Page 1

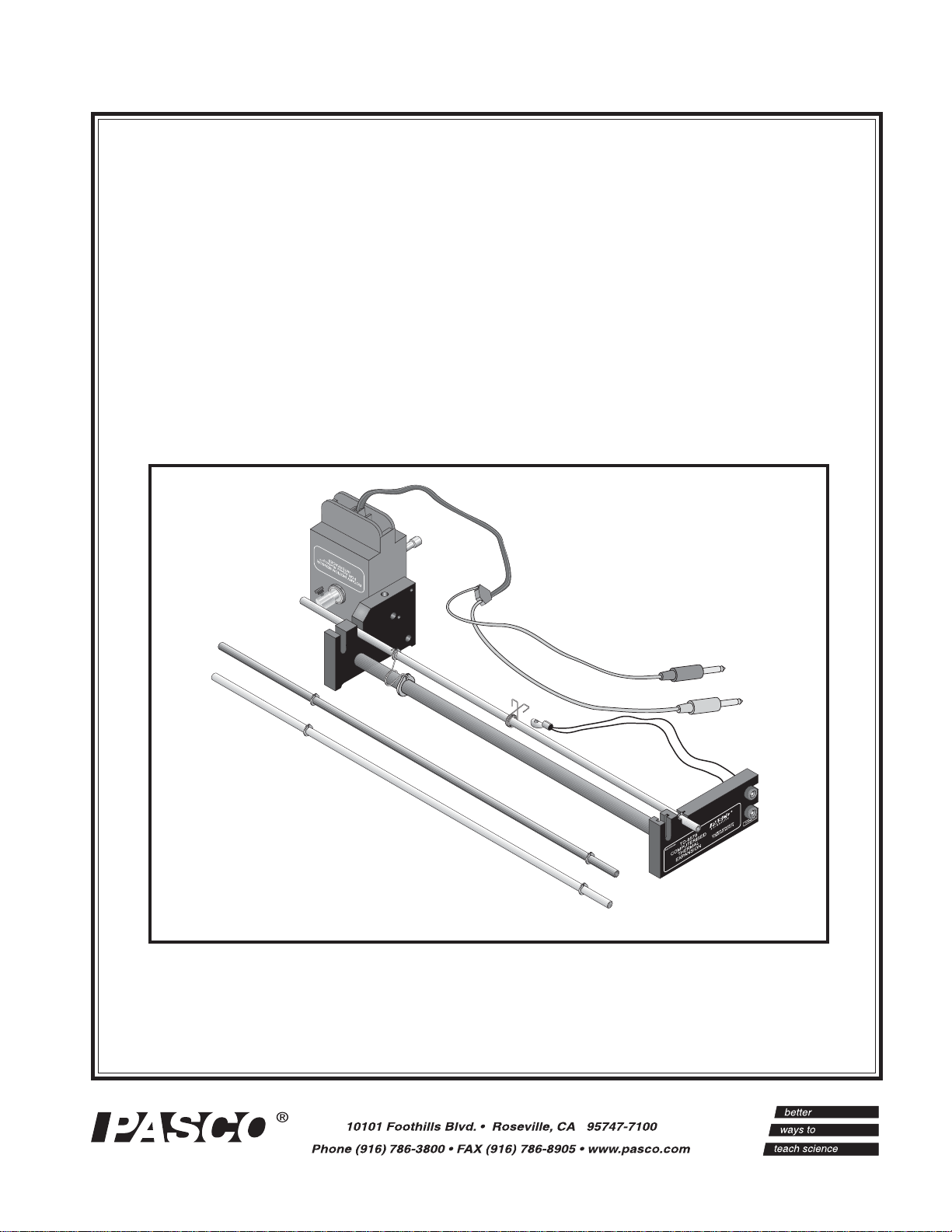

Instruction Manual and

Experiment Guide for the

PASCO scientific

Model TD-8579A

012-07599C

COMPUTER-BASED THERMAL

EXPANSION APPARATUS

© 2000 PASCO scientific

Page 2

012-07599C Computer-based Thermal Expansion Apparatus

Table of Contents

Section Page

Copyright, Warranty and Equipment Return....................................................i i

INTRODUCTION ..........................................................................................1

EQUIPMENT..................................................................................................2

APPARATUS SETUP....................................................................................3

EXPERIMENT SETUP: ................................................................................. 4

Calibration...............................................................................................4

Software Setup........................................................................................4

EXPERIMENT: Measuring the Coefficient of Linear Expansion for Copper,

Brass, and Aluminum:

Introduction ...................................................................................... 5-6

Procedure ......................................................................................... 5-6

Data and Calculations ..........................................................................7

Questions .............................................................................................7

SAMPLE DATA ............................................................................................. 8

TROUBLESHOOTING .................................................................................9

ADDITIONAL OR REPLACEMENT PARTS .......................................... 10

TECHNICAL SUPPORT .............................................................................11

i

Page 3

Computer-based Thermal Expansion Apparatus 012-07599C

Copyright, Warranty and Equipment Return

Please—Feel free to duplicate this manual

subject to the copyright restrictions below.

Copyright Notice

The PASCO scientific 012-07599 Computer-based

Thermal Expansion Apparatus manual is copyrighted and all rights reserved. However, permission is granted to non-profit educational institutions for reproduction of any part of the manual,

providing the reproductions are used only for their

laboratories and are not sold for profit. Reproduction under any other circumstances, without the

written consent of PASCO scientific, is prohibited.

Limited Warranty

PASCO scientific warrants the product to be free

from defects in materials and workmanship for a

period of one year from the date of shipment to the

customer. PASCO will repair or replace at its option

any part of the product which is deemed to be defective in material or workmanship. The warranty does

not cover damage to the product caused by abuse or

improper use. Determination of whether a product

failure is the result of a manufacturing defect or

improper use by the customer shall be made solely by

PASCO scientific. Responsibility for the return of

equipment for warranty repair belongs to the customer. Equipment must be properly packed to prevent

damage and shipped postage or freight prepaid.

(Damage caused by improper packing of the equipment for return shipment will not be covered by the

warranty.) Shipping costs for returning the equipment

after repair will be paid by PASCO scientific.

Equipment Return

Should the product have to be returned to PASCO

scientific for any reason, notify PASCO scientific by

letter, phone, or fax BEFORE returning the product.

Upon notification, the return authorization and

shipping instructions will be promptly issued.

➤ ➤

➤ NOTE: NO EQUIPMENT WILL BE

➤ ➤

ACCEPTED FOR RETURN WITHOUT AN

AUTHORIZATION FROM PASCO.

When returning equipment for repair, the units

must be packed properly. Carriers will not accept

responsibility for damage caused by improper

packing. To be certain the unit will not be damaged

in shipment, observe the following rules:

➀ The packing carton must be strong enough for

the item shipped.

➁ Make certain there are at least two inches of

packing material between any point on the apparatus and the inside walls of the carton.

➂ Make certain that the packing material cannot

shift in the box or become compressed, allowing

the instrument to come in contact with the packing

carton.

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: 1-800-772-8700 (outside the U.S.)

Or

(916) 786-3800

FAX: (916) 786-3292

email: techsupp@pasco.com

web: www.pasco.com

ii

Page 4

012-07599C Computer-based Thermal Expansion Apparatus

Introduction

Introduction

The PASCO Model TD-8579A Computer-based Thermal Expansion Apparatus provides easy and accurate

measurements for the coefficient of linear expansion for brass, copper, and aluminum. The PASCO

Model TD-8579A differs from the previous model TD-8578 in that it uses a Rotary Motion Sensor instead

of a dial gage for measuring length changes in the rod, a Thermistor Sensor instead of an ohmmeter, and

is compatible with a ScienceWorkshop® interface for recording sensor measurements in a computer.

The new PASCO CI-6527A Thermistor Sensor can be connected to the apparatus and a ScienceWorkshop

interface for viewing temperature readings inside DataStudio. With the new thermal expansion model,

students no longer have to convert resistance readings to temperature values using a conversion table.

DataStudio® provides immediate temperature feedback in either absolute temperature (degrees Kelvin),

degrees Celsius (C) or Fahrenheit (F). A setup diskette comes with the apparatus, which includes the predefined variables and equations for measuring temperature in degrees Celsius.

For the length measurement, the brass, copper, or aluminum tube is placed on the expansion base. The

length of the tube is measured at room temperature, then steam is passed through it. The expansion of the

length of the metal rod is measured with 0.006 mm resolution using the Rotary Motion Sensor. Temperatures are measured to within

the expansion of the metals at additional temperatures, hot or cold water can be passed through the metal

tubes.

+0.2 °C using a thermistor attached to the center of the tube. To investigate

Complete step-by-step instructions and a data sheet for results are provided in this manual.

Temperature Measurement with the Thermistor and Thermistor Sensor

A thermistor's resistance varies reliably with temperature. Typically, as the temperature of a metal rod

increases, the resistance decreases proportionally until the temperature equilibrates. Although the relationship between temperature and resistance is not linear, a linear approximation can be accurately used to

interpolate between table data points with an accuracy of approximately +0.2 0C.

The 10 kΩ thermistor used to measure the rod's temperature is embedded in the thermistor lug. Once

thermal equilibrium has been reached, the heat is highly uniform along the length of the rod. The foam

insulator is used to inhibit heat loss through the thermistor lug so the lug temperature closely follows the

rod's temperature. The insulator does not have any appreciable effect on the local temperature of the rod

itself.

Using the PASCO Thermistor Sensor with a ScienceWorkshop interface, the resistance is measured and

directly converted to a temperature measurement, which displays in DataStudio.

®

1

Page 5

Computer-based Thermal Expansion Apparatus 012-07599C

Equipment

Equipment Included:

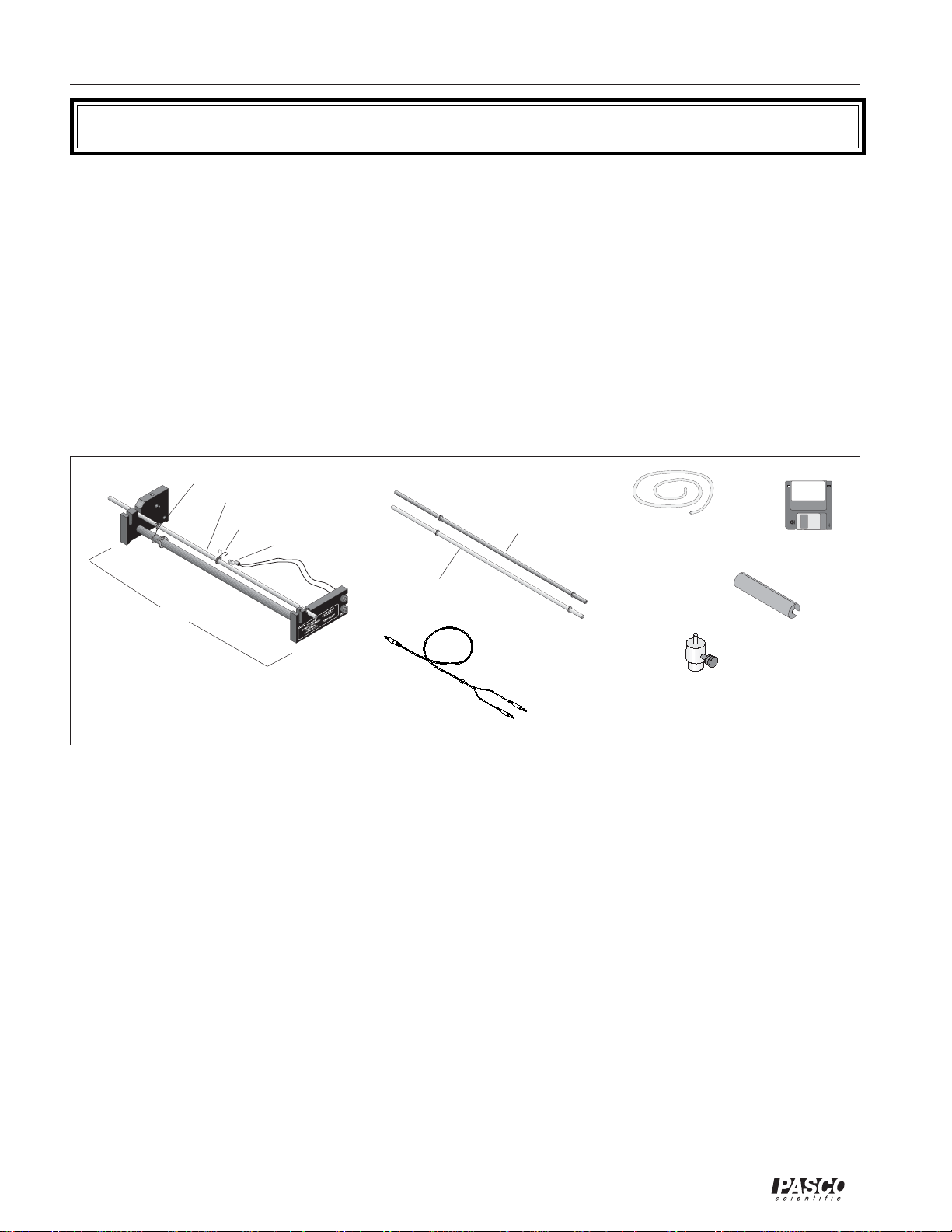

The TD-8579A Computer-based Thermal Expansion Apparatus includes:

• A 40-cm long expansion base with 10 kΩ thermistor

• 3 metal rods — brass, copper (99.5% Cu, 0.5% Te), and aluminum (98.9% Al, 0.7% Mg, 0.4%

Si): 6.4 mm outside diameter

• 1 foam insulator to avoid heat loss at the thermistor connection point

• Thermoplastic elastometer tubing with 6.4mm I.D.

• A 3.5 in. experiment setup diskette

• 1 pinion (6:1 ratio of disk radius to pin radius) for the Rotary Motion Sensor, Model CI-6538

• 1 stereo-to-dual banana plug cable for connecting a Thermistor Sensor (CI-5627A)

spring clip

aluminum rod

spring clamp

thermistor

brass rod

Expansion base

Thermal Expansion Apparatus (TD-8579A)

Stereo-to-dual banana plug cable for

connecting Thermistor Sensor (CI-6527A)

copper rod

copper and

brass rod

plastic tubing

6:1 ratio pinion for

a Rotary Motion

Sensor

Additional Equipment Required

In addition to the TD-8579A Thermal Expansion Apparatus, you need the following

items to perform the experiment, which is described on pages 5-6 of this manual:

• ScienceWorkshop Interface (500, 700 or 750)

• DataStudio®, version 1.5.2 or later

• PASCO Thermistor Sensor, Model No. CI-6527A

SETUP

013-07638

setup

diskette

foam wrap

• PASCO Rotary Motion Sensor, Model No. CI-6538

• A source of steam or hot water, such as the PASCO Model TD-8556A Steam

Generator

• A metric measuring tape or ruler

• A tube clamp to block off one side of the tubing from the Steam Generator

• A container to catch the water as it drains out of the metal rod

• Optional: If additional data points are desired, you will also need a source of

hot or cold water.

2

®

Page 6

012-07599C Computer-based Thermal Expansion Apparatus

Apparatus Setup

1. Attach the Rotary Motion Sensor (RMS) to

the large end block on the apparatus. Use

the black thumb screws to attach the RMS to

the holes in the larger of the black end blocks

(See Figure 1). Place the pinion onto the shaft

of the RMS and rotate clockwise to tighten.

pinion

shaft

end block

Figure 1: Mounting

the Rotary Motion

Sensor to the end block

of the Apparatus

Rotary Motion

Sensor

2. Align and anchor the copper rod in the expan-

sion base (Figure 2). The stainless steel ring on

the rod fits into the groove on the labeled mounting block, and the metal rod lies over and presses

against the pin on the Rotary Motion Sensor.

Hook the spring clip (on the support rod) over the

top metal rod and to the left side of the grip ring.

(Note: This anchors the rod and establishes the

zero position).

rotary motion

sensor pin

retaining ring

lug underneath the capture spring to attach the

thermistor lug beneath the clamp.

thermistor

capture

spring

Figure 3: Placing the Thermistor lug (with thermistor)

on the metal rod.

thermal rod

4. Plug the Sensors into the Interface. Insert the

DIN connector of the Thermistor Sensor into an

analog channel in the ScienceWorkshop interface. Attach the stereo plug of the Thermistor

Sensor cable into the 10 kΩ jack on the Thermistor Sensor. Insert the banana plugs for the

Rotary Motion Sensor into digital channels 1 and

2 (yellow=channel 1, black=channel 2) on the

ScienceWorkshop interface.

interface

cables to the Rotary

Motion Sensor

grip ring

spring clip

Detail A

Figure 2: Aligning and anchoring the metal rod in the

expansion base.

(see Detail A)

3. Attach the Thermistor lug beneath the spring

clamp on the metal rod. With one hand, place

the Thermistor lug over the top of the metal rod,

such that the concave side fits snugly over the

rod (Figure 3). Align the lug with the axis of the

rod, so that there is maximum contact between

the lug and the rod. With your other hand, press

the ends of the spring clamp together. Slide the

®

C

Thermistor

Sensor

Figure 4: Plugging the Thermistor and Rotary Motion

Sensors into the ScienceWorkshop Interface

3.5 Stereo Plug

5. Attach the Rotary Motion Sensor leads to

the apparatus. Insert the red and black

banana plugs into the jacks on the endblock

(the one with the Thermistor label).

Insert the red and

black banana

plugs here.

Figure 5: Attaching the banana plugs from the Thermistor Sensor to the end block of the apparatus

3

Page 7

Computer-based Thermal Expansion Apparatus 012-07599C

Experiment Setup

Calibration

The Thermistor Sensor and Rotary Motion Sensor are both factory-calibrated and do not require additional

calibration. However, if you wish to calibrate the Thermistor Sensor, you may do so. For calibration instruc-

tions, see the DataStudio (version 1.5.2 or later) online help.

Software Setup

Use the provided Thermal Expansion Setup diskette for setting up your experiment in DataStudio (v. 1.5.2 or

later). The Thermal Expansion Setup diskette includes the necessary sensor designation, pre-defined variables,

equations, etc., that you will need to run the experiment with the PASCO Thermal Expansion Apparatus (the

experiment on pages 5 to 6 of this manual).

Note: You must have DataStudio version 1.5.2 or later to run the setup diskette. PASCO provides a setup

diskette for either MacIntosh or Windows operating systems.

1) Insert the Thermal Expansion Setup diskette into your disk drive and open DataStudio. The Experiment

Setup window opens and shows the Rotary Motion Sensor icon and Thermistor Sensor icons. If your sensors

are connected to the thermal apparatus and ScienceWorkshop interface, and you have a heat source running

through the metal rod, you are ready to begin collecting data.

The following paragraphs describe the setup information contained in the setup diskette.

Sample Rate: The default sample rate for both the Rotary Motion and Thermistor Sensors is 5 Hertz

(Hz). If you want to change the sample rate, click on the sensor icon in the Experiment Setup window.

In the Sensor Properties dialog, use the plus and minus buttons to increase or decrease the sample rate.

Measurement units: The setup will give you temperature readings in degrees Celsius. If you also want to

view resistance measurements, go to the Experiment Setup window and doubleclick on the Thermistor

Sensor icon. In the Sensor Properties dialog, click on the Measurement tab and click to place a check in

the Resistance box.

Equation Setup: To view the pre-defined equations for temperature, position, etc., double click on the

appropriate Calculator icon in the Data List. The setup diskette includes the following equations:

Delta T = max(x) - min (x) (deg C), where delta T represents the change in temperature, max (x)

represents the maximum temperature achieved and min(x) represents the temperature at the initial start

time.

Position = x*radius (mm), where position is the linear position of the rod, x is the angular position in

radians, of the Rotary Motion Sensor, and the rotary pin radius is 1.327 mm.

Delta X = max(x) - min(x), where max(x) represents the longest position attained and min(x) represents

the initial position of the rod. The initial position is always zero.

Note: The position is calculated from the rotational change of the Rotary Motion Sensor pin. As the rod

expands, it pushes against the pin and causes the pin to rotate. From the radius of the pin and the amount of

angular rotation relative to the pin's zero position, the Rotary Motion Sensor determines the linear change in

length (L) for the rod.

4

®

Page 8

012-07599C Computer-based Thermal Expansion Apparatus

Experiment: Measuring the Coefficient of Linear

Expansion for Copper, Brass, and Aluminum

Introduction

Most materials expand when heated through a temperature range that does not produce a change in phase. The added heat increases the average amplitude of vibration

of the atoms in the material, which increases the average separation between the

atoms.

Suppose an object of length L undergoes a temperature change of magnitude ∆T. If

∆T is reasonably small, the change in length, ∆L, is generally proportional to L and

∆T. Stated mathematically:

∆L = αL ∆T;

where α is called the coefficient of linear expansion for the material.

Materials that are not isotropic, such as an asymmetric crystal for example, α can have

a different value depending on the axis along which the expansion is measured. The

coefficient (α) can also vary somewhat with temperature. Therefore, the degree of

expansion depends not only on the magnitude of the temperature change, but also on

the absolute temperature.

In this experiment, you will measure α for copper, aluminum, and brass. These

metals are isotropic, so it is necessary to measure α along only one dimension. Also,

within the limits of this experiment, α does not vary with temperature.

Procedure

rotary motion sensor

retaining pin

L = length

Figure 1: Measuring Tube Length

spring clamp

foam

Figure 2: Insulating the rod

1. With a measuring tape or

metric ruler, measure L, the

length of the aluminum rod,

at room temperature. Measure from the center of the

stainless steel ring (in the

groove of the small end

block), to the center of the

rotary pin at the other end

(see Figure 1). Record your

results in Table 1 in the Data

and Calculations section.

2. Insulate the rod and thermistor with

a slitted, tubular foam wrap. Slide

the foam wrap from underneath the

rod until the foam covers the

circumference of the rod. The

spring clamp should jut out from the

top of the foam slit (See Figure 2).

rotary

pin

®

5

Page 9

Computer-based Thermal Expansion Apparatus 012-07599C

Experiment (Continued)

3. Cut and place the plastic tubing over both

ports on top of the lid covering the Steam

Generator (See Figure 3). [Note: Cut the tubing

enough to allow it to reach the rod on the

apparatus, but keep the tubing as short as

possible, to prevent kinks and maximize rapid

heat transfer.] Plug one end off with a plastic

tube clamp. Connect the plastic tubing on the

other port to one end of the metal rod (the

labeled end block, away from the Rotary

Motion Sensor).

tube

clamp

Rotary

Motion

Sensor

STEAM

scientific

GENERATOR

MODEL TD-8556A

5

4

3

2

1

LOW HIGH

CAUTION: DO NOT IMMERSE IN WATER!

LOW WATER

115 VAC 5A

ON

6

220 VAC 2.5A

7

8

117VAC

OFF

4. In DataStudio, load the provided setup

diskette. (For more information on software

setup, see page 4).

5. Fill the Steam Generator half to threequarters full with water. Plug the Steam

Generator into a three-receptacle outlet.

[Do not use another outlet. Please refer to

the Steam Generator instruction sheet (012-

04696) for appropriate safety precautions

and settings.]

6. Turn on the Steam Generator and wait for it

to warm up. When you first hear a gurgle

sound, (but before the steam travels through

the clear tubing), click the START button to

begin recording the temperature. Steam will

begin flowing through the rod shortly

thereafter. As steam begins to flow, watch

the temperature rise in the DataStudio Graph

display as the rod heats.

CAUTION: THE STEAM GENERATOR AND

METAL ROD WILL BE HOT. TO AVOID

BURNS, DO NOT TOUCH!

Figure 3: Connecting the tubing from the Steam

Generator to the Thermal Expansion Apparatus

Figure 4: Experiment Setup

Note: Have a styrofoam cup or other basin available

to capture the steam running off the rod (the end

closest to the Rotary Motion Sensor.

When the temperature reading stabilizes, record the temperature change (∆T) in Table 1. Also record

the expansion of the rod's length (∆L), as indicated by the position displacement (x in mm). [Note: If

you want to increase the precision of your measurements, click on the Calculator button. In the

Calculator dialog, click on Properties. Under Precision, enter the number to indicate the number of

decimal places to display.]

7. In DataStudio, save your activity file for the aluminum rod. Repeat the experiment for the copper and

brass rods.

6

®

Page 10

012-07599C Computer-based Thermal Expansion Apparatus

Data and Calculations

1. In DataStudio, from the Digits display, record the maximum length change (delta ∆L) and the

temperature change (∆T) for each rod. Record your results in Table 1.

2. Using the equation ∆L = αL ∆T, calculate α for copper, brass, and aluminum. Record your results

in Table 2.

TABLE 1: Data and Calculations

TABLE 2: Coefficient of Thermal Expansion

lairetaM

reppoC71

ssarB91

munimulA32

ααααα 01x(tneiciffeoc

lairetaM)mm(L

reppoC

ssarB

munimulA

6-

/∞∞∞∞∞ )C ααααα )latnemirepxe(

∆∆∆∆∆ )mm(L ∆∆∆∆∆ (T)C°

ecnereffidtnecreP

)%(

Questions

1. Look at the accepted values for the linear expansion coefficient for copper, brass, and aluminum

(Table 2). Compare these values with your experimental values. What is the percentage

difference in each case? Is your experimental error consistently high or low?

2. On the basis of your answers in question 1, speculate on the possible sources of error in your

experiment. How might you improve the accuracy of the experiment?

®

7

Page 11

Computer-based Thermal Expansion Apparatus 012-07599C

Sample Data

The following are examples of data obtained using DataStudio™, a ScienceWorkshop® 750

Interface and the TD-8556A Steam Generator. The data will vary according to experimental

conditions, setup modifications, temperature of the heat source, type of experiment, temperature

units (degrees K, F, or C), etc.

Within Datastudio, you can use the cursor to adjust the axes to fit your data inside the

Graph display. Other displays, such as the Digits or Table display, may be simultaneously

or later opened to view actual data values. You can use the Smart Tool to display the

coordinates for the values at room temperature and at the final temperature at equilibrum.

Note: The displays shown are in DataStudio version 1.5.2. DataStudio

displays are subject to future modifications with continuous upgrades.

The displays shown may not appear identical to those of later versions.

maximum

temperature

change

temperature at

equilibrium

maximum

expansion at

boiling point

Figure 7: Data obtained during thermal expansion with

the aluminum tube

Resistance to Temperature Conversion Chart

(10K

16460W 14 °C 12,490W 20 °C 9,574W 26 °C 7,404W 32 °C

W

Thermistor)

maximum

length

change

15710W 15 °C 11,940W 21 °C 9,166W 27 °C 7,098W 33 °C

15000W 16 °C 11,420W 22 °C 8,778W 28 °C 6,808W 34 °C

14320W 17 °C 10,920W 23 °C 8,408W 29 °C 6,532W 35 °C

13680W 18 °C 10,450W 24 °C 8,058W 30 °C 6,268W 36 °C

13070W 19 °C 10,000W 25 °C 7,722W 31 °C 6,016W 37 °C

Table 3: Resistance to Temperature Conversion Chart

(10 kΩ Thermistor)

8

®

Page 12

012-07599C Computer-based Thermal Expansion Apparatus

Troubleshooting

Problem: During the experiment, temperature measurements do not appear in an open DataStudio

display.

Solution(s): a) Ensure that all connections between the Thermistor lug and rod, and Thermistor Sensor

and ScienceWorkshop interface are tight. (See Apparatus Setup on page 3 for instructions).

b) In DataStudio, double click on the Thermistor icon. Click on the Measurement tab.

Verify that there is a check in the box next to the Temperature option. If not, click to place

a check inside this box. Click OK to save the changes.

Problem: The temperature (or resistance if displaying) measurements do not appear accurate.

Solution(s): a) Ensure that all connections between the Thermistor lug and rod, and Thermistor Sensor

and ScienceWorkshop interface are tight. In the setup file the Thermistor Sensor is lugged

into Channel B of the interface. (See Apparatus Setup on page 3 for instructions). b) Make

sure that you have used the appropriate temperature equation for the units desired. The

setup diskette includes the equation for temperature in degrees Celsius (C). To perform

measurements in degrees Kelvin or Fahrenheit, define your own equation using the Calculator in DataStudio. c) If you have a couple of resistors available, you can calibrate and/or

check the resistance measurement accuracy of the Thermistor Sensor using a voltmeter or

multimeter. See the DataStudio online help for calibration instructions. d) If steps a), b),

and c) fail to correct the problem, you may have a faulty Thermistor Sensor. Call PASCO's

Technical Support Department (see page 11 of this manual) to order a replacement sensor.

Only Thermistor Sensor model CI-6527A measures a 10 kΩ thermistor. Model CI-6527

only measures 100 kΩ thermistors.

Problem: I want to view resistance measurements, but they do not appear in the Graph display.

Solution(s): The setup diskette does not include the settings for showing resistance measurements. This is

to help eliminate student confusion about resistance and shift the focus to temperature and

thermal expansion. However, if you want your students to see resistance data during the

experiment, do the following: a) In DataStudio setup window, double click on the Thermistor icon. Click on the Measurement tab. Verify that the box next to the Resistance option

is checked. If not, click to place a check inside this box. Click OK to save your changes.

Then perform another experiment run.

Problem: In DataStudio, position (length) measurements do not display or appear inaccurate.

Solution(s): a) Check to ensure that you have properly inserted the cables for the Rotary Motion Sensor

into the ScienceWorkshop interface. If you have reversed your banana plug connections,

you may observe negative readings. Also check that you have correctly aligned the rod in

the expansion base of the Thermal Expansion Apparatus. (See page 3 for instructions). b)

Check the software settings for the Rotary Motion Sensor in DataStudio. If you did not use

the setup diskette provided for this experiment, go to the Experiment Setup window and

double click on the Rotary Motion Sensor icon. In the General tab, set the sample rate to 5

Hz or try another sample rate. Click on the Measurement tab. Verify that Angular Position

(Rad) is checked. Click on the Rotary Motion Sensor tab. Verify that the divisions per

rotation is 1440. c) If steps a and b fail to yield accurate measurements, you may have a

faulty Rotary Motion Sensor. Call PASCO's Technical Support department (see page 11 of

this manual) for a replacement sensor.

®

9

Page 13

Computer-based Thermal Expansion Apparatus 012-07599C

Additional or Replacement Parts

You can order any of the following parts from PASCO scientific. See the Technical

Support section of this manual (page 11) for telephone and address information.

Description Part No.

Aluminum tube 648-07139

Banana plug connectors 517-010

Brass tube 648-07140

Copper tube 648-07141

Expansion base 003-07600

Experiment setup diskette 013-07599

Foam wrap, 6" length 716-041

Rotary Motion Sensor CI-6538

Spring clamp 632-07090

Steam Generator TD-8556A

Support tube 648-07086

Thermal Expansion Apparatus TD-8579A

Thermistor, 10 kΩ 150-040

Thermistor Sensor CI-6527A

Thermoplastic elastomer tubing with 6.4 I.D. 640-018

10

®

Page 14

012-07599C Computer-based Thermal Expansion Apparatus

Technical Support

Feedback

If you have any comments about the product or

manual, please let us know. If you have any suggestions on alternate experiments or find a problem in the

manual, please tell us. PASCO appreciates any

customer feedback. Your input helps us evaluate

and improve our product.

To Reach PASCO

For technical support, call us at 1-800-772-8700

(toll-free within the U.S.) or (916) 786-3800.

Fax: (916) 786-3292

E-mail: techsupp@pasco.com

Web: www.pasco.com

Contacting Technical Support

Before you call the PASCO Technical Support staff, it

would be helpful to prepare the following information:

➤ If your problem is with the PASCO apparatus, note:

- Title and model number (usually listed on the

label);

- Approximate age of apparatus;

- A detailed description of the problem/sequence of

events (in case you can’t call PASCO right away,

you won’t lose valuable data);

- If possible, have the apparatus within reach when

calling to facilitate description of individual parts.

➤ If your problem relates to the instruction manual,

note:

- Part number and revision (listed by month and

year on the front cover);

- Have the manual at hand to discuss your

questions.

®

11

Loading...

Loading...