Page 1

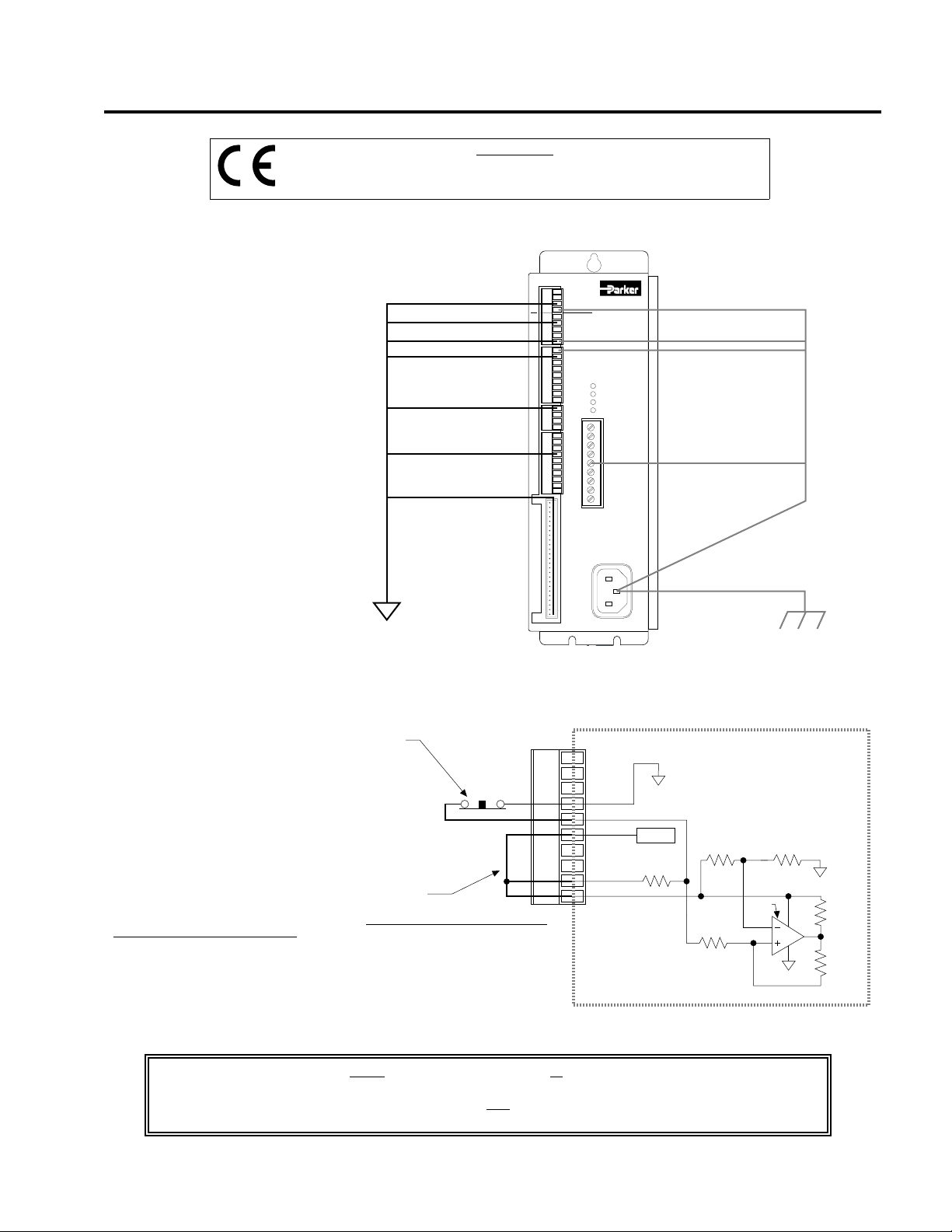

ZETA6104 Indexer/Drive

Installation Guide

Rx

Tx

COM 1 COM 2 ENCODER LIMITS I/O

GND

6104

Rx+

SHLD

INDEXER DRIVE

Rx-

+5V

Tx+

GND

Tx-

Rx

GND

Tx

SHLD

SHLD

GND

ZZ+

BB+

AA+

+5V

GND

HOM

NEG

POS

TRG-A

TRG-B

OUT-A

GND

P-CUT

+5V

OUT-P

IN-P

AUX-P

V_I/O

PROGRAMMABLE I/O

Compumotor

95-132 VAC95-132 VAC

50/60 Hz

POWER

STEP

OVER TEMPOVER TEMP

MOTOR FAULTMOTOR FAULT

INTERLOCK

CENTER TAP

A

A+

AEARTH

B+

B-

CENTER TAP

B

INTERLOCK

ZETA

MOTOR

AC POWER

Compumotor Division

Compumotor

Parker Hannifin Corporation

p/n 88-014782-02B September 1997

Page 2

User Information

! !

WARNING

6000 Series products are used to control electrical and mechanical

components of motion control systems. You should test your motion

system for safety under all potential conditions. Failure to do so can result

in damage to equipment and/or serious injury to personnel.

6000 Series products and the information in this user guide are the proprietary property of Parker Hannifin Corporation or its licensers, and

may not be copied, disclosed, or used for any purpose not expressly authorized by the owner thereof.

Since Parker Hannifin constantly strives to improve all of its products, we reserve the right to change this user guide and software and

hardware mentioned therein at any time without notice.

In no event will the provider of the equipment be liable for any incidental, consequential, or special damages of any kind or nature

whatsoever, including but not limited to lost profits arising from or in any way connected with the use of the equipment or this user guide.

© 1995-7, Parker Hannifin Corporation

All Rights Reserved

Motion Architect is a registered trademark of Parker Hannifin Corporation.

Motion Builder, CompuCAM and DDE6000 are trademarks of Parker Hannifin Corporation.

Microsoft and MS-DOS are registered trademarks, and Windows, DDE and NetDDE are trademarks of Microsoft Corporation.

Motion Toolbox is a trademark of Snider Consultants, Inc.

LabVIEW is a registered trademark of National Instruments Corporation.

Technical Assistance

North America and Asia:

Compumotor Division of Parker Hannifin

5500 Business Park Drive

Rohnert Park, CA 94928

Telephone: (800) 358-9070 or (707) 584-7558

Fax: (707) 584-3793

FaxBack: (800) 936-6939 or (707) 586-8586

BBS: (707) 584-4059

e-mail: tech_help@cmotor.com

Internet: http://www.compumotor.com

Automation

Contact your local automation technology center (ATC) or distributor, or ...

Europe (non-German speaking):

Parker Digiplan

21 Balena Close

Poole, Dorset

England BH17 7DX

Telephone: +44 (0)1202 69 9000

Fax: +44 (0)1202 69 5750

Germany, Austria, Switzerland:

HAUSER Elektronik GmbH

Postfach: 77607-1720

Robert-Bosch-Str. 22

D-77656 Offenburg

Telephone: +49 (0)781 509-0

Fax: +49 (0)781 509-176

Product Feedback Welcome

E-mail: 6000user@cmotor.com

Page 3

Change Summary

ZETA6104 Installation Guide

Rev B

September 1997

The following is a summary of the primary technical changes to this document.

This book, p/n 88-014782-02B, supersedes 88-014782-02A and 88-014782-01B.

Revision B Change Wiring diagrams (series/parallel connections) for RSxxx-xxNPS and RSxxx-xxC10 motor

Revision A Changes (from 88-014782-01 B)

Topic Description

New Hardware Revision These are the primary changes resulting from hardware enhancements:

New CE-marked OS Series

and RS Series Motors

Miscellaneous Corrections

and Clarifications

Continued . . .

options have been corrected Ð see page 9.

¥ New input circuit design for

inputs, you must now connect 5-24VDC (from an on-board

V_I/O terminal on the I/O connector. If V_I/O is connected to +5V, AUX-P can be connected

to a supply of up to +24V; if

also be connected to +24V (or to

V_I/O (£1/3 of V_I/O voltage = low, ³2/3 of V_I/O voltage = high).

¥ Jumper JU7 was added to the ZETA6104 PCA. The purpose of JU7 is to select either

4-wire or 2-wire RS-485 communication. The default is 4-wire (JU7 in position 3).

¥ A new chip is used for the programmable output circuit (UDK2559).

This manual has been updated with data to support the new CE-marked OS Series and RS

Series motors that may be ordered with your ZETA6104 system.

Corrections:

¥ Operating temperature range is 32-113°F (0-45°C);

previously documented as 32-122°F (0-50°C).

¥ The ZETA6104 does

¥ The Static Torque specs for the ZETA motors were incorrect. The DMTSTT (static torque)

command setting for the ZETA57-83 motor should be DMTSTT2 (not DMTSTT1).

¥ The parallel motor wiring diagrams (see back cover and page 9) were in error and have

now been corrected.

¥ The encoder test procedure on page 21 was corrected.

¥ The motor inductance requirements for non-Compumotor motors (see page 43) is:

recommended range = 5.0 to 50.0 mH; minimum = 0.5 mH; maximum = 80.0 mH.

Clarifications:

¥ All inputs and outputs are optically isolated from the internal microprocessor (not from the

other inputs and outputs).

¥ The programmable outputs (including

5-24VDC.

¥ You must select

power the

+5V terminal and to an external supply will damage the ZETA6104.

¥ If you are using an RS-232 connection between the host computer and the master

ZETA6104 connected to multiple ZETA6104s in an RS-485 multi-drop, make sure the

master ZETA6104 has these settings executed in the order given (you should place these

settings in your power-up STARTP program):

PORT1 (select RS-232 port, COM1, for configuration)

ECHO3 (echo to both COM ports)

PORT2 (select RS-485 port, COM2, for configuration)

ECHO2 (echo to the other COM port, COM1)

either the on-board +5V terminal or an external 5-24VDC power supply to

AUX-P, IN-P or OUT-P pull-up resistors. Connecting AUX-P, IN-P or OUT-P to the

P-CUT, HOM, NEG, POS, TRG-A and TRG-B. To power these

or external source) to the new

V_I/O is connected to an external +24V supply, AUX-P must

GND). Switching levels depend on the power applied to

not support RS-422 communication as noted in the previous rev.

OUT-A) will sink up to 300mA, or source up to 5mA at

Page 4

LVD and EMC Installation

Guidelines

The ZETA6104 is in compliance with the Low Voltage Directive (72/23/EEC) and the CE

Marking Directive (93/68/EEC) of the European Community.

When installed according to the procedures in the main body of this installation guide, the

ZETA6104 may not necessarily comply with the Low Voltage Directive (LVD). To install the

ZETA6104 so that it is LVD compliant, refer to supplemental installation instructions provided

in Appendix C. If you do not follow these instructions, the protection of the ZETA6104 may be

impaired.

The ZETA6104 is sold as a complex component to professional assemblers. As a component,

it is not required to be compliant with Electromagnetic Compatibility Directive 89/336/EEC.

However, Appendix D provides guidelines on how to install the ZETA6104 in a manner most

likely to minimize the ZETA6104Õs emissions and to maximize the ZETA6104Õs immunity to

externally generated electromagnetic interference.

Page 5

ABOUT THIS GUIDE

Chapter 1. Installation

What You Should Have (ship kit) ........................................................... 2

Before You Begin ..................................................................................... 2

Recommended Installation Process ............................................. 2

Electrical Noise Guidelines ........................................................... 2

General Specifications ............................................................................ 3

Pre-installation Adjustments................................................................... 4

DIP Switch Settings Ð Motor Current, Address, Autobaud .......... 4

Changing the COM 2 Connector from RS-232 to RS-485 .......... 5

Mounting the ZETA6104.......................................................................... 6

Electrical Connections ............................................................................ 7

Grounding System.......................................................................... 7

Pulse Cut-Off (P-CUT) Ñ Emergency Stop Switch ................... 7

Serial Communication ................................................................... 8

Motor (ZETA and OS/RS motors only) ........................................ 9

End-of-Travel and Home Limit Inputs......................................... 11

Encoder ......................................................................................... 12

Trigger Inputs................................................................................ 13

General-Purpose Programmable Inputs & Outputs ................... 14

RP240 Remote Operator Panel................................................... 18

Input Power ................................................................................... 18

Lengthening I/O Cables ................................................................ 19

Testing the Installation........................................................................... 20

Matching the Motor to the ZETA6104 (OPTIONAL) ........................... 22

Mounting & Coupling the Motor ............................................................ 24

Mounting the Motor....................................................................... 24

Coupling the Motor ....................................................................... 25

Optimizing System Performance (OPTIONAL) ................................. 26

Configuring Active Damping........................................................ 26

Configuring Electronic Viscosity (EV) ........................................ 29

Record Your SystemÕs Configuration .................................................. 30

Recommended Set-up Program Elements ................................ 30

WhatÕs Next? ......................................................................................... 32

Program Your Motion Control Functions.................................... 32

Chapter 2. Troubleshooting

Troubleshooting Basics......................................................................... 34

Reducing Electrical Noise ........................................................... 34

Diagnostic LEDs........................................................................... 34

Test Options.................................................................................. 34

Technical Support......................................................................... 34

Common Problems & Solutions........................................................... 35

Troubleshooting Serial Communication Problems............................. 36

Product Return Procedure .................................................................... 37

Appendix A (Resonance, Ringing & Damping) .......................... 39

Appendix B (Using Non-Compumotor Motors) ......................... 43

Appendix C (LVD Installation Instructions) ................................. 47

Appendix D (EMC Installation Guidelines) ................................. 49

Index.................................................................................................. 53

Purpose of This Guide

This document is designed to help you install and troubleshoot your ZETA6104 hardware

system. Programming related issues are covered in the 6000 Series ProgrammerÕs Guide and

the 6000 Series Software Reference.

The ZETA6104 product is often referred to the as the Ò6104Ó because it is part of the 6000

family of products. The ZETA6104Õs software and the 6000 Series software documentation

(i.e., the Software Reference and the ProgrammerÕs Guide) refer to this product as the Ò6104.Ó

What You Should Know

To install and troubleshoot the ZETA6104, you should have a fundamental understanding of:

¥ Electronics concepts, such as voltage, current, switches.

¥ Mechanical motion control concepts, such as inertia, torque, velocity, distance, force.

¥ Serial communication and terminal emulator experience: RS-232C and/or RS-485

Related Publications

¥ 6000 Series Software Reference, Parker Hannifin Corporation, Compumotor Division;

¥ 6000 Series ProgrammerÕs Guide, Parker Hannifin Corporation, Compumotor Division;

¥ Current Parker Compumotor Motion Control Catalog

¥ Schram, Peter (editor). The National Electric Code Handbook (Third Edition). Quincy,

ÒZETA6104Ó Synonymous with Ò6104Ó

part number 88-012966-01

part number 88-014540-01

MA: National Fire Protection Association

Online Manuals

This manual (in Acrobat PDF format) is available from our web site: http://www.compumotor.com

Page 6

LVD Installation Guidelines

The ZETA6104 is in compliance with the Low Voltage Directive (72/23/EEC) and the CE

Marking Directive (93/68/EEC) of the European Community.

When installed according to the procedures in the main body of this installation guide, the

ZETA6104 may not necessarily comply with the Low Voltage Directive (LVD). To install the

ZETA6104 so that it is LVD compliant, refer to supplemental installation instructions

provided in Appendix C. If you do not follow these instructions, the protection of the

ZETA6104 may be impaired.

The ZETA6104 is sold as a complex component to professional assemblers. As a component,

it is not required to be compliant with Electromagnetic Compatibility Directive 89/336/EEC.

However, Appendix D provides guidelines on how to install the ZETA6104 in a manner most

likely to minimize the ZETA6104Õs emissions and to maximize the ZETA6104Õs immunity

to externally generated electromagnetic interference.

ii z ZETA6104 Installation Guide

Page 7

CHAPTER ONE

Installation

1

IN THIS CHAPTER

¥ Product ship kit list

¥ Things to consider before you install the ZETA6104

¥ General specifications table

¥ Optional pre-installation alterations

- DIP switch settings Ð motor current, device address, autobaud feature

- Changing the COM 2 port from RS-232C to RS-485

¥ Mounting the ZETA6104

¥ Connecting all electrical components (includes specifications)

¥ Testing the installation

¥ Matching the motor to the ZETA6104

¥ Motor mounting and coupling guidelines

¥ Using the damping features to optimize performance

¥ Preparing for what to do next

To install the ZETA6104 so that it is LVD compliant, refer to the supplemental instructions in Appendix C. Appendix D provides guidelines on how to install the ZETA6104 in

a manner most likely to minimize the ZETA6104Õs emissions and to maximize the

ZETA6104Õs immunity to externally generated electromagnetic interference.

Page 8

What You Should Have (ship kit)

Part Name Part Number

ZETA6104 standard product (with ship kit).............. ZETA6104

Ship kit:

120VAC power cord.......................................... 44-014768-01

Motor connector ................................................ 43-008755-01

(ZETA series motors are factory wired with a motor connector)

Wire jumpers: Qty. 3....................................... 44-015142-01

Quick-reference magnet

(see side of ZETA6104 chassis) .................................. 87-014873-01

This user guide

(ZETA6104 Installation Guide)......................... 88-014782-02

6000 Series Software Reference ..................... 88-012966-01

6000 Series ProgrammerÕs Guide................... 88-014540-01

Motion Architect disks: Disk 1 ...................... 95-013070-01

If an item is missing, call the factory (see phone numbers on inside front cover).

Qty. 1....................................... 44-015741-01

Disk 2 ...................... 95-013070-02

Driver & Samples... 95-016324-01

MOTORS: These are the motors that can be ordered with the ZETA6104.

ZETA Motors: *

ZETA57-51 .............. Size 23 single-stack (57-51) motor

ZETA57-83 .............. Size 23 double-stack (57-83) motor

ZETA57-102 ............ Size 23 triple-stack (57-102) motor

ZETA83-62 .............. Size 34 single-stack (83-62) motor

ZETA83-93 .............. Size 34 double-stack (83-93) motor

ZETA83-135 ............ Size 34 triple-stack (83-135) motor

* If you ordered a ZETA6104 and a ZETA motor as a ÒsystemÓ, the

product part number reflects the motor size (e.g., ZETA6104-57-83).

OS Motors (CE Marked):

OS2HB-xxx-xx........ Size 23 half-stack (57-40) motor, 170VDC winding

OS21B-xxx-xx......... Size 23 single-stack (57-51) motor, 170VDC winding

OS21B-xxx-xx......... Size 23 double-stack (57-83) motor, 170VDC winding

RS Motors (CE Marked):

RS31B-xxx-xx......... Size 34 single-stack (83-62) motor, 170VDC winding

RS32B-xxx-xx......... Size 34 double-stack (83-93) motor, 170VDC winding

RS33B-xxx-xx......... Size 34 triple-stack (83-135) motor, 170VDC winding

Before You Begin

WARNINGS

The ZETA6104 is used to control your systemÕs electrical and mechanical components.

Therefore, you should test your system for safety under all potential conditions. Failure to do

so can result in damage to equipment and/or serious injury to personnel.

Always remove power to the ZETA6104 before:

¥ Connecting any electrical device (e.g., motor, encoder, inputs, outputs, etc.)

¥ Adjusting the DIP switches, jumpers, or other internal components

Recommended Installation Process

This chapter is

organized

sequentially to best

approximate a typical

installation process.

1. Review the general specifications

2. Perform configuration/adjustments (if necessary)

3. Mount the ZETA6104

4. Connect all electrical system components

5. Test the installation

6. Match the motor to the ZETA6104 Ñ optional

7. Mount the motor and couple the load

8. Optimize performance (using the ZETA6104Õs damping features) Ñ optional

9. Record the system configuration (record on the information label and/or in a set-up program)

10. Program your motion control functions. Programming instructions are provided in the

6000 Series ProgrammerÕs Guide and the 6000 Series Software Reference. We recommend

using the programming tools provided in Motion Architect for Windows (found in your

ship kit). You can also benefit from an optional iconic programming interface called

Motion Builder (sold separately).

Electrical Noise Guidelines

¥ Do not route high-voltage wires and low-level signals in the same conduit.

¥ Ensure that all components are properly grounded.

¥ Ensure that all wiring is properly shielded.

¥ Noise suppression guidelines for I/O cables are provided on page 19.

¥ Appendix D (page 49) provides guidelines on how to install the ZETA6104 in a manner

most likely to minimize the ZETA6104Õs emissions and to maximize the ZETA6104Õs

immunity to externally generated electromagnetic interference.

2 z ZETA6104 Installation Guide

Page 9

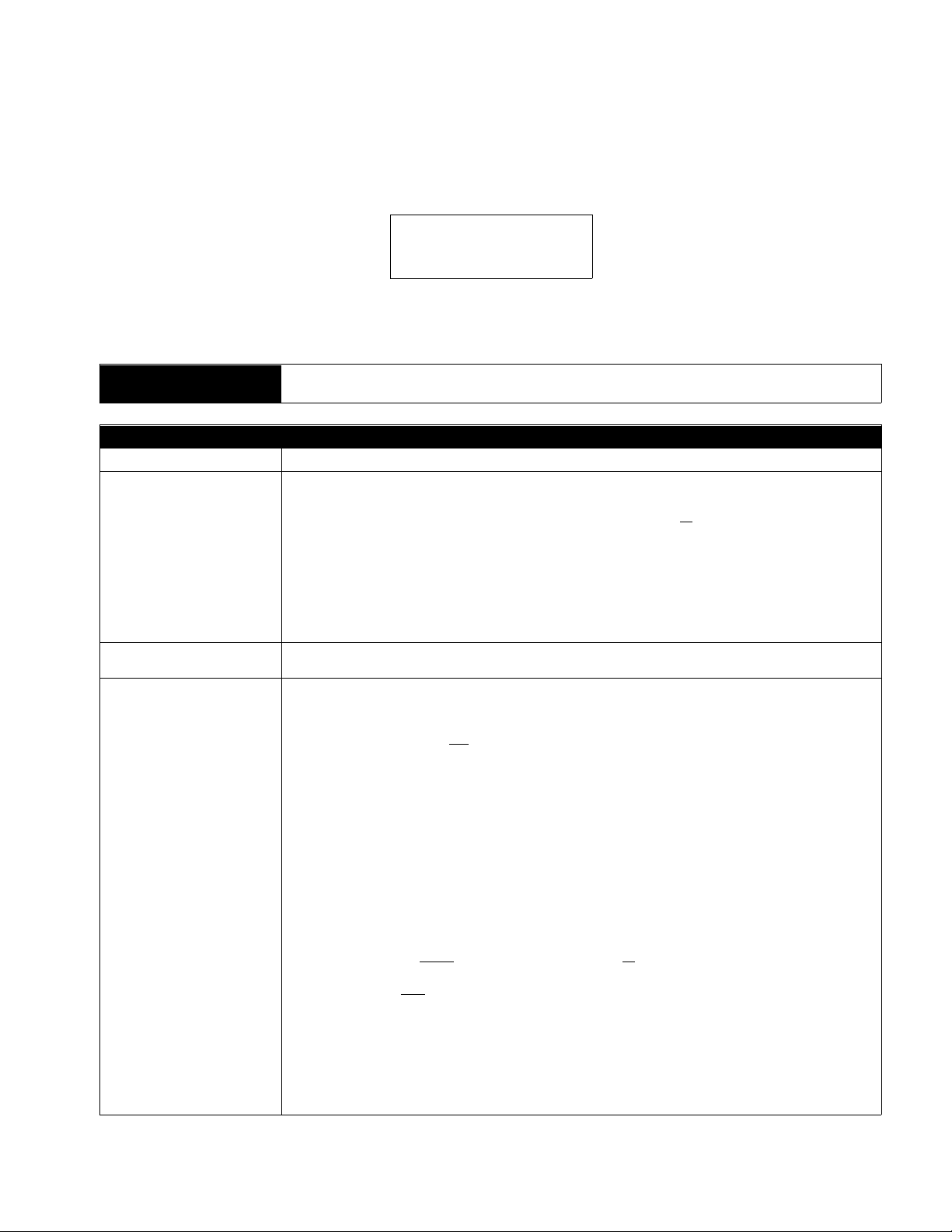

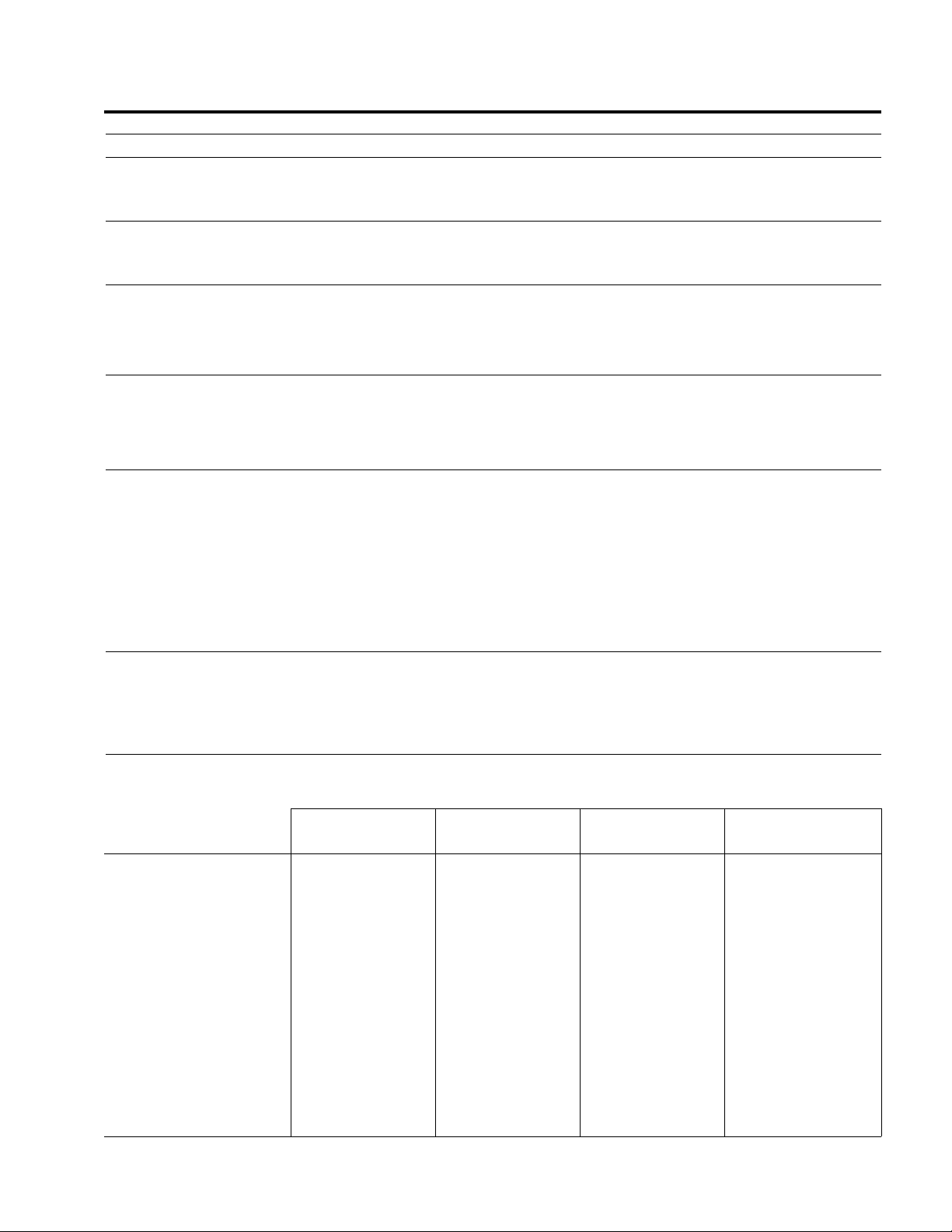

General Specifications

Parameter Specification

Power

AC input .................................................................... 95-132VAC, 50/60Hz, single-phase

Status LEDs/fault detection...................................... Refer to Diagnostic LEDs on page 34

Environmental

Operating Temperature .......................................... 32 to 113°F (0 to 45°C) Ñ over-temperature shutdown fault at 131°F (55°C)

Storage Temperature............................................... -22 to 185°F (-30 to 85°C)

Humidity ................................................................... 0 to 95% non-condensing

Performance

Position Range & Stepping Accuracy ..................... Position range: ±2,147,483,648 steps; Stepping accuracy: ±0 steps from preset total

Velocity Range, Accuracy, & Repeatability............ Range: 1-2,000,000 steps/sec; Accuracy: ±0.02% of maximum rate;

Acceleration Range.................................................. 1-24,999,975 steps/sec

Motion Algorithm Update Rate................................ 2 ms

Serial Communication RS-485 requires internal jumper and DIP switch configuration (see page 5).

Connection Options.................................................. RS-232C, 3-wire; RS-485 (default is 4-wire; for 2-wire move JU7 to position 1);

Maximum units in daisy-chain or multi-drop......... 99 (use DIP switch or ADDR command to set individual addresses for each unit)

Communication Parameters................................... 9600 baud (range is 19200-1200Ñsee AutoBaud, page 4), 8 data bits, 1 stop bit, no parity;

Inputs All inputs are optically isolated from the microprocessor (not from the other inputs).

HOM, POS, NEG, TRG-A, TRG-B, P-CUT .................. Powered by voltage applied to V_I/O terminal (switching levels: £1/3 of V_I/O voltage = low,

Encoder..................................................................... Differential comparator accepts two-phase quadrature incremental encoders with differential

16 General-Purpose Programmable ..................... HCMOS compatible* with internal 6.8 KW pull-ups to IN-P terminalÑconnect IN-P to power

Outputs All outputs are optically isolated from the microprocessor (not from the other outputs).

9 Programmable (includes OUT-A)......................... Open collector output with 4.7 KW pull-ups. Can be pulled up by connecting OUT-P to power

+5V Output................................................................ Internally supplied +5VDC. +5V terminals are available on the COM2, ENCODER and I/O

* HCMOS-compatible switching voltage levels: Low £ 1.00V, High ³ 3.25V.

TTL-compatible switching voltage levels: Low £ 0.4V, High ³ 2.4V.

(refer to page 18 for peak power requirements, based on the motor you are using)

Repeatability: ±0.02% of set rate

2

Change internal jumpers JU1-JU6 to position 1 to select RS-485 communication

RS-232: Full duplex; RS-485: Half duplex (change jumper JU6 to position 1)

³2/3 of V_I/O voltage = high). V_I/O can handle 5-24V with max. current of 100mA. Internal

6.8 KW pull-ups to AUX-P terminalÑconnect AUX-P to power source (+5V terminal or an

external 5-24V supply) to source current or connect AUX-P to GND to sink current; AUX-P can

handle 0-24V with max. current of 50mA. Voltage range for these inputs is 0-24V.

(recommended) or single-ended outputs.

Maximum voltage = 5VDC. Switching levels (TTL-compatible): Low £ 0.4V, High ³ 2.4V.

Maximum frequency = 1.6 MHz. Minimum time between transitions = 625 ns.

source (+5V pin #49 or an external 5-24V supply) to source current or connect IN-P to GND to

sink current; IN-P can handle 0-24V with max. current of 100 mA. Voltage range = 0-24V.

source (+5V terminal or an external 5-24V supply); OUT-P can handle 0-24V with max.

current of 50mA. Outputs will sink up to 300mA or source up to 5mA at 5-24VDC.

8 general-purpose outputs on the Programmable I/O connector, OUT-A on the I/O connector.

connectors. Load limit (total load for all I/O connections) is 0.5A.

Motor Specifications

Static Torque oz-in

Rotor Inertia oz-in

Bearings

Thrust load lb

Radial load lb

End play (Reversing load in

equal to 1 lb) (mm)

Radial play in

(Per 0.5 lb load) (mm)

Weight lb

(Motor+Cable+Connector) (kg)

Certifications UL Rec.

(N-m)

2

(kg-m2 x 10Ð6)

(kg)

(kg)

CE (LVD)

CE (LVD & EMC)

Size 23 ZETA Motors Size 34 ZETA Motors Size 23 OS Motors Size 34 RS Motors

ZETA

57-51

65

(0.46)

0.546

(9.998)

25

(11.3)

15

(6.8)

0.005

(0.13)

0.0008

(0.02)

1.6

(0.7)

No

No

No

ZETA

57-83

125

(0.88)

1.1

(20.1 )

25

(11.3)

15

(6.8)

0.005

(0.13)

0.0008

(0.02)

2.4

(1.1)

No

No

No

ZETA

57-102

148

(1.05)

1.69

(30.9)

25

(11.3)

15

(6.8)

0.005

(0.13)

0.0008

(0.02)

3.2

(1.5)

No

No

No

ZETA

83-62

141

(1.00)

3.47

(63.4)

50

(22.6)

25

(11.3)

0.005

(0.13)

0.0008

(0.02)

3.8

(1.7)

No

No

No

ZETA

83-93

292

(2.11)

6.76

(124)

50

(22.6)

25

(11.3)

0.005

(0.13)

0.0008

(0.02)

5.1

(2.3)

No

No

No

ZETA

83-135 OS2HB OS21B OS22B RS31B RS32B RS33B

382

(2.70)43(0.30)82(0.58)

10.47

(191)

50

(22.6)

25

(11.3)

0.005

(0.13)

0.0008

(0.02)

8.3

(3.8)

No

No

No

0.386

(0.070)

13

(5.9)

20

(9.1)

0.001

(0.025)

0.0008

(0.02)

1.0

(0.45)

No

Yes

No

0.656

(0.119)

13

(5.9)

20

(9.1)

0.001

(0.025)

0.0008

(0.02)

1.5

(0.68)

No

Yes

No

155

1.09)

1.390

(0.253)

13

(5.9)

20

(9.1)

0.001

(0.025)

0.0008

(0.02)

2.5

(1.14)

No

Yes

No

141

(1.00)

3.204

(0.583)

180

(81.6)

35

(15.9)

0.001

(0.025)

0.0008

(0.02)

3.2

(1.45)

Yes

Yes

w/C10 & EMC kit

292

(2.06)

6.563

(1.195)

180

(81.6)

35

(15.9)

0.001

(0.025)

0.0008

(0.02)

5.3

(2.41)

Yes

Yes

w/C10 & EMC kit

382

2.70)

9.652

(1.757)

180

(81.6)

35

(15.9)

0.001

(0.025)

0.0008

(0.02)

7.6

(3.45)

Yes

Yes

w/C10 & EMC kit

Speed/Torque Curves ------ Refer to page 10 ------ ------ Refer to page 10 ------ ------ Refer to page 10 ------ ------ Refer to page 10 ------

Dimensions ------ Refer to page 24 ------ ------ Refer to page 24 ------ ------ Refer to page 24 ------ ------ Refer to page 24 ------

Chapter 1. Installation 3

Page 10

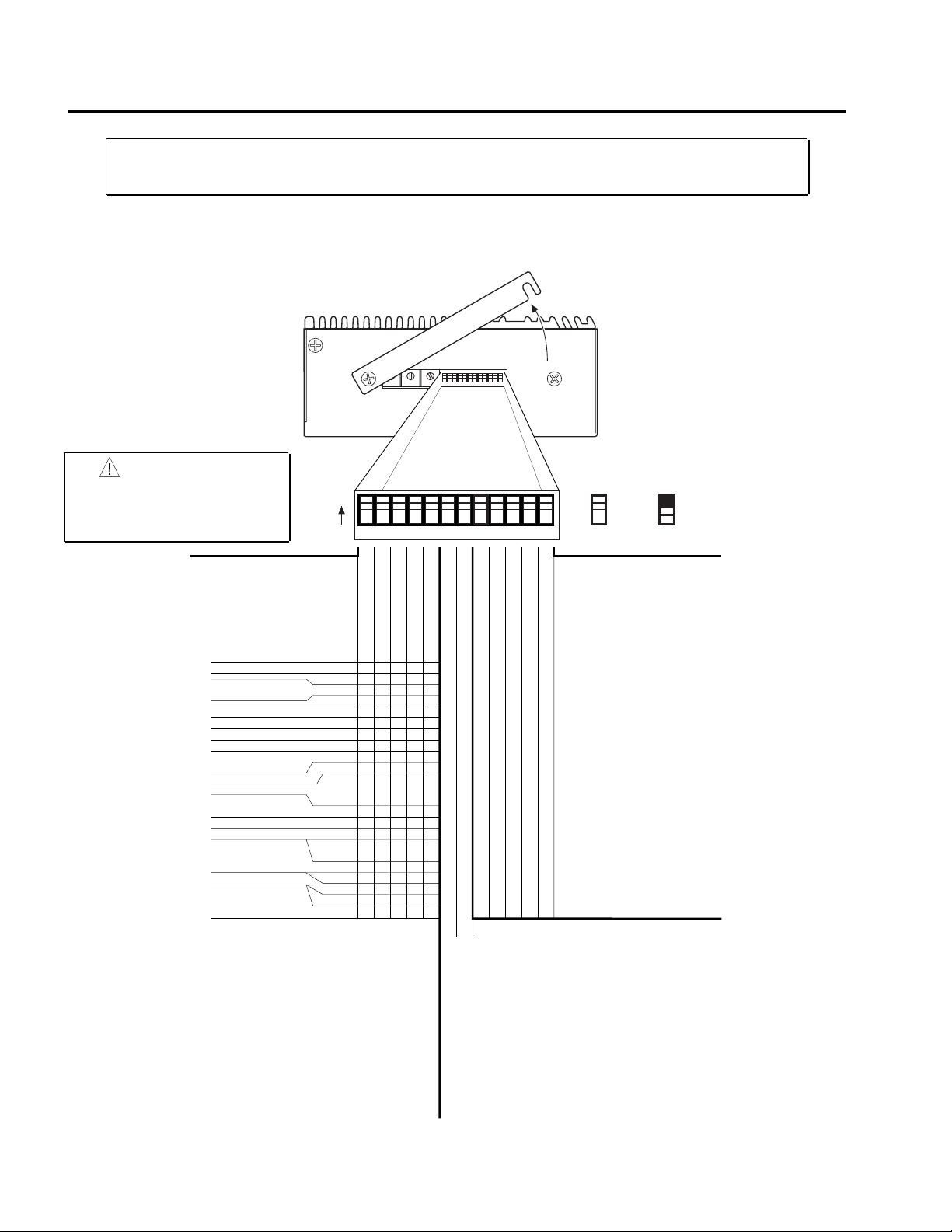

Pre-installation Adjustments

y

Factory Settings May Be Sufficient (if so, skip this section):

¥ Device address is set to zero (if daisy-chaining you can automatically establish with the ADDR command).

¥ Serial communication method is RS-232C.

DIP Switch Settings Ð Motor Current, Address, Autobaud

Move the

Cover

CAUTION

Do not set switches 6-11 to ON at the

same time. This invokes a factory test

mode in which the ZETA6104 executes

a motion sequence upon power up.

Top View of ZETA6104

off

12345 12

6 7 8 9 10 11

=

off

=

on

Motor Current

Zeta57-51 Series

Zeta57-83 Series

OS2HB Series

Zeta57-102 Series

OS21B Series

OS22B Series

Zeta83-62 Series

RS31B Series

Zeta57-51 Parallel

Zeta83-93 Series

RS32B Series

OS2HB Parallel

Zeta57-83 Parallel

Zeta57-102 Parallel

Zeta83-135 Series

RS33B Series

OS21B Parallel

Zeta83-xxx Parallel

OS22B Parallel

RS3xB Parallel

Factory Settings: If you ordered a ZETA Series

motor as part of your ZETA6104 ÒsystemÓ (e.g.,

ZETA6104-83-62), then the DIP switches will be

factory-configured to operate your specific motor in

a series wiring configuration.

If you ordered the ZETA6104 without a motor, or

with an OS or RS Series motor, or if you ordered

the ZETA Series motor separately (not as a

ÒsystemÓ), all DIP switches are factory-set to the

OFF position.

(Amps)

0.14 off off off off off

0.26 off off off off on

0.39 off off off on off

0.51 off off off on on

0.64 off off on off off

0.76 off off on off on

0.89 off off on on off

1.01 off off on on on

1.14 off on off off off

1.26 off on off off on

1.38 off on off on off

1.51 off on off on on

1.63 off on on off off

1.76 off on on off on

1.88 off on on on off

2.01 off on on on on

2.14 on off off off off

2.26 on off off off on

2.38 on off off on off

2.51 on off off on on

2.63 on off on off off

2.76 on off on off on

2.88 on off on on off

3.01 on off on on on

3.13 on on off off off

3.26 on on off off on

3.38 on on off on off

3.50 on on off on on

3.63 on on on off off

3.75 on on on off on

3.88 on on on on off

4.00 on on on on on

off off off off off 0 (default)

off off off off on 1

off off off on off 2

off off off on on 3

off off on off off 4

off off on off on 5

off off on on off 6

off off on on on 7

off on off off off 8

off on off off on 9

off on off on off 10

off on off on on 11

off on on off off 12

off on on off on 13

off on on on off 14

off on on on on 15

on off off off off 16

on off off off on 17

on off off on off 18

on off off on on 19

on off on off off 20

on off on off on 21

on off on on off 22

on off on on on 23

on on off off off 24

on on off off on 25

on on off on off 26

on on off on on 27

on on on off off 28

on on on off on 29

on on on on off 30

on on on on on 31

on off

The default baud rate is 9600. As an alternative, you can use

this procedure to automatically match your terminal's speed of

1200, 2400, 4800, 9600, or 19200 baud.

1. Set switch 6 to on and switch 7 to off.

2. Connect the ZETA6104 to the terminal.

3. Power up the terminal.

4. Cycle power to the ZETA6104 and immediately press the

space bar several times.

5. The ZETA6104 should send a message with the baud rate

on the first line of the response. If no baud rate message is

displayed, verify steps 1-3 and repeat step 4.

6. Change switches 6 & 7 to off.

7. Cycle power to the ZETA6104. This stores the baud rate

in non-volatile memor

NOTE: Autobaud works only on the ZETA6104Õs COM 1 serial port.

Automatic Addressing:

If you are connecting multiple

units (see page 8), you can

use the ADDR command to

establish a unique address for

each unit. The ADDR

command overrides the DIP

switch setting. For details,

refer to the 6000 Series

Software Reference or the

6000 Series Programmer's

Guide.

.

Address

AutoBaud

4 z ZETA6104 Installation Guide

Page 11

Changing the COM 2 Connector from RS-232 to RS-485

)

RS-232C Users

+5V

COM 2

Remove the two retainer screws.

(one on the top of the chassis,

one on the bottom of the chassis)

Slide the chassis forward, then

away from the heat sink.

(follow the dashed arrow)

GND

Rx

Tx

SHLD

Chassis

Rx+

RxÐ

Tx+

TxÐ

GND

RS-485 (optional)

RS-232 (factory default

The ZETA6104Õs COM 2 port is factory configured for RS-232C

communication (use the left-hand pin descriptions). If you

need to use RS-485 communication, you may ignore this section

and proceed to the Mounting instructions.

do not

Heatsink

Be careful not to catch

the 50-pin header clips

on the chassis.

Set the jumpers.

RS-232: Leave JU6 set to position 3 (factory default).

RS-485: Set jumper JU6 to position 1

(disables power-up messages, error messages, & echo).

COM 2 port for RS-232, set JU1-JU5 to position 3 (factory default).

COM 2 port for RS-485, set JU1-JU5 to position 1 (as illustrated).

4-wire RS-485, set JU7 to position 3 (factory default).

2-wire RS-485, set JU7 to position 1.

Set the DIP switches.

DIP switch #4: Rx Termination Resistor...........120 W

DIP switch #3: Tx+ Bias Resistor.....................681 W

DIP switch #2: Tx Termination Resistor...........120 W

DIP switch #1: TxÐ Bias Resistor.....................681 W

NOTE: Set the switches to ON (as illustrated) to use the internal resistors. Do this for a single unit or for the

last unit in a multi-drop only. If these resistor values are not appropriate for your application, set the switches

to OFF and connect your own external resistors. See page 8 for resistor calculations and wiring instructions.

(4-wire is full duplex: transmit and receive at the same time)

(2-wire is half duplex: transmit or

receive at any time)

1234

N

O

Reattach the chassis and replace the two retainer screws.

Chapter 1. Installation 5

Page 12

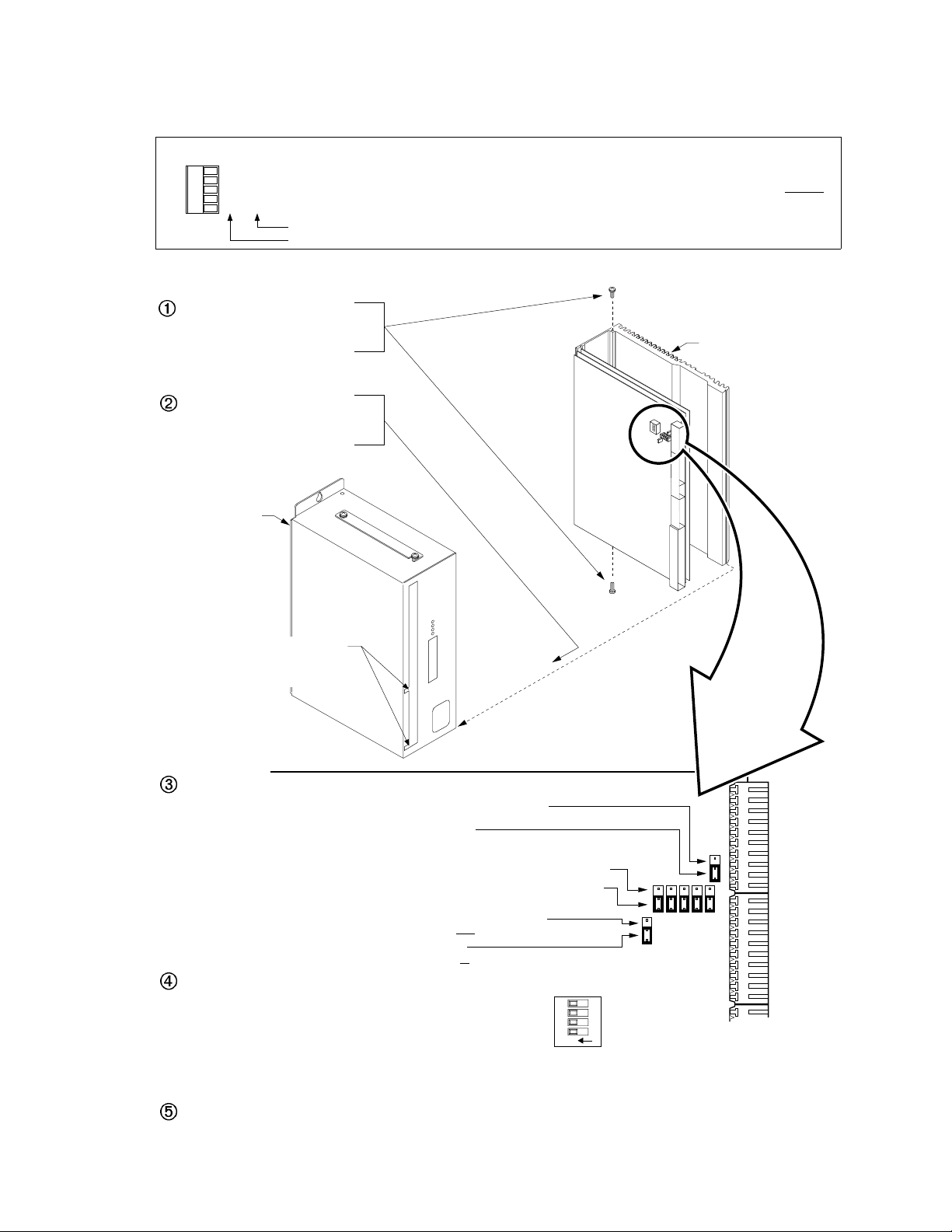

Mounting the ZETA6104

)

)

Before you mount the ZETA6104

Check the list below to make sure you have performed all the necessary configuration tasks that require

accessing internal components (DIP switches, potentiometers, and jumpers). You may, however, be able to

adjust DIP switches and pots after mounting, if you allow access to the top of the ZETA6104 chassis.

¥ Select motor current (DIP switches). If you ordered a ZETA motor with your system (e.g., ZETA6104-57-83) and you

intend to use series motor winding, use the factory setting. If you need to change this setting, refer to page 4 for instructions.

¥ Select device address (DIP switches). If you are not connecting multiple ZETA6104 units in an RS-232C daisy chain or an

RS-485 multi-drop, use the factory setting. If you need to change this setting, refer to page 4 for instructions.

¥ Select serial communication method (jumpers & DIP switches). If you are using RS-232C to communicate with the

ZETA6104, use the factory settings. If you need to change these settings (i.e., for RS-485), refer to page 5 for instructions.

¥ Be aware that if you exercise the motor matching procedures on page 22, you will need to access the potentiometers at the top

of the ZETA6104 chassis. (The motor matching procedures are placed after the Electrical Connections section of this manual

because the process requires that you first understand how to connect the motor, serial communication, and AC power.)

6.813 (173.1)

5.970 (151.6)

Dimensions in inches (millimeters).

1.465

(37.2)

0.965

(24.5)

4.000

(101.6)

1.000

(25.4)

0.133

(3.4)

8.000

(203.2)

8.600

(218.4)

8.850

(224.8)

3x ¯0.156 (3.9)

(clearance for #6 (M3.5)

mounting screw

Environmental

Considerations

Temperature. Operate the ZETA6104 in ambient

temperatures between 32°F (0°C) and 113°F (45°C). Provide a

minimum of 1 inch (25.4 mm) of unrestricted air-flow space

around the ZETA6104 chassis (see illustration). The ZETA6104

will shut itself down if its internal sensor reaches 131°F (55°C).

Humidity. Keep below 95%, non-condensing.

Airborne Contaminants, Liquids. Particulate

contaminants, especially electrically conductive material, such as

metal shavings and grinding dust, can damage the ZETA6104 and

the Zeta motor. Do not allow liquids or fluids to come in

contact with the ZETA6104 or its cables.

6 z ZETA6104 Installation Guide

Minimum Airflow Space = 1 inch

1.0 (25.4)

1.0

(25.4)

1.0 (25.4

Page 13

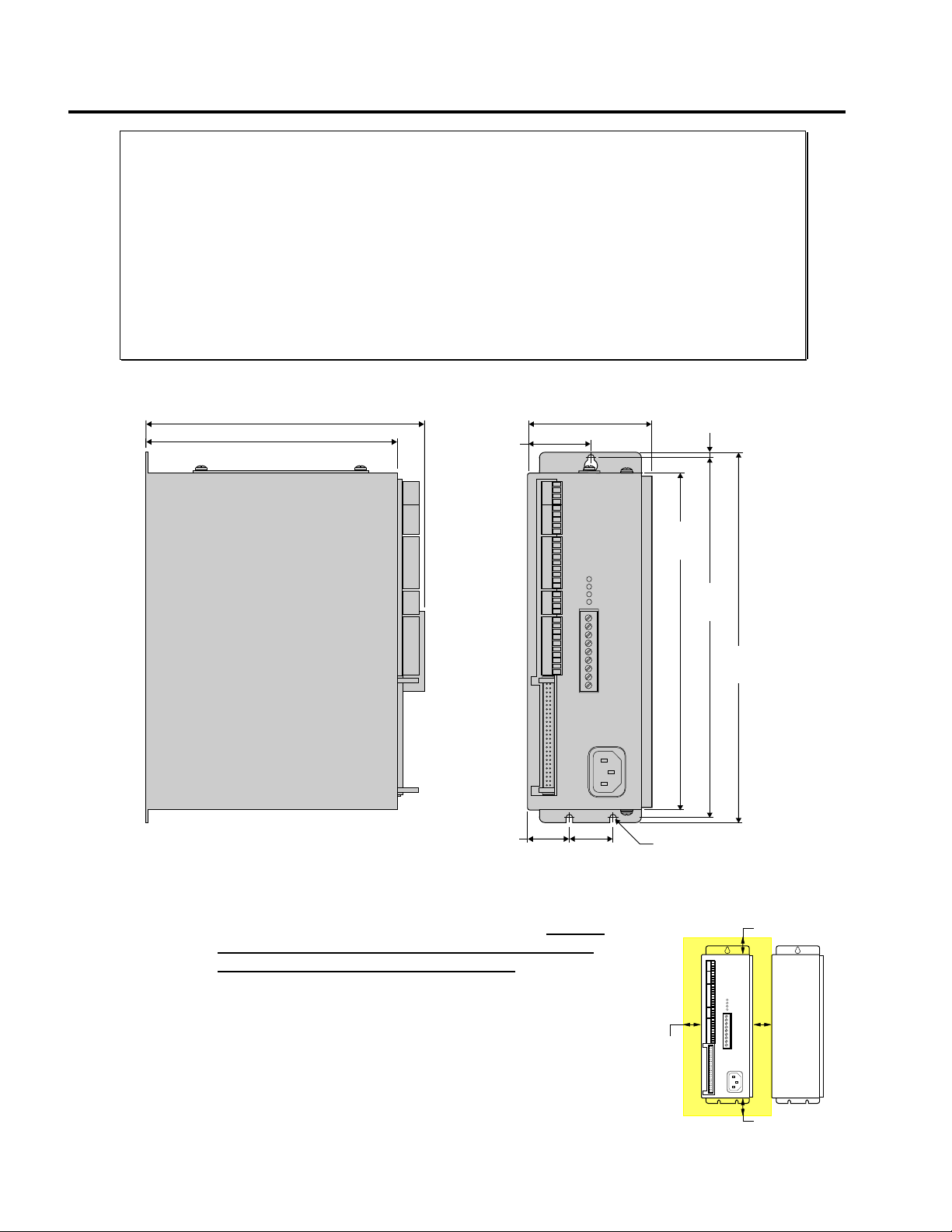

Electrical Connections

To install the ZETA6104 so that it is LVD compliant, refer also to the supplemental instructions in Appendix C. Appendix D provides guidelines on how to install the ZETA6104 in a

manner most likely to minimize the ZETA6104Õs emissions and to maximize the

ZETA6104Õs immunity to externally generated electromagnetic interference.

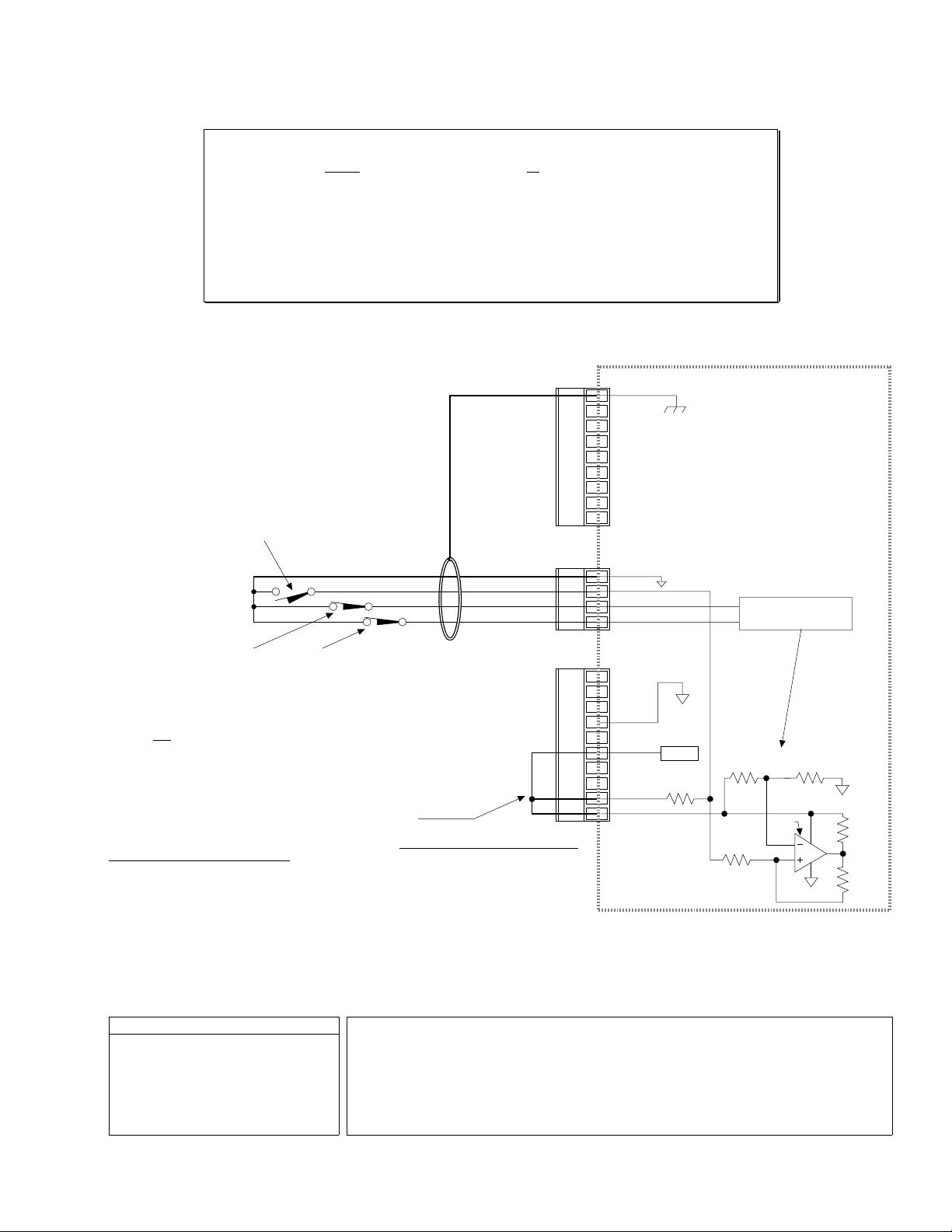

Grounding System

* The function of COM2Õs terminals depends

on whether it is configured for RS-232 (the

factory default configuration) or for RS-485

(see page 5 for configuration).

GND

GND (if COM2 is RS-232) *

GND (if COM2 is RS-485) *

GND

COM 1 COM 2

ENCODER

GND

SHLD

GND

SHLD

SHLD

GND

SHLD

GND

SHLD (if COM2 is RS-232) *

SHLD

NOTE: The inputs and outputs are isolated

from the internal microprocessor, but are not

isolated from the other inputs and outputs.

GND

GND

GND (even number pins)

LIMITS

GND

GND

I/O

1

2

PROGRAMMABLE I/O

49

50

Isolated

Ground

Pulse Cut-Off (P-CUT) Ñ Emergency Stop Switch

P-CUT connected to GND (normally-closed switch).

If this connection is opened, motion is killed and the

program in progress is terminated.

If the P-CUT input is not grounded when motion is

commanded, motion will not occur and the error message

ÒWARNING: PULSE CUTOFF ACTIVEÓ will be displayed in

the terminal emulator.

+5V connected to AUX-P and V_I/O (sourcing current).

Provides +5V power to the P-CUT pull-up resistor. As an alternative, you can

connect AUX-P to an external supply of up to +24V (but do not use both the on-board +5V

terminal and an external 5-24V supply). If V_I/O is connected to a +5V supply (on-board or

external), AUX-P can be connected to a supply of up to +24V. If V_I/O is connected to an

external +24V supply, AUX-P must also be connected to +24V (or to GND).

Switching levels depend on the voltage applied to V_I/O:

LOW £ 1/3 of V_I/O voltage; HIGH ³ 2/3 of V_I/O voltage

NOTE: AUX-P and V_I/O are also used by the HOM, NEG, POS & TRG inputs.

SINKING CURRENT: To make P-CUT (as well as HOM, NEG, POS & TRG) sink current,

connect AUX-P to GND.

I/O Connector

Compumotor

95-132 VAC

50/60 Hz

TRG-A

TRG-B

OUT-A

GND

P-CUT

+5V

OUT-P

IN-P

AUX-P

V_I/O

INTERLOCK

A

CENTER TAP

A+

A-

EARTH

B+

B-

CENTER TAP

B

INTERLOCK

MOTOR

AC POWER

ISO GND

+5VDC

6.8 KW

EARTH

Ground Pin

20.0 KW 18.2 KW

12.1 KW

EARTH

Internal Schematic

LM 339

10.0 KW

30.1 KW

CAUTION: You must select either the on-board +5V terminal or an external power supply to power the

AUX-P pull-up resistor (for the P-CUT, HOM, NEG, POS, TRG-A, and TRG-B inputs).

Connecting AUX-P to the +5V terminal and an external supply will damage the

ZETA6104. (The same rule applies to the IN-P and OUT-P terminals, see page 14.)

Chapter 1. Installation 7

Page 14

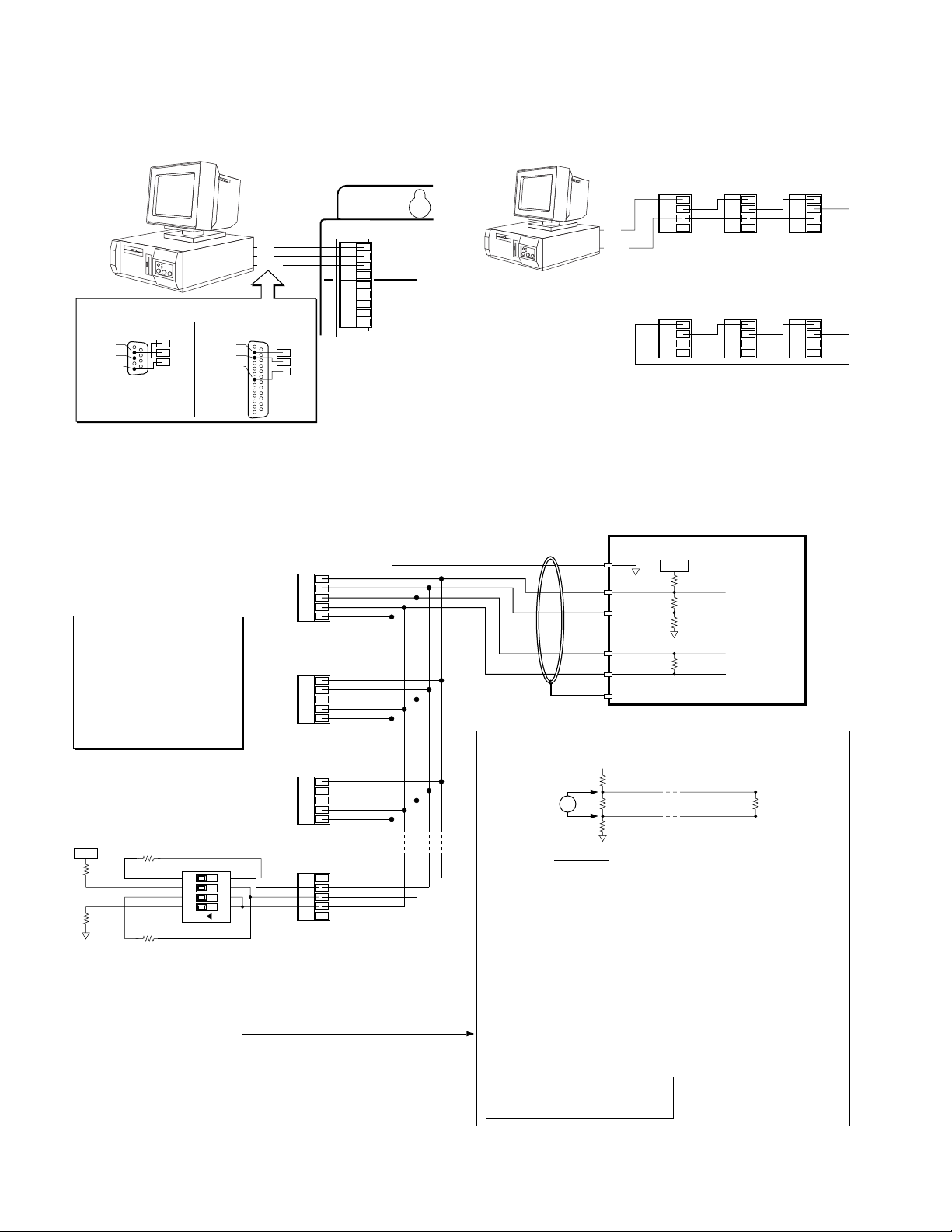

Serial Communication

RS-232C Connections

Tx

Rx

GND

COM 1 COM 2

Serial Port Connection

25-Pin COM Port:9-Pin COM Port:

Pin 2 (Rx)

Pin 3 (Tx)

Pin 5 (GND)

NOTE: Maximum RS-232C cable length is 50 feet (15.25 meters)

Rx

Tx

GND

Pin 2 (Tx)

Pin 3 (Rx)

Pin 7 (GND)

Rx

Tx

GND

Rx

Tx

GND

SHLD

+5V

GND

Rx

Tx

SHLD

Rx+

RxÐ

Tx+

TxÐ

GND

RS-485 Connections (4-wire interface, plus ground)

Unit #1

Rx+

COM 2

RS-485 Configuration

Before you can use RS-485

communication, you must reconfigure the COM 2 port by

setting internal jumpers JU1-JU6

Unit #2

COM 2

to position 1. 4-wire is default

(to use 2-wire, set JU7 to

position 1).

Refer to page 5 for instructions.

Unit #3

COM 2

681W

681W

120 W

120 W

34

12

O

Unit #31

COM 2

N

5VDC

DIP switch selects internal resistor values (ON selects the resistor).

Use these resistors only for the last unit (or for a single unit).

If your application requires terminating resistors other than 120W,

and/or bias resistors other than 681W, then make sure the internal

DIP switches are set to OFF and connect your own external resistors.

To calculate resistor values:

NOTE: Maximum RS-485 cable length is 4000 feet (1220 meters)

+5V

GND

Rx

Tx

SHLD

+5V

GND

Rx

Tx

SHLD

+5V

GND

Rx

Tx

SHLD

+5V

GND

Rx

Tx

SHLD

RxÐ

Tx+

TxÐ

GND

Rx+

RxÐ

Tx+

TxÐ

GND

Rx+

RxÐ

Tx+

TxÐ

GND

Rx+

RxÐ

Tx+

TxÐ

GND

RS-232C Daisy-Chain Connections*

Unit 0

Tx

Rx

GND

Daisy Chain to a Computer or Terminal

Unit 0

Stand-Alone Daisy Chain

Be sure to set unique devices addresses for each unit.

*

To set the address, use the DIP switch (see page 4),

or use the ADDR command (see 6000 Series ProgrammerÕs Guide).

Ground

TxÐ

Rx+

RxÐ

Shield

+5VDC

120 W

120 W

Calculating Resistor Values

Vcc

Ra

Balanced Cable.

Vb Rb

Example

Step 1 Calculate the equivalent resistance (Req)* of Rc / / Rb:

Step 2 Calculate the pull-up and pull-down resistor values knowing that

Assumptions: The cable's characteristic impedance (Zo) = 120W.

Rc / / Rb = 120W / / 120W = 60W

the FAILSAFE bias is 200mV and Vcc = 5V:

Vb = Vcc (Req / (Ra + Req + Rd))

solving for R' (defined as Ra + Rd)

R' = ((Req) Vcc / Vb) - Req

R' = ((60W) 5V / 0.2V) - 60W = 1440W

Since Ra and Rd are equal, Ra = Rd = 1440W / 2 = 720W

Step 3 Recalculate the equivalent resistance of RC / / (Ra + Rd):

Rc / / (Ra + Rd) = 120W / / (720W + 720W) = 110.77W

Since the equivalent resistance is close (within 10%) to the characteristic

impedance of the cable (Zo), no further adjustment of resistor values is

required.

* Actual calculation

for equivalent resistance

(e.g., R1 / / R2):

Rc

Rd

Rc and Rb are equal and are selected to match Zo

(Rc = Rb = Zo = 120W).

R1R

2

(R1 + R2)

Unit 1

Rx

Tx

GND

SHLD

Rx

Tx

GND

SHLD

Unit 1

Rx

Tx

GND

SHLD

Rx

Tx

GND

SHLD

Master

UnitTx+

For further information,

consult a communications

interface reference.

Unit 2

Unit 2

Rx

Tx

GND

SHLD

Rx

Tx

GND

SHLD

8 z ZETA6104 Installation Guide

Page 15

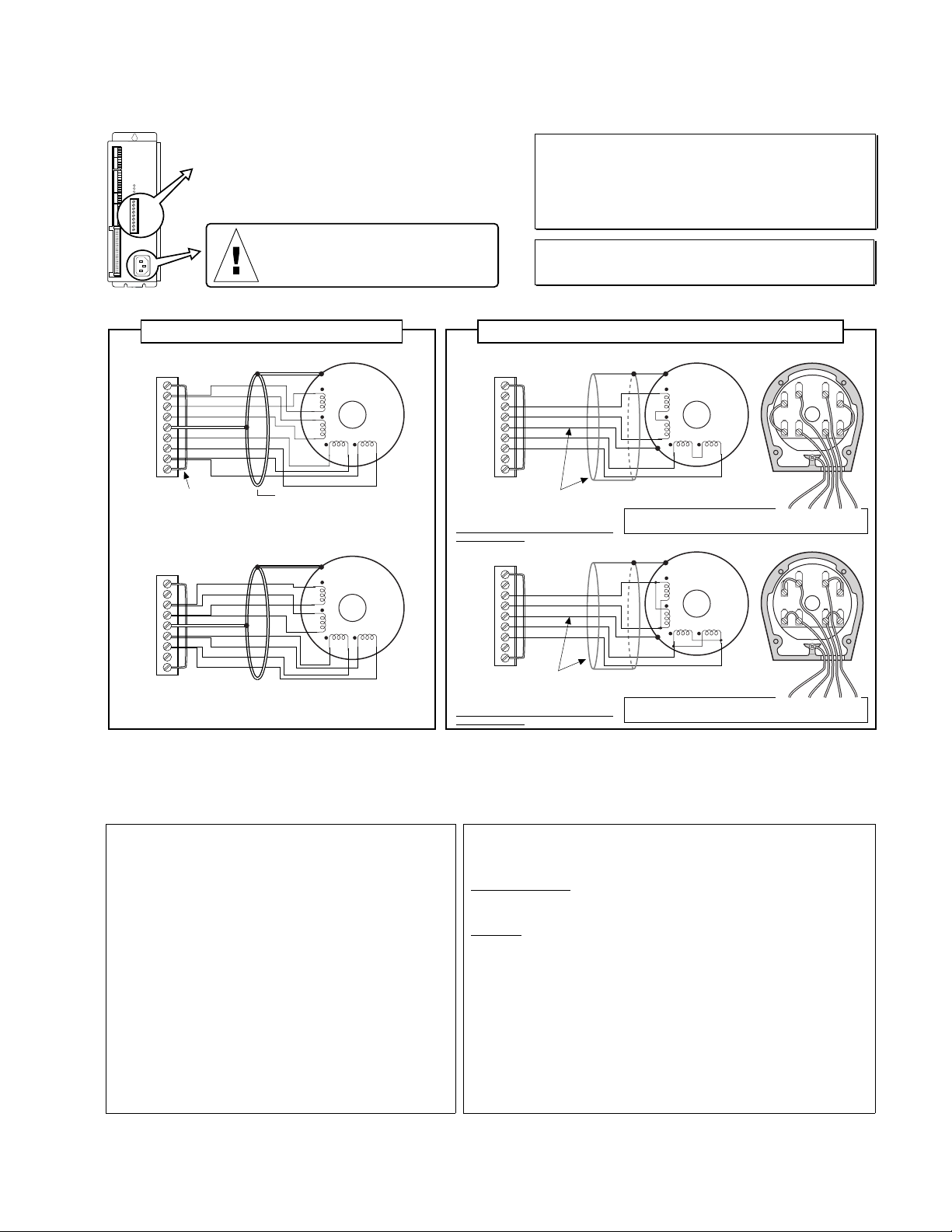

Motor (ZETA and OS/RS motors only)

Motor Connector

Specifications Ð see page 3.

ZETA, OS and RS Motors

Speed/Torque curves Ð see page 10.

Considerations for series & parallel wiring Ð see page 10.

INTERLOCK

A

CENTERTAP

A+

AÐ

EARTH

B+

BÐ

CENTERTAP

B

INTERLOCK

MOTOR

WARNING:

Remove AC power

before connecting or disconnecting

the motor. Lethal voltages are

present on the screw terminals

Current settings Ð see page 4. Dimensions Ð see page 24.

Cable extension Ð see table below.

ZETA & RSxxx-xxC10 motors include a rubber boot for safety.

Non-Compumotor Motors

If you intend to use a non-Compumotor motor, refer to

Appendix B for connection instructions and current selection.

ZETA, OS and RS Motor Connections RSxxx-xxNPS and RSxxx-xxC10 Motor Connections

Series Connection

INTERLOCK

ACENTERTAP

A+

AÐ

EARTH

B+

BÐ

B

CENTERTAP

INTERLOCK

Do not lengthen or

remove this jumper.

NOTE: ZETA motors are shipped from the factory wired to the connector in series.

Yellow

Blue

Red

Black

Shield

White

Green

Orange

Brown

Shield is connected to the motor case and

is internally connected to the ground pin

on the ZETA6104Õs AC power connector.

Parallel Connection

INTERLOCK

ACENTERTAP

EARTH

B

CENTERTAP

INTERLOCK

A+

AÐ

B+

BÐ

Red

Blue

Yellow

Black

Shield

White

Brown

Orange

Green

See page 10 for guidelines about using a motor in parallel.

Motor

Phase A

Windings

PM

Motor

Phase A

Windings

PM

Phase B

Windings

Phase B

Windings

Series Connection

INTERLOCK

ACENTERTAP

A+

AÐ

EARTH

B+

BÐ

B

CENTERTAP

INTERLOCK

The green/yellow (Gnd) wire is for safety

purposes. The shield connection to the motor

case is for EMI purposes (the C10 cable kit

provides hardware for the shield connection).

C10 cable assembly instructions are provided

in the C10 cable kit.

Wire #1

Wire #3

Gnd (Grn/Ylw)

Wire #2

Wire #4

Parallel Connection

INTERLOCK

ACENTERTAP

A+

AÐ

EARTH

B+

BÐ

B

CENTERTAP

INTERLOCK

The green/yellow (Gnd) wire is for safety

purposes. The shield connection to the motor

case is for EMI purposes (the C10 cable kit

provides hardware for the shield connection).

C10 cable assembly instructions are provided

in the C10 cable kit.

Wire #1

Wire #3

Gnd (Grn/Ylw)

Wire #2

Wire #4

Phase A

Windings

1

6

PM

5

3

Motor Terminal Number/Wire Number:

ZETA6104 Motor Connector Terminal:

1

6

5

3

Motor Terminal Number/Wire Number:

ZETA6104 Motor Connector Terminal:

Phase B

Windings

28 74

Phase A

Windings

PM

Phase B

Windings

28

74

End Cover RemovedSchematic View

4

3

6

8

7

5

2

1

Gnd1324

EARTH A+ A- B+ B-

4

3

6

8

7

5

2

1

Gnd1324

EARTH A+ A- B+ B-

Auto Current Standy Mode: Reduces motor current by 50% when step pulses from the ZETA6104 have stopped for one second

(CAUTION: torque is also reduced). Full current is restored upon the first step pulse. Enable with

the DAUTOS1 command; disable with the DAUTOS¯ command (default is disabled). For more

information, refer to the DAUTOS command in the 6000 Series Software Reference.

Extending ZETA Motor Cables

Standard length is 10 ft (3 m);

maximum extended length is 200 ft (61 m).

CAUTION: Cables longer than 50 feet (15 m) may degrade

performance.

Motor Type (amps) AWG mm

Max. Current < 100 ft (30 m) 100-200 ft (30-60 m)

ZETA57-51(S) 1.26 22 0.34 20 0.50

ZETA57-51(P) 2.38 22 0.34 20 0.50

ZETA57-83(S) 1.51 22 0.34 20 0.50

ZETA57-83(P) 3.13 22 0.34 20 0.50

ZETA57-102(S) 1.76 22 0.34 20 0.50

ZETA57-102(P) 3.50 20 0.50 18 0.75

ZETA83-62(S) 2.26 22 0.34 20 0.50

ZETA83-62(P) 4.00 20 0.50 18 0.75

ZETA83-93(S) 2.88 22 0.34 20 0.50

ZETA83-93(P) 4.00 20 0.50 18 0.75

ZETA83-135(S) 3.50 20 0.50 18 0.75

ZETA83-135(P) 4.00 20 0.50 18 0.75

(S) = Series Configuration (P) = Parallel Configuration

NOTE: Rated current in wire sizes shown may result in a maximum temperature rise of 18°F (10°C) above ambient.

2

AWG mm

2

-L10, -R10 & -C10 motors are shipped with 10 ft (3 m) cables;

-FLY motor is shipped with 1 ft (0.3 m) flying leads.

-NPS motor does not include cable/leads; 10-foot: use 18 AWG (0.75 mm2) wire.

LVD COMPLIANCE: Maximum DC resistance between the ZETA6104Õs

ÒEARTHÓ terminal (Òprotective conductor terminalÓ) and motor body must not

exceed 0.1ÊW. (This criteria must be taken into consideration when sizing

cross-section (gage) for extended cable lengths.)

NON-LVD: Maximum extended length is 200 ft (61 m), but cables longer than 50

feet (15 m) may degrade performance. See table below for guidelines:

Motor Type (amps) AWG mm

OS2HB(S) 1.51 22 0.34 20 0.50

OS2HB(P) 3.01 22 0.34 20 0.50

OS21B(S) 1.88 22 0.34 20 0.50

OS21B(P) 3.75 20 0.50 18 0.75

OS22B(S) 2.14 22 0.34 20 0.50

OS22B(P) 4.00 20 0.50 18 0.75

RS31B(S) 2.26 22 0.34 20 0.50

RS31B(P) 4.00 20 0.50 18 0.75

ZETA83-93(S) 2.88 22 0.34 20 0.50

ZETA83-93(P) 4.00 20 0.50 18 0.75

ZETA83-135(S) 3.50 20 0.50 18 0.75

ZETA83-135(P) 4.00 20 0.50 18 0.75

Extending OS and RS Motor Cables

Max. Current < 100 ft (30 m) 100-200 ft (30-60 m)

2

AWG mm

Chapter 1. Installation 9

2

Page 16

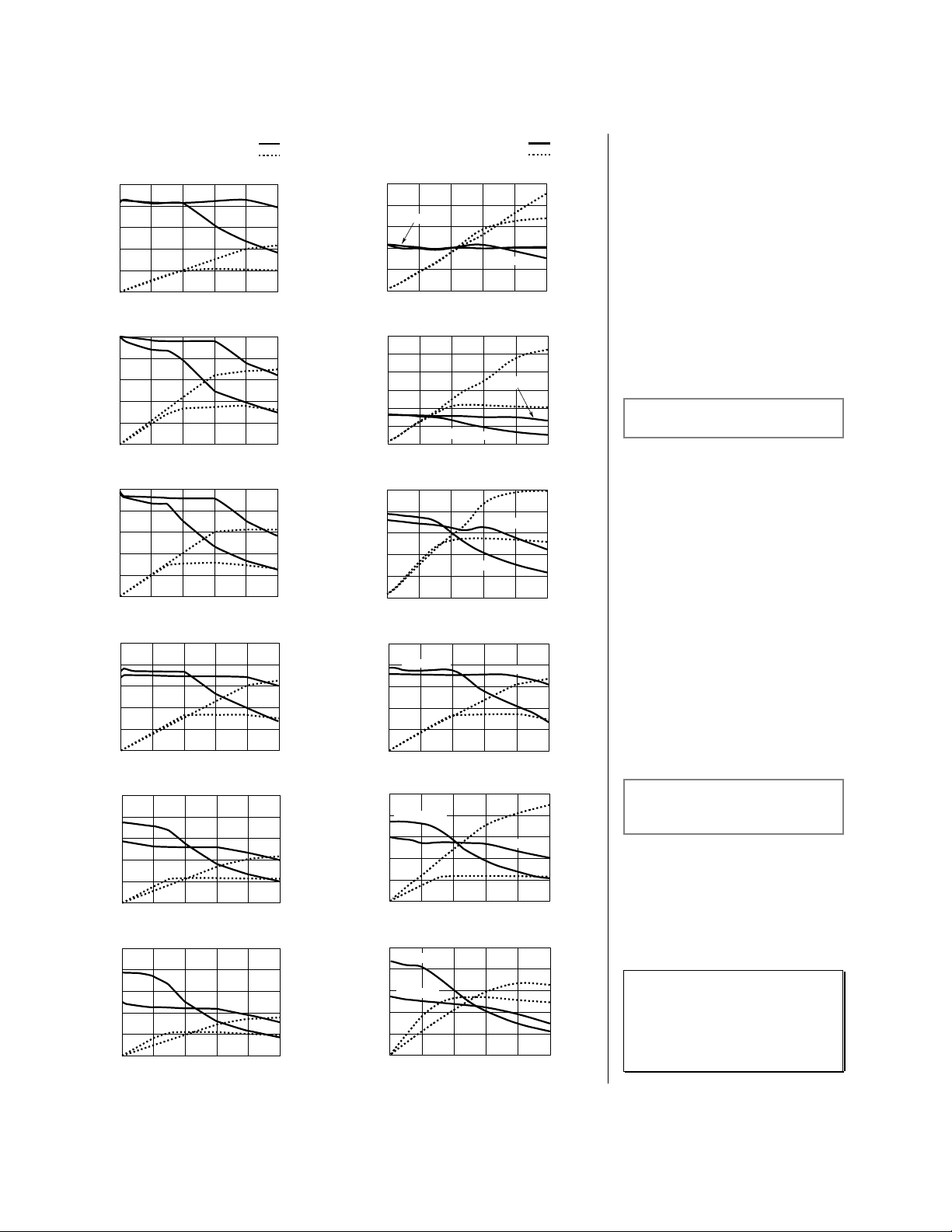

Selecting Series or Parallel Motor Wiring

Zeta Motor Curves

oz-in

(N-m) Power

75

(0.53)

60

(0.42)

45

(0.32)

Torque

30

(0.21)

15

(0.11)

0

0

oz-in

(N-m) Power

125

(0.88)

100

(0.70)

75

(0.53)

Torque

50

(0.35)

25

(0.18)

0

0

oz-in

(N-m) Power

150

(1.05)

120

(0.84)

90

(0.63)

Torque

60

(0.42)

30

(0.21)

0

0

oz-in

(N-m) Power

200

(1.40)

160

(1.12)

120

(0.84)

Torque

80

(0.56)

40

(0.28)

0

0

oz-in

(N-m) Power

400

(2.80)

320

(2.24)

240

(1.68)

Torque

160

(1.12)

80

(0.56)

0

0

oz-in

(N-m) Power

500

(3.50)

400

(2.80)

300

(2.10)

Torque

200

(1.40)

100

(0.70)

0

0

Parallel

ZETA57Ð51

20 30 40 50

10

Speed-RPS

ZETA57Ð83

Series

20 30 40 50

10

Speed-RPS

ZETA57Ð102

Series

20 30 40 50

10

Speed-RPS

ZETA83Ð62

Series

20 30 40 50

10

Speed-RPS

ZETA83Ð93

Series

Parallel

20 30 40 50

10

Speed-RPS

ZETA83Ð135

Series

20 30 40 50

10

Speed-RPS

Parallel

Series

Parallel

Parallel

Parallel

= Torque

= Power

watts (hp)

Parallel

129 (0.18)

Series

60 (0.08)

watts (hp)

Parallel

175 (0.23)

Series

80 (0.11)

watts (hp)

Parallel

186 (0.25)

Series

80 (0.11)

watts (hp)

Parallel

260 (0.35)

Series

120 (0.16)

watts (hp)

Parallel

350 (0.47)

Series

180 (0.24)

watts (hp)

Parallel

355 (0.48)

Series

193 (0.26)

O & R Motor Curves

oz-in

(N-m) Power

100

(0.70)

80

(0.56)

Parallel (3.01A

60

(0.43)

Torque

40

(0.28)

20

(0.14)

0

0

oz-in

(N-m) Power

300

(2.13)

205

(1.42)

200

(1.42)

Torque

150

(1.07)

100 (0.71)

50

(0.36)

0

0

oz-in

(N-m) Power

200

(1.42)

160

(1.14)

120

(0.85)

Torque

80

(0.56)

40

(0.28)

0

0

oz-in

(N-m) Power

200

(1.40)

160

(1.12)

120

(0.84)

Torque

80

(0.56)

40

(0.28)

0

0

oz-in

(N-m) Power

400

(2.80)

Series (2.88A

320

(2.24)

240

(1.68)

Torque

160

(1.12)

80

(0.56)

0

0

oz-in

(N-m) Power

500

(3.50)

Series (3.5A

400

(2.80)

300

(2.10)

Torque

Parallel (4A

200

(1.40)

100

(0.70)

0

0

OS2HB

pk)

20 30 40 50

10

Speed-RPS

OS21B

Series (1.88A

20 30 40 50

10

Speed-RPS

OS22B

20 30 40 50

10

Speed-RPS

RS31B

Series (2.26A

pk)

20 30 40 50

10

pk)

20 30 40 50

10

pk)

pk)

20 30 40 50

10

Series (2.26A

Speed-RPS

RS32B

Speed-RPS

RS33B

Speed-RPS

Series (1.51A

Parallel (3.75A

pk)

Parallel (4A

pk)

Parallel (4.0A

Parallel (4A

= Torque

= Power

watts (hp)

Parallel

91 (0.12)

Series

68 (0.09)

Use series wiring if your

application permits.

ZETA motors come from the factory

with a permanently attached motor

cable wired to the motor connector

for series motor current. The O and

R Series motors have flying leads or

pk)

pigtails that you must wire to the

motor connector yourself. The

operating temperature of a motor

connected in series will be lower

watts (hp)

Parallel

263 (0.36)

pk)

Series

102 (0.14)

watts (hp)

Parallel

199 (0.27)

pk)

Series

104 (0.14)

than that of a motor connected in

parallel. Typically, series

connections work well in high

torque/low speed applications.

Series motor wiring diagrams are

provided on page 9.

When to use parallel wiring.

At higher speeds, a motor connected

in parallel will produce more torque

than the same motor connected in

series. Use caution, however,

because the operating temperature of

watts (hp)

pk)

Parallel

230 (0.31)

the motor in parallel will be much

hotter. If you operate your motor in

parallel, measure motor temperature

under actual operating conditions. If

the motor exceeds its maximum case

Series

120 (0.16)

temperature, reduce the duty cycle to

limit motor heating. Compumotorsupplied motors have maximum

case temperatures of 212°F (100°C).

watts (hp)

Parallel

359 (0.48)

pk)

Series

186 (0.25)

watts (hp)

Parallel

327 (0.44)

Series

246 (0.33)

To wire the motor for parallel

motor current, refer to the wiring

diagrams on page 9.

Non-Compumotor Motors:

If you are using a nonCompumotor motor, refer to

Appendix B for connection

instructions and current-select

DIP switch settings.

10 z ZETA6104 Installation Guide

Page 17

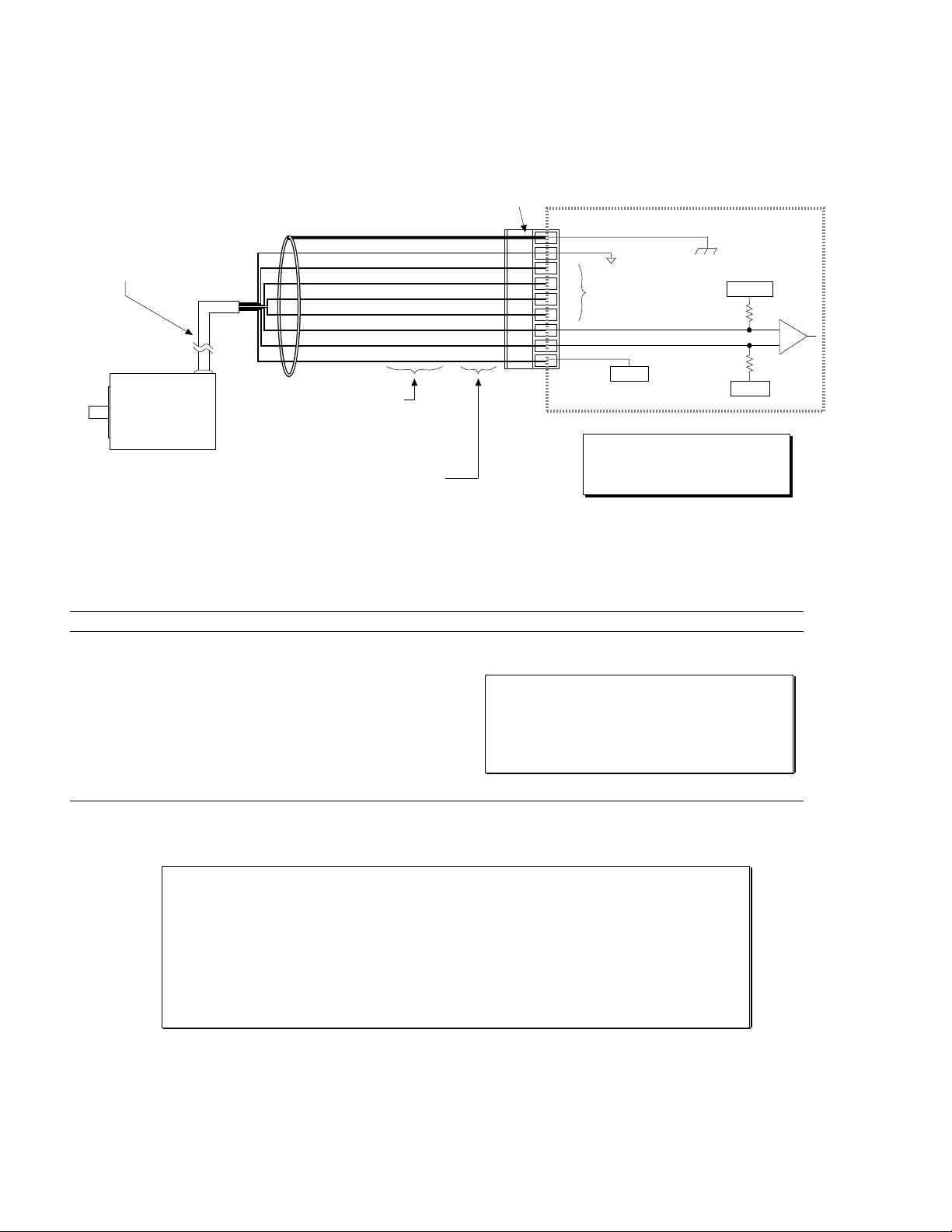

End-of-Travel and Home Limit Inputs

¥ CAUTION: Use either the on-board +5V terminal or an external power supply to power

the AUX-P pull-up resistor (using both will damage the ZETA6104).

¥ Motion will not occur until you do one of the following:

- Install end-of-travel (POS & NEG) limit switches.

- Disable the limits with the LH¯ command (recommended only if load is not coupled).

- Change the active level of the limits with the LHLVL command.

¥ Refer to the Basic Operation Setup chapter in the 6000 Series ProgrammerÕs Guide for

in-depth discussions about using end-of-travel limits and homing.

CONNECTIONS & INTERNAL SCHEMATICS

NOTES

ENCODER Connector

SHLD

HOM connected to GND

The home limit input is used during a homing move, which

is initiated with the HOM command. After initiating the

homing move, the controller waits for the home switch to

close, indicating that the load has reached the ÒhomeÓ

reference position. The active level (default is active low)

can be changed with the HOMLVL command. You can

also use an encoderÕs Z channel pulse, in conjunction with

the home switch, to determine the home position (this

feature is enabled with the HOMZ1 command).

(normally-open switch).

GND

ZZ+

BB+

AA+

+5V

LIMITS Connector

GND

HOM

NEG

POS

POS & NEG connected to GND

Mount each switch such that the load forces it to open before it

reaches the physical travel limit (leave enough room for the load to

stop). When the load opens the switch, the axis stops at the decel

value set with the LHAD command. The motor will not be able to

move in that same direction until you execute a move in the opposite

direction and

the limits with the LH¯ command, but this is recommended only if the

motor is not coupled to the load). The active level (default is active

low) can be changed with the LHLVL command.

+5V connected to AUX-P and V_I/O

Provides +5V power to the POS, NEG, and HOM input pull-up resistors. As an alternative,

you can connect AUX-P to an external supply of up to +24V (but do not use both the on-board +5V

terminal and an external 5-24V supply). If V_I/O is connected to a +5V supply (on-board or external),

AUX-P can be connected to a supply of up to +24V. If V_I/O is connected to an external +24V supply,

AUX-P must also be connected to +24V (or to GND).

Switching levels depend on voltage at V_I/O (LOW £ 1/3 of V_I/O volts; HIGH ³ 2/3 of V_I/O volts).

NOTE: AUX-P and V_I/O are also used by the P-CUT & TRG inputs.

SINKING CURRENT: To make the limit inputs (as well as P-CUT & TRG) sink current, connect AUX-P to GND.

clear the limit by closing the switch (or you can disable

(normally-closed switches).

(sourcing current).

I/O Connector

TRG-A

TRG-B

OUT-A

GND

P-CUT

+5V

OUT-P

IN-P

AUX-P

V_I/O

Chassis Ground

Iso Ground

Iso

Ground

+5VDC

6.8 KW

Internal Schematic

Similar circuits for NEG

and POS inputs.

20.0 KW 18.2 KW

LM 339

12.1 KW

10.0 KW

30.1 KW

PIN OUTS & SPECIFICATIONS (4-pin LIMITS Connector)

Name In/Out Description Specification for all limit inputs

GND

HOM

NEG

POS

Ñ

IN

IN

Isolated ground.

Home limit input.

Negative-direction endof-travel limit input.

IN

Positive-direction endof-travel limit input.

¥ Powered by voltage applied to V_I/O terminal (switching levels: Low £1/3 of V_I/O voltage,

High ³2/3 of V_I/O voltage). V_I/O can handle 5-24V with max. current of 100mA. Internal 6.8 KW

pull-ups to AUX-P terminalÑconnect AUX-P to power source (+5V terminal or an external 5-24V

supply) to source current, or connect AUX-P to GND to sink current; AUX-P can handle 0-24V with

max. current of 50mA. Voltage range for these inputs is 0-24V.

¥ Active level for HOM is set with HOMLVL (default is active low, requires n.o. switch).

¥ Active level for POS & NEG is set with LHLVL (default is active low, requires n.c. switch).

Chapter 1. Installation 11

Page 18

Encoder

CONNECTIONS & INTERNAL SCHEMATICS

Shield Shield Shield

Max. Cable Length is 100 feet.

Use 22 AWG wire.

Incremental

Encoder

Colors for Compumotor-supplied Encoders:

-E Series encoders

-RE encoder on OS motor (OSxxx-xxx-RE)

-RC encoder on OS motor (OSxxx-xxx-RC)

-EC encoder on RS motor (RSxxx-xxx-EC)

Colors for -HJ encoder on OS motor (OSxxx-xxx-HJ).

Ground Black Black

Z Channel Ð Orange/White (n/a)

Z Channel + Orange Blue

B Channel Ð Green/White (n/a)

B Channel + Green Brown

A Channel Ð Brown/White (n/a)

A Channel + Brown White

+5VDC Red Red

ENCODER Connector

SHLD

GND

ZZ+

BB+

AA+

+5V

Internal Schematic

Isolated Ground

Same Circuit

as A Channel

+5VDC

Chassis Ground

+1.8VDC

22 KW

22 KW

+5VDC

NOTE

If you are using a single-ended encoder,

leave the A-, B-, and Z- terminals on the

ZETA6104 unconnected.

PIN OUTS & SPECIFICATIONS (9-pin ENCODER Connector)

Pin Name In/Out Description

SHLD

GND

ZÐ

Z+

BÐ

B+

AÐ

A+

+5V

-----

-----

IN

IN

IN

IN

IN

IN

OUT

ShieldÑInternally connected to chassis ground (earth).

Isolated logic ground.

ZÐ Channel signal input.

Z+ Channel signal input.

BÐ Channel quadrature signal input.

B+ Channel quadrature signal input.

AÐ Channel quadrature signal input.

A+ Channel quadrature signal input.

+5VDC output to power the encoder.

Differential comparator accepts two-phase quadrature

incremental encoders with differential (recommended) or

single-ended outputs. Max. frequency is 1.6 MHz.

Minimum time between transitions is 625 ns.

TTL-compatible voltage levels: Low £ 0.4V, High ³ 2.4V.

Maximum input voltage is 5VDC.

Requirements for Non-Compumotor Encoders

¥ Use incremental encoders with two-phase quadrature output. An index or Z channel

output is optional. Differential outputs are recommended.

¥ It must be a 5V (< 200mA) encoder to use the ZETA6104Õs +5V output. Otherwise, it must

be separately powered with TTL-compatible (low £ 0.4V, high ³ 2.4V) or open-collector

outputs.

¥ The decoded quadrature resolution should be less than the motor resolution by a factor of

four to take advantage of the ZETA6104Õs position maintenance capability.

Specification for all encoder inputs

12 z ZETA6104 Installation Guide

Page 19

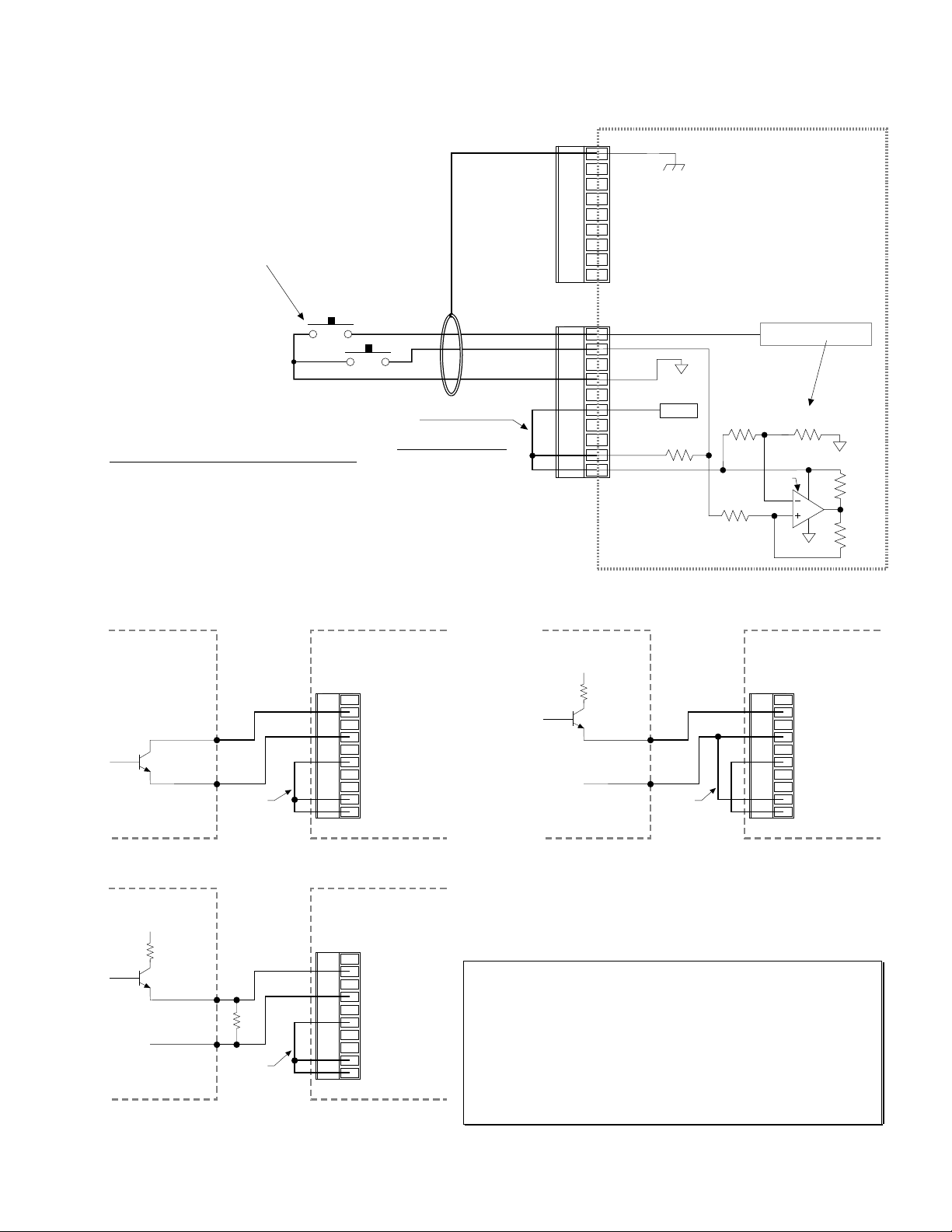

Trigger Inputs

ENCODER Connector

TRG-A/B connected to GND

The active level (default is active low) can be changed with the

INLVL command.

These inputs are like the general-purpose inputs on the 50-pin

header. The differences are (1) the triggers are pulled up via

the AUX-P pull-up terminal and powered by the voltage applied

to the V_I/O terminal; and (2) the triggers can be programmed

with the INFNCi-H command to function as position capture

inputs and registration inputs.

(normally-open switches).

I/O Connector

+5V connected to AUX-P and V_I/O

Provides +5V power to the TRG-A & TRG-B input pull-up resistors. As an alternative,

you can connect AUX-P to an external supply of up to +24V (but do not use both the

on-board +5V terminal and an external 5-24V supply). If V_I/O is connected to a +5V

supply (on-board or external), AUX-P can be connected to a supply of up to +24V.

If V_I/O is connected to an external +24V supply, AUX-P must also be connected to

+24V (or to GND).

Switching levels depend on voltage at V_I/O (LOW £ 1/3 of V_I/O volts; HIGH ³ 2/3 of V_I/O volts).

NOTE: AUX-P and V_I/O are also used by the HOM, NEG, POS & P-CUT inputs.

SINKING CURRENT: To make the trigger inputs (as well as HOM, NEG, POS & P-CUT) sink

current, connect AUX-P to GND.

(sourcing current).

SHLD

GND

ZZ+

BB+

AA+

+5V

TRG-A

TRG-B

OUT-A

GND

P-CUT

+5V

OUT-P

IN-P

AUX-P

V_I/O

Iso

Ground

+5VDC

6.8 KW

Chassis Ground

20.0 KW 18.2 KW

12.1 KW

Internal Schematic

Similar circuit for TRG-A.

LM 339

10.0 KW

30.1 KW

Connection to a Sinking Output Device Connection to a Sourcing Output Device

Electronic Device

The output should

be able to sink at

least 1mA of current.

Out 5-24 Volts

Output

Ground

Pulled up

to +5V

(sourcing)

ZETA6104

I/O Connector

TRG-A

TRG-B

OUT-A

GND

P-CUT

+5V

OUT-P

IN-P

AUX-P

V_I/O

(see schematic

drawing above)

Electronic Device ZETA6104

V

1

R

1

Out 5-24 Volts

Output

Ground

Pulled

down to

ground

(sinking)

I/O Connector

TRG-A

TRG-B

OUT-A

GND

P-CUT

+5V

OUT-P

IN-P

AUX-P

V_I/O

(see schematic

drawing above)

Connection to a Combination of Sinking & Sourcing Outputs

Electronic Device ZETA6104

V

1

R

1

Output

Out 5-24 Volts

Ground

Typical value for R = 450W (assuming R1 = 0)

Note: The value of R may vary depending on the value of R1 and V1.

R

Pulled up

to +5V

(sourcing)

I/O Connector

TRG-A

TRG-B

OUT-A

GND

P-CUT

+5V

OUT-P

IN-P

AUX-P

V_I/O

(see schematic

drawing above)

If you will be connecting to a combination of sourcing and sinking outputs,

connect AUX-P to +5-24V to accommodate sinking output devices. Then for each

individual input connected to a sourcing output, wire an external resistor between

the ZETA6104Õs trigger input terminal and ground (see illustration). The resistor

provides a path for current to flow from the device when the output is active.

PROGRAMMING TIP

Connecting to a sinking output? Set the trigger inputÕs active level to low

with the INLVL command (¯ = active low, default setting).

Connecting to a sourcing output? Set the trigger inputÕs active level to

high with the INLVL command (1 = active high).

Thus, when the output is active, the TIN status command will report a Ò1Ó

(indicates that the input is active), regardless of the type of output that is

connected.

For details on setting the active level and checking the input status refer to the

INLVL and TIN command descriptions in the 6000 Series Software

Reference.

Chapter 1. Installation 13

Page 20

General-Purpose Programmable Inputs & Outputs

0

VM50 ADAPTOR Ñ for screw-terminal connections

Color stripe

1

PROGRAMMABLE I/O

50

2-Foot Cable

(provided with VM50)

Color stripe

(pin #1)

(pin #1)

Pin outs on the VM50 are identical

to the pin outs for the 50-pin

connectors (only if the cable is

connected as illustrated).

The VM50 snaps

on to any standard

DIN rail.

PIN OUTS & SPECIFICATIONS

Pin Function Internal Schematics Specifications

1 Input #16 (MSB of inputs)

1

PROGRAMMABLE I/O

49

50-pin plug is

compatible with

OPTO-22ª

signal

conditioning

equipment.

3 Input #15

2

5 Input #14

7 Input #13

9 Input #12

11 Input #11

13 Input #10

15 Input #9

17 Output #8 (MSB of outputs)

19 Output #7

21 Output #6

23 Output #5

25 Input #8

27 Input #7

29 Input #6

31 Input #5

33 Output #4

5

35 Output #3

37 Output #2

39 Output #1 (LSB of outputs)

41 Input #4

43 Input #3

45 Input #2

47 Input #1 (LSB of inputs)

49 +5VDC

NOTE: All even-numbered pins are connected to a common logic ground (DC ground) Ñ see drawing on page 7.

LSB = least significant bit; MSB = most significant bit

2 4 6 8 10 12 14 16 18 20

1 3 5 7 9 11 13 15 17 19

22 24 26232825302732293431363338354037423944414643484550

VM50 Adaptor Board

Inputs

External 5-24VDC Supply

(an alternative to using the

on-board +5V terminal)

When connecting to a

sinking output device,

connect IN-P to the

+5V terminal OR to a

user-supplied external

supply of up to 24VDC

(but not to both).

Connection

Ground

Connection

ZETA6104

GND

+5V

IN-P

Input

Outputs (including OUT-A)

External 5-24VDC Supply

(an alternative to using the

on-board +5V terminal)

Pull-up:

Connect OUT-P to the

+5V terminal OR to a

user-supplied external

supply of up to 24VDC

(but not to both).

Output

Connection

Ground

Connection

ZETA6104

GND

+5V

OUT-P

UDK2559

+5VDC

6.8 KW

47 KW

+5VDC

4.7 KW

ISO GND

74HCxx

ISO GND

ISO GND

ISO GND

47 4921

Inputs

HCMOS-compatible voltage levels

(low £ 1.00V, high ³ 3.25V).

Voltage range = 0-24V.

Sourcing Current: On the I/O connector,

connect IN-P to +5V or connect IN-P to an

external 5-24VDC power supply (but not to

both).

Sinking Current: On the I/O connector,

connect IN-P to GND.

STATUS: Check with TIN or INFNC.

Active level: Default is active low, but can

be changed to active high with the INLVL

command.

Outputs (including OUT-A)

Open collector output.

Pull-up connection on I/O connector:

Connect OUT-P to +5V, or to an external

5-24VDC power supply (but not to both).

Outputs will sink up to 300mA or source up

to 5mA at 5-24VDC.

STATUS: Check with TOUT or OUTFNC.

Active level: Default is active low, but can

Open

Collector

be changed to active high with the OUTLVL

command.

ISO

GND

CAUTION: You must select either the on-board +5V terminal or an external power supply to power the

IN-P and OUT-P pull-up resistors. Connecting IN-P or OUT-P to the +5V terminal and an

external supply will damage the ZETA6104. (The same rule applies to the AUX-P terminal.)

14 z ZETA6104 Installation Guide

Page 21

INPUT CONNECTIONS Ñ Connecting to electronic devices such as PLCs

Connection to a

Sinking Output

Device

Connection to a

Sourcing Output

Device

Connection to a

Combination of

Sinking &

Sourcing

Outputs

Electronic

Device

The output should

be able to sink at

least 1mA of current.

Out 5-24 Volts

Output

Ground

Electronic

Device

V

1

R

1

Output

Out 5-24 Volts

Ground

Electronic

Device

V

1

R

1

Output

Out 5-24 Volts

Ground

Pulled up

to +5V

(sourcing)

Connection

Connection

Pulled

down to

ground

(sinking)

Connection

Connection

Pulled up

to +5V

(sourcing)

Connection

R

Connection

GND

+5V

IN-P

Input

Ground

GND

+5V

IN-P

Input

Ground

GND

+5V

IN-P

Input

Ground

ZETA6104

+5VDC

6.8 KW

47 KW

ISO GND

ZETA6104

+5VDC

6.8 KW

47 KW

ISO GND

ZETA6104

+5VDC

6.8 KW

47 KW

ISO GND

ISO GND

74HCxx

ISO GND

74HCxx

ISO GND

74HCxx

PROGRAMMING TIP

Connecting to a

sinking output? Set the

inputÕs active level to low

with the INLVL command

(¯ = active low).

Connecting to a

sourcing output? Set

the inputÕs active level to

high with the INLVL

command (1 = active high).

Thus, when the output is

active, the TIN status

command will report a Ò1Ó

(indicates that the input is

active), regardless of the

type of output that is

connected.

Details on setting the active

level and checking the input

status are provided in the

6000 Series ProgrammerÕs

Guide. Refer also to the

INLVL and TIN command

descriptions in the 6000

Series Software Reference.

Typical value for R = 450W (assuming R1 = 0)

Note: The value of R may vary depending on the value of R1 and V1.

NOTE: If you will be connecting to a combination of sourcing and sinking outputs, connect IN-P to +5V (or to an

external 5-24VDC supply) to accommodate sinking output devices. Then for each individual input

connected to a sourcing output, wire an external resistor between the ZETA6104Õs programmable input

terminal and ground (see ÒRÓ in above drawing). The resistor provides a path for current to flow from the

device when the output is active.

Chapter 1. Installation 15

Page 22

OUTPUT CONNECTIONS (includes OUT-A) Ñ for electronic devices such as PLCs

Connection to a Sinking Input (active high) Connection to a Sourcing Input (active low)

External Supply

Electronic

Device

Input

Ground

(up to 24VDC)

+

Ð

GND

+5V

OUT-P

Output

Connection

Ground

Connection

ZETA6104

ISO GND

+5VDC

4.7 KW

UDK2559

(open collector)

ISO GND

Connection to a Combination of Sinking & Sourcing Inputs

External Supply

Electronic

Devices

Sourcing Input

Sinking Input

V+

Input

Ground

Input

Ground

(up to 24VDC)

+

Ð

GND

OUT-P

Output 1

Output 2

Ground

Connection

+5V

ZETA6104

ISO GND

+5VDC

4.7 KW

UDK2559

(open collector)

4.7 KW

UDK2559

(open collector)

ISO GND

Combinations of sourcing

and sinking inputs can be

accommodated at the same

voltage level. Be aware of

the input impedance of the

sourcing input module, and

make sure that there is

enough current flowing

through the input module

while in parallel with the

OUT-P pull-up resistor.

Connection to an Inductive Load (active low)

External Supply

(up to 24VDC)

+

Ð

GND

OUT-P

Output

Connection

+5V

ZETA6104

ISO GND

+5VDC

4.7 KW

UDK2559

(open collector)

Use an external diode when driving

inductive loads. Connect the diode in

parallel to the inductive load,

attaching the anode to the ZETA6104

output and the cathode to the supply

voltage of the inductive load.

Electronic

Device

V+

Input

Ground

External Supply

(up to 24VDC)

+

Ð

GND

OUT-P

Output

Connection

Ground

Connection

+5V

ZETA6104

ISO GND

+5VDC

4.7 KW

UDK2559

(open collector)

ISO GND

PROGRAMMING TIP

Connecting to an activehigh sinking input? Set

the outputÕs active level to

high with the OUTLVL command

(1 = active high).

Connecting to an activelow sourcing input? Set

the outputÕs active level to low

with the OUTLVL command

(¯ = active low).

Thus, when the ZETA6104Õs

output is activated, current will

flow through the attached

input and the TOUT status

command will report a Ò1Ó

(indicates that the output is

active), regardless of the type

of input that is connected.

Details on setting the active

level and checking the output

status are provided in the

6000 Series ProgrammerÕs

Guide. Refer also to the

OUTLVL and TOUT command

descriptions in the 6000

Series Software Reference.

16 z ZETA6104 Installation Guide

Page 23

THUMBWHEEL CONNECTIONS Ñ for entering BCD data