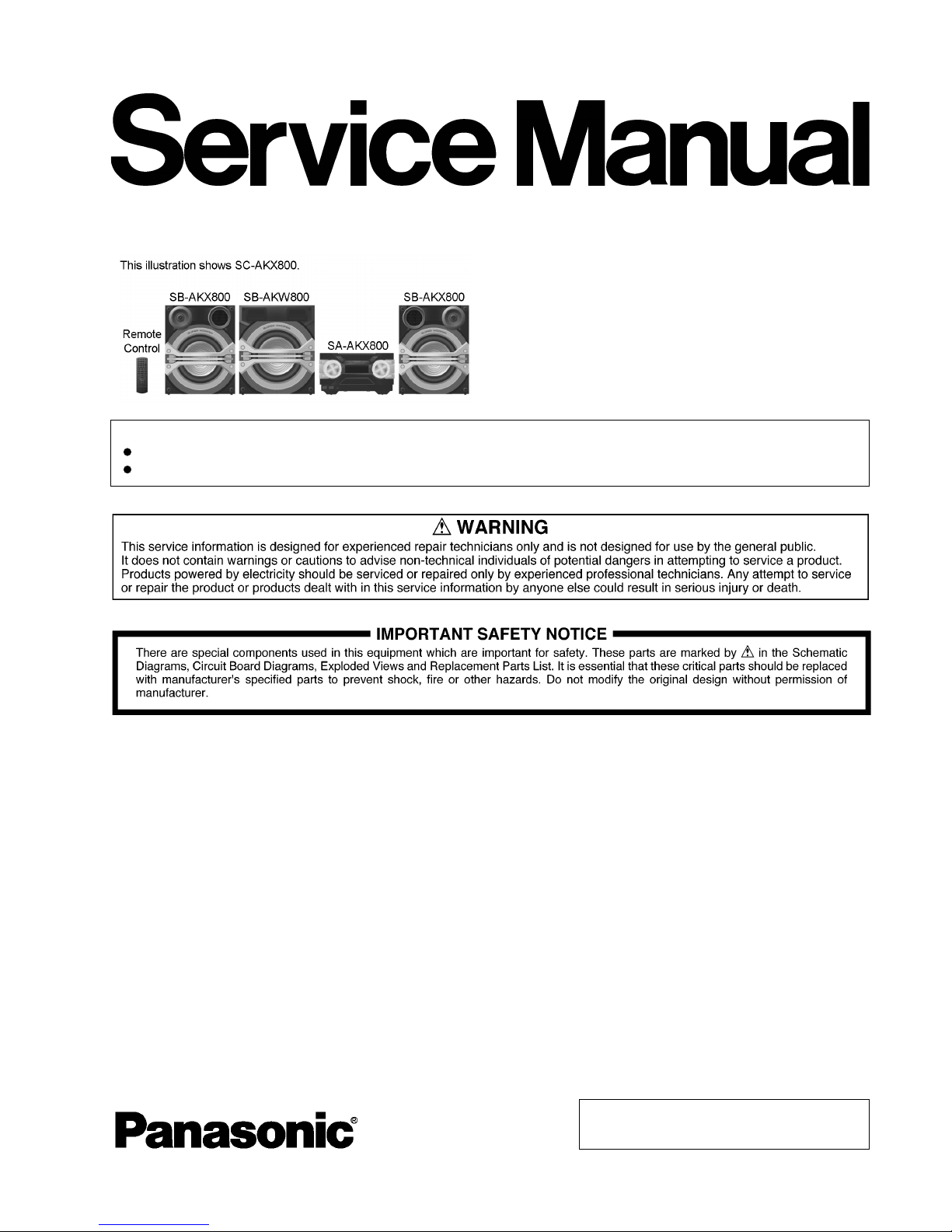

Panasonic SA-AKX600LM, SA-AKX800LM, SA-AKX600, SA-AKX800, SB-AKX800 Service Manual

...

© Panasonic Corporation 2015. All rights reserved.

Unauthorized copying and distribution is a violation

of law.

PMX1506006CE

CD Stereo System

Model No. SA-AKX600LM

SA-AKX800LM

Product Color: (K)...Black Type

TABLE OF CONTENTS

1 Safety Precautions

1.1. General Guidelines

1.2. Before Repair and Adjustment

1.3. Protection Circuitry

1.4. Power Supply using SMPS Module

1.5. Safety Parts Information

2 Warning

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices

2.2. Precaution of Laser Diode

2.3. General description about Lead Free Solder

(PbF)

2.4. Handling Precautions for Traverse Unit

2.5. Grounding for electrostatic breakdown

prevention

3 Service Navigation

3.1. Service Information

4 Specifications

5 Location of Controls and Components

5.1. Remote Control Key Button Operation

5.2. Main Unit Key Button Operation

6 Service Mode

6.1. Cold-Start

6.2. Sales Demonstration Lock Function

6.3. Doctor Mode Table

6.4. Self-Diagnostic Mode

6.5. Self-Diagnostic Error Code T

able

7 Troubleshooting Guide

8 Disassembly and Assembly Instructions

8.1. Types of Screws

8.2. Disassembly Flow Chart

8.3. Main Components and P.C.B. Locations

8.4. Disassembly of Top Cabinet

8.5. Disassembly of Front Panel Unit

Please refer to the original service manual for:

CD Mechanism Unit (BRS12C) , Order No. PSG1303059AE

Speaker system SB-AKX800LM, SB-AKW800LM Order No. PMX1506007CE

2

8.6. Disassembly of Panel P.C.B.

8.7. Disassembly of USB P.C.B.

8.8. Disassembly of Music Port P.C.B.

8.9. Disassembly of Rear Panel

8.10. Disassembly of Main P.C.B.

8.11. Disassembly of SMPS Module

8.12. Disassembly of Tuner P.C.B.

8.13. Disassembly of CD Mechanism Unit

8.14. Disassembly of CD Interface P.C.B.

9 Service Position

9.1. Checking of Panel P.C.B.

9.2. Checking of Main P.C.B. and SMPS Module

10 Block Diagram

10.1. System Control

10.2. Audio

10.3. Power Supply

11 Wiring Connection Diagram

12 Schematic Diagram

12.1. Schematic Diagram Notes

12.2. Main (CD Motor Driver) Circuit

12.3. Main (USB EMMC) Circuit

12.4. Main (SOC IO Expander) Circuit (1/2)

12.5. Main (SOC IO Expander) Circuit (2/2)

12.6. Main (Damp) Circuit (1/2)

12.7. Main (Damp) Circuit (2/2)

12.8. Main (Connector) Circuit

12.9. Main (DSP) Circuit

12.10. Main (VREG Fan) Circuit (1/2)

12.11.

Main (VREG Fan) Circuit (2/2)

12.12. Tuner Circuit

12.13. Panel Circuit

12.14. USB, CD Interface and Music Port Circuit

13 Printed Circuit Board

13.1. Main P.C.B. (Side A)

13.2. Main P.C.B. (Side B)

13.3. Tuner and CD Interface P.C.B.

13.4. Panel, USB and Music Port P.C.B.

14 Voltage and Waveform Measurement

14.1. Voltage Measurement

14.2. Waveform Chart

15 Exploded View and Replacement Parts List

15.1. Cabinet Parts Location 1

15.2. Cabinet Parts Location 2

15.3. Packaging (For SC-AKX600LM)

15.4. Packaging (For SC-AKX800LM)

15.5. Mechanical Replacement Part List

15.6. Electrical Replacement Parts List

3

1 Safety Precautions

1.1. General Guidelines

1. IMPORTANT SAFETY NOTICE

There are special components used in this equipment which are i mportant for safety. These parts are marked by in the

Schematic Diagrams, Circuit Board Layout, Exploded Views and Replacement Parts List. It is essential that these critical parts

should be replaced with manufacturer’s specified parts to prevent X-RADIATION, shock, fire, or other hazards. Do not modify

the original design without permission of manufacturer.

2. An Isolation Transformer should always be used during the servicing of AC Adaptor whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this protects the technician from accidents resulting in personal

injury from electrical shocks. It will also protect AC Adaptor from being damaged by accidental shorting that may occur during

servicing.

3. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

4. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properl y

installed.

5. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩ and 5.2MΩ.

When the exposed metal does not have a return path to the chassis, the reading must be

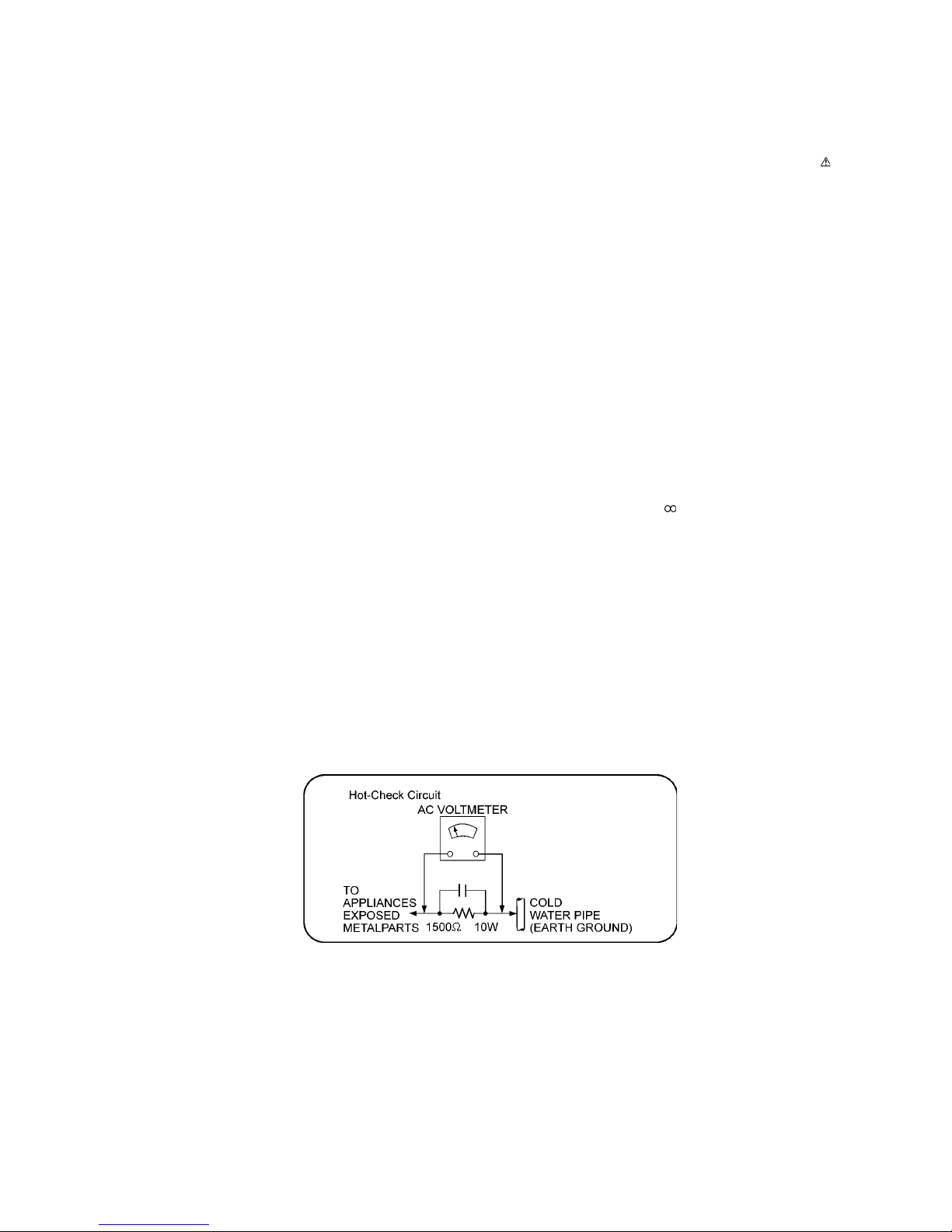

1.1.2. Leakage Current Hot Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15μF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1-1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent)

may be used to make the hot checks, leakage current must not exceed 1/2 milliamp. In case a measurement is outside of the

limits specified, there is a possibility of a shock hazard, and the equipment should be re paired and rechecked before it is

returned to the customer.

Figure 1-1

4

1.2. Before Repair and Adjustment

Disconnect AC power to discharge AC capacitor (in SMPS Module) as indicate below diagram through a 10 Ω, 10 W resistor to

ground.

Figure 1-2

Caution:

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac to avoid overcurrent.

Current consumption at AC 127 V, 60 Hz in Power ON, FM Tuner at volume minimal mode should be ~ 750 mA (LM).

1.3. Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

• No sound is heard when the power is turned on.

• Sound stops during a performance

.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

5

1.4. Power Supply using SMPS Module

This model uses Switching Mode Power Supply (SMPS Module) to provide the power supply to the unit. Here is the supplied part

no. for the Module

1) N0AB2GP00003

Figure 1-3

6

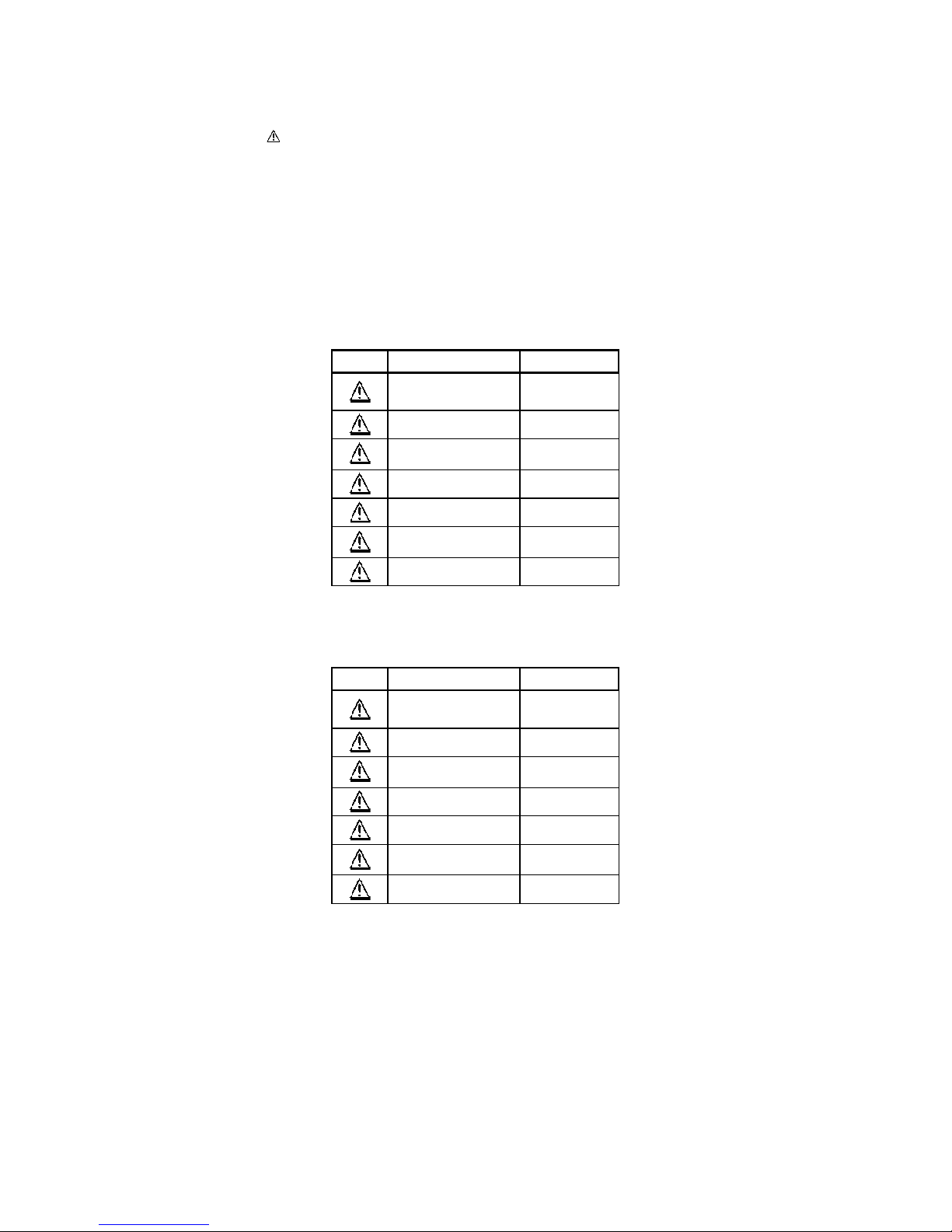

1.5. Safety Parts Information

Safety Parts List:

There are special components used in this equipment which are important for safety.

These parts are marked by in the Schematic Diagrams, Exploded View & Replacement Parts List. It is essential that these

critical parts should be replaced with manufacturer’s specified parts to prevent shock, fire or other hazards. Do not modify the

original design without permission of manufacturer.

Model:

SC-AKX600LM

Safety

K2CB2CB00022

RKM0765-KL

RKM0765Z-K

RD-DDL112-PX

RQT0A34-1M

N0AB2GP00003

CD UNIT

RGR0473B-G

Part No.

SWITCHING POWER

SUPPLIES(AC-DC CONVERTER

TOP CABINET (BEND)

TOP CABINET (UNBENT)

AC CORD.

O/I BOOK (SP)

Part Name

REAR PANEL

Model:

SC-AKX800LM

Safety

K2CB2CB00022

RKM0765-KL

RKM0765Z-K

RD-DDL112-PX

RQT0A34-1M

N0AB2GP00003

CD UNIT

RGR0473C-D

Part No.

SWITCHING POWER

SUPPLIES(AC-DC CONVERTER

TOP CABINET (BEND)

TOP CABINET (UNBENT)

AC CORD.

O/I BOOK (SP)

Part Name

REAR PANEL

7

2Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices.

The following techniques should be used to help reduce the incidence of compon ent damage caused by electrostatic discharge

(ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as al uminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

CAUTION:

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to damage an ES device).

2.2. Precaution of Laser Diode

Caution:

This product utilizes a laser diode with the unit turned “on”, invisible laser radiation is emitted from the pickup lens.

Wavelength: 790 nm (CD)

Maximum output radiation power from pickup: 100 μW/VDE

Laser radiation from the pickup unit is safety level, but be sure the followings:

1. Do not disassemble the pickup unit, since radiation from exposed laser diode is dangerous.

2. Do not adjust the variable resistor on the pickup unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at pickup lens for a long time.

8

2.3. General description about Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86°F) more than that

of the normal solder.

Definition of PCB Lead Free

Solder being used

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead

solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30 degrees

C (662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: tin (Sn), 96.5%, silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

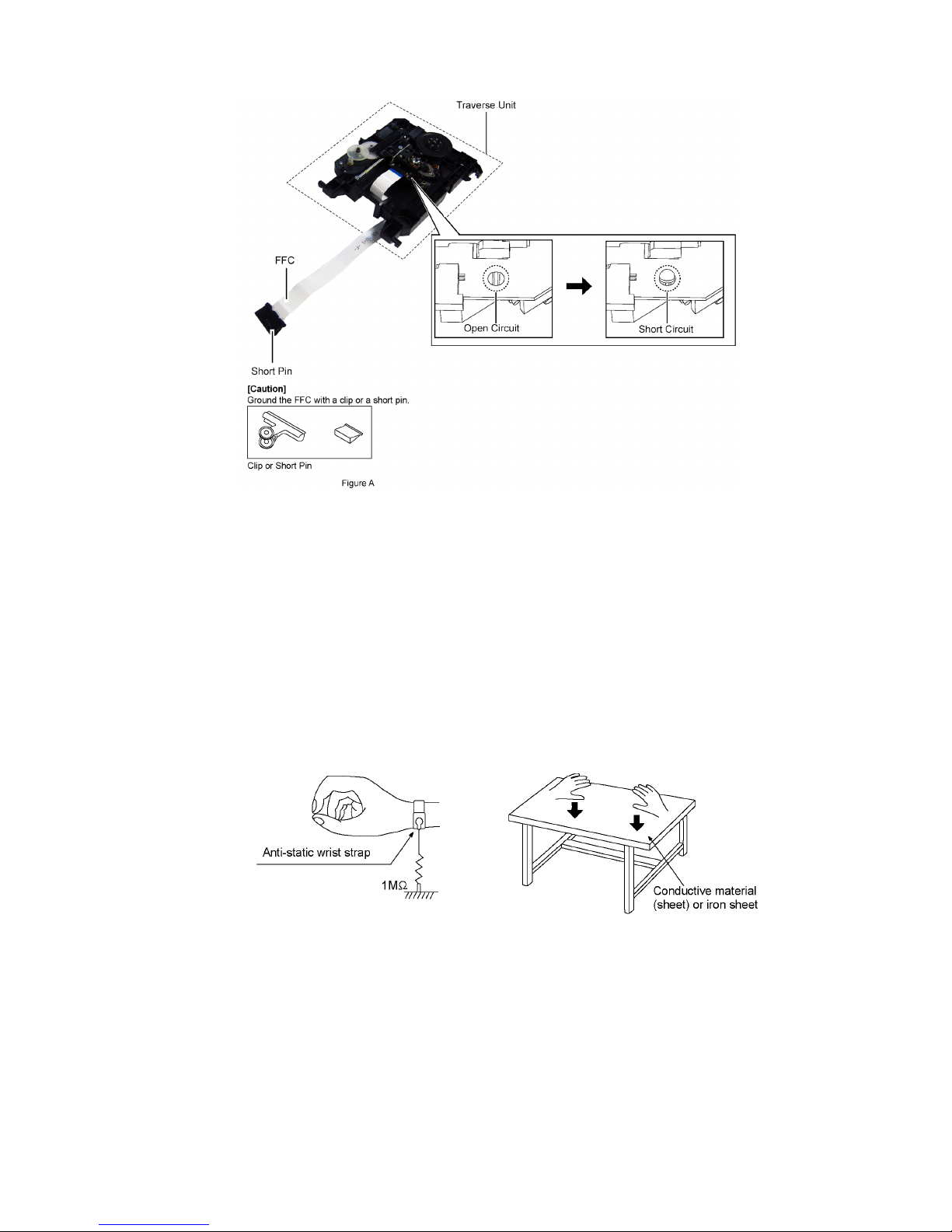

2.4. Handling Precautions for Traverse Unit

The laser diode in the optical pickup unit may break down due to static electricity of clothes or human body. Special care must be

taken avoid caution to electrostatic breakdown when servicing and handling the laser diode in the traverse unit.

2.4.1. Cautions to Be Taken in Handling the Optical Pickup Unit

The laser diode in the optical pickup unit may be damaged due to electrostatic discharge generating from clothes or human body.

Special care must be taken avoid caution to electrostatic discharge damage when servicing the laser diode.

1. Do not give a considerable shock to the optical pickup unit as it has an extremely high-precise

structure.

2. To prevent the laser diode from the electrostatic discharge damage, the flexible cable of the optical pickup unit removed

should be short-circuited with a short pin or a clip.

3. The flexible cable may be cut off if an excessive force is applied to it. Use caution when handling the flexible cable.

4. The antistatic FFC is connected to the new optical pickup unit. After replacing the optical pickup unit and connecting the flexi-

The letter of “PbF” is printed either foil side or components side on the PCB using the lead free solder.

(See right figure)

9

ble cable, cut off the antistatic FFC.

Figure 2-1

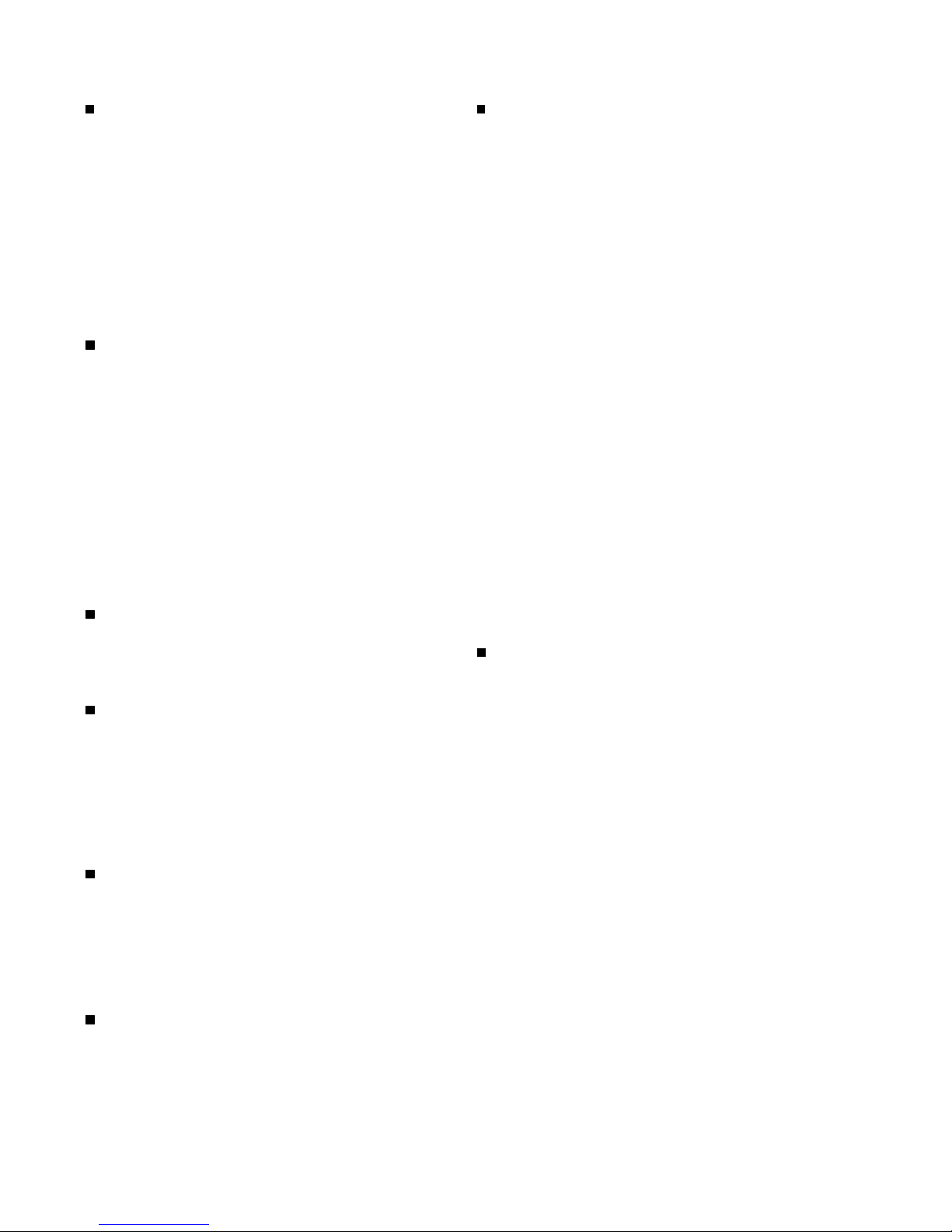

2.5. Grounding for electrostatic breakdown prevention

• As for parts that use optical pick-up (laser diode), the optical pick-up is destroyed by the static electricity of the working environment.

Repair in the working environment that is grounded.

2.5.1. Worktable grounding

• Put a conductive material (sheet) or iron sheet on the area where the optical pickup is placed and ground the sheet.

2.5.2. Human body grounding

• Use the anti-static wrist strap to discharge the static electricity form your body (Figure 2-2).

Figure 2-2

10

3 Service Navigation

3.1. Service Information

This service manual contains technical information which will allow service personnel’s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, this information will be follow ed by supplement service manual to be filed with original service

manual.

3.1.1. Software Update Procedure

UPDATE PROCEDURE

Perform the following steps.

Ɣ Step 1: Preparing USB devic

e

Ɣ Step 2: Software Update

Step 1: Preparing USB device

Before start creating the update USB, it is nessesary to check the update file.

It is important to use the correct file otherwise USB version up process will not

working.

Note: Please do not rename the file as the updating process will look for above naming. If different

name, version up process will not work.

To create USB update, copy the desired FRM file (depends on model) into USB device.

Please make sure there is no other files inside the USB device.

Step 2: Software Update

<Caution>

Ź During the update process, do not disconnect the AC power supply cord.

Ź Do not press any buttons, except as instructed. Failure to do so may result in the set

becoming unresponsive which will require repair.

Step:

Ź Set need to be turn ON in order to support USB update process.

Ź Go to USB selector until the display show "NODEVICE".

1. Insert USB device (With FRM file inside)

2. During the update process, the below message will shown on the display.

3. When "SUCCESS" display appear, unplug USB then ac out supply. Firmware updation process

completed.

Thisistheprecentageof

theupdateprocess.It

willstartwith0%until

99%

11

4 Specifications

Amplifier section

RMS output power stereo mode

Front Hi

340 W per channel (3 Ω),1 kHz, 30% THD (for AKX600)

295 W per channel (3 Ω),1 kHz, 30% THD (for AKX800)

Front Lo

460 W per channel (2 Ω),100Hz, 30% THD (for AKX600)

470 W per channel (2 Ω),100Hz, 30% THD (for AKX800)

Subwoofer Ch

470 W per channel (2 Ω),100Hz, 30% THD (for AKX800)

Total RMS stereo mode power

2000 W (for AKX800)

Tuner, terminals section

Preset memory FM 30 stations

AM 15 stations

Frequency modulation (FM)

egnar ycneuqerF

(100 kHz step)

87.9 MHz to 107.9 MHz (200 kHz step)

57slanimret annetnA Ω (unbalanced)

Amplitude modulation (AM)

egnar ycneuqerF (10 kHz step)

AUX 1

)metsys 1( kcaj niPtupni oiduA

AUX 2

k 7.4 ,Vm 001ytivitisneS Ω

Disc section

Discs played (8 cm or 12 cm) CD, CD-R/RW (CD-DA, MP3*)

* MPEG-1 Layer 3

Pick up

)DC( mn 097htgnelevaW

USB section

USB Port

deeps lluf 0.2 BSUdradnats BSU

)3pm.*( 3PM troppus tamrof elif aideM

USB device file system FAT12, FAT16, FAT32

USB recording

spbk 821etar tiB

)ylno DC( x3 ,x1deeps gnidrocer BSU

)3pm.*( 3PMtamrof elif gnidroceR

Internal memory section

Memory

BG 2ezis yromeM

)3pm.*( 3PMtroppus tamrof elif aideM

Memory recording

spbk 821 etar tiB

Memory recording s )ylno DC( x3 ,x1deep

)3pM .*( 3PMtamrof elif gnidroceR

Bluetooth

®

section

General

Power supply AC 127 V, 60 Hz

Power consumption 173 W

Dimensions (W x H x D) 348 mm x 192 mm x 303 mm

Weight 3.6 kg

Operating temperature range 0 °C to +40 °C

Operating humidity range 35% to 80% RH

(no condensation)

Power Consumption in

standby mode

Power Consumption in standby

mode

(With "BLUETOOTH STANDBY" set

to "ON")

9.2 Wh/day (approximate)

Note:

1. Specifications are subject to change without notice.

Weight and dimension are approximate

2. Total harmonic distortion is measured by the digital spectrum

analyzer.

PMPO Output Power 17600 W (for AKX600)

22000 W (for AKX800)

zHM 0.801 ot zHM 5.78

zHk 0171 ot zHk 025

USB port power Max 500mA

Version

Bluetooth

®

Ver.2.1 + EDR

Class Class 2

Supported profiles

A2DP, AVRCP, SPP, OPP, FTP

Operating frequency 2.4 GHz band, FH-SS

Operating distance 10 m line of sight

Speaker section

Speaker unit(s)

Impedance High 3 / Low 2

Output sound presure 87dB/W(1m)

Frequency range 42Hz a 28 kHz (-16 dB)

46Hz a 23 kHz (-10 dB)

Woofer 8 cm cone type

Super Woofer 20 cm cone type

Type 3 way, 3 speaker system

For SB-AKX800

Tweeter 6 cm cone type

Weight 7.1 kg

Ω Ω

Dimensions (W x H x D) 300 mm x 401 mm x 292 mm

Speaker unit(s)

Impedance 2

Output sound presure 88dB/W(1m)

Frequency range 42Hz a 250 Hz (-16 dB)

44Hz a 200 Hz (-10 dB)

Super Woofer 25 cm cone type

Type 1 way, 1 speaker system

For SB-AKW800

Weight 8.3 kg

Ω

Dimensions (W x H x D) 360 mm x 401 mm x 271 mm

Power Consumption in

normal mode

173 Wh/day (considering 1 hour

use per day)

6.9 Wh/day (considering 23 hours

a day standby)

1600 W (for AKX600)

12

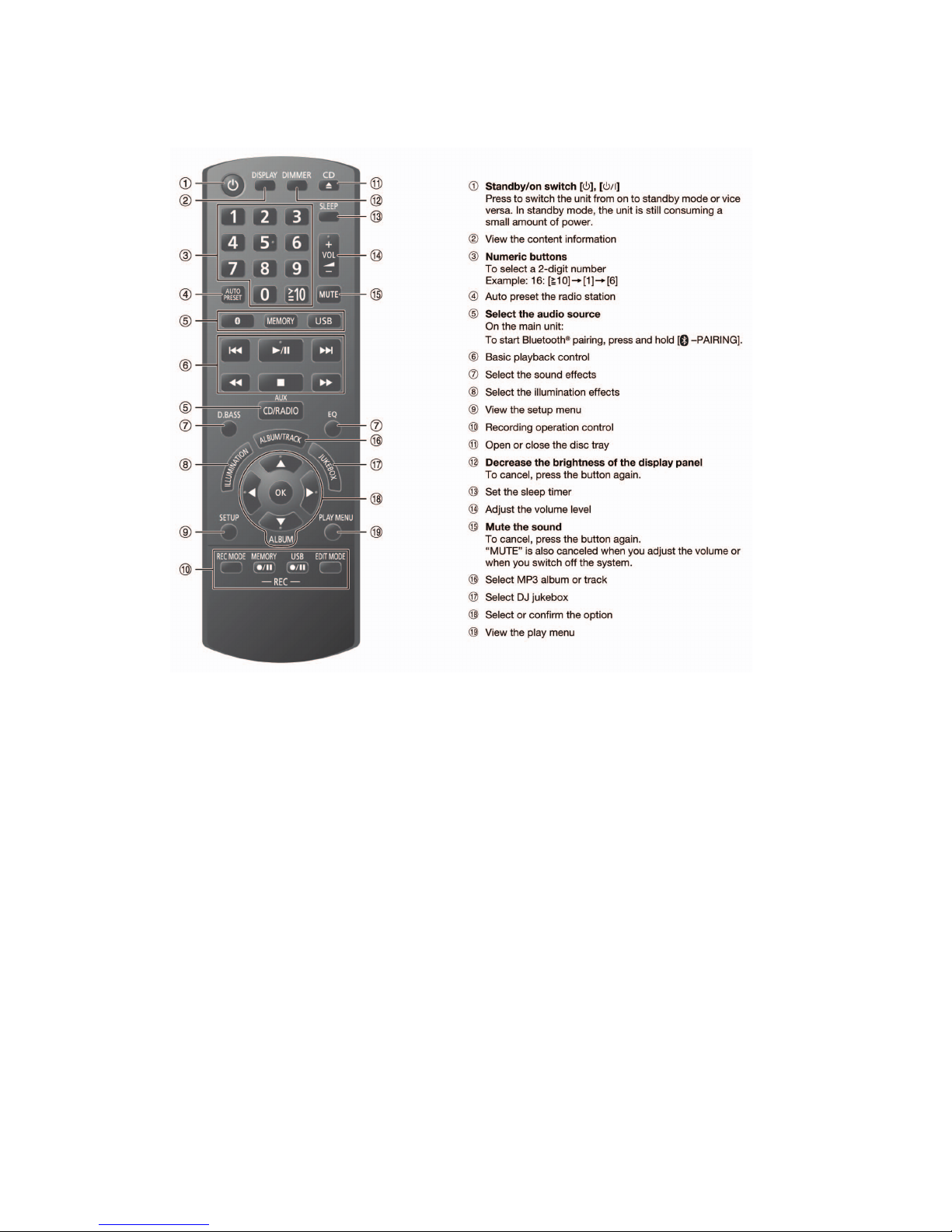

5 Location of Controls and Components

5.1. Remote Control Key Button Operation

13

5.2. Main Unit Key Button Operation

14

6 Service Mode

6.1. Cold-Start

6.2. Sales Demonstration Lock Function

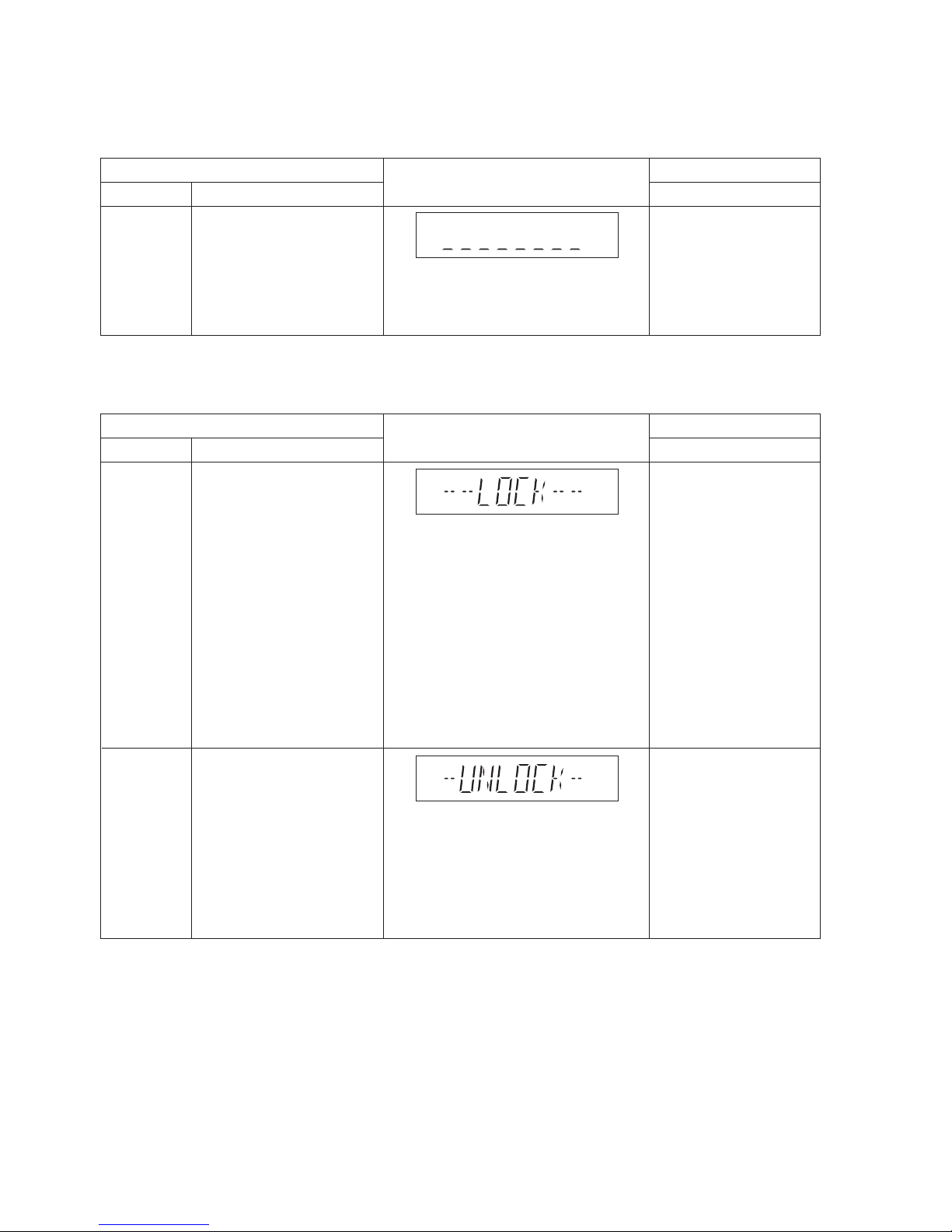

FL Display

Key Operation

Front Key

Item

DescriptionMode Name

Cold Start

To carry out cold-start or initialize

to shipping mode

1. Unplug AC power cord.

2. Press & hold [POWER]

button.

3. Plug in AC power cord

while [POWER] button

being pressed.

4. Release [POWER] button.

Entering into

Sales

Demonstration

Lock Mode

To enter into sales demonstration

lock mode.

1. Turn on the unit.

2. Select to any mode

function.

3. Press and hold

[;OPEN/CLOSE] and

[CD/RADIO/AUX] keys for

5 sec or more.

The display will show upon

entering into this mode for

2 sec.

Note: [;OPEN/CLOSE]

button is invalid and the main

unit displays "LOCKED" while

the lock function mode is

entered.

Cancellation of

Sales

Demonstration

Lock Mode

To cancel sales demonstration

lock mode.

1. Turn on the unit.

2. Select to CD mode function.

3. Set volume to Vol 19.

4. Press and hold

[;OPEN/CLOSE] and

[CD/RADIO/AUX] keys for

5 sec or more.

The display will show upon

entering into this mode for

2 sec.

FL Display

Key Operation

Front Key

Item

DescriptionMode Name

15

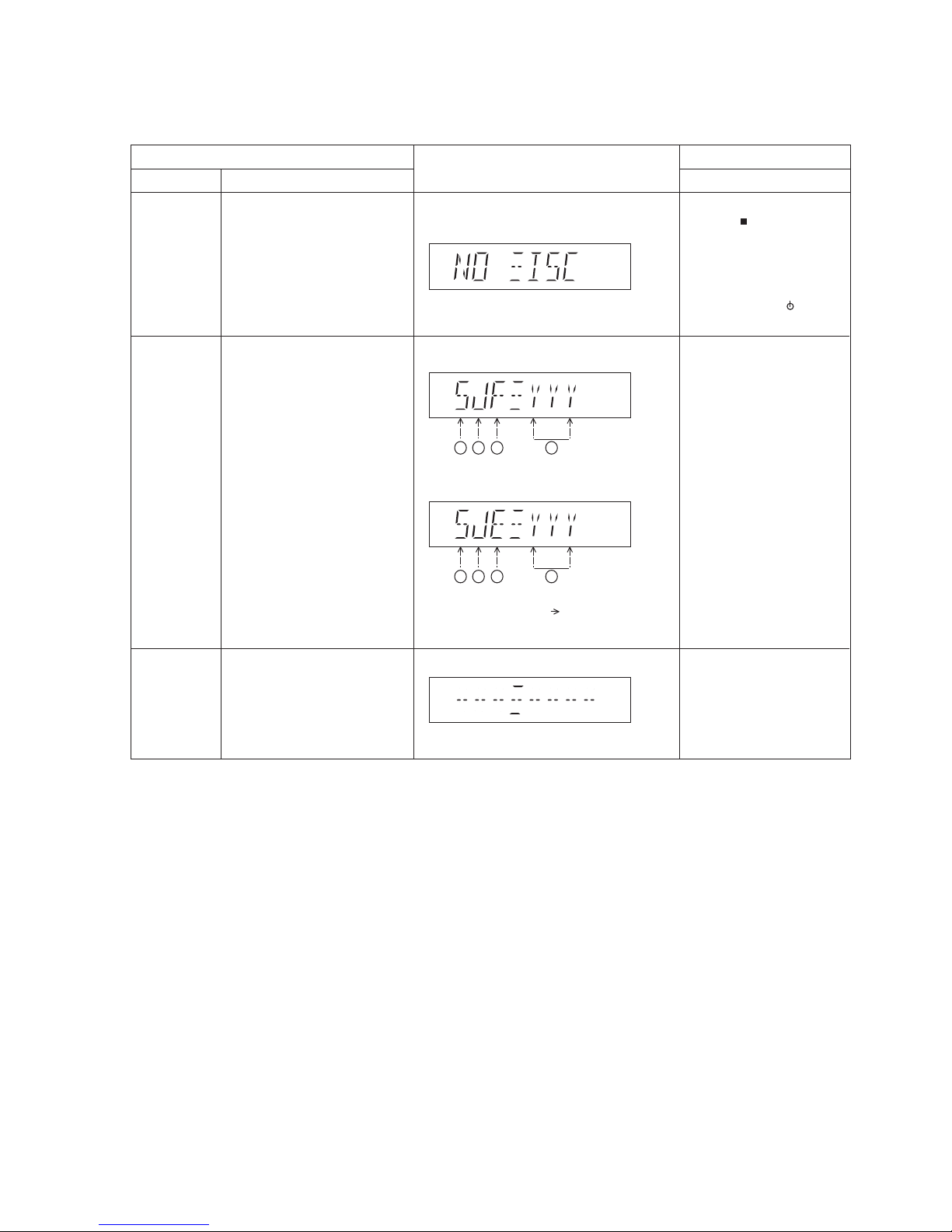

6.3. Doctor Mode Table

6.3.1. Doctor Mode Table 1

FL Display

Key Operation

Front Key

Item

DescriptionMode Name

Doctor Mode

EEPROM

checksum

check

(Display 1) (For AKX600)

(Decimal)

1 2 3 4

To enter into Doctor Mode In CD Mode:

1. Press [ ] button on

main unit follow by [4]

and [7] on remote control.

In CD mode:

1. Enter into Doctor Mode

2. To exit, press [DELETE]

button on remote control or,

press [POWER, /I] button

on Main Unit

Displaying of

1. Year Develop.

2. Model Type.

3. ROM Type.

4. Firmware Version.

(Display 2) (For AKX800)

Cold Start

To active cold start upon next AC

power up when reset start is

execute the next time.

In Doctor Mode:

1. Press [4] button on the

remote control.

Version No. (001 ~ 999) specific for each

firmware

(Decimal)1 2 3 4

16

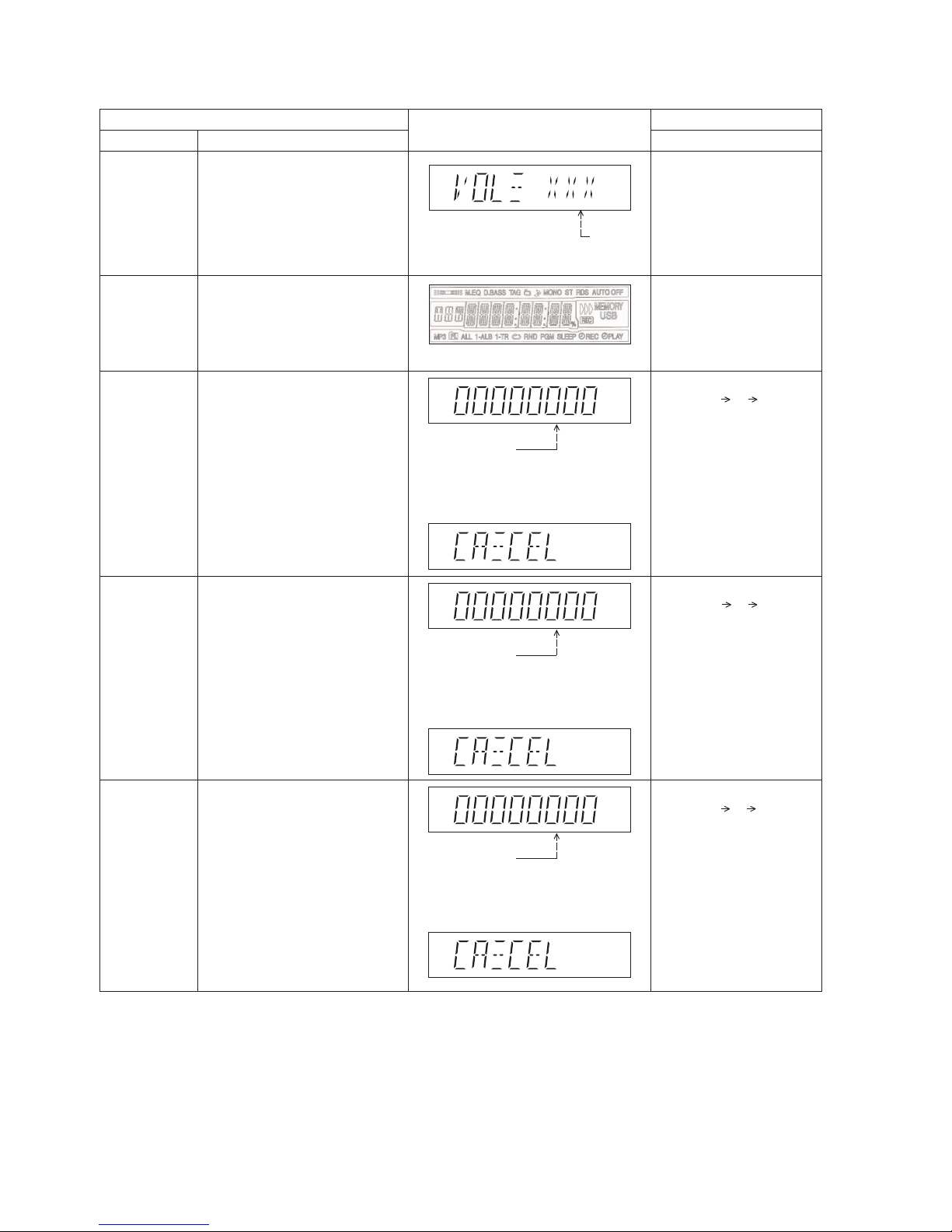

6.3.2. Doctor Mode Table 2

FL Display

Key Operation

Front Key

Item

DescriptionMode Name

Volume Setting

Check

FL Display Check

To check volume setting of the main

unit.

To check FL segment display.

All segments will light up while all LED

blink at 0.5s intervals.

In Doctor Mode:

1. Press [7], [8], [9] button on

the remote control.

In Doctor mode:

1. Press [1] button on the

remote control.

2. To cancel this mode, press

[0] button on the remote

control.

Press [7]: VOL50

Press [8]: VOL35

Press [9]: VOL0

Volume

In this mode, the tray will open & close

automatically.

Cancellation Display

Loading Test To determine open & close

operation of the CD Mechanism Unit.

The counter will

increment by one.

When reach 99999999

will change to 00000000

Cancellation Display

Traverse Test To determine traverse unit

operation for inner & outer access track.

The counter will

increment by one.

When reach 99999999

will change to 00000000

The counter will

increment by one.

When reach 99999999

will change to 00000000

Cancellation Display

Reliability Test

(Combination)

In this mode, ensure the CD is in the

main unit.

To determine traverse unit

operation & open/close operation of the

mechanism.

In this mode, ensure the CD is in the

main unit.

In Doctor Mode:

1. Press [10] [2] [1] button

on the remote control.

In Doctor Mode:

2. To cancel this mode, press

[0] button on the remote

control.

2. To cancel this mode, press

[0] button on the remote

control.

2. To cancel this mode, press

[0] button on the remote

control.

1. Press [10] [1] [2] button

on the remote control.

In Doctor Mode:

1. Press [10] [1] [5] button

on the remote control.

17

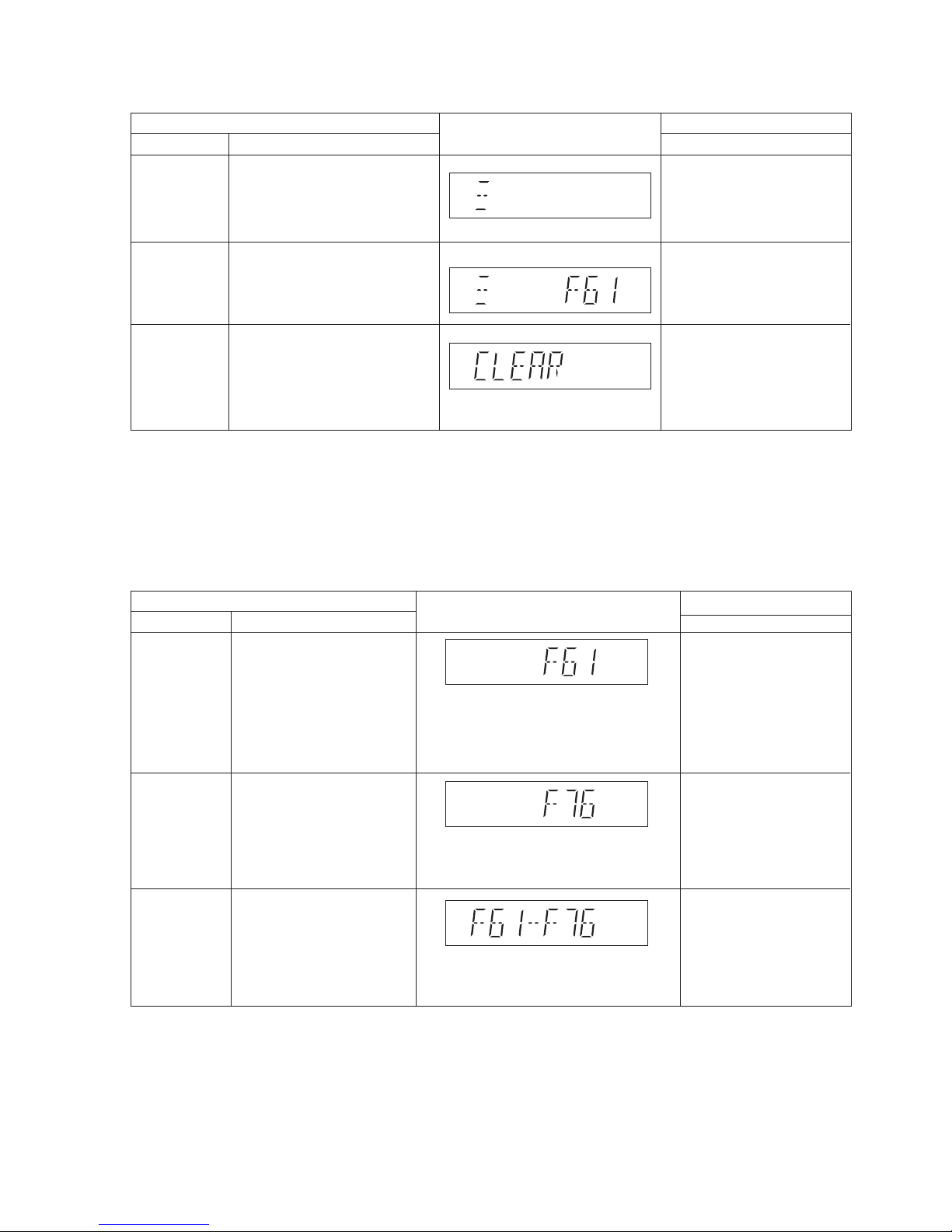

6.4. Self-Diagnostic Mode

6.5. Self-Diagnostic Error Code Table

Self-Diagnostic Function provides information on any problems occurring for the uni t and its respective components by displaying

the error codes. These error code such as U**, H** and F** are stored in memory and held unless it is cleared.

The error code is automatically display after entering into self-diagnostic mode.

6.5.1. Power Supply Error Code Table

FL Display

Key Operation

Front Key

Item

DescriptionMode Name

Self Diagnostic

Mode

To enter into self diagnostic checking Step 1: Select CD mode

(Ensure no disc is inserted).

To exit, press [8] on main unit or

remote control.

Step 2: Press & hold [g] button

follow by [y/i] on

main unit for 2 seconds.

Error Code

Information

System will perform a check on

any unusual/error code from the

memory

Example: Step 1: In self diagnostic mode,

Press [g] on main unit.

To exit, press [8] on main unit or

remote control.

Delete error code To clear the stored in memory

(EEPROM IC)

Step 1: In self diagnostic mode,

Press [0] on remote control.

FL Display

Key Operation

Front Key

Item

DescriptionMode Name

Error Code F61 Diagnosis Contents:

Power Amp IC output abnormal.

Upon power on, PCONT=HIGH,

DC_DET_AMP after checking LSI.

Error Code F76 Diagnosis Contents:

Power Amp IC output abnormal.

DC_DET_PWR.

Error Code

F61-76

Diagnosis Contents:

Power Amp IC output abnormal.

Both DCDET (NG).

Press [g] on main unit for next

error.

Press [g] on main unit for next

error.

Press [g] on main unit for next

error.

18

6.5.2. CD Mechanism Error Code Table

6.5.3. Bluetooth Error Code Table

FL Display

Key Operation

Front Key

Item

DescriptionMode Name

Error Code

CD H15

Diagnosis Contents:

CD Open Abnormal

.

During operation POS_SW_R On

fail to be detected within 4 sec.

Error No. shall be clear by force

or during cold start.

Error Code

CD H16

Diagnosis Contents:

CD Closing Abnormal

.

During operation POS_SW_CEN

On fail to be detected within 4 sec.

Error No. shall be clear by force

or during cold start.

Error Code

F26

Diagnosis Contents:

Communication between CD

servo LSI and micro-p abnormal.

During switch to CD function, if

SENSE = “L” within fail safe time

of 20ms.

Press [g] on main unit for next

error.

Press [g] on main unit for next

error.

Press [g] on main unit for next

error.

FL Display

Key Operation

Front Key

Item

DescriptionMode Name

Error Code F70 Diagnosis Contents:

Bluetooth Communication.

Communication between

Bluetooth module and micro-p

abnormal.

Error Code F77 Diagnosis Contents:

Bluetooth Address Error

If there is no valid Bluetooth

address stored in the

EEPROM IC.

Press [g] on main unit for next

error.

Press [g] on main unit for next

error.

19

7 Troubleshooting Guide

“Contents for this section is not available at time of issue”

20

8 Disassembly and Assembly Instructions

• Illustration is based on SA-AKX800LM.

Caution Note:

• This section describes the disassembly and/or assembly procedures for all major printed circuit boards & main components for the unit. (You may refer to the section of “Main components and P.C.B Locations” as described in the service

manual)

• Before carrying out the disassembly process, please ensure all the safety precautions & procedures are followed.

• During the disassembly and/or assembly process, please handle with care as there may be chassis components with

sharp edges.

• Avoid touching heatsinks due to its high temperature after prolong use. (See caution

as described below)

• During disassembly and assembly, please ensure proper service tools, equipments or jigs is being used.

• During replacement of component parts, please refer to the section of “Replacement Parts List” as described in the ser-

vice manual.

• Select items from the following indexes when disassembly or replacement are required.

• Disassembly of Top Cabinet

• Disassembly of Front Panel Unit

• Disassembly of Panel P.C.B.

• Disassembly of USB P.C.B.

• Disassembly of Music Port P.C.B.

• Disassembly of Rear Panel

• Disassembly of Main P.C.B.

• Disassembly of SMPS Module

• Disassembly of Tuner P.C.B.

• Disassembly of CD Mechanism Unit

• Disassembly of CD Interface P.C.B.

8.1. Types of Screws

RHD30007-K2J

RHD30119-S

RHD26046

RHD30111-31

RHDX30005-J

RHDX031008

21

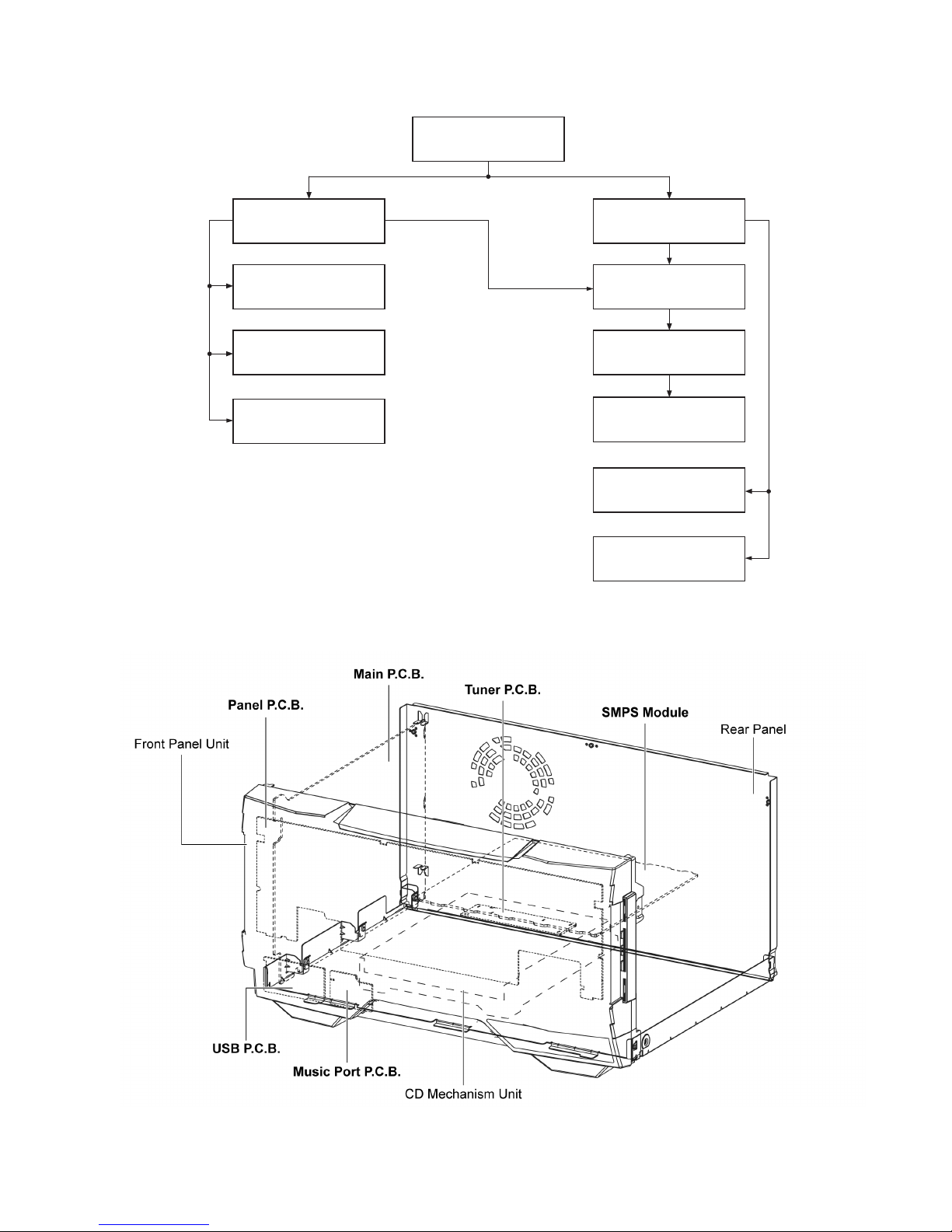

8.2. Disassembly Flow Chart

8.3. Main Components and P.C.B. Locations

Main P.C.B.

SMPS Module

Tuner P.C.B.

Rear Panel

CD Mechanism

Unit

CD Interface

P.C.B.

Front Panel Unit

Top Cabinet

Panel P.C.B.

USB P.C.B.

Music Port P.C.B.

22

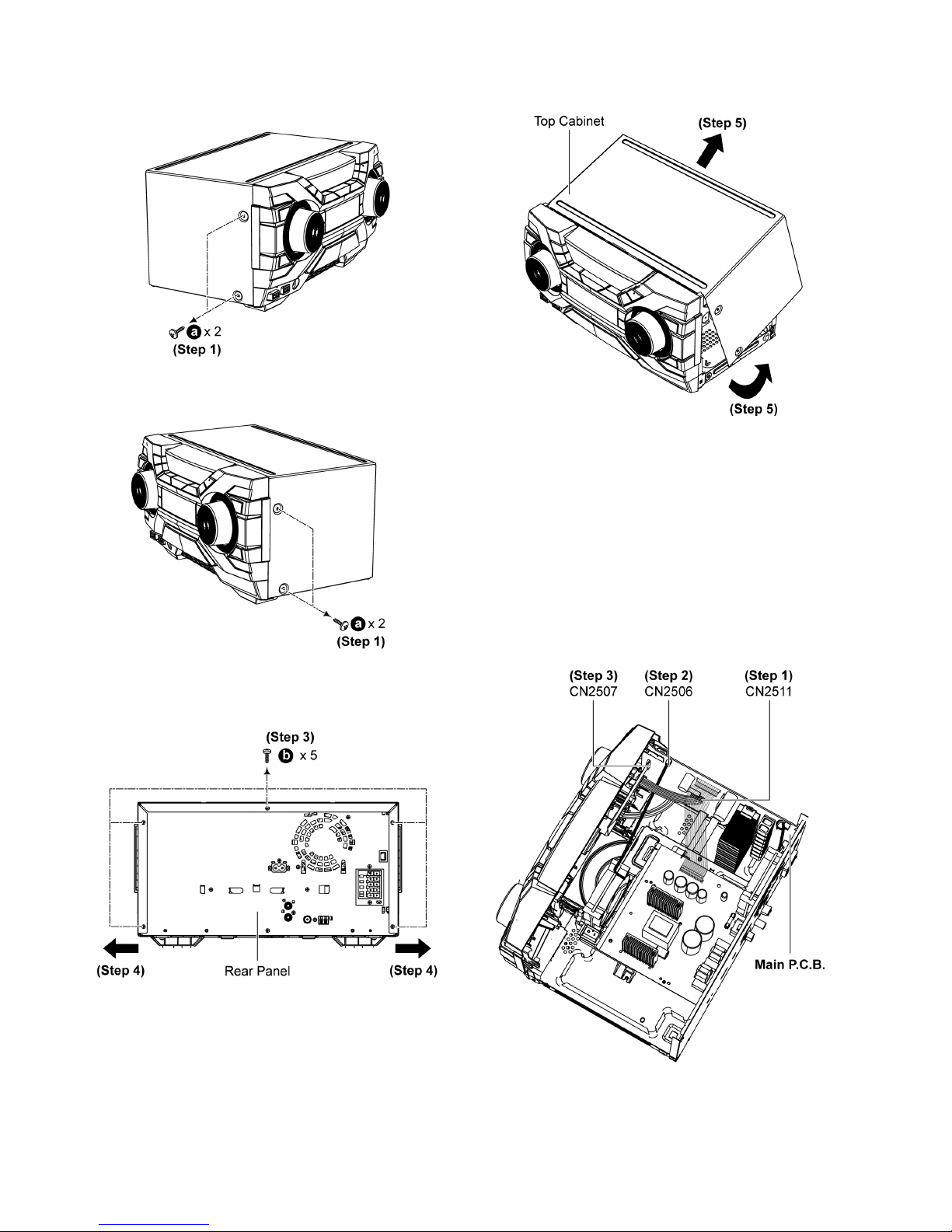

8.4. Disassembly of Top Cabinet

Step 1 Remove 2 screws.

Step 2 Remove 2 screws.

Step 3 Remove 5 screws.

Step 4 Slightly release both sides of Top Cabinet.

Step 5 Slightly lift up to remove Top Cabinet.

8.5. Disassembly of Front Panel

Unit

• Refer to “Disassembly of Top Cabinet”.

Step 1 Detach 9P Cable at connector (CN2511) on Main

P.C.B..

Step 2 Detach 22P FFC at connector (CN2506) on Main

P.C.B..

Step 3 Detach 4P Cable at connector (CN2507) on Main

P.C.B..

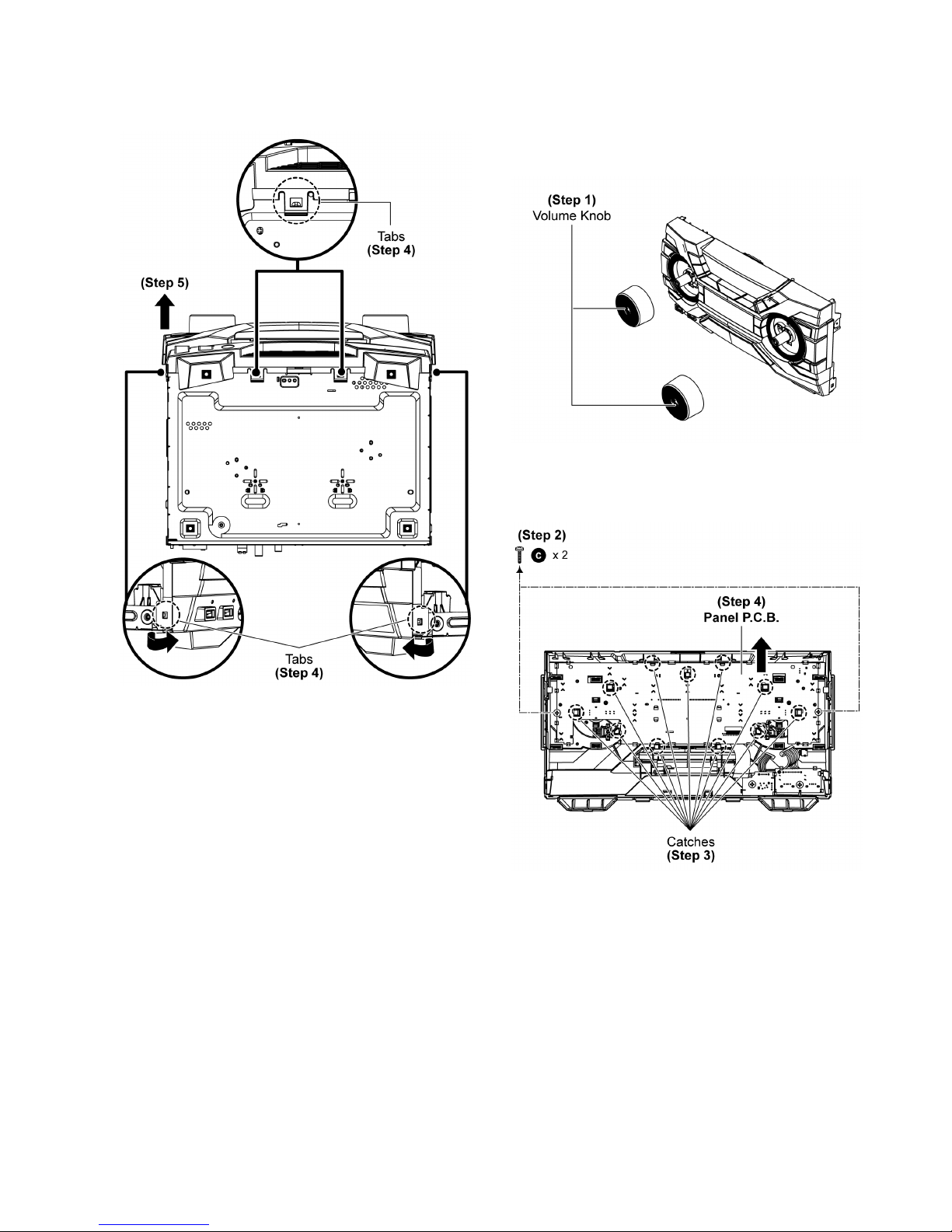

23

Step 4 Release tabs on both sides of Front Panel Unit and at

bottom of unit.

Step 5 Detach to remove Front Panel Unit.

8.6. Disassembly of Panel P.C.B.

• Refer to “Disassembly of Top Cabinet”.

• Refer to “Disassembly of Front Panel Unit”.

Step 1 Remove Volume Knob.

Step 2 Remove 2 screws.

Step 3 Release catches.

Step 4 Lift up to remove Panel P.C.B..

Loading...

Loading...