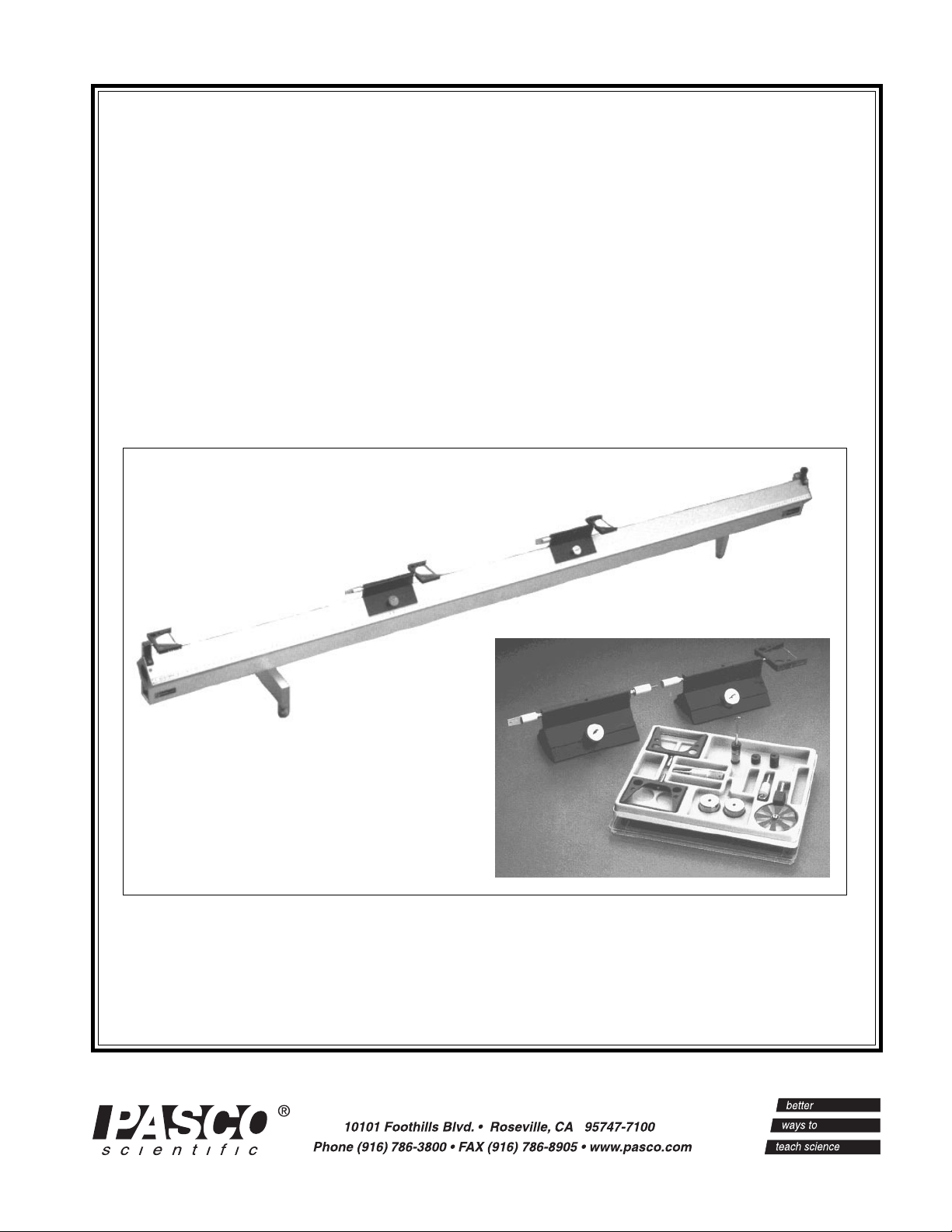

Page 1

Instruction Manual and

Experiment Guide for

the PASCO scientific

Model SF-9214

Precision 2.0 Meter

Air Track

012-02149B

9/91

Copyright © January 1988 $5.00

Page 2

Table of Contents

Section Page

Copyright, Warranty, and Equipment Return................................................... ii

Introduction ...................................................................................................... 1

Equipment......................................................................................................... 1

The Accessory Tray.......................................................................................... 2

Equipment Setup............................................................................................... 3

Accessories ....................................................................................................... 4

Maintenance...................................................................................................... 6

Experiments ...................................................................................................... 6

012-02149B

Replacement Parts ............................................................................................ 7

Recommended Equipment................................................................................ 8

i

scientific

Page 3

012-02149B

Copyright Notice

Copyright and Warranty

Please—Feel free to duplicate this manual

subject to the copyright restrictions below.

The PASCO scientific Model SF-9214 Precision 2.0

Meter Air Track manual is copyrighted and all rights

reserved. However, permission is granted to nonprofit educational institutions for reproduction of any

part of this manual providing the reproductions are

used only for their laboratories and are not sold for

profit. Reproduction under any other circumstances,

without the written consent of PASCO scientific, is

prohibited.

Limited Warranty

PASCO scientific warrants this product to be free from

defects in materials and workmanship for a period of

one year from the date of shipment to the customer.

Equipment Return

PASCO will repair or replace, at its option, any part of

the product which is deemed to be defective in material or workmanship. This warranty does not cover

damage to the product caused by abuse or improper

use. Determination of whether a product failure is the

result of a manufacturing defect or improper use by the

customer shall be made solely by PASCO scientific.

Responsibility for the return of equipment for warranty

repair belongs to the customer. Equipment must be

properly packed to prevent damage and shipped

postage or freight prepaid. (Damage caused by

improper packing of the equipment for return shipment

will not be covered by the warranty.) Shipping costs

for returning the equipment, after repair, will be paid

by PASCO scientific.

Should this product have to be returned to PASCO

scientific, for whatever reason, notify PASCO scientific by letter or phone BEFORE returning the product.

Upon notification, the return authorization and shipping instructions will be promptly issued.

NOTE: NO EQUIPMENT WILL BE

ACCEPTED FOR RETURN WITHOUT AN

AUTHORIZATION.

scientific

When returning equipment for repair, the units must be

packed properly. Carriers will not accept responsibility for damage caused by improper packing. To be

certain the unit will not be damaged in shipment, observe the following rules:

➀ The carton must be strong enough for the item

shipped.

➁ Make certain there is at least two inches of packing

material between any point on the apparatus and

the inside walls of the carton.

➂ Make certain that the packing material can not shift

in the box, or become compressed, thus letting the

instrument come in contact with the edge of the

box.

ii

Page 4

Page 5

012-02149B

Equipment

Introduction

The PASCO Model SF-9214 Air Track is 2.0 meters

long with a guaranteed straightness to within .04 mm

over its entire length. The track construction is a large

square aluminum extrusion of 3 mm thick walls that

are further strengthened by a supporting U-channel.

A single foot support at one end and a double foot at

the other end allows for lengthwise and sideways

leveling.

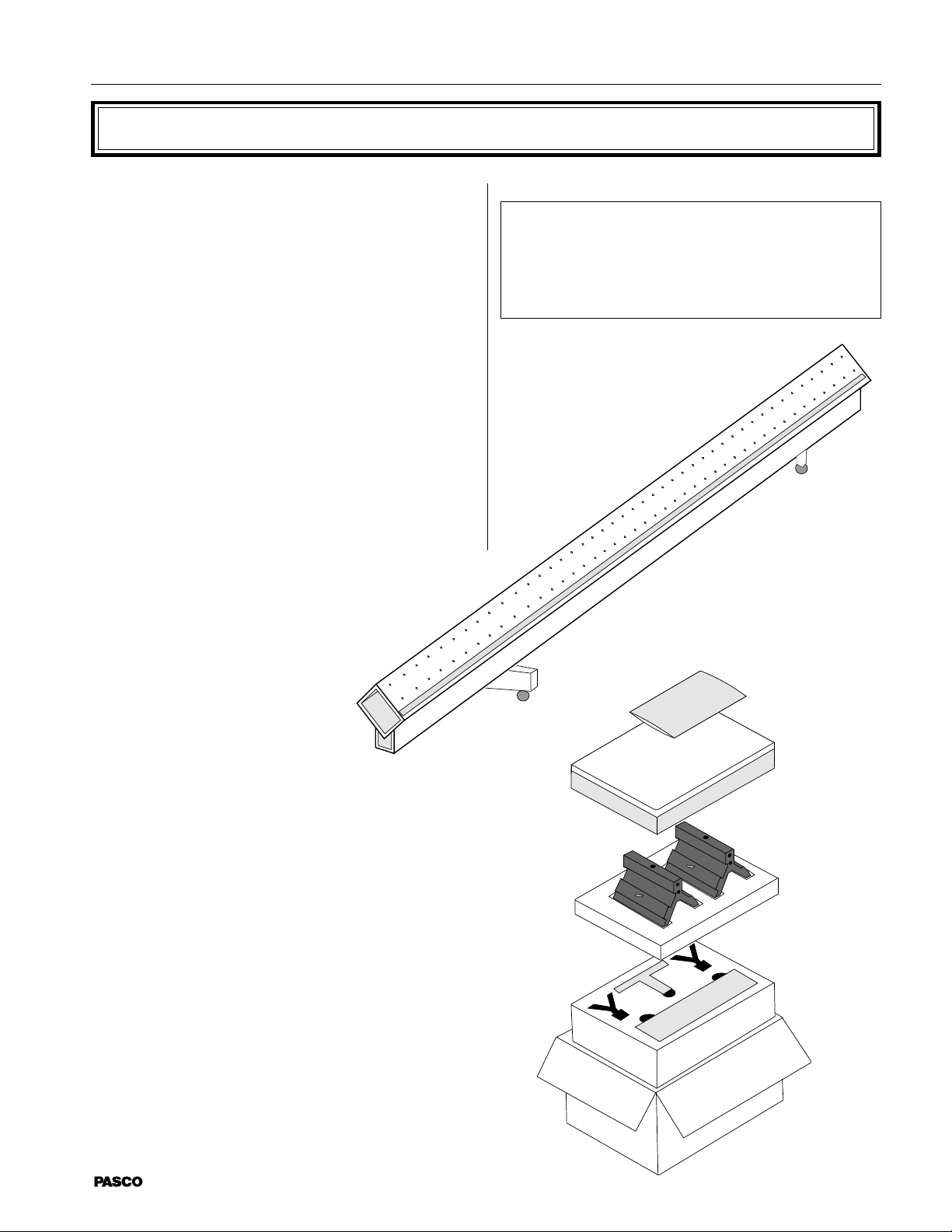

Unpacking and Setup

The SF-9214 Air Track is shipped in two containers, a

large tube (containing the track) and a cardboard box

(containing the accessories).

➧ CAUTION: Use care not to scratch or nick the

upper surfaces of the track. (Those containing the

airholes.) Any protrusion on this surface may

impede the motion of the glider.

Air Track

Gently remove one end from the air track shipping tube

and carefully pull the track, with the alignment beam

attached, from the tube.

Equipment included:

• 2 m Air Track

Accessories:

Envelope:

• 2 (100 mm) Flags

Top Layer:

• 1 Accessory tray

Middle Layer:

• 2 Gliders

• Mounting hardware (2 single leg screws, 2 double

leg screws, (1) 4 mm wrench, (1) 5 mm wrench)

Bottom Layer:

Envelope

Top Layer

Middle Layer

Bottom Layer

• 1 Single leg

• 1 Double leg w/adjustable feet

• 2 End Stops

Additional Equipment Required:

• Air Supply (Model SF-9416)

scientific

Accessories Box

1

Page 6

The Accessory Tray

1 Pulley

w/banana plug

012-02149B

50 g Additional Mass for

gliders (4PL)

Rubber Band Bumpers

w/banana plug (3PL)

Mounting Screw for

End Stops (4PL)

1 Mass hanger

and Mass set

Hook attachment

w/banana plug

Bumper Blade on

cylinder w/banana

plug (2PL)

1 Wax filled cylinder

w/banana plug

Needle on cylinder

w/banana plug

2

scientific

Page 7

012-02149B

Equipment Setup

Assembling the Air Track

1. Use the screws and Allen wrenches provided and

attach the single and double leveling foot to the Air

Track U-channel as shown in Figure 2.

Adjusting

4 mm Allen

wrench

Single foot

Figure 2 Attaching the Leveling Feet

2. Install one end stop at

each end of the Air Track

using the mounting

screws included in the

accessory tray.

feet

5 mm Allen

wrench

Bracket

End stop

Leveling the Air Track

Place the Air Track on a stable, level table and rotate

the two adjustable feet until the Air Track is as level as

possible. A bubble level may be used to approximately

level the track.

The final leveling, however, must be accomplished in

the following manner:

➀ Connect the Air Track to the Air Supply and turn

the Air Supply on.

➁ Place a glider in the middle of the track without

initial velocity.

➂ Adjust the leveling screws until the glider remains

at its initial position, not accelerating in either

direction.

➦ NOTE: The glider may oscillate slightly

about its position. This movement is caused by

air currents from the air holes in the track and

should be considered normal.

Adjusting the Air Supply

The Air Supply PASCO Model SF-9216 is connected

to the Air Track by the air fitting on one end of the

track. The output of the blower should be adjusted so

that the glider just floats on the track. Excessive air

pressure may cause the glider to wander on the track,

even in the absence of an accelerating force.

scientific

Figure 3 Installing

End Stops

The Air Supply will slightly heat the Air Track,

causing it to expand. The adjustment beam under the

track has been set such that the track will be straight to

+/- .04 mm when warm, or after 5 minutes of operation

with the Air Supply.

3

Page 8

Accessories

Glider

The black anodized aluminum glider has a mass of

180 g ± 1 g and a length of 129 mm ±1 mm.

To increase the mass of the glider simply place the

supplied masses on the steel pins protruding from each

side of the glider.

012-02149B

Flags

When using photogates to measure the velocity of the

glider, insert the 100 mm flags in the top surface of

each glider to interrupt the photogate beam.

The glider itself may also be used as a "flag". If a flag

of different length is required, simply cut a piece of

thin cardboard or aluminum to the desired length and

tape it to the top of the glider.

Additional Masses

50 g each

➦ NOTE: Masses must always be added sym-

metrically (the same number on each side), or the

glider will not function properly.

Glider accessories, such as the rubber band bumpers,

are mounted in one of the holes located at each end of

the glider.

➦ NOTE: In most cases the accessories should

be mounted in the lower hole, so as not to interfere with any photogate operation.

These accessories will increase the mass of the glider

and must be taken into account in all calculations.

➧ IMPORTANT: If an accessory (such as the

bumper plate) is placed on one end of the glider,

then an accessory of equal mass (such as a

bumper or the bumper plate) should be

placed at the opposite end.

This way the glider

will remain

level on the

Air Track

and will not

tend to propel

itself in one

direction.

➦ NOTE: The following accessories mount to

the Air Track End Stop or the Glider via standard

4 mm plugs. Except for the Pulley, each accessory weighs approximately 10 grams.

Always load a glider symmetrically, one accessory on each end

Rubber Band Bumpers

These bumpers provide a soft collision, eliminating any

vibration of the glider as it collides with another glider

or an end stop.

4

scientific

Page 9

012-02149B

When mounted on the End Stops,

these bumpers may also be used

as glider launchers:

– Pull the glider

back until it

touches the nut

on the end of the

bumper.

– Release the

glider.

– Change the

impulse imparted to the glider by moving the

rubber band to a different groove in the bumper.

Bumper Plate

This plate mounts on the end of the glider and is

designed to collide with the rubber band bumper.

Hook

The hook may be mounted to the end or top of the

glider. It is used to attach a string to the glider.

Pulley

The pulley is mounted in the

bottom hole of the end stop,

opposite the air input. A string

attached to the glider, passed over

the pulley and attached to a

hanging mass on the other end

can be used to accelerate the glider.

➦ NOTE: To protect the glider,

do not let it hit the End Stop.

Rubber Band Bumper

here OR here

Wax Tube and Needle

The wax tube is mounted on the end of a glider for an

inelastic collision. After a number of collisions the wax

should be pressed into the tube to maintain adequate

adhesion with the needle.

The needle is mounted on the end of the second glider.

It needs to be positioned so the needle will stick into

the wax tube of the other glider once the two gliders

collide, causing the gliders to stick together.

➦ NOTE: The needle is covered by a small cork

for protection . When the needle is stored in the

accessory tray, replace the cork on the needle.

Air Track Mass/Hanger Set

2 g mass hanger

2 g mass (plastic )

10 g mass (metal)

5 g mass (metal)

scientific

1 g mass (plastic)

5

Page 10

Maintenance

012-02149B

Air Track

The only maintenance required is to keep the Air Track

surface clean and free of scratches or nicks. When the

unit is stored make sure that nothing can damage the

Air Track surface. If the track becomes nicked, such

that a protrusion on the surface hinders the free motion

of the glider, gently file or sand down the protrusion.

The PASCO Air Track is factory aligned so the deviation from linearity is less than ±.04 mm. The construction of the unit is designed that the track should remain

within these specifications for many years. However,

through excessive stress on the track it is possible that

it may get out of alignment. This condition produces an

uneven velocity of the glider as it travels along the

track. The glider will speed up and slow down as it

traverses the slight curves in the track.

Should uneven motion of the glider make use of the

product objectionable, the Air Track should then be

realigned. This procedure requires a special test tool

and we recommend that the unit be returned to

PASCO for adjustment. Please contact PASCO scientific for information on returning your Air Track for

alignment.

Glider

Gliders must be handled with care to maintain a

friction-free motion the Air Track. If any scratches or

nicks develop on those surfaces that float on the track

they must be removed with a file or sandpaper. If the

glider is dropped or bent out of alignment, it must be

straightened so its profile matches that of the Air

Track. If the angle between the two sides of the glider

is too small the glider will stick to the track. If the

angle is too large the glider will wobble as it moves on

the track.

Rubber Band Bumper

The rubber bands may deteriorate with time. They may

be replaced with any elastic band that produces the

desired launch and "bounce" characteristics.

➦ NOTE: To extend the life of the rubber

bands, remove them from the rubber band

bumpers when not in use. Also, excessive handling of the rubber bands may remove the

protective powder used to coat the rubber.

Experiments

The specifics of the experiments performed on the Air

Track are a function of the timing system used.

Therefore, the experiments are included with the

various timing systems available from PASCO.

Please reference the manuals provided with the following PASCO products:

• ME-9218 Air Track and Self-contained Photogate

System

• ME-9394 Air Track and Computer Photogate

System (Apple II)

• ME-9363A Air Track and Computer Photogate

System (IBM PC and compatible)

• ME-9336 Air Track and Computer Sonic Ranger

System (Apple II)

• ME-9391 Air Track and Computer Sonic Ranger

System (IBM PC and compatible)

• ME-9226 Air Track and Spark Timer System

• ME-9206A Photogate Timer

• ME-9215A Photogate Timer with Memory

• PI-8025 Counter/Timer/Frequency Meter

• SF-9297 Coupled Harmonic Oscillators

6

scientific

Page 11

012-02149B

Replacement Parts

Air Track Accessories (included):

Description Part No.

Mass/hanger set 655-001

Bumper with holder 655-002

Bumper blade 655-003

Needle 655-004

Wax tube 655-005

Glider hook 655-006

Glider 655-007

Additional glider mass 655-008

Pulley 655-009

100 mm Flag 655-011

End stop, fixed 655-014

Accessory Kit SF-9295

(in molded case)

Accessories available (not included):

Description Part No.

End stop, adjustable 655-010

25 mm Flag 655-012

U-shaped flag 655-013

2 m Hose SF-9298

scientific

7

Page 12

Recommended Equipment

012-02149B

Model SF-9216 Air Supply –

A variable speed air supply suitable to power one or

two Model SF-9214 Air Tracks.

Model SF-9217 T-Adaptor and Hose –

Permits operating two Air Tracks from one air supply.

Model SF-9224 Additional Glider Kit –

This kit includes one glider with two additional 50 g

masses, a bumper plate and a rubber band bumper.

ME-9239 Riser Block Kit –

This set of four aluminum riser blocks (.25 to 2 cm

thickness) tilt the Air Track to precise and repeatable

angles.

Model SF-9296 Electric Launcher –

This launcher, designed for use only with the PASCO

Air Track, launches the glider repeatedly with the same

impulse and velocity.

➦ Note: Requires a power supply. Refer to the

PASCO catalog.

SF-9297 Coupled Harmonic Oscillators –

The kit includes three gliders, six 50 g masses, springs

and connecting plugs, allowing experiments with up to

five gliders in coupled harmonic motion.

ME-9356 Force Transducer to Air Track Mounting

Kit –

Mounting the PASCO Force Transducer to the Air

Track enables measuring the impulse in an air track

collision.

ME-9206A Basic Photogate Timer –

A self-contained timer with resolution to 1.0 mS and

1% accuracy

ME-9215A Photogate Timer with Memory –

A self-contained timer with resolution to .1 mS, 1%

accuracy and a memory feature for taking collision

measurements.

ME-9204A Accessory Photogate –

Plugs into any PASCO Photogate Timer or Counter/

Timer for taking "pulse" or timing measurements over

longer distances.

PI-8025 Counter/Timer/Frequency Meter –

The capability of operating as two independent timers

with memory, provides a total of four measurements in

a single experiment.

8

scientific

Page 13

Technical Support

Feedback

If you have any comments about the product or

manual, please let us know. If you have any suggestions on alternate experiments or find a problem in the

manual, please tell us. PASCO appreciates any

customer feedback. Your input helps us evaluate and

improve our product.

To Reach PASCO

For technical support, call us at 1-800-772-8700

(toll-free within the U.S.) or (916) 786-3800.

fax: (916) 786-3292

e-mail: techsupp@PASCO.com

web: www.pasco.com

Contacting Technical Support

Before you call the PASCO Technical Support staff,

it would be helpful to prepare the following information:

➤ If your problem is with the PASCO apparatus,

note:

- Title and model number (usually listed on the

label);

- Approximate age of apparatus;

- A detailed description of the problem/sequence

of events. (In case you can’t call PASCO right

away, you won’t lose valuable data.);

- If possible, have the apparatus within reach

when calling to facilitate description of individual parts.

➤ If your problem relates to the instruction manual,

note:

- Part number and revision (listed by month and

year on the front cover);

- Have the manual at hand to discuss your ques-

tions.

Page 14

Loading...

Loading...