A

A

TX-22LX2

LH35 Chassis

ORDER NO. PCZ0408011C2

Wide LCD TV

Power Source

C 220-240V, 50/60Hz

Power Consumption

verage use: 90W

Standby condition: 1.3W

LCD

Wide XGA (1,280 × 720 pixels)

16 : 9 aspect ratio LCD panel

Screen Size

487.7mm(W) × 274.3mm(H)

Sound

Speaker

12cm × 4cm, 2pcs, 16W

Audio Output

6W (3W + 3W), 10% THD

Headphones

M3 (3.5 mm) Jack x 1

Receiving Systems/ Band name

PAL I

UHF E21 - 68.

PAL 525/60

Playback of NTSC tape from some PAL Video recorders

(VCR).

M.NTSC

Playback from M.NTSC Video recorders (VCR).

NTSC (AV input only)

Playback from NTSC Video recorders (VCR).

Aerial-Rear

UHF

Operating Conditions

Temperature: 5°C-35°C

Humidity: 5%-90% RH (non-condensing)

Connection Terminals

AV1 (Scart connecter)

21 Pin terminal (Audio/Video in, Audio/Video out, RGB in,

Q-Link)

AV2 (Scart connecter)

21 Pin terminal (Audio/Video in, Audio/Video out, S-Video

in, Q-Link)

AV3

VIDEO

RCA PIN Type × 1

S-VIDEO

Mini DIN 4-pin

AUDIO L-R

RCA PIN Type × 2

Dimensions (W x H x D)

Including TV Stand

592mm × 503.1mm × 260mm

TV Set Only

592mm × 420mm × 99mm

Weight

10kg Net

Note:

Design and Specifications are subject to change without notice.

Weight and Dimensions shown are approximate.

© 2004 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

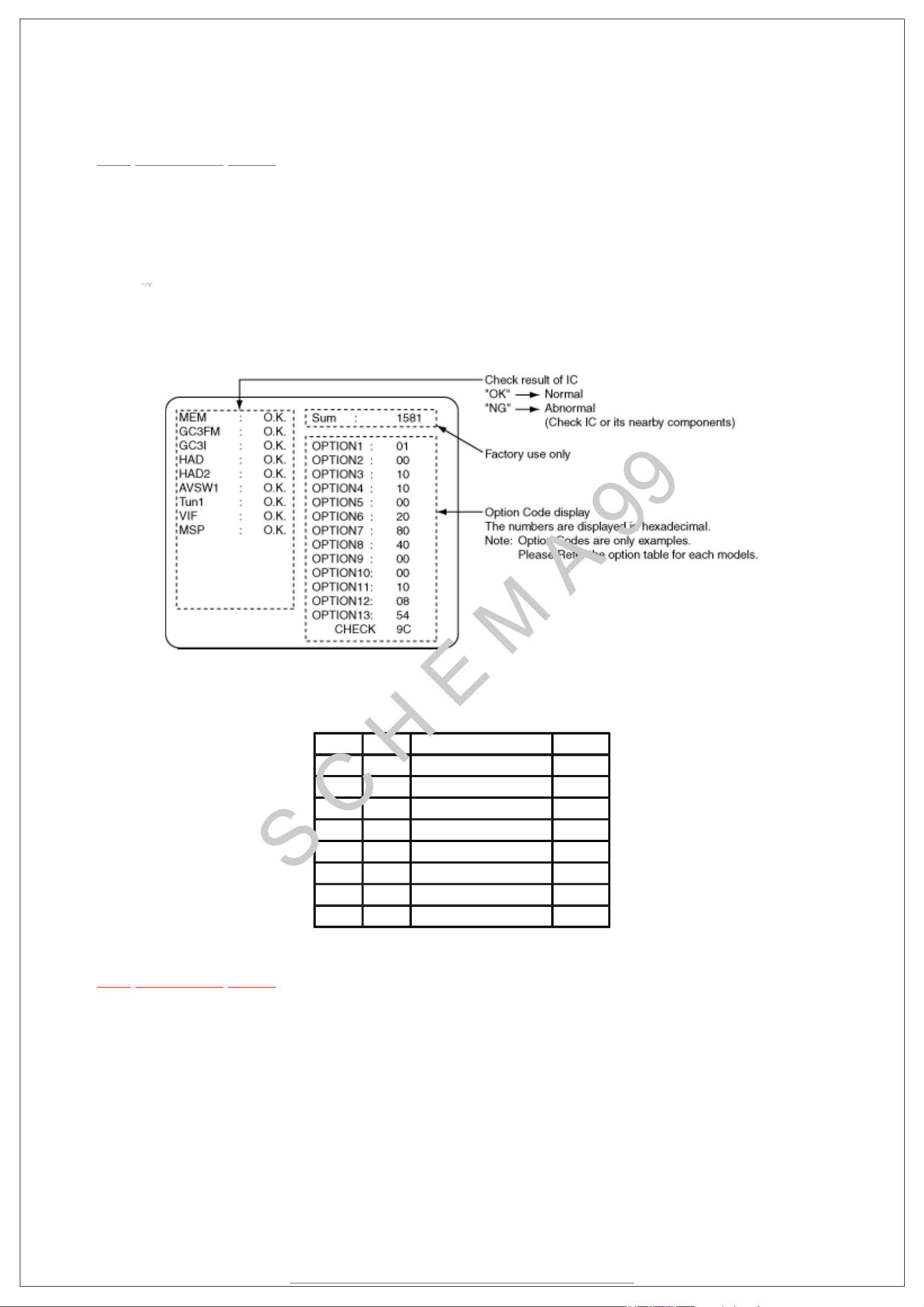

4 Self Check

TOP PREVIOUS NEXT

1.Self-Check is used to automatically check the bus lines and hexadecimal code of the TV set.

2.To get into the Self -Check mode press the Down (

) button on the customer controls at the front of the set, at the same time pressing the Recall

button on theremote control, and the screen will show :

3.Turn off the TV to reset JPEG Viewer circuit after SELF-CHECK.

If the CCU ports have been checked and found to be incorrect or not located then “--” will appear in

place of “O.K.”.

Display Ref .No. Description P.C.B.

MEM IC1107 EEPROM DG-Board

GC3FM IC4017 Global Core MAIN DG-Board

GC3I IC4003 Global Core DG-Board

HAD IC4001 SCART RGB A/D Converter DG-Board

HAD2 IC4002

AVSW1 IC3001 AV Selector A-Board

Tun1 TU101 Tuner B-Board

MSP IC2501 Stereo Decoder A-Board

OSD RGB A/D Converter DG-Board

TOP PREVIOUS NEXT

http://servis-manual.com/

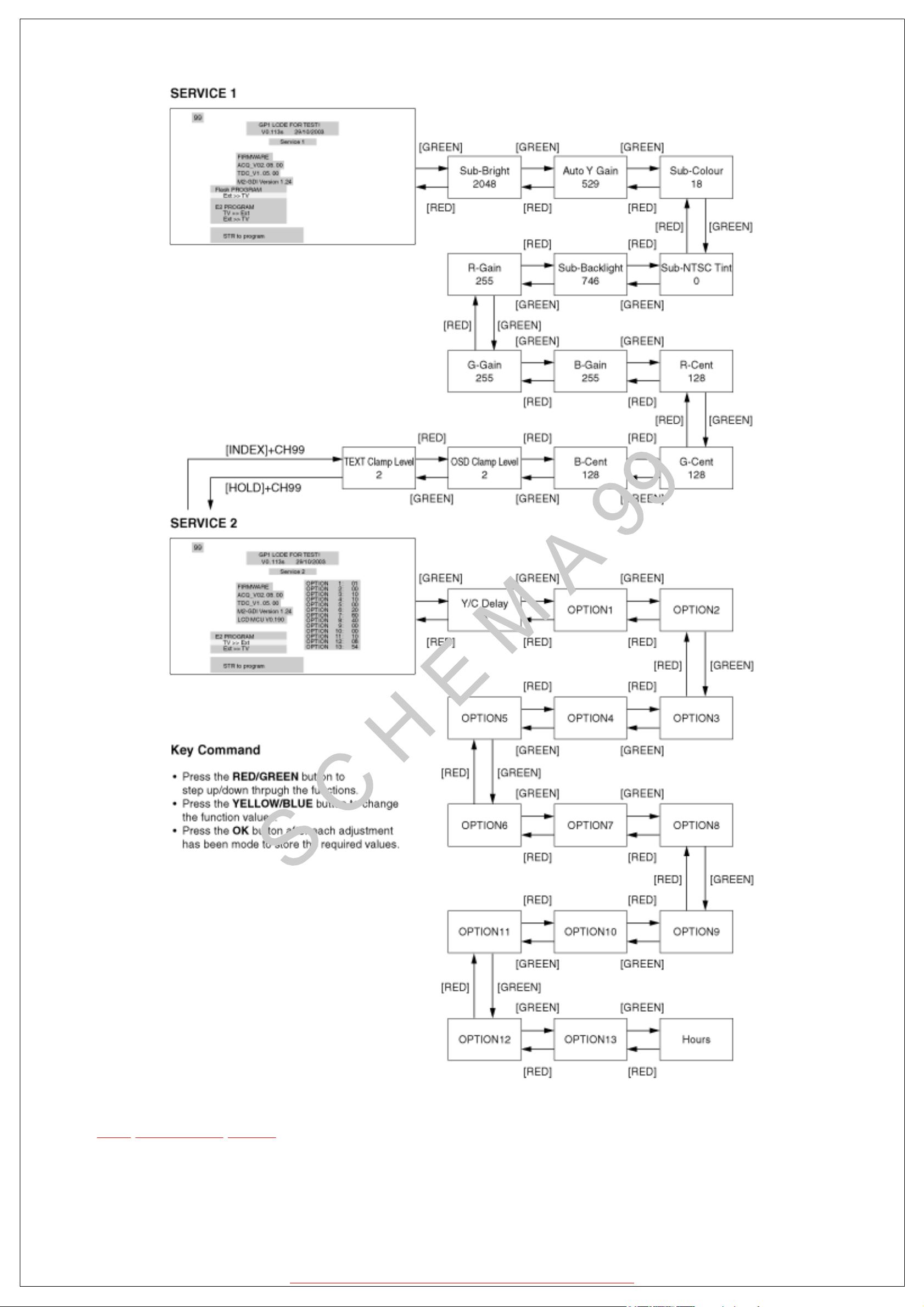

8.1 How to enter SERVICE 1

TOP PREVIOUS NEXT

1.In main menu, move to choose sound menu, set BASS to MAXIMUM, and set TREBLE to

MINIMUM.

2.Simultaneously press INDEX button on remote control and DOWN button [

] on the TV set.

TOP PREVIOUS NEXT

http://servis-manual.com/

8.2 How to enter SERVICE 2

TOP PREVIOUS NEXT

1.Select the TEXT Clamp Level (service 1).

2.Set the channel to CH99.

3.Press HOLD button on remote control.

Note:

To exit to Service mode, press N or Power button on remote control.

http://servis-manual.com/

TOP PREVIOUS NEXT

http://servis-manual.com/

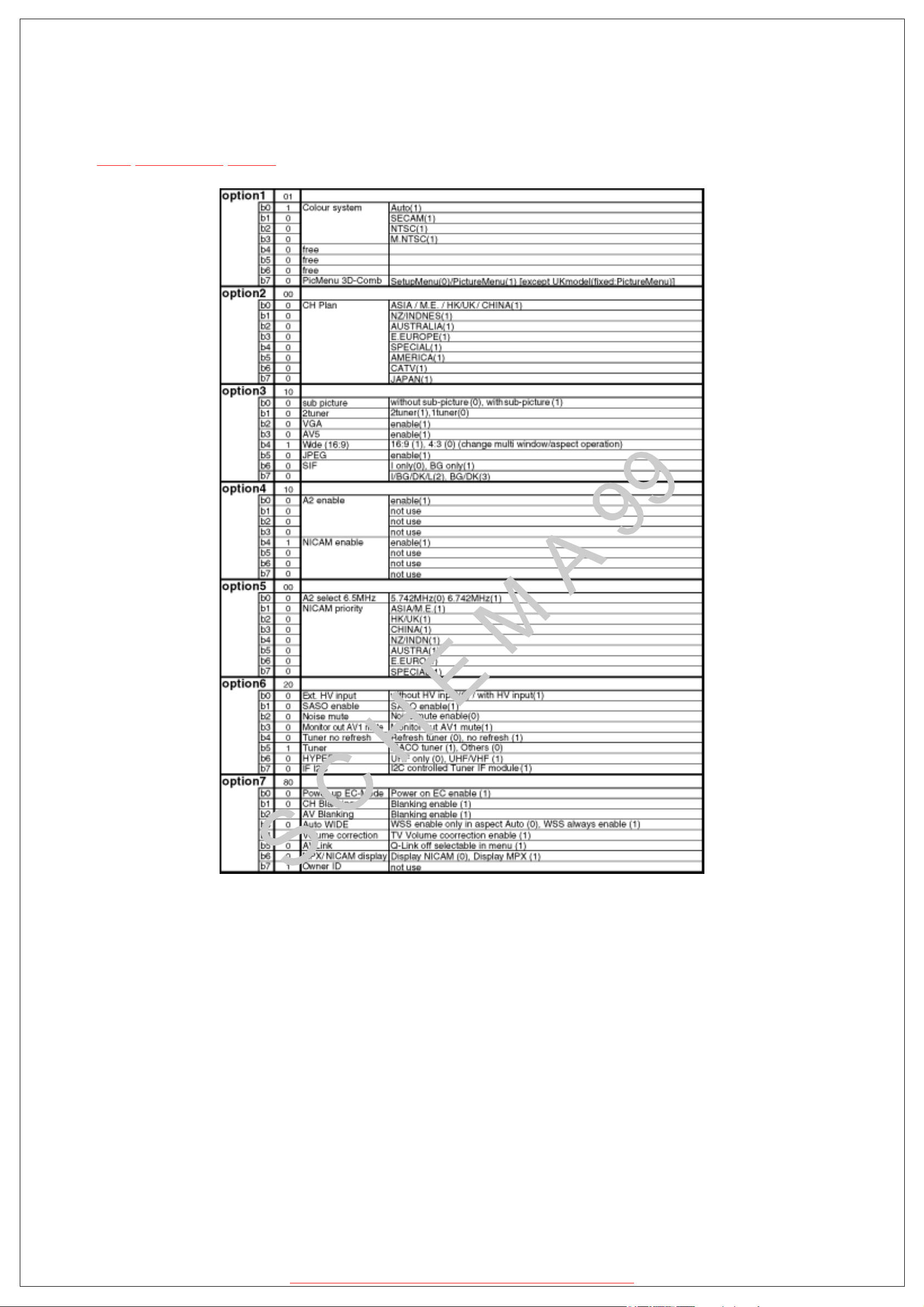

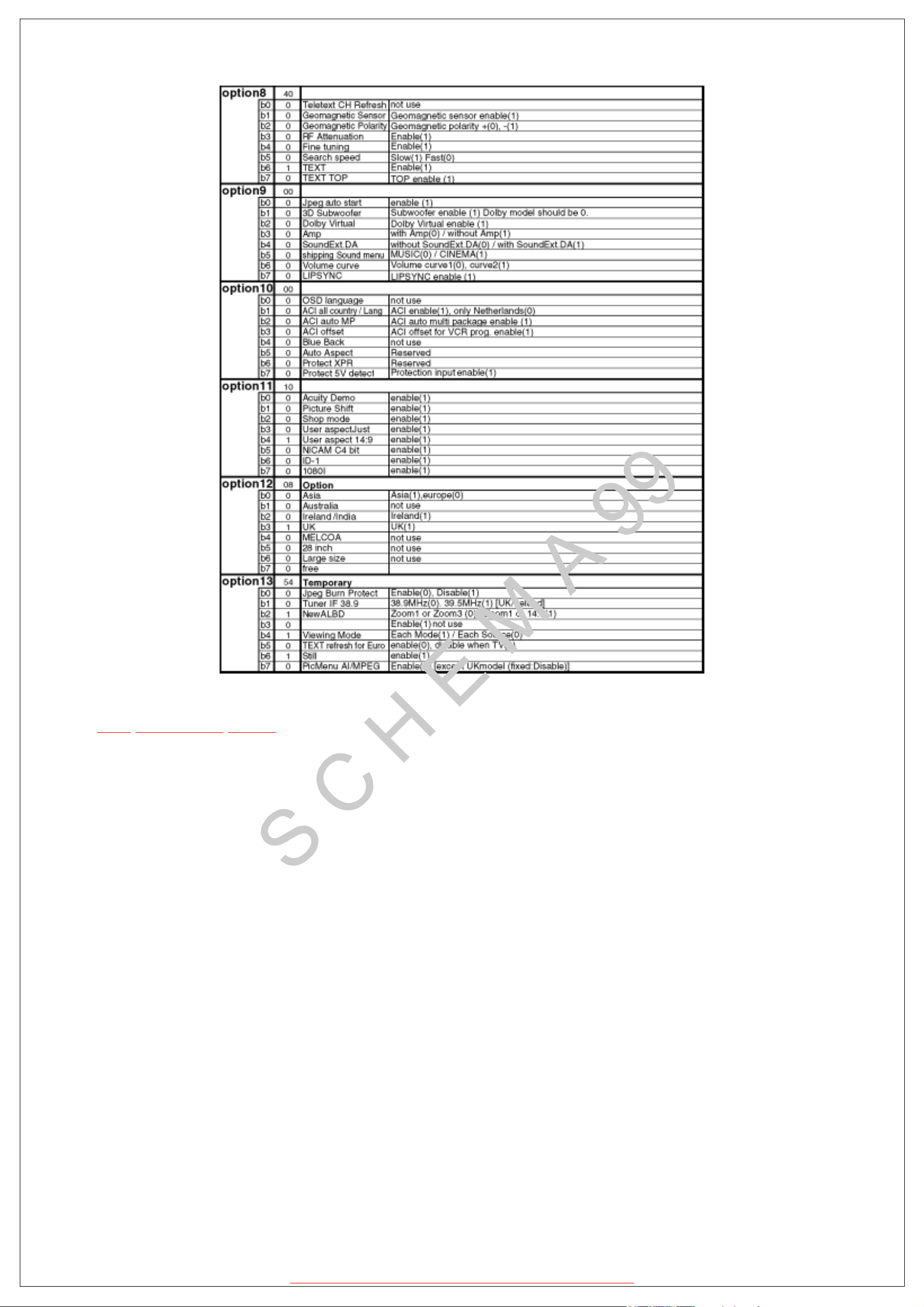

8.3 Option Description

TOP PREVIOUS NEXT

http://servis-manual.com/

TOP PREVIOUS NEXT

http://servis-manual.com/

9.1.1 RF video

TOP PREVIOUS NEXT

Instrument Name Connect to Remarks

Remote controller

Internal signal (studio color bar)

RF input

1.Receive full color bar by RF signal input.

(Aspect mode : wide, Viewing mode: standard, LCD AI: OFF)

2.Go to "Auto Y Gain" under Service 1 and make automatic adjustment of video signal level by

the blue key.

¡

When Service 1 appears, presetting takes place automatically as shown below.

¡

Sharpness: 0

¡ AI: OFF

¡

3D-Comb filter: On

3.Press STR key to write the value of adjustment results to EEPROM.

4.Check that the automatic adjustment of video signal level has completed normally.

¡ When the adjustment is completed normally, the "Auto Y Gain" color turns black.

Note:

In the adjustment mode, the M2 MCU changes automatically to the mode shown in the left.

TOP PREVIOUS NEXT

http://servis-manual.com/

9.2 WB Adjustment

TOP PREVIOUS NEXT

Instrument Name Connect to Remarks

1. Remote controller

2. LCD WB meter (Minolta CS-1000 equivalent)

3. Communication jig

4. Computer for external control

l

Basically perform checking using the production software and make automatic adjustment

Correlation can be also taken by CA-110 or equivalent

using external computer.

l

Let the panel stand for more than 3 hours at more than 20°C.

l

Basically perform assemble to completion in the ambient environment of room temperature

more than 20°C.

l

The aging time is more than 20 min at above room temperature.

1.Enter into WB adjustment in the plant adjustment mode and measure the WHITE brightness

data to check that it is higher than 400 cd /m2

(When it is below 400 cd /m2, make re-measurement in 30 minutes after cold-on.)

2.For the Excel calculation sheet, use "LX1 series, calculation software".

3.Using the jig, measure the brightness and chromaticity coordinates of single colors, white, red,

green and blue, at the maximum brightness (using basic data) and calculate the gamma data

corrected at the maximum brightness using Excel calculationsheet on the external computer.

4.Write the values calculated in 3 above in the gamma data part in EEPROM.

EEPROM Adr :

0C58h - 0C5Bh, 0C5Ch - C5Fh ...R(color temperature Normal)

0C08h - 0C0Bh, 0C0Ch - 0C0Fh ...G(color temperature Normal)

0C30h - 0C33h, 0C34h - 0C37h ...B(color temperature Normal)

5.Reflect the data in 4 above and select gray and measure the brightness and chromaticity

coordinate at that time and calculate the gamma data (color temperature, normal) and cool and

warm color temperatures, corrected at half-tone, using theexternal computer.

6.Write the values calculated in 5 above in the gamma data part in EEPROM.

EEPROM Adr:

0C58h - 0C5Bh, 0C5Ch - 0C5Fh ...R(color temperature Normal)

0C08h - 0C0Bh, 0C0Ch - 0C0Fh ...G(color temperature Normal)

http://servis-manual.com/

0C30h - 0C33h, 0C34h - 0C37h ...B(color temperature Normal)

0C50h - 0C53h, 0C54h - 0C57h ...R(color temperature Warm)

0C00h - 0C03h, 0C04h - 0C07h ...G(color temperature Warm)

0C28h - 0C2Bh, 0C2Ch - 0C2Fh ...B(color temperature Warm)

0C60h - 0C63h, 0C64h - 0C67h ...R(color temperature Cool)

0C10h - 0C13h, 0C14h - 0C17h ...G(color temperature Cool)

0C38h - 0C3Bh, 0C3Ch - 0C3Fh ...B(color temperature Cool)

7.Reflect the data in 6 above and CHECK that the chromaticity coordinates at check and GRAY,

are within the values given below.

CHECK: x= 0.264 ± 0.005 y= 0.269 ± 0.005

GRAY: x= 0.268 ± 0.005 y= 0.267 ± 0.005

¡

When writing data into EEPROM, make this procedure after sending the WP (write

protect) cancellation command (70 88 00).

Also, WP (write protect) setting command is 70 88 FF.

8.EEPROM DATA saving place for WB (gamma data) backup

<Housing address> <Writing address>

0C18h - 0C1Bh → 0C08h - 0C0Bh

0C1Ch - 0C1Fh → 0C0Ch - 0C0Fh

0C40h - 0C43h → 0C30h - 0C33h

0C44h - 0C47h → 0C34h - 0C37h

0C68h - 0C6Bh → 0C58h - 0C5Bh

0C6Ch - 0C6Fh → 0C5Ch - 0C5Fh

Note:

After completion of adjustment, record the completion time if it took more than 35 minutes after

aging.

LCD panels that do not fit in to the above check specification shall be discussed separately.

TOP PREVIOUS NEXT

http://servis-manual.com/

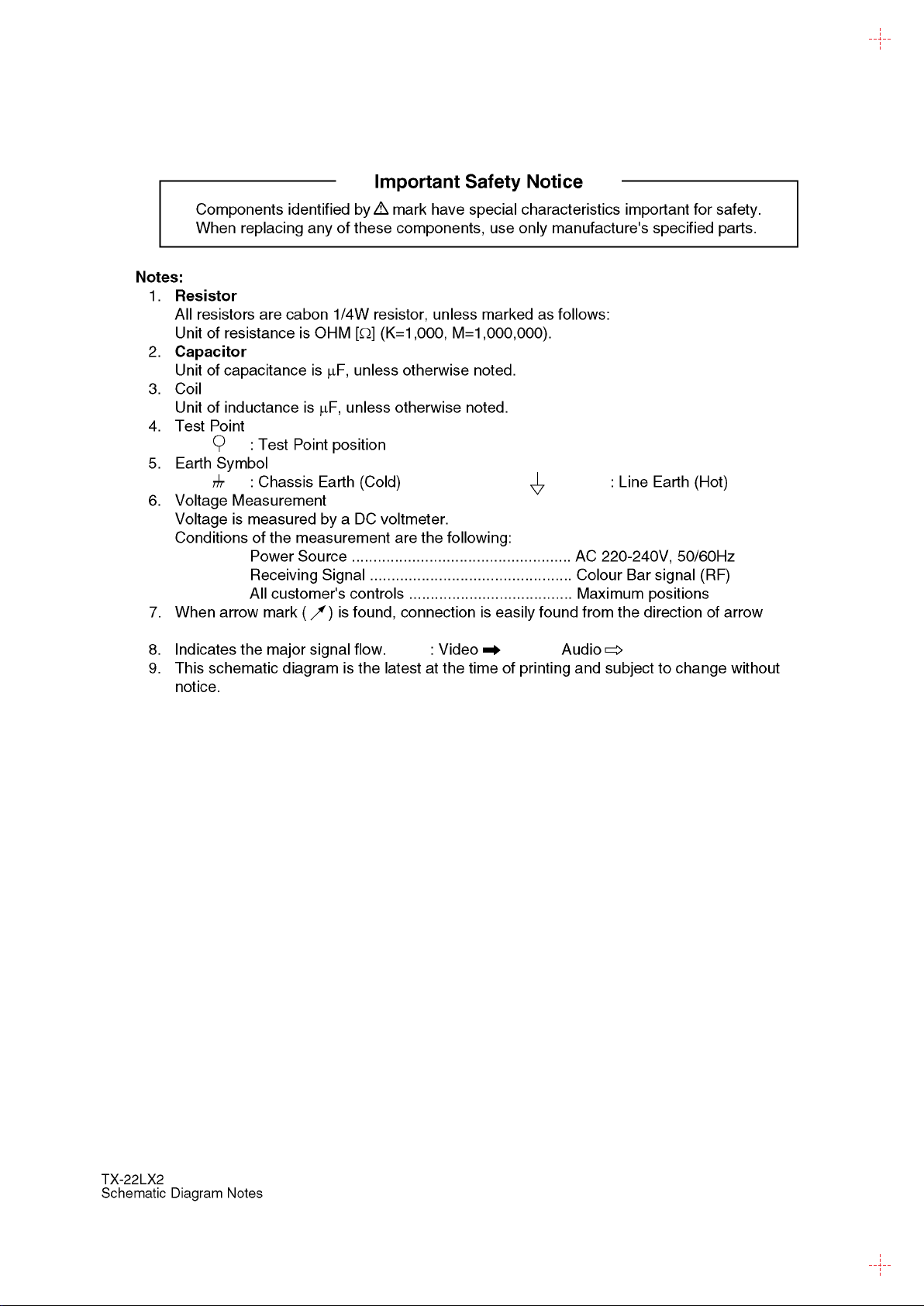

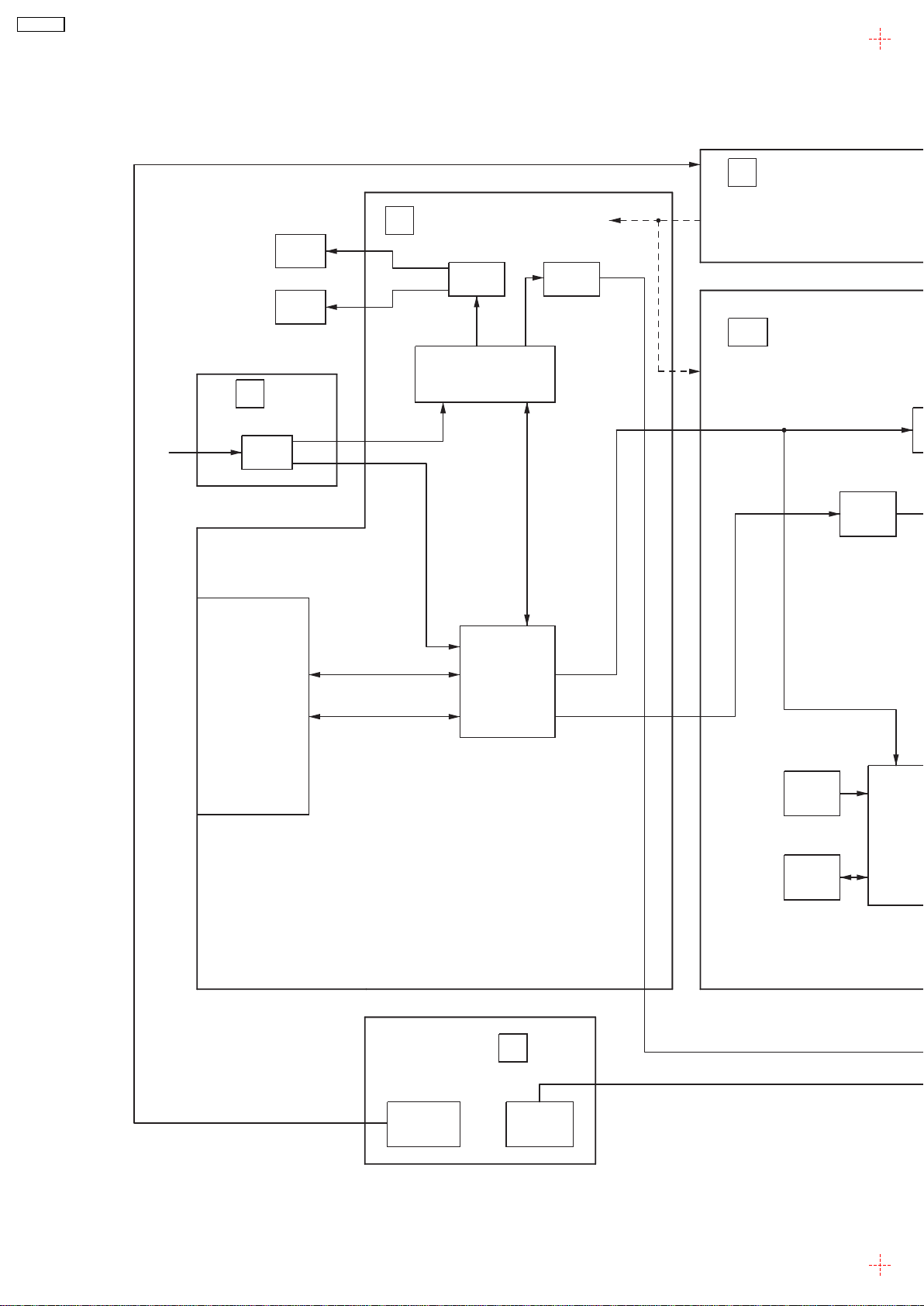

11 Block and Sche matic Diagrams

11.1. Schematic DiagramNotes

31

TX-22LX2

31

TX-22LX2

11.2. Main Block Diagram

B

SP

Left

SP

Right

P

UNIT

STB5V/REG5V

A

IC2100

Audio

Amp.

IC2200

HP

Amp.

INTERTER15V

UNREG32V

DG

Sound

processor

IC2501

PANEL VCC

STB5V,MAIN5V

STB3.3V,MAIN3.3V

MAIN1.8V,MAIN9V

IC4017

RF in

AV1

SCART

AV2

SCART

AV3/S

S-VIDEO

V

L,R

TU101

Tuner

L/R

V/R/G/B

TV_V

SIF

L/R

GC3FM

IC4002

RGB AD

AV

SW

V/Y

R/G/B

IC3001

IC1115

16M

FLASH

IC1104

IC1114

64M

SDRAM

TX-22LX2

Main Block Diagram

Main

Power SW

K

Key SW

32

Loading...

Loading...