PANJIT CP601, CP600, CP608, CP606, CP604 Datasheet

...

DATA SHEET

CP600~CP6010

SINGLE-PHASE SILICON BRIDGE-P.C. MTG 3A , HEAT-SINK MTG 6A

VOL TAGE 50 to 1000 Volts CURRENT - P.C. MTG 3A , HEA T-SINK MTG 6A

Recongnized File # E111753

FEA TURES

• Plastic package has Underwriters Laboratory

Flammability Classification 94V-O .

• Surge Overload Ratings to 125 Amperes.

• Low forward voltage, and reverse leakage.

• Small size , simple installation.

• Reliable low cost construction utilizing molded plastic technique.

MECHANICAL DAT A

Mounting Position: Any

Weight: 0.2 ounce, 5.6 gram

Terminals: Lead solderable per MIL-STD-202 Method 208

Mounting Torque: 5 in. lb. max.

.15(3.8)MIN

.044(1.1

.039(1.0

.445(11.3

.406(10.3

.618(15.7

.579(14.7

MIN

)

19.1

(

.752

)

)

)

)

11.3

10.3

(

(

.445

.406

)

)

)

)

MAXIMUM RATINGS AND ELECTRICAL CHARACTERISTICS

Ratings at 25°C ambient temperature unless otherwise specified.

Single phase , half wave ,60Hz, resistive or inductive load.

For capacitive load , derate current by 20%.

CP600 CP6010

Maximum Recurrent Peak Reverse Voltage

Maximum RMS Bridge input Voltage

Maximum DC Blocking Voltage

Maximum Average Forward Current at T

See Fig 2 at T

Peak Forward Surge Current ,8.3ms

single half sine-wave superimposed on rated load

Maximum Forward Voltage per Bridge Element

Specified Current at 3.0A DC & 25°C.See Fig 3

Maximum Reverse Leakage at RatedDC Blocking

Voltage per element. at 25°C

See Fig 4 at 100°C

2

I

t Rating for fusing ( t < 8.35 ms)

Typical junction capacitance per leg (NOTE 4)CJ

Typical Thermal resistance per leg ( NOTE 3) RθJA

Typical Thermal resistance per leg ( NOTE 2) RθJC

Operating Temperature Range T

Storage T emperature Range T

NOTES:

1.Bolt down on heat-sink with silicon thermal compound between bridge and mounting surface for maximum heat transfer with #6 screw.

2.Unit mounted on 5.0 X 6.0 X 0.11” thick ( 14 X 15 X 0.3 cm )AL.plate.

3.Unit mounted on P.C.B at 0.395”(9.5mm)lead length with 0.5 X 0.5” ( 12 X 12 mm )copper pads.

4.Measured at 1.0MHZ and applied reverse voltage of 4.0 volts.

J

A

=50°C

C

=25°C

A

50

35

50

100

70

100

200

140

200

400

280

400

6

3

125

1.1

10.0

1.0

127

186

22.0

7.3

-55 to +125

-55 to +150

600

420

600

CP608CP606CP604CP602CP601

800

560

600

1000

700

1000

)

6.8

(

.268

(5.8)

.228

)

15.7

(

.618

)

14.7

(

.579

UNITS

V

V

V

A

A

V

µA

mA

A2S

pF

°C/W

°C

°C

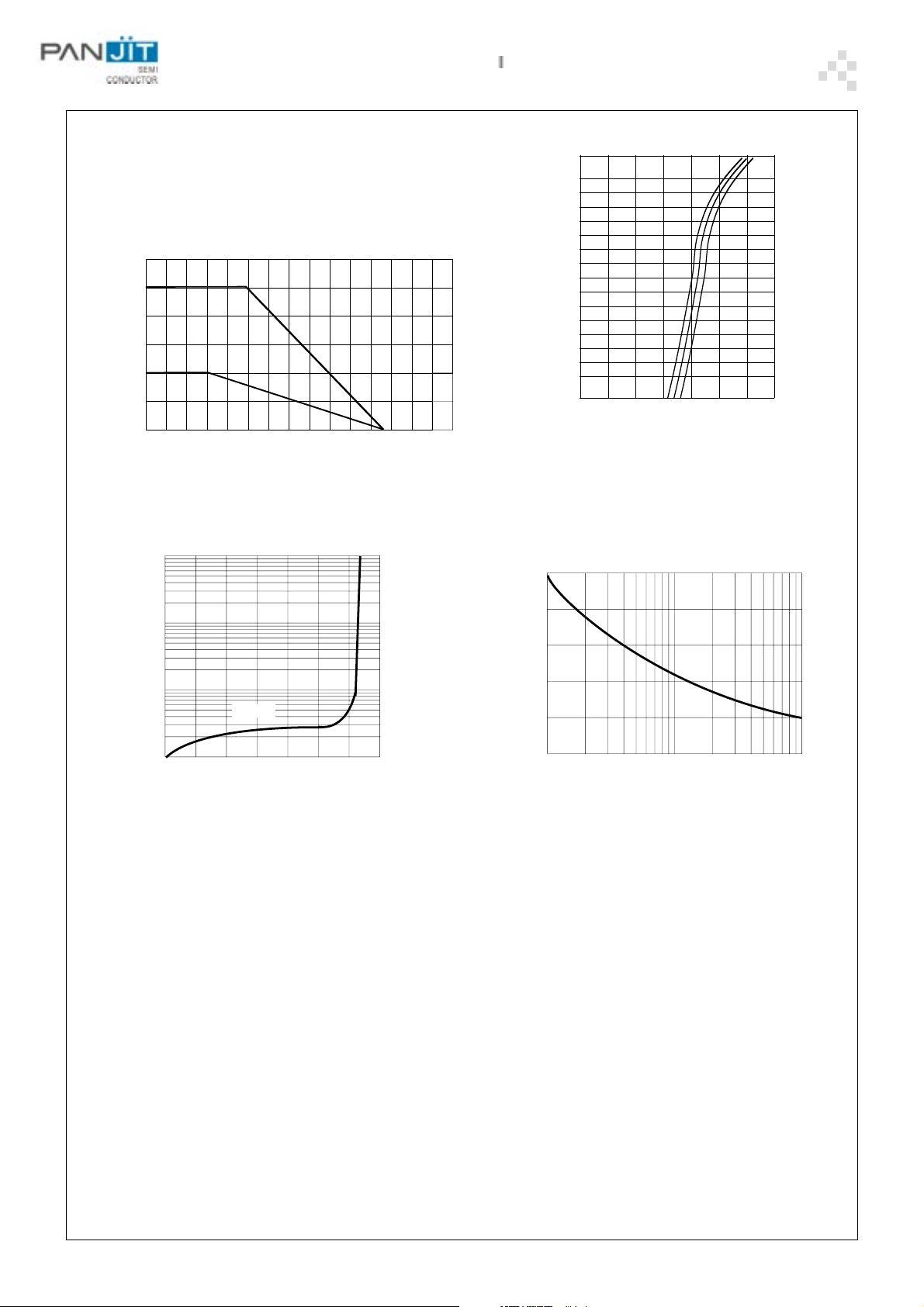

RATING AND CHARACTERISTIC CURVES

6.0

4.0

2.0

OUTPUT CURRENTAMPERES

0

0 50 100 150

5.0

4.0

3.0

2.0

1.0

.07

.05

.03

.02

.01

INSTANTANEOUS FORWARD CURRENT, AMPERES

.9

.8

.7

.5

.3

.2

.1

00.2

0.4

0.6

0.8

1.0

1.2 1.4

AMBIENT TEMPERATURE C

O

Fig. 1- DERATING CURVE FOR OUTPUT RECTIFIED CURRENT

100

10

1.0

MICROAMPERES

INSTANTANEOUS REVERSE CURRENT,

0.1

0 20 40 60 80 100 120 140

O

T=25C

A

PERCENT OF PEAK REVERSE VOLTAGE

Fig. 3- TYPICAL REAK REVERSE CHARACTERISTICS

INSTANTANEOUS FORWARD VOLTAGE, VOLTS

Fig. 2- TYPICAL INSTANTANEOUS FORWARD

CHARACTERISITCS (25

125

100

75

50

(HALF SINE-WAVE)

25

FPRWARD SURGE CURRENT, AMPERES pk

0

1

2

6

10 20 40 60 100

NO.OFCYCLESAT60Hz

O

C)

Fig. 4- MAXIMUM NON-REPETITEVE PEAK

FORWARD SURGE CURRENT

Loading...

Loading...