Panasonic TH-65LFB70E Schematic

ORDER No. PCZ1406138CE

Service Manual

Touch Screen LCD Display

TH-65LFB70E

LA54 Chassis

This service information is designed for experienced repair technicians only and is not designed for use by the general public. It does not

contain warnings or cautions to advise non-technical individuals of potencial dangers in attempting to service a product. Products

powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or repair the

product or products deal within this service information by anyone else could result in serious injury or death.

There are special components used in this equipment which are important for safety. These parts are marked in the

Schematic Diagrams, Circuit Board Diagrams, Explorer Views and Replacement Parts List. It is essential that these

critical parts should be replaced with manufacturer´s specified parts to prevent shock, fire or other hazards. Do not

modify the original design without permission of manufacturer.

IMPORTANT SAFETY NOTICE

Warning

© Panasonic Corporation 2014.

Unauthorized copying

distribution is a violation of law.

and

Contents

2

SAFETY PRECAUTIONS ........................................... 3

GENERAL GUIDE LINES ...................................... 3

TOUCH – CURRENT CHECK ............................... 3

PREVENTION OF ELECTROSTATIC DISCHARGE

(ESD) TO ELECTROSTATICALLY SENSITIVE (ES)

DEVICES ................................................................... 4

ABOUT LEAD FREE SOLDER (PBF) ......................... 5

SUGGESTED PB FREE SOLDER ........................ 5

SERVICE NAVIGATION ............................................. 6

CHASSIS BOARD LAYOUT ................................. 6

SERVICE HINTS ........................................................ 7

APPLICABLE INPUT SIGNALS .................................. 8

SPECIFICATIONS .................................................... 10

SERVICE MODE ...................................................... 12

CAT (COMPUTER AIDED TEST) MODE ................. 12

IIC MODE .................................................................. 12

CD MODE ................................................................. 13

NW MODE ................................................................ 14

SD MODE, MS MODE .............................................. 15

ID MODE ................................................................... 16

IIC MODE STRUCTURE...........................................17

SELF CHECK ........................................................... 18

POWER LED BLINKING TIMING CHART ................ 19

LCD PANEL TEST MODE ........................................ 20

DIAGNOSIS FLOW CHART ..................................... 21

DIAGNOSIS OF TOUCH PANEL .............................. 22

WIRING DIAGRAM ................................................... 23

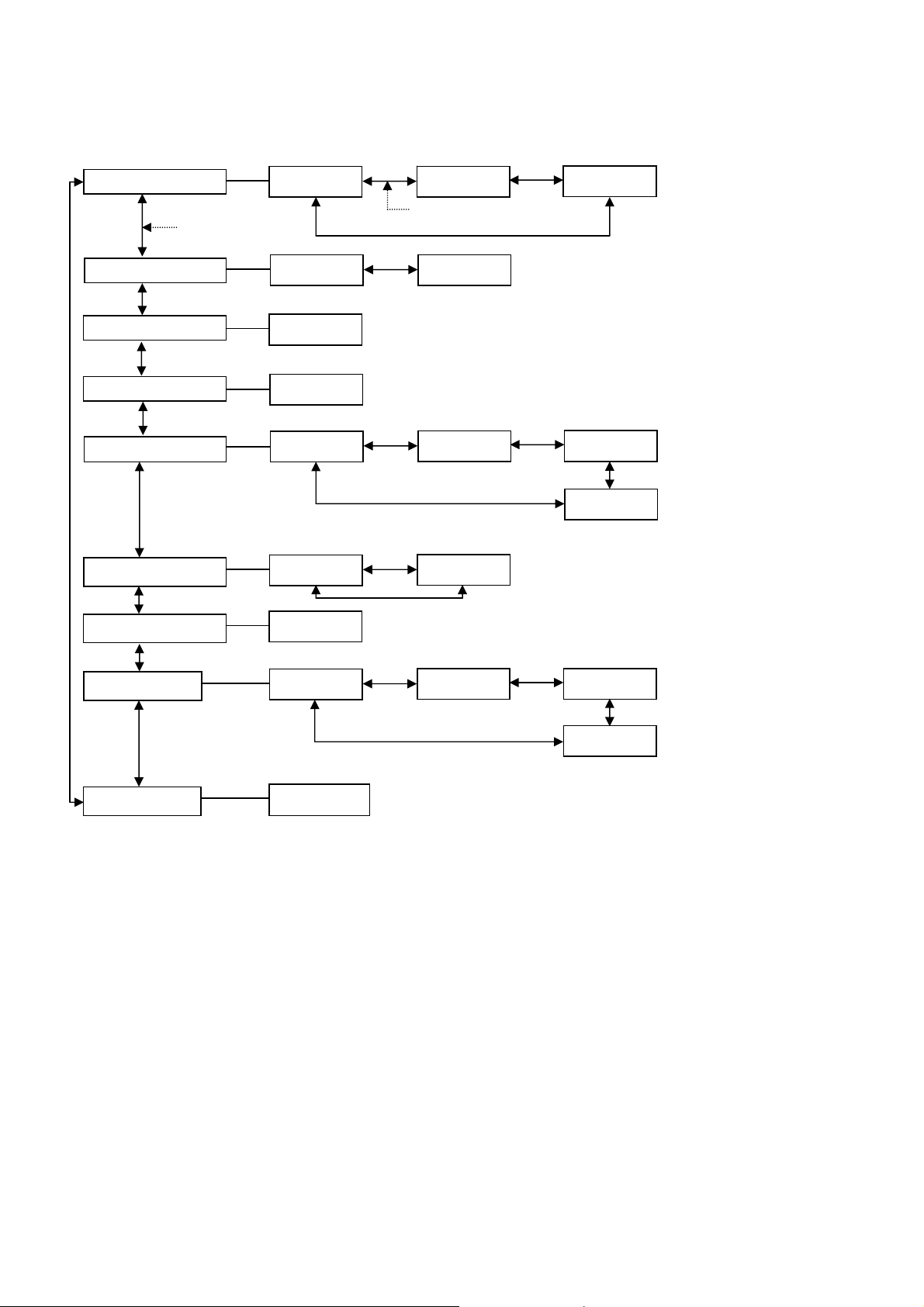

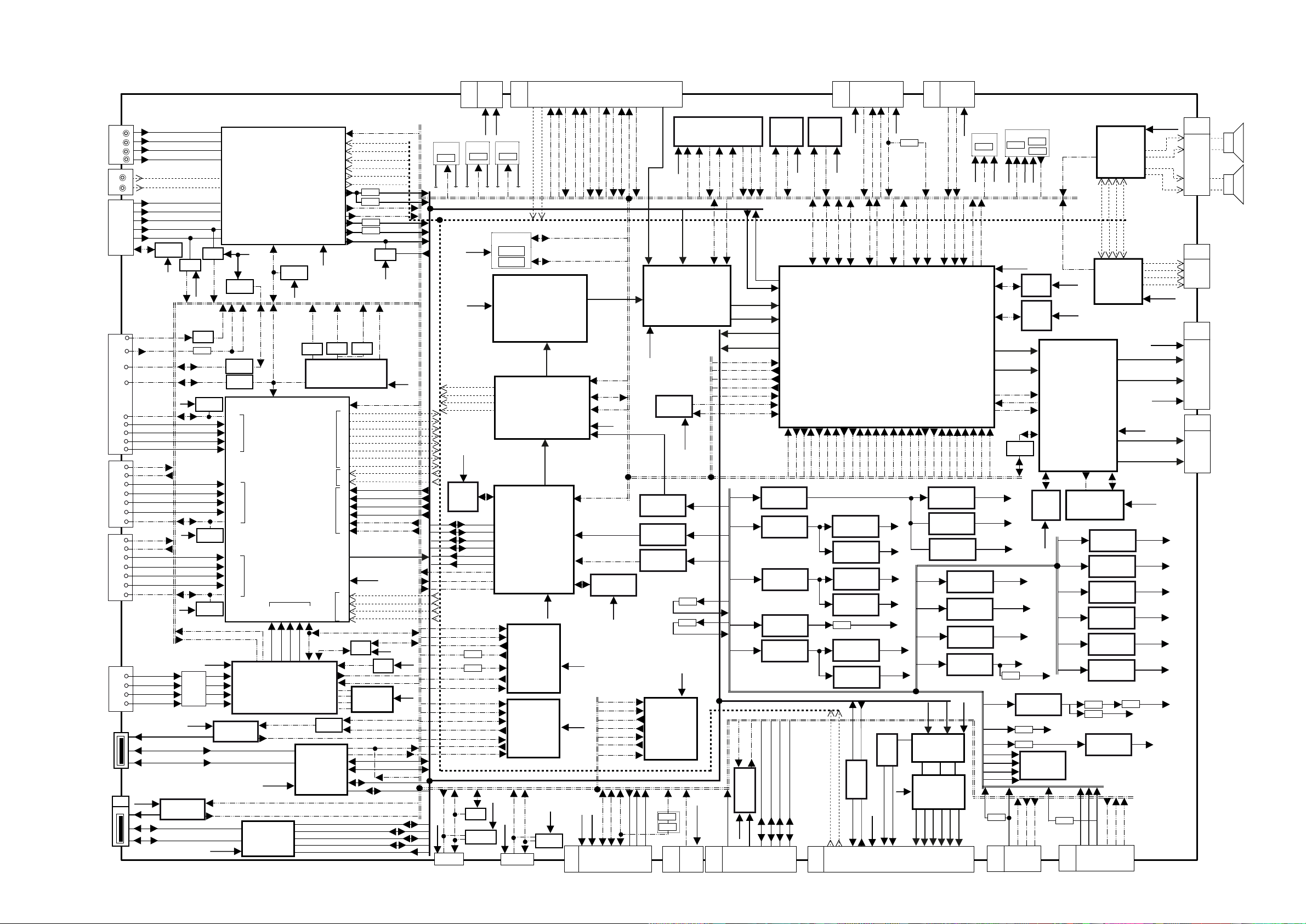

BLOCK DIAGRAM (1 OF 3) ..................................... 24

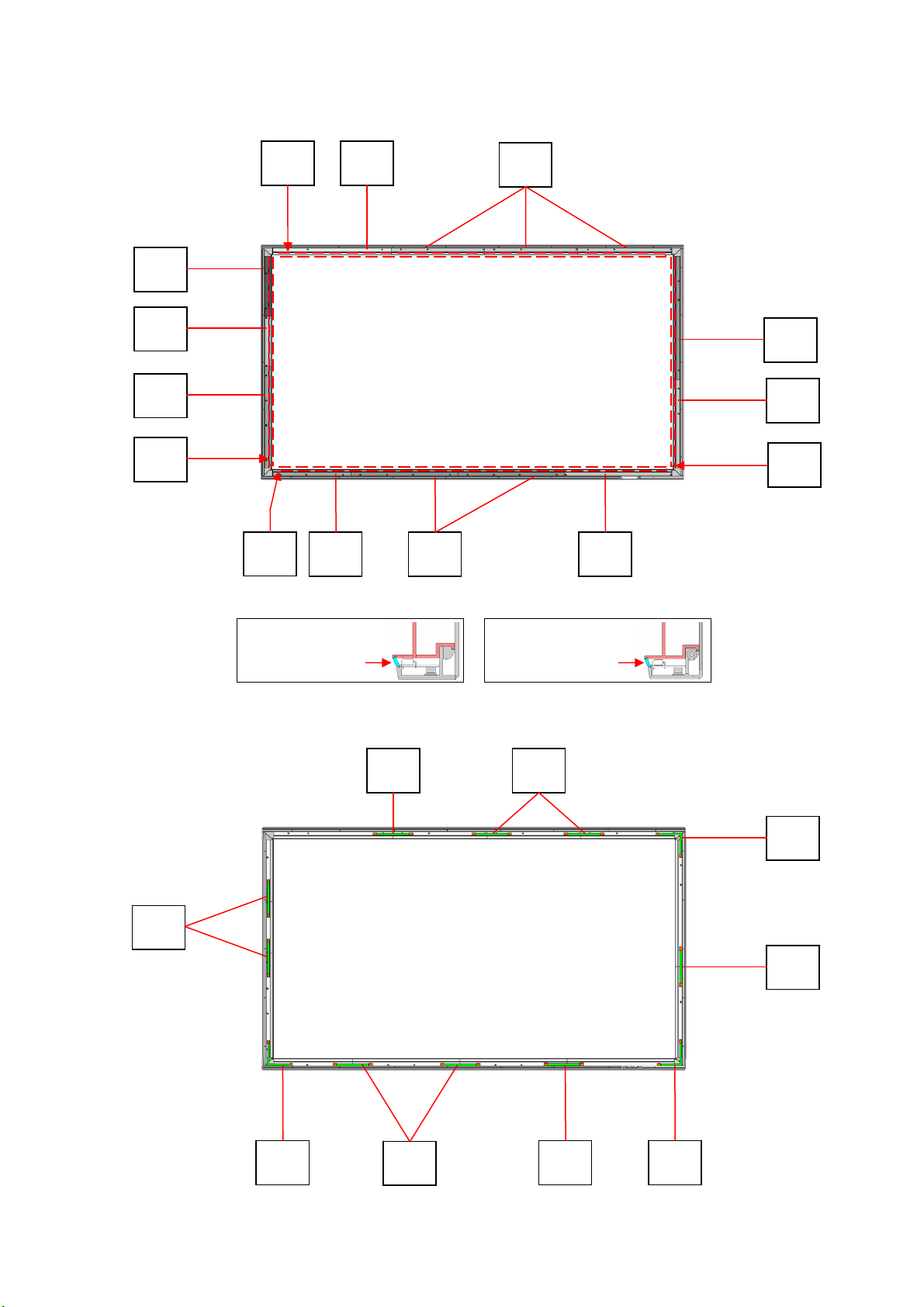

PARTS LOCATION ................................................... 27

LOCATION OF LEAD WIRING ................................. 31

REPLACEMENT PARTS LIST NOTE ....................... 32

REPLACEMENT PARTS LIST .................................. 33

SCHEMATIC DIAGRAMS NOTE .............................. 88

A-BOARD (1 OF 24) SCHEMATIC DIAGRAM .......... 89

DS-BOARD SCHEMATIC DIAGRAM ..................... 113

HX-BOARD SCHEMATIC DIAGRAM ..................... 114

H1-BOARD SCHEMATIC DIAGRAM ...................... 115

V1-BOARD SCHEMATIC DIAGRAM ...................... 116

V2-BOARD SCHEMATIC DIAGRAM ...................... 117

CONDUCTOR VIEWS ............................................ 118

Safety Precautions

3

General Guide Lines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated

or damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following touch current checks to prevent the customer from being exposed to shock hazards.

Touch-Current Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a measuring network for touch currents between each exposed metallic part on the set and a good earth

ground such as a water pipe, as shown in Fig. 1.

3. Use Leakage Current Tester (Simpson 228 or equivalent) to measure the potential acr oss the measuring network.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reserve the AC plug in the AC outlet and repeat each of the above measure.

6. The potential at any point (TOUCH CURRENT) expressed as voltage U1 and U2, does not exceed the following values:

For a. c.: U1 = 35 V (peak) and U2 = 0.35 V (peak);

For d. c.: U1 = 1.0 V,

Note:

The limit value of U2 = 0.35 V (peak) for a. c. and U1 = 1.0 V for d. c. correspond to the values 0.7 mA (peak) a. c. and

2.0 mA d. c.

The limit value U1 = 35 V (peak) for a. c. correspond to the value 70 mA (peak) a. c. for frequencies greater than 100

kHz.

7. In case a measurement is out of the limits specified, there is a possibility of a shock hazard, and the equipment shoul d

be repaired and rechecked before it is returned to the customer.

COLD

WATER PIPE

(EARTH GROUND)

TO

APPLIANCES

EXPOSED

METAL PARTS

Resistance values in ohms ()

V: Voltmetr or oscilloscope

(r.m.s. or peak reading)

NOTE – Appropriate measures should be taken to obtain the correct value in case of non-sinusoidal waveforms

Measuring network for TOUCH CURRENTS

=0.22F

Fig. 1

C

S

10k

(V)

U

1

=1500

R

S

R0=500

Input resistance: 1M

Input capacitance:200pF

Frequency range: 15Hz to 1MHz and d.c.respectively

0.022

F

V

U2 (V)

Prevention of Electrostatic Discharge (ESD) to Electrostatically

4

Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect

transistors and semiconductor "chip" components. The following techniques should be used to help reduce the incidence of

component damage caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on

your body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD

wrist strap, which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge build up or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD

protected)" can generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads electrically shorted together by cond uctive foam, aluminum foil

or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as th e

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity

(ESD) sufficient to damage an ES device).

There are special components used in this equipment which are important for safety.

These parts are marked by in schematic diagrams, exploded views and replacement parts list. It is essential that

these critical parts should be replaced with manufacturer’s specified parts to prevent shock, fire, or other hazards. Do

not modify the original design without permission of manufacturer.

IMPORTANT SAFETY NOTICE

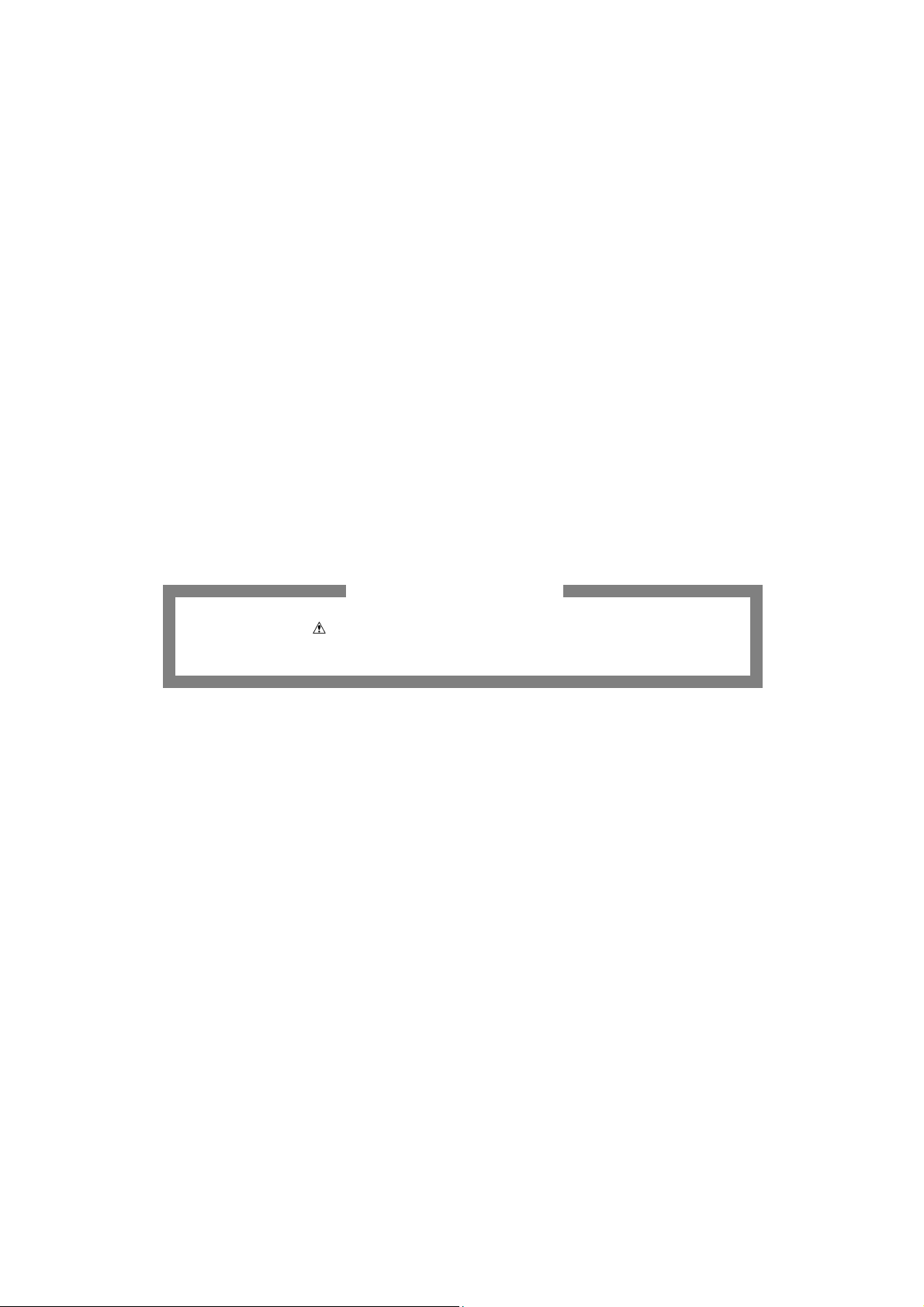

About lead free solder (PbF)

5

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work,

we’d suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol

stamped on the back of PCB.

Caution

Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40°C)

higher. Please use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before

applying Pb solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

After applying PbF solder to double layered boards, please check the component side for excess solder which may

flow onto the opposite side. (see Fig.2)

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder.

However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used. (see Fig.3)

Fig.2

Fig.3

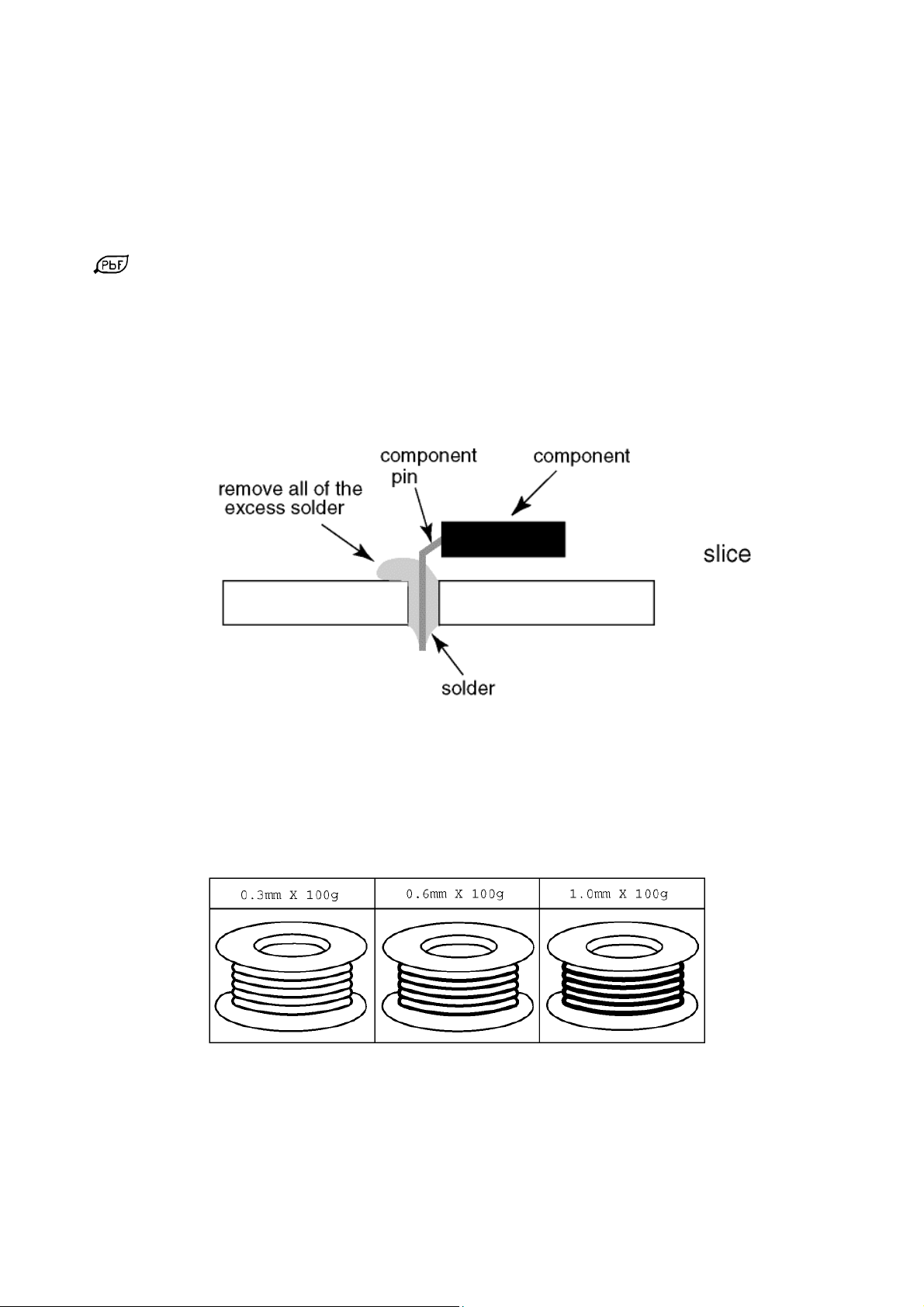

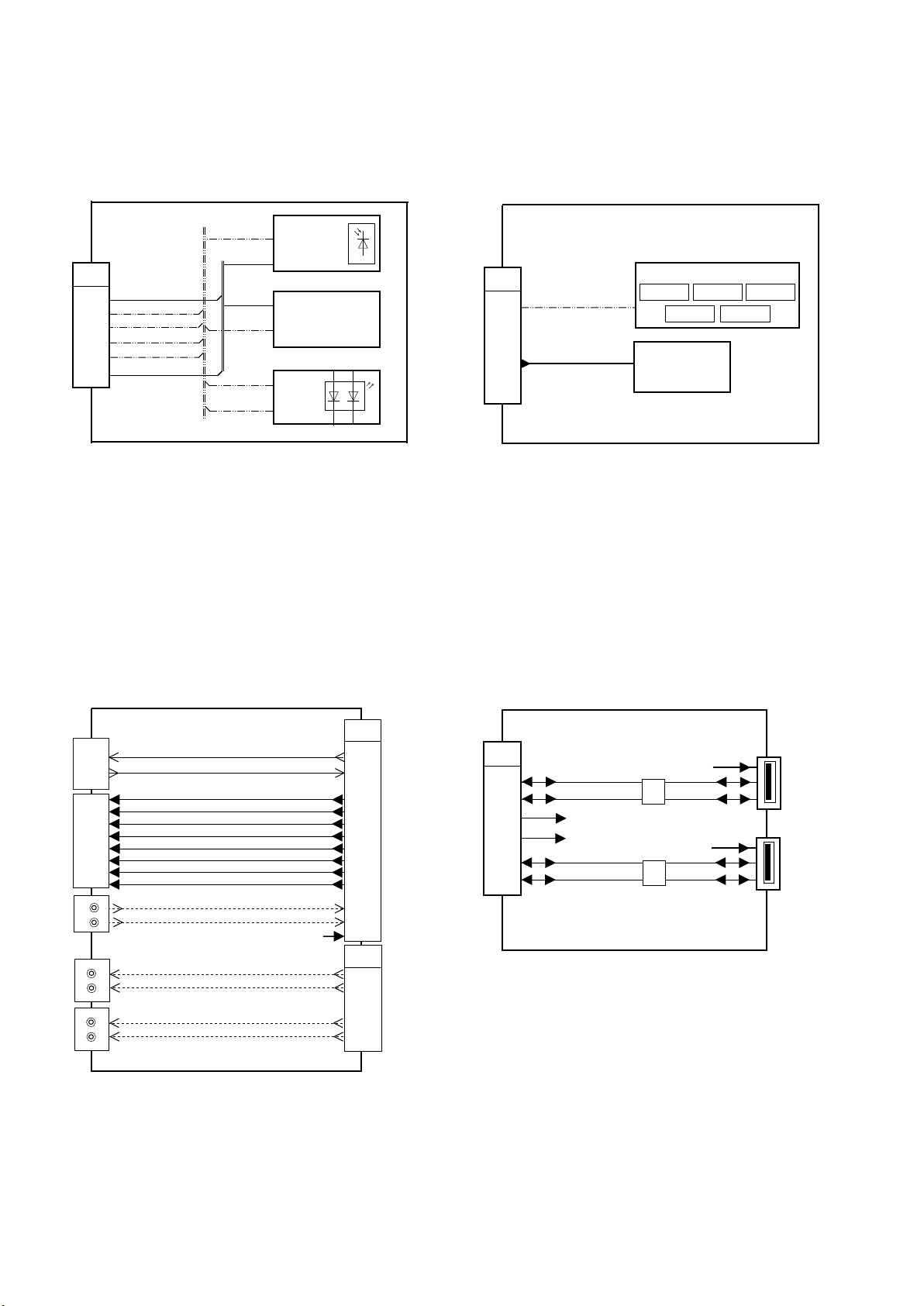

Service Navigation

6

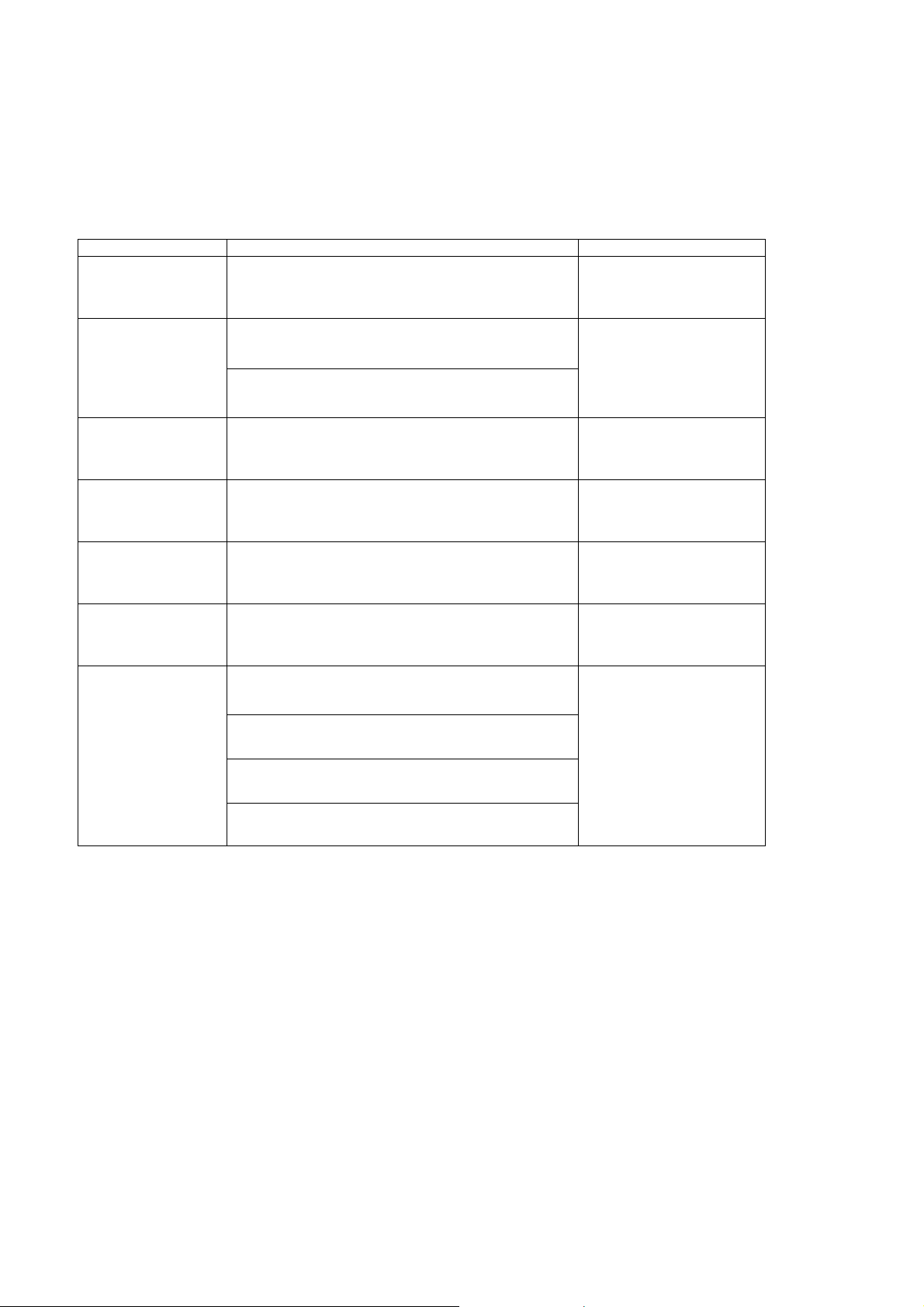

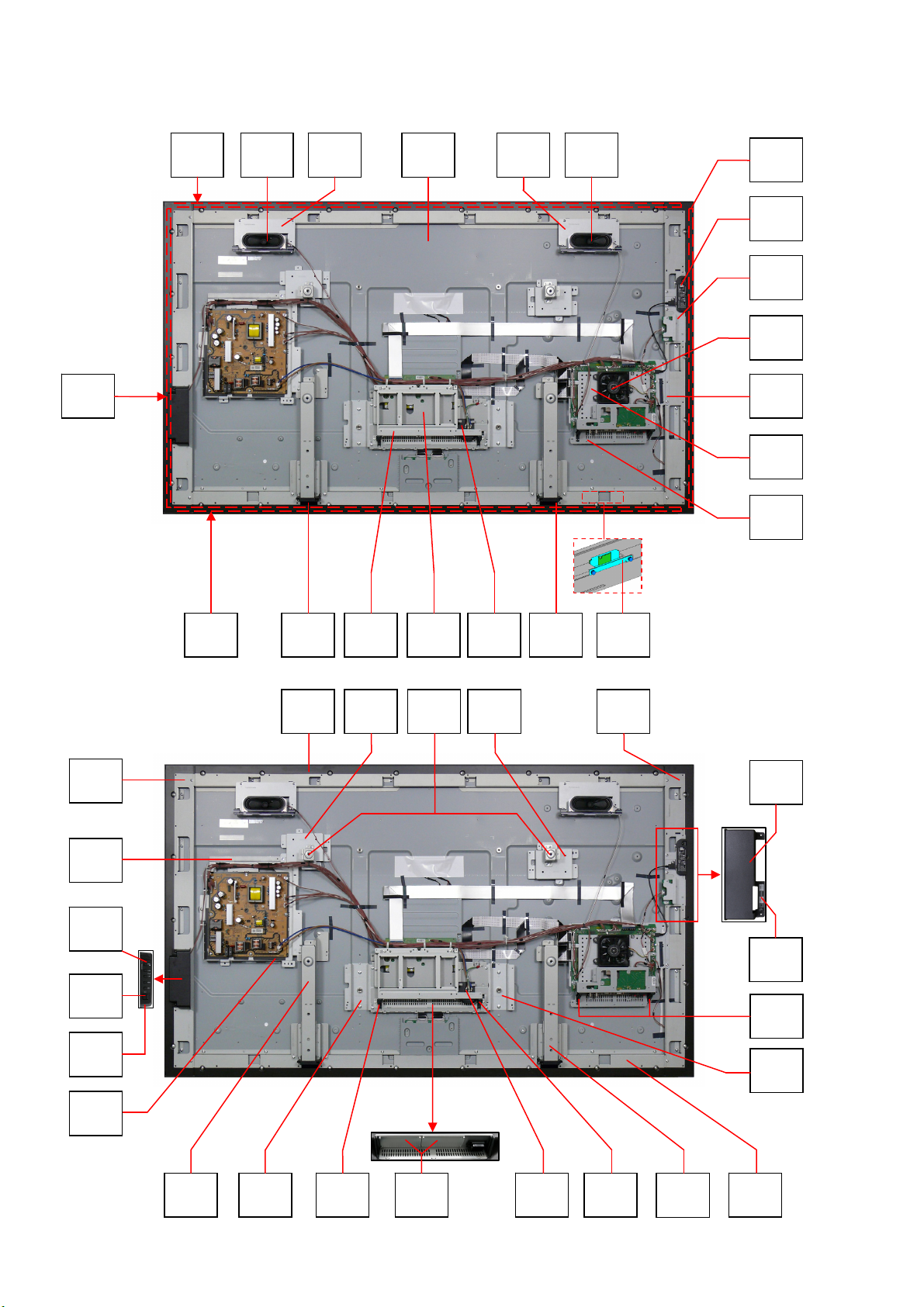

Chassis Board Layout

P-UNIT

V2-BOARD

Board Name Function

A-Board Main Processor, HDMI, DVI-D IN, PC-IN, Audio OUT / IN, Ethernet(LAN),

V2-Board Key control, Power switch

V1-Board Remote Reciever, Power and Timer LED, C.A.T.S

P-Unit Power Supply, Main Input

H1-Board USB Terminal

HX-Board Speakers Out, PC Out, Audio IN, RS-232C input

DS-Board Slot Interface

H1-BOARD

A-BOARD

HX-BOARD

DS-BOARD

WIFI,COMPONENT/RGB-IN, SPI Flash, EEP memory,

V1-BOARD

DDR memory

Service Hints

7

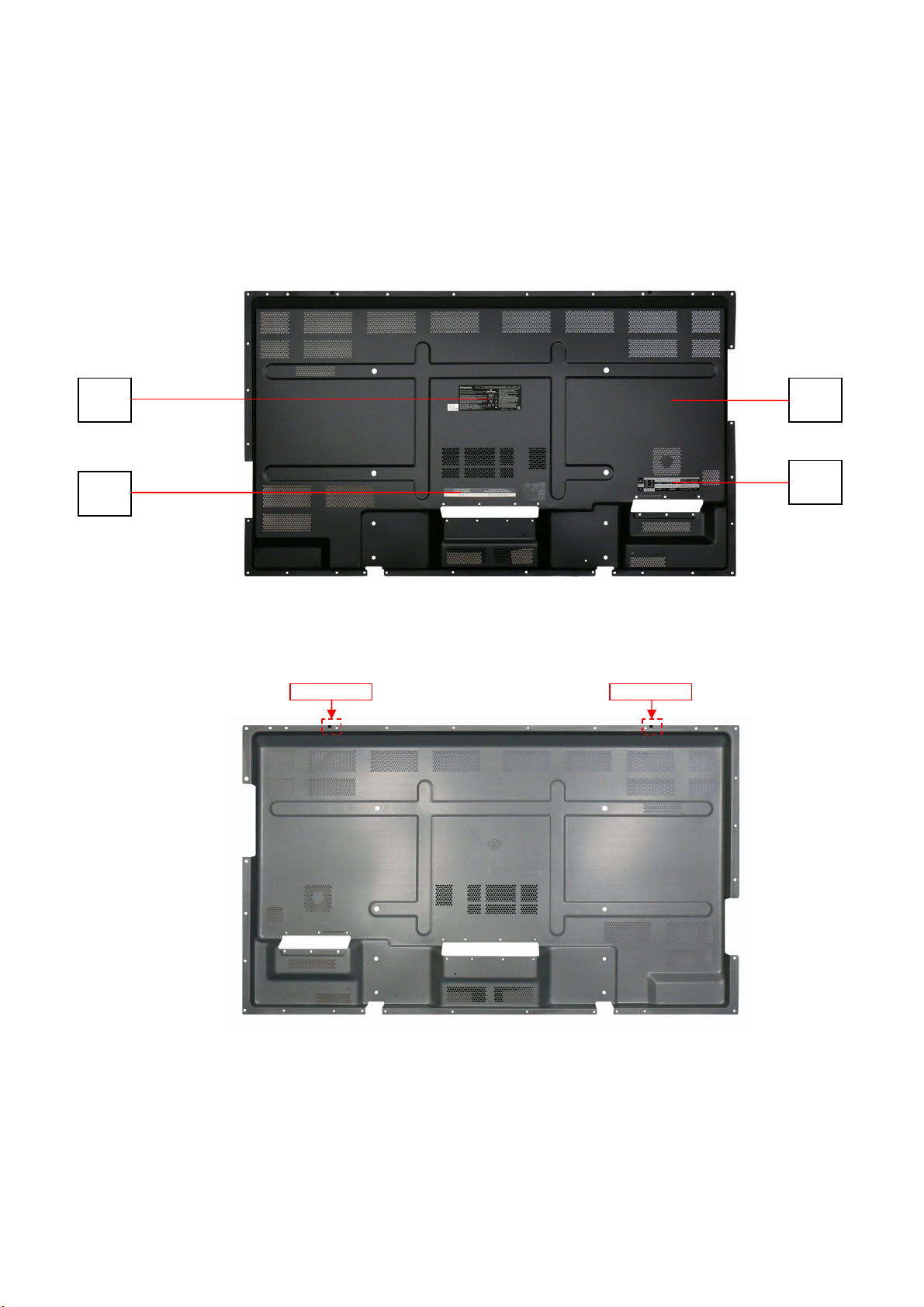

How to remove the backcover

Lay the main unit face down. (see Fig.4)

Remove the 44 fixing screws, 4 caps and backcover (see Fig.5)

(1)

(1)

(1)

(1) (1)

(1)

(1) (1) (1) (1) (1) (1) (1)

(3)

(2)

Fig.4

(2) (2) (2)

SCREWS

(1) THEJ025 /30 pcs /

(2) THEL0429 /14 pcs /

(3) TKKL5493 /4 pcs /

(1)

(3)(3)

(2)

(3)

(2)(2)

(1)

(1)

(1)

(1)

(2) (2) (2) (2)

(1)

(1) (1) (1) (1) (1) (1) (1) (1) (1)

(1)

(2)

(2)

(2)

(1)

Fig.5

Applicable Input Signals

8

*Mark: Applicable input signal

Signal name

Horizontal

frequency

(kHz)

Vertical

frequency

(Hz)

COMPONENT /

RGB IN/ PC IN

(Dot clock (MHz)

1 525(480)/60i 15.73 59.94 *(13.5) *(27.0) *

2 525(480)/60p 31.47 59.94 *(27.0) *5 *(27.0) *

3 625(575)/50i 15.63 50.00 *(13.5)

4 625(576)/50i 15.63 50.00 *(27.0) *

5 625(575)/50p 31.25 50.00 *(27.0)

6 625(576)/50p 31.25 50.00 *(27.0) *

7 750(720)/60p 45.00 60.00 *(74.25) *(74.25) *

8 750(720)/50p 37.50 50.00 *(74.25) *(74.25) *

9 1,125(1,080)/60p 67.50 60.00 *(148.5) *1 *(148.5) *

10 1,125(1,080)/60i 33.75 60.00 *(74.25) *1 *(74.25) *

11 1,125(1,080)/50p 56.26 50.00 *(148.5) *1 *(148.5) *

12 1,125(1,080)/50i 28.13 50.00 *(74.25) *1 *(74.25) *

13 1,125(1,080)/24psF 27.00 48.00 *(74.25) *2

14 1,125(1,080)/30p 33.75 30.00 *(74.25) *1 *(74.25)

15 1,125(1,080)/25p 28.13 25.00 *(74.25) *1 *(74.25)

16 1,125(1,080)/24p 27.00 24.00 *(74.25) *1 *(74.25) *

17 1,125(1,080)/50i 31.25 50.00 *(74.25) *3

18 2,048x1,080/24psF *7 27.00 48.00

19 2,048x1,080/24p *7 27.00 24.00

20 640x400@70Hz 31.46 70.07 *(25.17)

21 640x480@60Hz 31.47 59.94 *(25.18) *6 *(25.18) *

22 640x480@72Hz 37.86 72.81 *(31.5)

23 640x480@75Hz 37.50 75.00 *(31.5)

24 640x480@85Hz 43.27 85.01 *(36.0)

25 800x600@56Hz 35.16 56.25 *(36.0)

26 800x600@60Hz 37.88 60.32 *(40.0) *(40.0) *

27 800x600@72Hz 48.08 72.19 *(50.0)

28 800x600@75Hz 46.88 75.00 *(49.5)

29 800x600@85Hz 53.67 85.06 *(56.25)

30 852x480@60Hz 31.47 59.94 *(33.54) *6 *(34.24) *

31 1,024x768@50Hz 39.55 50.00 *(51.89) *

32 1,024x768@60Hz 48.36 60.00 *(65.0) *(65.0) *

33 1,024x768@70Hz 56.48 70.07 *(75.0)

34 1,024x768@75Hz 60.02 75.03 *(78.75)

35 1,024x768@85Hz 68.68 85.00 *(94.5)

36 1,066x600@60Hz 37.64 59.94 *(53.0) *(53.0) *

37 1,152x864@60Hz 53.70 60.00 *(81.62) *

38 1,152x864@75Hz 67.50 75.00 *(108.0)

39 1,280x768@60Hz 47.70 60.00 *(80.14)

40 1,280x800@60Hz (1) 49.31 59.91 *(71.0) *(71.0) *

41 1,280x800@60Hz (2) 49.70 59.81 *(83.5) *(83.5) *

42 1,280x960@60Hz 60.00 60.00 *(108.0)

43 1,280x960@85Hz 85.94 85.00 *(148.5)

44 1,280x1,024@60Hz 63.98 60.02 *(108.0) *(108.0) *

45 1,280x1,024@75Hz 79.98 75.03 *(135.0)

46 1,280x1,024@85Hz 91.15 85.02 *(157.5)

47 1,366x768@50Hz 39.55 50.00 *(69.92) *

48 1,366x768@60Hz 48.36 60.00 *(86.71) *(87.44) *

49 1,400x1,050@60Hz 65.22 60.00 *(122.61) *

50 1,440x900@60Hz (1) 55.47 59.90 *(88.75) *(88.75) *

51 1,440x900@60Hz (2) 55.93 59.89 *(106.5) *(106.5) *

52 1,600x1,200@60Hz 75.00 60.00 *(162.0) *(162.0) *

53 1,600x1,200@65Hz 81.25 65.00 *(175.5)

54 1,920x1,080@60Hz 67.50 60.00 *(148.5) *4 *(148.5) *

55 1,920x1,200@60Hz 74.04 59.95 *(154.0) *

56 Macintosh 13‘‘ (640 x 480) 35.00 66.67 *(30.24)

57 Macintosh 16‘‘ (832 x 624) 49.72 74.54 *(57.28)

58 Macintosh 21‘‘ (1,152 x 870) 68.68 75.06 *(100.0)

DVI-D IN

(Dot clock (MHz)

HDMI

*1: Based on SMPTE 274M standard.

9

*2: Based on SMPTE RP211 standard.

*3: Based on SMPTE 295M standard.

*4: The input signal is recognized as 1,125 (1,080) / 60p.

*5: When selected the RGB format and 525p signal input to the PC IN terminal, it is recognized as VGA 60 Hz signal.

*6: When inputted VGA 60Hz format signal from the other than PC IN terminal, it is recognized as 525p signal.

*7: Based on SMPTE 292M and 372M standards. These signals can be received when the Dual Link HD-SDI Terminal

Board (TY-FB11DHD) is installed.

Note: Signals without above specifications may not be displayed properly.

Specifications

10

Power Source: 220-240V AC, 50 / 60Hz

Rated Power Consumption: 215W

Stand-by Power Consumption: 0.5W

Operating Conditions: Temperature: 0°C 40°C

Humidity: 20% 80% RH (non condensing)

Applicable signals:

Colour System NTSC, PAL, PAL60, SECAM, Modified NTSC

Scanning Format 525(480) / 60i • 60p, 625(575) / 50i • 50p, 750(720) / 60p• 50p

1125(1080) / 60i • 60p • 50i • 50p • 24p • 25p • 30p • 24psF, 1250 (1080) / 50i

PC signal VGA, SVGA, XGA, SXGA, UXGA . . . . . (compressed)

Horizontal scanning frequency 15 - 110kHz

Vertical scanning freguency 48 - 120Hz

Terminals:

AV IN

VIDEO BNC 1.0 Vp-p (75

AUDIO 1 IN Stereo mini jack (M3) x 1 0.5 Vrms, Shared with COMPONENT/RGB IN

HDMI 1 TYPE A Connector x 2

HDMI 2

COMPONENT/RGB IN

Y/G BNC with sync 1.0 Vp-p (75

Pb/Cb/B BNC 0.7 Vp-p (75

Pr/Cr/R BNC 0.7 Vp-p (75

AUDIO 1 IN Stereo mini jack (M3) x 1 0.5 Vrms, Shared with VIDEO

DVI-D IN

DVI-D 24Pin Compliance with DVI Revision 1.0

Content Protection Compatible with HDCP 1.1

AUDIO 2 IN Stereo mini jack (M3) x 1 0.5 Vrms, Shared with PC IN

PC IN

High-Density Mini D-sub 15 Pin Y or G with sync 1.0 Vp-p (75

Y or G without sync 0.7 Vp-p (75

Pb/Cb/B: 0.7 Vp-p (75

Pr/Cr/B: 0.7 Vp-p (75

HD/VD: 1.0 – 5.0 Vp-p (high impedance)

AUDIO 2 IN Stereo mini jack (M3) x 1 0.5 Vrms, Shared with DVI-D IN

SERIAL External Control Terminal

D-sub 9 Pin RS-232C compatible

PC OUT R: 0.7 Vp-p (75

G: 0.7 Vp-p (75

B: 0.7 Vp-p (75

HD/VD: 1.0 – 5.0 Vp-p

USB (VIEWER) TYPE A USB connector

USB (TOUCH) TYPE B USB connector

DIGITAL LINK / LAN For RJ45 network and DIGITAL LINK connections, compatible with PJLink™

Communication method: RJ45 100BASE-TX

EXT SP 8

Sound:

Speakers 120mm x 40mm x 2pcs

Audio Output 20W [10W + 10W] (10% THD)

, 20W [10W + 10W] (10% THD)

)

)

)

)

)

)

)

)

)

)

)

11

LCD screen: L5EDDYY00643

1920 x 1080, 16:9

Visible Diagonal 1638mm

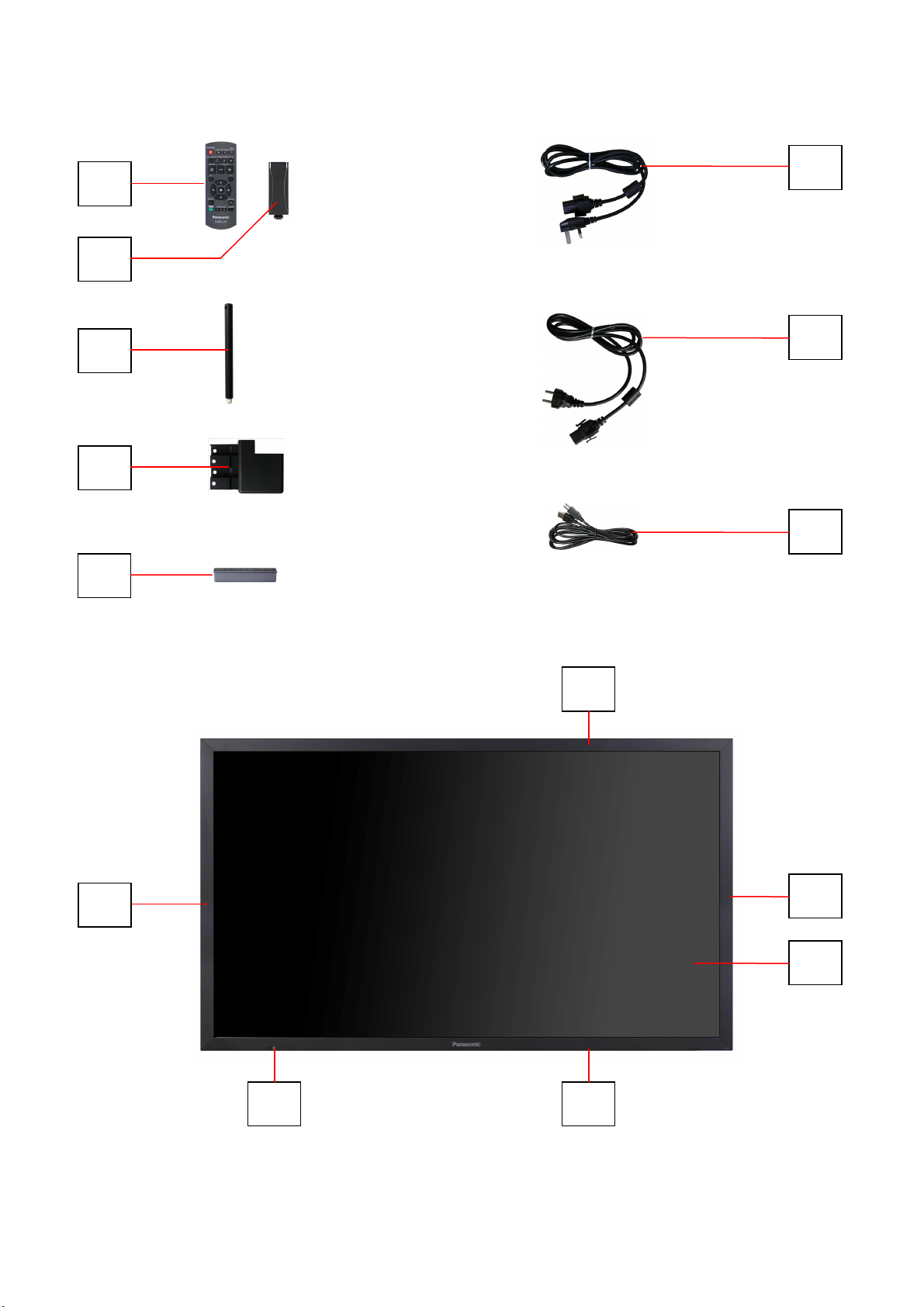

Accessories supplied : Remote Control

2 x R6 (UM3) Batteries

2 xPen

Pen Tray

Eraser

USB Cable

Dimensions: Width: Height: Depth:

1,517mm 892mm 106mm

Mass: 58.0kg

Design and Specifications are subject to change without notice. Mass and dimensions shown are approximate.

This equipment complies with the EMC standards listed below:

EN61000-3-2, EN61000-3-3, EN55022, EN55024

Service Mode

A

12

CAT (Computer Aided Test) Mode

CAT mode menu

CAT panel sys. 8.2

IIC Mode

CD Mode

NW Mode

SD Mode

MS Mode

ID mode

Mode Function Access Button

IIC Mode Service Alignment Action

CD (Complete

Diagnostic)

NW Mode LAN terminal check Action

SD (Status Display) MTBF parameter Action

MS Mode Market Select Mute

ID Mode LSI Check Mute

Software version

information EEPROM edit

Remote Control

Mute

more than 3 seconds

more than 3 seconds

more than 3 seconds

MUTE

VOL Up/Down

Up/Down

R

Left/Right

CTION

RECALL

How to access the CAT mode.

Method A Main unit + remote control operation

Press and hold the button on the right side of the unit and press

the RECALL button on the remote kontrol 3 times quickly within 2

seconds, this will placet he unit into the CAT mode.

Method B Remote control operation only

1. Set OFF timer except fot [0] minute by OFF TIMER button.

(30 minutes, 60 minutes, 90 minutes)

2. Set the volume level of sound to 0 by VOL down button / -button.

3. Set the RECALL button more than 3 seconds before a volume

display disappears.

To exit CAT mode, turn the power off by main unit or a remote control.

IIC Mode

Select the IIC mode by Up/Down buton on the remote control at the front page of CAT mode and then press the Action

button on the remote control.

OSD

Y 525/480)/60p

16:9 STANDARD Mid

LCD W/B Adj.

R Drive

FE FE

Subject and Item are mentioned on “IIC mode structure”.

To exit the IIC mode, press the R button on remote control.

Original data

on remote control.

on the remote control.

Subject

Item

on the remote control.

Subject (or Items).

New data

on the remote control or change the alignment

How to access the CAT mode.

1. Select the alignment Subject by Up/Down buttons

2. Select the alignment Item by Left/Right buttons

3. Adjust optimum setting by Volume Up/Down buttons

4. The data is memorized when press the R button

CD Mode

A

13

Select the CD mode by Up/Down buton on the remote control at the front page of CAT mode and then press the Mute

button on the remote control more than 3 seconds.

CD

MONITOR-MCU(50inch) *.****LFB70 OK

MONITOR-EEPROM **.** * BB 73

MONITOR-EEPROM Change Addr 00 01

Data 01 01

MONITOR-FPGA **.**

MONITOR-FRC **

LAN MCU **.**/**.**

HD-BaseT **.**.***

TOUCH PANEL *.*.*.*

LAN-MAC (WIRED) **:**:**:**:**:**

LAN-MAC (WIRELESS) **:**:**:**:**:**

SLOT BOARD EEPROM -- -- -- --

SLOT BOARD --/--/-- -- -- -SERIAL No **********

PTCT 01. 02. 03. 04. 05.

Memory data change

ddress

PTCT position: [01] [02] [03] [04] [05]

0

0

Change by Up/Down buttons on the remote control.

Factory use

New data

Original data

SOS history

Data

Change by Left/Right buttons on the remote control.

0

0

Change by VOL Up/Down buttons on the remote control.

The data is memorized when switch off the main power.

To exit the CD mode, press the R button on the remote control.

About the serial number display

As for the serial number of A-module for repair, a dummy value is displayed.

* By the set for which A-module was exchanged, a serial number is displayed as [-----]

About the history display of SOS for the power supply system

This unit adds the history display (5 times) of power supply failure to the CD mode as PTCT.

By the self check of a signal system, only one history is displayed (After a self check disappears). But PTCT display

5 times of histories (Abnormality of the latest 3 times. First time and second time after shipment) and after a self

check does not disappear.

You can see a detailed history of power failure sometimes.

*About the display contents of PTCT

PTCT : The position of [05] is the first time after shipment.

PTCT : The position of [04] is the second time after shipment.

PTCT : The position of [03] is second from last time.

PTCT : The position of [02] is last time.

PTCT : The position of [01] is the latest.

In [Contents & Check point] of [6.1.2 Power LED Blinking timing chart], the two-digit following PTCT are displayed

by a hexadecimal number.

Blinking times Contents &Check point Display contents

Ex. 1 4 times PTCT 04 H09 04

Ex. 2 8 times PTCT 08 H029 08

NW Mode

14

Note:

To use the network function, set each “Network Setup” setting and make sure to set the “Control I/F” to “LAN”

or “RS232C”

Select the NW mode by Up/Down buton on the remote control at the front page of CAT mode and then press the Action

button on the remote control.

NW

TEST OK

Version xx.xx/xx.xx

MAC(WIRED) xx:xx:xx:xx:xx:xx

MAC(WIRELESS) xx:xx:xx:xx:xx:xx

Control I/F Select xxxxxxxxxxxxxxx

DIGITAL LINK

Firmware xx.xx.xxx

*1

Link Status No link

HDMI Status HDMI on

BER V_/A_/B_/C_

*2

Max Count A X/B X/C X/D X

Est. Cable Length x (m)

Signal Quality

A - xx (dB)

B - xx (dB)

C - xx (dB)

D - xx (dB)

Min - xx (dB)

Max - xx (dB)

Model Name xxxxxxxx

*1: If you move a cursor to “Firmware” and press an Action button, “Only receiving side information display” and

“Receiving side / Transmitting side information simultaneous display” can be s witched.

*2: The value of “Max Count” is resettable if you move a cursor to “Max Count” and press an Action butto n.

[Example of Receiving / Transmitting side information simultaneous display]

NW

TEST OK

Version xx.xx/xx.xx

MAC(WIRED) xx:xx:xx:xx:xx:xx

MAC(WIRELESS) xx:xx:xx:xx:xx:xx

Control I/F Select xxxxxxxxxxxxxxx

DIGITAL LINK

Firmware xx.xx.xxx / xx.xx.xxx

Link Status DIGITAL LINK/DIGITAL LINK

HDMI Status HDMI on / HDMI on

BER V_/A_/B_/C_/T_

Max Count A X/B X/C X/D X

Est. Cable Length x (m)

Signal Quality

A - xx (dB)

B - xx (dB)

C - xx (dB)

D - xx (dB)

Min - xx (dB)

Max - xx (dB)

Model Name xxxxxxxx

To exit the NW mode, press the R button on the remote control.

Press the Action button to start TEST (Check of Ping).

Check to show “OK” in TEST column.

If “G_NG” shows, it is failure for Ping process.

If “L_NG” shows, it is failure for Link process.

Software Version

Mac address

Control I/F Select

DIGITAL LINK: Checking signal quality

Link Status : Connection state

No link : No connection

DIGITAL LINK : In DIGITAL LINK operation

Ethernet : In Ethernal operation

HDMI Status : Display the information of HDMI ON/OFF and HDCP

No HDMI : Can not be recognized as a signal of the HDMI

HDMI on : Non HDCP HDMI signal

HDCP on : HDCP HDMI signal

Error ratio of the transmission path information

V : VIDEO BER

A : AUDIO BER

B : BLANK BER

C : CONTROL BER (Max: 10)

Standard of momentary signal quality aggravation

When it is over 64, the imagine may have broken off.

(Max: 255)

Signal Quality: Display the signal quality at the time of

DIGITAL LINK operation

OK/LOW/NG is displayed as each

Channel (A,B,C,D, Min, Max)

-12 dB or more : Normal receivable range

-11 to -8 dB : Partial damage of data (possible image output)

-7 dBor less : Synchronization disorder occurrence

(impossible image output)

Transmitting side information is displayed on right-hand side.

T: total ber (Transmitting side)

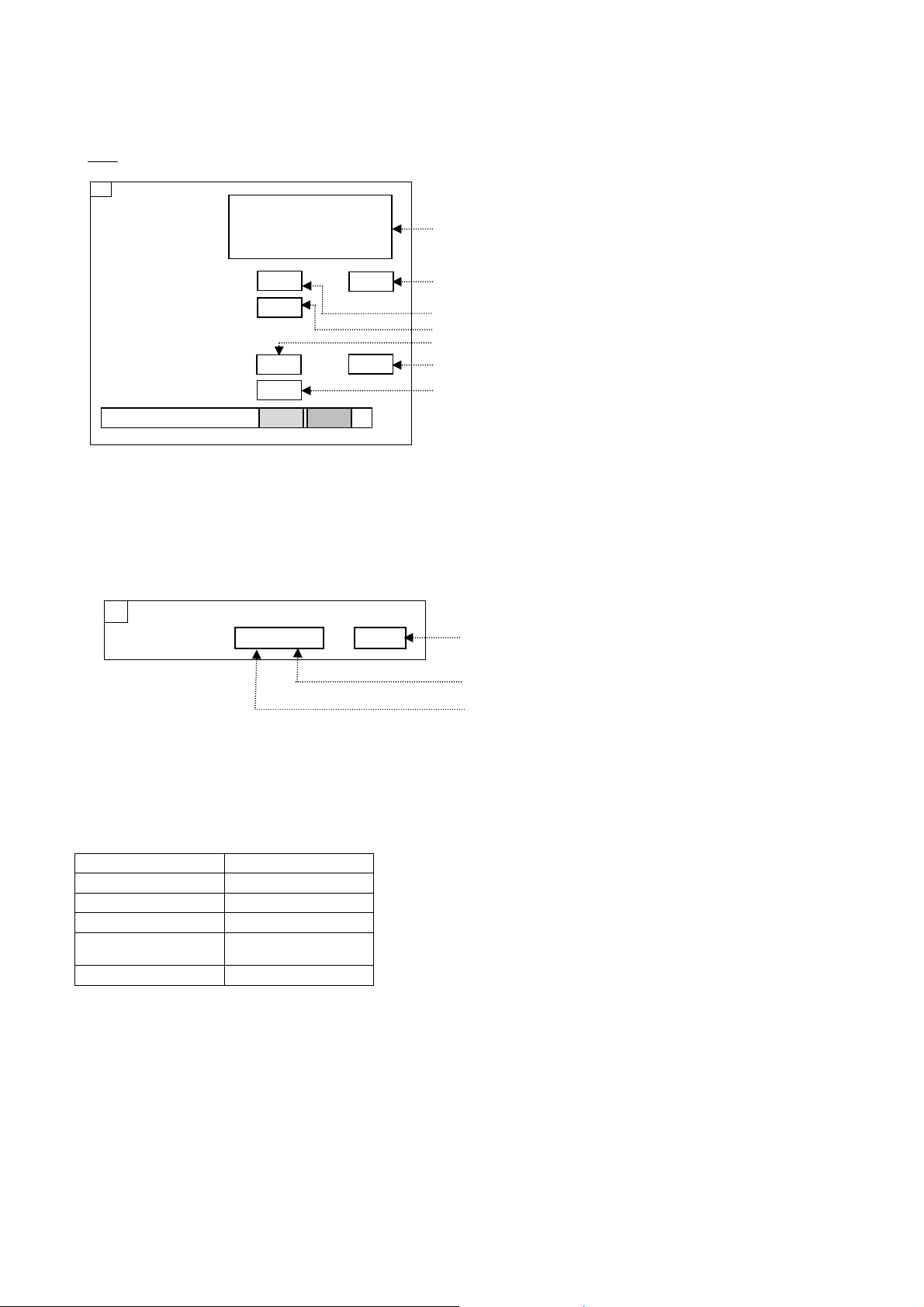

SD Mode

15

Select the SD mode by Up/Down button on the remote control at the front page of CAT mode and then press

the Action button on the remote control.

OSD

SD

Input command

check

MTBF Parameter WT PT

TE

Condition

Sensor

Remote Control Mode A B

To exit the SD mode, press the R button on the remote control.

** ** ** ** ** ** **

** ** ** ** ** ** **

** ** ** ** ** **

**

*

+**

---

BL

**

***

History of remote control command.

(Factory use).

Cumulative Time for power on condition. (unit :hour)

Counter of power on. (unit :time)

Counter of backlight OFF during abnormally high temperature(unit:time)

Temperature (unit :degrees)

Backlight Limit Value

Illumination sensor value

MS Mode

Select the MS mode by Up/Down button on the remote control at the front page of CAT mode and then press the Mute

button on the remote control more than 3 seconds.

MS

Market select **.** 2 2

Change by Left/Right buttons on the

remote control and press the action button

Present number

EEPROM data version

To exit the MS mode, press the R button on the remote control.

Caution:

Market Select should be set after exchange of A-Board.

Destination number:

Number Destination

0 Japan

1 US(North America)

2 Europe

3 Asia,

Oceania,ME,Africa

18 China

ID Mode

16

Select the ID mode by Up/Down button on the remote control at the front page of CAT mode and then press the Mute

button on the remote control more than 3 seconds.

ID

A H90MEM1 OK DS H51RTC OK

H65AVSW OK

H61ADV OK

H62TEMP OK

H63CPG OK

H66HDMIRX OK

H93LAN OK

H92MEM2 OK

H56LVDSRX OK

H67DLK OK

H68FRC OK

To exit the ID mode, press the R button on the remote control.

IIC1

IIC2

IIC3

IIC4

IIC Mode Structure

17

(following items value is sample data)

Panel W/B Adj.

R DRIVE

FE

by up / down button

DIGITAL LINK Update

Update Not

Ready

EDID Write Protect

Protect

Front Panel key Check

Key Check --

PICTURE Sub Adjust

Main Contrast1

0

G DRIVE

FC

by left / right button

Update Ready

R sub Bright1

0

B DRIVE

FA

G sub Bright1

0

TEMP CONTROL Adj

Chroma Control

Pos./Size

Aging

B sub Bright1

0

Threshold Temp

52

GUN OFF

0

H Position

81

Panel Color

White + Time, Temperature

WHITE

RED

GREEN

BLUE

BLACK

These are selected by Action buton of Remote control and press the R button to exit.

Offset Temp

3

V Position

80

WHITE Ramp

RED Ramp

GREEN Ramp

BLUE Ramp

Color Bar

Scrolling Vertical Window

H Size

80

B DRIVE

00

Self Check

18

Display Indication

1. Self check is used to automatically check the bus line controlled circuit of the LCD display.

2. To get into the Self check mode, press the volume down button on the customer controls at the right side of the set, at the

same time pressing the OFF TIMER button on the remote control, and the screen will show.

Method A Self-Check only ( A shipment setup is not carried out )

Select ID mode by UP/Down button on the remote control at the front page of CAT mode and then press the Mute button

on the remote control more then 3 seconds.

Method B Self-Check + Shipment setup

Press and hold the volume down button on the right side of the unit and press the OFF-TIMER button on the remote

control.

If the IIC ports have been checked and found to be incorret, or not located then “- -” will appear in place “OK”

“01” in the lie of the “PTCP” means the number of blinks of the Power LED is 1. (Reference_Power LED blinking timing

chart)

“H09” in the line of the “PTCP” is the error code

To exit the CAT mode switch off the main power.

Note:

The line of the “PTCP” display when you get into the Self check mode for first time only after the Power LED blinks.

ID

A H90MEM1 OK DS H51RTC OK

H65AVSW OK

H61ADV OK

H62TEMP OK

H63CPG OK

H66HDMIRX OK

H93LAN OK

H92MEM2 OK

H56LVDSRX OK

H67DLK OK

H68FRC OK

IIC1

IIC2

IIC3

IIC4

Power LED blinking timing chart

19

1. Subject

Information of LED Flashing timing chart.

2. Contents

When abnormality has occurred the unit, the protection circuit operates and reset to the stand by mode. At this time, the

defective block can be identified by number of blinking of the Power LED on the front panel of the unit.

Blinking times Contents & Check point Check point

1

2

4

8

10

11

13

PTCT 01 H09]*

PANEL SOS

(PTCT E2 H09)*

POWER SOS

(PTCT 04 H09)*

POWER SOS

(PTCT 04 H09)

PANEL 12V SOS

(PTCT 0A H09)

FRC SOS

(PTCT 0B H09)*

FAN SOS

(PTCT 0B H09)

FAN SOS

(PTCT 0D H09)*

REGULATOR SOS (A2 SOS)

(PTCT 1D H09)*

REGULATOR SOS (5V SOS)

(PTCT 2D H09)*

REGULATOR SOS (A2 SOS)

LCD PANEL

P-Board

A-Board

A-Board

LCD Panel

A-Board

DS-Board

SLOT Board

FAN

A-Board

A-Board

(PTCT 4D H09)*

AUDIO SOS

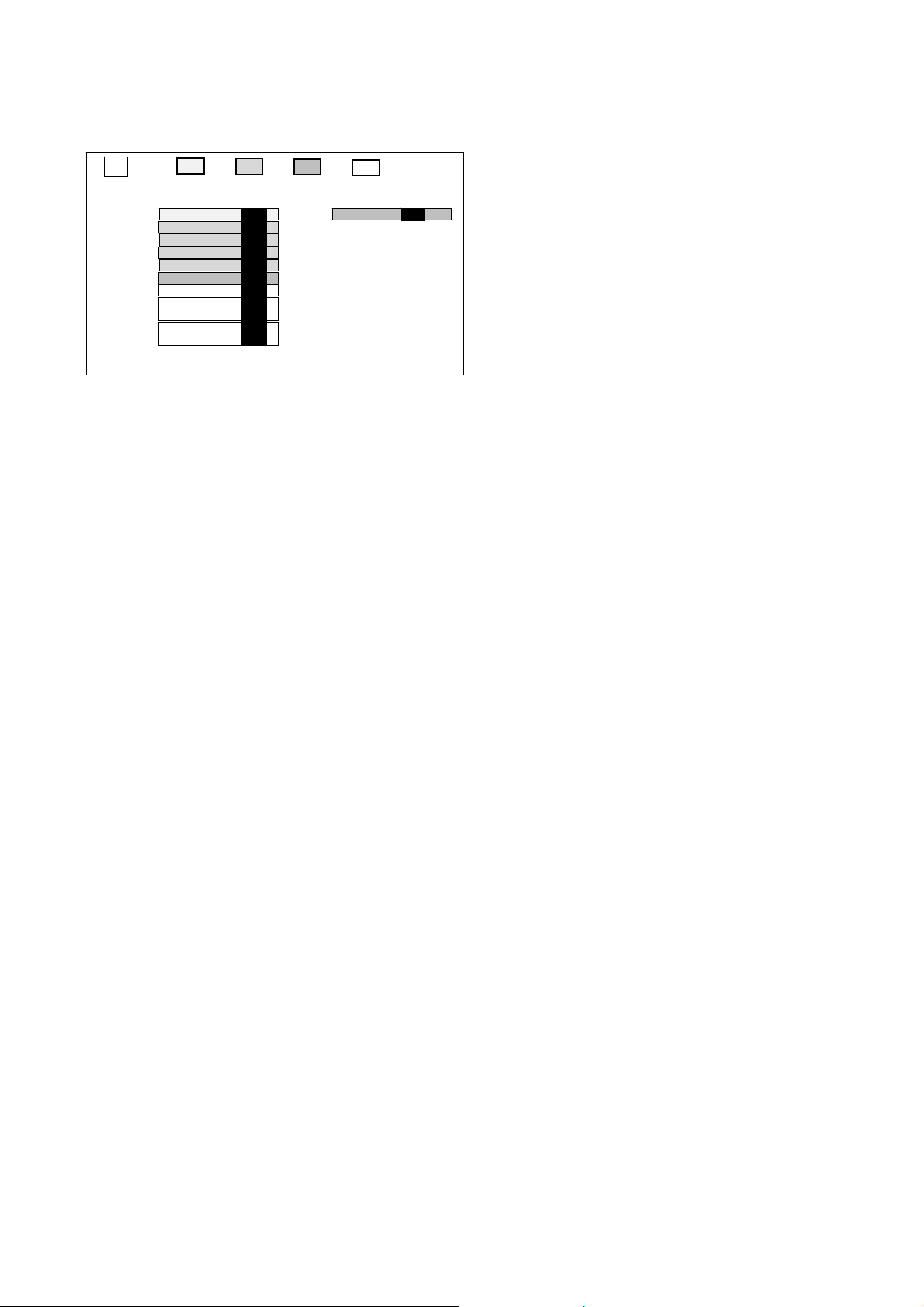

LCD Panel test mode

20

The failure-diagnosis by LCD Panel test mode

To find the possible failure point where in LCD Panel or Printed Circuit Board when the abnormal picture is displa yed.

How to display the test pattern:

(A) Main unit + remote control operation

1. While pressing [VOLUME (-)] button of the main unit, press [R] button of the remote control three times within 2 seconds.

2. Test pattern is displayed and Power LED lights red and orange alternately.

How to Exit: Turn off the unit.

(B) Remote control only

1. Press [Recall] button of the remote control.

2. Press [R] button of the remote control.

3. Press [N] button of the remote control for over 3 seconds.

4. Test pattern is displayed and Power LED lights red and orange alternately.

How to Exit: The unit automatically turns off after around 10 seconds.

[Display pattern]

It is unfixed from which color it starts.

WHITE MAGENTA YELLOW CYAN BLACK

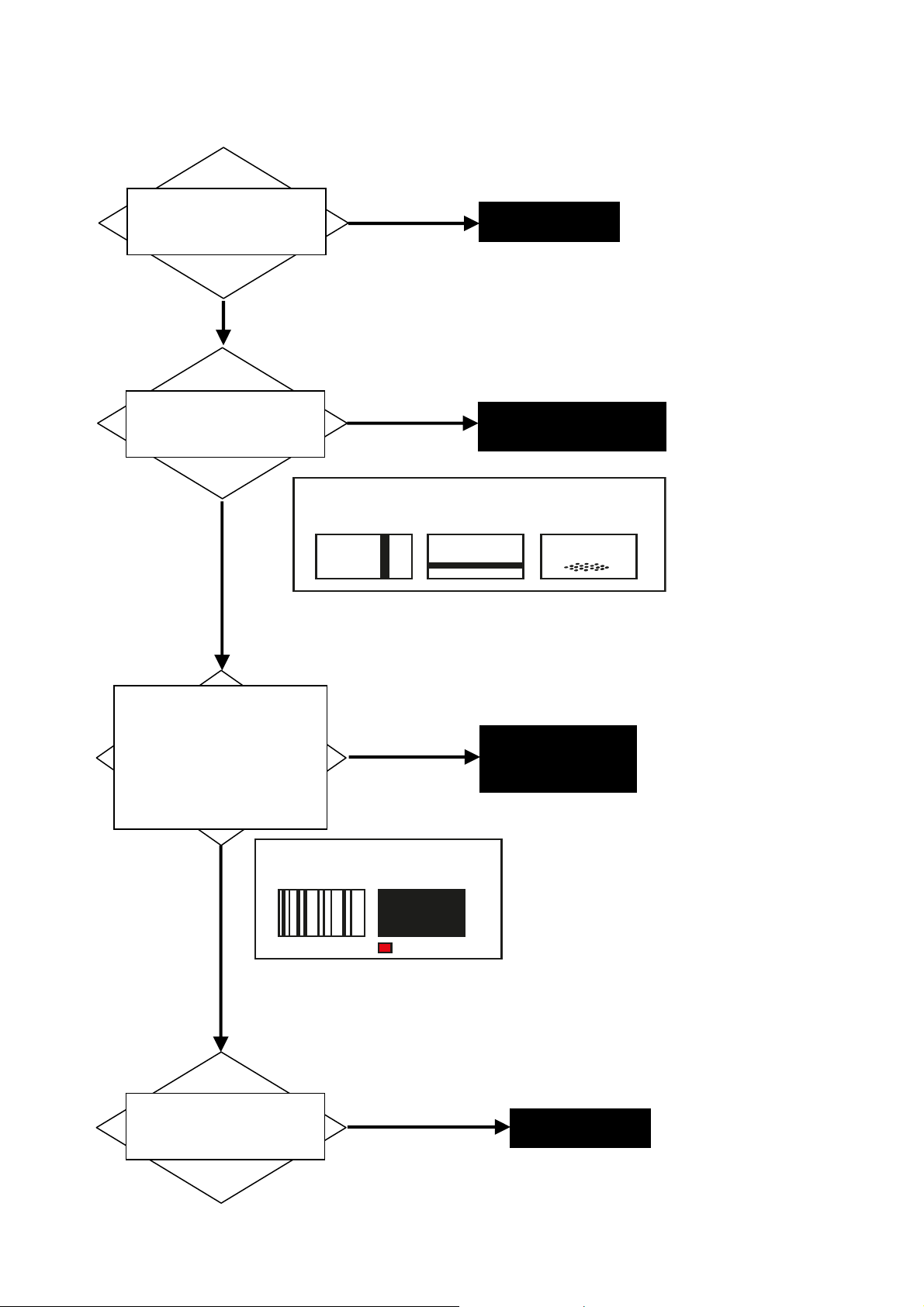

Diagnosis flow chart

21

Is a test pattern

displayed normally?

Yes

It displays.

Failure of A-Board

No

It is still abnormal.

Is a part abnormal

even in test pattern?

Yes

It is abnormal.

Failure of LCD Panel

(rarely failure of A-Board)

Vertical line Horizontal line Color

Vertical bar Horizontal bar unevenness

No

This is not an abnormality of part

-Is the whole abnormal

even in a test pattern?

or

-A test pattern is not displayed

but is the state of LED blink of

red and orange?

Yes

It is abnormal.

Yes

It is blinking.

Failure of A-Board

or

Rarely LCD Panel

Vertical line/ An image is

Vertical bar not displayed

LED blinking

No

- The whole is not abnormal.

- It is not blinking.

A test pattern is not

displayed but is the state

of LED green lighting?

Yes

It is green lighting.

Failure of A-Board

Diagnosis of Touch Panel

22

When a touch panel does not work, narrowing down of the failure part of a setup, and a touch panel or A-Board can be

performed.

Is a touch panel setting

carried out?

No

Check Touch Panel setting

Yes

Is the motion picture of a

USB memory played back?

Yes

Failure of touch panel

No

Failure of A-Board

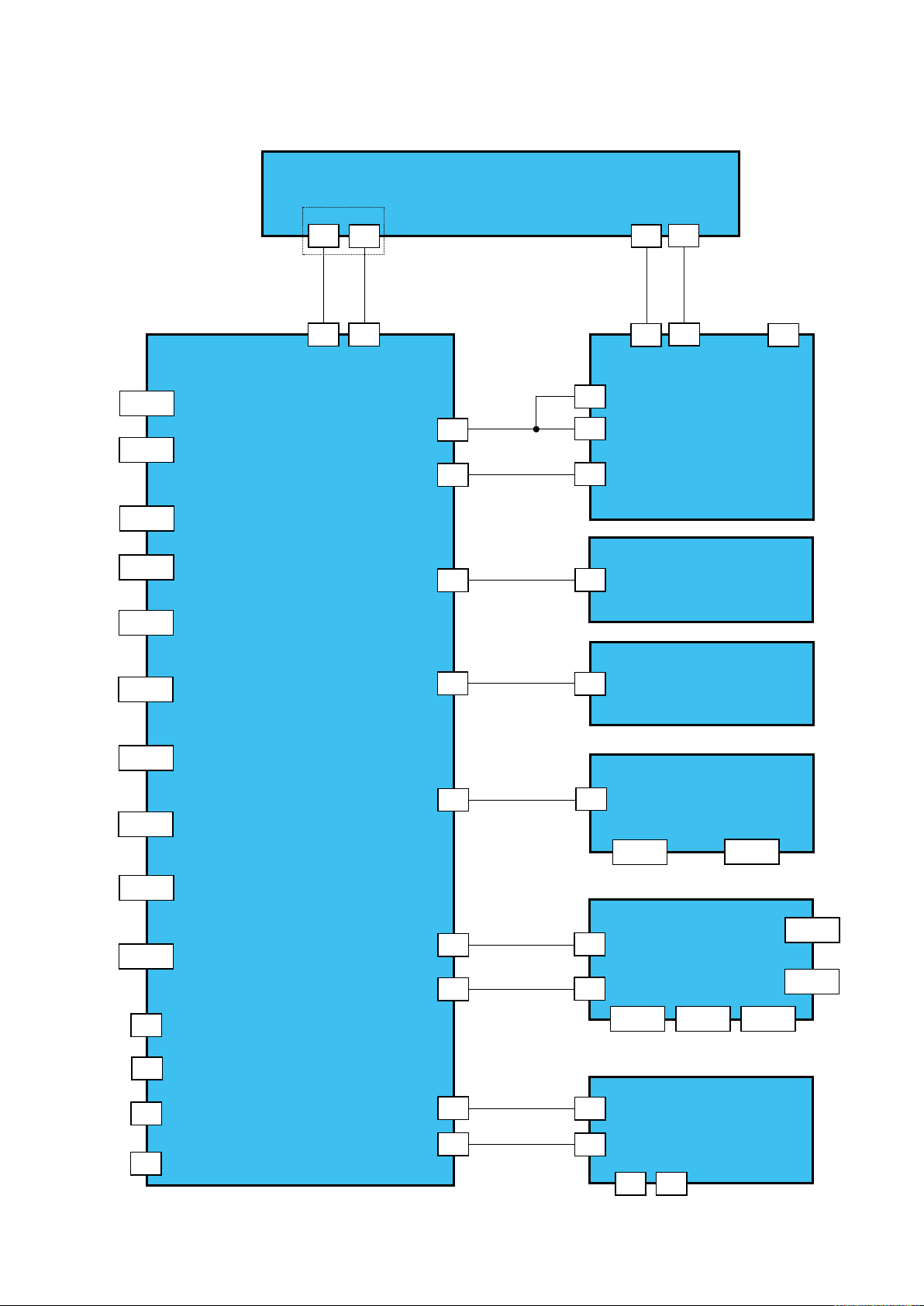

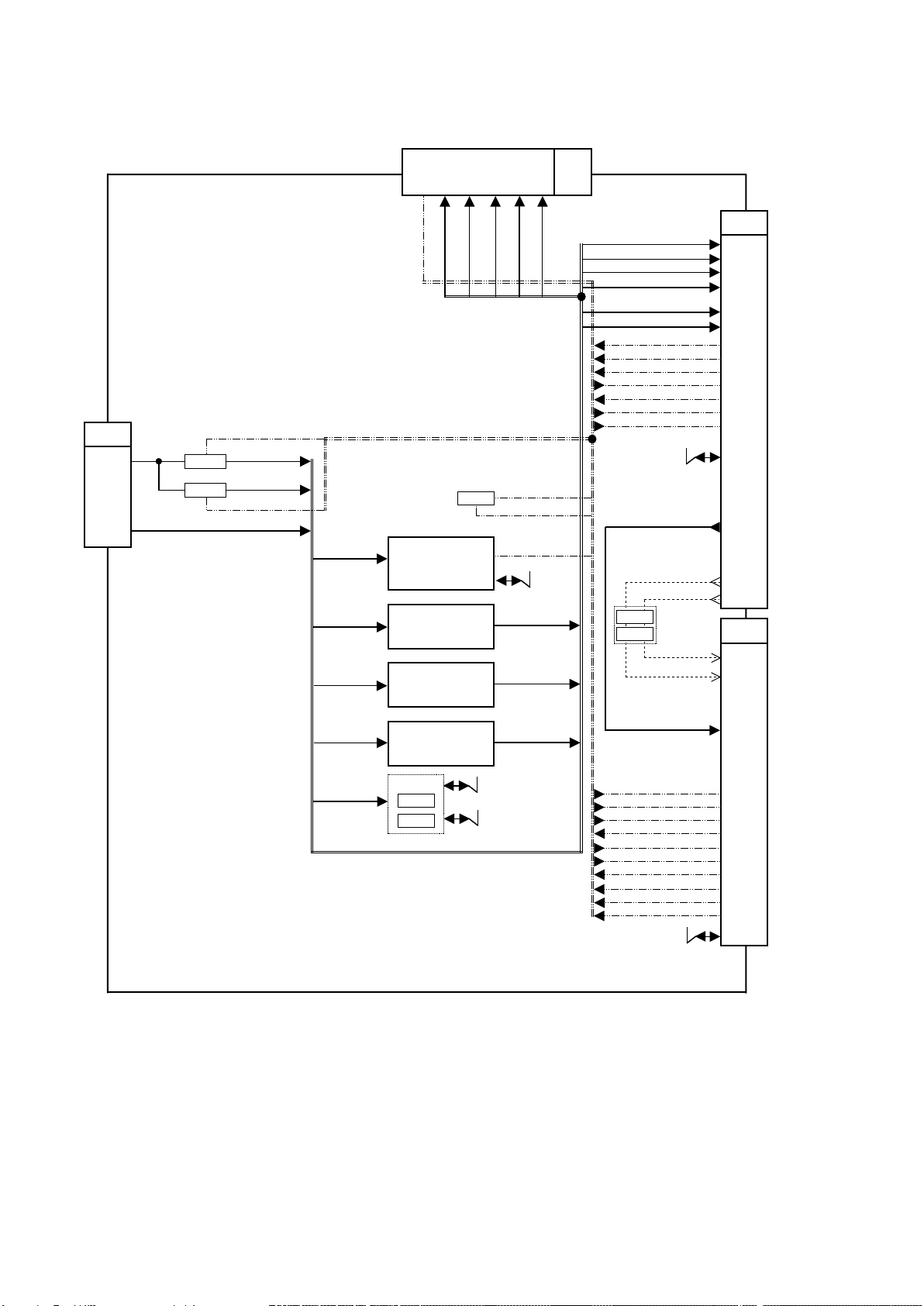

Wiring Diagram

23

A1

TCON

A2

LCD PANEL

P3

P4

MAIN IN

P1

SERVICE

SERVICE

WIFI

ETHERNET

HDMI2

HDMI1

DVI

PC IN

YUV

VIDEO IN

RCA

CN4002

CN2703

JK4801

JK2701

JK2107

JK4004

JK2106

JK2105

JK2104

JK2103

A-BOARD

A5

A4

A22

A11

A47

P2

P5

P6

V22

V11

H47

P-UNIT

V2-BOARD

V1-BOARD

H1-BOARD

JK3802

USB1

JK3801

USB2

Audio IN

FAN

SERVICE

TOUCH

JK2101

A17SPK

A7

A40

A57

A27

A37

A10

A13

HX27

HX37

DS10

DS13

HX-BOARD

JK3501

RS-232C

Input

DS-BOARD

DS3

DS2

JK3502

PC OUT

JK3504

SP_out_L

JK3503

SP_out_R

JK3506

Audio IN

Block Diagram (1/3)

24

A-BOARD

Y,PB,PR

JK2103

V

R

Audio IN

JK2101

PC

13

14

JK2104

12,15

DVI

JK2105

HDMI1

JK2106

HDMI2

JK2107

JK2701

ETHERNET

WIFI

JK4801

A57

TOUCH

CVBS

AUDIO_L_M3

L

AUDIO_R_M3

1

2

3

SDA,SCL

IIC_CONT

SDA1,SCL1

SDA2,SCL2

DDCD_SDA,SCL

TMDS_RXC_P/N

TMDS_RX0_P/N

TMDS_RX1_P/N

TMDS_RX2_P/N

HDMI1_DET

HPD1

HDMI1_CK_P/N

HDMI1_0_P/N

HDMI1_1_P/N

HDMI1_2_P/N

HDMI1_SDA,SCL

HDMI2_DET

HPD2

HDMI2_CK_P/N

HDMI2_0_P/N

HDMI2_1_P/N

HDMI2_2_P/N

HDMI2_SDA,SCL

HDBT_0

HDBT_1

HDBT_2

HDBT-3

1

2

3

F5V

1

2

3

PR_COMP

PB_COMP

Y_COMP

R_PC

G_PC

B_PC

HS_PC

VS_PC

IC2103

EEPROM

1

6

5V

IC2109

Logic IC

DPMS_

V D_SCX1

5V

5V

5V

HDBT_5VDET

HDBT_HPDT

T2701

IC4812

SW

STB3.3V

IC2112

SW

L2121

IC2110

EEPROM

IC2101

EEPROM

IC2102

EEPROM

F5V

3

4

IC2108

Logic IC

DPMS_

HD_SCX1

LAN3.3V

LAN1.8V

LAN1.0V

S3.3VLAN

100

IIC_CONT

1

6

USBP3_N

USBP3_P

97

93

95

17

62

63

3

1

99

2

STB3.3V

IC4006

EEPROM

DVI_DET

IC2104

Logic IC

IC2111

Logic IC

G4,F4

B5,A5

B4,A4

B3,A3

B2,A2

D2,D1

E2,E1

F2,F1

G2,G1

H4,J4

J2,J1

K2,K1

L2,L1

M2,M1

P4,R4

W3,Y3

Y4,W4

W8,Y8

Y9,W9

IC4803

DVI_DET2

DIGITAL INPUT

DIGITAL INPUT

DIGITAL INPUT

SW

7

8

C1AB00003384

AV SWITCH

28,29

3V_SDA1,SCL1

C1AB00003048

Y18

Y19

IC2701

TRANSMITTER/

RECEIVER

3

4

S3.3VLAN

IC4813

Multiplexer

IC2105

IC4009

Temp Sensor

P3V_SDA2,SCL2

F3V_SDA2,SCL2

IIC2

IC2509

AD AV

DIGITAL INPUT

P2,P1

R2,R1

HDBT_1_+/-

HDBT_0_+/-

HDBT_CK_+/-

L19,L20

N19,N20

VS100

SCX_USBOC2

USBP2_N

USBP2_P

1

2

3

4

9

3.3V

IC4019

Logic IC

10,11

T2,T1

U2,U1

HDBT_2_+/-

U19,U20

R19,R20

3

4

IC4802

[C1CB00003456]

USB 2.0HUB

USB_DP1

USB_DM1

USBP4_P

USBP4_N

USB_VBUS1

31

42,43

5V

9V

3.3V

28M_CLK2

CLKM_20MHz

IC4004

Logic IC

8

9

Clock Generator

M23

M22

AUDIO OUTPUT

Input

Sound

Analog

VIDEO

AUDIO INPUT

DIGITAL OUTPUT

VIDEO

Input

DTV Sound

T4,U4

IIC0_SDA,SCL

R1

B12

A11,B11

W19,Y20

A12

G1

D1

F1

E1

1

IC4815

4

Logic IC

2

Controller

18

67

66

59

58

49

50

32

34

33

35

CVBS_OUT

IC4013

C15

N23

N22

R23

R22

P23

P22

A21

B21

A14

A15

A12

A13

D13

D12

U20

T20

N20

N21

HDBT_SDA,SCL

IC4014

Reset IC

RESET_IN

CS

1

SDA

2

MO

5

SCL

6

27

30

31

1

2

AUDIO_R_DS

AUDIO_L_DS

AUDIO_R_M3_2

AUDIO_L_M3_2

Q2503

RGB_CVBS

Q2504

Q2502

R/PR_OUT

Q2501

IC2114

Logic IC

3.3V

28M_CLK

SPG_RESET

IC4020

Logic IC

2

12,7,4

R(9:0), G(9:0), B(9:0)

Control

1.8V,3.3V

3V_SDA4,SCL4

IC2702

Logic IC

IC2704

SPI FLASH

SCX_USBPSW2

USB_DM0

USB_DP0

USB_VBUS0

SCX_USBPSW3

S2_DET

AUD_R

AUD_L

G/Y_OUT

ADV_HD

ADV_VD

B/PB_OUT

ANMPIN

CLAMPY

F3.3V

28M_CLK

PWM2_SQ_L-

PWM2_SQ_L+

PWM2_SQ_R-

PWM2_SQ_R+

PWM_SQ_L-

PWM_SQ_L+

PWM_SQ_R-

PWM_SQ_R+

AUD_R

AUD_L

G/Y_OUT

RGB_CVBS

B/PB_OUT

R/PR_OUT

ADV_HD

ADV_VD

SPDIF1

SDIN1

BCLK1

LRCLK1

PWR5V

STB3.3V

3V3

PMS_TX

PMS_RX

3V3

WL_EN

USB_PWR

USB_OC

USBP1_N

USBP1_P

SCX_USBOC3

SW_5V

Q2327

PWR5V

15V_ON/OFF

PMS_RX

PMS_TX

IIC_INT

3V_SCL4,SDA4

STB5V

4,3 5

1

CN4002

TO DS13

A13

PWR15V

SW_15V

Q2318

5V

PWR15V

15V_ON/OFF

STB5V

3.3V

SPDIF1

SDIN1

BCLK1

LRCLK1

S1.5V_DDR

IC4820

IC4830

DDR2

2+2GBit

USB_DM1

USB_DP1

USB_DM0

USB_DP0

USB_VBUS1

USB_VBUS0

WL_EN

USB_PWR

USB_OC

UART_SEL1

RXD_SW3

UART0_RXD(Sigma)

PMS_TX

Q2711

PMS_RX

VJ2850

TXD_SW3

UART0_TXD(Sigma)

UART_SEL2

RXD_PC

RXD_SW3

RXD_PC_M

RXD_PC_M

TXD_SW3

TXD_PC

TXD_PC_M

3V_SCL4,

SDA4_SW

IC4021

Logic IC

IC4022

EEPROM

11

1-5

15V

SUB5V

SW_SUB5V

Q2331

STB5V

LINE_OFF

I2C_Level

shift

Q4018

A10

SUB5V

Q4019

IC5401

[C0ZBZ0001568]

LVDS Transmitter

76-81,84-87;88-92,95-99;

100-103,106-108,110-112;

LVDS_R(0-9),G)(0-9),B(0-9)

Control

74

38,36-30,28,27;53-51,49-43;

67-63,61-57;42,73,72,71

75

79

IC5402

80

[C1AB00004213]

HDMI Receicer

2,3; 5,6; 8,9; 11,12;

SIG_RXC-/+;RX0-/+

RX1-/+;RX2-/+

SIG_HPD,SDA,SCL

L1,L2;M1,M2;N1,N2;P1,P2;

W9

IC4801

Y9

[C2GBC0000383]

Secure Media

W6

Processor

Y6

W8

W7

W14

U14

V15

1,4,10,13

2,5

3

IC4023

6

[C0JBAZ000851]

Logic IC

9

8,11

12

1,4,10,13

2,5

3

IC4024

6

[C0JBAZ000851]

Logic IC

9

8,11

12

EDID_WP

STB3.3V

HDBT_SCL,SDA

LAN5V

1

4,3 5

CN2703

47

49

AUDIO_L_DS

15V_ON/OFF

AUDIO_R_DS

71-68,65-62,59-56

53-50,47,46,41-38

Digital input

7,8,9,15

Digital output

100,98,97

P6,N6,M6

LAN5V

IC2703

EEPROM

53

51

52

S2_DET

LAN15V_ON/OFF

S3.3VLAN

S1.5VLAN

S1.0VLAN

S2.5VLAN

STB3.3V

STB3.3V

TO DS10

57

55

54

58

RTC_INT

5VRXD_TU

REMOCON_OUT

5VNRST

5V_SDA3,SCL3

3V_SDA3,SCL3

LVDS

89

83,84

86

3.3V

1.8V

UART0_TXD(Sigma)

2.5V_PLL

NAND FLASH

HDBT232C_RXD

STB5V

STB3.3V

3V_SDA1,SCL1

1

14

A40

64

60

59

DS_SOS

5V_SDA3

5VTXD_TU

28M_CLK

AD76_SDA3

SCL3

LSI_RESET

IC4810

S3.3VLAN

UART_SEL1

PC_TXD

HDBT232C_TXD

TXD_PC_M

RXD_PC_M

PC_RXD

3V_SDA3,SCL3

F3V_SDA2,SCL2

6,7

8,9

4,5

SERVICE

63

65

5V_SCL3

IIC_CONT

TXD_PC

RXD_PC

10

2-3,5-6,8-9,11-12

14-15,17-18,20-21

23-24,26-27,29-30

32-33

LVDS

ASIC LVDS Input

CHB

CHA

ASIC3.3V

ASIC1.8V

IC DUAL SW

IC5403

Reg

IC4805

3

Reg

IC4806

4

Reset IC

1,4,10,13

2,5

3

6

[C0JBAZ000851]

9

8,11

12

SCL3

AD76_SDA3

Q4001

IIC_CONT

Q4002

12

11

1,2

STB5V

LED_G_0

Control

R(9-0),G(9-0),B(9-0)

ASIC Digital input

IC8001

[C1AB00002899]

ASIC

ASIC Digital output 2

ASIC Digital output 1

IC4026

F3.3V

STB3.3V

4

4

2

L8011

L8012

STB3.3V

IC4015

Logic IC

FAN_SOS

A7

FAN

12,13

LED_R_0

3.3V

3.3V_SIG

S3.3VLAN SYS_RESET

ASIC1.8V

ASIC3.3V

LAN_VOL_1V

4

3,6,9

IC4008

Logic IC

4,5

9,10

6

5VTXD_TU

3VTXD_TU

_SW

CLKM_20MHz

3V_SDA4,SCL4

D16

C15

D17

5V_ON

MAIN_ON

DCR_VBR

DCR_VBR

PANEL_SOS

VCX0_CLKIN

GIO

1.8V

3.3V

USB_VBUS1

A47

8

11

5VNRST

LED_RED

LSI_RESET

ANMPIN

CLAMPY

CLAMPY

ANMPIN

R(9-0),G(9-0),B(9-0)

Control

R(9-0),G(9-0),B(9-0)

Control

PWR15V

PWR15V

PWR15V

PWR15V

PWR24V

SCX_USBOC1

SCX_USBPSW1

3

4

SW

IC4804

6

1

F5V

USB_5V

2

1

TO H47

IC4016

1,2

3

LED_GREEN

LVDS

LVDS

IC2903

IC2333

2

IC2350

2,3

IC2312

2

IC2420

7

USBP4_P

USBP4_N

567

4

5VRXD_TU

DC/DC

DC/DC

DC/DC

Logic IC

DC/DC

DC/DC

USBP1_N

IC4018

Logic IC

1,2

4

5

STB3.3V

3VRXD_TU

A_REMOCON

F3V_SDA2,SCL2

AL27

AK27

AJ26

SCX2 Video

P3

SCX1_Input A from ASIC A

SCX1_Input B from ASIC B

LVDS OUTPUT 1

EVEN

ODD

AM24

AJ25

AM25

AJ8

M5

AC3

AL2

AB30

TXD_PC

RXD_PC

USBP1_P

AK25

B14

A14

UART_SEL2

UART0_RXD/TXD

LAN5V

7,82

F3.3V

3

F5V

7,8

F1.2V

3

PNL12V

8

AP25

AA32

4

5

STB5V

REMOCON_OUT

3V_SDA1,SCL1

AN27

AP26

AM27

AJ27

AC31

AB31

UART_SEL1

A_REM_IN

RTC_INT

AUDIO_R_M3_2

14

A37

TO V11

8

A11

F3.3V

3V_SDA3,SCL3

3V_SDA4,SCL4

AP27

AJ27

AH5

AD30

AJ3

LAN15V_ON/OFF

DPMS_HD_SCX1

15V_ON/OFF

IC2512

Reg

IC2513

Reg

IC2511

Reg

IC2510

Reg

Q2308

IC9301

DC/DC

IC9302

DC/DC

TXD_PC

RXD_PC

15

IC2113

17

RX_PC

TX_PC

AUDIO_L_M3_2

1

15

4

7

5

BACKLIGHT

LED_RED

LED_GREEN

5V_SAD3

5V_SCL3

SCX1

ARM IIC

IC4001

[C1AB00003896]

Image Processor

AD29

AL1

AG1

DPMS_VD_SCX1

IIC_CONT

1.8V

43

1.8V

43

43

3.3V

43

1.2V

FRC1.0V

68

FRC_1.8V

68

13

RS-232

16

9V

2

12

TO HX37

1

3

STB5V

Q4006

A_REMOCON

3VRXD_TU

3VTXD_TU

RXD,TXD

Tuner

AM3

AN3

AL3

HDMI1_DET

SPG_RESET

DVI_DET

LAN5V

3.3V

4,1

Logic IC

IC5104

6

3

5V

VSYNC_PCOUT

HSYNC_PCOUT

4

3

ALL_OFF

AN25

AC30

AM2

AM4

HDMI2_DET

HDBT_5VDET

PWR24V

FAN15V

PWR5V

PWR5V

G

(0-7)

3-10

27

B_PCOUT

B_PCOUTN

5

TO V22

A22

A_REM_IN

MAIN_SW

AM1

AH3

HPD2

HPD1

IC2904

IC2902

LVDS

LVDS

IC5101

Spartan-6

FPGA

B

(0-7)

16-23

IC5102

VIDEO DAC

31

28

G_PCOUTN

7

6

6

1

MAIN_SW

KEY_INPUT

KEY_INPUT

FAN_SOS

L5

L2

AG6

AH4

SCX_USBOC2

SCX_USBOC3

SCX_USBPSW2

Reg

DC/DC

IC2905

DC/DC

IC2450

7

IC2377

2

IC4807

2

IC4808

2

LVDS

R

(0-7)

41-48

33

32

G_PCOUT

R_PCOUT

R_PCOUTN

8

9

5

P_STB5V

SW_STB5V

Q2329

P_STB5V

DS_SOS

LED_G_0

L1

AL26

AL24

AH1

AG5

AG3

SCX_USBOC1

SCX_USBPSW3

34

32

7,82

DC/DC

DC/DC

DC/DC

DC/DC

3.3V

1.2V

34

10

STB5V

MAIN_SW

LED_R_0

LVDS RXA

ODD

LVDS RXB

EVEN

LVDS OUTPUT 2

FRC_XRST

AN24

3V_SDA4

SCL4

IIC_INT

SCX_USBPSW1

LAN3.3V

LAN1.8V

LAN1.0V

SOUND15V

8

FAN_VOL_1V

3

S1.0VLAN

7,8

NS3.3V

3

PWR5V

PWR5V

PWR15V

3.3V

1.5V_DDR

0.75V_DDR

DDR_REF

FAN15V

L2311

A4

MAKE_ALL_OFF

Q2401

STB5V

P_STB5V

MAIN_SW

1.5V_DDR

STB3.3V

STB1.2V

F3.3V

F1.2V

IC4007

MEMORY

IC4002

IC4003

FRC_DONE

OEBLK

FRC_SDA

SCL

IC4005

Logic IC

S3.3VLAN

Q4801

IC2315

2

Q2327

Q2318

DDR Termination

PWR15V

DCR_VBR

PANEL_SOS

7

1-3

TO P6

Q2405

Q2404

STB3.3V

ALL_OFF

FLASH

DDR2

1+1GBit

10-15

16-21

25-30

198,200

IC9350

SPI FLAHS

DC/DC

5V

15V

IC4017

SUB_ON

9

10

1-6

PNL3.3V

STB5V

LSI_RESET3

LSI_RESET3

STB3.3V

1.5V

IC9100

[C1AB00003847]

Image Processor

DDR Address

NS3.3V

STB5V

STB3.3V

3.3V

5V

5V

S1.5V

3

Q2329

A5

(0-12)

IC9250

DDR2

8

4

4

3

5

4

Q2354

JS4806

3

PWR5V

PWR24V

5-6

1-2

TO P5/P2

IC2004

AUDIO AMP

(C1AB00003705)

1

9

10

8

11

PWM2_SQ_R-

PWM2_SQ_L+

PWM2_SQ_L-

PWM2_SQ_R+

PWM_SQ_R-

PWM_SQ_L-

PWM_SQ_L+

PWM_SQ_R+

9

10

8

11

1

IC2002

AUDIO AMP

(C1AB00003705)

157-162

164-169

142-147

149-154

128-133

135-140

113-118

120-125

DDR Data

(0-15)

IC4809

Reg

IC4011

Reg

IC4012

Reg

IC8003

Reg

IC9303

Reg

IC9351

Reg

1.5V

S1.5VLAN

IC2390

4,2

Reg

MAIN_ON

LINE_OFF

P_STB5V

5V_ON

9

11

14

L-

32-34

L+

28-30

R-

25-27

R+

21-23

R-

32-34

R+

28-30

L-

25-27

L+

21-23

SOUND15V

LVDS TX CHB EVEN

LVDS TX CHB ODD

FRC_2.5V

FRC_1.8V

FRC1.0V

PNL3.3V

LVDS TX CHA EVEN

LVDS TX CHA ODD

FRC_1.8V

S2.5VLAN

1

STB3.3V

3

STB1.2V

3

1.8V

2,4

FRC_2.5V

1

PNL3.3V

3

1.5V_DDR

L4019

9V

15

SOUND15V

PNL3.3V

PNL12V

A17

1

2

3

4

A27

1

2

3

4

A1

45,47

40-35

33,32

30-27

24-19

17,15

14-11

1-4

A2

32-27

25,24

22-19

16-11

9,8

6-3

SP- L

SP- R

TO HX27

TO PANEL

TO PANEL

Block Diagram (2/3)

25

V11

1

2

4

5

TO A11

6

8

V1-BOARD

3.3V

BACKLIGHT

GREEN

RED

IR

STBY5V

IR

STBY5V

3.3V

BACKLIGHT

RED

GREEN

RM1501

OUT

VCC

VCC

3

OUT

1

D1501

SN1501

R

V2-BOARD

V22

KEY_IN

1

TO A22

G

2,4,6

STBY5V_SW

KEY CONTROL

SW1552 SW1553 SW1554

SW1555 SW1556

SW1551

HX-BOARD

JK3501

RS-232C

PC OUT

JK3502

Audio IN

JK3506

SP_out

JK3503

SP_out

JK3504

2

3

Input

1

2

3

6

7

8

13

14

L

R

R-

R+

L-

L+

TXD_PC

RXD_PC

R_PC_OUT

G_PC_OUT

B_PC_OUT

R_PC_OUTN

G_PC_OUTN

B_PC_OUTN

HSYNC_PC_OUT

VSYNC_PC_OUT

AUDIO_L_M3_2

AUDIO_R_M3_2

SP_OUT_-R

SP_OUT_+R

SP_OUT_-L

SP_OUT_+L

TXD_PC

RXD_PC

R_PC_OUT

G_PC_OUT

B_PC_OUT

R_PC_OUTN

G_PC_OUTN

B_PC_OUTN

HSYNC_PC_OUT

VSYNC_PC_OUT

AUDIO_L_M3_2

AUDIO_R_M3_2

SP_OUT_-R

SP_OUT_+R

SP_OUT_-L

SP_OUT_+L

H47

TO A47

4

5

1

2

6

7

H1-BOARD

USBP4_N

USBP4_P

VBUS(B)

VBUS(A)

USBP1_N

USBP1_P

L3803

L3807

DATA(B)

DATA(A)

VBUS(B)

VBUS(A)

JK3802

1

2

3

JK3801

1

2

3

HX37

6

7

15

TO A37

13

11

14

12

10

9

8

3

7

9V

1

HX27

1

2

TO A27

3

4

Block Diagram (3/3)

26

DS-BOARD

Q3002

Q3003

LAN15V_ON/OFF

LAN15V

SLOT15V

15V_ON/OFF

TO A13

DS13

1 - 5

11

F15V(PWR15V)

STB5V_S(SUB5V)

SLOT 2

A40

A19

A21

A17

B31

B17

AH_SOS

B21

SLOT3.3V

Q3102

STB5V_S

SLOT15V SLOT9V

SLOT15V SLOT5V

SLOT15V

STB5V_S

IC3120

VDD

8

RTC

IC3000

IN SW

8 2

DC/DC

IC3001

IN SW

8 2

DC/DC

IC3002

IN SW

8 2

DC/DC

5V_IIC_SW

Q3140

Q3141

SLOT9V

5

INT

IIC3

IIC0

B19

SLOT5V

A22

B40

LAN15V

STB5V_S

AH_SOS

DS_SOS

RTC_INT

IIC3

SLOT3.3V

DS3

A_EA+,-; A_OA+,-; A_EE+,A_EB+,-; A_OB+,-; A_EC+,A_OC+,-; A_CLK+,-; A_OD+,A_ED+,-; A_OE+,-

A_EA+,-; A_OA+,-; A_EE+,A_EB+,-; A_OB+,-; A_EC+,A_OC+,-; A_CLK+,-;

A_OD+,-; A_ED+,-; A_OE+,-

Q3140

Q3141

STB5V_S

SLOT5V

SLOT15V

LAN15V

SLOT9V

SLOT3.3V

SRQ

AH_SLOT1_DET

AH_SOS

AJ_TXD11

AJ_RXD11

REMOCON_5V

RESET

IIC3

AUD_L_DS1

AUD_R_DS1

AUD_R_DS1

AUD_L_DS1

SRQ

AH_SLOT1_DET

DS_SOS

AJ_TXD11

AJ_RXD11

RTC_INT

REMOCON_5V

RESET

LAN15V_ON/OFF

15V_ON/OFF

IIC0

DS2

A22

A19,B19

B37,B38

B40,A40

B33

A21,B21

B17,A17

B23

B28

B31

B27

B26

B30

B35

B25,B24

A3,B2,A4

B3,B6,B5

A5,A8,A7

A9,B8,A2

A10,B9

A12,B11

A13,B12

B14,A14

B15,A15

A26

A28

DS10

22

20

36,37,39

40,42,43

45,46,48

49,51,52

54,55,57

58,60,61

63,64,66

67

4

8

9

10

11

12

14

15

17

18

5,6

SLOT 1

TO A10

Parts Location

27

21

1

(UK)

6

(CONTINENTAL)

38

31

32

5

3

40

42

33

43

30

41

Parts Location

28

23

27

39

26

TMK0EA419 TMK0EA419

Parts Location

29

**

15

18

10

20

14

17

12

10

*

16

*

16

**

15

19 11 13

Touch Panel Filter Y ** Touch Panel Filter X

*

54 53

58

53

54

57 53 55

54

Parts Location

30

66

7 7 8

7070

68

22

65

68

46

67

9

59

61

69

643636 62 63 49

7473 7344

47

37

60

25

29

28

48

71

35

34

24

35

72

354 72

71

45

Loading...

Loading...