PANASONIC SU-HTB570EB, SU-HTB570EG, SB-HTB570EG, SB-HWA570EB, SB-HWA570EG Service Manual

...Page 1

PSG1302015CE

Home Theater Audio System

Model No. SU-HTB570EB

SU-HTB570EG

SB-HTB570EG

SB-HWA570EB

SB-HWA570EG

SC-HTB570EB

SC-HTB570EG

TABLE OF CONTENTS

1 Safety Precautions----------------------------------------------- 3

1.1. General Guidelines---------------------------------------- 3

1.2. Before Repair and Adjustment------------------------- 4

1.3. Protection Circuitry---------------------------------------- 4

1.4. Caution For Fuse Replacement------------------------ 4

1.5. Caution for AC Mains Plug (For EB only) ----------- 5

1.6. Safety Part Information----------------------------------- 6

1.7. Safety Installation Instructions ------------------------- 8

2 Warning-------------------------------------------------------------- 9

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices---------- 9

Product Color: (S)...Silver Type

PAGE PAGE

2.2. Service caution based on Legal restrictions

(Lead Free Solder, (PbF))------------------------------10

3 Service Navigation --------------------------------------------- 11

3.1. Service Information-------------------------------------- 11

4 Specifications----------------------------------------------------12

5 General/Introduction------------------------------------------- 13

5.1. About Bluetooth and Operation----------------------- 13

5.2. About VIERA Link---------------------------------------- 14

5.3. Others (Licenses)---------------------------------------- 15

6 Location of Controls and Components------------------16

6.1. Main Unit & Active Subwoofer Key Button

Operations------------------------------------------------- 16

© Panasonic Corporation 2013. All rights reserved.

Unauthorized copying and distribution is a violation of

law.

Page 2

6.2. Indicator illumination-------------------------------------18

6.3. Remote Control Key Button Operations------------19

7 Installation Instructions---------------------------------------20

7.1. Connections -----------------------------------------------20

8 Service Mode-----------------------------------------------------23

8.1. Method to enter into Service Mode------------------23

8.2. Model Display Details by LED Blinking

Indicators---------------------------------------------------23

8.3. Error Codes Display-------------------------------------26

8.4. Cold start (For SU-HTB570)---------------------------28

8.5. Pairing mode between Main Unit (SU) with

Active Subwoofer (SB-HWA)--------------------------28

8.6. SET AUDIO DELAY -------------------------------------28

9 Troubleshooting Guide----------------------------------------29

10 Service Fixture & Tools ---------------------------------------31

11 Disassembly and Assembly Instructions--------------- 32

11.1. Disassembly flow chart ---------------------------------33

1 1 .2. Types of Screws-------------------------------- ---------- 35

1 1 .3. Main Parts Location Diagram -------------------------36

11.4. Disassembly of Main Unit (SU-HTB570) ----------38

11.5. Disassembly of Front Speaker Units Position ----50

11.6. Disassembly of Front Speaker (L&R) (SBHTB570) --------------------------------------------------- 55

11.7. Disassembly of Active Subwoofer (SBHWA570)---------------------------------------------------74

12 Service Position -------------------------------------------------87

12.1. Main Unit (SU-HTB570) --------------------------------87

12.2. Active Subwoofer (SB-HWA570)---------------------92

13 Overall Simplified Block--------------------------------------95

13.1. Main Unit (SU-HTB570) --------------------------------95

13.2. Active Subwoofer (SB-HWA570)---------------------97

14 Block Diagram ---------------------------------------------------98

14.1. Main Unit (SU-HTB570) --------------------------------98

14.2. Active Subwoofer (SB-HWA570)------------------- 104

15 Wiring Connection Diagram------------------------------- 106

15.1. Main Unit (SU-HTB570) ------------------------------ 106

15.2. Active Subwoofer (SB-HWA570)------------------- 107

16 Schematic Diagram------------------------------------------- 109

16.1. Schematic Diagram Notes--------------------------- 109

16.2. Main Unit (SU-HTB570) -------------------------------11 1

16.3. Active Subwoofer (SB-HWA570)------------------- 122

17 Printed Circuit Board ---------------------------------------- 126

17.1. Main Unit (SU-HTB570) ----------------------------- 126

17.2. Active Subwoofer (SB-HWA570) ------------------ 131

18 Appendix Information of Schematic Diagram ------- 133

18.1. Voltage Measurement & Waveform Chart ------- 133

18.2. Illustration of IC’s, Transistors and Diodes ------ 141

18.3. Terminal Function of IC’s----------------------------- 143

19 Exploded View and Replacement Parts List--------- 145

19.1. Exploded View and Mechanical replacement

Parts List ------------------------------------------------- 145

19.2. Electrical Replacement Parts List------------------ 153

2

Page 3

1 Safety Precautions

1.1. General Guidelines

1. IMPORTANT SAFETY NOTICE

There are special components used in this equipment which are important for safety. These parts are marked by in the

Schematic Diagrams, Circuit Board Layout, Exploded Views and Replacement Parts List. It is essential that these critical parts

should be replaced with manufacturer’s specified parts to prevent X-RADIATION, shock, fire, or other hazards. Do not modify

the original design without permission of manufacturer.

2. An Isolation Transformer should always be used during the servicing of AC Adaptor whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this protects the technician from accidents resulting in personal

injury from electrical shocks. It will also protect AC Adaptor from being damaged by accidental shorting that may occur during

servicing.

3. When servicing, observe the original lead dress. If a short circuit is found, re place all parts which have been overheated or

damaged by the short circuit.

4. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

5. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Using an ohmmeter measure the resistance value, between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to th e

chassis, the reading should be between 1MΩ and 5.2Ω. When the exposed metal does not have a return path to the chassis,

the reading must be

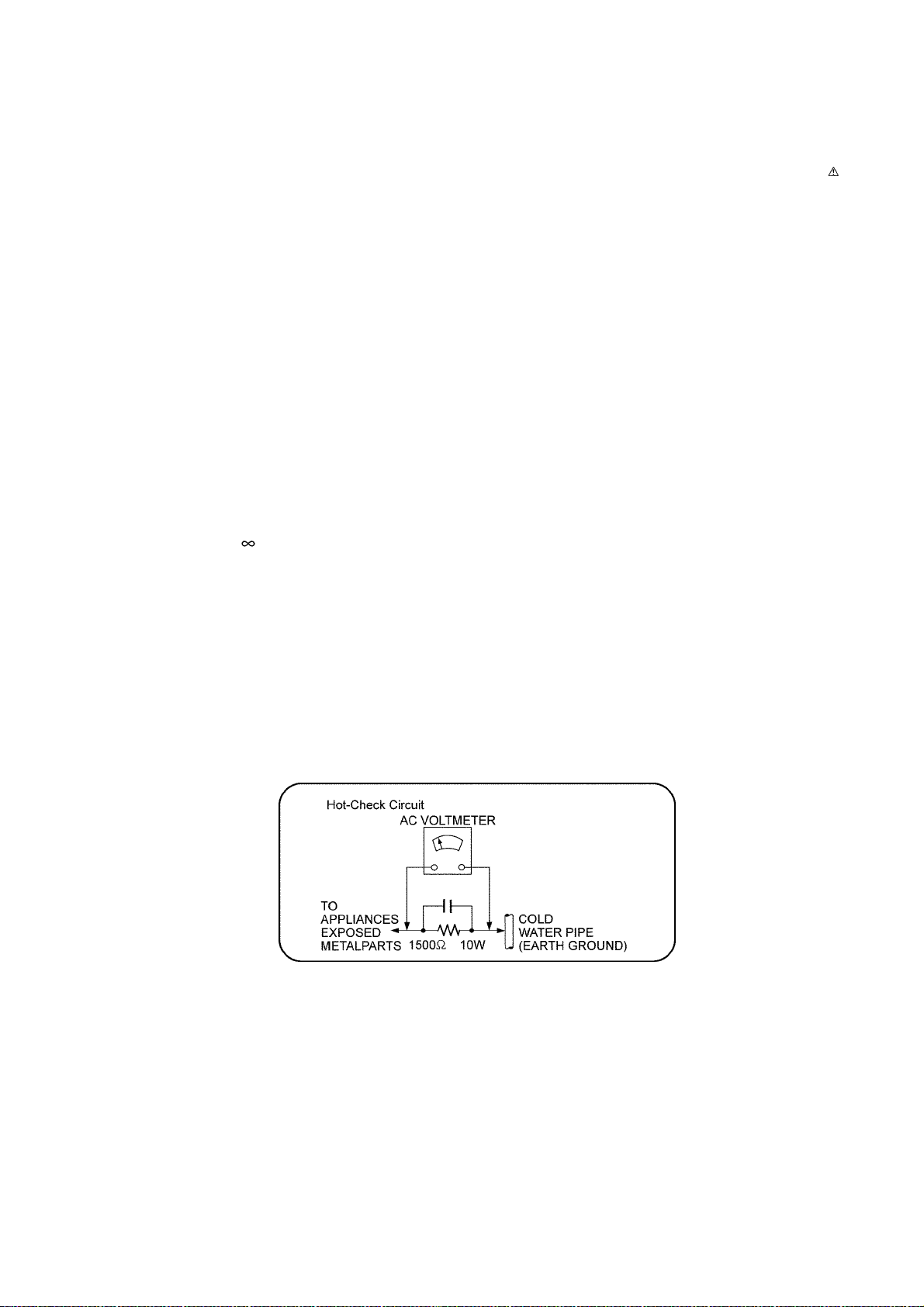

1.1.2. Leakage Current Hot Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15μF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1-1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or e quivalent)

may be used to make the hot checks, leakage current must not exceed 1/2 milliamp. should the measurement is outside of

the limits specified, there is a possibility of a shock hazard, and the equipment should be repaired and re-checked before it is

returned to the customer.

Figure 1-1

3

Page 4

1.2. Before Repair and Adjustment

Main Unit (SU-HTB570)

Disconnect AC power, discharge unit AC Capacitors (C5700, C5701, C5702, C5703, C5704 and C5705) through a 10W, 1W resistor to ground.

Caution : DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

• Current consumption at AC 220 V ~ 240 V, 50 Hz during power on at no signal with volume minimum, (Selector : CD mode)

should be ~150 mA.

Active Subwoofer (SB-HWA570)

Disconnect AC power, discharge unit AC Capacitors (C5700, C5701, C5702, C5703, C5704 and C5705) through a 10W, 1W resistor to ground.

Caution : DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

• Current consumption at AC 220 V ~ 240 V, 60 Hz during power on at link with volume minimum, (Selector : BD/DVD mode)

should be ~200 mA.

1.3. Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

• No sound is heard when the power is turned on.

• Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wir es are

"shorted", or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

1.4. Caution For Fuse Replacement

1.4.1. SU-HTB570/SB-HWA570

Figure 1-2

4

Page 5

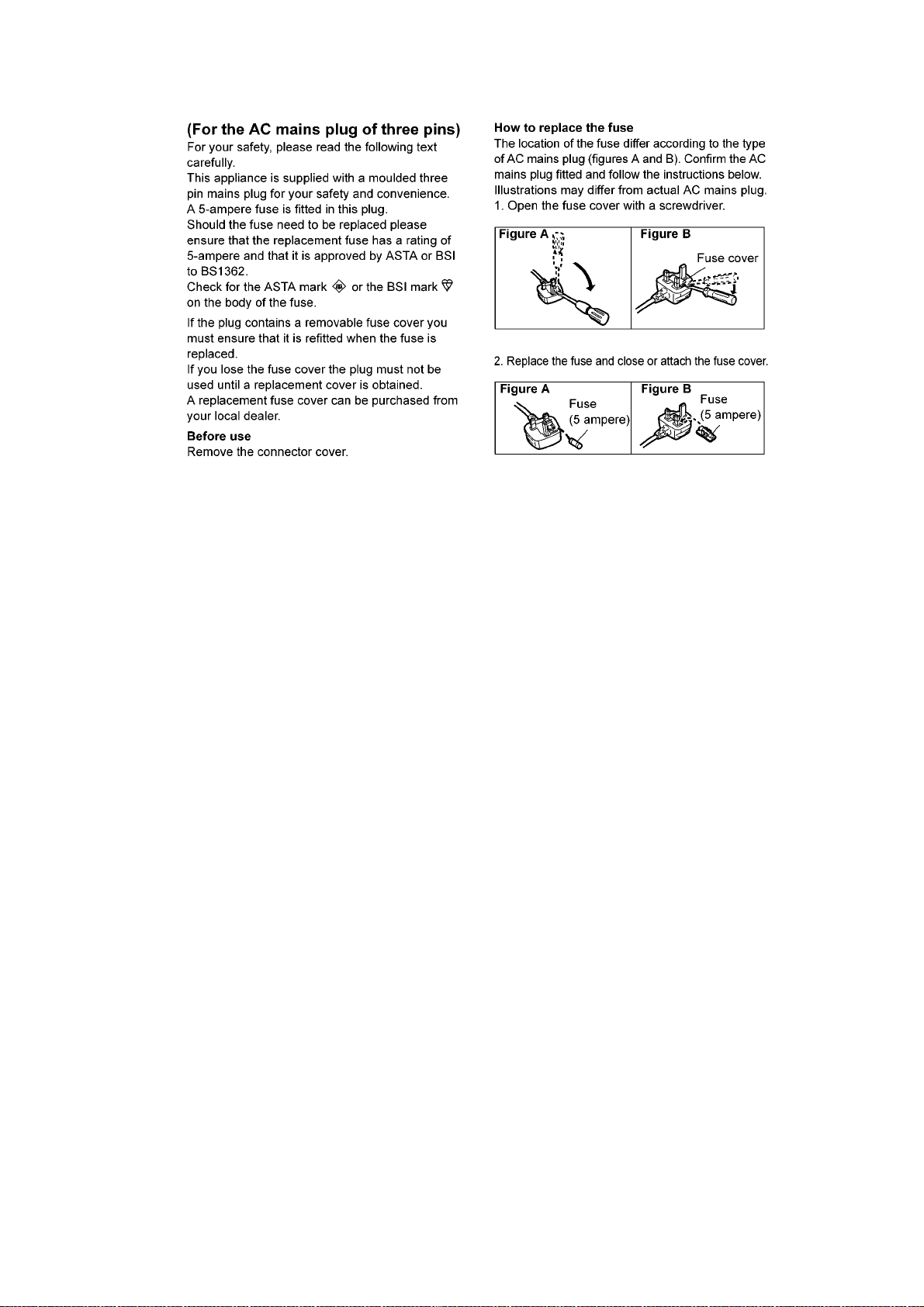

1.5. Caution for AC Mains Plug (For EB only)

Figure 1-3

5

Page 6

1.6. Safety Part Information

Safety Parts List:

There are special components used in this equipment which are important for safety.

These parts are marked by in the Schematic Diagrams & Replacement Parts List. It is essential that thes e critical p art s should

be replaced with manufacturer’s specified parts to prevent shock, fire or other hazards. Do not modify the original design without

permission of manufacturer.

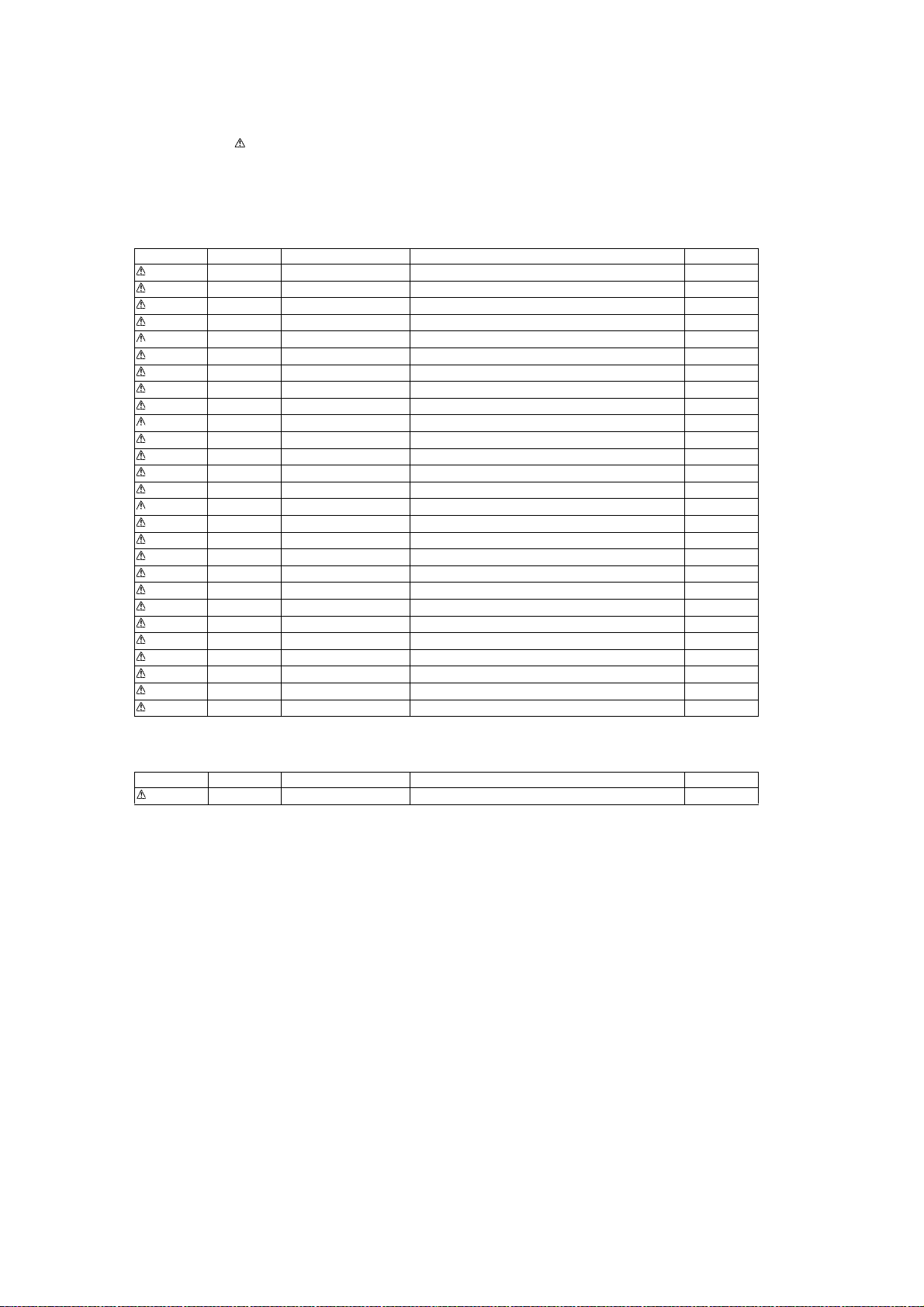

1.6.1. Main Unit (SU-HTB570)

Safety Ref. No. Part No. Part Name & Description Remarks

3 REX1579 1P RED WIRE (SMPS-AC INLET)

4 REX1580 1P BLACK WIRE (SMPS-AC INLET)

16 RKM0662B-S TOP PANEL

18 RGR0441C-B REAR PANEL EG

18 RGR0441C-F REAR PANEL EB

29 RMZ1268 SMPS TOP INSULATOR

C5700 F1BAF1020020 1000pF

C5701 F0CAF104A105 0.1uF

C5702 F0CAF104A105 0.1uF

C5703 F0CAF104A105 0.1uF

C5704 F1BAF471A013 470pF

C5705 F1BAF471A013 470pF

DZ5701 ERZV10V511CS ZNR (E.S.D)

F1 K5G312Y00007 FUSE

L5702 G0B922G00004 LINE FILTER

L5703 G0B922G00004 LINE FILTER

P5701 K2AA2B000011 AC INLET

PC5720 B3PBA0000579 PHOTO COUPLER

PC5760 B3PBA0000579 PHOTO COUPLER

PCB4 REP4860G SMPS P.C.B (RTL)

PCB5 REP4860G AC INLET P.C.B. (RTL)

PCB6 REP4864A DIGITAL TRANSMISTTER MODULE P.C.B.

PCB7 N5HZZ0000128 BLUETOOTH MODULE P.C.B.

R5700 ERJ8GEYJ105V 1M 1/4W

R5701 ERJ8GEYJ105V 1M 1/4W

R5710 ERJ8GEYJ105V 1M 1/4W

T5701 ETS35BL196AD TRANSFORMER

1.6.2. Front Speaker (SB-HTB570)

Safety Ref. No. Part No. Part Name & Description Remarks

43 RGN3322-K SPEC LABEL

6

Page 7

1.6.3. Active Subwoofer (SB-HWA570)

Safety Ref. No. Part No. Part Name & Description Remarks

67 RGN3351-S1 NAME PLATE EG

67 RGN3352-S NAME PLATE EB

75 RMZX0026-1 IC INSULATOR

80 REX1579 1P RED WIRE (SMPS - AC INLET)

84 REX1580 1P BLACK WIRE (SMPS - AC INLET)

C5700 F1BAF1020020 1000pF

C5701 F0CAF104A105 0.1uF

C5702 F0CAF104A105 0.1uF

C5703 F0CAF104A105 0.1uF

C5704 F1BAF471A013 470pF

C5705 F1BAF471A013 470pF

DZ5701 ERZV10V511CS ZNR (E.S.D)

F1 K5G312Y00007 FUSE

L5702 G0B922G00004 LINE FILTER

L5703 G0B922G00004 LINE FILTER

P5701 K2AA2B000011 AC INLET

PC5720 B3PBA0000579 PHOTO COUPLER

PC5760 B3PBA0000579 PHOTO COUPLER

PCB4 REP4860L SW SMPS P.C.B. (RTL)

PCB5 REP4860L SW AC INLET P.C.B. (RTL)

R5700 ERJ8GEYJ105V 1M 1/4W

R5701 ERJ8GEYJ105V 1M 1/4W

R5710 ERJ8GEYJ105V 1M 1/4W

T5701 G4DYA0000485 TRANSFORMER

1.6.4. System (SC-HTB570)

Safety Ref. No. Part No. Part Name & Description Remarks

A1 N2QAYC000083 REMOTE CONTROL

A2 K2CT2YY00097 AC CORD EB

A2 K2CQ2YY00119 AC CORD EG

A3 RQT9781-D O/I BOOK (Fi/Ru/Ur) EG

A3 RQT9782-D O/I BOOK (Fr/It/Ge) EG

A3 RQT9783-E O/I BOOK (Sp/Po/Cz) EG

A3 RQT9784-H O/I BOOK (Sw/Da/Du) EG

A3 RQT9785-B O/I BOOK (En)

7

Page 8

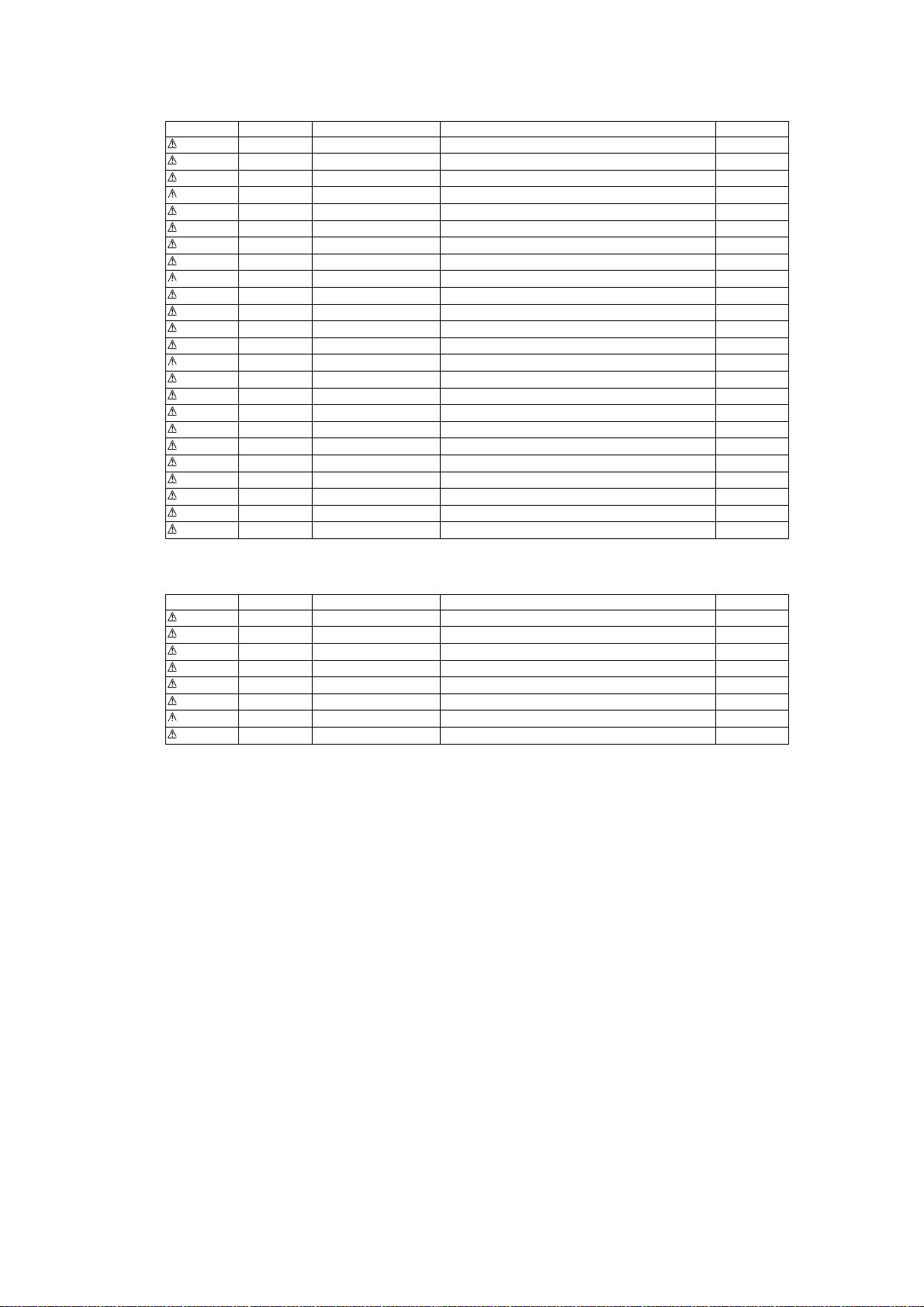

1.7. Safety Installation Instructions

Figure 1-4

8

Page 9

2Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices.

The following techniques should be used to help reduce the incidence of compon ent damage caused by electrostatic discharge

(ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a condu ctive surface such as al uminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

CAUTION:

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to damage an ES device).

9

Page 10

2.2. Service caution based on Legal restrictions (Lead Free Solder, (PbF))

The lead free solder has been used in the mounting process of all electrical comp onents on the printed circuit boards us ed for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86°F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

The letter of “PbF” is printed either foil side or components side on the PCB using the lead free solder.

(See right figure)

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

• Since the melting point of the lead free solder i s higher than that of the normal lead solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) e quipped with the tempe rature control after setting the te mperature at 350±30 degrees

C (662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: Tin (Sn), 96.5%, Silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

10

Page 11

3 Service Navigation

3.1. Service Information

This service manual contains technical information which will allow service personnel’s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, this information wil l be fol lowed by supp lement service ma nual to be filed with original servic e

manual.

• Flash IC :

The following components are supplied as an assembled part.

• Flash IC, IC2001 (RFKWEHTB370M).

11

Page 12

4 Specifications

Q Amplifier Section

RMS Output Power : Dolby Digital Mode

Front ch (L, R ch) 60 W per channel (6 Ω), 1 kHz,

10% THD

Subwoofer ch 120 W per channel (8 Ω), 100 Hz,

10% THD

Total RMS Dolby Digital mode

power

Q Wireless section

Wireless module

Frequency Range 2.40335 GHz to 2.47735 GHz

Number of channels 38

Q Terminal Section

HDAVI Control This unit supports “HDAVI Control

HDMI AV input (BD/DVD) 1

Input connector Type A (19 pin)

HDMI AV output (TV (ARC)) 1

Output connector Type A (19 pin)

Digital audio input

Optical digital input (TV, AUX) 2

Sampling frequency 32 kHz, 44.1 kHz, 48 kHz

88.2 kHz, 96 kHz (only LPCM)

Audio format LPCM, Dolby Digital, DTS Digital

IR Blaster

Terminal Type 3.5 mm jack

USB Port For service use only.

Q Speaker Section

Front speakers

3 way, 3 speaker system (Bass reflex type)

Speaker unit(s) Impedance 6 Ω

Woofer 5.7 cm cone type

Tweeter 2.5 cm semi-dome type

Super tweeter Piezo type

Output sound pressure 78 dB/W (1 m)

Frequency range 90 Hz to 32 kHz (-16 dB)

100 Hz to 23 kHz (-10 dB)

Active subwoofer

1 way, 1 speaker system (Bass reflex type)

Woofer 16 cm cone type

Output sound pressure 80 dB/W (1 m)

Frequency range 30 Hz to 180 Hz (-16 dB)

35 Hz to 160 Hz (-10 dB)

Q General

Power consumption Main Unit: 27 W

Active subwoofer: 19 W

In standby condition

Main Unit (When the other connected devices are turned off):

Active subwoofer (Power switch release):

Approx. 0.25 W

Power supply AC 220 V to 240 V, 50 Hz

Dimensions (W x H x D)

Main Unit

310 mm x 45 mm x 188 mm

Active subwoofer 180 mm x 408 mm x 306 mm

Mass (Weight)

Main Unit Approx. 1.15 kg

Active subwoofer 4.76 kg

Operating temperature range 0°C to +40°C

240 W

5” function.

Surround

Approx. 0.3 W

Operating humidity range 20% to 80 % RH

(no condensation)

Q Speaker General

- For wall mounting layout

Horizontal placement

Dimensions (W x H x D) 1060 mm x 68 mm x 41 mm

Mass (Weight)

Vertical placement

Dimensions (W x H x D) 68 mm x 541 mm x 41 mm

Mass (Weight) 0.78 kg

- For table top layout

Horizontal placement using the leg stands (High)

Dimensions (W x H x D) 1060 mm x 96 mm x 68 mm

Mass (Weight) 1.57 kg

Horizontal placement using the leg stands (Low)

Dimensions (W x H x D) 1060 mm x 87 mm x 68 mm

Mass (Weight) 1.57 kg

Horizontal placement using the support legs and the speaker feet

Dimensions (W x H x D) 1060 mm x 71 mm x 60 mm

Mass (Weight) 1.53 kg

Vertical placement using the bases

Dimensions (W x H x D) 148 mm x 552 mm x 148 mm

Mass (Weight) 0.89 kg

Center Speaker

Q Bluetooth Section

Bluetooth system specification Version 3.0

Wireless equipment classification

Supported profiles A2DP

Frequency band 2402 MHz to 2480 MHz

(Adaptive Frequency Hopping)

Operating distance 10 m Line of Sight

• Specifications are subject to change without notice. Weight and

dimensions are approximate.

• Total harmonic distortion is measured by the digital spectrum analyzer.

Q System: SC-HTB570EBS MAIN UNIT : SU-HTB570EBS

FRONT SPEAKERS : SB-HTB570EGS

ACTIVE SUBWOOFER : SB-HWA570EBS

Q System: SC-HTB570EGS MAIN UNIT : SU-HTB570EGS

FRONT SPEAKERS : SB-HTB570EGS

ACTIVE SUBWOOFER : SB-HWA570EGS

1.49 kg

Class 2

12

Page 13

5 General/Introduction

By using the Bluetooth®connection, you can listen

to the sound from the Bluetooth

®

audio device

from this system wirelessly.

Preparation

Turn on the Bluetooth®feature of the device and

place the device near the main unit.

Press [ ] to select “ ”.

If the “ ” indicator flashes quickly, go to step 3.

Press and hold [ ] until the “ ”

indicator flashes quickly.

If the “ ” indicator flashes slowly, repeat step 2.

Select “SC-HTB570” from the

Bluetooth

®

device’s Bluetooth

®

menu.

If prompted for the passkey on the Bluetooth® device, enter

“0000”.

Once the Bluetooth

®

device is connected, the “ ” indicator

stops flashing and lights up.

Press [ ] to select “ ”.

If the “ ” indicator lights, a Bluetooth® device is already

connected with this system. Disconnect it. (

below)

Select “SC-HTB570” from the

Bluetooth

®

device’s Bluetooth

®

menu.

Disconnecting a Bluetooth

®

device

Press and hold [ ] until the “ ” indicator flashes

slowly.

When “ ” is selected as the source, this system will

automatically try and connect to the last connected

Bluetooth

®

device.

The Bluetooth

®

device will be disconnected if a different

audio source (e.g. “TV“) is selected.

Refer to the operating instructions of the Bluetooth

®

device

for further instruction on how to connect a Bluetooth

®

device.

This system can only be connected to one device at a time.

You can register up to 8 devices with this system. If a 9th

device is paired, the device that has not been used for the

longest time will be replaced.

To change the sound quality, refer to OI Book “Bluetooth

®

communication mode”.

Bluetooth®connection

Bluetooth® pairing

Connecting a Bluetooth

®

device

About Bluetooth

®

Frequency band used

This system uses the 2.4 GHz frequency band.

Certification of this device

This system conforms to frequency restrictions and has

received certification based on frequency laws. Thus, a

wireless permit is not necessary.

The action below are punishable by law in some

countries:

Taking apart or modifying the unit.

Removing specification indications.

Restrictions of use

Wireless transmission and/or usage with all Bluetooth

®

equipped devices is not guaranteed.

All devices must conform to standards set by Bluetooth

SIG, Inc.

Depending on the specifications and settings of a

device, it can fail to connect or some operations can be

different.

This system supports Bluetooth

®

security features. But

depending on the operating environment and/or

settings, this security is possibly not sufficient. Transmit

data wirelessly to this system with caution.

This system cannot transmit data to a Bluetooth

®

device.

Range of use

Use this device at a maximum range of 10 m.

The range can decrease depending on the environment,

obstacles or interference.

Interference from other devices

This system may not function properly and troubles

such as noise and sound jumps may arise due t

o radio

wave interference if the main unit is located too close to

other Bluetooth

®

devices or the devices that use the 2.4

GHz band.

This system may not function properly if radio waves

from a nearby broadcasting station, etc. are too strong.

Intended usage

This system is for normal, general use only.

Do not use this system near equipment or in an

environment that is sensitive to radio frequency

interference (example: airports, hospitals, laboratories,

etc).

Panasonic bears no responsibility for data

and/or information that is compromised

during a wireless transmission.

-

-

5.1. About Bluetooth and Operation

13

Page 14

5.2. About VIERA Link

Linked operations with the TV

(VIERA Link

TM

“HDAVI ControlTM”)

Preparation

1 Confirm that the HDMI connection has been made.

2 Set the “HDAVI Control” operations on the connected

equipment (e.g., TV).

3 For the optimal “HDAVI Control” operations change

the following settings on the connected TV

1

.

Set the default speaker settings to this system.

2

Set the speaker selection settings to this system.

4 Turn on all “HDAVI Control” compatible equipment

and select the TV’s input for this system so that the

“HDAVI Control” function works properly.

5 If a device is connected to the HDMI IN t

erminal, start

play to check that the picture is displayed on the TV

correctly.

When the connection or settings are changed,

repeat this procedure.

1 The availability and function of the settings may vary

depending on the TV. Refer to the operating instructions

for the TV for details.

2 If the TV has a default speaker setting within the VIERA

Link setting items, choosing this system as the default

speaker will automatically change the speaker selection to

this system.

VIERA Link “HDAVI Control”, based on the control functions

provided by HDMI which is an industry standard known as

HDMI CEC (Consumer Electronics Control), is a unique

function that we have developed and added. As such, its

operation with other manufacturers’ equipment that

supports HDMI CEC cannot be guaranteed.

This unit supports “HDAVI Control 5” function.

“HDAVI Control 5” is the standard for Panasonic’s HDAVI

Control compatible equipment. This standard is compatible

with Panasonic’s conventional HDAVI equipment.

Please refer to individual manuals for other manufacturers’

equipment supporting VIERA Link function.

To make sure that the audio is output from this system,

turn the main unit on by using the TV’s remote control and

selecting home theater from the speaker menu of VIERA

Link menu. The availability and function of the settings

may vary depending on the TV. Refer to the operating

instructions for the TV for details.

Speaker control

You can select whether audio output is from this system or

the TV

speakers by using the TV menu settings.

Home theater

This system is active.

When the main unit is in standby mode, changing the TV

speakers to this system in the VIERA Link menu will

automatically turn the main unit on and select TV as the

source.

You can control the volume setting of this system using the

volume or mute button on the TV remote control.

If you turn off the main unit, the TV speakers will be

automatically activated.

Audio will automatically be output from this system if the TV

is compatible to VIERA Link “HDAVI Control 4” or later.

TV

TV speakers are active.

The volume of this system is set to its minimum.

Automatic input switching

When the following operations are performed, the main

unit will automatically change the input to the

corresponding source.

When play starts on an HDMI connected device.

3

When the TV input or the TV channel is changed.

3 If the speaker output setting on the TV is set to this

system, the TV and the main unit turn on automatically

(Power on link).

Power off link

When the TV is turned off, the main unit also turns off

automatically. (This function does not work when

Bluetooth

®

is the source.)

Automatic lip-sync function

(for HDAVI Control 3 or later)

Delay between audio and video is automatically adjusted

by adding time-lag to the audio output, enabling you to

enjoy smooth audio for the picture.

The delay information is automatically set if the TV is

compatible to VIERA Link “HDAVI Control 3” or later and the

VIERA Link is set to on.

What is VIERA Link “HDAVI

Control”?

VIERA LinkTM is a new name for EZ SyncTM.

VIERA Link “HDAVI Control” is a convenient

function that offers linked operations of this

system, and a Panasonic TV (VIERA) under

“HDAVI Control”.

You can use this function by connecting the

equipment with an HDMI cable. See the

operating instructions for connected

equipment for operational details.

What you can do with

VIERA Link “HDAVI

Control”

-

-

14

Page 15

5.3. Others (Licenses)

Manufactured under license from Dolby Laboratories.

Dolby, Pro Logic, and the double-D symbol are trademarks

of Dolby Laboratories.

Manufactured under license under U.S. Patent Nos:

5,956,674; 5,974,380; 6,487,535 & other U.S. and

worldwide patents issued & pending.

DTS, the Symbol, & DTS and the Symbol together are

registered trademarks & DTS Digital Surround and the DTS

logos are trademarks of DTS, Inc. Product includes

software.

© DTS, Inc. All Rights Reserved.

HDMI, the HDMI Logo, and High-Definition Multimedia

Interface are trademarks or registered trademarks of HDMI

Licensing LLC in the United States and other countries.

HDAVI Control™ is a trademark of Panasonic Corporation.

The Bluetooth

®

word mark and logos are owned by the

Bluetooth SIG, Inc. and any use of such marks by

Panasonic Corporation is under license. Other trademarks

and trade names are those of their respective owners.

15

Page 16

6 Location of Controls and Components

A

B

C

D

E

F

1

Press to switch the unit from on to standby

mode or vice versa. In standby mode, the unit

is still consuming a small amount of power.

2 Adjust the volume of this system

3 Select the input source

“TV” “BD/DVD” “AUX”

“”

4 Input selector indicators*

1

Bluetooth®indicator

Lights blue when the Bluetooth

®

device is

the audio source

TV indicator

Lights green when the TV is the audio

source

BD/DVD indicator

Lights amber when the device connected

to the BD/DVD terminal is the audio

source

AUX indicator

Lights amber when the device connected

to the AUX terminal is the audio source

5 Sound mode indicators*

1

STANDARD indicator

Lights when STANDARD is the current

sound mode

STADIUM indicator*

2

Lights when STADIUM is the current

sound mode

MUSIC indicator*

2

Lights when MUSIC is the current sound

mode

CINEMA indicator

Lights when CINEMA is the current

sound mode

NEWS indicator

Lights when NEWS is the current sound

mode

STEREO indicator

Lights when STEREO is the current

sound mode

6 Remote control signal sensor

7 WIRELESS LINK indicator

*1

The indicators will also blink in various conditions.

*2

The indicator blinks for 5 sec when the main unit detects an audio format.

To manually verify the current audio format and the corresponding indicators,

refer to O/I Book on

(Audio format indicator).

7

654

1

2

3

Main unit

Active subwoofer

This system (Front)

Standby/on switch ( /I)

G

H

I

J

6.1. Main Unit & Active Subwoofer Key Button Operations

6.1.1. Front View

16

Page 17

6.1.2. Rear View

1 AC IN terminal

2 Speaker terminals

3 OPTICAL DIGITAL AUDIO IN (TV) terminal

4 OPTICAL DIGITAL AUDIO IN (AUX) terminal

5 USB port (for service use only)

6 HDMI IN terminal

7 HDMI OUT terminal (ARC compatible)

8 Active subwoofer on/off button

* The I/D SET button is only used when the main unit is not paired with the active subwoofer.

*

AV OUT

TV(ARC)

AV IN

BD/DVD

AV OUT

TV(ARC)

AV IN

BD/DVD

This system (Rear)

17

Page 18

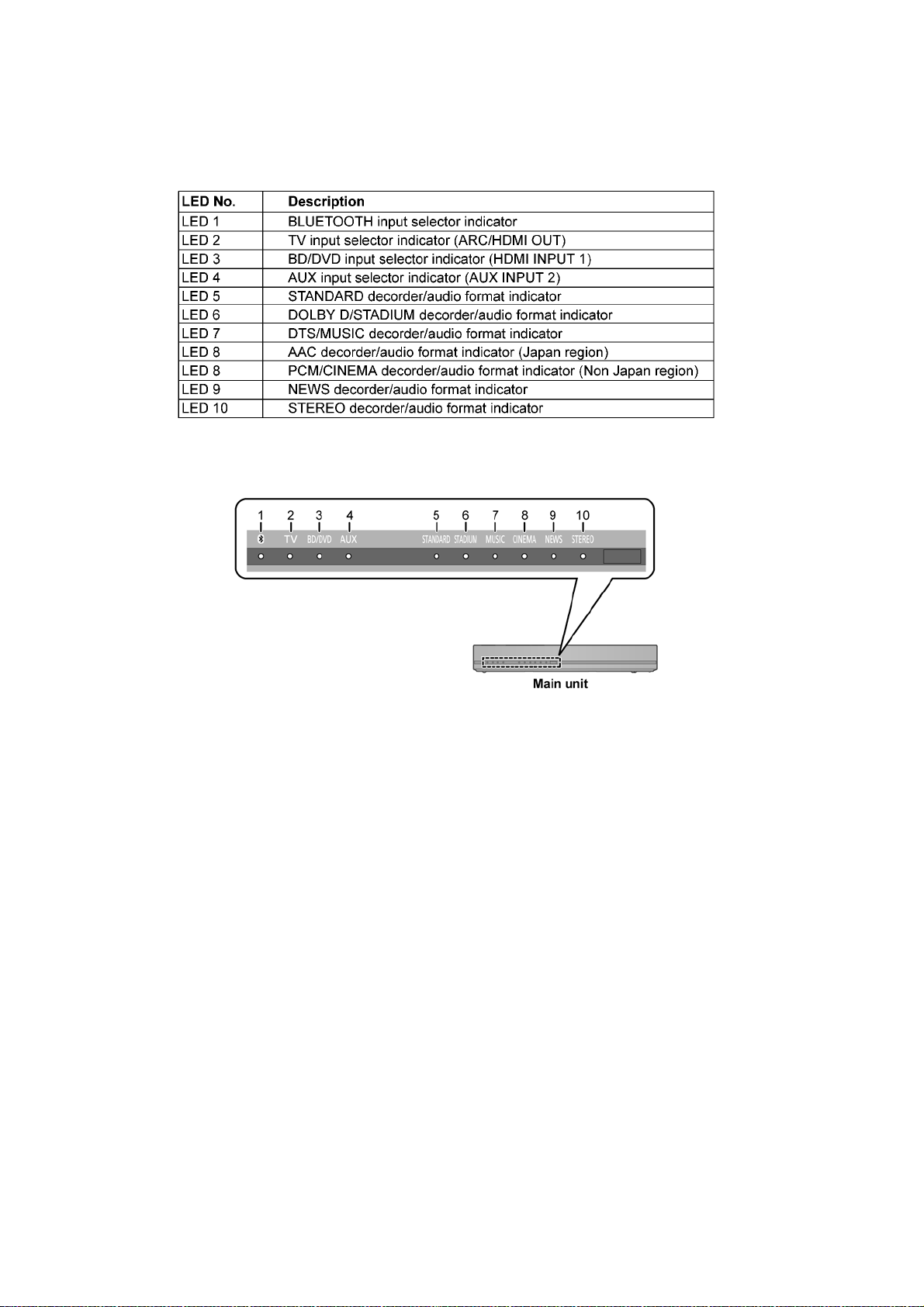

6.2. Indicator illumination

noitpircseDrotacidnI

The indicators display the condition of this system by flashing. The indicator patterns illustrated below

are displayed during normal operational conditions. They do not refer to the indications of a problem.

*1

The indicator for the current status remains lit.

*2

The BD/DVD indicator stops blinking and lights once the wireless pairing is successful.

*3

The indicator blinks only when [SOUND] is pressed for more than 4 sec and the audio format is PCM.

The BD/DVD indicator blinks*2and sound mode

indicators light up in sequence for 1 minute.

When the main unit is in wireless pairing mode with

the active subwoofer

The indicator blinks for 10 sec.

When the Bluetooth®communication is mode 1

The indicator blinks for 20 sec.

When 3D surround effect and clear-mode dialog

effect are on

When the dual audio setting is Main

When the auto gain control is on

When the auto standby function is on

The indicator blink

sfor5sec.

When the audio format is Dolby Digital

The indicator blinks for 5 sec.

When the audio format is DTS

The indicator blinks for 5 sec.

When the audio format is PCM*

3

The indicator blinks for 10 sec.

When the Bluetooth®communication is mode 2

The indicator blinks for 20 sec.

When 3D surround effect and clear-mode dialog

effect are off

When the dual audio setting is Secondary

(SAP: Secondary Audio Program)

When the auto gain control is o

ff

When the auto standby function is off

The indicators blink for 20 sec.

When the dual audio setting is Main and Secondary

The indicators blink for 10 sec.

When the remote control code is changed

The indicators blink once.

When changing the setting (“To reduce the clear-mode

dialog effect”, “To turn off VIERA Link “HDAVI Control””,

and “To turn off the volume limitation”)

The indicators blink twice.

When the main unit is reset

Bluetooth

®

indicator blinks quickly.

When the m

ain unit is ready for pairing

Bluetooth

®

indicator blinks slowly.

When the main unit is waiting to connect

Bluetooth

®

indicator turns on.

When the main unit is connected with a Bluetooth®device

*1

*1

*1

*1

18

Page 19

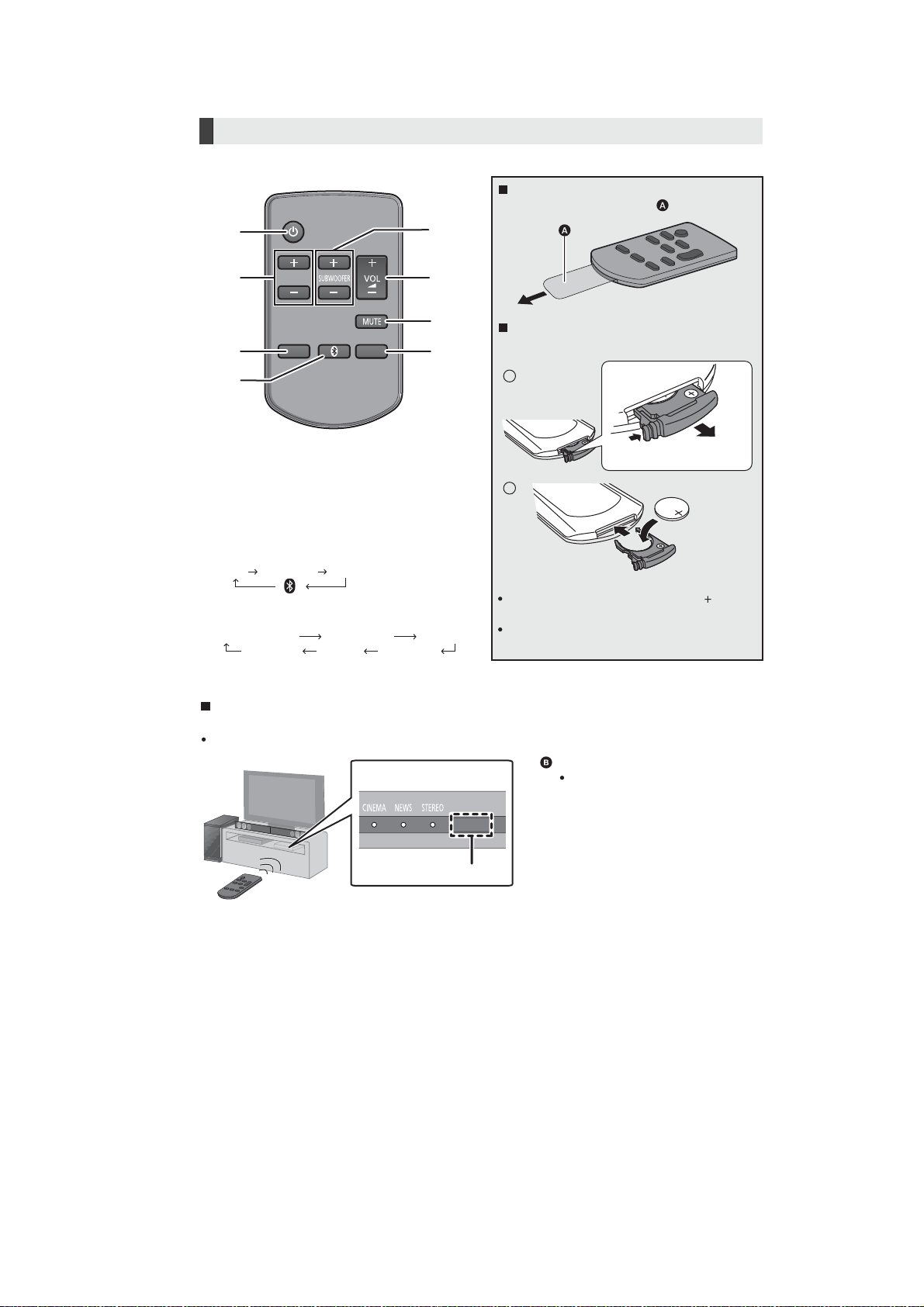

6.3. Remote Control Key Button Operations

“STANDARD” “STADIUM” “MUSIC”

“STEREO” “NEWS” “CINEMA”

1 Turn the main unit on or off

2 Adjust the dialog effect level

3 Adjust the output level of the active

subwoofer (bass sound)

4 Adjust the volume of this system

5 Mute the sound

6 Select the input source

“TV” “BD/DVD” “AUX”

“”

7 Select the Bluetooth

®

device as the source

8 Select the sound mode

Remote control operation range

The remote control signal sensor is located on the main unit.

Use the remote control within the correct operation range.

DIALOG LEVEL

LINK MODE

PAIRING

----

SOUND

1

6

7

2

3

4

5

8

INPUT

SELECTOR

Before using for the first time

Remove the insulation sheet .

To replace a button-type battery

Battery type: CR2025 (Lithium battery)

Set the button-type battery with its ( )mark

facing upward.

Keep the button-type battery out of reach of

children to prevent swallowing.

Remote control signal sensor

Operation range

Distance: Within approx. 7 m

directly in front

Angle: Approx. 30

o

left and right

Remote control

1

2

19

Page 20

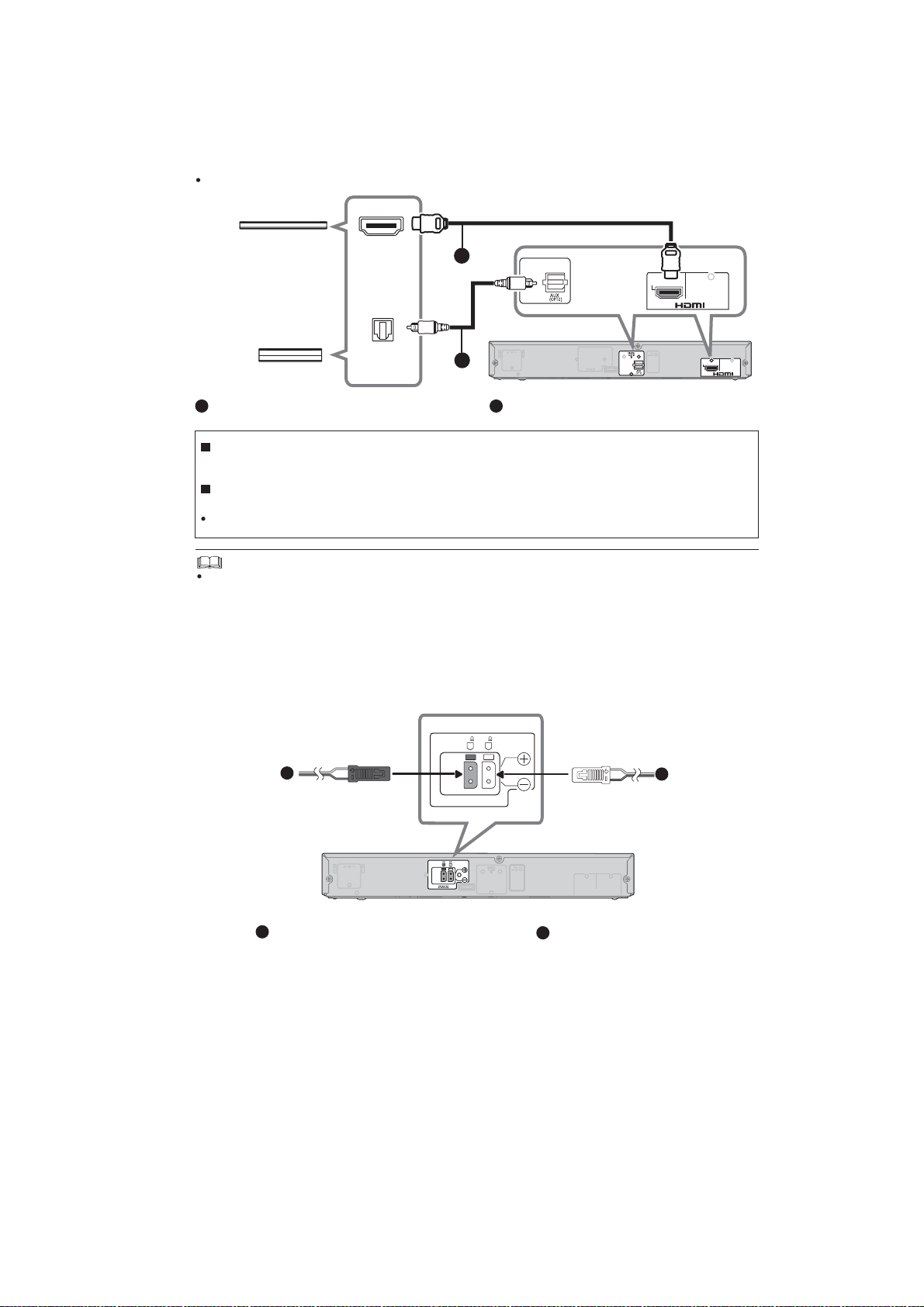

7 Installation Instructions

Turn off all equipment before connection and read the appropriate operating instructions.

Do not connect the AC mains lead until all other connections are completed.

HDMI

The HDMI connection supports VIERA Link “HDAVI Control” when used with a compatible Panasonic TV.

Use the ARC compatible High Speed HDMI cables. Non-HDMI-compliant cables cannot be utilized.

It is recommended that you use Panasonic’s HDMI cable.

B

Verify if the TV’s HDMI terminal is labeled “HDMI (ARC)”.

What is ARC?

ARC is an abbreviation of Audio Return Channel, also known as HDMI ARC. It refers to one of the HDMI functions. When you

connect the main unit to the terminal labeled “HDMI (ARC)” on the TV, the optical digital audio cable that is usually required in

order to listen to sound from a TV is no longer required, and TV pictures and sound can be enjoyed with a single HDMI cable.

Make the connection.

Connection differs depending on the label printed next to the HDMI terminal.

Labeled “HDMI (ARC)”: Connection

Not Labeled “HDMI (ARC)”: Connection

Labeled “HDMI (ARC)”

Not labeled “HDMI (ARC)”

A

Main unit

HDMI cable

A

AV OUT

TV(ARC)

HDMI IN (ARC)

AV OUT

TV(ARC)

Be sure to connect to the

TV’s ARC compatible

terminal. (Refer to the

operating instructions for

the TV.)

TV

A

B

A

HDMI cable

Optical digital audio cable

When you use the optical digital audio cable, insert the tip correctly into the terminal.

AV OUT

TV(ARC)

HDMI IN

OPTICAL

OUT

AV OUT

TV(ARC)

DIGITAL

AUDIO

IN

TV

(OPT1)

TV

B

A

7.1. Connections

7.1.1. Connection with the TV

20

Page 21

7.1.2. Connection with other devices

A B

You can direct the audio signal from the connected Blu-ray Disc player, DVD player, Set Top Box, etc. to

this system.

Preparation

Connect the main unit to the TV.

HDMI cable Optical digital audio cable

Refer to the operating instructions of the connected HDMI compatible device for the necessary setting, to output the video

and audio signals.

HDMI OUT

OPTICAL

OUT

AV IN

BD/DVD

AV IN

BD/DVD

DIGITAL

AUDIO

IN

e.g., Set top box

e.g., Blu-ray Disc player

HDMI standby pass-through

Even if the main unit is in standby mode, the audio and/or video signal from the device connected to the HDMI IN terminal will

be sent to the TV connected to the HDMI OUT terminal (the sound will not be output from this system).

3D compatibility

Compatible with FULL HD 3D TV and Blu-ray Disc player.

The main unit can pass-through the 3D video signal from a 3D compatible Blu-ray Disc player to a FULL HD 3D TV.

A

B

Main unit

Match the connector shape and connect to the terminals of the same colour.

A RED

Right speaker connector

B WHITE

Left speaker connector

A

B

A

B

7.1.3. Speaker cable connection

6 6

R

L

SPEAKERS

AV IN

AV OUT

TV(ARC)

BD/DVD

21

Page 22

7.1.4. AC mains lead connection

Active subwoofer

Connect only after all other connections are completed.

This system consumes a small amount of AC power even when it is turned off. In the interest

of power conservation, if you will not be using this system for a long time, unplug it from the household

mains socket.

To a household mains socket AC mains lead (supplied)

BE SU RE TO R EA D T HE CAUTION FOR T HE AC MAINS LEAD ON OI BOOK BEFOR E

CONNECTION.

Saving energy

The main unit is designed to conserve its power consumption and save energy.

The main unit will automatically switch to standby mode when no signal is input and no operation is

performed for approx. 2 hours. Refer to OI Book, “Auto standby function” to turn this function off.

AV OUT

TV(ARC)

AV IN

BD/DVD

D

C

C

DC

For customers in United Kingdom and Ireland

22

Page 23

8 Service Mode

This unit is equipped with features of self-d iagn ostic & spec ial mode setting for checking the functions & reliability of the

unit.

Special Note : Checking of the reliability (ageing) & operation must be carry out to ensure good working condition in unit.

8.1. Method to enter into Service Mode

Here are the procedures to enter into service mode:

Step 1 : Power up the unit.

Step 2 : Press & hold [VOL-] on the unit, follow by [SUB-] & [SUB+] on the remote control.

Note : All LEDs will blink 4 times followed b y all LEDs off.

Step 3 : It enters into service mode.

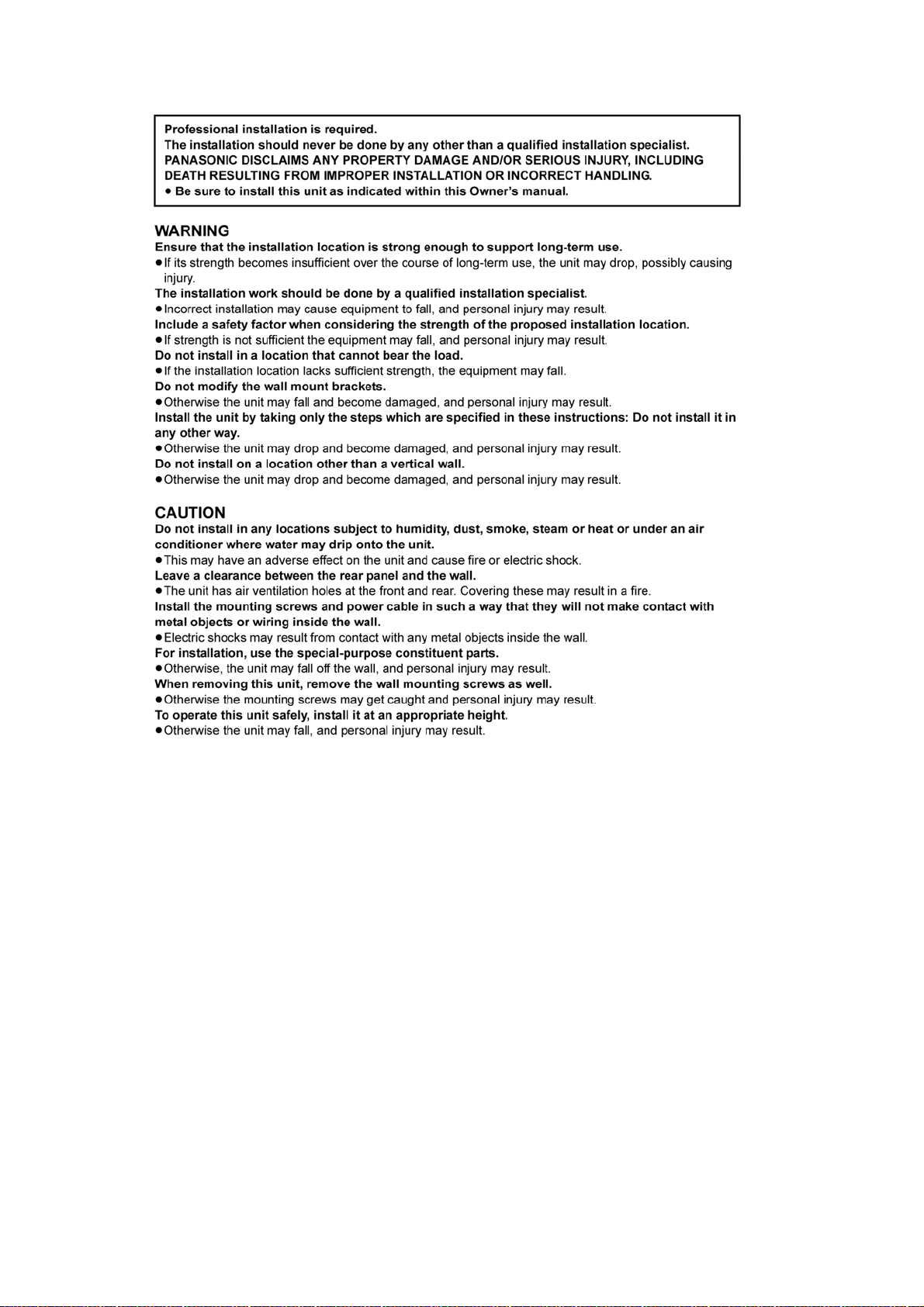

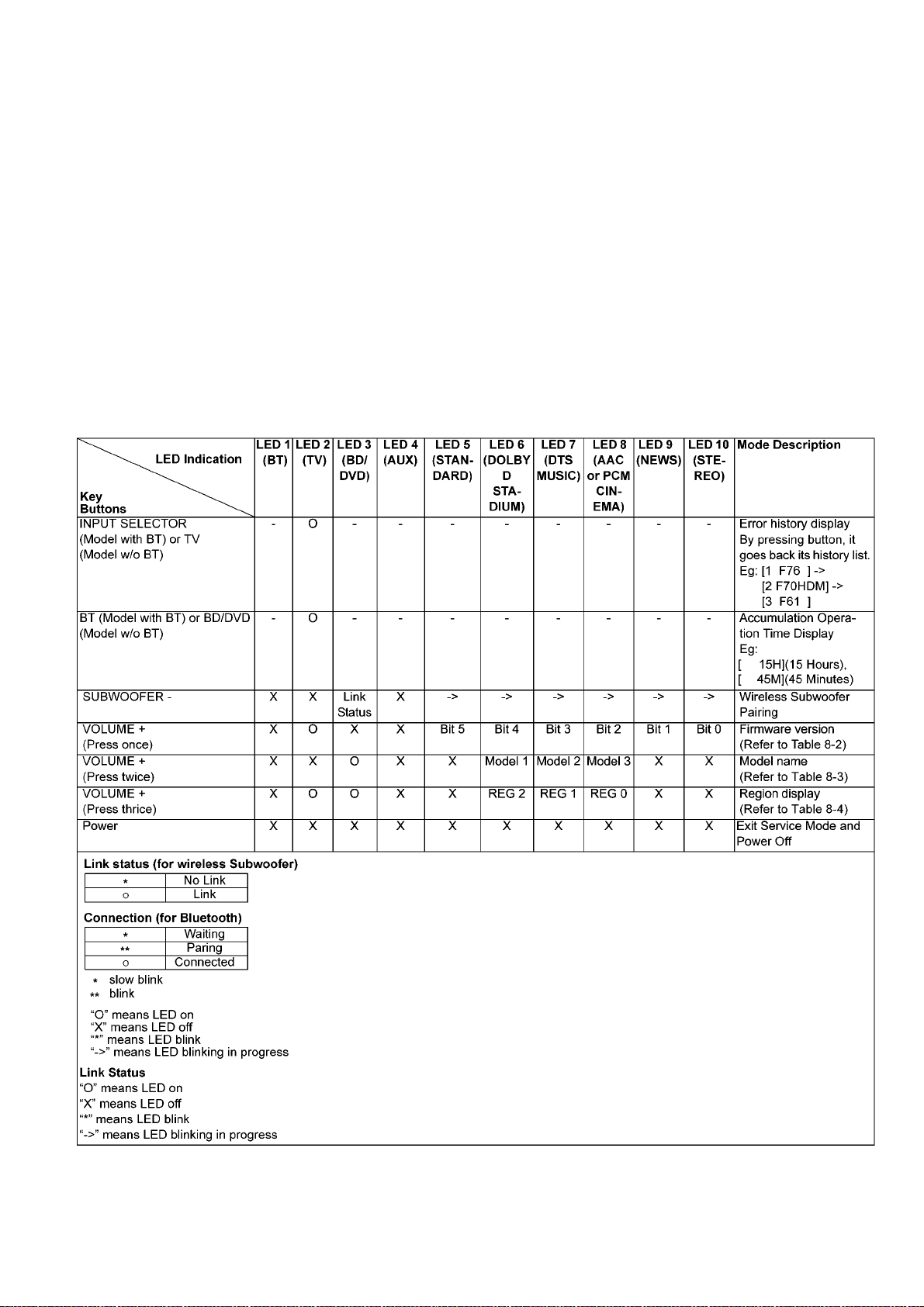

8.2. Model Display Details by LED Blinking Indicators

After entering into service mode, the following keys on the remote control can be pressed to determine:-

1. Microprocessor firmware version number

2. Model No.

3. Region setting

4. Wireless pairing

Note : The LED blinking process will stop when the unit is power off completely.

Table 8-1

23

Page 24

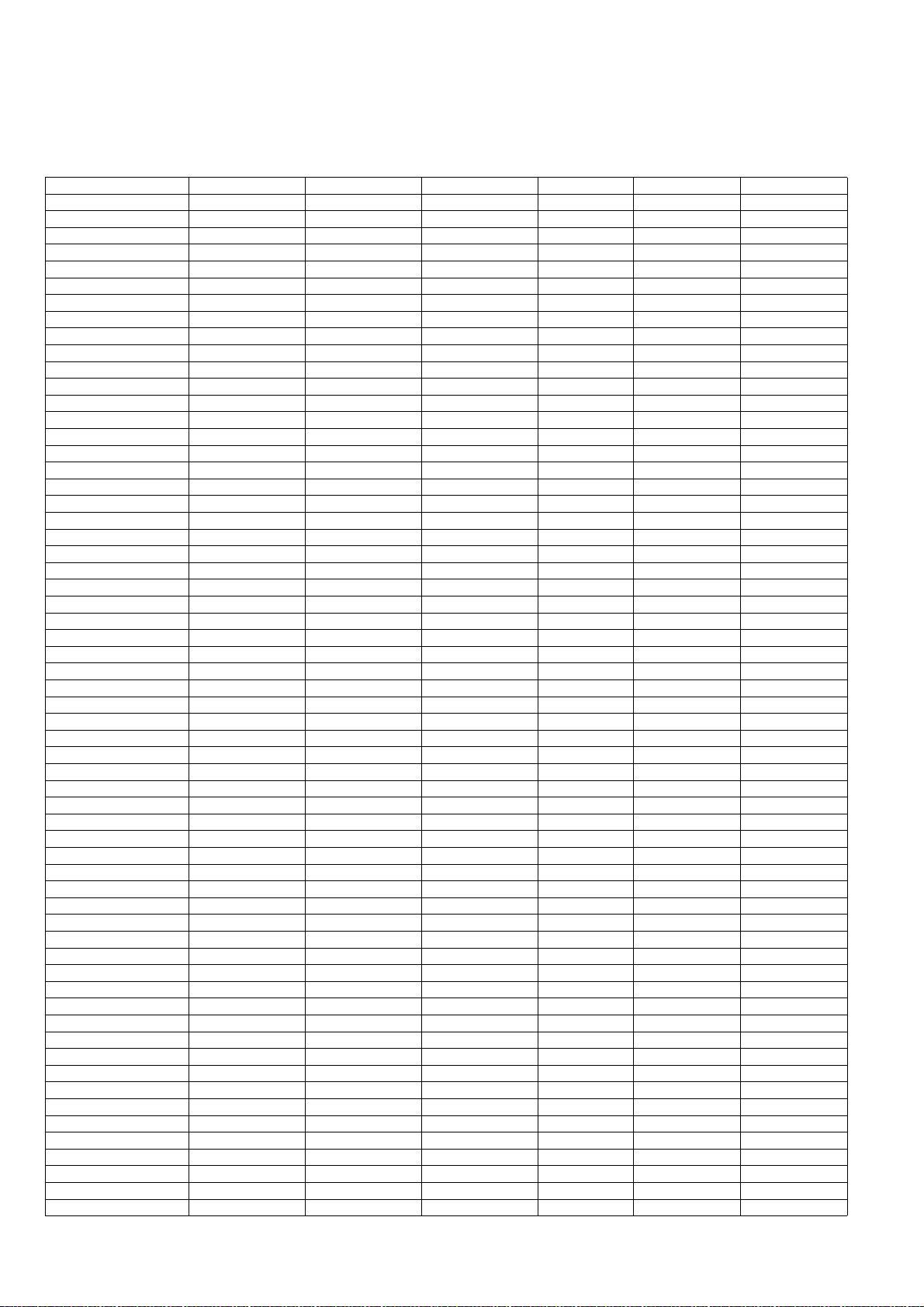

8.2.1. Firmware version

It is to indicate the firmware version no. (Refer to table 8-2 for more information).

The firmware version is represented by 5 bits.

Version number display are repeated every 64 releases.

Version No Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

01, 65 … X X X X X O

02, 66 … X X X X O X

03, 67 … X X X X O O

04, 68 … X X X O X X

05, 69 … X X X O X O

06, 70 … X X X O O X

07, 71 … X X X O O O

08, 72 … X X O X X X

09, 73 … X X O X X O

10, 74 … X X O X O X

11, 75 … X X O X O O

12, 76 … X X O O X X

13, 77 … X X O O X O

14, 78 … X X O O O X

15, 79 … X X O O O O

16, 80 ... X O X X X X

17, 81 … X O X X X O

18, 82 … X O X X O X

19, 83 … X O X X O O

20, 84 … X O X O X X

21, 85 … X O X O X O

22, 86 … X O X O O X

23, 87 … X O X O O O

24, 88 … X O O X X X

25, 89 … X O O X X O

26, 90 … X O O X O X

27, 91 … X O O X O O

28, 92 … X O O O X X

29, 93 … X O O O X O

30, 94 … X O O O O X

31, 95 … X O O O O O

32, 96 ... O X X X X X

33, 97 … O X X X X O

34, 98 … O X X X O X

35, 99 … O X X X O O

36, 100 … O X X O X X

37, 101 … O X X O X O

38, 102 … O X X O O X

39, 103 … O X X O O O

40, 104 … O X O X X X

41, 105 … O X O X X O

42, 106 … O X O X O X

43, 107 … O X O X O O

44, 108 … O X O O X X

45, 109 … O X O O X O

46, 110 … O X O O O X

47, 111 … O X O O O O

48, 112 ... O O X X X X

49, 113 … O O X X X O

50, 114 … O O X X O X

51, 115 … O O X X O O

52, 116 … O O X O X X

53, 117 … O O X O X O

54, 118 … O O X O O X

55, 119 … O O X O O O

56, 120 … O O O X X X

57, 121 … O O O X X O

58, 122 … O O O X O X

59, 123 … O O O X O O

60, 124 … O O O O X X

61, 125 … O O O O X O

24

Page 25

Version No Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

62, 126 … O O O O O X

63, 127 … O O O O O O

Link Status

“O” means LED on

“X” means LED off

Table 8-2

8.2.2. Model Number Display

It is to indicate the model number. (Refer to table 8-3 for more information).

Model 1 Model 2 Model 3 Model No.

X O O HTB770

O X X HTB570

O X O HTB370

O O X Reserve 1

OOOReserve 2

Link Status

“O” means LED on

“X” means LED off

Table 8-3

8.2.3. Region Bit No.

It is to indicate the region for the model number. (Refer to table 8-4 for more information).

REG2 REG1 REG0 Region

X X X Europe / Ocenia / Asia / South /

X O X US / Canada

X O O China

O X X Japan

O X O Reserve 1

O O X Reserve 2

OOOReserve 3

Link Status

“O” means LED on

“X” means LED off

Centr. America / China / Russia

Table 8-4

25

Page 26

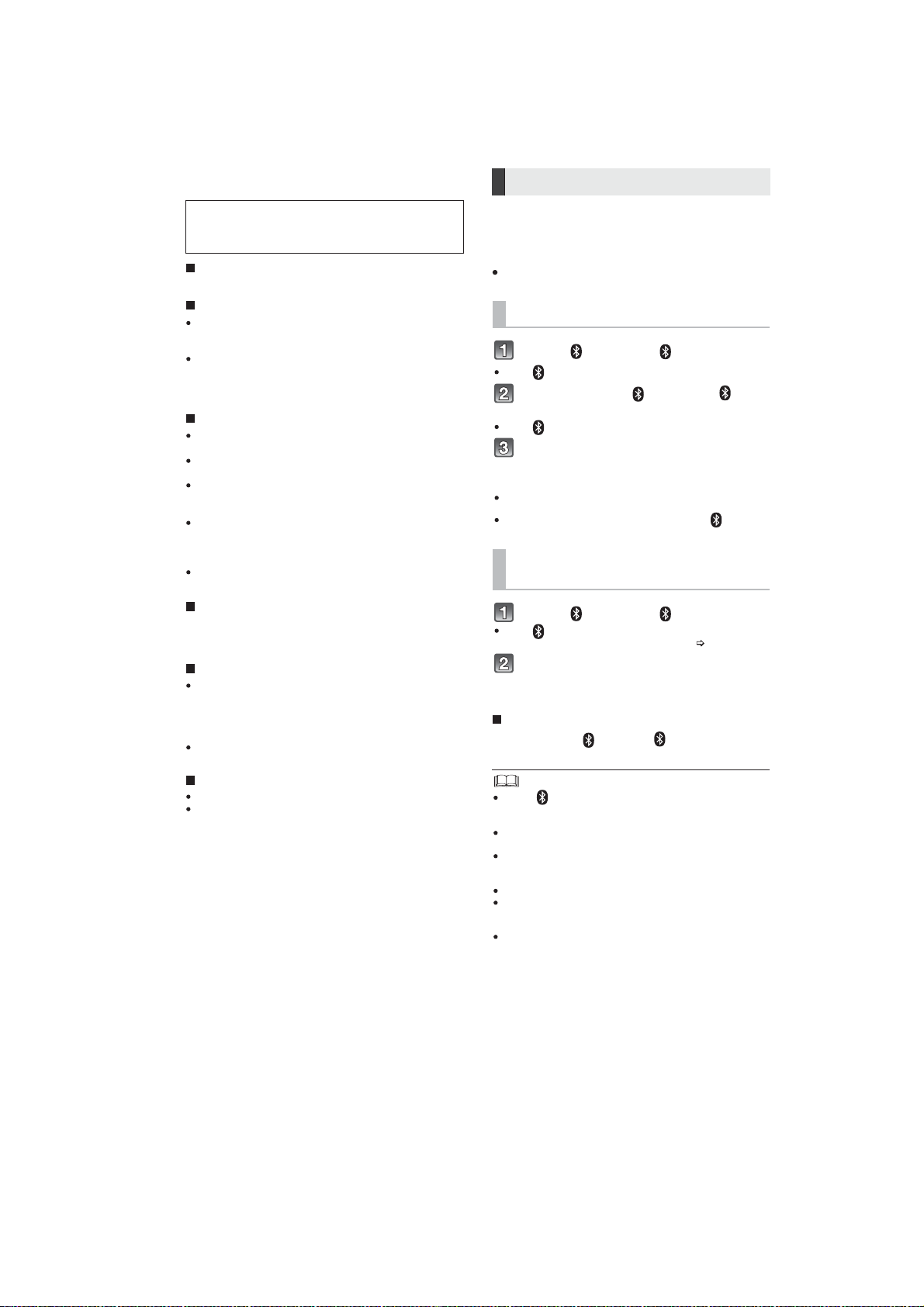

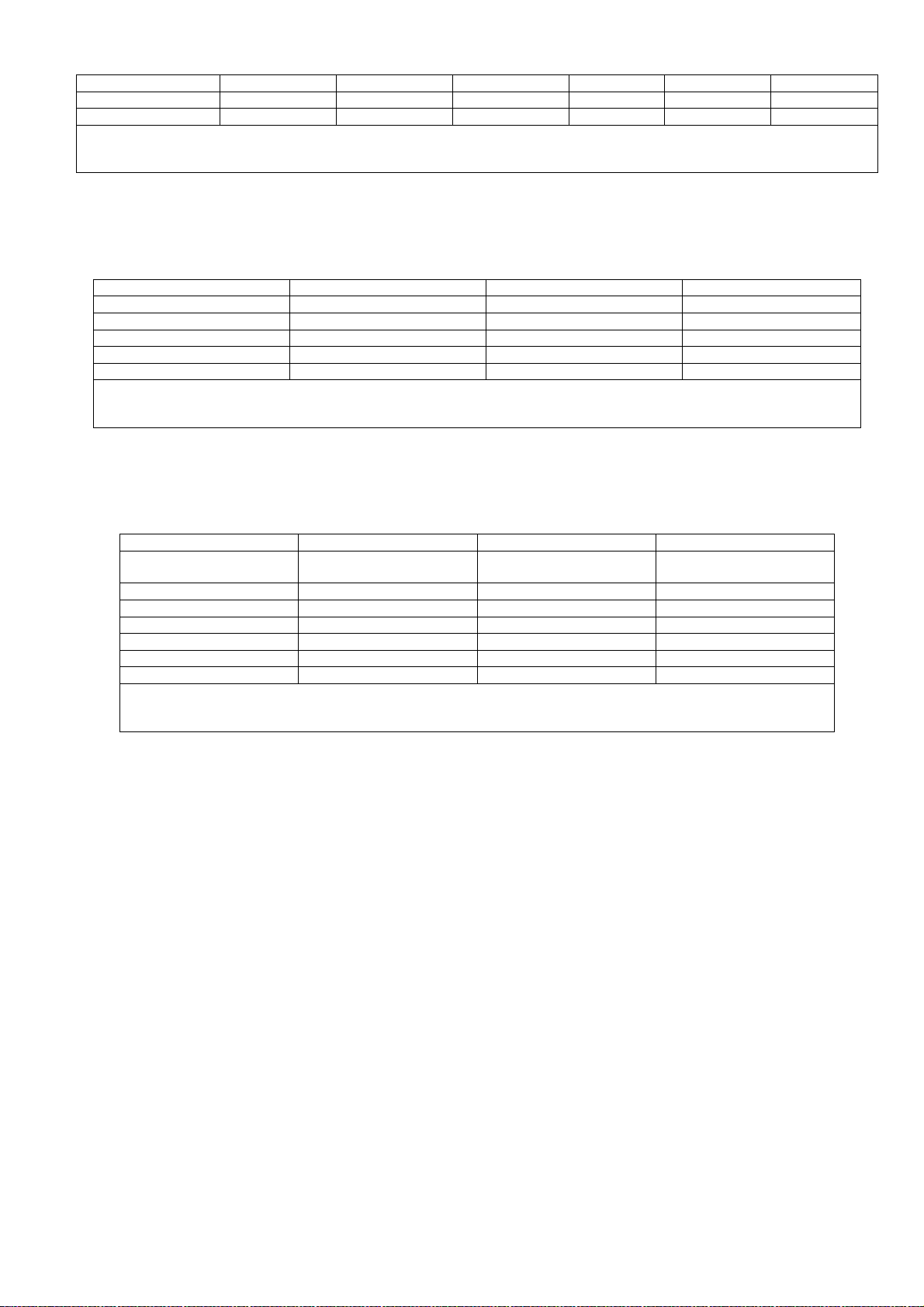

8.3. Error Codes Display

This unit does not have a FL/LCD display unit hence error code (w hen a fault condition occurs) is represented by the LED status

indicators. Refer to Figure 8-1

Here is the description of the LED status indicators:

Table 8-5

Figure 8-1

26

Page 27

8.3.1. Error Code Display Details by LED Blinking Indicators

This section describes the LED status indicators by its blinking to represent th e error codes.

Caution: The LED blinking process will stop only when the unit is power off completely .

Error Code LED 1

OVERLOAD (F61)

If this error occurs, main set

will automatically power off.

F76

If this error occurs, main set

will automatically power off.

F70 HDMI

F70 BT

U701 / U703 / U704

USB Update Fail

USB Overcurrent

“X” means LED off.

“*” means LED blink

(BT)

X**XXX X X XX

X*XXXX X X XX

X**XX* * * XX

***XXXX XXX

XX*XXX X X XX

XXXXXX X X X*

***X** * * **

LED 2

(TV)

LED 3

(BD/

DVD)

LED 4

(AUX)

LED 5

(STA

NDAR

D)

LED 6

(MUSIC/

(STADIUM/

DOLB

Y D)

Table 8-6

LED 7

DTS)

LED 8

(CIN-

EMA/

AAC or

PCM)

LED 9

(NEW

S)

LED 10

(STEREO)

Cause and Problem

Speaker protection, DAMP IC

abnormality. Check for faulty

parts and replace with new parts

if necessary.

DC Power/Voltage Supply abnormality. Check for faulty parts and

replace with new parts if necessary.

HDMI Micro-P to Main Micro-P IC

communication error. Check for

faulty parts and replace with new

parts if necessary.

Bluetooth communication error.

Check for faulty parts and replace

with new parts if necessary.

• Connected devices error

(HDCP non-compliance).

Check for faulty parts and

replace with new parts if necessary.

• HDMI connection abnormality

(cable damage, HDCP noncompliance etc). Check for

faulty parts and replace with

new parts if necessary.

• HDMI image format incompatibility. Check for faulty part s and

replace with new parts if necessary.

USB communication error. Check

for faulty parts and replace with

new parts if necessary.

USB communication error. Check

for faulty parts and replace with

new parts if necessary.

27

Page 28

8.4. Cold start (For SU-HTB570)

Step 1 : Power up the unit.

Step 2 : Press & hold [POWER] button on the unit for 4s or more.

All LED will light-up and blink for 2 times (at frequency of 4Hz)

Figure 8-2

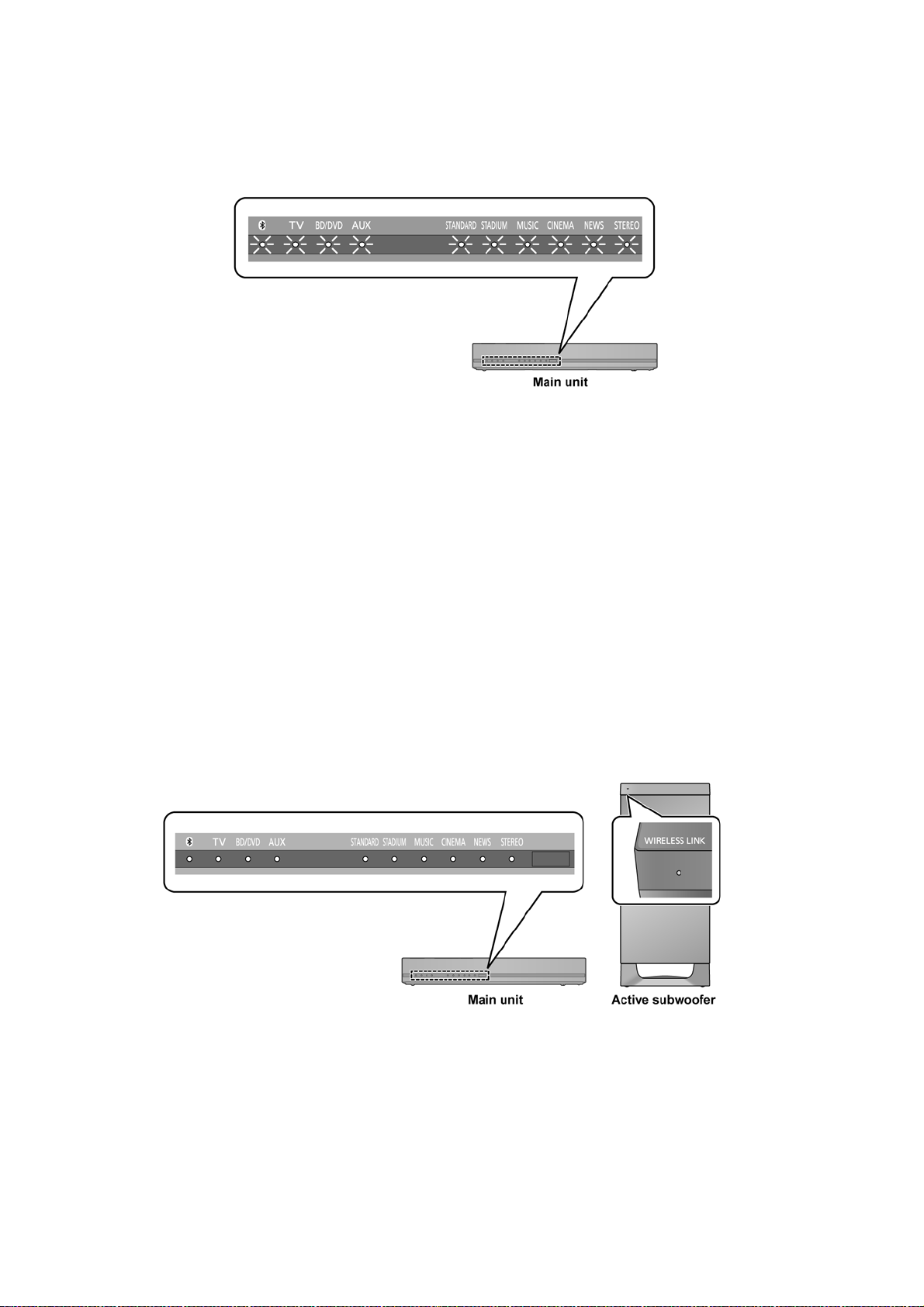

8.5. Pairing mode between Main Unit (SU) with Active Subwoofer (SB-HWA)

Here are the procedures to do pairing between Main Unit (SU-HTB570) with Active Subwoofer (SB-HWA570)

Step 1 : Power up the Main Unit & Active Subwoofer.

Note : Please check the connections in Main Unit and Active Subwoofer when either fails to power up.

(WIRELESS LINK indicator on Active Subwoofer should turn RED if it is not linked)

Step 2 : Press [ID SET] on the rear of Active Subwoofer for more that 3 sec. (The WIRELESS LINK indicator will blink in red)

WIRELESS LINK indicator on Active Subwoofer shall blinking for up to 1 minutes to indicate it is in ready for pairing mode.

Step 3 : During WIRELESS LINK indicator on Active Subwoofer blinking, press [INPUT SELECTOR] or [AUX] on remote control followed by [VOL +] on Main Unit for more than 4 sec. (Pairing begins)

This step also can be carried out under Service Mode by press [SUB-] on remote control. (Pairing begins)

Note :

1. Under Pairing Mode, [BD/DVD] LED blinking and 6 indicators LEDs (STANDARD, STADIUM(Dolby D), MUSIC(DTS),

CINEMA(AAC/PCM), NEWS and STEREO) will run one by one (shifting) for every 1 sec from left to right to indicate it

is searching for the receiver to be linked and repeated the cycle after reached the [STEREO] LED.

2. When pairing is completed. [BD/DVD] LED on Main Unit will light up and WIRELESS LINK indicator on Active Sub-

woofer turns GREEN if pairing is successful.

3. Wireless pairing automatically exit after 1 minute.

Figure 8-3

8.6. SET AUDIO DELAY

If the video from TV late compared to audio output from this unit, this unit can be set the audio delay to 150ms fixed delay.

Step 1 : Power up the main unit.

Step 2 : Press & hold [VOL-] button on main unit and follow by [VOL-] and [SUB-] on remote control.

All LED will light-up and blink once for confirmation display and audio delay setting is set to 150ms.

28

Page 29

9 Troubleshooting Guide

䞉How to reset䚷䠄Factory setup condition䠅

䠍䠊Turn on the power of main set.

䠎䠊Press and hold the power button for 5 seconds.

(Repeat the flashing of all LED twice)

3䠊Turn off the power.

䞉The entering method of Service Mode䚷(after turn off the power, you can exit from Service Mode)

䠍䠊 Setting main set in power on status.

䠎䠊 Press the main set [Volume-] button, then continue press the [SUB -] & [SUB +] of remote control.

(All LEDs will blink four times, followed by all LEDs OFF)

SC-HTB570

Main set power ON Power do not turn on Power on by remote control ・OK

Power on by remote control ・NG

Check the connection of FFC connector

FFC wire checking

Switch operation checking

LED display checking

(The input display LED not lit)

Power input but turn off immediately

・Check the 13P of [Panel]-[Main] & 26P of [HDMI]-[Main] & 10P of [Switching power module]-[Main] & each FFC connector.

・Check the 13P of [Panel]-[Main] & 26P of [HDMI]-[Main] & 10P of [Switching power module]-[Main] & each FFC wire.

・7KHERWKHQGYROWDJHRI>3DQHO@SRZHUVZLWFK6LVSUHVVĺ09UHOHDVHĺ9

Check the connection of FFC connector ・wire

Checking the system 5V circuit

Checking the AC inlet code

Checking fuse cut

・&KHFN>3DQHO@&1ĺ9&1ĺ9))&FRQQHFWRURI3FRQQHFWLRQ

・[Switching power module] CN1(5)ĺ9WR9、[Main] IC2202(ĺ9WR9

・Check [Switching power module]-[ACinlet] wire & patterns,solder.

・Check the continuity of [Switching power module] F1.

・Check the IC overcurrent ・overheating ・failure of [Digital Amplifier] ĺ [Digital Amplifier] exchange.

Fuse cut

LED display checking

After replacement, cut again at

outlet connection

The primary side of main power

supply abnormal

Check the continuity of primary side power circuit ・Short-open power transformer, electrolytic diode IC · [switching power module]..

・(D5701,C5712,IC5701,T5701).

After replacement, cut again at

power onon

The secondary side of main power

supply abnormal

Check the continuity of secondary side power circuit ・Short-open power-electrolytic IC diode [switching power module].

・'&,&

Check the display by Service Mode Some not lighting ・not light off Failure of drive IC ・Failur of not lights up LED ・>3DQHO@,&/(':21ĺ92))ĺ9

All not lighting Check drive IC ・serial signal ・FFC ・>3DQHO@,&ĺ9、D6001(Anode)ĺ9

・Check [Panel] IC6001(2,3,4)serial signal.

Video / Audio

confirmation

HDMI

No video and audio

(Power ON / Standby Pass Through)

1) External Connection checking

i) Check whether HDMI Input and

Output is reversed.

ii) Check whether HDMI cable properly inserted.

Check Cable connection

Check Cable connection

Error contents F61

Error contents F76 Television LED flashing, power off

・&KHFNWKHHDFKSRZHU)$1'$0399

Television & external 1 LED flashing, power off

Power input but LED error display

・[Main] DSP & communication error of the microcomputer ĺ [Main] board exchange.

・[Main], IC of [Digital Amplifier] DAMP & communication error of the microcomputer ĺ [Digital Amplifier] baord exchange.

・[Main] IC of HDMI & communication error of the microcomputer ĺ [Main] board.

Error contents U701/703/704

Error contents F70 DSP

Error contents F70 DAP

Error contents F70 HDMI

Television & external 1, dolby LED flashing

Television & external 1, dolby, DTS LED flashing

Television & external 1, dolby, DTS , AAC

LED flashing

・Try once to "On / Off" the power of the connected device. Try to connect or disconnect the HDMI cable.

External 1 LED only repeat flashing

Cable not reverse

Cable inserted properly

2) HDMI Supply Voltage checking

i) Check whether +3.3V is present

LL&KHFNZKHWKHU9LVSUHVHQW

Check IC1100 (Pin 1) , IC1200 (Pin 5)

Check IC1101 (Pin 1) , IC1200 (Pin 5)

+3.3V Supply is present

96XSSO\LVSUHVHQW

3) HDMI Output Voltage Checking

i) +5V supply to TV : HDMI_OUT_+5V &KHFN783LQ/%,&3LQ

+5V Supply is present

4) Hot Plug Voltage checking

i) Hot Plug voltage from TV &KHFN783LQ,&3LQ

+5V Supply is present

5) Parts availability and solderbility condition

i) HDMI Tx/Rx LSI

ii) TMDS output swing amplitude control resistor

iii) HDMI Output Connector

iv) HDMI Output Common-Mode Choke

v) HDMI Output +5V Regulator

vi) HDMI Input Connector

vii) HDMI Input Common-Mode Choke

viii) HDMI Input +5V detect

Check IC1000

Check R1001

Check TU1200

Check L1200, L1201

Check IC1200

Check TU1300, TU1325, TU1350

Check Input A : L1300, L1301

Check Input B : L1325, L1326

Check Input C : L1350, L1351

Check D1104, D1105, D1106

All pins fully soldered. No Short.

No missing and all pins fully soldered. No Short.

All pins fully soldered. No Short.

No missing and all pins fully soldered. No Short. There is connections between IC1000 and TU1200

No missing and all pins fully soldered. No Short.

No missing and all pins fully soldered. No Short.

No missing and all pins fully soldered. No Short.

No missing and all pins fully soldered. No Short.

6) HDMI Connections Checking

i) HDMI Output TMDS and DDC signal lines

ii) HDMI Input TMDS and DDC signal lines

Check Pattern between IC1000 and TU1200

Check Pattern between IC1000 and TU1300 or

TU1325 or TU1350

There is connection from IC1000 pin to TU1200 pin

There is connection from IC1000 pin to TU1300 or TU1325 or TU1350 pin

7) HDMI Communication line checking

i) HDMI I2C control line from Main Micon

&KHFN&13LQ,&3LQ There is signal present

29

Page 30

Bluetooth (BT)

Module

SubWoofer RF

Receiver Module

SB-HWA

Video / Audio

confirmation

HDMI

No audio from Main set speaker

(Video is present)

(Power ON Mode only)

1) HDMI audio line checking

i) For 2ch Source : Check HDMI_SPDIF line

For Multi-ch Source : Check HDMI I2S lines

ii) Check HDMI LRCK and SCLK line

Check CN1000 (Pin 17)

Check CN1000 (Pin 19, 20, 21, 22)

Check CN1000 (Pin 24, 25)

There is SPDIF signal present (Duty Cycle > 50%)

There is signal present when playing

There is signal present when playing

Audio confirmation

Sound skip from front speaker

(Bluetooth input)

Check the radio wave interference of other wireless

equipment (cordless phone, microwave oven,

WiFi, other BT devices).

Place subwoofer & other wireless equipment more than 2 meters away from main unit

No sound from front speaker

(Bluetooth input)

Check the connection to front speaker Check Main board (Micon/DSP & Digital Amplifier Circuit)--> Main board change

3) Parts availability and solderbility condition

i) HDMI Output +5V Regulator

ii) HDMI Output Connector

iii) HDMI Output Common-Mode Choke

iv) TMDS Output swing amplitude control resistor

Check IC1200

Check TU1200

Check L1200, L1201

Check R1001

No missing and all pins fully soldered. No Short.

All pins fully soldered. No Short.

No missing and all pins fully soldered. No Short. There is connections between IC1000 and TU1200

No missing and all pins fully soldered. No Short.

2) Parts solderbility condition

i) HDMI SPDIF line

ii) HDMI I2S lines

iii) HDMI LRCK and SCLK line

Check R1406

Check FL/FR : R1405

Check C/LFE : R1404

Check SL/SR : R1403

Check SBL/SBR : R1402

Check R1400, R1401

3) HDMI Audio Lines Connection Checking

i) HDMI SPDIF, I2S, LRCK and SCLK lines

Check Pattern between IC1000 and CN1000 There is connection from IC1000 pin to CN1000 pin

4) HDMI audio setting checking

i) Check TV Viera Link Menu Speaker selection

setting is set to "Home Theater"

Speaker Selection is set to "Home Theater"

Video / Audio

confirmation

HDMI

Video / Audio

confirmation

HDMI

No audio form TV

(Video is present)

(Power ON / Standby Pass Through)

1) HDMI audio setting checking

i) Check TV Speaker selection setting

ii) Check Player Audio output is set to "ON"

Check TV Menu (Viera Menu Link foir Panasonic TV)

Check Player Setup Menu

Speaker Selection is set to "TV"

HDMI Audio Output setting is set to "ON"

No video and audio from TV

(Audio present from set speakers)

1) HDMI Output Voltage Checking

i) +5V supply to TV : HDMI_OUT_+5V

BT LED blinks quickly then becomes steady

(PAIRING OK)

Subwoofer(SB-HWA)sound skip

Check the radio wave interference of other

wireless equipment(2.4GHz band)

Place subwoofer & other wireless equipment more than 2 meters away from main unit

Failure of Digital Amplifier Circuit of the subwoofer.

Front speaker voice normal

Check BT module connection to main board Check Main board CN2003(1) and IC2203(1)-->3.3V;

Check L2003 or R2044,R2045

Check LB2014 and LB2015

Check USB Switch circuit --> IC2003(10)-->+5V

If all above are OK, replace BT module

BT LED does not blink quickly/no change

(PAIRING FAILED)

Unable to view HTB in list of BT devices in

external BT device

Check TU1200 (Pin 18) , LB1203, IC1200 (Pin4) +5V Supply is present

2) Hot Plug Voltage checking

i) Hot Plug voltage from TV

Check TU1200 (Pin 19) , IC1000 (Pin 41)

Check the OPT terminal ・OPT cable &KHFNWKH>0DLQ'LJLWDO$PSOLILHU@-.-.ĺ9、output (3) SPDIF waveform.

+5V Supply is present

Audio confirmation

No audio output (OPT input 2 systems)

HDMI input (1 system) voice appear

The failure of Input ・DSP systems, DAMP systems Check the [HDMI]-[Main Digital Amplifier] 26P FFC・connector

No audio output (HDMI input 1 systems)

OPT (2 system) voice appear

Check the ARC circuit failure・HDMI cable Check the [HDMI]-[Main Digital Amplifier] 26P FFC・connector

No audio output (HDMI/ARC support)

OPT (2 system) voice appear

Check AUX circuit and PCB Check the [AUX]- [Main Digital Amplifier] 4P wire conector

No audio ouput at AUX input

OPT (2 system) voice appear

The failure of PWM driver from IC2000, FET

Amplifier Q5303, Q5304, Q5403 and Q5404

Check PWM out at pin3 of Q5303 and Q5304 for front left channel

Check PWM out at pin3 of Q5403 and Q5404 for front right channel

No sound from front speaker

Subwoofer voice normal

Subwoofer(SB-HWA)no sound

Check the main unit & subwoofer wireless

connection (2-wire cable assembly)

Front speaker voice normal

Wireless link light checking

(SB-HWA upper left front)

Check the connection from Digital Amplifier board

to SW speaker

Wireless Link LED lights GREEN

Power cycle the main unit and subwoofer.

Redo pairing (refer to OI)

Failure of Transmitter board on Main Unit or Receiver board on Subwoofer

Check the wireless link

Check the pairing status

Wireless Link LED lights RED

HTB570

HTB570

HTB370

HTB570/HTB370

30

Page 31

10 Service Fixture & Tools

Prepare service tools before process service position.

Ref. No. Part No. Description Remarks

SFT1 REXX1194 2P WIRE (SPK-SW DAMP) SB-HWA570

31

Page 32

11 Disassembly and Assembly Instructions

Caution Note:

• This section describes the disassembly and/or assembly procedures for all major printed circuit boards & main components for the unit. (You may refer to the section of “Main components and P.C.B Locations” as described in this service

manual)

• Before carrying out the disassembly process, please ensure all the safety precautions & procedures are followed.

• During the disassembly and/or assembl y process, please handle with car e as there may be chassis components with

sharp edges.

• Avoid touching heatsinks due to its high temperature after prolong use. (See caution as described below)

• During disassembly and assembly, please ensure proper service tools, equipments or jigs is being used.

• During replacement of component parts, please refer to the section of “Replacement Parts List” as described in the service manual.

• Select items from the following indexes when disassembly or replacement are required.

Disassembly of Main Unit (SU-HTB570)

• Disassembly of Top Cabinet

• Disassembly of SMPS and AC Inlet P.C.B.

• Replacement of Switching Regulator IC (IC5701)

• Replacement of Rectifier Diode (D5802)

• Disassembly of Main P.C.B.

• Disassembly of HDMI P.C.B.

• Disassembly of Rear Panel

• Disassembly of Front Panel Block

• Disassembly of Bluetooth Module P.C.B.

• Disassembly of Panel P.C.B.

• Disassembly of Digital Transmitter Module P.C.B.

Disassembly of Front Speaker Units Position

• Disassembly of Front Speaker Units in Bar position

• Disassembly of Front Speaker Unit in Standing position

Disassembly of Front Speaker (L/R) (SB-HTB570)

• Disassembly of Rear Cabinet Assembly

• Disassembly of Tweeter Speaker (SP1)

• Disassembly of Woofer Speaker (SP2)

• Replacement of the Speaker Wire Assembly

Disassembly of Active Subwoofer (SB-HWA570)

• Disassembly of Rear Panel Block

• Disassembly of Digital Receiver Module P.C.B.

• Disassembly of SW DAMP P.C.B.

• Replacement of Digital Amplifier IC (IC5200)

• Disassembly of Power Button P.C.B.

• Disassembly of SW SMPS and SW AC Inlet P.C.B.

• Replacement of Switching Regulator IC (IC5701)

• Replacement of Rectifier Diode (D5802)

• Disassembly of Bottom Panel Assembly

• Disassembly of Woofer Speaker (SP61)

32

Page 33

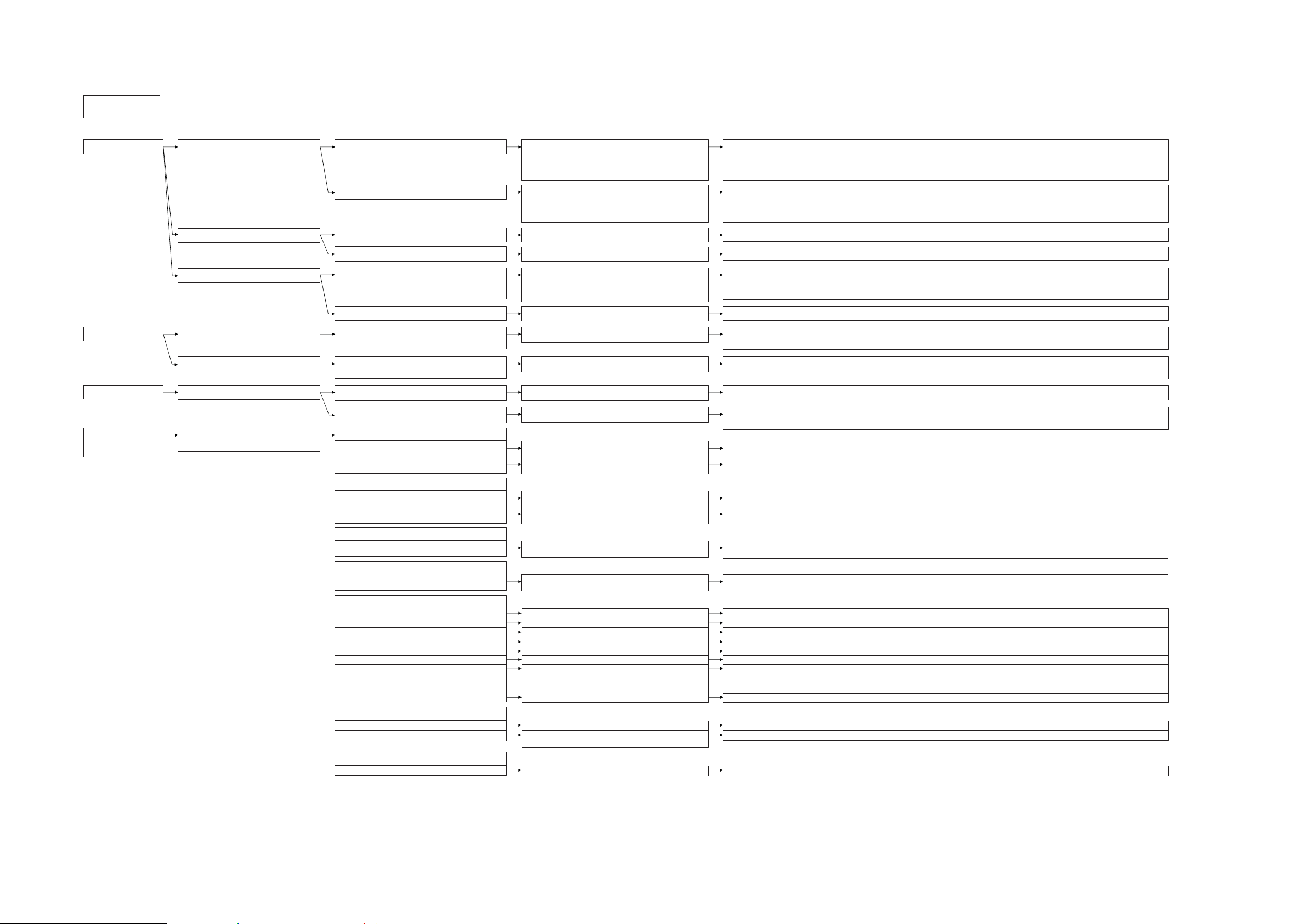

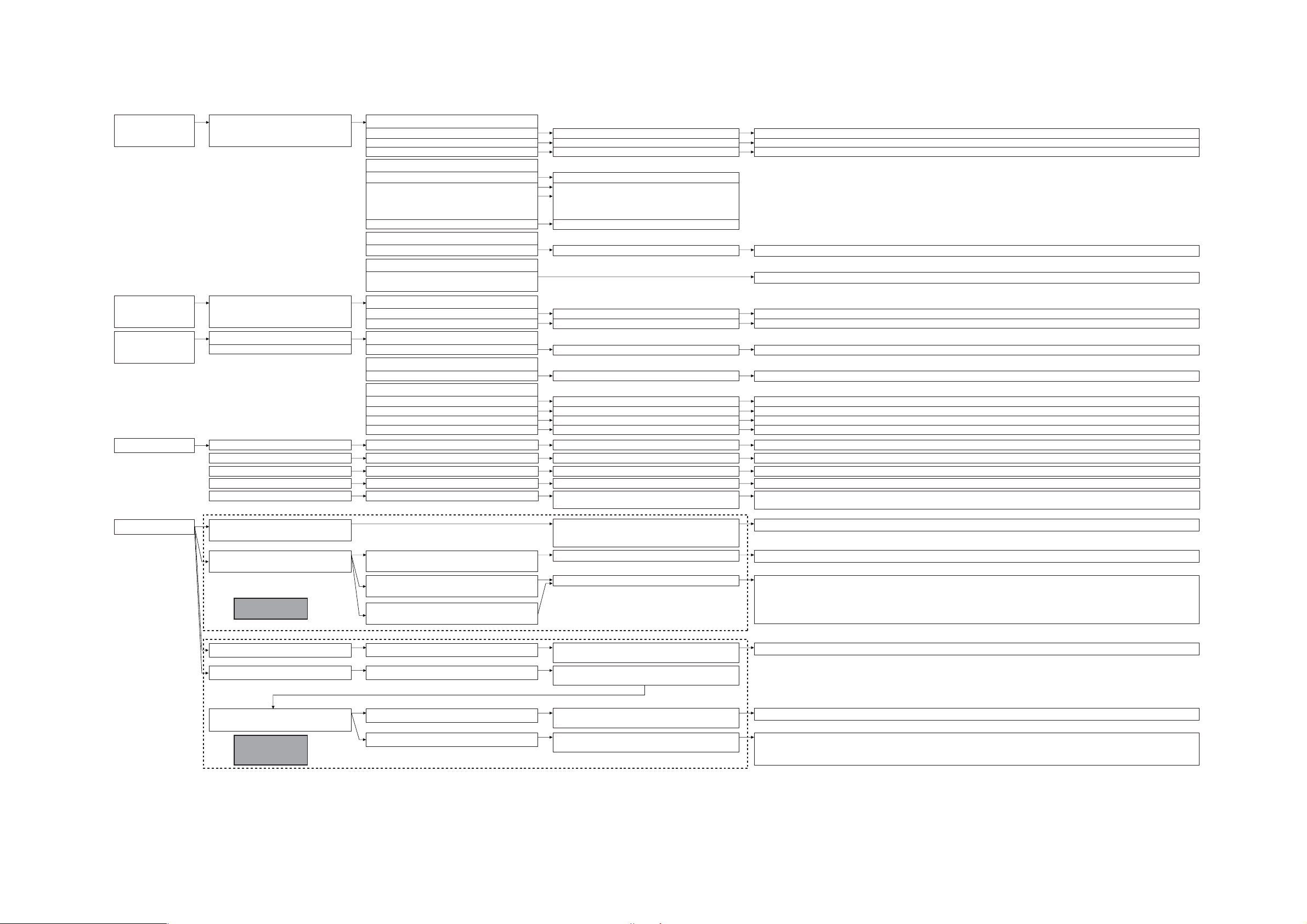

11.1. Disassembly flow chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying o ut the servicing.

To assemble the unit, reverse the steps shown in the chart below.

11.1.1. Main Unit (SU-HTB570)

11.1.2. Front Speakers (SB-HTB570)

33

Page 34

1 1.1.3. Active Subwoofer (SB-HWA570)

34

Page 35

11.2. Types of Screws

11.2.1. Main Unit (SU-HTB570)

11.2.2. Front Speakers (SB-HTB570)

11.2.3. Active Subwoofer (SB-HWA570)

35

Page 36

11.3. Main Parts Location Diagram

11.3.1. Main Unit (SU-HTB570)

11.3.2. Front Speakers (SB-HTB570)

11.3.2.1. Bar Position

36

Page 37

11.3.2.2. Standing Position

11.3.3. Active Subwoofer (SB-HWA570)

37

Page 38

11.4. Disassembly of Main Unit (SU-HTB570)

1 1.4.1. Disassembly of Top Cabinet

Step 1 : Remove 2 screws.

Step 2 : Remove 3 screws.

Step 4 : Slightly lift up the Top Cabinet as shown.

Step 5 : From within the Top Cabinet, gently push upwards to

release the catches in sequence as shown.

Step 3 : Slightly pull outwards the Top Cabinet for both sides.

Caution: During assembling, ensure that the edges of Top

Cabinet is inserted properly into the Front Panel Block.

38

Page 39

11.4.2. Disassembly of SMPS and AC Inlet P.C.B.

• Refer to “Disassembly of Top Cabinet”.

Step 1 : Detach 10P Cable Wire at the connector (CN2004) on

the Main P.C.B..

Step 2 : Remove 1 screw.

Step 3 : Lift up the AC Inlet P.C.B..

Caution: During assembling, ensure that the AC Inlet

P.C.B. is inserted properly into the guides at the Rear

Panel.

Step 4 : Remove 4 screws.

Step 5 : Slightly lift up to remove the SMPS and AC Inlet

P.C.B..

39

Page 40

11.4.3. Replacement of Switching Regulator IC (IC5701)

• Refer to “Disassembly of SMPS and AC Inlet P.C.B.”.

1 1.4.3.1. Disassembly of Switching Regu-

lator IC (IC5701)

Caution: Handle the SMPS P.C.B. with caution. Avoid

touching the Heatsink Unit A due to it’s high temperature

after prolonged use. Touching it may lead to injuries.

Step 1 : Desolder the pi ns of Switching Regulator IC (IC5701 )

on the solder side of SMPS P.C.B..

11.4.3.2. Assembly of Switching Regulator IC (IC5701)

Step 1 : Apply grease on the Heatsink Unit A.

Step 2 : Fix the Switching Regulator IC (IC5701) to the SMPS

P.C.B..

Caution: Ensure the pins of Switching Regulator IC

(IC5701) are inserted and seated properly on the SMPS

P.C.B..

Step 3 : Fix the Switching Regulator IC (IC5701) onto the Heat-

sink Unit A with a screw.

Caution: Ensure the Switching Regulator IC (IC5701) is

tightly screwed to the Heatsink Unit A.

Step 2 : Remove 1 screw.

Step 3 : Remove the Switching Regulator IC (IC5701) from the

Heatsink Unit A.

Step 4 : Solder the pins of Switching Regulator IC(IC5701) on

the solder side of SMPS P.C.B..

40

Page 41

11.4.4. Replacement of Rectifier Diode (D5802)

• Refer to “Disassembly of SMPS and AC Inlet P.C.B.”.

11.4.4.1. Disassembly of Rectifier Diode

(D5802)

Caution: Handle the SMPS P.C.B. with caution. Avoid

touching the Heatsink Unit B due to it’s high temperature

after prolonged use. Touching it may lead to injuries.

Step 1 : Desolder the pins of the Rectifier Diode (D5802) on the

solder side of SMPS P.C.B..

11.4.4.2. Assembly of Rectifier Diode (D5802)

Step 1 : Apply grease on the Heatsink Unit B.

Step 2 : Fix the Rectifier Diode (D5802) onto the SMPS P .C.B..

Caution: Ensure the pins of Rectifier Diode (D5802) are

inserted and seated properly on the SMPS P.C.B..

Step 3 : Fix the Rectifier Diode (D5802) onto the Heatsink Unit

B with a screw.

Caution: Ensure the Rectifier Diode (D5802) is tightly

screwed to Heatsink Unit B.

Step 2 : Remove 1 screw.

Step 3 : Remove the Rectifier Diode (D5802) from the Heatsink

Unit B.

Step 4 : Solder the pins of the Rectifier Diode (D580 2) on the

solder side of SMPS P.C.B..

41

Page 42

1 1.4.5. Disassembly of Main P.C.B.

• Refer to “Disassembly of Top Cabinet”.

Step 1 : Detach 10P Cable Wire at the connector (CN2004) on

the Main P.C.B..

Step 2 : Detach 24P FFC at the connector (CN2005) on the

Main P.C.B..

Step 3 : Detach 13P FFC at the connector (CN2002) on the

Main P.C.B..

Step 4 : Detach 5P Wire at the connector (CN2003) on the

Main P.C.B..

Step 5 : Detach 26P FFC at the connector (CN2000) on the

Main P.C.B..

Step 7 : Remove 3 screws.

Step 8 : Slightly lift up to remove the Main P.C.B..

Step 6 : Remove 4 screws.

Caution : During assembling, ensure that the Main P .C.B. is

inserted and seated properly onto the 2 locators of the Bottom Chassis.

42

Page 43

1 1 .4.6. Disassembly of HDMI P.C.B.

• Refer to “Disassembly of Top Cabinet”.

Step 1 : Detach 26P FFC at the connector (CN1000) on the

HDMI P.C.B..

Step 4 : Release the catch on the right side of the Rear Panel.

Caution: During assembling, ensure that the Rear Panel is

catched properly onto the Bottom Chassis.

Step 5 : Remove the HDMI P.C.B..

Step 2 : Remove 2 screws.

Step 3 : Remove 2 screws.

Caution: During assembling, ensure that the HDMI P.C.B. is

inserted and seated properly onto the 2 locators of the Bottom Chassis.

43

Page 44

1 1.4.7. Disassembly of Rear Panel

• Refer to “Disassembly of Top Cabinet”.

Step 1 : Remove 10 screws.

Step 2 : Lift up the AC Inlet P.C.B..

Caution: During assembling, ensure that the AC Inlet

P.C.B. is inserted properly into the guide.

Step 3 : Release the catches on the both side of the Rear

Panel.

Caution: During assembling, ensure that the Rear Panel is

catched properly onto the Bottom Chassis.

Step 4 : Remove the Rear Panel.

44

Page 45

1 1 .4.8. Disassembly of Front Panel Block

• Refer to “Disassembly of Top Cabinet”.

Step 1 : Detach 24P FFC at the connector (CN2005) on the

Main P.C.B..

Step 2 : Detach 13P FFC at the connector (CN2002) on the

Main P.C.B..

Step 3 : Detach 5P Wire at the connector (CN2003) on the

Main P.C.B..

Step 4 : Release the catches in sequence (1-5) as shown.

Caution: During assembling, ensure that the Front Panel

Block is catched and inserted properly onto the Bottom

Chassis.

45

Page 46

Step 5 : Remove the Front Panel Block.

11.4.9. Disassembly of Bluetooth Module P.C.B.

• Refer to “Disassembly of Top Cabinet”.

• Refer to “Disassembly of Front Panel Block”.

Step 1 : Remove 1 screw by using T5 Screwdriver.

Step 2 : Remove the Bluetooth Module Unit.

46

Page 47

Caution : During assembling, ensure that the Bluetooth

Module Unit is seated properly onto the locator.

Step 3 : Remove the Bluetooth Module P.C.B. from the Blue-

tooth Holder.

11.4.10. Disassembly of Panel P.C.B.

• Refer to “Disassembly of Top Cabinet”.

• Refer to “Disassembly of Front Panel Block”.

Step 1 : Remove 1 screw by using T5 Screwdriver.

Step 2 : Remove the Bluetooth Module Unit.

47

Page 48

Caution: During assembling, ensure that the Bluetooth

Module Unit is seated properly onto the locator.

Step 3 : Remove 2 screws.

Step 4 : Release the catch.

Caution: During assembling, ensure that the Panel P.C.B.

is catched and seated properly onto the locators of the

Front Panel Block.

Step 5 : Remove the Panel P.C.B..

48

Page 49

11.4.11. Disassembly of Digital Transmitter Module P.C.B.

• Refer to “Disassembly of Top Cabinet”.

• Refer to “Disassembly of Front Panel Block”.

Step 1 : Remove 1 screw.

Step 2 : Remove the Digital Transmitter Module Unit.

Step 5 : Remove the Digital Transmitter Module P.C.B. from the

Digital Transmitter Holder.

Step 3 : Detach 24P FFC at the connector (CN1) on the Digital

Transmitter Module P.C.B..

Step 4 : Remove 1 screw.

49

Page 50

11.5. Disassembly of Front Speaker Units Position

11.5.1. Disassembly of Front Speaker Units in Bar position

• Front Speaker Unit with Stands

Step 1 : Remove 2 screws.

Step 2 : Remove 2 Stands.

• Front Speaker Unit with Support Legs

Step 1 : Remove 2 screws.

Step 2 : Remove 2 Support Legs.

50

Page 51

Step 3 : Release the White (+) and Blue (-) Speaker Wire from the Terminal.

Step 4 : Release the Speaker Wire through the groove.

Step 5 : Remove 2 screws.

Step 6 : Lift up and remove the Metal Bracket.

51

Page 52

Step 7 : Detach the Front Speaker Unit (L) and (R).

52

Page 53

1 1 .5.2. Disassembly of Front Speaker Unit in Standing position

Note : Front Speaker Unit (L) and (R) have the same mechanical structure. Therefore only the disassembly method for Front

Speaker Unit (L) will be described in this section.

Step 1 : Remove 1 screw.

Step 2 : Release the Speaker Wire from the groove.

Step 3 : Slightly lift up the Speaker Base.

Caution: Do not remove the Speaker Base entirely.

53

Page 54

Step 4 : Release the White (+) and Blue (-) Speaker Wire from the Terminal.

Step 5 : Remove the Speaker Wire through the grooves.

Step 6 : Remove 1 screw.

Step 7 : Remove the Stand Neck.

54

Page 55

11.6. Disassembly of Front Speaker (L&R) (SB-HTB570)

Note : Front Speaker Unit (L) and (R) have the same mechanical structure. Therefore only the disassembly method for Front

Speaker Unit (L) will be described in this section.

11.6.1. Disassembly of Rear Cabinet Assembly

• Refer to “Disassembly of Front Speaker Unit”.

Step 1 : Remove 12 screws.

Caution: During assembling, fixed the screws in sequence of 1 to 12 as shown.

Step 2 : Detach the Rear Cabinet Block from the Front Cabinet Block in sequence (1-4) as shown.

55

Page 56

Step 3 : Upset the Rear Cabinet Block by the side of the Front Cabinet Block.

Step 4 : Detach the Red (+) and Black (-) wire from the Terminal.

Step 5 : Remove the Sound Absorber.

Caution: Safe keep the Sound Absorber and place them back during assembling.

Step 6 : Remove the Front Cabinet Block.

Step 7 : Remove 1 screw.

Step 8 : Unbend the Terminal Contacts (+) and (-).

Caution: Do not exert too much force as it may damage the Terminal Contacts.

56

Page 57

Step 9 : Remove the Terminal.

Step 10 : Remove the Rear Cabinet Assembly.

57

Page 58

11.6.2. Disassembly of Tweeter Speaker (SP1)

• Refer to “Disassembly of Front Speaker Unit”.

• Refer to “Disassembly of Rear Cabinet Assembly” (Step 1) to (Step 3).

Step 1 : Release the Speaker Wire Assembly from the ribs of the Front Cabinet Block.

Step 2 : Detach the Yellow (+) and Black (-) wire from the terminal of the Tweeter Speaker (SP1).

58

Page 59

Step 3 : Remove 4 screws.

Step 4 : Remove the Tweeter Speaker (SP1) and the Eva Packing.

59

Page 60

Caution 1: During assembling, ensure that the Tweeter Speaker (SP1) and the Eva Packing is seated properly onto the 3

locators of the Front Cabinet Block.

Caution 2: During assembling, ensure that the S p eaker Wire Assembly is dressed properly between the ribs of the Front

Cabinet Block as shown.

60

Page 61

11.6.3. Disassembly of Woofer Speaker (SP2)

• Refer to “Disassembly of Front Speaker Unit”.

• Refer to “Disassembly of Rear Cabinet Assembly” (Step 1) to (Step 3).