Panasonic SAXR-55-E, SAXR-55-EB, SAXR-55-EG Service manual

Specification

n AMPLIFIER SECTION

Power output (at AC 230-240 V)

DIN 1 kHz (T.H.D. 1 %)

20 Hz-20 kHz continuous power

output both channels driven

Total harmonic distortion

rated power at 20 Hz-20 kHz

Power bandwidth

both channels driven, -3 dB 4 Hz-88 kHz

Power output each channel driven (at AC 230-240 V)

DIN 1 kHz (T.H.D. 1 %)

Front (L/R) 100 W (6 Ω)

Center 100 W (6 Ω)

Surround (L/R) 100 W (6 Ω)

Surround Back (L/R) 100 W (6 Ω)

Load impedance

Front (L/R)

AorB 6-16 Ω

A and B 6-16 Ω

BI-WIRE

Center 6-16 Ω

Surround (L/R) 6-16 Ω

Surround Back (L/R) 6-16 Ω

Frequency response

CD, TAPE, TV, DVD, DVD RECORDER,

VCR1, VCR2

DVD 6CH 4 Hz-44 kHz, ±3 dB

Input sensitivity and impedance

CD, TAPE, TV, DVD/DVD 6CH, DVD

RECORDER, VCR1, VCR2

2 x 100 W (6 Ω)

2x80W(6Ω)

0.09 % (6 Ω)

(6 Ω,0.9%)

4 Hz-88 kHz, ±3 dB

200 mV/22 kΩ

6-16 Ω

ORDER NO. MD0505214C2

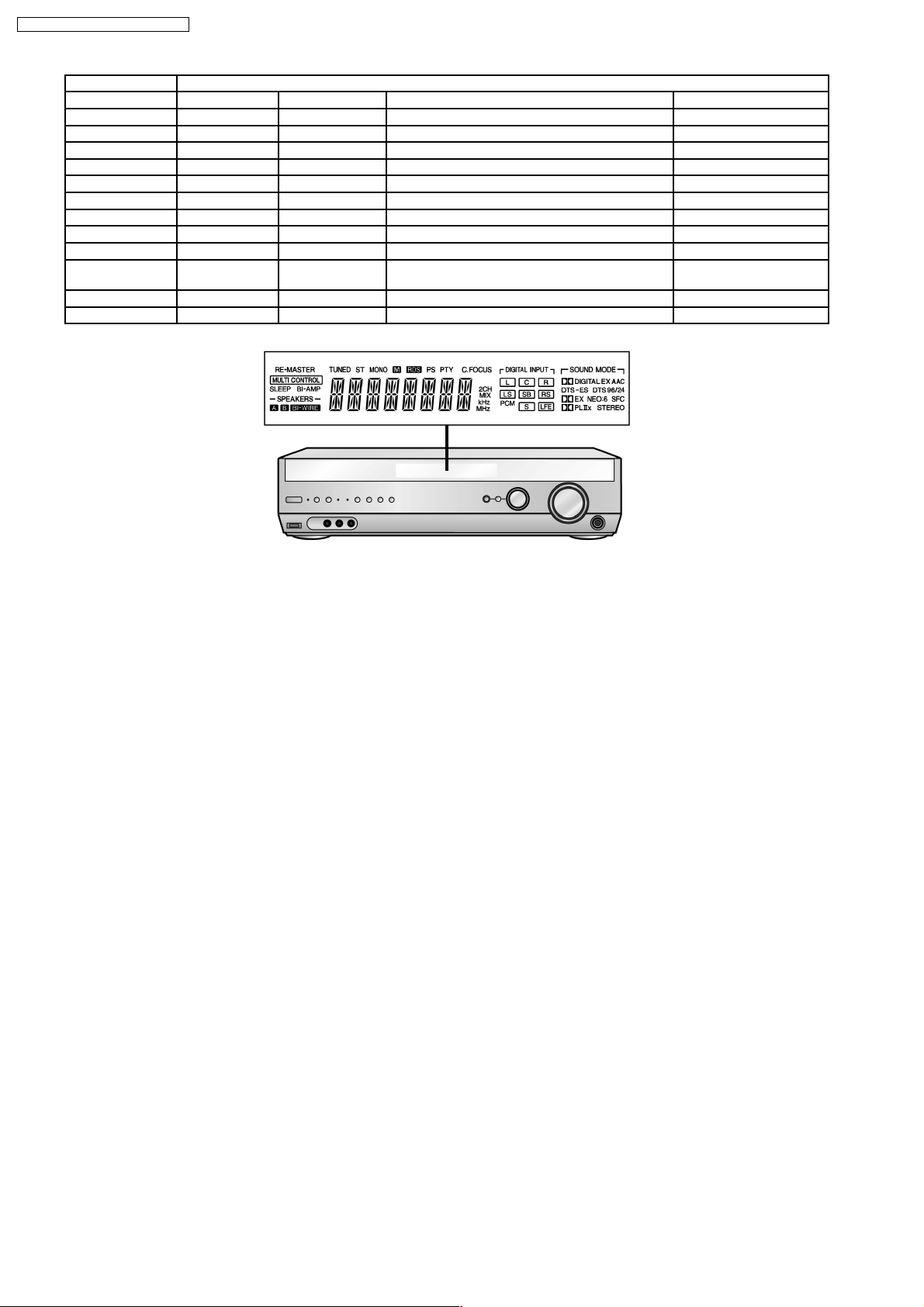

AV Control Receiver

SA-XR55E

SA-XR55EB

SA-XR55EG

Colour

(S)...............Silver Type

(K)...............Black Type (E/EG only)

S/N at rated power (6 ΩΩΩΩ)

CD, TV, DVD, DVD RECORDER

(Digital Input)

Tone controls

BASS 50 Hz, +10 to -10 dB

TREBLE

Output voltage

TAPE, DVD RECORDER

Channel balance (250 Hz-6.3 kHz) ±1 dB

Channel separation 55 dB

Subwoofer frequency response (-6 dB) 7 Hz-200 Hz

n FM TUNER SECTION

Frequency range 87.50-108.00 MHz

Sensitivity

S/N 30 dB

S/N 26 dB 1.3 µV/75 Ω

S/N 20 dB 1.2 µV/75 Ω

IHF usable sensitivity (IHF ’58) 1.5 µV/75 Ω

IHF 46 dB stereo quieting sensitivity 22 µV/75 Ω

Total harmonic distortion

MONO 0.2%

STEREO 0.3%

S/N

MONO 60 dB

STEREO 58 dB

Frequency response

(IHF, A: 103 dB)

20kHz,+10to-10dB

90 dB

200 mV

1.5 µV/75 Ω

© 2005 Matsushita Electric Industrial Co. Ltd.. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

SA-XR55E / SA-XR55EB / SA-XR55EG

20 Hz-15 kHz +1 dB, -2 dB

Alternate channel selectivity

±400 kHz 65 dB

Capture ratio 1.5 dB

Image rejection at 98 MHz 40 dB

IF rejection at 98 MHz 70 dB

Spurious response rejection at 98 MHz 70 dB

AM suppression 50 dB

Stereo separation

1 kHz

Carrier leak

19 kHz

38 kHz

Channel balance (250 Hz-6.3 kHz) ±1.5dB

Limiting point 1.2 µV

Bandwidth

IF amplifier 180 kHz

FM demodulator 1000 kHz

Antenna terminal

75 Ω (unbalanced)

40 dB

-30 dB

-50 dB

n VIDEO SECTION

Output voltage at 1 V input (unbalanced) 1±0.1 Vp-p

Maximum input voltage 1.5 Vp-p

Input/output impedance 75 Ω (unbalanced)

S-Video

Input TV, DVD, DVD

RECORDER

Output TV MONITOR

Component Video

Input

Output

n GENERAL

Power supply AC 230-240 V, 50 Hz

Power consumption

Dimensions (W × H × D)

Mass 4.6 kg

TV, DVD, DVD

RECORDER

TV MONITOR

135 W

430 mm × 107.5 mm ×

394 mm

n AM TUNER SECTION

Frequency range 522-1611 kHz

(9 kHz step)

530-1620 kHz

(10 kHz step)

Sensitivity

Selectivity (at 999 kHz)

IF rejection (at 999 kHz) 50 dB

20 µV, 330 µV/m

55 dB

Notes:

1. Specifications are subject to change without notice.

Mass and dimensions are approximate.

2. Total harmonic distortion is measured by the digital spectrum

analyzer.

CONTENTS

Page Page

1 SAFETY PRECAUTIONS

1.1. GENERAL GUIDELINES

2 Caution for AC Mains Lead

3 Before Repair and Adjustment

4 Protection Circuitry

5 Handling the Lead-free Solder

5.1. About lead free solder (PbF)

6 Accessories

7 Operating Instructions

7.1. Main Unit

7.2. Remote Control

7.3. Home Theater Connections

7.4. Other Connections

8 Disassembly and Main Component Replacement Procedures

and Operational Check

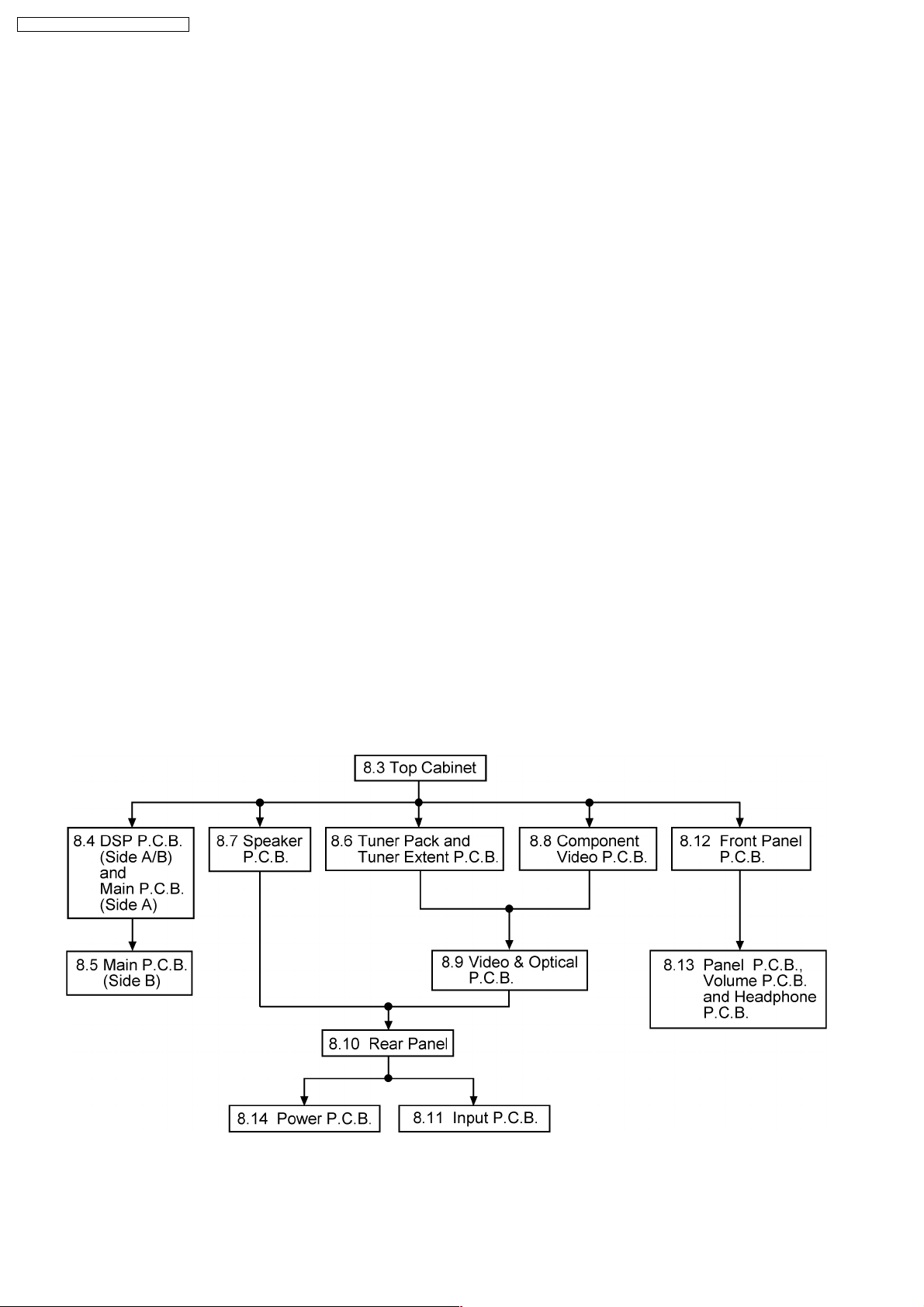

8.1. Disassembly flow chart

4

4

5

6

6

6

6

7

8

8

9

10

15

18

18

8.2. P.C.B. Positions

8.3. Disassembly of Top Cabinet.

8.4. Checking for the DSP P.C.B. (Side A/B) and Main P.C.B.

(Side A).

8.5. Disassembly and Checking of Main P.C.B. (Side B)

8.6. Disassembly of Tuner Pack and Tuner Extent P.C.B.

8.7. Disassembly and Checking of Speaker P.C.B.

8.8. Disassembly and Checking of Component Video P.C.B.

8.9. Disassembly and Checking of Video & Optical P.C.B.

8.10. Disassembly of Rear Panel

8.11. Disassembly and Checking of Input P.C.B.

8.12. Disassembly of Front Panel

8.13. Disassembly and Checking of Panel P.C.B., Volume

P.C.B. and Headphone P.C.B.

8.14. Disassembly and Checking of Power P.C.B.

9 Self Diagnosis Display Function

19

19

20

21

21

22

22

23

23

24

25

26

27

28

2

SA-XR55E / SA-XR55EB / SA-XR55EG

9.1. Automatically Displayed Error Codes 28

9.2. Display Details

9.3. Returning to Normal Display

9.4. Overload/Shutdown Detection intenal Condition

9.5. Overload/Thermal Detection Display

9.6. Activating Self Diagnosis Function (Servicing Mode)

9.7. Analog 6.1 CH Output Check Method

9.8. Returning to Normal Display

9.9. Activating Self Diagnosis Function (Doctor Mode)

10 Voltage Measurement and Waveform Chart

10.1. Voltage Measurement

10.2. Waveform Chart

11 Block Diagram

12 Notes of Schematic Diagram

13 Schematic Diagram

13.1. DSP Circuit

13.2. Main Circuit

13.3. Input Circuit &Tuner Extent Circuit

13.4. Panel Circuit

13.5. Speaker Circuit, Headphone Circuit & Volume Circuit

13.6. Power Circuit

13.7. Video & Optical Circuit

28

28

28

28

28

29

29

29

31

31

38

40

52

53

53

58

76

81

83

13.8. Component Video Circuit

14 Printed Circuit Board

14.1. DSP P.C.B. (Side A & B)

14.2. Main P.C.B. (Side A & B)

14.3. Input P.C.B.

14.4. Tuner Extent P.C.B., Panel P.C.B. & Headphone P.C.B.

14.5. Volume P.C.B. & Speaker P.C.B.

14.6. Power P.C.B.

14.7. Video & Optical P.C.B. & Component Video P.C.B.

15 Wiring Connection Diagram

16 Type Illustration of ICエs, Transistors and Diodes

17 Terminal Function of ICs

17.1. IC6801 (C2BBGF000669): Microprocessor

18 Parts Location and Replacement Parts List

18.1. Cabinet Parts Location

18.2. Electrical Parts List

18.3. Packing Materials & Accessories Parts List

18.4. Packaging

84

88

91

92

92

94

98

100

102

103

104

106

108

109

109

110

111

114

130

130

3

SA-XR55E / SA-XR55EB / SA-XR55EG

1 SAFETY PRECAUTIONS

1.1. GENERAL GUIDELINES

1. When servicing. observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

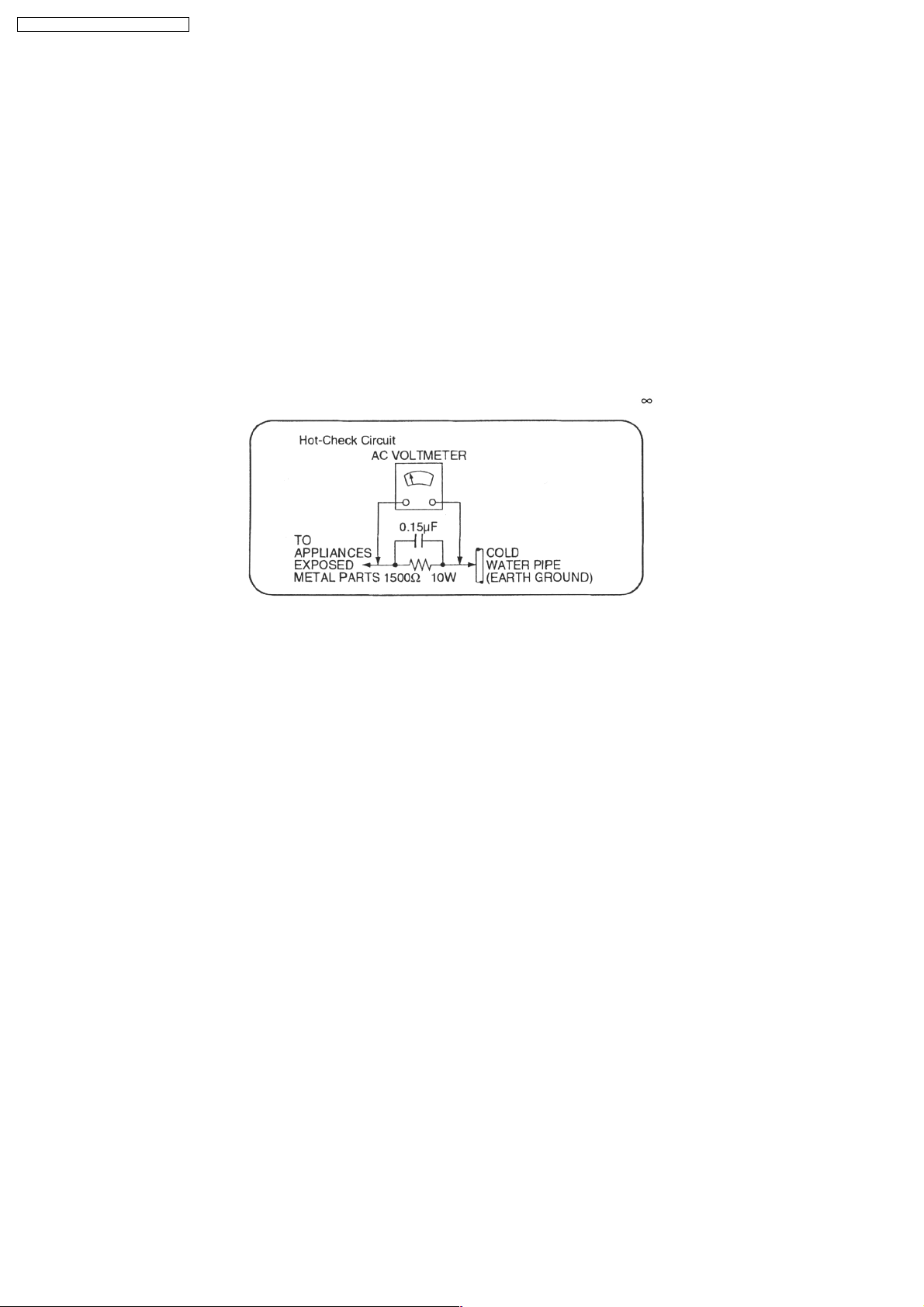

1.1.1. LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩand 5.2Ω.

When the exposed metal does not have a return path to the chassis, the reading must be

.

Fig. 1

1.1.2. LEAKAGE CURRENT HOT CHECK (See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent) may

be used to make the hot checks, leakage current must not exceed 1/2 milliamp. In case a measurement is outside of the limits

specified, there is a possibility of a shock hazard, and the equipment should be repaired and rechecked before it is returned to

the customer.

4

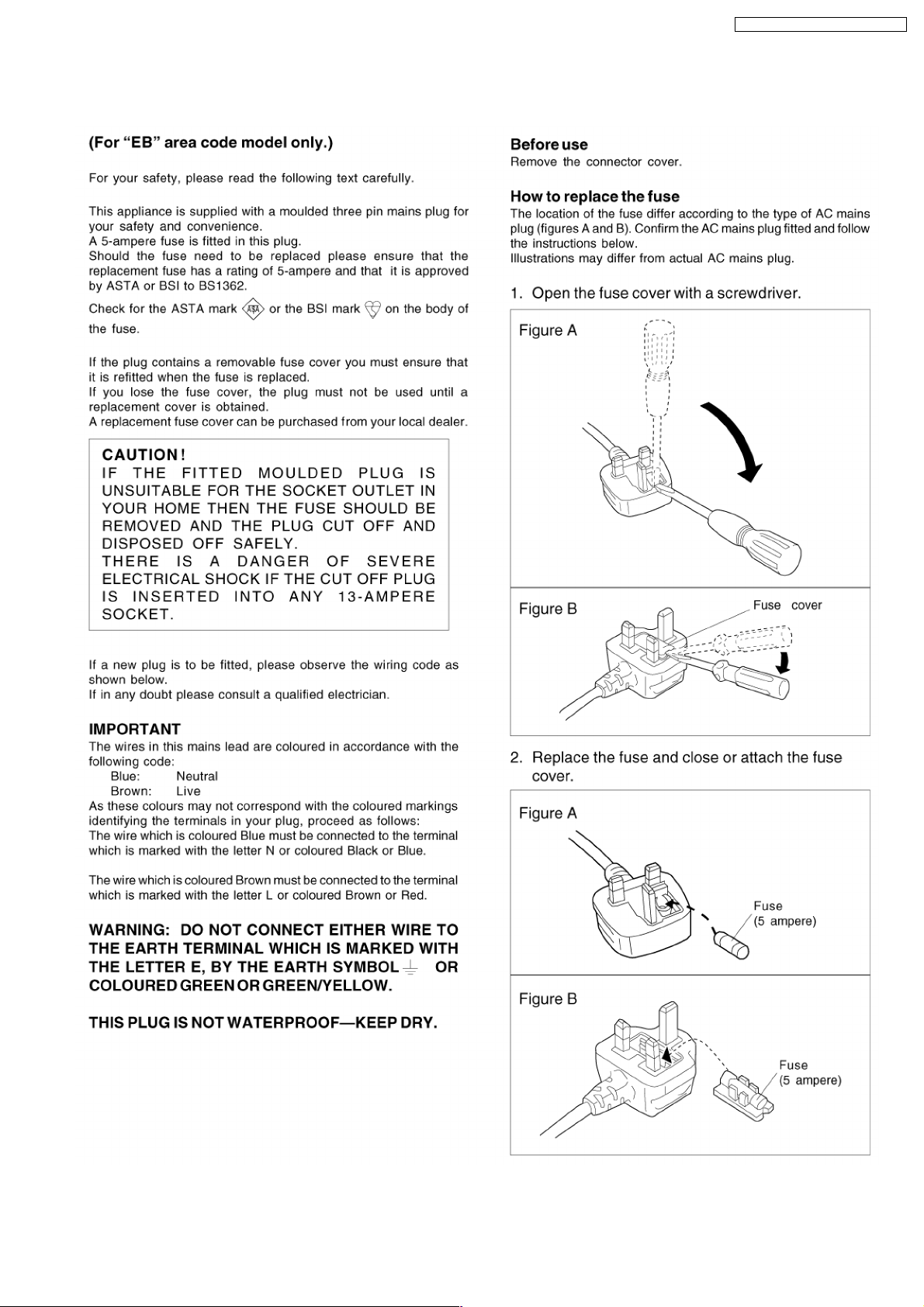

2 Caution for AC Mains Lead

SA-XR55E / SA-XR55EB / SA-XR55EG

5

SA-XR55E / SA-XR55EB / SA-XR55EG

3 Before Repair and Adjustment

Disconnect AC power, discharge Power Supply Capacitors C707, C717, C718 and C924 through a 10Ω, 10 W resistor to ground.

DO NOT SHORT-CIRCUIT DIREC

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

· Current consumption at AC 230-240 V, 50 Hz in NO SIGNAL mode should be ~400 mA.

TLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

4 Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

· No sound is heard when the power is turned on.

· Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note :

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

5 Handling the Lead-free Solder

5.1. About lead free solder (PbF)

Distinction of PbF P.C.B.:

P.C.B.s (manufactured) using lead free solder will have a PbF stamp on the P.C.B.

Caution:

· Pb free solder has a higher melting point than standard solder; Typically the melting point is 50 - 70°F (30 - 40°C) higher. Please

use a high temperature soldering iron. In case of soldering iron with temperature control, please set it to 700 ± 20°F (370 ±

10°C).

· Pb free solder will tend to splash when heated too high (about 1100°F/600°C).

· W hen soldering or unsoldering, please completely remove all of the solder on the pins or solder area, and be sure to heat the

soldering points with the Pb free solder until it melts enough.

6

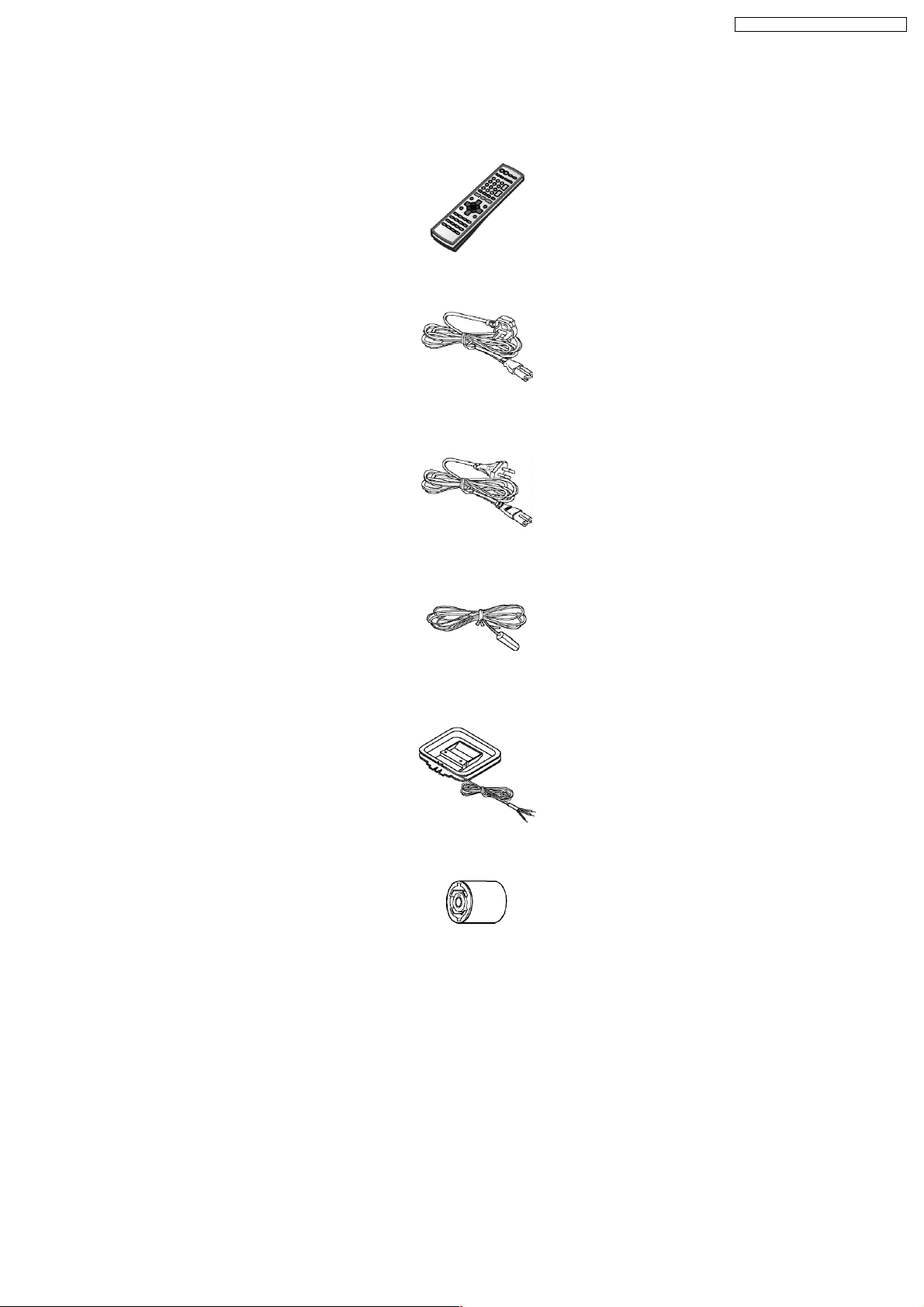

6 Accessories

Note : Refer to Packaging Materials & Accessories Part List (Section 18.3) for part number.

Remote control

AC cord (For EB

only)

SA-XR55E / SA-XR55EB / SA-XR55EG

AC cord (For E/EG

only)

FM indoor

antenna

AM loop antenna

Antenna

plug

adaptor

(For EB

only)

7

SA-XR55E / SA-XR55EB / SA-XR55EG

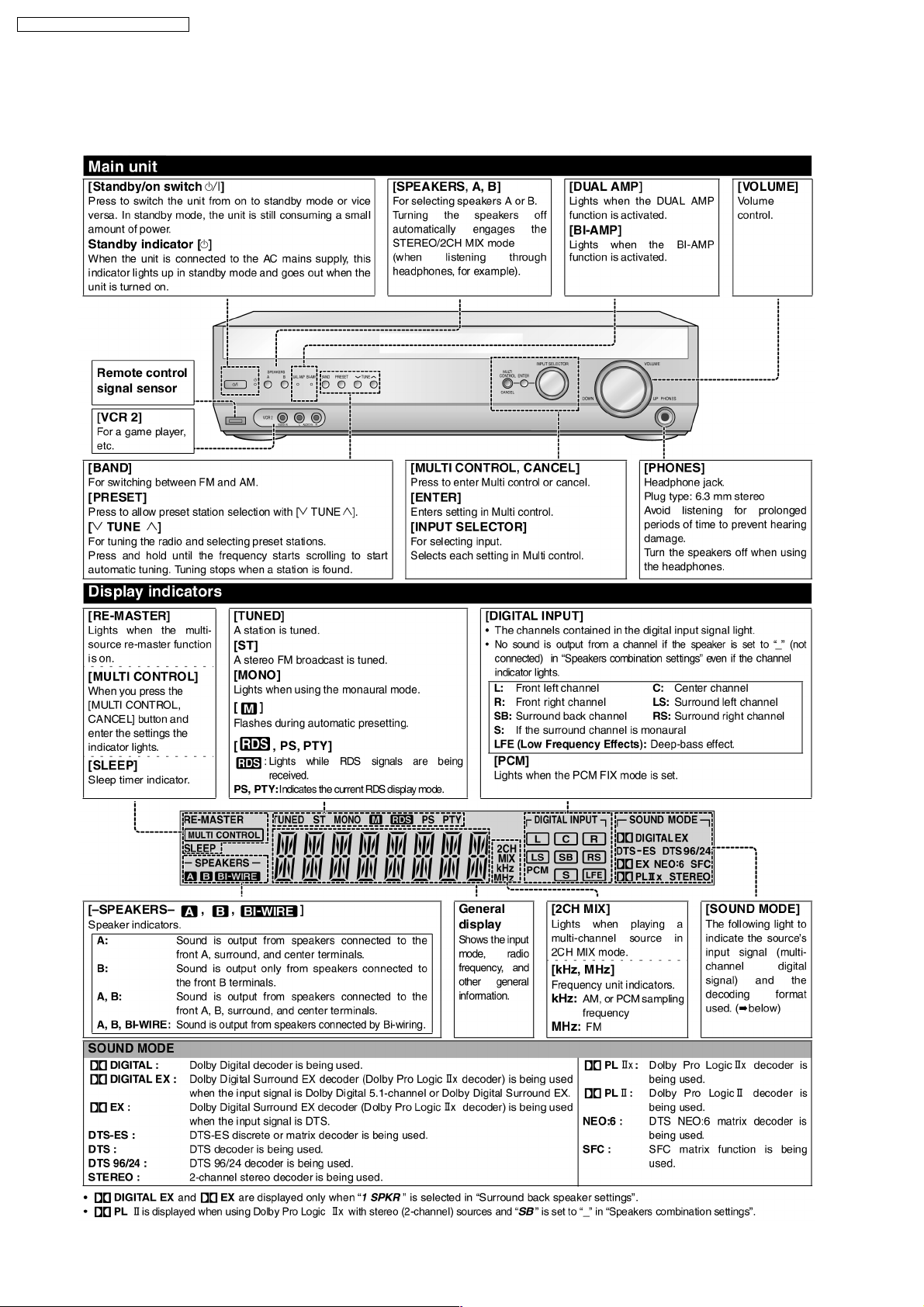

7 Operating Instructions

7.1. Main Unit

8

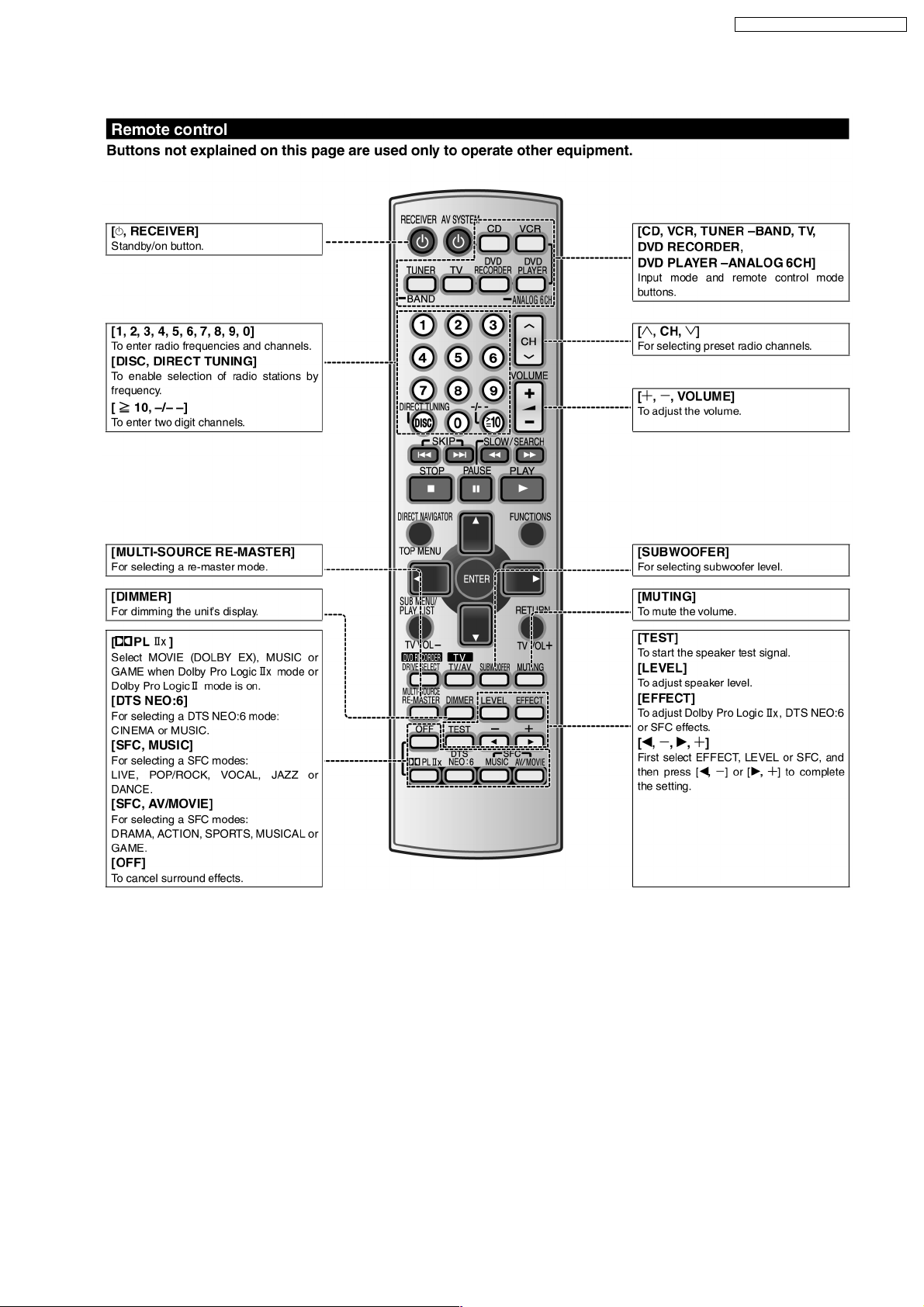

7.2. Remote Control

SA-XR55E / SA-XR55EB / SA-XR55EG

9

SA-XR55E / SA-XR55EB / SA-XR55EG

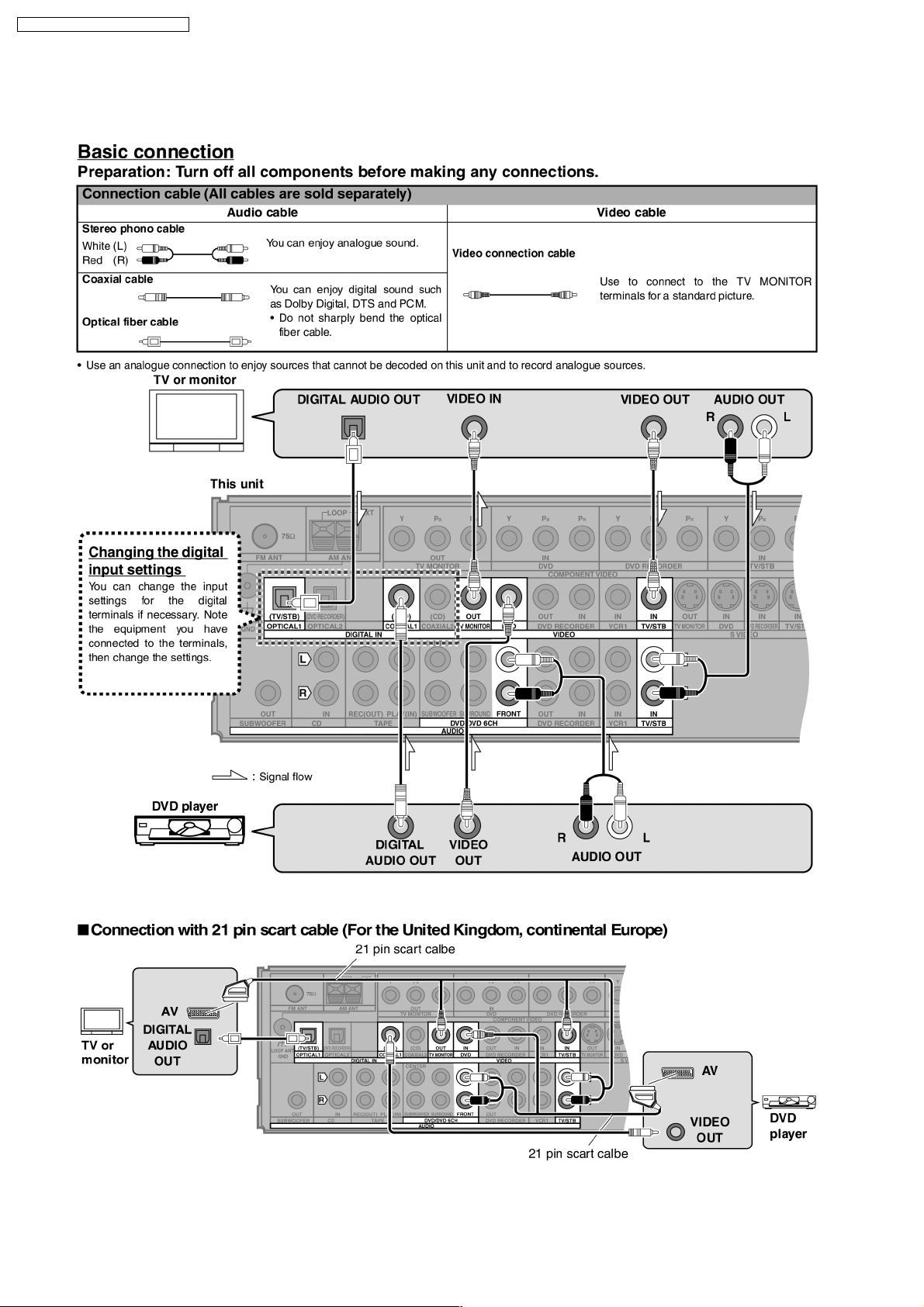

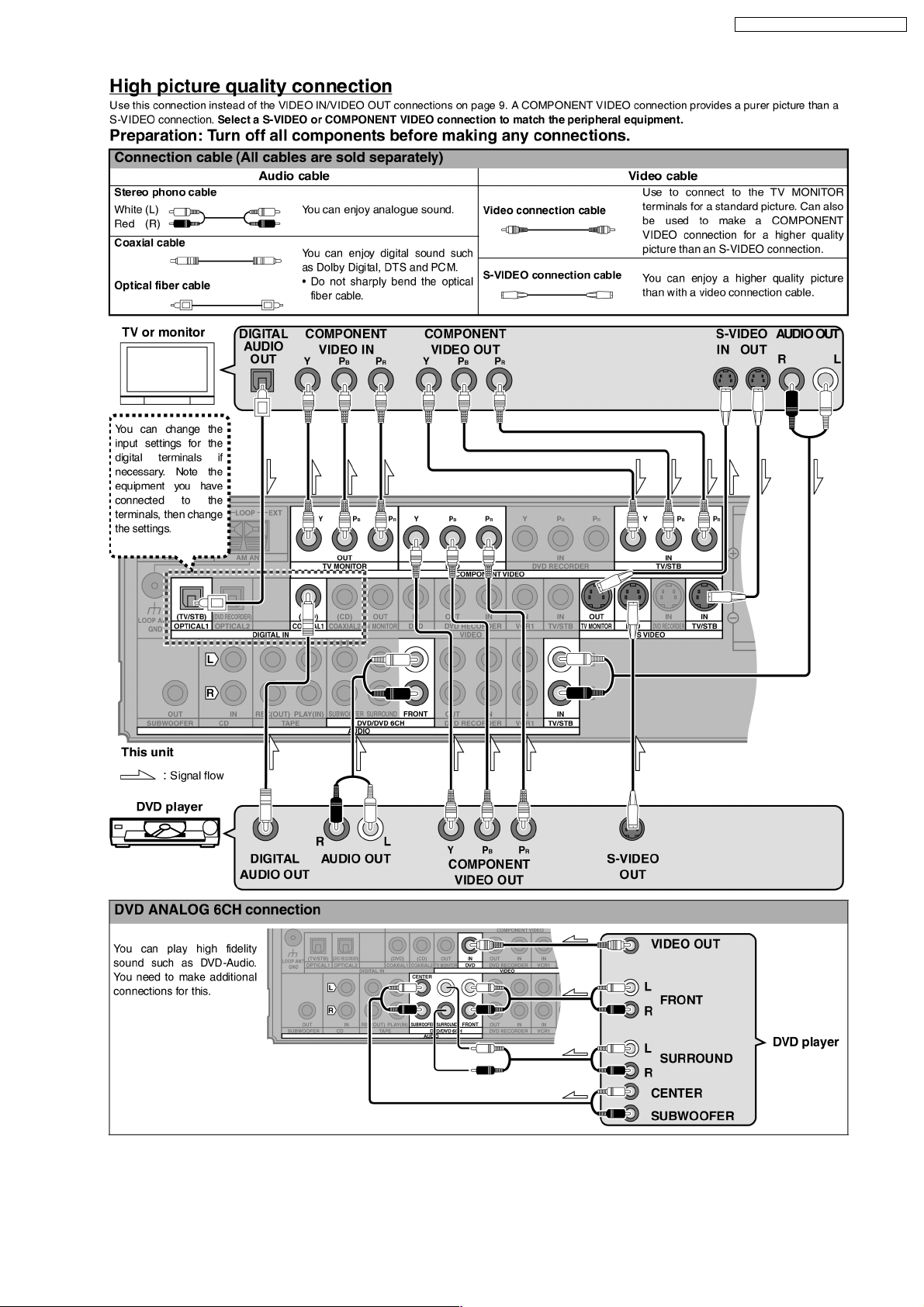

7.3. Home Theater Connections

7.3.1. TV and DVD Player

10

SA-XR55E / SA-XR55EB / SA-XR55EG

11

SA-XR55E / SA-XR55EB / SA-XR55EG

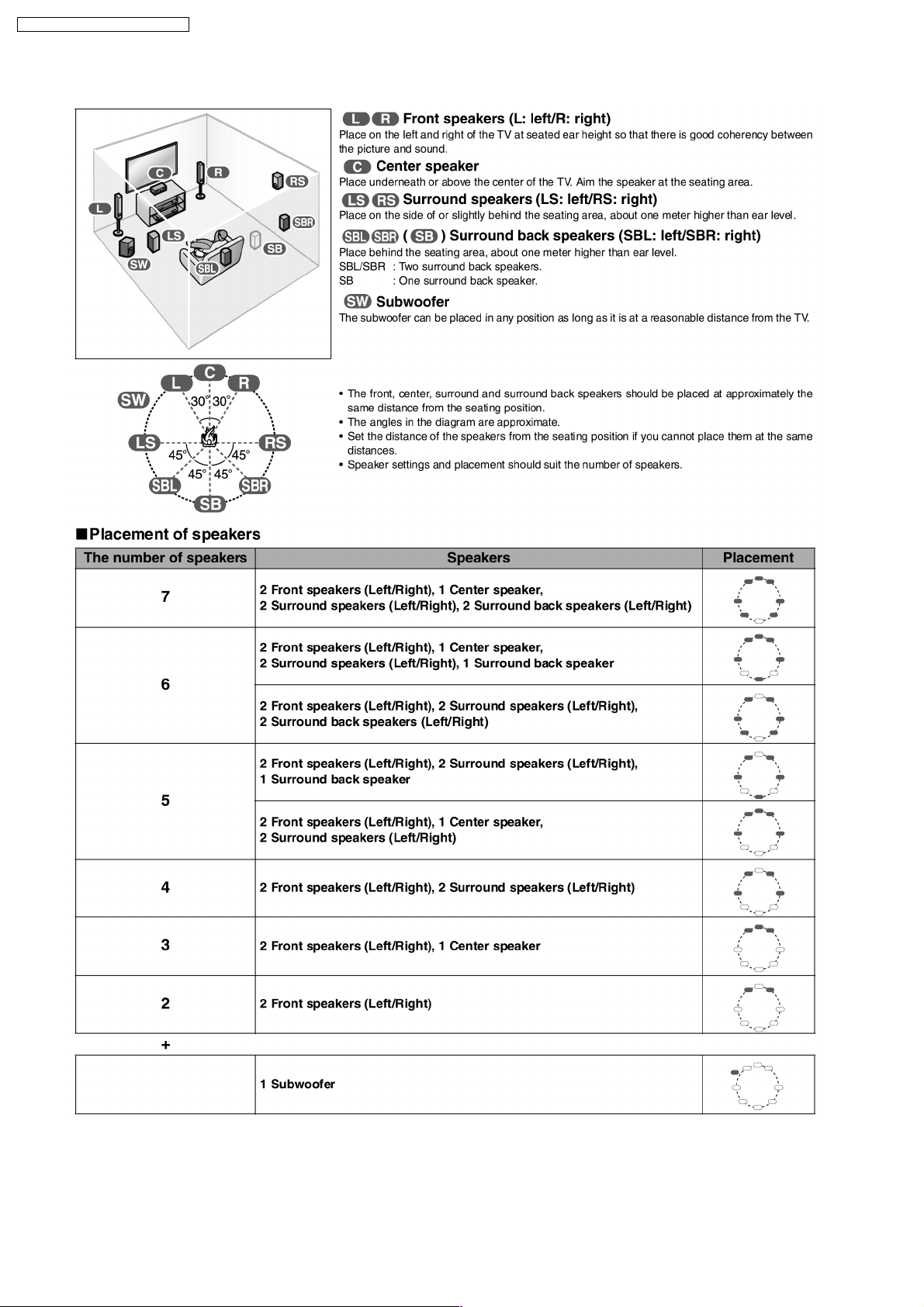

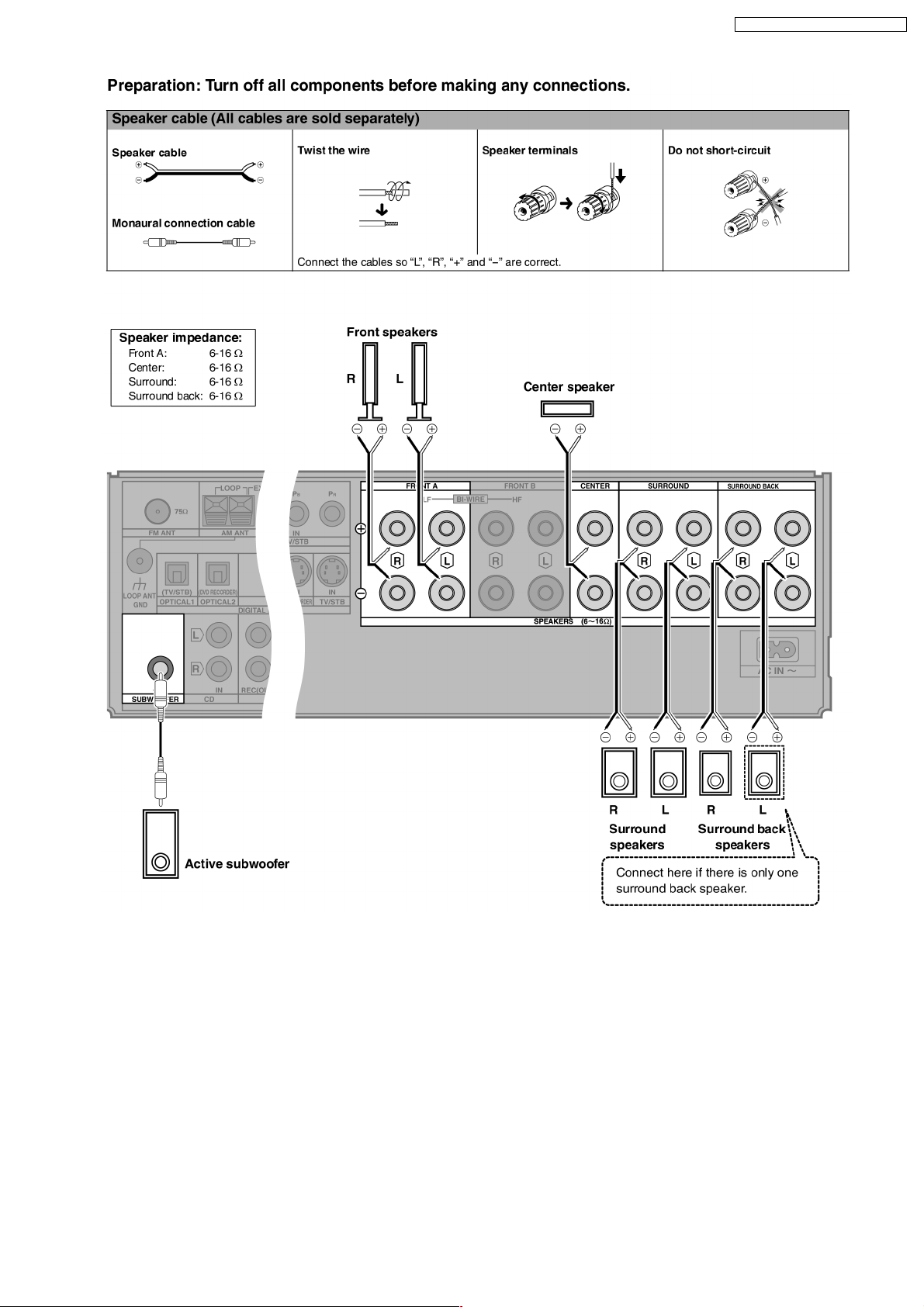

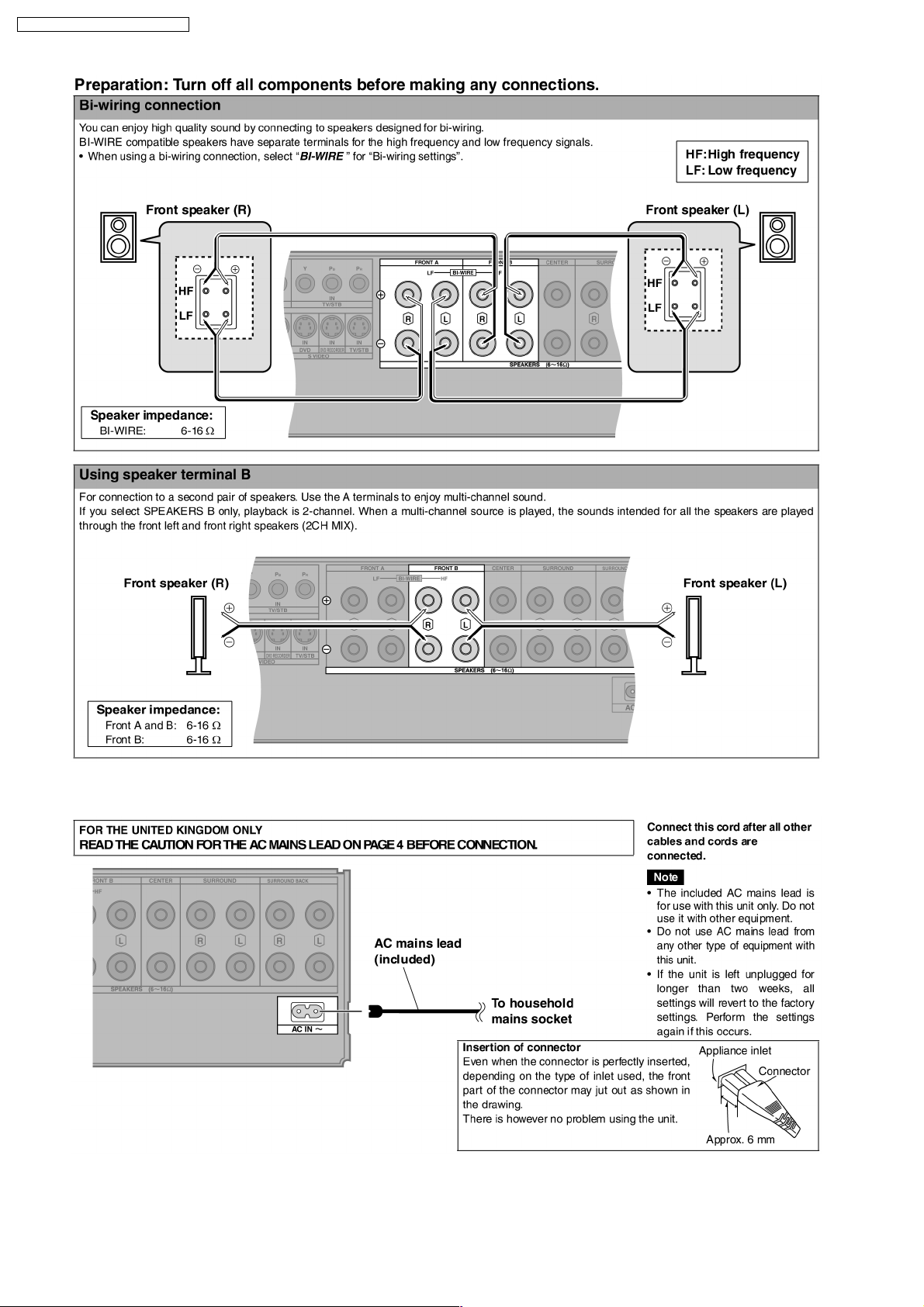

7.3.2. Speakers

12

SA-XR55E / SA-XR55EB / SA-XR55EG

13

SA-XR55E / SA-XR55EB / SA-XR55EG

7.3.3. AC Power Supply Cord

14

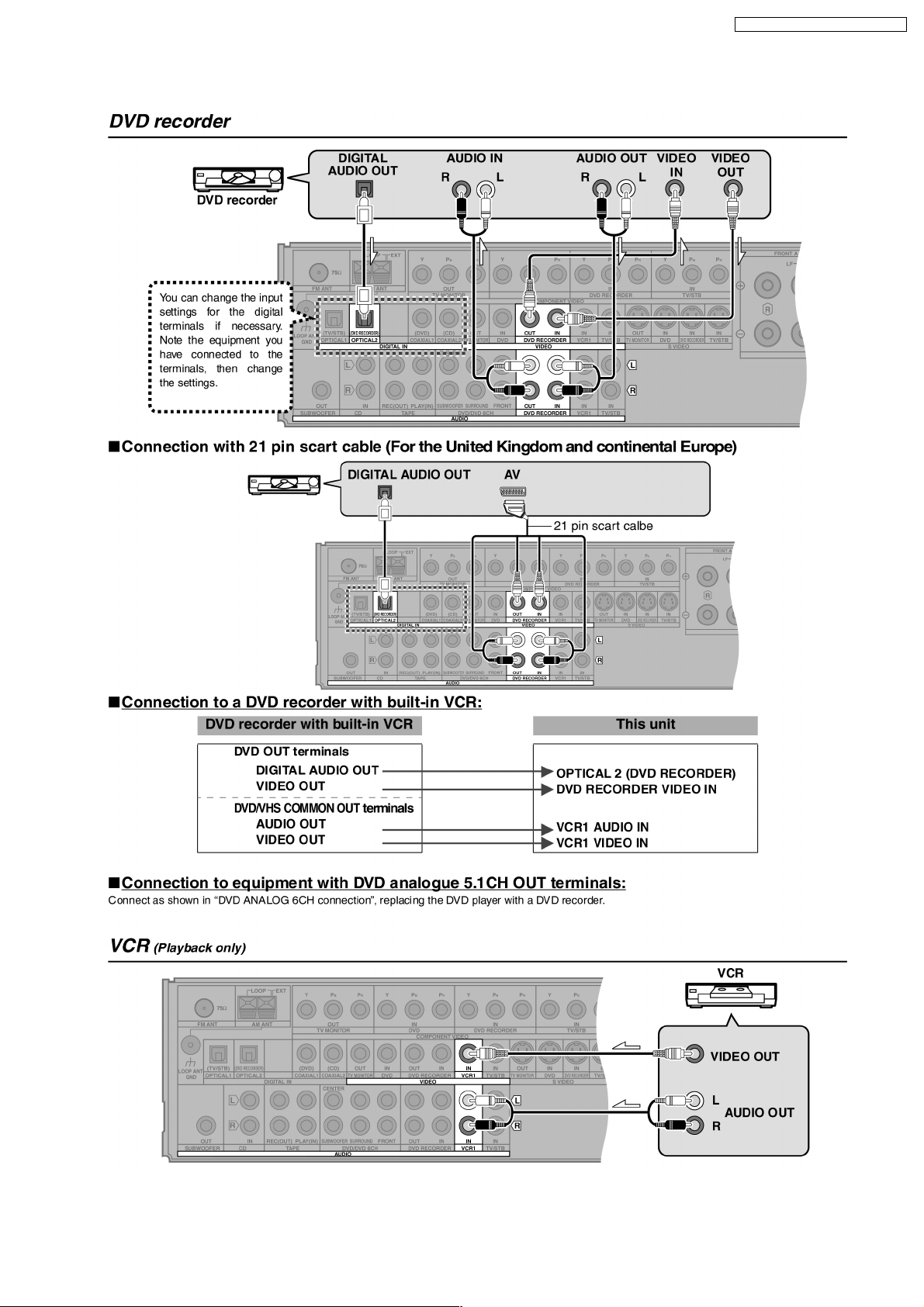

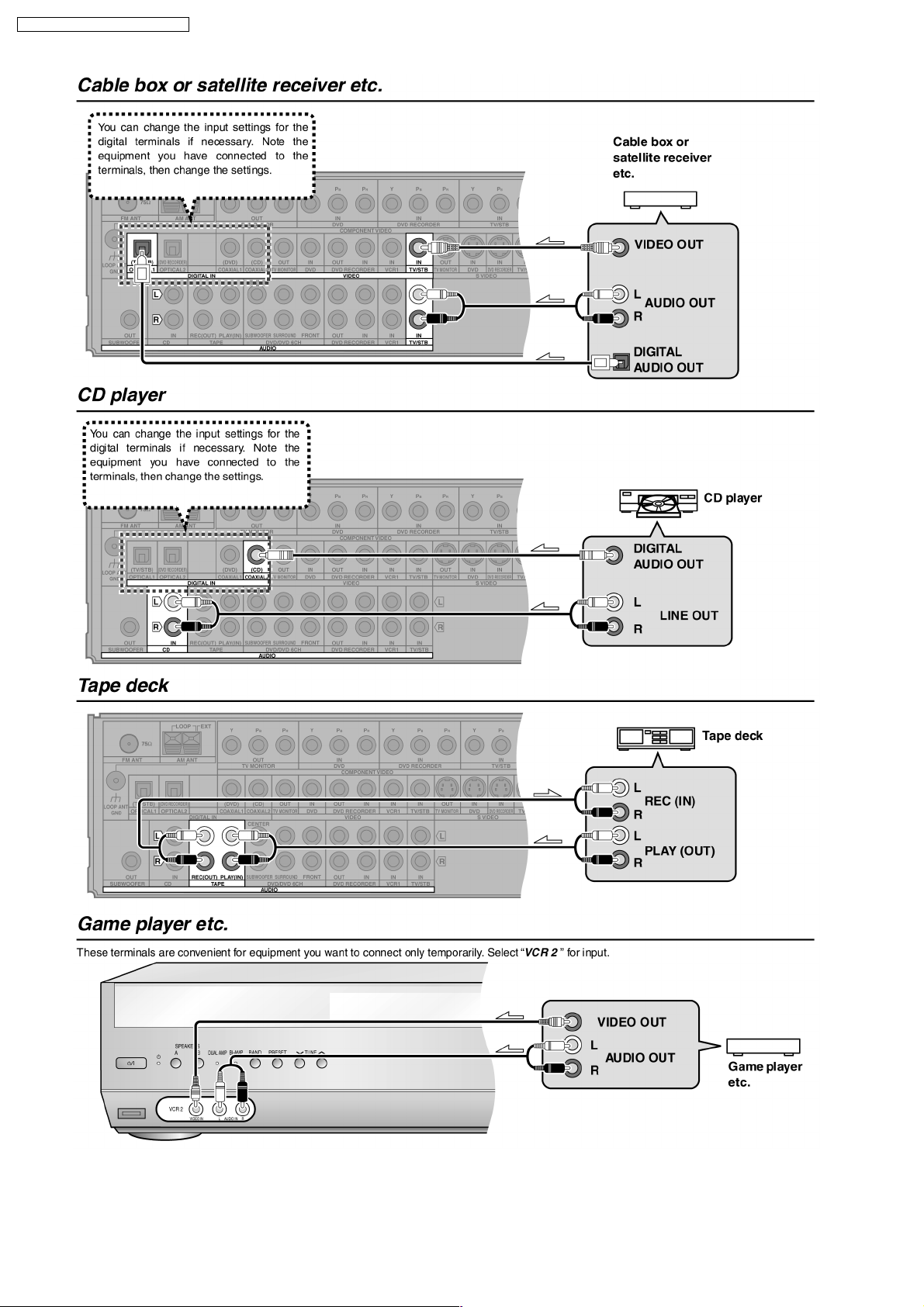

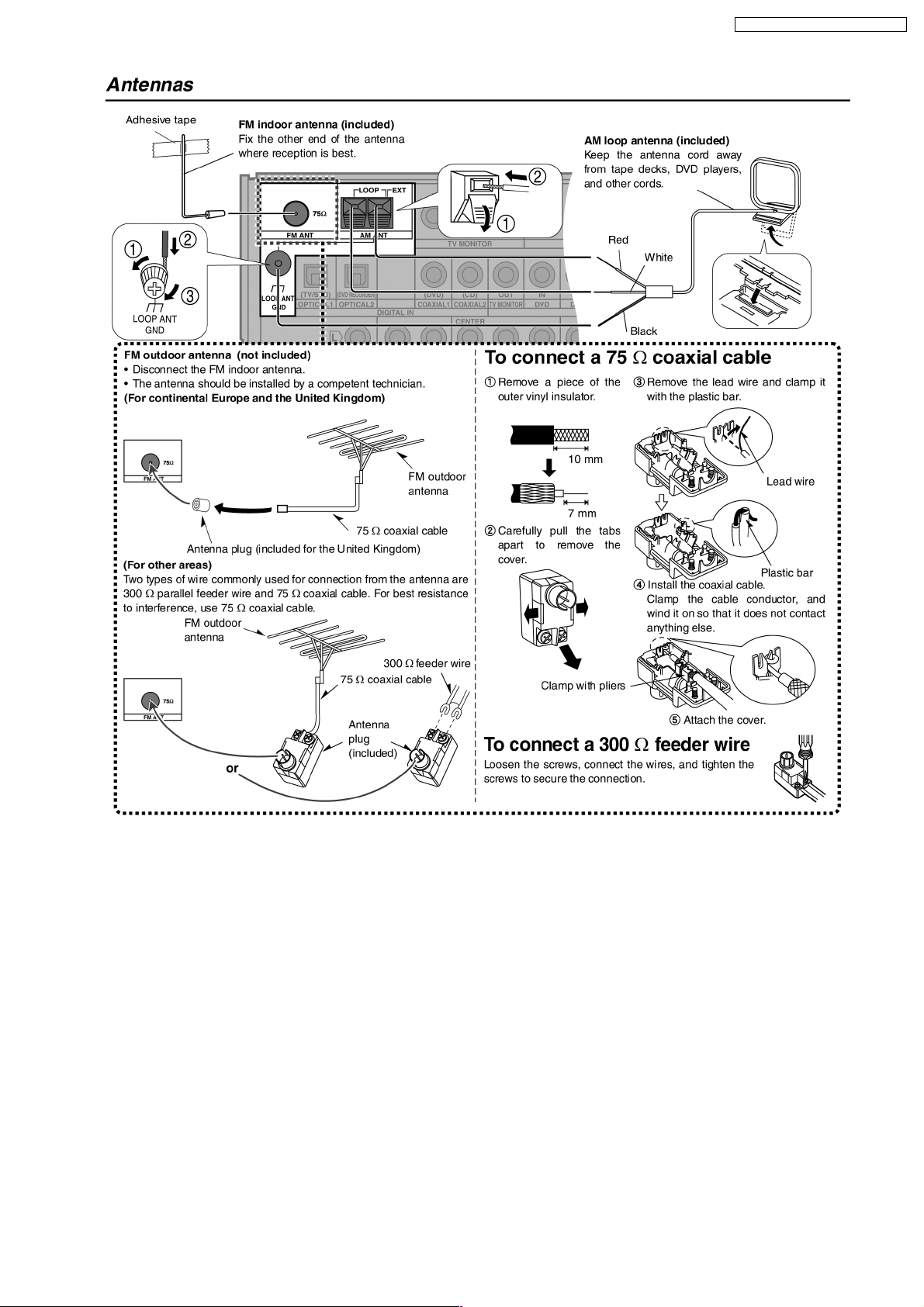

7.4. Other Connections

SA-XR55E / SA-XR55EB / SA-XR55EG

15

SA-XR55E / SA-XR55EB / SA-XR55EG

16

SA-XR55E / SA-XR55EB / SA-XR55EG

17

SA-XR55E / SA-XR55EB / SA-XR55EG

8 Disassembly and Main Component Replacement

Procedures and Operational Check

“ATTENTION SERVICER”

Some chassis components may be have sharp edges. Be careful when disassembling and servicing.

1. This section describes procedures for checking the operation of the major printed circuit boards and replacing the main

components.

2. For reassembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

3. Select items from the following index when checks or replacement are required.

· Disassembly of Top Panel

· Checking for the DSP P.C.B. (Side A/B) and Main P.C.B. (Side A)

· Disassembly and checking of Main P.C.B. (Side B)

· Disassembly of Tuner Pack and Tuner Extent P.C.B.

· Disassembly and Checking of Speaker P.C.B.

· Disassembly and Checking of Component Video P.C.B.

· Disassembly and Checking of Video & Optical P.C.B.

· Disassembly of Rear Panel

· Disassembly of Checking of Input P.C.B.

· Disassembly of Front Panel

· Disassembly and Checking of Panel P.C.B., Volume P.C.B. and Headphone P.C.B.

· Disassembly and Checking of Power P.C.B.

8.1. Disassembly flow chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the

servicing.

To assemble the unit, reverse the steps shown in the chart below.

18

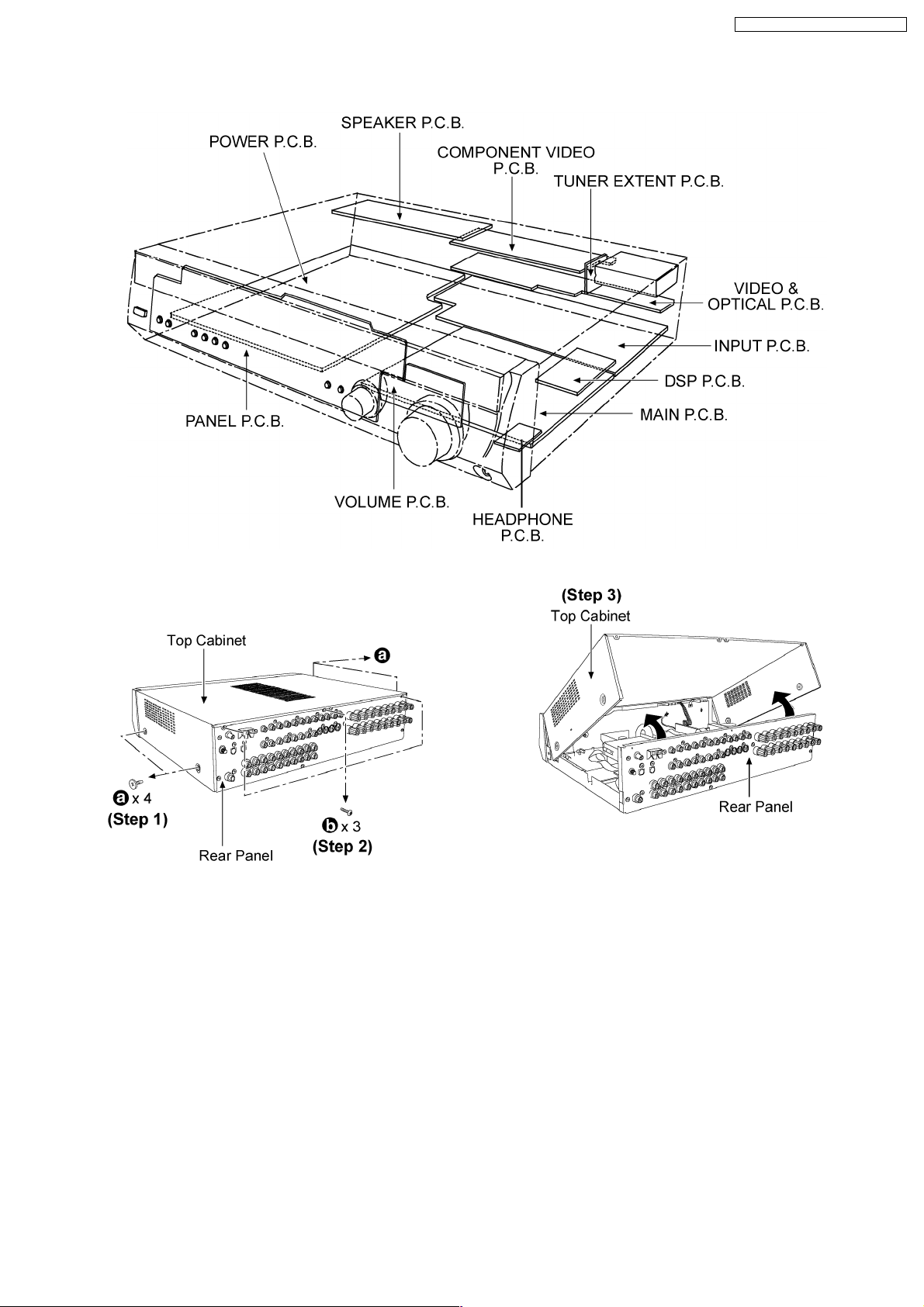

8.2. P.C.B. Positions

SA-XR55E / SA-XR55EB / SA-XR55EG

8.3. Disassembly of Top Cabinet.

Step 1 : Remove 4 screws from the top cabine t.

Step 2 : Remove 3 screws from the rear panel.

Step 3 : Lift up the top cabinet as arrow shown.

19

SA-XR55E / SA-XR55EB / SA-XR55EG

Step 4 : Remove the top cabinet.

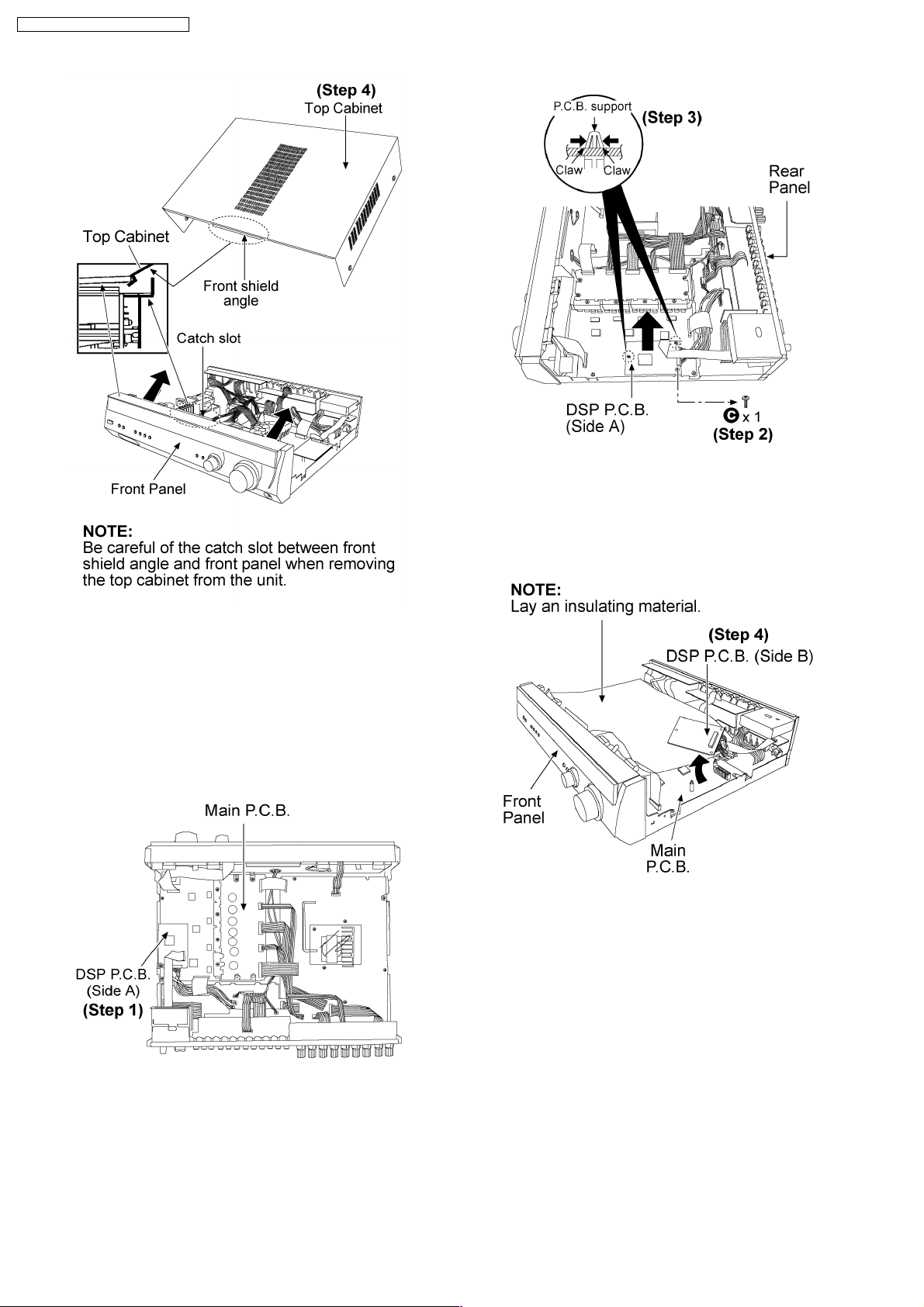

8.4. Checking for the DSP P.C.B.

(Side A/B) and Main P.C.B.

(Side A).

· Follow the (Step 1) - (Step 4) of item 8.3.

Step 2 : Remove 1 screw.

Step 3 : Release the claws of the P.C.B support then detach

the DSP. P.C.B.

Step 4 : Flip over the DSP P.C.B. as arrow shown.

Step 1 : Check the DSP P.C.B. (Side A).

20

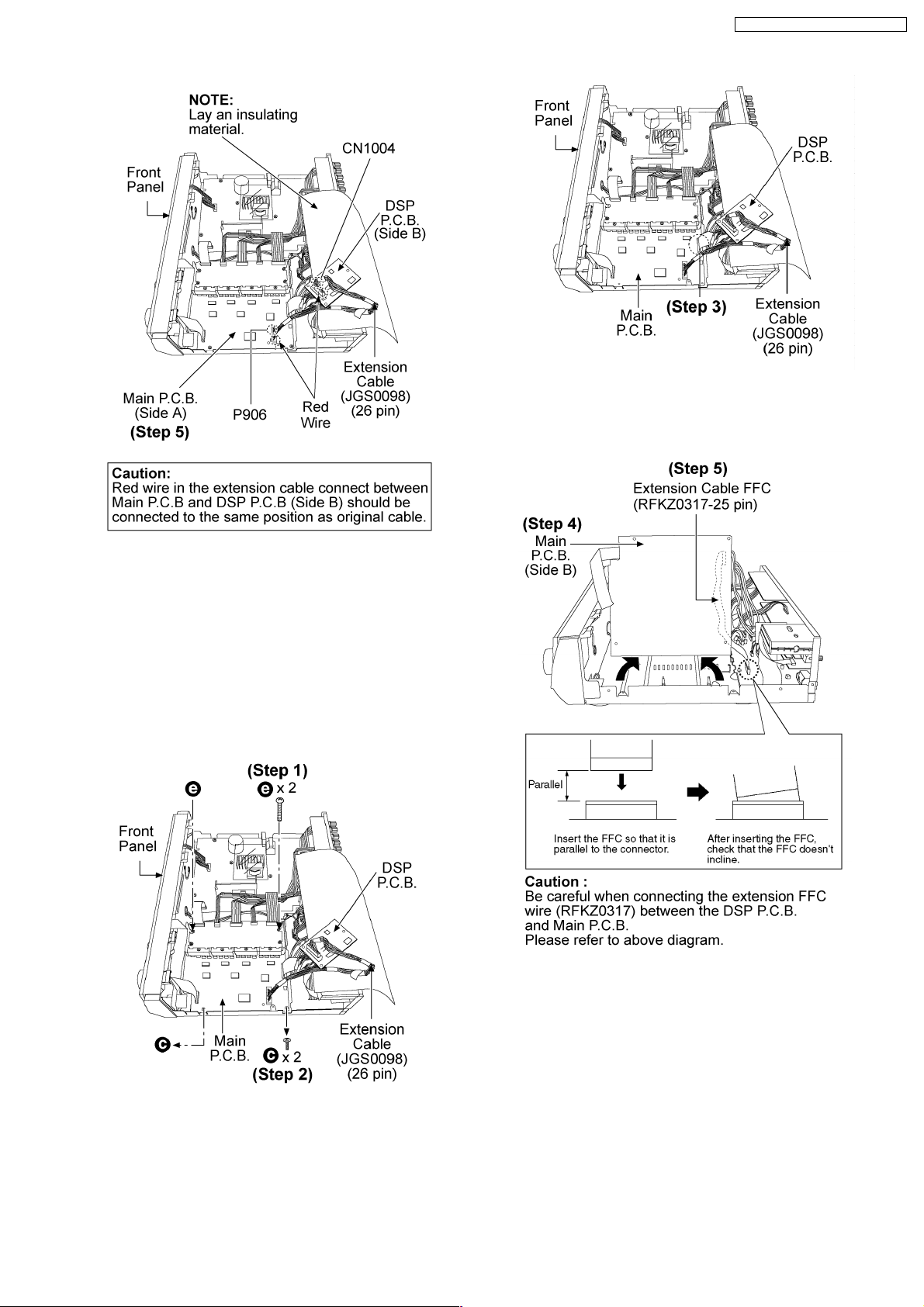

SA-XR55E / SA-XR55EB / SA-XR55EG

Step 3 : Detach the 25 pin FFC wire (REE1324) between

connectors P6501B (Main P.C.B.) and P6501A (Input P.C.B.)

Step 5 : Conne ct the DSP P.C.B. (Side B) and Main P.C.B.

(Side A) by using the extension cable then proceed with the

checking.

8.5. Disassembly and Checking of

Main P.C.B. (Side B)

· Follow the (Step 1) - (Step 4) of item 8.3.

· Follow the (Step 1) - (Step 5) of item 8.4.

Step 4 : Flip over the Main P.C.B. as arrow shown.

Step 5 : Check the Main P.C.B (Side B) by connecting the

extension cable (RFKZ0317-25 pin).

Steps 1 and 2 : Remove 4 screws altogether.

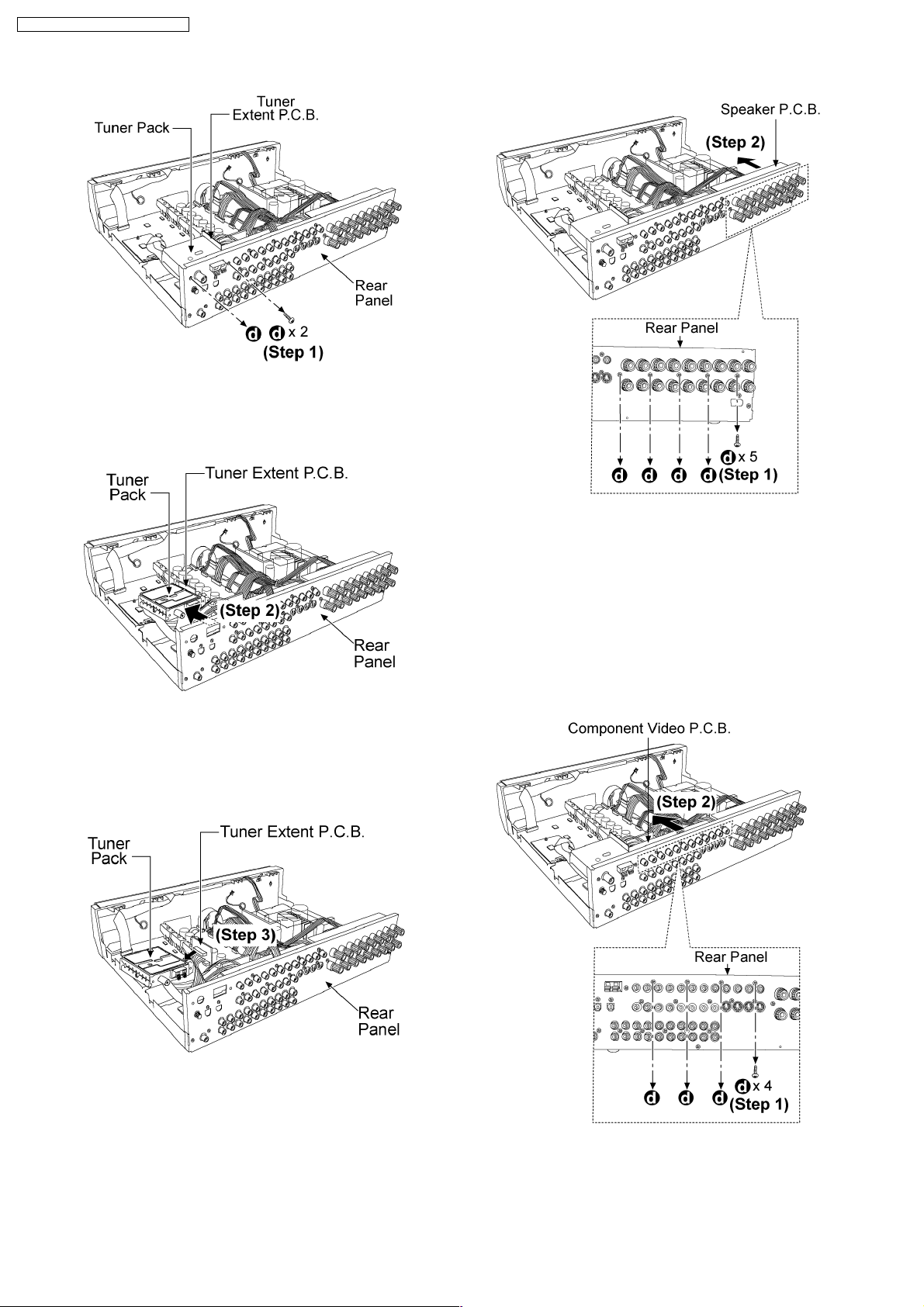

8.6. Disassembly of Tuner Pack

and Tuner Extent P.C.B.

· Follow the (Step 1) - (Step 4) of item 8.3.

21

SA-XR55E / SA-XR55EB / SA-XR55EG

Step 1: Remove 2 screws.

Step 2: Remove the tuner pack together with the Tuner Extent

P.C.B. from the rear panel as arrow shown.

Step 1: Remove 5 screws.

Step 2: Remove the Speaker P.C.B. from rear panel as arrow

shown for checking.

8.8. Disassembly and Checking of

Component Video P.C.B.

· Follow the (Step 1) - (Step 4) of item 8.3.

Step 3: Detach the tuner pack from the Tuner Extent P.C.B. as

arrow shown.

8.7. Disassembly and Checking of

Speaker P.C.B.

· Follow the (Step 1) - (Step 4) of item 8.3.

Step 1: Remove 4 screws.

Step 2: Remove the Component Video P.C.B. from rear panel

as arrow shown.

22

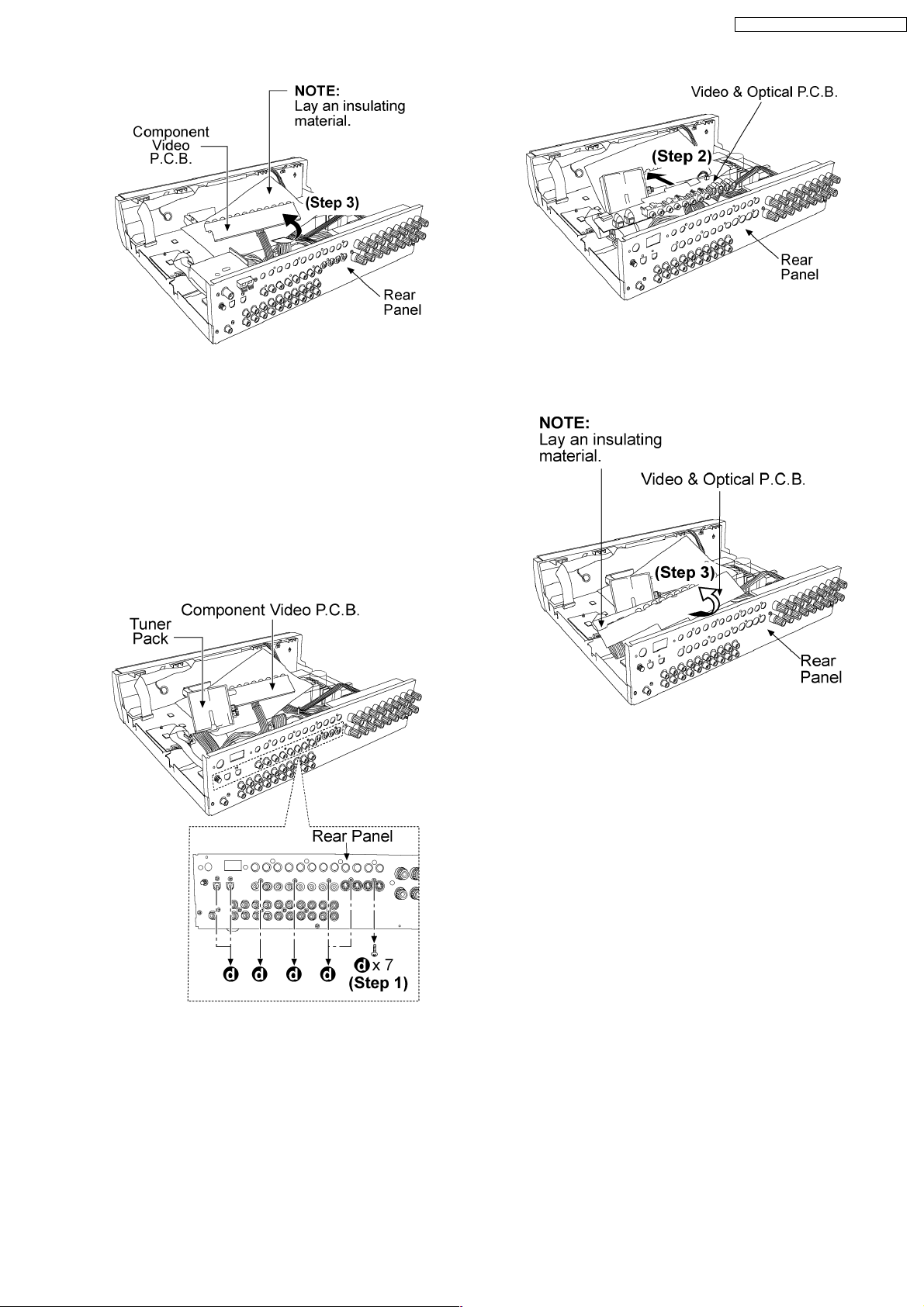

Step 3: Flip over the Component Video P.C.B. as arrow shown

for checking

8.9. Disassembly and Checking of

Video & Optical P.C.B.

SA-XR55E / SA-XR55EB / SA-XR55EG

Step 2: Remove the Video & Optical P.C.B. from rear panel as

arrow shown.

· Follow the (Step 1) - (Step 4) of item 8.3.

· Follow the (Step 1) - (Step 2) of item 8.6.

· Follow the (Step 1) - (Step 3) of item 8.8.

Step 3: Flip over the Video & Optical P.C.B. as arrow shown for

checking

8.10. Disassembly of Rear Panel

· Follow the (Step 1) - (Step 4) of item 8.3.

· Follow the (Step 1) of item 8.6.

· Follow the (Step 1) of item 8.7.

· Follow the (Step 1) of item 8.8.

· Follow the (Step 1) of item 8.9.

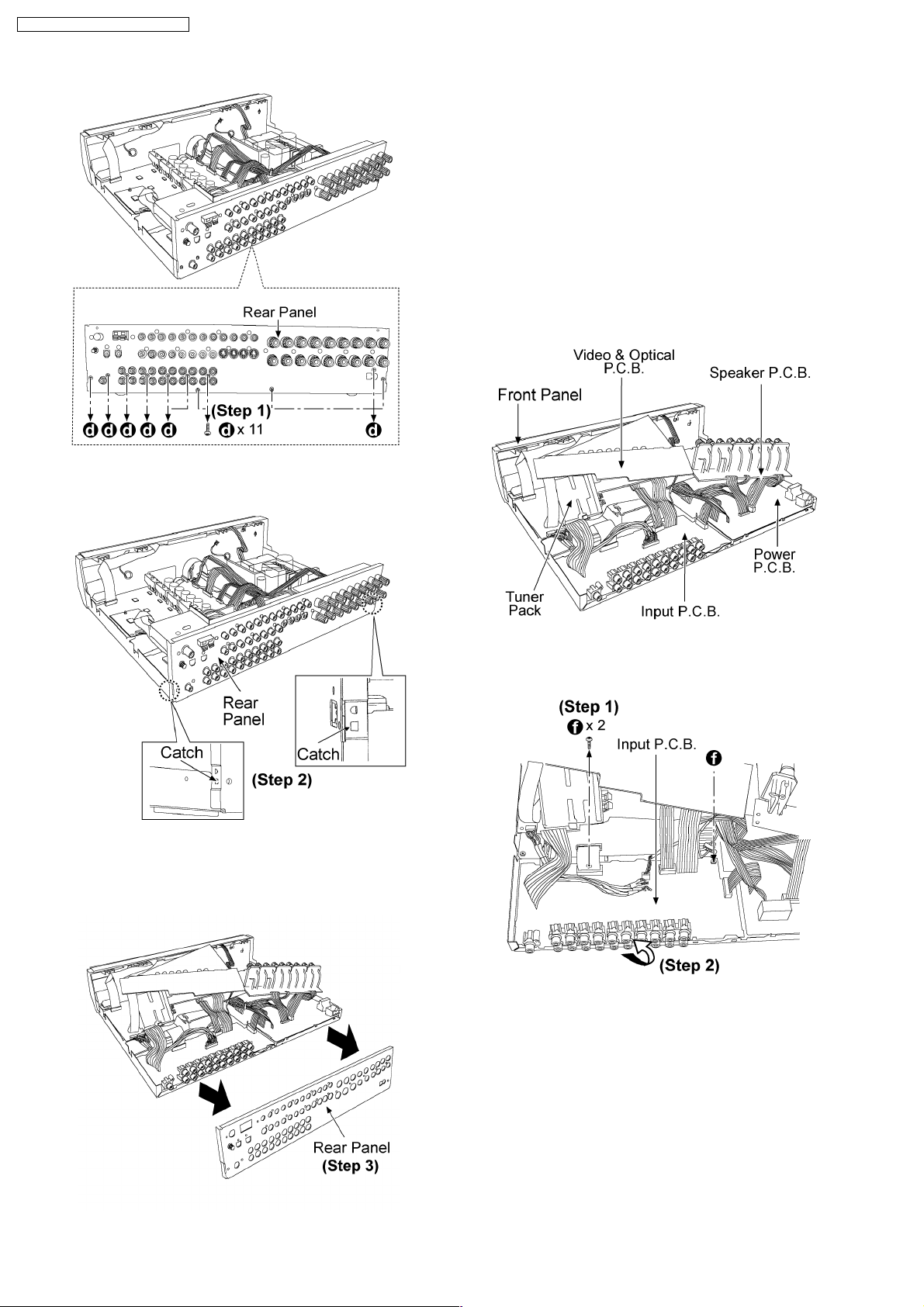

Step 1: Remove 7 screws.

23

SA-XR55E / SA-XR55EB / SA-XR55EG

Step 1: Remove 11 screws.

Step 3: Remove the rear panel as arrows shown.

8.11. Disassembly and Checking of

Input P.C.B.

· Follow the (Step 1) - (Step 4) of item 8.3.

· Follow the (Step 1) of item 8.6.

· Follow the (Step 1) of item 8.7.

· Follow the (Step 1) of item 8.8.

· Follow the (Step 1) of item 8.9.

· Follow the (Step 1) - (Step 3) of item 8.10.

Step 2: Be careful of the both side catches when remove the

rear panel.

Step 1: Remove 2 screws.

Step 2: Flip over the Input P.C.B. as arrow shown .

24

Step 3: Proceed to check the Input P.C.B.

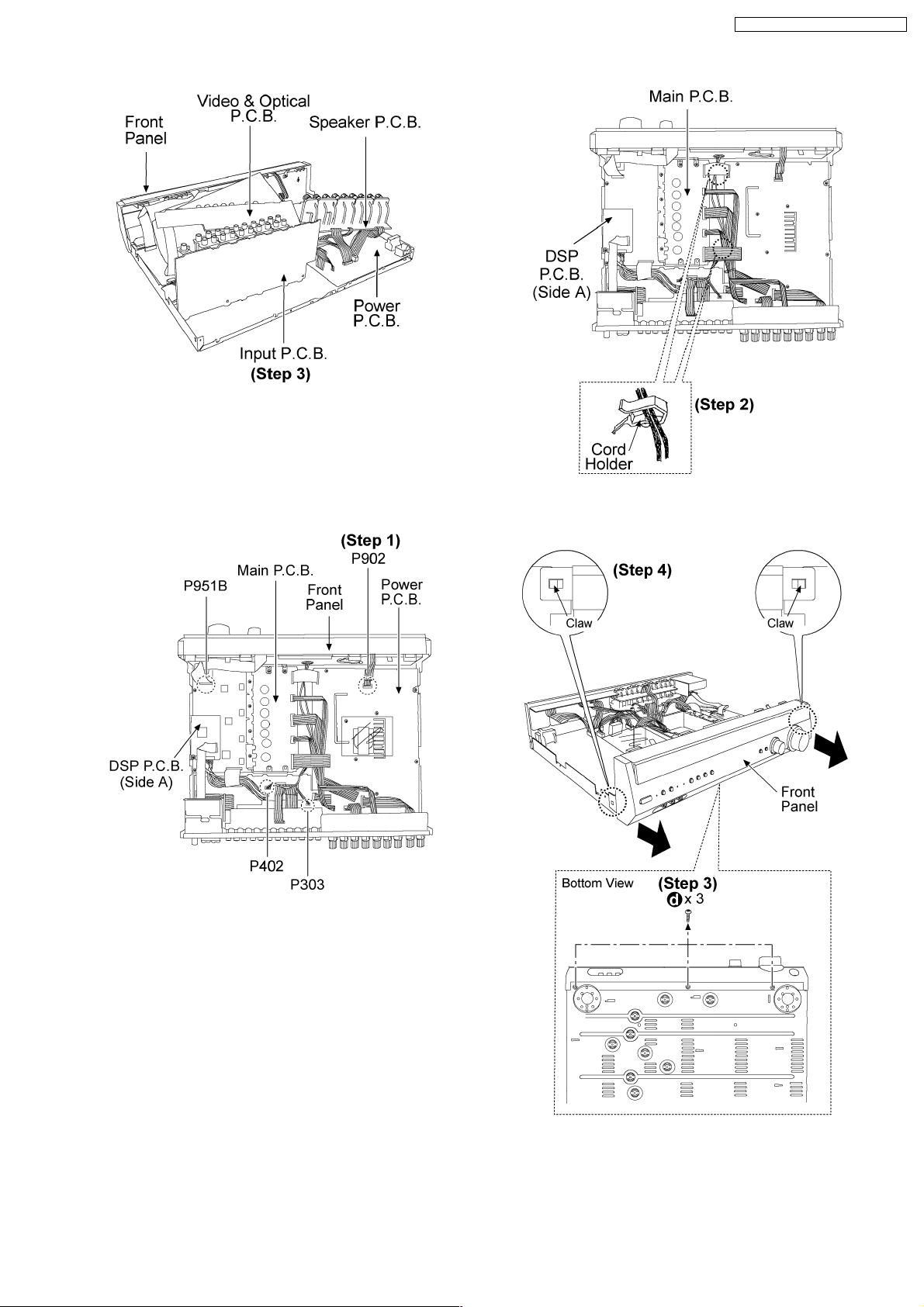

8.12. Disassembly of Front Panel

SA-XR55E / SA-XR55EB / SA-XR55EG

· Follow the (Step 1) - (Step 4) of item 8.3.

Step 1: Disconnect all the connectors (P951B, P902, P402,

P303).

Step 2: Be careful when remove the wires from the cord holder.

Step 3: Remove 3 screws.

Step 4: Release the both claws and remove the front panel as

arrows shown.

25

SA-XR55E / SA-XR55EB / SA-XR55EG

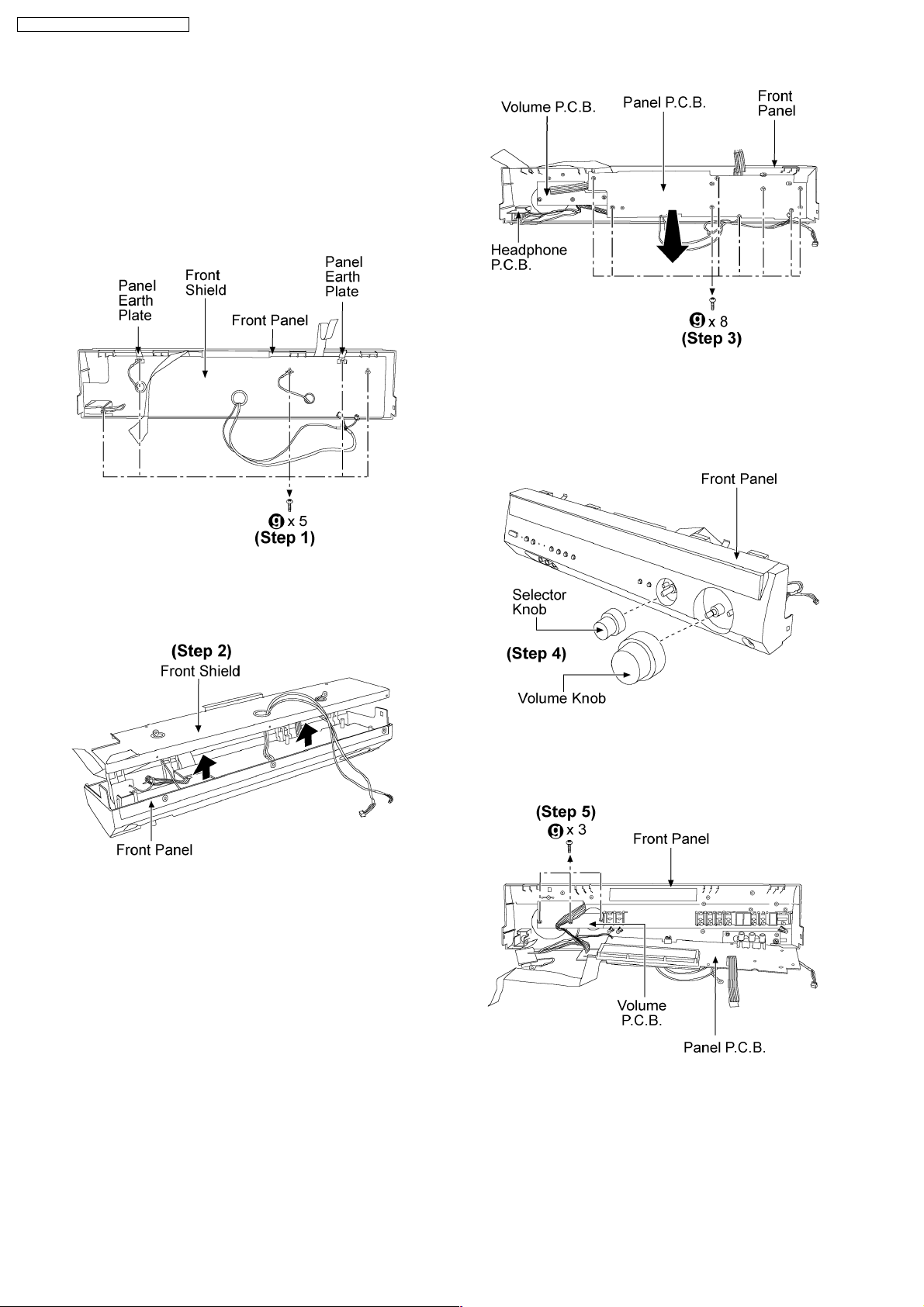

8.13. Disassembly and Checking of

Panel P.C.B., Volume P.C.B.

and Headphone P.C.B.

· Follow the (Step 1) - (Step 4) of item 8.3.

· Follow the (Step 1) - (Step 4) of item 8.12.

Step 3: Remove 8 screws then remove the Panel P.C.B. as

arrow shown.

Step 1: Remove 5 screws.

Step 2: Remove the front shield from the front panel as arrows

shown

Step 4: Remove the Selector and Volume knobs.

Step 5: Remove 3 screws then remove the Volume P.C.B.

26

Step 6: Reconnect all the connectors and checking for Volume

P.C.B., Panel P.C.B. and Headphone P.C.B.

SA-XR55E / SA-XR55EB / SA-XR55EG

Step 3: Flip over the Power Supply P.C.B. as arrow shown.

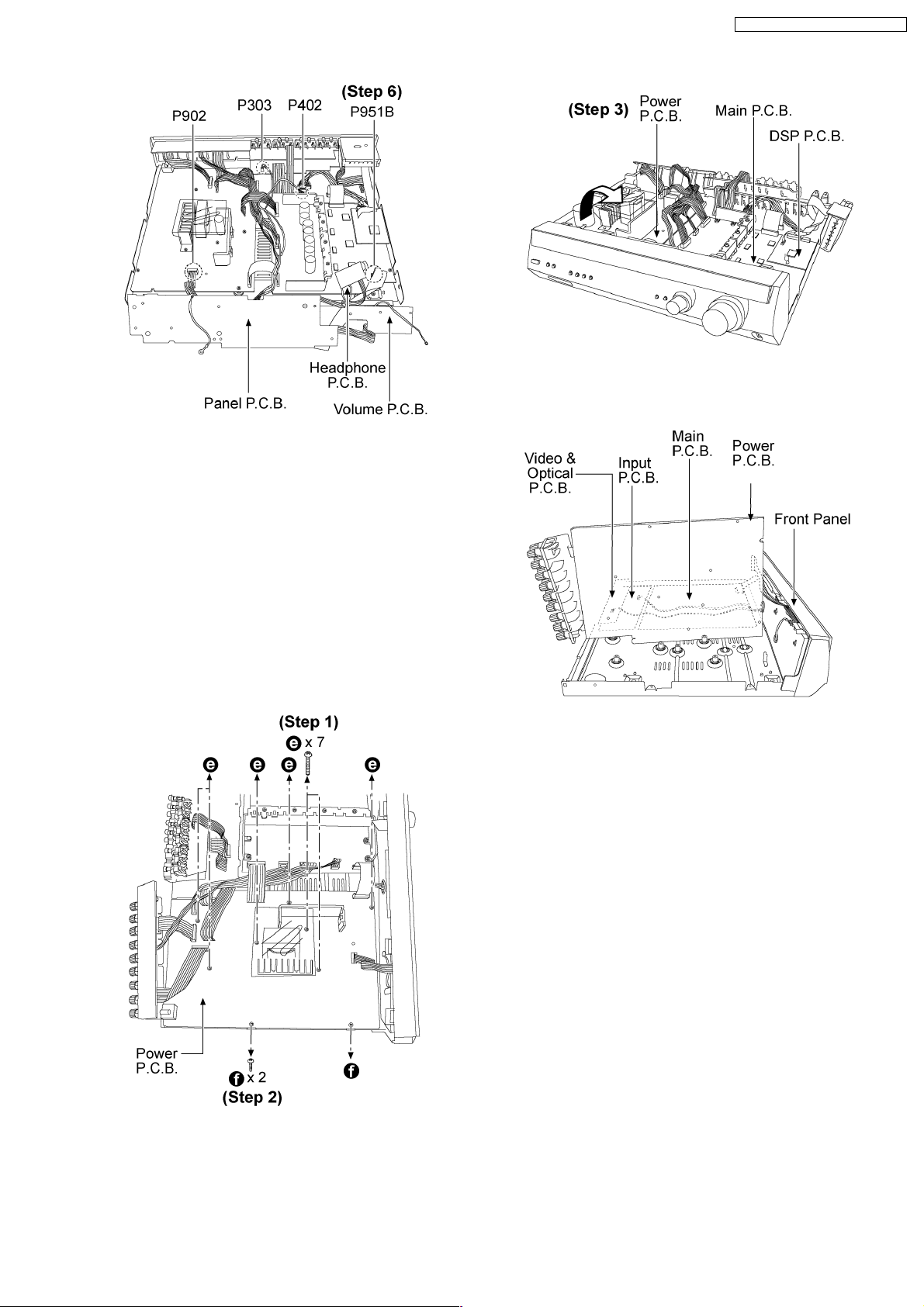

8.14. Disassembly and Checking of

Power P.C.B.

· Follow the (Step 1) - (Step 4) of item 8.3.

· Follow the (Step 1) of item 8.6.

· Follow the (Step 1) of item 8.7.

· Follow the (Step 1) of item 8.8.

· Follow the (Step 1) of item 8.9.

· Follow the (Step 1) - (Step 3) of item 8.10.

Step 4: Checking for Power P.C.B.

Steps 1 and 2: Remove 9 screws altogether.

27

SA-XR55E / SA-XR55EB / SA-XR55EG

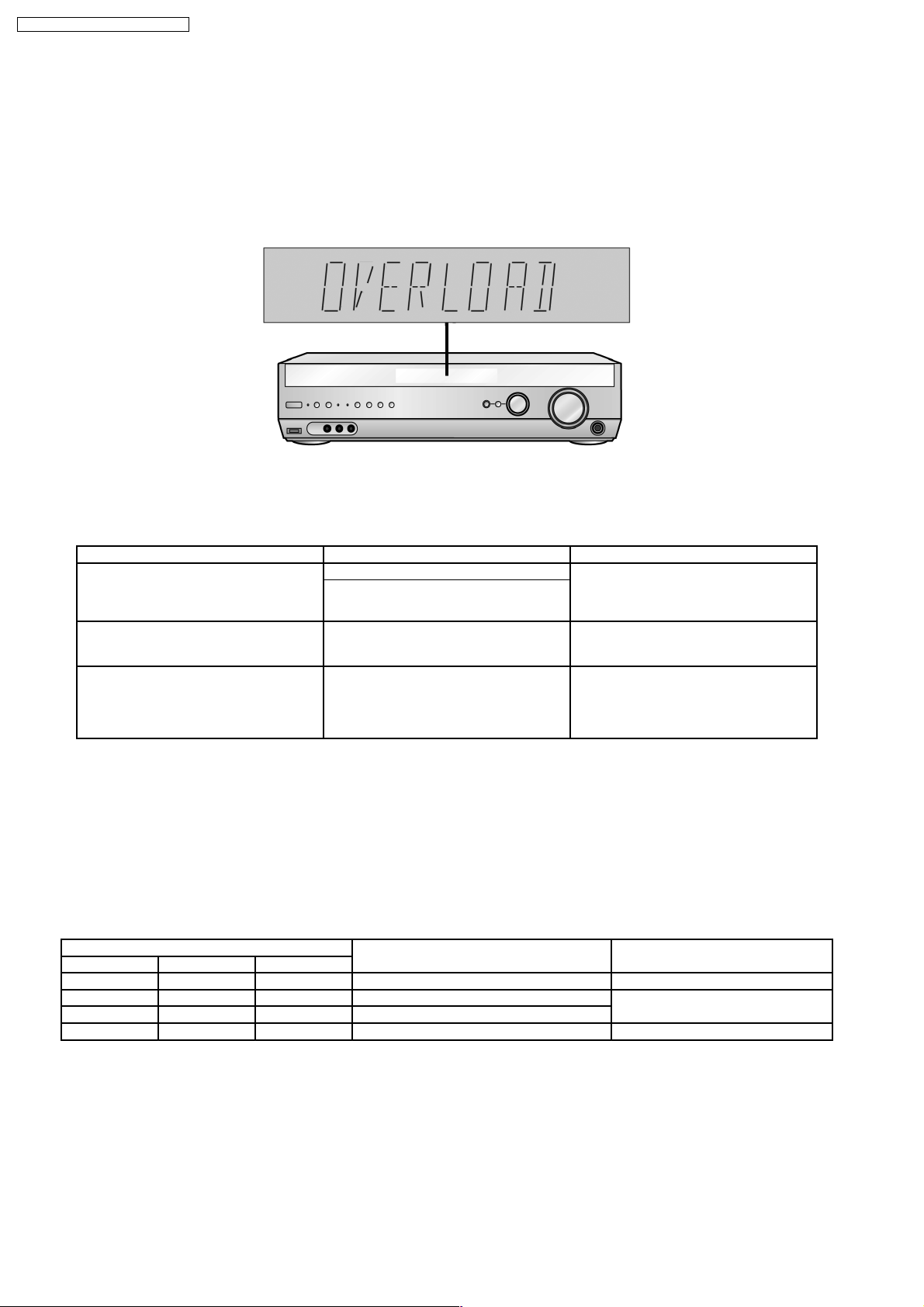

9 Self Diagnosis Display Function

This unit is equipped with the self diagnosis display function, which alarms faulty operation with error code. Use this function during

servicing.

9.1. Automatically Displayed Error Codes

An error code automatically appears on the display (LCD) when faulty operation is detected. Refer to Fig. 9.1.

Fig. 9.1

9.2. Display Details

Refer to the following table.

LCD display Symptom Cause and Remedy

OVERLOAD Speaker short, amplifier failure Speaker short and failure in power

Humidity protection activated

F70 Communication error between sub micro-

processor and its peripheral LSI

F76 When the power is turned on, the unit

power automatically turns off; the power

cannot be turned on.

amplifier, pre-amplifier circuits. Check for

faulty parts and replace with new parts if

necessary.

Failure sub-micro processor and its

peripherals LSI. Check for faulty parts and

replace with new parts if necessary.

Failure in the power circuit system of the

unit. This may happen when the direct

current electricity is supplied to speaker

terminals. Check for the above and replace

with new parts if necessary.

9.3. Returning to Normal Display

Press the POWER button on the unit to exit the function. The power is turned off.

9.4. Overload/Shutdown Detection intenal Condition

It detects OVERLOAD, POWER MALFUNCTION with [THRM_DET], [SHORT_DET] and [DC_DET] input port. It detects the

following condition depending on the input of the port as below table.

(H: DC ± 5V / L: DC ± 0V)

PROT Detection of malfunction Display and operation

SHORT_DET THRM_DET DC_DET

H L H Normal -----

L L H Speaker Short, Malfunction of Amplifier [OVERLOAD] / POWER OFF

L H H Detection of THERMAL PROTECTION

- - L Detection of POWER MALFUNCTION [ _ _ _ F76 _ _ _ ] / POWER OFF

9.5. Overload/Thermal Detection Display

When overload is detected, automatic POWER OFF will occur. But if any key on the remote control other than the [POWER] key

is pressed before that (including the [HELP] key), the scroll display will show [SWITCH_OFF_POWER]. Then, 1 second after

display of message, [OVERLOAD] will be shown on the scroll display .

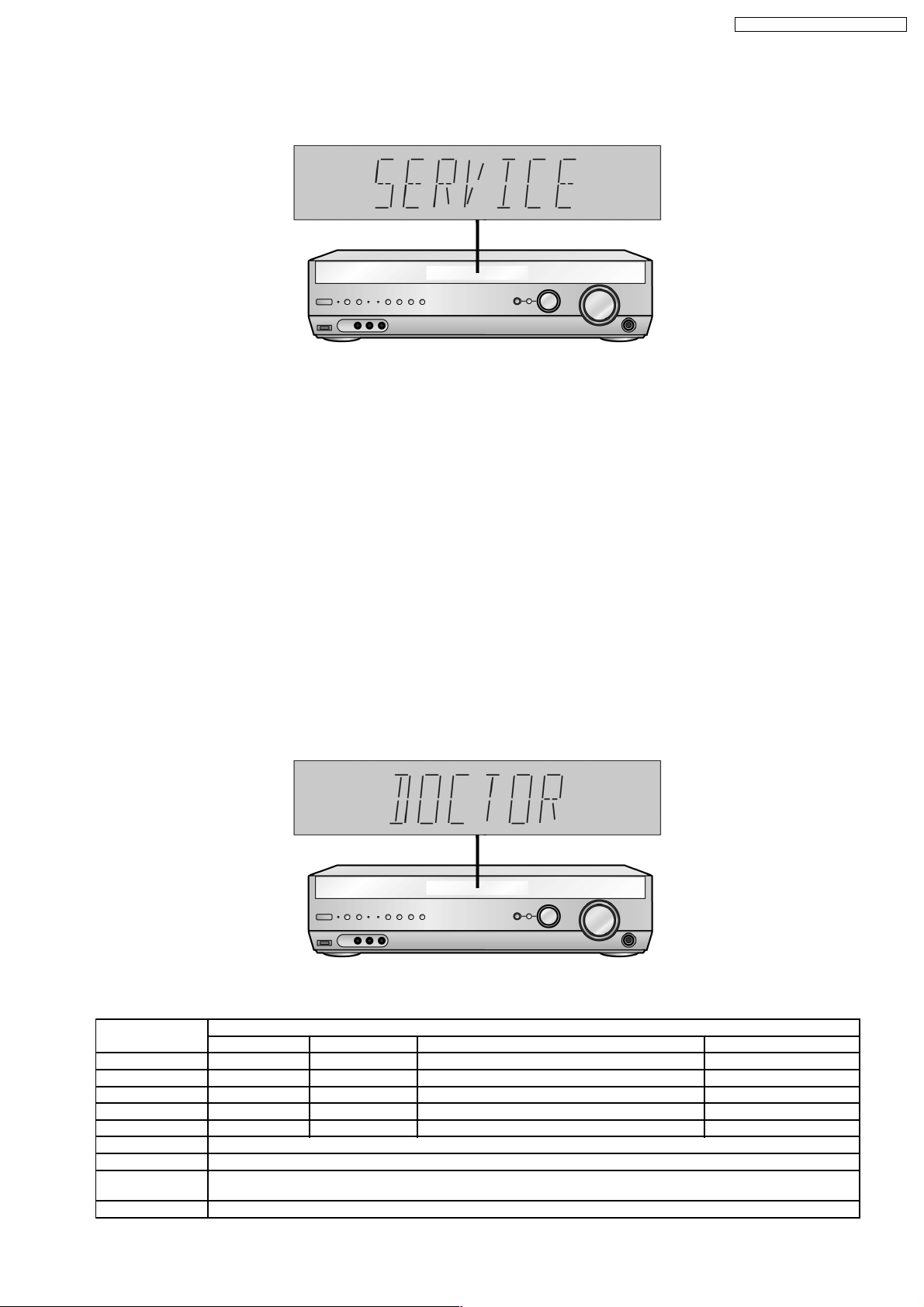

9.6. Activating Self Diagnosis Function (Servicing Mode)

This mode can be used during servicing.

28

SA-XR55E / SA-XR55EB / SA-XR55EG

1. Plug the AC adapter to the power source. Press and hold down the [MULTI CONTROL] button and the [SPEAKERS A] button,

and then press the [POWER] button at the same time.

2. The message, [SERVICE] appears on the display for three seconds, and then disappears. Refer to Fig. 9.2.

Fig. 9.2

3. When the [TUNING DOWN] button is pressed, the current program filing number (ex. "M45_ ***" for MA123 _45) appears. The

*** digit indicates the ROM checksum used for ROM collection, and if the unit is not loaded with ROM, "NO" appears.

When the TUNING UP button is pressed, the sub micro computer program filing number (ex. 523_***" for MA678_90) appears.

The *** digit indicates the ROM checksum used for ROM collection, and if the unit is not loaded with ROM, "NO" appears.

9.7. Analog 6.1 CH Output Check Method

When the [SUBWOOFER] button on the remote controller, the function is switched to "Input Inspection Mode", which output analog

input signals at L channel of VCR analog input to all channels.

9.8. Returning to Normal Display

Press the POWER button on the unit to exit the function. The power is turned off.

9.9. Activating Self Diagnosis Function (Doctor Mode)

This mode can be used during servicing.

1. Plug the AC adapter to the power source. Press and hold down the MULTI-SOURCE RE-MASTER button and the SPEAKERS

A button, and then press the POWER button at the same time.

2. Initialize all the setting and set the frequency “99.7MHz” to Tuner.

The message, “_DOCTOR_” appears on the display for three seconds, and then disappears. Refer to Fig. 9.3.

Fig. 9.3

3. Doctor mode function at some remote control codes as below table.

Remote Control Test Mode Function and settings

Selector Sound Mode other settings Vol/Tone

CH 1 TUNER STEREO Frequency : FM min -48dB/0dB

CH 2 TUNER STEREO Frequency : FM max -48dB/0dB

CH 3 TUNER STEREO FM 98.3MHz -18dB/0dB

CH 4 TUNER STEREO Frequency : AM min -48dB/0dB

CH 5 TUNER STEREO Frequency : AM max -48dB/0dB

CH 8 If the input selector is TUNER, auto tuning function is started to upward on current frequency.

CH 9 If the input selector is TUNER, auto tuning function is started to downward on current frequency.

CH 0 All indicators of FL are displayed. All LED are off. Refer to Fig. 9.4.

CH UP Check Main µP software version.

Note : After this setting, only ‘POWER’ button or ‘Checker Command’ code by the remote control can be entered.

29

SA-XR55E / SA-XR55EB / SA-XR55EG

CH DOWN Check Sub µP software version.

SUBWOOFER VCR 1 (Analog) - All CH Output Mode -18dB/0dB

MUTING DVD 6CH - - -18dB/0dB

PLIIx CD STEREO Analog -18dB/0dB

NEO:6 TV STEREO Analog -18dB/0dB

RE-MASTER DVD STEREO Analog -18dB/0dB

LEVEL DVR/DVD_REC STEREO Analog -18dB/0dB

EFFECT CD STEREO Digital (COAX 2) -48dB/0dB

OFF TV STEREO Digital (OPT 1) -48dB/0dB

SFC AV/MOVIE DVD STEREO Digital (COAX 1) -48dB/0dB

SFC MUSIC DVR/DVD_REC STEREO Digital (OPT 2) -48dB/0dB

TEST No change SURROUND Scan the test noise output channel with 500ms

-/L CD STEREO Balance is set to leftmost -18dB/0dB

+/R CD STEREO Balance is set to rightmost -18dB/0dB

intervals

-18dB/0dB

Fig. 9.4

30

Loading...

Loading...