Page 1

ORDER NO.MTNC100328CE

B01 Canada: B61

42 inch Class 1080p LCD HDTV

Model No. TC-L42U22

LA03 Chassis

© Panasonic Corporation 2010.

Unauthorized copying and distribution is a violation

of law.

Page 2

TABLE OF CONTENTS

PAGE PAGE

1 Safety Precautions -----------------------------------------------3

1.1. General Guidelines ----------------------------------------3

2 Warning --------------------------------------------------------------4

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices ----------4

2.2. About lead free solder (PbF) ----------------------------5

3 Service Navigation------------------------------------------------6

3.1. Service Hint--------------------------------------------------6

3.2. Applicable signals------------------------------------------6

4 Specifications------------------------------------------------------7

5 Service Mode-------------------------------------------------------8

5.1. How to enter into Service Mode------------------------8

5.2. SRV-TOOL-------------------------------------------------10

5.3. Hotel mode------------------------------------------------- 11

5.4. Data Copy by SD Card ---------------------------------12

6 Troubleshooting Guide---------------------------------------- 15

6.1. Check of the IIC bus lines------------------------------15

6.2. Power LED Blinking timing chart-------------- -------16

6.3. No Power--------------------------------------------------- 17

7 Disassembly and Assembly Instructions---------------18

7.1. Pedestal ----------------------------------------------------18

7.2. Rear cover ------------------------------------------------- 1 8

7.3. AC cord-----------------------------------------------------18

7.4. P-Board-----------------------------------------------------18

7.5. Side AV bracket-------------------------------------------19

7.6. A-Board-----------------------------------------------------19

7.7. Control panel---------------------------------------------- 19

7.8. Speaker-----------------------------------------------------19

7.9. Metal bracket CH frame --------------------------------20

7.10. Metal bracket P top & Metal bracket P right-------20

7.11. Metal bracket vertical------------------------------------ 20

7.12. Metal bracket----------------------------------------------21

7.13. Barrier-------------------------------------------------------21

7.14. LCD Panel -------------------------------------------------21

7.15. V-Board-----------------------------------------------------21

7.16. EMI processing -------------------------------------------22

8 Measurements and Adjustments --------------------------30

8.1. Voltage chart of A-board--------------------------------30

8.2. Picture level adjustment (RF) -------------------------30

9 Block Diagram ---------------------------------------------------31

9.1. Main Block Diagram-------------------------------------31

9.2. Block (1/2) Diagram -------------------------------------32

9.3. Block (2/2) Diagram -------------------------------------33

10 Wiring Connection Diagram---------------------------------35

10.1. Caution statement.---------------------------------------35

10.2. Wiring -------------------------------------------------------35

11 Sch ematic Diagram--------------------------------------------- 37

11.1. Schematic Diagram Notes----------------------------- 37

11.2. A-Board (1/12) Schematic Diagram -----------------38

11.3. A-Board (2/12) Schematic Diagram -----------------39

11.4. A-Board (3/12) Schematic Diagram -----------------40

11.5. A-Board (4/12) Schematic Diagram -----------------41

11.6. A-Board (5/12) Schematic Diagram -----------------42

11.7. A-Board (6/12) Schematic Diagram -----------------43

11.8. A-Board (7/12) Schematic Diagram -----------------44

11.9. A-Board (8/12) Schematic Diagram -----------------45

11 .10. A-Board (9/12) Schematic Diagram----------------- 46

11.11. A-Board (10/12) Schematic Diagram ---------------47

11.12. A-Board (11/12) Schematic Diagram --------------- 48

11.13. A-Board (12/12) and V-Board Schematic

Diagram---------------------------------------------------- 49

12 Printed Circuit Board------------------------------------------ 50

12.1. A-Board ---------------------------------------------------- 50

12.2. V-Board----------------------------------------------------- 52

13 Exploded View and Replacement Parts List----------- 53

13.1. Exploded View and Mechanical Replacement

Parts List--------------------------------------------------- 53

13.2. Electrical Replacement Parts List ------------------- 57

2

Page 3

1 Safety Precautions

1.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

4. When conducting repairs and servicing, do not attempt to modify the equipment, its parts or its materials.

5. When wiring units (with cables, flexible cables or lead wires) are supplied as repair parts and only one wire or some of the

wires have been broken or disconnected, do not attempt to repair or re-wire the units. Replace the entire wiring unit instead.

6. When conducting repairs and servicing, do not twist the Faston connectors but plug them straight in or unplug them straight

out.

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohmmeter,

between the jumpered AC plug and each exposed metallic cabinet part on the equipment such as screwheads,

connectors, control shafts, etc. When the exposed metallic part has a return path to the chassis, the reading

should be 100 Mohm and over.

When the exposed metal does not have a return path to

the chassis, the reading must be .

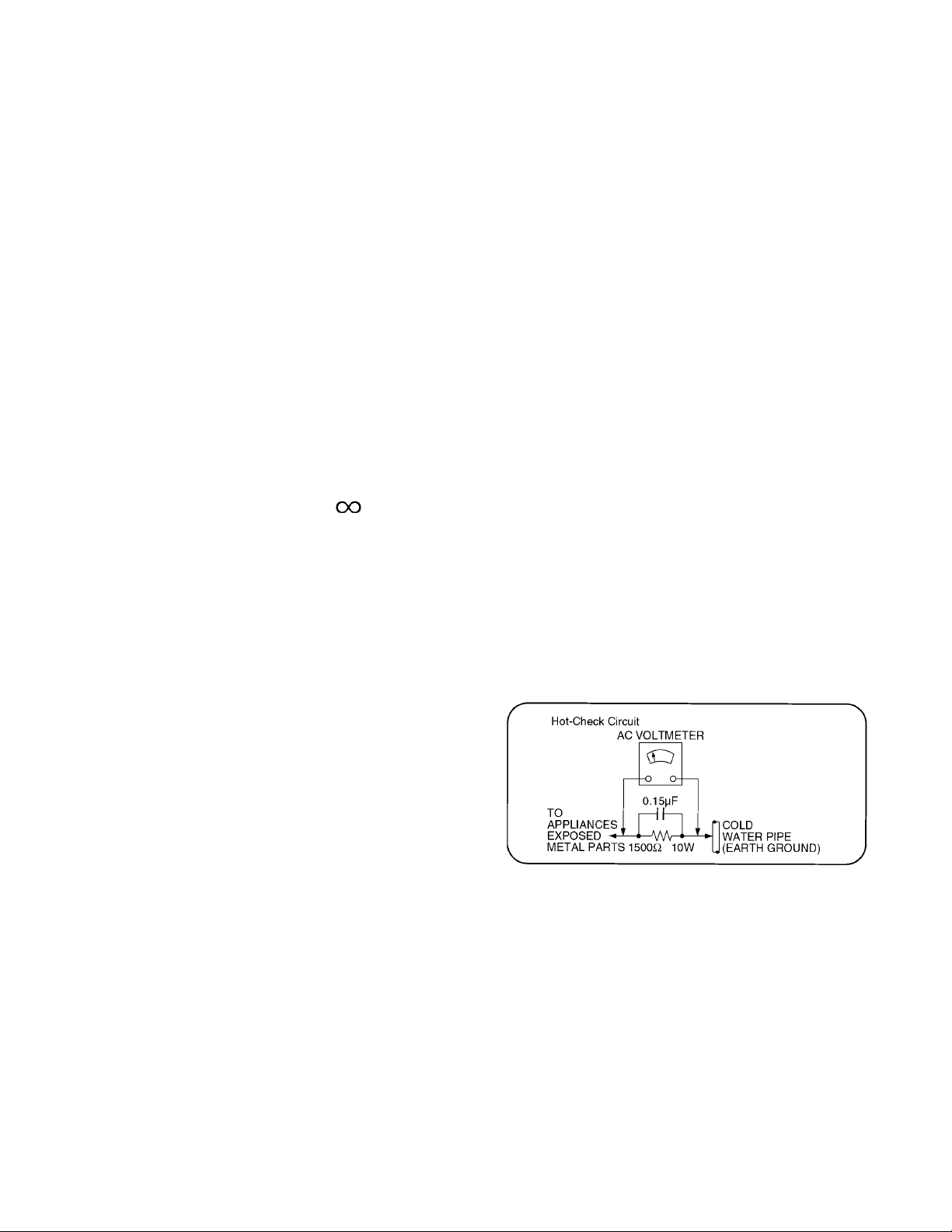

1.1.2. Leakage Current Hot Check (See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer for this check.

2. Connect a 1.5kohm, 10 watts resistor, in parallel with a

0.15μF capacitors, between each exposed metallic part

on the set and a good earth ground such as a water pipe,

as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks, leakage

current must not exceed 1/2 milliamp. In case a measurement is outside of the limits specified, there is a possibility

of a shock hazard, and the equipment should be repaired

and rechecked before it is returned to the customer.

Figure 1

3

Page 4

2 Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor [chip] components. The following techniques should be used to help reduce the incidence of component damage

caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as [anti-static (ESD protected)] can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise ham less motion such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient

to damage an ES device).

4

Page 5

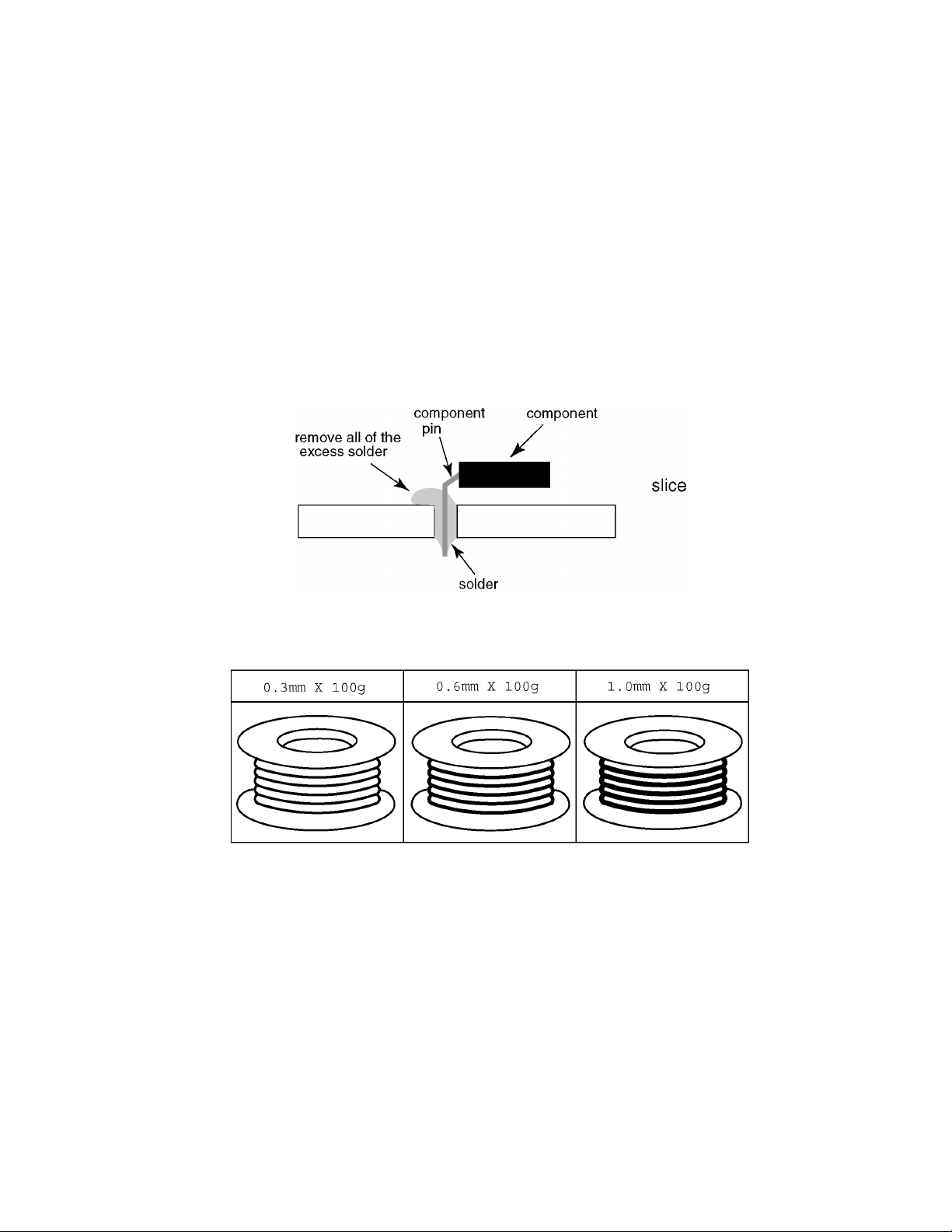

2.2. About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work, we’d

suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol PbF stamped on the back of PCB.

Caution

• Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40 °C) higher. Please

use a high temperature soldering iron and set it to 700 ± 20 °F (37 0 ± 10 °C).

• Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

• After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto the

opposite side. (see figure below)

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder. However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used.

5

Page 6

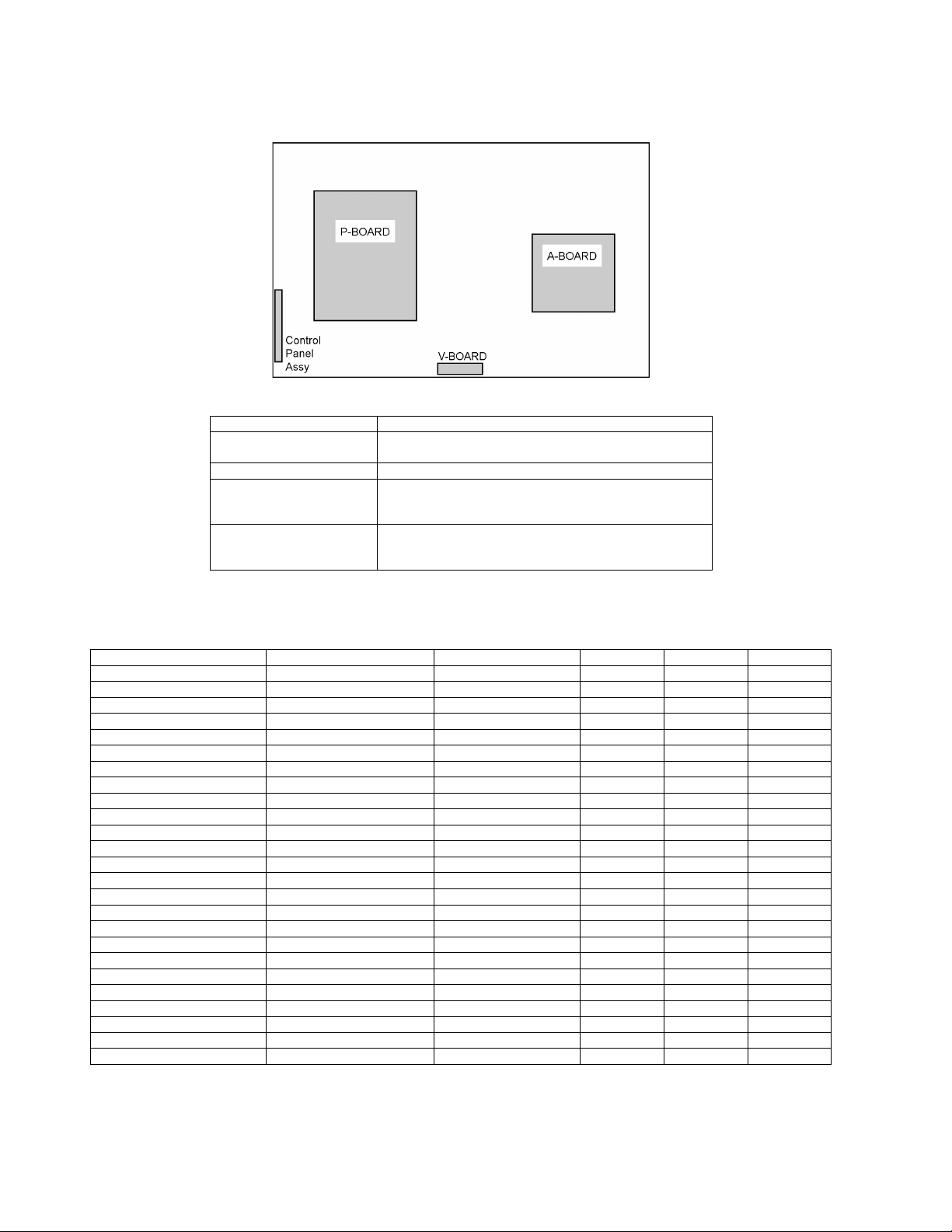

3 Service Navigation

3.1. Service Hint

Board Name Function

A-Board Speaker out, AV Terminal, HDMI in, SD Card, PC in,

V-Board Remote Receiver, LED

P-Board Power (AC/DC), DC-DC

Control Panel Assy Control Button, Power switch

Digital Signal Processor, Nile-Tcon, Tuner

Non serviceable

P-Board should be exchanged for service.

Non serviceable

Control Panel Assy should be exchanged for service.

3.2. Applicable signals

* Mark: Applicable input signal for Component (Y, PB, PR), HDMI and PC

horizontal frequency (kHz) vertical frequency (Hz) COMPONENT HDMI PC

525 (480) / 60i 15.73 59.94 * *

525 (480) /60p 31.47 59.94 * *

750 (720) /60p 45.00 59.94 * *

1,125 (1,080) /60i 33.75 59.94 * *

1,125 (1,080) /60p 67.43 59.94 *

1,125 (1,080) /60p 67.50 60.00 *

1,125 (1,080) /24p 26.97 23.98 *

1,125 (1,080) /24p 27.00 24.00 *

640 × 400 @70 31.47 70.08 *

640 × 480 @60 31.47 59.94 *

Macintosh13 inch (640 × 480) 35.00 66.67 *

640 × 480 @75 37.50 75.00 *

852 × 480 @60 31.44 59.89 *

800 × 600 @60 37.88 60.32 *

800 × 600 @75 46.88 75.00 *

800 × 600 @85 53.67 85.08 *

Macintosh16 inch (832 × 624) 49.73 74.55 *

1,024 × 768 @60 48.36 60.00 *

1,024 × 768 @70 56.48 70.07 *

1,024 × 768 @75 60.02 75.03 *

1,024 × 768 @85 68.68 85.00 *

Macintosh 21 inch (1,152 ×870) 68.68 75.06 *

1,280 × 768 @60 47.78 59.87 *

1,280 × 1,024 @60 63.98 60.02 *

1,366 × 768 @60 48.39 60.04 *

Note

• Signals other than above may not be displayed properly.

• The above signals are reformatted for optimal viewing on your display.

6

Page 7

4 Specifications

Power Source AC 110-127 V, 60 Hz

Power Consumption

Maximum 199 W

Standby Condition 0.3 W

Display panel

Aspect Ratio 16:9

Visible screen size 42 inch class (42.0 inches measured diagonally)

(W × H × Diagonal) 36.6 inch × 20.6 inch × 42.0 inch (930 mm × 523 mm × 1,067 mm)

(No. of pixels) 2,073,600 (1,920 (W) × 1,080 (H)) [5,760 × 1,080 dots]

Sound

Speaker 1-way 2 speakers slim under SP System

Audio Output 20 W [10 W + 10 W] ( 10 % THD )

PC signals VGA, SVGA, XGA, WXGA, SXGA

Channel CapabilityATSC/NTSC (Digital/Analog)

Operating Conditions Temperature: 32 °F - 95 °F (0 °C - 35°C)

Connection Terminals

VIDEO IN 1-2 VIDEO: RCA PIN Type × 1 1.0 V [p-p] (75 Ω)

COMPONENT IN Y: 1.0 V [p-p] (including synchronization)

HDMI 1-3 TYPE A Connector × 3.

PC D-SUB 15PIN: R,G,B / 0.7 V [p-p] (75 Ω)

Card slot SD CARD slot × 1

DIGITAL AUDIO OUT PCM / Dolby Digital, Fiber Optic

FEATURES 3D Y/C FILTER, CLOSED CAPTION,

Dimensions (W × H × D)

Including TV stand 40.2 inch × 26.8 inch × 12.2 inch (1,021 mm

TV Set only 40.2 inch × 25.1 inch × 4.2 inch (1,021 mm × 637 mm × 105 mm)

Mass

Including TV stand 45.2 lb. (20.5 kg) NET

TV Set only 39.7 lb. (18.0 kg) NET

Horizontal scanning frequency 31 - 69 kHz

Vertical scanning frequency 59 - 86 Hz

VHF/ UHF: 2 - 69, CATV: 1 - 135

Humidity: 20 % - 80 % RH (non-condensing)

AUDIO L - R: RCA PIN Type × 2 0.5 V [rms]

PB, PR: ±0.35 V [p-p]

AUDIO L-R: RCA PIN Type × 2 0.5 V [rms]

O This TV supports [HDAVI Control 5] function.

HD, VD / 1.0 - 5.0 V [p-p] (high impedance)

V-Chip, HDAVI Control 5

Vesa compatible, VIERA IMAGE VIEWER

× 680

mm × 310 mm)

Note

Design and Specifications are subject to change without notice. Mass and Dimensions shown are approximate.

7

Page 8

5 Service Mode

5.1. How to enter into Service Mode

While pressing [VOLUME ( - )] button of the main unit, press [INFO] button of the remote control three times within 2 seconds.

5.1.1. Key command

[1] button...Main items Selection in forward direction

[2] button...Main items Selection in reverse direction

[3] button...Sub items Selection in forward direction

[4] button...Sub items Selection in reverse direction

[VOL] button...Value of sub items change in forward direction ( + ), in reverse direction ( - )

8

Page 9

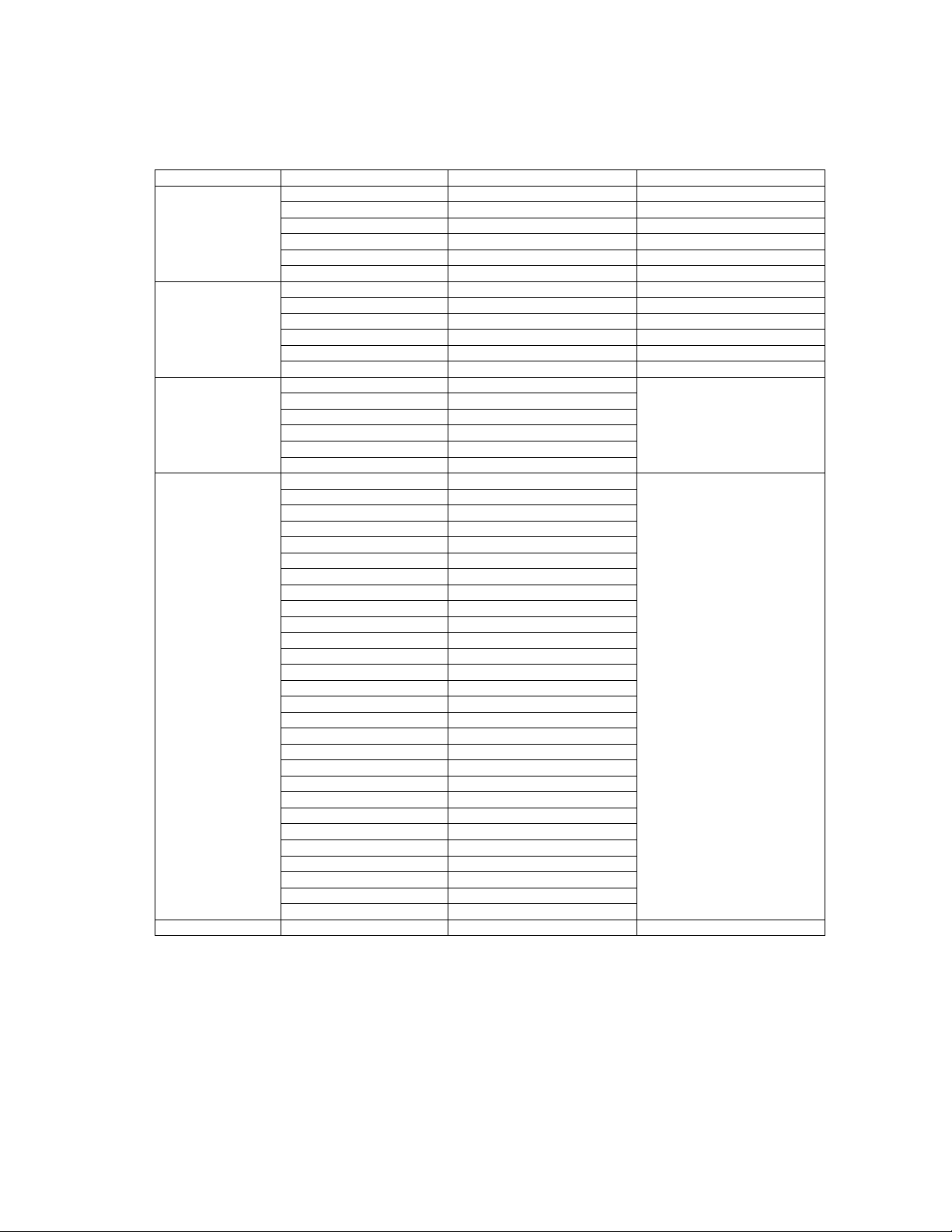

5.1.2. Contents of adjustment mode

• Value is shown as a hexadecimal number.

• Preset value differs depending on models.

• After entering the adjustment mode, take note of the value in each item before starting adjustment.

Main item Sub item Sample Data Remark

ADJUST CONTRAST 01

COLOR 00

TINT 00

SUB-BRT 000

BACKLGT 9FFF

V COM 1B4

WB-ADJ R-GAIN F7

G-GAIN FB

B-GAIN DB

R-CENT 82

G-CENT 80

B-CENT 86

OPTION Boot ROM Factory Preset.

STBY-SET 00

EMERGENCY ON

CLK MODE OFF

CLOCK FC4

EDID-CLK HIGH

AGING COUNT Built-in test patterns can be

ALL WHITE

ALL BLACK

ALL RED

ALL GREEN

ALL_BLUE

RASTER1

RASTER2

RASTER3

RASTER4

4DIN1

4DIN2

GRAY WHITE

GRAY RED

GRAY GREEN

GRAY BLUE

FLICKER0

GS1

1 PIX STRIPE

2 PIX STRIPE

1 LINE_STRIPE

COLORBAR

WIDHT COLORBAR

OUTER

LIGHT CHECK

FLICKER1

FLICKER2

FLICKER3

SRV-TOOL 00 See next.

displayed.

5.1.3. How to exit

Switch off the power with the [POWER] button on the main unit or the [POWER] button on the remote control.

9

Page 10

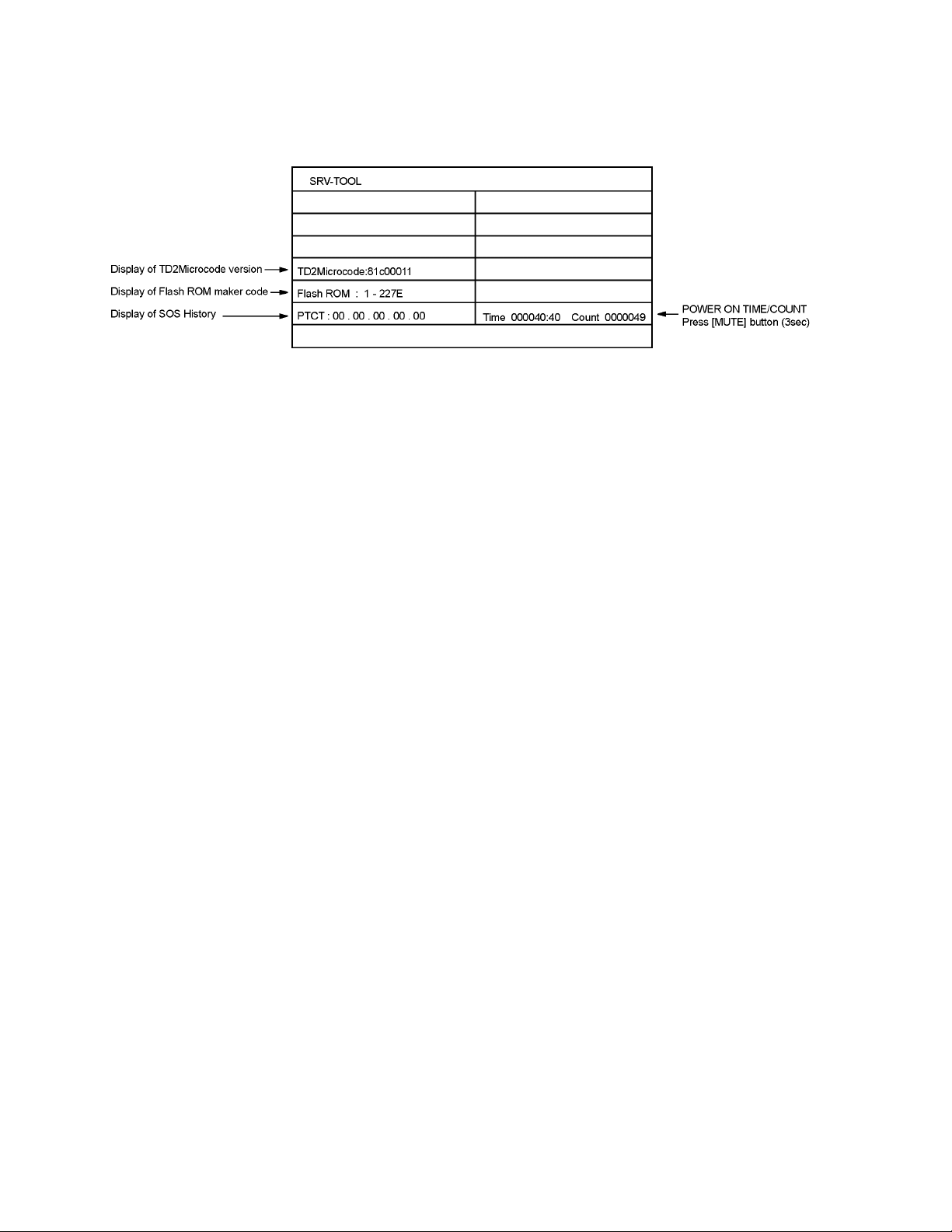

5.2. SRV-TOOL

5.2.1. How to access

1. Select [SRV-TOOL] in Service Mode.

2. Press [OK] button on the remote control.

5.2.2. Display of SOS History

SOS History (Number of LED blinking) indication.

From left side; Last SOS, before Last, three occurrence before, 2nd occurrence after shipment, 1st occurrence after shipment.

This indication except 2nd and 1st occurrence after shipment will be cleared by [Self-check indication and forced to factory shipment setting].

5.2.3. POWER ON TIME/COUNT

Note : To display TIME/COUNT menu, highlight position, then press MUTE for 3sec.

Time : Cumulative power on time, indicated hour : minute by decimal

Count : Number of ON times by decimal

Note : This indication will not be cleared by either of the self-checks or any other command.

5.2.4. Exit

1. Disconnect the AC cord from wall outlet.

10

Page 11

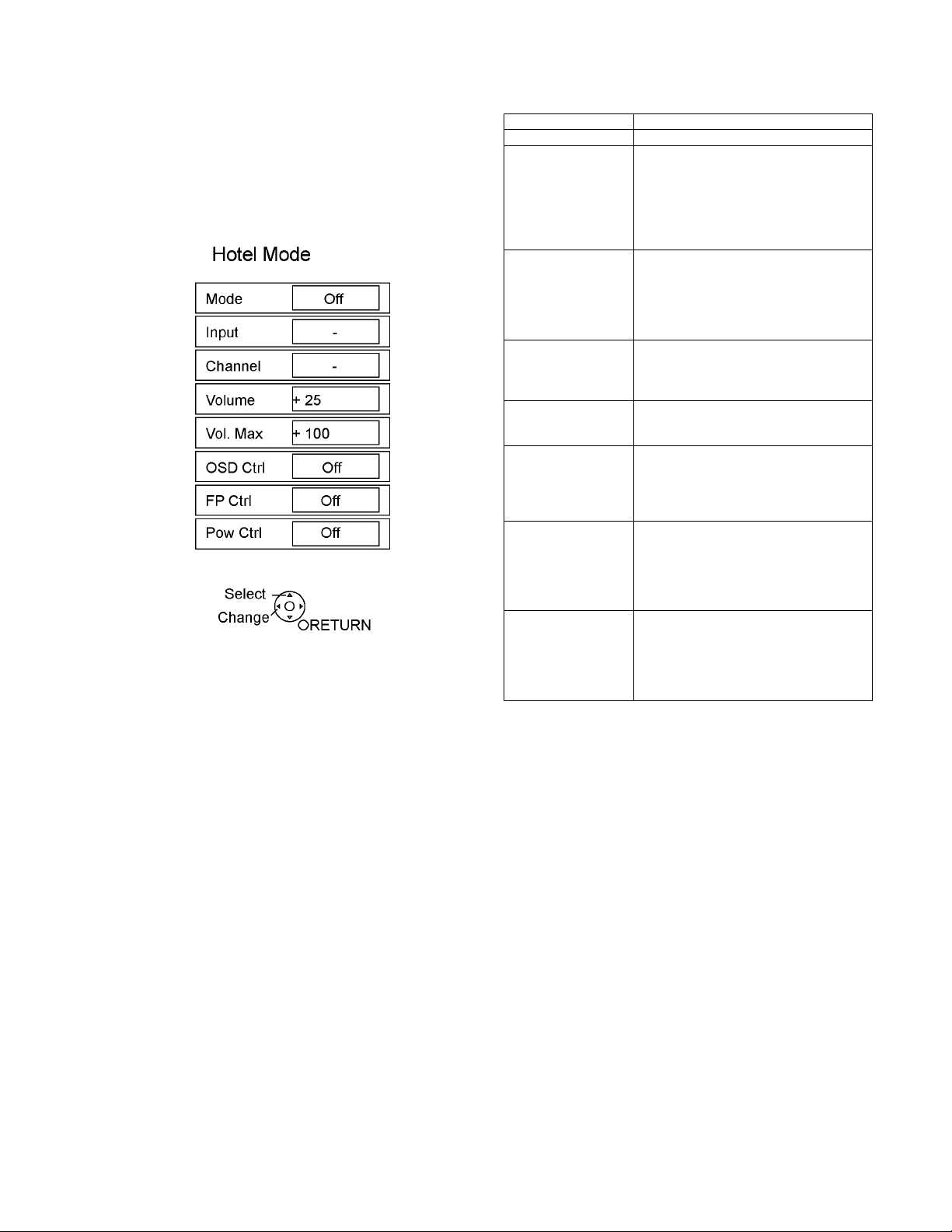

5.3. Hotel mode

1. Purpose

Restrict a function for hotels.

2. Access command to the Hotel mode setup menu

In order to display the Hotel mode setup menu, please

enter the following command (within 2 second).

[TV] : Vol. [Down] + [REMOTE] : INPUT (3 times)

Then, the Hotel mode setup menu is displayed.

3. To exit the Hotel mode setup menu

Disconnect AC power cord from wall outlet.

4. Explain the Hotel mode setup menu

item Function

Mode Select hotel mode off/on

Input Select input signal modes.

Set the input, when each time power is

switched on.

Selection:

-/RF/HDMI1/HDMI2/HDMI3/Component/

Video1/Video2/PC

• OFF: give priority to a last memory.

Channel Select channel when input signal is RF.

Set the channel, each time power is switched

on.

Selection:

Any channel number or [-].

[-] means the channel when turns off.

Volume Adjust the volume when each time powe r is

switched on.

Range:

0 to 100

Vol. Max Adjust maximum volume.

Range:

0 to 100

OSD Ctrl Restrict the OSD.

Selection:

OFF/PATTERN1

• OFF: No restriction

• PATTERN1: restriction

FP Ctrl Selec t front key conditions .

Selection:

OFF/ALL/PATTERN1

• OFF: altogether valid.

• ALL: altogether invalid.

• PATTERN1: only input key is valid.

Pow Ctrl Select POWER-ON/OFF con dition when AC

power cord is disconnected and then connected.

OFF: The same condition when AC power

cord is disconnected.

ON: Forced power ON condition.

11

Page 12

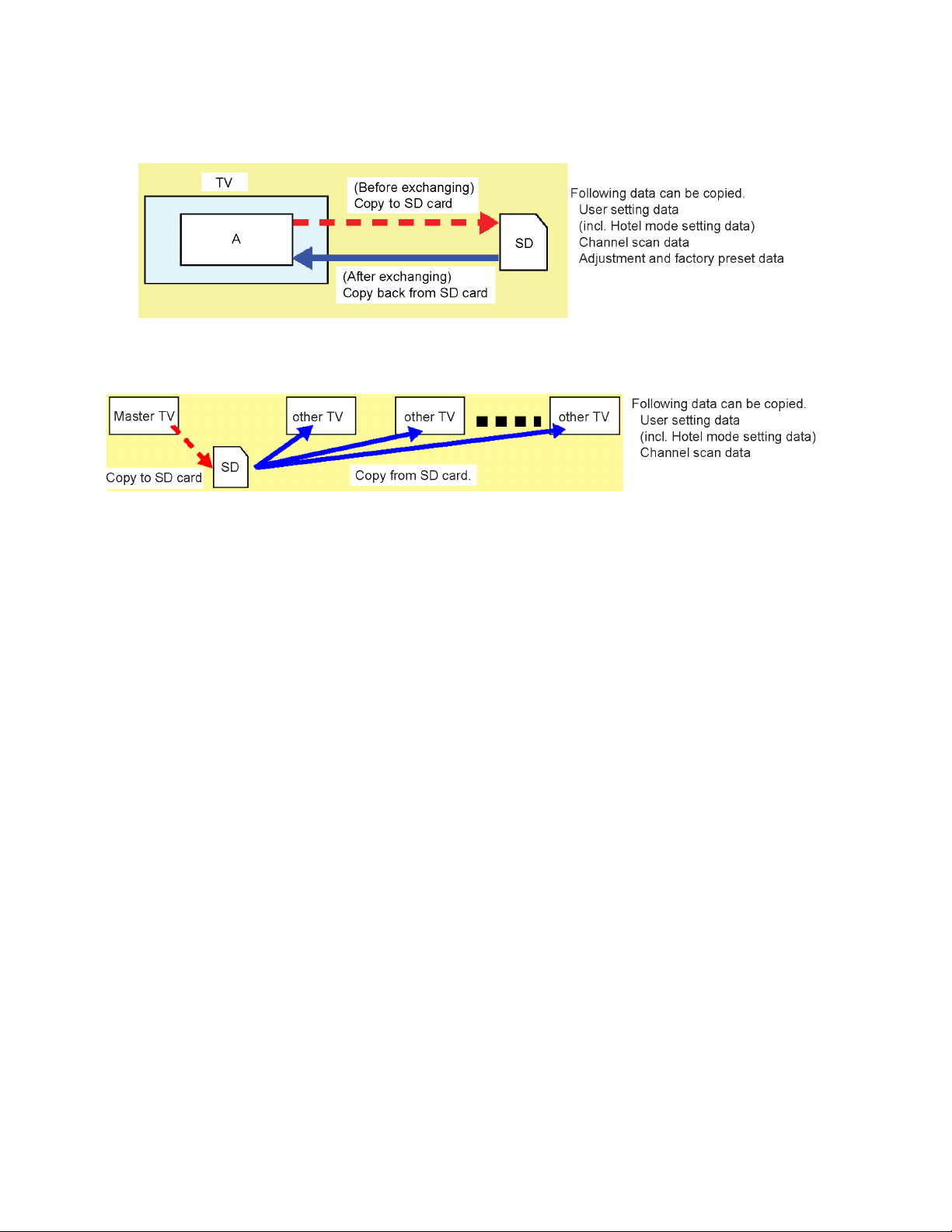

5.4. Data Copy by SD Card

5.4.1. Purpose

(a) Board replacement (Copy the data when exchanging A-board):

When exchanging A-board, the data in original A-board can be copied to SD card and then copy to new A-board.

(b) Hotel (Copy the data when installing a number of units in hotel or any facility):

When installing a number of units in hotel or any facility, the data in master TV can be copied to SD card and then copy to other

TVs.

5.4.2. Preparation

Make pwd file as startup file for (a) or (b) in a empty SD card.

1. Insert a empty SD card to your PC.

2. Right-click a blank area in a SD card window, point to New, and then click text document. A new file is created by default

(New Text Document.txt).

3. Right-click the new text document that you just created and select rename, and then change the name and extension of the

file to the following file name for (a) or (b) and press ENTER.

File name:

(a) For Board replacement : boardreplace.pwd

(b) For Hotel : hotel.pwd

Note:

Please make only one file to prevent the operation error.

No any other file should not be in SD card.

12

Page 13

5.4.3. Data copy from TV set to SD Card

1. Turn on the TV set.

2. Insert SD card with a startup file (pwd file) to SD slot.

On-screen Display will be appeared according to the startup file automatically.

3. Input a following password for (a) or (b) by using remote control.

(a) For Board replacement : 2770

(b) For Hotel : 4850

Data will be copied from TV set to SD card.

It takes around 2 to 6 minutes maximum for copying.

4. After the completion of copying to SD card, remove SD card from TV set.

5. Turn off the TV set.

Note:

Following new folder will be created in SD card for data from TV set.

(a) For Board replacement : user_setup

(b) For Hotel : hotel

13

Page 14

5.4.4. Data copy from to SD Card to TV set

1. Turn on the TV set.

2. Insert SD card with Data to SD slot.

On-screen Display will be appeared according to the Data folder automatically.

3. Input a following password for (a) or (b) by using remote control.

(a) For Board replacement : 2771

(b) For Hotel : 4851

Data will be copied from SD card to TV set.

4. After the completion of copying to SD card, remove SD card from TV set.

(a) For Board replacement : Data will be deleted after copying (Limited one copy).

(b) For Hotel : Data will not be deleted and can be used for other TVs.

5. Turn off the TV set.

Note:

1. Depending on the failure of boards, function of Data copy for board replacement does not work.

2. This function can be effective among the same model numbers.

14

Page 15

6 Troubleshooting Guide

Use the self-check function to test the unit.

1. Checking the IIC bus lines

2. Power LED Blinking timing

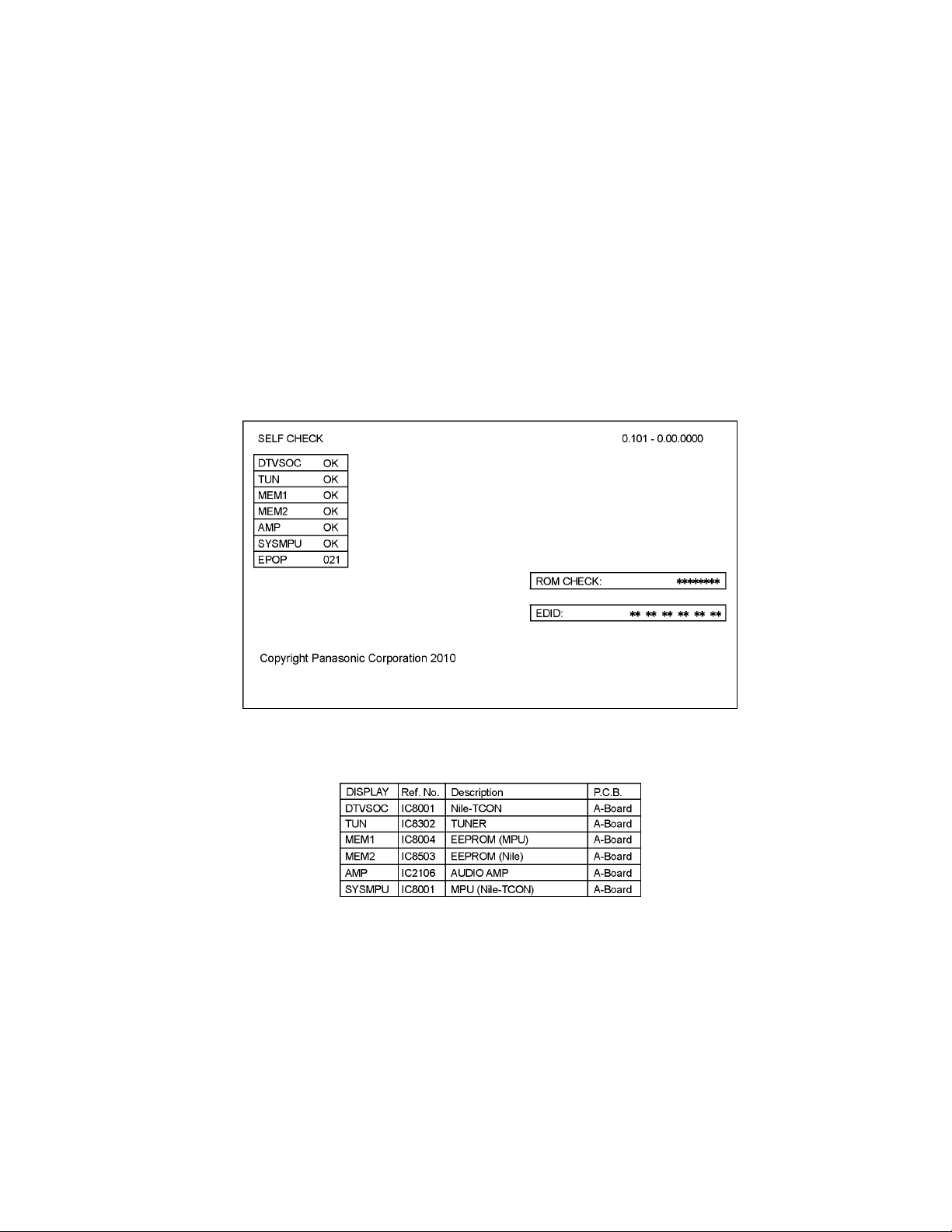

6.1. Check of the IIC bus lines

6.1.1. How to access

Self-check indication only:

Produce TV reception screen, and while pressing [VOLUME ( - )] button on the main unit, press [OK] button on the remote control

for more than 3 seconds.

Self-check indication and forced to factory shipment setting:

Produce TV reception screen, and while pressing [VOLUME ( - )] button on the main unit, press [MENU] button on the remote con-

trol for more than 3 seconds.

6.1.2. Exit

Disconnect the AC cord from wall outlet.

6.1.3. Screen display

6.1.4. Check Point

Confirm the following parts if NG was displayed.

15

Page 16

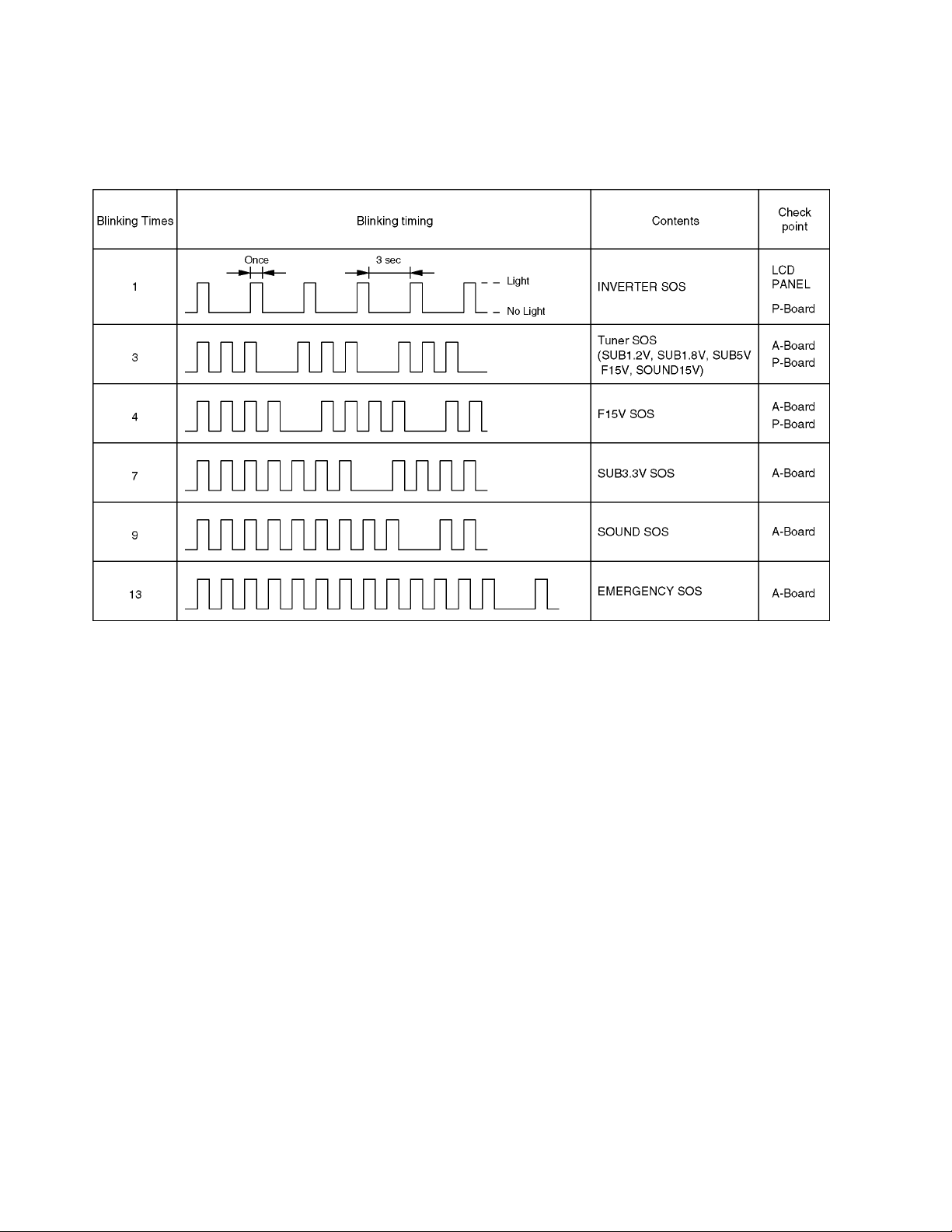

6.2. Power LED Blinking timing chart

1. Subject

Information of LED Flashing timing chart.

2. Contents

When an abnormality has occurred the unit, the protection circuit operates and reset to the stand by mode. At this time, the

defective block can be identified by the number of blinks of the Power LED on the front panel of the unit.

16

Page 17

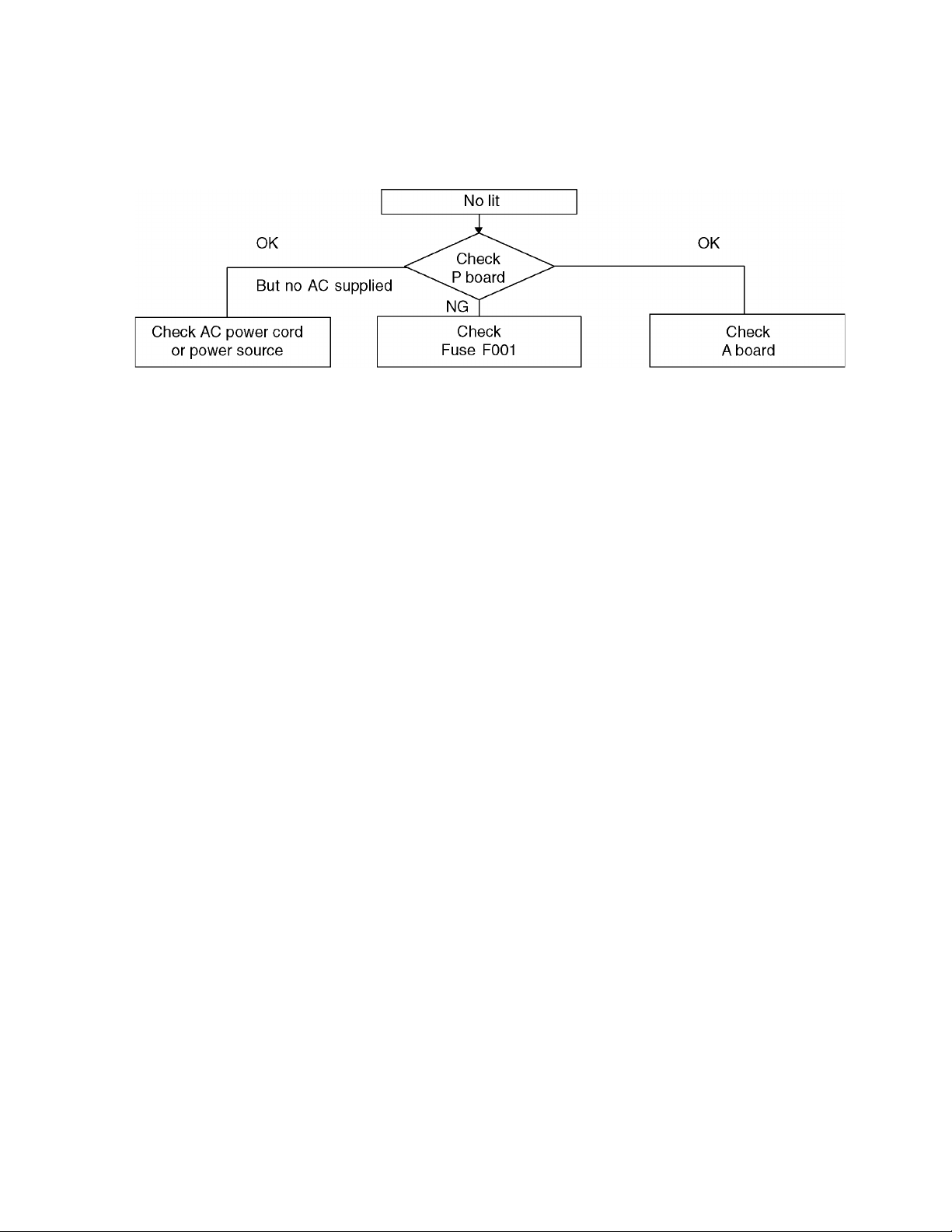

6.3. No Power

First check point

There are following 2 states of No Power indication by power LED.

1. No lit

2. Red is lit then turns red blinking a few seconds later. (See 6.2.)

17

Page 18

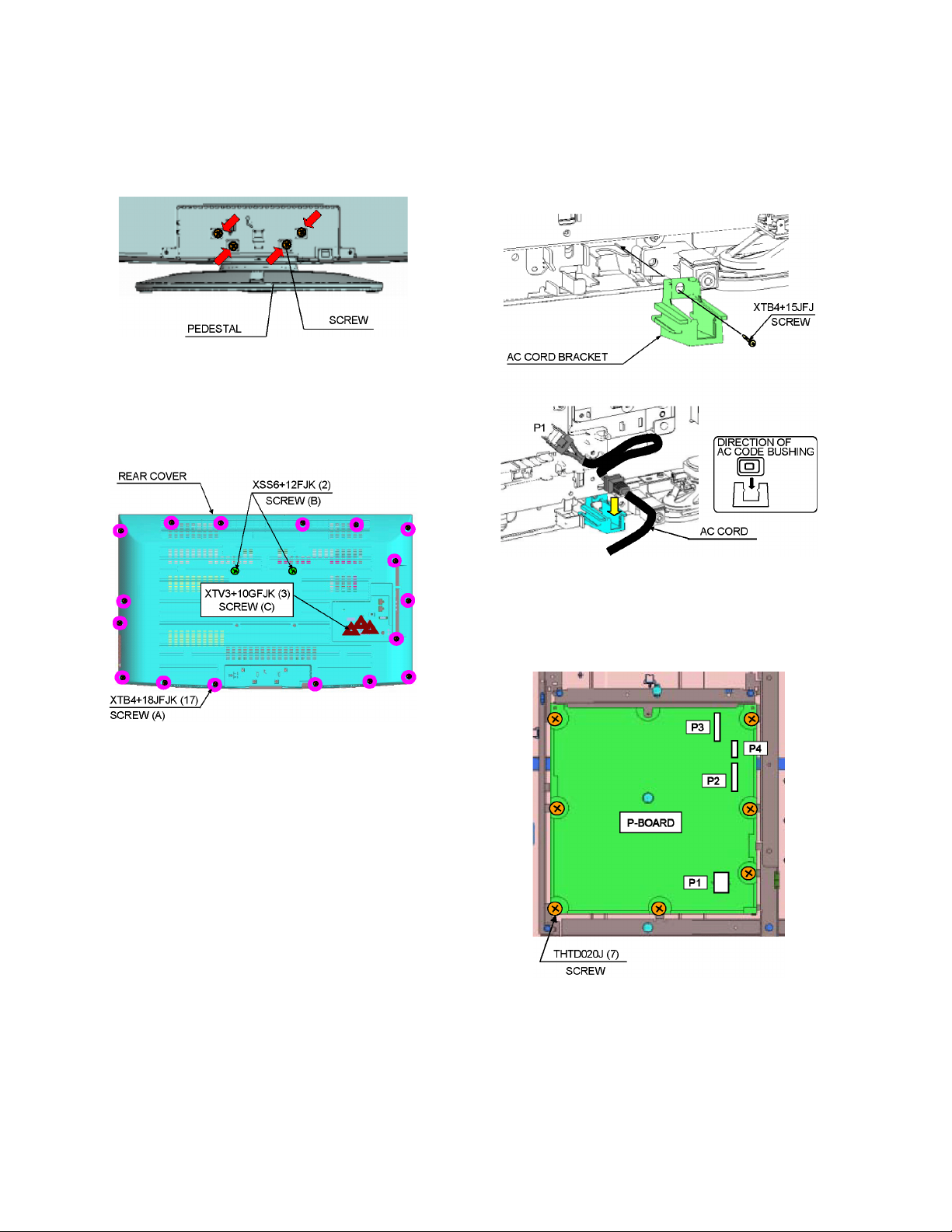

7 Disassembly and Assembly Instructions

7.1. Pedestal

1. Lay down the unit so that the rear cover faces upward.

2. Remove the 4 screws.

3. Remove the pedestal.

7.2. Rear cover

1. Remove the 17 screws (A).

2. Remove the 2 screws (B).

3. Remove the 3 screws (C).

4. Remove the rear cover.

7.3. AC cord

1. Remove the screw and Remove the AC cord bracket.

2. Remove the bushing of the AC cord from the AC cord

bracket.

3. Disconnect the connector (P1) of AC cord.

7.4. P-Board

1. Remove the 7 screws.

2. Disconnect the connectors (P1, P2, P3 and P4).

3. Remove the P-Board.

18

Page 19

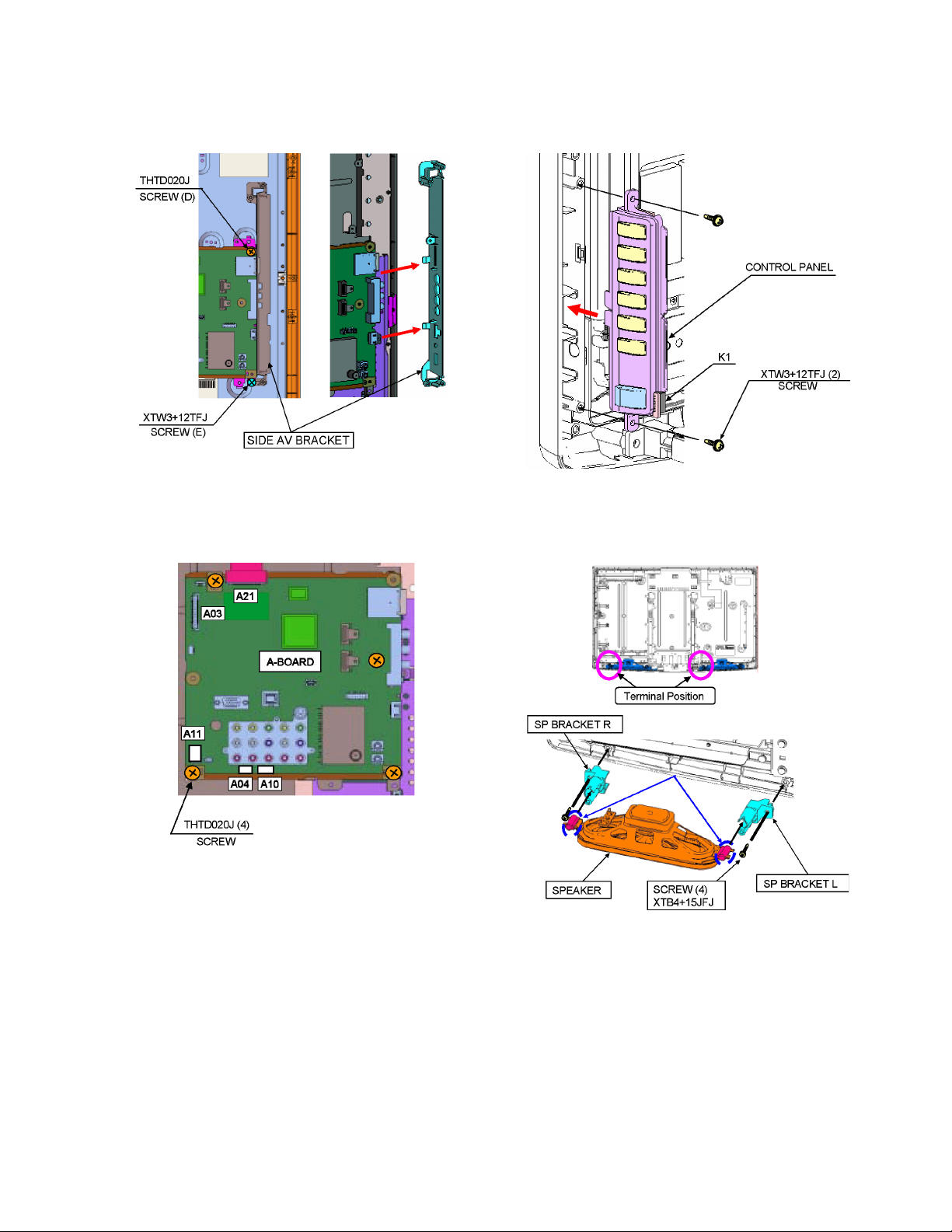

7.5. Side AV bracket

1. Remove the 1 screw (D).

2. Remove the 1 screw (E).

3. Remove the side AV bracket.

7.6. A-Board

1. Remove the 4 screws.

2. Disconnect the connector (A03, A04, A10, A11 and A21).

3. Remove the A-Board.

7.7. Control panel

1. Disconnect the connector (K1).

2. Remove the 2 screws.

3. Remove the control panel.

7.8. Speaker

1. Remove the 4 screws.

2. Remove the speaker.

19

Page 20

7.9. Metal bracket CH frame

1. Remove the 4 screws.

2. Remove the Metal bracket CH frame.

7.10. Metal bracket P top & Metal

3. Remove the 2 screws.

4. Remove the Metal bracket P right.

bracket P right

1. Remove the 2 screws.

2. Remove the Metal bracket P top.

7.11. M etal bracket vertical

1. Remove the 6 screws.

2. Remove the Metal bracket vertical.

20

Page 21

7.12. Metal bracket

1. Remove the 6 screws (F).

2. Remove the 8 screws (G).

3. Remove the Metal bracket top and Metal bracket bottom.

7.14. LCD Panel

1. Remove the 6 screws (H).

2. Remove the LCD side MTG.

3. Remove the 4 screws (I).

4. Remove the LCD panel.

7.13. Barrier

1. Remove the barrier.

7.15. V-Board

1. Remove the 1 screw.

2. Disconnect the connector (V10).

3. Remove the V-Board.

21

Page 22

7.16. EMI processing

22

Page 23

23242526272829

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

8 Measurements and Adjustments

8.1. Voltage chart of A-board

VOLTAGE TEST POINT SPECIFICATION

STB3.3V TP4716 3.3 ± 0.16 V

SUB5V TP4724 5 ± 0.25 V

PANEL12V TP5413 12 ± 0.6 V

SOUND15V TP2765 18 ± 2 V

5VS TP2768 6.1 ± 0.3 V

SUB6V TP2767 6.1 ± 0.3 V

(Reception state)

8.2. Picture level adjustment (RF)

Instrument Name Remarks

1. REMOTE TRANSMITTER

2. Ex. Signal (Sprit color bar)

Adjustment or Inspection Procedure Remarks

< procedure >

1. Receive the Sprit color bar.

(Screen mode: ZOOM or FULL Picture mode: DYNAMIC AI: OFF AI Picture: OFF)

*BACK LIGHT +30

< Inspection >

1. Enter Service mode, and select MAIN_ADJ PICTURE.

Volume UP/DOWN key makes GAIN displayed under PICTURE to set.

Pushing the remote controller [OK] key for about 3 seconds, GAIN is suited

to the adjustment value automatically.

(The Sprit Color Bar Pattern)

30

Page 31

(LED:1TIMES)

(LED:7TIMES)

**

L/R

HDMI1

SUB5V

SPEAKER(L)

SOS

L/R

OUT

POWER LED

TMDS DATA

+3.3V(STB)

COMP1

R

V

SD

IFD_OUT

(SIDE)

A11

REMOTE IN

SD0

VIDEO1

STB5V

V10

F15V

HDMI3

DIGITAL SIGNAL PROCESSOR

SUB5V

LVDS DATA

R/G/B/H/V

AUDIO

V

TMDS DATA

REMOTE RECEIVER

A

C.A.T.S. SENSOR

V

A10

SUB5V

KEYSCAN3

V

SD CARD DATA

SOS

L/R

C.A.T.S. SENSOR

AMP

STB3.3V

DCDC

SD CARD DATA

OPTICAL AUDIO OUT

REMOTE RECEIVER

VIDEO2

L

TMDS DATA

Y/PB/PR

POWER LED(R)

C.A.T.S. SENSOR

HDMI2

OPTICAL

PC

AUDIO

+3.3V(STB)

TUNER

OPTICAL OUT

SPEAKER(R)

SUB1.8V

DCDC

SUB1.8V

DCDC

SUB1.2V

SUB1.2V

SUB1.8V DET

SUB5V DET

SUB1.2V DET

KEYSCAN1

(SIDE)

SD CARD

SLOT

ANALOG-ASIC

INV_SOS

INV_PWM

STB5V

SUB_ON

INV_ON

RELAY

SOUND15V

F15V

POWER LED

CONTROL

PANEL

LCD PANEL

PANEL

BACK LIGHT

CONTROL

PANEL ASSY

A04

K1

DCDC

PANEL12V

PANEL12V

SUB_ON

LVDS DATA

A03

STB5V

INV_SOS

INV_PWM

INV_ON

INV_ON

INV_PWM

INV_SOS

DCDC

SUB5V

SUB3.3V

LVDS DATA

A21

Nile-TCON

HDMI I/F

RECEIVER

MPU

FRONT END

AV SW

PROCESSOR

CPU BUS

I/F

CPU BUS

NAND

FLASH

DDR2

EEPROM

EEPROM

SIF_OUT

PANEL12V

SUB 3.3V SENSE

17V

PROCESS

VOLTAGE

RECTIFIER

DCDC

PROCESS

VOLTAGE

RECTIFIER

STB5V

PFC

CONTROL

24V

P3,P4

NEUTRAL

AC CORD

RECTIFIER

LIVE

P1

LINE

FILTER

P2

POWER

CONTROL

(LED:1TIMES)

(LED:7TIMES)

(LED:3TIMES)(LED:3TIMES)

POWER SUPPLY

P

9 Block Diagram

9.1. Main Block Diagram

31

Page 32

9.2. Block (1/2) Diagram

COLDHOT

COLDHOT

(LED:3TIMES)

V

POWER LED

REMOTE RECEIVER

C.A.T.S. SENSOR

A

DIGITAL SIGNAL PROCESSOR

P

D001

RECTIFIER

LINE

FILTER

F001

T4AL AC250V

POWER SUPPLY

L005

Q701

D004

Q702

AC

DET

D005

L001

L002

NEED

HOLDER

NEUTRAL

LIVE

1

4

P1

AC CORD

Q001

CONTROL

IC801

PFC

VCC

Q301

PFC ON

D016

Q302

STB ON

D002

D003

IC101

POWER

CONTROL

Q410,Q412

POWER

CONTROL

Q420

RESONANCE

Q401

RESONANCE

**

D106

PC101

PHOTO COUPLER

PC302

PHOTO COUPLER

PC301

PHOTO COUPLER

RELAY

MAIN ON

RL002

RL001

T101

COLDHOT

RELAY

RUSH ON

Q363

D151

COLDHOT

T401

C420

PC401

PHOTO COUPLER

PC701

PHOTO COUPLER

Q364

Q362

15V

+

IC151

12V

ERROR DET

D501

D451,452

OVP

IC451

24V

ERROR DET

CONTROL PANEL ASSY

17V

24V

IC261

+5V

IC251

Q351

Q161

15V

12V

DET

Q361

MAIN ON

SN2501

C.A.T.S.

SENSOR

RM2501

REMOTE

RECEIVER

+5V

Q171

D2500

POWER LED

V10

7

4

3

1

5

K1

P2

7

4

5

1

2

11

9

10

14

13

12

P3

1

4

P4

1

4

14

12

13

R_LED_ON

C.A.T.S.

REMOTE IN

SUB+5V

STB+3.3V

KEYSCAN1

KEYSCAN3

SOUND15V

F15V

F15V

STB5V

TUNER_6V

RELAY

SUB_ON

PANEL_VCC_ON

INV_PWM

INV_ON

INV_SOS

INV_SOS

INV_ON

INV_PWM

A10

POWER LED(R)

7

4

3

1

5

A04

2

4

A03

9

12

11

15

14

5

7

6

2

3

4

Q4770

Q2760

Q2761

C.A.T.S.

REMOTE IN

KEYSCAN1

KEYSCAN3

TV_SUB_ON

INV

PANEL_

VCC_ON

INV_PWM

INV_ON

INV_SOS

PA4803

BACK LIGHT

INVERTER

CIRCUIT

SOUND15V

F15V

D5629

Q5613

F15V DET

PANEL

STB5V

F15V

D5600

STB5V

IC5608

IC5610

Q5612

ON/OFF

SUB5V

+5V

SUB1.8V

+1.8V

IC5606

Q5602

Q5616

VOLTAGE

DROP

ERROR DET

SUB1.2V

+1.2V

PANEL

CONTROL

SUB5V

Q5615

SUB1.2V

IC5605

3.3V

SUB5V

SUB3.3V

SUB1.8V

SUB5V

STB5V

VCC12V

LVDS DATA

(RxB_0-3)

LVDS DATA

(RxA_0-3)

AG_SOS

SOS

(LED:3TIMES)

A21

STB3.3V

IC4700

ANALOG-ASIC

SOS

1

4

13

24

29

40

STB

+3.3V

STB

+1.2V

Q5412

+12V

PANEL12V

LVDS DATA

(RxB_0-3)

LVDS DATA

(RxA_0-3)

STB3.3V

STB1.2V

MCU_RESET

SUB1.2V DET

SUB1.8V DET

SUB5V DET

PA4202

D5604

D5605

Q4702

IC5601

D5603

RESET

Q4704

MCU_RESET

KEYSCAN3

Q4703

D2753

INV LED

PANEL_

LED_ON

Q5495

PANEL_VCC_ON

LVDS DATA

1

2

3

4

5

6

7

8

9

10

LCD PANEL

32

Page 33

9.3. Block (2/2) Diagram

(LED:1TIMES)

(LED:7TIMES)

(LED:3TIMES)

PC

PC_R

PC_G

SUB1.2V

PC_B

JK2102

VIDEO2

(SIDE)

V2_R

V2_L

JK2108A

PC_H

PC_V

1

2

3

4

5

6

7

8

9

F15V

V2_V

STB1.2V

D1_R

JK2101A

COMP1

D1_L

STB3.3V

D1_PR

D1_PB

D1_Y

VIDEO1

V1_R

V1_L

V1_V

ANT IN

SUB5V

SUB3.3V

SUB1.8V

TV_V

VIDEO

TU8302

TUNER

5V

SUB5V

TUNER

P

VJ5500

DDC IIC

+5V

HDMI_CEC

JK4500

HDMI IN 3

(SIDE)

TMDS DATA

CLOCK

DDC IIC

+5V

HDMI_CEC

Q8005

HDMI_CEC

JK4502

HDMI IN 1

IIC0_TU

IFD_OUT1

IF_AGC

SIF_OUT

IFD_OUT2

AFT

TMDS DATA CLOCK

AFT

DDC IIC

+5V

HDMI_CEC

JK4501

HDMI IN 2

TMDS DATA

CLOCK

3.3V

SD DATA:4bit

SUB5V

JK8502

SD CARD

SUB3.3V_SD

IC5613

IC5607

3.3V

IC5609

3.3V

VINP_VSB

VINN_VSB

IC2110

INVERTER

SIF

AGC

VSB_I/F

SIF_IN

AGC

AFT

TV

V

VIDEO1

V

L/R

VIDEO2

V

L/R

COMP1

Y/PB/PR

L/R

COMP2

Y/PB/PR

L/R

PC

R/G/B

L/R

H/V

SUB3.3V_A

FRONT END

PROCESSOR

AV SW

IC8002

DDR2 #0

RESET

IC8502

128Mbit

NOR FLASH

IC8503

EEPROM

IIC2

STB3.3V

MCU_

SUB3.3V_HDMI

CPU BUS

DDR I/F

RX2

RX1

RX3

HDMI I/F RECEIVER

I/F

IC8850

3.3V

DDC_C_IIC

LVDS3.3V

DDC5V_C

DDC_A_IIC

DDC_B_IIC

VCC CLK

STB3.3V

STB1.2V

DDC5V_B

DDC5V_A

SUB3.3V

SUB1.8V

HDMI_CEC_

IN_OUT

IC8001

Nile-TCON

SUB1.2V

X IN

X8000

25MHz

INV_PWM

Q9901

F15V

X OUT

Q9902,04

Q9900

SD CARD

I/F

MPU

INV_PWM

INV_ON

PWM_

POWER_ON

(LED:1TIMES)

INV_SOS

INV_ON

INV_SOS

VDD25_EN

PWM_POWER_ON

VDD25_EN

PWM_POWER_ON

HOT START(DAC_ENB)

PANEL_VCC_ON

HOT START(DAC_ENB)

PANEL_VCC_ON

SUB3.3V

Q4515

ARC_OFF

TV SUB ON

PANEL_LED_ON

PANEL_LED_ON

TV SUB ON

IIC1

MCU_

IIC

D2142

OPTICAL

AUDIO

OUT

(LED:3TIMES)

MCU_RESET

SOS

SOS

MCU_RESET

IC4701

TEMP SENSOR

IC8004

EEPROM

OPTICAL AUDIO OUT

IC2106

AUDIO AMP

SUB3.3V

SOUND15V

SPDIF

REMOTE IN

C.A.T.S. SENSOR

REMOTE IN

C.A.T.S.

POWER LED(R)

A11

POWER LED(R)

STB3.3V

2

1

L(-)

L(+)

L_OUT

SPEAKER

3.3V

15V

KEY3/STBY_LED_ON

KEYSCAN1

Q5605

KEYSCAN1

SUB3.3V

SDIN

SD

KEYSCAN3

SPEAKER_RSPEAKER_L

4

3

R(-)

R(+)

R_OUT

SPEAKER

IIC1

LVDS_OUT

SUB 3.3V SENSE

(LED:7TIMES)

SBO0

SBI0

MCU_

IIC

A17

FOR

A18

A19

SBO0

SBI0

FACTORY

USE

FOR

FACTORY

USE

FOR

FACTORY

USE

IIC0_TU

IIC1

IIC2

MCU_IIC

LVDS DATA

SBO0

SBI0

IIC0

IIC0

IIC1

IIC1

IIC2

IIC2

DIGITAL SIGNAL PROCESSOR

A

LVDS DATA

10

33

Page 34

34

Page 35

10 Wiring Connection Diagram

10.1. Caution statement.

Caution:

Please confirm that all flexible cables are assembled correctly.

Also make sure that they are locked in the connectors.

Verify by giving the flexible cables a very slight pull.

10.2. Wiring

35

Page 36

36

Page 37

11 Schematic Diagram

11.1. Schematic Diagram Notes

37

Page 38

11.2. A-Board (1/12) Schematic Diagram

!

A-BOARD TXN/A10QHMS (1/12)

A

B

C

GPIO/IRQ_MCU

TO 8/12

*IC8004

TVRR334S

EEPROM

TO 12/12

TO 12/12

TO 9/12

TO 12/12

TO 12/12

TO 7/12

HDMI_CEC

MCU_I2CCLK

MCU_I2CDATA

INVERTER_SOS

CATS_EYE

SD_BOOT

R8050

100

IC8001 M4 P76_CEC_IN

IC8001 N5 P75_AVLINK1IN

R8051

100

STB3.3V

27k

G

S

Q8005

B1CBGD000001

IC8001 W5 P80_BL_ONOFF

R8059

IC8001 R5 MCU_SCL

S

R8063

IC8001 T5 MCU_SDA

S

C8012

16V

0.1u

R8049

100

D

P80 MCU_EEP_WP

R8048

STB3.3V

16V

STB3.3V

STB3.3V

C8011

0.1u

8

Vcc

TP8027

7

WP

TP8025

6

SCL

TP8026

5

SDA

R8062

4.7k

R8100

22k

R8045

47k

R8043

47k

R8044

1k

TP8028

1

A0

2

A1

3

A2

4

Vss

KEY1

RF_AFT

SRQ

SOS

TP8030

TP8031

R8040

4.7k

R8041

4.7k

R8064

S

R8065

S

IC8001 U6 SLOW_AD0

IC8001 V6 SLOW_AD1

IC8001 W6 SLOW_AD2

IC8001 Y6 SLOW_AD3

IC8001 AA6 SLOW_AD4

IC8001 AC7 SLOW_AD5

IC8001 AD7 SLOW_AD6

IC8001 AE7 SLOW_AD7

TP8029

R8039

4.7k

INVERTER_SOS

SLOW1 KEY1

SLOW2 CATS_EYE

SLOW3 RF_AFT

SLOW4 SRQ

SLOW5 SOS[Power, Sub9, Sub5, FAN, Sound]

SLOW6 DPMS_STS

SLOW7 FACT

TO 11,12/12

TO 11/12

TO 3,4,7/12

PANEL_STBY_ON/PANEL_VCC_ON

GRAB_MODULE_IIC/PWM_POW_ON

TO 12/12

TO 4/12

TO 12/12

TO 1/12

TO 12/12

TO 8/12

TV_SUB_ON

POWER_LED_ON

KEY3/STBY_LED_ON

ECO_ON/INVERTER_ON

POWER_DET_24KEC

MCU_XRST

DDC5V_A

DDC5V_B

DDC5V_C

HPLUG_A

HPLUG_B

HPLUG_C

IC8001

C1AB00003249

Nile-TCON

IC8001 M3 COLDRST_N

IC8001 AC5 P12_PW_PROTECT

IC8001 Y5 P81_POWER_LCD

IC8001 D18 P72_PPG

IC8001 U4 P70_POWER_LED

IC8001 U5 P71_STANDBY_LED

RM_IN

SUB3.3V

R8089

0

STB3.3V

*R8103

4.7k

R8098

4.7k

R8037

10k

*R8104

4.7k

*R8094

4.7k

IC8001 AB7 P13_REMOTEIN

IC8001 AB6 P02_POWER_TV

IC8001 D19 P22_EXT_MUTE

IC8001 AB5 P73_POWER_DB

IC8001 AA5 P74_POWER_SIG

IC8001 M5 P77_AVLINK0IN

IC8001 N4 PB7_CEC_OUT

T4 P03_POWERKEY

IC8001

IC8001 V5 P25_BL_STATUS

IC8001 P5 P11_AC_DETECT

IC8001 F5 P10_DDC5V_A

IC8001 H4 P01_DDC5V_B

IC8001 J5 P00_DDC5V_C

IC8001 F4 PB4_HPLUG_A

IC8001 G4 PB5_HPLUG_B

IC8001 J4 PB6_HPLUG_C

IC8001 R3 OCD_CLOCK

IC8001 R4 OCD_DATA

IC8001 P3 MODE_IN

IC8001 K6 TESTIN

P12 TV_SUB_ON

P81 PANEL_STBY_ON/PANEL_VCC_ON

P72 GRAB_MODULE_IIC / PWM_POW_ON

P70 POWER_LED_ON

P71 KEY3/STBY_LED_ON

P13 RM_IN

P02 ECO_ON / INVERTER_ON

P22 HP_MUTE1

P73 IPOD_XDET / HOTEL_SERIAL_SW

P74 HOT_START[DDR_Self_Refresh]

P77 SUB3.3V_SENSE

PB7 IPOD_SOS

P03 MON_MUTE / IPOD_PWR_ON

P25 GUARD_DOG_EXE

P11 POWER_DET

P10 DDC5V_A

P01 DDC5V_B

P00 DDC5V_C

PB4 HPLUG_A

PB5 HPLUG_B

PB6 HPLUG_C

VCC

SUB1.2V

C8030

10V

10u

L8007

ELJRF10NJFB

C8046

22u

J0JHC0000045

L8006

C8033

IC8001 U19 VDDC

10u10V

IC8001

IC8001 T19 VDDC IC8001 P11 VSS

C8034

16V

0.1u

IC8001 T20 VDDC

C8133

50V

1000p

C8035

10u10V

IC8001 T23 VDDC

IC8001 T24 VDDC

C8036

16V

0.1u

IC8001 U23 VDDC

IC8001

C8039

10u10V

IC8001 M19 VDDC

IC8001 M20 VDDC

C8040

16V

0.1u

IC8001 N19 VDDC

IC8001 N20 VDDC IC8001 L16 VSS

C8041

10u10V

IC8001 P8 VDDC

IC8001 R8 VDDC

C8136

16V

0.1u

IC8001 H10 VDD12PLL

C8037

16V

0.1u

4V

C8043

1u

10V

C8038

16V

0.1u

IC8001 L19 VDD12PLL

IC8001 L20 VDD12PLL

C8044

1u

10V

C8042

16V

0.1u

IC8001 L25 VDD12PLL

C8045

IC8001 L26 VDD12PLL

1u

10V

STB3.3V

IC8001 T8 VDD33MCU

L8012

C8078

6.3V

1u

U20 VDDC

U24 VDDC

J0JHC0000045

C8049

L8008

J0JHC0000045

C8051

L8016

J0JHC0000045

C8132

L8017

J0JHC0000045

C8059

6.3V

STB1.2V

J0JHC0000045

6.3V

1u

10V

10u

6.3V

1u

1u

L8011

C8047

16V

0.1u

C8048

50V

1000p

C8050

16V

0.1u

C8053

16V

0.1u

C8054

16V

0.1u

C8056

16V

0.1u

C8139

16V

0.1u

L8009

J0JHC0000045

C8058

10V

10u

C8060

16V

C8061

0.1u

50V

1000p

C8062

C8063

16V

50V

1000p

0.1u

IC8001 U8 VDD12MCU

C8064

6.3V

1u

IC8001 K8 VDD12HDMI

IC8001 L8 VDD12HDMI

IC8001 U12 VDD12DDR

IC8001 U14 VDD12DDR

IC8001 U16 VDD12DDR

IC8001 AB8 VDD12DDR

IC8001 AB13 VDD12DDR

IC8001 AB17 VDD12DDR

IC8001 AB21 VDD12DDR

IC8001 AB15 VDD12DDRPLL

C8116

16V

0.1u

IC8001

H14 AVDD12V

IC8001 H15 AVDD12SIF

IC8001 H11 AVDD12V

DDR_VCC_POST

C8082

SUB3.3V

R8029

LVDS3.3

R8030

0

SUB3.3V_A

SUB3.3V_HDMI

C8009

10V

4.7u

10V

10u

0

L8002

J0JHC0000045

L8003

J0JHC0000045

L8004

J0JHC0000045

L8005

J0JHC0000045

L8010

J0JHC0000045

C8127

16V

0.1u

IC8001 AC10 VDD18DDR

C8140

50V 1000p

IC8001 AC14 VDD18DDR

C8141

16V

0.1u

IC8001 AC16 VDD18DDR

C8143

10V

1u

IC8001 AC21 VDD18DDR

C8144

1u

10V

IC8001 AC23 VDD18DDR

C8145

16V

0.1u

IC8001 AE11 VDD18DDR

C8146

50V

1000p

IC8001 AE20 VDD18DDR

C8147

16V

0.1u

IC8001 AF8 VDD18DDR

IC8001 AF17 VDD18DDR

C8067

6.3V

1u

C8069

C8068

16V

6.3V

0.1u

1u

C8079

6.3V

1u

C8080

C8073

6.3V

16V

1u

0.1u

C8081

6.3V

1u

C8130

16V

0.1u

IC8001 P19 VDD33

C8065

IC8001

P20 VDD33

16V

0.1u

IC8001 AF25 VDD33 IC8001 T11 VSS

IC8001 AF26 VDD33

IC8001 R19 VDD33LVDS

C8070

IC8001 R20 VDD33LVDS

50V

1000p

IC8001 H13 AVDD33V

IC8001 H12 AVDD33V

C8071

16V

0.1u

IC8001 C19 AVDD33AADC

C8074

IC8001 C21 AVDD33ADAC

50V

1000p

C8075

IC8001 H16 AVDD33AADC

16V

IC8001 H17 AVDD33ADAC

0.1u

IC8001 M8 VDD33HDMI

C8131

50V

IC8001 N8 VDD33HDMI

1000p

DVSS/AVSS

A1 VSS

IC8001

IC8001 A2 VSS

IC8001 B1 VSS

IC8001 B2 VSS

IC8001 P10 VSS

IC8001 P12 VSS

IC8001 P13 VSS

IC8001 P14 VSS

IC8001 P15 VSS

IC8001 P16 VSS

IC8001 P17 VSS

IC8001 P24 VSS

IC8001 R10 VSS

IC8001 R11 VSS

IC8001 R12 VSS

IC8001 R13 VSS

IC8001 R14 VSS

IC8001 R15 VSS

IC8001 R16 VSS

IC8001 R17 VSS

IC8001 R24 VSS

IC8001 T10 VSS

IC8001 T12 VSS

IC8001 T13 VSS

IC8001 T14 VSS

IC8001 T15 VSS

IC8001 T16 VSS

IC8001 T17 VSS

IC8001 U10 VSS

IC8001 U11 VSS

IC8001 U13 VSS

IC8001 U15 VSS

IC8001 U17 VSS

IC8001 AB9 VSS

IC8001 AB12 VSS

IC8001 AB16 VSS

IC8001 AB22 VSS

IC8001 A19 AVSS

IC8001 A26 AVSS

IC8001 A10 AVSS

IC8001 B10 AVSS

IC8001 B19 AVSS

IC8001 B26 AVSS

IC8001 D10 AVSS

IC8001 D15 AVSS

IC8001 AC19 VSS

IC8001 AD9 VSS

IC8001 AD18 VSS

IC8001 AE19 VSS

IC8001 AE13 VSS

IC8001 AE15 VSS

IC8001 AE22 VSS

IC8001 AF1 VSS

IC8001 AF2 VSS

IC8001 AF18 VSS

IC8001 K10 VSS

L1 VSS

IC8001

IC8001 L2 VSS

IC8001 L10 VSS

IC8001 L11 VSS

IC8001 L12 VSS

IC8001 L13 VSS

IC8001 L14 VSS

IC8001 L15 VSS

IC8001 L17 VSS

IC8001 M10 VSS

IC8001 M11 VSS

IC8001 M12 VSS

IC8001 M13 VSS

IC8001 M14 VSS

IC8001 M15 VSS

IC8001 M16 VSS

IC8001 M17 VSS

IC8001 M24 VSS

IC8001 N10 VSS

IC8001 N11 VSS

IC8001 N12 VSS

IC8001 N13 VSS

IC8001 N14 VSS

IC8001 N15 VSS

IC8001 N16 VSS

IC8001 N17 VSS

IC8001 N24 VSS

IC8001 D17 AVSS

IC8001 K11 AVSS

IC8001 K12 AVSS

IC8001 K13 AVSS

IC8001 K14 AVSS

IC8001 K15 AVSS

IC8001 K16 AVSS

IC8001 K17 AVSS

TO 8/12

TO 8/12

TO 12/12

TO 8/12

TO 8/12

TO 3/12

SDDAT3

SDDAT2

SDDAT1

SDDAT0

SDCLK

SDCMD

SDCD

SDWP

SCL_DDC_A

SDA_DDC_A

ACK_DDC_A

SCL_DDC_B

SDA_DDC_B

ACK_DDC_B

SCL_DDC_C

SDA_DDC_C

ACK_DDC_C

RXNC_A

RXPC_A

RXN0_A

RXP0_A

RXN1_A

RXP1_A

RXN2_A

RXP2_A

RXNC_B

RXPC_B

RXN0_B

RXP0_B

RXN1_B

RXP1_B

RXN2_B

RXP2_B

RXNC_C

RXPC_C

RXN0_C

RXP0_C

RXN1_C

RXP1_C

RXN2_C

RXP2_C

IC8001 AD6 SDDATA3

IC8001 AE6 SDDATA2

IC8001 AF6 SDDATA1

IC8001 AF7 SDDATA0

IC8001 AF5 SDCLK

IC8001 AE5 SDCMD

IC8001 AC6 SDCD

IC8001 AD5 SDWP

R8025

2k

1%

R8026

2k

R8027

2k

1%

int P.U.

int P.U.

int P.U.

int P.U.

int P.D.

IC8001 B6 RXNC_A

IC8001 A6 RXPC_A

IC8001 B5 RXN0_A

IC8001 A5 RXP0_A

IC8001 B4 RXN1_A

A4 RXP1_A

IC8001

IC8001 B3 RXN2_A

IC8001 A3 RXP2_A

IC8001 M6 SCL_DDC_A

IC8001 L6 SDA_DDC_A

IC8001 G5 ACK_DDC_A

IC8001 G6 REXT_A

IC8001 D6 HDMITEST2

IC8001 C6 HDMITEST1

IC8001 C2 RXNC_B

IC8001 C1 RXPC_B

IC8001 D2 RXN0_B

IC8001 D1 RXP0_B

IC8001 E2 RXN1_B

IC8001 E1 RXP1_B

IC8001 F2 RXN2_B

IC8001 F1 RXP2_B

IC8001 L5 SCL_DDC_B

IC8001 K4 SDA_DDC_B

IC8001 H5 ACK_DDC_B

IC8001 H6 REXT_B

IC8001 D3 HDMITEST5

IC8001 C3 HDMITEST4

IC8001 G2 RXNC_C

IC8001 G1 RXPC_C

IC8001 H2 RXN0_C

IC8001 H1 RXP0_C

IC8001 J2 RXN1_C

IC8001 J1 RXP1_C

IC8001 K2 RXN2_C

IC8001 K1 RXP2_C

IC8001 L4 SCL_DDC_C

IC8001 L3 SDA_DDC_C

IC8001 K5 ACK_DDC_C

IC8001 J6 REXT_C

IC8001 K3 HDMITEST7

IC8001 J3 HDMITEST6

Digital Audio

int P.U.

int P.U.

int P.U.

5V tolerant

8mACell

5V tolerant

8mACell

int P.D.

5V tolerant

8mACell

5V tolerant

8mACell

int P.D.

5V tolerant

8mACell

5V tolerant

8mACell

TO 8,10/12

TO 6/12

LVDS/LCD

RA_E+

RA_E-

RB_E+

RB_E-

RC_E+

RC_E-

RCLK_E+

RCLK_E-

RD_E+

RD_E-

RA_O+

RA_O-

RB_O+

RB_O-

RC_O+

RC_O-

RCLK_O+

RCLK_O-

RD_O+

RD_O-

MCLK

LRCLK

BCLK

SDIN

SPDIF

R8106

0

IC8001 E26 AMCLKOX

IC8001 D26 ALRCKOX

IC8001 E25 ABCKOX

IC8001 D24 ASDOX1

IC8001 D25 ASDOX2

IC8001 C26 ATXO

TO 11/12

TP8039

IC8001 M26 TA1

TP8012

IC8001 M25 TA1_N

TP8014

IC8001 N26 TB1IC8001 J22 GPIO17

TP8013

IC8001 N25 TB1_N

TP8016

IC8001 P26 TC1

TP8015

IC8001 P25 TC1_N

TP8018

IC8001 R26 TCLK1

TP8017

IC8001 R25 TCLK1_N

TP8020

IC8001 T26 TD1

TP8019

IC8001 T25 TD1_N

TP8022

IC8001 U26 TE1

TP8021

IC8001 U25 TE1_N

IC8001 V26 TF1

IC8001 V25 TF1_N

TP8001

IC8001 W26 TA2

TP8000

IC8001 W25 TA2_N

TP8003

IC8001 Y26 TB2

TP8002

IC8001 Y25 TB2_N

TP8005

IC8001 AA26 TC2

TP8004

IC8001 AA25 TC2_N

TP8007

IC8001 AB26 TCLK2

TP8006

IC8001 AB25 TCLK2_N

TP8009

IC8001 AC26 TD2

TP8008

IC8001 AC25 TD2_N

TP8011

IC8001 AD26 TE2

TP8010

IC8001 AD25 TE2_N

IC8001 AE26 TF2

IC8001 AE25 TF2_N

TP8023

IC8001 K23 TCN_POLL

IC8001 L24 TCN_POLR

IC8001 K24 TCN_LPL

IC8001 L23 TCN_LD

IC8001 M23 AGWU

IC8001 N23 AGWK

IC8001 R22 BL1PWM

BL0PWM

IC8001 R23 BL0PWM

IC8001 P23 MTEST

GPIO/IRQ_24KEc

SUB3.3V_SD

TO 1/12

POWER_DET_24KEC

R8099

1k

IC8001 E24 IRQ0

IC8001 F24 IRQ1

IC8001 G24 IRQ2

IC8001 AA21 IRQ3

D

SD_LED_OFF

SUB3.3V_SD_XDET

ETHER_IRQ

POWER_DET_24KEC

TO 11/12

FAN_MAX/LCD_EEP_WP/ZWEI_VOUT_ENB

TO 3/12

TO 12/12

PANEL_TEST_ON/VDD25_EN

TO 8/12

TO 6/12

PANEL_ALARM/PANEL_LED_ON

TO 9/12

IIC_24KEc

E

4.7k

R8102

R8101

PANEL_AGW/AVDD_ENB

24KEC_EEP_WP

TO 11/12

TV_SYNC/TUNERBOX_SEL

IC8001 A7 GPIO0

4.7k

IC8001 B7 GPIO1

IC8001 F6 GPIO3

IC8001 AA23 GPIO4

IC8001 AA22 GPIO5

IC8001 Y23 GPIO6

IC8001 Y22 GPIO7

IC8001 W23 GPIO8

IC8001 W22 GPIO9

IC8001 V23 GPIO10

IC8001 V22 GPIO11

IC8001 P22 GPIO12

ARC1_OFF

IC8001 N22 GPIO13

IC8001 M22 GPIO14

IC8001

IC8001 K22 GPIO16

AUDIO_XRST EBDAT12

IC8001 C25 GPIO18

IC8001 C24 GPIO19

DISPEN

IC8001 C23 GPIO20

IC8001 C22 GPIO21

IC8001 C9 DCIN0

IC8001 D9 DCIN1

TO 12/12

24KEC_I2CCLK0

24KEC_I2CDATA0

24KEC_I2CCLK1

24KEC_I2CDATA1

24KEC_I2CCLK2

24KEC_I2CDATA2

IPOD_CTRL_SW

LCD_EEP_WP

PANEL_TEST_ON/VDD25_EN

PANEL_AGW/AVDD_ENB

FAN_MAX/LCD_EEP_WP/ZWEI_VOUT_ENB

FAN_OFF

RED_LED(for debug)

GREEN_LED(for debug)

24KEc_EEP_WP

SP_LED_OFF

SP_LED_DIM

IPOD_CP_RST

TUNER_SW1

TUNER_SW2

SIF_FIL_ON

YUV_DET

L22 GPIO15

S_XDET

AUDIO_XRST

PANEL_READY/FV_SEL

PANEL_ALARM/PANEL_LED_ON

DISPEN

TV_SYNC/TUNERBOX_SEL

IPOD_ACC_PWR_XDET

HP_DET

IC8001 E4 I2CCLK0

IC8001 E5 I2CDATA0

IC8001 F26 I2CCLK1

IC8001 F25 I2CDATA1

IC8001 G26 I2CCLK2

IC8001 G25 I2CDATA2

I2C0:TU/iPOD

I2C1:AMP/PANEL/HP

I2C2:24KEC_EEPROM

UART_24KEc

IC8001 H25 UATXD0

UATXD0

UARXD0

TO 12/12

TO 12/12

CLOCK

F

X8000

C8007

H0J250500094

6p

50V

25MHz

C8008

50V

7p

TP8024

TP8040

R8024

1.5k

IC8001 M1 XIN

R8023

1M

IC8001 M2 XOUT

IC8001 N3 MCUCLKOUT

UACTS0_N

UARTS0_N

UA0EXCLK

UARXD1

UATXD1

R8070

S

TP8036

R8071

S

TP8037

R8072

S

TP8038

R8073

S

IC8001 H26 UARXD0

IC8001 H23 UACTS0_N

IC8001 H24 UARTS0_N

IC8001 J26 UA0EXCLK

IC8001 K26 UARXD1

IC8001 K25 UATXD1

IC8001 J24 UARXD2

IC8001 J23 UATXD2

IC8001 J25 UA2EXCLK

IC8001 N1 RTC_XIN

IC8001 N2 RTC_XOUT

IC8001 G22 VCXOI

IC8001 G23 VCXPWMOUT

IC8001 F22 PANELCLKI

IC8001 F23 PANELCLKO

IC8001 H22 CLKIN42

PIO02 TCON_CPV

PIO03 TCON_GDATA1

PIO04 TCON_GDATA2

TU

AVSW

TO 11/12

SUB3.3V_A

SUB3.3V_A

RIEXT_A

TO 9/12

TP8032

IC8001 E23 TSI1CLKI

TP8033

IC8001 E22 TSI1SYNC

TP8034

IC8001 D22 TSI1DATA

TP8035

IC8001 D23 TSI1VALID

16V

0.1u

C8013

C8014

C8016

C8017

C8018

C8019

C8028

L8013

J0JHC0000045

IC8001B8DAOUT2

C8027

C8022

C8020

J0JHC0000045

IC8001B9DAOUT3

R8057

1.5k

C8029

C8015

C8021

C8001

6.3V

Q8002

B1ABCF000231

R8056

1.5k

R8053

C8023

1k

50V

5p

R8058

220

16V

0.1u

16V

0.01u

16V

0.1u

L8014

C8002

6.3V

Q8003

B1ABCF000231

C8025

R8054

16V

1.2k

5p

R8055

2.2k

25V

0.015u

150p

16V

16V

0.1u

C8101

16V

0.1u

IC8001 D16 VREFAIN

16V

0.1u

IC8001 C15 VREFBIN

16V

0.1u

IC8001 C11 VREFCIN

16V

0.1u

IC8001 C10 VREFDIN

16V

0.1u

IC8001 E13 VREFEIN

16V

0.1u

IC8001 E12 VBG

16V

0.1u

IC8001 D13 VBGE

1u

IC8001 A8 P2CKIN

C8024

25V

0.01u

IC8001 E10 P2FIL

IC8001 D11 BIASDA2

1u

IC8001 A9 P3CKIN

C8026

25V

0.01u

IC8001 D12 P3FIL

IC8001 E11 BIASDA3

IC8001 D21 HDMITEST3

IC8001 T22 TEST

IC8001 U22 RIEXT_A

IC8001 D14 AADVCML

VSB_INP

VSB_INN

IFAGC

RFAGC

SIFIN

VCVS1IN

VCVS2IN

VCVS4IN

VG1IN

VB1IN

VR1IN

TO

VG3IN

5/12

VB3IN

VR3IN

ALIN1

ARIN1

ALIN4

ARIN4

ALIN5

ARIN5

VCVS3IN

SYNCIN1

SYNCIN2

SYNCIN3

VY1IN

VC1IN

VG2IN

VB2IN

VR2IN

AHDIN

AVDIN

ALIN2

ARIN2

ALIN3

ARIN3

IC8001 A11 VSB_INP

IC8001 B11 VSB_INN

IC8001 E7 IFAGCIC8001 E6 GPIO2

IC8001 E8 RFAGC

IC8001 E9 ANTCON

IC8001 A18 SIFIN

IC8001 B16 VY1IN

IC8001 C16 VC1IN

IC8001 B18 VCVS1IN

IC8001 C18 VCVS2IN

IC8001 A17 VCVS3IN

IC8001 B17 VCVS4IN

IC8001 A15 VG1IN

IC8001 B15 VB1IN

IC8001 A16 VR1IN

IC8001 C14 SYNCIN1

IC8001 B14 VG2IN

IC8001 A13 VB2IN

IC8001 A14 VR2IN

IC8001 C13 SYNCIN2

IC8001 A12 VG3IN

IC8001 B12 VB3IN

IC8001 B13 VR3IN

IC8001 C12 SYNCIN3

IC8001 D8 AHDIN

IC8001 C8 AVDIN

IC8001 A24 ALTUNEOUT

IC8001 B24 ARTUNEOUT

IC8001 A25 ALSPOUT

IC8001 B25 ARSPOUT

IC8001 C17 VMONIOUT

IC8001 A23 ALIN1

IC8001 B23 ARIN1

IC8001 A22 ALIN2

IC8001 B22 ARIN2

IC8001 A21 ALIN3

IC8001 B21 ARIN3

IC8001 A20 ALIN4

IC8001 B20 ARIN4

IC8001 C20 ALIN5

IC8001 D20 ARIN5

IC8001 C7 FBINA

5V tolerant

IC8001 D7 FBINB

5V tolerant

SD

HDMI

VJ8000

SUB3.3V_HDMI

P

VJUMP1608-P

JTAG

IC8001 AE24 DBGTDO

IC8001 AF24 DBGTCK

IC8001 AD24 DBGTDI

IC8001 Y21 DBGTMS

IC8001 W21 DBGTRST_N

EBUS

TO 3/12

IC8001 AB2 EBDAT15

EBDAT15

EBDAT14

IC8001 AB1 EBDAT14

IC8001 AC4 EBDAT13

EBDAT13

IC8001 AC3 EBDAT12

IC8001 AC2 EBDAT11

EBDAT11

EBDAT10

IC8001 AC1 EBDAT10

EBDAT9

IC8001 AD3 EBDAT9

EBDAT8

IC8001 AD2 EBDAT8

EBDAT7

IC8001 AD1 EBDAT7

EBDAT6

IC8001 AE2 EBDAT6

EBDAT5

IC8001 AE1 EBDAT5

EBDAT4

IC8001 AE3 EBDAT4

EBDAT3

IC8001 AF3 EBDAT3

EBDAT2

IC8001 AD4 EBDAT2

EBDAT1

IC8001 AE4 EBDAT1

EBDAT0

IC8001 AF4 EBDAT0

IC8001 R2 EBCE3_N

EBADD24

EBADD23/NABSY_N

int P.U.

8mACell

int P.U.

8mACell

8mACell

int P.U.

int P.U.

8mACell

int P.U.

int P.U.

int P.D.

int P.D.

int P.U.

EBADD22/NAALE

EBADD21/NACLE

EBADD20

EBADD19

EBADD18

EBADD17

EBADD16

EBADD15

EBADD14

EBADD13

EBADD12

EBADD11

EBADD10

EBADD9

EBADD8

EBADD7

EBADD6

EBADD5

EBADD4

EBADD3

EBADD2

EBADD1

XECS0

XEWE0

XERE

IC8001 R1 EBCE2_N

IC8001 T3 DCIN2

IC8001 T2 EBCE5_N

IC8001 T1 EBCE4_N

IC8001 U3 DCIN3

IC8001 U2 EBACK_N

IC8001 U1 SPI_CLK

IC8001 V4 EBBE0_N

IC8001 V3 EBALE_N

IC8001 W4 EBBE1_N

IC8001 W3 NABSY_N

IC8001 W2 EBADD12

IC8001 W1 EBADD11

IC8001 Y4 EBADD10

IC8001 Y3 EBADD9

IC8001 Y2 EBADD8

IC8001 Y1 EBADD7

IC8001 AA4 EBADD6

IC8001 AA3 EBADD5

IC8001 AA2 EBADD4

IC8001 AA1 EBADD3

IC8001 AB4 EBADD2

IC8001 AB3 EBADD1

IC8001 P4 ICERST_N

IC8001 P1 EBCE0_N

IC8001 V1 EBOE_N

IC8001 V2 EBWE_N

IC8001 P2 EBCE1_N

1 7

3

4

38

82

965

Page 39

11.3. A-Board (2/12) Schematic Diagram

CH0A10

CH0DQ11

CH0A2

CH0DQ5

CH0DQ12

CH0A8

CH0XWE

CH0DQ6

CH0A1

CH0BA1

CH0DQ14

CH0DQ10

CH0A11

CH0DQ3

CH0BA0

CH0A6

CH0XCS0

CH0DQ1

CH0DQ2

CH0A9

CH0XCAS

CH0DM1

CH0A3

CH0DQS1

CH0A5

CH0DQ15

CH0XBA2

CH0DQ13

CH0A12

CH0DQ7

CH0A4

CH0DQS0

CH0DM0

CH0A7

CH0DQ8

CH0A0

CH0DQ0

CH0XRAS

CH0DQS0_N

CH0DQ9

CH0DQS1_N

CH0DQ4

CH0XCK

CH0CK

CH0ODT

CH0CKE

C8102

50V

5p

C8120

16V

0.1u

C8113

6.3V 1u

C8003

16V

0.1u

C8004

16V

0.1u

C8111

10u10V

C8097

10u10V

C8005

16V

0.1u

C8006

16V

0.1u

C8110

16V

0.1u

C8112

50V

1000p

C8105

50V

1000p

C8148

50V

1000p

C8104

50V

1000p

C8121

50V

1000p

IC8002 A1 VDD

IC8001AB23DDRAD6

IC8001AB19DDRAD2

IC8001AE8DDRDQ5

IC8001

AF11DDRDQ14

IC8001AB14DDRWE_N

IC8001AF15DDRODT0

IC8001

AF21 DDRREFCLKA

IC8001AE10DDRDQ3

IC8001AB11DDRDQ15

IC8001AC20DDRVCAL

IC8001AE14DDRDQ9

IC8001AD21DDRAD4

IC8001AC9DDRDQ4

IC8001AC15DDRCAS_N

IC8001AF13DDRDQS1

IC8001AE18DDRBA1

IC8001AC22DDRAD11

IC8001AF14DDRDQ8

IC8001AD20DDRAD3

IC8001AD15DDRCLK

IC8001AF19DDRAD0

IC8001AD14DDRDQ10

IC8001AE17DDRCS0_N

IC8001AE23DDRAD10

IC8001AB10DDRD0_VREF

IC8001AC12DDRDQ12

IC8001AD23DDRAD12

IC8001AF23DDRAD9

IC8001AD16DDRBCLK

IC8001AF12DDRDQSN1

IC8001AF9DDRDQSN0

IC8001AF16DDRCKE

IC8001AD13DDRDM1

IC8001AD22DDRAD8

IC8001AD17DDRBA2

IC8001AE9DDRDQS0

IC8001AE16DDRRAS_N

IC8001

AE21 DDRREFCLKAN

IC8001AD11DDRDQ0

IC8001AC8DDRDQ7

IC8001AB18DDRRODT

IC8001AC17DDRAD1

IC8001AD10DDRDM0

IC8001AE12DDRDQ13

IC8001AB20DDRAD7

IC8001AD12DDRDQ11

IC8001AF20DDRBA0

IC8001

AD19 RQDRVEN

IC8001AC11DDRDQ2

IC8001AF22DDRAD5

IC8001AF10DDRDQ1

IC8001AD8DDRDQ6

IC8001AC18DDRRDRV

IC8001AC13DDRD1_VREF

IC8002

M9 VDD

IC8002 G8 DQ0

IC8002 K8 CK

IC8002 D3 DQ11

IC8002 K7 RAS

IC8002 D7 DQ10

IC8002 L2 BA0

IC8002 F7 LDQS

IC8002 F2 VSSQ

IC8002 P3 A9

IC8002 G3 VDDQ

IC8002 A7 VSSQ

IC8002 L3 BA1

IC8002 E2 NC

IC8002 J7 VSSDL

IC8002 M8 A0

IC8002 A2 NC

IC8002 G7 VDDQ

IC8002 N8 A4

IC8002 D1 DQ12

IC8002 M2 A10

IC8002 H9 DQ5

IC8002 K3 WE

IC8002 L7 CAS

IC8002 A3 VSS

IC8002 P8 A8

IC8002 F8 VSSQ

IC8002 P7 A11

IC8002 B7 UDQS

IC8002 G9 VDDQ

IC8002 E8 LDQS

IC8002 N2 A3

IC8002 F9 DQ7

IC8002 C9 VDDQ

IC8002 C7 VDDQ

IC8002 R8 NC

IC8002 H1 DQ4

IC8002 C3 VDDQ

IC8002 K9 ODT

IC8002 P9 VSS

IC8002 P2 A7

IC8002 N1 VSS

IC8002 M3 A1

IC8002 A9 VDDQ

IC8002 J9 VDD

IC8002 N3 A5

IC8002 D8 VSSQ

IC8002 G2 DQ1

IC8002 R2 A12

IC8002 F1 DQ6

IC8002 R3 NC

IC8002 M7 A2

IC8002 D2 VSSQ

IC8002 R1 VDD

IC8002 A8 UDQS

IC8002 J1 VDDL

IC8002 E7 VSSQ

IC8002

R7 NC

IC8002

B1 DQ14

IC8002 C2 DQ9

IC8002 C1 VDDQ

IC8002 L1 NC

IC8002 E9 VDDQ

IC8002 J3 VSS

IC8002 B2 VSSQ

IC8002 B8 VSSQ

IC8002 D9 DQ13

IC8002 H2 VSSQ

IC8002 B3 UDM

IC8002 E3 VSS

IC8002 F3 LDM

IC8002 L8 CS

IC8002 H8 VSSQ

IC8002 E1 VDD

IC8002 K2 CKE

IC8002 N7 A6

IC8002 C8 DQ8

IC8002 G1 VDDQ

IC8002 H7 DQ2

IC8002 H3 DQ3

IC8002 B9 DQ15

IC8002 J2 VREF

IC8002 J8 CK

L8000

J0JHC0000045

DDR_VCC_POST

DDR_VCC_POST

SUB1.8V

R8014

EXB28V101JX

R8018

EXB28V101JX

R8015

EXB28V101JX

R8010

EXB28V101JX

R8017

EXB28V101JX

R8016

EXB28V101JX

R8011

EXB28V101JX

R8013

EXB28V101JX

R8019

EXB28V101JX

R8012

EXB28V101JX

R8006

402

R8004

402

R8003

301

R8008

1k

R8001

1k

R8000

1k

R8079

73.2

R8007

102

R8009

1k

R8068

150

R8005

102

R8091

80.6

84FBGA DDR2 800Mz x 16bit

DDR2IF

1612 14 1810 13 1511 17

!

A-BOARD TXN/A10QHMS (2/12)

Nile-TCON

C1AB00003249

IC8001

C3ABSY000043

IC8002

DDR2

39

Page 40

11.4. A-Board (3/12) Schematic Diagram

!

A-BOARD TXN/A10QHMS (3/12)

SD_CARD

TO 1/12

SDDAT0

SDCD

SDDAT1

SDDAT2

SDDAT3

SDCLK

SDCMD

SDWP

SDDAT0

SDCD

SDDAT1

SDDAT2

SDDAT3

SDCLK

SDCMD

SDWP

TP8509

C8503

16V

1

A0

2

A1

3

A2

4

Vss

*IC8503

TVRR343AAS

EEPROM

R8539

EXB2HV680JV

0.1u

AE_SDDAT0

AE_SDDAT1

AE_SDDAT2

AE_SDDAT3

AE_SDCD

AE_SDCLK

AE_SDCMD

AE_SDWP

SUB3.3V

8

R8538

Vcc

4.7k

TP8510

7

WP

R8510

S

6

SCL

R8511

S

5

SDA

EXB2HV103JV

C8520

16V

0.1u

EXB2HV330JV

TP8512

TP8511

AE_SDWP

R8543

R8530

JK8502

K1NA12E00017

SD CARD SLOT

24KEC_EEP_WP

24KEC_I2CCLK2_EEP

24KEC_I2CDATA2_EEP

AE_SDCMD

AE_SDCLK

AE_SDDAT3

AE_SDDAT2

AE_SDDAT1

AE_SDCD

AE_SDDAT0

TO 1/12

TO 12/12

TP8508

TP8507

1234567

9

SDDAT3

SDDAT2

C8513

16V

0.1u

C8512

16V

47u

SD/IC_CARD

TP8506

C8517

GND

SDCMD

EXB2HV680JV

EXB2HV680JV

R8513

EXB2HV680JV

R8515

EXB2HV680JV

R8516

EXB2HV680JV

R8514

R8512

R8501

68

STB3.3V

R8521

4.7k

4.7k

4.7k

4.7k

R8522

R8502

R8523

4.7k

4.7k

R8560

R8557

EBDAT0

EBDAT1

EBDAT2

EBDAT3

EBDAT4

EBDAT5

EBDAT6

EBDAT7

EBDAT8

EBDAT9

EBDAT10

EBDAT11

EBDAT12

EBDAT13

EBDAT14

EBDAT15

EBADD1

EBADD2

EBADD3

EBADD4

EBADD5

EBADD6

EBADD7

EBADD8

EBADD9

EBADD10

EBADD11

EBADD12

EBADD13

EBADD14

EBADD15

EBADD16

EBADD19

EBADD18

EBADD17

EBADD22/NAALE

EBADD21/NACLE

EBADD20

EBADD23/NABSY_N

EBADD24

TO 1/12

TO

1/12

AA_ED0

STB3.3V

L8500

J0JHC0000045

R8528

SUB3.3V_SD

L8501

J0JHC0000045

TP8503

TP8504

TP8502

SDDAT0

TP8501

47k

47k

0.01u

25V

C8514

R8548

R8547

R8546

100

0.1u

0.1u

16V

16V

C8505

C8504

101112

8

D.SW

W.P.

SDDAT1

TP8505

10u

10V

S

L8502

3.3V

GND

SDCLK

+

4.7k

10u10V

C8515

AA_ED7

AA_EA17

AA_ED15

AA_ED14

C8501

16V

0.1u

52

53

54

55

49

50

51

Vss

A16

N.C.56N.C.

DQ7

BYTE

DQ14

DQ15/A-1

*IC8502

TVRR300AMS

(A23)

N.C.2A223A154A145A136A127A118A109A910A811A1912A2013WE14RESET15A2116WP/ACC17RY/BY18A1819A1720A721A622A523A424A325A226A127N.C.28N.C.

1

AA_EA12

AA_EA24

AA_EA23

AA_EA13

AA_EA15

AA_EA16

AA_EA11

AA_EA14

(for 256Mb)

AA_ED6

48

AA_EA10

AA_ED3

AA_ED5

AA_ED4

AA_ED2

AA_ED11

AA_ED13

AA_ED10

AA_ED12

40

41

42

43

44

45

46

47

Vcc

DQ3

DQ4

DQ5

DQ6

DQ10

DQ11

DQ12

DQ13

128Mbit NOR FLASH

MCU_XRST

AA_EA21

AA_EA19

AA_EA20

AA_XEWE0

AA_EA9

AA_EA22

AA_ED9

AA_EA18

AA_EA1

AA_ED1

AA_ED8

AA_ED0

AA_XERE

AA_XECS0

C8506

16V

0.1u

29

30

31A032CE33

34OE35

Vio

Vss

N.C.

DQ036DQ837DQ138DQ939DQ2

(VIO)

AA_EA4

AA_EA8

AA_EA6

AA_EA2

AA_EA3

AA_EA5

AA_EA7

AA_XECS0

AA_XERE

AA_XEWE0

MCU_XRST

STB3.3V

R8531

68

XECS0

R8532

68

TO 1/12

XERE

R8533

68

XEWE0

MCU_XRST

TO 1,4,7/12

*C8519

6.3V

1u

AA_ED1

AA_ED2

AA_ED3

AA_ED4

AA_ED5

AA_ED6

AA_ED7

AA_ED8

AA_ED9

AA_ED10

AA_ED11

AA_ED12

AA_ED13

AA_ED14

AA_ED15

AA_EA1

AA_EA2

AA_EA3

AA_EA4

AA_EA5

AA_EA6

AA_EA7

AA_EA8

AA_EA9

AA_EA10

AA_EA11

AA_EA12

AA_EA13

AA_EA14

AA_EA15

AA_EA16

AA_EA19

AA_EA18

AA_EA17

AA_EA22

AA_EA21

AA_EA20

AA_EA23

AA_EA24

21 2423

40

2720 262519 22

Page 41

11.5. A-Board (4/12) Schematic Diagram

+

(FIN)

Thermal Pad Thermal Pad Thermal Pad

S

P

P

P

MCU_XRST

C5736

6.3V

1u

C5713

0.1u

25V

C5701

4.7u

6.3V

C5771

0.033u

25V

C5734

1u

25V

C5725

0.015u

16V

C5702

1u

10V

C5731

10u

25V

C5726

0.015u

16V

C5777

10u

10V

C5765

1u

10V

C5738

6.3V

1u

C5703

1u

10V

*C5663

10V

10u

C5694

0.1u

25V

C5704

25V

10u

C5776

10u

10V

*C5667

50V

100p

C5700

4.7u

6.3V

C5705

10u

25V

C5709

22u

6.3V

C5707

0.1u

16V

C5708

22u

6.3V

C5715

8200p

25V

C5692

10u

25V

C5722

10u

25V

C5724

0.1u

25V

*C5664

10V

10u

C5690

22u

6.3V

C5737

6.3V

1u

C5711

10u

25V

C5719

22u

6.3V

C5739

6.3V

1u

C5689

22u

6.3V

C5714

0.015u

16V

C5720

22u

6.3V

C5730

25V

10u

C5764

1u

10V

C5780

1000p

50V

C5779

1000p

50V

C5778

1000p

50V

*C5652

50V

1000p

C5706

0.01u

25V

C5696

0.01u

25V

C5695

0.01u

25V

C5733

25V

47u

D5770

B0JCPG000030

*D5606

B0JCCE000008

*D5603

B0ACCJ000048

*D5604

B0ACCJ000048

*D5605

B0ACCJ000048

D5772

B0JCPG000030

D5765

B0HCMM000014

D5633

B0ACCJ000048

D5671

B0ACCJ000048

D5771

B0JCPG000030

D5670

B0ACCJ000048

D5629

B0BC8R100004

C0EBF0000354

*IC5601

4

OUT

3

CD

1

VSS

2

VDD

C0DBGYY00887

IC5609

4

VDD

3

VOUT

1CE2

VSS

C0DBGYY00887

IC5607

4

VDD

3

VOUT

1CE2

VSS

C0DBAGF00030

IC5605

1

ON/OFF

2

VSS

3

NC

5

VOUT

4

VIN

C0DBEYG00002

IC5613

1

Vin2Vc4Vadj5GND

3

Vo

IC5606

C0DBAYY00755

1

BOOT

2

VIN

3

SW

4

GND

5

FB

6

COMP

7

EN

8

SS

Thermal_Pad

IC5610

C0DBAYY00755

1

BOOT

2

VIN

3

SW

4

GND

5

FB

6

COMP

7

EN

8

SS

Thermal_Pad

IC5608

C0DBAYY00755

1

BOOT

2

VIN

3

SW

4

GND

5

FB

6

COMP

7

EN

8

SS

Thermal_Pad

L5613

J0JHC0000075

L5609

G1C6R8MA0416

L5611

G1C220MA0416

L5610

G1C100MA0416

SUB5V

F15V

F15V_FIL

SUB1.8V

SUB5V

SUB5V_TUNER

SUB1.2V

F15V

STB5V

SUB5V

SUB5V

SUB5V

SUB3.3V_HDMI

STB3.3V

SUB3.3V_A

SUB3.3V_SD

SUB3.3V

*R5628

VJ5500

VJ5503

VJ5504

MCU_XRST

KEY3

KEY3/STBY_LED_ON

Q5612

B1ABCF000231

Q5616

DSC2001S0L

Q5615

B1ABGC000011

Q5613

B1ABCF000231

*Q5605

B1ADCE000022

R5673

47k

*R5705

0

*R5710

2.2

R5668

10k

R5676

47k

R5682

10k

R5674

2.2k

R5697

3.3k

*R5626

100k

*R5709

15

*R5712

2.2

R5715

4.3k

*R5631

470

R5681

47k

*R5706

0

R5667

4.3k

R5678

9.1k

*R5707

15

*R5629

1M

*R5627

10k

*R5711

2.2

R5672

10k

R5675

10k

R5696

10k

R5713

6.2k

*R5632

100

*R5708

15

*R5624

47k

R5683

6.8k

R5701

2k

R5702

1k

R5679

10k

*R5625

68k

*R5623

10k

R5714

1.24k

R5669

2.2k

R5671

68k

*R5630

100

R5680

2.2k

1%

R5670

22k

SUB3.3V_A

SUB3.3V

SUB3.3V_HDMI

SUB1.2V

SUB5V

SUB1.8V

SUB3.3V_SD

30 35 3629 3331 32 34

28

!

A-BOARD TXN/A10QHMS (4/12)

SUB1.2V

SUB1.8V

SUB5V

SUB3.3V

SUB3.3V_A

SUB3.3V_HDMI

SUB3.3V_SD

RESET

TO 1,3,7/12

TO 1/12

TO 12/12

41

Page 42

11.6. A-Board (5/12) Schematic Diagram

PC MODEL

TO 10/12

L2123

TU

!

A-BOARD TXN/A10QHMS (5/12)

FL2102

PC_R_TERMINAL

PC_B_TERMINAL

PC_G_TERMINAL

PC_VD_TERMINAL

PC_HD_TERMINAL

J0HABB000004

1

R2114

2

75

1%

FL2104

J0HABB000004

1

R2116

2

75

B

1%

FL2103

J0HABB000004

1

2

R2115

75

1%

FL2101

J0HABB000003

3

4

R2198

4.7k

FL2100

J0HABB000003

3

R2199

4

4.7k

US AV1_S

AS AV2_S

US AV1

AS AV2

U_AV1_V/A_AV2_V__TERMINAL

TO 10/12

C2107

6.3V

R2117

1u

47

3

4

C2108

6.3V

R2118

1u

47

3

4

C2111

25V

R2122

0.01u

220

C2109

6.3V

R2119

1u

47

3

4

1

2

1

2

IC2110

C0JBAB000854

INVERTER

1

1A

2

1Y

3

2A

4

2Y

5

3A

6

3Y

7

GND

SUB3.3V_A

S

R2205

C2279

0.1u

14

VCC

13

6A

12

6Y

11

5A

R2218

10

5Y

9

4A

8

4Y

R2223

VR3IN

VB3IN

TO 1/12

SYNCIN3

VG3IN

16V

68

AVDIN

TO 1/12

68

AHDIN

PDP US YPBPR2

LCD US YPBPR1

US iPOD V

AS AV1

TO 10/12

AS AV1 V

US iPOD V

TO 10/12

PDP US YPBPR1

US AV2

AS AV3

AS AV1 YDET