Page 1

Instruction Manual

Wilberforce

Pendulum

Model No. ME-8091

Manual No. 012-08397A

Items Included

Page 2

Page 3

Pendulum Model No. ME-8091

Table of Contents

Equipment List........................................................ 3-4

Introduction ............................................................. 5

Setup Options ........................................................... 5

Equipment Setup ..................................................... 6-9

Suggested Experiment .............................................. 9-11

Sample Data/Results...................................................11

Troubleshooting ........................................................12

Appendix A: Specifications............................................ 13

Appendix B: Laser Safety Information ..........................14-15

Appendix C: DataStudio Setup Instructions for Wilberforce Pendulum

Experiments with

ScienceWorkshop

Interfaces ..................... 16

Appendix D: DataStudio Setup Instructions for Wilbeforce Pendulum

Experiments with PASPORT Interfaces .............................. 17

Appendix E: Technical Support ....................................... 18

Appendix F: Copyright and Warranty ................................ 18

2

®

Page 4

Model No. ME-8091 Wilberforce Pendulum

Wilberforce Pendulum

Model No. ME-8091

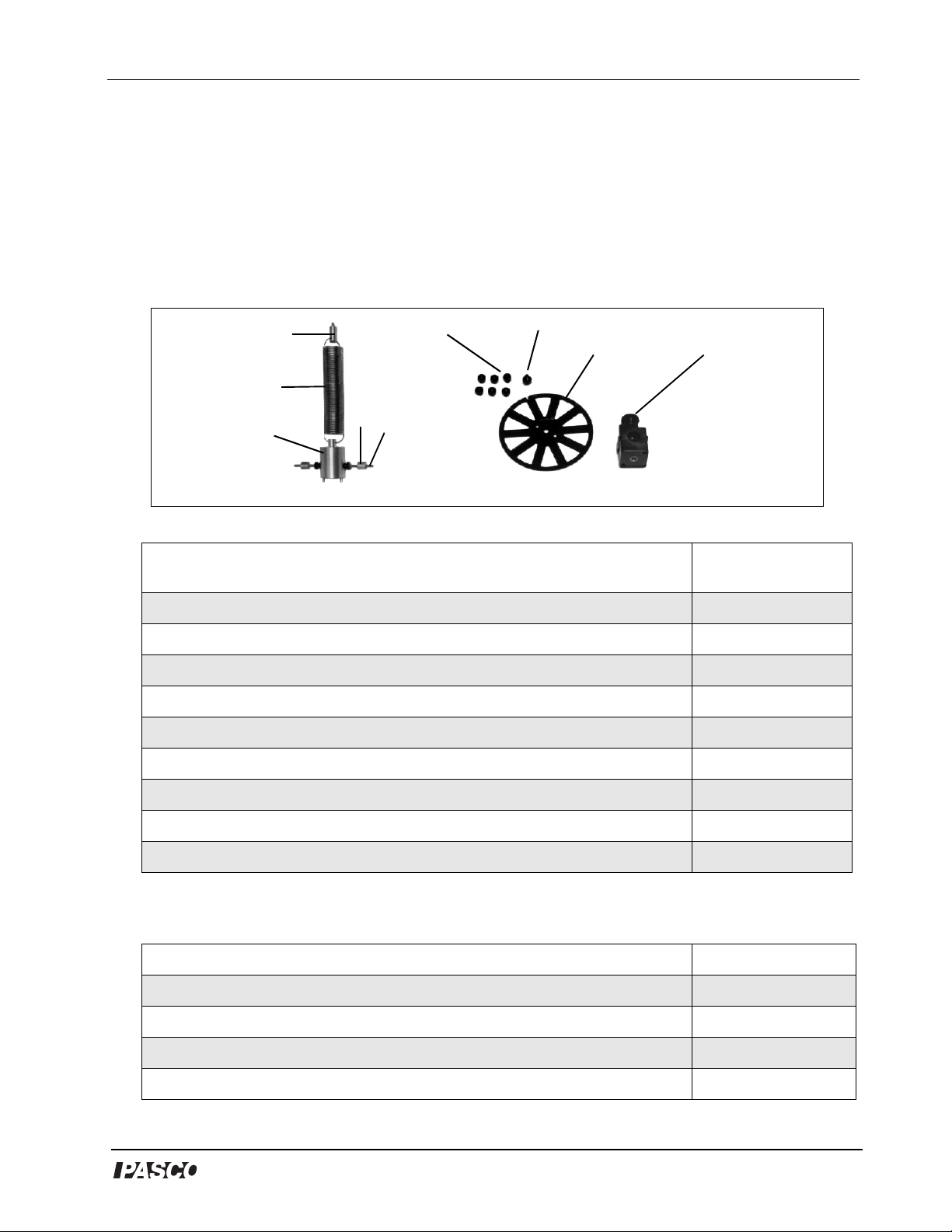

Equipment List

4

1

3

5

Included Equipment Replacement

1. Spring (1)

2. Threaded rod (1)

3. Brass Cylinder Mass, 0.9 cm diameter, 5.5 g (2)

4. Brass Cylinder Mount Holder, 0.9 cm diameter, 11 g (1)

5. Brass Cylinder Bob, 3.0 cm diameter, 234 g (1)

6. Photogate Wheel (1)

2

9

7

6

1

8

Model Number*

632-056

648-08341

615-231

648-08325

648-08324

648-08323

7. Thumbscrew for Photogate Wheel (1)

8. Rod Clamp (1)

9. Plastic masses (with thumbscrews), 0.5 g

616-141

003-05134

614-029

*Use Replacement Model Numbers to expedite replacement orders.

Additional Equipment Required (for setups with or without an interface) Model Number*

Large Rod Base (1)

Stainless Steel Rods (120 cm) (2)

Stainless Steel Rod (45 cm or 90 cm) (1)

Multi-Clamps (2)

®

ME-8735

ME-8741

ME-8736 or ME-8738

SE-9442

3

Page 5

Wilberforce Pendulum Model No. ME-8091

(Equipment Continued from Page 3)

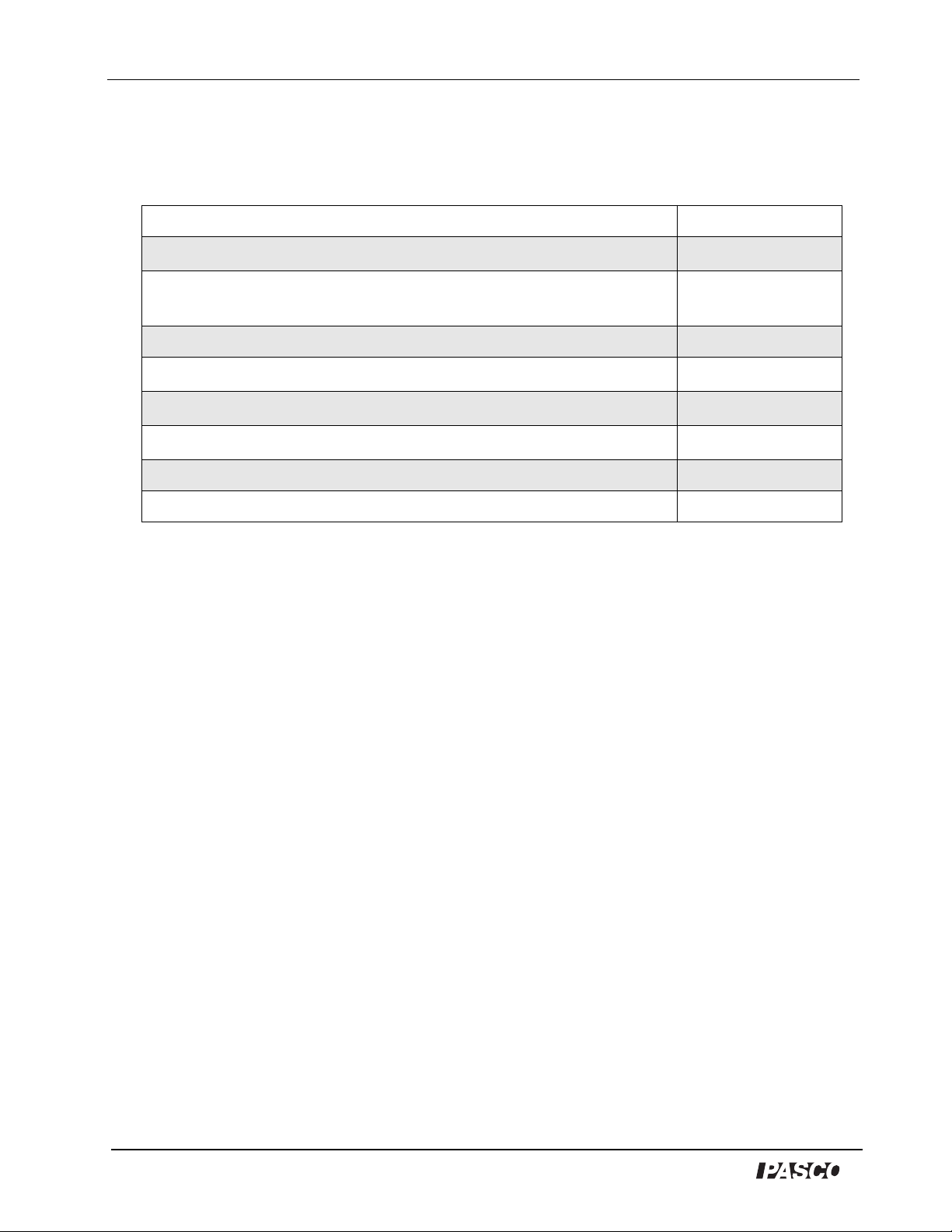

Equipment Recommended (for setups with interfaces) Model Number*

A computer

Any PASCO data acquisition device (

PA SP O RT

™

interface, etc.)

ScienceWorkshop®

DataStudio Software

Force Sensor (1)

Motion Sensor (1)

Laser Switch (1)

X-Y Adjustable Diode Laser (1)

Adjustable Angle Clamp (1)

NA = not available for sale from PASCO scientific

interface,

NA

Various

CI-6870C

CI-6637 or PS-2104

CI-6688 or PS-2103

ME-9259A

OS-8526

ME-8744

4

®

Page 6

Model No. ME-8091 Wilberforce Pendulum

Introduction

The Wilberforce Pendulum allows students to investigate the

relationship between translational and torsional motion in an

oscillating pendulum. With force and motion sensors, a laser, laser

switch, and DataStudio software, students can collect real-time data of

the period, velocity, and acceleration of the pendulum’s oscillations.

Using the pendulum with the included Photogate Wheel, students can

observe the effect of rotational inertia on the oscillations. Brass

masses slide onto the crossbar of the pendulum bob, allowing students

to discover the affect of mass position on the period of oscillation. The

angular velocity, position, and acceleration during rotation can also be

plotted in a Graph display in DataStudio, enabling students to see a

visual display of the oscillatory periods and to isolate the point at

which the vertical and angular periods become equal.

WARNING: Before

setting up your equipment,

Setup Options

The Wilberforce Pendulum can be used with or without an interface

[either ScienceWorkshop interfaces or PASPORT interfaces (USB

Links etc),] and with various attachment pieces. With the spring and

attachments included, you can attach a Photogate Wheel for rotary

inertia experiments or use the brass mass to study the effect of mass on

the oscillatory period (Figures 1a and 1b).

please inform your

students of the hazards of

lasers and enforce

appropriate safety

precautions in your

classroom. For more

information, see Appendix

B: Laser Safety in this

manual.

Photogate

Plastic

Masses

Wheel

Cross

Bars

Figure 1a:

Setup with

Photogate

Wheel

Brass

Mass

Figure 1b:

Setup with

Brass

Masses

and Crossbars

Figure 1: Setup with ScienceWorkshop Interface and Sensors

®

Plastic

Mass

5

Page 7

Wilberforce Pendulum Model No. ME-8091

Equipment Setup

Equipment Setup (without an Interface or Sensors)

To mount the pendulum, perform steps 1-4 below. You will need a

stopwatch to record the period of the oscillations. Figure 2 below

shows the setup without an interface.

Equipment Setup (with an Interface and Sensors)

You will need a Rod Stand (ME-8735), three Stainless Steel Rods

(ME-8736 or 8738), two Multi-Clamps (SE-9442), one Adjustable

Angle Clamp (ME-8744), a Laser, and Laser Switch. (See the

Equipment lists on pages 3-4.)

1. Insert two 120 cm rods into the base of a rod stand. Keep the rods

upright in a vertical position.

2. Attach a Multi-Clamp to the

upper end of each rod (See

Figure 2). Slide a 45 (or 90

cm) steel rod through the hole

in the Multi-Clamps. Adjust

multi-clamps

rod clamp

mount

holder

the Multi-Clamps to hold the

rod horizontally in place.

3. Loop one end of a spring hook

through the hole on the top of

the brass cylinder bob. Loop

the hook on the other end of

the spring through the

cylindrical, brass mount

Figure 2: Standalone

Setup (without sensors)

holder.

(If using the pendulum without an interface, mount a rod clamp to the

horizontal rod, screw the brass mount holder (medium-sized

cylindrical brass mass) into the bottom hole of the rod clamp, and hook

the spring through the hole in the mount holder. See Figure 2.)

6

®

Page 8

Photogate Wheel

Model No. ME-8091 Wilberforce Pendulum

4. a) For setup with Photogate

Wheel: Use a thumbscrew

Plastic Masses

provided to attach the wheel to the

bottom of the large brass mass.

Screw two plastic masses onto

each side of the brass cylinder bob

(Figure 3). Add another plastic

mass to each side, allowing a gap

between the second mass and the

Figure 3: Setup with

Photogate Wheel

first mass. Finally, add a third

plastic mass to each side; the third mass is to hold the second mass

in place. (Note: When using the Photogate Wheel, do not put the

brass masses on the crossbar.)

OR

4b) For setup without the Photogate Wheel: Screw a small, plastic

mass over each side on the horizontal cross bar jutting from the large

brass mass. Screw on a brass mass on each side of the crossbar. Use a

measuring tape to ensure each brass mass is equidistant from the bob

in the center. Use two more plastic masses to hold the brass masses in

place (Figures 4a and 4b).

crossbar

equal distance

Figure 4a: Crossbar

with plastic masses

plastic

masses

plastic

mass

equal distance

Figure 4b: Brass

masses on crossbar

If using an interface, proceed with steps 5-12 that follow.

5. Use the center hole in the Force

Sensor to slide the Force Sensor

Laser

over the horizontal rod (Figure 5).

6. Insert the screw from the

cylindrical mount holder into the

bottom hole of the Force Sensor

Force Sensor

and rotate to tighten.

Figure 5: Force Sensor and

Laser Mounted on Rods

brass

mass

®

7

Page 9

Wilberforce Pendulum Model No. ME-8091

7. Mount an Adjustable Angle

Clamp to the lower end of the

base rod. Insert the Laser

Switch through the hole in the

rod clamp such that the Laser

clamp

Switch remains in a vertical

position and the opening

faces up (See Figure 6). Slide

the Motion Sensor over the

Laser Switch. Turn the

Adjustable Angle Clamp until

the laser switch holds

vertically in place. Do not

allow the Laser Switch room

to move, slip, or fall out of

place.

8. Plug the Motion Sensor into digital

channels 1 and 2 on the

ScienceWorkshop interface.

Motion

Sensor

Figure 6: Mounting the

Motion Sensor with Laser

laser switch

Laser

Diode

WARNING: Never look

directly at the laser light source (from

the Laser Diode) or reflected light

from the laser, such as from a mirror.

Although the lasers used in this

experiment are of low power, looking

directly into the laser light source or its

reflected light from a mirror could

cause severe eye injuries or burns. To

Laser

Switch

interface

avoid eye injury, do not look directly

into the beam of the laser and wear

laser protective eyewear. To align the

Laser Diode with the Laser Switch, use

an alignment marker (i.e ruler, piece of

Figure 7: Setup

tape, etc.) to check the alignment

before turning on the lasers. For more information about laser safety,

see Appendix B of this manual.

9. Align the Laser Diode vertical over the opening on the laser switch.

Use the adjustment knobs on the Laser Diode to move the laser

horizontally.

8

®

Page 10

Model No. ME-8091 Wilberforce Pendulum

10. Plug from the Laser Switch to digital channel 3 on the

ScienceWorkshop interface. For a picture of the complete setup,

see Figure 7.

11. Follow the DataStudio setup instructions in Appendices C

(ScienceWorkshop interfaces) and D (PASPORT interfaces.)

12. When you are ready to collect data, plug the Laser Diode into a

wall outlet. (Note: As a safety precaution, unplug the Laser Diode

and Laser Switch until just before you are ready to begin data

collection.)

Suggested Experiment: Investigating

Translational and Torsional Motion in a

Pendulum

This experiment has two parts: In Part I, you will investigate the

relationship between translational and torsional oscillatory motion in a

pendulum with a brass mass hanging from a spring. In Part II, you will

examine the effect of the inertia from a Photogate Wheel on a

pendulum.

Note: When using the Photogate Wheel, use the plastic masses instead

of the brass masses on the crossbar. If you attach the disk, you must

use the plastic, black masses on the crossbar because the brass masses

have too much rotational inertia. To change the period of the

pendulum’s oscillations, change the distance of the masses from the

center.

Part I: Effect of Mass on Oscillatory Periods in a Pendulum

1. Follow the equipment setup procedure described on pages 5-6 of this

manual.

2. Move the position of the masses on the crossbar until they are

equidistant from the centermost point on the pendulum bob.

3. Record the weight of the brass masses in Table 1. (Note: If a mass

balance is not available, see the Specifications section in Appendix

A.)

4. With a metric measuring tape, measure the distance of each mass

from the center point on the bob. Record your measurement in

Table 1.

®

9

Page 11

Wilberforce Pendulum Model No. ME-8091

5. Pull on the bob to begin moving the pendulum in a vertical

direction. The crossbar will rotate as the pendulum bobs up and

down.

6. In DataStudio, click the Start button to begin collecting data.

Observe the data in real-time as the pendulum oscillates. (If using

the pendulum without a computer and interface, use a stopwatch to

time both the vertical and rotational periods of the oscillations and

the time when the periods become equal.)

7. Move the masses on the crossbar to a new position and repeat steps

4 through 6. (Encourage students to move the masses on the

crossbar to various positions to see the affect that mass position has

on the period and angular velocity. Have students adjust the

masses until the periods of the vertical and rotational oscillations

are the same.)

Note: The periods of the vertical and rotational oscillations must be

exactly the same (quantitatively equal) for the oscillations to switch

completely between the vertical and rotational modes. If the periods

are not equal, adjust the masses on the crossbar and pull the pendulum

again. This may take a few runs of trial and error.)

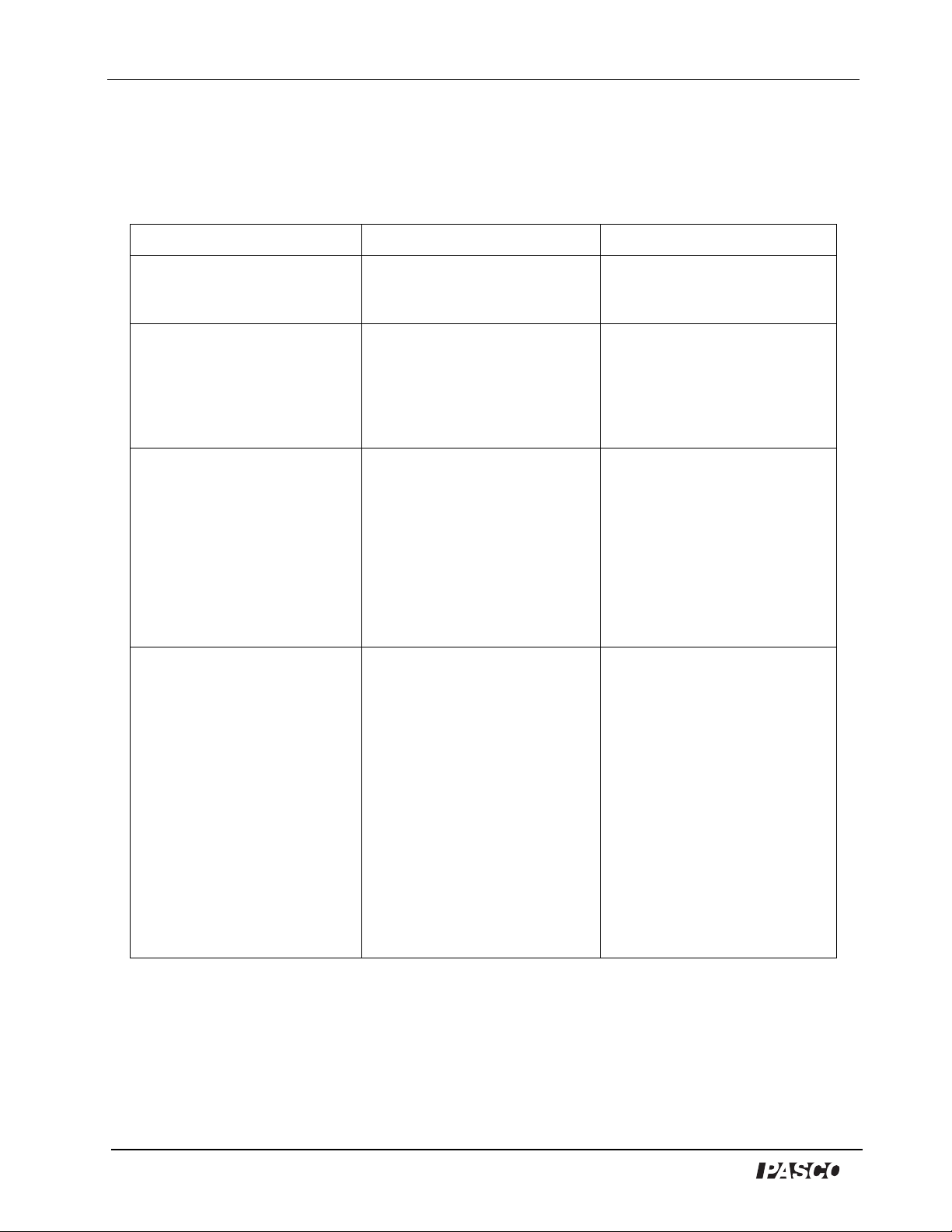

Table 1: Oscillatory Periods with Varying Mass on a Pendulum Bob

Run

No.

1 vertical:

Distance of

Mass from

Pendulum

Bob (cm)

Oscillatory

Period

(seconds)

rotational:

*

Maximum

Angular

Velocity

(rad/s)

Maximum

Force

(N/m)

Tip: If the masses on the

crossbar are not equidistant from the center, the

crossbar will not spin

smoothly.

2 vertical:

rotational:

3 vertical:

rotational:

4 vertical:

rotational:

5 vertical:

rotational:

*To measure the period in DataStudio, use the Smart Tool to measure

the difference between wave crests or troughs.

10

®

Page 12

Model No. ME-8091 Wilberforce Pendulum

Part II: The Effect of Rotational Inertia on Oscillatory Periods

from a Pendulum Swing

Table 2: The Effect of Rotational Inertia on a Pendulum’s Oscillation

Run

No.

1 vertical:

2 vertical:

3 vertical:

4 vertical:

5 vertical:

Disk

Radius

(cm)

Rotational

Inertia

2

(kg/m

)

Oscillation

Period

(seconds)

rotational:

rotational:

rotational:

rotational:

rotational:

Sample Data/Results

Maximum

Angular

Velocity

(rad/s)

Maximum

Force

(N/m)

®

11

Page 13

Wilberforce Pendulum Model No. ME-8091

Troubleshooting

Problem(s) Possible Reason(s) Possible Solution(s)

No position reading appears

in DataStudio.

The period for the torsional

and vertical motions are not

the same.

Force reading is negative. Improper calibration or direction

Rotational data does not

appear in software during

data collection.

Motion Sensor is not plugged

into the interface.

Masses are unequal distances

from the center of the crossbar.

of force measurement is not

defined in DataStudio.

a) The Laser Switch is not

plugged into an interface. b)

Laser Diode is not turned on. c)

Laser Switch and Diode are not

vertically aligned. d) Smart

Pulley option was not selected

in the DataStudio Setup window

(applies to

interfaces).

e) Timing sequence for the

laser switch is not defined in

DataStudio (applies to

PASPORT interfaces).

ScienceWorkshop

Plug the digital channels of the

Motion Sensor into the

interface.

Move the masses on the cross

bar. Moving the masses out

increases the period. Keep

adjusting the distance of the

masses until the periods are

the same.

Calibrate the Force Sensor both

at zero and with a known mass.

Follow the calibration

instructions in the Force Sensor

Manual or the DataStudio

online help. If using a

PASPORT Force Sensor, open

the Setup window, scroll to the

Force Sensor, and select the

“Pull Positive” option.

a) Plug the Laser Switch into a

digital channel on the interface.

b) Plug the Laser Diode into a

power outlet. c) Adjust the

beam position on the Laser

Diode until it aligns with the

Laser Switch. d) In the Sensors

list of the Experiment Setup

window, select the Smart Pulley

option.

e) In DataStudio, define a

timing sequence for the laser

switch. (See the table of

contents in the online help for

defining timing sequences with

photogates and other timers.)

12

®

Page 14

Model No. ME-8091 Wilberforce Pendulum

Appendix A: Specifications

Wilberforce Pendulum

Components

Springs 10.2 cm length, 48.5 g

Brass Cylinder Bob 234.0 g, 3.0 cm (diameter) x 1.0 cm

length

Brass Cylinder Mount 11.0 g, 0.9 cm (diameter) x 1.9 cm

(length)

Brass Cylindrical Masses

Photogate Wheel 10 cm diameter, 7.5 g, 31.4 cm

Plastic Masses 0.5 g

Crossbar 6.0 g, 10 cm length

5.5 g, 0.9 cm (diameter) x 3.7 cm

(length)

circumference

®

13

Page 15

Wilberforce Pendulum Model No. ME-8091

Appendix B: Laser Safety Information

The OS-8528 Diode is a low power, Class I laser. When Class I lasers

are used in accordance with Occupational Health and Safety

Administration (OSHA) standards, Class I lasers are not harmful.

PASCO cannot be held liable for negligent use in the classroom. As a

courtesy, we are providing you with the following laser safety

instructions. These reminders are not a comprehensive list of all

possible safety measures or hazards. For more information, see the

OSHA web site (http://www.osha.gov). Also see http://

www.safetymanual.com or www.laserinstitute.org

Safety Reminders:

• Never look directly into the laser.

Laser Diode

laser beam

WARNING:

DO NOT LOOK

DIRECTLY UP

OR DOWN INTO

THE BEAM.

Laser Switch

Figure 5a: Harmful ways to look at a laser beam

• Do not point a laser at your own eye or at the eyes of other

individuals.

14

®

Page 16

Model No. ME-8091 Wilberforce Pendulum

• Never remove any of the covering or components of the AP-8586

Diode Laser. If the laser is defective, return the defective laser

immediately to PASCO scientific.

• Although laser protective eyewear is not typically required for class I

lasers, if you are uncomfortable or unsure about working around

lasers, wear protective laser goggles or spectacles.

About Laser Protective Eyewear

The eyewear must be designed for use with lasers and meet OSHA

standards specific to the type and class of laser you are using. You can

tell if the type of goggle or spectacle you are using meets laser

standards by looking at the insignia on the side of the frame. Any type

of plastic chemical protective goggle will not suffice. Also, you need

to select protective eyewear with the correct filter for the wavelength

range of the laser (For the Laser Diode, you need a 660-680 nm filter.)

Example: Laser goggles designed to protect for Class I lasers do not

provide maximum protection when using Class II lasers. For more

information, see the OSHA web site (www.osha.gov).

®

15

Page 17

Wilberforce Pendulum Model No. ME-8091

Appendix C: DataStudio Setup Instructions for

Wilberforce Pendulum Experiments with

ScienceWorkshop

Interfaces

1. Connect the sensors to the ScienceWorkshop interface, as follows:

a) Plug the stereo plugs on the Motion Sensor to digital channels 1

and 2 on the interface. b) Plug the DIN connector on the Force

Sensor to any analog channel on the interface. c) Plug the stereo

plug of the Laser Switch into digital channel 3 on the

ScienceWorkshop interface.

2. Open DataStudio and select “Create Experiment.”

3. Click the Setup button to open the Experiment Setup window.

4. In the Sensors list, drag the Motion Sensor icon to the first two

digital channels on the picture of the interface. Drag the Force

Sensor to the same channel you have the sensor plugged into on

the picture of the interface.

5. Select the Smart Pulley from the Sensors list and drag it to the third

digital channel on the interface. [For the Laser Switch, you will use

the Smart Pulley icon (instead of the Laser Switch icon) in the

Setup window. If you use the Laser Switch icon, you need to set up

a timing scheme in DataStudio.]

6. Double click on the Smart Pulley icon to open the Sensor Properties

dialog. In the Measurement tab, click to check the Angular

Position (rad), Angular Velocity (rad/s), and Angular Acceleration

(rad/s/s) options.

7. Your experiment is setup in DataStudio. On the main toolbar, click

the Start button to begin recording data. You will obtain six

graphs: position vs. time, velocity vs. time, force vs. time, angular

position vs. time, angular velocity vs. time, and angular

acceleration vs. time.

Note: If you do not see the

Sensor list, click the Setup

button on the main toolbar. In the Experiment

Setup window, click the

Change button. In the

“Please Choose Data

Source” window, select

the appropriate interface

and click the OK button.

Note: Calibration of the

Force Sensor is optional.

However, if you wish to

calibrate, click on the Calibration tab and follow the

“General Procedure for

Calibrating Sensors” in

the DataStudio online

help. You will need a set

of known masses for calibrating the Force Sensor.

16

®

Page 18

Model No. ME-8091 Wilberforce Pendulum

Appendix D: DataStudio Setup Instructions for

Wilberforce Pendulum Experiments with

PASPORT

1. Connect two USB links (or other PASPORT interfaces) to a USB port

(or USB hub) on your computer.

Interfaces

2. Plug the Motion Sensor and Force Sensor each to a USB Link or

other PASPORT interface.

3. Plug the Laser Switch into either port on a PASPORT Photogate

Port (PS-2123).

4. Click the Setup button to open the Experiment Setup window.

5. In the Experiment Setup window, scroll to the Force Sensor options

and select “Force, pull positive.” Scroll to the Motion Sensor and

click (to check) the boxes next to “Velocity.”

6. In the PASPORT Setup window, click the Add Timer button,

select Recordable Timer from the Choose Timer window, and

click OK. You will use a custom timing sequence to record each

time the rotation disk passes the beam of the laser.

7. In the Setup window, scroll to and doubleclick the Recordable

Timer option. When you are ready to begin collecting data, click

the Record Sequence button. Blocked and unblocked events will

appear in the open display.

8. You will obtain six graphs: position vs. time, velocity vs. time, and

force vs. time, angular position vs. time, angular velocity vs. time,

and angular acceleration vs. time.

Note: If you do not see the

Sensor list, click the Setup

button on the main toolbar. To view the entire list

of sensors, click the Maximize button in the upper

right-hand corner of the

screen.

Note: Calibration of the

Force Sensor is optional.

However, if you wish to

calibrate, ”General Procedure for Calibrating

Sensors” in the DataStudio online help. You will

need a set of known

masses for calibrating the

Force Sensor.

®

17

Page 19

Wilberforce Pendulum Model No. ME-8091

Appendix E: Technical Support

For assistance with the ME-8091 Wilberforce Pendulum or any other PASCO products,

contact PASCO as follows:

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: (916) 786-3800

FAX: (916) 786-3292

Web: www.pasco.com

Email: techsupp@pasco.com

Appendix F: Copyright and Warranty Information

Copyright Notice

The PASCO scientific 012-08397A Wilberforce Pendulum Manual is copyrighted and all

rights reserved. However, permission is granted to non-profit educational institutions for

reproduction of any part of the 012-08397A Wilberforce Pendulum Manual, providing the

reproductions are used only for their laboratories and are not sold for profit. Reproduction

under any other circumstances, without the written consent of PASCO scientific, is

prohibited.

Limited Warranty

PASCO scientific warrants the product to be free from defects in materials and workmanship

for a period of one year from the date of shipment to the customer. PASCO will repair or

replace, at its option, any part of the product which is deemed to be defective in material or

workmanship. The warranty does not cover damage to the product caused by abuse or

improper use. Determination of whether a product failure is the result of a manufacturing

defect or improper use by the customer shall be made solely by PASCO scientific.

Responsibility for the return of equipment for warranty repair belongs to the customer.

Equipment must be properly packed to prevent damage and shipped postage or freight

prepaid. (Damage caused by improper packing of the equipment for return shipment will not

be covered by the warranty.) Shipping costs for returning the equipment after repair will be

paid by PASCO scientific.

18

®

Page 20

Loading...

Loading...