Paragon DTC 1000 Maintenance Manual

DTC 1000

Digital Temperature Controller

Complete Operation & Maintenance Instructions

See page 22 for instructions on upgrading your DTC

100, 600 or 800 series board to the DTC 1000.

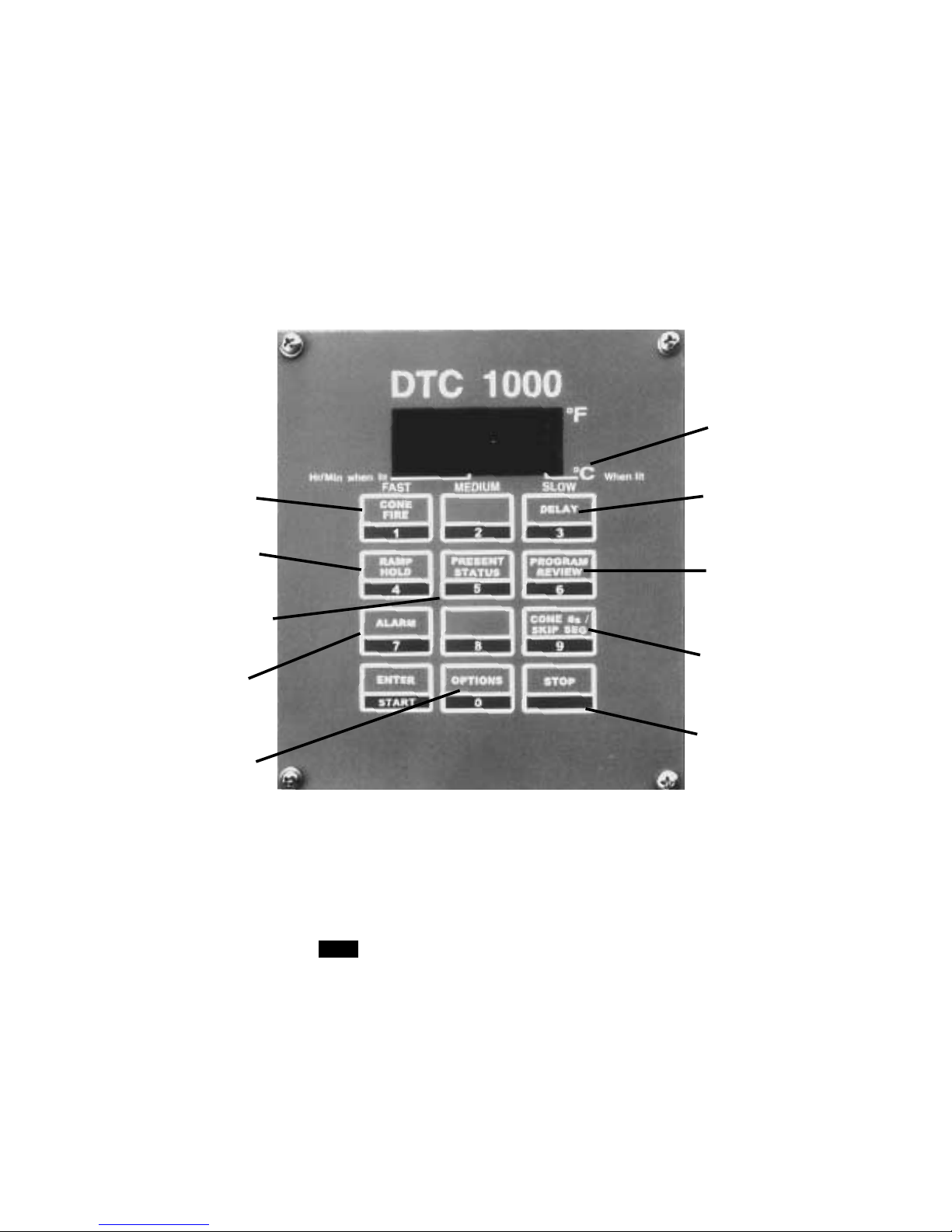

°F / °C

Display

Page 12

Cone-Fire

Page 6

Ramp-Hold

Page 9

Present Status

(Current seg. &

Board temp.)

Page 13

Alarm

Page 13

Options

Page 14

(Cone Table)

Skip Segment

The Keypad

The controller is easy to master once you understand that the keys have two functions:

1 Select an operation.

Press akey to start the operation shown in the top half of the key. Most operations begin by

pressing START from IdLE display. Some operations begin during firing.

Delay

Page 13

Program

Review

Page 5

Cone #s

Page 8

Page 11

Stop

Page 5

2 Type Numbers.

After beginning an operation, press keys to enter numbers, such as time and temperature.

1

Introduction

Thank you for purchasing the DTC 1000 controller, our latest generation of digital

controllers.

The DTC 1000 operates in Cone-Fire and Ramp-Hold the same as the earlier DTC

600 and 800 series. If you are already familiar with the earlier controllers, you can follow

most of the same operating procedures with the DTC 1000.

The DTC 1000 includes new features not found in earlier controllers. These features

are accessed through the Options key. If you do not need them, they will remain hidden

until you press Options. Thus, the DTC 1000 remains as simple to operate as earlier

controllers.

The Cone-Fire mode applies to ceramics only. If you purchased a heat treating, glass

fusing, enameling or jewelry furnace, your version of the DTC 1000 will include only the

Ramp-Hold mode, not the Cone-Fire. In this case, please disregard “FAST,” “MED,”

“SLOW,” “Cone Fire” and “Cone #s” on your keypad.

If you purchased the TnF II portable controller, you should find a TnF II installation

instruction sheet in addition to these instructions.

Though you should read this entire manual to fully enjoy your DTC 1000, you can

begin firing after reading these sections: “Safety Rules” page 4, “Getting Started” pages

4-6, and the basics section of “Cone-Fire” pages 6-8 or “Ramp-Hold” pages 9-10. Though

the DTC 1000 is simple to operate, using it without reading instructions could ruin your

kiln or the ware inside. This is not covered by warranty. The time you spend reading now

could save you untold hours of wasted effort later when you begin firing.

Once you learn the basic features of the DTC 1000, you will be able to control every

stage of firing. This offers learning opportunities and convenience difficult to imagine with

a manual-controlled kiln.

We thank those who helped produce this manual, especially Amy Parker and Steven

Drollinger, who offered many suggestions.

©1999, byParagon Industries, Inc. IM-167/7-00

2

Contents

Getting Started

Safety Rules. . . . . . . . . . . . . . . . . . . . .4

Testing and Recording . . . . . . . . . . . 4

Room Temperature and Humidity. . 4

IdLE and CPL Messages. . . . . . . . . . 4

Which Instructions to Use. . . . . . . . . 4

Care of the Thermocouple . . . . . . . . 5

Display Dots . . . . . . . . . . . . . . . . . . . . 5

Correcting Entries . . . . . . . . . . . . . . . 5

Stop Key . . . . . . . . . . . . . . . . . . . . . . . 5

Cool-Down Temperature Display . . 5

Repeat Firings. . . . . . . . . . . . . . . . . . . 5

Program Review . . . . . . . . . . . . . . . . . 5

Pyrometric Witness Cones

In Ceramic Firings. . . . . . . . . . . . . . . 5

When Kiln Shuts Off Too Soon . . . . 6

Portable Controller

(TnF II) Installation. . . . . . . . . . . . . . 6

Ceramic Cone-Fire

Cone-Fire Quick Reference . . . . . . 23

Basics

Firing Speeds . . . . . . . . . . . . . . . . . . . 6

Cone-Fire Programming. . . . . . . . . . 6

Hold. . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Pre-Heating the Ware . . . . . . . . . . . . 7

AOP . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Advanced

Cone Table . . . . . . . . . . . . . . . . . . . . . 8

Firing History in Cone-Fire . . . . . . . 8

Fine-Tuning Shelf Cones

With Cone Offset (CnoS) . . . . . . . . . 8

Interpreting Cone Bending . . . . . . . . 9

When Cone Temperature is

Off More Than 50°F. . . . . . . . . . . . . . 9

Ramp-Hold

Ramp-Hold Quick Reference . . . . . 24

Basics

User Programs . . . . . . . . . . . . . . . . . . 9

Segments. . . . . . . . . . . . . . . . . . . . . .10

Rate . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Hold. . . . . . . . . . . . . . . . . . . . . . . . . . 10

AOP . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Ramp-Hold Programming. . . . . . . . 10

Advanced

Segments for Controlled Cooling. . 11

Skip Segment . . . . . . . . . . . . . . . . . . 11

Sample Firing Schedules. . . . . . . . .11

Cone-Fire Program

Modified in Ramp-Hold . . . . . . . . . . . 11

Sculptured Stoneware Bisque

Firing Schedule, Cone 04. . . . . . . . . . 11

Glass Fusing Firing Schedule . . . . . . 11

Glass Slumping Firing Schedule. . . . 12

16 Segment Firing (16-S) . . . . . . . . 12

Additional Features

Selecting °F or °C (CHG°) . . . . . . . 12

°F/°C Temperature

Conversion Formula. . . . . . . . . . . . . 12

Delay Fire . . . . . . . . . . . . . . . . . . . . . 13

Temperature Alarm . . . . . . . . . . . . . 13

Setting Alarm From Idle. . . . . . . . . . .13

Setting Alarm During Firing . . . . . . . 13

Present Status:

Current Segment &

Circuit Board Temperature. . . . . . . . 13

Checking Circuit Board

Temperature From Idle . . . . . . . . . . . 13

Power Failures . . . . . . . . . . . . . . . . . 13

Firing Ceramics After an

Extended Power Failure. . . . . . . . . . . 14

Thermocouple Offset (tCoS). . . . . 14

Setting Thermocouple Offset . . . . . . 14

Options Quick Reference List . . . . 14

Turning Off Error Codes (ErCd). . 15

Trouble-Shooting &

Maintenance

Element Glow Test . . . . . . . . . . . . . 15

Board Upgrades . . . . . . . . . . . . . . . . 22

Controller Display

Does Not Light Up. . . . . . . . . . . . . . 16

Controller Display Lights

Up Normally, Some or All

Heating Elements Do Not Fire. . . . 16

Firing Interrupted by PF or ErrP . . 17

FAIL Message. . . . . . . . . . . . . . . . . . 18

Err 0 Message. . . . . . . . . . . . . . . . . . 18

Err 1 Message. . . . . . . . . . . . . . . . . . 18

Err 2 Message. . . . . . . . . . . . . . . . . . 18

Err 3 Message. . . . . . . . . . . . . . . . . . 18

Err 4 Message. . . . . . . . . . . . . . . . . . 19

Err 6 Message. . . . . . . . . . . . . . . . . . 19

Err 8 Message. . . . . . . . . . . . . . . . . . 19

Err A Message. . . . . . . . . . . . . . . . . . 19

Err B Message. . . . . . . . . . . . . . . . . . 19

Err d Message. . . . . . . . . . . . . . . . . . 19

Err E Message. . . . . . . . . . . . . . . . . . 19

Err H Message . . . . . . . . . . . . . . . . . 19

Err t . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Err - . . . . . . . . . . . . . . . . . . . . . . . . . . 19

StUC Message . . . . . . . . . . . . . . . . . 19

Erratic Temperature Readings. . . . 20

Overfire . . . . . . . . . . . . . . . . . . . . . . . 20

Stuck Display . . . . . . . . . . . . . . . . . . 20

Relay Chatters or Buzzes. . . . . . . . .20

Kiln Switch Box Fuse

Blows Repeatedly . . . . . . . . . . . . . . . 20

Unwanted Beeping Sound. . . . . . . . 20

Replacing Switch Box Parts

Circuit Board Fuse . . . . . . . . . . . . . . . 21

Thermocouple. . . . . . . . . . . . . . . . . . . 21

TnF II Thermocouple . . . . . . . . . . . . 21

Controller Board . . . . . . . . . . . . . . . . . 21

Transformer . . . . . . . . . . . . . . . . . . . . 21

3

Safety Rules

The warranty on your DTC 1000 controller does not cover

damagefromoverfiring,regardlessofthe circumstances. It is

the operator’s responsibility to make sure the kiln turns offat

theendofthe firing.Followthesesafetyrulesinadditiontothe

ones in your kiln or furnace manual.

When not in use, unplug kiln or furnace or turn off

breaker.

any wall or combustible surface. (See manufac

turer’s recommendation for your model.)

Do not open lid or door until kiln or furnace has

cooled and all switches are off.

Fireonly in a well-ventilated,coveredand protected

area away from flammable materials. Keep cordset

away from hot sides of kiln or furnace.

Donotleave the kiln unattended, especiallynearthe

expected shut-off time.

DANGEROUS VOLTAGE! Do not touch heating

elements with anything. Disconnect kiln or furnace

Wear firing safety glasses (available from Paragon)

before servicing.

when looking into peephole of a hot kiln.

Do not operate if the controller itself is hotter than

Do not touch hot sides of kiln or furnace. Keep un

supervised children away.

Install your kiln or furnace at least 12 inches from

-

150°F/66°C.(Seeinstructions on page 13 forcheck

ingboardtemperature.) Neverallowthefiringroom

temperature to exceed 110°F/43°C. (Measure room

temperature at least three feet away from the kiln.)

Getting Started

Do NOT fire your kiln or furnace until you have read this section and “Cone-Fire

Basics” or “Ramp-Hold Basics.” To use your controller to its fullest capacity, read the advanced sections and “Additional Features.”

-

-

Testing and Recording

You will learn much by testing. How slowly should clay be

heated through quartz inversion? How slowly must you cool

glass through the annealing range? Find out for yourself by

testing.TheDTC1000canpreciselycontroleverystageoffir

ing, so you can easily experiment and test.

Keep a notebook of firing records. When you fire similar

projectsweekslater,after youhaveforgottenthedetailsofyour

previous firing, you will be grateful for your records.

Room Temperature and Humidity

ItisokaytostoretheDTC1000atsub-zerotemperatures.

But before operating, raise the room temperature to at least

0°F/-18°C.

The circuit board is rated for 155°F/68°C maximum oper

atingtemperature. However,maximumtemperature forrated

accuracyis125°F/52°C.Iftheboardgetshotter,openwindows

and exhaust hot air from the room. (See page 13 for instruc

tions on checking circuit board temperature.)

High humidity will not adversely affect the DTC 1000 un

less water condenses on the circuit board. If this happens, do

not fire the kiln until the moisture has evaporated from the

board.

IdLE and CPL Messages

The controller displays ErrP when you first apply power.

PressENTER. ErrP will change to IdLE anda flashing temperature. Operations begin from IdLE .

-

If the display shows FAIL instead of IdLE , the thermo

couple is either disconnected or burned out. (See page 18.)

CPL means “completed.” The controller will display

CPL , then IdLE , after it performsactionssuchaschanging

°Fto°C display. CPL mayremainfor awhilebefore IdLE ap

pears. Please be patient—the controller is processing data.

Which Instructions to Use

The DTC 1000 fires in two modes:

-

-

-

1) Ceramic Cone-Fire, based on pyrometric cones.

2) Ramp-Hold, based on firing rates and target tempera

tures.

Ceramickilns,usuallytop-loading,usebothCone-Fireand

Ramp-Hold. Heat treating, glass fusing, and enameling fur

naces and kilns usually come with Ramp-Hold only.

FAST, MEDIUM, SLOW, CONE-FIRE, and Cone #s

printed on the controller faceplate apply only to

Cone-Fire mode.

-

-

-

-

4

How to Tell if You Have Cone-Fire

1 From IdLE display, press ENTER, then 1.If ConE

appears, you have Cone-Fire mode. If ---- appears,

you have Ramp-Hold mode only.

2 Bring the controller back to IdLE display:

a) From ---- , press STOP. IdLE will appear.

b) From ConE , press ENTER 3 times slowly. CPL ,

then IdLE , will appear.

If you have Cone-Fire, all of this manual applies to your

controller. If you have Ramp-Hold only, skip Cone-Fire on

pages 6-9.

Care of the Thermocouple

The small metal rod protruding into the firing chamber is

the temperature sensor, or thermocouple. Do not let shelves,

posts or ware touch the thermocouple. This could affect the

temperature reading.

Bumping the thermocouple during loading can damage it

orpushit outofthefiringchamber.Itshouldprotrude intothe

firing chamber at least

thermocouple extends into the firing chamber even farther.)

Avoid firing clay with a high sulphur content. The sulphur

eatsintothethermocouple,makingitbrittleandeasytobreak.

1

5

"-

". (Do not be concerned if your

2

8

Display Dots

Single Center Dot: Time

Alower centerdot appearsduringtimedisplay.It separates

hoursfromminutes(i.e.1hour,30minutesdisplaysas01.30).

During temperature display, the dot disappears.

Single Right-Hand Dot: °C

When a temperature is displayed in °C, a lighted dot appears in the lower right. In °F it disappears.

Three Dot Display: Power Monitoring

To adjust temperature, the DTC 1000 sends power to the

relay(s) intermittently. The relays, inturn, power the heating

elements. To monitor when the relays are turned on, press 8

during firing. When three dots appear along the bottom dis

play, relays are receiving power.

ToturnoffPowerMonitoring,press8again.Thisfeatureis

used mostly for diagnostics.

Correcting Entries

If you enter the wrong temperature, cone, time, etc., while

programming, enter 0000. Then enter the correct numbers

before pressing ENTER.

The Stop Key

You can stop a firing at any time by pressing STOP.

Ifyou inadvertentlyenter Ramp-Hold,you donot haveto go

through all the prompts to get back out. Press STOP when

USEr appears. That will take you back to IdLE .

If you inadvertently enter Cone-Fire, STOP will NOT take

youback to IdLE . PressENTERafter eachCone-Fireprompt

until CPL , then IdLE , appears.

If you inadvertently press OPTIONS, you can get back to

IdLE by pressing STOP.

Cool-Down Temperature Display

When the firing is finished, CPLt will display alternating

with the total firing time in hours and minutes. To view the

current kiln temperature as the kiln cools, press ENTER.

CPLt will disappear. Then temperature will display.

Repeat Firings

To repeat the last firing, press ENTER twice from IdLE .

The kiln will begin firing. This works in both Cone-Fire and

Ramp-Hold.But first,make sureyouare repeatingthe correct

firing by using “Program Review” below.

Program Review

When you select a firing program in Cone-Fire or

Ramp-Hold and go back to IdLE , you have called a program

fromstorage. It is thenreadyto fire. “Program Review”shows

you the values for that program.

TostartProgramReview from IdLE ,pressENTER,then 6.

Valuesfor theprogramselected forfiring will displayone after

theother. Youcan alsouseProgram Reviewduring firingsimply by pressing 6.

TIP:InProgramReview,values for a program display

about one per second. You can speed up this display by

pressing 1repeatedly. If you hold down the 1key,values

will speed by. This works from both IdLE and during

firing.

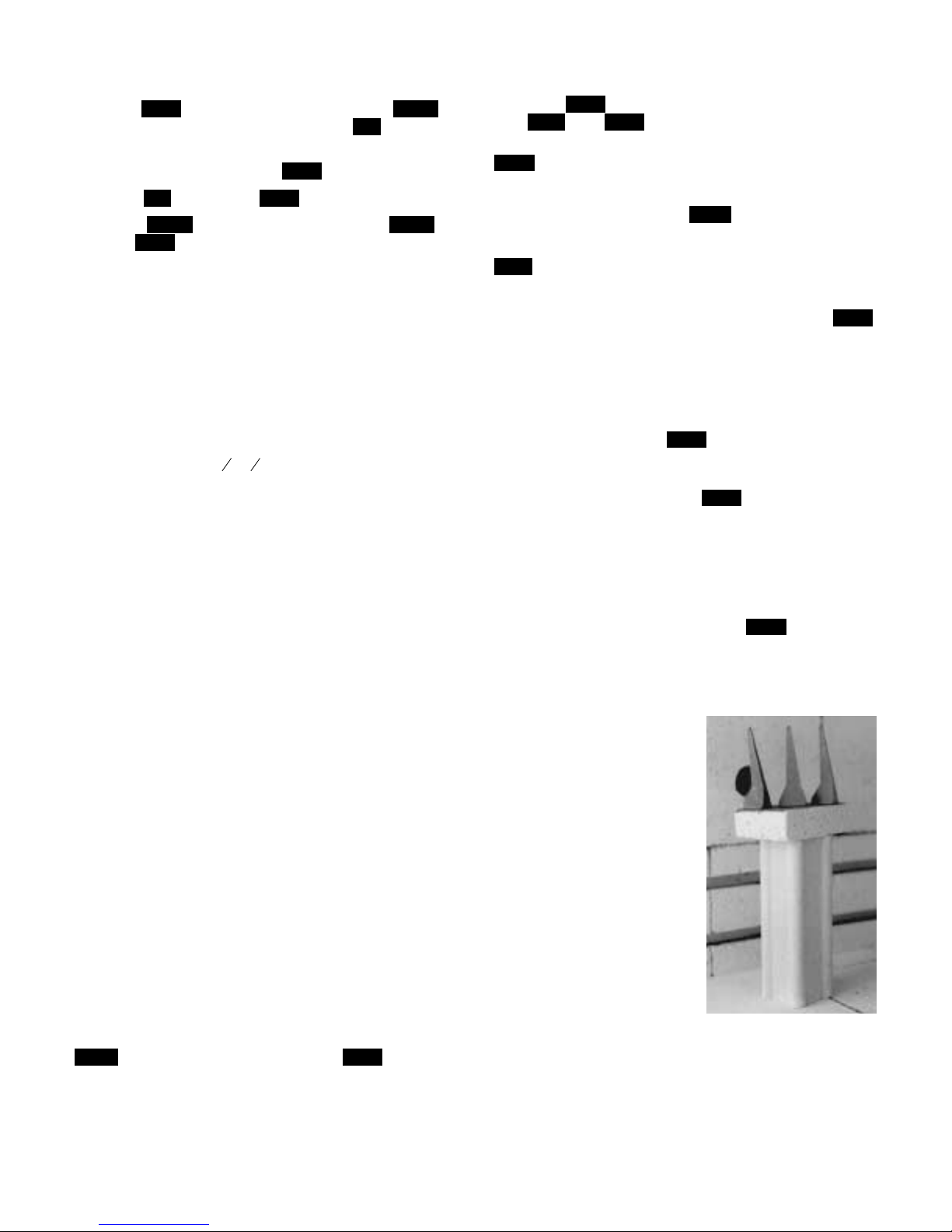

Pyrometric Witness Cones in

Ceramic Firings

Though the DTC 1000 fires

electronically,every ceramicfir

ing should include shelf, or wit

ness,cones.Theymeasureheat

work accurately and give a his

-

tory of the firing.

If you fire the same size load

and type of ware regularly, the

shelf cones let you compare one

firing to the next and alert you

when something is wrong. For

example,if the shelf conebends

farther and farther with each

consecutive firing, this may in

dicate thermocouple tempera

ture drift.

Keep cones 3" from the

peepholeto avoidcoolair drafts.

Wearfiring safetyglasses whenviewingthe conesat hightem

perature. Your dealer can tell you which cone number to use

for each clay and glaze.

-

-

-

-

-

-

5

When Kiln Shuts Off Too Soon

If the kiln shuts off below maturity, you can turn it back on

andkeepfiring.Simply program a higher temperature or hot

ter cone. Then from IdLE , press START twice. The kilnwill

begin firing, taking up where it left off.

Ceramicfirings: if thekiln shuts offwithin100°F/55°C of

maturity, and the temperature drops 50°F/28°C or more after

the kiln shuts off, do not depend on the pyrometric witness

cones in the kiln. Once the cones cool 50°F/28°C after they

Ceramic Cone-Fire

have been heated to within 100°F/55°C of maturity, they will

not bend properly. This is because they form a hard shell.

-

Portable Controller (TnF II) Installation

The wall-hanging portable DTC 1000 TnF II includes a

temperaturesensorcalledathermocouple.Keepthethermo

couplewireawayfromelectrical wires. Wrapping the thermo

couple wire around the kiln’s power cord or taping it to the

cord may cause erratic temperature display.

-

-

Cone-Fire mode is based on pyromet

ric cones. It is not designed for heat treat

-

ing, glass fusing and enameling. For these

firings, see “Ramp-Hold,” page 9. Use

Ramp-Hold to fire ceramic pieces that re

quire a custom firing schedule, such as

some types of stoneware sculpture or crys

talline glaze. To fire faster than Cone-Fire

Fast speed, use Ramp-Hold.

Do NOT use Cone-Fire until you have

read “Cone-Fire Basics” and “Cone-Fire

Programming.” To take full advantage of

other features in Cone-Fire mode, read

“Advanced Cone-Fire,” pg 8.

Cone-Fire Basics

Firing Speeds

Cone-Fire operates in Fast, Medium or Slow speed. The

instructions that follow will show you how to select speed.

To view the firing segment of a cone-fire, press 5 during

firing.(See“Present Status,” page 13.) Thesegmentnumber

willappear(seeleft columninthefollowingcharts),informing

you of how far the firing has progressed.

Fast (1)

Consider Fast for overglazes, decals, china paint, or small,

thin-walled ceramic greenware.

Cone-Fire Fast Firing Schedule

Segment in

“Present Actual

Status” Segment Rate of Firing Per Hour

5 — Pre-Heat (if any)

6 1 570° F. per hour until the last 250° F.

7 2 200° F. per hour during last 250° F.

Cone-Fire Programming

Use these instructions for your first firings. Later

youmayprefer“Cone-FireQuickReference,”pg.23.

AstheDTC1000promptsforcone,speed,etc.,val

uesenteredforthelastfiringwill appear.To usethese

-

values again, press ENTER.

To fire without Delay or Alarm: Follow steps 1

through 6 below. Then from IdLE press START

twice. To use Delay or Alarm, first read page 13.

1 Apply power to the kiln.

2 ErrP will appear. Press ENTER. IdLE will

appear.

3 Press ENTER then 1. ConE will appear. En-

ter cone number. (If ---- appears instead of

ConE , your controller uses Ramp-Hold

only.)

4 PressENTER. SPd willappear.Enterspeed:

FAST (1), MEDIUM (2), SLOW (3).

5 Press ENTER. HLd will appear. Enter hold

time, if any, in hours and minutes (e.g. 12

hours,30minutes=12.30).Nohold=00.00.

6 Press ENTER. IdLE will appear.

7 Toset alarm,press ENTERthen7. ALAr will

appear. Enter alarm temperature. (Enter

9999 to turn alarm off.) Then press ENTER.

8 Tosetdelay fire,press ENTER then3. dELA

will appear. Enter delay time in hours and

minutes(e.g. 12 hours, 30minutes= 12.30).

Press ENTER. (Delay zeroes out after each

firing.)

9 To start program, press ENTER twice.

-On- will appear, thenkiln temperature. Ifa

delay was programmed, -On- will appear,

then time remaining until start. To stop the

program during firing, press STOP.

When program fires to completion, CPLt will ap

pear alternating with total firing time in hours and

-

-

6

Medium (2)

Use Medium for larger slip-cast pieces or more tightly

loaded kilns.

Cone-Fire Medium Firing Schedule

Segment in

“Present Actual

Status” Segment Rate of Firing Per Hour

4 — Pre-Heat (if any)

5 1 110° F. per hour until 250° F.

6 2 400° F. per hour until the last 250° F.

7 3 120° F. per hour during the last 250° F.

Slow (3)

Use Slow for hand-thrown or heavily-cast pieces, stone

ware and porcelain.

Cone-Fire Slow Firing Profile

Segment in

“Present Actual

Status” Segment Rate of Firing Per Hour

2 — Pre-Heat (if any)

3 1 80°F per hour to 250°F

4 2 250°F per hour until temperature

5 3 110°F per hour until temperature

6 4 225°F per hour until the last 200°F

7 5 90°F per hour during the last

8 6 150°F per hour, cooling down to

reaches 950°F

reaches 1100°F

200°F of firing

1000°F

Hold

Cone-Fire“Hold” heat-soaksthe wareatthe endof thefir

ing. Without Hold time, the kiln shuts off after it reaches the

conetemperature.WithHoldtime,thekilnmaintainsthecone

temperature for the period you specify. Hold time helps even

outthe temperature throughoutthekiln. It alsohelps the heat

topenetratecompletely into the clay. Rapid firingislike cook

ing: the turkey will be done on the outside but not on the in

side.Hold helpsglaze absorbchina paint.It helpsto healglaze

defects such as bubbles. A little hold time can yield dramatic

results.

CAUTION: Too much hold time can overfire your

ware and burn out colors.

One way to add Hold time without over-firing is to fire to

one cone cooler than needed. Then add enough hold time to

bendthenexthotter cone.Holdtimeneededwillvary.As arule

of thumb, one hour of hold = one cone of heat work.

Example: to fire to cone 05

and add 30 minutes of hold time.

1

, program Cone-Fire for 05

2

Watch the pyrometric shelf cones through the peephole.

Press STOP when the correct shelf cone bends, noting how

much Hold time was needed. Program that much Hold time

thenext timeyou firethesame typeof wareloaded tothesame

capacity. You can hold for up to 99 hours and 99 minutes.

Youwill learn by experimentingwith ceramics. Hold isone

more tool to experiment with.

Pre-Heating the Ware

Moist greenware can explode during firing. This happens

when the moisture in the clayturns to steam rapidly and can

noteasilyescape. TheDTC1000“Pre-Heat”feature driesthe

ware at low temperature before the moisture can turn to

steam.

-

-

-

-

Pre-Heatis necessarywhenfiring thickgreenware, suchas

stoneware. It may also be necessary in humid weather, which

inhibits drying. If possible, however, avoid using Pre-Heat to

dry greenware. If the greenware feels damp or cool when you

touch it to your cheek, dry it longer before firing. Use a

dehumidifier in humid weather. Drying greenware in the kiln

tends to rust the kiln.

TIP:DuringPre-Heat, vent the lid. Otherwise the fire

bricks will absorb moisture, leading to rust behind the

stainless steel case. Moisture in the firebrick will also

slow the kiln to a crawl when firing begins.

VentingthelidduringPre-Heatissoimportantthatsome

ceramistsuse theextended ventpositionor evenleavethe

lid open. If you do this, you must be near your kilnatthe

end of Pre-Heat to lower the lid.

Pre-Heat raises the temperature 60°F/33°C per hour to

200°F/93°C.Thenitholdsat200°F/93°Cforthetimeyouspecify. Pre-Heat works in Cone-Fire only. After Pre-Heat is finished, the kiln will automatically begin firing to the cone you

have selected. Pre-Heat zeroes out after each firing.

CAUTION: At high altitude, water boils at a lower

temperature.This maycausethe ware todrytoo rapidly

even during Pre-Heat.

After entering cone number, speed, etc., in the Cone-Fire

program, activate Pre-Heat as follows. Then begin firing.

1 Press ENTER.

2 Press 0repeatedly until PrHt appears.

3 Press ENTER. Hld will appear, alternating with

00.00 .

4 EnterPre-Heat hold time in hoursand minutes (i.e. 1

hour, 30 minutes = 01.30).

5 Press ENTER. CPL will appear, then IdLE .

-

-

7

Mirror Test

Knowing how much Pre-Heat to use is a matter of experi

ence. There is no substitute. However, this mirror test will

help. Occasionally during

Pre-Heat, hold a mirror near

the top peephole. (Be careful

to avoid burns.) The mirror

mustbeatroomtemperature,

not hot, so hold it near the

peephole for only several sec

onds.

If the mirror fogs, mois

ture is still escaping from the

ware. When the mirror no

longer fogs, make a note of

howmuchPre-Heattimeyourware needed.Thatwill helpyou

determine how much Pre-Heat to use next time.

If you decide to interrupt Pre-Heat and begin firing to the

cone in Cone-Fire, press STOP. Follow the steps above that

you used to program Pre-Heat. But instead of entering

Pre-Heat hold time, enter 00.00. Press ENTER to go back to

IdLE . Press ENTER twice to begin firing again.

-

-

AOP

Theoptional“AOP” (AuxiliaryOutput)isanelectrical outlet, usually mounted in the kiln’s switch box. The AOP outlet

can power a kiln vent or other appliance. If your kiln is

equipped with AOP, AOP will appear in Cone-Fire after

HoLD . (If AOP does not appear in the display, your kiln is

not equipped with AOP.)

Whensetto OFF,theAOPoutletreceives powerduringthe

Cone-Fire firing. At the end of the firing, the AOP shuts off.

When set to On, the AOP remains powered during both

ConeFire firing and cooling. It shuts off after the kiln cools to

°150F/66°C.

TIP: For slow cooling in Cone-Fire, select AOP OFF.

Adjusting AOP in Cone-Fire

1 AfterprogrammingCone,Speed andHold, AOP will

appear, alternating with On or OFF .

2 To change the setting, press 1, then ENTER. CPL

will appear, followed by IdLE .

2 Enter the pyrometric cone number you are looking

-

up. Then touch ENTER. The display will show the

cone temperature. If you enter a non-existent cone

number, the display will show ConE , ready for you

to enter a different cone number.

Cone temperatures displayed are for self-supporting

cones fired at a rate of 108° F. during the last hour.

Firing History in Cone-Fire

Whenthekiln fires to completion, CPLt with flash, alter

nating with total firing time inhours/minutes. To view the fi

naltemperaturethe kilnreached, pressENTER. IdLE willap

pear. Press ENTER, then 6 (Program Review). Final firing

temperaturewilldisplayalongwiththecone,speedandhold.

Fine-Tuning Shelf Cones

With Cone Offset (CnoS)

SometimesthepyrometricconeprogrammedinCone-Fire

doesnotmatchthebendingoftheconeonthekilnshelf.Using

“Cone Offset,” you can adjust Cone-Fire to fire hotter or

cooler.

IMPORTANT: Cone Offset adjusts the firing temper

ature individually for each pyrometric cone number.

Adjusting one cone has no effect on the other cones. To

adjust all the cones equally, use “Thermocouple Offsets,” page 14.

Forinstance, the controllerfiresshelf cone 018toa perfect

sixo’clockbend.Butat cone6, theshelfconeover-fires.Using

Cone Offset, you could lower cone 6 firing temperature without affecting the perfect results you are getting at cone 018.

TIP:Before using Cone Offset, check that the thermo-

couple is protruding into the firing chamber by at least

1

5

"-

".Sometimes bumpingashelfagainstthe thermo-

2

8

couple pushes it out of the firing chamber, thereby preventing accurate temperature readings.

How to Use Cone Offset

1 From IdLE , press ENTER.

2 Press 0until CnoS appears.

3 PressENTER. ConE willappear,alternatingwiththe

last cone number entered in Cone-Fire. Enter the

new cone number.

-

-

-

-

Advanced Cone-Fire

Built-in Cone Table

Foryourconvenience,thecontrollercanlookupapyromet

ric cone temperature. Do not be concerned, however, if your

kiln’scone shut-offtemperaturedoes notmatch thetempera

ture in the Cone Table.The temperature of a cone varies de

pending on firing speed.

1 From IdLE, touchENTER then9. ConE willappear,

then the cone currently programmed in Cone-Fire

Mode.

8

4 Press ENTER. °FOS (or °COS for Celcius) will ap

pear, alternating with 9000 or an adjustment num

ber.

5 Enter adjustment number (see chart). Then press

-

-

-

ENTER. CPL will appear, then temperature and

IdLE .

Youcan raiseor lowerfiring chambertemperaturefor each

conefrom1 - 50°F/1 - 28°C.Place00infront ofthenumberto

make the kiln fire hotter. Place 90 in front to make it fire

cooler.

-

-

Loading...

Loading...