Page 1

INSTALLATION INSTRUCTIONS

3WAY VRF System Air Conditioner

This air conditioner uses the refrigerant R410A.

NOTE

External diameter of service port R410A: 5/16"

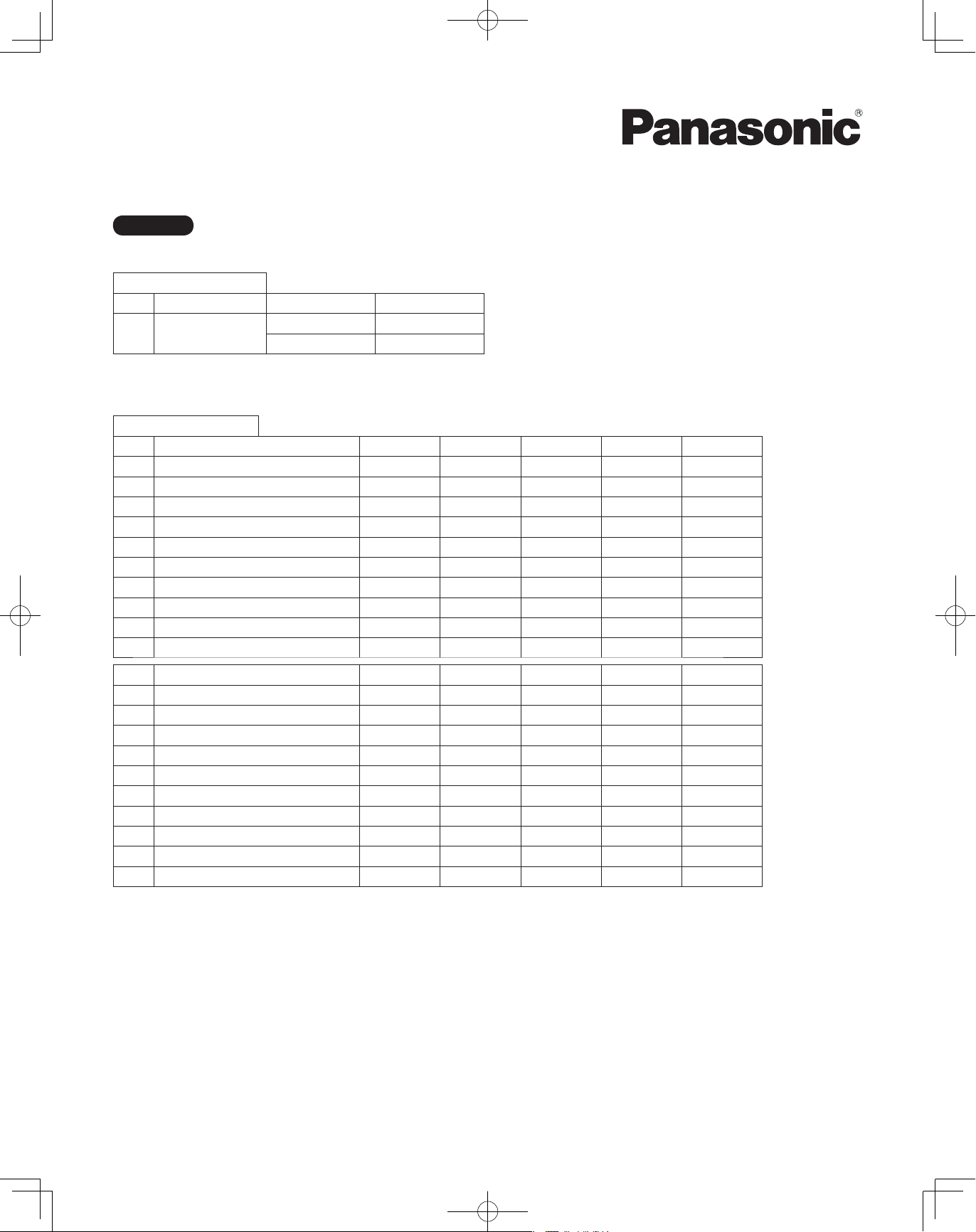

Model No.

Outdoor Units

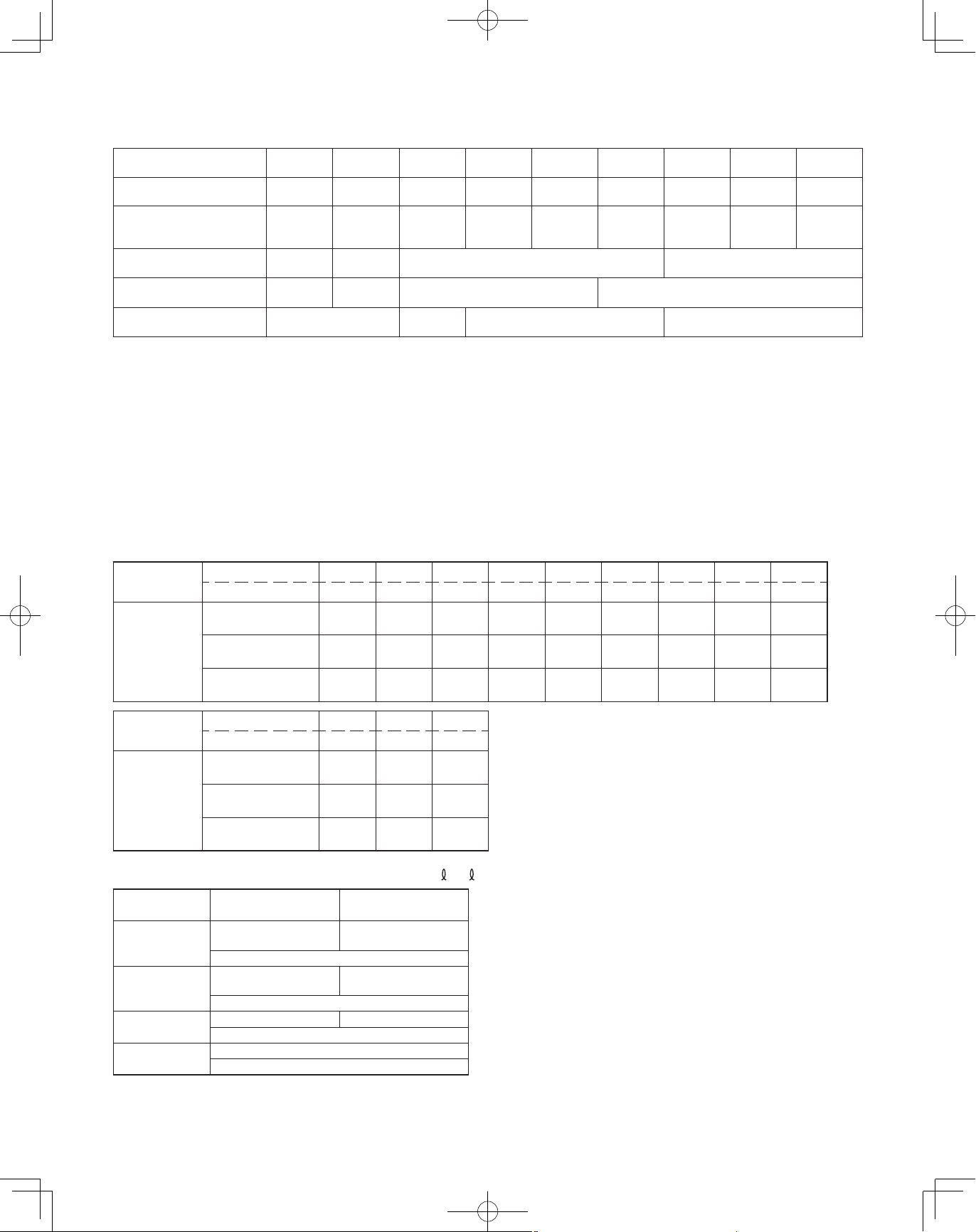

Type Outdoor Unit Type 72 96

U 3WAY VRF System

* Salt-Air Damage Resistant Specifi cations.

Indoor Units

Type Indoor Unit Type 7 9 12 15 18

D1 1-Way Cassette S-07MD1U6 S-09MD1U6 S-12MD1U6

U1 4-Way Cassette S-12MU1U6 S-18MU1U6

Y1 4-Way Cassette 60 × 60 S-12MY1U6 S-18MY1U6

K1 Wall Mounted S-07MK1U6 S-09MK1U6 S-12MK1U6 S-18MK1U6

T1 Ceiling S-12MT1U6 S-18MT1U6

F1 Low Silhouette Ducted S-07MF1U6 S-09MF1U6 S-12MF1U6 S-15MF1U6 S-18MF1U6

M1 Slim Low Static Ducted S-07MM1U6 S-09MM1U6 S-12MM1U6 S-15MM1U6 S-18MM1U6

E1 High Static Pressure Ducted

P1 Floor Standing S-07MP1U6 S-09MP1U6 S-12MP1U6 S-15MP1U6 S-18MP1U6

R1 Concealed Floor Standing S-07MR1U6 S-09MR1U6 S-12MR1U6 S-15MR1U6 S-18MR1U6

U-72MF1U9 U-96MF1U9

U-72MF1U9E* U-96MF1U9E*

Type Indoor Unit Type 19 24 36 48 54

D1 1-Way Cassette

U1 4-Way Cassette S-24MU1U6 S-36MU1U6

Y1 4-Way Cassette 60 × 60

K1 Wall Mounted S-19MS1U6*

T1 Ceiling S-24MT1U6

F1 Low Silhouette Ducted S-24MF1U6 S-36MF1U6 S-48MF1U6 S-54MF1U6

M1 Slim Low Static Ducted

E1 High Static Pressure Ducted S-36ME1U6 S-48ME1U6

P1 Floor Standing S-24MP1U6

R1 Concealed Floor Standing S-24MR1U6

1

S-24MK1U6

*1 Necessary to install the External Electronic Expansion Valve Kit (Optional : CZ-P56SVK1U)

85464369528012 CV6233186887

W-3WAYECO-iU.indbaW-3WAYECO-iU.indba 2011/11/0716:29:282011/11/0716:29:28

Page 2

IMPORTANT!

Please Read Before Starting

This air conditioning system meets strict safety and

operating standards. As the installer or service person, it

is an important part of your job to install or service the

system so it operates safely and effi ciently.

For safe installation and trouble-free operation, you

must:

Carefully read this instruction booklet before beginning.

●

Follow each installation or repair step exactly as shown.

●

Observe all local, state, and national electrical codes.

●

Pay close attention to all warning and caution notices

●

given in this manual.

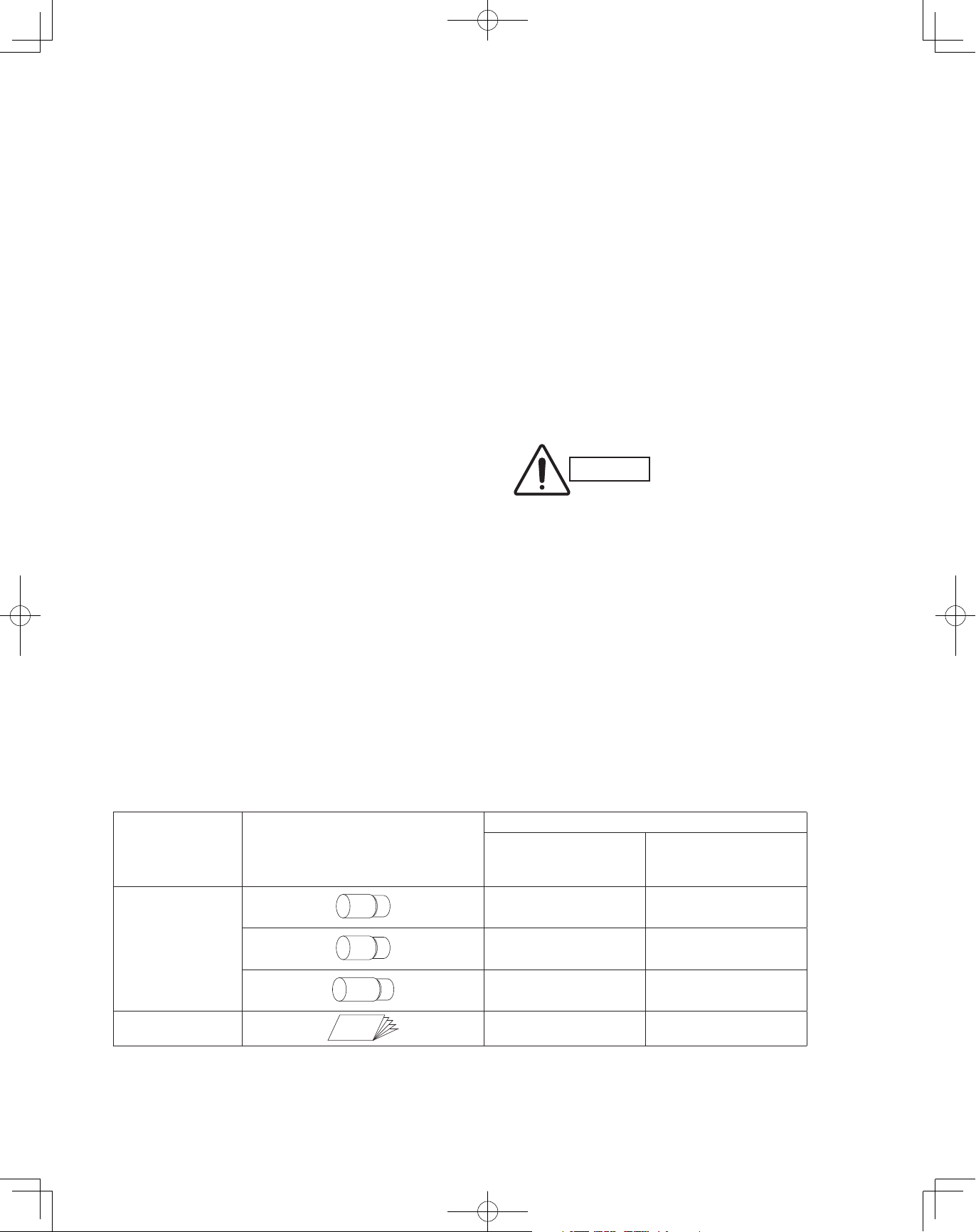

This symbol refers to a hazard or

WARNING

CAUTION

If Necessary, Get Help

These instructions are all you need for most installation

sites and maintenance conditions. If you require help for a

special problem, contact our sales/service outlet or your

certifi ed dealer for additional instructions.

In Case of Improper Installation

The manufacturer shall in no way be responsible for

improper installation or maintenance service, including

failure to follow the instructions in this document.

SPECIAL PRECAUTIONS

WARNING

Do not supply power to the unit until all wiring and tubing •

are completed or reconnected and checked.

Highly dangerous electrical voltages are used in this •

system. Carefully refer to the wiring diagram and these

instructions when wiring. Improper connections and

inadequate grounding can cause accidental injury or

death.

Ground the unit• following local electrical codes.

Connect all wiring tightly. Loose wiring may cause •

overheating at connection points and a possible fi re

hazard.

To prevent possible hazards from insulation failure, •

the unit must be grounded.

When Transporting

Be careful when picking up and moving the indoor and

outdoor units. Get a partner to help, and bend your knees

when lifting to reduce strain on your back. Sharp edges or

When Wiring

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH.

ONLY A QUALIFIED, EXPERIENCED

ELECTRICIAN SHOULD ATTEMPT TO

WIRE THIS SYSTEM.

unsafe practice which can result

in severe personal injury or death.

This symbol refers to a hazard or

unsafe practice which can result

in personal injury or product or

property damage.

thin aluminum fi ns on the air conditioner can cut your

fi ngers.

When Installing…

Select an installation location which is rigid and strong

enough to support or hold the unit, and select a location

for easy maintenance.

…In a Room

Properly insulate any tubing run inside a room to prevent

“sweating” that can cause dripping and water damage to

walls and fl oors.

Keep the fi re alarm and the air

CAUTION

…In Moist or Uneven Locations

Use a raised concrete pad or concrete blocks to provide a

solid, level foundation for the outdoor unit. This prevents

water damage and abnormal vibration.

…In an Area with High Winds

Securely anchor the outdoor unit down with bolts and a

metal frame. Provide a suitable air baffl e.

…In a Snowy Area (for Heat Pump-type Systems)

Install the outdoor unit on a raised platform that is higher

than drifting snow. Provide snow vents.

outlet at least 5 feet away from the

unit.

When Connecting Refrigerant Tubing

Ventilate the room well, in the event that is refrigerant •

gas leaks during the installation. Be careful not to allow

contact of the refrigerant gas with a fl ame as this will

cause the generation of poisonous gas.

Keep all tubing runs as short as possible.•

Use the fl are method for connecting tubing.•

Apply refrigerant lubricant to the matching surfaces of •

the fl are and union tubes before connecting them, then

tighten the nut with a torque wrench for a leak-free

connection.

Check carefully for leaks before starting the test run.•

When performing piping work do •

not mix air except for specifIed

refrigerant (R410A) in refrigeration

cycle. It causes capacity down,

and risk of explosion and injury

due to high tension inside the

WARNING

Do not leak refrigerant while piping work for an •

installation or re-installation, and while repairing

refrigeration parts.

Handle liquid refrigerant carefully as it may cause

frostbite.

refrigerant cycle.

Refrigerant gas leakage may •

cause fi re.

Do not add or replace refrigerant •

other than specifi ed type. It may

cause product damage, burst and

injury etc.

2

W-3WAYECO-iU.indb2W-3WAYECO-iU.indb2 2011/11/0716:29:292011/11/0716:29:29

Page 3

When Servicing

Turn the power OFF at the main power box (mains) •

before opening the unit to check or repair electrical

parts and wiring.

Keep your fi ngers and clothing away from any moving •

parts.

Clean up the site after you fi nish, remembering to check •

that no metal scraps or bits of wiring have been left

inside the unit being serviced.

WARNING

Do not clean inside the indoor and •

outdoor units by users. Engage

authorized dealer or specialist for

cleaning.

In case of malfunction of this •

appliance, do not repair by yourself.

Contact to the sales dealer or service

dealer for a repair.

Others

CAUTION

CAUTION

Do not touch the air inlet or the •

sharp aluminum fi ns of the

outdoor unit. You may get injured.

Ventilate any enclosed areas when •

installing or testing the refrigeration

system. Escaped refrigerant gas, on

contact with fi re or heat, can produce

dangerously toxic gas.

Confi rm after installation that no •

refrigerant gas is leaking. If the gas

comes in contact with a burning stove,

gas water heater, electric room heater

or other heat source, it can cause the

generation of poisonous gas.

Do not touch the air inlet or the •

sharp aluminum fi ns of the

outdoor unit. You may get injured.

Do not sit or step on the unit, •

you may fall down accidentally.

Do not stick any object into the •

FAN CASE.

You may be injured and the unit

may be damaged.

Check of Density Limit

The room in which the air conditioner is to be

installed requires a design that in the event of

refrigerant gas leaking out, its density will not

exceed a set limit.

The refrigerant (R410A), which is used in the air

conditioner, is safe, without the toxicity or combustibility

of ammonia, and is not restricted by laws imposed to

protect the ozone layer. However, since it contains more

than air, it poses the risk of suffocation if its density

should rise excessively. Suffocation from leakage of

refrigerant is almost non-existent.

With the recent increase in the number of high density

buildings, however, the installation of multi air

conditioner systems is on the increase because of the

need for effective use of fl oor space, individual control,

energy conservation by curtailing heat and carrying

power, etc.

Most importantly, the multi air conditioner system is able

to replenish a large amount of refrigerant compared to

conventional individual air conditioners. If a single unit of

the multi air conditioner system is to be installed in a

small room, select a suitable model and installation

procedure so that if the refrigerant accidentally leaks

out, its density does not reach the limit (and in the event

of an emergency, measures can be made before injury

can occur).

ASHRAE and the International Mechanical Code of the

ICC as well as CSA provide guidance and defi ne

safeguards related to the use of refrigerants, all of which

defi ne a Refrigerant Concentration Level (RCL) of 25

pounds per 1,000 cubic feet for R410A refrigerant.

For additional guidance and precautions related to

refrigerant safety, please refer to the following

documents:

International Mechanical Code 2009 (IMC-2009)

(or more recently revised)

ASHRAE 15

ASHRAE 34

3

W-3WAYECO-iU.indb3W-3WAYECO-iU.indb3 2011/11/0716:29:292011/11/0716:29:29

Page 4

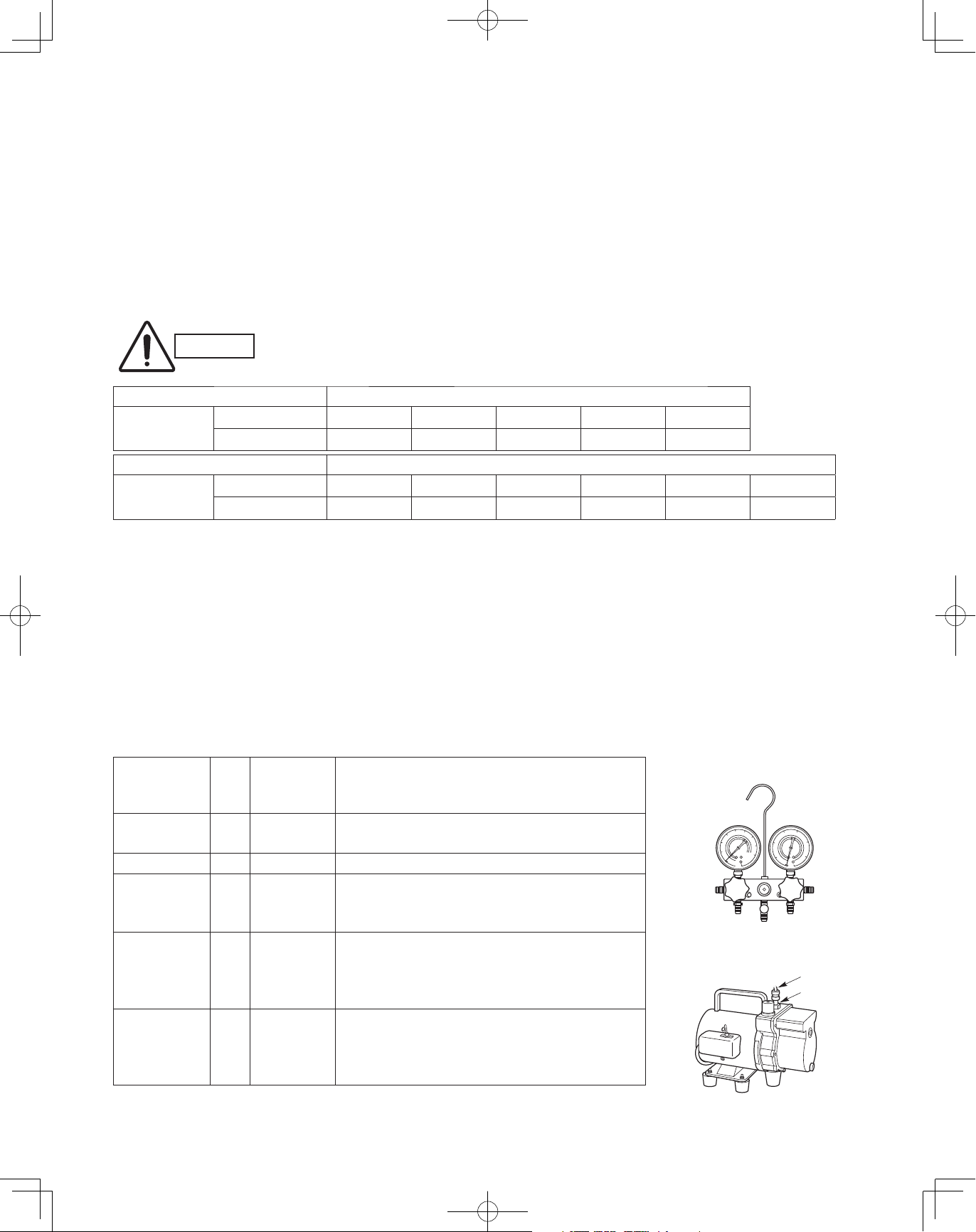

Precautions for Installation Using New Refrigerant

CAUTION

1. Care regarding tubing

1-1. Process tubing

● Material: Use C1220 phosphorous deoxidized copper specified in JIS H3300 “Copper and Copper Alloy Seamless

Pipes and Tubes.”

For tubes of ø7/8" (ø22.22 mm) or larger, use C1220 T-1/2H material or H material, and do not bend the tubes.

● Tubing size: Be sure to use the sizes indicated in the table below.

● Use a tube cutter when cutting the tubing, and be sure to remove any flash. This also applies to distribution joints

(optional).

● When bending tubing, use a bending radius that is 4 times the outer diameter of the tubing or larger.

Use suffi cient care in handling the tubing. Seal the tubing ends with caps or tape to

prevent dirt, moisture, or other foreign substances from entering. These substances

Copper tube

Copper tube

can result in system malfunction.

Material O

Outer diameter 1/4 (6.35) 3/8 (9.52) 1/2 (12.7) 5/8 (15.88) 3/4 (19.05)

Wall thickness 1/32 (0.8) 1/32 (0.8) 1/32 (0.8) 5/128 (1.0)

Material 1/2 H, H

Outer diameter

Wall thickness

7/8 (22.22) 1 (25.4) 1-1/8 (28.58) 1-1/4 (31.75) 1-1/2 (38.1) 1-5/8 (41.28)

5/128 (1.0) 5/128 (1.0) 5/128 (1.0) 3/64 (1.1)

Unit: in. (mm)

over 5/128 (1.0)

over 3/64 (1.15) over 3/64 (1.20)

Unit: in. (mm)

1-2. Prevent impurities including water, dust and oxide from entering the tubing. Impurities can cause R410A

refrigerant deterioration and compressor defects. Due to the features of the refrigerant and refrigerating machine

oil, the prevention of water and other impurities becomes more important than ever.

2. Be sure to recharge the refrigerant only in liquid form.

2-1. Since R410A is a non-azeotrope, recharging the refrigerant in gas form can lower performance and cause defects

in the unit.

2-2. Since refrigerant composition changes and performance decreases when gas leaks, collect the remaining

refrigerant and recharge the required total amount of new refrigerant after fixing the leak.

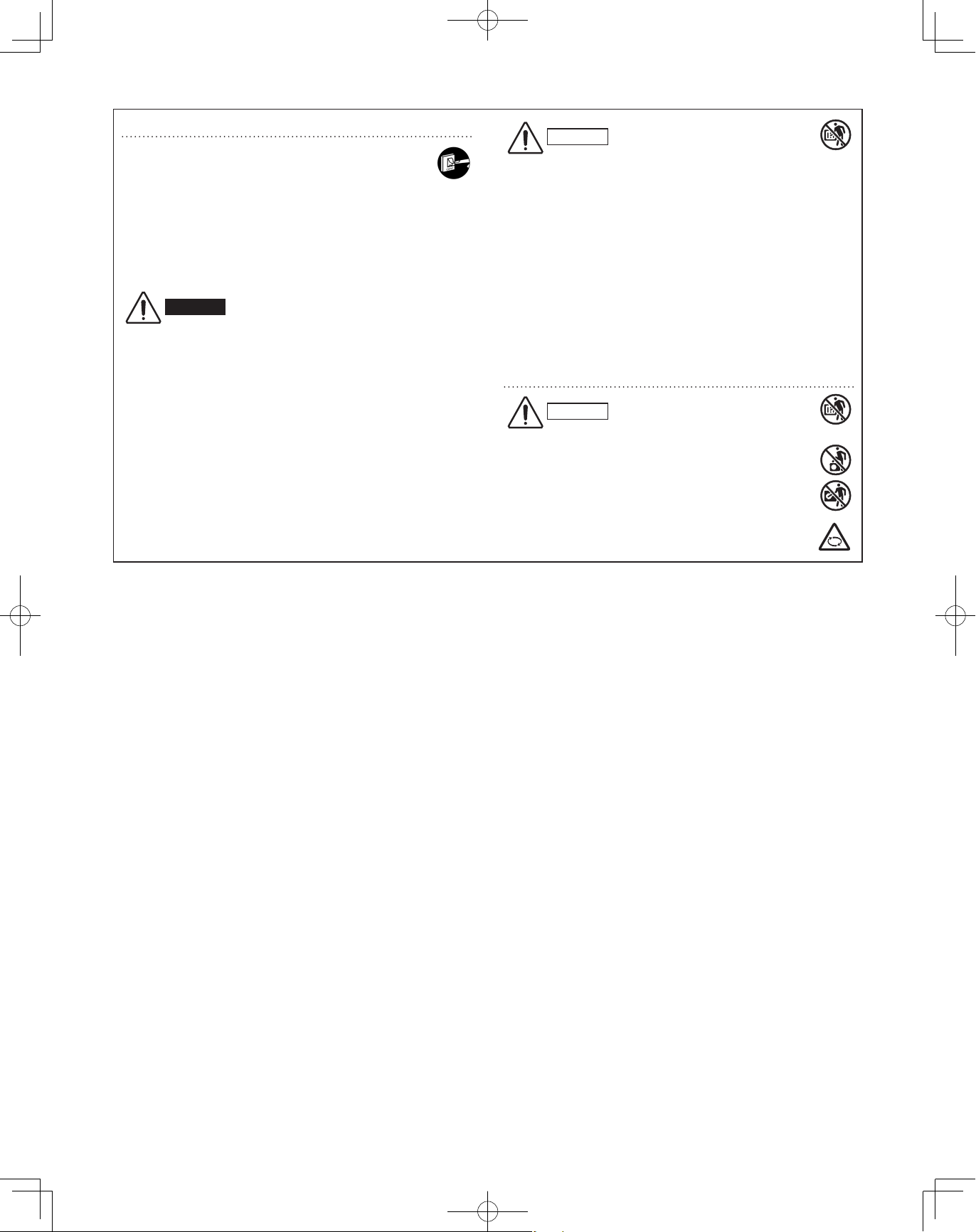

3. Different tools required

3-1. Tool specifications have been changed due to the characteristics of R410A.

Some tools for R22- and R407C-type refrigerant systems cannot be used.

R407C tools

New

Item

Manifold gauge Yes No Types of refrigerant, refrigerating machine oil, and

Charge hose Yes No To resist higher pressure, material must be changed.

Vacuum pump Yes Yes Use a conventional vacuum pump if it is equipped

Leak detector Yes No Leak detectors for CFC and HCFC that react to

Flaring oil Yes No For systems that use R22, apply mineral oil (Suniso

* Using tools for R22 and R407C and new tools for R410A together can cause defects.

tool?

compatible

with R410A?

pressure gauge are different.

with a check valve. If it has no check valve,

purchase and attach a vacuum pump adapter.

chlorine do not function because R410A contains no

chlorine. Leak detector for HFC134a can be used for

R410A.

oil) to the flare nuts on the tubing to prevent

refrigerant leakage. For machines that use R407C or

R410A, apply synthetic oil (ether oil) to the flare nuts.

Remarks

Manifold gauge

Vacuum pump

Outlet

Inlet

4

W-3WAYECO-iU.indb4W-3WAYECO-iU.indb4 2011/11/0716:29:292011/11/0716:29:29

Page 5

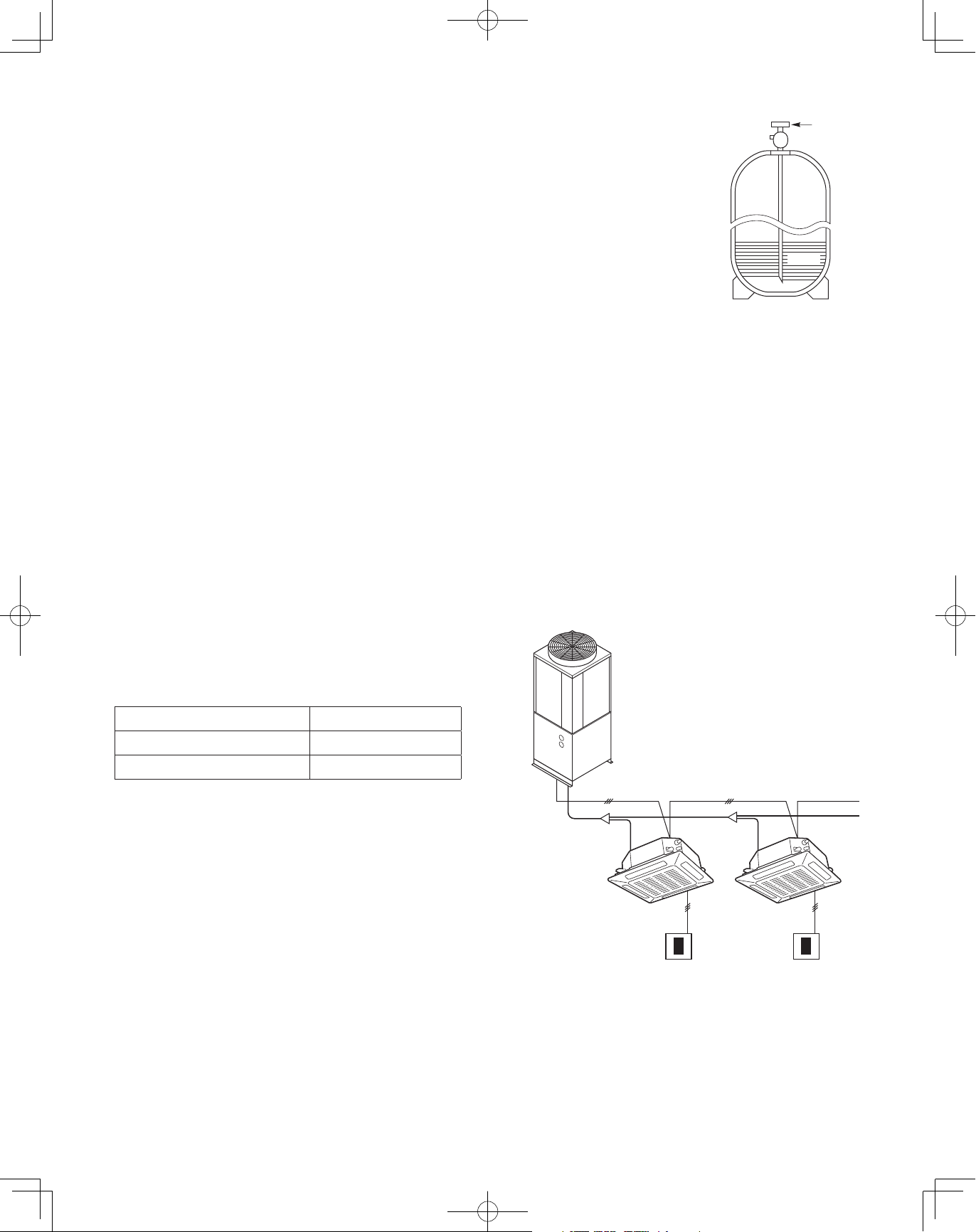

3-2. Use R410A exclusive cylinder only.

New refrigerant R410A cannot be used for

earlier models

1. Compressor specifications are different.

If recharging a R22 or R407C compressor with R410A,

durability will significantly decrease since some of the

materials used for compressor parts are different.

2. Existing tubing cannot be used (especially R22).

Completely cleaning out residual refrigerating

machine oil is impossible, even by flushing.

Valve

Single-outlet valve

(with siphon tube)

Liquid refrigerant should be recharged

with the cylinder standing on end as

shown.

Liquid

3. Refrigerating machine oil differs (R22).

Since R22 refrigerating machine oil is mineral oil, it

does not dissolve in R410A. Therefore, refrigerating

machine oil discharged from the compressor can cause

compressor damage.

R22 refrigerating machine oil Mineral oil (Suniso oil)

R407C refrigerating machine oil Synthetic fluid (ether oil)

R410A refrigerating machine oil Synthetic fluid (ether oil)

5

W-3WAYECO-iU.indb5W-3WAYECO-iU.indb5 2011/11/0716:29:292011/11/0716:29:29

Page 6

CONTENTS

Page Page

IMPORTANT! ............................................................... 2

Please Read Before Starting

Check of Density Limit

Precautions for Installation Using New Refrigerant

New refrigerant R410A cannot be used for earlier models

1. GENERAL ............................................................... 7

1-1. Tools Required for Installation (not supplied)

1-2. Accessories Supplied

1-3. Type of Copper Tube and Insulation Material

1-4. Additional Materials Required for Installation

1-5. Tubing Length

1-6. Tubing Size

1-7. Straight Equivalent Length of Joints

1-8. Additional Refrigerant Charge

1-9. System Limitations

1-10. Installation Standards

1-11. Check of Limit Density

1-12. Installing Distribution Joint

1-13. Optional Distribution Joint Kits

1-14. Optional Solenoid Valve Kit

1-15. Example of Tubing Size Selection and

Refrigerant Charge Amount

2. SELECTING THE INSTALLATION SITE ............. 20

2-1. Outdoor Unit

2-2. Removing Fin Guard for Heat Exchanger

2-3. Shield for Horizontal Exhaust Discharge

2-4. Installing the Outdoor Unit in Heavy Snow

Areas

2-5. Precautions When Installing in Heavy Snow

Areas

2-6. Dimensions of Wind Ducting

2-7. Dimensions of Snow Ducting

5. HOW TO PROCESS TUBING .............................. 32

5-1. Connecting the Refrigerant Tubing

5-2. Connecting Tubing Between Indoor and

Outdoor Units

5-3. Insulating the Refrigerant Tubing

5-4. Taping the Tubes

5-5. Finishing the Installation

6. AIR PURGING ...................................................... 36

■ Air Purging with a Vacuum Pump (for Test Run)

Preparation

7. TEST RUN ............................................................ 39

7-1. Preparing for Test Run

7-2. Test Run Procedure

7-3. Main Outdoor Unit PCB Setting

7-4. Auto Address Setting

7-5. Remote Controller Test Run Settings

7-6. Caution for Pump Down

7-7. Meaning of Alarm Messages

3. HOW TO INSTALL THE OUTDOOR UNIT .............. 24

3-1. Transporting

3-2. Installing the Outdoor Unit

3-3. Remove the Brackets Used for Transport

3-4. Routing the Tubing

3-5. Prepare the Tubing

3-6. Connect the Tubing

4. ELECTRICAL WIRING ......................................... 28

4-1. General Precautions on Wiring

4-2. Recommended Wire Length and Wire

Diameter for Power Supply System

4-3. Wiring System Diagram

6

W-3WAYECO-iU.indb6W-3WAYECO-iU.indb6 2011/11/0716:29:292011/11/0716:29:29

Page 7

1. GENERAL

CAUTION

This booklet briefly outlines where and how to install the air conditioning system. Please read over the entire set of instructions for

the outdoor unit and make sure all accessory parts listed are with the system before beginning.

1-1. Tools Required for Installation (not supplied)

1. Flathead screwdriver

2. Phillips head screwdriver

3. Knife or wire stripper

4. Tape measure

5. Level gauge

6. Sabre saw or key hole saw

7. Hacksaw

8. Core bits

9. Hammer

10. Drill

11. Tube cutter

12. Tube flaring tool

13. Torque wrench

14. Adjustable wrench

15. Reamer (for deburring)

1-2. Accessories Supplied

See Table 1-1.

1-3. Type of Copper Tube and Insulation Material

If you wish to purchase these materials separately from a local

source, you will need:

1. Deoxidized annealed copper tube for refrigerant tubing.

2. Foamed polyethylene insulation for copper tubes as

required to precise length of tubing. Wall thickness of the

insulation should be not less than 5/16".

3. Use insulated copper wire for field wiring. Wire size varies

with the total length of wiring.

“

Refer to

4. ELECTRICAL WIRING” for details.

Check local electrical codes and

regulations before obtaining

wire. Also, check any specifi ed

instructions or limitations.

1-4. Additional Materials Required for Installation

1. Refrigeration (armored) tape

2. Insulated staples or clamps for connecting wire

(See your local codes.)

3. Putty

4. Refrigeration tubing lubricant

5. Clamps or saddles to secure refrigerant tubing

6. Scale for weighing

Table 1-1 Outdoor Unit

Q’ty

Part name Figure

U-72MF1U9

U-72MF1U9E

(6 ton)

Connection tubing

Instruction manual

Outer

diameter

ø1-1/8"(ø28.58)

Outer

diameter

ø7/8"(ø22.22)

Outer

diameter

ø3/4"(ø19.05)

Inner

diameter

ø3/4"(ø19.05)

Inner

diameter

ø3/4"(ø19.05)

Inner

diameter

ø5/8"(ø15.88)

paper

01

11

01

11

7

W-3WAYECO-iU.indb7W-3WAYECO-iU.indb7 2011/11/0716:29:292011/11/0716:29:29

U-96MF1U9

U-96MF1U9E

(8 ton)

Page 8

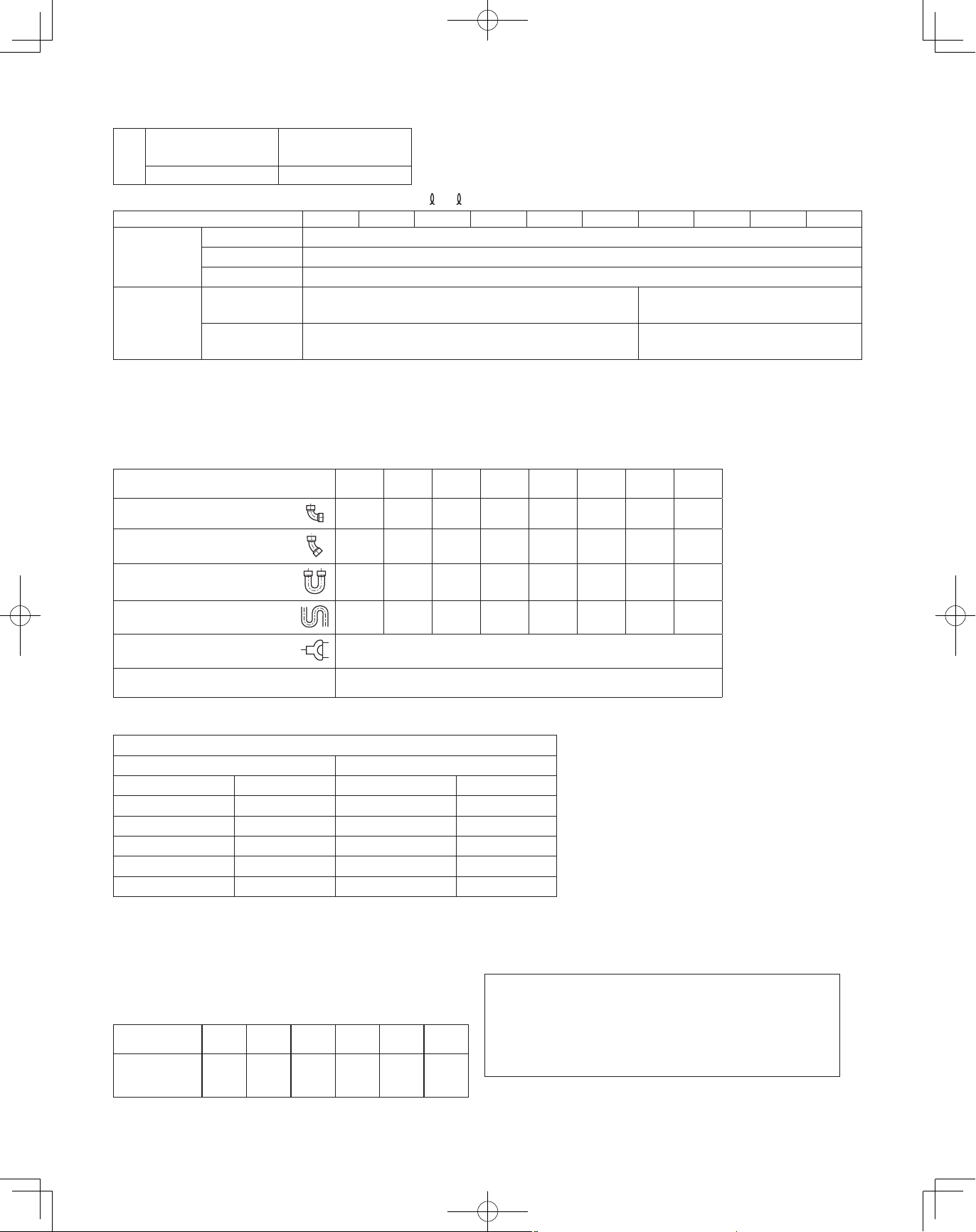

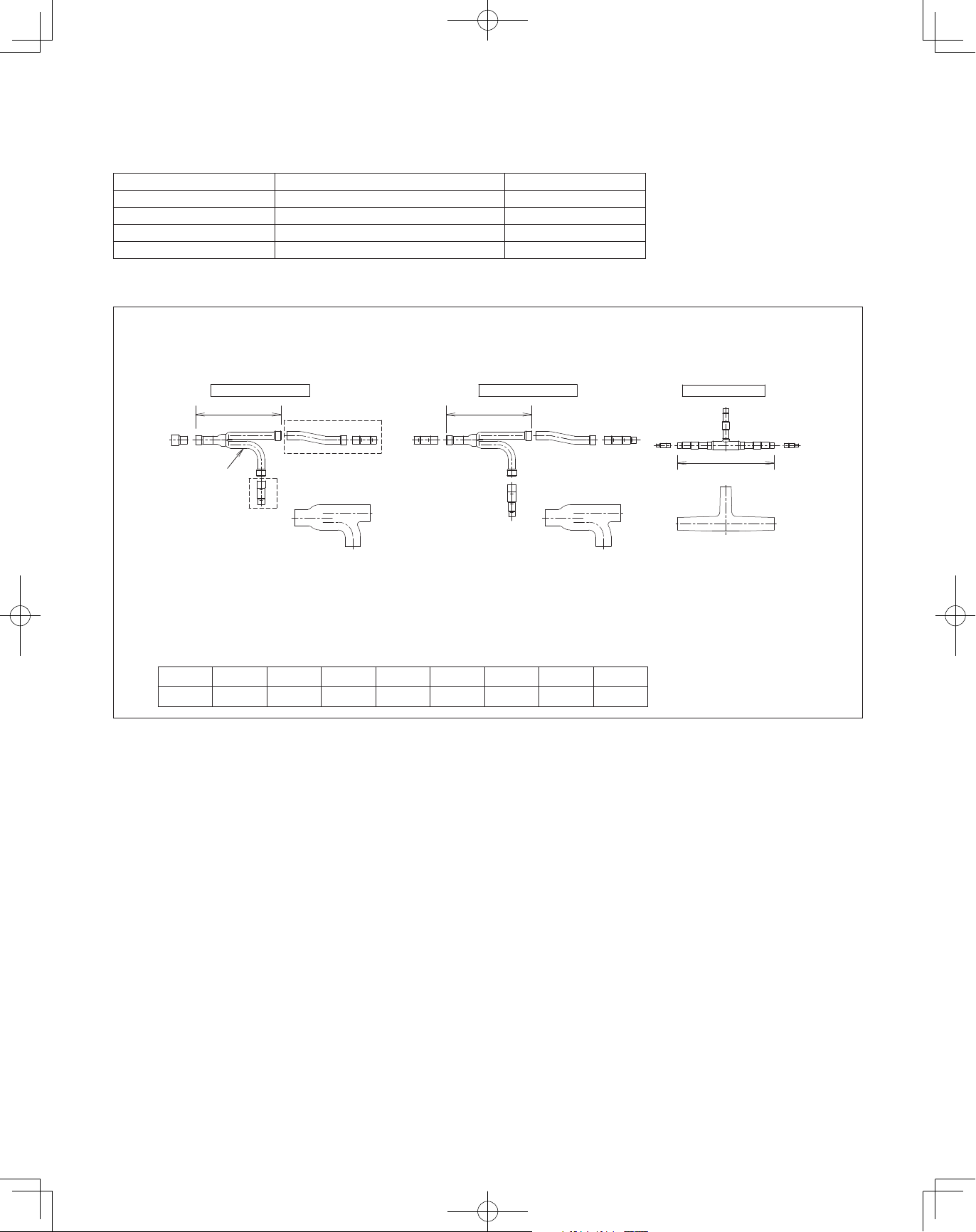

1-5. Tubing Length

Select the installation location so that the length and size of refrigerant tubing are within the allowable range shown in

the fi gure below.

1. Main tubing length LM = LA + LB … b 262 ft

2. Main distribution tubes LC – LH are selected according to the capacity after the

3. The outdoor connection main tubing (LO portion) is determined by the total capacity of the

outdoor units that are connected to the tube ends.

4. Sizes of indoor unit connection tubing

distribution joint.

1 – 40 are determined by the connection

tubing sizes on the indoor units.

L5

H3

C

LM

Balance tubing

3/8"

)

(ø

Explanation of symbols

Distribution joint

(purchased separately)

Ball valve (field supply)

T-joint (field supply)

Solidly welded shut

(pinch weld)

Note: Do not use commercially available T-joints for the liquid tubing

* Be sure to use special R410A distribution joints (CZ: purchased separately) for outdoor

unit connections and tubing branches.

LO

AB

LA

LF

LB LC

Max.

1.3 ft

1.3 ft

Max.

LG

L4

For

extension

For

extension

LD

4

LH

1

L1

L2

LE L3

5

2

and parts.

T-joint tubing

(header joint system)

6

3

7

Solenoid valve kit

R410A distribution joint

CZ-P900PH1U (for outdoor unit)

CZ-P224BH1U (for indoor unit)

CZ-P680BH1U (for indoor unit)

CZ-P1350BH1U (for indoor unit)

40

H1

H2

Table 1-2 Ranges that Apply to Refrigerant Tubing Lengths and to Differences in Installation Heights

Item Mark Contents Length (ft.)

Allowable

tubinglength

Allowable

elevationdifference

Allowable length of

joint tubing

L = Length, H = Height

L1 Max. tubing length

ΔL (L2 – L4)

Difference between max. length and min. length from

the No. 1 distribution joint

LM Max. length of main tubing (at max. diameter)

1, 2... 40

1+ 2... 40+

L1+

A+ B+LF+LG+LH

Max. length of each distribution tube

Total max. tubing length including length of each

distribution tube (only liquid tubing)

L5 Distance between outdoor units

H1 When outdoor unit is installed higher than indoor unit

When outdoor unit is installed lower than indoor unit

H2 Max. difference between indoor units

H3 Max. difference between outdoor units

L3

T-joint tubing (fi eld-supply); Max. tubing length between

the fi rst T-joint and solidly welded-shut end point

Actual length

Equivalent length

≤ 492

≤ 574

≤ 131

≤ 262*²

≤ 98

≤ 984

≤ 32

≤ 164

≤ 131

≤ 49

≤ 13

≤ 6.6

NOTE

1: The outdoor connection main tubing (LO portion) is determined by the total capacity of the outdoor units that are

connected to the tube ends.

2: If the longest tubing length (L1) exceeds 295 ft. (equivalent length), increase the sizes of the main tubes (LM) by 1

rank for the discharge tubes, suction tubes, and narrow tubes. (fi eld supplied)

3: If the longest main tube length (LM) exceeds 164 feet, increase the main tube size at the portion before 164 ft. by 1

rank for the suction tubes and discharge tubes. (fi eld supplied)

(For the portion that exceeds 164 feet, set based on the main tube sizes (LA) listed in the table on the following page.)

8

W-3WAYECO-iU.indb8W-3WAYECO-iU.indb8 2011/11/0716:29:302011/11/0716:29:30

Page 9

1-6. Tubing Size

Table 1-3 Main Tubing Size (LA)

BTU/h (kW)

Total system tonnage 6 8 12 14 16 18 20 22 24

Combined outdoor models

Suction tubing

Discharge tubing

Liquid tubing

72,000

(21.1)

U-72MF1U9(E) U-96MF1U9(E) U-72MF1U9(E)

ø3/4"

(ø19.05)

ø5/8"

(ø15.88)

*1: If future extension is planned, select the tubing diameter based on the total tonnage after extension.

However extension is not possible if the resulting tubing size is two ranks higher.

*2: The balance tube (outdoor unit tube) diameter is ø3/8" (ø9.52).

*3: Type 1 tubing should be used for the refrigerant tubes.

*4: If the length of the longest tube (L1) exceeds 295 ft. (equivalent length), increase the main tube (LM) size by 1 rank for the

suction, discharge, and liquid tubes. (Use field-supply reducers.) (Select from Table 1-3 and Table 1-9.)

*5: If the longest main tube length (LM) exceeds 164 ft., increase the main tube size at the portion before 164 ft. by 1 rank for the

suction tubes and discharge tubes.

(For the portion that exceeds 164 ft., set based on the main tube sizes (LA) listed in the table above.)

ø3/8"

(ø9.52)

96,000

(28.1)

ø7/8"

(ø22.22)

ø3/4"

(ø19.05)

139,000

(40.7)

U-72MF1U9(E)

ø1/2"

(ø12.7)

168,000

(49.2)

U-96MF1U9(E)

U-72MF1U9(E)

ø1-1/8"

(ø28.58)

ø7/8"

(ø22.22)

192,000

(56.3)

U-96MF1U9(E)

U-96MF1U9(E)

ø5/8"

(ø15.88)

203,000

(59.5)

U-72MF1U9(E)

U-72MF1U9(E)

U-72MF1U9(E)

240,000

(70.3)

U-96MF1U9(E)

U-72MF1U9(E)

U-72MF1U9(E)

ø1-1/8"

(ø28.58)

264,000

(77.4)

U-96MF1U9(E)

U-96MF1U9(E)

U-72MF1U9(E)

ø1-3/8"

(ø34.92)

ø3/4"

(ø19.05)

Unit: in. (mm)

288,000

(84.4)

U-96MF1U9(E)

U-96MF1U9(E)

U-96MF1U9(E)

■ Size of tubing (LO) between outdoor units

Select the size of tubing between outdoor units based on the main tubing size (LA) as given in the table above.

Table 1-4 Main Tubing Size After Distribution (LB, LC...)

Total capacity

after distribution

Tubing size

Below BTU/h 24.200 54.600 85.300 102.400 124.200 143.300 162.400 200.600 238.900

Over BTU/h – 24.200 54.600 85.300 102.400 124.200 143.300 162.400 200.600

Suction tubing

Discharge tubing

Liquid tubing

ø5/8"

(ø15.88)

ø1/2"

(ø12.70)

ø3/8"

(ø9.52)

ø3/4"

(ø19.05)

ø5/8"

(ø15.88)

ø3/8"

(ø9.52)

ø3/4"

(ø19.05)

ø5/8"

(ø15.88)

ø3/8"

(ø9.52)

ø7/8"

(ø22.22)

ø3/4"

(ø19.05)

ø3/8"

(ø9.52)

ø1-1/8"

(ø28.58)

ø3/4"

(ø19.05)

ø1/2"

(ø12.70)

ø1-1/8"

(ø28.58)

ø7/8"

(ø22.22)

ø1/2"

(ø12.70)

ø1-1/8"

(ø28.58)

ø7/8"

(ø22.22)

ø1/2"

(ø12.70)

ø1-1/8"

(ø28.58)

ø7/8"

(ø22.22)

ø5/8"

(ø15.88)

Unit: in. (mm)

ø1-1/8"

(ø28.58)

ø1-1/8"

(ø28.58)

ø5/8"

(ø15.88)

Total capacity

after distribution

Tubing size

Below BTU/h 258.000 334.400 –

Over BTU/h 238.900 258.000 334.400

Suction tubing

Discharge tubing

Liquid tubing

ø1-3/8"

(ø34.92)

ø1-1/8"

(ø28.58)

ø3/4"

(ø19.05)

ø1-3/8"

(ø34.92)

ø1-1/8"

(ø28.58)

ø3/4"

(ø19.05)

ø1-1/2"

(ø38.10)

ø1-1/8"

(ø28.58)

ø3/4"

(ø19.05)

Table 1-5 Outdoor Unit Tubing Connection Size (A – D)

BTU/h

(kW)

Suction tubing

Discharge

tubing

Liquid tubing

Balance tubing

72,000

(21.1)

ø3/4"*¹

(ø19.05)*¹

Brazing connection

ø5/8"

(ø15.88)

Brazing connection

ø3/8" (ø9.52) ø3/8" (ø9.52)

Flare connection

ø3/8" (ø9.52)

Flare connection

96,000

(28.1)

ø7/8"*²

(ø22.22)*²

ø3/4"

(ø19.05)

Unit: in. (mm)

*1: The outdoor unit connection tubing (LO) is

determined by the total capacity of the outdoor

units connected to the tube ends. The tubing

size is selected based on the table of main

tube sizes after the branch.

*2: If the total capacity of the indoor units

connected to the tube ends is different from

the total capacity of the outdoor units, then the

main tube size is selected based on the total

capacity of the outdoor units.

(For LA, LB, and LF in particular)

*1 If the size of tubing (LA) is less than 16.4 feet,

it is recommended that the tubing diameter be

larger than ø7/8" (ø22.22).

*2 If the size of tubing (LA) is less than 16.4 feet,

it is recommended that the tubing diameter be

larger than ø1-1/8" (ø28.58).

9

W-3WAYECO-iU.indb9W-3WAYECO-iU.indb9 2011/11/0716:29:302011/11/0716:29:30

Page 10

Table 1-6 Refrigerant Charge Amount at Shipment (for outdoor unit)

DC

(oz)

U-72MF1U9

U-72MF1U9E

416 416

Table 1-7 Indoor Unit Tubing Connection Size ( 1 – 40)

Indoor unit type 7 9 12 15 18 19 24 36 48 54

Distribution

joint-solenoid

valve kit tubing

Solenoid valve

kit-Indoor unit

tubing

connection

*1: For the solenoid valve kits, use type 160 with parallel specifi cations. Branch the tubing before and after the solenoid valve kits.

Suction tubing ø5/8" (ø15.88)

Discharge tubing ø1/2" (ø12.7)

Liquid tubing ø3/8" (ø9.52)

Gas tubing ø1/2" (ø12.7) ø5/8" (ø15.88)

Liquid tubing ø1/4" (ø6.35) ø3/8" (ø9.52)

U-96MF1U9

U-96MF1U9E

Unit: in. (mm)

1-7. Straight Equivalent Length of Joints

Design the tubing system by referring to the following table for the straight equivalent length of joints.

Table 1-8 Straight Equivalent Length of Joints

Gas tubing size (in.(mm))

90° elbow

45° elbow

U-shape tube bent

(R2–23/64–3–15/16 in.)

Trap bend

1/2"

(12.7)

1 ft.

(0.30 m)

0.8 ft.

(0.23 m)

3 ft.

(0.90 m)

7.5 ft.

(2.30 m)

5/8"

(15.88)

1.1 ft.

(0.35 m)

0.9 ft.

(0.26 m)

3.4 ft.

(1.05 m)

9.2 ft.

(2.80 m)

3/4"

(19.05)

1.4 ft.

(0.42 m)

1 ft.

(0.32 m)

4.1 ft.

(1.26 m)

10.5 ft.

(3.20 m)

7/8"

(22.22)

1.6 ft.

(0.48 m)

1.2 ft.

(0.36 m)

4.7 ft.

(1.44 m)

12.5 ft.

(3.80 m)

1"

(25.4)

1.7 ft.

(0.52 m)

1.3 ft.

(0.39 m)

5.1 ft.

(1.56 m)

14.1 ft.

(4.30 m)

1-1/8"

(28.58)

1.9 ft.

(0.57 m)

1.4 ft.

(0.43 m)

5.6 ft.

(1.71 m)

15.4 ft.

(4.70 m)

1-1/4"

(31.8)

2.3 ft.

(0.70m)

1.7 ft.

(0.53 m)

6.9 ft.

(2.10 m)

16.4 ft.

(5.00 m)

1-1/2"

(38.1)

2.6 ft.

(0.79 m)

1.9 ft.

(0.59 m)

7.8 ft.

(2.37 m)

14.0 ft.

(5.80 m)

Y-branch distribution joint

Ball valve for service Equivalent length conversion not needed.

Table 1-9 Refrigerant tubing (Existing tubing can be used.)

Tubing size (in. (mm))

Material O Material 1/2H • H

ø1/4" (ø6.35) t1/32 (t0.8)

ø3/8" (ø9.52) t1/32 (t0.8) ø1-1/8" (ø28.58) t5/128 (t1.0)

ø1/2" (ø12.7) t1/32 (t0.8) ø1-1/4" (ø31.75) t3/64 (t1.1)

Equivalent length conversion not needed.

* When bending the tubes, use a bending

radius that is at least 4 times the outer

diameter of the tubes.

In addition, take sufficient care to avoid

crushing or damaging the tubes when

bending them.

ø5/8" (ø15.88) t5/128 (t1.0) ø1-1/2" (ø38.10) over t3/64 (t1.15)

ø3/4" (ø19.05) over t5/128 (t1.0) ø1-5/8" (ø41.28) over t3/64 (t1.20)

ø7/8" (ø22.22) t5/128 (t1.0)

1-8. Additional Refrigerant Charge

Additional refrigerant charge amount is calculated from the liquid tubing total length and a type of outdoor unit as

follows.

Required amount of additional refrigerant charge =

Table 1-10-1 Amount of Refrigerant Charge Per ft.,

According to Liquid Tubing Size

Liquid tubing

size

Amount of

refrigerant

charge (oz/ft.)

ø1/4"

(ø6.35)

ø3/ 8"

(ø9.52)

ø1/2"

(ø12.7)

ø5/8"

(ø15.88)

ø3/4"

(ø19.05)

ø7/ 8"

(ø22.22)

0. 279 0.602 1. 38 1.9 9 2.78 3.9 3

[ (Amount of additional refrigerant charge per ft. of

each size of liquid tube × its tube length) + (...) + (...)]

+ [(Necessary amount of additional refrigerant charge

per outdoor unit + (...) + (...)]

* Always charge accurately using a scale for weighing.

10

W-3WAYECO-iU.indb10W-3WAYECO-iU.indb10 2011/11/0716:29:302011/11/0716:29:30

Page 11

Table 1-10-2 Necessary Amount of Refrigerant Charge Per Outdoor Unit

Outdoor unit Outdoor unit Indoor unit

Suction tube

Discharge tube

Liquid tube

Balance tube

Suction tube

Discharge tube

Liquid tube

Gas tube

Liquid

tube

4-tube layout 3-tube layout 2-tube layout

Solenoid

valve kit

Indoor unit

Room

Hallway

Indoor unit

Room

Indoor unit

Room

Hallway

Indoor unit

Room

Solenoid

valve kit

Solenoid

valve kit

Further charge a certain amount listed below in addition to the amount of refrigerant charge.

U-72MF1U9

U-72MF1U9E

42 oz/unit 42 oz/unit

U-96MF1U9

U-96MF1U9E

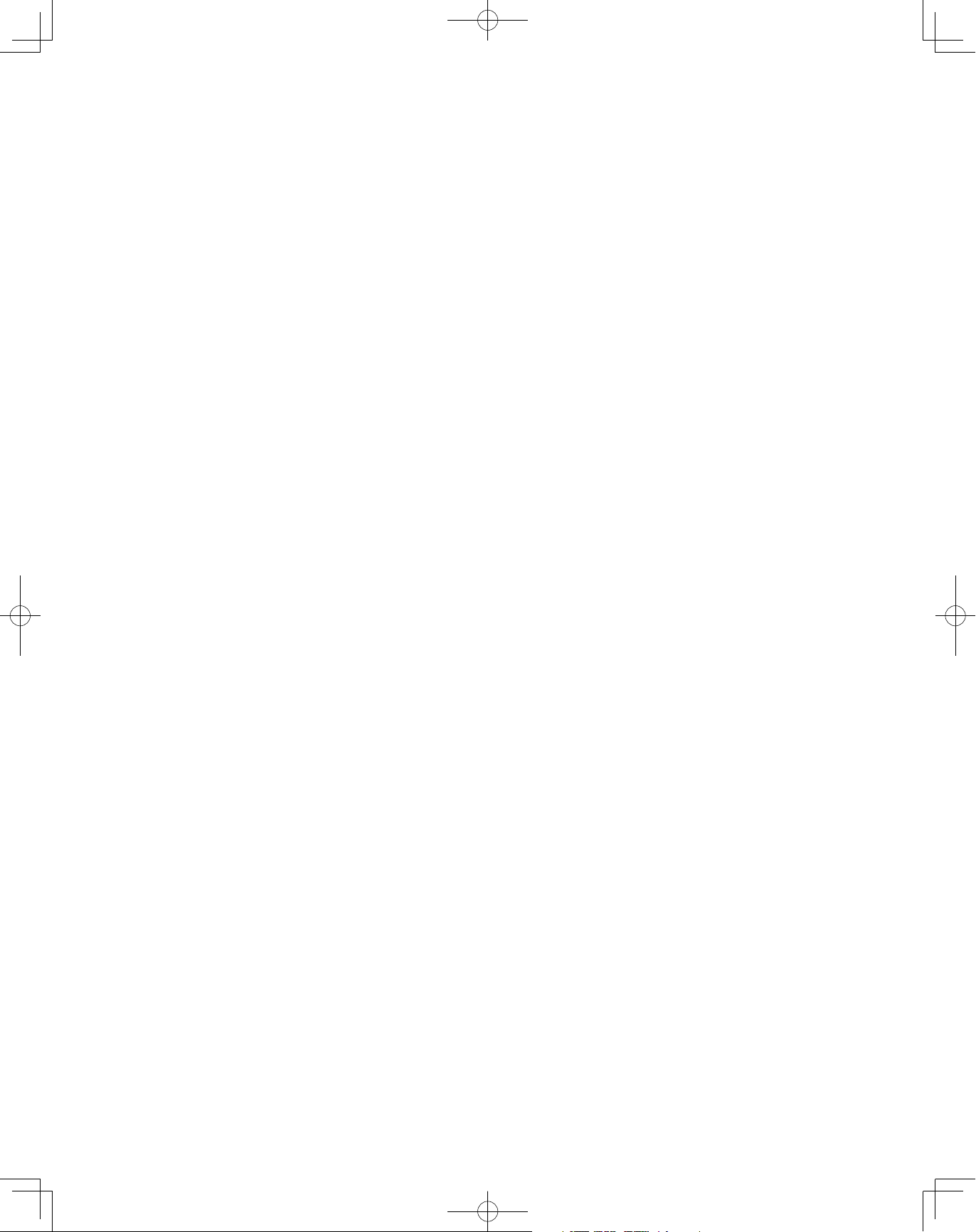

1-9. System Limitations

Table 1-11 System Limitations

Max. No. allowable connected outdoor units 3

Max. capacity allowable connected outdoor units

288,000 BTU/h (24 ton, 84.4 kw)

Max. connectable indoor units 40*¹

Max. allowable indoor/outdoor capacity ratio 50 – 130 %

*1: In the case of 16 ton (type 192,000 BTU/h) or smaller units, the number is limited by the total capacity of the connected indoor

units.

1-10. Installation Standards

Relationship between A/C units and refrigerant tubing

● Install the solenoid valve kit 98 ft. or less from the indoor unit.

● In quiet locations such as hospitals, libraries, and hotel rooms, the refrigerant noise may be somewhat noticeable. It

is recommended that the solenoid valve kit be installed inside the corridor ceiling, at a location outside the room.

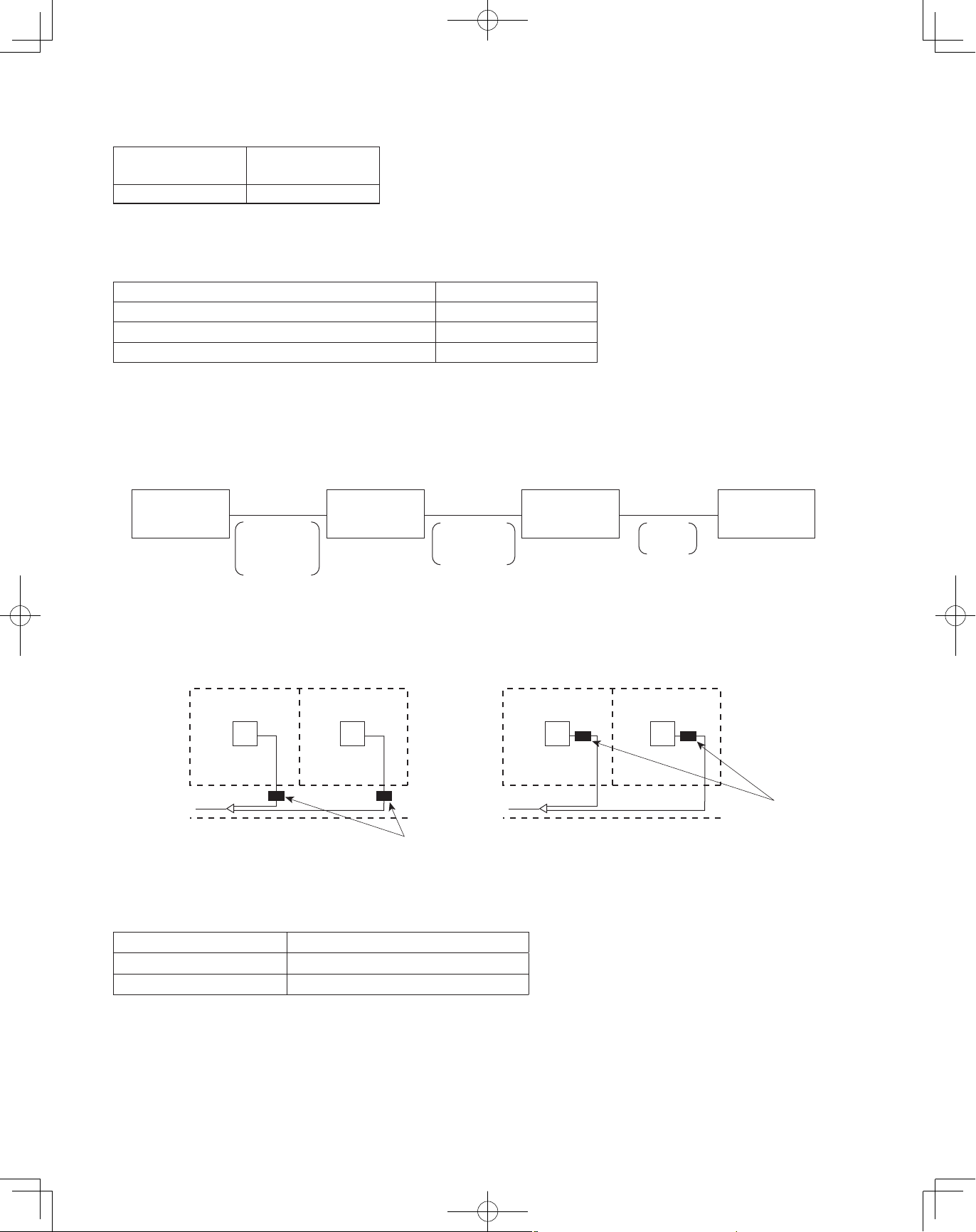

Desirable Undesirable

Common solenoid valve kit

Multiple indoor units under group control can utilize a solenoid valve kit in common.

●

Categories of connected indoor unit capacities are determined by the solenoid valve kit.

●

Type of solenoid valve kit Total capacity of indoor units (BTU/h)

160 19.000 < Total capacity < 54.600

56 7.500 < Total capacity < 19.000

If the capacity range is exceeded, use 2 solenoid valves connected in parallel.

●

11

W-3WAYECO-iU.indb11W-3WAYECO-iU.indb11 2011/11/0716:29:312011/11/0716:29:31

Page 12

15 to 30

B

A

B

A

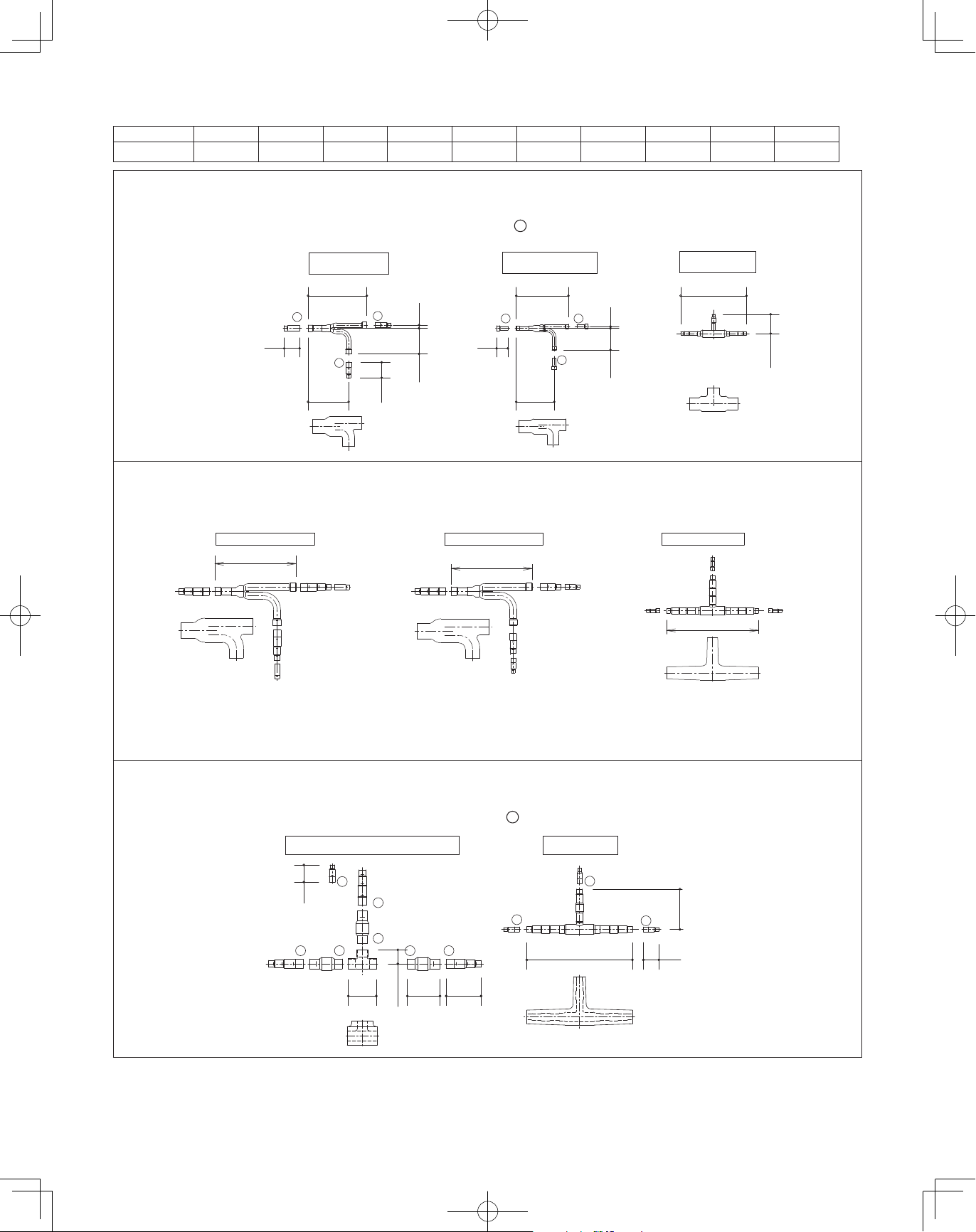

Tube branching methods (horizontal use)

Arrow view

Horizontal

line

View as seen

from arrow

WARNING

Always check the gas density

CAUTION

limit for the room in which the

unit is installed.

1-11. Check of Limit Density

When installing an air conditioner in a room, it is necessary

to ensure that even if the refrigerant gas accidentally leaks

out, its density does not exceed the limit level for that room.

1-12. Installing Distribution Joint

Pay special attention to any

location, such as a basement,

etc., where leaking refrigerant can

accumulate, since refrigerant gas

is heavier than air.

(1) Refer to “HOW TO ATTACH DISTRIBUTION JOINT”

enclosed with the optional distribution joint kit

(CZ-P900PH1U, CZ-P224BH1U, CZ-P680BH1U,

CZ-P1350BH1U).

(2) When creating a branch using a commercially available

T-joint (header joint system), orient the main tubing

so that it is either horizontal (level) or vertical. In order

to prevent accumulation of refrigerant oil in stopped

units, if the main tubing is horizontal then each branch

tubing length should be at an angle that is greater than

horizontal. If the main tubing is vertical, provide a raised

starting portion for each branch.

[Header joint system]

Be sure to solidly weld shut the T-joint end (marked

●

by “X” in the figure). In addition, pay attention to the

insertion depth of each connected tube so that the

flow of refrigerant within the T-joint is not impeded.

When using the header joint system, do not make

●

further branches in the tubing.

Header joint system (Indoor)

Outdoor

Indoor

Horizontal

line

L3 6.56 ft.

Types of vertical trap specifications

(When using ball valve)

Main tubing

Ball valve

(BV: purchased

separately)

Indoor unit (1)

(When not using ball valve)

Main tubing

Indoor unit is directed downward

Indoor unit (more than 2 units)

(If only 1 unit is connected, a ball

valve is also needed on this side.)

Branch tubing is

directed upward.

More than

7–7/8"

Install at a

positive angle

Indoor

Indoor

Horizontal

line

Horizontal

Indoor unit

Install at a

positive angle

(15 – 30°)

Solidly welded

shut (X)

(Each unit is connected

to tubing that is either

level or is directed

downward.)

Do not use the header joint system on the outdoor unit

●

side.

(3) If there are height differences between indoor units or if

branch tubing that follows a distribution joint is connected

to only 1 unit, a trap or ball valve must be added to that

distribution joint. (When adding the ball valve, locate it

within 1.3 ft. of the distribution joint.)

If a trap or ball valve is not added, do not operate

the system before repairs to a malfunctioning unit

are completed. (The refrigerant oil sent through the

tubing to the malfunctioning unit will accumulate

and may damage the compressor.)

W-3WAYECO-iU.indb12W-3WAYECO-iU.indb12 2011/11/0716:29:312011/11/0716:29:31

12

Page 13

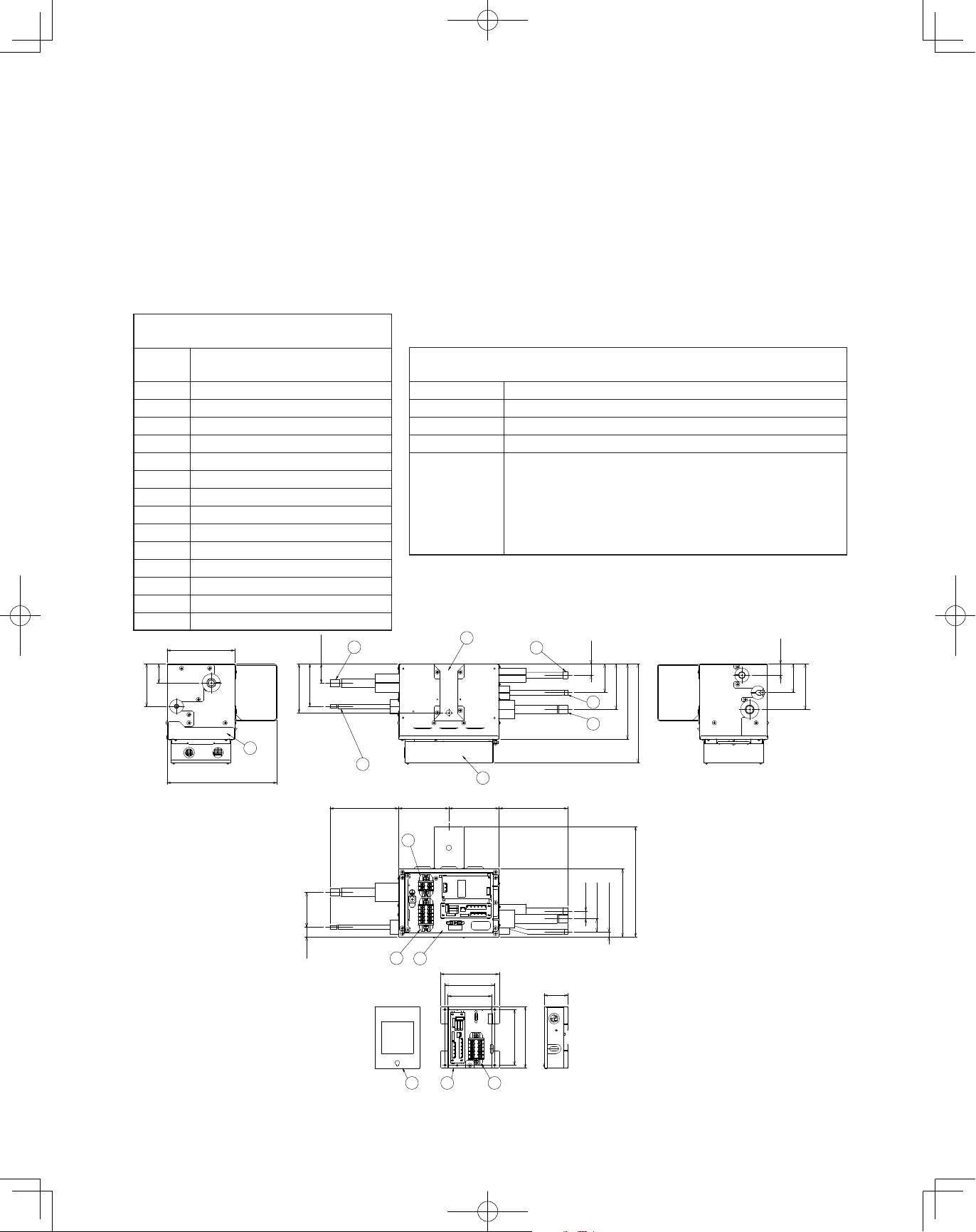

1-13. Optional Distribution Joint Kits

See the installation instructions packaged with the distribution joint kit for the installation procedure.

Table 1-12

Model name Cooling capacity after distribution Remarks

1. CZ-P900PH1U 307.100 BTU/h or less For outdoor unit

2. CZ-P224BH1U 76.400 BTU/h or less For indoor unit

3. CZ-P680BH1U 232.000 BTU/h or less For indoor unit

4. CZ-P1350BH1U 460.700 BTU/h or less For indoor unit

■ Tubing size (with thermal insulation)

1. CZ-P900PH1U

For outdoor unit (Capacity after distribution joint is 307.100 BTU/h or less.)

Note that the dimension marked with every alphabetical letter in the diagram shows the inner diameter.

Suction Tube

B

Distribution

Joint

11-13/16 11-13/16

C

#C

#C

D

E

D

C

E

DE

Insulation

*Insulators for both the Suction tube and the Discharge tube are the same.

C

Discharge Tube

#C

#C

D

E

F

Liquid Tube

G

F

EDF

C

F

G

H

I

E

E

13-25/64

EFG

HI

InsulationInsulation

Unit: in.

*Suction tube and Discharge tube are similar in sizes and both the tube entrances have the same diameter. So the both

Distribution joints can fit into different tubes. Since the diameter of the tube ends for both Suction and Discharge tube are

different, take care not to connect the distribution joint different. See the “ # ” marks on the above figures.

Table 1-13 Dimensions for connections of each part

Size Part B Part C Part D Part E Part F Part G Part H Part I

Inch ø1-1/4 ø1-1/8 ø1 ø7/8 ø3/4 ø5/8 ø1/2 ø3/8

13

W-3WAYECO-iU.indb13W-3WAYECO-iU.indb13 2011/11/0716:29:312011/11/0716:29:31

Page 14

Table 1-14 Dimensions for connections of each part

HG

G

Insulation

Insulation

Insulation

*Insulators for both the Suction tube and the Discharge tube are the same.

*Suction tube and Discharge tube are similar in sizes and both the tube entrances have the same diameter. So the both

Distribution joints can fit into different tubes. Since the diameter of the tube ends for both Suction and Discharge tube are

different, take care not to connect the distribution joint different. See the “ # ” marks on the above figures.

Note that the dimension marked with every alphabetical letter in the diagram shows the inner diameter.

I

H

IH

I

H

EFD

D

C

C

#C

#D

#D

#C

EF

GF E

EFG

E

F

G

E

F

D

E

F

FED

FE

H

G

G

Suction Tube

Discharge Tube

Liquid Tube

11-13/16

13-25/64

11-13/16

Position A B C D E F G H I J

Dimension ø1-1/2" ø1-1/4" ø1-1/8" ø1" ø7/8" ø3/4" ø5/8" ø1/2" ø3/8" –

2. CZ-P224BH1U

Use: For indoor unit (Capacity after distribution joint is 76.400 BTU/h or less.)

Example: (F below indicates inner diameter. below indicates outer diameter.)

F

Unit: in.

Liquid tubing

9–1/4

I

H

HIIH

2–23/32

2–11/64

F

G

F

Suction tubing

8–17/64

F

F

F

G

H

5–45/64

F

GH

2–11/64

3–5/8 15/32

1–37/64

Discharge tubing

7–21/64

H

G

5–23/64

H

G

HH

H

H

G

3–1/32 9/32

Thermal insulation

Thermal insulation

Thermal insulation

3. CZ-P680BH1U

Use: For indoor unit (Capacity after distribution joint is greater than 76.400 BTU/h and no more than 232.000 BTU/h.)

Unit: in.

4. CZ-P1350BH1U

Use: For indoor unit (Capacity after distribution joint is greater than 232.000 BTU/h and no more than 460.700 BTU/h.)

Example: (B below indicates inner diameter. below indicates outer diameter.)

3UCTIONTUBINGs$ISCHARGETUBING

H

G

2–11/64

Thermal insulation

F

BB

3–35/64

F

E

$

C

C

A

B

B

BBC

4–9/64 4–13/32

1–49/64

C

W-3WAYECO-iU.indb14W-3WAYECO-iU.indb14 2011/11/0716:29:312011/11/0716:29:31

B

Liquid tubing

I

H

G

G

F

G

E

G

F

I

H

EC $AFFA$ CE

E

13–25/64

G

E

F

Thermal insulation

14

G

Unit: in.

5–1/8

HI

1–31/32

Unit: in.

Page 15

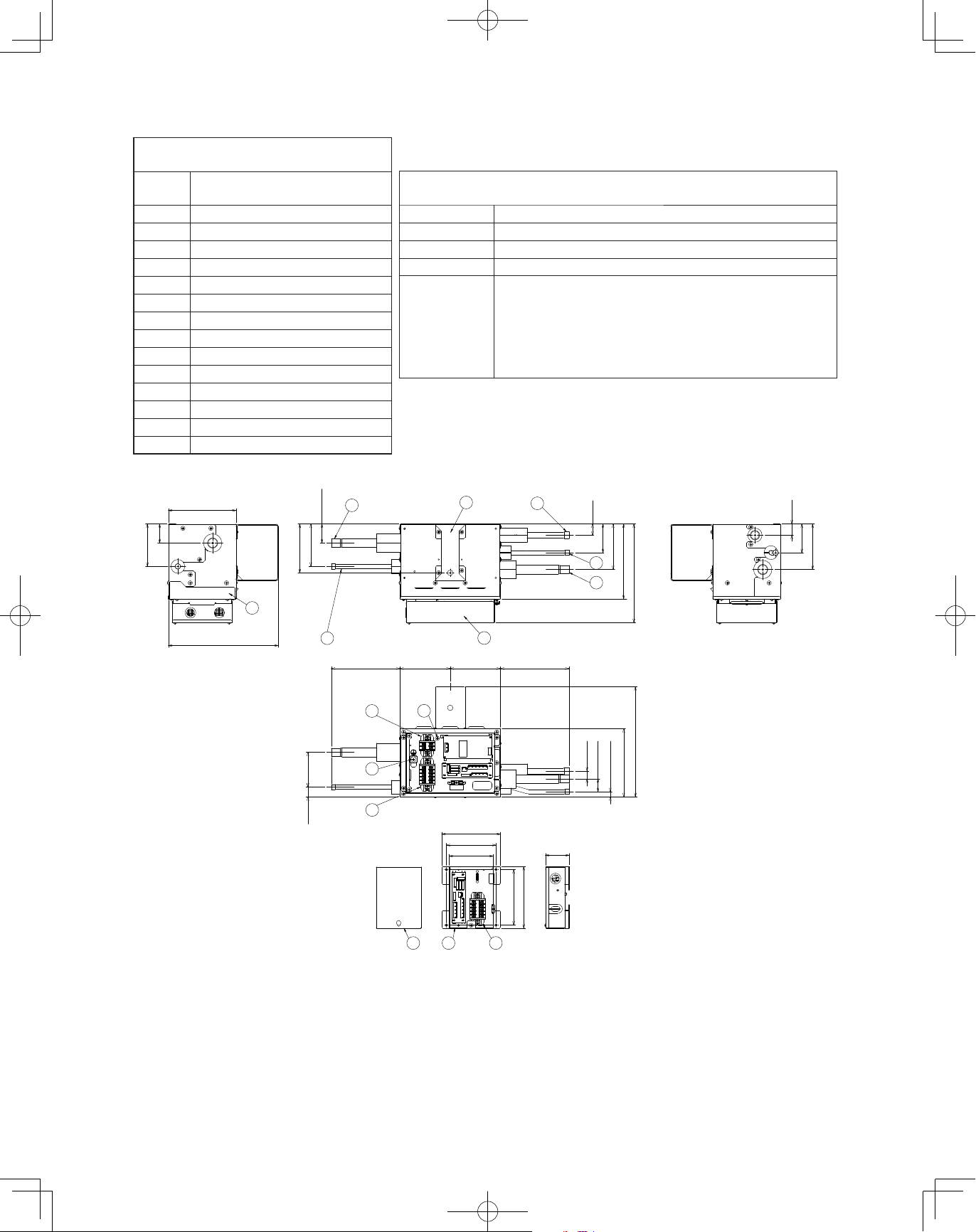

1-14. Optional Solenoid Valve Kit

Precautions on Installation of Solenoid Valve Kit

(1) Clean base metals thoroughly.

(2) Use proper ventilation to carry fumes away from the work area.

(3) Use a high quality silver based solder of at least 15 % silver.

(4) Heat the base materials broadly and uniformly.

(5) Take precautions not to overheat the device which could damage sensitive internal components.

(6) Insure compliance with all local codes!

Part

Number

1

2

3

4

5

6

7

8

9

0

!

@

#

$

1-21/32

3-21/32

CZ-P56HR1U

Types and specifi cations of

tubing connections

Gas tube: ID1/2"

Liquid tube: ID1/4"

Suspension hook

Liquid tube: ID3/8"

Suction tube: ID5/8"

Discharge tube: ID1/2"

Service panel

Base of control box

Terminal for power line

Terminal for communication line

Earth (M5 with washer)

Cover of control box

Relay kit

Cover of relay kit

5-25/32

1-21/32

3-21/32

4-7/32

• Specifications

CZ-P56HR1U

Compatibility

7.500 ≤ Total capacity of indoor units (BTU/h) < 19.000

Power source Single-phase AC 208–230V 60Hz (supplied by indoor unit)

Power input 33 W max.

Net weight 151.7 oz.

Accessories Washer x 2

Hanging hook

M4 screw x 4

Tapping screw x 4

Wire holder

3-WAY connect wire

ACC-3WAY-AAB (Solenoid Valve Relay Kit)

1

3

6

63/64

4

5

2-31/64

3-15/16

6-29/64

8-15/32

63/64

2-31/64

3-15/16

9-13/32

7

53/64 2-63/64

2

5-55/64

4-21/64 4-21/64

9

11

8

5-3/64

4-1/4

3-25/32

12

5-55/64

9-29/64

7/16

43/64

1-7/64

5-55/64

2-3/64

5-9/32

4-49/64

Unit: in.

1314

10

15

W-3WAYECO-iU.indb15W-3WAYECO-iU.indb15 2011/11/0716:29:322011/11/0716:29:32

Page 16

CZ-P160HR1U

• Specifications

Part

Number

1

2

3

4

5

6

7

8

9

0

!

@

#

$

1-21/32

3-21/32

Types and specifi cations of

tubing connections

Gas tube: ID5/8"

Liquid tube: ID3/8"

Suspension hook

Liquid tube: ID3/8"

Suction tube: ID5/8"

Discharge tube: ID1/2"

Service panel

Base of control box

Terminal for power line

Terminal for communication line

Earth (M5 with washer)

Cover of control box

Relay kit

Cover of relay kit

5-25/32

4-7/32

7

1

1-21/32

3-21/32

CZ-P160HR1U

Compatibility

19.000 ≤ Total capacity of indoor units (BTU/h) < 54.600

Power source Single-phase AC 208–230V 60Hz (supplied by indoor unit)

Power input 40 W max.

Net weight 165.8 oz.

Accessories Washer x 2

Hanging hook

M4 screw x 4

Tapping screw x 4

Wire holder

3-WAY connect wire

ACC-3WAY-AAB (Solenoid Valve Relay Kit)

3

6

63/64

4

5

2-31/64

3-15/16

6-29/64

8-15/32

63/64

2-31/64

3-15/16

9-13/32

53/64 2-63/64

1314

5-3/64

4-1/4

3-25/32

12

2

5-55/64 5-55/64

9

11

10

4-21/64 4-21/64

8

9-29/64

7/16

43/64

1-7/64

5-55/64

2-3/64

5-9/32

4-49/64

Unit: in.

10

16

W-3WAYECO-iU.indb16W-3WAYECO-iU.indb16 2011/11/0716:29:322011/11/0716:29:32

Page 17

Suspension bolt (3/8" or M10) (field supplied)

Nut (field supplied) (3/8" or M10)

Washer

M4 screws

(12 pcs.)

Suspension hook

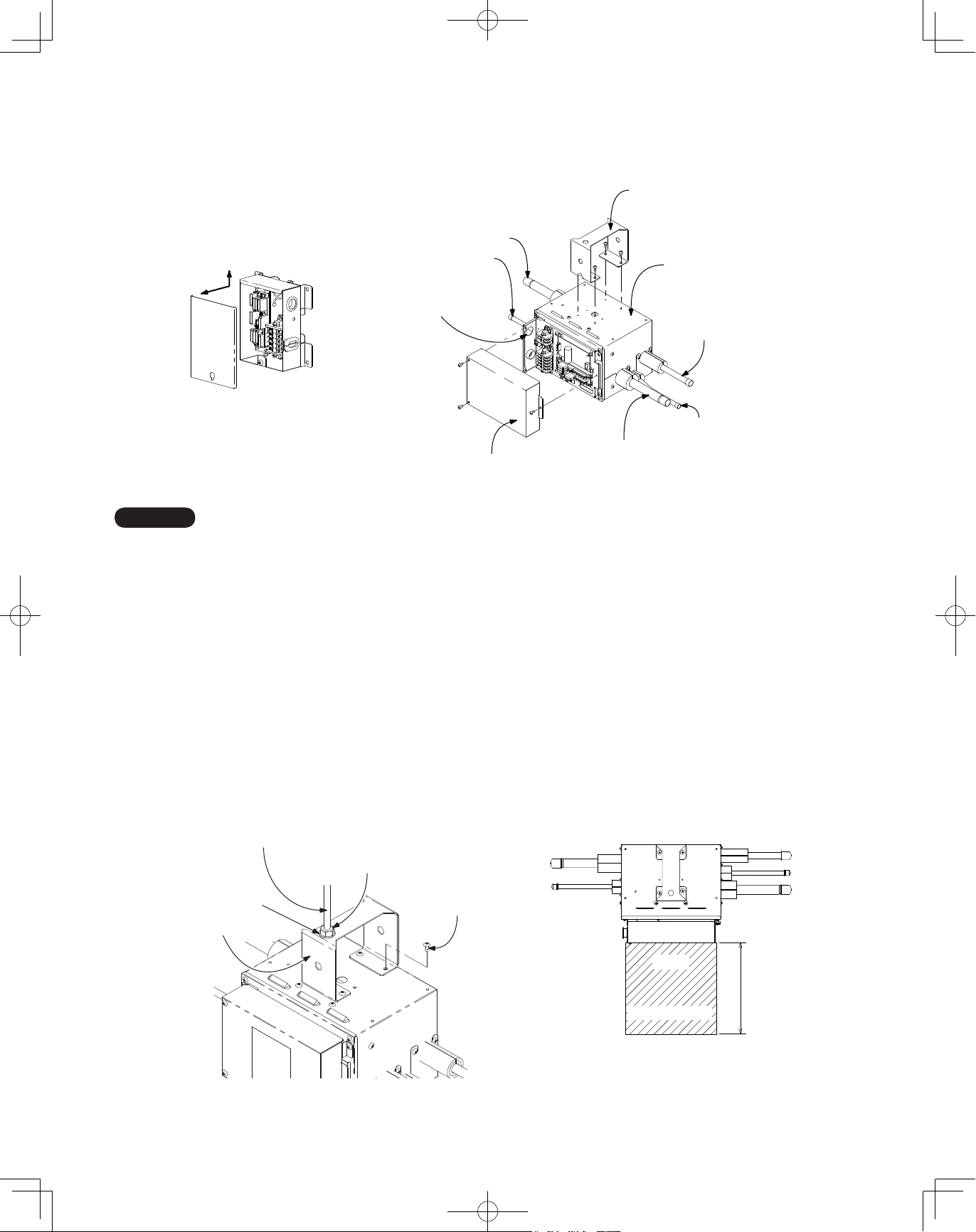

Installation of Solenoid Valve Kit

1. Install the relay kit into the indoor unit.

Refer to the Installation Manual for the solenoid valve kit.

2. Connect the solenoid valve kit and the relay kit in the field.

Gas tube

Liquid tube

Connect with

conduit for

power supply

Suspension hook

Top surface

Discharge tube

Relay kit

Front

Liquid tube

Suction tube

Cover of control box

NOTE

Notes on Installation

• Be sure to secure the valve body by using its structure with the suspension bolt, etc.

• Install the valve body within a distance of 98 ft. from the indoor unit.

Some refrigerant noise will be produced. Therefore in hospitals, libraries, hotel guest rooms, and other quiet

locations, it is recommended that the solenoid valve kit be installed on the ceiling reverse side of a hallway or

another location separated from the room.

• When installing the valve body, install with the top surface facing up. Secure 7-7/8" or more of space to the front

so that the front service panel can be removed.

• If the supplied suspension hook will not be used, and other fastening devices will be attached in the field, use

the 4 screw holes on the top surface. DO NOT use any long screws other than the supplied screws. Use of other

screws may puncture the internal tubing, resulting in refrigerant leakage.

• Do not block the air holes.

W-3WAYECO-iU.indb17W-3WAYECO-iU.indb17 2011/11/0716:29:322011/11/0716:29:32

Front

Service space

7-7/8" or more

17

Page 18

1-15. Example of Tubing Size Selection and Refrigerant Charge Amount

CAUTION

Additional refrigerant charging

Based on the values in Tables 1-3, 4, 5, 9 and 10-2 use the liquid tubing size and length, and calculate the amount of additional

refrigerant charge using the formula below.

Required additional

refrigerant charge (oz)

(a) : Liquid tubing Total length of ø7/8" (ft.) (d) : Liquid tubing Total length of ø1/2" (ft.)

(b) : Liquid tubing Total length of ø3/4" (ft.) (e) : Liquid tubing Total length of ø3/8" (ft.)

(c) : Liquid tubing Total length of ø5/8" (ft.) (f ) : Liquid tubing Total length of ø1/4" (ft.)

● Charging procedure

Be sure to charge with R410A refrigerant in liquid form.

1. After performing a vacuum, charge with refrigerant from the liquid tubing side. At this time, all valves must be in the “fully

closed” position.

2. If it was not possible to charge the designated amount, operate the system in Cooling mode while charging with refrigerant

from the gas tubing side. (This is performed at the time of the test run. For this, all valves must be in the “fully open” position.

However if only one outdoor unit is installed, a balance tube is not used. Therefore, leave the valves fully closed.)

Charge with R410A refrigerant in liquid form.

With R410A refrigerant, charge while adjusting the amount being fed a little at a time in order to prevent liquid refrigerant from

backing up.

● After charging is completed, turn all valves to the “fully open” position.

● Replace the tubing covers as they were before.

3.93 × (a) + 2.78 × (b) + 1.99 × (c) + 1.38 × (d) + 0.602 × (e) + 0.279 × (f) + Necessary amount of

=

additional refrigerant charge per outdoor unit

1. R410A additional charging absolutely

must be done through liquid charging.

2. The R410A refrigerant cylinder has a gray

base color, and the top part is pink.

Balance tube

Use a flathead screwdriver

and open by turning the part

with the screw groove to the

right, from “ ” to “ ”

3. The R410A refrigerant cylinder includes a

siphon tube. Check that the siphon tube is

present. (This is indicated on the label at

the top of the cylinder.)

4. Due to differences in the refrigerant,

pressure, and refrigerant oil involved in

installation, it is not possible in some

cases to use the same tools for R22 and

B

for R410A.

A

Example:

Outdoor unit

96 type 96 type

● Example of each tubing length

LB

LA

1 2 3 4

48 type 48 type 48 type 36 type

LC

Liquid tube

Use a hex wrench (width 5/32 inch)

and turn to the left to open.

Discharge tube

Use a flathead screwdriver

and open by turning the part

with the screw groove to the

right, from “ ” to “ ”

Main tubing Distribution joint tubing

LA = 131 ft. Outdoor side Indoor side

LB = 16 ft.

LC = 16 ft.

A = 7 ft. 1 = 98 ft.

B = 7 ft. 2 = 16 ft.

3 = 16 ft.

4 = 65 ft.

Suction tube

Use a flathead screwdriver

and open by turning the part

with the screw groove to the

right, from “ ” to “ ”

18

W-3WAYECO-iU.indb18W-3WAYECO-iU.indb18 2011/11/0716:29:332011/11/0716:29:33

Page 19

● Obtain liquid tubing size from Tables 1-3, 4, 5 and 9.

CAUTION

Main tubing

LA = ø5/8 (ft.) (Total capacity of indoor unit is 179,400 BTU/h) The longest tubing length in this example

LB = ø1/2 (ft.) (Total capacity of indoor unit is 131,600 BTU/h) (LA = 131 ft.)

LC = ø3/8 (ft.) (Total capacity of indoor unit is 83,800 BTU/h)

Distribution joint tubing

Outdoor side

Indoor side

A: ø3/8 (ft.) B: ø3/8 (ft.) (from outdoor unit connection tubing)

1: ø3/8 (ft.) 2: ø3/8 (ft.) 3: ø3/8 (ft.) 4: ø3/8 (ft.) (from indoor unit connection tubing)

● Obtain charge amount for each tubing size

Note1: The charge amounts per 1 ft. are different for each liquid tubing size.

ø5/8 (ft.) → LA : 131 ft. × 1.99 oz/ft. = 261 oz

ø1/2 (ft.) → LB : 16 ft. × 1.38 oz/ft. = 22 oz

ø3/8 (ft.) → LC +

A – B + 1 – 4 : 225 ft. × 0.602 oz/ft. = 135 oz

Total 418 oz

Additional refrigerant charge amount is 418 oz.

Note 2: Necessary amount of additional refrigerant charge per outdoor unit (U-96MF1U9) is 42 oz. (See the Table 1-10-2.)

Note 1) Amount of additional charge per tubing length : 418 oz

Note 2) Amount of additional charge for outdoor unit : 84 oz (42+42)

Total of additional refrigerant charge amount : 502 oz

Therefore, the total of additional refrigerant charge amount reaches 502 oz.

● Obtain overall refrigerant charge amount.

Overall refrigerant charge amount of the system indicates the calculated value shown above the addition al charge amount in

addition to the total of the refrigerant charge amount (shown in the Table 1-6) at the shipment of each outdoor unit.

Refrigerant charge amount at shipment:

U-96MF1U9 : 416 oz

U-96MF1U9 : 416 oz

Additional charge amount : 502 oz

Grand total : 1334 oz

Therefore, overall refrigerant charge amount of the system reaches 1334 oz.

Remark:

Be sure to include the values in Table 1-10-2 Necessary Amount of Refrigerant Charge Per Outdoor Unit.

Be sure to check the limit density for

the room in which the indoor unit is

installed.

19

W-3WAYECO-iU.indb19W-3WAYECO-iU.indb19 2011/11/0716:29:332011/11/0716:29:33

Page 20

2. SELECTING THE INSTALLATION SITE

CAUTION

More than

2 in.

More than

1.7 ft.

* More than 4 in.

* More than 4 in.

* More than 4 in.

Example of installation of 2 units

(When wall height is below 6 ft.)

* However, be sure to ensure a space of 1 ft. or more at

either the right side or the rear of the unit.

Exhaust fan

2-1. Outdoor Unit

AVOID:

● heat sources, exhaust fans, etc.

● damp, humid or uneven locations

● indoors (no-ventilation location)

DO:

● choose a place as cool as possible.

● choose a place that is well ventilated.

● allow enough room around the unit for air intake/

exhaust and possible maintenance.

● use lug bolts or equal to bolt down unit, reducing vibration

and noise.

Installation Space

Install the outdoor unit where there is enough space for

ventilation. Otherwise the unit may not operate properly. Fig.

2-2 shows the minimum space requirement around the outdoor

units when 3 sides are open and only 1 side is shuttered,

with open space above the unit. The mounting base should

be concrete or a similar material that allows for adequate

drainage. Make provisions for anchor bolts, platform height,

and other site-specific installation requirements.

● Leave space open above the

unit.

● Construct louvers or

other openings in the wall,

if necessary, to ensure

adequate ventilation.

(Ceiling panel dimensions)

Hot air

Outdoor

unit

Fig. 2-1

Fig. 2-2

113 (Ceiling panel dimensions)

4435

(Ceiling panel dimensions)

35

Heat

source

(Ceiling panel dimensions)

35

NOTE

● Do not do any wiring or tubing within 1 ft. of the front

panel, because this space is needed as a servicing

space for the compressor.

● Ensure a base height of 4 in. or more to ensure that

drainage water does not accumulate and freeze

around the bottom of the unit.

● If installing a drain pan, install the drain pan prior to

installing the outdoor unit.

* Make sure there is at least 6 in. between the outdoor

unit and the ground.

Also, the direction of the tubing and electrical wiring

should be from the front of the outdoor unit.

31-1/8

(Installation hole pitch)

20

7-7/8

31-1/8

(Installation hole pitch)

109-1/16 (Installation hole pitch)

Top view

Fig. 2-3

7-7/8

(Installation hole pitch)

31-1/8

35(Ceiling panel dimensions)

36-1/4 (Installation hole pitch)

37-1/2 (Maximum dimensions)

Unit: in.

W-3WAYECO-iU.indb20W-3WAYECO-iU.indb20 2011/11/0716:29:342011/11/0716:29:34

Page 21

2-2. Removing Fin Guard for Heat Exchanger

CAUTION

After installation of the outdoor unit, detach the fin guard for

heat exchangers as following steps.

1. Cut out the fin guard entirely attached to the panel and

remove it from the outdoor unit. Pay careful attention not

to damage the fin when cutting out the fin guard.

2. If there is a case where easy to touch the sharp

aluminum fin of the outdoor unit, be sure to attach a

snow-proof ducting to the unit. It is recommended that

the outdoor unit be located away from the touched with

hands.

2-3. Shield for Horizontal Exhaust Discharge

It is necessary to install an air-discharge chamber (field

supply) to direct exhaust from the fan horizontally if it is

difficult to provide a minimum space of 7 ft. between the

air-discharge outlet and a nearby obstacle. (Fig. 2-4)

In regions with heavy snowfall,

the outdoor unit should be

provided with a solid, raised

platform and snow-proof

ducting (field supply). (Fig. 2-5)

Fig. 2-4

DO

2-4. Installing the Outdoor Unit in Heavy Snow

Areas

In locations where wind-blown snow can be a problem, snow-

proof ducting (field supply) should be fitted to the unit and

direct exposure to the wind should be avoided as much as

possible. (Fig. 2-6) The following problems may occur if proper

countermeasures are not taken:

● The fan in the outdoor unit may stop running, causing the

unit to be damaged.

● There may be no air flow.

● The tubing may freeze and burst.

● The condenser pressure may drop because of strong wind,

and the indoor unit may freeze.

2-5. Precautions When Installing in Heavy Snow

Areas

a) The platform should be higher than the maximum snow

depth. (Fig. 2-5)

b) The 2 anchoring feet of the outdoor unit should be used

for the platform, and the platform should be installed

beneath the air-intake side of the outdoor unit.

c) The platform foundation must be solid and the unit must

be secured with anchor bolts.

d) When installing on a roof subject to strong wind,

countermeasures must be taken to prevent the unit from

being overturned.

AVOID

Without snowproof ducting

(Without platform)

Fig. 2-5

Fig. 2-6

Fallen snow

With snowproof ducting

(High platform)

21

W-3WAYECO-iU.indb21W-3WAYECO-iU.indb21 2011/11/0716:29:342011/11/0716:29:34

Page 22

2-6. Dimensions of Wind Ducting

Reference diagram for air-discharge chamber (field supply)

unit: in.

33-3/16

35

(Ceiling panel dimensions)

35-1/4

(Maximum bracket dimensions)

Front view Front viewRight side view Right side view

3-unit installation

(2-unit installation: maximum dimensions)

(Installation hole pitch)

Ceiling panel

Air direction: Front direction Air direction: Right direction

35

(Ceiling panel dimensions)

21

(32-1/8)

106-1/8

74-1/16

Note: Can be installed so that the air direction is to the front, right, left or rear direction.

(3-unit installation: maximum dimensions)

113

74-1/4

33-3/16 33-3/16 33-3/16

31-1/8

5-3/4

31-1/8

(Installation hole pitch)

5-3/4

31-1/8

(Installation hole pitch)

Top view

33-1/4

35

(Ceiling panel dimensions)

1

2

35

(32-1/8)

74-1/16

Ceiling panel

35-1/4

(Ceiling panel dimensions)

(Maximum bracket dimensions)

106-1/8

unit: in.

36-1/4

7-7/8 7-7/8

Front view Right side view

22

(Installation hole pitch)

(32-1/8)

106-1/8

74-1/16

35

(Ceiling panel dimensions)

21

W-3WAYECO-iU.indb22W-3WAYECO-iU.indb22 2011/11/0716:29:342011/11/0716:29:34

Page 23

2-7. Dimensions of Snow Ducting

Reference diagram for snow-proof ducting (field supply)

Air direction:

Front direction

31-1/2

Air direction:

Right direction

54

31-1/2

31-1/2

(Air intake duct)

33-3/16

9-1/2 9-1/2

53-5/8

(Air outlet duct)

35

(Ceiling panel dimensions)

(54)

44-3/8

1 pc.

4 pc.

Front view

Ceiling panel Ceiling panel

31-1/2

9-1/2

(32-1/8)

106-1/8

74-1/16

35

(Ceiling panel dimensions)

32-7/8

1

9-1/2 9-1/2 9-1/2

53-5/8

44-3/8

Right side view

Note: Can be installed so that the air direction is to the front, right, left or rear direction.

3-unit installation

35 35 35

113

44

31-1/2

54

35

(Ceiling panel dimensions)

32-7/8

1

Front view

31-1/2

(Air intake duct)

35

33-3/16

(54)

(Air outlet duct)

(Ceiling panel dimensions)

9-1/2 9-1/2

Right side view

unit: in.

Snowfall protection duct

(Field supply)

31-1/2

Air-discharge chamber

(Field supply)

Snowfall protection

duct (Field supply)

53-5/8

44-3/8

3

31-1/8

7-7/8 7-7/8

Board

(Field supply)

31-1/8 31-1/8

Board (Field supply)

Air-discharge chamber (Field supply)

131-3/4

Front view

35

37-3/8

36-1/4

Top view (Before installation of snowfall protection duct)

Snowfall protection duct

(Field supply)

31-1/2

35 (Ceiling panel dimensions)

Ceiling panel

Snowfall protection

duct (Field supply)

53-5/8

44-3/8

23

9-1/2 9-1/2

7/82-1/8

106-1/8

74

44-3/8

Right side view

unit: in.

Air-discharge chamber

(Field supply)

Snowfall protection duct

(Field supply)

53-5/8

W-3WAYECO-iU.indb23W-3WAYECO-iU.indb23 2011/11/0716:29:342011/11/0716:29:34

Page 24

3. HOW TO INSTALL THE OUTDOOR UNIT

CAUTION

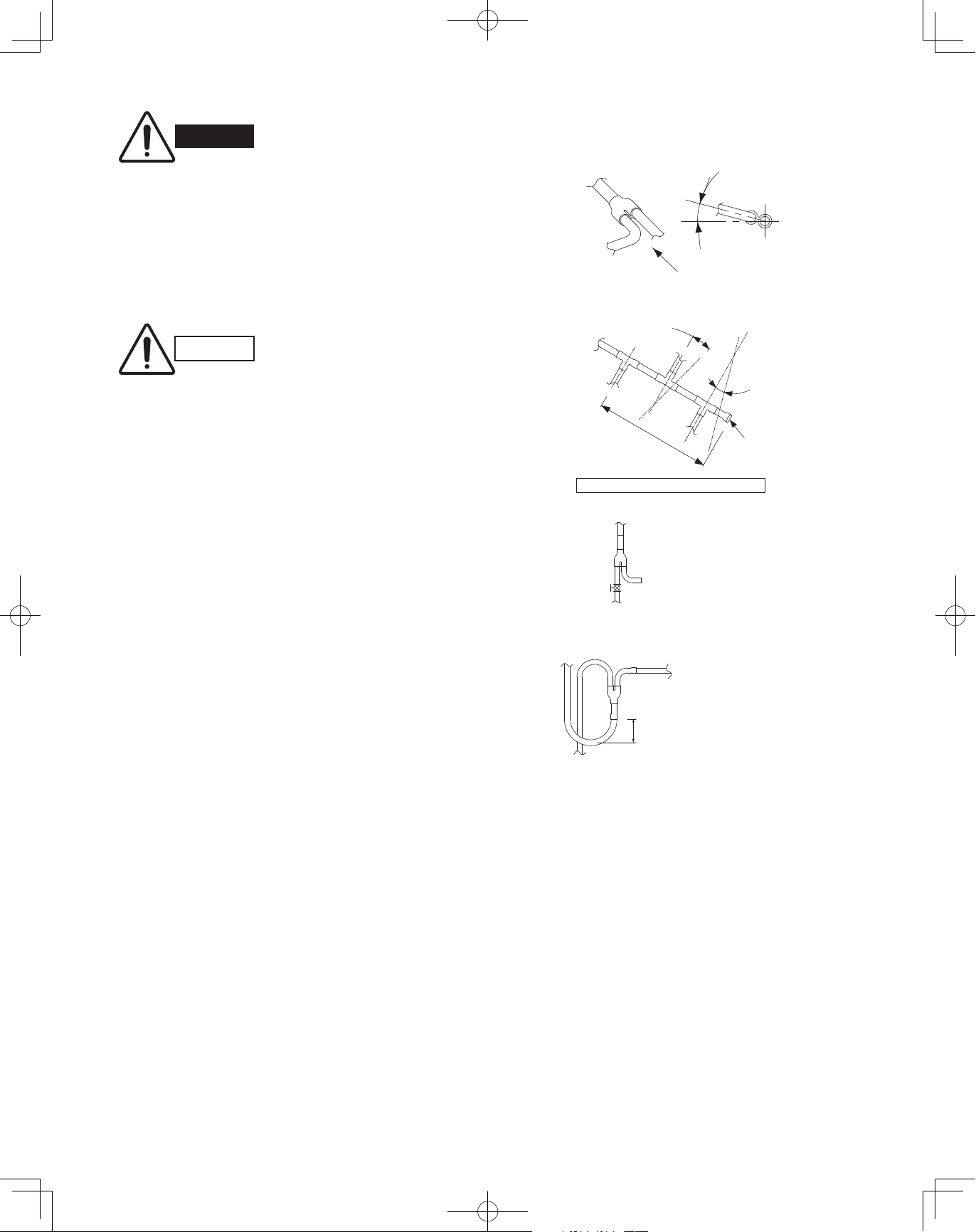

3-1. Transporting

When transporting the unit, have it delivered as close to the installation site as

possible without unpacking. Use a hook for suspending the unit. (Fig. 3-1)

● When hoisting the outdoor unit, pass ropes or straps under the bottom plate

as shown in the figure at right. When hoisting, the angle between the rope

and top panel must be 70° or greater so that the rope does not come into

contact with the fan guard.

(Use 2 lengths of rope 25 ft. long or longer.)

● When passing the ropes through the square holes of the bottom plate:

Place the rope in the outer edge of the square holes.

● Use protective panels or padding at all locations where the rope contacts the

outer casing or other parts to prevent scratching. In particular, use protective

material (such as cloth or cardboard) to prevent the edges of the top panel

from being scratched.

● Be careful of the fan.

There is danger of injury if the fan starts to turn during inspection. Be sure to

turn OFF the remote power switch before beginning inspection.

3-2. Installing the Outdoor Unit

(1) Use anchor bolts (M12 or 15/32") or similar to securely anchor the unit in

place. (Fig. 3-2)

(2) Be sure the rubber vibration insulator and platform extend to the inside of

the legs. In addition, the washers used to anchor the unit from the top must

be larger than the installation anchor holes. (Figs. 3-2 and 3-3)

(Positions where anchor bolts are fastened)

Installation anchor hole (4-19/32 25/32 oval holes)

Fig. 3-1

Plate leg

Anchor bolts

Washer

25/32

3-15/32

(3-15/16)

(3-15/16)

Vibration insulator

1-31/32

Base

Unit: in.

The vibration insulator, base, or platform must

be large enough to bear the full surface of the

base plate legs.

Fig. 3-2

31-1/8

(Installation hole pitch)

35

(Ceiling panel dimensions)

35

(Ceiling panel dimensions)

3

31-1/8

(Installation hole pitch)

35

113 (Ceiling panel dimensions)

(Ceiling panel dimensions)

109 (Installation hole pitch)

37-1/2

36-1/4

(Installation hole pitch)

(Ceiling panel dimensions)

(Installation hole pitch)

(Maximum dimensions)

35

31-1/8

Top view

Fig. 3-4

(Ceiling panel dimensions)

35

31-1/8

(Installation hole pitch)

24

unit: in.

4 – 19/32 25/32 hole

35

37-1/2

36-1/4

(Installation hole pitch)

(Ceiling panel dimensions)

(Maximum dimensions)

Surface where

installation anchor

brackets are

installed

1-31/32

(Detailed view of legs)

19/32

Unit: in.

1-33/64

Fig. 3-3

W-3WAYECO-iU.indb24W-3WAYECO-iU.indb24 2011/11/0716:29:342011/11/0716:29:34

Page 25

3-3. Remove the Brackets Used for Transport

● After installing the unit, remove the

2 transport brackets from the front

and rear (4 brackets total). (Fig. 3-5)

Remove the 2 screws

(8 screws total)

Remove the 2 transport brackets from

the front and rear (4 brackets total)

Fig. 3-5

3-4. Routing the Tubing

● The tubing can be routed out either from the front or from the bottom. (Fig. 3-6)

● The connecting valve is contained inside the unit. Therefore, remove the front panel. (Fig. 3-6)

(1) If the tubing is routed out from the front, use cutting pliers or a similar tool to cut out the tubing outlet slit (part

indicated by ) from the tubing cover. (Figs. 3-6 and 3-7)

Front

Bottom

Tubing cover

Remove 2 screws

Use cutting pliers or similar

tool to cut cover out

(2) If the tubing is routed out from the bottom, remove

the slit part ( ).

● Use a drill bit approximately 13/64" dia. to create

holes at the 4 slit hole indentations (openings).

● Punch out the slit part ( ).

● Be careful not to damage the base plate.

Remove 11 panel

screws from front

panel

Fig. 3-6

Indentation

(4 locations)

Slit hole

Fig. 3-7

25

W-3WAYECO-iU.indb25W-3WAYECO-iU.indb25 2011/11/0716:29:352011/11/0716:29:35

Page 26

3-5. Prepare the Tubing

CAUTION

● Material: Use C1220 phosphorous deoxidized copper as described in JIS H3300, “Copper and Copper Alloy

Seamless Pipes and Tubes.”

(For tubes that are ø1" (ø25.4 mm) or larger, use 1/2H material or H material. For all others use O material.)

● Tubing size

Use the tubing size indicated in the table below.

● When cutting the tubing, use a tube cutter, and be sure to remove any burrs.

(The same applies to distribution tubing (optional).)

● When bending the tubes, bend each tube using a radius that is at least 4 times the outer diameter of the tube.

When bending, use sufficient care to avoid crushing or damaging the tube.

● For flaring, use a flare tool, and be sure that flaring is performed correctly.

Use sufficient caution during preparation of the tubing. Seal the tube ends by

means of caps or taping to prevent dust, moisture, or other foreign substances

from entering the tubes.

Refrigerant tubing (Existing tubing can be used.)

Tubing size (mm)

Outer dia. Thickness Outer dia. Thickness

ø1/4" (ø6.35) t1/32" (t0.8) ø3/4" (ø19.05) over t5/128" (t1.0)

ø3/8" (ø9.52) t1/32" (t0.8) ø7/8" (ø22.22) t5/128" (t1.0)

ø1/2" (ø12.7) t1/32" (t0.8) ø1-1/8" (ø28.58) t5/128" (t1.0)

ø5/8" (ø15.88) t5/128" (t1.0) ø1-3/8" (ø34.92) over t3/64" (t1.1)

3-6. Connect the Tubing

● Use the supplied connector tubing. (See figure below.)

72 type (6-Ton)

2

34

96 type (8-Ton)

34

1

Refrigerant

tubing

Suction tube Brazed connection No

1

Discharge tube Brazed connection No

2

Liquid tube Brazed connection No

3

Balance tube Flared connection No

4

2

1

Refrigerant

tubing

Suction tube Brazed connection

1

Discharge tube Brazed connection

2

Liquid tube Brazed connection No

3

Balance tube Flared connection No

4

Connection method

Connection method

Use supplied

connector tube?

Use supplied

connector tube?

Yes (ø3/4" → ø7/8")

Yes (ø5/8" → ø3/4")

Refrigerant tube port

● Use caulking, putty, or a similar material to fill any

gaps at the refrigerant tube port ( ) in order to

Tubing

cover

Base plate

prevent rainwater, dust or foreign substances from

entering the unit.

* Perform this work even if the tubing is routed out

in a downward direction.

Tubing routed out forward

26

W-3WAYECO-iU.indb26W-3WAYECO-iU.indb26 2011/11/0716:29:362011/11/0716:29:36

Tubing routed out downward

Page 27

CAUTION

Brazing locations

Field-supply tube

Taping

Remote valve

Nitrogen

Pressure-reducing valve (regulator)

Use two adjustable wrenches, as shown in the figure,

when removing the liquid tube valve flare nut.

1. Do not apply a wrench to the valve cap when removing or

installing the flare nuts. Doing so may damage the valve.

Do not apply an adjustable wrench

to the hexagonal part.

Do not use two adjustable wrenches

when removing or installing the balance

tube flare nut. In particular, do not apply

an adjustable wrench to the hexagonal

part at the top of the valve.

(If force is applied to this part,

gas leakage will occur.)

2. If the valve cap is left off for a long period of time, refrigerant

leakage will occur. Therefore, do not leave the valve cap off.

3. Applying refrigerant oil to the flare surface can be effective in

preventing gas leakage, however be sure to use a refrigerant

oil which is suitable for the refrigerant that is used in the system.

(This unit utilizes R410A refrigerant, and the refrigerant oil is

ether oil (synthetic oil). However, hub oil (synthetic oil) can also

be used.)

● Tighten each cap as specified below.

Valve cap

Flare nut

Service port cap

Tightening torque for each cap

Service port cap

(width 19/32")

Valve cap

(width 55/64")

Flare nut

(valve dia. ø3/8")

60 – 100 lbs · in (70 – 120 kgf · cm)

170 – 220 lbs · in (200 – 250 kgf · cm)

300 – 360 lbs · in (340 – 420 kgf · cm)

● Precautions for brazing

Be sure to replace the air inside the tube with nitrogen to prevent oxide film from forming during the brazing process.

Be sure to use a damp cloth or other means to cool the valve unit during brazing.

Work method

1. Be sure to use nitrogen. (Oxygen, CO2, and CFC must not be used.)

2. Use a pressure-reducing valve on the nitrogen tank.

3. Do not use agents intended to prevent the formation of oxide film. They will adversely affect the

refrigeration oil, and may cause equipment failure.

4. The balance tube is not used if only 1 outdoor unit is installed.

Use the unit in the same conditions as when it was shipped from the factory.

W-3WAYECO-iU.indb27W-3WAYECO-iU.indb27 2011/11/0716:29:362011/11/0716:29:36

27

Page 28

4. ELECTRICAL WIRING

4-1. General Precautions on Wiring

(1) Before wiring, confirm the rated voltage of the unit

as shown on its nameplate, then carry out the

wiring closely following the wiring diagram.

(2) Provide a power outlet to be used exclusively for

each unit, and a power supply disconnect, circuit

breaker and earth leakage breaker for overcurrent

protection should be provided in the exclusive line.

(3) To prevent possible hazards from insulation failure,

the unit must be grounded.

(4) Each wiring connection must be done in

accordance with the wiring system diagram. Wrong

wiring may cause the unit to misoperate or become

damaged.

(5) Do not allow wiring to touch the refrigerant tubing,

compressor, or any moving parts of the fan.

(6) Unauthorized changes in the internal wiring can be

very dangerous. The manufacturer will accept no

responsibility for any damage or misoperation that

occurs as a result of such unauthorized changes.

(7) Regulations on wire diameters differ from locality

to locality. For field wiring rules, please refer to your

LOCAL ELECTRICAL CODES before beginning.

You must ensure that installation complies with all

relevant rules and regulations.

(8) To prevent malfunction of the air conditioner caused

by electrical noise, care must be taken when wiring

as follows:

● The remote control wiring and the inter-unit control

wiring should be wired apart from the inter-unit

power wiring.

● Use shielded wires for inter-unit control wiring

between units and ground the shield on both sides.

(9) If the power supply cord of this appliance is

damaged, it must be replaced by a repair shop

appointed by the manufacture, because special

purpose tools are required.

4-2. Recommended Wire Length and Wire Diameter for Power Supply System

Outdoor unit

Time delay fuse or

circuit capacity

U-72MF1U9

U-72MF1U9E

U-96MF1U9

U-96MF1U9E

Indoor unit

Type

K1 10 – 16 A

D1, U1, Y1, F1, M1, T1, P1, R1 10 – 16 A

E1 10 – 16 A

Control wiring

(A) Inter-unit (between outdoor and

indoor units) control wiring*

AWG #18 (0.75 mm²) AWG #18 (0.75 mm²) AWG #18 (0.75 mm²)

Max. 3,280 ft. Max. 1,640 ft. Max. 650 ft. (Total)

Time delay fuse or

40 A

45 A

circuit capacity

(B) Remote control wiring (C) Control wiring for group control

NOTE

* With ring-type wire terminal.

28

W-3WAYECO-iU.indb28W-3WAYECO-iU.indb28 2011/11/0716:29:372011/11/0716:29:37

(D) Inter-outdoor unit control wiring

AWG #18 (0.75 mm²)

Max. 980 ft.

Page 29

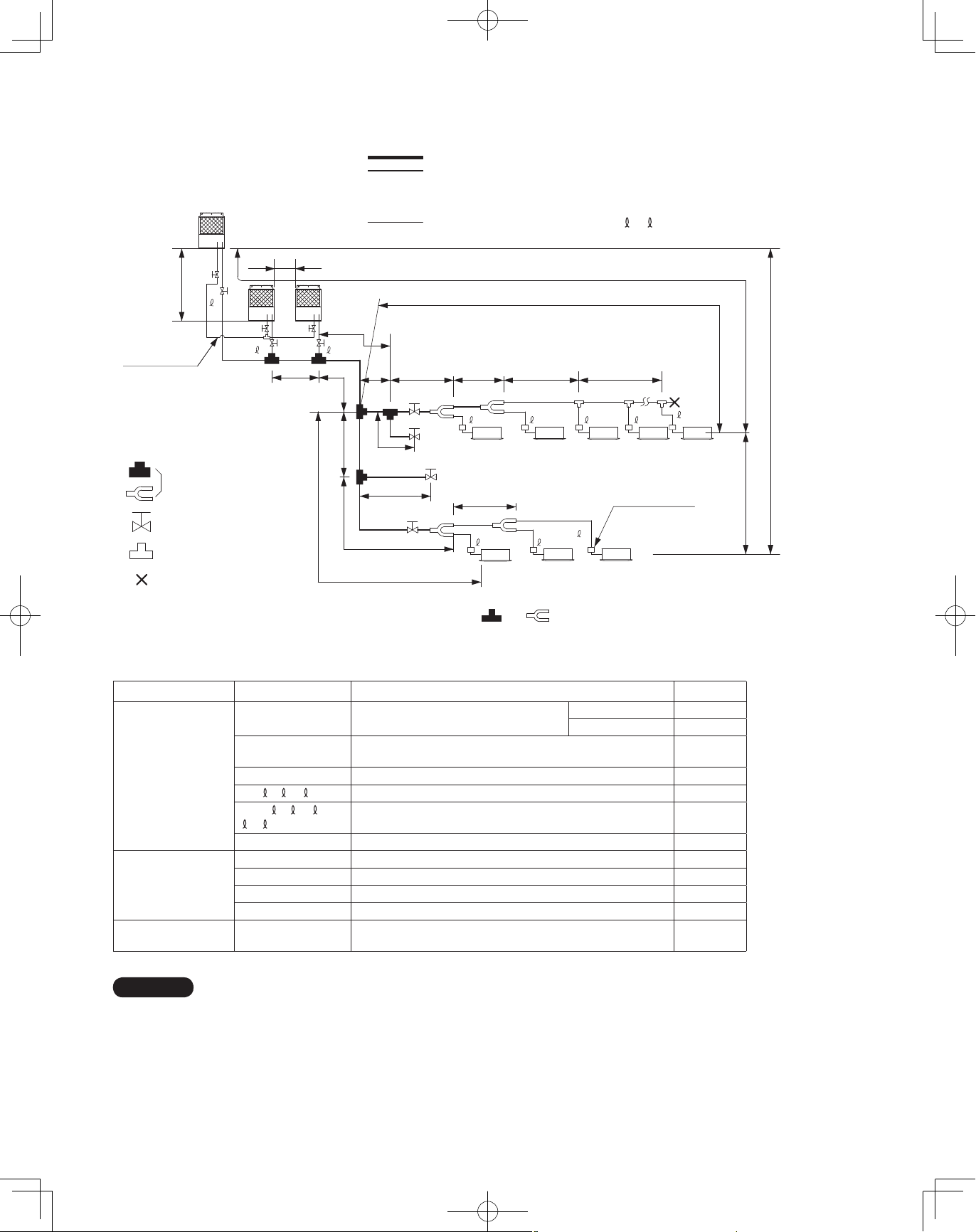

4-3. Wiring System Diagram

Power supply

208 / 230V, 60Hz, 1-PH

Remote

Controller

WHT

BLK

Power supply

208 / 230V, 60Hz, 1-PH

Remote

Controller

WHT

BLK

Group control:

Power supply

208 / 230V, 60Hz, 1-PH

L1

L2

Ground

1

1

2

2

L1

L2

Ground

1

1

2

2

L1

L2

Ground

Indoor

C

unit (No. 1)

L1

L2

U1

U2

R1

R2

Indoor

unit (No. 2)

L1

L2

U1

U2

R1

R2

Indoor

unit (No. 3)

L1

L2

U1

U2

R1

R2

Outdoor unit

A

INV unit

1

2

3

4

L1

L2

L3

*

L1

Power supply

L2

208 / 230V, 60Hz, 3-PH

L3

Ground

A

Inter-outdoor unit control wiring

D

Outdoor unit

INV unit

L1

L2

3

L3

4

A

*

L1

Power supply

L2

208 / 230V, 60Hz, 3-PH

L3

Ground

Disconnect switch

*

(Field Supply)

* NOTE:

Disconnect Switch may be needed by the

National/Local code.

ALWAYS COMPLY WITH NATIONAL AND

LOCAL CODE REQUIREMENTS.