Page 1

9/t~ inch wrench

inch wrench

inch wrench

~ odiustable wrench

¯ hammer or rubber mallet

¯ s~2 allen wrench

¯ THE PARABODY FACTOR 625 BASE UNIT MUST BE ASSEMBLED ON A FLAT, LEVEL SURFACE TO ASSURE ITS PROPER FUNC1

¯ PARABODY STRONGLY RECOMMENDS THAT THIS PRODUCT BE ASSEMBLED BY TWO PERSONS TO AVOID POSSIBLE INJURY.

,, KEEP ALL FRAME BOLT CONNECTIONS LOOSE UNTIL INSTRUCTED IN THE ASSEMBLY STEP SEQUENCES TO SECURELY TIGHTi

MAKE SURE SNAP HOOKS ARE FASTENED BEFORE DOING EXERCISES.

NOTE:We recommend cleaning your produd (pads and the frame members

PoraBody Customer Service Representative at 1-800-328-9714.

BOLT LENGTH

NOTE: Bolt length ismensured from the underside of the head of the bolt.

BOLT LENGTH RULER:

on a regular basis, using worm soapy water. Also, touch-up paint can be purchnsed from your

Page 2

TTS/PARTS:

~

~~- -- (PB3047-01)

NAME/DESCRIPTION

Back Pod

Leg Press Frame

Telescoping Tube Plated ~"-’~43-01)

Pivot Axle __

Leg Press Cable 17

Non-Skid Strip 4" x

~(P~78-011

~--~B0-01 )

~PB3170-01)

[PB3OBI-01)

(PB3236-01)

’~

~634-01)

count all parts before beginning assembly.

OTY.

1

1

1

l

1

1

l

4

’ARE:

-

~Compressi.___~on Spr~

NAME/DESCRIPTION

’

Gr---’-~p I I/4" x S"

~/4" x I" Oilite Bushing

Co~e~ Pin

P~unger

Spacer

Knob

~" Square E.nd_ Cop (I 0-I 4 ga)~

Weight Stock Bumper

’’

3/B" x l lh

-~e" Washer

~osher

~ Washer

~Pulley

Bol~ ’t

3/~" x 4~/~" Bol~

QTY.

2

-- I

l

l

1

l

l

5

7

2

2

4

1

3

Page 3

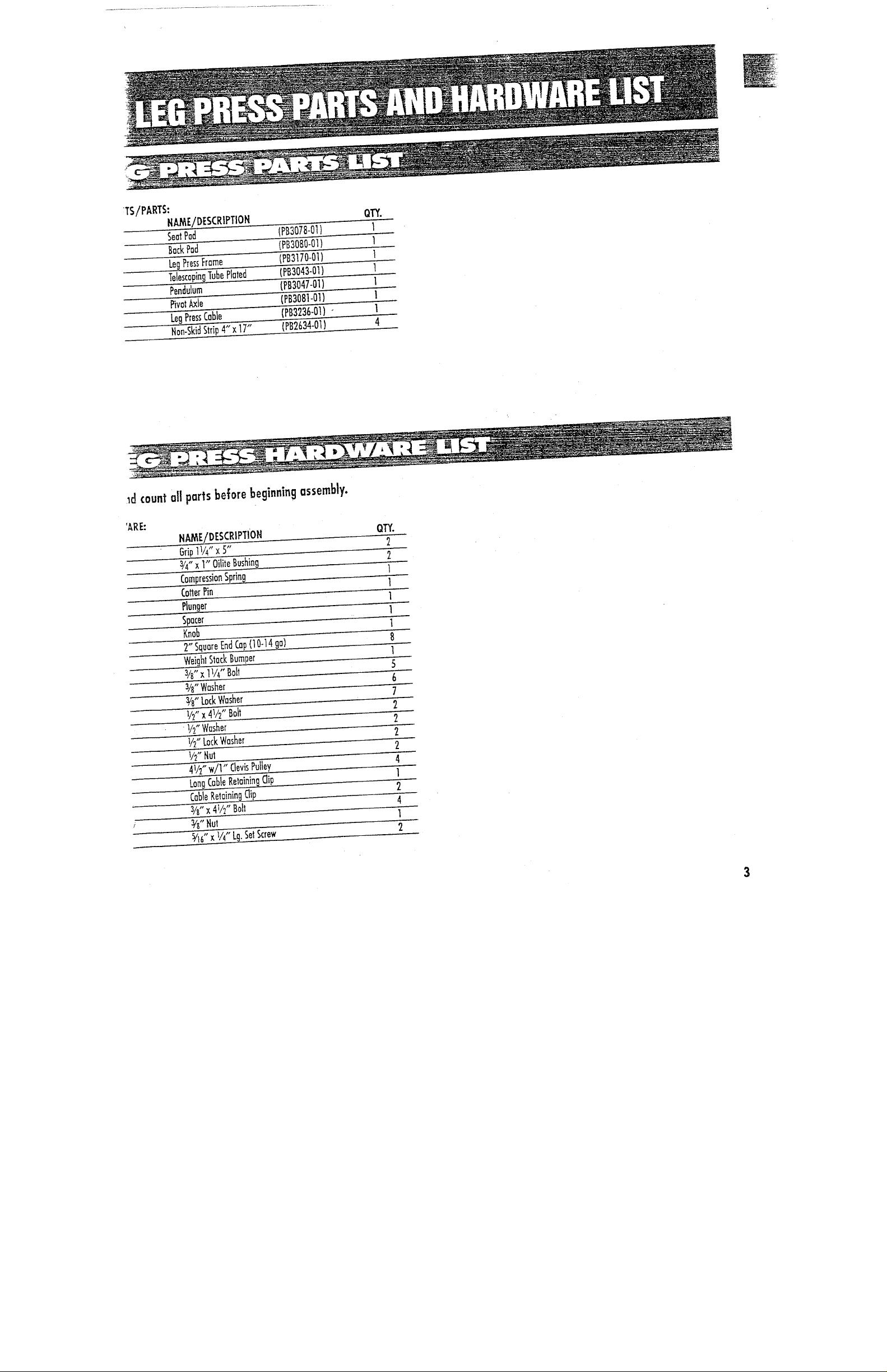

If you have installed a second weight stack, go to

Figure 5.

If you have not purchased the second weight

stack, please camp]ere the folJowing steps before

proceeding to F~gure 5.

1.Remove the blank shroud from the rear of the

Factor 625.

2.Remove the rotary cable from the unit and

also the assadated shock cord.

3.Load the Leg Press Cable into the

D-Ring in the position the Rotary Cable was

removed from. Remove the elastic shock cord

from the Rotary Cable and attach to the Leg

Press Cable as shown (same routing of elastic

cord as on Rotary Cable).

ELASTIC SHOCK CORD

LEG PRESS CABLE

(PB3236-01)

-- D:RING

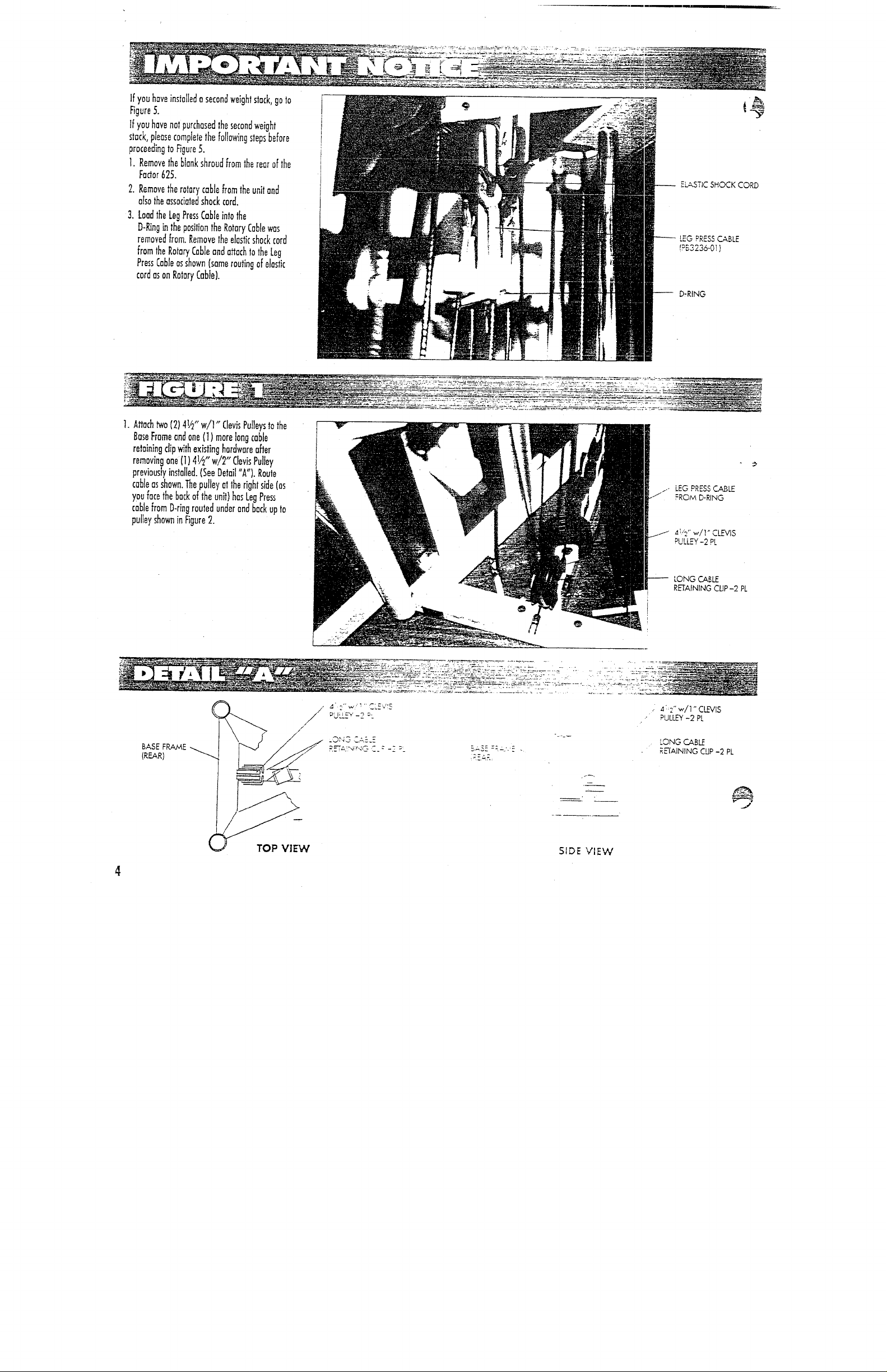

1. Attach two (2) 4V2 w/l Clev;s Pulleys to the

Base Frame and one {I) mare long cable

t

retaining clip with existing hardware after

removing one (1) 41/2" w/2" Clevis Pulley

previously installed. (See Detail "A"). Route

cable as shown. The pulley at the right side (as ~k~.

you face the back of the unit) has Leg Press

cable from D-ring routed under and back up to

pulley shown in Figure 2.

’~ ’--:~ ~ --~’-

~

LEG PRESS C.ABLE

FRO,~ D-RING

PULLEY-2 PL

LONG

R~AINING CUP-2 PL

. PULL~ -2 PL

SIDE VIEW

Page 4

~tinue to route Leg Press cable as shown.

,. ,~emave the boll used to hold the la~ boom 1o

~’he tube an the rear of" lhe Main Frame and

~aih one I1) 4~.,~" w/l" Clevis Pulley and

one (1) cable retaining clip using one (t)

~-~" x 4(.’~’" bolt and the existing 34" Locknu~

and 34" Washer supplied. Raule cable as

shown. Locme ~able retaining clip

approxim~ety as shown.

,4: 2" w/1 " CLL-VIS

PULLEY- 2 PL

Remove the bolt used to hold the pulley in the

..

!m boom (pulley to rear of D-Ring} and attach

one (1) 4!.~" w/l" Clevis Pulley and one (1)

cable retaining clip using one (I) 3/if’ x 4V~"

Ba]t and existing :ks" Lockwasher.

~

"antinue to route the cable dawn and under

e left pulley shown in Figure 1.

iO~ Position both cable retaining clips as shown.

Make sure cable does hal rub on cable

retaining clips after cable is completely

routed.

CA.BL~ RETAINING CLIP

LEG PRESS CA,BLE

(PB3626-01)

LAT BOOM

CABLE RETAINING CLIP

D-RING

LEG PRESS CABLE ’

(PB3236-01)

See PBF604 Optional Shroud Kit for optional

)TL

shroud ~sembly.

Secure leg press Shroud as shown in Figure 4.

~G PRESS SHROUD

!

L

Page 5

AHach the Leg Press Frame to the Main Frame

1.

on lop using two {2) l~"x 41~" Bolts,

two (2) 1/2" Washers, two (2) I/2" Lockwashers

and two (2) 1,~,, nuts.

Attach four (4) 4" x17" Non-Skid Strips to the

2.

angled foot pl~e on the Leg Press Frame as

shown.

3.Install two (2) 2" Square End Caps {10-14 ga)

into the angled tubes on the Leg Press Frame

and two (2) 2" Square End Caps

(10-14 ga)into the base tubes of the

Leg Press Frame.

Slide one (1) Weight Stock Cushion over the

4.

Pin Stop of the base of the Leg Press Frame.

---~

V:’x4V2"BOLT-2 ~

b"2~ WASHER - 2 PL

b~" LOCK WASHER - 2 PL

~,,’2" NUT - 2 PL

2" SQ. END CAP - 2 PL

NON-SKID ,~" X 17" - 4 PL

j

WEIGHT STACK CUSHION

1.Attach the Leg Press Frame to the Main Frame

al lhe base using two (2) ~’8" x 41~" Bolts,

two (2} ~" ~kwasher~ and two (2)

~hers.

2" SQ. END CAP-2 ~"~

~" LOCKWASHER - 2 PL

Page 6

".--~~ble the spring pin assemblT to the

~autum Frame using one (1) knob, one (I)

plunger, one (1) spring, one (1) spacer, and

(1) co~e~ pin, using the folJowing steps:

~ ~semble the knob to the p~ungsr

B. In~d the plunger through the fi~ housing

and through the fir~ hole of the second

housing.

C Slip ~e Spring and the spacer over the end

of the plunger (in that order).

D. Insed the plunger through the second hole of

the housing.

E PulJ back the spacer on the plunger and

inse~ the co~er pin through the hole.

E (See 0etail B)

~ Slide ~ (2} 1~/4" x 5" grips over the handles

of ~e ~ndulum flame. (NOTE: If a ~ubricant is

requ red, rubbing alcohol thoroughly coating

~e i~de of the grip, ~ ~e b~ material to u~).

3. In~lJ ~ (2) 2" Square End Caps (10-14

to pendulum as shown.

2" SQ. END ~P - 2 PL

~~

SPACER

SPR~NG

co~ P~N

~kUNG~

~os

G~ ~ ~" x 5

~-

2 ~k

SPRING ~ PLUNGER

KNOB

C

7

Page 7

If]

Fig

If’

1.

nser~ the seat adjustment tube Into the front end

of the Pendulum flame. Pull back the spring pin

a~mb/y, and advance the seat adjustment tube

al1 the way in. (Make sure tab ai the front end of

the seat adiustment tube is up. See figure] I).

2..Securely fasten one fl) 3~,’ x 1 ]/4" Bob one (1)

3/e" Lockwasher, and one (1 }3,~,, Nut to ~he hole s,,~- LOCK WASHE~

in ~e rear of the seat adju~ment tube, on the

~’~" ~ 1,4 BOLT

W ~

unde~ide of the Pendulum Frame be~een the

sbt. ~See Detai~ C}.

SLOT

] Install t~a (2) ~ D Flange Bearings Into each

end of the pivot tube on the lop of the Pendulum

Frame. ~is step may be pre-assembbd).

3z~~ LOCKWASHER

NOTE:

SLOT IS ON BOTTOM

OF PENDULUM FRAME

3,,~,, I.D. F~NGE B~R~,

2 PL

PENDULUM FRAME

""

Page 8

. _~.nch the Pendulum Frame to the leg press

e by sliding the pivot axle thrnugh the col!ars

on the pivot tabs of the leg press flame and

through the pivot tube at the top of the pendulum

flame. Thread two (2) sA6" x I/4" Ig. set

screws into both collars and tighten. {This ~ep

may be pre-nssembled)

LEG PRESS FI

PENDULUM FRAME

5/16" x 1/4~ LG SET SCR.~v’

-2 PL

PIVOT AXLE

Atlach the cable assembly to the telescoping tube with

1.

the Clevis pin and wire clip supplied on cable.

LEG PRESS CABLE

(PB3236-01)

CLEVIS PiN

TELESCOPING TUBE

9

Page 9

ock res~ tube on the Pendulum Frame using two(2).~/8"x 11/~’~Bohs’ two (2) ~,~" Lockwashe~,

ana ~o ~2) ~8’ Washe~.

NOTE: HOL~ IN ~E BACK OF THE S~T BACK PAD

AND ~E S~T PAD.

2.

Iflse~ on~ ( ~ ) 2"~quare ~nd cap ( ~ 0-14 g~;)in

the top ot ~he back re~ tuoe and one (1)

square end cop in the end of the pendulum frame

under ~he back rest tube.

lure Frame, uu,,g two {’2) 3~ x ] i ,,

two "

f2) ~ Lockwasher% and two 121 ~"

Washers.

8 74 Bolt~,

2" SQ. END CAP - 2 PL

3/e" x 11/,,- BOLT -- 2 PL

3/e" LOCKWASHE~S _ 2 PL

3,,~ WASHER .- 2 PL

" .......

~-=

"

10

/

SEAT PLATES

.SEAT PAD

/ /

PENDULUM FRAME

3/~ x 1 ~,,’~" BOLT - 2 PL

~’e" LOCKWASHER _ 2 PL

3/e" WASHER - 2 P.

Page 10

ten any loose connedions at this time.

~r

FACTOR 625 should be assembled as

11

Loading...

Loading...