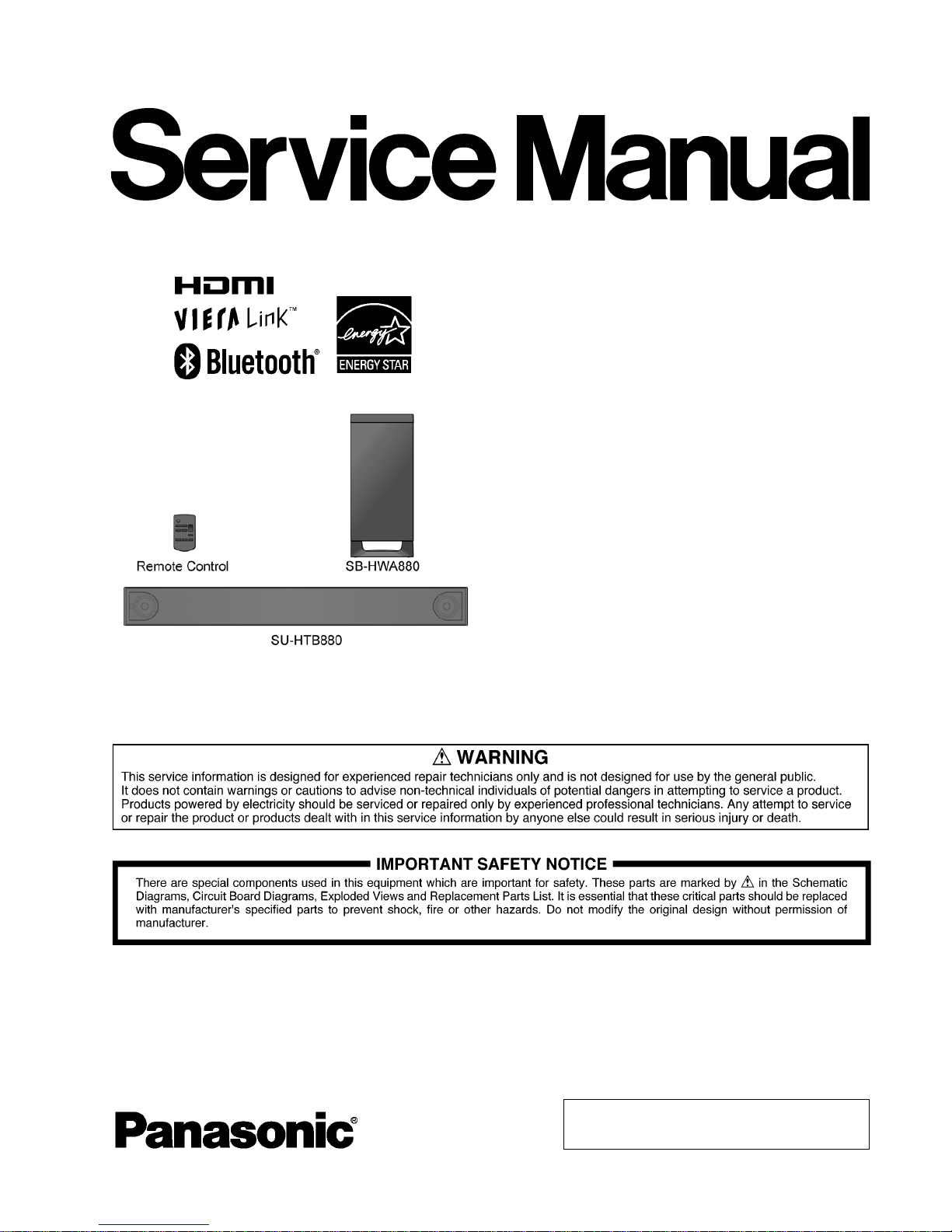

Panasonic SU-HTB880EB, SB-HWA880GN, SU-HTB880PP, SB-HWA880EG, SB-HWA880PP Service Manual

...

© Panasonic Corporation 2014. All rights reserved.

Unauthorized copying and distribution is a violation of

law.

PSG1405017CE

A6

Home Theater Audio System

Model No. SU-HTB880EB

SU-HTB880EG

SU-HTB880GN

SU-HTB880PP

SB-HWA880EB

SB-HWA880EG

SB-HWA880GN

SB-HWA880PP

SC-HTB880EB

SC-HTB880EG

SC-HTB880GN

SC-HTB880PP

Product Color: (K)...Black Type

TABLE OF CONTENTS

PAG E PAG E

1 Safety Precautions----------------------------------------------- 3

1.1. General Guidelines---------------------------------------- 3

1.2. Caution for AC Cord (For EB only)-------------------- 4

1.3. Before Repair and Adjustment ------------------------- 5

1.4. Protection Circuitry ----------------------------------------5

1.5. Caution For Fuse Replacement ------------------------5

1.6. Safety Part Information ----------------------------------- 6

2Warning--------------------------------------------------------------8

2

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices ----------8

2.2. Service caution based on Legal restrictions

(Lead Free Solder, (PbF))--------------------------------9

3 Service Navigation---------------------------------------------- 10

3.1. Service Information -------------------------------------- 10

4 Specifications---------------------------------------------------- 11

5 Location of Controls and Components------------------ 12

5.1. Main Unit & Active Subwoofer Key Button

Operations ------------------------------------------------- 12

5.2. Remote Control Key Button Operations ------------ 13

6 Service Mode----------------------------------------------------- 14

6.1. Service Mode Table 1----------------------------------- 14

6.2. Service Mode Table 2----------------------------------- 15

6.3. Service Mode Software Version Check Table----- 16

6.4. HDMI Version Display Table--------------------------- 17

6.5. Bluetooth Version Display Table---------------------- 17

6.6. Service Mode Model Name Display Table--------- 17

6.7. Service Mode Region Display Table ---------------- 17

6.8. Service Function Error Code -------------------------- 18

7 Troubleshooting Guide---------------------------------------- 19

8 Disassembly and Assembly Instructions--------------- 20

8.1. Service Fixture & Tools --------------------------------- 20

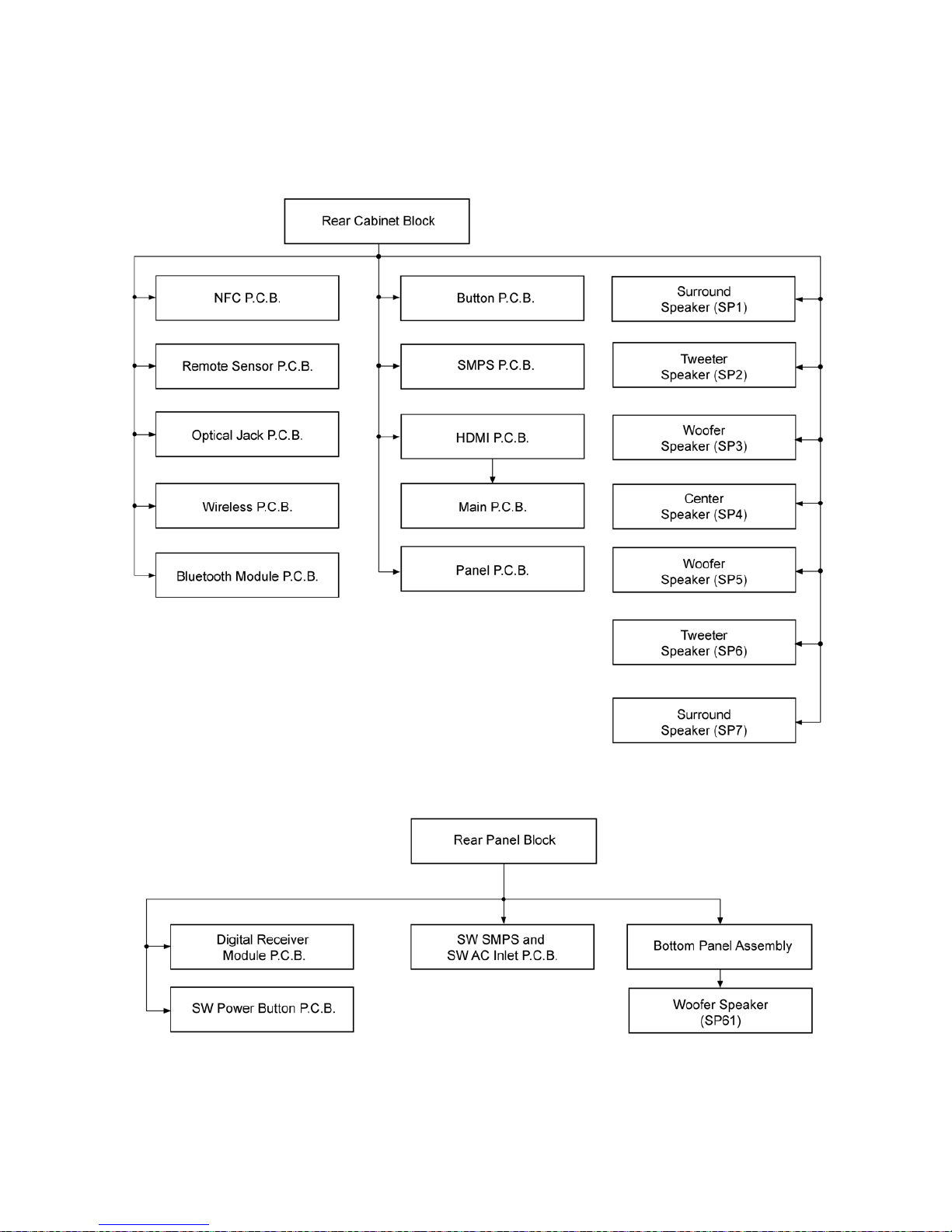

8.2. Disassembly flow chart ---------------------------------21

8.3. Type of Screws -------------------------------------------22

8.4. Main Parts Location Diagram ------------------------- 23

8.5. Disassembly of Main Unit (SU-HTB880) ---------- 24

8.6. Disassembly of Active Subwoofer (SBHWA880)--------------------------------------------------- 37

9 Service Position------------------------------------------------- 41

9.1. Main Unit (SU-HTB880) -------------------------------- 41

9.2. Active Subwoofer (SB-HWA880)--------------------- 45

10 Block Diagram --------------------------------------------------- 47

10.1. Main Unit (SU-HTB880) -------------------------------- 47

10.2. Active Subwoofer (SB-HWA880)--------------------- 52

11 Wiring Connection Diagram--------------------------------- 54

11.1. Main Unit (SU-HTB880) -------------------------------- 54

11.2. Active Subwoofer (SB-HWA880)--------------------- 55

12 Schematic Diagram--------------------------------------------- 57

12.1. Schematic Diagram Notes ----------------------------- 57

12.2. Main Unit (SU-HTB880) -------------------------------- 59

12.3. Active Subwoofer (SB-HWA880)--------------------- 76

13 Printed Circuit Board ------------------------------------------ 81

13.1. Main Unit (SU-HTB880) ------------------------------- 81

13.2. Active Subwoofer (SB-HWA880) -------------------- 87

14 Voltage and Waveform Measurement -------------------- 89

14.1. Voltage Measurement----------------------------------- 89

15 Exploded View and Replacement Parts List----------- 99

15.1. Cabinet Parts Location-1 (SU-HTB880) ------------ 99

15.2. Cabinet Parts Location-2 (SU-HTB880) ---------- 100

15.3. Cabinet Parts Location-3 (SU-HTB880) ---------- 101

15.4. Cabinet Parts Location (SB-HWA880)------------ 102

15.5. Packaging (SC-HTB880) ----------------------------- 103

15.6. Mechanical Replacement Parts List --------------- 105

15.7. Electrical Replacement Parts List ------------------ 107

3

1 Safety Precautions

1.1. General Guidelines

1. IMPORTANT SAFETY NOTICE

There are special components used in this equipment which are important for safety. These parts are marked by in the

Schematic Diagrams, Circuit Board Layout, Exploded Views and Replacement Parts List. It is essential that these critical parts

should be replaced with manufacturer’s specified parts to prevent X-RADIATION, shock, fire, or other hazards. Do not modify

the original design without permission of manufacturer.

2. An Isolation Transformer should always be used during the servicing of AC Adaptor whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this protects the technician from accidents resulting in personal

injury from electrical shocks. It will also protect AC Adaptor from being damaged by accidental shorting that may occur during

servicing.

3. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

4. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

5. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Using an ohmmeter measure the resistance value, between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩ and 5.2Ω. When the exposed metal does not have a return path to the chassis,

the reading must be

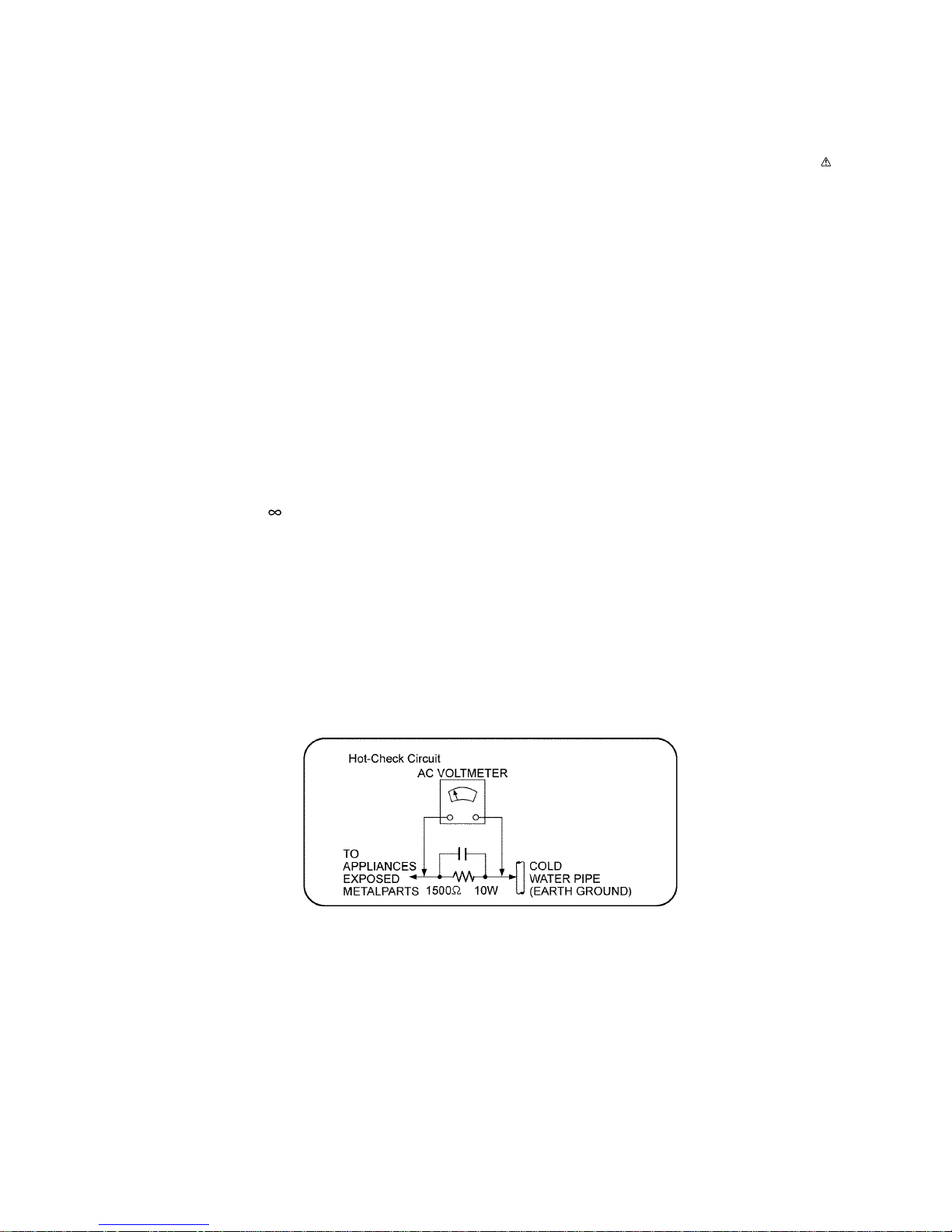

1.1.2. Leakage Current Hot Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15μF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1-1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent)

may be used to make the hot checks, leakage current must not exceed 1/2 milliamp. should the measurement is outside of

the limits specified, there is a possibility of a shock hazard, and the equipment should be repaired and re-checked before it is

returned to the customer.

Figure 1-1

4

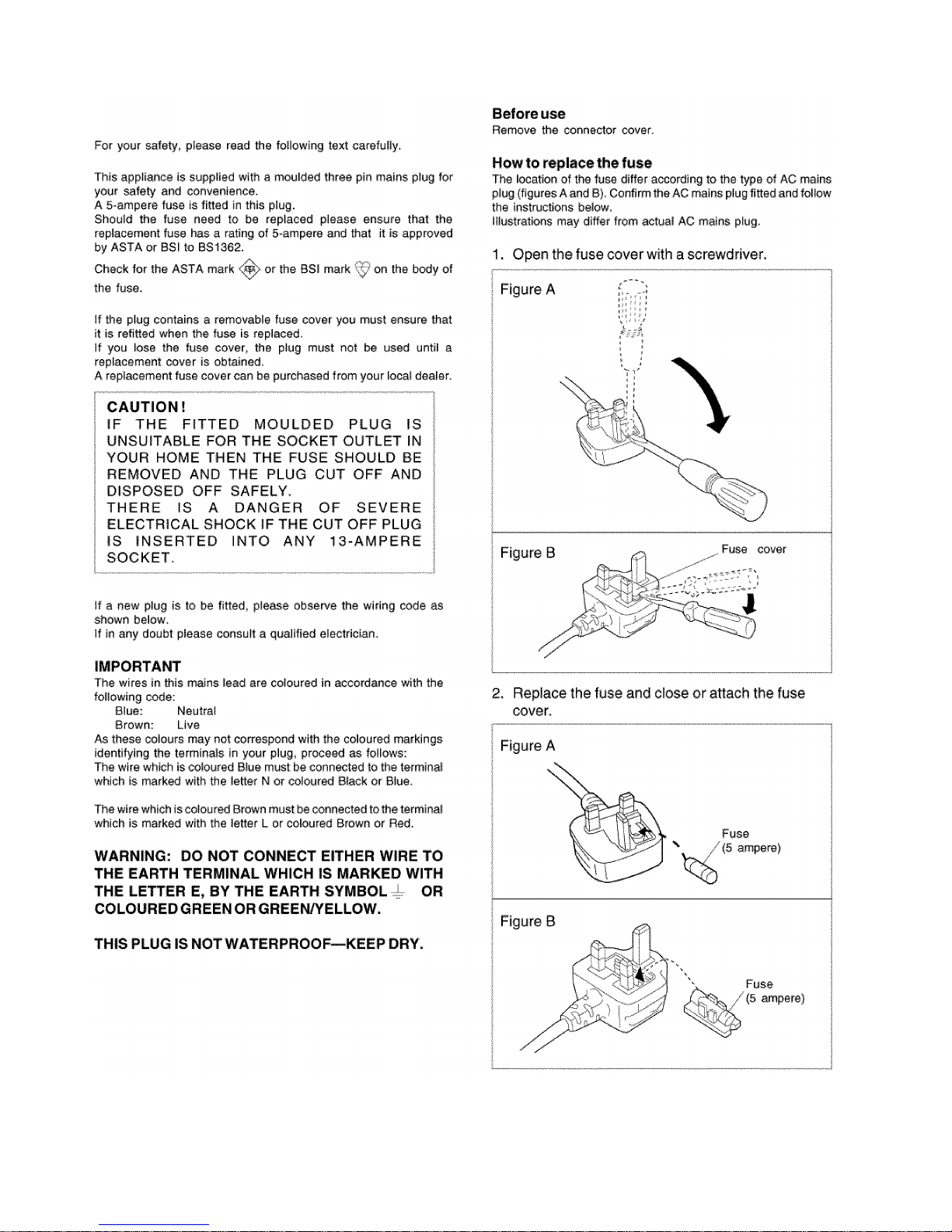

1.2. Caution for AC Cord (For EB only)

5

1.3. Before Repair and Adjustment

1.3.1. Main Unit (SU-HTB880)

Disconnect AC power, discharge unit AC Capacitors (C5700, C5701, C5702, C5703, C5704 and C5705) through a 10W, 1W resistor to ground.

Caution : DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

• Current consumption at AC 120 V, 60 Hz during power on at no signal with volume minimum, should be ~150 mA (For PP only).

• Current consumption at AC 220 V ~ 240 V, 50 Hz during power on at no signal with volume minimum, should be ~200 mA (For

EB/EG/GN only).

1.3.2. Active Subwoofer (SB-HWA880)

Disconnect AC power, discharge unit AC Capacitors (C5700, C5701, C5702, C5703, C5704 and C5705) through a 10W, 1W resistor to ground.

Caution : DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

• Current consumption at AC 120 V, 60 Hz during power on at link with volume minimum, (Selector : BD/DVD mode) should be

~200 mA (For PP only).

• Current consumption at AC 220 V ~ 240 V, 50 Hz during power on at link with volume minimum, (Selector : BD/DVD mode)

should be ~200 mA (For EB/EG/GN only).

1.4. Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

• No sound is heard when the power is turned on.

• Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

"shorted", or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

1.5. Caution For Fuse Replacement

6

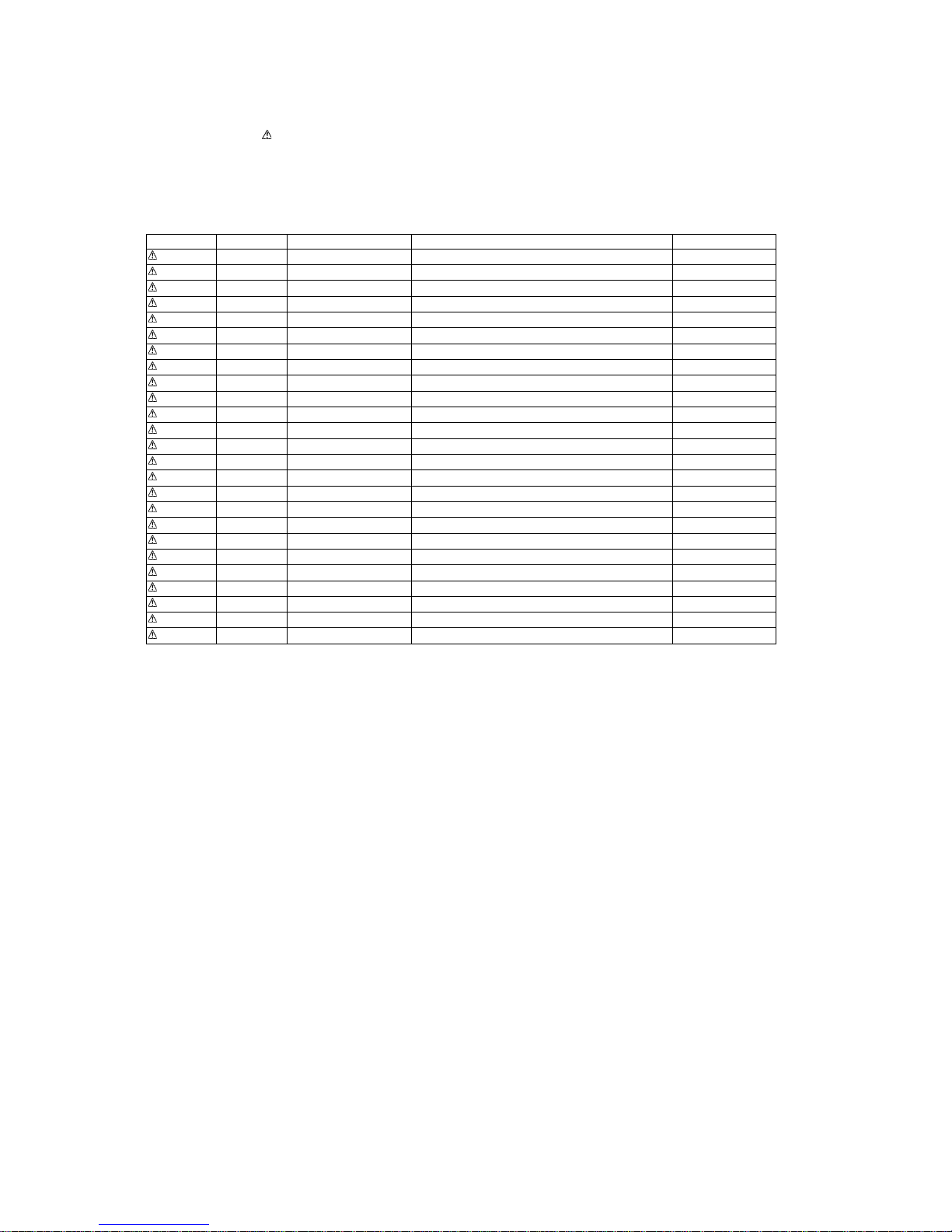

1.6. Safety Part Information

Safety Parts List:

There are special components used in this equipment which are important for safety.

These parts are marked by in the Schematic Diagrams & Replacement Parts List. It is essential that these critical parts should

be replaced with manufacturer’s specified parts to prevent shock, fire or other hazards. Do not modify the original design without

permission of manufacturer.

1.6.1. Main Unit (SU-HTB880)

Safety Ref. No. Part No. Part Name & Description Remarks

14 RGN3455-K1 NAME PLATE EB,EG

14 RGN3456-K NAME PLATE PP

14 RGN3458-K1 NAME PLATE GN

39 RMZ1443A SMPS PC SHEET

40 RMZ1455 MAIN PC SHEET

PCB2 REP5073B SMPS P.C.B. (RTL)PP

PCB2 REP5073C SMPS P.C.B. (RTL)EB, EG, GN

DZ5701 ERZV10V511CS ZNR (E.S.D)

L5702 G0B922G00004 LINE FILTER

L5703 G0B203G00005 LINE FILTER

T5701 G4DYA0000573 TRANSFORMER

PC5720 B3PBA0000579 PHOTO COUPLER

PC5760 B3PBA0000579 PHOTO COUPLER

F1 K5G312Y00007 FUSE

P5701 K2AA2B000011 AC INLET EB,EG,GN

P5701 K2AB2B000007 AC INLET PP

R5700 ERJ8GEYJ105V 1M 1/4W

R5701 ERJ8GEYJ105V 1M 1/4W

R5710 ERJ8GEYJ105V 1M 1/4W

C5700 F1BAF1020020 1000pF

C5701 F0CAF104A105 0.1uF

C5702 F0CAF104A105 0.1uF

C5703 F0CAF104A105 0.1uF

C5704 F1BAF471A013 470pF

C5705 F1BAF471A013 470pF

7

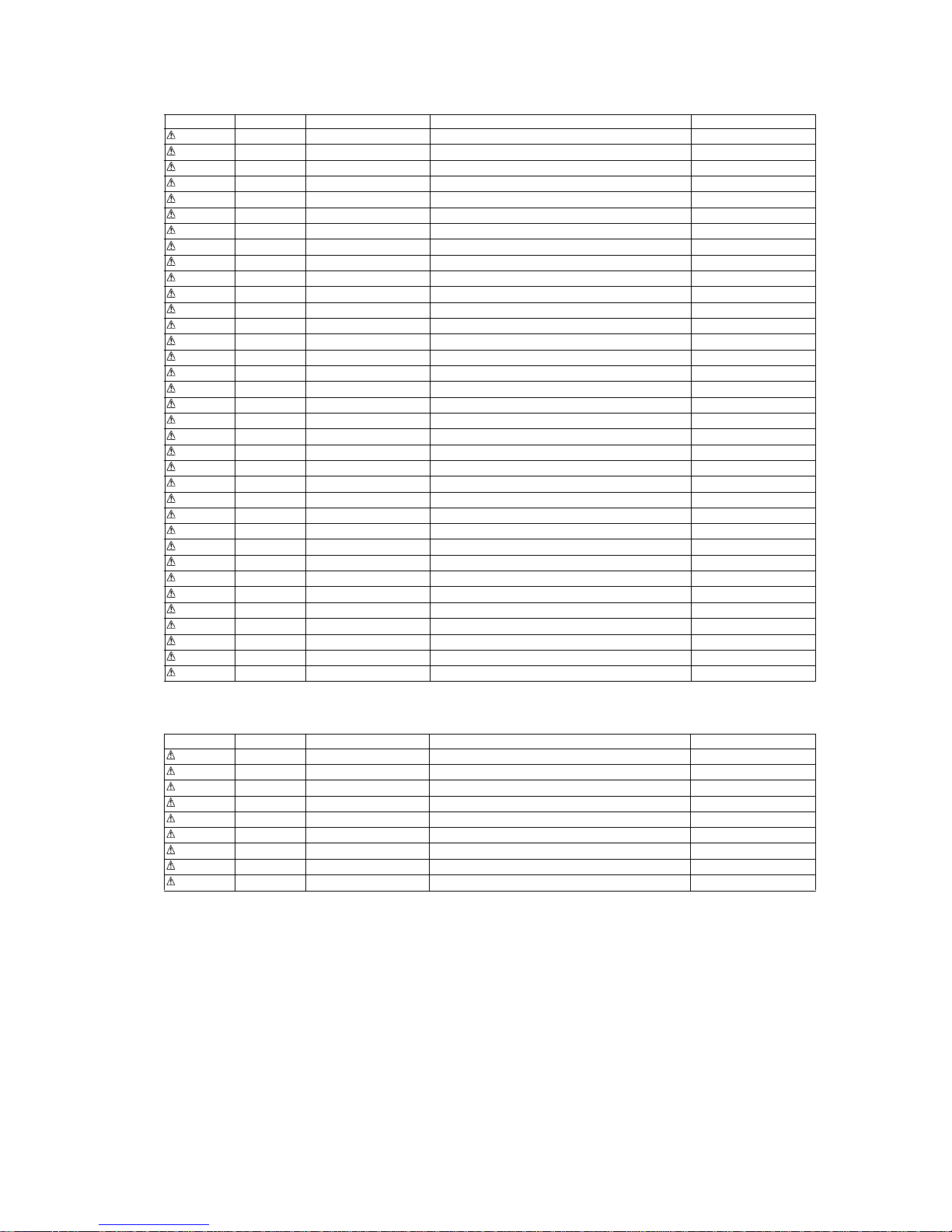

1.6.2. Active Subwoofer (SB-HWA880)

1.6.3. System (SC-HTB880)

Safety Ref. No. Part No. Part Name & Description Remarks

65 RGN3442-K SPEC LABEL EB, EG

65 RGN3444-K SPEC LABEL GN

65 RGN3446-K SPEC LABEL PP

75 REX1703 1P RED WIRE (SMPS - SW AC INLET)

77 REX1704 1P BLACK WIRE (SMPS - SW AC INLET)

PCB2 REP5036BB SW AC INLET P.C.B. (RTL) PP

PCB2 REP5036CB SW AC INLET P.C.B. (RTL) EB, EG, GN

DZ5701 ERZV10V511CS ZNR

L5702 G0B203G00005 LINE FILTER

L5703 G0B612H00005 INDUCTOR PP

L5703 G0B203G00005 INDUCTOR EB, EG, GN

T5701 G4DYA0000441 TRANSFORMER PP

T5701 G4DYA0000485 TRANSFORMER EB, EG, GN

T5751 G4DYA0000592 TRANSFORMER

PC5701 B3PBA0000579 PHOTO COUPLER

PC5720 B3PBA0000579 PHOTO COUPLER

PC5799 B3PBA0000579 PHOTO COUPLER

F1 K5G312Y00007 FUSE

P5701 K2AA2B000011 AC INLET EB, EG, GN

P5701 K2AB2B000007 AC INLET PP

R5700 ERJ8GEYJ105V 1M 1/4W EB, EG, GN

R5700 ERJ8GEYJ155V 1.5M 1/4W PP

R5701 ERJ8GEYJ105V 1M 1/4W EB, EG, GN

R5701 ERJ8GEYJ155V 1.5M 1/4W PP

R5710 ERJ8GEYJ105V 1M 1/4W EB, EG, GN

R5710 ERJ8GEYJ155V 1.5M 1/4W PP

C5700 F1BAF1020020 1000pF

C5701 F0CAF104A105 0.1uF

C5702 F0CAF104A105 0.1uF

C5703 F0CAF104A105 0.1uF

C5704 F1BAF1020020 1000pF PP

C5704 F1BAF471A013 470pF EB, EG, GN

C5705 F1BAF1020020 1000pF PP

C5705 F1BAF471A013 470pF EB, EG, GN

C5706 F1BAF1020020 1000pF

Safety Ref. No. Part No. Part Name & Description Remarks

A2 K2CB2CB00022 AC CORD PP

A2 K2CJ2YY00093 AC CORD GN

A2 K2CQ2YY00119 AC CORD EG

A2 K2CT2YY00097 AC CORD EB

A3 RQT9903-Y O/I BOOK (En/Cf) PP

A3 RQT9904-1B O/I BOOK (En) EB,GN

A3 RQT9905-1D O/I BOOK (Ge/Fr/It) EG

A3 RQT9906-1E O/I BOOK (Sw/Da/Du) EG

A3 RQT9907-1H O/I BOOK (Sp/Fi) EG

8

2Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices.

The following techniques should be used to help reduce the incidence of component damage caused by electrostatic discharge

(ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

CAUTION:

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to damage an ES device).

9

2.2. Service caution based on Legal restrictions (Lead Free Solder, (PbF))

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86°F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30 degrees

C (662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: Tin (Sn), 96.5%, Silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

The letter of “PbF” is printed either foil side or components side on the PCB using the lead free solder.

(See right figure)

10

3 Service Navigation

3.1. Service Information

This service manual contains technical information which will allow service personnel’s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, this information will be followed by supplement service manual to be filed with original service

manual.

11

4 Specifications

Q Amplifier Section

RMS output power: Dolby Digital Mode

Front ch (L, R ch) 50 W per channel (6 Ω), 1 kHz,

10% THD

Center ch (C ch) 50 W per channel (6 Ω), 1 kHz,

10% THD

Surround ch (L, R ch) 50 W per channel (6 Ω), 1 kHz,

10% THD

Subwoofer ch 250 W per channel (8 Ω), 100 Hz,

10% THD

Total RMS Dolby Digital mode

power

500 W

FTC output power: Dolby Digital Mode (For PP only)

Front ch (L, R ch) 30 W per channel (6 Ω), 120 Hz to

20 kHz, 1% THD

Center ch (C ch) 30 W per channel (6 Ω), 120 Hz to

20 kHz, 1% THD

Surround ch (L, R ch) 30 W per channel (6 Ω), 120 Hz to

20 kHz, 1% THD

Subwoofer ch 90 W per channel (8 Ω), 40 Hz to

200 Hz, 1% THD

Total FTC Dolby Digital mode

power

245 W

Q Terminal Section

HDAVI Control This unit supports “HDAVI Control

5” function.

HDMI AV input (BD/DVD, AUX) 2

Input connector Type A (19 pin)

HDMI AV output (TV (ARC)) 1

Output connector Type A (19 pin)

Digital audio input (TV)

Optical digital input Optical terminal

Sampling frequency 32 kHz, 44.1 kHz, 48 kHz

88.2 kHz, 96 kHz (only LPCM)

Audio format LPCM, Dolby Digital, DTS Sound

Surround

IR Blaster

Terminal Type 3.5 mm (1/8”) jack

USB Port For service use only.

Q General

Power consumption Main Unit: 33 W

Main Unit: 31 W (For PP)

Active subwoofer: 46 W

In standby condition

Main Unit

*1

(When “BLUETOOTH STANDBY” is “OFF”) : Approx. 0.49 W

(When “BLUETOOTH STANDBY” is “OFF”) : Approx. 0.4 W (For PP)

(When “BLUETOOTH STANDBY” is “ON”) : Approx. 3.0 W

Active subwoofer

Power switch off : Approx. 0.2 W

The wireless link is not activated : Approx. 0.4 W

Power supply AC 120 V, 60 Hz (For PP)

AC 220 V to 240 V, 50 Hz (For EB/EG/GN)

Dimensions (W x H x D)

Main Unit

For table top layout 1125 mm x 51 mm x 121 mm

(44 9/32" x 2" x 4 3/4")

For wall mounting layout 1125 mm x 122.5 mm x 56.5 mm

(44 9/32" x 4 13/16" x 2 7/32")

Active subwoofer 180 mm x 408 mm x 306 mm

(7 3/32" x 16 1/16" x 12 1/16")

Mass (Weight)

Main Unit

For table top layout Approx. 3.1 kg (6.8 lbs)

For wall mounting layout Approx. 3.2 kg (7.1 lbs)

Active subwoofer 5.4 kg (11.9 lbs)

Operating temperature range 0°C to +40°C

(+32°F to +104°F)

Operating humidity range 20% to 80 % RH

(no condensation)

Q Speaker Section

Front speakers (Build-in)

Woofer 6.5 cm (2 1/2”) cone type x 1/ch

Tweeter 2.5 cm (1”) Semi-Dome type x 1/

ch

Center speaker (Build-in)

Full range 6.5 cm (2 1/2”) cone type x 1

Surround speakers (Built-in)

Full range 6.5 cm (2 1/2”) cone type x 1/ch

Active subwoofer

Woofer 16 cm (6 1/2”) cone type x 1

Q Wireless section

Wireless module

Frequency Range 2.40335 GHz to 2.47735 GHz

Number of channels 38

Q Bluetooth

®

Section

Bluetooth

®

system specifica-

tion

Bluetooth® Ver.3. 0

Wireless equipment classification

Class 2

Supported profiles A2DP

Operating frequency 2.4 GHz band FH-SS

Operating distance 10 m (33 ft) Line of Sight

Supported codec

aptX

®

, AAC, SBC

• Specifications are subject to change without notice.

• Mass and dimensions are approximate.

• Total harmonic distortion is measured by the digital spectrum analyzer.

*1

: When the other connected devices are turned off

Q System: SC-HTB880EBK

MAIN SPEAKER UNIT : SU-HTB880EBK

ACTIVE SUBWOOFER : SB-HWA880EBK

Q System: SC-HTB880EGK

MAIN SPEAKER UNIT : SU-HTB880EGK

ACTIVE SUBWOOFER : SB-HWA880EGK

Q System: SC-HTB880GNK

MAIN SPEAKER UNIT : SU-HTB880GNK

ACTIVE SUBWOOFER : SB-HWA880GNK

Q System: SC-HTB880PPK

MAIN SPEAKER UNIT : SU-HTB880PPK

ACTIVE SUBWOOFER : SB-HWA880PPK

12

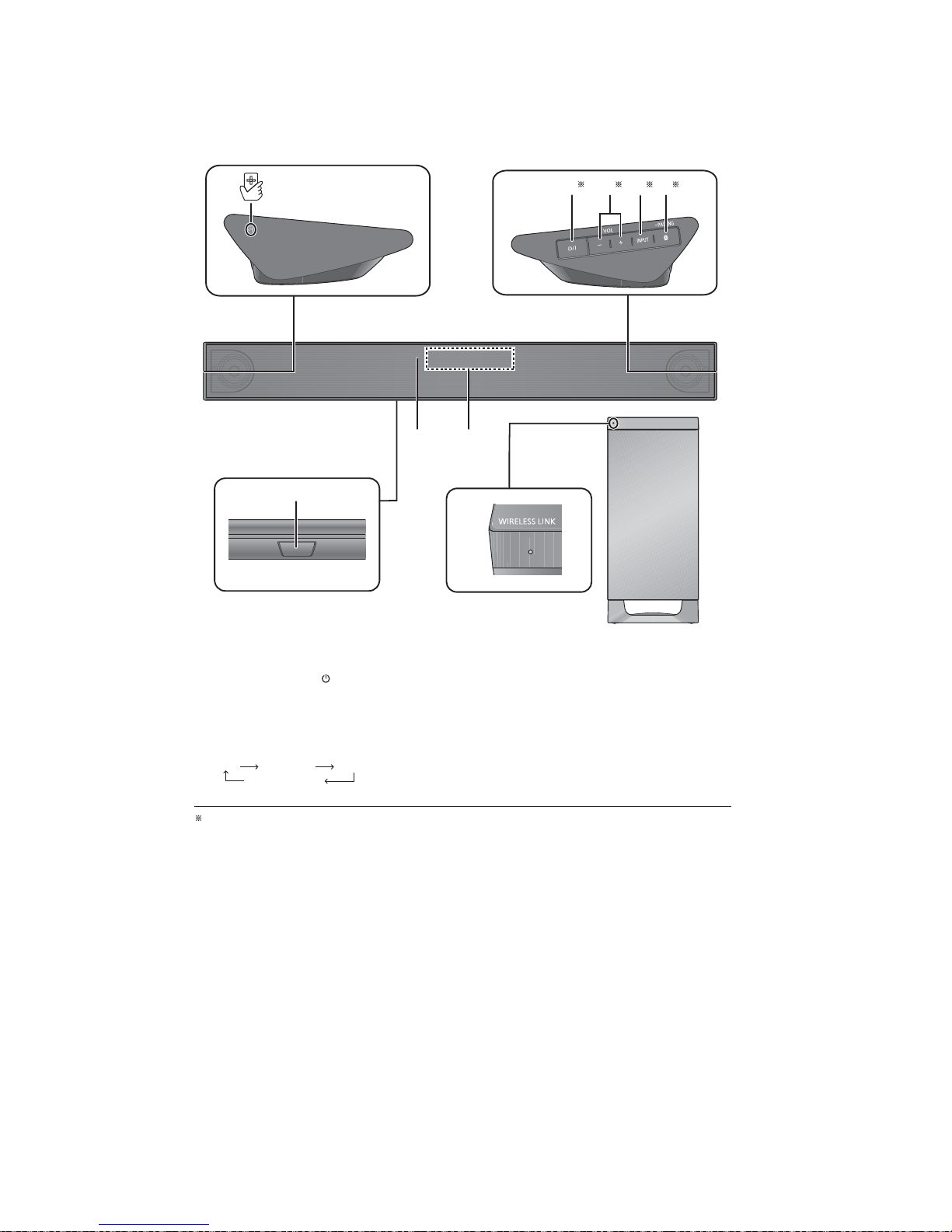

5 Location of Controls and Components

5.1. Main Unit & Active Subwoofer Key Button Operations

1 NFC touch area

2 Standby/on switch ( )

Touch to switch the unit from on to standby

mode or vice versa. In standby mode, the unit

is still consuming a small amount of power.

3 Adjust the volume on this system

4 Select the input source

“TV” “BD/DVD” “AUX”

“BLUETOOTH”

5 Select the Bluetooth device as the source

6 Remote control signal sensor for table top

layout

7 Remote control signal sensor for wall

mounting layout

8 Display

9 WIRELESS LINK indicator

These switches workjust by touching the marks. Each time you touch the switch, therewill be a beep sound.

8

9

7

1

3 4 52

6

Main unit

Active subwoofer

/I

®

13

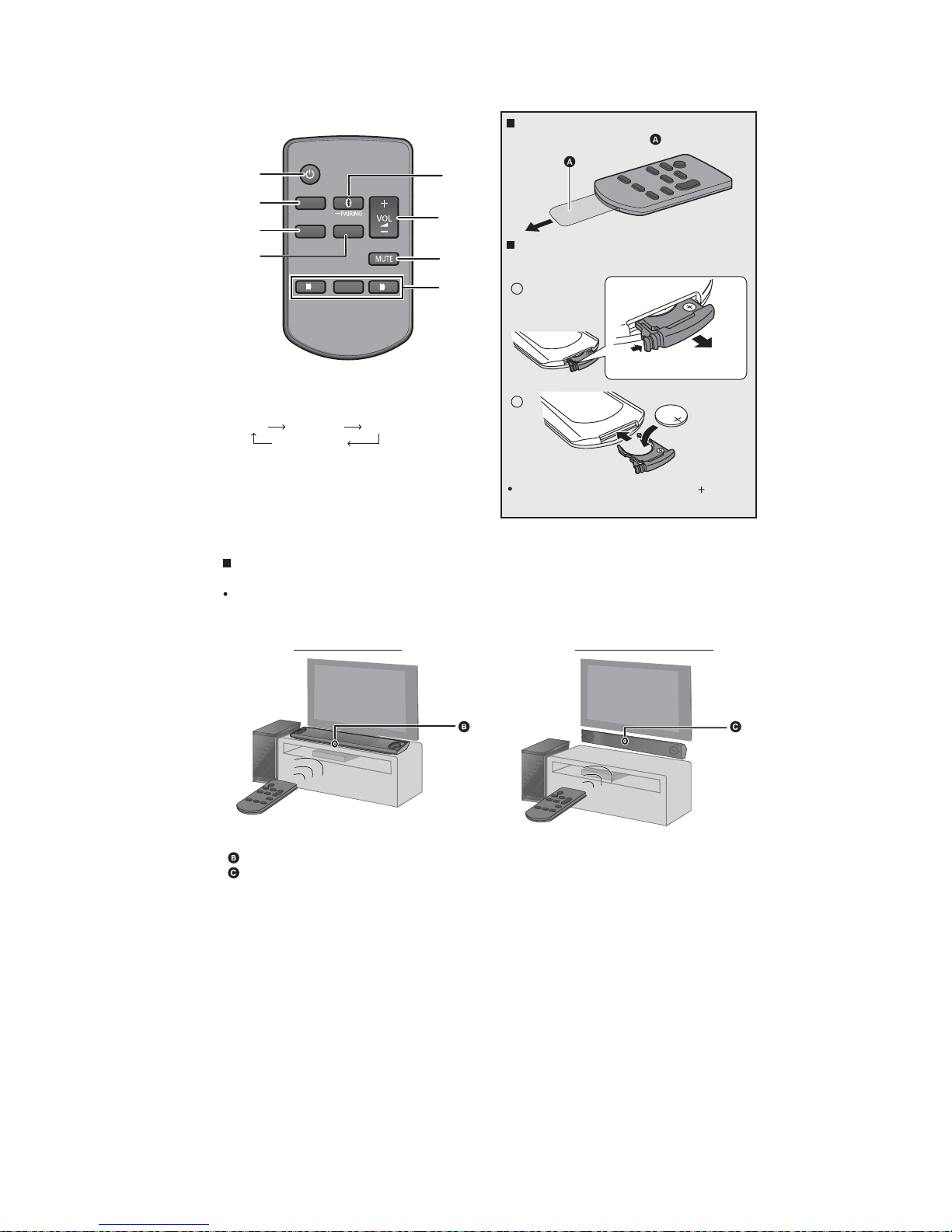

5.2. Remote Control Key Button Operations

1 Turn the main unit on or o

2 Select the input source

“TV” “BD/DVD” “AUX”

“BLUETOOTH”

3 Select the setup menu

4 Select the sound menu

5

Select the Bluetooth device as the source

6 Adjust the volume on this system

7Mute

8 Select and conrm the option

About remote control signal sensor

The remote control signal sensor is located on the main unit.

Use the remote control within the correct operation range.

Distance: Within approx. 7 m (23 ft) directly in front

Angle: Approx. 30

o

left and right

Remote control signal sensor for table top layout

Remote control signal sensor for wall mounting layout

SOUND

1

5

6

7

8

2

INPUT

SETUP

OK

3

4

Before using for the first time

Remove the insulation sheet .

To replace a button-type battery

Battery type: CR2025 3V (Lithium battery)

Set the button-type battery with its ( ) mark

facing upward.

For table top layout

For wall mounting layout

®

2

1

14

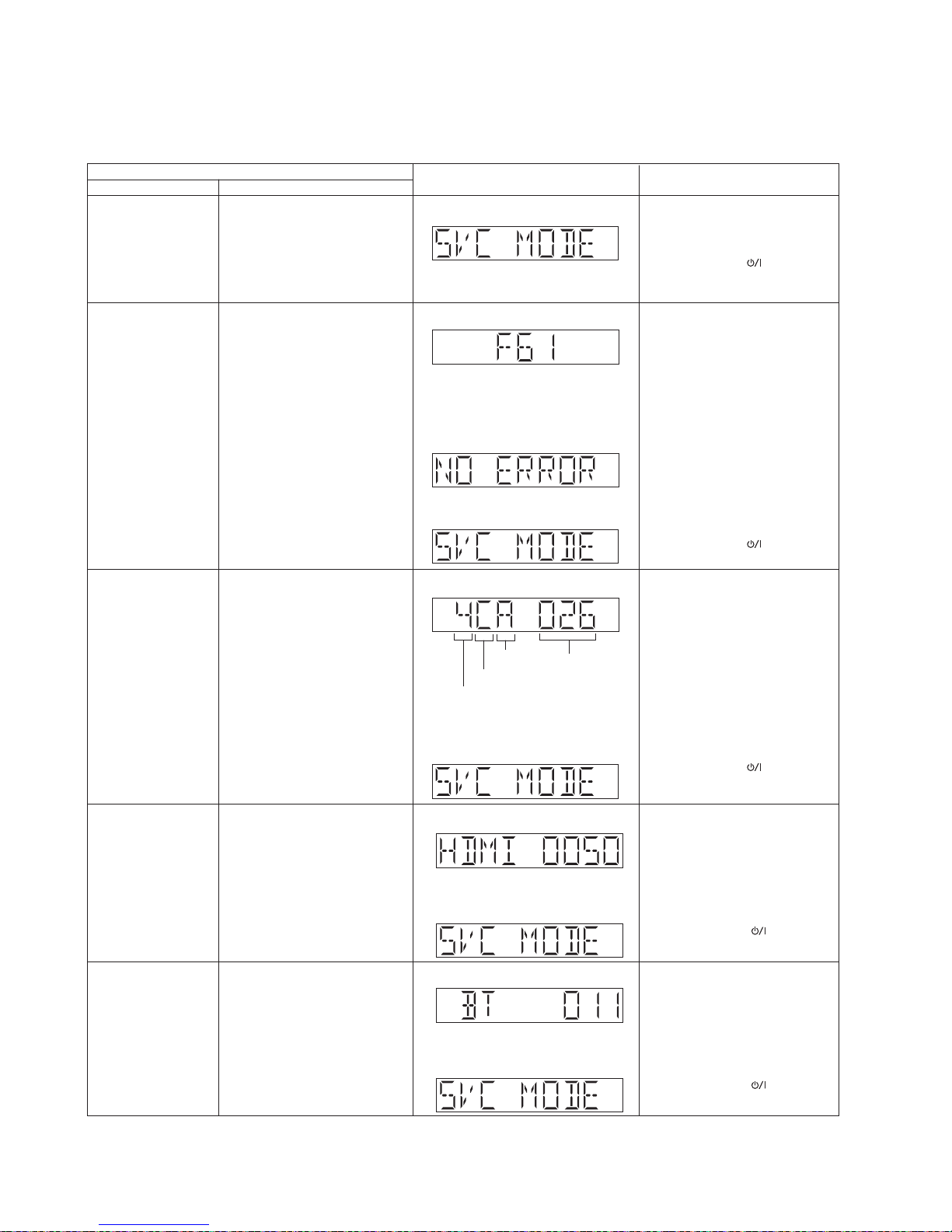

6 Service Mode

This unit is equipped with features of service mode mode setting for checking the functions & reliability.

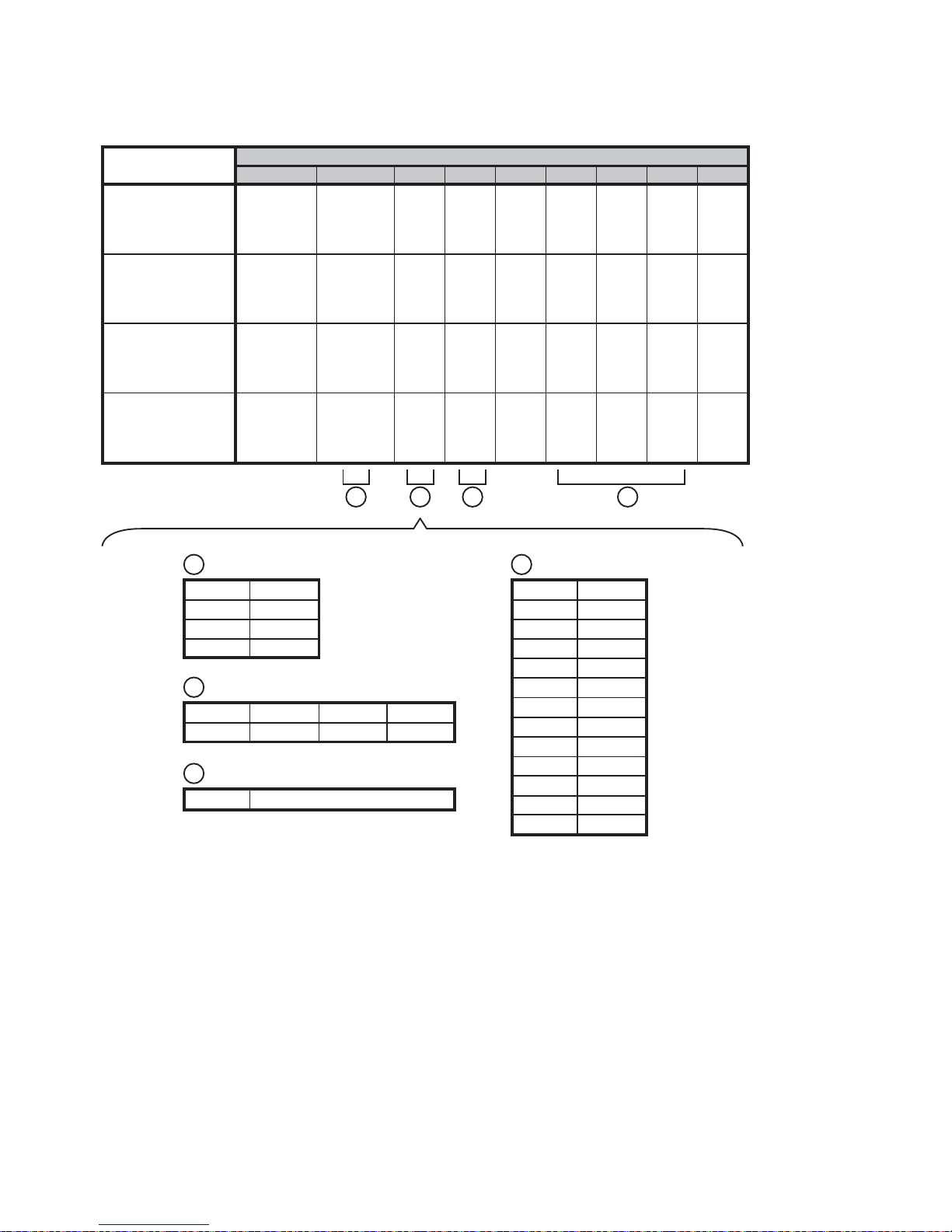

6.1. Service Mode Table 1

Press [VOL+] button 2 times on the

remote control.

Service Mode Upon entering into Service Mode

Item

FL display Key operation

Mode name Description

Error code information Example: F61, F76,F70HDMI

Example:

Example:

Error History Display by pressing

button, it goes back its history list.

Software Version

information

Display the current SW version

Software Version display is being

indicated in FL display in the

format of [4CB XXX].

1) 4 represent the Sales Year

2) C represent the Model Type

3) B represent the ROM Type

4) xxx represent the Version

number (Range from 000-999)

Refer to 6.3 for more information

HDMI Version display is being

indicated in FL display in the

format of [HDMI XXXX].

Refer to 6.4 for more information

HDMI Version

information

Display the HDMI Version number

The [SVC MODE] display will appear

after 3s,

The [SVC MODE] display will appear

after 3s,

Example:

Year of sales

ROM type

Model type

Running

version

number

In service mode:

Press [INPUT] button on the remote

control.

Error History Display by pressing

button, it goes back its history list.

After Pressing [INPUT] key, display

the last encounter Error display,

subsequent pressed will displayed

the second last Error and so on.

(Maximun of 10 display and if the

11th Error occurred, it will replace

the 1st error display, First IN First

OUT approach)

Refer to 6.6 for more information

In self diagnostic mode:

Press [VOL+] button 1 time on the

remote control.

Example: If already at the last error

display (earlier error) or No Error Log,

pressing [INPUT] key on the remote

control, [NO ERROR] will display

Pressing and hold [VOL-] on main

XQLWWKHQSUHVV>ź@IROORZE\>Ÿ@

using the remote control.

7RH[LWSUHVVWKH>TA] on the main

unit or using the remote control.

8QSOXJWKH$&FRUG

7RH[LWSUHVVWKH>TA] on the main

unit or using the remote control.

7RH[LWSUHVVWKH>TA] on the main

unit or using the remote control.

7RH[LWSUHVVWKH>TA] on the main

unit or using the remote control.

The [SVC MODE] display will appear

after 3s,

Press [VOL+] button 3 times on the

remote control.

Bluetooth Version display is being

indicated in FL display in the

format of [ BT XXX].

Refer to 6.5 for more information

Bluetooth Version

information

Display the Bluetooth Version

number

The [SVC MODE] display will appear

after 3s,

Example:

7RH[LWSUHVVWKH>TA] on the main

unit or using the remote control.

15

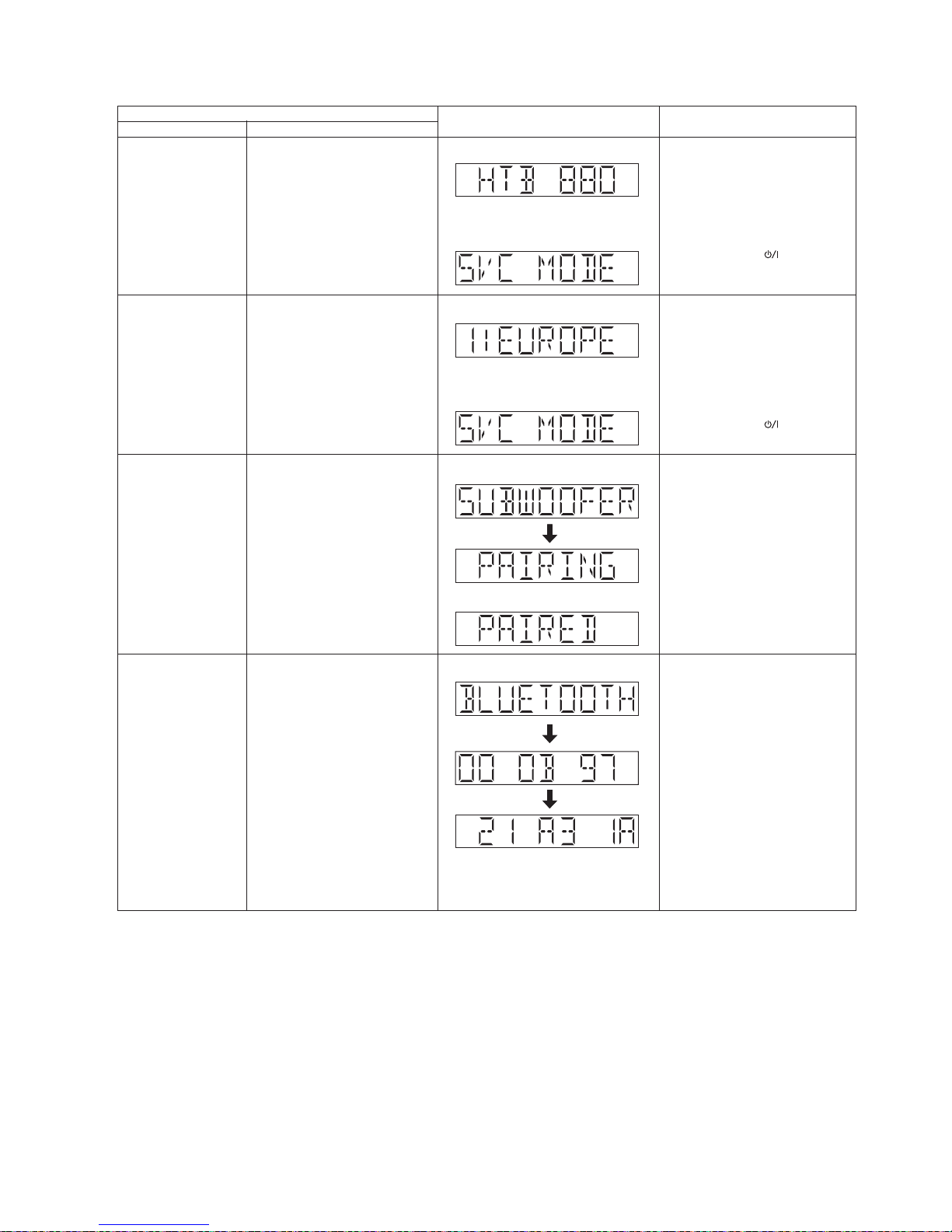

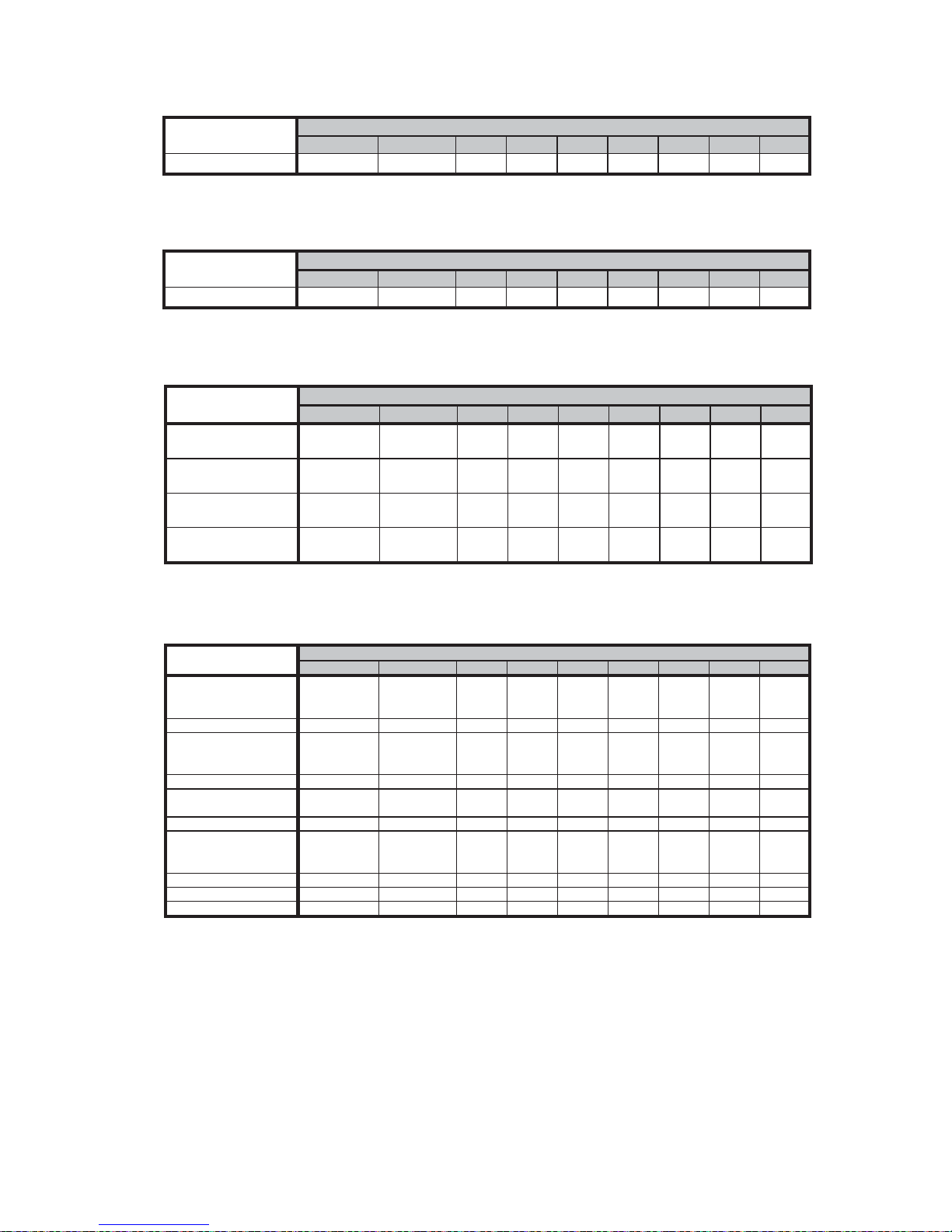

6.2. Service Mode Table 2

Item

FL display Key operation

Mode name Description

Press [VOL+] button 5 times on the

remote control.

Region information Region Setting

Example:

Refer to 6.7 for more information

7RH[LWSUHVVWKH>7$] on the main

unit or using the remote control.

7RH[LWSUHVVWKH>7$] on the main

unit or using the remote control.

Press [VOL+] button 4 times on the

remote control.

02'(/+7%;;;;;;VWDQG

IRUPRGHOQXPEHU(J

Refer to 6.6 for more information

0RGHO1DPH

information

'LVSOD\WKHPRGHOQDPH

The [SVC MODE] display will appear

after 3s,

Example:

The [SVC MODE] display will appear

after 3s,

3UHVV>%/8(7227+@EXWWRQRQWKH

remote control.

%OXHWRRWKinformation %OXHWRRWK6HWWLQJ

'LVSOD\VWE\WHRI%OXHWRRWK

0RGXOH0$&$''5(66IRU

VHFDQGIROORZHGE\ODVWWKE\WH

;;;;;; VWE\WHRIPDF,'

/()7DOLJQHG

Example:

3UHVV>6(783@EXWWRQRQWKHUHPRWH

control.

3UHVVDQGKROG>,1387@EXWWRQRQ

the remote control.

Press [VOL +] button on the main set

for 4sec.

or

+

:LUHOHVV6XEZRRIHU

Pairing

Pairing Setting

$FWXDO'LVSOD\GXULQJ

6XEZRRIHU3DLULQJ

>68%:22)(5@!>3$,5,1*@

7RJJOHGLVSOD\

$FWXDO'LVSOD\DIWHU6XEZRRIHU

KDGEHHQ3DLUHG

>3$,5('@

'LVSOD\/DVWE\WHRI%OXHWRRWK

0RGXOH0$&$''5(66IRU

VHFEHIRUHUHWXUQWRGLVSOD\RI

1st 6 byte

<<<<<< ODVWE\WHRIPDF,'

5,*+7DOLJQHG

Example: During Pairing

Example: PDLUHG

16

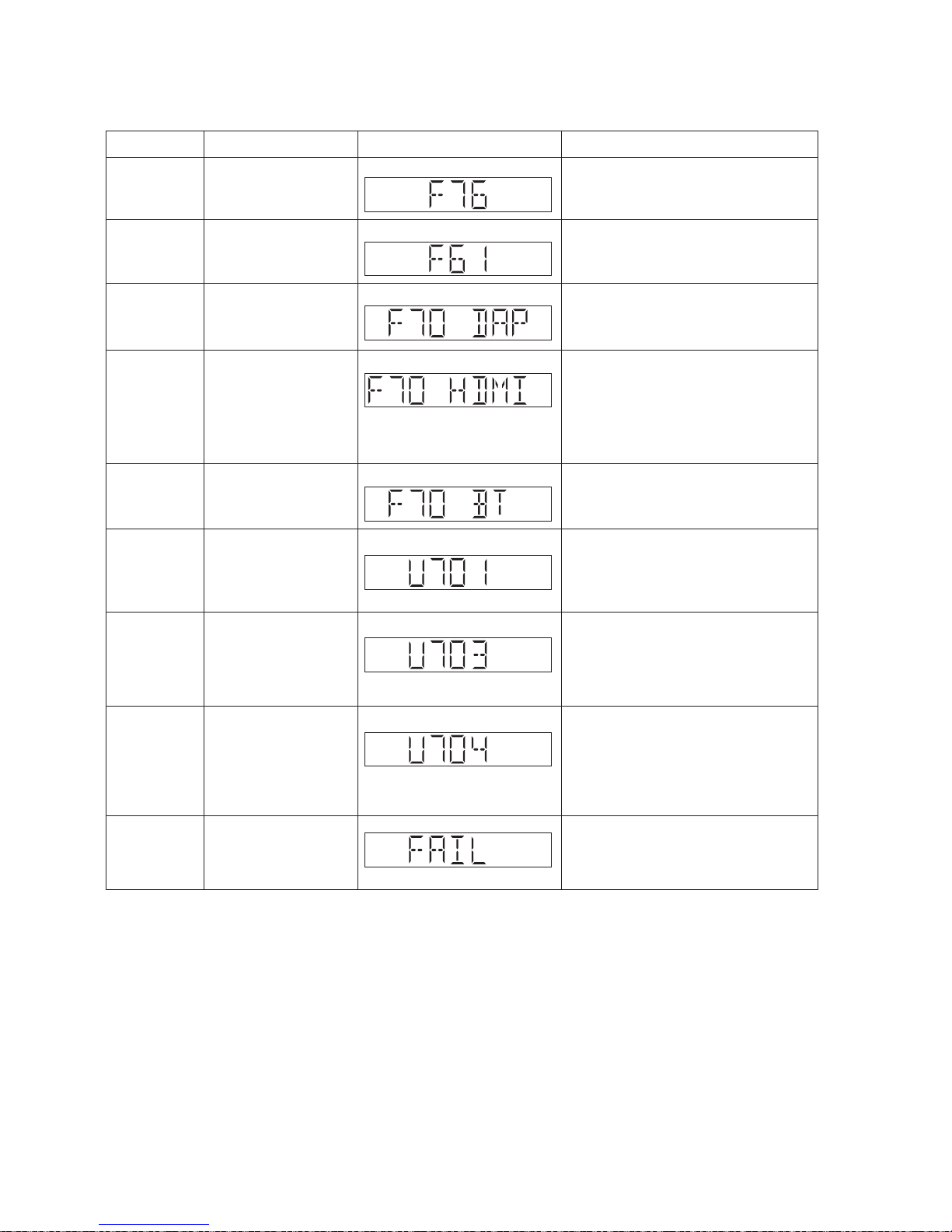

6.3. Service Mode Software Version Check Table

Some example of the actual FL display can be found in below table

POS 9 POS 8 POS 7 POS 6 POS 5 POS 4 POS 3 POS 2 POS 1

HTB880 with

software version 36

for Year 2014 (ROM

TYPE A)

4 CA 036

HTB580 with

software version 03

for Year 2014 (ROM

TYPE B)

4 CB 003

HTB680 with

software version 26

for Year 2014 (ROM

TYPE C)

4 CB 026

HTB480 with

software version 21

for Year 2014 (ROM

TYPE D)

4 CB 021

FL Display Position

Examples:

1 2 3 4

Sales Year

1 2011

2 2012

3 2013

4 2014

Range from 000 ~999

ROM Type

HTB880 HTB580 HTB680 HTB480

4CA 4CB 4CB 4CB

3

Running Version Number

XXX

4

1

Model Type

AHC

BXH

C HTB

D HTE

E HTF

F HTR

G HTX

HPM

I PMX

J AKX

K VKX

L

M

2

17

6.4. HDMI Version Display Table

6.5. Bluetooth Version Display Table

6.6. Service Mode Model Name Display Table

6.7. Service Mode Region Display Table

POS 9 POS 8 POS 7 POS 6 POS 5 POS 4 POS 3 POS 2 POS 1

HDMI Version

Display

H D M 0 050I

FL Display Position

POS 9 POS 8 POS 7 POS 6 POS 5 POS 4 POS 3 POS 2 POS 1

B T 011

Bluetooth Version

Display

FL Display Position

POS 9 POS 8 POS 7 POS 6 POS 5 POS 4 POS 3 POS 2 POS 1

For HTB880 display

HTB 880

For HTB680 display

HTB 680

For HTB580 display

HTB 580

For HTB480 display

HTB 480

FL Display Position

Exam

p

les:

POS 9 POS 8 POS 7 POS 6 POS 5 POS 4 POS 3 POS 2 POS 1

Display for

Europe/Russia

(

EB/EG/EE series

)

1:EUROPE

Reserve

2:RESV

Display for North

America region (P, PC,

PP series

)

3:US/C AN

Reserve

4:RESV

Display for Japan

re

g

ion

(

Do series

)

5:JAPAN

Reserve

6:RESV

Display for G/Other

(GN/GS/GT/PH/GK

series

)

7:G/OTHER

Reserve

8:RESV

Reserve

9:RESV

Reserve 10:RESV

Re

g

ion Displa

y

FL Display Position

18

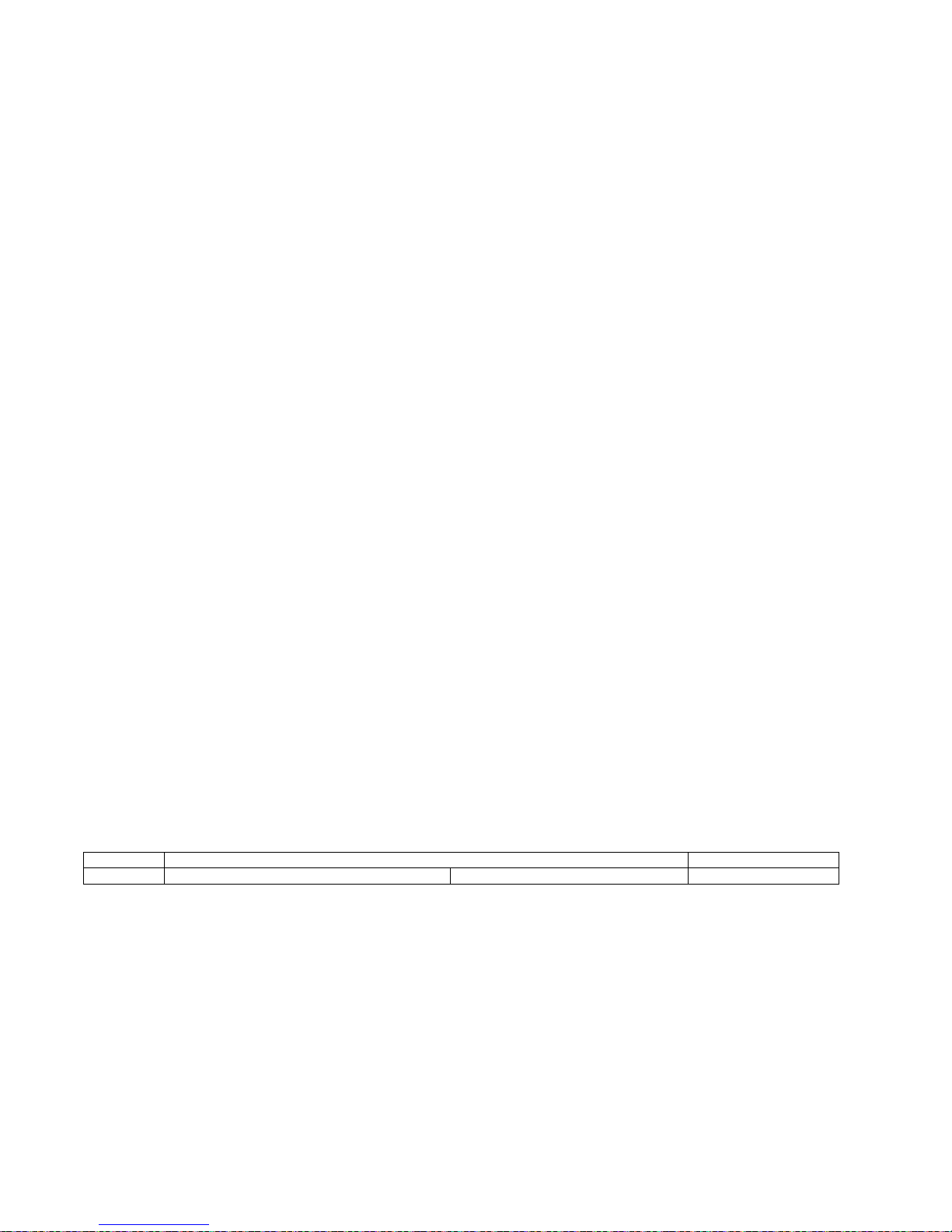

6.8. Service Function Error Code

FL display will also be able to display the Error Code of the respective model indicated in the table below

F76 Abnormality in the stabilized Power Supply

Power off the unit during

blinking.

F61 Power AMP Output Error

Power off the unit during

blinking.

F70 DAP Communication error between DAP module and

microprocessor

Blinking repeatedly

unless user power off.

Example:

Example:

Example:

Example:

F70 HDMI Communication error between HDMI Module

and microprocessor

HDMI Module broken and cannot communicate

with main microprocessor.

* I2C control line (no reply for 10 times)

* HDCP keys read error

Blinking repeatedly

unless user power off.

Example:

F70 BT Communication error between Bluetooth

Module and microprocessor

Blinking repeatedly

unless user power off.

Example:

U701 HDMI connection acts unusually

When HDMI IC cannot read TV HDCP register

from TV side or TV does not support HDCP.

* I2C error (usually no ACK)

Blinking repeatedly

unless user power off.

Example:

U703 HDMI connection acts unusually

Authentication Error.

* Bad receive BKSV

* Link verification mismatch

* Timed out waiting for downstream repeater

Blinking repeatedly

unless user power off.

Example:

U704 HDMI connection acts unusually

HDMI repeater receive unsupported video

format (resolution) from source device.

* Not support PC format - XVGA and cannot

support Vsync vertical frequency other than

60Hz/59.94Hz, 50Hz, 24Hz

Blinking repeatedly

unless user power off.

Error Code Description of error Automatic FL Display Diagnostic Contents

Example:

USB Update Fail USB updating of Software

Failed

Display Remained unless

user power off.

19

7 Troubleshooting Guide

This section is not available at the time of issue

20

8 Disassembly and Assembly Instructions

Caution Note:

• This section describes the disassembly and/or assembly procedures for all major printed circuit boards & main components for the unit. (You may refer to the section of “Main components and P.C.B Locations” as described in this service

manual)

• Before carrying out the disassembly process, please ensure all th e safety precautions & procedures are followed.

• During the disassembly and/or assembl y process, please handle with care as ther e may be chassis components with

sharp edges.

• Avoid touching heatsinks due to its high temperature after prolong use.

• Be sure to use proper service tools , equipments or jigs during repair.

• Select items from the following indexes when disassembly or replacement are required.

Disassembly of Main Unit (SU-HTB880)

• Disassembly of Rear Cabinet Block

• Disassembly of NFC P.C.B.

• Disassembly of Remote Sensor P.C.B.

• Disassembly of Optical Jack P.C.B.

• Disassembly of Wireless P.C.B.

• Disassembly of Bluetooth P.C.B.

• Disassembly of Button P.C.B.

• Disassembly of SMPS P.C.B.

• Disassembly of HDMI P.C.B.

• Disassembly of Main P.C.B.

• Disassembly of Panel P.C.B.

• Disassembly of Surround Speaker (SP1)

• Disassembly of Tweeter Speaker (SP2)

• Disassembly of Woofer Speaker (SP3)

• Disassembly of Center Speaker (SP4)

• Disassembly of Woofer Speaker (SP5)

• Disassembly of Tweeter Speaker (SP6)

• Disassembly of Surround Speaker (SP7)

Disassembly of Active Subwoofer (SB-HWA880)

• Disassembly of Rear Panel Block

• Disassembly of Digital Receiver Module P.C.B.

• Disassembly of SW Power Button P.C.B.

• Disassembly of SW SMPS and SW AC Inlet P.C.B.

• Disassembly of Bottom Panel Assembly

• Disassembly of Woofer Speaker (SP61)

8.1. Service Fixture & Tools

Prepare service tools before process service position.

Ref. No. Service Tools Remarks

SFT1 2P WIRE (SPK-SW DAMP) REXX1194 (2P Extension Cable) SB-HWA880

21

8.2. Disassembly flow chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the servicing.

To assemble the unit, reverse the steps shown in the chart below.

8.2.1. Main Unit (SU-HTB880)

8.2.2. Active Subwoofer (SB-HWA880)

22

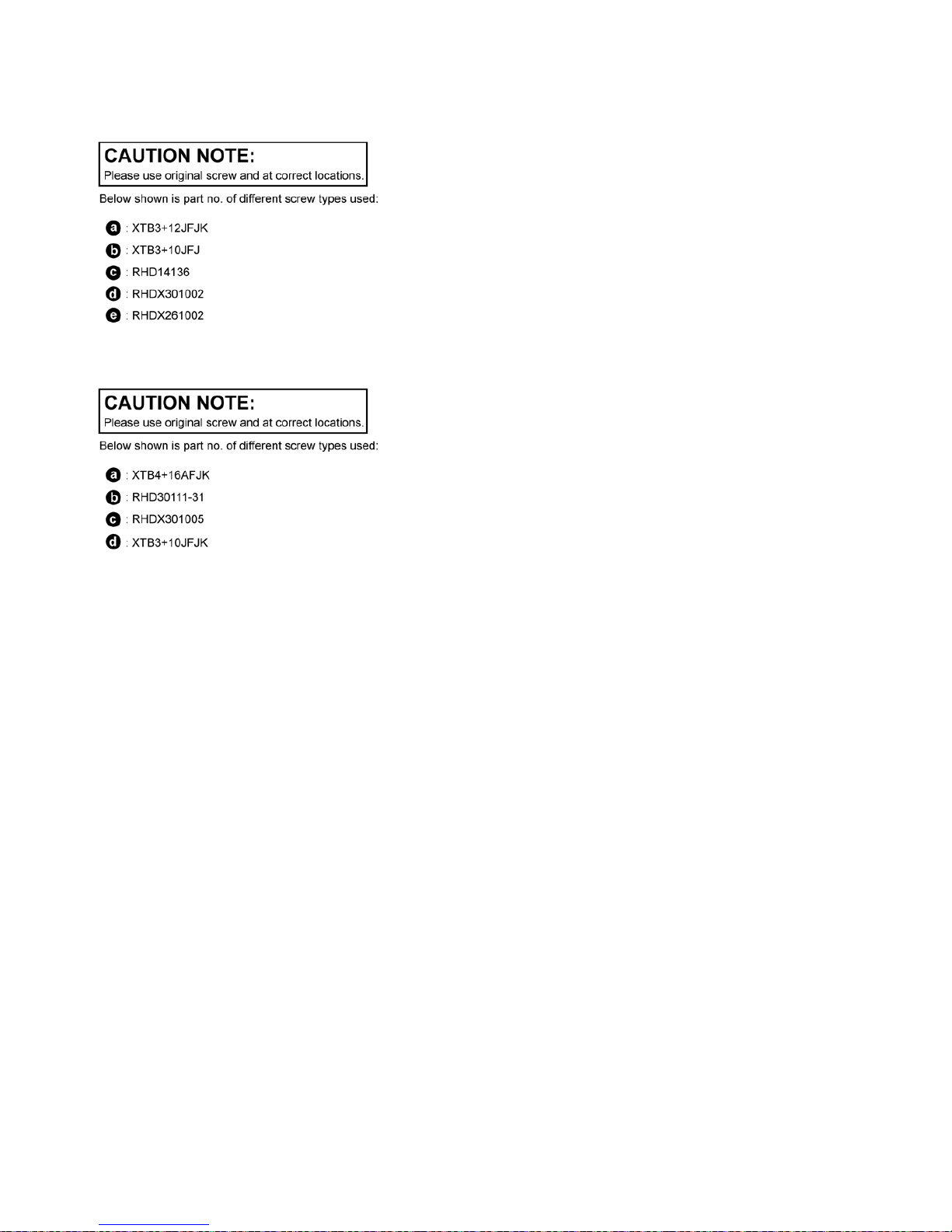

8.3. Type of Screws

8.3.1. Main Unit (SU-HTB880)

8.3.2. Active Subwoofer (SB-HWA880)

23

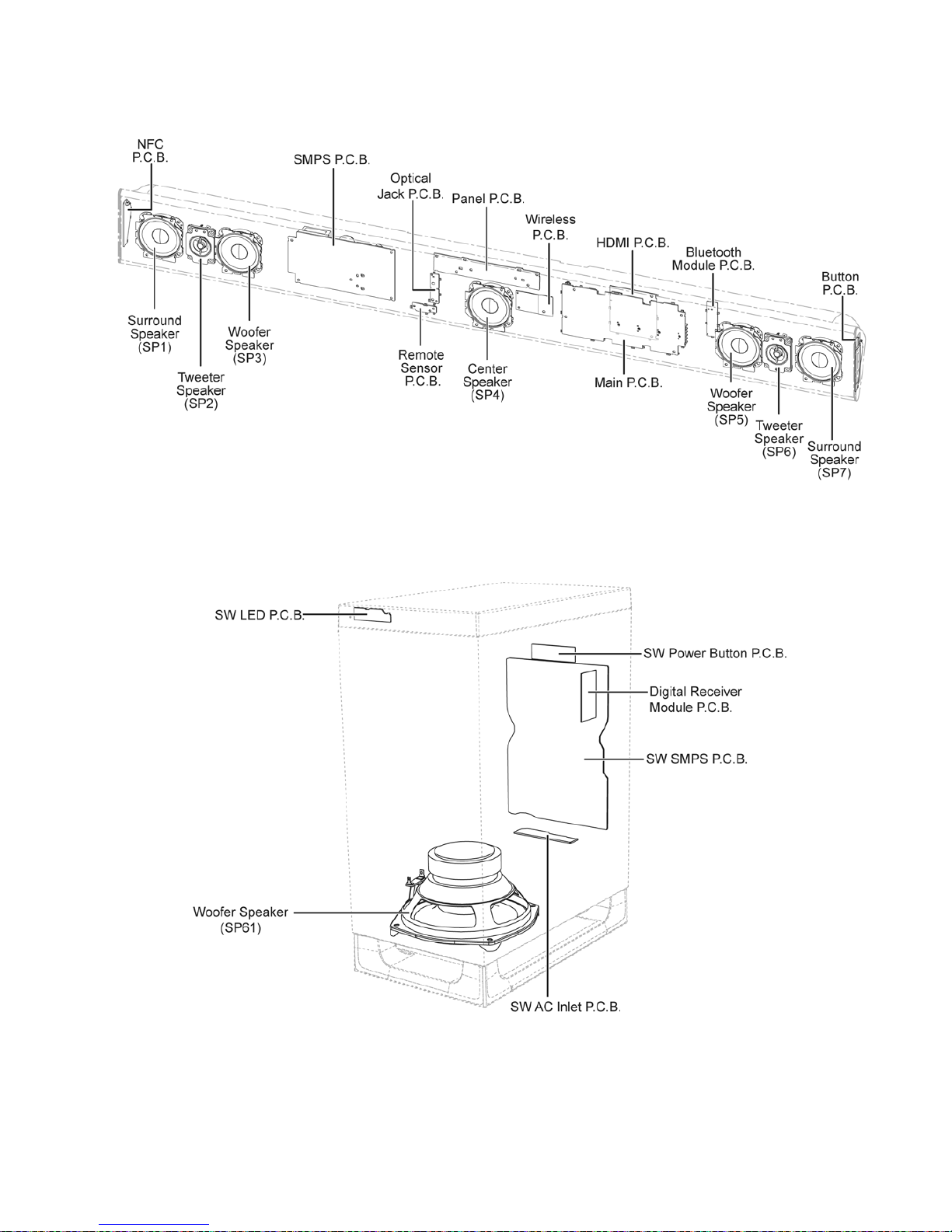

8.4. Main Parts Location Diagram

8.4.1. Main Unit (SU-HTB880)

8.4.2. Active Subwoofer (SB-HWA880)

24

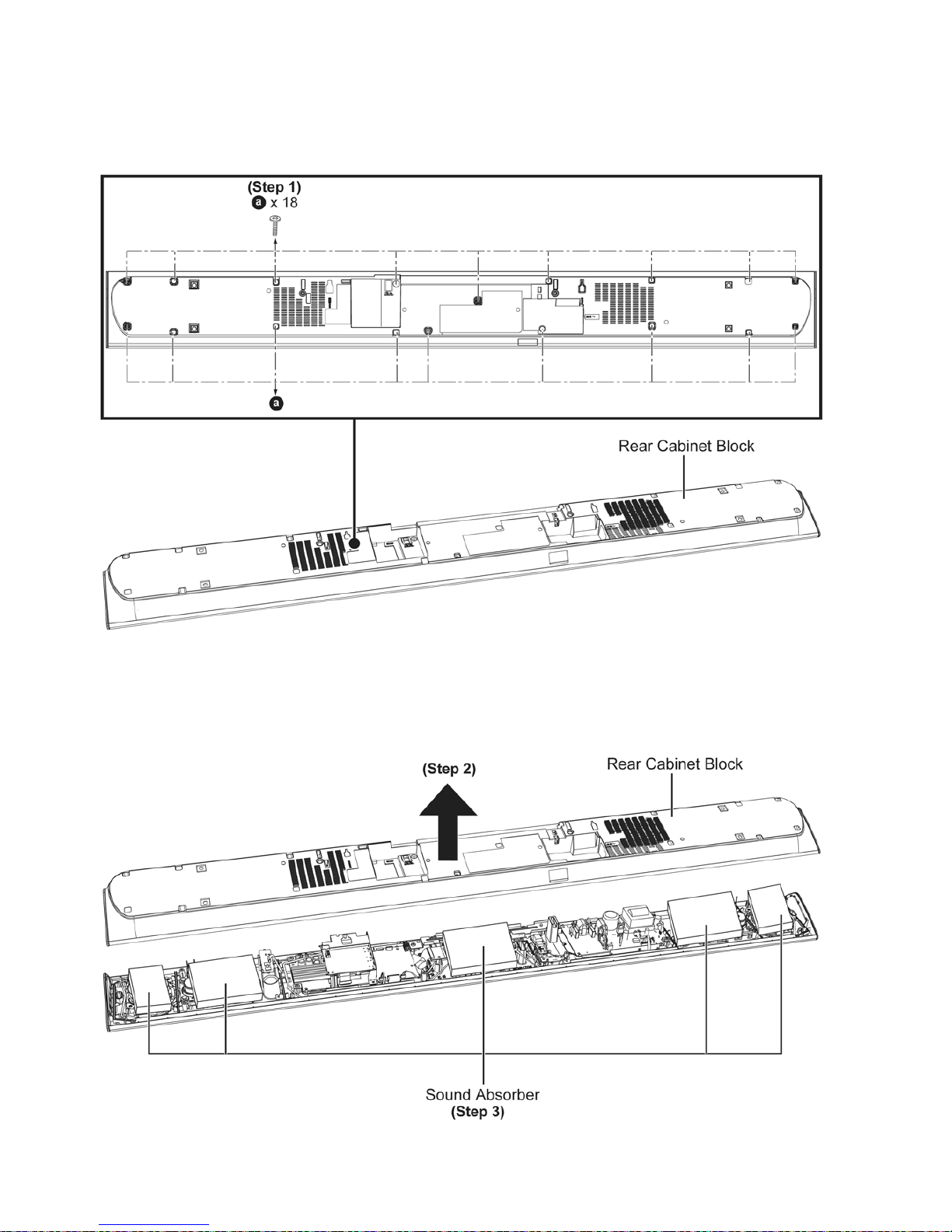

8.5. Disassembly of Main Unit (SU-HTB880)

8.5.1. Disassembly of Rear Cabinet Block

Step 1 : Remove 18 screws.

Step 2 : Remove Rear Cabinet Block.

Caution : Do not exert too much force as it may damage the wiring within.

Step 3 : Remove Sound Absorber.

Caution : Safe keep the Sound Absorber and place it back during assembling.

25

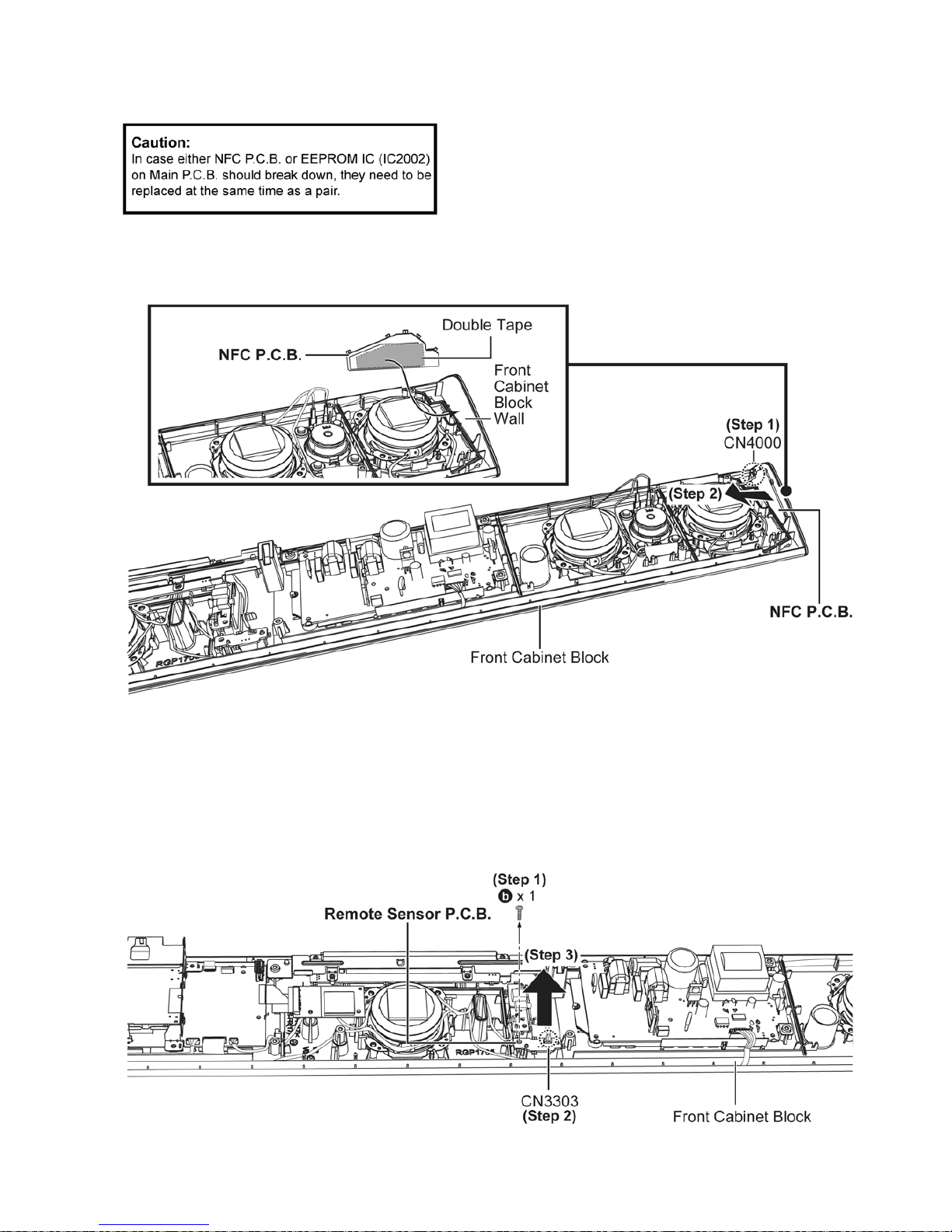

8.5.2. Disassembly of NFC P.C.B.

• Refer to “Disassembly of Rear Cabinet Block”.

Step 1 : Detach 3P wire at connector (CN4000) on NFC P.C.B..

Step 2 : Remove NFC P.C.B..

Caution : During assembly, ensure to push NFC P.C.B. to Front Cabinet Block Wall.

8.5.3. Disassembly of Remote Sensor P.C.B.

• Refer to “Disassembly of Rear Cabinet Block”.

•

Step 1 : Remove 1 screw.

Step 2 : Detach 3P wire at connector (CN3303) on Remote Sensor P.C.B..

Step 3 : Remove Remote Sensor P.C.B..

26

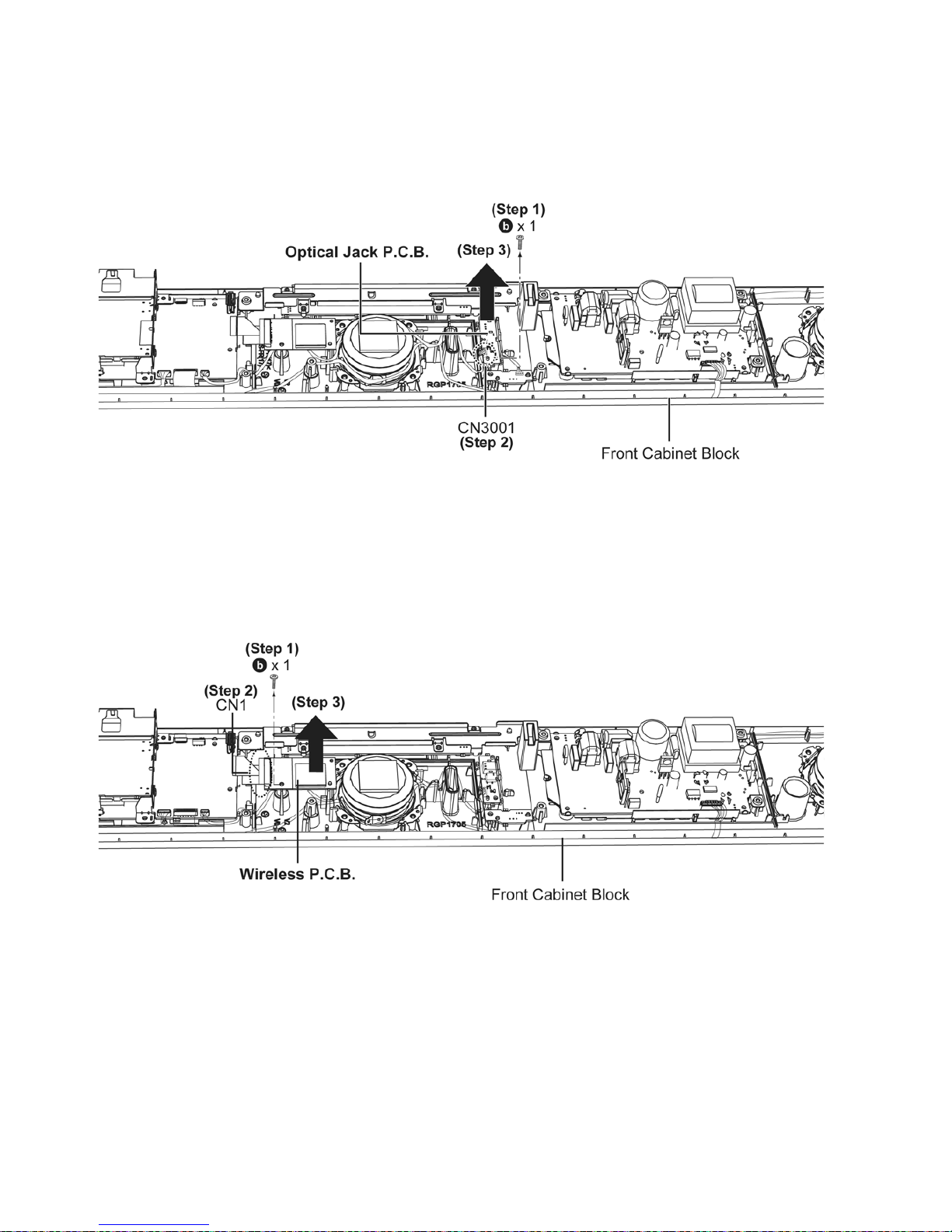

8.5.4. Disassembly of Optical Jack P.C.B.

• Refer to “Disassembly of Rear Cabinet Block”.

Step 1 : Remove 1 screw.

Step 2 : Detach 5P wire at connector (CN3001) on Optical Jack P.C.B..

Step 3 : Remove Optical Jack P.C.B..

8.5.5. Disassembly of Wireless P.C.B.

• Refer to “Disassembly of Rear Cabinet Block”.

Step 1 : Remove 1 screw.

Step 2 : Detach 24P FFC at connector (CN1) on Wireless P.C.B..

Step 3 : Remove Wireless P.C.B..

27

8.5.6. Disassembly of Bluetooth Module P.C.B.

• Refer to “Disassembly of Rear Cabinet Block”.

Step 1 : Remove 1 screw.

Step 2 : Detach 16P FFC at connector (CN1701) on Bluetooth Module P.C.B..

Step 3 : Remove Bluetooth Module P.C.B..

8.5.7. Disassembly of Button P.C.B.

• Refer to “Disassembly of Rear Cabinet Block”.

Step 1 : Detach 8P wire at connector (CN6103) on Button P.C.B..

Step 2 : Remove Button P.C.B..

Caution : During assembly, ensure to push Button P.C.B. to Front Cabinet Block Wall.

28

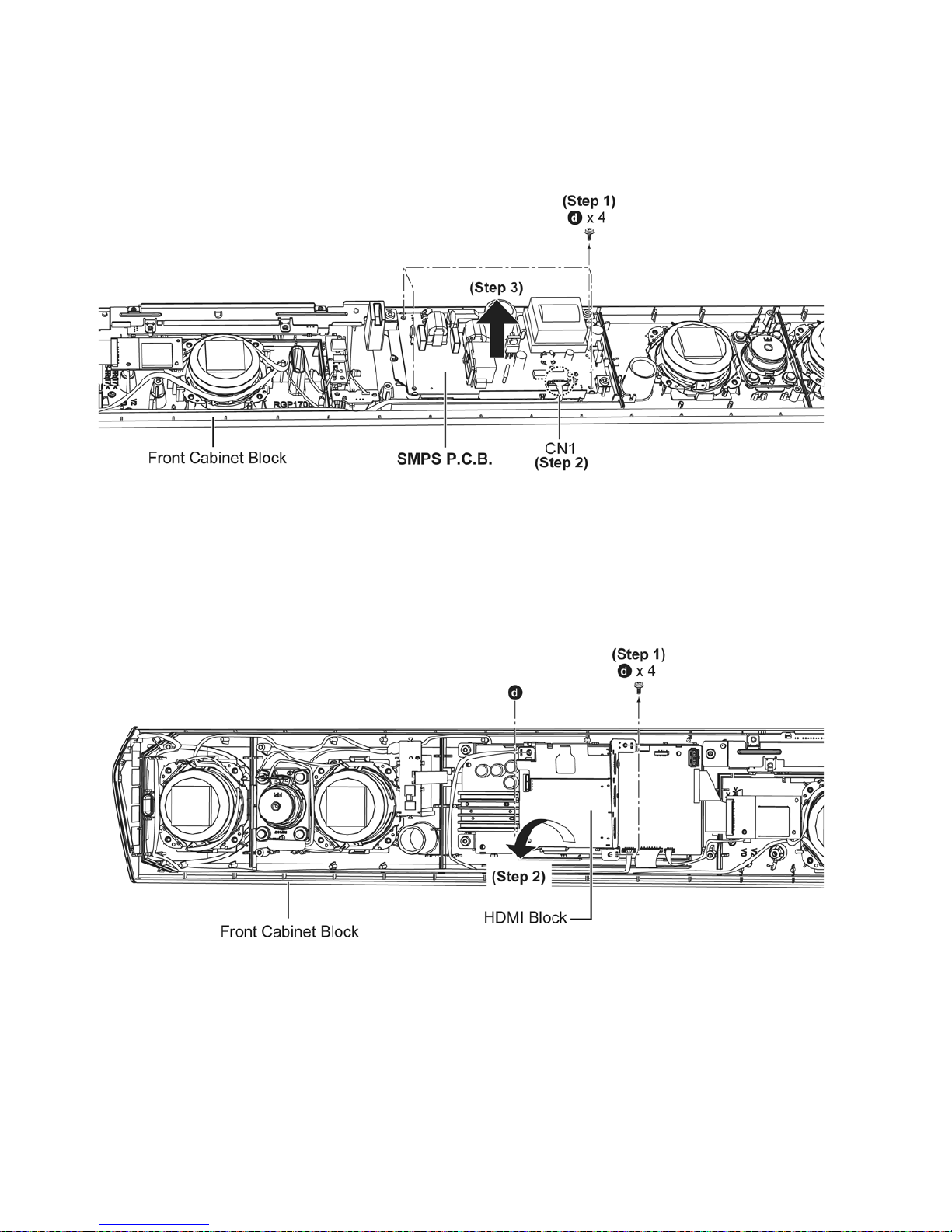

8.5.8. Disassembly of SMPS P.C.B.

• Refer to “Disassembly of Rear Cabinet Block”.

Step 1 : Remove 4 screws.

Step 2 : Detach 7P wire at connector (CN1) on SMPS P.C.B..

Step 3 : Remove SMPS P.C.B..

8.5.9. Disassembly of HDMI P.C.B.

• Refer to “Disassembly of Rear Cabinet Block”.

Step 1 : Remove 4 screws.

Step 2 : Upset HDMI Block.

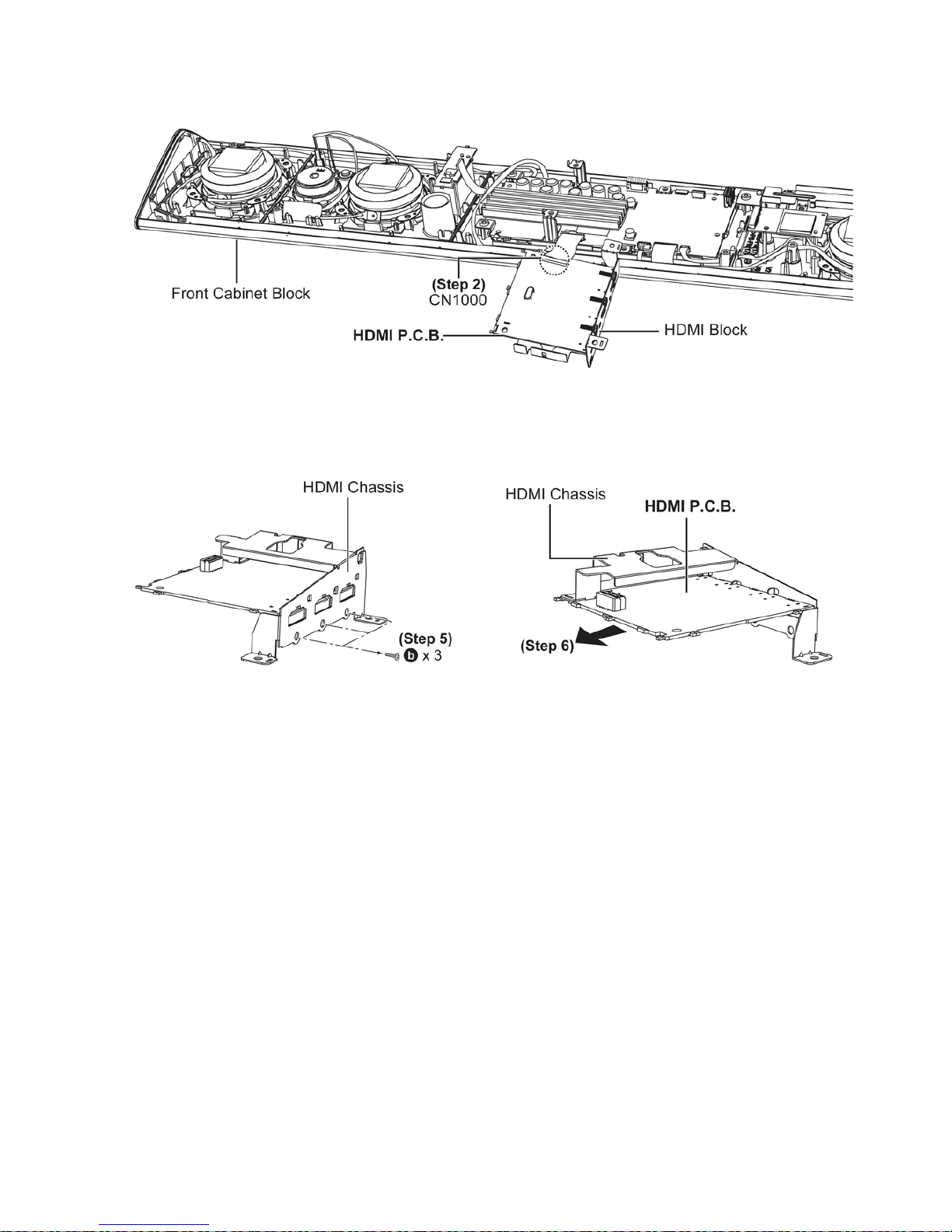

29

Step 3 : Detach 30P FFC at connector (CN1000) on HDMI P.C.B..

Step 4 : Remove HDMI Block.

Step 5 : Remove 3 screws.

Step 6 : Remove HDMI P.C.B..

30

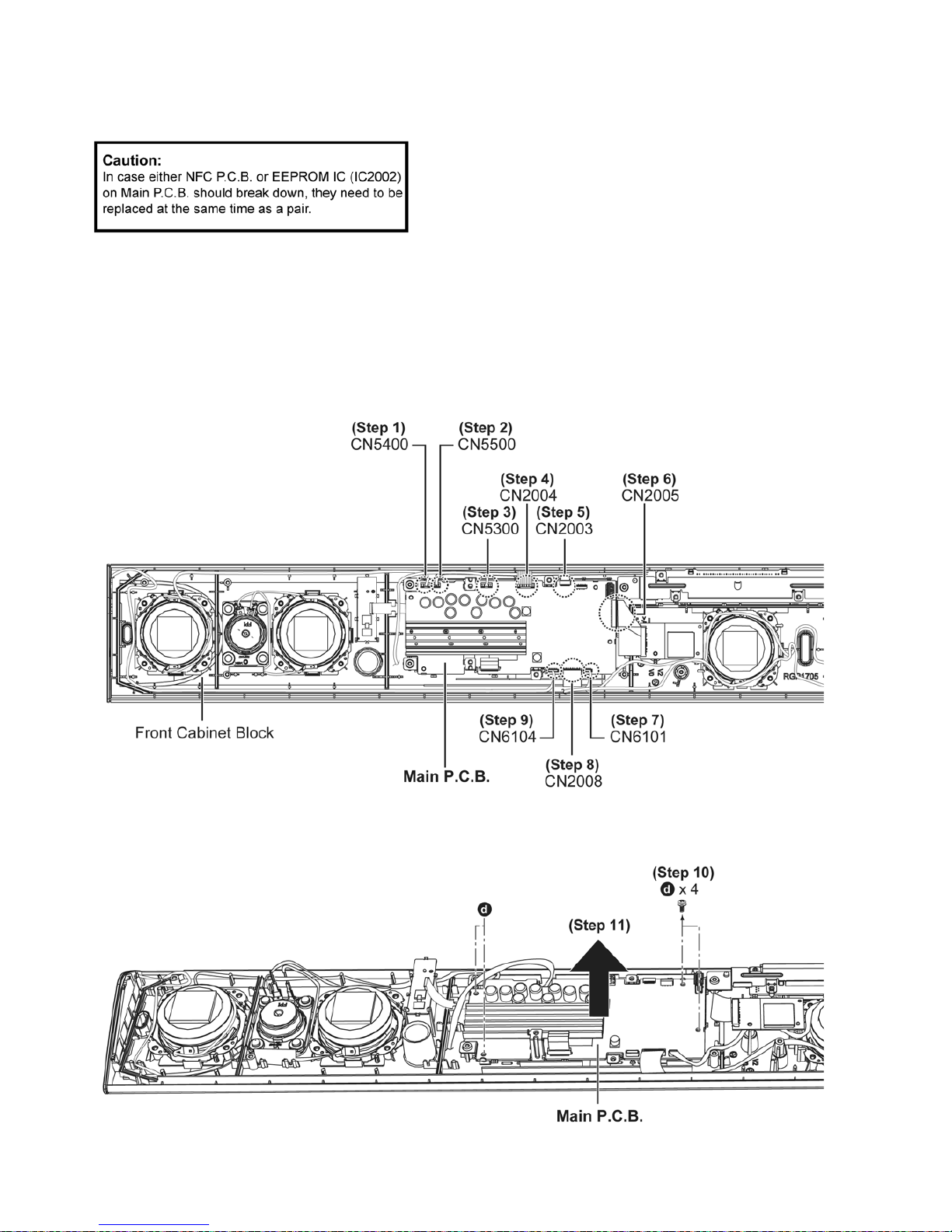

8.5.10. Disassembly of Main P.C.B.

• Refer to “Disassembly of Rear Cabinet Block”.

• Refer to (Step 1) - (Step 4) of item 8.5.9.

Step 1 : Detach 4P wire at connector (CN5400) on Main P.C.B..

Step 2 : Detach 2P wire at connector (CN5500) on Main P.C.B..

Step 3 : Detach 4P wire at connector (CN5300) on Main P.C.B..

Step 4 : Detach 7P wire at connector (CN2004) on Main P.C.B..

Step 5 : Detach 16P FFC at connector (CN2003) on Main P.C.B..

Step 6 : Detach 24P FFC at connector (CN2005) on Main P.C.B..

Step 7 : Detach 5P wire at connector (CN6101) on Main P.C.B..

Step 8 : Detach 15P FFC at connector (CN2008) on Main P.C.B..

Step 9 : Detach 8P wire at connector (CN6104) on Main P.C.B..

Step 10 : Remove 4 screws.

Step 11 : Remove Main P.C.B..

Loading...

Loading...