in these wires when the same tension is applied to e

ach.

16

Page 21

012-03489E Sonometer

T eacher’s Guide

Experiment 1: Resonance Modes of a Stretched String

Note

To avoid cross-talk between the detector and driver, keep

the detector coil at least 10 cm from the driver coil during

measurements.

Notes on Analysis

Wavelength v. String Length

0.3

f(x) = 4.000000E-1*x + 1.084202E-19

R^2 = 10.000000E-1

0.25

n = 5 (constant)

This verifies that wavelength = 2L/n

0.2

0.15

0.1

Wavelength (m)

0.05

0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

X

X

X

String Length (m)

X

X

X

There is a linear relationship between resonant wavelength and string length.

The overtones are all multiples of the fundamental

frequency.

X

X

X

Optional

➀

Frequency v. Tension

1600

1400

1200

1000

800

600

Frequency (Hz)

400

200

0

0 5 10 15 20 25 30 35 40 45 50

1200

1000

800

600

400

Frequency (Hz)

200

0

0.0002 0.0007 0.0012 0.0017 0.0022 0.0027

X

X

X

f(µ) = 2.163996E+1 * (µ^-5.088207E-1 )

R^2 = 9.991369E-1

This verifies that f ` µ

X

f(T) = 2.105721E+2 * (T^5.045696E-1 )

R^2 = 9.994170E-1

This verifies that f ` T

Tension (N)

Frequency v. Mass/Length

X

µ (kg/m)

X

X

1/2

X

-1/2

X

X

17

Page 22

Sonometer 012-03489E

Note

To avoid cross-talk between the detector and driver, keep

the detector coil at least 10 cm from the driver coil during

measurements.

Analysis

➁

400

350

300

250

200

150

Velocity (m/s)

X

100

50

0

0 5 10 15 20 25 30 35 40 45 50

➂

Velocity v. Tension

X

X

X

f(x) = 5.053730E+1 * (x^5.045696E-1 )

R^2 = 9.994170E-1

µ = 0.00039 kg/m

Theoretical: 50.637

Experimental constant is 0.2% low.

This verifies that V ` T

1/2

Tension (N)

X

Notes on Conclusions

➀ As shown in Experiment 1, l = 2L/n.

➂ From the Analysis section, V = sqrt(T/µ). Since

l = 2L/n, substituting and rearranging gives us

n = (n/2L)*sqrt(T/µ)

The graphs below verify this equation.

Frequency v. n

1400

f(x) = 1.357518E+2*x + -5.901176E+0

R^2 = 9.995529E-1

1200

T = 9.8 N; µ = 0.00039 kg/m; L = 0.60 m

Theoretical slope: 1/2L * sqrt(T/µ) = 132.099

1000

Experimental value 2.8% above theoretical.

X

800

600

Frequency (Hz)

400

200

X

X

X

X

X

X

0

012345678910

n

X

X

X

X

X

X

X

X

300

X

Velocity v. Mass/Length

250

200

150

f(x) = 5.193590E+0 * (x^-5.088207E-1 )

R^2 = 9.991369E-1

Velocity (m/s)

100

T = 29.4 N

Theoretical: 5.4222

50

Experimental constant is 4.2% low.

This verifies that V ` µ

0

X

X

X

X

-1/2

0.0002 0.0007 0.0012 0.0017 0.0022

µ (kg/m)

Frequency v. Tension

1600

1400

1200

1000

X

X

800

600

Frequency (Hz)

400

X

f(T) = 2.105721E+2 * (T^5.045696E-1 )

R^2 = 9.994170E-1

Theoretical: (n/2L)*sqrt(1/µ) = 210.99

200

Experimental constant is 0.2% low.

0

0 5 10 15 20 25 30 35 40 45 50

Tension (N)

X

X

18

Page 23

012-03489E Sonometer

T echnical Support

Feed-Back

If you have any comments about this product or this

manual please let us know. If you have any suggestions on alternate experiments or find a problem in the

manual please tell us. PASCO appreciates any customer feed-back. Your input helps us evaluate and

improve our product.

To Reach PASCO

For Technical Support call us at 1-800-772-8700 (tollfree within the U.S.) or (916) 786-3800.

Internet: techsupp@PASCO.com

Tech Support Fax: (916)786-3292

Contacting Technical Support

Before you call the PASCO Technical Support staff it

would be helpful to prepare the following information:

• If your problem is with the PASCO apparatus, note:

Title and Model number (usually listed on the label).

Approximate age of apparatus.

A detailed description of the problem/sequence of

events. (In case you can't call PASCO right away,

you won't lose valuable data.)

If possible, have the apparatus within reach when

calling. This makes descriptions of individual parts

much easier.

• If your problem relates to the instruction manual,

note:

Part number and Revision (listed by month and year

on the front cover).

Have the manual at hand to discuss your questions.

19

Page 24

Loading...

Loading...