Page 1

®

Instruction Manual

012-11726A

*012-11726*

Hydraulics Structures Set

ME-6984

Page 2

®

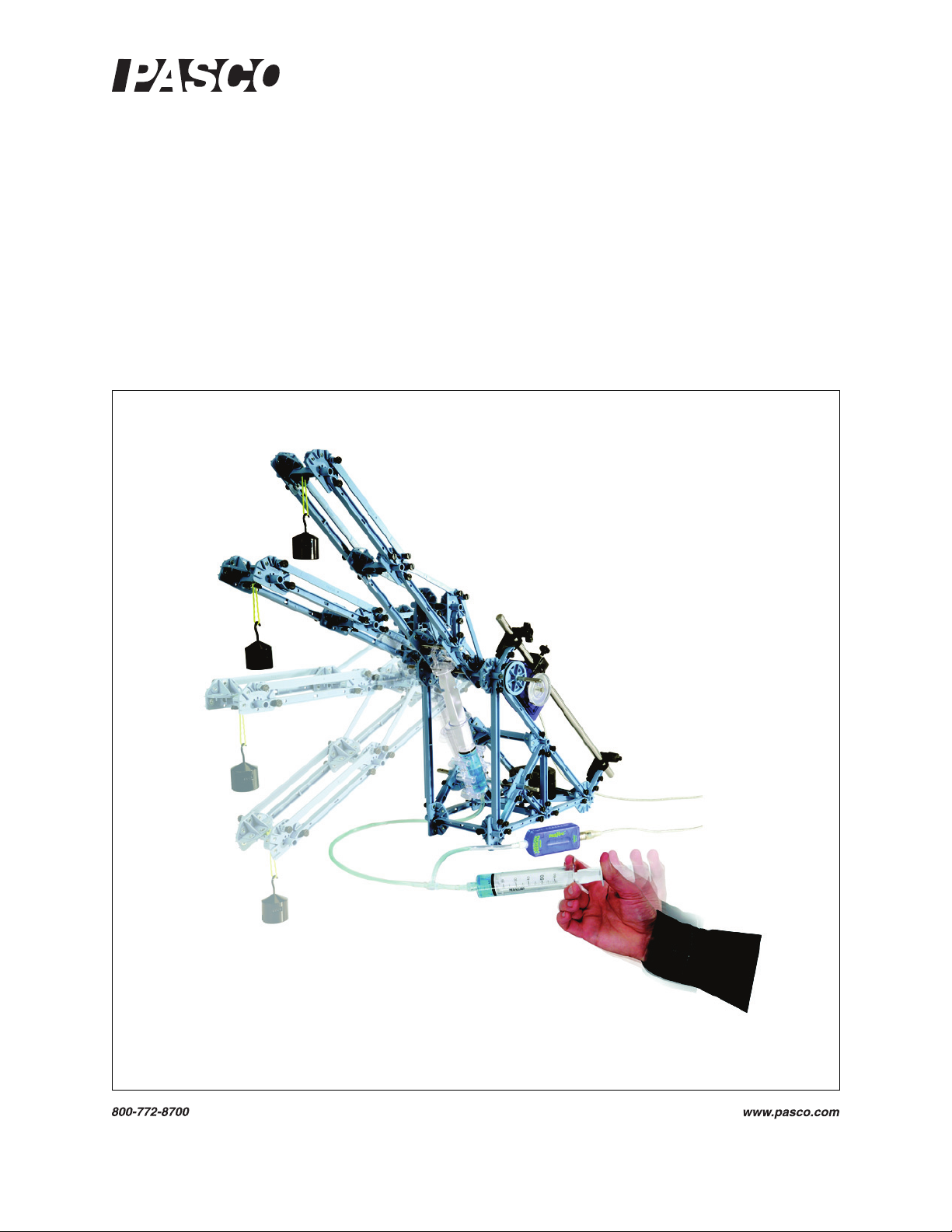

The cover page shows the ME-6984 Hydraulics Structures model of a hydraulic boom. Pressurized fluid moves

from the syringe to the hydraulic cylinder. As the piston moves out of the cylinder, it lifts the boom structure.

ii

Page 3

®

Table of Contents

Included Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Related, Required and Recommended Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

About the Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Adding Load Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Hydraulic Boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Fork Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Scissors Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Ideal Gas Law . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Spares Part Numbers and Summary of Extra Equipment . . . . . . . . . . . . . . . . . . . . . . . 14

Technical Support, Warranty, and Copyright. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

iii

Page 4

®

Hydraulics Structures Set

iv

Page 5

Hydraulics Structures Set

®

1

2

3

4

5

6

7

8

9

ME-6984

Included Items Included Items

1. Pressure Sensor Coupler 6. 10 mL Syringe

2. Syringe Coupler 7. 20 mL Syringe

3. Extension Tubing 8. 60 mL Syringe

4. Check Valve 9. Hydraulic Cylinder

5. Bleeder Valve O-ring Drive Belt (not shown)

1

Page 6

®

Hydraulics Structures Set Introduction

The ME-6984 Hydraulics Structures Set is designed to be used with parts from the PASCO Structures System*.

ME-6985 Flexible I-Beams ME-6992A Advanced Structures Set

ME-6987 Flat Beams ME-6993 Truss Set Members

ME-6989 Physics Structures Set ME-6997 Full Round Connectors

ME-6990 Truss Set ME-6999A Angle Connectors

ME-6991 Bridge Set ME-7009 Cast Beam Structures Set

*See the PASCO catalog or Web site at www.pasco.com for information about the PASCO Structures System.

The following PASCO equipment is required for the structures shown in this manual..

Required Equipment Required Equipment

ME-6992A Advanced Structures Set PS-2146 Pressure/Temperature Sensor

ME-8736 45-cm Steel Rod TD-8596A Ideal Gas Law Syringe

PS-2107 Absolute Pressure Sensor PASPORT Interfaces*

PS-2120 Rotary Motion Sensor Data Acquisition Software*

*See the PASCO catalog or Web site at www.pasco.com for more information about interfaces and software.

Recommended Equipment Recommended Equipment

Hooked Mass Set (SE-8759) Large Slotted Mass Set (ME-7566 or ME-7489)

Introduction

Use the ME-6984 Hydraulics Structures Set with members of the PASCO Advanced Structures Set to build models that move and do work. Build a fork lift, scissors lift, or hydraulic boom. Use sensors to measure the pressure

and temperature of the gas or liquid in the hydraulic system, and use a sensor to measure the amount of movement

of a structure as the hydraulic system does work.

Advanced Structures Set (ME-6992A) - This set contains structure members (see the table) for building cranes,

bridges, cars, catapults, and other models.

Included Items Qty Included Items Qty Included Items Qty

#5 Beam (24 cm long) 24 Flat 2 X 3 Beam (12.5 cm) 16 “O” Ring 12

#4 Beam (17 cm long) 54 Flat Round Connector 6 Pulley 12

#3 Beam (11.5 cm long) 54 Full Round Connector 6 Collet 24

#2 Beam (8 cm long) 24 Half Round Connector 42 Spacer 12

#1 Beam (5.5 cm long) 24 Axle (2 each of 3 lengths) 6 Sliding Connector 12

#3 Flexible Beam (11.5 cm) 16 Drive Wheel and Tire 4 Angle Connector 24

#4 Flexible Beam (17 cm) 16 Straight Connector 24 Cord Tensioning Clip 32

#5 Flexible Beam (24 cm) 16 Structures Rod Clamp 2 Yellow Cord 1 roll

Flat 3 X 4 Beam (19 cm) 16 PAStrack Connector 6 Storage box 1

Flat #4 Beam (17 cm) 16 Screw (6-32) 300

2

Page 7

®

Model No. ME-6984 Theory

Figure 1: Syringe (60 mL)

Cylinder

Piston

Male Luer

Lock

Vol um e

Markings

Figure 2: Hydraulic Cylinder

Mounting

Holes

Trunnion

Holes

Cylinder

Piston

Theory

Hydraulics is a topic in applied science and engineering that deals with the mechanical properties of liquids. Pneumatics is a topic that deals with the study and application of the use of pressurized gas to affect mechanical motion.

Blaise Pascal described the behavior of a fluid (gas or liquid) in a closed container. Pressure applied to an enclosed

fluid is transmitted undiminished to every part of the fluid, as well as to the walls of the container. A hydraulic lift

is an example of a device that demonstrates the principle. A model of a hydraulic (or pneumatic) lift consists of a

syringe that has a large diameter piston connected to another syringe that has a small diameter piston. The pressure

is the ratio of force to area and will be the same throughout the system. For example, if the large diameter piston

has an area five times larger than the small diameter piston, the hydraulic lift will have a theoretical mechanical

advantage of five to one. In other words, a force of 10 N applied to push the small piston into the syringe would

cause a force of 50 N to be applied to push the large piston out of the piston. The large piston does the same

amount of work as is done to the small piston. The distance that the small piston is pushed into the small syringe is

five times more than the distance that the large piston will move out of the large syringe.

About the Components

Syringes

The set has three sizes of syringes (60 mL, 20 mL, and 10 mL), each with a male luer (pronounced “loo-er”) lock

at one end. The luer lock allows the syringe to be connected to couplers (tubing) or valves. There is a retainer ring

on the inside of the large end of the cylinder that helps prevent the piston from being pulled out of the cylinder too

easily.

Hydraulic Cylinder

The hydraulic cylinder is a modified 60 mL syringe with six trunnions (cylindrical protrusions used as a mounting

or pivot point) on the cylinder and two mounting holes on the end of the syringe. The holes allow the hydraulic

cylinder to be mounted between two axles. When the hydraulic cylinder is attached to a structure and a gas (such

as air) or a liquid (such as water) is pumped into the cylinder, the pressurized fluid will cause the piston to be

pushed out of the cylinder. The part of the structure that the piston is attached to will move.

3

Page 8

®

Hydraulics Structures Set Operation

Figure 3: Connector onto Pressure Port

Quick ConnectorPressure Port

Figure 4: Luer Locks

Female luer lock

Male luer lock

Figure 5: Bleeder Valve

Open position

Closed position

Val ve A

Val ve B

Piston

When the piston is

pulled out, fluid goes

through valve A into

the cylinder.

When the piston is

pushed in, fluid goes

through valve B to the

rest of the apparatus..

Cylinder

Figure 6: Check Valve Assembly

Couplers

Pressure Sensor Coupler

The pressure sensor coupler has a “T” shape. The shorter arms

of the “T” have a male luer lock at one end and a female luer

lock at the other. The longer arm of the “T” has an inline quick

connector at the end for connecting to the pressure port on a

pressure sensor. Push the inline quick connector onto the pressure port, and turn the quick connector clockwise (left to right)

until the connector locks in place.

Syringe Coupler

The syringe coupler is a length of tubing about 27 cm long with a female luer lock

at each end. For example, the coupler connects one syringe to another, or a syringe

to the hydraulic cylinder. The syringe coupler can also connect to the other couplers and to the valves. The female luer lock screws into a threaded male luer lock.

Extension Tubing

The extension tubing is about 60 cm long with a female luer lock at one end

and a male luer lock at the other. It can be used to increase the distance

between components of the hydraulics structures set.

Valves

O-Ring Drive Belt

Bleeder Valve

The bleeder valve has a stopcock that can be opened and closed to allow

fluid to flow through the valve or not. When the stopcock handle is perpendicular to the tubing, the valve is closed. When the stopcock handle is parallel to the tubing, the valve is open.

Check Valve Assembly

The check valve assembly is a “T” shaped assembly that

has two one-way valves that allow fluid to flow through

the valve in specific directions. For example, when the

check valve assembly is connected to a syringe, fluid can

flow into the cylinder of the syringe through valve A when

the piston is pulled out. When the piston is pushed in, fluid

can flow out of the cylinder through valve B. The arrow on

each valve indicates the direction that fluid may flow

through the valve.

The included O-ring can be used as a ‘drive belt’ when it is

looped from one pulley to another pulley, or from a pulley

to a Rotary Motion Sensor.

Operation

To demonstrate Pascal’s Principle as described in the Theory section, connect the 60 mL syringe to the syringe

coupler. Pull the piston halfway out. Get a 20 mL syringe and pull its piston halfway out. Connect the smaller

syringe to the syringe coupler. Have one person hold the 60 mL syringe and another person hold the 20 mL

syringe. Have each person push in the piston of their syringe. You should notice that it is much harder to push on

4

Page 9

®

Model No. ME-6984 Operation

Syringe

Coupler*

20 mL

Syringe

60 mL

Syringe

Figure 7: Demonstration

*not to scale

20 mL

Syringe

Check

Val ve

Assembly

Bleeder

Val ve*

Syringe

Coupler*

Hydraulic

Cylinder

*not to scale

Figure 8: Example

Stopcock

the piston of the smaller syringe than it is to push on the piston of the larger syringe. Can you push the 20 mL

syringe’s piston all the way in? If so, can you push the 60 mL syringe’s piston all the way in while holding the 20

mL syringe’s piston in place?

To find out how the various components work together, set up the following combination of parts: 20 mL syringe,

check valve, bleeder valve, syringe coupler, and hydraulic cylinder. Start with the pistons of both the hydraulic

cylinder and the 20 mL syringe pushed all the way in.

• Connect the check valve assembly to the 20 mL syringe.

• Connect the bleeder valve to the check valve assembly.

• Connect the syringe coupler from the bleeder valve to the male luer lock on the hydraulic cylinder.

• Twist the handle on the stopcock of the bleeder valve to the closed position.

• Pull out the piston of the 20 mL syringe until the tip of the piston is at the 20 mL mark on the syringe.

• Next, push the piston of the syringe all the way in. What happens to the hydraulic cylinder? You should have

noticed that the piston of the hydraulic cylinder moved out until the tip of the piston was close to the 20 mL

mark on the cylinder. Try it again.

• Pull the piston of the 20 mL syringe so the piston is next to the 20 mL mark. Did the piston of the hydraulic

cylinder go back into the cylinder as you pulled the piston out of the syringe? The piston of the hydraulic

cylinder should not have moved because the check valve assembly only allows fluid to flow in specific

directions. Next, push the piston of the syringe all the way in. The piston of the hydraulic cylinder should

move to the 40 mL mark (approximately).

• Repeat the procedure a third time and see whether the piston in the hydraulic cylinder was able to move to

the 60 mL mark.

To empty the hydraulic cylinder without disconnecting any tubing, twist the handle of the stopcock to the open

position and push the piston of the hydraulic cylinder all the way in. Fluid can flow out of the bleeder valve, but

cannot go back into the cylinder of the 20 mL syringe because of the one-way check valve.

5

Page 10

®

Hydraulics Structures Set Adding Load Cells

Leave an air space

between the liquid

and the sensor

Air space

Liquid

Figure 9: Air Space

Figure 10: A load cell combined with two #2 beams is

the same length as a #4 beam

Figure 11:

Calibration fixture

Using a Liquid Instead of a Gas

Fill a syringe with a liquid. Connect the syringe to the syringe

coupler. Push the piston slowly to force liquid from the

syringe into the syringe coupler until all the air is pushed out

of the coupler. Finally, connect a second syringe (or the

hydraulic cylinder) with the piston all the way in to the liquid

filled syringe coupler. When you push on the piston of the liquid filled syringe, the liquid will push against the piston of the

second syringe (or cylinder).

CAUTION: If you use the Pressure Sensor Coupler and a

pressure sensor in your hydraulics structure, be sure that no

liquid enters the pressure port of the sensor. Liquid can go partway into the tubing of the Pressure Sensor Coupler

where it connects to the sensor, but leave an air space in the tubing between the liquid and the sensor.

Using a Rotary Motion Sensor to Measure Volume

You can mount a Rotary Motion Sensor (PS-2120) on a rod and attach the rod to your hydraulics structure using

Structures Rod Clamps* (ME-6986). Please see the illustration of the Hydraulic Boom on page 8. Use a thumbscrew to secure a Drive Wheel* to an axle that will turn when a part of the structure moves. Arrange the sensor and

drive wheel so that the included O-ring will fit over the drive wheel and the largest pulley on the sensor.

Use the data acquisition software to calibrate the Rotary Motion Sensor. Set the structure so that the volume in the

hydraulic cylinder is zero. In the software, set the corresponding position of the Rotary Motion Sensor to be 0 mL

(zero milliliters). Move the structure so that the volume in the hydraulic cylinder is at its maximum. Set the corresponding position of the Rotary Motion Sensor to be the maximum volume (e.g., 60 mL).

Adding Load Cells

To measure the compression and tension forces in individual members of a structure, add load cells (e.g.,

PASCO Model PS-2200 or PS-2201) to any PASCO

Structure. Replace a beam with two shorter beams and a

load cell.

#5 beam = load cell + two #3 beams

#4 beam = load cell + two #2 beams

#3 beam = load cell + two #1 beams

*Included in the

Advanced

Structures Set.

Use thumbscrews to attach two beams to a load cell as shown in the figure.

When using load cells, assemble your structure with the screws loose. This

will simplify the analysis by ensuring that the members experience only tension and compression without moments.

Calibration

See the instructions that came with the load cells for details about how to connect the load cells to an interface or datalogger. Follow the instructions to calibrate the load cells and use them to collect data. (Load cells are factory

calibrated; however, you can re-calibrate them in software or on the datalogger. See the documentation for your software or datalogger for instructions.)

6

Page 11

®

Model No. ME-6984 Hydraulic Boom

Full

Round

Half

Round

Axle

(Medium)

#1

#3

#3Absolute Pressure

Sensor

#4

Structures

Rod

Clamp

#5

#4

#4

45 cm

Rod

2 X 3

3 X 4

2 X 3

#2

Hooked

Mass

Hydraulic

Cylinder

Axle

(Small)

#2

#3

#4

#4

A. Place large slotted

masses at the end of the

base as a counterweight.

Extra Equipment Model

Structures Rod Clamp ME-6986

45-cm Steel Rod ME-8736

Hooked Mass Set SE-8759

Large Slotted Mass Set ME-7566 or ME-7489

Rotary Motion Sensor PS-2120

Absolute Pressure Sensor PS-2108

PASPORT Interface see catalog

Axle

(Long)

Ye l l o w

Cord

Rotary

Motion

Sensor

Half Round

#5

Full

Round

#3

Pressure Sensor

Coupler

Syringe Coupler

#2

Flat

Round

Support for slotted masses

60 mL

Syringe

A

Structures

Rod

Clamp

Three

Step

Pulley

• Use the sensors to measure pressure and

volume as the hooked mass is lifted. The

work done is the area under the curve.

Air space*

Liquid*

* Optional: If you use a liquid,

leave an air space between

the liquid and the sensor.

The O-ring Drive Belt loops

from the Drive Wheel to the

Three Step Pulley on the

Rotary Motion Sensor.

Hydraulic Boom

7

Page 12

®

Hydraulics Structures Set Hydraulic Boom Details

Medium Axle Detail

#2

#3

#2

Collet

Medium

Axle

Hydraulic

Cylinder

#2

Half

Round

#2

• Put the medium axle through a trunnion hole on the hydraulic cylinder.

• Use collets and thumbscrews on both

sides of the hydraulic cylinder to position the cylinder at the middle of the

axle.

• Use thumbscrews to attach the

medium axle to the half round connectors.

Thumbscrew

Short Axle Detail

Thumbscrew

Short

Axle

#1

#1

Put the axle through

the mounting hole at

the top of the piston.

Half

Round

Long Axle Detail

Half

Round

Half

Round

Flat

Round

Collet

Collet

Thumbscrew

#1

#1

Spacer

Spacer

#1

Long Axle

Drive

Wheel

#4

#5

Align the drive wheel with

the larger step of the

three-step pulley on the

Rotary Motion Sensor.

Stretch the O-ring drive

belt from the drive wheel

to the step pulley.

Thumbscrew

Hydraulic Boom Details

8

Page 13

®

Model No. ME-6984 Fork Lift

Extra Equipment Model

Hooked Mass Set SE-8759

Large Slotted Mass Set ME-7566 or ME-7489

Yellow Cord (2 pack) ME-9876

Foam core board not included

#5

#5

#5

#4

#4

#4

3 X4

#4

#3

Angle

Connector

Angle

Connector

#2

#2

#3

#3

#3

Sliding

Connector

Axle

(Medium)

Sliding

Connector

Cord

Tensioning

Clip

Axle

(Medium)

Full

Round

Full

Round

Axle

(Long)

Syringe

Coupler

Bleeder

Val ve

Check

Val ve

Assembly

C

#4

#2

Hooked

Mass

A

C. Place large slotted

masses at the end of the

base as a counterweight.

A. Put a short axle

through the longer

hole in the piston cap.

Half

Round

B

B. Put collets on both sides of

the trunnion at the bottom of the

hydraulic cylinder.

Yellow

Cord

Ye l l o w

Cord

#2

#1

Cord

Flat

Round

#3

Support for slotted masses

Cord detail

Sliding

Connector

Sliding

Connector

Tie one end of the

cord to the middle

of the #3 beam.

Ye l l o w

Cord

Full

Round

Cord

Tensioning

Clip

Sliding

Connector

E. Tighten the cord so that it is

parallel to the top of the boom

when the base of the fork lift

is parallel to the ground.

E. Base of fork lift is

parallel to the ground

E. Cord is parallel to

the top of the boom

D. Tie cords diagonally to

cross-brace the back of

the base.

D

Fork Lift

Foam core

board (not

included)

To 10 mL

Syringe

9

Page 14

®

Hydraulics Structures Set Fork Lift Details

#1

#1

Half

Round

Hydraulic

Cylinder

Collet

Thumbscrew

#4

#2

Axle

(Medium)

Axle

(Short)

Axles and Hydraulic Cylinder Details

Boom Axle Details

Axle

(Long)

Collet

Thumbscrew

#2

#1

#1

#4

Piston

Cap

Piston Cap

Fork Lift Details

Short axle

through the

longer hole

on the piston

goes

cap.

10

Page 15

®

Model No. ME-6984 Scissors Lift

Flat

Round

Hydraulic

Cylinder

Collet

Half

Round

Ye l l o w

Cord

#3

#5

#5

#1

Cord

Collet

A. The piece of foam core

board shown is approximately

12.5 cm by 17 cm.

Half

Round

Axle

(Long)

Cord

Cord

Tensioning

Clip

Full

Round

Axle

(Medium)

#2

#1

#1

Foam Core Board Detail

Full

Round

Hooked

Mass

#1

Pulley

Full

Round

Half

Round

Axle

(Long)

Axle

(Medium)

Foam core

board (not

included)

Sliding

Connector

Collet

Cord

Tensioning

Clip

A

B

B. Use cord to cross-brace the

legs of the scissors lift.

Axle

(Short)

C

C. Tie one end of the

cord to the short axle.

Use a thumbscrew

to attach the foam

core board.

Extra Equipment Model

Hooked Mass Set SE-8759

Yellow Cord (2 pack) ME-9876

Foam core board n.a.

Sliding Connector

Lower Axle Details

#1

#1

Axle

(Long)

Pulley

Collet

Tie one end of the

cord to the short axle.

Cord

Use a #1 Beam to connect the

two Half Rounds together

Scissors Lift

Straight

Connector

The sliding

connector

clamps onto

the collet.

Thumbscrew

11

Page 16

®

Hydraulics Structures Set Ideal Gas Law

Ideal Gas Law

Apparatus

Quick-release

Connector

(remove for this

experiment)

Temperature

Connector

Thermistor

Male luer lock

PS-2500 PASport

Extension Cable

Ideal Gas Law

Introduction

The Ideal Gas Law Apparatus, TD-8596A, allows simultaneous

measurements of temperature and pressure of a gas as it is compressed. A low thermal mass thermistor is built into the base of

the syringe to measure temperature changes inside the syringe.

The response time is around 0.5 second. The plunger is equipped

with a mechanical stop that protects the thermistor, and also

allows for a predetermined change in volume. The apparatus has a

mini stereo plug temperature connector that connects directly to a

port on a temperature sensor and a quick-release pressure connector. As the plunger of the syringe is depressed, the volume

decreases while pressure and temperature increase. NOTE: This

experiment requires the “A” version of the Ideal Gas Law Apparatus.

Equipment Setup

Use the Hydraulic Boom structure with the Ideal Gas Law Apparatus (TD-8596A) and the Pressure/Temperature

Sensor (PS-2146).

• Unscrew the male luer lock at the base of the Ideal Gas Law (IGL) Apparatus to remove the short

quick-release connector from the apparatus.

• Connect the Pressure Sensor Coupler to the female luer lock on the base of the IGL Apparatus in place of the

quick-release connector.

• Connect the side arm of the Pressure Sensor Coupler to the pressure port on the Pressure/Temperature

Sensor.

• Connect the Syringe Coupler from the Pressure Sensor Coupler to the Hydraulic Cylinder.

• Plug the mini stereo plug of the Temperature Connector from the IGL Apparatus into the

temperature port on the Pressure/Temperature sensor.

• Plug the Pressure/Temperature Sensor and the Rotary Motion Sensor into a

PASCO Interface. (NOTE: You may want to use a PASport Extension

Cable to connect the Pressure/Temperature Sensor to the interface.)

12

Page 17

®

Model No. ME-6984 Ideal Gas Law

Ideal Gas Law

Apparatus

TD-8596A

Pressure/Temperature

Sensor PS-2146

Syringe Coupler

Pressure

Sensor

Coupler

To PASport

Interface

sidearm

Temperature

Connector plug

PASport Extension

Cable PS-2500

Procedure

Set the plunger for a volume of 40 cubic centimeters (cc). Hold the base of the IGL Apparatus firmly against a

sturdy horizontal surface.

Slap down on the plunger with the palm of your hand

to fully compress the gas inside the syringe. Hold this

position until the temperature and pressure have

equalized and are no longer changing.

Extra Equipment Model

Hooked Mass Set SE-8759

Pressure/Temperature Sensor PS-2146

Ideal Gas Law Apparatus TD-8596A

PASCO Interface see catalog

PASport Extension Cable* PS-2500

*Optional

13

Page 18

®

Hydraulics Structures Set Spares Part Numbers

Spares Part Numbers

ME-6985 Flexible I-Beam Set ME-6997 Full Round (XYZ) Connectors

#5 Flexible Beam (24 cm) - 16 Full Round Connector - 6

#4 Flexible Beam (17 cm) - 16 Flat Connector - 6

#3 Flexible Beam (11.5 cm) - 16 PAStrack Connector* - 6

ME-6986 Structures Rod Clamp (2 pack) ME-6998A Axle Spares

ME-6987 Flat Structures Members 1/2 by 1/4 by 1/4 Spacer - 12

Flat 3 x 4 Beam (19 cm) - 16 “O” Ring - 12

Flat #4 Beam (17 cm) - 16 Axle, Short (10.4 cm) - 2

Flat 2 x 3 Beam (12.5 cm) - 16 Axle, Medium (21.3 cm) - 2

ME-6993 Truss Set Members Axle, Long (26.6 cm) - 2

#5 Beam (24 cm long) - 24 Collet - 24

#4 Beam (17 cm long) - 54 Pulley - 12

#3 Beam (11.5 cm long) - 54 Wheel - 4

*1/4 - 20 Thumbscrew

and Square Nut

#2 Beam (8 cm long) - 24 Tire - 4

#1 Beam (5.5 cm long) - 24 ME-6999A Angle Connector Spares

Half Round Connector - 42 Angle Connector - 24

ME-6994 Truss Set Screws Straight Connector - 24

Screw (6 - 32) - 300 Sliding Connector - 12

ME-6996 Cord Lock Spares ME-9876 Yellow Cord (2 pack)

Cord Tensioning Clip - 32 Cord, Braided, #18 Yellow - 2 rolls

Cord, Braided, #18 Yellow - 1 roll

Summary of Extra Equipment Needed

Extra Equipment (Model) Where Used

Hooked Mass Set (SE-8759) All

Yellow Cord (ME-9876) All

Large Slotted Mass Set (ME-7566 or ME-7589) Hydraulic Boom, Fork Lift, Ideal Gas Law

Structures Rod Clamp (ME-6986) Hydraulic Boom, Ideal Gas Law

45-cm Steel Rod (ME-8736) Hydraulic Boom, Ideal Gas Law

Rotary Motion Sensor (PS-2120) Hydraulic Boom, Ideal Gas Law

Ideal Gas Law Apparatus (TD-8596A) Ideal Gas Law

Pressure/Temperature Sensor (PS-2146) Ideal Gas Law

Absolute Pressure Sensor (PS-2108) Hydraulic Boom

PASport Interface (see catalog or web site) Hydraulic Boom, Ideal Gas Law

Foam core board (art or office supply store) Fork Lift, Scissors Lift

14

Page 19

®

Model No. ME-6984 Technical Support

Technical Support

For assistance with any PASCO product, contact PASCO at:

Address: PASCO scientific

10101 Foothills Blvd.

Roseville, CA 95747-7100

Phone: 916-786-3800 (worldwide)

800-772-8700 (U.S.)

Fax: (916) 786-7565

Web: www.pasco.com

Email: support@pasco.com

For more information about the Hydraulics Structures Set and the latest revision of this Instruction Manual, visit:

www.pasco.com/go?ME-6984

Limited Warranty For a description of the product warranty, see the PASCO catalog.

Copyright The PASCO scientific 012-11726A Hydraulics Structures Set Instruction Manual is copyrighted with all rights reserved.

Permission is granted to non-profit educational institutions for reproduction of any part of this manual, providing the reproductions are

used only in their laboratories and classrooms, and are not sold for profit. Reproduction under any other circumstances, without the

written consent of PASCO scientific, is prohibited.

Trademarks PASCO and PASCO scientific are trademarks or registered trademarks of PASCO scientific, in the United States and/or

in other countries. All other brands, products, or service names are or may be trademarks or service marks of, and are used to identify, products or services of, their respective owners. For more information visit www.pasco.com/legal.

Patents Pending: The following PASCO products have patents pending:

ME-6990 Truss Set ME-6991 Bridge Set

ME-6992A Advanced Structures Set ME-6993 Truss Set Members

ME-6994 Truss Set Screws ME-6995 Road Bed Spares

ME-6996 Cord Lock Spares ME-6997 Full Round (XYZ) Connector Spares

ME-6998 Axle Spares ME-6999A Angle Connector Spares

PS-2198 Load Cell Amplifier PS-2199 Load Cell and Amplifier Set

PS-2200 100 N Load Cell PS-2201 5 N Load Cell

PS-2205 Dual Load Cell Amplifier

15

Page 20

®

Hydraulics Structures Set Technical Support

16

Loading...

Loading...