Page 1

Instruction Manual

®

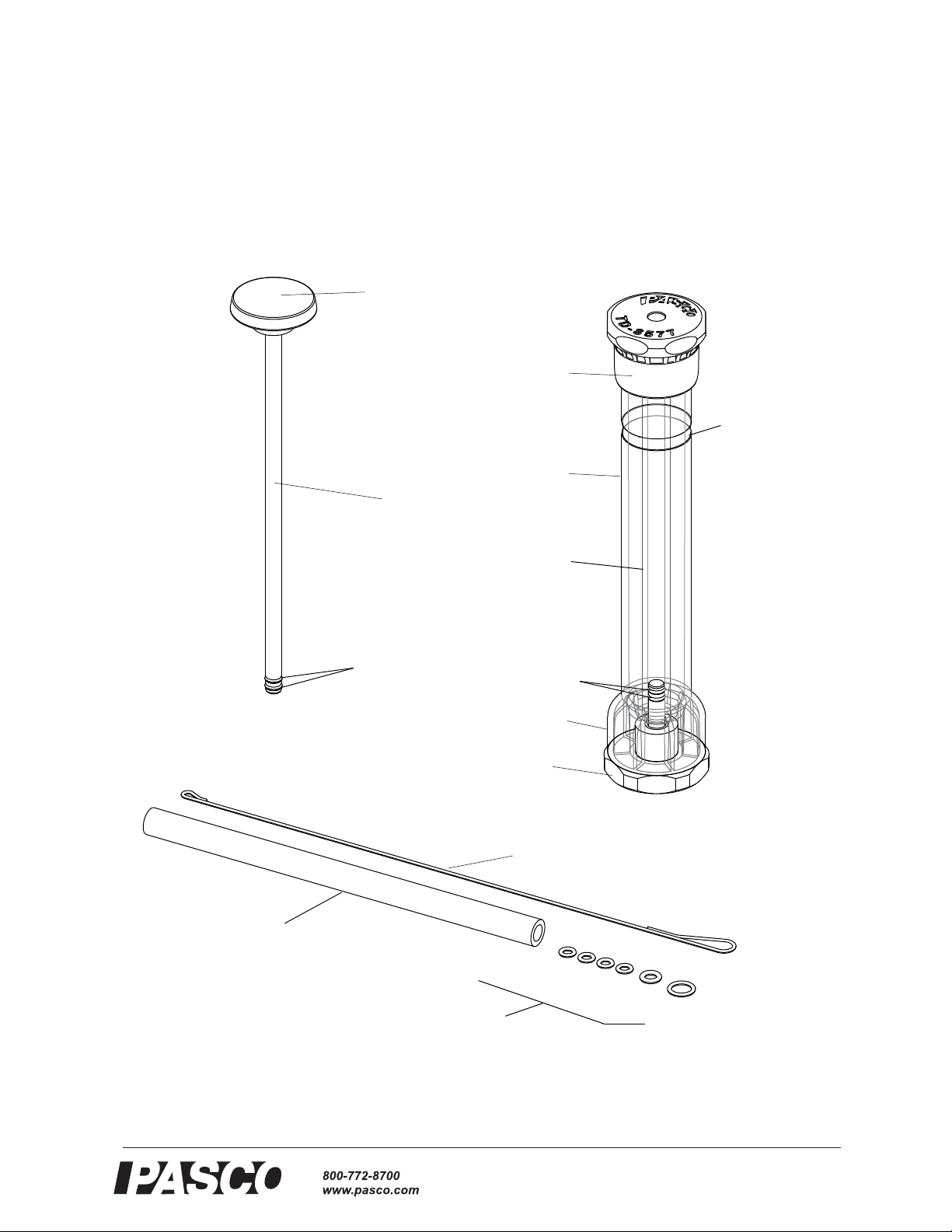

Outer Safety

Tube

(polycarbonate)

Piston

Removable

Base

Bottom

Removable Top

Knob

Loading/Cleaning

Rod

“O” rings

“O” rings

Replacement

Glass Tube

Small O-ring (4)

Inner Glass

Tube

Medium O-ring (1)

IMPORTANT!

Piston Starting

Position label

Large O-ring (1)

Replacement

O-rings (6)

PASCO Compression Igniter

TD-8577

n

o

i

t

i

s

o

P

t

o

g

n

n

i

t

S

r

t

a

P

i

s

012-13028B

Page 2

PASCO Compression Igniter 012-13028B Introduction

®

PVconstant=

PVP0V

0

=

PVP015V

=

P 15

P

0

=

The ignition temperature of

paper is about 451 °F.

See the science fiction

novel Fahrenheit 451

by

Ray Bradbury.

P0V

0

nRT0 and =

PV nRT=

Included Equipment Included Equipment

PASCO Compression Igniter Replacement Glass Tube*

Loading/Cleaning Rod Replacement O-rings* (6)

Lubricant, silicone compound, (2 packets), not shown Material Safety Data Sheet for Lubricant

Additional Item Needed Cotton, tissue paper, “flash paper”

* The TD-8498A Replaceable Glass Tubes includes two replacement tubes and twelve O-rings.

Introduction

The TD-8577 PASCO Compression Igniter (or “fire syringe”) illustrates what happens inside the cylinder of a diesel engine. It demon s trat es the high temperatures produced during adiabatic compression of air by igniting a small amount of cotton, tissue

paper, or magician’s “flash paper” inside a replaceable, thick-wall glass tube. The

glass tube is encased in a polycarbonate safety tube that protects users from injury if

the glass tube breaks. The piston has two rubber “O” rings at its end that provide a

tight seal against the inside of the glass tube. When the piston is rapidly pressed down

into the glass tube, the temperature inside the tube rises quickly.

The Compression Igniter comes with one replacement glass tube and six O-rings. The

large O-ring is a replacement for the ring at the top of the inner glass tube. The

medium O-ring is a replacement for the ring at the top of the piston rod where it joins

the knob. The small O-rings are replacements for the rings on the end of the piston

rod and for the rings on the post that is part of the removable base.

Theory

The compression of air inside a hollow cylinder is an adiabatic process since the

compression is so fast that there is no time for thermal energy to leave or enter the

cylinder.

For an adiabatic compression of gas, , where P is the pressure of the

gas, V is the volume of the gas, and is the ratio of specific heats of the gas (specific

heat at constant pressure divided by specific heat at constant volume)

Therefore, when the gas in the cylinder is at its original volume V

and then is compressed to a small volume V and pressure P,

With the compression igniter, it is possible to compress the gas in the cylinder by a

factor of about 15, so V

= 15V. With this assumption, the final pressure at maximum

0

compression can be calculated in terms of the initial (atmospheric) pressure:

and pressure P0

0

2

The quantity that is of interest is the final temperature: Is it high enough to ignite

paper? To arrive at the temperature, assume that the gas is air and that it is an ideal

gas. For an ideal gas,

Page 3

Model No.TD-8577 012-13028B Operation

®

PV

P

0V0

T

T

0

----------------

=

T

PV

P

0V0

------------

T

0

15P0V

P

0

15V

-------------------- -

T

0

==

P

i

s

t

o

n

S

t

a

r

t

i

n

g

P

o

s

i

t

i

o

n

Combustible

material

Piston

Push knob

down rapidly

Grip

tube

firmly

Watch

here

Piston Starting

Position label

Bottom

Top

Safety Tube

Glass Tube

Insert combustible

material here.

Removable

Base

where n is the number of moles of gas, R is the gas constant, and T is the absolute

(thermodynamic) temperature. Solving the initial equation for nR and substituting the

expression into the final equation gives:

Solving for the final temperature, T, and substituting the final pressure, P, derived

from the adiabatic equation and the final volume, V, which is 1/15 the initial volume

gives:

Simplifying this expression gives T = 15

1.4, so this gives T = 15

(297 K), then T = 15

0.4

T0. Assuming that the initial temperature is about 24 °C

0.4

(297 K) = 877 K. Converting to celsius, T = 604 °C. Since

( - 1)

T0. For air, which is mainly diatomic , =

604 °C = 1120 °F, the temperature is high enough to ignite paper.

Operation

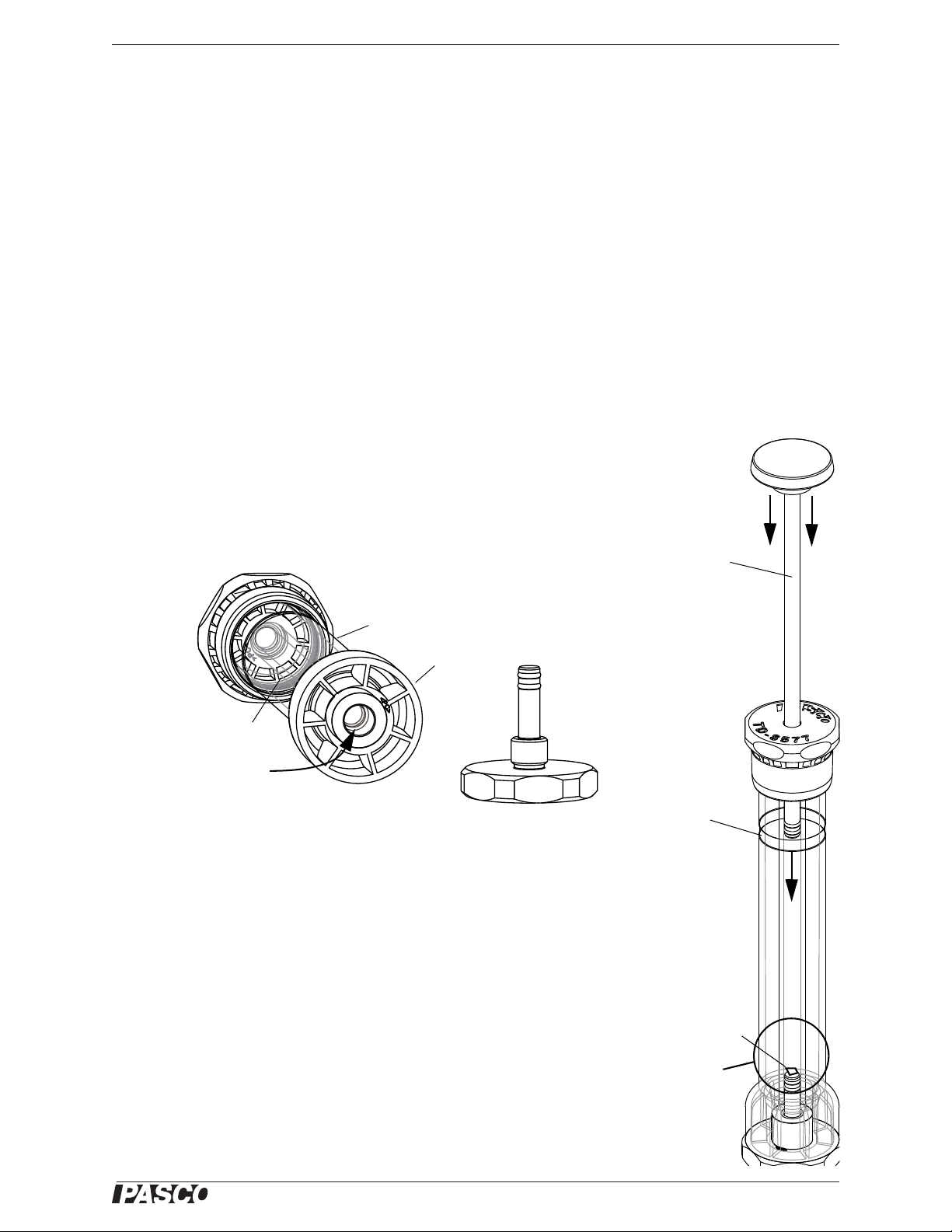

1. Turn the removable base counterclockwise to unscrew it from the bottom of the

igniter. Remove the base and set it aside.

2. Insert a small piece (~ 1 cm

pulled from the end of a cotton swab) into the bottom of the glass tube.

2

) of tissue paper or a few strands of cotton fiber (e.g.,

3. Use the loading/cleaning rod to push the material up into the lower part of the

glass tube. Carefully remove the loading/cleaning rod without pulling the material out of the lower part of the glass tube.

4. IMPORTANT: Insert the piston into the top of the igniter and push it in far

enough that the end of the piston lines up with or is slightly below the

“Piston Starting Position” label on the outer tube 2.5 cm (1 inch) below the top.

5. Replace the removable base by screwing it clockwise into the bottom.

6. Place the base of the igniter on a sturdy horizontal surface and securely hold the

tube with one hand. Make sure that the combustible material in the bottom of the

glass tube is visible.

7. Watch the piece of combustible material at the bottom of the glass cylinder.

8. With the palm of your other hand, quickly slap down on the knob of the piston so

the end of the piston goes down into the cylinder rapidly.

3

Page 4

PASCO Compression Igniter 012-13028B Caution

®

• Do not ‘clump’ or compress the combustible material. Allow it to remain

flat and spread out. The more surface area it has, the better.

• If the material does not ignite, try reducing the amount of material you put

into the glass tube.

• If you are using a piece of tissue paper, remove the paper and tear it in half.

Put one half of the paper back into the glass tube and try again.

• If you are using cotton and it does not ignite, reduce the number of strands

of cotton and try again.

Wad of tissue

paper

Loading/Cleaning

Rod

Glass

Tube

.

Maintenance

Cleaning

To remove fragments of burned material from the igniter, unscrew the removable base from the bottom of the igniter. Use the loading/cleaning rod to scrape

any residue out of the lower part of the glass tube.

To clean the glass tube, remove the piston and the base. Use the loading/cleaning rod to push a small wad of tissue paper through the glass tube.

After cleaning, screw the removable base back into the bottom of the igniter.

Do not use a wrench or other tool to tighten the removable base or the top.

Instead, they should be only as tight as you can make them using your hand.

Lubrication

The “O” rings on the piston and the removable base are lubricated at the factory . If the “O” rings on the piston become dry , tear or cut the tip off the packet

of lubricant. Squeeze a small drop (1 to 2 mm diameter) of lubricant onto an

applicator (such as a toothpick, cotton-tipped swab, etc.), and rub the lubricant

onto the two “O” rings. Store the open packet in a plastic bag or a small jar.

CAUTION: Do not use a different lubricant than the kind provided.

Storage

Store the compression igniter with the piston removed from the inner glass

tube.

Caution

The inner cylinder in the Compression Igniter is thick-wall glass, but it can

break if the Compression Igniter is dropped or if the piston is not far enough

down into the glass tube when the igniter is used. Before using the igniter, be

sure that the bottom of the piston is at least to the “Piston Starting Position”

label.

Be careful when handling the Compression Igniter, and always store the igniter

with the piston removed from the glass tube.

The Compression Igniter is shipped with a replacement inner glass tube packed

separately to minimize the possibility of damage during transit.

4

Page 5

Model No.TD-8577 012-13028B Caution

®

P

i

s

t

o

n

S

t

a

r

t

i

n

g

P

o

s

i

t

i

o

n

Safety Tube

Glass Tube

Post

Base

Insert the glass

tube over the post

and O-rings.

Top

Glass

Tube

1. Remove

the top.

2. Clear the

broken glass.

3. Insert the

replacement

glass tube.

4. Replace

the top.

Replacing a Glass Tube

Top

O-ring

installed

O-ring

Removable

Top

Top View

Side View

(cutaway)

Replacing a Large O-ring into the Top

Replacing the Inner Glass Tube

If the glass tube in the Compression Igniter should break, replace it with the

included replacement glass tube*.

• Hold the igniter over a receptacle to catch any falling glass and remove the

piston.

• Unscrew the removable base from the bottom, and unscrew the top from

the safety tube.

• Carefully remove any broken glass from inside the safety tube and dispose

of the glass properly.

• Check the condition of the O-rings and replace them if necessary. NOTE: If

the O-rings show no abrasion damage, they do not need replacing.

• Screw the removable base into the bottom of the igniter. Leave the top off

the igniter.

• Carefully insert the replacement glass tube into the igniter so that the bottom end of the glass tube fits over the post at the bottom of the igniter.

• Replace the top on the igniter. Be careful to line up the upper end of the

Replacing a Large O-ring

inner glass tube with the hole in the top.

*

The TD-8498A Replaceable Glass Tubes kit includes two more replacement tubes and

twelve O-rings

• To replace the large O-ring in the top of the igniter, unscrew the top from

the safety tube.

• Remove the old O-ring. (You may need to use a small, flat-blade screwdriver to remove the ring.)

• Place the replacement O-ring in the groove at the bottom of the hole. Make

sure that the O-ring is flat against the bottom of the hole..

• Replace the top on the igniter. Line up the top end of the glass tube with the hole

in the top and then turn the top clockwise to screw it onto the igniter.

5

Page 6

PASCO Compression Igniter 012-13028B Technical Support

®

Specifications

Inside diameter of glass

tube = 0.797 cm

Compressible length of glass

tube = 18.308 cm

Compression ratio

(approximate) = 15 to 1

Technical Support

For assistance with any PASCO product, contact PASCO at:

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: +1 916-786-3800 (worldwide)

800-772-8700 (U.S.)

Web: www.pasco.com

Email: support@pasco.com

For more information about the P ASCO Compression Igniter and the latest revision of

this Instruction Manual, visit the PASCO web site at www.pasco.com and enter

TD-8577 in the Search window.

Limited Warranty

For a description of the product warranty, see the PASCO catalog.

Copyright

The PASCO scientific 012-13028B PASCO Compression Igniter Instruction Manual is copyrighted with all rights reserved. Permission

is granted to non-profit educational institutions for reproduction of any part of this manual, providing the reproductions are used only

in their laboratories and classrooms, and are not sold for profit. Reproduction under any other circumstances, without the written consent of PASCO scientific, is prohibited.

Trademarks

PASCO and PASCO scientific are trademarks or registered trademarks of PASCO scientific, in the United S t ates and/or in other countries. For more information visit www.pasco.com/legal.

Material Safety Data Sheet

Please see the next four pages.

6

Page 7

Model No.TD-8577 012-13028B Material Safety Data Sheet

®

DOW CORNING CORPORATION

Material Safety Data Sheet

Page: 1 of 7

Version: 1.5

Revision Date: 2011/01/28

DOW CORNING(R) 111 VALVE LUBRICANT & SEALANT

1. PRODUCT AND COMPANY IDENTIFICATION

Dow Corning Corporation

South Saginaw Road

Midland, Michigan 48686

24 Hour Emergency Telephone:

Customer Service:

Product Disposal Information:

CHEMTREC:

(989) 496-5900

(989) 496-6000

(989) 496-6315

(800) 424-9300

MSDS No.: 01889834 Revision Date: 2011/01/28

Generic Description: Silicone grease.

Physical Form: Grease

Color: Translucent white

Odor: Odorless

NFPA Profile: Health 0 Flammability 1 Instability/Reactivity 0

Note: NFPA = National Fire Protection Association

2. HAZARDS IDENTIFICATION

POTENTIAL HEALTH EFFECTS

Acute Effects

Eye: Direct contact may cause tempor ary redness and discomfort.

Skin: No significant irritation expected f rom a single short-term exposure.

Inhalation: No significant effects expected fr om a single short-term exposure.

Oral: Low ingestion hazar d in normal use.

Prolonged/Repeated Exposure Effects

Skin: No known applicable inform ation.

Inhalation:

No known applicable information.

Oral: No known applicable information.

Signs and Symptoms of Overexposure

No known applicable information.

Medical Conditions Aggravated by Exposure

No known applicable information.

DOW CORNING CORPORATION

Material Safety Data Sheet

Page: 2 of 7

Version: 1.5

Revision Date: 2011/01/28

DOW CORNING(R) 111 VALVE LUBRICANT & SEALANT

The above listed potential effects of overexposure are based on actual data, results of studies performed upon similar compositions,

component data and/or expert review of the product. Please refer to Section 11 for the detailed toxicology information.

3. COMPOSITION/INFORMATION ON INGREDIENTS

None present. This is not a hazardo us material as defined in the OSHA Hazard Communication S tandard.

4. FIR ST AID ME ASURES

Eye: If irritation occurs, flush eye(s) with lukewarm gently flowing water for 5 minutes. Obtain

medical attention.

Skin: No health effects expected. If irr itation does occur flush with lukewarm, gently flowing wat er

for 5 minutes. If irritation pers ists, obtain medical advice.

Inhalation: If symptoms are experienced rem ove source of contamination or move victim to fresh air . If

irritation persists, obtain medic al advice.

Oral: If irritation or disc omfort occur, obtain medical advice.

Notes to Physician: Treat accor ding to person's condition and specifics of exposure.

5. FIRE FIGHTING MEASURES

Flash Point: > 214 °F / > 101.1 °C (Closed Cup)

Autoignition Temperature: Not determined.

Flammability Limits in Air: Not determ ined.

Extinguishing Media: On large fires use dry chemic al, foam or water spray. On small fires use carbon dioxide

(CO2), dry chemical or water spra y. Water can be used to cool fire exposed containers.

Fire Fighting Measures: Self-contained breathing apparatus and protect ive clothing should be worn in fighting large

fires involving chemicals. Deter mine the need to evacuate or isolate the area accord ing to

your local emergency plan. Use water spray to keep fire exposed containers cool.

Unusual Fire Hazards: None.

6. ACCIDENTAL RELEASE MEASURES

7

Page 8

PASCO Compression Igniter 012-13028B Material Safety Data Sheet

®

Suitable Respirator: None should be needed.

Personal Protective Equipment for Spills

Personal Protective Equipment for Routine Handling

Engineering Controls

8. EXPOSURE CONTROLS / PERSON AL PROTECTION

Component Exposure Limits

There are no components with work place exposure limits.

Use with adequate ventilation. Av oid eye contact.

Use reasonable care and store awa y from oxidizing materials. This material in its finel y divided form presents an

explosion hazard. Follow NFPA 654 (for chemical dusts) or 484 (for metal dusts) as appropria te for managing dust

hazards to minimize secondary explos ion potential.

Note: See Section 8 for Personal Protective Equipment for Spills. Call (989) 496-5900 , if additional information is

required.

7. HANDLING AND STORAGE

Local Ventilation: None should be needed.

General Ventilation: Recommended.

Eyes: Use proper protection - safety glass es as a minimum.

Skin: Washing at mealtime and end of shift is adequate.

Suitable Gloves: Handle in accordance with good indus trial hygiene and safety practices.

Inhalation: No respiratory protection should be needed.

Containment/Clean up: Observe all personal protection eq uipment recommendations described in Sections 5 and 8.

DOW CORNING(R) 111 VALVE LUBRICANT & SEALANT

Wipe up or scrape up and contain for salvage or disposal. Clean area as appropriate since

spilled materials, even in sm all quantities, may present a slip hazard. Final clean ing may

require use of steam, solvents or det ergents. Dispose of saturated absorbant or cleaning

materials appropriately, since spontan eous heating may occur. Local, state and federal laws

and regulations may apply to rele ases and disposal of this material, as well as those materials

and items employed in the cleanup of releases. You will need to determine which federal,

state and local laws and regulatio ns are applicable. Sections 13 and 15 of this MSDS provide

information regarding certain feder al and state requirements.

DOW CORNING CORPORATION

Material Safety Data Sheet

Page: 3 of 7

Revision Date: 2011/01/28

Version: 1.5

Materials to Avoid: Oxidizing material can cause a reac tion.

Hazardous Decomposition Products

Thermal breakdown of this product d uring fire or very high heat conditions may evolve t he following decomposition

products: Carbon oxides and traces of incompletely burned carbon compounds. Silicon dioxid e. Formaldehyde.

Hazardous polymerization will not oc cur.

Note: The above information is not intended for use in preparing product specifications. Contact Dow Corning before writing

specifications.

10. STABILITY AND REACTIVITY

Flammability Limits in Air: Not determined.

Autoignition Temperature: Not determined.

Flash Point: > 214 °F / > 101.1 °C (Closed Cup)

Volatile Content: Not determined.

pH: Not determined.

Solubility in Water: Not determined.

Vapor Density: Not determined.

Vapor Pressure @ 25°C: Not determined.

Boiling Point: Not determined.

Freezing/Melting Point: Not determined.

Viscosity: Not determined.

Specific Gravity @ 25°C: 1.1

9. PHYSICAL AND CHEMICAL PROPERT IES

Physical Form: Grease

Color: Translucent white

Odor: Odorless

Chemical Stability: Stable.

Hazardous

Polymerization:

Conditions to Avoid: None.

Precautionary Measures: Avoid eye contac t. Use reasonable care.

Note: These precautions are for room temperature handling. Use at elevated temperature or aerosol/spray applications may require

added precautions.

DOW CORNING(R) 111 VALVE LUBRICANT & SEALANT

No respiratory protection should be n eeded.

Eyes: Use proper protection - safety glass es as a minimum.

Skin: Washing at mealtime and end of shift is adequate.

Inhalation/Suitable

Respirator:

DOW CORNING CORPORATION

Material Safety Data Sheet

Page: 4 of 7

Revision Date: 2011/01/28

Version: 1.5

8

Page 9

Model No.TD-8577 012-13028B Material Safety Data Sheet

®

Hazard Parameters (LC50 or EC50) High Medium Low

Acute Aquatic Toxicity (mg/L) <=1 >1 and <=100 >100

Not subject to DOT.

DOT Road Shipment Information (49 CFR 172.101)

Ocean Shipment (IMDG)

14. TRANSPORT INFORMATION

State or local laws may impose ad ditional regulatory requirements regarding dispo sal. Call (989) 496-6315, if additional

information is required.

When a decision is made to discard t his material, as received, is it classified as a hazardo us waste? No

RCRA Hazard Class (40 CFR 261)

13. DISPOSAL CONSIDERATIONS

Acute Terrestrial Toxicity <=100 >100 and <= 2000 >2000

This table is adapted from "Environmental Toxicology and Risk Assessment", ASTM STP 1179, p.34, 1993.

This table can be used to classify the ecotoxicity of this product when ecotoxicity data is listed above. Please read the other information presented in the

section concerning the overall ecological safety of this material.

Complete information is not yet a vailable.

Environmental Effects

Fate and Effects in Waste Water T reatment Plants

Complete information is not yet a vailable.

12. ECOLOGICAL INFORMATION

Environmental Fate and Distribution

Complete information is not yet a vailable.

11. TOXICOLOGICAL INFORMATION

Special Hazard Information on Components

No known applicable inform ation.

DOW CORNING(R) 111 VALVE LUBRICANT & SEALANT

DOW CORNING CORPORATION

Material Safety Data Sheet

Ecotoxicity Classification Criteria

Page: 5 of 7

Revision Date: 2011/01/28

Version: 1.5

Not subject to IMDG code.

Not subject to IATA regulations.

15. REGULATORY INFORMATION

Call Dow Corning Transportation, (989) 496-8577, if additional information is required.

Air Shi pment (I ATA)

DOW CORNING(R) 111 VALVE LUBRICANT & SEALANT

TSCA Status: All chemical substances in this m aterial are included on or exempted from listing on th e TSCA

Massachusetts

and Toxic Enforcement Act of 1986 (Pr oposition 65) as being known to cause cancer, birth defects or other

reproductive harm.

None known.

Warning: This product contains the f ollowing chemical(s) listed by the State of California under the Saf e Drinking Water

Supplemental State Compliance Information

California

None present or none present in regulated quantities.

Reactive: No

Section 313 Toxic Chemicals (40 CFR 372):

Note: Chemicals are listed under the 313 Toxic Chemicals section only if they meet or exceed a reporting threshold.

Section 311/312 Hazard Class (40 CFR 370):

None.

Pressure: No

Chronic: No

Acute: No

Fire: No

EPA SARA Title III Chemical Listings

Section 302 Extremely Hazardous Substances (40 CFR 355):

None.

Section 304 CERCLA Hazardous Substances (40 CFR 302):

Contents of this MSDS compl y with the OSHA Hazard Communication Standard 29 CFR 1910.1200.

Inventory of Chemical Substances.

DOW CORNING CORPORATION

Material Safety Data Sheet

Page: 6 of 7

Revision Date: 2011/01/28

Version: 1.5

9

Page 10

Model No.TD-8577 012-13028B Material Safety Data Sheet

®

DOW CORNING CORPORATION

Material Safety Data Sheet

Page: 7 of 7

Version: 1.5

Revision Date: 2011/01/28

DOW CORNING(R) 111 VALVE LUBRICANT & SEALANT

CAS Number Wt % Component Name

7631-86-9 7.0 - 13.0 Silica, amorphous

New Jersey

CAS Number Wt % Component Name

63148-62-9 70.0 - 90.0 Polydim ethylsiloxane

7631-86-9 7.0 - 13.0 Silica, amorphous

70131-67-8 5.0 - 10.0 Dimethyl siloxane, hydroxy-terminated

Pennsylvania

CAS Number Wt % Component Name

63148-62-9 70.0 - 90.0 Polydim ethylsiloxane

7631-86-9 7.0 - 13.0 Silica, amorphous

70131-67-8 5.0 - 10.0 Dimethyl siloxane, hydroxy-terminated

16. OTHER INFORMATION

Prepared by: Dow Corning Corporatio n

These data are offered in good fait h as typical values and not as product specifications. No warranty, either expressed or

implied, is hereby made. The recommended in dustrial hygiene and safe handling procedures are believed to be generall y

applicable. However, each user shou ld review these recommendations in the specific c ontext of the intended use and

determine whether they are appropriate.

(R) indicates Registered Tradem ark

10

Loading...

Loading...