Page 1

Specifications

ORDER NO. ITD0107005C0

D10

Wide Plasma Display

TH-42PW4

TH-42PWD4

GP4D Chassis

Power Source:

Power Consumption: 395 W (US model)

Plasma Display panel: Drive method AC type

Contrast Ratio 3000:1

Brightness Capability (Panel only) 780 cd / m

Screen size: 920 mm (W)×518 mm (H)×1056 mm

Operating condition:

Temperature 34 °F - 104 °F (0 °C - 40 °C)

Humidity 20 % - 80 %

Applicable signals:

Color System NTSC, PAL, PAL60, SECAM, Modified NTSC

Scanning format 525i (480i), 625i (575i), 525p (480p), 625

PC signals VGA display

AC120V 50/60Hz (US model)

AC220-240V 50/60Hz (Except US model)

295W (Except US model)

1.2W (stand-by condition) (US model)

1.8W (stand-by condition)

(Except US model)

0.9W (Power off condition) (US model)

1.6W (Power off condition)

(Expct US model)

42-inch, 16:9 aspect ratio

2

(As a set) 400 cd / m

(diagonal)

No. of pixels

408,960 (852 (W)×480 (H)) [2,556×480 dots]

(575p), 750p (720p), 1125/60i, 50i, 24p, 24SF

(1080/60i, 50i, 24p, 24SF) ........SMPTE 274M

VGA

SVGA, SXGA, UXGA ...... (compressed)

Horizontal scanning frequency 15.5 - 110kHz

Vertical scanning frequency 48 - 120Hz

2

Connection terminals:

AV

Video in 1.0 Vp-p (75-ohm)

S-VIDEO IN

(MINI DIN 4PIN)

AUDIO IN

(RCA PIN JACK × 2)

COMPONENT/RGB

Y/G 1.0 Vp-p/composite (75-ohm)

PB/B 0.7 Vp-p (75-ohm)

PR/R 0.7 Vp-p (75-ohm)

HD 1.0 - 5.0 Vp-p (high impedance)

VD 1.0 - 5.0 Vp-p (high impedance)

AUDIO IN

(RCA PIN JACK×2)

PC

(HIGH-DENSITY

D-SUB15PIN)

AUDIO IN (M3.5 JACK) 0.5Vrms (high impedance)

SERIAL

EXTERNAL CONTROL

TERMINAL (D-SUB9PIN)

SPEAKERS (External

speakers)

Dimensions (W×H×D): 40.2” (1020 mm)24” (610mm) 3.5” (89 mm)

Weight (Mass) approx. 65.0 Ibs (29.0 kg) (main unit only)

Y: 1 Vp-p (75-ohm), C: 0.286 Vp-p

(75-ohm)

0.5 Vrms (high impedance)

0.7 Vp-p/non-composite (75-ohm)

0.5 Vrms (high impedance)

R,G,B/0.7 Vp-p (75-ohm)

HD, VD/1.0 - 5.0 Vp-p (high

impedance)

RS-232C COMPATIBLE

6Ω 8W×2 (10% THD)

approx. 74.3 Ibs (33.2kg) (with speakers)

© 2001 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

TH-42PW4 / TH-42PWD4

CONTENTS

Page Page

1 Safety Precautions 4

1.1. General Guidelines

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

3 PCB Structure sheet of GP4D chassis

4 Service Hint

5 Location of Lead Wiring

6 Adjustment Procedure

6.1. +B Set-up

6.2. Driver Set-up

6.3. Initialization Pulse Adjust

6.4. P.C.B. (Printed Circuit Board) exchange

6.5. Adjustment Volume Location

6.6. Test Point Location

7 Serviceman mode

7.1. CAT (computer Aided Test) mode

7.2. IIC mode structure (following items value is sample data.)

8 Alignment

8.1. NTSC panel white balance

8.2. PAL/SECAM panel white balance

8.3. Pedestal setting

8.4. PC/RGB panel white balance

8.5. HD/ 525i /525p panel white balance

8.6. 625i panel balance

8.7. Sub brighness setting

9 Trouble shooting guide

9.1. Self Check

9.2. No Power (US model)

9.3. No Power (Except US)

9.4. No Picture

9.5. Local screen failure

9.6. D-Board

10 Option Setting

11 IC Block Diagram

12 Conductor Views

12.1. F-Board

12.2. P-Board (US model)

12.3. P1-Board (Except US)

12.4. P3, P5, P6, P7 and P8-Board (Except US)

12.5. HX-Board

12.6. H-Board (Option TY-42TM4H)

12.7. HY-Board (Option TY-42TM4Y)

12.8. HZ-Board (Option TY-42T\M4Z)

10

11

11

11

12

12

14

15

15

16

18

19

21

23

24

26

26

27

28

29

29

30

32

35

37

37

38

41

44

46

47

49

51

4

5

6

7

8

9

9

9

12.9. J-Board 53

12.10. D-Board

12.11. C1, C2, C3 and C4-Board

12.12. SC-Board

12.13. SU and SD-Board

12.14. SS, SS2 and SS3-Board

12.15. H3, S1 and V1-Board

13 Block and Schematic Diagrams

13.1. Schematic Diagram Notes

13.2. Main Block (US model) Diagrams

13.3. Main (Except US) Block Diagram

13.4. Power (US model) Block Diagram

13.5. P-Board (US model) Schematic Diagrams

13.6. Power (Except US) Block Diagram

13.7. P1-Board (Except US) Schematic Diagrams

13.8. F and P3-Board (Except US) Schematic Diagram

13.9. P5, P6, P7 and P8-Board (Except US) Schematic diagram

13.10. HX and H Block Diagram

13.11. HX-Board Schematic Diagrams

13.12. H-Board (Option TY-42TM4H) Schematic Diagram

13.13. HY and HZ Block Diagrams

13.14. HY-Board (1/2) (Option TY-42TM4Y) Schematic Diagrams

13.15. HY-Board (2/2) (Option TY-42TM4Y) Schematic Diagrams

13.16. HZ-Board (1/2) (Option TY-42TM4Z) Schematic Diagram

13.17. HZ-Board (2/2) (Option TY-42TM4Z) Schematic Diagram

13.18. J-Board Block Diagrams

13.19. J-Board (1/5) Schematic Diagrams

13.20. J-Board (2/5) Schematic Diagrams

13.21. J-Board (3/5) and H3-Board Schematic Diagrams

13.22. J-Board (4/5) Schematic Diagrams

13.23. J-Board (5/5) Schematic Diagrams

13.24. D-Block Diagrams

13.25. D-Board (1/14) Schematic Diagrams

13.26. D-Board (2/14) Schematic Diagrams

13.27. D-Board (3/14) Schematic Diagrams

13.28. D-Board (4/14) Schematic Diagrams

13.29. D-Board (5/14) Schematic Diagrams

13.30. D-Board (6/14) Schematic Diagrams

13.31. D-Board (7/14) Schematic Diagrams

55

58

60

63

65

68

69

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

2

Page 3

13.32. D-Board (8/14) Schematic Diagrams 101

13.33. D-Board (9/14) Schematic Diagrams

13.34. D-Board (10/14) Schematic Diagrams

13.35. D-Board (11/14) Schematic Diagrams

13.36. D-Board (12/14) Schematic Diagrams

13.37. D-Board (13/14) Schematic Diagrams

13.38. D-Board (14/14) Schematic Diagrams

13.39. C1-Board Schematic Diagrams

13.40. C2-Board Schematic Diagrams

13.41. C3-Board and V1-Board Schematic Diagrams

13.42. C4-Board Schematic Diagrams

13.43. SC-Board Block Diagrams

13.44. SC-Board (1/2) Schematic Diagrams

13.45. SC-Board (2/2) Schematic Diagrams

13.46. SU/SD Block Diagram

103

104

105

106

107

108

109

110

111

112

113

114

115

116

13.47. SU-Board Schematic Diagrams

13.48. SD-Board Schematic Diagrams

13.49. SS-Board Block Diagrams

13.50. SS, SS2, SS3 and S1-Board Schematic Diagrams

14 Parts Location

15 Mech anica l Replaceme nt Parts List

15.1. US model

15.2. Except US model

16 Repla ceme nt Parts List

16.1. Relpacement Parts List Notes

16.2. US model Electrical Replacement Parts List

16.3. Expect US model Electrical Replacement Parts List

16.4. Option (TY-42TM4H) Replacement Parts List

16.5. Option (TY-42TM4Y) Replacement Parts List

16.6. Option (TY-42TM4Z) Replacement Parts List

TH-42PW4 / TH-42PWD4

117

118

119

120

121

123

123

123

126

126

127

145

166

167

170

3

Page 4

TH-42PW4 / TH-42PWD4

1 Safety Precautions

1.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

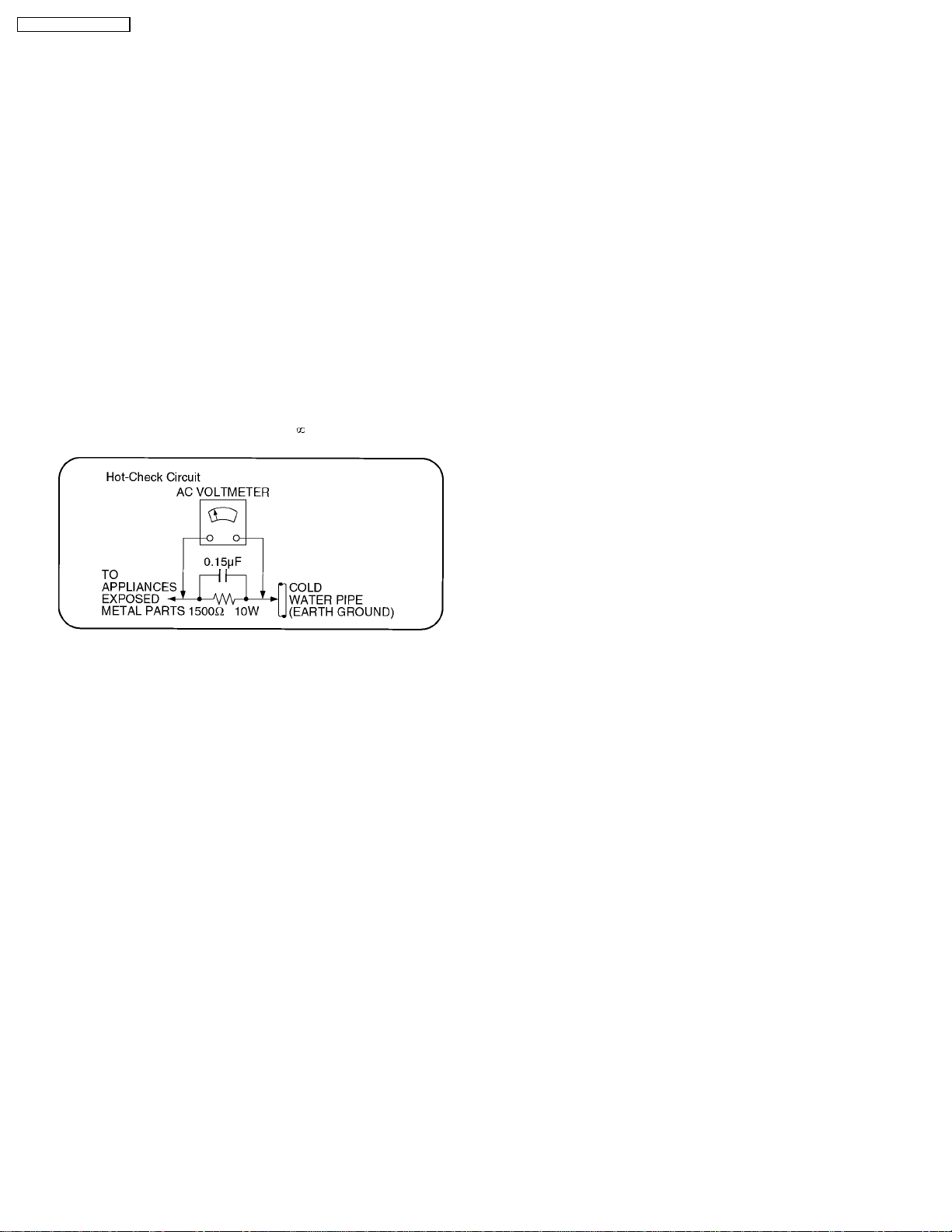

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two

prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the equipment such as screwheads, connectors,

control shafts, etc. When the exposed metallic part has a

return path to the chassis, the reading should be between

1MΩ and 5.2MΩ.

When the exposed metal does not have a return path to

the chassis, the reading must be

.

Figure 1

1.1.2. Leakage Current Hot Check (See

Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use an

isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF

capacitors, between each exposed metallic part on the set

and a good earth ground such as a water pipe, as shown in

Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the ACplugin the ACoutlet and repeat each of the

above measurements.

6. The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks, leakage

current must not exceed 1/2 milliamp. In case a

measurement is outside of the limits specified, there is a

possibility of a shock hazard, and the equipment should be

repaired and rechecked before it is returned to the

customer.

4

Page 5

TH-42PW4 / TH-42PWD4

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on aconductive surface such as alminum

foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, alminum foil or comparable

conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ESdevices. (Otherwise hamless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to

damage an ES device).

5

Page 6

TH-42PW4 / TH-42PWD4

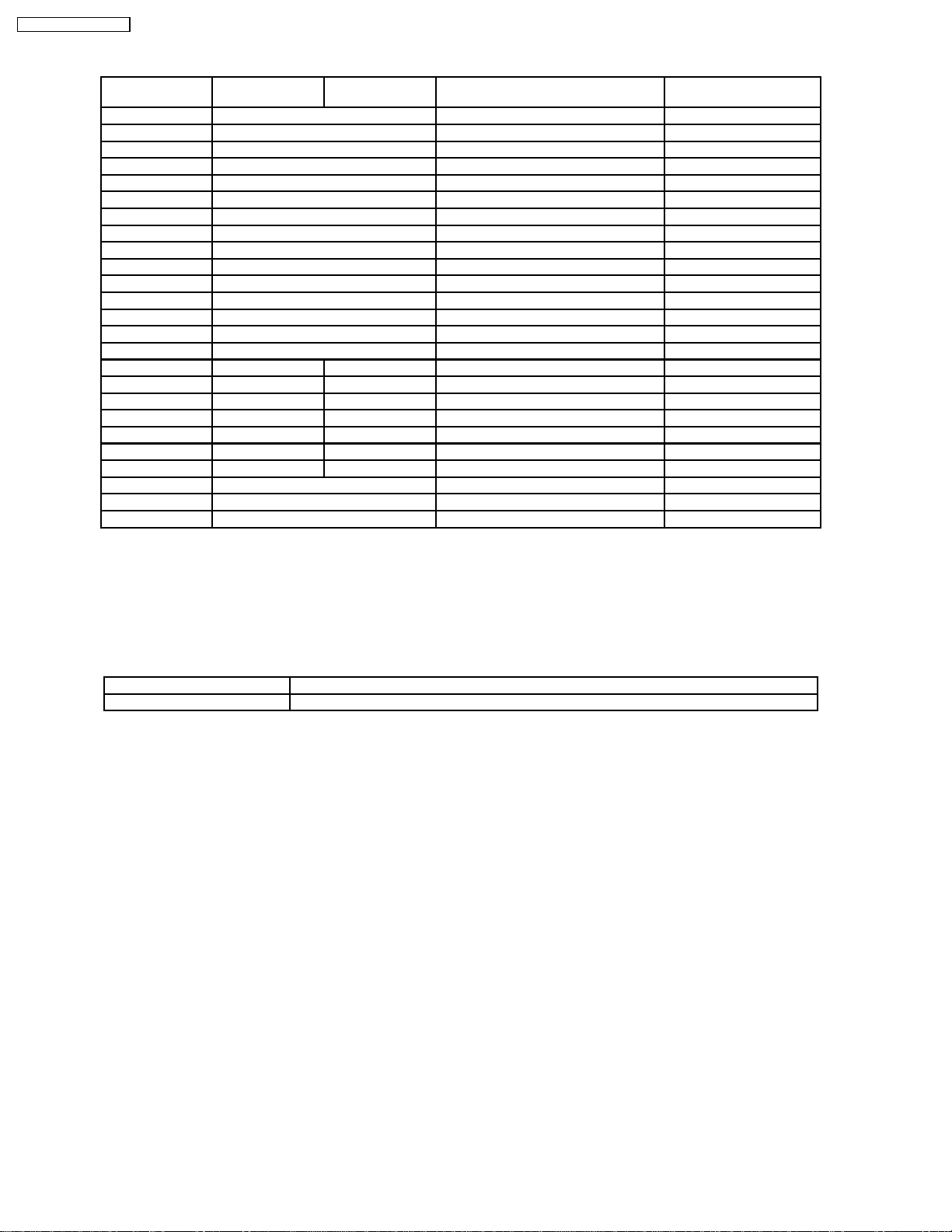

3 PCB Structure sheet of GP4D chassis

Board Name US model

Parts Number

D TZTNP01JCSE Digital process & control 1, 4

J TNPA2244 Separator / Audio Out 1

SS TNPA2262 Scan out 1

SC TNPA2261 Scan out 1

SU TNPA2259 Sustain connection (Upper) 1

SD TNPA2260 Sustain connection (Lower) 1

C1 TNPA2253 Data Drive (Upper Left)

C2 TNPA2254 Data Drive (Upper Right)

C3 TNPA2255 Data Drive (Lower Right)

C4 TNPA2256 Data Drive (Lower Left)

H3 TNPA2249 Speaker terminal

S1 TNPA2283 Power switch

SS2 TNPA2263 Sustain connection (Upper)

SS3 TNPA2264 Sustain connection (Lower)

V1 TNPA2282 Front SW. & Remote receiver

F TXN/F10JAS TXN/F1JASE Line filter

P TXN/P10JAS TXNP11JASE Power supply 1

P3 ---- TNPA1777 Drive voltage oscillator

P5 ---- TNPA1778 Primary oscillator

P6 ---- TNPA1779 PFC oscillator

P7 ---- TNPA1780 Drive voltage protection

P8 ---- TNPA1781 Process voltage protection

HX TZTNP020JAS PC_type_Input terminal

HY TNPA2245 BNC_type_Input terminal 2

HZ TNPA2248 RCA type_Input terminal 3

except US model

Parts Number

Function Remarks

Remarks

1. Recommend PCB´s for initial service for GP4D chassis.

2. For System model except UK, Europe

3. For Consumer model except UK, Europe

4. Parts number of System model is TZTNP01JASE

Note:

US model TH-42PW4UZ, TH-42PW D4UY

Except US model TH-42PW4AZ/B X/EX/HZ/RZ, TH-42PWD4AY/BX/EX/HY/RY

6

Page 7

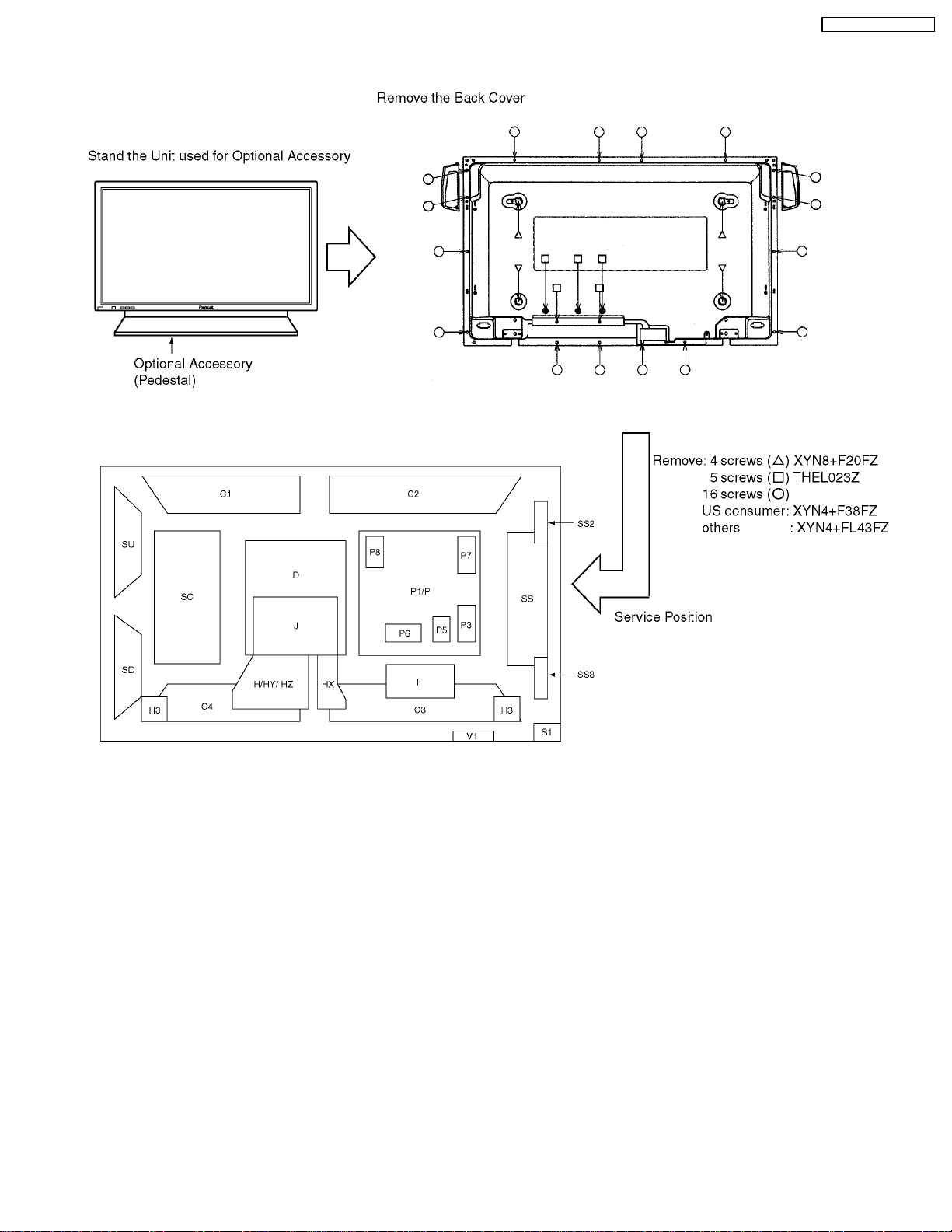

4 Service Hint

TH-42PW4 / TH-42PWD4

7

Page 8

TH-42PW4 / TH-42PWD4

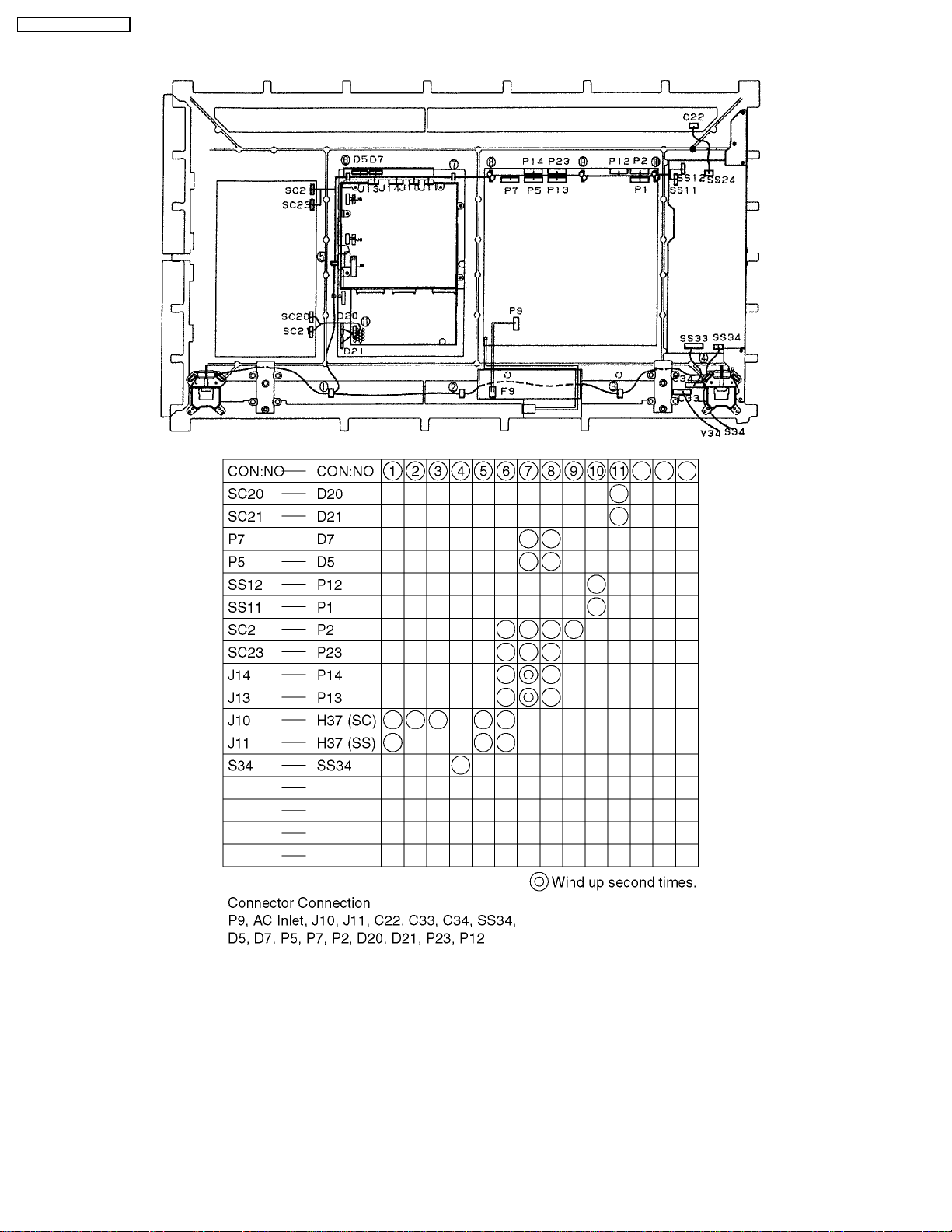

5 Location of Lead Wiring

8

Page 9

6 Adjustment Procedure

TH-42PW4 / TH-42PWD4

6.1. +B Set-up

6.1.1. Item / Preparation

1. Input a Grey scale signal.

2. Set the picture controls: Picture mode: Normal

White balance: Normal

6.1.2. Adjustments

Adjust and confirm indicated test point for the specified voltage.

Adjust

Test point Voltage Volume Name

P4 pin 1 (Hot) 400V ±1V R426 (P1)

Except US

P1 pin 3 170V ±1V R476 (P) US model Vsus

R625 (P3)

Expect US

P2 pin 3 160V ±1V R505 (P) US model Vbk

R498 (P1)

Except US

P12 pin 1 67V ±0.5V R473 (P) US model Vda

R519 (P1)

Except US

Confirm

Test point Voltage Volume Name

P23 pin 2 15V ±0.5V +15V

P5 pin 1 13.5V ±0.5V +13V

P13 pin 1 13.5V ±0.5V Audio 15V

P13 pin 3 -13.5V ±0.5V Audio -15V

P5 pin 5 5.1V ±0.3V 5V

P7 pin4 5V ±0.2V STB5V (1)

P14 pin 8 5.0V ±0.3V STB5V (2)

P10 pin 1 17.0V ±0.5V FAN +B

P10 pin 4 5.1V ±0.3V FAN 5V

PFC

6.2. Driver Set-up

6.2.1. Item / Preparation

1. Input an APL 100 % white signal.

2. Set the picture controls: Picture mode: Normal

White balance: Cool

Aspect: 16:9

6.2.2. Adjustments

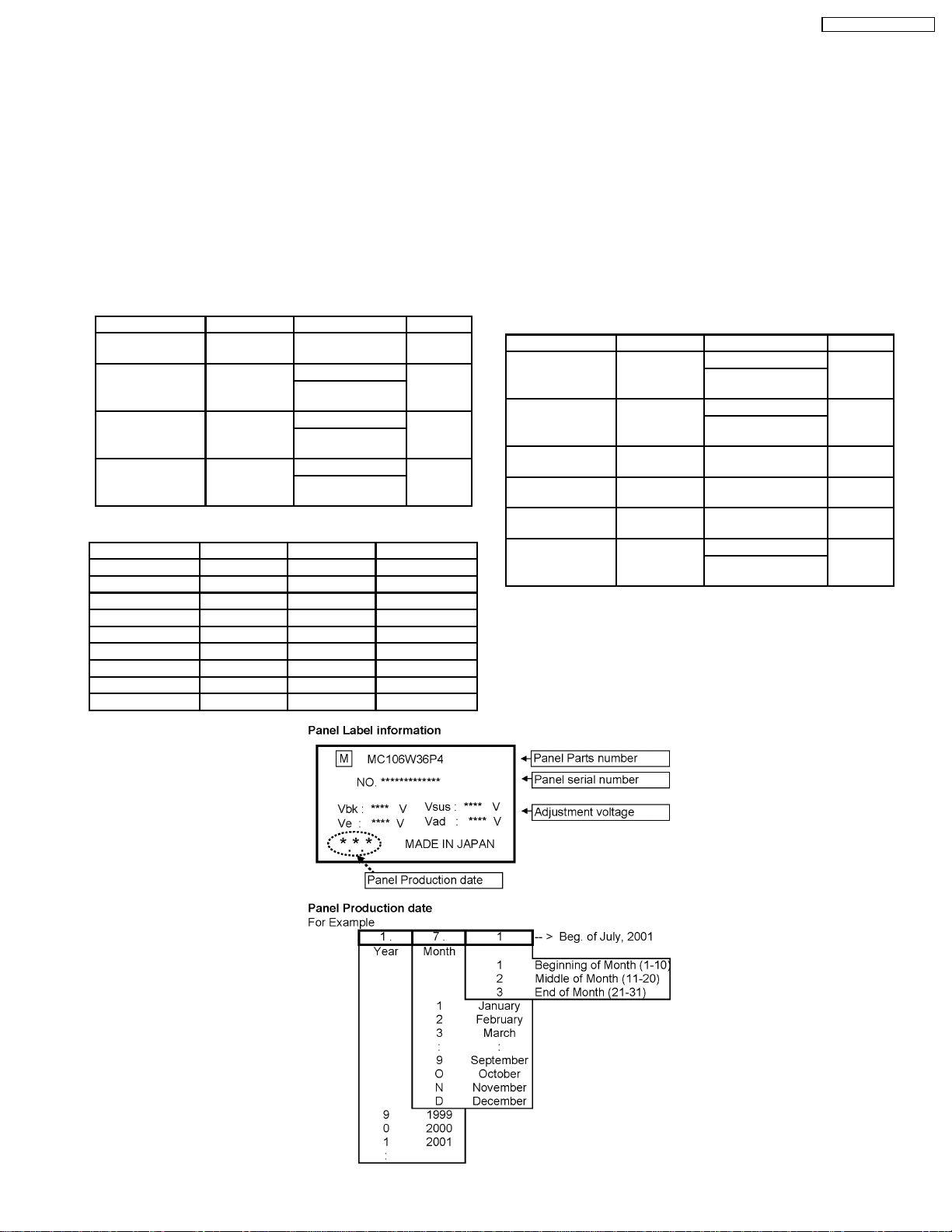

Adjust driver section voltages referring the panel data on the

panel data label.

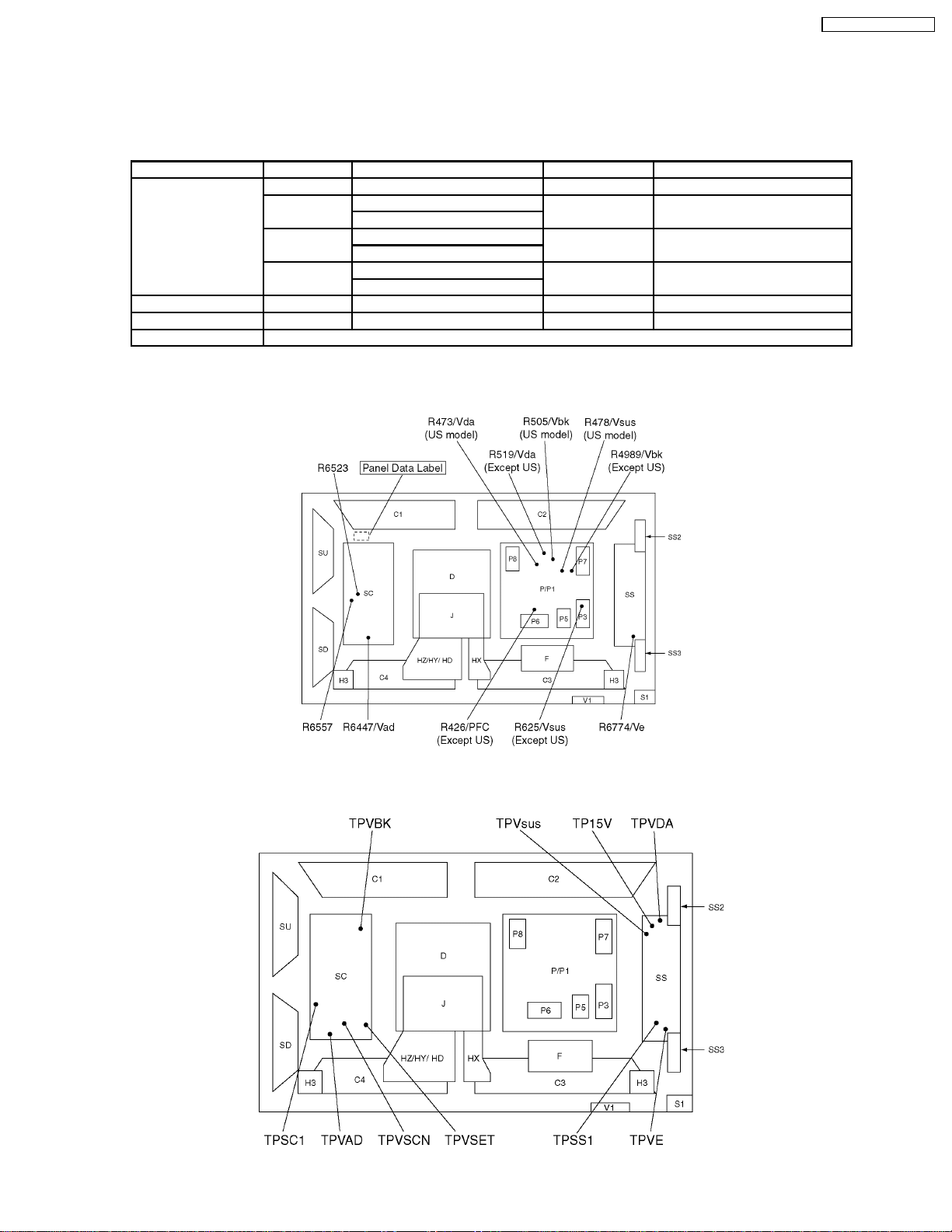

Test point Voltage Volume Name

TPVSUS

(SS-BOARD)

TPVBK

(SC-BOARD)

TPVE

(SS-BOARD)

TPVSET

(SC-BOARD)

TPVAD

(SC-BOARD)

TPVDA

(SC-BOARD)

*See the Panel label.

Vsus ±1V* R478 (P) US model Vsus

R625 (P3)

Except US

Vbk ±1V* R505 (P) US model Vbk

R498 (P1)

Except US

Ve ± 1V* R6774 (SS) Ve

218 V ±6V --- Vset

Vad ±1V* R6477 (SC) Vad

67V±1V R473 (P) US model Vda

R519 (P1)

Except US

9

Page 10

TH-42PW4 / TH-42PWD4

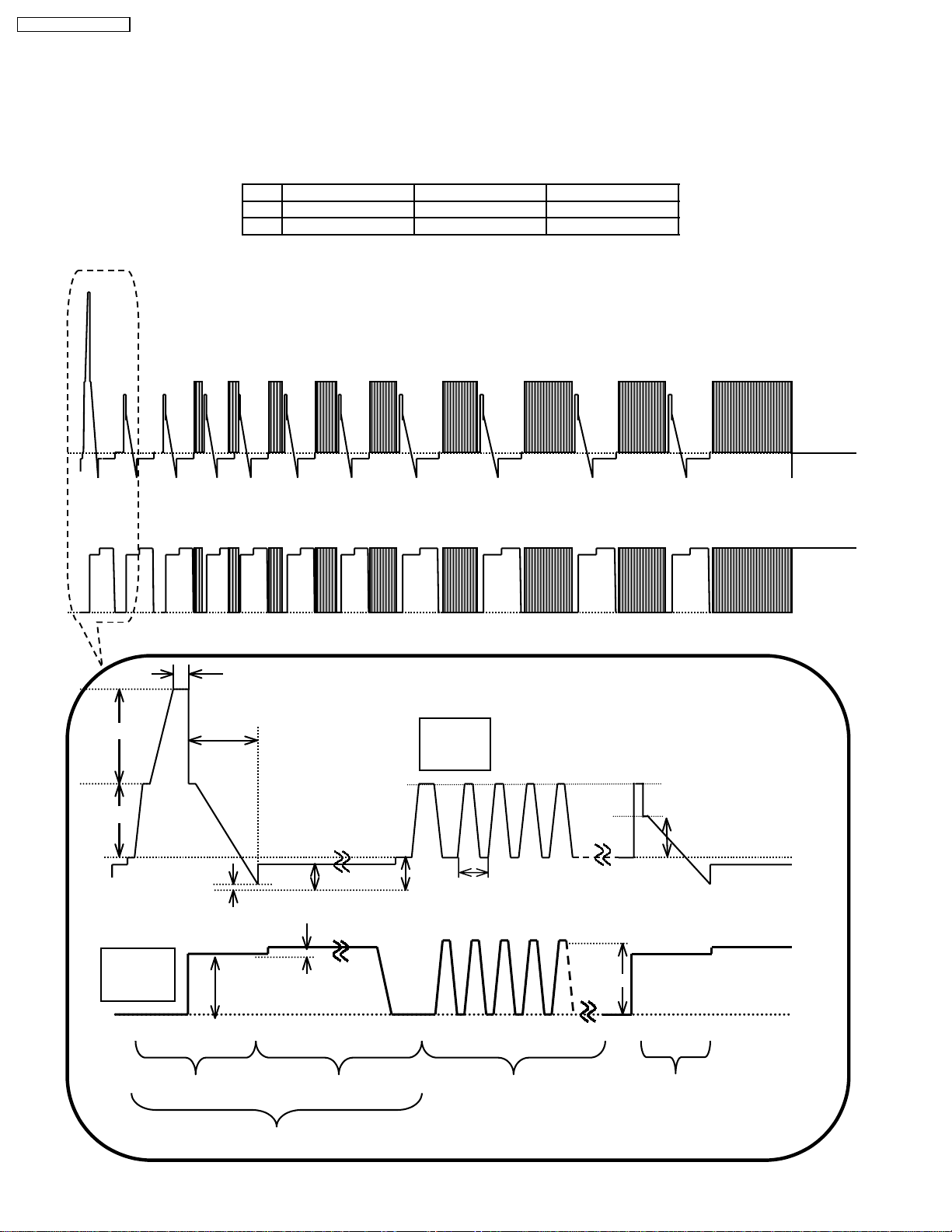

6.3. Initialization Pulse Adjust

1. Input a Cross hatch signal.

2. Set the picture controls: Picture mode: Normal

White balance: Cool

Adjust the indicated test point for the specified wave form.

Test point Volume Level

T1 TPSC1 (SC) R6523 (SC) 20 ± 15µ Sec

T2 TPSC1 (SC) R6557 (SC) 170 ± 20µ Sec

TPSC1 SCAN OUTPUT

TPSS1 SUSTAIN OUTPUT

T1 20±15µs

VSET

T2 170±20µs

Scan

TPSC1

VSUS VBK

VSCN VAD

VSET2

6µs

VSUS

Sustain

TPSS1

INITIALIZE SCAN PRE-INITIALIZE

VE

ADDRESS PERIOD

VE2

SUSTAIN

10

VSUS

Page 11

6.4. P.C.B. (Printed Circuit Board) exchange

6.4.1. Caution

1. To remove P.C.B. , wait 1 minute after power was off for discharge from electrolysis capacitors.

6.4.2. Quick adjustment after P.C.B. exchange

P.C.B. Item Volume Test point Level

P board PFC R426 (3) Except US P4 connector pin 1 400V ± 1 V

Vsus R478 (P) US model TPVsus (SS) 175V ± 1 V

R625 (P3) Except US

Vbk R505 (P) US model TPVBK (SC) 160V ± 5 V

R498 (P1) Except US

Vda R473 (P) US model TPVDA (SS) 67V ± 1 V

R519 (P1) Except US

SC board Vad R6477 TPVAD (SC) -90 ± 1 V

SS board Ve R6774 TPVE (SS) 150 ± 1 V

D board White balance, Pedestal and Sub brightness for NTSC, PAL, HD, PC and 625I signals.

6.5. Adjustment Volume Location

TH-42PW4 / TH-42PWD4

6.6. Test Point Location

11

Page 12

TH-42PW4 / TH-42PWD4

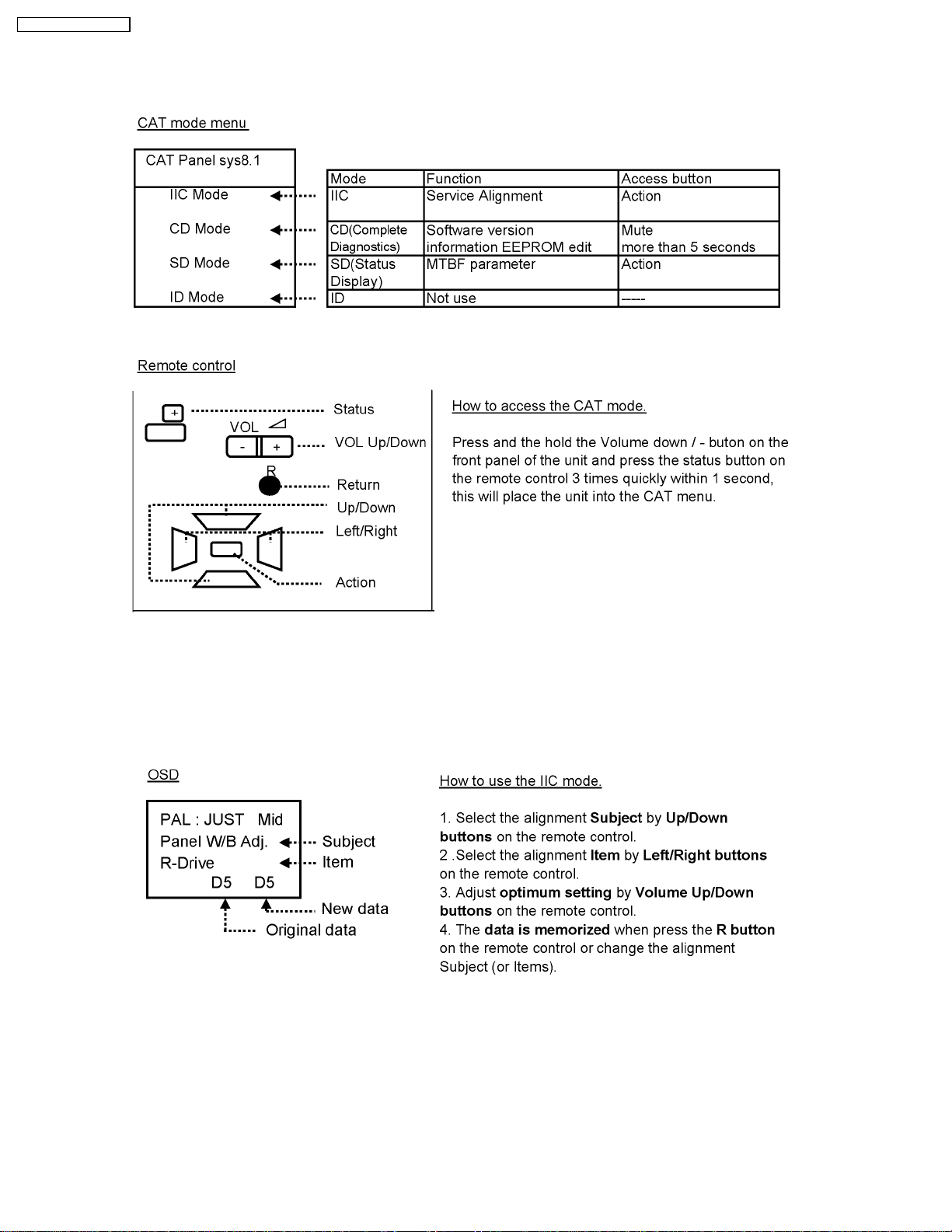

7 Serviceman mode

7.1. CAT (computer Aided Test) mode

To exit the CAT mode, access the ID mode and switch off the main power.

7.1.1. IIC mode

Select the IIC mode by Up/Down button on the remote control at the front page of CAT mode then press the Action button on

the remote control.

Subject and item are mentioned on page 14.

To exit the IIC mode, press the R button on the remote control.

12

Page 13

TH-42PW4 / TH-42PWD4

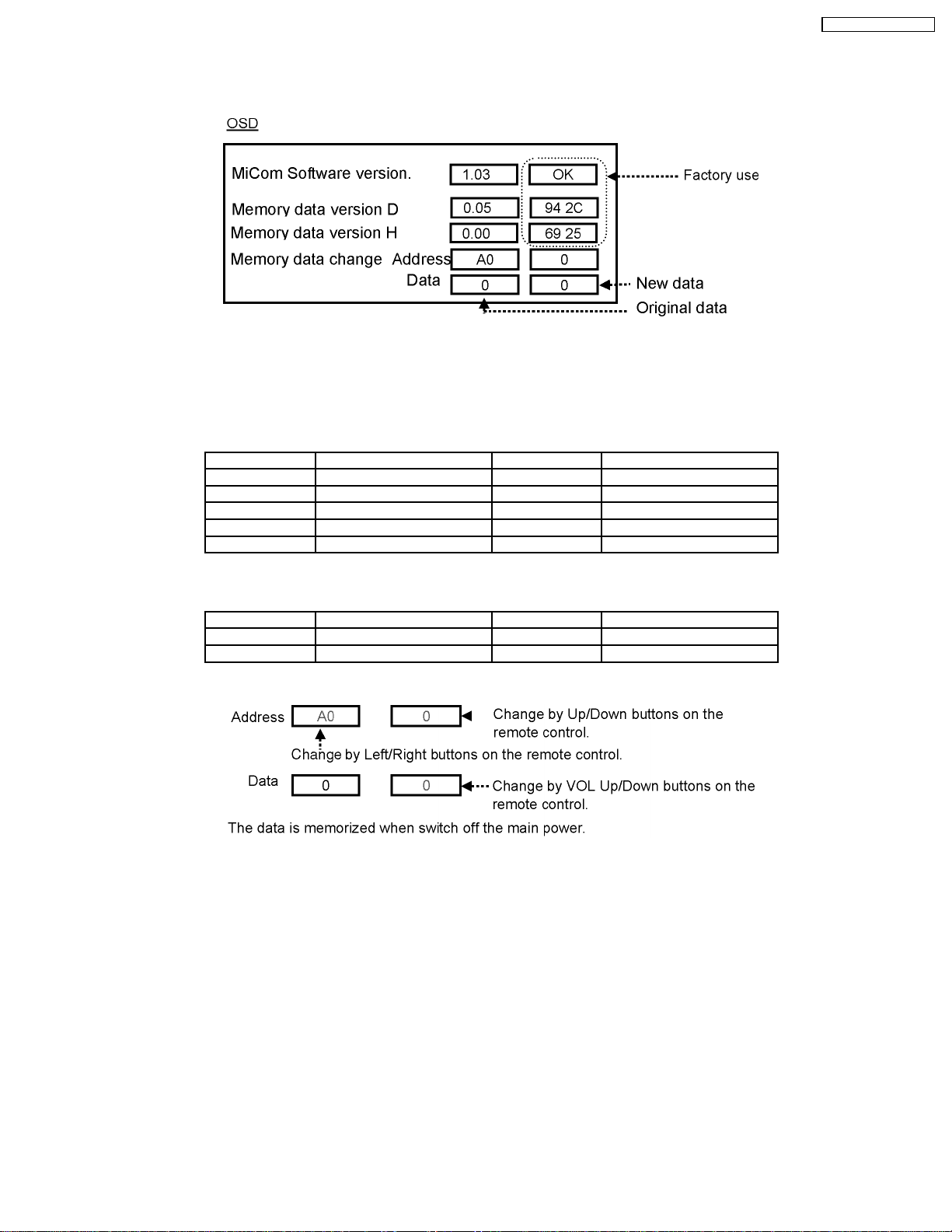

7.1.2. CD mode

Select the CD mode by Up/Down button on the remote control at the front page of CAT mode then press the Mute button on the

remote control more than 5 sec.

Micom software version ( IC9705 / TVRJ562), this version can be upgrade by

1. replace of new version IC

2. Loading the new version software from loader tool, TZSC07036.

Memory data version D (IC9706 /TVRJ601) in the D board

Version Model Type Destination

3.** PW4UZ Consumer USA

4.** PWD4UY System USA

5.** PW4BX,HZ, Consumer U.K.H.K.,

6.** PWD4AY,BX, EX, HY, RY System U.K. / Euro / Australia

7.** PW4AZ, EX, RZ Consumer Euro / Australia

Memory data version H (IC3699) in the H board

This version is difference depends on the H board type.

Version Type of H borad Version Type of H borad

1.** HY (BNC) 3.** HD (DVI)

2.** HZ (RCA) 4.** H (tuner)

Memory data change

To exit the CD mode, press the R button on the remote control.

13

Page 14

TH-42PW4 / TH-42PWD4

7.1.3. SD mode

Select the SD mode by Up/Down button on the remote control at the front page of CAT mode then press the Action button on the

remote control.

To exit the SD mode, press the R button on the remote control.

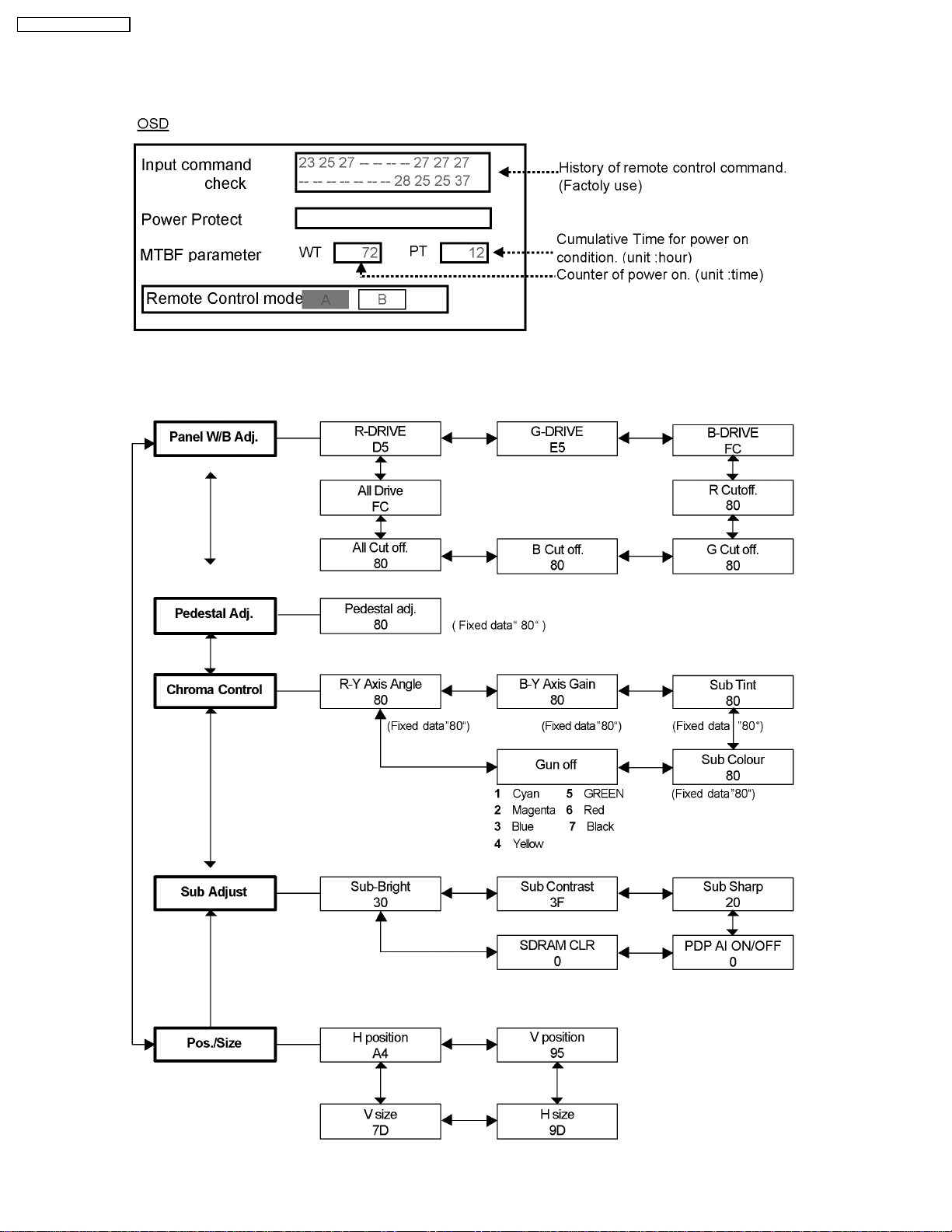

7.2. IIC mode structure (following items value is sample data.)

14

Page 15

8 Alignment

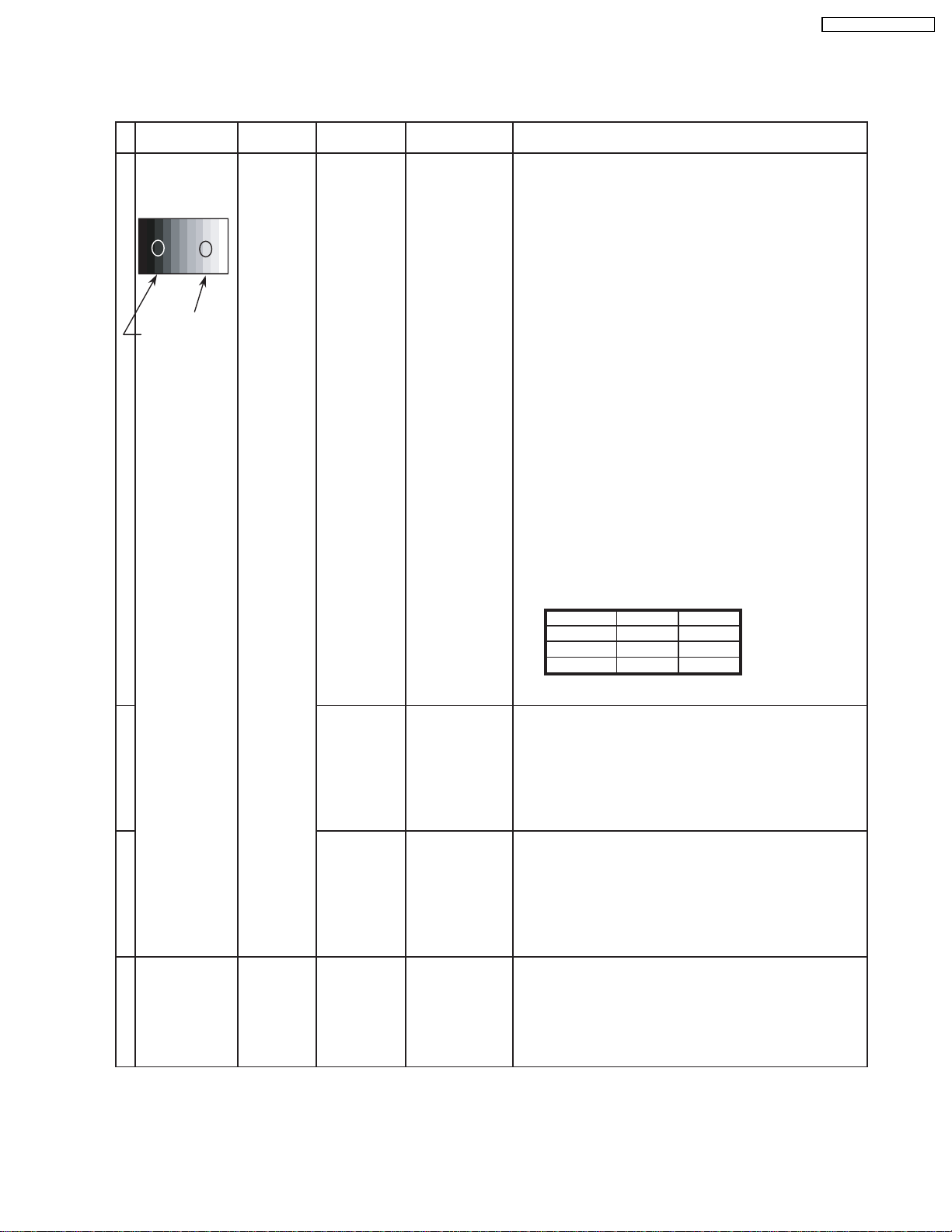

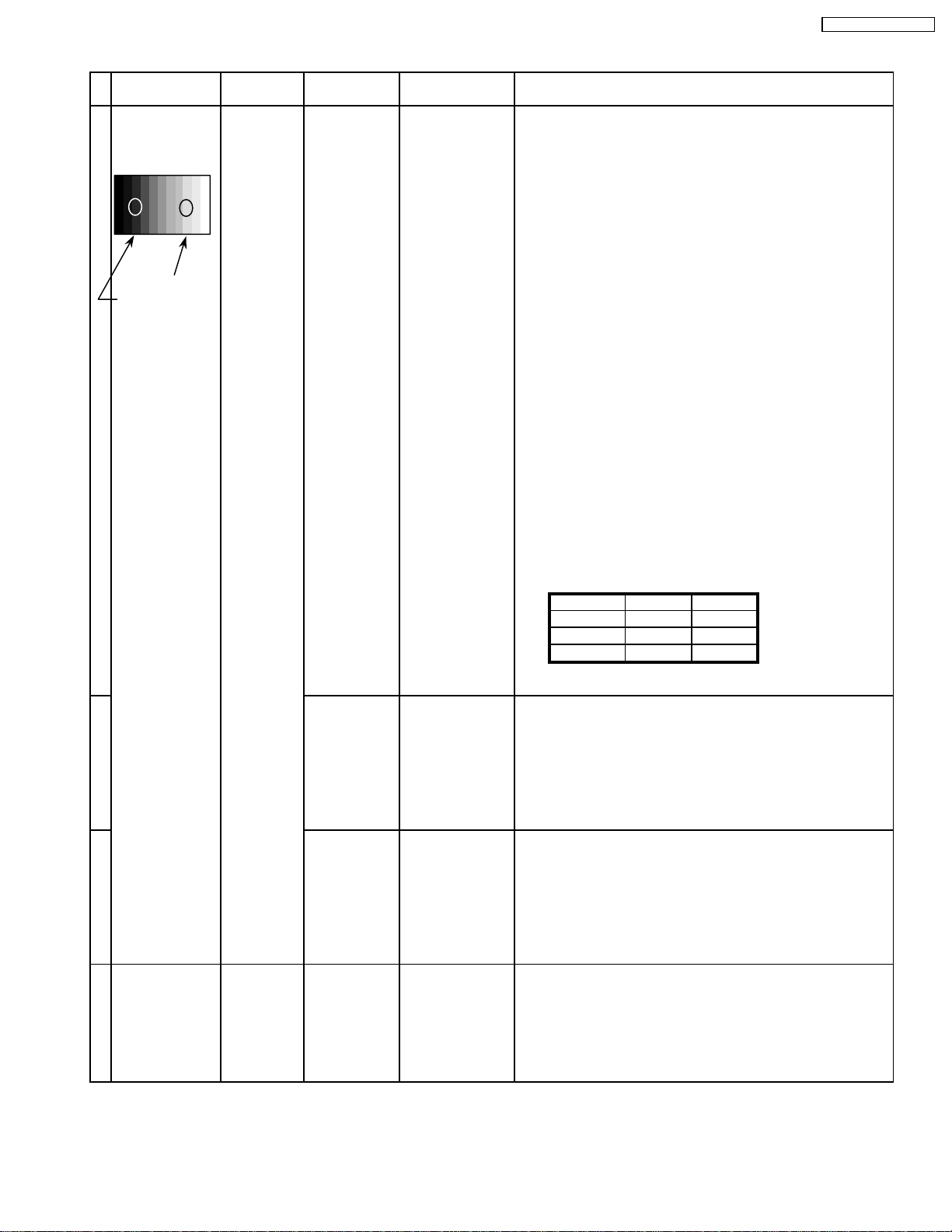

8.1. NTSC panel white balance

INPUT Alignment menu ProcedureEquipment Setting

1 NTSC Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off shown Fig.-01.

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

PANEL W/B

PANEL W/B

exactly.

2

to 10 cd/m

6)Find 75% of white area by color sensor.

G Drive 7) Set G Drive to " D8 ".

B Drive 8) Adjust B and R Drive to set color temperature

R Drive as shown Fig.-01.

.

TH-42PW4 / TH-42PWD4

2

9) Repeat item 4) to 7) to set both Low light and

high light.

PANEL W/B

R,G,B Drive 10) Increase same steps of R, G and B Drive to set

R,G,B Drive largest level of 3 color drive to "FC".

PANEL W/B

R,G,B cut off 11) Re-adjust Low light level again.

Color Temp. x y

Cool(Hi) 0.272 0.290

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -01

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal

PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Warm".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm

PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

Note:

OSD is the difference between US model and Except US model.

Picture:Normal (Except US)/Standard (US model)

White balance (Except US)/Color Temp (US model)

15

Page 16

TH-42PW4 / TH-42PWD4

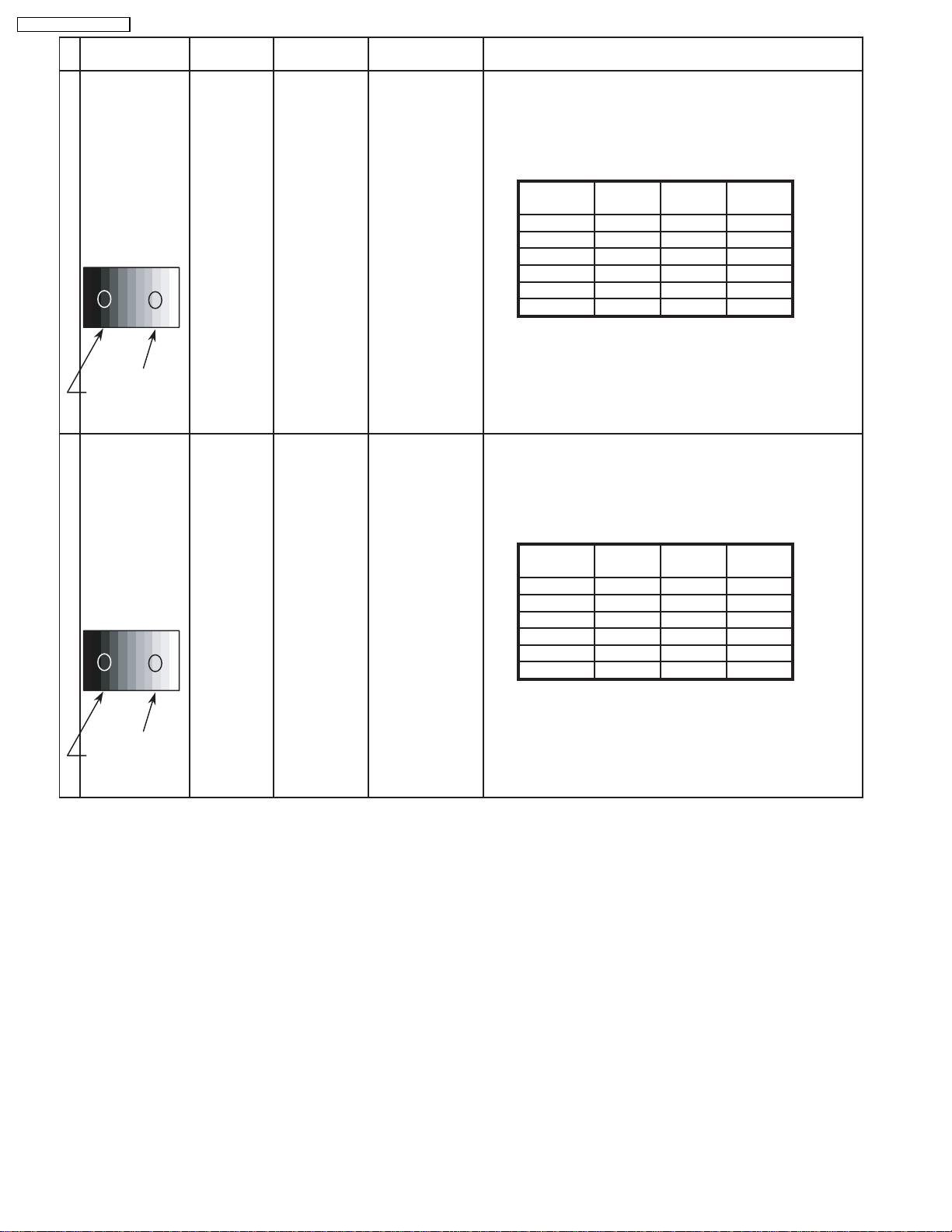

8.2. PAL/SECAM panel white balance

INPUT Alignment menu ProcedureEquipment Setting

1 PAL Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool exactly.

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

PANEL W/B

PANEL W/B

PANEL W/B

PANEL W/B

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off shown Fig.-02.

to 10 cd/m

2.

6)Find 75% of white area by color sensor.

G Drive 7) Set G Drive to " D8 ".

B Drive 8) Adjust B and R Drive to set color temperature

R Drive as shown Fig.-02.

9) Repeat procedure 4) to 7) to set both Low light and

high light.

R,G,B Drive 10) Increase same steps of R, G and B Drive to set

R,G,B Drive largest level of 3 color drive to "FC".

R,G,B cut off 11) Re-adjust Low light level again.

2

Color Temp. x y

Cool(Hi) 0.272 0.290

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -02

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Warm".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

16

Page 17

TH-42PW4 / TH-42PWD4

Alignment menu ProcedureEquipment Setting

5 Picture: 1) Write down each color temaparature of R,G,B drive and

Normal Cut off data as follows.

Aspect:

16:9

White

White balance:

Cool

Normal

Warm

Balance Cool Normal Warm

R Drive

G Drive

B Drive

R Cut off

G Cut off

B Cut off

SECAM signal 2) Input SECAM signal.

3) Copy PAL R,G,B drive and cut off data of each white

balance mode to SECAM position.

17

Page 18

TH-42PW4 / TH-42PWD4

8.3. Pedestal setting

INPUT Alignment menu ProcedureEquipment Setting

1 Component Picture: PANEL W/B

(525i, 525p, 625i, Normal R cut off 1) Set R,G and B cut off to "

720i or 1080i) White balance: G cut off

Gray Scale Aspect:

Pattern 16:9

Black 2 %

Black 0 % at black 2% area and no emission at black 0% area.

Cool B cut off

Chroma Control:

Gun off

RGB Sub Adjust:

G Sub Bright

Chroma Control:

Gun off

RGB Sub Adjust:

B Sub Bright

Chroma Control:

Gun off

RGB Sub Adjust:

R Sub Bright

** Adjust at the dark room.

80 ".

2) Set Gun off to "

3) Adjust G Sub bright to start some of green pixels emission

at black 2% area and no emission at black 0% area.

4) Set Gun off to "

5) Adjust B Sub bright to start some of blue pixels emission

6) Set Gun off to "

7) Adjust R Sub bright to start some of red pixels emission

at black 2% area and no emission at black 0% area.

5". (Only green pixels can emit.)

3". (Only blue pixels can emit.)

6". (Only red pixels can emit.)

2 RGB(PC) Picture: 1) Change input to RGB signal.

Gray Scale Normal PANEL W/B

Pattern White balance: R,G,B cut off 2) Repeat procedure 1) to 7) of Component input signal.

Cool PANEL W/B

Aspect: R,G,B Drive

16:9

Black 2 %

Black 0 %

18

Page 19

8.4. PC/RGB panel white balance

INPUT Alignment menu ProcedureEquipment Setting

1 PC Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool exactly.

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off shown Fig.-03.

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

to 10 cd/m

6)Find 75% of white area by color sensor.

PANEL W/B

G Drive 7) Set G Drive to " D8 ".

PANEL W/B

B Drive 8) Adjust B and R Drive to set color temperature

R Drive as shown Fig.-03.

9) Repeat item 4) to 7) to set both Low light and

high light.

PANEL W/B

R,G,B Drive 10) Increase same steps of R, G and B Drive to set

R,G,B Drive largest level of 3 color drive to "FC".

PANEL W/B

R,G,B cut off 11) Re-adjust Low light level again.

2

.

TH-42PW4 / TH-42PWD4

2

Color Temp. x y

Cool(Hi) 0.272 0.290

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -03

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Warm".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

19

Page 20

TH-42PW4 / TH-42PWD4

5 Picture: 1) Write down each color temaparature of R,G,B drive and

RGB

Gray Scale

Pattern

High light 75%

Low light 15% 3) Copy PC R,G,B drive and cut off data of each white

6 Picture: 1) Write down each color temaparature of R,G,B drive and

INPUT Alignment menu ProcedureEquipment Setting

Normal Cut off data as follows.

Aspect:

White balance:

Normal G Drive

Normal Cut off data as follows.

Aspect:

16:9

White

Balance Cool Normal Warm

Cool R Drive

Warm B Drive

R Cut off

G Cut off

B Cut off

2) Input RGB signal.

balance mode to RGB position.

16:9

White

DVI

Gray Scale

Pattern

White balance:

Cool R Drive

Normal G Drive

Warm B Drive

Balance Cool Normal Warm

R Cut off

G Cut off

B Cut off

2) Input DVI signal.

High light 75%

Low light 15% 3) Copy PC R,G,B drive and cut off data of each white

balance mode to DVI position.

20

Page 21

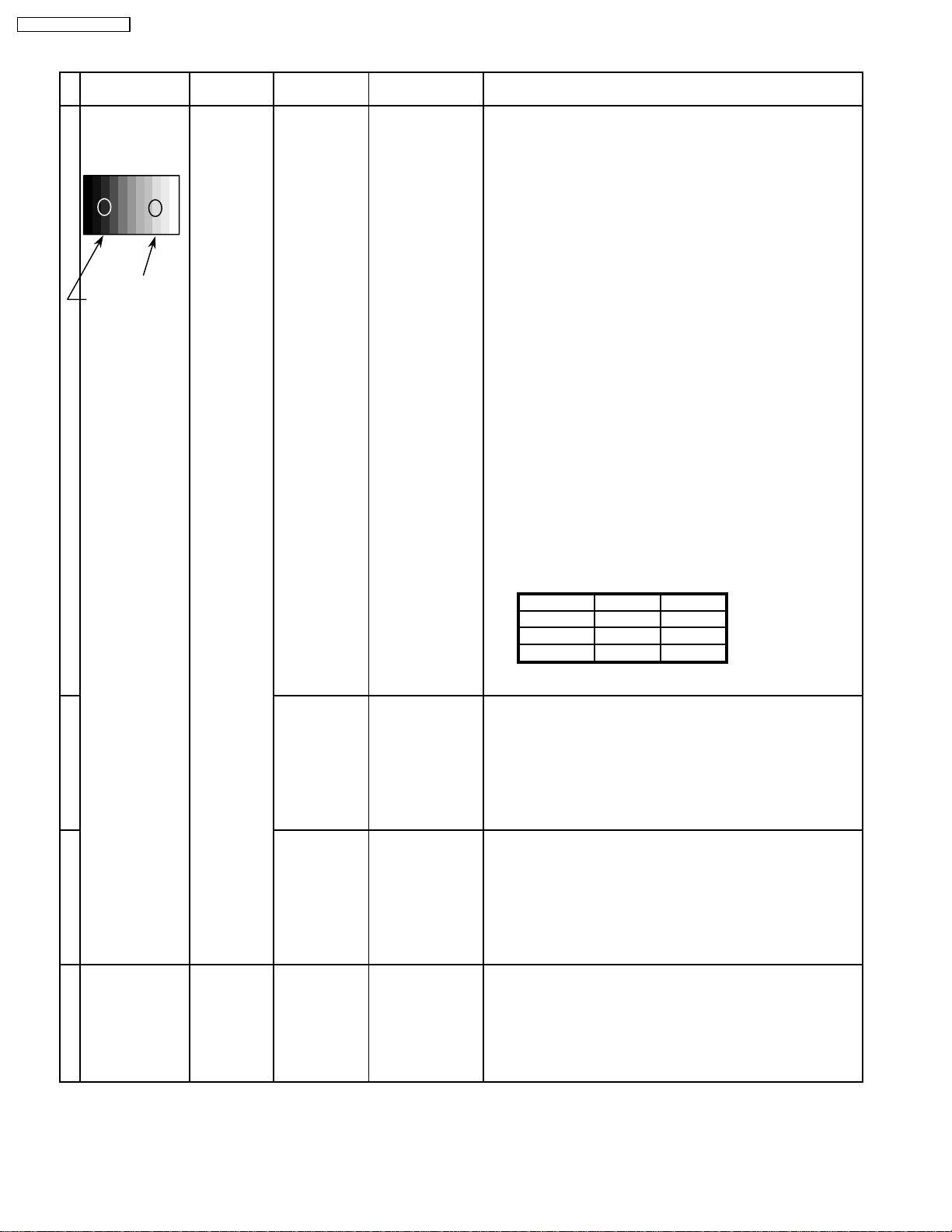

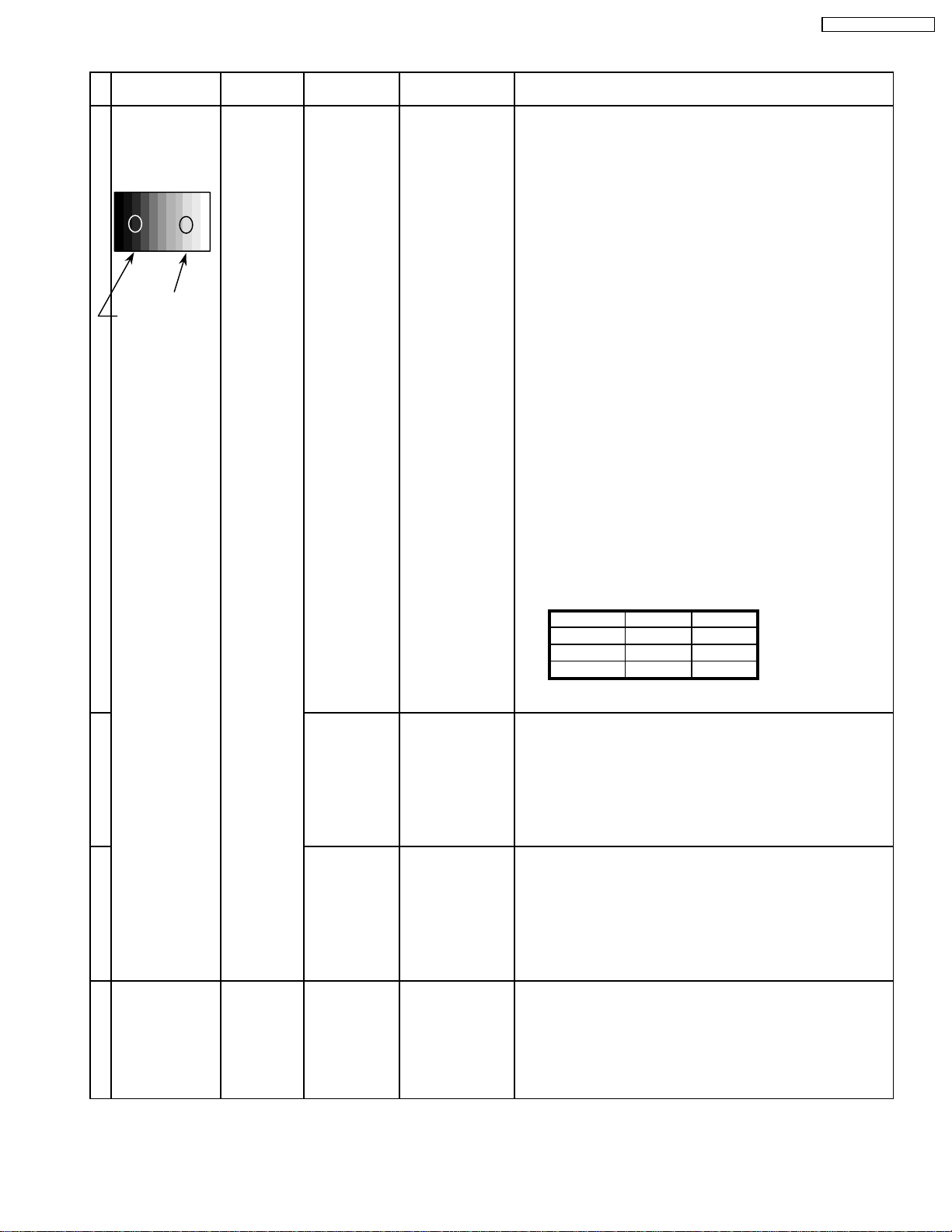

8.5. HD/ 525i /525p panel white balance

INPUT Alignment menu ProcedureEquipment Setting

1HD(720i or 1080i) Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool

exactly.

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off shown Fig.-04.

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

2

to 10 cd/m

.

6)Find 75% of white area by color sensor.

PANEL W/B

G Drive 7) Set G Drive to " D8 ".

PANEL W/B

B Drive 8) Adjust B and R Drive to set color temperature

R Drive as shown Fig.-04.

2

TH-42PW4 / TH-42PWD4

9) Repeat item 4) to 7) to set both Low light and

high light.

PANEL W/B

R,G,B Drive 10) Increase same steps of R, G and B Drive to set

R,G,B Drive largest level of 3 color drive to "FC".

PANEL W/B

R,G,B cut off 11) Re-adjust Low light level again.

Color Temp. x y

Cool(Hi) 0.272 0.290

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -04

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal

PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Warm".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm

PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

21

Page 22

TH-42PW4 / TH-42PWD4

5 Picture: 1) Write down each color temaparature of R,G,B drive and

RGB

Gray Scale

Pattern

High light 75%

Low light 15% 3) Copy HD drive and cut off data of each white

INPUT Alignment menu ProcedureEquipment Setting

Normal Cut off data as follows.

Aspect:

White balance:

Normal

16:9

Cool

Warm

White

Balance Cool Normal Warm

R Drive

G Drive

B Drive

R Cut off

G Cut off

B Cut off

2)Change input signal to 525i and 525p.

balance mode to each signals position.

22

Page 23

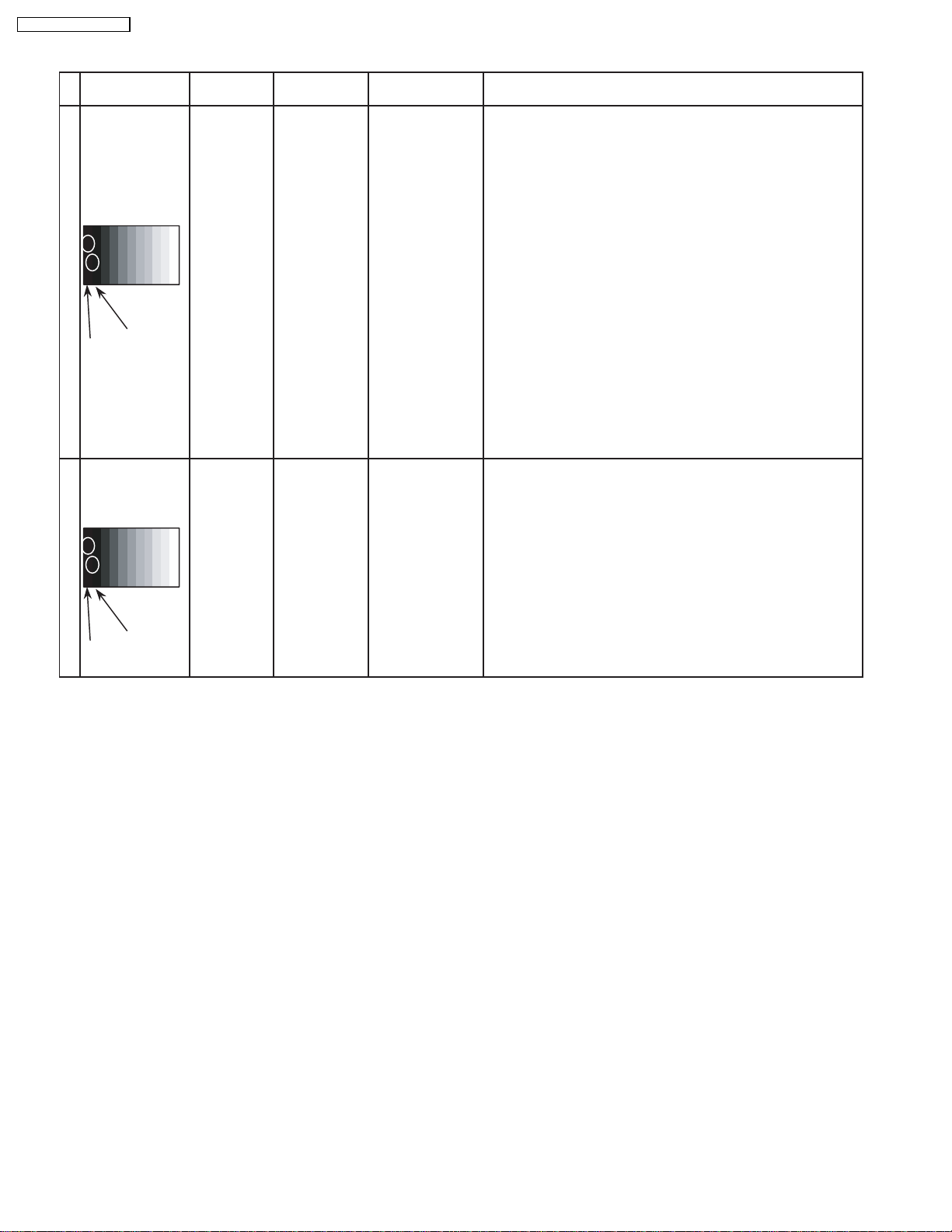

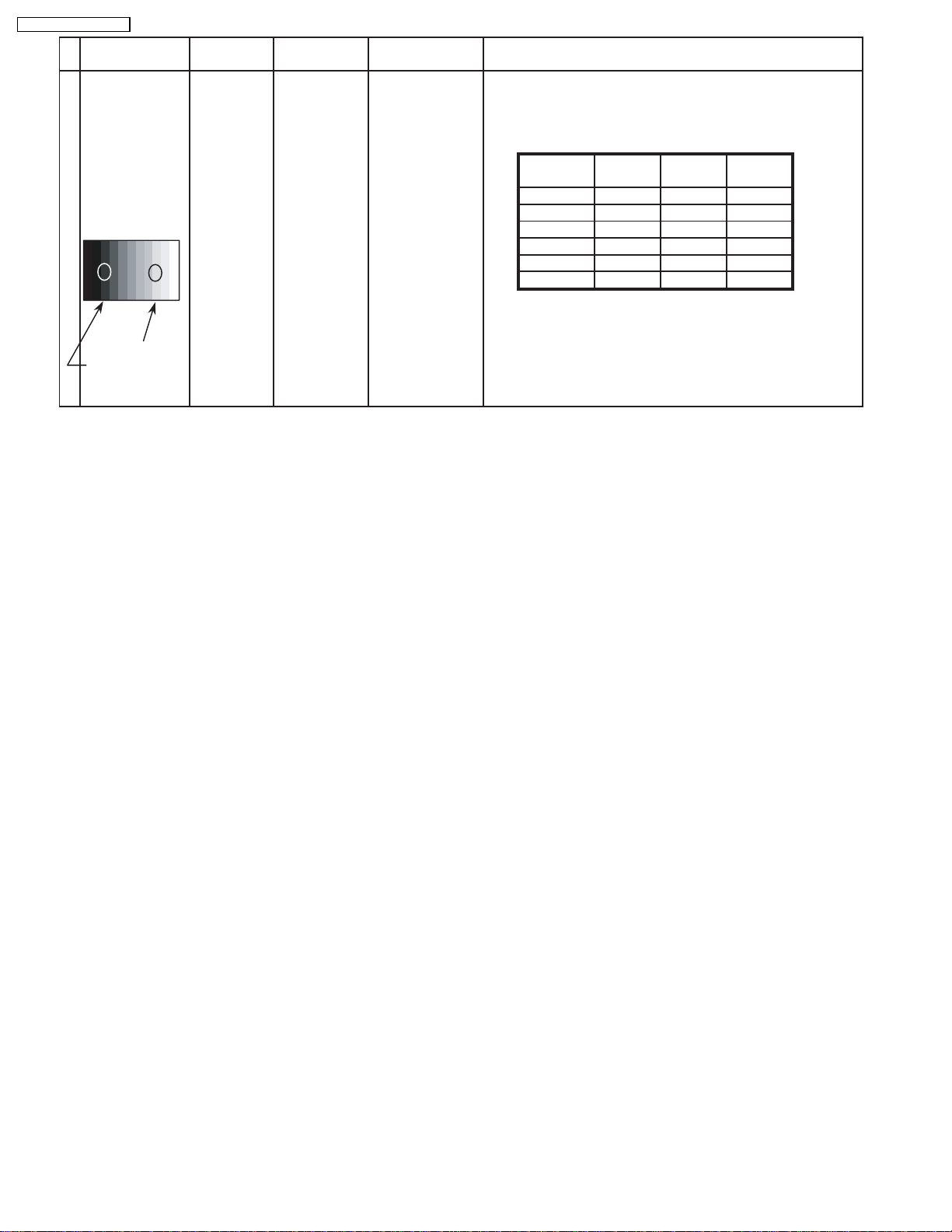

8.6. 625i panel balance

INPUT Alignment menu ProcedureEquipment Setting

1 625i Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool exactly.

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off shown Fig.-05.

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

to 10 cd/m

2

.

6)Find 75% of white area by color sensor.

PANEL W/B

G Drive 7) Set G Drive to " D8 ".

PANEL W/B

B Drive 8) Adjust B and R Drive to set color temperature

R Drive as shown Fig.-05.

9) Repeat item 4) to 7) to set both Low light and

high light.

PANEL W/B

R,G,B Drive 10) Increase same steps of R, G and B Drive to set

R,G,B Drive largest level of 3 color drive to "FC".

PANEL W/B

R,G,B cut off 11) Re-adjust Low light level again.

2

TH-42PW4 / TH-42PWD4

Color Temp. x y

Cool(Hi) 0.272 0.290

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -05

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Warm".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

23

Page 24

TH-42PW4 / TH-42PWD4

8.7. Sub brighness setting

INPUT Alignment menu ProcedureEquipment Setting

1 NTSC Picture: PANEL W/B

Gray Scale Normal All cut off 1) Set white balance to

Pattern Aspect:

** Adjust at the dark room.

Cool

.

16:9 2) Adjust All cut off to start some pixels emission

at black 2% area and no emission at black 0% area.

3) Write down all cut off data.

4) Set white balance to

Black 2 %

Black 0 % 5) Adjust All cut off to set same data of Cool mode.

6) Set white balance to

7) Adjust All cut off to set same data of Cool mode.

** Adjust at the dark room.

2 PAL Picture: PANEL W/B

Gray Scale Normal All cut off 1) Set white balance to

Pattern Aspect:

16:9 2) Adjust All cut off to start some pixels emission

at black 2% area and no emission at black 0% area.

3) Write down all cut off data.

4) Set white balance to

Black 2 %

Black 0 % 5) Adjust All cut off to set same data of Cool mode.

6) Set white balance to

7) Adjust All cut off to set same data of Cool mode.

SECAM 8) Change to SECAM signal.

Gray Scale

Pattern 9) Copy PAL All cut off data to SECAM mode.

Nornal

warm

Cool

Nornal

warm

.

.

.

.

.

** Adjust at the dark room.

3 PC Picture: PANEL W/B

Gray Scale Normal All cut off 1) Set white balance to

Pattern Aspect:

16:9 2) Adjust All cut off to start some pixels emission

at black 2% area and no emission at black 0% area.

3) Write down all cut off data.

4) Set white balance to

Black 2 %

Black 0 % 5) Adjust All cut off to set same data of Cool mode.

6) Set white balance to

7) Adjust All cut off to set same data of Cool mode.

RGB

Gray Scale

Pattern

DVI

Gray Scale

Pattern

8) Change to RGB input signal.

9) Copy PC All cut off data to RGB mode.

10) Change to DVI input signal.

11) Copy PC All cut off data to DVI mode.

Cool

Nornal

warm

.

.

.

24

Page 25

Alignment menu ProcedureINPUT Equipment Setting

** Adjust at the dark room.

4 525i Picture: PANEL W/B

Gray Scale Normal All cut off 1) Set white balance to

Pattern Aspect:

16:9 2) Adjust All cut off to start some pixels emission

at black 2% area and no emission at black 0% area.

3) Write down all cut off data.

Cool

TH-42PW4 / TH-42PWD4

.

4) Set white balance to

Nornal

.

Black 2 %

Black 0 % 5) Adjust All cut off to set same data of Cool mode.

6) Set white balance to

warm

.

7) Adjust All cut off to set same data of Cool mode.

525p 8) Change to 525p signal.

Gray Scale

Pattern 9) Copy 525i All cut off data to 525p mode.

HD

(720i or 1080i) 8) Change to HD signal.

Gray Scale

Pattern 9) Copy 525i All cut off data to HD mode.

** Adjust at the dark room.

5 625i Picture: PANEL W/B

Cool

Gray Scale Normal All cut off 1) Set white balance to

.

Pattern Aspect:

16:9 2) Adjust All cut off to start some pixels emission

at black 2% area and no emission at black 0% area.

3) Write down all cut off data.

4) Set white balance to

Nornal

.

Black 2 %

Black 0 % 5) Adjust All cut off to set same data of Cool mode.

6) Set white balance to

warm

.

7) Adjust All cut off to set same data of Cool mode.

25

Page 26

TH-42PW4 / TH-42PWD4

9 Trouble shooting guide

9.1. Self Check

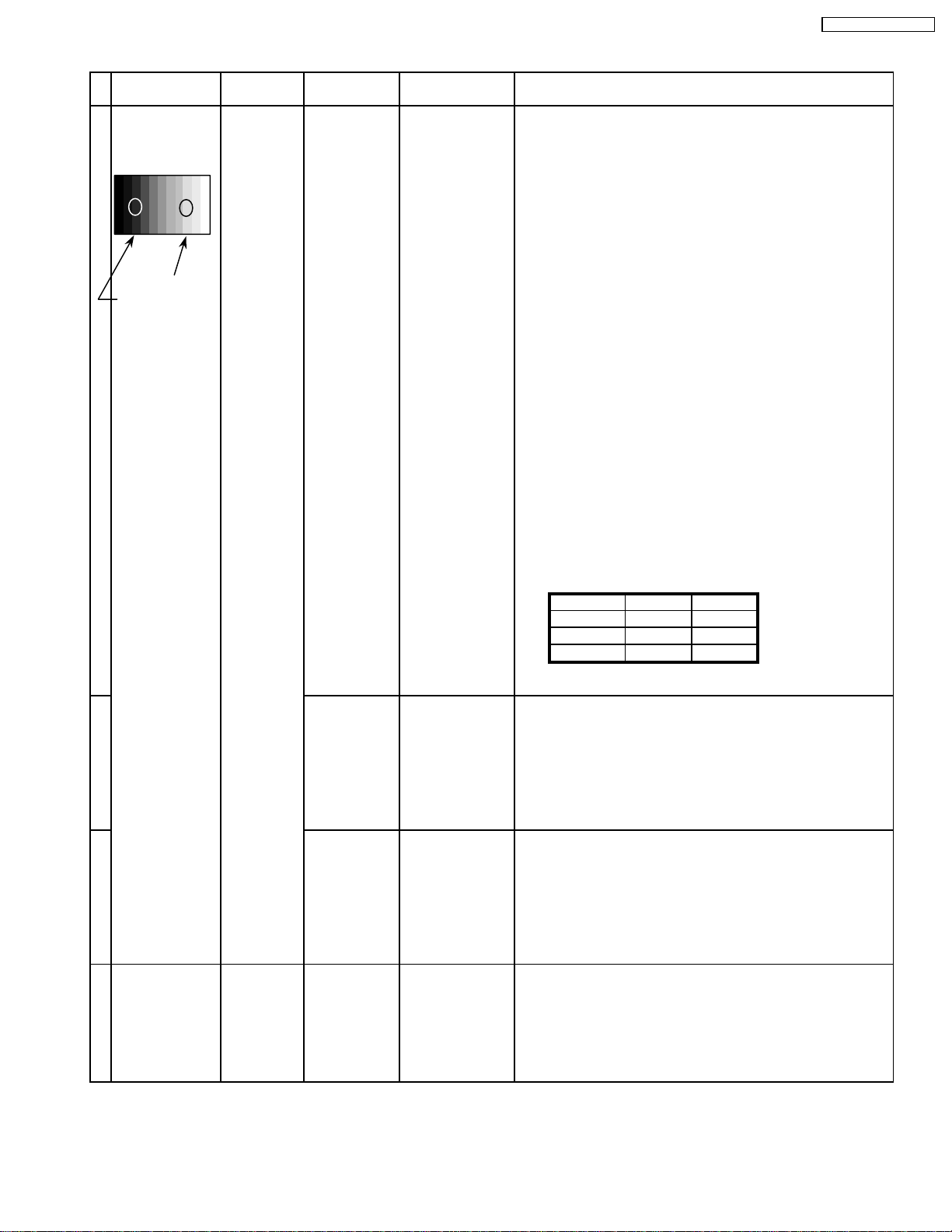

9.1.1. Display Indication

1. Self-check is used to automatically check the bus line

controlled circuit of the Plasma display.

2. To get into the Self-check mode press the volume down

button on the customer controls at the front of the set, at the

same time pressing the OFF-TIMER button on the remote

control, and the screen will show :-

If the CCU ports have been checked and found to be incorrect

Or not located then " - - " will appear in place of " OK "

Note:

In case of disconnected of H/HY/HZ “IC3699 - -” is

displayed.

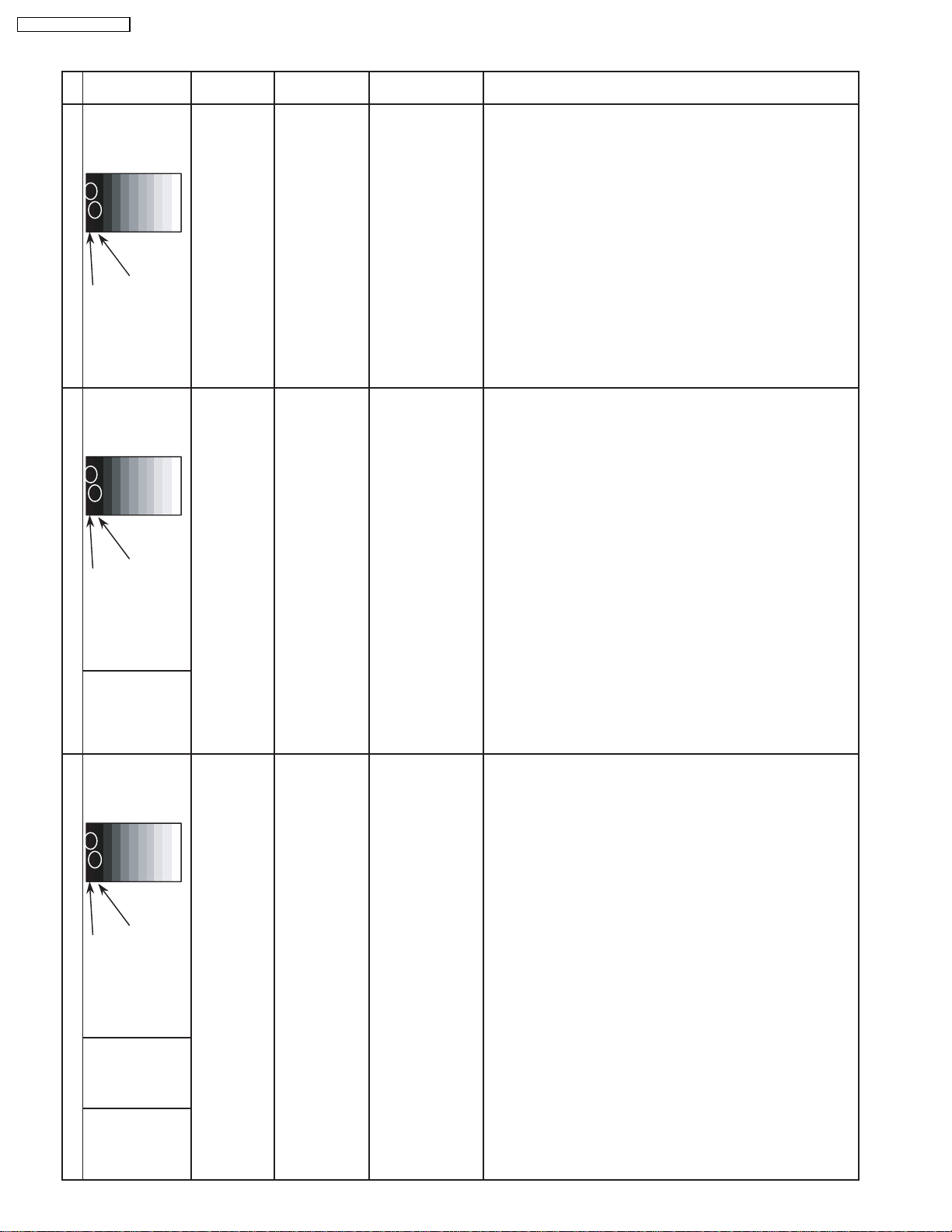

9.1.2. Power LED Flashing timing chart

When an abnormality has occurred the unit, the protection circuit operates and cuts the power supply. At this time, the defective

part can be identified by the number of flashes of the Power LED at the front of the unit.

Above Fan function is operated during the fan is set.

26

Page 27

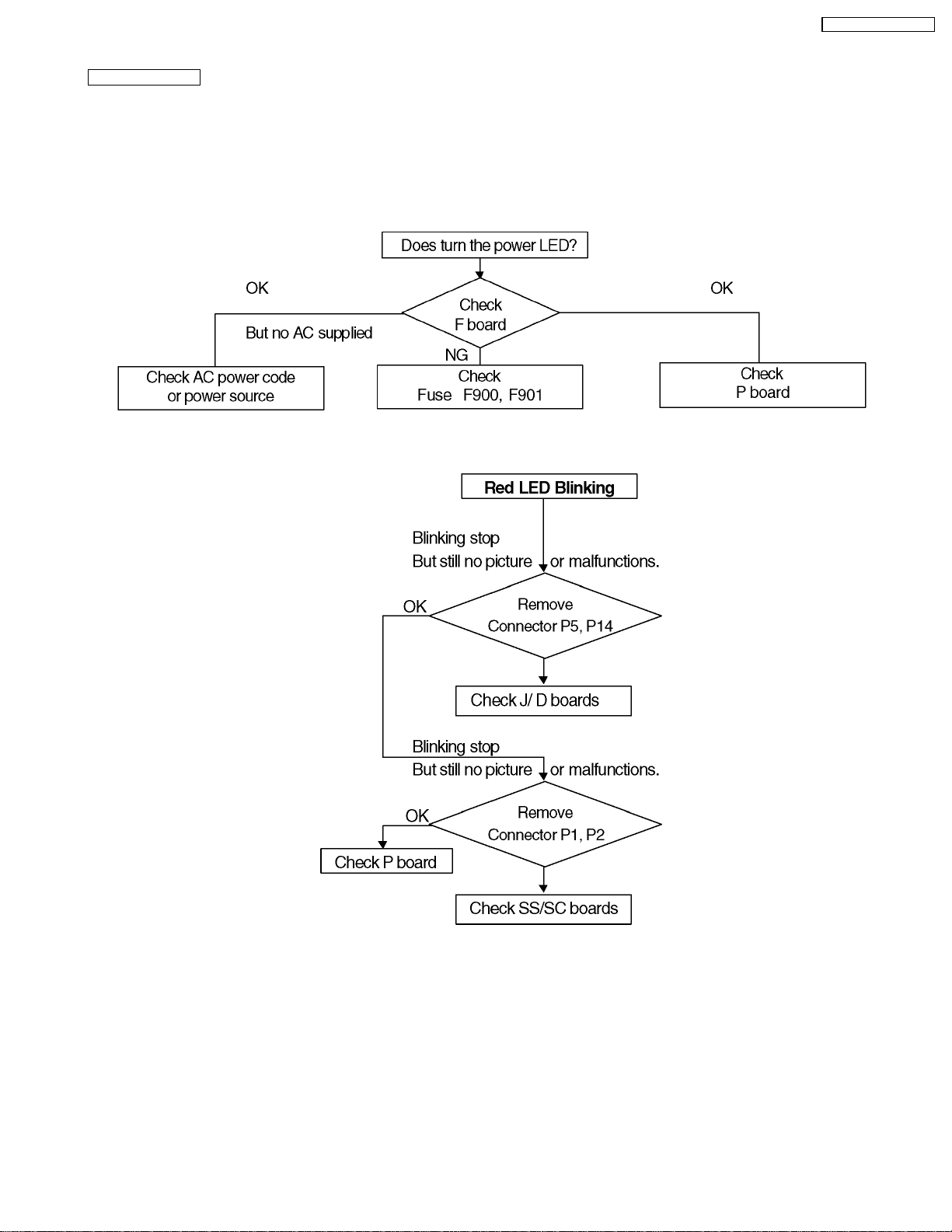

9.2. No Power (US model)

First check point

There are following 3 states of No Power indication by power LED.

1. No lit

2. Green is lit then turns red blinking a few seconds later.

3. Only red is lit.

1. No lit

2. Red LED Blinking

When one or some of supply voltages from power supply circuit are declined red LED will be blinking as power

TH-42PW4 / TH-42PWD4

27

Page 28

TH-42PW4 / TH-42PWD4

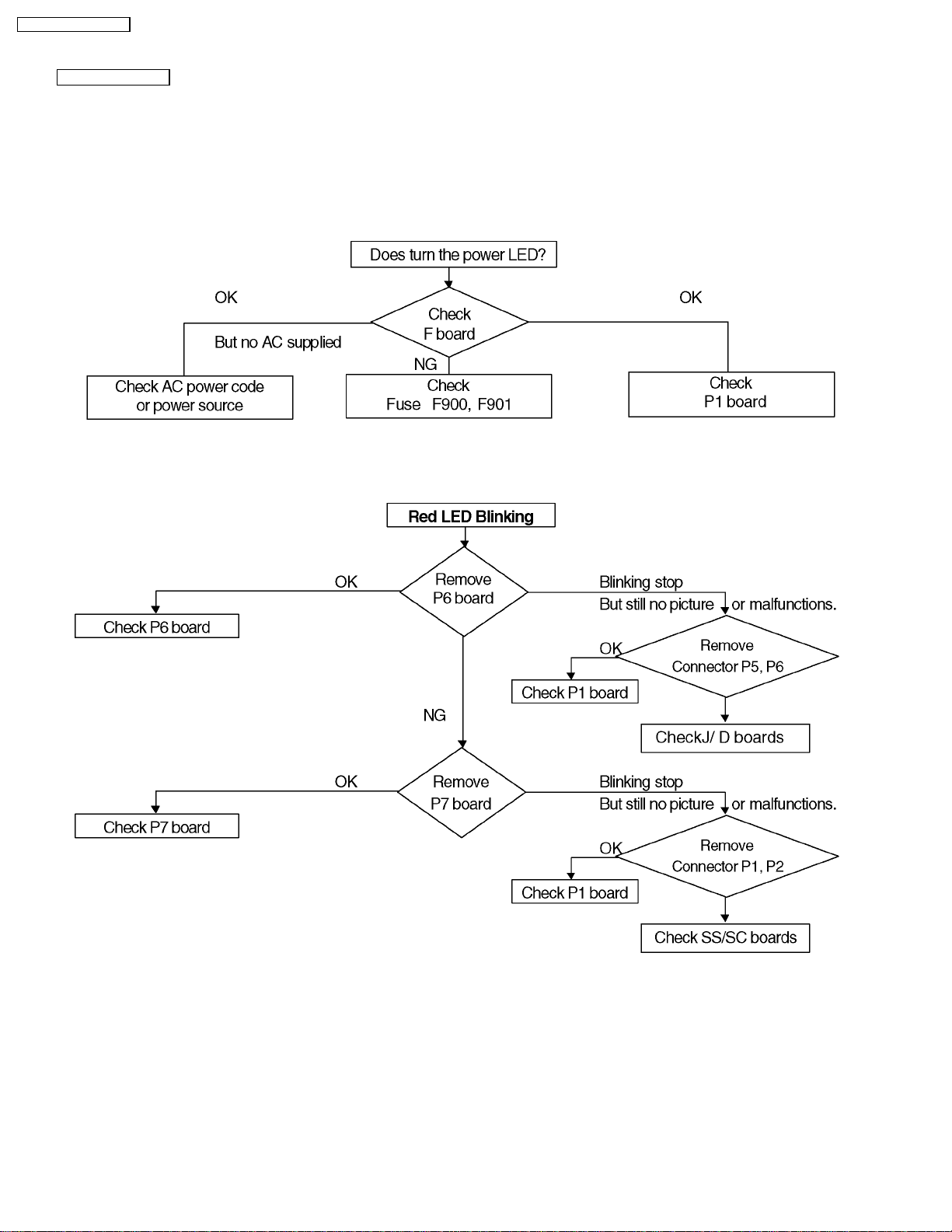

9.3. No Power (Except US)

First check point

There are following 3 states of No Power indication by power LED.

1. No lit

2. Green is lit then turns red blinking a few seconds later.

3. Only red is lit.

1. No lit

2. Red LED Blinking

When one or some of supply voltages from power supply circuit are declined red LED will be blinking as power

28

Page 29

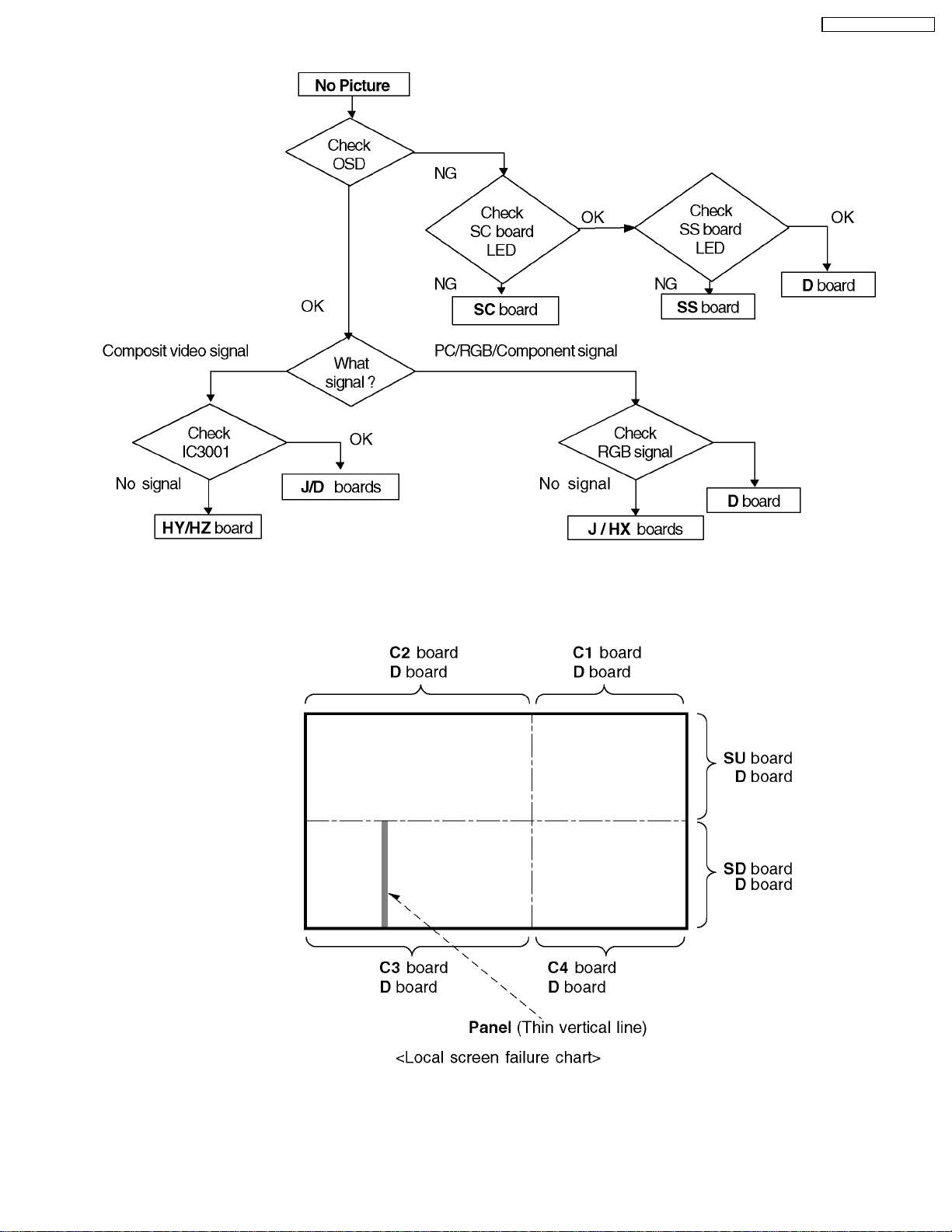

9.4. No Picture

TH-42PW4 / TH-42PWD4

9.5. Local screen failure

Plasma display may have local area failure on the screen. Fig - 1 is the possible defect P.C.B. for each local area.

Fig - 1

29

Page 30

TH-42PW4 / TH-42PWD4

9.6. D-Board

9.6.1. OUTLINE

D board is consists of Analogue and Digital signal process, Discharge control and Micro control block.

D-board is operated by supply voltages of 3.3V, 5V, 13,5V and Standby 5V , RGB analogue (0.7Vp-p) and Sync. Signal.

D-board output parallel data video signal with control signal for the data driver circuit, Discharge control signal for Scan and Sustain

drive circuits and Micro control signals.

9.6.2. MAIN IC OPERATION

IC9007 ~ 9009 A/D Converter

RGB analogue signals are converted to 8 bits digital signal.

IC9204 FORMAT CONVERTER (LSI33)

Number of Horizontal line of input signals are converted to 480 lines.

This IC uses two clock lines, one is 15M 55MHz for input signal (ICK) and other one is 25M to 40MHz for out put signal. (OCK)

IC9400 PLASMA AI (LSI27)

At first input 8 bit signal data is memorized into two field memory (IC9402, IC9403), Plasma AI analyze APL level and

distribution of dark and bright components.

Plasma AI re-arrange 8 bit signal data to 12 bit signal data.

This IC also insert OSD (On-Screen Display signal) from Micro.

IC9501 SUB FIELD PROCESSOR

R,G and B 12 bit signal data is layout to fit with each electrodes of panel.

One field signal data is separated to upper 240 lines and lower 240 lines.

Both upper and lower signals are again separated odd and even number line and output.

9.6.3. DIAGNOSTIC

(1) General

Depend on the phenomenon possible defective section from Signal processing, Discharge control or Micro control section on

D-board can be diagnosed as follows.

1. Signal Processing section

a. No picture but panel has discharge.

b. Missing R, G or B signal

c. Dark Picture.

d. No OSD signal.

e. Vertical band noise appeared.

f. No picture or distortion on 1/4 area on the screen.

2. Micro control section

a. Does not turn on power.

b. No panel discharge.

3. Discharge control section

a. No discharge but Micro control is operated.

b. Dark picture

30

Page 31

(2) First Check Point

Confirm that follow signals are input to D board.

Power Supply

Connector Pin Function Connector Pin Function

D5

1 13.5 V DC

3 5.0 V DC 2 3.3 V DC

- - 3 3.3 V DC

Input Signal

Connector Function Pin Function

D8-12 Analogue Green signal

D8-13 Analogue Blue signal 29 VD (Vertical Drive pulse)

D8-14 Analogue Red signal 34 CLP (Clamp pulse)

(3) Trouble shooting

TH-42PW4 / TH-42PWD4

1 STB 5 V DC

D6

37 HD (Horizontal Drive pulse)

D9

31

Page 32

TH-42PW4 / TH-42PWD4

10 Option Setting

How to access the Option menu

32

Page 33

(Not available for TH-42PW4 series models)

System route models TH-42PWD4 series have special function and operation setting facility called

Option Menu. This Option Menu is useful for special function required customers. This should be set

at the installation stage. The end user could not set or change these because of hidden On screen menu.

Option menus

default

setting

Contents

Wobbling Off

Screen image shift OFF.

Turns off the screen shift function that prevents after-images from

appearing on the screen.

Off-timer function Enable

Off-timer operation invalidation.

The off-timer function is made invalid.

On Screen display On

On-screen display OFF.

Turns off the on-screen display that indicates power on, input modes

and when no signal is received.

Initial Input Off

Startup input setting.

Sets the input mode when the power is turned on (VIDEO,

COMPONENT, VIDEO/RGB, PC). Input mode switching is possible

after the power is turned on.

Initial VOL. level Off

Startup volume setting.

Sets the volume level when the power is turned on. Volume can be

adjusted after the power is turned on.

Maximum VOL. Level Off

Maximum volume setting Fix input mode.

Sets the maximum volume level. Volume cannot exceed this limit.

INPUT lock Off

Input mode cannot be switch.

Fixes the input mode to (VIDEO, COMPONENT, VIDEO/RGB, PC) and

input mode cannot be switched.

Button lock Off

Front operation button invalidation.

Front operation buttons are made invalid. Several combinations of

button invalidation are possible ; just the selection keys (VOL. keys, just

the INPUT key, or both VOL. keys and INPUT key.).

Studio W/B Off

Set the screen color temperature to 3,200 kelvin.

(use when the contents displayed on the screen needs to be firmed for

use in news programs or other purposes.) This is valid when the setting

is turned ON and the WHITE BALANCE in the PICTURE menu is set to

WARM.

Remocon User Level Off

Remocon key invalidation.

Off : Valid key is all key of remocon.

User1 : Valid key are only Stand-by (ON/OFF), Input, Status, Surround,

Sound mute On/Off, and volume adjustment.

User2 : Valid key is only Stand-by (ON/OFF).

Note of Remocon User Level:

All key of remote control is valid in the service mode (CAT-mode) regardless of the setting of Remocon

User Level. To change the option setting when the Remocon User Level is set in the User1 or User2,

access the service mode (CAT-mode) first, then display the option menu the same method.

Hidden Option Menu for TH-42PWD4 series

TH-42PW4 / TH-42PWD4

33

Page 34

TH-42PW4 / TH-42PWD4

34

Page 35

11 IC Block Diagr am

TH-42PW4 / TH-42PWD4

35

Page 36

TH-42PW4 / TH-42PWD4

INPUTA

A

36

Page 37

12 Conductor View s

12.1. F-Board

6

5

TH-42PW4 / TH-42PWD4

F

4

F-BOARD

TXN/F10JAS (US model)

TXN/F1JASE (Except US)

3

2

1

ABCDEFGH I

37

Page 38

TH-42PW4 / TH-42PWD4

12.2. P-Board (US model)

6

5

P-BOARD(FOIL SIDE)

TXN/P10JAS

4

3

2

1

ABCDEFGH I

38

Page 39

TH-42PW4 / TH-42PWD4

P

Parts Location

IC

IC401 F-1

IC403 D-5

IC426 E-3

IC427 E-2

IC461 C-2

IC462 C-3

IC464 C-2

IC465 C-3

IC468 B-5

IC470 B-4

IC471 C-6

IC472 B-2

IC473 C-5

IC474 C-3

P-BOARD (FOIL SIDE)

TRANSISTOR TP

Q461 C-3

Q463 C-3

Q464 C-2

Q465 C-2

Q467 C-3

Q469 C-6

Q480 B-2

Q481 B-3

Q483 B-6

Q485 C-6

Q500 C-6

Q515 C-5

Q516 C-5

TPP1 D-4

Parts Location

P-BOARD (COMPONENT SIDE)

IC

IC401 C-1

IC403 D-5

IC426 C-3

IC427 C-2

IC461 E-2

IC462 E-3

IC464 E-2

IC465 E-3

IC468 F-5

IC470 F-5

IC471 E-6

IC472 F-2

IC473 E-5

IC474 F-3

TRANSISTOR

Q461 E-3

Q463 E-3

Q464 E-2

Q465 E-2

Q467 E-3

Q469 E-6

Q480 F-2

Q481 F-2

Q483 F-6

Q485 E-6

Q500 F-6

Q515 E-5

Q516 E-5

39

Page 40

TH-42PW4 / TH-42PWD4

6

5

P-BOARD(COMPONENT SIDE) US Model

TXN/P10JAS

4

3

2

1

ABCDEFGH I

40

Page 41

12.3. P1-Board (Except US)

P1-BOARD (FOIL SIDE)

TXNP11JASE

6

5

TH-42PW4 / TH-42PWD4

4

3

2

1

ABCDEFGH I

41

Page 42

TH-42PW4 / TH-42PWD4

P1

Parts Location

IC

IC401 F-3

IC402 F-3

IC403 D-5

IC406 D-2

IC407 C-5

IC409 C-3

IC410 C-5

IC411 C-5

IC412 B-3

IC464 D-1

P-BOARD (FOIL SIDE)

TRANSISTOR

Q401 F-4

Q402 E-3

Q404 F-3

Q405 F-2

Q406 F-2

Q407 F-1

Q408 F-1

Q409 E-2

Q410 E-3

Q412 C-6

Q413 B-5

Q414 C-6

Q415 C-6

Q416 E-3

Q417 E-3

Q418 B-5

Q419 B-4

Q420 B-3

Q421 B-5

Q422 F-4

Q423 B-5

Q464 C-1

Q465 D-1

Parts Location

P-BOARD (COMPONENT SIDE)

IC

IC401 B-3

IC402 B-3

IC403 E-5

IC406 E-2

IC407 E-5

IC409 F-3

IC410 F-5

IC411 F-5

IC412 F-3

IC464 E-1

TRANSISTOR

Q401 B-3

Q402 C-4

Q404 B-3

Q405 B-2

Q406 B-2

Q407 B-1

Q408 B-1

Q409 C-2

Q410 D-3

Q413 F-5

Q414 E-6

Q415 E-6

Q416 C-3

Q417 C-3

Q418 F-5

Q419 F-4

Q420 F-3

Q421 F-5

Q422 B-3

Q423 F-5

Q464 E-1

Q465 D-1

42

Page 43

TH-42PW4 / TH-42PWD4

P1-BOARD(COMPONENT SIDE) Except US

TXNP11JASE

6

5

4

3

2

1

ABCDEFGH I

43

Page 44

TH-42PW4 / TH-42PWD4

12.4. P3, P5, P6, P7 and P8-Board (Except US)

P5-BOARD (FOIL SIDE)

TNPA1778

6

5

P7-BOARD (FOIL SIDE)

TNPA1780

4

P6-BOARD (FOIL SIDE)

TNPA1779

P8-BOARD (FOIL SIDE)

TNPA1781

P8 P7

P6

P5 P3

3

P3-BOARD (FOIL SIDE)

TNPA1777

2

1

ABCDEFGH I

44

Page 45

TH-42PW4 / TH-42PWD4

P6-BOARD (COMPONENT SIDE)

TNPA1779

P5-BOARD (COMPONENT SIDE)

TNPA1778

P8 P7

6

5

P6

P5 P3

P8-BOARD (COMPONENT SIDE)

TNPA1781

P7-BOARD (COMPONENT SIDE)

TNPA1780

4

3

P3-BOARD (COMPONENT SIDE)

TNPA1777

2

1

ABCDEFGH I

45

Page 46

TH-42PW4 / TH-42PWD4

12.5. HX-Board

6

HX-BOARD(FOIL SIDE)

TZTNP020JAS

HX-BOARD(COMPONENT SIDE)

TZTNP020JAS

5

HX

4

Parts Location

HX-BOARD

IC

3

IC3502 F-2

IC3515 E-2

TRANSISTOR

Q3507 F-3

Q3508 F-3

Q3509 F-3

Q3513 E-4

Q3514 E-4

Q3515 F-4

Q3516 F-4

Q3531 E-3

Q3532 F-3

2

1

ABCDEFGH I

46

Page 47

12.6. H-Board (Option TY-42TM4H)

6

H-BOARD(FOIL SIDE)

TXN/H10JKS

5

A24

A25 A1

B24

B25

TH-42PW4 / TH-42PWD4

A2

A20

A1

A19

B2

B20

B1

H1

B19

H2

A2

B2

B1

IC3699

8

54

1

4

H

TNPA2247

SEE REVERSE FOR ORDER NO.

2H

3

2

JK3311

1

10

19 26

9

18

1

ABCDEFGH I

47

Page 48

TH-42PW4 / TH-42PWD4

6

5

H-BOARD(COMPONENT SIDE)

TXN/H10JKS

H2

JS28

JS29

JS30

IC3699

C3506

R3522

R3521

H1

4

H

TNPA2247

2H

L3460

R3482

Q3451

R3467

R3476

R3465

R3475

C3468

Q3458

R3497

R3492

R3469

L3458

C3463

R3466

R3496

C3457

R3491

R3470

C3465

R3471

C3458

Q3457

D3452

R3479

Q3454

D3451

R3483

C3466

R3484

C3464

R3480

Q3455

L3459

R3472

R3473

C3459

R3459

L3455

R3460

R3474

Q3452

R3478

L3456

R3488

R3461

R3481

L3457

R3486

C3461

R3485

C3451

C3460

C3452

Q3456

R3453

R3451

IC3451

R3489 R3490

R3494

C3462

R3493

C3453

R3452

R3454

R3495

Q3459

R3498 R3499

C3454

Parts Location

H-BOARD (COMPONENT SIDE)

IC

IC3451 B-2

IC3699 D-2

TRANSISTOR

Q3451 A-2

Q3452 B-3

Q3453 A-2

Q3454 B-2

Q3455 B-2

Q3456 B-3

Q3457 B-2

Q3458 A-2

Q3459 B-3

3

C3467

R3487

Q3453

R3468

R3477

R3462

R3463

R3464

C3455

R3455

L3451

R3456

L3452

R3457

L3453

C3456

R3458

L3454

2

JK3311

1

ABCDEFGH I

48

Page 49

12.7. HY-Board (Option TY-42TM4Y)

6

HY-BOARD(FOIL SIDE)

TNPA2245

5

4

5

JS32

JS31

41

IC699

TH-42PW4 / TH-42PWD4

A2

A24

A25

B24

B25

H1

R516

R522

R521

R517

R866

R519

R520

R518

C705

C709

8

C506

C706

C896

C707

C702

C704

R841

C854

Q816

C895

R883

C888

R888

C869

R887

C862

C867

C863

R847

R843

JS15

R872

R880

R882

C876

R878

C889

Q814

R851

R881

R842

JS14

JS16

R860

R861

C891

R852

C899

R870

Q817

A20

A1

A19

B2

B20

B1

B19

JS30

JS29

R537

R550

R534

R509

JS19

JS13

C885

C877

R853

C874

C882

C884

C897

R864

R865

R848

R874

R877

R503

R869

R875

R873

R846

C729

C878

C880

C881

H2

JS28

R536

R549

R514

R508

R868

R879

R886

JS36

JS35

R535

R548

R507

R513

R506

R502

JS23

R876

R885

A2

A1

B2

B1

C507

R511

R505

R504

R532R533

JS21

R501

JS22

JS24

JS20

HY

CR NO.

R301

C843

JS8

HY

3

R307

R303

R814

Q808

C807

R809

R810

R805

R804

Q804

R310

C302

R319

C301

R304

JK303

R819

R807

C819

R817

R821

R822

R322

R384

R381 R382

C356

R359

R352

LR

C824

C840

C841

R831

R830

C839

R829

Q810

R832

R833

R823

R824

Q809

R825

R827

R383

R380

C355

R358

R351

GAP11

3

R340

Q306

R337

R346

2

R330

R331

JK300

R

R336

R347

C306

R328

R327

C307

R329

L

R306

R308

R345

R348

R342

R344

R343

R341

R326

R321

R315

R305

R350

R309

JK301

Y

Q302

C309

R324

R320

R312

R317

R313

R314

R349

C

R302

TNPA2245

SEE REVERSEFOR ORDERNO.

JK302

R828

C825

R826

JS9

C828

R834

C832

C822

R378

R366

R379

R361

R367

C352

R357

GAP10

R836

C826

C820

R816

R806

R389

R393

C351

JK304

C842

JS10

R813

R812

L807

C805

R808

C801

R803

R394

R390

R356

R392

R391

R360

C359

R355

GAP9

L805

Parts Location

HY-BOARD (FOIL SIDE)

IC

IC3699 C-4 Q3302 B-2

R385

C360

C357

R368

R365

C358

C354

R354

C353

R353

GAP7

GAP8

TRANSISTOR

Q3306 B-2

Q3804 C-2

Q3808 D-2

Q3809 D-2

Q3810 D-2

Q3814 D-4

Q3816 D-4

Q3817 D-3

1

ABCDEFGH I

49

Page 50

TH-42PW4 / TH-42PWD4

6

5

HY-BOARD(COMPONENT SIDE)

TNPA2245

C513

Q510

R552

R538

TPHY1

Q501

C502

Q507

4

L817

L815

C701

3

L805

JS4

JS1

Q351

2

C363

L359

R373

R363

R364

R377

R362

C362

H2

R551

TPHR1

TPHB1

R539

Q502

C503

Q813

L818

C898

C700

L830

C723

C726

C844

C812

C803

C814

C813

L804

Q357

Q356

R386

R374

R388

L354

L353

R540

Q508

Q503

C504

Q815

L819

R856

R884

R890

R889

TPHV1

TPHH1

IC303

JS18

L820L821

L809

JS7

C815

L803

C802

L806

R811

Q801

R387

D352

L355

JK304

L501

R892

Q509

Q308

R891

R858

R854

R867

Q812

C887

R855

C365

R845

R844

C864

C855

IC809

C852

R835

D801

C808

IC802

Q805

Q803

L801

R801

Q358

C806

C804

Q359

L356

C512

C717

C718

R894

L814

C892

C893

R849

R857

C879

C883

R859

R850

C870

IC804

C833

C836

R818

C818

L808

JS3

C838

C835

IC801

C817

Q352

Q353

D351

L357

H1

C511

L825

C712C713

JS17

C875

L813

R863

C872

R871

R862

C868

C830

C834

C837

C821

C823

C816

C361

R371

R375

C364

L358

C510

C509

L822

C711

L824

C710

C716

C714

C728

C727

C890

C871

C873

L812

C886

C865

C866

C861

C853

C851

C850

C846

C831

C847

X801

R820

Q354

JS2

R372

L351

GAP5

JS12

C810

Q807

C809

R815

Q806

Q355

C313

R370

R376

R369

L307

L352

GAP6

C505

L823

C501

IC501

R895

C715

R541

L816

C894

C703

IC805

JK303

IC803

JS6

JS5

LC805

L802

R311

R316

C708

C860

TNPA2245

IC806

L811

C849

R840

C845

R838

C859

JS11

R802

Q802

Q301

L301

GAP1

C314

L829

IC699

C856

R837

CR NO.

H0

L826

L827

L828

HY

C857

C858

C848

R839

L810

C829

Parts Location

HY-BOARD (COMPONENT SIDE)

R396

C811

HY

3

C303

L302

JK302

GAP2

Q307

C304

L303

IC302

R893

Q309

R395

R335

R334

C312

R323

C305

Q303

R325

Q304

R318

GAP12

JK301

IC301

C310

L306

C311

Q305

R332

R338

R339

R333

GAP3

L305

GAP4

JK300

L304

IC

IC3301 E-2

IC3302 E-3

IC3303 B-4

IC3501 D-4

IC3699 D-4

IC3801 B-2

IC3802 B-3

IC3803 D-2

IC3804 C-4

IC3805 C-4

IC3806 C-4

IC3809 B-3

TRANSISTOR

Q3301 D-1

Q3303 E-2

Q3304 E-2

Q3305 F-2

Q3307 E-2

Q3308 B-4

Q3309 E-2

Q3351 A-2

Q3352 C-2

Q3353 B-2

Q3354 C-2

Q3355 C-2

Q3356 A-2

Q3357 B-2

Q3358 B-2

Q3369 B-2

Q3501 A-4

Q3502 A-4

Q3503 B-4

Q3507 A-4

Q3508 B-4

Q3509 B-4

Q3510 A-5

Q3801 B-2

Q3802 C-2

Q3803 B-2

Q3805 B-3

Q3806 C-2

Q3807 C-2

Q3812 B-4

Q3813 B-4

Q3815 B-4

TP

TPHB B-5

TPHH B-4

TPHR B-5

TPHV B-4

TPHY A-4

1

ABCDEFGH I

50

Page 51

12.8. HZ-Board (Option TY-42T\M4Z)

6

HZ-BOARD(FOIL SIDE)

TNPA2248

5

A24

A25

B24

B25

R516

R522

R521

R517

R519

5

JS32

JS31

41

R520

IC699

4

R518

C705

C709

8

C506

C706

C896

C707

C702

C704

C862

R841

C854

TH-42PW4 / TH-42PWD4

A2

A20

A1

A19

B2

B20

B1

B19

H1

JS15

R866

C895

R883

C888

C869

R887

C863

R843

R872

Q816

R880

R882

C876

R878

C889

Q814

R888

R851

C867

R881

R847

R842

JS14

JS13

JS16

C885

R860

R861

C877

C891

R852

C899

R870

R853

C874

R864

Q817

R865

JS30

JS28

JS29

R537

R550

R534

R869

R846

C729

C897

C878

C880

C881

C882

C884

R848

R874

R877

R549

R509

R514

R508

JS19

R503

R879

R886

R875

R873

JS36

JS35

H2

R536

R533

R868

R535

R548

R507

R513

R506

R502

JS23

R876

R885

A2

A1

B2

B1

C507

R511

R505

R504

R532

JS21

R501

JS22

JS24

JS20

1

HZ

HZ

3

CR NO.

R340

R337

Q306

R345

R348

2

R346

C306

R328

R330

C307

R327

R331

R329

JK305

R306

R

R336

R347

R342

C309

R344

R343

R341

R326

R321

R315

R314

R308

B

C843

JS8

R814

Q808

3

R810

Q302

R324

R320

R307

R312

R317

R313

R301

GR

R303

R305

R309

R350

JK301

Y

C807

R809

R805

R804

Q804

R310

R319

C302

C301

R304

R349

C

R819

R807

C819

R817

R821

R822

R322

R384

R381 R382

C356

R359

R352

R

C824

C840

C841

R831

R833

R823

R830

R829

R824

C839

Q810

Q809

R825

R827

R383

R380

C355

R358

R351

L

R828

R826

C825

JS9

C828

R834

R832

C832

C822

R378

R366

R379

R361

R367

C352

R357

JK308

GAP11

R

GAP10

R836

C826

C820

R816

R806

R389

C351

L

C842

JS10

R813

R812

L807

C805

R808

C801

R803

R393

R394

R390

R360

R391

C359

R356

R355

GAP9

R

L805

R392

R385

R368

GAP8

R365

C358

C354

R354

C353

R353

GAP7

C360

C357

JK306JK307

SEE REVERSEFOR ORDERNO.

TNPA2248

Parts Location

HZ-BOARD (FOIL SIDE)

IC

IC3699 B-4 Q3302 B-2

GRB

TRANSISTOR

Q3306 A-2

Q3804 B-2

Q3808 C-3

Q3809 C-2

Q3810 C-2

Q3814 C-4

Q3816 C-4

Q3817 C-3

1

ABCDEFGH I

51

Page 52

TH-42PW4 / TH-42PWD4

6

5

HZ-BOARD(COMPONENT SIDE)

TNPA2248

C513

R552

R538

TPHY1

Q501

C502

4

TNPA2248

L817

Q507

Q502

C503

L815

C701

C700

C723

HZ

3

2

C363

C362

L359

C844

L805

C814

JS4

JS1

Q356

Q351

R362

R373

R363

R364

R377

L353

JK306

TPHR1

TPHB1

Q813

L818

C898

L830

C726

C812

C803

C813

L804

Q357

R386

R374

R388

L354

R540

R539

Q508

Q503

C504

Q815

L819

Q812

R889

R856

R890

R884

TPHV1

TPHH1

JS18

L820L821

L809

JS7

C815

Q805

L803

C802

L806

R811

Q801

R387

D352

L355

L501

R892

Q509

Q308

R891

R858

R867

R854

C887

R855

C365

R845

IC303

R844

C864

C855

IC809

C852

R835

D801

C808

IC802

Q803

L801

R801

Q358

C806

C804

Q359

L356

JK308

C512

C718

C717

R894

L814

C892

C893

R849

R857

C879

C883

R859

R850

C870

IC804

C833

C838

C836

R818

C818

C835

IC801

L808

C817

JS3

Q352

Q353

D351

L357

H2

R551

Q510

L813

R863

R862

C868

C834

C837

C821

C823

C361

L358

H1

C511

L825

C712C713

JS17

C875

C872

R871

C830

C816

R371

R375

C364

GAP5 GAP6

C510

C509

L822

C711

L824

C710

C716

C714

C728

C890

C727

C871

C873

L812

C886

C865

C866

C861

C853

C851

C850

C846

C831

C847

X801

R820

Q354

JS2

R372

L351

JS12

C810

Q807

C809

R815

Q806

Q355

C313

R370

R376

R369

L307

L352

JK307

C505

L823

C501

IC501

R895

C715

R541

L816

C894

C703

IC805

C708

IC803

L811

IC806

C849

R840

C845

R838

IC699

H0

L826

L827

L828

L829

C856

R837

C857

C858

C848

R839

L810

C829

Parts Location

HZ

HZ-BOARD (COMPONENT SIDE)

IC

C859

JS11

LC805

JS5

CR1NO.

L802

R802

Q802

Q301

R316

R311

L301

C314

GAP1

L302

JK301

C860

JS6

3

C303

GAP2

C811

R396

IC302

R893

Q309

R335

Q307

C304

L303

R395

R334

C312

R323

C305

Q303

R318

GAP12

JK305

L306

C310

C311

Q305

R332

IC301

Q304

R339

R338

R325

L304

R333

GAP4

GAP3

L305

IC3301 E-2

IC3301 E-2

IC3302 D-2

IC3303 B-4

IC3501 D-4

IC3699 D-4

IC3801 B-2

IC3802 B-3

IC3803 D-3

IC3804 C-4

IC3805 C-4

IC3806 C-4

IC3809 B-3

TRANSISTOR

Q3301 D-2

Q3303 D-2

Q3304 E-2

Q3305 E-2

Q3307 D-2

Q3308 B-4

Q3309 D-2

Q3351 A-2

Q3352 C-2

Q3353 B-2

Q3354 C-2

Q3355 C-2

Q3356 A-2

Q3357 B-2

Q3358 B-2

Q3359 B-2

Q3501 A-4

Q3502 A-4

Q3503 B-4

Q3507 A-4

Q3508 B-4

Q3509 B-4

Q3510 B-5

Q3801 B-2

Q3802 C-2

Q3803 B-2

Q3805 B-3

Q3806 C-2

Q3807 C-2

Q3812 B-4

Q3813 B-4

Q3815 B-4

TP

TPHB1 B-5

TPHH1 B-4

TPHR1 B-5

TPHV1 B-4

TPHY1 A-4

1

ABCDEFGH I

52

Page 53

12.9. J-Board

J-BOARD(FOIL SIDE)

TNPA2244

6

TH-42PW4 / TH-42PWD4

J4

1

6

J6

1

A25

B25

A24

B24

R3046

R3045

6

D3001

C3028

C961

5

C3030

C2342

R2301

C2437

R2452

C2317

R2304

C2333

R2327

C2332

C2313

C2325

C2324

C2346

C2452

R2453

C2434

R2307

R2431

R2308

C2329

JS2301

R2347

R2346

C2319

C2343

R2434

C2438

C2315

C2461

C2436

D2309

C2426

R2456

Q2306

L2302

C2321

R2447

R2318

R2317

R2348

C2347

20

1

D2305

JS2303

R2441

C2327

C2432

C2463

R2305

IC2302

R2476

JS2302

R2449

R2448

R2333

11 10

L2303

R3048 R3049R3050

R3016

R1018

C3046

C3048

C3009

R3019

R3069

R1017

R3058

R3072

R3064

R3020

Q3007

R3021

R3004

R1062

R1016

R3031

R1055

R1015

R3051 R3052R3053

C3043

C3044

R1053

Q3001

R3063

R3027

R3030

R1054

R1014

R3054

C3004

C3008

R8023

R8024

C8016

C8018

C8021

R3028

R3029

R3024

R3025

R3026

R1006

R1048

R1049

R1050

R1012

R1013

R1010

R1011

14

R1008

11

10

JS8019

R8007

R8001

Q1001

R8034

R8026

J3002

R8021

R8022

R8031

R1044

R1043

R1034

R1032

R1030

R1024

R1020

JS8023

R8032

Q8030

R8030

R8028

R8029

R8010

C8014

C8012

C8013

R8006

R8005

R2482

C2480

C2442

R2481

R3032R3033

R1070

Q1005

Q1003

R1065

R1067

R1063

R2484

R2457

R3034 R3035

R8033

R8027

R1068

C1006

C2314

R2467

R2468

R8013

C8015

C2453

C8020

R2336

7

C2350

C2339

R8025

R2324

R2331

R2329

C2336

1

C2433

32

Q2302

11 10

L2304

C2312

C2431

C2429

TNPA2244

JS8022

JS8021

C8022

R8011

R8015

R8018

IC8001

20

R2466

R2463

R2460

1

R8008

C8007

R8002

R8003

R8004

C2484

C3050

C1005

R1019

Q1004

C1014

R1069

R1066

R1064

C1013

Q1002

J3001

1

J1

B2A1A2

B1

4

A20

A19

C3020

B20

B19

JS3006

JS3005

JS3004

R3013

C3017

R3012

C3016

R3011

C3019

C3015

R3056

R3066

R3067

C3018

Q3003

R3073

Q3009

C3045

C3047

C3014

Q3005

R3070

R3074

Q3011

C3013

R3105

R3104

R3103

J2

R3095

R3096

R3097

3

B2

A2

A1

B1

A20

B20

A19

B19

R3023

R1072

R3022

C1010

C1009

R3018

R3017

R1059

J99

2

R1047

18

J3

B2A1A2

B1

R1033

R1027

R1021

R1041

R1039

R1060

R1061

R1056

R1035

R1029

R1023

R1045

R1042

R1037

R1025

R1031

R1057

SEE REVERSE FOR ORDERNO.

D2306

C2337

16 17

IC2401

D2308

R2477

C2330

C2316

C2458

R2321

R2335

R2330

C2460

Q2301

C2349

C2338

R2319

R954

C2340

C2462

C2464

C2331

R2326

R951

C2318

C2323

C2322

C2344

C2320

L953

C960

R960

R961

R955

D951

Q951

R953

C954

C3035

C2341

C2328

R2322 R2323

1

J

R956

L2301

R959

R958

R957

1

J13

C955

C957

7

C951

C952

D952

L951

C953

110

J

J14

R3043

R3042

J11

C3033

C2345

20

1

C2326

IC2301

J10

1413

Parts Location

IC

IC2301 E-2

IC2302 E-2

IC2401 E-3

IC8001 D-4

J-BOARD (FOIL SIDE)

TRANSISTOR

Q951 E-4

Q1001 C-2

Q1002 C-2

Q1003 C-2

Q1004 C-2

Q1005 C-2

Q2301 E-3

Q2302 D-3

Q2306 D-3

Q3001 C-5

Q3003 B-5

Q3005 C-5

Q3007 C-4

Q3009 B-2

Q3011 C-4

1

ABCDEFGH I

53

Page 54

TH-42PW4 / TH-42PWD4

6

J-BOARD(COMPONENT SIDE)

TNPA2244

J4

R3010

R3007

C3025

R3009

R3061

R3076

R1003

R1001

R1004

R3057

R3068

IC3009

C3042

R3094

R3093

R3092

R3087

IC3008

C3049

R3047

C3019

Q3086

R3014

R3015

C3034

L3001

R3088

R3106

R3108

R3107

JS3003

JS3002

JS3001

J2J3

Q3085

J1

D3002

R3109

Parts Location

IC

IC951 B-4

IC1001 D-2

IC1002 E-1

IC1003 E-3

IC1004 D-1

IC2301 B-2

IC2302 C-2

IC2304 C-4

IC2401 C-3

IC3001 E-3

IC3002 E-3

IC3003 D-3

IC3004 D-2

IC3006 C-5

IC3007 B-3

IC3008 E-1

IC3009 E-2

IC8001 D-4

IC8002 D-4

IC8003 D-5

J

J-BOARD (COMPONENT SIDE)

TRANSISTOR TP

Q2303 C-3

Q2304 C-3

Q2305 C-3

Q2406 C-4

Q2408 D-3

Q2410 D-3

Q3002 E-5

Q3004 E-5

Q3006 E-5

Q3008 E-4

Q3010 E-4

Q3012 E-4

Q3085 E-2

Q3086 E-5

Q8021 D-3

TP3085 D-4

TP3086 D-5

TP3087 D-4

TP3088 D-4

TP3089 D-4

TP3110 B-5

TP3111 B-3

TP3112 B-3

TP3113 B-3

J6

R3038

IC8002

IC8001

C1006

R3037

R8020

J3001

L1001

C8010

Q8021

D1001

L2401

C2455

R8019

C8004

L3007

R3036

R8014

L8001

C1011

R2483

R2480

R8012

X1001

J8

R8036

IC8003

R8035

TP3087

C8023

R8017

C8002

R1046

R1040

R1038

R1036

R2438

R8016

C8019

C8017

D8001

C8003

R2464

Q2410

Q2408

C1012

IC1004

L8002L8003

D8002

C8008

C8005

C3023

IC3004

R1071

C1015

L3003

C1001

R1052

R1009

TP3089

C3001

R8009

C8011

C8009

C8006

R3001

C8001 C2435

C3024

R1005

R1007

IC1001

R1051

R1028

R1026

R1022

C1016

J3002

C2450

C2429

C2437

C2390C2391

C2314

R2343

R2344

L2304

C2325

R2325

R2410

D2315

R2461

C3029

IC3006

L2306

R2473

IC2304

C2335

C2456

R2470

R2471

R2462

R2472

C2465

C2440

C2441

R3039

C961

C2344

R3043

TP3110

L953

D2306

C960

C959

C956

C958

IC951

R952

C3031

C3038

C2427

C2430

R2450

C2422

C2466

C2467

C3032

IC2401

IC3007

C2474

C2417

Q2305

R2408

TP3112

R2341

R2342

R2320

R2328

D2314

C2347

C2323

C2334

IC2301

C2388

C2389

C2316

L2303

D2301

D2302D2303 D2304

R2445

C2457

C2348

R2439

R2332

IC2302

D2305

L2305

C2313

R2440

C2419

R2442

Q2406

C2423

C2438

C2451

L2302

R2334

R2469

C2459

R2345

Q2303

Q2304

R2310