Page 1

®

Instruction Manual

PASCO Structures Systems

Large Structures Set

ME-7003

012-12670A

*012-12670*

Page 2

®

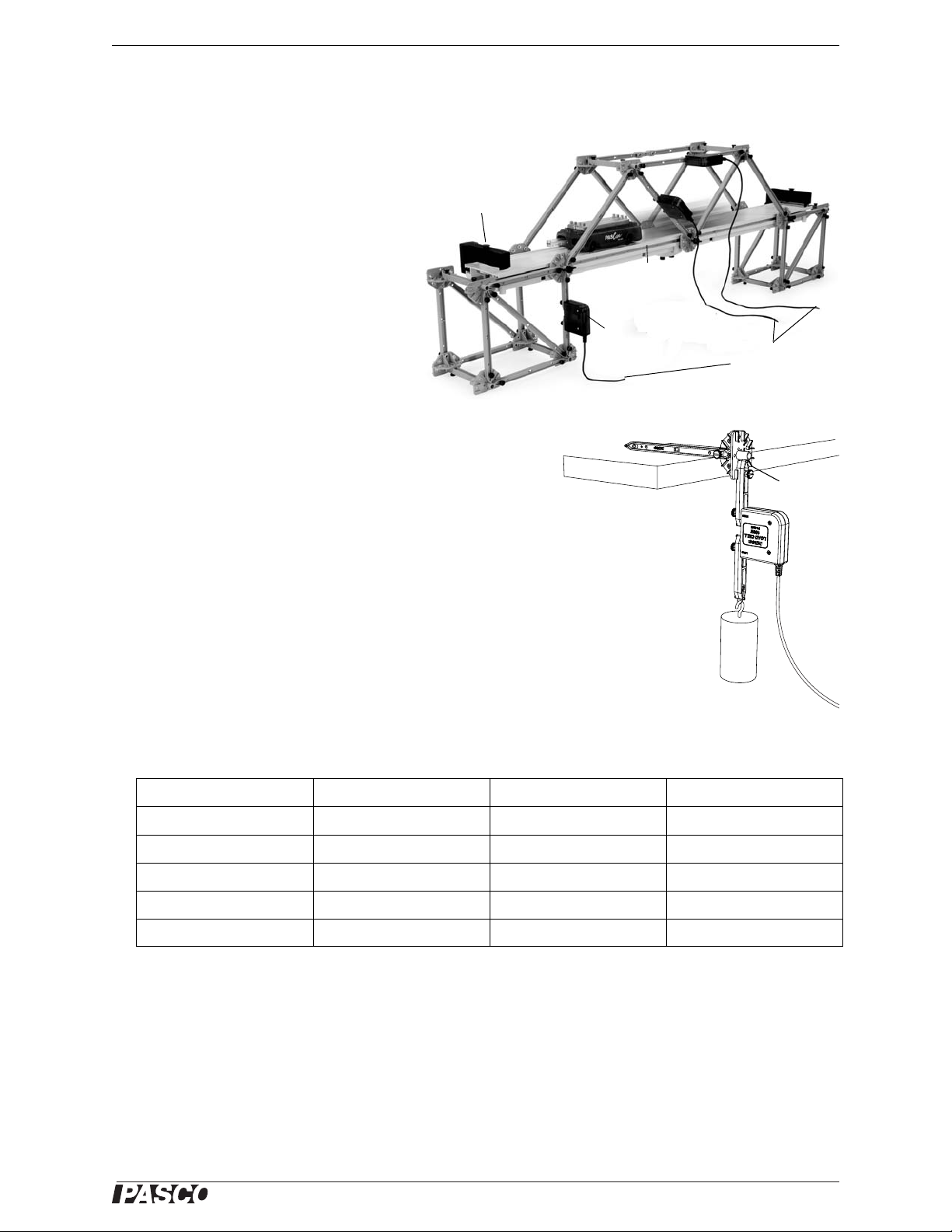

The cover page shows an Angle Crane model built with components from the ME-7 003 Lar ge S tru ctures Set. The

picture shows Load Cells, a Load Cell Amplifier, Large Slotted Masses, and the Hydraulics Structures Set which

are available separately. The ME-7003 Large Structures Set can be used to build over a dozen different models.

Instructions for building twenty models are includ ed in this manual.

ii

Page 3

®

Table of Contents

Included Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

About the Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Adding Load Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Large Structures Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1. Car Building Jump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2. Cable Stayed Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3. Arch Truss Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4. Roller Coaster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5. Canyon Car Jump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6. Suspension Bridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7. High Road/Low Road. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8. Tied Arch Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

9. Baltimore Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

10. Double Tied Arch Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

11. Cantilever Truss Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

12. Brachistochrone. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

13. Drawbridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

14. Vertical Lift Drawbridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

15. Tower Crane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

16. Arch Causeway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

17. Skyscraper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

18. House Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

19. Angle Crane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

iii

Page 4

®

Large Structures Set

20. Windmill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Technical Support, Warranty, and Copyright. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Windmill Sail Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

iv

Page 5

®

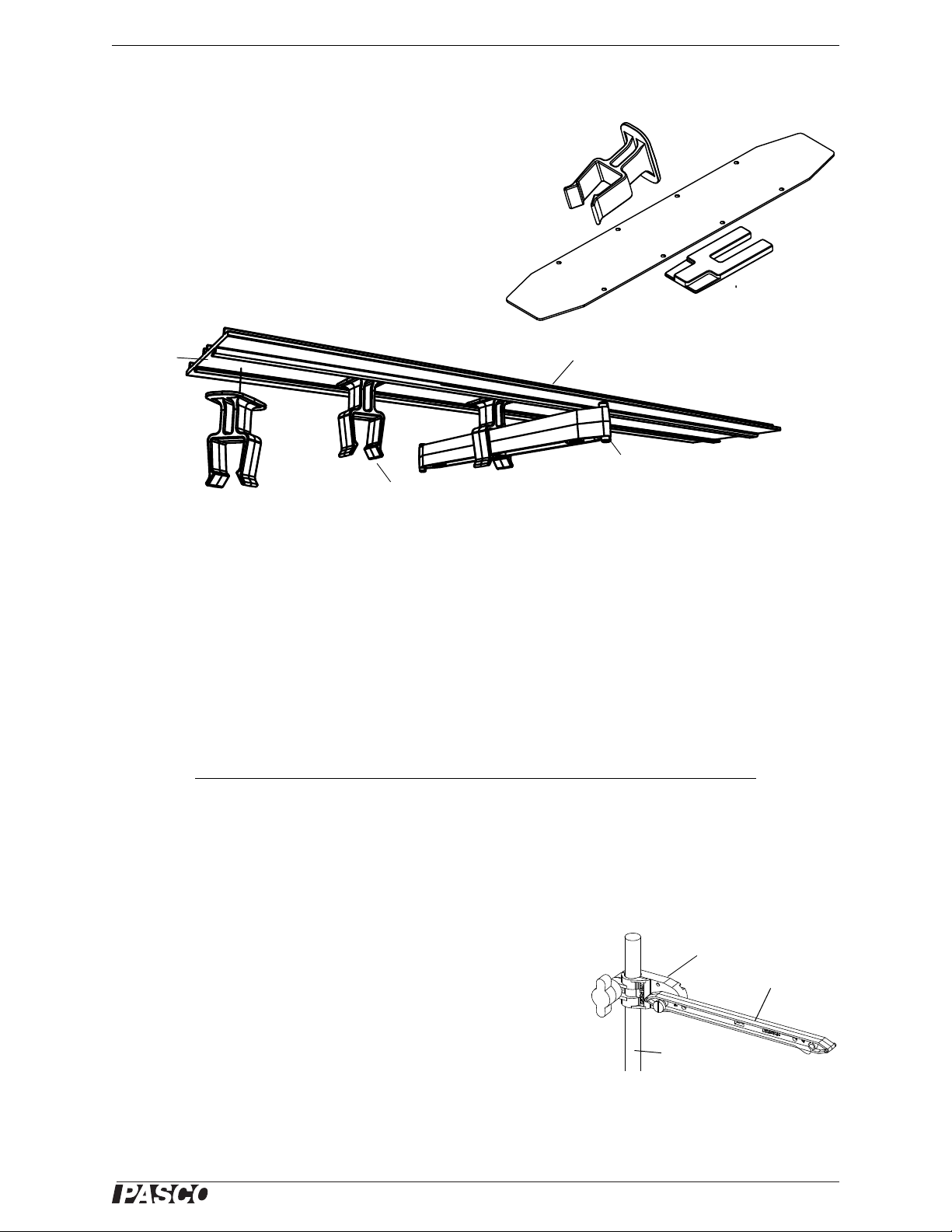

ME-6997 Full Round

Connector Set

ME-6993 Truss Set Members

ME-6988A Force Platform Structure

ME-7002 Connector

Spares

ME-6996 Cord Lock Spares

ME-6994 Truss Set Screws

ME-6999A Angle

Connectors

ME-6974 Large

Structure Parts

ME-6985 Flexible I-Beams

ME-6986 Structures

Rod Clamp

ME-6998A Axle Spares

ME-7008 #6 I-Beams

ME-9814 Coaster Track (9.1 m)

ME-9839 and ME-9840 Mini Cars

ME-6987 Flat Structures

Members

ME-9856 Mini Car Starter Bracket

Large Structures Set

ME-7003

1

Page 6

®

Large Structures Set Introduction

Included Items Qty Included Items Qty

ME-6974 Large Structures Parts 1 set ME-6998A Axle Spares 1 set

ME-6986 Structures Rod Clamps (2/set) 1 set ME-6999A Angle Connectors 1 set

ME-6985 Flexible I-Beams 1 set ME-7002 Connector Spares 2 sets

ME-6987 Flat Structures Members 1 set ME-7008 #6 I-Beam Spares 1 set

ME-6988A Force Platform Structure 1 set ME-9814 Coaster Track (9.1 m) 1

ME-6993 Truss Set Members 3 sets ME-9839 Mini-car, Green 1

ME-6994 Truss Set Screws (75/set) 6 sets ME-9840 Mini-car, Yellow 1

ME-6996 Cord Lock Spares 1 set ME-9856 Mini-car Starter Bracket 1

ME-6997 Full Round Connector Set 1 set Container (not shown) 2

The ME-7003 Large Structures Set can be used with other sets from the PASCO Structures System* such as the

following:.

ME-6984 Hydraulics Structures Set ME-6991 Bridge Set

ME-6990 Truss Set ME-6992A Advanced Structures Set

*See the PASCO catalog or Web site at www.pasco.com for information about the PASCO Structures System.

The following equipment* is recommended for use with a PASCO Interface to measure tension and compression

forces in the structures or to measure the motion of a Mini Car as it moves on a structure..

Recommended Equipment* Recommended Equipment*

Load Cell Amplifier (PS-2198, PS-2206 or CI-6464) PS-2204 Displacement Sensor

PS-2200 100 N Load Cell PS-2159 PASPORT Digital Adapter

PS-2201 5 N Load Cell ME-9498A Photogate Head

*See the PASCO catalog or Web site at www.pasco.com for more information about the recommended items.

Introduction

The ME-7003 Large Structures Set is one part of the PASCO Structures System and can be combined with other

parts of the Structures System. The Large Structures Set allows you to build a variety of realistic tru ss structures.

You can add Load Cells to the structures in order to measure the forces anywhere in the structure. This manual

describes t he construction of sixteen structures.

Load Cell Amplifier (PS-2198 or CI-6464) - The amplifier r equires a PASPORT o r ScienceWorkshop interface to

connect to a computer. The PS-2198 accepts up to six Load Cells and the CI-6464 supports one Load Cell.

100 N Load Cell (PS-2 200) and 5 N Load Cell (2201) - Strain gauges mou nted on a b eam with no electronics s o

a Load Cell requires a Load Cell Amplifier (PS-2198), Dual Load Cell Amplifier (PS-2206), ScienceWorkshop

Load Cell Amplifier (CI-6464), or CI Sensor Voltage Monitor (CI-6611).

Displacement Sensor (PS-2205) - A PASPORT Sensor and a digital displacement indicator designed to measure

the deflection of parts of a structure such as a truss or a bridge as forces are applied.

2

Page 7

®

Model No. ME-7003 012-12670A About the Components

Photogate

Flag

Coupler

Track

Clip

Coaster Track

Track Clip

Rotate the clip one-quarter turn.

Beam

Channel

Beam

Clamp

Rod

About the Components

Large Structures Parts (ME-6974)

The ME-6974 Large Structures Parts set consists of two

Mini Car Photogate Flags, two Couplers for the Coaster

Track, and a set of 24 Track Clips. The Photogate Flags

mount on any Mini Car. When the flag on a moving car

travels through a photogate and interrupts the beam, the

car’s motion can be measured. The Couplers are used to

connect Coaster Tracks together, and the Track Clips are

used to connect a Coaster Track to a PASCO structure.)

Use track clips to connect the Coaster Track to the structure beams. Slide the clip into the channel on the underside

of the track. Move the clip into position and lock it into place with a quarter twist as shown.

Flexible I-Beams (ME-6985)

The Flexible I-Beam Set contains forty-six flexible beams of three dif ferent lengths . The flexible beams have the

same lengths as three of the I-beams from the Truss Set Members (ME-6993). The flexible beams allow you to

explore the concept of structural failure. By replacing a #3, #4, or #5 I-beam in a structure with one of the flexible

I-beams you can observe the effect of a load that causes deformation. These I-beams are designed to demonstrate

stress and failure and then return to their original shape once the load is removed.

Flexible I-Beam Set (ME-6985) Qty Equivalent Truss Set Members

#3 Flexible I-Beam (11.5 cm) 18 #3 I-Beam

#4 Flexible I-Beam (17 cm) 18 #4 I-Beam

#5 Flexible I-Beam (24 cm) 10 #5 I-Beam

Please note that the flexible I-beams are a different color (beige) than the other I-beams (light blue).

Structures Rod Clamp (ME-6986)

Use a rod clamp to attach a structure beam to any 12.7 mm (1/2”) diameter rod.

3

Page 8

®

Large Structures Set About the Components

#4 Beam

#3 Beam

3 X 4

Beam

Half Round

Truss

3 X 4

Beam

2 X 3

Flat #4

Beam

#1 Beam

#2 Beam

#3 Beam

#4 Beam

#5 Beam

Half Round

Connector

Screw

#1 #1

#3

#3#3

#5

#2 #2

#4

Flat Structures Members (ME-6987)

This set contains three types of flat structures: Flat 3 X 4 Beam (19 cm), Flat #4 Beam (17 cm), and Flat 2 X 3

Beam (12.5 cm). There are sixteen of each type of beam in the set.

Force Platform Structure (ME-6988A)

The PASCO model ME-7003 Force Platform Structures Bra cket includes two brack ets and fo ur thum bscrews. Th e

adapter bracket is designed to connect memb ers of the PASCO Structures System to a P ASCO Force Platform (not

included). The brackets can also serve as foundation plates for larger structure models.

(Please see the Force Platform Structures Bracket instruction sheet for more information.)

Truss Set Members (ME-6993)

The Truss Set Members consis ts of five typ es of “I- beams ” and

one type of connector. Each set has the following quantities:

Item Qty Item Qty

#1 Beam (5.5 cm) 8 #4 Beam (17 cm) 18

#2 Beam (8 cm) 8 #5 Beam (24 cm) 8

#3 Beam (11.5 cm) 18 Half Round Connector 14

When connected at 180° to a connector, two identical beams

have a combined length equal to one longer beam. For example,

two #1 beams connected at 180° have the same length as a #3

beam.

Truss Set Screws (ME-6994)

Each set of Truss Set Screws contains 75 Thumbscrews for attaching I-beams to connectors or load cells.

Cord Lock Spares (ME-6996)

A set of Cord Lock Spares includes 32 Cord Tensioning Clips (Cord Clips) and one roll of yellow braided cord.

When attaching cords for lateral bracing or for suspension or cable-stayed brid ges, Cord Clips are used to assist in

adjusting the tension in the cords.

The Cord Clip does not come apart. It is best to thread the cord through the clip before the clip is installed on the

bridge or structure. Prepare to thread the cord by holding the top half of the clip as shown in Figure A so the two

4

Page 9

®

Model No. ME-7003 012-12670A About the Components

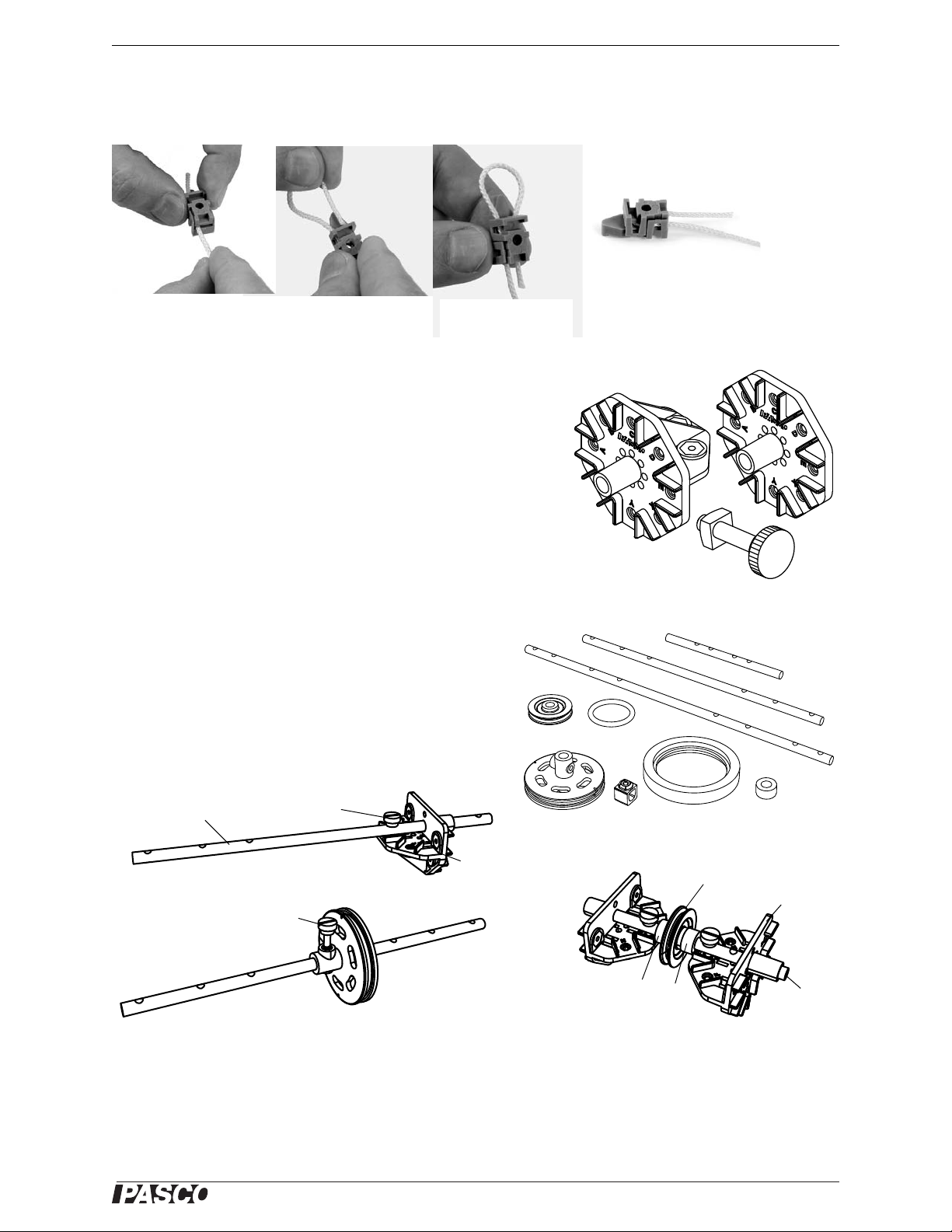

Figure A: Hold half of

the cord clip so the

two halves separate

Figure B: Loop the

cord back through the

cord clip

Figure C: The cord

goes around the

screw hole

Figure D: The cord clip is

ready to be attached to the

structure using a screw

Full

Round

Flat

Round

PASt rack

Connector

Pulley

O-ring

Drive

wheel

Collet Tire Spacer

Axles

Pulley

Spacers

This pulley is free to rotate.

Half

Round

Axle

Axle attached to a half-round connector

Axle

Half

Round

Thumbscrew

Drive wheel attached to an axle

Thumbscrew

halves of the clip will separate, leaving an opening through which the cord is threaded. The cord is inserted into

the end opposite the pointed end of the clip. The cord should be looped back through the clip as shown in Figure C.

Then the Cord Clip can be used in the structure, using the attachment screw to tighten the clip shut. To adjust the

cord tension, loosen the screw and pull on the cord to the desired tension and then tighten the screw.

Full Round Connectors Spares (ME-6997)

Full Round Connector: The Full Round Connector has eleven slots,

labeled A through H and X, Y, and Z, for attaching beams. There are

six Full Round Connectors in the set.

Flat Round Connector: The Flat Connector has eight slots, labeled

A through E, and X, Y, and Z, for attaching beams. There are six

Flat Connectors in the set.

PAStrack Connector: The PAStrack Connector is a nut and bolt that

allows a PAStrack to be connected to a structures model. There are

six PAStrack Connectors in the set.

Axle Spares (ME-6998A)

The Axle Spares set includes two Axles each of three different lengths, twelve Pulleys, twelve O-rings, four Drive

Wheels, four Tires, 24 Collets, and twelve Spacers.

The illustrations show example uses of axles, pulleys, and

wheels.

5

Page 10

®

Large Structures Set About the Components

Sliding Connector on a #1 Beam

Straight

Angle

Straight Connector

Angle Connector

Side rail

Center

rails

Track

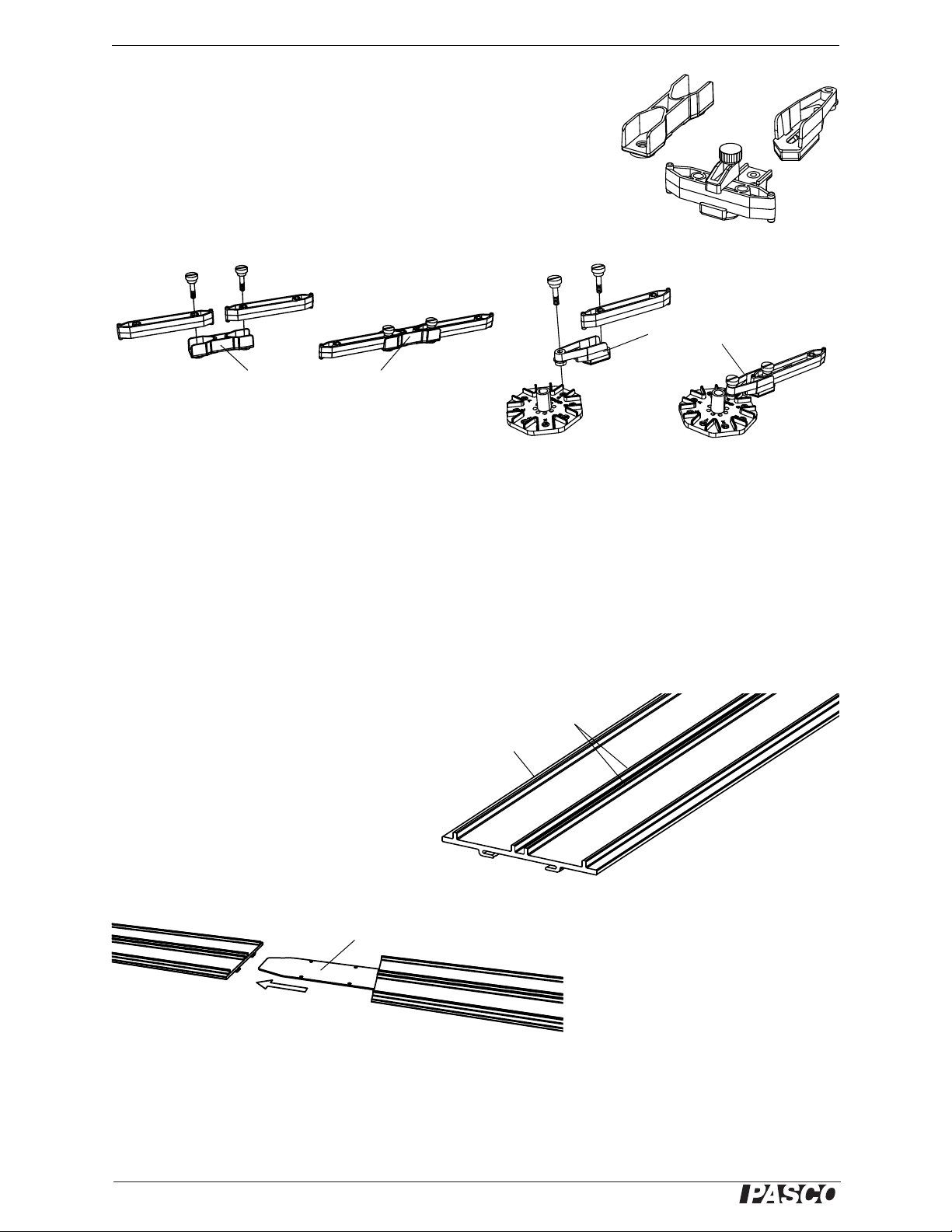

Angle Connectors (ME-6999A)

The Angle Connectors set includes 24 Straight Connectors, 24 Angle Connectors, and twelve Sliding Connectors. The Straight Connector can connect

two beams to make a longer beam. T he Angle Co nnector can allow a beam to

be connected to a half round connector, full round connector, or flat round

connector at an angle different than zero, 45, or 90 degrees. The angle connector also allows for a small adjustment of the length of the beam. The Sliding Connector allows one beam to be connected to another beam at any

position along the length of the second beam..

To use the sliding connector, loosen the thumbscrew and rotate the top “jaw” to the side. Place the beam onto the

lower part of the connector, rotate the top “jaw” into place, and tighten the thumbscrew. The Structures Set

includes two Angle Connector sets.

Connector Spares (ME-7002)

Each set of Connector Spares includes fourteen Half Round Connectors.

#6 I-Beam Spares (ME-7008)

The #6 I-Beam is 35 cm long. There are 24 beams per set.

Coaster Track (ME-9814)

The ME-9814 Coaster Track is a section of f lexible track that is 9.1 m long. Side rails and center rails help to keep a Mini Car on the track.

Use a sharp knife or scissors to cut the track to

the desired length.

Use a Track Coupler to connect two sections of

Coaster Track together.

Slide the Track Coupler into the channel on the underside of each Coaster Track section.

6

Page 11

®

Model No. ME-7003 012-12670A About the Components

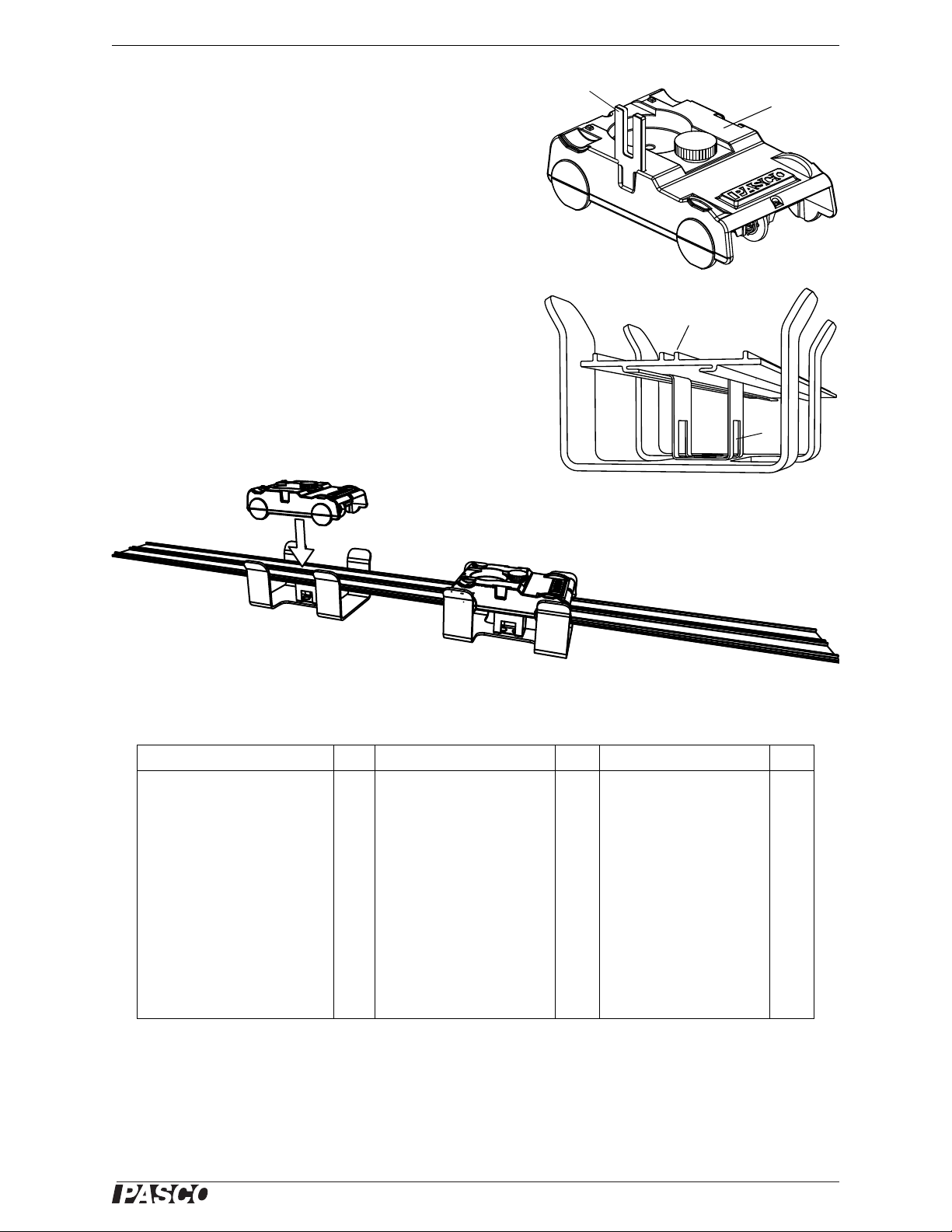

Mini Car

Photogate flag

Metal

Coaster

track

Mini Car

Starter Bracket

Car aligned in bracket

Mini Cars (ME-9839 and ME-9840)

The ME-9839 Green Mini Car and ME-9840 Yellow Mini Car

are designed to run on the Coaster Track.

If you are using a photogate (available separately) to measure

the speed of the car, attach a photogate flag (included with the

ME-6974) as pictured. The flag will interrupt the photogate

twice as the car passes, allowing the speed to be calculated.

Mini Car Starter Bracket (ME-9856)

The ME-9856 Mini Car Starter Bracket is designed to help

align the wheels of the Mini Car on the Coaster Track. Squeeze

the metal clip of the starter bracket and insert it into the channel

on the underside of the track.

Slide the bracket along the track to the desired position.

Drop the Mini Car into the bracket as shown.

Total Quantities

Included Items Qty Included Items Qty Included Items Qty

#6 Beam (35 cm long) 24 #4 Flexible Beam (17 cm) 18 Force Platform Structure 2

#5 Beam (24 cm long) 24 #3 Flexible Beam (11.5 cm) 18 Cord Tensioning Clip 32

#4 Beam (17 cm long) 54 Angle Connector 24 Yellow Cord 1 roll

#3 Beam (11.5 cm long) 54 Straight Connector 24 Coaster Track (9.1 m) 1

#2 Beam (8 cm long) 64 Sliding Connector 12 Mini Car (Green and Yellow) 2

#1 Beam (5.5 cm long) 24 Flat Round Connector 6 Mini Car Starter Bracket 1

Flat 2 X 3 Beam (12.5 cm) 16 Full Round Connector 6 Track Clip 24

Flat 3 X 4 Beam (19 cm) 16 Half Round Connector 70 Track Coupler 2

Flat #4 Beam (17 cm) 16 PAStrack Connector 6 Mini Car Photogate Flat 2

#5 Flexible Beam (24 cm) 10 Screw (6-32) 450 Container (not shown) 2

7

Page 12

®

Large Structures Set Operation

Attaching beams to connectors

A load cell combined with two #2 beams is the same

length as a #4 beam

Load Cell

#2

#2

#4

Bridge with Load Cells

1.0 N()21.0 N()

2

+ 1.4 N=

Operation

Assembling Beams

All beams attach to connectors in the same way. Use the included screws (6-32, slotted) to attach beams to a con nector (such as the half round connector) as illustrated.

Adding Load Cells

To measure the compression and tension forces in individual members of a structure, add load cells (available

separately) to the PASCO Structure. Replace a beam

with two shorter beams and a load cell.

#5 beam = load cell + two #3 beams

#4 beam = load cell + two #2 beams

#3 beam = load cell + two #1 beams

Use thumbscrews to attach two beams to a load cell as

shown in the fi gure.

When using load cells, assemble your structure with the screws loose. This will simplify the analysis by ensuring

that the members experience only tension and compression without moments.

Example: Bridge with Load Cells

Static Load

The bridge shown in the figu re incorporates six load

cells to measure the tension or compression in various members. A hanging mass is used to apply loa d.

The mass is adjusted so that th e compression in one

of the legs is 1.0 N. Compression is registered as a

positive value and tension as a negative value.

If the screws are loose, then the theoretical analysis

of the bridge can be carried out by assuming that the net force at each node is zero. Thus, the vertical component

of compression in the left-most diagonal member must be 1 N (to oppose the force applied by the leg). The horizontal component must also be 1 N since the member is at a 45° angle. The predicted resultant force is:

8

Page 13

®

Model No. ME-7003 012-12670A Large Structures Construction

Recording the forces measured by the load cells as the cart traverses the

PAStrack bridge.

PAStra ck

Load

Cell

Adjustable

end stop

To Load Cell

Amplifier

Calibration fixture

Load

Cell

Mass

Half

Round

Dynamic Load

With the load cells inserted as shown in

the figure, push a Cart with its extra

mass across the bridge. Zero the load

cells before the measurement. Examine

which members are under tension or

compression.

Note that the Load Cell Amplifier can

support up to six Load Cells in any

combination (5 N, 100 N, or both).

Calibration.

See the instructions that came with the load cells for details about

how to connect the load cells to an interface or datalogger. Follow

the instructions to calibrate the load cells and use them to collect

data. (Load cells are factory calibrated; however, you can re-calibrate them in software or on the datalog ger. See the documentation

for your software or datalogger for instructions.)

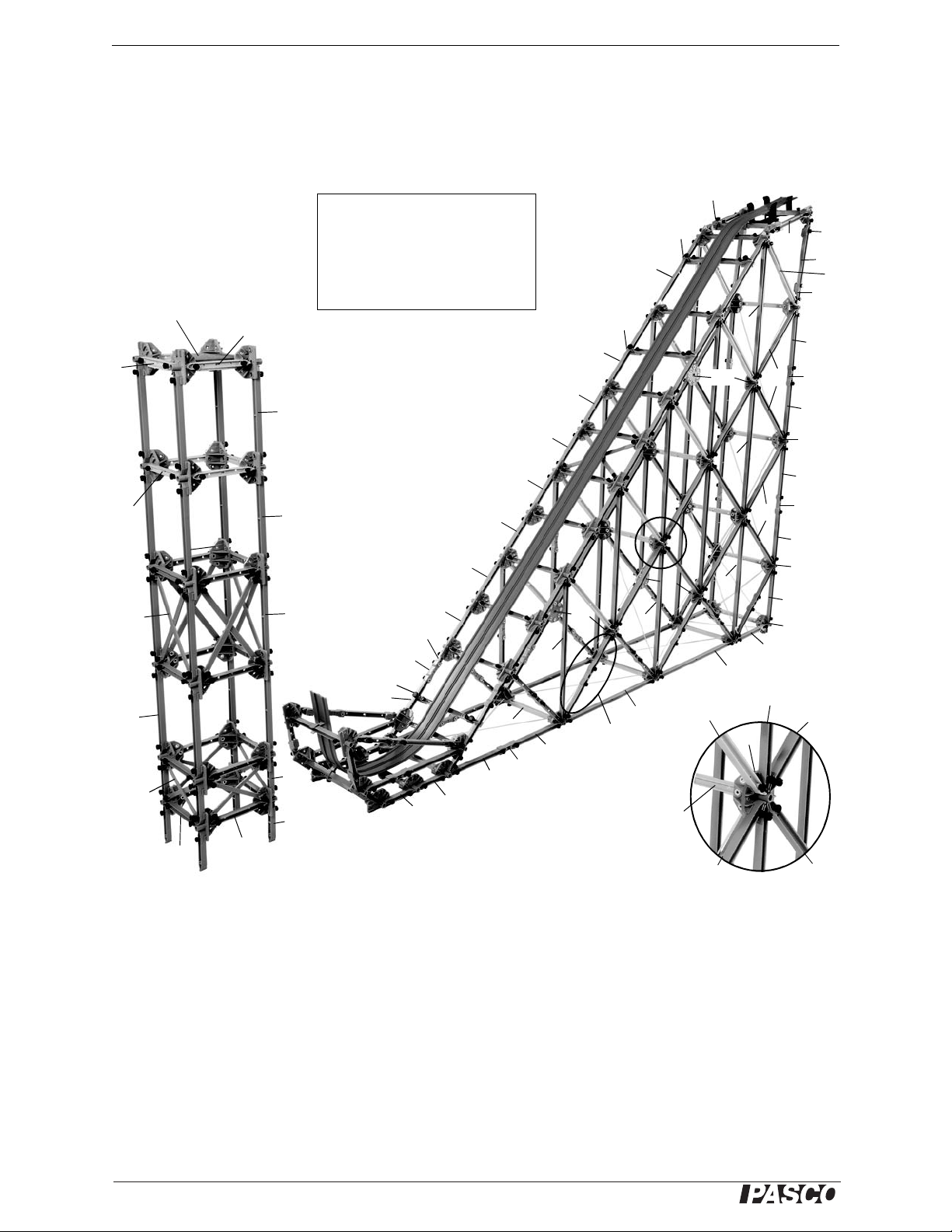

Large Structures Construction

The manual illustrates construction of twenty large structures such

as trusses, bridges, and cranes. The descriptions show what components are used for each structure and how they are connected to

each other. Close-up photographs show the details of construction

where possible.

Table 1.1:

Structure Structure Structure Structure

Car Building Jump Suspension Bridge Cantilever Truss Arch Causeway

Cable Stayed Bridge High Road/Low Road Brachistochrone Skyscraper

Arch Truss Tied Arch Bridge Drawbridge House Frame

Roller Coaster Baltimore Bridge Vertical Lift Drawbridge Angle Crane

Canyon Car Jump Double Tied Arch Bridge Tower Crane Windmill

9

Page 14

®

Large Structures Set Car Building Jump

Figure: Car Building Jump

Flex 4

Legend:

AC = Angle Connector

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

ST = Straight Connector

AC

AC

#4

#4

#4

#4

#4

#4

ST

ST

#4

SL

#5

SL

SL

#5

#3

#3

#3

#3

#3

#3

SL

ST

#1

#3

#2

#2

#4

#6

#6

#4

#4

ST

#5

#5

#6

#6

#6

#6

#6

Use two #3 beams

and a Straight

Connector to make

twelve #5 beams.

FT

FT

HR

HR

FL

Flex 3

#4

#4

#4

#3

HR

FR

#6

#5

#5

#5

Flex 5

Flex 4

#4

#3

2 x

3 x

#2

#2

Landing

platform*

Car Building Jump

Use beams, connectors, cord (for cr os s b racing), and a section of Coaster Track to build a ramp next to a building.

Use Track Clips to attached the Coaster Track to the ramp. Add a Mini Car Starter Bracket to the top of the ramp

and let a Mini Car roll down the ramp and “jump” onto the adjacent building’s landing platform.

Flex 3

Flex 5

Flex 3

Adjust the position of the building as needed so that the car lands on top of the building.

*Make a landing platform using a square of cardboard or foam core board.

If the building is too high or too low, change the beams at the bottom of the building. Replace the #2 beams with

#1 beams, or remove the bottom beams altogether.

10

Page 15

®

Model No. ME-7003 012-12670A Car Building Jump

Figure: Top Detail

Mini Car Starter Bracket

#4

Flex 5

AC

AC

AC

#4

SL

SL

#6

#5

AC

#4

SL

Use Track Clips to attach the Coaster

Track to the #4 cross beams. Attach the

Mini Car Starter Bracket to the underside

of the Coaster Track.

AC

AC

ST

#4

#4

AC

#2

Flex 4

Flex 4

Flex 4

#2

#2

#2

#4

ST

#4

Track Clip

#1

Track Clip

HR

HR

Cord

Use cord to cross brace

the base of the ramp.

ST

Figure: Bottom Details

For the bottom of the ramp, attach

Track Clips to the Coaster Track and

then to the #4 beams in the locations

indicated by the arrows in the diagram.

Loosen the Angle Connectors to adjust

the angle of the upward-curved section

at the end of the Coaster Track so that

the Mini Car is able to “jump” to the

top of the landing platform. Tighten the

connectors to keep the angle.

#1

#1

#2

#2

#2

#4

#2

#2

#4

AC

AC

#2

ST

#4

#2

ST

#4

AC

Car Building Jump Details

11

Page 16

®

Large Structures Set Car Building Jump

Tie the cords

to the

connectors.

Cord

Lace the

cord through

the

connectors.

Cord

Cord

Cord

Tensioning

Clips

Figure: Back of Ramp Details

Tie the

cords.

Lace the

cords.

Cord

Tensioning

Clip

Cord

Tensioning

Clip

Car Building Jump Details

Use cord and Cord Tensioning Clips to cross brace the back of

the ramp.

Tie the cords to the Half Round Connectors near the top of the

ramp,

Lace the cord through holes in the Half Round Connectors that

are between the top and bottom of the back of the ramp.

12

Attach the cords to Cord Tensioning Clips on the bottom connectors.

Page 17

®

Model No. ME-7003 012-12670A Cable Stayed Bridge

Figure: Cable Stayed Bridge

#3

#6

#6

#4

Flat 4

#5

Flat 4

#5

#4

#5

AC

AC

AC

ST

#3

#2

AC

#4

#3

SL

Legend:

AC = Angle Connector

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

ST = Straight Connector

FT

#4

#3

AC

FR

#2

3 x 4

2 x 3

Tow er s

Deck

Deck

Support

Struct ure

#4

#4

Cord

Tensioning

Clip

Coaster Track

Cable Stayed Bridge

The Cable Stayed Bridge has a d eck that is susp ended on cords fr om two towers. There is a deck support s tructure

at each end of the deck.

The modular approach to the construction of this structure is to build the deck in two halves and also build each

tower and deck support structure before trying to suspend the deck. Do not attach the Coaster Track to the deck

halves yet. Next, insert one half of the deck through one of the towers and use cord to suspend the deck from the

top of the tower. Repeat for the other half of the deck. Connect the ends of the deck halves to the deck support

structures and then connect the deck halves between the towers. Adjust the length of the cords so that the deck is

level. Finally, use T rack Clips to attach the Coaster Track to the finished deck..

13

Page 18

®

Large Structures Set Cable Stayed Bridge

#3

FR

Screw

D

C

B

A

Overhand

knot

Figure: Tower Detail

AC

HR

Cord

Tensioning

Clip

#2

2 x 3

2 x 3

At the middle of the tower, use 2 x 3 beams to cross brace the tower.

ABCD

Figure: Suspend the Deck

DCBA

Cable Stayed Bridge Details

There are eight strands of cord from each side of the top of the tower that are used to suspend each half of the deck.

Start with the strands of cord closest to the tower (for example, A and B in the figure). Get a piece of cord that is

twice as long as the distance from the top of the tower to the deck. Make an overhand knot near the middle of the

piece of cord and fasten the loop of the knot to the Full Round Connector at the top of the tower using a screw as

shown. Put the two ends of the cord into Cord Tensioning Clips and attach the clips to two of the Half Round Connectors on the side of the deck. Repeat the process for strands C and D and the rest of the strands of cord.

14

Page 19

®

Model No. ME-7003 012-12670A Arch Truss Bridge

Figure: Arch Truss Bridge

#4

#4

#6

#6

#5

#5

#3

#2

ST

Legend:

AC = Angle Connector

F4 = Flat 4 Member

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

ST = Straight Connector

#4

#3

#4

FR

F4

3 X

FT

F4

AC

ST

ST

#1

#3

SL

Flex 3

Flex 5

Flex 3

Flex 5

AC

AC

#1

ST

#3

AC

AC

AC

#2

Cord

Cross

brace with

cord.

Cross brace with 3 X 4.

Cross brace with 3 X 4.

Figure: Arch Truss Top Detail

Flex 5

Flex 5

#1

SL

SL

ST

ST

#1

#4

AC

#2

Arch Truss Bridge

The Arch Truss design is one of the most frequently used designs in history. Construct the end supports and then

add the deck. Tie cords from the base of one end support to the base of the other end support. Next, add the arch

and suspension beams. Use Flat 3 X 4 members to cro ss brace the deck at the point where it joins the top of the end

supports. Use cord to cross brace the bottom sections of the arch. Finally, use Track Clips to attach the Coaster

Track.

Connect the

center of the

arch with

Straight Connectors and a #1

Beam.

Use Sliding

Connectors and

#1 Beams to

suspend the

center of the

arch.

15

Page 20

®

Large Structures Set Arch Truss Bridge

Figure: Arch Truss Bridge Details

ST

SL

AC

FR

FL

Cord

Tensioning

Clip

Tie a knot.

ST

ST

SL

AC

AC

AC

ST

#3

#1

#1

#3

Flex

#3

Figure: Arch Truss Bridge Bottom

Arch Truss Bridge Details

Use two pieces of cord to cross brace the two lower

sections of the arch. Attach the cords with Cord

T ensioni ng Clips at one end. Lace the cords through

the Sliding Connectors. Tie the cords to holes in the

Full Round Connectors at the other end..

Repeat for the other side of the bridge.

Bridge Details

16

Page 21

®

Figure: Roller Coaster Left Detail

#4

#1

Use a cord to stop

the Mini Car.

AC

AC

ST

#3

#4

#4

#4

#5

FR

#4

#6

#5

#6

Flex 5

#5

Legend:

AC = Angle Connector

CT = Cord Tensioning Clip

F4 = Flat 4 Member

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

ST = Straight Connector

#4

AC

AC

Flex 4

#4

AC

#4

#5

ST

#3

AC

#4

Knot

#6

Cord

CT

SL

#5

Track

Clip

3 X 4

Model No. ME-7003 012-12670A Roller Coaster

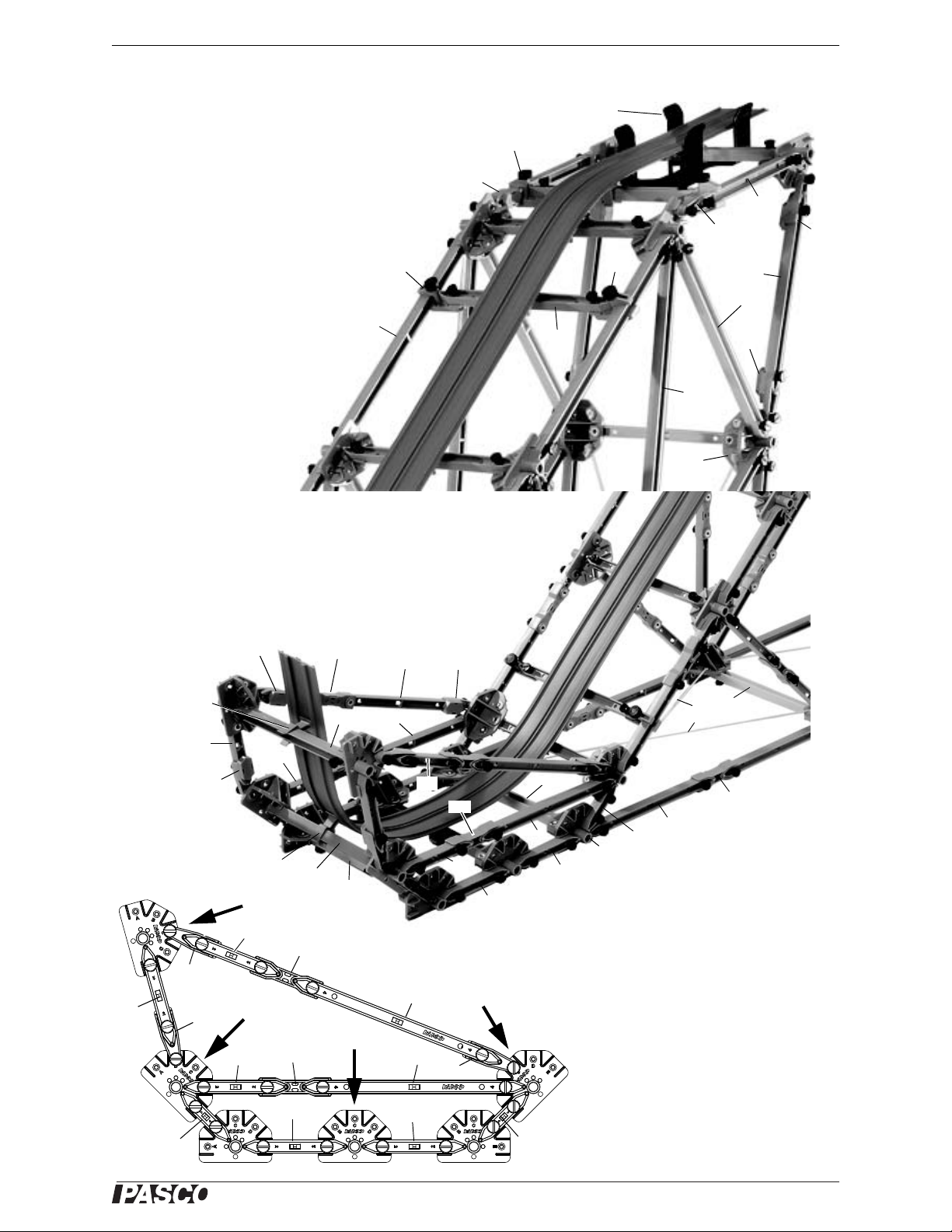

Roller Coaster

Use set components to build a “loop-the-loop” roller coaster model.

17

Page 22

®

Large Structures Set Roller Coaster

Figure: Roller Coaster Right Details

#6

#6

#6

Legend:

AC = Angle Connector

CT = Cord Tensioning Clip

F4 = Flat 4 Member

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

ST = Straight Connector

#4

#3

#3

#6

“#5” = #3 + ST + #3

“#5”

“#5”

#5

#5

Flex 5

#4

AC

AC

FT

FR

Flex 5

#4

“#5”

#6

#6

#6

“#5”

#4

AC

SL

SL

Flex 4

AC

SL

#4

Mini Car Starter Bracket

AC

SL

#4

#4

#4

Roller Coaster Details - Right End

Make fourteen extra “#5” Beams using fourteen Straight Connectors and twenty-eight #3 Beams. Use cord to

cross brace the bottom and the back of the ramp.

18

Page 23

®

Model No. ME-7003 012-12670A Roller Coaster

Figure: Roller Coaster Center Details

#6

#6

#5

#5

#5

FR

#6

#5

#3

#3

#3

#3

#3

#2

#1

#1

#4

#1

AC

#2

#5

3 X 4

3 X 4

SL

SL

FR

2 X 3

SL

SL

#1

AC

#2

#5

Figure: Roller Coaster Inset Details

#4

Roller Coaster Details - Center

Attach the Track Clip to a Flexible #4 Beam at the top of the Roller Coaster.

19

Page 24

®

Large Structures Set Canyon Car Jump

Figure: Canyon Car Jump Landing Ramp

Legend:

AC = Angle Connector

CT = Cord Tensioning Clip

F4 = Flat 4 Member

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

ST = Straight Connector

#5

#4

#4

3 X 4

AC

AC

#4

#5

#5

#4

#2

#3

ST

AC

#3

#3

#4

#5

#4

#5

CT

AC

AC

AC

#1

CT

AC

CT

#4

Tie a knot.

Coaster

Track

Trac

k

Landing

Ramp

Launch

Ramp

Canyon Car Jump

Use beams, connectors, clips and cord to construct a landing ramp.

Use cord and Cord Tensioning Clips to cross br ace b oth ends of the landin g ramp. Also use cord to cross brace the

side panels at the right-hand end of the landing ramp. Use Track Clips to attach two sections of Coaster Track

side-by-side to the #4 Beam cross members.

20

Page 25

®

Model No. ME-7003 012-12670A Canyon Car Jump

Figure: Canyon Car Jump Launch Ramp

#1

ST

#6

#6

AC

#5

SL

3 X 4

#3

AC

#6

#5

#5

#6

#6

Legend:

AC = Angle Connector

CT = Cord Tensioning Clip

F4 = Flat 4 Member

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

ST = Straight Connector

#3

#3

“#5” = #3 + ST + #3

“#5” = #3 + ST + #3

“#5” = #3 + ST + #3

“#5”

“#5”

“#5”

#4

#6

#6

#6

FL

“#5”

FL

#5

Flex 5

Flex 5

#5

#3

SL

AC

FR

#3

#4

#4

Figure: Canyon Car Jump Ramp Detail

SL

AC

AC

#3

#3

SL

AC

AC

SL

A

#5

#3

#3

FR

#4

AC

SL

#4

#3

Track

Clip

Mini Car Starter Bracket

AC

Canyon Car Jump Launch Ramp.

Use connectors, cord,

clips, and beams to

construct a launch

ramp. Include a Mini

Car Starter Bracket at

the top of the ramp

Make fourteen “#5”

Beams using fourteen Straight Connectors and twenty-eight

#3 Beams.

Use cord and Cord

Tensioning Clips to

cross brace the bottom and back of the

launch ramp.

Use Track Clips to

attach the Coaster

Track to the #4 B eam

cross members.

Add the Mini Car

Starter Bracket.

21

Page 26

®

Large Structures Set Suspension Bridge

End

Support

To we rs

Deck

Arch

Figure: Suspension Bridge

Legend:

AC = Angle Connector

CT = Cord Tensioning Clip

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

ST = Straight Connector

#4

#4

#3

Long

Axle

#5

3 X 4

#4

#4

#4

#4

#3

3 X 4

#2

2 X 3

Flex 3

Flex 4

Flex 4

Flex 5

ST

ST

ST

SL

#1

Medium

Axle

Collet

FT

#6

3 X 4

FR

HR

#3

CT

#3

#4

#3

#1

#1

Track Clip

Flex 3

FR

Long

Axle

Put a Collet at the

middle of the Long

Axle. Attach a Track

Clip to the Collet.

AC

Cord

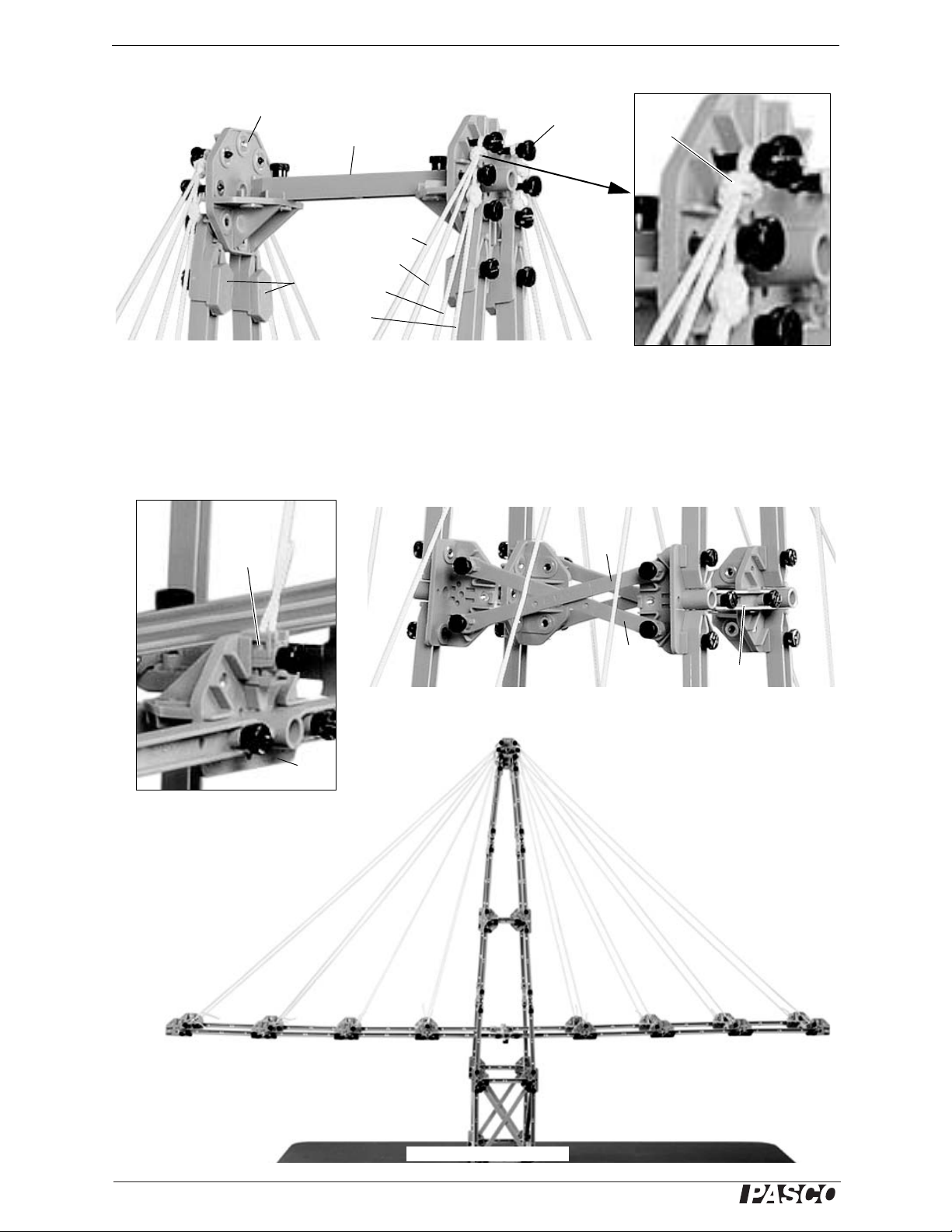

Suspension Bridge

The construction of the Suspension Bridge uses a modular approach. The construction involves building the End

Supports, Towers, Arches, and Deck, and then suspending the Deck from the Arches and connecting the Deck to

the End Supports.

22

Page 27

®

Model No. ME-7003 012-12670A Suspension Bridge

Medium

Axle

Collet

Sliding

Connector

Screw

through

Collet

Straig ht

Connector

Flat Round

Connector

Angle

Connector

Figure: Suspension Bridge Tower Detail

#1

Straig ht

Connector

Sliding

Connector

#1

Flat Round

Connector

Collet

Screw through

Collet

Figure: Suspension Bridge Tower Detail Sketch

Collet

Long Axle

Track Clip

Half

Round

Full

Round

3 X 4

#4

3 X 4

#3

Figure: Suspension Bridge End Support Detail

Suspension Bridge Details

Put a screw through the center hole of a Collet and attach the screw to the Flat Round Connector. Clamp the jaws

of the Sliding Connector over the Collet. Connect a #1 Beam to the Sliding Connector and connect a Straight Connector to the #1 Beam. Repeat for the other arches.

Suspend the deck from the arches using cord and Cord Tensioning Clips. Tie one end of each cord to the arch and

attach the other end of the cord to the Cord Tensioning Clip.

Connect the end of the deck to the end support. Put one end of a Long Axle through

the Half Round Connector of the end support and the Full Round Connector of the

deck, Add a Collet to the Long Axle and

then put the Long Axle through the Full

Round Connector and Hal f Ro und Con nector on the other side to attach the end of the

deck to the end support. Position the Collet

at the middle of the Long Axle and use a

Track Clip to attach the Coaster Track to

the Collet on the axle.

23

Page 28

®

Large Structures Set High Road/Low Road

#6

#6

#6

Legend:

AC = Angle Connector

CT = Cord Tensioning Clip

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

ST = Straight Connector

#4

AC

Long Axle

#5

#5

#3

#3

#6

#4

#4

#5

#5

#5

#3

3 X 4

#6

#2

#4

#1

#1

SL

SL

#4

#6

Use cord and

Cord

Tensioning

Clips to cross

brace the

back of the

starting ramp.

Use cord and Cord

Tensioning Clips to cross

brace the base of the

starting ramp.

FR

AC

Figure: High Road/Low Road Starting Ramp

Use 2 X 3

Flat Members

to cross

brace the

base of the

starting ramp.

2 X 3

Slotted masses

SL

High Road/Low Road

Build a support for two Coaster Tracks side-by- side. One Coaster Track (the “High Road”) has a constant gradual

slope from start to finish. The oth er C oaster Track (the “Low Road”) has a steep drop near the start and an equ ally

steep rise near the end. If two Mini Cars start together on the two “roads”, which car finishes first?

24

Page 29

®

Model No. ME-7003 012-12670A High Road/Low Road

Long Axle

Collet

Collet

Collet on Axle

Track Clip

on Collet

High Road

Coaster Track

Low Road

Coaster Track

Figure: Starting Ramp Reverse View

#6

#6

#1

#4

#4

AC

AC

Long Axle goes here.

SL

#2

#3

3 X 4

2 X 3

#3

Use #3 Beams as

cross members on the

Low Road.

Use #2 Beams as

cross members on the

High Road.

FR

High Road/Low Road Details

The Long Axle extends through the support structures at the starting ramp for both the High Road and the Low

Road.

This illustration shows the High Road/Low Road starting ramp from anot her angle.

25

Page 30

®

Figure: High Road/Low Road Finishing Ramp

#3

#4

#4

#4

#2

#3

#4

AC

AC

ST

#5

#3

#4

#5

#3

#3

FT

#6

SL

SL

SL

#6

Legend:

AC = Angle Connector

CT = Cord Tensioning Clip

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

ST = Straight Connector

#4

#3

#4

AC

#1

CT

FR

Use 2 X 3 Flat

Members to cross

brace the base of

the finish ramp.

3 X 4

#4

Figure: Tied Arch Bridge

Legend:

AC = Angle Connector

CT = Cord Tensioning Clip

F4 = Flat 4 Member

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

ST = Straight Connector

#4

#3

#3

#2

#4

#6

#5

3 X 4

AC

#2

ST

#3

AC

#4

#4

#4

#4

#4

#4

ST

ST

AC

F4

Cord

F4

Flex 5

Flex 5

F4

#4

CT

Tie a

knot.

Use cord and

CT clips to

cross brace.

Use cord to

catch the

Mini Cars.

Large Structures Set Tied Arch Bridge

High Road/Low Road Details

This view shows the finishing ramp..

Tied Arch Bridge

26

Flex 5

#4

F4

Page 31

®

Model No. ME-7003 012-12670A Tied Arch Bridge

Figure: Tied Arch Bridge End Support

Flex 4

FL

FR

Medium

Axle

#6

#6

#5

AC

SL

SL

#1

AC

FL

FR

#5

#5

#3

ST

CT

#1

SL

#3

#5

#4

#3

Track

Clip

Long

Axle

Long

Axle

Slotted

masses

#2

Coaster

Track

HR

Cord

Cord

AC

Tied Arch Bridge Details

Use a #3 Beam and two Sliding Connectors to support the slotted masses at the back of the end support.

Use cord and Cord Tensioning Clips to cross brace the back of the end support. Tie cords between the bottoms of

the two end supports.

27

Page 32

®

Large Structures Set Baltimore Bridge

Figure: Tied Arch Bridge Top Detail

#3

#3

#4

#4

#4

#4

#4

#4

#3

#3

F4

F4

F4

Flex 5

Flex 5

Flex 5

Flex 5

Flex 3

Flex 3

#4#4

Flex 5

Flex 3

FT

F4

F4

F4

F4

FT

Figure: Baltimore Bridge

Flex 3

FT

#5

#5

#6

#6

#6

#6

#6

#4

#4

#4

#4

#4

#4

#4

#4

#3

#4

Flex 4

Flex 4

#5

Support the

slotted

masses on

a #4 Beam.

Tied Arch Bridge Details

At the top of the Arch, use a Flat Round Connector and four Flex 3 Beams to form a cross brace.

Baltimore Bridge

Use 40 #3 Beams and twenty Straight Connectors to make twenty extra “#5 Beams”.

Use Flat Round Connectors and four Flexible #3 Beams to make four cross braces for the deck. Place one at each

end of the deck where it joins the end support and put the other two on both sides of the center of the deck.

28

Page 33

®

Model No. ME-7003 012-12670A Baltimore Bridge

Flex 5

Flex 4

Flex 4

F4

F4

F4

#6

#6

F4

Cord

CT

Cord

FR

3 X 4

Cord

Cord

Cord

Legend:

AC = Angle Connector

CT = Cord Tensioning Clip

F4 = Flat 4 Member

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

ST = Straight Connector

Track

Clip

Figure: Baltimore Bridge Details

Baltimore Bridge Details

Use cord and Cord Tensioning Clips to add cross bracing to each panel on t he top of the truss and to several of the

diagonal panels. Use Flexible #5 Beams to cross brace several of the panels of the deck.

29

Page 34

®

Large Structures Set Baltimore Bridge

Cord

Cord

FR

#5

#6

FT

Flex 3

Cross brace

structure

Flex 4

F4

F4

F4

#6

#6

Baltimore Bridge Details

Use a Full Round Connector at the center of the bridge.

Add two of the cross brace structures to

the deck on both sides of the center of

the deck.

Figure: Baltimore Bridge Details

30

Page 35

®

Model No. ME-7003 012-12670A Double Tied Arch Bridge

Legend:

AC = Angle Connector

CT = Cord Tensioning Clip

F4 = Flat 4 Member

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

ST = Straight Connector

FT

Medium

Axle

#5

FR

#5

#4

#4

#3

F4

ST

#1

#6

#5

#4

#5

#5

3 X 4

#2

ST

Flex 3

Flex 5

#3

3 X 4

Flex 4

Flex 4

Flex 3

ST

ST

SL

SL

Flex 5

Flex 5

#1

Flex 4

#4

#5

#6

#4

#4

#4

#4

#4

FT

FT

AC

FR

Figure: Double Tied Arch Bridge

Medium

Axle

FT

#1

ST

#6

FR

Collet

on Axle

Track

Clip

#3

#4

3 X 4

AC

#5

#5

#4

F4

FT

Figure: Double Tied Arch Bridge Detail

Double Tied Arch Bridge

In the end supports, put a Collet in the middle of the Medium Axle and use a T rack C lip

to attach the Coaster Track to the Collet. Use

a 3 X 4 Flat Beam to cross brace the top of

the end support.

31

Page 36

®

Large Structures Set Double Tied Arch Bridge

Figure: Arch Details

#4

#4

#3

Flex 4

Flex 4

Flex 4

Flex 4

Flex 5

Flex 4

Flex 5

Flex 3

Flex 5

3 X 4

SL

#1

#1

#1

#1

SL

SL

ST

ST

#1

CT

CT

Figure: Cords and Cord Tensioning Clips

Cord

Double Tied Arch Bridge Details

Use cord and Cord Clips to support the deck from both sides of the arch..

Note that there are three different positions on the

Half Round Connector for the Cord Clip. Choose

the position that makes the cord as vertical as possible.Adjust the length of the cords to make the deck

level.

Add Masses

The mass hanger usually hangs from the #3 Beam

that is near the #1 Beam where the 5 N Load Cell

will be attached.Re-adjust the tension in the supporting cords to make the Deck level and give the

bridge is proper shape.

32

Page 37

®

Model No. ME-7003 012-12670A Cantilever Truss Bridge

Figure: Cantilever Truss Bridge

Legend:

AC = Angle Connector

CT = Cord Tensioning Clip

F4 = Flat 4 Member

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

ST = Straight Connector

#3

ST

#3

SL

#3

#3

#6

Flex 3

#5

#4

F4

#4

#4

#4

#5

#2

#1

ST

SL

SL

FR

Flex 3

#4

#3

FR

AC

AC

AC

#4

#4

#4

3 X 4

#3

CT

Cord

Slotted

Masses

3 X 4

#5

3 X 4

3 X 4

Figure: Tower Details

#3

#4

#5

#6

#3

#3

ST

AC

AC

AC

#6

#3

#4

#4

#3

#2

ST

Flex 5

Flex 5

AC

AC

SL

AC

CT

Knot

FR

Cord

Flex 3

FR

#2

#1

#3

2 X 3

#3

F4

#4

#4

#4

F4

Cantilever Truss Bridge

The Cantilever Truss Bridge balances the torque on one side of the center tower with the torque on the other side.

Use cord and Cross Tensioning Clips to cross brace the top section of the truss at the end of the bridge. Use Track

Clips to attach the Coaster Track to the #3 Beam cross members. On each “arm” of the bridge, use a Flat 3 X 4

Member to cross brace the first section and the fifth section (counting from the end toward the tower).

Cantilever Truss

Bridge Tower Details

Use cord and Cross Tensioning

Clips to cross brace the top sections of the truss tower. Use Full

Round Connectors at the top and

the bottom of the #6 Beams at

the center of the tower. Use two

Sliding Connectors and a #3

Beam as a cross member

between the #6 Beams at the

center of the tower.

33

Page 38

®

Large Structures Set Brachistochrone

#5

#4

#4

#4

#4

#4

#4

#4

#4

#4

#4

#4

Legend:

AC = Angle Connector

CT = Cord Tensioning Clip

F4 = Flat 4 Member

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

ST = Straight Connector

FR

#1

Flex 5

Flex 4

AC

#2

AC

AC

#3

#3

#1

ST

#6

#5

#4

#6

FR

3 X 4

2 X 3

AC

AC

AC

ST

FR

FT

FT

Figure: Brachistochrone

Cord

CT*

AC

Flex 4

Flex 4

Flex 4

AC

#2

#2

#1

2 X 3

SL

SL

ST

#3

#1

2 X 3

*Do not tighten the

Cord Tensioning Clip

on the cord next to the

finish line. Leave extra

cord so that the cord

can slide through the

clip when the Mini

Cars hit the cord.

SL

See the next page for a

more detailed view of

the ramp structure.

Inverted

cycloid

Point on

circle

Brachistochrone

curve

Ramp

Brachistochrone

curve

A

B

Brachistochrone

The word “brachistochrone” is from the Greek words meaning “shortest” (Βραχιοτοζ) and “time” (χρονοζ).

Imagine two fixed points in a vertical plane so that one of the points is not directly below the other. If a particle

starts from rest at one of the points and descends to th e other point under its own weight, t he brachistochrone is the

path the particle must take to reach its destina tion in the br iefest time. The brachistochrone may not be the shortest

path, but it is the quickest path..

AC

SL

#4

AC

#3

#5

#6

#5

#1

Track

Clip

Set up the structure with two Coaster Tracks side-by-side. Place two Mini Cars at different starting points on the

track and let them go. What happens?

Use cord and Cord Tensioning Clips to cross brace the back of the high end of the ramp.

The brachistochrone curve is p art of an

inverted cycloid. A cycloid is the path

of a point that is fixed on the edge of a

circle as the circle rolls along a straight

line.

Imagine a straight ramp and a brachistochrone curve as shown. In a race

from A to B between a ball rolling

down the brachistochrone curve and a

ball rolling down the straight ramp,

which ball will finish first?

34

#5

#6

Page 39

®

Model No. ME-7003 012-12670A Drawbridge

Flex 4

Flex 4

Flex 4

2 X 3

SL

SL

FR

FT

FT

2 X 3

#5

#6

FT

#4

AC

#3

ST

#1

AC

#2

#3

ST

#1

AC

AC

AC

Flex 4

Flex 5

Flex 5

Flex 5

Flex 4

#5

#6

AC

#3

Flex 4

#6

Figure: Brachistochrone Details

Figure: Drawbridge

#6

#6

#6

#6

#2

#3

ST

#3

AC

AC

#2

AC

AC

ST

Flex 4

Flex 3

#4

#4

#5

#5

3 X 4

3 X 4

#3

#3

#3

#4

#4

#4

#4

#4

#4

#4

#3

#5 (as cross brace)

#3

#2

ST

AC

Legend:

AC = Angle Connector

CT = Cord Tensioning Clip

F4 = Flat 4 Member

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

FR

FR

AC

#3

#6

#6

#5

(as cross brace)

Long Axle

SL

SL

#4

#4

#5

Coaster Track

Brachistochrone Details

Drawbridge

The drawbridge structure is a “working” model. You can use parts from the ME-6984 Structures Hydraulic System

(not included*) in order to raise and lower the drawbridge. Use #4 Beams or Flexible #4 Beams as cross members

on the bridge support section. Use two #3 Beams and a Straight Connector to build extra #5 Beams. Use two #2

Beams and a Straight Connector to ma ke extra #4 Beams. Note: Additional members from PASCO Structures Sets

are needed in order to extend the right hand end of the bridge shown in the illustration.

(*See the PASCO catalog or the PASCO Web site at www.pasco.com for information about the

ME-6984 Structures Hydraulics System.)

35

Page 40

®

Large Structures Set Drawbridge

3 X 4

Cord

Cord

Cord

Cord

CT

CT

#2

#2

ST

Cord

#4

#5

AC

AC

#5

SL

Long Axle (pivot)

#6

#6

#6

#6

#4

#4

SL

SL

Legend:

AC = Angle Connector

CT = Cord Tensioning Clip

F4 = Flat 4 Member

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

FT

#5

Figure: Drawbridge Details

Figure: Drawbridge Pivot and Support

#4

#4

#4

#5

#5

#5

#4

#5

#4

SL

SL

Coaster Track

#3

#2

AC

AC

ST

This view shows the

bridge in the “down”

position. Items in bold

font are part of the

bridge. Other items are

part of the support.

#5

#5

#3

HR

Long Axle

FT

HR

#4

#2

#2

AC

Cord

FT

FT

Collet

SL

#3

1-kg

#3

#4

#3

#4

AC

Tie the two

cords to the

#3 Beam.

Tie the two cords

to this Beam.

#3

CT

Drawbridge Details

Use #3 Beams as cross

members on the bridge.

Use cord and Cord Tensioning Clips to cross

brace sections of the

bridge and the bridge support.

#4

#5

Support the slotted masses

on a #4 Beam with Sliding

Connectors at each end.

#5

Slotted

masses

36

Page 41

®

Model No. ME-7003 012-12670A Drawbridge

Figure: Drawbridge Syringe

#5

#5

#2

SL

Flex 4

Flex 4

Pulley

Collet

#2

FT

Medium Axle

#1

Medium Axle

FT

Short Axle

(through second

mounting hole)

Collet

Pulley

HR

Short

Axle

Medium

Axle

Medium

Axle

Hydraulic

Cylinder

Pulley

Collet

Pulley

Collet

#2

#2

#1

Cord

Cord

Cord

Tie one end of the cords

to the front medium axle.

Tie the other end of the

cords to the #3 Beam on

the drawbridge.

#1

This beam is a “stop”

for the bridge in the

open position.

Slotted

masses

Hydraulic

Cylinder

Drawbridge Syringe Details

Figure: Drawbridge Syringe Details

37

Page 42

®

Large Structures Set Drawbridge

Flex 4

#3 or Flex 3

3 X 4

#4

#5

#3

#2

ST

FR

SL

SL

3 X 4

#4 or

Flex 4

AC

AC

Figure: Drawbridge Right Side

Slotted

masses

Drawbridge Details Continued

Use a #4 Beam or Flexible

#4 Beam and two Sliding

Connectors to form a

“stop” bar for the drawbridge when it is in the

closed position.

38

Page 43

®

Model No. ME-7003 012-12670A Vertical Lift Drawbridge

Figure: Vertical Lift Drawbridge

Bridge in the

“up” position.

Bridge in

the “down”

position.

Legend:

AC = Angle Connector

CT = Cord Tensioning Clip

F4 = Flat 4 Member

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

#4

#3

#2

#1

AC

AC

ST

#4

#4

#4

#3

#5

#3

F4

#6

#3

SL

#3

SL

#2

AC

3 X 4

#4

F4

#5

#4

#3

#4

FR

FT

#2

#6

Long

Axle

Medium Axle

#6

#6

#6

F4

#4

#4

#4

#4

#4

#4

#5

#5

SL

Flex 3

Flex 3

Long

Axle

Medium

Axle

#2

#3

#3

3 X 4

FR

FT

Pulley

Cord

Cord

#3

#4

3 X 4

Vertical Lift Drawbridge

The Vertical Lift Drawbridge has a middle section that slides up and down between the two towers.

The middle section is counterbalanced by hanging masses connected by cords over pulleys. The hanging masses

move up and down inside each tower.

Figure: Vertical Lift Drawbridge Detail

39

Page 44

®

Large Structures Set Vertical Lift Drawbridge

FT

SL

SL

#3

#4

#2

#6

#4

#1

SL

Flex 3

Cord

Hanging

Mass

SL

#2

Cord

#3

#1

#1

#1

SL*

CT

SL

FT

HR

Pulley

AC

Pulley

Cord

#5

#6

#6

#4

Figure: Vertical Lift Drawbridge Detail

Figure: Vertical Lift Drawbridge Reverse View

Vertical Lift Drawbridge Details

(*Do not overtighten the Sliding Connectors that grasp the vertical #6 Beams. The middle section must be able to

slide up and down the #6 Beam.)

Use cord and Cord Tensioning Clips to cross brace the tower and the tower support. For the hanging mass cord,

determine how long the cord must be so that the middle section can slide up and down on the #6 Beam on the outside of the tower while the hang ing mass moves up an d down insid e the tower . Double that l ength. Thread t he ends

of the cord through the #1 Beams at the top edge of the middle section. Fasten the ends of the cords to Cord Tensioning Clips on the Half Round Connectors. Place the cords over the pulley, and hang the mass hanger from the

middle of the cord. Adjust the amount of mass on the mass hangers so that the middle section of the bridge can be

lifted or lowered easily.

40

Page 45

®

Model No. ME-7003 012-12670A Tower Crane

#5

Legend:

AC = Angle Connector

CT = Cord Tensioning Clip

F4 = Flat 4 Member

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

ST = Straight Connector

#5

#5

#5

#5

#5

#5 = #3 + ST + #3*

#4

#6

#6

#6

#6

#4

Flex

Flex

(*Use two #3 Beams and a Straight

Connector to make extra #5 Beams.)

#5 = #3 + ST + #3*

#4

#3

#3

#4

3 X 4

#4

#4

#4

#4

#1

ST

AC

AC

#3

#4

#2

FR

Short

Axle

Double

Cord

CT

Pulley

#3

Force Platform Structure Brackets

CT

#6

#6

#6

#6

#6

SL

#4

Figure: Tower Crane

Cord

Tower Cr ane

The T owe r Crane st ands 2 .3 meters tall and c an be m ounted on a PASPORT Force Platform (PS- 2141 or PS-2 142)

or a ScienceWorkshop Force Platform (CI-6461) using the Force Platform Structure Brackets (ME-6988).

Use a Cord Tensioning

Clip to attach the end of

the single cord to a Sliding Connector mounted

on a #4 Beam.

41

Page 46

®

Large Structures Set Tower Crane

Double

Cord

#4

CT

#3

#2

#2

FT

#3

3 X 4

FT

FR

FR

#3

FR

FR

#4

#3

#4

Long

Axle

Long

Axle

Pulley

FT

Cord

Cord

#3

#4

Figure: Tower Crane Details

Double

Cord

Slotted

Masses

FR

#4

#2

#3

#3

#4

#4

ST

#1

Short

Axle

Pulley

AC

AC

Cord

The Tower Crane consists of three parts: tower, rear boom and front boom. The tower has a #4 Beam by #4 Beam

cross section, uses #4 and #6 Beams for the vertical members, and #5 Beams fo r the cross braces. The rear boom is

a #3 Beam in width and the front boom is a #2 Beam in width. Flexible beams are used when there are no more #5

or #3 Beams.

Put a Collet on each side of the Pulley to keep it in place on the front Long Axle. Make sure that the front Full

Round Connectors are oriented so that the “fin” is vertical.

Flex 3

42

Figure: Tower Crane Details

Page 47

®

Model No. ME-7003 012-12670A Arch Causeway

Front Boom

Details

Rear Boom

Details

#3

#3

#43 X 4

Flex 3

Flex 3

Full Round

Flat Round

#3

#3

#4

#4

#2

Flex 3

Figure: Tower Crane Boom Details

Flex 3

#3

#4

#4

#4

#4

#4

Figure: Arch Causeway

Legend:

AC = Angle Connector

CT = Cord Tensioning Clip

F4 = Flat 4 Member

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

ST = Straight Connector

#6

SL

#6

SL

SL

#6

#6

SL

#6

AC

Flex 4

Flex 4

Flex 4

Flex 4

#1

#3

#4

#4

#4

#4

#4

Cord

Cord

Cord

Cord

Tower Crane Boom Details

Arch Causeway

Use cord to connect the two support structures and to cross brace the tallest vertical sections. The arch uses four #6

Beams on each side with #3 Beams and Sliding Connectors as cross members.

43

Page 48

®

Large Structures Set Arch Causeway

#4

#6

SL

Flex 4

Flex 4

Flex 4

Flex 4

#4

#3

3 X 4

#3

3 X 4

#6

A

A

#3

#4

ST

CT

FR

#3

#4

A

#1

ST

A

#4

Flex 3

#2

#1

ST

#2

#1

ST

Use 3 X 4 Flat

Members to

cross brace.

CT

Cord

Cord

Figure: Arch Causeway Details

#4

#4

#4

#4

Flex 3

Cord

#1

Arch Causeway Details

Use Flexible #3 Beams as cross members in the base of the support when there are no more #3 Beams.

44

Page 49

®

Model No. ME-7003 012-12670A Skyscraper

#6

#4

#4

#3

#3

#5

#2

#4

#4

ST

#3

#3

ST

Slotted

Masses

Force Platform

Structures Brackets

Large Table

Clamp

(ME-9472)

Motion

Sensor

Mechanical

Wave Driver

Function

Generator

Banana plug

patch cords

100 N Load

Cell

#1

CT

Cord

HR

Figure: Skyscraper with Driver

Skyscraper

After the invention of the elevator, “skyscraper” building s became

a reality . Use #2 Beams to attach the bottom o f the structure to the

Force Platform Structures Bracket as shown.

The skyscraper structure models a sixteen story building. Use #4

Beams as the vertical members for the bottom eight stories and

use #3 Beams as the vertical members for the top eight stories.

Use #6 Beams and #6 Beams for the horizontal members of each

story. Use two #3 Beams and a Straight Connector to make extra

#5 Beams. Use two #4 Beams and a Straight Connector to make

extra #6 Beams.

The skyscraper structure can be used to demons trate what happens

to a building during the shaking caused by an earthquake.

For example, replace a Straight Connector with a Half Round

Connector. Add a #1 Beam to the Half Round. Attach a 100 N

Load Cell (PS-2200) to the #1 Beam. Use cord to connect the

Load Cell to the shaft of a Mechanical Wave Driver (SF-9324).

Connect banana plug patch cords (SE-9750) from the wave driver

to a Function Generator (PI-8127 ) and use the function generator

to power and control the wave driver .

Mount a Motion Sensor (PS-2103) on a support rod (ME-8988).

Connect the Motion Sensor and the 100 N Load Cell to a PASCO

interface to record, display, and analyze the data as the skyscraper

shakes.

Figure: Skyscraper

45

Page 50

®

Large Structures Set House Frame

#6

#6#6

#6

#6

#5

#5

#5

#5

#5

#2

ST

FR

FR

FR

FR

#4

#4

#5

#5

#5

ST

ST

FT

FT

Flex 5

#6

3 X 4

SL

#2

Struct ure s

Rod Clamp

Displacement

Indicator

Displacement

Sensor

Load Cell

Amplifier

Structures

Rod Clamp*

Aluminum

Table Clamp

(ME-8995)

#5

Rod

Figure: House Frame

HR

#6

#6

Load

Cell

#2

Support rod

Struct ures

Rod Clamp

Half Round

Connector

*Detail of Structures Rod Clamp

House Frame

To hold the House Frame in place, attach

a #2 Beam to the Half Round Connector

at one corner. Put a clamp on the edge of

the table and use it to hold a support rod

(ME-8995). Attach a Structures Rod

Clamp between the support rod and the #2

Beam at the corner of the House Frame.

To make measurements of the flexing of

the House Frame when masses are hung

from the members, mount the Displacement Indicator of the Displacement Sensor (PS-2204) on another Struct u res Rod

Clamp and mount the clamp on the support rod so that the plunger of the indicator contacts a beam on the House Frame.

To make measurements of the forces in

the members, mount 100 N Load Cells as

shown and connect them to a Load Cell

Amplifier (PS-2198).

46

Page 51

®

Legend:

AC = Angle Connector

CT = Cord Tensioning Clip

F4 = Flat 4 Member

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

ST = Straight Connector

Boom

Tow er

Base

#4

#6

#5

#5

#5

#5

#5

#3

#4

F4

#3

#3

#3

#4

F4

#3

#3

FR

AC

#6

AC

Medium Axle

Pulleys

#5

#2

ST

Medium Axle

Pulley

AC

F4

#4

F4

F4

F4

#3

#3

#3

#3

#3

#6

ST

#6

#3

#6

#4

#2

#1

#4

AC

AC

#1

Short

Axle

Pulley

#4

Long Axle

Long Axle

Load Cell

#3

20-g mass

HR

#4

Load Cell Amplifier

Load cord

Figure: Angle Crane

Cords from

Hydraulic Cylinder

Cord (CB)

CT

Model No. ME-7003 012-12670A Angle Crane

Angle Crane

The Angle Crane is one of the largest structures to be built with the Large Structures Set. The crane’s boom can be

raised or lowered using the Hydraulic Cylinder and other parts from the ME-6984 Structures Hydraulics System

(available separately). The Angle Crane has three main parts: Boom, Tower, and Base. The Tower is joined to the

Base by an axle mounted on the Base, and the Boom pivots on another axle near the top of the Tower.

Use two #3 Beams and a Straigh t Connector to mak e ten ex tra #5 Beam s for th e Base an d Tower. The hook on the

end of the cord is a 20 g mass from the Hooked Mass Set (SE-8759). Slotted masses on the back of the base are

counterweights for the Tower and Boom, and forces in the Tower and Base are measured by 100 N Load Cells

connected to a Load Cell Amplifier. The Base width is a #4 Beam, the Tower width is a #3 Beam, and the Boom

width is a #1 Beam.

47

Page 52

®

Large Structures Set Angle Crane

Long Axle

Two Pulleys (see Detail A)

AC

#2

ST

#5

CT

CT

#3

#3

F4

SL

#3

#3

#3

ST

3 X 4

#4

#6

Use cord and Cord

Tensioning Clips to

cross brace (CB).

CB

CB

CB

CB

#3

#3

#3

#3

#6

SL

Tie a

knot

Two cords for

extra strength.

SL

CT

Cord to the load.

#3

HR with fin

facing outward.

F4

#4

Detail A

Long Axle

Two Pulleys

#4

F4

Collet

Cord

Tensioning

Clip

Sliding

Connector

Tie the cord from the load to

the Cord Tensioning Clip.

Attach the clip to the Sliding

Connector and fasten the

connector onto the Collet on

the axle.

Figure: Angle Crane Base Details

(See

Detail B)

AC

Angle Crane Details

48

Page 53

®

Model No. ME-7003 012-12670A Angle Crane

Detail B

Short

Axle

Collet

Pulley B

Hydraulic

Cylinder

Long

Axle

Pulley A

#3

#3

#5

AC

SL

SL

#3

#3

Cords to top

of Tower and

the Boom.

Use the #3 Beam with

Sliding Connectors to

support the end of the

Hydraulic Cylinder.

SL

SL

Cords from

Hydraulic Cylinder

Pulley

Medium

Axle

Collet

#6

#5

AC

AC

AC

ST

#2

Medium

Axle

#4

#3

#6

#2

#1

CT

HR has “fin”

facing outward.

#6

1. Tie cord

to Short

Axle.

2. Loop

cord over

Pulley A.

3. Loop

cord around

Pulley B.

Tie cord

here.

Load

cord

Figure: Angle Crane Tower Details

Angle Crane Details

49

Page 54

®

Large Structures Set Windmill

Figure: Windmill

#2

#3

ST

Legend:

AC = Angle Connector

CT = Cord Tensioning Clip

F4 = Flat 4 Member

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

ST = Straight Connector

AC

AC

SL

CT

#6

HR

Mass hanger and

slotted mass

#5

#5

#6

#4

#3

#5

#4

#4

#4

3 X 4

#5

Cord

Slotted

masses

FT

Sail

Cord

Windmill

The Windmill is another working model that can demonstrate how the kinetic energy of the wind can be converted

into other forms of energy, including gravitational potential energy. In this case, the windmill turns an axle that

winds up a cord attached to a hanging mass.

A template for the paper sails is included at the end of the instructions. Copy (or trace) the template and cu t out the

sail from a sheet of 8.5 by 11 inch (21.5 by 28 cm) paper.

50

Page 55

®

Model No. ME-7003 012-12670A Windmill

Figure: Windmill Base

#5

#5

#5

#5

#5

#6

#4

#3

#4

#4

#4

3 X 4

#4

FT

FR

#4

#4

#2

#2

#3

#1

AC

AC

ST

FR

Legend:

AC = Angle Connector

CT = Cord Tensioning Clip

F4 = Flat 4 Member

FR = Full Round Connector

FT = Flat Round Connector

HR = Half Round Connector

SL = Sliding Connector

ST = Straight Connector

Long Axle here.

Windmill Details

Make a sleeve in each sail to slide over the #6 Beams by folding the lower part of the sail to the dotted line, and

then taping the edge in place. Clamp the small end of the sail between a Sliding Connector and a Cord Tensioning

Clip.

51

Page 56

®

Clip a Sliding Connector to the #3 Beam. Lay the end of the

sail on the Sliding Conn ector. Attach a Cord Tensioning Clip

to the Sliding Connector to clamp the end of the sail between

the Sliding Connector and the Cord Tensioning Clip.

CT

SL

End of sail

#3

ST

AC

FR

Cord

Tie a

knot

Long

Axle

FT

CT

CT

Cord

Cord

FR

#6

#2

#3

AC

ST

AC

CT

SL

CT

Figure: Windmill Reverse View

Figure: Windmill Side View

Figure: Windmill Hub Detail

Long

Axle

Long

Axle

Slide the sail’s sleeve

over the #6 Beam.

Large Structures Set Windmill

Windmill Details

52

Page 57

®

Model No. ME-7003 012-12670A Windmill

Long

Axle

Long

Axle

Collet

Drive

Wheel

Photogate

Head

Double

Cord

Mass

Hanger

Slotted

mass

Tie a

knot

HR

SL

SL

#4

#4

#3

#1

#1

Long

Axle

SL

SL

HR

HR

Figure: Windmill Axle Detail

Figure: Windmill Photogate Support Detail

See

detail

below.

Windmill Details

53

Page 58

®

Large Structures Set Technical Support

Technical Support

For assistance with any PASCO product, contact PASCO at: