Page 1

Instruction Manual and

Experiment Guide for

the PASCO scientific

Model ME-8960

DEMONSTRATION

GYROSCOPE

012-05327B

4/94

ME-8960

DEMONSTRATION

GYROSCOPE

© 1994 PASCO scientific $10.00

10101 Foothills Blvd. • P.O. Box 619011 • Roseville, CA 95678-9011 USA

Phone (916) 786-3800 • FAX (916) 786-8905 • TWX 910-383-2040

better

ways to

teach physics

Page 2

Page 3

012-05327B Demonstration Gyroscope

T able of Contents

Section Page

Copyright, Warranty, and Equipment Return..................................................ii

Introduction .....................................................................................................1

Equipment........................................................................................................2

Assembly

ME-8960 Demonstration Gyroscope.........................................................3

ME-8961 Additional Gyroscope Disk....................................................... 5

Experiments

Experiment 1: Precession ....................................................................7

Experiment 2: Counter-rotating Disks - Demonstration.....................13

Experiment 3: Precession - Demonstration ........................................15

Experiment 4: Nutations - Demonstration..........................................17

Technical Support................................................................................. Back Cover

i

Page 4

Demonstration Gyroscope 012-05327B

Copyright, Warranty and Equipment Return

Please—Feel free to duplicate this manual

subject to the copyright restrictions below.

Copyright Notice

The PASCO scientific Model ME-8960 Demonstration

Gyroscope manual is copyrighted and all rights reserved.

However, permission is granted to non-profit educational

institutions for reproduction of any part of this manual

providing the reproductions are used only for their

laboratories and are not sold for profit. Reproduction

under any other circumstances, without the written

consent of PASCO scientific, is prohibited.

Limited Warranty

PASCO scientific warrants this product to be free from

defects in materials and workmanship for a period of one

year from the date of shipment to the customer. PASCO

will repair or replace, at its option, any part of the product

which is deemed to be defective in material or workmanship. This warranty does not cover damage to the product

caused by abuse or improper use. Determination of

whether a product failure is the result of a manufacturing

defect or improper use by the customer shall be made

solely by PASCO scientific. Responsibility for the return

of equipment for warranty repair belongs to the customer.

Equipment must be properly packed to prevent damage

and shipped postage or freight prepaid. (Damage caused

by improper packing of the equipment for return shipment will not be covered by the warranty.) Shipping

costs for returning the equipment, after repair, will be

paid by PASCO scientific.

Equipment Return

Should this product have to be returned to PASCO

scientific, for whatever reason, notify PASCO scientific

by letter or phone BEFORE returning the product. Upon

notification, the return authorization and shipping instructions will be promptly issued.

➤ NOTE: NO EQUIPMENT WILL BE AC-

CEPTED FOR RETURN WITHOUT AN AUTHORIZATION.

When returning equipment for repair, the units must be

packed properly. Carriers will not accept responsibility

for damage caused by improper packing. To be certain

the unit will not be damaged in shipment, observe the

following rules:

➀ The carton must be strong enough for the item

shipped.

➁ Make certain there is at least two inches of packing

material between any point on the apparatus and the

inside walls of the carton.

➂ Make certain that the packing material can not shift in

the box, or become compressed, thus letting the instrument come in contact with the edge of the box.

Address: PASCO scientific

10101 Foothills Blvd.

Credits

This manual authored by: Jon Hanks

This manual edited by: Jon Hanks

P.O. Box 619011

Roseville, CA 95678-9011

Phone: (916) 786-3800

FAX: (916) 786-8905

ii

Page 5

012-05327B Demonstration Gyroscope

Introduction

The PASCO ME-8960 Gyroscope has an open design

that makes all the parts easily accessible to the student.

The gyroscope consists of a disk that can be rotated by

hand or by pulling a string that is wrapped around the

pulley. A movable counterweight balances the disk.

The small counterweight is used to make fine adjustments to the balance. An add-on mass can be easily

placed on the end of the shaft to cause a torque and

precession. The rotational inertia of the disk is easily

obtained by accelerating the disk using a string around

the pulley that is attached to the disk.

1

Page 6

Demonstration Gyroscope 012-05327B

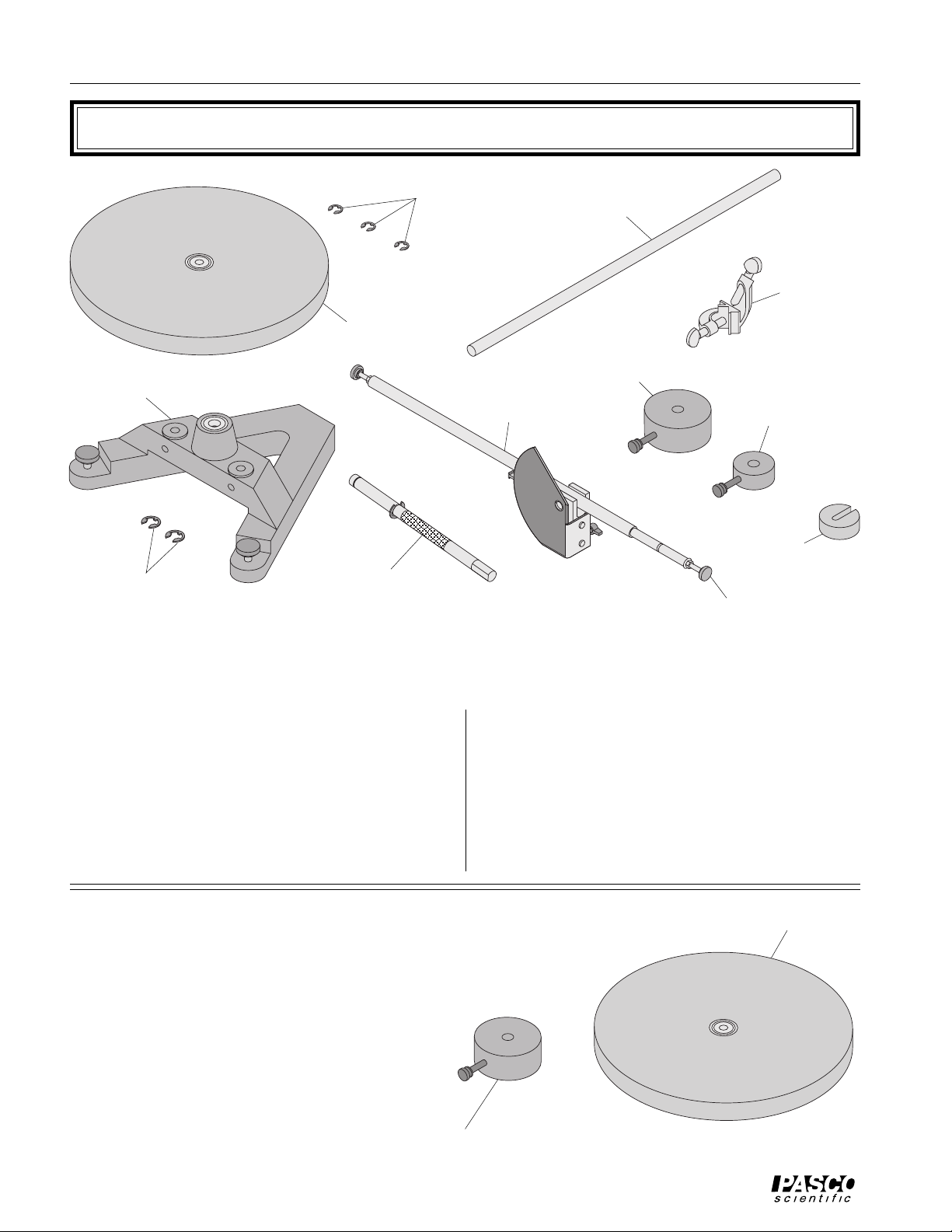

Equipment

cast iron

“A” base

“E” rings (2,

one extra

for rotating

axle)

rotating disk

rotating axle

“E” rings (3,

one extra for

rotating disk)

gyroscope

axle

ME-8960

DEMONSTRATION

GYROSCOPE

45 cm

support rod

right angle

rod clamp

900g

counterweight

30g

counterweight

150g add-

on mass

thumbscrews (2)

ME-8960 Demonstration Gyroscope Equipment

The ME-8960 Demonstration Gyroscope includes

the following:

– PASCO cast iron “A” base with rotating shaft

– axle (48 cm long) with pivot block, protractor

plate, and pointer

– one 900g large counterweight

– one 30g small counterweight

– one 150g add-on mass

The ME-8961 Additional Gyroscope Disk includes

the following:

– 25cm diameter rotating disk with pulley

– one 900g large counterweight

– 25cm diameter rotating disk with pulley

– 45 cm support rod

– right angle rod clamp

– extra “E” rings to secure rotating shaft and rotat-

ing disk

– two thumbscrews

rotating disk

900g

counterweight

2

ME-8961 Additional Gyroscope Disk

Page 7

012-05327B Demonstration Gyroscope

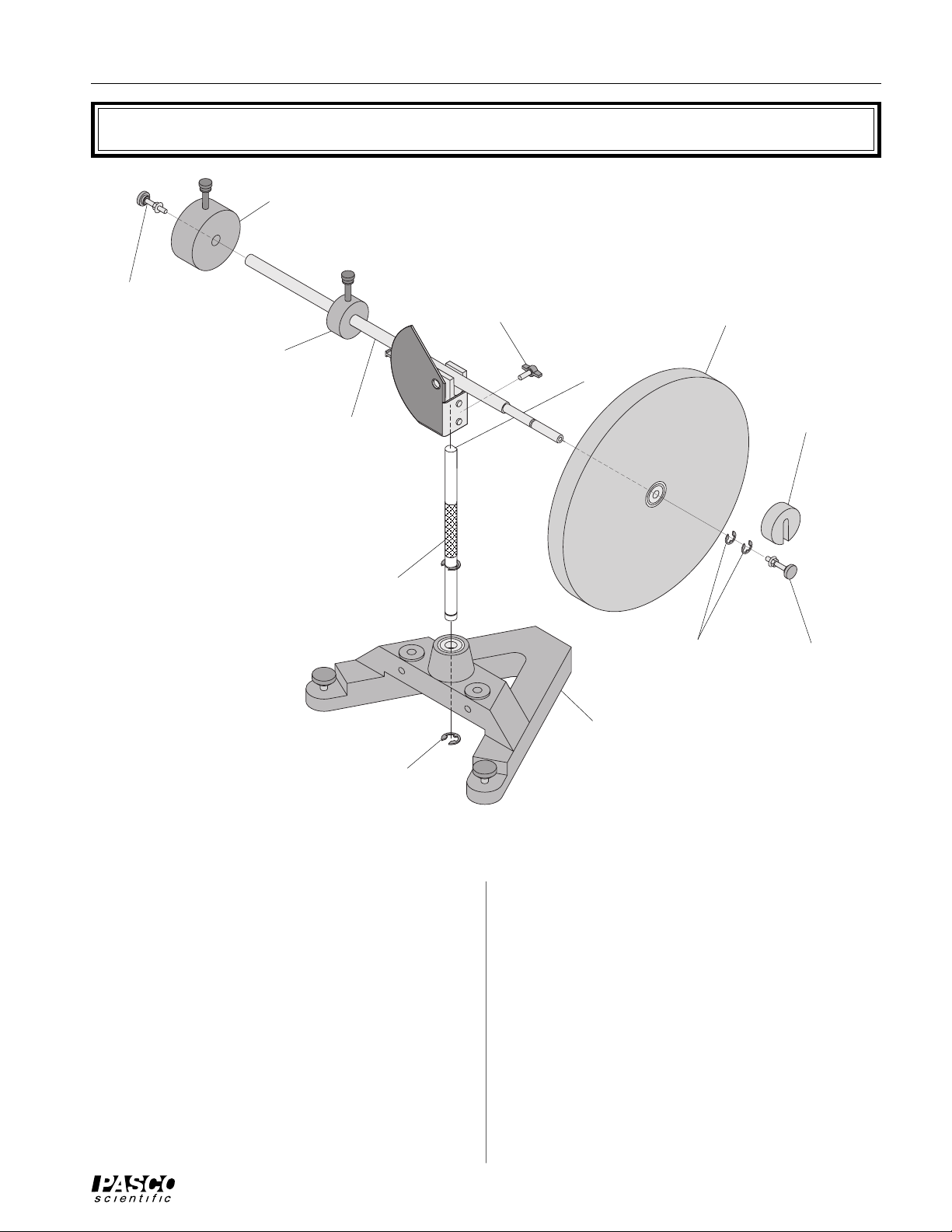

Assembly

900g

counterweight

thumbscrew

thumbscrew

rotating disk

30g

counterweight

gyroscope axle

rotating axle

“E” ring for

rotating axle

ME-8960

DEMONSTRATION

GYROSCOPE

flat of

rotating axle

cast iron “A” base

“E” rings (2) for

rotating disk

add-on mass

thumbscrew

Figure 1: Demonstration Gyroscope Assembly

ME-8960 Demonstration Gyroscope

Assembling the Demonstration Gyroscope

➀ Insert the cylindrical end of the vertical shaft into

the bearings on the top-side of the A-shaped iron

base. Secure the shaft in place by inserting the re-

taining ring in the slot at the bottom of the shaft.

See Figure 1.

➁ Attach the gyroscope axle to the vertical shaft and

tighten the thumb screw against the flat side of the

“D” on the vertical shaft.

➂ Slide the smaller of the two counterweights (30g)

onto the long side of the gyroscope axle and tighten

the thumbscrew. Then slide the larger of the two

counterweights (900g) onto the same end of the

shaft and tighten its thumbscrew.

➃ Put the disk on the other end of the gyroscope axle

with the pulley side of the disk facing the center of

the gyro. Secure the disk in place with the retaining

rings (2). See Figure 1.

➄ Screw the thumbscrew into the end of the shaft un-

til the nut is tight against the end of the shaft

3

Page 8

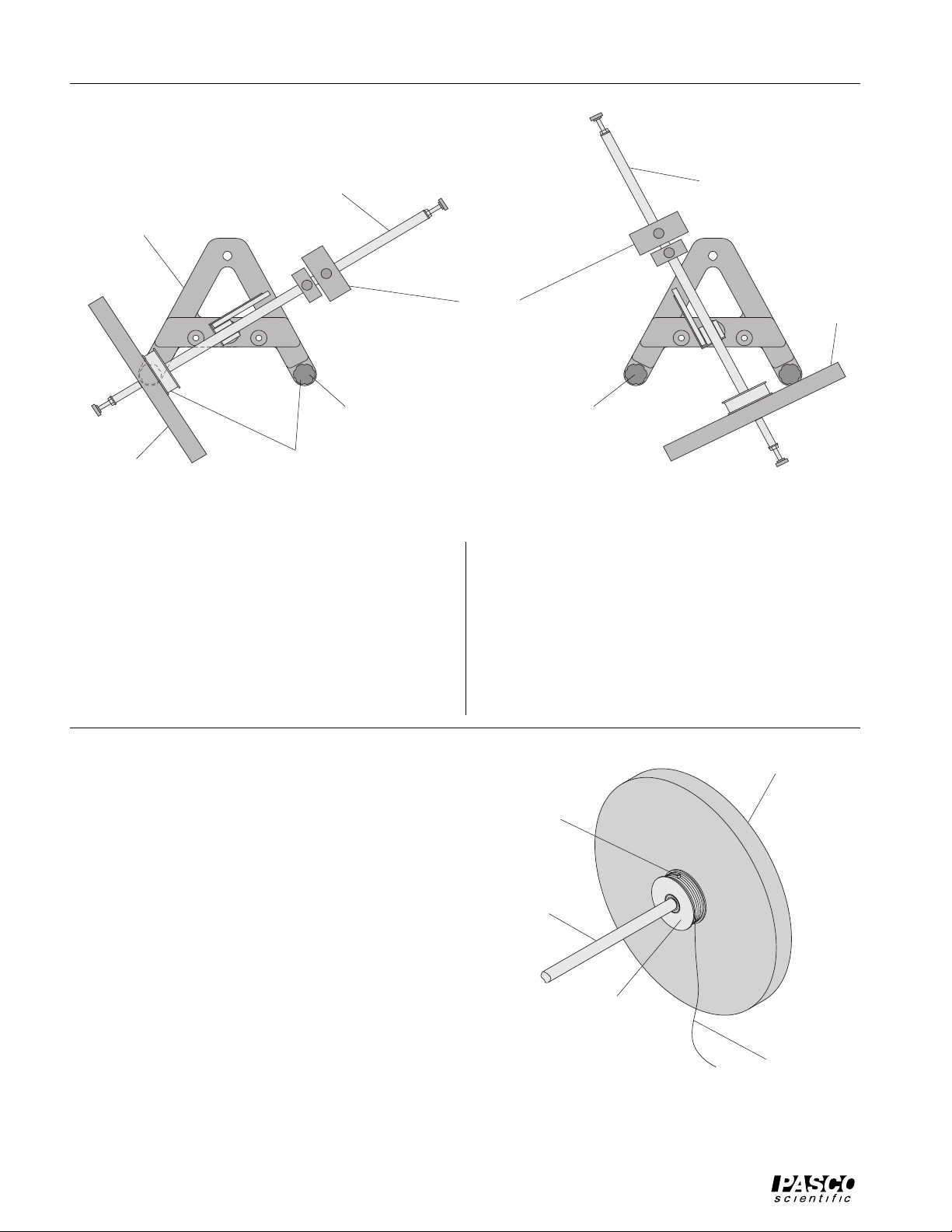

Demonstration Gyroscope 012-05327B

gyroscope axle

gyroscope axle

“A” base

(rotated 90˚)

adjust this foot first

rotating

disk

leveling feet

Figure 2: Leveling the Base

Leveling the Base

➀ Purposely make the apparatus unbalanced by mov-

ing the 900g counterweight towards the center.

➁ Adjust the leveling foot on one of the legs of the

base until the gyroscope disk is aligned over the

leveling foot on the other leg of the base. See Figure 2.

900g

counterweight

then adjust this foot

➂ Rotate the gyroscope 90 degrees so the gyroscope

axle is parallel to one side of the “A” and adjust the

other leveling foot until the shaft will stay in this

position. See Figure 2.

➃ Adjust the position of the 900g counterweight until

the gyroscope is balanced without the add-on mass.

The 30g counterweight can be used to fine tune the

balance.

rotating

disk

Using the Rotating Disk Pulley

➀ Make sure the rotating disk is secure on the gyro-

scope axle and decide which direction you want the

disk to rotate.

➁ Tie a loop in the end of a length of thread (approxi-

mately 1.5 meters long) and put the loop around the

dowel pin located on the surface of the rotating disk

pulley and wind the thread around the surface of

the pulley. See Figure 3.

➂ Holding the gyroscope axle in place, pull the thread

to rotate the disk at the desired speed.

rotating disk

dowel pin

gyroscope

axle

pulley

thread

Figure 3: Using the Rotating Disk Pulley

4

Page 9

012-05327B Demonstration Gyroscope

included 900g

counterweight

additional

gyroscope axle

(part of ME-8960)

Demonstration

ME-8960

Gyroscope

ME-8960

DEMONSTRATION

GYROSCOPE

gyroscope disk

add-on mass

(part of ME-8960)

Figure 4: Using the Additional Gyroscope Disk

ME-8961 Additional Gyroscope Disk

Using the Additional Gyroscope Disk

➀ Slide the included 900g counterweight onto the

long side of the gyroscope axle and tighten the

thumbscrew.

thumbscrew (part of

ME-8960)

➁ Put the Additional Gyroscope Disk on the other end

of the gyroscope axle with the pulley side of the

disk facing away from the center of the gyroscope

apparatus. Secure the disk in place with the supplied thumbscrew. See Figure 4.

5

Page 10

Demonstration Gyroscope 012-05327B

Notes:

6

Page 11

012-05327B Demonstration Gyroscope

dt

d

φ

dt

Experiment 1: Precession

EQUIPMENT NEEDED

– Gyroscope (ME-8960) – meter stick

– stopwatch (SE-8702) – table clamp for pulley

– Super Pulley (ME-9450) – thread (1.5 meters)

– Pulley Mounting Rod (SA-9242) – computer (optional)

– Mass and Hanger Set (ME-9348) – Smart Pulley (optional)

– balance – Smart Pulley software (optional)

Purpose

The purpose of this experiment is to measure the precession rate of a gyroscope and compare it to the theoretical value.

Theory

A torque is applied to the gyroscope by hanging a mass on the end of the shaft. This torque

causes the gyroscope to precess at a certain angular speed, Ω.

Assume that the gyroscope is initially balanced in the horizontal position, θ = 90˚. The disk

is spun at an angular speed (ω) and then a mass, m, is attached to the end of the gyroscope

shaft at a distance, d, from the axis of rotation. This causes a torque: τ = mgd. But the

torque is also equal to dL/dt, where L is the angular momentum of the disk. As shown in

Figure 1.1, for small changes in angle, dφ, dL = L dφ.

dφ

→

L

130

120

110

100

90

80

70

60

50

side view

d

ω

140

CAUTION

MAGNET

ME-8960

DEMONSTRATION

GYROSCOPE

40

30

mg

top view

Figure 1.1: Torque Applied to Horizontal Gyroscope

dL

→

→

L

Substituting for dL in the torque equation gives

τ

= mgd =

dL

= L

7

Page 12

Demonstration Gyroscope 012-05327B

Ω

ω

τ

α

F

Since dφ/dt = Ω, the precession speed,

mgd = L

and the precession rate is given by

mgd

Ω

=

I

where I is the rotational inertia of the disk and ω is the angular speed of the disk.

To find the rotational inertia of the disk experimentally, a known torque is applied to the

disk and the resulting angular acceleration is measured. Since τ = Iα,

I =

where α is the angular acceleration which is equal to a/r and τ is the torque caused by the

weight hanging from the thread which is wrapped around the pulley on the disk.

τ

= r

where r is the radius of the pulley about which the thread is wound and F is the tension in

the thread when the disk is rotating.

Applying Newton’s Second Law for the hanging mass, m, gives (See Figure 1.2)

Σ

F = mg – F = ma

F

pulley

hanging

mass

rotating disk

mg

Figure 1.2: Rotating Disk and Free-Body Diagram

α

Solving for the tension in the thread gives

F = m (g – a)

8

Page 13

012-05327B Demonstration Gyroscope

So, once the linear acceleration of the mass (m) is determined, the torque and the angular

acceleration can be obtained for the calculation of the rotational inertia. The acceleration is

obtained by timing the fall of the hanging mass as it falls from rest a certain distance (y).

Then the acceleration is given by

2y

a =

2

t

Part I: Measuring the Precession Rate

Setup

➀ Level the gyroscope base as described on page 4 in the Assembly section of this manual.

➁ Adjust the position of the large counterweight until the gyroscope is balanced without the

add-on mass. The small counterweight can be used to fine-tune the balance.

Procedure

➀ Weigh the add-on mass and record its mass in Table 1.1. Attach the add-on mass to the end

of the shaft. Measure the distance (d) from the axis of rotation to the center of the add-on

mass. Record this distance in Table 1.1

➁ While holding the gyroscope so it can’t precess, spin the disk at about two revolutions per

second. Time 10 revolutions of the disk to determine the angular speed (ω) of the disk.

Record in Table 1.1.

➂ Let the gyroscope precess and time two revolutions to find the precession rate. Record in

Table 1.1.

➃ Immediately repeat the measurement of 10 revolutions of the disk. The before-and-after

Table 1.1: Angular Speed Measurements

Add-On Mass

Distance (d)

Time for 10 Revolutions (initial)

Time for Precession

Time for 10 Revolutions (final)

data will be used to find the average angular speed of the disk during the precession.

9

Page 14

Demonstration Gyroscope 012-05327B

Part II: Measuring Quantities For the Theoretical Value

Setup

➀ Clamp the gyroscope shaft in the horizontal position. See Figure 1.3.

➁ Attach a Super Pulley with rod to the table using a table clamp.

➂ Wind a thread around the pulley on the center shaft and pass the thread over the Super

Pulley.

right angle rod

clamp

140

130

120

110

100

CAUTION

MAGNET

90

80

70

60

ME-8960

DEMONSTRATION

50

GYROSCOPE

40

30

rotating disk

support rod

Figure 1.3: Experiment Setup

Procedure

Accounting For Friction

Because friction is not included in the theory, it will be compensated for in this experiment

by finding out how much mass over the pulley it takes to overcome kinetic friction. When

the mass drops at a constant speed, the weight of the mass is equal to the kinetic friction.

Then this “friction mass” will be subtracted from the mass used to accelerate the apparatus.

➀ To find the mass required to overcome kinetic friction, put just enough mass hanging over

the pulley so that the velocity is constant. Record this friction mass in Table 1.2.

Finding the Acceleration of the Disk

➀ To find the acceleration, put about 30 g (record the exact hanging mass in Table 1.2) over

the pulley. Wind the thread up and let the mass fall from the table to the floor, timing the

fall.

➁ Repeat this for a total of 5 times, always starting the hanging mass in the same position.

➂ Measure the height that the mass falls and record this height in Table 1.2.

10

Page 15

012-05327B Demonstration Gyroscope

Alternate Computer Method:

If a computer and Smart Pulley are used, the acceleration of the disk can be obtained by

finding the slope of the velocity vs. time graph.

Measure the Radius

➀ Using calipers, measure the diameter of the pulley about which the thread is wrapped and

calculate the radius. Record the radius in Table 1.2.

Table 1.2 Rotational Inertia Data

Friction Mass

Hanging Mass

Height Mass Falls

Radius of Pulley

Times

Average:

Analysis

➀ Using the average time from Table 1.2, calculate the acceleration and record the result in

Table 1.3.

➁ Calculate the rotational inertia:

(a) Subtract the “friction mass” from the hanging mass used to accelerate the disk to

determine the mass, m, to be used in the equations.

(b) Calculate the experimental value of the rotational inertia and record it in Table 1.3.

➂ Using the times for 10 revolutions in Table 1.1, divide by 10 to find the periods. Average

these two periods and calculate the average angular speed (ω = 2π/T). Record the angular

speed in Table 1.3.

➃ Find the experimental value for the precession rate by dividing the precession time by two

and calculating Ω = 2π/T. Record in Table 1.3.

➄ Calculate the theoretical value for the precession rate and record in Table 1.3.

➅ Calculate the percent difference between the experimental and theoretical values of the

precession rate.

11

Page 16

Demonstration Gyroscope 012-05327B

Table 1.3: Results

Acceleration

Rotational Inertia

Average Angular Speed of Disk

Experimental Precession Rate

Theoretical Precession Rate

% Difference

Questions

➀ What happens to the direction of precession if the spin of the disk is reversed?

➁ How does the rate of precession change if the angular speed of the disk is increased?

12

Page 17

012-05327B Demonstration Gyroscope

Experiment 2: Counter-rotating Disks

- Demonstration

EQUIPMENT NEEDED

– Gyroscope (ME-8960)

– Accessory Disk and Extra Counterweight (ME-8961)

– Physics String (SE-8050)

Purpose

It is shown that two disks spinning in opposite directions at the same angular speed will not

precess when a torque is applied.

Setup

➀ Remove the screw in the end of the shaft and slide the second disk onto the shaft with the

pulley side facing away from the first disk. Secure the second disk by tightening the screw

in the end of the shaft. See Figure 2.1.

➁ Put the second counterweight on the other end of the shaft and slide the counterweights

until the gyroscope is balanced. Spin the disks and check the balance by seeing if the

gyroscope precesses. If it precesses, the balance needs further adjustment.

➂ Cut two pieces of string, each 1 meter long. Tie one end of each string to the ends of a pen.

The pen will be used to pull the two strings simultaneously. Tie a loop in the other end of

each string to hook over the dowel pins.

➃ To make the direction of rotation more visible to the students, stick a white paper dot on the

edge of each disk.

rotating disk (part of

additional 900g

counterweight (part

of ME-8961)

900g counterweight

(part of ME-8960)

“A” base

ME-8960)

140

130

120

110

100

CAUTION

MAGNET

90

80

70

60

ME-8960

DEMONSTRATION

50

GYROSCOPE

40

30

add-on mass

additional rotating disk

(part of ME-8961)

Figure 2.1: Counter-rotating disks

13

Page 18

Demonstration Gyroscope 012-05327B

Procedure

➀ Use your hand to spin both disks in the same direction. Show that the gyroscope does not

precess.

➁ Put the add-on mass on the end of the shaft and secure with a screw. Spin both disks in the

same direction and show that the gyroscope now precesses.

➂ Stop the disks and reverse the spin of both disks to show that the gyroscope now precesses

in the opposite direction.

➃ Now counter-rotate the disks. To do this, wrap an equal number of turns of string in oppo-

site directions around the pulleys on each of the disks. Pull on both strings simultaneously

using the pen as a handle. Point out that even though a torque is still being applied to the

gyro, the gyroscope does not precess when the two disks are spinning in opposite directions.

14

Page 19

012-05327B Demonstration Gyroscope

Experiment 3: Precession - Demonstration

EQUIPMENT NEEDED

– Gyroscope (ME-8960)

Purpose

It is shown that if a precessing gyroscope is restricted from precessing, the disk will fall.

See Figure 3.1.

rotating disk

140

130

120

110

100

CAUTION

MAGNET

90

80

70

60

ME-8960

DEMONSTRATION

50

GYROSCOPE

40

30

add-on mass

counterweights

rotating

axle

Figure 3.1: Precession

Procedure

➀ Adjust the counterweights until the gyroscope is balanced.

➁ Put the add-on mass on the end of the shaft.

➂ Spin the disk and allow the gyroscope to precess.

“A” base

rotating

axle

100

90

80

130

120

110

70

60

50

140

CAUTION

MAGNET

ME-8960

DEMONSTRATION

GYROSCOPE

40

30

rotating disk

➃ Slow or stop the precession by grabbing the center vertical shaft with your hand. As you do

so, the disk will fall.

➄ You can also cause the disk to rise by spinning the center vertical shaft in the same direc-

tion as the precession.

15

Page 20

Demonstration Gyroscope 012-05327B

Notes:

16

Page 21

012-05327B Demonstration Gyroscope

Experiment 4: Nutations - Demonstration

EQUIPMENT NEEDED

– Gyroscope (ME-8960)

Purpose

Three different types of nutation are shown.

Procedure

➀ Adjust the counterweights until the gyroscope is balanced.

➁ Put the add-on mass on the end of the shaft.

➂ Spin the disk and release the gyroscope from rest at an angle of about 30˚. See Figure 4.1.

rotating disk

140

counterweights

110

100

90

80

70

130

120

60

DEMONSTRATION

50

40

CAUTION

MAGNET

ME-8960

GYROSCOPE

30

add-on mass

rotating

axle

“A” base

Figure 4.1: Release Position of Gyro

➃ The resulting nutation will look like pattern (A) in Figure 4.2.

➄ Stop the precession and spin the disk again. Release the gyroscope from the same angle but

give it an initial push in the direction of precession. The resulting nutation will look like

pattern (B) in Figure 4.2.

➅ Stop the precession and spin the disk again. Release the gyroscope from the same angle but

give it an initial push in the direction opposite to the precession. The resulting nutation will

look like pattern (C) in Figure 4.2.

➆ Spin the disk at a different speed and check the effect this has on the speed of the nutation.

➇ Release the disk from a different angle and check the effect this has on the nutation.

17

Page 22

Demonstration Gyroscope 012-05327B

(A) Released from rest

(B) Released with

forward speed

Figure 4.2: Patterns of Resultant Nutations

(C) Released with

backward speed

18

Page 23

012-05327B Demonstration Gyroscope

T echnical Support

Feed-Back

If you have any comments about this product or this

manual please let us know. If you have any suggestions on alternate experiments or find a problem in the

manual please tell us. PASCO appreciates any customer feed-back. Your input helps us evaluate and

improve our product.

To Reach PASCO

For Technical Support call us at 1-800-772-8700 (tollfree within the U.S.) or (916) 786-3800.

Contacting Technical Support

Before you call the PASCO Technical Support staff it

would be helpful to prepare the following information:

• If your problem is computer/software related, note:

Title and Revision Date of software.

Type of Computer (Make, Model, Speed).

Type of external Cables/Peripherals.

• If your problem is with the PASCO apparatus, note:

Title and Model number (usually listed on the label).

Approximate age of apparatus.

A detailed description of the problem/sequence of

events. (In case you can't call PASCO right away,

you won't lose valuable data.)

If possible, have the apparatus within reach when

calling. This makes descriptions of individual parts

much easier.

• If your problem relates to the instruction manual,

note:

Part number and Revision (listed by month and year

on the front cover).

Have the manual at hand to discuss your questions.

19

Page 24

Loading...

Loading...