Page 1

A

A

A

A

A

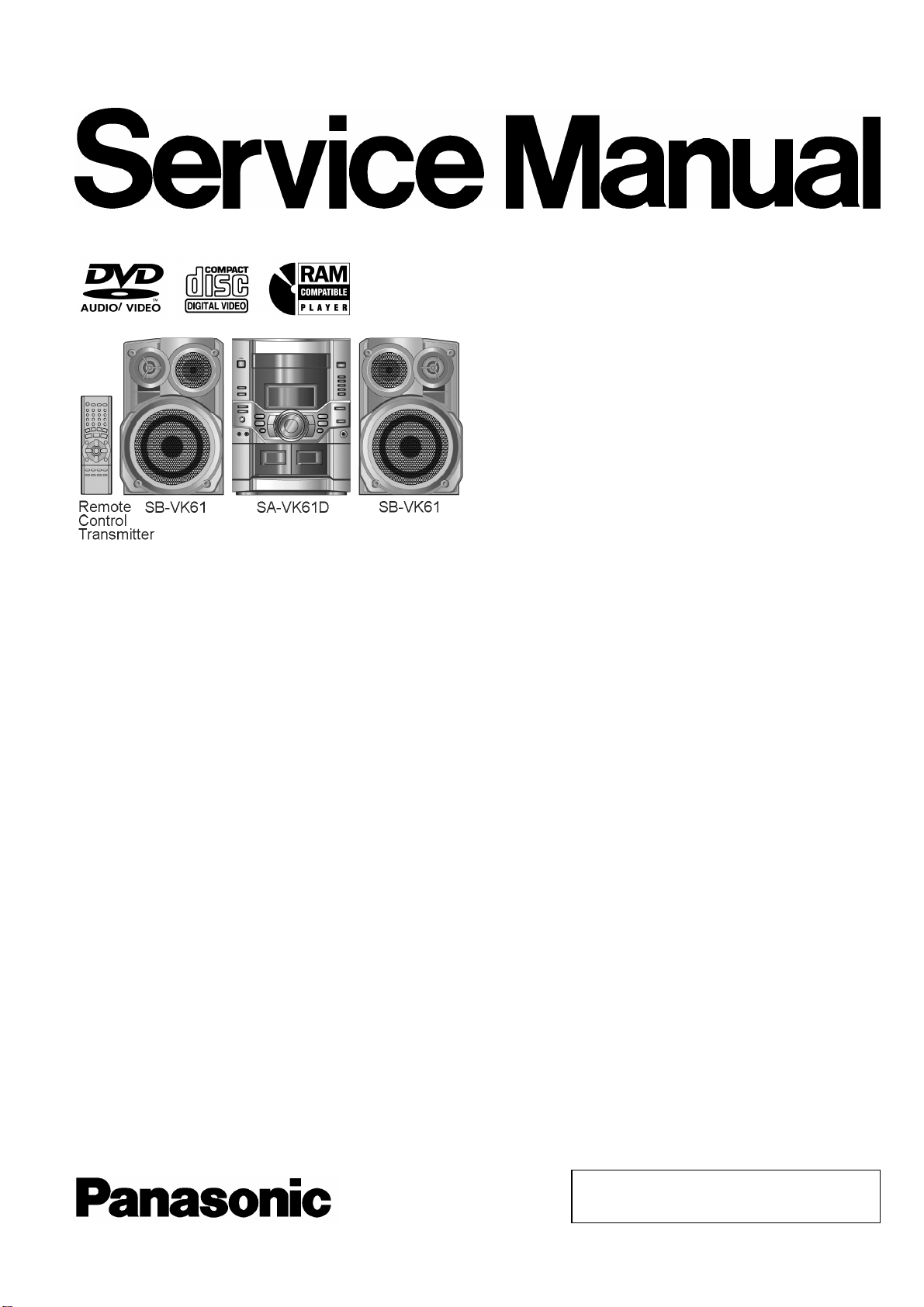

DVD Stereo System

SA-VK61DGC

SA-VK61DGCS

Colour

(S)... Silver Type

ORDER NO. MD0404158C3

Specifications

n AMPLIFIER SECTION

RMS Output Power both channel driven: 10 % Total Harmonic

Distortion

1 kHz Front CH 100 W per channel (6 Ω)

Total RMS Dolby Digital Mode Power

200 W

PMPO Output Power 2200 W

n FM/AM TUNER, TERMINALS SECTION

Preset station FM 15 stations

AM 15 stations

FM

Frequency range 87.50 - 108.00 MHz (50 kHz step)

Sensitivity 2.5 µV (IHF)

S/N 26dB 2.2 µV

ntenna terminals 75 Ω (unbalanced)

M

Frequency range 522 - 1629 kHz (9 kHz step)

520 - 1630 kHz (10 kHz step)

M Sensitivity S/N 20dB at 999 kHz

560 µV/m

udio performance (Amplifier)

Input sensitivity/Input impedance

ux 250 mV, 13.3 kΩ

Digital audio output

Optical digital output Optical terminal

Phone jack

Terminal Stereo, 3.5 mm jack

Mic jack

Sensitivity 0.7 mV, 680 Ω

n CASSETTE DECK SECTION

Track system 4 Track, 2 Channel

Heads

Record/playback Solid permalloy head

Erasure Double gap ferrite head

Motor DC servo motor

Recording system AC bias 100 kHz

Erasing system AC erase 100 kHz

Tape speed 4.8 cm/s

Overall frequency response (+3, -6 dB) at DECK OUT

Normal (TYPE I) 35 Hz - 14 kHz

S/N ratio 50 dB (A weighted)

Wow and flutter 0.18 % (WRMS)

Fast forward and rewind time Approx. 120 seconds with

C-60 cassette tape

n DISC SECTION

Disc played [8 cm or 12 cm]

(1) DVD-RAM (DVD-VR compatible, JPEG formatted discs)

(2) DVD-Audio

(3) DVD-Video

(4) DVD-R (DVD-Video compatible)

(5) CD-Audio (CD-DA)

© 2004 Panasonic AVC Networks Singapore Pte.

Ltd. All rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

A

A

SA-VK61DGC / SA-VK61DGCS

(6) Video CD

(7) SVCD (Conforming to IEC62107)

(8) CD-R/CD-RW (CD-DA, Video CD, SVCD, MP3, WMA, JPEG

formatted disc)

(9) MP3/WMA

· Compatible compression rate:

MP3: between 32 kbps and 320 kbps

WMA: between 48 kbps and 192 kbps

(10) JPEG

· Exif Ver 2.1 JPEG Baseline files

(11) HighMAT Level 2 (Audio and Image)

Sampling frequency

CD 44.1 kHz

MP3 32 kHz, 44.1 kHz, 48 kHz

DVD-Video 48 kHz, 96 kHz

DVD-Audio 44.1 kHz - 192 kHz

Decoding 16/20/24 bit linear

Wow and flutter

Less than possible measurement data

Digital filter 8fs

D/A converter Delta sigma DAC

Pick up

Wavelength

CD 780 nm

DVD 658 nm

Beam Source Semiconductor Laser

udio output (Disc)

Number of channels 2ch(stereo)

udio performance (measured at LINE OUT terminal)

Frequency response

CD-Audio 20 Hz - 20 kHZ (+1, -2dB)

n VIDEO SECTION

Video system PAL625/50, PAL525/60, NTSC

Composite video output

Output level 1Vp-p(75Ω)

Terminal Pin jack (1 system)

S-video output

Y output level 1Vp-p(75Ω)

C output level 0.3 Vp-p (75 Ω)(PAL)

0.286 Vp-p (75 Ω)(NTSC)

Terminal S terminal (1 system)

Component video output

Y output level 1Vp-p(75Ω)

PBoutput level 0.7 Vp-p (75 Ω)

PRoutput level 0.7 Vp-p (75 Ω)

Terminal

Pin jack (Y: green, PB:blue,PR:red)(1system)

n GENERAL

Power supply AC 110V/127V/220-230V/240 V,

50/60Hz

Power consumption 146 W

Power consumption in standby mode:

0.9 W

Dimensions (W x H x D) 250 x 330 x 358 mm

Mass 9.1 kg

n SYSTEM

SC-VK61D(GC) Music Center: SA-VK61D (GC)

Speaker: SB-VK61 (GC)

SC-VK61D(GCS) Music Center: SA-VK61D (GCS)

Speaker: SB-VK61 (GC1)

Notes:

1. Specifications are subject to change without notice. Mass and

dimensions are approximate.

2. Total harmonic distortion is measured by the digital spectrum

analyzer.

CONTENTS

Page Page

1 Before Use

2 Before Repair and Adjustment

3 Protection Circuitry

4 Safety Precautions

4.1. General Guidelines

5 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

6 Handling the Lead-free Solder

6.1. About lead free solder (PbF)

7 Cautions to be taken when handling Optical Pickup

7.1. Handling Optical Pickup

7.2. Replacing Precautions for Optical Pickup Unit

3

3

4

4

4

5

5

5

6

6

6

7.3. Grounding for Preventing Electrostatic Destruction

8 Precaution of Laser Diode

9 Accessories

10 Operation Procedures

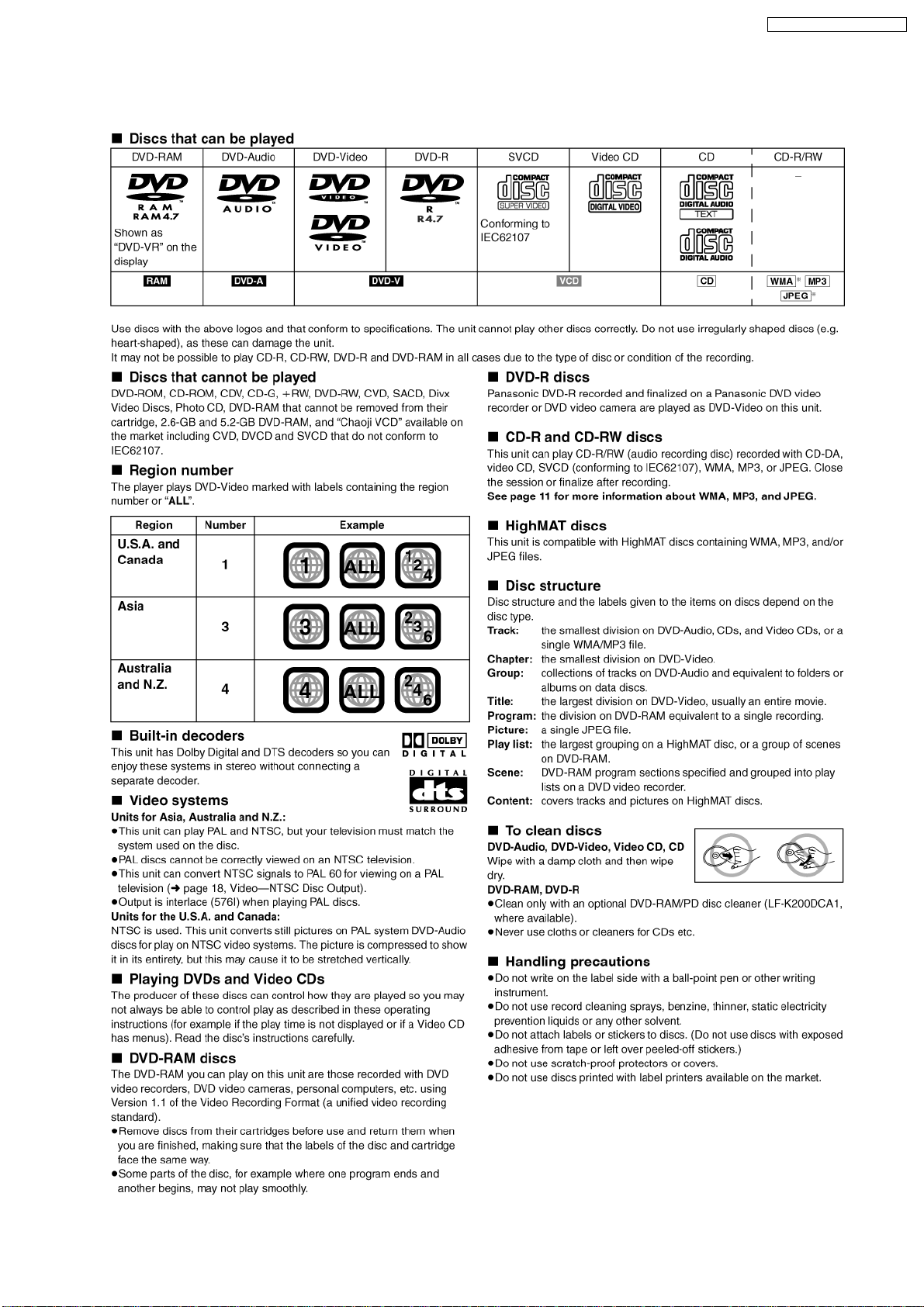

11 Disc information

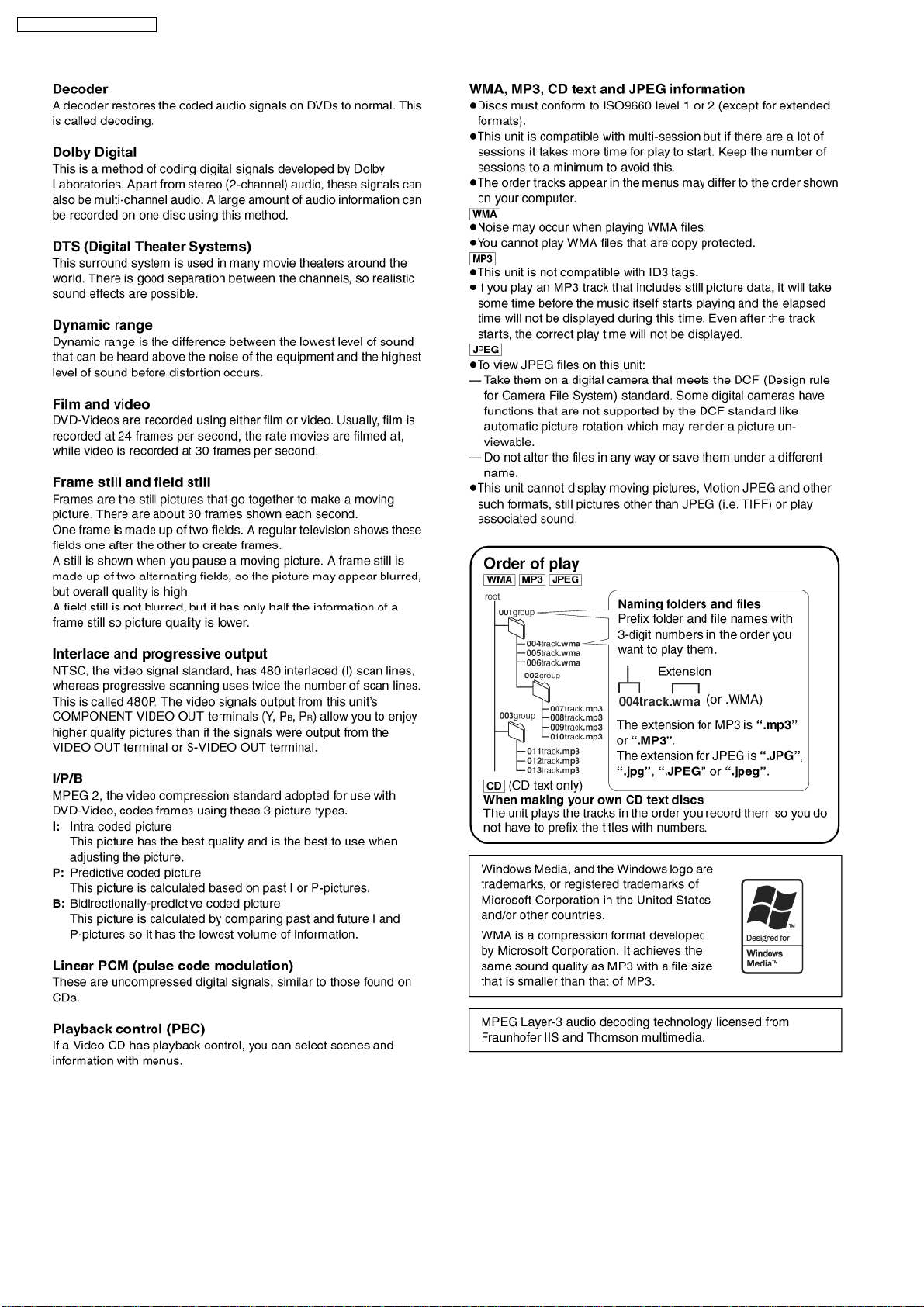

12 About HighMAT

12.1. What is HighMAT?

12.2. Why use HighMAT?

12.3. The advantages of using HighMAT

12.4. Outline of the HighMAT standard

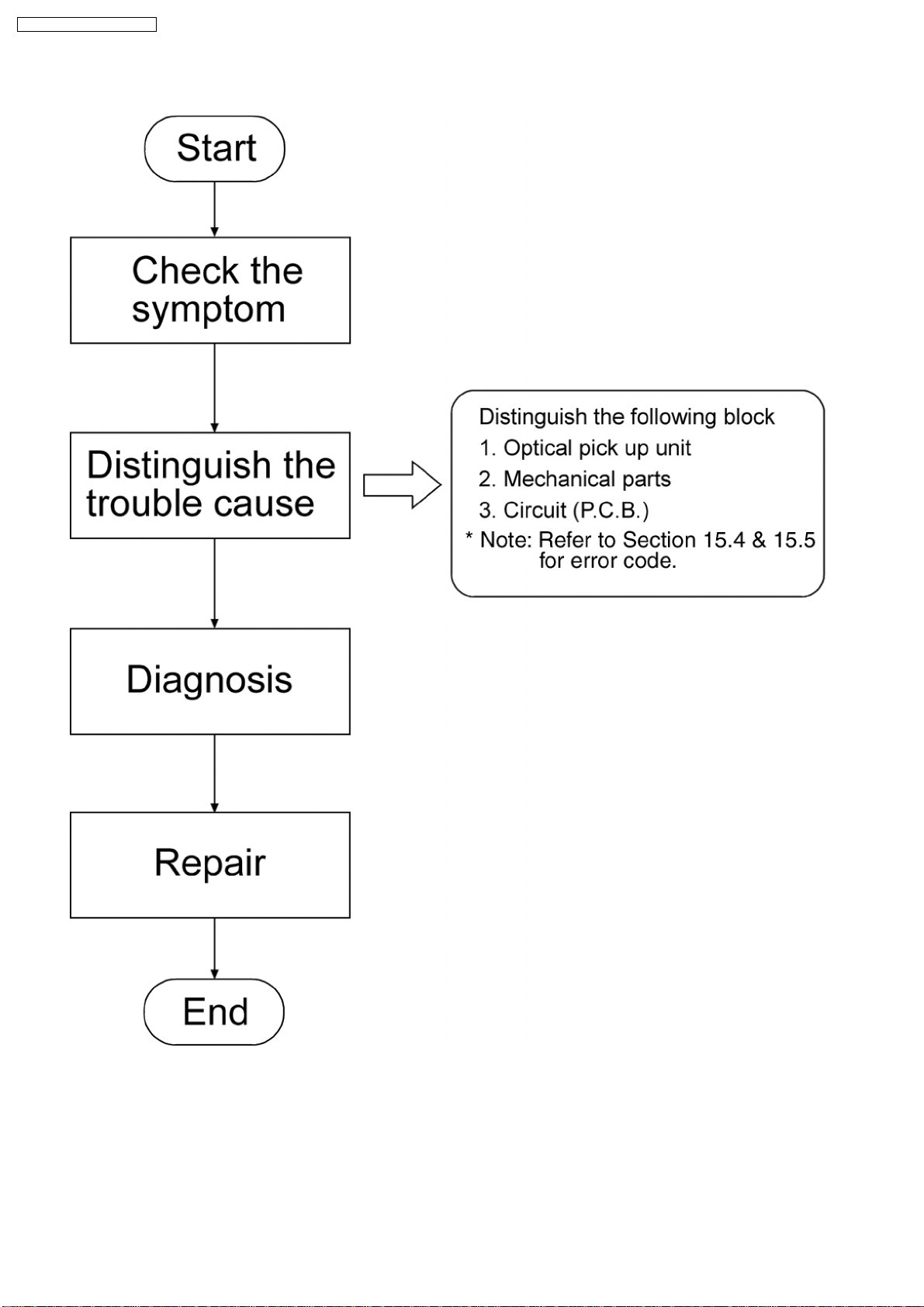

13 Procedure for repairing the set

13.1. Distinguish the trouble cause

2

6

7

8

9

11

13

13

13

13

14

16

17

Page 3

SA-VK61DGC / SA-VK61DGCS

13.2. Diagnosis of Optical Pick-up Unit 19

14 Optical Pickup Self-Diagnosis and Replacement Procedure

14.1. Self-diagnosis

14.2. Cautions to Be Taken During Replacement of Optical

Pickup and Spindle Motor

15 Self-Diagn osis Function

15.1. Automatic Displayed Error Codes

15.2. Memorized Error Codes

15.3. Mode Table 1

15.4. DVD/CD Self-Diagnosis Error Code Description

15.5. Error Codes Stored During No Play

15.6. Mode Table 2

15.7. Tray Lock Function

15.8. Things to Do After Repair

16 Cautions To Be Taken During Servicing

16.1. Recovery after the dvd player is repaired

16.2. DVD Player Firmware Version Upgrade Process

16.3. Firmware Version Upgrade Process by Using Disc and

Recovery Process

16.4. Using Recovery Disc

16.5. Total Usage Time Display

17 Disassemb ly and Assembly of Main Component

17.1. Disassembly flow chart

17.2. Disassembly of Top Cabinet

17.3. Disassembly of DVD Module (2) P.C.B.

17.4. Disassembly for the Top Ornament Unit

17.5. Disassembly for DVD changer unit

17.6. Disassembly for Panel P.C.B., LED P.C.B. & Tact Switch

P.C.B.

17.7. Disassembly of Main P.C.B., Power P.C.B., Transformer

P.C.B. & Voltage Selector P.C.B.

17.8. DVD Changer Unit Main Component Replacement

Procedures

17.9. Disassembly of Deck Mechanism Unit

17.10. Replacement for the cassette lid ass 馳

17.11. Counter-measure for tape trouble

18 Measurem ents and Adjustments

18.1. Cassette Deck Section

18.2. Tuner Section

18.3. Alignment Points

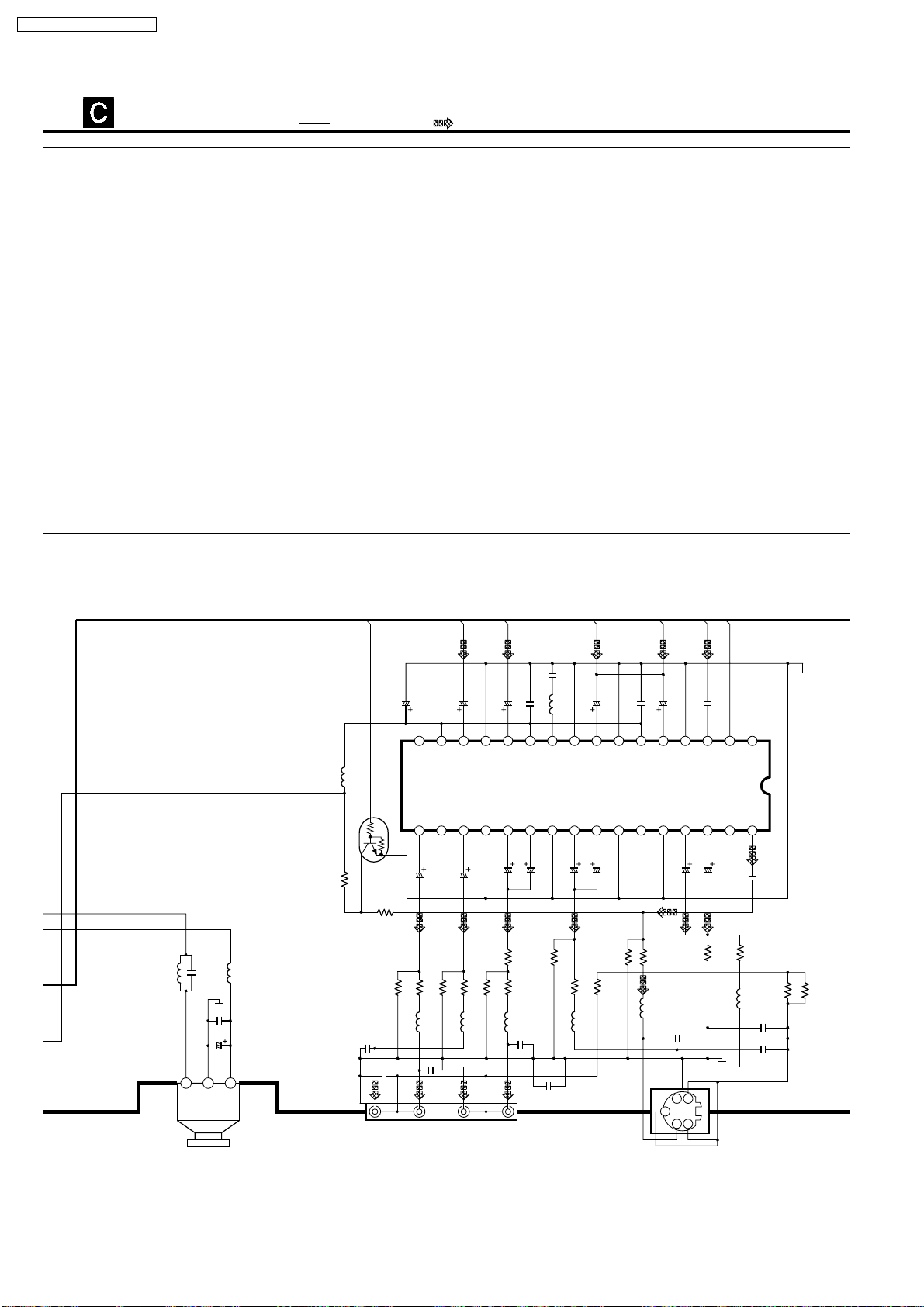

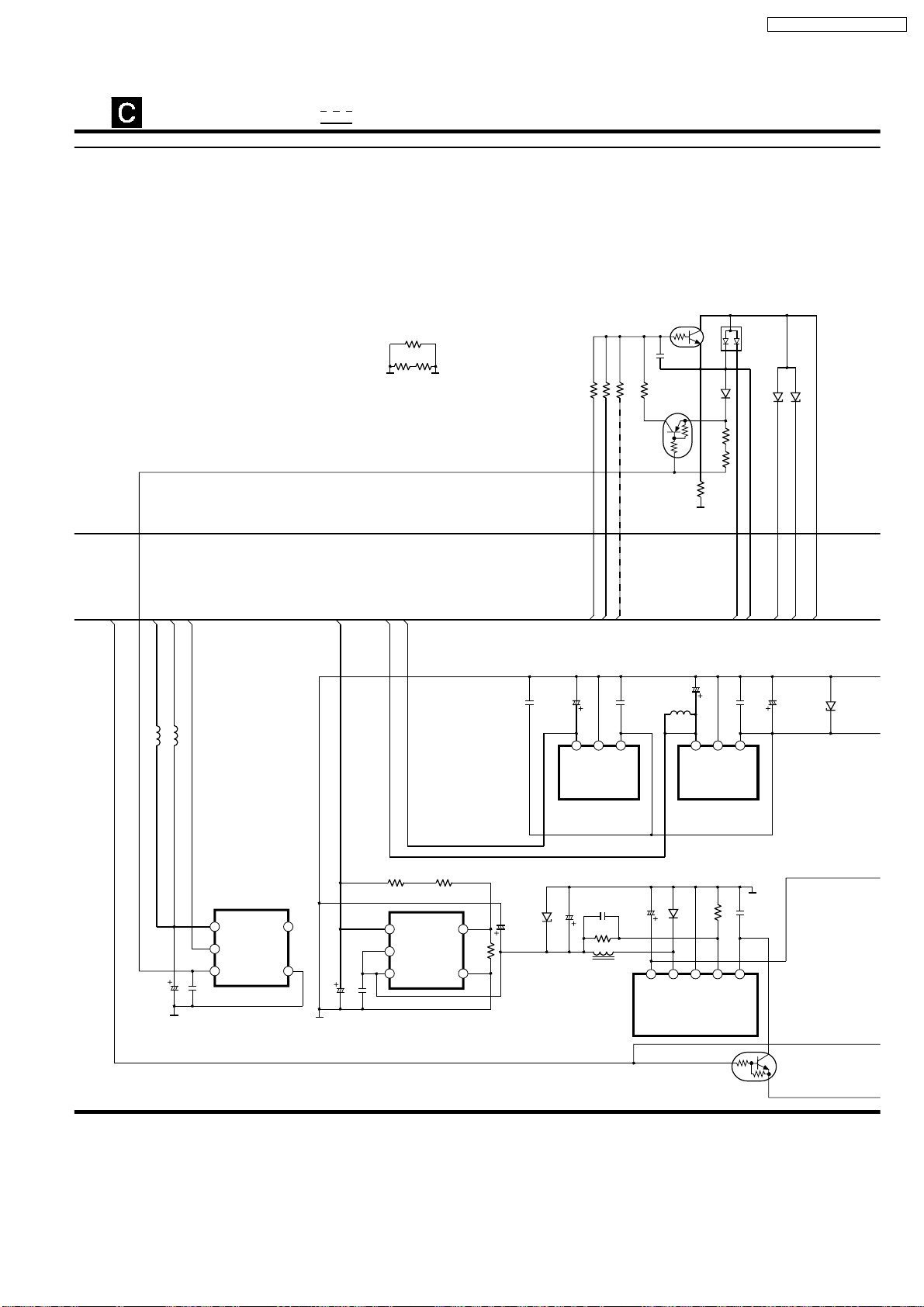

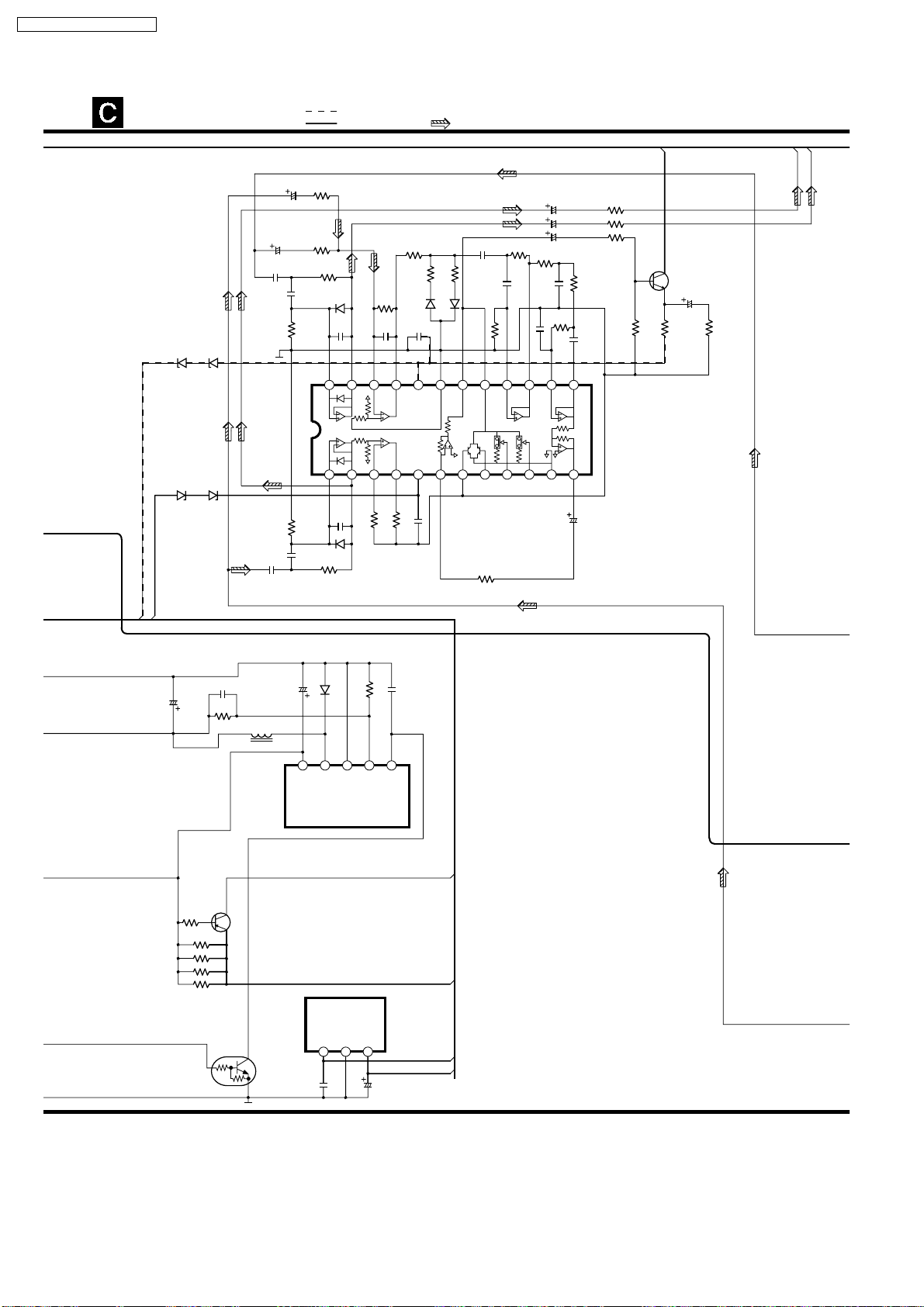

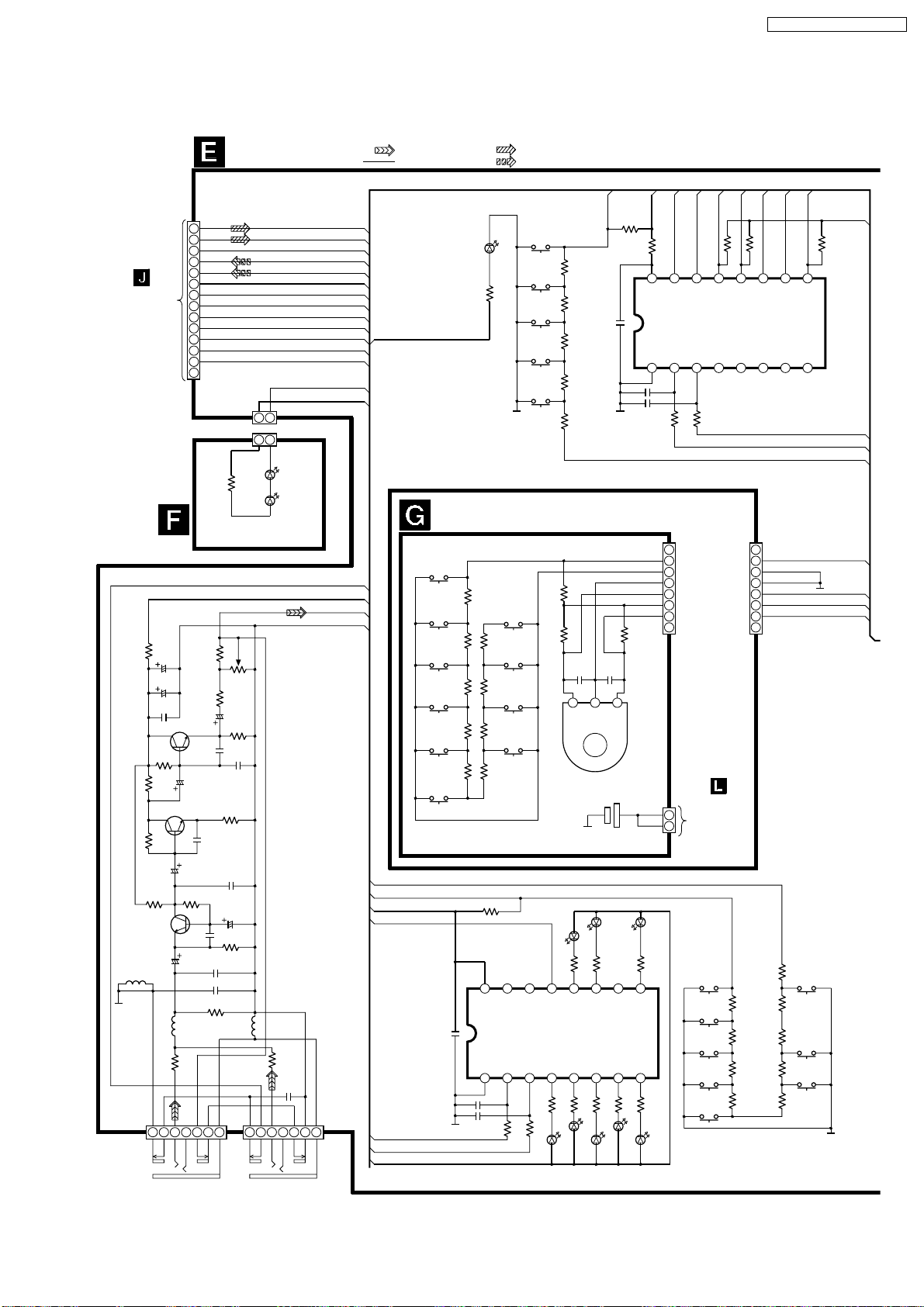

19 Block Diagram

20 Schematic Diagram

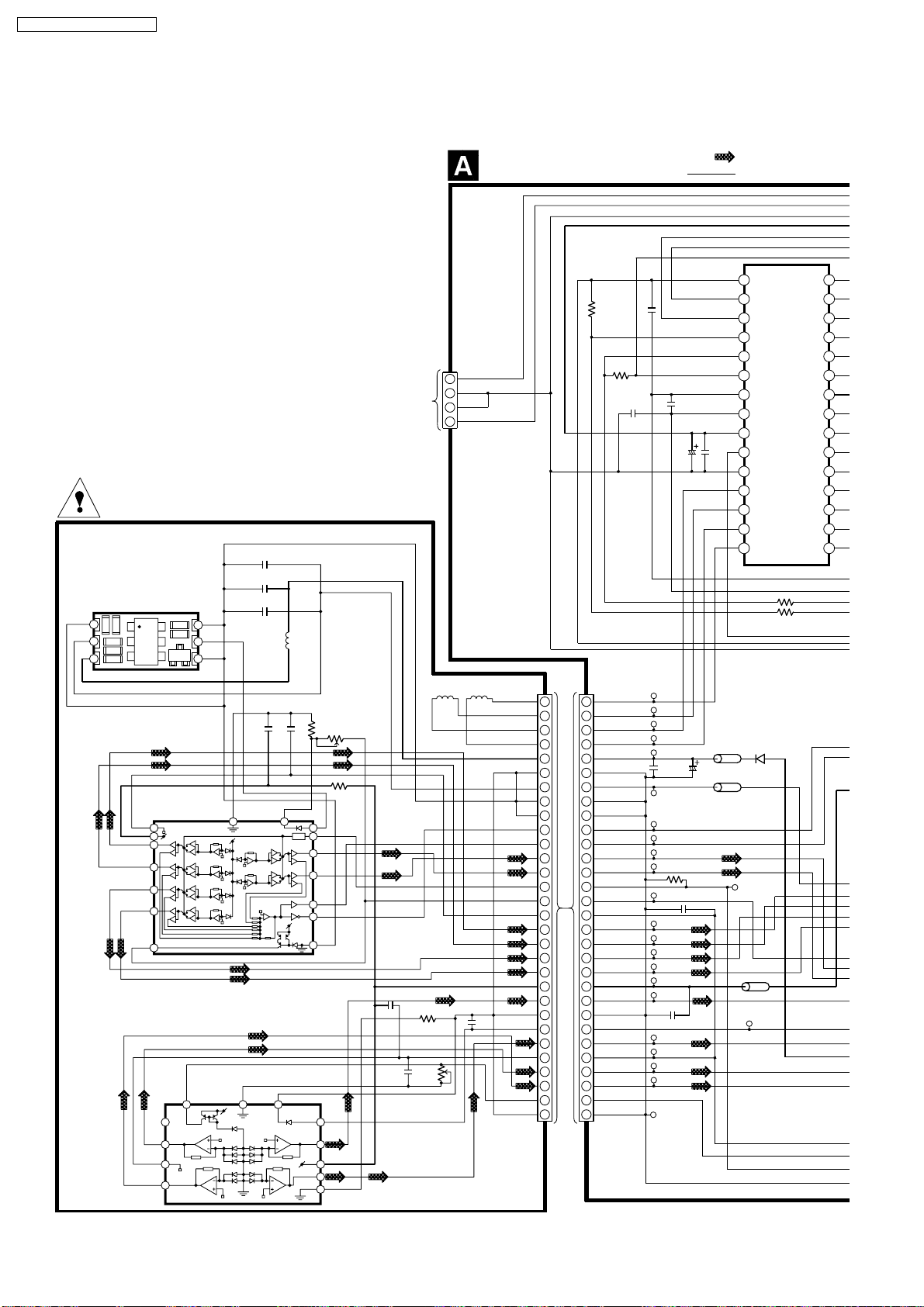

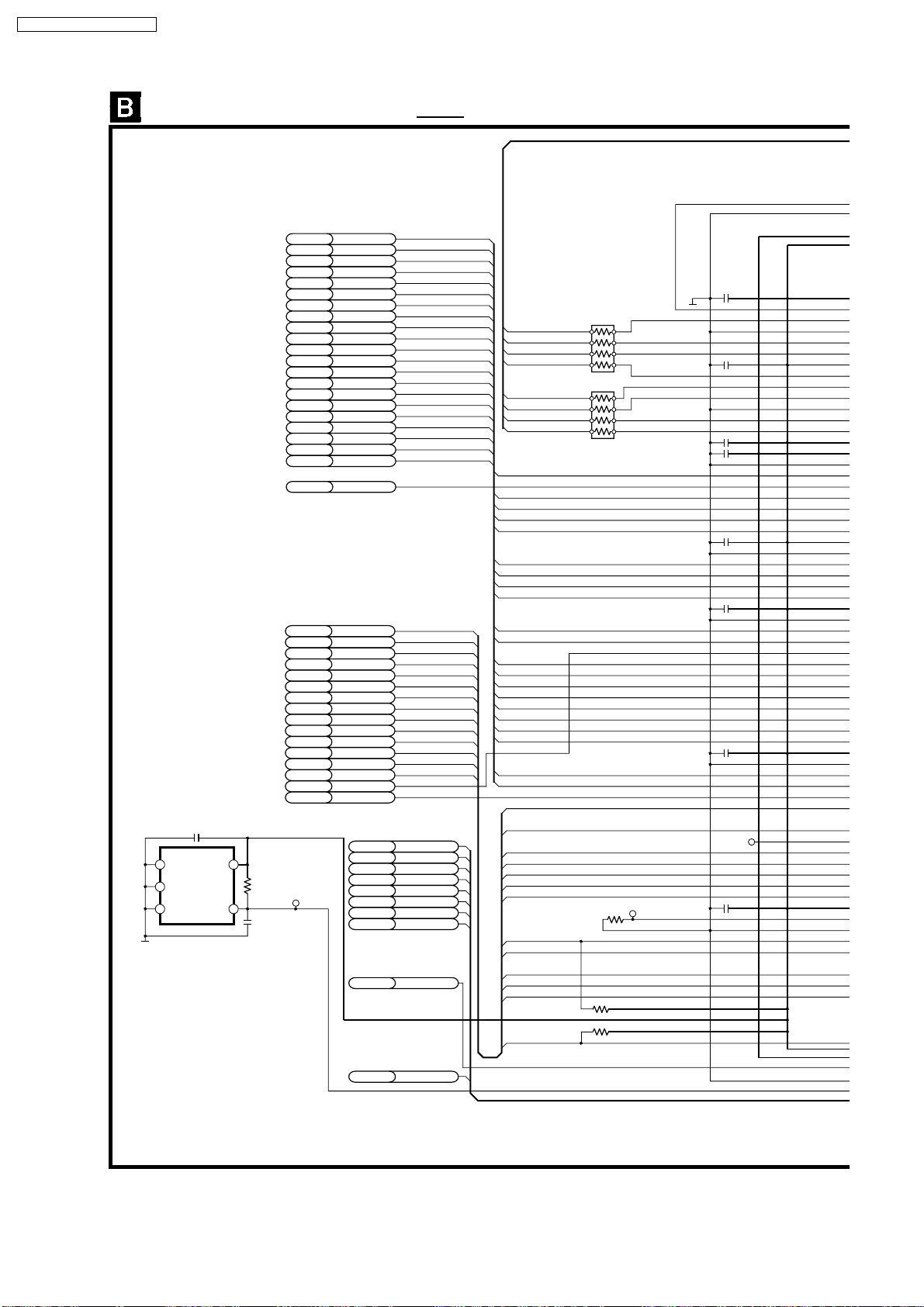

20.1. (A) DVD Module (1) Circuit

21

21

22

23

23

23

23

24

24

24

27

27

28

28

28

28

28

29

30

30

31

31

31

33

33

34

36

49

52

53

54

54

55

56

57

67

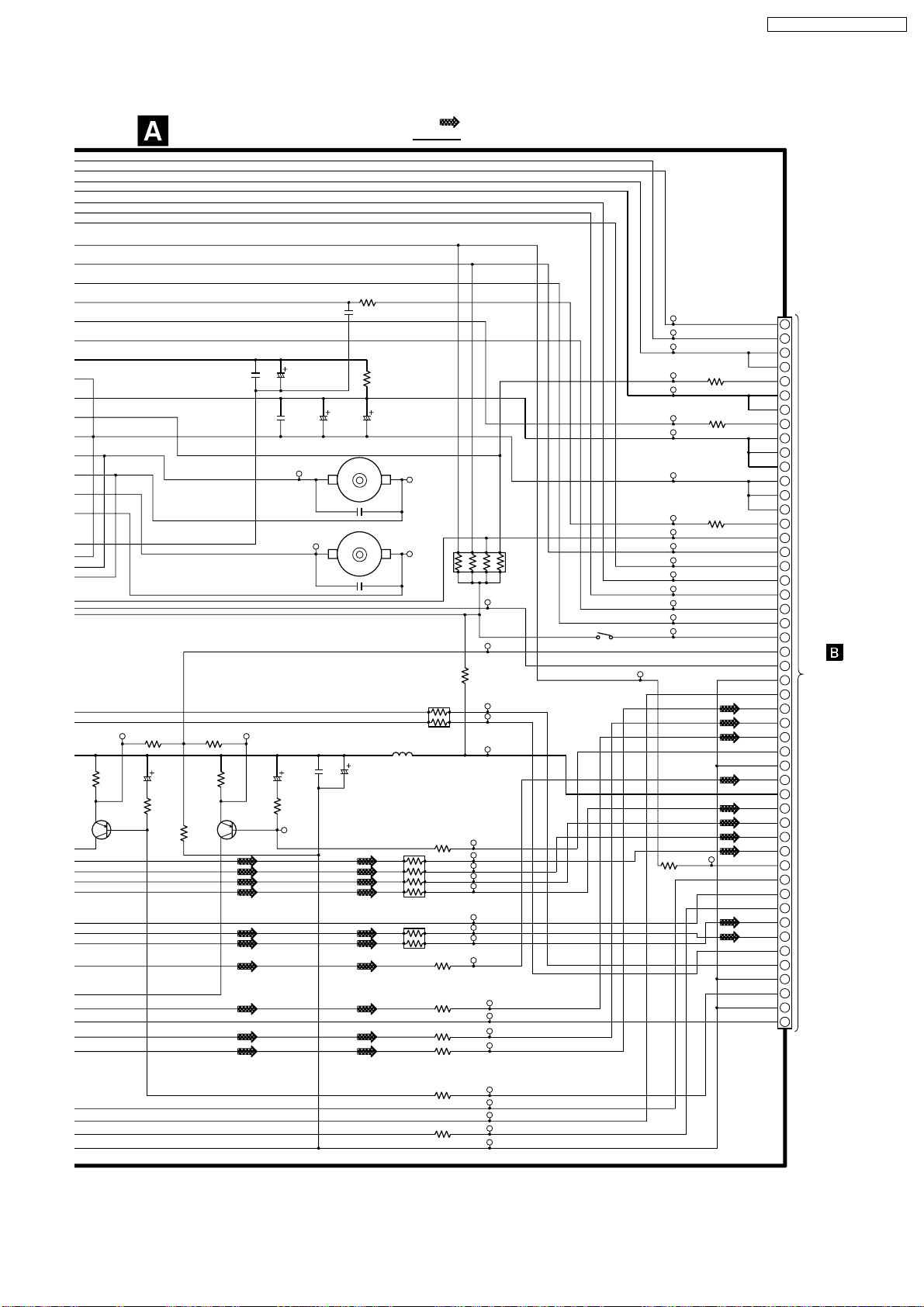

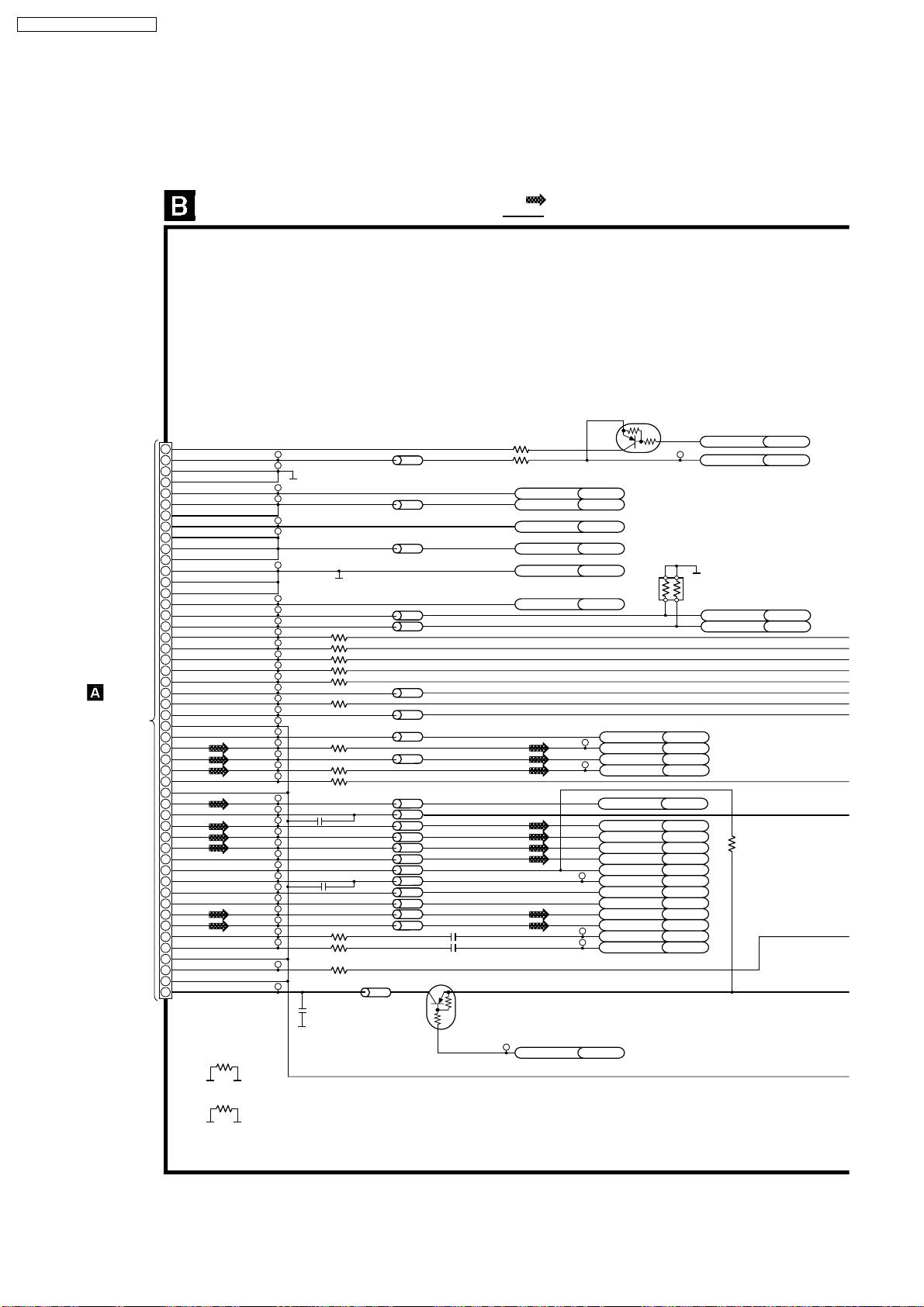

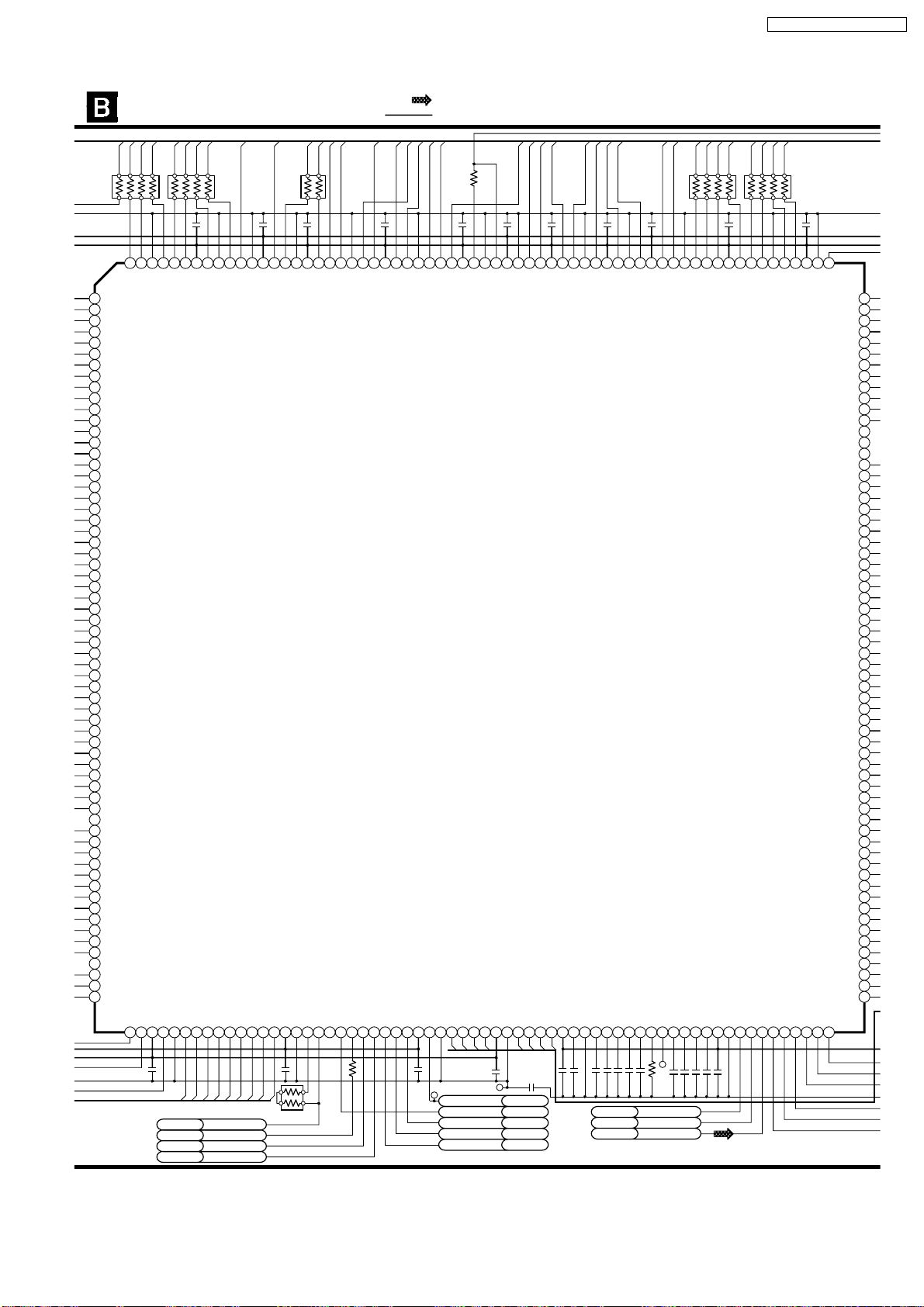

20.2. (B) DVD Module (2) Circuit

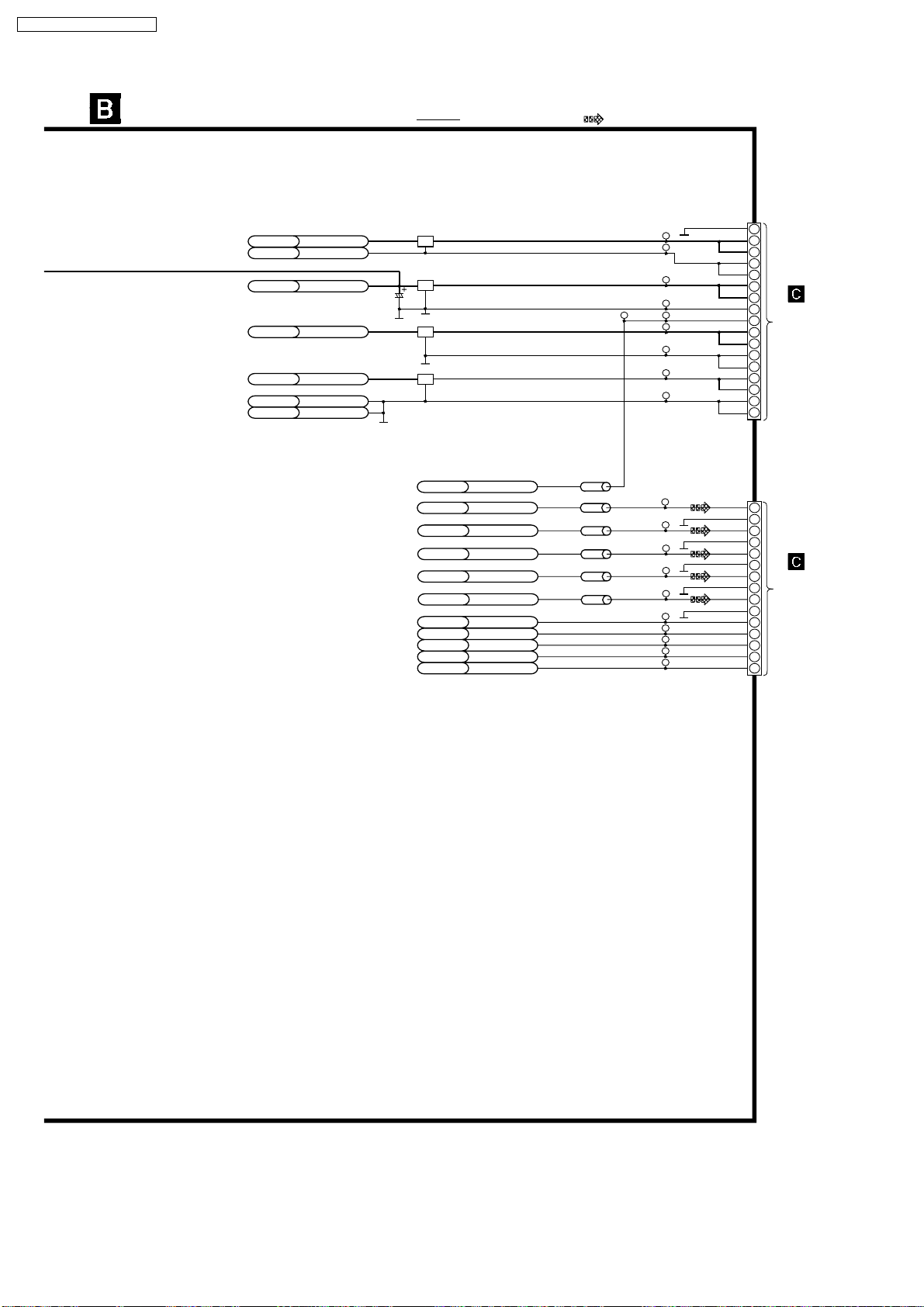

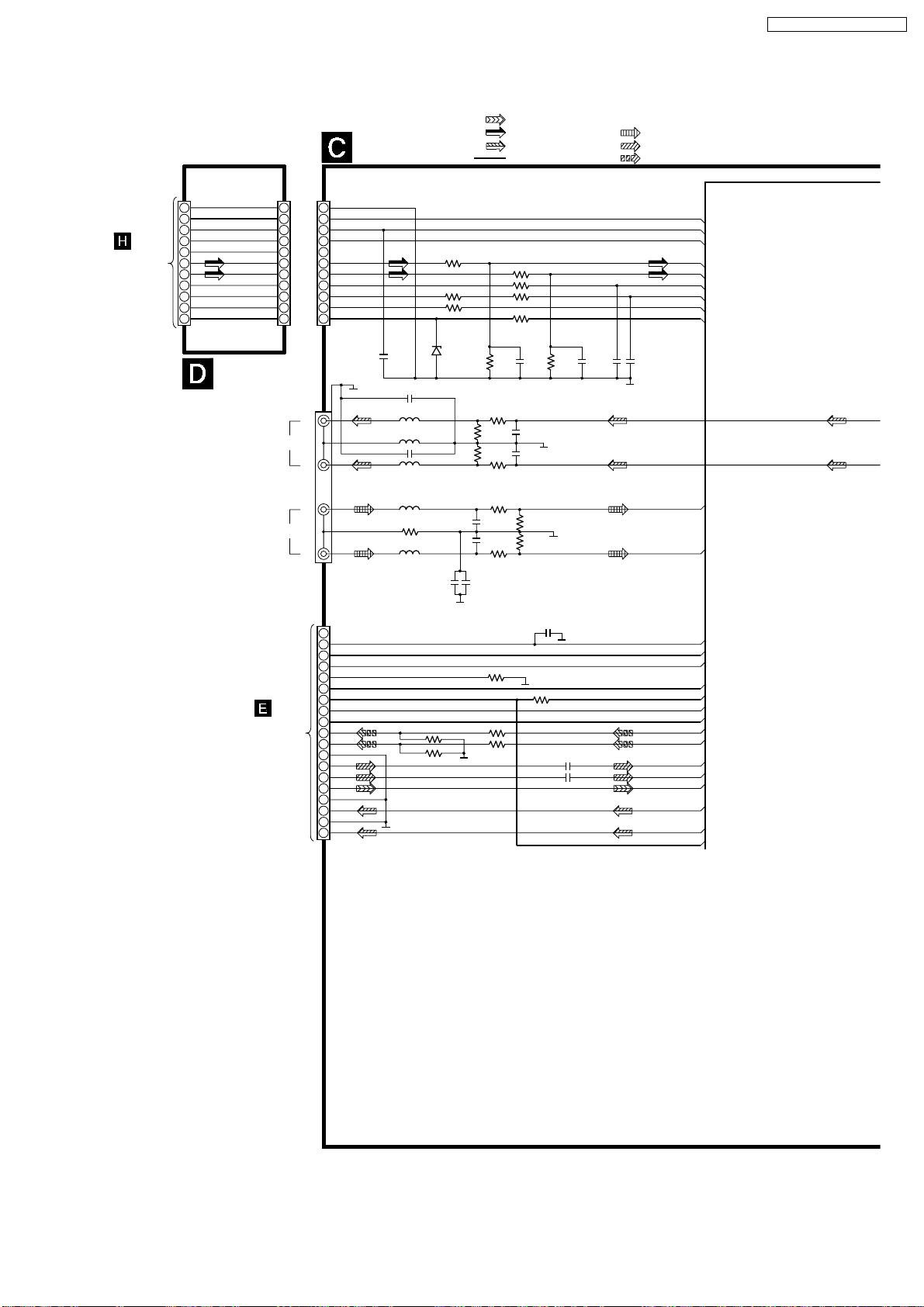

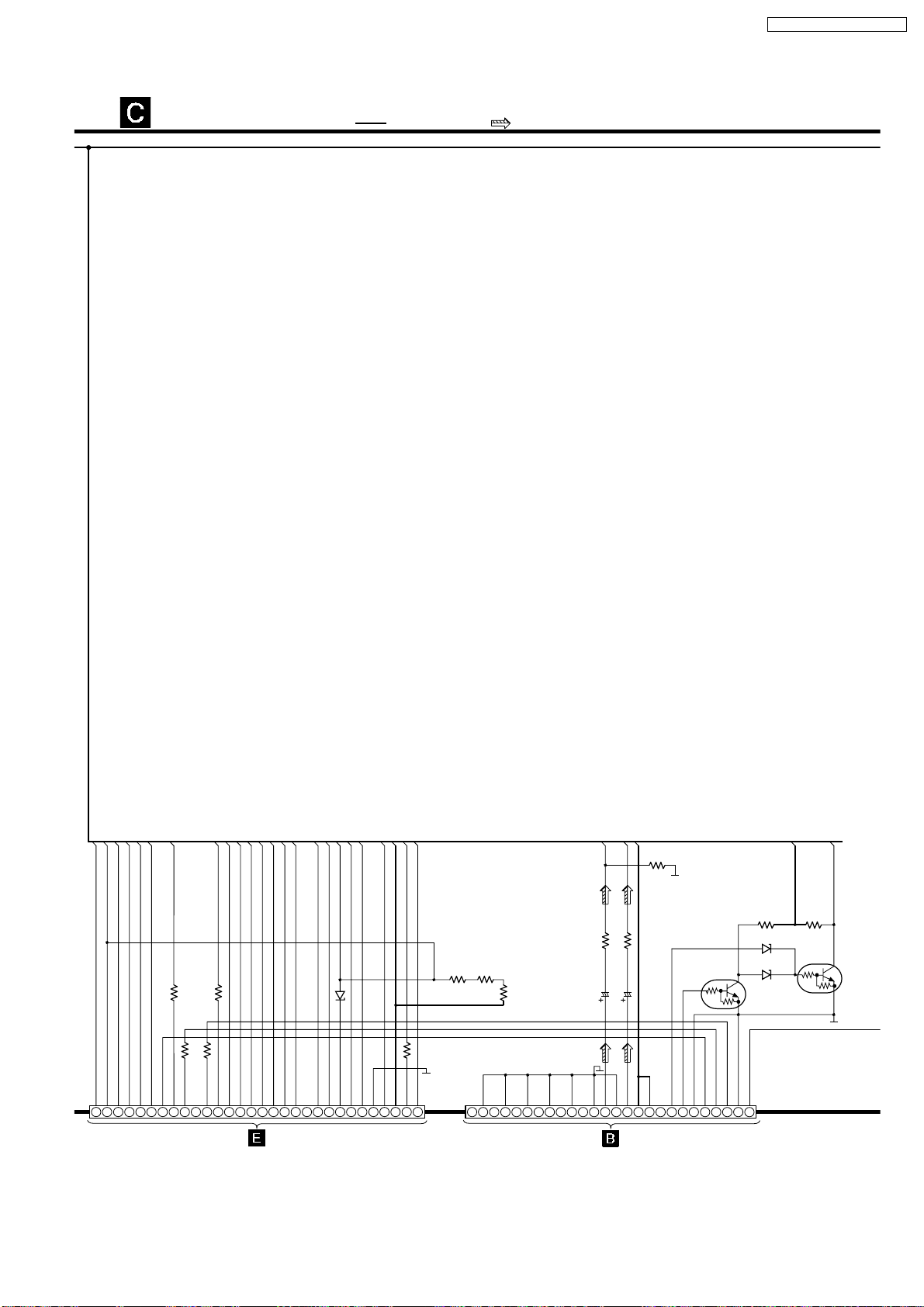

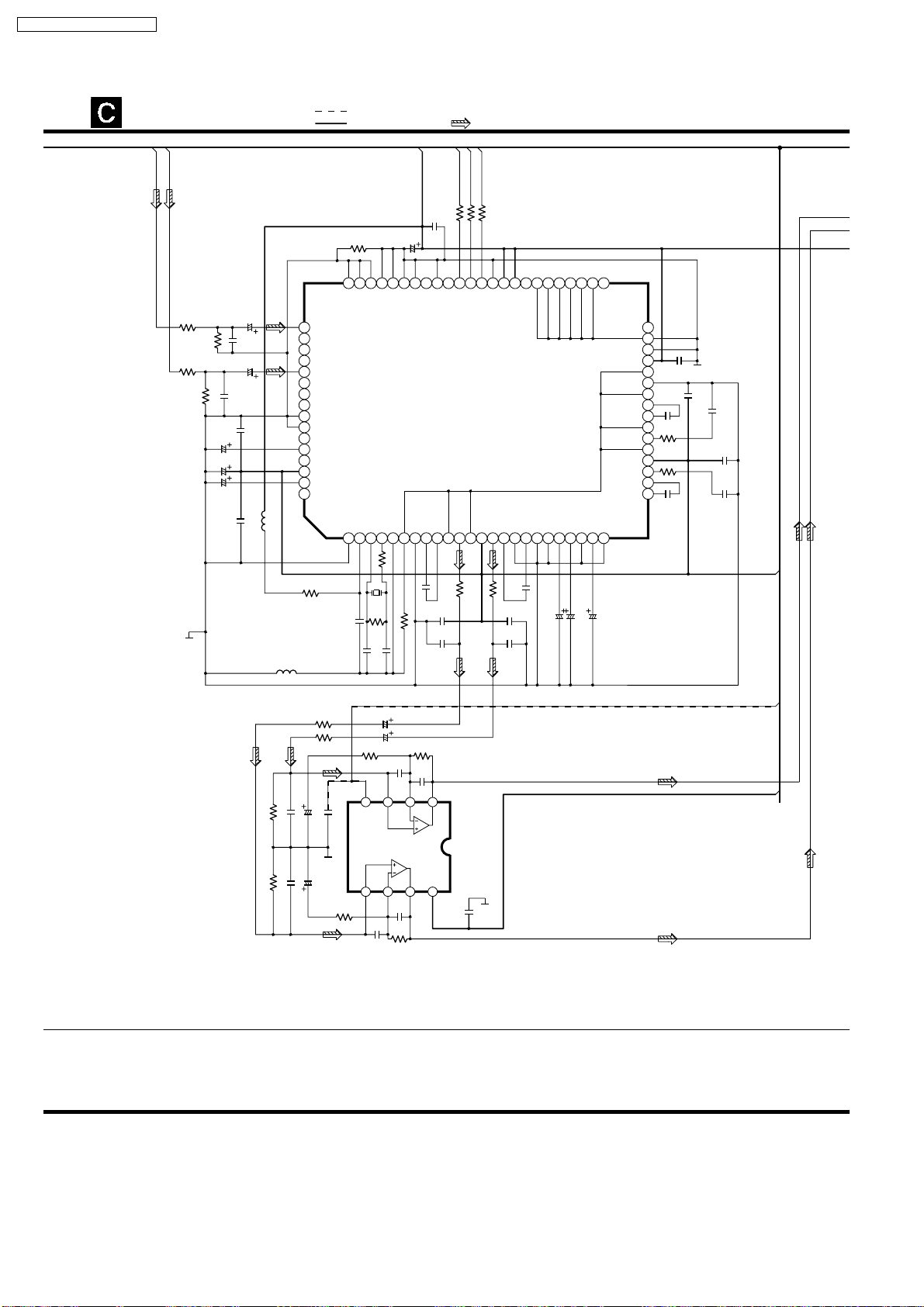

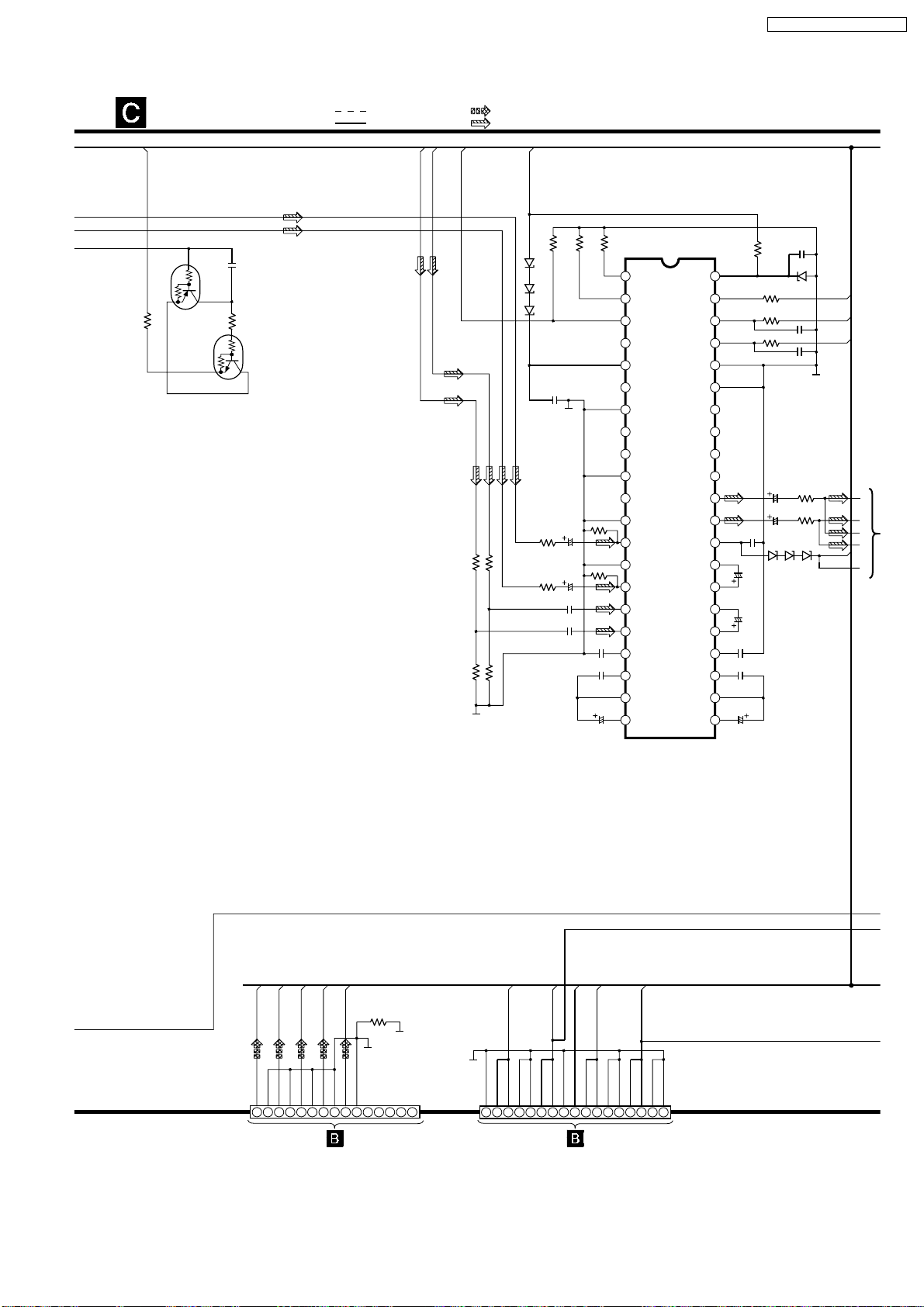

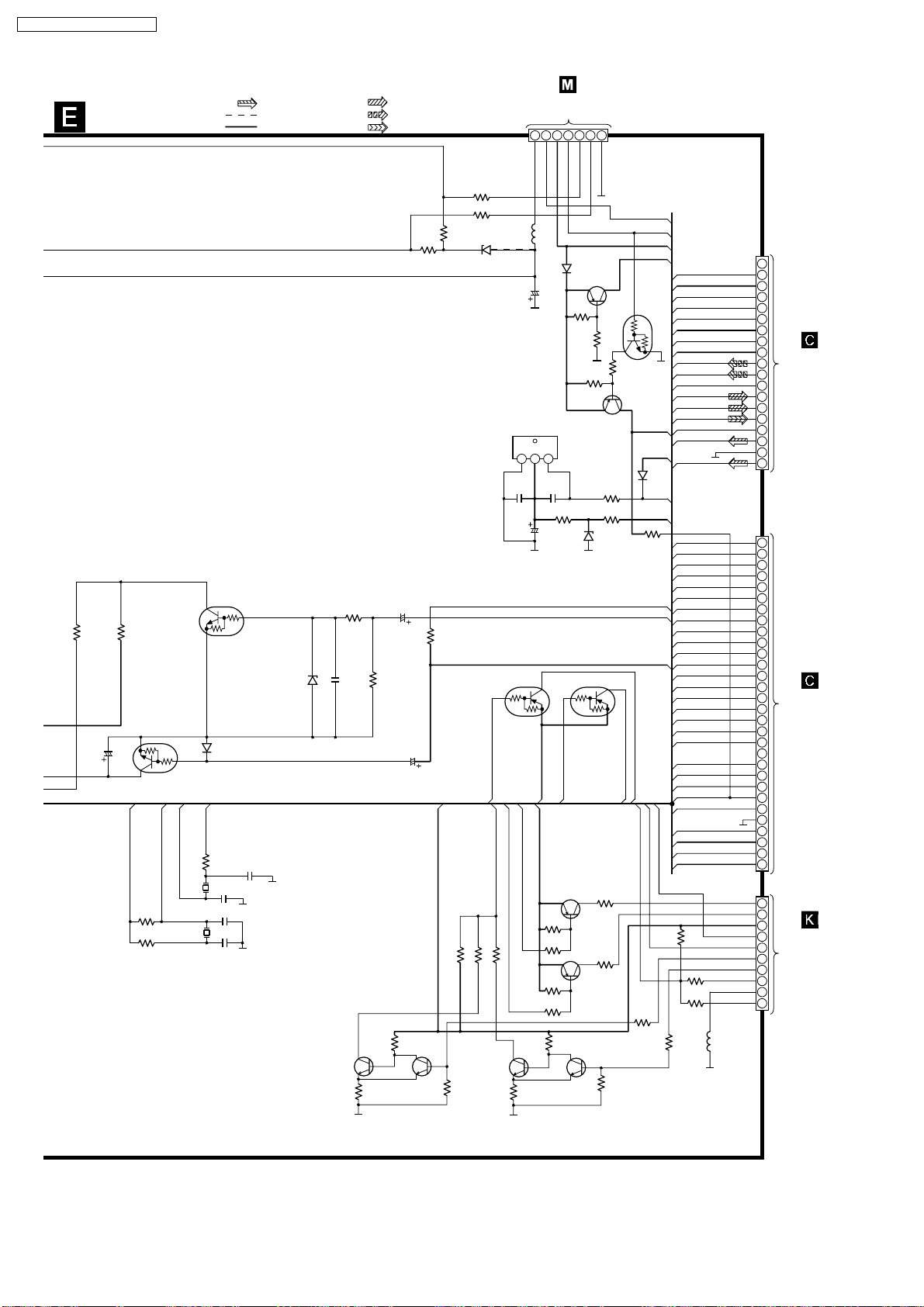

20.3. (C) Main Circuit & (D) Tuner Extent Circuit

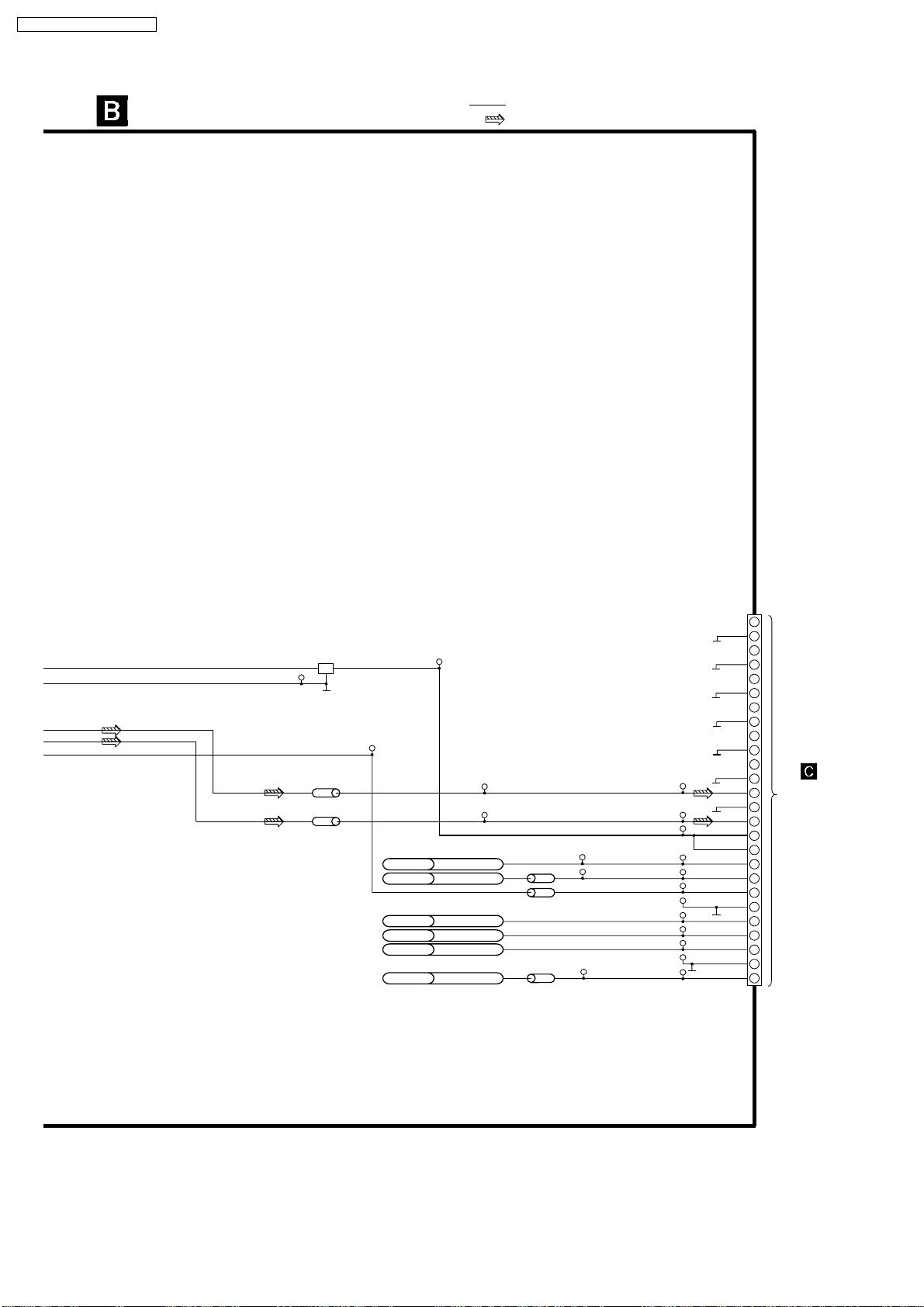

20.4. (E) Panel Circuit, (F) LED Circuit & (G) Tact Switch Circuit

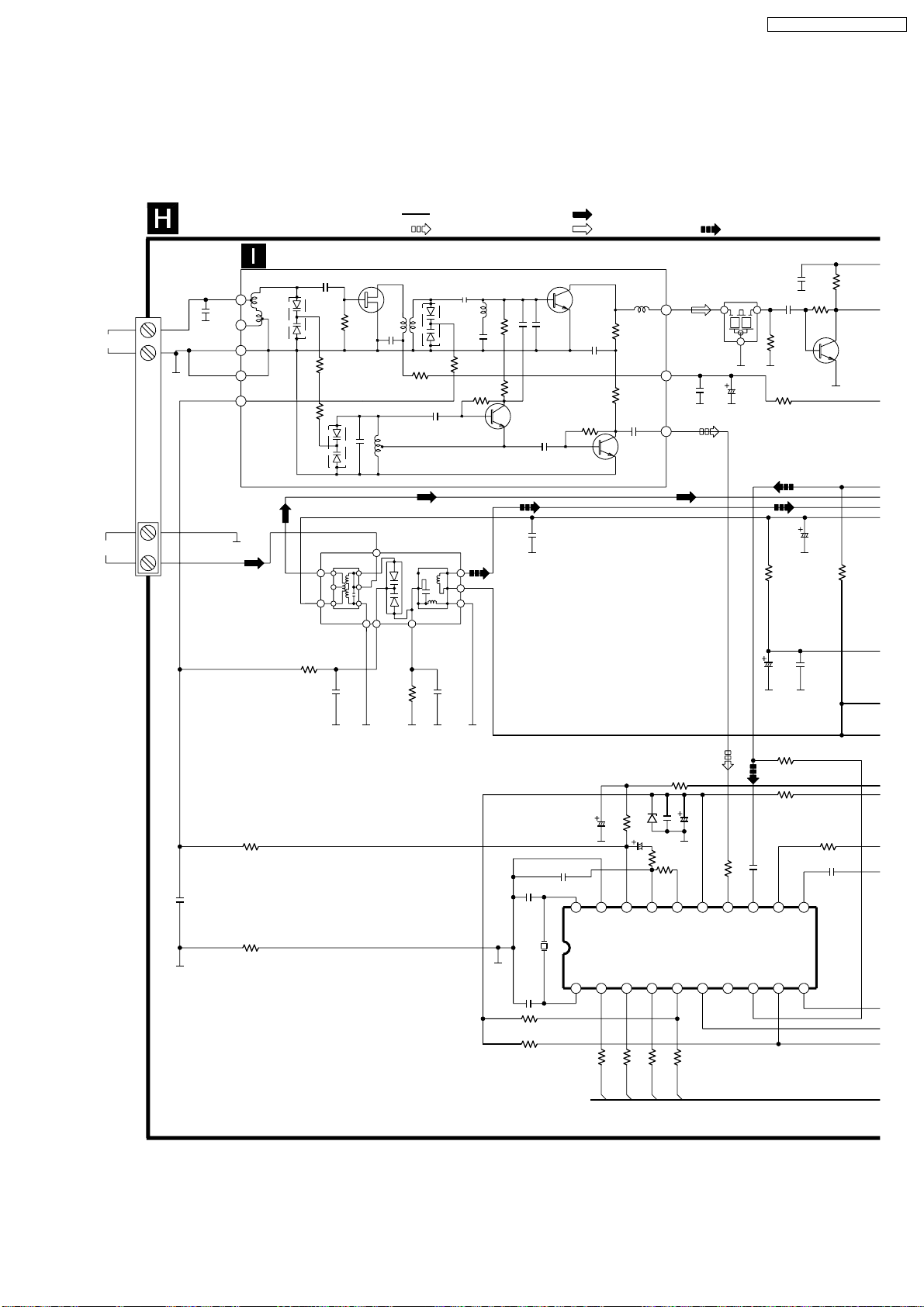

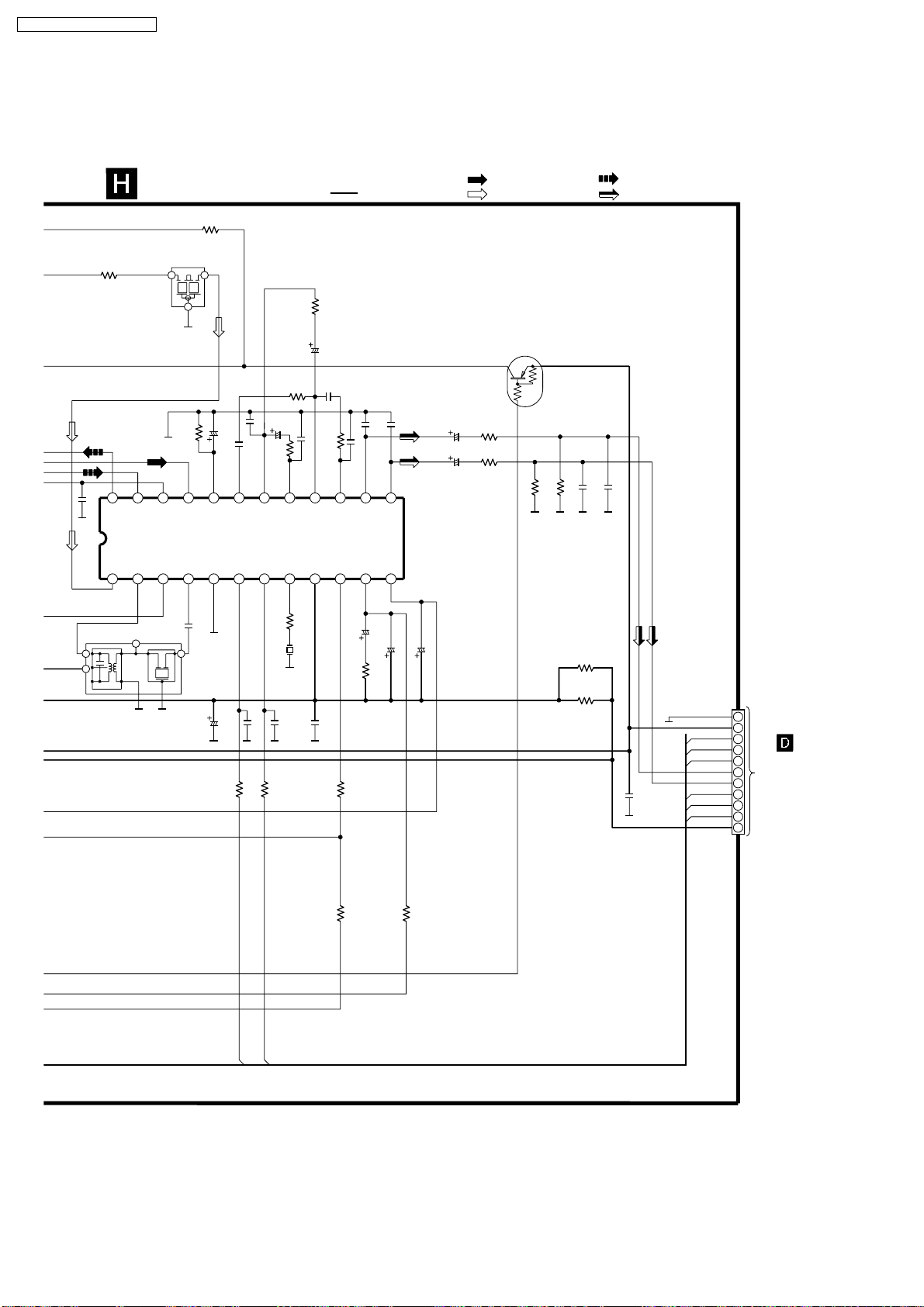

20.5. (H) Tuner Circuit

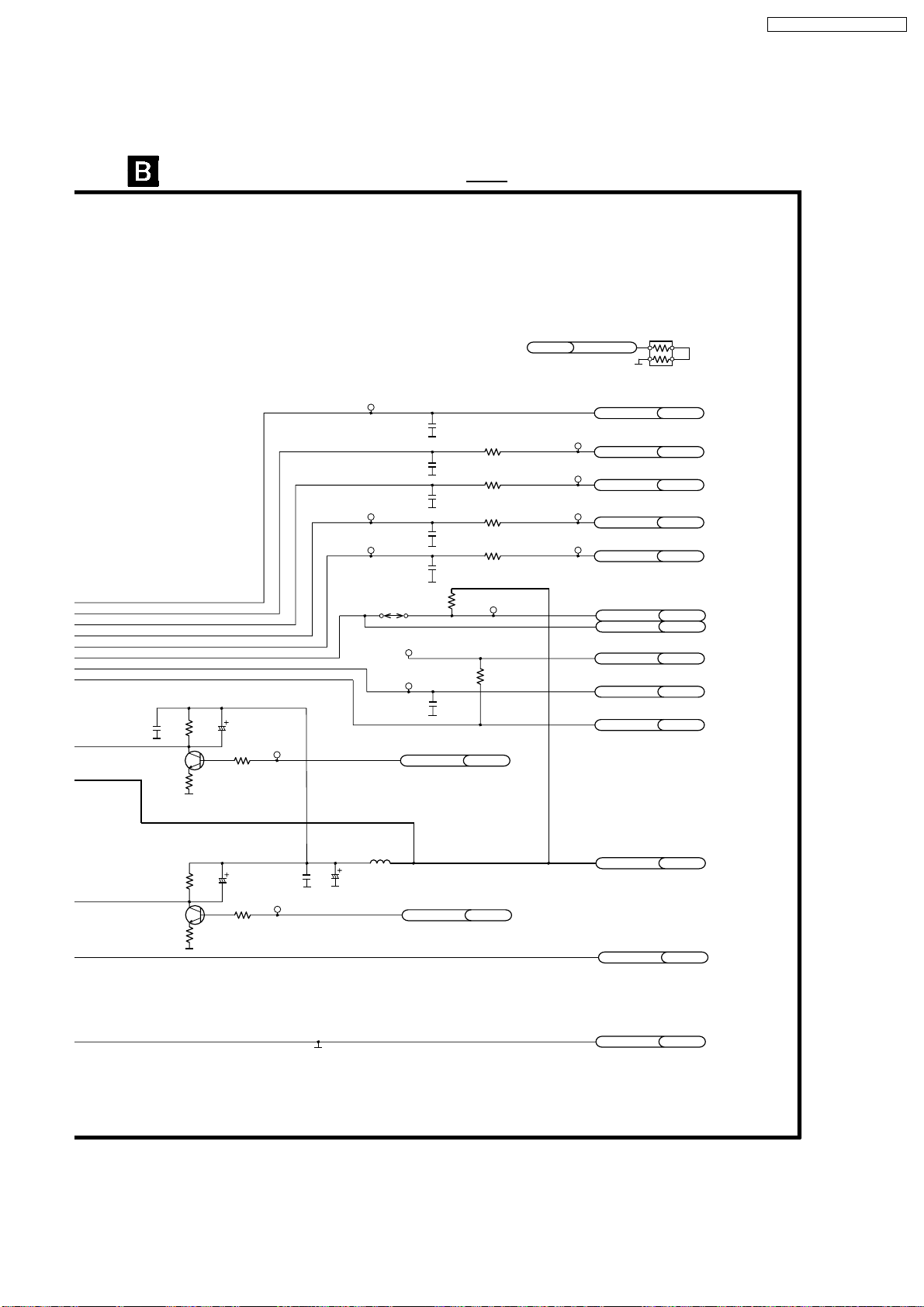

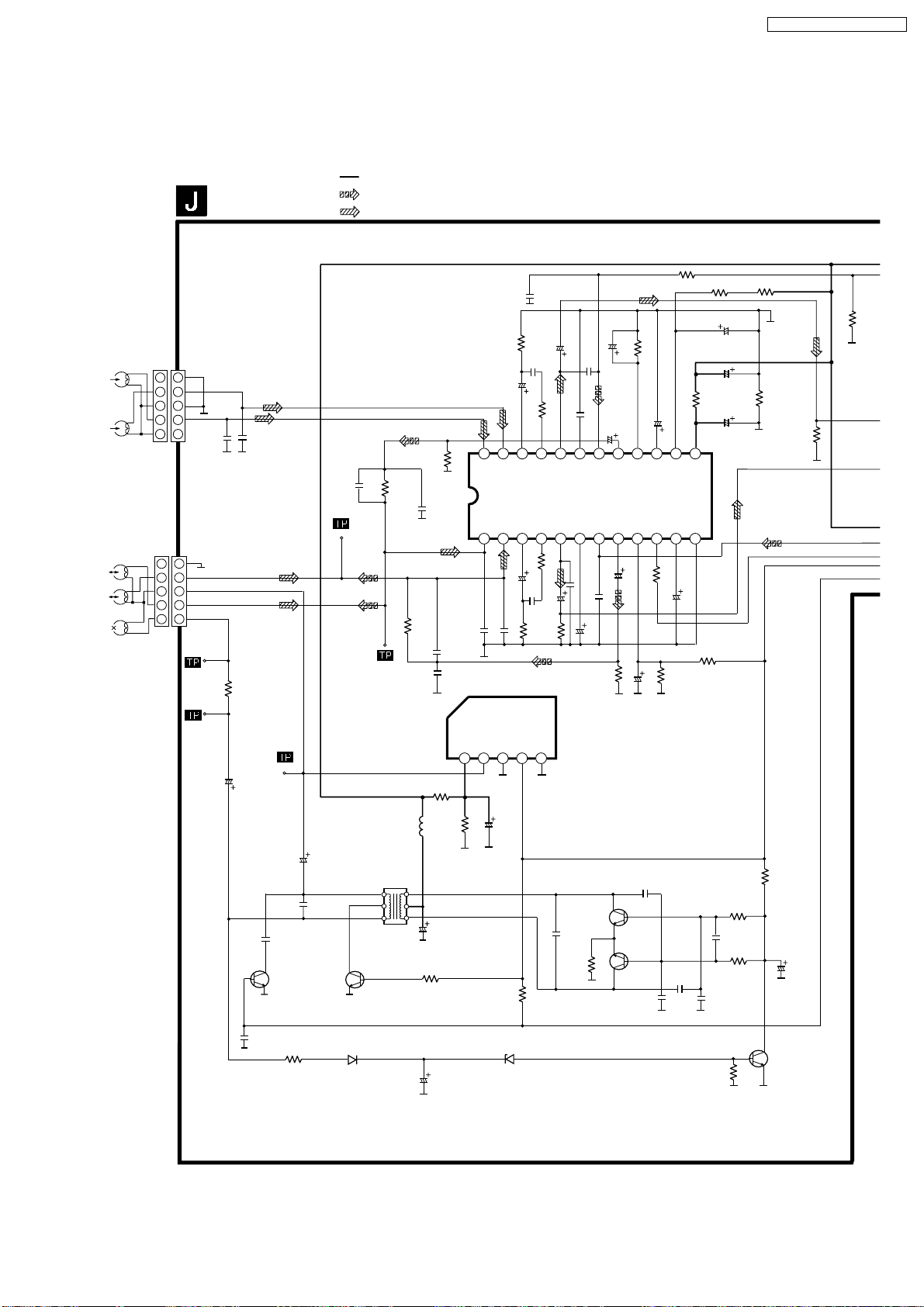

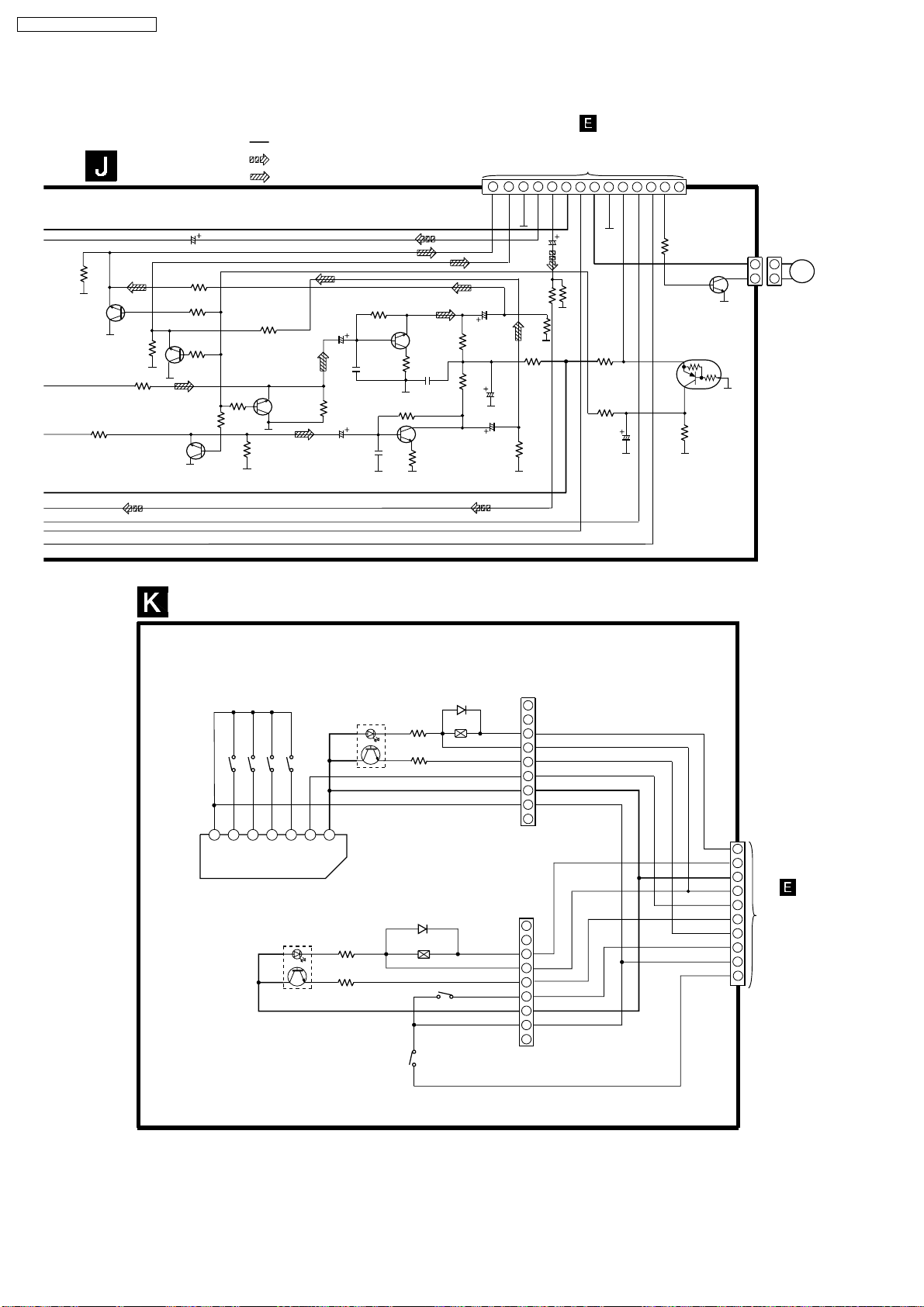

20.6. (J) Deck Circuit & (K) Deck Mechanism Circuit

20.7. (L) Power Supply Circuit

20.8. (M) Power Circuit

20.9. (N) Transformer Circuit, (O) AC Inlet Circuit, (P) Voltage

Selector Circuit, (Q) CD Loading Circuit, (R) CD Detect

Circuit & (S) Spindle Position Circuit

21 Printed Circuit Board

21.1. (A) DVD Module (1) P.C.B. (Component & Foil Side)

21.2. (B) DVD Module (2) P.C.B. (Side A & B)

21.3. (B) Main P.C.B.

21.4. (D) Tuner Extent P.C.B., (F) LED P.C.B. & (G) Tact P.C.B.

21.5. (E) Panel P.C.B.

21.6. (H) Tuner P.C.B. & (I) Tuner Pack P.C.B.

21.7. (J) Deck P.C.B. & (K) Deck Mechanism P.C.B.

21.8. (L) Power Supply P.C.B.

21.9. (M) Power P.C.B.

21.10. (N) Transformer P.C.B.

21.11. (O) AC Inlet P.C.B. & (P) Voltage Selector P.C.B.

21.12. (Q) CD Loading P.C.B., (R) CD Detect P.C.B. & (S)

Spindle Position P.C.B.

22 Wiring Connection Diagram

23 Illustration of ICs, Transistors and Diodes

24 Terminal Function of IC

24.1. IC600 (C2BBHF000076

) (GC) IC600 (C2BBHF000077) (GCS) System

Microprocessor

25 Parts Location and Replacement Parts List

25.1. Deck Mechanism (RAA3412-S)

25.2. CD Loading Mechanism (RD-DAC036-S)

25.3. Cabinet

25.4. Electrical Parts List

25.5. Packing Materials & Accessories Parts List

25.6. Packaging

68

70

81

93

97

99

101

103

105

106

106

107

111

113

114

116

117

118

120

122

123

124

125

127

128

128

129

130

133

137

140

153

154

1 Before Use

Be sure to disconnect the mains cord before adjusting the voltage selector.

Use a minus(-) screwdriver to set the voltage selector (on the rear panel) to the voltage setting for the area in which the unit will

be used. (If the power supply in your area is 117V or 120V, set to the “127V” position.)

Note that this unit will be seriously damaged if this setting is not made correctly. (There is no voltage selector for some countries,

the correct voltage is already set.)

2 Before Repair and Adjustment

Disconnect AC power, discharge Power Supply Capacitors C531~C534, C588~C589, C598~C599 and C954 through a 10Ω,5W

3

Page 4

SA-VK61DGC / SA-VK61DGCS

resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Current consumption at AC 110/127/220~230V, 50/60 Hz in NO SIGNAL (vol. min, at CD mode) & AC 240 V, 50 Hz should be

~770mA .

3 Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

No sound is heard when the power is turned on.

·

Sound stops during a performance.

·

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note :

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

4 Safety Precautions

4.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

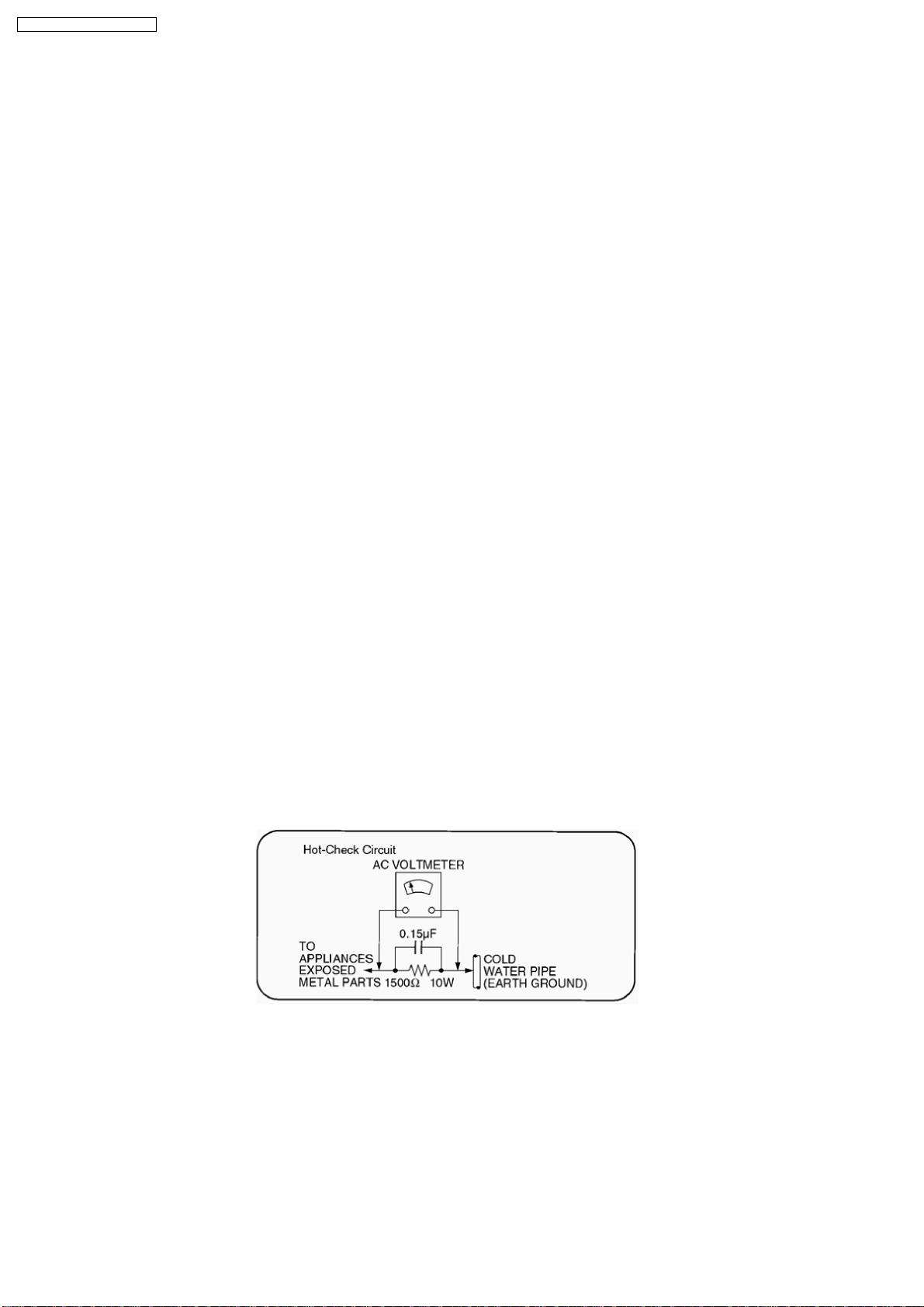

4.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩ and 5.2MΩ.

When the exposed metal does not have a return path to the chassis, the reading must be ・.

Figure 1

4.1.2. Leakage Current Hot Check

(See Figure 1)

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF capacitor, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

4

Page 5

SA-VK61DGC / SA-VK61DGCS

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent) may

be used to make the hot checks, leakage current must not exceed 1/2 milliamp. In case a measurement is out of the limits

specified, there is a possibility of a shock hazard, and the equipment should be repaired and rechecked before it is returned to

the customer.

5 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor “chip” components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equiped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equiped with ES devices, place the assembly on a conductive surface such as aluminium

foil, to prevent electrostatic charge build up or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder remover device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminium foil or

comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize body motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to

damage an ES device).

6 Handling the Lead-free Solder

6.1. About lead free solder (PbF)

Distinction of PbF P.C.B.:

P.C.B.s (manufactured) using lead free solder will have a PbF stamp on the P.C.B.

Caution:

· Pb free solder has a higher melting point than standard solder; Typically the melting point is 50 - 70°F (30 - 40°C) higher. Please

use a high temperature soldering iron. In case of soldering iron with temperature control, please set it to 700 ± 20°F (370 ±

10°C).

· Pb free solder will tend to splash when heated too high (about 1100°F/600°C).

· When soldering or unsoldering, please completely remove all of the solder on the pins or solder area, and be sure to heat the

soldering points with the Pb free solder until it melts enough.

5

Page 6

SA-VK61DGC / SA-VK61DGCS

7 Cautions to be taken when handling Optical Pickup

The laser diode used inside optical pickup could be destroyed due to static electricity as a potential difference is caused by

electrostatic load discharged from clothes or human body. Handling the parts carefully to avoid electrostatic destruction during

repair.

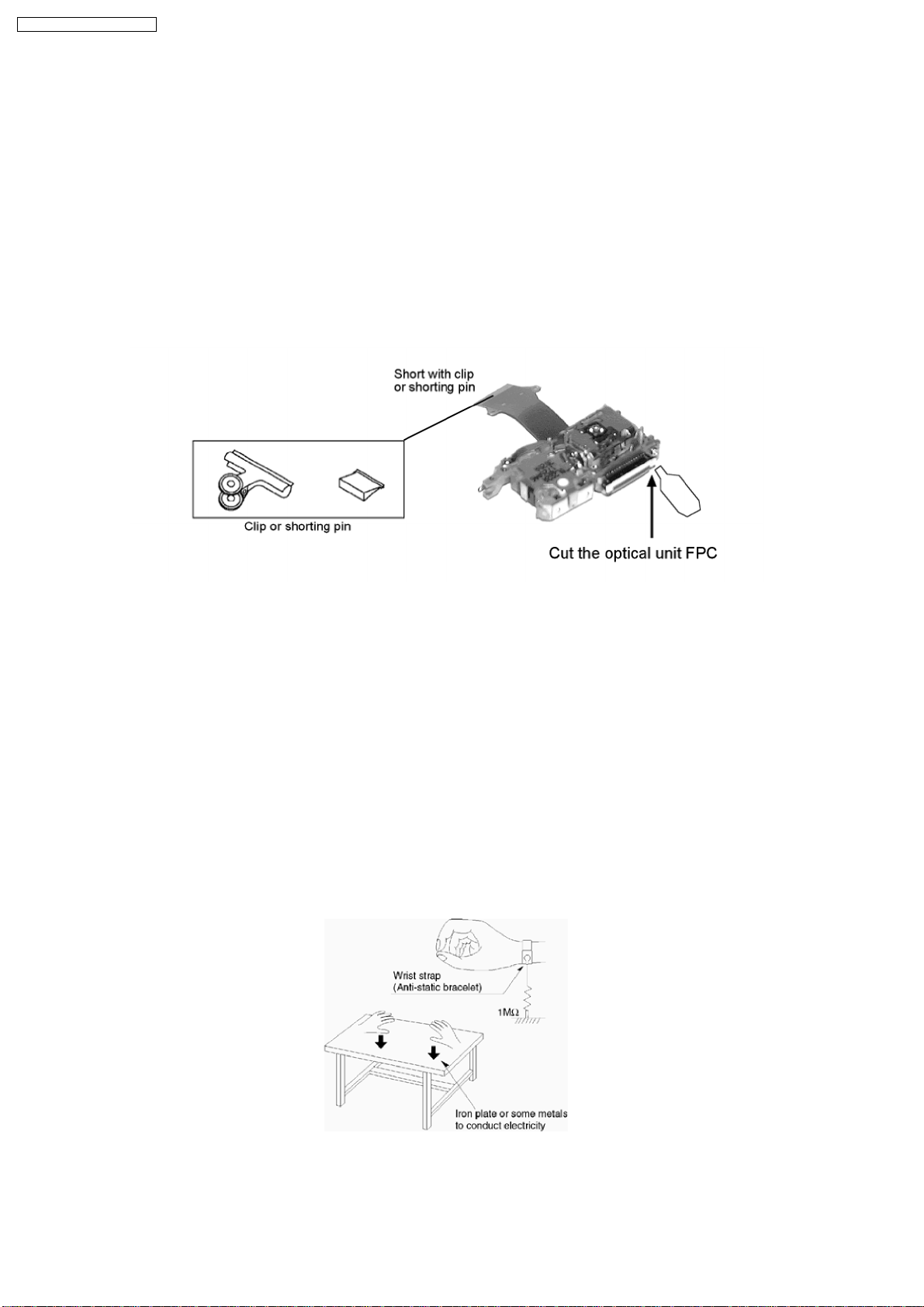

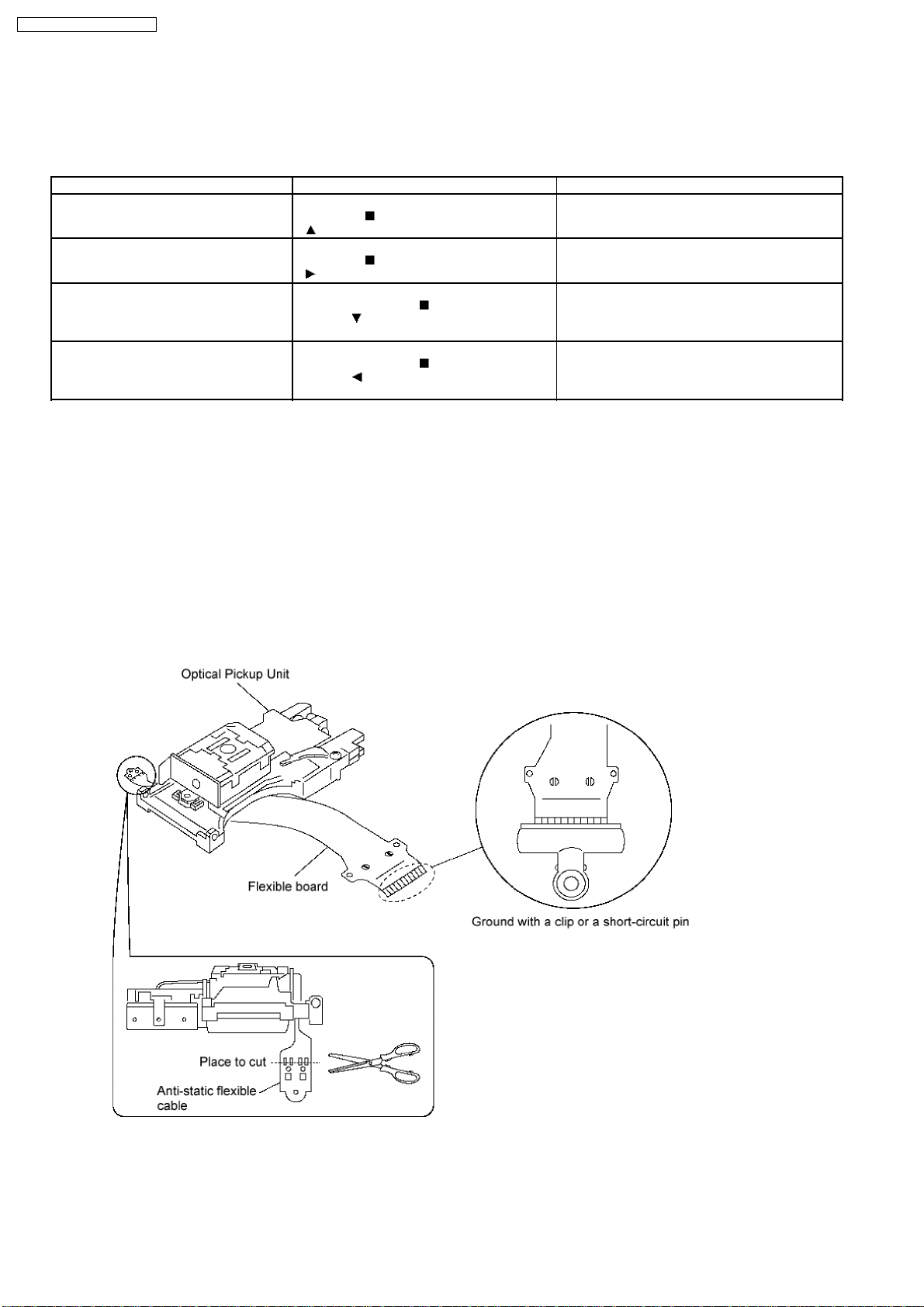

7.1. Handling Optical Pickup

1. Do not impact on optical pickup as the unit structurally uses an extremely precise technology.

2. Short-circuit the flexible cable of optical pickup remove from the circuit board using a short-circuit pin or clip in order to prevent

laser diode from electrostatic destruction (Refer to Fig. 7.1 and Fig. 7.2)

3. Do not handle flexible cables forcibly as this may cause snapping. Handle the parts carefully (Refer to Fig. 7.1)

4. A new optical pickup is equipped with an anti-static flexible cable. After replacing and connecting to the flexible board, cut the

anti-static flexible cable. (Refer to Fig. 7.1)

Fig. 7.1

7.2. Replacing Precautions for Optical Pickup Unit

DVD/CD Optical Pickup

The optical pickup by which part supply was carried out attaches the short clip to the flexible board for laser diode electrostatic

discharge damage prevention. Please remove the short clip and be sure to check that the short land is open, before connecting.

(Please remove solder, when the short land short-circuits.)

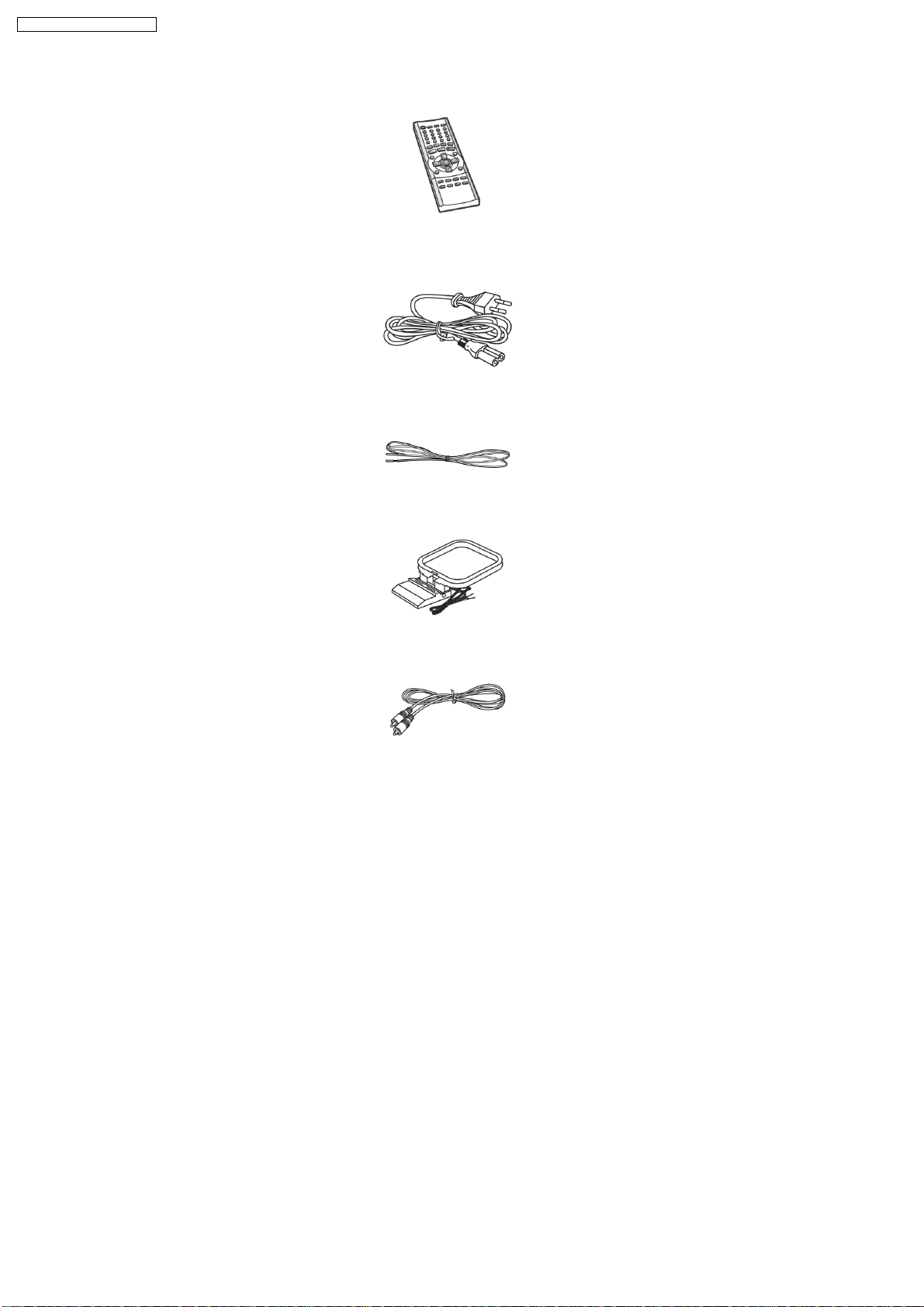

7.3. Grounding for Preventing Electrostatic Destruction

1. Human body grounding

Use the anti-static wrist strap to discharge the static electricity accumulated in your body. (Refer to Fig. 7.2)

2. Work place grounding

Place a conductive material (conductive sheet) or ironboard where optical pickup is placed. (Refer to Fig. 7.2)

Note :

Keep your clothes away from optical pickup as wrist strap does not release the static electricity charged in clothes.

Fig. 7.2

6

Page 7

SA-VK61DGC / SA-VK61DGCS

8 Precaution of Laser Diode

Caution :

This product utilizes a laser diode with the unit turned "ON", invisible laser radiation is emitted from the pick up lens.

Wavelength : 780 nm(CD)/658 nm(DVD)

Maximum output radiation power from pick up : 100 µW/VDE

Laser radiation from pick up unit is safety level, but be sure the followings:

1. Do not disassemble the optical pick up unit, since radiation from exposed laser diode is dangerous.

2. Do not adjust the variable resistor on the pick up unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at pick up lens for a long time.

CAUTION!

THIS PRODUCT UTILIZES A LASER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT

IN HAZARDOUS RADIATION EXPOSURE.

n Use of Caution Labels

7

Page 8

SA-VK61DGC / SA-VK61DGCS

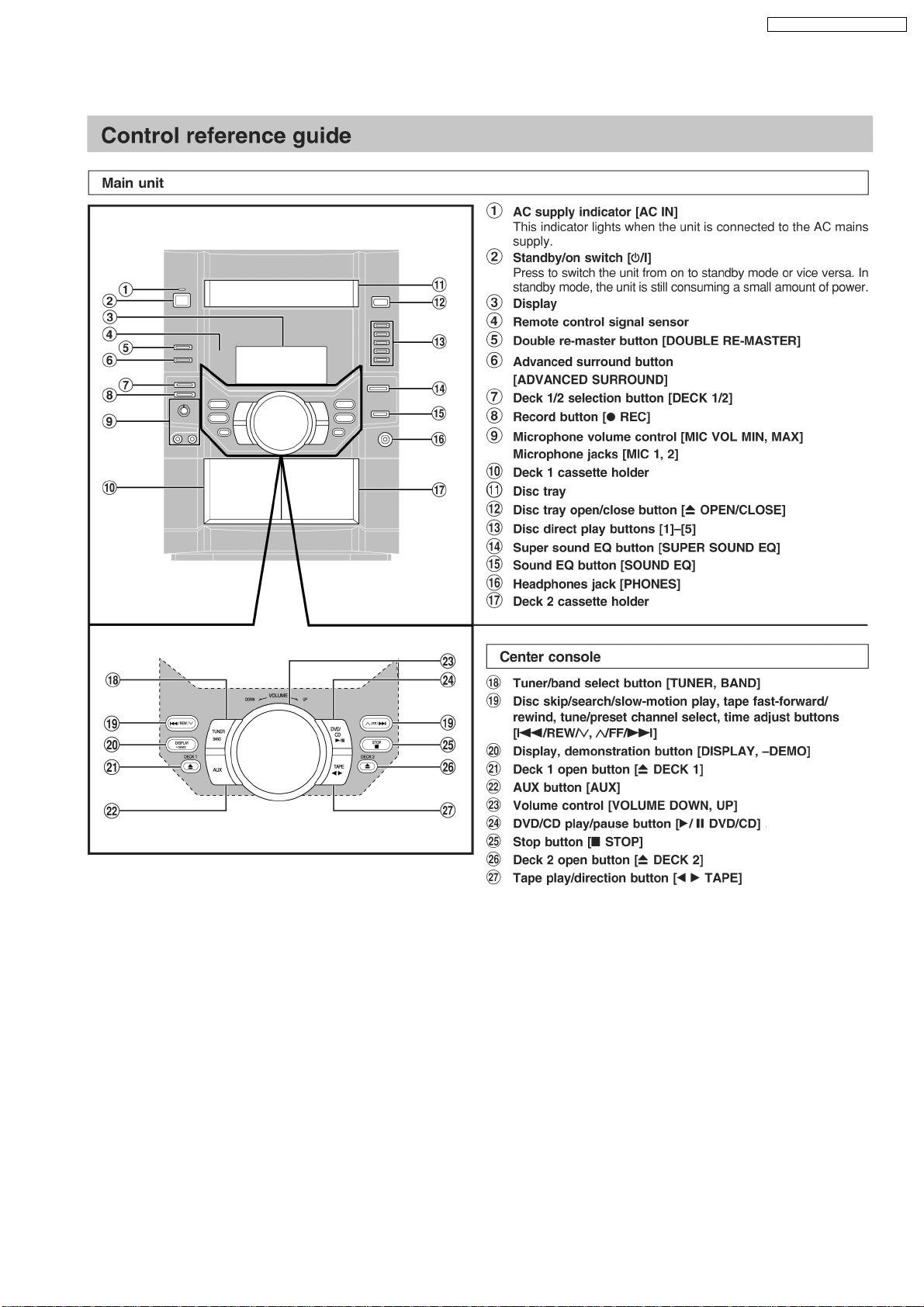

9 Accessories

Remote

control

AC power supply cord

FM indoor antenna

AM indoor antenna

Video cable

8

Page 9

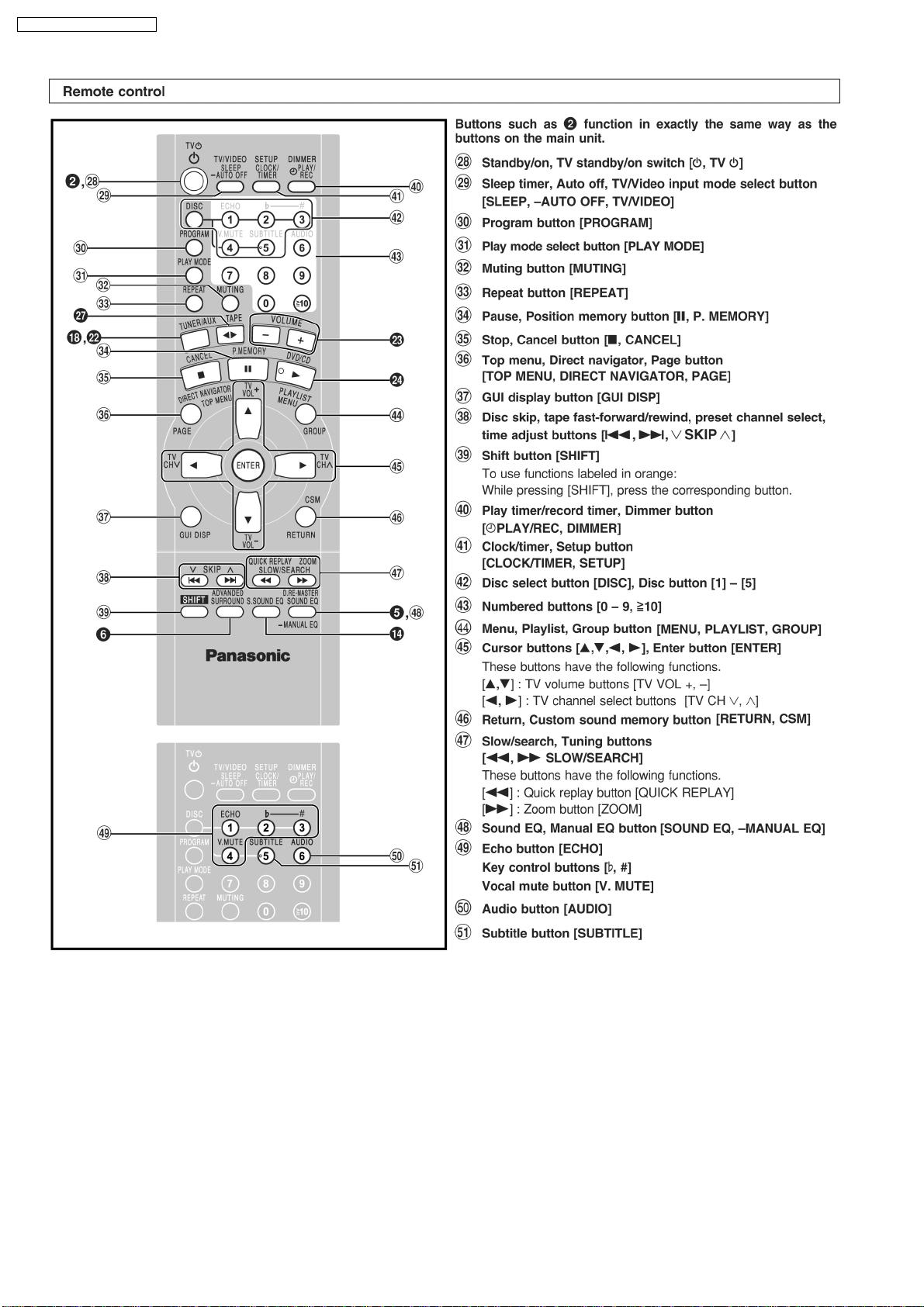

10 Operation Procedures

SA-VK61DGC / SA-VK61DGCS

9

Page 10

SA-VK61DGC / SA-VK61DGCS

10

Page 11

11 Disc information

SA-VK61DGC / SA-VK61DGCS

11

Page 12

SA-VK61DGC / SA-VK61DGCS

12

Page 13

SA-VK61DGC / SA-VK61DGCS

12 About HighMAT

12.1. What is HighMAT?

This word combines the abbreviations of Matsushita Electric Industrial Co. Ltd. and High Performance Media Access Technology,

and is a trademark of Microsoft Corporation. The products with the HighMAT logo shown below are made according to the

HighMAT standard.

HighMAT is a format that allows users to save digital contents such as photographs, audio, and images on a CD. This gives

consistency in the way of reading data when general consumer products (such as DVD players) and PCs are used, and thus, it is

easy to operate for the user.

12.2. Why use HighMAT?

Up to now, there was no harmonized standard from playing digital content stored in CD-ROM formats (including CD-R) on

consumer products like DVD players.Therefore, we used to have problems such as follow:

· There was no common play list or attached information on contents, which is called metadata.

· The data compression method differed according to the equipment.

· As the number of CD-ROMs recorded increased retrieved the contents became more difficult.

· Because display and operation methods were different depending on the equipment, the play order of the content on the same

disc could change.

12.3. The advantages of using HighMAT

Applying the HighMAT standard will solve the following problems and will improve usability.

· It will create a common user interface for both PC and consumer products.

· Regardless of the types of consumer products, such as DVD players, portable CD players, car stereos, and micro computers,

a consistent way to pay for digital content will be created and it will make it easier to retrieve data.

13

Page 14

SA-VK61DGC / SA-VK61DGCS

· You can also play digital content on the disc, which was created in accordance with the HighMAT format with a conventional

CD-ROM player.

12.4. Outline of the HighMAT standard

1. Recording medium

· CD-R/CD-RW

· Supports ISO 9660 Level Expanded Joliet

· For multiple session

2. Support data format

· Level 1 player: WMA, MP3 (MPEG-1 Audio Layer 3)

· Level 2 player: WMA, MP3 (MPEG-1 Audio Layer 3), JPEG

· Level 3 player: WMA, MP3 (MPEG-1 Audio Layer 3), JPEG, WMV, MPEG4 (optional)

3. Limitation of data format

14

Page 15

SA-VK61DGC / SA-VK61DGCS

· WMA, MP3 (MPEG-1 Audio Layer 3) 64 kbps - 160.999 kbps, 44.1 KHz, stereo, fixed bit rate/ variable bit rate.

· WMA, V2 and above, excluding Lossless/Voice/Pro

· JPEG: Max 6M pixel, Maximum file size: 3 MB

4. Limitations regarding the number of files on the media, etc.

· Total number of audio files: Maximum 450

· Total number of still picture files: Maximum 999

· Total number of animation files: Maximum 200

· Total number of directories: Maximum 400

· Length of a file name: Maximum 108 characters (Unicode)

· Total number of play lists: Maximum 200

· Number of contents in the playlist: Maximum 900

5. Composition of HighMAT disc

· Menu: Classified for the navigation of the HighMAT digital contents. When menu selected, its submenu or the play list will

be displayed.

· Play list: A list in which one or more digital contents are arranged in order

· Group: Sub-divided group of a play list.

· Digital Contents: Audio, still picture, and animation data.

15

Page 16

SA-VK61DGC / SA-VK61DGCS

13 Procedure for repairing the set

16

Page 17

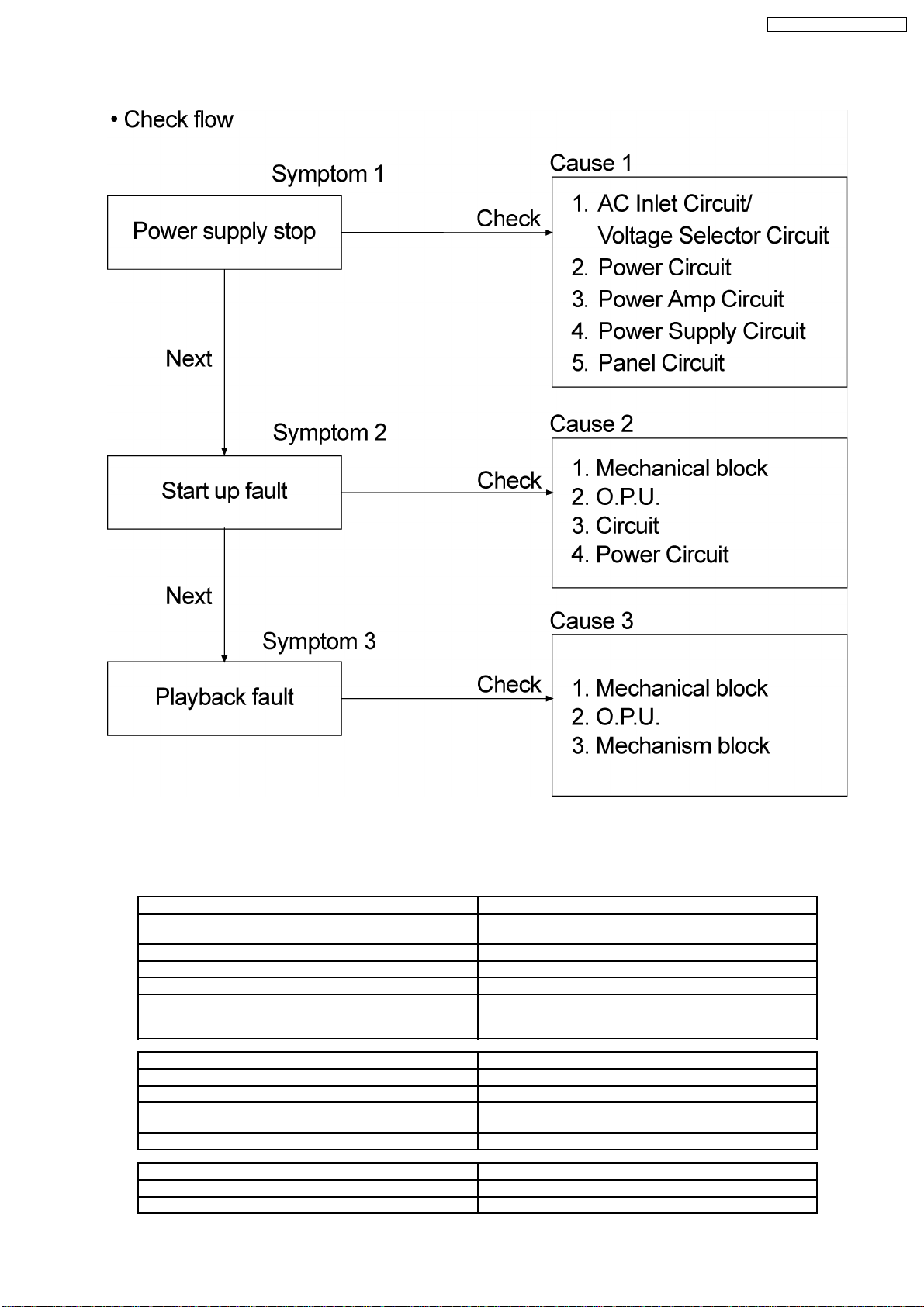

13.1. Distinguish the trouble cause

SA-VK61DGC / SA-VK61DGCS

How to distinguish the trouble

1. View mechanical part if visual damage occurred.

Confirm the movement of mechanical parts assembly

(tray ass’y, loading mechanism ass’y, etc.).

Cause 1 Possible fault

1. AC Inlet Circuit/Voltage Selector Circuit Fuse Blow (F1,F2), Power Transformer Problem(T501,

2. Power Circuit Fuse Blow (F3, F4) FP951, FP950 open

3. Power Amp Circuit IC502 faulty

4. Power Supply Circuit IC500, IC501 faulty

5. Panel Circuit FL Display Problem (-VP → Q950 faulty/ FP951 open/ D961

Cause 2 Possible fault

1. Mechanical block Tray and loading mechanical block, traverse unit, deck unit

2. O.P.U. Refer to the diagnosis of OPU

3. Circuit IC307 faulty (check for pin 31, 32)

4. Power circuit Refer to Cause 1

Cause 3 Possible fault

1. Mechanical block Traverse block (Tilt adjustment)

2. O.P.U. Refer to the diagnosis of OPU

2. Diagnose if Optical Pickup Unit is faulty (refer to

diagnosis of Optical Pickup Unit).

3. If mechanism and OPU are OK, it is P.C.B.

T502), Wrong Selection of Selector (S501)

faulty)

SVS6V to Micro-P (Q951/ D965 faulty) Problem

IC701 faulty (check for pin 2, 23)

17

Page 18

SA-VK61DGC / SA-VK61DGCS

3. DVD Module (1) Circuit IC2501 (Tracking - pin 11 & 12)

4. Main Circuit IC50 faulty (pin 17, 19, 21, 22, 24, 25 & 32 to JK302/JK301)

Cause 3 Possible fault

IC2501 (Focus - pin 13 & 14)

IC2501 (spindle motor - pin 17, 18)

IC2501 ( Traverse motor - pin 15, 16)

FG unit (pin 1, 2 at FP5102)

IC3001, Video Problem (pin 158 (Y/PY/G), pin 160

(CB/PB/B), pin 161 (CR/PR/R), pin 163 (Y) and pin 164 (C))

JK301 & JK302 faulty

IC700 (DSP IC) faulty (ckeck for pin 65, 69, 11, 14)

18

Page 19

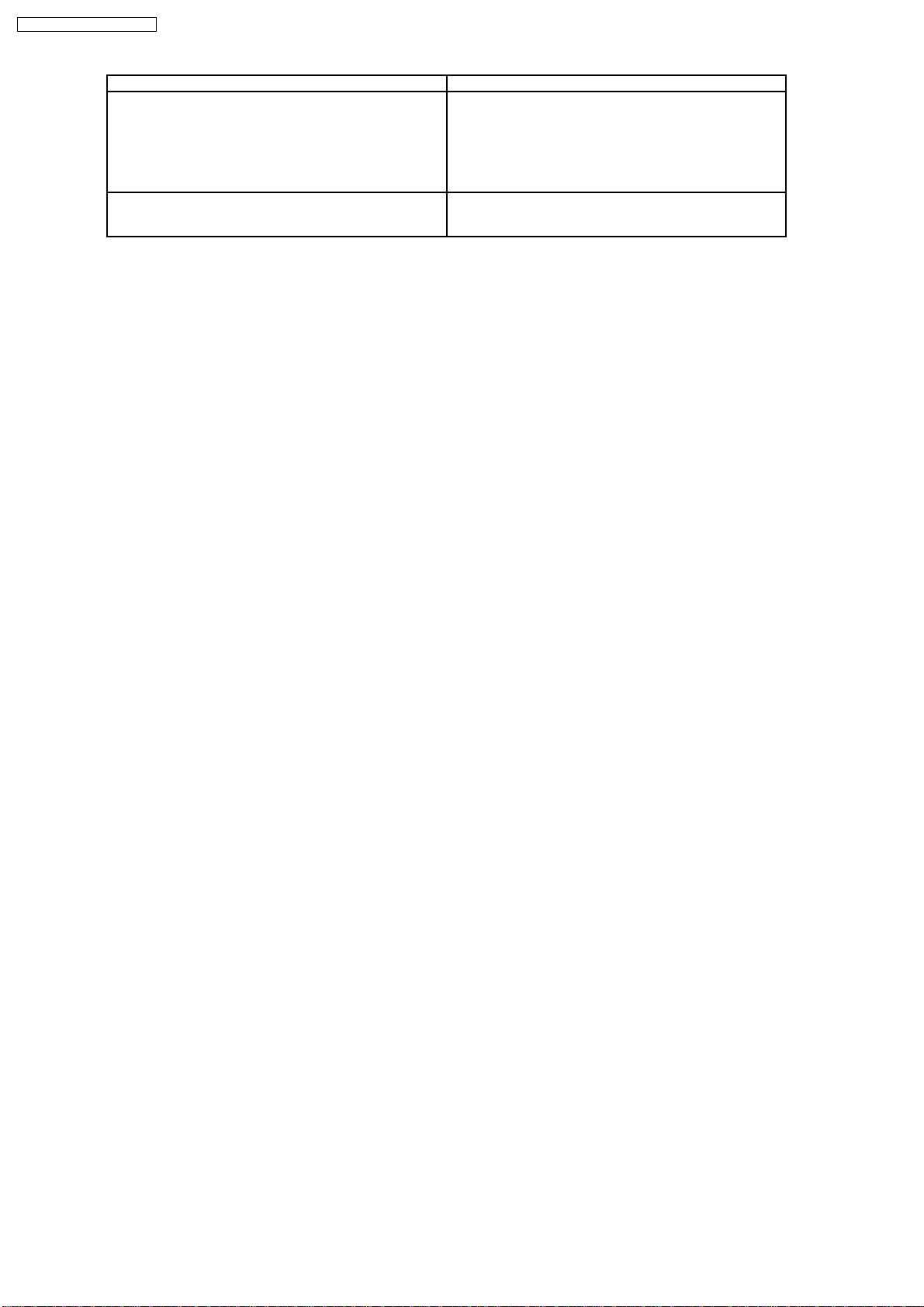

13.2. Diagnosis of Optical Pick-up Unit

SA-VK61DGC / SA-VK61DGCS

How to distinguish Laser destruction/damage

Confirmation 1

Remove cover of mechanism block so that you will see the lens of optical pickup.

Confirm emission of laser at the moment when power switch is turned on.

If there is no laser emission, laser diode is faulty.

Confirmation 2

19

Page 20

SA-VK61DGC / SA-VK61DGCS

While pressing & hold “Stop” button on main unit, press “Display” button on the remote controller. Unit display laser current on

FL.

From the reading of display, you can judge if laser diode is damaged or not.

Reading on the right side should be less than 70. If reading is more than 70, laser is damaged.

How to confirm if Optical Pickup is OK

Confirmation 1

1. Confirmation of jitter value with test disc. (Refer below for how to check jitter)

2. Lens cleaning.

3. Reconfirm jitter value.

4. Perform tile adjustment. (Refer to tilt adjustment)

5. Reconfirm jitter value. (To confirm jittervalue, while pressing & hold “Stop” button on main unit, press numeric “5” on remote

controller.)

Unit display jitter value on FL.

Confirmation 2

If servo is very unstable due to optical error and you cannot confirm jitter value, clean the lens and check appearance of pick

up unit (cutting coil of actuator, etc), then check circuitry.

20

Page 21

SA-VK61DGC / SA-VK61DGCS

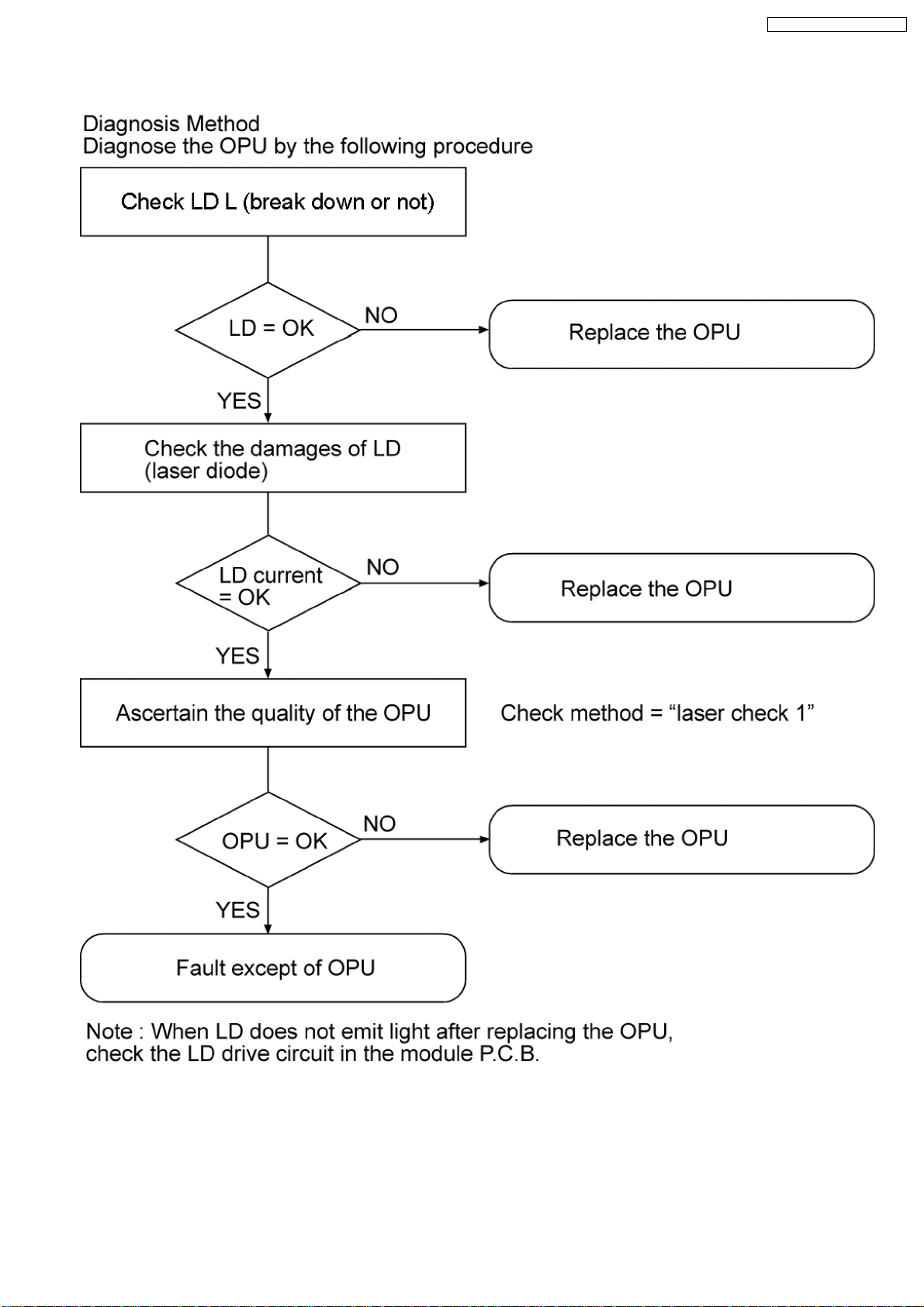

14 Optical Pickup Self-Diagn osis and Replacem ent

Procedure

14.1. Self-diagnosis

This unit is equipped with the optical pickup self-diagnosis function and the tilt adjustment check function. Follow the procedure

described below during repair in order to perform self-diagnosis and tilt adjustment effectively. Especially when “NO DISC” is

displayed, be sure to apply the self-diagnosis function before replacing with an optical pickup. Replacement of optical pickup

generally requires when the present value of laser drive exceeds 45 (DVD) or 45 (CD).

Note:

Start diagnosis within three minutes after turning on the power (as diagnosis fails when the unit becomes warm).

21

Page 22

SA-VK61DGC / SA-VK61DGCS

14.2. Cautions to Be Taken During Replacement of Optical Pickup and

Spindle Motor

Before replacing the optical pickup and spindle motor, check a total usage time respectively. Follow the checking method described

below.

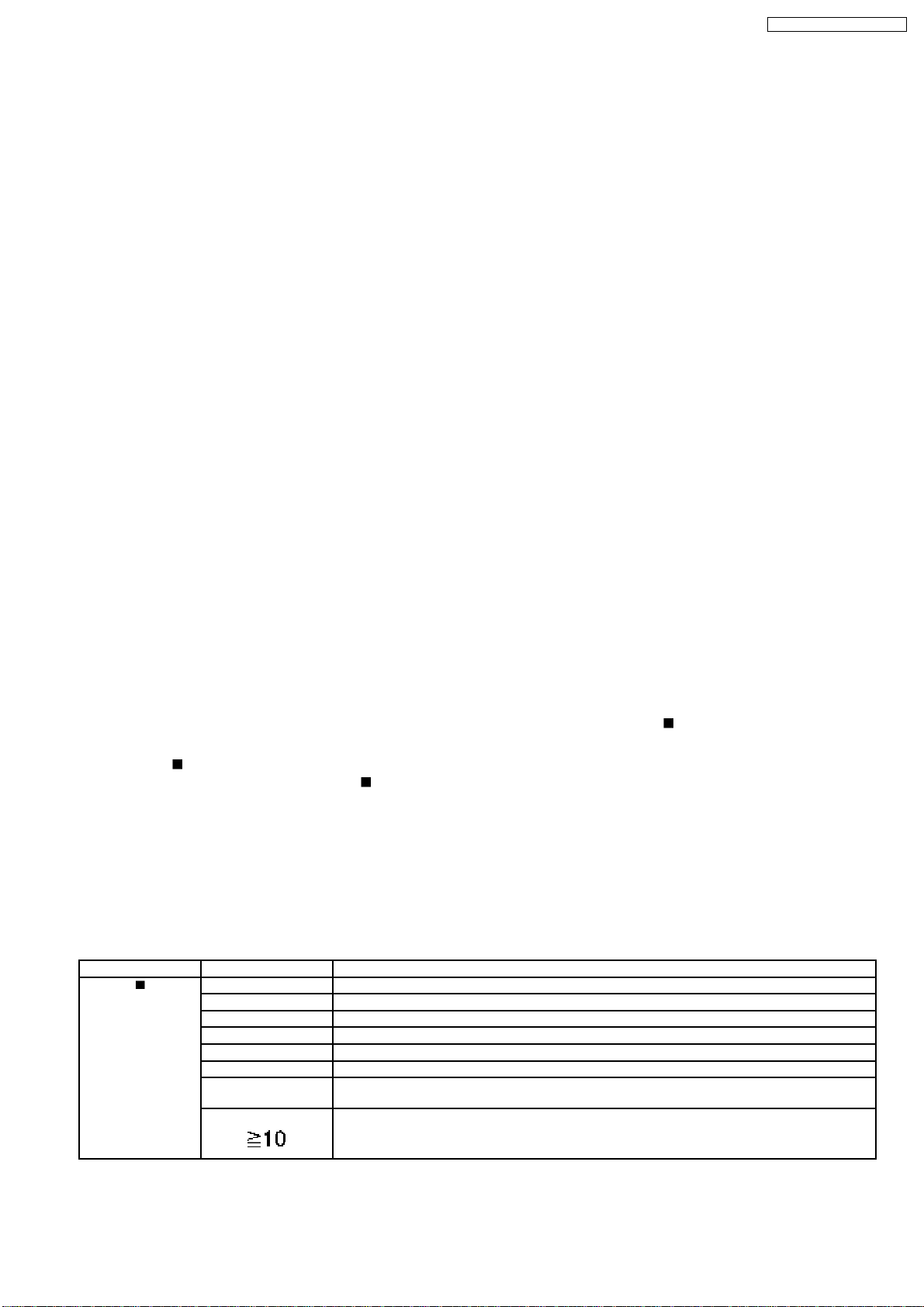

Item Status and Key Function Display

Checking DVD, CD laser usage time With the unit stopped and no disc inserted,

press the.

button on the remote controller unit.

Checking spindle motor usage time With the unit stopped and no disc inserted,

press the

button on the remote controller unit.

Resetting DVD, CD laser usage time While the DVD and CD laser usage times are

displayed, press the

and the

unit.

Resetting spindle motor usage time While the spindle motor usage time is

displayed, press the

and the

unit.

button on the player and the

button on the player and the

button on the player

button on the remote controller

button on the player

button on the remote controller

14.2.1. Cautions to be taken during replacement of optical pickup

Optical pickup could be damaged due to the static electricity discharged from human body. Wear proper protection gear against

static electricity during optical pickup and its peripheral repair. (Refer to “Cautions to Be Taken When Handling Optical Pickup”.)

· Do not touch laser diode, actuator and their peripherals.

· Do not check laser diode with a tester and such. (The tester will be destroyed.)

· For short-circuiting or removing laser diode, the use of an anti-static soldering iron is recommended. (Recommended model:

HAKKO ESD product)

· Solder the land of the flexible cable in the optical pickup.

Note:

If an anti-static soldering iron is not available, short-circuit the terminal surface of the flexible cable and then the land using a

clip or equivalent device.

T1_xxxx_yyyy

xxxx(DVD), yyyy(CD): total time is displayed with a

four-digit number by the ten hours.

T2_xxxxx

xxxxx: total time is displayed with a four-digit

number by the ten hours.

T1_0000_0000

T2_0000

22

Page 23

SA-VK61DGC / SA-VK61DGCS

15 Self-Diagnosis Function

This unit is equipped with the self-diagnosis function, which displays an error when it occurs, for use during servicing.

15.1. Automatic Displayed Error Codes

15.1.1. Automatic Display Function

For a power unit error, the code is automatically displayed.

F61: Automatically displayed on the LCD of the player.

15.1.2. Re-Display

· For F61 Display

−

− When the code, F61 is displayed, the power is automatically turned off.

− −

−

− The code, F61 is displayed for three seconds, and then the current time appears.

− −

−

− To retrieve the code, turn on the power button so that the code F61 appears, however, is switched to time display after three

− −

seconds, and the power is automatically turned off.

· For F76 Display

−

− The abnormalities is an output or the abnormalities in a power supply of POWER AMP.

− −

15.1.3. Description of Error Code

15.1.3.1. F61

· State, Condition

When the power is turned on, the unit is automatically turned off. The power does not turn on.

· Cause, Troubleshooting

Power circuit system failure and/or direct current flown to speaker terminal

Identify the cause and replace with new parts.

15.2. Memorized Error Codes

15.2.1. Activating Self-Diagnosis Function and Displaying Method

1. Turn on the power.

2. Select DVD/CD function. With no DVD/CD inserted in the player, press and hold down the

and press the “0” button on the remote control for at least two seconds in order to display “DVD_F_ _ _ ”.

3. Press the

If several errors are detected, press the

button. If a memorized error is detected, the result of self diagnosis is displayed. (Ex.: T H15)

button to display each.

button for at least two seconds,

15.2.2. Re-Display

· Press the power button to turn off the power, and then turn on the power.

· The details of self diagnosis are stored in the unit memo ry.

To retrieve them, follow the procedure described the above, “Activating Self-Diagnosis Function and Displaying Method”.

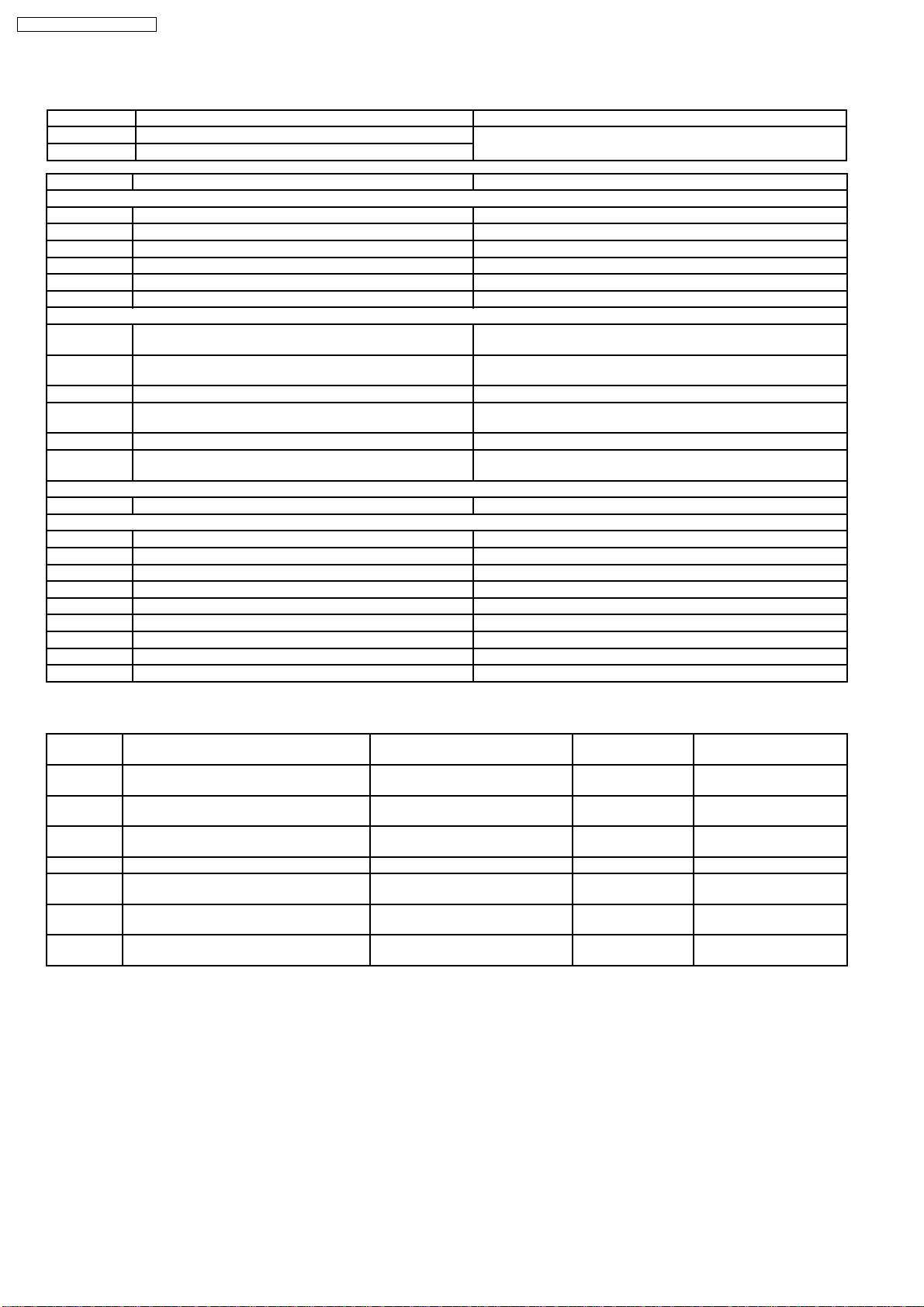

15.3. Mode Table 1

Following modes are available with combinations of the pressed buttons on the player and on the remote controller unit.

Player Remote Controller Unit Usage

button

0 Error code display (Refer to the Item 15.4. DVD Error Code Description)

5 Tilt adjustment (Jitter)

6 Region number and broadcasting system check

8 Bulit-in program version check (Micro-P)

DISPLAY DVD laser drive current check

3 CD laser drive current check

PAUSE Writing of laser drive current value after replacement of optical pickup

(Do use this function only when optical pickup is replaced.)

Initialization of the player (factory setting is restored.)

Used after replacement of micro-computer and its peripherals and printed circuit board.

23

Page 24

SA-VK61DGC / SA-VK61DGCS

15.4. DVD/CD Self-Diagnosis Error Code Description

Error Code State, Conditon Cause, Troubleshooting

H15 The disc tray cannot be opened: it closes spontaneously. Disc tray open/close detection switch (S1001) failure.

H16 The disc tray cannot be closed: it opens spontaneously.

Error Code Meaning Details

U. H. Error

U11 Focus servo failure

H01 Tray loading failure

H02 Spindle servo failure (Spindle servo, DSC, SP motor, CLV servo failure)

H03 Traverse motor failure

H04 Tracking servo error

H05 Seek timeout failure

DSC system

F500 DSC failure DSC stops due to servo failure.

F501 DSC not Ready failure Communication failure between DSC and system computer

F502 DSC Time out failure See F500.

F503 DSC communication failure Communication failure (Result failure occurs after communication

F505 DSC Attention Error See F500.

F506 Invalid media Disc is placed upside down; TOC is unreadable or invalid disc is

Disc Code

F103 Ilegal highlight position Disc standard is possibly illegal when highlight is displayed.

IIC Error

F4FF Forced initialization failure (Time out)

F880 Unsuitable task number When a message arrives from not existing task

F890 A message is sent during AV task transmission During transmission of a message to AV task

F891 Unable to transmit a message to AV task When transmission of a message to AV task starts

F893 FROM altered

F894 EEPROM failure

F895 Firmware version compatibility problem

F897 Incomplete initialization

F8A0 Unsuitable message command When transmission of a message to AV task starts

(Check and replace)

(Startup, focus failure, etc.)

(No communication because DSC does not move)

command is transmitted.)

inserted.

15.5. Error Codes Stored During No Play

Error Code Meaning System Computer Item Setting Task Internal error in system

F0BF 6) Unable to replay due to physical layer

identification failure

F0C0 8) DVD: Unable to replay due to no DVD

Video/Audio/VR

F0C1 9) DVD: Prohibited due to illegal regional

code

F0C2 A) DVD: No replay due to PAL system PCND_NOPLAY_PAL 0x90 DiscManager 0xD0C2

F0C3 B) DVD: All title replay prohibited in parental

setting

F0C4 C) VCD: Prohibited due to PHOTO CD

format

F0C5 D) VCD/CD: Prohibited due to CD-ROM

without CD-DA

PCND_NOPLAY_PHYSICAL 0x50 DriveManager 0xD0BF

PCND_NOPLAY_VIDEO 0x70 DiscManager 0xD0C0

PCND_NOPLAY_RCD 0x80 DiscManager 0xD0C1

PCND_NOPLAY_PTL 0xA0 DiscManager 0xD0C3

PCND_NOPLAY_PHOTOCD 0xB0 DiscManager 0xD0C4

PCND_NOPLAY_CDROM 0xC0 DiscManager 0xD0C5

computer

15.6. Mode Table 2

Following modes are available with combinations of the pressed buttons on the player and on the remote controller unit.

24

Page 25

SA-VK61DGC / SA-VK61DGCS

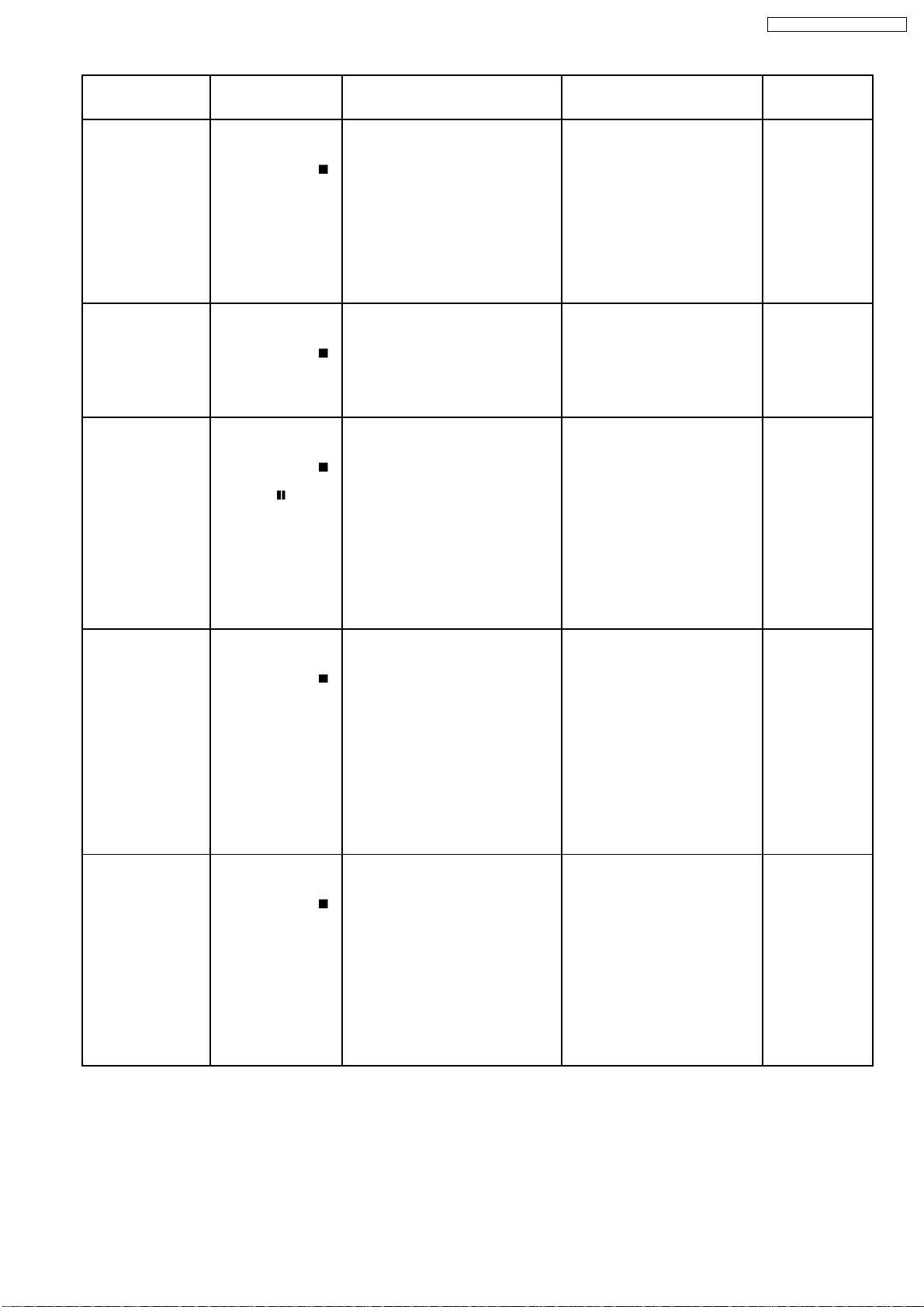

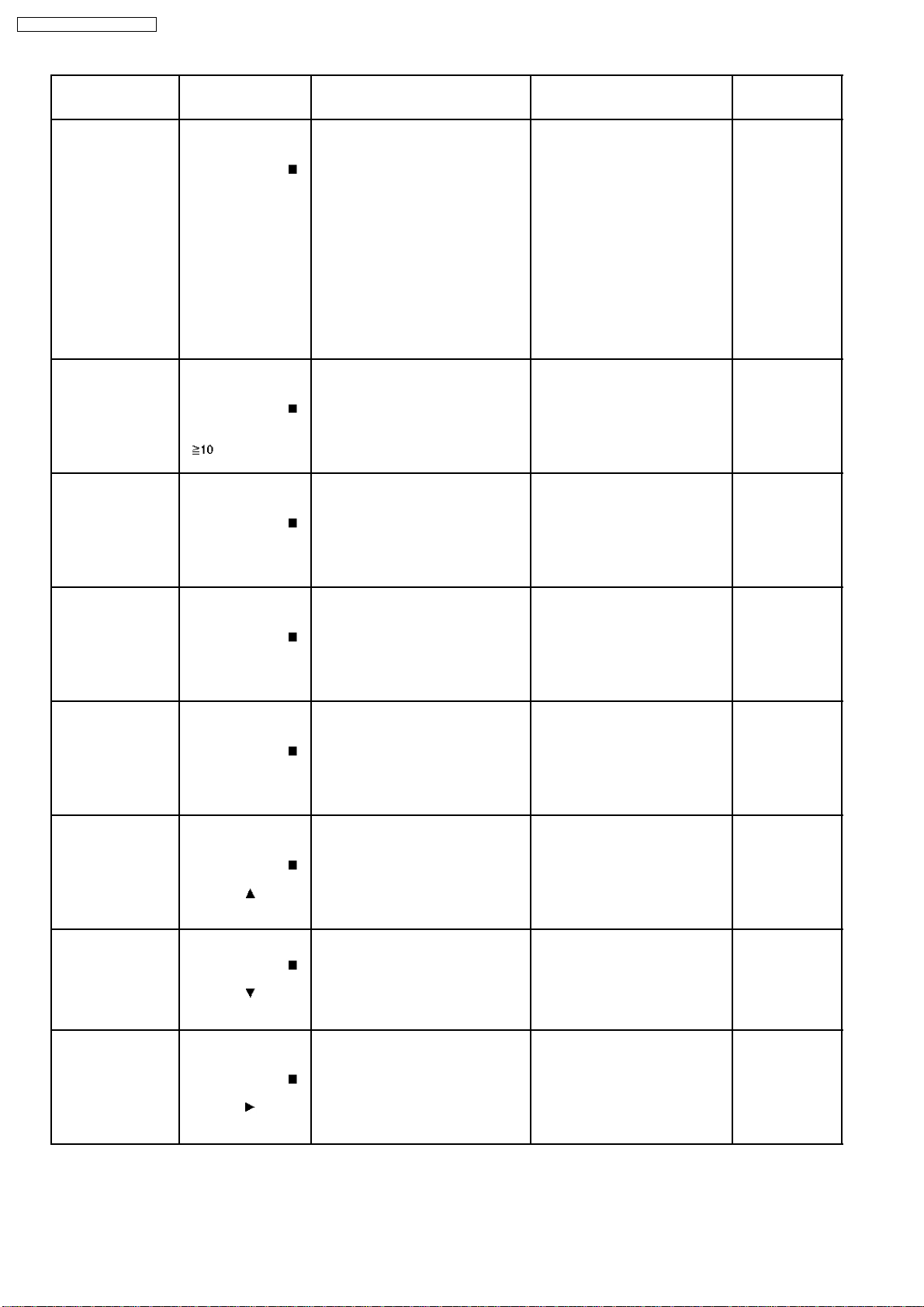

Item Operational

Condition and Key

Function

Jitter display While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the number

button, “5” on the

remote controller unit.

Error code display While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the number

button, “0” on the

remote controller unit.

Measurement of laser

current electricity

initialization value

While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the

button

on the remote

controller unit.

Details Display TO Exit Mode

Jitter display

Measures and displays jitter.

Measurement is repeated every

second. Read error counter starts at 0

at the mode setting, and increased by

one as data read fails at target block. A

small defect is allowed to correct by

retry. Any possibility is counted as one

increment. Repetitive errors after retry

increase by two levels or more.

Error code display

Displays the latest error code stored in

EEPROM.

Measurement of laser current

electricity initialization value

Memorizes each initialization value of

DVD and CD in EEPROM.

J*1xxx*2_yyy*3_zz

*1

: Jitter display mode

*2

: Jitter measurement value

*3

: Read error counter

*4

: Focus driving value

*4

Values are shown to one decimal

place in the decimal digit.Focus

driving value is displayed in the

hexadecimal digit.

DVDnn_F---

*nn: Error history

*--: Error number

DVD 01 FOBF

LDO*1_013*2_032

*1

: Laser current electricity

measurement mode

*2

: DVD current electricity value

*3

: CD current electricity value

*3

Press the STOP or

OPEN button.

Press the OPEN

button.

Automatically exits

the mode after five

seconds.

Measurement of DVD

laser current electricity

ADSC internal RAM

display

While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the DISPLAY

button on the remote

controller unit.

While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the number button

“1” or “2” on the remote

controller unit.

Measurement of DVD laser current

electricity

Measures DVD laser current electricity

and displays the result together with

the initialization value stored in

EEPROM. After measurement, DVD

laser is lit till the power is turned off (or

goes off when the primary power is

turned off).

ADSC internal RAM display

Reads and displays the RAM value

inside ADSC. The address is renewed

when the CLEAR key is pressed so

that the values at eleven points appear.

Values are shown in the decimal

digit. The above example indicates

that the current electricity

initialization value is 13mA at DVD

laser and 32mA at CD laser when

laser is turned on.

LDD*1_012*2_014

*1

: DVD laser current electricity

measurement mode

*2

: Current electricity initialization

value stored in EEPROM

*3

: Present value of current

*3

electricity

Values are shown in the decimal

digit. The above example indicates

that the current electricity

initialization value is 12mA and its

present value is 14mA.

A*1_FB0*2_0000

*1

:ADSC internal RAM display

mode

*2

: Address

*3

: RAM value at displayed

*3

address

Automatically exits

the mode after five

seconds.

Press the STOP or

OPEN button.

25

Values are shown in the

hexadecimal digit. The above

example indicates that ADSC

value at the address, FB0h is

0000h.

Page 26

SA-VK61DGC / SA-VK61DGCS

Item Operational

Condition and Key

Function

Measurement of CD

laser current electricity

While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the number button

“3” on the remote

controller unit.

User initialization While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the number button

on the remote

controller unit.

Region display While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the number

button, “6” on the

remote controller unit.

Firmware version

display

While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the number

button, “7” on the

remote controller unit.

Region and firmware

display

While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the number

button, “8” on the

remote controller unit.

Laser use time While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the

button

on the remote

controller unit.

Reset laser use time While the usage time 1

is displayed, press and

hold down the

button on the player

and the

button

on the remote

controller unit.

Spindle use time While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the

button

on the remote

controller unit.

Details Display TO Exit Mode

Measurement of CD laser current

electricity

Measures CD laser current electricity

and displays the result together with

the initialization value stored in

EEPROM. After measurement, CD

laser is lit till the power is turned off (or

goes off when the primary power is

LDC*1_032*2_032

*1

: CD laser current electricity

measurement mode

*2

: Current electricity initialization

value stored in EEPROM

*3

: Present value of current

electricity

turned off).

Values are shown in the decimal

digit. The above example indicates

the current electricity initialization

value is 28mA and its present

value is 26mA when laser is turned

on.

User initialization

“INITIALIZE” The user setting recovers the factory

setting.

Region display [srrrxxyzzzz]

s : Panecon model type

rrr : Panecon release number

x : Syscon generation (45)

y: Syscon model type

zzz: Syscon release number

Firmware version display rrr*1_xx*2y*3zzz

*1

: Panel computer release number

*2

: System computer generation

*3

: System computer model type

*4

: System computer release

number

Region and firmware version display _r*1__xx*2y*3zzz

*1

: Region number

*2

: System computer generation

*3

: System computer model type

*4

: System computer release

number

Laser usage time

T1_1234_5678

Measures each for DVD and CD

respectively.

The numbers in the left show

usage time for DVD laser and

those in the right for CD laser. The

four-digit number is shown by the

ten hours in the decimal digit. The

number after 0000 is 9999.

Laser usage time reset

T1_0000_0000 Automatically exits

Resets both for DVD and CD at once.

Spindle motor usage time T2_12345

The four-digit number is shown by

the ten hours in the decimal digit.

The number after 00000 is 99999.

*3

Automatically exits

the mode after five

seconds.

Automatically exits

the mode after five

seconds.

*4

Automatically exits

the mode after five

seconds.

*4

Automatically exits

the mode after five

seconds.

Automatically exits

the mode after five

seconds.

the mode after five

seconds.

Automatically exits

the mode after five

seconds.

26

Page 27

SA-VK61DGC / SA-VK61DGCS

Item Operational

Reset spindle use

time

Communication error

display

Condition and Key

Function

While the usage time 2

is displayed, press and

hold down the

button on the player

and the

on the remote

controller unit.

While the player is

stopped and no disc is

inserted, press and

hold down the

button on the player

and the MENU button

on the remote

controller unit.

button

Usage time 2 reset

Spindle motor usage time

Displays frequency of communication

errors between system computer firm

IC and mechanical computer IC during

DVD module.

Details Display TO Exit Mode

T2_00000 Automatically exits

the mode after five

seconds.

ERR_00/30 Automatically exits

the mode after five

seconds.

15.7. Tray Lock Function

15.7.1. Setting

· Disc Lock Function

1. With the SELECTOR on DVD/CD and POWER ON, hold down the [

[POWER] KEY on the remote control for 3 seconds to enter to Lock mode A.[_ _ _LOCKED_] will be displayed for 3

seconds, and then current disc will begin playing.

2. In Lock mode A, the following key is disabled.

[OPEN/CLOSE]

· Operation Lock Function

1. With the SELECTOR on DVD/CD and POWE R ON, hold down the [CD PLAY] KEY on the main unit, and then press the

[POWER] KEY on the remote control for 3 seconds to enter Lock mode B.

[_ _ _ LOCKED_] will be displayed for 3 seconds, and the current disc will begin playing.

2. Lock mode B primarily controls the selector and disc operations, and disenables for the following keys.

Note:

OPEN/CLOSE

· Prohibiting operation of selector and disk

button are invalid and the player displays “___LOCKED_” while the lock function mode is entered.

1. Select the DVD/CD function.

2. Press and hold down the

button on the player and the power button on the remote controller unit for at least three

seconds. (The message, “___LOCKED_” appears when the function is activated.)

Note:

The following buttons are invalid and the player displays “___LOCKED_” while the lock function mode is entered.

STOP] KEY on the main unit, and then press the

15.8. Things to Do After Repair

Follow the procedure described below after repair.

1. While the power is on, press the

2. Press the power button to turn off the power.

3. Unplug the power cable.

Note:

It is prohibited to unplug the power cable while the tray is opened and to close the tray manually.

button to close the tray.

27

Page 28

SA-VK61DGC / SA-VK61DGCS

16 Cautions To Be Taken During Servicing

16.1. Recovery after the dvd player is repaired

· When Flash ROM or module(2) P.C.B. is replaced, carry out the recovery processing to optimize the drive. Playback the

recovery disc to process the recovery automatically.

· Recovery disc (Product number=RFKZD03R004)

· Performing recovery

1. Load the recovery disc (Product number: RFKZD03R004) to the player and run it.

2. Recovery is performed automatically. When it is finished, a message appears on the screen.

3. Remove the recovery disc.

4. Turn off the power.

Note:

This unit requires no initialization process carried out after the traditional DVD players were repaired. When the recovery

measures are taken, the customer setting will return to the factory setting as same as the procedure described in item

“Initialization” in 9.6 is carried out. Write down the contents of the setting before recovery processing, and reset the player.

16.2. DVD Player Firmware Version Upgrade Process

Firmware of DVD player may upgrade to conform to improvement of its performance and quality including operational range,

playability of non-standardized discs, etc. The version upgrade disc contains the recovery function, and the recovery disc is not

necessary.

Note:

Version upgrade process cannot be complete if the AC power is cut off due to power failure and other occasions during the

process. If this occurs, replace FLASH ROM and restart version upgrade. Version upgrade disc number is informed when

ordered.

16.3. Firmware Version Upgrade Process by Using Disc and Recovery

Process

· Recovery process

· Firmware version upgrade process

Both of the above procedures automatically start when the recovery disc is replayed.General CD-R disc allows version upgrade

process and recovery process, making version upgrade through disc simple.

Recovery process: Optimization process of player after replacement of FLASH ROM, EEPROM, or module circuit board

Version upgrade process: Renewal of firmware for improvement of operational range and performance

16.3.1. Self-Diagnosis Function

· Total usage time display (spindle motor, DVD/CD laser)

· ADSC internal RAM display

· Others: Last error count......20 items

Efficiency of failure diagnosis is expected to improve by using the above functions together with the repair process.

[Purpose of Use]

Total usage time display: used for estimating a failure due to exhausted spindle motor, laser, or other parts.

ADSC internal RAM display: used for deciding servo system failure according to servo learning values.

16.4. Using Recovery Disc

16.4.1. Recovery Process

1. Insert the recovery disc (RFKZD03R004) to the player to replay.

2. The recovery process automatically starts, and a message of completion prompts on the screen.

3. Remove the disc.

4. Turn off the power.

16.4.2. Version Upgrade Process

1. Insert the recovery disc to the player to replay.

28

Page 29

SA-VK61DGC / SA-VK61DGCS

2. The version of player is automatically checked and prompts if necessary.

3. Select version upgrade process using the cursor keys on the remote controller unit. (Select YES or NO)

4. a. If YES is selected, the process starts.

b. If NO is selected, only the recovery process is applied.

5. a. When the version upgrade proces s is complete, a message of completion appears on the screen. Remove the disc.

b. Follow the instruction appearing on the screen, and remove the disc.

6. Turn off the power.

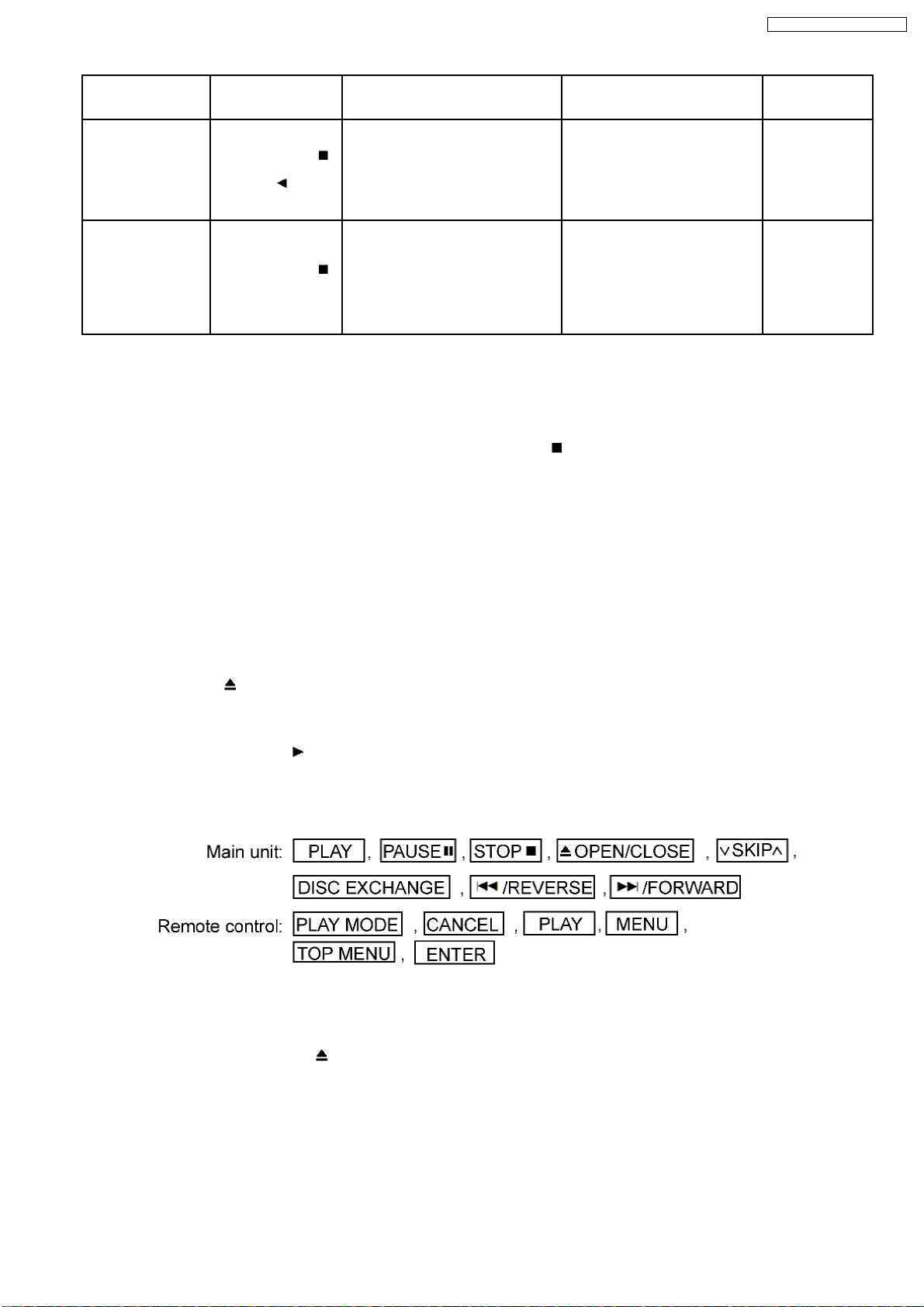

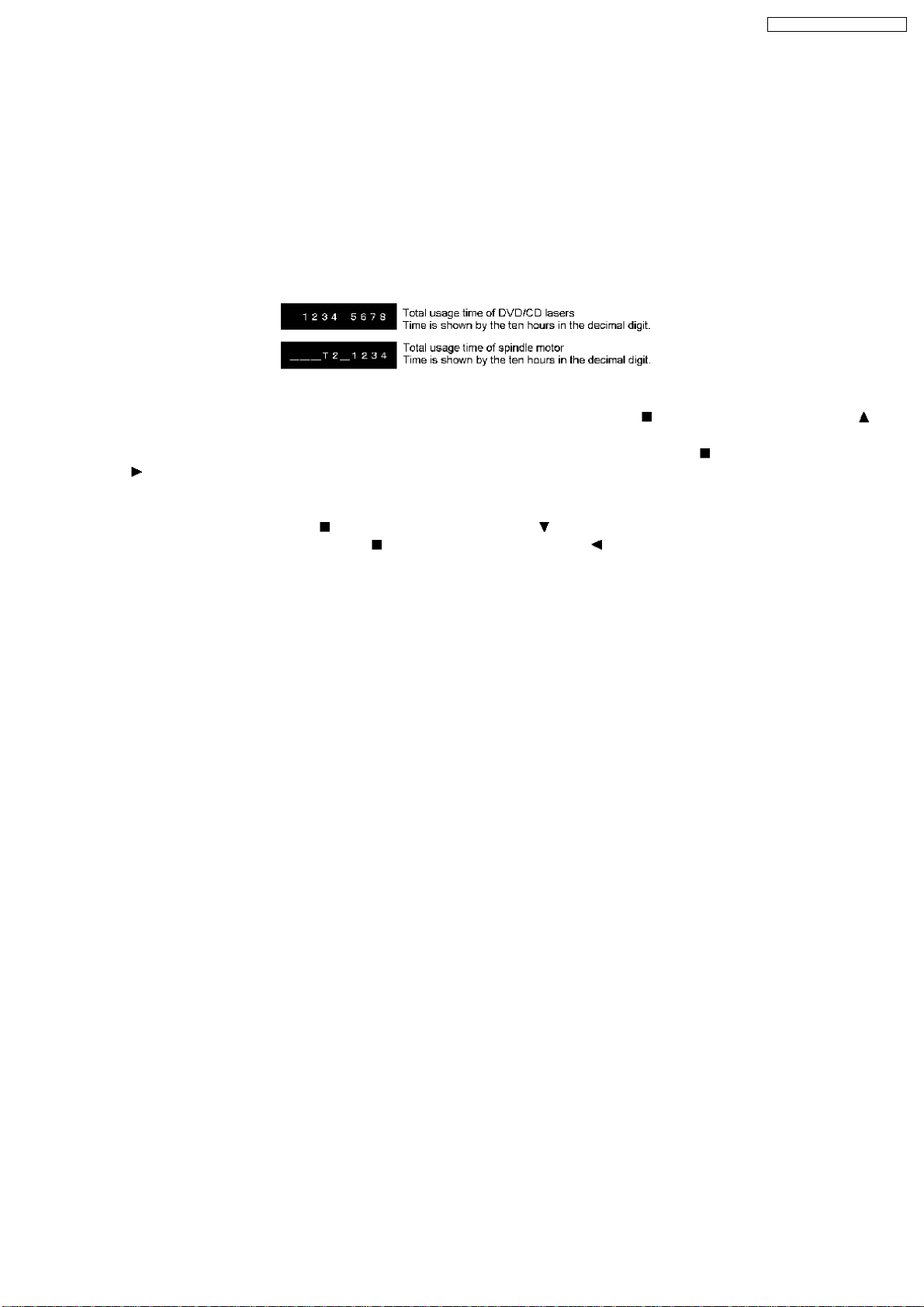

16.5. Total Usage Time Display

1. Details of Operation/Display

Keys for Operation:

Laser usage time: While the player is stopped and no disc is inserted, press both the

button on the remote controller unit.

Spindle motor usage time: While the player is stopped and no disc is inserted, press both the

the

button on the remote controller unit.

button on the player and the

button on the player and

To reset the usage time, while the usage time is displayed:

Laser usage time: press both the

Spindle motor usage time: press both the

2. Purpose of Use

To obtain reference data of laser and spindle motor systems during failure diagnosis.

To check faulty parts during re-repair.

button on the player and the button on the remote controller unit.

button on the player and the button on the remote controller unit.

29

Page 30

SA-VK61DGC / SA-VK61DGCS

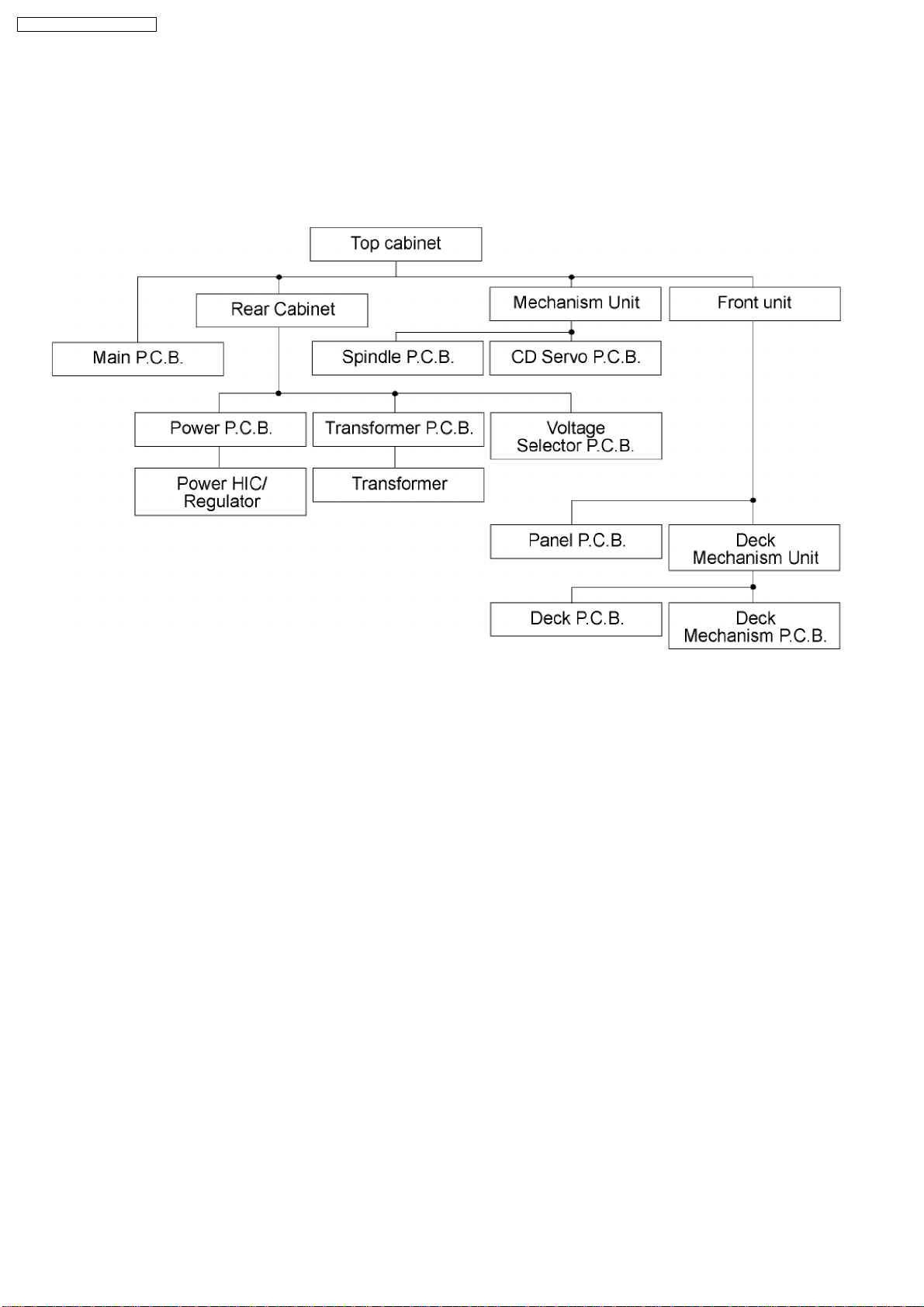

17 Disassem bly and Assembly of Main Component

17.1. Disassembly flow chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the

servicing.

To assemble the unit, reverse the steps shown in the chart as below.

30

Page 31

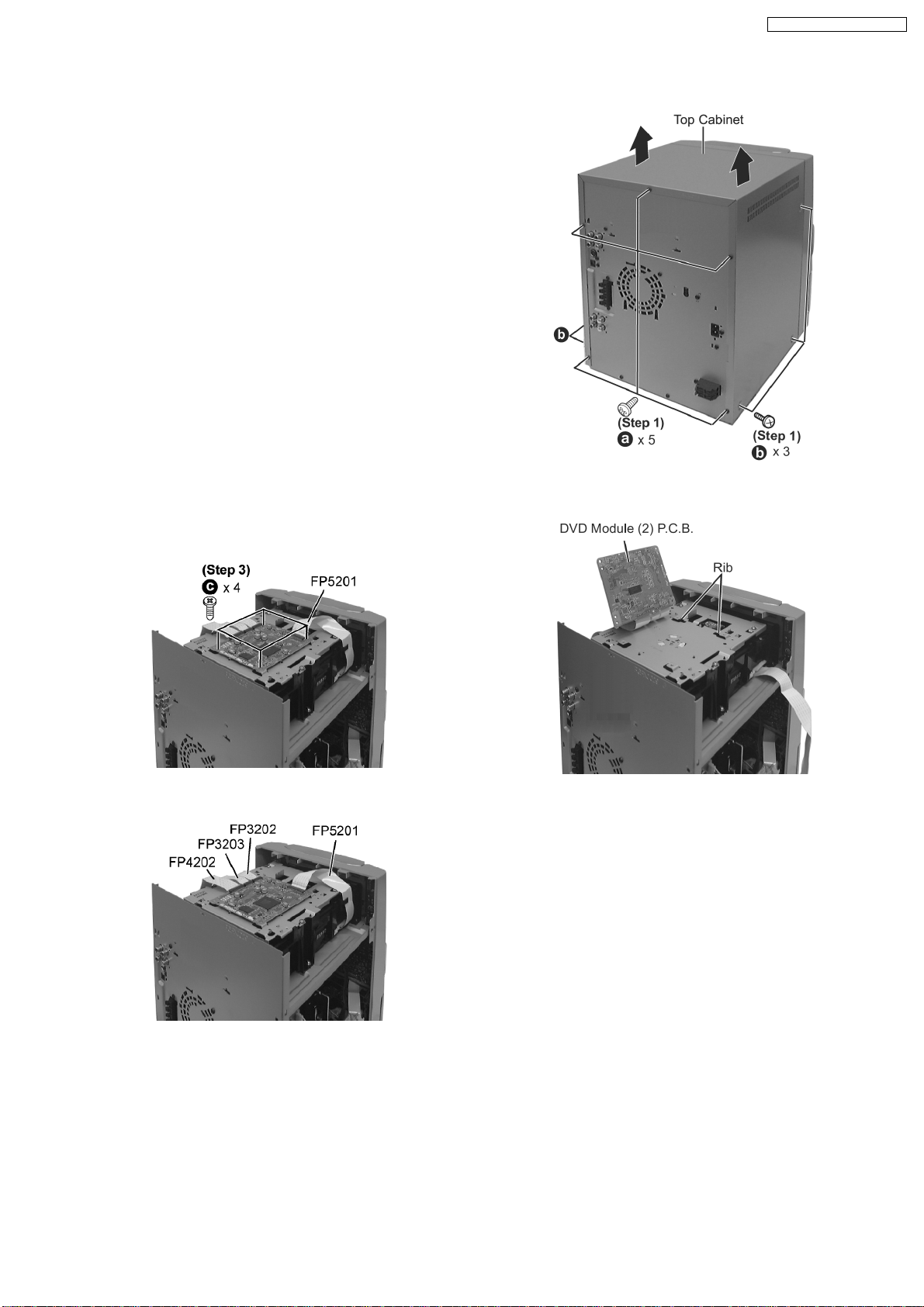

17.2. Disassembly of Top Cabinet

Step 1 Remove 3 screws each side and 5 screws at rear panel.

Step 2 Lift up both sides of cabinet ass’y, push the cabinet

ass’y toward the rear and remove the top cabinet.

SA-VK61DGC / SA-VK61DGCS

17.3. Disassembly of DVD Module (2) P.C.B.

· Follow the (Step 1) - (Step 2) of Item 17.2.

Step 1 Remove 4 screws.

Step 2 Detach FFC boards (FP5201, FP3202, FP3203 &

FP4202).

Step 3 Lift up DVD Module (2) P.C.B. as shown to remove it.

17.4. Disassembly for the Top Ornament Unit

(The DVD changer unit can be removed after the Top

Ornament Unit is removed)

· Follow the (Step 1) - (Step 2) of Item 17.2.

When opening the disc tray automatically (Using Power

Supply)

Step 1 Connect the AC power cord.

Step 2 Press the power button to power up the main unit.

Step 3 Press the OPEN/CLOSE button, the disc tray will be

open automatically.

31

Page 32

SA-VK61DGC / SA-VK61DGCS

Step 4 Release the 2 claws, and then remove the Top

Ornament Unit.

Step 1 Insert the gear tool into the hole on the underside of

changer chasis and then rotate in the direction of arrow. The

disc tray will be open.

Step 2 Release the 2 claws, and then remove the CD lid cover.

Step 5 Press the OPEN/CLOSE button, the disc tray will be

close.

[Open the disc tray manually (Using service tools)]

Step 3 Repeat Step 1 but rotate in anti-clockwise direction.

32

Page 33

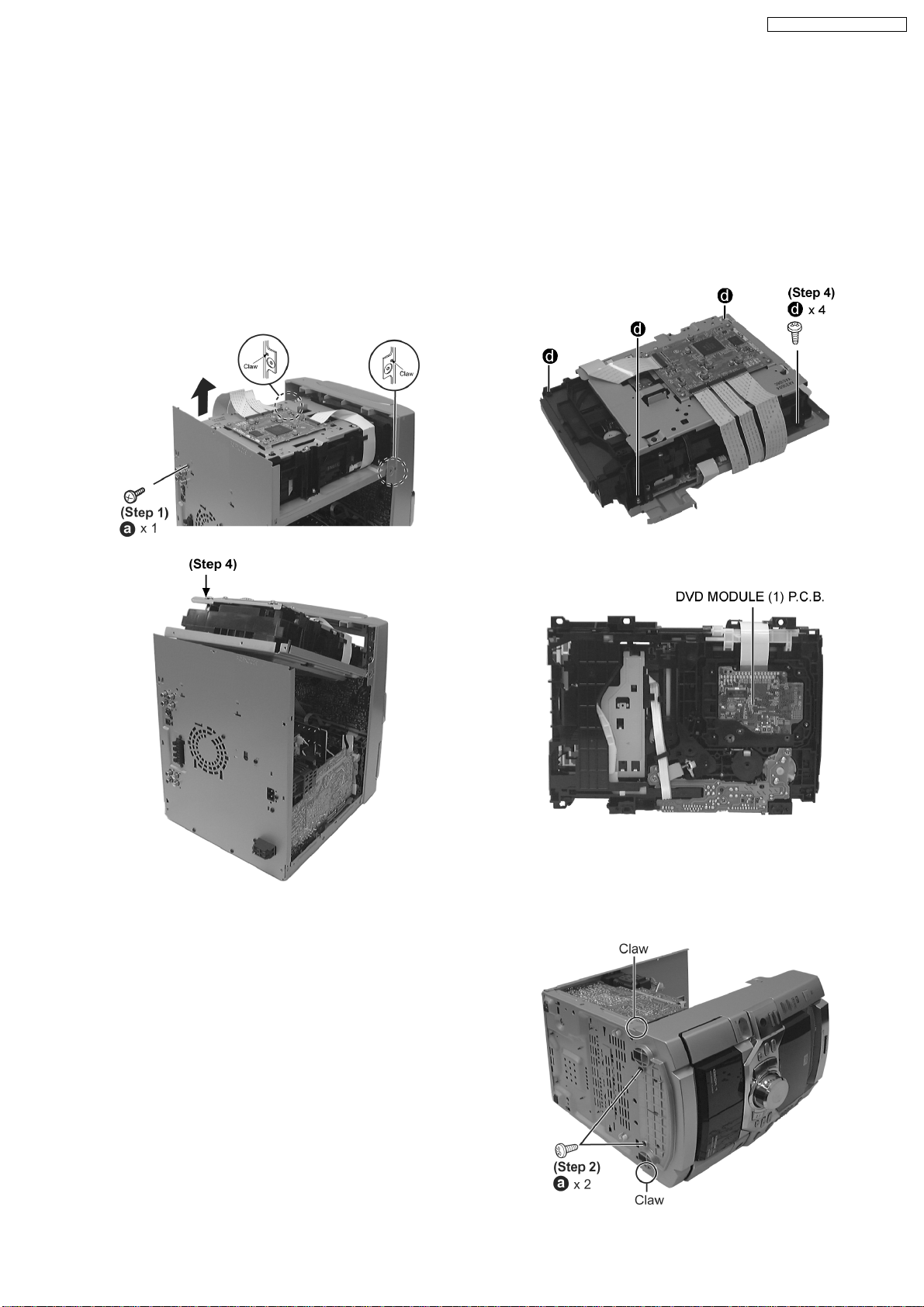

17.5. Disassembly for DVD changer unit

· Follow the (Step 1) - (Step 2) of Item 17.2.

· Follow the Disassembly for the Top Ornament Unit of Item

17.4.

Step 1 Detach FFC Boards (FP5201, FP3202, FP3203 &

FP4202).

Step 2 Remove 1 screw at rear cabinet as show below.

Step 3 Lift up the mechanism unit cover, and then push in the

mechanism unit cover.

Step 4 Release the claws of both ends, and then lift up the

DVD changer unit.

SA-VK61DGC / SA-VK61DGCS

17.5.1. Disassembly of the DVD Module

(1) P.C.B.

· Follow the (Step 1) - (Step 2) of Item 17.2.

· Follow the Disassembly for the Top Ornament Unit of Item

17.4.

· Follow the (Step 1) - (Step 4) of Item 17.5.

Step 1 Remove 4 screws.

Step 2 Remove the mechanism unit cover.

Step 3 Lay the unit.

Step 4 Connect the FFCs board from DVD Module (1) P.C.B..

17.6. Disassembly for Panel P.C.B., LED P.C.B. & Tact Switch P.C.B.

· Follow the (Step 1) - (Step 2) of Item 17.2.

· Follow the Disassembly for the Top Ornament Unit of Item

17.4.

Step 1 Lay the unit as shown below.

33

Page 34

SA-VK61DGC / SA-VK61DGCS

Step 2 Remove 2 screws at bottom chassis.

Step 3 Release the 2 claws, and then draw the front panel

ass’y forward.

· Disassembly of Panel P.C.B.

Step 4 Remove the 8 screws.

Step 5 Disconnect FFC board (CN601 & CN602).

Step 6 Draw the Panel P.C.B. forward to remove it.

· Disassembly of Tact Switch P.C.B. & LED P.C.B.

Step 7 Remove the volume knob.

Step 8 Disconnect connector W601B.

Step 9 Remove 6 screws.

Step 10 Draw Tact Switch P.C.B. forward.

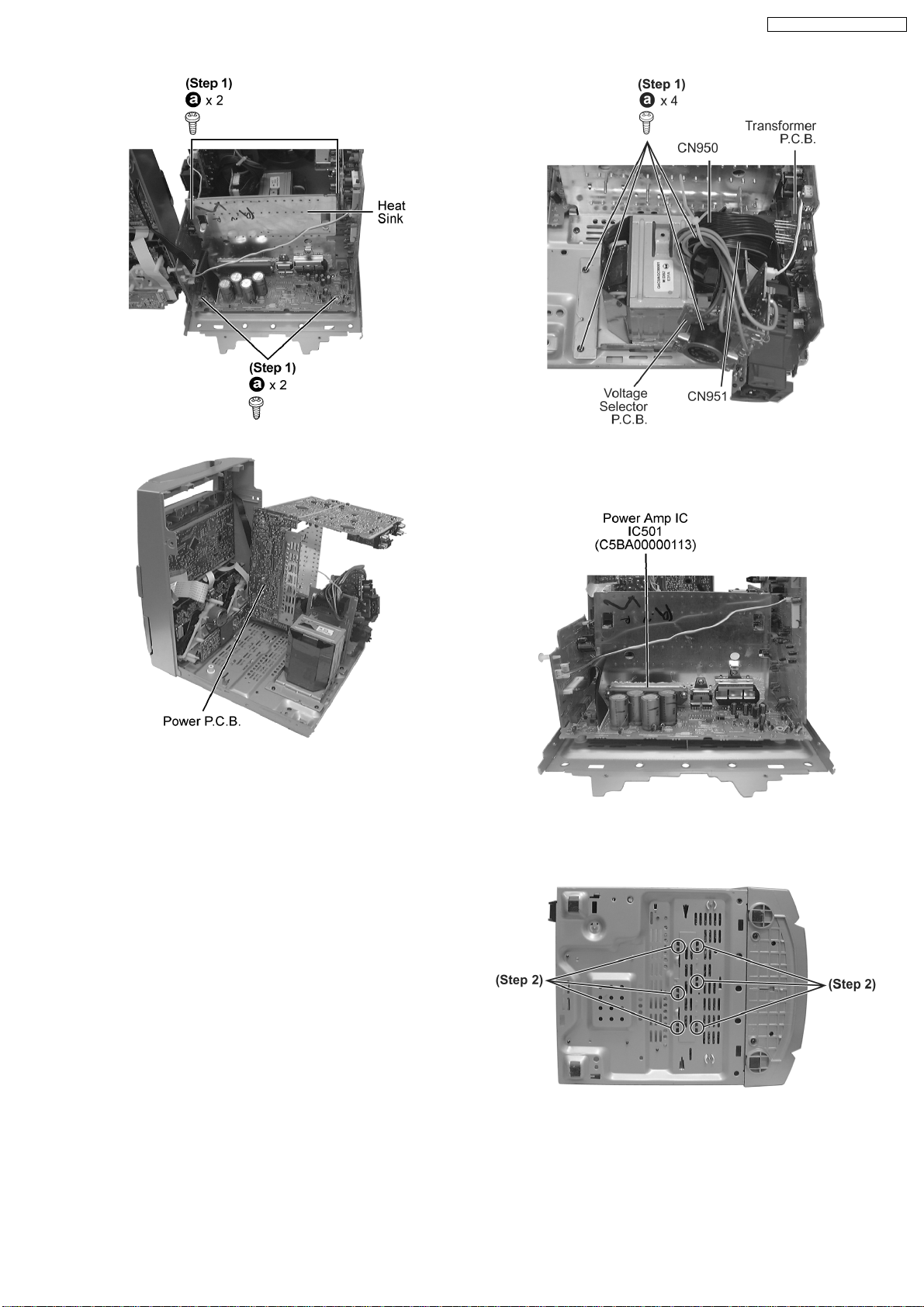

17.7. Disassembly of Main P.C.B., Power P.C.B., Transformer P.C.B. &

Voltage Selector P.C.B.

· Follow the (Step 1) - (Step 2) of Item 17.2.

· Follow the Disassembly for the Top Ornament Unit of Item

17.4.

Step 1 Remove the 11 screws.

Step 2 Push the catch outwards & draw the rear panel

backwards to remove it.

· Disassembly of Power P.C.B.

−

− Follow the (Step 1) - (Step 2) of Item 17.2.

− −

−

− Follow the Disassembly for the Top Ornament Unit of

− −

Item 17.4.

−

− Follow the (Step 1) - (Step 4) of Item 17.5.

− −

−

− Follow the (Step 1) - (Step 4) of Item 17.6.

− −

Step 3 Detach connectors (CN601, CN602 and CN302).

Step 4 Lift up the Main P.C.B. to remove it.

Caution Note:

Avoid using/ exerted strong force when removing the Main

P.C.B.

34

Page 35

SA-VK61DGC / SA-VK61DGCS

Step 1 Remove the 4 screws.

Step 2 Detach wire.

NOTE:

Insulate Power P.C.B. with insulation material to avoid short

circuit.

· Disassembly of the Transformer P.C.B. & Voltage

Selector P.C.B.

−

− Follow the (Step 1) - (Step 2) of Item 17.2.

− −

−

− Follow the Disassembly for the Top Ornament Unit of

− −

Item 17.4.

−

− Follow the (Step 1) - (Step 4) of Item 17.5.

− −

Step 1 Remove 4 screws.

Step 2 Disconnect connector CN950 & CN951.

· Replacement of Power Amp IC

Step 1 Remove the 2 screws fixed to the Power Amplifier IC.

Step 2 Remove 2 screws fixed to the Power Amplifier IC and

Transistor Holders.

Step 3 Break the joint with a metal cutter as shown below.

Step 4 Unsolder the terminals of Power Amp IC, replace the

component.

35

Page 36

SA-VK61DGC / SA-VK61DGCS

Step 5 Fix back the bottom chasis with a screw as shown.

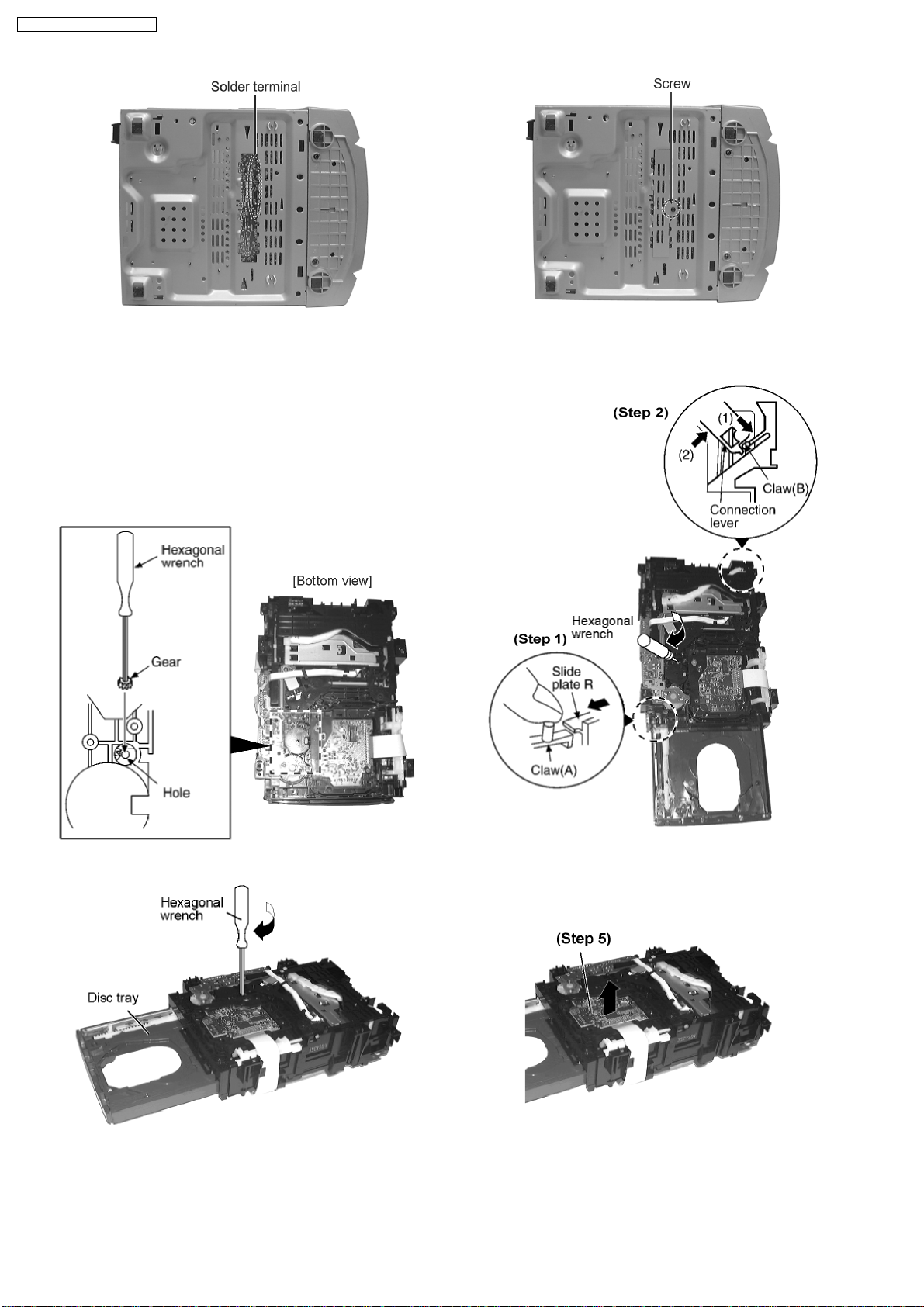

17.8. DVD Changer Unit Main Component Replacement Procedures

17.8.1. Replacement of the Traverse Deck

· Follow the (Step 1) - (Step 2) of Item 17.2.

· Follow the Disassembly for the Top Ornament Unit of Item

17.4.

· Follow the (Step 1) - (Step 4) of Item 17.5.

· Follow the (Step 1) - (Step 2) of Item 17.5.1.

Step 1 Insert the gear with hexagonal wrench into the hole.

Step 2 Rotate the hexagonal wrench in the direction of arrow

(clockwise), and then open the disc tray fully.

Step 3 With pressing the claw (A), rotate the hexagonal wrench

clockwise. (The slide plate R moves for a little amount.)

Step 4 Pressing the claw (B) in the direction of arrow (1), the

connection lever moves in the direction of arrow (2).

Step 5 Lift up the traverse deck ass’y.

36

Page 37

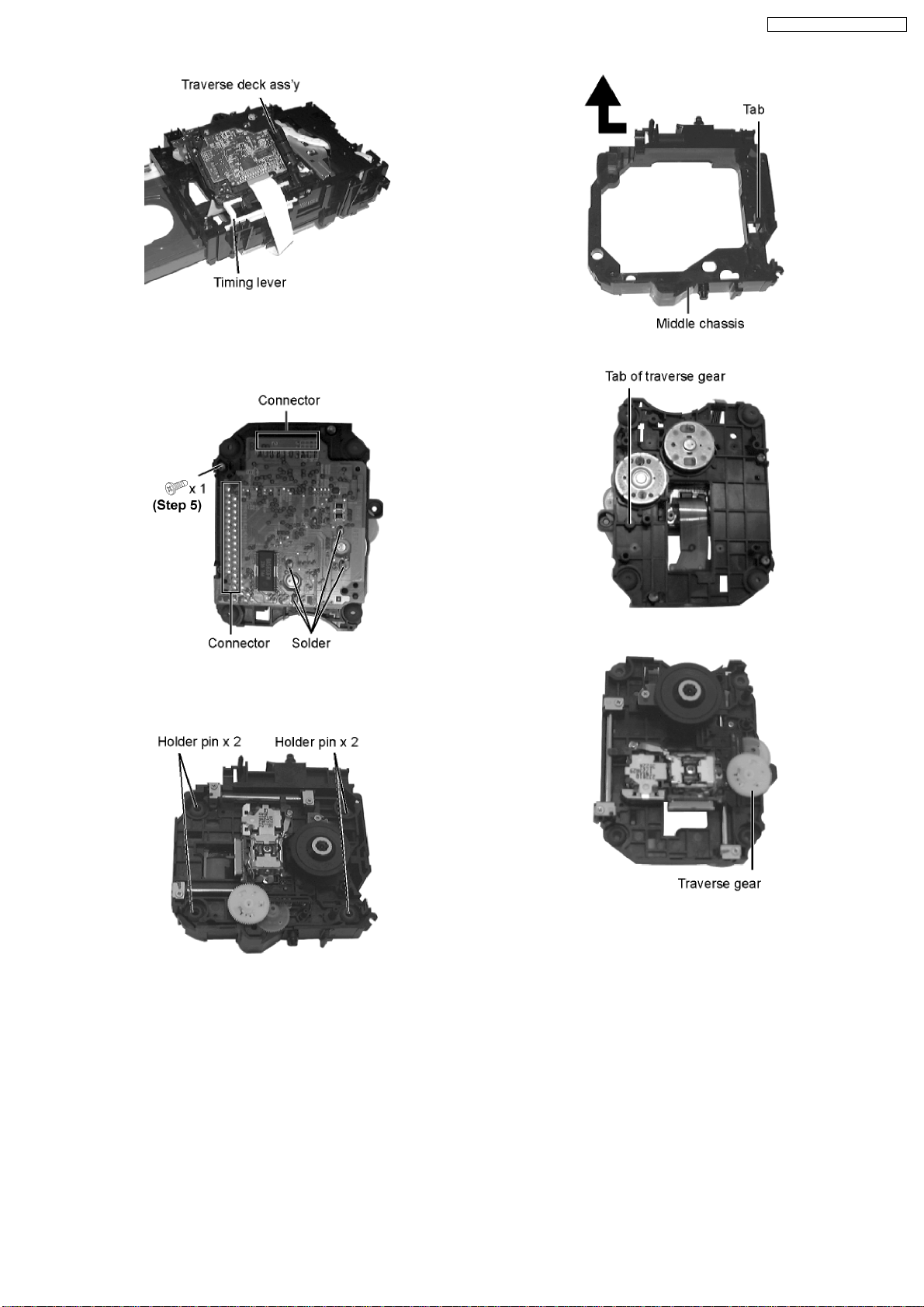

Step 6 Remove the traverse deck ass’y from the timing lever.

Caution:

When removing or inserting the traverse deck avoid touching

the OPU lens and pressing onto the turntable.

SA-VK61DGC / SA-VK61DGCS

Step 11 Disengage the tabs from the traverse gear.

Step 7 Remove 3 screws.

Step 8 Unsolder the motor terminals (4 points).

Step 9 Remove the holder pins.

Step 10 Remove the tab.

Step 12 Remove the traverse gear.

Step 13 Unscrew the screws.

Step 14 Remove the spring holders and the springs.

Step 15 Pull out the drive shaft and guide shaft.

37

Page 38

SA-VK61DGC / SA-VK61DGCS

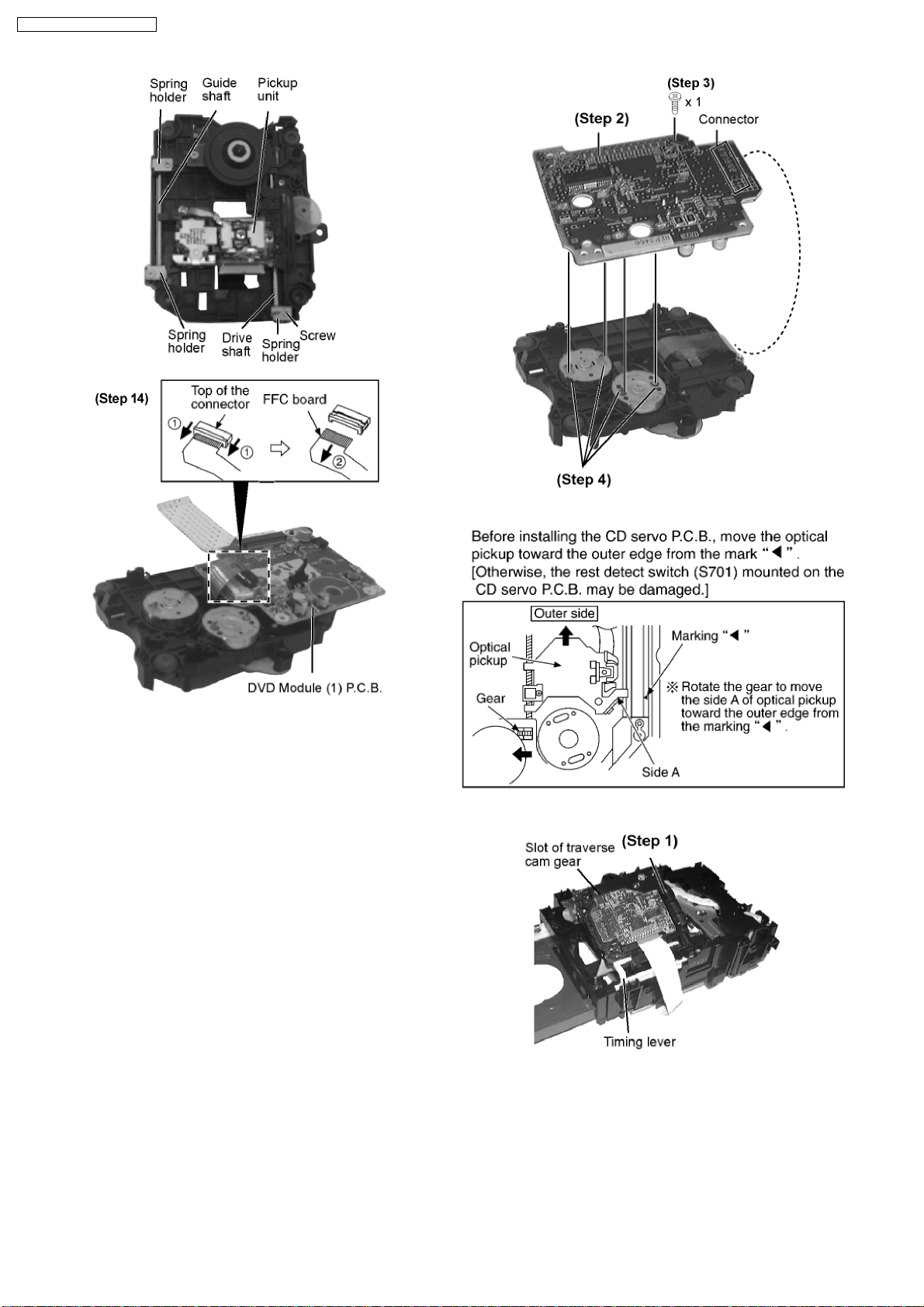

Step 16 Remove the FFC board from the connector, and then

remove the DVD Module (1) P.C.B.

· Installation of the DVD Module (1) P.C.B. after

replacement

Step 1 Connect the FFC board.

Step 2 Install the DVD Module (1) P.C.B. in the traverse deck

ass’y.

Step 3 Remove 3 screws.

Step 4 Solder.

· Note for installation of the DVD Module (1) P.C.B.

· Installation for traverse deck ass’y

Step 1 Install the traverse deck ass’y to the timing lever.

Step 2 Align the boss of traverse deck ass’y with the slot of

traverse cam gear.

38

Page 39

Step 3 Force the claw of timing lever.

SA-VK61DGC / SA-VK61DGCS

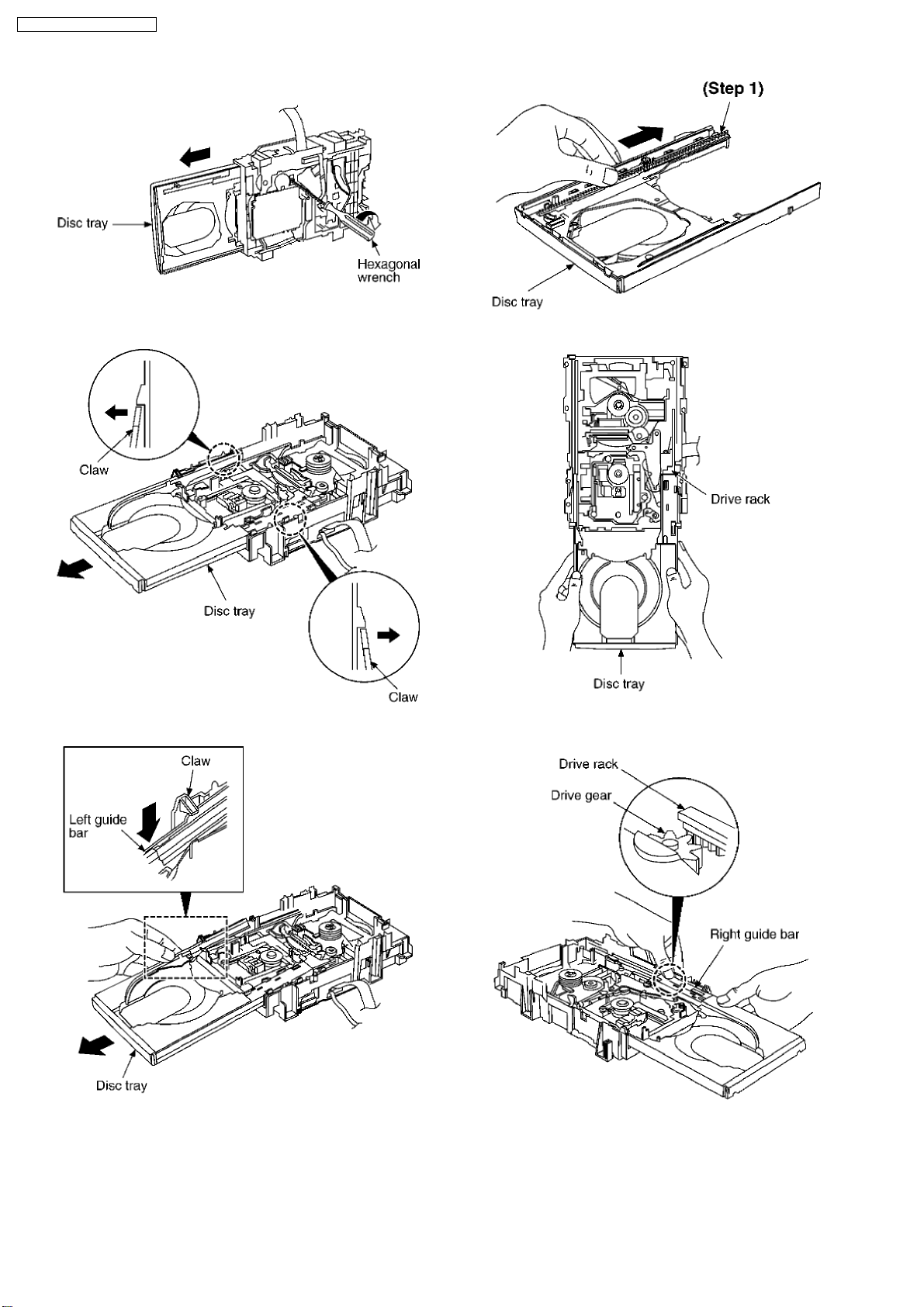

17.8.2. Replacement for the disc tray

Step 1 Remove 4 screws.

Step 2 Remove the upper plate.

Step 3 Remove 3 screws.

Step 4 Force the disc tray fully.

Step 5 With pressing the claw (B) in the direction of arrow (1),

force the connection lever in the direction of arrow (2).

Step 4 With lifting the claw in the direction of (1), draw the

clamp SW P.C.B. in the direction of arrow (2).

Step 5 Remove the mechanism cover.

39

Page 40

SA-VK61DGC / SA-VK61DGCS

Step 6 Insert the gear with hexagonal wrench into the hole.

Step 7 Rotate the hexagonal wrench in the direction of arrow,

and then open the disc tray fully.

Step 1 Slide the drive rack fully in the direction of arrow.

Step 8 Release the both claws, and then draw the disc tray.

Step 9 With forcing the left guide bar manually because the left

guide bar interfers with claw, draw the disc tray.

[Installation of the disc tray after replacement]

Step 2 Holding the drive rack not to move, install the disc tray.

Step 3 Align the drive rack with the drive gear.

NOTE:

Force the right guide bar of tray base manually not to move

upwards.

40

Page 41

Step 4 Holding the disc tray manually, push the disc tray in the

direction of the arrow.

17.8.3. Disassembly and reassembly for

mechanism base drive unit

· Follow the (Step 1) - (Step 9) of Item 17.8.2.

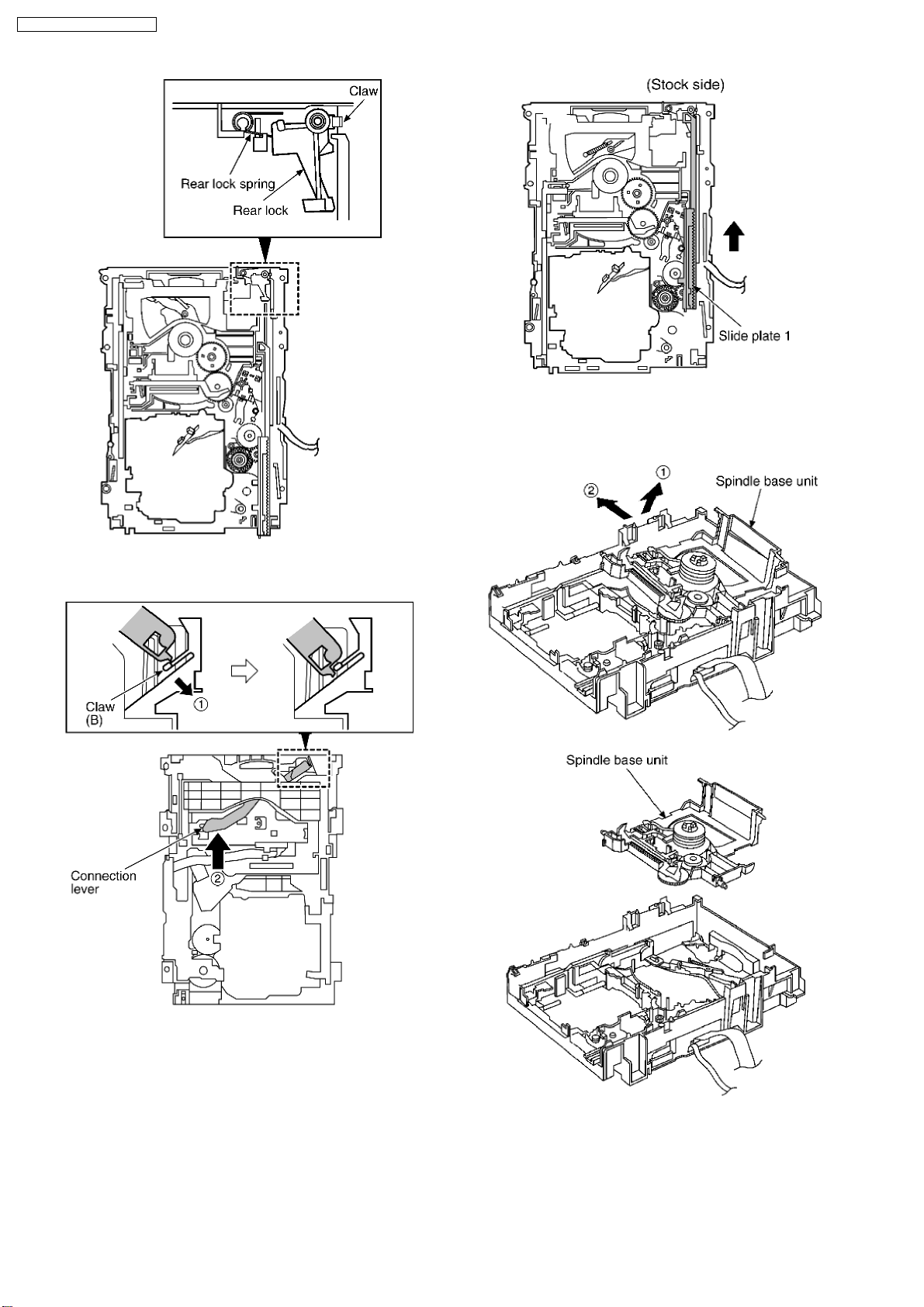

Step 1 Remove 3 screws.

SA-VK61DGC / SA-VK61DGCS

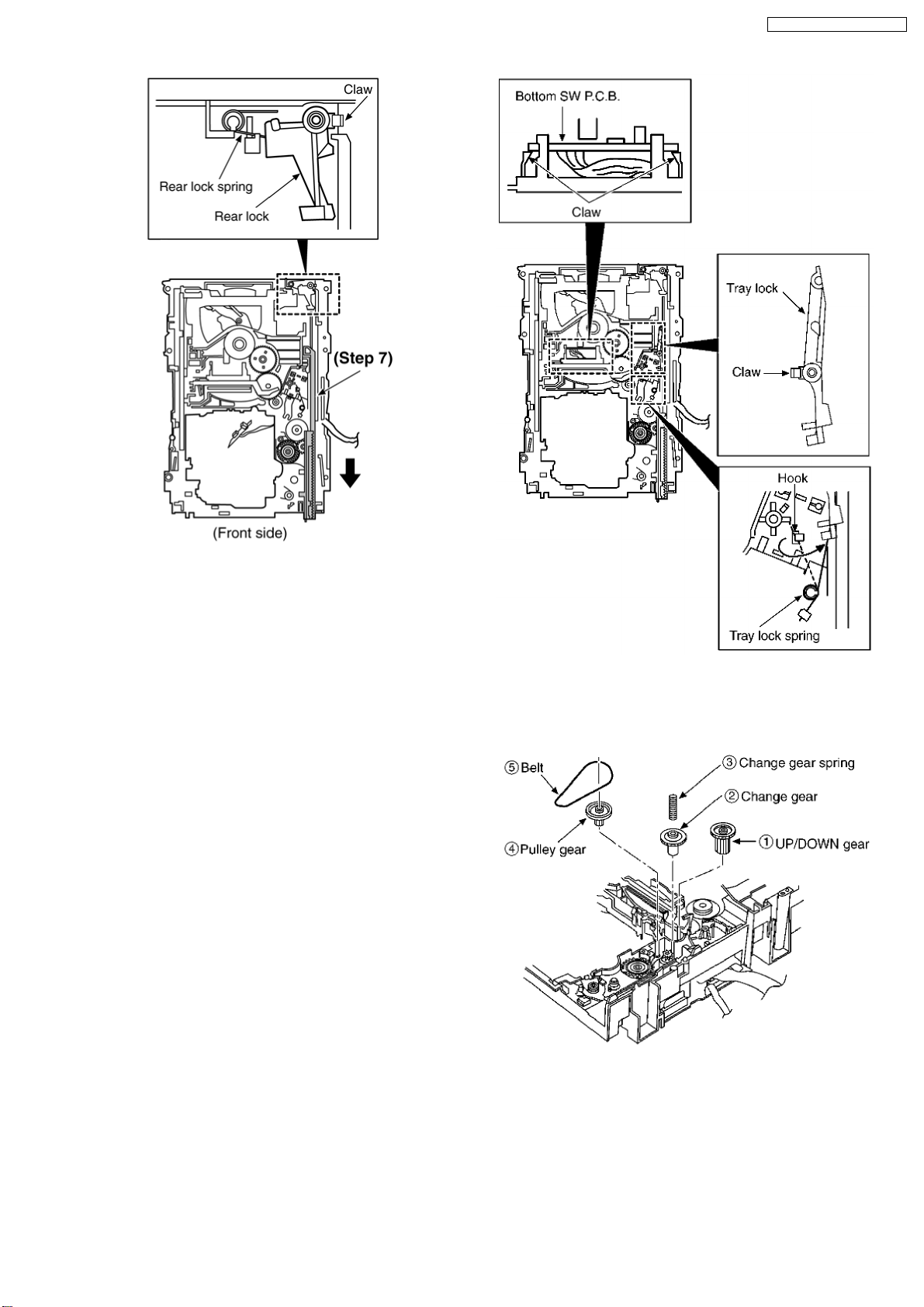

Step 5 Release the 2 claws, and then remove the bottom SW

P.C.B..

Step 2 Release the claw, and then remove the gear holder.

Step 3 Remove the belt and change gear spring.

NOTE:

Take care not to lose the change gear spring.

Step 4 Remove the pulley gear, change gear and UP/DOWN

gear.

Step 6 Install the tray lock spring to hook temporary.

Step 7 Release the claw, and then remove the tray lock.

Step 8 Release the claw, and then remove the rear lock.

41

Page 42

SA-VK61DGC / SA-VK61DGCS

Step 11 Lift up the left end of spindle base unit in the direction

of arrow (1), and then remove the unit in the direction of arrow

(2).

Step 9 Pressing the claw (B) in the direction of arrow (1), force

the connection lever in the direction of arrow (2).

Step 10 Move the slide plate 1 to the end of stock side.

Step 12 Remove slide plate 1 and slide plate 2.

42

Page 43

Step 13 Remove the traverse relay gear, traverse cam gear

and drive gear.

SA-VK61DGC / SA-VK61DGCS

Step 3 Rotate the disc lever in the direction of arrow (1), draw

the disc lever.

[Dissassembly/reassembly for the spindle base unit]

Step 1 Draw the 5 disc spacers.

Step 2 Pushing the claw, slide the support plate in the direction

of arrow, and then remove it.

NOTE:

Take care not to lose the disc lever spring.

Step 4 Release the 2 claws, and then draw the relay gear B.

Step 5 Release the 2 claws as shown below.

43

Page 44

SA-VK61DGC / SA-VK61DGCS

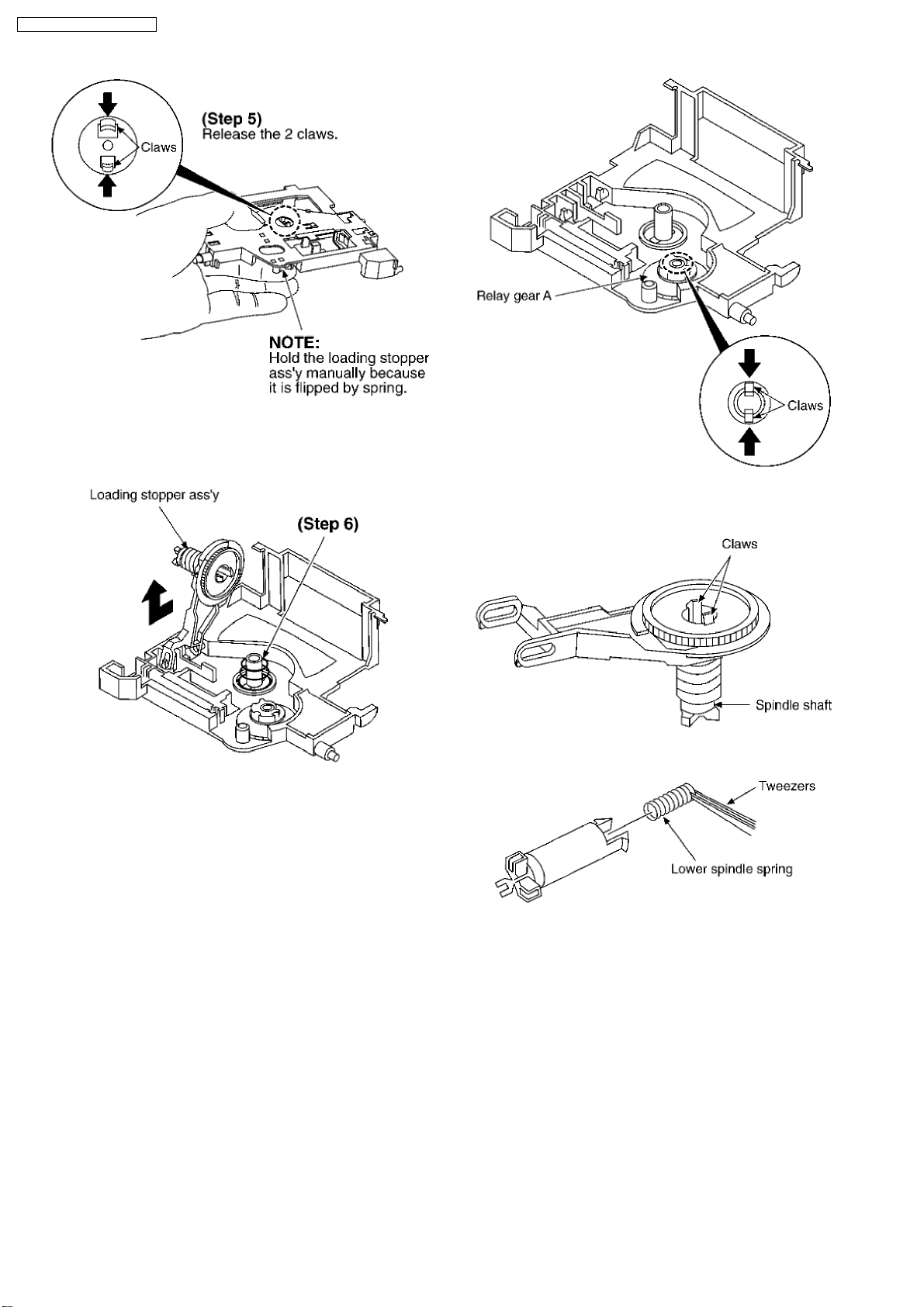

NOTE:

Hold the loading stopper ass’y manually bacause it is flipped by

spring.

Step 6 Remove the cushion spring.

Step 7 Remove the loading stopper ass’y in the direction of

arrow.

Step 8 Release the 2 claws, and then remove the relay gear A.

Step 9 Release the 2 claws, and then remove the spindle shaft.

Step 10 Remove the lower spindle spring with tweezers.

Step 11 Force the lower hook with thin tip of minus screwdriver.

44

Page 45

SA-VK61DGC / SA-VK61DGCS

spread the hold bars of loading stopper and remove the

UP/DOWN base.

[Installation for loading stopper ass’y]

Step 1 Align the claw of loading stoppers ass’y with the slot of

spindle base. (Caution should be exercised when alignment of

claw due to the size of claws.)

Step 12 Squeeze the shaft of lower hook, and then draw it.

Step 13 Rotate the lower spindle in the direction of arrow until

the lower spindle interferes with stopper.

Step 14 Insert the thin tip of minus screwdriver between the

lower spindle and UP/DOWN base, and then slacken the lower

spindle to release the stopper. Then, rotate the lower spindle

and remove it.

Step 2 Lower the loading stopper ass’y, and then align the

lower spindle with the trapezoid tooth of relay gear A.

Step 3 Force the loading stopper ass’y, latch the claw firmly.

Step 15 Rotate the UP/DOWN base at a 90° angle. Then,

[Reassembly for mechanism base drive unit]

45

Page 46

SA-VK61DGC / SA-VK61DGCS

Step 1 Install the traverse cam gear.

Step 2 Rotate the traverse cam gear to the direction of arrow.

Step 3 Install the drive gear and traverse relay gear.

*When installing the traverse relay gear, align the trapezoid

tooth of gear with tooth of traverse cam gear.

Step 4 Install the slide plate 2 to the mechanism base, and

then match to the connection lever.

Step 5 Install the slide plate 1 to the mechanism base, and

then match to the connection leve and align the trapezoid tooth

of traverse relay gear with the slide plate 1.

Step 6 Install the spindle base unit. (First, slide plate 1.)

46

Page 47

SA-VK61DGC / SA-VK61DGCS

Step 7 Move the slide plate 1 to forward fully.

Step 8 Install the rear lock. (The claw should be latched.)

Step 9 Install the bottom SW P.C.B.. (The claw should be

latched.)

Step 10 Install the tray lock. (The claw should be latched.)

Step 11 Remove the tray lock spring from hook,and then latch

to the tray lock.

Step 12 Install the UP/DOWN gear, change gear, change gear

spring, pulley gear and belt in the order of (1) - (5).

Step 13 Install the gear holder, and then tighten the screw (a).

47

Page 48

SA-VK61DGC / SA-VK61DGCS

Step 14 Install the tray base, traverse ass’y, mechanism cover

and upper plate.

[Operation check after servicing]

Check the proper operation of following items with gear and

hexagonal screwdriver.

1. Open/close of tray base.

2. Moving the tray base to the stock side.

3. UP/DOWN operation of spindle base unit.

4. UP/DOWN operation of traverse ass’y.

Step 4 Unsolder the plunger terminals (2 points).

Step 5 Unsolder the motor terminals (2 points).

17.8.4. Replacement for the motor ass’y

· Follow the (Step 1) - (Step 7) of Item 17.8.2.

Step 1 Install the belt temporarily.

NOTE:

Take care not apply the grease to the belt.

Step 2 Upset the CD loading unit.

Step 3 Remove 3 screws.

Step 6 Release the 2 claws (A), and then remove the Motor

P.C.B.

Step 7 Release the claw (B), and then remove the motor ass’y.

[Notice for motor ass’y installation]

1. Locate the name plate of motor to the traverse ass’y.

2. Align the hole of motor with the ribs.

48

Page 49

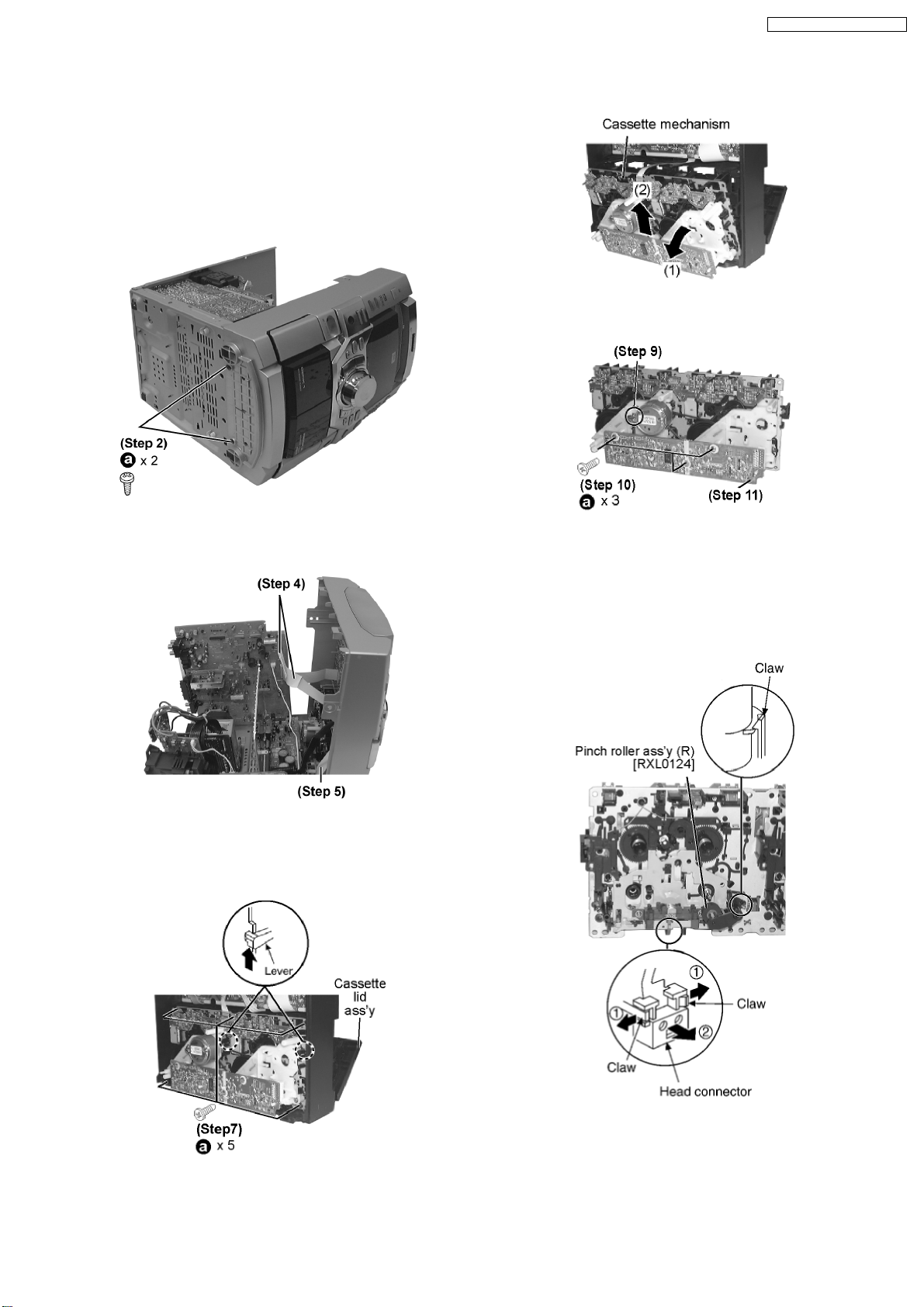

17.9. Disassembly of Deck Mechanism Unit

· Follow the (Step 1) - (Step 2) of Item 17.2.

· Follow the Disassembly for the Top Ornament Unit of Item

17.4.

· Follow the Disassembly for the DVD changer unit of Item

17.5.

Step 1 Lay the unit as shown.

Step 8 Tilt the cassette mechanism in the direction of arrow (1),

and then remove it in the direction of arrow (2).

SA-VK61DGC / SA-VK61DGCS

Step 2 Remove 2 screws.

Step 3 Release the 2 claws, and then draw the front panel

ass’y forward.

Step 4 Detach FFC Board (CN601 & CN602).

Step 5 Detach flat cable wire (CN1001).

Step 6 Push the lever upward, and then open the cassette lid

ass’y (For DECK1 and DECK2).

· Disassembly of Deck P.C.B.

Step 9 Unsolder the motor terminals.

Step 10 Remove 4 screws.

Step 11 Remove Deck P.C.B.

* The mechanism as shown below is for DECK1. For the

one of DECK 2, perform the same procedures.

Step 7 Remove the 5 screw.

· Disassembly of pinch roller ass’y & head block

Step 12 Release the 2 claws, and then remove the pinch roller

(R), (F).

Step 13 Release ther 2 claws, and then remove the head

connector.

49

Page 50

SA-VK61DGC / SA-VK61DGCS

Step 14 Remove 2 screws.

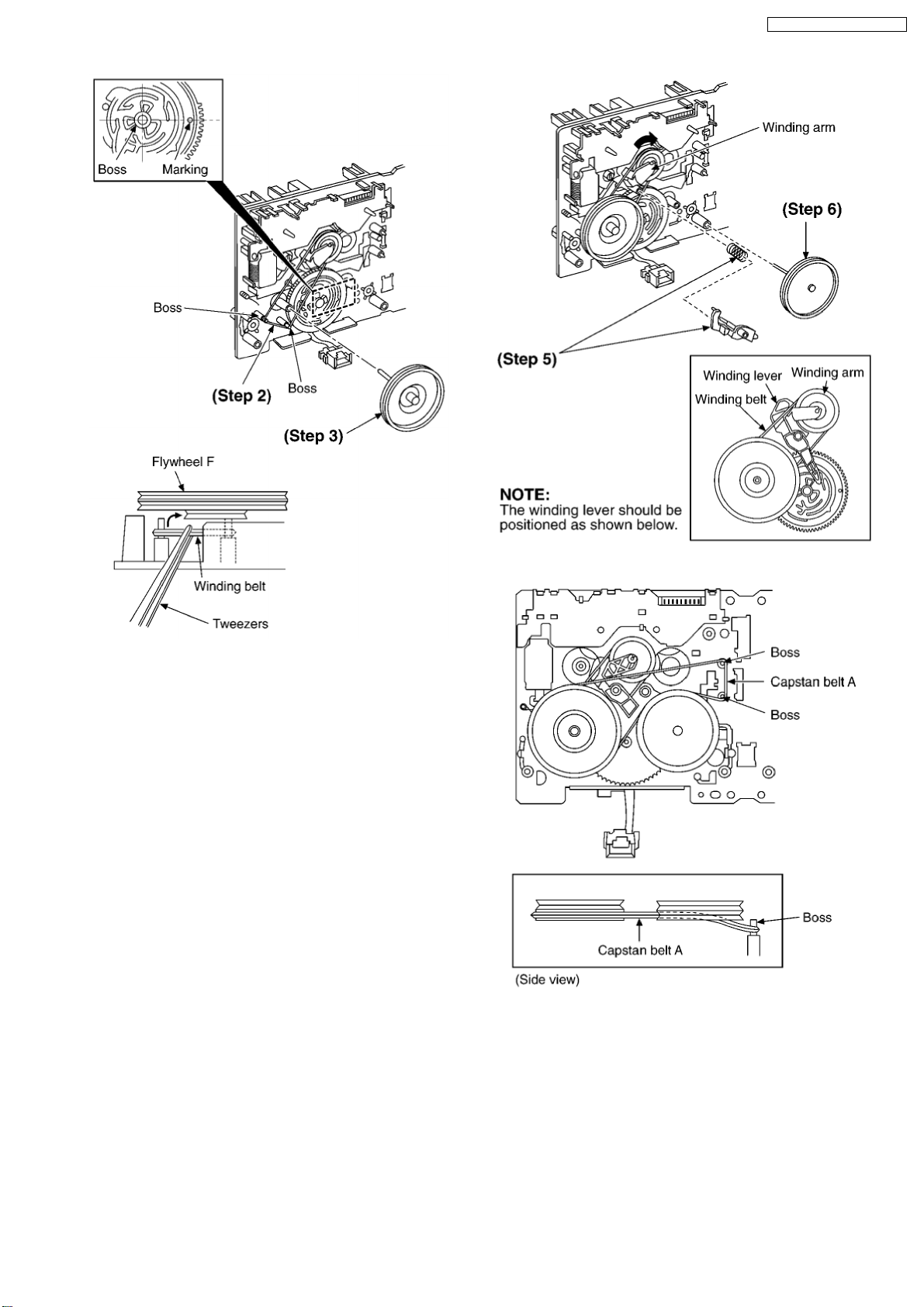

17.9.1. Replacement for the CD motor ass’y, capstan belt A, capstan belt B and winding

belt

Step 1 Release the 2 claws, and then remove the head

connector.

Step 2 Remove 6 screws.

Step 3 Remove the sub chassis.

Step 4 Remove 2 screws.

Step 5 Remove the flywheel R.

Step 6 Release the claw of tape side, and then remove the

winding lever and spring.

Step 7 Remove the flywheel F.

[Installation of the belt]

Step 1 The boss and marking should be positioned

horizontally.

50

Page 51

SA-VK61DGC / SA-VK61DGCS

Step 2 Put the winding belt on the pulley temporarily.

Step 3 Install the flywheel F.

Step 4 Put the winding belt on the flywheel F.

Step 5 Install the winding lever and spring while pressing the

winding arm in the direction of arrow.

Step 6 Install the flywheel R.

Step 7 Put the capstan belt A temporarily as shown below.

Step 8 Put the capstan belt B on the motor ass’y pulley.

Step 9 Install the sub chassis to the mechanism, and then

tighten screws.

51

Page 52

SA-VK61DGC / SA-VK61DGCS

17.10. Replacement for the cassette

lid ass’y

· Follow the (Step 1) - (Step 2) of Item 17.2.

Step 1 Force the lever upward, open the cassette lid ass’y. (For

DECK1 and DECK2)

Step 10 Remove 3 screws.

Step 11 Put the capstan belt B as shown below.

Step 12 Put the capstan belt A on the motor ass’y pulley.

Step 2 Lift up the cassette lid ass’y in the direction of arrow.

(For DECK1 and DECK2).

Step 3 Remove the cassette lid ass’y. (For DECK1 and

DECK2).

52

Page 53

17.11. Counter-measure for tape

trouble

· Follow the (Step 1) - (Step 2) of Item 17.2.

Step 1 If a cassette tape cannot be removed from the deck

since the tape is caught by the capstan or pinch roller during

playback or recording, rotate the flywheel F in the direction of

the arrow to remove the tape.

SA-VK61DGC / SA-VK61DGCS

Step 2 Force the lever upward and open the cassette lid ass’y.

Take the cassette tape off.

53

Page 54

SA-VK61DGC / SA-VK61DGCS

18 Measurements and Adjustments

18.1. Cassette Deck Section

· Measurement Condition

−

− Reverse-mode selector switch:

− −

−

− Tape edit: NORMAL

− −

−

− Make sure head, capstan and press roller are clean.

− −

−

− Judgeable room temperature 20 ± 5 °C (68 ± 9°F)

− −

· Measuring instrument

−

− EVM (DC Electronic volmeter)

− −

−

− Digital frequency counter

− −

· Test Tape

−

− Tape speed gain adjustment (3 kHz, -10 dB);

− −

QZZCWAT

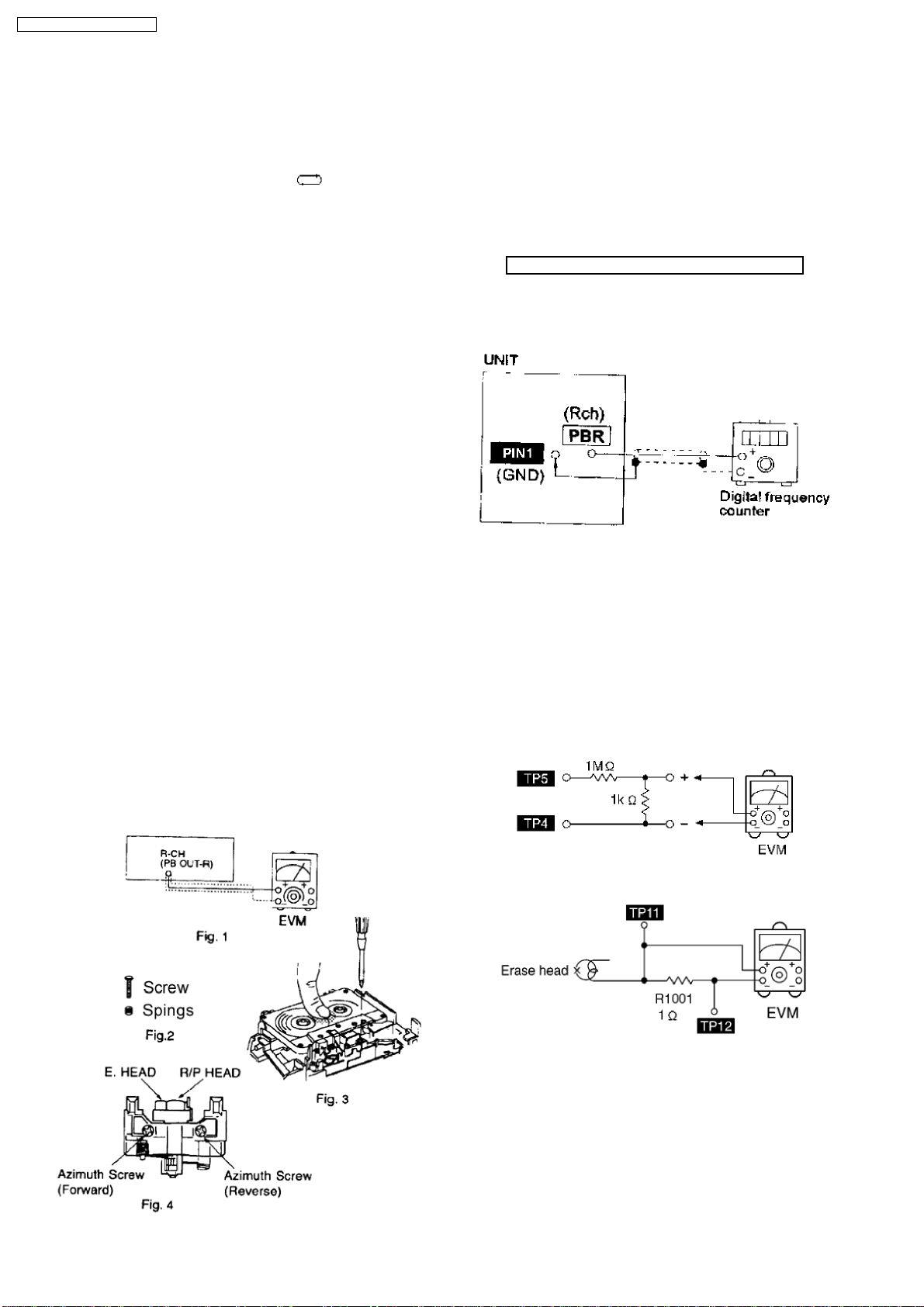

18.1.1. Head Azimuth Adjustment (Deck

1/2)

Caution:

· Please replace both azimuth adjustment screw and springs

simultaneously when readjusting the head azimuth. (shown

in Fig. 2) Even if you wish to readjust the head azimuth

without replacing the acrews and springs, a fine adjustment

to the azimuth screw and spring.

· Please remove the screw-locking bond left on the head

base when replacing the azimuth screw.

· If you wish to readjust the head azimuth, be sure to adjust

with adhering the cassette tape closely to the mechanism

by pushing the center of cassette tape with your finger.

(shown in Fig. 3)

1. Playback the azimuth adjustment portion (8 kHz, -20dB) of

the test tape (QZZCFM) in the forward play mode. Vary the

azimuth adjustment screw until the output of the R-CH (PB

OUT-R) are maximized.

2. Perform the same adjustment in the reverse play mode.

3. After the adjustment, apply screwlock to the azimuth

adjusting screw.

18.1.2. Tape Speed Adjustment (Deck 1/2)

1. Set the tape edit button to “NORMAL” position.

2. Insert the test tape (QZZCWAT) to DECK 2 and playback

(FWD side) the middle portion of it.

3. Adjust Motor VR (DECK 2) for the output value shown

below.

Adjustment target: 2940 ~ 3060 Hz (NORMAL speed)

4. After alignment, assure that the output frequency of the

DECK 1 FWD are within ±60 Hz of the value of the output

frequency of DECK 2 FWD.

Fig. 1

18.1.3. Bias and Erase Voltage Check

1. Set the unit “AUX” position.

2. Insert the Normal blank tape (QZZCRA) into DECK 2 and

the unit to “REC” mode (use “l REC/STOP” key).

3. Measure and make sure that the output is within the

standard value.

Bias voltage for Deck 2 14±4mV (Normal)

Erase voltage for Deck 2 80mV (Normal)

54

Fig. 2

Fig. 3

Page 55

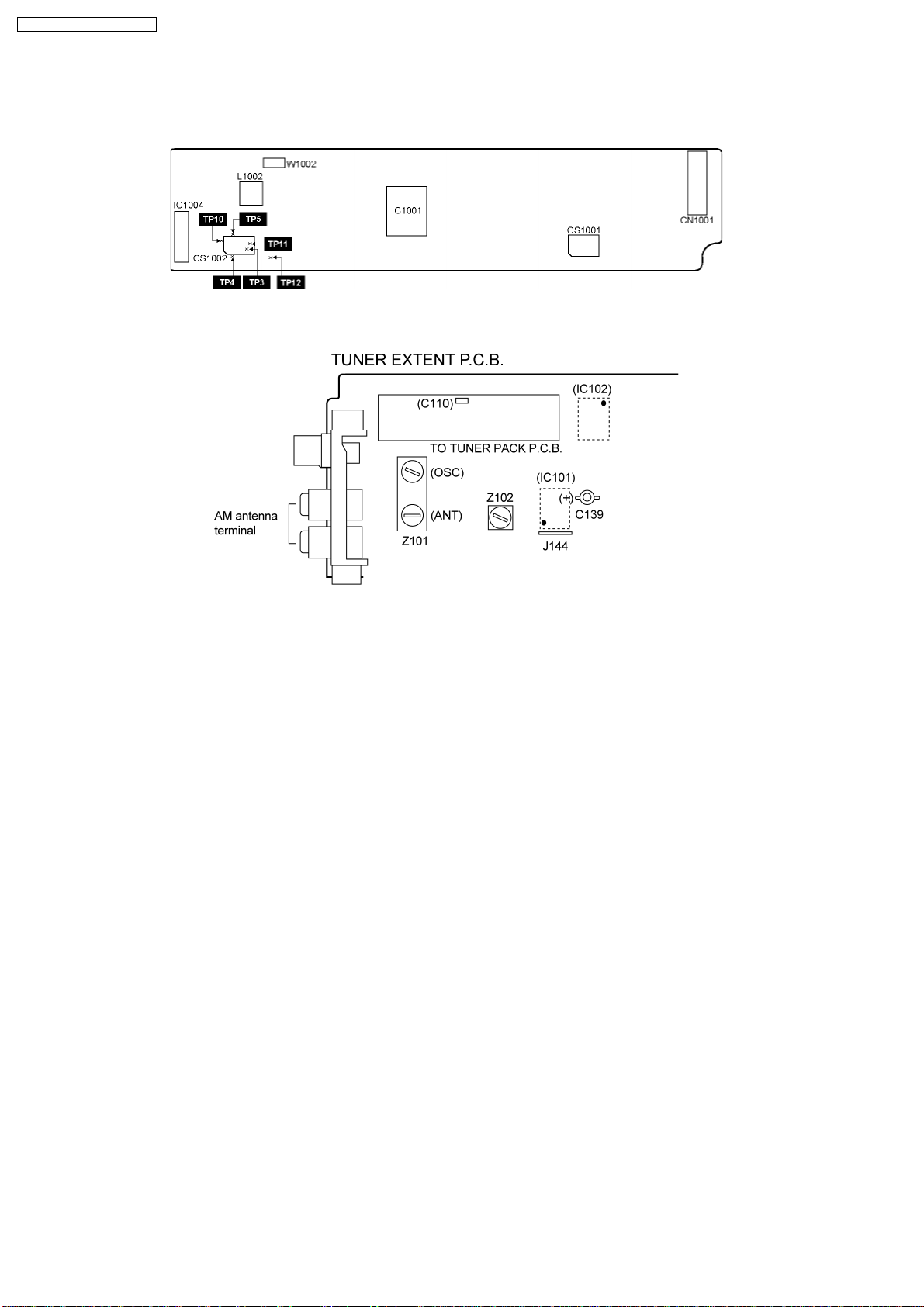

18.1.4. Bias Frequency Adjustment (Deck

1/2)

1. Set the unit to “AUX” position.

2. Insert the Normal blank tape (QZZCRA) into DECK 2 and

set the unit to “REC” mode (l use “REC/STOP” key).

3. Adjust L1002 so that the output frequency is within the

standard value.

Standard Value: 97 ±8 kHz

18.2. Tuner Section

18.2.1. AM-IF Alignment

1. Connect the instrument as shown in Fig. 5.

2. Set the unit to AM mode.

3. Apply signal as shown in Fig. 5 from AM-SG.

4. Adjust Z102 so that the output frequency is maximized in

Fig. 6.

SA-VK61DGC / SA-VK61DGCS

Fig. 4

Fig. 5

Fig. 6

18.2.2. AM RF Adjustment

1. Connect the instrument as shown in Fig. 7.

2. Set the unit to AM mode.

3. Set AM-SG to 520kHz.

4. Receive 520kHz in the unit.

5. Adjust Z101 (OSC) so that the EVM-AC is maximized.

6. Set AM-SG to 600Hz.

7. Receive 600Hz in the unit.

8. Adjust Z101 (ANT) so that the EVM-SG is maximized.

9. Set AM-SG to 520kHz.

10. Receive 520kHz in the unit.

11. Adjust Z101 (OSC) so that the EVM-DC value is with

1.1±0.5V.

Fig. 7

55

Page 56

SA-VK61DGC / SA-VK61DGCS

18.3. Alignment Points

18.3.1. Cassette Deck Section

18.3.2. Adjustment Point

56

Page 57

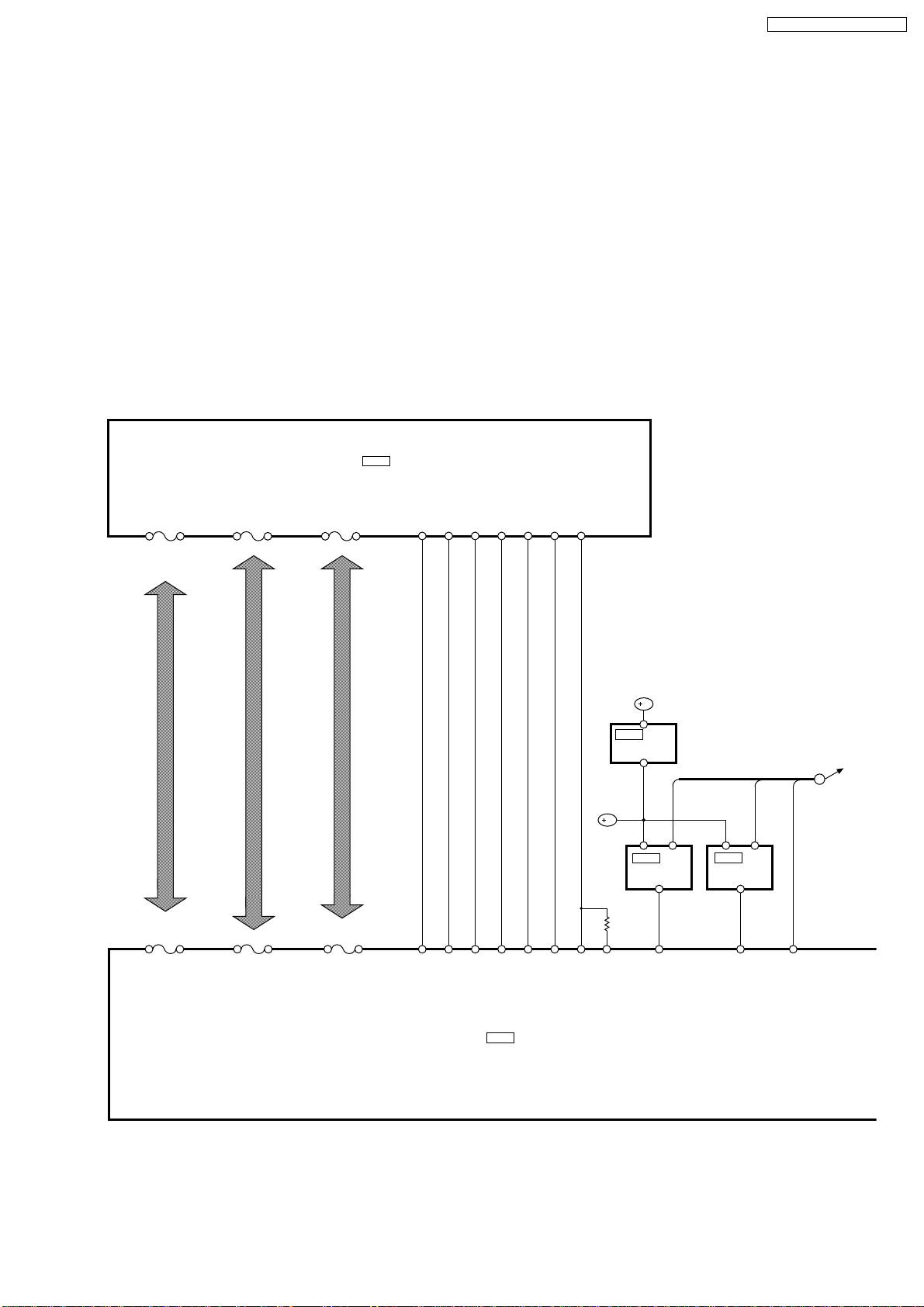

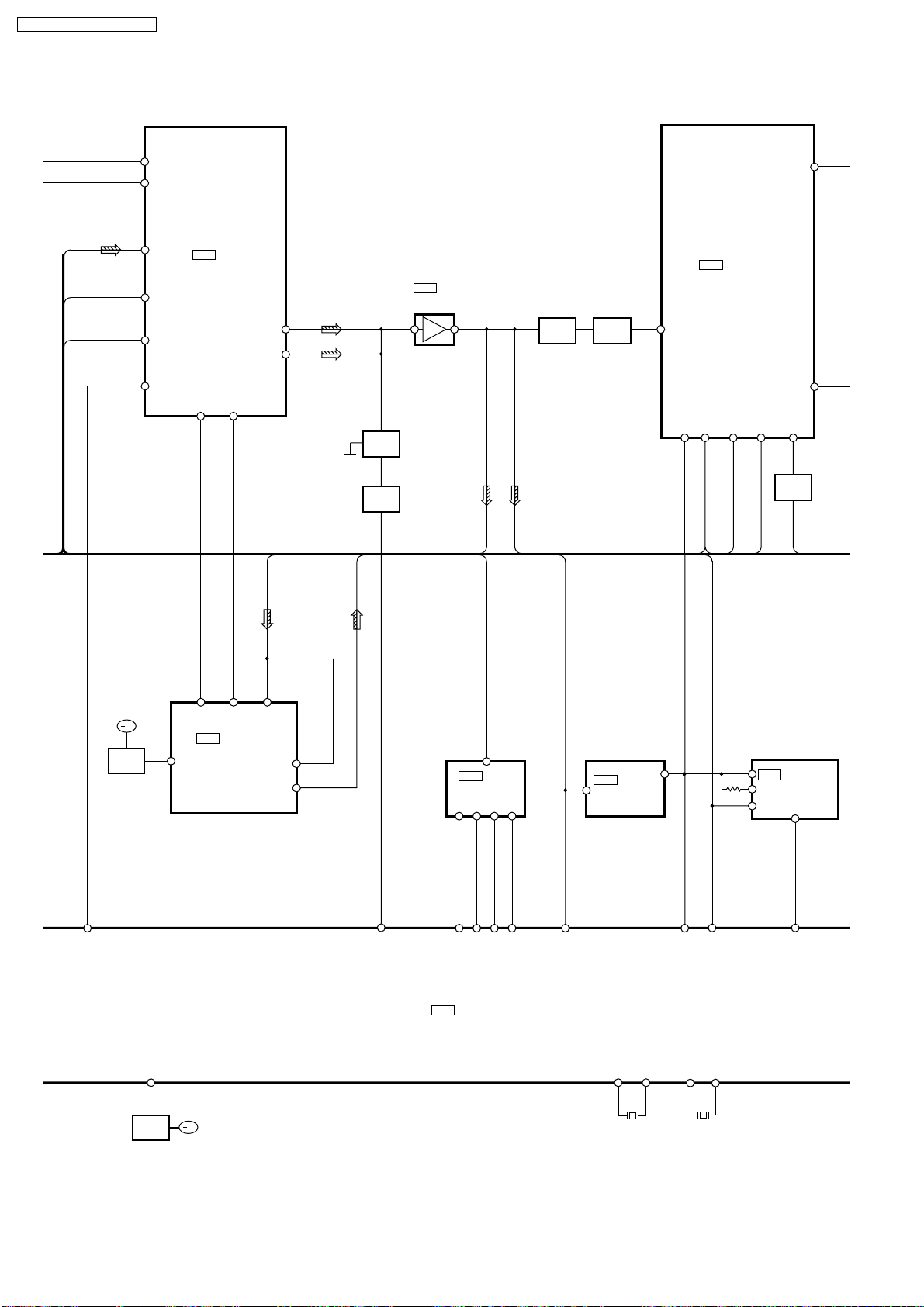

19 Block Diagram

IC3051

C3ABPJ000017

64M SDRAM

SA-VK61DGC / SA-VK61DGCS

DQ0

DQ31

2,4,5,7,8,10,

11,13,31,33,34,

36,37,39,40,42,

45,47,48,50,51,

53,54,56,74,76,

77,79,80,82,83,85

2,3,5,6,8~10,12,

13,184,185,187,188,

190~193,196,197,

199~201,203~205,247,

249,251~253,255,256

MDQ0

MDQ15

DQM0

16,28,

59,71

207,208,

243,246

DQM0

DQM3

DQM3

A0

21,24~27,

60~66

210,212,214,

216,217,219,

220,227~229,

231,235

MA0

A11

WE

CAS

17

RAS

18

19CS20

BS022BS1

CLK

23

68

B

IC6251

C0CBCBE00003

REGULATOR

TO MAIN BLOCK

A

CMD

B

NRAS

234

238

NCSM

237

223

225

BA1

BA0

MCKI

MCK

232

MA11

NWE

239

242

NCAS

DSPCLK

5 4

IC6261

C0JBAA000001

INVERTER

1,2

62

P2

STATUS

5

4

IC6262

C0JBAA000001

INVERTER

1,2

63

P3

64

P1

MN2DS0002AP1

57

IC3001

AV DECODER

Page 58

SA-VK61DGC / SA-VK61DGCS

29,31,

33,35,

38,40,

42,44

DQ0

DQ7

1~8,

18~25

A15

DQ15

DQ14

DQ13

DQ8

30

41

45

43

A0

IC6301

RFKFMV71W160

16M FLASH

A20

10

9

26

XCE

DQ9

32,34,

36,39

DQ12

12

XRESET

A16

A17

A19

17

NC

48

16

13

XWE

XOE

NC

11

28

IC6201

C0EBE0000070

RESET IC

TO FG UNIT

FP2501

QR2045

SWITCH

19~22,27,28,

31,32,34~37,

40,41,44,45

33

NEXCE

EXADT0

EXADT15

94~97,

100~103

MONI(0)

MONI(7)

82

84

EXTRG0

85

EXTRG1

90

TRCST

TRCCLK

MN2DS0002AP1

17

39

EXADR20

38

EXADT19

EXADT17

IC3001

25

47

P15

EXADR16

AV DECODER

26

46

EXADR18

NEXOE

18

NEXWE

TRCDATA(0)

86~89

TRCDATA(3)

68

75

NRST

66

DRV5

FG

58

Page 59

MON

F

284

OPTICAL PICKUP

CDM HFM DVDM

5

15

LDOUT

F1

F2

10

LD

E

6

11

LDIN

2

LD

T1T2T3

4

T4

5

7

12

6

SA-VK61DGC / SA-VK61DGCS

SW

MON

F1

F2

13

RFP

RFN

14

10

8

11

FOCUS COIL

F- F+ T- T+

TRACKING COIL

M2501

M2502

M M

13

VO2-

14

12

VO1-

VO2+

VO1+

VIN1

BIAS1

1

2

VHALF

152

150

DAC1

137

AD1

11

Q5115

CD

SUPPLY

SWITCH

Q5225 Q5221

SWITCH SWITCH

VIN5

133

131

VIN10

LPC02