Page 1

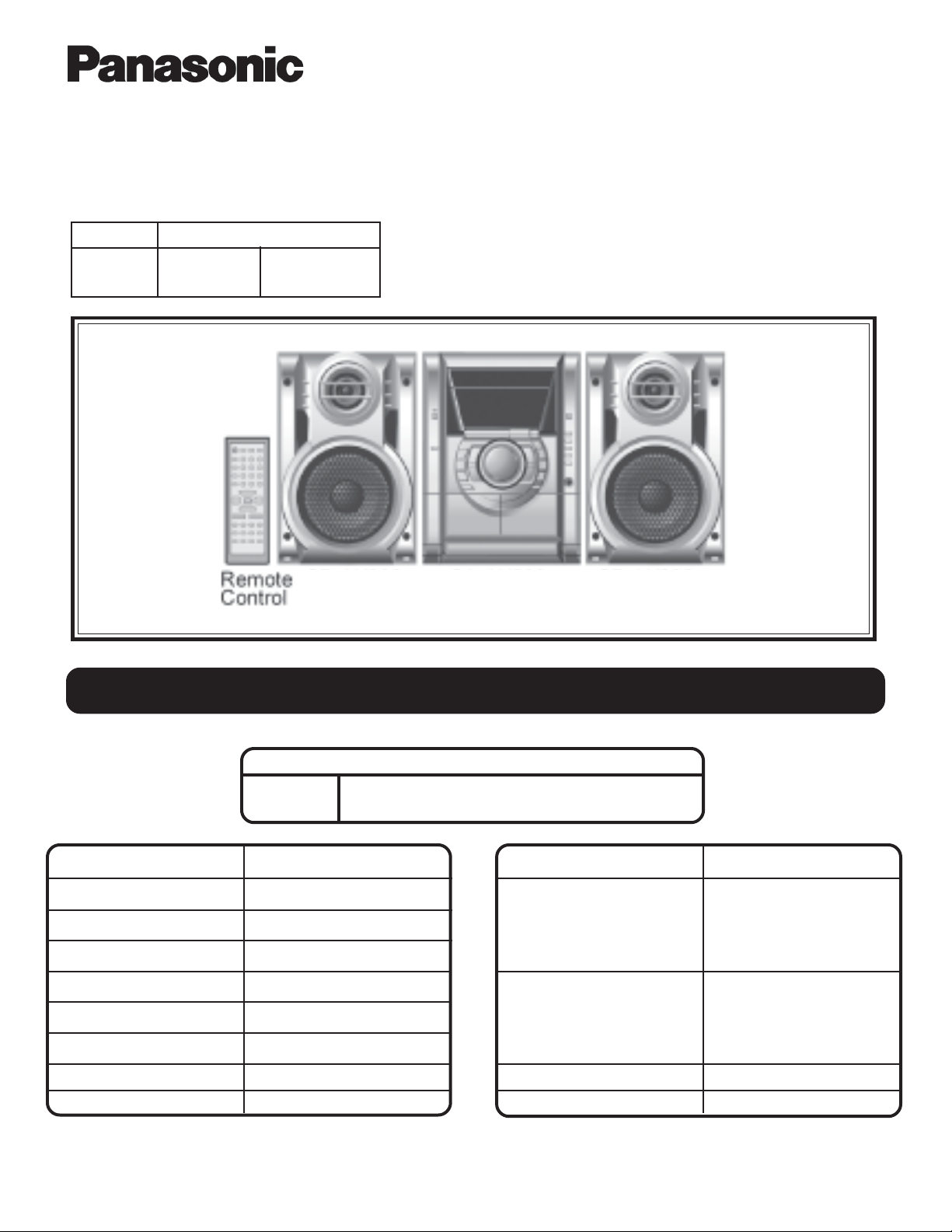

ORDER NO. MD0411547C1

Service Manual

A6

MODEL UNIT

SC-TM23 SA-TM23 STEREO

SB-TM23 FRONT SPEAKER

SB-TM23 SA-TM23 SB-TM23

SC-TM23

Specifications

Potencia de salida

SC-TM 23 Frontal 90W RCM por canal (5Ω)

Amplificador SA-TM23

Potencia de salida 2000 W (P.M.P.O)

Consumo de potencia 145 W

Alimentaciòn 127 V ca ±10% 60 Hz

Sencibilidad Aux: 250 mV

Rango de sintonìa AM:

Rango de sintonìa FM:

Dimensiones (b x h x l) 250 mm x 330 mm x 320mm

Peso: 6.4 kg aprox

520-1710MHz (paso de 0,2 MHz)

87.9-107.9 MHz (paso de 0,2 MHz

87.5-108.0 MHz (paso de 0,1 MHz

1kHz, 10% DAT

Bafles SB-TM23

FRONTAL

Bocina Super Tweeter - - - - - Bocina Tweeter 6 cm

Bocina Woofer 16 cm

IMPEDANCIA

Frontal 5 Ω

Alto - - - - - Bajo - - - - - -

Dimensiones (b x h x l) 220 mm x 330 mm x 201mm

Peso: 2.7 kg aprox.

Notes: Specifications are subject to change without notice. Mass and dimensions are approximate.Total harmonic distortion is measured by the digital spectrum analyzer.

© 2004 Matsushita Electric Industrial Co. Ltd.. All rights reserved. Unauthorized copying and distribution is a violation of law.

Page 2

!

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general

public.

It does not contain warnings or cautions to advise non-technical individuals of potencial dangers in attemping to

service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt

to service or repair the product or products dealt with in this service information by anyone else could result in serious

injury or death.

Contents

1 Safety Precaution

1.1 Insulation Resistance Test

1.2 Caution for fuse replacement

2 Before Repair and Adjustment

3 Protection Circuitry

4 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

5 Handling the Lead-free Solder

5.1 About lead free solder (PbF)

6 Handling Precautions For Traverse Deck

7 Precaution of Laser Diode

8 Accessories

9 Operation Procedures

10 Disassembly and Assembly of Main Component 10.1

Disassembly flow chart

10.2 Gear for servicing (jig) Information

10.3 Disassembly of Top Cabinet

10.4 Disassembly of CD Lid

10.5 Disassembly of Rear Panel

10.6 Disassembly of CD Mechanism Unit

10.7 Disassembly of Main P.C.B.

10.8 Disassembly of Power P.C.B.

10.9 Disassembly of Transformer P.C.B.

10.10 Disassembly of Front Panel Unit

10.11 Disassembly of Deck Mechanism Unit

10.12 CD Mechanism Main Component Replacement

Procedures

10.12.1 Replacement of the Traverse Deck

10.12.2 Replacement for the Disc Tray

10.12.3 Disassembly and reassembly for mechanism

base drive unit

10.12.4 Replacement for the motor ass ’ y

10.13 Replacement for the pinch roller ass ’ y and head

block

10.14 Replacement for the Deck motor ass ’ y, capstan

belt A, capstan belt B and winding belt

10.15 Replacement for the cassette lid ass ’ y

10.16 Rectification for tape jam problem

11 Checking for major P.C.Bs

11.1 Checking of Main P.C.B.

11.2 Checking of Transformer P.C.B.

11.3 Checking of Panel, Deck & Deck Mechanism P.C.B.

11.4 Checking of Power P.C.B.

12 Self-Diagnostic Function

12.1 Self-diagnostic display

12.2 How to enter the Self-Diagnostic Function

12.3 Cassette Mechanism Test (For error code H01, H02,

H03, F01)

12.4 CD Mechanism Test (F15, F26, F16, F17, F27, F28, F29,

F30, H15 & H16)

12.5 To clear all Error code

12.6 To exit from Self-Diagnostic function

12.7 Power Amplifier Failure (F61)

12.8 Description of Error Code

12.8.1 Abnormality detection for Deck Mechanism block

12.8.2 Abnormality detection for CD / Changer block

12.8.3 Power supply related error detection

12.8.4 Error Code (CR20 Mechansim)

13 CD Test Mode Function

13.1 How to set CD test mode

13.2 CD Automatically Adjustment result indication

13.3 CD Mecha Aging Test Mode (CR20)

13.4 Micon ROM Checksum and Version Display Mode

14 Measurements and Adjustments

14.1 Cassette Deck Section

14.1.1 Tape Speed Adjustment (Deck 1 / 2)

14.1.2 Bias and Erase Voltage Check

14.1.3 Bias Frequency Adjustment (Deck 1 / 2)

14.2 Tuner Section

14.2.1 AM-IF Alignment

14.2.2 AM RF Adjustment

14.3 Alignment Points

14.3.1 Cassette Deck Section

14.3.2 Tuner Section

15 Block Diagram

16 Voltage Measurement

17 Schematic Diagram

17.1 (A) CD Servo Circuit

17.2 (B) Main (Tuner) Circuit

17.3 (B) Main Circuit

17.4 (C) Panel Circuit

17.5 (D) Transformer Circuit, (E) CD Detect Circuit, (F)

Spindle Position Circuit & (G) CD Loading Circuit

17.6 (H) Power Circuit

17.7 (I) Deck Circuit & (J) Deck Mechanism Circuit

18 Printed Circuit Board

18.1 (A) CD Servo P.C.B.

18.2 (B) Main P.C.B.

18.3 (C) Panel P.C.B.

18.4 (D) Transformer P.C.B.

18.5 (E) CD Detect P.C.B., (F) Spindle Position P.C.B., (G) CD

Loading P.C.B. & (K) Tuner Pack P.C.B.

18.6 (H) Power P.C.B.

18.7 (I) Deck P.C.B. & (J) Deck Mechanism P.C.B.

19 Wiring Connection Diagram

20 Illustration of IC ’ s, Transistors and Diodes

21 Terminal Function of IC ’ s

21.1 IC7002 (MN6627953HB) Servo processor / Digital signal

processor / Digital filter / D / A converter

21.2 IC7003 (AN8739SBTE2) Focus coil / Tracking coil /

Traverse motor / Spindle motor drive

21.3 IC2801 (C2CBJG000565) System Microprocessor

22 Troubleshooting Guide

23 Parts Location and Replacement Parts List

23.1 Deck Mechanism (RAA4502-S)

23.1.1 Deck Mechanism Parts Location

23.1.2 Deck Mechanism Parts List

23.2 CD Loading Mechanism (RD-DAC026-S)

23.2.1 CD Loading Mechanism Parts Location

23.2.2 CD Loading Mechanism Parts List

23.3 Cabinet

23.3.1 Cabinet Parts Location

23.3.2 Cabinet Parts List

23.4 Electrical Parts List

23.5 Packing Materials & Accessories Parts List

23.6 Packaging

Page 3

1 Safety Precaution

(This “Safety Precaution” is applied only in U.S.A.)Before servicing, unplug the power cord to prevent an electric shock.

When replacing parts, use only manufacturer’s recommended components for safety.

Check the condition of the power cord. Replace if wear or damage is evident.

After servicing, be sure to restore the lead dress, insulation barriers, insulation papers, shields, etc.

Before returning the serviced equipment to the customer, be sure to make the following insulation resistance test

to prevent the customer from being exposed to a shock hazard.

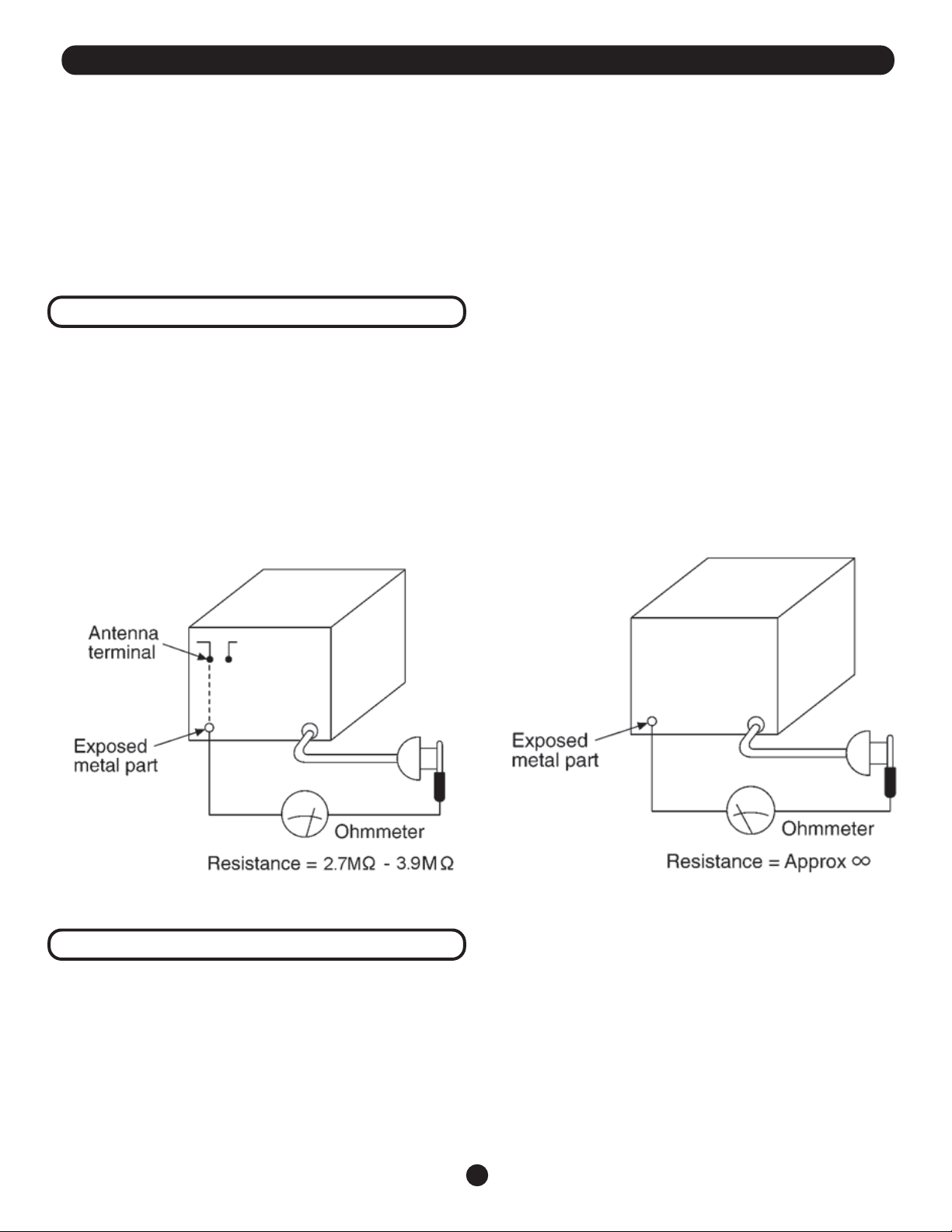

1.1 Insulation Resistance Test

Unplug the power cord and short the two prongs of the plug with a jumper wire.

Turn on the power switch.

Measure the resistance value with ohmmeter between the jumper AC plug and each exposed metal cabinet part, such as

screwheads, antenna, control shafts, handle brackets, etc.Measure the resistance value with ohmmeter between the

jumper AC plugand each exposed metal cabinet part, such as screwheads, antenna, control shafts, handle brackets, etc.

Equipment with antenna terminals should read between 2.7M˜ and 3.9M˜ to all exposed parts*. ( Fig.1 )

Equipment without antenna terminals should read approximately infinity to all exposed parts. ( Fig.2 )

*Note : Some exposed parts may be isolated from the chassisby design. These will read infinity.

If the measurement is outside the specified limits, there is a possibility of a shock hazard. The equipment should be repaired

and re-checked before it is returned to the customer.

Fig.1

1.2 Caution for fuse replacement

(For English)

CAUTION:

Fig.2

Replace with the same type fuse:

(Manufacturer: LITTELFUSE, INC, Type: F1, 2.5A, 125V)

(For Canadian French)

ATTENTION:

Utiliser un fusible de rechanche de méme type:

(Manufacturer: LITTLEFUSE, INC, Type: F1, 2.5A, 125V)

3

Page 4

2 Before Repair and Adjustment

Disconnect AC power, discharge Power Supply Capacitors C5820 and C5840 through a 10Ω, 5W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Current consumption at AC 120V, 60 Hz in NO SIGNAL mode (volume min at CD mode) should be ~600mA.

3 Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

· No sound is heard when the power is turned on.

· Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection

wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1.Turn off the power.

2.Determine the cause of the problem and correct it.

3.Turn on the power once again after one minute.

Note :

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

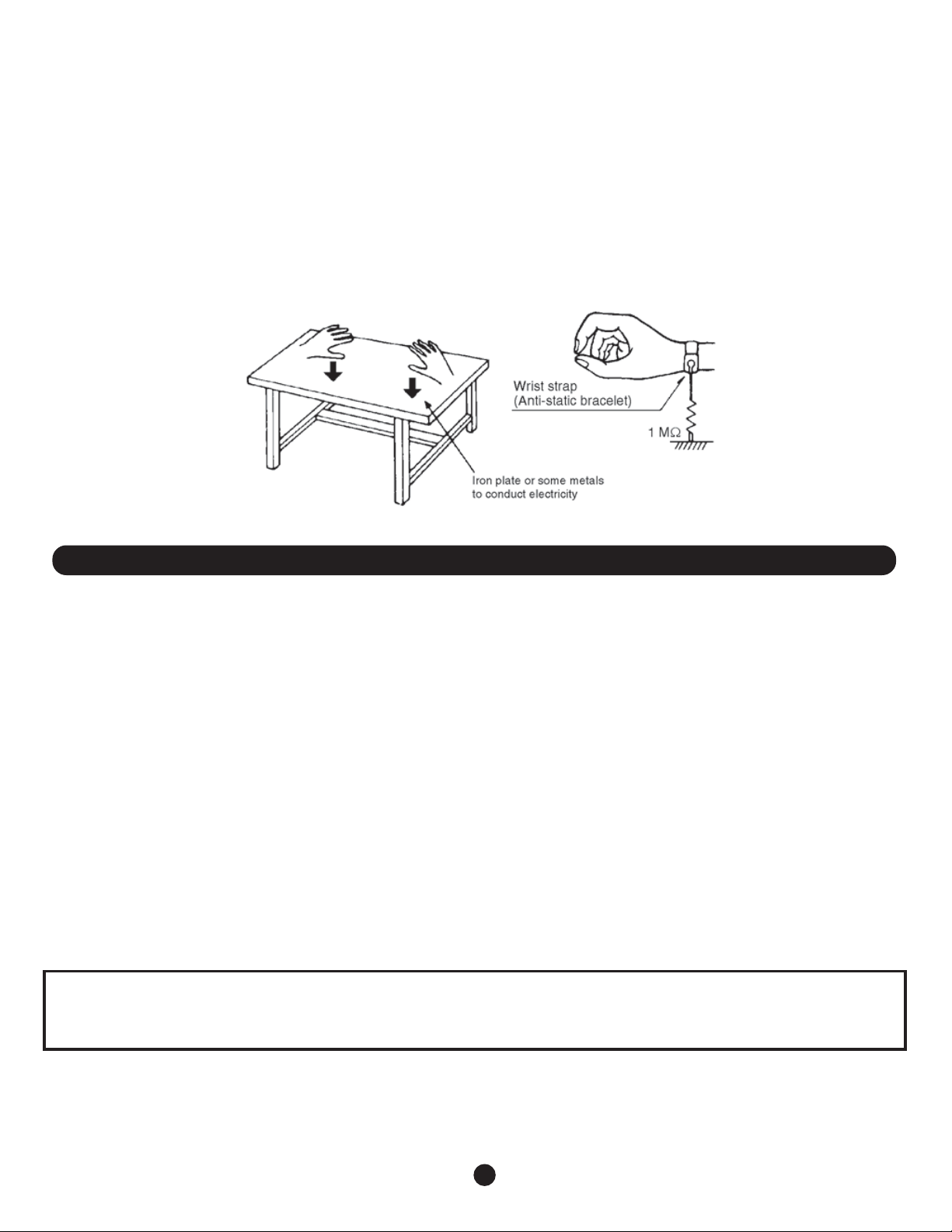

4 Prevention of Electro Static Discharge (ESD) to Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect

transistorsand semiconductor “chip” components. The following techniques should be used to help reduce the incidence

of component damage caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equiped assembly, drain off

any ESD on your body by touching a known earth ground. Alternatively, obtain and wear a commercially available

discharging ESD wrist strap, whichshould be removed for potential shock reasons prior to applying power to the unit under

test.

2. After removing an electrical assembly equiped with ES devices, place the assembly on a conductive surface

such as aluminium foil, to prevent electrostatic charge build up or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder remover device. Some solder removal devices not classified as “anti-static (ESD

protected)” can generate electrical charge to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready

to install it. (Most replacement ES devices are packaged with leads electrically shorted together by conductive foam,

aluminium foil orcomparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the

protective material to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize body motions when handling unpackaged replacement ES devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static

electricity (ESD) sufficient todamage an ES device).

IMPORTANT SAFETY NOTICE

There are special components used in this equipment which are important for safety.

These parts are marked by in the schematic diagrams, Exploded Views and replacement parts list. It is essential that these

critical parts should be replaced with manufacturer´s specified parts to prevent shock, fire, or other hazards. Do not modify the

original design without permission of manufacturer.

!

4

Page 5

5 Handling the Lead-free Solder

5.1 About lead free solder (PbF)

Distinction of PbF P.C.B.:

P.C.B.s (manufactured) using lead free solder will have a PbF

stamp on the P.C.B.

Caution:

· Pb free solder has a higher melting point than

standard solder; Typically the melting point is 50 - 70°F (30 40°C) higher. Please use a high temperature soldering iron.

In case of soldering iron with temperature control,please set

it to 700 ± 20°F (370 ± 10°C).

· Pb free solder will tend to splash when heated too

high (about 1100°F/600°C).

· When soldering or unsoldering, please completely

remove all of the solder on the pins or solder area, and be

sure to heat the soldering points with the Pb free solder until

it melts enough.

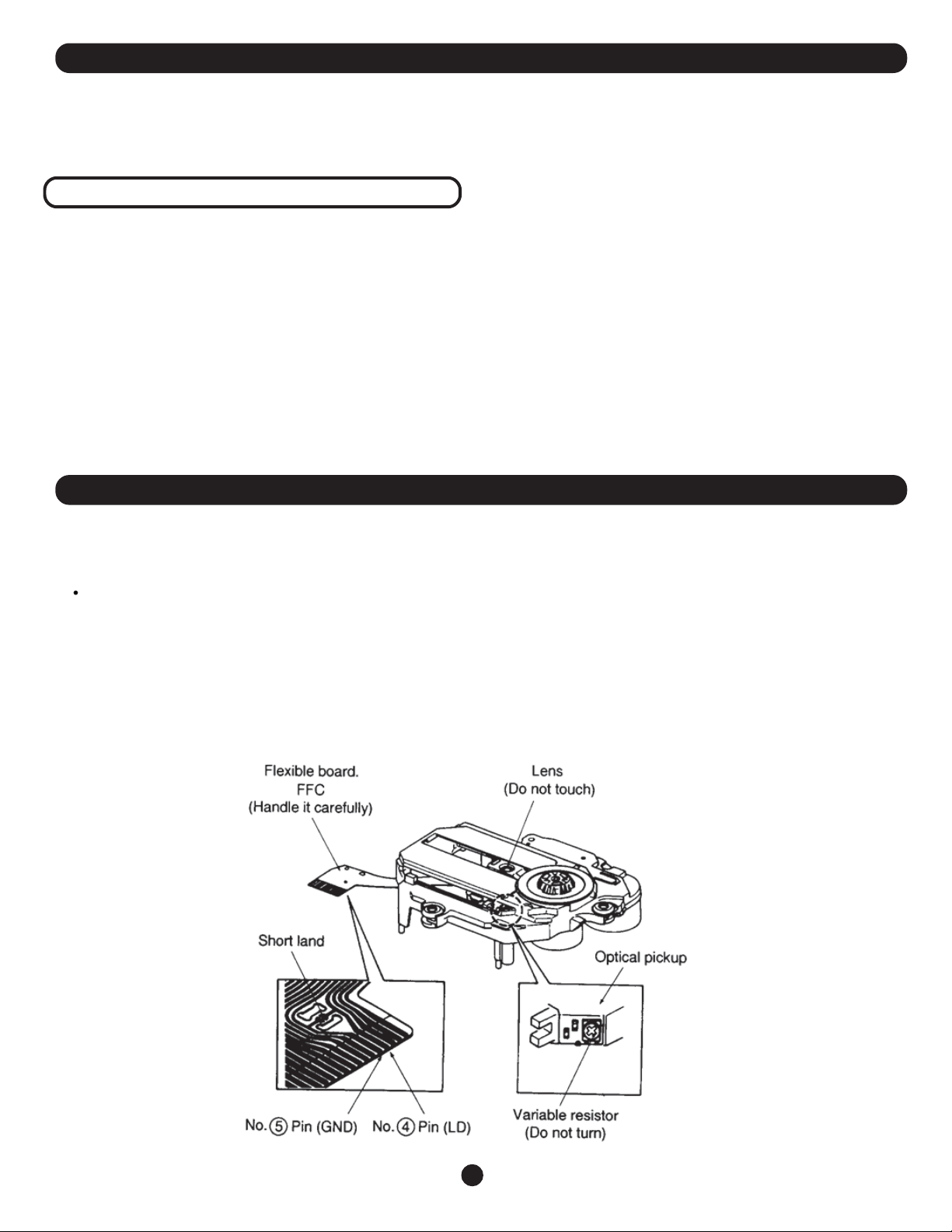

6 Handling Precautions For Traverse Deck

The laser diode in the traverse deck (optical pickup) may break down due to potential difference caused by static electricity

of clothes or human body.

So, be careful of electrostatic breakdown during repair of the traverse deck (optical pickup).

Handling of traverse deck (optical pickup)

1. Do not subject the traverse deck (optical pickup) to static electricity as it is extremely sensitive to electrical shock.

2. To prevent the breakdown of the laser diode, an antistatic shorting pin is inserted into the flexible board (FFC board).

3. Take care not to apply excessive stress to the flexible board (FFC board). When removing or connecting the short pin,

finish the job in as short time as possible.

4. Do not turn the variable resistor (laser power adjustment). It has already been adjusted.

5

Page 6

Grounding for electrostatic breakdown prevention

1. Human body grounding

Use the anti-static wrist strap to discharge the static electricity from your body.

2. Work table grounding

Put a conductive material (sheet) or steel sheet on the area where the traverse deck (optical pickup) is place, and

ground the sheet.

Caution :

The static electricity of your clothes will not be grounded through the wrist strap. So, take care not to let your clothes touch the

traverse deck (optical pickup).

Caution when replacing the Traverse Deck

The traverse deck has a short point shorted with solder to protect the laser diode against electrostatics breakdown. Be sure to

remove the solder from the short point before making connections.

7 Precaution of Laser Diode

CAUTION:

This unit utilizes a class 1 laser.

Invisible laser radiation is emitted from the optical pickup lens.

Wavelength: 780nm

When the unit is turned on:

1. Do not look directly into the pick up lens.

2. Do not use optical instruments to look at the pick up lens.

3. Do not adjust the preset variable resistor on the pickup lens.

4. Do not disassemble the optical pick up unit.

5. If the optical pick up is replaced, use the manufacturer’s specified replacement pick up only.

6. Use of control or adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION!

THIS PRODUCT UTILIZES A LASER.USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN

THOSE SPECIFIED HEREIN

MAY RESULT IN HAZARDOUSRADIATION EXPOSURE.

Use of caution label (Except for U.S.A.)

6

Page 7

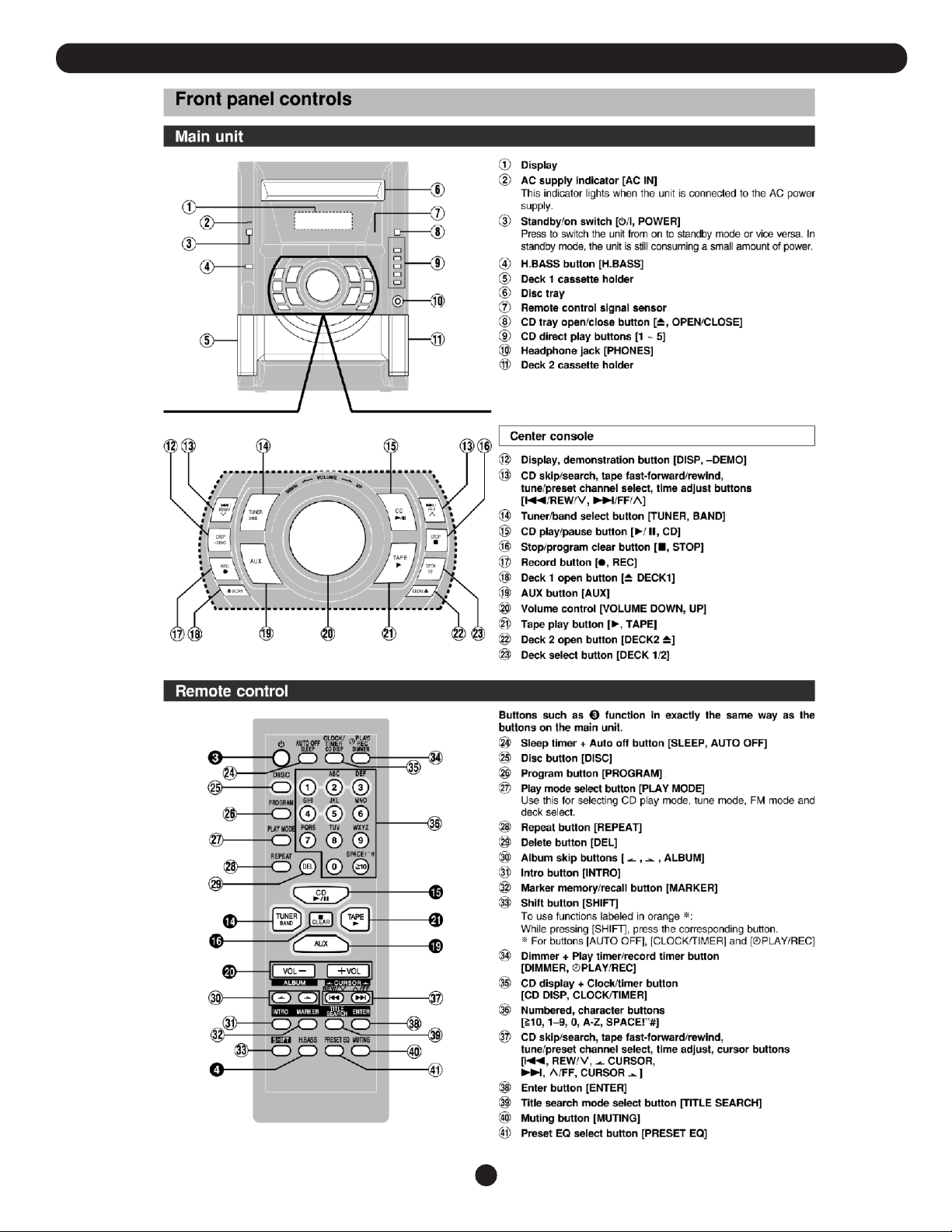

8 Accessories

Remote Control

EUR7710020

(1 Pc)

AC Cord

SJA168-1A

(1 Pc)

FM Antenna

RSA0006-L

(1 Pc)

AM Loop Antenna

N1DAAAA00001

(1 Pc)

7

Page 8

9 Operation Procedures

8

Page 9

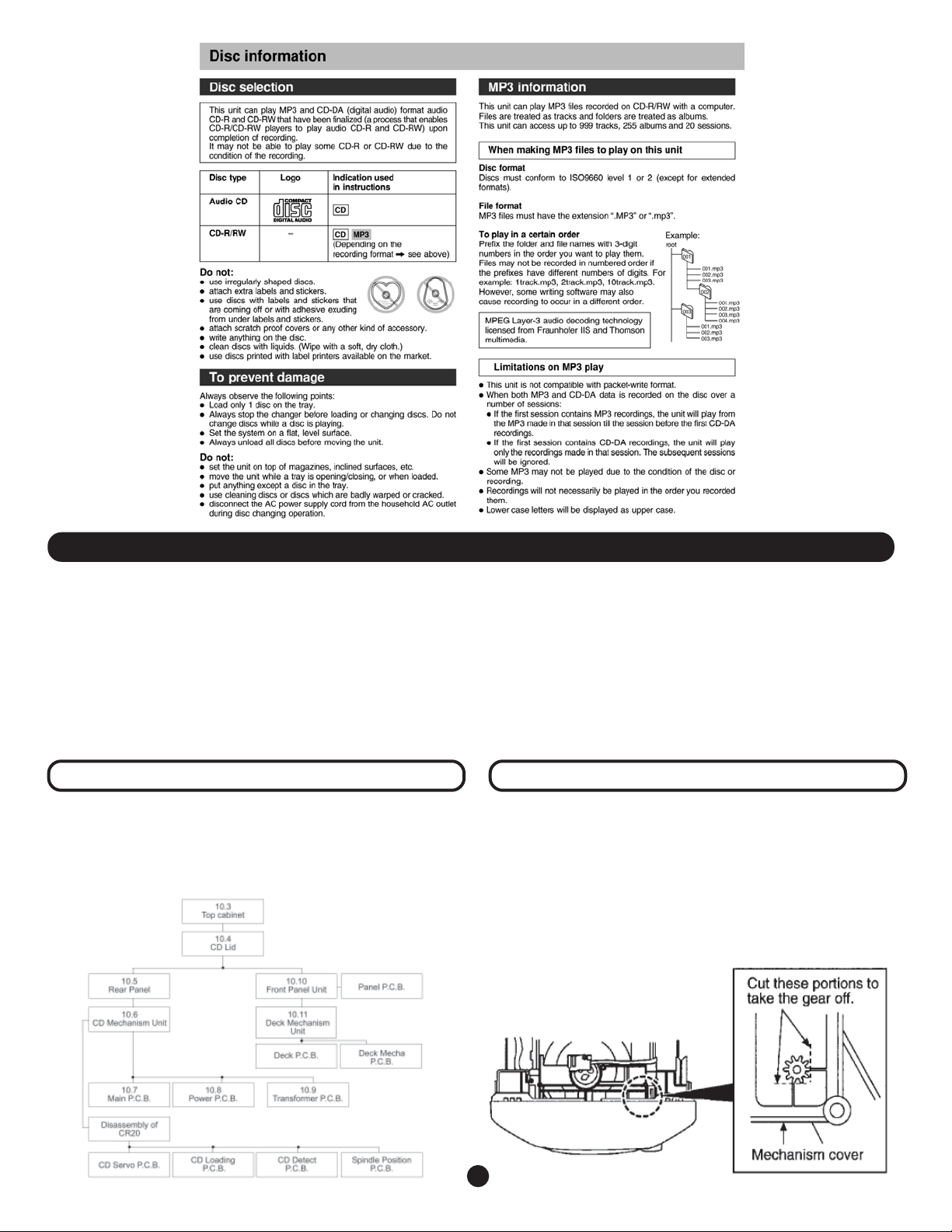

10 Disassembly and Assembly of Main Component

“ATTENTION SERVICER”

Some chassis components may have sharp edges. Be careful when disassembling and servicing.

main components.

Special reassembly procedures are described only when required.

1.-This section describes procedures for checking the operation of the major printed circuit boards and replacing the

2.-For reassembly after operation checks or replacement, reverse the respective procedures.

3.-Select items from the following index when checks or replacement are required.

4.-Refer to the Parts No. on the page of “Main component Replacement Procedures”, if necessary.

10.1 Disassembly flow chart

The following chart is the procedure for disassembling the

casing and inside parts for internal inspection when carrying

out the servicing.

To assemble the unit, reverse the steps shown in the chart as

below.

(Open/Close of disc tray, up/down operation of traverse unit

by manually) when servicing.

procedures as follows.

servicing” may has been taken off because it has been used.

The “gear for servicing” must be stored.

· Remove the gear provided with mechanism cover as

shown below.

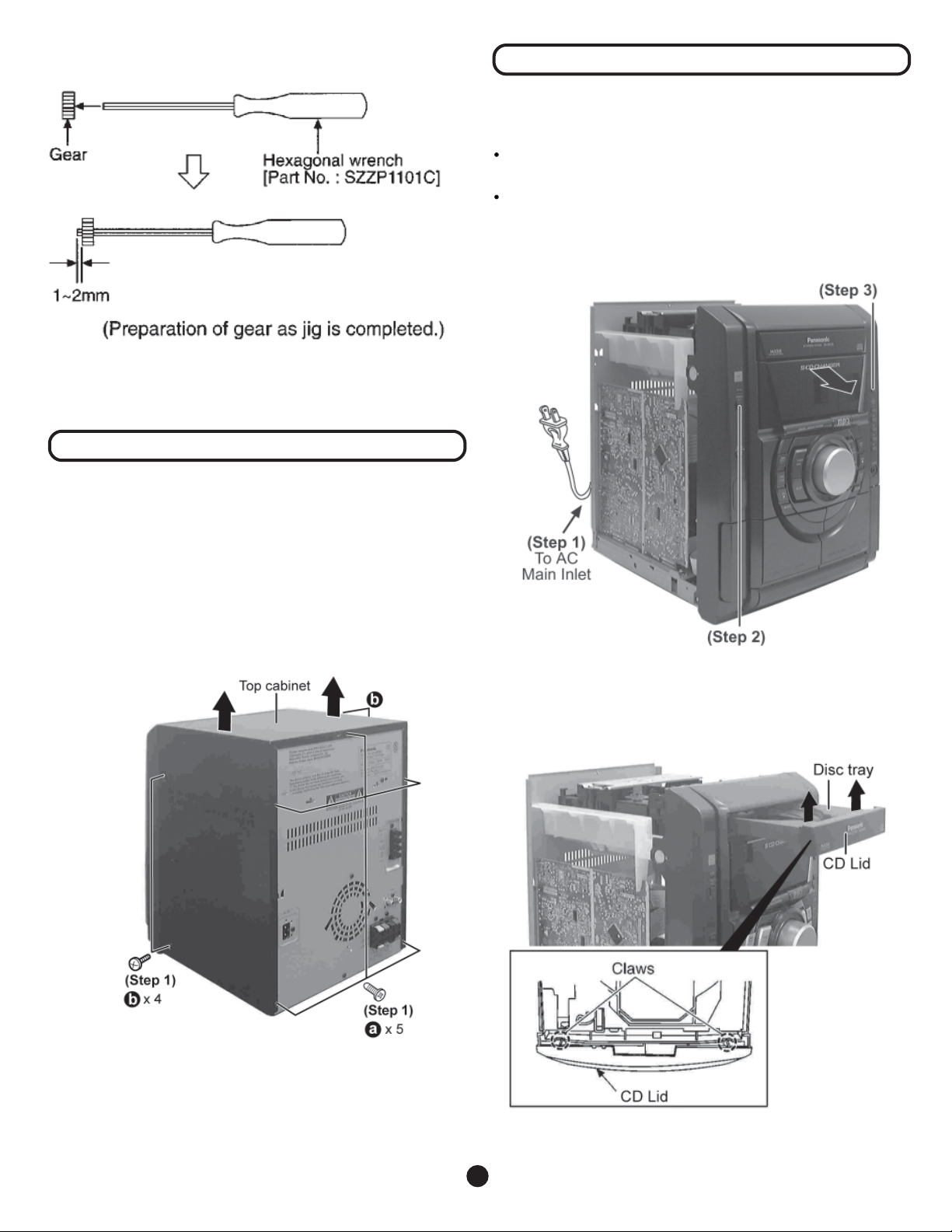

10.2 Gear for servicing (jig) Information

1.-This unit has a gear which is used for checking items

2.-For preparation of gear (for servicing), perform the

3.-In case of re-servicing the same set, the “gear for

9

Page 10

Insert the hexagonal screwdriver (2mm) into the gear, and

then project the tip of screwdriver for 1~ 2 mm in length.

10.3 Disassembly of Top Cabinet

10.4 Disassembly of CD Lid

(The CD changer unit can be removed after the CD Lid is

removed)

· Follow the (Step 1) - (Step 2) of Item 10.3 Disassembly of Top Cabinet

· Opening the disc tray automatically (Using Power

Supply)

Step 1 Connect the AC power cord.

Step 2 Press the POWER button to power up the main unit.

Step 1 Remove 2 screws at each side and 5 screws at

rear panel.

Step 2 Lift up both sides of the top cabinet, push the

top cabinet

towards the rear and remove the top cabinet.

Step 3 Press the OPEN/CLOSE button, the disc tray will open

automatically.

10

Page 11

Step 4 Release the 2 claws, and then remove the CD Lid.

Step 5 Press the OPEN/CLOSE button, the disc tray will close.

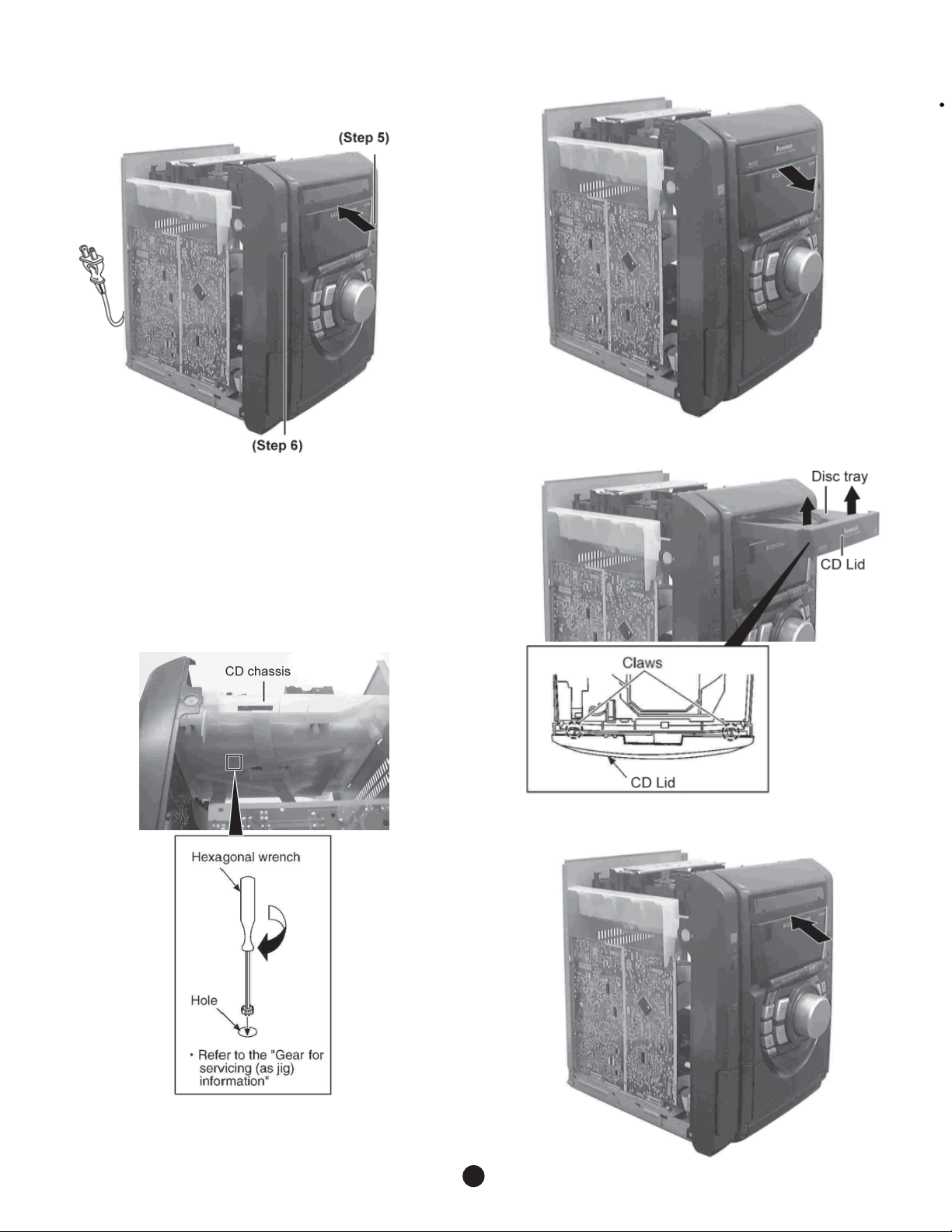

Step 1 Insert the gear tool into the hole on the underside of

CD chassis and then rotate in the direction of arrow. The disc

tray will be opened.

Step 2 Release the 2 claws, and then remove the CD lid

cover.

Step 6 Press the POWER button to turn the power off.

· [Opening the disc tray manually (Using service

tools)]

Step 3 Repeat Step 2 but rotate the gear tools in anti-

clockwise direction

Step 4 The disc tray will be closed.

11

Page 12

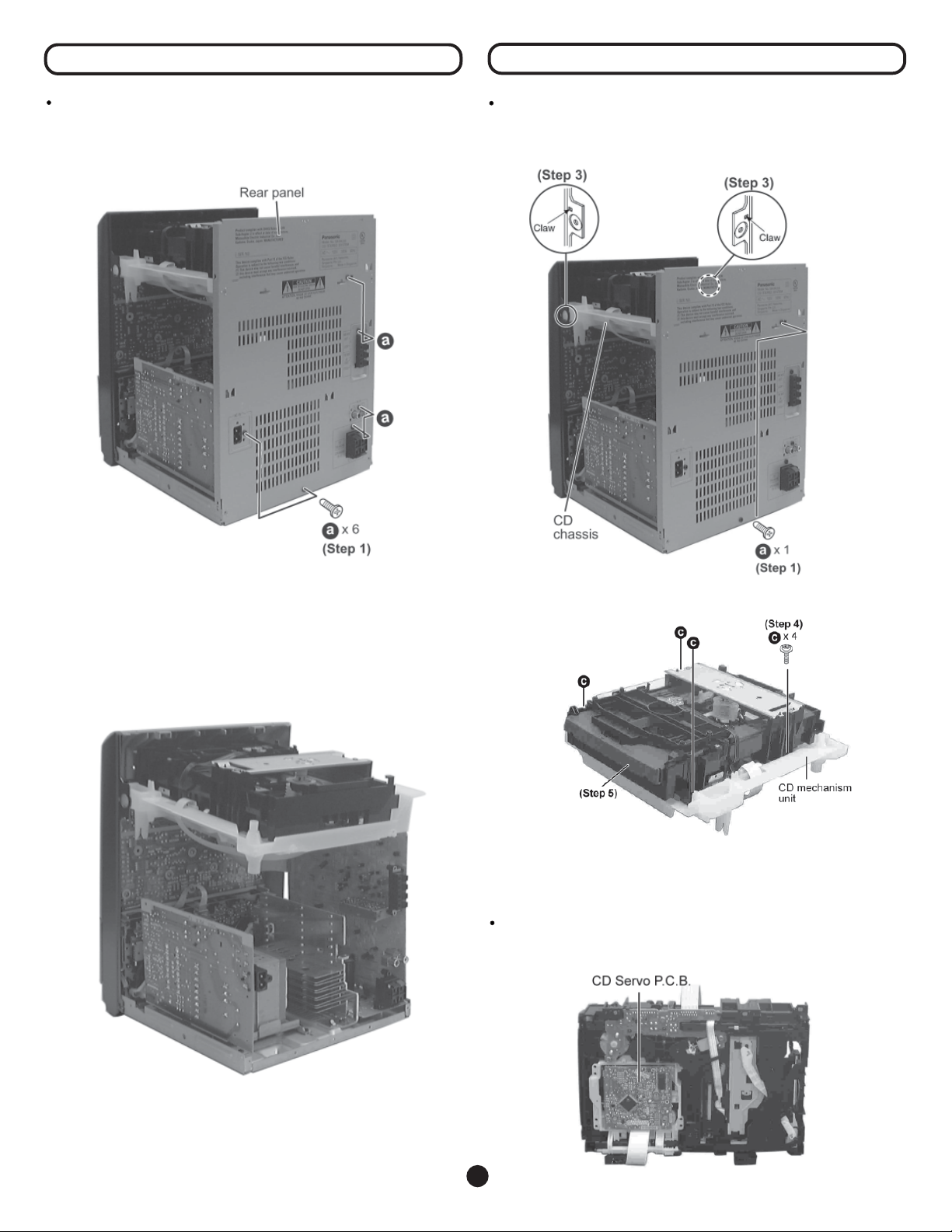

10.5 Disassembly of Rear Panel

10.6 Disassembly of CD Mechanism Unit

· Follow the (Step 1) - (Step 2) of Item 10.2 - Disassembly

of Top Cabinet

Step 1 Remove 6screws and disconnect wire CN2810 (Fan)

at rear cabinet as shown.

· Follow the (Step 1) - (Step 2) of Item 10.3 Disassembly of Top Cabinet

Step 1 Remove one screw at rear panel.

Step 2 Detach the FFC wires (CN2801 & CN2805).

Step 3 Release the claws of both ends, and then lift up the

CD Mechanism Unit.

Step 4 Remove 4 screws.

Step 5 Remove the CD chassis.

Step 6 Lay the CD mechanism unit as shown.

· For disassembly of CD mechanism unit, please

refer to Section 10.11 of this manual.

12

Page 13

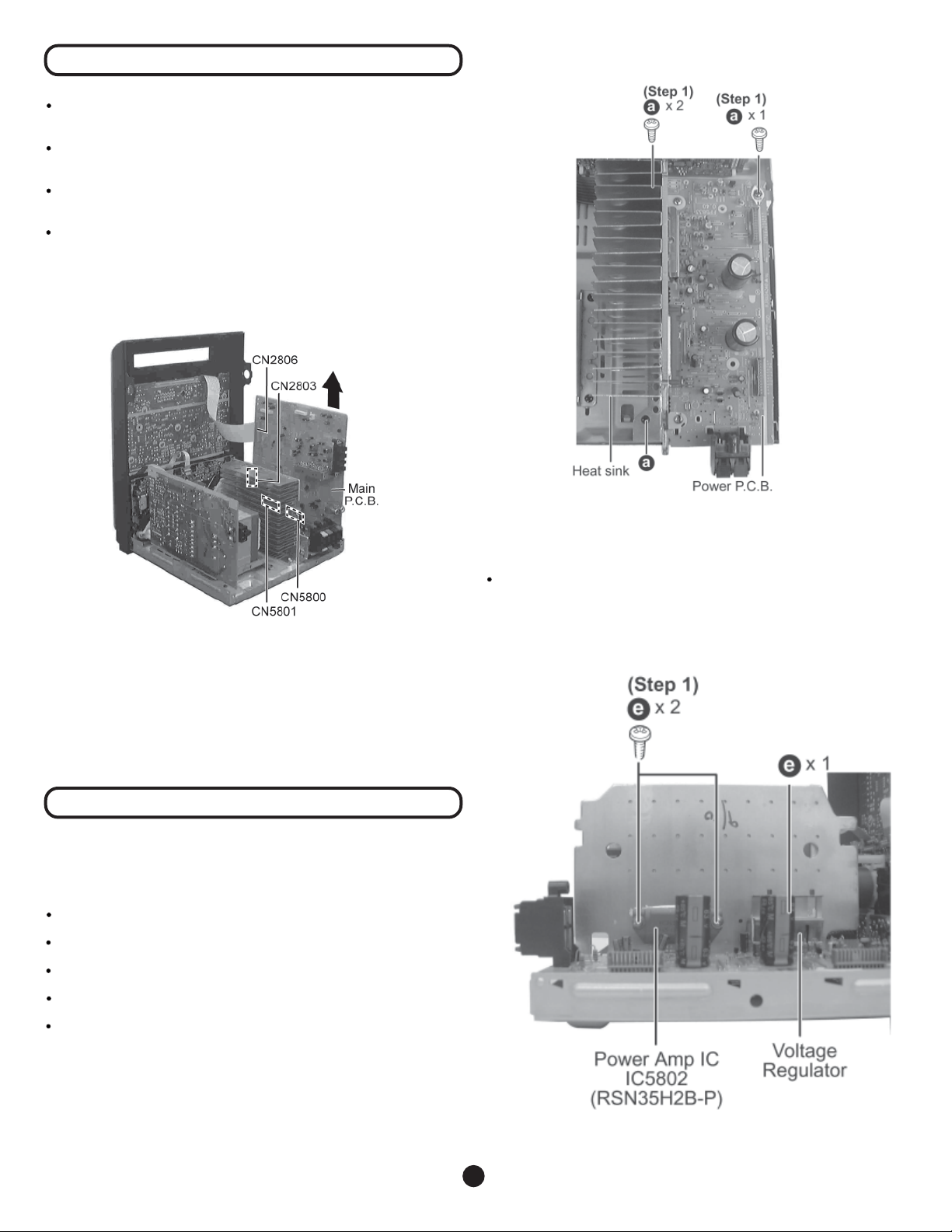

10.7 Disassembly of Main P.C.B.

· Follow the (Step 1) - (Step 2) of Item 10.3 Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 6) of Item 10.4 Disassembly of CD Lid

· Follow the (Step 1) of Item 10.5 - Disassembly of the

Rear Panel

· Follow the (Step 1) - (Step 3) of Item 10.6 Disassembly of the CD Mechanism Unit

Step 1 Disconnect FFC wires CN2803 & CN2806 from Main

P.C.B.

Step 1 Remove the 2 screws fixed at heat sink and 1 screw

fixed at Power P.C.B..

Step 2 Lift up Main P.C.B. by disconnecting connectors

CN5800 & CN5801 as arrow shown above.

10.8 Disassembly of Power P.C.B.

· Follow the (Step 1) - (Step 2) of Item 10.3 - Disassembly

of Top Cabinet

· Follow the (Step 1) - (Step 6) of Item 10.4 - Disassembly

of CD Lid

· Follow the (Step 1) of Item 10.5 - Disassembly of the

Rear Panel

· Follow the (Step 1) - (Step 3) of Item 10.6 - Disassembly

of the CD Mechanism Unit

· Follow the (Step 1) - (Step 2) of Item 10.7 - Disassembly

of the Main P.C.B.

Note:

Insulate the Power P.C.B. with insulation material to avoid

short circuit.

· Replacement of the Power Amplifier IC/ Voltage

Regulator

Step 1 Remove 2 screws fixed to the Power Amplifier IC and 1

screw to Voltage Regulator.

13

Page 14

Step 2 Break the joint with a metal cutter as shown below.

Step 3 Unsolder the terminals of Power Amp IC, transistor and

replace the components.

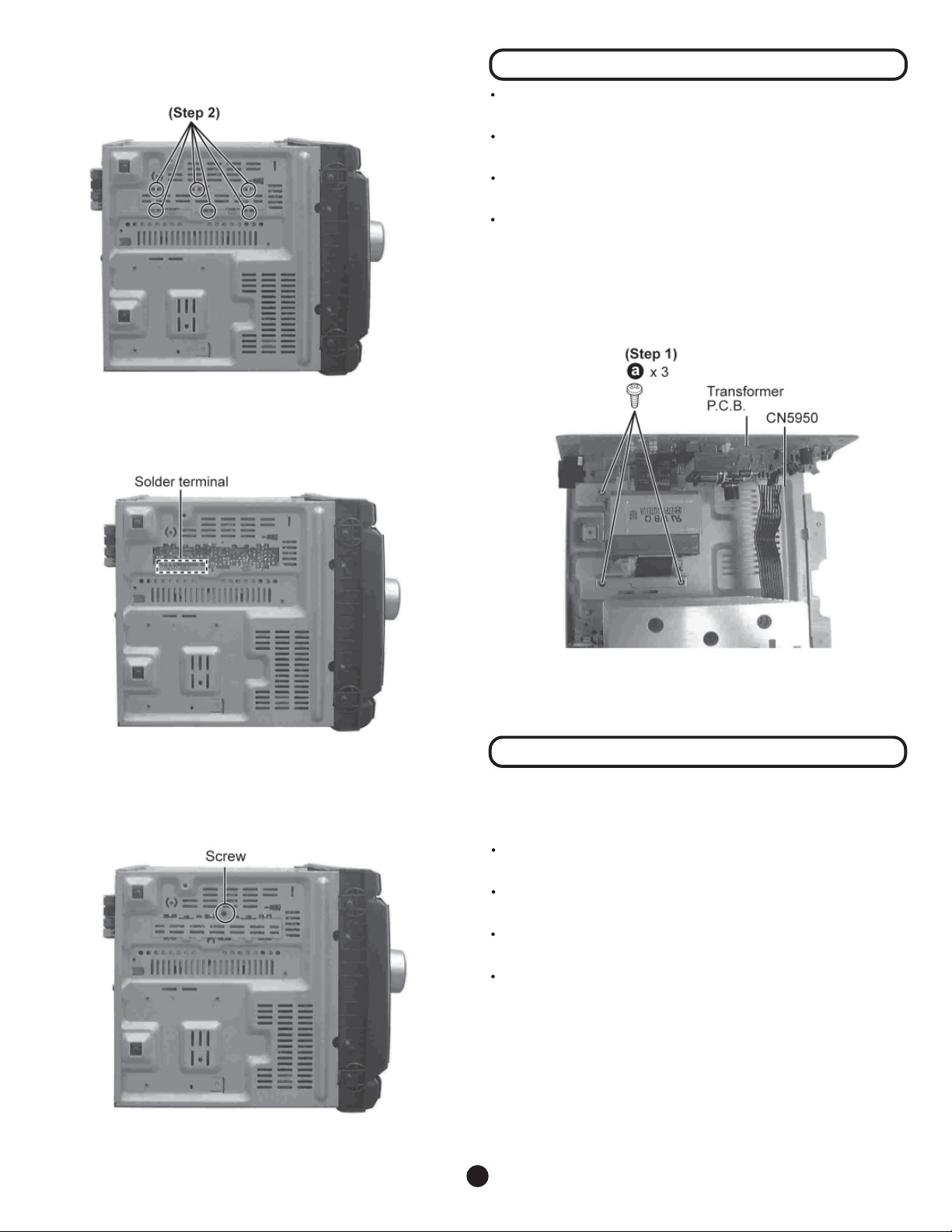

10.9 Disassembly of Transformer P.C.B.

· Follow the (Step 1) - (Step 2) of Item 10.3 Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 6) of Item 10.4 Disassembly of CD Lid

· Follow the (Step 1) of Item 10.5 - Disassembly of the

Rear Panel

· Follow the (Step 1) - (Step 3) of Item 10.6 Disassembly of the CD Mechanism Unit

Step 1 Remove 3 screws, disconnect connector CN5950.

Step 4 Fix back the cut portion with a screw as shown.

10.10 Disassembly of Front Panel Unit

· Follow the (Step 1) - (Step 2) of Item 10.3 Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 6) of Item 10.4 Disassembly of CD Lid

· Follow the (Step 1) of Item 10.5 - Disassembly of the

Rear Panel

· Follow the (Step 1) - (Step 3) of Item 10.6 Disassembly of the CD Mechanism Unit

Step 1 Lay the unit as shown below.

14

Page 15

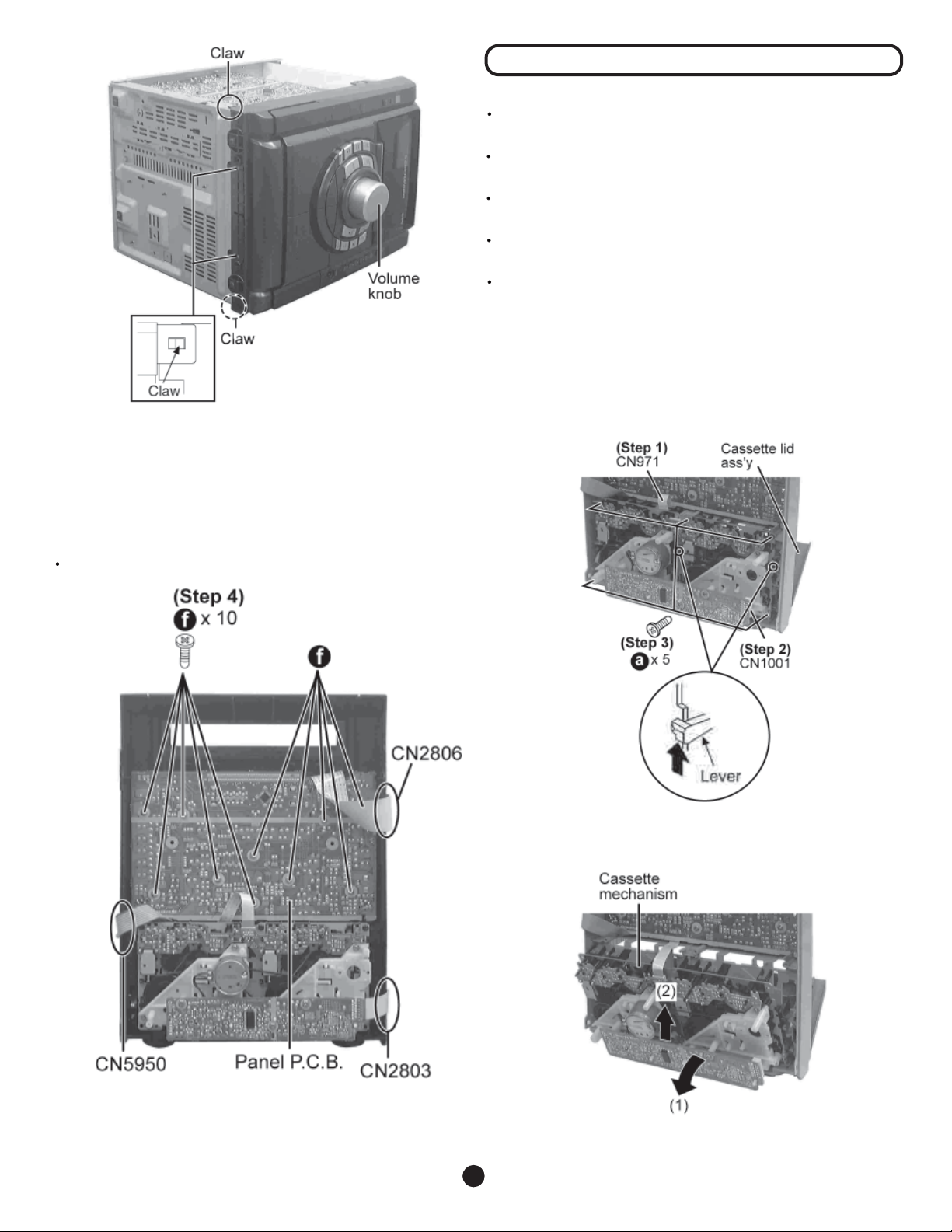

Step 2 Release 2 claws at bottom and 2 claws each side,

draw the front panel ass’y forward.

10.11 Disassembly of Deck Mechanism Unit

· Follow the (Step 1) - (Step 2) of Item 10.3 - Disassembly

of Top Cabinet

· Follow the (Step 1) - (Step 6) of Item 10.4 - Disassembly

of CD Lid

· Follow the (Step 1) of Item 10.5 - Disassembly of the

Rear Panel

· Follow the (Step 1) - (Step 3) of Item 10.6 - Disassembly

of the CD Mechanism Unit

· Follow the (Step 1) - (Step 3) of Item 10.10 Disassembly of the Front Panel Unit

Step 1 Detach FFC wire (at CN971).

Step 2 Disconnect FFC flat cable from the connector

(CN1001).

Step 3 Remove the 5 screws.

Step 3 Remove volume knob.

· Disassembly of Panel P.C.B.

Step 4 Remove the 10 screws.

Step 5 Disconnect connectors CN2806, CN2803 and CN5950.

15

Page 16

Step 4 Push the lever upward, and then open the cassette lid

ass’y (For DECK1 and DECK2).

Step 5 Tilt the cassette mechanism unit in the direction of

arrow (1), and then remove it in the direction of arrow (2).

· For replacement of Deck Mechanism P.C.B.

Step 6 Remove 3 screws.

Step 7 Unsolder the motor terminals.

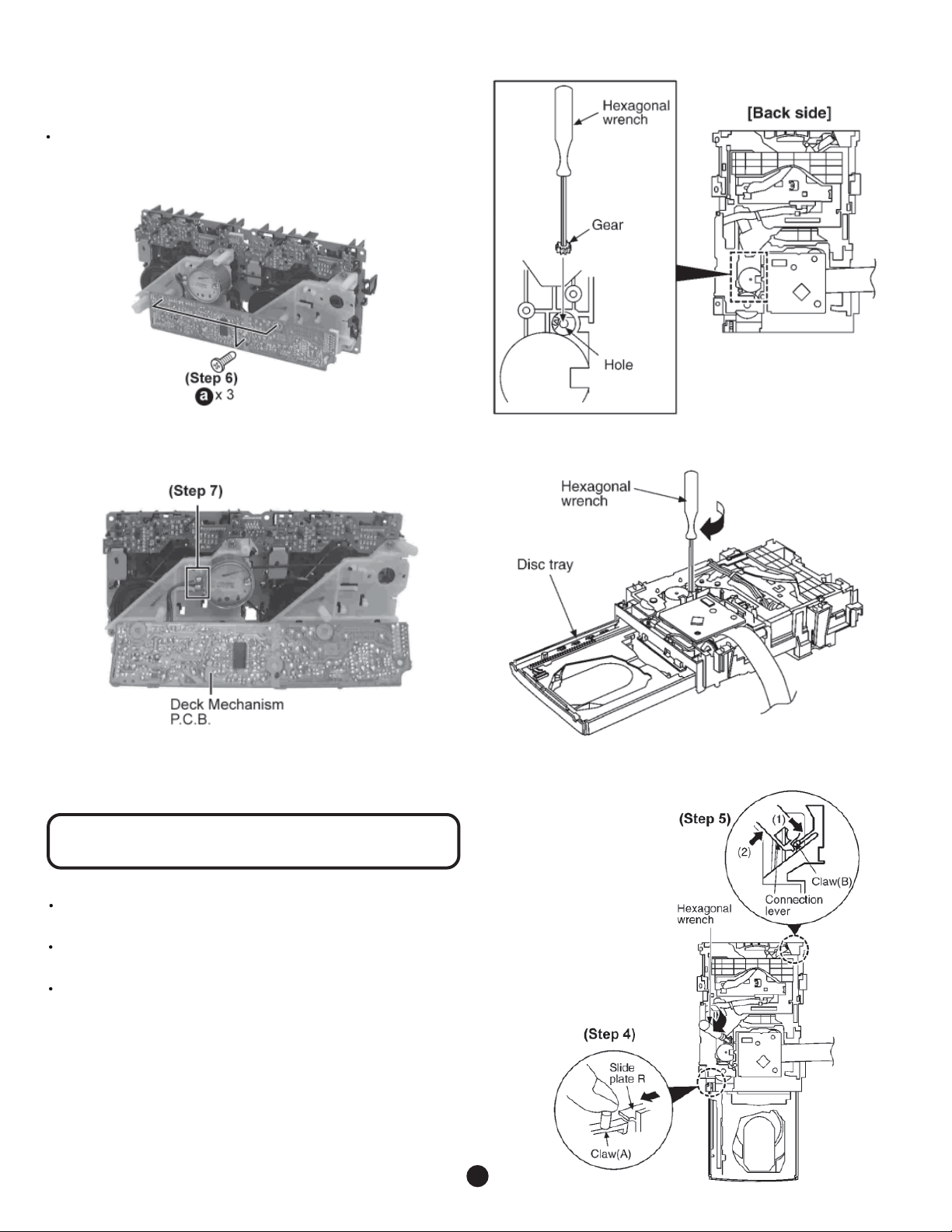

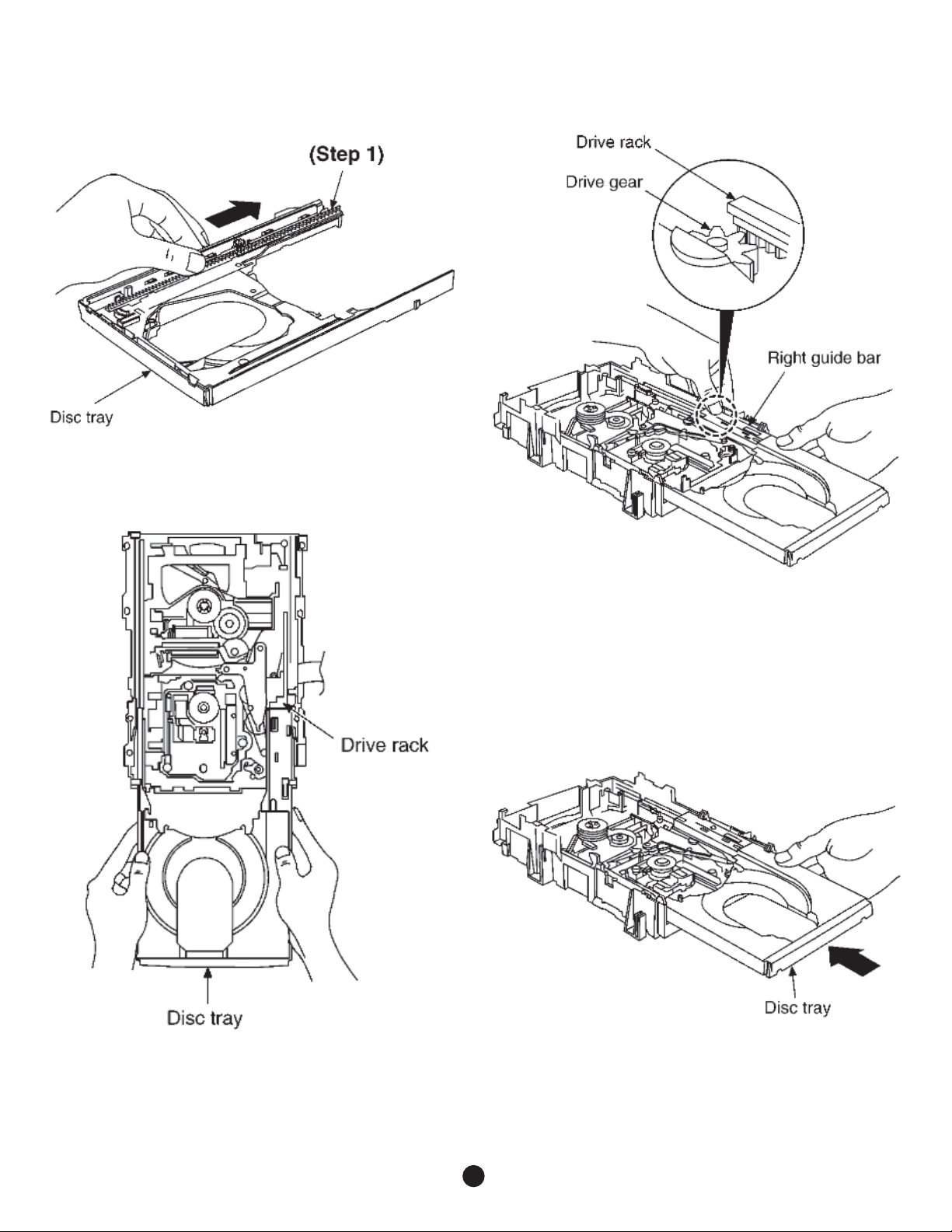

10.12.1 Replacement of the Traverse Deck

Step 2 Insert the gear with hexagonal wrench into the hole.

Step 8 Remove Deck Mechanism P.C.B.

10.12 CD Mechanism Main Component

Replacement Procedures

· Follow the (Step 1) - (Step 2) of Item 10.3 Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 6) of Item 10.4 Disassembly of CD Lid

· Follow the (Step 1) - (Step 6) of Item 10.6 Disassembly of the CD Mechanism Unit

Step 3 Rotate the hexagonal wrench in the direction of

arrow (clockwise), and then open the disc tray fully.

16

Page 17

Step 4 With pressing the claw (A), rotate the hexagonal

wrench clockwise. (The slide plate R moves for a little

amount.)

Step 5 Pressing the claw (B) in the direction of arrow (1), the

connection lever moves in the direction of arrow (2).

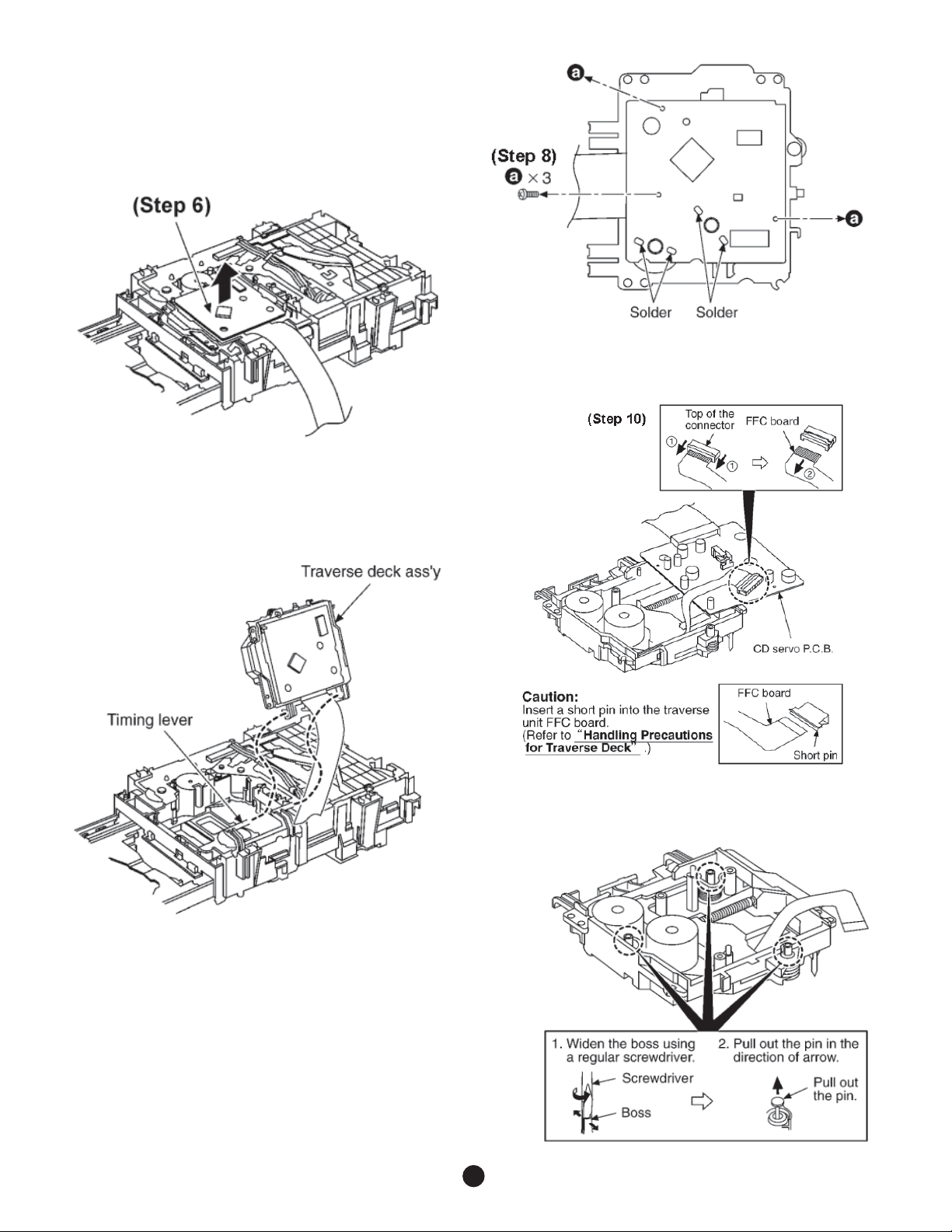

Step 6 Lift up the traverse deck ass’y.

Step 8 Remove 3 screws.

Step 9 Unsolder the motor terminals (4 points).

Step 7 Remove the traverse deck ass’y from the timing

lever.

Caution:

When removing or inserting the traverse deck avoid

touching the OPU lens and pressing onto the turntable.

Step 10 Remove the FFC board from the connector, and

then remove the CD Servo P.C.B.

Step 11 Remove the pin.

17

Page 18

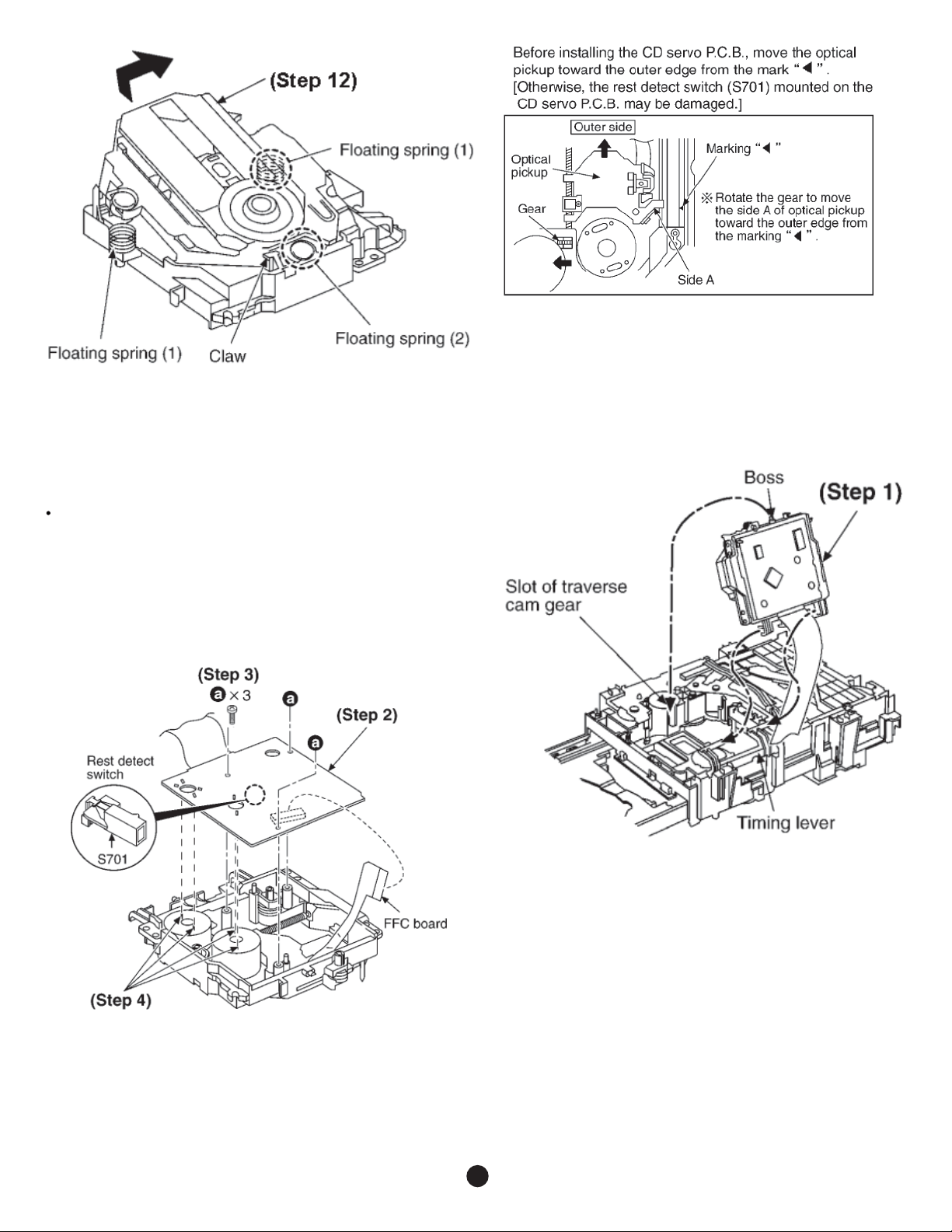

Step 12 Release the claw, and then remove the traverse

deck ass’y.

Note:

Be careful not to lose the 3 floating spring because those will

also be removed on removal of the traverse deck ass’y.

· Installation of the CD Servo P.C.B. after replacement

Step 1 Connect the FFC board.

Step 2 Install the CD servo P.C.B. in the traverse deck ass’y.

Step 3 Remove 3 screws.

Step 4 Solder.

Installation for traverse deck ass’y

Note for installation of the CD servo P.C.B.

Step 1 Install the traverse deck ass’y to the timing lever.

Step 2 Align the boss of traverse deck ass’y with the slot of

traverse cam gear.

18

Page 19

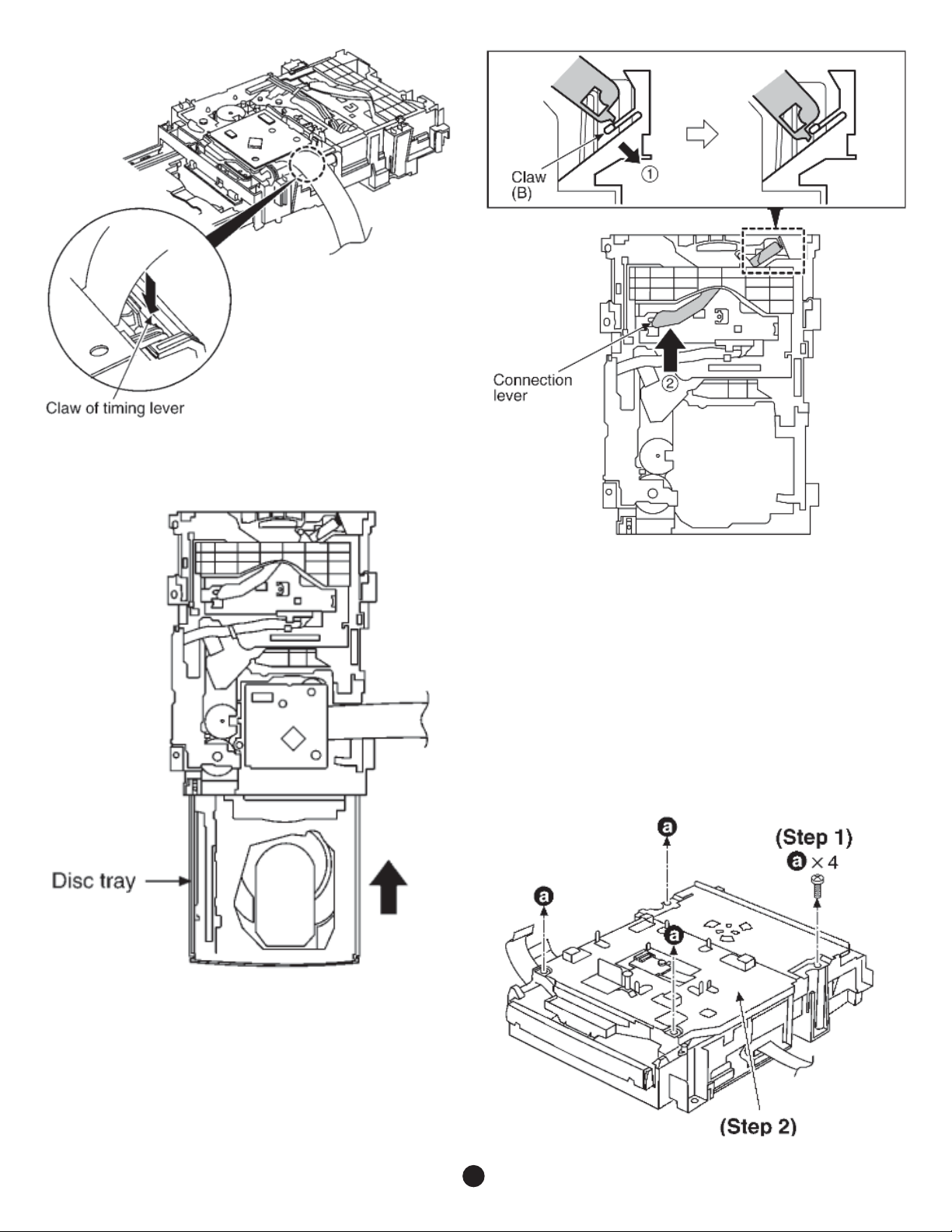

Step 3 Force the claw of timing lever.

Step 5 With pressing the claw (B) in the direction of arrow (1),

force the connection lever in the direction of arrow (2).

10.12.2 Replacement for the Disc Tray

Step 1 Remove 4 screws.

Step 2 Remove the upper plate.

Step 3 Remove 3 screws.

Step 4 Force the disc tray fully.

19

Page 20

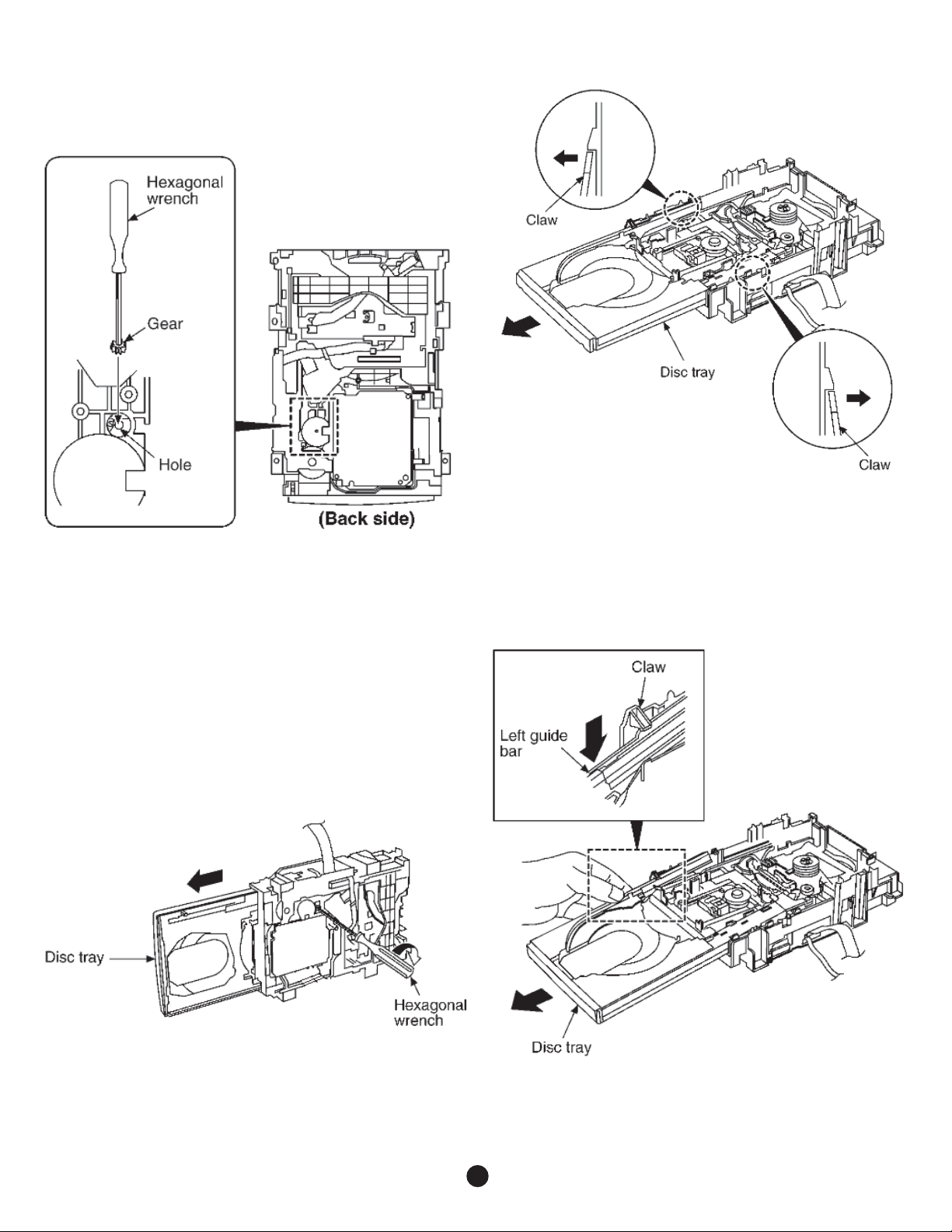

Step 4 With lifting the claw in the direction of (1), draw the

CD Detect P.C.B. in the direction of arrow (2).

Step 5 Remove the mechanism cover.

Step 7 Rotate the hexagonal wrench in the direction of arrow,

and then open the disc tray fully.

Step 6 Insert the gear with hexagonal wrench into the hole.

Step 8 Release the both claws, and then draw the disc tray.

20

Page 21

Step 9 With forcing the left guide bar manually because the

left guide bar interfers with claw, draw the disc tray.

Step 2 Holding the drive rack not to move, install the disc

tray.

[Installation of the disc tray after replacement]

Step 1 Slide the drive rack fully in the direction of arrow.

Step 3 Align the drive rack with the drive gear.

NOTE:

Force the right guide bar of tray base manually not to move

upwards.

Step 4 Holding the disc tray manually, push the disc tray in

the direction of the arrow.

21

Page 22

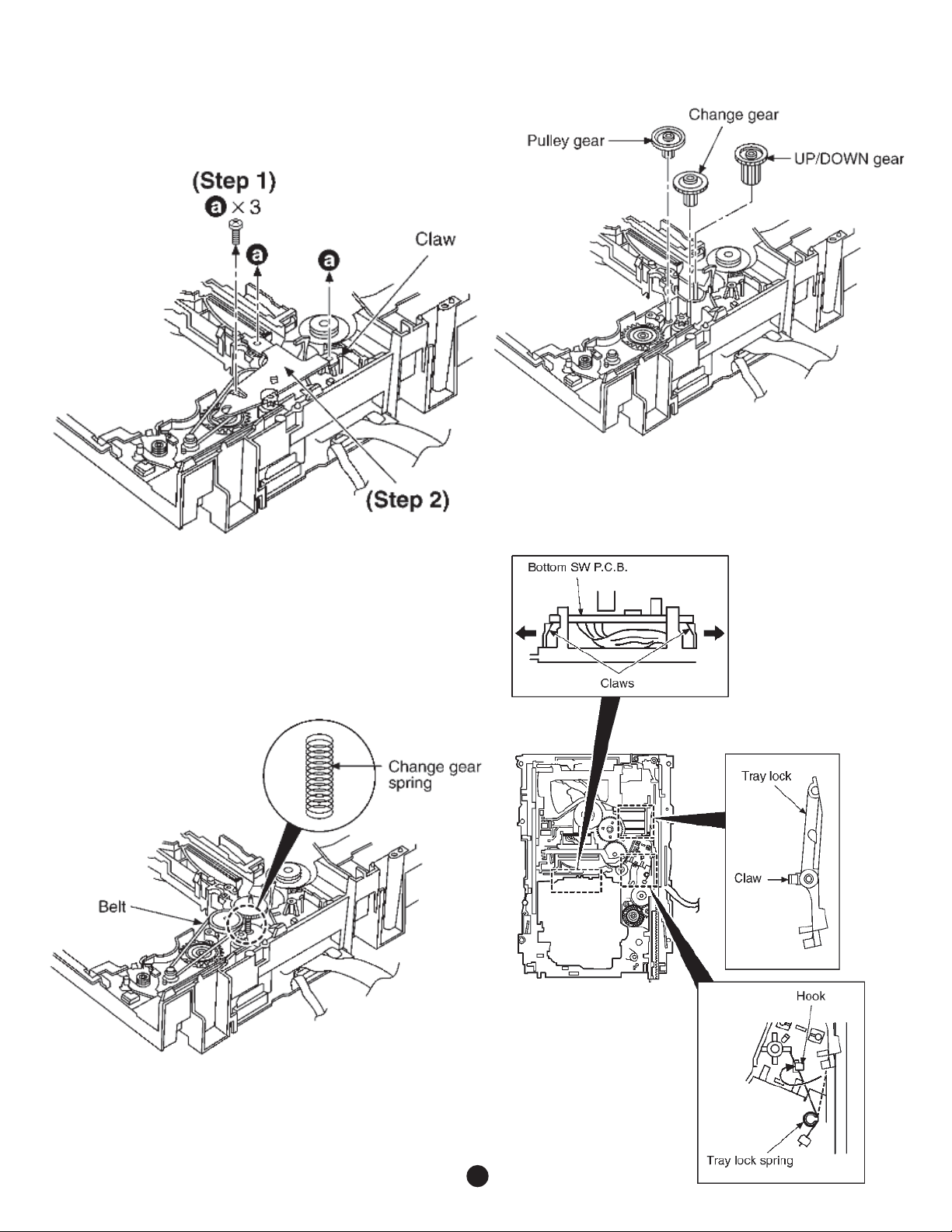

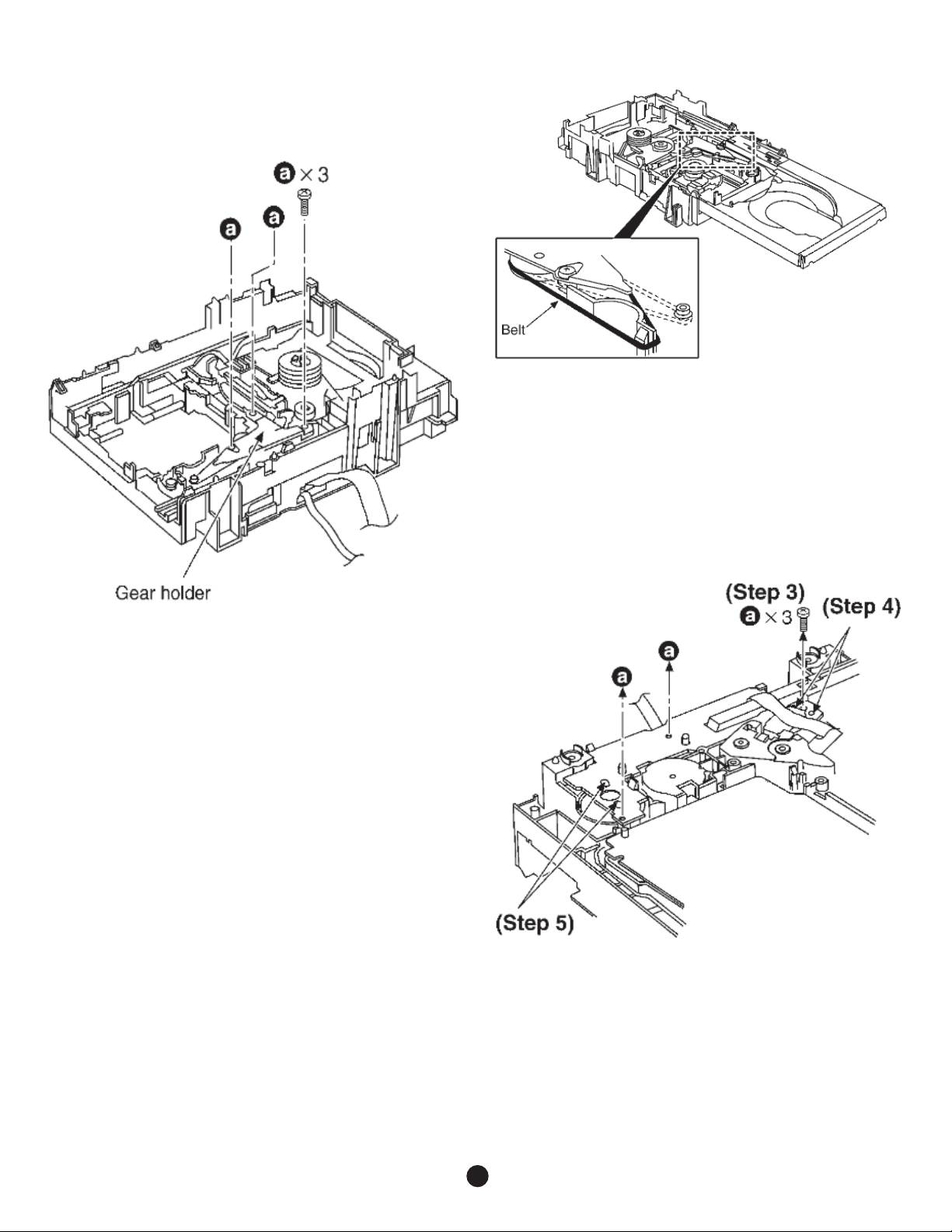

10.12.3 Disassembly and reassembly for

mechanism base drive unit

Step 1 Remove 3 screws.

Step 4 Remove the pulley gear, change gear and UP/DOWN

gear.

Step 2 Release the claw, and then remove the gear holder.

Step 3 Remove the belt and change gear spring.

Step 5 Release the 2 claws, and then remove the bottom SW

P.C.B..

NOTE:

Take care not to lose the change gear spring.

22

Page 23

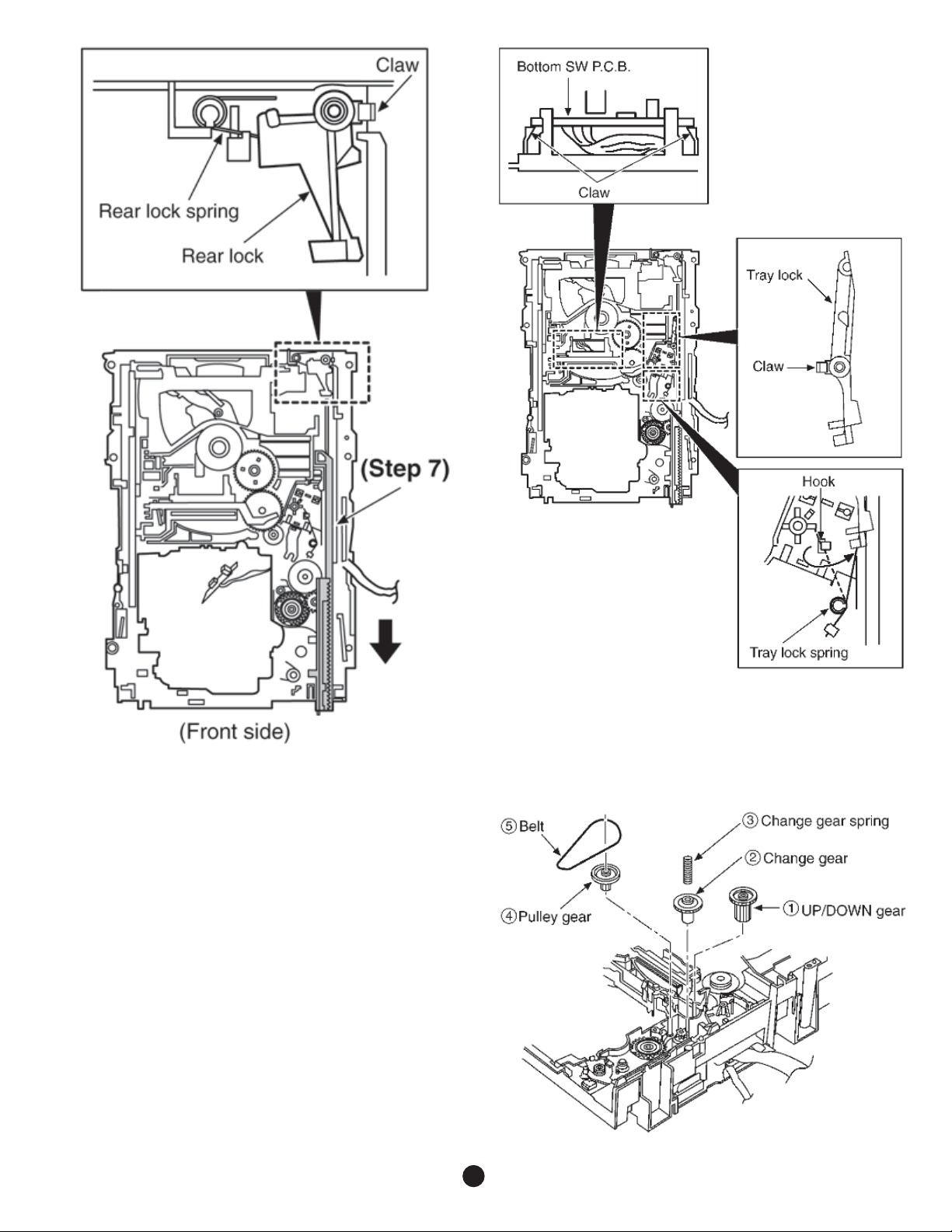

Step 6 Install the tray lock spring to hook temporary.

Step 7 Release the claw, and then remove the tray lock.

Step 8 Release the claw, and then remove the rear lock.

Step 9 Pressing the claw (B) in the direction of arrow (1), force

the connection lever in the direction of arrow (2).

Step 10 Move the slide plate 1 to the end of stock side.

23

Page 24

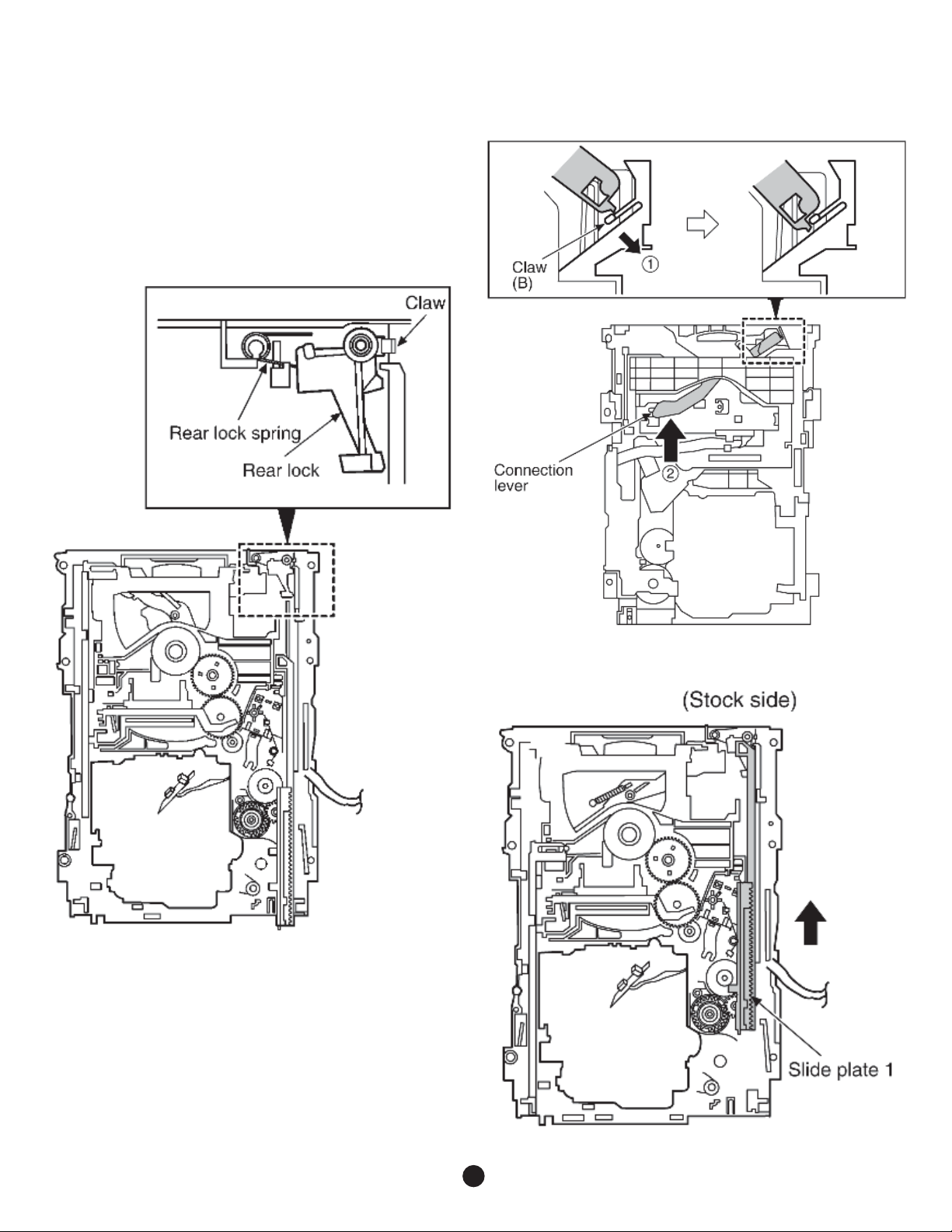

Step 11 Lift up the left end of spindle base unit in the

direction of arrow (1), and then remove the unit in the

direction of arrow (2).

Step 12 Remove slide plate 1 and slide plate 2.

Step 13 Remove the traverse relay gear, traverse cam gear

and drive gear.

[Dissassembly/reassembly for the spindle base unit]

Step 1 Draw the 5 disc spacers.

24

Page 25

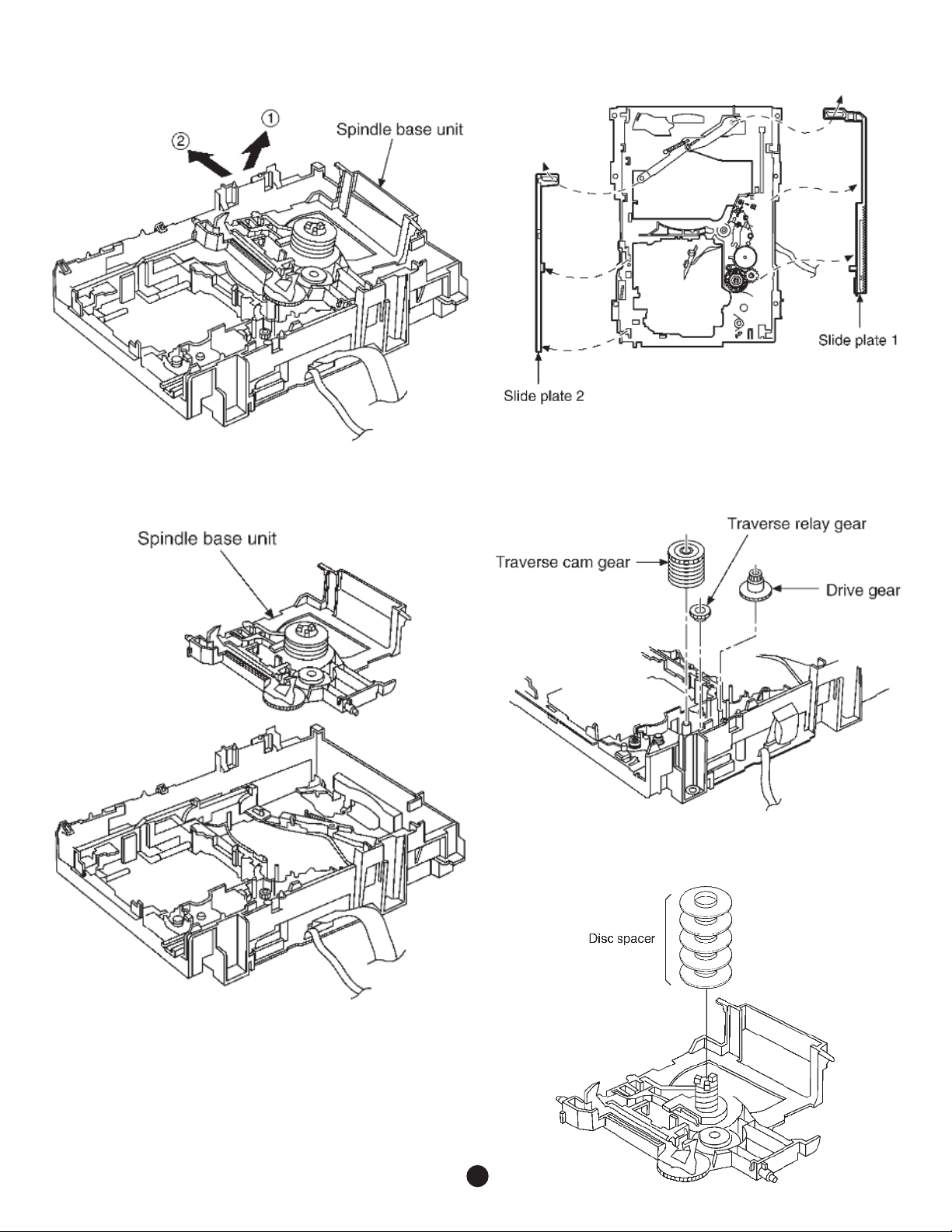

Step 2 Pushing the claw, slide the support plate in the

direction of arrow, and then remove it.

Step 3 Rotate the disc lever in the direction of arrow (1),

draw the disc lever.

Step 4 Release the 2 claws, and then draw the relay gear B.

Step 5 Release the 2 claws as shown below.

NOTE:

Take care not to lose the disc lever spring.

NOTE:

Hold the loading stopper ass’y manually bacause it is flipped

by spring.

25

Page 26

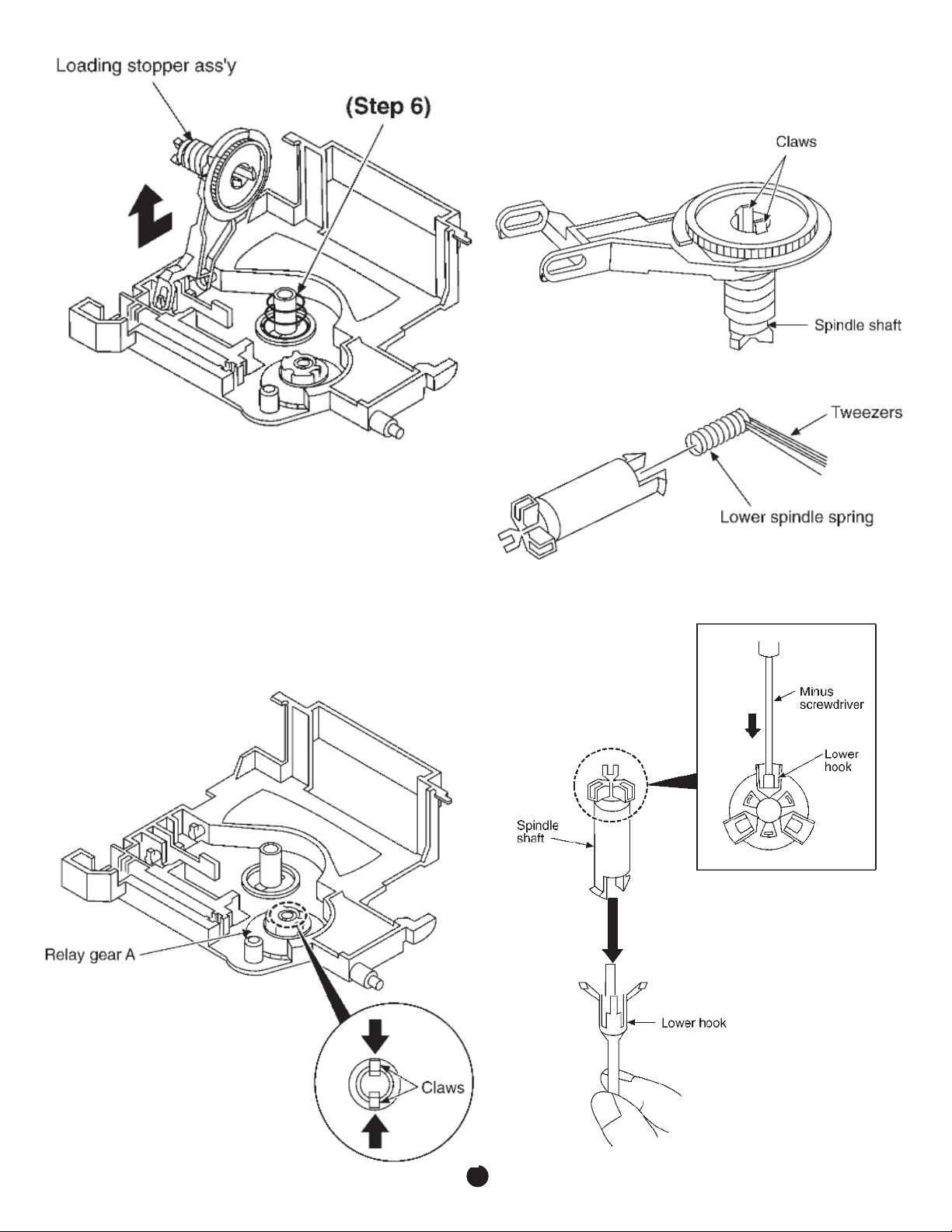

Step 8 Release the 2 claws, and then remove the relay gear

A.

Step 9 Release the 2 claws, and then remove the spindle

shaft.

Step 6 Remove the cushion spring.

Step 7 Remove the loading stopper ass’y in the direction of

arrow.

Step 10 Remove the lower spindle spring with tweezers.

Step 11 Force the lower hook with thin tip of minus

screwdriver.

Step 12 Squeeze the shaft of lower hook, and then draw

26

it.

Page 27

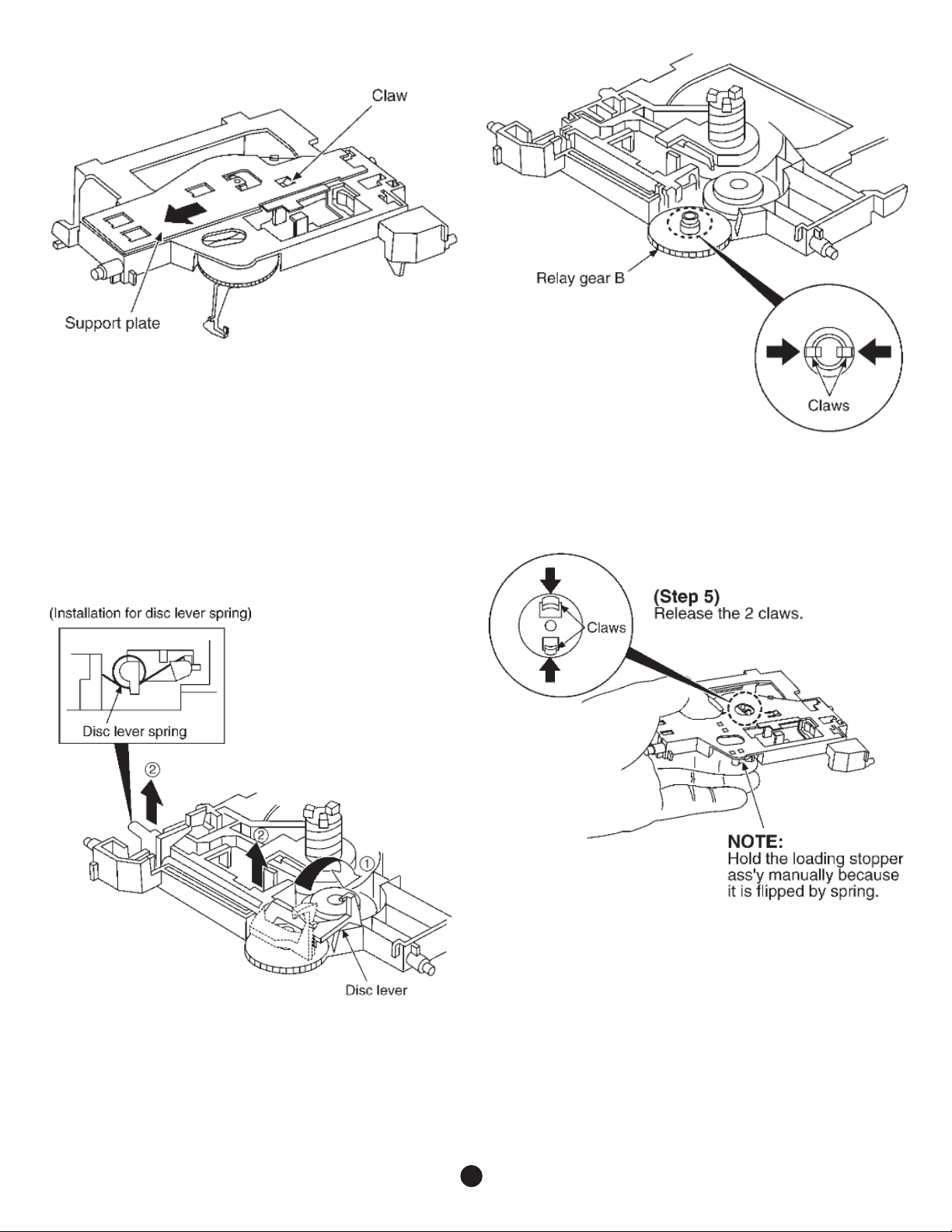

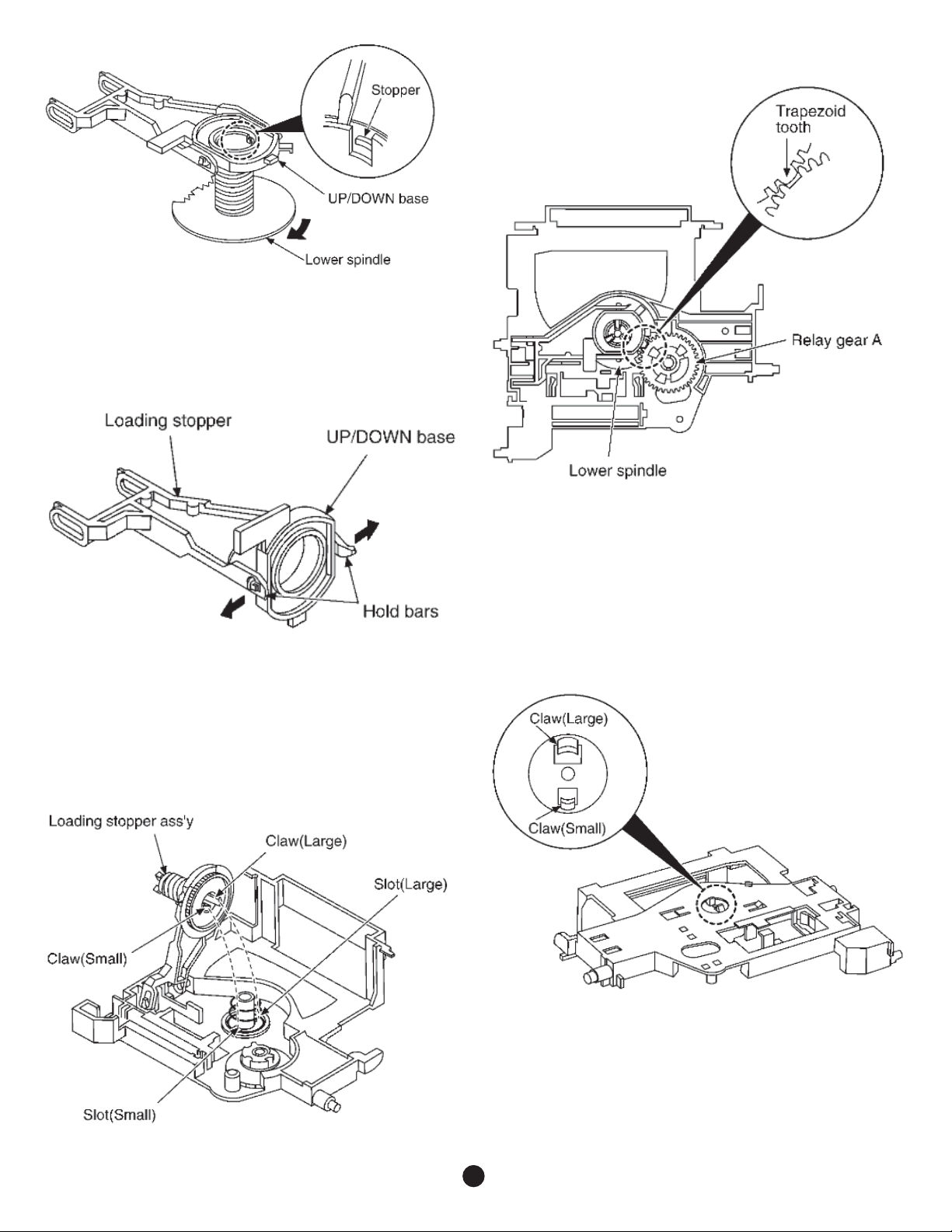

Step 13 Rotate the lower spindle in the direction of arrow

until the lower spindle interferes with stopper.

Step 14 Insert the thin tip of minus screwdriver between the

lower spindle and UP/DOWN base, and then slacken the

lower spindle to release the stopper. Then, rotate the lower

spindle and remove it.

Step 2 Lower the loading stopper ass’y, and then align the

lower spindle with the trapezoid tooth of relay gear A.

Step 15 Rotate the UP/DOWN base at a 90° angle. Then,

spread the hold bars of loading stopper and remove the UP/

DOWN base.

[Installation for loading stopper ass’y]

Step 1 Align the claw of loading stoppers ass’y with the slot of

spindle base. (Caution should be exercised when alignment

of claw due to the size of claws.)

Step 3 Force the loading stopper ass’y, latch the claw firmly.

[Reassembly for mechanism base drive unit]

27

Page 28

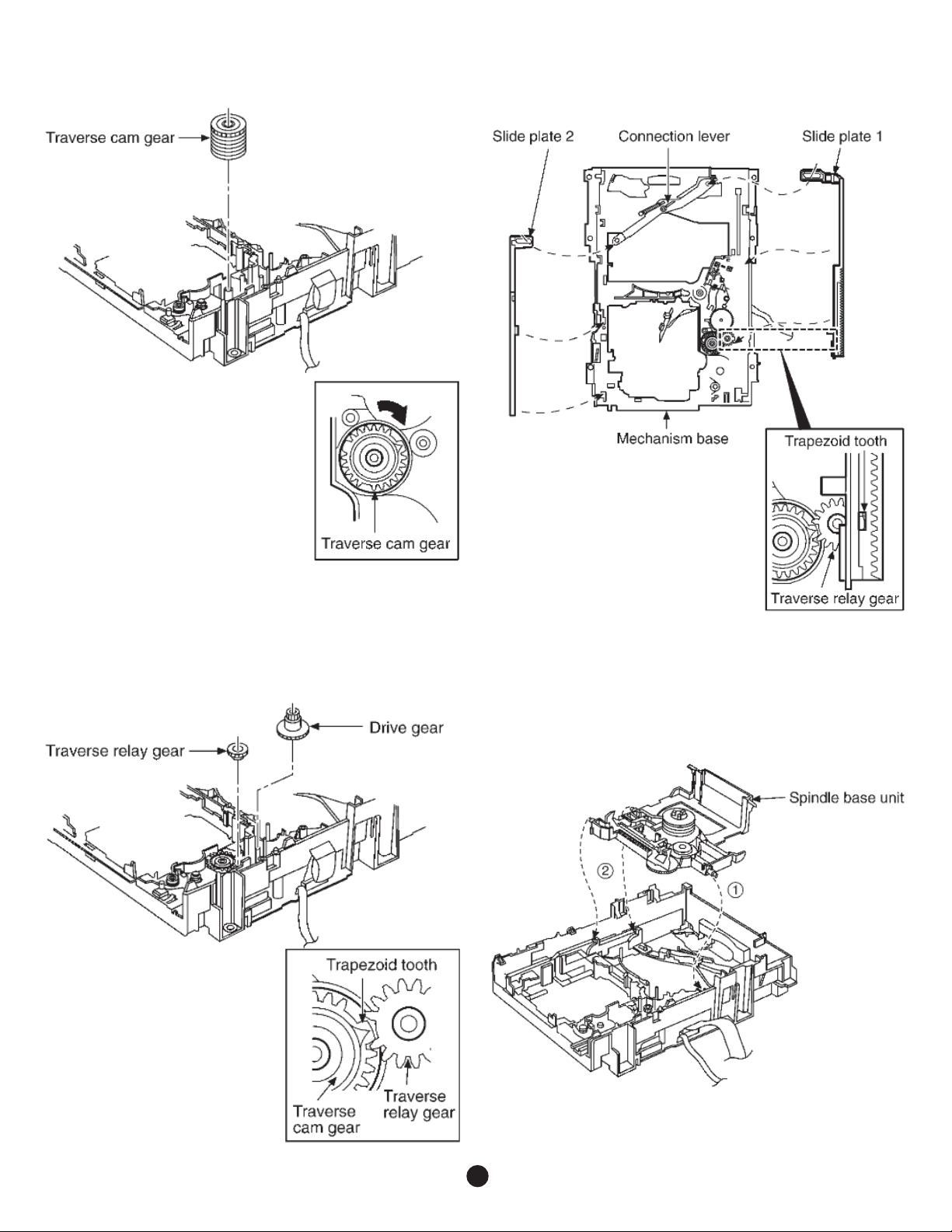

Step 1 Install the traverse cam gear.

Step 2 Rotate the traverse cam gear to the direction of arrow.

*When installing the traverse relay gear, align the

trapezoid tooth of gear with tooth of traverse cam gear.

Step 3 Install the drive gear and traverse relay gear.

Step 4 Install the slide plate 2 to the mechanism base, and

then match to the connection lever.

Step 5 Install the slide plate 1 to the mechanism base, and

then match to the connection leve and align the trapezoid

tooth of traverse relay gear with the slide plate 1.

Step 6 Install the spindle base unit. (First, slide plate 1.)

28

Page 29

Step 7 Move the slide plate 1 to forward fully.

Step 8 Install the rear lock. (The claw should be latched.)

Step 9 Install the Spindle Position P.C.B.. (The claw should be

latched.)

Step 10 Install the tray lock. (The claw should be latched.)

Step 11 Remove the tray lock spring from hook,and then

latch to the tray lock.

Step 12 Install the UP/DOWN gear, change gear, change

gear spring, pulley gear and belt in the order of (1) - (5).

29

Page 30

Step 13 Install the gear holder, and then tighten the screw

(a).

10.12.4 Replacement for the motor ass’y

Step 1 Install the belt temporarily.

NOTE:

Take care not apply the grease to the belt.

Step 2 Upset the CD loading unit.

Step 3 Remove 3 screws

Step 14 Install the tray base, traverse ass’y, mechanism

cover and upper plate.

[Operation check after servicing]

Check the proper operation of following items with gear

and hexagonal screwdriver.

1. Open/close of tray base.

2. Moving the tray base to the stock side.

3. UP/DOWN operation of spindle base unit.

4. UP/DOWN operation of traverse ass’y.

Step 4 Unsolder the plunger terminals (2 points).

Step 5 Unsolder the motor terminals (2 points).

30

Page 31

10.13 Replacement for the pinch roller ass’y

and head block

· Follow the (Step 1) - (Step 2) of Item 10.2 Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 6) of Item 10.3 Disassembly of CD Lid

· Follow the (Step 1) of Item 10.4 - Disassembly of the

Rear Panel

· Follow the (Step 1) - (Step 3) of Item 10.5 Disassembly of the CD Mechanism Unit

· Follow the (Step 1) - (Step 3) of Item 10.9 Disassembly of the Front Panel Unit

· Follow the (Step 1) - (Step 5) of Item 10.10 Disassembly of the Deck Mechanism Unit

* The mechanism as shown below is for DECK1. For DECK 2,

perform the same procedures.

Step 6 Release the 2 claws (A), and then remove the Motor

P.C.B.

Step 7 Release the claw (B), and then remove the motor

ass’y.

[Notice for motor ass’y installation]

1. Locate the name plate of motor to the traverse

ass’y.

2. Align the hole of motor with the ribs.

Step 1 Release the 2 claws, and then remove the pinch

roller (R), (F).

Step 2 Release ther 2 claws, and then remove the head

31

connector

Page 32

Step 3 Remove 2 screws.

10.14 Replacement for the pinch roller ass’y

, capstan belt A, capstan belt B and

winding belt

· Follow the (Step 1) - (Step 2) of Item 10.3 - Disassembly

of Top Cabinet

· Follow the (Step 1) - (Step 6) of Item 10.4 - Disassembly

of CD Lid

· Follow the (Step 1) of Item 10.5 - Disassembly of the

Rear Panel

· Follow the (Step 1) - (Step 3) of Item 10.6 - Disassembly

of the CD Mechanism Unit

· Follow the (Step 1) - (Step 3) of Item 10.10 - Disassembly

of the Front Panel Unit

· Follow the (Step 1) - (Step 5) of Item 10.11 - Disassembly

of the Deck Mechanism Unit.

Step 1 Release the 2 claws, and then remove the head

connector.

Step 2 De-solder plunger point.

Step 3 Remove the Deck Mechanism P.C.B.

Step 4 Remove 3 screws.

Step 5 Remove the flywheel R.

Step 6 Release the claw of tape side, and then remove

the winding lever and spring.

Step 7 Remove the flywheel F.

32

Page 33

[Installation of the belt]

Step 4 Put the winding belt on the flywheel F.

Step 1 The boss and marking should be positioned

horizontally.

Step 5 Install the winding lever and spring while pressing the

winding arm in the direction of arrow.

Step 6 Install the flywheel R.

Step 2 Put the winding belt on the pulley temporarily.

Step 3 Install the flywheel F.

Step 7 Put the capstan belt A temporarily as shown below.

33

Page 34

Step 8 Put the capstan belt B on the motor ass’y pulley.

Step 9 Install the sub chassis to the mechanism, and then

tighten screws.

10.15 Replacement for the cassette lid ass’y

· Follow the (Step 1) - (Step 2) of Item 10.3 Disassembly of Top Cabinet

Step 1 Force the lever upward, open the cassette lid ass’y.

(For DECK1 and DECK2)

Step 2 Lift up the cassette lid ass’y in the direction of arrow.

(For DECK1 and DECK2).

Step 10 Remove 3 screws.

Step 11 Put the capstan belt B as shown below.

Step 12 Put the capstan belt A on the motor ass’y pulley.

34

Page 35

10.16 Rectification for tape jam problem

· Follow the (Step 1) - (Step 2) of Item 10.3 Disassembly of Top Cabinet

Step 1 If a cassette tape cannot be removed from the

deck since the tape is caught by the capstan or pinch

roller during playback or recording, rotate the flywheel F in

the direction of the arrow to remove the tape.

Step 2 Force the lever upward and open the cassette lid

ass’y. Take the cassette tape off.

35

Page 36

11 Checking for major P.C.B.

Note:

Checking of all major P.C.Bs (Main P.C.B., Panel P.C.B., Deck P.C.B., Deck Mechanism P.C.B., Transformer P.C.B., Power

P.C.B.) can be carried out using below procedures.

For the disassembling procedure, see Section 10.

11.1 Checking for Main P.C.B.

1. Remove Top Cabinet and Rear Panel.

2. Remove CD Lid.

3. Remove CD Mechanism Unit.

4. Connect FFC wires (CN2801 & CN2805) from CD

Mechanism Unit

11.2 Checking for Transformer P.C.B.

1. Remove Top Cabinet and Rear Panel.

2. Remove CD Lid.

3. Remove CD Mechanism Unit.

4. Connect FFC wires (CN2801 & CN2805) from CD

Mechanism Unit.

36

Page 37

11.3 Checking of Panel, Deck& Deck

Mechanism P.C.B.

11.4 Checking the Power P.C.B.

1. Remove Top Cabinet and Rear Panel.

1. Remove Top Cabinet.

2. Remove CD Lid.

3. Remove CD Mechanism Unit.

4. Remove volume knob at front panel.

5. Remove Panel P.C.B.

6. Remove Deck Mechanism Unit.

7. Use the extension cable (A) to reconnect (CN1001)

Deck P.C.B. and (CN2803) Main P.C.B.

8. Use the extension cable (B) to reconnect (CP6401)

Panel P.C.B. and (CN971) Deck Mechanism P.C.B.

2. Remove CD Lid.

3. Remove CD Mechanism Unit.

4. Remove 3 screws at Transformer P.C.B..

5. Remove 2 screws at heat sink and 1 screw at

Power P.C.B.

6. Flip the Power P.C.B.

7. Insulate the Power P.C.B. with insulation material to

avoid short circuit.

8. Use the extension cable (A) to reconnect (CN1001)

Deck P.C.B. and (CN2803) Main P.C.B.

9. Use the extension cable (B) to reconnect (CP6401)

Panel P.C.B. and (CN971) Deck Mechanism P.C.B.

10. Use the extension cable (C) to reconnect (H5950/

W5950) Power P.C.B. and (CN5950) Transformer P.C.B.

Service Tools

Extension FFC

(A) Deck P.C.B. - Main P.C.B. REEX0485

(14 Pins)

(B) Panel P.C.B. - Deck Mechanism P.C.B. REEX0484

(10 Pins)

Service Tools

Extension FFC

(A) Deck P.C.B. - Main P.C.B. REEX0485 (14 Pins)

(B) Panel P.C.B. - Deck Mechanism P.C.B. REEX0484 (10 Pins)

(C) Power P.C.B. - Transformer P.C.B. RFKAK330 (9 Pins)

37

Page 38

12 Self-Diagnostic Function

12.1 Self-diagnostic display

This unit is equipped with a self-diagnostic display function

which, if a problem occurs, will display an error code

corresponding to the problem.

Use this function when performing maintenance on the unit.

12.2 How to enter the Self-Diagnostic Function

12.3 Cassette Mechanism Test (For error

code H01, H02, H03, F01)

1. Press “TAPE, DECK 1/2” to select Deck 2.

2. Load a cassette tape with the erasure prevention

tab, remove from left side only and close the cassette

holder.

3. Press “FAST FORWARD MEMORY” (Tape will be stop

after 2 seconds)

4. Load a cassette tape with the erasure prevention

tab, remove from right side only and close the cassette

holder.

5. Press “REVERSE FM MODE/BP” (Tape will be stop

after 2 seconds)

6. Load a pre-recorded tape with both side record

tabs intact and close the cassette holder.

7. Press “PLAY/TUNE/TIME ADJ UP” (After TPS function,

tape will stop automatically)

8. Press “REC/STOP” (Tape will not move)

9. Press “STOP/TUNE MODE” to indicate Error code.

· If several problem exist, error code will change

each time when “ /STOP” is pressed. (e.g. H01 ! H03 ! F01

.....etc.)

10. Press “TAPE, DECK 1/2” to select Deck 1.

11. Repeat step 2 to 9 to test Deck 1. (Tape Deck 1

will not check H02 because of no recording function)

12.4 CD Mechanism Test (F15, F26, F16, F17,

F27, F28, F29, F30, H15& H16)

1. Press “CD”.

2. Press “OPEN/CLOSE (1)” and place a CD.

3. Press “OPEN/CLOSE (1)” to close the tray.

4. Press “OPEN/CLOSE (5)” and wait until the tray is

open.

5. Press “OPEN/CLOSE (1)” and remove the CD.

6. Press “OPEN/CLOSE (1)” to close the tray.

7. Press “/STOP” to indicate Error Code.

each time when “/STOP” is pressed. (e.g. F15 ! F26 ! F16

....etc).

If several problem exist, error code will change

38

Page 39

12.5 To clear all Error code

1. Press “STOP/TUNE MODE” button for 5 seconds.

change to “T”.

12.6 How to get out from Self-Diagnostic function

1. Press “Power” button OFF.

2. FL indicator shows “CLEAR” for 1 second and

12.7 Power Amplifier Failure (F61)

1. When power amplifier fail, F61 will indicate

automatically.

12.8 Description of Error Code

12.8.1 Abnormality detection for Deck

Mechanism block

No. Abnormal Items Error Method of Detection

Display

1 MODE SW abnormal H01 Normal operation during mecha transition, MODE SW abnormal is memorized. The

abnormality can be confirmed in the abnormal detection mode explained in the

2 REC INH SW abnormal H02 The content of abnormality can be confirmed in the abnormal detection mode

section.

3 HALF SW abnormal H03 The content of abnormality can be confirmed in the abnormal detection mode

section.

content of

later section.

explained in the later

explained in the later

4 Reel pulse abnormal F01 The content of abnormality can be confirmed in the abnormal detection mode

section.

explained in the later

12.8.2 Abnormality detection for CD/Changer

block

No. Abnormal Items Error Method of Detection

Display

1 REST SW abnormal F15 Under normal operation (Self-Diagnostic Mode inclusive), this error occurs

2 Transmission error between F26 Under normal operation (Self-Diagnostic Mode inclusive), this error occurs

CD servo LSI and micon the selection is set to CD and SENSE=’H’ is

within a fail safe time (20ms) after system command transmission was sent.

3 CLAMP SW abnormal F16 Refer to section 12.8.4 (Mechanism Error Code Table) [M-0A] error is

4 BOTTOM SW abnormal F17 Refer to section 12.8.4 (Mechanism Error Code Table) [M-09] error is

5 POSITION SW abnormal F27 Refer to section 12.8.4 (Mechanism Error Code Table) [M-05 ~ M-08] error is

6 SW1 abnormal F28 Refer to section 12.8.4 (Mechanism Error Code Table) [M-02 ~ M-08] error is

7 SW2 abnormal F29 Refer to section 12.8.4 (Mechanism Error Code Table) [M-02 ~ M-08] error is

8 OPEN SW abnormal H15 Refer to section 12.8.4 (Mechanism Error Code Table) [M-01] error is

9 CLOSE SW abnormal H16 Refer to section 12.8.4 (Mechanism Error Code Table) [M-01] error is

10 DISC SENSOR F30 Refer to section 12.8.4 (Mechanism Error Code Table) [M-01] error is

when the REST SW ON

is not detected within the specified time and shall be memorized.

when

detected and SENSE=’L’ is notdetected

detected.

detected.

detected.

detected.

detected.

detected.

detected.

detected.

39

Page 40

12.8.3 Power supply related error detection

No. Abnormal Items Error Method of Detection

Display

1 POWER AMP F61 During normal operation, if DCDET 1/2 becomes ‘L’, normal POWER OFF process

shallnot be output abnormal executed, PCNT shall be switched to ‘L’ immediately.

GOODBYE shall not be displayedand the error display F61 will be displaye instead.2

seconds after the F61display, ECONO shall be set to ‘L’ and FL display shall be

turned off.The error content shall be memorized when the abnormality occurs and

canbe displayed in the C-mecha self-diagnostic mode described later.

12.8.4 Error Code (CR20 Mechansim)

1. If mechanism problem occurs during normal or aging

mode,

the error code is “remembered” and shown on the FL

display.

2. Reset Condition of Error Code

A During cold start of micro-processor IC.

B Restart of aging mode for the mechanism unit.

3. Mechanism Error Code

Mechansim Error Code Table

Error Code Description

M-00 No Error

M-01 OPEN Position - Horizontal Motion Abnormality at play position

M-02 PLAY Position - Horizontal Motion Abnormality at stock position

M-03 PLAY Position - Horizontal Motion Abnormality during changing position

M-04 CHANGE Position - Horizontal Error of Stock position

M-05 CHANGE Position - Ascending motion Error

M-06 CHANGE Position - Descending motion Error

M-07 STOCK Position - Ascending motion Error

M-08 STOCK Position - Descending motion Error

M-09 Abnormality during change position (bottom switch)

M-0A Clamp Error

M-0B Access Failure - Access Time of more tha 30 secs (Total time of automatic ! Read TOC ! Track

access)

4. When the mechanism unit stops due to error during

aging model, error code is remembered and counts of the

errors are displayed on the FL display.

40

Page 41

13 CD Test Mode Function

This CD test mode is provided to check CD unit without connecting to changer loading mechanism. This mode shall operate

CD PLAY with CD unit being connected only and CD Automatic Alignment result is shown on FL display.

13.1 How to set CD test mode

13.3 CD Mecha Aging Test Mode (CR20)

1. Functional summary of CD aging test mode

It is for the purpose to determine the reliability of the CD

changer.

2. To enter into CD aging test mode

a) First, enter into self-diagnostic mode (Refer to

Section 12.2. How to enter the Self-Diagnostic Function)

b) In the self-diagnostic mode, switch the SELECTOR

to

and press

. It will enter into CD aging test mode.

When in CD Aging test mode, the following operation will

begin and repeated:

1. [DISC STOCKER] DISC LOAD TRAY OPEN (2

secs) TRAY

CLOSE] as one count.

2. DISC 1 DISC 2 DISC 3 DISC 4 DISC 5

DISC1........repeating this endlessly.

· While performing the above operation, the FL

display will show the number of its operations starting from

00001. With reference to figure as below.

· It shall move up one counter when the above

operations ends. The counter will reset to 00000 when 99999

is reached.

13.2 CD Automatically Adjustment result

indication

Under CD test mode, pressing the numeric key ‘0’ on the

remote controller will display the auto adjustment result.

FLOCK, TLOCK and CLVS status shall be shown as below:

During the above display, executing CD PLAY will display auto

adjustment result for CD PLAY mode.

· To exit CD aging test mode, press

button, the tray will return to its PLAY

position and power will be off.

13.4 Micon ROM Checksum and Version

Display Mode

1. Functional Summary

Display version number and calculated checksum of the

micon software.

2. To enter into Micon ROM checksum and

Version Display Mode.

a) Enter into Self-Diagnostic Mode (Refer to

Section 12.2).

b) In the Self-Diagnostic Mode, Press

twice.

The version number and the calculated ROM Checksum of

the current software will be displayed on the FL as shown in

this example:

* Note: The Software Version No. & Micon Software

Checksum differs from set to set.

· The ROM Checksum is calculated on demand, not

hard coded.

· The ROM Checksum is calculated by talking the

arithmetic SUM of the ROM contents form the programs’s

START address until the END address.

START address = [1080]H

41

END address = [FFFD]H

Page 42

14 Measurements and Adjustments

14.1 Cassette Deck Section

Measurement Condition

· Make sure head, capstan and press roller are clean.

· Judgeable room temperature 20 ± 5 °C (68 ± 9°F)

Measuring instrument

· EVM (DC Electronic voltmeter)

· Digital frequency counter

Test Tape

· Tape speed gain adjustment (3 kHz, -10 dB);

QZZCWAT

14.1.1 Tape Speed Adjustment (Deck 1/2)

1. Set the tape edit button to “NORMAL” position.

2. Insert the test tape (QZZCWAT) to DECK 2 and

playback (FWD side) the middle portion of it.

3. Adjust Motor VR (DECK 2) for the output value

shown below.

Adjustment target: 2940 ~ 3060 Hz (NORMAL speed)

4. After alignment, assure that the output frequency

of the DECK 1 FWD are within ±60 Hz of the value of the

output frequency of DECK 2 FWD.

Fig.3

14.1.3 Bias Frequency Adjustment (Deck 1/2)

1. Set the unit to “AUX” position.

2. Insert the Normal blank tape (QZZCRA) into

DECK 2 and set the unit to “REC” mode (• use “REC/STOP”

key).

3. Adjust L1002 so that the output frequency is

within the standard value.

Standard Value: 97 ±8 kHz

Fig.4

Fig.1

14.1.2 Bias and Erase Voltage Check

1. Set the unit “AUX” position.

2. Insert the Normal blank tape (QZZCRA) into

DECK 2 and the unit to “REC” mode (use “• REC/STOP” key).

3. Measure and make sure that the output is within

the standard value.

Bias voltage for Deck 2 14±4mV (Normal)

Erase voltage for Deck 2 80mV (Normal)

Fig.2

14.2 Tuner Section

14.2.1 AM-IF Alignment

1. Connect the instrument as shown in Fig.5.

2. Set the unit to AM mode.

3. Apply signal as shown in Fig. 5 from AM-SG.

4. Adjust Z2602 so that the output frequency is

maximized in Fig.

6.

42

Page 43

Fig.5

Fig.6

14.3 Alignment Points

14.3.1 Cassette Deck Section

14.2.2 AM RF Adjustment

Connect the instrument as shown in Fig. 7.

Set the unit to AM mode.

Set AM-SG to 520kHz.

Receive 520kHz in the unit.

Adjust Z2602 (OSC) so that the EVM-AC is maximized.

Set AM-SG to 600Hz.

Receive 600Hz in the unit.

Adjust Z2602 (ANT) so that the EVM-SG is maximized.

Set AM-SG to 520kHz.

Receive 520kHz in the unit.

Adjust L2602 (OSC) so that the EVM-DC value is with

1.1±0.5V.

Fig.7

14.3.2 Tuner Section

43

Page 44

15 Block Diagram

44

Page 45

454647

Page 46

Page 47

6601

6601

565

Page 48

48

Page 49

9

565

49

Page 50

50

Page 51

16 Voltage Measurement

51

Page 52

52

Page 53

17 Schematic Diagram

(All schematic diagrams may be modified at any time with

the development of the new technology)

Note:

· SW1

: Push switch

· SW2

: Push switch

· SW3

: Open switch

· SW4

: CD switch

· SW5

: Load switch

· S951

: Mode switch

· S952

: Half switch

· S971

: Mode switch

· S972

: Half switch

· S975

: Recinh_F switch

· S6101

: Open/ Close switch

· S6102

: CD 1 switch

· S6103

: CD 2 switch

· S6104

: CD 3 switch

· S6105

: CD 4 switch

· S6106

: CD 5 switch

· S6201

: Rew switch

· S6202

: Tuner switch

· S6203

: CD switch

· S6204

: FF switch

· S6205

: Stop switch

· S6206

: Deck 1/2 switch

· S6207

: Deck 2 Open switch

· S6208

: TAPE switch

· S6209

: AUX switch

· S6210

: Deck 1 Open switch

· S6301

: Power switch

· S6303

: SSEQ switch

· S6304

: REC switch

· S6305

: Demo/Display switch

· S7201

: Rest switch

· VR6491

: VR Volume Jog

· The voltage value and waveforms are the

reference voltage of this unit measured by DC electronic

voltmeter (high impedance) and oscilloscope on the basis

of chassis. Accordingly, there may arise some error in

voltage values and waveformsdependingupon the internal

impedance of the tester or the measuring unit.

No mark: Playback << >> : Rec < > : FM (( )) : CD

· Importance safety notice :

Components identified by mark have special

characteristics important for safety. Furthermore, special

parts which have purposes of fire-retardant (resistors), highquality sound (capacitors), low-noise (resistors), etc. are

used. Whenreplacing any of components, be sure to use

only manufacturer´s specified parts shown in the parts list.

Caution !

IC, LSI and VLSI are sensitive to static electricity.

Secondary trouble can be prevented by taking care

during repair.

· Cover the parts boxes made of plastics with

aluminium foil.

· Put a conductive mat on the work table.

· Ground the soldering iron.

· Do not touch the pins of IC, LSI or VLSI with fingers

directly.

53

Page 54

17.1 (A) CD Servo Circuit

545556

Page 55

Page 56

17.2 (B) Main (Tuner) Circuit

Page 57

17.3 (B) Main Circuit

57

Page 58

585960

Page 59

Page 60

Page 61

17.4 (C) Panel Circuit

616263

Page 62

Page 63

17.5 (D) Transformer Circuit, (E) CD Detect

Circuit, (F) Spindle Position Circuit& (G) CD

Loading Circuit

Page 64

17.6 (H) Power Circuit

64

Page 65

17.7 (I) Deck Circuit& (J) Mechanism Circuit

65

Page 66

66

Page 67

18 Printed Circuit Board

Note: Circuit board diagrams may be modified at any time with the development of new technology.

18.1 (A) CD Servo P.C.B.

67

Page 68

18.2 (B) Main P.C.B.

68

Page 69

69

Page 70

18.3 (C) Panel P.C.B.

70

Page 71

71

Page 72

18.4 (D) Transformer P.C.B.

72

Page 73

18.5 (E) CD Detect P.C.B., (F) Spindle Position

P.C.B., (G) CD Loading P.C.B.& (K) Tuner Pack

P.C.B.

73

Page 74

18.6 (H) Power P.C.B.

74

Page 75

75

Page 76

18.7 (I) Deck P.C.B.& (J) Deck Mechanism

P.C.B.

76

Page 77

19 Wiring Connection Diagram

77

Page 78

20 Illustration of IC’s, Transistors and Diodes

78

Page 79

21 Terminal Function of IC’s

21.1 IC7002 (MN6627953HB) Servo processor/

Digital signal processor/ Digital filter/ D/A

converter

Pin No. Mark I/O Function

1 EXT0 I/O Extend input/output port 0

2 EXT1 I/O Extend input/output port 1

3 EXT2 I/O Extend input/output port 2

4 PWMSEL I PWM output selectioninput(:

Direct; H: Tri-State

5 SPOUT O Spindle driver output signal

6 SPPOL O Spindle driver output signal

7 TRVP O Spindle driver output signal

8 TRVM O Spindle driver output signal

9 TRVP2 O Traverse driver output

signal 2 (+)

10 TRVM2 O Traverse driver output

signal 2 (-)

11 TRP O Traverse driver output

signal (+)

12 TRM O Traverse driver output

signal (-)

13 FOP O Traverse driver output

signal (+)

14 FOM O Traverse driver output

signal (-)

15 IOVDD3 - I/O power supply 3

16 DVDD1 - Power supply 1 for digital

circuit

17 DVSS1 - Digital circuit GND 1

18 ADPVCC I Power voltage monitor.

Power voltage input

19 TEIN I DSP traverse error signal

input

20 FEIN I DSP focus error signal input

21 CE A I/O HPF-Amp capacitance

connection terminal

22 RFENV O RF envelope signal monitor

23 FEOUT O FE Amp output

24 FEN I FE Amp reversal input

25 TEN I TE Amp reversal input

26 TEOUT O TE Amp output

27 VREF O VREF output

28 PD I APC Amp input

29 LD O APC Amp output

30 E I Tracking input signal 1

31 F I Tracking input signal 2

32 D I Tracking input signal 4

33 B I Tracking input signal 2

Pin No. Mark I/O Function

34 C I Tracking input signal 3

35 A I Focus input signal 1

36 DCDET I Detection HPF capacitance

terminal

37 RFVDD - RF Amp power supply

38 RESERVE - AVSS2

39 RFOUT O RF Amp output

40 RFIN I AGC input

41 CAGC I/O AGC control terminal

42 ARFOU T O AGC output (Audio RF)

43 AVS S2 - Analog circuit GND 2

44 ARFIN I RF signal input

45 DSLF O DSL loop filter

46 IREF I I (current), Reference input

47 PLLF O PLL loop filter

48 PLLF0 O PLL loop filter

49 AVDD2 - Analog circuit power supply

2

50 OUTL O LCH output signal

51 AVSS1 - Audio output circuit GND 1

52 N.C. - No Connection

53 AVDD1 - Power supply 1 for analog

circuit

54 OUTR O RCH output signal

55 DVSS2 - Digital circuit GND 2

56 IOVDD1 - I/O power supply 1

57 DVDD2 - Power supply 2 for Digital

circuit

58 REGON I Laser diode control (H: ON)

59 IOMODE I I/O switching setting input

60 NTEST I Test mode setting input (H:

ON)

61 TX O Digital audio interface

output

62 FLAG O Flag signal output

63 MCLK I Micro-P serial command

CLK

64 MDATA I Micro-P serial command

DATA

65 MLD I Micro-P serial command

LOAD

66 STAT O Status signal output

79

Page 80

Pin No. Mark I/O Function

67 BLKCK O Subcode block clock

21.3 IC2801 (CC2CBJG000564) System

Microprocessor

68 NRST I LSI reset input (L: RESET)

69 DVSS3 - Digital circuit GND 3

70 X2 O Crystal oscillator circuit

output

71 X1 I Crystal oscillator circuit

input

72 IOVDD2 I I/O power supply 2

73 DQSY O Pack signal output for CD-

Text data

74 TXTD O CDText signal output

75 TXTCK I External clock signal input

for CD-Text register

76 GIO0 I/O General purpose input/

output Terminal 0

77 GIO1 I/O General purpose input/

output Terminal 1

78 GIO2 I/O General purpose input/

output Terminal 2

79 GOUT0 O General purpose output

Terminal 0

80 GOUT1 O General purpose output

Terminal 1

21.2 IC7003 (AN8739SBTE2) Focus coil/

Tracking coil/ Traverse motor/ Spindle motor

drive

Pin No. Mark I/O Function

1 /RST O RESET output terminal

2 NC - N.C.

3 IN2 I Motor drive (2) input

4 PC2 I Turntable motor drive signal

(“L” :ON)

5 NC - N.C.

6 IN1 I Motor driver (1) input

7 PVCC1 - Power supply (1) for driver

8 PGND1 - Ground connection (1) for

driver

9 NC - N.C.

10 D1- O Motor driver (1) reverse-

action output

11 D1+ O Motor driver (1) forward-

action output

12 D2- O Motor driver (2) reverse-

action output

13 D2+ O Motor driver (2) forward-

action output

14 D3- O Motor driver (3) reverse-

action output

15 D3+ O Crystal oscillating circuit

input (f = 16.9344MHz)

16 D4- O Motor driver (4) reverse-

action output

17 D4+ O Motor driver (4) forward-

action output

18 NC - N.C.

19 PGND2 - Ground connection (2) for

driver

20 PVCC2 - Power supply (2) for driver

21 VCC - Power supply terminal

22 VREF - Reference voltage input

23 IN4 I Motor driver (4) input

24 IN3 I Motor driver (3) input

25 RSTIN I Reset terminal

26 NC - N.C.

Pin No. Mark I/O Function

1 LM_1 I Level Meter Left

2 N.C. - No Connection

3 PLL_CE O PLL Chip Select

4 RDS_DAT I RDS Data

Input

5 RDS_CLK I RDS Clock Input

6 N.C. - No Connection

7 N.C. - No Connection

8 BYTE I External Data Bus Width

Select Input

9 CNVss/EFP_ - Flash Mode Terminal

CNVss (Connect to ground)

10 Xcin - 32.768 kHz Sub Clock

11 Xcout - 32.768 kHz Sub Clock

12 /RESET/EFP_ I Reset Input (ACTIVE L)

RESET

13 Xout - 10 MHz Main Clock

14 Vss - Ground (0V)

15 Xin - 10 MHz Main Clock

16 Vcc - Power Supply (+5V)

17 /NMI - Connect to Vcc (+5V)

18 RMT I Remote Control

Input

19 BLKCK I CD Block Clock Input

(Inverted)

20 SYNC I AC Failure Detect Input

21 ST/DO I Tuner IF Data/ Stereo

Input

22 SD I Tuner Signal Detect Input

23 Harmonic_ I/O *3 Harmonic Switch

SW (Active L)

24 SW_LVL 1 O *4 Sub-Woofer Level 1

25 SW_LVL 2 O *4 Sub-Woofer Level 2

26 ASP_DAT O ASP Data

27 ASP_CLK O ASP Clock

28 N.C. - No Connection

29 PLL_DATA O PLL DATA

30 PLL_CLK O PLLCLK

31 REG 8/EFP_ I Region Setting 8

RxD1 (Subwoofer)

32 REG 7/ EFP_ I Region Setting 7 (MIC)

RxD1

33 REG 6/EFP_ I Region Setting 6 (RDS)

SCLK

34 REG 5/ EFP_ I Region Setting 5 (Optical

BUSY Out)

35 REG 4 I Region Setting 4 (Deck

Mechanism)

36 REG 3 I Region Setting 3 (Tuner)

37 REG 2 I Region Setting 2 (Tuner)

38 REG 1 I Region Setting 1 (Tuner)

39 MUTE_H O HIC Mute

40 MUTE_A O Audio Mute

41 EE_CS/EFP_ O EEPROM Chip Select

/EPM

42 EE_CLK O EEPROM Clock

43 EE_DAT I/O EEPROM Data

44 N.C. - No Connection

45 N.C. - No Connection

46 PCONT/ EFP O Main Transformer Control

_/CE Output

47 DCDET I DC Detect Input

48-51 N.C. - No Connection

52 HALF_1 I Deck 1 Half Playback

Input

53 MODE_1 I Deck 1 Mode Playback

Input

54 SW_LED O *2 Sub Woofer LED

55 N.C. - No Connection

56 PLG1 O Deck 1 plunger control

57 PLG2 O Deck 2 plunger control

58 MTR I/O Deck motor control

(“L” for motor ON)

80

Page 81

Pin No. Mark I/O Function

59 REC /O L when record circuit is

60 DECK1_H O H when DECK 1 P/B head

61 N.C. - No Connection

62 Vcc - Power Supply (+5V)

63 N.C. - No Connection

64 Vss - Ground (0V)

65-66 N.C. - No Connection

67 V_JOG_A I Volume Jog A

68 V_JOG_B I Volume Jog B

69 EX1_CLK I/O *1 I/O Expander Clock

70 EX1_DAT I *1 I/O Expander Data

71 /FL_RESET O Reset Input (ACTIVE L)

72 FL_CS I / O FL Driver Chip Select

73 FL_DOUT O Serial Data To FL Driver

74 FL_CLK I/O Serial Clock To FL Driver

75 N.C. - No Connection

76 SSEQ_LED O Super Sound EQ LED

77 CD_RST O CD Reset Output

78 STATUS I CD Servo LSI Status Input

79 MLD O CD Command Load

80 MDATA_OUT O CD Command Data

81 MCLK O CD Command Clock

82 /RESTSW I CD Limit Switch Input for

83 CHG_HLF O Changer Half Drive

84 CHG_CW O Changer Motor Clockwise

85 CHG_CCW O Changer Motor

86 CHG_SW1 I CD Changer Switch 1

87 CHG_SW2 I CD Changer Switch 2

88 CHG_PLR O Changer Plunger Output

89 CHG_AD2 I Changer AD Detection

90 CHG_AD1 I Changer AD Detection

91 DECK2 I DECK CONDITION

92 KEY3 I KEY3 INPUT

93 KEY2 I KEY2 INPUT

94 KEY1 I KEY1 INPUT

95 PHOTO_2 I Rotation Detection Signal

96 AVss - Analog Power Supply

97 PHOTO_1 I Rotation Detection Signal

98 VREF - Reference for A-D (5V)

99 AVcc - Analog Power Supply

100 Demo Selector I (H= default demo on, L=

operating

is selected

(Output)

Output

Output

Output

the Most Inner Point

(Active Low)

Output

Output

Counterclockwise Output

Input

Input

Input (Position/Bottom)

Input (Open/Clamp)

INPUT 2(R_INHF/

MODE2/HALF2)

(Deck 2)

Input (Connect to GND)

(Deck 1)

Input

default demo off.)

81

Page 82

22 Troubleshooting Guide

82

Page 83

23 Parts Location and Replacement Parts List

Notes:

· Important safety notice:

Components identified by mark have special characteristics important for safety.

Furthermore, special parts which have purposes of fire-retardent (resistors), high-quality sound (capacitors),

low noise (resistors), etc are used.

When replacing any of these components, be sure to use only manufacturer’s specified parts shown in the

parts list.

· The parenthesized indications in the Remarks columns specify the areas or colour. (Refer to the cover page

for area or colour)

Parts without these indications can be used for all areas.

· Warning: This product uses a laser diode. Refer to caution statements on “Precaution of Laser Diode”.

· Capacitor values are in microfarads (˜F) unless specified otherwise, P= Pico-farads (pF), F= Farads.

· Resistance values are in ohms, unless specified otherwise, 1K=1,000 (OHM).

· The marking (RTL) indicates that the Retention Time is limited for this items. After the discontinuation of this

assembly in production, the item will continue to be available for a specific period of time. The retention period of a

availabilityis dependent on the type of assembly, and in accordance with the laws governing part and product retention.

After the end of this period, the assembly will no longer be available.

· [M] Indicates in the Remarks columns indicates parts supplied by PAVCSG.

· The “(SF)” mark denotes the standard part.

· Reference for O/I book languages are as follows:

Ar: Arabic Du: Dutch It: Italian Sp Spanish

Cf: Canadian French En: English Ko: Korean Sw: Swedish

Cz: Czech Fr: French Po: Polish Co: Traditional Chinese

Da: Danish Ge: German Ru: Russian Cn: Simplified Chinese

Pe: Persian

83

Page 84

23.1 Deck Mechanism (RAA4502-S)

23.1.1 Deck Mechanism Parts Location

112

101

133-2

121

133

135

111

103

133-1

122

104

113

111

122

103

121

136

120

113

122

120

139

130

130-1

112

102

133-2

111

103

122

104

111

103

133-1

133

130

130-1

84

Page 85

138

123

124

107

137

129

126

137

105

135

108

134

115

118

132

119

137

135

128

123

124

S972

137

129

S971

126

137

CN971

S975

109

118

115

137

S952

138

S951

110

116

117

114

125

139

85

110

125

107

116

105

132

128

119

117

114

Page 86

23.1.2 Deck Mechanism Parts List

86

Page 87

23.2 CD Loading Mechanism (RD-DAC026-S)

23.2.1 CD Loading Mechanism Parts Location

324

373

305

351

374

307

364

313

348

a

346

304

349

325

310

311

352

c

303

b

325

315

326

318

317

314

309

308

312

322

350

370

316

369

320

323

372

321

c

a

347

353

1

355

357

1

356

301

c

306

344

325

339

87

302

CN1

W2

345

341

W1

W1

319

325

Page 88

336

325

329

326

337

325

W2

325

334

335

331

358

333

358-10

332

362

358-1

338

330

362

358-1

325

343

358-6

358-5

358-2

358-9

371

327

325

361

c

d

CN70002

358-3

358-4

358-7

358-8

360

363

359

360

CN70001

363

88

Page 89

23.2.2 CD Loading Mechanism Parts List

89

Page 90

23.3 Cabinet

23.3.1 Cabinet Parts Location

5

(To CN2806)

CN6601

CP6401

31

3

(To CN2803)

32

VR6491

CN1001

32

2(To CN1)

24

CS1001

31

7-1

32

W6555/

H6555

32

JK6551

W1002

CS1002

32

32

32

32

11

31

3

31

7

34

34

29

34

23

10

34

12

13

26

27

20

17

25

26

26

18

20

16

27

33

33

16

90

Page 91

33

19

33

14

CN2801

9

14

14

33

33

33

CN2805

(To CN7002)

CN2806

35

35

4(To CN01)

6

JK2601

JK2801

33

21

30

14

35

JK5952

33

33

28

33

30

CN5950

33

CN5951

33

33

33

33

CN2803

CN2808

CN2809

CN5801

E5800

CN5800

91

H5950/

W5950

22

16

16

Page 92

23.3.2 Cabinet Parts List

Ref. No Part No. Part Name/ Description

1

2

3

4

5

6

7

07-gen

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

L6FALEFH0030 VENTILADOR

REEX0352 SPEAKER CORD(RED/BLACK)

REEX0352 SPEAKER CORD(RED/BLACK)

REEX0212-1 MULTICABLE

REEX0447 MULTICABLE

REEX0202-2 MULTICABLE

REEX0211 14P FFC WIRE (CHANGER TO MAIN)

REEX0401 30 PIN MULTICABLE

RYPM0183 CONJUNTO FRONT PANEL

RKWX0239A-H FL WINDOW

RGRX0042G-L TAPA POSTERIO TM23

RGUX0593-S BOTONERA FUNCION

RGUX0594-S POWER/SSEQ BTN

RGUX0595-S CD EJECT BTN/CONTROL BTN

RGWX0088-S VOLUME KNOB

RHD30004-2S SIDE SCR EW

RKA0072-KJ LEG

RKFX0125 CASS LID (L)

RKFX0126 CASS LID(R)

RKMX0105Z-SL1 TOP CABINET SIN DOBLAR

RMBX0036 CASS OPEN SPRING

RMCX0021 TRANSISTOR CLI P

RMKX0099-LM1 BOTTOM CHASSIS 23/43/53

RMKX0100-SL CD CHASSIS

RMNX0119-K FL HOLDER SC-TM22

RGWX0088-S VOLUME KNOB

RUS757ZAA RESORTE CASSETTE

RXGX0002 DAMPER GEAR

RXXX0057A DISIPADOR DEL TM23

RYPM01 77 CD LID ACABADO

XTB3+10J-A TORNILLO

XTB3+10JFZ-A TORNILLO

XTBS26+10J-A TORNILLO

XTBS3+8JFZ1-A TORNILLO

XTW3+12T-A TORNILLO MECANISM O CD

XTW3+15T-A TORNILLO PARA INTEGRADO

92

Page 93

23.4 Electrical Parts List

Ref. No. Part No. Part Name & Description

REPM05230A CONJUNTO MANUAL TRANSFORMADOR SC-TM23

RENM05230A CONJUNTO RADIAL TRANSFORMADOR SC-TM23

RENM05230AZ CONJUNTO AXIAL TRANSFORMADOR SC-TM23

RENM05230AJ CONJUNTO JUMPER TRANSFORMADOR SC-TM23

REPM05231A CONJUNTO MANUAL PODER SC-TM23

RENM05231A CONJUNTO RADIAL PODER SC-TM23

RENM05231AZ CONJUNTO AXIAL PODER SC-TM23

RENM05231AJ CONJUNTO JUMPER PODER SC-TM23

REPM05232A CONJUNTO MANUAL MAIN SC-TM23

REAM05232A CONJUNTO SMT MAIN SC-TM23

RENM05232A CONJUNTO RADIAL MAIN SC-TM23

RENM05232AZ CONJUNTO AXIAL MAIN SC-TM23

RENM05232AJ CONJUNTO JUMPER MAIN SC-TM23

RENM03815A CONJUNTO TUNER PACK RADIAL

RENM03815AZ CONJUNTO TUNER PACK AXIAL

RENM03815AJ CONJUNTO TUNER PACK JUMPER

REPM05233A CONJUNTO MANUAL PANEL SC-TM23

RENM05233A CONJUNTO RADIAL PANEL SC-TM23

RENM05233AZ CONJUNTO AXIAL PANEL SC-TM23

RENM05233AJ CONJUNTO JUMPER PANEL SC-TM23

CAPACITORS

C5961 ECA1AM471B CAPACITOR ELECTROLITICO

C5962 ECA1AM471B CAPACITOR ELECTROLITICO

C5957 ECA1HM100B C.ELECTROLITICO

C5956 F2A1H470A147 CAPACITOR

C5952 F2A1A470A011 CAPACITOR

C5963 ECEA1VKA4R7B CAPACITOR ELECTROLITICO

C5951 F1B1H1030003 CAPACITOR

C5954 F1B1H1030003 CAPACITOR

C5959 F1B1H1030003 CAPACITOR

C5960 ECQE2104KF3 CAPACITOR PP

C5958 F1B1H1030003 CAPACITOR

C5953 F1B1H1030003 CAPACITOR

C5955 ECA1HM220B C.ELECTROLITICO

C5950 ECA1EM222B CAPACITOR

C5810 F2A1E101A122 CAPACITOR

C5807 F2A1C100A196 CAPACITOR

C5808 F2A1C100A196 CAPACITOR

C5813 ECEA1EKA100B CAPACITOR ELECTROLITICO

C5812 ECEA1EKA330B CAPACITOR ELECTROLITICO

C5803 F1D1H101A012 CAPACITOR CERAMICO

C5501 F1D1H103A046 CAPACITOR

C5243 ECBT1H150J5 CAPACITOR

C5441 ECBT1H150J5 CAPACITOR

93

Page 94

C5442 F1D1H471A012 CAPACITOR CERAMICO

C5240 F1D1H471A012 CAPACITOR CERAMICO

C5440 F1D1H821A012 CAPACITOR CERAMICO

C5242 F1D1H821A012 CAPACITOR CERAMICO

C5814 F1D1H103A046 CAPACITOR

C5811 F1D1H103A046 CAPACITOR

C5809 F1D1H103A046 CAPACITOR

C5806 F1D1H103A046 CAPACITOR

C5804 F1D1H103A046 CAPACITOR

C5814 F1D1H103A046 CAPACITOR

C5811 F1D1H103A046 CAPACITOR

C5809 F1D1H103A046 CAPACITOR

C5806 F1D1H103A046 CAPACITOR

C5804 F1D1H103A046 CAPACITOR

C5846 F1D1H1040002 CAPACITOR

C5447 F1D1H1040002 CAPACITOR

C5444 F1D1H1040002 CAPACITOR

C5244 F1D1H1040002 CAPACITOR

C5805 ECA1CM101B CAPACITOR

C5521 ECA2AM100B CAPACITOR ELECTROLITICO

C5443 ECA2AM100B CAPACITOR ELECTROLITICO

C5547 F2A1H1R0A015 CAPACITOR

C5545 F2A1H1R0A015 CAPACITOR

C5802 ECA0JAK221XB CAPACITOR ELECTROLITICO

C5838 F2A1H2R2A015 CAPACITOR

C5838 F2A1H2R2A015 CAPACITOR

C5840 ECA1HM222B CAPACITOR

C5820 ECA1HM222B CAPACITOR

C2412 ECJ1VB1A154K CAPACITOR CHIP

C2312 ECJ1VB1A154K CAPACITOR CHIP

C2218 ECJ1VB1C104K CAPACITOR

C2102 ECJ1VB1C104K CAPACITOR

C2107 ECJ1VB1C104K CAPACITOR

C2111 ECJ1VB1C104K CAPACITOR

C2118 ECJ1VB1C104K CAPACITOR

C2121 ECJ1VB1C104K CAPACITOR

C2202 ECJ1VB1C104K CAPACITOR

C2207 ECJ1VB1C104K CAPACITOR

C2211 ECJ1VB1C104K CAPACITOR

C2221 ECJ1VB1C104K CAPACITOR

C2226 ECJ1VB1C104K CAPACITOR

C2231 ECJ1VB1C104K CAPACITOR

C2236 ECJ1VB1C104K CAPACITOR

C2588 ECJ1VB1C104K CAPACITOR

C2751 ECJ1VB1C104K CAPACITOR

C2753 ECJ1VB1C104K CAPACITOR

C2851 ECJ1VB1C104K CAPACITOR

94

Page 95

C2853 ECJ1VB1C104K CAPACITOR

C2901 ECJ1VB1C104K CAPACITOR

C2998 ECJ1VB1C104K CAPACITOR

C2831 ECJ1VB1C223K CAPACITOR

C2583 ECJ1VB1C224K CHIP CAPACITOR

C2616 ECJ1VB1C333K CAPACITOR CHIP

C2607 ECJ1VB1E473K CAPACITOR CHIP

C2208 ECJ1VB1H102K CHIP CAPACITOR

C2203 ECJ1VB1H102K CHIP CAPACITOR

C2166 ECJ1VB1H102K CHIP CAPACITOR

C2119 ECJ1VB1H102K CHIP CAPACITOR

C2108 ECJ1VB1H102K CHIP CAPACITOR

C2103 ECJ1VB1H102K CHIP CAPACITOR

C2219 ECJ1VB1H102K CHIP CAPACITOR

C2906 ECJ1VB1H102K CHIP CAPACITOR

C2647 ECJ1VB1H102K CHIP CAPACITOR

C2636 ECJ1VB1H102K CHIP CAPACITOR

C2632 ECJ1VB1H102K CHIP CAPACITOR

C2613 ECJ1VB1H102K CHIP CAPACITOR

C2609 ECJ1VB1H102K CHIP CAPACITOR

C2604 ECJ1VB1H102K CHIP CAPACITOR

C2266 ECJ1VB1H102K CHIP CAPACITOR

C2610 ECJ1VB1H103K CHIP CAPACITOR

C2114 ECJ1VB1H103K CHIP CAPACITOR

C2214 ECJ1VB1H103K CHIP CAPACITOR

C2520 ECJ1VB1H103K CHIP CAPACITOR

C2521 ECJ1VB1H103K CHIP CAPACITOR

C2601 ECJ1VB1H103K CHIP CAPACITOR

C2603 ECJ1VB1H103K CHIP CAPACITOR

C2606 ECJ1VB1H103K CHIP CAPACITOR

C2612 ECJ1VB1H103K CHIP CAPACITOR

C2617 ECJ1VB1H103K CHIP CAPACITOR

C2618 ECJ1VB1H103K CHIP CAPACITOR

C2638 ECJ1VB1H103K CHIP CAPACITOR

C2648 ECJ1VB1H103K CHIP CAPACITOR

C2903 ECJ1VB1H103K CHIP CAPACITOR

C2951 ECJ1VB1H103K CHIP CAPACITOR

C2952 ECJ1VB1H103K CHIP CAPACITOR

C2584 ECJ1VB1H221K CHIP CAPACITOR

C2585 ECJ1VB1H221K CHIP CAPACITOR

C2832 ECJ1VB1H331K CHIP CAPACITOR

C2833 ECJ1VB1H331K CHIP CAPACITOR

C2106 ECJ1VB1H332K CHIP CAPACITOR

C2637 ECJ1VB1H332K CHIP CAPACITOR

C2206 ECJ1VB1H332K CHIP CAPACITOR

C2907 ECJ1VB1H471K CHIP CAPACITOR

C2116 ECJ1VB1H681K CHIP CAPACITOR

95

Page 96

C2216 ECJ1VB1H681K CHIP CAPACITOR

C2608 ECJ1VC1H080D CHIP CAPACITOR

C2401 ECJ1VC1H100J CHIP CAPACITOR

C2301 ECJ1VC1H100J CHIP CAPACITOR

C2631 ECJ1VC1H151J CHIP CAPACITOR

C2840 ECJ1VC1H180J CHIP CAPACITOR

C2841 ECJ1VC1H180J CHIP CAPACITOR

C2302 ECJ1VC1H470J CAPACITOR

C2402 ECJ1VC1H470J CAPACITOR

C2649 ECJ1VF1C104Z CHIP CAPACITOR

C2936 ECJ1VF1C474Z CAPACITOR

C2501 ECEA1HKN2R2B CAPACITOR

C2977 ECA1CM101B CAPACITOR

C2582 ECA1CM101B CAPACITOR

C2602 F2A1C100A196 CAPACITOR

C2611 F2A1H4R70009 CAPACITOR

C2614 F2A1H3R3A015 CAPACITOR

C2615 F2A1H4R70009 CAPACITOR

C2620 F2A1C100A196 CAPACITOR

C2621 F2A1HR47A015 CAPACITOR

C2622 F2A1H1R0A015 CAPACITOR

C2581 ECA1CAK330XB CAPACITOR ELECTROLITICO

C2623 F2A1H1R0A015 CAPACITOR

C2625 F2A1C220A017 CAPACITOR

C2627 F2A1C220A017 CAPACITOR

C2639 F2A1H4R70009 CAPACITOR

C2641 F2A1H1R0A015 CAPACITOR

C2642 F2A1H1R0A015 CAPACITOR

C2852 ECA1CM101B CAPACITOR