WCS-SIF-01

Pneumatic Division

Richland, Michigan 49083

Training & Maintenance Manual

ISSUED: November, 2006

Supersedes: June, 2006

Pneumatic Spotwelding

Control Systems

Training & Maintenance Manual

WCS-SIF-01

Pneumati

c

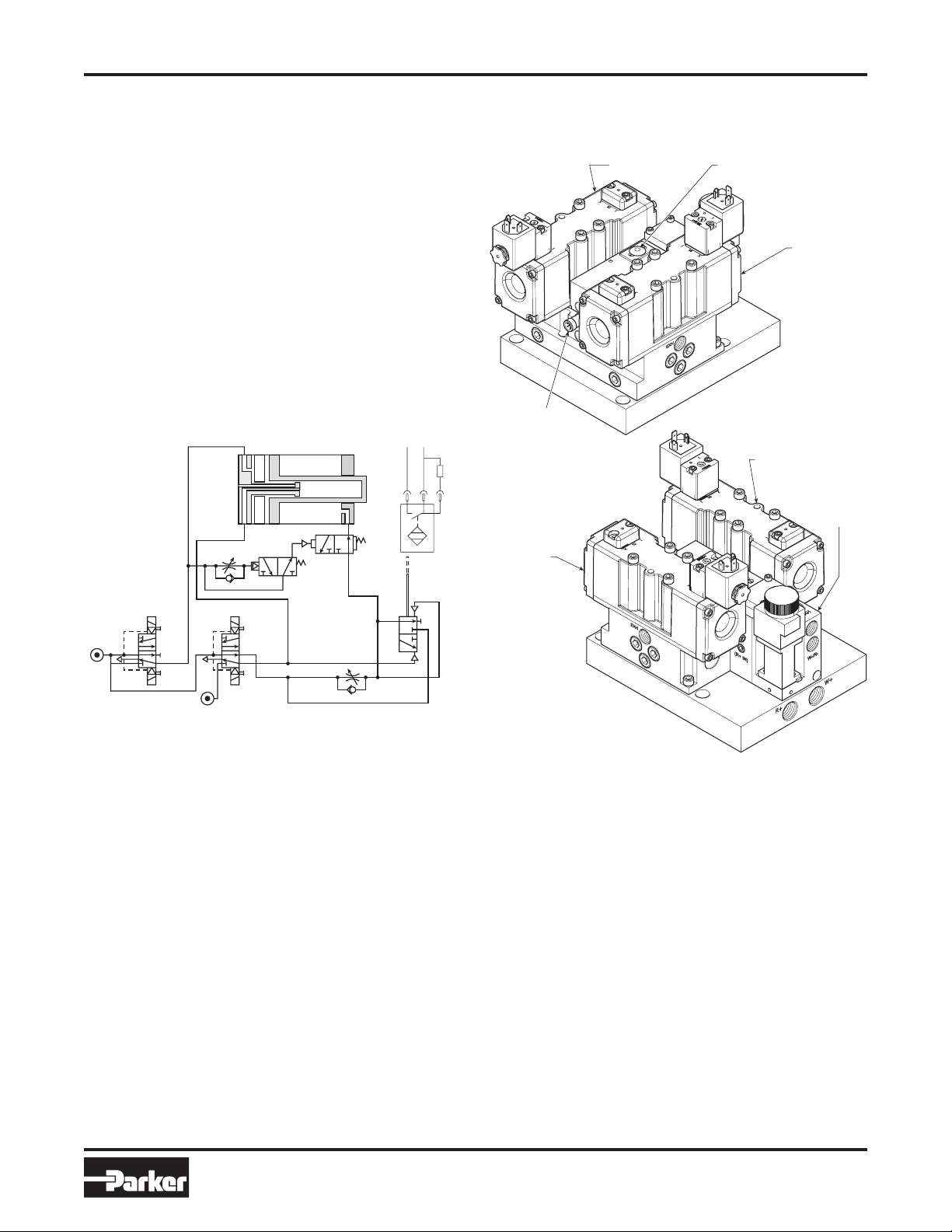

Front View

Back View

Weld Stroke

Valve

Retract

(Pre-Stroke)

Valve

Feedback

Sensor

Flow

Control

Weld Stroke

Valve

Quick

Exhaust

(Air

Operated)

Retract

(Pre-Stroke)

Valve

WR-

ANSI (3 Ported Cylinder Option)

Inductive Sensor / Connection: Turck

Connection Diagram Inductive Sensor

1 Brown +24 VDC Power Supply

3 Blue 0 V Power Supply

4 Black Switch Wire

W+R+

Pw

Pr

Retract (Pre-Stroke)

Valve

Weld Stroke

Valve

14 4 2 12

14 4 2 12

1

pnp

+3-

4

Description & Operation

General Description of Spotwelding Units

The spotwelding system is an integrated pneumatic

controlled circuit that is specifically designed to increase

production throughput, while improving weld quality and

reducing decibel noise level.

Each unit consists of 2 independent, 2 position, directional

control valves for retract (pre-stroke) and weld stroke. Each

valve is dual pressure, with single solenoid / spring assist

return or double solenoid available. Also included with each

unit is a proportional / quick dump valve, a feedback sensor

for initiating the welding process, and a flow control for

metering the impact speed of the weld tips.

Training & Maintenance Manual

General Operation of

Spotwelding Units – 3 ported guns

Spotwelding systems control both retract (pre-stroke) and

weld stroke motions. When a 3 ported cylinder is used, the

control block functions as follows:

1. The pre-stroke (retract) valve is energized, allowing

the weld cylinder to extend under full line pressure by

actuating the quick exhaust valve and moving to its

predetermined position prior to welding.

2. The quick exhaust valve time is adjusted by the knob

on top of the unit. To start, the white line on the dial

is set at top dead center. Turn knob clockwise to set

quick exhaust valve open time. Continuing to turn knob

clockwise will lengthen time until it reaches a full 360°

rotation, which covers the complete timing range.

3. The weld stroke valve is then energized using a selected

weld schedule pressure. The closure speed of the weld

tips is controlled by the use of an adjustable flow control,

thus creating “low impact”.

4. Immediately following weld tip contact with the sheet

metal, two actions take place.

a. The proportional / quick dump valve that senses

pressure allows the front end of the cylinder to exhaust

(by-passing the flow control), providing weld schedule

pressure instantly.

b. The proportional / quick dump valve also actuates a

feedback sensor to start the weld cycle.

5.

Once the weld cycle is complete, the weld stroke valve

is de-energized, allowing the weld tips to open under

full pressure.

6. The retract (pre-stroke) valve is then de-energized,

allowing the weld cylinder to open completely under

full line pressure.

Note: Dual pressure is provided to the control block. Line

(high) pressure is used for both retract stroke and weld

stroke open. Weld schedule pressure is used for weld stroke

close. Dual pressure provides for weld tips to be closed for

tip dressing using any pressures available, from as low as

5 PSIG to maximum line pressure.

2

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

WCS-SIF-01

Pneumati

c

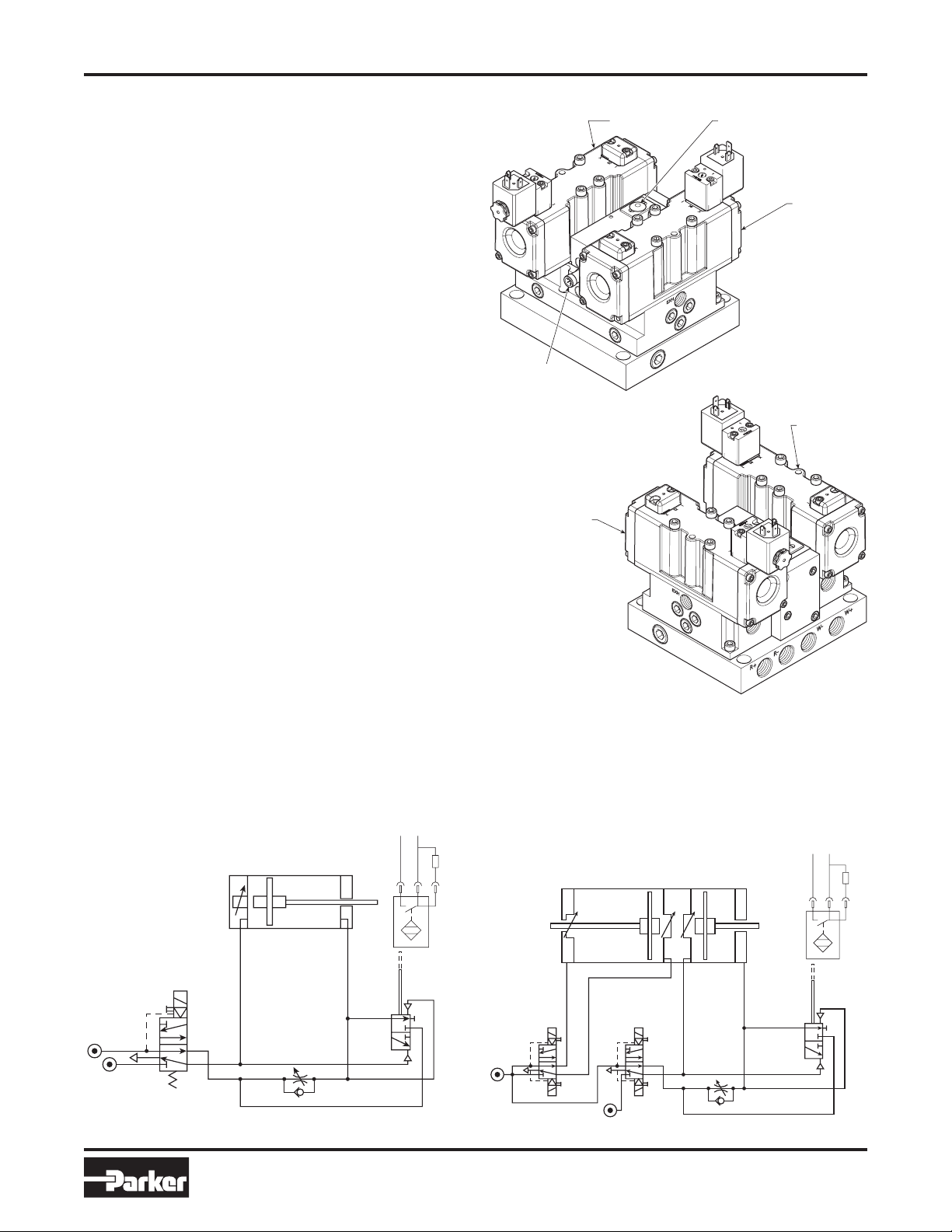

W-

Pw

Pr

ANSI (2 Ported Cylinder Option)

Inductive Sensor / Connection: Turck

Connection Diagram Inductive Sensor

1 Brown +24 VDC Power Supply

3 Blue 0 V Power Supply

4 Black Switch Wire

W+

1

pnp

+3-

4

W-

ANSI (4 Ported Cylinder Option)

Inductive Sensor / Connection: Turck

Connection Diagram Inductive Sensor

1 Brown +24 VDC Power Supply

3 Blue 0 V Power Supply

4 Black Switch Wire

W+R-

R+

Pw

Pr

1

pnp

+3-

4

Front View

Back View

Weld Stroke

Valve

Retract

(Pre-Stroke)

Valve

(4 Ported

Gun Only)

Feedback

Sensor

Flow

Control

Weld Stroke

Valve

Retract

(Pre-Stroke)

Valve

(4 Ported

Gun Only)

Description & Operation

General Operation of

Spotwelding Units – 2 and 4 ported guns

Spotwelding systems control both retract (pre-stroke) and

weld stroke motions. When a 4 ported cylinder is used, the

control block functions as follows:

1. The retract (pre-stroke) valve is energized, allowing

the weld cylinder to extend under full line pressure and

moving to its predetermined position prior to welding.

2. The weld stroke valve is then energized using a selected

weld schedule pressure. The closure speed of the weld

tips is controlled by the use of an adjustable flow control,

thus creating “low impact”.

3. Immediately following weld tip contact with the sheet

metal, two actions take place.

a. The proportional / quick dump valve that senses

pressure allows the front end of the cylinder to exhaust

(by-passing the flow control), providing weld schedule

pressure instantly.

b. The proportional / quick dump valve also actuates a

feedback sensor to start the weld cycle.

4.

Once the weld cycle is complete, the weld stroke valve is deenergized, allowing the weld tips to open under full pressure.

5.

The retract (pre-stroke) valve is then de-energized, allowing

the weld cylinder to open completely under full line pressure.

Training & Maintenance Manual

Note: Dual pressure is provided to the control block. Line

(high) pressure is used for both retract stroke and weld stroke

open. Weld schedule pressure is used for weld stroke close.

Dual pressure provides for weld tips to be closed for tip

dressing using any pressures available, from as low as

5 PSIG to maximum line pressure. 2 ported guns perform

the same steps as above, except that the retract (pre-stroke)

portion of the cylinder does not exist. Steps 2–4 only apply.

3

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

WCS-SIF-01

Pneumati

c

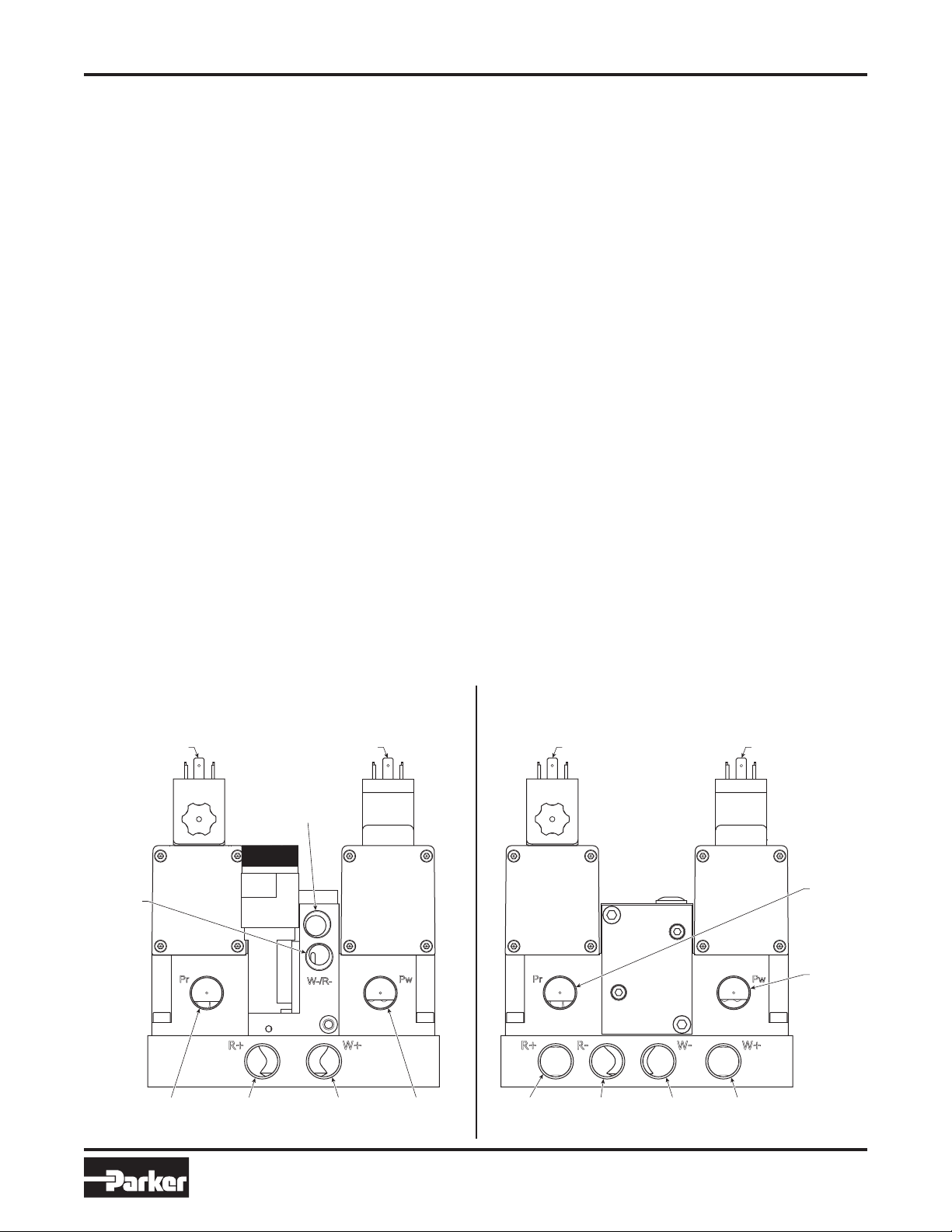

3 Ported Installation 4 Ported Installation

Weld Stroke

Connector(s)

Exhaust

High

Pressure

Inlet

Retract

Extend

Weld

Extend

Weld

Pressure

Inlet

Weld

Return

High

Pressure

Inlet

Weld

Pressure

Inlet

Weld Stroke

Connector(s)

Retract

(Pre-Stroke)

Connector(s)

Retract

(Pre-Stroke)

Connector(s)

Retract

Extend

Weld

Extend

Weld

Return

Retract

Return

Installation & Setup Instructions

Installation – Air and Electrical

A. Installing Weld Block with Existing Equipment

1. Shut off air supply to weld gun and turn power off to cell.

2. Disconnect air hoses from existing weld block ports. This

will vary depending on weld gun type, and whether the

existing weld block is single or dual pressure.

Note: If the current weld block is mounted directly to the

cylinder, then only the inlet port hoses will be disconnected.

3. Disconnect solenoid connectors from valves. Be sure

to note which connectors are being used for pre-stroke

(retract) valves and weld stroke valves.

4. Remove current weld block from gun.

B. Installing Weld Block on New Equipment

5.

Mount weld block spotwelding system to robot using (4) M8

screws and torque to 130 to 145 in. lbs (14.7 to 16.4 Nm).

6. Connect all air hoses to weld block (see schematic on

pages 2 or 3).

Note: An additional air hose may be necessary for the

inlet, since this unit is dual pressure. If so, connect the

already existing hose to the Pw port (pressure weld).

This hose should be supplying scheduled pressures from

a proportional regulator. Connect the additional hose

before the proportional regulator using a T-fitting so that

full line pressure is being used. This hose should be

connected to the Pr port (pressure retract).

7. Connect the solenoid cables to the proper valves.

Connect an M12 sensor cable to the feedback sensor on

the unit. The other end of this cable should be wired to

the PLC controller.

Training & Maintenance Manual

8. Turn air supply and power on.

9. Check for air leaks. The weld cylinder should be in the

home position (completely open). If not, check that all

air hoses are connected to the correct ports. Verify that

all solenoids are de-energized, and valve overrides are

unactuated. Once this is done, verify the function of the

weld block, by actuating the weld block valves using the

manual overrides. Press and hold the retract (pre-stroke)

valve manual override. The weld cylinder should move to

the weld stroke position. Press and hold the weld stroke

valve manual override [still holding the retract (pre-stroke)

override]. The weld cylinder should now close. Release

the weld stroke override and the retract (pre-stroke)

override. The weld cylinder will return to home position.

Note: The weld stroke portion of the cylinder will move

slower than the pre-stroke. This is due to the regulated

pressure being used, as well as the flow control.

Adjusting the speed of the cylinder will be covered in the

Setup Instructions. Repeat this process, now energizing

the solenoids. The cylinder should perform the same. If

not, verify that the solenoid connectors are located on the

proper valves. Once the unit has been properly installed,

the following setup procedure can be used to ensure that

the Parker weld system is used to its fullest potential.

Wiring

Refer to valve Instruction Sheet for proper wiring connections.

Available at: www.parker.com/pneumatic (see B6 and ISO

size 2 valves Installation and Service Instructions).

4

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

WCS-SIF-01

Pneumati

c

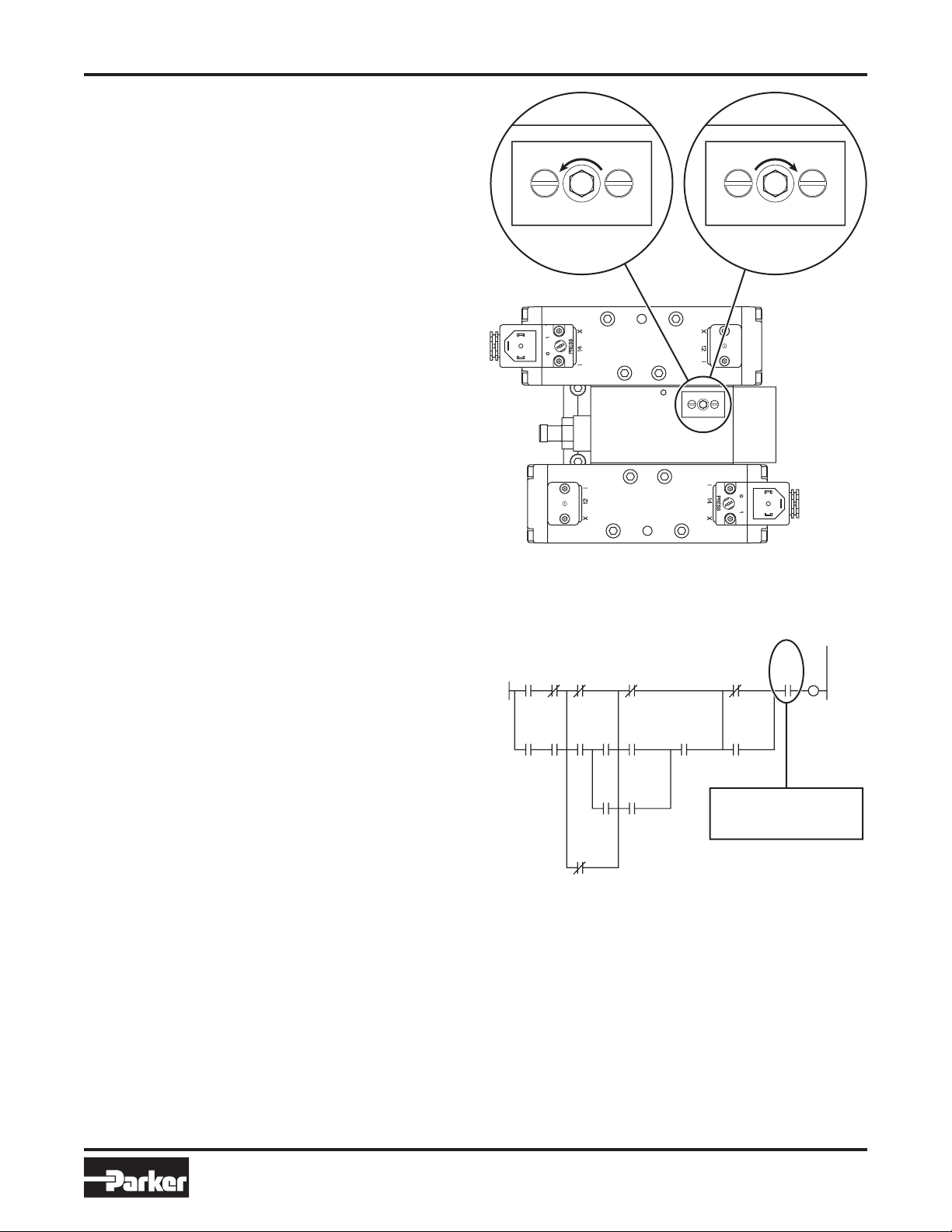

Open

Flow Control

Close

Flow Control

5mm

Allen Wrench

Required For

Flow Control

Adjustment

Electrical Changes (Sample):

GUN PR

ESS

TEACHI

NG

M005

00061

CUT CA RE-WEL

BLE CH D(PB)

ECKING

M052 M03C P1-M00F

K2 STR

OKE CH

ANGE

P1-M00F

TEACHI

NG

P1-M00F

GUN PR

ESS

M005

CUT CA RE-WEL

BLE CH D(PB)

ECKING

M052

RE-WEL

D(PB)

WELD R

EADY S

ENSOR

X024 1022 WELD START

M00B M03C

CHECK

MODE/P

ROGRAM

P1-L04B

STROKE

CHANG

E TIME

T015

AUTO R

E-WELD

M05B

RE-WEL

D

M00B

MANUAL

WELD

P1-L058

Insert contact on the

WELD START rung of

the Robot PLC program.

Installation & Setup Instructions

Setup

Below are the step by step setup procedures for properly

setting the flow control and feedback sensor.

How to Set the Flow Control Properly

Begin by turning the flow control clockwise until it stops. If

this is done properly, then the weld stroke should move

extremely slow or not at all.

Note: As stated in the Installation procedure, the pre-stroke

valve must be actuated prior to the weld stroke valve in order

for the weld cylinder to move correctly.

Slowly (1/4 to 1/2 turn at a time) begin to open the flow

control by turning counterclockwise. The weld tips should

now close upon actuation of the valves. At this point, you

should begin to hear a second exhaust coming from the

weld unit once the weld tips have made contact. This

second exhaust is the air from the front side of the cylinder

bypassing the flow control. As you continue to speed up the

weld stroke by turning the flow control, the delay between

the tips closing and the second exhaust will get shorter.

Also, check the feedback sensor while this is occurring. The

indicator light from the sensor should illuminate when you

hear the second exhaust. This is the key to determining the

proper setting of the flow control. The optimum setting for

each weld block will be different for each gun, based on the

bore size and weld stroke used. Continue to open the flow

control, allowing the weld tips to close faster until:

Training & Maintenance Manual

1. You have reached an impact speed you are happy with.

2. You have reached an acceptable decibel noise level.

3. You see that the second exhaust and feedback sensor

illumination occur “just” as the weld tips contact.

Note:

This is a judgement call. If the flow control is set

too far open, then the weld block could result in welding

misfire causing the gun to fire before the weld tips close

fully. The reason this would occur is because the flow

control has been opened so much that all the air on the

front side of the cylinder has exhausted before the tips fully

close, thus negating the “low impact” benefit of the system.

To guarantee proper performance, find the setting where

the exhaust / illumination occurs “just” as the tips close,

and then adjust the flow control 1/2 turn clockwise.

How to Set the Feedback Sensor Properly

The purpose of the feedback sensor is to provide an input

signal at the exact moment that full weld pressure has been

obtained at the weld tips. Traditionally this is achieved using

squeeze time. An experienced weld / electrical engineer

is needed to place the feedback sensor input into the PLC

program. The location of this input will vary depending on

the PLC manufacturer. Consult the robot manufacturer for

the proper input location.

Above is a sample PLC program where the feedback sensor

was placed during a typical install. The location of the input

should be right before the weld start command. Once the input

has been placed into the program, disconnect the sensor cable

from the feedback sensor. This will allow you to determine

whether or not the input was placed in the correct spot.

Perform a trial run. If on the first weld, the weld tips close

and the robot stops, then the sensor input has been located

correctly in the program. If the robot continues to run, despite

the cable being disconnected, then the sensor input is not

correct. Review the location and then try the trial run again.

Note: The weld block should perform the same whether the

robot is in manual or automatic mode.

5

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

WCS-SIF-01

Pneumati

c

Specifications

Training & Maintenance Manual

Pneumatic System

with Low Impact and

Rapid Approach Control

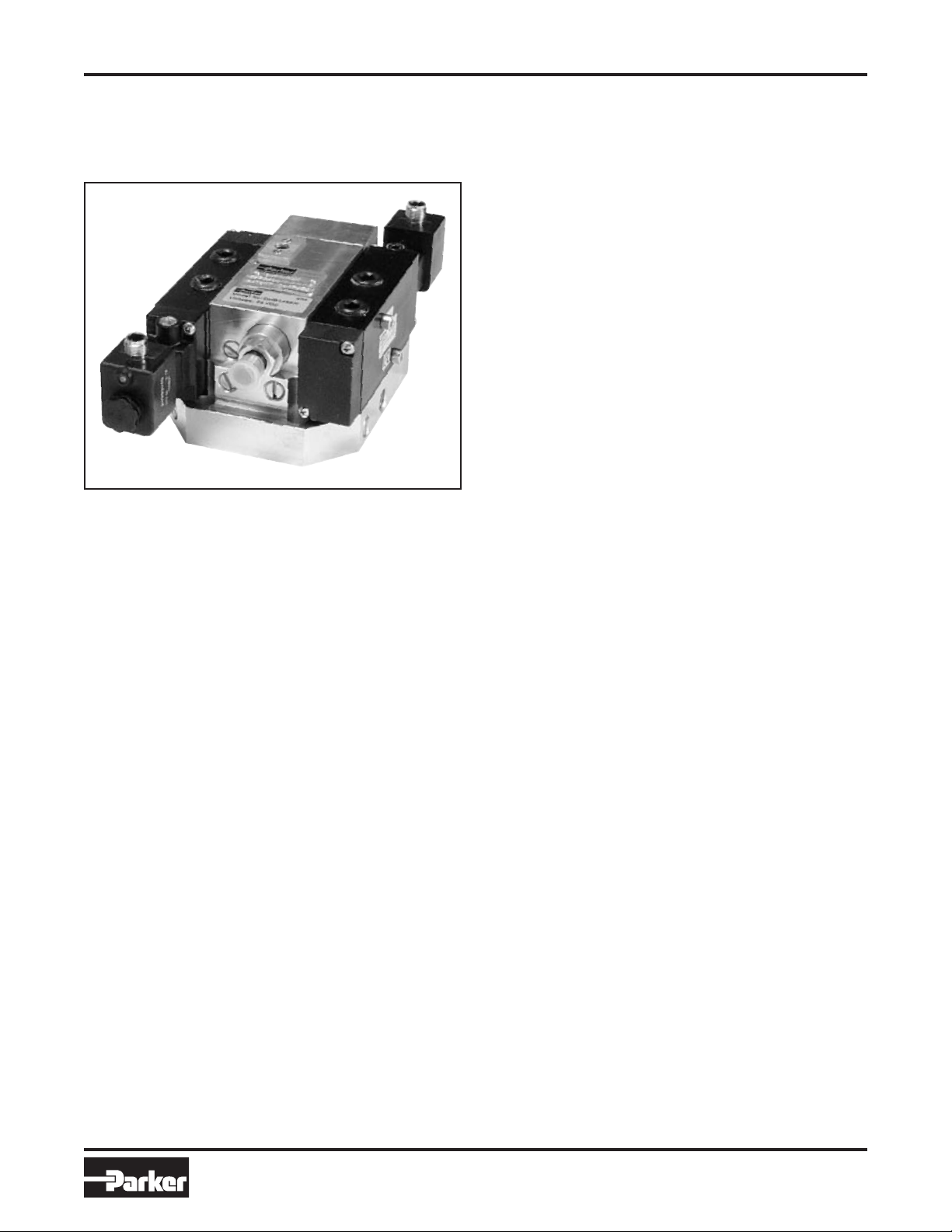

Description

Pneumatic valve block for use with pneumatic weld

gun cylinders. The block has an integrated low impact

system and is provided with two solenoid operated

“Namur” or ISO size 2 valves. One valve for the retract

(pre-stroke) and one for the weld stroke. The valves

can be of the single solenoid type or the double

solenoid type. The block is available for different

constructions of cylinders:

DH / WH = 3 Ported Cylinders

DP / WP = 2 and 4 Ported Cylinders

Ordering Code: See pages 7 – 13.

Dimensions: See pages 15 – 18.

Applications

The Spotwelding System can be used with any

Pneumatic Spot Weld Cylinder.

Mounting

The weld block can either be mounted on the side of

the robot or directly to the cylinder. See pages 10 – 12

for bolt hole patterns for robot mount. Consult Parker

for cylinder mount application.

Technical Data

Medium .......................... Compressed air, filtered to

40µ and dried to a dewpoint

of 37°F (3°C), lubricated

or non-lubricated. Once

lubricated air is applied, this

must be maintained.

Working Pressure ..........37 to 145 PSIG (2.5 to 10 bar)

WH Series Air Operated

Quick Exhaust ..........40 to 115 PSIG (2.7 to 7.9 bar)

Ambient Temperature ...... 41°F to 120°F (5°C to 49°C)

Weight –

DP ................................................. 12.0 lbs (5.4 kgs)

DH ................................................... 7.0 lbs (3.2 kgs)

WP (with Baseplate) ...................... 14.0 lbs (6.4 kgs)

WH (with Baseplate) ...................... 18.0 lbs (8.2 kgs)

Pneumatic Valve

24 VDC

Operating Voltage Solenoids

Power Consumption .....................................4.8W

Class of Protection ....................... IP65 (with plug

mounted)

Connector ............................ M12, 22mm, 30mm,

Auto (ISO 2 only)

120 VAC

Operating Voltage Solenoids

Frequency ............................................50 / 60 Hz

Power Consumption ..................... 7.8 VA / 6.3 VA

Class of Protection ....................... IP65 (with plug

mounted)

Connector ............................ M12, 22mm, 30mm,

Auto (WP / WH only)

Proximity Sensor

24 VDC

Supply Voltage ................................10 to 30 VDC

Rated Operational Current ........................200mA

Degree of Protection .....................................IP67

Ambient Temperature Range ....... -13°F to 158°F

(-25°C to 70°C)

Switching Indication ................... By LED (Yellow)

Output ..............................................PNP or NPN

120 VDC (Consult factory for availability)

Supply Voltage .............................. 20 to 140 VAC

Frequency ......................................... 50 or 60 Hz

Supply Voltage Indication ........... By LED (Green)

Rated Operational Current .......................400 mA

Degree of Protection .....................................IP67

Ambient Temperature Range ...... -13°F to 158°F

(-25°C - +70°C)

Switching Indication ................. By LED (Orange)

....24 VDC +10/-15%

...120 VAC +10/-15%

Service Kits: See page 9.

6

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

WCS-SIF-01

Pneumati

c

Training & Maintenance Manual

Ordering Information

Model Number Index – B6 Namur Valves (2 and 4 Ported Guns)

Valve Valve Block Valve Block

Valve Block Operators Operators Port

Series Block Sensor Retract Valve Weld Stroke Valve Voltage Type

DP A 1 S S D N

DP B6 NAMUR

(2 or 4

Cylinder

Ports

Note: NAMUR valves mounted on

valve block have BSPP porting.

A Valve Block

w/Base Plate

X Valve Block

for Base Plate

Less Base Plate

1 PNP

Sensor24 VDC

S Single

Solenoid

D Double

Solenoid

X Valve

Block w/o

Pre-Stroke

Valve

Model Selection Examples

Valve Block Only ...............................................DPX1SSDN

S Single

D Double

X Valve

Solenoid

Solenoid

Block w/o

Weld Stroke

Valve

Valve Block with Base .......................................DPA1SSDN

Model Number Index – B6 Namur Valves (3 Ported Guns)

Valve Valve Block Valve Block

Valve Block Operators Operators Port

Series Block Sensor Retract Valve Weld Stroke Valve Voltage Type

A 120VAC

22mm Coil

B 120VAC

30mm Coil

D 24VDC

22mm Coil

E 24VDC

30mm Coil

F 24VDC M12

Connector

X Without

Valves

N NPT

G BSPP

DH G 1 S S D N

DH B6 NAMUR

(3 Cylinder

Ports

Note: NAMUR valves mounted on

valve block have BSPP porting.

4 Valve Block

High Pressure

Quick Exhaust

Mounted

(w/o base)

G Valve Block

High Pressure

Quick Exhaust

Mounted

(w/Base)

1 PNP

Sensor24 VDC

S Single

Solenoid

D Double

Solenoid

X Valve

Block w/o

Pre-Stroke

Valve

S Single

D Double

X Valve

Solenoid

Solenoid

Block w/o

Weld Stroke

Valve

A 120VAC

22mm Coil

B 120VAC

30mm Coil

D 24VDC

22mm Coil

E 24VDC

30mm Coil

F 24VDC M12

Connector

X Without

Valves

N NPT

G BSPP

Model Selection Examples

Valve Block with Quick Exhaust (w/o Base) ..... DH41SSDN

Valve Block with Quick Exhaust (w/ Base) ...... DHG1SSDN

7

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

WCS-SIF-01

Pneumati

c

Training & Maintenance Manual

Ordering Information

Model Number Index – ISO Size 2 Cylinder & Base Plate Mountable (2 and 4 Ported Guns)

Valve Valve Block Valve Block

Valve Block Operators Operators Port

Series Block Sensor Retract Valve Weld Stroke Valve Voltage Type

WP A 1 S S F N

A Valve Block

w/Base Plate

X Valve Block

w/o Base Plate

WP ISO 2

(2 or 4

Cylinder

Ports)

1 PNP Sensor-

24 VDC

Model Number Index – ISO Size 2

Valve Valve Block Valve Block

Valve Block Operators Operators Port

Series Block Sensor Retract Valve Weld Stroke Valve Voltage Type

S Single

Solenoid

D Double

Solenoid

X Valve

Block w/o

Pre- Stroke

Valve

S Single

D Double

X Valve

Solenoid

Solenoid

Block

w/o

Weld

Stroke

Valve

B 120VAC 30mm Square 3-Pin ISO 4400

E 24VDC 30mm Square 3-Pin ISO 4400

F 24VDC M12 Euro

H 120VAC 5-Pin Mini Auto Straight (GM)

J 120VAC 5-Pin Mini Auto Straight (Ford)

K 120VAC 5-Pin Mini Auto Straight (Chrysler)

M 24VDC 4-Pin M12 Micro Auto Straight (GM)

N 24VDC 4-Pin M12 Micro Auto Straight (Ford)

P 24VDC 4-Pin M12 Micro Auto Straight (Chrysler)

Q 24VDC 5-Pin Mini Auto Straight (GM)

R 24VDC 5-Pin Mini Auto Straight (Ford)

S 24VDC 5-Pin Mini Auto Straight (Chrysler)

X Without Valves

Cylinder & Base Plate Mountable

N NPT

G BSPP

(3 Ported Guns)

WH B 1 S S F N

WH ISO 2

(3 Cylinder

Ports)

4 Valve Block Quick

B Valve Block w/Base Plate

G Valve Block w/Base Plate

H Valve Block w/Base Plate

Y Valve Block Less Base

Z Valve Block Less Base

1 PNP Sensor-

24 VDC

Exhaust Mounted

(Cylinder Mount)

(Air Operated High Flow

Quick Exhaust)

(High Pressure Quick

Exhaust)

(Solenoid Operated High

Flow Quick Exhaust)

Plate (Air Operated High

Flow Quick Exhaust)

Plate (Solenoid Operated

Quick Exhaust)

S Single

Solenoid

D Double

Solenoid

X Valve

Block w/o

Pre-Stroke

Valve

8

S Single

Solenoid

D Double

Solenoid

X Valve

Block

w/o

Weld

Stroke

Valve

E 24VDC 30mm Square 3-Pin ISO 4400

F 24VDC M12 Euro

M 24VDC 4-Pin M12 Micro Auto Straight (GM)

N 24VDC 4-Pin M12 Micro Auto Straight (Ford)

P 24VDC 4-Pin M12 Micro Auto Straight (Chrysler)

Q 24VDC 5-Pin Mini Auto Straight (GM)

R 24VDC 5-Pin Mini Auto Straight (Ford)

S 24VDC 5-Pin Mini Auto Straight (Chrysler)

X Without Valves

N NPT

G BSPP

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

WCS-SIF-01

Pneumati

c

Training & Maintenance Manual

Ordering Information

Model Number Index – ISO Size 2 Manifold Mountable (2 and 4 Ported Guns)

Valve Valve Block Valve Block

Valve Block Operators Operators Port

Series Block Sensor Retract Valve Weld Stroke Valve Voltage Type

WP J 1 X X X N

WP ISO 2

(2 or 4

Cylinder

Ports)

J Valve Block (Standard)

ISO 2 Manifold Mountable

Plug-In

M Valve Block (Standard)

ISO 2 Manifold Mountable

Non Plug-In

1 PNP Sensor-

24 VDC

Model Number Index – ISO Size 2

Valve Valve Block Valve Block

Valve Block Operators Operators Port

Series Block Sensor Retract Valve Weld Stroke Valve Voltage Type

X Valve

Block w/o

Pre-Stroke

Valve

X Valve Block

Manifold Mountable

w/o

Weld

Stroke

Valve

X Without

Valves

(3 Ported Guns)

N NPT

G BSPP

WH ISO 2

(3 Cylinder

Ports)

WH K 1 X X X N

1 PNP Sensor-

K Valve Block ISO Manifold

Mountable Plug-In

(Air Operated High Flow

Quick Exhaust)

L Valve Block ISO Manifold

Mountable Plug-In

(Solenoid Operated High

Flow Quick Exhaust)

N Valve Block ISO Manifold

Mountable Non Plug-In

(Air Operated High Flow

Quick Exhaust)

P Valve Block ISO Manifold

Mountable Non Plug-In

(Solenoid Operated High

Flow Quick Exhaust)

24 VDC

X Valve

Block w/o

Pre-Stroke

Valve

X Valve Block

w/o

Weld

Stroke

Note: ISO Size 2 manifold mountable weld units cannot be ordered

with valves or manifold bases. See pages 10 and 11 for valve and

manifold base ordering information.

Valve

9

X Without

Valves

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

N NPT

G BSPP

WCS-SIF-01

Pneumati

c

H2

H2

H2

Training & Maintenance Manual

Ordering Information

Model Number Index – 5599-1 CNOMO - Size 2

Enclosure / Automotive

Basic Operator / Pilot Source / Overrides / Lead Voltage & Wiring Engineering

Series Function Mounting Pilot Exhaust Lights Length Frequency Options Level

H2 E WX H B L 49 — C

5599-1

Basic Series

ISO 5599-1

Size 2

5599-1

Operator / Function

2 Double Solenoid, 2-Position

E Single Solenoid, 2-Position -

Air Return, Spring Assist

5599-1

Mounting

WX Valve

Less Base

5599-1

Pilot Source /

Pilot Exhaust

H #5 Port / Vented

5599-1

Overrides / Lights

B Non-Locking, Flush,

Push - w/o Light

G* Non-Locking, Flush,

Push - w/ Light

* Apply to Voltage Code “19” &

Enclosure / Lead Length “6”.

5599-1

Enclosure /

Lead Length

6* 2-Pin M12 Euro

Connector with

CNOMO Operator

L 3-Pin 30mm

DIN 43650A with

CNOMO Operator

*

Only available with

Voltage / Wiring “19000FC”.

5599-1

Automotive

Wiring Options

Blank None

000F* SAE / Ford

* Required with Enclosure “6” Only.

5599-1

Voltage & Frequency

Code

19* 24

49 24

*

LED & Surge Suppression.

Only Available with Enclosure “6”.

AC

60Hz 50Hz

5599-1

Engineering

Level

C Current

DC

Model Number Index – 5599-1 AUTO - Size 2

Enclosure / Automotive

Basic Operator / Pilot Source / Overrides / Lead Voltage & Automotive Wiring Engineering

Series Function Mounting Pilot Exhaust Lights Length Frequency Enclosure Options Level

H2 E WX H G 2 B9 000 F C

5599-1

Basic Series

ISO 5599-1

Size 2

5599-1

Operator / Function

2 Double Solenoid,

2-Position

E Single Solenoid,

2-Position - Air Return,

Spring Assist

Mounting

WX Valve

Less

Base

5599-1

Overrides / Lights

G* Non-Locking, Flush,

Push - w/ Light

5599-1

Pilot Source /

Pilot Exhaust

H #5 Port / Vented

5599-1

5599-1

Enclosure /

Lead Length

2 4-Pin M12 Micro

Straight Connector

3 5-Pin Mini

Automotive

Straight Connector

5599-1

Automotive

Wiring Options

C Chrysler

F SAE / Ford

G General Motors

5599-1

Voltage & Frequency

Code

B9* 24 LED & Sup

* Solenoid is Blue color.

AC

60Hz 50Hz

Engineering

C Current

DC

Surge Sup

5599-1

Level

Light &

Model Number Index – 5599-2 Size 2

Enclosure /

Basic Operator / Pilot Source / Overrides / Lead Voltage & Engineering

Series Function Mounting Pilot Exhaust Lights Length Frequency Level

H2 E VX H G 0 B9 C

5599-2

Basic Series

ISO 5599-2

Size 2

5599-2

Operator / Function

2 Double Solenoid, 2-Position

E Single Solenoid, 2-Position -

Air Return, Spring Assist

5599-2

Mounting

VX Valve

Less Base

H #5 Port / Vented

Overrides / Lights

G Non-Locking, Flush,

Push - w/ Light

BOLD OPTIONS ARE MOST POPULAR

5599-2

Pilot Source /

Pilot Exhaust

5599-2

10

Enclosure / Lead Length

0 None, Remote Pilot Valve

or Valve Less Base

5599-2

Voltage & Frequency

Code

B9* 24 LED & Sup

* Solenoid is Blue color.

AC

60Hz 50Hz

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

5599-2

Engineering

C Current

DC

Surge Sup

5599-2

Level

Light &

WCS-SIF-01

Pneumati

c

H2

Training & Maintenance Manual

Ordering Information

Manifold and Subbase Kit Ordering Code

Mounting Base Style / Enclosures / Wiring Engineering Factory

Basic Series Port Size Lead Length Options Level Designator

PS4111 55 A — C P

0 None, No Electrical Plug - 5599-1

7† 3-Pin Mini Connector in Base

8*† 4-Pin M12 Micro Connector in Base

9† 5-Pin Mini Connector in Base

A 6" Leads

C Terminal Block

J‡ Circuit Board, Single Address

M‡ Circuit Board, Double Address

T* SAM Gen 3.0 Wiring

* Valve Voltage Code “B9” Only.

† Must Specify Valve Auto Wiring Option “C”,

“F”, or “G”.

‡ Not Available with Subbase Kits.

Mounting Base Style / Port Size

H2

17 Subbase: 1/2 NPT Side Ports

18* Subbase: 1/2 BSPP Side Ports

57 Manifold: 1/2 NPT End Port

58* Manifold: 1/2 BSPP, End Ports

* BSPP ISO 1179 Specifications.

Enclosures / Lead Length

Wiring Options

Blank None

C Chrysler

F SAE / Ford

G General Motors

Engineering

Level

C Current

Subbase Kits Manifold Kits

H2 H2

Automotive Connectors

Mounted in 1/2" Conduit Port

• 3-Pin - Wired for Single Solenoid

• 4-Pin / 5-Pin - Wired for Double Solenoid

Automotive Connectors

Mounted in Individual Manifold Conduit Cover

• 3-Pin - Wired for Single Solenoid

• 4-Pin / 5-Pin - Wired for Double Solenoid

11

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

WCS-SIF-01

Pneumati

c

Ordering Information

How To Order Add-A-Fold

Assemblies

1. List Add-A-Fold Assembly call out. This automatically

includes the end plate kit assembly.

2. List complete Valve and Base model number. List left to

right, LOOKING AT THE CYLINDER PORTS on the #12

end of the manifold. The left most station is station 1.

Training & Maintenance Manual

Station 1

#14 End

#12 End

Station 2

Add-A-Fold Assembly Model Number

Valve End Plate Port Number of

Series Type Type Stations

AA H2 S 0 02

Valve Series

H2 Right & Left

End Plate

Example

Application requires a 2-Station manifold with weld block and

valves, and requires isolation between station 1 and 2 for port

#3 galley only.

Item Qty. Part No.

01 1 AAH2E002

02 1 H22VXHG0B9C ................................... Station 1 & 2

03 2 PS411157MCP .................................... Station 1 & 2

04 1 WPJ1XXXN .................................................Station 2

05 1 H2EVXHG0B9C ..........................................Station 2

06 1 PS3632P .....

Galley 3 Isolation Between Station 1 & 2

End Plate Type

D† 25-Pin

E† 19-Pin

G† M23, 12-Pin

S Standard -

Non-collective Wiring

† Collective Wiring Module

Included.

Example:

2-Station Manifold with (2) H2 Valves

On Manifold Bases

Port Type

0 NPT

1 BSPP “G”

NOTE: Construct manifold assemblies from left to right while looking at

the cylinder ports.

Number of

Stations

02

* Only Available

with 2-Station

Manifold when

Used in Welding

Applications.

12

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

WCS-SIF-01

Pneumati

c

Training & Maintenance Manual

Ordering Information

Model Number Index – Generation 3.0

Basic Valve Manifold / Engineering

Series Series Protocol Subbase Stations Power I/O Options Level

S3 H2 D 2 D 0 C

Basic Series

S3 Serial Generation 3.0

Valve Series

H2 Size 2 ISO 5599-2 Valves

Notes:

1. Not available with single subbase option.

2. 2 inputs come standard with subbase or manifold options.

3. 2 additional auxiliary inputs can be ordered by selecting this option.

Protocol

D DeviceNet

TM

Subbase Stations

1 1 - Station Manifold

2 2 - Station Manifold

5 Single Subbase

Manifold /

2

2

2

Power I/O

A 2 In / 4 Out, Bus Power

B 2 In / 4 Out, Ext. Power

C 4 In / 4 Out, Bus Power

D 4 In / 4 Out, Ext Power

E Subbase, Bus Power

F Subbase, Ext. Power

Options

0 None

1

1

1,3

1,3

Engineering Level

C Current

13

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

WCS-SIF-01

Pneumati

c

11 12

2

4

5

10

10

115 to 130 in. lb.

Torque (4)

15 to 18 in. lb.

Torque (4)

3

3

7

3

Bore

Hand Tight

Torque

Hand Tight

Torque

4 to 6 in. lb.

Torque (2)

115 to 130 in. lb.

Torque (4)

115 to 130 in. lb.

Torque (4)

85 to 100 in. lb.

Torque (2)

85 to 100 in. lb.

Torque (2)

6

8

Not Shown

9

Bore

11 12

2

4

5

10

10

115 to 130 in. lb.

Torque (4)

15 to 18 in. lb.

Torque (4)

3

3

7

3

Bore

Hand Tight

Torque

Hand Tight

Torque

4 to 6 in. lb.

Torque (2)

115 to 130 in. lb.

Torque (4)

115 to 130 in. lb.

Torque (4)

85 to 100 in. lb.

Torque (2)

85 to 100 in. lb.

Torque (2)

6

8

Not Shown

9

Bore

Training & Maintenance Manual

Components

Replacement Components

Item Kit Number Description Item Kit Number Description

1 6505953

2 3534400 Quick Exhaust Kit - High Pressure 9 3087800 PNP 24 VDC Sensor Kit

3 3538600 High Flow Quick Exhaust Kit 10 See page 10

4 PRTF10

5 WHQE49

6 3059500 Flow Control Kit 13

7 3059900 Check Valve Kit — — —

DP/DH Weld Block Sleeve Kit (1 pc.) (Not Shown)

Air Operated Timer for High Flow Quick Exh.

Sol. Oper. Kit for High Flow Quick Exh. 24VDC

8 3087900 Sensor Valve Kit

ISO 2 Replacement Valve for WP/WH Weld Blocks

11 PS2828A49P 24 VAC 30mm Coil Kit

12 PS2828619P 24 VDC M12 Euro Coil Kit

Contact Parker

Lightly grease with provided lubricant.

Lightly grease with provided lubricant.

Inspect for nicks, scratches, and surface imperfections.

Inspect for nicks, scratches, and surface imperfections.

If present, reduced service life is probable and future

If present, reduced service life is probable and future

replacement should be planned.

replacement should be planned.

Clean with lint-free cloth.

Clean with lint-free cloth.

B6 Replacement Valve for DP/DH Weld Blocks

ISO 2 Weld Block - Exploded View

14

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

WCS-SIF-01

Pneumati

c

100% ED

100% ED

0 1

0 1

139.8

(5.50)

125

(4.92)

7.3

(0.29)

258.7

(10.19)

136

(5.35)

9

(0.35)

50.7

(2.00)

127.3

(5.01)

102

(4.02)

28

(1.10)

44.8

(1.76)

28

(1.10)

58.8

(2.31)

11.5

(0.45)

81.5

(3.21)

29.5

(1.16)

15

(0.59)

33

(1.30)

0 1

0 1

100% ED

100% ED

113.6

(4.47)

258.7

(10.19)

50.7

(2.00)

58

(2.28)

83.2

(3.28)

85.5

(3.37)

42.7

(1.68)

12.5

(0.49)

11.5

(0.45)

21

(0.83)

B6 Series Dimensions

DH Series – 3 Ported Guns Dimensions

Training & Maintenance Manual

DP Series – 2 and 4 Ported Guns Dimensions

mm

(inches)

15

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

WCS-SIF-01

Pneumati

c

170.5

(6.71)

248.65

(9.79)

192.3

(7.57)

67

(2.64)36(1.42)

34.5

(1.36)

136

(5.35)

100.2

(3.94)

15

(0.59)

55

(2.17)

76

(2.99)

79.25

(3.12)

88

(3.46)

9

(0.35)

136

(5.35)

12.75

(0.50)

145

(5.71)

(R + IN)

Pr Pw

R+ W+

W-/R-

EXH

X I12

X I12

XI 14

10

PRESS

XI 14

10

PRESS

WH Series – For 3 Ported Gun Dimensions

WH ISO Size 2 Cylinder & Base Plate

Mountable

Training & Maintenance Manual

mm

(inches)

16

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

WCS-SIF-01

WH Series – For 3 Ported Gun Dimensions

WP ISO Size 2 Cylinder & Base Plate

Mountable

Training & Maintenance Manual

79.25

(3.12)

XI 14

10

PRESS

X I12

170.5

(6.71)

PRESS

10

X I12

XI 14

216.31

(8.52)

192.3

(7.57)

88

(3.46)

12.75

(0.50)

145

(5.71)

(0.35)

Pr Pw

55

(2.17)

(0.59)

R+ R-

15

32

(1.26)30(1.18)30(1.18)38(1.50)

34.5

(1.36)

W+W-

101.5

(4.00)

136

9

(5.35)

mm

(inches)

Pneumatic

17

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

WCS-SIF-01

Pneumati

c

X I12

X14

10

PRESS

58

(2.28)

109.5

(4.31)

31.5

(1.24)

16.1

(0.63)

63

(2.48)32(1.26)

88.8

(3.49)

46.5

(1.83)

146.7

(5.78)

80.7

(3.18)

187.5

(7.38)

208.7

(8.22)

X I12

X14

10

PRESS

W-/R-

88.8

(3.49)

113.5

(4.47)

46.5

(1.83)

146.7

(5.78)

80.7

(3.18)

187.5

(7.38)

208.7

(8.22)

16.1

(0.63)

63

(2.48)32(1.26)

58

(2.28)

31.5

(1.24)

WP Series – For 2 & 4 Ported Gun Dimensions

WH ISO Size 2 Manifold Mountable

Training & Maintenance Manual

WP ISO Size 2 Manifold Mountable

mm

(inches)

18

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

WCS-SIF-01

Pneumati

c

!

!

!

Maintenance, Troubleshooting & Warnings

Training & Maintenance Manual

Scheduled Maintenance

Silencer – Periodic maintenance of the exhaust mufflers may

be required. The frequency of maintenance depends on the

environment and condition of the air supply.

Cautions

• Filtrate the inlet air to protect the weld block against

contaminating matter typically found in compressed air

systems (i.e. rust, water, compressor oil, or other foreign

particles). A standard 40 micron filter is recommended.

If liquid aerosols, both water and oil, and submicron

particulate matter need to be removed from your air system,

then a coalescing filter is required.

• The inlet compressed air must be filtered, regulated, and

periodically maintained to ensure maximum operating

performance and warranty.

Weld Block Troubleshooting

Always verify that air and electrical are connected properly

per Installation Instructions on page 4. At startup, cylinder

should be open fully with no electrical signal to solenoids.

All air lines, filters, regulators, tubing, hoses, fittings and

electrical cables should be in good working condition as

specified in automotive plant maintenance schedule.

1. Cylinder does not extend / retract.

• Does the cylinder move using manual overrides?

– If yes, then check electrical conditions.

Check the following:

• Solenoid connections

• Coils – replace if necessary

• PLC program

–

If no, does the cylinder move freely with air turned off?

• If no, then cylinder should be repaired / replaced.

• If yes, is the flow control open?

– If no, open flow control. See Setup Instructions

on page 5.

– If yes, verify with gauges that there is pressure

on back side of cylinder when valve shifts. There

is a possibility that the metering of exhaust

air on the front side of the cylinder, due to the

flow control, is creating a “Joe Block” effect

occurring between the piston face and cylinder.

Contact Parker Representative for assistance.

– If yes, replace valves on System

2. Cylinder tips close too fast / slow.

• Adjust flow control. See Setup Instructions on page 5.

• Quick Exhaust only – Adjust air timer on quick exhaust.

• Check muffler for proper operation. If covered with

weld slag, then replace muffler.

3. Weld gun does not fire weld.

• Is cable connected to sensor?

– If no, connect to sensor

– If yes, is cable connected to PLC?

• If no, wire to controller

• If yes, check PLC program on location of weld

signal to start weld. Also verify feedback sensor

is operating properly.

4. Weld gun fires before tips are closed

• Adjust flow control so that weld tips close slower. See

Setup Instructions on page 5.

• Is sensor input in the PLC correct? See Setup

Instructions on page 5.

Warnings

WARNING

To avoid unpredictable system behavior that can cause personal

injury and property damage:

• Disconnect electrical supply (when necessary) before installation,

servicing, or conversion.

• Disconnect air supply and depressurize all air lines connected

to this product before installation, servicing, or conversion.

• O pe ra te within the m anufacturer’s sp ecified pre ss ur e,

temperature, and other conditions listed in these instructions.

• Medium must be moisture-free if ambient temperature is below

freezing.

• Service according to procedures listed in these instructions.

• Installation, service, and conversion of these products must be

performed by knowledgeable personnel who understand how

pneumatic products are to be applied.

After installation, servicing, or conversion, air and electrical

•

supplies (when necessary) should be connected and the product

tested for proper function and leakage. If audible leakage is present,

or the product does not operate properly, do not put into use.

• Warnings and specifications on the product should not be

covered by paint, etc. If masking is not possible, contact your

local representative for replacement labels.

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF

THE PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR

RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND

PROPERTY DAMAGE.

This doc ument an d other informat ion from Pa rke r Hannif in

Corporation, its subsidiaries and authorized distributors provide

product and/or system options for further investigation by users having

technical expertise. It is important that you analyze all aspects of your

application, including consequences of any failure and review the

information concerning the product or systems in the current product

catalog. Due to the variety of operating conditions and applications

for these products or systems, the user, through its own analysis

and testing, is solely responsible for making the final selection of the

products and systems and assuring that all performance, safety and

warning requirements of the application are met.

The products described herein, including without limitation, product

features, specifications, designs, availability and pricing, are subject

to change by Parker Hannifin Corporation and its subsidiaries at any

time without notice.

EXTRA COPIES OF THESE INSTRUCTIONS ARE AVAILABLE FOR

INCLUSION IN EQUIPMENT / MAINTENANCE MANUALS THAT UTILIZE

THESE PRODUCTS. CONTACT YOUR LOCAL REPRESENTATIVE.

19

WARNING

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

WCS-SIF-01

Pneumati

c

Training & Maintenance Manual

Offer of Sale

The items described in this document and other documents or descriptions provided by Parker Hannifin Corporation, its subsidiaries and its authorized

distributors, are hereby offered for sale at prices to be established by Parker Hannifin Corporation, its subsidiaries and its authorized distributors. This

offer and its acceptance by any customer (“Buyer”) shall be governed by all of the following Terms and Conditions. Buyer’s order for any such item, when

communicated to Parker Hannifin Corporation, its subsidiaries or an authorized distributor (“Seller”) verbally or in writing, shall constitute acceptance

of this offer.

1. Terms and Conditions of Sale: All descriptions, quotations, proposals, offers,

acknowledgments, acceptances and sales of Seller’s products are subject to and

shall be governed exclusively by the terms and conditions stated herein. Buyer’s

acceptance of any offer to sell is limited to these terms and conditions. Any terms

or conditions in addition to, or inconsistent with those stated herein, proposed by

Buyer in any acceptance of an offer by Seller, are hereby objected to. No such

additional, different or inconsistent terms and conditions shall become part of the

contract between Buyer and Seller unless expressly accepted in writing by Seller.

Seller’s acceptance of any offer to purchase by Buyer is expressly conditional upon

Buyer’s assent to all the terms and conditions stated herein, including any terms

in addition to, or inconsistent with those contained in Buyer’s offer. Acceptance

of Seller’s products shall in all events constitute such assent.

2. Payment: Payment shall be made by Buyer net 30 days from the date of

delivery of the items purchased hereunder. Amounts not timely paid shall bear

interest at the maximum rate permitted by law for each month or portion thereof

that the Buyer is late in making payment. Any claims by Buyer for omissions or

shortages in a shipment shall be waived unless Seller receives notice thereof

within 30 days after Buyer’s receipt of the shipment.

3. Delivery: Unless otherwise provided on the face hereof, delivery shall be made

F.O.B. Seller’s plant. Regardless of the method of delivery, however, risk of loss

shall pass to Buyer upon Seller’s delivery to a carrier. Any delivery dates shown are

approximate only and Seller shall have no liability for any delays in delivery.

4.

Warranty: Seller warrants that the items sold hereunder shall be free from

defects in material or workmanship for a period of 18 months from date of shipment

from Parker Hannifin Corporation. THIS WARRANTY COMPRISES THE SOLE

AND ENTIRE WARRANTY PERTAINING TO ITEMS PROVIDED HEREUNDER.

SELLER MAKES NO OTHER WARRANTY, GUARANTEE, OR REPRESENTATION

OF ANY KIND WHATSOEVER. ALL OTHER WARRANTIES, INCLUDING BUT NOT

LIMITED TO, MERCHANTABILITY AND FITNESS FOR PURPOSE, WHETHER

EXPRESS, IMPLIED, OR ARISING BY OPERATION OF LAW, TRADE USAGE,

OR COURSE OF DEALING ARE HEREBY DISCLAIMED.

NOTWITHSTANDING THE FOREGOING, THERE ARE NO WARRANTIES

WHATSOEVER ON ITEMS BUILT OR ACQUIRED WHOLLY OR PARTIALLY,

TO BUYER’S DESIGN OR SPECIFICATIONS.

5. Limitation of Remedy: SELLER’S LIABILITY ARISING FROM OR IN ANY

WAY CONNECTED WITH THE ITEMS SOLD OR THIS CONTRACT SHALL

BE LIMITED EXCLUSIVELY TO REPAIR OR REPLACEMENT OF THE ITEMS

SOLD OR REFUND OF THE PURCHASE PRICE PAID BY BUYER, AT

SELLER’S SOLE OPTION. IN NO EVENT SHALL SELLER BE LIABLE FOR ANY

INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES OF ANY KIND OR

NATURE WHATSOEVER, INCLUDING BUT NOT LIMITED TO LOST PROFITS

ARISING FROM OR IN ANY WAY CONNECTED WITH THIS AGREEMENT

OR ITEMS SOLD HEREUNDER, WHETHER ALLEGED TO ARISE FROM

BREACH OF CONTRACT, EXPRESS OR IMPLIED WARRANTY, OR IN TORT,

INCLUDING WITHOUT LIMITATION, NEGLIGENCE, FAILURE TO WARN OR

STRICT LIABILITY.

6. Changes, Reschedules and Cancellations: Buyer may request to modify the

designs or specifications for the items sold hereunder as well as the quantities

and delivery dates thereof, or may request to cancel all or part of this order,

however, no such requested modification or cancellation shall become part of

the contract between Buyer and Seller unless accepted by Seller in a written

amendment to this Agreement. Acceptance of any such requested modification

or cancellation shall be at Seller’s discretion, and shall be upon such terms and

conditions as Seller may require.

7. Special Tooling: A tooling charge may be imposed for any special tooling,

including without limitations, dies, fixtures, molds and patterns, acquired to

manufacture items sold pursuant to this contract. Such special tooling shall be

and remain Seller’s property notwithstanding payment of any charges by Buyer.

In no event will Buyer acquire any interest in apparatus belonging to Seller which

is utilized in the manufacture of the items sold hereunder, even if such apparatus

has been specially converted or adapted for such manufacture and notwithstanding

any charges paid by Buyer. Unless otherwise agreed, Seller shall have the right

to alter, discard or otherwise dispose of any special tooling or other property in

its sole discretion at any time.

8. Buyer’s Property: Any designs, tools, patterns, materials, drawings, confidential

information or equipment furnished by Buyer, or any other items which become

Buyer’s property, may be considered obsolete and may be destroyed by Seller

after two (2) consecutive years have elapsed without Buyer placing an order

for the items which are manufactured using such property. Seller shall not

be responsible for any loss or damage to such property while it is in Seller’s

possession or control.

9. Taxes: Unless otherwise indicated on the face hereof, all prices and charges

are exclusive of excise, sales, use, property, occupational or like taxes which

may be imposed by any taxing authority upon the manufacture, sale or delivery

of the items sold hereunder. If any such taxes must be paid by Seller or if Seller

is liable for the collection of such tax, the amount thereof shall be in addition to

the amounts for the items sold. Buyer agrees to pay all such taxes or to reimburse

Seller therefore upon receipt of its invoice. If Buyer claims exemption from any

sales, use or other tax imposed by any taxing authority, Buyer shall save Seller

harmless from and against any such tax, together with any interest or penalties

thereon which may be assessed if the items are held to be taxable.

10. Indemnity For Infringement of Intellectual Property Rights: Seller shall

have no liability for infringement of any patents, trademarks, copyrights, trade

dress, trade secrets or similar rights except as provided in this Part 10. Seller

will defend and indemnify Buyer against allegations of infringement of U.S.

patents, U.S. trademarks, copyrights, trade dress and trade secrets (hereinafter

“Intellectual Property Rights”). Seller will defend at its expense and will pay the

cost of any settlement or damages awarded in an action brought against Buyer

based on an allegation that an item sold pursuant to this contract infringes the

Intellectual Property Rights of a third party. Seller’s obligation to defend and

indemnify Buyer is contingent on Buyer notifying Seller within ten (10) days after

Buyer becomes aware of such allegations of infringement, and Seller having sole

control over the defense of any allegations or actions including all negotiations

for settlement or compromise. If an item sold hereunder is subject to a claim

that it infringes the Intellectual Property Rights of a third party, Seller may, at

its sole expense and option, procure for Buyer the right to continue using said

item, replace or modify said item so as to make it noninfringing, or offer to accept

return of said item and return the purchase price less a reasonable allowance

for depreciation. Notwithstanding the foregoing, Seller shall have no liability for

claims of infringement based on information provided by Buyer, or directed to

items delivered hereunder for which the designs are specified in whole or part

by Buyer, or infringements resulting from the modification, combination or use

in a system of any item sold hereunder. The foregoing provisions of this Part 10

shall constitute Seller’s sole and exclusive liability and Buyer’s sole and exclusive

remedy for infringement of Intellectual Property Rights.

If a claim is based on information provided by Buyer or if the design for an item

delivered hereunder is specified in whole or in part by Buyer, Buyer shall defend

and indemnify Seller for all costs, expenses or judgements resulting from any

claim that such item infringes any patent, trademark, copyright, trade dress, trade

secret or any similar right.

11. Force Majeure: Seller does not assume the risk of and shall not be liable for

delay or failure to perform any of Seller’s obligations by reason of circumstances

beyond the reasonable control of Seller (hereinafter “Events of Force Majeure”).

Events of Force Majeure shall include without limitation, accidents, acts of God,

strikes or labor disputes, acts, laws, rules or regulations of any government or

government agency, fires, floods, delays or failures in delivery of carriers or

suppliers, shortages of materials and any other cause beyond Seller’s control.

12. Entire Agreement/Governing Law: The terms and conditions set forth

herein, together with any amendments, modifications and any different terms

or conditions expressly accepted by Seller in writing, shall constitute the entire

Agreement concerning the items sold, and there are no oral or other representations

or agreements which pertain thereto. This Agreement shall be governed in all

respects by the law of the State of Ohio. No actions arising out of sale of the

items sold hereunder or this Agreement may be brought by either party more

than two (2) years after the cause of action accrues.

Parker Hannifin Corporation

Pneumatic Division

8676 E. M89

P.O. Box 901

Richland, MI 49083 USA

Tel: (269) 629-5000

Fax: (269) 629-5385

WCS-SIF-01 11/06 5M IGS Printed in U.S.A.

20

Customer/Technical Service

Tel: (269) 629-5575

Fax: (269) 629-5385

Web site: www.parker.com/pneumatics

E-mail: PDNMKTG@parker.com

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

Loading...

Loading...