Paragon DTC 1000, DTC 600, DTC 800, DTC 100 Troubleshooting Manual

DTC 1000, 800, 600 & 100 Series

Controller Trouble Shooter

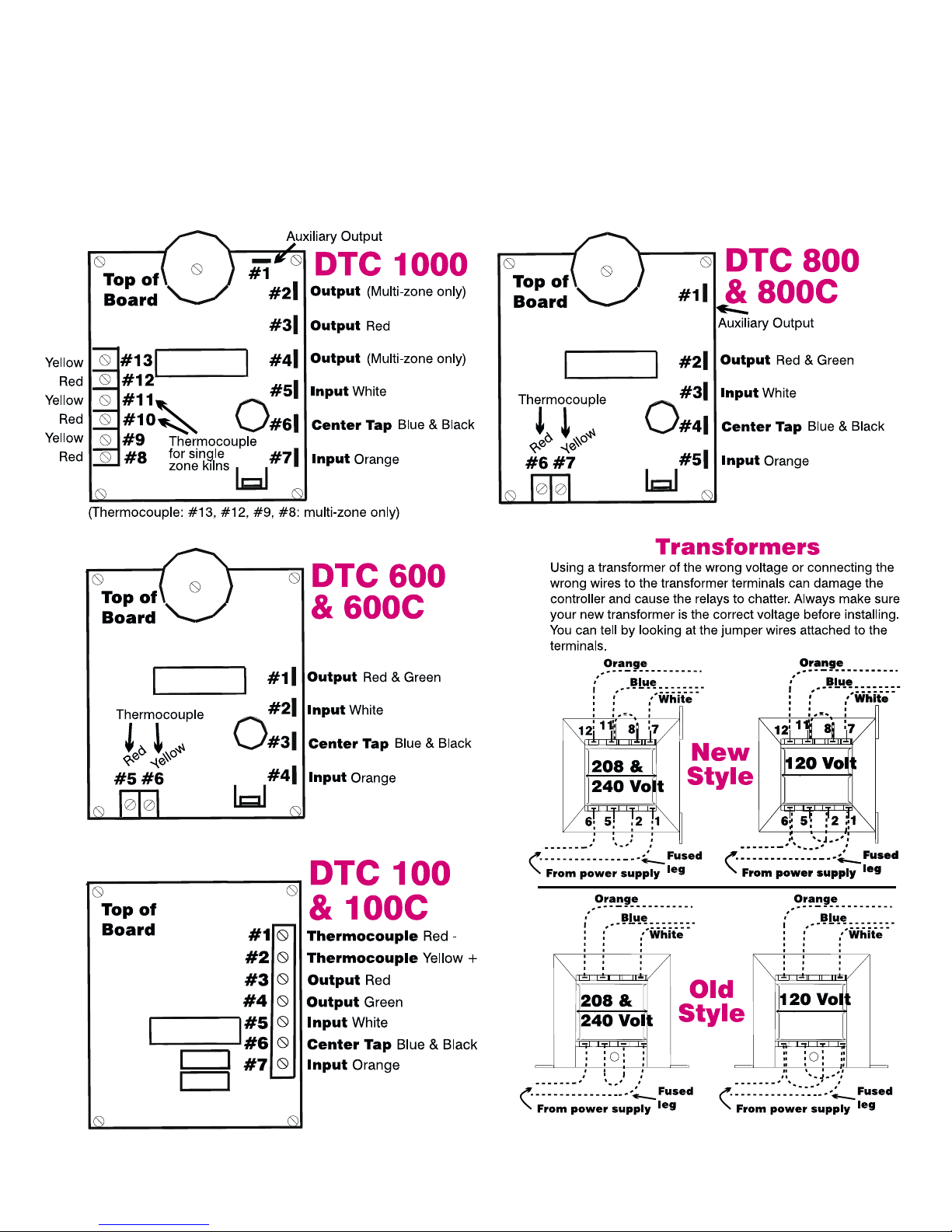

CAUTION: Attaching the INPUT wires (white, orange) to the controller’s OUTPUT

connectors can destroy the controller! Use care when connecting wires.

©Paragon Industries, Inc. IM-195/9-00

1

2011 South Town East Blvd.

Mesquite, Texas 75149-1122

800-876-4328 / 972-288-7557

Toll Free Fax: 888-222-6450

Paragonind@worldnet.att.net

www.paragonweb.com

2

Dear Customer:

Contents

Paragon kilns have proven to be very de

pendable. However, as with all mechanical de

vices, kilns do occasionally need maintenance.

We have packed this guide with information

from the minds of our top engineers and tech

nicians. If you are ever under deadline to get

your kiln running, you will be glad you had this

guide.

If your local dealer does not have a repair

technician, feel free to call the Paragon factory

with questions. But first, try to find the answer

in this trouble shooter. This is usually faster

than a phone inquiry. When calling, please have

in front of you the information on your kiln’s

electrical data plate. You will find this on the

side of the kiln switch box.

-

-

Electrical Power Problems

Controller display does NOT turn on. No heat in kiln.. . . . . . . 4

Controller display turns on. No heat in kiln.. . . . . . . . . . . . . . . 5

Kiln fires too slowly or will not reach temperature. . . . . . . . . . 6

-

Some elements do not fire. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Kiln heats unevenly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Circuit breaker trips or circuit fuse blows. . . . . . . . . . . . . . . . . 9

Kiln connection box fuse blows. (Heavy amperage kilns.) . . . 9

Kiln switch box ½ amp fuses keep blowing. . . . . . . . . . . . . . 10

Wall outlet gets too hot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Temperature Problems

Controller reads wrong temperature.. . . . . . . . . . . . . . . . . . . 10

The kiln overfires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

The display shows erratic temperature readings. . . . . . . . . . 11

The display remains stuck. . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Display digits burn out (parts of display missing). . . . . . . . . 12

Noises

The relay chatters or buzzes. . . . . . . . . . . . . . . . . . . . . . . . . . 12

The controller keeps beeping. . . . . . . . . . . . . . . . . . . . . . . . . 12

Please have all of the information from you kiln’s electrical

data plate in front of you before calling us.

Make a record of all your firings. Include

firing time, temperature, witness cones, and

firing results. These records will be a valuable

trouble-shooting aid. Firing record blanks are

available from Paragon.

The controller is easy to remove from the

switch box. It is held in place with four screws.

Before removing, please disconnect the power

from the kiln. Certain components on the back

of the controller can be damaged if they touch a

grounded object while the kiln is plugged in.

Please follow the diagrams on page one

carefully when connecting wires to the control

ler. Attaching input wires to output terminals

can damage the controller.

Most of the error messages shown in this

manual do not apply to the DTC 100 series.

Periodically we hold an in-plant kiln main

tenance seminar in Mesquite, Texas. Call for

the next scheduled dates.

-

Error Messages

PF or ErrP during firing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

FAIL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Err 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Err 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Err 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Err 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Err 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Err 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Err 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Err A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Err B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Err d . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Err E, Err H, Err t. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Err - . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Trouble Shooting Tests

-

Wall Receptacle No-Load Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Switch Box ½ Amp Fuse Ohmmeter Test. . . . . . . . . . . . . . . . . . . . . . . . 4

Controller Power Input Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Element Ohmmeter Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Controller Power Output Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Door/Lid Switch Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Receptacle Under Load Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Wall Receptacle Ammeter Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Kiln Switch Box High Amperage Fuse Test . . . . . . . . . . . . . . . . . . . . . . 8

Element Glow Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Kiln ½ Amp Fuse Power Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Relay Coil Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Controller Paperclip Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Relay 12 Volt Battery Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3

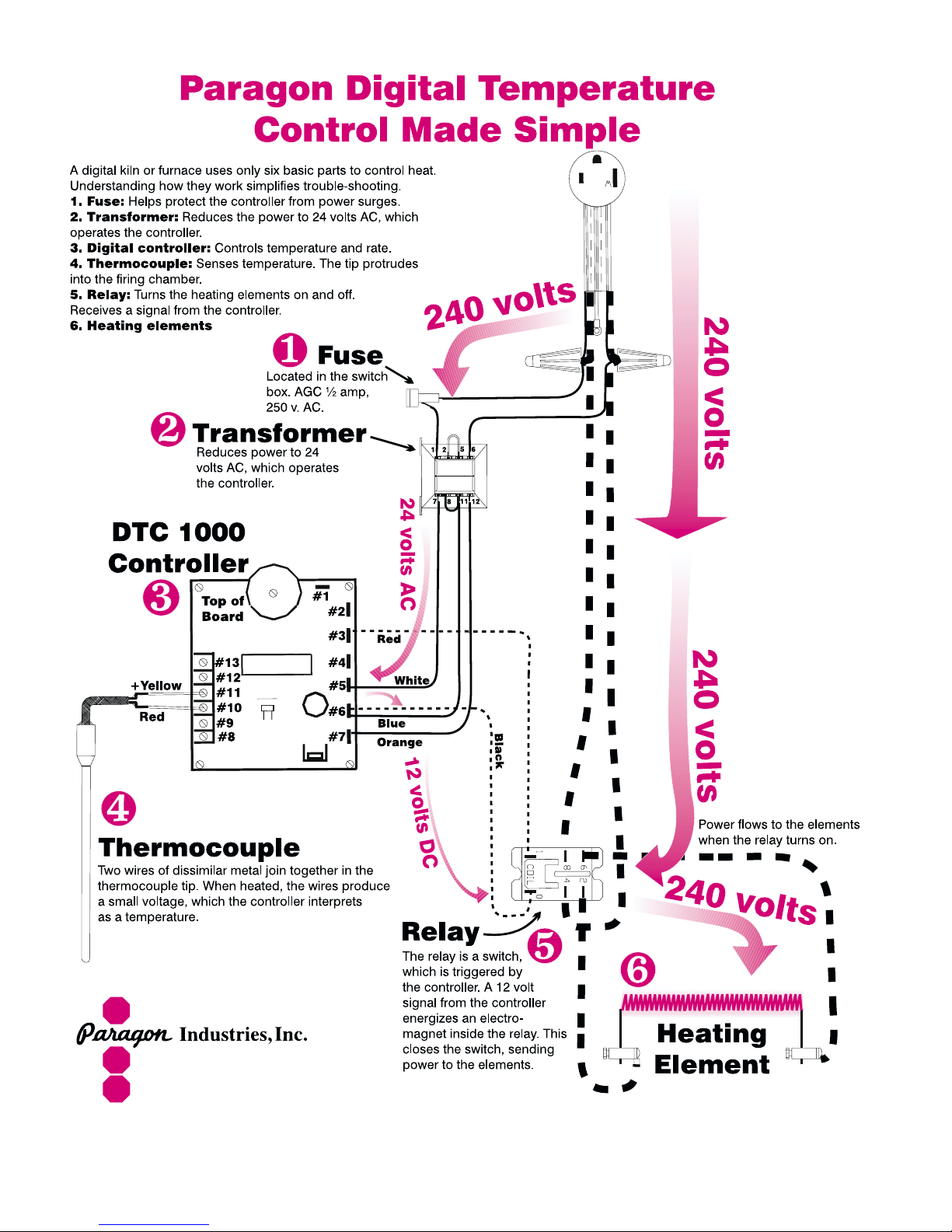

Electrical Power Problems

Controller display does NOT turn on. No heat in kiln.

I

Is the kiln connected to the power?

Make sure the kiln is plugged in. If the kiln’s wall circuit

includes apower disconnectlever, makesure thelever is

in the on position.

I

Has the circuit breaker tripped or fuse

blown?

I

Is power reaching the wall receptacle?

Test with a voltmeter.

Wall Receptacle

No-Load Test

This test should be performed only by an experienced repair person.

Touch only the plastic or rubber handle of the voltmeter probes dur

ing this test. Do not remove the receptacle faceplate.

Follow the instructions that came with your voltmeter, setting it to the AC mode.

Insert the voltmeter

probes in the recepta

cle’s two slotted, hot

connections.

-

Be sure the power disconnect

switch is in the on position.

Know the location of the circuit

breaker panel. Label the breaker that

controls your kiln’s circuit.

-

I

I

Disconnect

Power before

removing

controller and

switch box.

Has the kiln switch box ½ amp fuse blown?

Switch Box ½ Amp Fuse Ohmmeter Test

The kiln’s ½ amp fuse is located in the switch box. Remove by pressing on the fuse holder and turning counter-clockwise half a turn. Check the fuse by placing the

probes of an ohmmeter on the ends of the fuse.If the ohmmeter reads less than an ohm (digital meter) or reads 0 ohms (analog meter), the fuse is okay. If the reading is OPEN (digital meter) or infinity/no needle

movement (analog meter), the fuse is

bad. Replacement fuse:

AGC 1/2 A 250V AC

If replacement kiln fuses keep blow

ing, see “Kiln switch box ½ amp fuses

keep blowing,” page 10.

Is the controller receiving

power? Test INPUTS with

-

Use an ohmmeter to test the switch box fuse.The fuseholder ison the side of most kiln switch

boxes.

Place voltmeter probes in the two

slotted, hot connections of the outlet.

The round connection is the safety

ground.

a voltmeter.

Controller Power Input Test

Make sure the kiln is unplugged, and remove the 4 screws holding the

controller board faceplate to the switch box. Lift faceplate out of box

and letthe boardhang onthe boxwith theback ofthe boardfacing you.

Plug the kiln back in. Touch voltmeter probes (in AC mode) to both INPUT con

nections (the white and orange wires). See diagrams, page 1.

Do not let the back of the boardtouch agrounded object.Make surethe voltmeteris in

the AC mode when placing the probes on INPUT connections.

Controller Input Test Result: the controller is not getting power.

UNPLUG kiln.Check theswitch boxfor disconnectedwires betweenthe cord,trans

former, and controller. If wiring is okay, replace the transformer.

-

-

Disconnect power before removing

the board from the switch box.

4

Controller Input Test Result: the controller is getting 20 - 24 volts

AC.

If you find 20 - 24 volts, correct current is reaching the board from the trans

former. But since the board is not lighting up, it is probably defective. Try

turning off the power to the kiln for ten seconds. The board maylight upwhen

you turnthe power back on. If it does not light up, return the controller forre

pair or replacement.

Controller Input Test Result: the controller is getting less than 20

volts AC.

Did you recently replace the transformer? It may be the wrong voltage. (See

diagrams, page 1.) The voltage is below 20, which is not enough power for the

controller. To find out the cause of low voltage, continue below:

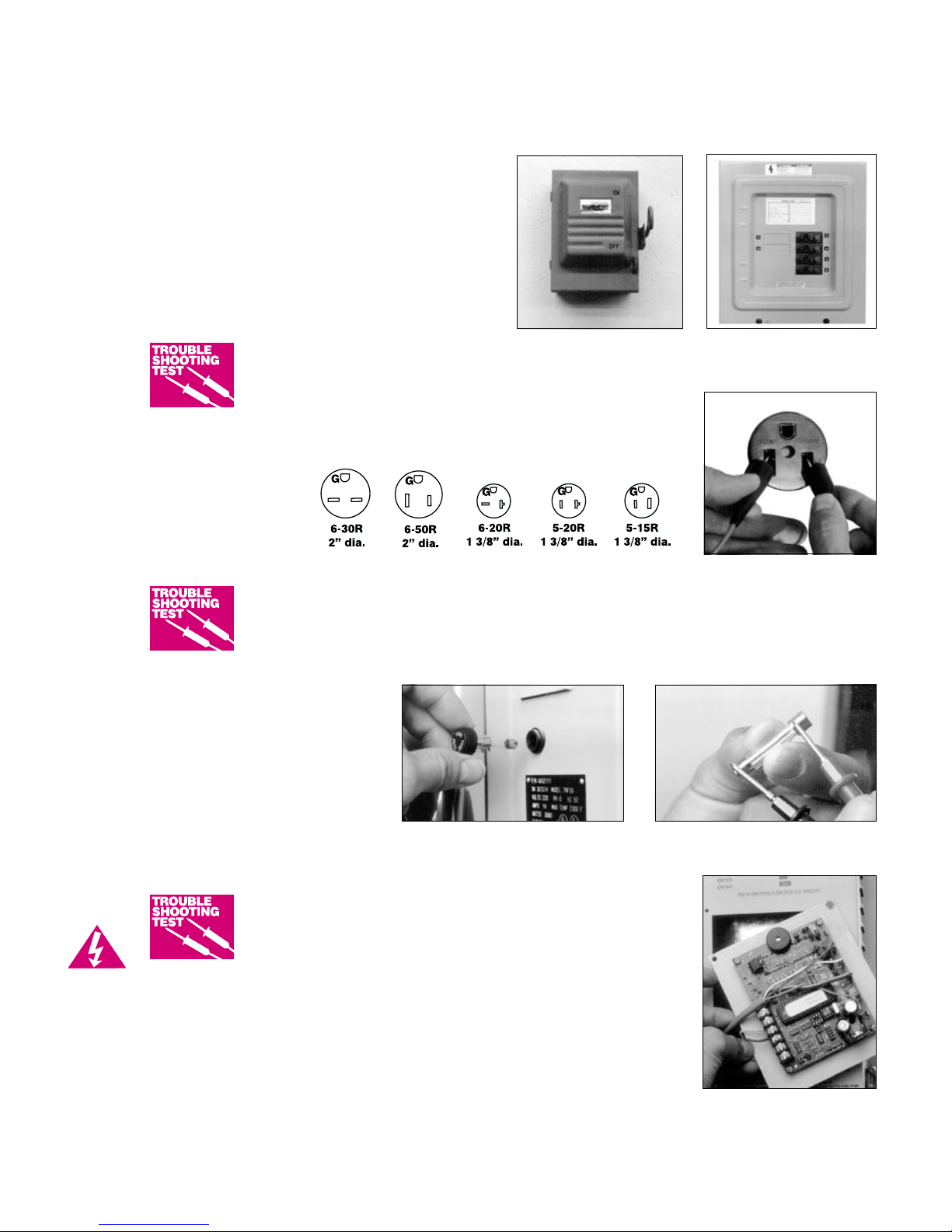

The back of the board is still facing you. Unplug/disconnect the kiln. Remove

the white and orange wires from the board INPUT terminals. Clamp a volt

meter probe to the white wire and the other probe to the orange wire. Use alli

gator clip probes. Do not let the wires touch a grounded object. Plug the kiln

back in.

Result: voltage at disconnected INPUT wires is less than 20: There are

two possiblereasons: 1) Low voltage at thewall receptacle; 2) defective trans

former. If wall receptacle voltage is correct, replace the transformer.

-

-

Testing for voltage at the controller’s INPUT ter

minals.

-

-

Use alligator clips to test for voltage at the dis

-

connected INPUT wires.

-

-

Result: voltage at disconnected INPUT wires is 20 - 24: The transformer is sending correct voltage to the con

troller. Yet when the input wires wereconnected to the controller, voltage was less than 20.This means the control

ler is draining the voltage and is defective. Return the controller for repair or replacement.

CAUTION: Attaching the INPUT wires (white, orange) to the controller’s OUTPUT connectors can destroy the controller! Use care when connecting wires.

Controller display turns on. No heat in kiln.

I

Has a delay been programmed?

The elements will not fire until the delay time has elapsed.

I

Is the relay making its normal clicking sound?

Yes, the relay is clicking.

Test the elements with an ohmmeter:

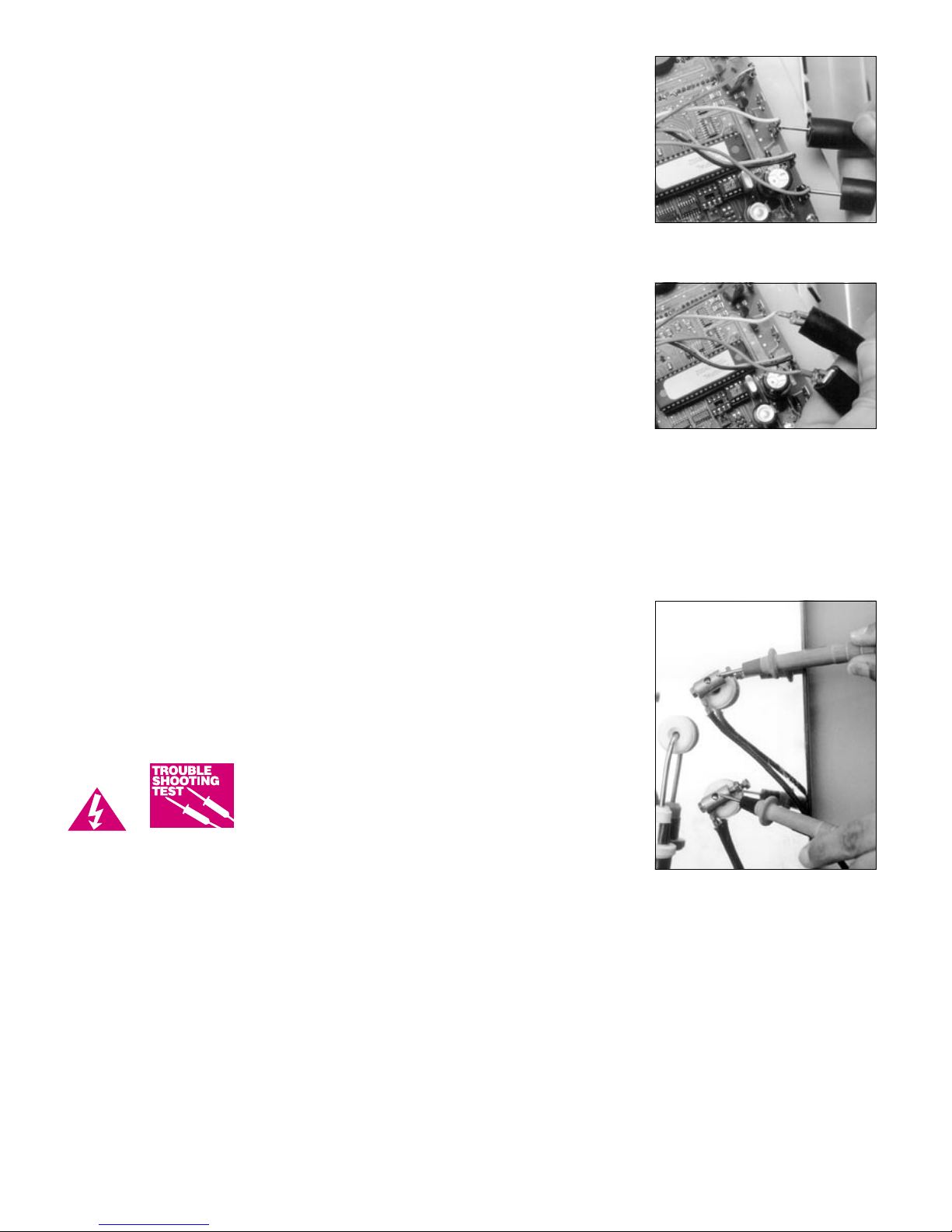

Element Ohmmeter Test

1 UNPLUG kiln/disconnect the power. Open the kiln’s switch

box. Make sure the wires connecting the relays to the ele

Disconnect

Power before

opening kiln

switch box or

removing the

controller.

ments with an ohmmeter as follows:

2 Touch the ohmmeter leads to the two element connectors of each element.

A no-needle-movement reading on an analog meter, or OPEN on a digital

meter, indicates a broken element.

ments are secure. If connections are okay, check the ele

-

-

-

-

The ohmmetersends an electric current through

the element. If the element is broken, the meter

will show an OPEN circuit.

3 If your elements are wired in parallel, temporarily disconnect the lead wires from one end of the element you are

testing. Holdelement connector with pliersas you remove thescrew. Begentle toavoid breakingthe element.Do

not disturb the screw holding the element, only the one holding the lead wires.

Rule of thumb: ifboth leadwires of an element connect to another element,the elementsare wiredin parallel. Discon

nect the lead wire(s) from one end of the element you are testing.

If the elements check out okay, perform the “Relay 12 Volt Battery Test,” page 14.

No, the relay is not clicking.

We know the controller is receiving voltage, because the display is lit. But the voltage from the transformer may be

too low to power the relays. Perform the “Controller Power Input Test,” page 4. If your controller passes the input

test, perform the “Controller Power Output Test” on the next page:

-

5

Loading...

Loading...