Panasonic VDR-D210P, VDR-D230P, VDR-D210PC, VDR-D220PC, VDR-D230PC Service Manual

...

Digital Video Camcorder

VDR-D210P

VDR-D220P

VDR-D230P

VDR-D210PC

VDR-D220PC

VDR-D230PC

Vol. 1

ORDER NO. MKE0701450CE

B17

Colours

(S)...................Silver Type

© 2007 Panasonic Shikoku Electronics Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

VDR-D210P / VDR-D220P / VDR-D230P / VDR-D210PC / VDR-D220PC / VDR-D230PC

CONTENTS

Page Page

1 Safety Precautions 3

1.1. General Guidelines

2 Warning

2.1. Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

2.2. How to Recycle the Lithium Battery

2.3. How to Replace the Lithium Battery

3 Service Navigation

3.1. Introduction

3.2. About Lead Free Solder (PbF)

4 Specifications

5 Service Mode

5.1. Error Display

5.2. Service Menu

6 Service Fixture & Tools

6.1. Service Fixture and Tools

6.2. Service Position

6.3. Removal/Installation of F.P.C. From Non ZIF (Zero

Insertion Force) Connector

6.4. Method for Ejecting the DVD Tray Manually

6.5. EEPROM Data

6.6. Special Note

6.7. Model No. Identification Mark

7 Disassembly and Assembly Instructions

7.1. Cabinet Section

8 Measurements and Adjustments

8.1. Electrical Adjustment

9 Maintenance

9.1. Cleaning Lens, Viewfinder and LCD Panel

9.2. Cleaning disc and optical pickup

10 Tr oubleshooting

11 Voltage Chart of Connectors on Main P.C.B.

3

12 Block Diagrams

4

13 Schematic Diagrams

13.1. SCHEMATIC DIAGRAM & CIRCUIT BOARD LAYOUT

4

4

5

6

6

6

7

8

8

8

10

14 Printed Circuit Board

10

11

13

14

14

15 Ex ploded View

15

15

16

16

35

35

37

16 Replacement Parts Lists

37

37

39

NOTES

13.2. FRONT SCHEMATIC DIAGRAM

13.3. BOTTOM SCHEMATIC DIAGRAM

13.4. LCD BACKLIGHT SCHEMATIC DIAGRAM

13.5. SIDE R / EVF FPC / EVF BACKLIGHT / LED LIGHT

SCHEMATIC DIAGRAMS

13.6. CCD / REAR CASE / LCD SW SCHEMATIC DIAGRAMS

13.7. SIDE L/OPERATION / DISK COVER LOCK SCHEMATIC

DIAGRAMS

13.8. INTERCONNECTION SCHEMATIC DIAGRAM

14.1. FRONT P.C.B.

14.2. BOTTOM P.C.B.

14.3. LCD BACKLIGHT P.C.B.

14.4. SIDE R P.C.B.

15.1. MAIN PARTS SECTION

15.2. FRONT HOOD AND FRONT P.C.B. SECTION

15.3. SIDE R OPERATION AND LCD SECTION

15.4. CCD AND LENS SECTION

15.5. GRIP COVER AND EVF SECTION

15.6. PACKING PARTS AND ACCESSORIES SECTION

16.1. REPLACEMENT NOTES

16.2. MECHANICAL REPLACEMENT PARTS LIST

16.3. ELECTRICAL REPLACEMENT PARTS LIST

48

49

51

51

52

53

54

55

56

57

58

59

59

60

61

62

63

63

64

65

66

67

68

69

69

70

71

2

1 Safety Precautions

1.1. General Guidelines

1. IMPORTANT SAFETY NOTICE

There are special components used in this equipment

which are important for safety. These parts are marked by

in the Schematic Diagrams, Circuit Board Layout,

Exploded Views and Replacement Parts List. It is essential

that these critical parts should be replaced with

manufacturer’s specified parts to prevent shock, fire, or

other hazards. Do not modify the original design without

permission of manufacturer.

2. An Isolation Transformer should always be used during the

servicing of AC Adaptor whose chassis is not isolated from

the AC power line. Use a transformer of adequate power

rating as this protects the technician from accidents

resulting in personal injury from electrical shocks. It will also

protect AC Adaptor from being damaged by accidental

shorting that may occur during servicing.

3. When servicing, observe the original lead dress. If a short

circuit is found, replace all parts which have been

overheated or damaged by the short circuit.

4. After servicing, see to it that all the protective devices such

as insulation barriers, insulation papers shields are properly

installed.

5. After servicing, make the following leakage current checks

to prevent the customer from being exposed to shock

hazards.

VDR-D210P / VDR-D220P / VDR-D230P / VDR-D210PC / VDR-D220PC / VDR-D230PC

3

VDR-D210P / VDR-D220P / VDR-D230P / VDR-D210PC / VDR-D220PC / VDR-D230PC

2 Warning

2.1. Prevention of Electro Static Discharge (ESD) to Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an antistatic solder removal device. Some solder removal devices not classified as "antistatic (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable

conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

CAUTION :

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient to damage an ES device).

2.2. How to Recycle the Lithium Battery

4

VDR-D210P / VDR-D220P / VDR-D230P / VDR-D210PC / VDR-D220PC / VDR-D230PC

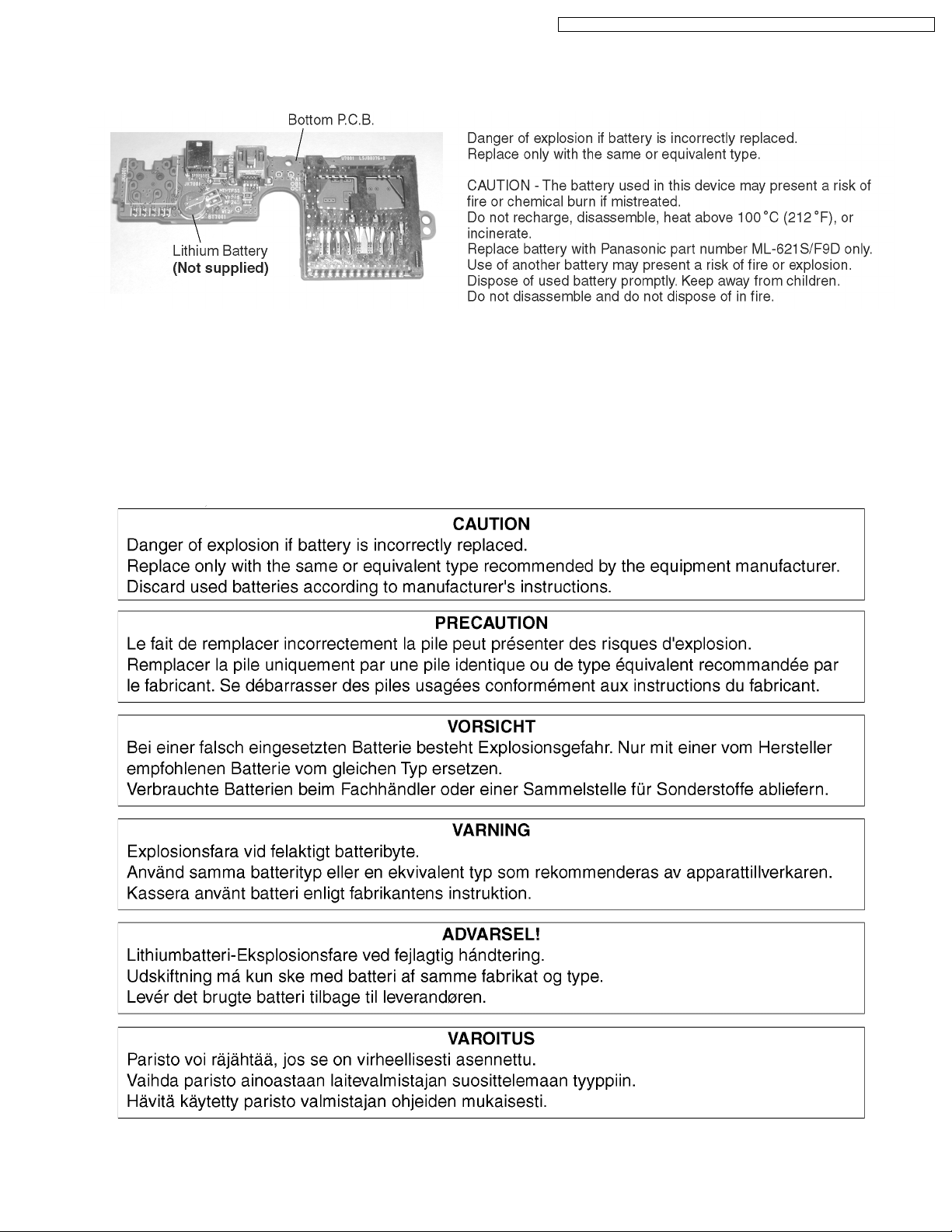

2.3. How to Replace the Lithium Battery

The lithium battery (CGR-F/202AW) is not supplied as a service part and must be replaced as part of the Bottom P.C.B. (Refer to

“Disassembly and Assembly Instructions.")

NOTE:

This Lithium battery is a critical component. (Type No.: CGR-F/202AW Manufactured by Panasonic.) (Not supplied)

It must never be subjected to excessive heat or discharge.

It must therefore only be fitted in equipment designed specifically for its use.

Replacement batteries must be of the same type and manufacture.

They must be fitted in the same manner and location as the original battery, with the correct polarity contacts observed.

Do not attempt to re-charge the old battery or re-use it for any other purpose.

It should be disposed of in waste products destined for burial rather than incineration.

5

VDR-D210P / VDR-D220P / VDR-D230P / VDR-D210PC / VDR-D220PC / VDR-D230PC

3 Service Navigation

3.1. Introduction

This service manual contains technical information which will allow service personnel´s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, this information will be followed by supplement service manual to be filed with original service

manual.

Note 1:

AC Adaptor used on these movie camera is PV-DAC14D. However, DE-974FB is supplied as a replacement part for PVDAC14D. This AC Adaptor is supplied only as a unit.

3.2. About Lead Free Solder (PbF)

6

4 Specifications

VDR-D210P / VDR-D220P / VDR-D230P / VDR-D210PC / VDR-D220PC / VDR-D230PC

7

VDR-D210P / VDR-D220P / VDR-D230P / VDR-D210PC / VDR-D220PC / VDR-D230PC

5 Service Mode

5.1. Error Display

"PUSH THE RESET SWITCH" is displayed automatically on the EVF or the LCD Monitor when an undesirable condition has

occurred.

Fig. 1

Note:

When "PUSH THE RESET SWITCH" is displayed repeatedly, service is required. Check the Error Code which is listed in the

Service Menu.

5.2. Service Menu

When abnormal detection contents are confirmed, do the following operation. Automatic diagnosis code will bedisplayed. (Service

Menu)

To enter the Service Menu

Push the [DELETE], [JOYSTICK CONTROL LEFT] and [RECORDING START/STOP] simultaneously for 3 seconds (with no

SD Card inserted).

Note:

If a Disc or SD Card is inserted, the above operation will not work.

Fig. 2-1

8

Note:

Only perform items 1, 3, and 4 in the Service Menu.

To select the Item

1. Set to Service Menu.

2. Press [JOYSTICK CONTROL UP/DOWN] to select item [1], [3], or [4].

3. Press [JOYSTICK CONTROL RIGHT] to display [YES/NO] screen.

4. Press [JOYSTICK CONTROL UP/DOWN] to select [YES].

5. Press [JOYSTICK CONTROL CENTER] to end.

VDR-D210P / VDR-D220P / VDR-D230P / VDR-D210PC / VDR-D220PC / VDR-D230PC

To exit the Service Menu

Unplug the AC Cord.

Fig. 2-2

9

VDR-D210P / VDR-D220P / VDR-D230P / VDR-D210PC / VDR-D220PC / VDR-D230PC

6 Service Fixture & Tools

6.1. Service Fixture and Tools

10

6.2. Service Position

VDR-D210P / VDR-D220P / VDR-D230P / VDR-D210PC / VDR-D220PC / VDR-D230PC

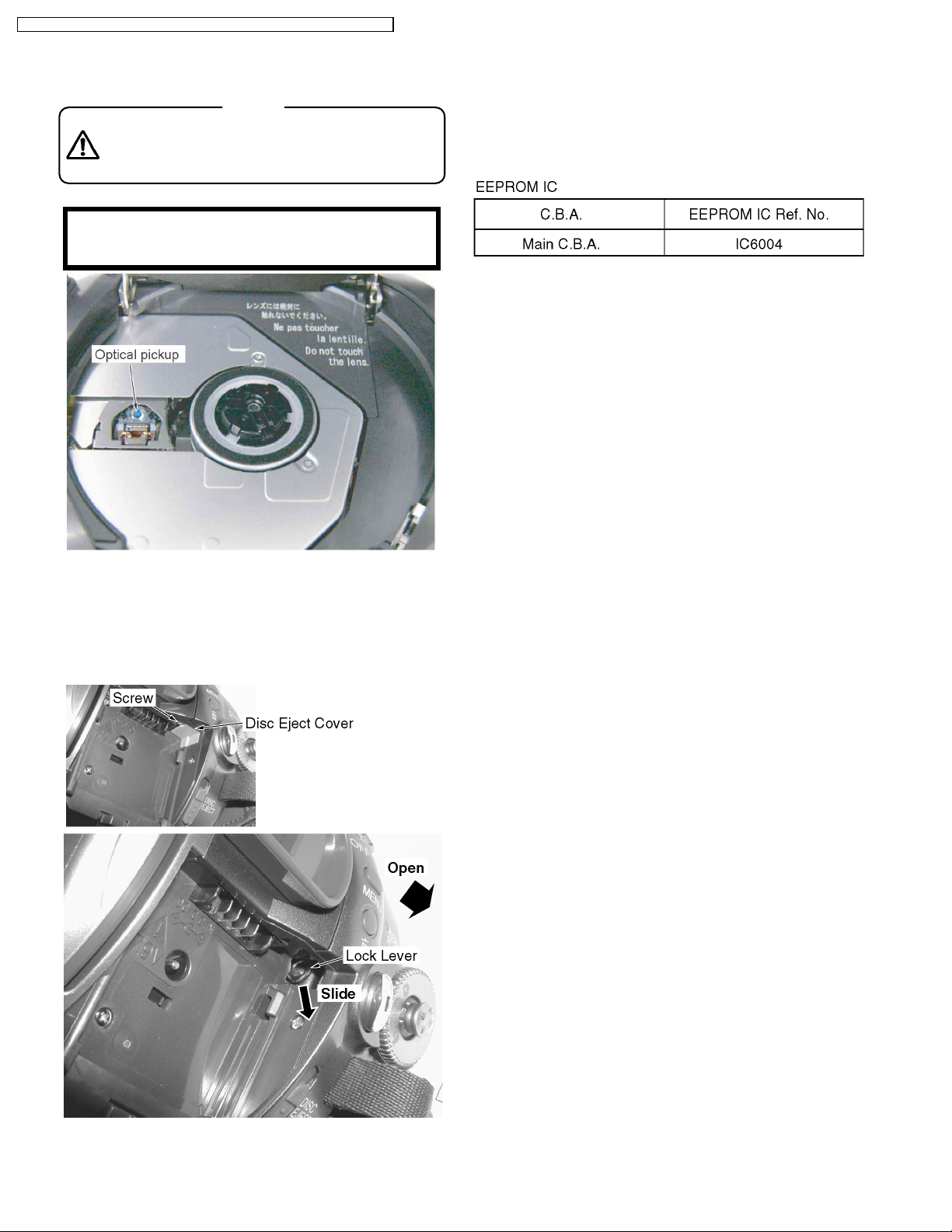

Laser light striking the eye may cause your eyesight

to be lost: For safety, be sure to remove any power

supply (AC adaptor/charger, battery, etc.) from the

DVD video camera/recorder before starting work.

CAUTION: VISIBLE LASER RADIATION DO NOT

STARE INTO THE BEAM OR VIEW DIRECTLY WITH

OPTICAL INSTRUMENTS CLASS 2M

Optical pickup

Caution

<CSA requirement>

6.2.1. Extension Cables for Service Position

Using the following Extension Cables, place the unit as shown for check and service.

Note :

1. The LCD open/close Switch is for changing between LCD Display or EVF Display. When turning on EVF Display, close the LCD

Shaft or place some paper or tape, etc. on LCD open/close Switch so that LCD open/close Switch stays ON.

2. To eject the DVD manually, slide the Lock lever on the Disc Cover Lock Unit for a short time or slide the EJECT switch.

3. Use a grounded ESD wrist strap while disassembling the Lens portion.

4. Connect the F.P.C.s to the connectors, verifying the direction of F.P.C.s.

The Main P.C.B. or a chip part will be damaged if the 60 Pin Extension Cable (LSUA0061) is misconnected.

5. Use extreme care when plugging in or unplugging connectors.

11

VDR-D210P / VDR-D220P / VDR-D230P / VDR-D210PC / VDR-D220PC / VDR-D230PC

Fig. 3

12

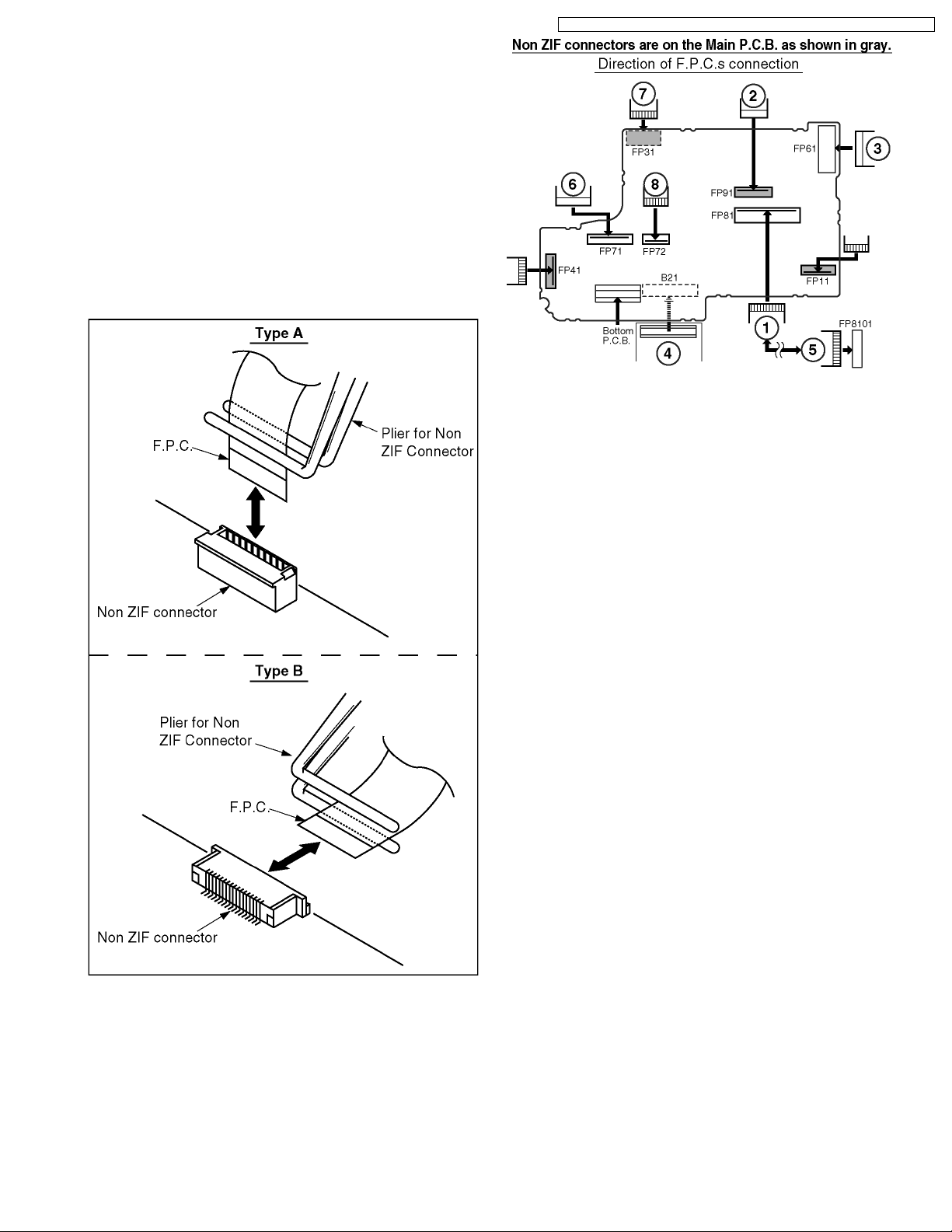

6.3. Removal/Installation of F.P.C.

From Non ZIF (Zero Insertion

Force) Connector

Removal/Installation of F.P.C. from the Non ZIF (Zero

Insertion Force) connector:

1. The Non ZIF connectors and the ZIF connectors are used

on the unit. And there are 2 types (Type A, Type B) of Non

ZIF connectors.

2. To remove the F.P.C. from the Non ZIF connector, use the

Plier for Non ZIF Connector (LSVQ0028) to pull out the

F.P.C. as shown. The same Plier for Non ZIF Connector

(LSVQ0028) should also be used to install the F.P.C. to the

Non ZIF Connector.

VDR-D210P / VDR-D220P / VDR-D230P / VDR-D210PC / VDR-D220PC / VDR-D230PC

Fig. 4-2

Fig. 4-1

3. Connect the F.P.C.s to the Non ZIF connectors, verifying

the direction of F.P.C as shown.

13

VDR-D210P / VDR-D220P / VDR-D230P / VDR-D210PC / VDR-D220PC / VDR-D230PC

6.4. Method for Ejecting the DVD Tray Manually

Caution

Laser light striking the eye may cause your eyesight

to be lost: For safety, be sure to remove any power

supply (AC adaptor/charger, battery, etc.) from the

DVD video camera/recorder before starting work.

<CSA requirement>

CAUTION: VISIBLE LASER RADIATION DO NOT

STARE INTO THE BEAM OR VIEW DIRECTLY WITH

OPTICAL INSTRUMENTS CLASS 2M

Optical pickup

6.5. EEPROM Data

CAUTION:

Be sure to save the EEPROM data using PC-EVR

Adjustment Program before service and adjustment in

order to make sure to avoid an accidental data loss, etc.

using PC-EVR Adjustment Program by first.

Perform the following procedures;

1. Remove the Disc Eject Cover by removing the screw.

2. Slide the Lock Lever with a screwdriver, etc., to open the

Disc Cover.

3. Remove the Disc from the Tray.

Fig. 5

14

6.6. Special Note

All integrated circuits and many other semiconductor devices

are electrostatically sensitive and therefore require the special

handlings techniques described under the

"ELECTROSTATICALLY SENSITIVE (ES) DEVICES" section

of this service manual.

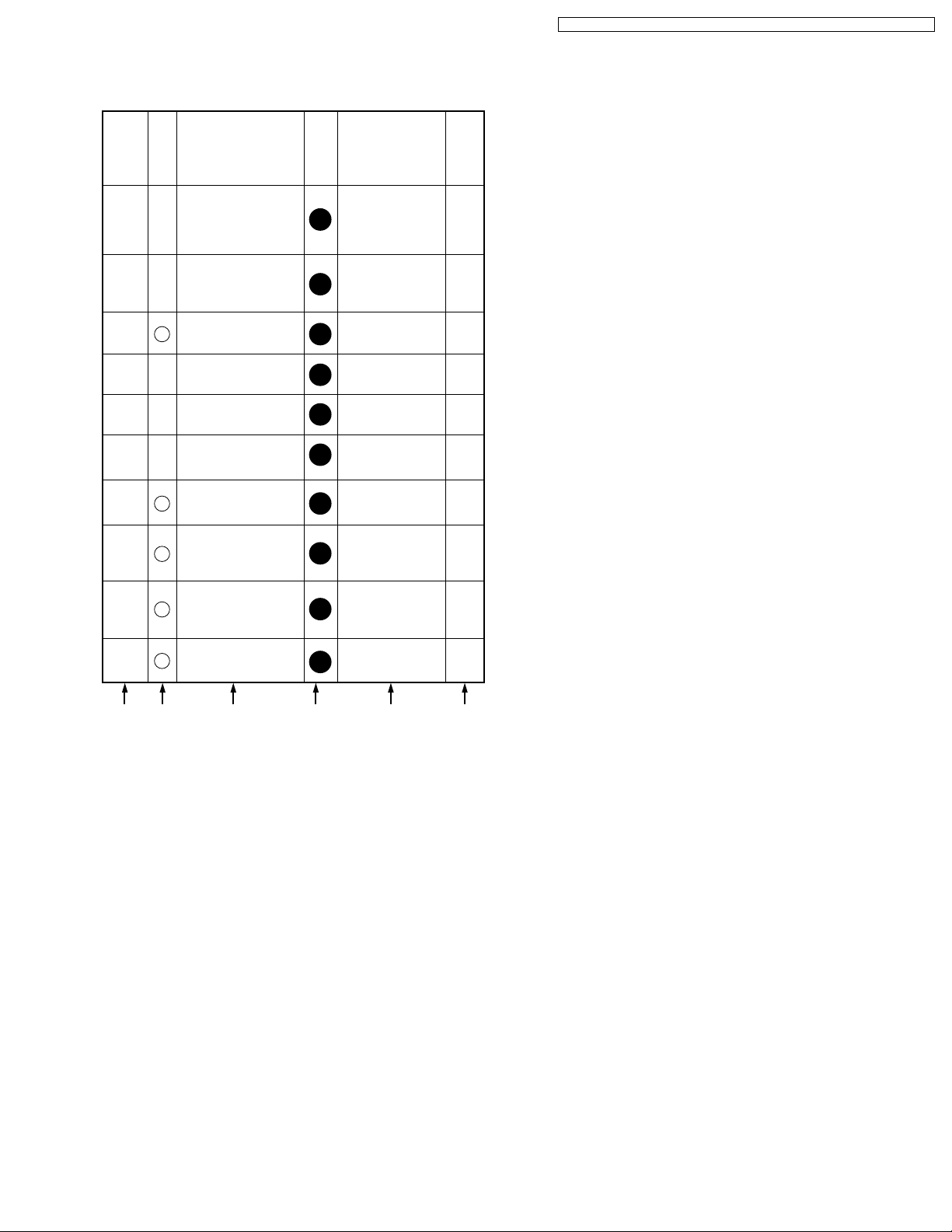

6.7. Model No. Identification Mark

Use Marks shown in the chart below to distinguish the different

models included in this Service Manual.

VDR-D210P / VDR-D220P / VDR-D230P / VDR-D210PC / VDR-D220PC / VDR-D230PC

15

VDR-D210P / VDR-D220P / VDR-D230P / VDR-D210PC / VDR-D220PC / VDR-D230PC

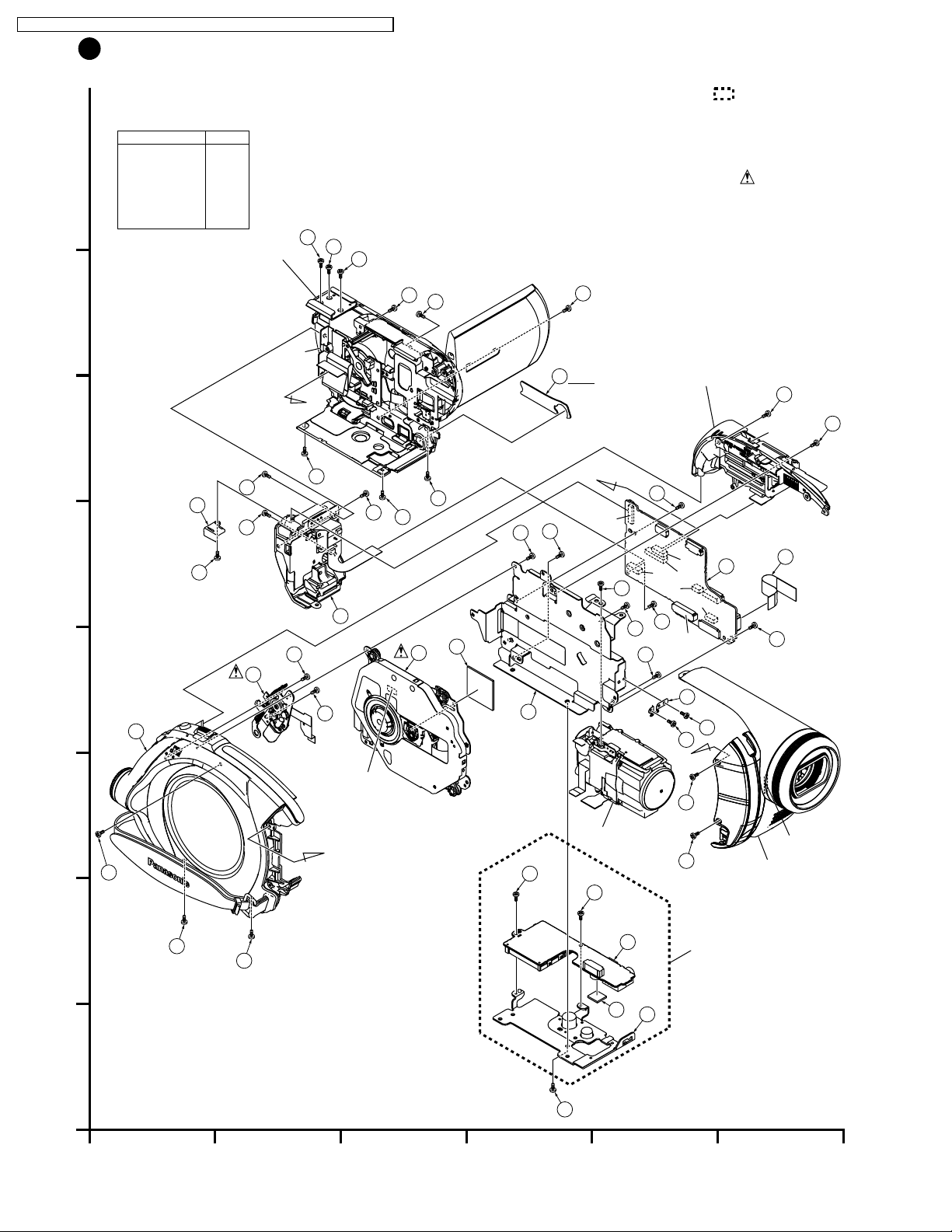

7 Disassembly and Assembly Instructions

7.1. Cabinet Section

7.1.1. DISASSEMBLY FLOWCHART

This flow chart indicates the disassembly steps of the

cabinet parts and the P.C.Boards in order to gain access to

item (s) to be serviced. When reassembling, perform the

step (s) in the reverse order. Bend, route and dress the

wires as they were originally.

Caution

Laser light striking the eye may cause your eyesight

to be lost: For safety, be sure to remove any power

supply (AC adaptor/charger, battery, etc.) from the

DVD video camera/recorder before starting work.

<CSA requirement>

CAUTION: VISIBLE LASER RADIATION DO NOT

STARE INTO THE BEAM OR VIEW DIRECTLY WITH

OPTICAL INSTRUMENTS CLASS 2M

Optical pickup

Note :

1. When removing the cabinet, work with care so as not to

break the Locking Tabs.

2. Place a cloth or some other soft material under the P.C.

Boards or Unit to prevent damage.

3. When reinstalling, ensure that the connectors are

connected and electrical components have not been

damaged.

4. Do not supply power to the unit during disassembly and

reassembly.

16

7.1.2. Disassembly Method

MAIN PARTS PORTION

STEP

No.

Ref.

No.

-

1

2

-

27

3

PART REMOVE

Front/Mic Ass'y

Side R &

LCD Ass'y

Rear Case Unit

Section

No.

1

1

1

(518), (537),

2(519), 2(533),

FP6501, Hand

Strap

2(518), 4(519),

(537), FP81,

2(L-1), (Shoe)

(537), (16)

(519), FP11

VDR-D210P / VDR-D220P / VDR-D230P / VDR-D210PC / VDR-D220PC / VDR-D230PC

NOTE

1

2

3

-

4

5 - Bottom Ass'y

6 - Lens Ass'y

7

8

9

10

Grip/EVF Ass'y

E10

Main P.C.B.

DVD Drive Frame

2

Unit

Disc Cover Lock

3

Unit

Side L Operation

1

Unit

2(519), (537),

1

FP91

3(519), B51

1

(456), FP31,

1

FP71, FP72

3(519), FP61,

1

B21

2(540), (28)

4(537), (6),

1

Connector

2(537)

1

-----

1

4

5

6

7

8

8

-

A B C D E F

How to read chart shown above:

A: Order of Procedure steps.

When reassembling, perform steps(s) in reverse order.

B: Ref No.

C: Part to be removed or installed.

D: Section No.

E: Identification of part to be removed, unhooked, unlocked,

released, unplugged, unclamped, or unsoldered.

3(404)= 3 Screws (404), 2(L-1) = 2 Looking Tabs (L-1)

F: Refer to "Notes in chart."

17

VDR-D210P / VDR-D220P / VDR-D230P / VDR-D210PC / VDR-D220PC / VDR-D230PC

1

MAIN PARTS SECTION

COMPARISON CHART

OF MODELS & MARKS

MODEL

VDR-D210P

VDR-D210PC

H

G

VDR-D220P

VDR-D220PC

VDR-D230P

VDR-D230PC

MARK

A

B

C

D

E

F

Side R & LCD Ass'y

518

2

518

-

2

518

-

1

(L-1)

B

F

537

Note:

1. Parts with no Ref. No. in "EXPLODED VIEW" are not supplied.

And some Ref. No. will be skipped. Be sure to make your

orders of replacement parts according to the parts list.

2. The parts indicated by the dotted line are for Ass'y only

and are not supplied.

3. Disregard Ref. No. suffixes when ordering parts. They are used to

describe parts in "Disassembly and Assembly Instructions" section.

IMPORTANT SAFTY NOTICE:

COMPONENTS IDENTIFIED BY THE SIGN HAVE

SPECIAL CHARACTERISTICS IMPORTANT FOR SAFETY.

WHEN REPLACING ANY OF THESE COMPONENTS,

USE ONLY THE SPECIFIED PARTS.

519

-

10

(A,B)

2

Grip / EVF Ass'y

-

4

519

-

4

(L-1)

519

-

2

537

-

1

519

-

519

-

2

16

519

-

2

E

537

-

3

2

-

1

519

-

519

3

-

1

519

537

-

8

27

8

537

-

8

2

537

B

519

-

7

FP61

-

8

-

6

456

537

-

8

537

FP11

FP72

519

-

-

8

FP91

FP81

7

B21

FP31

B51

E10

FP71

519

11

-

7

3

D

537

-

8

6

1

28

540

-

540

8

-

8

A

Connector

533

-

533

1

FP6501

-

1

Front / Mic Ass'y

C

Lens Ass'y

A

537

-

4

519

519

B

A

519

-

5

1

-

5

519

-

519

2 3 4 5 6

706

E30

7

Bottom Ass'y

5

18

FRONT/HOOD PORTION

STEP

No.

Ref.

No.

E20

1

PART REMOVE

Front P.C.B.

Section

No.

3(537), FP6502

2

VDR-D210P / VDR-D220P / VDR-D230P / VDR-D210PC / VDR-D220PC / VDR-D230PC

NOTE

9

2

3

4

(For models with Light)

53

LED Light F.P.C.

(For models with Light)

52

LED Light Lens

51

Front/Hood Unit

2(537), (54)

2

-----

2

-----

2

2

9

9

9

A B C D E F

How to read chart shown above:

A: Order of Procedure steps.

When reassembling, perform steps(s) in reverse order.

B: Ref No.

C: Part to be removed or installed.

D: Section No.

E: Identification of part to be removed, unhooked, unlocked,

released, unplugged, unclamped, or unsoldered.

3(404)= 3 Screws (404), 2(L-1) = 2 Looking Tabs (L-1)

F: Refer to "Notes in chart."

19

VDR-D210P / VDR-D220P / VDR-D230P / VDR-D210PC / VDR-D220PC / VDR-D230PC

2

FRONT HOOD AND FRONT P.C.B. SECTION

COMPARISON CHART

OF MODELS & MARKS

MODEL

VDR-D210P

H

VDR-D210PC

VDR-D220P

VDR-D220PC

VDR-D230P

VDR-D230PC

MARK

A

B

C

D

E

F

Note:

1. Parts with no Ref. No. in "EXPLODED VIEW" are not supplied.

And some Ref. No. will be skipped. Be sure to make your

orders of replacement parts according to the parts list.

2. The parts indicated by the dotted line are for Ass'y only

and are not supplied.

3. Disregard Ref. No. suffixes when ordering parts. They are used to

describe parts in "Disassembly and Assembly Instructions" section.

G

F

E

537

537

537

FP6502

E20

(C,D,E,F)

537

51

701

705

702

D

(C,D,E,F)

537

(C,D,E,F)

54

(C,D,E,F)

C

B

A

1

2 3 4 5 6

53

(C,D,E,F)

52

20

VDR-D210P / VDR-D220P / VDR-D230P / VDR-D210PC / VDR-D220PC / VDR-D230PC

SIDE R OPERATION PORTION

STEP

No.

Ref.

No.

E60

1

PART REMOVE

Side R P.C.B.

A B C D E F

How to read chart shown above:

A: Order of Procedure steps.

When reassembling, perform steps(s) in reverse order.

B: Ref No.

C: Part to be removed or installed.

D: Section No.

E: Identification of part to be removed, unhooked, unlocked,

released, unplugged, unclamped, or unsoldered.

3(404)= 3 Screws (404), 2(L-1) = 2 Looking Tabs (L-1)

F: Refer to "Notes in chart."

Section

No.

2(537), P6301

3

NOTE

10

LCD PORTION

STEP

No.

Ref.

No.

5

1

33

2

44

3

E40

4

34

5

-

6

35

PART REMOVE

LCD Protector

LCD Case A Unit

LCD Case B Unit

LCD Backlight

P.C.B.

LCD Case B

LCD Panel Ass'y

LCD Shield Case

A B C D E F

Section

No.

(533)

3

2(519), 8(L-1)

3

FP8101

3

(533), 3(L-3),

3

FP8102

3(L-2)

3

3(L-4)

3

NOTE

11

11

11

12

12

12

STEP

No.

Ref.

No.

42

1

39

2

37

3

38

4

40

5

41

6

36

7

PART REMOVE

LCD Panel

Reflect Sheet

Lead Light Panel

Diffusion Sheet

BEF Sheet

BEF Sheet A

Panel Holder Unit

Section

No.

3

3

3

3

3

3

3

-----

-----

-----

-----

-----

-----

-----

NOTE

13

13

13

13

13

13

13

A B C D E F

How to read chart shown above:

A: Order of Procedure steps.

When reassembling, perform steps(s) in reverse order.

B: Ref No.

C: Part to be removed or installed.

D: Section No.

E: Identification of part to be removed, unhooked, unlocked,

released, unplugged, unclamped, or unsoldered.

3(404)= 3 Screws (404), 2(L-1) = 2 Looking Tabs (L-1)

F: Refer to "Notes in chart."

21

VDR-D210P / VDR-D220P / VDR-D230P / VDR-D210PC / VDR-D220PC / VDR-D230PC

3

SIDE R OPERATION AND LCD SECTION

H

34

G

A

F

B

(L-4)

LCD Panel Ass'y

35

(L-2)

42

(L-2)

Note:

1. Parts with no Ref. No. in "EXPLODED VIEW" are not supplied.

And some Ref. No. will be skipped. Be sure to make your

orders of replacement parts according to the parts list.

2. The parts indicated by the dotted line are for Ass'y only

and are not supplied.

3. Disregard Ref. No. suffixes when ordering parts. They are used

to describe parts in "Disassembly and Assembly Instructions"

section.

44

36

(L-4)

(L-4)

41

40

38

37

(L-2)

E

39

FP8101

E40

(L-3)

(L-3)

D

5

A

(L-3)

FP8102

533

(L-1)

31

C

(L-1)

(L-1)

(L-1)

(L-1)

B

533

B

P6301

519

(L-1)

33

(L-1)

537

E60

519

(L-1)

537

A

43

1

2 3 4 5 6

22

Loading...

Loading...