Page 1

Includes

Teacher's Notes

and

Typical

Experiment Results

Instruction Manual and

Experiment Guide for

012-03349D

5/94

the PASCO scientific

Model TD-8561

THERMAL CONDUCTIVITY

APPARATUS

© 1987 PASCO scientific $5.00

Page 2

Page 3

012-03349D Thermal Conductivity Apparatus

T able of Contents

Section.............................................................................................................. Page

Copyright, Warranty and Equipment Return..........................................................ii

Introduction ............................................................................................................ 1

Experiment:

Measuring Thermal Conductivity..................................................................... 3

Equipment Needed ..................................................................................... 3

Data and Calculations................................................................................. 4

Teacher’s Guide...................................................................................................... 5

Technical Support....................................................................... Inside Back Cover

i

Page 4

Thermal Conductivity Apparatus 012-03349D

Copyright, Warranty and Equipment Return

Please—Feel free to duplicate this manual

subject to the copyright restrictions below.

Equipment Return

Copyright Notice

The PASCO scientific Model TD-8561 Thermal

Conductivity Apparatus manual is copyrighted and all

rights reserved. However, permission is granted to

non-profit educational institutions for reproduction of

any part of this manual providing the reproductions

are used only for their laboratories and are not sold for

profit. Reproduction under any other circumstances,

without the written consent of PASCO scientific, is

prohibited.

Limited Warranty

PASCO scientific warrants this product to be free

from defects in materials and workmanship for a

period of one year from the date of shipment to the

customer. PASCO will repair or replace, at its option,

any part of the product which is deemed to be defective in material or workmanship. This warranty does

not cover damage to the product caused by abuse or

improper use. Determination of whether a product

failure is the result of a manufacturing defect or

improper use by the customer shall be made solely by

PASCO scientific. Responsibility for the return of

equipment for warranty repair belongs to the customer. Equipment must be properly packed to prevent

damage and shipped postage or freight prepaid.

(Damage caused by improper packing of the equipment for return shipment will not be covered by the

warranty.) Shipping costs for returning the equipment, after repair, will be paid by PASCO scientific.

Should the product have to be returned to PASCO

scientific for any reason, notify PASCO scientific by

letter, phone, or fax BEFORE returning the product.

Upon notification, the return authorization and

shipping instructions will be promptly issued.

ä

NOTE: NO EQUIPMENT WILL BE

ACCEPTED FOR RETURN WITHOUT AN

AUTHORIZATION FROM PASCO.

When returning equipment for repair, the units

must be packed properly. Carriers will not accept

responsibility for damage caused by improper

packing. To be certain the unit will not be

damaged in shipment, observe the following rules:

➀ The packing carton must be strong enough for the

item shipped.

➁ Make certain there are at least two inches of

packing material between any point on the

apparatus and the inside walls of the carton.

➂ Make certain that the packing material cannot shift

in the box or become compressed, allowing the

instrument come in contact with the packing

carton.

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: (916) 786-3800

FAX: (916) 786-3292

email: techsupp@pasco.com

web: www.pasco.com

ii

Page 5

012-03349D Thermal Conductivity Apparatus

Introduction

Thermal Conductivity Apparatus

Heat can be transferred from one point to another by three

common methods: conduction, convection and radiation.

Each method can be analyzed and each yields its own

specific mathematical relationship. The TD-8561 Thermal

Conductivity Apparatus allows one to investigate the rate

of thermal conduction through five common materials

used in building construction.

The equation giving the amount of heat conducted through

a material is:

∆Q = k A ∆T ∆t / h.

In this equation,

is the area through which conduction takes place,

temperature difference between the sides of the material,

∆t is the time during which the conduction occurred and h

is the thickness of the material. The remaining term, k, is

the thermal conductivity of a given material.

The units for k depend upon the units used to measure the

other quantities involved. Some sample conversions

between different possible sets of units are shown in Table

1.

Watt cm 1.338 x 10

cm2 °K

Watt m 1.338 x 10-54.818 x 10-20.5782 6.938

m2 °K

Watt in. 9.485 x 10

in.2 °R

Cal cm 5.600 x 10

cm2 sec °K

∆Q is the total heat energy conducted, A

∆T is the

Btu in. Btu in. Btu ft Btu in.

in.2 sec °R in.2 hr °Rft2 hr °Rft2 hr °R

-2

4.818 57.82 693.8

-4

3.414 40.97 491.7

-3

20.16 241.9 2.903 x 10

The technique for measuring thermal conductivity is

straightforward. A slab of the material to be tested is

clamped between a steam chamber, which maintains a

constant temperature of 100 °C, and a block of ice, which

maintains a constant temperature of 0°C. A fixed temperature differential of 100 °C is thereby established between

the surfaces of the material. The heat transferred is

measured by collecting the water from the melting ice. The

ice melts at a rate of 1 gram per 80 calories of heat flow

(the latent heat of melting for ice).

The thermal conductivity, k, is therefore measured using

the following equation:

k = (cal cm/cm

2

sec) =

(mass of melted ice) (80 cal/gm) (thickness of material)

(area of ice) (time during which ice melted) (temp.

differential)

where distances are measured in centimeters, masses in

grams, and time in seconds.

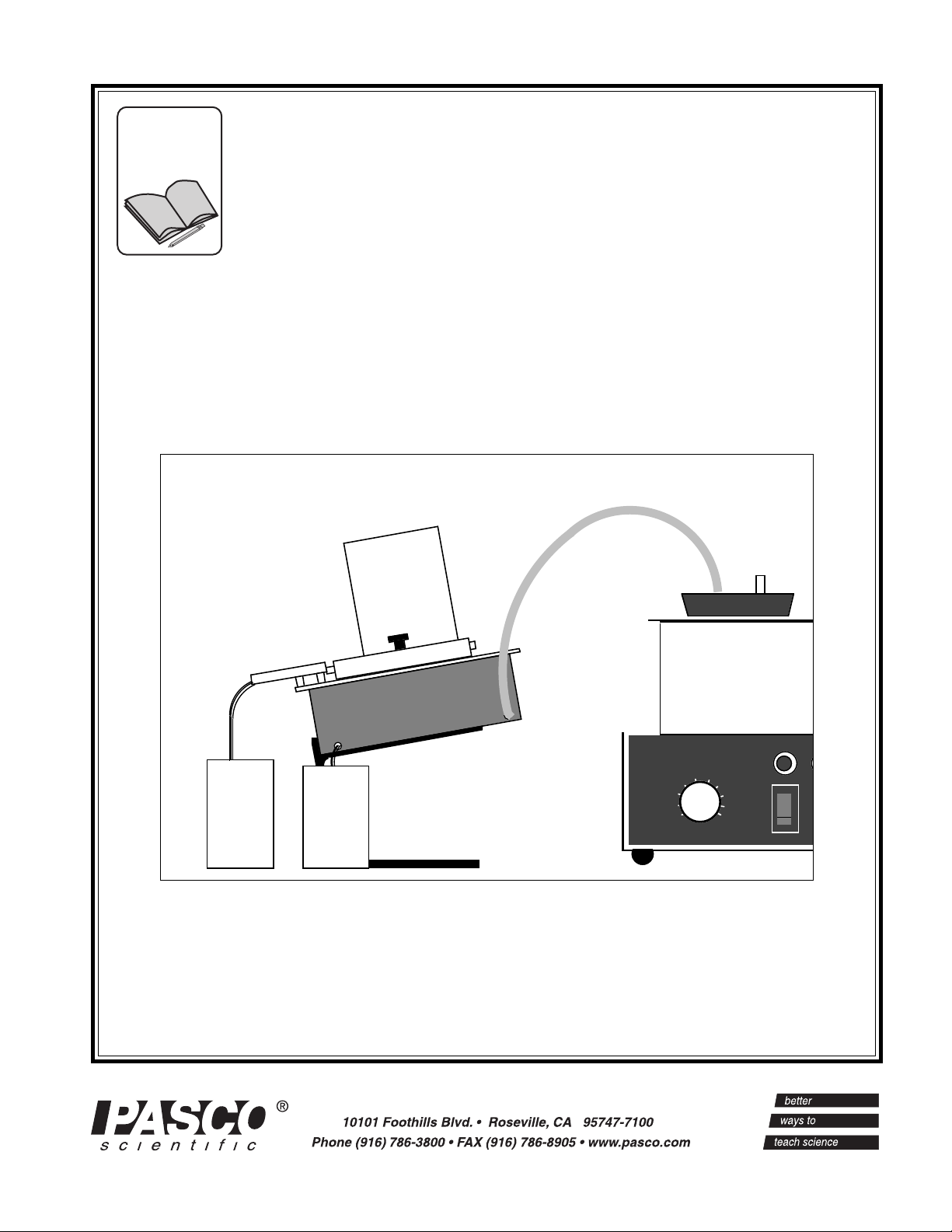

The Thermal Conductivity Apparatus includes the following equipment (see Figure 1):

• Base

• Steam chamber with hardware for mounting sample

• Ice mold with cover (Part # 648-03427)

• Materials to test: Glass, wood, lexan, masonite, and

sheet rock (The wood, masonite, and sheet rock are

covered with aluminum foil for waterproofing.)

3

Table 1

The importance of k lies in whether one wishes to conduct

heat well (good conductor) or poorly (good insulator).

Therefore, the relative size of k is of importance to

designers and builders, and should be of importance to

home owners.

Note further that choosing a material with a small value

for k does not guarantee a well-insulated structure. The

amount of heat conducted out in winter (and therefore

needing to be replaced) depends also upon three other

factors: area, thickness and temperature difference. The

same holds true for heat conducted in during the summer.

The equation for determining k is:

k =

∆Q h / A ∆T ∆t = _____

Steam

chamber

with hardware

for

mounting

sample

Figure 1 Equipment Included with the Thermal

Conductivity Apparatus

1

Base

Materials to test

(Glass, wood,

lexan, masonite,

sheet rock)

(Part# 648-03427)

Ice mold

Page 6

Thermal Conductivity Apparatus 012-03349D

Notes

2

Page 7

012-03349D Thermal Conductivity Apparatus

Experiment: Measuring Thermal Conductivity

EQUIPMENT NEEDED:

— Steam generator that will deliver approxi-

mately 10 grams/minute (e.g., PASCO’s

Model TD-8556 Steam Generator)

— Freezer

— Container to collect melted ice (a paper

cup is fine)

— Gram balance to weigh collected water

(you could collect the water in a graduated

flask, but your results will be less accurate)

— Container to collect condensed steam

— Grease such as petroleum jelly

("Vaseline")

Measuring Thermal Conductivity

➀ Fill the ice mold with water and freeze it. Do not freeze water with lid on jar. (A few drops of

a non-sudsing detergent in the water before freezing will help the water to flow more freely

as it melts and will not significantly effect the results.)

➁ Run jar under warm water to loosen the ice in the mold.

➤ NOTE: Do not attempt to “pry” the ice out of the mold.

➂ Measure and record h, the thickness of the sample material.

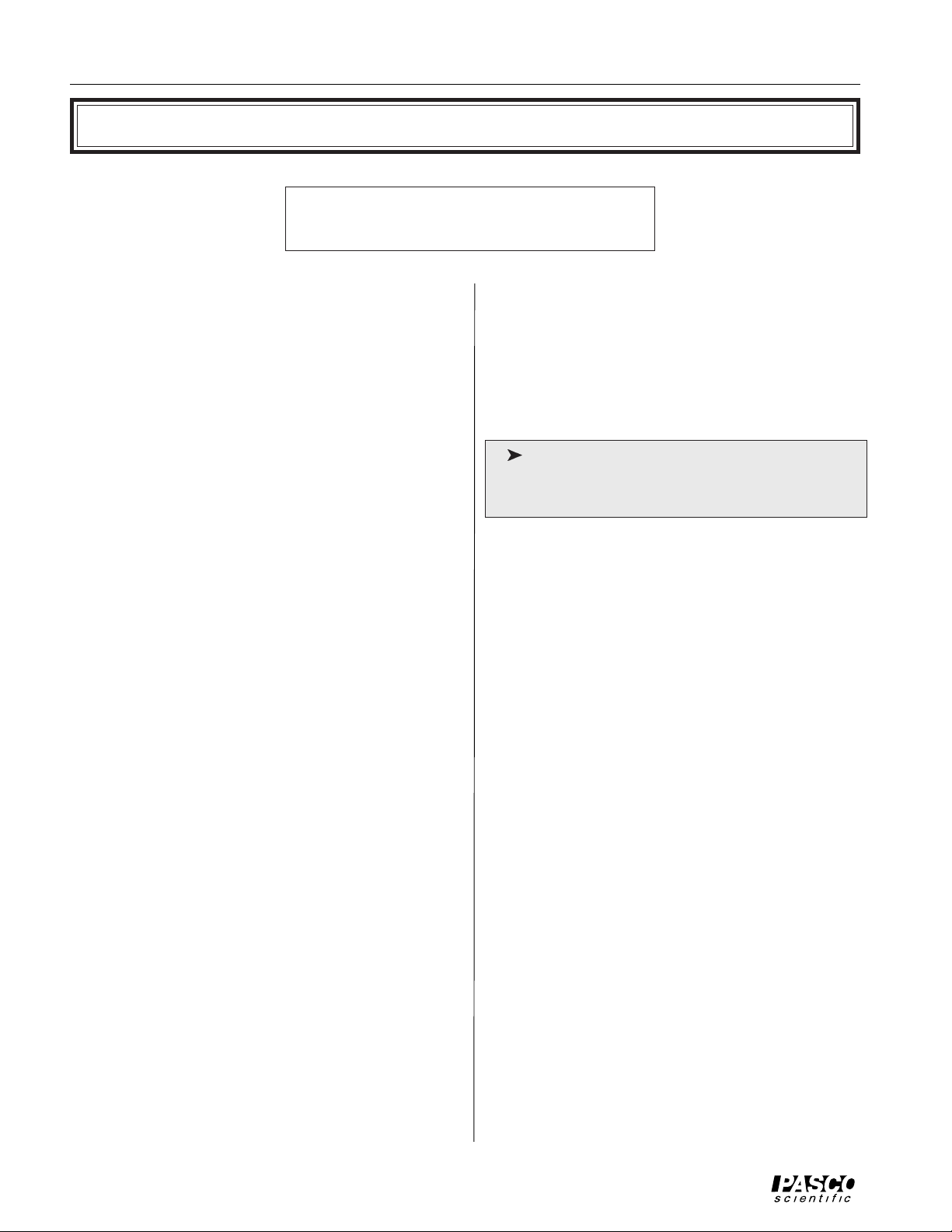

Mount the sample material onto the steam chamber as shown in Figure 2.

➃

➤ NOTE: Take care that the sample material is flush against the water channel, so water will

not leak, then tighten the thumbscrews. A bit of grease between the channel and the sample

will help create a good seal.

➄ Measure the diameter of the ice block. Record this value as d

. Place the ice on top of the

1

sample as shown in Figure 2. Do not remove the ice but make sure that the ice can move

freely in the mold. Just place the open end of the mold against the sample, and let the ice

slide out as the experiment proceeds.

(Top View)

Water channel

Container for collecting

melted ice

Ice in Mold with bare ice

against material sample

Clamps

Material

sample

Container for collecting

condensed steam

Figure 2 Experimental Setup

Steam

Generator

3

Page 8

Thermal Conductivity Apparatus 012-03349D

Let the ice sit for several minutes so it begins to melt and comes in full contact with the sample. (Don't

➅

begin taking data before the ice begins to melt, because it may be at a lower temperature than 0 °C.)

Obtain data for determining the ambient melting rate of the ice, as follows:

➆

a. Determine the mass of a small container used for collecting the melted ice and record it.

b. Collect the melting ice in the container for a measured time t

(approximately 10 minutes).

a

c. Determine the mass of the container plus water and record it.

d. Subtract your first measured mass from your second to determine m

, the mass of the melted ice.

wa

➇ Run steam into the steam chamber. Let the steam run for several minutes until temperatures stablize so

that the heat flow is steady. (Place a container under the drain spout of the steam chamber to collect the

water that escapes from the chamber.)

➈ Empty the cup used for collecting the melted ice. Repeat step 7, but this time with the steam running

into the steam chamber. As before, measure and record m

, the mass of the melted ice, and t, the time

w

during which the ice melted (5-10 minutes).

➉ Remeasure the diameter of the ice block and record the value as d

DATA AND CALCULATIONS

➀ Take the average of d

➁ Use your value of d

and d2 to determine d

1

to determine A, the area over which the heat flow between the ice and the steam

avg

, the average diameter of the ice during the experiment.

avg

chamber took place. (Assume that A is just the area of the ice in contact with the sample material.)

➂ Divide m

by ta and mw by t to determine Ra and R, the rates at which the ice melted before and after

wa

the steam was turned on.

Subtract R

➃

from R to determine R0, the rate at which the ice melted due to the temperature differential

a

only.

➄ Calculate k, the conductivity of the sample:

k (cal cm/cm

2

sec) = _________

∆T = Boiling point of water (100 °C at sea level) - 0°C.

Data and Calculations Table

hd1d

2

t

a

m

wa

tmwd

avg

.

2

ARaRR

0

(R0) (80 cal/gm) (h)

(A) (∆T);

4

Page 9

012-03349D Thermal Conductivity Apparatus

T eacher’s Guide

Experiment: Thermal Conductivity Apparatus

Notes on Procedure

➀ Expect 10-15% error under normal (student labora-

tory) operating conditions.

➁ Keep the ice as isolated from the surroundings as

possible. Our best results were obtained using a

PASCO styrofoam calorimeter cup as an ice mold;

however, this has the disadvantage of splitting the

cup when the water freezes. (Medium-sized

styrofoam cups also work very nicely.) Whatever

mold you use, leave it

on the ice during the experi-

ment.

Accepted Values

Substance cal•cm/cm2•sec•°C watt•m/m2•K

Masonite 1.13 x 10-

Wood (Pine) 206 - 3.3 x 10-

➂ Apply a dab of grease to the joint between the plate

and the water trough to prevent leakage. Vaseline

works well; it melts, but still seals the gap.

➃

A note about the aluminum covers on some

samples: This was found experimentally to have no

measurable effect on the conductivity of the

samples. We tested this using a glass plate which

we measured both with and without an aluminum

cover, and there was no statistically significant difference between multiple readings in both states.

4

4

0.047

0.11 - 0.14

®

Lexan 4.6 x 10-

Sheet Rock 10.3 x 10-

Glass 17.2 - 20.6 x 10-

4

4

4

0.19

0.43

0.72 - 0.86

Note

Values (with the exception of Lexan) from the Handbook of Chemistry and Physics, 46th Edition, published by

The Chemical Rubber Company. Value for Lexan is from a specifications sheet provided by the manufacturer.

Values for Masonite and for Sheet Rock will vary considerably.

5

Page 10

Thermal Conductivity Apparatus 012-03349D

Notes

6

Page 11

012-03349D Thermal Conductivity Apparatus

T echnical Support

Feed-Back

If you have any comments about this product or this

manual please let us know. If you have any suggestions on alternate experiments or find a problem in the

manual please tell us. PASCO appreciates any customer feed-back. Your input helps us evaluate and

improve our product.

To Reach PASCO

For Technical Support call us at 1-800-772-8700 (tollfree within the U.S.) or (916) 786-3800.

Contacting Technical Support

Before you call the PASCO Technical Support staff it

would be helpful to prepare the following information:

• If your problem is computer/software related, note:

Title and Revision Date of software.

Type of Computer (Make, Model, Speed).

Type of external Cables/Peripherals.

• If your problem is with the PASCO apparatus, note:

Title and Model number (usually listed on the label).

Approximate age of apparatus.

A detailed description of the problem/sequence of

events. (In case you can't call PASCO right away,

you won't lose valuable data.)

If possible, have the apparatus within reach when

calling. This makes descriptions of individual parts

much easier.

• If your problem relates to the instruction manual,

note:

Part number and Revision (listed by month and year

on the front cover).

Have the manual at hand to discuss your questions.

7

Page 12

Loading...

Loading...