Page 1

A

A

A

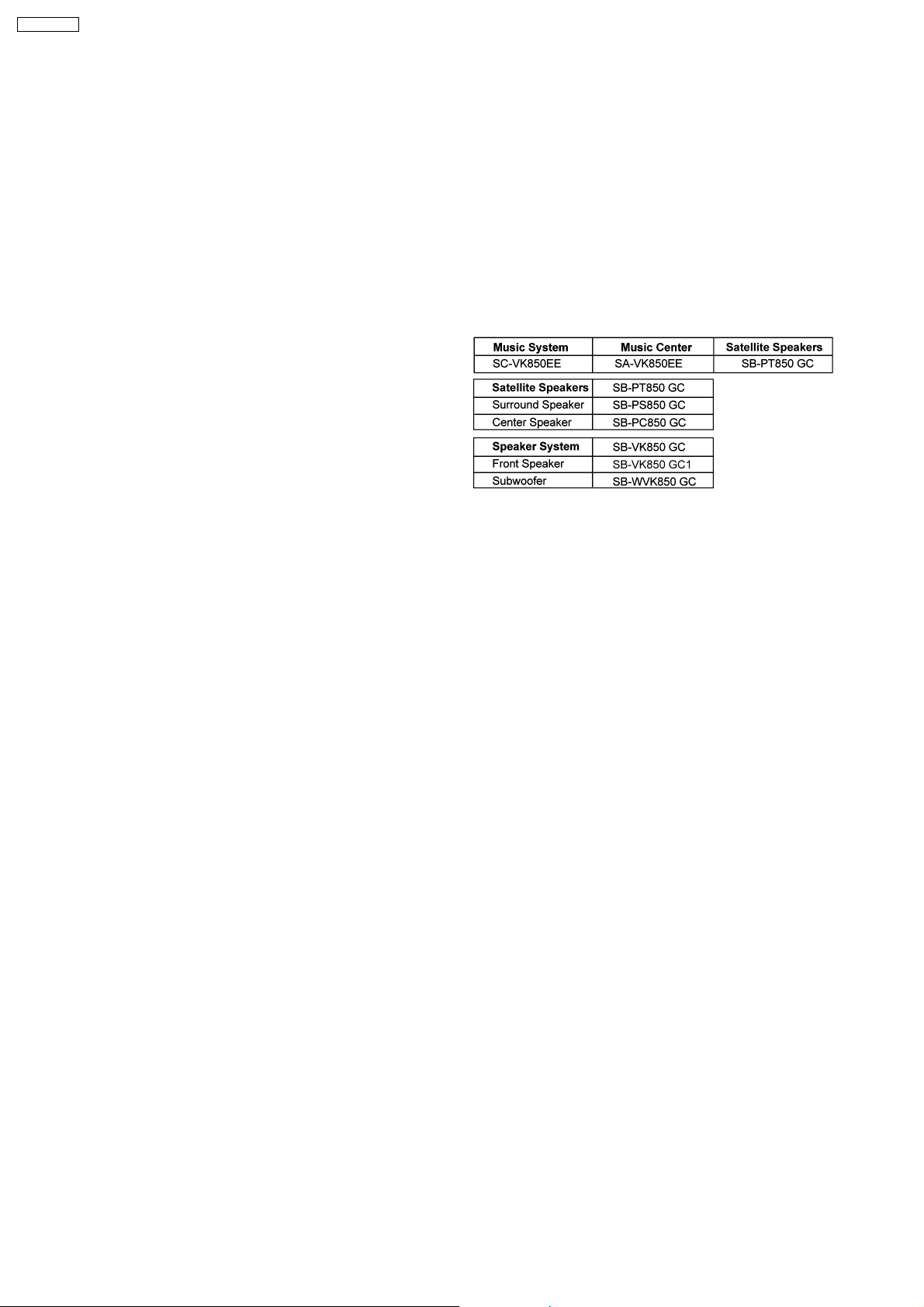

DVD Stereo System

SA-VK850EE

Colour

(S)... Silver Type

ORDER NO. MD0607234CE

Notes: This model’s DVD mechanism changer unit is CRS1D. Please refer to the original Service Manual

(Order No. MD0603065A3) for this mechanism.

Specifications

n AMPLIFIER SECTION

RMS Output Power: Dolby Digital Mode

Front - Ch

110 W per channel (3 Ω ), 1 kHz, 10% THD

Surround Ch

110 W per channel (3 Ω ), 1 kHz, 10% THD

Center Ch

110 W per channel (3 Ω ), 1 kHz, 10% THD

Subwoofer Ch

110 W per channel (3 Ω), 100 Hz, 10% THD

Total RMS Dolby Digital mode power

660 W

PMPO output power 7000 W

n FM/AM TUNER, TERMINALS SECTION

Preset stations FM 15 stations

AM 15 stations

Frequency Modulation (FM)

Frequency range

87.50 MHz to 108.00 MHz (50-kHz step)

Sensitivity 4.0 µV (IHF)

S/N 26 dB 2.2 µV

ntenna terminals 75 Ω (unbalanced)

mplitude Modulation (AM)

Frequency range 522 kHz to 1629 kHz (9-kHz step)

M sensitivity S/N 20 dB at 999 kHz

1000 µV/m

Phone jack

Terminal Stereo, 3.5-mm jack

Mic jack

Sensitivity 0.7 mV, 600 Ω

Terminal Mono, 6.3-mm jack (2 system)

Music Port jack (Front)

Sensitivity 100-mV, 4.7 kΩ

Terminal Stereo, 3.5-mm jack

n CASSETTE DECK SECTION

Type Auto Reverse

Track system 4-Track, 2 Channel

Head Record/Playback Solid permalloy head

Erasure Double Gap Ferrite Head

Motor DC Servo Motor

Recording system AC Bias 100 kHz

Erase System AC Erase 100 kHz

Tape Speed 4.8 cm/s

Overall Frequency Response (+3, -6 dB) at DECK OUT

Normal 35 Hz to 14 kHz

S/N Ratio 50 dB (A weighted)

Wow and Flutter 0.18% (WRMS)

Fast Forward and Rewind Time Approx. 120 seconds with

© 2006 Matsushita Electric Industrial Co. Ltd.. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

A

A

SA-VK850EE

C-60 cassette tape

n DISC SECTION

Disc played [8 cm or 12 cm]

(1) DVD (DVD-Video, DivX )

(2) DVD-RAM (DVD-VR, JPEG , MP3 , MPEG4 , DivX )

(3) DVD-R (DVD-Video, DVD-VR, JPEG , MP3 , MPEG4 ,

# 1,#2

DivX

)

#1,#2

#2,#3

#2,#4

#2,#3

#2,#4

#2,#5

#1,#2

#2,#5

(4) DVD-R DL (DVD-Video, DVD-VR)

(5) DVD-RW (DVD-Video, DVD-VR, JPEG , MP3 , MPEG4

2,#5

, DivX

# 1,#2

)

#2,#3

#2,#4

#

(6) +R/ +RW (Video)

(7) +R DL (Video)

#6

(8) CD,CD-R/RW [CD-DA, Video CD, SVCD , MP3 , WMA ,

JPEG

# 2,#3

, MPEG4

# 2,#5

, DivX

# 1,#2

, HighMAT Level 2 (Audio and

#2,#4

#2,#7

Image)]

#1

Plays all versions of DivX video (including DivX 6) with standard

® ®

playback of DivX®media files. Certified to the DivX Home Theater

Profile. GMC (Global Motion Compensation) is not supported.

#2

The total combined maximum number of recognizable audio,

picture and video contents and groups: 4000 audio, picture and video

contents and 400 groups.

#3

Exif Ver 2.1 JPEG Baseline files

Picture resolution: between 160 x 120 and 6144 x 4096 pixels

(Sub sampling is 4:0:0, 4:2:0, 4:2:2 or 4:4:4). Extremely long and

narrow pictures may not be displayed.

#4

MPEG-1 Layer 3, MPEG-2 Layer 3

#5

MPEG4 data recorded with the Panasonic SD multi cameras or

DVD video recorders.

Conforming to SD VIDEO specifications (ASF standard) / MPEG4

(Simple Profile) video system / G.726 audio system

#6

Conforming to IEC62107

#7

Windows Media Audio Ver. 9.0 L3

Not compatible with Multiple Bit Rate (MBR)

Pick up

Wavelength (DVD/CD) 662 nm/785 nm

Laser power (DVD/CD) CLASS 1 / CLASS 1M

udio output (Disc)

Number of channels (FL,FR,C,SL,SR,SW),5.1ch

udio performance (measurement at: Rec out terminal)

Frequency response (CD-Audio) 4Hzto20kHz

n VIDEO SECTION

Video system

Signal system PAL625/50, PAL525/60, NTSC

Composite video output

Output level 1Vp-p(75Ω)

Terminal Pin jack (1 system)

S-video output

Y output level 1Vp-p(75Ω)

C output level 0.3 Vp-p (75 Ω )(PAL)

0.286 Vp-p (75 Ω )(NTSC)

Terminal S terminal (1 system)

Component video output

[NTSC : 480p / 480i, PAL: 576p / 576i]

Y output level 1Vp-p(75Ω)

PBoutput level 0.7 Vp-p (75 Ω )

PRoutput level 0.7 Vp-p (75 Ω )

Terminal

Pin jack (Y: green, PB:blue,PR:red)(1system)

n GENERAL

Power supply AC 230 V, 50Hz

Power consumption 290 W

Power consumption in standby mode:

0.5 W (approximate)

Dimensions (W x H x D) 250 x 330 x 334.6 mm

Mass 5.5 kg

Operating temperatur e range +5to+35°C

Operating humidity range 5% to 90% RH (no condensation)

n SYSTEM

For information on speaker system, please refer to the original

Service Manual (Order No. MD0606210CE) for SB-VK850GC1-S,

(Order No. MD0606211CE) for SB-PS850GC-S, (Order No.

MD0606212CE) for SB-PC850GC-S & (Order No. MD0606213CE) for

SB-WVK850GC-S.

2

Page 3

Notes:

1. Specifications are subject to change without notice.

Mass and dimensions are approximate.

2. Total harmonic distortion is measured by the digital spectrum

analyzer.

SA-VK850EE

3

Page 4

SA-VK850EE

CONTENTS

Page Page

1 Safety Precautions 6

1.1. General Guidelines

1.2. Before Repair and Adjustment

1.3. Protection Circuitry

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

3 Handling Precautions for Traverse Unit

3.1. Handling Optical Pickup

3.2. Replacing Precautions for Optical Pickup Unit

3.3. Grounding for Preventing Electrostatic Destruction

4 Precaution of Laser Diode

5 Warning

5.1. Service caution based on legal restrictions

6 Accessories

7 Operation Procedures

7.1. Main Unit Operation Control

7.2. Remote Control Operation Control

7.3. Disc Information

7.4. DivX VOD Content

8 New Features

8.1. CRS1D Mechanism Overview

8.2. Music Port

9 About HighMAT

9.1. What 痴 HighMAT?

9.2. Why take advantage of HighMAT?

9.3. Benefits of HighMAT?

10 Self diagnosis and special mode setting

10.1. Service Mode Summary Table

10.2. Service Mode Table 1

10.3. Special Mode Table 2

11 Assembling and Disassembling

11.1. Caution

11.2. Disassembly flow chart

11.3. Main Parts Location

11.4. Disassembly of Top Cabinet

11.5. Disassembly of CD/DVD Changer Unit (CRS1D)

11.6. Disassembly of Rear Panel

11.7. Disassembly of Main P.C.B.

11.8. Disassembly of Front Panel Unit

11.9. Disassembly of Digital Amp P.C.B.

11.10. Replacement for Power Amp IC (Digital Amp P.C.B.)

11.11. Disassembly of SMPS P.C.B.

11.12. Replacement of Power Amp IC (SMPS P.C.B.)

11.13. Disassembly of Panel P.C.B., Mic P.C.B. & Tact Switch

P.C.B.

10

10

11

12

12

13

14

16

17

17

19

20

20

20

21

24

24

24

32

40

40

41

42

43

43

44

45

45

46

46

47

47

48

6

6

6

7

8

8

8

8

9

11.14. Disassembly of Deck mechanism unit

11.15. Disassembly of Deck P.C.B.

11.16. Disassembly of Traverse Unit

11.17. Disassembly of optical pickup unit (CD/DVD mechanism )

11.18. Disassembly of Deck Mechanism

11.19. Replacement for cassette lid

11.20. Rectification for tape jam problem

12 Service Fixture and Tools

13 Service Positions

13.1. Checking and Repairing of Main P.C.B.

13.2. Checking and Repairing of SMPS P.C.B. & Digital Amp

P.C.B.

13.3. Checking and Repairing of Panel, Deck & Deck

Mechanism P.C.B.

14 Adjustment Procedures

14.1. Cassette Deck Section

14.2. Alignment Points

15 Voltage and Waveform Chart

15.1. DVD Module P.C.B.

15.2. Main P.C.B.

15.3. Panel P.C.B.

15.4. Deck P.C.B. & Deck Mechanism P.C.B.

15.5. Damp P.C.B. & Mic P.C.B.

15.6. Waveform Chart

16 Wiring Connection Diagram

17 Block Diagram

18 Notes of Schematic Diagrams

19 Schematic Diagram

19.1. Optical Pickup Unit Circuit

19.2. (A) DVD Module (DV3.2) Circuit

19.3. (B) Main Circuit

19.4. (C) Panel Circuit

19.5. (D) Tact Switch Circuit & (E) Mic Circuit

19.6. (F) Damp Circuit

19.7. (G) Speaker Circuit

19.8. (H) SMPS Circuit

19.9. (I) Deck Circuit & (J) Deck Mechanism Circuit

20 Printed Circuit Board

20.1. (A) DVD Module P.C.B. (Side A & B )

20.2. (B) Main P.C.B.

20.3. (C) Panel P.C.B.

20.4. (D) Tact Switch P.C.B., (E) Mic P.C.B., (I) Deck P.C.B. &

(J) Deck Mechanism, P.C.B.

20.5. (F) Damp P.C.B. & (G) Speaker P.C.B.

49

49

50

51

53

57

57

58

58

58

59

60

61

61

62

63

64

66

69

70

71

72

81

83

89

91

91

92

96

100

101

102

104

105

107

109

110

111

112

113

114

4

Page 5

SA-VK850EE

20.6. (H) SMPS P.C.B. 115

21 Basic Troubleshooting Guide for Backend Module

21.1. Firmware and Key Download

21.2. Initialisation and Playability

22 Illustration of ICs, Transistors and Diodes

23 Terminal Function of IC

117

117

117

118

119

23.1. IC2600 (C2CBYY0 00269) System Microprocessor

24 Exploded Views

24.1. Cabinet Parts Location

24.2. Deck Mechanism Parts Location (RAA3413-1S)

24.3. Packaging

25 Replacement Parts List

119

121

121

123

124

129

5

Page 6

SA-VK850EE

1 Safety Precautions

1.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the expose d metallic part has a return path to the

chassis, the reading should be between 1MΩ and 5.2MΩ.

When the exposed metal does not have a return path to the chassis, the reading must be

.

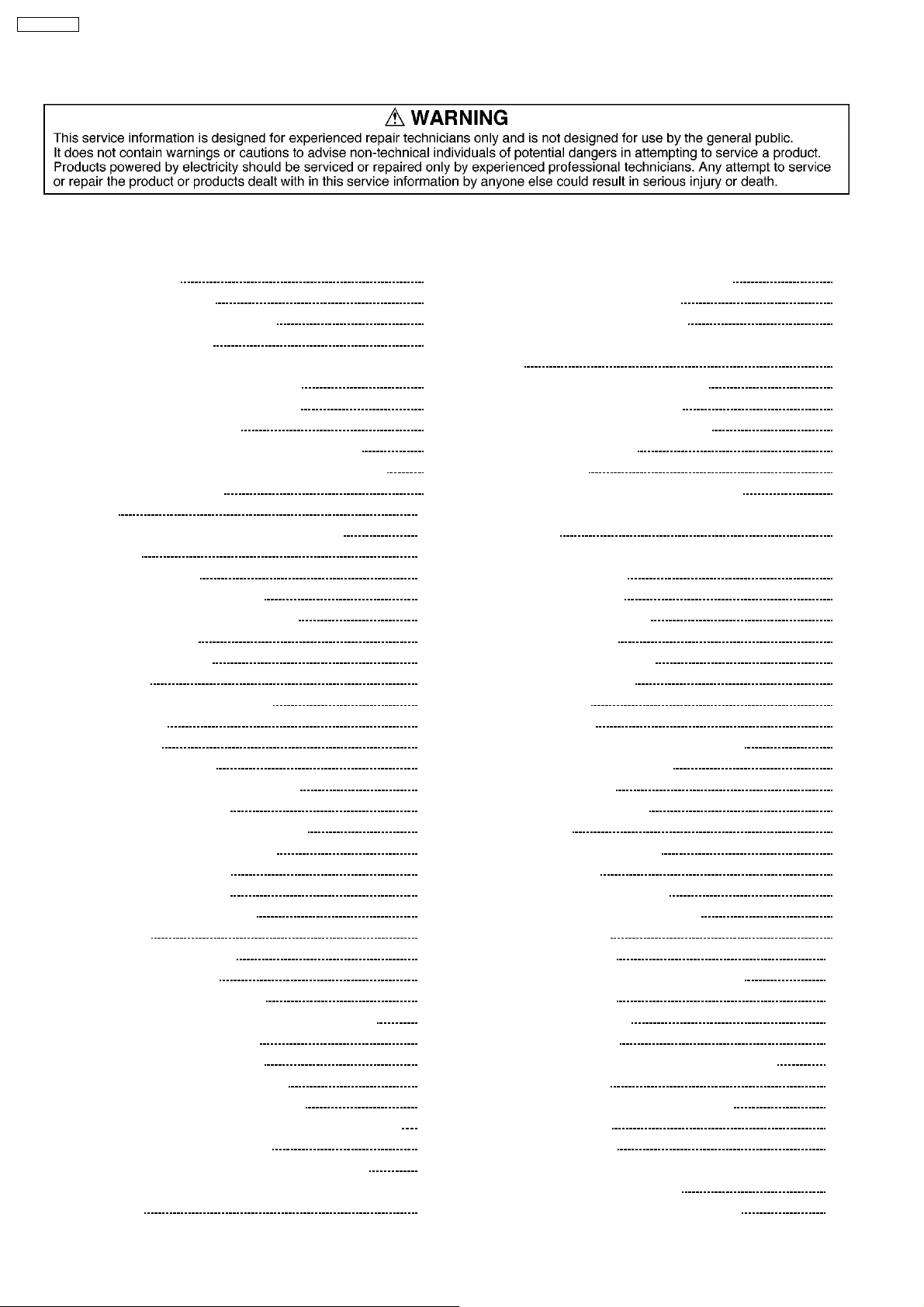

Figure 1

1.1.2. Leakage Current Hot Check

(See Figure 1)

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF capacitor, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent) may

be used to make the hot checks, leakage current must not exceed 1/2 milliamp. In case a measurement is out of the limits

specified, there is a possibility of a shock hazard, and the equipment should be repaired and rechecked before it is returned to

the customer.

1.2. Before Repair and Adjustment

Disconnect AC power, discharge Power Supply Capacitors C2254, C2256, C2288, C2289, C2632, C2721, C2725, C2811, C2815,

C2817, C5512, C5513, C5514, C5712, C5713, C5715, C5805 , C5806, C5807, C5914 , C5916 , C5917 , C5929 , C5930, C5971 and

C5977 through a 10Ω, 5W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Current consum ption at AC 230V, 50Hz in NO SIGNAL (vol. min, at CD mode) should be ~500mA.

1.3. Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

· No sound is heard when the power is turned on.

· Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

6

Page 7

SA-VK850EE

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note :

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconducto r (solid state) devices can be damaged easily by electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor “chip” components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touchin g a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminium foil, to prevent electrostatic charge build up or exposu re of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder remover device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminium foil or

comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize body motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to

damage an ES device).

7

Page 8

SA-VK850EE

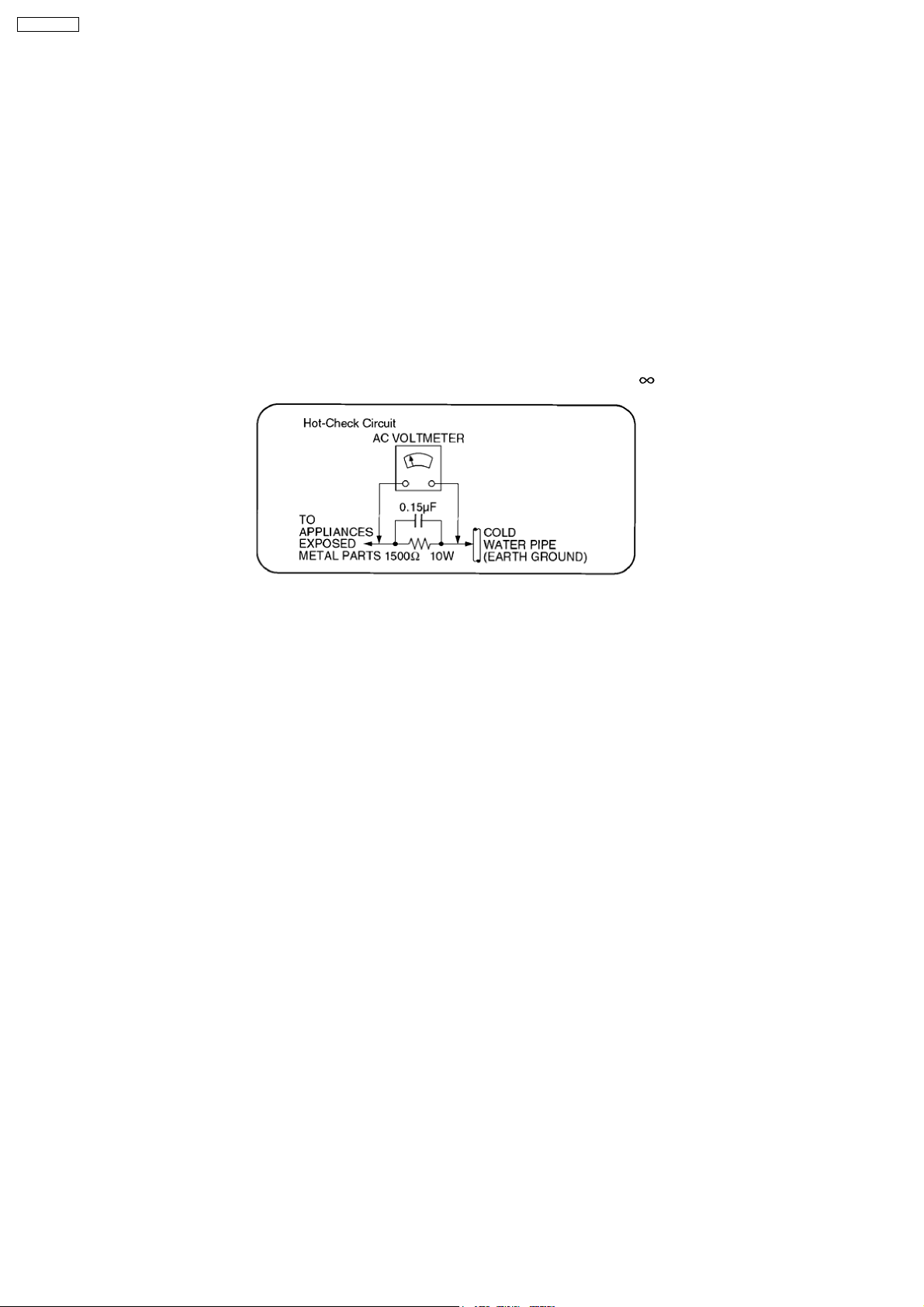

3 Handling Precautions for Traverse Unit

The laser diode used inside optical pickup could be destroyed due to static electricity as a potential difference is caused by

electrostatic load discharged from clothes or human body. Handling the parts carefully to avoid electrostatic destruction during

repair.

3.1. Handling Optical Pickup

1. Do not impact on optical pickup as the unit structurally uses an extremely precise technology.

2. Short-circuit the flexible cable of optical pickup remove from the circuit board using a short-circuit pin or clip in order to prevent

laser diode from electrostatic destruction (Refer to Fig. 3.1 and Fig. 3.2)

3. Do not handle flexible cables forcibly as this may cause snapping. Handle the parts carefully (Refer to Fig. 3.1)

4. A new optical pickup is equipped with an anti-static flexible cable. After replacing and connecting to the flexible board, cut the

anti-static flexible cable. (Refer to Fig. 3.1)

Fig 3.1

3.2. Replacing Precautions for Optical Pickup Unit

CD/DVD Optical Pickup

The optical pickup by which part supply was carried out attaches the short clip to the flexible board for laser diode electrostatic

discharge damage prevention. Please remove the short clip and be sure to check that the short land is open, before connecting.

(Please remove solder, when the short land short-circuits.)

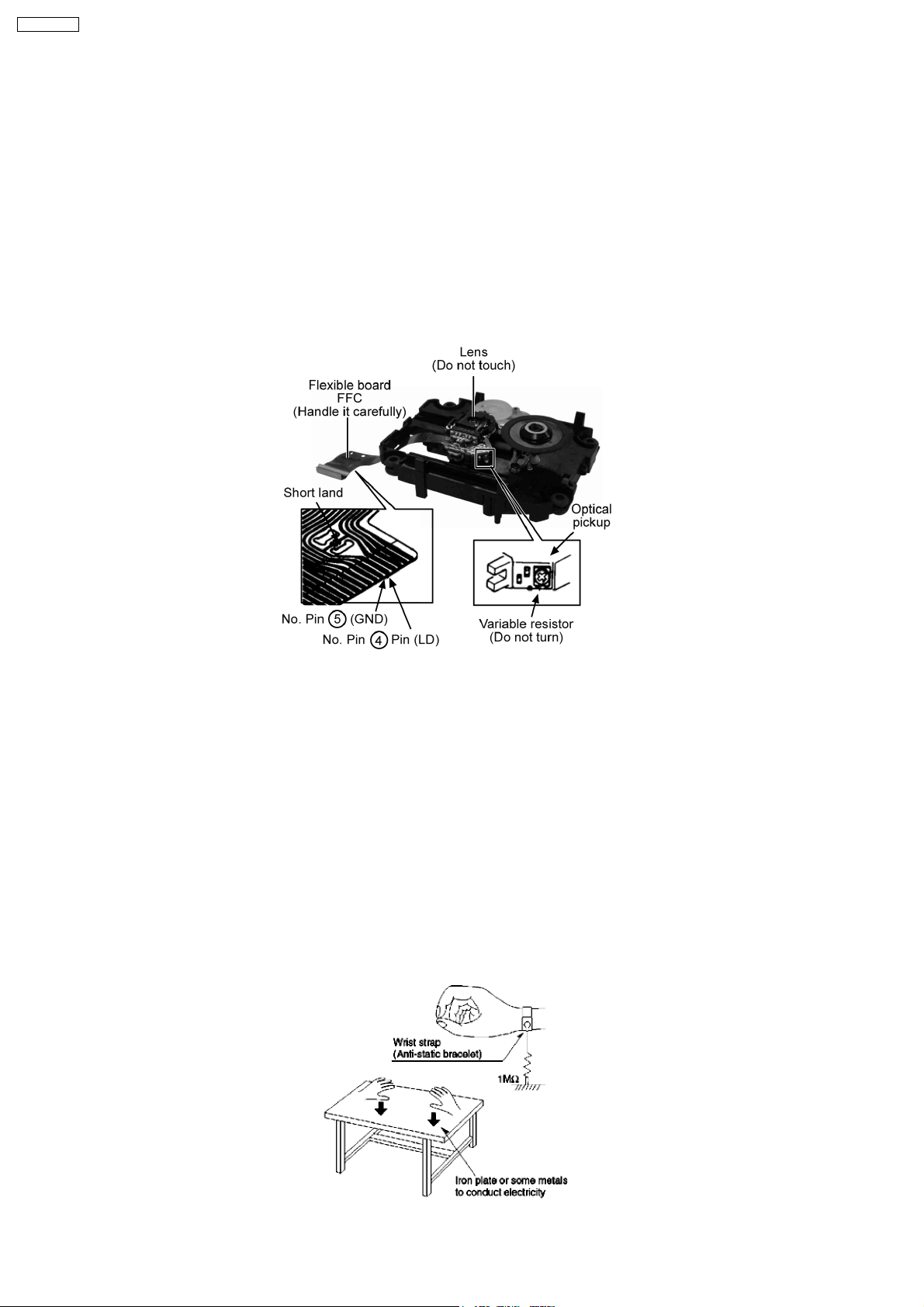

3.3. Grounding for Preventing Electrostatic Destruction

1. Human body grounding

Use the anti-static wrist strap to discharge the static electricity accumulated in your body. (Refer to Fig. 3.2)

2. Work place grounding

Place a conductive material (conductive sheet) or ironboard where optical pickup is placed. (Refer to Fig. 3.2)

Note :

Keep your clothes away from optical pickup as wrist strap does not release the static electricity charged in clothes.

Fig. 3.2

8

Page 9

SA-VK850EE

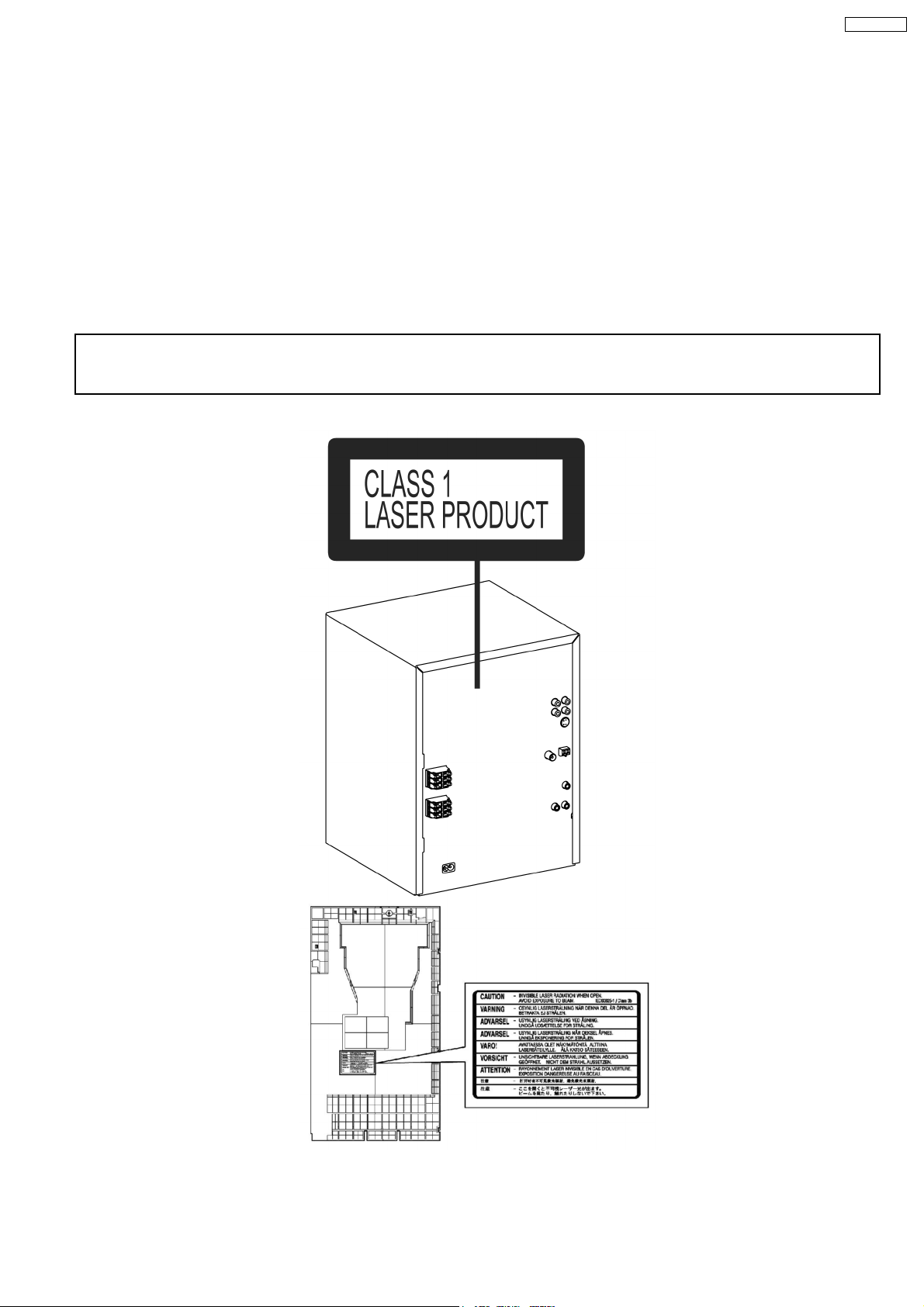

4 Precaution of Laser Diode

Caution :

This product utilizes a laser diode with the unit turned "ON", invisible laser radiation is emitted from the pick up lens.

Wavelength : 785 nm(CD)/662 nm(DVD)

Maximum output radiation power from pick up : 100 µW/VDE

Laser radiation from pick up unit is safety level, but be sure the followings:

1. Do not disassemble the optical pick up unit, since radiation from exposed laser diode is dangerous.

2. Do not adjust the variable resistor on the pick up unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at pick up lens for a long time.

CAUTION!

THIS PRODUCT UTILIZES A LASER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT

IN HAZARDOUS RADIATION EXPOSURE.

n Use of Caution Labels

9

Page 10

SA-VK850EE

5 Warning

5.1. Service caution based on legal restrictions

5.1.1. General description about Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86°F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

The letter of “PbF” is printed either foil side or components side on the PCB using the lead free solder.

(See right figure)

Service caution for repair work using Lead Free Solder (PbF)

· The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

· To put lead free solder, it should be well molten and mixed with the original lead free solder.

· Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

· Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt

the lead free solder.

· Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30

degrees C (662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

· The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: Tin (Sn), 96.5%, Silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

10

Page 11

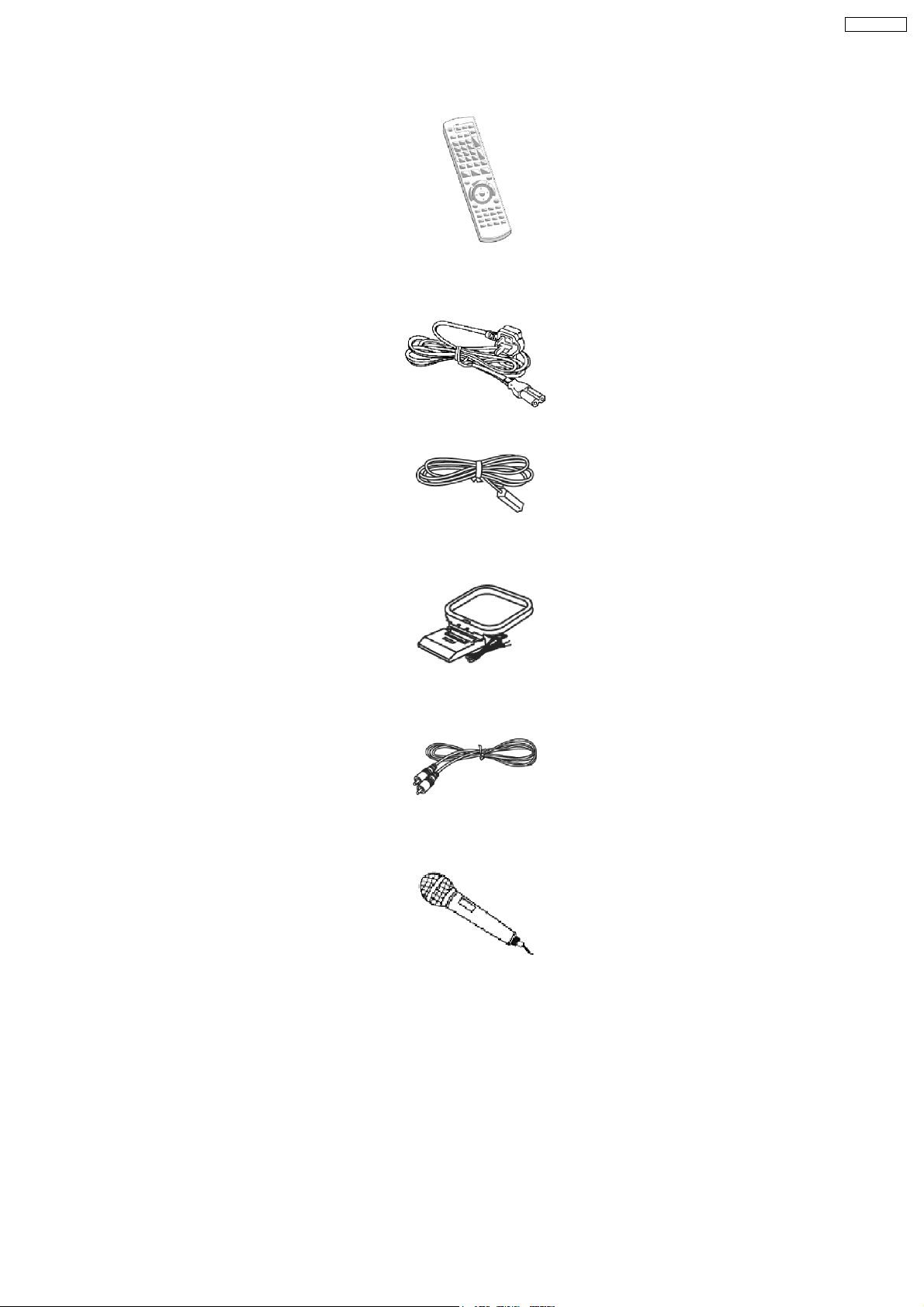

6 Accessories

SA-VK850EE

Remote

control

AC power supply cord

FM indoor antenna

AM loop antenna

Video cable

Microphone

11

Page 12

SA-VK850EE

7 Operation Procedures

7.1. Main Unit Operation Control

12

Page 13

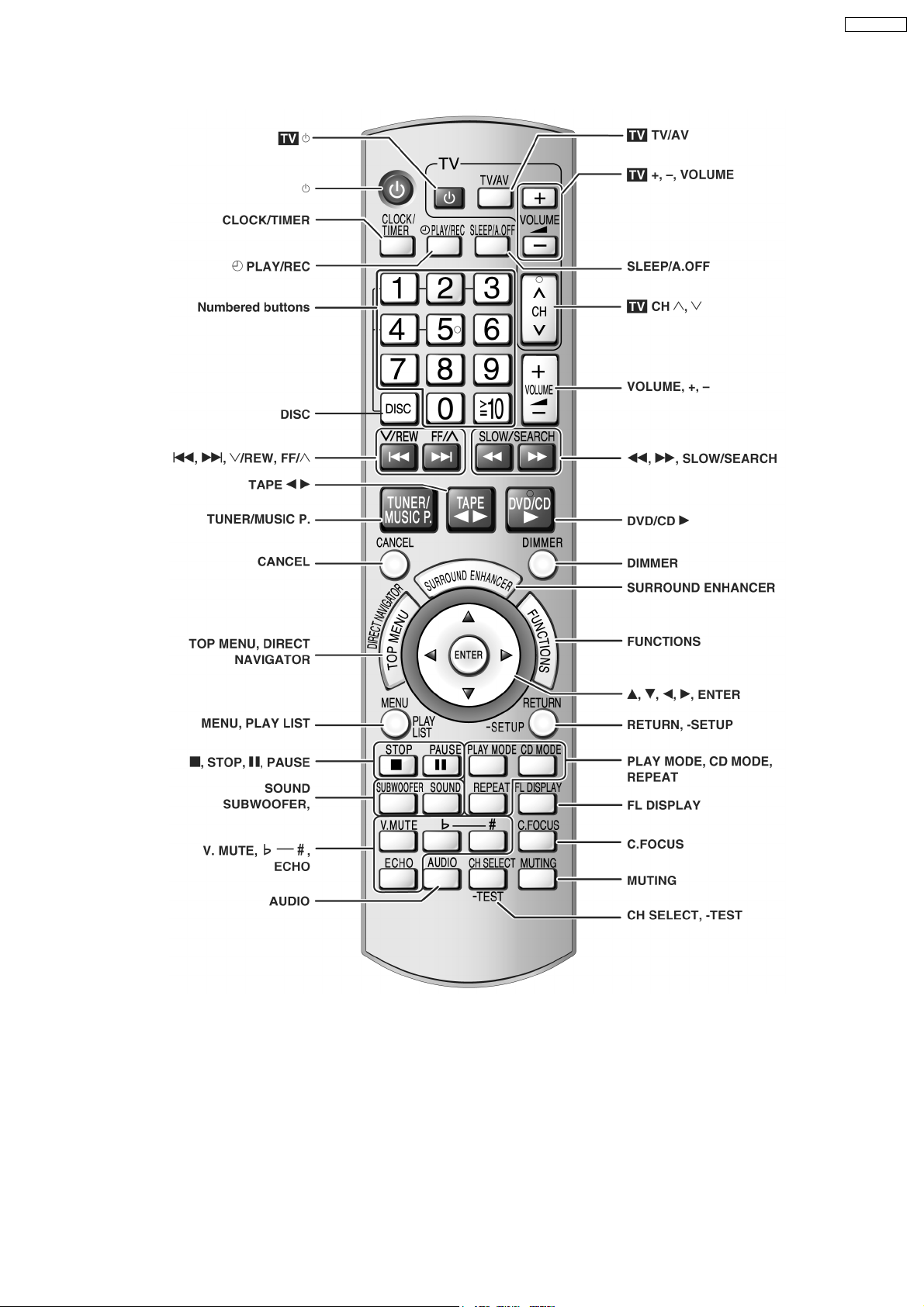

7.2. Remote Control Operation Control

SA-VK850EE

13

Page 14

SA-VK850EE

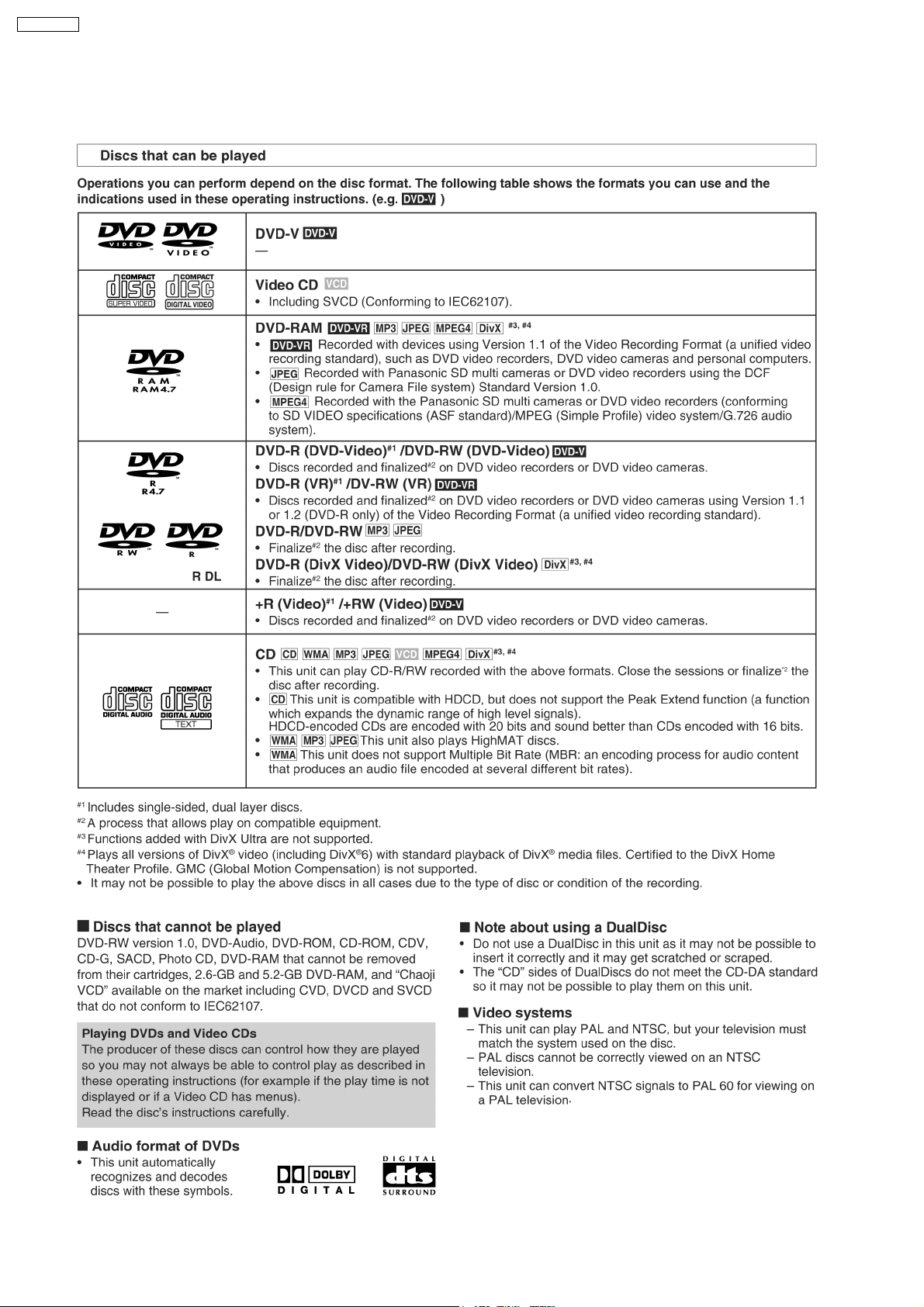

7.3. Disc Information

7.3.1. Disc Playability

14

Page 15

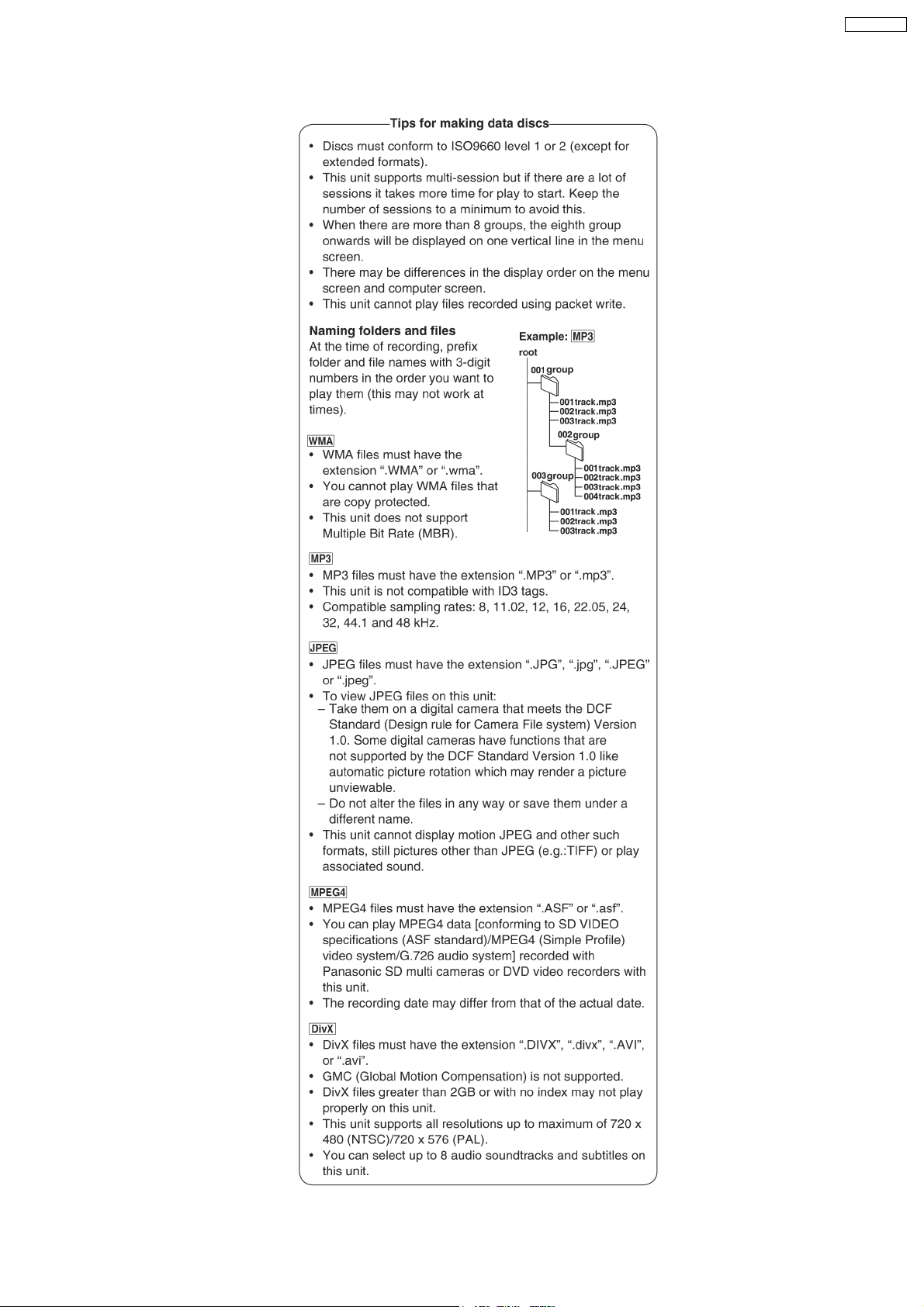

7.3.2. To Play MP3/ WMA and still Pictures (JPEG/ tiff)

SA-VK850EE

15

Page 16

SA-VK850EE

7.4. DivX VOD Content

16

Page 17

8 New Features

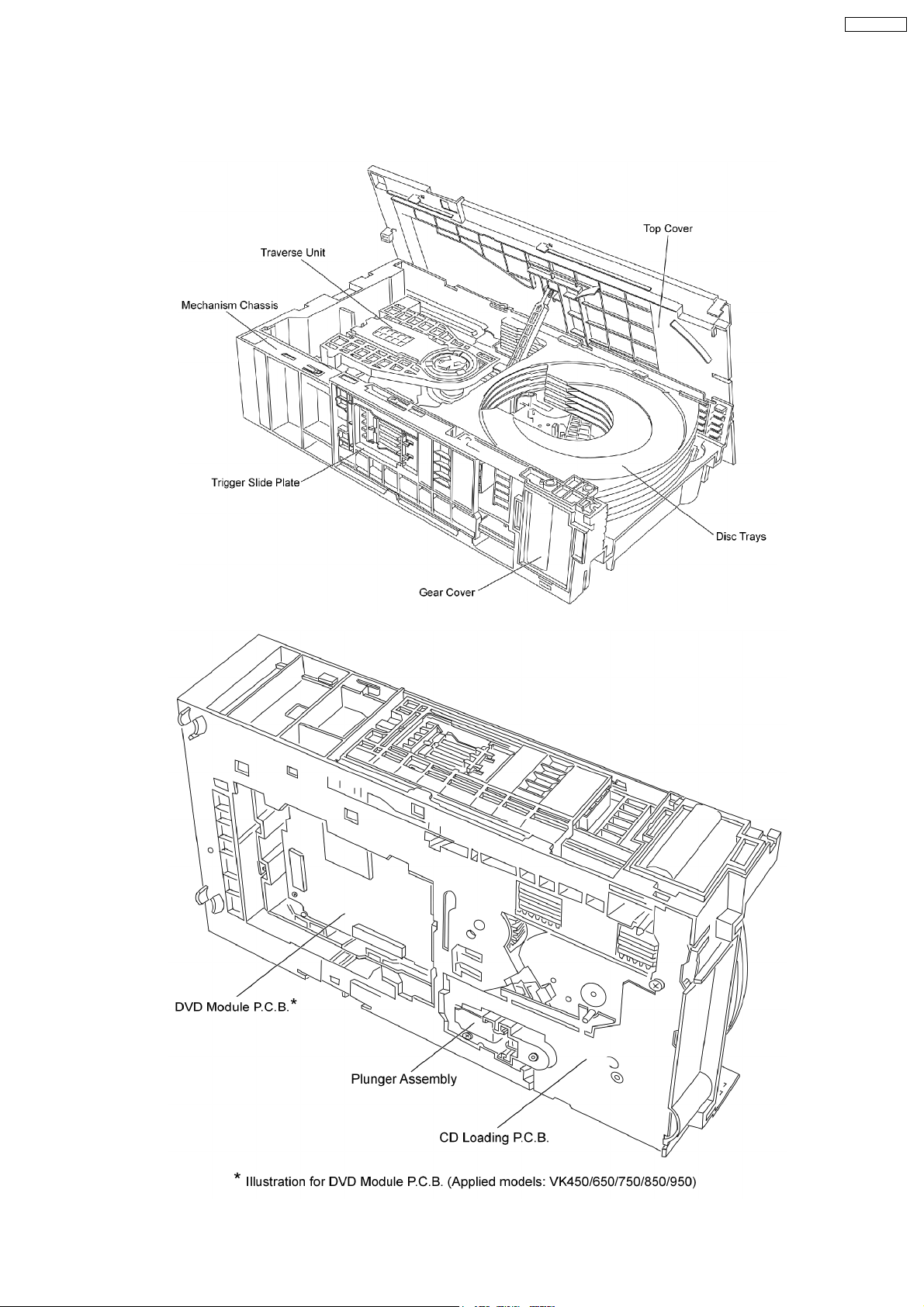

8.1. CRS1D Mechanism Overview

SA-VK850EE

17

Page 18

SA-VK850EE

8.1.1. General Feature

· This is a five disc changer mechanism for CD/DVD. The outline figure is shown below.

· The mechanism has "CHANGE WHILE PLAY" function. It open other trays for disc exchan ging while one tray is at PLAY

position performing recording or reproducing.

· The mechanism can quickly change all trays with "CHANGE ALL" function. All trays can be move to OPEN position with one

operation.

· There is no sensor to indicate presence of disc on any tray.

8.1.2. Hardware composition

· Below is the hardware components of the mechanism

Name Function

Open Switch (OPEN-SW) The switch is used to detect normal tray opening

The switch is used for detect tray being manually push/trigger when full open

Home Switch (HOME-SW) Is used to detect cam gear home position

Close Sensor (CLOSE-SENSOR) Used for normal single tray closing

Used to detect cam gear rotate to Play Driving position

Play Switch (PLAY-SW) Detect TRV clamping complete position

Stocking Switch (STOCK-SW) Detect tray completely transfer for play position to stocking position

UD Sensor (UD-SENSOR) Detect TRV vertical movement position

Top Switch (TOP-SW) Detect a default position of TRV vertical movement position

Driver IC To drive Motor

Motor Main driving source for changer

Plunger Switching the driving source from motor to:

1. Tray open/close

2. Drive tray to play/stock position and TRV vertical movement

8.1.3. Mechanism Operation

· This mechanism has the following state:

1. Driving of a tray to open/close

2. Up/down operation of a traverse performs a state changes of tray.

By using the plunger to lift/release of a switching gear, and the cam gear to lift/release the function gear the motor can be link

to several gear trains to perform various operations.

· The functions that can be perform in this mechanism are described as below:

Condition Explanation

Open current playing tray The state to change current playing disc. All tray will be open at once and current tray at PLAY position

Open All The state where all trays being driven to OPEN position. The disc can be taken in or out from tray to tray

Stock The state where the trays are stored in STOCK position

Play The state where one of the tray 5 trays is being driven to PLAY position and clamped by traverse unit

Play & Open Tray-* The state where one of the tray is in playing position performing recording or reproducing, other trays can

will be expose.

by close tray one by one from top to bottom.

be used (OPEN position) for disc exchanging without stopping the recording or reproducing process.

18

Page 19

Condition Explanation

Change The state when one of the opened tray being driven from OPEN position to STOCK position and other

opened trays remain still at OPEN position.

Close All The state where all open trays will being driven from OPEN position to STOCK position, one by one from

top to bottom

Note: * represent tray number (from 1 ~ 5)

8.1.4. New CD/DVD Mechanism (CRS1D)

Note:

This service manual does not contain the following information for the mention CD/DVD Mechanism drive:

· Schematic Diagram, Block Diagram and P.C.B. layout of CD/DVD Loading P.C.B.

· Part List for individual parts of the mechanism.

· Explode d View and Parts List for individual parts of the CD/DVD Mechanism drive.

Please refer to the original service manual (Order No. MD0603065A3) for the CD/DVD Mechanism Drive CRS1D.

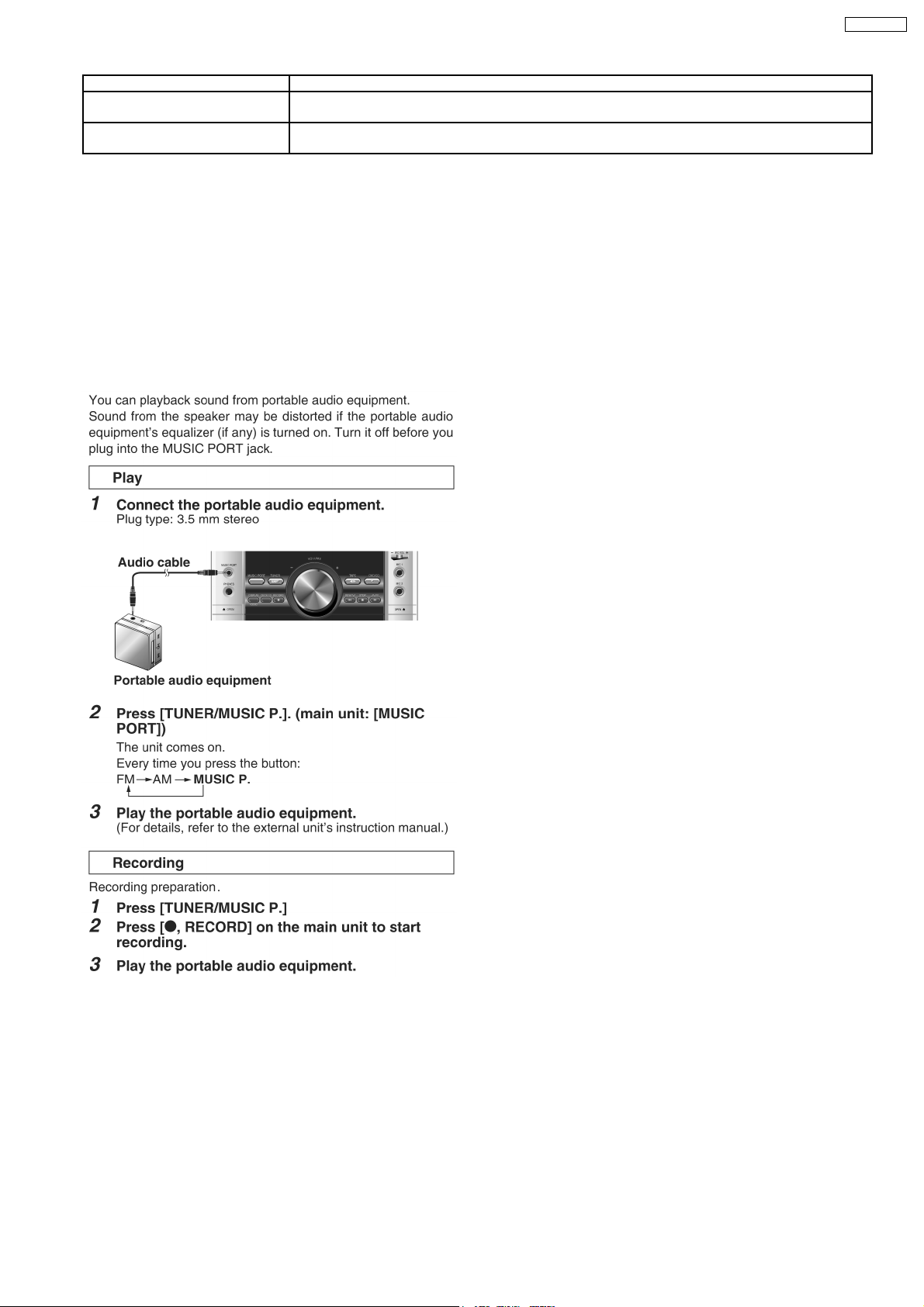

8.2. Music Port

SA-VK850EE

With reference to page 31 of the operating instruction manual.

19

Page 20

SA-VK850EE

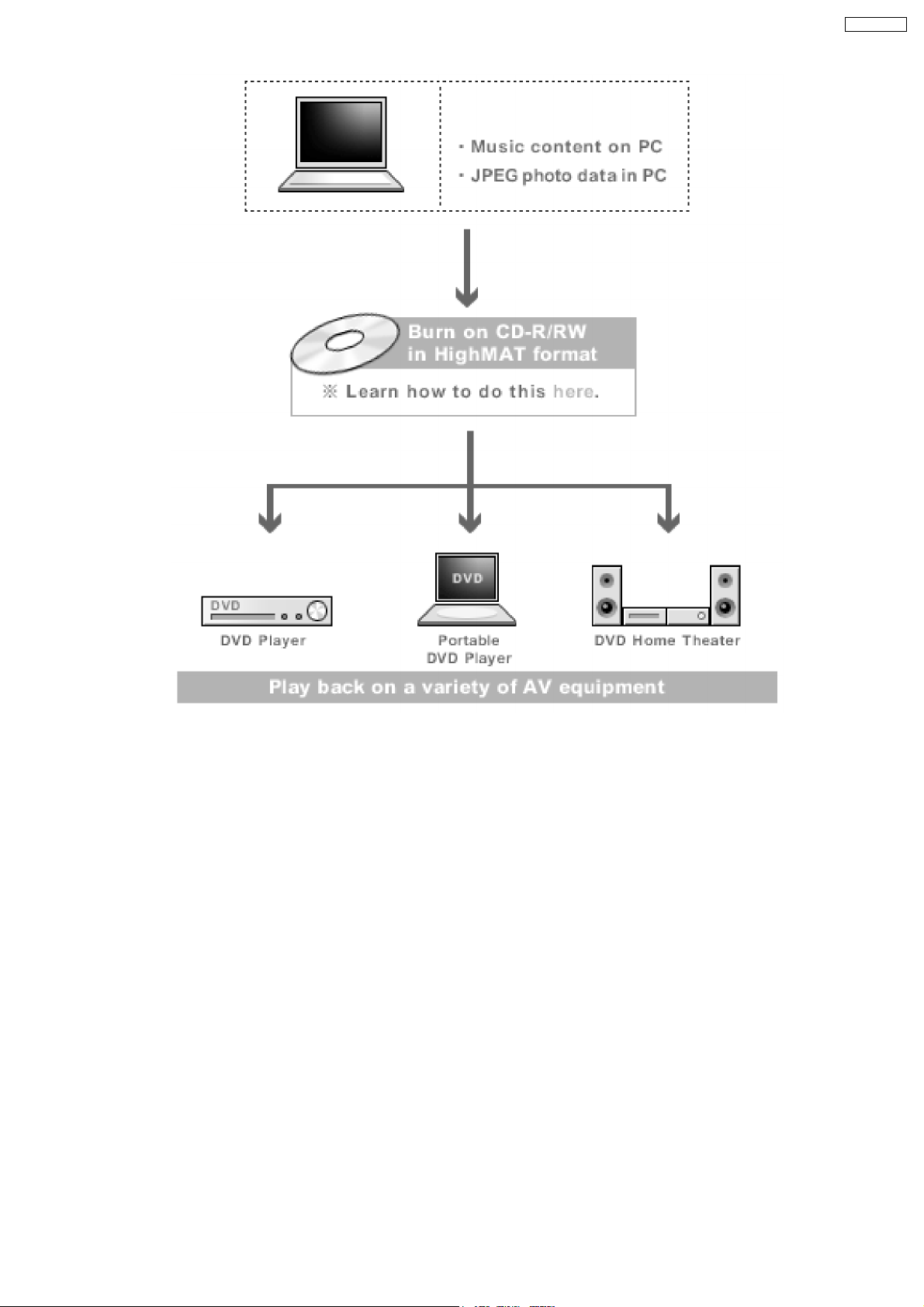

9 About HighMAT

9.1. What’s HighMAT?

Consumers worldwide are using PCs to create their own collections of music, photos and even video by burning them onto CDs.

But how these collections can be experienced across different devices can be confusing to navigate, time consum ing to access for

a DVD player, and be incomplete in terms of music information available to the customer.

HighMAT offers a solution to this growing consumer problem. HighMAT dramatically improves the digital media experience on

consumer electronic devices by delivering a simple, standardized approach that allows consumers who have created personal

collections of digital music, photography and video on their PC to:

>> Create a HighMAT CD or DVD which can be easily played back on consum er electronics devices such as CD and DVD players ,

and car stereos.

>> Move digital media files (using recordable media such as CD-R and CD-RW) between the PC and various playback devices

such as CD and DVD players.

A new standard for creating personal media on consumer electronic devices, HighMAT enable easier and more seamless

interoperability between Windows PCs and devices designed for your living room, or the car.

9.2. Why take advantage of HighMAT?

A Problem Defined:Toda y, when consumers create their own digital audio, video or photo collections on CD-R or other physical

formats, there are numerous, inconsistent ways that devices read the data. For the consumer, the playba ck experie nce can be

confusing:

20

Page 21

SA-VK850EE

A Solution Created: HighMAT delivers a better digital media access experience by creating a standard approach for PCs to

structure digital media on various physical formats and for playback devices to read the data.

9.3. Benefits of HighMAT?

Conventional HighMAT

Even though DVD player is CD-R/RW compatible, the inconsistent ways

that various DVD players can read the music or photos files often leads

to a confusing and inconsistant playback experince.

HighMAT compatible products play content back with consistent

interface. This includes products which are JPEG compatible products

without HighMAT support.

21

Page 22

SA-VK850EE

22

Page 23

SA-VK850EE

HighMAT is now available for CD Burning and in Leading DVD PlayersHighMAT is a new technology that is now available in leading

software and consumer electronic devices to dramatically improve the digital media experience when you create homemade

CDsHighMAT delivers a simple, standardized way for PC software and consumer electronics devices to talk to each other and work

better together.

When you create your homemade CDs with software that supports HighMAT CD burning, and then play them back on a DVD

player that supports HighMAT, you get better, easier navigation. You get folders you can access with a single click of your DVD

player´s remote control. You can view important information about your music like full song names, artist titles, album names and

genre. And you can get faster startup on your home entertainment device.

To enjoy the benefits of HighMAT, all you need is software that supports HighMAT for CD burning of music or photos, as well as

a home entertainment device like a DVD player that supports HighMAT for playback. Always look for the HighMAT logo on your

software or home entertainment device to ensure it supports the HighMAT experience.

23

Page 24

SA-VK850EE

10 Self diagnosis and special mode setting

This unit is equipped with functions for checking and inspecting namely: Self-Diagnostic and Test Mode.

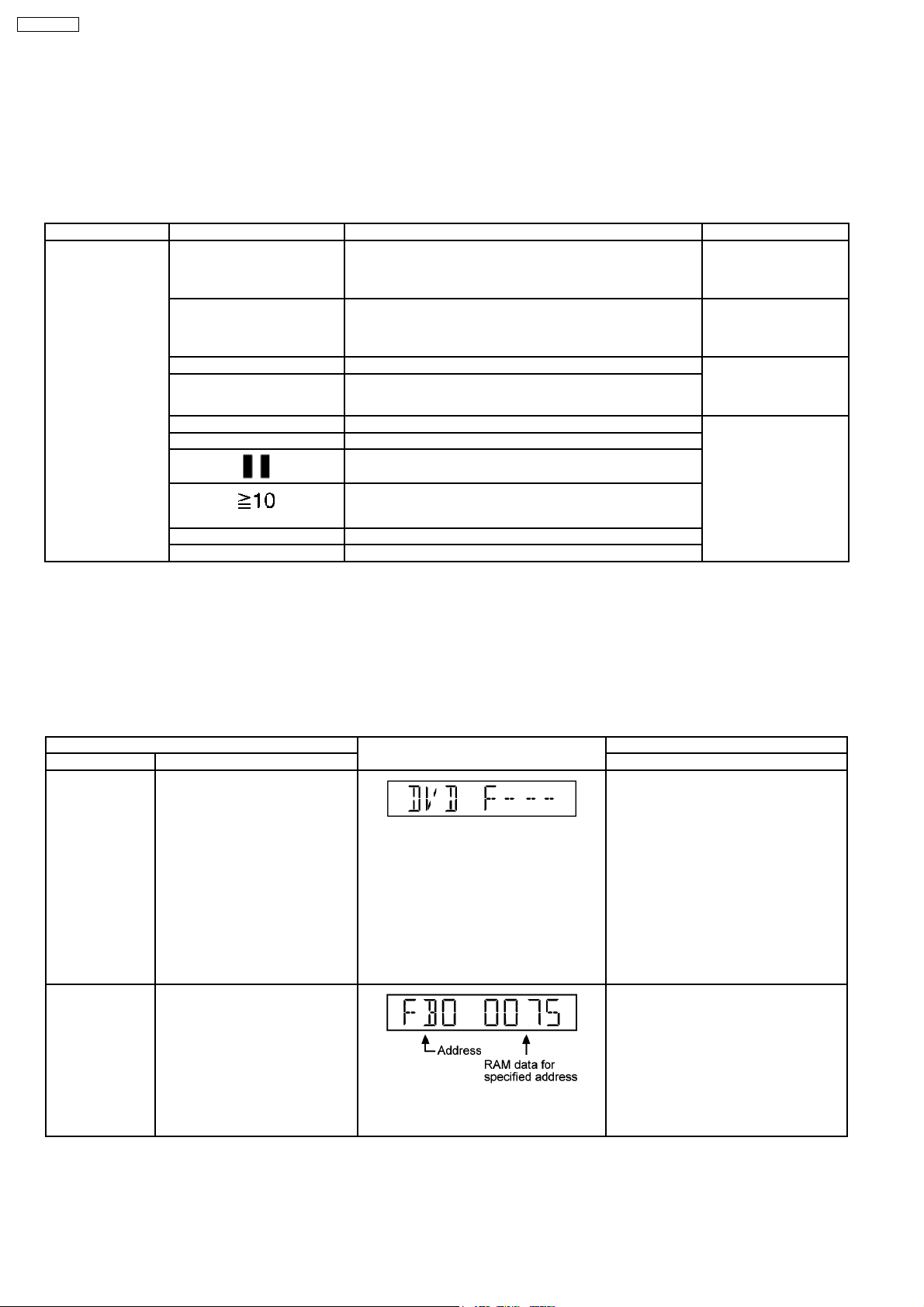

10.1. Service Mode Summary Table

The service modes can be activated by pressing various button combination on the player and remote control unit.

Below is the summary of major checking:

Player buttons Remote control unit buttons Application Note

STOP 0 Error code display (Refer to the section,

5 Jitter checking (Refer to the section

6 Region display and mode (Refer to the section

7 Micro-processor firmware version check

FUNCTIONS DVD laser drive current check

3 CD laser drive current check

Initial setting of laser drive current

“10.2.2 DVD Self

Diagnostic Function-Error

Code”).

“10.2.1 Service Mode

Table 1 for more

information”).

“10.2.1 Service Mode

Table 1 for more

information”).

Initialization of the player (factory setting is restored.)

Used after replacement of micro-computer, FLASH ROM IC,

EEPROM and HDMI module.

8 Region and Firmware version display

ENTER DVD Module Reset (In Initialization Mode)

10.2. Service Mode Table 1

By pressing various button combin ations on the player and remote control unit can activate the various service modes for checking.

Special Note:

Due to the limitations of the no. characters that can be shown on FL Display, the “FL Display” button on the remote control unit

is used to show the following page. (Display 1 / Display 2).

10.2.1. Service Mode Table 1

Item FL Display Key Operation

Mode Name Description Remote Control Key

Error code check Error code check.

ADSC internal

RAM data check

The latest error code stored in the

EEPROM IC is displayed.

ADSC internal RAM data check.

ADSC internal RAM data is read

out and displayed.

Error code (play_err) is expressed in the

following convention.

Error code = 0 x DAXX is expressed: DVDnn

UXX

Error code = 0 x DBXX is expressed: →

DVDnn HXX

Error code = 0 x DXXX is expressed: →

DVDnn FXXX

Error code = 0 x 0000 is expressed: →

DVDnn F--* “xx” denotes the error code →

In STOP (no disc) mode, press STOP

button on the player, and “0” button on the

remote control unit. *With pointing of cursor

up and down on display.

Cancelled automatically 5 seconds later.

To exit, press [POWER] button on main

unit or remote control.

In STOP (no disc) mode, press STOP

button on the player, and “1” or “2” button

on the remote control unit.

Press STOP or PLAY button to exit.

The value is shown in hexadecimal notation.

The above example shows the data in

ADSC address OFAh is 6901h.

24

Page 25

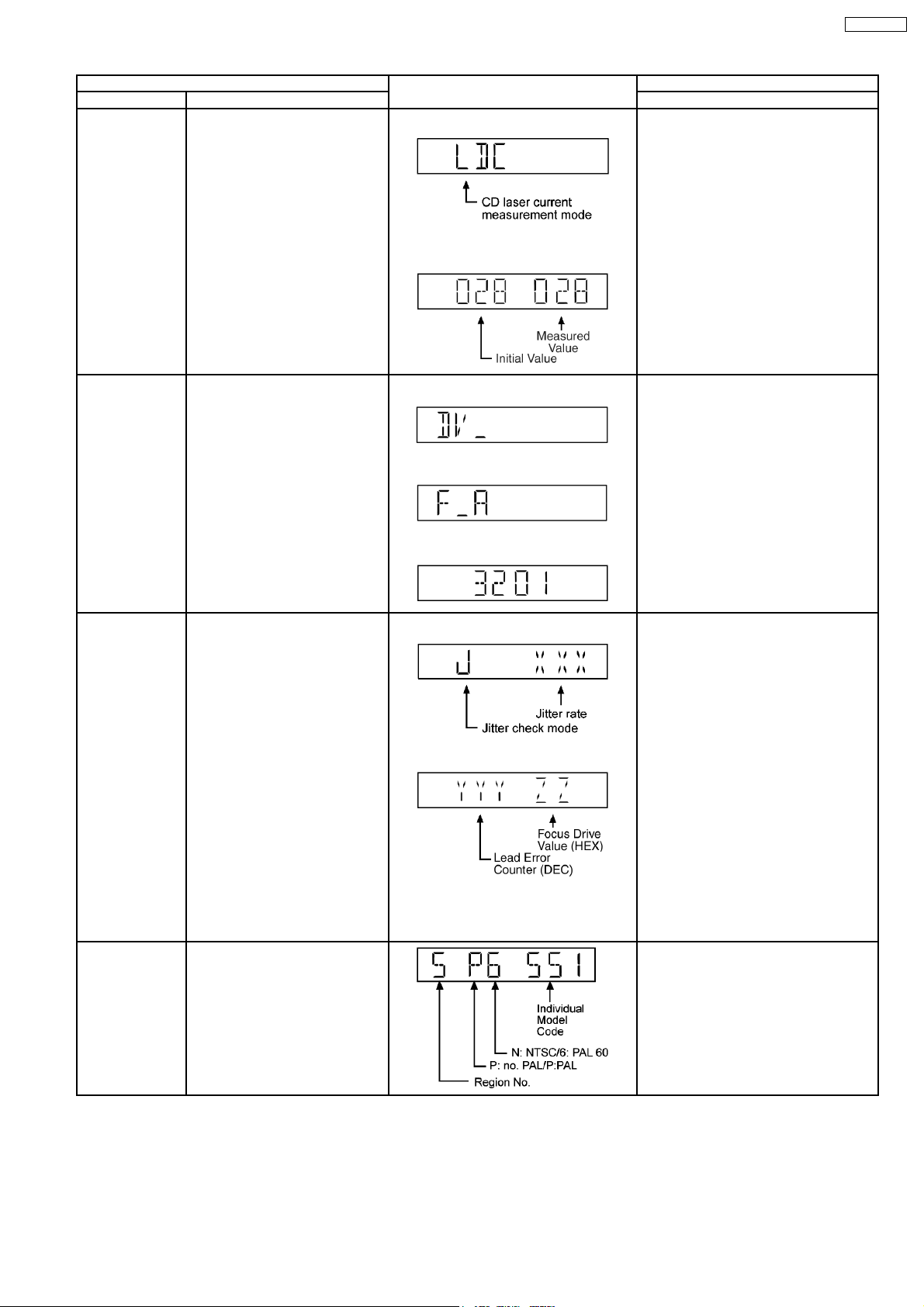

Item FL Display Key Operation

Mode Name Description Remote Control Key

CD laser drive

current

measurement

CD laser drive current

measurement.

CD laser drive current measured

and the result is displayed together

with the initial value stored in the

EEPROM IC.

1. For CD laser drive current mode

In STOP (no disc) mode, press STOP

button on the player, and “3” button on the

remote control unit.

Cancelled automatically 5 seconds later.

Press “FL Display” button on remote

control unit for next page (FL Display).

After the measurement, CD laser

emission is kept on. It is turned off

when POWER key is switched off.

(It is also turned off when POWER

button on the player is switched

2. The measurement Value (In decimal

notation)

off.)

SA-VK850EE

Device Name Display the device name. 1.

2.

3.

Jitter check Jitter check.

1. For jitter measurement mode

Jitter rate is measured and

displayed.

Measurement is repeatedly done in

the cycle of one second. Read

error counter starts from zero upon

mode setting. When target block

data failed to be read out, the

counter advances by one

increment. When the failure is

caused by minor error, it may be

2.

corrected when retired to enable

successful reading. In this case,

the counter advances by one.

When the error persists even after

retry, the counter may jump by two

or more.

In STOP (no disc) mode, press STOP

button on the player, and “4” button on the

remote control unit. *With pointing of cursor

up and down on display.

Cancelled automatically 5 seconds later.

To exit, press [POWER] button on main

unit or remote control.

In STOP (no disc) mode, press STOP

button on the player, and “5” button on the

remote control unit.

Press STOP or OPEN button to exit.

Press “FL DISPLAY” button on remote

control unit for next page (FL Display).

Jitter rate is shown in decimal notation to

one place of decimal.

Focus drive value is shown in hexadecimal

notation.

Region display Region display & mode In STOP (no disc) mode, press STOP

button on the player, and “6” button on the

remote control unit.

Cancelled automatically 5 seconds later.

25

Page 26

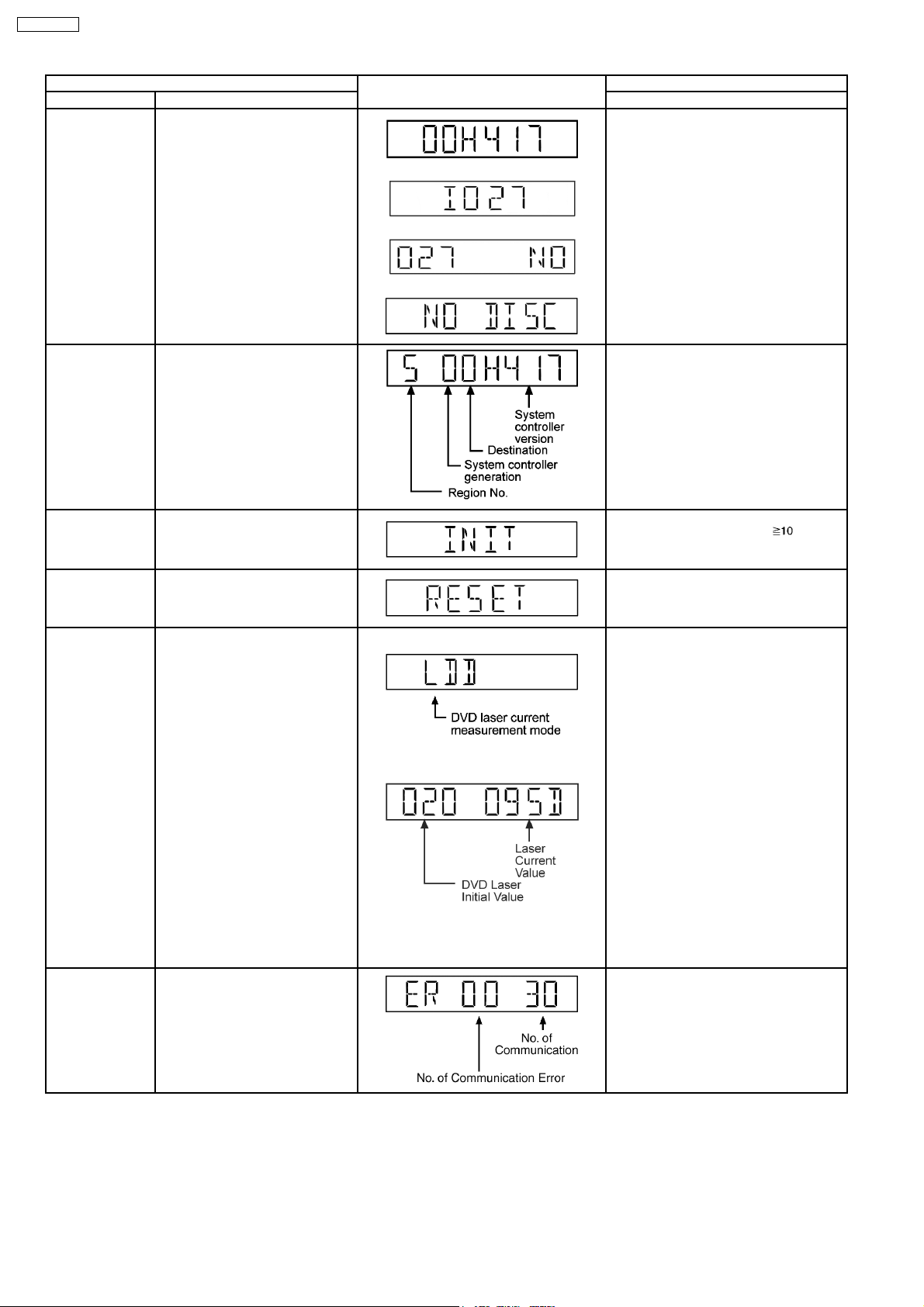

SA-VK850EE

Item FL Display Key Operation

Mode Name Description Remote Control Key

Micro- processor

firmware version

display &

EEPROM

checksum display.

Micro-processor firmware version

display & EEPROM checksum

display.

In STOP (no disc) mode, press STOP

button on the player, and “7” button on the

remote control unit.

Cancelled automatically 5 seconds later.

Press “FL Display” button on remote

control unit for next page. (FL Display)

Refer to Section 10.3.1 for more

information.

DVD module

firmware version

DVD module firmware version

display is on the FL Display.

display

Initialization Initialization.

User settings are cancelled and

player is initialized to factory

setting.

DVD Module

Reset

To reset DVD Module.

In initialisation when the FLASH

ROM IC or DVD Module is

replaced.

DVD laser drive

current

measurement

DVD laser drive current

measurement.

DVD laser drive current is

measured and the result is

displayed together with the initial

value stored in the EEPROM IC.

After the measurement, DVD laser

emission is kept on. It is turned off

when POWER key is switched off.

(It is also turned off when POWER

button on the player is switched

off.)

1. For DVD laser drive current mode

2. The measurement value (In decimal

notation)

In STOP (no disc) mode, press STOP

button on the player, and “8” button on the

remote control unit.

Cancelled automatically 5 seconds later.

In STOP (no disc) mode, press STOP

button on the player, and

button

on the remote control unit.

In initialisation mode, press and hold STOP

button on the player followed by “Enter”

button on the remote control.

Cancelled automatically 5 seconds later.

In STOP (no disc) mode, press STOP

button on the player, and FUNCTIONS

button on the remote control unit.

Cancelled automatically 5 seconds later.

Press “FL Display” button on remote

control unit for next page (FL Display) on

values of DVD drive current.

Communication error display

Displays the frequency of

communication errors between

system control IC and mechanism

control IC.

The value denotes the current in decimal

notation.

The above example shows the initial current

is 20mA and the measured value is 20mA.

In STOP (no disc) mode, press STOP

button on the player, and “MENU” button

on the remote control unit.

Cancelled automatically 5 seconds later.

26

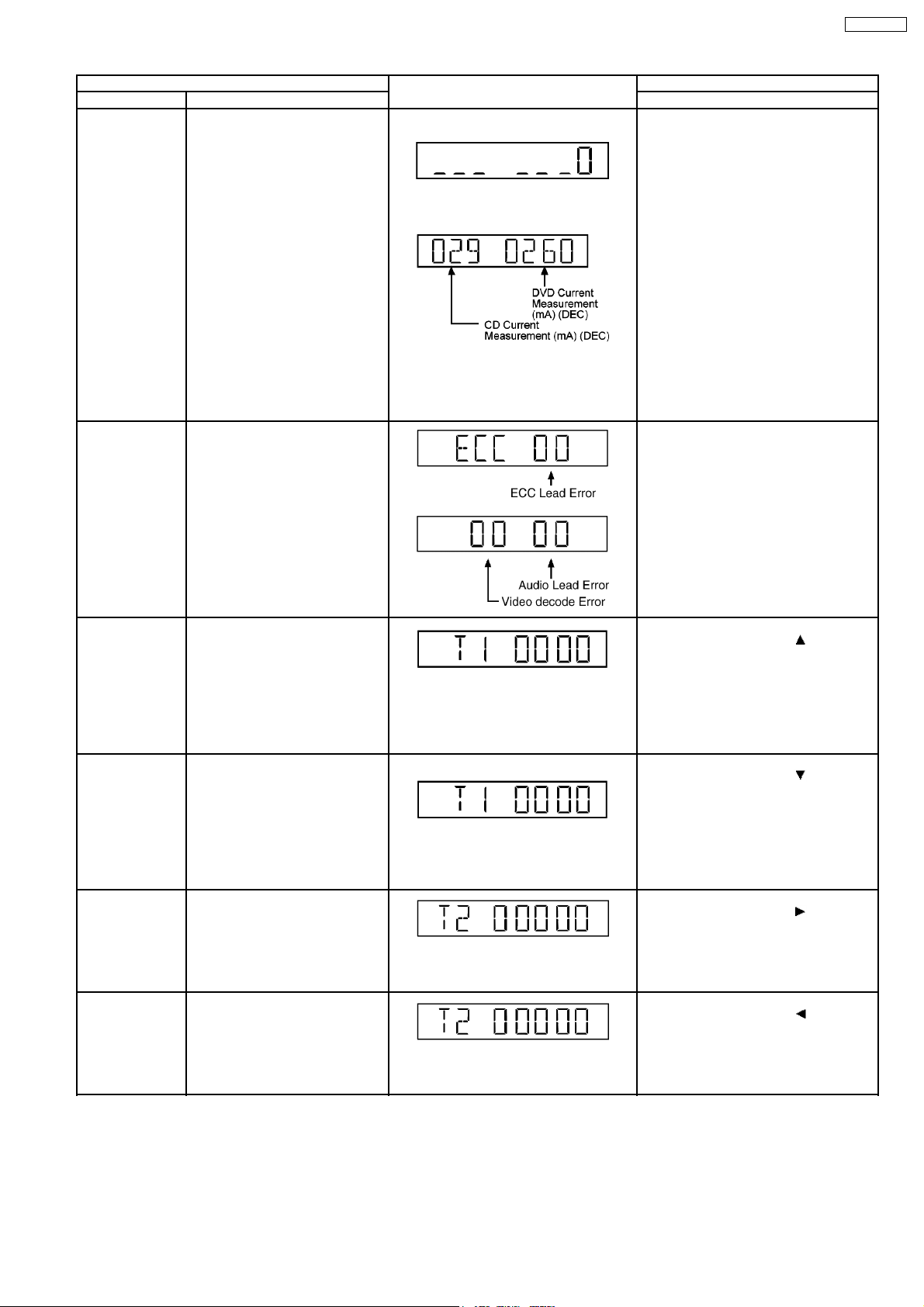

Page 27

SA-VK850EE

Item FL Display Key Operation

Mode Name Description Remote Control Key

Initial setting of

laser drive current

Initial setting of laser drive current.

Initial current value for each of

DVD laser and CD laser is

separately saved in the EEPROM

IC.

1. For DVD/CD drive current mode

2. The measurement value (In decimal

notation)

In STOP (no disc) mode, press STOP

button on the player, and PAUSE button on

the remote control unit.

Cancelled automatically 5 seconds later.

Press “FL Display” button on remote

control unit for next page (FL Display) on

values of laser drive current.

The value denotes the current in decimal

notation. The above example shows the

initial current 20mA and 23mA for DVD

laser and CD laser respectively when the

laser is switched on.

ECC error display ECC decode error display. In STOP (no disc) mode, press STOP

button on the player, and TOP MENU

button on the remote control unit.

Cancelled automatically 5 seconds later.

Press “FL Display” button on remote

control unit for next page (FL Display) on

values of laser drive current.

Time 1 check Timer 1 check.

Laser operation time is measured

separately for DVD laser and CD

laser.

Press “FL Display” button for next

page of FL Display (to show CD

laser time).

Timer 1 reset Timer 1 reset.

Laser operation time of both DVD

laser and CD laser is reset all at

once.

Timer 2 check Timer 2 check.

Spindle motor operation timer.

Press “FL Display” button for next

page of FL Display.

Timer 2 reset Timer 2 reset.

Spindle motor operation timer.

Shown to the left is DVD laser time, and to

the right CD laser time.

Time is shown in 4 digits of decimal notation

in a unit of 10 hours.

“0000” will follow “9999”.

T1_0000/0000 (display1/display2)

Shown to the left is DVD laser time, and to

the right CD laser time.

Time is shown in 4 digits of decimal notation

in a unit of 10 hours.

Time is shown in 5 digits of decimal notation

in a unit of 10 hours.

“0000” will follow “9999”.

Time is shown in 5 digits of decimal notation

in a unit of 10 hours.

It clears to “0000” upon reset.

In STOP (no disc) mode, press STOP

button on the player, and “

” button on

the remote control unit.

Cancelled automatically 5 seconds later.

While display Timer 1 data, press STOP

button on the player, and “

“ button on

the remote control unit.

Cancelled automatically 5 seconds later.

In STOP (no disc) mode, press STOP

button on the player, and “

“ button on

the remote control unit.

Cancelled automatically 5 seconds later.

While display Timer 2 data, press STOP

button on the player, and “

“ button on

the remote control unit.

Cancelled automatically 5 seconds later.

27

Page 28

SA-VK850EE

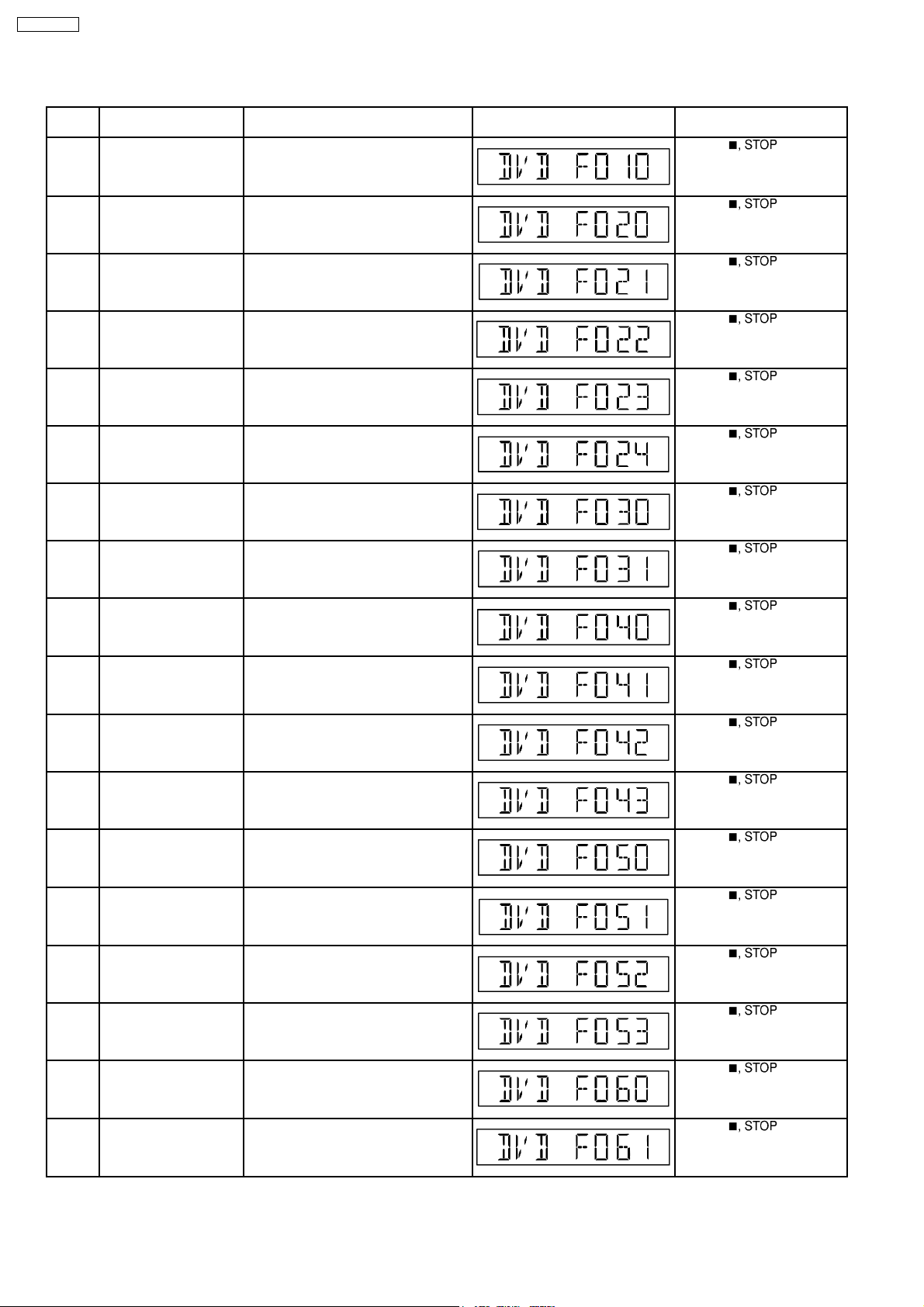

10.2.2. DVD Self-Diagnostic Function Error Code

Error

Code

F010 DVD Media disk A specification value is size from the

F020 DVD Media disk There is no TT_SRPT. (RLBN is 0). Press [ ] on main

F021 DVD Media disk The number of TT_SRP is 0. Press [ ] on main

F022 DVD Media disk A specification value. It is size from the

F023 DVD Media disk VTSN or in agreement with VTS_TTN.

F024 DVD Media disk A specification value. It is size from

F030 DVD Media disk The number of TTU_SRP is 0. Press [ ] on main

F031 DVD Media disk A specification value. It is size from the

Diagnosis Contents Description of error Automatic FL Display Remarks

PARENTAL LOCK value of the

appointed country.

number of TT_SRP.

There is no SRP.

TT_SRP. PTT_Ns

number of TTU_SRP.

Press [ ] on main

unit for next error.

unit for next error.

unit for next error.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

unit for next error.

Press [ ] on main

unit for next error.

F040 DVD Media disk The number of SRP1 is 0. Press [ ] on main

F041 DVD Media disk The number of PGCI_SRP is 0. Press [ ] on main

F042 DVD Media disk A specification value. It is size from the

number of PGCI_SRP.

F043 DVD Media disk It is in agreement with Menu ID. There is

no PGCI_SRP.

F050 DVD Media disk The number of TMAP_SRP is 0. Press [ ] on main

F051 DVD Media disk A specification value. It is size from the

number of TMAP_SRP.

F052 DVD Media disk Specification TMAP_SA is 0. Press [ ] on main

F053 DVD Media disk The number of MAP_EN is 0. Press [ ] on main

unit for next error.

unit for next error.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

unit for next error.

Press [ ] on main

unit for next error.

unit for next error.

unit for next error.

F060 DVD Media disk Although C_POSIT exists, it is in PGC.

There is no PGMAP.

F061 DVD Media disk Although C_POSIT exists, it is in PGC.

There is no PGMAP.

28

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

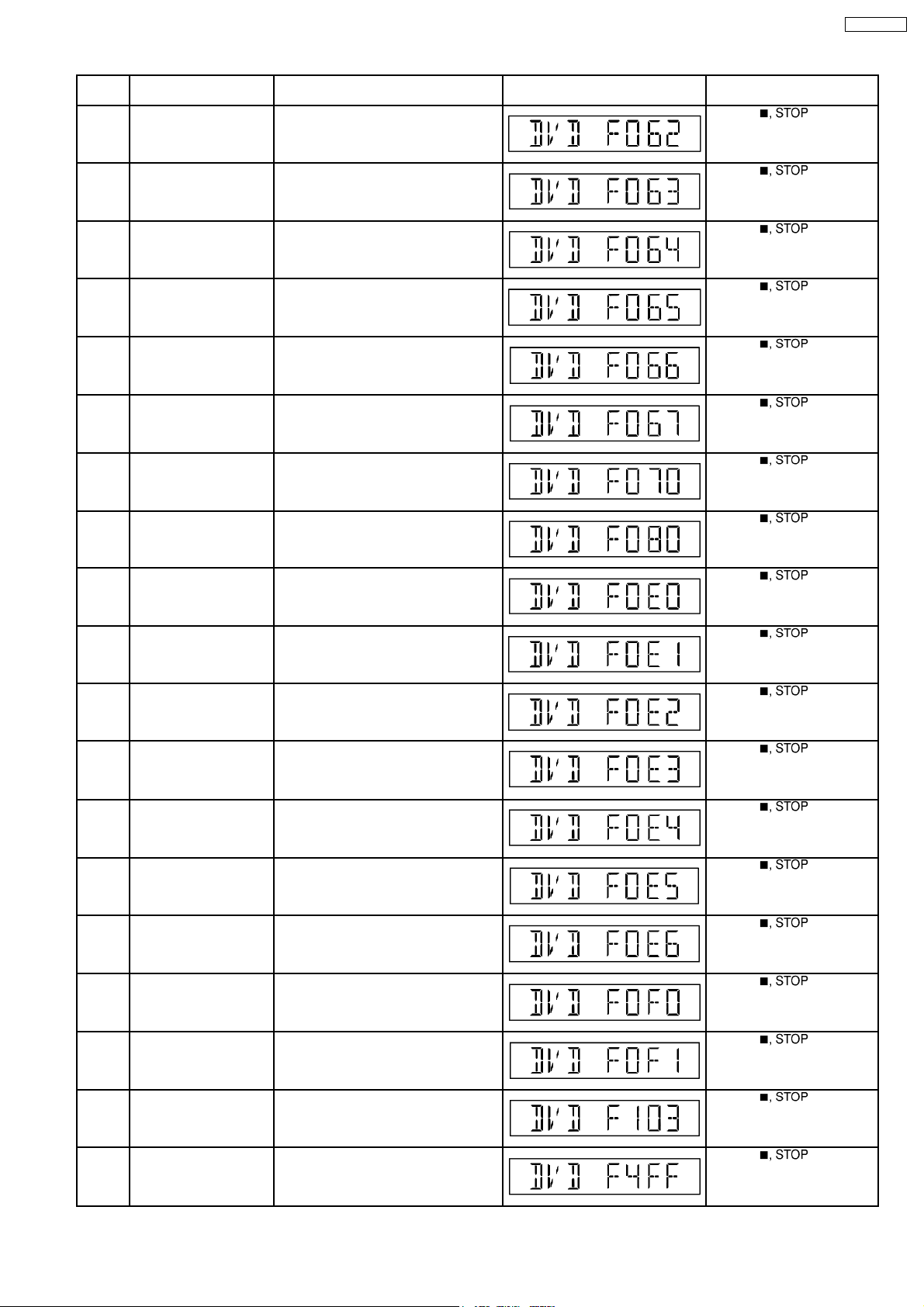

Page 29

SA-VK850EE

Error

Diagnosis Contents Description of error Automatic FL Display Remarks

Code

F062 DVD Media disk A specification value inside of PGC. It is

size from the number of PGes.

F063 DVD Media disk Although C_POSIT exists, it is in PGC.

There is no C_PBIT.

F064 DVD Media disk Although C_POSIT exists, it is in PGC.

The number of PGes is 0.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

F065 DVD Media disk Specification A cell number is 0.‘ Press [ ] on main

unit for next error.

F066 DVD Media disk A specification value inside of PGC. It is

size from the number of Cell(s).

Press [ ] on main

unit for next error.

F067 DVD Media disk A blocked cell is present. Press [ ] on main

unit for next error.

F070 DVD Media disk There is no NV_PACK data. Press [ ] on main

unit for next error.

F080 DVD Media disk Under reference. There is no Cell

number.

Press [ ] on main

unit for next error.

F0E0 DVD Media disk For [used as a DFD object] a user guide.

A PGC control file < impossible.

F0E1 DVD Media disk DFD main microcomputer. Compatibility

with a DFD type < download is

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

impossible.

F0E2 DVD Media disk DFD download start. PGC reproduction

error.

F0E3 DVD Media disk Waiting for the completion of DFD

download. PGC reproduction error.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

F0E4 DVD Media disk At the time of DFD download AVDEC. Press [ ] on main

unit for next error.

F0E5 DVD Media disk It is the farm file lead error at the time of

DFD download.

F0E6 DVD Media disk DFD alteration check error of the read

firmware.

F0F0 DVD Media disk There is no farm file used as a DFD

object and it is downloading needlessly.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

F0F1 DVD Media disk The firware which is in agreement with

DFD download conditions <

unnecessary.

F103 Illegal highlight Position Big possibility of disc specification

violation during highlight display

F4FF Force initialize failure

Timeout when force initialization fails Press [ ] on main

(time out)

29

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

unit for next error.

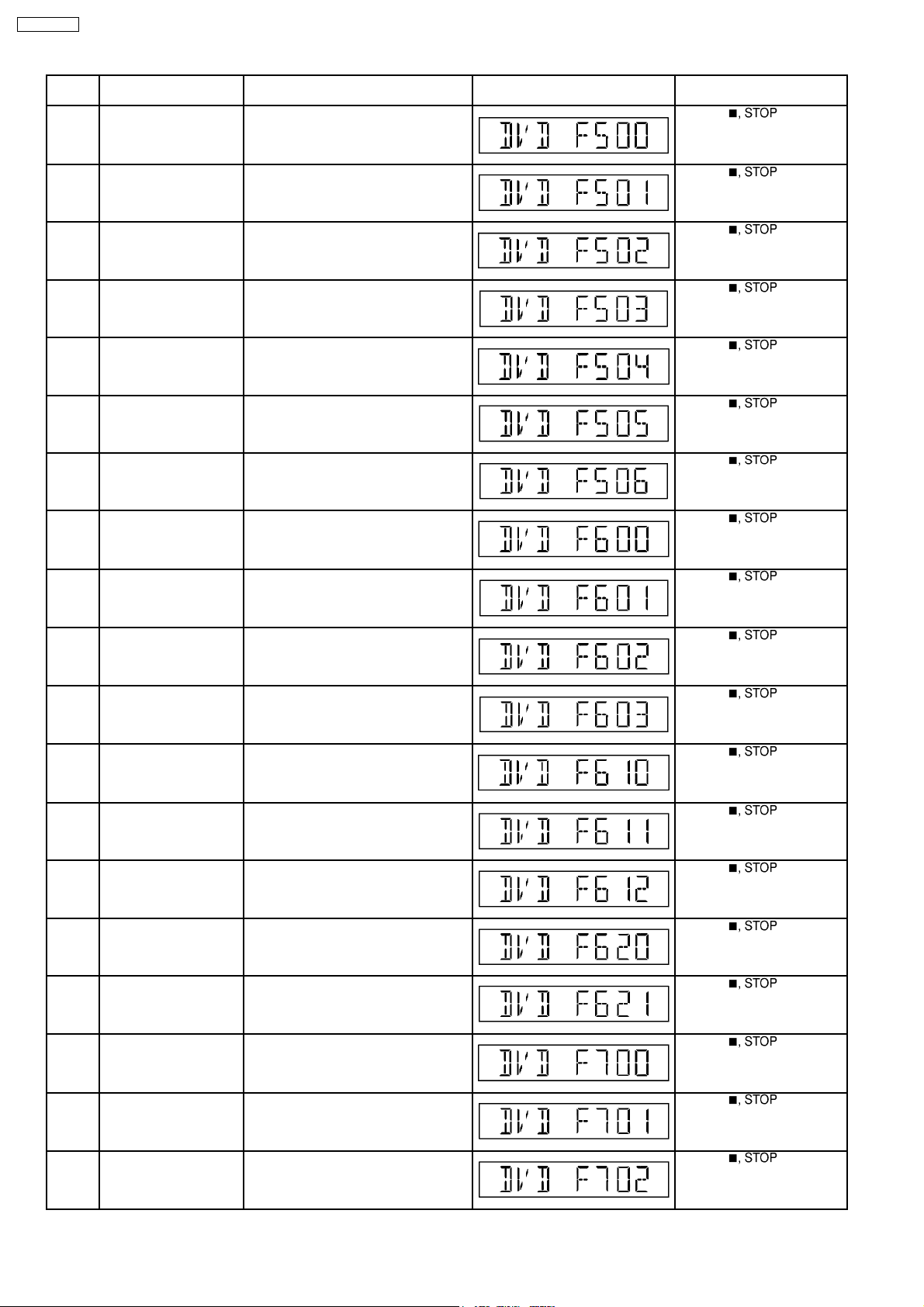

Page 30

SA-VK850EE

Error

Diagnosis Contents Description of error Automatic FL Display Remarks

Code

F500 DSC error DSC (IC8251) stops in the occurrence of

servo error (startup, focus error, etc.)

F501 DSC not Ready error DSC-system computer communication

error (Communication failure caused by

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

idling of DSC)

F502 DSC Time out error Similar as F500 Press [ ] on main

unit for next error.

F503 DSC communication

Failure

Communication error (result error

occurred although communication

Press [ ] on main

unit for next error.

command was sent)

F504 Abnormal adjusting DSC

data slice offset

Press [ ] on main

unit for next error.

F505 DSC Attention error Similar as F500 Press [ ] on main

unit for next error.

F506 Invalid media Disc is flipped over, TOC unreadable,

incompatible disc media

F600 Access failure to

management information

caused by demodulation

Operation stopped because navigation

data is not accessible caused by the

demodulation defect

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

error

F601 Indeterminate sector ID

requested

Operation stopped caused by the

request to access abnormal ID data

Press [ ] on main

unit for next error.

F602 Access failure to LEAD-

IN caused by

LEAD IN data unreadable Press [ ] on main

unit for next error.

demodulation error

F603 Access failure to

KEYDET caused by

Access failure to CSS data of disc Press [ ] on main

unit for next error.

demodulation error

F610 ODC abnormality No permission for command execution Press [ ] on main

unit for next error.

F611 No CRC OK for a

specific time (CD)

F612 No CRC OK for a

specific time (DVD)

F620 Laser safeguard: high

temperature condition

F621 Laser safeguard: circuit

failure condition

Access failure to seek address in CD

series

Press [ ] on main

unit for next error.

Access failure to ID data in DVD series Press [ ] on main

unit for next error.

High temperature of the laser guide unit

(OPU unit)

Circuitry failure of the laser guide unit

(OPU unit)

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

F700 MBX overflow When replying message to disc manager Press [ ] on main

unit for next error.

F701 Message command

does not end

F702 Message command

changes

Next message is sent before replying to

disc manager

Message is changed before it is sent as

a reply to disc manager

30

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

Page 31

SA-VK850EE

Error

Code

F880 Task number is not

F890 Sending message when

F891 Message couldn’t be

F893 FLASH ROM IC problem FLASH ROM IC installed is not operating

F894 EEPROM abnormality EEPROM IC installed is not operating in

F895 Region setting

F896 No existence model Firm version agreement check for factory

F897 Initialize is not

Diagnosis Contents Description of error Automatic FL Display Remarks

appropriate

message is being sent to

AV task

sent to AV task

abnormality

completed

Message coming from a non-existing

task

Sending message to AV task Press [ ] on main

Begin sending message to AV task Press [ ] on main

properly (Neccessary replacement of

FLASH ROM IC) or firmware problem

normal condition (EEPROM contains

neccessary data)

Firm version agreement check for factory

preset setting failure prevention. Check

region setting & re-initialize

preset setting failure prevention

Initialize completion check for factory

preset setting failure prevention

Press [ ] on main

unit for next error.

unit for next error.

unit for next error.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

F898 Disagreement of

hardware and software

F8A0 Message command is

not appropriate

Unsuitable combination of AV

DECORDER, SDRAM and FLASH ROM

(firmware)

Message command is not suitable Press [ ] on main

Press [ ] on main

unit for next error.

unit for next error.

Note:

An error code will be canceled if a power supply is turned OFF.

*1: CPPM is the copy guard function beforehand written in the disk for protection of copyrights.

10.2.3. Optical Pickup Breakdown Diagnosis

This unit is equipped with the optical pickup self-diagnosis function and the tilt adjustment check function. Follow the procedure

described below during repair in order to perform self-diagnosis and tilt adjustment effectively. Especially when “NO DISC” is

displayed, be sure to apply the self-diagnosis function before replacing with an optical pickup. Replacement of optical pickup

generally requires when the present value of laser drive exceeds 45 (DVD) or 45 (CD).

Note:

Start diagnosis within three minutes after turning on the power (as diagnosis fails when the unit becomes warm).

31

Page 32

SA-VK850EE

10.3. Special Mode Table 2

Item FL Display Key Operation

Mode Name Description Front Key

Self -Diagnostic

Mode

CD Changer

Reliability Test

(CRS1D)

To enter into self

diagnostic checking for

main unit.

To determine the

reliability of CD/DVD

Changer Unit. (For more

infomation, refer to

section 10.3.2.)

1. Select [ ] for DVD/CD mode.

2. Press and hold [

To exit, press

unit or remote control.

In Self-Diagnostic Mode:

1. Select [

2. Press [1] on remote control..

To exit, press

unit or remote control.

(The tray will return to PLAY position and then

power off)

32

(Ensure no disc is inserted into the drive

unit.)

] button for 3

seconds follow by [

] for CD mode.

].

button on main

button on main

Page 33

Item FL Display Key Operation

Mode Name Description Front Key

Doctor Mode To enter into “Doctor

Mode” for purpose of

checking various

functions of the main unit

(Example: Micro-p

Firmware version &

EEPROM IC check etc)

1. FL will light up for all segments

2. Device display

3.

4. In doctor mode (under CD mode)

In CD mode:

1. Press [

To exit, press [ENTER] button on remote

control or

or remote control.

Note: In firmware version & checksum data

(EEPROM IC) displayed when the buttons is

pressed twice.

SA-VK850EE

] button on main unit

follow by [4] and [7] on remote control.

(Ensure no disc is inserted into drive unit.)

button on main unit

Cold Start Initialize backup data and

FL Display Test To check the FL

Tape Eject Test To check on the tape

Firmware version

check &

EEPROM IC

Information

Firmware version

checking (For

DVD Module)

start the micro-processor.

segments display (All

segments will light up and

LED will blink at 0.5

second interval)

eject function (For deck

1/2)

To display the microprocessor firmware

version & checksum date

when there is an

EEPROM IC istalled

To display the firmware

version for the DVD

Module

(Firmware is loaded to

FLASH ROM IC)

1. All segments will light up for 1 second.

In doctor mode:

1. Press [4] on remote control.

To exit, press [ENTER] button on remote

control or

or remote control.

In doctor mode:

1. Press

control.

Both deck will be eject automatically. In doctor mode:

1. Press [0] button on remote control.

1. Firmware version display & the EEPROM. In doctor mode:

1. Press [

follow by [4] and [7] on remote control.

To exit, press [ENTER] button on remote

control or

or remote control.

Refer to Section 10.3.1 for more information.

In doctor mode:

1. Press [

follow by [CANCEL] on remote control.

To exit, press [ENTER] button on remote

control or

or remote control.

button on main unit

button on remote

] button on main unit

button on main unit

] button on main unit

button on main unit

10.3.1. EEPROM Checksum (ROM Correction)

Purpose: To check for microprocessor firmware version and EEPROM checksum (ROM correction).

Below are the procedures for this mode.

Step 1: Enter into Doctor mode (for more information, refer to section 10.3 on the key operation to enter into this mode.

Step 2: Check for firmware version and EEPROM checksum (By pressing STOP button on main unit followed by “4” and “7” on

remote control).

· W hen entering into DOCTOR MODE, the firmware version and checksum data of EEPROM (if applicable) will appear on FL

33

Page 34

SA-VK850EE

display. Below is the information on the EEPROM IC (ROM correction) under 3 possible situations:

1. In the case that the correction point existence data is other than 0 (ie. correction file exists), EEPROM checksum display for

the microprocessor shall be made after calculating checksum by summing up the content of data area from EEPROM IC.

2. In the case when no EEPROM IC is installed. It is display as below (no display of checksum data)

3. In cases that the filename is different even though a EEPRO M is installed, or no correction file exists, [NG] shall be display ed

(the correction point existence data is set to 0 at this condition).

Note: Microprocessor firmware refers to version number for microprocessor IC located on PANEL P.C.B.. It is subject to change

which would be update d accordingly. ROM correction checksum refers to the HEX code that is displayed upon key buttons pressed

if an EEPROM is loaded in the unit.

10.3.2. CD/DVD changer unit ageing test mode

Below is the process flow chart of ageing for the CD/DVD changer unit. (CRS1D)

34

Page 35

SA-VK850EE

35

Page 36

SA-VK850EE

10.3.3. Error Code Table

Self-Diagnosis Function (refer Section 10.3) provides information on any problems occuring for the unit and its respective

components by displaying the error codes. These error code such as U**, H** and F** are stored in memory and held unless it is

cleared.

The error code is automatically display after entering into self-diagnostic mode.

Error Code Diagnosis Contents Description of error Automatic FL Display Remarks

H01 Mode SW, plunger

and capstan motor

abnormal

H02 Rec INH SW

abnormal

H03 HALF SW abnormal (Traverse motor,

F15 RESET SW

abnormal

F26 Transmission error

between CD Servo

LSI IC and

microprocessor IC

The tray is not able to

open.

(Spindle servo, DSC

(IC8251) Spindle motor,

CLV servo error)

IC8251)

REST SW: ON is not

detected within the

specified time.

When set to CD mode,

the sense signal does

not turn “Low”, a fail safe

time after system

command transmission

is sent.

For deck mechanism unit (For deck 1/2).

Press [

next error.

For deck mechanism unit (For deck 2).

Press [

next error.

For deck mechanism unit (For deck 1/2).

Press [

next error.

For DVD unit (For Traverse).

Press [

next error.

For DVD unit (For Traverse).

Press [

next error.

] on main unit for

] on main unit for

] on main unit for

] on main unit for

] on main unit for

36

Page 37

Error Code Diagnosis Contents Description of error Automatic FL Display Remarks

F61 Power Amp IC output

abnormal

Upon power on,

PCONT=HIGH,

DCDET=L after checking

For power.

Press [

next error.

LSI.

IHMS Cam gear

abnormality

Cam gear does not

rotate to “HOME”

position.

For CD/DVD changer unit (CRS1D).

Press [SINGLE CHANGE] on main unit

for next error.

SA-VK850EE

] on main unit for

ICSL Cam gear/gear units

abnormal

Cam gear does not

rotate to “PLAY” driving

position and hence does

not drive playing tray to

“STOCK” position.

ISTK Drive rack/gear

assembly abnormal

The tray drive rack does

not move to “STOCK”

position. (Tray does not

move to “STOCK”

position)

IPLY Drive rack/gear

assembly abnormal

The tray drive rack does

not move to “PLAY”

position. (Tray does not

move to “PLAY” position)

ITOP UD assembly UD Rack does not move

to front direction. This

lead to UD base not

raise to top position.

For CD/DVD changer unit (CRS1D).

Press [SINGLE CHANGE] on main unit

for next error.

For CD/DVD changer unit (CRS1D).

Press [SINGLE CHANGE] on main unit

for next error.

For CD/DVD changer unit (CRS1D).

Press [SINGLE CHANGE] on main unit

for next error.

For CD/DVD changer unit (CRS1D).

Press [SINGLE CHANGE] on main unit

for next error.

IUDS UD assembly After TOP SW is

detected, UD rack does

not move into tray 1

position.

HOME Cam gear/gear

assembly abnormal

Cam gear does not

move to “HOME”

position under following

conditions

1. After tray is load to

“PLAY” position.

2. After tray is unload

to “STOCK” position.

For CD/DVD changer unit (CRS1D).

Press [SINGLE CHANGE] on main unit

for next error.

For CD/DVD changer unit (CRS1D).

Press [SINGLE CHANGE] on main unit

for next error.

37

Page 38

SA-VK850EE

Error Code Diagnosis Contents Description of error Automatic FL Display Remarks

LOAD Tray drive assembly

abnormal

Tray unit does not move

from “STOCK” to “PLAY”

position

For CD/DVD changer unit (CRS1D).

Press [SINGLE CHANGE] on main unit

for next error.

PDRV Cam gear/gear

assembly abnormal

UDU UD base asssembly

abnormal

UDD UD base asssembly

abnormal

UD1 UD base asssembly

abnormal

F1NG Fail - safe mode. (For

open/close tray

unit(s))

Cam gear does not

move from “HOME” to

“PLAY” drive position.

UD Base assembly does

not move upwards from

tray 5 to tray 2

UD Base assembly does

not move downwards

from tray 1 to tray 5.

UD Base assembly does

not move to tray 1.

When the tray open

operation is performed, it

fails to open. It will

automatically close all

trays after the time-out

by the microprocessor.

During this time when it

fails, the error code will

appear.

For CD/DVD changer unit (CRS1D).

Press [SINGLE CHANGE] on main unit

for next error.

For CD/DVD changer unit (CRS1D).

Press [SINGLE CHANGE] on main unit

for next error.

For CD/DVD changer unit (CRS1D).

Press [SINGLE CHANGE] on main unit

for next error.

For CD/DVD changer unit (CRS1D).

Press [SINGLE CHANGE] on main unit

for next error.

For CD/DVD changer unit (CRS1D).

Press [SINGLE CHANGE] on main unit

for next error.

F2NG Fail - safe mode. (For

open/close tray

unit(s))

SRVC_TRV To unlock the

traverse unit for

service

RSET Cam gear jam/close

sensor faulty

When the tray close

operation is performed, it

fails to close. It will

automatically open all

trays after the time-out

by the microprocessor.

During this time when it

fails, the error code will

appear.

1. All trays set to

“STOCK” position

2. Mechanism set to

tray 5

3. Cam gear set to

“HOME” position

During tray re-open, the

cam gear will rotate in

the opposite direction to

reset the cam gear

position. When it fails,

the error code will

appear.

For CD/DVD changer unit (CRS1D).

Press [SINGLE CHANGE] on main unit

for next error.

For CD/DVD changer unit (CRS1D).

Press [SINGLE CHANGE] on main unit.

For CD/DVD changer unit (CRS1D).

Press [SINGLE CHANGE] on main unit

for next error.

CRS1D Error Code display

1. The errors that occured in CRS1D Mechanism can be recalled and displayed, in the order of the occurence under selfdiagnostic (Refer to Section 10.3 for procedures to enter this mode.

· Only the first 5 errors will be memorized (in backup memory). The subsequence error shall be ignored and not memorize.

38

Page 39

For system with EEPROM as memory backup,memory space in EEPROM is neccesary.

2. To display all error code memorized

In CRS1D Self-Diagnostic mode, press [SINGLE CHANGE] to display subsequence error code.

It shall repeat after reaching error no. 5.

e.g.:

[1____IHMS]→ [SINGLE CHANGE]

[2____ITOP]→ [SINGLE CHANGE]

[3____HOME]→ [SINGLE CHANGE]

[4____LOAD]→ [SINGLE CHANGE]

[5_____UDD]→ [SINGLE CHANGE]

3. To clear the error code memory

In CRS1D Self-Diagnostic mode, long press [SINGLE CHANGE] key (2s or more)

SA-VK850EE

39

Page 40

SA-VK850EE

11 Assembling and Disassembling

11.1. Caution

Special Note:

This model uses a new CD/DVD changer unit CRS1D. In this following section does not contain the necessary disassembly &

assembly information for the CD/DVD changer unit (CRS1D) except the disasembly & assembly of traverse unit. Kindly refer

to the original service manual for the CD/DVD changer unit. (Order No. MD0603065A3).

“ATTENTION SERVICER”

Some chassis components may have sharp edges. Be carefu l when disassembling and servicing.

1. This section describes procedures for checking the operation of the major printed circuit boards and replacing the main

components.

2. For reassembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

3. Select items from the following index when checks or replacement are required.

4. Refer to the Parts No. on the page of “Parts Location and Replacement Parts List” (Section 25), if necessary.

Warning :-

This product uses a laser diode. Refer to caution statement Precaution of Laser Diode.

Caution:

After replacing of CD/DVD Changer Unit, ageing test is necessary. Please confirm operation for CD/DVD Changer Unit.

Below is the list of disassembly sections

· Disasse mbly of Top Cabinet

· Disasse mbly of CD/DVD Changer Unit

· Disasse mbly of Rear Panel

· Disasse mbly of Main P.C.B.

· Disasse mbly of Front Panel Unit

· Disasse mbly of Digital Amp P.C.B.

· Replacement for Power Amp IC (Digital Amp P.C.B.)

· Disasse mbly of SMPS P.C.B.

· Replacement of Power Amp IC (SMPS P.C.B.)

· Disasse mbly of Panel P.C.B., Mic P.C.B. & Tact Switch P.C.B.

· Disasse mbly of Deck Mechanism Unit

· Disasse mbly for Deck P.C.B.

· Disasse mbly of Traverse Unit

· Disasse mbly of Optical Pickup Unit (CD/DVD Mechanism)

· Disasse mbly of Deck Mechanism

· Replacement for cassette lid

· Rectification for tape jam problem

40

Page 41

SA-VK850EE

11.2. Disassembly flow chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the

servicing.

To assemble the unit, reverse the steps shown in the chart as below.

41

Page 42

SA-VK850EE

11.3. Main Parts Location

42

Page 43

11.4. Disassembly of Top Cabinet

Step 1 Remove 3 screws at each side and 5 screws at rear

panel.

Step 2 Lift up both sides of the top cabinet, push the top

cabinet towards the rear to remove the top cabinet.

SA-VK850EE

11.5. Disassembly of CD/DVD Changer Unit (CRS1D)

· Follow the (Step 1) - (Step 2) of Item 11.4 - Disassembly of Top Cabinet

Step 1 Remove 2 screws at rear panel.

Step 2 Detach the FFC cables (CN2038 & CN2036).

Step 3 Release the claws on both ends.

Step 4 Lift the CD/DVD changer unit upwards to remove it.

43

Page 44

SA-VK850EE

· Disasse mbly of Mecha Chassis

Step 5 Remove 2 screws.

Step 6 Remove the Mecha Chassis.

Note:

For disassembly & assembly of traverse unit, please refer to

section 11.16 of this service manual. Please refer to original

Service Manual for the Disassembly and Assembly of the

CD/DVD Changer Unit (CRS1D), section 5.

11.6. Disassembly of Rear Panel

· Follow the (Step 1) - (Step 2) of Item 11.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 4) of Item 11.5 - Disassembly of CD/DVD Changer Unit

Step 1 Remove 8 screws.

Step 2 Remove 2 screws at Speaker P.C.B..

Step 3 Detach the fan wires CNP2913 from Main P.C.B..

Step 4 Remove rear panel.

44

Page 45

11.7. Disassembly of Main P.C.B.

· Follow the (Step 1) - (Step 2) of Item 11.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 4) of Item 11.5 - Disassembly of CD/DVD Changer Unit

· Follow the (Step 1) - (Step 4) of Item 11.6 - Disassembly of Rear Panel

Step 1 Disconnect FFC cables (CNP2101, CNP2601 and

CNP2602).

Step 2 Detach 3 connectors (CNP2810, CNP23 70 &

CNP2710).

Step 3 Remove Main P.C.B.

SA-VK850EE

11.8. Disassembly of Front Panel Unit

· Follow the (Step 1) - (Step 2) of Item 11.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 4) of Item 11.5 - Disassembly of CD/DVD Changer Unit

Step 1 Disconnect connectors (CN2602, CNP2601, CNP2101

and CN5904).

Step 2 Bent the front panel unit slightly forward as shown.

Step 3 Release 2 claws.

45

Page 46

SA-VK850EE

11.9. Disassembly of Digital Amp P.C.B.

Step 4 Remove the front panel unit.

Note: Ensure 2 claws located at the bottom chassis is seated

into the 2 slots at bottom of front panel at 2 catches (one on

each side) of bottom chassis to be aligned to front panel’s slot.

Assembly is secured upon hearing clicking sound.

· Follow the (Step 1) - (Step 2) of Item 11.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 4) of Item 11.5 - Disassembly of CD/DVD Changer Unit

· Follow the (Step 1) - (Step 4) of Item 11.6 - Disassembly of Rear Panel

· Follow the (Step 1) - (Step 3) of Item 11.7 - Disassembly of Main P.C.B.

· Follow the (Step 1) - (Step 4) of Item 11.8 - Disassembly of Front Panel Unit

Step 1 Detach cable CN5604.

Step 2 Disconnect connector CN550 2.

Step 3 Remove the 3 screws on Digital Amp P.C.B..

Step 4 Remove Digital Amp P.C.B..

Note:

Make sure P.C.B. slot insert to bottom chassis guide.

11.10. Replacement for Power Amp IC (Digital Amp P.C.B.)

· Follow the (Step 1) - (Step 3) of Item 11.9 - Disassembly of Digital Amp P.C.B.

Replacement of Power Amp IC (IC5100)

Step 1 Remove IC clip.

· IC5100

Step 2 Flip over the P.C.B..

46

Page 47

Step 3 Desolder IC5100.

Step 4 Remove the Power Amp IC.

Replacement of Power Amp IC (IC5300 & IC5400)

SA-VK850EE

Repeat (Step 1) - (Step 3) of Item 11.10 for IC5300 & IC5400.

11.11. Disassembly of SMPS P.C.B.

· Follow the (Step 1) - (Step 2) of Item 11.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 4) of Item 11.5 - Disassembly of CD/DVD Changer Unit

· Follow the (Step 1) - (Step 4) of Item 11.6 - Disassembly of Rear Panel

· Follow the (Step 1) - (Step 3) of Item 11.7 - Disassembly of Main P.C.B.

· Follow the (Step 1) - (Step 4) of Item 11.8 - Disassembly of Front Panel Unit

Step 1 Disconnect connector (CN5502 at Digital Amp P.C.B.).

Step 2 Remove 2 screws.

11.12. Replacement of Power Amp IC (SMPS P.C.B.)

· Follow the (Step 1) - (Step 2) of Item 11.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 4) of Item 11.5 - Disassembly of CD/DVD Changer Unit

· Follow the (Step 1) - (Step 4) of Item 11.6 - Disassembly of Rear Panel

· Follow the (Step 1) - (Step 3) of Item 11.7 - Disassembly of Main P.C.B.

· Follow the (Step 1) - (Step 4) of Item 11.8 - Disassembly of Front Panel Unit

47

Page 48

SA-VK850EE

Step 1 Remove 1 screw.

Step 2 Flip over the PCB.

Step 3 Desolder IC5701.

Step 4 Remove IC5701.

· Relacement of Regulator Diodes

Step 1 Desolder D5904 & D5905.

11.13. Disassembly of Panel P.C.B., Mic P.C.B. & Tact Switch P.C.B.

· Follow the (Step 1) - (Step 2) of Item 11.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 4) of Item 11.5 - Disassembly of CD/DVD Changer Unit

· Follow the (Step 1) - (Step 4) of Item 11.8 - Disassembly of Front Panel Unit

Step 1 Remove 1 screw.

Step 2 Disconnect connector CN6701 at Mic P.C.B..

Step 3 Lift up the Mic P.C.B to remove it.

Step 4 Remove 6 screws.

Step 5 Release 2 catches.

Step 6 Remove Panel P.C.B..

11.13.1. Disassembly of Tact Switch P.C.B.

Step 7 Remove the Volume knob.

48

Page 49

Step 8 Remove 6 screws..

SA-VK850EE

11.13.2. Disassembly of Lid

Step 1 Lift the spring sideward.

Step 2 Remove Lid.

Note: Do not misplace the spring.

11.14. Disassembly of Deck mechanism unit

· Follow the (Step 1) - (Step 2) of Item 11.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 4) of Item 11.5 - Disassembly of CD/DVD Changer Unit

· Follow the (Step 1) - (Step 4) of Item 11.8 - Disassembly of Front Panel Unit

Step 1 Detach FFC cable (CN971).

Step 2 Disconnect FFC cable (CN1001).

Step 3 Remove the 5 screws.

Step 4 Push the lever upward, and then open the cassette lid

ass’y (For DECK1 and DECK2).

Step 5 Tilt the cassette mechanism unit in the direction of

arrow (1), and then remove it in the direction of arrow (2).

Note: For disassembly of parts for deck mechanism unit,

refer to Section 11.18.

11.15. Disassembly of Deck P.C.B.

· Follow the (Step 1) - (Step 2) of Item 11.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 4) of Item 11.5 - Disassembly of CD/DVD Changer Unit

· Follow the (Step 1) - (Step 4) of Item 11.8 - Disassembly of Front Panel Unit

Step 1 Remove 2 screws.

49

Page 50

SA-VK850EE

Step 2 Desolder wire at deck motor terminals (W1002).

Step 3 Remove Deck P.C.B.

11.16. Disassembly of Traverse Unit

· Follow the (Step 1) - (Step 2) of Item 11.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 4) of Item 11.5 - Disassembly of CD/DVD Changer Unit

Important notes: Ensure all the trays are in the “STOCK”

position before proceeding to the disassemble of traverse

unit. For procedures to set the trays in “STOCK” position,

please refer to original Service Manual for CRS1D , Section

4.3. Setting the trays in “STOCK” position, Order No.

MD0603065A3.

· Assembly of Traverse Unit

50

Page 51

SA-VK850EE

11.17. Disassembly of optical pickup unit (CD/DVD mechanism)

· Follow the (Step 1) - (Step 2) of Item 11.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 4) of Item 11.5 - Disassembly of CD/DVD Changer Unit

· Follow the (Step 1) - (Step 2) of Item 11.16 - Disassembly of Traverse Unit

Step 1 Pull out FFC.

Step 3 Remove 4 pins.

Step 2 Widening the catch, push the pin in.

51

Page 52

SA-VK850EE

Step 4 Remove the traverse deck.

Note: As floating springs (4 pieces) come off at the same time,

be careful not to lose them.

Step 8 Remove the catch of the drive rack, and take out the

drive rack.

Step 5 Remove 4 screws.

Step 6 Remove the DVD Servo P.C.B. and turn it over.

Note: Insert a short pin into FFC of the optical pickup.

Step 7 Rotate the traverse deck (B) to the arrow direction and

shift the optical pickup to the furthest backward.

Step 9 Place the convex part of an optical pickup to the

concave part of a traverse base, then take out the optical

pickup.

52

Page 53

SA-VK850EE

11.18. Disassembly of Deck Mechanism

· Follow the (Step 1) - (Step 2) of Item 11.4 - Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 4) of Item 11.5 - Disassembly of CD/DVD Changer Unit

· Follow the (Step 1) - (Step 4) of Item 11.8 - Disassembly of Front Panel Unit

· Follow the (Step 1) - (Step 5) of Item 11.14 - Disassembly of Deck Mechanism Unit

11.18.1. Disassembly of the pinch roller ass’y and head block

* The mechanism as shown below is for DECK1. For DECK

2, perform the same procedures.

53

Page 54

SA-VK850EE

Step 1 Release the catch, and then remove the pinch roller (F).

Step 2 Release 2 claws and detach the head block connector.

Step 3 Remove 2 screws.

Step 4 Remove head block.

11.18.2. Disassembly of capstan motor ass’y, capstan belt A, capstan belt B and winding

belt

Step 1 Detach the head block connector (Deck P.C.B.).

Step 2 Desolder wire(W1002) at motor assembly.

Step 3 Remove Deck P.C.B.

Step 5 Remove capstan belt A/B.

Step 4 Remove 3 screws (for deck 1 & 2).

Step 6 Remove the flywhe el R.

Step 7 Release the claw and remove the winding lever and

spring.

[Installation of the belt]

Step 1 The boss and marking should be positioned

horizontally.

54

Page 55

SA-VK850EE

Step 2 Put the winding belt on the pulley temporarily.

Step 3 Install the flywheel F.

Step 4 Put the winding belt on the flywheel F.

Step 5 Install the winding lever and spring while pressing the

winding arm in the direction of arrow.

Step 6 Install the flywheel R.

Step 7 Put the capstan belt A temporarily as shown below.

Step 8 Put the capstan belt B on the motor ass’y pulley.

Step 9 Install the sub chassis to the mechanism, and then

tighten screws.

55

Page 56

SA-VK850EE

Step 10 Install 3 screws.

Step 11 Put the capstan belt B as shown below.

Step 12 Put the capstan belt A on the motor ass’y pulley.

56

Page 57

11.19. Replacement for cassette lid

· Follow the (Step 1) - (Step 2) of Item 11.4 - Disassembly of Top Cabinet

Step 1 Lift up the lever upward, open the cassette deck. (For

DECK1 and DECK2)

Step 2 Push up the cassette lid (L/R) in the direction of arrow.

(For DECK1 and DECK2).

SA-VK850EE