Page 1

®

Instruction Manual and

Experiment Guide

012-05035G

*012-05035*

1.2 m Classic Dynamics System

ME-9429B

Page 2

Page 3

1.2 m Classic Dynamics System Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

About the Experiments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Experiment 1: Conservation of Momentum in Explosions . . . . . . . . . . . . . . . . . . . . . . . 11

Experiment 2: Conservation of Momentum in Collisions . . . . . . . . . . . . . . . . . . . . . . . . 13

Experiment 3: Simple Harmonic Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Experiment 4: Oscillations on an Incline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Experiment 5: Springs in Series and Parallel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Experiment 6: Launch Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Experiment 7: Newton’s Second Law . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Experiment 8: Acceleration Down an Incline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Experiment 9: Conservation of Energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Additional Experiment Suggestions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Page 4

1.2 m Classic Dynamics System

®

2

3

4

5

6

7

8

a

c

b

1

13

12

11

10

9

ME-9429B

4

Page 5

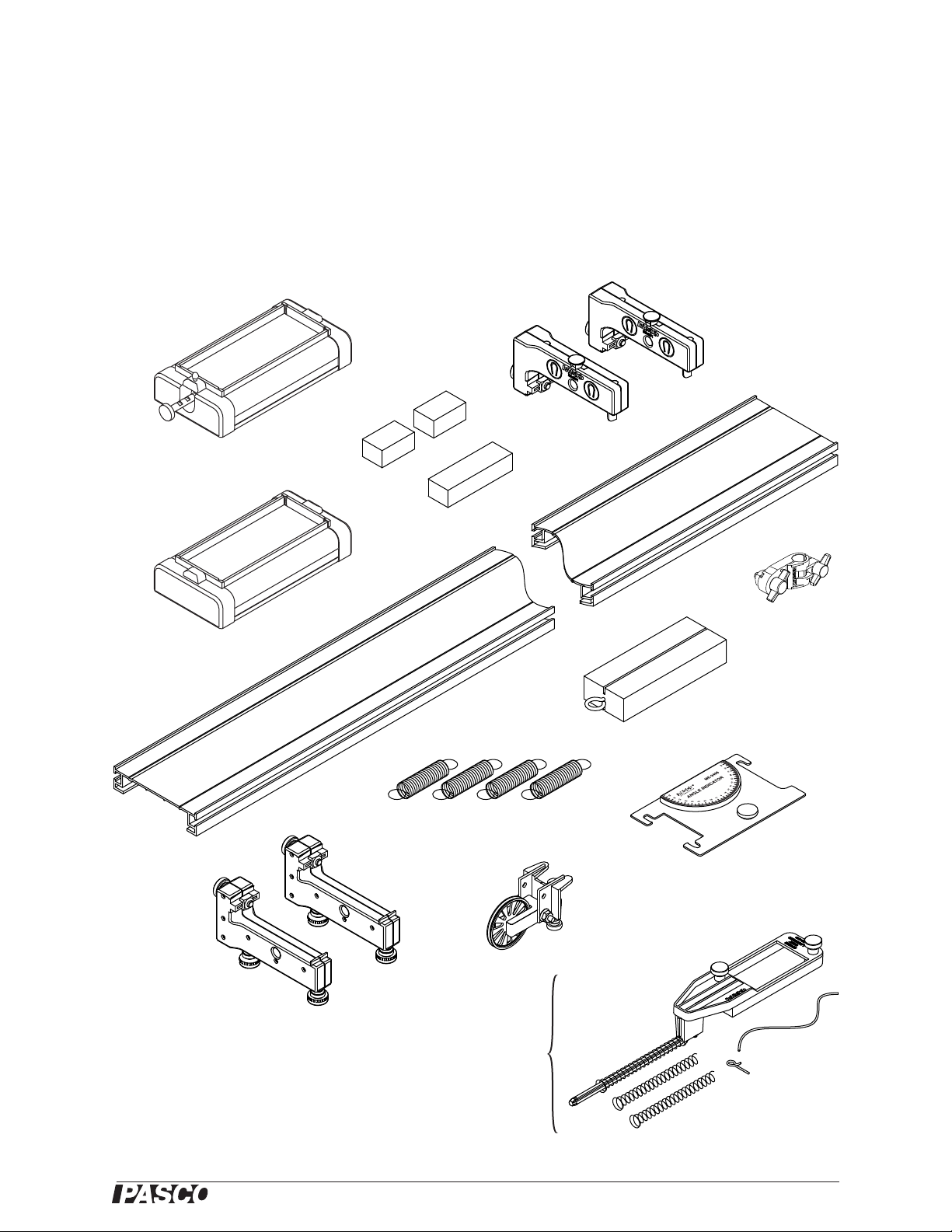

Included Equipment Quantity Replacement Part Number

1. Plunger Cart 1 ME-9340

2. Collision Cart 1 ME-9454

3. 250 g Compact Cart Masses 2 ME-6755

4. 500 g Cart Mass 1 ME-6757

5. Adjustable End Stops 2 ME-8971 (2-pack)

6. 1.2 m Dyna mic s Track 1 ME-9779

7. Adjustable Feet 2 ME-8972 (2-pack)

8. Harmonic Springs 4 ME-9803 (3-pack)

9. Friction Block 1 ME-9807

10. Pivot Clamp 1 ME-9810

11. Super Pulley with Clamp 1 ME-9448A

12. Angle Indicator 1 ME-9495

13. Spring Cart Launcher with: ME-6843

a. Compression Springs 3

b. Release Pin 2

c. String 1 m

ME-6847 (6 springs, 4 release pins)

Introduction

The 1.2 m Classic Dynamics System includes every thing you need for a variety of experiments and demonstrations. You can also combine it with many other PASCO products—both traditional and computer-based—for an

even greater range of uses.

This manual contains descriptions of the included equipment, complete instructions for nine experiments, and

ten additional experiment suggestions.

®

5

Page 6

®

1.2 m Classic Dynamics System About the Equipment

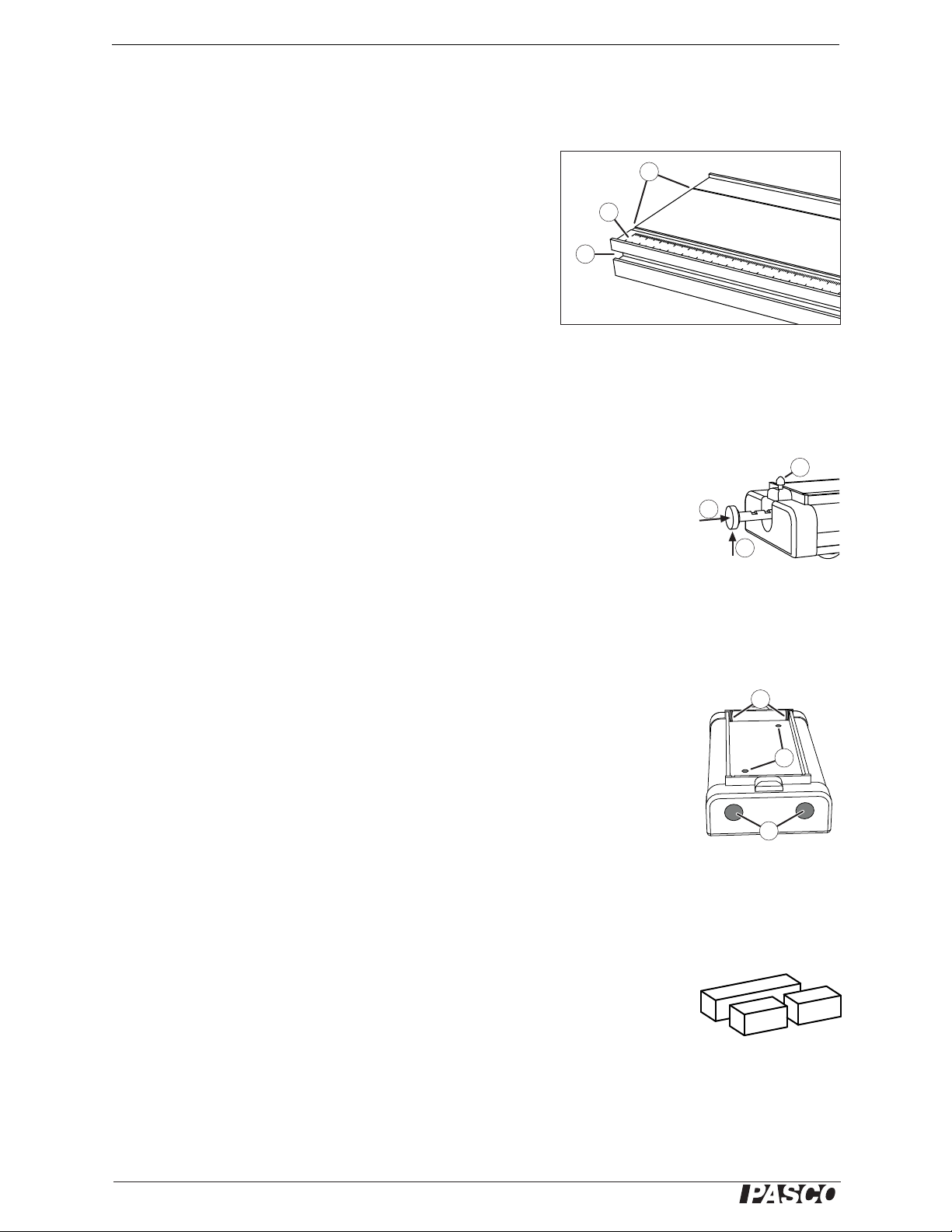

Track Features

1: Grooves 2: Metric sclae 3: T- slot

2

3

1

1

2

3

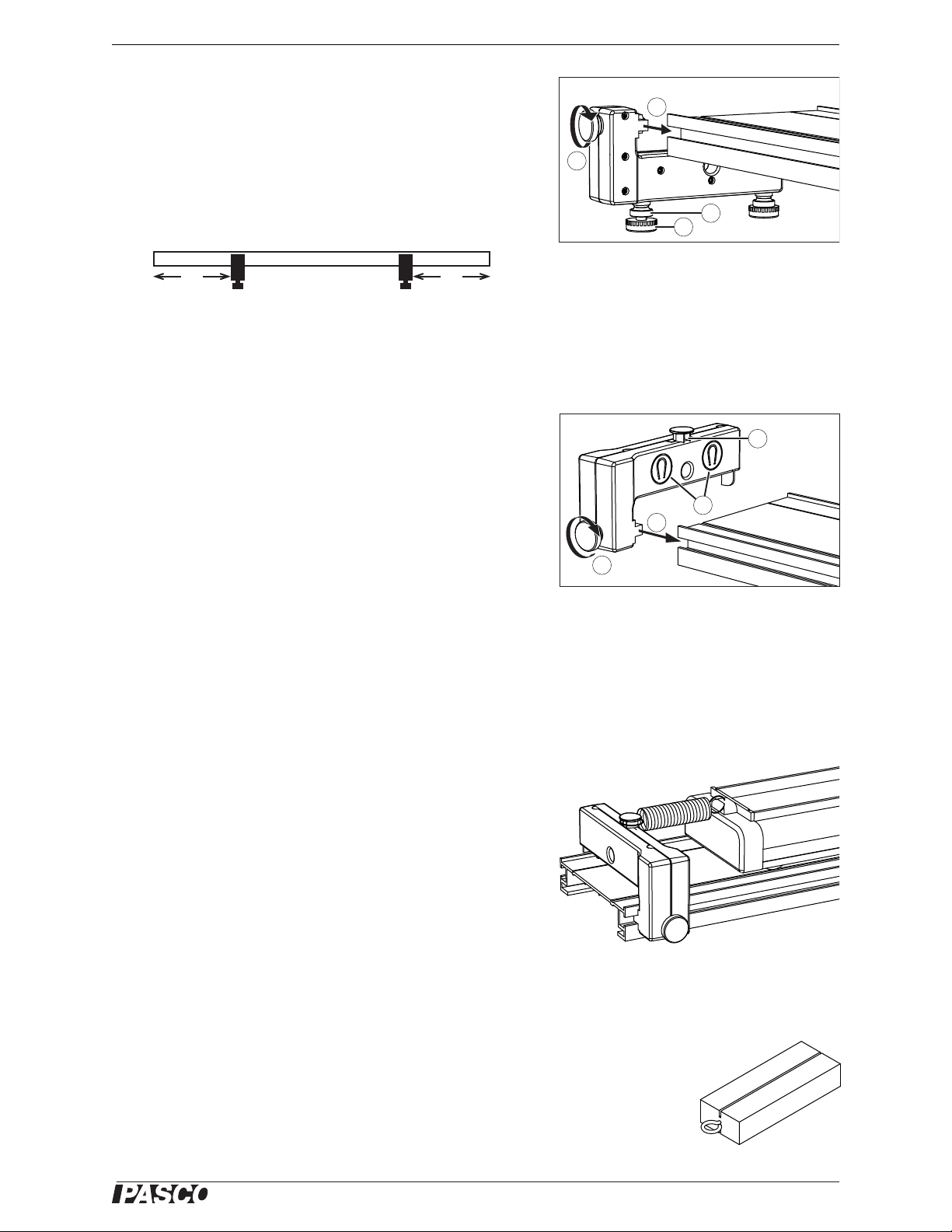

Plunger Cart

1: Push plunger in.

2: Push up to lock.

3: Tap button to trigger.

2

Cart Features

1: Slots 2: Tapped holes

3: Bumpers

Cart Masses

About the Equipment

Track The 1.2 m aluminum track has two groves to guide the

wheels of carts, a metric scale for measuring cart positions, and

T-slots on both sides for attaching end stops, leveling feet and

other accessories.

Tip: The track is designed to support the weight of carts and related

apparatus. Excess weight will warp it. When you store the track, ensure

that no heavy object will be placed on top of it.

Plunger Cart and Collision Cart These carts run along the track on low-friction wheels.

The plunger cart includes a spring-loaded plunger that launches the cart off of an end

stop or another cart. Push the plunger in to the first, second, or third “click” (for a

slow, medium, or fast launch); then push up to make the trigger catch. To make the

plunger pop out, tap the trigger button with a hard object (such the included 500 g

mass). When the plunger is not in use, push it all the way in to the third position.

For elastic and inelastic collisions, both carts have hook-and-loop bumpers on one

end and magnetic bumpers on the other end. When the hook-and-loop bumpers collide, the carts stick to each other. When the magnetic bumpers collide, the carts repel

each other without touching. The magnetic bumpers also repel the magnets in the end

stops.

The top or each cart forms a tray designed to hold the included masses. The carts also

feature tapped holes for attaching accessories and sensors, and slots for holding a

picket fence (such as PASCO part ME-9804) or the included angle indicator.

For more information, see the manuals packaged with both carts.

1

3

Cart Masses These masses are designed to be placed on the upper tray of a cart.

6

Page 7

®

Model No. ME-9452 About the Equipment

2

1

3

4

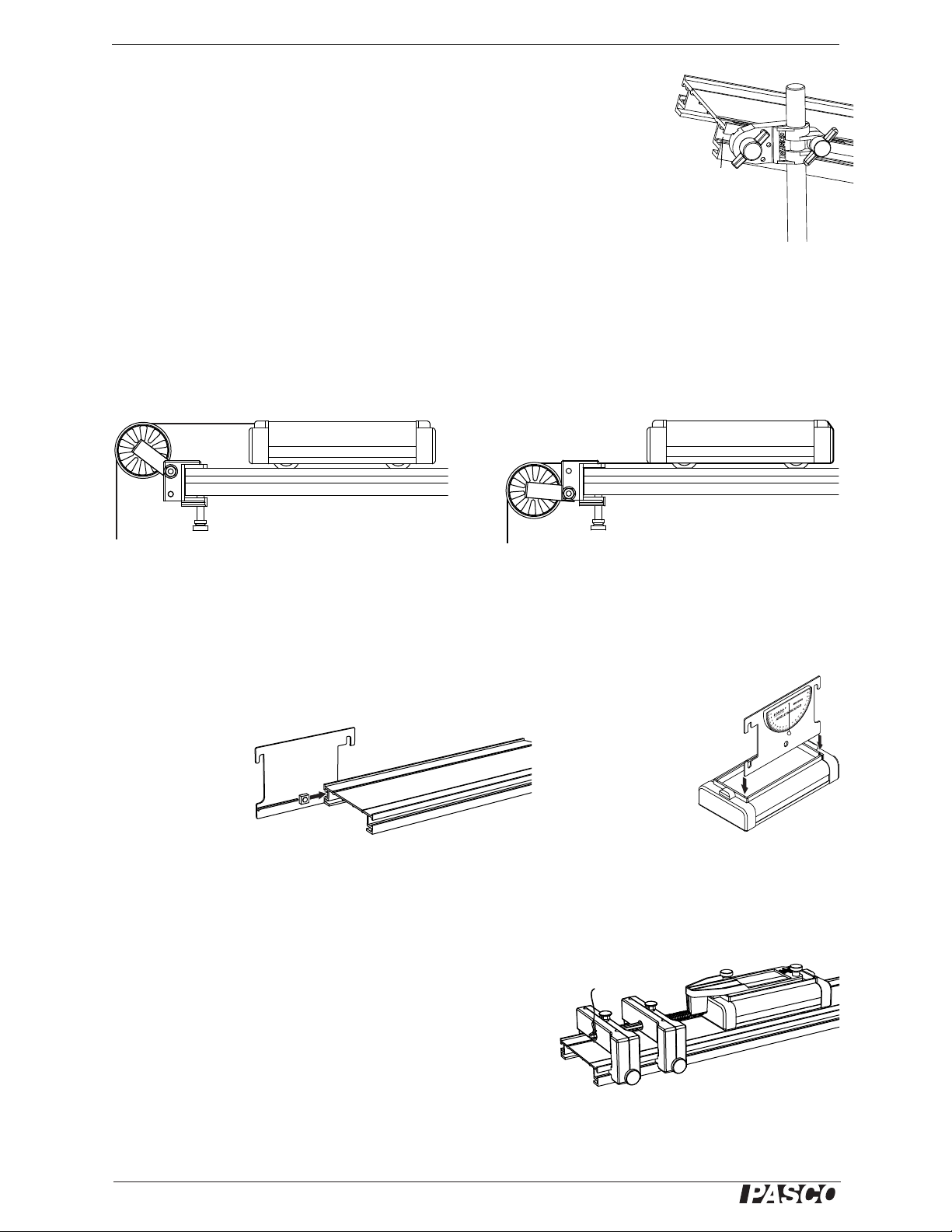

Adjustable Feet

1: Slide tab into T-slot. 2: Tighten thumbscrew to

secure feet set. 3: Turn feet screws to level track.

4: Tighten lock nuts to secure feet screws.

1/4 1/4

1

2

3

4

Adjustable End Stop

1: Slide tab into T-slot on side of track. 2: Tighten

thumbscrew to secure end stop. 3: Magnets repel

cart’s magnetic bumper 4: Spring attachment stud

Harmonic Spring

Friction Block

Adjustable Feet Attach the feet to the track as illustrated.

Turn the feet screws to level the track then tighten the lock nuts

to secure them.

For maximum stability, position the feet about 1/4 of the track

length from each end

Adjustable End Stops Attach the end stops to the track

as illustrated. The end stops contain magnets to repel the magnetic bumper of a cart. A stud is provided as an attachment

point for a spring.

Harmonic Springs Ideal for studying harmonic oscillation

of carts on a flat or inclined track, these spring hook onto holes

at the ends of the carts and to studs on top of the end stops. The

springs are packed in storage tubes, which include adhesive

tape so that they may be permanently attached to the underside

of the track.

Friction Block The friction block has two different surfaces (wood and felt) and

two different surface areas for studying friction. It includes an eye screw for attaching

a string and slots on both broad surfaces for holding a picket fence (such as PASCO

part ME-9804) or the included angle indicator.

7

Page 8

®

1.2 m Classic Dynamics System About the Equipment

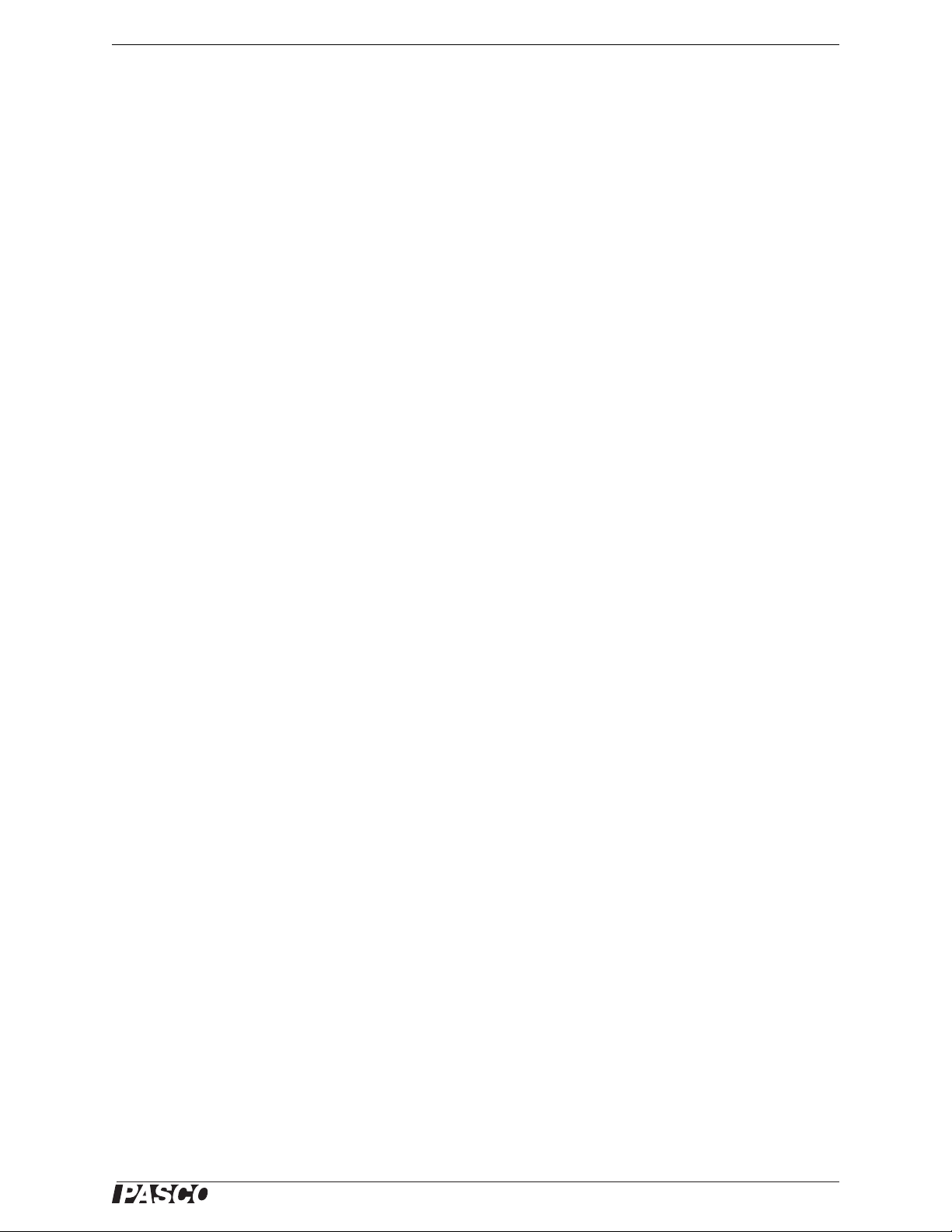

Pivot Clamp

T-slot

Angle Indicator on cart

Spring Cart Launcher

Pivot Clamp Attach the pivot clamp to the T-slot of the track (as illustrated) to ele-

vate one end of the track on a vertical rod.

Super Pulley with Clamp This low-friction, low-inertia pulley is designed for

clamping onto the end of the track. Tie a string to the hole in the end of the cart an run

it over the pulley. Adjust the height of the pulley to make the string parallel to the

track.

The pulley can also be mounted in the lower position as illustrated. Tie the string to

the opposite end of the cart and wrap it underneath the cart. In the lower position, the

string can be run under an end stop, another cart, or a motion sensor.

Super Pulley with string in normal position (left) and lower position (right)

Angle Indicator Attach the angle indicator to the track as illustrated, or remove

the attachment screw and slip it into the slots of a cart or friction block. The hanging

thread indicates the angle or incline.

Angle Indicator on track

Spring Cart Launcher This accessory is designed for the

study of force and motion, potential energy, conservation of

energy, the work-energy theorem, Hooke’s Law, and spring

constants. Use it to launch either cart by compressing and

releasing one of three interchangeable springs. The included

release pin, in combination with two end stops, allows you to

use precisely the same spring compression for multiple

launches.

8

For more information, see Experiment 9 on page 29 and the manual

packaged with with the launcher.

Page 9

®

Model No. ME-9452 Spare Parts

Spare Parts

You can order any of the major components of the system using the part numbers

listed in the table on page 5. For an assortment of smaller parts, the following kits are

available.

IDS Spares Kit (ME-9823) This kit includes assorted thumbscrews, square nuts,

and harmonic springs.

Cart Launcher Springs Kit (ME-6847) This kit includes four compression

springs and four release pins for the Spring Cart Launcher.

For help identifying a part, contact PASCO technical support (see page 34).

About the Experiments

These nine experiments can be done with the equipment included in the system and

other equipment commonly found in introductory physics labs. See each experiment

for a specific equipment list.

1. Conservation of Momentum in Explosions (page 11): Demonstrate conserva-

tion of momentum when two carts push off from each other.

2. Conservation of Momentum in Collisions (page 13): Demonstrate conserva-

tion of momentum in elastic and inelastic collisions.

3. Simple Harmonic Oscillator (page 15): Study how the period of oscillation of a

system varies with its mass.

4. Oscillations on an Incline (page 18): Study the oscillation of a cart attached to a

spring on an inclined track.

5. Springs in Series and Parallel (page 21): Examine how springs combined in

different ways affect the period of oscillation of a cart.

6. Launch Speed (page 23): Show qualitatively how the final speed of the plunger

cart depends on its mass and the initial compression of the plunger spring.

7. Newton’s Second Law (page 24): Show quantitatively how the acceleration of a

cart is related its mass and net force.

8. Acceleration Down an Incline (page 26): Determine the strength of earth’s

gravity (g) by measuring the acceleration of a cart on an inclined track.

9. Conservation of Energy (page 29): Use the spring cart launcher to launch a cart

up an incline. Compare the potential energy initially stored in the spring to the

maximum gravitational potential energy achieved by the cart.

Additional Experiment Su ggestion s (page 32): Many of these suggestions are variations on the above experiments. Some require additional carts.

9

Page 10

®

1.2 m Classic Dynamics System About the Experiments

10

Page 11

®

Model No. ME-9429A Experiment 1: Conservation of Momentum in Explosions

pm1v1m2v

2

–0==

v

1

v

2

---- -

m

1

m

2

------

=

v

1

v

2

---- -

x

1

t

-------- -

x

2

t

-------- -

-------------- -

x

1

x

2

-------- -

==

x

1

x

2

-------- -

m

1

m

2

------

=

Experiment 1: Conservation of Momentum in Explosions

Required Equipment from Dynamics System

Track with Feet and End Stops

Plunger Cart

Collision Cart

Cart Masses

Other Required Equipment Suggested Model Number

Mass set ME-9348

Purpose

The purpose of this experiment is to demonstrate conservation of momentum with

two carts pushing away from each other.

Theory

When two carts push away from each other (and there is no net force on the system),

the total momentum is conserved. If the system is initially at rest, the final momentum

of the two carts must be equal in magnitude and opposite in direction to each other so

the resulting total momentum of the system is zero:

Therefore, the ratio of the final speeds of the carts is equal to the ratio of the masses of

the carts.

T o simpli fy this experiment, the starti ng point for the carts at rest is chosen so that the

two carts will reach the ends of the track simultaneously. The speed, which is the distance divided by the time, can be determined by measuring the distance traveled since

the time traveled by each cart is the same.

Thus the ratio of the distances is equal to the ratio of the masses:

Procedure

1. Instal the feet on the track and level it. Install one end stop at each end with the

magnetic sides facing away from the carts.

11

Page 12

®

1.2 m Classic Dynamics SystemExperiment 1: Conservation of Momentum in Explosions

Figure 1.1

2. For each of the cases in Table 1.1, place the two carts against each other with the

plunger of one cart pushed completely in and latched in its maximum position

(see Figure 1.1).

3. Tap the plunger release button with a short stick and watch the two carts move to

the ends of the track. Experiment with different starting positions until the two

carts reach the ends of the track at the same time. Measure the masses of the

carts. Record the masses and the starting position in Table 1.1.

Table 1.1: Results

Additional

Mass on

Cart 1

00

500 g 0

1000 g 0

500 250

Additional

Mass on

Cart 2

m

1

m

2

Starting

Position

x

1

Data Analysis

1. For each of the cases, calculate the distances traveled from the starting position to

the end of the track. Record the result in Table 1.1.

2. Calculate the ratio of the distances traveled and record in the table.

3. Calculate the ratio of the masses and record in the table.

Questions

1. Does the ratio of the distances equal the ratio of the masses in each of the cases?

In other words, is momentum conserved?

x

2

x1/x

2

m2/m

1

2. When carts of unequal masses push away from each other, which cart has more

momentum?

3. When the carts of unequal masses push away from each other, which cart has

more kinetic energy?

4. Is the starting position dependent on which cart has the plunger? Why?

12

Page 13

®

Model No. ME-9429A Experiment 2: Conservation of Momentum in Collisions

Experiment 2: Conservation of Momentum in Collisions

Required Equipment from Dynamics System

Track with Feet

Plunger Cart

Collision Cart

Other Required Equipment

Paper (for drawing diagrams)

Purpose

The purpose of this experiment is to qualitatively explore conservation of momentum

for elastic and inelastic collisions.

Theory

When two carts collide with each other, the total momentum of both carts is conserved regardless of the type of collision.

An elastic collision is one in which the carts bounce off each other with no loss of

kinetic energy . In this experiment, magnetic bumpers are used to minimize the energy

losses due to friction during the collision. In reality, this “elastic” collision is slightly

inelastic.

A completely inelastic collision is one in which the carts hit and stick to each other . In

this experiment, this is accomplished with the hook-and-loop bumpers on the carts.

Part I: Elastic Collisions

Figure 2.1

1. Instal the feet on the track and level it.

2. Orient the two carts on the track so their magnetic bumpers are toward each

other.

3. Test cases A1 through A3 and B1 through B3 described below. Draw two dia-

grams (one for before the collision and one for after the collision) for each case.

In every diagram, show a velocity vector for each cart with a length that approximately represents the relative speed of the cart.

A. Carts with Equal Mass

Case A1: Place one cart at rest in the middle of the track. Give the other cart an initial

velocity toward the cart at rest.

13

Page 14

®

1.2 m Classic Dynamics System Experiment 2: Conservation of Momentum in Collisions

Case A2: Start the carts with one at each end of the track. Give each cart approximately the same velocity toward each other.

Case A3: Start both carts at one end of the track. Give the first cart a slow velocity

and the second cart a faster velocity so that the second cart catches the first cart.

B. Carts with Unequal Mass

Put two mass bars in one of the carts so that the mass of one cart is approximately

three times the mass (3M) of the other cart (1M).

Case B1: Place the 3M cart at rest in the middle of the track. Give the other cart an

initial velocity toward the cart at rest.

Case B2: Place the 1M cart at rest in the middle of the track. Give the 3M cart an initial velocity toward the cart at rest.

Case B3: Start the carts with one at each end of the track. Give each cart approximately the same velocity toward each other.

Case B4: Start both carts at one end of the track. Give the first cart a slow velocity

and the second cart a faster velocity so that the second cart catches the first cart. Do

this for both cases: with the 1M cart first and then for the 3M cart first.

Part II: Completely Inelastic Collisions

1. Orient the two carts so their hook-and-loop bumpers are toward each other. Push

the plunger in all the way so it will not interfere with the collision.

2. Repeat test cases A1 through A3 and B1 through B3 and draw diagrams for each

case.

Questions

1. When two carts having the same mass and the same speed collide and stick

together, they stop. Is momentum conserved?

2. When two carts having the same mass and the same speed collide and bounce off

of each other elastically, what is the final total momentum of the carts?

14

Page 15

®

Model No. ME-9429A Experiment 3: Simple Harmonic Oscillator

T 2

m

k

--- -=

Experiment 3: Simple Harmonic Oscillator

Required Equipment from Dynamics System

Track with Feet and End Stops

Cart

Super Pulley with Clamp

Harmonic Springs (2)

500 g Cart Mass

Other Required Equipment Suggested Model Number

Mass hanger and mass set ME-9348

Stopwatch ME-1234

Mass balance SE-8723

String (about 2 m)

Graph paper

Purpose

The purpose is to measure the period of oscillation of a spring and mass system and

compare it to the theoretical value.

Theory

For a mass attached to a spring, the theoretical period of oscillation is given by

where T is the time for one complet e back -and-forth motion, m is the mass that is

oscillating, and k is the spring constant.

According to Hooke’s Law, the force, F, exerted by the spring is proportional to the

distance, x, by which the spring is comp ressed or stretched: F = kx, where k is the

spring constant. Thus the spring constant can be experimentally determined by applying different forces to stretch the spring different distances. If force is plotted versus

distance, the slope of the resulting straight line is equal to k.

Procedure

Measurements to Find the Spring Constant and Theoretical Period

1. Measure the mass of the cart and record it in Table 3.1.

2. Instal the feet on the track and level it.

3. Instal the end stops about 1 m apart.

4. Clamp the pulley at one end of the track.

5. Set the cart on the track and attach a spring to each end. Attach the other ends of

the springs to the end stops (see Figure 3.1).

15

Page 16

®

1.2 m Classic Dynamics System Experiment 3: Simple Harmonic Oscillator

Figure 3.1

6. Tie a string to the end of the cart farther from the pulley. Wrap the string under

the cart; then run it under one end stop and over the pulley as shown in Figure

3.1. Attach the mass hanger to the other end of the string. Adjust the pulley so

that the string runs parallel to the track.

7. Let the mass hang freely and wait for the cart to come to rest. Record the mass of

the hanger and the resting equilibrium position of the cart in Table 3.1.

8. Add mass to the hanger. Record the hanging mass and the new equilibrium posi-

tion of the cart in Table 3.1. Repeat this for a total of 5 different masses, being

careful not to over-stretch the springs.

Table 3.1: Data and Analysis

Mass of cart = __________

Hanging Mass Position Force

Measuring the Experimental Per iod

9. Displace the cart from equilibrium and let it go. Time 5 oscillations and record

the time in Table 3.2.

10. Repeat this measurement at 5 times, using the same initial displacement.

11. Add a 500 g mass to the cart and repeat steps 9 and 10.

Calculations

Spring Constant and Theoretical Period

1. Calculate the forces applied by the hanging mass and write them in Table 3.1.

2. Using the data in Table 3.1, plot force versus position. Draw the best-fit straight

line through the data points and determine the slope of the line. The slope is equal

to the effective spring constant, k.

k = ______________

16

Page 17

®

Model No. ME-9429A Experiment 3: Simple Harmonic Oscillator

3. Using the mass of the cart and the spring constant, calculate the theoretical period

of the cart alone and with added mass.

theoretical period of cart alone ________________

theoretical period of cart with added mass ________________

Experimental Period

1. Using the data in Table 3.2, calculate the average time for 5 oscillations with and

without the 500 g mass in the cart.

2. Calculate the period by dividing these average times by 5 and record the periods

in Table 3.2.

Table 3.2: Experimental Data

Trial Time for 5

Oscillations

1 period of cart without added mass

2

3

4

5

Average

1 period of cart with 500 g added mass

2

3

4

5

Average

Period

Comparison

Calculate the percent difference between the measured and theoretical values:

cart alone percent difference = ________________

cart with added mass percent difference = ________________

Questions

1. Does the period of oscillation increase or decrease as the mass is increases? Does

a more massive cart oscillate faster or slower?

2. If the initial displacement from equilibrium (the amplitude) is changed, does the

period of oscillation change? Try it.

17

Page 18

®

1.2 m Classic Dynamics System Experiment 4: Oscillations on an Incline

T 2

m

k

--- -=

q

Figure 4.1: Equipment Setup

Experiment 4: Oscillations on an Incline

Required Equipment from Dynamics System

Track with End Stop

Cart

Pivot Clamp

Harmonic Spring

Other Required Equipment Suggested Model Number

Base and support rod ME-9355

Mass hanger and mass set ME-9348

Stopwatch ME-1234

Mass balance SE-8723

Purpose

In this experiment, you will measure the period of oscillation of a spring and mass

system on an incline at different angles and compare it to the theoretical value.

Theory

For a mass attached to a spring, the theoretical period of oscillation is given by

where T is the time for one complete back-and-forth cycle, m is the mass that is oscillating, and k is the spri ng constant.

According to Hooke’s Law, the force exerted by the spring is proportional to the distance, x, by which the spring is compressed or stretched, F = kx, where k is the proportionality constant. The spring constant can be experimentally determined by

applying different forces to stretch the spring different distances. When the force is

plotted versus distance, the slope of the resulting straight line is equal to k.

Procedure

Measurements to Find the Spring Constant and Theoretical Period

1. Measure the mass of the cart and record it in Table

4.1.

2. Instal the end stop on the track near one end.

3. Set the cart on the track and attach a spring to one

end. Attach the other end of the spring to an the end

stop (see Figure 4.1).

4. Incline the track by raising the end of the track where the spring attached. As the

end of the track is raised the spring will stretch. Keep the angle of inclination of

the track small enough so the spring is not stretched more than about 50 cm. Use

18

Page 19

®

Model No. ME-9429A Experiment 4: Oscillations on an Incline

the pivot clamp and support stand to hold the track at this angle. Measure this

angle and record it in Table 4.1.

5. Let the cart hang freely and come to rest. Record the equilibrium position in

Table 4.1.

6. Add mass to the cart and record the new resting position. Repeat this for a total of

5 different masses, being careful not to over-stretch the spring.

Table 4.1: Measurements to Find Theoretical Period

Original Position (without added mass) = __________

Mass of Cart = __________

Angle of Incline = __________

Added Mass Position Force

Measuring the Experimental Per iod

7. Remove all of the added mass from the cart.

8. Displace the cart from equilibrium a specific distance and let it go. Time 3 oscil-

lations and record the time in Table 4.2.

9. Repeat this measurement at least 5 times, using the same initial displacement.

10. Change the angle of the incline and repeat steps 8 and 9. Follow steps 8 and 9 for

a total of three different angles.

Calculations

Spring Constant and Theoretical Period

1. Using the data in Table 4.1, calculate the force caused by the mass of the cart:

F = mg sin , where is the angle of incline.

2. Plot force versus position. Draw the best-fit st rai ght line through the data points

and determine the slope of the line. The slope is equal to the effective spring constant, k.

k = ______________

3. Using the mass of the cart and the spring constant, calculate the period using the

theoretical formula.

T = ______________

Experimental Period

1. Using the data in Table 4.2, calculate the average time for 3 oscillations.

19

Page 20

®

1.2 m Classic Dynamics System Experiment 4: Oscillations on an Incline

2. Calculate the period by dividing these average values by 3 and record the periods

in Table 4.2.

Table 4.2: Experimental Period

Time for 3 Oscillations

Angle

Questions

1. Does the period vary as the angle is changed?

2. How do the experimental values compare with the theoretical values?

3. Does the equilibrium position change as the angl e is changed?

4. What would be the period if the angle was 90°?

Average PeriodTrial 1 Trial 2 Trial 3 Trial 4 Trial 5

20

Page 21

®

Model No. ME-9429A Experiment 5: Springs in Series and Parallel

T 2

m

k

--- -=

k

4

2

m

T

2

-------------

=

Experiment 5: Springs in Series and Parallel

Required Equipment from Dynamics System

Track with End Stops

Cart

Pivot Clamp

Harmonic Springs (2)

Other Required Equipment Suggested Model Number

Base and support rod ME-9355

Stopwatch ME-1234

Mass balance SE-8723

Purpose

In this experiment, you will measure and compare the periods of oscillation of a cart

attached to various combinations of springs.

Theory

For a mass attached to a spring, the theoretical period of oscillation is given by

where T is the time for one complete back-and-forth cycle, m is the mass that is oscillating, and k is the spring constant. If the period of oscillation is measured, the spring

constant can be determined by

You will determine spring constant of a spring by measuring the period of oscillation

and mass of a cart attached to the spring. You will use the same method to determine

the effective spring constant of two identical springs combined in series and in parallel. For each type of combination, you will discover the relationship between the

spring constant of the single spring and the effective spring constant of the combination.

Procedure

Measuring the Spring Constant of a Single Spring

1. Measure the mass of the cart. Record this value at the top of Table 5.1.

2. Install the end stop on the track near one end.

3. Set the cart on the track and attach a spring to one end. Attach the other end of the

spring to the end stop (see Figure 5.1).

21

Page 22

®

1.2 m Classic Dynamics System Experiment 5: Springs in Series and Parallel

Figure 5.1: Single spring

Figure 5.2: Springs in series

Figure 5.3: Springs in parallel

Figure 5.4: Springs on opposite ends

4. Incline the track by raising the end where the

spring is attached. As the end of the track is

raised the spring will stretch. Incline the track

by raising the end of the track where the spring

attached. As the end of the track is raised the

spring will stretch. Keep the angle of inclination of the track small enough so the spring is

not stretched more than about 50 cm. Use the

pivot clamp and support stand to hold the track

at this angle.

5. Displace the cart from equilibrium and let it go.

Time 2 oscillations and record the time in

Table 5.1. Repeat this measurement at least 5

times, using the same initial displacement.

Measuring the Effective Spring Constant of

Spring Combinations

6. Add a second spring in series as shown in Fig-

ure 5.2 and repeat step 5.

7. Put the two springs in parallel as shown in Fig-

ure 5.3 and repeat step 5.

8. Arrange the springs as shown in Figure 5.4 and

repeat step 5.

Calculations

1. Using the data in Table 5.1, calculate the aver-

age time for 2 oscillations.

2. Calculate the period by dividing these times by

2 and record the periods in Table 5.1.

3. Using the periods and the mass of the cart, calculate the effective spring constants.

Table 5.1: Experimental Period

Time for 2 Oscillations

Springs

Single

Series

Parallel

Average PeriodTrial 1Trial 2Trial 3Trial 4Trial 5

Opposite ends

Questions

1. For which type of combination (series of parallel) is the effective spring constant equal to 2k?

2. For which type of combination (series of parallel) is the effective spring constant equal to k/2?

3. Is the arrangement with springs at opposite ends a series or parallel combination?

22

Page 23

®

Model No. ME-9429A Experiment 6: Launch Speed

Experiment 6: Launch Speed

Required Equipment from Dynamics System

Track with Feet and End Stops

Plunger Cart

Pivot Clamp

Cart Masses

Purpose

In this experiment, you will qualitatively demonstrate how the final speed of the

plunger cart depends on its mass and the initial compression of the plunger spring.

Procedure

1. Install the feet on the track and level it.

2. Install and end stop at each end of the track.

3. Push the plunger of the cart into the first, second, or third position. Place the cart

on the track with the plunger against one end stop. Tap the trigger button to

launch the cart.

4. Varying Spring Compression: Repeat step 3 three times. Perform the first trial

with the spring plunger cocked to the first possible position (the least compression) and then do two more trials increasing the force applied to the cart by

increasing the compression of the spring plunger.

5. Va rying Mass: For these trials, always cock the spring plunger to the maximum.

Observe the relative accelerations of the cart alone and with 250 g, 500g, 750 g,

and 1000 g of added mass.

Questions

1. When does the spring apply force to the cart? When is the net force on the cart

(ignoring friction) zero?

2. Does the final speed of the cart increase or decrease with increasing initial spring

compression?

3. Does the final speed of the cart increase or decrease with increasing cart mass?

23

Page 24

®

1.2 m Classic Dynamics System Experiment 7: Newton’s Second Law

Figure 7.1

a 2dt2=

Experiment 7: Newton’s Second Law

Required Equipment from Dynamics System

Track with Feet and End Stop

Cart

Super Pulley with Clamp

500 g Cart Mass

Other Required Equipment Suggested Model Number

Stopwatch ME-1234

Mass hanger and mass set ME-9348

Mass balance SE-8723

String (about 2 m)

Purpose

In this experiment, you will verify

Newton’s Second Law, F = ma.

Theory

According to Newton’s Second Law, F = ma, where F is the net force acting on the

object of mass m, and a is the resulting acceleration of the object.

For a cart of mass m

hanging mass m

ing mass) is the weight of hanging mass, F = m

on a horizontal track with a string attached over a pulley to a

1

(see Figure 7.1), the net force F on the entire system (cart and hang-

2

g, (assuming that friction is negligi-

2

ble).

According to Newton’s Second Law, this net force should be equal to ma, where m is

the total mass that is being accelerated, which in this case is m

to see if m

g = (m1 + m2)a as predicted by theory.

1

T o determine the acceleration, you will release the cart from rest and measure the time

(t) for it to travel a certain distance (d). Since d = (1/2)at

+ m2. You will check

1

2

, the acceleration can be cal-

culated using .

Procedure

1. Install the feet on the track and level it.

2. Install the end stop on the track near one end with the magnets facing away from

the track.

3. Measure the mass of the cart and record it in Table 7.1.

4. Attach the pulley and end stop to the track as shown in Figure 7.1. Place the cart

on the track. Tie a string to the end of the cart farther from the pulley. Wrap the

string under the cart. Tie a mass hanger on the other end of the string. Run the

string under the end stop and over the pulley. Adjust the pulley so that the string

runs parallel to the track. The string must be just long enough so the cart reaches

the end stop before the mass hanger reaches the floor.

24

Page 25

®

Model No. ME-9429A Experiment 7: Newton’s Second Law

5. Pull the cart back until the mass hanger reaches the pulley. Record this initial

release position in Table 7.1. This will be the release position for all the trials.

Make a test run to determine how much mass is required on the mass hanger so

that the cart takes about 2 seconds to complete the run. Because of reaction time,

too short of a total time will cause too much error. However, if the cart moves too

slowly, friction causes too much error. Record the hanging mass in Table 7.1.

6. Place the cart against the end stop on the pulley end of the track and record the

final position of the cart in Table 7.1.

7. Pull the cart back to the initial release position. Release it and time how long it

takes to reach the end stop. Record the time in Table 7.1.

8. Measure the time at least 5 times with the same mass and record these values in

Table 7.1.

Table 7.1: Experimental Period

Initial release position = __________

Final position = __________

Distance traveled (

d) = __________

Cart

Mass

Hanging

Mass

Time

9. Add a 500 g mass to the cart and repeat the procedure.

Data Analysis

1. Calculate the average times and record them in Table 7.1.

2. Record the distance traveled (from initial to final position) in Table 7.1.

3. Calculate the accelerations and record them Table 7.2.

4. For each case, calculate (m

5. For each case, calculate the net force, F

6. For each case, calculate the percent difference between F

record in Table 7.2.

+ m2)a and record in Table 7.2.

1

, and record in Table 7.2.

NET

Table 7.2:

and (m1 + m2)a and

NET

Average

TimeTrial 1 Trial 2 Trial 3 Trial 4 Trial 5

Cart Mass Acceleration

(m1 + m2)aF

= m2g % Difference

NET

Questions

1. Did the results of this experiment verify that F = ma?

2. Why must the mass in F = ma include the hanging mass as well as the mass of

the cart?

25

Page 26

®

1.2 m Classic Dynamics System Experiment 8: Acceleration Down an Incline

mg sin q

mg

q

Figure 8.1

a 2dt2=

q

Experiment 8: Acceleration Down an Incline

Required Equipment from Dynamics System

Track with End Stop

Cart

Pivot Clamp

Other Required Equipment Suggested Model Number

Base and support rod ME-9355

Stopwatch ME-1234

Graph paper

Purpose

In this experiment, you will investigate how the acceleration of a cart rolling down an

inclined track depends on the angle of incline. From you data, you will calculate the

acceleration of an object in free-fall.

Theory

A cart of mass m on an incline will roll down the incline as it is pulled by gravity. The

force of gravity (mg) is straight down as shown in Figure 8.1. The component of that

is parallel to the inclined surface is mg sin .

T o determine the acceleration, you will release the cart from rest and measure the time

(t) for it to travel a certain distance (d). Since d = (1/2)at

2

, the acceleration can be cal-

culated using .

A plot of a versus sin will be a straight line with a slope equal to the acceleration of

an object in free-fall, g.

Figure 8.2

Procedure

1. Set up the track as shown in Figure 8.2 with a pivot clamp and support stand. Ele-

vate the end of the track by about 10 cm.

2. Set the cart on the track against the end stop and record this final position in

Table 8.1. (Use the non-magnetic end of the cart so it touches the end stop.)

3. Pull the cart up to the top of the track and record the initial position where the

cart will be released from rest.

4. Release the cart from rest and use the stopwatch to time how long it takes the cart

to reach the end stop. The person who releases the cart should also operate the

26

Page 27

®

Model No. ME-9429A Experiment 8: Acceleration Down an Incline

stopwatch. Repeat this measurement 10 times (with different people doi n g the

timing). Record all the values in Table 8.1.

5. Lower the end of the track by 1 cm and repeat step 4. Use the same release posi-

tion.

6. Repeat step 4 for a total of 7 angles, lowering the end of the track by 1 cm for

each new angle.

Table 8.1: Data

Initial release position = __________

Final position = __________

Distance traveled (

10 cm 9 cm 8 cm 7 cm 6 cm 5 cm 4 cm

Trial 1

Trial 2

Trial 3

Trial 4

d) = __________

Height of Track

Trial 5

Trial 6

Time

Trial 7

Trial 8

Trial 9

Trial 10

Average

Data Analysis

1. Calculate the average time for each angle and record it in Table 8.1.

2. Calculate the distance traveled, d, from the initial to the final position.

3. Use the distance traveled and average time to calculate the acceleration for each

angle and record it in in Table 8.2.

Table 8.2: Analysis

Height Acceleration

10 cm

sin

9 cm

8 cm

7 cm

6 cm

5 cm

4 cm

27

Page 28

®

1.2 m Classic Dynamics System Experiment 8: Acceleration Down an Incline

4. Measure the hypotenuse of the triangle formed by the track and use this to calcu-

late sin for each angle.

Hypotenuse = __________

5. Plot acceleration versus sin . Draw the best-fit straight line and calculate its

slope. Calculate the percent difference between the slope and g = 9.8 m/s

slope = ______________________

% difference = _______________

Questions

1. Does your reaction time in operating the stopwatch cause a greater percentage

error at higher or lower track angles?

2. How will doubling the mass of the cart affect the results? Try it.

2

.

28

Page 29

®

Model No. ME-9429A Experiment 9: Conservation of Energy

k

F

x

x

----- -

=

Spring constant

U

spring

1

2

-- -

kx

2

=

Potential energy stored in

a spring

U

gravity

mgs sin=

Potential energ y of a cart

on an inclined track

Experiment 9: Conservation of Energy

Required Equipment from Dynamics System

Track with Feet and End Stops

Cart

Pivot Clamp

Spring Cart Launcher (with a spring and release pin)

Super Pulley with Clamp

Other Required Equipment Suggested Model Number

Base and support rod ME-9355

Mass hanger and mass set ME-9348

Graph paper

String (40 cm)

Purpose

In this experiment, you will determine the spring constant of a compression spring

and use the spring to launch a cart up an incline. You will compare the potential

energy initially stored in the spring to the maximum gravitational potential energy

achieved by the cart.

Theory

The spring constant of a spring is

(eq. 1)

where F

pressed.

The potential energy stored in a spring is

(eq. 2)

The change in gravitational potential energy of a cart moving up an inclined track is

(eq. 3)

is the force applied to the spring and x is the distance by with it is com-

x

2

where m is the mass of the cart, g = 9.8 m/s

, s is the distance traveled along the

track (in the uphill direction), and is the track’s angle of incline.

29

Page 30

®

1.2 m Classic Dynamics System Experiment 9: Conservation of Energy

Part I: Spring Constant

Procedure

1. Fit the spring cart launcher onto the top of the cart (as illustrated).

Tighten the thumbscrews to secure it.

2. Select

one of the included springs. Slide it onto

the launcher shaft with the flared end out. Turn the

spring to secure the end in the spring retention hole as illustrated.

Thumbscrews

3. Tie the string to the release pin.

Release pin String

Flared

end

4. Install an end stop about 20 cm from the end of the track.

5. Clamp a pulley to the same end of the track.

6. Position the track so that a mass hanging from the pulley is free

to hang over the edge of your lab bench.

7. Level the track so that the cart does not roll when release

d from a

standstill.

8. Place the cart on the

track with the

launcher shaft

through the hole in

the end stop.

9. Tie a piece of string (about 40 cm long) to the launcher shaft. Run the string over

the pulley and hang a 100 g mass from the string.

Spring

retention

hole

10. Adjust the pulley so that the string is horizontal between the pulley and the

launcher shaft.

11. In a table, record the position of the cart on the track and the total mass hanging

from the string.

12. Add 100 g to the hanging mass.

13. Repeat steps 11 and 12 up to about 500 g.

Data Analysis

1. Calculate the force applied to the spring at each step: Fx= mhg, where mh is the

hanging mass and g = 9.8 m/s

2. Make a graph of F

versus cart position.

x

3. Draw a best-fit line on your graph. The slope of that line equals the spring con-

stant, k.

Untie the string from the launcher shaft and remove the pulley for the next part.

30

2

.

Page 31

®

Model No. ME-9429A Experiment 9: Conservation of Energy

q

Part II: Spring Potential Energy and Kinetic Energy

Procedure

1. Place a second end stop on the track about 8 cm behind the first end stop.

2. Elevate one end of the track by about 20 cm.

3. Hold the cart on the track with the launcher shaft through the hole in

the first end stop, and with the spring just touching the end stop, but

not compressed. Record this position of the cart as x

.

1

4. Push the shaft through both and stops and put the release pin into the shaft. Let

the pin rest against the second end stop. Record this position of the cart as x

.

2

5. Pull out the release pin with a quick jerk.

6. Watch the cart carefully as it ascends the track. Observe the highest position

achieved. Try to read it to the nearest centimeter. Record this position as x

.

3

Data Analysis

1. Calculate the spring compression: x = x1 - x

2

2. Use x, the value of k that you found in the previous part, and Equation 2 to calcu-

late the initial potential energy of the spring.

3. Calculate the distance traveled by cart: s = x

3

- x

2

4. Measure the mass, m, of the cart with the cart launcher and spring attached.

5. Measure the angle, , of the track.

6. Use Equation 3 to calculate the change in gravitational potential energy of the

cart.

7. Compare the initial potential energy of the spring to the maximum gravitationa l

potential energy of the cart. Are they equal? If not, what might account for the

difference?

31

Page 32

®

1.2 m Classic Dynamics System Additional Experiment Suggestions

Additional Experiment Suggestions

Conservation of Center of Mass

Set up the track in the configuration shown in Figure 1.1 in Experiment #1 but instead

of putting the track directly on the table, place it on a 500 g mass bar so that the bar

acts as a fulcrum. Position the bar so the carts and track are balanced. First use two

carts of equal mass. Trigger the plunger and watch the carts move to the ends of the

track. Since the center of mass of the system does not move, the track remains balanced. Repeat this procedure using carts of unequal mass.

Oscillation Modes of T wo Carts and Three Springs

Place two carts of equal mass on the track. Attach a spring between the carts and connect each cart to their respective ends of the track with springs. Pull the carts away

from each other and release and observe the mode of oscillation. Then displace both

carts in the same direction initially and observe. Add a mass bar to one cart and

repeat.

Newton’s Second Law: Uphill Acceleration

Repeat Experiment 7 with the track inclined so the pulley is on the high end and the

cart accelerates up the incline.

Damped Motion

Incline the track with the end stop at the bottom. Release the cart from a measured

distance up the track. Use the magnetic bumpers in the cart and end stop so the cart

rebounds. On each rebound, when the cart reaches its peak, record the time and position. Make a graph of amplitude versus time.

Rocket Cart with Balloon

Attach an untied inflated balloon to the cart with the neck of the balloon directed out

the back of the cart. Let the air propel the cart.

For the following experiment suggestions, a 2.2 m track (such as model ME-9779) is recommended.

Oscillation modes of Three Carts and Four Springs

Place three carts of equal mass on the track. Attach springs between the carts and connect the end carts to the ends of the track with springs. Displace the two end carts

away from the middle cart and release and observe the mode of oscillation. Displace

the two carts on the left away from the cart on the right and release and observe the

mode of oscillation. Displace the middle cart and release and observe the mode of

oscillation.

Multiple Elastic Collisions

Use two Collision Carts and one Dynamics Cart. Try this experiment with carts of the

same mass and then with carts of different masses. Set the three carts on the track with

the Dynamics Cart on the right end with its magnetic bumper oriented toward the Collision Carts. Push the left Collision Cart into the middle cart, which in turn wi ll collide with the right cart. Note the resulting final velocities of each cart.

32

Page 33

®

Model No. ME-9429A Additional Experiment Suggestions

Multiple Inelastic Collisions

Use three carts with the magnets removed from the middle cart. Push the left cart into

the middle cart, which in turn will collide with the right cart. The carts will all stick

together. Note the resulting final velocity of the carts.

Rocket Staging

Use three or more plunger carts to simulate a rocket expelling fuel. Push the plungers

in on each cart and attach the carts together in a line. Use tape to lightly attach the

carts to each other. Position the carts at one end of the track. The lead cart represents

the rocket and the rest of the carts are fuel. Use a meter stick to release the plungers in

succession by striking the plunger-release of each cart, beginning with the last fuel

cart (furthest from the rocket cart). As each plunger is released, each cart will separate

from the rest, one at a time. Note the final speed of the rocket cart compared to its

speed when all the fuel is dumped at once.

Longitudinal Wave

Use six or more carts with magnetic bumpers installed on both ends. Install end stops

on the track with the magnetic side toward the center of the track. Start a longitudinal

pulse by displacing one of the carts. The carts will rebound off each other and the end

stops. Oscillate the end cart to keep a longitudinal wave going down the track.

33

Page 34

®

1.2 m Classic Dynamics System Technical Support

Technical Support

For assistance with any PASCO product, contact PASCO at:

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: 916-786-3800 (worldwide)

800-772-8700 (U.S.)

Fax: (916) 786-7565

Web: www.pasco.com

Email: support@pasco.com

Limited Warranty

For a description of the product warranty, see the PASCO catalog.

Copyright

The PASCO scientific 012-05035G 1.2 m Classic Dynamics System Instruction Manual is copyrighted with all rights reserved. Permission is granted to non-profit educational institutions for reproduction of any part of this manual, providing the reproductions are

used only in their laboratories and classrooms, and are not sold for profit. Reproduction under any other circumstances, without the

written consent of PASCO scientific, is prohibited.

Trademarks

PASCO and PASCO scientific are trademarks or registered trademarks of PASCO scientific , in the United States and/or in other countries. All other brands, products, or service names are or may be trademarks or service marks of, and are used to identify , products or

services of, their respective owners. For more information visit www.pasco.com/legal.

Authors: Ann Hanks

Jon Hanks

Eric Ayars

Alec Ogston

34

Loading...

Loading...