Panasonic KX MC6020 - Color Laser - All-in-One, KX-MC6020HX KX-FAP317E, X-FAP317X, KX-FAB318E, X-FAP318X Service Manual

© Panasonic Communications Co., Ltd. 2008. Unauthorized copying and distribution is a violation of law.

ORDER NO. KMF0811207CE

Colour Laser Multi-Function Printer

Model No. KX-MC6020HX

KX-FAP317E/X

(Optional lower input tray)

KX-FAB318E/X

(Optional Automatic duplex

unit)

(for Eastern Europe)

2

KX-MC6020HX

TABLE OF CONTENTS

PAG E PAG E

1 Safety Precautions -----------------------------------------------3

1.1. For Service Technicians ---------------------------------3

1.2. AC Caution---------------------------------------------------3

1.3. Personal Safety Precautions ----------------------------4

1.4. Service Precautions ---------------------------------------5

2Warning--------------------------------------------------------------5

2.1. About Lead Free Solder (PbF: Pb free) --------------5

2.2. Discarding of P. C. Board --------------------------------6

2.3. Insulation Resistance Test ------------------------------6

2.4. Battery Caution ---------------------------------------------6

2.5. Laser Beam and Fuser Unit Section ------------------7

3 Specifications ------------------------------------------------------8

4 General/Introduction---------------------------------------------9

4.1. Optional Accessories--------------------------------------9

4.2. Translation Lists --------------------------------------------9

4.3. Precautions for Shipping -------------------------------17

5Features------------------------------------------------------------ 30

5.1. General Features----------------------------------------- 30

5.2. Hardware Requirements for Multi-Function

Software ---------------------------------------------------- 30

6 Technical Descriptions---------------------------------------- 31

6.1. Connection Diagram------------------------------------- 31

6.2. General Block Diagram --------------------------------- 32

6.3. Main Board Section-------------------------------------- 35

6.4. NCU Section----------------------------------------------- 53

6.5. ITS (Integrated Telephone System) and

Monitor Section ------------------------------------------- 54

6.6. CIS Control Section-------------------------------------- 55

6.7. Motor Drive Section-------------------------------------- 56

6.8. Timing Chart and Waveform of Scanner

Motors------------------------------------------------------- 65

6.9. Timing Chart and Waveform of Optional Unit

Motors------------------------------------------------------- 69

6.10. Fan Section ------------------------------------------------ 70

6.11. Solenoid Driver Section -------------------------------- 72

6.12. LSU (Laser Scanning Unit) Section ----------------- 73

6.13. Sensors and Switches Section ----------------------- 78

6.14. Operation Board Section ----------------------------- 101

6.15. LCD Section --------------------------------------------- 102

6.16. Heat Lamp Control Circuit --------------------------- 103

6.17. HVU (High Voltage Power Supply Board)

Section ---------------------------------------------------- 107

6.18. Main Board Section-------------------------------------112

6.19. PSU (Low Voltage Power Supply Board)

Section -----------------------------------------------------116

6.20. Mechanical Operation----------------------------------117

7 Location of Controls and Components---------------- 134

7.1. Overview ------------------------------------------------- 134

7.2. Control Panel-------------------------------------------- 135

8 Installation Instructions------------------------------------- 136

8.1. Installation------------------------------------------------ 136

8.2. Connections --------------------------------------------- 150

9 Operating Instructions -------------------------------------- 152

9.1. YOUR LOGO ------------------------------------------- 152

10 Test Mode-------------------------------------------------------- 154

10.1. Test Functions------------------------------------------- 154

11 Serv ice Mode --------------------------------------------------- 157

11.1. Programming and Lists ------------------------------- 157

11.2. User Mode (The list below is an example of

the SYSTEM SETUP LIST the unit prints out.) -163

11.3. Service Mode Settings (Example of a printed

out list)----------------------------------------------------- 165

11.4. History ----------------------------------------------------- 166

12 Troubleshooting Guide --------------------------------------168

12.1. User Recoverable Errors -----------------------------168

12.2. User Recoverable Network Errors ----------------- 171

12.3. Remote Programming --------------------------------- 174

12.4. Troubleshooting Details -------------------------------180

12.5. Recording Paper Jam --------------------------------- 300

12.6. Document Jams (Automatic Document

Feeder)---------------------------------------------------- 306

13 Service Fixture & Tools--------------------------------------309

14 Disassembly and Assembly Instructions -------------310

14.1. First of All -------------------------------------------------310

14.2. Flow Chart for Disassembly--------------------------314

14.3. Disassembly for Main Parts --------------------------316

14.4. Disassembly for Main Drive Unit-------------------- 333

14.5. How to Remove STR ----------------------------------345

14.6. Note for Assembling -----------------------------------347

14.7. Installation Position of the Lead---------------------352

15 Measurements and Adjustments -------------------------361

15.1. Color Registration Skew Adjustment -------------- 361

16 Maintenance -----------------------------------------------------364

16.1. Maintenance Items and Component Locations -364

16.2. Maintenance ---------------------------------------------366

16.3. Terminal Guide of the ICs, Transistors and

Diodes -----------------------------------------------------370

16.4. How to Replace the Flat Package IC -------------- 373

16.5. Main Board Section ------------------------------------375

16.6. Test Chart-------------------------------------------------377

17 Schematic Diagram ------------------------------------------- 379

17.1. For Schematic Diagram -------------------------------379

17.2. Main Board -----------------------------------------------380

17.3. Sensor Board -------------------------------------------- 406

17.4. Scanner Board ------------------------------------------ 407

17.5. Operation Board ---------------------------------------- 408

17.6. High Voltage Power Supply Board ----------------- 410

17.7. Low Voltage Power Supply Board------------------413

17.8. Optional ADU Board -----------------------------------414

17.9. Optional OPF Board ----------------------------------- 415

17.10. Optional Hook Switch Board------------------------- 416

18 Printed Circuit Board----------------------------------------- 417

18.1. Main Board -----------------------------------------------417

18.2. Sensor Board -------------------------------------------- 419

18.3. Scanner Board ------------------------------------------ 423

18.4. Operation Board ---------------------------------------- 425

18.5. High Voltage Power Supply Board ----------------- 427

18.6. Low Voltage Power Supply Board------------------429

18.7. Optional ADU Board -----------------------------------431

18.8. Optional OPF Board ----------------------------------- 431

18.9. Optional Hook Switch Board------------------------- 433

19 Exploded View and Replacement Parts List---------- 434

19.1. Cabinet, Mechanical and Electrical Parts

Location ---------------------------------------------------434

19.2. Replacement Parts List ------------------------------- 463

3

KX-MC6020HX

1 Safety Precautions

1. Before servicing, unplug the AC power cord to prevent an electric shock.

2. When replacing parts, use only the manufacturer's recommended components.

3. Check the condition of the power cord. Replace if wear or damage is evident.

4. After servicing, be sure to restore the lead dress, insulation barriers, insulation papers, shields, etc.

5. Before returning the serviced equipment to the customer, be sure to perform the following insulation resistance test to prevent

the customer from being exposed to shock hazards.

1.1. For Service Technicians

• Repair service shall be provided in accordance with repair technology information such as service manual so as to pre-

vent fires, injury or electric shock, which can be caused by improper repair work.

1. When repair services are provided, neither the products nor their parts or members shall be remodeled.

2. If a lead wire assembly is supplied as a repair part, the lead wire assembly shall be replaced.

3. FASTON terminals shall be plugged straight in and unplugged straight out.

• ICs and LSIs are vulnerable to static electricity.

When repairing, the following precautions will help prevent recurring malfunctions.

1. Cover the plastic part's boxes with aluminum foil.

2. Ground the soldering irons.

3. Use a conductive mat on the worktable.

4. Do not touch the IC or LSI pins with bare fingers.

1.2. AC Caution

For safety, before closing the lower cabinet, please make sure of the following precautions.

1. The earth lead is fixed with the screw.

2. The AC connector is connected properly.

4

KX-MC6020HX

1.3. Personal Safety Precautions

1.3.1. Moving Sections of The Unit

Be careful not to let your hair, clothes, fingers, accessories, etc., become caught in any moving sections of the unit.

The moving sections of the unit are the rollers and a gear. There is a separation roller and a document feed roller which are rotated

by the document feed motor. A gear rotates the two rollers. Be careful not to touch them with your hands, especially when the unit

is operating.

1.3.2. Live Electrical Sections

All the electrical sections of the unit supplied with AC power by the AC power cord are live.

Never disassemble the unit for service with the AC power supply plugged in.

CAUTION:

AC voltage is supplied to the primary side of the power supply board. Therefore, always unplug the AC power cord before disassembling for service.

5

KX-MC6020HX

1.4. Service Precautions

1.4.1. Precautions to Prevent Damage From Static Electricity

Electrical charges accumulate on a person. For instance, clothes rubbing together can damage electric elements or change their

electrical characteristics. In order to prevent static electricity, touch a metallic part that is grounded to release the static electricity.

Never touch the electrical sections such as the power supply unit, etc.

2Warning

2.1. About Lead Free Solder (PbF: Pb free)

Note:

In the information below, Pb, the symbol for lead in the periodic table of elements, will refer to standard solder or solder that contains lead.

We will use PbF solder when discussing the lead free solder used in our manufacturing process which is made from Tin, (Sn),

Silver, (Ag), and Copper, (Cu).

This model, and others like it, manufactured using lead free solder will have PbF stamped on the PCB. For service and repair

work we suggest using the same type of solder although, with some precautions, standard Pb solder can also be used.

Caution

• PbF solder has a melting point that is 50° ~ 70° F, (30 ° ~ 40°C) higher than Pb solder. Please use a soldering iron with temperature control and adjust it to 700° ± 20° F, (370° ± 10°C). In case of using high temperature soldering iron, please be careful not to

heat too long.

• PbF solder will tend to splash if it is heated much higher than its melting point, approximately 1100°F, (6 0 0°C).

• If you must use Pb solder on a PCB manufactured using PbF solder, remove as much of the original PbF solder as possible and

be sure that any remaining is melted prior to applying the Pb solder.

• When applying PbF solder to double layered boards, please check the component side for excess which may flow onto the

opposite side (See figure, below).

2.1.1. Suggested PBF Solder

There are several types of PbF solder available commercially. While this product is manufactured using Tin, Silver, and Copper,

(Sn+Ag+Cu), you can also use Tin and Copper, (Sn+Cu), or Tin, Zinc, and Bismuth, (Sn+Zn+Bi). Please check the manufacturer’s specific instructions for the melting points of their products and any precautions for using their product with other

materials.

The following lead free (PbF) solder wire sizes are recommended for service of this product: 0.3mm, 0.6mm and 1.0mm.

6

KX-MC6020HX

2.2. Discarding of P. C. Board

When discarding P. C. Board, delete all personal information such as telephone directory and caller list or scrap P. C. Board.

2.3. Insulation Resistance Test

1. Unplug the power cord and short the two prongs of the plug with a jumper wire.

2. Turn on the power switch.

3. Measure the resistance value with an ohmmeter between the jumpered AC plug and each exposed metal cabinet part

(screw heads, control shafts, bottom frame, etc.).

Note: Some exposed parts may be isolated from the chassis by design. These will read infinity.

4. If the measurement is outside the specified limits, there is a possibility of a shock hazard.

2.4. Battery Caution

CAUTION

Danger of explosion if the battery is incorrectly replaced. Replace only with the same or equivalent type recommended by the

manufacturer. Dispose used batteries according to the manufacturer’s instructions:

The lithium battery is a critical component (type No. CR2354(B300)). Please observe for the proper polarity and exact location

when replacing it and soldering the replacement lithium battery in.

2.4.1. Information for Users on Collection and Disposal of Old Equipment

and used Batteries

7

KX-MC6020HX

2.5. Laser Beam and Fuser Unit Section

• The printer of this unit utilizes a laser. Use of controls or adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

• The fuser unit is inside of the unit and gets hot. Do not touch it when removing the jammed paper.

8

KX-MC6020HX

3 Specifications

* Transmission speed depends on the contents of the pages, resolution, telephone line conditions and capability of the other party’s

machine.

** Transmission speed is based on the ITU-T No. 1 Test Chart. (Refer to ITU-T No.1 Test Chart (P.377).) If the capability of the

other party's machine is inferior to your unit, the transmission time may be longer.

Note:

• Design and specifications are subject to change without notice.

• The pictures and illustrations in these instructions may vary slightly from the actual product.

• The accuracy of the clock is approximately

±60 seconds a month.

Applicable Lines: Public Switched Telephone Network

Document Size: Max. 216 mm in width

Max. 600 mm in length

Effective Scanning Width: 208 mm

Effective Printing Width: A4: 202 mm

Letter/ Legal: 208 mm

Transmission Time*: Approx. 4 s/page (ECM-MMR Memory transmission)**

Scanning Density: Scanning resolution:

Up to 600 × 1200 dpi (Optical)

Up to 9600 × 9600 dpi (Interpolated)

Copy resolution:

Up to 600 × 600 dpi

FAX res olution:

Horizontal:

8 pels/mm

Vertical:

3.85 lines/mm-STANDARD

7.7 lines/mm-FINE/PHOTO

15.4 lines/mm-SUPER FINE

Photo resolution: 64-level

Scanner Type: Colour Contact Image Sensor

Printer Type: Laser printer

Data Compression System: Modified Huffman (MH), Modified READ (MR), Modified Modified READ (MMR)

Modem Speed: 33,600 / 31,200 / 28,800 / 26,400 / 24,000 / 21,600 / 19,200 / 16,800 / 14,400 / 12,000 /

9,600 / 7,200 / 4,800 / 2,400 bps; Automatic Fallback

Operating Environment: 10°C—32.5°C, 20—80% RH (Relative Humidity)

Dimensions (W×D×H): Approx. width 520 mm × depth 438 mm × height 546 mm

Mass (Weight): Approx. 30kg

Power Consumption: Standby: Approx. 16 W

Preheat: Approx. 35 W

Copy: Approx. 550 W

Maximum: Approx. 1100 W (When the fuser lamp turns on)

Power Supply: 220-240 V AC, 50/60 Hz

Memory Capacity (for operation and

storing memory):

192 MB

Fax Memory Capacity: 10 MB in total

Approx. 630 pages of memory reception

(max. 255 pages per one reception)

Approx. 150 pages of memory transmission

(Based on the ITU-T No.1 Test Chart (P.377) in standard resolution, without using the Error

Correction Mode.)

Scan to e-mail server memory

capacity:

5 MB in total (including the e-mail message)

Scan to FTP server memory capacity:

20 MB in total

Laser diode properties: Laser output: Max. 6.5 mW

Wave length: 770 nm—800 nm

Emission duration: Continuous

Print Speed: Colour:

A4: Approx. 20 ppm (page per minute)

Letter: Approx. 21ppm (page per minite)

B/W:

A4: Approx. 20 ppm (page per minute)

Letter: Approx. 21ppm (page per minite)

Printing Resolution: Up to 1200 × 1200 dpi

Product Life: One hundred-thousand (except drum unit, toner cartridge)

9

KX-MC6020HX

4 General/Introduction

4.1. Optional Accessories

Replacement toner cartridge*

1

Replacement toner cartridge (high capacity)*

2

*1Prints about 2,000 sheets of A4-size pages with a 5 % coverage using KX-FATC501E / KX-FATC501X / KX-FATM502E / KX-

FATM502X / KX-FATY503E / KX-FATY503X and about 2,500 sheets using KX-FATK504E / KX-FATK504X.

*

2

Prints about 4,000 sheets of A4-size pages with a 5 % coverage using KX-FATC506E / KX-FATC506X / KX-FATM507E / KX-

FATM507X / KX-FATY508E / KX-FATY508X / KX-FATK509E / KX-FATK509X.

Other accessories

4.2. Translation Lists

4.2.1. Help Function

Color Model No.

Cyan KX-FATC501E/KX-FATC501X

Magenta KX-FATM502E/KX-FATM502X

Yellow KX-FATY503E/KX-FATY503X

Black KX-FATK504E/KX-FATK504X

Color Model No.

Cyan KX-FATC506E/KX-FATC506X

Magenta KX-FATM507E/KX-FATM507X

Yellow KX-FATY508E/KX-FATY508X

Black KX-FATK509E/KX-FATK509X

Model No. Description Specifications

KX-FADC510E/KXFADC510X

Replacement color drum cartridge 1 drum cartridge

KX-FADK511E/KXFADK511X

Replacement monochrome drum cartridge 1 drum cartridge

KX-FAW505E/KXFAW5 05X

Waste toner cartridge 1 toner cartridge

KX-FAP317E/KXFAP317X

Optional lower input tray 1 tray

KX-FAB318E/KXFAB318X

Optional automatic duplex unit 1 unit

10

KX-MC6020HX

4.2.2. Error Message (Report)

4.2.2.1. CZECH

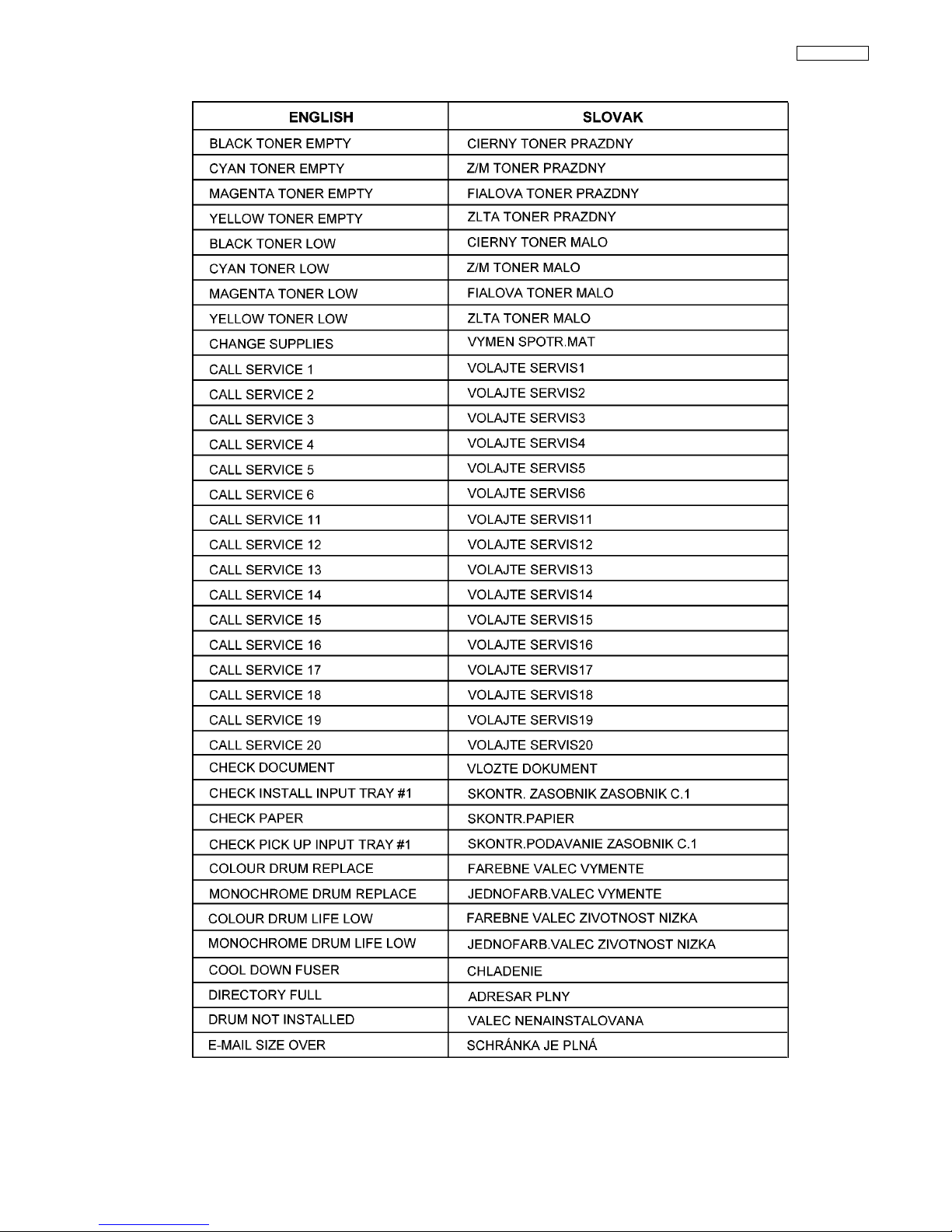

4.2.2.2. SLOVAK

4.2.2.3. HUNGARIAN

11

KX-MC6020HX

4.2.3. Error Message (Display)

4.2.3.1. CZECH

12

KX-MC6020HX

13

KX-MC6020HX

4.2.3.2. SLOVAK

14

KX-MC6020HX

15

KX-MC6020HX

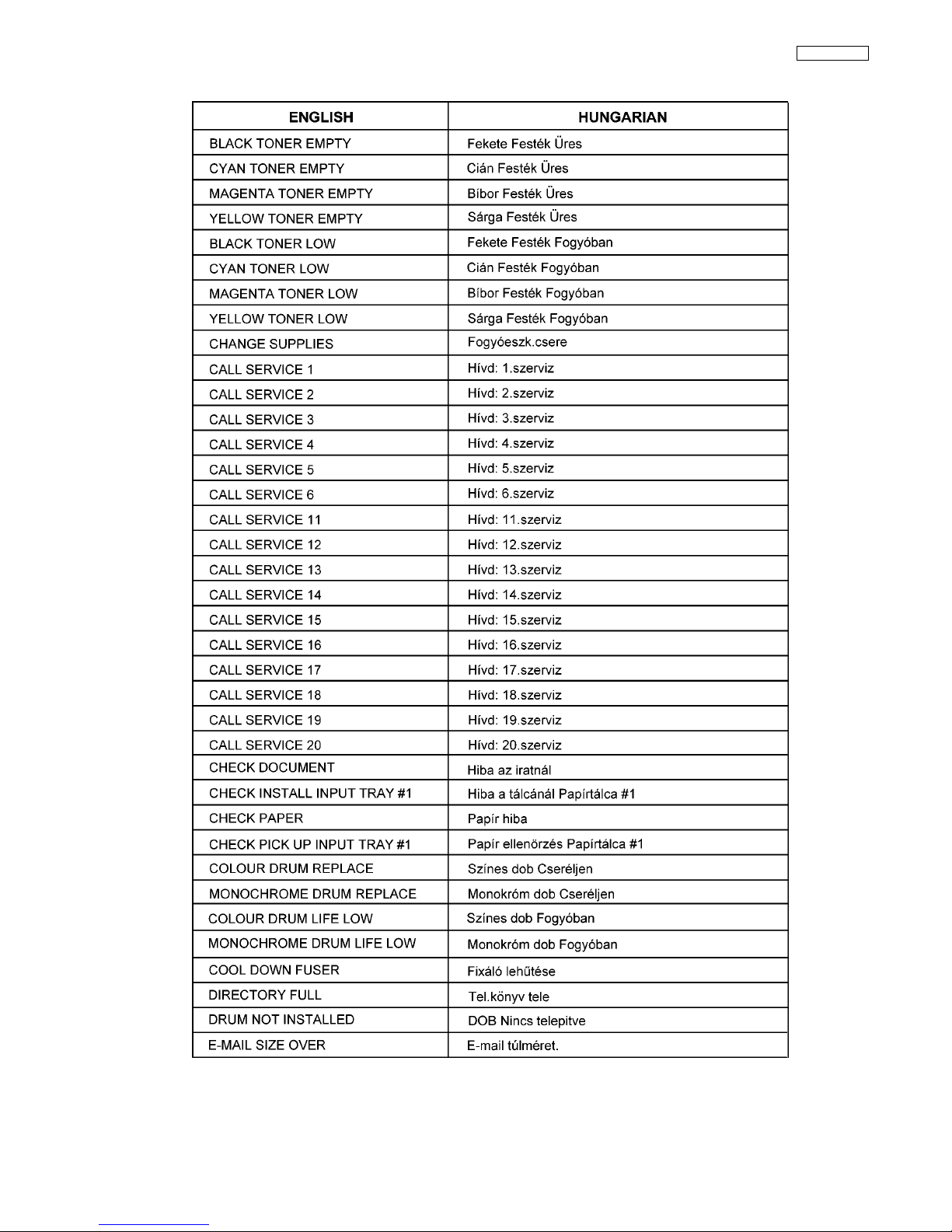

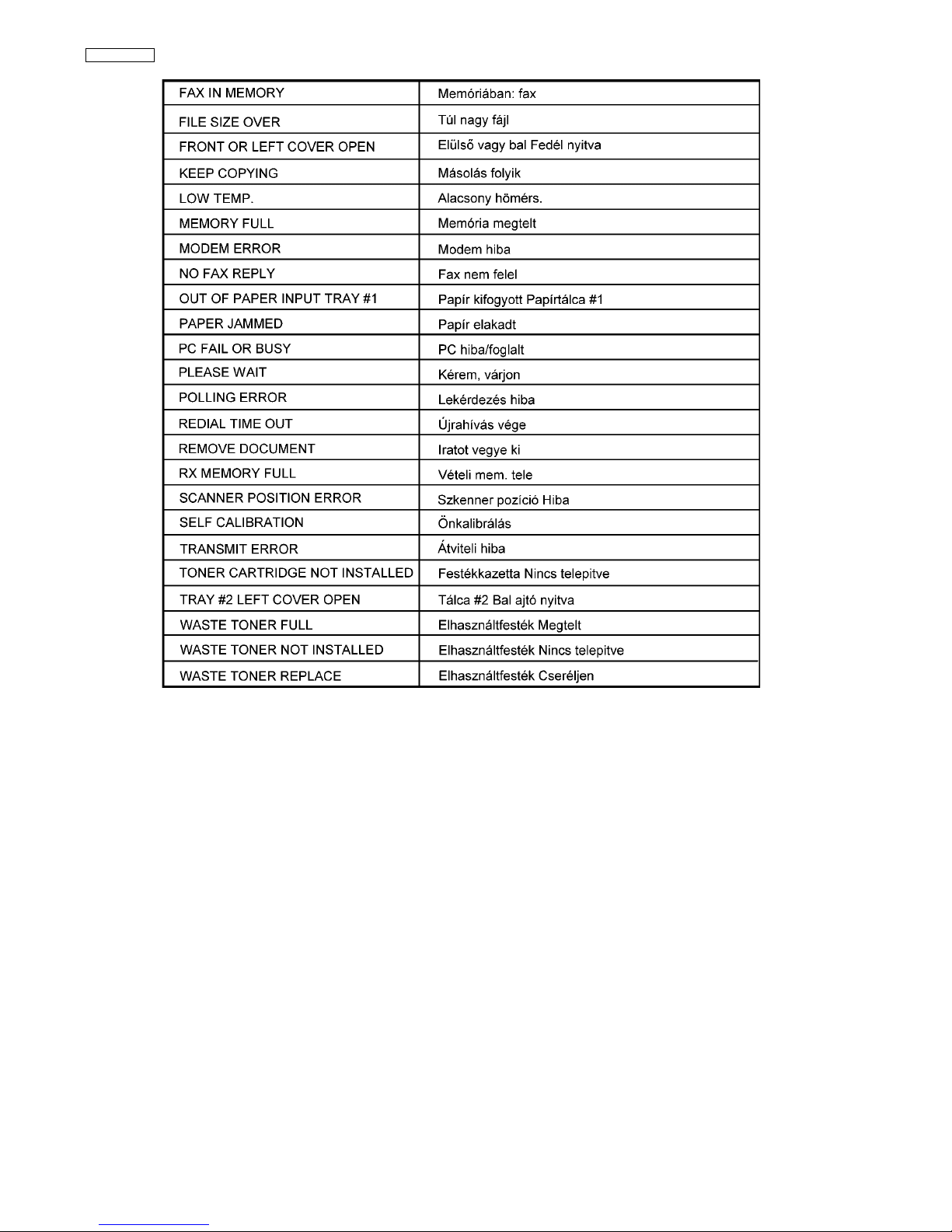

4.2.3.3. HUNGARIAN

16

KX-MC6020HX

17

KX-MC6020HX

4.3. Precautions for Shipping

KX-MC6000 series have structural possibility that the waste toner may leak due to the vibration or the condition of the shipping.

Therefore, appropriate preventive measures for toner leaking should be taken for each service type. Precautions for each service

type are mentioned below.

4.3.1. Necessary Items and Procedures for Each Service Type

18

KX-MC6020HX

Case 1) Exchange Service

This service sends the replacement unit to customers first. Then the broken unit is sent to the service center.

1. Install dummy cartridges, which are used for toner leak prevention, before shipping the replacement units.

• This prevents leaking of the waste toner from the accumulator unit.

2. Request customers that install dummy cartridges, preliminarily installed in the replacement unit, to the broken unit and send it

to the service center.

3. Request customers to reinstall currently used toners and drums to the replacement unit.

Caution:

If the broken unit is shipped without dummy cartridges, the waste toner leaks into the inside of the units as shown below so that

it becomes unrepairable.

*Dummy cartridges are provided as Service parts. (P/N: PNZE2MC6020M) (Refer to FIXTURES AND TOOLS (P.485).)

19

KX-MC6020HX

Case 2) Regular Service

1. Request customers that send the broken unit with consumable supplies.

2. Response of service center after completing repairs

• Remove all toners and drums and repack the repaired

unit to ship. (Refer to Repack Procedure (P.20))

• Shipping Kit is provided as service parts (P/N:

PNZE1MC6020M). (Refer to FIXTURES AND TOOLS

(P.485).)

Case 3) On site Service

The unit is not shipped to anywhere so that no need to take toner leaking precautions.

20

KX-MC6020HX

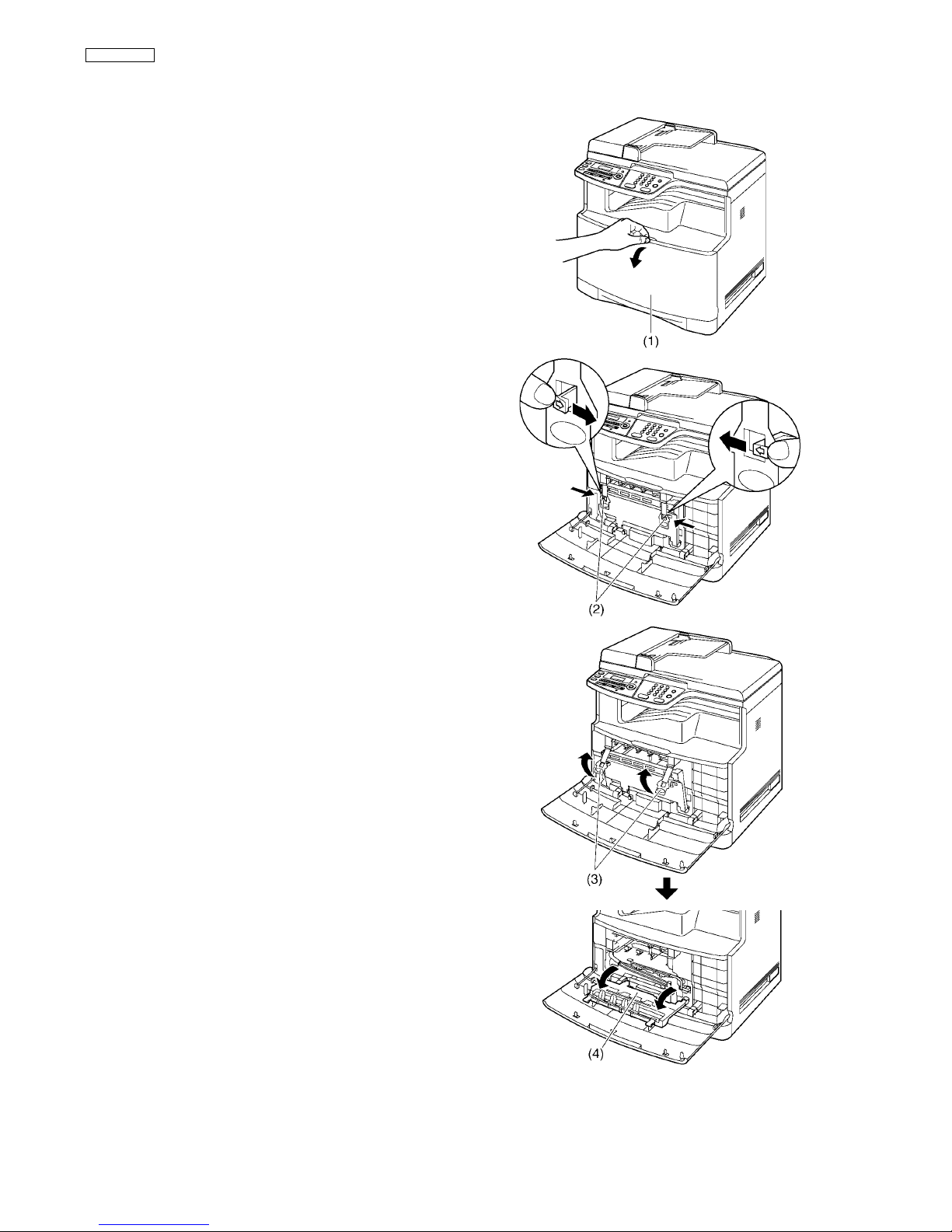

4.3.2. Repack Procedure

1.

Open the front cover (1) by holding the center part.

2.

Unlock the drum cartridge cover by pushing the tabs (2) in the direction

of the arrows.

3.

Lift up the levers (3) and open the drum cartridge cover (4).

21

KX-MC6020HX

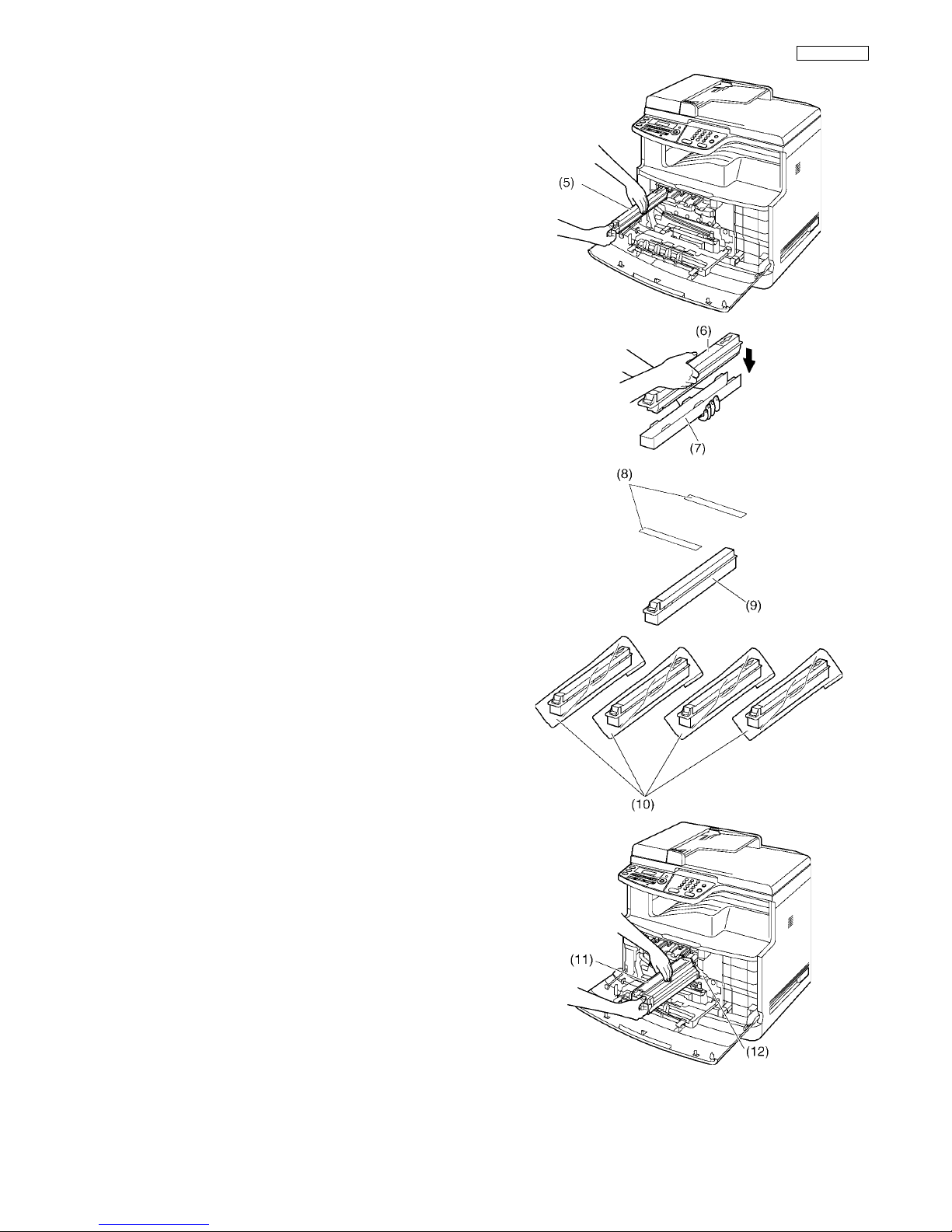

4.

Remove each toner cartridge (5) from the main unit. From left to right,

yellow, magenta, cyan, black.

• Do not touch the toner cartridge shutter at the bottom of the toner

cartridge. The toner may spill out of the toner cartridge.

5.

Put each toner cartridge (6) into protective tray (7).

6.

Apply shipping tapes (8) to each toner cartridge (9).

7.

Put the 4 toner cartridges into the protection bags (10).

8.

Remove the monochrome drum cartridge (11) from the main unit.

• Do not touch or scratch the accumulator unit (12).

22

KX-MC6020HX

9.

Firmly grip the monochrome drum cartridge (13) and insert the protective tray (14) by sliding it toward you.

• Do not touch or scratch the green drum surface (15) at the bottom

of the drum cartridge.

10.

Put the protective cover (16).

11.

Apply shipping tapes (17) to the monochrome drum cartridge (18).

12.

Put the monochrome drum cartridge into the protection bag (19).

13.

Hold and pull the front part of the color drum cartridge (20) using your

right hand to remove it from the main unit, then hold the green lever

(21) of the color drum cartridge using your left hand to support removing.

• Do not touch or scratch the accumulator unit (22).

23

KX-MC6020HX

14.

Firmly grip the color drum cartridge (23) and insert protective tray (24)

by sliding it toward you.

• Do not touch or scratch the green drum surface (25) at the bottom

of the drum cartridge.

15.

Put the protective cover (26).

16.

Apply shipping tapes (27) to color drum cartridge (28).

17.

Put the color drum cartridge into the protection bag (29).

24

KX-MC6020HX

Caution;

18.

Put the orange protector (30) to the main unit.

25

KX-MC6020HX

Installing Orange protector

26

KX-MC6020HX

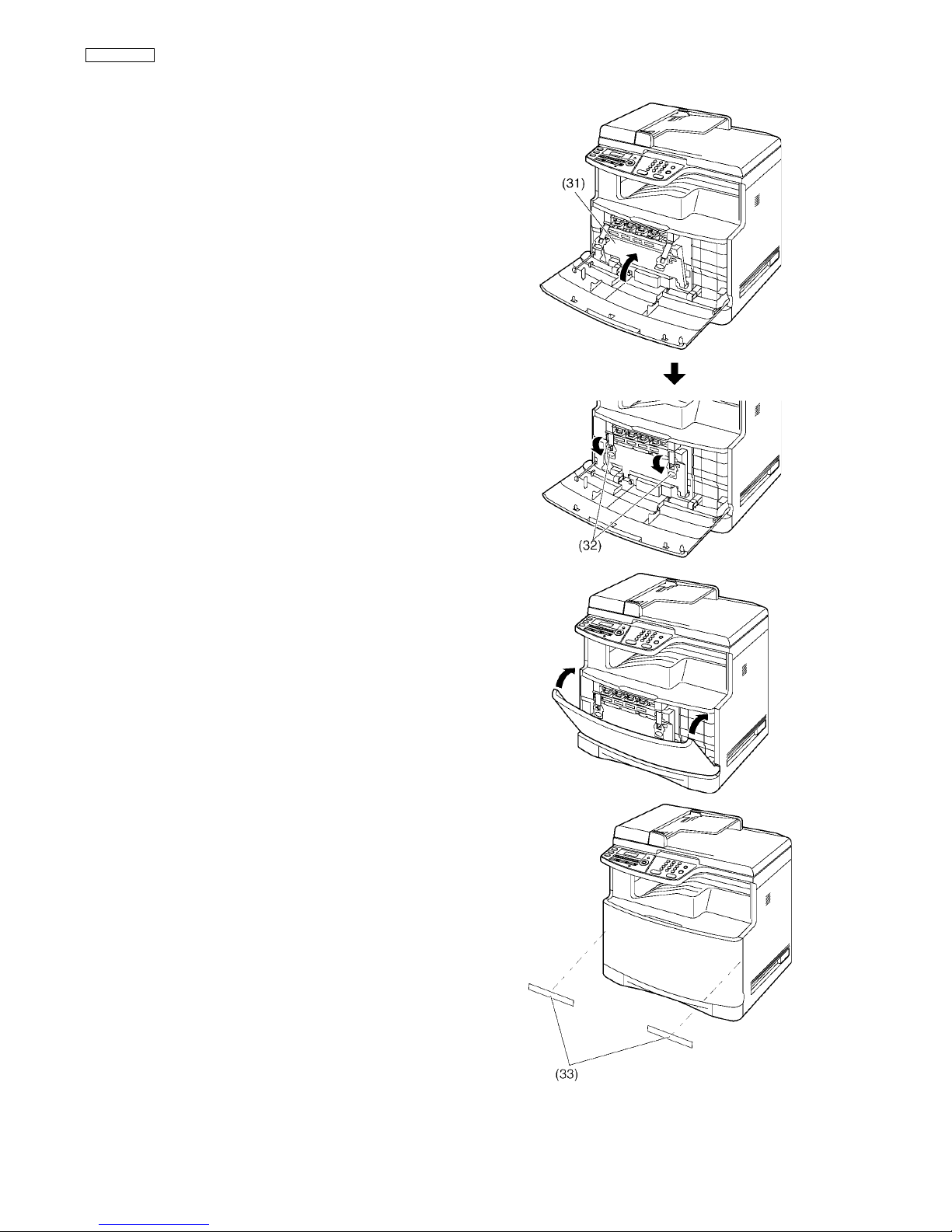

19.

Lift the drum cartridge cover (31) and push down on the levers (32) to

close.

• Push the levers down until you hear a click to ensure that the cover

is locked.

20.

Close the front cover.

21.

Apply shipping tapes (33) to the main unit.

27

KX-MC6020HX

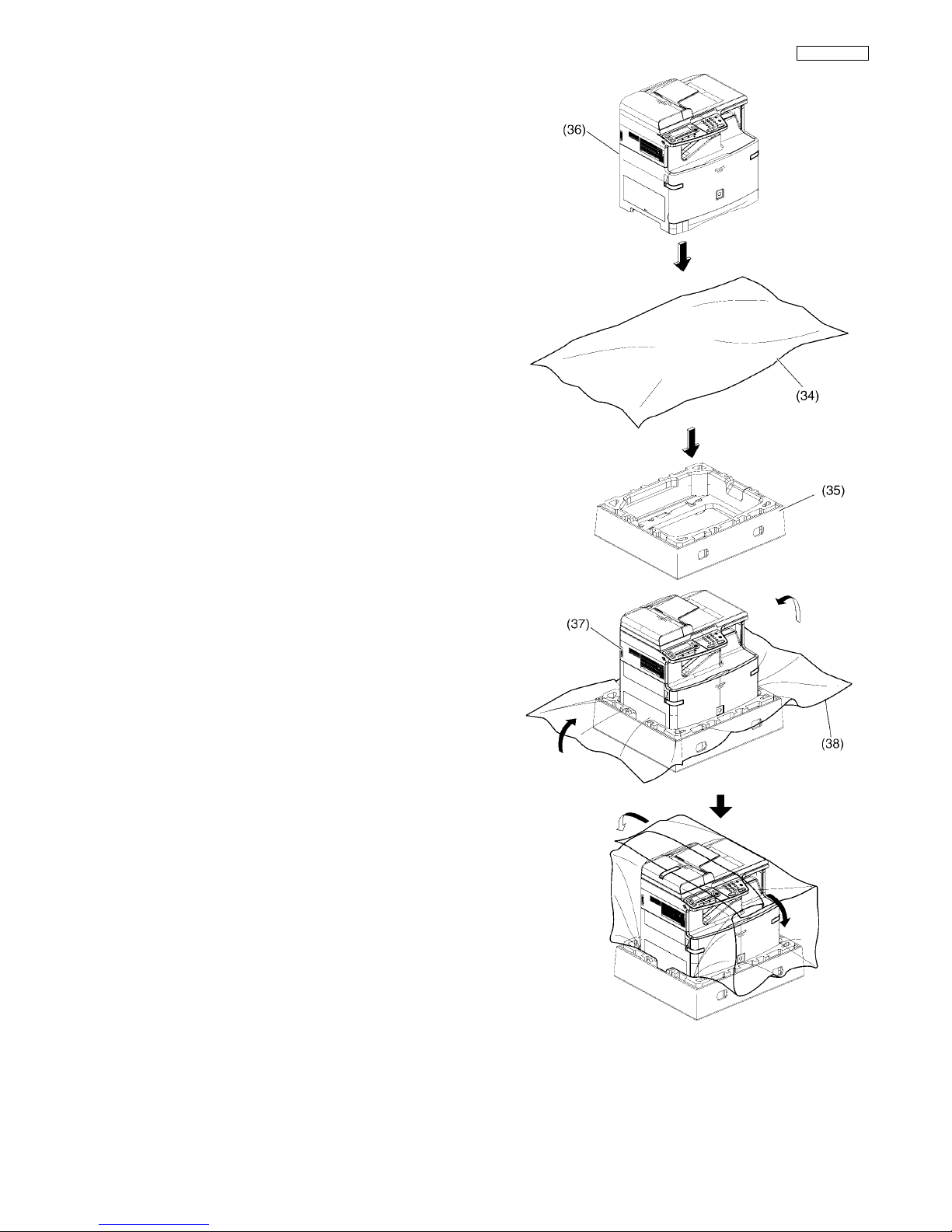

22.

Put the packing sheet (34) on the lower packing case (35). Then put

the main unit (36) on them.

23.

Wrap the main unit (37) by the packing sheet (38).

28

KX-MC6020HX

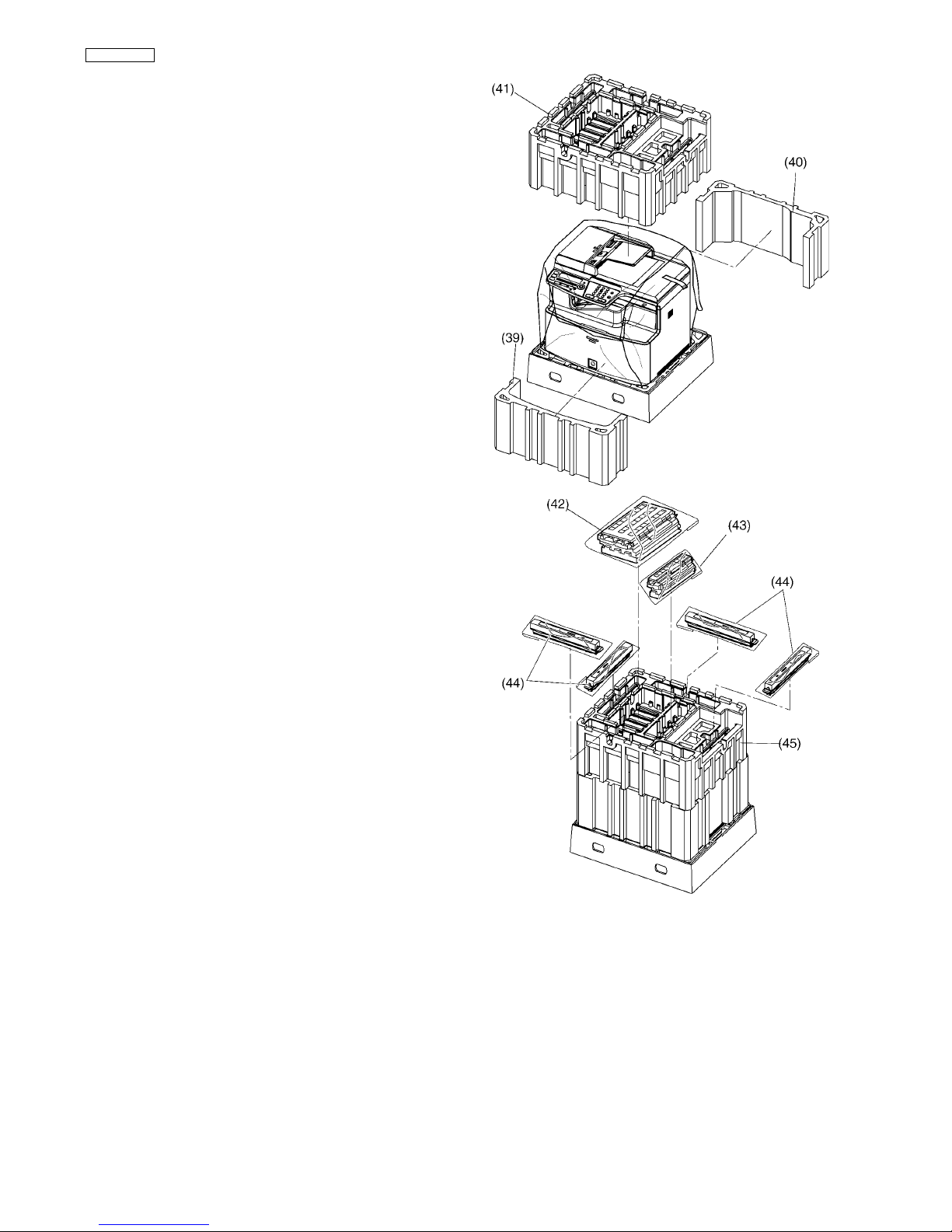

24.

Put the protection cover (39), (40) and (41).

25.

Pack the color drum cartridge (42), the monochrome drum cartridge

(43) and 4 toner cartridges (44) into the upper protection cover (45).

29

KX-MC6020HX

26.

Pack the pad (46) and the accessory box (47) into the upper protection

cover (48). Then put the upper packing cover (49).

27.

Put 4 joints (50) into the packing case (51).

30

KX-MC6020HX

5Features

5.1. General Features

General

• Help function

Display:

1. FEATURE LIST

2. DIRECTORY

3. FAX RECEIVING

4. CALLER ID

• LCD (Liquid Crystal Display) readout

Plain Paper Facsimile Machine

Recording paper exit (approx. 100 sheets)

Letter/A4/Legal, G3 compatible

Automatic document feeder (Up to 50 sheets)

Quick scan

Resolution: Standard/Fine/Super fine/Photo (64 level).

STANDARD: For normal-sized characters.

FINE: For small-sized characters.

SUPER FINE: For very small-sized characters.

PHOTO: For photographs, shaded drawings, etc.

Broadcast

• 250-sheet paper capacity (75 g/m

2

)

Distinctive ring detection.

Large Memory... Performed by DRAM

Approx. 150 pages of memory transmission

Approx. 630 pages of memory reception (max. 255 pages per

one reception.)

Enhanced Copier Function

Multi-copy function (up to 99 copies)

Enlargement and reduction

64-Level halftone

5.2. Hardware Requirements for Multi-Function Software

To use Multi-Function Station on your computer, the following are required:

Operating System:

Windows 98 / Windows Me / Windows 2000 / Windows XP / Windows Vista

CPU:

Windows 98/Windows Me/Windows 2000: Pentium

®

or higher processor

Windows XP: Pentium or higher processor

Windows Vista: Pentium 4 or higher processor

RAM:

Windows 98/Windows Me: 64 MB (128 MB or more recommended)

Windows 2000/Windows XP: 128 MB (256 MB or more recommended)

Windows Vista: 512 MB (1024 MB or more recommended)

Other Hardware:

CD-ROM drive

Hard disk drive with at least 150 MB of available space

USB interface

LAN interface (10Base-T / 100Base-TX)

Other:

Internet Explorer

®

5.0 or later

Warning;

• To assure continued emission limit compliance;

- use only shielded USB cable (Example: Hi-Speed USB 2.0 certified cable).

- use only shielded LAN cable (category 5 straight cable).

• To protect the unit, use only shielded USB cable in areas where thunderstorms occur.

Loading...

Loading...