Panasonic TX-25P80T Service Manual

TX-25P80T

MX-10 Chassis

Order No. MTV0110238C3

Colour Television

Specification

Power Source AC Auto 110-240 V, 50/60 Hz

Power Consumption 138 W

Standby condition : 0.8 W

Aerial Terminal Impedance : 75Ω, Coaxial type

Tuning System Frequency Synthesizer

Auto Search Tuning

Pos : 100 Positions

Receiving System 17 Systems

Receiving Channels Regular TV

VHF BAND

UHF BAND

21-69 (PAL G,H,I/SECAM G,K,K1)

CATV

Intermediate Frequency

2-12 (PAL/SECAM B, K1)

0-12 (PAL B AUST.)

1-9 (PAL B N.Z.)

1-12 (PAL/SECAM D)

1-12 (NTSC M Japan)

2-13 (NTSC M U.S.A.)

28-69 (PAL B AUST.)

13-57 (PAL D,K)

13-62 (NTSC M Japan)

14-69 (NTSC M U.S.A.)

S1-S20 (OSCAR)

1-125 (U.S.A. CATV)

C13-C49 (JAPAN)

S21-S41 (HYPER)

Z1-Z37 (CHINA)

Video

Sound

Colour

Receiving Stereo Sound System QUADRA STEREO / TEXT

Video/Audio/Terminals

AV 1, 2, 3

Y/PB/PR

Monitor Out

High Voltage 31.0 (+0.7, -1.5kV) at zero beam

Picture Tube A60LUQ085X Type 25 (60 cm)

Audio Output 16 W speaker

Dimensions (WxDxH) 634 mm x 471 mm x 534 mm

Weight (Mass) 37 kg (Net)

Accessories Supplied

Remote Control Transmitter 1. R6(AA) Battery x 2

31.5 MHz (D,K) / 32.5 MHz (B,G)

32.0 MHz (I) / 32.5 MHz (M)

33.57 MHz (PAL) /

33.6 MHz (SECAM)

34.42 MHz (NTSC) /

33.75 MHz (SECAM)

IN S-Video Y:1.0Vp-p 75Ω

DVD IN S-Video C:0.3Vp-p 75Ω

(Phone type) Y:1.0Vp-p 75Ω PB,

PR:0.7Vp-p 75Ω Video 1.0Vp-p

75Ω Audio Approx. 400mV 47KΩ

Video 1,0Vp-p 75Ω

Audio Approx. 400mV 47KΩ

Measured diagonally, 104°

38.0 MHz

current

deflection

© 2001 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

TX-25P80T

Partlist

Note:

Specifications are subject to change without notice. Mass and

Dimensions shown are approximate.

CONTENTS

Page Page

1 Safety Precautions

1.1. General Guide

1.2. Leakage Current Cold Check

1.3. Leakage Current Hot Check (See Fig. 1)

1.4. X-Radiation

2 Location of Controls and Circuit Boards

2.1. BACK VIEW

2.2. LOCATION AND FUNCTION NAME OF CIRCUIT BOARD

3 Service Hints

3.1. HOW TO MOVE CHASSIS INTO SERVICE POSITION.

4 MARKET MODE FUNCTION

5 ADJUSTMENT PROCEDURE

5.1. B VOLTAGE

5.2. RF AGC

5.3. HIGH VOLTAGE

5.4. SUB TINT

5.5. SUB CONTRAST

5.6. PAL COLOUR OUTPUT

5.7. NTSC COLOUR OUTPUT

3

3

3

3

3

4

4

4

5

5

6

8

8

8

8

8

8

9

9

5.8. COLOUR PURITY

5.9. CONVERGENCE

5.10. WHITE BALANCE (MARKET MODE CHK 3)

6 CONDUCTOR VIEWS

6.1. T-Board (TNP4G115AH) and L-Board (TNP4G107AW)

6.2. A-Board (TNP4G164AQ)

6.3. H-Board (TNP4G173AB), X-Board (TNP4G108BC) and

7 SCHEMATIC DIAGRAMS

7.1. SCHEMATIC DIAGRAM FOR MODEL TX-25P80T (MX10A CHASSIS)

7.2. Main Board (TNP4G164AQ)

7.3. Rear AV Circuit (TNP4G173AB)

7.4. CRT Circuit (TNP4G107AW)

7.5. Pincushion Circuit (TNP4G108BC)

7.6. Teletext Circuit (TNP4G115AH)

9 Replacement Parts List

9.1. Replacement Parts List Notes

9.2. Replacement Parts List

10

10

11

13

13

14

16

17

17

18

20

21

22

23

27

29

29

30

2

TX-25P80T

1 Safety Precautions

1.1. General Guide

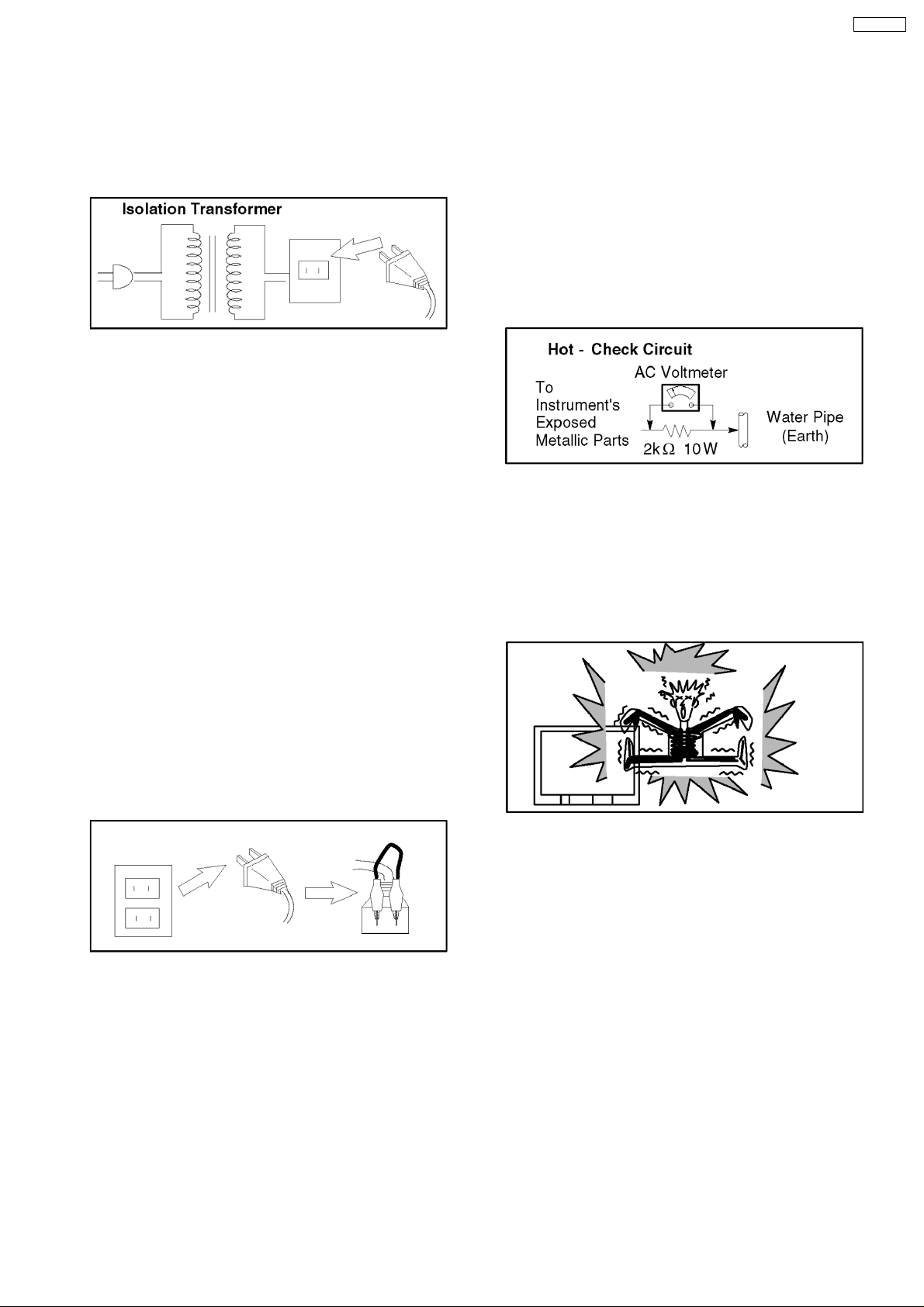

1. It is advisable to insert an isolation transformer in the AC

supply before servicing a hot chassis. Fig. 1.

Fig. 1

2. When servicing, observe the original lead dress, especially

the lead dress in the high voltage circuits. If a short circuit is

found, replace all parts which have been overheated or

damaged by the short circuit.

3. After servicing, observe that all the protective devices such

as insulation barriers, insulation papers, shields, and

isolation R-C combinations, are properly installed.

4. When the receiver is not to be used for a long period of

time, unplug the power cord from the AC outlet.

5. Potential, as high as

is in operation. Operation of the receiver without the

receiver power supply. Servicing should not be attempted

by anyone who is not thoroughly familiar with the

precautions necessary when working on high voltage

equipment. Always discharge the anode of the picture tube

to the receiver chassis before handling the tube.

After servicing make the following leakage current checks to

prevent the customer from being exposed to shock

hazards.

30.0

kV is present when this receiver

1.3. Leakage Current Hot Check

(See Fig. 1)

1. Plug the AC cord directly into the AC outlet. Do not use an

isolation transformer for this check.

2. Connect a 2 kΩ, 10 W resistor in series with an exposed

metallic part on the receiver and an earth such as a water

pipe.

3. Use an AC voltmeter, with high impedance type, to

measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point. Fig. 3.

Fig. 3

5. Reverse the ACplug in the AC outlet and repeat each of the

above measurements.

6. The potential any point should not exceed

case of a measurement being outside of the limits specified,

there is a possibility of a shock hazard, and the receiver

should be repaired and re-checked before it is returned to

the customer. Fig. 4.

1.0 V rms

. In the

1.2. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two

prongs on the plug. Fig. 2.

Fig. 2

2. Turn on the receiver’s power switch.

3. Measure the resistance value, with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the receiver, such as screw heads, aerials,

connectors, control shafts, etc. When the exposed metallic

part has a return path to the chassis, the reading should be

ΩΩΩΩ

4M

between

not have a return path to the chassis, the reading must be

zero.

and 20 M

ΩΩΩΩ

. When the exposed metal does

Fig. 4

1.4. X-Radiation

Warning :

1. The potential sources of X-Radiation in TV sets are the EHT

section and the picture tube.

2. When using a picture tube test rig for service, ensure that

the rig is capable of handling

Radiation.

Note:

It is important to use an accurate periodically calibrated

high voltage meter.

1. Set the brightness to minimum.

2. Measure the High Voltage. The meter reading should

indicate

tolerance, immediate service and correction is required to

prevent the possibility of premature component failure.

3. To prevent the possibility of X-Radiation, it is essential to

use the specified picture tube.

30.0 +0.7, -1.5kV

28.5 kV

. If the meter indication is out of

without causing X-

3

TX-25P80T

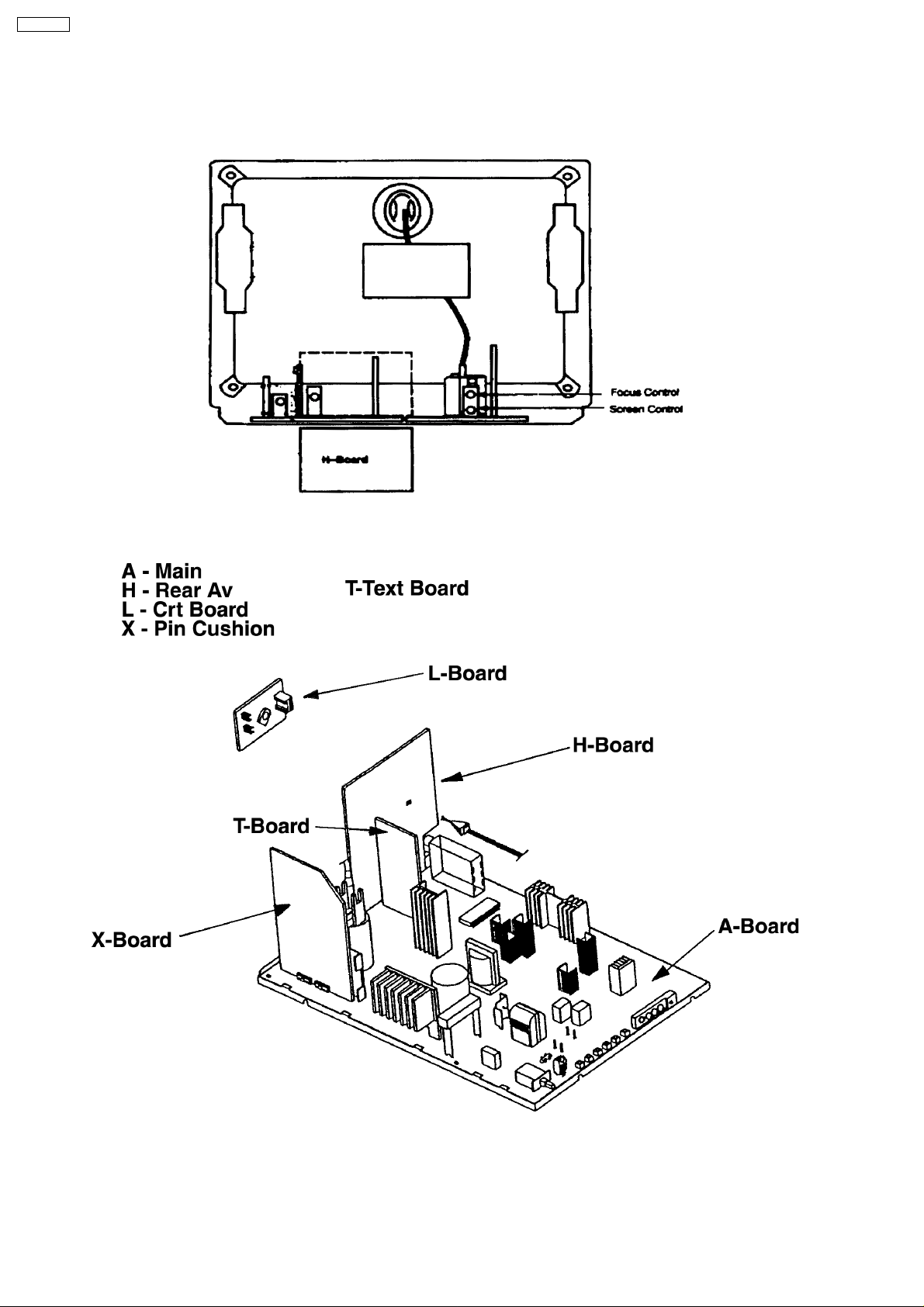

2 Location of Controls and Circuit Boards

2.1. BACK VIEW

2.2. LOCATION AND FUNCTION NAME OF CIRCUIT BOARD

4

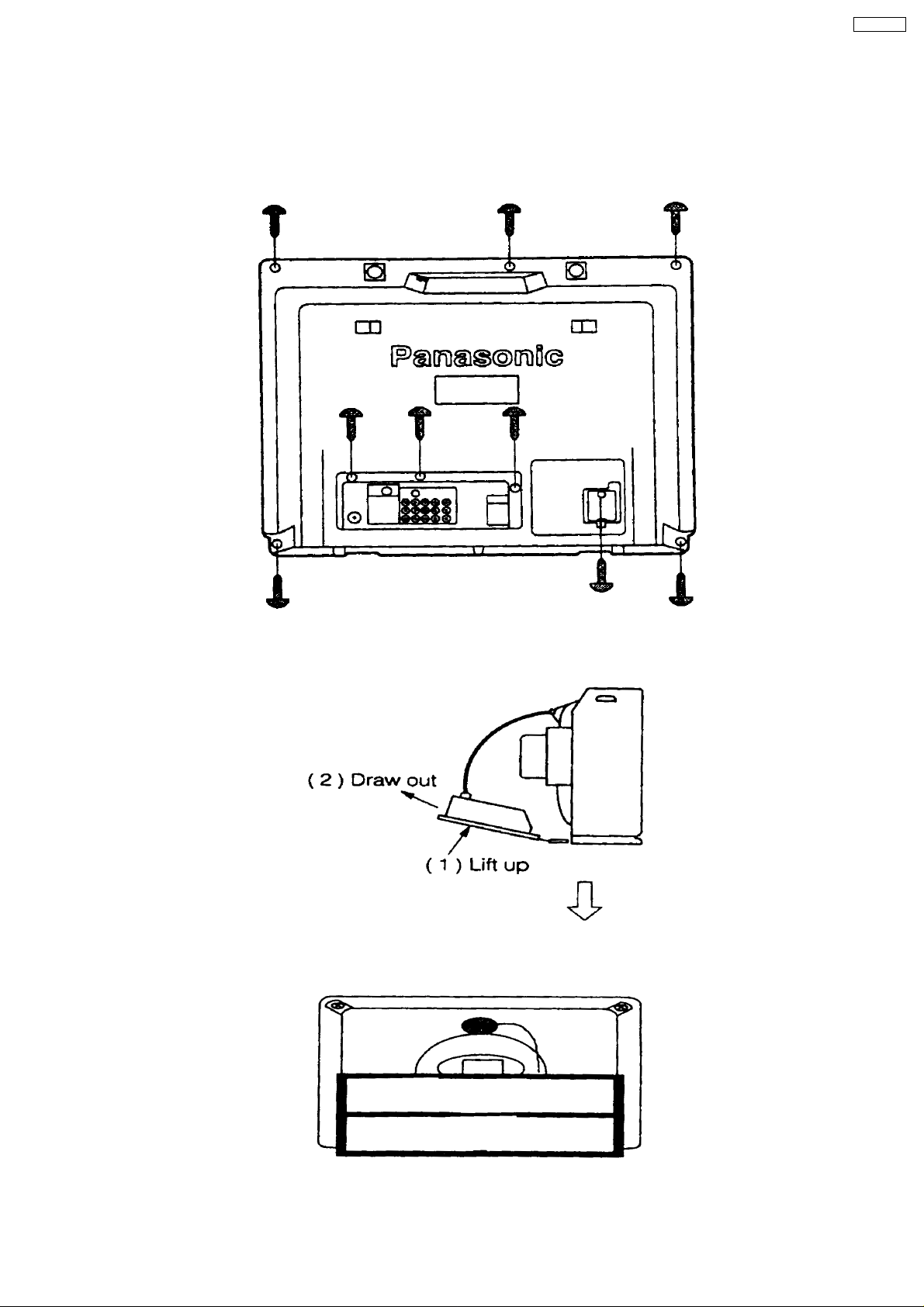

3 Service Hints

3.1. HOW TO MOVE CHASSIS INTO SERVICE POSITION.

1. Remove 9 screws.

TX-25P80T

2. Draw out Main Chassis.

3. Stand the Main Chassis.

5

TX-25P80T

4 MARKET MODE FUNCTION

Outline:

MPU controls the functions switching for each ICs through IIC bus in this chassis. The following setting and adjustment can be

adjusted by remote control in Market Mode.

1. Selection of Market Mode

Adjust the VOLUME “zero” and set OFF TIMER Button to 30 min. Then, simultaneously press the RECALL Button on the

remote control and the VOLUME DOWN button - the TV set.

2. Selection of CHK Mode

Cursor moves each CHK Mode by pressing “1” or “2” of 10 key button on the remote control.

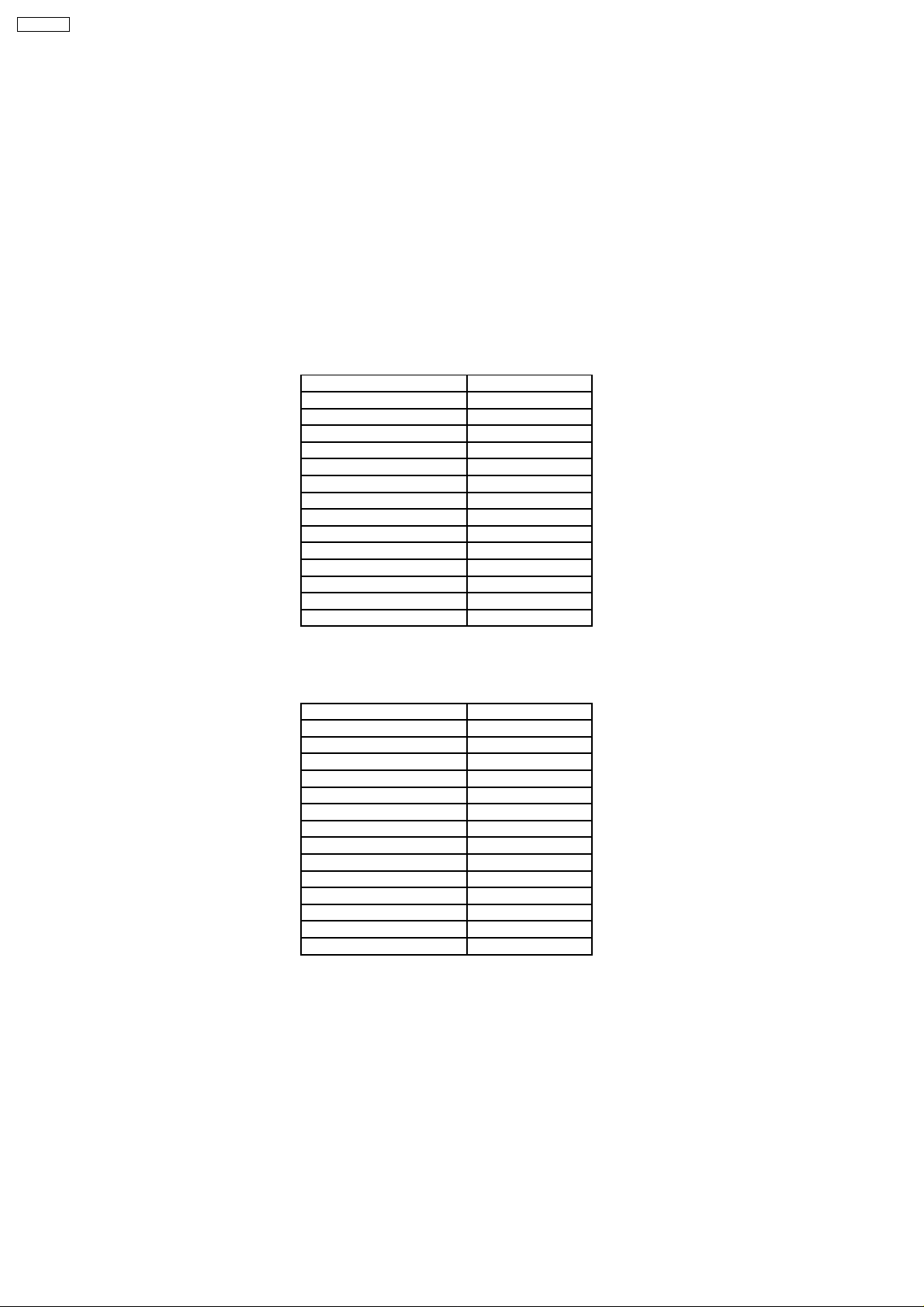

1. Option Code Setting Mode (CHK 1)

If the memory IC (IC1102) is replaced, option code should be re-memorized. Option code can be changed by pressing Volume

“+” or “-” button. To memorize, press “0” of the 10 key button.

Display Adj. Range

COLOUR SYSTEM 0~6

MX 10A OFF / ON

C4 BIT OFF / ON

NOISE MUTE OFF / ON

SPEED OFF / ON

VCR / GAME OFF / ON

YUV OFF / ON

AV3 OFF / ON

STEREO OFF / ON

GEO 0~2

SASO 0~2

TEXT OFF / ON

PANA DISPLAY OFF / ON

SOUND SYS 0~5

2. VCJ Adjustment Mode

To change the screen (item) in CHK mode, press “3” or “4” of the 10 key button. Then the Date and Level changes by pressing

Volume “+” or “-” button.

Display Adj. Range

SUB COLOUR 00H ~ 3FH

COLOUR 0~63

RF AGC 00H ~ FFH

SECAM B-Y 00H ~ 0FH

SECAM R-Y 00H ~ 0FH

B-Y 00H ~ 0FH

R-Y 00H ~ 0FH

SUB TEXT CONT 00H ~ 3FH

SHARPNESS 0~63

SUB Y CONT 00H ~ 3FH

CONT 0~63

SUB BRIGHT 00H ~ FFH

BRIGHT 0~63

SUB NTS-TINT 00H ~ 3FH

6

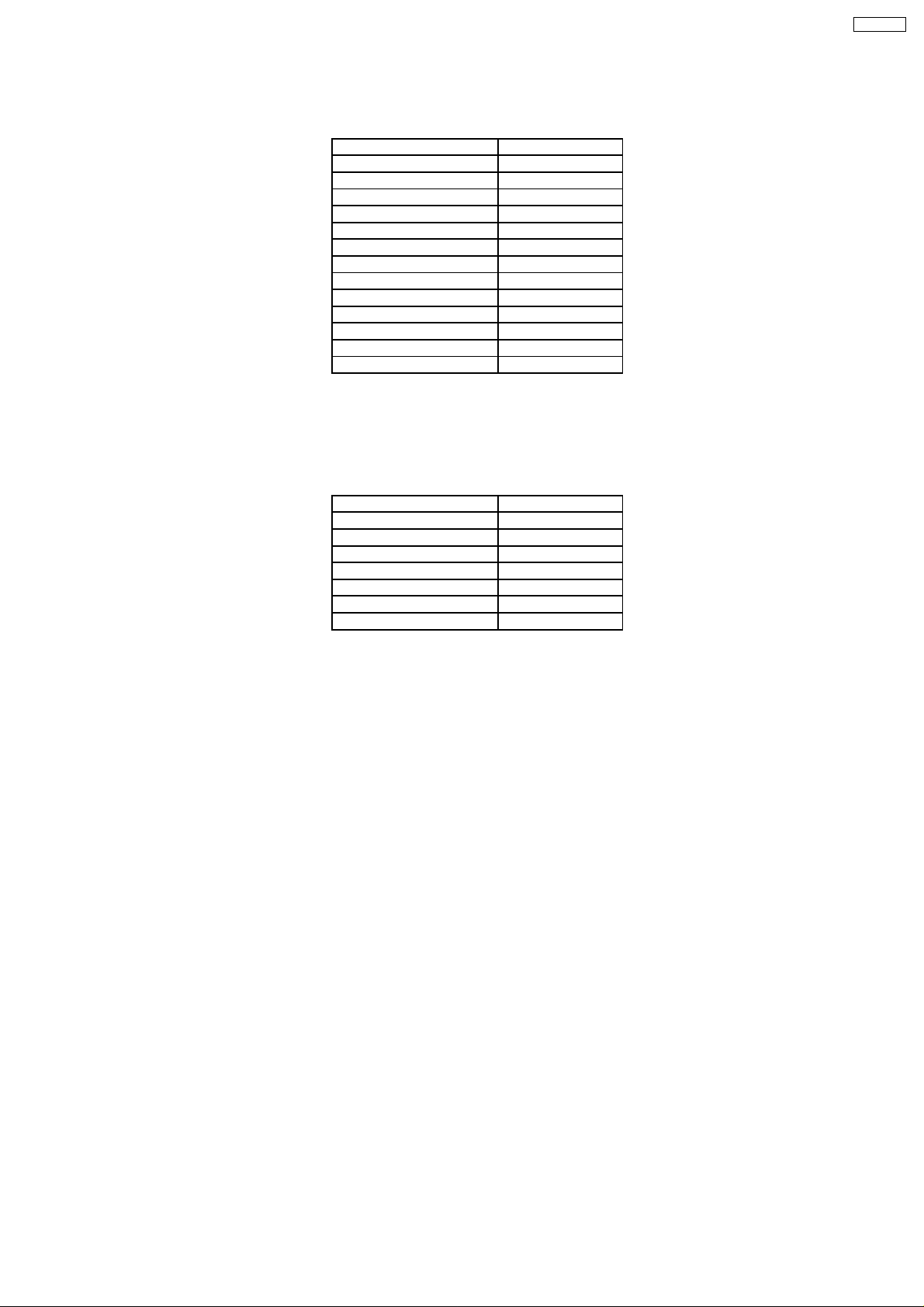

3. Pincushion Adjustment Mode

To change the screen (item) in CHK mode, press “3” or “4” of the 10 key buttons. Then the Date and Level changes by pressing

Volume “+” or “-” button.

Display Adj. Range

PARABOLA 00H ~ 3FH

60 V-HEIGHT 00H ~ 3FH

50 V-HEIGHT 00H ~ 3FH

SUB GEO 00H ~ 3FH

GEOMAGNETIC -9 AUTO 9

V CENTER 00H ~ 07H

50Hz CENTER 00H ~ 1FH

EW-CORNER 1 00H ~ 0FH

TRAPEZOID 00H ~ 3FH

V-LINEAR 00H ~ 3FH

60 VS CORRECT 00H ~ 3FH

50 VS CORRECT 00H ~ 3FH

H-WIDTH 00H ~ 3FH

Note : Picture will be changed to one horizontal line by pressing “5” of the 10 key button in the remote control. (1 - 5).

4. White Balance Adjustment Mode

To change the screen (item) in CHK mode, press “3” or “4” of the 10 key buttons. Then the Date and Level changes by pressing

Volume “+” or “-” button.

Display Adj. Range

B. DR 00H ~ FFH

G. DR 00H ~ FFH

SUB.BR 00H ~ FFH

BRIGHT 0~63

B - CUT 00H ~ FFH

G - CUT 00H ~ FFH

R - CUT 00H ~ FFH

TX-25P80T

7

TX-25P80T

5 ADJUSTMENT PROCEDURE

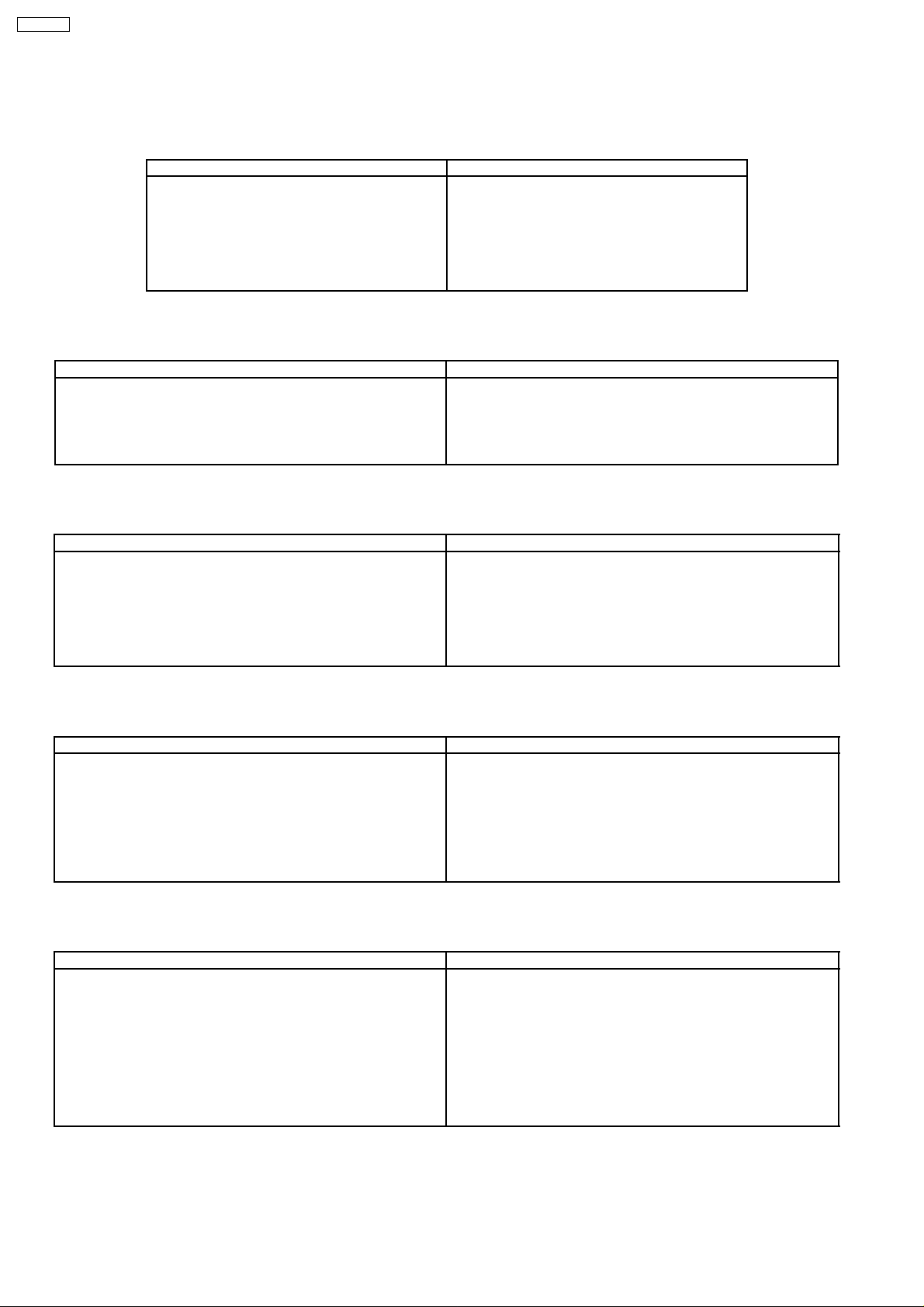

5.1. B VOLTAGE

Item/Preparation Adjustment Procedure

1. Operate the TV set.

2. Set controls : (MARKET MODE CHK 2)

Bright ............. Minimum

Contrast ......... Minimum

Volume ............. Minimum

5.2. RF AGC

Item/Preparation Adjustment Procedure

1. Receive a colour bar pattern.

2. Set the input level to 66 (+1.2) db.

(75Ω opened)

3. Connect an oscilloscope to AGC : TPA 20 with DC mode.

1. Confirm that the indicated test points for the

specified voltage:

TPA 140 : 141±2V

TPA 12 : 12±1.0V

TPA 9 : 9±1V

TPA 5 & TPA 32 : 5±1V

TPA 220 : 220±15V

1. Set RF AGC Control such as to procedure a snowy picture.

2. Set RF AGC Control at the point just before the voltage at AGC :

TPA 20 begins to drop.

3. Increase the input level by 3 db and confirm that the voltage

changes.

5.3. HIGH VOLTAGE

Item/Preparation Adjustment Procedure

1. Operate the TV set.

2. Receive the crosshatch pattern.

3. Set to 0 Beam

(Screen Control : min. CONTRAST : min)

5.4. SUB TINT

Item/Preparation Adjustment Procedure

1. Receive a 3.58 MHz NTSC rainbow pattern

2. Connect oscilloscope to A21 pin 6.

3. Set controls:

BRT................CENTER

COLOUR........CENTER

CONTRAST....MAX

NTSC TINT.....CENTER

AI....................OFF

5.5. SUB CONTRAST

Item/Preparation Adjustment Procedure

1. Receive a colour bar pattern.

2. Connect an oscilloscope to TPA40.

3. Connect a short jumper between D11-1 and D11-2 / TPA53 and

TPA54 FBT pin 3 or TPA34 and TPA32.

4. Set controls:

Picture menu ........ Dynamic Normal

AI ............................. off

1. Connect a DC voltage meter to D850 cathode and confirm the

voltage is 141.0±2.0V.

2. Connect a high voltage meter (Electrostatic Type) to an anode of

the picture tube.

3. Confirm that the high voltage is within the range of 31.0+0.7V,

-1.5V.

1. Adjust Sub NTSC Tint so that the peak of level of waveform is

similar to Fig. 3

2. Receive the Rainbow pattern (3.58 MHz NTSC) on both of Main

and Sub pictures.

3. Adjust Sub NTSC Tint 2 so that the peak of level of 1.3±0.5V

1. Adjust Bright Colour:

a=2.4±0.2Vp-p

2. Adjust Sub Contrast Colour:

b=2.4±0.1Vp-p

8

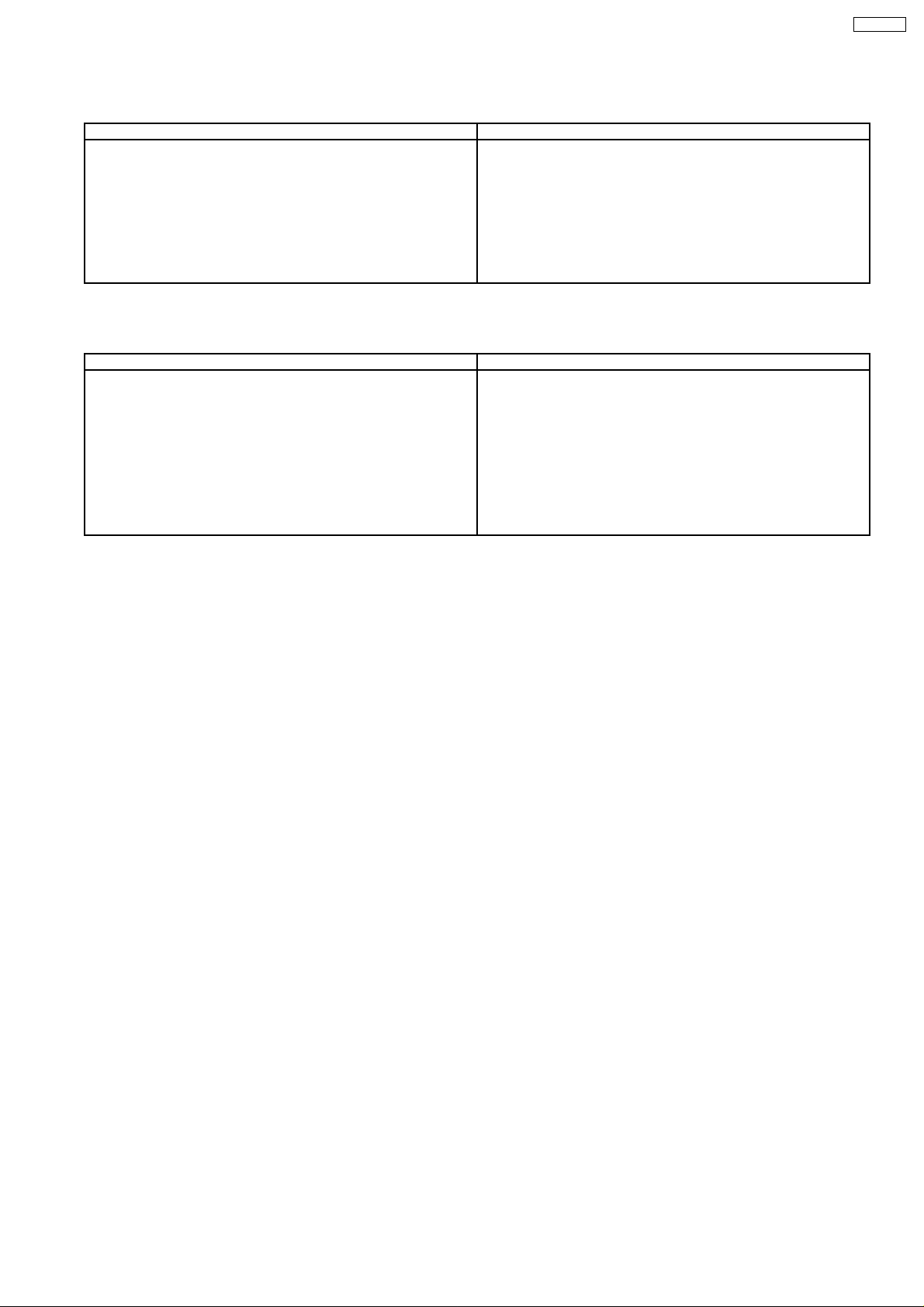

5.6. PAL COLOUR OUTPUT

Item/Preparation Adjustment Procedure

1. Receive PAL colour bar pattern.

2. Connect an oscilloscope probe to TPA40.

3. Connect a short jumper to FBT pin 3 or TPA34 and TPA32.

4. Set control :

Picture menu.....................DYNAMIC NORMAL

AI.................................... ..off (for model with AI only)

5.7. NTSC COLOUR OUTPUT

Item/Preparation Adjustment Procedure

1. Apply 3.58MHz NTSC Rainbow pattern.

2. Connect an oscilloscope to TPA40.

3. Connect a short jumper to FBT pin 3 or TPA34 and TPA32.

4. Set control :

Picture menu.......................DYNAMIC CONTROL

Channel Colour Set...........STD

TX-25P80T

1. Adjust Bright Control.

a = 2.3±-0.2Vp-p

2. Adjust Sub Colour control.

3. Connect the osciloscope probe to TPA40.

4. Connect the waveform.

b = 3.1±-0.5Vp-p

1. Adjust Bright Control.

a = 2.3±-0.2Vp-p

2. Connect the waveform.

b = 1.3±-0.5Vp-p

9

Loading...

Loading...