Parker Products OEM350, OEM650X, OEM650, OEM350X User Manual

OEM650/OEM650X

OEM

OEM350/OEM350X

Drive and Drive/Indexer

User Guide

r

to

o

m

u

p

m

o

C

OEM

s

e

r

i

e

s

R

I

D

V

E

E

V

D

I

R

R

I

D

V

E

E

V

I

D

R

TE

O

F

M

E

E

R

R

T

POWER

N

E

R

P

FAULT

R

M

U

U

C

+

D

C

D

-

V

C

D

V

+

A

-

A

+

B

-

B

Compumotor Division

Parker Hannifin Corporation

Compumotor

p/n 88-013157-02 A

OEM650/OEM650X • OVERVIEW

For assistance in the United States, contact:

For assistance in Europe, contact:

Important User Information

Installation & Operation of Compumotor Equipment

It is important that Compumotor motion control equipment is installed and operated in such a

way that all applicable safety requirements are met. It is your responsibility as a user to ensure

that you identify the relevant standards and comply with them. Failure to do so may result in

damage to equipment and personal injury. In particular, you should review the contents of the

user guide carefully before installing or operating the equipment.

Under no circumstances will the suppliers of the equipment be liable for any incidental,

consequential, or special damages of any kind whatsoever, including but not limited to lost

profits arising from or in any way associated with the use of the equipment or this user guide.

Safety Warning

High-performance motion control equipment is capable of producing rapid movement and very

high forces. Unexpected motion may occur especially during the development of controller

programs. KEEP CLEAR of any machinery driven by stepper or servo motors and never touch

them while they are in operation.

High voltages exist with in enclosed units, on rack system backplanes, and on transformer

terminals. KEEP CLEAR of these areas when power is applied to the equipment.

Parker Compumotor constantly strives to improve all of its products. We reserve the right to

modify equipment and user guides without prior notice. No part of this user guide may be

reproduced in any form without prior consent from Parker Compumotor.

For assistance in the United States, contact:

For assistance in the United States, contact:

Compumotor Division of Parker Hannifin

Compumotor Division of Parker Hannifin

5500 Business Park Drive

5500 Business Park Drive

Rohnert Park, CA 94928

Rohnert Park, CA 94928

Telephone: (800) 358-9070

Telephone: (800) 358-9070

Fax: (707) 584-8015

Fax: (707) 584-8015

Compumotor

For assistance in Europe, contact:

For assistance in Europe, contact:

Parker Digiplan

Parker Digiplan

21 Balena Close

21 Balena Close

Poole, Dorset

Poole, Dorset

England BH17 7DX

England BH17 7DX

Telephone: 0202-690911

Telephone: 0202-690911

Fax: (707) 584-8015

Fax: (707) 584-8015)

© Compumotor Division of Parker Hannifin 1993 All rights reserved

88-013157-02A

i

OVERVIEW • OEM650/OEM650X

Contents

How To Use This User Guide .................................................................................. iv

Assumptions ........................................................................................................ iv

User Guide Contents ........................................................................................... iv

Installation Process Overview.............................................................................. iv

Installation Preparation ......................................................................................... v

Software Reference Manual ................................................................................. v

Warnings & Cautions ............................................................................................ v

1 Introduction 1

Chapter Objective .....................................................................................................1

OEM650 Description.................................................................................................1

OEM650X Description .............................................................................................. 1

OEM350/350X Description ....................................................................................... 1

Features....................................................................................................................2

2 Installation 3

Chapter Objectives ................................................................................................... 3

OEM650/OEM650X Ship kit ..................................................................................... 3

Quick Test (OEM650/OEM650X)..............................................................................4

Quick Test: OEM650 with Separate Indexer......................................................10

Quick Test: OEM650X .......................................................................................11

OEM650/OEM650X Mounting ................................................................................ 13

Panel Layout ....................................................................................................... 14

Jumper Functions ................................................................................................... 19

Jumper #1: Motor Current Range .....................................................................19

Jumpers #2 - #5: Motor Resolution...................................................................19

Jumpers #6 - #8: Motor Waveform Shape ........................................................ 20

Jumpers #9 - #10: Auto Standby ...................................................................... 20

Jumper #11: Auto Test......................................................................................21

Motor Mounting ....................................................................................................... 22

Attaching the Load .............................................................................................. 22

Couplings ............................................................................................................ 23

OEM650 Inputs and Outputs .................................................................................. 24

Step Input Signal Specification ...........................................................................24

Direction Input Signal Specification ................................................................... 24

OEM650X Inputs and Outputs ................................................................................ 26

Step (Signal 1) & Direction (Signal 2) Outputs...................................................26

CW (Signal 3) & CCW (Signal 4) Limit Inputs.....................................................27

Home Position Input (Signal 5) ...........................................................................27

Reserved (Signal 6) ............................................................................................27

Output #1 (Signal 10) and Output #2 (Signal 8)................................................27

Dedicated Fault Output (Signal 9).......................................................................27

Sequence Inputs #1 - #3 (Signals 11 - 13) ......................................................... 28

RS-232C—Tx (Signal 14), Rx (Signal 15), and Ground (Signal 7) ..................... 28

Shutdown Output (Signal 16)..............................................................................28

Closed Loop Operation ....................................................................................... 28

Trigger Inputs #1 - #3 (Signals 20 - 22) ..............................................................29

Address Signals #1 - #3 (Signals 23 - 25) .......................................................... 29

Sizing Power Supply ............................................................................................... 31

ii

OEM650/OEM650X • OVERVIEW

3 Tuning & Specifications 33

Chapter Objectives ............................................................................................. 33

Short-Circuit Protection...........................................................................................33

Resonance..............................................................................................................33

Mid-Range Instability .............................................................................................. 33

Tuning Procedures..............................................................................................33

Gauging Motor Resonance ................................................................................. 34

Tuning the Drive to the Motor ............................................................................. 35

Motor Waveforms................................................................................................35

Performance Specifications ....................................................................................36

Accuracy .............................................................................................................36

Repeatability .......................................................................................................36

Hysteresis ...........................................................................................................36

Rotor Inertia ........................................................................................................36

Motor Performance .............................................................................................36

4 Troubleshooting 41

Chapter Objectives ................................................................................................. 41

Drive Maintenance .................................................................................................. 41

Motor Maintenance .................................................................................................41

Problem Isolation ....................................................................................................41

Front Panel LEDs....................................................................................................42

Common Problems and Solutions ...................................................................... 42

Testing the Motor ................................................................................................ 45

RS-232C Problems ............................................................................................. 45

Software Debugging Tips....................................................................................46

Returning the System ......................................................................................... 46

Index 49

iii

OVERVIEW • OEM650/OEM650X

How To Use This User Guide

This user guide is designed to help you install, develop, and maintain

your system. Each chapter begins with a list of specific objectives

that should be met after you have read the chapter. This section will

help you find and use the information in this user guide.

Assumptions

To use this product and its instructions effectively, you should have

a fundamental understanding of the following information.

❏ Electronics concepts (voltage, switches, current, etc.)

❏ Motion control concepts (torque, velocity, distance, force, etc.)

User Guide Contents

Chapter 1: Introduction

This chapter provides a description of the product and a brief

account of its specific features.

Chapter 2: Installation

This chapter contains a ship kit list of items you should have

received with your OEM650 or OEM650X. Instructions to mount

and connect the system properly are included. Upon completion of

this chapter, your system should be completely installed and ready

to perform basic operations.

Chapter 3: Tuning & Specifications

This chapter contains information on system performance specifica-

tions (speed/torque curves, environmental specifications, etc.).

Tuning procedures that are designed to help you operate your

system at peak performance are also provided.

Chapter 4: Troubleshooting

This chapter contains information on identifying and resolving

system problems. Descriptions of LED signals, debugging tools,

problems/solutions table are included.

Installation Process Overview

To ensure trouble-free operation, pay special attention to the envi-

ronment in which the equipment will operate, the layout and mount-

ing, and the recommended wiring and grounding. These recommen-

dations will help you easily and safely integrate the OEM650/OEM-

650X into your manufacturing facility. If your environment contains

conditions that may adversely affect solid-state equipment (electrical

noise or atmospheric contamination), be sure to follow any special

instruction to ensure the safety and long life of your equipment.

iv

OEM650/OEM650X • OVERVIEW

Installation Preparation

Before you install this product, complete the following steps:

1. Review this user guide. Become familiar with the user guide’s

contents so that you can quickly find the information you need.

2. Develop a basic understanding of all system components, their

functions, and interrelationships.

3. Complete the basic system configuration and wiring instructions

(in a simulated environment, not a permanent installation) provided in Chapter 2, Installation.

4. Perform as many basic functions as you can with the preliminary

configuration. Try to simulate the task(s) that you expect to

perform when you permanently install your application (however,

do not attach a load at this time). This will give you a realistic

preview of what to expect from the complete configuration.

5. After you have tested the system’s functions and become familiar

with the system’s basic features, carefully read Chapter 2.

6. After you have read Chapter 2 and clearly understand what must

be done to properly install the system, begin the installation

process. Do not deviate from the instructions provided.

7. Before you customize your system, check all of the system functions and features to ensure that you have completed the installation process correctly.

The successful completion of these steps will prevent subsequent

performance problems and allow you to isolate and resolve potential

system difficulties before they affect your system’s operation.

Software Reference Manual

A separate Software Reference Manual contains descriptions for all

software commands applicable to the OEM650X and OEM350X.

Warnings & Cautions

Warning and caution notes alert you to problems that may occur if

you do not follow the instructions correctly. Situations that may

cause bodily injury are presented as warnings. Situations that may

cause system damage are presented as cautions.

WARNING

Do not touch the motor immediately after it has been in use for an extended period of

time. The motor may be hot.

v

OVERVIEW • OEM650/OEM650X

vi

OEM650/OEM650X • INTRODUCTION

1 Introduction

Chapter Objective

The information in this chapter will enable you to:

❐ Understand the product’s basic functions and features

OEM650 Description

The OEM650 Drive is intended to be a high-performance basic

engine around which the original equipment manufacturer (OEM)

designs his motion control system. Its single-power DC input makes

it a convenient and cost effective motion control module. The drive

offers a basic set of customer configurable features. These features

are designed to meet the needs of most customers. The OEM650 is

optimized to operate size 23 and 34 motors.

The OEM650 is a bipolar, recirculating, microstepping drive designed

to drive two-phase permanent magnet hybrid step motors. The drive

uses a custom ASIC, surface mount, and MOSFET technologies to

give high performance in a small package while providing short

circuit protection. The OEM650 is compatible with all Compumotor

indexers.

The mechanical design is a fully enclosed product that uses a

heatplate technique to provide a heat dissipation path. The user

must attach the OEM650 module to a suitable mounting surface.

OEM650X Description

The OEM650X Drive/Indexer is the same drive product as the

OEM650, but it includes an indexer (position controller). The

OEM650X is the same size as the OEM650 and it incorporates the

same design technologies (bipolar, recirculating, microstepping drive

designed to drive two-phase permanent magnet hybrid step motors,

custom ASIC, surface mount, and MOSFET technologies).

The indexer utilizes commands from Compumotor’s popular and

easy-to-use X Series Language. The indexer also provides additional

I/O control and communication

OEM350/350X Description

The OEM350/OEM350X is a low power version of the OEM650 drive.

It is designed for use with step motors that have lower current

ratings and higher inductance (10 mH to 80 mH) than Compumotor

1

INTRODUCTION • OEM650/OEM650X

step motors. Operation of the OEM350/OEM350X is identical to that

of the OEM650/OEM650X. For clarity, instructions in this manual

use only the name OEM650/OEM650X. Except where differences are

specifically noted (resistor values for motor current settings, for

example), OEM650 instructions also apply to the OEM350, and

OEM650X instructions also apply to the OEM350X.

Features

The OEM650 requires an external power supply. It uses 24VDC 75VDC for its power input. Compumotor’s motors are two-phase

hybrid motors (permanent magnet type). Four, six, or eight leaded

motors may be used with the internal phases connected for either

parallel or series operation. The motor’s inductance cannot drop

below 0.5 mH. For best performance, motor inductance should be

between 1 mH and 10 mH, but motors with inductance ratings as low

as 0.5 mH may be used. Use the OEM350/OEM350X with motors

whose inductance is in the 10 mH to 80 mH range. The OEM650/

OEM650X provides the following features:

❐ Microprocessor controlled microstepping provides smooth opera-

tion over a wide range of speeds

❐ Full short circuit protection for phase-to-phase and phase-to-

ground short circuits

❐ Motor regeneration protection

❐ Over-temperature protection

❐ Uses low-inductance motors for improved high-speed performance

(23, 34 frame size motors available with torques from 65 - 400 ozin)

❐ Three-state current control for reduced motor/drive heating

❐ LED status indicators: POWER and FAULT (latched)

❐ Optically coupled step, direction, and shutdown inputs are

compatible with all Compumotor indexers (25-pin D connector)

❐ A fault output to signal other equipment if a fault occurs

❐ 24VDC - 75VDC single power input

❐ 16 jumper selectable motor resolutions (200 - 50,800 steps/rev)

❐ 2 Mhz step input

❐ Waveform correction and phase offset for improved smoothness

❐ Built-in indexer (position controller)

❐ -M2 option allows users to store programmed sequences in

nonvolatile memory

❐ I/O for motion and basic machine coordination

2

OEM650/OEM650X • INSTALLATION

2 Installation

Chapter Objectives

The information in this chapter will enable you to:

❐ Verify that each component of your system has been delivered

safely and completely

❐ Become familiar with components and their interrelationships

❐ Ensure that each component functions properly by bench testing

❐ Mount unit within recommended thermal specifications

OEM650/OEM650X Ship kit

Inspect the OEM650 or OEM650X upon receipt for obvious damage

to its shipping container. Report any such damage to the shipping

company. Parker Compumotor cannot be held responsible for

damage incurred in shipment. You should receive either a drive

(OEM650) or drive/indexer (OEM650X). Compare your order with

the units shipped.

Part Part Number

OEM Microstepping Drive OEM650

OEM Microstepping Drive/Indexer OEM650X

Table 2-1. OEM650 Drive & OEM650X Drive/Indexer

The following options may be used with the OEM650X.

Option Description

-M2 Nonvolatile Memory (2k BBRAM)

Table 2-2. OEM650X Options

The following motor(s) may be used with the OEM650 and

OEM650X. Compare your order with the motors shipped.

Part Part Number

Size 23—1/2 Stack Stepping Motor OEM57-40-MO

Size 23—1 Stack Stepping Motor OEM57-51-MO

Size 23—2 Stack Stepping Motor OEM57-83-MO

Size 34—1 Stack Stepping Motor OEM83-62-MO

Size 34—2 Stack Stepping Motor OEM83-93-MO

Size 34—3 Stack Stepping Motor OEM83-135-MO

Table 2-3. OEM650 & OEM650X Motors

The standard OEM650 Series motor is single-shafted. Motors can be

purchased with a double-shaft option.

3

INSTALLATION • OEM650/OEM650X

Option Description

-DS23 Double Shaft Size 23 Motors

-DS34 Double Shaft Size 34 Motors

Table 2-4. Double Motor Shaft Option

The following accessories are available.

Accessories Part Number

OEM650/OEM650X User Guide 88-013157-02

OEM Series Software Ref. Guide 88-013785-01

Low Current Heatsink OEM-HS1

High Current Heatsink OEM-HS2

Table 2-5. OEM650/OEM650X Accessories

Evaluation kits

Evaluation kits include all items necessary to evaluate the OEM650

(OEM650-EK) and OEM650X (OEM650X-EK) in a simulated production environment. The kits are intended to be used to prototype a

machine or operation before production units are purchased. The

following items are included in an evaluation kit. Motors must be

ordered separately—they are not included in the kit. If a component

is missing, contact Compumotor's Customer Service Department.

Part Part Number

Drive or Drive/Indexer OEM650 or OEM650X

OEM650/OEM650X User Guide 88-013157-02

OEM Series Software Ref. Guide 88-013785-01

High Current Heatsink OEM-HS2

Ship kit Items:

❐ Resistors (for current selection—the following types are available)

• 21.0KΩ 1% Resistor 12-008319-01

• 5.76KΩ 1% Resistor 12-008265-01

• 15.8KΩ 1% Resistor 12-008307-01

• 2.05KΩ 1% Resistor 12-008222-01

• 12.7KΩ 1% Resistor 12-008298-01

• 0.00KΩ 5% Resistor 12-003645-01

• 9.53KΩ 1% Resistor 12-008286-01

• 4.87KΩ 1% Resistor 12-008258-01

• 1.27KΩ 1% Resistor 12-008202-01

❐ Screwdriver 58-013155-01

❐ 25-Pin D Mating Connector 43-001989-01

❐ X-Ware Support Disk (OEM650X-EK Only)

• 3 1/2" Disk 95-013066-01

• 5 1/4" Disk 95-013067-01

Table 2-6. OEM650 Series Evaluation kit Contents

Quick Test (OEM650/OEM650X)

Use the following steps to set the drive’s jumpers, wire the unit, and

test your system. You will need the following tools:

❐ Needle nose pliers or tweezers

❐ Flathead screw driver (1/10")

4

OEM650/OEM650X • INSTALLATION

WARNING

The drive and motor should be mounted to a heatsink. Drive mounting does not affect

the following tests, but if you operate the OEM650/OEM650X for extended periods

without proper mounting, it will damage the drive and/or motor. When you complete

the quick tests, remove power to the drive.

Perform installation and test procedures in a properly grounded

environment. Compumotor recommends the use of a grounding

strap.

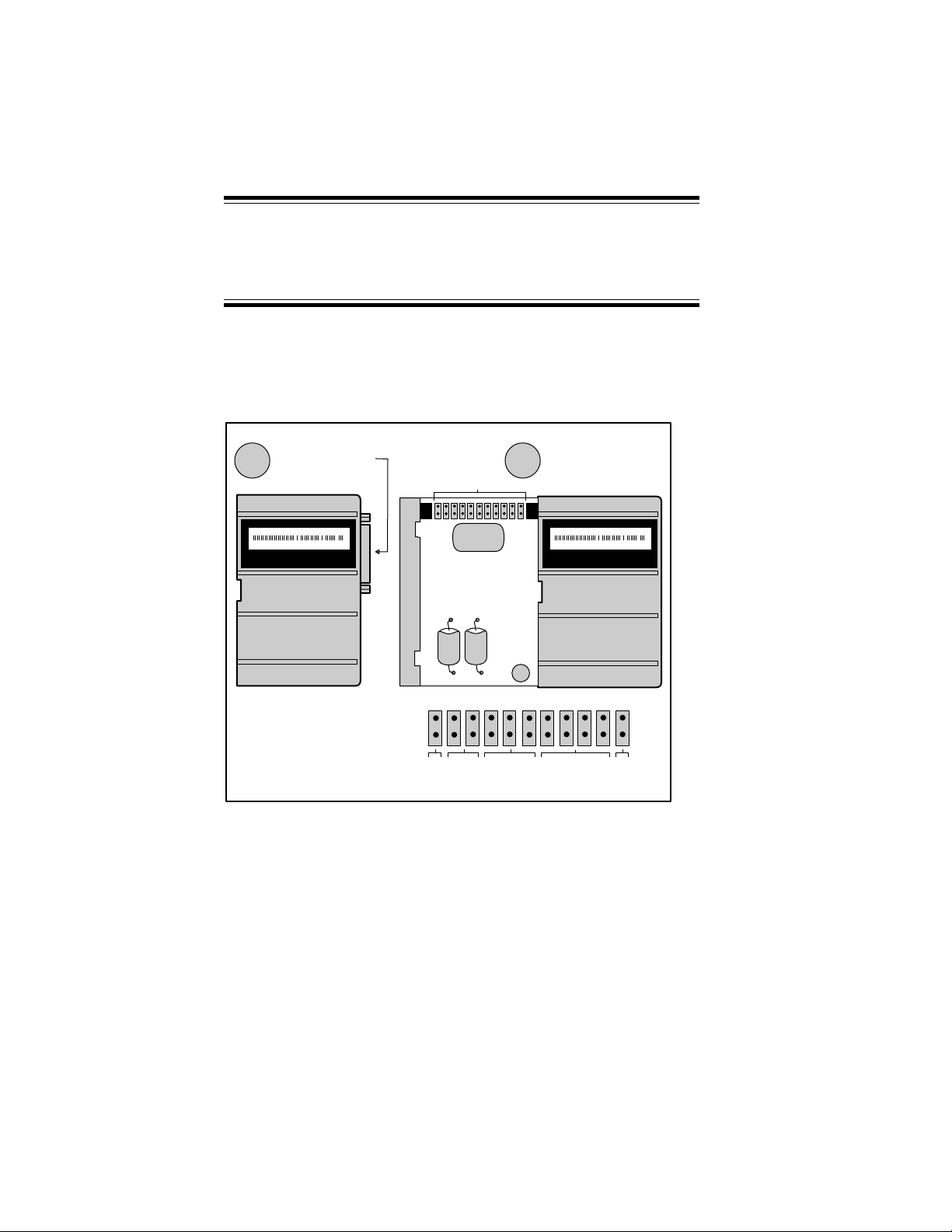

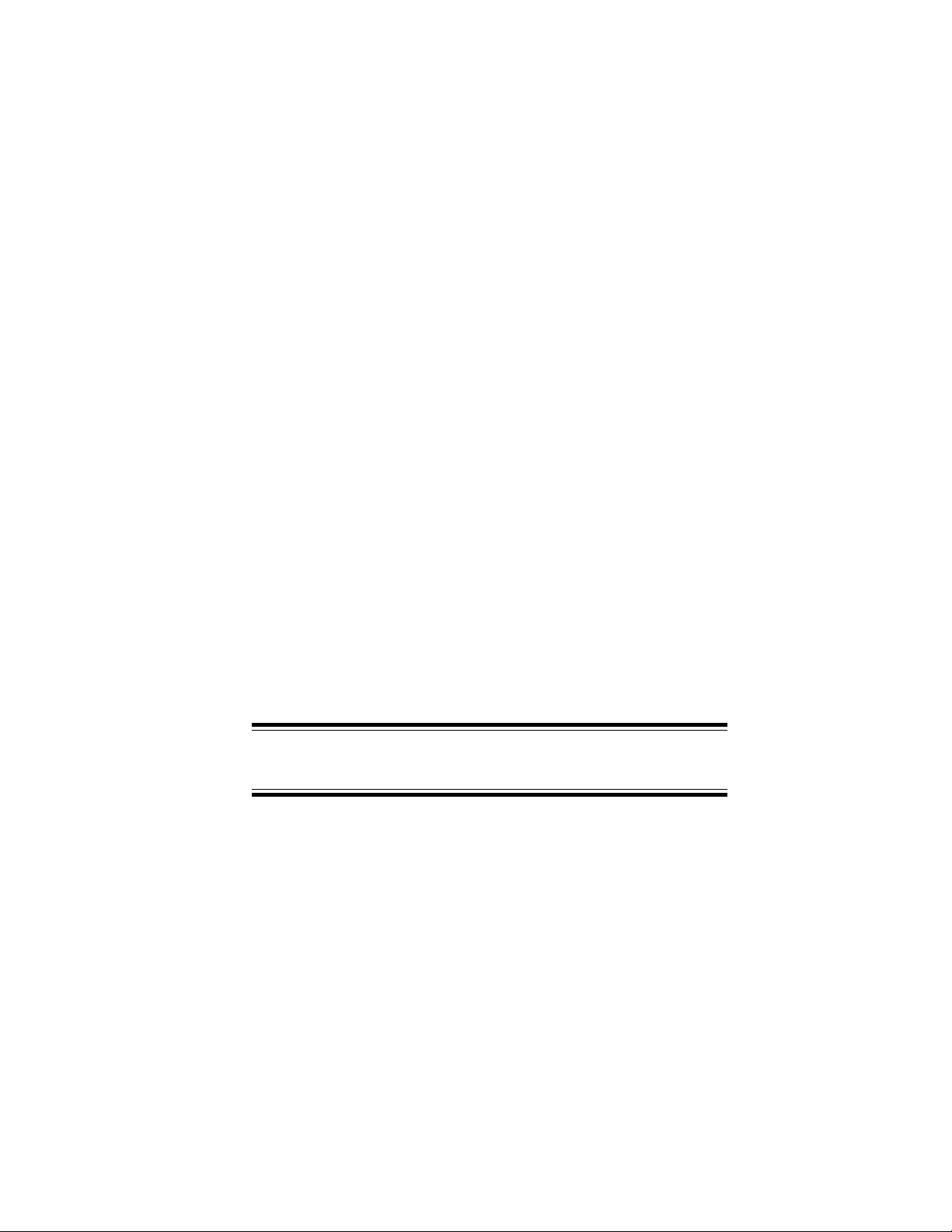

1. Remove the cover by applying pressure to the 25-pin D connector.

To remove cover,

push the 25-pin D

connector in while

A

holding the sides of

the unit.

Compumotor

Prod: Ø571Ø2-2-6-Ø17-Ø1Ø

5500 Business Park Dr.

Rohnert Park, CA 94928

Made In USA

Enlarged view of jumpers

Jumpers

1110987654321

Auto

Auto

Test

Standby

Motor

Waveform

Shape

B

When the cover is

removed, the

jumpers will be

visible at the upper

portion of the unit.

Compumotor

Prod: Ø571Ø2-2-6-Ø17-Ø1Ø

5500 Business Park Dr.

Rohnert Park, CA 94928

Resolution

Motor

Made In USA

Motor

Current

Range

Figure 2-1. OEM650/OEM650X Jumpers

2. To test the system, you will use the Automatic Test function,

jumper 11. Remove jumper 11 to enable the function (save for

later installation). Do not remove any other jumpers. When

power is applied to the drive with jumper 11 removed, the Automatic Test function will rotate the motor in an Alternating mode

approximately 6 revolutions at 1 rps.

5

INSTALLATION • OEM650/OEM650X

3. Slide the drive cover back on.

4. Attach the motor (to A+, A-, B+, B-). Do not connect the motor to

the load at this time (refer to Figure 2-2 for 23 size motors or

Figure 2-3 for 34 size motors). OEM size 23 motors may be wired

in a series or parallel configuration. If you are using a 75VDC

power supply (OEM300) with the drive or drive indexer, Compumotor recommends that you use a series configuration, however; a

parallel configuration should be used when the power supply is

24VDC - 48VDC. Parallel configurations will cause the drive to

dissipate slightly more heat than a serial configuration. This

increase in drive temperature will not affect the unit's performance,

but it may adversely affect heat-sensitive devices that are stored

within the same enclosure.

❐ Size 23 motors may be wired in series or parallel configurations

(OEM57-40-MO, OEM57-51-MO, OEM57-83-MO)

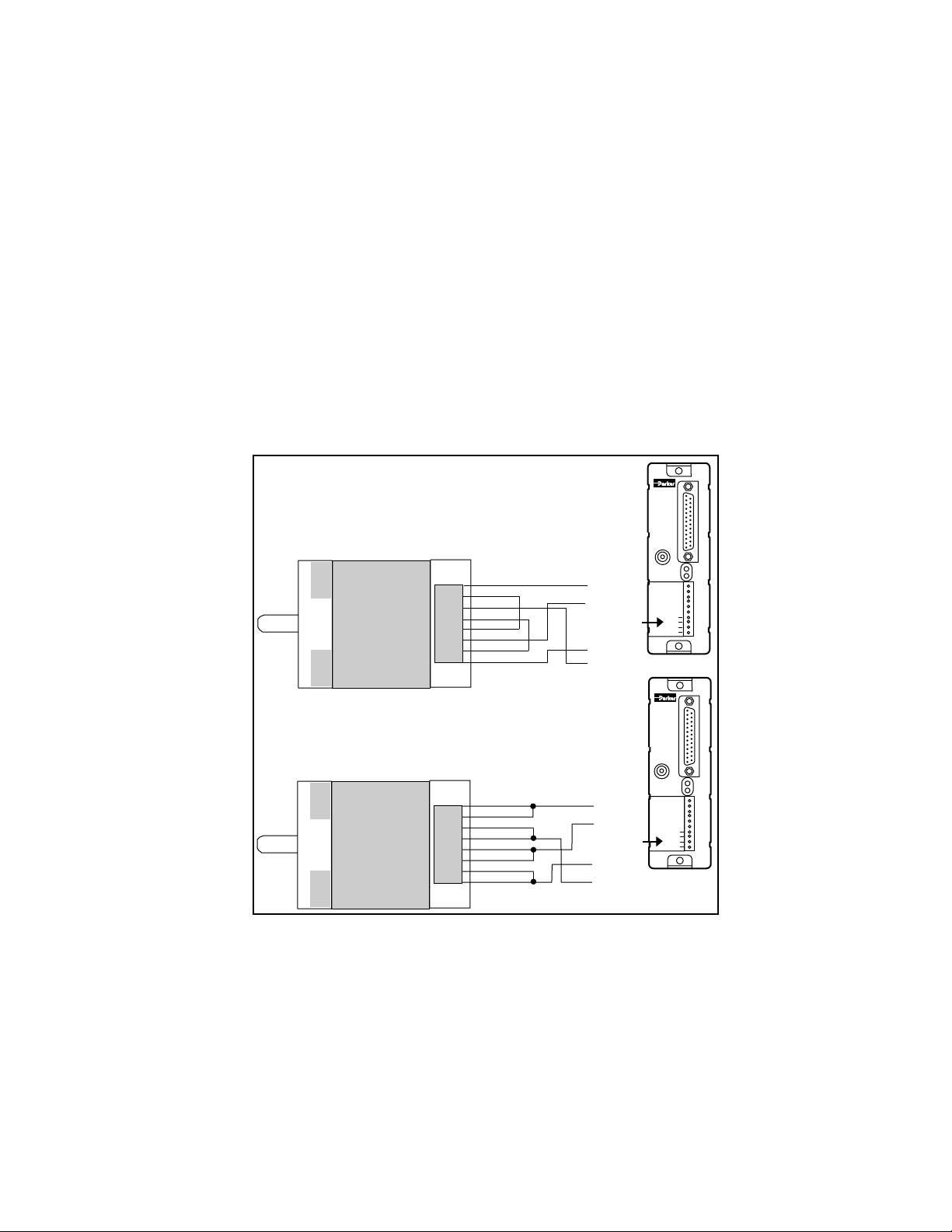

Size 23 OEM650 Motors: Series Wiring

RED

BLUE

GREEN

ORANGE

Top View

YELLOW

BLACK

BROWN

WHITE

A+

A-

B+

B-

}

OEM

s

e

r

i

e

s

POWER

FAULT

REMOTE

CURRENT

DUMP

VDC+

REF

VDC-

A+

A-

B+

B-

Size 23 OEM650 Motors: Parallel Wiring

RED

BLUE

GREEN

ORANGE

Top View

Figure 2-2. NEMA 23 Size OEM Motor Wiring—Series & Parallel

6

YELLOW

BLACK

BROWN

WHITE

A+

A-

B+

B-

}

OEM

s

e

r

i

e

s

POWER

FAULT

REMOTE

CURRENT

DUMP

VDC+

REF

VDC-

A+

A-

B+

B-

OEM650/OEM650X • INSTALLATION

OEM size 34 motors are internally wired in parallel. A 75VDC

power supply (OEM300) must be used to achieve maximum performance; however, lower voltage power supplies may be used (less

than 75VDC but must be greater than 24VDC). The lower voltage

power supply will not adversely affect the system's low-speed

performance, but it will not yield the optimum high-speed performance achieved by using the 75VDC power supply.

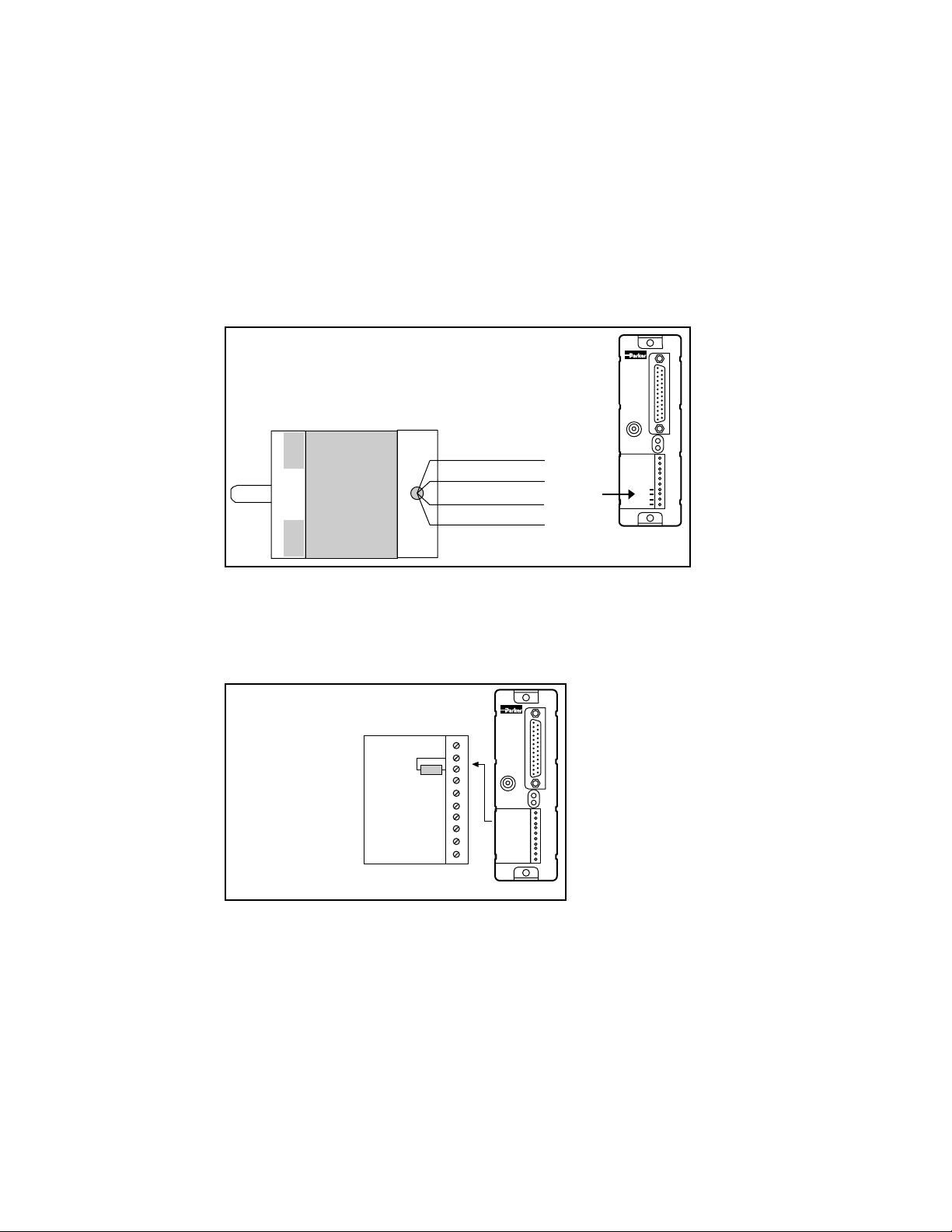

❐ Size 34 motors are internally wired in a parallel configuration

(OEM83-62-MO, OEM83-93-MO, OEM83-135-MO)

Size 34 OEM Series Motors: Parallel Wiring

Top View

RED

BLACK

WHITE

GREEN

A+

A-

B+

B-

}

OEM

s

e

r

i

e

s

POWER

FAULT

REMOTE

CURRENT

DUMP

VDC+

REF

VDC-

A+

A-

B+

B-

Figure 2-3. NEMA 34 Size OEM Motor Wiring—Series

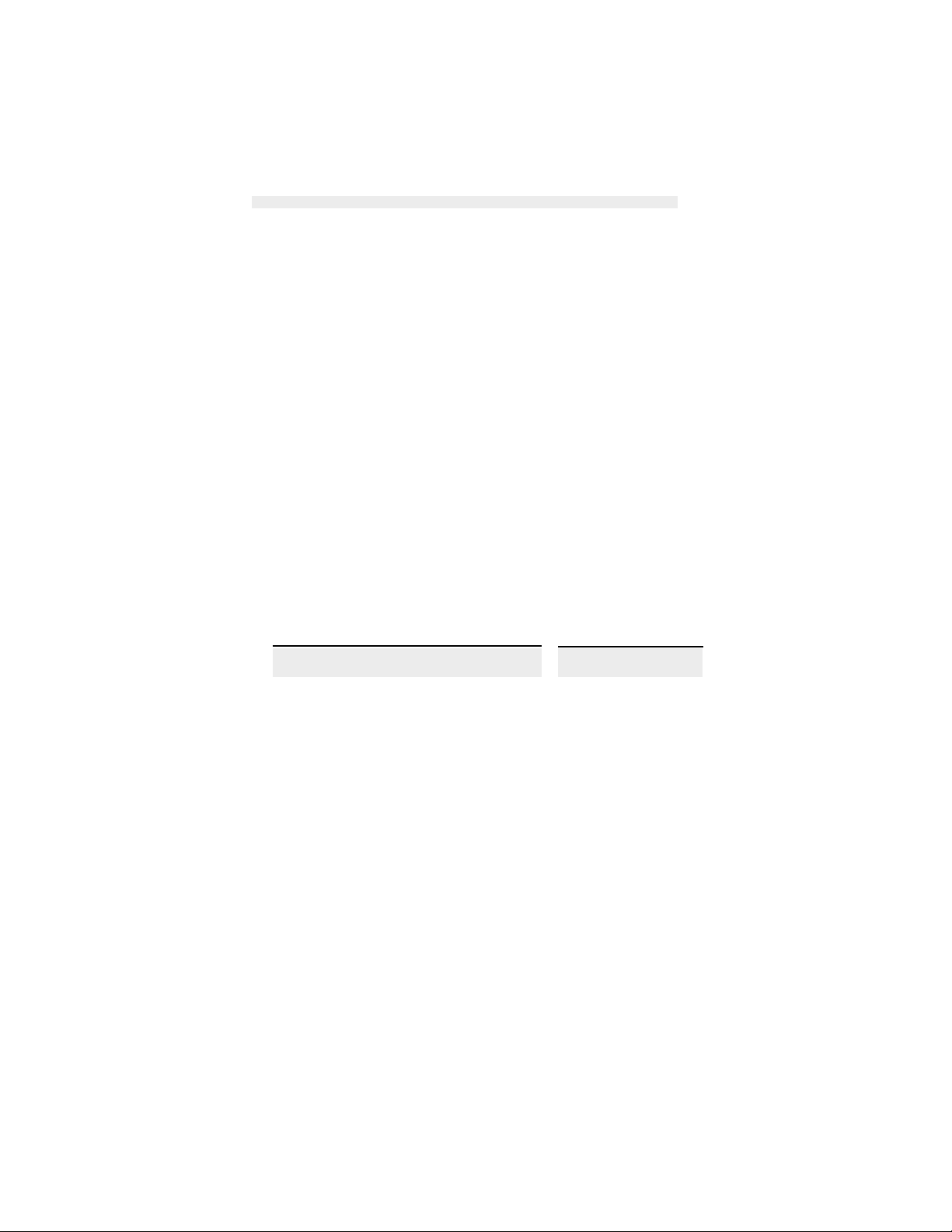

5. Set motor current. Table 2-7 contains the proper motor current

settings for Compumotor OEM motors. A 1/4 watt resistor

connected between REF and CURRENT sets motor current.

Adjust the drive current to match the motor that you are using.

Motor Current

Selection Resistor

REMOTE

REF

For best installation

results, be sure that the

resistor lead wire is long

enough for easy insertion

into the REF and

CURRENT terminals.

CURRENT

DUMP

VDC+

VDC-

A+

A-

B+

B-

OEM650/OEM650X

Terminals

Figure 2-4. Motor Current Selection Resistor

OEM

s

e

r

i

e

s

POWER

FAULT

REMOTE

CURRENT

DUMP

VDC+

REF

VDC-

A+

A-

B+

B-

7

INSTALLATION • OEM650/OEM650X

Motor Size Current Resistor Voltage

OEM57-40-MOS 2.65A 21.0 kΩ 48 - 75VDC

OEM57-40-MOP 5.3A 5.76 kΩ 24 - 48VDC

OEM57-51-MOS 3.3A 15.8 kΩ 48 - 75VDC

OEM57-51-MOP 6.6A 2.05 kΩ 24 - 48VDC

OEM57-83-MOS 3.8A 12.7 kΩ 48 - 75VDC

OEM57-83-MOP 7.5A 0.00 kΩ 24 - 48VDC

OEM83-62-MO* 4.4A 9.53 kΩ 24 - 75VDC

OEM83-93-MO* 5.6A 4.87 kΩ 24 - 75VDC

OEM83-135-MO* 6.9A 1.27 kΩ 24 - 75VDC

S: Series Configuration P: Parallel Configuration

*34 size motors are internally wired in parallel

Table 2-7. OEM Drive Motor Current (Compumotor Motors)

If you use a non-Compumotor motor, carefully follow the motor

manufacturer's instructions regarding motor wiring and the

proper operating current. Compumotor recommends a motor

inductance of 2 mH measured in series or parallel (0.5 mH - 10

mH is acceptable). Table 2-8 shows resistor values that you must

use to properly set motor current when using the OEM650/

OEM650X with a non-Compumotor motor. When the motor

current range jumper (jumper 1—see Figure 2-1) is installed, the

drive can generate 2.5 to 7.5 amps. When jumper 1 is removed,

the drive can generate 0.83 to 2.5 amps. If you use the OEM350/

OEM350X, use Table 2-9 for resistor and current values to use

with high-inductance (10 mH to 80 mH), low current motors.

Current Resistance Current Resistance Current Resistance

(Amps) (Ohms) (Amps) (Ohms) (Amps) (Ohms)

7.5 0 Ω 4.9 7.32 kΩ 2.5 0 Ω

7.4 205 Ω 4.8 7.68 kΩ 2.4 619 Ω

7.3 412 Ω 4.7 8.06 kΩ 2.3 1.27 kΩ

7.2 619 Ω 4.6 8.45 kΩ 2.2 2.05 kΩ

7.1 825 Ω 4.5 8.87 kΩ 2.1 2.80 kΩ

7.0 1.02 kΩ 4.4 9.53 kΩ 2.0 3.57 kΩ

6.9 1.27 kΩ 4.3 10.0 kΩ 1.9 4.53 kΩ

6.8 1.54 kΩ 4.2 10.5 kΩ 1.8 5.49 kΩ

6.7 1.78 kΩ 4.1 10.0 kΩ 1.7 6.49 kΩ

6.6 2.05 kΩ 4.0 11.5 kΩ 1.6 7.68 kΩ

6.5 2.26 kΩ 3.9 12.1 kΩ 1.5 8.87 kΩ

6.4 2.55 kΩ 3.8 12.7 kΩ 1.4 10.5 kΩ

6.3 2.80 kΩ 3.7 13.3 kΩ 1.3 12.1 kΩ

6.2 3.09 kΩ 3.6 13.7 kΩ 1.2 13.7 kΩ

6.1 3.32 kΩ 3.5 14.3 kΩ 1.1 15.8 kΩ

6.0 3.57 kΩ 3.4 15.0 kΩ 1.0 18.2 kΩ

5.9 3.92 kΩ 3.3 15.8 kΩ 0.9 20.5 kΩ

5.8 4.22 kΩ 3.2 16.5 kΩ 0.83 22.6 kΩ

5.7 4.53 kΩ 3.1 17.4 kΩ

5.6 4.87 kΩ 3.0 18.2 kΩ

5.5 5.11 kΩ 2.9 19.1 kΩ

5.4 5.49 kΩ 2.8 20.0 kΩ

5.3 5.76 kΩ 2.7 20.5 kΩ

5.2 6.19 kΩ 2.6 21.5 kΩ

5.1 6.49 kΩ 2.5 22.6 kΩ

5.0 6.81 kΩ

Table 2-8. OEM650/650X Resistor Selection for Motor Current

8

Jumper #1 Installed Jumper #1 Removed

OEM650/OEM650X • INSTALLATION

Current Resistance Current Resistance Current Resistance

Jumper #1 Installed Jumper #1 Removed

(Amps) (Ohms) (Amps) (Ohms) (Amps) (Ohms)

2.0 0 Ω 1.3 7.32 kΩ 0.7 0 Ω

1.9 787 Ω 1.2 8.87 kΩ 0.6 2.21 kΩ

1.8 1.62 kΩ 1.1 10.7 kΩ 0.5 5.36 kΩ

1.7 2.49 kΩ 1.0 13.0 kΩ 0.4 10.0 kΩ

1.6 3.57 kΩ 0.9 15.4 kΩ 0.3 16.2 kΩ

1.5 4.64 kΩ 0.8 18.2 kΩ 0.2 27.4 kΩ

1.4 5.90 kΩ 0.7 21.5 kΩ

Table 2-9. OEM350/350X Resistor Selection for Motor Current

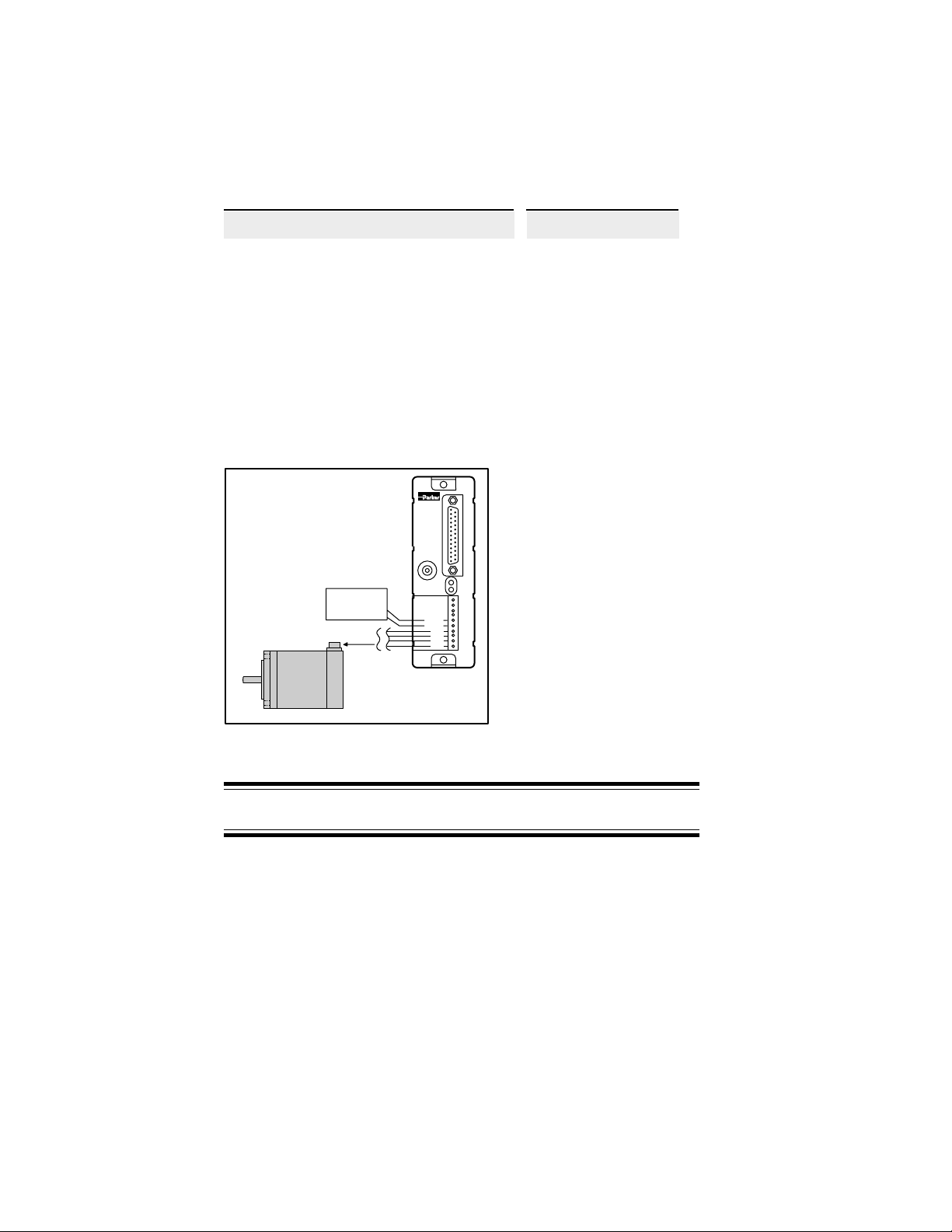

6. Connect a 24VDC - 75VDC power supply to VDC+ and VDC-.

Refer to Figure 2-5 for a diagram of this connection and the

complete OEM650 test configuration.

OEM

s

e

r

i

e

s

POWER

FAULT

REMOTE

REF

CURRENT

+

DUMP

-

VDC+

VDC-

A+

A-

B+

B-

OEM

Series

Motor

Power

Supply

Refer to Figures 2-2 and

2-3 for specific motor

wiring instructions

Figure 2-5. OEM650 Test Configuration

WARNING

Reversing VDC+ and VDC- can seriously damage the drive.

7. Apply power. The OEM’s green power LED should be on. If the

red FAULT LED is on, consult Chapter 4, Troubleshooting. After

verifying that the motor moves CW and CCW, turn off power.

❐ Disconnect cables and resistor.

❐ Snap off cover.

❐ Install jumper 11.

❐ Replace cover.

9

INSTALLATION • OEM650/OEM650X

Quick Test: OEM650 with Separate Indexer

1. Complete steps 1- 6 from the OEM650 Quick Test, but do not

remove jumper #11 (Auto Test Function).

2. To connect a Compumotor indexer to the OEM650’s 25-pin D

connector refer to Figure 2-6.

To connect a non-Compumotor indexer to the OEM650's 25-pin

D connector, refer to Figure 2-7.

3. Apply power. The OEM’s green power LED should be on. If the

red FAULT LED is on, consult Chapter 5, Troubleshooting.

This test assumes that your indexer’s motor resolution is set to

25,000 steps/rev. This is the default motor resolution setting

for the OEM650.

4. Using the indexer, send step pulses to the drive that will rotate the

motor one CW revolution (25,000 step pulses) at 1 rps (25,000

steps per second).

5. Using the indexer, send step pulses to the drive that will rotate the

motor one CCW revolution at 1 rps. The drive's default direction

is CCW (i.e., if the the direction input is not activated, the motor

will rotate CCW—if the direction input is activated, the motor will

rotate CW). If the motor does not rotate in the desired direction,

reverse the direction sense for your system by reversing the leads

going to the A+ and A- terminals.

WARNING

Never connect or disconnect any component to or from the drive with power

applied. System damage or personal injury may occur.

6. After verifying that the motor moves CW and CCW, turn off power.

❐ Disconnect cables and resistor.

10

OEM650/OEM650X • INSTALLATION

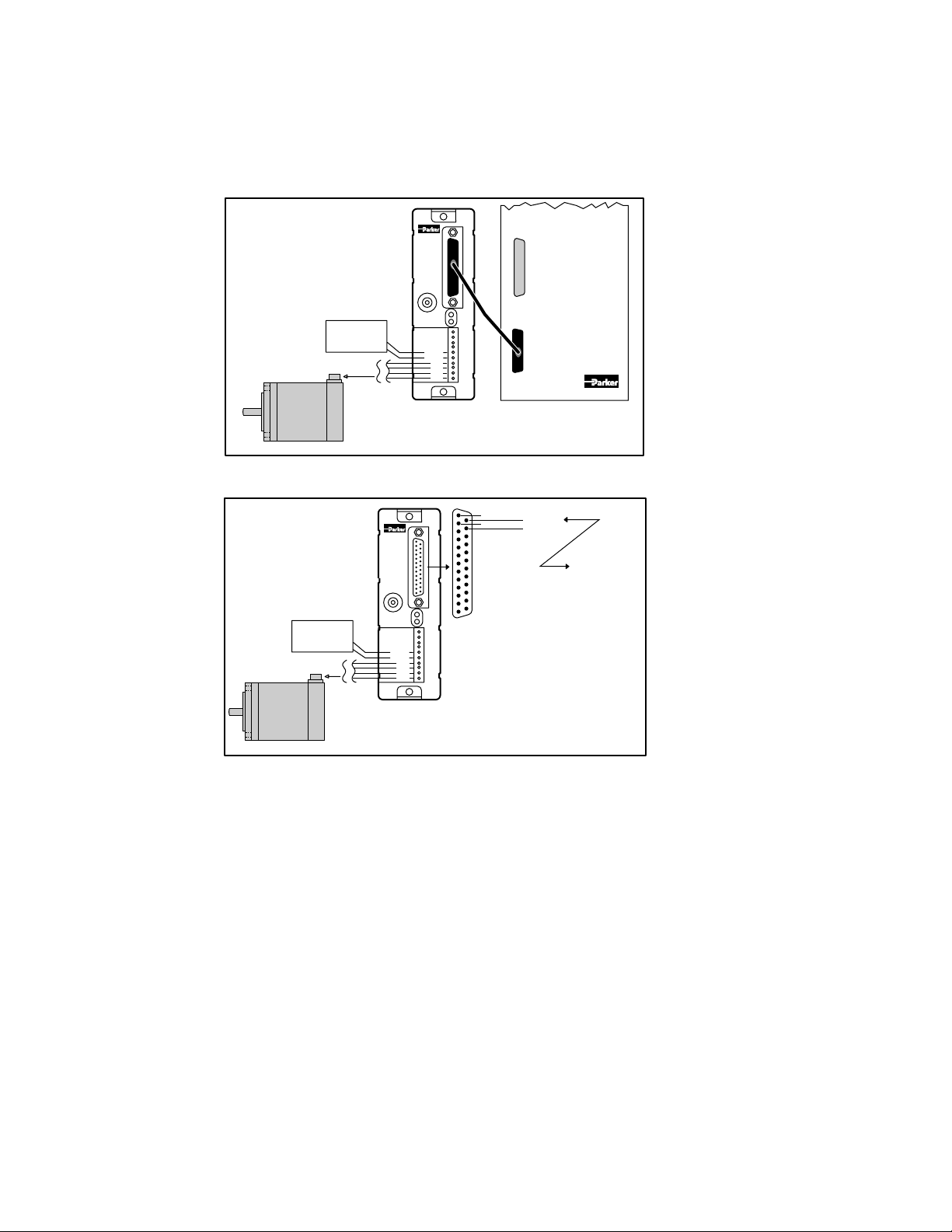

To connect the OEM650 to the Compumotor

indexer, use the cable provided with the

indexer. The cable should fit into the OEM650's

25-pin D connector as shown in this figure. No

additional wiring is necessary. Refer to the

indexer's user guide for any specific instructions

associated with the Compumotor indexer.

Power

Supply

OEM

Series

Motor

Refer to Figures 2-2 and

2-3 for specific motor

wiring instructions

OEM

s

e

r

i

e

s

POWER

FAULT

REMOTE

REF

CURRENT

+

DUMP

-

VDC+

VDC-

A+

A-

B+

B-

Compumotor

Drive

Figure 2-6. OEM650 with Compumotor Indexer Test Configuration

1 Step+

14 Step—

2 Direction+

15 Direction—

Connect to non-Compumotor

Indexer or Pulse Generator

To connect the OEM650 to a nonCompumotor indexer or pulse generator,

use the pinouts of the OEM650's 25-pin D

connector as shown in this figure. Refer to

the indexer or pulse generator's user guide

for any specific instructions associated with

the device.

OEM

Series

Motor

Power

Supply

+

-

Refer to Figures 2-2 and

2-3 for specific motor

wiring instructions

OEM

s

e

r

i

e

s

POWER

FAULT

REMOTE

CURRENT

DUMP

VDC+

VDC-

REF

A+

AB+

B-

Indexer

Compumotor

Figure 2-7. OEM650 with non-Compumotor Indexer or Pulse Generator Test Configuration

Quick Test: OEM650X

1. Complete steps 1- 6 from the OEM650 Quick Test. but do not

remove jumper #11 (Auto Test Function)

2. Connect the OEM650X to an RS-232C communications device

(i.e., computer, PLC, etc.). The OEM650X's communication

parameters are listed below:

❏ Baud Rate: 9600

❏ Data Bits: 8

❏ Stop Bit: 1

❏ Parity: None

11

Loading...

Loading...