Page 1

ORDER NO. MTV1708112CE

LED TV

Model No. TH-43EX400K

TH-43EX400S

TH-43EX400T

TH-49EX400K

TH-49EX400S

TH-49EX400T

Destination : K: Malaysia

S: Singapore

T: Thailand

© Panasonic Corporation 2017.

Page 2

TABLE OF CONTENTS

1 Safety Precautions -----------------------------------------------3

1.1. General Guidelines ----------------------------------------3

1.1.1. Leakage Current Cold Check ----------------------3

1.1.2. Leakage Current Hot Check (See Figure

1.)----------------------------------------------------------3

2Warning--------------------------------------------------------------4

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices ----------4

2.2. About lead free solder (PbF) ----------------------------5

3 Service Navigation------------------------------------------------6

3.1. Service Hint--------------------------------------------------6

4 Specifications ------------------------------------------------------7

5 Test and Alignment -----------------------------------------------9

5.1. Keyboard, IR receiver and Remote Control ---------9

5.1.1. To navigate the Menu using Keyboard -----------9

5.1.2. To navigate the Menu using Remote

Control ---------------------------------------------------9

5.2. Video Functional Check ----------------------------------9

5.2.1. PC ---------------------------------------------------------9

5.2.2. YPbPr -------------------------------------------------- 10

5.3. HDMI --------------------------------------------------------10

5.3.1. DVI mode ---------------------------------------------- 10

5.3.2. HDMI mode ------------------------------------------- 10

5.4. RF ------------------------------------------------------------ 11

5.4.1. Analog RF signal input ----------------------------- 11

5.4.2. Digital RF signal input ------------------------------ 11

5.5. CVBS-------------------------------------------------------- 11

5.5.1. CVSBS input------------------------------------------ 11

5.6. ADC Calibration ------------------------------------------ 11

5.6.1. Input Signal Specification ------------------------- 11

5.6.2. Component ADC calibration ---------------------- 12

5.6.3. PC ADC calibration --------------------------------- 12

5.7. Software Upgrade Instruction ------------------------- 13

5.7.1. Keyboard upgrade by USB ----------------------- 13

5.7.2. OSD upgrade by USB ------------------------------ 13

5.7.3. ESN app key upgrade by USB ------------------- 13

5.7.4. HDCP app key upgrade by USB ---------------- 13

5.7.5. HDCP 2.2 app key upgrade by USB ----------- 13

5.7.6. MAC app key upgrade by USB ------------------ 13

6 Troubleshooting Guide---------------------------------------- 14

6.1. Standby LED does NOT turn off. The TV is

dead --------------------------------------------------------- 14

6.2. Power on, but LCD backlights are not working

or shut down soon --------------------------------------- 15

6.3. Back Light is OK while no video or OSD ----------- 16

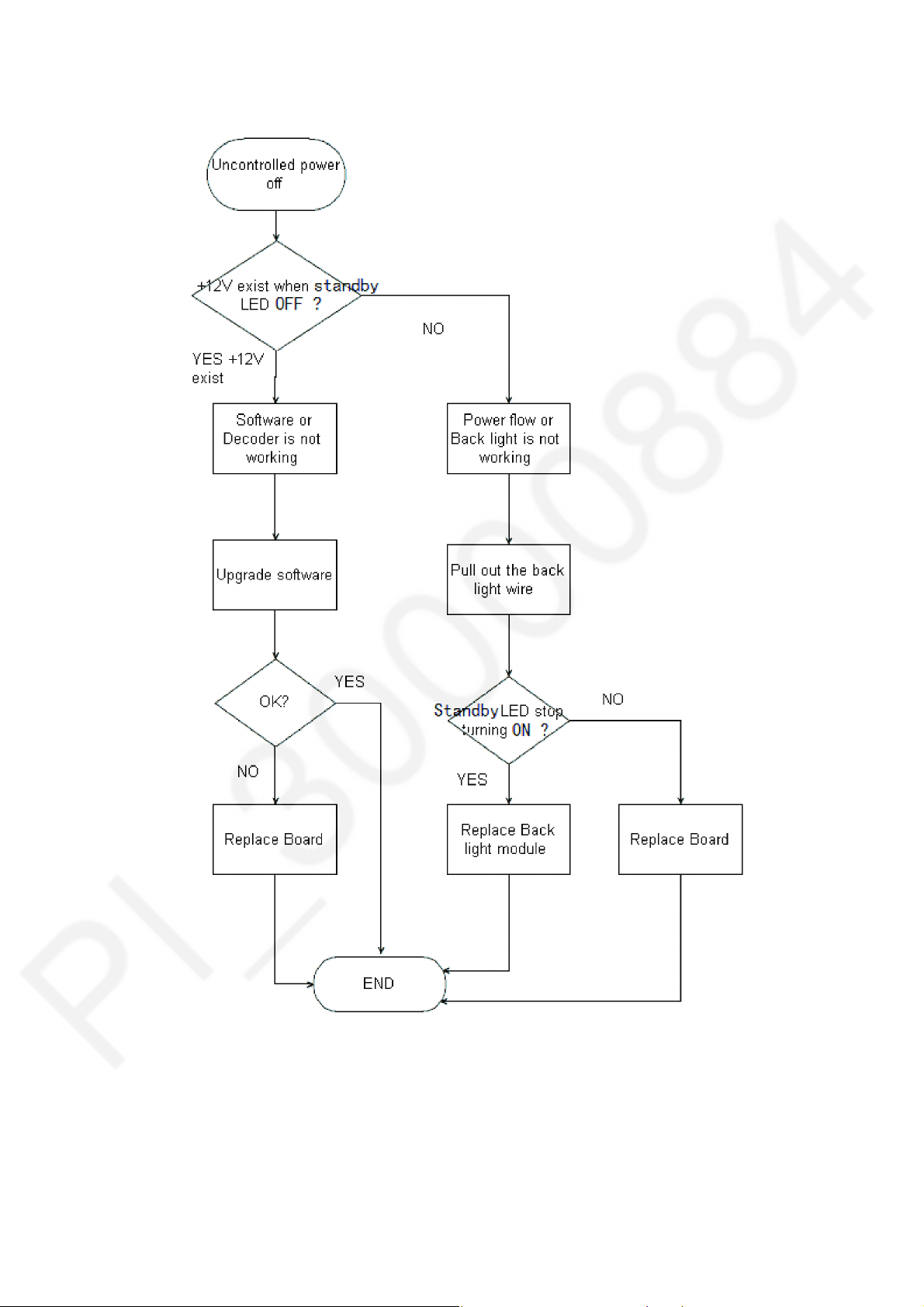

6.4. Uncontrolled power off ---------------------------------- 17

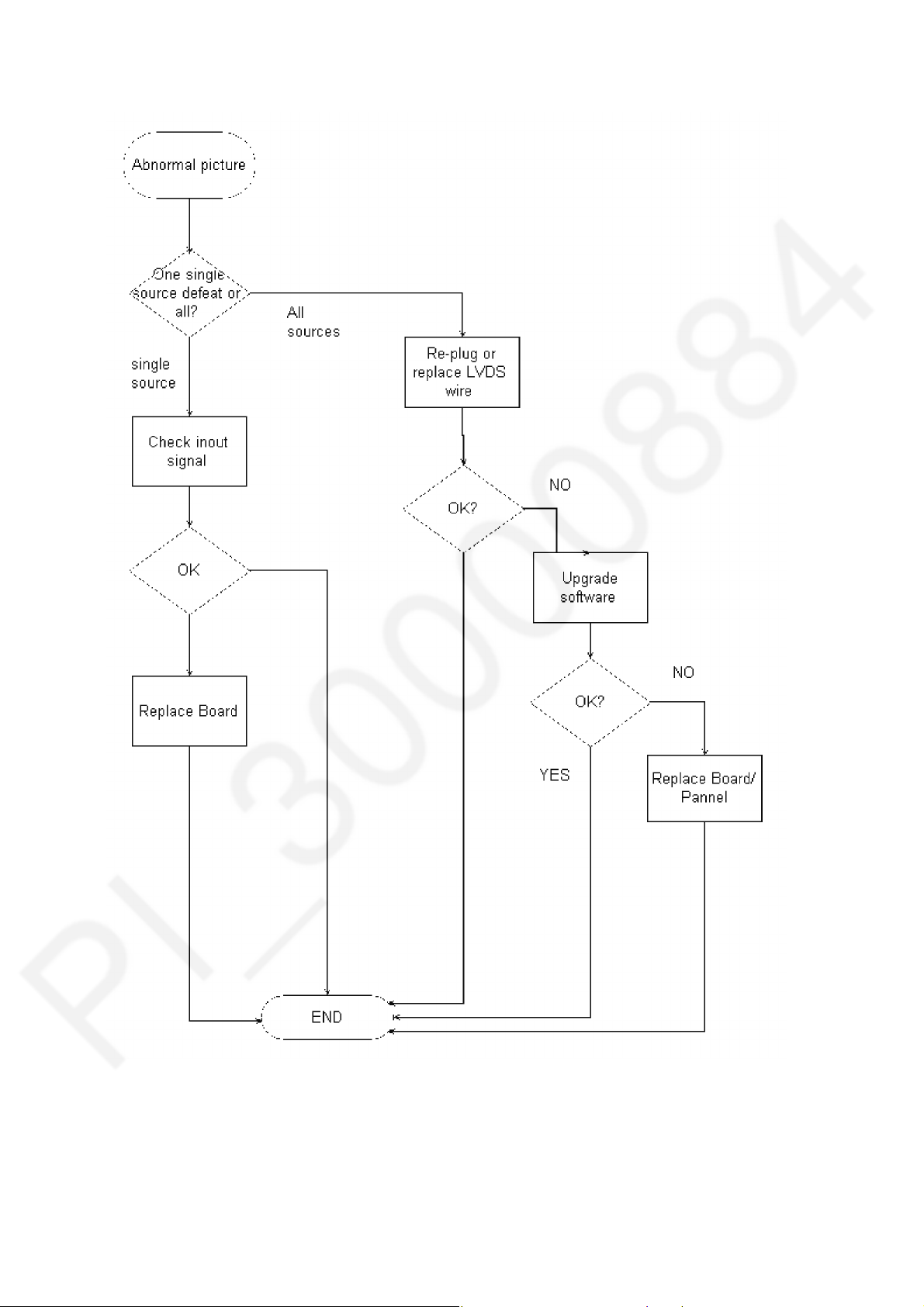

6.5. Abnormal picture -----------------------------------------18

6.6. No sound --------------------------------------------------- 19

7 Disassembly and Assembly Instructions --------------- 20

7.1. Back Cover Removal (TH-43EX400) --------------- 20

7.2. Lens and Panel (TH-43EX400) ----------------------- 21

7.3. Boards (TH-43EX400) ---------------------------------- 22

7.4. Speaker (TH-43EX400)--------------------------------- 23

7.5. Key Button Assy (TH-43EX400)---------------------- 24

7.6. FFC Assy (TH-43EX400)------------------------------- 25

7.7. Back Cover Screw (TH-43EX400) ------------------- 26

7.8. Power Boards Assembly (TH-49EX400) ----------- 27

7.9. Main Boards Assembly (TH-49EX400) ------------- 28

PAG E PAG E

7.10. WIFI & Key Button Assembly (TH-49EX400)----- 29

7.11. WIFI & Key Button Installation (TH-49EX400) --- 30

7.12. Speaker & Wire Installation (TH-49EX400) ------- 31

7.13. Key Button (TH-49EX400) ---------------------------- 32

7.14. Speaker & Wire Installation (TH-49EX400) ------- 33

7.15. Back Cover Installation (TH-49EX400)------------- 34

7.16. Label Sticking (TH-49EX400)------------------------- 35

7.17. Handling SPEC------------------------------------------- 36

8 Measurements and Adjustments -------------------------- 37

8.1. Key Check Points---------------------------------------- 37

8.2. Power Flow Diagram------------------------------------ 38

9 Block Diagram --------------------------------------------------- 39

9.1. System Block Diagram --------------------------------- 39

10 Wiring Connection Diagram -------------------------------- 40

10.1. Wire Dressing (TH-43EX400) ------------------------ 40

10.2. Wire Dressing (TH-49EX400) ------------------------ 41

11 Schematic Diagram -------------------------------------------- 42

12 Exploded View and Replacement Parts List----------- 51

12.1. Parts Location (TH-43EX400) ------------------------ 51

12.2. Parts Location (TH-49EX400) ------------------------ 52

12.3. Packing Instruction (TH-43EX400) ------------------ 53

12.4. Packing Instruction (TH-49EX400) ------------------ 55

12.5. Replacement Partlist (TH-43EX400) --------------- 57

12.6. Replacement Partlist (TH-49EX400) --------------- 58

2

Page 3

1 Safety Precautions

1.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

4. When conducting repairs and servicing, do not attempt to modify the equipment, its parts or its materials.

5. When wiring units (with cables, flexible cables or lead wires) are supplied as repair parts and only one wire or some of the

wires have been broken or disconnected, do not attempt to repair or re-wire the units. Replace the entire wiring unit instead.

6. When conducting repairs and servicing, do not twist the Faston connectors but plug them straight in or unplug them straight

out.

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohmmeter,

between the jumpered AC plug and each exposed

metallic cabinet part on the equipment such as

screwheads, connectors, control shafts, etc. When the

exposed metallic part has a return path to the chassis, the

reading should be 8.5Mohm to 13Mohm.

When the exposed metal does not have a return path to

the chassis, the reading must be .

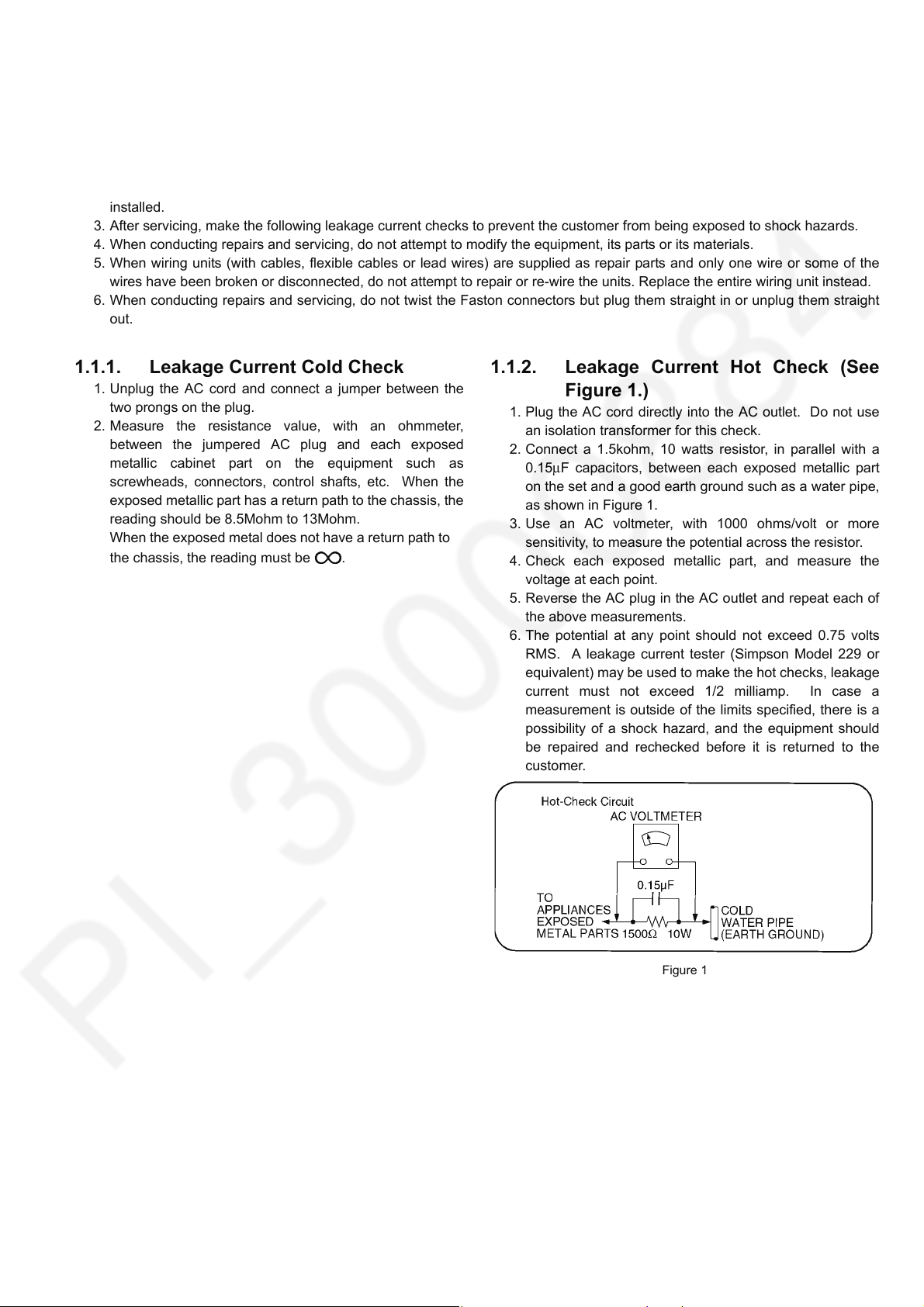

1.1.2. Leakage Current Hot Check (See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer for this check.

2. Connect a 1.5kohm, 10 watts resistor, in parallel with a

0.15μF capacitors, between each exposed metallic part

on the set and a good earth ground such as a water pipe,

as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks, leakage

current must not exceed 1/2 milliamp. In case a

measurement is outside of the limits specified, there is a

possibility of a shock hazard, and the equipment should

be repaired and rechecked before it is returned to the

customer.

Figure 1

3

Page 4

2Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor [chip] components. The following techniques should be used to help reduce the incidence of component damage

caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as [anti-static (ESD protected)] can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or

comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient to damage an ES device).

4

Page 5

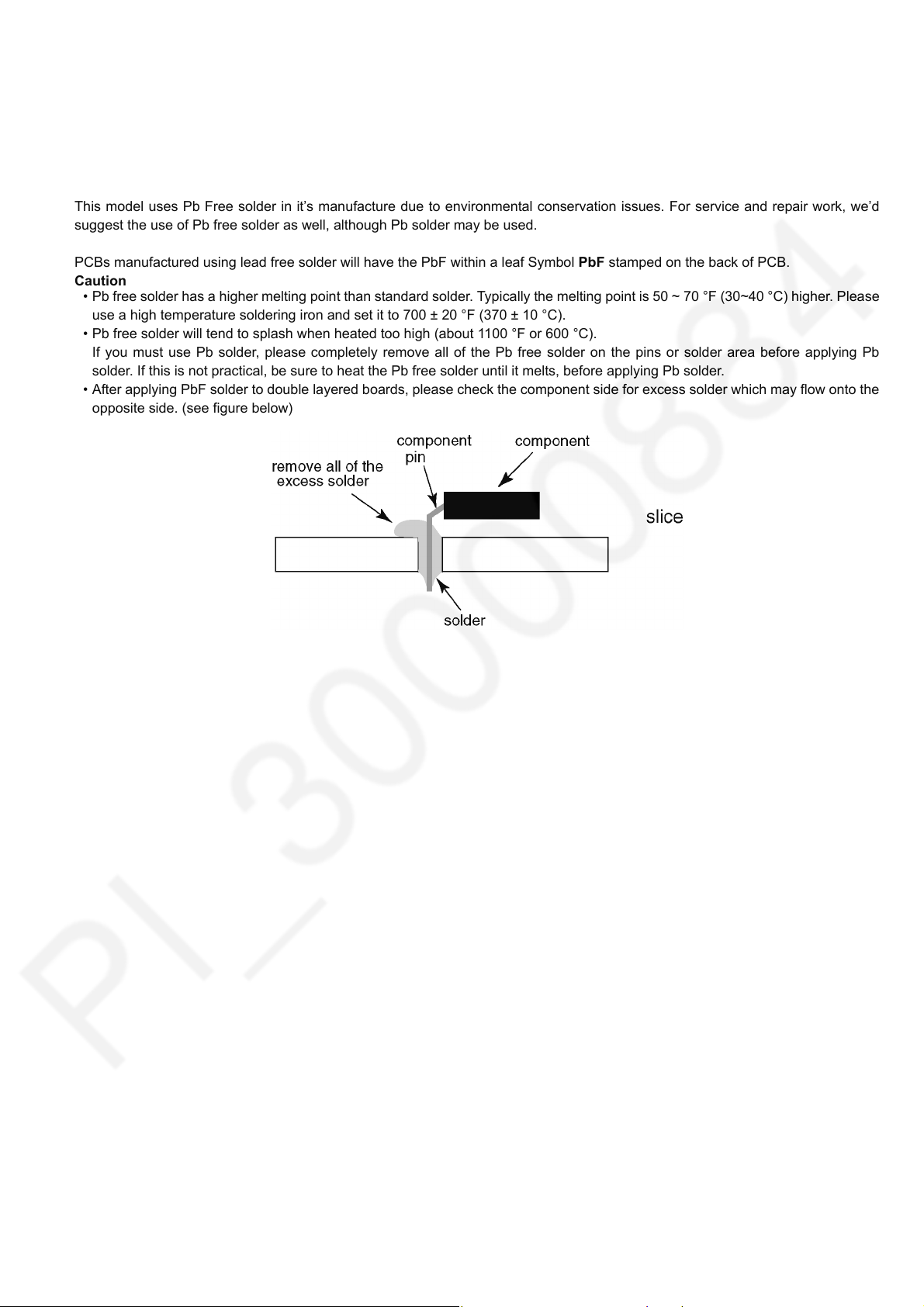

2.2. About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work, we’d

suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol PbF stamped on the back of PCB.

Caution

• Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40 °C) higher. Please

use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

• Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb

solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

• After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto the

opposite side. (see figure below)

5

Page 6

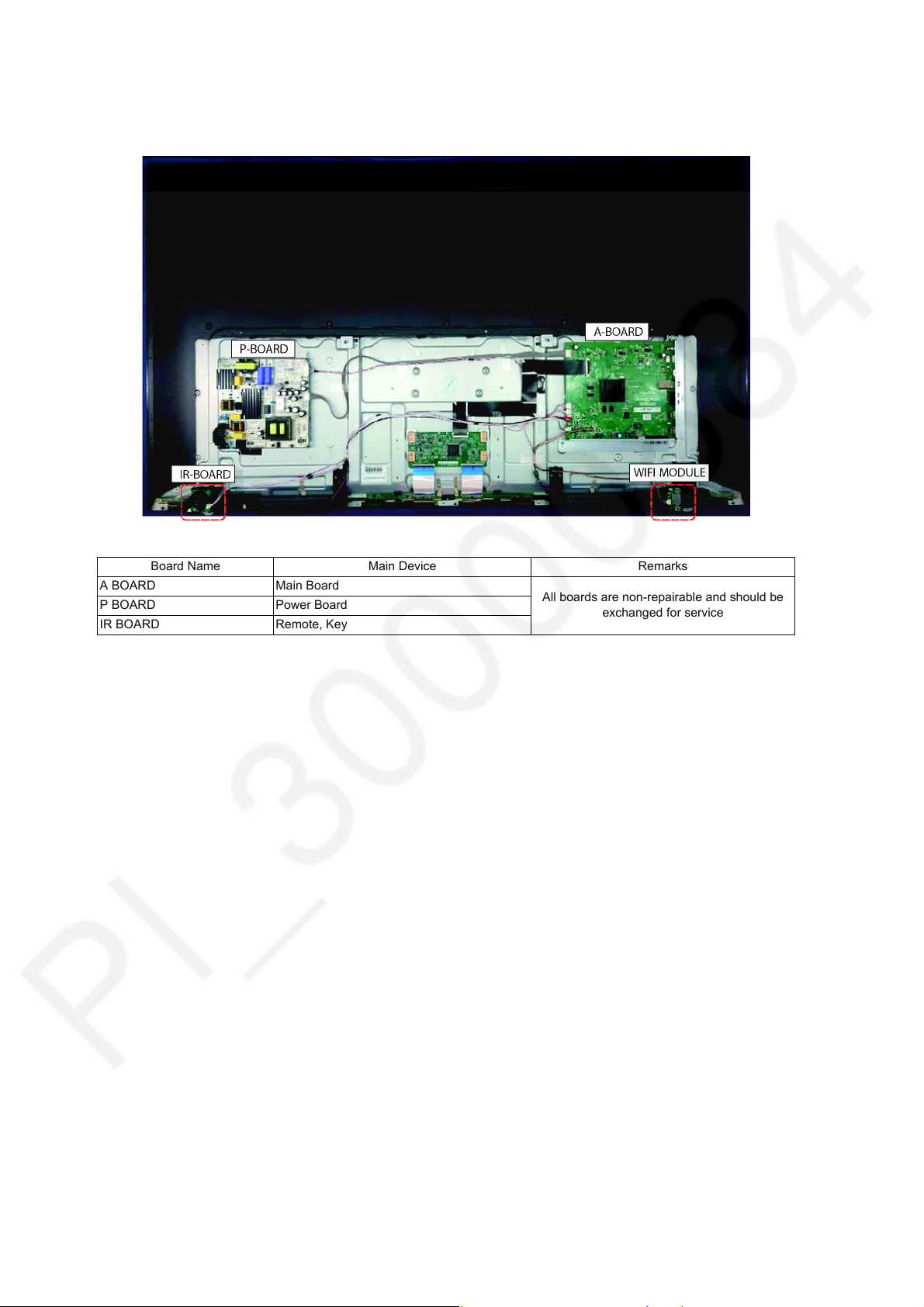

3 Service Navigation

3.1. Service Hint

Board Name Main Device Remarks

A BOARD Main Board

P BOARD Power Board

IR BOARD Remote, Key

All boards are non-repairable and should be

exchanged for service

6

Page 7

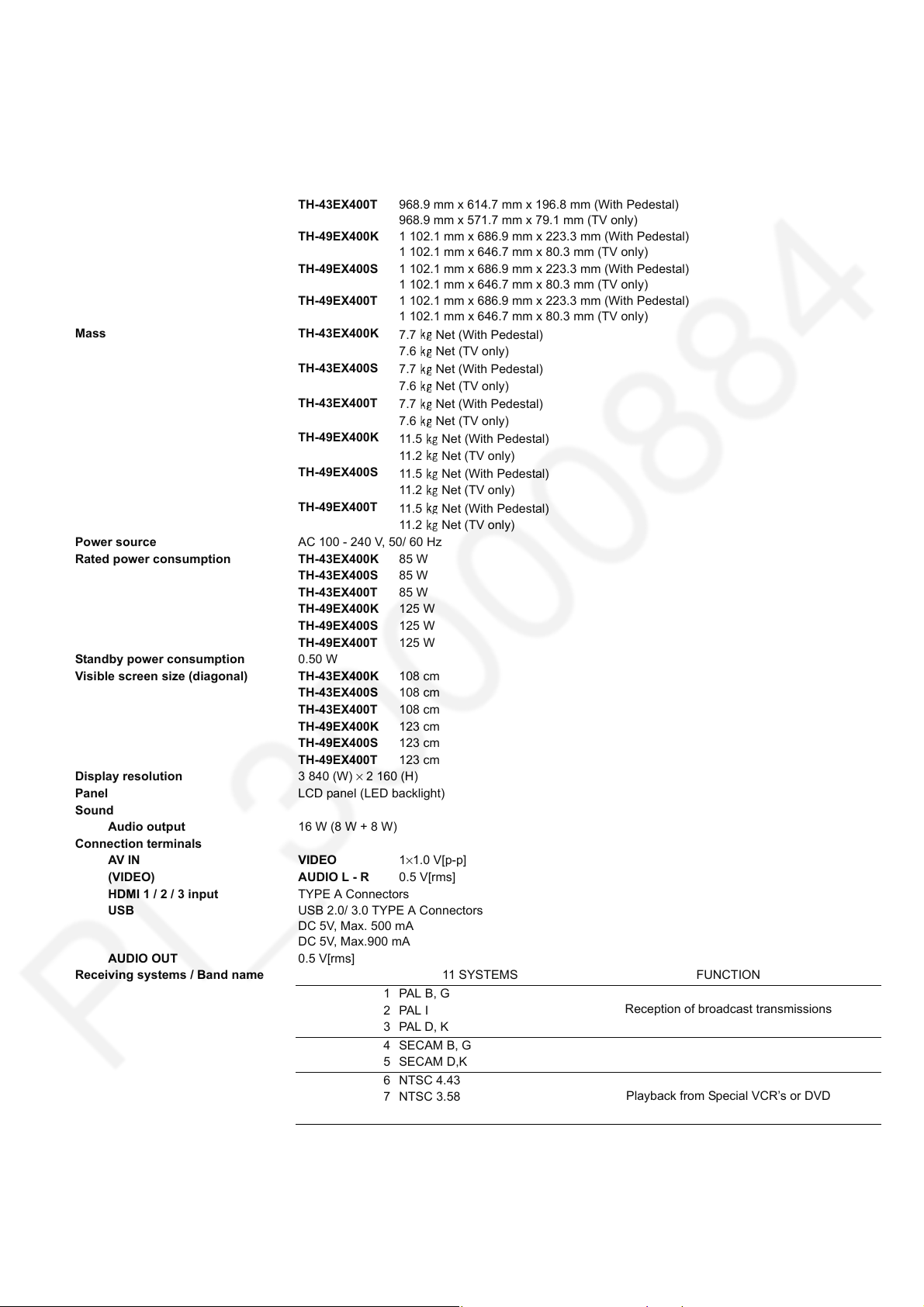

4 Specifications

Dimensions (W × H × D) TH-43EX400K 968.9 mm x 614.7 mm x 196.8 mm (With Pedestal)

968.9 mm x 571.7 mm x 79.1 mm (TV only)

TH-43EX400S 968.9 mm x 614.7 mm x 196.8 mm (With Pedestal)

968.9 mm x 571.7 mm x 79.1 mm (TV only)

TH-43EX400T 968.9 mm x 614.7 mm x 196.8 mm (With Pedestal)

TH-49EX400K 1 102.1 mm x 686.9 mm x 223.3 mm (With Pedestal)

TH-49EX400S 1 102.1 mm x 686.9 mm x 223.3 mm (With Pedestal)

TH-49EX400T 1 102.1 mm x 686.9 mm x 223.3 mm (With Pedestal)

Mass TH-43EX400K

TH-43EX400S

TH-43EX400T

TH-49EX400K

TH-49EX400S

TH-49EX400T

Power source AC 100 - 240 V, 50/ 60 Hz

Rated power consumption TH-43EX400K 85 W

TH-43EX400S 85 W

TH-43EX400T 85 W

TH-49EX400K 125 W

TH-49EX400S 125 W

TH-49EX400T 125 W

Standby power consumption 0.50 W

Visible screen size (diagonal) TH-43EX400K 108 cm

TH-43EX400S 108 cm

TH-43EX400T 108 cm

TH-49EX400K 123 cm

TH-49EX400S 123 cm

TH-49EX400T 123 cm

Display resolution 3 840 (W) × 2 160 (H)

Panel LCD panel (LED backlight)

Sound

Audio output 16 W (8 W + 8 W)

Connection terminals

AV I N VI D EO 1×1.0 V[p-p]

(VIDEO) AUDIO L - R 0.5 V[rms]

HDMI 1 / 2 / 3 input TYPE A Connectors

USB USB 2.0/ 3.0 TYPE A Connectors

DC 5V, Max. 500 mA

DC 5V, Max.900 mA

AUDIO OUT 0.5 V[rms]

Receiving systems / Band name 11 SYSTEMS FUNCTION

968.9 mm x 571.7 mm x 79.1 mm (TV only)

1 102.1 mm x 646.7 mm x 80.3 mm (TV only)

1 102.1 mm x 646.7 mm x 80.3 mm (TV only)

1 102.1 mm x 646.7 mm x 80.3 mm (TV only)

7.7 Net (With Pedestal)

7.6 Net (TV only)

7.7 Net (With Pedestal)

7.6 Net (TV only)

7.7 Net (With Pedestal)

7.6 Net (TV only)

11.5 Net (With Pedestal)

11.2 Net (TV only)

11.5 Net (With Pedestal)

11.2 Net (TV only)

11.5 Net (With Pedestal)

11.2 Net (TV only)

1PAL B, G

2PAL I

PAL D , K

3

4 SECAM B, G

5SECAM D,K

6 NTSC 4.43

7 NTSC 3.58

8

PAL

9 PAL 60 Hz / 5.5 MHz Playback from Special Disc Players and

10 PAL 60 Hz / 6.0 MHz

11 PAL 60 Hz / 6.5 MHz

Reception of broadcast transmissions

Playback from Special VCR’s or DVD

Special VCR’s or DVD

Receiving channels (Analogue TV)

7

Page 8

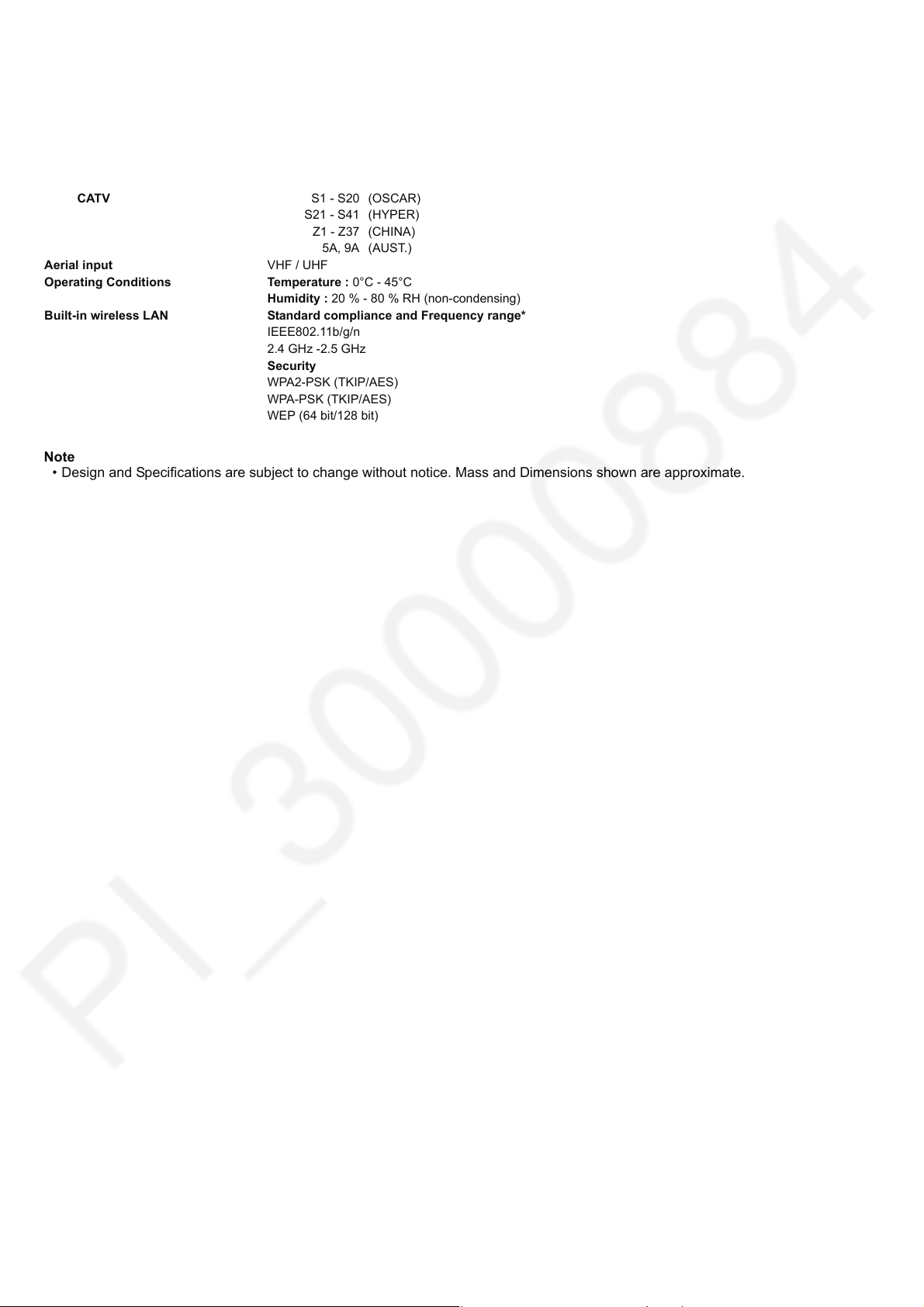

VHF BAND 2 - 12 (PAL / SECAM B, K1)

0 - 12 (PAL B AUST.)

1 - 9 (PAL B N.Z.)

1 - 12 (PAL / SECAM D)

UHF BAND 21 - 69 (PAL G, H, I / SECAM G, K, K1)

28 - 69 (PAL B AUST.)

13 - 57 (PAL D, K)

CATV S1 - S20 (OSCAR)

S21 - S41 (HYPER)

Z1 - Z37 (CHINA)

5A, 9A (AUST.)

Aerial input VHF / UHF

Operating Conditions Temperature : 0°C - 45°C

Humidity : 20 % - 80 % RH (non-condensing)

Built-in wireless LAN Standard compliance and Frequency range*

IEEE802.11b/g/n

2.4 GHz -2.5 GHz

Security

WPA2-PSK (TKIP/AES)

WPA-PSK (TKIP/AES)

WEP (64 bit/128 bit)

Note

• Design and Specifications are subject to change without notice. Mass and Dimensions shown are approximate.

8

Page 9

5 Test and Alignment

5.1. Keyboard, IR receiver and Remote Control

• Apply 100 - 240 V AC to mains input.

• LED should light up with RED color, when power on, standby LED turn off.

5.1.1. To navigate the Menu using Keyboard

Function Action Observe

To turn on/ off the TV set Press Power key on keyboard Power key equals POWER on remote control.

To enter MENU Screen Press MENU key on keyboard Menu screen should shown at LCD screen.

During Menu Screen Press Menu key Menu key equals RETURN function.

Press Input key Input key equals ENTER function.

Press Vol- key Vol- key equals LEFT key on remote control.

Press Vol+ key Vol+ key equals RIGHT key on remote control.

Press CH- key CH- key equals DOWN key on remote control.

Press CH+ key CH+ key equals UP key on remote control.

5.1.2. To navigate the Menu using Remote Control

Function Action Observe

To enter MENU Screen Press MENU key in remote control Menu screen should shown at LCD screen.

During Menu Screen Press UP key or DOWN key Highlight will goes up and down.

Press RIGHT key or ENTER key User will enter to the selection highlighted.

Press Menu key User will exit from the selection.

5.2. Video Functional Check

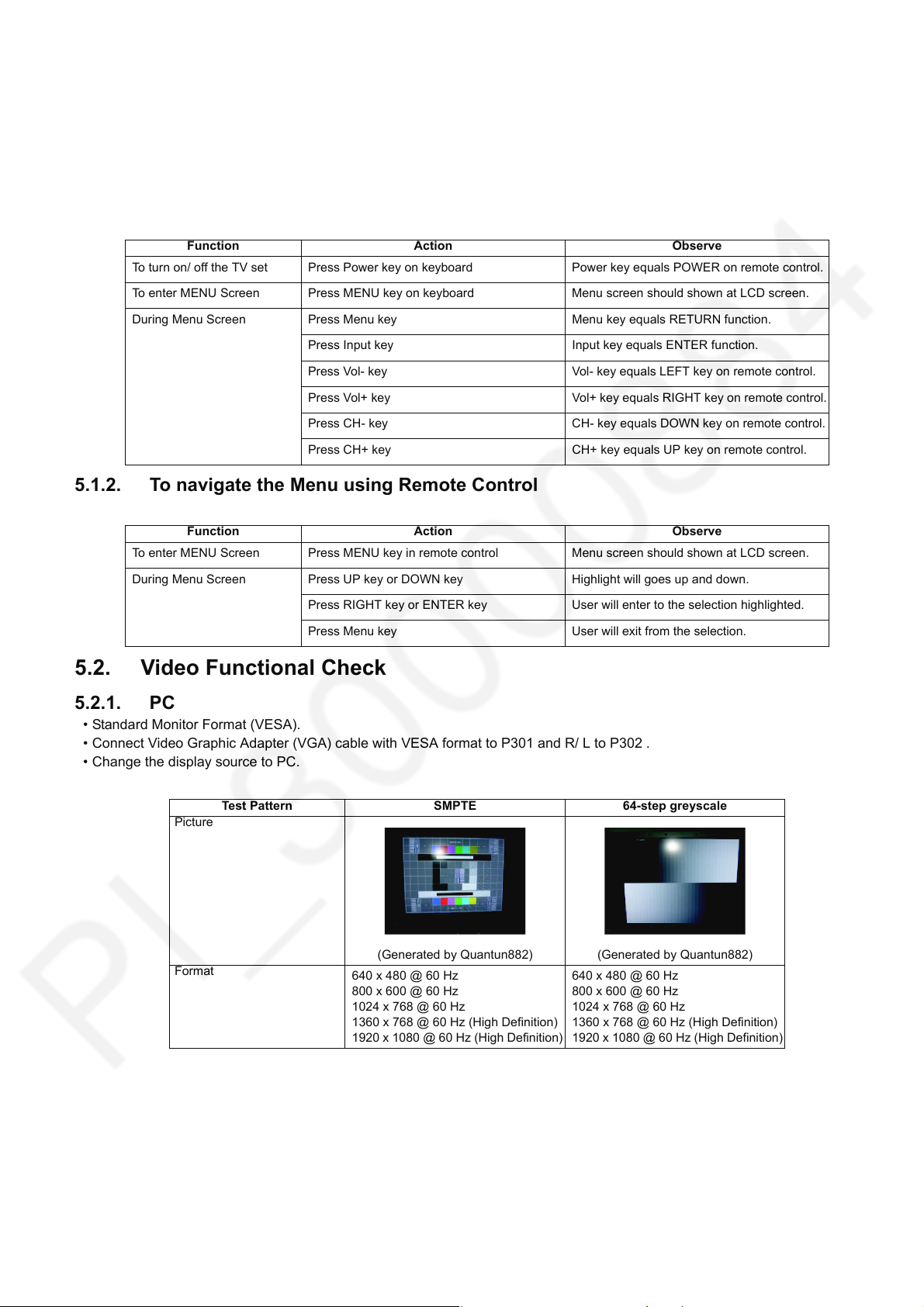

5.2.1. PC

• Standard Monitor Format (VESA).

• Connect Video Graphic Adapter (VGA) cable with VESA format to P301 and R/ L to P302 .

• Change the display source to PC.

Test Pattern SMPTE 64-step greyscale

Picture

(Generated by Quantun882) (Generated by Quantun882)

Format

640 x 480 @ 60 Hz

800 x 600 @ 60 Hz

1024 x 768 @ 60 Hz

1360 x 768 @ 60 Hz (High Definition)

1920 x 1080 @ 60 Hz (High Definition)

640 x 480 @ 60 Hz

800 x 600 @ 60 Hz

1024 x 768 @ 60 Hz

1360 x 768 @ 60 Hz (High Definition)

1920 x 1080 @ 60 Hz (High Definition)

9

Page 10

5.2.2. YPbPr

• Connect Y, Pb, Pr signals to connector Component.

• Change the display source to Component.

Signal Parameter Source Impedance Minimum (Vp-p) Typical (Vp-p) Maximum (Vp-p)

Y : Sync to Peak

White

P

R : Sync to Peak

White

P

B : Sync to Peak

White

Test Pattern SMPTE RP-133 32-step greyscale

Picture

(Generated by Chroma 22291 or 22293) (Generated by Chroma 22291 or 22293)

Format

4:3 16:9 4:3 16:9

480i @ 59.94 Hz 1080i @ 60 Hz 480i @ 60 Hz

480p @ 59.94 Hz 720p @ 60 Hz 480p @ 60 Hz 1080p @ 60 Hz

75 Ω 0.67 0.7 0.73

75 Ω -±0.30-

75 Ω -±0.30-

5.3. HDMI

5.3.1. DVI mode

• Standard Monitor Format (VESA).

• Connect HDMI cable with HDMI1, and then change the display source to HDMI1.

Test Pattern SMPTE 64-step greyscale

Picture

(Generated by Quantun881) (Generated by Quantun881)

Format

5.3.2. HDMI mode

• Connect HDMI cable with HDMI1, and then change the display source to HDMI1.

Test Pattern SMPTE 64-step greyscale

Picture

640 x 480 @ 60 Hz

800 x 600 @ 60 Hz

1024 x 768 @ 60 Hz

1360 x 768 @ 60 Hz (High Definition)

640 x 480 @ 60 Hz

800 x 600 @ 60 Hz

1024 x 768 @ 60 Hz

1360 x 768 @ 60 Hz (High Definition)

Format

(Generated by Quantun881)

4:3 16:9

10

(Generated by Quantun881)

Page 11

Test Pattern SMPTE 64-step greyscale

1H

2H

5.4. RF

5.4.1. Analog RF signal input

• Connect Antenna cable to tuner.

• Change the display source to TV Channels.

480i @ 60 Hz 1080i @ 60 Hz

480p @ 60 Hz 720p @ 60 Hz/ 1080p @ 60 Hz

Test Pattern

Channel

Picture Frequency

Channel Band VHF-L VHF-H UHF

5.4.2. Digital RF signal input

• Connect Antenna cable to tuner.

• Change the display source to TV Channels.

Test Pattern

Channel

Picture Frequency

Channel Band VHF-L VHF-H UHF

5.5. CVBS

5.5.1. CVSBS input

• Connect AV cable with AV.

• Change the display source to AV.

Test Pattern SMPTE RP-133 32-step greyscale

Picture

Depended on factory Depended on factory Depended on factory

Depended on factory Depended on factory Depended on factory

(Generated by Chroma 22291) (Generated by Chroma 22291)

Format NTSC M NTSC M

5.6. ADC Calibration

• In order to have defined conditions for the alignment procedure, the TV set should be warmed up for 30 minutes.

• ADC calibration should be applied just for Component and PC channel.

5.6.1. Input Signal Specification

Specification Component ADC PC ADC

Picture

11

Page 12

ADC Mode 720 @ 60 Hz 1024*768 @ 60 Hz

Pattern 100/ 0/ 100/ 0

8 Steps Color bar (100%)

5.6.2. Component ADC calibration

Step for Component ADC calibration:

• Input 100% color bar of 720 @ 60 Hz format to Component source.

• Entry factory menu and choose the ADC menu with the Remote Control.

• Change ADC source to “YUV”.

• Adjust the cursor to “AUTO Color”, press “ENTER”/ “Right” key on the Remote Control.

• If ENTER, ADC “status” item will show “ENTER”.

• If FAIL, do one more time till it shows “ENTER”.

5.6.3. PC ADC calibration

Step for PC ADC calibration:

• Input 100% color bar of 1024*768 @ 60 Hz format to PC source.

• Entry factory menu and choose the ADC menu with the Remote Control.

• Change ADC source to “PC”.

• Adjust the cursor to “AUTO Color”, press “ENTER”/ “Right” key on the Remote Control.

• If ENTER, ADC “status” item will show “ENTER”.

• If FAIL, do one more time till it shows “ENTER”.

12

Page 13

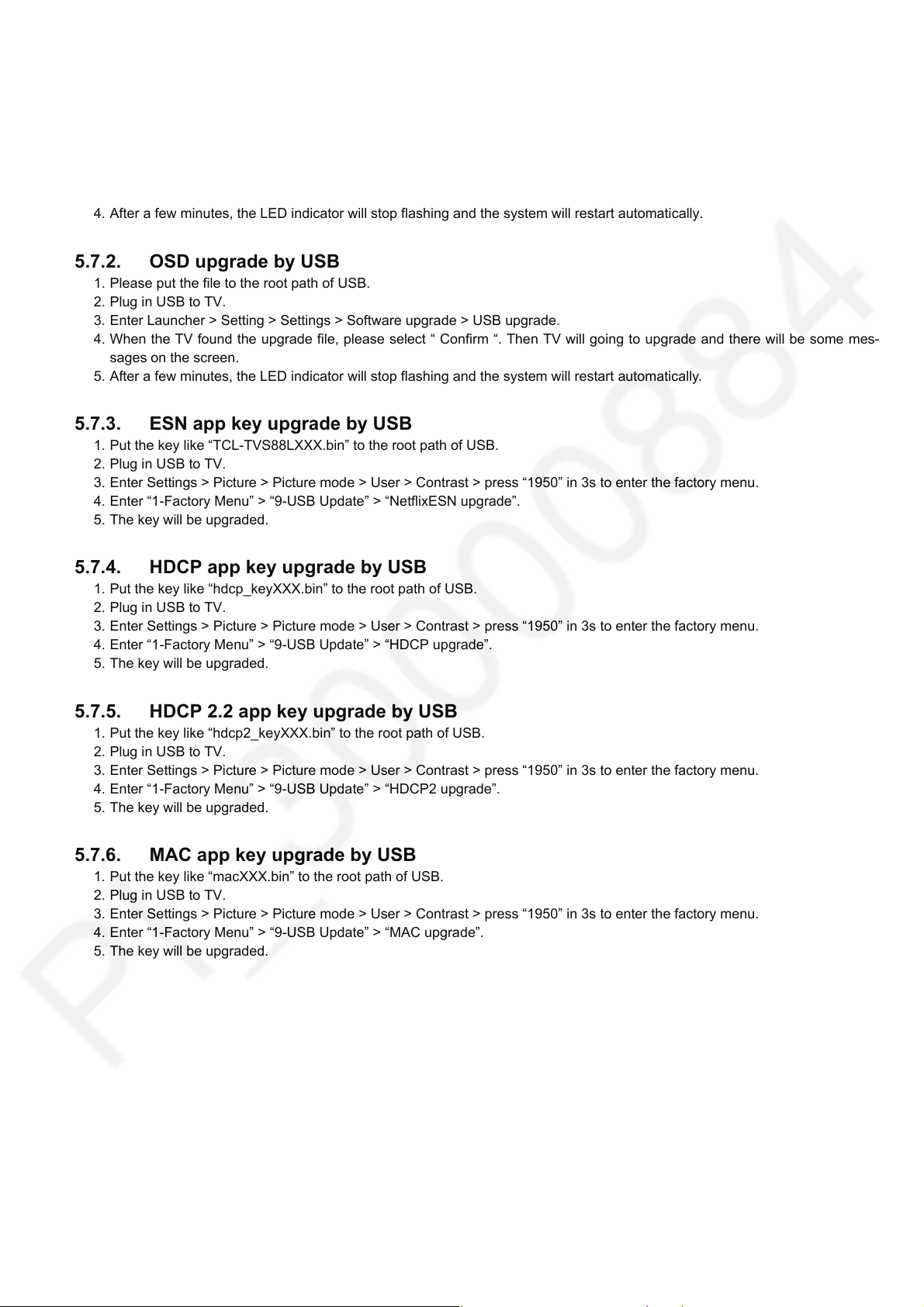

5.7. Software Upgrade Instruction

5.7.1. Keyboard upgrade by USB

1. Please put the file to the root path of USB.

2. Plug in USB to TV.

3. Press the power key for about 5s when the TV is powered on. Then, the TV will go to upgrade. When upgrading, the LED indicator will be flashing, and there will be some messages on the screen.

4. After a few minutes, the LED indicator will stop flashing and the system will restart automatically.

5.7.2. OSD upgrade by USB

1. Please put the file to the root path of USB.

2. Plug in USB to TV.

3. Enter Launcher > Setting > Settings > Software upgrade > USB upgrade.

4. When the TV found the upgrade file, please select “ Confirm “. Then TV will going to upgrade and there will be some mes-

sages on the screen.

5. After a few minutes, the LED indicator will stop flashing and the system will restart automatically.

5.7.3. ESN app key upgrade by USB

1. Put the key like “TCL-TVS88LXXX.bin” to the root path of USB.

2. Plug in USB to TV.

3. Enter Settings > Picture > Picture mode > User > Contrast > press “1950” in 3s to enter the factory menu.

4. Enter “1-Factory Menu” > “9-USB Update” > “NetflixESN upgrade”.

5. The key will be upgraded.

5.7.4. HDCP app key upgrade by USB

1. Put the key like “hdcp_keyXXX.bin” to the root path of USB.

2. Plug in USB to TV.

3. Enter Settings > Picture > Picture mode > User > Contrast > press “1950” in 3s to enter the factory menu.

4. Enter “1-Factory Menu” > “9-USB Update” > “HDCP upgrade”.

5. The key will be upgraded.

5.7.5. HDCP 2.2 app key upgrade by USB

1. Put the key like “hdcp2_keyXXX.bin” to the root path of USB.

2. Plug in USB to TV.

3. Enter Settings > Picture > Picture mode > User > Contrast > press “1950” in 3s to enter the factory menu.

4. Enter “1-Factory Menu” > “9-USB Update” > “HDCP2 upgrade”.

5. The key will be upgraded.

5.7.6. MAC app key upgrade by USB

1. Put the key like “macXXX.bin” to the root path of USB.

2. Plug in USB to TV.

3. Enter Settings > Picture > Picture mode > User > Contrast > press “1950” in 3s to enter the factory menu.

4. Enter “1-Factory Menu” > “9-USB Update” > “MAC upgrade”.

5. The key will be upgraded.

13

Page 14

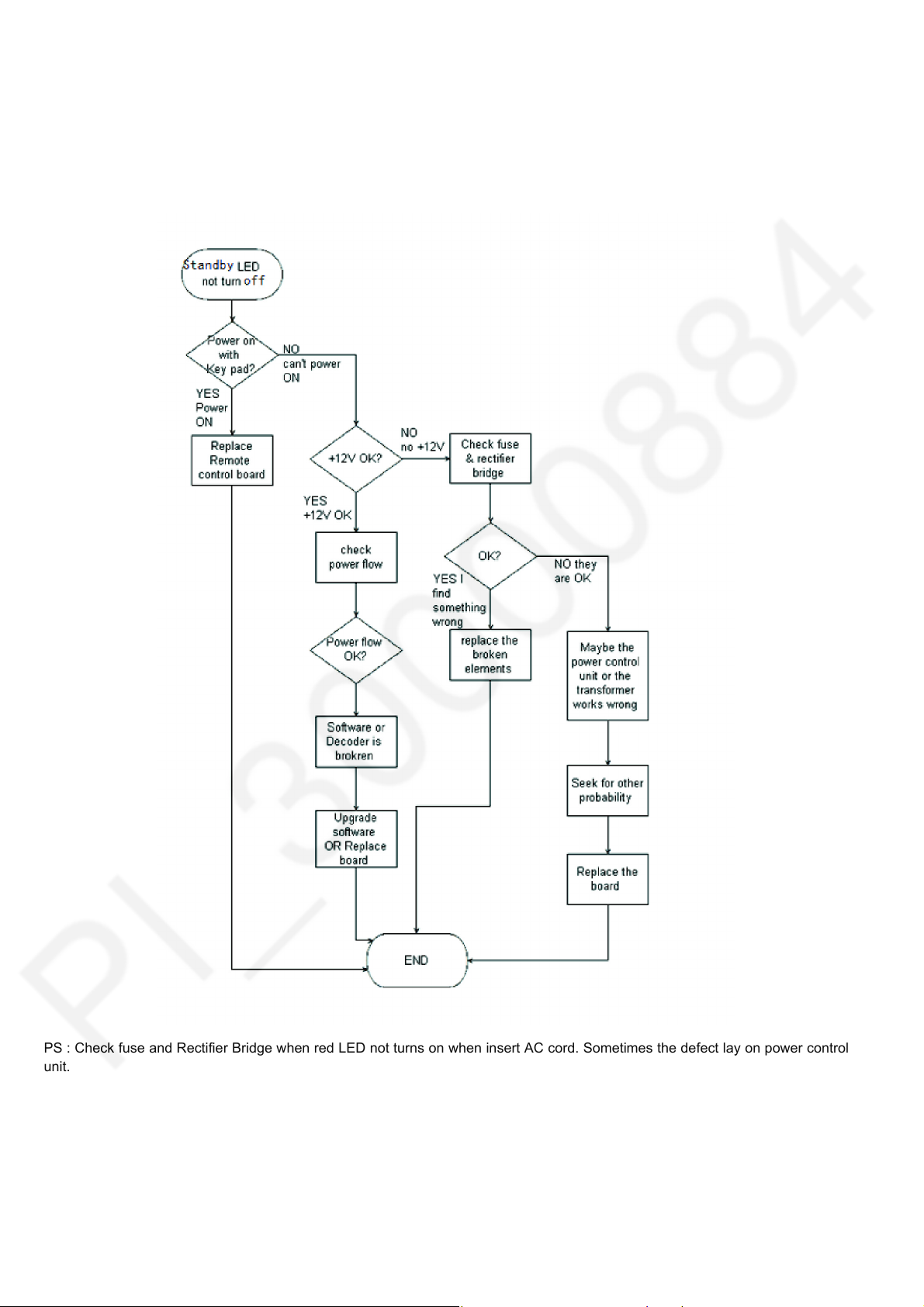

6 Troubleshooting Guide

These flow charts may not match every single defeat TV set, but they can give you useful advices when you meet the same defeats

described on the titles below.

6.1. Standby LED does NOT turn off. The TV is dead

PS : Check fuse and Rectifier Bridge when red LED not turns on when insert AC cord. Sometimes the defect lay on power control

unit.

14

Page 15

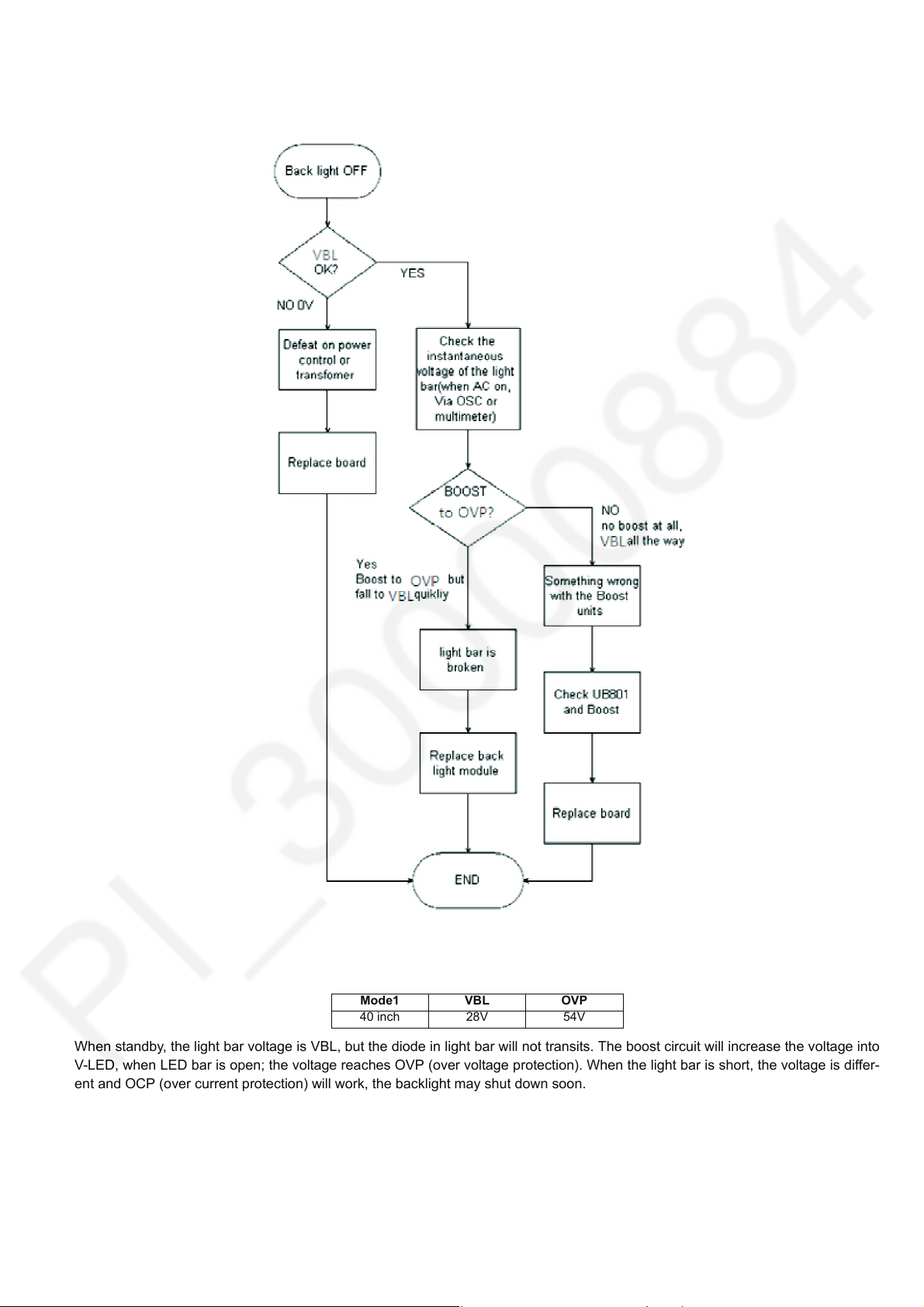

6.2. Power on, but LCD backlights are not working or shut down soon

Mode1 VBL OVP

40 inch 28V 54V

When standby, the light bar voltage is VBL, but the diode in light bar will not transits. The boost circuit will increase the voltage into

V-LED, when LED bar is open; the voltage reaches OVP (over voltage protection). When the light bar is short, the voltage is differ-

ent and OCP (over current protection) will work, the backlight may shut down soon.

15

Page 16

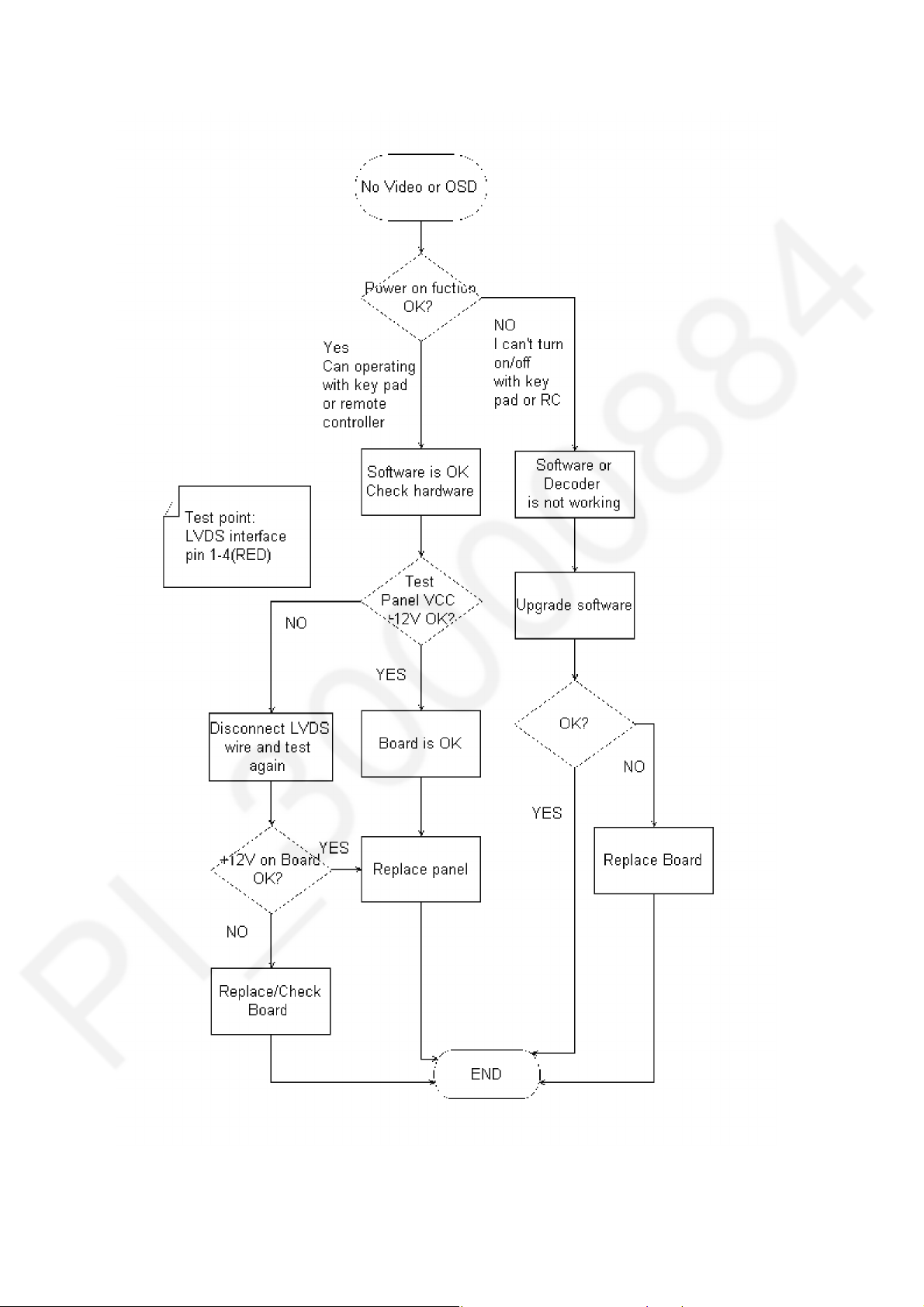

6.3. Back Light is OK while no video or OSD

16

Page 17

6.4. Uncontrolled power off

17

Page 18

6.5. Abnormal picture

18

Page 19

6.6. No sound

19

Page 20

7 Disassembly and Assembly Instructions

7.1. Back Cover Removal (TH-43EX400)

1. Unfasten screw components according to spec.

2. Picture is for illustration purpose only.

No Decription Qty

01 SCREW 63-T30060-105G70 16

02 SCREW 63-B4010T-BF5G 3 4 ± 1 Kgf.cm

03 SCREW 63-B4012T-BF5G 1 4 ± 1 Kgf.cm

20

Remark

4 ± 1 Kgf.cm

Page 21

7.2. Lens and Panel (TH-43EX400)

1. Assemble components accordingly.

2. Picture is for illustration purpose only.

No Decription Qty

01 PANEL SUPPORT 2

02 HOLDER SPEAKER 62-747180-1HAG 1

03 HOLDER SPEAKER 62-747180-1HAG 1

04 LENS 1

05 IR BOARD 1

06 IR CABLE 1

07 SCREW 64-B40080-104G 4

08 SCREW 64-B30040-104G 2

09 EVA PAD 1

21

Remark

Page 22

7.3. Boards (TH-43EX400)

1. Assemble P-Board and A-Board according to spec.

2. Do not overtighten screw.

3. Picture is for illustration purpose only.

No Decription Qty

01 MAIN BOARD 1

02 POWER BOARD 1

03 AV BRACKET 1

04 DOUBLE ADHESIVE TAPE 3

05 CONDUCTION CLOTH 0.10 20 mm x 1

06 CONDUCTION CLOTH 0.10 80 mm x 1

07 SCREW 64-B30060-104G 8 3 ± 0.5 Kgf.cm

08 SCREW 64-B30040-104G 2 3 ± 0.5 Kgf.cm

22

Remark

Page 23

7.4. Speaker (TH-43EX400)

1. Assemble speaker according to spec.

2. Make sure all pins are inserted fully.

3. Picture is for illustration purpose only.

No Decription Qty

01 SPEAKER 2

02 SPEAKER CABLE 1

03 SPEAKER CABLE 1

Remark

23

Page 24

7.5. Key Button Assy (TH-43EX400)

1. Assemble LED Panel according to spec.

2. Make sure all parts are clipped fully.

No Decription Qty

01 KEYPAD BOARD 1

02 KEYPAD CABLE 1

03 WIFI BOARD 1

04 WIFI CABLE 1

24

Remark

Page 25

7.6. FFC Assy (TH-43EX400)

1. Assemble FFC cable.

2. Make sure all parts are clipped fully.

3. Picture is for illustration purpose only.

No Decription Qty

01 V-BY-ONE CABLE 1

02 DC WIRE 1

25

Remark

Page 26

7.7. Back Cover Screw (TH-43EX400)

1. Unfasten screw components according to spec.

2. Picture is for illustration purpose only.

No Decription Qty

01 RATING LABEL 1

02 AV LABEL-RIGHT 1

03 AV LABEL-DOWN 1

04 DIGITAL LICENSE LABEL 1

26

Remark

Page 27

7.8. Power Boards Assembly (TH-49EX400)

1. Fix all board.

2. Stick the adhesive tape.

No Decription Qty

01 MAIN BOARD 1

02 POWER BOARD 1

03 AV BRACKET 1

04 DOUBLE ADHESIVE TAPE 2

05 CONDUCTION CLOTH 1

27

Remark

Page 28

7.9. Main Boards Assembly (TH-49EX400)

1. Fix all screw follow the specification.

No Decription Qty

01 SCREW 10 3 - 5 Kgf.cm

Remark

28

Page 29

7.10. WIFI & Key Button Assembly (TH-49EX400)

1. Assemble the panel support.

2. Assembly the speaker holder.

3. Fix all board and cable.

No Decription Qty

01 PEDESTAL SUPPORT 10

02 PEDESTAL SUPPORT 1

03 HOLDER SPEAKER RIGHT 1

04 HOLDER SPEAKER LEFT 1

05 LENS 1

06 IR BOARD 1

07 IR CABLE 1

08 SCREW 8

09 3M TAPE 0.05

29

Remark

Page 30

7.11. WIFI & Key Button Installation (TH-49EX400)

1. Fix panel support and the screw.

No Decription Qty

01 PANEL SUPPORT 2

02 SCREW 4 3 - 5 Kgf.cm

30

Remark

Page 31

7.12. Speaker & Wire Installation (TH-49EX400)

1. Assemble the speaker that fix to position.

2. Fix wire to the board.

No Decription Qty

01 SPEAKER 2

02 SPEAKER CABLE 1

03 SPEAKER CABLE 1

31

Remark

Page 32

7.13. Key Button (TH-49EX400)

1. Assemble the Keypad board.

2. Fix the wifi board.

3. Stick the eva pad.

No Decription Qty

01 KEYPAD BOARD 10

02 KEYPAD CABLE 1

WIFI BOARD 1

03

04 WIFI CABLE 1

EVA PAD 1

05

32

Remark

Page 33

7.14. Speaker & Wire Installation (TH-49EX400)

1. Assemble the V-By-One Cable.

2. Peel the adhesive tape.

No Decription Qty

01 V-BY-ONE CABLE 1

33

Remark

Page 34

7.15. Back Cover Installation (TH-49EX400)

1. Screw the Back Cover following the torque.

No Decription Qty

SCREW 64-T30060-105G70

01

SCREW 64-TC60120-105G

02

SCREW 63-B4012T-BF5G

03

19

4

3

Remark

3 - 5 Kgf.cm

3 - 5 Kgf.cm

3 - 5 Kgf.cm

34

Page 35

7.16. Label Sticking (TH-49EX400)

1. Stick Model Name Plate and serial label.

No Decription Qty

01 MODEL NAME PLATE 1

02 AV LABEL SIDE 1

AV LABEL DOWN 1

03

04 WARNING LABEL 1

05 DIGITAL LICENSE LABEL 1

Remark

35

Page 36

7.17. Handling SPEC

Moving the LCD module

The module should be handle by two people and hold on that top and bottom long side by both hands without module

warping. Never handle the module with keeping horizontal position when moving the module in order to avoid internal

damage and deformation. Never drop or hit the module.

About the work table

When tightening a screw, retention structures are required not to deform the LCD module.

Moving the TV (Case with a stand)

Hold the specified parts as shown to stand the TV up and move it with two people.

36

Page 37

8 Measurements and Adjustments

8.1. Key Check Points

The most special characteristic for this model is that use one board instead of three (Main Board, Power Board and Driver Board).

This picture is the top view of TP VST59S PB781-75W1 PCB; key elements and ports are marked.

Key Check Point Function

AC Jack Alternating current input.

Fuse Overcurrent protection.

EMC groupware For electromagnetic compatibility.

Rectifier bridge Transform Alternating Current (AC) to Direct Current (DC).

Filter capacitor Store electric energy and output in a mild way.

Power control unit Power supply controller.

Transformer Transform high voltage to low voltage.

Diodes for VCC 12V for DC output, key check point.

DC-DC unit Transform high DC voltage (12V) to low voltage.

AMP contol Receive audio signal and amplify for speaker use. Mute controller.

Flash memory Random Access Memory for TV software and user information.

Decoder TV function controller and video signal decoder.

LVDS interface Power supply and video signal output for panel.

Backlight controller Adjusting backlight luminance via current control. The voltage of

LED bar will automatically boost to specification setting.

Tuner TV signal receiver.

Crystal Provide clock signal for decoder.

Power LED/ Key pad/ IR board interface Control signal for power LED, KEY PAD and IR.

37

Page 38

8.2. Power Flow Diagram

38

Page 39

9 Block Diagram

MS6488A system diagram

UT1

WIFI

USB2.0

USB3.0

CAN TUNER

PANEL_ON

UART-RX

UART-TX

HDMI1_DET

HDMI2_DET

HDMI3_DET

SYS_SDA

SYS_SCL

1V5_DDR

1V5_DDR

3V3

3V3

12V

CORE_POWER

1V8

1V5_DDR

3V3

3V3SB

3V3SB

AMP_VCC

1V8

1V2_VDDC

5V

5V

NAND 4Gb

NAND_CLK

NAND_CMD

NAND_RBZ

NAND_D[0:7]

GND

1V8

3V3

C385

1nF/2KV

C385

1nF/2KV

AV OUT

AV1_V

AV1_L

AV1_R

7575

EMMC 16GB

EMMC_CLK

EMMC_CMD

EMMC_RESET

EMMC_D[0:7]

GND

1V8

3V3

U604 2G

1.5V

GND

RAMCTL[0..13]

RAMDAT[16..31]

RAMADR[0..14]

RAMBAK[0..2]GND

+5V

DP

DM

1.5V

GND

RAMBAK[0..2]

RAMADR[0..14]

RAMDAT[0..15]

RAMCTL[0..13]

MXL661

LIF_P

SDA

LIF_N

GND

3.3V

AGC2

SCL

SPDIF OUT

SPDIF_OUT

7575

HDMI2

GND

RX[0..8]

DDC_SDA

DDC_SCL

HPD

CEC

+5V

ARC

RT9711A

5V USB_5V

EN

RESET

3V3SB

RESET

MOS SWITCH

LVDSPW_ON

12V

PANEL_VCC

HDMI1

GND

RX[0..8]

DDC_SDA

DDC_SCL

HPD

CEC

VBUS

CD_SENSE

AV IN

AV1_V

AV1_L

AV1_R

7575

U501

MS6488A

A_RAMBAK[0..2]

HDMI0_RX[0..8]

DP0

DM0

3V3

33VSTB

DM1

DP1

A_RAMADR[0..13]

A_RAMDAT[0..15]

HDMI_CEC

HDMI1_HPD

HDMI0_SCL

VIFN

VIFP

B_RAMDAT[0..15]

B_RAMBAK[0..2]

B_RAMADR[0..13]

A_RAMCTL[0..13]

B_RAMCTL[0..13]

SYS_SDA

SYS_SCL

I2S_OUT[0..3]

IF_AGC

TU_SDA

TU_SCL

HDMI0_SDA

HDMI1_HPD

HDMI1_SCL

HDMI1_SDA

HDMI1_RX[0..8]

HDMI2_HPD

HDMI2_SCL

HDMI2_SDA

HDMI2_RX[0..8]

1V5_DDR

CORE_POWER

1V8

MCU_RESET

GPIO_PM

PWR-ON/OFF

TAS_SDA

TAS_SCL

EMMC_CLK

EMMC_CMD

EMMC_RESET

EMMC_D[0:7]

OSD_VB1[0:3]

VB1[0:7]

1V2_VDD

A_RAMDAT[16:31]

B_RAMDAT[16:31]

DP3

USB_TXN

USB_TXP

USB_RXN

USB_RXP

DM3

HDMI_ARC

AV1_V

AV1_L

AV1_R

AVOUT_V

SPDIF

AVOUT_L

AVOUT_R

PHY_TP

PHY_TN

PHY_RP

PHY_RN

CAMADR[0-14]

CAMDAT[0-7]

CAMCTL[0-9]

TS0 IN[0-10]

TS1 IN/ OUT[0-10]

EARPHONE_OUT

RJ45RJ45

TD+

1

TD-

2

RD+

3

TDCT

4

RDCT

5

RD-

6

NC

7

CH_GND

8

GND1

13

GND2

14

U901

HST-0041

SMDTR16P

U901

HST-0041

SMDTR16P

TD+

1

TD-

3

RD+

6

RD-

8

RX-

9

TCM-

10

RX+

11

TX-

14

TCM

15

TX+

16

G524

5V

VBUS

EN

U602 2G

1.5V

GND

RAMCTL[0..13]

RAMDAT[16..31]

RAMADR[0..14]

RAMBAK[0..2]

GND

+5V

DP

DM

YPBPR IN

Y

PB

PR

AUDIO_L

AUDIO_R

HDMI3

GND

RX[0..8]

DDC_SDA

DDC_SCL

HPD

CEC

+5V

GND +5V

DP

USB_RXP

USB_RXN

USB_TXP

USB_TXN

DM

DMDM

DP

7575

AMP 5707

+3.3V

GND

I2S[0..3]

OUT_R-

SCL

SDA

24V

OUT_R+

OUT_L-

OUT_L+

PDN#

RESET#

EARPHONE OUT

EARPHONE_OUT

12V

GND

SDA

SCL

VB1[0:7]

OSD_VB1[0:3]

U603 2G

1.5V

GND

RAMBAK[0..2]

RAMADR[0..14]

RAMDAT[0..15]

RAMCTL[0..13]

DEBUGDEBUG

1

2

3

4

C387

1nF/2KV/1206

C387

1nF/2KV/1206

9.1. System Block Diagram

U601 2G

39

Page 40

10 Wiring Connection Diagram

10.1. Wire Dressing (TH-43EX400)

• Stick tape for wire dressing.

No Decription Qty Remark

01 3M TAPE 0.49

02 ALUMINIUM FOIL 2

70 mm x 7

40

Page 41

10.2. Wire Dressing (TH-49EX400)

• Stick tape for wire dressing.

No Decription Qty Remark

01 DC WIRE 1 70 mm x 7

02 KEYPAD CABLE 1

03 IR CABLE 1

04 SPEAKER CABLE 1

05 SPEAKER CABLE 1

06 WIFI CABLE 1

07 3M TAPE 0.35 0.05 x 7

08 ALUMINIUM FOIL 2

41

Page 42

11 Schematic Diagram

4K7

R161A

GND

GND

GND

GND

GND

GND

GND

12V_M

24V_M

2.2U

CDM0

2.2U

CDM1

CDM2

0.1U

RDM2

150K

RDM3

20K

CDM3

0.1U

0.01U

CDM4

EN

GND

VSENSE

PH

SS

BOOT

COMP

VIN

UDM1

TPS54531

2

6

1

4

8

5

7

3

B540C

DDM1

RDM4

22K

CDM5

2200P

47P

CDM6

LDM1

6.8UH

CDM8

10U

10U

CDM9

CDMA

10U

CDMB

0.1U

RDM5

39K

RDM6

2K7

47P

CDMC

24V_M

GND

C133

2U2

GND

GND

GND

GND

GND

GND

3K3

R131

GND

GND

GND

CDE4

22U

CDE5

0.1U

CDE1

10U

CDE2

0.1U

GND

GND

22P

CDE6

RDE4

150K

T

1V5_DDR

NC

LX

EN

SGND

PGND

IN

PG

FB

UD015

AN_SY8034

1

2

3

4

8

7

6

5

RDE1

100K

CDE3

22U

LDE1

2.2UH

1V5_DDR

RDE2

91K

RDE3

3K6

GND

GND

GND

5V

GND

10U

CDH8

0.1U

CDH9

GND

GND

0.1U

CDH3

CDH2

10U

CDH1

10U

10U

CDH7

10U

CDHB

CDHC

10U

GND

CDHA

220P

RDH4

33K

RDH5

3K6

RDH6

820R

0.1U

CDH4

RDH7

6R8

CDH6

47P

CDH5

P104

1

2

C102

220U

35V

220R

C134

UDB0

MP8765

9

13

2

15

1

8

2200P

16

14711

543

10

12

6

RDB1

36K

RDB6

2K4

R124

220K

2U2

CDM7

CDB4

1U

47P

120K

RDH1

3K3

R106

0.47UC118

21

P102

6

4

C135

D105

11

9

7

5

3

10

12

8

BAS316

BAS316

DM2

DH1

BAS316

L108

R161

4K7

6.8UH

R163A

0R

0R

R164A

SYS_SDA_1

SYS_SCL_1

10U

C137

(5)

Vref=0.6V

@max3A

(0.85MHz<Fosc<1.15MHz)

Vout=1.55V

VREF=0.8V

max 4A

f=570KHz

1.5V

PS=3.7mW

(vin=3.5V-28V)

PS=3.7mW

1.5V

f=570KHz

max 4A

VREF=0.8V

(vin=3.5V-28V)

C138

Vo=0.6-7V

5A max

(Vin=4.5V-18V,PS=1mW)

1.86V

Fsw=650KHz

Vref=0.6V

5V TO DDR 1V5

24V

DIM_PWMBL_ON

POWER_ON

3.3VSB

GND

GND

24V

24V

(5)

L

(5)

A_DIM

GND

Fixed Fsw=500KHZ

12V TO 1V2_VDDC

(5)

(Vin=4.5V-17V)

Vref=0.6V

Fixed OCP=8.5A

(5)

(5)

(5)

(5)

(Vin=5V-22V)

max5A

1V2_VDDC

H

(Vin=2.7V-6V)

(5)

12V TO 5V

POWER BD CONNECTOR

(5)

(5)

(5)

(5)

GPIO_VID_0

0.95V

L 50% ADIMING_MAX(3D_CTRL AND ADIM SHARE PIN)

H 100% ADIMING_MAX(SEPARATED 3D_CTRL AND ADIM)

0.95V

R142

Core Power

1V

39K

2.2U

C129

C130

0.1U

R105

C117

R120

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

NC

LX

EN

SGND

PGND

IN

PG

FB

T

GND

GND

GND

GND

GND

T

GND

SW

VBST

VIN

PG

VREG5

VFB

EN

T

GND

T

T

GND

GND

GND

T

T

T

GND

TT

GND

GND/ADJ

OUT

VIN

4

GND

T

GND

GND

SW4

AGND

VOUT

VCC

NC2

PG

NC1

BST

FB

MODE

EN

SW2

PGND

SW3

VIN

SW1

T

T

GND

GND

T

GND

T

EN

GND

VSENSE

PH

SS

BOOT

COMP

VIN

GND

GND

GND

GND

GND

GND

GND

EN

GND

VSENSE

PH

SS

BOOT

COMP

VIN

4K7

3V3

SYS_SDA

SYS_SCL

R161A

POWER_ON

12V_M

24V_M

CDM0

2.2U

0.1U

RDM2

150K

RDM3

20K

CDM3

0.1U

CDM4

0.01U

1

4

8

5

7

3

B540C

DDM1

22K

RDM4

2200P

CDM5

CDM6

47P

LDM1

6.8UH

CDM8

10U

CDM9

10U 10U

CDMA

0.1U

CDMB

39K

2K7

RDM5

CDMC

RDM6

47P

LED_OUT

KEY

VID

DIM_OUT

POWER_ON_OUT

AMP_Vcc

POWER_ON

FAST_BOOST

POWER_ON

24V_M

KEY_IN

3V3SB

3D_CTRL

VID

IR

LED

SYS_SDA_1

IR_IN

POWER_ON

BL_ON_OUT

3V3SB_1

SYS_SCL_1

3V3

3V3

DIMING_DET

GPIO_VID_0

KEY

POWER_ON

R131

C133

3K3

22U

0.1U

CDE4

10U

CDE5

0.1U

CDE1

22P

CDE2

150K

CDE6

1V5_DDR

RDE4

AN_SY8034

6

7

8

4

3

2

1

UD015

5

100K

RDE1

CDE3

22U

LDE1

2.2UH

1V5_DDR

RDE2

91K

RDE3

3K6

GND

5V

10U

CDH8

GND

0.1U

CDH9

0.1U

CDH2

10U

10U

GND

CDHC

220P

CDHA

33K

RDH4

RDH5

3K6

CDH4

RDH6

820R

0.1U

RDH7

6R8

CDH6

47P

CDH5

0.47U

CDHD

LDH1

4.7UH

TPS56528

1U

5

6

7

8

4

3

2

1

UDH1

RDH2

22K

24V_1

0.01U

C103

GND

1000P

GND

GND

3V3SB

C108

220R

R102

BL-ON

R101

10K

STB-3V3

1V2_VDDC

C107

10U

CDB9

22U

CDB8

22U

CDB5

0.22U

CDB2

0.1U

CDB3

0.1U

22U

0.1U

CDB7

0.1U

CDBA

22U

10U

CDBD

CDB0

220P

1UH

CDBB

LDB0

220P

CDB6

1M

RDB4

4R7

RDB5

22U

C121

0.1U

C124

K_GND

KEY_2

GND

AS1117-3.3

UD033

4

321

C105

10U

C104

10U

3V3

22K

R119

5V

LED IR

KEY

L106

2.2UH

0.1U

C120

CORE_POWER

3V3

10R

RDB7

1V2_VDDC

4K7

R130

22U

C123

22U

C122

0.1U

C114

22K

RDB2

C112

0.01U

PWM-DIM

GND

C149

0.1U

470R

R116

1K

R117

470R

RDB3

0.1U

C115

0R

RDBA

18K

R122

3V3SB

R115

10K

3V3SB

GND

R103

10K

R134

R135

10K

R157

220R

100K

R132

47K

RDB9

MSH6110A

U101

1

2

3

4

8

7

6

5

330P

C125

L102

120RPW-ON

GND

GND

L105

220R

220R

L103

12V_M

R153

220R

C111

470P

D101

PESD5V0S1BL

21

12V_M

12V_M

R156

10K

R104

2K2

220R

R105

C117

10U

R125

3V3SB

0.1U

C101

1U

C119

220P

C110

IR_STB

3V3SB

R129

4K7

2N7002K

Q102

CORE_POWER

100K

RDB0

3K3

R120

10K

R133

3V3SB

GND

GND

10K

3V3SB

5V

CMS06

D103

R137

0R

12V_PANEL

CMS06

D102

C109

0.01U

C113

0.01U

C127

0.01U

R136

0R

10U

GND

CDH1

10U

CDH3

CDBC

CDM1

2.2U

GND

GND

GND

GND

SCL

SW

BSR

PVDD

SDA

VREG5

FB

EN

CDM2

TPS54531

UDM1

2

6

P_DIMING

24V_M

2U2

CDH7

10U

CDHB

10U

CDB1

1000P

C106

C128

2.2U 2.2U

C129

C130

0.1U

R144

150K

R140

20K

C131

0.1U

0.01U

C132

U102

TPS54531

3

7

5

8

4

1

6

2

D104

B540C

R141

22K

C134

2200P

47P

C135

L108

6.8UH

C136

10U

10U

C137 C138

10U

C139

0.1U

C140

47P

2K7

R143

L100

220R

L104

GND

T

ADIM_1

(5)

10K

R152

A_DIMING

GND

R154

220R

ADIM_1

ADIM_1

T

GND12

P103

7

6

5

4

3

2

1

P101

4

3

2

1

C102A

0.1U

GND

T

KEY_STB

3V3SB

T

GND

GND

GND

GND

GND

GND

SW OUT

GND

FBEN

6.8UH/NC

L109

3V3SB

WIFI_5V

R158

330K

C154

1000P

C150

2.2U 2.2U

C151

R159

100K

D106

SR34

C155

22U

C152

0.1U

0.1U

C157

C156

22U

WIFI_5V

3K3

R160

FSW=550KHz

1.19V

(Vin=2.5V-4.2V)

max:800mA

WIFI_WAKEUP POWER

U103

mp3410/NC

51

2

34

GND

300K

R164

R118

47K

21

D108

PESD5V0S1BL

21

D109

PESD5V0S1BL

NC/

24V_2

GND

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC/

NC/

NC/

NC/

NC/

NC

NC/

NC/

NC/

NC/

NC/

NC/

NC/

NC/

NC/

NC/

NC/

NC/

NC/

NC/

42

Page 43

R206

10K

GND

GND

GND

GND

22P

CT28

22P

CT29

0.1U

CM33

CM31

0.1U

CM1

0.1U

TU_IFAGC_OUT

TU_IF+_IN

TU_IF-_IN

CM3

0.022U

GNDGND

10U

CT41

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND/ADJ

OUT

VIN

4

LX

GND

EN

VIN

FB

GNDGND

GND

T

GND

GND

GND

GND

CT43

10U

1V1

C208

22U

C209

0.1U

C204

10U

C205

0.1U

C207

22U

C206

22P

3V3_DEMO

RM6

10K

3V3_DEMO

RM3

10K

CM23

0.1U10U

CM20 CM21

2U2

0.1U

CM22

0.1U

CM24

1V1

1V1

CM25

0.1U

CM15

2U2

CM14

10U

CM13

22U

L201

2.2UH

0.1U

CT42

5V

5V

R201

100K

R205

100K

R202

100K

R203

8K2

AS1117-3.3

UT2

4

321

U202

RT8096A

5

4

1

2

3

3V3_DEMO

1V1_DEMO

TU_3V3

RT12

0R

CT21

0.022U

RM22

10K

3V3

TUNER_FAT+

TUNER_FAT-

(5)

(Vin=2.7V-7)

Vref=0.6V

495mA

@max1A

(5)

5V TO TUNER 3V3

5V TO DEMO 1V15

DEMO MSB102KT FOR T2

Close to SOC

Close to SOC

GND GND

GND

IF_AGC_D

IF-AN

IF-AP

NC1

NC2

RF_SW

SCL

GND

SDA

VCC

NC3

CT205

10U

CT204

0.1U

RT205

470R

TU01

9

5

4

2

3

1

8

7

10

11

6

TUNER_FAT+

TUNER_FAT-

RF_SW

TU_3V3

RT7

100R

CT7

0.1U

GND

TUNER_SCL

TUNER_SDA

GND

GND6GND2

GND3

GND4

GND1

IF_N

VCC

IF_P

IF_AGC

GND5

SDA

SCL

TU02

11

10

9

5

4

2

3

1

8

7

612

TUNER_AGC

TUNER_FAT+

TUNER_FAT-

TU_3V3

GND

GND

22P

CT33

RT10

4K7

RT11

4K7

TU_3V3

Or connect to the nearest 3V3

Close to SOC

33R

RT16

TUNER_SCL

33R

RT15

TU_SCL

TU_SDA

TU_SDA

TUNER_SDA

22P

CT34

REMARK=NC/

NC/

22R

RM10

RM11

22R

22R

RM12

RM13

22R

RM14

22R

22R

RM15

RM16

22R

22R

RM17

CI_TSI0

CI_TSI1

CI_TSI2

CI_TSI3

CI_TSI4

CI_TSI5

CI_TSI6

CI_TSI7D_TSDATA7

D_TSDATA4

D_TSDATA5

D_TSDATA6

D_TSDATA0

D_TSDATA1

D_TSDATA2

D_TSDATA3

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

GND

CM26

10P

RM7

22R

22R

RM8

RM9

22R

CM28

10P

CM27

10P

CI_TSICLK

CI_TSIVLD

CI_TSISYNC

TSSYNC

TSCLK

TSVLD

(5)

(5)

(5)

TU_SCL

LT001

0.22UH

LT002

0.22UH

T

3V3_DEMO

0R

R237

3V3_DEMO

0R

R236

TSCLK

D_TSDATA7

D_TSDATA6

D_TSDATA5

D_TSDATA4

D_TSDATA3

D_TSDATA2

D_TSDATA1

D_TSDATA0

TSVLD

TSSYNC

GND

GNDGND

CM11

10P

CM10

10P

100R RM20

100R RM19

TUNER_SDA

(5)

(5)

CM40

0.1U

CM41

0.1U

GND

GND GND

24M

X24M1

33P

CM30

CM29

33P

0R

RM32

1M

RM33

GND

D_IF_AGC

3V3_DEMO

3V3_DEMO

GND GND

1V1

GND

GND

10K

RM31

GND GND

CM42

0.1U

CM43

0.1U

0

RM30

3V3_DEMO

T

D_SCL

T

D_SDA

1V1

3V3_DEMO

GND

GND

GND

3V3_DEMO

MSPI_CSZ

MSPI_DO

MSPI_DI

MSPI_CLK

MSPI_CSZ

GND

MSPI_DO

10K

RM34

3V3_DEMO

MSPI_WP

3V3_DEMO

0.1U

CM44

GND

MSPI_CLK

MSPI_DI

0.1U

CM45

0.1U

CM46

3V3_DEMO

TS_ERR

I2C slave address:

TS_ERR=0,I2C slave address=0XD2

TS_ERR=1,I2C salve address=0XF2

GND

D_IF_AGC

GND

RM5

0R

3V3_DEMO

Close to Demod

1V1

GNDGND

100P

CT50

100P

CT49

0R

RM36

0R

RM35

CM48

0.1U

CM47

0.1U

TUNER_FAT+

TUNER_FAT-

NC

NC/

NC/

NOT THIS P/N

NC/

NC/

NC/

NC

NC

NC

NC

NC

CM19

0.1U

CM18

0.1U

CM17

0.1U

CM16

0.1U

Close to Demod

Close to Demod

Close to Demod

10U

CM7

TUNER_AGC

U200

13

12

11

9

8

32

10

5

4

3

2

1

48

4722454443

424140

39

38

37

36

35

34

6

27

26

7

31

28

19

30

29

17

24

23

18

25

21

20

46

33

141516

DISEQ_OUT1

QM_S

QP_S

MSPI_CSZ/SSPI_CLK

GND-1

I2CM_SCL

I2CM_SDA

VDD-3

GND-5

VDD33-2

DISEQ_IN1/TS_ERR

VDD-1

RESETZ

GND-7

GPIO0

MSPI_CLK/SSPI_CSZ

MSPI_DI/SSPI_DO

IFAGC_T

GND-6

VDD33-1

IFAGC_S

TS_CLK

TS_D7

TS_D6

TS_D5

TS_D4

TS_D3

TS_D2

TS_D1

TS_D0

TS_VLD

TS_SYNC

VDD33-3

GND-4

VDD-2

I2CS_SDA

I2CS_SCL

GND-2

XTAL_OUT

XTAL_IN

AVDD33-1

GND-3

MSPI_DO/SSPI_DI

IP_T

IM_T

IP_S

IM_S

AVDD33-2

*

MSB102KT

RM38

0R

T2_RST

NC

U201

1

2

3

4

8

7

6

5

DIO

CLK

HOLD

VCC

GND

WP

DO

CS

W25X40A

TUNER_SCL

RT208

68R

RT8

330R

RT9

330R

Close to TUNER

CT8

0.1U

GND

10U

CT9

GNDGND

TU03

9

5

4

2

3

1

8

7

6

NG

IF_N

IF_P

GND1

SCL

3V3

SDA

GND2

IF_AGC

TU_3V3

TU_SCL

TU_SDA

TUNER_FAT-

TUNER_FAT+

TUNER_AGC

GND

GND

43

Page 44

USB_5V

0.1U

C333

GND

GND

T

AV1_R_IN

GND

R346

10K

T

GND2

GND

GNDGND

R329

12K

C330

470P

10K

R312

R313

10K

C336

470P

470P

C337

C338

0.047U

C309

1U

C310

1U

R314

33R

R328

12K

C303

22U

R330

4R7

4R7

R331

3V3SB

C302

22U

R345

1K

T

HP_L

C353

0.1U

C350

0.1U

T

HP_DET

C349

0.1U

GND

T

HP_R

GND

C331

470P

GND

R300

470R

470R

R301

D311

PESD5V0S1BL

12

GND

T

AUDIO_R_OUT

T

AUDIO_L_OUT

GND

C352

120P

GND

C351

120P

GND

D313

PESD5V0S1BL

12

GND

PESD5V0S1BL

D312

12

T

AV1_L_IN

T

AV1_V_IN

R348

10K

R347

10K

75R

R315

GND

D303

PESD5V0U1UL

T

SPDIF

SPDIF_OUT

GND

R334

470R

T

U2_D-

T

GND10

T

USB_5V

T

USB4+

T

U2_D+

GND

C316 0.1U

T

USB4-

C317

3P3

3P3

C318

GND

GND

GND

10U

C301

C305

0.1U

16V

470U

C304

USB_5V

GND

VIN

EN/EN# NC

GND

VOUT

U300

RT9711A

1

2

34

5

GND

R332

100R

R340

10K

T

GND6

MNT-HOLE1

MNT-HOLE2

P303

9

8

7

6

5

2

3

4

1

11

10

C313

3P3

3P3

C314

PESD5V0U1UL

D305

D300

PESD5V0U1UL

PESD5V0U1UL

D301

D304

PESD5V0U1UL

PESD5V0U1UL

D302

R341

2R2

2R2

R342

R333

470R

T

UART_TX

0.1U

C315

2R2

R335

2R2

R336

2R2

R338

R337

2R2

USB3_EN

GND

R339

22K

10U

C300

GND

T

USB5V

T

UART_RX

R344

220R

GND

PESD5V0S1BL

D310

12

GND

AV/Y

GND

PR/L

PB/R

P301

2

3

1

4

5

ISLAND

VDD

NC2

I/O5

I/O4

I/O2

I/06

NC1

I/O1

GND

I/O3

U301

AZ1065-06F

5

9

1

3

10

4

6

7

8

2

11

GND

C332

220U

16V

1UC312

C311 1U

PESD5V0S1BL

D309

12

GND

GND

T

GND4

GND

120R

R343

C327

220P

C329

0.1U

5V

SPDIF

USB_5V

USB_5V

USB_5V

UART_TX

UART_RX

AV1_V_IN

AVOUT1_R_OUT

AVOUT1_L_OUT

HP_DET

SC_R_IN

SC_L_IN

EARPHONE_R

EARPHONE_L

U_RXN

U_RXN

U_RXP

U_RXP

U4_D+

U4_D+

U4_D+

U4_D+

U2_D-

U2_D-

U2_D-

U2_D+

U2_D+

U2_D+

U_TX

U_TX

USB2_D-

USB2_D+

USB_TXN

USB_TXP

USB4_D-

USB4_D+

USB_RXP

USB_RXN

U_TXP

U_TXP

U_TXN

U_TXN

U4_D-

U4_D-

U4_D-

U4_D-

U_RX

U_RX

SCT1_AUR_OUT

SCT1_AUL_OUT

AV OUT

CLOSE TO IC

(5)

(5)

(5)

INCONNECTED=H

CONNECTED=L

(5)

(5)

headphone out

(5)

(5)

(5)

CLOSE TO SOC

SPDIF

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

USB3.0

(5)

AV IN

USB2.0+ RS232

close to p304

close to p303

P302

2

1

BLACK

P304

9

8

7

6

5

2

3

4

1

11

10

MNT-HOLE1

MNT-HOLE2

P306

6

5

4

3

2

1

WHITE

YELLOW

RED

T

GND

VCC

VIN

GND

GND1

GND2

TX

LED

IC

DRIVE

GND

T

T

Z1

3V3

2

P302A

5

NC/

4

1

3

C328A

NC/

0.1U

3V3

GND5

3V3_1

SPDIF

CLOSE TO SOC

SPDIF_OUT SPDIF

PESD5V0S1BL

D320

12

75R

R315A

GND

NC/

NC/

NC/

NC/

NC/

NC/

NC/

NC/

NC/

NC/

NC/

NC/

NC/

NC/

P305

4

3

2

1

WHITE

RED

R327

75R

R326

0R

GND

AVOUT1_V_OUT

T

CVBS_OUT

CVBS OUT TEST

(5)

44

Page 45

R410

100R

R438

200K

200K

R439

GND

R436

200K

R435

200K

D418

12

10

8

7

65

4

3

1

2

ESD

D408

9

GND

GND

GND

GND

GND

ESD

D409

9

10

8

7

65

4

3

1

2

R426

10K

10K

R425

R428

100R

BT3904

Q403

E

C

B

GND

R423

10K

100R

R427

22K

R424

GND

10K

R430

1K

R429

4K7

R431

GND

H1_HPD_OUT

D406

ESD

9

10

8

7

65

4

3

1

2

GND

GND

GND

GND

GND

GND

GND

GND

GND

H1_SCL_OUT

GND

H1_SDA_OUT

R409

4K7

R407

1K

RX2+

GND1

RX2-

RX1+

GND2

RX1-

RX0+

GND3

RX0-

RXC+

GND4

RXC-

NC1

NC2

DDCCLK

DDCDA

GND5

VCC

HPD

P402

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

R408

10K

GND

R405

100R

GND

GND

R401

10K

R419

10K

GND

BT3904

E

C

B

Q401

GND

D403

ESD

9

10

8

7

65

4

3

1

2

C406

0.1U

C407

10U

VBUS

D405

ESD

9

10

8

7

65

4

3

1

2

100R

R406

R403

10K

0.047U

C409

GND

10K

R404

VBUS

C405

10U

D404

ESD

9

10

8

7

65

4

3

1

2

GND

GND

D416

12

R402

22K

R420

22K

R412

100R

R413

100R

5V

GND

10K

R415

R414

10K

R434

200K

200K

R437

GND

5V

R416

100R

C408

0.1U

GND

AVDD5V_MHL

D401

CMS06

VBUS

R418

10R

5V

R433

4K7

R421

33R

10R

R440

R432

D417

12

D415

12

D412

12

D411

12

330K

R417

C401 1U

D410

12

D413

12

D414

12

RX2+

GND1

RX2-

RX1+

GND2

RX1-

RX0+

GND3

RX0-

RXC+

GND4

RXC-

NC1

NC2

DDCCLK

DDCDA

GND5

VCC

HPD

P401

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

RX2+

GND1

RX2-

RX1+

GND2

RX1-

RX0+

GND3

RX0-

RXC+

GND4

RXC-

NC1

NC2

DDCCLK

DDCDA

GND5

VCC

HPD

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

P403

19

18

17

16

EN/EN# OC

GND

OUTIN

U401

G524

51

2

34

5V

H_ARC

H_ARC

H_ARC

HDMI_ARC

H3_RXC+_IN

H3_RXC+_INH3_RXC+_IN

H3_RXC-_IN

H3_RXC-_IN H3_RXC-_IN

H3_RX0-_IN

H3_RX0-_INH3_RX0-_IN

H3_RX2+_IN

H3_RX2+_IN H3_RX2+_IN

H3_RX0+_IN

H3_RX0+_INH3_RX0+_IN

H3_RX1-_IN

H3_RX1-_INH3_RX1-_IN

H3_RX1+_IN

H3_RX1+_INH3_RX1+_IN

H3_RX2-_IN

H3_RX2-_INH3_RX2-_IN

H3_HPD_OUT

H3_5V

H3_5V

H3_5V

HDMI3_DET

H3_SDA_OUT

H3_SCL_OUT

H3_HPD

H3_HPD

H1_HPD

H1_HPD

H1_HPD

H1_HPD_OUT

VBUS

VBUS

VBUS

H1_RXC+_IN H1_RXC+_IN

H1_RXC+_IN

H1_RX0+_IN H1_RX0+_IN

H1_RX0+_IN

H1_RX1+_IN H1_RX1+_IN

H1_RX1+_IN

H1_RX2-_IN H1_RX2-_IN

H1_RX2-_IN

H1_RX1-_IN H1_RX1-_IN

H1_RX1-_IN

H1_RX0-_IN H1_RX0-_IN

H1_RX0-_IN

H1_RX2+_IN

H1_RX2+_INH1_RX2+_IN

H1_RXC-_IN

H1_RXC-_INH1_RXC-_IN

H2_5V

H2_5V

H2_5V

H2_HPD

H2_HPD

H2_RX0+_IN

H2_RX0+_IN

H2_RX0+_IN

H2_RX1-_IN

H2_RX1-_IN

H2_RX1-_IN

H2_RX2-_INH2_RX2-_IN

H2_RX2-_IN

H2_RXC+_INH2_RXC+_IN

H2_RXC+_IN

H2_RX1+_IN

H2_RX1+_INH2_RX1+_IN

H2_RX2+_IN

H2_RX2+_INH2_RX2+_IN

H2_RX0-_IN H2_RX0-_IN

H2_RX0-_IN

H2_RXC-_IN

H2_RXC-_IN H2_RXC-_IN

H2_SCL_OUT

H2_SDA_OUT

HDMI2_DET

H2_HPD_OUT

MHL_CABLE_DET

H1_SCL

H1_SCL

H1_SCL

HDMI1_DET

MHL_VBUS_EN

H1_SDA

H1_SDA

H1_SDA

H2_SDA

H2_SDA

H2_SDA

H2_SCL

H2_SCL

H2_SCL

H3_SCL

H3_SCL

H3_SCL

H3_SDA

H3_SDA

H3_SDA

MHL_CD_SENSE

MHL_CD_SENSE

MHL_CD_SENSE

MHL_CD_SENSE

CEC

CEC

CEC

CEC

HDMI_CEC

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

(5)

HDMI 2

HDMI ESD Protection

HDMI ESD Protection

HDMI ESD Protection

HDMI 1

(5)

(5)

(5)

HDMI 3

NC/ NC/

NC/

NC/

NC/

NC/

NC/

NC/

NC/

NC/

NC/

NC/

45

Page 46

GND

GND

R532

0R

0.1U

C596

0.1U

C597

GND

3V3

C592

0.1U

GND

GND

R520

10K

R521

10K

GND

GND

C585 0.47U

0.47UC583

1V5_DDR_SOC

0.47UC584

0.1U

C543

1V5_DDR_SOC

0.1U

C535

C534

0.1U

10U

C533

22U

C532

C528

0.1U

0.1U

C526

C524

0.1U

0.1U

C525

C523

0.1U

C527

0.1U

0.1U

C519

0.1U

C517

0.1U

C513

C515

0.1U

0.1U

C514

C516

0.1U

GND

GND

T

MCU_RESET

R514

100R

GND

C590

1000P

GND

GND

R513

47K

R512

47K

C588

1U

C589

10U

R510

47K

GND

R517

22K

10K

R518

GND

C518

0.1U

GND

0.1U

C522

C529

0.1U

0.1U

C530

C531

0.1U

0.1U

C503

C504

0.1U

C505

0.1U

0.1U

C536

0.1U

C580

C581

0.1U

C537

0.1U

GND

GND

GND

GND

GND

C549 0.1U

C563

2U2

1V5_DDR_SOC

C582 0.47U

GND

C501

22U

0.1UC538

C539 0.1U

C540 1U

0.1UC546

C547 0.1U

C548 2U2

C551

0.1U

0.1U

C552

2U2

C560

C561

0.1U

10U

C559

0.1U

C562

0.1U

C564

C565

0.1U

0.1U

C571

AVDD5V_MHL

GND

Q503

BT3906

C

E

B

GND

R522

1K

GND

L503 120R

C591

10U

Q501

BT3906

C

E

B

1V2_VDDC

3V3SB

1V2_VDDC

3V3SB

CORE_POWER

1V2_VDDC

1V2_VDDC

1V2_VDDC

CORE_POWER

CORE_POWER

1V2_VDDC

3V3

C550

10U

3V3SB

GND

0.1U

C558

3V3SB

1V2_VDDC

0.1U

C509

C508

0.1U

0.1U

C507

0.1U

C506

GND

0.1U

C595

C594

0.1U

10U

C572

22U

C510

L501

120R

R515

3K3

R516

4K7

3V3SB

D501

0BAV99

2

3

1

120RL505

3V3

3V3

GND

GND

22U

C520

3V3SB

0R

R533

C502

10U

C511

22U

C512

0.1U

10U

C599

GND

L506

1000R

C502A

1000P

GND

R531

0R

0R

R525

C557 0.1U

GND

C503A

1U

GND

3V3SB

L502

120R

GND

0.1U

C542

0.1U

C544

C541A

0.1U

R548

68R

R526

68R

GND

R519

100K

C573

4U7

C574

2U2

2U2

C575

0.1U

C576

C577

0.1U

C578

0.1U

0.1U

C579

C501A

0.1U

0.047UC506A

0.047U

C504A

68R

R547

GND

0.1U

C553

C555

0.1U

120R

L504

0.1U

C556

C554

0.1U

1V5_DDR_SOC

1V5_DDR

C541

0.1U

C545 0.1U

C570

0.1U

GND

GND

0.1UC566

GND

10UC567

C521

0.1U

C593

0.1U

2U2

C598

0R

R530

1V5_DDR_SOC

R501

4K7

3V3

R505

4K7

4K7

R504

R508

4K7

R506

47K

R503

47K

4K7

R502

C568

10U

C569

0.1U

4K7

R507

C505A

0.047U

GND

12V_M

0R

R511

Q502

BC807

C

E

B

12P

C587

KEY0

SAR1

PANEL_ON/OFF

SAR3

BRI_ADJ

PWM1

PWM2

NC

PWM_PM

SPI_CK

SPI_CZ1/GPIO_PM6

SPI_DI

SPI_DO

DDCA_CK/UART0_RX

DDCA_DA/UART0_TX

DDCR_DA

GPIO3/TX1

GPIO4/RX1

TESTPIN

POWER_DETECT

A0M__G_ODD[3]_

A0P__G_ODD[2]_

A1M__G_ODD[1]_

A1P__G_ODD[0]_

A2M__B_ODD[7]_

A2P__B_ODD[6]_

ACKM__B_ODD[5]_

ACKP__B_ODD[4]_

A3M__B_ODD[3]_

A3P__B_ODD[2]_

A4M__B_ODD[1]_

A4P__B_ODD[0]_

B0M__R_ODD[7]_

B0P__R_ODD[6]_

B1P__R_ODD[4]_

B2M__R_ODD[3]_

B2P__R_ODD[2]_

BCKM__R_ODD[1]_

BCKP__R_ODD[0]_

B3M__G_ODD[7]_

B4M__G_ODD[5]_

B4P__G_ODD[4]_

VBL_CTRL

GPIO_PM1

PWR-ON/OFF

GPIO_PM5

GPIO_PM7

GPIO_PM8

GPIO_PM11

VID0

VID1

LED0

LED1

WOL_INT_OUT

B1M__R_ODD[5]_

B3P__G_ODD[6]_

LCK

LDE

LHSYNC

LVSYNC

GPIO2

DDCR_CK

PWM

SAR

SPI

I2C

GPIO

/UART

LVDS

60Hz

PM_GPIO

U501

MSD6A828

P6

AH14

AF32

AF31

AF30

AG31

AL30

AH30

N5

AH4

AH5

R7

R6

L5

AD5

AF4

AG5

AG6

AG4

AJ12

AM29

AK29

AM31

AL31

AL32

AK31

AJ30

AJ32

AH32

AH31

AF27

AF28

AF29

AG29

AK25

AL25

AL26

AM26

AM27

AL27

AL28

AK28

AJ7

J11

AH13

AJ13

P5

AC5

AC4

AH12

AG13

AG12

AG14

AG7

T11

AG8

AH8

AJ8

AF8

AH7

AH11

AF9

NAND_ALE/EMMC_IO15/SDIO_D[1]

NAND_WPZ/EMMC_IO17/SDIO_D[2]

NAND_CEZ/EMMC_IO9

NAND_CLE/EMMC_IO14/SDIO_D[0]

NAND_REZ/EMMC_IO10

NAND_WEZ/EMMCIO16/SDIO_D[3]

NAND_RBZ/EMMC_IO11

TS1CLK

TS1SYNC

TS1VALID

TS1DATA__[0]

TS1DATA_[1]

TS1DATA_[2]

TS1DATA_[3]

TS1DATA_[4]

TS1DATA_[5]

TS1DATA_[6]

TS1DATA_[7]

TS0CLK

AL21

TS0SYNC

TS0VALID

TS0DATA_[0]

AK20

TS0DATA_[1]

TS0DATA_[2]

TS0DATA_[3]

TS0DATA_[4]

TS0DATA_[5]

TS0DATA_[6]

TS0DATA_[7]

TGPIO0

TGPIO1

TGPIO2/SCK1

TGPIO3/SDA1

IF_AGC

VIFM

VIFP

NAND_CEZ1/EMMC_IO12/SDIO_CMD

TS2_CLK

PCMDATA[6]/CI_DATA[6]

PCMIORD/CI_RD

PCMDATA[7]/CI_DATA[7]

PCMIOWR/CI_WR

PCMDATA[2]/CI_DATA[2]

PCMADR[1]/CI_A[1]

PCMADR[2]/CI_A[2]

PCMADR[10]/CI_A[10]

PCMADR[12]/CI_A[12]

PCMADR[6]/CI_A[6]

PCMADR[13]/CI_A[13]

PCMDATA[3]/CI_DATA[3]

PCMIRQA/CI_INT

PCMCD/CI_CD

PCMOEN

PCMWAIT/CIWACK

PCMADR[8]/CI_A[8]

PCMADR[11]/CI_A[11]

PCMREG/CI_CLK

PCMDATA[0]/CI_DATA[0]

PCMADR[0]/CI_A[0]

PCMDATA[1]/CI_DATA[1]

PCMADR[5]/CI_A[5]

PCMADR[3]/CI_A[3]

PCMRST/CI_RST

PCMWEN

PCMDATA[4]/CI_DATA[4]

PCMADR[9]/CI_A[9]

PCMADR[7]/CI_A[7]

PCMCEN/CI_CS

PCMADR[4]/CI_A[4]

PCMADR[14]/CI_A[14]

PCMDATA[5]/CI_DATA[5]

NAND_DQS/EMMC_IO8

TS2_D0

TS2_SYNC

TS2_VLD

NAND_AD0/EMMC_IO6

NAND_AD1/EMMC_IO7

NAND_AD2/EMMC_IO2

NAND_AD3/EMMC_IO1

NAND_AD4/EMMC_IO0

NAND_AD5/EMMC_IO3

NAND_AD6/EMMC_IO4

NAND_AD7/EMMC_IO5

EMMC_IO13/SDIO_CLK

PCM2_RESET

PCM2_WAIT_N

CI

TS1

(In/Out)

(In)

TS0PCMCIA

NAND

Front End

EMMC

TS2

D3

D1

AG15

AH15

AG16

B4

AG18

AJ22

AJ25

AH19

AG25

AG22

AH18

AH23

AH26

AJ26

AH25

AJ29

AJ28

AH28

AG27

AH21

AG23

AH24

AJ20

AH17

AJ23

AJ17

AH22

AG26

AG24

AJ19

AJ27

AH27

AH29

AG21

AG20

AH20

AG19

AF15

J5

AM7

AL7

AM6

AL4

AM4

AL1

AK8

AM21

AK22

AM22

AL22

AK23

AM19

AL19

AK21

AL20

AJ16

AM15

AK16

AK17

AL17

AK18

AL18

AM18

AL16

AK19

AM16

E3

G3

F3

G1

F1

J4

G2

U501

MSD6A828

AH16

AG17

M5

B3

A3

A2

B2

B1

C2

GIN0P

GIN0M

HSYNC0

VSYNC0

GIN1P

VSYNC1/SOGIN1

GIN2M

CVBS0

CVBS1

VCOM

CVBSOUT1

HWRESET

XIN

XOUT

IRIN

USB0_DM

USB0_DP

USB1_DM

USB1_DP

RIN0P

BIN0P

RIN1P

GIN1M

BIN1P

RIN2P

GIN2P

BIN2P

USB2_DM

USB2_DP

USB_SSTXP

USB_SSTXN

USB_DM_PSS

USB_DP_PSS

USB_SSRXP

USB_SSRXN

TN

TP

RN

RP

GPIO19/LAN_LED[0]

USB_SSTXP_1

USB_SSTXN_1

USB_DM_PSS1

USB_DP_PSS1

USB_SSRXP_1

USB_SSRXN_1

GPIO20/LAN_LED[1]

RGB

CVBS

USB3.0

PHY

USB

U501

MSD6A828

K2

AL11

AK11

AM10

AK10

AL9

AK9

K3

L3

L2

M1

M2

AM12

AL12

AL13

AM13

AK15

AL14

K1

J3

AG2

AG3

AH3

AE3

AF3

AG1

AD1

AE2

J1

J2

H3

H2

M4

AM2

AM3

N4

AF5

AF6

AE5

AF7

AH2

AF2

AF1

AE4

AD4

AD3

AD2

LINE_OUT_0L

LINE_OUT_0R

LINE_OUT_2L

LINE_OUT_2R

LINE_IN_0L

LINE_IN_0R

LINE_IN_1L

LINE_IN_1R

AUVAG

AUVRM

SPDIF_IN

SPDIF_OUT

I2S_OUT_BCK

I2S_OUT_MCK

I2S_OUT_WS

I2S_OUT_SD

RXA0N