Panasonic VBHN330SA16, VBHN325SA16 installation

VBHNxxxSA16 series

General Installation Manual

Photovoltaic Module HIT®

VBHNxxxSA16 series

Thank you for choosing Panasonic HIT®.

Please read this manual completely

before installation or use of Panasonic

PV(photovoltaic) modules. With proper

operation and maintenance, Panasonic

HIT® will provide you with clean,

renewable solar electricity for many

years. This manual contains important

installation, maintenance and safety

information. The word “module” as

used in this manual refers to one or

more PV modules. Retain this manual

for future reference. The module is

considered to be in compliance with UL

1703 only when the module is mounted

in the manner specified by the

mounting instructions below.

SANYO is part of the Panasonic Group

and is in charge of the manufacturing

process for Panasonic HIT®.

Model No.

VBHN330SA16 and 16B

VBHN325SA16 and 16B

1

Contents

Please read before installation

Safety Precautions

General Information :3

Warning :3

Cautions :3

General Safety :3

UL Listing Information :3

Installation

General :3

Notes on Installation :3

Operating Conditions :4

Special Conditions :5

Specifications

Note on Specifications :5

Mechanical Loading :5

Unpacking and handling :5

Wiring

General :5

Module Wiring :5

Array Wiring :5

Earth Ground Wiring :5

Grounding Locations :6

Grounding Methods :6

Module Terminations :7

Junction Box and Terminals :7

Conduit :7

Diodes :7

Maintenance :7

Disclaimer of Liability :7

Contact Information :7

“HIT” is a registered trademark of

Panasonic Group.

Other product and service names listed

in this manual are trademarks or

registered trademarks of their

respective companies.

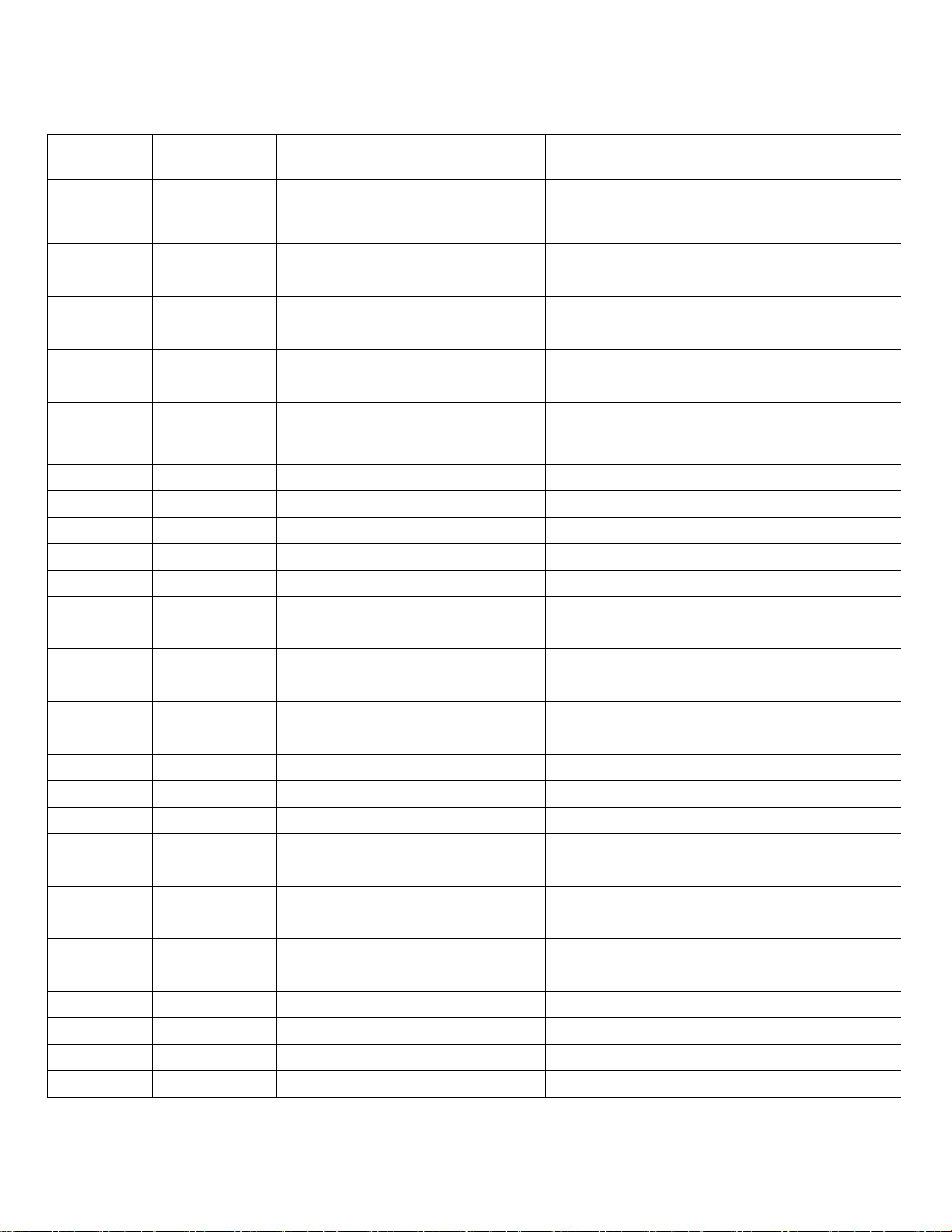

Edition

Revision

Date

Revised Item

Revised Content

New Edition

2016.2.10

2nd Edition

2016.3.17

Name change

・ Change from connection box to connection

devices

3rd Edition

2016.4.20

Changing installation condition

・Change from ambient to operating

・ Clearance between the roof surface and the

module

4th Edition

2016.11.18

・Addition of figures of clamps

・Addition of limitation of connectors

・Add the figures and requirement specification of

clamps

・Add the limitation of connectors

5th Edition

2017.3.6

・Changing inscription of installation

condition

・Addition of mounting method

・Change inscription of installation condition

・Add the mounting method of using a bolt and

nut

6th Edition

2017.9.20

・Change figure

・As for figure 2, 3-1, 4-2, the shape of the junction

box was changed.

2

Safety Precautions

General Information

The installation of solar modules requires a

great degree of skill and should only be

performed by qualified licensed professionals,

including, without limitation, licensed

contractors and electricians.

WARNING

All instructions should be read and

understood before attempting to install,

wire, operate, and maintain a

photovoltaic module.

Contact with electrically active parts of

the module such as terminals can result in

burns, sparks, and lethal shock whether

the module is connected or disconnected.

The installer assumes the risk of all injury

that might occur during installation,

including, without limitation, the risk of

electric shock.

The modules generate DC (direct current)

electrical energy when exposed to

sunlight or other light sources. Even a

single module produces enough voltage

and current, to cause shocks and burns if

safety precautions are not followed.

The shock hazard increases as modules

are connected in parallel, producing

higher current, and as modules are

connected in series, producing higher

voltages.

Do not hit the back sheet of a module by

the connector or other things.

To avoid the hazard of electric sparks,

shock, fire, burns, damage and injury:

Work only in dry conditions, with dry

modules and dry tools.

In order to avoid submerging cables and

connectors in the water, cables must be

fixed either to the module frame using

cable fixing holes or to the mounting

structure.

Do not stand or step on modules. Do not

puncture, cut, scratch or damage the

backsheet of a module. Backsheet

damage will void a module’s Limited

Warranty and may cause fire. Never use

modules with a damaged back sheet.

Do not allow children and unauthorized

persons near the installation or storage

site of modules.

Completely ground all modules.

Do not disassemble a module, attempt

any repair, open the junction box cover,

nor remove any parts installed by

Panasonic. There are no user serviceable

parts within the module or junction box.

Unauthorized persons - except the

qualified licensed professional - should

not perform any electrical work,

including wiring,

Wear suitable clothing, guards, eye

protection and gloves to prevent you

from direct contact with 30 VDC or

greater.

Wear non-slip gloves and carry modules

by the frame using both hands. Do not

attempt to carry a module by yourself.

Do not carry a module by its wires or

junction box.

Do not drop anything on the surface of a

module.

Ensure all system components are

compatible, and they do not subject the

module to mechanical or electrical

hazards.

Sparks may occur; do not install modules

where flammable gases or vapors are

present.

Never rest or leave a module unsupported

or unsecured.

Do not drop modules.

Do not use or install broken modules.

Do not artificially concentrate sunlight on

a module.

Do not touch the junction box terminals.

Do not change the wiring of bypass

diodes.

Do not touch a module unnecessarily. The

glass surface and frames get hot. There is

a risk of burn.

CAUTIONS

Use a module for its intended purpose

only.

Do not treat the back sheet, frame, or

front surface with paint or adhesives, to

avoid reducing its’ functionality, damage,

and causing inoperable conditions, and

other unknown troubles.

Do not insert PV cable between back side

and mounting structure rail.

GENERAL SAFETY

Follow all permissions, installation and

inspection requirements.

Before installing modules, contact the

appropriate authorities having jurisdiction

to determine permissions, installation and

inspection requirements, which should be

followed.

Electrically ground modules for all systems

of any voltage. If not otherwise specified,

it is recommended that requirements of

the latest National Electrical Code (USA)

or Canadian Electric Code (Canada) or

other national or international electrical

standards be followed. Refer to “Earth

Ground Wiring” section for more

information.

Be sure that the building or structure

(roof, façade, etc.) where the modules are

being installed has enough strength to

support the load of the modules.

For modules mounted on roofs, special

structures may be required to help

provide proper installation support.

The fire rating of this module is valid only

when mounted in the manner specified in

the mechanical mounting instructions.

Both, roof construction and module

installation design have an effect on the

fire resistance of a building. Improper

installation may contribute to fire hazards.

The models in this instructions are suitable

to maintain the System Fire Class Rating A

when used with a Listed mounting system

and a roof covering that have been rated

as a Class A System when installed on a

steep slope roof and/or a low slope roof

with "Type 2" modules.

Additional devices such as ground fault,

fuses, and disconnects may be required.

Do not use modules of different

specifications in the same system.

Follow all safety precautions of other

system components which are used.

UL Listing Information

To satisfy UL requirements, when installing

the modules, be sure to:

1) Use only stranded or solid copper single–

conductor sunlight-resistant cable rated

for outdoor use (e.g. type UF or USE) , for

all wiring that is exposed to weather.

2) Observe the requirements described in

sections labeled INSTALLATION and

SPECIFICATIONS.

INSTALLATION

General

Please read this guide completely before

installing or using your Panasonic PV modules.

This section contains important electrical and

mechanical specifications.

Modules should be firmly fixed in place in

a manner suitable to withstand all

expected loads, including wind and snow

loads.

Metals used in locations that are exposed

to moisture shall not be employed alone

or in combinations that could result in

deterioration or corrosion.

Install modules where they are not

shaded by obstacles like buildings and

trees. Pay special attention to avoid

partially shading the modules by objects

during the daytime.

If needed, contact an Authorized

Representative with questions regarding

mounting profiles for Panasonic HIT®.

Notes on Installation

Clearance between the roof surface and

module frame is required to allow cooling

air to circulate around the back of the

module. This also allows any condensation

or moisture to dissipate. The required

clearance between the roof surface and

the module is more than 4 inch.

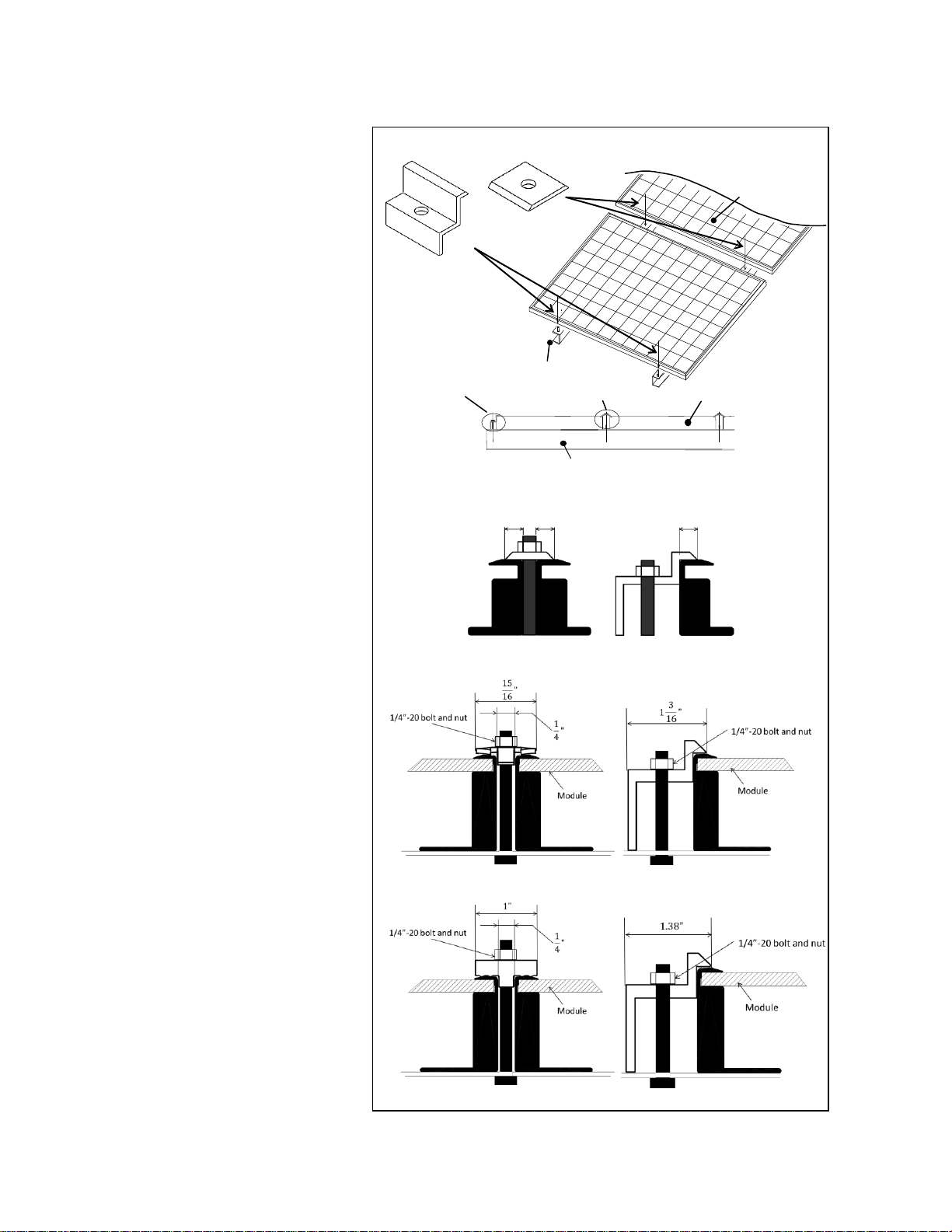

Panasonic recommends the installation

method and mounting profile shown in

Figure 1-1 and Figure 1-2.

Figure 1-1 shows that a module should be

attached on a mount or support structure

rail by corrosive-resistant metal clamps.

3

Installation (reference)

Figure 1-1. Installation

<Unirac clamps>

Mid clamp

End clamp

Grounding Mid clamp

End clamp

<Ironridge clamps>

Solar Module

Mid Clamp

(2 places)

End Clamp

(2 places)

Mounting

Structure Rail

Mid Clamp

Solar Module

End Clamp

Mounting Structure

Rail

<Cross section of clamps>

Overlap range ≧ 0.24” (6mm)

Mid clamp

End clamp

The clamps should be made of aluminum

alloy or other material that will

reasonably protect against a risk of

electrolytic corrosion.

Figure 1-2 shows using a bolt and nut for

mounting.

Recommendation of bolt torque: 10 ft-lbs.

The module was tested using Unirac or

IronRidge clamps with the specifications

see figure 1-1 and below;

1) Unirac clamps:

Provider: Unirac, Inc.

Product Line: SolarMount

Clamps type: Top Mounting Clamps

(Mid clamp and End clamp)

Unirac Part No. 302022C, 302022D,

302027C, 302027D

Width: Mid clamp; 1.5”(38 mm), End

clamp; 1.9”(48 mm)

Thickness: Mid clamp; Nominal

thickness 0.075”(1.9mm), End clamp;

Nominal thickness 0.125”(3.17mm)

Torque: 13.6 N.m(10 ft-lbs).

Material: Mid clamp; 300 Stainless

steel, End clamp; 6000 Aluminum

alloys

Note: Please refer to Unirac manual,

for installation method.

2) IronRidge clamps:

Provider: IronRidge Inc.

Product Line: RoofMount

Clamps type: Top Mounting Clamps

(Grounding mid clamp and End

clamp)

IronRidge Part No. RS-GD-MCL-225,

RS-GD-MCL-225B, 29-7000-224, 297000-224B

Width: Grounding mid clamp;

1.16”(29.5 mm), End clamp; 1.5”(38

mm)

Thickness: Grounding mid clamp;

Nominal thickness 0.11”(2.85mm),

End clamp; Nominal thickness

0.125”(3.17mm)

Torque: 9.5 N.m (85 in-lbs).

Material: Grounding mid clamp; 304

Stainless steel, End clamp; 5000 &

6000 Aluminum alloys

Note: Please refer to IronRidge

manual, for installation method.

Panasonic does not provide a warranty

for clamps. The module warranty

Panasonic provides shall be voided if

clamps selected by the customer are of an

improper material or size

Operating Conditions

Panasonic requires that modules are operated

within the following Operating Conditions:

1) Terrestrial applications only-no outer

space or Special Conditions (see below).

2) The operating temperature must be

within –40°C (-40 °F) to 85°C (185 °F).

3) The wind pressure load of the installation

site should be less than 2,400N/m2

(50PSF)

4

Loading...

Loading...