Panasonic SL-VMEL-Q Instruction Manual

INSTRUCTION MANUAL

VMEL-Q

Flexible Wire-saving Link System S-LINK V

Mitsubishi Electric Corportaion PLC MELSEC-Q Series

Bus Direct-connection Type S-LINK V Controller

SL-

MJE-SLVMELQ No.0071-18V

MEMO

1. INTRODUCTION

WARNING

Thank you very much for purchasing Panasonic products. Read this Instruction Manual carefully

and thoroughly for the correct and optimum use of this product. Kindly keep this manual in a convenient place for quick reference.

● Never use this product in a device for personnel protection.

● In case of using devices for personnel protection, use products which meet laws and standards, such

as OSHA, ANSI or IEC etc., for personnel protection applicable in each region or country.

● Before touching this product, remove any electrostatic charge that may be present on your body.

There is a danger of this product getting damaged due to the electrostatic charge.

2. CAUTIONS

Power supply

● This product has no short-circuit protective function. Use a power supply having a short-circuit

protective function (e.g. fuse, etc. ).

● Verify that the supply voltage variation is within the rating. Also, verify the voltage variation at

the end terminal of the transmission route, since voltage drop occurs depending on the diameter or the length of the transmission cable.

● If power is supplied from a commercial switching regulator, ensure that the frame ground (F.G.)

terminal of the power supply is connected to an actual ground.

● Do not use during the initial transient time after the power supply is switched ON. Transmission

is not performed when the system is in BUSY condition (at the time of turning the power ON or

setting the system).

● Make sure to use an isolation transformer for the DC power supply. If an auto-transformer (single winding transformer) is used, this product or the power supply may get damaged.

● In case a surge is generated in the power supply used, connect a surge absorber to the supply

and absorb the surge.

Wiring

● Do not run the wires together with high-voltage lines or power lines or put them in the same

raceway. This can cause malfunction due to induction.

● Make sure to carry out the installation and wiring in the power supply OFF condition.

● In order to reduce noise, make the wiring as short as possible.

● Always use the specied transmission cable.

● Take care wrong wiring will damage the product.

● Take care that if connect +24V-0V to 0V-G of this product by mistake, blown fuse of internal cir-

cuit protection will occur. The blown fuse cannot be restored.

Environment

● This product has been developed / produced for industrial use only.

● In case noise generating equipment (switching regulator, inverter motor, etc.) is used in the

vicinity of this product, connect the frame ground (F.G.) terminal of the equipment to an actual

ground.

● This product does not have a dust-proof or water-proof construction. Do not use it in a place

having excessive vapor, dust, etc. or a place where the product may be come in contact with

oil, water, chemicals or organic solvents. Furthermore, do not use it in an environment having

corrosive gas.

● Do not use the product in places where the ambient temperature or the humidity exceeds the

specications.

Terminal

● Do not tighten the screws with a torque exceeding the specications.

1

Others

For the details of MELSEC-Q, refer to “MELSEC-Q

The contents described in this manual are only about the

S-LINK V User’s Manual

● Please refer to “

● Any protective devices or safety circuits against system malfunction should be designed to be

external to the system.

● To use this product together with the PLC (programmable logic controller) manufactured by Mit-

subishi Electric Corporation and to conform to the requirements of the EMC order, observe the

following items.

(1) Install the system while referring to the “PLC User’s Manual” prepared by Mitsubishi Electric

Corporation.

(2) Be sure to put this product in a conductive box.

(3) Install a ferrite core to the cable (including the main line in

● There are some cases that even if the power indicators of other units are turned OFF when the

PLC is turned ON or OFF, the power indicator (POWER) of this product may not be turned OFF.

This is not a malfunction or an error.

S-LINK V User’s Manual

” for details of the system design.

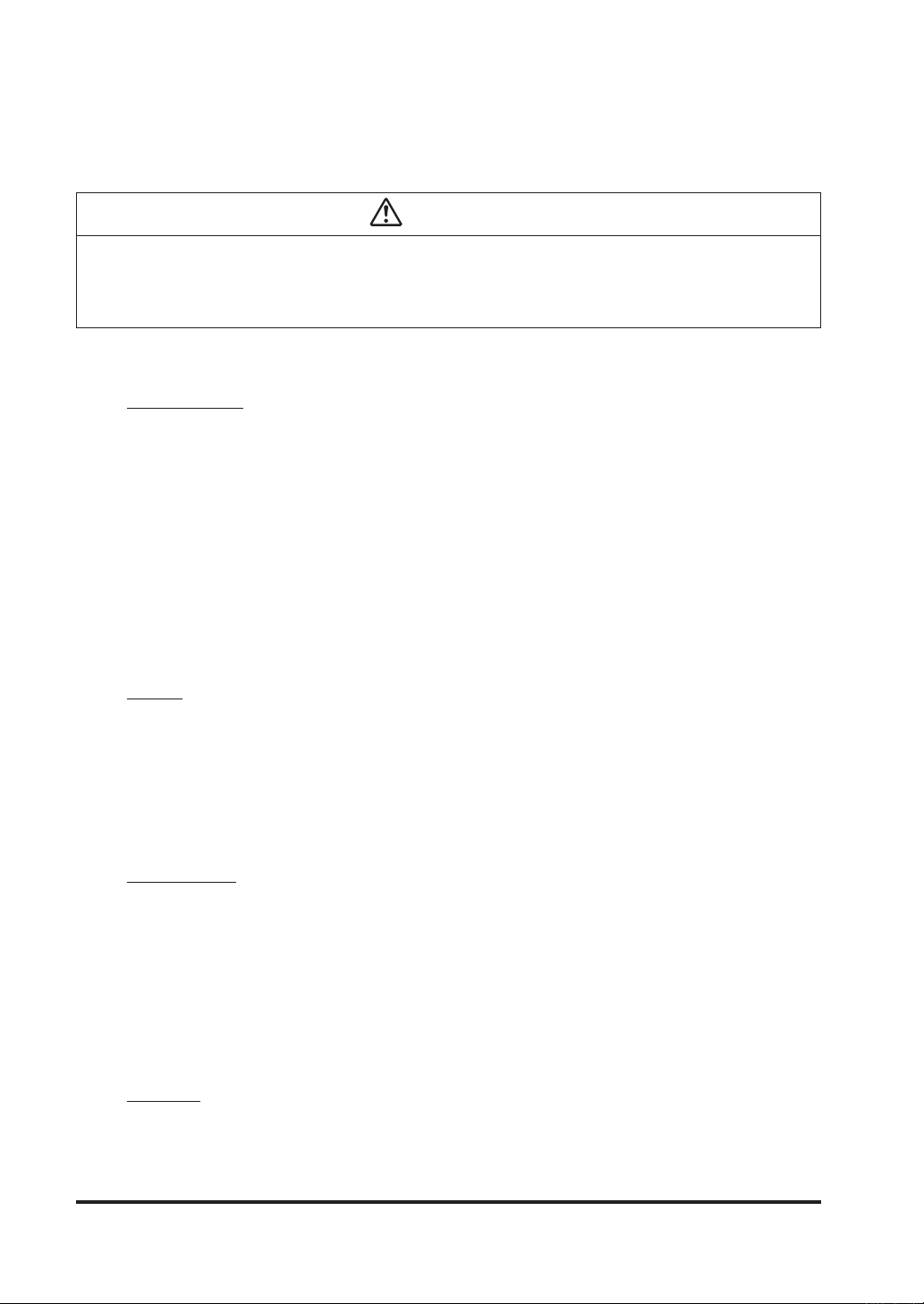

3. ExampleofSystemConguration

Following is an example of system conguration for

S-LINK V

Manual” prepared by Mitsubishi Electric Corporation.

setting and wiring of this product.

S-LINK V

unit.

system) if required.

Mitsubishi Electric Corporation

MELSEC-Q Series

For the details of each unit, refer to “

Wiring of S-LINK V system

.”

2

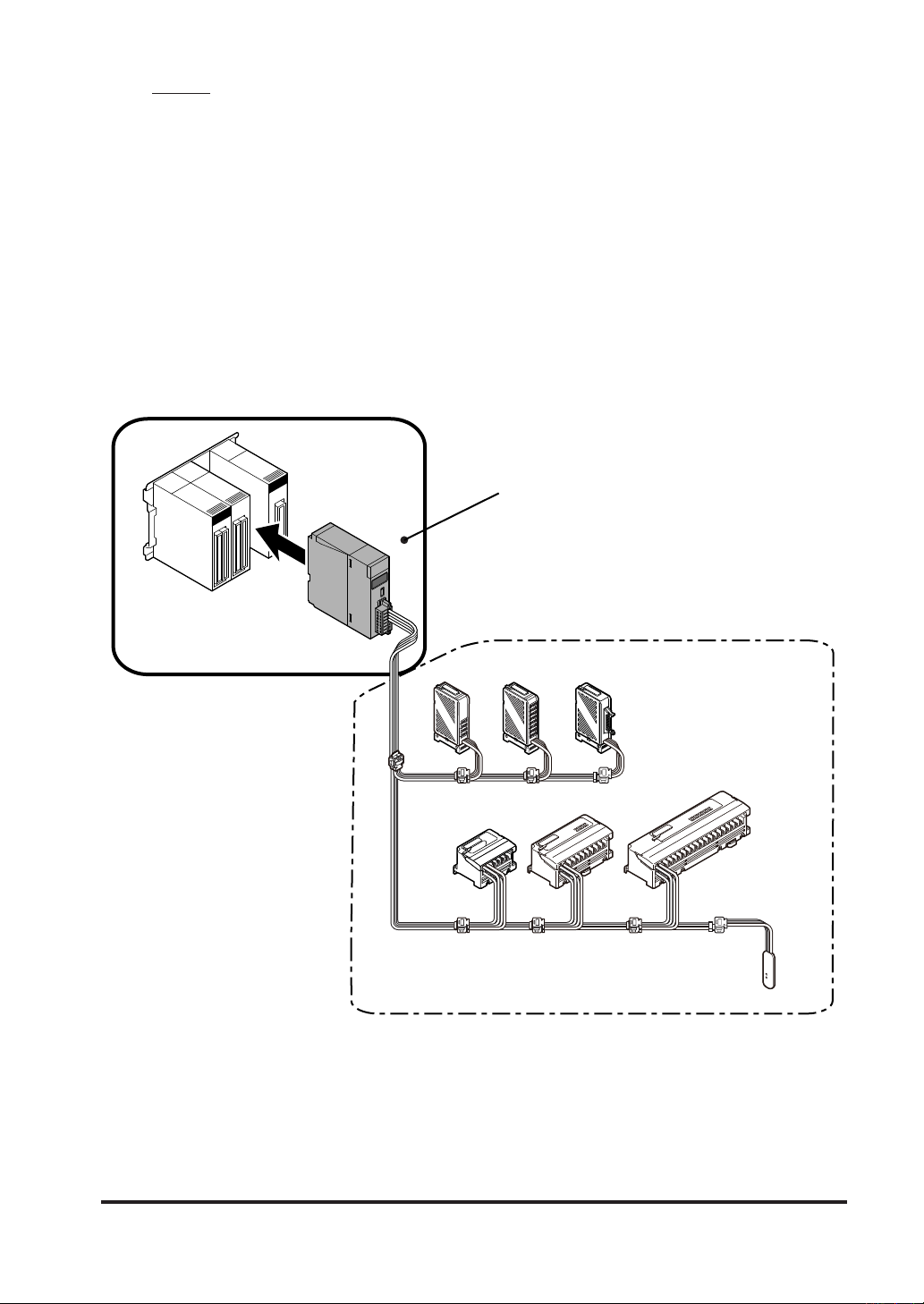

4. FUNCTIONAL DESCRIPTION

terminal block connector

6. Transmission mode

9. Power indicator (Green)

10. RUN indicator (Green)

4. SELECT keys

5. MODE selector switch

SL-VMEL-Q

POWER

RUN

CHECK

G

D

0

24

0

24

FG

SEND

ERRORRUN

HEX

ENTER

indicator (Green)

7. Error indicataor (Red)

1. Hexadecimal number display

mode indicataor (Green)

2. Address display (Red)

3. ENTER key

8. S-LINK V

3

No. Designation Function

Mode

Mode

Mode

Hexadecimal number

1

display mode indicator

(Green)

2 Address display (Red)

Indicates the current display mode of the address display.

• ON: Hexadecimal number display mode is selected.

• OFF: The decimal number display mode is selected.

The displayed item depends on the mode (“RUN,” “CHECK,” or “CONFIG” mode).

Use the mode selector switch to switch the mode.

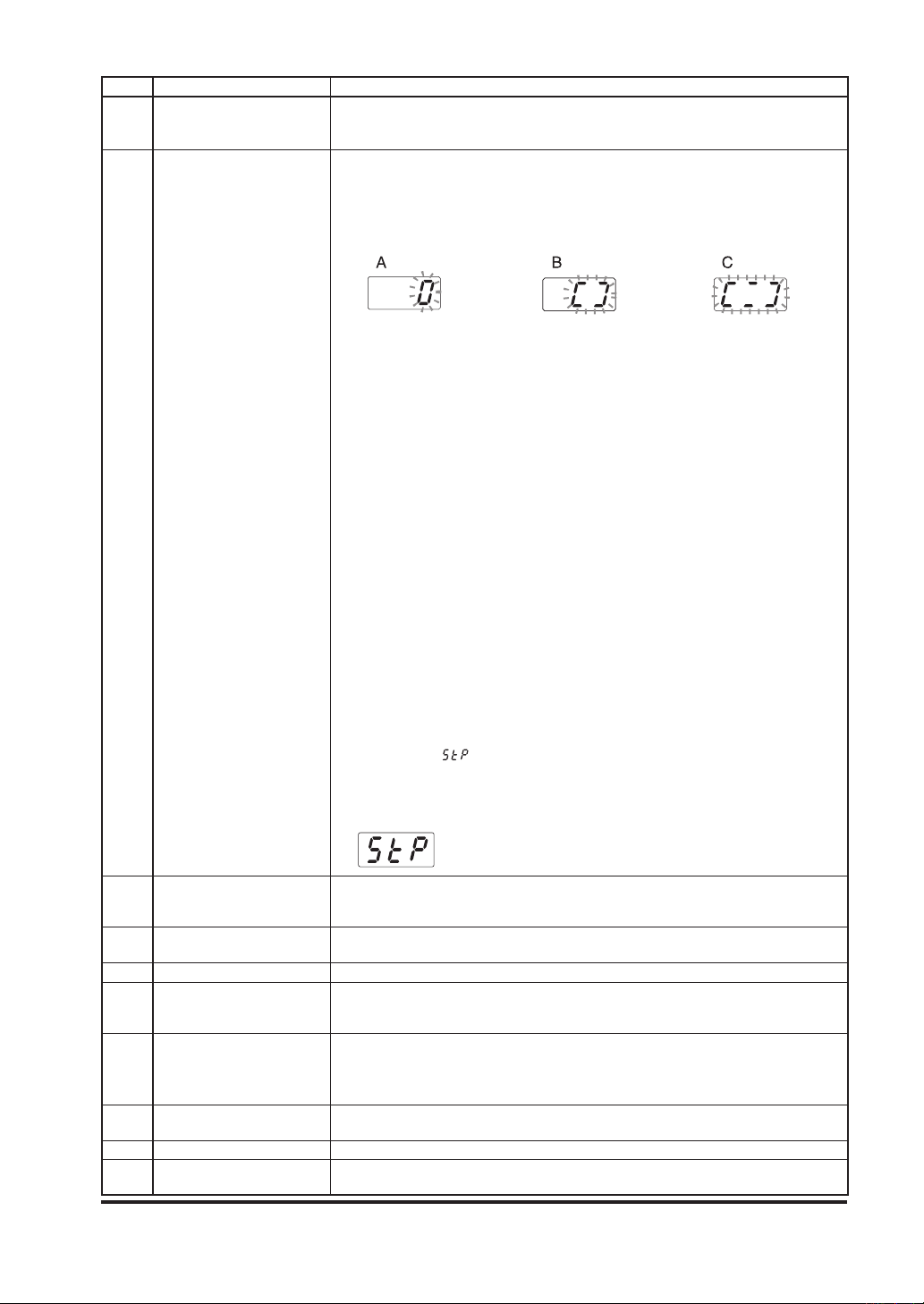

<RUN mode>

• Each transmission mode (3 modes in total) will be indicated by the following character,

and the LED of each character will sequentially light up just like rotating clockwise.

• If an error occurs, the error message will appear.

Note : After eliminating the cause of the error, press ENTER key and SELECT

keys (2 types of keys) at the same time.

<CHECK mode>

• The number of connected nodes will be displayed rst.

SELECT key is pressed, the recognized addresses will be displayed one after another.

Number of connected nodes:

Using the decimal or hexadecimal number, the number of I/O units' nodes

will be displayed.

Address:

Using the decimal or hexadecimal number, the addresses of the I/O units

will be displayed sequentially.

Note: In the hexadecimal number display mode, the hexadecimal number indi-

cator (green) will light up.

• If an error occurs, the number of nodes having the error and the error addresses will be displayed sequentially (for errors 3, 4, and 5).

The error message will disappear.

After that, each time

<CONFIG mode>

• Settings will be displayed sequentially. To switch the displayed setting, use SELECT key.

• When RUN mode is switched to CONFIG mode, dierent item will be displayed compared with the displayed item just after power-ON.

If setting the operation at PLC halt condition to transmission halt, and when the

PLC is halted, “ ” is displayed in RUN mode and CHECK mode, while each

item can be conrmed in CONFIG mode. In case setting the operation at PLC halt

condition to “transmission continued,” content of each item is displayed.

<RUN and CHECK modes>

3 ENTER key

4 SELECT keys

5 MODE selector switch Switches the mode (RUN, CHECK, or CONFIG mode).

Transmission mode

6

indicator (Green)

7 Error indicator (Red)

S-LINK V

8

connector

9 Power indicator (Green) Lights up when the power is supplied from the PLC to this product.

10 RUN indicator (Green)

terminal block

Press ENTER key to determine the set condition value.

In the system setting mode, press and hold ENTER key for 3 seconds or more,

then the system will be set.

Use these keys to switch the displayed item or set item. Also use these keys

to change the set condition value.

This indicator will blink during transmission (during the transmission signal is

being output). The indicator blinking cycle depends on the transmission mode.

(A mode: fast ↔ C mode: slow)

The indicator indicates the error status as follows:

• Lights up when an error occurs.

• Blinks when the cause of the error is eliminated.

• Turns OFF when operation is normal.

Receives +24V, 0V, and F.G. from the external power supply unit, and supplies

+24V, 0V, D, and G to the I/O units.

Lights up when this product is running (Xn0 = ON at the same time). Also

lights up when transmission with the CPU unit is started.

4

Base unit 1

Unit connector

2

5. MOUNTING

Base unit

Unit

connector

Mounting

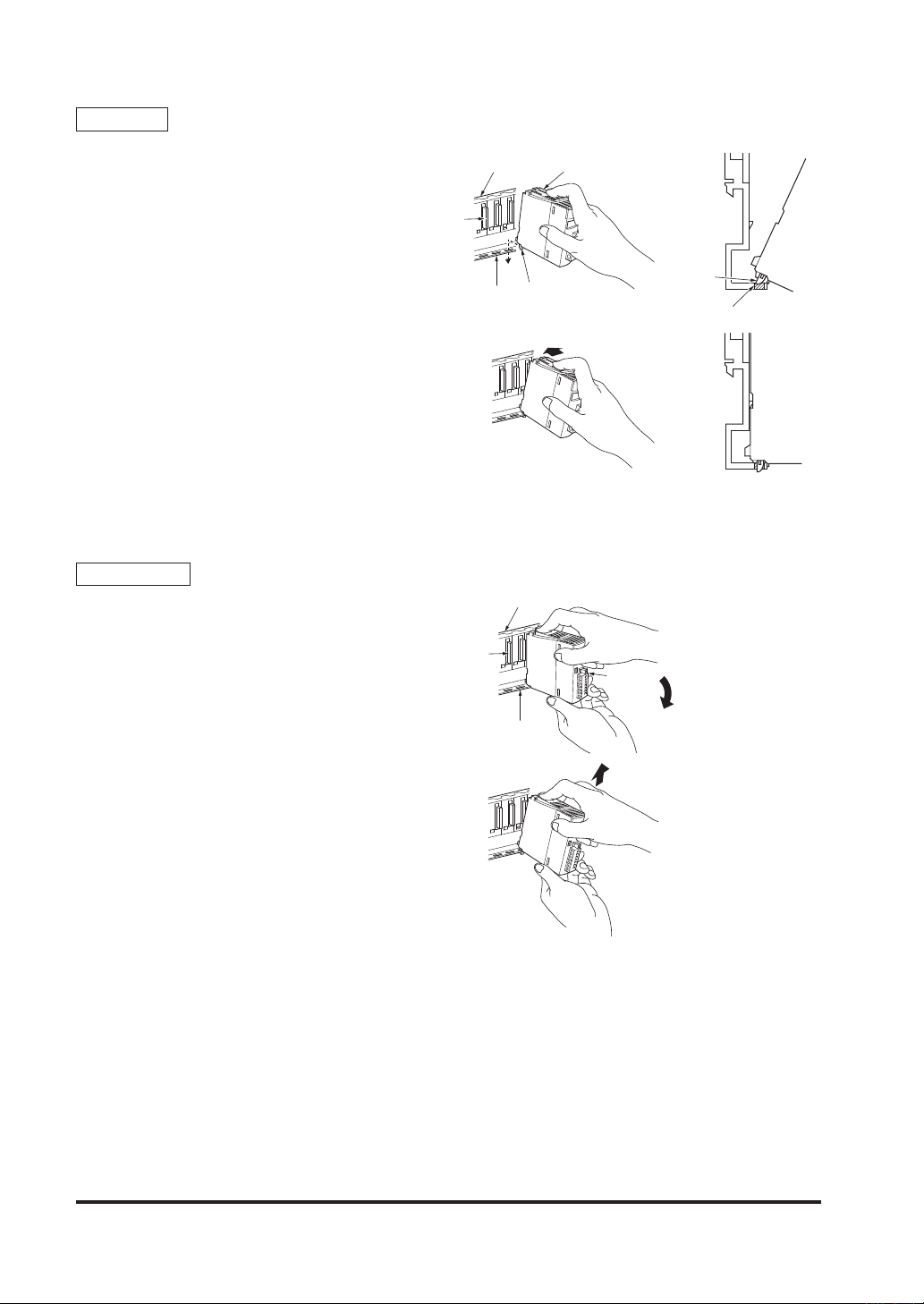

1. Insert the unit fixing projection of this

product into the unit fixing hole of the

base unit.

2.

Push the product in the direction of the

arrow, and t it on the base unit.

3. Check if the product is completely fitted

on the base unit.

Notes: 1) Make sure to insert the xing projection

Dismantling

1. Hold the product with both hands and

2. While pushing the hook, pull the product

3. While lifting up the product to the upper

Note : In case the product is mounted with

into the xing hole to mount the product. Take care that if you forcibly mount

the product without inserting the projection into the hole, connector of the

product and the base unit can break.

2) In case using the product in a place

having excessive vibration or shock,

mount the product on the base unit

with M3 (length 12mm) screws (please

arrange separately).

push the upper hook of the product until

the product stops.

to your side.

side, remove the xing projection of the

product from the xing hole.

screws, make sure to remove the screws

rst, and then remove the xing projection

from the unit xing hole. Take care that if

you forcibly remove the product from the

base unit, the product can break.

Base unit Unit

Unit fixing hole

Unit fixing hole

1

Unit fixing

projection

2

Unit fixing

projection

Unit fixing hole

Unit

3

5

6. CONNECTION

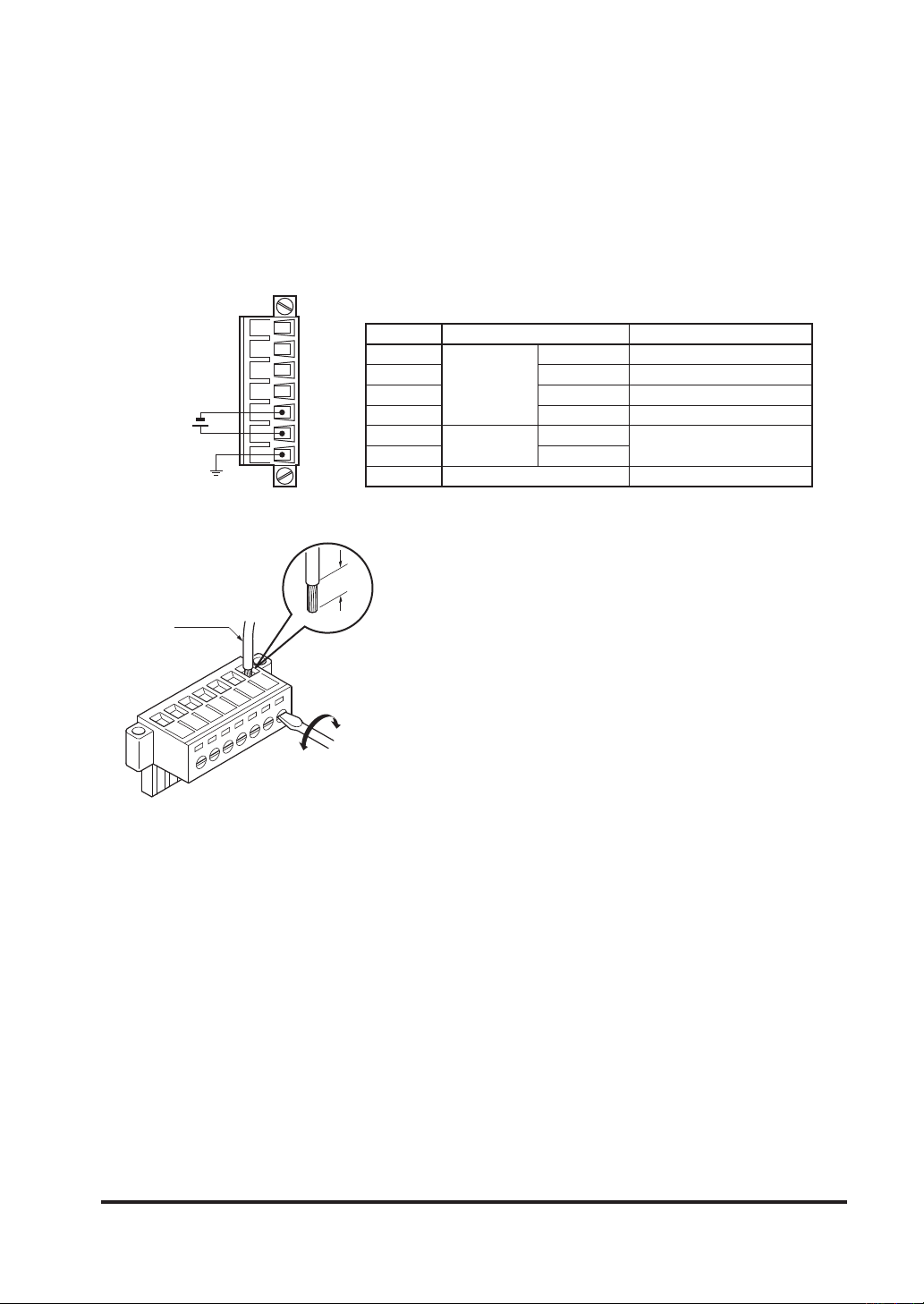

24V DC

+10

- 5

Wire processing dimension

(Width = 3.8mm or less, thickness = 0.7mm or less)

● Take care that wrong wiring will damage the product.

● Do not short-circuit “0V” and “G” on the S-LINK V terminal block connector side.

● A large current may ow through the external power supply input, depending on the load.

Use wires having sucient current capacity. Further, when supplying power to the load from

this product, make sure not to exceed the allowable through current.

● Tighten the screws of the ange also, so that the terminal block connector does not come out.

The tightening torque should be 0.2N·m, or less.

Do not apply solder, etc., on the tips of the wires to be connected to the S-LINK V terminal

block connector. This can cause loosening of the screws, resulting in wire disconnection.

G

7

D

6

0V

5

24V

−

%

+

24V

4

0V

3

2

FG

1

No.

7

6

5

4

3

2

1

● Process and tighten the wires as follows.

7mm

Terminal block

Main line in

S-LINK V

system

Input

G

D

0V

+24V

0V

+24V

F.G.

Description

Black

White

Blue

Brown

External power input

Frame ground

Lead wire

Loosen

Tighten

<Tightening torque>

0.4N·m or less

Recommended tool: Small-sized flathead screwdriver

6

7. BuerMemory

ON / OFF data for each unit on S-LINK V system, error addresses, and number of connected

units on S-LINK V system are stored in buer memory within the product.

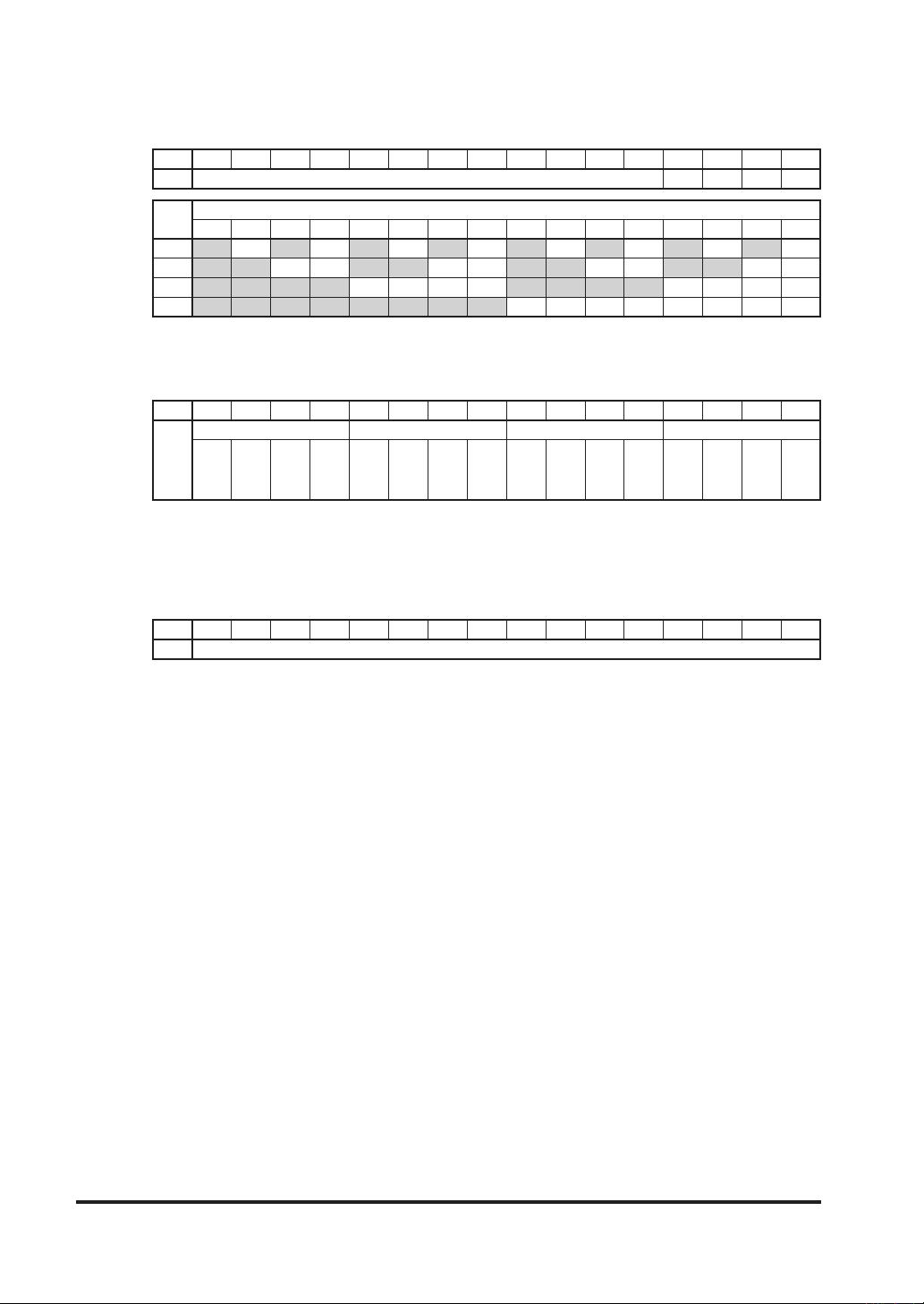

Buermemorycongurationofthisproduct

Address

K0

to

K31

K32 I/O control points FROM order only

K33 I/O setting 0 to 3 FROM order only

K34 S-LINK V I/O unit connected nodes FROM order only

K35

to

K66

K67 Number of nodes of error 3 FROM order only

K68

to

K99

K100 Number of nodes of error 4 FROM order only

K101

to

K132

K133 Number of nodes of error 5 FROM order only

K134

to

K165

K166

K167

K168

K169

K170

K171

K172

K173

K174

K175

K176

K177

K178

to

K184

Note: Set a date of CPU in the PLC to store dates that error 1 to 6 occurs.

I/O data of S-LINK V I/O unit (for 512 addresses)

S-LINK V system connected I/O unit address

Error 3 I/O unit address (for 512 units) FROM order only

Error 4 I/O unit address (for 512 units) FROM order only

Error 5 I/O unit address (for 512 units) FROM order only

Date that Error 1 occurs (month, day, time, minute)

(Note)

Date that Error 2 occurs (month, day, time, minute)

(Note)

Date that Error 3 occurs (month, day, time, minute)

(Note)

Date that Error 4 occurs (month, day, time, minute)

(Note)

Date that Error 5 occurs (month, day, time, minute)

(Note)

Date that Error 6 occurs (month, day, time, minute)

(Note)

Allocation FROM / TO order

Input: FROM order only

Output: TO order (FROM order can be

performed as well)

(for 512 units)

Program setting reading

TO order (FROM order can be performed as well)

FROM order only

FROM order only

FROM order only

FROM order only

FROM order only

FROM order only

FROM order only

7

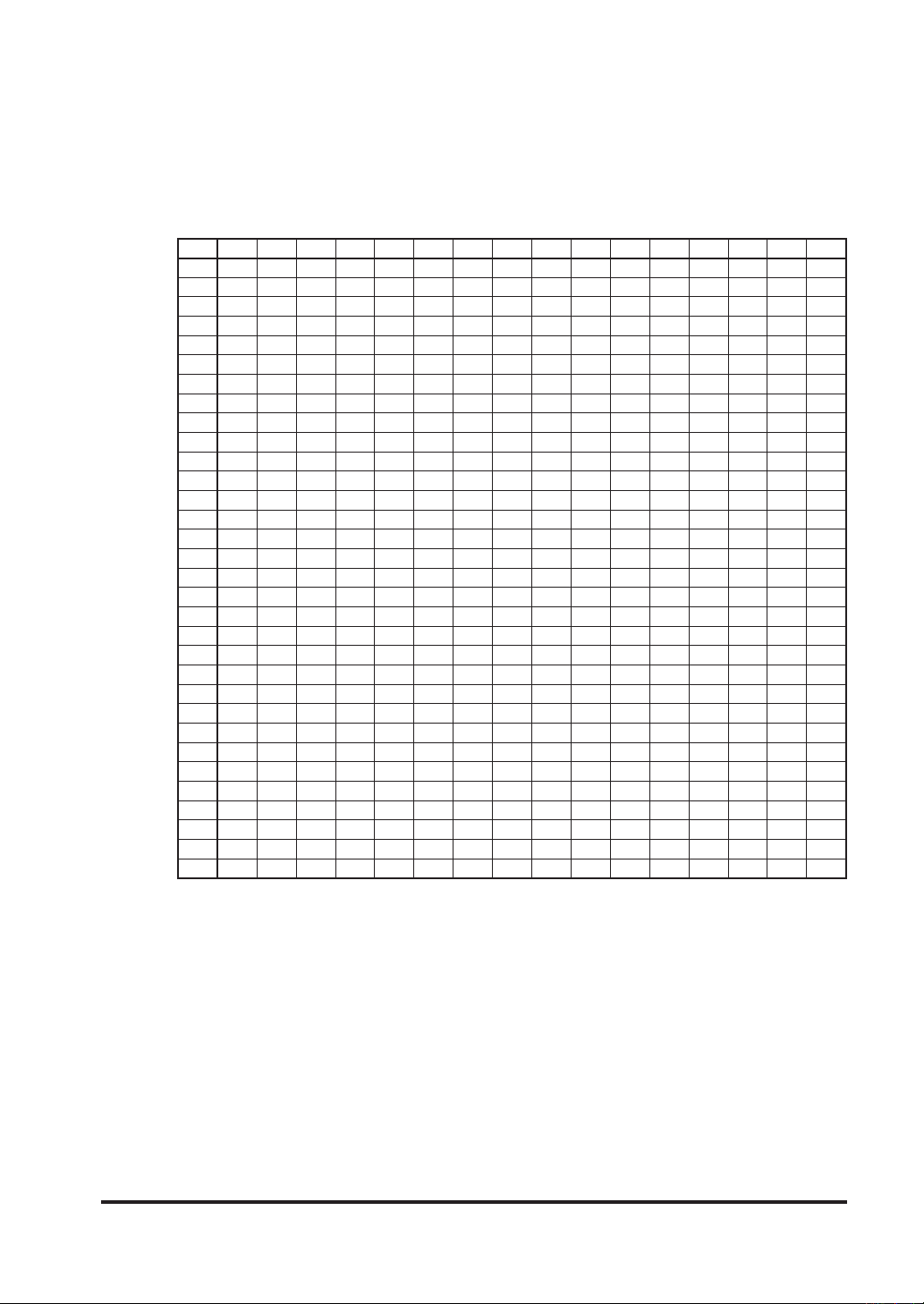

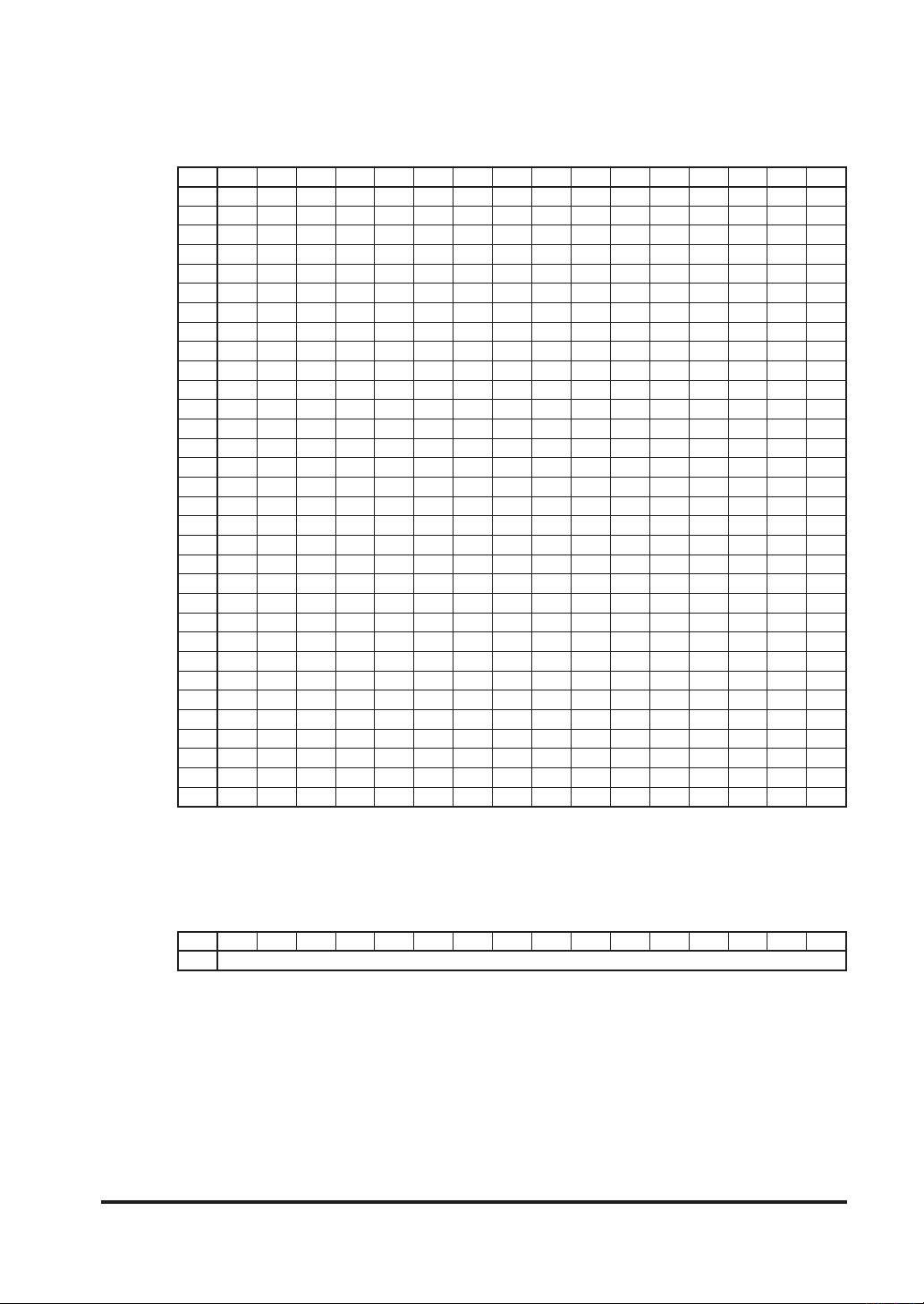

1) I/O data of S-LINK V I/O unit

It is I/O data area of

In case of setting to input, bit corresponding to each address will be set to “1” when

input unit is ON. Read the input data in “FROM” order. (in case not in

mission, input data maintains the former states.)

In case of setting to output, when write “1” to corresponding bit of each

address, output of

I/O data of S-LINK V I/O unit

bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

K0 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

K1 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16

K2 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33 32

K3 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49 48

K4 79 78 77 76 75 74 73 72 71 70 69 68 67 66 65 64

K5 95 94 93 92 91 90 89 88 87 86 85 84 83 82 81 80

K6 111 110 109 108 107 106 105 104 103 102 101 100 99 98 97 96

K7 127 126 125 124 123 122 121 120 11 9 118 117 11 6 115 114 11 3 112

K8 143 142 141 140 139 138 137 136 135 134 133 132 131 130 129 128

K9 159 158 157 156 155 154 153 152 151 150 149 148 147 146 145 144

K10 175 174 173 172 171 170 169 168 167 166 165 164 163 162 161 160

K11 191 190 189 188 187 186 185 184 183 182 181 180 179 178 177 176

K12 207 206 205 204 203 202 201 200 199 198 197 196 195 194 193 192

K13 223 222 221 220 219 218 217 216 215 214 213 212 211 210 209 208

K14 239 238 237 236 235 234 233 232 231 230 229 228 227 226 225 224

K15 255 254 253 252 251 250 249 248 247 246 245 244 243 242 241 240

K16 271 270 269 268 267 266 265 264 263 262 261 260 259 258 257 256

K17 287 286 285 284 283 282 281 280 279 278 277 276 275 274 273 272

K18 303 302 301 300 299 298 297 296 295 294 293 292 291 290 289 288

K19 319 318 317 316 315 314 313 312 311 310 309 308 307 306 305 304

K20 335 334 333 332 331 330 329 328 327 326 325 324 323 322 321 320

K21 351 350 349 348 347 346 345 344 343 342 341 340 339 338 337 336

K22 367 366 365 364 363 362 361 360 359 358 357 356 355 354 353 352

K23 383 382 381 380 379 378 377 376 375 374 373 372 371 370 369 368

K24 399 398 397 396 395 394 393 392 391 390 389 388 387 386 385 384

K25 415 414 413 412 411 410 409 408 407 406 405 404 403 402 401 400

K26 431 430 429 428 427 426 425 424 423 422 421 420 419 418 417 416

K27 447 446 445 444 443 442 441 440 439 438 437 436 435 434 433 432

K28 463 462 461 460 459 458 457 456 455 454 453 452 451 450 449 448

K29 479 478 477 476 475 474 473 472 471 470 469 468 467 466 465 464

K30 495 494 493 492 491 490 489 488 487 486 485 484 483 482 481 480

K31 511 510 509 508 507 506 505 504 503 502 501 500 499 498 497 496

Note: Do not write the data to address which is set to input.

will be ignored on

sion (refresh time).

S-LINK V

S-LINK V

S-LINK V

I/O unit which is connected to

output unit turns ON. Write the output data in “TO order.”

system and correct input data will be set after completion of transmis-

S-LINK V

system.

S-LINK V

S-LINK V

Written data is temporarily maintained, but it

system trans-

S-LINK V

(1: ON, 0: OFF)

output unit

8

2) I/Ocontrolpoints

I/O control points are stored.

I/Ocontrolpoints

bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

K32 Unused (= 0) 3 2 1 0

Storage

place

512 480 448 416 384 352 320 288 256 224 192 160 128 96 64 32

bit 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0

bit 1 1 1 0 0 1 1 0 0 1 1 0 0 1 1 0 0

bit 2 1 1 1 1 0 0 0 0 1 1 1 1 0 0 0 0

bit 3 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0

I/O control points

3) I/O setting 0 to 3

I/O setting state of each address is stored.

I/O setting 0 to 3

bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

I/O setting 3 I/O setting 2 I/O setting 1 I/O setting 0

480

448

416

384

352

320

288

256

224

192

160

K33

to

511

to

479

to

447

to

415

to

383

to

351

to

319

to

287

to

255

to

223

to

191

128

to

159

(0: Input, 1: Output)

96

64

95

32

to

to

63

to

127

4) S-LINKVI/Ounitconnectednodes

Number of connected nodes of S-LINK V I/O units which are connected to S-LINK V system

are stored.

The storage value is from 0000 to 0100H (0 to 256).

NumberofconnectednodesofS-LINKVI/Ounits

bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

K34 Number of connected nodes of S-LINK V I/O units

0

to

31

9

5)S-LINKVsystemconnectedI/Ounitaddress

Connection states of

Bit corresponding to initial address of

S-LINK V systemconnectedI/Ounitaddress

bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

K35 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

K36 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16

K37 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33 32

K38 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49 48

K39 79 78 77 76 75 74 73 72 71 70 69 68 67 66 65 64

K40 95 94 93 92 91 90 89 88 87 86 85 84 83 82 81 80

K41 111 11 0 109 108 107 106 105 104 103 102 101 100 99 98 97 96

K42 127 126 125 124 123 122 121 120 119 11 8 117 116 11 5 114 113 11 2

K43 143 142 141 140 139 138 137 136 135 134 133 132 131 130 129 128

K44 159 158 157 156 155 154 153 152 151 150 149 148 147 146 145 144

K45 175 174 173 172 171 170 169 168 167 166 165 164 163 162 161 160

K46 191 190 189 188 187 186 185 184 183 182 181 180 179 178 177 176

K47 207 206 205 204 203 202 201 200 199 198 197 196 195 194 193 192

K48 223 222 221 220 219 218 217 216 215 214 213 212 211 210 209 208

K49 239 238 237 236 235 234 233 232 231 230 229 228 227 226 225 224

K50 255 254 253 252 251 250 249 248 247 246 245 244 243 242 241 240

K51 271 270 269 268 267 266 265 264 263 262 261 260 259 258 257 256

K52 287 286 285 284 283 282 281 280 279 278 277 276 275 274 273 272

K53 303 302 301 300 299 298 297 296 295 294 293 292 291 290 289 288

K54 319 318 317 316 315 314 313 312 311 310 309 308 307 306 305 304

K55 335 334 333 332 331 330 329 328 327 326 325 324 323 322 321 320

K56 351 350 349 348 347 346 345 344 343 342 341 340 339 338 337 336

K57 367 366 365 364 363 362 361 360 359 358 357 356 355 354 353 352

K58 383 382 381 380 379 378 377 376 375 374 373 372 371 370 369 368

K59 399 398 397 396 395 394 393 392 391 390 389 388 387 386 385 384

K60 415 414 413 412 411 410 409 408 407 406 405 404 403 402 401 400

K61 431 430 429 428 427 426 425 424 423 422 421 420 419 418 417 416

K62 447 446 445 444 443 442 441 440 439 438 437 436 435 434 433 432

K63 463 462 461 460 459 458 457 456 455 454 453 452 451 450 449 448

K64 479 478 477 476 475 474 473 472 471 470 469 468 467 466 465 464

K65 495 494 493 492 491 490 489 488 487 486 485 484 483 482 481 480

K66 511 510 509 508 507 506 505 504 503 502 501 500 499 498 497 496

S-LINK V

I/O units which are memorized at system setting are stored.

S-LINK V

I/O unit will be set to “1.

S-LINK V

(1:

”

I/O unit is connected)

6) Number of nodes of error 3

Number of nodes of error 3 (error of recognized unit, disconnection or blown fuse) is stored.

Storage value is from 0000 to 0100H (0 to 256). In case error 3 does not occur or is eliminated, the past number of nodes of error 3 is stored (It is cleared when Y(n+1)A is turned ON).

Number of nodes of error 3

bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

K67 Number of nodes of error 3

10

Loading...

Loading...