Page 1

SMD2000-24T 24-Port SHDSL Mini DSLAM

Installation Instructions

Document Number SMD2-A2-GN11-00

July 2005

Contents

Software and Firmware License Agreement ................................................. 2

Product Documentation Online ..................................................................... 3

Unpacking and Inspecting the Equipment .................................................... 4

Site Selection Criteria ................................................................................... 4

Installing Uplink Interface Modules (Optional) .............................................. 5

Tabletop Installation ...................................................................................... 7

Rack Installation ............................................................................................ 8

Powering Up the SMD2000-24T ................................................................... 9

Connecting the SHDSL RJ21 Cable ............................................................. 11

Connecting to the Remote SHDSL Modems ................................................ 12

Verifying the Connection(s) ........................................................................... 13

Connecting the Uplink Lines ......................................................................... 14

Default Settings ............................................................................................. 15

Data Storage ................................................................................................. 17

Reset Button ................................................................................................. 19

LED Indicators .............................................................................................. 20

Pin Assignments ........................................................................................... 23

Technical Specifications ................................................................................ 26

EMI Notices .................................................................................................. 27

ACTA Customer Information ......................................................................... 27

CE Marking ................................................................................................... 28

Japan Notice ................................................................................................. 29

Important Safety Instructions ........................................................................ 30

Warranty, Sales, Service, and Training Information ...................................... 31

1

Page 2

Software and Firmware License Agreement

ONCE YOU HAVE READ THIS LICENSE AGREEMENT AND AGREE TO ITS

TERMS, YOU MAY USE THE SOFTWARE AND/OR FIRMWARE INCORPORATED

INTO THE PARADYNE PRODUCT. BY USING THE PARADYNE PRODUCT YOU

SHOW YOUR ACCEPTANCE OF THE TERMS OF THIS LICENSE AGREEMENT.

IN THE EVENT THAT YOU DO NOT AGREE WITH ANY OF THE TERMS OF THIS

LICENSE AGREEMENT, PROMPTLY RETURN THE UNUSED PRODUCT IN ITS

ORIGINAL PACKAGING AND YOUR SALES RECEIPT OR INVOICE TO THE

LOCATION WHERE YOU OBTAINED THE PARADYNE PRODUCT OR THE

LOCATION FROM WHICH IT WAS SHIPPED TO YOU, AS APPLICABLE, AND YOU

WILL RECEIVE A REFUND OR CREDIT FOR THE PARADYNE PRODUCT

PURCHASED BY YOU.

The terms and conditions of this License Agreement (the “Agreement”) will apply to the

software and/or firmware (individually or collectively the “Software”) incorporated into

the Paradyne product (the “Product”) purchased by you and any derivatives obtained

from the Software, including any copy of either. If you have executed a separate written

agreement covering the Software supplied to you under this purchase, such separate

written agreement shall govern.

Paradyne Corporation (“Paradyne”) grants to you, and you (“Licensee”) agree to accept

a personal, non-transferable, non-exclusive, right (without the right to sublicense) to use

the Software, solely as it is intended and solely as incorporated in the Product

purchased from Paradyne or its authorized distributor or reseller under the following

terms and conditions:

1. Ownership: The Software is the sole property of Paradyne and/or its licensors. The

Licensee acquires no title, right or interest in the Software other than the license

granted under this Agreement.

2. Licensee shall not use the Software in any country other than the country in which

the Product was rightfully purchased except upon prior written notice to Paradyne

and an agreement in writing to additional terms.

3. The Licensee shall not reverse engineer, decompile or disassemble the Software in

whole or in part.

4. The Licensee shall not copy the Software except for a single archival copy.

5. Except for the Product warranty contained in the manual, the Software is provided

“AS IS” and in its present state and condition and Paradyne makes no other

warranty whatsoever with respect to the Product purchased by you. THIS

AGREEMENT EXPRESSLY EXCLUDES ALL OTHER WARRANTIES, WHETHER

EXPRESS OR IMPLIED, OR ORAL OR WRITTEN, INCLUDING WITHOUT

LIMITATION:

a. Any warranty that the Software is error-free, will operate uninterrupted in your

operating environment, or is compatible with any equipment or software

configurations; and

2

Page 3

b. ANY AND ALL IMPLIED WARRANTIES, INCLUDING WITHOUT LIMITATION

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE AND NON-INFRINGEMENT.

Some states or other jurisdictions do not allow the exclusion of implied warranties

on limitations on how long an implied warranty lasts, so the above limitations may

not apply to you. This warranty gives you specific legal rights, and you may also

have other rights which vary from one state or jurisdiction to another.

6. IN NO EVENT WILL PARADYNE BE LIABLE TO LICENSEE FOR ANY

CONSEQUENTIAL, INCIDENTAL, PUNITIVE OR SPECIAL DAMAGES,

INCLUDING ANY LOST PROFITS OR LOST SAVINGS, LOSS OF BUSINESS

INFORMATION OR BUSINESS INTERRUPTION OR OTHER PECUNIARY LOSS

ARISING OUT OF THE USE OR INABILITY TO USE THE SOFTWARE,

WHETHER BASED ON CONTRACT, TORT, WARRANTY OR OTHER LEGAL OR

EQUITABLE GROUNDS, EVEN IF PARADYNE HAS BEEN ADVISED OF THE

POSSIBILITY OF SUCH DAMAGES, OR FOR ANY CLAIM BY ANY THIRD

PARTY.

7. The rights granted under this Agreement may not be assigned, sublicensed or

otherwise transferred by the Licensee to any third party without the prior written

consent of Paradyne.

8. This Agreement and the license granted under this Agreement shall be terminated

in the event of breach by the Licensee of any provisions of this Agreement.

9. Upon such termination, the Licensee shall refrain from any further use of the

Software and destroy the original and all copies of the Software in the possession of

Licensee together with all documentation and related materials.

10. This Agreement shall be governed by the laws of the State of Florida, without

regard to its provisions concerning conflicts of laws.

Product Documentation Online

Complete documentation for Paradyne products is available at www.paradyne.com.

Select Support → Technical Manuals. Select:

Command Line Interface for 4000E and 12000E BACs, Micro DSLAMs, and

Network Extenders User's Guide (Document Number CLI-A2-GB20)

Network Management System User's Guide (Document Number NMS-A2-GB20)

SNMP for 12000/4000 BLCs and Micro DSLAMs User's Guide (Document Number

SNMP-A2-GB20)

To order a paper copy of a Paradyne document, or to speak with a sales representative,

please call 1-727-530-2000.

3

Page 4

Unpacking and Inspecting the Equipment

!

HANDLING PRECAUTIONS FOR STATIC-SENSITIVE DEVICES

This product is designed to protect sensitive components from

damage due to electrostatic discharge (ESD) during normal

operation. When performing installation procedures,

however, take proper static control precautions to

prevent damage to equipment. If you are not sure

of the proper static control precautions, contact

your nearest sales or service representative.

The following components should be included in your package:

1 – SMD2000-24T

4 – Rubber Pads

2 – Rack Mount Brackets

10 – #6 Phillips Bracket Screws

4 – #10 Phillips Rack Screws

4 – #12 Phillips Rack Screws

1 – DB9 Socket to RJ45 Plug Adapter

If there is visible damage, do not attempt to connect the device. Contact your sales

representative.

Site Selection Criteria

In choosing a location for the installation of this product:

Select a restricted access area where admittance is limited to trained and

authorized service personnel.

Ensure that the internal temperature of a rack containing this equipment will not

exceed the maximum recommended ambient temperature of 149° F (65° C).

Place the chassis such that connecting cables will not become a tripping hazard or

pull loose from the chassis.

Do not block power supply vents or otherwise restrict airflow when installing this

equipment.

Ensure that installation of this equipment in a rack will not cause the rack to become

top-heavy or unstable.

Do not overload the electrical branch circuit of the power source for this equipment.

For tabletop use, attach the enclosed rubber feet to the bottom of the chassis.

For rack installation, attach the enclosed rack mount brackets to the sides of the

chassis with the screws provided.

4

Page 5

Installing Uplink Interface Modules (Optional)

An SMD2000-24T does not require installation of an Uplink Interface Module (UIM) for

operational purposes. A UIM offers additional upstream network ports to supplement the

two T1 uplink ports already provided. You may wish to install a UIM if your network

requires an Ethernet uplink connection or if you require an additional E1 or T1 backhaul.

The SMD2000-24T supports the following 1-port UIMs only:

UIM-E1

UIM-T1

UIM-10/100

CAUTION:

Disconnect all power sources from the SMD2000 before installing a UIM.

Procedure

To install a UIM:

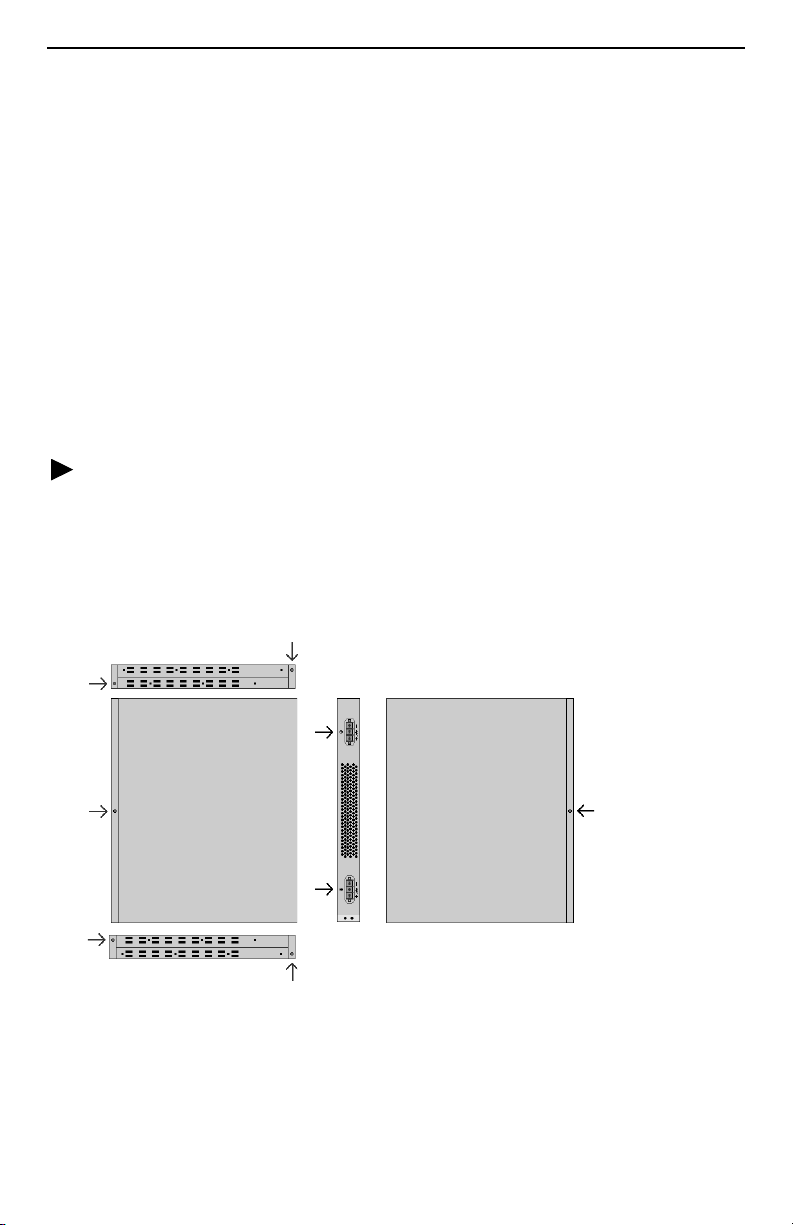

1.

Remove the Chassis Cover. Using a Phillips Screwdriver, remove the eight

flathead screws securing the SMD2000-24T chassis cover and set them aside.

Carefully lift off the chassis cover and set it aside.

Side

To p

Side

Rear

Bottom

5

Page 6

Mount the UIM on the SMD2000-24T Printed Circuit Board (PCB). A

2.

UIM may be installed in either Port 1 or Port 2, or both for redundancy purposes.

Using a Phillips screwdriver, remove the flathead screws from both sides of the

chosen port on the chassis faceplate. Remove the slot cover.

CAUTION:

If a slot cover is removed from Port 1 or Port 2, it must be replaced with a UIM.

Do not operate the SMD2000-24T with an open UIM port.

3. Carefully slide the faceplate of the UIM under the lip of the SMD2000-24T faceplate

at the selected port opening such that the UIM PCB is face down and the UIM label

shows through the port opening with the UIM model name along the right edge.

Align and secure the PCBs. Ensure that the connector key pins and the four

4.

mounting holes on the UIM PCB are lined up with the board-to-board connector and

the four corresponding standoffs on the SMD2000-24T PCB. Gently press down

with even pressure on all four corners of the UIM until the board-to-board connector

is fully seated. Using a Phillips screwdriver, secure the UIM PCB to the

SMD2000-24T PCB at the standoffs with the four provided pan-head screws.

UIM Side View

Standoffs

6

Page 7

5. Secure the faceplate. Using a Phillips screwdriver, secure the UIM faceplate to

the SMD2000-24T faceplate with the two flathead screws included in your UIM

packaging.

6. Replace the chassis cover. Replace the chassis cover and secure with the

original eight flathead screws as depicted in Step 1 on page 5.

Tabletop Installation

Procedure

To install the SMD2000-24T on a table, desk, shelf, or remote cabinet:

1. Affix the four provided rubber pads to the bottom of the chassis for surface grip.

Bottom of Chassis

2. Place the SMD2000-24T such that the cables will not become a tripping hazard or

pull loose from the chassis. Ensure that the air supply vents on the sides of the

chassis are not blocked.

7

Page 8

Rack Installation

Procedure

To install the SMD2000-24T in a rack:

1. Using a Phillips screwdriver, attach the two provided rack mount brackets to the

sides of the SMD2000-24T with the ten provided bracket screws.

2. Mount the chassis onto the rack and secure the rack mount brackets to the sides of

the rack using one of the two provided sets of four rack mount screws (whichever

size fits the rack being used).

3. Check the rack for stability, ensuring that installation of the SMD2000-24T has not

caused the rack to become top-heavy. Ensure that all cables are secured such that

they will not become a tripping hazard or pull loose from the chassis.

8

Page 9

Powering Up the SMD2000-24T

CAUTION:

Turn your DC power source off until you have completed connection of the

SMD2000-24T as described below.

Do not operate your SMD2000-24T without a ground connection.

Procedure

To connect the SMD2000-24T to power:

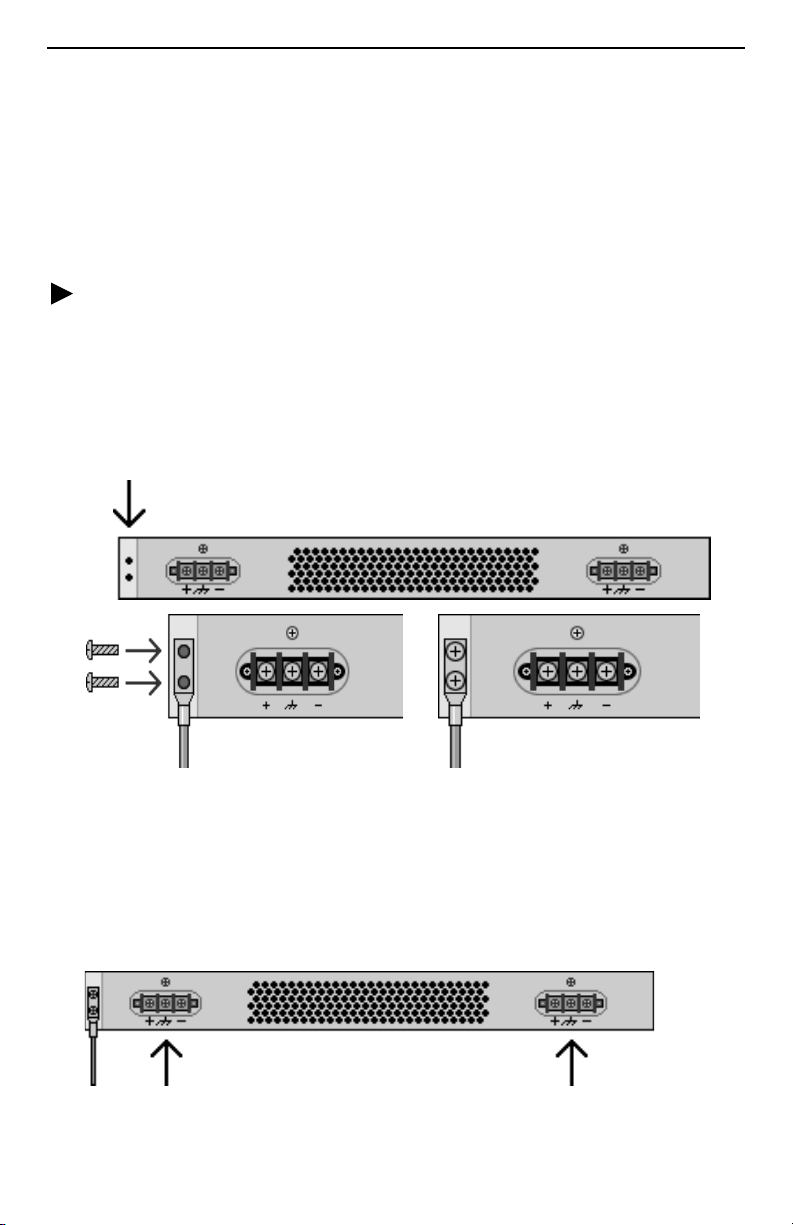

1. Connect a ground wire to the SMD2000-24T. Line up the 2-hole terminal lug of

your ground wire with the two holes on the small, unpainted section on the left side

of the back of the chassis. Secure the terminal lug to the chassis with two #10-32

screws.

2. Connect the other end of the ground wire to a frame ground. This can vary

from location to location, but typically all equipment in a Central Office is grounded

to a common copper bus.

3. Select a terminal block. Either terminal block on the back of the SMD2000-24T

may be used to power the chassis. Both terminals may be connected if redundancy

(backup) is desired.

9

Page 10

The two terminal blocks on the SMD2000-24T are independent feeds. Chassis

power is supplied by only one terminal block at a time; the second supply is merely

backup. Likewise, the two terminal blocks do not load-share. Each terminal block

must be supplied with the adequate amperage to run the chassis.

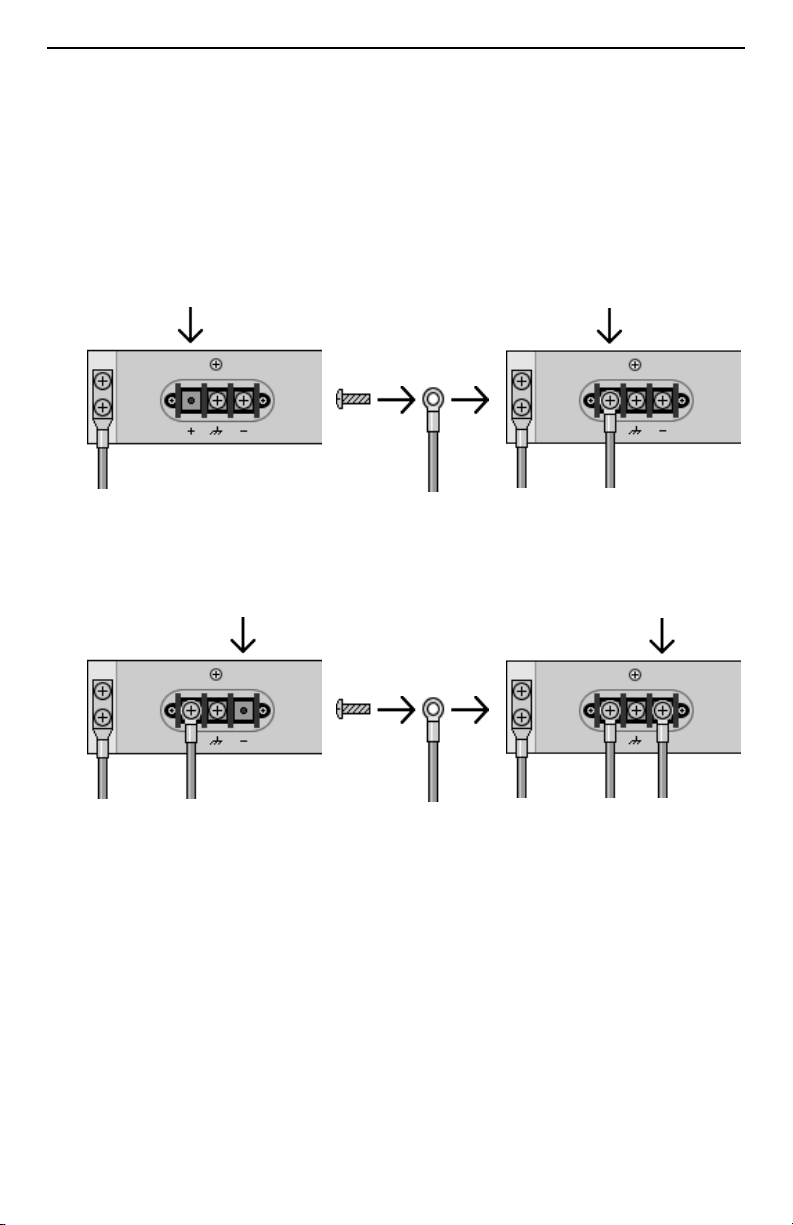

4. Using a Phillips screwdriver, remove the left screw from the chosen terminal block

(labeled "+" on the chassis). Slide the ring terminal of your positive power lead onto

the shaft of the screw and re-insert the screw into the terminal block (same "+"

terminal from which it was removed).

Positive (Return) Lead

5. Remove the right-hand screw (labeled "–") from the same terminal block, slide the

ring terminal of your negative lead onto the shaft of the screw and re-insert the

screw into the terminal block (same "–" terminal from which it was removed).

Negative (Batt) Lead

CAUTION:

Be sure to attach the positive lead to the positive terminal and the nagative

lead to the negative terminal as indicated on your SMD2000-24T terminal

block labels.

6. Attach the other ends of the power leads to a fuse panel. The negative (–) lead

connects to a "Batt" (Battery) terminal and the positive (+) lead connects to a

"Return" terminal on your DC power supply.

10

Page 11

7. Verify the connection. Turn your power source ON. The PWR (power) LED on

your SMD2000-24T faceplate will illuminate solid green to indicate that the chassis

is receiving power.

Connecting the SHDSL RJ21 Cable

Procedure

To connect the SHDSL cable to the SMD2000-24T RJ21 connector:

1. Configure the SHDSL lines.

No configuration is necessary for the SMD2000-24T to operate at default settings.

However, if you wish to run subscriber lines at settings other than the

SMD2000-24T defaults, configure the subscriber lines prior to connection.

Parameter settings may be changed using the Command Line Interface (CLI),

Simple Network Management Protocol (SNMP), or the web-based management

system. SHDSL Parameter Defaults on page 15 lists the device defaults. Product

Documentation Online on page 3 lists the user interface manuals.

2. Detach the hook-and-loop fastener strap from the RJ21 socket on the front of the

chassis and pull it upward, leaving it looped under the connector frame at the top.

11

Page 12

3. Slide the RJ21 plug connector of your SHDSL cable underneath the hook-and-loop

fastener from the right and press it firmly into the RJ21 socket on the chassis.

4. Pull the hook-and-loop fastener strap upward, making sure that it is snug against

the RJ21 connector, and then pull the strap back down over itself such that the

hook-and-loop fastener layers stick to one another.

5. Screw the left side of the RJ21 plug connector into the jack screw on the left side of

the RJ21 socket on the chassis.

left and right sides of the RJ21 plug connector should be secured to the socket.

If you are using a 120 or 180 degree cable, both the

Connecting to the Remote SHDSL Modems

A primary feature of the SMD2000-24T is its capability to support multiple loop bonded

SHDSL connections. However, it is equally capable of supporting up to 24 single line

connections, as well as combinations of both single and loop bonded connections.

Loop Bonded SHDSL Connection

Multiple SHDSL ports (consecutive or not) may be connected with a single remote

SHDSL modem as long as the remote modem is also loop bonding capable. Refer to

Product to Product SDSL Loop Bonding Compatibility, (Document Number

COMP-A2-GK42), for a complete list of SDSL loop bonding capable products.

12

Page 13

The speed and data passing capability of multiple SHDSL lines, as used for one network

connection, is cumulative. For example, loop bonding three SHDSL lines for one

network connection nets three times the speed and data passing capability of a

single-line SHDSL connection. Additionally, use of multiple SHDSL lines for one

connection provides automatic backup should one or more lines in the bonded group

experience problems or become disabled.

NOTE:

Upon connection, all ports in a bonded group will automatically default to the

configurations of the lowest numbered port of the group. Hence, the lowest

numbered port of the group should be configured prior to connection if you intend to

run the group with parameter settings other than the defaults.

Single Line SHDSL Connection

A single line SHDSL subscriber connection may be established with any standard

SHDSL subscriber equipment.

Verifying the Connection(s)

The LK (link) LED for each port connected with a remote modem will flash green to

indicate a connection has been established. An ACT LED flashing amber indicates

SHDSL activity. Link establishment time between the SMD2000-24T and remote SHDSL

modems can vary from one to five minutes depending on the quality, gauge, and length

of the copper cable pairs being used.

Note:

If any of the cable distances are greater than the configured bandwidth will support,

the units may not link up or, if they do achieve link, traffic quality may be affected (for

example, packets may be dropped).

13

Page 14

Connecting the Uplink Lines

To connect the SMD2000-24T to T1 service:

1. Configure the T1 uplinks.

No configuration is necessary for the SMD2000-24T to operate at default settings.

However, if you wish to run uplinks at settings other than the SMD2000-24T

defaults, configure the uplinks prior to connection. Parameter settings may be

changed using the Command Line Interface (CLI), Simple Network Management

Protocol (SNMP), or the web-based management system. T1 Uplink Parameter

Defaults on page 15 lists the device defaults for the T1 uplinks. Product

Documentation Online on page 3 lists the user interface manuals.

2. Plug your T1 cable into an RJ48C T1 uplink port on the SMD2000-24T faceplate.

For most applications, a straight-through T1 cable is required. A connection to Port

2 is shown.

3. Connect to the remote T1 equipment. The SMD2000-24T requires only one uplink

connection for operational purposes, although a second T1 uplink connection may

be desired for redundancy. Additionally, the two T1 uplink ports may be bonded

together for a single connection as long as the remote T1 equipment is loop

bonding capable. Refer to Product to Product T1 Loop Bonding Compatibility,

(Document Number COMP-A2-GK44) for a list of loop bonding capable products.

Using two T1 lines for one uplink connection nets twice the speed and data passing

capability of a single-line T1 connection. Additionally, use of a second T1 line

provides automatic backup should one of the lines experience problems or become

disabled.

A single line T1 uplink connection may be established between T1 Port 1 or T1

Port 2 and any standard T1 provider equipment.

4. Verify Your Connections. The Port 1 Link (LK) LED flashing or pulsing green

indicates that a T1 Port 1 uplink connection has been established. The Port 2 Link

(LK) LED flashing or pulsing green indicates that a T1 Port 2 uplink connection has

been established.

14

Page 15

Default Settings

SHDSL Parameter Defaults

Table 1. SHDSL Defaults

Parameter Default

Backbone-VLAN 0 (off)

Circuit Identification n/a (no default)

Flood Uplink

IP Range 1 0.0.0.0 – 255.255.255.255

IP Range 2 0.0.0.0 – 0.0.0.0

Protocol All

Speed 272 kbps

VLAN Priority 0 (none)

VLAN Range 0 - 0 (off)

T1 Uplink Parameter Defaults

Table 2. T1 Defaults

Parameter Default

Frame Type Extended Super Frame (ESF)

Line Attenuation 0 dB

Line Code Bipolar with 8 Zero Substitution (B8ZS)

Speed* n/a (T1 uplink speed is determined via communication with the

remote T1 provider equipment to which the SMD2000-24T is

connected)

Timing*

* Speed and timing are non-configurable parameters for the SMD2000-24T T1

uplink ports.

Loop

15

Page 16

System and Management Defaults

No configuration is necessary for an SMD2000-24T to operate at default settings.

Table 3. System and Management Defaults

Parameter Default

IP Address 192.168.254.252

Subnet Mask 255.255.255.0

Gateway 0.0.0.0

Inband Management disabled

Inband Management VLAN ID 0 (off)

TFTP (Trivial File Transfer Protocol) on

Management IP Address Filter Range 0.0.0.0 – 255.255.255.255 (all)

Uplink DSLAM Interconnection 1 (neither/off)

User Access Defaults

Table 4. Username and Password Defaults

Username/Passwords

Access Username*

read/write superuser Password

read only general Password

* Usernames and passwords are case sensitive.

Password*

Table 5. SNMP Access Defaults

Community String

Access Community String*

read/write Password

read only Password

* Community strings are case sensitive.

16

Page 17

Data Storage

Configuration backup is inherent in the SMD2000-24T. Default parameters remain in

place unless changed using the CLI, web management system, or SNMP.

Memory

Parameter configurations are automatically recorded in both Random Access Memory

(RAM) and Non-Volatile Random Access Memory (NVRAM).

Data stored only in RAM, such as traffic statistics and link up/down time, will be erased if

the SMD2000-24T loses power.

Data stored in NVRAM, such as management and port parameter configurations, will

remain intact (even if the SMD2000-24T loses power) unless deliberately cleared or

reconfigured.

Saving to Local Files

SMD2000-24T management and port configurations can be uploaded to a local file on

your PC or local network via the Trivial File Transfer Protocol (TFTP) GET command.

Configuration files can also be downloaded from a local file to an SMD2000-24T with a

TFTP PUT command. Refer to your TFTP program’s help for further instructions.

SMD2000-24T Backup

An SMD2000-24T backup file records all management and port configurations.

Table 6. Backup Criteria

Item Data Needed for Backup Example

Host Name DSLAM_IP Address (xxx.xxx.xxx.xxx) 193.166.254.98

Remote

Filename

Local

Filename

NVR_BACKUP.BIN.[superuser password] nvr_backup.bin.Password

user preference smd4_backup.bin

17

Page 18

SMD2000-24T Template

An SMD2000-24T template file records all management and port configurations except

IP Address.

Table 7. Template Criteria

Item Data Needed for Backup Example

Host Name DSLAM_IP Address

(xxx.xxx.xxx.xxx)

Remote

Filename

Local

Filename

NVR_CFG.BIN.[superuser

password]

user preference

193.166.254.98

nvr_cfg.bin.Password

smd2000_template.bin

SHDSL Port Template

A SHDSL port configuration file records all of one port's configurations except Circuit ID.

Table 8. Template Criteria

Item Data Needed for Backup Example

Host Name DSLAM_IP Address

(xxx.xxx.xxx.xxx)

Remote

Filename

Local

Filename

NVR_PORTCFG.BIN.[superus

er password].[1][port]

user preference shdsl_servicelevel4_template.bin

193.166.254.98

nvr_portcfg.bin.Password.[1][4]

A previously saved port configuration file can be downloaded to multiple ports on your

SMD2000-24T simultaneously by entering the port value [port] as:

A comma separated list:

nvr_portcfg.bin.Password.[1][4,6,8]

A dash indicated range:

nvr_portcfg.bin.Password.[1][6-12]

Or using the keyword "all"

nvr_portcfg.bin.Password.[1][all]

18

Page 19

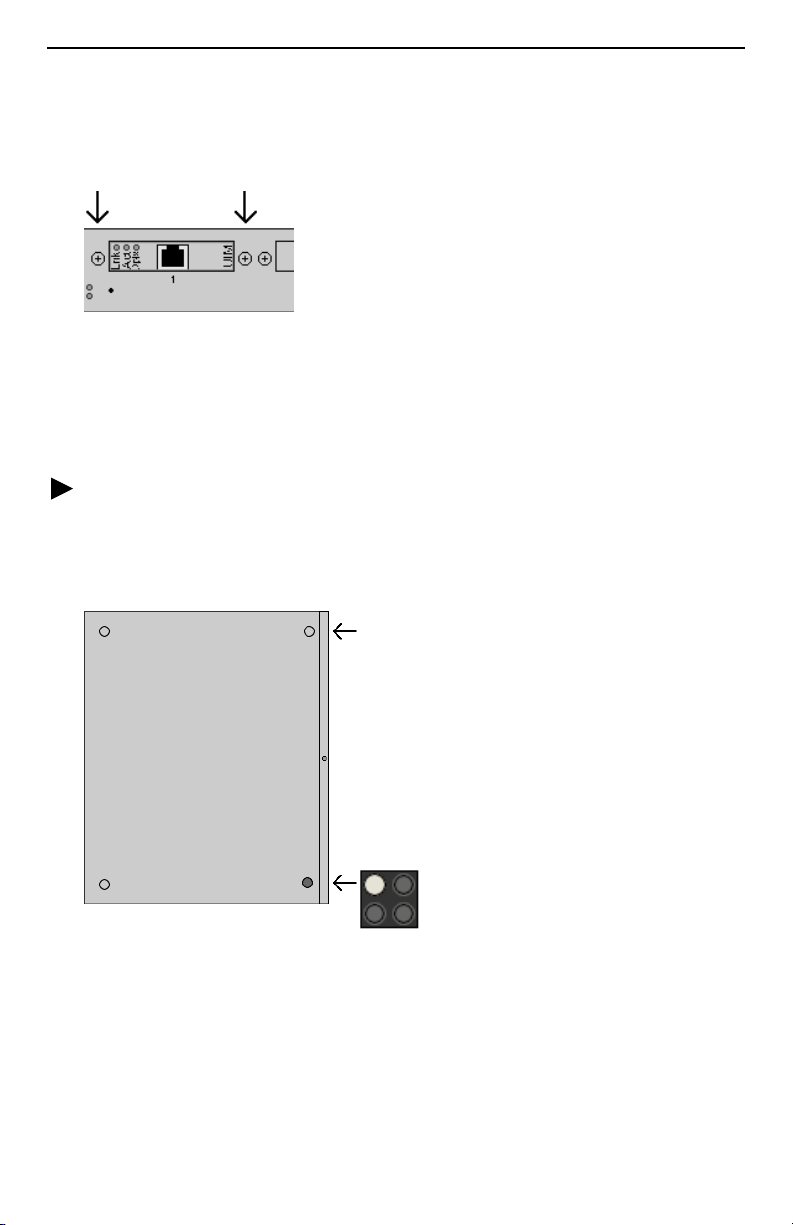

Reset Button

The reset button is a small, unmarked button just to the right of the T1 uplink LEDs on

the chassis faceplate. The button is recessed and you need a paper clip, mechanical

pencil, or similar tool to press it.

Reset Button

System Reset

A system reset will clear all statistical data (stored in RAM) and restart the

SMD2000-24T. It will not clear NVRAM; management settings and port configurations

will remain unchanged.

To perform a system reset, press the Reset Button for one second. The reset takes

approximately one minute to complete.

System Clear

A system clear will erase both RAM and NVRAM and restart the SMD2000-24T,

restoring all management and port configurations to their original default settings. To

clear the system, press the Reset Button for one second, release, and, within five [5]

seconds, press the Reset Button again for one second.

After the first pressing of the Reset Button, the passage of five seconds is indicated by

the successive flashing of the SHDSL Link (LK) LEDs for Ports 1-5; if you do not press

the Reset Button a second time within the allotted five seconds, the SMD2000-24T will

perform a system reset (see System Reset, above), rather than a system clear. The

clear takes approximately one minute to complete.

CAUTION:

Clearing NVRAM to restore original default settings includes restoring the default IP

Address, Subnet Mask and Gateway. Additionally, Inband Management will revert to

its original default setting (OFF) and you will be required to establish a direct PC to

SMD2000-24T connection for any subsequent configurations. Refer to the

19

Page 20

Command Line Interface for 4000E and 12000E BACs, Micro DSLAMs, and

Network Extenders User's Guide (Document Number CLI-A2-GB20) or the Network

Management System User's Guide (Document Number NMS-A2-GB20) for further

information.

LED Indicators

For purposes of the following descriptions, a pulsing LED blinks steadily at a rate of

once per second. A flashing LED blinks at a more rapid, less constant rate.

Table 9. LEDs (1 of 3)

State Indication Additional Information

PWR

(power)

FAN Solid green All four fans are fully

Solid green SMD2000-24T is receiving

power

Solid

amber

No

illumination

Solid

amber

No

illumination

SMD2000-24T is receiving

power

No power If the SMD2000-24T is not

functional

Fan failure At least one of the four

Total fan failure None of the four chassis

Both power terminals are

connected.

One of the two power

terminals is connected.

receiving power, none of the

LEDs will be illuminated.

chassis fans is not

functioning properly.

fans is functioning properly.

20

Page 21

Table 9. LEDs (2 of 3)

State Indication Additional Information

LNK

(10/100

Ethernet

Management

Link)

LK: T1

Uplink

Por t 1

and 2

Flashing

green

Solid green 100 Mbps management

Flashing

amber

Solid

amber

No

illumination

Flashing

green

Solid green T1 uplink connection is

100 Mbps management

connection is established

and active

connection is established

10 Mbps management

connection is established

and active

10 Mbps management

connection is established

No management connection NOTE: The LNK LED

T1 uplink connection is

established and active

established

Traffic is flowing at 100

Mbps.

No current traffic flow.

Traffic is flowing at 10 Mbps.

No current traffic flow.

pertains only to direct

connections between the

SMD2000-24T and your PC;

it does not pertain to remote

network access of the

SMD2000-24T.

The uplink port has received

valid data from the remote

T1 provider equipment

within the last second.

A T1 uplink connection

exists and the port may be

transmitting but it has not

received any data from the

remote T1 provider

equipment within the last

second.

No

illumination

Red Alarm: The T1 uplink's

incoming connection has

been lost; no data is being

received.

21

If the T1 uplink's outgoing

connection has also been

lost then the remote T1

provider equipment is in Red

Alarm as well.

Page 22

Table 9. LEDs (3 of 3)

State Indication Additional Information

AL: T1

Alarm

Por t 1

and 2

SHDSL

LK: Ports

1-24

No

illumination

Solid

amber

Pulsing

amber

Flashing

green

Solid green Problematic SHDSL

T1 uplink connection is

operational

Yellow Alarm: The T1

uplink's outgoing connection

has been lost; no data is

being transmitted.

Blue Alarm: An indirect

connection has been lost;

the T1 uplink port may no

longer be receiving data

from the remote T1 provider

equipment.

SHDSL connection is

established and active

connection

An established T1 uplink

connection has no alarm

indications and is

operational UNLESS the T1

LK LED remains unlit as

well, in which case the T1

uplink connection is in Red

Alarm.

The remote T1 provider

equipment has lost its

incoming connection and is

in Red Alarm.

The remote T1 provider

equipment has lost a

connection with an

intermediate device and is in

Red or Yellow Alarm.

The port has received valid

data from the remote

SHDSL modem within the

last second.

A connection exists but there

is indication of a problem

with the SHDSL line.

SHDSL

ACT:

Por ts

1-24

No

illumination

Flashing

amber

Solid

amber

No

illumination

No SHDSL connection

SHDSL connection is

established and active

Heavy traffic The port is receiving

No activity A link may exist but no data

22

Traffic is flowing.

unusually large amounts of

data from, and/or

transmitting unusually large

amounts of data to, the

remote SHDSL modem.

is being transmitted to the

remote SHDSL modem.

Page 23

Pin Assignments

SHDSL RJ21 Pinouts

Table 10. SHDSL RJ21 Pinouts

Connector Pins

Port

Port 1 1, 26 Port 13 13, 38

Port 2 2, 27 Port 14 14, 39

Port 3 3, 28 Port 15 15, 40

Port 4 4, 29 Port 16 16, 41

Port 5 5, 30 Port 17 17, 42

Port 6 6, 31 Port 18 18, 43

Port 7 7, 32 Port 19 19, 44

Port 8 8, 33 Port 20 20, 45

Port 9 9, 34 Port 21 21, 46

Port 10 10, 35 Port 22 22, 47

Port 11 11, 36 Port 23 23, 48

Port 12 12, 37 Port 24 24, 49

(Ring, Tip) Port

Connector Pins

(Ring, Tip)

Pins 25 and 50 are not used.

23

Page 24

10/100BaseT RJ45 Pinouts

Table 11. Ethernet RJ45 Connection

Pin Connection

1Rx+

2Rx–

3Tx+

4 not used

5 not used

6Tx–

7 not used

8 not used

T1 RJ48C Pin Assignments

Table 12. T1 RJ48C Pin Assignments

Pin Function

Pin 1 Rx Ring

Pin 2 Rx Tip

Pin 3 not used

Pin 4 Tx Ring

Pin 5 Tx Tip

Pin 6 not used

Pin 7 not used

Pin 8 not used

24

Page 25

DB9 to 8-Pin Modular Adapter Pinouts

To connect the COM port to the DB9 serial port of a PC, use an adapter wired as shown:

Tabl e 13. D B9 t o 8-P i n Modular Adapter Pinouts

Pin 8-Pin Modular Port Direction PC RS232 Serial Port Pin

1Transmit Data TxD → RxD Receive Data 2

2 Data Set Ready DSR ← RTS Request to Send 7

4 Receive Data RxD ← TxD Transmit Data 3

5 Ground GND ↔ GND Ground 5

6 Data Terminal Ready DTR → CTS Clear to Send 8

Pins not shown are unused.

25

Page 26

Technical Specifications

Table 14. SMD2000-24T Technical Specifications

Specification Criteria

Bandwidth and Distance

Capabilities – SHDSL

Por ts

Bandwidth and Distance

Capabilities – T1 Uplinks

Compliance NEBS: GR-63-CORE, GR-1089-CORE

Environment Operating Temperature: –40° F to 149° F (–40° C to

Interfaces 24 SHDSL ports (1 RJ21 50-pin Telco)

Default is 272 kbps at up to 20,200 ft (6,157 m)

Maximum distance is up to 24,000 ft (18,000 m) at

144 kbps

Maximum bandwidth is 2320 kbps at up to 11,300 ft

(3,444 m)

Maximum bandwidth is 1,536 kbps with all 24 timeslots

Maximum distance is 5,000 ft (1,524 m)

EMC: FCC Part 15; CSA/C108.8; EN55022; EN55024

Safety: UL 1950, CSA C22.2 No. 950; EN60950

CE Marking

65° C)

Storage Temperature: –40° F to 158° F (-40° C to 70° C)

Humidity: 5 % to 95 %, Non-condensing

Altitude: –200 ft to 16,500 ft (–60 m to 5,000 m)

2 fixed RJ48C T1 uplink ports

1 RJ45 10/100BaseT management interface

1 RJ45 RS-232 COM port

2 Uplink Interface Module (UIM) slots supporting

10/100BaseT, E1, and T1

Power –48V DC

1 amp minimum / 1.6 amp maximum

(Actual power draw depends on chassis configuration)

Size 1.75" High x 17" Wide x 14" Deep

(4.4 cm High x 43.2 cm Wide x 35.6 cm Deep)

Weight 12.5 lbs (5.73 kg)

26

Page 27

EMI Notices

United States – EMI Notice

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

The authority to operate this equipment is conditioned by the requirements that no

modifications will be made to the equipment unless the changes or modifications are

expressly approved by Paradyne Corporation.

If the equipment includes a ferrite choke or chokes, they must be installed as described

in the installation instructions.

Canada – EMI Notice

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

ACTA Customer Information

This equipment complies with Part 68 of the FCC rules and the requirements adopted

by the Administrative Council for Terminal Attachments (ACTA). On the bottom of the

network extender is a label that contains, among other information, a product identifier in

the format US:AAAEQ##TXXXX. If requested, this number must be provided to the

telephone company.

The T1 network connections should be made using a Universal Service Order Code

(USOC) type RJ48C jack. The Service Order Code 6.0F should be specified to the

telephone company when ordering the T1 line. In addition, the proper Facility Interface

Code must be specified to the Telephone Company. The network extender can be

configured to support any of the following framing format and line signaling techniques.

The network extender's configuration must correspond to the T1 line's parameters.

Facility Interface Codes Code Description

04DU9-BN 1.544 Mbps superframe format (SF) without line power

04DU9-DN 1.544 Mbps SF and B8ZS without line power

04DU9-1KN 1.544 Mbps ANSI ESF without line power

04DU9-1SN 1.544 Mbps ANSI ESF and B8ZS without line power

27

Page 28

A plug and jack used to connect this equipment to the premises wiring and telephone

network must comply with the applicable FCC Part 68 rules and requirements adopted

by the ACTA. See installation instructions for details.

If the network extender causes harm to the telephone network, the telephone company

will notify you in advance that temporary discontinuance of service may be required. But

if advance notice isn't practical, the telephone company will notify the customer as soon

as possible. Also, you will be advised of your right to file a complaint with the FCC if you

believe it is necessary.

The telephone company may make changes in its facilities, equipment, operations or

procedures that could affect the operation of the equipment. If this happens the

telephone company will provide advance notice in order for you to make necessary

modifications to maintain uninterrupted service.

If trouble is experienced with this equipment, please contact your local sales

representative, service representative, or distributor directly for any help needed. For

additional information concerning warranty, sales, service, repair, installation,

documentation, training, distributor locations, or Paradyne worldwide office locations,

use one of the following methods:

Internet: Visit the Paradyne World Wide Web site at www.paradyne.com. (Be sure

to register your warranty at www.paradyne.com/warranty.)

Telephone: Call our automated system to receive current information by fax or to

speak with a company representative.

— Within the U.S.A., call 1-800-870-2221

— Outside the U.S.A., call 1-727-530-2340

If the equipment is causing harm to the telephone network, the telephone company may

request that you disconnect the equipment until the problem is resolved.

The customer may make no repairs to the equipment.

Connection to party line service is subject to state tariffs. Contact the state public utility

commission, public service commission or corporation commission for information.

CE Marking

When the product is marked with the CE mark on the equipment label, a supporting

Declaration of Conformity may be downloaded from the Paradyne World Wide Web site

at www.paradyne.com. Select Library → Technical Manuals → CE Declarations of

Conformity.

28

Page 29

Japan Notice

Class A ITE

This is a Class A product based on the standard of the Voluntary Control Council for

interference by Information Technology Equipment (VCCI). If this equipment is used in a

domestic environment, radio disturbance may arise. When such trouble occurs, the user

may be required to take corrective actions.

29

Page 30

!

Important Safety Instructions

1. Read and follow all warning notices and instructions marked on the product or

included in the manual.

2. Slots and openings in the cabinet are provided for ventilation. To ensure reliable

operation of the product and to protect it from overheating, these slots and

openings must not be blocked or covered.

3. Do not allow anything to rest on the power cord and do not locate the product where

persons will walk on the power cord.

4. Do not attempt to service this product yourself, as opening or removing covers may

expose you to hazardous voltage or to other risks. Refer all servicing to qualified

service personnel.

5. General purpose cables are used with this product for connection to the network.

Special cables, which may be required by the regulatory inspection authority for the

installation site, are the responsibility of the customer. Use a UL Listed, CSA

certified, minimum No. 26 AWG line cord for connection to the Digital Subscriber

Line (DSL) network.

6. When installed, the product must comply with the applicable Safety Standards and

regulatory requirements of the country in which it is installed. If necessary, consult

with the appropriate regulatory agencies and inspection authorities to ensure

compliance.

7. A rare phenomenon can create a voltage potential between the earth grounds of

two or more buildings. If products installed in separate buildings are

interconnected, the voltage potential may cause a hazardous condition. Consult a

qualified electrical consultant to determine whether or not this phenomenon exists

and, if necessary, implement corrective action prior to interconnecting the products.

8. Input power to this product must be provided by one of the following: (1) a UL

Listed/CSA certified power source with a Class 2 or Limited Power Source (LPS)

output for use in North America, or (2) a certified power source, with a Safety Extra

Low Voltage (SELV) output having a maximum of 240 VA available, for use in the

country of installation.

9. In addition, since the equipment is to be used with telecommunications circuits, take

the following precautions:

— Never install telephone wiring during a lightning storm.

— Never install telephone jacks in wet locations unless the jack is specifically

designed for wet locations.

— Never touch uninsulated telephone wires or terminals unless the telephone line

has been disconnected at the network interface.

— Use caution when installing or modifying telephone lines.

— Avoid using a telephone (other than a cordless type) during an electrical storm.

There may be a remote risk of electric shock from lightning.

— Do not use the telephone to report a gas leak in the vicinity of the leak.

Copyright 2005 Paradyne Corporation. Printed in U.S.A.

30

Page 31

Warranty, Sales, Service, and Training Information

Contact your local sales representative, service representative, or distributor directly for

any help needed. For additional information concerning warranty, sales, service, repair,

installation, documentation, training, distributor locations, or Paradyne worldwide office

locations, use one of the following methods:

Internet: Visit the Paradyne World Wide Web site at www.paradyne.com. (Be sure

to register your warranty at www.paradyne.com/warranty.)

Telephone: Call our automated system to receive current information by fax or to

speak with a company representative.

— Within the U.S.A., call 1-800-870-2221

— Outside the U.S.A., call 1-727-530-2340

31

Page 32

*SMD2-A2-GN11-00*

*SMD2-A2-GN11-00*

32

Loading...

Loading...