Page 1

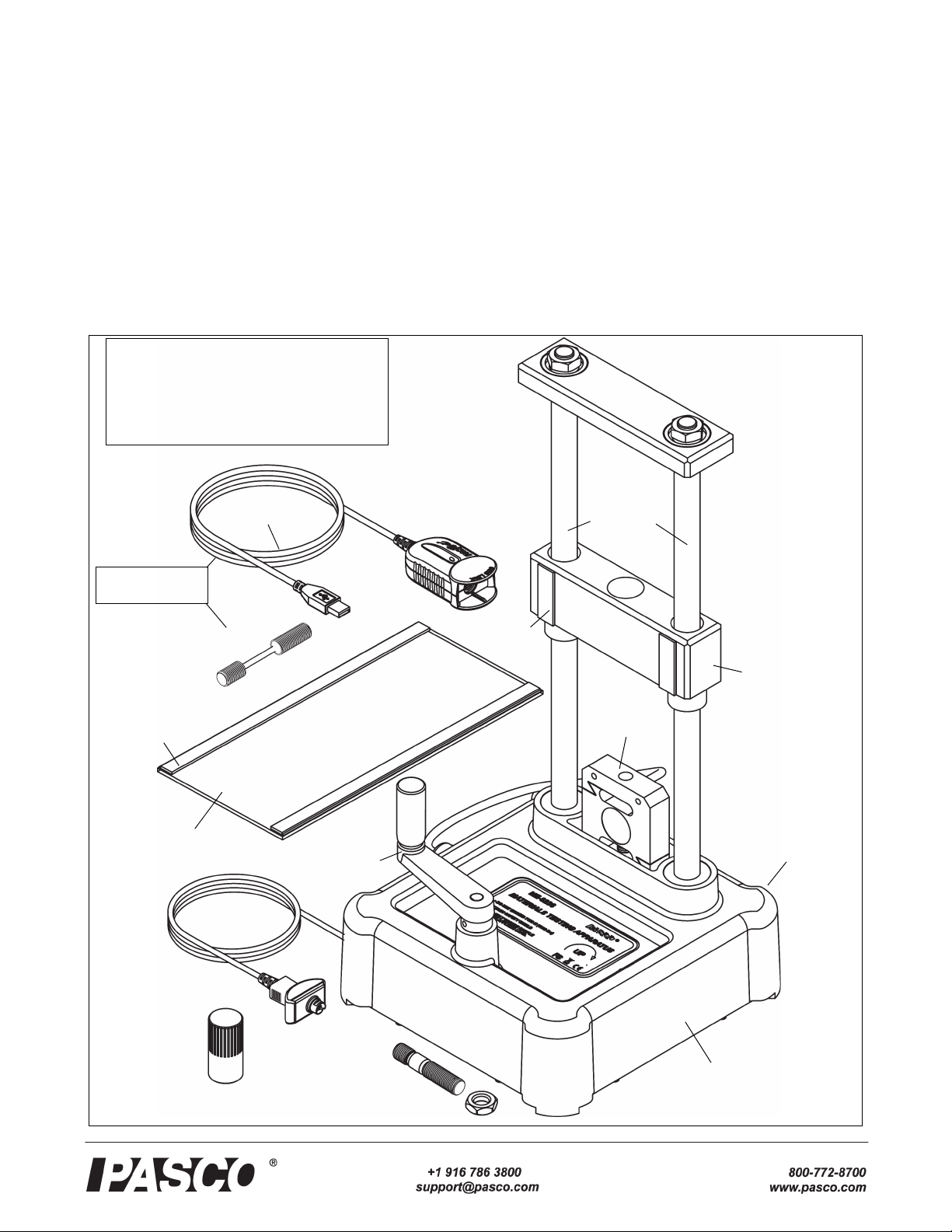

Materials Testing Machine

7100 N

Load Cell

Leadscrews

Calibration

Rod and Nut

Load Bar

(crosshead)

Tensile Samples*

(60)

Sensor

Cable

Load Bar

Round Nut

Velcro® Loop

Material

Safety Shield (2)

Velcro® Hook

Material

WARNING: Provide proper eye

protection when using the Materials

Testing Machine or its Accessories.

Operate the Materials Testing Machine

behind protective Safety Shields.

Crankshaft

Base

USB Link*

*Items from the

ME-8230 Materials

Testing System

Materials Testing

Machine

Materials Testing System

Instruction Manual

012-13762D

ME-8236

Part of the

Comprehensive

ME-8244

Page 2

Materials Testing Machine Introduction

Materials Testing Machine (ME-8236)

.

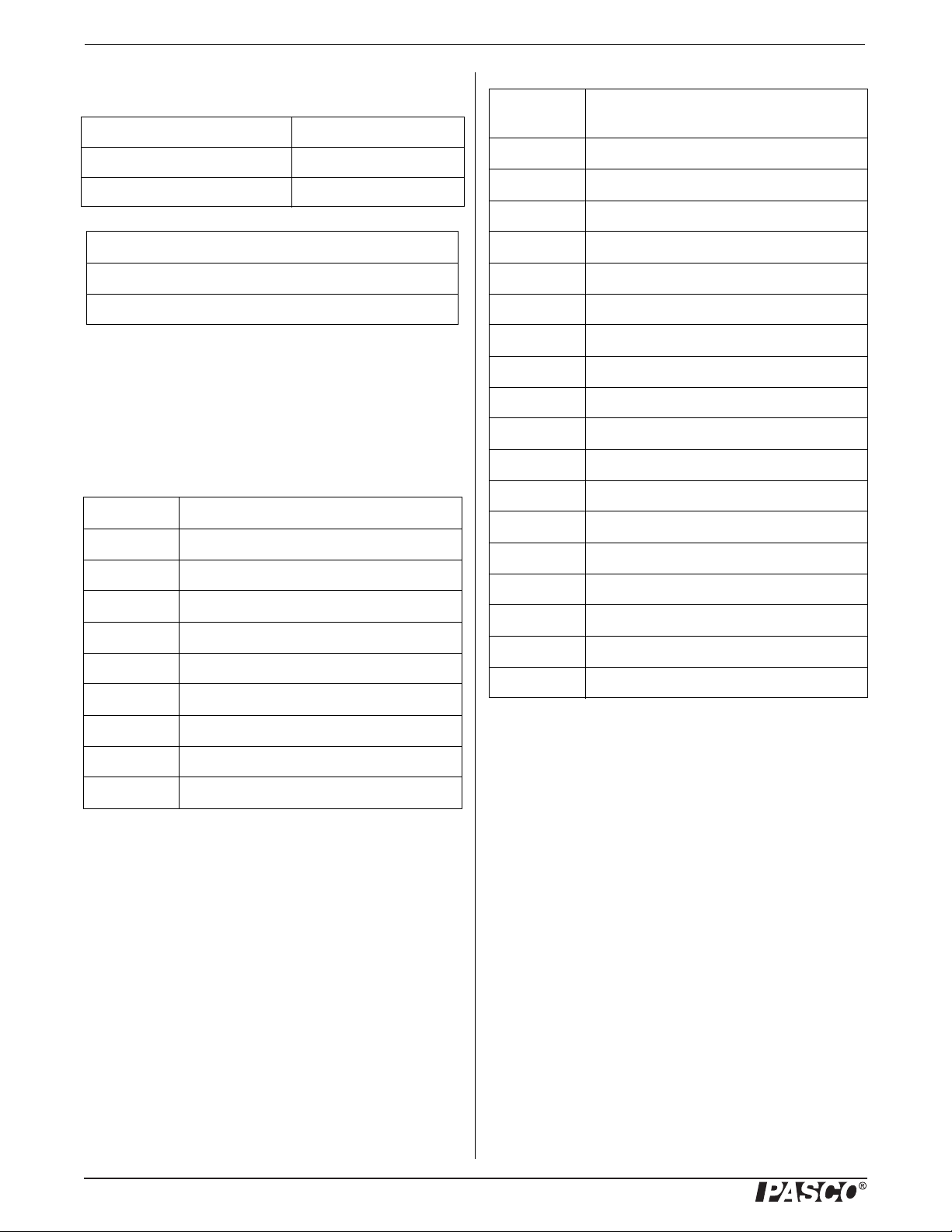

Included Items Included Items

Materials Testing Machine Calibration Rod and Nut

Load Bar Round Nut Safety Shield (2)

Required Items*

PASCO Interface (PASPORT compatible)

PASCO Capstone Data Collection Software

*See the PASCO catalog or web site at

WWW.PASCO.COM

Materials Testing System (ME-8230)

The Materials Testing System includes the items in the

Materials Testing Machine PLUS an interface, software, and

sixty tensile samples as shown in Table 1.

Table 1: .Materials Testing System

Model Materials Testing System Items

ME-8236 Materials Testing Machine

PS-2100A USB Link

UI-5401 PASCO Capstone Software

ME-8231 Tensile Sample, Aluminum (10)

ME-8232 Tensile Sample, Brass (10)

ME-8233 Tensile Sample, Annealed Steel (10)

ME-8234 Tensile Sample, Acrylic (10)

ME-8235 Tensile Sample, Polyethylene (10)

Table 2: Comprehensive Materials Testing System

Model Comprehensive Materials Testing

System Items

ME-8230 Materials Testing System (MTS)

ME-8229 Materials Testing System Base

ME-8237 Materials Bending Accessory

ME-8238 Materials Coupon Adapter

ME-8239 Materials Shear Accessory

ME-8240 Materials Shear Samples (3 ea. of 3)

ME-8241 Materials Photoelasticity Accessory

ME-8242 Materials Structures Beam Adapter

ME-8245 Material Testing System Clevis Clip

ME-8246 MTS 10-32 Adapter

ME-8247 MTS Compression Accessory

ME-8248 MTS Compression Samples (20)

ME-8249 MTS Four-point Load Anvil

ME-6983 Cast Beam Spares Kit (10 molds)

ME-7011 Photoelastic I-Beams (24 each size)

ME-7012 Thin I-Beams (24 each size)

AP-8222* Coupons, Plastic (10 each of 4 types)

AP-8223* Coupons, Metal (10 each of 5 types)

*AP-8217A Replacement Test Coupons (Full Set) consists of the AP-8222 Plastic Coupons and the AP-8223

Metal Coupons.

ME-8243 Tensile Sample, Steel (10)

Comprehensive Materials Testing System (ME-8244)

The Comprehensive Materials Testing System includes all

the items in the Materials Testing System shown in Table 1

PLUS the accessories and other items shown in Table 2.

2

012-13762D

Introduction

The PASCO Materials Testing Machine is a device for measuring force and displacement for various materials as the

materials are stretched, compressed, sheared, or bent. The

Materials Testing Machine has a built-in load cell (strain

gauge transducer) capable of measuring up to 7100 newtons

(N) of force (1600 pounds), and an optical encoder module

that measures displacement of the load bar. A crank-and-gear

system raises or lowers the load bar on two leadscrews (also

known as power screws or translation screws). Force data

from the load cell and displacement data from the encoder

module can be recorded, displayed, and analyzed by a

PASCO Interface with PASCO Data Collection Software.

The sensor cable from the Materials Testing Machine connects to a PASPORT input port. (See the PASCO catalog or

web site at www.pasco.com for more information about

PASCO interfaces and data collection software.)

Page 3

Model No.ME-8236 Materials Testing System

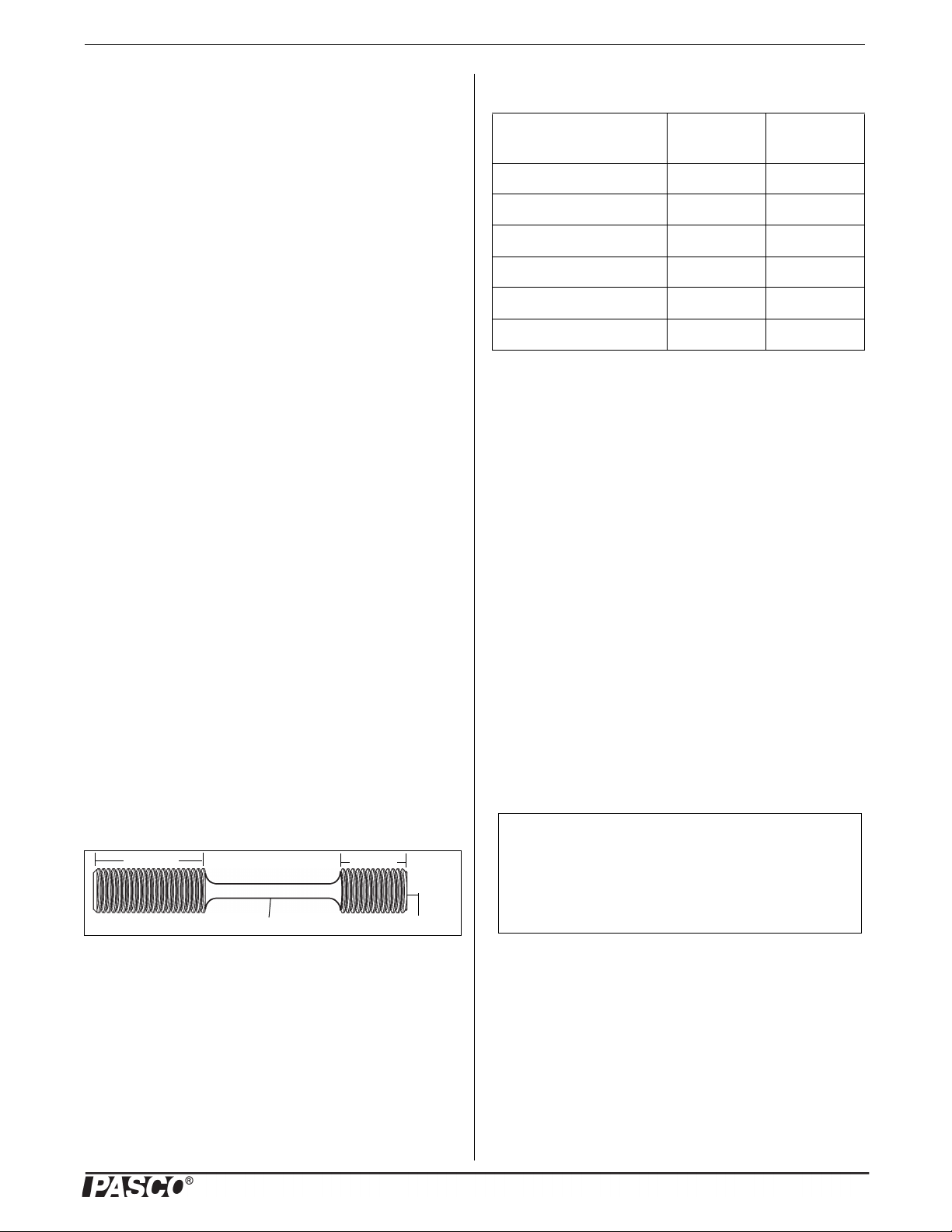

diameter = 3.3 mm

M12 x 1.75

19 mm

31.7 mm

NOTE: An Experiment Guide in electronic format

is available to download from www.pasco.com.

Enter “Materials Testing System” in the Search

window and look for the downloadable file(s)

under “Resources”.

Included Equipment

The Materials Testing Machine (ME-8236) includes a cali-

bration rod and nut, a load bar round nut, and a pair of safety

shields with Velcro® hook material.

Calibration Rod and Nut, Load Bar Round Nut, Safety Shields

• The calibration rod and nut can be used to determine

how much the Machine itself flexes as force is applied,

either in tension or in compression.

• The load bar round nut is used to connect one end of a

tensile sample to the load bar, for example, or can be

used to attach an accessory or adapter to the bottom side

of the load bar.

• The safety shields attach to the Velcro® loop material

on the front and back of the load bar.

Materials Testing System

The Materials Testing System (ME-8230) consists of the

Materials Testing Machine, plus a PASPORT interface called

the USB Link, PASCO Capstone Software, and sixty tensile

samples.

The USB Link connects the sensor cable of the Materials

Testing Machine to a USB port on a computer. The PASCO

Capstone software records, displays, and analyzes the data

from the Materials Testing Machine. (The software is available as an automatic digital download from PASCO.)

The tensile samples include four metals: aluminum, brass,

annealed steel, and steel and two plastics: acrylic and polyethylene, for tensile strength testing. There are ten samples

for each material.

Tensile Sample Information

All the tensile samples (ME-8231 through ME-8235 and

ME-8243) have an overall length of 90 millimeters (mm) or

3.5 inches. The center section of each sample has an approx-

imate diameter of 3.3 mm or 0.131 inches. The threaded

ends are metric M12 x 1.75.

The table shows typical values.

Table 3: Typical Values

Material Tensile

Strength

Aluminum (2024-T3) 400 MPa 70 GPa

Brass (360) 500 MPa 80 GPa

Steel (1018) 700 MPa 200 GPa

Annealed Steel (1018) 400 MPa 200 GPa

Polyethylene 30 MPa 1 GPa

Acrylic 80 MPa 3 GPa

Young’s

Modulus

Accessories

Table 2 lists accessories and adapters that are included in the

Comprehensive Materials Testing System and are available

separately for the Material Testing Machine.

Other accessories and adapters are being developed.

Replacement Items

Also available separately are replacement items such as the

previously mentioned Tensile Samples, the Materials Shear

Samples (ME-8240) with nine metal rods (three each of aluminum, brass, and steel), the Plastic Coupons (AP-8222)

with ten samples each of four different plastics, the Metal

Coupons (AP-8223) with ten samples each of five different

metals, and the MTS Compression Samples (ME-8248).

About This Manual

The manual describes the basic setup of the Materials Testing Machine and the accessories and replacement items

included in the Comprehensive Materials Testing System. It

also describes the procedure for calibrating the Materials

Testing Machine using the included calibration rod and nut.

Experiment Guide

The tensile samples can be ordered separately.

Operation

Caution: Be sure to wear adequate eye protection when using the Materials Testing Machine or its accessories. Operate the Machine from behind a protective shield.

Basic operation involves mounting the Materials Testing

Machine firmly to a sturdy support, calibrating the Machine,

mounting the item to be tested onto the Materials Testing

Machine, connecting the Materials Testing Machine to an

012-13762D

3

Page 4

Materials Testing Machine Operation

Storage Base

Sturdy support*

C-clamp*

Bolt*

Nut*

(*Items not included)

interface for data recording, and then turning the crank to

apply tension (stretching), compression (squeezing), bending, or shearing (cutting) forces to the test item.

ME-8229 MTS Storage Base

Secure the Materials Testing Machine

There are two holes through the base of the Materials Testing

Machine that can be used for bolting the Machine to a sturdy

support. The two 6 millimeter (mm) diameter holes are 15

centimeters apart; one on either side of the label.

Bolting the Machine will avoid the problem of the Machine

moving during a sample test. The Materials Testing System

Storage Base (ME-8229) is designed for two purposes: provide a sturdy base to which the Materials Testing Machine

can be bolted, and serve as a storage place for accessories,

tools, and other items in the Comprehensive Materials Testing System.

The Storage Base includes two screws and two washers and

has two threaded holes that match the spacing of the holes in

the Materials Testing Machine base. Place the Materials

Testing Machine on the Storage Base. Put the washers on the

screws, and put one screw through a hole in the base of the

Materials Testing Machine. Align the screw with the

threaded hole in the Storage Base, and tighten the screw

using your fingers. Put the other screw through the base and

align it with the other threaded hole. Use a 7/16 inch (11

mm) wrench to tighten the screws in place. Use C-clamps to

fasten the Storage Base to a sturdy table or bench. An option

is to bolt the Machine directly to a table or bench as shown.

The Storage Base has through holes at each of its corners.

PASCO Capstone data collection software includes a “calibration wizard” that allows the calibration information called a “compliance calibration” - for the Materials Testing

Machine to be stored for later use. (PASCO Capstone is provided in the ME-8230 Materials Testing System.)

Lab 02: Compliance Calibration Tutorial

NOTE: A PASCO Capstone workbook file about compliance

calibration is available to download from the PASCO web

site. Go to www.pasco.com and enter “Materials Testing

System” in the Search window. In the web page that opens,

select Materials Testing System. Click “Sample Labs” and

then download the ZIP file for Lab 02.

Information covered in the Compliance Calibration Tutorial

includes:

• How a compliance calibration works.

• How to create, save, and delete calibrations.

• Hints and practice in making an accurate calibration.

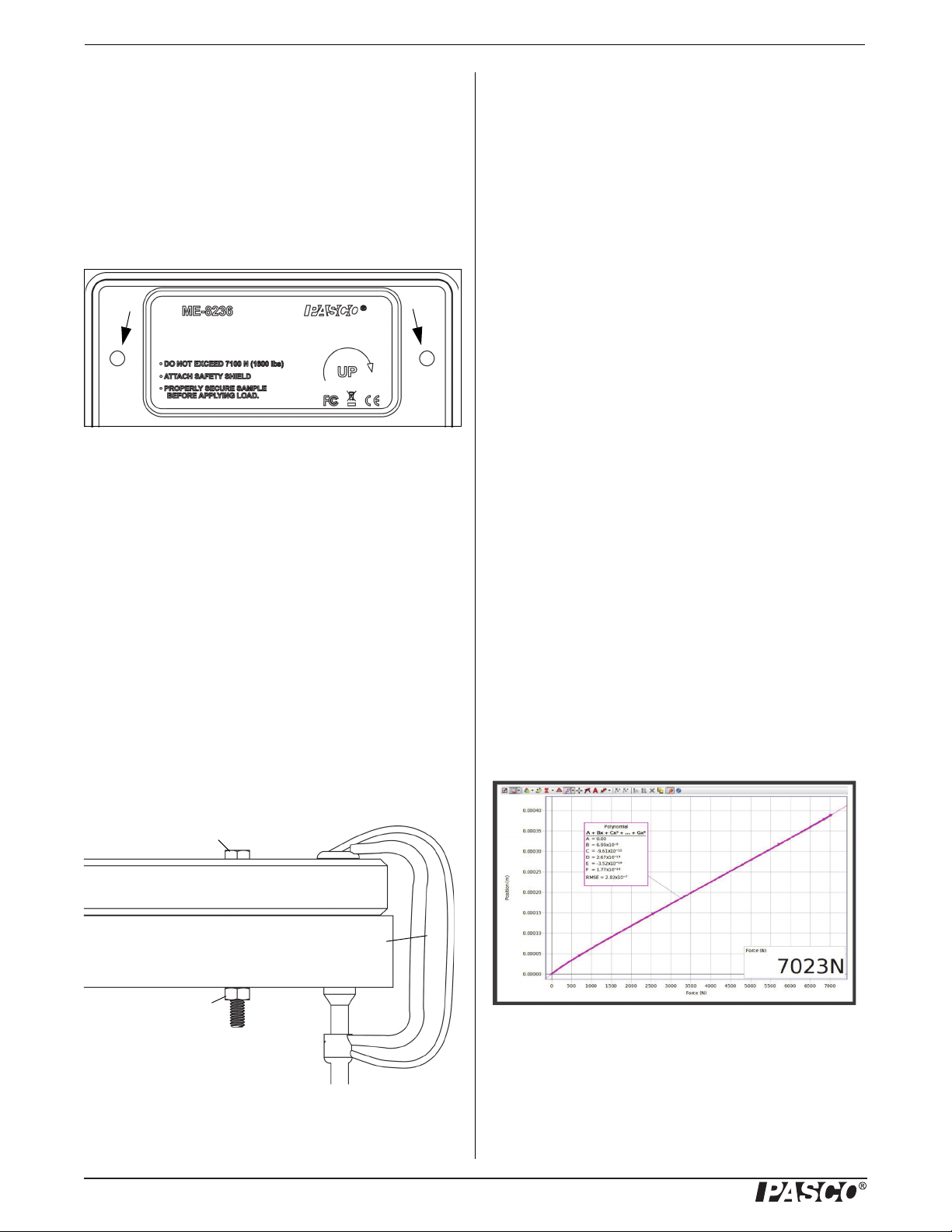

Reason for Calibration

The reason for the compliance calibration procedure is this:

if the Materials Testing Machine were perfectly rigid it

would give completely accurate measurements of force and

displacement. However, the Machine is not perfectly rigid.

To correct for the fact that the Machine “flexes” slightly, the

stiffness of the Machine is characterized and a calculation is

performed in the software to adjust the raw position data and

compute the displacement that is due only to the distortion of

the sample being tested. The compliance calibration information for the Machine can then be stored within the

Machine or stored in a Capstone file.

The calibration rod will not change shape significantly under

tension or compression. This means that any displacement

measured when the calibration rod is used is due to the flexing of the Materials Testing Machine itself.

Calibration Setup

The calibration rod and nut can be used for calibrating the

Materials Testing Machine for compression or tension. The

4

012-13762D

For example, the sample graph shows that the Machine

flexes 0.2 mm per 3,500 newtons of force when the calibration rod is stretched. If you use the Machine to stretch a

material sample, then the “flex” amount of 0.2 mm per 3,500

N would need to be subtracted.

Page 5

Model No.ME-8236 Operation

Load Bar

Round

Nut

Load Bar

(crosshead)

Calibration

Rod

Crank

Handle

Load

Cell

Figure: Mount Calibration Rod for Tension

Calibration

Nut

Figure: Mount Calibration Rod and Nut for Compression

Load

Cell

Load Bar

(crosshead)

Sensor

Cable Plug

USB Link

Creating the Compliance Calibration Information

In the software, a polynomial curve fit is applied to the plot

of position versus force data. The coefficients of the polynomial curve fit are saved as the calibration information.

Once the compliance calibration is created for the Machine,

the software automatically subtracts the amount of “flex”

from the raw data. After the calibration information is stored

in the Machine, it cannot be edited. However, it you make a

new calibration, it will replace the stored calibration data.

Saving the Calibration Information

The calibration information can be saved in two ways: in the

Capstone file or in the Materials Testing Machine itself. If

the calibration information is saved in the Capstone file, it

can be used with any Materials Testing Machine. If the calibration information is stored in the Materials Testing

Machine, the information stays with that unit (even when it

is unplugged) and can be used with any Capstone file in the

future.

Mount the Calibration Rod for Tension

To mount the calibration rod for tension, screw the

short-threaded end of the rod into the top of the load cell.

Lower the load bar until the threaded part at the top of the

calibration rod goes through the hole in the load bar. Screw

the load bar round nut onto the top of the calibration rod.

section. Lower the load bar until the bottom of the load bar

rests on the top of the calibration nut.

Attach the Safety Shields

Attach the Velcro® hook material on the two safety shields

to the Velcro® loop material on the front and back of the

Load Bar. Adjust the position of the shields so that they will

block any fragments that may come from the calibration rod

in case it accidentally breaks.

Mount the Calibration Rod for Compression

To mount the calibration rod for compression, screw the

short-threaded end of the rod into the top of the load cell.

Screw the calibration nut onto the top threaded part of the

calibration rod until the nut is at the bottom of the threaded

Prepare to Record Calibration Data

Connect the plug on the sensor cable into a PASPORT interface, such as the USB Link (included in the Materials Testing System). Connect the interface to a USB port on a

computer.

See Appendix A for details of the Calibration Procedure.

After the Calibration Procedure is complete, return to this point.

Mount a Tensile Sample

Select a tensile sample to mount onto the Materials Testing

Machine. Put the end of the sample with the short threaded

section into the threaded hole in the top of the load cell.

Screw in the sample until the top edge of the short threaded

section is flush with the top of the load cell.

012-13762D

5

Page 6

Materials Testing Machine Operation

Load Bar

Sample

Nut

Tensile

Sample

Crank

Handle

Load

Cell

Figure: Mount Tensile Sample

Loop

Material

for Safety

Shield

Load Bar

(crosshead)

Figure: Materials Bending Accessory

Load

Cell

Plunger

Sample

Anvil

Anvil

Crank

Handle

Sample

Nut

Base

Load Bar

(crosshead)

Lower the load bar so that the longer threaded section of the

sample goes up through the hole in the center of the load bar.

Adjust the load bar until the bottom edge of the longer

threaded section is flush with the bottom of the load bar.

While holding the tensile sample so it does not turn, screw

the sample nut onto the longer threaded section until the

sample is held tightly in place.

bar using the sample nut. The base for the adjustable anvils

is screwed onto the top of the load cell.

The spacing between the two triangular support anvils can be

adjusted. Use the hex key to loosen the screws holding the

anvils and slide them closer together or farther apart. Tighten

the screws securely.

Use the sample nut to secure the plunger in place on the load

bar. Remove the screws from the base for the anvils and

align the base on top of the load cell. Use the screws and the

hex key to fasten the base in place.

Place a sample for testing on the two support anvils.

Attach the Safety Shields

Attach the Velcro® hook material on the two safety shields

to the Velcro® loop material on the front and back of the

Load Bar and adjust the position of the shields if needed.

Apply a Force

Turn the crank counterclockwise to apply a compression

force through the plunger onto the sample.

Attach the Safety Shields

Attach the Velcro® hook material on the two safety shields

to the Velcro® loop material on the front and back of the

Load Bar. Adjust the position of the shields so that they will

block any fragments that may come from the sample.

Record Data

Prepare PASCO Capstone software to record data. (If there is

a stored calibration file that is to be used, select it in the

“Calibration” window.)

Start data recording. Turn the crank in a clockwise direction

to apply a tension force to the tensile sample. Observe the

graph display of force and position. (Note that the default for

the Materials Testing Machine in the software shows force

and position as ‘negative’ when a tension force is applied.

See Appendix A for information about changing signs.))

When the sample breaks, or is stretched the maximum

amount, stop data recording.

Materials Bending Accessory (ME-8237)

The Materials Bending Accessory includes a plunger, a

adjustable support anvils, and a small hex key (allen

wrench). The plunger is mounted on the bottom of the load

Materials Coupon Adapter (ME-8238)

The Materials Coupon Adapter includes two coupon clamps,

a “tee-handle”, and a 3/8” socket (12 point). One clamp fits

in the load cell and the other fits in the load bar. They can be

used to mount a plastic coupon (AP-8222) or metal coupon

(AP-8223) onto the Materials Testing Machine for testing of

tensile strength.

6

012-13762D

Page 7

Model No.ME-8236 Operation

Movable

Jaw

Fixed

Jaw

Hex Nut

Upper

Clamp

Lower

Clamp

Metal

Coupon

Plastic

Coupon

Figure: Materials Coupon Adapter

Front

Piece

Back

Piece

0.067”,

1.7 mm

0.099”,

2.5 mm

0.161”,

4.0 mm

0.130”,

3.3mm

Mounting

Screws

Hold the upper clamp so it remains parallel to the lower

clamp and tighten the sample nut slightly to remove any

slack in the coupon.

Attach the Safety Shields

Attach the Velcro® hook material on the two safety shields

to the Velcro® loop material on the front and back of the

Load Bar and adjust the position of the shields if needed.

Loosen but do not remove the hex nut on each clamp. The

jaws of the clamp are spring loaded, so the moveable jaw

will separate from the fixed jaw. Screw the clamp with the

shorter threaded section into the load cell. Put the threaded

section of the other clamp up through the hole in the load

bar, and use the sample nut to hold the upper clamp. NOTE:

Do not completely tighten the sample nut yet.

Materials Shear Accessory (ME-8239)

The Materials Shear Accessory consists of two pieces of

hardened steel - a front piece and a back piece - held together

by a pair of permanent screws, and a package of Materials

Shear Samples. The front piece can slide vertically relative

to the back piece, which is designed to be mounted on the

load cell using an included hex key (allen wrench). The two

pieces have pairs of matching holes with four different diameters to fit a variety of samples for testing. The hole diameters are approximately 1/16”, 3/32”, 1/8”, and 5/32”. The

Materials Shear Samples includes three 1/8” diameter rods

each of three metals: aluminum, brass, and mild steel.

NOTE: Do not use a sample with a hardness greater

than mild steel.

Carefully place one end of a coupon between the jaws of the

bottom clamp. While holding the moveable jaw to keep it

aligned with the fixed jaw, use the tee-handle and socket to

tighten the hex nut. CAUTION: Each coupon is fragile. Do

not let the moveable jaw twist out of alignment with the

fixed jaw as this might bend the coupon.

Turn the upper clamp so that it is aligned with the lower

clamp. Adjust the position of the load bar so that you have

room to carefully put the other end of the coupon between

the jaws of the upper clamp. Keep the movable jaw aligned

with the fixed jaw so that the coupon does not twist or bend.

Once again, tighten the hex nut.

Use the two mounting screws and the included hex key

(allen wrench) to attach the back piece of the Materials Shear

Accessory to the top of the load cell. Note that when the

front piece is raised by hand as far as it will go, the holes in

the front piece align with the matching holes in the back

piece.

Insert the test sample through the pair of holes that best

match the diameter of the sample. Use a sample that is long

enough so that it extends about 1/4” (6 mm) beyond the front

and back pieces. Doing this makes it easier to remove the

sample remnants from the accessory after the test.

012-13762D

7

Page 8

Materials Testing Machine Operation

Materials Shear

Accessory

Figure: Materials Shear Accessory

Polarizer

Hook

Material

Figure: Polarizers on Load Bar

Figure: Materials Structures Beam Adapter

Clamp for

Load Bar

Clamp for

Load Cell

To place the polarizers on the Load Bar, align a polarizer

with the strips of loop material on the front of the Load Bar

and press the edges of the polarizer so that the hook material

adheres to the loop material. Repeat the process with the second polarizer on the other side of the load bar.

Adjust the position of the load bar so that it rests on the top

surface of the front piece.

Attach the Safety Shields

Place a light source so that it shines through the polarizers

from behind.

Attach the Velcro® hook material on the two safety shields

to the Velcro® loop material on the front and back of the

Load Bar. Adjust the position if needed.

Materials Structure Beam Adapter (ME-8242)

Materials Photoelasticity Accessory (ME-8241)

Clear plastic samples that are viewed through crossed polarizers reveal patterns of different colors that show stress distribution. The Materials Photoelasticity Accessory is

designed to demonstrate the photoelastic phenomenon in

clear plastic samples.

The Accessory consists of two rectangles of polarizer material that can be attached to the Velcro® loop material on the

Load Bar of the Materials Testing Machine.

The PASCO Structures System includes a variety of beams

that can be used with the Materials Testing Machine. The

beams are models of I-beams and other structure elements.

The Materials Structure Beam Adapter is designed to hold a

structures beam so that it can be tested under tension and

compression.

The Materials Structures Beam Adapter consists of two

clamps and an included hex key. Each clamp has two jaws,

one of which can be removed so that an end of a structures

beam can be put in the clamp. The threaded ends of the two

clamps fit in the load bar and load cell of the Materials Testing Machine.

8

Use the included hex key to remove the screws that hold the

two parts of the clamp together. Put the ends of a structures

beam, such as a #3 I-Beam, into one part of each clamp, and

then use the screws to reattach the other part of each clamp.

012-13762D

Page 9

Model No.ME-8236 Operation

Structures

Beam

Remember to attach the two safety shields to the Load Bar.

MTS 10 – 32 Adapter (ME-8246)

There are several devices used in material testing that hold

materials in place and have a threaded 10 - 32 hole designed

for mounting the device on a materials tester, such as the

Materials Testing System. The Materials 10 - 32 Adapter is

designed to connect devices with a threaded 10 - 32 hole to

the Load Bar and Load Cell of the Materials Testing

Machine.

The 10 - 32 Adapter with the longer larger diameter threaded

section is mounted in the Load Bar of the Materials Testing

Machine, and the 10 - 32 Adapter with the shorter threaded

section and the hex nut is mounted in the top of the Load

Cell.

Screw the clamp with the short threaded end into the top of

the load cell, and put the other clamp through the hole in the

load bar. Use the sample nut to secure the clamp to the load

bar.

Attach the Safety Shields

Attach the Velcro® hook material on the two safety shields

to the Velcro® loop material on the front and back of the

Load Bar. Adjust the position if needed.

MTS Clevis Clip (ME-8245)

The Materials Testing System Clevis Clip is designed to tensile test a wide variety of samples that have hooked ends or

through holes. The diameter of each clevis pin is 0.187 in

(0.47 cm). Each pin contains a pair of small, spring-loaded

spheres near its end to keep the pin from slipping out of the

clip.

The Clevis Clip with the longer threaded section is mounted

in the Load Bar of the Materials Testing Machine, and the

Clevis Clip with the shorter threaded section and the hex nut

is mounted in the top of the Load Cell.

MTS Compression Accessory (ME-8247)

The Materials Compression Accessory is designed to work

with the Materials Testing Machine to compress samples.

The Compression Accessory consists of two one inch (2.54

cm) diameter platforms that provide a sturdy base for compression samples.

The Materials Compression Accessory includes twenty

Materials Compression Samples (ME-8248). The polyethylene cylinders are approximately 0.5 in (1.3 cm) in diameter

and 0.75 in (2 cm) long.

MTS Four-point Load Anvil (ME-8249)

The Materials Four-point Load Anvil extends the capabilities of the Materials Bending Accessory. When used with the

Bending Accessory and the Materials Testing Machine, data

to find the flexural plastic modulus and the modulus of rup-

012-13762D

9

Page 10

Materials Testing Machine Operation

Rebar Member

Mold

#3 Beam

#4 Beam

ture of tested samples can be measured, recorded, and analyzed.

Cast Beam Spares Kit (ME-6983)

The Cast Beam Spares Kit includes 30 “Rebar” members

and 10 “molds”. A Cast Beam consists of a beam that is a

model of the reinforcement bars (“rebar”) used in construction, and a mold that is used to produce a model of a beam of

reinforced “concrete” or prestressed “concrete”. A mixture

of fine sand, plaster, and water is poured into the assembled

rebar beam and mold. After the mixture hardens and the

mold is removed, the beam can be used as a #4 beam in any

PASCO Structure Set, or tested on the Materials Testing

Machine.

Photoelastic I-Beams (ME-7011)

The Photoelastic I-Beams are similar to the #3 I-Beams and

#4 I-Beams that are part of the PASCO Structures Systems

(such as the Truss Set, ME-6990). However, the Photoelastic

I-Beams differ in that they are clear polycarbonate plastic

and do not have any holes in the web area of the beam. They

can be mounted on the Materials Testing Machine using the

Materials Structures Beam Adapter. When viewed with the

Materials Photoelasticity Accessory, the distribution of stress

in the beams can be studied.

The set includes twenty-four each of the two sizes of

I-beams. The #3 I-Beam is 11.5 cm long, and the #4 I-Beam

is 17 cm long.

Thin I-Beams (ME-7012)

The Thin I-Beams set consists of 48 thin I-Beams of two

sizes: #3 Beam (24) and #4 Beam (24). The beams are like

those in the PASCO Structures Systems, but there are no

holes in the web area. Therefore, when used with the Materials Testing Machine, the test results are more like the results

would be for the type of metal I-Beam used in construction.

Maintenance

The illustration shows a Cast Beam with the Materials Testing Machine and the Four-point Load Anvil attached to the

Bending Accessory.

Regular maintenance for this equipment is minimal. The

leadscrews need to be kept clean, and they may need to be

re-lubricated at some point. Use a food grade anti-seize

grease containing PTFE (polytetrafluoroethylene, commonly

known as Teflon®).

If problems arise with the Materials Testing Machine, notify

PASCO scientific. It is not recommended that you attempt to

fix this equipment yourself. (See the Technical Support

information at the end of this manual.)

Specifications

Item Description

Load Cell capacity 7100 N (1600 lbs)

Load Cell maximum 100% of capacity

Experiment Guide

NOTE: An Experiment Guide in electronic format is available to download from www.pasco.com. The Experiment

Guide includes information about the calibration procedure

and also describes the available Capstone Workbook files for

the Materials Testing Machine.

Enter “Materials Testing System” in the Search window and

look for the downloadable file(s) under “User Resources”.

10

The list of Capstone Workbook files for the Materials Testing Machine includes the following. Each lab is available as

012-13762D

Page 11

Model No.ME-8236 Technical Support

a downloadable ZIP folder containing a PDF setup file and a

Capstone data file:

Sample Labs

• Lab 01: Intro to Materials Tester

• Lab 02: Compliance Calibration Tutorial

• Lab 03: Tensile Testing - Brass

• Lab 04: Young’s Modulus

• Lab 05: Tensile Testing - Annealed Steel

• Lab 06: Tensile Testing - Metal Coupons

• Lab 07: Tensile Testing - Plastic Coupons

• Lab 08: Tensile Testing - Plastic Samples

• Lab 09: Three Point Bending

• Lab 10: Round Rod Bending

• Lab 11: Bend Testing Beams

• Lab 12: Tensile Testing Beams

• Lab 13: Column Buckling and Slenderness Ratio

• Lab 14: Euler Column Buckling

will be recycled in a manner that protects human health and

the environment. To find out where you can drop off your

waste equipment for recycling, please contact your local

waste recycle/disposal service, or the place where you purchased the product.

The European Union WEEE (Waste Electronic and Electrical Equipment) symbol

(to the right) and on the product or its

packaging indicates that this product must

not be disposed of in a standard waste container.

Technical Support

For assistance with any PASCO product, contact PASCO at:

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: +1 916-462-8384 (worldwide)

877-373-0300 (U.S.)

E-mail: support@pasco.com

Web www.pasco.com

For the latest information about the Materials Testing

Machine or the replacement items and accessories, so to the

PASCO web site at www.pasco.com and enter the model

number in the search window.

Limited Warranty For a description of the product warranty, see the

PASCO catalog. Copyright The PASCO scientific Instruction Manual

is copyrighted with all rights reserved. Permission is granted to

non-profit educational institutions for reproduction of any part of this

manual, providing the reproductions are used only in their laboratories and classrooms, and are not sold for profit. Reproduction under

any other circumstances, without the written consent of PASCO scientific, is prohibited. Trademarks PASCO, PASCO Capstone,

PASPORT, SPARK Science Learning System, SPARK SLS, and

SPARKvue are trademarks or registered trademarks of PASCO scientific, in the United States and/or in other countries. For more information visit www.pasco.com/legal.

Product End of Life Disposal Instructions:

This electronic product is subject to disposal and recycling

regulations that vary by country and region. It is your

responsibility to recycle your electronic equipment per your

local environmental laws and regulations to ensure that it

012-13762D

11

Page 12

Materials Testing Machine Appendix A: Calibration

Materials Testing Machine

icon

Properties

icon

Appendix A: Calibration

General Information: Pre-Calibration

Lab 02: Compliance Calibration Tutorial

REMINDER: A PASCO Capstone workbook file about compliance calibration is available to download from the PASCO web

site. Go to www.pasco.com and enter “Materials Testing System” in the Search window. In the web page that opens, select

Materials Testing System. Click “Sample Labs” and then download the ZIP file for Lab 02.

Information covered in the “Lab 02 Compliance Calibration Tutorial” includes:

• How a compliance calibration works.

• How to create, save, and delete calibrations.

• Hints and practice in making an accurate calibration.

Optional: Change Sign

NOTE: The default for the Materials Testing Machine in the software is

a negative value for force and position as ‘negative’ when a tension

force is applied. Although it is possible to use the Materials Testing

Machine with negative values for force and position, it is easier to

change the sign convention to be positive while you use the “Calibration Wizard” for the calibration procedure.

• To change the sign for the force and position data, click the “Hardware Setup” icon in the Tools palette.

• In the Hardware Setup window, click the “Properties” icon (shaped

like a gear wheel) to open the “Properties” window for the Materials Testing Machine.

• In the “Properties” window, note that the default for the

“Change Sign” is an un-checked box. This means there is a

positive value for both position and force when the Load Bar is

moving down, as in a compression.

• If you want positive values for both position and force when

the Load Bar is moving up, as in tension, click the check box

for “Change Sign”.

• Click OK to close the “Properties” window.

• Click the “Hardware Setup” icon to close the “Hardware

Setup” window.

Prepare to use the software to calibrate the Material Testing

Machine.

12

012-13762D

Page 13

Model No.ME-8236 Appendix A: Calibration

Calibration Procedure

The following steps describe how to use the “calibration wizard” in PASCO Capstone to create a compliance calibration for

the Materials Testing Machine. Please preview the steps to become familiar with the procedure before doing the calibration.

Step One: Choose the Type of Measurement to Calibrate

In the Capstone software, select the “Calibration” icon ( ) in the

Tools palette to open the “Calibration” window.

There are two types of calibration for the Materials Testing Machine.

One is a simple calibration of the force measured by the Load Cell. The

other, the default choice, is “Materials Testing System: Compliance

Calibration”. Use this choice to setup the program to automatically

make corrections on position data.

• Click Next to show Step Two, the “Choose Calibration Action” menu.

Step Two: Choose Calibration Action

There are several choices in “Create New Calibration” that allow you to create, select, save, modify, and delete calibrations.

• Create New Calibration: This is the default choice. In this selec-

tion, the “calibration wizard” will take you through the steps

needed to create and save a new compliance calibration. This

includes prompting you to install the calibration rod (Step Three),

record a data run on the graph provided (Step Four), and create a

polynomial curve fit (Step Five) that will be stored as your compliance calibration.

The following is a description of the other Calibration Action choices.

• Use Calibration: If the text window below “Use Calibration” is

blank, it means that there is no “active” calibration being used.

However, if any compliance calibrations have been saved previously in this Capstone file, they will be displayed in the pull down

menu (click the down arrow). (The previously saved compliance

calibration “7000 N cal (Tue Dec 17 11:37:30 2013)” is shown as

an example.) If you select a previously saved compliance calibration from the pull down menu, it becomes the “active” calibration.

When you click Finish, the selected calibration will be used to

make the compliance correction to any future data you collect.

012-13762D

13

Page 14

Materials Testing Machine Appendix A: Calibration

• Import Calibration From Sensor: If any compliance calibrations

have been stored in the Materials Testing Machine (the “Sensor”),

they will be displayed in the pull down menu. (The stored calibration “7100N 100N pre (Tue Feb 25)” is shown as an example.) If

you click Finish, the selected stored calibration will be imported

and added to the list for use. It will also become the “active” calibration. NOTE: Calibrations stored in the Material Testing

Machine (the Sensor) can not be used or renamed until they are

imported.

• Use Raw Values: If this choice is selected and you click Finish,

the selected compliance calibration (if any) is temporarily disabled. Any future data collected will not be adjusted. NOTE: The

calibration is still saved.

• Manage Existing Calibration: If this choice is selected and you

click Next, Step 3 is revealed as shown in the illustration. Your

choices are: Delete Calibration, Rename Calibration, or Save Calibration in Sensor (the Materials Testing Machine).

• If you wish to delete a calibration, select the calibration you want

to delete from the pull down menu and then select “Delete Calibration”. Click Finish to delete the calibration.

• If you select “Rename Calibration” (the default choice) and click

Next, a text window opens and you can enter a new name for a

calibration. ADVICE: Create a name that includes the maximum

force used. It is also helpful to record any pre load that is used.

Click Finish after entering a name.

• If you select “Save Calibration in Sensor” and click Next, the window shows “Store Calibration” and “Choose which calibration to

overwrite”. The default view of the pull down menu shows

“Empty Calibration 0”. If you click Finish, the calibration you

wish to store will take the place of “Empty Calibration”.

CAUTION: Only four calibrations can be stored in the Materials Testing Machine. If you already have four calibrations stored, and you wish

to store another calibration, you will be prompted to select which calibration you want to replace.

NOTE: You can have any number of calibrations saved as part of the

Capstone file. When you name your calibration as in Step Six “Name

the calibration” (see below), create a name that includes the maximum

force used. It is also helpful to record any pre load that is used. When

the saved Capstone file is re-opened, the calibrations will still be available.

• After you have made your Calibration Action choice (REMINDER: “Create New Calibration” is the default), click Next

to show the illustration in Step Three, “Install the calibration rod”.

14

012-13762D

Page 15

Model No.ME-8236 Appendix A: Calibration

Position (m)

Force (N)

Digits display of

Force (N)

Position versus

force data

Polynomial curve fit

Step Three: Install the Calibration Rod

The ‘calibration wizard” changes to show an illustration about how to

install the calibration rod.

In addition to the illustration, a Graph display of Position (m) versus

Force (N) opens. A Digits display of Force (N) is part of the Graph display.

• Click Next to show Step Four: “Record a smooth data run”.

Step Four: Record a Smooth Data Run

NOTE: To make a calibration that will accurately correct for compliance, it is necessary to calibrate the Materials Testing Machine over the

same range of force and the same conditions you expect to use when

you are testing your samples.

• Click Record and collect a smooth run of position versus force

data.

• When the data collection is finished, click Stop.

REMINDER: If the run of data is not smooth, delete the run and try again.

NOTE: A Polynomial curve fit is automatically applied to the run of position versus

force data.

• Click Next to open Step Five, “Polynomial Fit”.

012-13762D

15

Page 16

Materials Testing Machine Appendix A: Calibration

Step Five: Polynomial Fit

NOTE: By default, the “Show Curve Fit Editor” window is open in the

“Polynomial Fit” window. The Curve Fit Editor window shows the

default values for the coefficients of the polynomial.

In the Curve Fit Editor window you can change the “Number of Terms”,

enter an “Initial Guess” for each coefficient and lock or unlock a coefficient value.

• If the message “Curve fit was successful” is shown, click Next to

open Step Six, “Name the calibration”.

NOTE: If the curve fit was not successful, use “trial-and-change” in the

Curve Fit Editor to adjust the coefficients until the curve fit is successful.

Click “Update Fit” to determine if the new coefficients made a better

curve fit

Step Six: Name the Calibration.

• Type a name for the calibration in the text area. (Example names

might be “Calibration 7000” or “Tension Calibration”.)

• Click Finish to store the calibration as part of the Capstone file.

Finishing Step

NOTE: The “Calibration” window goes back to Step One. When you

click Next, the “Choose Calibration Action” window (Step Two) will show a menu of the saved and/or stored calibration(s).

• Click “Use Calibration” and select a specific saved calibration

from the pull down menu below “User Calibration”, or click

“Import Calibration From Sensor” to load a selected stored calibration from the pull down menu below “Import Calibration From

Sensor”.

• Click Finish. The “Calibration” window goes back to Step One.

• Click the “Calibration” icon in the Tools palette to close the “Calibration” window. Save the Capstone file for future use.

16

012-13762D

Page 17

Model No.ME-8236 Appendix A: Calibration

• From the “File” menu, save the Capstone file for future use.

012-13762D

17

Page 18

Materials Testing Machine Appendix B: “Seating” a Test Sample and Setting a Pre-Load

Appendix B: “Seating” a Test Sample and Setting a Pre-Load

In the following procedure, a test sample is stretched and relaxed to properly “seat” the sample (remove any slack) and a

pre-load is set.

“Seat” the Sample

1. Mount a test sample onto the Materials Testing Machine. Make sure that the Load Bar Round Nut is slightly loose and not

applying a force on the test sample.

2. In the Capstone software, set up a Graph display of Position versus Force, and a Digits display of Force.

3. Click Record.

• NOTE: If the position and force data on the graph are not zero, check the “Properties” window in the “Hardware Setup”

panel. The check box for “Zero Sensor Measurement at Start” should be checked.

4. Turn the crank clockwise about a quarter of a turn and note that the position and force data are being plotted on the Graph

display.

5. With data still being recorded, slowly turn the crank back counter-clockwise. Watch the Digits display, and turn the crank

to reduce the force to between 10 and 20 N. Don’t let the force go back to zero.

6. Turn the crank clockwise to increase the force as before. Notice how the second plot of data looks on the graph compared

to the first. If the second plot of data “tracks” on top of the first plot, then the sample is properly “seated” and you can

click Stop. If not, repeat the process of applying force and then unloading the force.

• NOTE: Usually it is necessary to load and unload the system several times to remove all the slack and “seat” the test sample.

7. When two consecutive plots of data track on top of each other, the test sample is properly “seated”. Click Stop.

Set a Pre-Load

8. Click Record to begin collecting data and increase the force back up to 100 N. Click Stop and DO NOT change the crank

position. Since the Materials Testing Machine is set to automatically zero itself the next time you start recording data, this

puts a pre-load of 100 N on the sample, which results in better data.

18

012-13762D

Loading...

Loading...