Page 1

Order Number MTV1112129CE

FULL HD LCD Display

Model No. TH-42LF25W

TH-47LF25W

TABLE OF CONTENTS

1 Safety Precautions ----------------------------------------------- 3

1.1. General Guidelines---------------------------------------- 3

1.2. Touch-Current Check ------------------------------------- 3

2 Warning-------------------------------------------------------------- 4

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices---------- 4

2.2. About lead free solder (PbF)---------------------------- 5

3 Service Navigation ----------------------------------------------- 6

3.1. Applicable signals ----------------------------------------- 6

4 Specifications ----------------------------------------------------- 8

5 Operating Instructions------------------------------------------ 9

6 Service Mode -----------------------------------------------------11

6.1. Service Menu Function (1) -----------------------------11

6.2. Service Menu Function (2) -----------------------------12

6.3. Service Mode Function (1) -----------------------------13

6.4. Service Mode Function (2) -----------------------------14

7 Troubleshooting Guide ----------------------------------------15

8 Disassembly and Assembly Instructions ---------------16

8.1. Flowchart for disassembly------------------------------16

PAG E PAG E

8.2. Preparations----------------------------------------------- 17

8.3. Pedestal (option) removal------------------------------ 17

8.4. Rear cover removal-------------------------------------- 17

8.5. Replacement method for main board and jack

board -------------------------------------------------------- 18

8.6. Replacement method for Power board ------------- 19

8.7. Replacement method for AC cord bracket -------- 19

8.8. Cabinet back removal (42 type) ---------------------- 20

8.9. Cabinet back removal (47 type) ---------------------- 20

8.10. When removing the cabinet back with the

board connected ----------------------------------------- 20

8.11. Replacement method for speakers ------------------ 20

8.12. Key SW board replacement --------------------------- 20

8.13. Connector board removal ------------------------------ 21

8.14. LCD panel replacement -------------------------------- 21

8.15. Replacement method for RC+LED board---------- 22

8.16. Cabinet front replacement ----------------------------- 22

8.17. Cabinet back replacement ----------------------------- 23

9 Block Diagram --------------------------------------------------- 27

© Panasonic Corporation 2011

Unauthorized copying and distribution is a violation

of law.

Page 2

TH-42LF25W / TH-47LF25W

9.1. Block (1 of 2) Diagram ---------------------------------- 27

9.2. Block (2 of 2) Diagram ---------------------------------- 28

10 Wiring Connection Diagram--------------------------------- 29

10.1. Wiring Connection Diagram (1)----------------------- 29

10.2. Wiring Connection Diagram (2)----------------------- 31

10.3. Wiring Connection Diagram (3)----------------------- 32

10.4. Wiring Connection Diagram (4)----------------------- 33

11 Exploded View and Replacement Parts List ----------- 34

11.1. Exploded View and Mechanical Replacement

Parts List --------------------------------------------------- 34

11.2. Mechanical Replacement Parts List (42 inch) ---- 50

11.3. Mechanical Replacement Parts List (47 inch) ---- 51

11.4. Electrical Replacement Boards list (42 inch) ------ 52

11.5. Electrical Replacement Boards list (47 inch) ------ 52

11.6. Boards Layout--------------------------------------------- 52

2

Page 3

TH-42LF25W / TH-47LF25W

1 Safety Precautions

1.1. General Guidelines

1. When conducting repairs and servicing, do not attempt to modify the equipment, its parts or its materials.

2. When wiring units (with cables, flexible cables or lead wires) are supplied as repair parts and only one wire or some of the

wires have been broken or disconnected, do not attempt to repair or re-wire the units. Replace the entire wiring unit instead.

3. When conducting repairs and servicing, do not twist the Fasten connectors but plug them straight in or unplug them straight

out.

4. When servicing, observe the original lead dress.If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

5. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

6. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

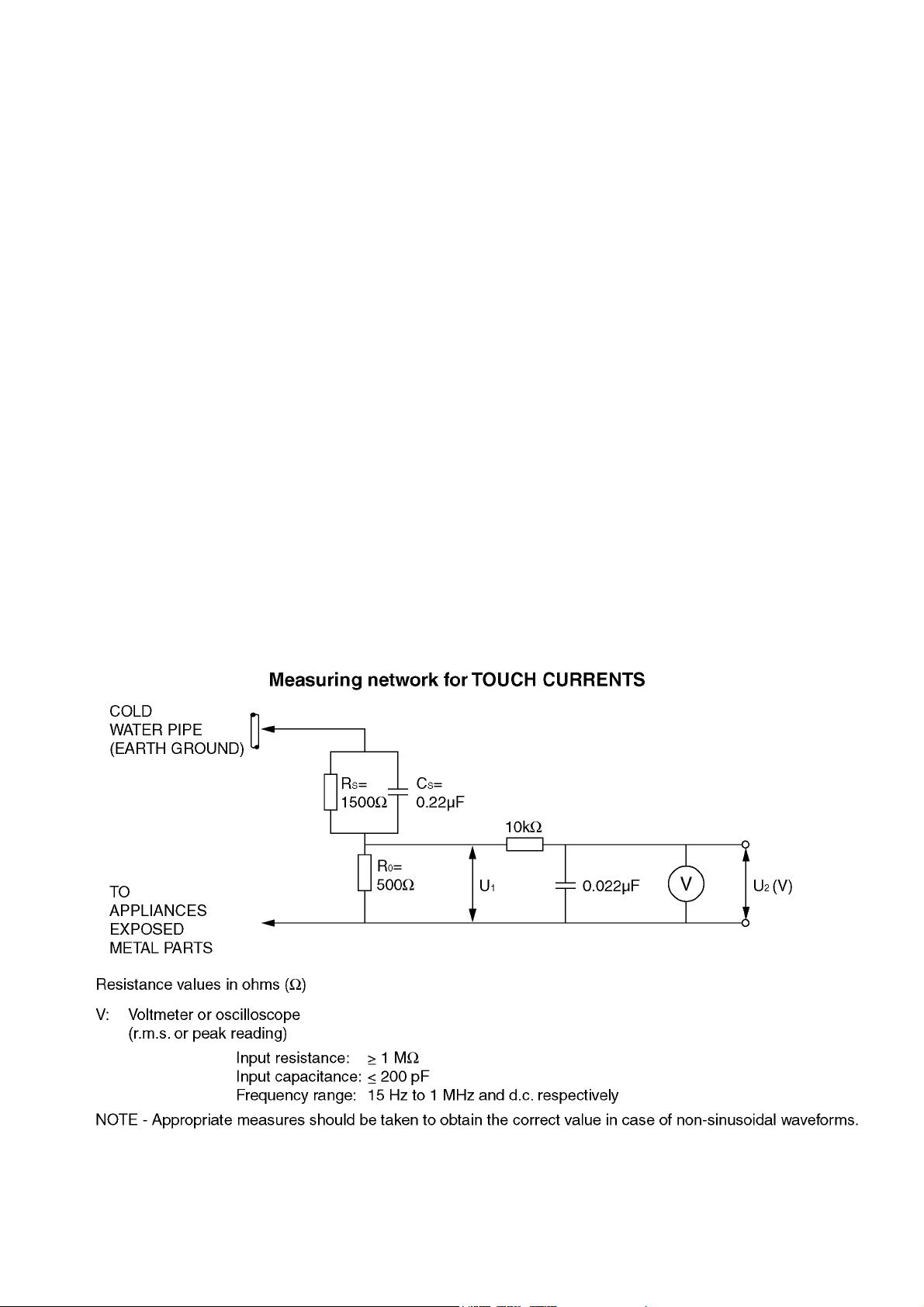

1.2. Touch-Current Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a measuring network for touch currents between each exposed metallic part on the set and a good earth ground

such as a water pipe, as shown in Figure 1.

3. Use Leakage Current Tester (Simpson 228 or equivalent) to measure the potential across the measuring network.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reserve the AC plug in the AC outlet and repeat each of the above measure.

6. The potential at any point (TOUCH CURRENT) expressed as voltage U

For a. c.: U1 = 35 V (peak) and U2 = 0.35 V (peak);

For d. c.: U

Note:

The limit value of U

mA d. c.

The limit value U

7. In case a measurement is out of the limits specified, there is a possibility of a shock hazard, and the equipment should be

repaired and rechecked before it is returned to the customer.

= 1.0 V,

1

= 0.35 V (peak) for a. c. and U1 = 1.0 V for d. c. correspond to the values 0.7 mA (peak) a. c. and 2.0

2

= 35 V (peak) for a. c. correspond to the value 70 mA (peak) a. c. for frequencies greater than 100 kHz.

1

and U2, does not exceed the following values:

1

Figure 1

3

Page 4

TH-42LF25W / TH-47LF25W

2Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor “chip” components. The following techniques should be used to help reduce the incidence of component damage

caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise ham less motion such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient

to damage an ES device).

4

Page 5

TH-42LF25W / TH-47LF25W

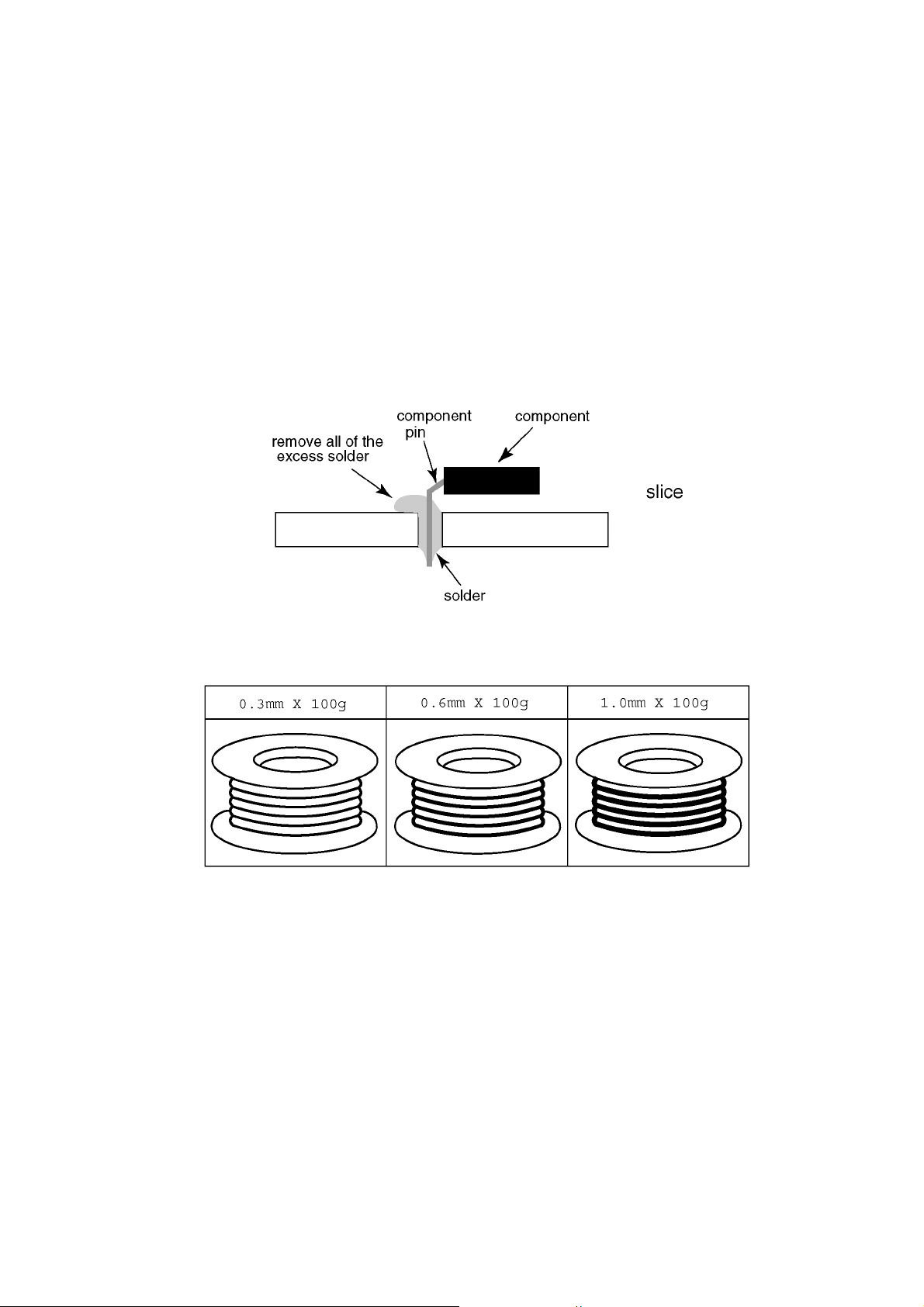

2.2. About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work, we’d

suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol PbF stamped on the back of PCB.

Caution

• Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40 °C) higher. Please

use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

• Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

• After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto the

opposite side. (see figure below)

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder. However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used.

5

Page 6

TH-42LF25W / TH-47LF25W

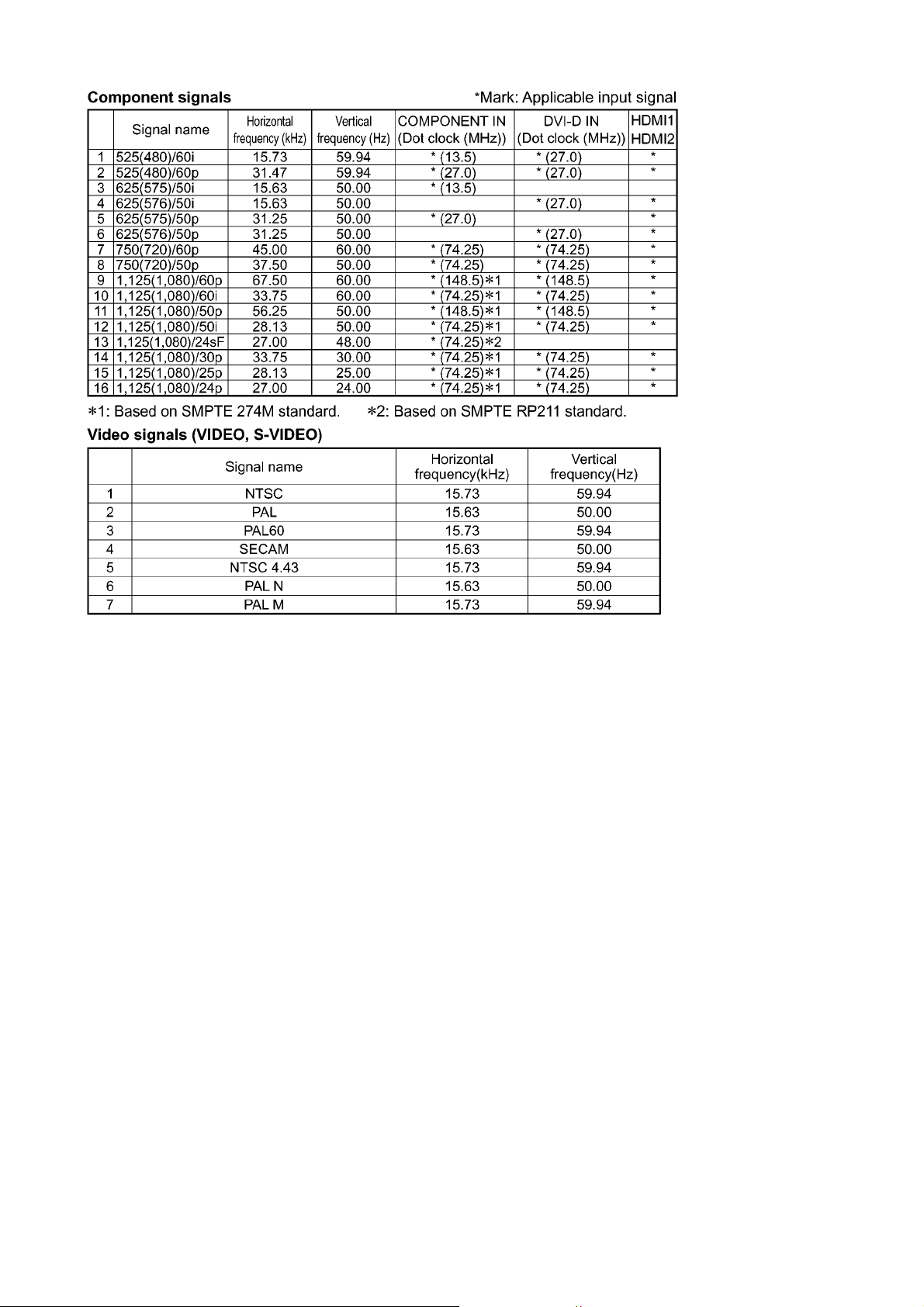

3 Service Navigation

3.1. Applicable signals

6

Page 7

TH-42LF25W / TH-47LF25W

7

Page 8

TH-42LF25W / TH-47LF25W

4 Specifications

Power Source 220 - 240 V AC, 50/60Hz

Power Consumption

Power on 240 W (42 inch) 290 W (47 inch)

Stand-by condition 0.2 W (42 inch) 0.2 W (47 inch)

Power off condition 0.2 W (42 inch) 0.2 W (47 inch)

LCD Display panel 42-inch IPS panel, 16:9 aspect ratio (42 inch) 47-inch IPS panel, 16:9 aspect ratio (47 inch)

Screen size 930 mm (W) × 523 mm (H) × 1,067 mm (diagonal) (42 inch)

1,040 mm (W) × 585 mm (H) × 1,193 mm (diagonal) (47 inch)

(No.of pixels) 2,073,600 (1,920 (W) × 1,080 (H)) (42 inch) 2,073,600 (1,920 (W) × 1,080 (H)) (47 inch)

[5,760 × 1,080 dots] [5,760 × 1,080 dots]

Operating condition

Temperature 0 °C - 40 °C

Humidity 20 % - 80 %

Applicable signals

Colour System NTSC, PAL, PAL60, SECAM, NTSC 4.43, PAL M, PAL N

Scanning format

PC signals VGA, SVGA, XGA, SXGA

Connection terminals

AV IN VIDEO BNC 1.0 Vp-p (75-ohm)

S-VIDEO Mini DIN 4PIN Y: 1.0 Vp-p (75-ohm), C: 0.286 Vp-p (75-ohm)

AUDIO L-R RCA Pin jack × 2 0.5 Vrms

HDMI 1/2 TYPE A Connector

COMPONENT / RGB IN

G/Y BNC with sync 1.0 Vp-p (75-ohm)

B/P

B/CB

R/P

R/CR

AUDIO L-R RCA Pin jack × 2 0.5 Vrms

DVI-D IN DVI-D 24 Pin Compliance with DVI Revision 1.0

AUDIO Stereo mini jack (M3) × 1 0.5 Vrms, Shared with PC IN

PC IN High-Density Mini D-sub 15 Pin G with sync 1.0 Vp-p (75-ohm)

AUDIO Stereo mini jack (M3) × 1 0.5 Vrms, Shared with DVI-D IN

SERIAL External Control Terminal

Sound

Speakers 50 mm × 90 mm × 2 pcs

Audio Output 10 W [5 W + 5 W] (10 % THD)

Accessories Supplied

Remote Control Transmitter N2QAYB000535

Batteries R6 Size × 2

Dimensions (W × H × D) 968 mm × 561 mm × 101 mm (42 inch) 1,079 mm × 624 mm × 101 mm (47 inch)

Mass (weight) approx. 18.0 kg (42 inch) approx. 23.0 kg (47 inch)

Note:

• Design and specifications are subject to change without notice. Mass and dimensions shown are approximate.

525 (480) / 60i 60p, 625 (575) / 50i 50p, 750 (720) / 60p 50p, 1125 (1080) /

60i 60p 50i 50p 24p 25p 30p 24sF

UXGA ..... (compressed)

Horizontal scanning frequency 30 - 110 kHz

Vertical scanning frequency 48 - 120 Hz

BNC 0.7 Vp-p (75-ohm)

BNC 0.7 Vp-p (75-ohm)

Content Protection Compatible with HDCP 1.1

G without sync 0.7 Vp-p (75-ohm)

B:0.7 Vp-p (75-ohm)

R:0.7 Vp-p (75-ohm)

HD / VD:1.0 - 5.0 Vp-p (high impedance)

D-sub 9 Pin RS-232C compatible

8

Page 9

5 Operating Instructions

TH-42LF25W / TH-47LF25W

9

Page 10

TH-42LF25W / TH-47LF25W

10

Page 11

6 Service Mode

6.1. Service Menu Function (1)

TH-42LF25W / TH-47LF25W

11

Page 12

TH-42LF25W / TH-47LF25W

6.2. Service Menu Function (2)

12

Page 13

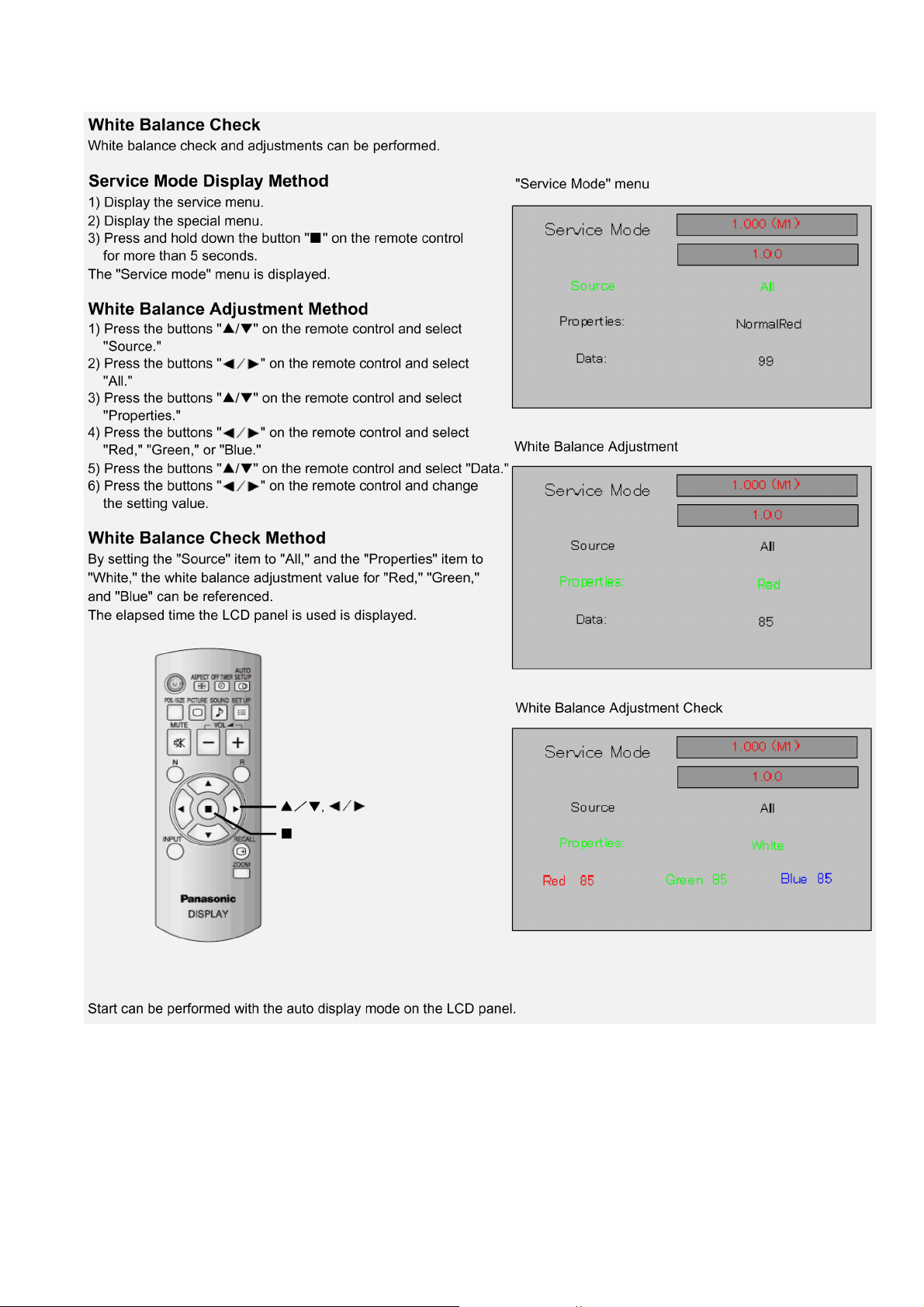

6.3. Service Mode Function (1)

TH-42LF25W / TH-47LF25W

13

Page 14

TH-42LF25W / TH-47LF25W

6.4. Service Mode Function (2)

14

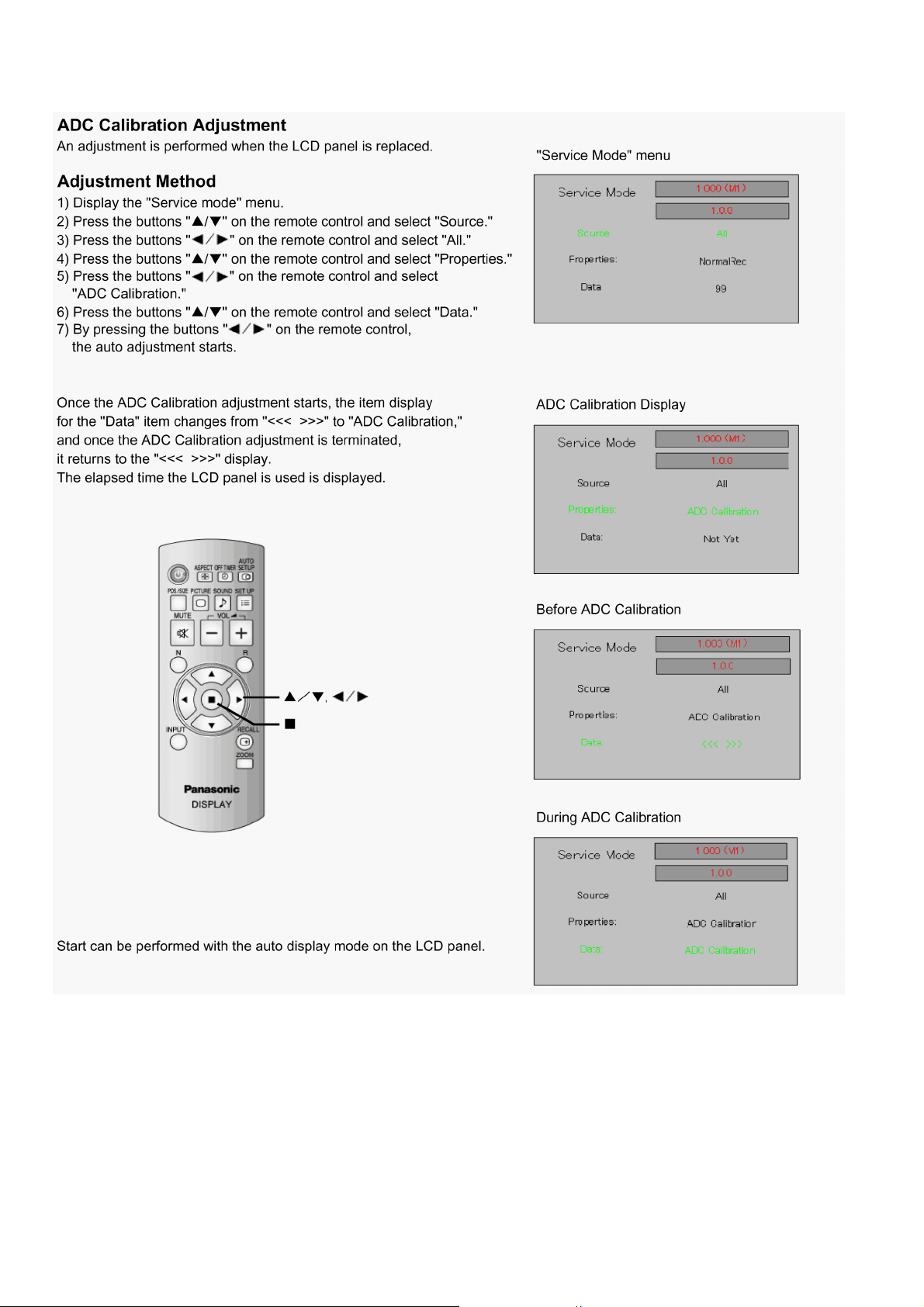

Page 15

7 Troubleshooting Guide

TH-42LF25W / TH-47LF25W

15

Page 16

TH-42LF25W / TH-47LF25W

8 Disassembly and Assembly Instructions

8.1. Flowchart for disassembly

16

Page 17

TH-42LF25W / TH-47LF25W

8.2. Preparations

To avoid damaging the LCD panel, lay out a soft cloth or towel

and lay down the unit so the front side is facing down.

Precautions when replacing each module

• Always perform the procedure below when replacing each

module.

• Be careful not to overtighten the screws when installing each

module.

8.3. Pedestal (option) removal

If the pedestal (option) is installed, remove the 2 screws for the

pedestal on each side, and then remove the pedestal.

8.4. Rear cover removal

First remove the 10 screws on the rear cover, and then remove

the rear cover. (SCR TPG BRZ 4x10)

Boards & Parts location

This unit is designed so that removing the rear cover reveals

the configuration of the boards.

17

Page 18

TH-42LF25W / TH-47LF25W

8.5. Replacement method for main board and jack board

1. The terminal section is screwed in from the outside, so

remove the screws as shown in the illustration.

2. Remove 1 screw on the jack board that screws in the

earth terminal which comes off from the left side of the

main board. (SCR PAN+SW+W 3X8)

3. Remove the 7 screws that screw the shield casing onto

the main board. (SCR PAN+SW+W 3X8)

4. Remove the coupler that is connected to the main board,

and then carefully remove the main board. Couplers on

the main board:

K16C, KSPR, KSPL, KLVP, K16B, K16A, K8F, K72E,

K72D

5. Replace the main board with the replacement board.

6. Remove the 4 screws that screw in the jack board.

(SCR PAN+SW+W 3X8)

7. Remove the couplers that is connected to the jack board

and carefully remove the jack board.

Couplers on the jack board: K39H, K39G, K19F, K10E,

K10D

8. Replace the jack board with the replacement board.

Precautions when removing and installing

• The lead wire is affixed to the shield casing on the main

board with aluminum foil tape. Re-use the shield casing

with the lead wire affixed as is.

• The gasket is affixed to both sides of the main board.

The gasket is not included on the replacement board, so

replace the gasket at the same time as well.

18

Page 19

TH-42LF25W / TH-47LF25W

8.6. Replacement method for

Power board

1. Remove the couplers that are connected to the Power

board.

Couplers on the Power board: K601, KIV2, KIV1, K6C,

K6B, K6A

8.7. Replacement method for AC cord bracket

1. Remove the K601 connector for the AC cord bracket from

the Power board.

2. Remove 1 screw that screws in the earth wire for the AC

cord.

Screw: SCR BIN 4X6

3. Pull out the AC cord bracket from the slit on the cabinet

back.

4. Remove the screws (Qty. 2) and nuts (Qty. 2) shown in

the illustration, and then remove the AC cord component.

Screw: SCR BRZ 3X10, Nut: NUT HEX 3

2. Remove the screws (47V type: 9 screws, 42V type: 8

screws) that screw the Power board in place. (SCR

PAN+SW+W 3X8) Pull out the boss (plastic) that holds

the Power board.

3. Remove the Power board carefully and replace it with the

replacement board. (The replacement board is equipped

with a fuse.)

5. Replace the AC cord.

Precautions when removing and installing

• The lead wire is affixed to the shield casing on the main

board with aluminum foil tape. Re-use the shield casing

with the lead wire affixed as is.

• The gasket is affixed to both sides of the main board.

The gasket is not included on the replacement board, so

replace the gasket at the same time as well.

19

Page 20

TH-42LF25W / TH-47LF25W

8.8. Cabinet back removal (42 type)

Precautions when removing and installing

• Be careful not to strip the screw's thread, etc., as the screws

that screw into the cabinet back's periphery impact the outward appearance.

• When re-installing the rear cover, be careful which holes the

wires come out from. (Refer to the wiring connection diagram)

1. Remove the screws (Qty. 23) on the periphery of the cabinet back. (SCR FLT 4X12)

2. Remove the screws (Qty. 4) on the inside part of the rear

cover. (SCR BIN 4X6)

3. Remove the cabinet back carefully.

8.10. When removing the cabinet back with the board connected

1. Remove the following board couplers.

Jack board: K39H

Main board: KLVP

Power board: KIV1, KIV2

2. Remove according to the previous section "Cabinet back

removal".

8.11. Replacement method for speakers

1. Remove the cabinet back.

2. Peel off the tape halfway that affixes the speaker lead on

the inside of the cabinet back, and then remove the

speaker lead. (Refer to the wiring connection diagram)

3. Remove the screws (Qty. 4 on each side) that screw in

the speaker unit and then replace it with the repair

speaker unit. (SCR S-TPG BRZ+FLG 3.0X8.0 V)

8.9. Cabinet back removal (47 type)

Precautions when removing and installing

• Be careful not to strip the screw's thread, etc., as the screws

that screw into the cabinet back's periphery impact the outward appearance.

• When re-attaching the cabinet back, be careful which holes

the wires come out from. (Refer to the wiring connection diagram)

1. Remove the screws.

2. Remove the cabinet back carefully.

8.12. Key SW board replacement

1. Remove the cabinet back.

2. Peel off the tape halfway that affixes the lead wire for the

key SW board on the inside of the cabinet back, and then

remove the lead wire. (Refer to the wiring connection diagram)

3. Remove the 4 screws and replace the key SW board.

(SCR S-TPG BRZ+FLG 3.0X8.0 V)

Precautions when installing

• The lead wire is affixed to the shield casing on the main

board with the earth part on the key SW board, do not

forget to install so the key SW board is at a right

angle.minum foil tape. Re-use the shield casing with the

lead wire affixed as is.

• Secure the speaker and key SW board lead wires down

onto the inside of the cabinet back with tape so they do

not pop up.

• When re-attaching the rear cover, be careful which holes

the wires come out from. (Refer to the wiring connection

diagram)

20

Page 21

TH-42LF25W / TH-47LF25W

8.13. Connector board removal

1. Peel off the tape halfway that affixes the FFC cable and

lead wire for the connector board to the rear side of the

LCD panel, and remove them from the rear side of the

panel. (Refer to the wiring connection diagram)

2. Remove the FFC cable (K38I) and the coupler (K38H)

from the connector board.

3. Remove the screw (Qty. 1), and remove the connector

board from the rear side of the LCD panel, and then

replace. (SCR PAN+SW 4X6)

8.14. LCD panel replacement

Precautions when replacing the LCD panel

• The 2 lead wires for the inverter (Couplers KIV1 and KIV2),

the black-out tape and the spacer sheet, etc., are supplied

already affixed to the LCD panel.

• The tape that is affixed to the FFC cable and the lead wires

on the connector board are supplied as repair parts. Replace

them at the same time as the LCD panel.

3. While widening the mounting that connects the cabinet

front and the LCD panel, remove the cabinet front from

the LCD panel. When lifting up the LCD panel, hold the

mounting component.

4. Remove the screws (Qty. 8), and then remove the mounting from the rear side of the LCD panel. (SCR BIN 4X6)

5. (47V type only) Remove the screws (Qty. 2) and then

remove the Power board holder fittings from the rear side

panel. (SCR BIN 4X4)

• The Power board holder fittings are not available in the

repair parts.

6. Replace the LCD panel with the replacement LCD panel.

7. Use 2 pieces of replacement aluminum foil tape and

cover the screw hole on the upper part of the mounting so

it is affixed to and crosses over the mounting top and the

rear side of the LCD panel.

1. Follow the procedure mentioned previously, and remove

the connector board, the FFC cable and the lead wire

from rear side of the LCD panel.

2. Peel off the 2 pieces of aluminum foil tape that are affixed

to and cross over the rear side of the LCD panel and the

upper part of the mounting that connects the cabinet front

and LCD panel.

21

Page 22

TH-42LF25W / TH-47LF25W

8.15. Replacement method for RC+LED board

1. Slide the 2 fittings on the inside of the cabinet front toward

the outside and remove.

2. Remove the FFC cable from the RC+LED board's coupler

(K19I), and replace the board with the replacement

board.

8.16. Cabinet front replacement

Precautions when replacing

• The parts that are necessary for replacement (spacer sheet,

Panasonic badge, etc.) are not included. They are supplied

as replacement parts. Replace them at the same time as the

cabinet front.

1. Remove the spacer sheet that is affixed to the inside of

the cabinet front.

2. Slide off the mounting and remove it from the cabinet

front.

3. When replacing the cabinet front, remove the shield RC

and the DEC LED (clear plate) on the inside.

The gasket is affixed to the shield RC. When replacing,

also replace the gasket.

4. The spacer sheet and the gasket are affixed to the fittings

that hold down the RC+LED board.

When replacing the fittings, also replace the spacer sheet

and the gasket.

3. Affix the Panasonic badge to the replacement cabinet

front beforehand.

22

Page 23

TH-42LF25W / TH-47LF25W

4. Install the RC+LED board onto the cabinet front.

5. Slide the mounting on and install it onto the cabinet front.

6. Affix the spacer sheet onto the mounting.

8.17. Cabinet back replacement

Precautions when replacing

• The parts that are necessary for replacement (DEC button,

DEC AV, etc.) are not included. They are supplied as

replacement parts. Replace them at the same time as the

cabinet back.

1. Remove each board, speaker and fitting from the cabinet

back.

2. Remove the screws (Qty. 4) shown in the illustration, and

remove the terminal holder fitting.

(SCR S-TPG BRZ+FLG 3.0X8.0 V)

7. Install the cabinet front, that is prepared beforehand, onto

the set.

3. Remove the screws shown in the diagram, and then

remove the main board holder fitting.

(42V type: Qty. 1 SCR S-TPG BRZ+FLG 3.0X8.0 V)

(47V type: Qty. 3 SCR S-TPG BRZ+FLG 3.0X8.0 V)

23

Page 24

TH-42LF25W / TH-47LF25W

4. (42 type only) Remove the screws shown in the illustration, and then remove the Power board holder fitting.

(SCR S-TPG BRZ+FLG 3.0X8.0 V)

5. Affix the DEC button and DEC AV beforehand to the

repair cabinet back.

When replacing the cabinet back, secure the lead wires

for the speaker and key SW board to the cabinet back

with replacement tape. The circle mark in the picture

below shows where to affix the tape. (Adhesive cloth

tape)

Caution

• Affix the tape so the lead wire is sealed tightly onto the

cabinet back. If the lead wire pops up, it may get close to

the board or a high temperature area and cause a chattering noise.

6. Install the main board holder fitting and the terminal

holder fitting to the replacement cabinet back.

7. Affix 3 pieces of aluminum tape to the metal section of the

main board holder fitting and the terminal holder fitting so

they are connected.

8. Install the replacement cabinet back, that is prepared

beforehand, onto the set.

Precautions for replacing

• The terminal holder fitting, the main board holder fitting,

and the Power board holder are available in the replacement parts.

• Use the gasket with the holder fitting that is affixed as is.

• The type of tape for affixing, in order to set up the lead

wire on the rear side of the cabinet back, is not included.

When replacing the cabinet back, also replace the type

of tape that is used.

When replacing the button unit that is installed onto the

key SW board, affix a spacer sheet onto the button unit.

24

Page 25

When replacing the cabinet back, secure the lead wires

for the speaker and main board to the cabinet back with

replacement tape.

TH-42LF25W / TH-47LF25W

25

Page 26

TH-42LF25W / TH-47LF25W

26

Page 27

9 Block Diagram

9.1. Block (1 of 2) Diagram

TH-42LF25W / TH-47LF25W

POWER BOARD

412V

L605

(42 ONLY)

1

MAX:AC264V/2.7A

NOISE

FILTER

K601

4

D603

4

2

1

IC633

1

11

12

IC602

400V

3

7

8

VSTR

LUVP

1

200V

2

MAX:AC264V/2.7A

14

15

16

OUT

HVG

VBOOT

DELAY

CSS

1

2

3CF4

9

10

42 :Q6801

47 :Q600,Q601,Q605,Q606

5

IC1601

OUT6VCC

GND

CS/FB

3

4

Q1606

MAX:AC264V/2.7A

5

8

1

2

3

4

13

N.C.

RFMIN

S/OCP

GND

FB/OLP

Q602

12

VCC

STBY

5

6

7

Q1601

400V

IC605

D/ST

D/ST

BR

VCC

11

LVG

ISEN

6

DC416V

8

7

5

10

GND

LINE

7

400/3A

9

PFC_STOP

DIS

8

Q604

400/3A

520V

Q604

D650

T6011

6

4

3

2

1

D651

D652

RL601

T652

1

2

3

4

5

COLDHOT

42 :T602

47 :T600

7

8

11

12

10

9

8

7

42 :PC603

47 :D6809

Q6800

Q613

Q612

MAIN-ON/OFF

24VP

24VH

5VSTB

24VP

12VH

12VA

24VH

24VP

Q690~692

Q614

Q615

PWR-30V

IC603

F_5V

Q684

Q685

SWICH1

SWICH

24VP

BLON

I_PWN

E_PWN

SEL

24VP

12VA

24VP

KIV1

KIV2

12

1

14

1

F_5V

12

11

10

9

8

7

6

5

4

3

2

1

14

13

12

11

10

9

8

7

6

5

4

3

2

1

BLON

I_PWN

E_PWN

SEL

12VA

Q607

ON/OFF

5VSTB

24VP

F_5V

MAIN-ON/OFF

SWICH1

SWICH

LCD PANEL

K6C

11

11

10

9

8

7

6

5

4

3

2

1

1

12VA

12VH

K6B

13

13

12

11

10

9

8

7

6

5

4

3

2

1

1

K6A

1

1

2

3

4

5

6

7

7

K16C

11

11

10

9

8

7

6

5

4

3

2

1

1

K16B

13

12

11

10

9

8

7

6

5

4

3

2

1

K16A

1

2

3

4

5

6

7

13

1

1

7

BLON

DCR_VBR

L6605

12V/24V_EN

L6604

L6603

MCU_5V

MAIN_EN

SWICH2

SWICH1

SWICH

KLVP

12V_PWR

Q6620

P_FAIL1

24V

P_FAIL1

IC6600

2

3

7

12VPAN_EN

OPC_EN

PANEL_12V

5VSTB

Q6621

P_FAIL1

5VSTB

3.3V_I/O

DCR_VBR

DCR_IN

3.3V_I/O

PEL-TEST

PANEL_12V

12V

MAIN BOARD

IC7501

3

Q7501

8

7

6

IC7505

3

3

123

678

PWM1

OPC_EN

PEL-TEST

BLON

DCR_VBR

12VPAN_EN

MAIN_EN

SWICH2

SWICH1

SWICH

P_FAIL1

4

2

1

1

2

3

45

4

2

1

4

IC7503

2

1

45

9

MAIN CHIP

IC7200

(NEXT PAGE)

3.3VSTB

4

IC7504

3

2

Q7502

3.3V_DDR

3.3V_SW

IC5503

1

8

7

2

3

6

4

5

9

0.9_DDR_VREF

4

IC7506

3

2

1

1.2V

1.8V_DDR

3.3V

1.2VSTB

1

5VSTB

5VD_PWR

3.3V_AUD

1.2V_AUD

3.3V

3.3V_LBADC

3.3V_I/O

3.3V_LVDS

3.3V_ADC

3.3V_HDMI

1.8V_DDR

1.2V

1.2V_CORE

1.2V_ADC

1.2V_DPRX

1.2V_HDMI

Q4001

IC6612

27

Page 28

TH-42LF25W / TH-47LF25W

9.2. Block (2 of 2) Diagram

12V_PWR

IC2009

MUTE

IC2010

AMP_STBY

IC8134

12V

OUT_R

TO POWER BOARD

FROM CONNECTOR BORD K16A

SP-LSP-R

TX

RX

DRXD

DTXD

5VSTB

Q7206

IC2006

KEY_POWER

LED_GREEN

UART-SW

RXD1

3.3VSTB

IC2005

TXD1

AV1_ Y

AV1_C

AV1_S

AV3_CVBS+

KEY 0

LED_RED

LIGHT_DET

AV_IN_L

AV_IN_R

PC_R

PC_L

DVI_IN_L

DVI_IN_R

AV2_Y/G

AV2_PB/R

AV2_PR/B

VGA_G/Y

VGA_R/PB

VGA_B/PR

H_SINC

V_SINC

VGA_IIC

TXD0

RXD1

UART-SW

Cross

Point

Switch

MUX

TXD1

Main Chip

IC7200

Triple

10-bit

ADC 1

Triple

10-bit

ADC 2

Digital

Input

DVI \

HDMI

Display

Port Rx

ADC

inputs,

I2S\

SPDIF Rx

3D Video

Decoder

Audio

Mux

VBI Data

Processor

I2S SPDIF Tx

IC5500

Audio

DSP

MCU_5V

IC2007

MCU_5V

RXD0

RTC

IC2008

SUB MCU

IC7201

10

IC2003

PC_DET

SYNC_DET

20

19

IR

18

17

16

15

14

5VD_PWR

13

12

11

SWICH

KSPLKSPR

R+

43

PVD144PVD1

MUTE

STBY

VIN1+

L-

R-

L+

36

OUT1-37OUT1-41OUT1+42OUT1+

PLC

VIN2+

25

OUT2+26OUT2+30OUT2-31OUT2-

45

RXD0

MCU_5V

TXD0

AUDIO AMP.

IC001

SPEAK_SW_R

Q615

MAIN_EN

SWICH2

SWICH1

SWICH

OUT_L

SWH-SPEK

RS-232C SW

DDR SDRAM

IC5501

Memory

Controller

DCDi, Motion Adaptive

De-interlacing, Scaling,

Shaping Filter,

2nd Channel

Processing +

DCDi EdgeTM

Audio

DAC

OSD

Controller

Enhancer, ACC II,

ACM-3D, 3x3 Matrix,

PicBlend, CLUTs,

OSD Blend

3x3 Matrix

Embedded

Microprocessor

I2C BUS

LVDS Tx

Output

Formatter

Display

Port Tx

General

Purpose

I \ O

SPI Interface

ADC

IR I/F

MAIN BOARD

PWM1

OPC_EN

PEL-TEST

TO LCD PANEL

FROM CONNECTOR BOARD(KLVP)

EEPROM

MSTR1_SCL

MSTR1_SDA

SPI Serial

SPI_CEN

SPI_DI

SPI_DO

SPI_CLK

FAIL P_FAIL 1

IC8001

IC8000

Q7207

Q7208

KEY SW BOARD

ENTER

POS+

POS-

MENU

INPUT

SW1906

SW1902SW1903SW1904SW1905

K19G

SW1901

MCU5V

IC1951

IR

GREEN

RED

IC1952

D1951

IOUT

VCC

GREEN

3.3STB

BACKLIGHT

RED

GND

K19I

IR

5V

K39H

RC+LED BOARD

K39G

3.3VSTB

Q1902

Q1901

KEY0

K19F

IC2012

LIGHT_DET

BACKLIGHT

KEY-POWER

5VD

3.3VSTB

RED

IR

GREEN

3.3STB

SWICH2(F-5V)

SWICH1

AV1_C

K72E K72D

K10E K10D

AV1_C

3.3VSTB

JACK BOARD

RX

TX

RS232C

IN

AV1_Y

AV1_Y

AV1_C

DVI_IN_L

DVI_IN_L

DVI_IN_R

Y / C

IN

DVI_IN_R

AV1_Y

TX

AV1_S

TX

RX

RX

DVI_IN_R

DVI

L / R

IN

DVI_IN_L

AV3

CVBS

PC_L

PC_R

PC_R

PC_L

PC_L

AV3_CVBS+

L / R

IN

AV_IN_L

AV3_CVBS+

AV3_CVBS+

AV_IN_L

PC_R

PC

IN

AV_IN_R

AV_IN_R

AV_IN_L

AV_IN_R

AV

L / R

IN

AV1_S

AV1_S

MUTE

OUT_R

AMP_STBY

PC_DET

Q1501

Q1502

Q1503

OUT_L

SWH-SPEK

MCU_5V

IC804

RTC

REAL TIME CLOCK

VGA_R/PB

VGA_G/Y

SDA

SCL

H_SINC

VGA_B/PR

PC IN

RTC

V_SINC

CLOCKOUT

CLOCKOUT

IIC

SCL

SDA

EEPROM

IC1501

VGA_IIC

POW_SINK

HDMI_SDA

HDMI_SCL

SYNC_DET

Q2001

Q2003

HDMI1_DATA_CLOCK

3.3VSTB

IC805

AV2_Y/G

AV2

HDMI_HPD

AV2_PR/B

AV2_PB/R

IN

HDMI/DVI-D SW

IC750

HDMI1_HPD

HDMI1_SDA

HDMI1_SCL

HDMI1_DATA_CLOCK

HD5V1

HDMI1_HPD

HD5V1

Q310

HDMI1_CEC

+5V

HDMI1_IIC

HDMI1_DATA_CLOCK

HDMI 1

IN

POW_SINK

HDMI_SDA

HDMI_SCL

HDMI2_HPD

HDMI2_SDA

HDMI2_IIC

HDMI2_DATA_CLOCK

HDMI 2

HDMI1_DATA_CLOCK

IIC

HDMI2_SCL

HDMI2_DATA_CLOCK

HD5V2

HDMI2_CEC

+5V

IN

SCL

HD5V2

HDMI2_HPD

Q311

SDA

HD5V3

TMDS_DATA_CLOCK

HDMI_HPD

Q701

3.3VSTB

TMDS_DATA_CLOCK

DVI_SCL

DVI_SDA

HOT_PLUG

HD5V3

+5V

DVI_IIC

DVI-D

HOT_PLUG

Q309

28

Page 29

10 Wiring Connection Diagram

10.1. Wiring Connection Diagram (1)

TH-42LF25W / TH-47LF25W

29

Page 30

TH-42LF25W / TH-47LF25W

30

Page 31

10.2. Wiring Connection Diagram (2)

TH-42LF25W / TH-47LF25W

31

Page 32

TH-42LF25W / TH-47LF25W

10.3. Wiring Connection Diagram (3)

32

Page 33

10.4. Wiring Connection Diagram (4)

TH-42LF25W / TH-47LF25W

33

Page 34

TH-42LF25W / TH-47LF25W

11 Exploded View and Replacement Parts List

11.1. Exploded View and Mechanical Replacement Parts List

11.1.1. Exploded View

11.1.1.1. Cabinet front (1)

34

Page 35

11.1.1.2. Cabinet front (2)

TH-42LF25W / TH-47LF25W

35

Page 36

TH-42LF25W / TH-47LF25W

11.1.1.3. Lid back

36

Page 37

11.1.1.4. Screws for Cabinet back (42”)

TH-42LF25W / TH-47LF25W

37

Page 38

TH-42LF25W / TH-47LF25W

11.1.1.5. Screws for Cabinet back (47”)

38

Page 39

11.1.1.6. Cabinet back (42”)

TH-42LF25W / TH-47LF25W

39

Page 40

TH-42LF25W / TH-47LF25W

11.1.1.7. Cabinet back (47”)

40

Page 41

11.1.1.8. Inside of Cabinet back

TH-42LF25W / TH-47LF25W

41

Page 42

TH-42LF25W / TH-47LF25W

11.1.1.9. Screws for board (42”)

42

Page 43

11.1.1.10. Screws for board (47”)

TH-42LF25W / TH-47LF25W

43

Page 44

TH-42LF25W / TH-47LF25W

11.1.1.11. Screws for board holder (42”)

44

Page 45

11.1.1.12. Screws for board holder (47”)

TH-42LF25W / TH-47LF25W

45

Page 46

TH-42LF25W / TH-47LF25W

11.1.1.13. Gasket around the AC inlet and Main board

46

Page 47

11.1.1.14. Wire, Panel mounting bracket

TH-42LF25W / TH-47LF25W

47

Page 48

TH-42LF25W / TH-47LF25W

11.1.1.15. Packing, Accessories (42”)

48

Page 49

11.1.1.16. Packing, Accessories (47”)

TH-42LF25W / TH-47LF25W

49

Page 50

TH-42LF25W / TH-47LF25W

11.2. Mechanical Replacement Parts List (42 inch)

Safety Ref.

1 T6103566948 CABINET FRONT

2 TBMA162 PANASONIC BADGE

4 T6103528212 SPACER SHEET 4

5 T6550038838 SPACER SHEET 4

6 T6103578989 ASSY,MTG CF & CB 4

7 T6103578996 ASSY,MTG CF & CB

8 T6103579009 ASSY,MTG CF & CB

13 T6103579016 ASSY,MOUNTING

16 T6103579023 ASSY,SHIELD RC 1

17 T6103504179 DEC LED 1

19 T6451037602 FLEXIBLE FLAT

20 T6103504148 LID BACK 1

21 T4112062406 SCREW TPG BRZ

22 T6103566856 LABEL RATING 1

23 T6103511931 LABEL FOR WARNED 1

24 T6103504407 LABEL FOR AC

25 T4112168603 SCREW FLT 4X12 23

26 T4111899003 SCREW BIN 4X6 13

27 T6103530932 CABINET BACK

32 T6103531052 DEC BUTTON

33 T6103504421 DEC AV ENGLISH 1

34 T6103579030 BUTTON UNIT ASSY 1

35 T6103450971 EARTH LVDS 1

36 T4111926402 SCR S-TPG

38 T6520036871 L-SPEAKER,8 SER-

39 T6520036888 R-SPEAKER,8 SER-

40 T6550022554 ADHESIVE CLOTH

44 T4110365509 SCREW PAN+SW+W

45 T6103505701 FIXER BOSS B 1

46 T6103505695 FIXER BOSS 1

47 T4110418403 SCREW PAN 3X6 1

49 T3120730406 SPECIAL SCREW 6

50 T4110759407 SCREW TPG BRZ

51 T4110418601 SCREW PAN 3X6 2

52 T6103579047 AC HOLDER ASSY 1

53 T6103505688 FIXER AC CORD A-11

Part No. Part Name &

No.

Description

ASSY

LOGO SHEET

TOP

BTM

DEC

CABLE

(4X10)

CORD

ASSY

ENGLISH

BRZ+FLG 3.0X8.0

V

VICE

VICE

TAPE

3X8

3X8

Pcs Remarks

1

1

1

1

2

1

10

1

1

1

25

1

1

16

19

3

Safety Ref.

65 T6103579054 ASSY,MOUNTING

66 T6103579061 ASSY,MOUNTING

67 T6103567211 CASE ACCESSORIES 1

68 T6103567242 CARTON CASE 1

69 T6103504537 BAG 1

70 T6103566801 CUSHION TOP 1

71 T6103566818 CUSHION BTM 1

73 K2CK3YY00016 AC CORD(Oblique

74 TMMX169 FIXER AC CORD B-12

75 N2QAYB000535 REMOTE CONTROL 1

76 T6103528281 BAG MANUAL 1

78 T6103567617 INSTRUCTIONS

78 T6103567624 INSTRUCTIONS

86 T6103519784 FIXER CABLE 1

87 T4111922503 SCREW PAN+SW 4X6 1

89 T6103531670 T-ALUMINUM 2

90 T6103533506 T-ALUMINUM A 2

91 T6103575193 HEAT CAUTION

93 T6103534107 T-ALUMINUM C 1

94 T6103535043 T-EPOXY 2

95 K2CN3YY00004 AC CORD(Round 2

96 K2CT3YY00016 AC CORD(Rectan-

97 TMMX168-1 FIXER AC CORD B-21

Part No. Part Name &

No.

PANEL C

PANEL D

flat blade) -

2.0MK

MANUAL

MANUAL (ARABIC)

CARD

pins) -2.0MK

gular blade)-

2.0MK

T6451051493 LCD ASSY FHD 1

T6520033184 CORD, 51P-

T6103556185 STANDARD WIRE

T6103556208 STANDARD WIRE

T6103556215 STANDARD WIRE

T6103556246 STANDARD WIRE

T6103556277 STANDARD WIRE

T6103556307 STANDARD WIRE

T6103556369 STANDARD WIRE

51P(LVDS)

(K39G-K19G)

(K16A-K6A)

ASSY-JPN (K38HK39H)

(K72E-K10E)

ASSY-JPN (K16CK6C)

(K72D-K10D)

ASSY-JPN (K16BK6B)

Description

Pcs Remarks

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

55 T6520033634 AC INLET-150MM

56 T4112205902 SCREW BRZ 3X10 2

57 T4112206206 NUT HEX 3 2

59 T6103407241 GASKET AW 1

60 T6103341279 GASKET AW 2

61 T9550003837 FIXER HOOK 3

62 T9101305540 FIXER

64 T6520019041 CORE,CLAMP 1

SERVICE

HOOK,D13(PP)

1

1

50

Page 51

11.3. Mechanical Replacement Parts List (47 inch)

TH-42LF25W / TH-47LF25W

Safety Ref.

1 T6103566955 CABINET FRONT

2 TBMA162 PANASONIC BADGE

4 T6103528212 SPACE SHEET 4

5 T6550038821 SPACER SHEET 2

6 T6103578989 ASSY,MTG CF & CB 4

7 T6103580005 ASSY,MTG C/F &

8 T6103580012 ASSY,MTG C/F &

13 T6103579016 ASSY,MOUNTING

16 T6103579023 ASSY,SHIELD RC 1

17 T6103504179 DEC LED 1

19 T6451037602 FLEXIBLE FLAT

20 T6103511887 LID BACK 1

21 T4112062406 SCREW TPG BRZ

22 T6103566900 LABEL RATING 1

23 T6103511931 LABEL FOR WARNED 1

24 T6103504407 LABEL FOR AC

25 T4112168603 SCREW FLT 4X12 26

26 T4111899003 SCREW BIN 4X6 11

27 T6103553122 CABINET BACK

32 T6103531052 DEC BUTTON 1

33 T6103504421 DEC AV ENGLISH 1

34 T6103579030 BUTTON UNIT ASSY 1

35 T6103450971 EARTH LVDS 1

36 T4111926402 SCR S-TPG

38 T6520036871 L-SPEAKER,8 SER-

39 T6520036888 R-SPEAKER,8 SER-

40 T6550022554 ADHESIVE CLOTH

44 T4110365509 SCREW PAN+SW+W

45 T6103505701 FIXER BOSS B 1

49 T3120730406 SPECIAL SCREW 6

50 T4110759407 SCREW TPG BRZ

51 T4110418601 SCREW PAN 3X6 2

52 T6103579047 AC HOLDER ASSY 1

53 T6103505688 FIXER AC CORD A-11

55 T6520033412 AC INLET-150MM

56 T4112205902 SCREW BRZ 3X10 2

57 T4112206206 NUT HEX 3 2

59 T6103407241 GASKET AW 1

60 T6103341279 GASKET AW 2

61 T9550003837 FIXER HOOK 3

64 T6520019041 CORE,CLAMP 1

67 T6103567211 CASE ACCESSORIES 1

68 T6103567280 CARTON CASE 1

69 T6103507200 BAG 1

70 T6103566825 CUSHION TOP 1

71 T6103566832 CUSHION BTM 1

Part No. Part Name &

No.

Description

ASSY

LOGO SHEET

C/B TOP

C/B BTM

DEC

CABLE

(4X10)

CORD

ASSY

BRZ+FLG 3.0X8.0

V

VICE

VICE

TAPE

3X8

3X8

SERVICE

Pcs Remarks

1

1

1

1

2

1

10

1

1

19

1

1

25

20

3

1

Safety Ref.

73 K2CK3YY00016 AC CORD(Oblique

74 TMMX169 FIXER AC CORD B-

75 N2QAYB000535 REMOTE CONTROL 1

76 T6103528281 BAG MANUAL 1

78 T6103567617 INSTRUCTIONS

78 T6103567624 INSTRUCTIONS

80 T6550038838 SPACER SHEET 2

81 T6103580029 ASSY,MTG PANEL

82 T6103580036 ASSY,MTG PANEL

83 T6103552361 MTG PANEL BTM LA1

84 T6103552378 MTG PANEL BTM RA1

85 T6103567310 SPACER CUSHION

86 T6103519784 FIXER CABLE 1

87 T4111922503 SCREW PAN+SW 4X6 1

88 T4111898907 SCREW BIN 4X4 2

89 T6103531670 T-ALUMINUM 2

90 T6103533506 T-ALUMINUM A 2

91 T6103575193 HEAT CAUTION

92 T6103537528 POLY SHEET

93 T6103534107 T-ALUMINUM C 1

94 T6103535043 T-EPOXY 1

95 K2CN3YY00004 AC CORD(Round 2

96 K2CT3YY00016 AC CORD(Rectan-

97 TMMX168-1 FIXER AC CORD B-

Part No. Part Name &

No.

flat blade) -

2.0MK

1-N9AB

MANUAL

MANUAL (ARABIC)

TOP L

TOP R

BTM

CARD

1700X1300 NC

pins) -2.0MK

gular blade)-

2.0MK

T6451051509 LCD ASSY FHD 1

T6103556192 STANDARD WIRE

T6103556208 STANDARD WIRE

T6103556215 STANDARD WIRE

T6103556246 STANDARD WIRE

T6103556277 STANDARD WIRE

T6103556307 STANDARD WIRE

T6103556369 STANDARD WIRE

T6520033184 CORD, 51P-

2-N9AC

(K39G-K19G)

(K16A-K6A)

ASSY-JPN (K38HK39H)

(K72E-K10E)

ASSY-JPN (K16CK6C)

(K72D-K10D)

ASSY-JPN (K16BK6B)

51P(LVDS)

Description

Pcs Remarks

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

51

Page 52

TH-42LF25W / TH-47LF25W

11.4. Electrical Replacement Boards list (42 inch)

Note: All boards are Non serviceable.

Safety Ref.

15 T6103500829 CIRCUIT BOARD

37 T6103500836 CIRCUIT BOARD

41 T6103565026 CIRCUIT BOARD

42 T6103568188 CIRCUIT BOARD

43 T6103500812 CIRCUIT BOARD

63 T6103516394 CIRCUIT BOARD

Part No. Part Name &

No.

Description

RC+LED

KEY SW

POWER

MAIN

JACK

CONNECTOR

Pcs Remarks

1

1

1

1

1

1

11.5. Electrical Replacement Boards list (47 inch)

Note: All boards are Non serviceable.

Safety Ref.

15 T6103500829 CIRCUIT BOARD

37 T6103500836 CIRCUIT BOARD

41 T6103565033 CIRCUIT BOARD

42 T6103565002 CIRCUIT BOARD

43 T6103500812 CIRCUIT BOARD

63 T6103516394 CIRCUIT BOARD

Part No. Part Name &

No.

Description

RC+LED

KEY SW

POWER

MAIN

JACK

CONNECTOR

Pcs Remarks

1

1

1

1

1

1

11.6. Boards Layout

Ref.No. Board Name Function Remarks

15 RC+LED Remote Receiver, LED

37 KEY SW Control Button

41 POWER

42 MAIN Main, Audio & Video Signal Processor, HDMI in, PC in

43 JACK AV Terminal

63 CONNECTOR Connection board for RC+LED

Power (AC/DC), DC-DC

Non serviceable

P-Board should be exchanged for service.

All boards are Non serviceable.

52

Loading...

Loading...