Page 1

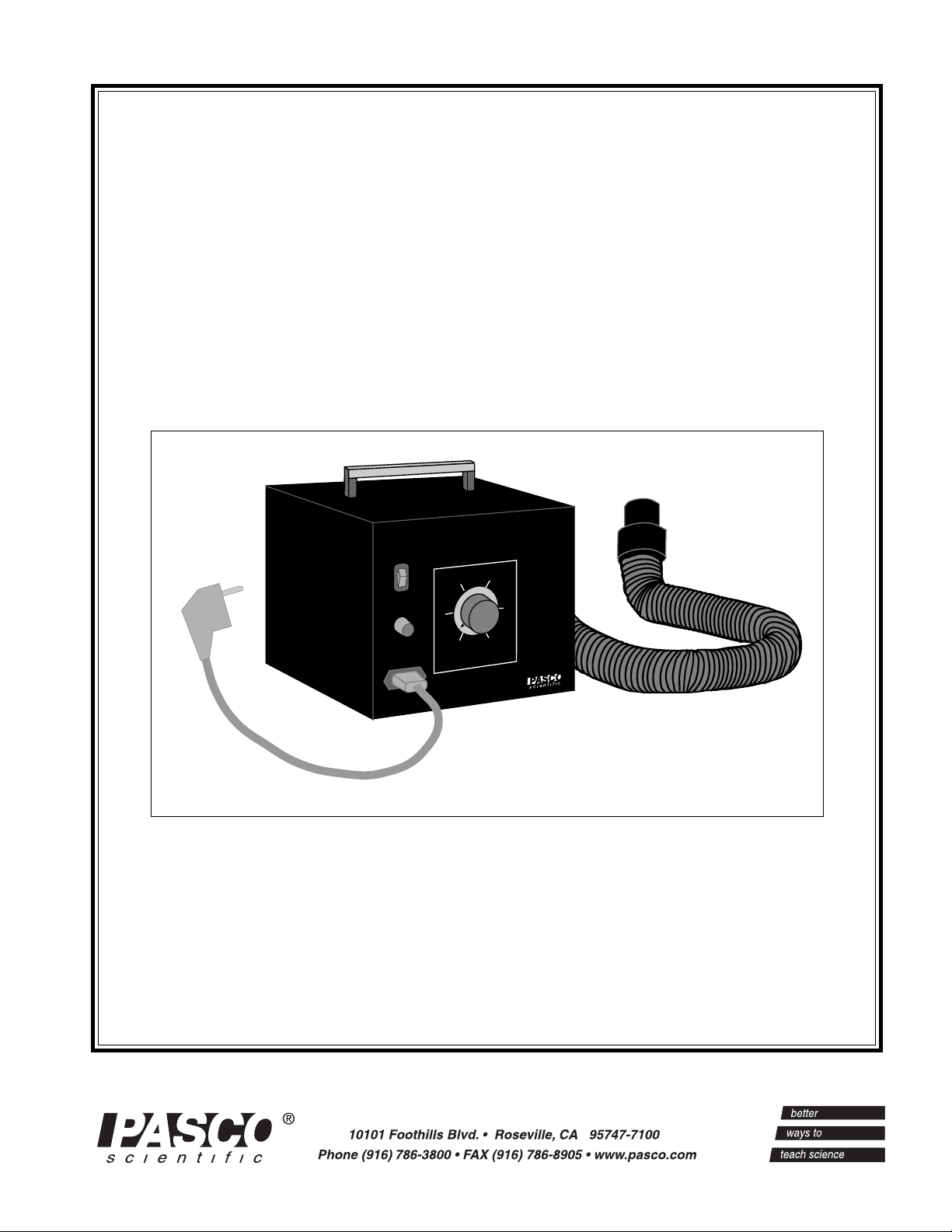

Instruction Manual for

012-02141H

the PASCO scientific

Model SF-9216

Variable Output Air Supply

1/96

POWER

ON

OFF

SF-9216

AIR SUPPLY

2

1

6

AIR OUTPUT

3

4

5

© 1991 PASCO scientific $5.00

Page 2

Variable Output Air Supply 012-02141H

The lightning flash with arrowhead,

within an equilateral triangle, is intended

to alert the user of the presence of

uninsulated “dangerous voltage” within

the product’s enclosure that may be of

sufficient magnitude to constitute a risk

of electric shock to persons.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION:

TO PREVENT THE RISK OF

ELECTRIC SHOCK, DO NOT

REMOVE BACK COVER. NO USER

SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL.

The exclamation point within an equilateral triangle is intended to alert the

user of the presence of important

operating and maintenance (servicing) instructions in the literature accompanying the appliance.

®

Page 3

012-02141H Variable Output Air Supply

T able of Contents

Section..........................................................................................................Page

Copyright, Warranty, and Equipment Return..................................................ii

Introduction .....................................................................................................1

Operation .........................................................................................................1

Operating Two Air Tracks...............................................................................2

PCB Schematic ................................................................................................3

PCB Layout .....................................................................................................4

®

i

Page 4

Variable Output Air Supply 012-02141H

Copyright, Warranty and Equipment Return

Please—Feel free to duplicate this manual

subject to the copyright restrictions below.

Copyright Notice

The PASCO scientific Model SF-9216 Variable Output

Air Supply manual is copyrighted and all rights reserved.

However, permission is granted to non-profit educational

institutions for reproduction of any part of this manual

providing the reproductions are used only for their

laboratories and are not sold for profit. Reproduction

under any other circumstances, without the written

consent of PASCO scientific, is prohibited.

Limited Warranty

PASCO scientific warrants this product to be free from

defects in materials and workmanship for a period of one

year from the date of shipment to the customer. PASCO

will repair or replace, at its option, any part of the product

which is deemed to be defective in material or workmanship. This warranty does not cover damage to the product

caused by abuse or improper use. Determination of

whether a product failure is the result of a manufacturing

defect or improper use by the customer shall be made

solely by PASCO scientific. Responsibility for the return

of equipment for warranty repair belongs to the customer.

Equipment must be properly packed to prevent damage

and shipped postage or freight prepaid. (Damage caused

by improper packing of the equipment for return shipment will not be covered by the warranty.) Shipping

costs for returning the equipment, after repair, will be

paid by PASCO scientific.

Equipment Return

Should the product have to be returned to PASCO

scientific for any reason, notify PASCO scientific by

letter, phone, or fax BEFORE returning the product.

Upon notification, the return authorization and

shipping instructions will be promptly issued.

ä

NOTE: NO EQUIPMENT WILL BE

ACCEPTED FOR RETURN WITHOUT AN

AUTHORIZATION FROM PASCO.

When returning equipment for repair, the units

must be packed properly. Carriers will not accept

responsibility for damage caused by improper

packing. To be certain the unit will not be

damaged in shipment, observe the following rules:

➀ The packing carton must be strong enough for the

item shipped.

➁ Make certain there are at least two inches of

packing material between any point on the

apparatus and the inside walls of the carton.

➂ Make certain that the packing material cannot shift

in the box or become compressed, allowing the

instrument come in contact with the packing

carton.

Credits

This manual edited by: Dave Griffith

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: (916) 786-3800

FAX: (916) 786-3292

email: techsupp@pasco.com

web: www.pasco.com

ii

®

Page 5

012-02141H Variable Output Air Supply

SF-9216

AIR SUPPLY

5

4

3

2

1

6

AIR OUTPUT

POWER

ON

OFF

Introduction

The PASCO Air Supply is exceptionally quiet, and its

variable output lets you precisely match the air flow to the

experiment. (Too much air causes turbulence, resulting in

glider drift.)

A 2.0 meter hose is included. By adding the SF-9217

T-Adapter and Hose described below, the Air Supply can

be used to operate two PASCO SF-9214 Air Tracks at the

same time.

➤ NOTE: This Air Supply is for use with the

SF-9214 Precision Air Track. If used with a

different track, the total area of the air flow holes

must be ≥ 2.6 cm

2

(0.4 in2).

(220/240 VAC,

50 Hz shown)

Figure 1 SF-9216 Air Supply

Operation

Setting Up the Air Supply

Insert the short, thick-wall coupling on one end of the

hose into the hole in rear of the air supply. The other end

of the hose, with the longer, thin-wall coupling, fits into

the hole of the PASCO 2 meter Precision Air Track

(square cross section, aluminum color).

Connect the air supply to a wall socket (115 VAC, 60 Hz

or 220/240 VAC, 50 Hz). The respective line voltages are

marked on the rear panel. Turn the unit on with the

power switch.

Leave at least three inches of clearance around all sides of

the blower for air intake and cooling.

If you wish to connect the SF-9216 Air Supply to the

Daedalon 1.5 m Air Track (triangular cross section, black

color) it will be necessary to wrap one or two layers of

electrician’s tape around the air coupling on the track.

The hose from the Air Supply should now fit snugly over

the coupling.

®

Adjusting the Air Supply

The air flow from the Air Supply is easily adjusted by the

knob on the front panel. Once the air track is set up and

operating, adjust the air flow until the gliders just glide

freely on the track.

If the air flow is too low, the glider will touch the track

and lose energy.

A higher air flow may cause the gliders to move randomly in response to air turbulence around the surface of

the track.

➤ NOTE: The apparatus is calibrated at 220 VAC, 50

Hz and must be re-calibrated for 220 VAC, 60 Hz.

Please follow the instructions in the following section.

1

Page 6

Variable Output Air Supply 012-02141H

Adjusting the Motor Speed (Air Flow)

Turn the control knob fully COUNTER-clockwise. After

switching on the motor, slowly turn the control knob

CLOCKWISE. The motor should begin running when the

pointer on the control knob is near the “2” position. If it

does not, then follow this procedure:

➤CAUTION: When the case is opened, there will

be exposed high voltages. This unit should be

serviced or adjusted only by trained technicians.

➀ Remove the four screws which attach the control

panel to the main unit.

➁ On one end of the printed circuit board are two trim

potentiometers designated as TR1 and TR2 (See Figure 3).

Operating T wo Air Tracks

➂ Set TR1 and TR2 to their mid position and turn the

power switch to “ON”.

➃ Set the speed control knob (P1) fully counter-clock-

wise (“1”) and turn TR1 clockwise until the motor just

begins to turn smoothly.

➄ Set the speed control knob fully clockwise (“6”) and

adjust TR2 until the motor runs at maximum speed.

➅ Replace the control panel.

Fuse Replacement

The fuse is a dual-element delay type. Replace with the

following fuse ratings:

For the 110V version use a 5A/117V fuse.

For the 220V version use a 2.5A/250V fuse.

Operating Two Air Tracks

Two air tracks may be operated on a single Air Supply by

using the optional ‘T’ and hose, Model SF-9217. The ‘T’

is inserted into the Air Supply and one hose is connected

to one of the outlets. Naturally, both air tracks must be

connected to maintain air pressure.

Specifications

➀ When connected to the SF-9214 Precision Air Track

(382 holes @ 1 mm (0.038 in) diameter each, total

hole area 300 mm2 (0.433 in2), the volume and pressure is sufficient to lift a glider with a 200 g load (setting at 50% of full range).

➁ The input current at full speed is 2.2 Amps maximum.

➂ The sound output is typically 10 - 20 dB above ambi-

ent noise. The maximum sound output is low enough

to allow normal conversation to be heard when the

motor is on.

➃ The volume of air produced is 1.02 m

min) and the pressure is 867 Pascals (0.0867 N/cm2 or

0.122 lbs/in2) or 6.5 mm Hg at full speed.

3

/min (36 ft3/

➤ CAUTION:

For those using SF-9216 Air Supply with equipment other than the PASCO Model SF- 9214

Precision Student Air Track: This air supply is

designed for use with equipment for which the total

area of air flow is at least 2.6 cm2 (0.4 in2). (For air

tracks, this area is determined by multiplying the

number of air holes on the surface of the track by

the surface area per hole).

When used with equipment for which the air flow

orifice is less than this value, the rate of air flow is

insufficient to cool the air supply, and the supply

may overheat and be damaged.

You may remedy this problem either by hooking up

the air supply to additional equipment (to meet the

2.6 cm2 or 0.4 in2 requirement) or by bleeding the

air line at some point to increase the area of the

unrestricted air flow to an acceptable level.

®

2

Page 7

012-02141H Variable Output Air Supply

PCB Schematic

Figure 2

®

3

Page 8

Variable Output Air Supply 012-02141H

PCB Layout

Figure 3

4

®

Page 9

012-02141H Variable Output Air Supply

T echnical Support

Feed-Back

If you have any comments about this product or this

manual please let us know. If you have any suggestions

on alternate experiments or find a problem in the manual

please tell us. PASCO appreciates any customer feedback. Your input helps us evaluate and improve our

product.

To Reach PASCO

For Technical Support call us at 1-800-772-8700 (tollfree within the U.S.) or (916) 786-3800.

email: techsupp@PASCO.com

Tech support fax: (916) 786-3292

Contacting Technical Support

Before you call the PASCO Technical Support staff it

would be helpful to prepare the following information:

• If your problem is with the PASCO apparatus, note:

Title and Model number (usually listed on the label).

Approximate age of apparatus.

A detailed description of the problem/sequence of

events. (In case you can't call PASCO right away, you

won't lose valuable data.)

If possible, have the apparatus within reach when calling. This makes descriptions of individual parts much

easier.

• If your problem relates to the instruction manual, note:

Part number and Revision (listed by month and year on

the front cover).

Have the manual at hand to discuss your questions.

®

5

Page 10

Loading...

Loading...