Page 1

Instruction Manual and

Experiment Guide for the

PASCO scientific

Model TD-8572

HEAT ENGINE/ GAS LAW

APPARATUS

10101 Foothills Blvd. Roseville, CA 95678-9011 USA

®

Phone (916) 786-3800 FAX (916) 786-8905 web: www.pasco.com

better

ways to

teach science

Page 2

The exclamation point within an equilateral

triangle is intended to alert the user of the

presence of important operating and maintenance (servicing) instructions in the literature

accompanying the appliance.

Page 3

012-06014C Heat Engine/Gas Laws Apparatus

Table of Contents

Section Page

Copyright, Warranty, and Equipment Return ....................................................ii

Introduction......................................................................................................1

Equipment ........................................................................................................1

Experiments

1) Operation of a Heat Engine........................................................................3

2) Charles’ Law .............................................................................................5

3) Boyle’s Law ..............................................................................................7

4) Combined Gas Law (Gay-Lussac’s) ..........................................................9

5) The Mass Lifter Heat Engine................................................................. 11–18

Technical Support ................................................................................... Back Cover

®

i

Page 4

Heat Engine/Gas Laws Apparatus 012-06014C

®

Copyright, Warranty, and Equipment Return

Please—Feel free to duplicate this manual

subject to the copyright restrictions below.

Copyright Notice

The PASCO scientific 012-06014B Heat Engine/Gas Law

Apparatus manual is copyrighted and all rights reserved.

However, permission is granted to non-profit educational

institutions for reproduction of any part of the manual

providing the reproductions are used only for their

laboratories and are not sold for profit. Reproduction

under any other circumstances, without the written

consent of PASCO scientific, is prohibited.

Limited Warranty

PASCO scientific warrants the product to be free from

defects in materials and workmanship for a period of one

year from the date of shipment to the customer. PASCO

will repair or replace at its option any part of the product

which is deemed to be defective in material or workmanship. The warranty does not cover damage to the product

caused by abuse or improper use. Determination of

whether a product failure is the result of a manufacturing

defect or improper use by the customer shall be made

solely by PASCO scientific. Responsibility for the return

of equipment for warranty repair belongs to the customer.

Equipment must be properly packed to prevent damage

and shipped postage or freight prepaid. (Damage caused

by improper packing of the equipment for return shipment

will not be covered by the warranty.) Shipping costs for

returning the equipment after repair will be paid by

PASCO scientific.

Equipment Return

Should the product have to be returned to PASCO

scientific for any reason, notify PASCO scientific by

letter, phone, or fax BEFORE returning the product. Upon

notification, the return authorization and shipping instructions will be promptly issued.

➤➤

➤

NOTE: NO EQUIPMENT WILL BE

➤➤

ACCEPTED FOR RETURN WITHOUT AN

AUTHORIZATION FROM PASCO.

When returning equipment for repair, the units must

be packed properly. Carriers will not accept responsibility for damage caused by improper packing. To

be certain the unit will not be damaged in shipment,

observe the following rules:

➀ The packing carton must be strong enough for the item

shipped.

➁ Make certain there are at least two inches of packing

material between any point on the apparatus and the

inside walls of the carton.

➂ Make certain that the packing material cannot shift in

the box or become compressed, allowing the

instrument come in contact with the packing carton.

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Credits

Editor: Sunny Bishop

Phone: (916) 786-3800

FAX: (916) 786-3292

email: techsupp@pasco.com

web: www.pasco.com

ii

Page 5

012-06014C Heat Engine/Gas Law Apparatus

Introduction

The PASCO TD-8572 Heat Engine/Gas Law Apparatus is

used for quantitative experiments involving the Ideal Gas

Law (as described below) and for investigations of a

working heat engine. The equipment allows the amount

of work done by thermal energy to be measured.

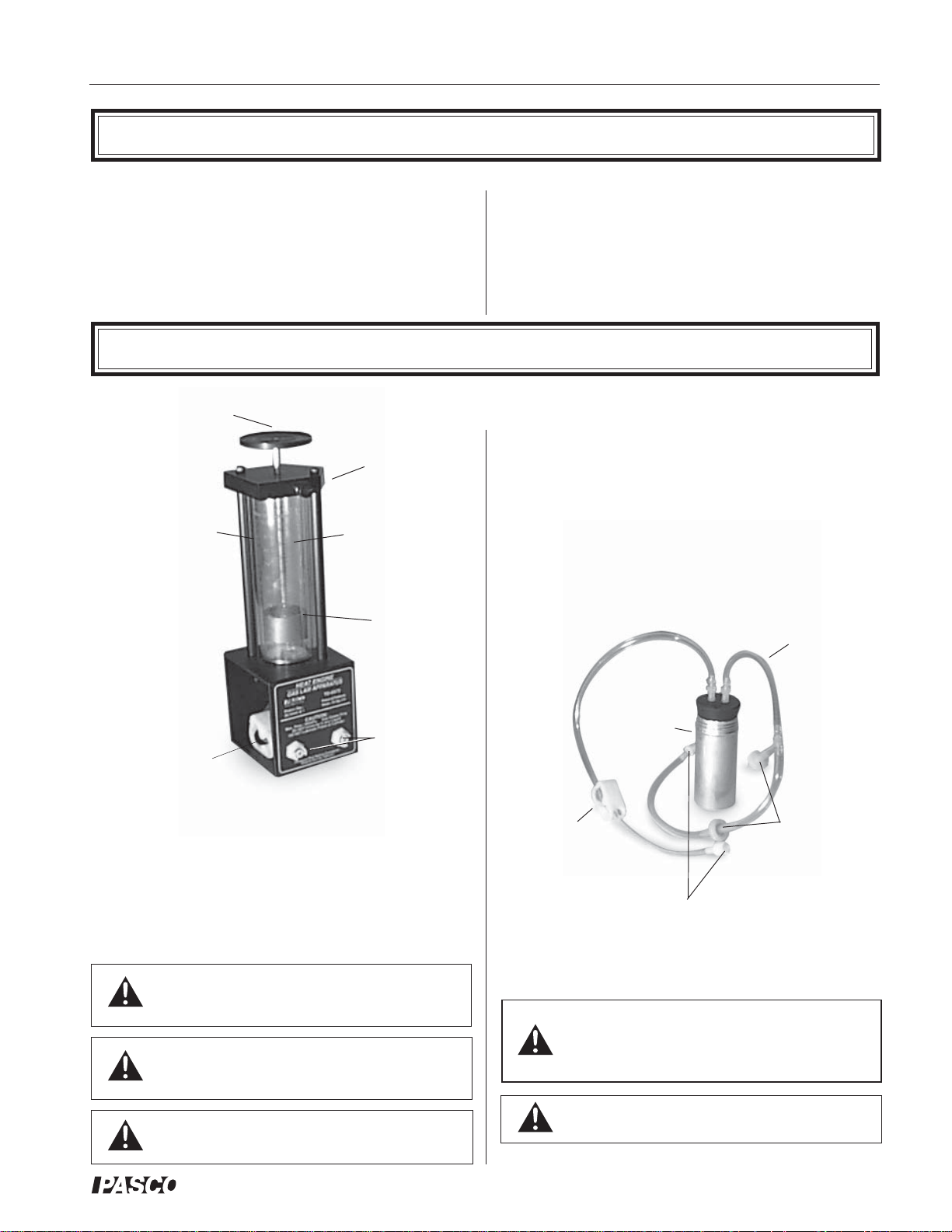

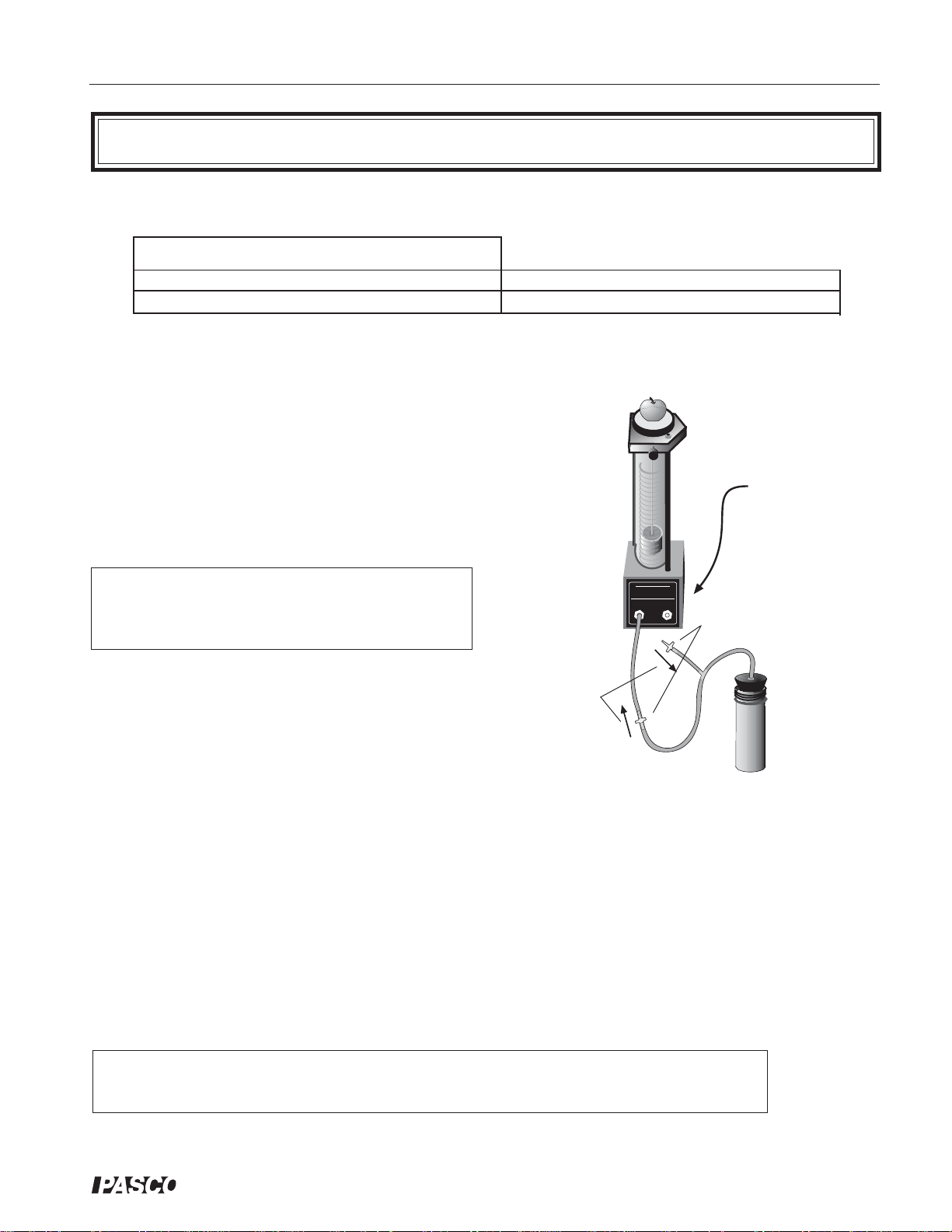

Equipment

mass platform for adding

a load to do work

experiments

piston-holding

thumbscrew

precision-bore pyrex

cylinder inside a

protective plastic shield

two port shut-off

valves

millimeter scale for

measuring piston

displacement

graphite piston

pressure port

mating

connectors

The heart of this apparatus is a nearly friction-free piston/

cylinder system. The graphite piston fits snugly into a

precision-ground Pyrex cylinder so that the system

produces almost friction-free motion and negligible

leakage.

The apparatus includes the following equipment

• base apparatus (Figure 1)

- piston diameter: 32.5 mm ± 0.1

- mass of piston and platform: 35.0 g ± .06

• air chamber (Figure 2)

• 3 hose configurations: one with one-way check

valves and one with a clamp (Figure 2), and one

plain piece of tubing (not shown)

• 1 each, one-holed and two-holed rubber stopper

tubing for

connecting

chamber to

cylinder

air chamber for

immersing in hot

or cold water

Figure 1. Base apparatus

The Heat Engine/Gas Law Apparatus is designed with

two pressure ports with quick-connect fittings for connecting to the air chamber tubing.

The apparatus can be connected to a Low Pressure Sensor

for use with PASCO computer interfaces.

Do not apply lubricant to the piston or

cylinder.

Do not immerse the base apparatus in

liquid.

Note: Use only non-caustic/non-toxic gases

such as air or helium.

®

clamp

pressure port mating connectors

one-way

check valves

Figure 2. Air chamber and tubing

Always release the tubing clamps prior to

storage to avoid permanently deforming the

tubing.

Maximum Pressure: 345 kPa.

1

Page 6

Heat Engine/Gas Law Apparatus 012-06014C

Notes:

2

®

Page 7

012-06014C Heat Engine/Gas Law Apparatus

HEAT ENGINE

GAS LAW APPARATUS

Piston Dia.:

32.5mm±0.1

TD-8572

CAUTION:

Max. Pres.: 345kPa. Use Gases Only

DO NOT

Immerse in any Liquid

DO NOT Lubricate Piston or Cylinder

Pressure Port Mating Connector:

PASCO Part No. 640-021

Piston&Platform

Mass:

35.0g±0.6

m

Experiment 1: Operation of a Heat Engine

Equipment Required:

• Heat Engine/Gas Law Apparatus

• 100 – 200 g mass

Equipment Setup

➀ Using the one-holed stopper, connect the tubing

with the one-way valves to the air chamber and

to a connecting port on the base assembly.

• container of hot water

• container of ice water

Procedure

➁ Close the shut-off valve on the tubing from the

unused port.

➂ Set a mass of 100 to 200 g on the mass platform.

➤ Note: Use a maximum mass of 200 grams in

the experiment. A larger mass will cause the

valve seals to leak.

➀ Move the air chamber from an ice water bath to a

direction of

air flow

one-way check

hot water bath. You will note that the air in the

chamber quickly expands through the tubing and

moves the piston up. Note also that the one-way

check valve in the tubing connecting the base

apparatus and the air chamber permits air to enter

Figure 1.1. Setup for the Heat Engine

the cylinder, while the other one-way check valve

prevents air from leaving through the branched

tube.

➁ Move the air chamber back to the cold bath and note that external air is sucked into the air

chamber through the one-way valve located at the end of the branched tube. Note also that the

one-way valve in the connecting tube prevents the air from escaping from the piston, so the

height of the piston remains the same.

Close the shut-off

valve on the

tubing from the

unused port.

valves

➂ Repeat steps 3 and 4 until the mass has been completely lifted.

➤ Note: The greater the temperature differential between the hot and cold water baths, the

greater the lift achieved through each cycle through them.

®

3

Page 8

Heat Engine/Gas Law Apparatus 012-06014C

➤ Note: For a more detailed, quantitative investigation of the operation of a heat engine, see

Experiment 5 (page 11).

4

®

Page 9

012-06014C Heat Engine/Gas Law Apparatus

Experiment 2: Charles’ Law

Equipment Required:

• Heat Engine/Gas Law Apparatus

• thermometer

Theory

Charles’ law states that at a constant pressure, the volume of a fixed mass or quantity of gas varies

directly with the absolute temperature:

V = cT (at constant P and where T is expressed in degrees Kelvin)

Setup

• container of hot water

• ice

➀ Using the one-holed stopper and plain tubing, connect the base apparatus and the air chamber.

➁ Close the shut-off valve on the tubing from the unused port.

➂ Turn the base apparatus on its side. (In this position, the force acting on the apparatus is the

atmospheric pressure and is equal throughout the range of operation of the piston.)

Close the shut-off valve on

the tubing from the unused

port.

y

l

.6

rm

n

0

r

S

±

e

O

2

tfo

g

d

d

i

s

U

:

7

n

la

r

i

.0

u

e

l

5

P

o

T

5

s

t

y

q

i

8

3

c

&

a

E

1

C

-

L

A

e

:

n

2

r

G

n

s

y

0

D

N

o

to

n

-

R

s

:

n

e

I

o

0

a

T

n

is

s

a

4

A

C

N

o

P

M

t

6

U

G

n

g

i

s

.

P

i

O

n

o

i

I

e

N

P

t

P

N

.

s

a

T

r

e

t

a

t

E

r

M

e

a

a

P

A

U

t

r

c

k

m

P

i

o

T

r

A

5

m

W

P

b

O

I

4

C

u

A

C

e

3

A

T

r

L

S

:

1

u

:

.

.

E

O

.

T

s

s

0

L

PA

a

s

N

i

O

e

±

H

e

r

r

S

N

D

O

m

P

P

D

n

.

A

O

m

o

x

D

5

t

.

a

G

s

i

2

M

3

P

Add ice.

Do not allow the tip of the

thermometer to touch the

bottom of the container.

Hot

Procedure

➀

Place the air chamber in a container of hot water. After the chamber equilibrates to the

temperature, record the temperature and the height of the piston.

➁ Add ice to the container and record the temperature and pressure at regular time intervals.

➂ Calculate the gas volumes at the various piston positions you measured and make a graph of plots

of temperature versus volume. (Hint: The diameter of the piston is 32.5 mm.)

®

5

Page 10

Heat Engine/Gas Law Apparatus 012-06014C

Notes:

6

®

Page 11

012-06014C Heat Engine/Gas Law Apparatus

P

P

A

S

C

O

Experiment 3: Boyle’ s Law

Equipment Required:

• Heat Engine/Gas Law Apparatus

• Pressure Sensor (CI-6532)

*For details on setting up and operating the Pressure Sensor with Science Workshop, please

consult the instruction sheet for the Pressure Sensor and the User’s Guide for Science Workshop.

Theory

Boyle’s law states that the product of the volume of a gas times its pressure is a constant at a fixed

temperature:

PV = a

Therefore, at a fixed temperature, the pressure will be inversely related to the volume, and the

relationship will be linear:

=

Setup

• Science Workshop computer interface*

a

V

➀ With the platform raised to its uppermost posi-

tion, connect the Pressure Sensor to a port on the

base apparatus with a short piece of tubing

(Figure 3.1).

➁ Close the shut-off valve on the tubing from the

unused port.

➂ Connect the Pressure Sensor to the computer

interface and set up Science Workshop to record

pressure. Be sure that you set up the keyboard

sampling option so you can enter height data by

hand. (Consult the Science Workshop User’s

Guide, “Keyboard Sampling,” for details.)

Procedure

➀ Record the height of the piston and the pressure

when the platform is raised to its highest position.

➁ Press the platform down to a series of levels and

record the height and pressure at each level.

➂ Convert the height measurements to gas volume

measurements. (Hint:

The diameter of the piston is 32.5 mm.)

to computer interface

HEAT ENGINE

GAS LAW APPARATUS

TD-8572

Piston Dia.:

Piston&Platform

32.5mm±0.1

35.0g±0.6

Mass:

CAUTION:

Max. Pres.: 345kPa. Use Gases Only

DO NOT

Immerse in any Liquid

E

C

O

A

T

F

R

E

E

T

N

R

I

U

R

S

O

a

S

P

S

E

k

T

N

R

0

U

E

0

L

P

7

S

O

-

0

S

B

A

(

Y

L

N

O

T

R:

CI-6532

OR

TO

R

0-021

I

O

RE P

. 64

A

C

U

NNEC

S

NO

E

Y

I

CO

A

R

R

RESS

E

0

P

ART

C

P

S

A

0

D

P

TING

F

A

5

R

M

E

6

SCO

T

E

N

PA

I

E

R

U

X

S

T

A

S

R

M

E

O

a

R

P

P

P

k

0

0

7

DO NOT Lubricate Piston or Cylinder

)

E

Pressure Port Mating Connector:

PASCO Part No. 640-021

Pressure Sensor

Figure 3.1. Experimental setup

Close the shut-off

valve on the tubing

from the unused

port.

➃ Prepare a graph of pressure versus volume.

➤ Note: The relationship between pressure and volume may not be linear at pressures greater

than 120 kPa because of air leakage from the valves and ports at higher pressures.

®

7

Page 12

Heat Engine/Gas Law Apparatus 012-06014C

8

®

Page 13

012-06014C Heat Engine/Gas Law Apparatus

P

A

S

C

O

Experiment 4: Combined Gas Law (Gay-Lussac’ s )

Equipment Required:

• Pressure Sensor (CI-6532)

• Science

Workshop computer interface*

• Temperature Sensor (CI-6505)

*For details on setting up and operating the Pressure Sensor and the Temperature Sensor with

Science Workshop, please consult the instruction sheets for the Pressure Sensor and the Temperature Sensor and the User’s Guide for Science Workshop.

Theory

Charles’ law states that V is proportional to T, and Boyle’s law states that V is proportional to 1/P.

Combining these, we have:

The combined gas law predicts that for a given mass of gas, if V is held constant, P is proportional

to T.

V=

aT

P

• hot plate

• Pyrex beaker with water

• ice

Setup

➀ The Gas Law Apparatus is not used in this

experiment. Use a short piece of tubing to

connect the pressue sensor to the air chamber

fitted with the 2-hole stopper.

➁ Insert the Temperature Sensor into the other

hole of the rubber stopper.

➂ Connect the Pressure Sensor and the Tem-

perature Sensor to the computer interface, and

set up the Science Workshop program to

graph temperature versus pressure.

Use a silicon lubricant on the end of

the Temperature Probe to aid

insertion and to prevent damage to

the probe.

➃ Place the air chamber in the Pyrex container

and turn on the hot plate.

to computer interface

to

computer

interface

E

C

O

A

T

F

R

E

E

T

N

R

I

U

R

S

O

a

)

S

P

S

E

E

k

T

N

R

0

U

E

0

L

P

7

S

O

0

S

B

A

(

2

3

5

Y

L

N

I-6

:

T

1

R

O

R

2

O

C

0

O

-

T

R

P

0

C

I

4

E

E

6

O

R

N

.

A

C

U

N

O

S

O

N

S

E

Y

S

C

I

T

E

A

R

R

G

R

R

E

0

P

A

C

N

P

I

S

P

A

0

D

T

F

O

A

5

R

C

M

E

6

S

T

E

A

N

P

I

E

R

U

X

S

T

A

S

R

E

M

O

a

R

P

P

P

k

0

0

7

Pressure

hot plate

Sensor

Figure 4.1. Experimental setup

Temperature

Sensor

➤ Note: You can substitute a thermometer in the water container for the Temperature Sensor.

Be sure to keep the tip of the thermometer from touching the bottom of the container.

®

9

Page 14

Heat Engine/Gas Law Apparatus 012-06014C

Procedure

Record the temperature and pressure as the water heats.

➀

➁ Display a graph of temperature versus pressure in Science Workshop.

10

®

Page 15

012-06014C Heat Engine/Gas Law Apparatus

Experiment 5: The Mass Lifter Heat Engine

The Heat Engine/Gas Law Apparatus is ideal for use in the calculus-based experiment 18.10 of the

Workshop Physics Activity Guide. Following is a slightly modified reprint of the experiment:

Equipment Required:

• Heat Engine/Gas Law Apparatus

• 2 Pyrex beakers, 1000 ml (to use as reservoirs)

• 1 ruler

• 1 barometer pressure gauge

Optional:

• a computer-based laboratory system with barometer sensor

Your working group has been approached by the Newton Apple Company about testing a

heat engine that lifts apples that vary in mass from 100 g to 200 g from a processing

conveyer belt to the packing conveyer belt that is 10 cm higher. The engine you are to

experiment with is a "real" thermal engine that can be taken through a four-stage expansion and compression cycle and that can do useful mechanical work by lifting small

masses from one height to another. In this experiment we would like you to verify experimentally that the useful mechanical work done in lifting a mass, m, through a vertical

distance, y, is equal to the net thermodynamic work done during a cycle as determined by

finding the enclosed area on a P-V diagram. Essentially you are comparing useful mechanical “magy” work (which we hope you believe in and understand from earlier studies)

with the accounting of work in an engine cycle as a function of pressure and volume

changes given by the expression:

W

=PdV

net

• 1 calipers

• 1 mass set, 20 g, 50 g, 100 g, 200 g

• 1 hot plate

• 1 vat to catch water spills

1

Although you can prove mathematically that this relationship holds, the experimental

verification will allow you to become familiar with the operation of a real heat engine.

m

y

b

c

P

m

0

a

V

Figure 5.1. Doing useful mechanical work

by lifting a mass, m, through a height, y.

1

Priscilla W. Laws, et al. Workshop Physics Activity Guide, 1996 by John Wiley & Sons, Inc.

Figure 5.2 Doing thermodynamic

work in a heat engine cycle.

Reprinted by permission of John Wiley & Sons, Inc.

®

11

d

Page 16

Heat Engine/Gas Law Apparatus 012-06014C

The Incredible Mass Lifter Engine

The heat engine consists of a hollow cylinder with a graphite piston that can move along the axis of the

cylinder with very little friction. The piston has a platform attached to it for lifting masses. A short

length of flexible tubing attaches the cylinder to an air chamber (consisting of a small can sealed with a

rubber stopper that can be placed alternately in the cold reservoir and the hot reservoir. A diagram of

this mass lifter is shown in Figure 5.2.

m

Close the shut-off valve

on the tubing from the

unused port.

HEAT ENGINE

GAS LAW APPARATUS

TD-8572

Piston Dia.:

Piston&Platform

32.5mm±0.1

35.0g±0.6

Mass:

CAUTION:

Max. Pres.: 345kPa. Use Gases Only

DO NOT

Immerse in any Liquid

DO NOT Lubricate Piston or Cylinder

Pressure Port Mating Connector:

PASCO Part No. 640-021

Cold

Hot

Figure 5.2. A schematic diagram of the incredible mass lifter heat engine.

If the temperature of the air trapped inside the cylinder, hose, and can is increased, then its

volume will increase, causing the platform to rise. Thus, you can increase the volume of the

trapped air by moving the can from the cold to the hot reservoir. Then, when the apple has

been raised through a distance y, it can be removed from the platform. The platform should

then rise a bit more as the pressure on the cylinder of gas decreases a bit. Finally, the volume

of the gas will decrease when the air chamber is returned to the cold reservoir. This causes

the piston to descend to its original position once again. The various stages of the mass lifter

cycle are shown in Figure 5.3.

Before taking data on the pressure, air volume, and height of lift with the heat engine, you

should set it up and run it through a few cycles to get used to its operation. A good way to

start is to fill one container with room temperature water and another with hot tap water or

preheated water at about 60–70°C. The engine cycle is much easier to describe if you begin

with the piston resting above the bottom of the cylinder. Thus, we suggest you raise the

piston a few centimeters before inserting the rubber stopper firmly in the can. Also, air does

leak out of the cylinder slowly. If a large mass is being lifted, the leakage rate increases, so

we suggest that you limit the added mass to something between 100 g and 200 g. After

observing a few engine cycles, you should be able to describe each of the points a, b, c, and

d of a cycle carefully, indicating which of the transitions between points are approximately

adiabatic and which are isobaric. You can observe changes in the volume of the gas directly

and you can predict how the pressure exerted on the gas by its surroundings ought to change

from point to point by using the definition of pressure as force per unit area.

12

®

Page 17

012-06014C Heat Engine/Gas Law Apparatus

m

m

y

y

m

Point A Point B Point C Point D

0

Cold Cold Hot Hot

m

0

0

Figure 5.3. A simplified diagram of the mass lifter heat engine at different stages of its cycle.

5.1 Activity: Description of the Engine Cycle

a. Predicted transition a➔b: Close the system to outside air but leave the can in the cold

reservoir. Make sure the rubber stopper is firmly in place in the can. What should happen

to the height of the platform when you add a mass? Explain the basis of your prediction.

b. Observed transition a

➔

b: What happens when you add the mass to the platform? Is this

what you predicted?

c. Predicted transition b

➔

c: What do you expect to happen when you place the can in the hot

reservoir ?

d. Observed transition b

➔

c: Place the can in the hot reservoir and describe what happens to

the platform with the added mass on it. Is this what you predicted? (This is the engine

power stroke!)

➔

e. Predicted transition c

d: Continue to hold the can in the hot reservoir and predict what

will happen if the added mass that is now lifted is removed from the platform and moved

onto an upper conveyor belt. Explain the reasons for your prediction.

®

13

Page 18

Heat Engine/Gas Law Apparatus 012-06014C

f. Observed transition c➔d: Remove the added mass and describe what actually happens. Is

this what you predicted?

➔

g. Predicted transition d

a: What do you predict will happen if you now place the can back in

the cold reservoir? Explain the reasons for your prediction.

➔

h. Observed transition d

a: Now it's time to complete the cycle by cooling the system down to

its original temperature for a minute or two before placing a new mass to be lifted on it. Place

the can in the cold reservoir and describe what actually happens to the volume of the trapped

air. In particular, how does the volume of the gas actually compare to the original volume of

the trapped air at point a at the beginning of the cycle? Is it the same or has some of the air

leaked out?

i. Theoretically, the pressure of the gas should be the same once you cool the system back to its

original temperature. Why?

Determining Pressures and Volumes for a Cycle

In order to calculate the thermodynamic work done during a cycle of this engine, you will

need to be able to plot a P-V diagram for the engine based on determinations of the volumes

and pressures of the trapped air in the cylinder, tubing, and can at the points a, b, c, and d in

the cycle.

5.2 Activity: Volume and Pressure Equations

a. What is the equation for the volume of a cylinder that has an inner diameter of d and a length

L?

b. Use the definition of pressure to derive the equation for the pressure on a gas being contained

by a vertical piston of diameter d if the total mass on the piston including its own mass and

any added mass is denoted as M. Hints: (1) What is the definition of pressure? (2) What is

the equation needed to calculate the gravitational force on a mass, M, close to the surface of

the Earth? (3) Don't forget to add in the atmospheric pressure, P

hence the gas at sea level.

, acting on the piston and

atm

Now that you have derived the basic equations you need, you should be able to take your

engine through another cycle and make the measurements necessary for calculating both the

volume and the pressure of the air and determining a P-V diagram for your heat engine.

Instead of calculating the pressures, if you have the optional equipment available, you might

want to measure the pressures with a barometer or a barometer sensor attached to a computerbased laboratory system.

14

®

Page 19

012-06014C Heat Engine/Gas Law Apparatus

5.3 Activity: Determining Volume and Pressure

a. Take any measurements needed to determine the volume and pressure of air in the

system at all four points in the engine cycle. You should do this rapidly to avoid air

leakages around the piston and summarize the measurements with units in the space

below.

b. Next you can use your measurements to calculate the pressure and volume of the system

at point a. Show your equations and calculations in the space below and summarize your

results with units. Don't forget to take the volume of the air in the tubing and can into

account!

=

P

a

V

=

a

c. Use the measurements at point b to calculate the total volume and pressure of the air in the

system at that point in the cycle. Show your equations and calculations in the space below

and summarize your results with units.

P

=

b

V

=

b

d. What is the height, y, through which the added mass is lifted in the transition from b to c?

e. Use the measurements at point c to calculate the total volume and pressure of the air in the

system at that point in the cycle. Show your equations and calculations in the following

space and summarize your results with units.

P

=

c

V

=

c

®

15

Page 20

Heat Engine/Gas Law Apparatus 012-06014C

f. Remove the added mass and make any measurements needed to calculate the volume and

pressure of air in the system at point d in the cycle. Show your equations and calculations in

the space below and summarize your results with units.

P

=

d

V

=

d

➔

g. We suspect that transitions from a

b and from c➔d are approximately adiabatic. Explain

why.

h. You should have found that the transitions from b

➔

c and from d➔a are isobaric. Explain

why this is the case.

Finding Thermodynamic Work from the Diagram

In the next activity you should draw a P- V diagram for your cycle and determine the thermodynamic work for your engine.

5.4 Activity: Plotting and Interpreting a

P-V

Diagram

a. Fill in the appropriate numbers on the scale on the graph frame that follows and plot the P-V

diagram for your engine cycle. Alternatively, generate your own graph using a computer

graphing routine and affix the result in the space below.

16

®

Page 21

012-06014C Heat Engine/Gas Law Apparatus

b . On the graph in part a, label each of the points on the cycle ( a, b, c, and d). Indicate on

the graph which of the transitions (a➔b, b➔c, etc.) are adiabatic and which are isobaric.

Next you need to find a way to determine the area enclosed by the P- V diagram. The

enclosed area doesn't change very much if you assume that P is approximately a linear

function of V for the adiabatic transitions. By making this approximation, the figure is

almost a parallelogram so you can obtain the enclosed area using one of several methods.

Three of the many possibilities are listed below. Creative students have come up with even

better methods than these, so you should think about your method of analysis carefully.

Method I

Since the pressure doesn't change from point b to point c, you can take the pressure of

those two points as a constant pressure between points. The same holds for the transition

from d to a. This gives you a figure that is approximately a parallelogram with two sets of

parallel sides. You can look up and properly apply the appropriate equation to determine

the net thermodynamic work performed.

Method II

Display your graph with a grid and count the boxes in the area enclosed by the lines

connecting points a, b, c, and d. Then multiply by the number of joules each box represents. You will need to make careful estimates of fractions of a box when a "leg" of a

cycle cuts through a box.

Method III

b

PdV = PdV

a

c

+PdV

b

+PdV

d

c

a

+PdV

d

Fit a straight line to each of the starting and ending points for the four transitions in the

cycle. Each equation will give you a function relating P and V. Perform an integral for

each of these equations, since

5.5 Activity: Comparing the Thermodynamic and Useful Mechanical Work

a. Choose a method for computing the thermodynamic work in joules, describe it in the space

below, and show the necessary calculations. Report the result in joules.

®

17

Page 22

Heat Engine/Gas Law Apparatus 012-06014C

b. What is the equation you need to use to calculate the useful mechanical work done in lifting

the mass from one level to another?

c. Use the result for the height that the mass is lifted in the power stroke of the engine to

calculate the useful mechanical work performed by the heat engine.

d. How does the thermodynamic work compare to the useful mechanical work? Please use the

correct number of significant figures in your comparison (as you have been doing all along,

right?)

The Incredible Mass Lifter Engine Is Not So Simple

Understanding the stages of the engine cycle on a P-V diagram is reasonably straightforward. However, it is difficult to use equations for adiabatic expansion and compression and

the ideal gas law to determine the temperature (and hence the internal energy of the air

throughout the cycle. There are several reasons for this. First, air is not an ideal gas.

Second, the mass lifter engine is not well insulated and so the air that is warmed in the hot

reservoir transfers heat energy through the cylinder walls. Thus, the air in the can and in the

cylinder are probably not at the same temperature. Third, air does leak out around the

piston, especially when larger masses are added to the platform. This means that the

number of moles of air decreases over time. You can observe this by noting that in the

transition from point d to point a, the piston can actually end up in a lower position than it

had at the beginning of the previous cycle. However, the Incredible Mass Lifter Engine

does help us understand typical stages of operation of a real heat engine.

➤ Note: The previous experiment was intended to help students consolidate the concepts

of pressure and volume by taking their own data for height and mass in each part of the

cycle and then calculating the pressures using the basic definition of pressure vs. force

per unit area. An alternate method for doing this experiment is to use the Science

Workshop computer interface with the Pressure Sensor (CI-6532) in conjunction with

either a Motion Sensor (CI-6529) or Rotary Motion Sensor (CI-6538) to detect pressure,

volume, and height automatically with a computer.

18

®

Page 23

Technical Support

Feedback

If you have any comments about the product or manual,

please let us know. If you have any suggestions on

alternate experiments or find a problem in the manual,

please tell us. PASCO appreciates any customer feedback. Your input helps us evaluate and improve our

product.

To Reach PASCO

For technical support, call us at 1-800-772-8700 (toll-free

within the U.S.) or (916) 786-3800.

fax: (916) 786-3292

e-mail: techsupp@pasco.com

web: www.pasco.com

Contacting Technical Support

Before you call the PASCO Technical Support staff, it

would be helpful to prepare the following information:

➤ If your problem is with the PASCO apparatus, note:

- Title and model number (usually listed on the

label);

- Approximate age of apparatus;

- A detailed description of the problem/sequence of

events. (In case you can’t call PASCO right away,

you won’t lose valuable data.);

- If possible, have the apparatus within reach when

calling to facilitate description of individual parts.

➤ If your problem relates to the instruction manual, note:

- Part number and revision (listed by month and year

on the front cover);

- Have the manual at hand to discuss your questions.

Loading...

Loading...