Panasonic TC-26LX60, TC-32LX60 Service manual

TC-26LX60

TC-32LX60

LH58

MTNC060371CE

B05 Canada: B07

LCD TV

CONTENTS

Page Page

1 Safety precautions 3

2 Warning

2.1. Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

3 About lead free solder (PbF)

4 Receiver feature table

5 Chassis Board Layout

6 Location of controls (EUR7613ZG0)

7 Service Mode

7.1. How to enter into adjustment mode

7.2. Adjustment method.....Use the remote control.

7.3. Cancellation

7.4. Contents of adjustment mode

8 Troubleshooting Guide

8.1. Self-check function

8.2. How to access

8.3. Screen Display

9 Disassembly Instructions 9

3

3

4

5

6

7

8

8

8

8

8

8

8

8

8

9.1. Removing the LCD panel assembly and LCD L/R MTG

9.2. Removing the LCD panel and LCD T/B MTG

10 Measurements and Adjustments

10.1. White Balance Adjustment

11 Boards Assemblies

11.1. AP-Board

11.2. A-Board

11.3. P-Board

11.4. G-Board

11.5. DT-Board

11.6. DT-Board with shield

11.7. V-Board

12 Block Diagram

12.1. Block Diagram for K, P and AP (DC-DC CONV.) (1 of 2)

12.2. Block Diagram for K, P and AP (DC-DC CONV.) (2of 2)

© 2006 Panasonic Corporation of North America. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

12

12

13

13

14

14

15

16

17

18

19

20

21

21

22

12.3. ATSC Interface Block Diagram (1 of 2) 23

12.4. ATSC Interface Block Diagram (2 of 2)

12.5. Main Block Diagram (1 of 6)

12.6. Main Block Diagram (2 of 6)

12.7. Main Block Diagram (3 of 6)

12.8. Main Block Diagram (4 of 6)

12.9. Main Block Diagram (5 of 6)

12.10. Main Block Diagram (6 of 6)

13 Schematic Diagrams

13.1. Schematic Diagrams Notes

13.2. Reference of PDF links color

13.3. AP-Board (1 of 4) Schematic Diagram

13.4. AP-Board (2 of 4) Schematic Diagram

13.5. AP-Board (3 of 4) Schematic Diagram

13.6. AP-Board (4 of 4) Schematic Diagram

13.7. V-Board Schematic Diagram

24

25

26

27

28

29

30

31

31

32

33

34

35

36

13.8. G-Board Schematic Diagram

14 Printed Circuit Boards

14.1. A-Board Top Side

14.2. A-Board Bottom Side

14.3. AP-Board

14.4. DT-Board Bottom Side

14.5. DT-Board Top Side

14.6. V & G-Board

15 Parts Location

15.1. Packing Exploded View

16 Parts list

16.1. Description of abbreviations guide

16.2. Partslist

37

38

39

39

40

41

42

43

44

45

46

47

47

48

2

1 Safety precautions

General guidelines

1. When servicing, observe the original lead dress. If a

short circuit is found, replace all parts which have been

overheated or damaged by the short circuit.

2. After servicing, see to it that all the protective devices

such as insulation barriers, insulation papers shields are

properly installed.

3. After servicing, make the following leakage current

checks to prevent the customer from being exposed to

shock hazards.

Leakage current cold check

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohmmeter,

between the jumpered AC plug and each exposed

metallic cabinet part on the equipment such as

screwheads, connectors, control shafts, etc. When the

exposed metallic part has a return path to the chassis,

the reading should be between 1MΩ and 5.2MΩ. When

the exposed metal does not have a return path to the

chassis, the reading must be infinite.

Figure 1. Hot check circuit

Leakage current hot check

1. Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer for this check.

2. Connect a 1.5k, 10 watts resistor, in parallel with a

0.15F capacitors, between each exposed metallic part

on the set and a good earth ground such as a water

pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks,

leakage current must not exceed 0.5 milliamp. In case a

measurement is outside of the limits specified, there is

a possibility of a shock hazard, and the equipment

should be repaired and rechecked before it is returned

to the customer.

2 Warning

2.1. Prevention of Electro Static

Discharge (ESD) to

Electrostatically Sensitive (ES)

Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some fieldeffect transistors and semiconductor "chip" components.

The following techniques should be used to help reduce the

incidence of component damage caused by electro static

discharge (ESD).

1. Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain off

any ESD on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available

discharging ESD wrist strap, which should be removed for

potential shock reasons prior to applying power to the unit

under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as alminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static solder removal device. Some solder

removal devices not classified as "anti-static (ESD

protected)" can generate electrical charge sufficient to

damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, alminum

foil or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and

observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise hamless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static

electricity (ESD) sufficient to damage an ES device).

3

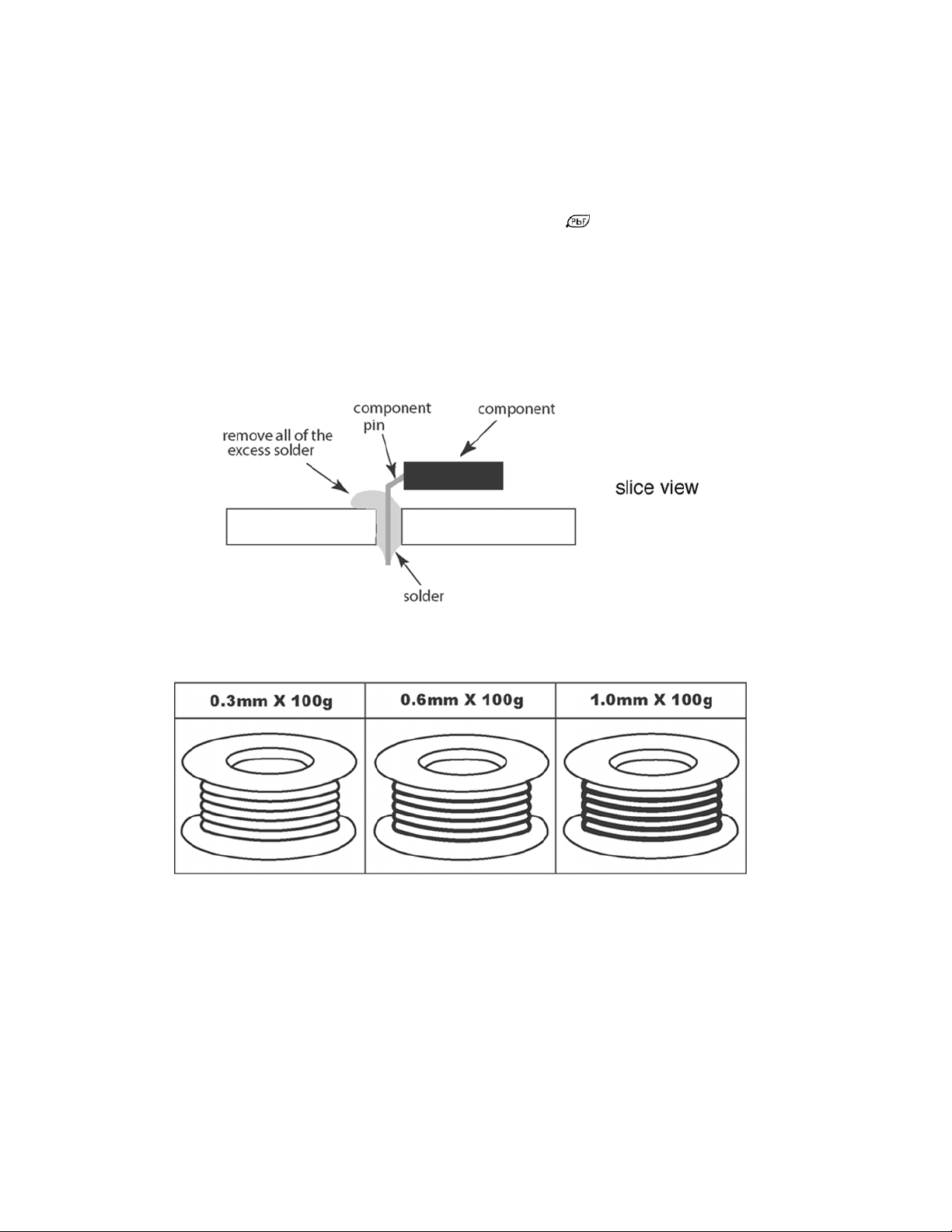

3 About lead free solder (PbF)

NOTE

Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to lead solder, and PbF will refer to Lead Free Solder.

The lead free solder used in our manufacturin g process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work, we’d

suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the “PbF” or a leaf symbol

CAUTION

• Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30 ~ 40 °C) higher.

Please use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

• Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb

solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

• After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto

the opposite side.

stamped on the back of PCB.

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder.

However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used.

4

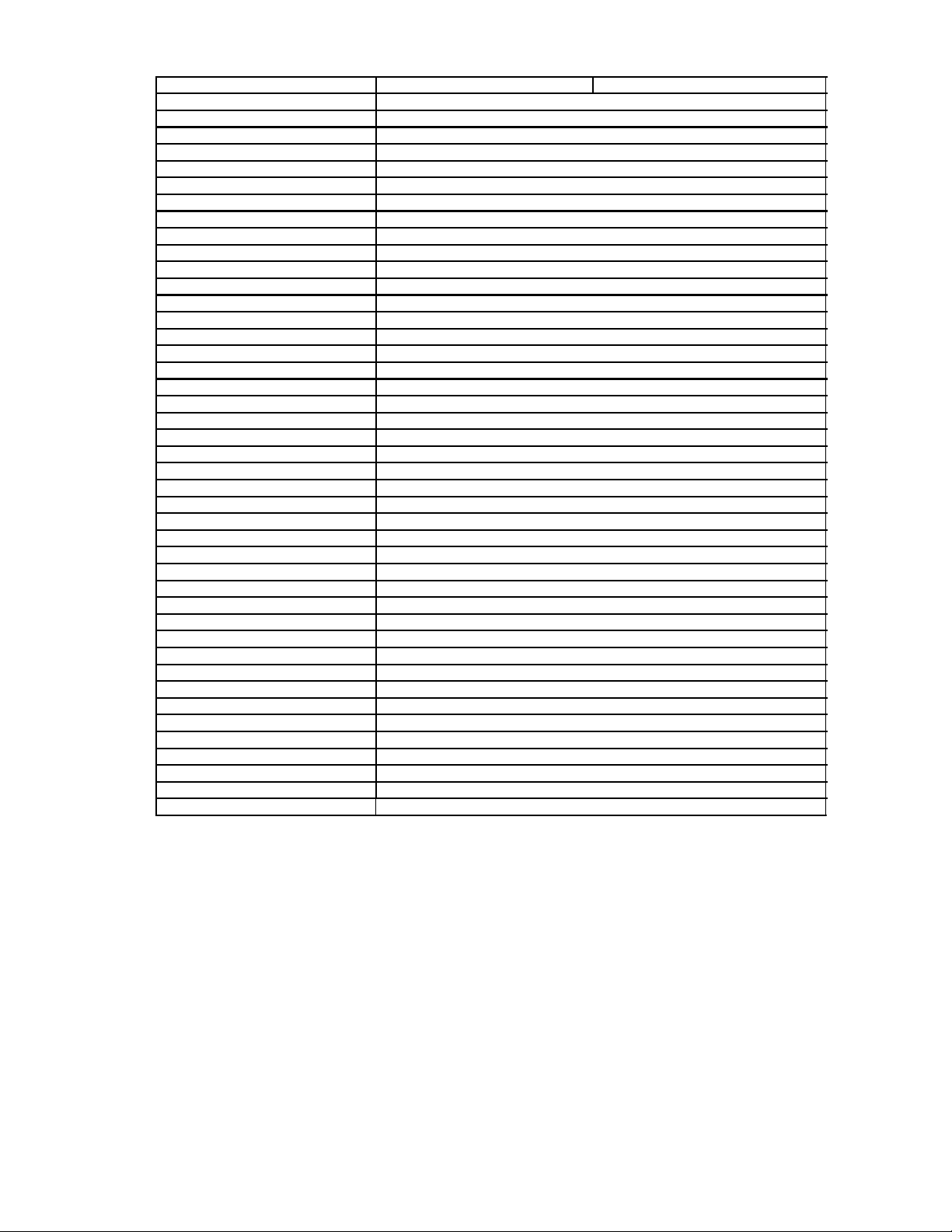

4 Receiver feature table

FEATURE / MODEL TC-26LX60 TC-32LX60

LCD TYPE IPS (WXG A)

LCD PANEL MAKER LG

CHASSIS LH58

SYSTEM ATSC

TUNING FST

STEREO MTS/SAP

CATV USA CATV 181CH

POWER SUPPLY AC120, 60HZ

AV-IN 3 (RCA)

S-VHS-IN 2

COMPONENT VIDEO-IN VIDEO 1 / AUDIO 1 (RCA)

AV-OUT 1 (RCA)

HDMI 2 (AUDIO 2 IS COMMON VIDEO 2)

DVI NONE

PC-INPUT NONE

HEAD PHONE X

OPT DIGITAL AUDIO X

PEAKS SYSTEM PEAKS LITE

GC SYSTEM MICRONAS VCTP

PROGRESSIVE X

3D Y/CCOMB FILTER X

AUDIO OUTPUT 10W + 10W

SPEAKER SYSTEM UNDER/1 WAY - SPEAKER

BASS/TREBLE X

BALANCE X

SURROUND X

AUDIO OUT PERFORMANCE FAO

SAFETY-STANDARD UL6500/CUL

STANDARD-ORGANIZATION E-STAR

EMC (EMISSION) FCC-B/BETS-7

MECHANICAL ISTA

ASPECT X

OFF TIMER X

AUTO SEARCH X

DEMOSTRATION MODE X

CLOSED CAPTION X

V-CHIP X

VESA COMPATIBLE

OSD LANGUAGE ENGLISH (US) / FRENCH / SPANISH

REMOTE CONTROLLER EUR7613ZG0

CEC OF HDMI CONNECTION DIGA

PEDESTAL SWIVEL ONLY (NO TILTED)

SD SLOT FOR DL BACK SIDE

Note:

Specifications are subject to change without notice or obligation.

5

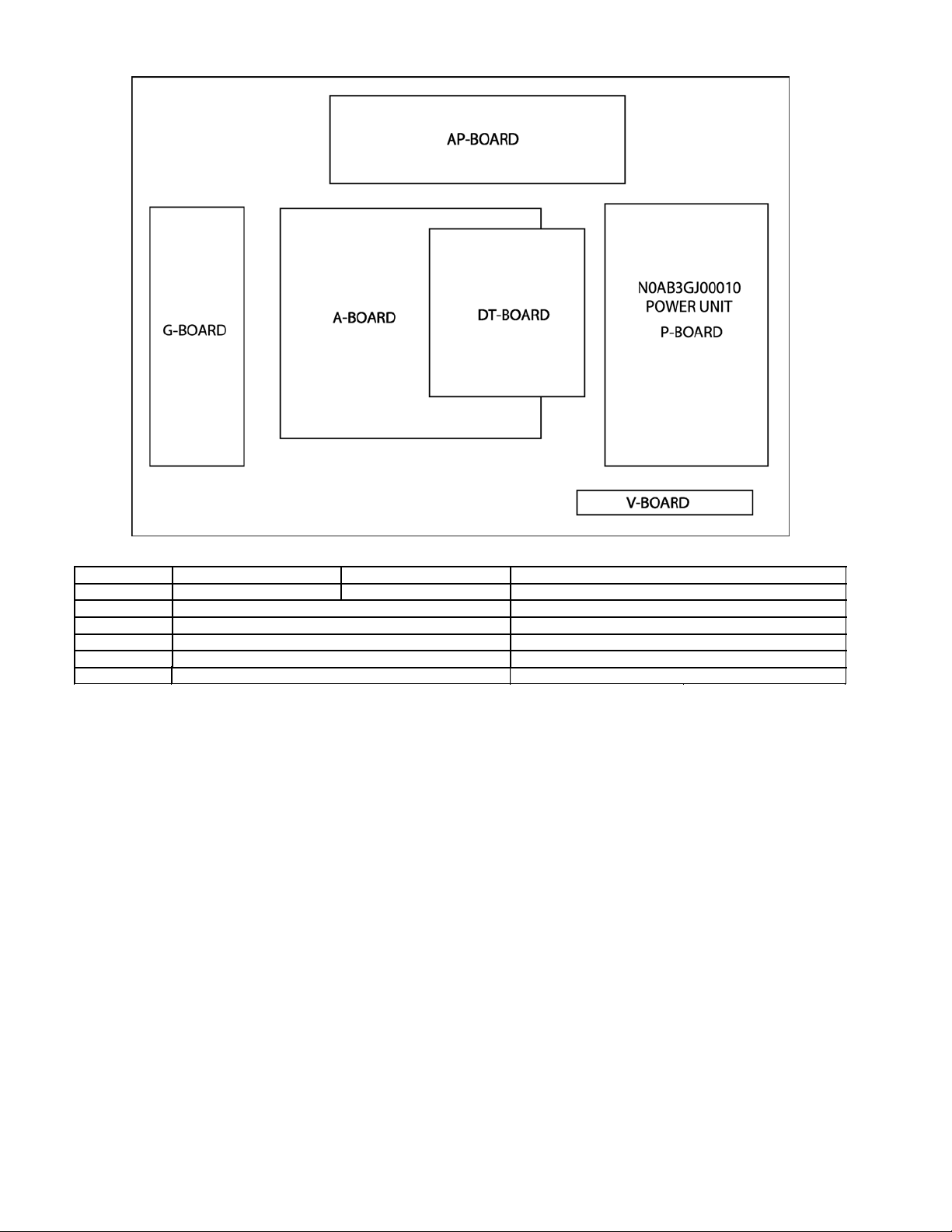

5 Chassis Board Layout

Board Layout

Board Name TC-26LX60 TC-32LX60 Function

A-Board TZRXN010MZK TZRXN010MYK Main (AV Switch, Audio, MCU, Global Core, AV connector)

AP-Board TZRXN020MYK DC-DC

DT-Board TNAG169S Digital Tuner

G-Board TNPA3784S Front Terminal

V-Board TNPA3749ACS Remote Reciever, LED

P-Board N0AB3GJ00010 AC-DC

6

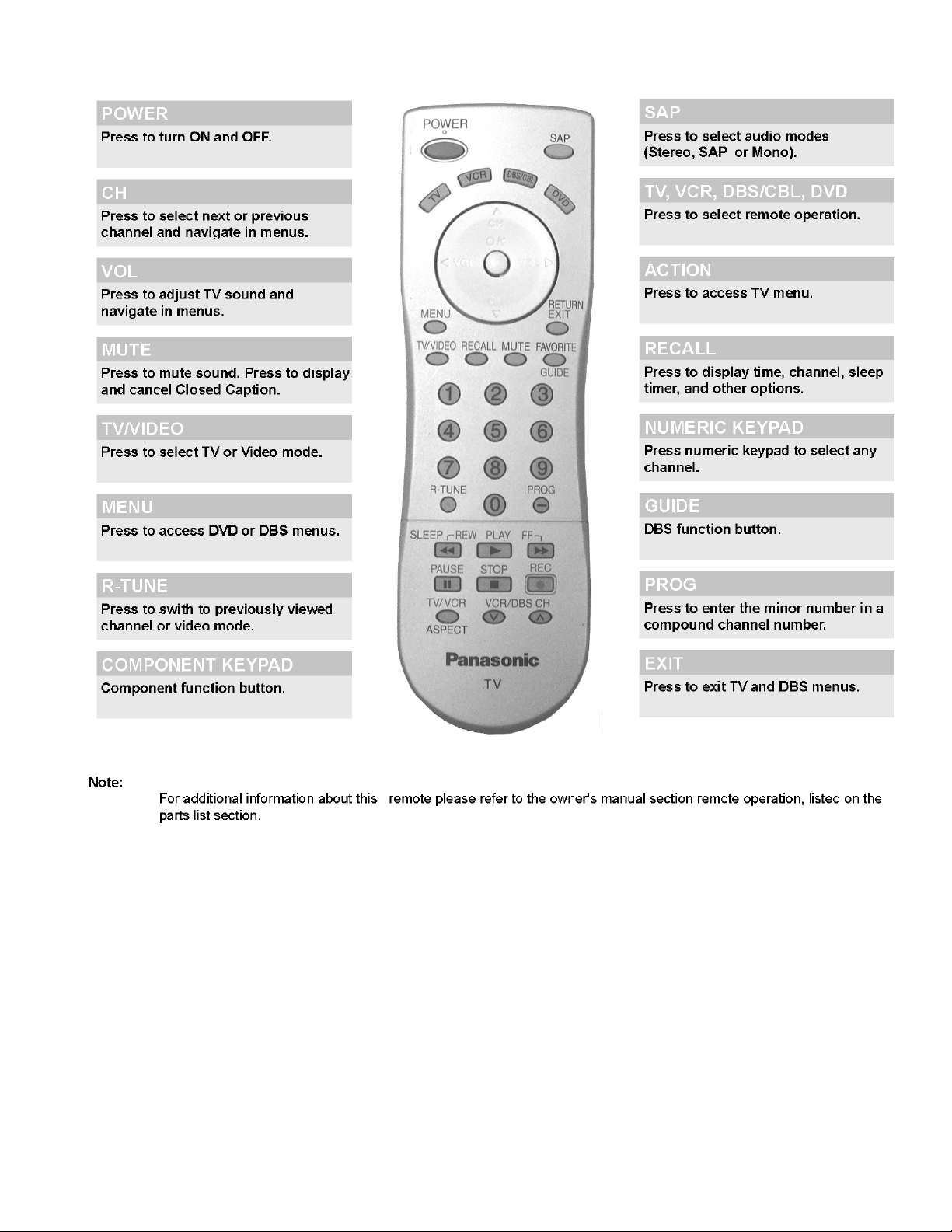

6 Location of controls (EUR7613ZG0)

7

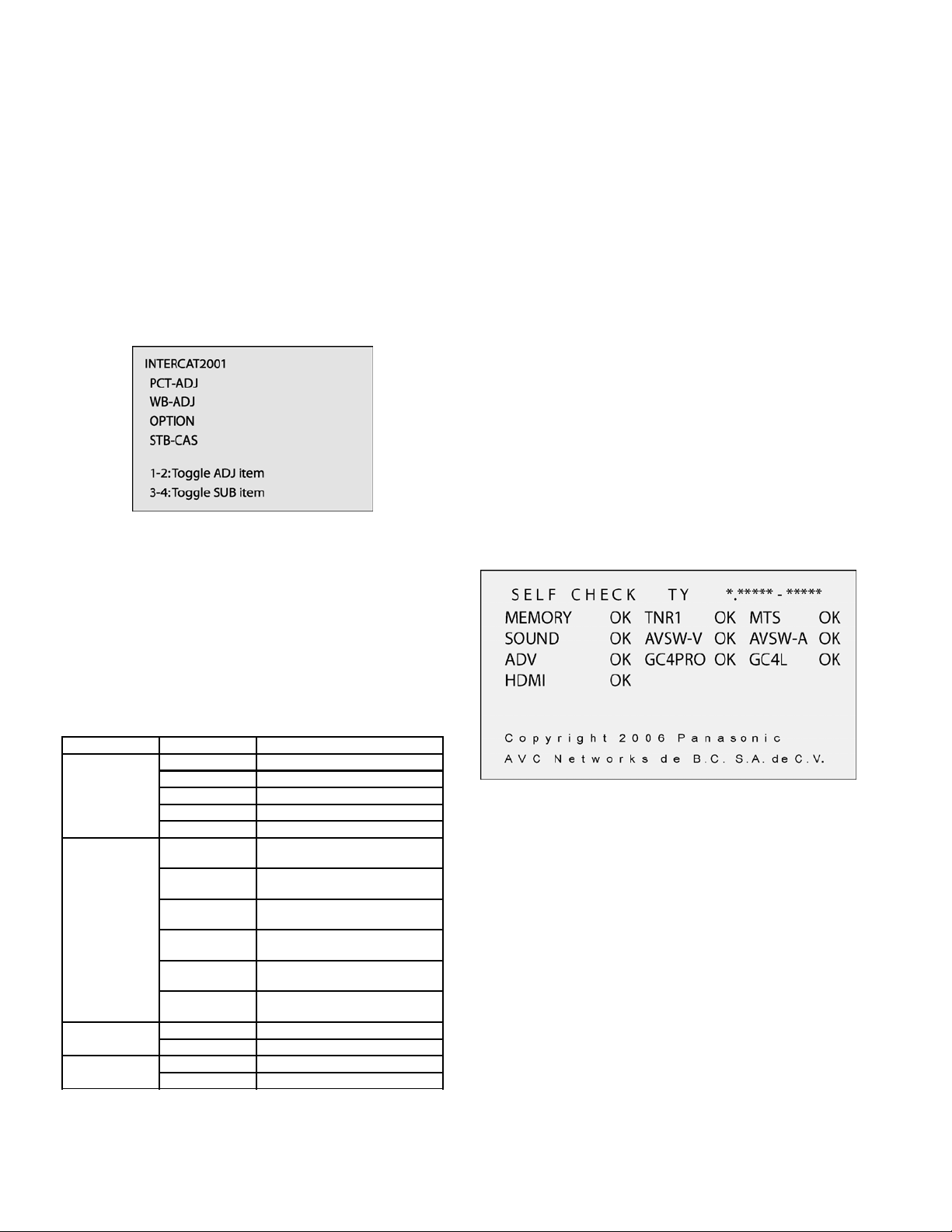

7 Service Mode

8 Troubleshooting Guide

7.1. How to enter into adjustment

mode

While pressing [VOLUME-] button of the main unit, press

[RECALL] button of the remote control transmitter three times

in a row (within 2 seconds).

7.2. Adjustment method.....Use the

remote control.

“1” button...Main items Selection in forward direction

“2” button...Main items Selection in reverse direction

“3” button...Sub items Selection in forward direction

“4” button...Sub items Selection in reverse direction

7.3. Cancellation

8.1. Self-check function

When phenomena like "the power fails from time to time" or

"the video/audio fails from time to time" can not be

confirmed at the time of servicing, the self-check function

can be used to confirm the occurrence and to limit the

scope for the defective circuits. Also, when "the power fails

from time to time", display on the screen can be used to

confirm the occurrence and to limit the scope for the

defective circuits.

Any programmed channels, channels caption data and

some other user defined settings will be erased and return

to factory setting.

8.2. How to access

Access

Produce TV reception screen and, while pressing

[VOLUME -] button on the main unit, press [SLEEP] button

on the remote controller unit simultaneously.

Exit

Press the POWER button twice (off/on) to return to the

normal screen.

8.3. Screen Display

Switch off the power with the [POWER] button on the main unit

or the [POWER] button on the remote control.

7.4. Contents of adjustment mode

• Value is shown as a hexadecimal number.

• Preset value differs depending on models.

• After entering the adjustment mode, take note of the value

in each item before starting adjustment.

Main Item Sub Item Remarks

PCT-ADJ COLOR Sub color

R-Y-A R-Y recovery axis (R-Y)

R-Y-G B-Y Gain (B-Y)

BACK-L Sub backlight

TINT Tint Adjustment

WB-ADT B-CENT Adjustment of Blue gain by test

G-CENT Adjustment of Green gain by test

R-CENT Adjustment of Red gain by test

B-GAIN Adjustment of Blue gain by test

G-GAIN Adjustment of Green gain by test

R-GAIN Adjustment of Red gain by test

OPTION OPTDD White 100% (Not ADJ)

BOOT Red 100% (Not ADJ)

STB-CAS

pattern (50% white)

pattern (50% white)

pattern (50% white)

pattern (100% white)

pattern (100% white)

pattern (100% white)

8

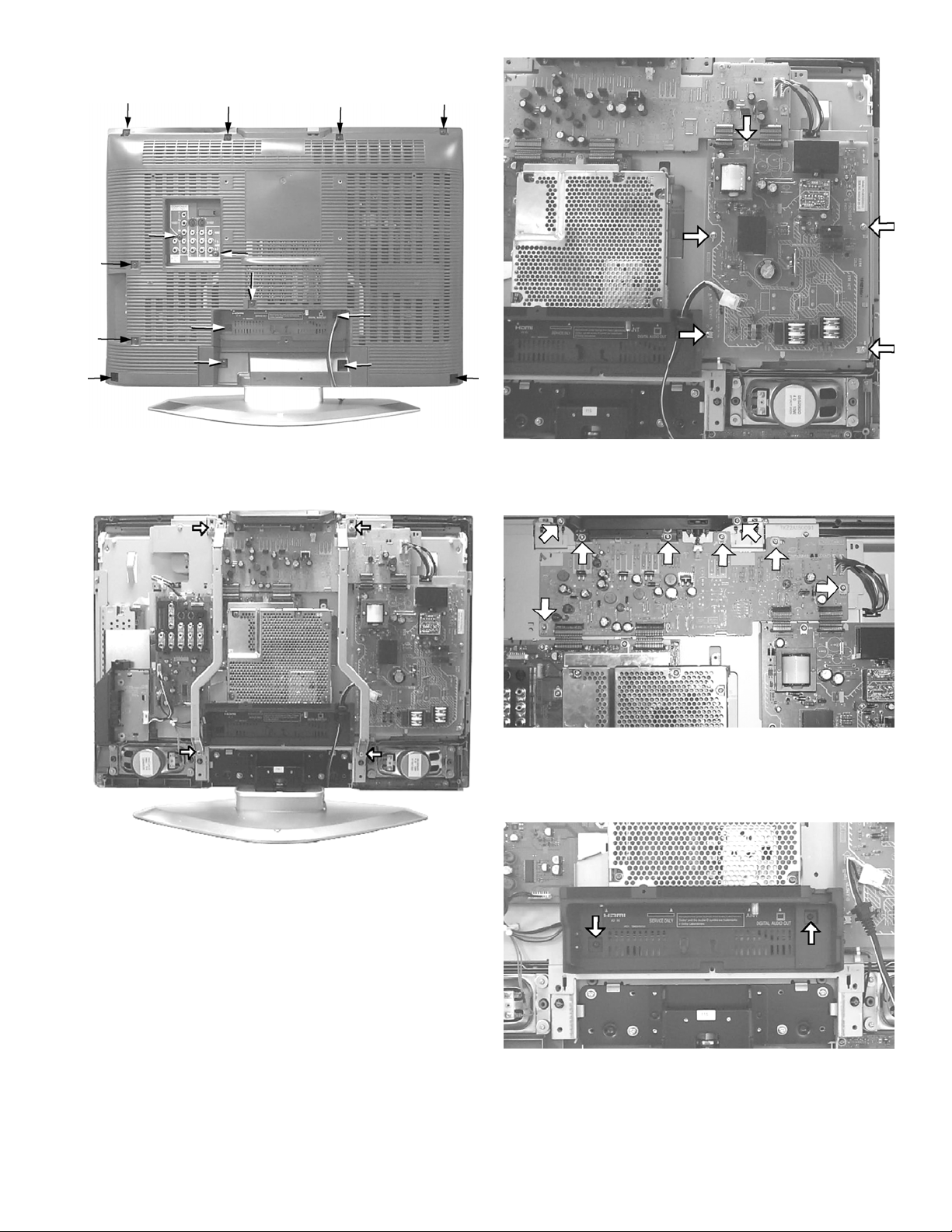

9 Disassembly Instructions

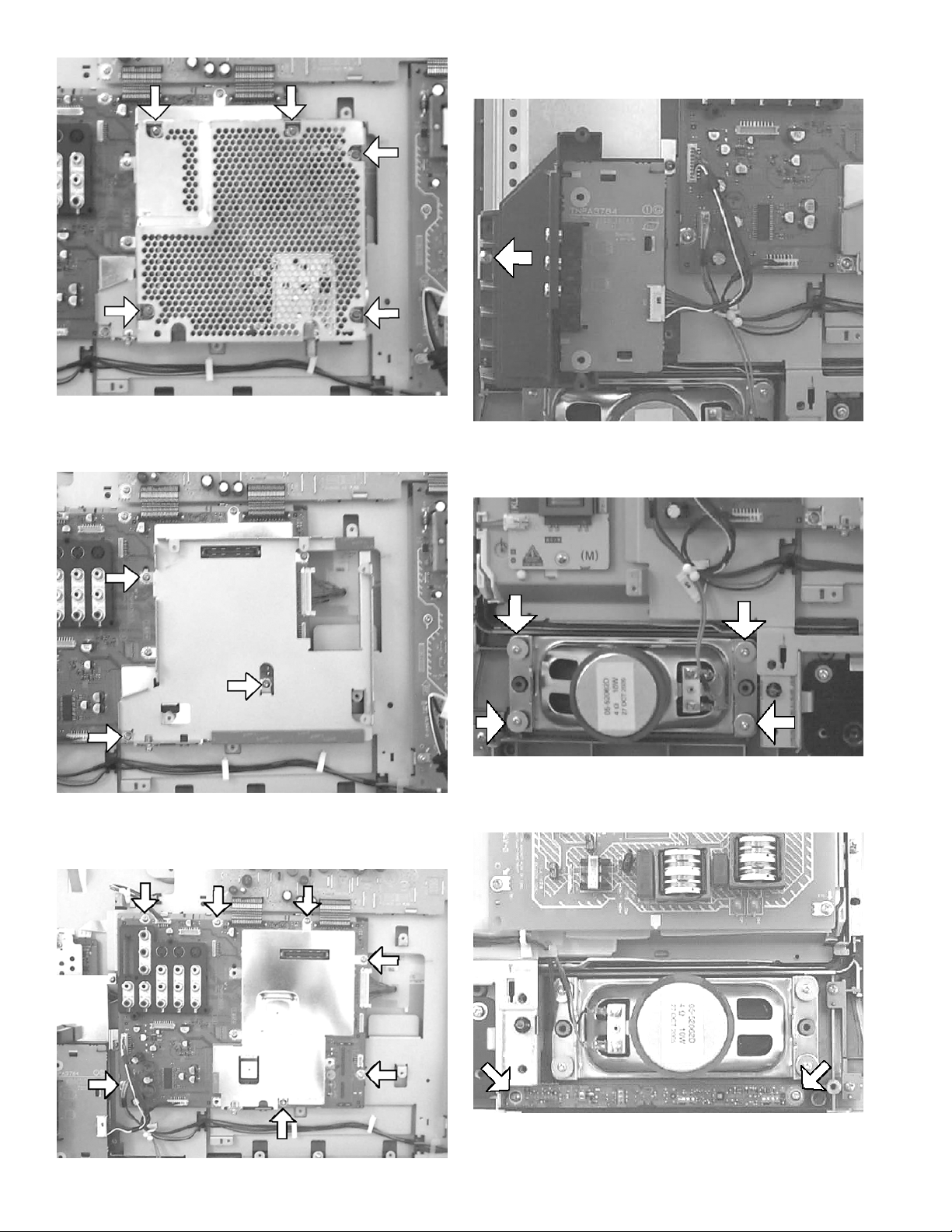

Back cover removal (screw location)

P-Board Disassembly

1. Remove all the screw from the back cover indicated with

arrows.

Without the back cover

1. First remove the two screws from each bracket one

located on top and one on the bottom.

1. To remove the P-Board remove the screws indicated on

the figure above by arrows.

AP-Board Disassembly

1. To remove the AP-Board first lift the four connectors

then remove the screws indicated on the figure above

by arrows.

Bracket Disassembly

1. To remove the bracket shown above remove the screws

indicated on the figure above by arrow.

9

DT-Board Disassembly

1. To remove the DT-Board shown above remove the

screws indicated on the figure by arrows.

DT-Board Bracket Disassembly

1. To remove the A-Board bracket shown above remove

the screws indicated on the figure above by arrows.

G-Board Disassembly

1. To remove the G-Board shown above remove the screw

indicated on the figure by arrow.

Speaker Disassembly

1. To remove the DT-Board bracket shown above remove

the screws indicated on the figure above by arrows.

A-Board Disassembly

1. To remove the speaker remove the screws indicated on

the figure by arrows, each speaker is located on sides.

V-Board Disassembly

1. To remove the V-Board remove the screws indicated on

the figure by arrows.

10

Removing the pedestal

1. Lay down the unit so that the rear cover faces upward.

2. Remove the 4 screws.

3. Then remove the pedestal.

11

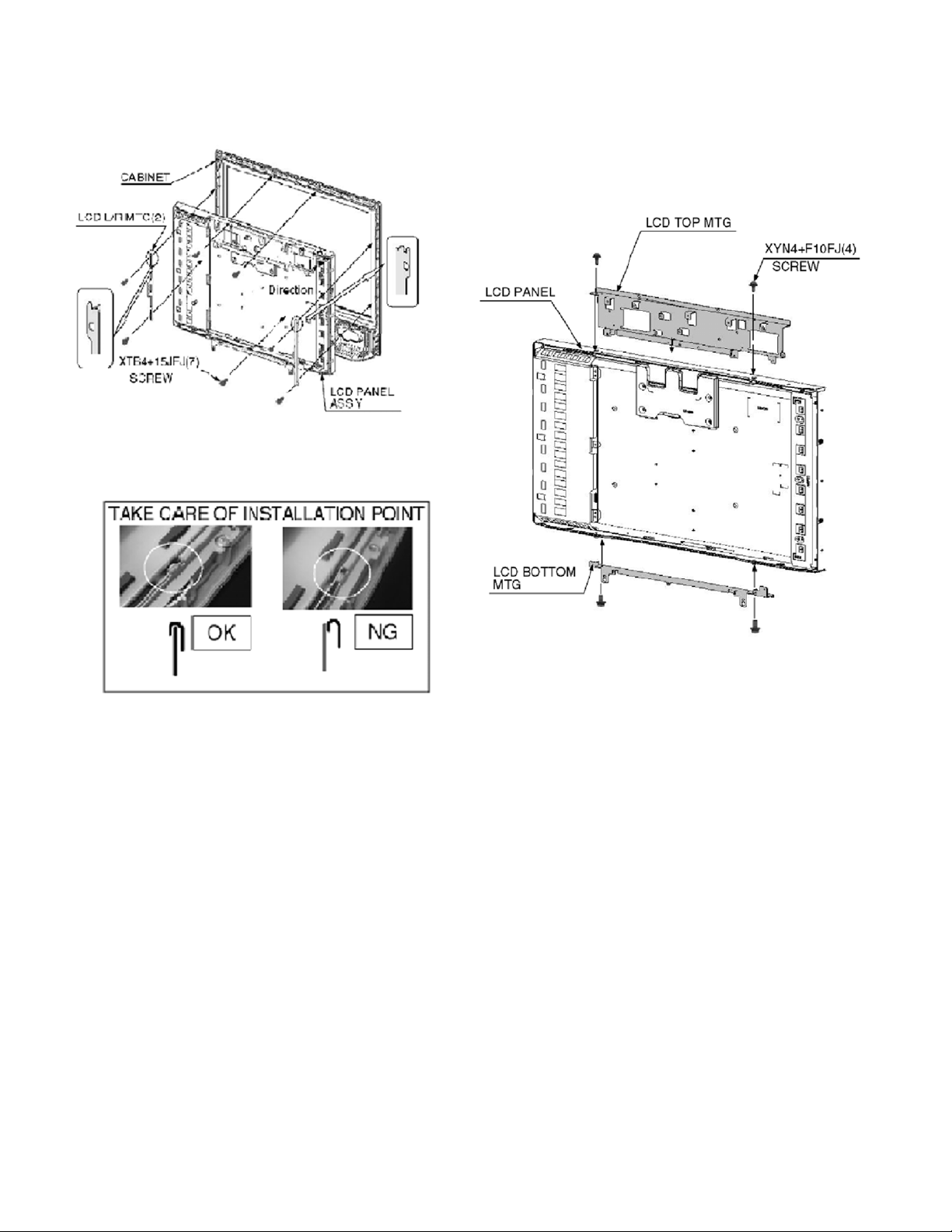

9.1. Removing the LCD panel

assembly and LCD L/R MTG

1. Remove the 4 screws.

2. Remove the LCD panel ass’y and LCD L/R MTG.

9.2. Removing the LCD panel and

LCD T/B MTG

1. Remove the 4 screws.

2. Remove the LCD panel and LCD T/B MTG.

12

10 Measurements and

Adjustments

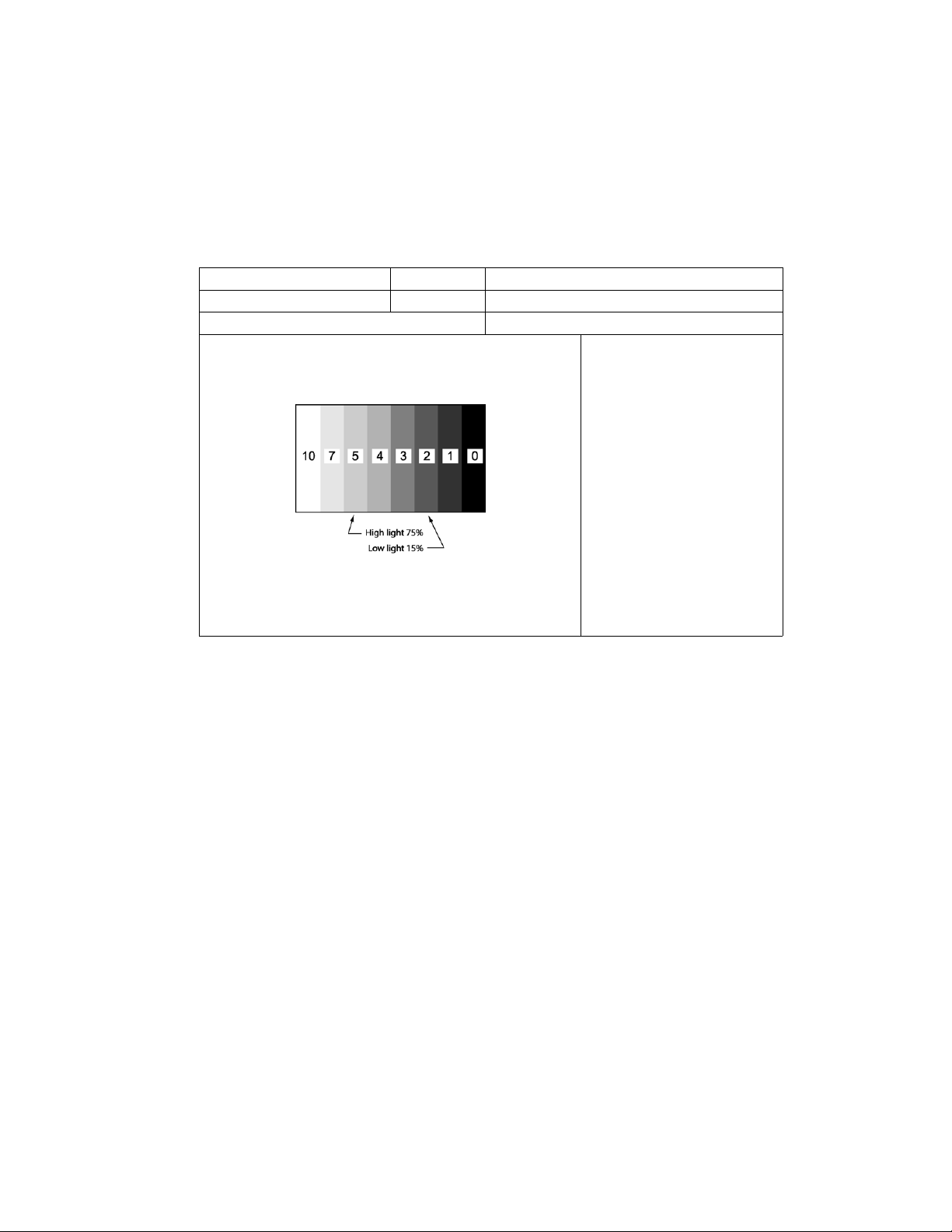

10.1. White Balance Adjustment

!"#$%&'("$)*+'( ,-""(.$)$- /0(.121.+$1-"

3('-$().-"$%-44(%

5%-.(6&%(

78 9004:)+);<1$()0+$$(%")-"()<-&%)=(2-%()+6>&#$'("$8

?8 51.$&%()'-6()$-)@1A168

B8 C+.DE1F<$)$-)GBH8

I8 9!))51.$&%()$-)-228

J8 9004:)+).-4-%)=+%)0+$$(%"8

U1)41F<$)V"-%'+4WX)YZ?RJ[JN)\Z?TB[J]

U1)41F<$)V;+%'WX)YZB7I[JN)\ZB?I[J]

E-;)41F<$)V"-%'+4WX)YZ?RJ[JN)\Z?TB[J]

U1)41F<$)V;+%'WX)YZB7I[JN)\ZB?I[J]

K8 /($)$<().-4-%)$-)'1"1'&'8

L8 M<(")=4&()1#)4(##))4&'1"+".()$<+")%(6)-%)F%(("N)COP+1")=:)6(2+&4$)1#)QQ8)

R8 96>&#$)S+.#)3OP+1")+"6)POP+1")$-)-=$+1")#0(.121.+$1-"8

T8 /($)PO,("$)+#)%(2(%(".(8

7H8 96>&#$)S+.#)3O,("$)+"6)CO,("$)$-)-=$+1")#0(.121.+$1-"8

778 3(0(+$)0%-.(6&%()$-)-=$+1").--61"+$(#8

13

11 Boards Assemblies

11.1. AP-Board

14

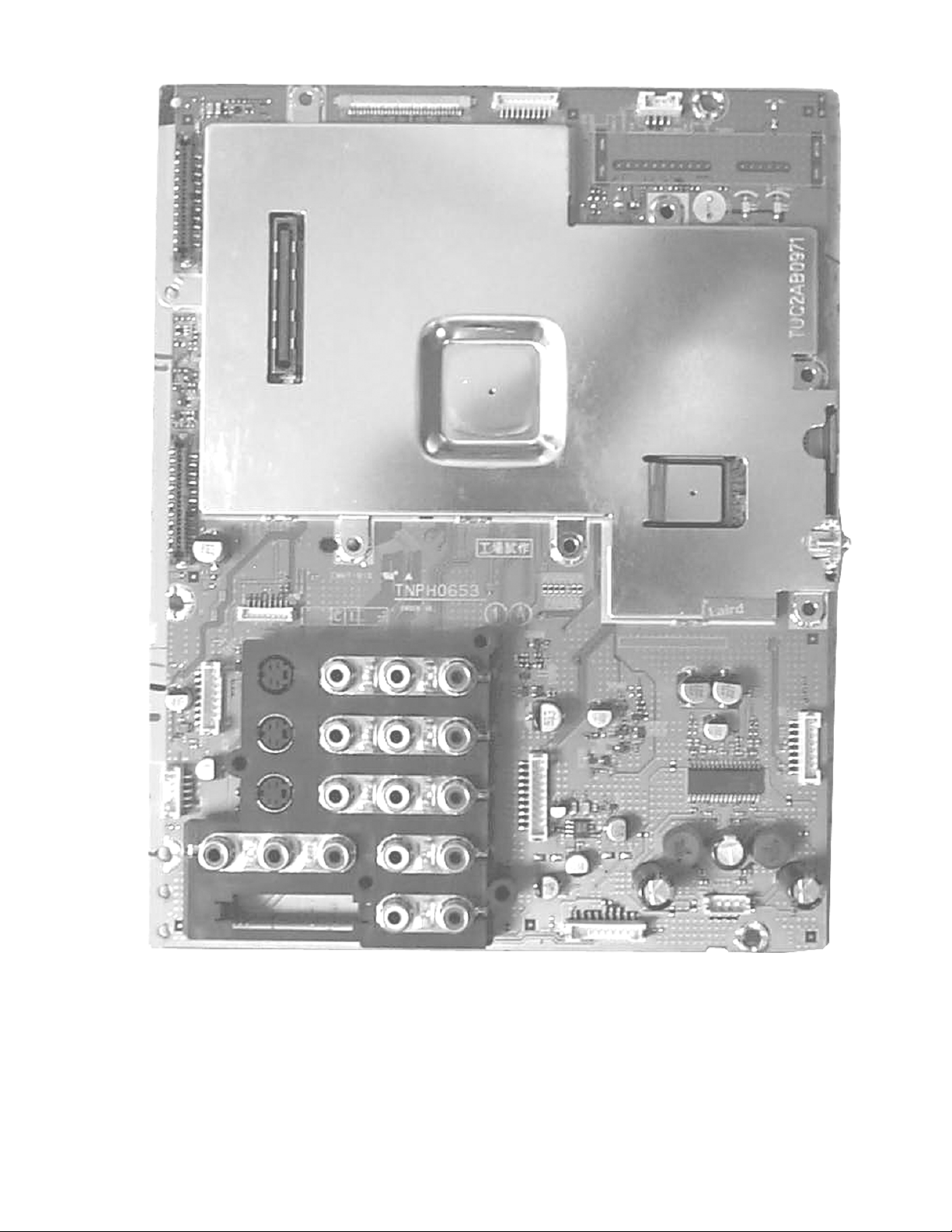

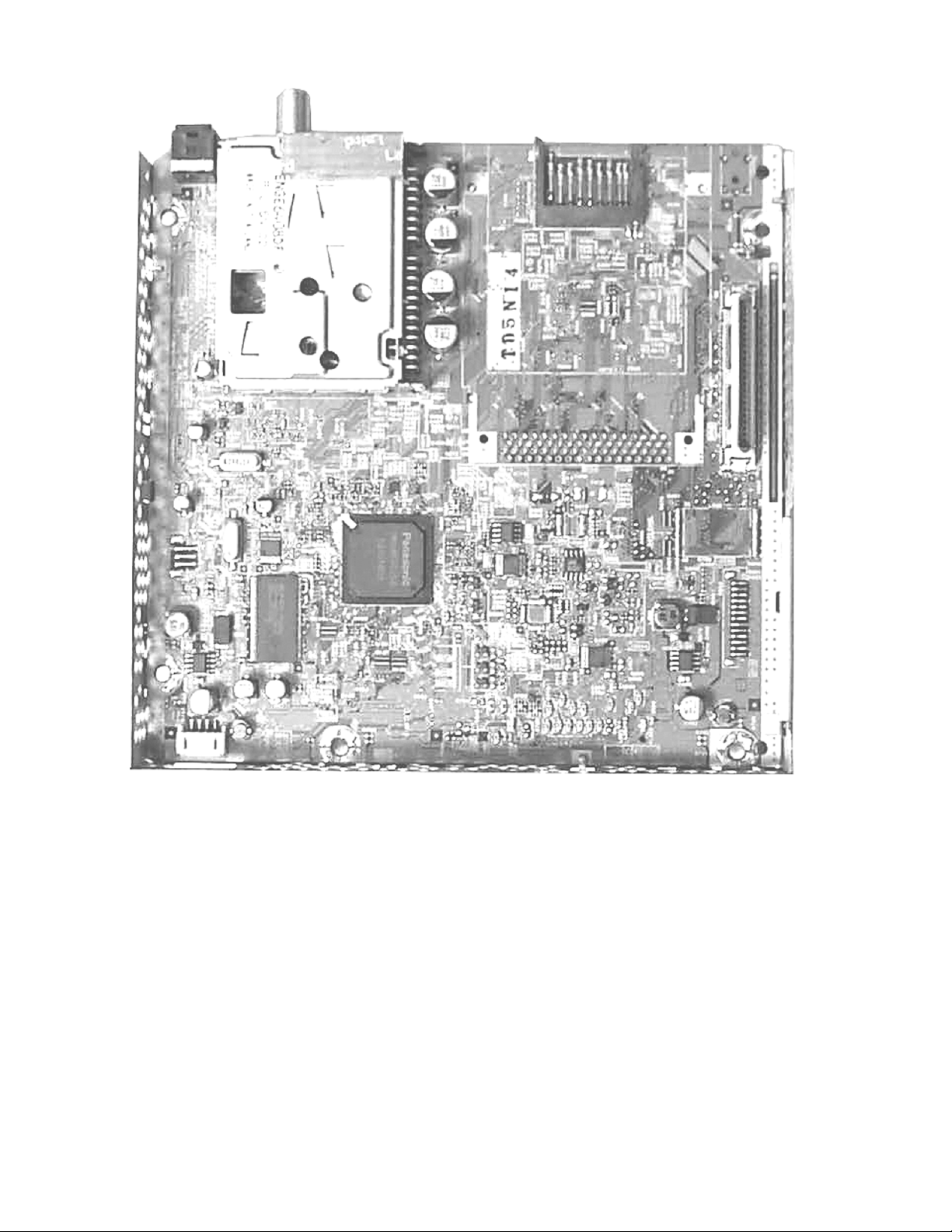

11.2. A-Board

15

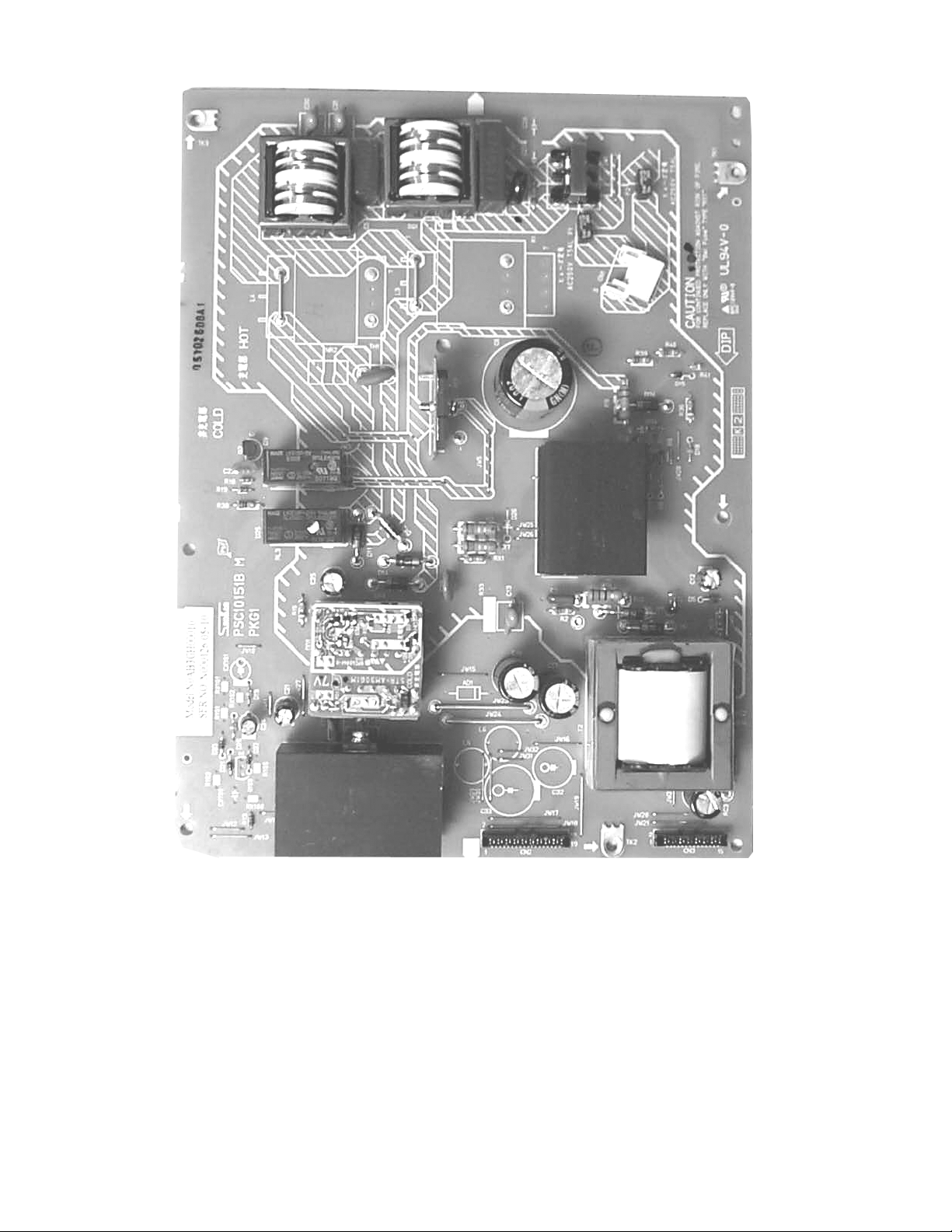

11.3. P-Board

16

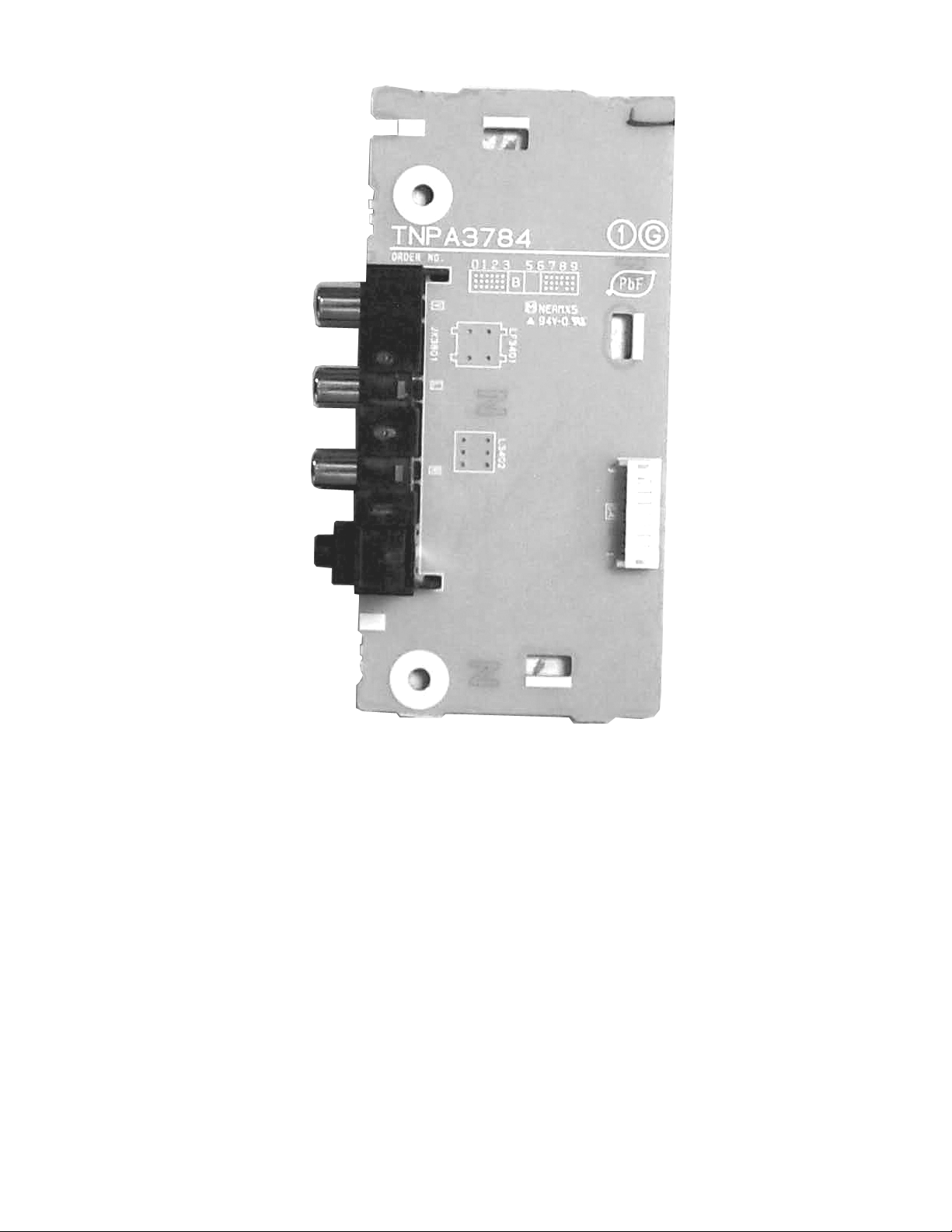

11.4. G-Board

17

11.5. DT-Board

18

Loading...

Loading...