Panasonic TH-50PHD3, TH-50PHW3 Service manual

Specifications

ORDER NO. ITD0105002C0

D10

High Definition Plasma Display

TH-50PHD3

TH-50PHW3

GPH3D Chassis

Power Source: AC220 - 240V 50/60Hz (A,B, and E version)

AC120V 50/60Hz (U version)

Power Consumption: 530 W

3.0W (stand-by condition)

1.4W (Power off condition)

Plasma Display panel: Drive method AC type

50-inch, 16:9 aspect ratio

Contrast Ratio 3000:1

Brightness Capability (Panel only) 500 cd / m

(As a set) 300 cd / m

Screen size: 1106 mm (W)×622 mm (H)×1269 mm

(diagonal)

No. of pixels

1,049,088 (1366 (W)×768 (H)) [4,098×768

dots]

Operating condition:

Temperature 34 °F - 104 °F (0 °C - 40 °C)

Humidity 20 % - 80 %

Applicable signals:

Color System NTSC, PAL, PAL60, SECAM, Modified NTSC

Scanning format 525i (480i), 625i (575i), 525p (480p), 750p

(720p), 1125i (1080i)

PC signals XGA displa y

VGA, SVGA

SXGA, UXGA (compressed)

Horizontal scanning frequency 15.5 - 110kHz

Vertical scanning frequency 48 - 120Hz

Connection terminals:

AV

2

2

Video in (BNC) 1.0 Vp-p (75-ohm)

S-VIDEO IN (MINI DIN 4PIN) Y: 1 Vp-p (75-ohm), C: 0.286 Vp-p

(75-ohm)

AUDIO IN (RCA PIN JACK × 2)0.5 Vrms (high impedance)

COMPONENT/RGB

Y/G (BNC) 1.0 Vp-p/composite (75-ohm)

0.7 Vp-p/non-composite (75-ohm)

PB/B (BNC) 0.7 Vp-p (75-ohm)

PR/R (BNC) 0.7 Vp-p (75-ohm)

HD (BNC) 1.0 - 5.0 Vp-p (high imped ance)

VD (BNC) 1.0 - 5.0 Vp-p (high impedance)

AUDIO IN (RCA PIN JACK×2) 0.5 Vrms (high impedance)

PC

(HIGH-DENSITY D-SUB15PIN) R,G,B/0.7 Vp-p (75-ohm)

HD, VD/1.0 - 5.0 Vp-p (high

impedance)

AUDIO IN (M3.5 JACK) 0.5Vrms (high imped ance)

SERIAL

EXTERNAL CONTROL

TERMINAL (D-SUB9PIN)

SPEAKERS (6!) 16W [8 W×8 W] (10 % THD)

Dimensions (W×H×D): 47.6” (1210 mm)28.5” (724mm) 3.9” (98 mm)

Weight (Mass) approx. 99.2 Ibs (main unit only) 45.0 kg

RS-232C COMPATIBLE

For TY-SP50PHD3W only

approx. 1093 Ibs (with speakers) 49.6 kg

© 2001 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

TH-50PHD3 / TH-50PHW3

CONTENTS

Page Page

1 Plasma Display Technology 4

1.1. Plasma display panel

1.2. Plasma display panel structure

1.3. Rear Glass Structure

1.4. Front Glass Structure

1.5. Pixel Structure

1.6. Sub Field Drive system

1.7. Initialization

1.8. Write

1.9. Wall Voltage

1.10. Sustain Step 1

1.11. Sustain Step 2

1.12. Sustain Step 3

1.13. Sustain Step 4

1.14. Sustain Step 5

1.15. Repeat Step 1 to Step 5

1.16. Sub-Field drive

1.17. Dual Scan

1.18. Plasma AI (Adaptive brightness Intensifier)

1.19. Real Black drive

2 Service Hint

3 Adjustment Procedure

3.1. +B Set-up

3.2. Driver Set-up

3.3. Adjustment Volume Location

3.4. Test Point Location

3.5. Initialization Pulse Adjust

4 Alignment Setting

4.1. How to access Alignment

4.2. Exit

4.3. IIC menu structure

5 Alignment

5.1. DG contrast

5.2. DVCO adjust

5.3. NTSC panel white balance

5.4. PAL/SECAM panel white balance

5.5. Pedestal setting

5.6. PC/RGB panel white balance

5.7. HD/ 525i /525p panel white balance

5.8. 625i panel balance

5.9. Sub brighness setting

5.10. Pos./Size setting

5.11. Panel APL/ABL

5.12. SG Hold

5.13. Aging

5.14. LSI 33 Adjust

10

10

10

11

11

12

13

13

13

14

16

16

16

17

18

20

21

23

25

26

28

28

28

28

28

4

4

4

4

5

5

5

5

6

6

6

6

7

7

7

7

8

8

8

9

5.15. CAT (Computer Aided Test) mode 28

6 Self Check

6.1. Display Indication

7 Trouble shooting guide

7.1. No Power

7.2. No Picture

7.3. Local screen failure

8 P.C.B. (Printed Circuit Board) exchange

8.1. Caution

8.2. Quick adjustment after P.C.B. exchange

9 Location of Lead Wiring

10 Basic Circuit Explanation

10.1. Power Supply Circuit

10.2. Energy Recovery Drive Pulse Output

11 IC Block Diagram

12 Conductor Views

12.1. F-Board

12.2. P1-Board

12.3. P4-Board

12.4. P3, P5, P6, P7, P8, P9 and T11-Board

12.5. H, H3, S1 and V1-Board

12.6. DG-Board

12.7. D-Board

12.8. C1-Board

12.9. C2-Board

12.10. C3-Bo ard

12.11. C4-Bo ard

12.12. C5-Bo ard

12.13. C6-Bo ard

12.14. C7-Bo ard

12.15. C8-Bo ard

12.16. SC-Bo ard

12.17. SD-Bo ard

12.18. SU-Bo ard

12.19. SS, SS2 and SS3-Board

13 Block and Schematic Diagrams

13.1. Schematic Diagram Notes

13.2. Main Block Diagram

13.3. Power (F, P1, P3, P4, P5, P6, P7, P8 and P9 Board)

Block Diagram

13.4. P1-Board (1/2) Schematic Diagram

13.5. P1-Board (2/2) Schematic Diagram

13.6. P3 and P4-Board Schematic Diagram

13.7. P5, P6, P7 and P8-Board Schematic Diagram

13.8. P9 and F-Board Schematic Diagram

13.9. H-Board Block Diagram

29

29

30

30

31

31

32

32

32

33

34

34

35

36

39

39

40

43

45

47

50

52

55

56

57

58

59

60

61

62

63

66

67

68

71

71

72

73

74

75

76

77

78

79

2

13.10. H-Boa rd (1/4) Schematic Diagram 80

13.11. H-Boa rd (2/4) Schematic Diagram

13.12. H-Boa rd (3/4) Schematic Diagram

13.13. H-Boa rd (4/4) Schematic Diagram

13.14. DG Board Block Diagram

13.15. DG-B oard (1/4) Schematic Diagram

13.16. DG-B oard (2/4) Schematic Diagram

13.17. DG-B oard (3/4) Schematic Diagram

13.18. DG-B oard (4/4) Schematic Diagram

13.19. T11 Board Schem atic Diagram

13.20. D-Boa rd IC Locat ion

13.21. D-Boa rd Information (1/4)

13.22. D-Boa rd Information (2/4)

13.23. D-Boa rd Information (3/4)

13.24. D-Boa rd Information (4/4)

13.25. D-Boa rd Block Diagram

13.26. D-Boa rd (1/36) Schematic Diagram

13.27. D-Boa rd (2/36) Schematic Diagram

13.28. D-Boa rd (3/36) Schematic Diagram

13.29. D-Boa rd (4/36) Schematic Diagram

13.30. D-Boa rd (5/36) Schematic Diagram

13.31. D-Boa rd (6/36) Schematic Diagram

13.32. D-Boa rd (7/36) Schematic Diagram

13.33. D-Boa rd (8/36) Schematic Diagram

13.34. D-Boa rd (9/36) Schematic Diagram

13.35. D-Boa rd (10/36) Schematic Diagram

13.36. D-Boa rd (11/36) Schematic Diagram

13.37. D-Boa rd (12/36) Schematic Diagram

13.38. D-Boa rd (13/36) Schematic Diagram

13.39. D-Boa rd (14/36) Schematic Diagram

13.40. D-Boa rd (15/36) Schematic Diagram

13.41. D-Boa rd (16/36) Schematic Diagram

13.42. D-Boa rd (17/36) Schematic Diagram

13.43. D-Boa rd (18/36) Schematic Diagram

13.44. D-Boa rd (19/36) Schematic Diagram

13.45. D-Boa rd (20/36) Schematic Diagram

13.46. D-Boa rd (21/36) Schematic Diagram

13.47. D-Boa rd (22/36) Schematic Diagram

13.48. D-Boa rd (23/36) Schematic Diagram

13.49. D-Boa rd (24/36) Schematic Diagram

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

TH-50PHD3 / TH-50PHW3

13.50. D-Boa rd (25/36) Schematic Diagram

13.51. D-Boa rd (26/36) Schematic Diagram

13.52. D-Boa rd (27/36) Schematic Diagram

13.53. D-Boa rd (28/36) Schematic Diagram

13.54. D-Boa rd (29/36) Schematic Diagram

13.55. D-Boa rd (30/36) Schematic Diagram

13.56. D-Boa rd (31/36) Schematic Diagram

13.57. D-Boa rd (32/36) Schematic Diagram

13.58. D-Boa rd (33/36) Schematic Diagram

13.59. D-Boa rd (34/36) Schematic Diagram

13.60. D-Boa rd (35/36) Schematic Diagram

13.61. D-Boa rd (36/36) Schematic Diagram

13.62. C1, C2, C3, C4, C5, C6, C7 and C8 Board Block Diagram

13.63. C1-Bo ard Schematic Diagram

13.64. C2-Bo ard Schematic Diagram

13.65. C3-Bo ard Schematic Diagram

13.66. C4-Bo ard and V1-Board Schematic Diagram

13.67. C5-Bo ard Schematic Diagram

13.68. C6-Bo ard Schematic Diagram

13.69. C7-Bo ard Schematic Diagram

13.70. C8-Bo ard Schematic Diagram

13.71. SC-Bo ard Block Diagram

13.72. SC-Bo ard (1/2) Schematic Diagram

13.73. SC-Bo ard (2/2) Schematic Diagram

13.74. SD-Bo ard (1/2) Schematic Diagram

13.75. SD-Bo ard (2/2) Schematic Diagram

13.76. SU-Bo ard (1/2) Schematic Diagram

13.77. SU-Bo ard (2/2) Schematic Diagram

13.78. SS, SS2 amd SS3 Board Block

13.79. SS-Bo ard (1/2) Schematic Diagram

13.80. SS-Bo ard (2/2) SS2-Board, SS3-Board and S1-Board

Schematic Diagram

14 Panel drive signal wave form

15 Signal Waveform

16 Parts Location

17 Mechanical Replacement Parts List

18 Replacement Parts List

18.1. Relpacement Parts List Notes

18.2. Electrical Replacement Parts List

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

155

157

157

158

3

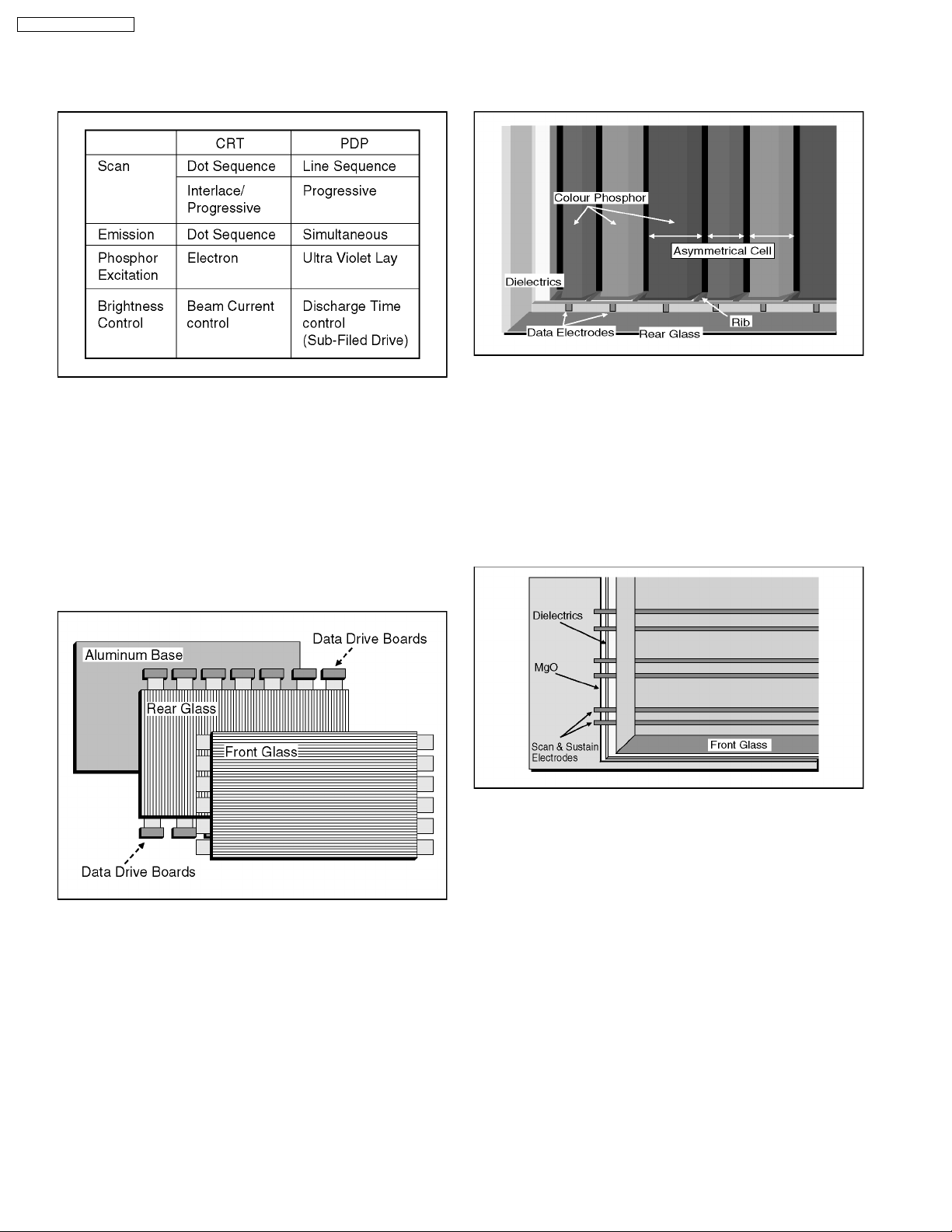

TH-50PHD3 / TH-50PHW3

1 Plasma Display Technology

1.1. Plasma display panel

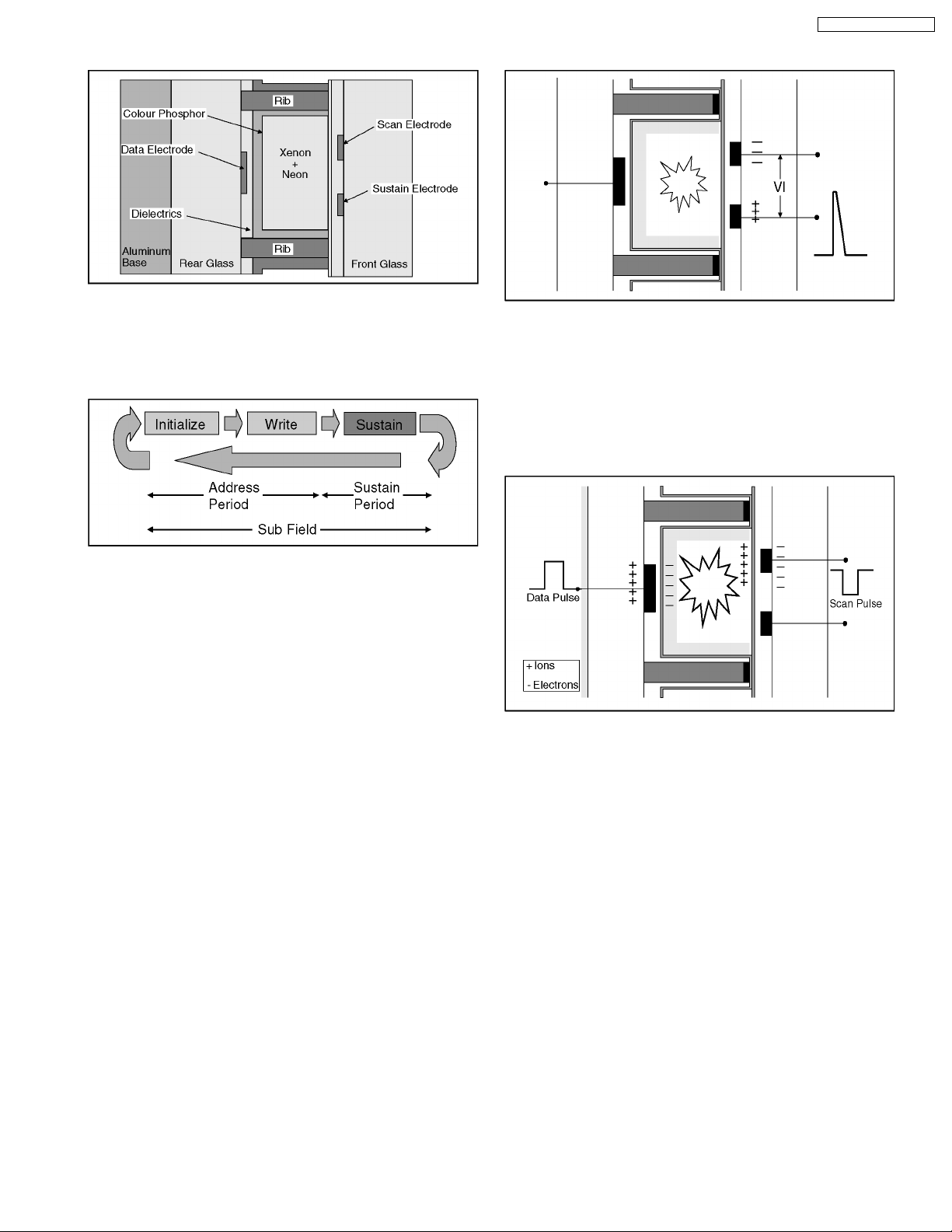

Fig. A

Panasonic 42 inch wide plasma display panel is develope for

large screen multimedia display with space saving.

The plasma display panel use AC type Sub-field drive system

with Dual scanning system.

This panel have also Panasonic original Asymmetric cell and

Plasma AI technology.

Fig. A Is the CRT and Plasma Display Panel(PDP) comparison

chart.

1.3. Rear Glass Structure

Fig. C

On the rear glass the data electrode is mounted.

The dielectric is coated on the rear glass.

Red, Green and Blue colour phosphors are formed on the data

electrode with the ribs. However to improve colour reproduction

and brightness, each colour phosphors are formed different

width This is called " Asymmetrical cell " as Panasonic original

technology.

1.4. Front Glass Structure

1.2. Plasma display panel structure

Fig. B

Plasma display panel structure

Panasonic Plasma display panel is consist of front glass, rear

glass and Aluminum base.

The front glass has each 768 lines scan and sustain

transparence electrodes.

The rear glass has 4098 (1366 x 3 ) data electrodes on the

inner surface. These electrodes are connected to the data drive

circuit boards directory.

Fig. D

On the front glass scan and sustain transparent electrodes are

mounted in pair.

The dielectrics is coated on the front grass.

MgO over coat is also applied on the dielectrics.

The front and rear glasses are piled and sealed . And low

presser gas are charged between two glasses.

4

1.5. Pixel Structure

Fig. E

50 inch plasma display panel has 1,049,088 pixels.

Each pixels structure is shown fig. E.

1.6. Sub Field Drive system

TH-50PHD3 / TH-50PHW3

1.7. Initialization

Fig. G

To clear any remaining electric charge into the pixel, trapezoid

voltage is applied between the scan and sustain electrodes.

Plasma discharge is started but the discharge become small

gradually.

Then any electric charge is cleared.

1.8. Write

Fig. F

Brightness control of plasma display panel is carried out by

plasma discharge time change. To control each pixelís

brightness Sub-field drive system is used.

A sub-field is consist of Initialize, Write and sustain operation.

Fig. H

Data Pulse which is positive polarity is input to data electrode

and Scan pulse which is negative polarity is input to scan

electrode simultaneously.

That means sum of data and scan pulses voltage is applied

between two electrodes as discharge start voltage.

Discharge is started into the pixel and gas is ionized.

During discharging Ion is charged on the scan electrode side

and electron is charged on data electrode side.

5

TH-50PHD3 / TH-50PHW3

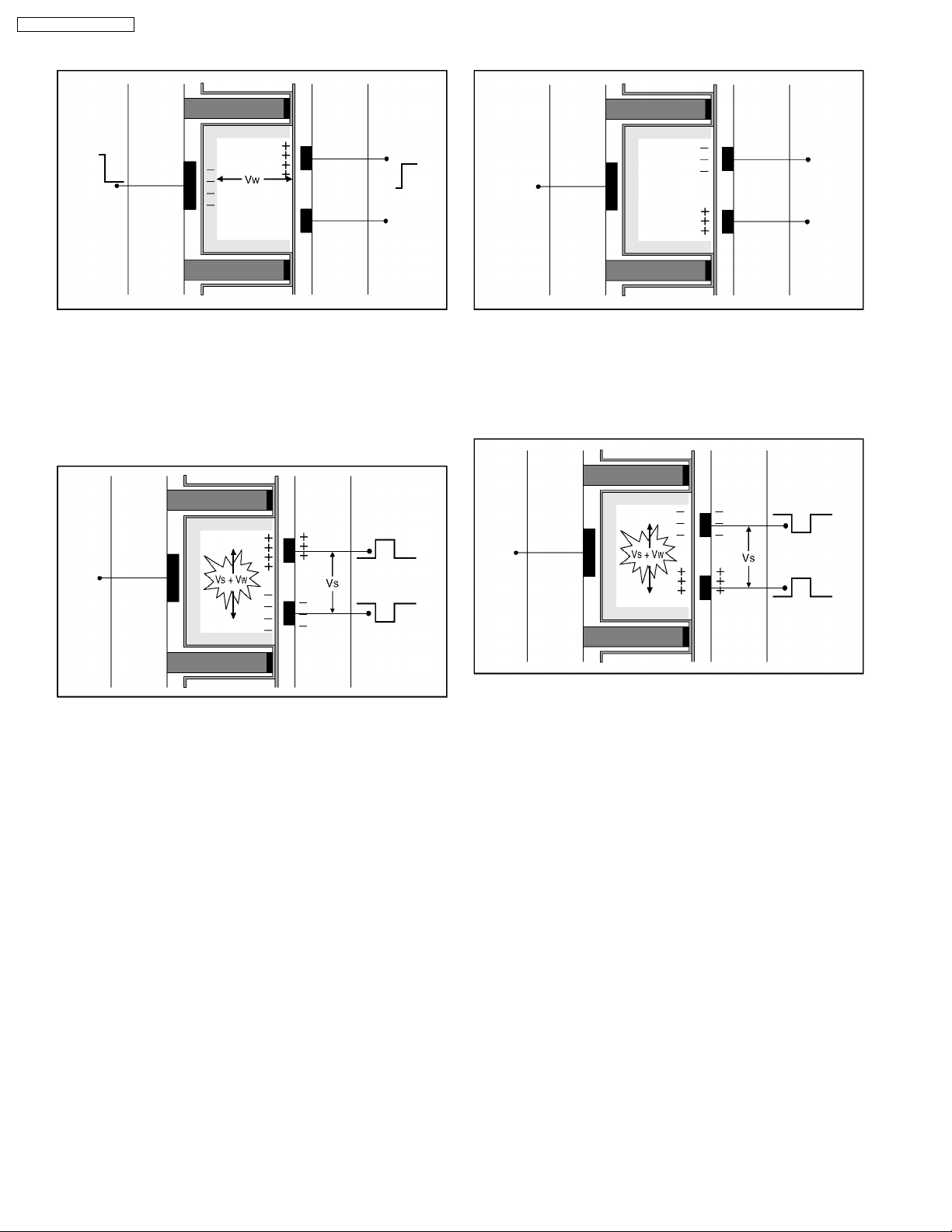

1.9. Wall Voltage

1.11. Sustain Step 2

Fig. I

When input pulses are stopped, Ions and Electrons which are

charged on the dielectric around the electrodes are remained.

This charge is called Wall Voltage (Pilot voltage).

This operation is called Write .

1.10. Sustain Step 1

Fig. J

Negative polarityís Sustain pulse is input between sustain and

scan electrodes and voltage potential between two electrodes

becomes sum of Sustain pulse and wall voltage.

Then discharge start.

Fig. K

When sustain pulse is stopped, Ions and Electrons are

remained again as Wall voltage. However polarity of wall

voltage is reversed.

1.12. Sustain Step 3

Fig. L

Positive polarity´s Sustain pulse is input between sustain and

scan electrodes and discharge start again.

6

1.13. Sustain Step 4

TH-50PHD3 / TH-50PHW3

1.15. Repeat Step 1 to Step 5

Fig. M

When sustain pulse is stopped, Ions and Electrons are

remained again as Wall voltage. However polarity of wall

voltage is reversed.

1.14. Sustain Step 5

Fig. N

Ions and Electrons which is generated by 2nd sustain

discharge are charged on the pixel wall(dielectric) around the

electrodes.

Fig. O

To keep discharge continuously step 1 to 5 operation will be

repeated.

As the result sustain pulse is alternated. Therefore we call this

drive system AC Drive type.

If sustain operation is repeated longer, brightness level of the

pixel is increased. Therefore depend on sustain discharge time

brightness of pixel is controlled.

1.16. Sub-Field drive

Fig. P

Sub-Field drive is PDP unique system.

While one TV field period, 8 bits digital video signal component

is reproduced by 8 sub-fields operation.

Each Sub-Field´s address period are all same.(Consist of one

initialization and 768 scanning operation)

But Sustain period of each Sub-Field are different.1st SubField(SF) reproduce only 1 step brightness.

2nd SF reproduce 2 steps brightness.

Each sub-field´s sustain period are increased gradually.

However total 256 brightness difference can be reproduced on

the screen.

7

TH-50PHD3 / TH-50PHW3

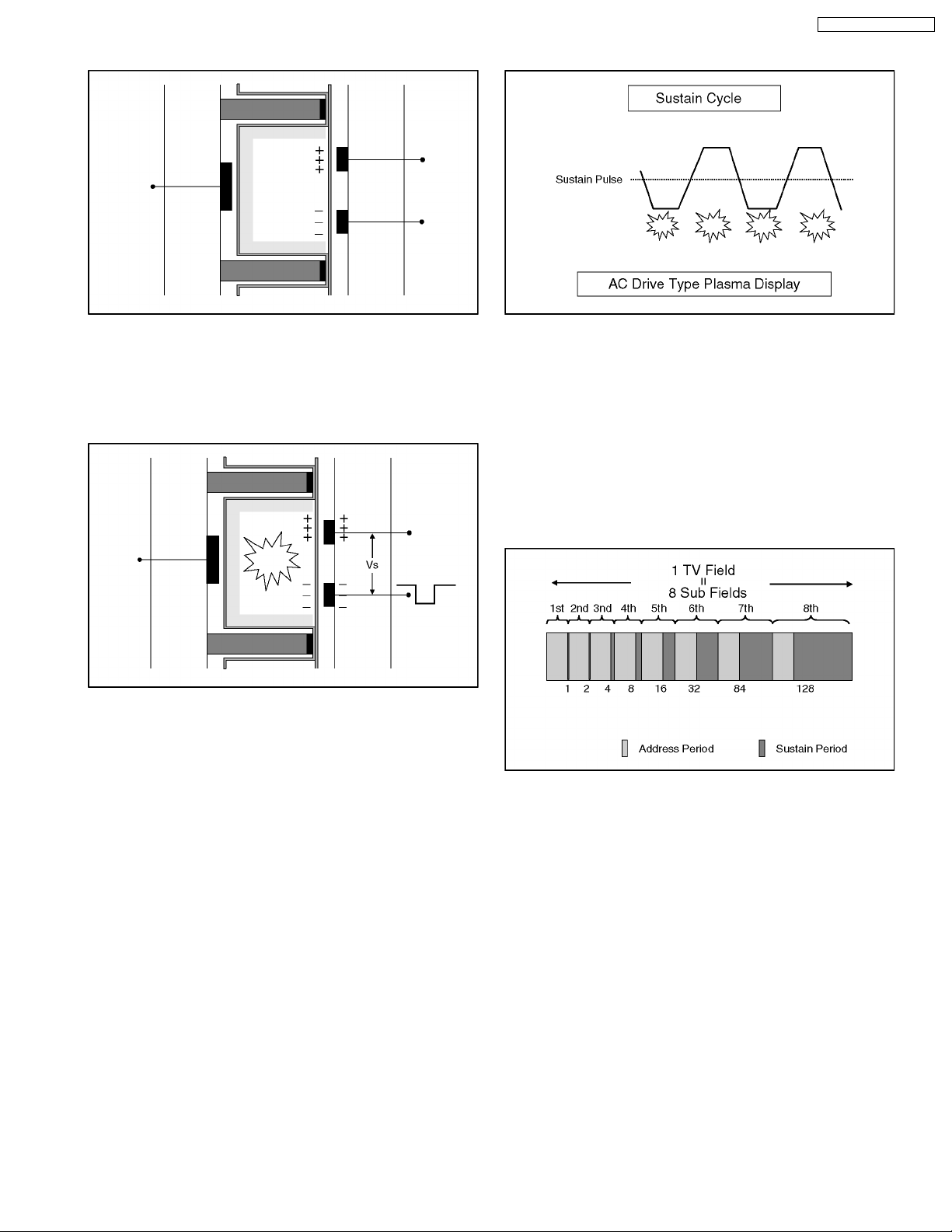

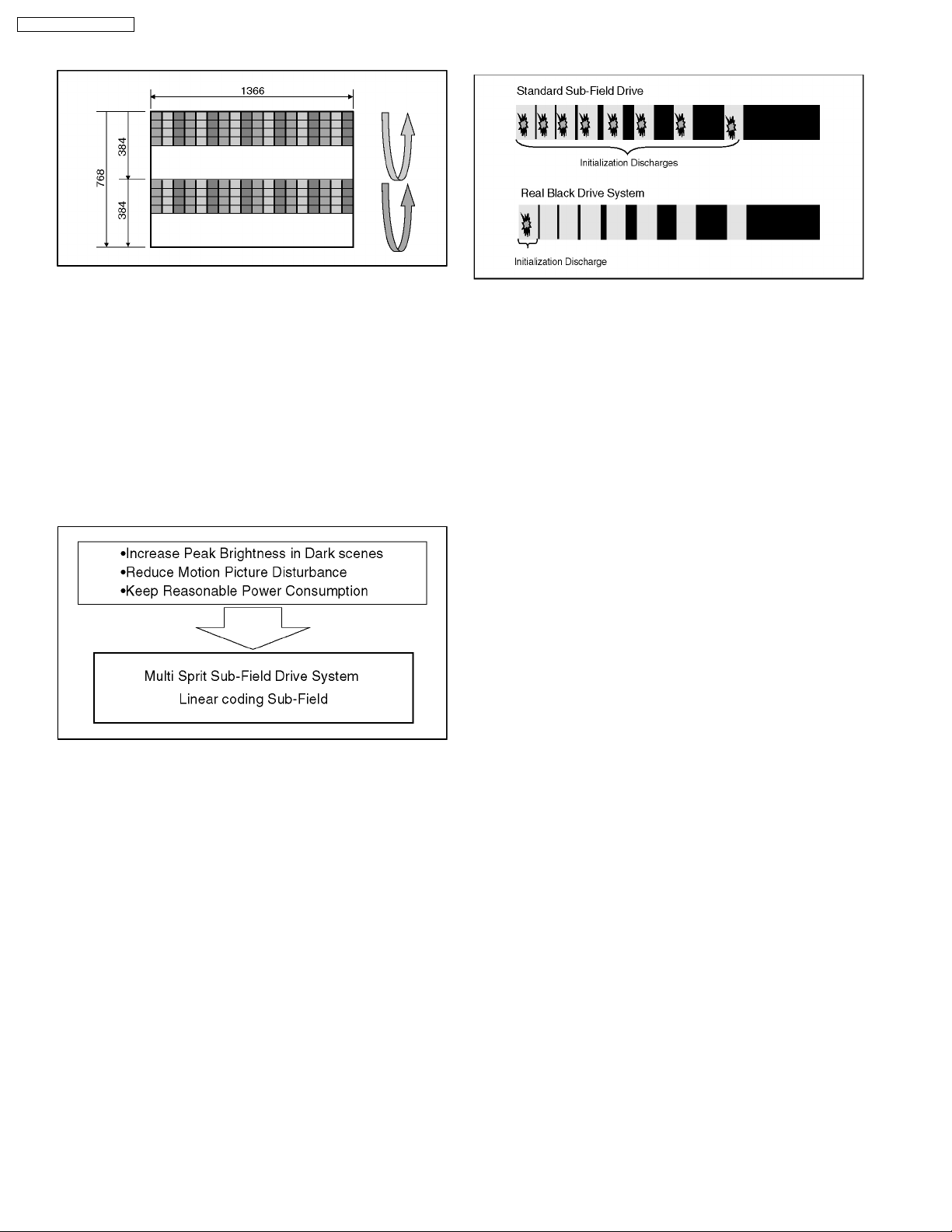

1.17. Dual Scan

1.19. Real Black drive

Fig. Q

The sustain period of sub-field drive system. Therefore

brightness peak is limited. Because 768 horizontal lines

scanning is carried out during address period.

Dual scan system can reduce scanning time from 768 to 384 in

the address period.

Then spaced time by dual scanning can be used for sustain

operation.

As the result Brightness peak level can be increased.

1.18. Plasma AI (Adaptive

brightness Intensifier)

Fig. S

For standard sub field drive, initialization discharge is done at

each sub field. So that during one TV field period same sub

field numbers of discharges are done even black signal was

displayed.

Therefore there are small emission at the black area.

Panasonic Real Black drive system improve black

reproduction.

Initialization discharge is done at first sub field only.

Remaining sub field are not required discharge because Real

Black drive circuit applies initialization electric field remainder

pulse.

Fig. R

Panasonic plasma AI control sub-field drive operation which is

called Multi-Sprit Sub-Field drive control system.

Depend on the picture contents ( APL : Average Picture Level

) sustain time format of each sub-field are also rearranged from

binary format to linear cording sustain time. (Linear coding subfield)

Plasma AI select the best display condition for Plasma display

panel to display natural and crisp picture.

8

2 Service Hint

TH-50PHD3 / TH-50PHW3

Baord name Function Board name Function

C1 Data drive (Upper Left) P4 Panel drive power

C2 Data drive (Upper Center) P5 Processing voltage control

C3 Data drive (Upper Right) P6 PFC oscillator

C4 Data drive (Lower Left) P7 High Voltage protect

C5 Data drive (Lower Center) P8 Low Voltage protect

C6 Data drive (Lower Right) P9 Regulator

C7 Saving power S1 Power switch

C8 Saving power SC Scan drive

D Digital process & control SD Scan drive output (Lower)

DG RGB/IF SS Sustain drive

F Line Filter SS2 Sustain conne ction (Upper)

F Line Filter SS3 Sustain conne ction (Lower)

H Rear terminal SU Scan drive output (Upper)

H3 Speaker terminal T11 Interface

P1 Power supply V1 Front switch & Remote Receiver

P3 Sustain voltage control

9

TH-50PHD3 / TH-50PHW3

3 Adjustment Procedure

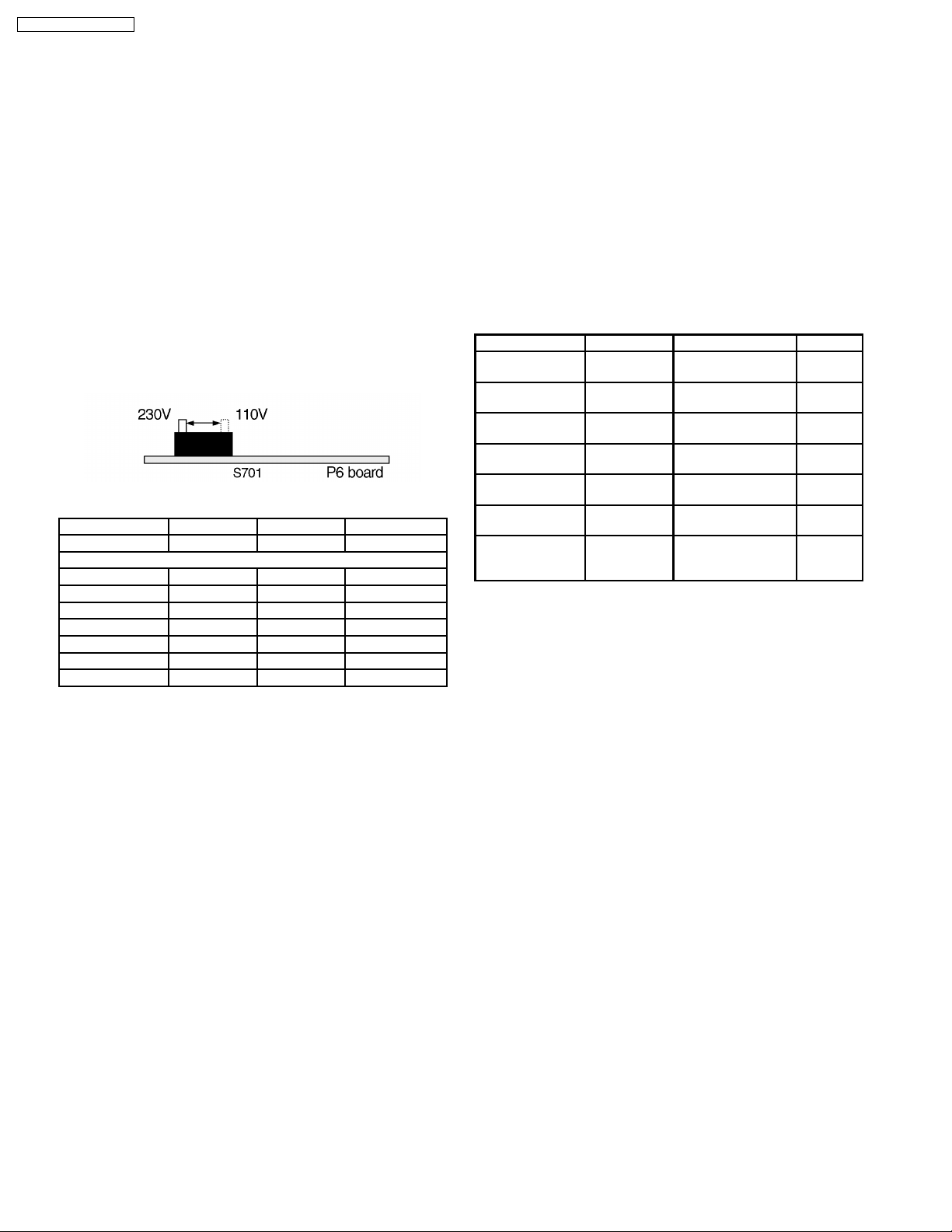

3.1. +B Set-up

3.1.1. Item / Preparation

1. Confirm the main voltage set switch Is set to 230V. (A, B,

and E version) Confirm the main voltage set switch is set to

110V. (U version)

Note:

230V covers input AC voltage from 200V till 260V, and

110V covers from 90V till 130V.

2. Input a Grey scale signal.

3. Set the picture controls: -

Picture mode: Normal

White balance: Normal

3.1.2. Adjustments

Adjust and confirm indicated test point for the specified voltage.

Test point Voltage Volume Name

P4 pin 1 (Hot) 400V ±1V R548 PFC

Confirmation (Cold)

P27 pin 5 16V ±0.5V +15V

D5 pin 1 14V ±0.5V +13.5V

DG6 pin 1 14V ±0.5V Audio15V

DG6 pin 3 -14V ±0.5V Audio-15V

D5 pin 5 5.2V ±0.3V +5.25V

D5 pin 8 3.6V ±0.2V +3.65V

D7 pin 4 5V ±0.3V STB5V

3.2. Driver Set-up

3.2.1. Item / Preparation

1. Input an APL 100 % white signal.

2. Set the picture controls: -

Picture mode: Normal

White balance: Cool

Aspect: 16:9

3.2.2. Adjustments

Adjust driver section voltages referring the panel data on the

panel data label.

Test point Voltage Volume Name

TPVSUS

(SS-BOARD)

TPVBK

(SC-BOARD)

TPVE

(SS-BOARD)

TPVSET

(SC-BOARD)

TPVAD

(SC-BOARD)

P27 pin2 (P1BOARD

Between TPVscn

and TPVAD

(SC-BOARD)

VSUS ±1V R639(P3-BOARD) Vsus

140 V ±5V R513(P1-BOARD) Vbk

VE ±0.5V R6829(SS-BOARD) Ve

224 V ±1V R6490(SC-BOARD) Vset

VAD ±1V R960(P4-BOARD) Vad

75 V ±0.5V R528 (P1-BOARD) Vda

120 + (Vad)

±0.5V

R967 (P4-BOARD) Vscan

10

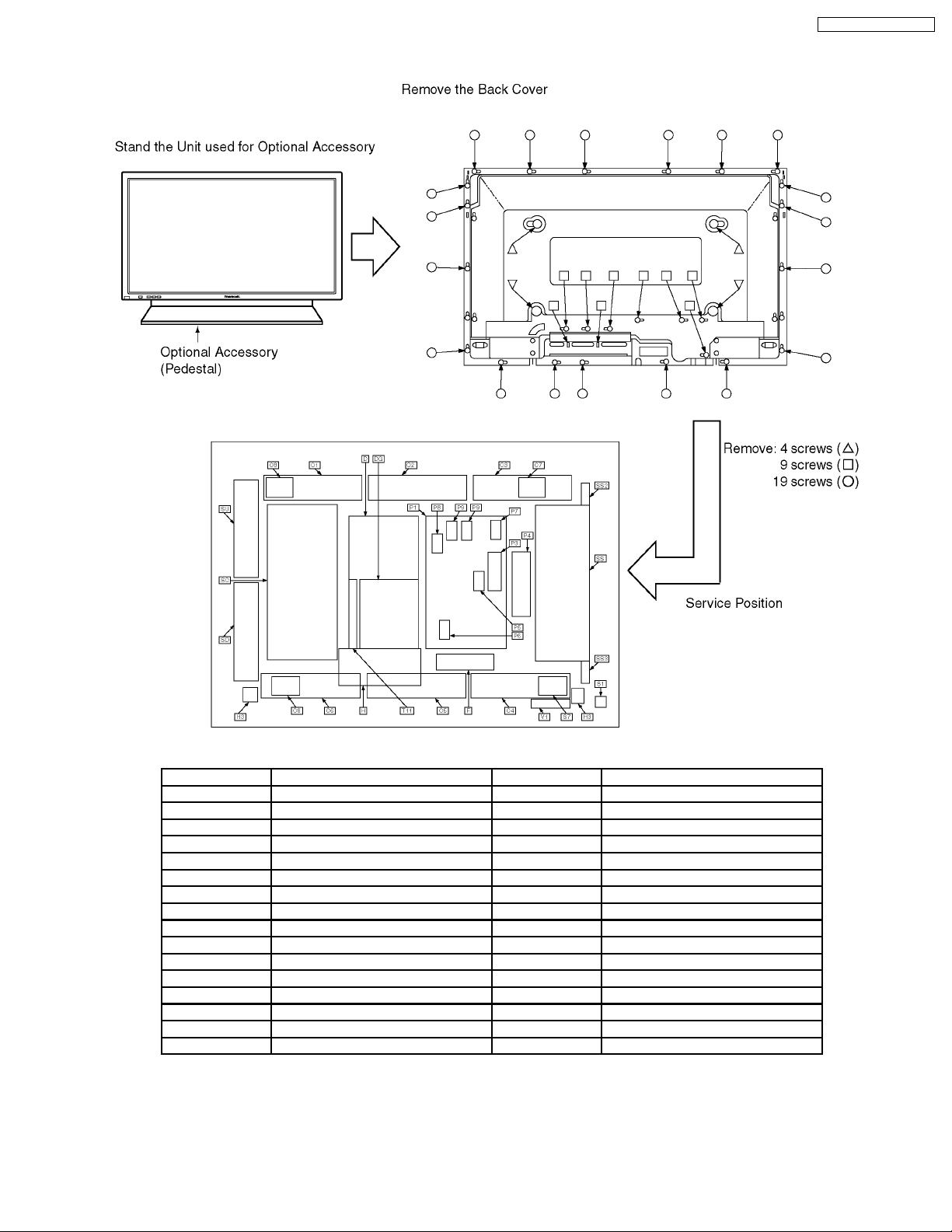

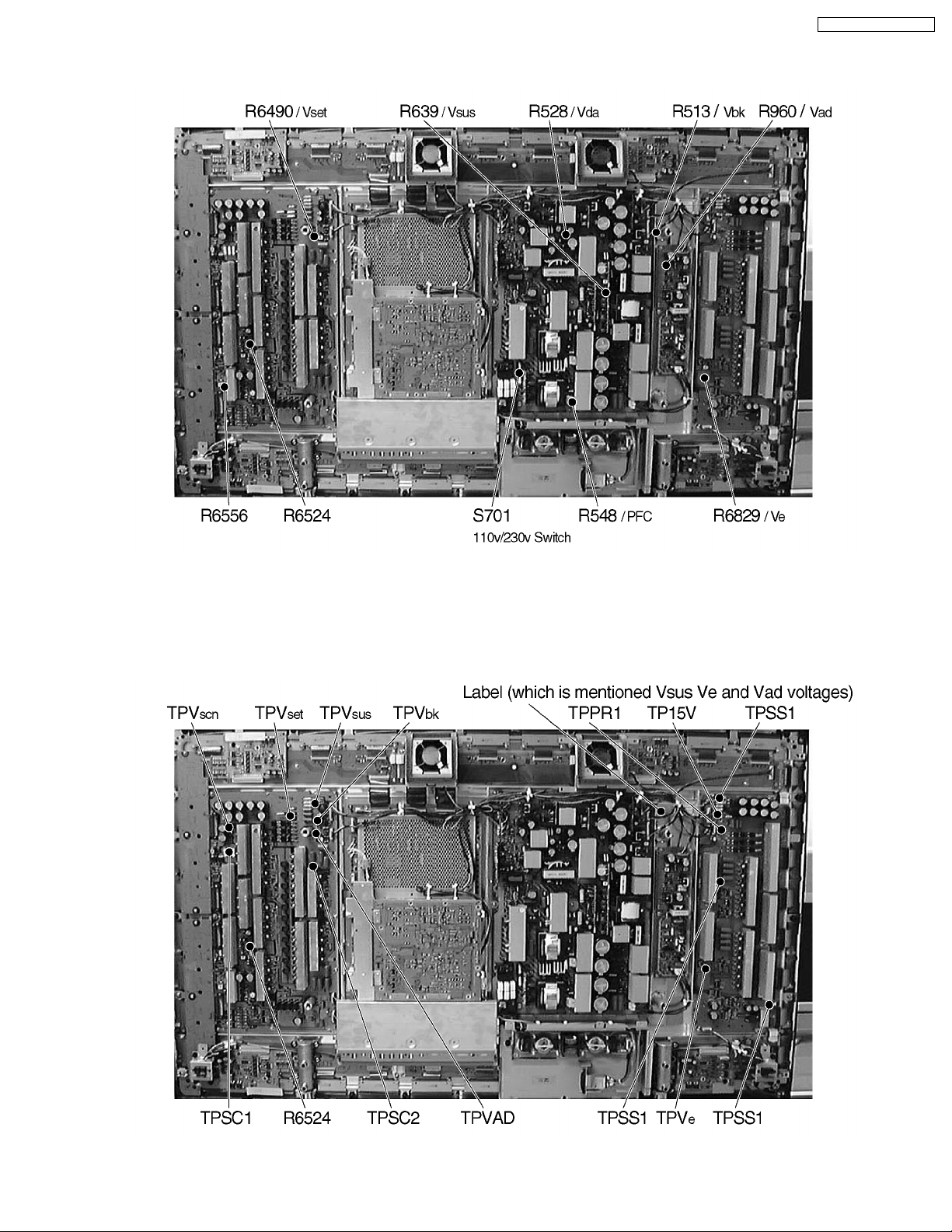

3.3. Adjustment Volume Location

TH-50PHD3 / TH-50PHW3

3.4. Test Point Location

11

TH-50PHD3 / TH-50PHW3

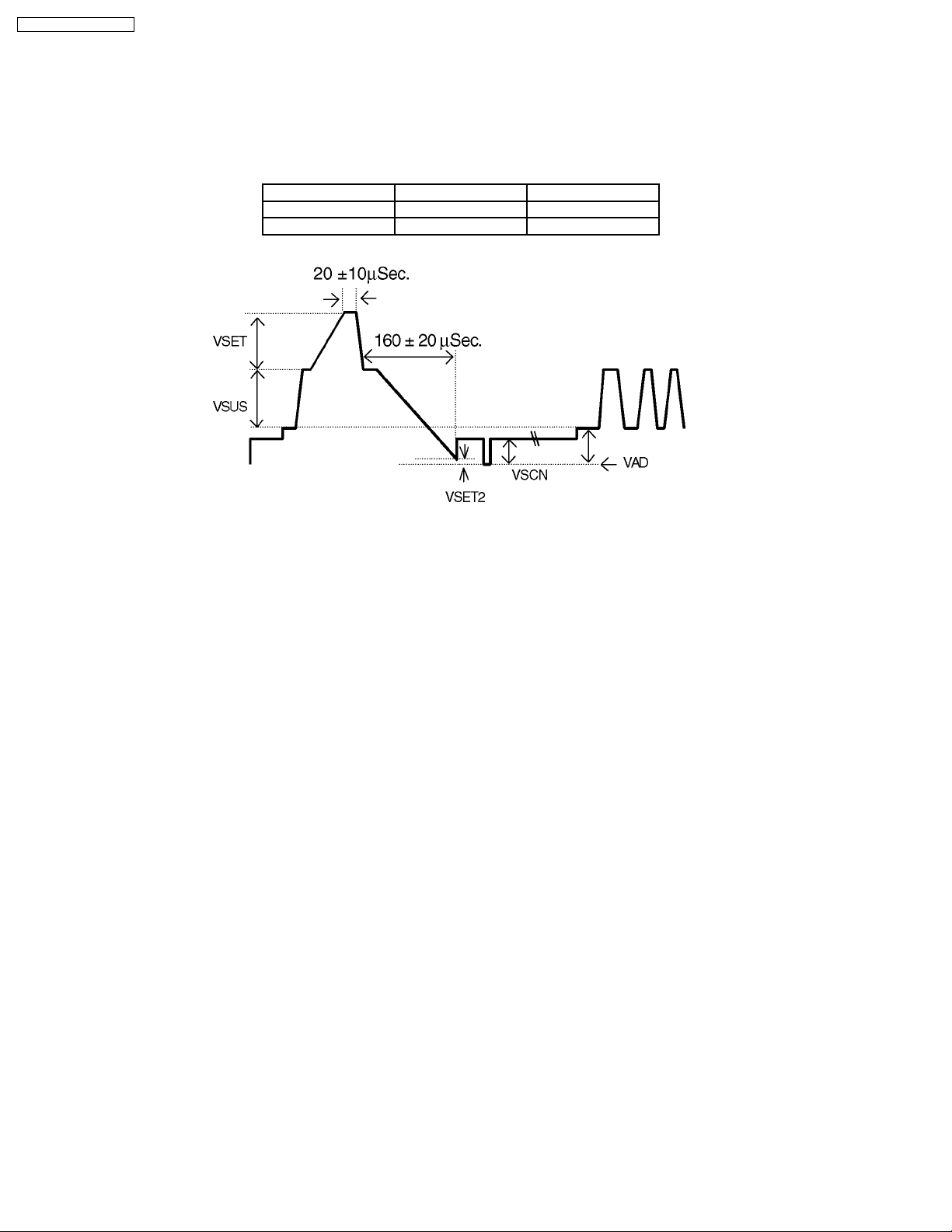

3.5. Initialization Pulse Adjust

1. Input a Cross hatch signal.

2. Set the picture controls: -

Picture mode: Normal

White balance: Cool

Adjust the indicated test point for the specified wave form.

Test point Volume

TPSC1 (SC) R6524 (SC) 20±10µ Sec

TPSC1 (SC) R6556 (SC) 160±20µ Sec

12

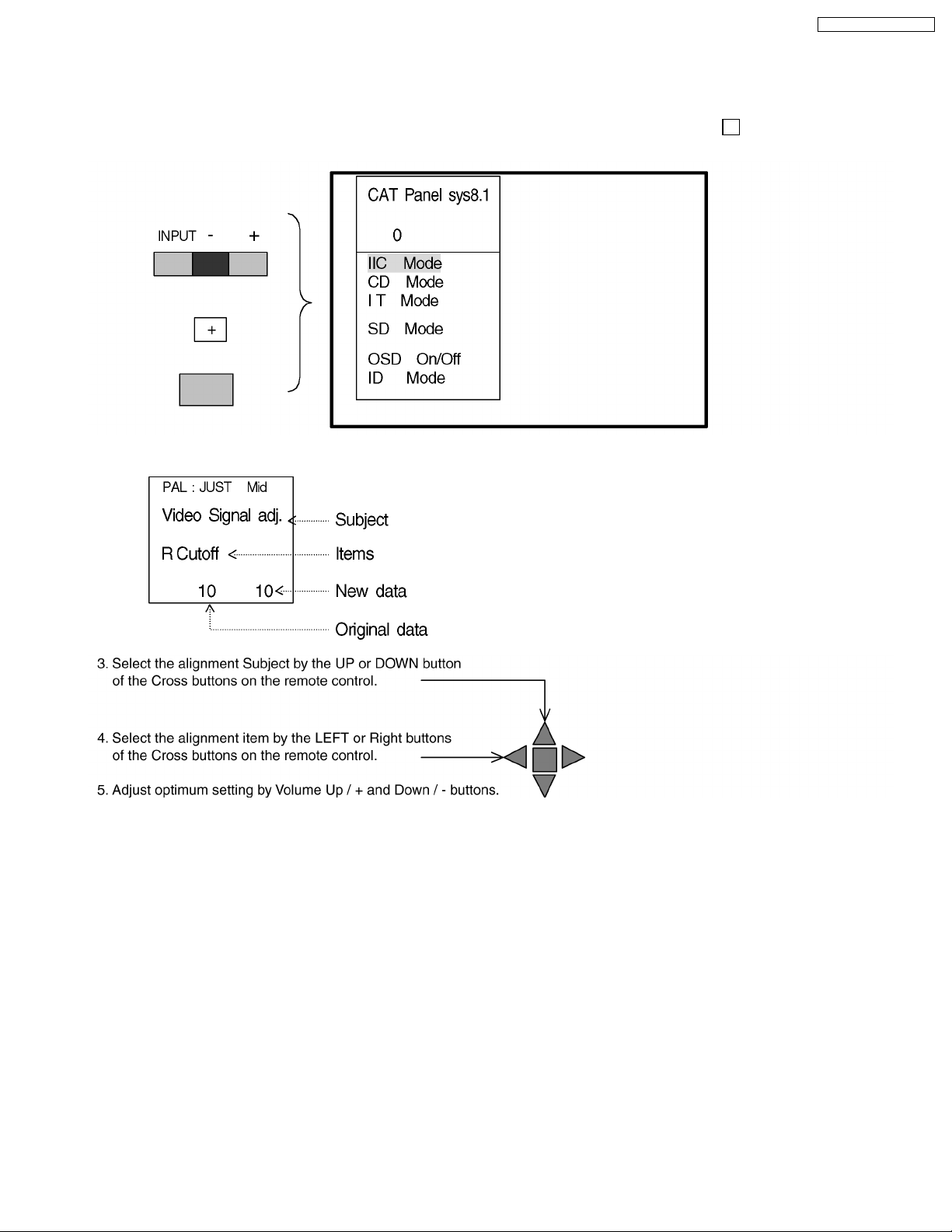

4 Alignment Setting

4.1. How to access Alignment

TH-50PHD3 / TH-50PHW3

1. Press and hold the

control 3 times quickly within 1 second, this will place the unit into the CAT menu (Main service mode)

2. Press the Access button on the remote control.

Volume down / -

button on the front panel of the unit and press the

status [ +

]

button on the remote

4.2. Exit

1. To exit the

2. To exit the

CAT mode

IIC mode

, press theRbutton on the remote control.

, access the

ID mode

by the down button of cross buttons and switch off the main power and on again.

13

TH-50PHD3 / TH-50PHW3

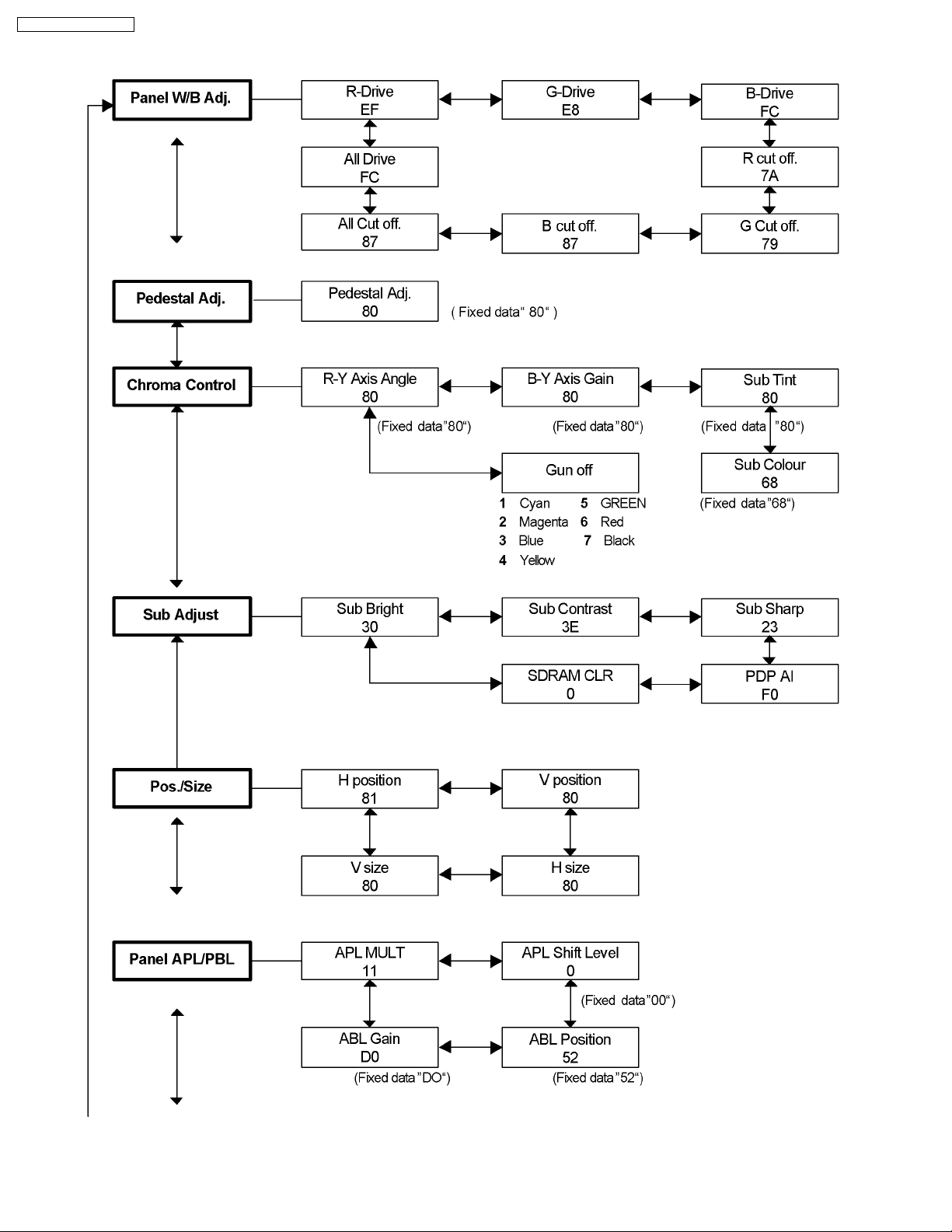

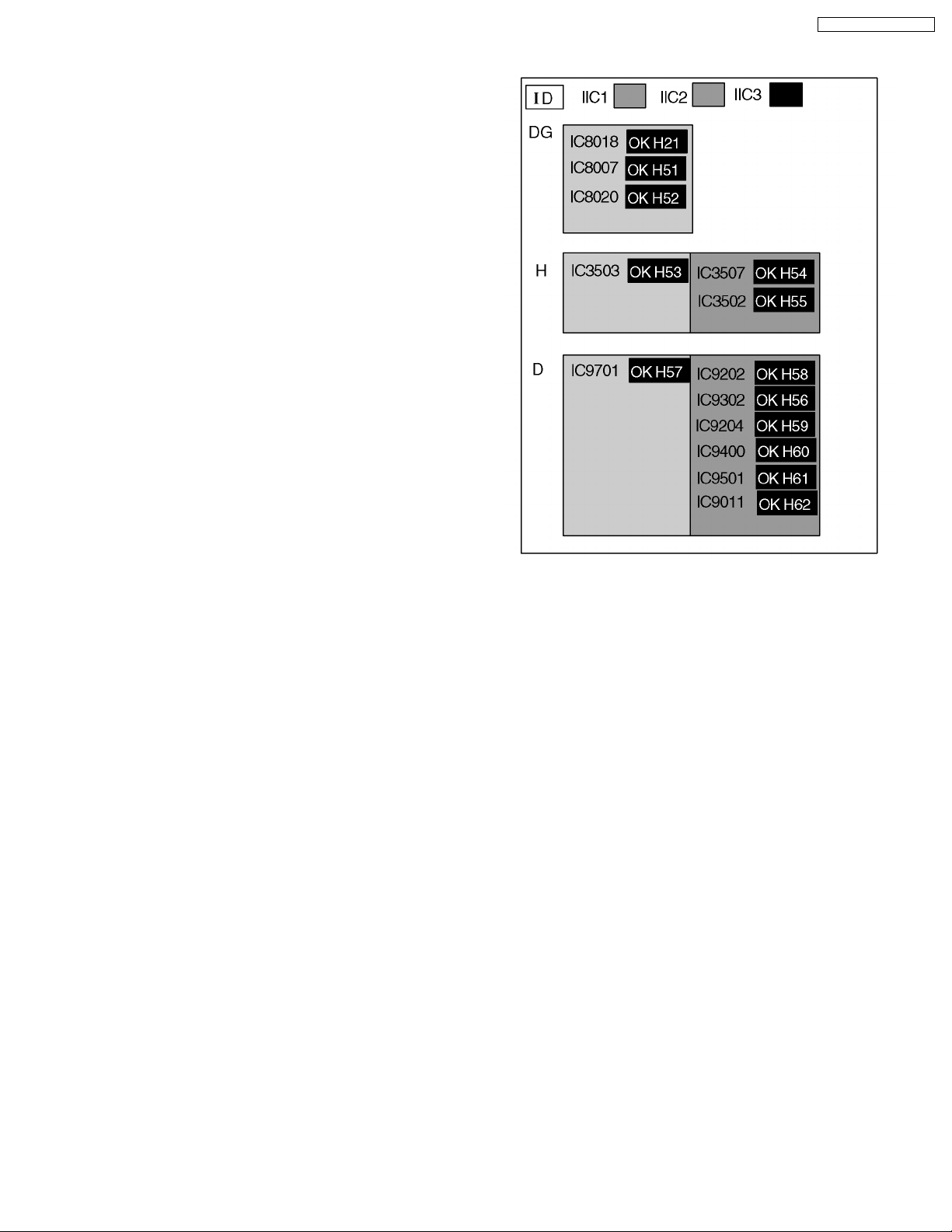

4.3. IIC menu structure

14

TH-50PHD3 / TH-50PHW3

15

TH-50PHD3 / TH-50PHW3

5 Alignment

5.1. DG contrast

(Composit video signal)

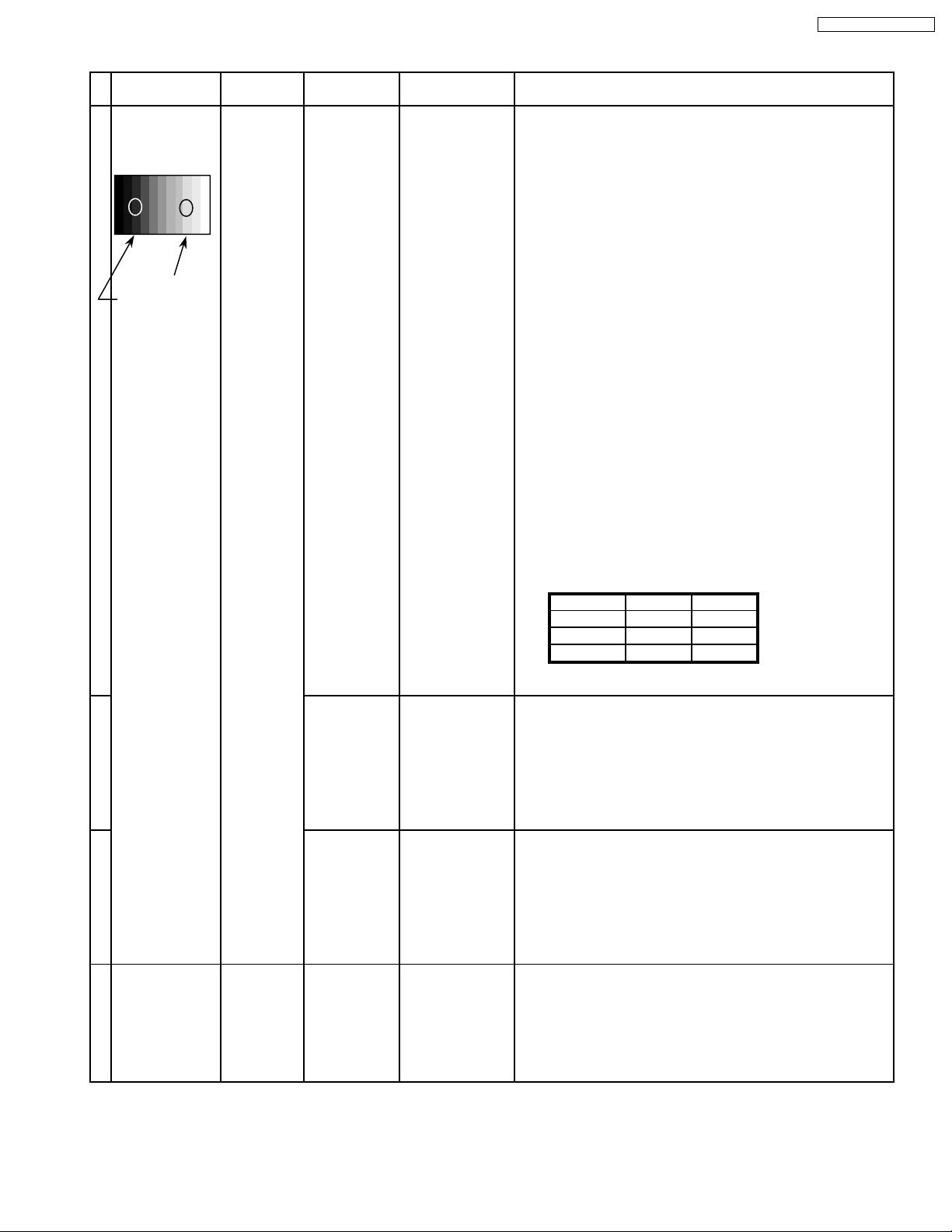

INPUT Equipment Test Point Level Remark

Alignment menu

Subject Item

1 NTSC Oscilloscope TP8004 VPC SETTING

Colour Bar

2 PAL Oscilloscope TP8004 VPC SETTING

Colour Bar

(DG Boad)

(DG Board)

5.2. DVCO adjust

Alignment menu

Subject Item

1 NTSC or PAL - - VPC SETTING

Colour Bar

Standard signal

DG CONTRAST

DG CONTRAST

DVCO SETTING

0.7V+-0.02V

(3A)

100IRE

0.55V+-0.02V

(3A)

ProcedureINPUT Equipment Test Point

1) Access to DVCO SETTING mode.

2) Press ACCESS key on remote then automatic

DVCO setting is started.

3) When data becomes " 1 "adjustment is completed. .

* Do not use this function without input signal.

16

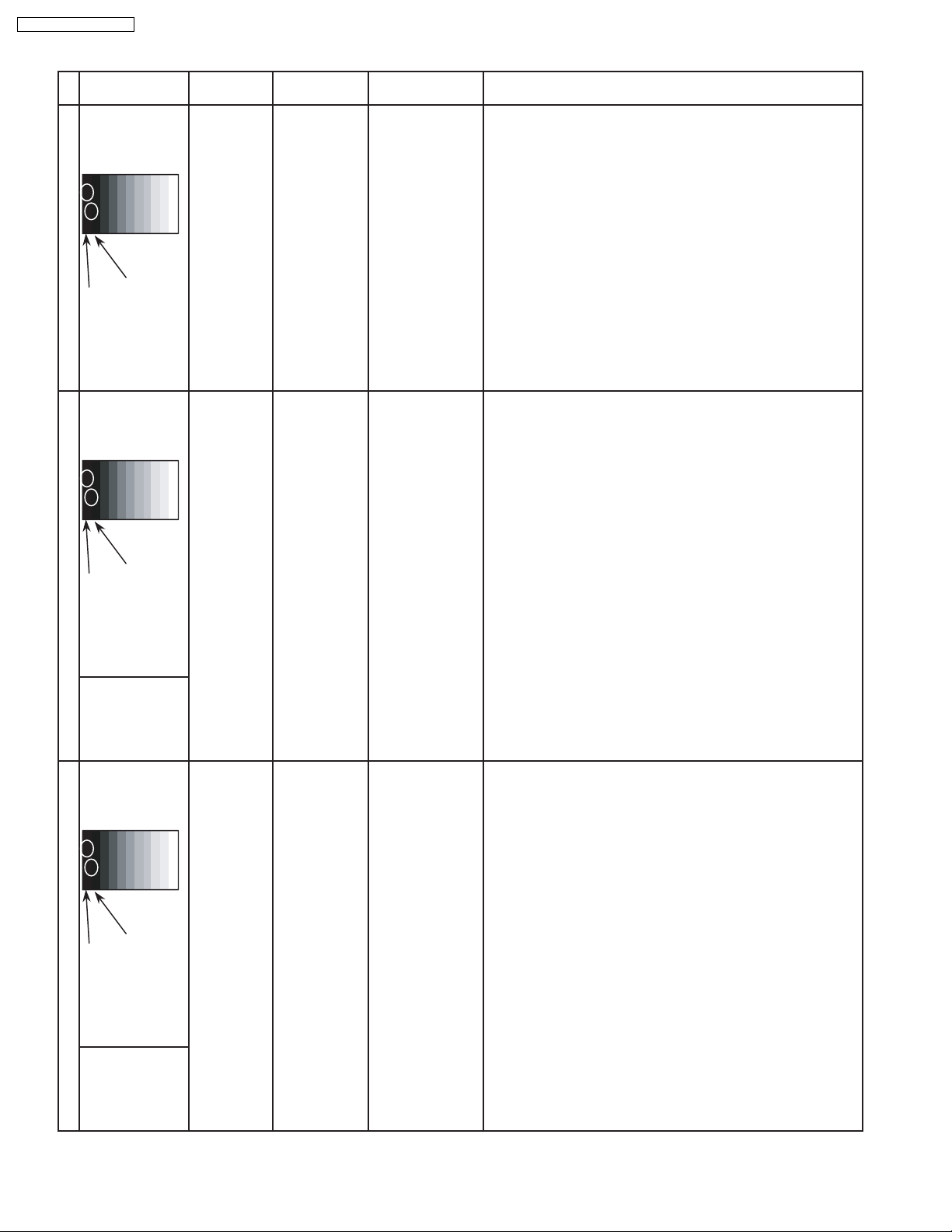

5.3. NTSC panel white balance

INPUT Alignment menu ProcedureEquipment Setting

1 NTSC Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool exactly.

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off shown Fig.-01.

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

to 10 cd/m

6)Find 75% of white area by color sensor.

PANEL W/B

G Drive 7) Set G Drive to " D8 ".

PANEL W/B

B Drive 8) Adjust B and R Drive to set color temperature

R Drive as shown Fig.-01.

9) Repeat item 4) to 7) to set both Low light and

high light.

PANEL W/B

R,G,B Drive 10) Increase same steps of R, G and B Drive to set

R,G,B Drive largest level of 3 color drive to "FC".

PANEL W/B

R,G,B cut off 11) Re-adjust Low light level again.

2

.

TH-50PHD3 / TH-50PHW3

2

Color Temp. x y

Cool(Hi) 0.272 0.290

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -01

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

17

TH-50PHD3 / TH-50PHW3

5.4. PAL/SECAM panel white balance

INPUT Alignment menu ProcedureEquipment Setting

1 PAL Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool exactly.

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

PANEL W/B

PANEL W/B

PANEL W/B

PANEL W/B

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off shown Fig.-02.

to 10 cd/m

2.

6)Find 75% of white area by color sensor.

G Drive 7) Set G Drive to " D8 ".

B Drive 8) Adjust B and R Drive to set color temperature

R Drive as shown Fig.-02.

9) Repeat procedure 4) to 7) to set both Low light and

high light.

R,G,B Drive 10) Increase same steps of R, G and B Drive to set

R,G,B Drive largest level of 3 color drive to "FC".

R,G,B cut off 11) Re-adjust Low light level again.

2

Color Temp. x y

Cool(Hi) 0.272 0.290

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -02

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

18

TH-50PHD3 / TH-50PHW3

Alignment menu ProcedureEquipment Setting

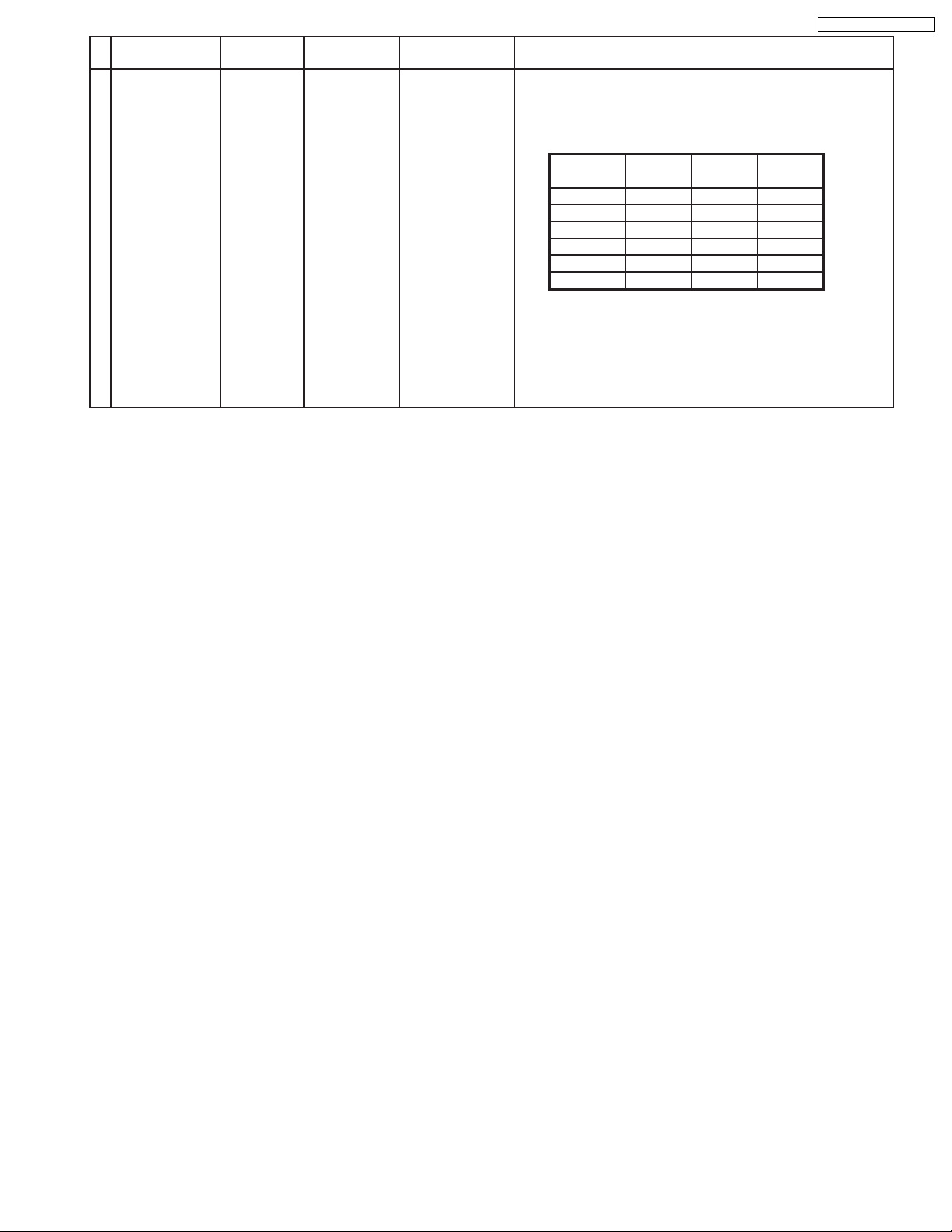

5 Picture: 1) Write down each color temaparature of R,G,B drive and

Normal Cut off data as follows.

Aspect:

16:9

White

White balance:

Cool

Normal

Warm

Balance Cool Normal Warm

R Drive

G Drive

B Drive

R Cut off

G Cut off

B Cut off

SECAM signal 2) Input SECAM signal.

3) Copy PAL R,G,B drive and cut off data of each white

balance mode to SECAM position.

19

TH-50PHD3 / TH-50PHW3

5.5. Pedestal setting

INPUT Alignment menu ProcedureEquipment Setting

1 Component Picture: PANEL W/B

(525i, 525p, 625i, Normal R cut off 1) Set R,G and B cut off to "

720i or 1080i) White balance: G cut off

Gray Scale Aspect:

Pattern 16:9

Black 2 %

Black 0 % at black 2% area and no emission at black 0% area.

Cool B cut off

Chroma Control:

Gun off

RGB Sub Adjust:

G Sub Bright

Chroma Control:

Gun off

RGB Sub Adjust:

B Sub Bright

Chroma Control:

Gun off

RGB Sub Adjust:

R Sub Bright

** Adjust at the dark room.

80 ".

2) Set Gun off to "

3) Adjust G Sub bright to start some of green pixels emission

at black 2% area and no emission at black 0% area.

4) Set Gun off to "

5) Adjust B Sub bright to start some of blue pixels emission

6) Set Gun off to "

7) Adjust R Sub bright to start some of red pixels emission

at black 2% area and no emission at black 0% area.

5". (Only green pixels can emit.)

3". (Only blue pixels can emit.)

6". (Only red pixels can emit.)

2 RGB(PC) Picture: 1) Change input to RGB signal.

Gray Scale Normal PANEL W/B

Pattern White balance: R,G,B cut off 2) Repeat procedure 1) to 7) of Component input signal.

Cool PANEL W/B

Aspect: R,G,B Drive

16:9

Black 2 %

Black 0 %

20

5.6. PC/RGB panel white balance

INPUT Alignment menu ProcedureEquipment Setting

1 PC Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool exactly.

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off shown Fig.-03.

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

to 10 cd/m

6)Find 75% of white area by color sensor.

PANEL W/B

G Drive 7) Set G Drive to " D8 ".

PANEL W/B

B Drive 8) Adjust B and R Drive to set color temperature

R Drive as shown Fig.-03.

9) Repeat item 4) to 7) to set both Low light and

high light.

PANEL W/B

R,G,B Drive 10) Increase same steps of R, G and B Drive to set

R,G,B Drive largest level of 3 color drive to "FC".

PANEL W/B

R,G,B cut off 11) Re-adjust Low light level again.

2

.

TH-50PHD3 / TH-50PHW3

2

Color Temp. x y

Cool(Hi) 0.272 0.290

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -03

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

21

TH-50PHD3 / TH-50PHW3

INPUT Alignment menu ProcedureEquipment Setting

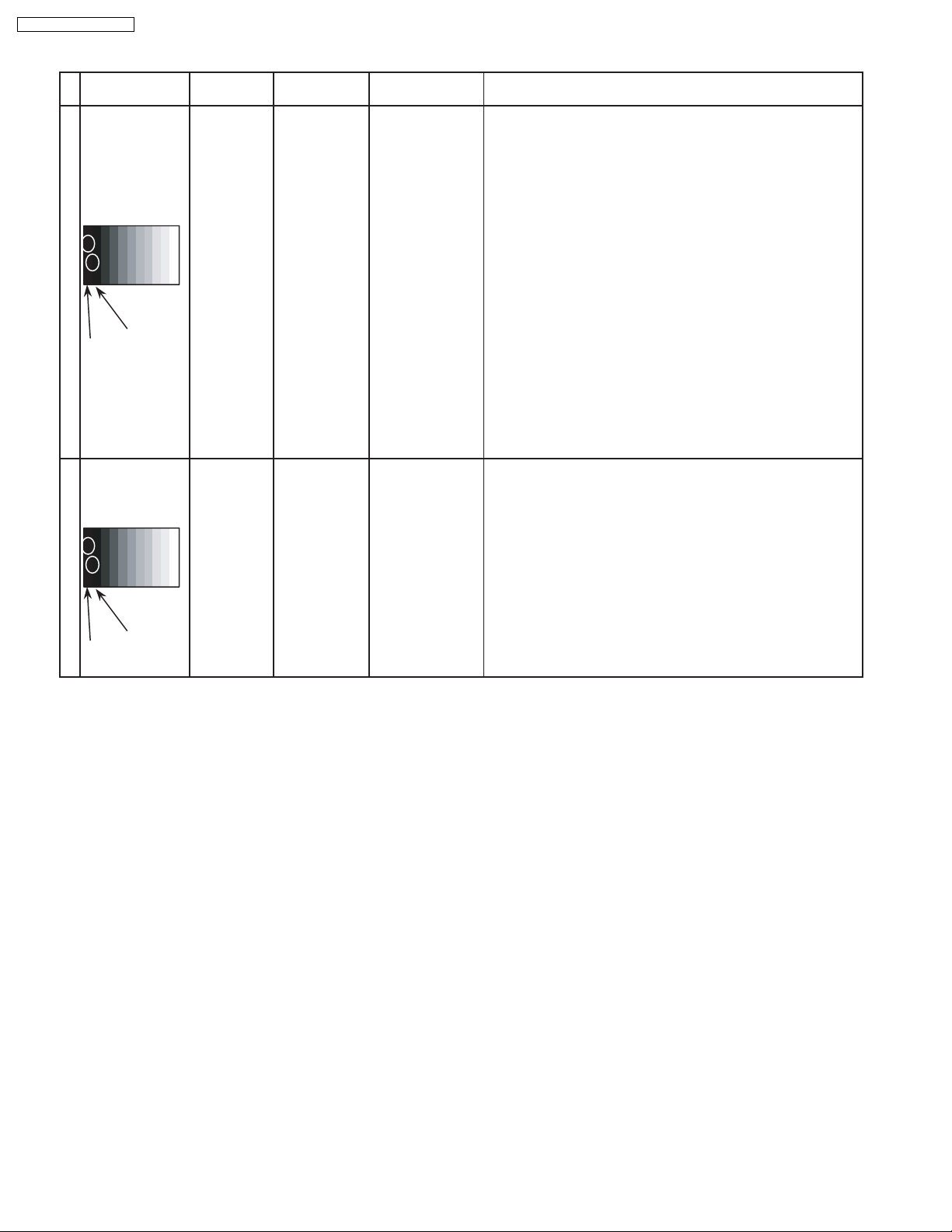

5 Picture: 1) Write down each color temaparature of R,G,B drive and

RGB

Gray Scale

Pattern

High light 75%

Low light 15% 3) Copy PC R,G,B drive and cut off data of each white

Normal Cut off data as follows.

Aspect:

16:9

White balance:

Cool

Normal

Warm

White

Balance Cool Normal Warm

R Drive

G Drive

B Drive

R Cut off

G Cut off

B Cut off

2) Input RGB signal.

balance mode to RGB position.

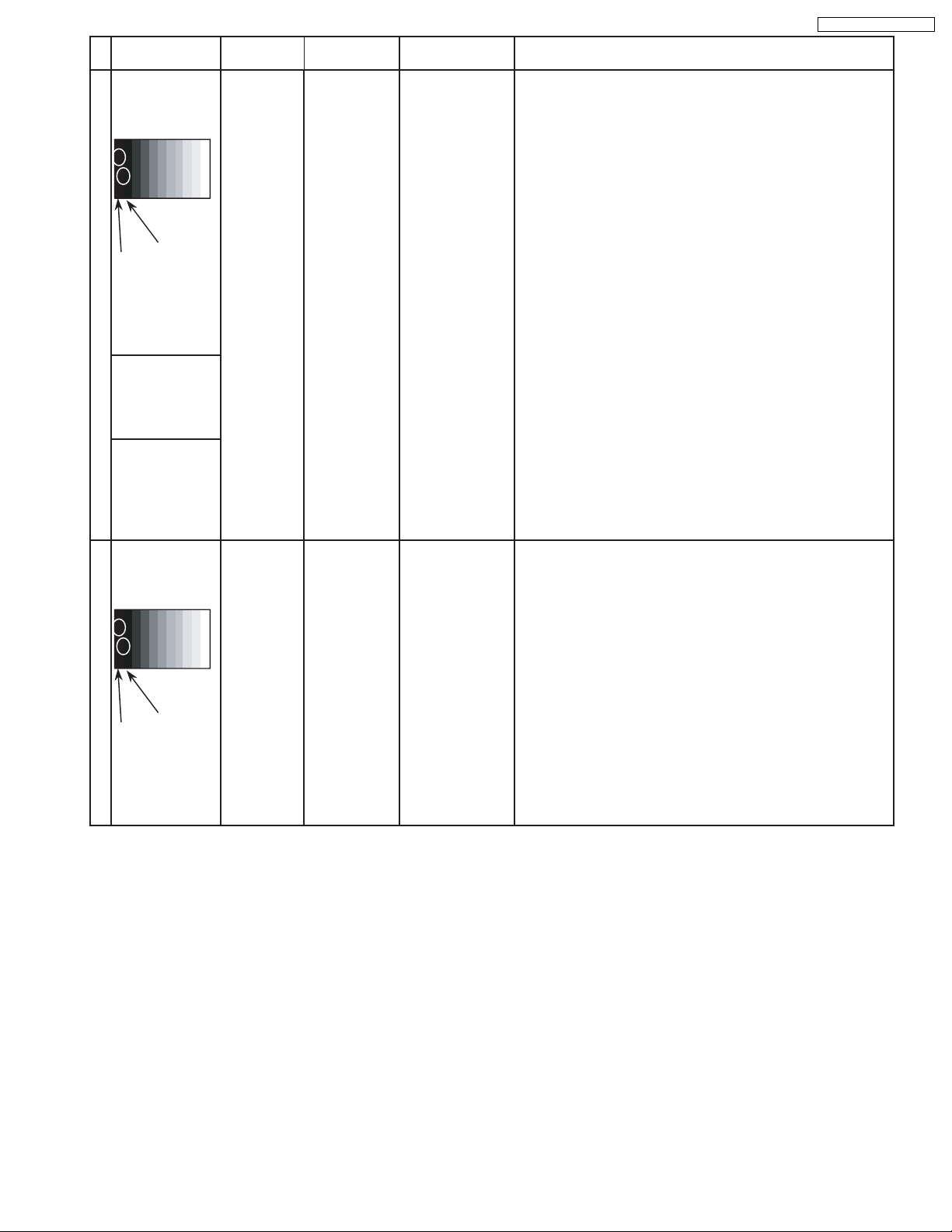

22

5.7. HD/ 525i /525p panel white balance

INPUT Alignment menu ProcedureEquipment Setting

1HD(720i or 1080i) Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off shown Fig.-04.

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

PANEL W/B

G Drive 7) Set G Drive to " D8 ".

PANEL W/B

R Drive as shown Fig.-04.

exactly.

to 10 cd/m

2

.

6)Find 75% of white area by color sensor.

B Drive 8) Adjust B and R Drive to set color temperature

TH-50PHD3 / TH-50PHW3

2

9) Repeat item 4) to 7) to set both Low light and

high light.

PANEL W/B

R,G,B Drive 10) Increase same steps of R, G and B Drive to set

R,G,B Drive largest level of 3 color drive to "FC".

PANEL W/B

R,G,B cut off 11) Re-adjust Low light level again.

Color Temp. x y

Cool(Hi) 0.272 0.290

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -04

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal

PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm

PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

23

TH-50PHD3 / TH-50PHW3

INPUT Alignment menu ProcedureEquipment Setting

5 Picture: 1) Write down each color temaparature of R,G,B drive and

RGB

Gray Scale

Pattern

High light 75%

Low light 15% 3) Copy HD drive and cut off data of each white

Normal Cut off data as follows.

Aspect:

16:9

White balance:

Cool

Normal

Warm

White

Balance Cool Normal Warm

R Drive

G Drive

B Drive

R Cut off

G Cut off

B Cut off

2)Change input signal to 525i and 525p.

balance mode to each signals position.

24

5.8. 625i panel balance

INPUT Alignment menu ProcedureEquipment Setting

1 625i Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool exactly.

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off shown Fig.-05.

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

to 10 cd/m

6)Find 75% of white area by color sensor.

PANEL W/B

G Drive 7) Set G Drive to " D8 ".

PANEL W/B

B Drive 8) Adjust B and R Drive to set color temperature

R Drive as shown Fig.-05.

9) Repeat item 4) to 7) to set both Low light and

high light.

PANEL W/B

R,G,B Drive 10) Increase same steps of R, G and B Drive to set

R,G,B Drive largest level of 3 color drive to "FC".

PANEL W/B

R,G,B cut off 11) Re-adjust Low light level again.

2

.

TH-50PHD3 / TH-50PHW3

2

Color Temp. x y

Cool(Hi) 0.272 0.290

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -05

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

25

TH-50PHD3 / TH-50PHW3

5.9. Sub brighness setting

INPUT Alignment menu ProcedureEquipment Setting

1 NTSC Picture: PANEL W/B

Gray Scale Normal All cut off 1) Set white balance to

Pattern Aspect:

** Adjust at the dark room.

Cool.

16:9 2) Adjust All cut off to start some pixels emission

at black 2% area and no emission at black 0% area.

3) Write down all cut off data.

4) Set white balance to

Black 2 %

Black 0 % 5) Adjust All cut off to set same data of Cool mode.

6) Set white balance to

7) Adjust All cut off to set same data of Cool mode.

** Adjust at the dark room.

2 PAL Picture: PANEL W/B

Gray Scale Normal All cut off 1) Set white balance to

Pattern Aspect:

16:9 2) Adjust All cut off to start some pixels emission

at black 2% area and no emission at black 0% area.

3) Write down all cut off data.

4) Set white balance to

Black 2 %

Black 0 % 5) Adjust All cut off to set same data of Cool mode.

6) Set white balance to

7) Adjust All cut off to set same data of Cool mode.

SECAM 8) Change to SECAM signal.

Gray Scale

Pattern 9) Copy PAL All cut off data to SECAM mode.

Nornal.

warm.

Cool.

Nornal.

warm.

** Adjust at the dark room.

3 PC Picture: PANEL W/B

Gray Scale Normal All cut off 1) Set white balance to

Pattern Aspect:

16:9 2) Adjust All cut off to start some pixels emission

at black 2% area and no emission at black 0% area.

3) Write down all cut off data.

4) Set white balance to

Black 2 %

Black 0 % 5) Adjust All cut off to set same data of Cool mode.

6) Set white balance to

7) Adjust All cut off to set same data of Cool mode.

RGB 8) Change to RGB input signal.

Gray Scale

Pattern 9) Copy PAL All cut off data to SECAM mode.

Cool.

Nornal.

warm.

26

Alignment menu ProcedureINPUT Equipment Setting

** Adjust at the dark room.

4 525i Picture: PANEL W/B

Gray Scale Normal All cut off 1) Set white balance to

Pattern Aspect:

16:9 2) Adjust All cut off to start some pixels emission

at black 2% area and no emission at black 0% area.

3) Write down all cut off data.

Cool

TH-50PHD3 / TH-50PHW3

.

4) Set white balance to

Nornal

.

Black 2 %

Black 0 % 5) Adjust All cut off to set same data of Cool mode.

6) Set white balance to

warm

.

7) Adjust All cut off to set same data of Cool mode.

525p 8) Change to 525p signal.

Gray Scale

Pattern 9) Copy 525i All cut off data to 525p mode.

HD

(720i or 1080i) 8) Change to HD signal.

Gray Scale

Pattern 9) Copy 525i All cut off data to HD mode.

** Adjust at the dark room.

5 625i Picture: PANEL W/B

Gray Scale Normal All cut off 1) Set white balance to

Cool

.

Pattern Aspect:

16:9 2) Adjust All cut off to start some pixels emission

at black 2% area and no emission at black 0% area.

3) Write down all cut off data.

4) Set white balance to

Nornal

.

Black 2 %

Black 0 % 5) Adjust All cut off to set same data of Cool mode.

6) Set white balance to

warm

.

7) Adjust All cut off to set same data of Cool mode.

27

TH-50PHD3 / TH-50PHW3

5.10. Pos./Size setting

1. Receive the test pattern signal which can be found the

center and edge position and align properly.

Alignment Item Reference Setting/Special feature

H Position 9A Optimum setting

V Position C3 Optimum setting

H Size A8 Optimum setting

V Size 5E Optimum setting

5.11. Panel APL/ABL

1. Confirm each data.

Alignment Item Reference Setting/Special feature

APL Shift Level E2 Confirmation only

ABL Point 10 Confirmation only

ABL Gain E0 Confirmation only

ABL Bank Select 3F Confirmation only

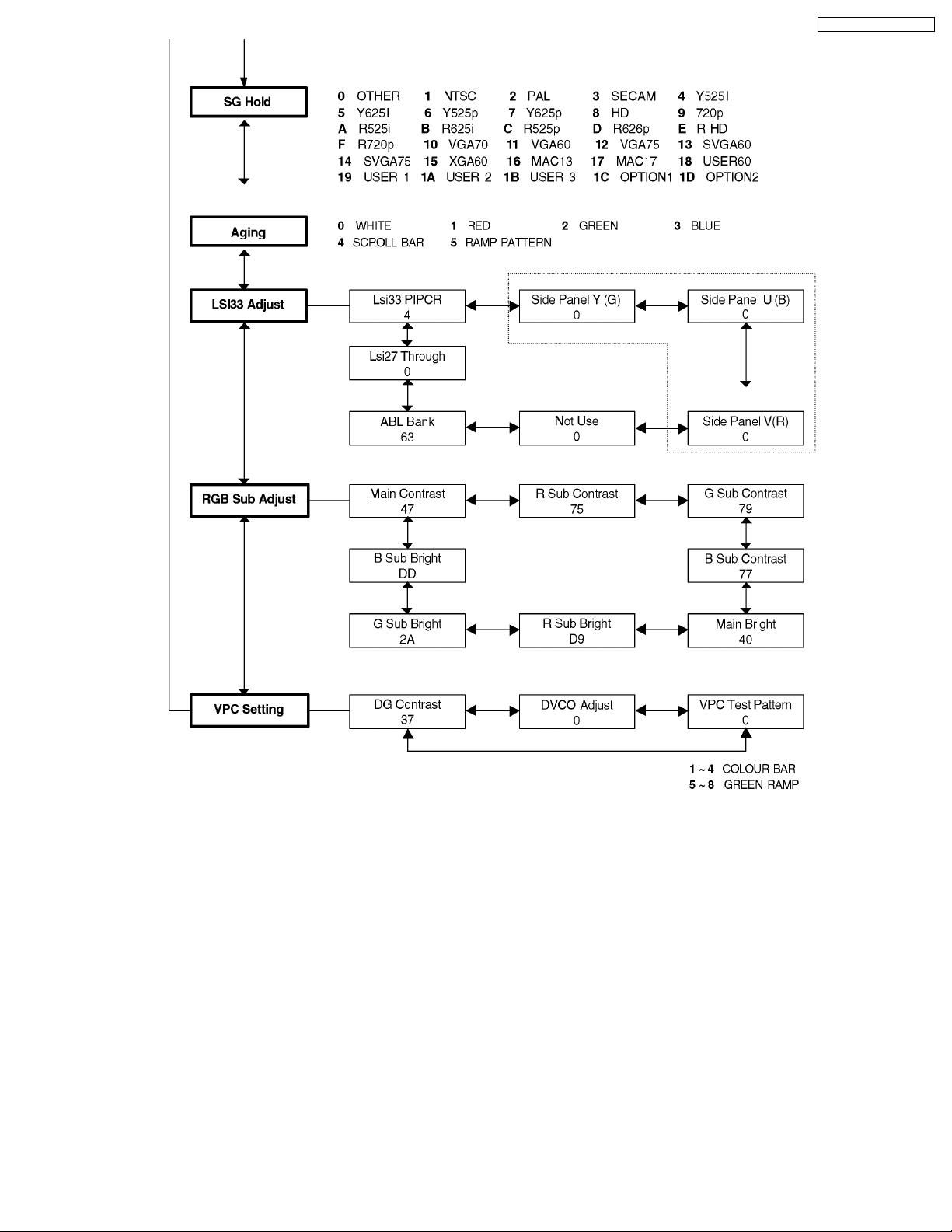

5.12. SG Hold

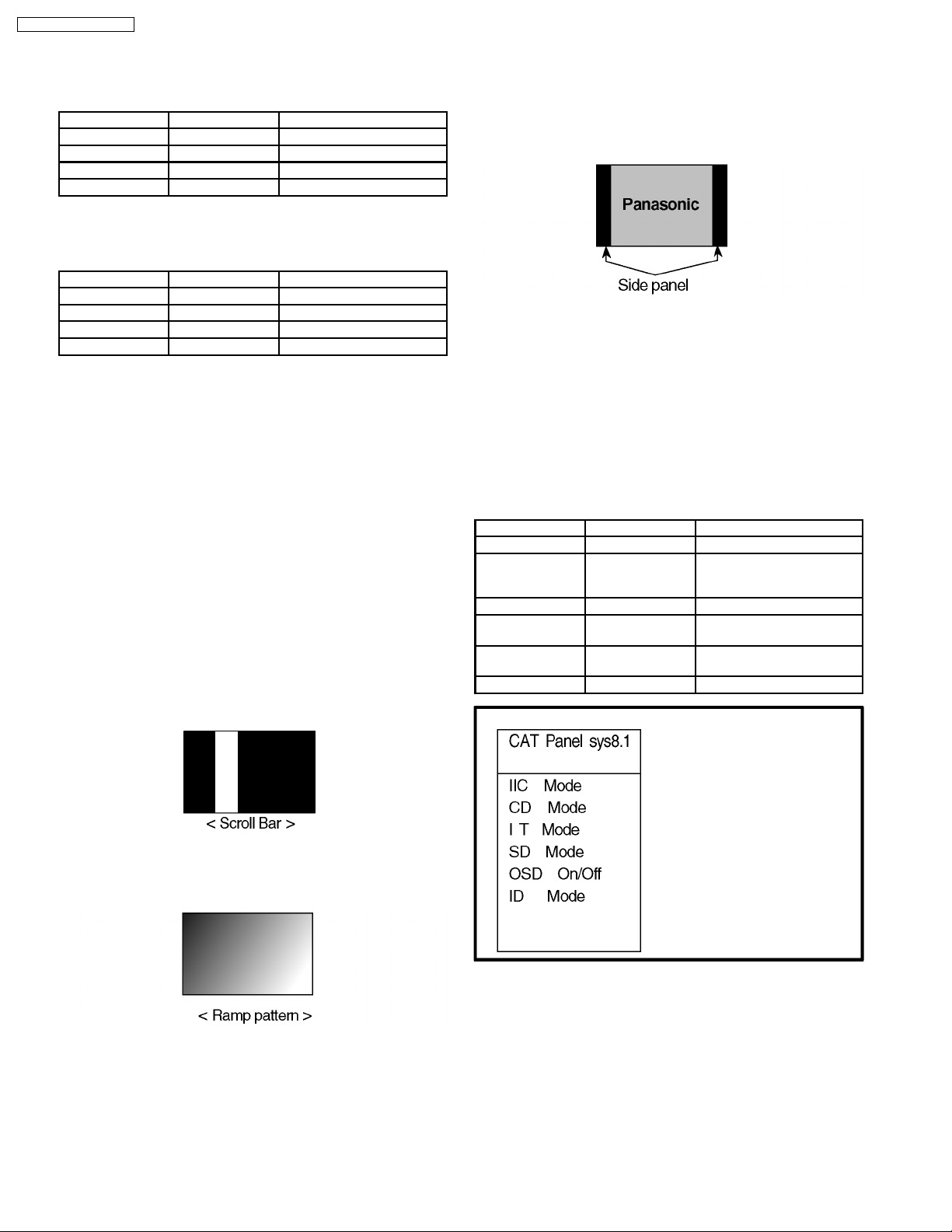

SG Hold is the alignment tool for data copy function. Color /

Signal system can be set regardless of input signal.

5.13. Aging

Aging mode is internal pattern generator for panel setting

confirmation and the after image removal.

1. Access desired colour pattern by the Volume Up or Down

button on the remote control.

2. To exit press Menu button

5.13.1. Panel Colour

There are 4 colour pattern White, Red, Blue and Green.

5.13.2. Scroll Bar

Scroll bar is for the after image removal. Display scroll bar

approximately 15 minutes after alignment is competed.

5.14.1. Side panel color setting

Colour of side panel which are left and right side blank area of

4:3 aspect mode can be adjusted as desired color and

brightness.

1. Access Side panel Y(G), U(B) and V(R) by the left or right

button on the remote control.

2. Adjust desired color and brightness of side panel Y(G), U(B)

and V(R) by Volume UP or Down button on the remote

control.

(If 4:3 aspect will be used long time, change side panel

brightness optimum level for screen burn protection.)

5.15. CAT (Computer Aided Test)

mode

Mode Function Access button

IIC Service Alignment Action

CD

(Complete

Diagnostics)

IT (Integrated Text) Not use

SD

(Status Display)

OSD on/off OSD display

ID (Initial Data) Not use

Software version

information EEP

ROM edit

Factory use Action

switch

Mute

Mute

5.13.3. Ramp pattern

Ramp pattern is for digital contrast reproduction confirmation.

5.14. LSI 33 Adjust

LSI 33 PIPCR, LSI 27 Through and ABL Bank are for factory

parameter setting for Format converter (IC9204).

(IT Mode, and ID Mode is unused in serving.)

28

6 Self Check

6.1. Display Indication

1. Self-check is used to automatically check the bus line

controlled circuit of the Plasma display.

2. To get into the Self-check mode press the volume down

button on the customer controls at the front of the set, at the

same time pressing the OFF-TIMER button on the remote

control, and the screen will show :-

If the CCU ports have been checked and found to be incorrect

Or not located then " - - " will appear in place of " OK "

TH-50PHD3 / TH-50PHW3

29

TH-50PHD3 / TH-50PHW3

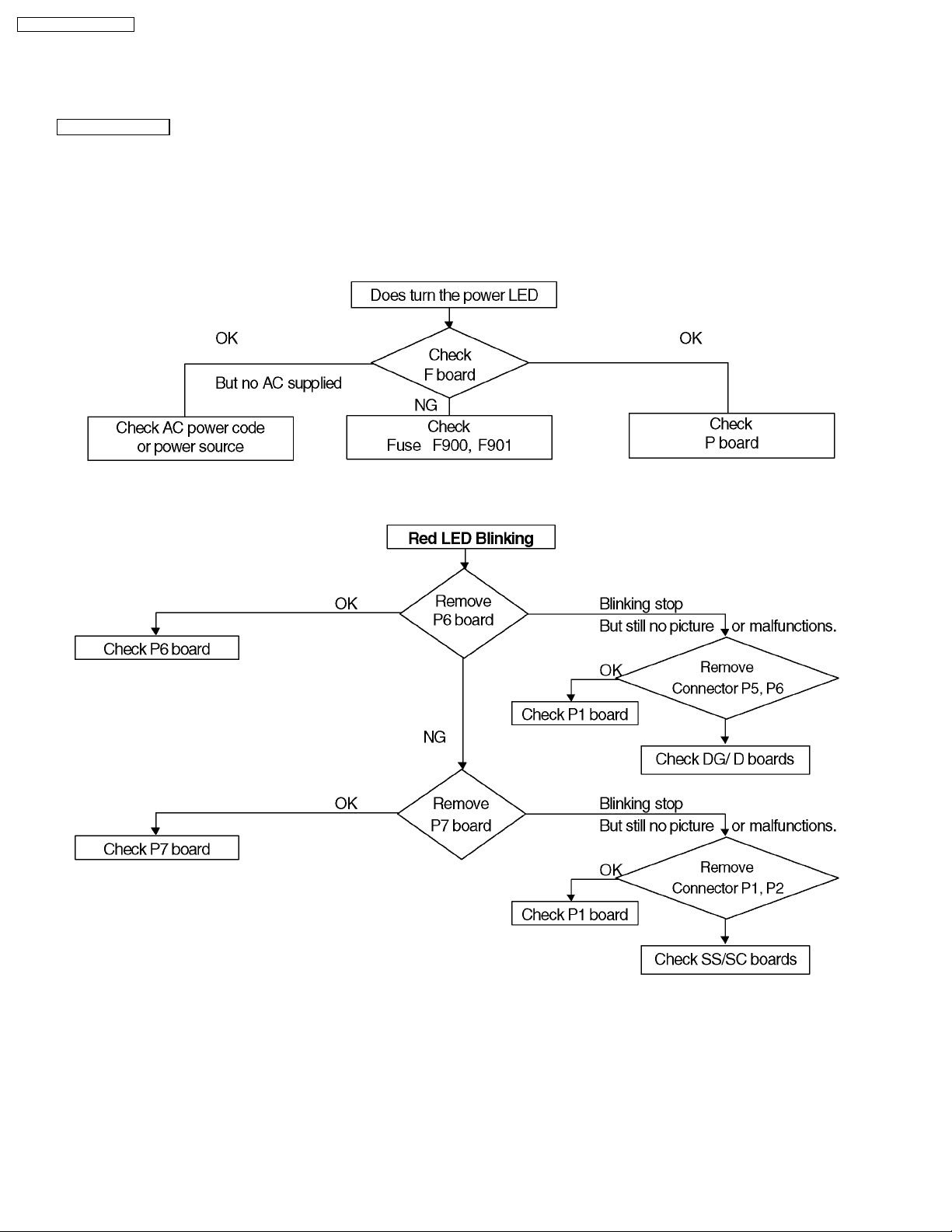

7 Trouble shooting guide

7.1. No Power

First check point

There are following 3 states of No Power indication by power LED.

1. No lit

2. Green is lit then turns red blinking a few seconds later.

3. Only red is lit.

1. No lit

2. Red LED Blinking

When one or some of supply voltages from power supply circuit are declined red LED will be blinking as power

30

Loading...

Loading...