Parker Products OIL-X EVOLUTION User Manual

OIL-X EVOLUTION

The most energy efficient

compressed air filters

in the world

www.domnickhunter.com

COMPRESSED AIR - THE 4TH UTILITY

COMPRESSED AIR IS A SAFE AND RELIABLE POWER SOURCE THAT IS WIDELY USED THROUGHOUT INDUSTRY.

APPROXIMATELY 90% OF ALL COMPANIES USE COMPRESSED AIR IN SOME ASPECT OF THEIR OPERATIONS,

OWEVER UNLIKE GAS, WATER AND ELECTRICITY, COMPRESSED AIR IS GENERATED ON-SITE, GIVING THE USER

H

RESPONSIBILITY FOR AIR QUALITY AND OPERATIONAL COSTS.

COMPRESSED AIR IS NOT WITHOUT IT’S PROBLEMS, WITH ALL SYSTEMS SUFFERING FROM PERFORMANCE

ND RELIABILITY ISSUES. ALMOST ALL OF THESE CAN BE DIRECTLY ATTRIBUTED TO CONTAMINATION, THE

A

MAIN SOURCES OF WHICH ARE :

• THE AMBIENT AIR BEING DRAWN INTO THE COMPRESSOR

• THE TYPE AND OPERATION OF THE AIR COMPRESSOR

• COMPRESSED AIR STORAGE VESSELS

• DISTRIBUTION PIPEWORK

There are 10 major contaminants found in a compressed air system, these are:

• Water Vapour

• Condensed Water

• Water Aerosols

• Atmospheric Dirt

• Rust

• Pipescale

The largest quantity of contamination introduced into the

compressed air system originates from the atmospheric air

drawn into the compressor and not as often believed,

introduced by the compressor itself. The most prolific and

problematic of the contaminants is water which accounts

for 99.9% of the total liquid contamination found in a

compressed air system.

• Liquid Oil

• Micro-organisms

• Oil Aerosols

• Oil Vapour

High efficiency compressed air filtration is not only used

to remove particulate and oil, but more importantly it

removes water aerosols and is key to operating an efficient

and cost effective compressed air system.

Regardless of what type of compressor is installed,

the same level of filtration is required.

Contaminant removal

Failure to remove this contamination can cause numerous

oblems in the compressed air system, such as:

pr

osion within storage vessels and the

Corr

•

distribution system

• Blocked or frozen valves, cylinders, air motors

and tools

• Damaged production equipment

• Premature unplanned desiccant changes

for adsorption dryers

w highlights each of the purification technologies required to remove the different contaminants present

able bel

The t

in the compressed air system.

Purification Equipment Technologies

1

o

Bulk Condensed

Water

Water Separator ✓✗ ✗✗ ✗ ✗ ✗ ✗

Coalescing Filter ✗✗ ✓✓✓ ✗ ✓✓

Adsorption Filter ✗✗ ✗✗✗ ✓ ✗✗

Adsorption Dryer ✗✓ ✗✗✗ ✗ ✗ ✗

Refrigeration Dryer ✗✓ ✗✗ ✗ ✗ ✗ ✗

val Filter

emo

Dust R

obiological Filter

Micr

✗

✗

Water Vapour Water Aerosols

✗

✗

In addition t

air sys

particulat

o problems associated with the compressed

ontamination such as water,

wing c

em itself, all

t

e, oil and micr

o

o-organisms to exhaust from valves,

cylinders, air motors and tools, can lead to an unhealthy

working environment with the potential for personal injury,

staff absences and financial compensation claims.

Compressed air contamination will ultimately lead to:

Inefficient pr

•

oduction proc

esses

• Spoiled, damaged or reworked products

• Reduced production efficiency

• Increase manufacturing costs

CONTAMINANTS

Atmospheric Dirt

& Solid Particulate

✗✓ ✓ ✗ ✗ ✓

✗

✓

Micro-organisms Oil Vapour

✓✗ ✗✗

Liquid Oil & Oil

Aerosols

Rust &

Pipescale

ARE ALL COMPRESSED AIR FILTERS THE SAME?

COMPRESSED AIR PURIFICATION EQUIPMENT IS ESSENTIAL TO ALL MODERN PRODUCTION FACILITIES.

IT MUST DELIVER UNCOMPROMISING PERFORMANCE AND RELIABILITY WHILST PROVIDING THE RIGHT

ALANCE OF AIR QUALITY WITH THE LOWEST COST OF OPERATION. TODAY, MANY MANUFACTURERS

B

OFFER PRODUCTS FOR THE FILTRATION AND PURIFICATION OF CONTAMINATED COMPRESSED AIR,

HICH ARE OFTEN SELECTED ONLY UPON THEIR INITIAL PURCHASE COST, WITH LITTLE OR NO REGARD

W

FOR THE AIR QUALITY THEY PROVIDE OR THE COST OF OPERATION THROUGHOUT THEIR LIFE. WHEN

PURCHASING PURIFICATION EQUIPMENT, THE DELIVERED AIR QUALITY, COST OF OPERATION AND THE

OVERALL COST OF OWNERSHIP MUST ALWAYS BE CONSIDERED.

THE DOMNICK HUNTER DESIGN PHILOSOPHY

ALL DOMNICK HUNTER FILTRATION AND PURIFICATION PRODUCTS

ARE DESIGNED WITH THE PHILOSOPHY OF AIR QUALITY, ENERGY

EFFICIENCY AND LOW LIFETIME COSTS.

Air quality

Compressed air purification

equipment is installed to deliver high

quality, clean dry air, and to eliminate

the problems and costs associated

with contamination. When selecting

this type of equipment, the delivered

air quality and the verification of

performance must always be the

primary driver, otherwise why install

it in the first place.

Energy efficiency

After air quality, the next

ation when sel

onsider

c

ompressed air filter is the cost of

c

operation. OIL-X EVOLUTION filters

not only provide air quality in

accordance with the international

ds, they are designed to do

andar

t

s

so with the l

owest operational

costs available.

ecting a

• OIL-X EVOLUTION filters provide

air quality in accordance with

ISO 8573.1:2001, the international

standard for compressed air quality

• OIL-X EVOLUTION coalescing filters are

the first range of filters specifically

designed to deliver air quality in

accordance with ISO 8573.1 : 2001 when

tested with the stringent requirements

of the new ISO 12500-1 international

standard for Compressed Air Filter

Testing

• OIL-X EVOLUTION dust removal filters

and adsorption filters are also tested in

accordance with the test methods of the

ISO 8573 series

OIL-X EV

•

l

osses to a minimum

Deep pleat el

•

OLUTION filt

ement technology and specially treated filtration media

ers use aerospace technology to keep pressure

• OIL-X EVOLUTION filter

performance has been

independently verified by Lloyds

Register

• OIL-X EVOLUTION coalescing and

dust removal filters are covered by

a one year compressed air quality

guarantee

• The air quality guarantee

is automatically renewed with

annual maintenance

provides a low pressure loss filter element with 450% more filtration

surface area when compared to a conventional wrapped filter, and 200%

greater area than typical pleated filter elements

• Overall pressure losses start low and stay low throughout the

12 month life of the filter element

• Can help to significantly reduce your carbon footprint

e based upon :

e Manuf

ernativ

Alt

Initial Saturated Differential

essure (mbar)

Pr

200 4,973 2,139

250 6,259 2,691

300 9,619 4,136

atur

UTION

er

Annual Savings with OIL-X EV

OLUTION

EV

gy Saving Kw

Ener

OL

EVOLUTION

Environmental Saving Kg/CO

Exampl

System Pressure : 7 bar g

Compressor Size : 120 Kw

ation of Oper

Dur

2

OIL-X EVOLUTION Grade AA Coalescing Filter

0.01 micron (0.01mg/m

ernativ

Alt

0.01 micron (0.01mg/m

e Manuf

ation : 8000 Hr

3

)

er's Coal

actur

3

)

s

escing Filt

er

350 12,979 5,581

400

450

500

16,339

19,699

23,059 9,915

7,026

8,470

Low lifetime costs

Equipment with a low purchase price may turn out to be a more costly investment in the long term. By guaranteeing

UTION filters can

air quality and ensuring ener

t of ownership and help improve your bottom line through improved manufacturing efficiencies.

os

al c

ot

e the t

educ

r

onsumption is k

gy c

o a minimum, domnick hunt

ept t

er OIL-X EV

OL

2

AIR QUALITY

THE DOMNICK HUNTER OIL-X EVOLUTION RANGE OF COMPRESSED AIR FILTERS HAS BEEN DESIGNED FROM THE

OUTSET TO MEET THE REQUIREMENTS OF ISO 8573.1 : 2001, THE INTERNATIONAL STANDARD FOR COMPRESSED

IR QUALITY, WHEN VALIDATED IN ACCORDANCE WITH THE REQUIREMENTS OF ISO 12500, THE INTERNATIONAL

A

STANDARD FOR FILTER TESTING AND THE TEST METHODS OF ISO 8573.2, ISO 8573.4 AND ISO 8573.5.

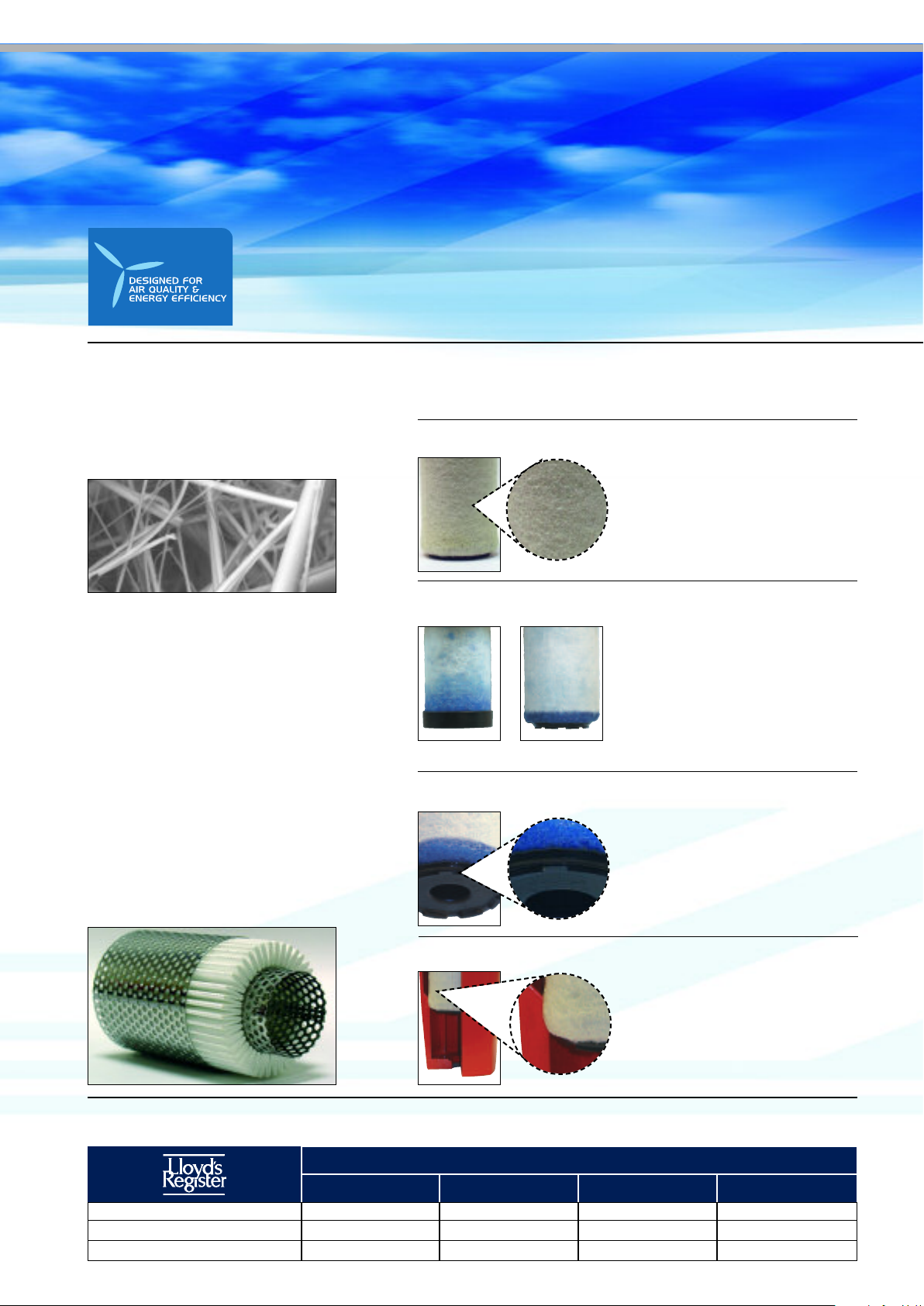

Correct selection of filtration media

oalescing and dust removal filters use a high

C

efficiency borosilicate glass nanofibre material

which has a 96% voids volume, providing

media with excellent filtration efficiency and

a high dirt holding capacity.

Construction of the filtration media

into a filter element

OIL-X EVOLUTION filter elements use

pleated not wrapped filter media, which

is constructed using a unique deep bed

pleating technique. This provides 450% more

filtration surface area when compared to

a traditional wrapped filter element and

around 200% more surface area compared

to a traditional pleated element.

Deep bed pleating also reduces the air flow

velocity within the media, which further

o

impr

Additionally, the high efficiency AA and AAR

ade el

gr

density media construction which provides

en gr

v

e

adding to pressure loss or energy

consumption.

es filtr

v

ements hav

er filtr

eat

ation perf

e a unique gr

ation perf

ormanc

ormanc

e.

aded

e without

OIL-X EVOLUTION coalescing filters utilise four drainage methods

to ensure high performance, whilst conventional filters only use one.

Drainage method 1

ainage method 2

Dr

Typical element

Wet band in air

ow path

fl

OIL-X EVOLUTION

No wet band in air

ow path

fl

Drainage method 3

High efficiency drainage layer provides

increased liquid drainage, improved

chemical compatibility and higher

operational temperatures when compared

to conventional materials.

Traditional elements have a build up of liquid

known as a “wet band” where the drainage

layer is glued into the lower endcap.

The OIL-X EVOLUTION design wraps the

drainage layer under lower endcap removing

coalesced liquid from the air flow path,

increasing liquid removal efficiency, and

providing more usable filtration surface area.

Surface tension breakers are moulded into

the lower filter element endcap to prevent

liquid from sticking, and to ensure fast and

efficient dr

ainage of coalesced liquid.

AIR QUALITY - GUARANTEED

ormance of OIL

ation perf

Filtr

escing filt

Coal

articulat

Dry P

apour Remo

3

Oil V

ers

e filt

al filt

v

ainage ribs c

Drainage method 4

e not only tried and tested by domnick hunter, but has also been independently validated by Lloyds Register.

s ar

ilter

OLUTION f

-X EV

e Validation in Accordance with:

ormanc

Independent P

ISO 12500.1

OIL AEROSOL

✓

s

er

sX X X

er

XX

erf

ISO 8573.2

OIL AEROSOL

✓

Dr

compress the lower part of the filter

ement, all

el

from the filter element through capillary

action.

ISO 8573.4

SOLID PARTICULATE

o

✓

✓ X

t into the filter bowl

as

wing bulk liquid t

ISO 8573.5

OIL VAPOUR

o r

X

✓

apidl

y dr

ain

Loading...

Loading...