COMPAX-M /-S (L)

COMPAX User Guide

Compact Servo Controller

From software version V6.26 October 2001

Parker Hannifin GmbH

D

EMD Hauser

P. O. Box: 77607-1720

Robert-Bosch-Str. 22

D-77656 Offenburg, Germany

M

E

Phone: +49 (0)781 509-0

T

Fax: +49 (0)781 509-176

We automate motion

R

E

C

DIN EN ISO 9001

Q

U

A

L

I

T

Reg. Nr. 36 38

I

T

F

I

E

S

Y

Y

S

http://www.parker-emd.com

Subject to technical modification. 11.10.01 11:01 192-040053 N2

Data correspond to the state of technical development at the time of printing.

Parker Hannifin plc

Electromechanical Division

21 Balena Close

Poole, Dorset

BH17 7DX UK

Phone: +44 (0)1202 69 9000

Fax: +44 (0)1202 69 5750

http://www.parker-emd.com

Contents

COMPAX-M / -S

1. Contents

1. Contents...................................................................................................2

2. Un i t a s s i g n m e n t : ....................................................................................7

3. Sa f e t y i n s t r u c t i o n s.................................................................................8

3.1 General dangers........................................................................................8

3.2 Safe working practices.............................................................................8

3.3 Special safety instructions.......................................................................8

3.4 Conditions of warranty.............................................................................9

4. COMPAX – CD...........................................................................................9

5. Sw i t c h - o n s t a t u s...................................................................................10

5.1 Configuration when supplied.................................................................10

5.2 Commissioning .......................................................................................10

5.3 Equipment replacement..........................................................................12

6. Co n d i t i o n s f o r u s a g e ...........................................................................13

7. St a r t - u p m a n u a l ....................................................................................14

7.1 Overview: .................................................................................................14

7.1.1 Components required....................................................................................... 14

7.1.2 Overview of unit technology............................................................................ 15

7.2 COMPAX-M unit features........................................................................17

7.2.1 Connector and terminal assignment............................................................... 17

7.2.2 COMPAX-M system network, NMD10 / NMD20 mains module...................... 18

7.2.3 COMPAX-M dimensions/installation ............................................................... 20

7.2.4 Connector assignment COMPAX-M ................................................................ 21

7.3 Mains module NMD10/NMD20................................................................22

7.3.1 Overview NMD................................................................................................... 22

7.3.2 Dimensions / installation.................................................................................. 22

7.3.3 NMD connector assignment............................................................................. 23

7.3.4 Technical data / power features NMD.............................................................. 23

7.4 COMPAX 35XXS unit features................................................................26

7.4.1 Plug and connection assignment COMPAX 35XXM....................................... 26

7.4.2 Installation and dimensions of COMPAX 35XXM........................................... 27

7.4.3 Wiring COMPAX 35XXM.................................................................................... 28

2

7.4.4 COMPAX 35XXM connector assignment ........................................................ 29

7.5 COMPAX 25XXS unit characteristics ....................................................30

7.5.1 COMPAX 25XXS connector and connection assignment.............................. 30

7.5.2 COMPAX 25XXS-specific technical data......................................................... 32

7.5.3 COMPAX 25XXS dimensions / installation ..................................................... 33

7.5.4 Connector assignment COMPAX 25XXS ........................................................ 34

7.6 COMPAX 45XXS/85XXS unit characteristics........................................35

7.6.1 Plug and connection assignment COMPAX 45XXS/85XXS........................... 35

7.6.2 COMPAX 45XXS/85XXS installation / dimensions ......................................... 36

7.6.3 COMPAX 45XXS/85XXS-specific wiring.......................................................... 37

7.6.4 COMPAX 45XXS/85XXS connector and pin assignment............................... 39

7.7 COMPAX 1000SL Unit characteristics...................................................40

7.7.1 Connector and terminal assignment for COMPAX 1000SL........................... 40

7.7.2 Connector assignment COMPAX 1000SL (overview) .................................... 42

7.7.3 Mounting and dimensions COMPAX 1000SL ................................................. 43

7.7.4 Safety chain / emergency stop functions ....................................................... 44

7.8 Connections to the motor.......................................................................46

7.8.1 Resolver / SinCos.............................................................................................. 46

7.8.2 Additional brake control................................................................................... 51

7.9 Interfaces .................................................................................................52

7.9.1 Digital inputs and outputs (excluding COMPAX 1000SL).............................. 52

7.9.2 Digital inputs and outputs for COMPAX 1000SL............................................ 53

7.9.3 Technical data / Connections of inputs and outputs..................................... 54

7.9.4 Initiators and D/A monitor................................................................................ 55

7.9.5 Service D/A monitor / override......................................................................... 56

7.9.6 Service D/A monitor.......................................................................................... 56

7.9.7 D/A monitor option D1...................................................................................... 58

7.9.8 RS232 interface ................................................................................................. 59

7.9.9 Absolute value sensor (option A1).................................................................. 59

7.9.10 X13: Encoder interfaces, ... .............................................................................. 60

7.9.10.1 Encoder interfaces / analogue rpm specification for COMPAX............ 60

7.9.10.2 Area of application of process interfaces ............................................. 60

7.9.10.3 Encoder interfaces / Analogue rpm specification / Step direction

input for COMPAX 1000SL .................................................................. 61

7.9.11 HEDA interface (option A1/A4)......................................................................... 63

7.9.12 Bus connection ................................................................................................. 63

7.10 Technical data .........................................................................................64

8. Operating Instructions...........................................................................67

8.1 Overview: .................................................................................................67

8.1.1 Block structure of the basic unit (not applicable for COMPAX 1000SL)...... 68

8.1.2 Password protection......................................................................................... 70

8.2 Configuration...........................................................................................71

8.2.1 Front plate operation (not available with COMPAX 1000SL)......................... 71

8.2.2 Configuration when supplied........................................................................... 72

3

Contents

8.2.3 Configuration process...................................................................................... 72

8.2.4 Safety instructions for initial start-up ............................................................. 73

8.2.5 Configurationparameters ................................................................................. 74

8.2.6 Absolute value function with standard resolver ............................................ 79

8.2.7 Machine zero mode........................................................................................... 80

8.2.8 Limit switch operation...................................................................................... 89

COMPAX-M / -S

8.3 Configuration via PC using "ServoManager".......................................91

8.3.1 Installing ServoManager................................................................................... 91

8.3.2 Configuring COMPAX....................................................................................... 91

8.3.3 Individual configuration of synchronous motors........................................... 91

8.4 Positioning and control functions.........................................................95

8.4.1 Absolute positioning [POSA]........................................................................... 96

8.4.2 Relative positioning [POSR]............................................................................. 96

8.4.3 Process velocity [SPEED] ................................................................................ 97

8.4.4 Acceleration and braking time [ACCEL] ......................................................... 97

8.4.5 Setting/resettingan output [OUTPUT] ............................................................. 98

8.4.6 Setting multiple digital outputs [OUTPUT O12=1010]................................... 98

8.4.7 Switch off drive unit. [OUTPUT O0]................................................................. 98

8.4.8 OUTPUT O0=... in program............................................................................... 98

8.4.9 Password [GOTO] ............................................................................................. 99

8.4.10 External velocity specification. [SPEED SYNC] ............................................. 99

8.4.11 Mark-related positioning [POSR]................................................................... 100

8.4.12 Preparatory instructions................................................................................. 101

8.4.13 Changes in speed within a positioning process [POSR SPEED] ............... 101

8.4.14 Comparators during positioning [POSR OUTPUT]...................................... 103

8.4.15 Cam controller with compensation for switching delays............................ 104

8.4.16 Programmable waiting time [WAIT]............................................................... 107

8.4.17 Program jump [GOTO].................................................................................... 107

8.4.18 Sub-program jump [GOSUB].......................................................................... 107

8.4.19 Instruction to end a sub-program. [RETURN] .............................................. 107

8.4.20 END instruction [END].................................................................................... 107

8.4.21 Start a program loop [REPEAT]..................................................................... 108

8.4.22 Branching [IF I7=1].......................................................................................... 108

8.4.23 Binary IF query of inputs [IF I12=101-1]........................................................ 108

8.4.24 Comparative operations................................................................................. 109

8.4.25 Specific processing of data record groups. WAIT START.......................... 109

8.4.26 Jump with data record selection [GOTO EXT] ............................................. 109

8.4.27 Sub-program jump with data record selection [GOSUB EXT] ................... 110

8.4.28 Error handling [IF ERROR GOSUB]............................................................... 110

8.4.29 STOP / BREAK handling [IF STOP GOSUB xxx] .......................................... 111

8.4.30 Arithmetic ........................................................................................................ 113

8.4.30.1 Parameter assignments ..................................................................... 113

8.4.30.2 Arithmetic and variables..................................................................... 114

8.4.31 Position monitoring (P93=1, 2, 3) .................................................................. 117

8.4.32 Idle display....................................................................................................... 119

8.4.33 Speed monitoring in speed control mode (P93="4") ................................... 120

8.4.34 PLC sequential step tracking......................................................................... 122

8.4.35 Engaging and disengaging the motor brake ................................................ 123

8.4.36 Output of variable voltage.............................................................................. 124

4

8.5 Optimization functions .........................................................................125

8.5.1 Optimization parameters................................................................................ 127

8.5.2 Speed monitor................................................................................................. 132

8.5.3 Optimization display....................................................................................... 133

8.5.4 External position localization with position adjustment ............................. 136

8.6 Interfaces ...............................................................................................138

8.6.1 Digital inputs and outputs.............................................................................. 138

8.6.1.1 Digital inputs and outputs for COMPAX 1000SL................................ 140

8.6.1.2 Free assignment of inputs and outputs.............................................. 143

8.6.1.3 COMPAX virtual inputs ...................................................................... 145

8.6.1.4 I/O assignment of variants ................................................................. 147

8.6.1.5 Function of inputs............................................................................... 148

8.6.1.6 Synchronous STOP using I13............................................................ 151

8.6.1.7 Function of outputs ............................................................................ 153

8.6.1.8 Diagrams:........................................................................................... 154

8.6.2 PLC data interface (function not available with COMPAX 1000SL)............ 156

8.6.3 RS232 interface ............................................................................................... 160

8.6.3.1 Interface description........................................................................... 160

8.6.3.2 Interface functions.............................................................................. 162

8.6.3.3 Read and write program sets and parameters................................... 163

8.6.3.4 Binary data transfer using RS232 ...................................................... 166

8.6.4 Process coupling using HEDA (Option A1 / A4)........................................... 168

9. Accessories and options..................................................................173

9.1 System concept.....................................................................................173

9.2 Overview ................................................................................................174

9.3 Motors ....................................................................................................176

9.4 HAUSER linear actuators .....................................................................177

9.5 Data interfaces.......................................................................................178

9.5.1 RS232............................................................................................................... 178

9.5.2 Bus systems.................................................................................................... 178

9.5.2.1 Interbus-S / Option F2........................................................................ 178

9.5.2.2 RS485 / Option F1/F5........................................................................ 178

9.5.2.3 Profibus / option F3............................................................................ 178

9.5.2.4 CAN - Bus / Option F4 ....................................................................... 178

9.5.2.5 CANopen / Option F8......................................................................... 178

9.5.2.6 CS31system bus / Option F7 ............................................................. 178

9.6 Process interfaces ................................................................................179

9.6.1 Encoder interface............................................................................................ 179

9.6.2 Absolute value sensor (A1)............................................................................ 183

9.6.3 High resolution SinCos sensor system (S1/S2)

9.6.4 Option S3 for linear motors............................................................................ 184

9.6.5 HEDA interface................................................................................................ 185

9.6.6 D/A monitor (D1) (option not available with COMPAX 1000SL) ................. 185

9.6.7 Analogue speed specification (E7) (option not available with COMPAX

1000SL) ............................................................................................................ 186

......................................... 183

9.7 Accessories ...........................................................................................187

5

Contents

9.7.1 External control panel (not available for COMPAX 1000SL) ....................... 187

9.7.2 Terminal module for COMPAX 1000SL (EAM).............................................. 188

9.7.3 EAM5/01: DC feed for COMPAX-M................................................................. 189

9.7.4 EMC measures ................................................................................................ 191

9.7.4.1 Power filter......................................................................................... 191

9.7.4.2 Motor output throttle........................................................................... 192

9.7.5 External ballast resistors................................................................................ 193

9.7.6 ServoManager ................................................................................................. 200

9.7.7 Hand-held terminal.......................................................................................... 200

COMPAX-M / -S

9.8 Appendix: COMPAX components.......................................................206

10.Appendix ..............................................................................................207

10.1 Status values of the standard unit (COMPAX XX00)..........................207

10.2 Additional COMPAX measuring quantites..........................................210

10.3 COMPAX

10.3.1 VP parametercan be modified "On Line"..................................................... 212

10.3.2 COMPAX standard parameters...................................................................... 212

10.3.3 Monitoring and limitation characteristics..................................................... 222

parameter..............................................................................212

10.4 Error handling and error messages ....................................................223

11 .A p p l i c a t io n e x a m p l e s ........................................................................226

11.1.1 Overview.......................................................................................................... 226

11.1.2 External data record selection....................................................................... 227

11.1.3 Mark-referenced positioning.......................................................................... 229

11.1.4 Speed step profiling / comparator switching points.................................... 231

11.1.5 SPEED SYNC................................................................................................... 233

11.1.6 Speed control mode........................................................................................ 234

11.1.7 Fast start.......................................................................................................... 236

11.1.8 Implementing a torque controller.................................................................. 237

12.Index .....................................................................................................238

Data security

6

The parameter and program memory are created using ZP-RAM. This memory is

unaffected by mains power failure.

This module has a guaranteed service life of 10 years (calculated from the first

start-up).

ZP-RAM failure causes data loss; COMPAX contains wild data.

If you encounter problems of this kind, contact HAUSER.

SinCos is a registered trademark of Firma Stegmann.

2. Unit assignment:

This documentation applies to the following units:

!!!!

COMPAX 10XXSL

!!!!

COMPAX 25XXS

!!!!

COMPAX 45XXS

!!!!

COMPAX 85XXS

!!!!

COMPAX P1XXM

!!!!

COMPAX 02XXM

!!!!

COMPAX 05XXM

!!!!

COMPAX 15XXM

!!!!

COMPAX 35XXM

General dangers

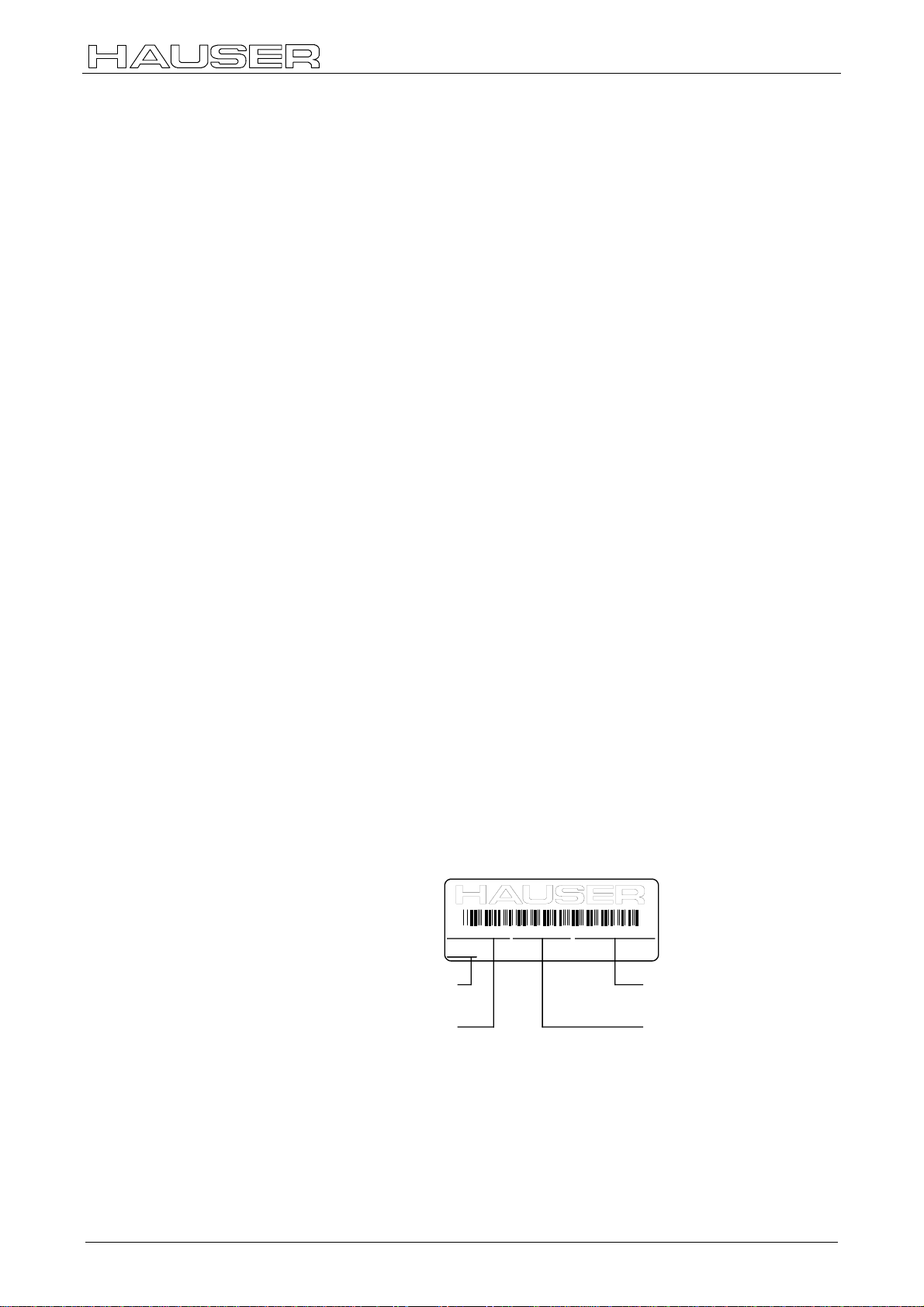

Key to unit

designation

HAUSER type plate

XX: Unit variants

e.g.: COMPAX 0260M:

COMPAX: name

02: performance class

60: Variant e.g. "00": Standard model

"60": electronic transmission

M: unit type "M": multi-axis model

"S": single-axis unit

...

The type plate is located on the upper side of the unit and contains the

following:

038106 0001 951-160101 Compax 0260M

E2

option name

equipment

name

part numberserial number

Notes for repeat

customers

regarding

modified software

versions:

Please check the software version of your unit.

Despite all efforts on our part, software modifications may change procedures as

well as cause functional changes.

Please notify us immediately if you detect unexplainable problems when using a

new software version.

7

Safety instructions

3. Safety instructions

3.1 General dangers

General dangers when safety instructions are not complied with

The unit described contains leading edge technology and is operationally reliable.

However, hazards may occur if the unit is employed incorrectly or for improper use.

Energized, moving or rotating parts can

!

cause fatal injury to the user

!

cause material damage

Proper use

This unit is designed for use in high voltage units (VDE0160). This unit automates

motion processes. The ability to switch several units at once makes it possible to

combine several motion processes. Reciprocal interlocks must be installed in such

cases.

3.2 Safe working practices

COMPAX-M / -S

The unit must be operated by skilled staff only.

!

When used in this manual, the term "trained staff" refers to people who,

•

due to their training, experience and knowledge of current standards,

guidelines, accident prevention regulations and operating conditions, have

received authorization from the head of health and safety at the site to perform

the necessary activities, while recognizing and avoiding any associated dangers

(definition of personnel as per VDE105 or IEC364)

•

are familiar with first aid and the on-site safety equipment,

•

have read and observed the safety instructions

•

have read and observed the User Guide (or the section which applies to the

tasks to be executed).

This applies to all tasks relating to set-up, start-up, configuration, programming and

modification of the operating conditions, operating modes and maintenance.

Please note in particular the functions contained in the start-up manual relating to

operational readiness and emergency stop.

The User Guide must be present at the unit at all times.

3.3 Special safety instructions

!

Check the arrangement of unit and documentation.

!

Never disconnect the electrical connections when energized.

!

Use safety equipment to ensure that moving or rotating parts cannot be touched.

!

Ensure that the unit is in perfect working order before operation.

!

Include the operational readiness and emergency stop functions of the unit (see

start-up manual) in the safety and emergency stop functions of your machine.

!

Only operate unit with the front cover attached.

!

Ensure mains module has sufficient nominal and peak power ratings.

!

Ensure that the unit arrangement enables the units with higher power ratings to

be fitted more closely to the power unit than the units with lower ratings

(COMPAX-M).

!

Ensure that motors and linear drive units (if available) are sufficiently secured.

!

Ensure that all energized connectors cannot be touched. The unit carries

voltages ratings of up to 750V, which could fatally injure the operator.

!

Please mind the limits of the mechanical equipment connected.

8

3.4 Conditions of warranty

!

The unit must not be opened.

!

Do not make any alterations to the unit, except for those described in the User

Guide.

!

Only activate inputs, outputs and interfaces as described in the User Guide.

!

When installing units, ensure that the heat sinks receive sufficient ventilation.

!

Secure units as per the assembly instructions contained in the start-up manual

using the securing bores provided for this purpose. We cannot assume any

responsibility for any other methods used for securing the units.

Note on option exchange

In order to check hardware and software compatibility, it is necessary for COMPAX

options to be changed at the factory.

4. COMPAX – CD

Conditions of warranty

On the accompanying CD, you will find all instructions for COMPAX and the

operating software "ServoManager".

Once the CD is inserted in a Windows – computer, the HTML desktop (default.htm)

is normally automatically started – if an Internet browser is present. If you do not

have an Internet browser on your computer, please install a version: the software is

usually available to download free of charge.

If the desktop does not start automatically, please execute the file "default.htm"

(e.g. by double clicking on the file or via "Start":"Run"). The "default.htm" file is

located directly on the CD (not in the sub-directory).

Use Language selection (top right in window) to select the language required.

Follow the CD instructions shown on the window in the center of the screen.

Use the list on the left-hand side to select the required instructions or software.

9

Switch-on status

5. Switch-on status

5.1 Configuration when supplied

When supplied, COMPAX is not configured. Parameter P149 is set to "0":

P149="0": COMPAX is not configured and switches to OFF mode when switched

on (24V DC and operating voltage) (motor switched off). In addition to

this, when switched on, all parameters (apart from bus settings P194,

P195, P196 and P250) are set to their default values.

P149="1": COMPAX is configured and once switched on (24V DC and operating

voltage) tries to engage the motor.

5.2 Commissioning

Meaning of LEDs on the front panel

COMPAX-M / -S

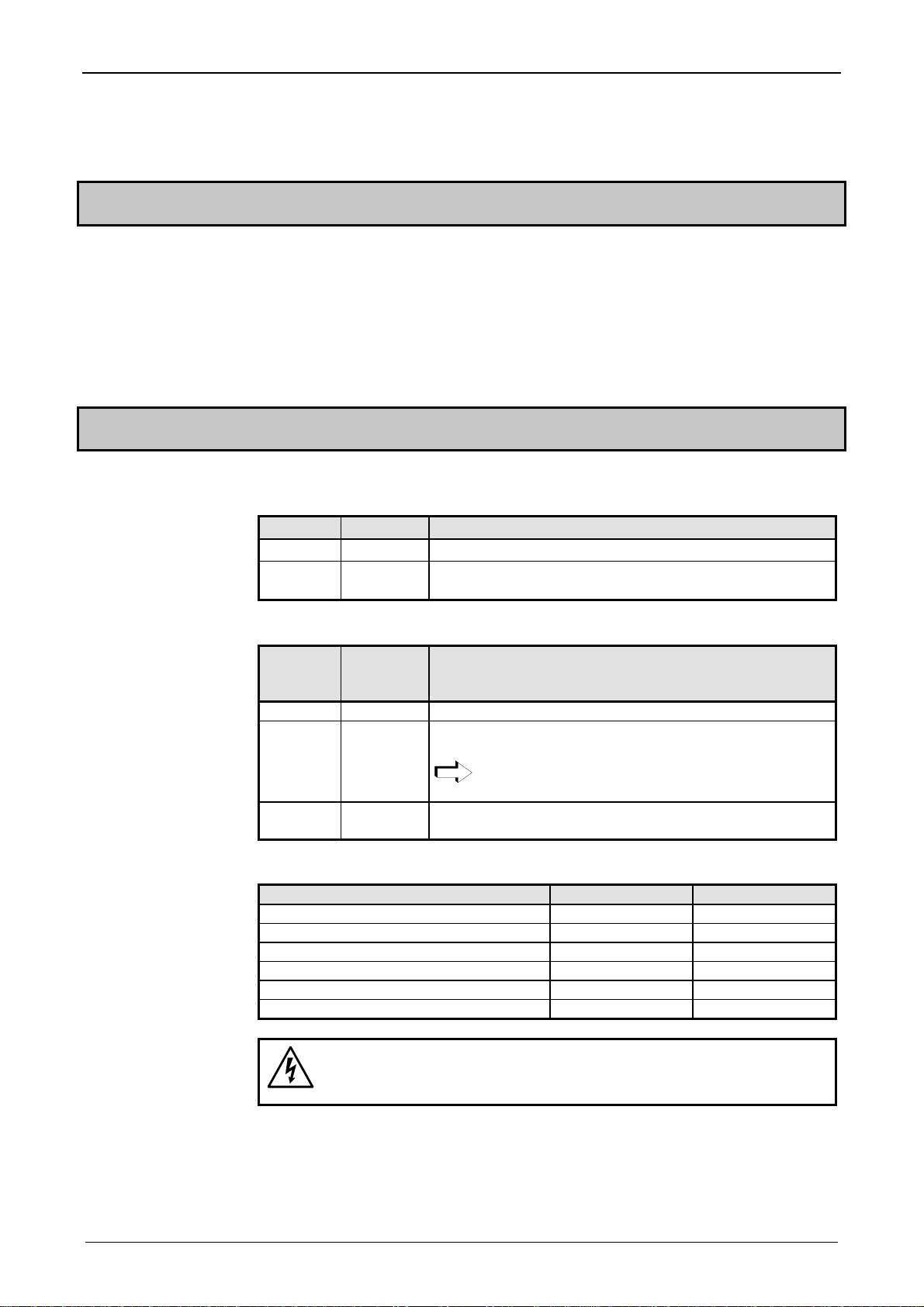

LED Color Meaning, when switched on

Ready green

Error red

24V DC present and initialization complete

COMPAX - Error (E1...E56) present or COMPAX is

initialized.

COMPAX-M / -S

Mains module

LED

red

Error

off on no errors

on off Heat sink temperature too high or

on on Ballast switching unit overload or

LED

green

Ready

Possible errors

error in logic voltage (24V DC too low or unit is defective)

Emergency stop is activated and ready contact is

released.

undervoltage (<100V DC or <80V AC).

COMPAX 1000SL

Status Red LED (H2) Green LED (H1)

24V not available off off

24V are switched on, boot up on off

Unit OFF off blinking

Unit error; drive switched off on blinking

Unit error; drive powered on on

Unit RUNNING off on

Caution!

If there is no control voltage, no displays will appear to indicate

that operating voltage is present.

10

Note:

With Error E40, external enabling is missing with COMPAX 45XXS, COMPAX

85XXS and COMPAX 1000SL (Hardware input).

Commissioning

After 24V DC of control voltage is switched on, COMPAX has two statuses

available once the initialization phase has been completed:

1. COMPAX is OFF

COMPAX is not configured (P149="0") or

with COMPAX XX70:

I12="0" (final stage blocked).

Now configure COMPAX (e.g. using the ServoManager / ParameterEditor).

Set P149="1"

Configuration is accepted with VC and VP of COMPAX.

2. COMPAX displays error E57

COMPAX is configured (P149="1"). However, operating voltage is not present.

Check COMPAX configuration

Alterations are accepted with VC and VP of COMPAX.

*)

Configuring

a) Using ServoManager:

P149="1", VP and VC are transferred when being downloaded to COMPAX

from the ServoManager.

b) Using hand-held terminal:

P149="1", VP and VC are generated by the hand-held terminal.

c) Without an auxiliary device, e.g. a terminal:

P149="1", VP and VC must be transmitted after COMPAX configuration.

Switch on operating voltage

With E57: acknowledge error by pressing Enter.

When OFF: command: "OUTPUT O0=0" or

switch 24V DC on / off

Motor is powered; COMPAX display shows "RUN".

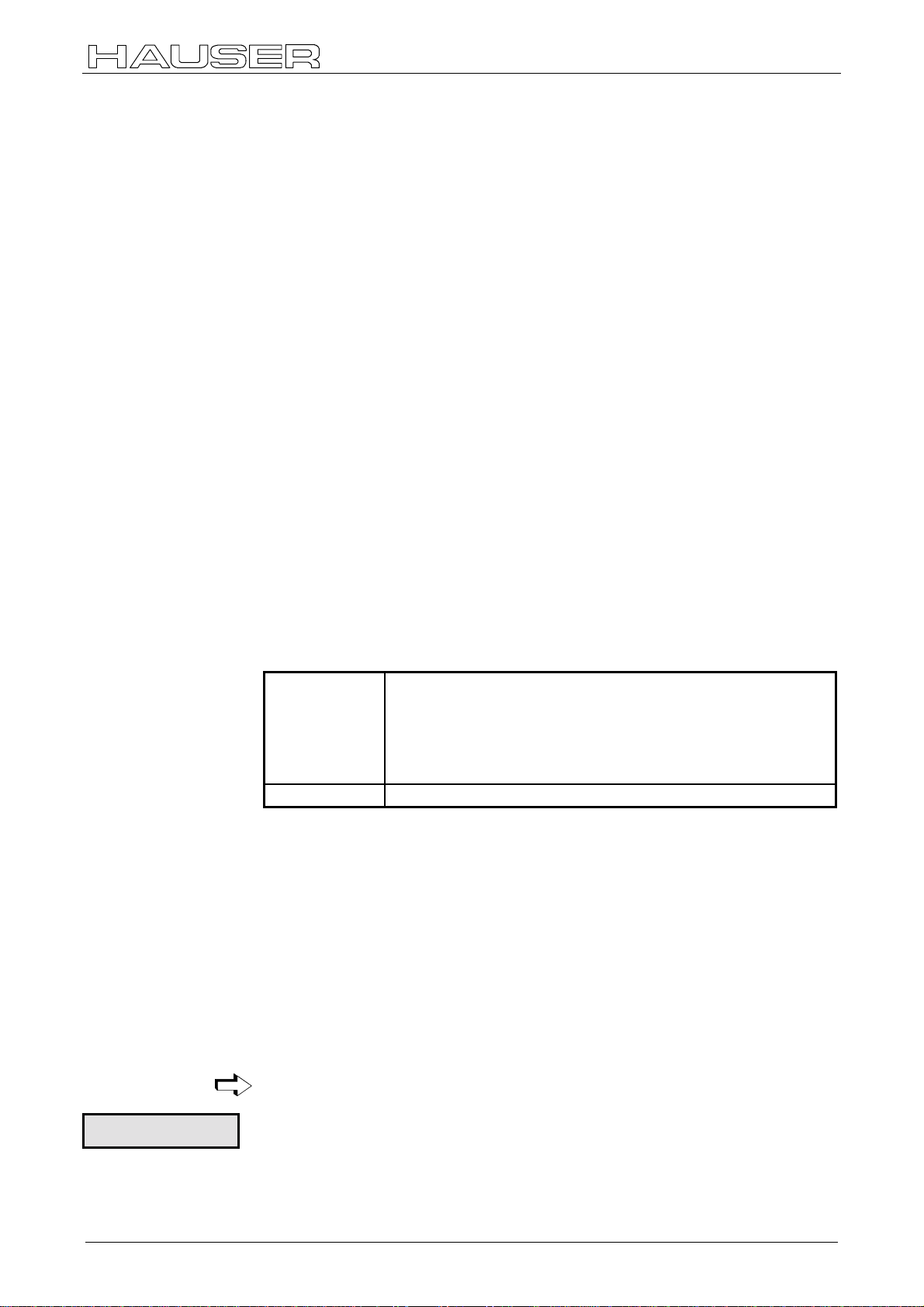

Flow chart:

*

.

connection of control

initializing stage

COMPAX configured

(P149="1")

error E57

in COMPAX

display

check

configuration

VC, VP

connect

DC bus

voltage

clear

error E57

voltage 24 V DC

COMPAX not configured

configuration

24V DC

ON / OFF

RUN

motor enabled

(P149="0")

OFF in

Display

execute

P149="1",

VC, VP

connect

DC bus

voltage

OUTPUT

O0="0"

11

Switch-on status

5.3 Equipment replacement

COMPAX-M / -S

Previous software

!

Procedure for copying the complete COMPAX setting onto a new unit

!

Start ServoManager.

!

Connect old COMPAX via RS232.

!

Use menu "Insert: Axis: From controller" to set up an axis which contains all

≥≥≥≥

V2.0

COMPAX settings (all parameters: including system parameters, data records

and (with COMPAX XX70) existing curves).

!

Connect new COMPAX.

!

Use menu "Online: Download" to transfer data (without system parameters1) into

the new COMPAX.

Transferring system parameters

!

Call up ParameterEditor (Menu: PC Tools: ParameterEditor)

!

Use menu "Online: Copy" menu to transfer all parameters (including system

parameters) to COMPAX.

Previous software

Procedure for copying the complete COMPAX setting onto a new unit

!

Start ServoManager.

!

Connect old COMPAX via RS232.

!

Use menu "Insert: Axis: New" to set up a new axis.

!

Use menu "Online: Upload" to load all COMPAX settings (all parameters:

including system parameters, data records, and (in COMPAX XX70) existing

curves) into the new axis.

!

Connect new COMPAX.

!

Use menu "Online: Download" to transfer data (without system parameters) into

the new COMPAX.

≤≤≤≤

V2.0

Transferring system parameters

!

Call up ParameterEditor (Menu: PC Tools: ParameterEditor)

!

Use menu "Online: Copy" menu to transfer all parameters (including system

parameters) to COMPAX.

1

System parameters are internal parameters; you will only obtain an identical

COMPAX – setting if these are also transferred.

12

6. Conditions for usage

- for CE-compliant operation in industrial and

business sectors -

The EU guidelines on electromagnetic compatibility 89/336/EEC and electrical

means of production for use within particular voltage limits 73/23/EEC are satisfied,

if the following peripheral conditions are complied with.

Only operate the units in the condition in which they are supplied, i.e. with all

housing plates and the front cover.

COMPAX P1XXM, COMPAX 02XXM, COMPAX 05XXM and COMPAX 15XXM

may only be operated with HAUSER mains modules (NMD10 or NMD20) or on

COMPAX 35XXM.

Equipment replacement

Power filter:

Motor and

resolver cable:

Motors:

Control:

A power filter is required in the power line. The filtering can be executed

once for the entire system or as separate process for each unit.

The following power filters are required for standalone operation:

NMD10 / COMPAX 45XXS / COMPAX 85XXS: Order No.: NFI01/02

NMD20: Order No.: NFI01/03

COMPAX 35XXM: Order No.: NFI01/04 or /05

COMPAX 25XXS: Order No.: NFI01/01 or /06

COMPAX 10XXSL: Order No.: NFI01/01 or /02

Length of connection:

Only operate the unit with a HAUSER motor and resolver cable (with

connectors containing special surface screening).

In such cases, the following cable lengths are permitted.

Motor cable

Resolver cable < 100m

Operation with HAUSER motors.

Only operate with calibrated controller (avoid feedback oscillation).

connection between power filter and unit: unscreened: < 0.5m

screened: < 5m

< 100m (the cable must not be rolled up)

For motor lines of >20m, a motor output throttle must be used

Up to 16A nominal motor current: Type: MDR01/01 16A / 2mH.

Between 16A and 30A: Type: MDR01/02 30A / 1.1mH.

Over 30A nominal motor current: Type: MDR01/03 >30A /

0.64mH.

Earthing:

Cable laying:

Accessories

Warning:

!

The filter housing, the mains module and the COMPAX must be surface

connected with good metal conductivity and low inductivity to the cabinet ground.

!

Never secure the filter housing or the unit to coated surfaces.

!

Ensure that you have largest spacing possible between the signal and load lines.

!

Signal lines must never pass sources of strong interference (motors,

transformers, relays,...).

!

Only use accessories recommended by HAUSER (absolute value sensor,

encoder,...).

Provide large surface contact areas down both sides of all cable screening.

This is a product of the restricted sales class as per IEC 61800-3. In a domestic

environment, this product may cause high frequency disturbances, in which case

the user can be requested to implement suitable measures.

13

Start-up manual

COMPAX-M / -S

7. Start-up manual

Compact Servo Controller

14

7.1 Overview:

7.1.1 Components required

In addition to a COMPAX, you will require the following

components for a COMPAX application:

!

a motor with or without a transmission.

!

mains supply.

!

emergency stop circuit.

!

various cables for connecting components.

!

motor cable and resolver cable.

!

supply line for voltage supply.

!

supply line for 24V DC control voltage.

!

hand-held terminal or PC (with RS232 cable)

containing the ServoManager program for

configuring COMPAX.

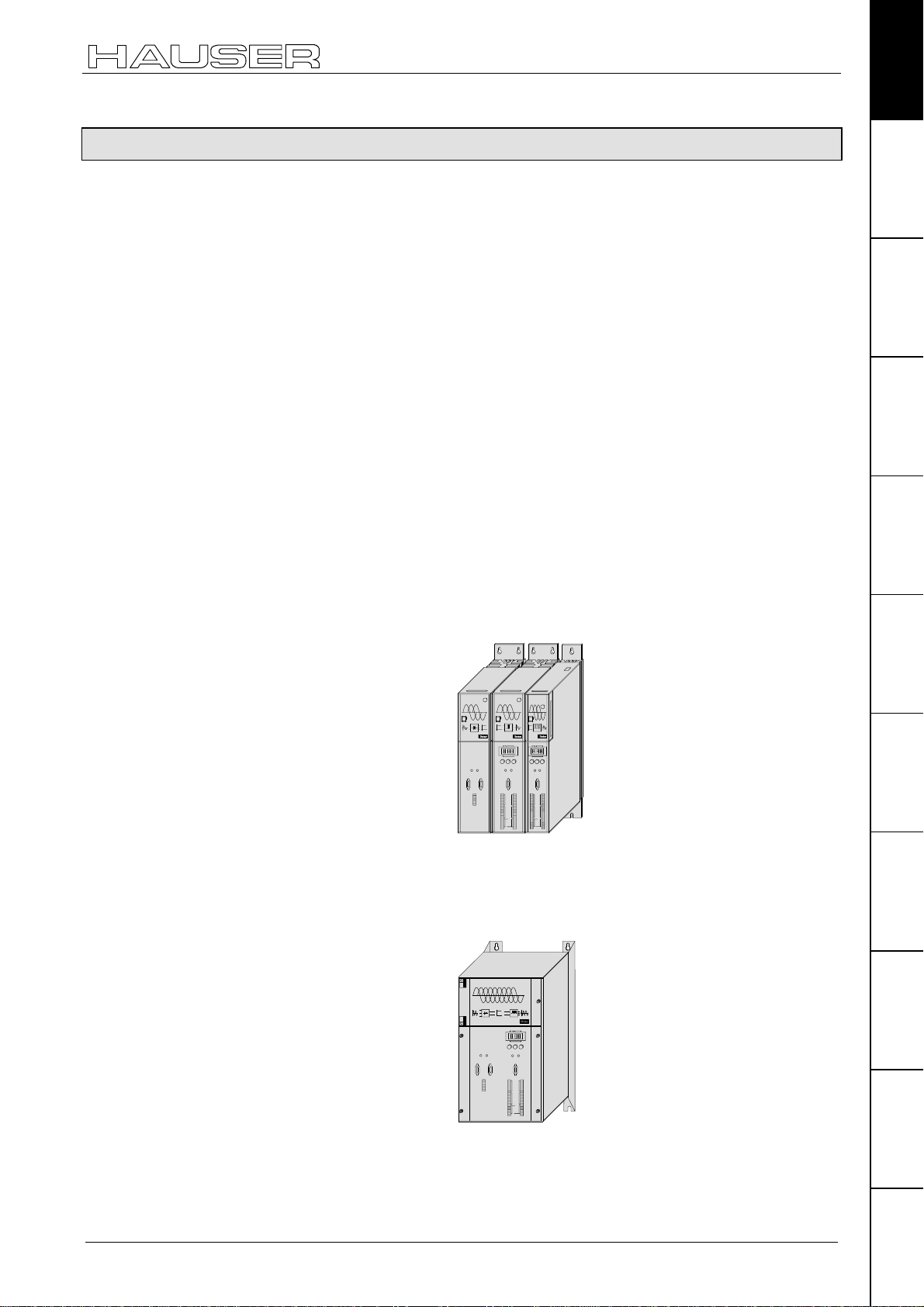

7.1.2 Overview of unit technology

Overview:

Overview of unit technology

Unit

hardware

Common function

characteristics:

COMPAX P1XXM

COMPAX 02XXM

COMPAX 05XXM

COMPAX 15XXM

COMPAX-M and COMPAX-S

!!!!

work with the same firmware,

yet have differences with regard to

!

housing and assembly technology and

!

power areas.

The following table shows the main features of the range of available units

Interfaces: 16 (8 with COMPAX 1000SL) digital inputs/outputs,

RS232; machine zero, limit switch, override input

Fieldbus options: RS485, Interbus-S, Profibus, CS31, CAN – Bus,

CANopen, HEDA (synchronous serial realtime interfaces)

Other options (excluding COMPAX 1000SL): absolute encoder sensor; encoder

input; encoder simulation; D/A monitor

Supply via central mains module: NMD10 / NMD20: Up to max. 3*500V AC

Dimensions (DxHxW): COMPAX P1XXM:

340*400*60 [mm]

Design:

COMPAX-M with NMD

mains module

Installation: in series

Power Supply COMPAX-M

Ready Error

X6 X7

RS485IN OUT

X8

Control

Status Number

-+Enter

Ready E rror

X8 X10

X9 X11

COMPAX-M

DIGITAL

DIGITAL

Status

Number

Value

Value

-+Enter

Ready

Error

X6

X6

RS232

RS232

X8

X10

Input

Input

Output

Output

Test

Test

Control

Control

X9

X11

COMPAX-M:

340*400*85 [mm]

Power:

COMPAX ...

P1XXM: 3.8 kVA

02XXM: 4.5 kVA

05XXM: 8.0 kVA

15XXM: 17 kVA

Connector

assignment / cable

Technical dataConfigurationPositioning and

control functions

functions

Optimization

InterfacesAccessories /

COMPAX 35XXM

Supply Up to max. 3 * 500V AC (integrated power unit)

Dimensions

(DxHxW): 40 * 400 * 220 [mm]

Design:

COMPAX-M

Digital

Automation

StatusNumber

Value

-+Enter

Ready Error

Ready Error

X6 X7

X6

RS485IN OUT

RS232

X8

X8 X 10

Control

Input

Output

Test

Control

X9 X 11

options

Power

35.0 kVA

StatusParameterError list

15

Start-up manual

COMPAX-M / -S

COMPAX 1000SL

COMPAX 25XXS

COMPAX 45XXS

COMPAX 85XXS

Supply Up to max. 1*250V AC (integrated power unit)

Dimensions (DxHxW): 146*180*85 [mm]

Design:

Supply

Up to max. 1 (3)*250V AC (integrated power unit)

H2

H1

X15

X6X5X13

X17

Input

+-

24 V DC

RS232

Limit Switch

X7

X14

PE

HEDA Out HEDA In

Fieldbus In

Dump

Fieldbus Out

R

X12

X1 X4 X3

Encoder

Resolver

PE+ W

Motor Brake

UV

X19

X2

Input / Output

230 V AC

L1 N PE

COMPAX - SL

Dimensions (DxHxW): 220*240*130 [mm]

Design:

Status Number

COMPAX-S

Value

-+Enter

Ready Error

X6

RS232

X8 X1 0

Input

Output

Test

Control

Motion & Control

X9 X1 1

Supply Up to max. 3*500V AC (integrated power unit)

Dimensions (DxHxW): 275*350*125 [mm]

Power

1 kVA

Power

2.5 kVA

Design:

COMPAX-S

DIGITAL

Status Number

Value

Ready Error

RS232

Input

Output Output

Test Control

Power

4.5 kVA

8.6 kVA

ENTER+-

Input

X10X6X8

X11X9

16

7.2 COMPAX-M unit features

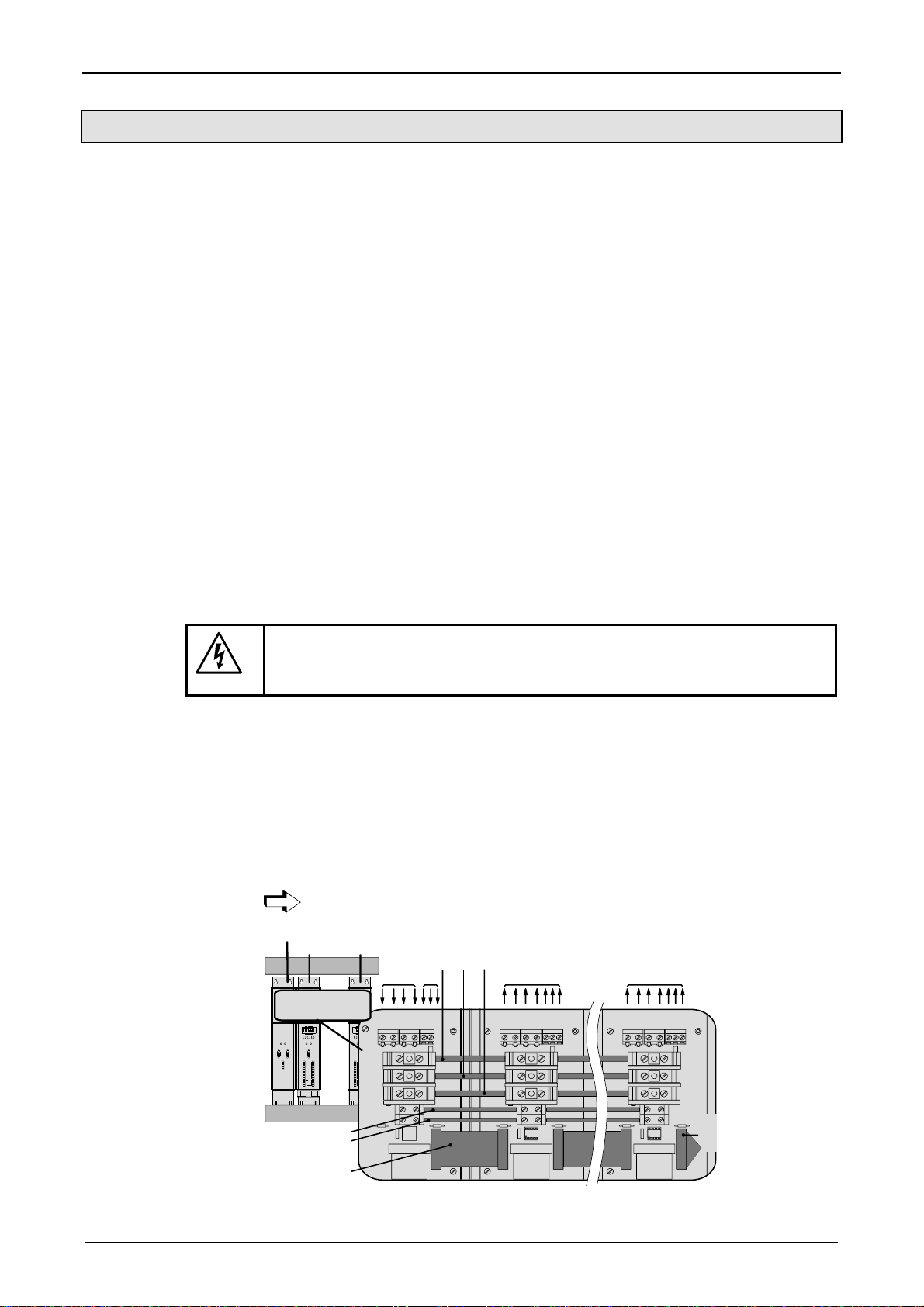

COMPAX-M unit features

Connector and terminal assignment

Unit

hardware

7.2.1 Connector and terminal assignment

COMPAX-M

X5 control- and

status- signal

bus-signals

input

X8 Input

/ Output

Number

Status

Value

+- Enter

Ready Error

X6

RS 232

X8 X10

Input

X1 motor

X2 intermediate loop

power connections

X3 24V control voltage

X4 control- and status

signals / bus signals

or short circuit plug

X6 RS232

X10 Input / Output

Connector

assignment / cable

Technical dataConfigurationPositioning and

control functions

Meaning of LEDs on

front plate

Output

X9 Test

X12 resolver

X14 HEDA

X16 absolute

encoder

X18 fan

Test

Control

X9 X11

X11 Control

X13 Encoder

X15 HEDA

X17 initiators

Before wiring up, always de-energize the unit.

Even once the mains supply has been switched off,

dangerous levels of voltage can remain in the system for

up to 5 min.

LED Color Meaning, when switched on

Ready green 24V DC present and initialization complete

Error red COMPAX - fault (I1...E56) present.

functions

Optimization

InterfacesAccessories /

options

StatusParameterError list

17

Start-up manual

COMPAX-M / -S

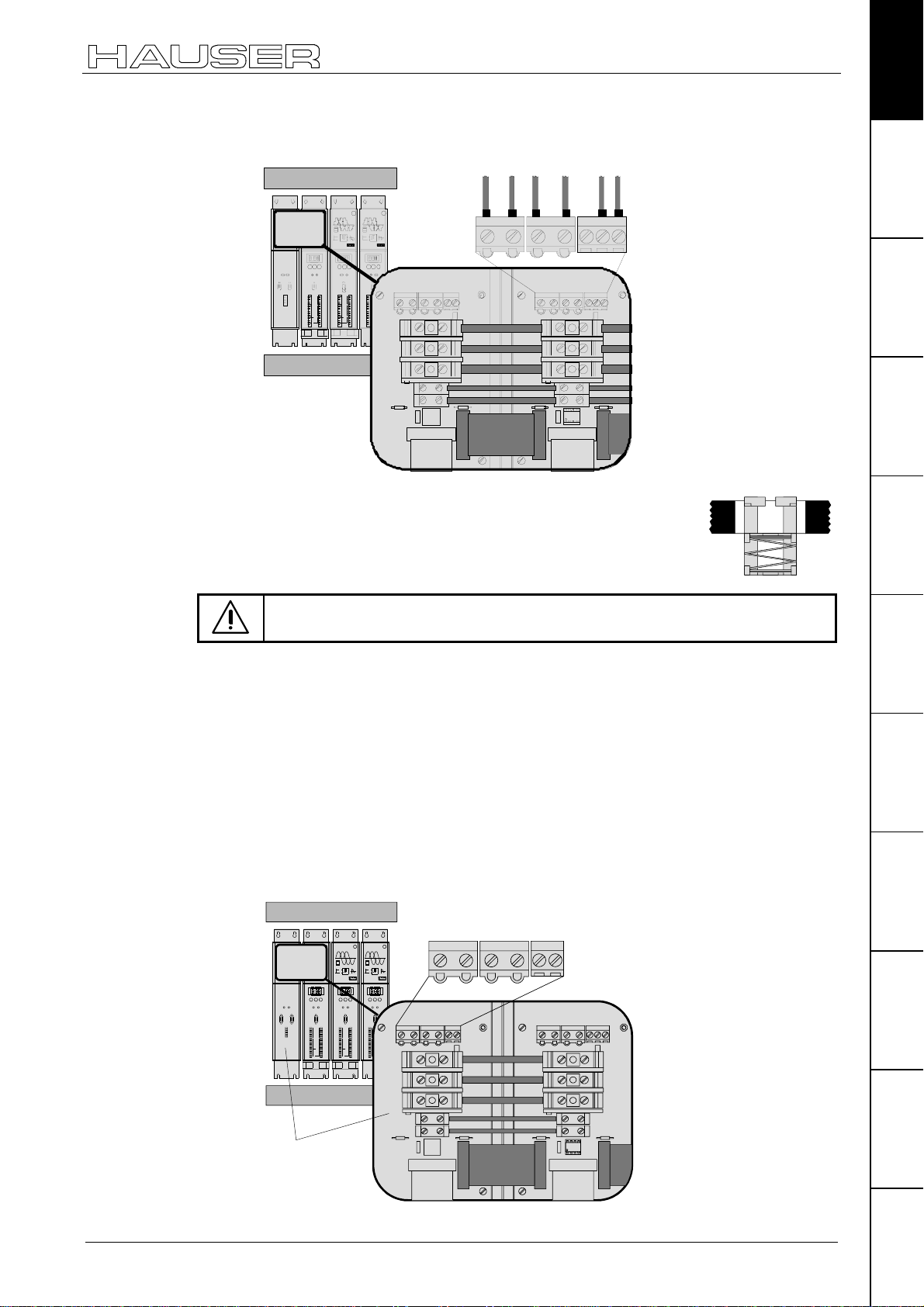

7.2.2 COMPAX-M system network, NMD10 / NMD20 mains module

A COMPAX-M drive system consists of one mains module and one or more drive

controllers. The units are coupled with one another with flatband cables (see

below). These are arranged behind the front plate cover of the power unit and the

drive controller.

The power unit converts mains power (up to 3 * 500V AC) into DC current for the

intermediate circuit.

The two connectors for connection to the bus systems are located on the front

plate of the power unit. The connection assignment complies with the specifications

for 2-cable remote bus.

The 24V DC control voltage required by the system network is supplied from the

power unit.

A connector terminal on the front of the power unit is used for connecting the

control and status signals (EMERGENCY STOP, readiness) which you can

incorporate in the control of the entire system.

These signals and the bus lines are connected internally via a preformed

doublesided flatband cable. These cables are included with the drive controller.

The connectors which receive these connection cables are housed under the front

plate cover of the mains module and the drive controller.

Short circuit

connectors

Wiring up the

system network

Attach a short circuit connector to the outgoing connector on the drive controller

that is furthest away from the mains module. The short circuit connector (order No.

102-908000) is included with the mains module.

Installation arrangement

Before wiring up, always de-energize the unit.

Even once the mains supply has been switched off, dangerous

levels of voltage can remain in the system for up to 5 min.

The wires required for creating the system network are included in the delivery.

Open the front cover (upper section of front side) by loosening the top right knurled

screw and wire up the following:

!

24V DC voltage supply.

!

PE and DC current.

!

Emergency stop, ready and bus signals with a terminating connector on the last

unit.

From the mains module to the individual COMPAX-M.

When delivered, the terminating connector is located on the mains module.

power supply module

COMPAX-M COMPAX-M

cable conduit

HAUSER

HAUSER

DIGITAL

POWER SUPPLY

COMPAX-M

Status

Number

Value

-

+Enter

Ready

Error

Ready Error

X6

X6 X7

...

RS232

RS485IN OUT

X10

X8

X8

Control

Input

Output

Test

Control

X9

X11

voltage supply

24V

emergency stop,

stand by and bus

signals

{

main 24V motor

HAUSER

DIGITAL

L1 L2L3 PE 24V

COMPAX-M

StatusNumber

Value

-+Enter

X1

Ready Error

X6

RS232

PE

X8 X10

Input

X2

Output

Test

+LS

Control

X9 X11

-LS

+

24V

X3

-

PE LS+ LS-

+-

X4

UVWPEbrake

X1

X2

X3

X5

PE+ -

motor

UVWPEbrake

PE+ -

X1

X2

X3

X4

X5

X4

last device

equiped

with

terminal

plug

18

COMPAX-M unit features

COMPAX-M system network, NMD10 / NMD20 mains module

Unit

hardware

Wiring up the

motor

Screened

connection

Unit side

cable conduit

HAUSER

HAUSER

POWER SUPPLY

COMPAX- M

ReadyError

X6 X7

RS485INOUT

X8

Control

StatusNumber

-+Enter

X8 X10

X9 X11

UVWPE

black 1

black 2

COMPAX-M

COMPAX-M

DIGITAL

DIGITAL

DIGITAL

Motion & Control

Motion & Control

StatusNumber

Value

ReadyError

X6

RS232

Input

Output

Test

Control

StatusNumb er

Value

Value

-+Enter

-+Enter

ReadyError

ReadyError

X6

X6

RS232

X8 X10

Input

Output

Test

Control

X9 X11

L1L2L3PE 24V

RS232

X8 X10

Input

X1

Output

Test

Control

PE

X9 X11

123 45

X1

+-

X2

+LS

-LS

+

24V

X3

-

black 3

UVWPEbrake

X1

X2

X5

brake

-

+

PE

free

green/

yellow

black 4

black 5

PE + -

X3

X4X4

Note the screened connection of the motor cable on the

upper unit side.

Clamp the motor cable with the open place of the screen

braid under the ground terminal (see figure on the right).

Connector

assignment / cable

Technical dataConfigurationPositioning and

control functions

Wiring up mains

power / control

voltage

Only wire up brake in motors which have a holding brake! If not, do not

wire.

The mains supply and the control voltage supply are provided by the mains

module.

Power supply:

!

3*80V AC – max. 3*500V AC; 45 - 65Hz

!

Fuse protection:

NMD10: 16A (K circuit breaker in 20A)

Control voltage

!

24V DC ±10%

Ripple <1V

Fuse protection: max. 16A

SS

NMD20: 35A

K circuit breaker or similar Neozed

fusible cut-out.

cable conduit

HAUSER

HAUSER

POWER SUPPLY

COMPAX-M

Ready Error

X6 X7

RS485IN OUT

X8

Control

StatusNumber

-+Enter

Ready Error

X8 X10

X9 X11

L1 L2L3 PE

1

COMPAX-M

COMPAX-M

DIGITAL

DIGITAL

Motion & Control

StatusNumber

Value

Value

-+Enter

Ready Error

X6

X6

RS232

RS232

X8 X10

Input

Input

Output

Output

Test

Test

Control

Control

X9 X11

DIGITAL

Motion & Control

StatusNumber

Value

-+Enter

Ready Error

X6

L1 L2L3 PE 24V

RS232

X8 X10

Input

X1

Output

Test

Control

X9 X11

PE

X1

X2

+LS

-LS

+

X3

24V

-

23 45

+-

24V

-

+

UVWPEbrake

X1

X2

X3

PE+ -

power supply

module

X5

X4X4

functions

Optimization

InterfacesAccessories /

options

StatusParameterError list

19

Start-up manual

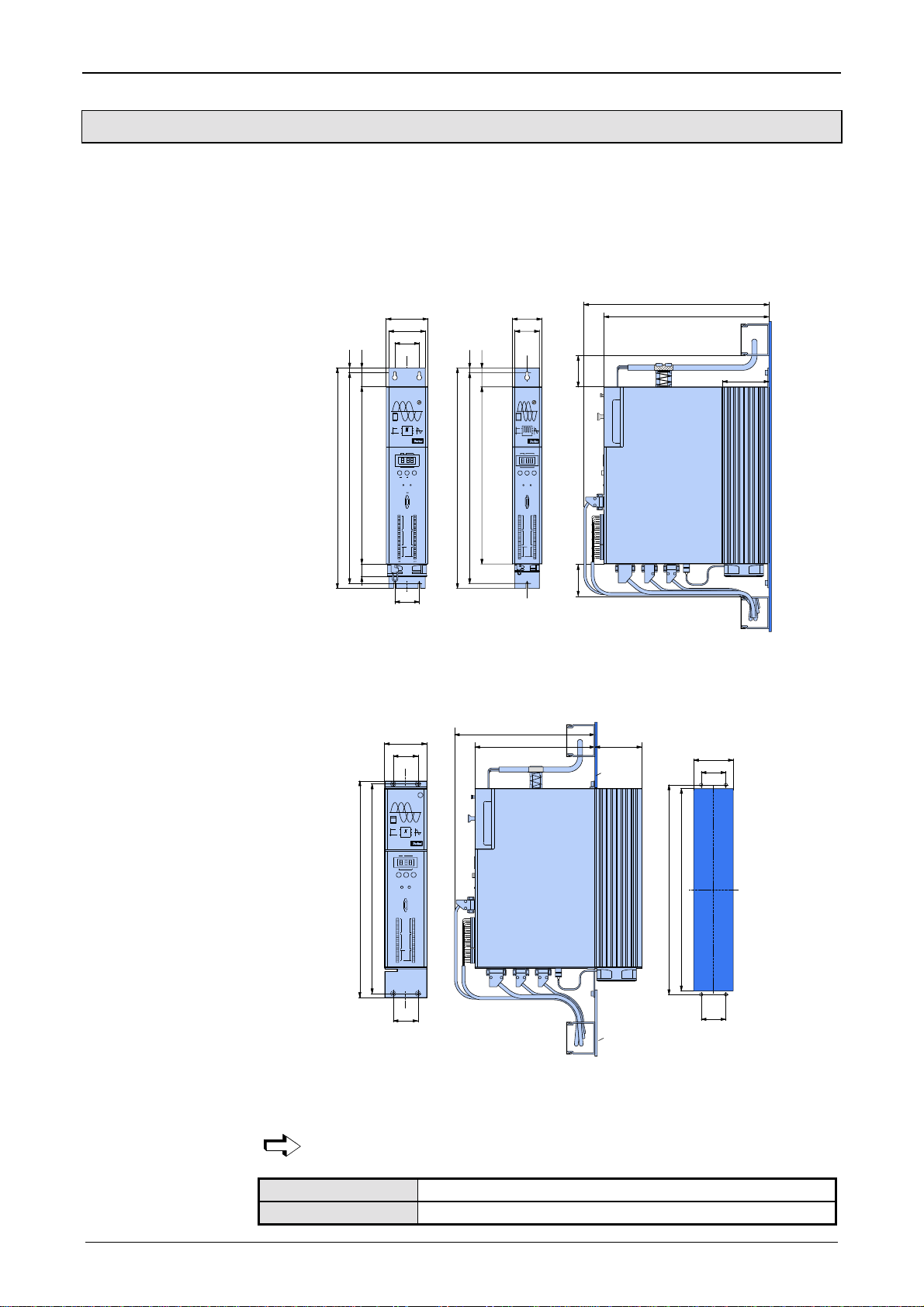

7.2.3 COMPAX-M dimensions/installation

The specific design of the COMPAX-M controller allows for wall installation

(distance: 61mm in COMPAX P1XXM and 86mm in larger units) in two different

ways.

COMPAX-M / -S

Direct

wall installation:

Indirect

wall installation:

Direct wall installation and dimensions of COMPAX-M and the mains

modules.

02XXM, 05XXM,

15XXM, NMD10

10

40

450

430

364

31

Attach with four 6-mm

hex-socket-head-screws

& NMD20

85

75

50

COMPAX-M

DIGITAL

Status Number

Value

Enter

Ready Error

RS232

X8 X10

Input

Output

Test

Control

50

450

P1XXM

60

49

10

40

COMPAX-M

DIGITAL

StatusNumber

Value

430

-+Enter

364

Ready Error

X6

RS232

X10

X8

Input

Output

Test

Control

X9

X11

Attach with two 6-mm

hex-socket-head-screws

390

340

65

96

65

The controllers are attached to the mounting plate with the back of the heat sink.

Indirect wall installation of COMPAX 02XXM, COMPAX 05XXM and COMPAX

15XXM and the mains modules NMD10 and NMD20.

294

244 96

mounting

plate

82

50

COMPAX-M

85

50

Fan configuration

20

DIGITAL

Status Number

Value

-+Enter

Ready Error

424

X8 X10

Output

Test

X9 X11

X6

RS232

Input

Control

441,5

50

mounting

plate

424

408

50

The heat sink is pushed back through a hole in the panel (on right of diagram). A

separate heat chamber is created between the installation plate and the rear wall

of the control cabinet. The angles required under designation MTS2 must be

complied with.

Indirect wall installation is not possible with COMPAX P1XXM.

Units with fan:

COMPAX P1XXM, COMPAX 05XXM, COMPAX 15XXM

Units without fan: COMPAX 02XXM, NMD10, NMD20

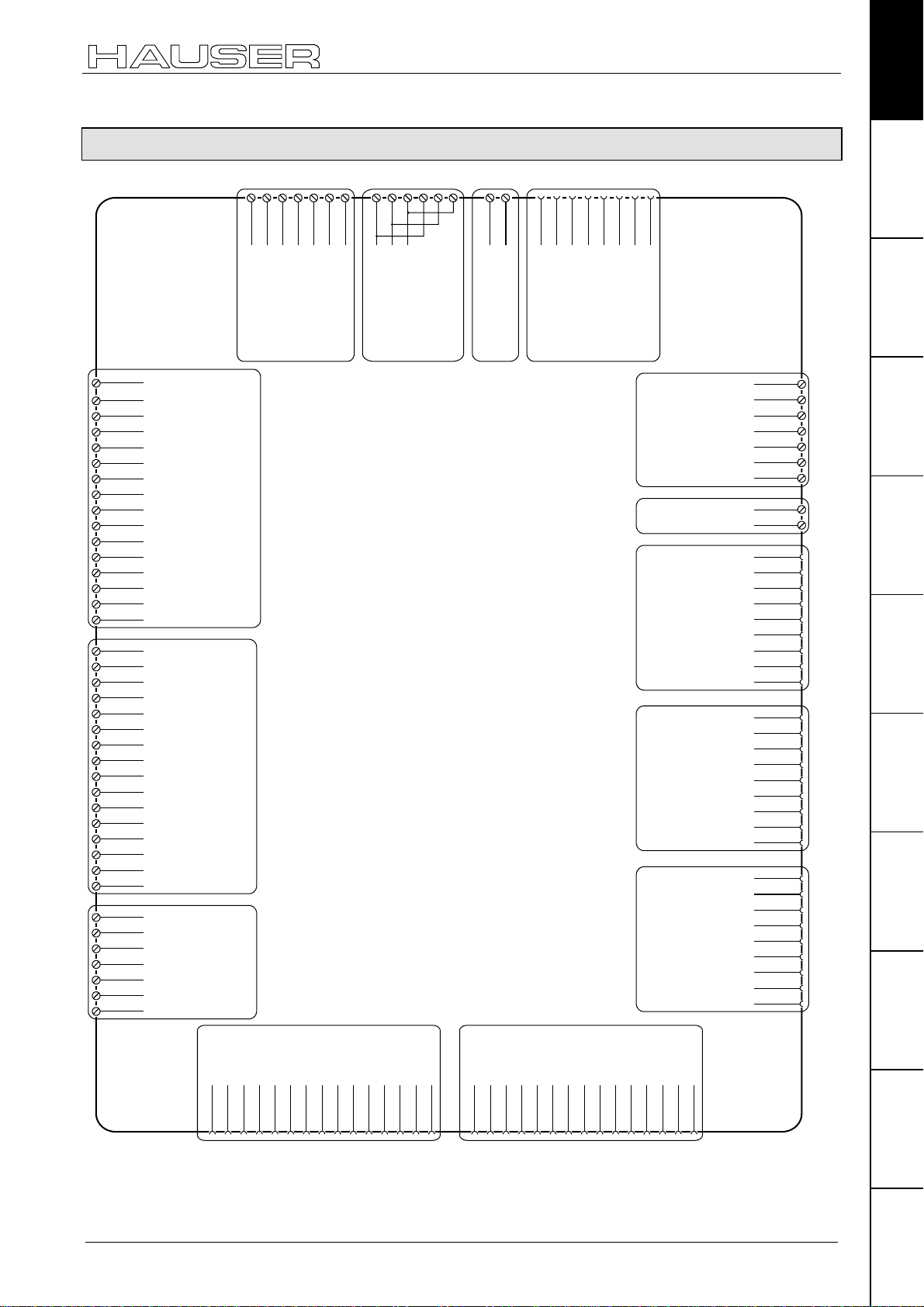

7.2.4 Connector assignment COMPAX-M

X1/2

X1/1UX1/3

V

X1/4

X1/5

W

PE

PE

Br-

Br+

PE

+LS

-LS

X3/1

X3/20VX6/2

+24 V

COMPAX-M unit features

Connector assignment COMPAX-M

X6/3

X6/4

X6/5

X6/6

X6/7

X6/8

X6/9

RxD

TxD

DTR

GND

DSR

RTS

CTS

+5V

Unit

hardware

Connector

assignment / cable

X8/1

I1

X8/2

I2

X8/3

I3

X8/4

I4

X8/5

I5

X8/6

I6

X8/7

I7

X8/8

I8

X8/9

O1

X8/10

O2

X8/11

O3

X8/12

O4

X8/13

O5

X8/14

O6

X8/15

O7

X8/16

O8

X10/1

I9

X10/2

I10

X10/3

I11

X10/4

I12

X10/5

I13

X10/6

I14

X10/7

I15

X10/8

I16

X10/9

O9

X10/10

O10

X10/11

O11

X10/12

O12

X10/13

O13

X10/14

O14

X10/15

O15

X10/16

O16

X9/1

+24V

X9/2

GND

X9/3

reserviert

X9/4

reserviert

X9/5

24V*

15V - 24V emergency

X9/6

stop*

X9/7

housing

* can be

parameterized

X8:

input /

output

I1...I8

O1...O8

X10:

input /

output

I9...I16

O9...O16

X9

housing

+8V

REF-

X1:

motor

brake

SIN-

GND

ST+

+5 V

TEMP

X2:

power intermediate loop

COS-

COS+

SIN+

REF+

X3:

control

voltage

ST-

housing

X6:

RS232

Technical dataConfigurationPositioning and

X11/1

+24V

X11/2

GND

shield

24V

0V

shield

+24V

GND

Sig.MN

Sig. E2

Sig. E1

NC

RxC

TxC

RxD

TxD

RxC/

TxC/

RxD/

TxD/

NC

NC

GND

NC

D+

+24V

T-

D-

T+

X11/3

X11/4

X11/5

X11/6

X11/7

X18/+

X18/-

X17/1

X17/2

X17/3

X17/4

X17/5

X17/6

X17/7

X17/8

X17/9

X14(15)/1

X14(15)/2

X14(15)/3

X14(15)/4

X14(15)/5

X14(15)/6

X14(15)/7

X14(15)/8

X14(15)/9

X16/1

X16/2

X16/3

X16/4

X16/5

X16/6

X16/7

X16/8

X16/9

control functions

functions

Optimization

InterfacesAccessories /

options

StatusParameterError list

Override

DA-channel 2

X11

DA-channel 3

Override (old)

X18: fan

(option D1)

X17:

DA-channel 0

DA-channel 1

GND 24V

DA-monitor

initiators

X14/X15:

HEDA

X16:

Absolut

encoder

X13: encoderX12: resolver / SinCos

+5V

N2/

B2/

A2/

N1/

B1/

A1/

GND

X12/1

X12/2

X12/3NCX12/4

X12/5

X12/6NCX12/7

X12/8

X12/9

X12/10

X12/11

X12/12

X12/13

X12/14

X12/15

X13/1

X13/2N2X13/3B2X13/4A2X13/5N1X13/6B1X13/7A1X13/8

X13/9

X13/10

X13/11

X13/12

X13/13

X13/14

X13/15

The assignment of X12 does not apply for the S3 option.

The bus connections are made via the mains module.

21

Start-up manual

7.3 Mains module NMD10/NMD20

The mains module ensures the supply of current to the COMPAX-M (not COMPAX

35XXM) axis controller and the SV drive connected into the network. It is

connected to the 3-phase power supply with 3 * 400V AC and PE. 24V DC voltage

must be provided for the control electronics.

7.3.1 Overview NMD

COMPAX-M / -S

Power Supply

X6 bussystems IN

L1 L2 L3 PE 24V

X1

PE

X2

+LS

-LS

+

24V

X3

-

IN OUTRS 485

X18 fan

X6

Ready Error

voltage supply

PE + -

X8

3*(80-500)V AC/

X1 24V CC

PE

X2 power inter-

+LS

mediate loop

-LS

X3 control

+

24V

-

voltage 24 V

X4

X4 control- and

status-signals

Bus signals

continuation

X7

Control

X7 bus-systems

OUT

X8 Control

Before wiring up, always de-energize the unit.

Even once the mains supply has been switched off, dangerous

levels of voltage can remain in the system for up to 5 min.

The PE connection must be a 10mm

7.3.2 Dimensions / installation

Dimensions and installation of the NMD10 and NMD20 power units correspond to

the data for COMPAX-M (see Page 20).

22

2

version

7.3.3 NMD connector assignment

Mains module NMD10/NMD20

NMD connector assignment

Unit

hardware

X1/1

X1/1

L1

L1

X1/2

X1/2

L2

L2

X1/3

X1/3

X1/4

X1/4

X1/5

X1/5

X1/6

X1/6

X6: input bus systems X7: output bus systems

Assignment depends on the

bus system

X1:

L3

L3

voltage

supply

PE

PE

+24V

+24V

0V

0V

PF

PE

X2:

power inter-

+LS

+LS

mediate loop

-LS

-LS

X8

15V-24 V emerg. stop

Assignment depends on the

bus system

X3:

Control

voltage

7.3.4 Technical data / power features NMD

Function

Generates DC current when run directly off a mains source.

CE conformity

!

EMC immunity/emissions as per EN61800-3.

!

Safety: VDE 0160/EN 50178.

stand by

housing

+24V

GND

+24V

+24V

0V

X8/1

X8/2

X8/3

P

X8/4

S

X8/5

X8/6

X8/6

Connector

assignment / cable

Technical dataConfigurationPositioning and

control functions

Output power

Nominal power Peak power

NMD10: 10 kW 20 kW (<3s)

NMD20: 20 kW 40 kW (<3s)

Mains fuse protection

NMD10: 16A (K circuit breaker in 20A)

NMD20: 35A

K circuit breaker or similar Neozed fusible cut-out.

Supply voltage up to max. 3*500V AC

!

Operating range: 3*80V AC - 3*500V AC, 45 - 65 Hz.

Typical AC mains: 400V ±10%; 460V ±10%; 480V ±5%

!

Layout of contactors for the power supply:

Capacity according to device performance: Application group AC3.

Control voltage

!

21.6V up to 26.4V DC (0.8A)

!

Ripple: < 1V

!

Fuse protection: max. 16A

SS

Dissipation power

!

without fan: max. 120W (standard)

!

with fan: max. 250W.

functions

Optimization

InterfacesAccessories /

options

StatusParameterError list

23

Start-up manual

Overvoltage limitation

Energy recuperated during braking is stored in the supply capacitors. The capacity

and storable energy is:

NMD10/NMD20: 1100µµµµF / 173 Ws

If the energy recuperated from braking causes overvoltage, then ballast

resistances are engaged.

COMPAX-M / -S

Activation of the

internal ballast

resistance for

NMD20

Maximum braking

power:

The internal ballast resistance is activated by a bridge between +LS and X5/1.

In the NMD20 delivery status this bridge is fitted.

UVWPEBrake

X1

X2

X3

X5

PE+ -

X4X4

X3

24V

+-

L1 L2 L3 PE

X1

X2

PE

+LS

-LS

ext

int

RB

RB

1

X5

2

Braking power Duration Cooling down time

NMD10

17 kW <50 ms

4.0 kW <1s

≥

≥

10s

50s

Without fan: 120W unlimited

With fan: 250W unlimited

NMD20

9.5 kW <50 ms

2.5 kW <1s

≥

≥

10s

50s

Without fan: 120W unlimited

With fan: 200W unlimited

Connecting the

external ballast

resistance

External ballast resistances can be used with NMD20 (see Page 193).

If the braking power of the internal ballast resistance is insufficient, an external

ballast resistance can be connected.

The external ballast resistance is connected between +LS and X5/2.

To do this, the bridge between +LS and X5/1 must be removed.

The full braking power cannot be used with this bridge present.

UVWPEBrake

X1

X2

X3

X5

PE+ -

X4X4

RB

L1 L2 L3 PE

X1

X2

PE

+LS

-LS

ext

ext

int

RB

RB

1

X5

2

24V

+-

X3

Output X5 is protected from short circuits.

Thermal protection

An emergency stop is triggered at 85°C heat sink temperature, the ready contact is

released and the red LED lights up.

24

Mains module NMD10/NMD20

Technical data / power features NMD

If a phase malfunctions, no displays appear

Unit

hardware

Error diagnosis in

the mains module

LED red

Error

off on

on off

LED green

Ready

Possible errors

no errors

!

Heat sink temperature too high

or

!

error in logic voltage (24V DC too low or unit is

defective)

Emergency stop is activated and ready

contact is released.

on on

!

Ballast switch overloaded

or

!

undervoltage (<100V DC or <80V AC).

Ready contact and green LED are coupled.

Caution!

If the unit has no control voltage, no displays will indicate that operating voltage is

present.

Connector

assignment / cable

Technical dataConfigurationPositioning and

control functions

functions

Optimization

InterfacesAccessories /

options

StatusParameterError list

25

Start-up manual

7.4 COMPAX 35XXS unit features

The 35 kW servo control COMPAX 35XXM - a performance upgrade to the

COMPAX family.

!

Compact unit with output currents of 50

unit.

!

Additional COMPAX-M controllers of up to 15 KW can be arranged in rows.

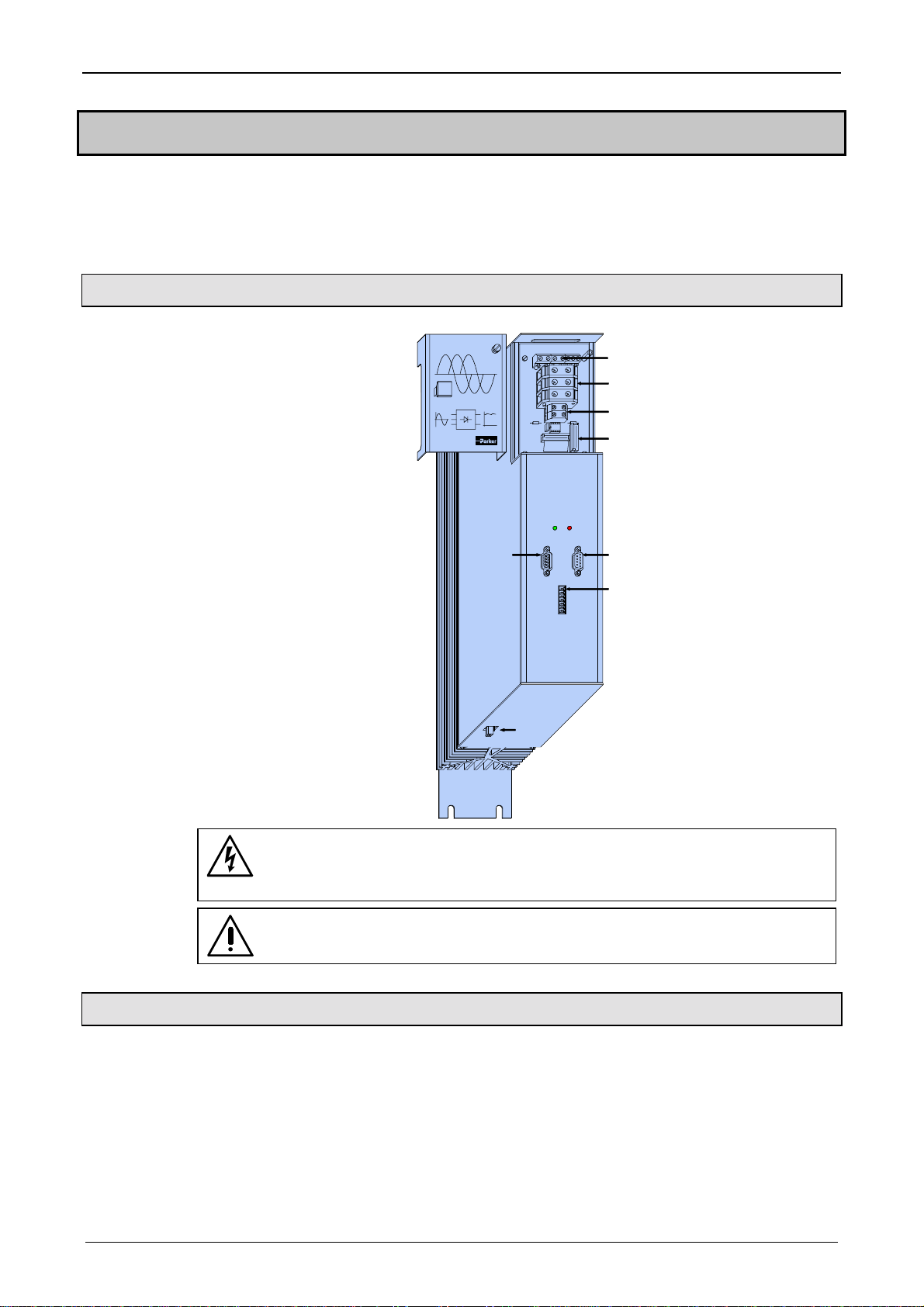

7.4.1 Plug and connection assignment COMPAX 35XXM

COMPAX-M

Aeff

/ 100

Digital

Number

Status

Aeff

COMPAX-M / -S

(<5s) with integrated power

Bus

systems:

X7 OUT

X5 IN

X19

Control

X9 Test

X13

Encoder

X12

Resolver

H1

X5 X7

IN OUT

X19

Control

Value

+-

Ready

Error

X6

X8 X10

Input

Output

Test

Control

X9 X11

Enter

RS 232

X6 RS232

X8/X10 In-/

Output

X11 Control

X14/X15

HEDA

X17 Initiators

X16 Absolute

encoder

Before wiring up, always de-energize the unit.

Even once the mains supply has been switched off, dangerous

levels of voltage can remain in the system for up to 5 min.

When working with motors without a holding brake, the brake lines

must not be connected to COMPAX

26

Caution!

If the unit has no control voltage, no displays will indicate that operating

voltage is present.

Plan view

AC - voltage

up to 500V AC

L1 L2 L3

Mains Input

X 20

24V control

voltage

PE

PE

+

DC - In

24 V

X 21

external

ballast

resistor

-

Resistance

PE

Braking

X 22 X 1

COMPAX 35XXS unit features

Installation and dimensions of COMPAX 35XXM

motor

brake

Motor

Brake

X 23

F1

3.16A

F1

-

motor

U

VW

Motor

+

PE

Unit

hardware

Connector

assignment / cable

Technical dataConfigurationPositioning and

Specific technical

data

Supply voltage up to max. 3 * 500V AC

Operating range: 3*80V AC - 3*500V AC; 45 - 65 Hz.

Typical AC mains: 400V ±10%; 460V ±10%;480V ±5%

!

Layout of contactors for the power supply:

Capacity according to device performance: Application group AC3

Note!

Switching on the operating voltage for a second time:

Before switching on the operating voltage for a second time, you must wait for at

least 2.5 minutes otherwise you may overload the condenser load resistance.

Control voltage

!

21.6V to 26.4V DC • Ripple: < 1VSS • fuse protection: max. 16A

Mains supply fuse protection

62A K circuit breaker or suitable Neozed conventional fuse.

Regeneration mode

!

Storable energy: 3450µF/542 Ws

!

External ballast resistance: 10Ω/2 kW

For the external ballast resistors available, please see Page 193.

7.4.2 Installation and dimensions of COMPAX 35XXM

390

340

86

14

10

38

218

190

COMPAX-M

control functions

functions

Optimization

InterfacesAccessories /

options

Digital

Number

Status

Value

430

363

IN OUT

X5 X7

+-Enter

H1

Ready Error

X19

X8 X10

Control

Output

Test

X9 X11

190

450

X6

RS 232

Input

Control

65 65

Fastening with 4 M6 hex-socket head screws.

StatusParameterError list

27

Start-up manual

7.4.3 Wiring COMPAX 35XXM

Wiring up motor,

mains power /

control voltage

and external

ballast resistance

500V AC

Supply up to

L1 L2 L3

PE

green / yellow

COMPAX-M / -S

Connection for

external contact

for brake control

Motor

U

VW

PE

green / yellow

black 3

black 2

black 1

Motor

black 5

black 4

F1

3.16A

brake*

F1

+

24V Control voltage

-

External

braking resistance

PE

green / yellow

Wiring up system

network

W

11121314

+

PE

Motor

Brake

-

X 23

123

L1 L2 L3

Mains Input

X 20

45

68910

7

-

+

PE

DC - In

24 V

X 21

PE

Braking

Resistance

X 22 X 1

UV

Motor

* max. 1.6A

The PE connection must be a version of at least 10mm

COMPAX 35XXM

X5 X7

IN OUT

COMPAX-M / SV-M

Cable conduit

H1

X19

Control

...

...

HAUSER

DIGITAL

COMPAX-M

Status Number

Value

-+Enter

Ready Error

X6

RS232

X8 X10

Input

Output

Test

Control

X9 X11

+

24V

-

Voltage supply 24V

Emergency stop,

stand by and

bus signals

LS-

LS+

Motor

PE

UVWPEBrake

PE+ -

X1

18

17

16

15

X2

Last device

equiped with

X3

X5

terminal plug

X4

2

28

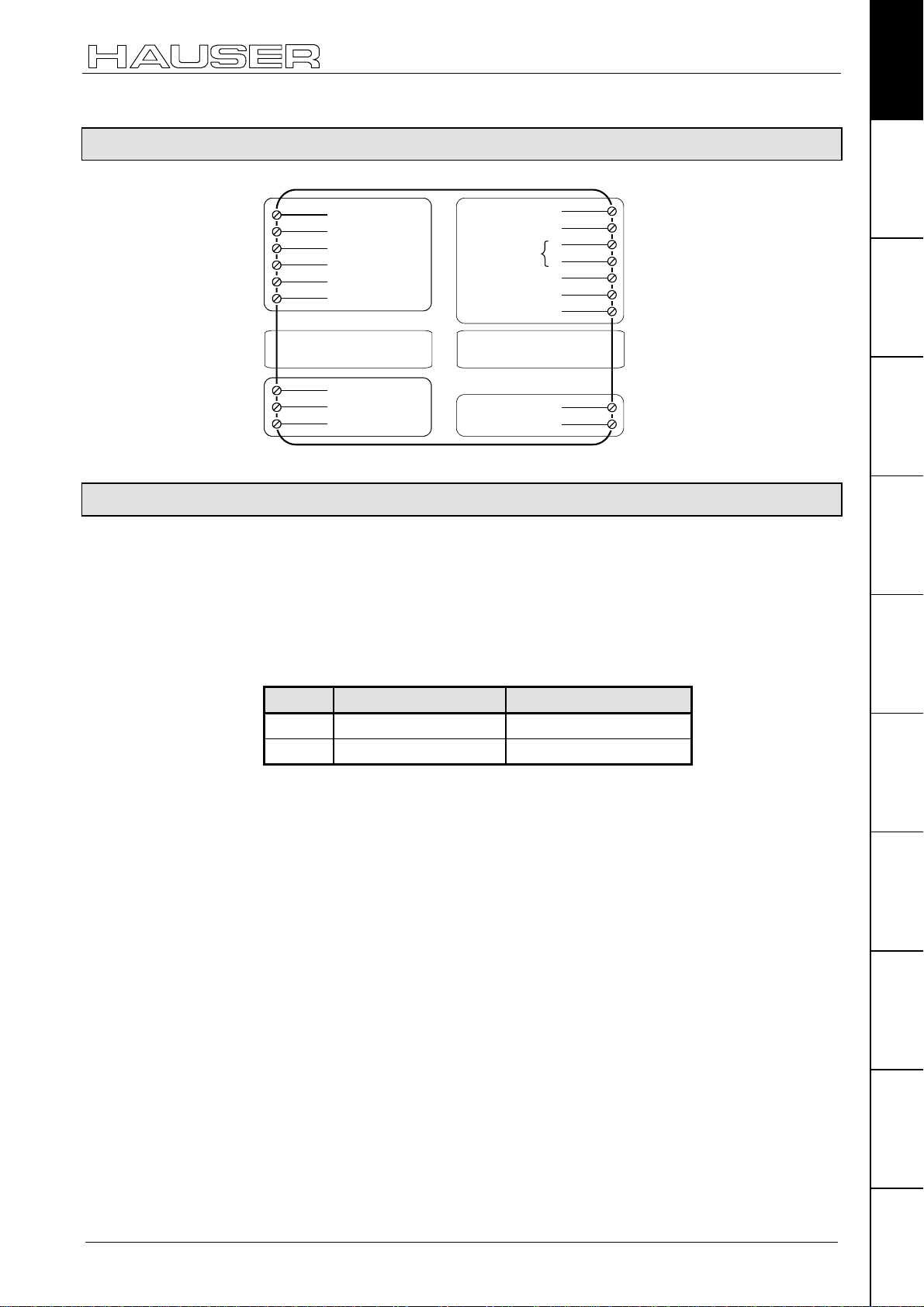

7.4.4 COMPAX 35XXM connector assignment

X21/1

X21:

Control

voltage

PE

+LS

-LS

+24V

0V

+24V

GND

+24V

24V

+24V

Enable

Shield

RxD

TxD

DTR

GND

DSR

RTS

CTS

+5V

X21/2

+24 V

X19/1

X19/2

X19/3

X19/4

X19/5

X19/6

X19/7

X19/8

X19/9

X19/10

X19/11

X6/2

X6/3

X6/4

X6/5

X6/6

X6/7

X6/8

X6/9

0V

X3/1

X3/2

X3/2

PE

Braking

resistance

X22: Braking

resistance

Enable final stage

X12/1

X12/2

X12/3

X12/4

X12/5

X12/6

X12/7

X12/8

X12/9

X12/10

X12/11

X12/12

X12/13

X12/14

X12/15

X13/1

X13/2

X13/3

X13/4

X13/5

X13/6

X13/7

X13/8

X13/9

X13/10

X13/11

X13/12

X13/13

X13/14

X13/15

X8/1

X8/2

X8/3

X8/4

X8/5

X8/6

X8/7

X8/8

X8/9

X8/10

X8/11

X8/12

X8/13

X8/14

X8/15

X8/16

X10/1

X10/2

X10/3

X10/4

X10/5

X10/6

X10/7

X10/8

X10/9

X10/10

X10/11

X10/12

X10/13

X10/14

X10/15

X10/16

X9/1

X9/2

X9/3

X9/4

X9/5

X9/6

X9/7

X20/2

X20/1L1X20/3

X20:

AC Supply

I1

I2

I3

I4

I5

I6

I7

I8

O1

O2

O3

O4

O5

O6

O7

O8

I9

I10

I11

I12

I13

I14

I15

I16

O9

O10

O11

O12

O13

O14

O15

O16

+24V

GND

reserved

reserved

24V

15-24V Emerg. stop*

Housing

X8:

Input / output

I1...I8; O1...O8

X10:

Input / output

I9...I16; O9...O16

X9

* can be parameterized

L2

L3

PE

PE

HV dc and 24V

for additional

COMPAX-M

X7: output bus systems

Assignment depends on

the bus system

output bus systems

X5:

Assignment depends on

the bus system

Stand by P

Stand by S

15-24V Emerg.stop

reserved

X19

X6:

RS232

COMPAX 35XXS unit features

COMPAX 35XXM connector assignment

X1/2

X1/1UX1/3

V

X1:

Motor

Housing

+8V

NC

REFSINNC

GND

ST+

+5 V

TEMP

COSCOS+

SIN+

REF+

ST-

Housing

N2

B2

A2

N1

B1

A1

+5V

N2/

B2/

A2/

N1/

B1/

A1/

GND

W

PE

X12: Resolver / SinCos

X13: Encoder

X23/3

X23/1

X23/2

Br-

Br'+

Br'+

X23:

Motor brake

X23/4

Br+

Override

DA-channel 2

X11

DA-channel 3

Override (old)

Shield

X18:

Fan

DA-channel 0

DA-channel 1

Shield

(Option D1)

GND 24V

Sig.MN

Sig. E2

X17: DA-monitor

initiators

Sig. E1

X14/X15:

HEDA

X16:

Absolute

encoder

+24V

GND

24V

0V

+24V

GND

NC

RxC

TxC

RxD

TxD

RxC/

TxC/

RxD/

TxD/

NC

NC

GND

T+

NC

D+

+24V

X14(15)/1

X14(15)/2

X14(15)/3

X14(15)/4

X14(15)/5

X14(15)/6

X14(15)/7

X14(15)/8

X14(15)/9

T-

D-

X11/1

X11/2

X11/3

X11/4

X11/5

X11/6

X11/7

X18/+

X18/-

X17/1

X17/2

X17/3

X17/4

X17/5

X17/6

X17/7

X17/8

X17/9

X16/1

X16/2

X16/3

X16/4

X16/5

X16/6

X16/7

X16/8

X16/9

Unit

hardware

Connector

assignment / cable

Technical dataConfigurationPositioning and

control functions

functions

Optimization

InterfacesAccessories /

options

StatusParameterError list

The assignment of X12 does not apply for the S3 option.

29

Start-up manual

COMPAX-M / -S

7.5 COMPAX 25XXS unit characteristics

7.5.1 COMPAX 25XXS connector and connection assignment

Statu s

Number

Meaning of the

LEDs on the front

plate

COMPAX-S

X8 input

/ output

X9 test

X12 resolver

X14 HEDA

X16 absolute

Value

+-Enter

Ready

Error

X6

RS 232

X8

X9

X10

Input

Outp ut

Test

Control

X11

X6 RS232

X10 digital input

and output

X11 control

X13 encoder

X15 HEDA

X17 initiators

X18 fan

LED / color Meaning, when switched on

Ready / green 24V DC present and initialization complete

Error / red

COMPAX - fault (E1...E56) present.

Plan view of

COMPAX 25XXS

30

X5 Bus

systems IN

F19

3.16 AT

L3

C

A

V

0

3

2

L1

C

A

230V AC

V

0

3

2

L2

line to line voltage

!

max. 230V AC +10%

3 x 230V AC

X2/

X3/

X1/

X4/

1 x 230V AC

PE

PE

4

3

L3

L2

2

1

2

1

8

7

6

5

4

3

2

1

3

2

1

N

L1

L

-

+

-

+

PE

W

V

U

PE

BB-

+

Bus systems

X7

X2

supply

24V DC

X3

supply

motor and

X1

motor brake

braking

X4

resistance

OUT

AC

COMPAX 25XXS unit characteristics

COMPAX 25XXS connector and connection assignment

Before wiring up, always de-energize the unit.

Even once the mains supply has been switched off, dangerous

levels of voltage can remain in the system for up to 5 min.

When working with motors without a holding brake, the brake lines

must not be connected to COMPAX

Unit

hardware

Connector

assignment / cable

Wiring up motor

The PE connection occurs with 10mm2 under a fixing bolt

Caution!

If the unit has no control voltage, no displays will indicate that operating

voltage is present.

On unit side

X5 RS485 IN

RS485

X7

OUT

AC

X2

supply

F19 3.16 AT

24V DC

X3

supply

motor and

X1

motor brake

braking

X4

resistance

L3

C

A

V

0

3

2

L1

C

A

230V AC

V

0

3

2

L2

line to line voltage

!

max. 230V AC +10%

3 x 230V AC

1 x 230V AC

PE

PE

L3

L2

N

L1

L

+

+

PE

W

V

U

PE

BB-

+

sheetshielding of motor cable

connection for

X1

external contact

for brake control

black 5

-

black 4

brake

+

green/yellow

PE

black 3

W

black 2

black 1

V

U

Technical dataConfigurationPositioning and

control functions

functions

Optimization

InterfacesAccessories /

Wiring up mains

power / control

voltage

! Note the screened connection of the motor cable on the upper side of the unit.

! Clamp the motor cable with the open section of the screen braid under the

ground terminal.

Motor side

! Via connectors.

The mains supply and control voltage supply are located on the upper side of the

unit.

Power supply: there are 2 options (with the same output power):

••••

3 * 80V AC - 3 * 250V AC

1 * 100V AC - 1 * 250V AC

! Layout of contactors for the power supply:

45-65Hz

••••

45-65Hz

••••

fuse protection: 10A

••••

Fuse protection: 16A

Capacity according to device performanc: Application group AC3.

options

StatusParameterError list

31

Start-up manual

COMPAX-M / -S

! Control voltage 24V DC ±10% ripple <1V

Fuse protection: 16A

Bus system