Page 1

I

T

T

I

y

A

A

A

ORDER NO. MD0803011CE

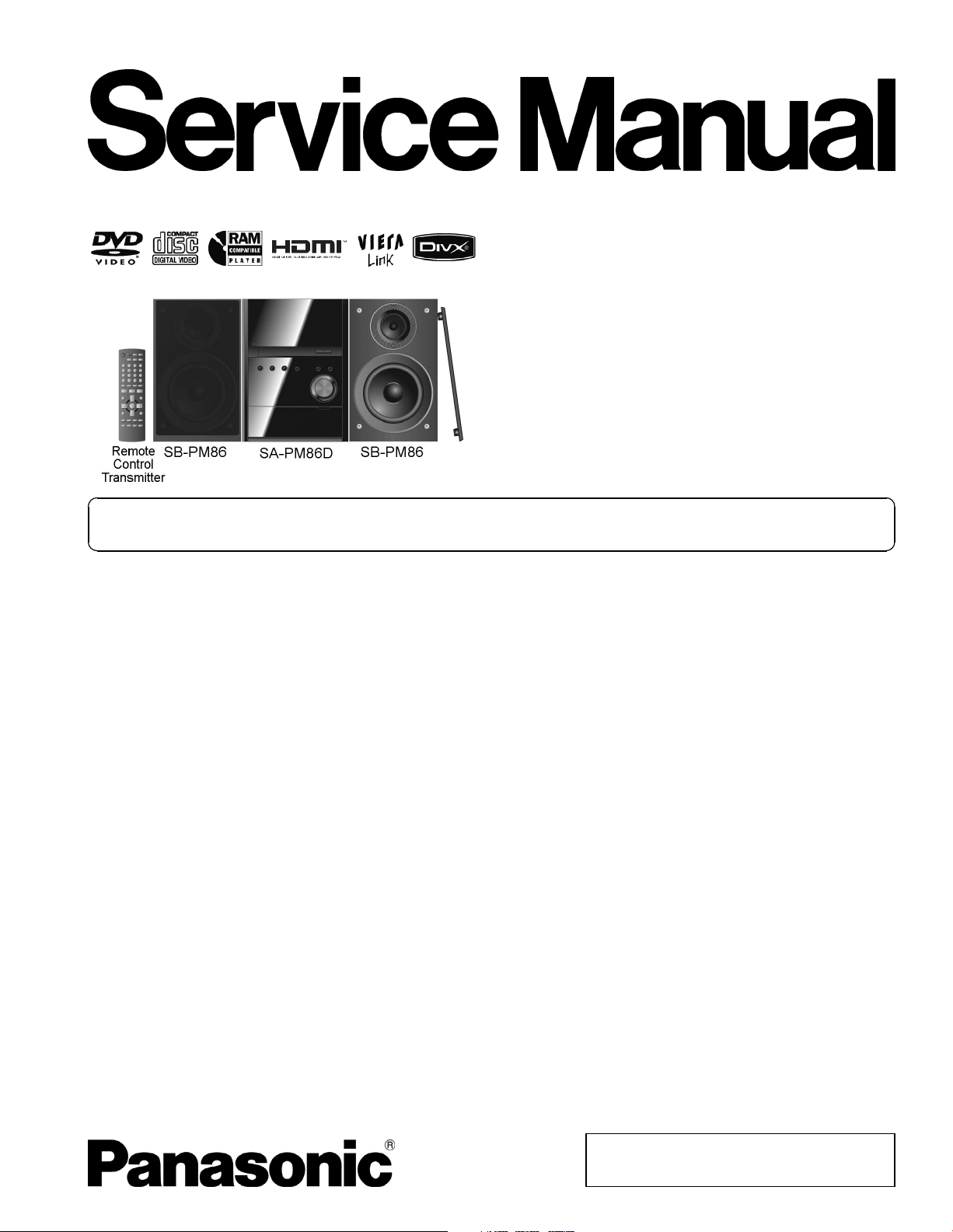

DVD Stereo System

SA-PM86DGCS

SA-PM86DEE

Colour

(K)... Black Type

Notes: This model’s mechanism unit is DLS6. Please refer to the original Service Manual (Order No.

MD0801003CE) for this mechanism.

Specifications

AMPLIFIER SECTION

RMS Output Power

HD 10% 80 W per channel (3 Ω), 1 kHz

otal RMS Dolby Digital Mode

power

PMPO Output Power 1800 W

FM/AM TUNER, TERMINALS SECTION

Preset station FM 30 stations

FrequencyModulation (FM)

Frequencyrange 87.50 to 108.00 MHz

Sensitivit

S/N 26dB 2.2 µV

ntenna terminals 75 Ω (unbalanced)

mplitude Modulation (AM)

Frequencyrange 522 to 1629 kHz (9 kHz step)

520 to 1630 kHz (10 kHz step)

M Sensitivity S/N 20 dB at 999

kHz

Digital audio output

Coaxial digital output Pin jack

Music Port (front)

160 W

AM 15 stations

(50 kHz step)

2.5 µV (IHF)

(GCS)

1000 µV/m

Sensitivity 100 mV, 10 kΩ

Terminal Stereo, 3.5 mm jack

Phone jack

Terminal Stereo, 3.5 mm jack

Output level (CD, 1 kHz, -20dB) 32 Ω

Mic jack

Sensitivity 0.7 mV, 600 Ω

Terminal Mono, 3.5 mm jack (2 system)

I VIDEO SECTION

Video system PAL625/50, PAL525/60, NTSC

Composite video output

Output level 1Vp-p(75Ω)

Terminal Pin jack (1 system)

Component video output

Y output level 1Vp-p(75Ω)

PBoutput level 0.7 Vp-p (75 Ω)

PRoutput level 0.7 Vp-p (75 Ω)

Terminal Pinjack(Y:green,PB:blue,PR:

red) (1 system)

HDMI AV output

Terminal Type A connector (19 pin)

This unit supports “HDAVI Control 2” function

I USB SECTION

© 2008 Matsushita Electric Industrial Co. Ltd.. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

SA-PM86DGCS / SA-PM86DEE

USB Port

USB Standard USB 2.0 full speed

Media file format support MP3 (*.mp3)

JPEG (*.jpg, *.jpg)

USB device file system FAT12, FAT16, FAT32

USB port power 500 mA (Max)

I DISC SECTION

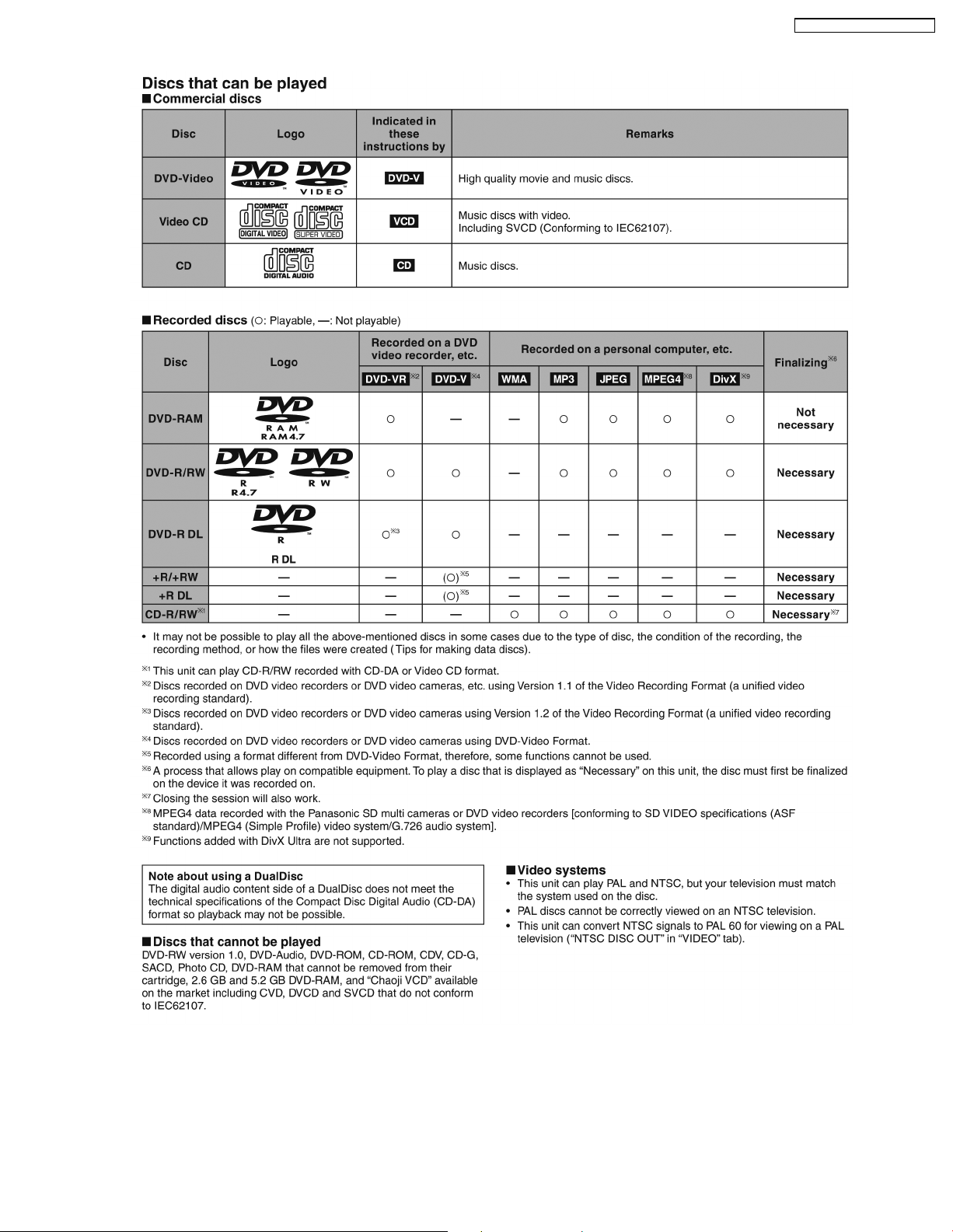

Discs played (8 cm or 12 cm)

(1) DVD (DVD-Video, DivX

(2) DVD-RAM (DVD-VR, MP3

(3) DVD-R (DVD-Video, DVD-VR, MP3

*6, *7

)

DivX

*6, *7

)

*2, *7

, JPEG

*2, *7

*4, *7

, JPEG

, MPEG4

*4, *7

*5, *7

, MPEG4

(4) DVD-R DL (DVD-Video, DVD-VR)

(5) DVD-RW (DVD-Video, DVD-VR, MP3

*6, *7

)

DivX

*2, *7

, JPEG

*4, *7

(6) +R/+RW (Video)

(7) +R DL (Video)

(8) CD, CD-R/RW (CD-DA, Video CD, SVCD*1, MP3

JPEG

*4, *7

, MPEG4

*5, *7

, DivX

*6, *7

)

*2, *7

*1Conforming to IEC62107

*2MPEG-1 Layer 3, MPEG-2 Layer 3

*3Windows Media Audio Ver.9.0 L3

Not compatible with Multiple Bit Rate (MBR)

*4Exif Ver 2.1 JPEG Baseline files

Picture resolution: between 160 x 120 and 6144 x 4096 pixels

(Sub sampling is 4:0:0, 4:2:0, 4:2:2 or 4:4:4). Extremely long and

narrow pictures may not be displayed.

*5MPEG4 data recorded with Panasonic SD multi cameras or DVD

video recorders

Conforming to SD VIDEO speci. cations (ASF standard)/MPEG4

(Simple Profile) video system/G.7 26 audio system

WMA (*.wma)

MPEG4 (*.asf)

*6, *7

, DivX

, MPEG4

, WMA

*5, *7

*3, *7

)

,

*5, *7

,

*6Plays all versions of DivX®video (including DivX®6) with standard

playback of DivX®media files. Certified to the DivX Home Theater

Profile.

*7The total combined maximum number of recognizable audio,

picture and video contents and groups: 4000 audio, picture and

video contents and 400 groups.

Pick up

Wavelength (DVD/CD) 655/785 nm

Laser power (DVD/CD) CLASS 1/CLASS 1M

Audio output (Disc)

Number of channels 2 channels (FL, FR)

I GENERAL

Power supply AC 230 V, 50 Hz (EE)

AC 220 to 240 V, 50/60 Hz

Power consumption 95 W

,

Dimensions (WxHxD) 175.0 mm x 240.0 mm x 342.3

Mass 4.5 kg

Operating temperature range 0°C to 40°C

Operating humidity range 35% to 80% RH (no

Power consumption in standby mode approx. 0.7 W

I SYSTEM

SC-PM86DEE-K Main unit: SA-PM86DEE-K

Speakers: SB-PM86EG-K

SC-PM86DGCS-K Main unit: SA-PM86DGCS-K

Speakers: SB-PM86EG-K

Note:

1. Specifications are subject to change without notice. Mass and

dimensions are approximate.

2. Total harmonic distortion is measured by the digital spectrum

analyzer.

(GCS)

mm

condensation)

CONTENTS

Page Page

1 Safety Precautions

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

3 Precaution of Laser Diode

4 Handling Precaution s for Traverse Unit

5 Handling the Lead Free Solder

6 Operation Procedures

7 Self-Diagnosis and Special Mode Setting

8 Assembling and Disassembling

9 Assembling and Disassembling of Mechanism Unit

10 Service Fixture and Tools

11 Service Position

3

12 Voltage Measurement & Waveform Chart

5

13 Wiring Connection Diagram

6

14 Block Diagram

15 Notes Of Schematic Diagram

7

9

16 Schematic Diagram

10

17 Printed Circuit Board

18 Illustration of IC’s, Transistors and Diodes

16

28

19 Terminal Function of IC’s

51

20 Exploded Views

21 Replacement Parts List

55

2

56

61

69

71

77

79

95

101

102

105

109

Page 3

SA-PM86DGCS / SA-PM86DEE

1 Safety Precautions

1.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, ensure that all the protective devices such as insulation barriers, insulation papers shields are properly installed.

3. After servicing, check for leakage current checks to prevent from being exposed to shock hazards.

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Using an ohmmeter measure the resistance value, between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩ and 5.2Ω.

When the exposed metal does not have a return path to the chassis, the reading must be

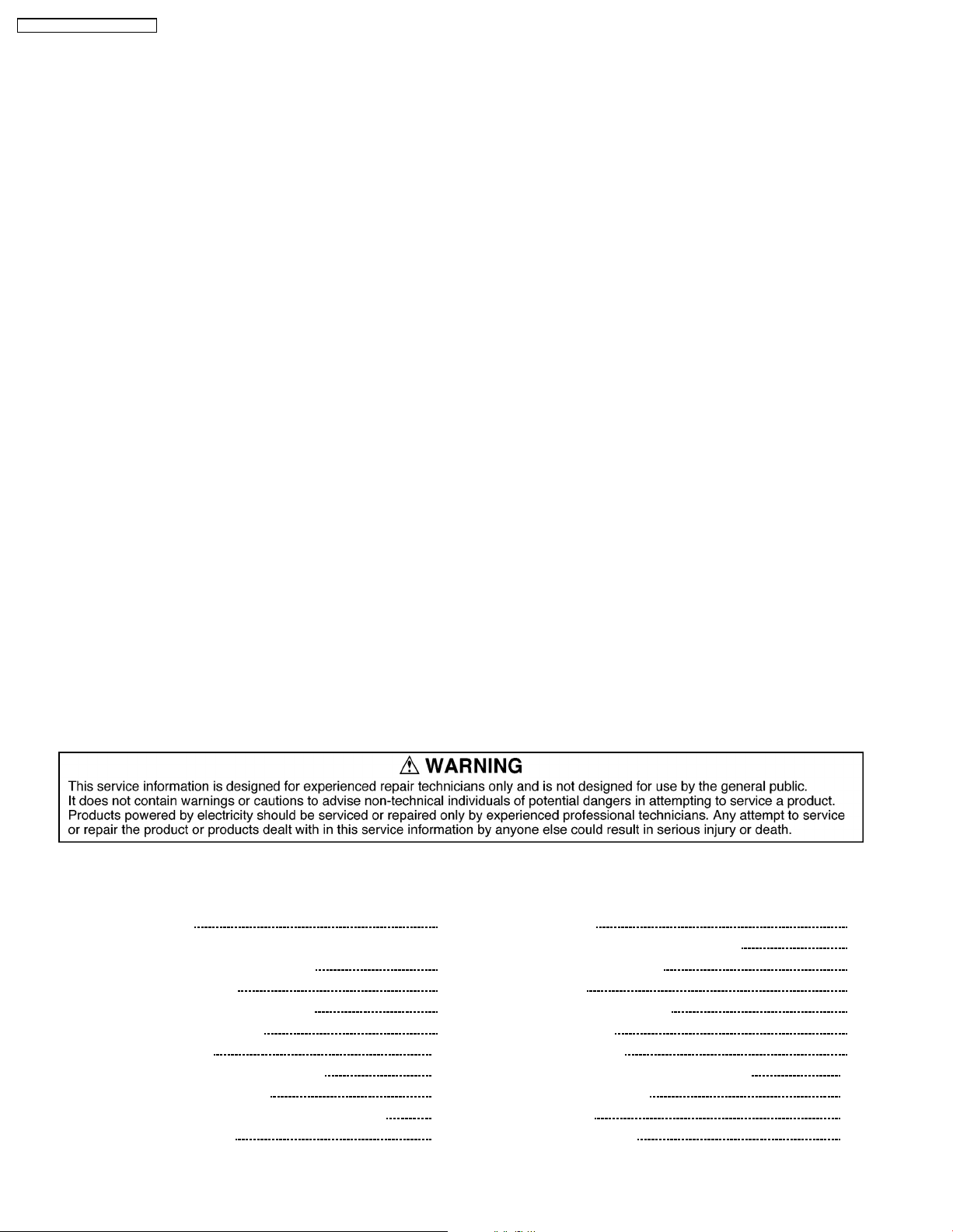

1.1.2. Leakage Current Hot Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent) may

be used to make the hot checks, leakage current must not exceed 1/2 milliamp. should the measurement is outside of the limits

specified, there is a possibility of a shock hazard, and the equipment should be repaired and re-checked before it is returned

to the customer.

.

Figure 1

3

Page 4

SA-PM86DGCS / SA-PM86DEE

1.2. Before Repair and Adjustment

Disconnect AC power, discharge Power Supply Capacitors C2207, C2210, C2211, C2212, C2742, C5105, C5106 , C5916, C5917,

C5938, C5562, C5954 , C5979 and C5993 through a 10Ω, 1W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

• Current consumption at AC 220 - 240 V, at 50/60 Hz in NO SIGNAL mode (at volume min) should be ~500 mA. (GCS)

• Current consumption at AC 230 V 50 Hz in NO SIGNAL mode (at volume min) should be ~500 mA. (EE)

1.3. Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

• No sound is heard when the power is turned on.

• Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

"shorted", or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

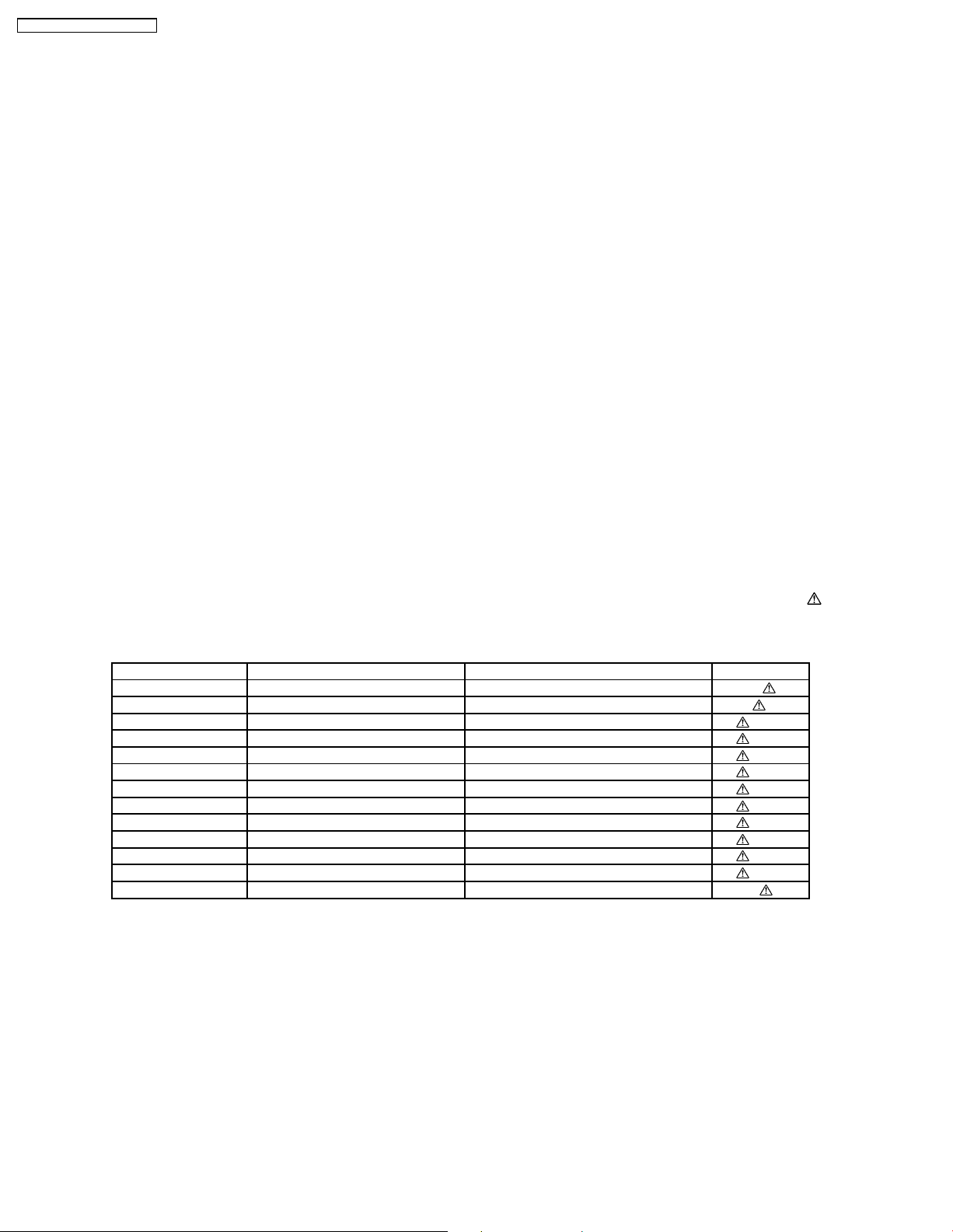

1.4. Safety Part Information

Safety Parts List:

There are special components used in this equipment which are important for safety.These parts are marked by

Schematic Diagrams & Replac ement Parts List. It is essential that these critical parts should be replaced with manufacturer’s

specified parts to prevent shock, fire or other hazards. Do not modify the original design without permission of manufacturer.

Table 1

Reference No. Part No. Part Name & Description Remarks

A2 K2CQ2CA00006 AC CORD [M]GCS

A2 K2CQ2CA00007 AC CORD [M]EE

JK5970 K2AA2B000017 AC INLET [M]

T5900 G5CYBYY0 0007 POWER TRANSFORMER [M]

T5901 G4C2AAJ00005 POWER TRANSFORMER [M]

F5970 K5D162BLA013 FUSE [M]

L5970 ELF15N035AN LINE FILTER [M]

RL5970 K6B1AEA00003 POWER RELAY [M]

Z5970 ERZVA5Z471 ZENER [M]

FP5920 K5G402A00025 FUSE PROTECTOR [M]

FP5921 K5G102A00039 FUSE PROTECTOR [M]

FP5922 K5G202AA0002 FUSE PROTECTOR [M]

PCB7 REPX0633D TRANSFORMER P.C.B. [M]RTL

in the

4

Page 5

SA-PM86DGCS / SA-PM86DEE

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor “chip” components. The following techniques should be used to help reduce the inciden ce of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equiped assembly, drain off any ESD on your

body by touchin g a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applyin g power to the unit under test.

2. After removing an electrical assembly equiped with ES devices, place the assembly on a conductive surface such as aluminium

foil, to prevent electrostatic charge build up or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder remover device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminium foil or

comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize body motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to

damage an ES device).

5

Page 6

SA-PM86DGCS / SA-PM86DEE

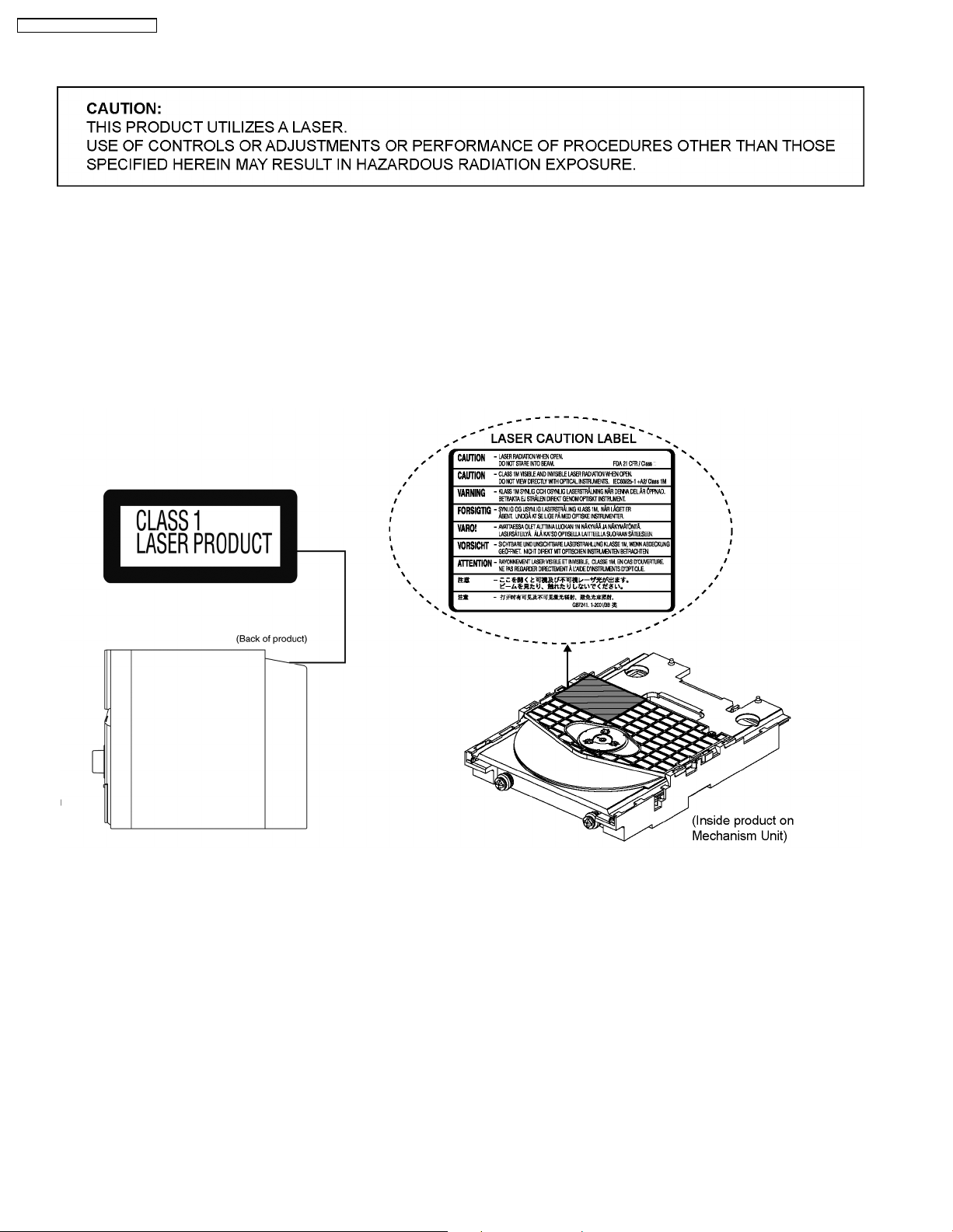

3 Precaution of Laser Diode

CAUTION :

This product utilizes a laser diode with the unit turned "on", invisible laser radiation is emitted from the pickup lens.

Wavelength: 655 nm (DVD)/785 nm (CD)

Maximum output radiation power from pickup: 100 µW/VDE

Laser radiation from the pickup unit is safety level, but be sure the followings:

1. Do not disassemble the pickup unit, since radiation from exposed laser diode is dangerous.

2. Do not adjust the variable resistor on the pickup unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at pickup lens for a long time.

6

Page 7

SA-PM86DGCS / SA-PM86DEE

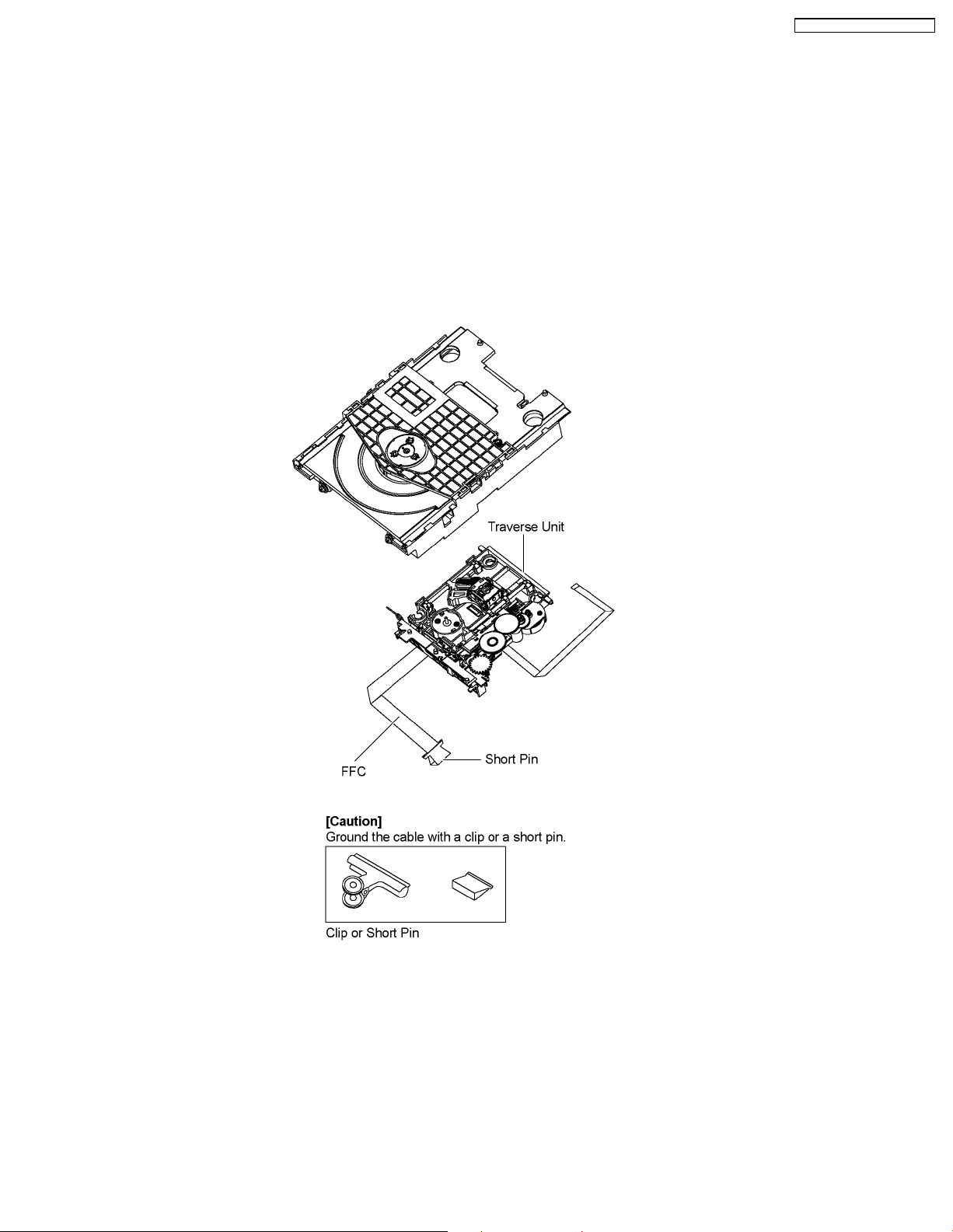

4 Handling Precautions for Traverse Unit

The laser diode in the optical pickup unit may break down due to static electricity of clothes or human body. Special care must be

taken avoid caution to electrostatic breakdown when servicing and handlin g the laser diode in the traverse unit.

4.1. Cautions to Be Taken in Handling the Optical Pickup Unit

The laser diode in the optical pickup unit may be damaged due to electrostatic discharge generating from clothes or human body.

Special care must be taken avoid caution to electrostatic discharge damage when servicing the laser diode.

1. Do not give a considerable shock to the optical pickup unit as it has an extremely high-precise structure.

2. To prevent the laser diode from the electrostatic discharge damage, the flexible cable of the optical pickup unit removed should

be short-circuited with a short pin or a clip.

3. The flexible cable may be cut off if an excessive force is applied to it. Use caution when handling the flexible cable.

4. The antistatic FPC is connected to the new optical pickup unit. After replacing the optical pickup unit and connecting the flexible

cable, cut off the antistatic FPC.

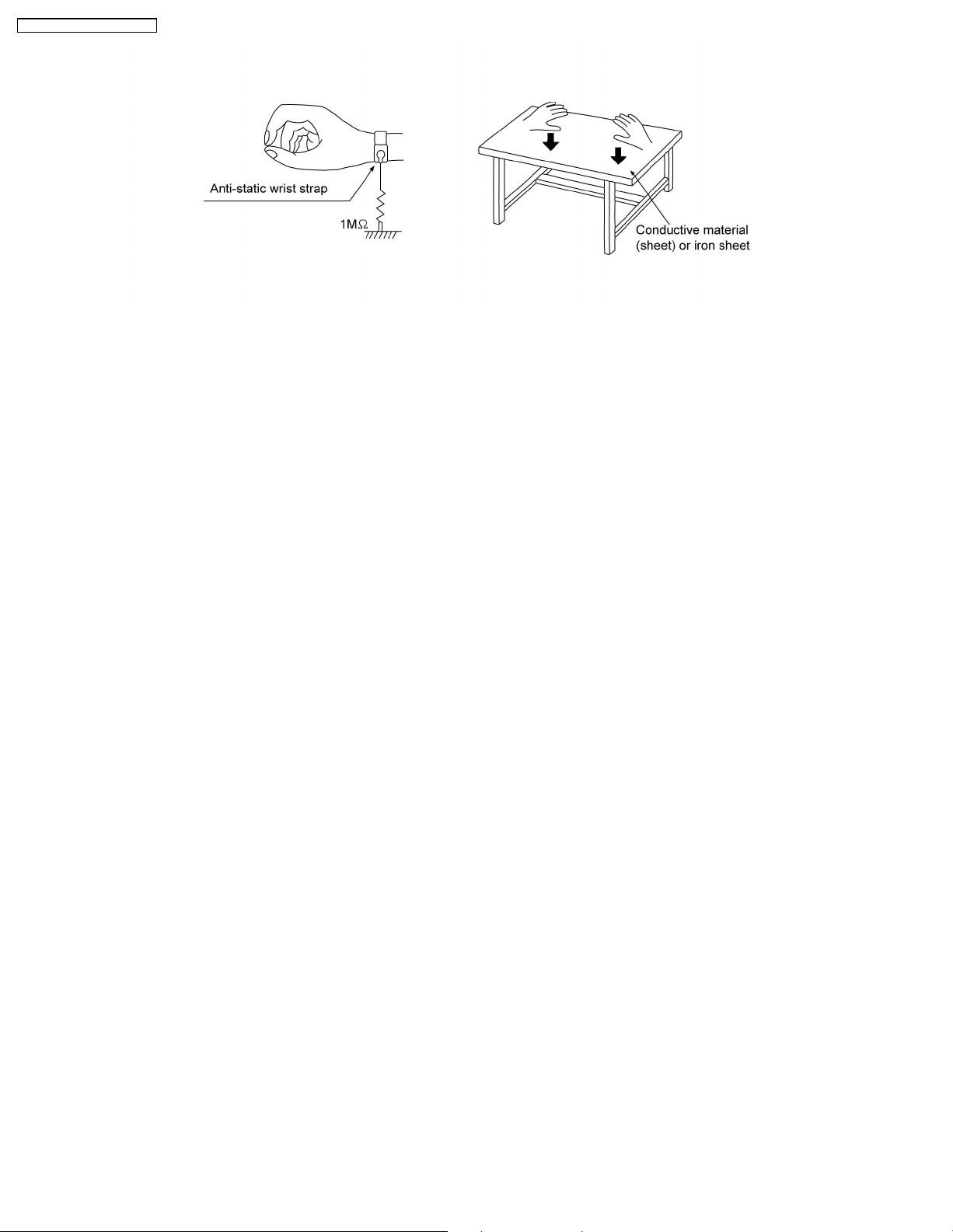

4.2. Grounding for electrostatic breakdown prevention

Some devices such as the DVD player use the optical pickup (laser diode) and the optical pickup will be damaged by static

electricity in the working environment. Proceed servicing works under the working environment where grounding works is

completed.

4.2.1. Worktable grounding

1. Put a conductive material (sheet) or iron sheet on the area where the optical pickup is placed, and ground the sheet.

4.2.2. Human body grounding

1. Use the anti-static wrist strap to discharge the static electricity form your body.

7

Page 8

SA-PM86DGCS / SA-PM86DEE

8

Page 9

SA-PM86DGCS / SA-PM86DEE

5 Handling the Lead Free Solder

5.1. General description about Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86°F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

The letter of “PbF” is printed either foil side or components side on the PCB using the lead free solder.

(See right figure)

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt

the lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30

degrees C (662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: Tin (Sn), 96.5%, Silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

9

Page 10

SA-PM86DGCS / SA-PM86DEE

6 Operation Procedures

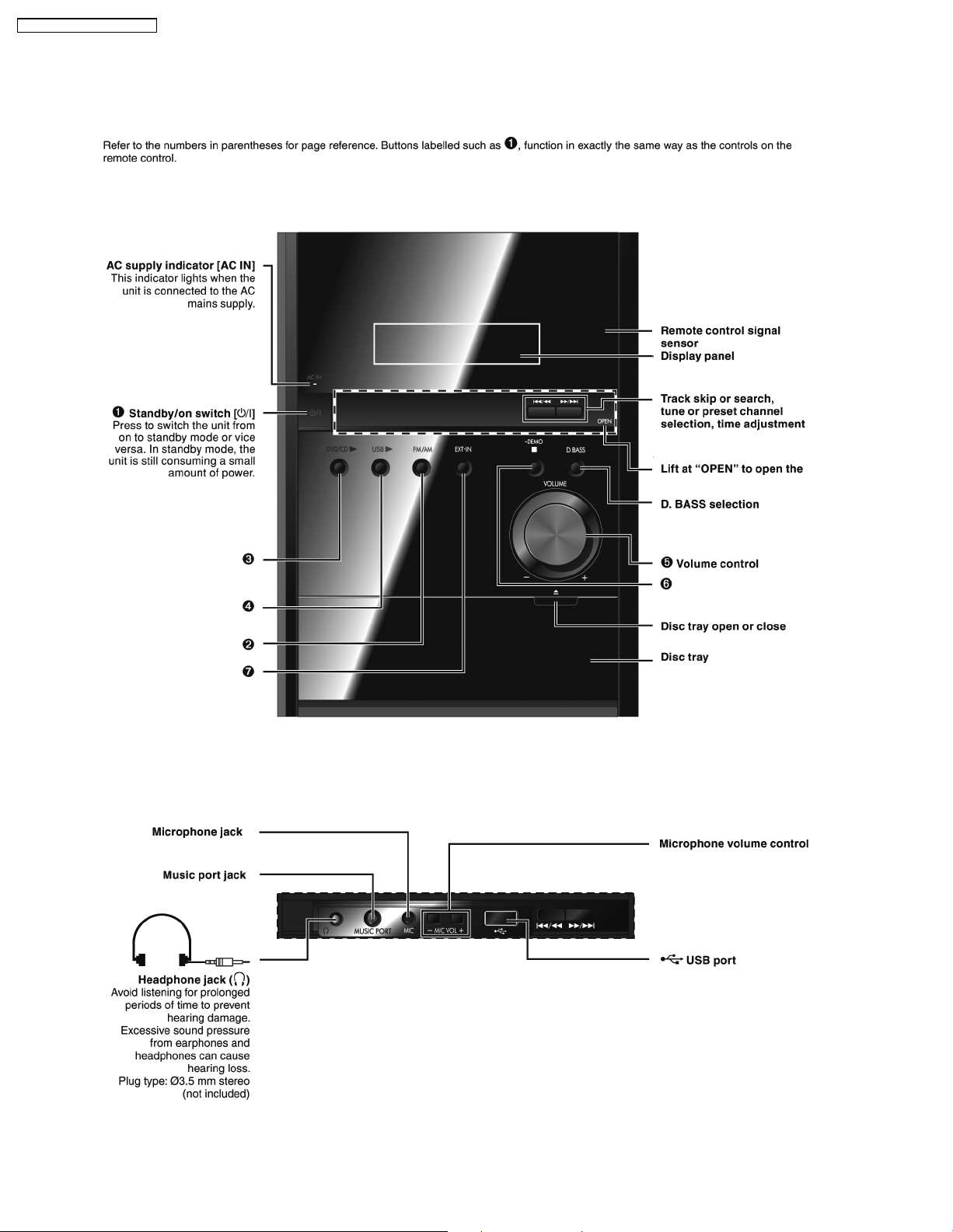

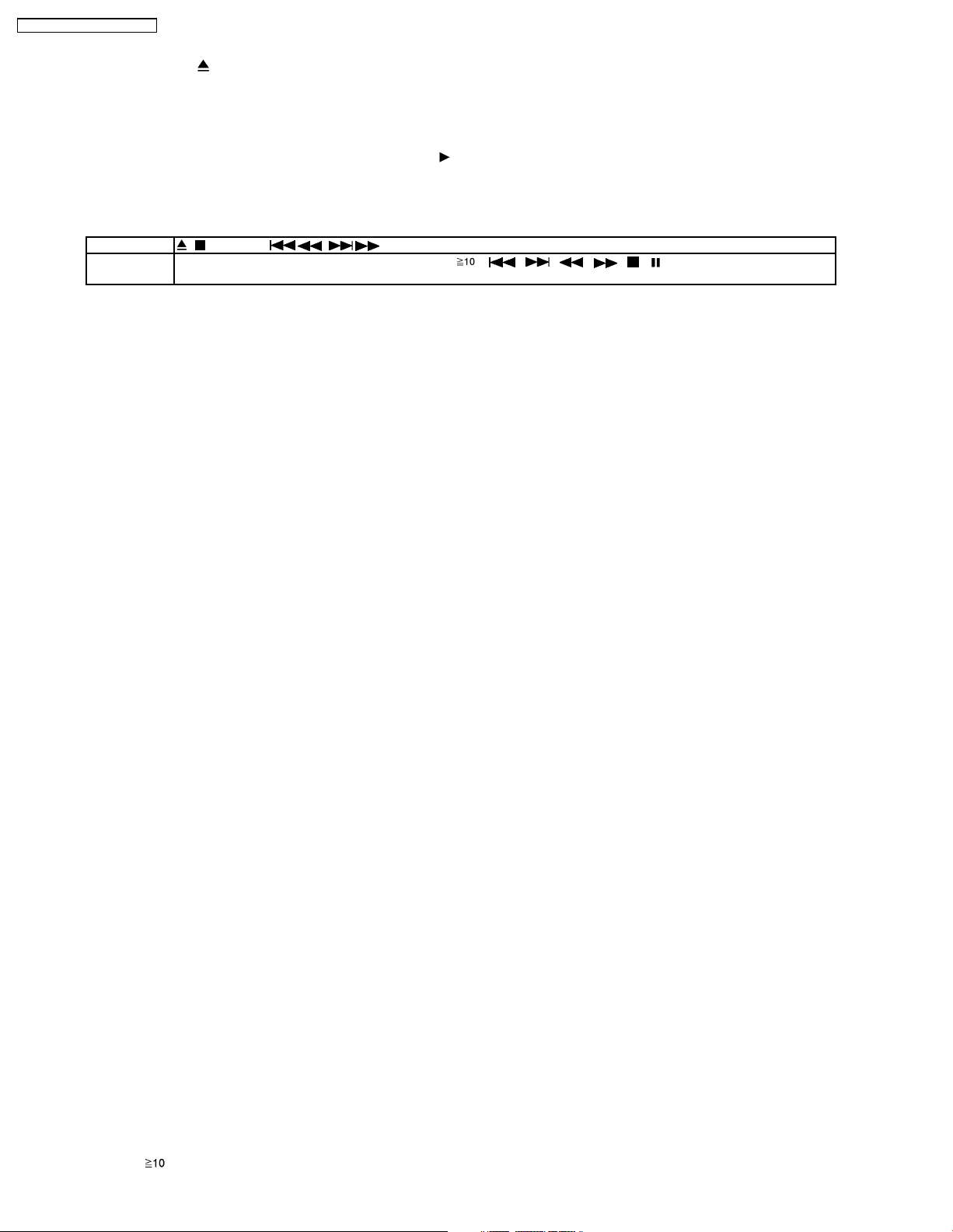

6.1. Main Unit Key Buttons Operation

10

Page 11

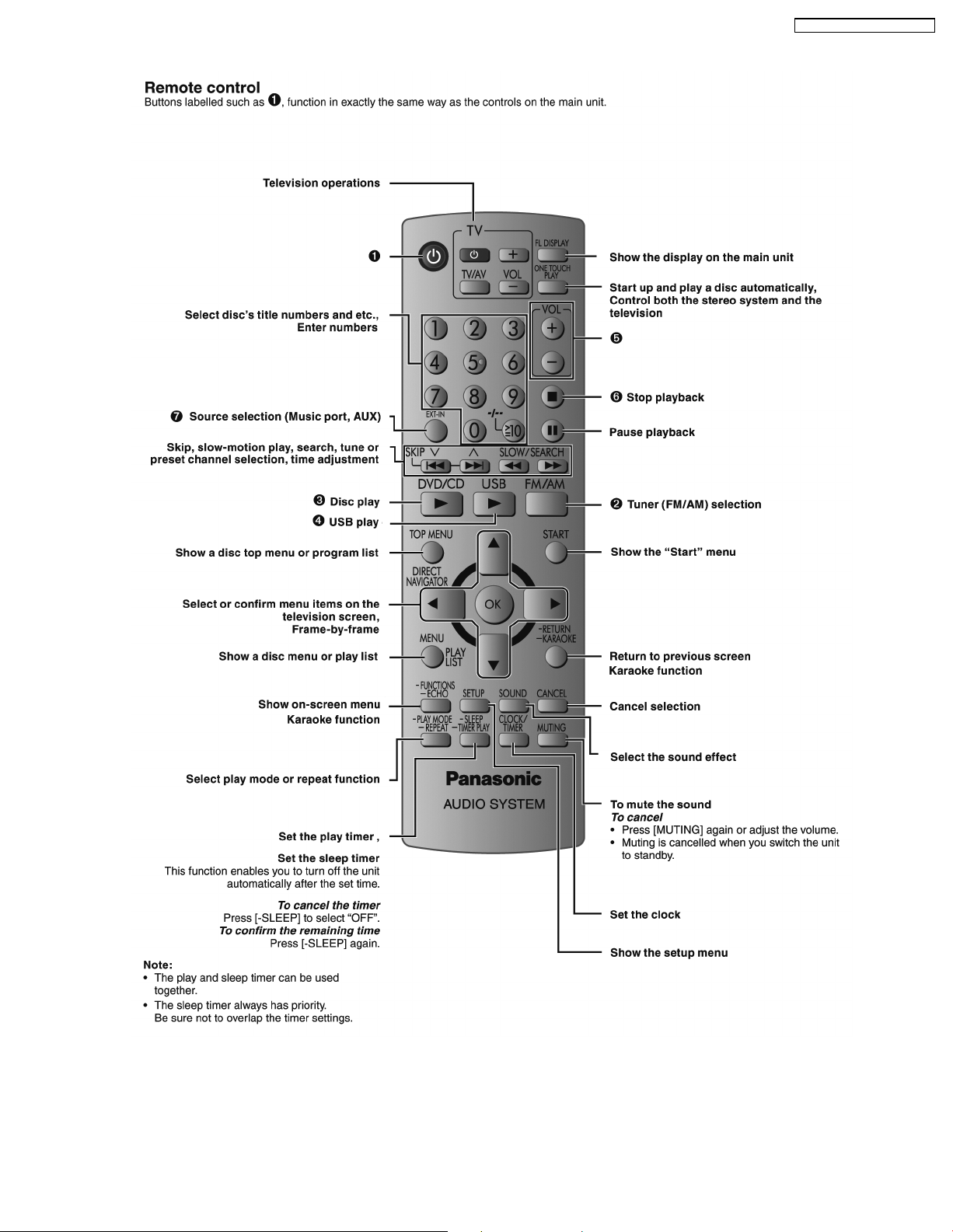

6.2. Remote Control Key Buttons Operation

SA-PM86DGCS / SA-PM86DEE

11

Page 12

SA-PM86DGCS / SA-PM86DEE

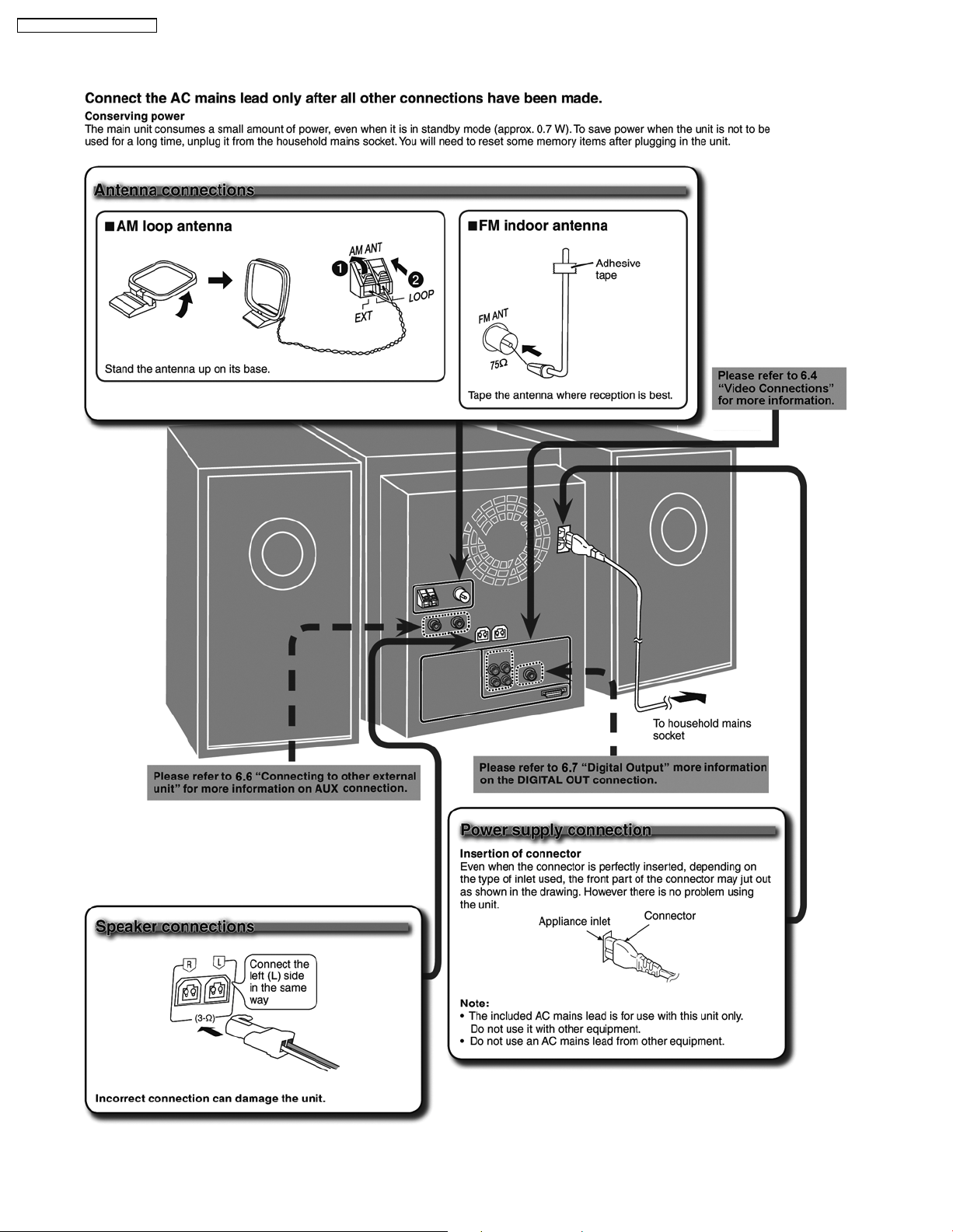

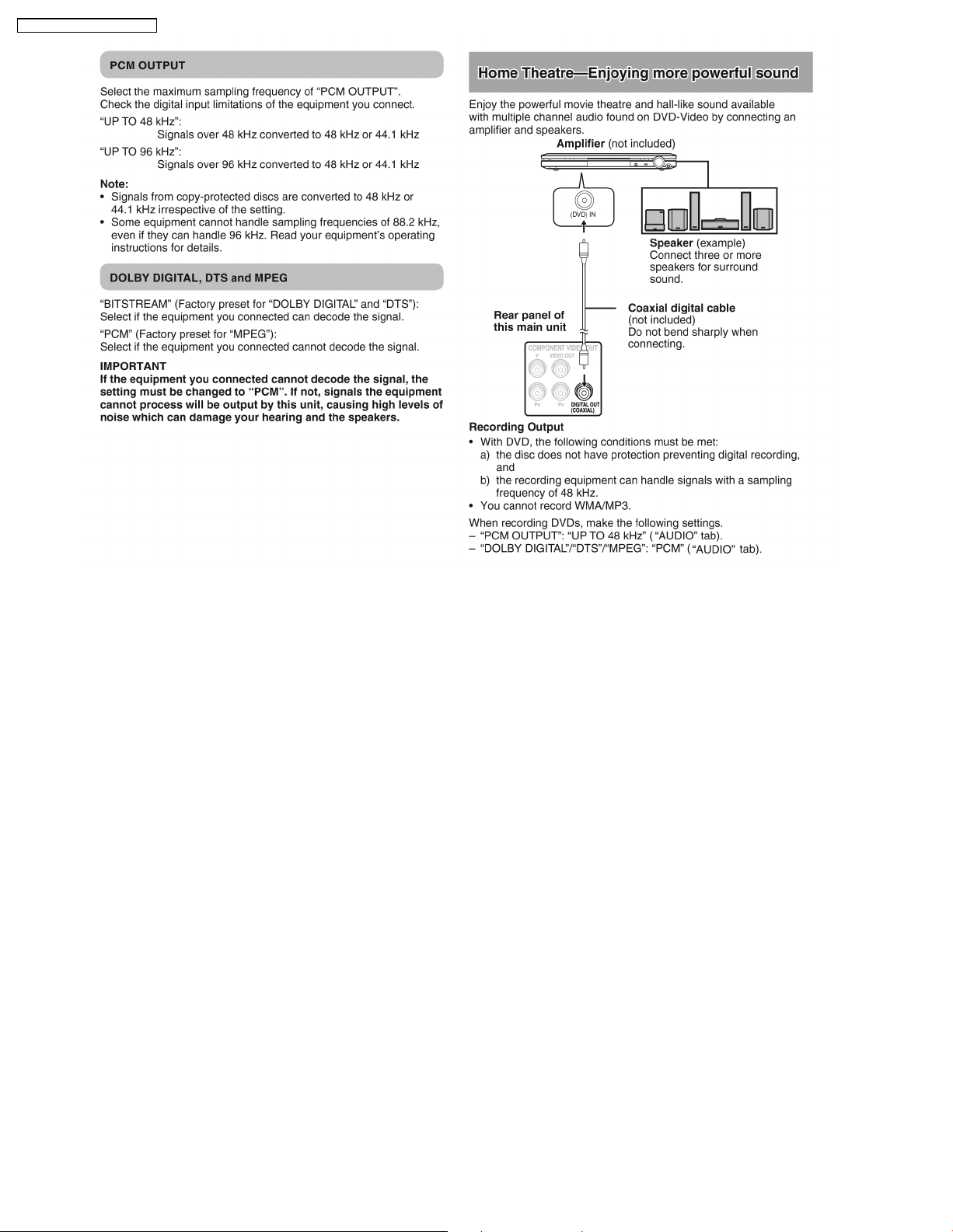

6.3. Connections

12

Page 13

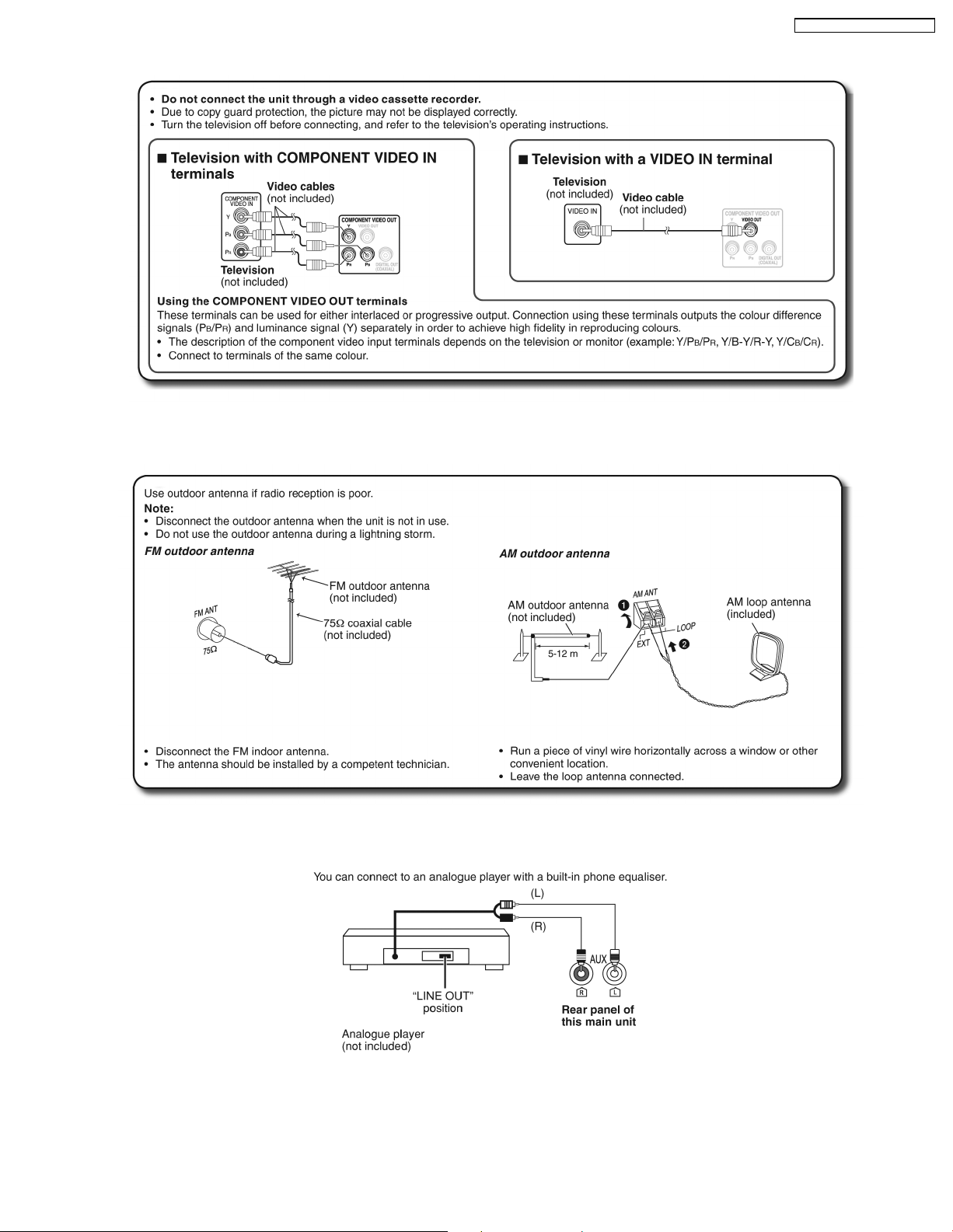

6.4. Video connections

6.5. Optional antenna connections

SA-PM86DGCS / SA-PM86DEE

6.6. Connecting to other external unit

6.7. Digital Output

Change the settings when you have connected equipment through this unit’s DIGITAL OUT terminal.

13

Page 14

SA-PM86DGCS / SA-PM86DEE

14

Page 15

6.8. Disc Information

SA-PM86DGCS / SA-PM86DEE

15

Page 16

SA-PM86DGCS / SA-PM86DEE

7 Self-Diagnosis and Special Mode Setting

7.1. Service Mode Summary Table

The service modes can be activated by pressing various button combination on the main unit and remote control unit.

Below is the summary for the various modes for checking:

Main unit buttons Remote control unit buttons Application Note

[STOP] [0] Error code check. (Refer to the section

[5] Jitter checking.

[ ] Initial setting of laser drive current.

[FUNCTIONS] DVD laser drive current check. (Refer to the section

[3] CD laser drive current check.

[6] Region display and mode.

[SOUND] CPPM/CRM keys check.

[7] Micro-processor firmware version check. (Refer to the section

[ ] Initialization of the player (factory setting is restored).

Used after replacement of Micro-processor (DV5 LSI) IC,

FLASH ROM IC (IC8651), EEPROM IC (IC8611) and DVD

Module P.C.B.

[OK] DVD Module P.C.B. reset.

[8] DVD Module P.C.B. firmware version check. (Refer to the section

[ ] Timer 1 check.

[ ] Timer 1 reset.

[ ] Timer 2 check.

[ ] Timer 2 reset.

“7.2.1. Service Mode

Table 1” for more

information.)

“7.2.2. Service Mode

Table 2” for more

information.)

“7.2.3. Service Mode

Table 3“ for more

information.)

“7.2.4. Service Mode

Table 4“ for more

information.)

Note:

An error code will be canceled if a power supply is turned OFF.

*1: CPPM is the copy guard function beforehand written in the disk for protection of copyrights.

*2: CEC is the consumer electronic control used for high-level user control of HDMI-connected devices.

*3: HDCP is the specification developed to control digital audio & video contents transmission for DVI or HDMI connections.

7.2. Service Mode Table

By pressing various button combinations on the main unit and remote control unit, you can activate the various service modes for

checking.

Special Note:

• Due to the limitations of the no. characters that can be shown on the FL Display, the “FL Display” button on the remote

control unit can be used to show the two display pages. (Display 1 / Display 2).

• Refer to Section 6.2 for the section on “Remote Control Key Buttons Operations”.

16

Page 17

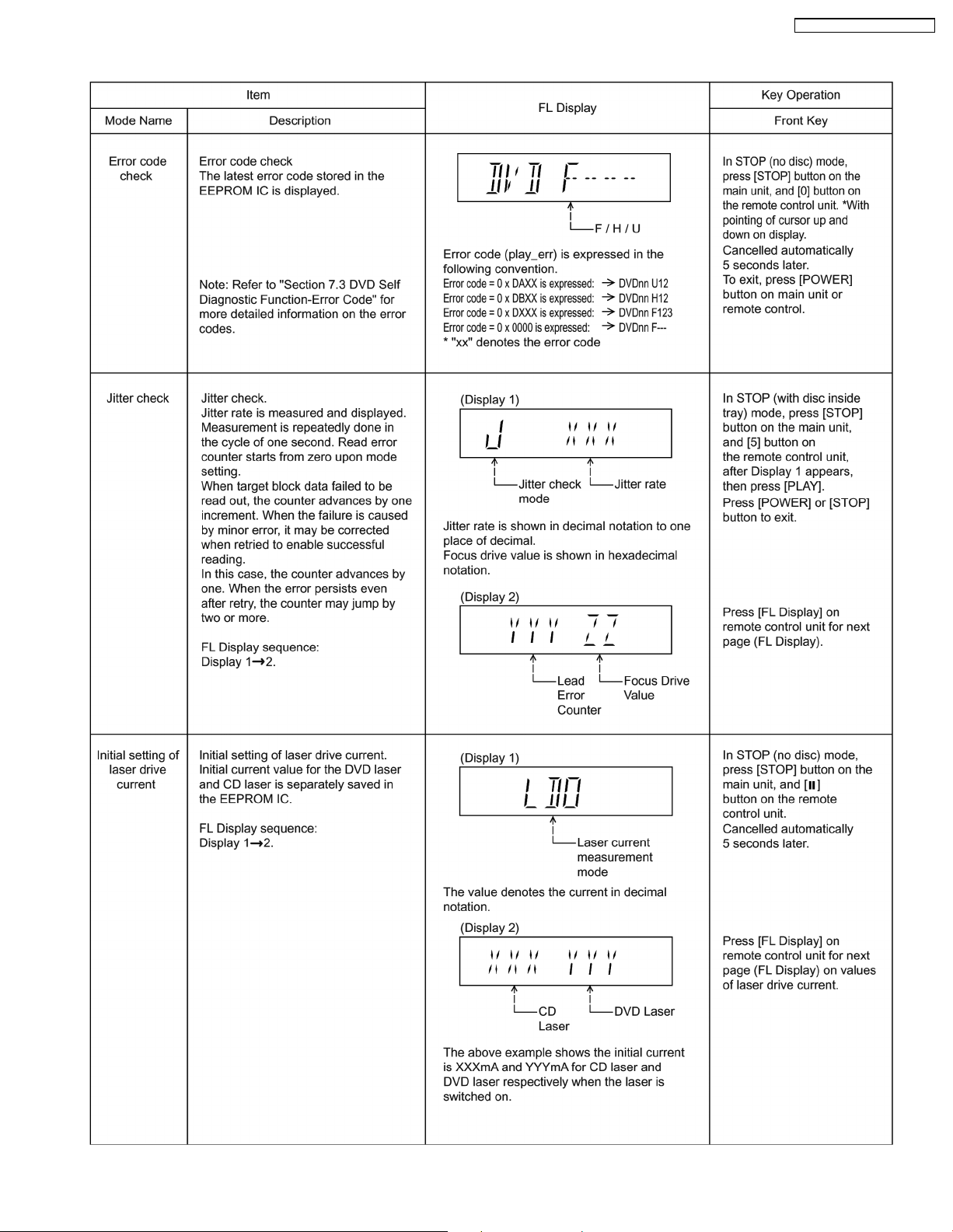

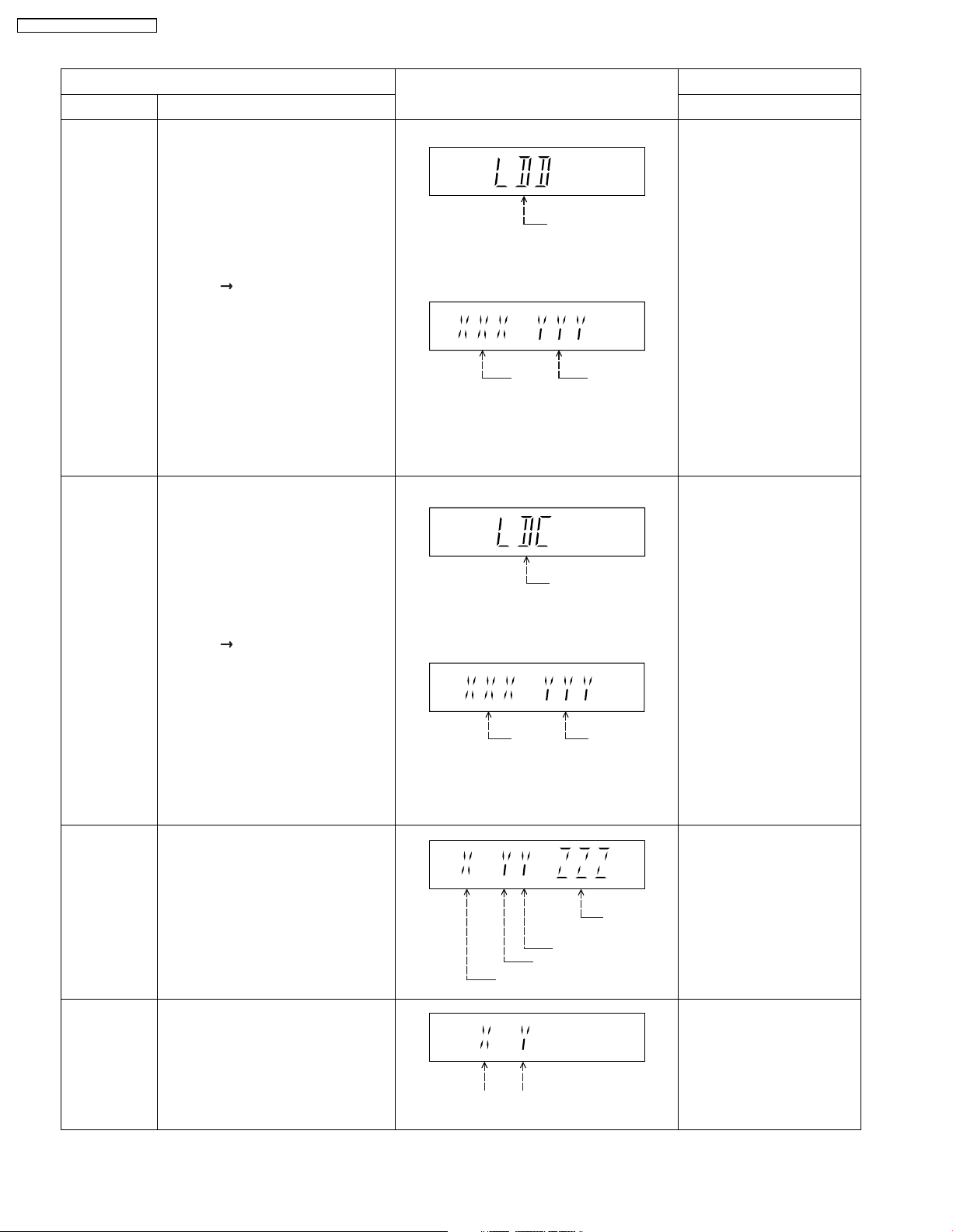

7.2.1. Service Mode Table 1

SA-PM86DGCS / SA-PM86DEE

17

Page 18

SA-PM86DGCS / SA-PM86DEE

7.2.2. Service Mode Table 2

DVD laser

drive current

measurement

CD laser drive

current

measurement

Item

DescriptionMode Name

DVD laser drive current measurement.

DVD laser drive current is measured

and the result is displayed together

with the initial value stored in the

EEPROM IC.

After the measurement, DVD laser

emission is kept on. It is turned off

when POWER key is switched off.

FL Display sequence:

Display 1 2.

CD laser drive current measurement.

CD laser drive current is measured

and the result is displayed together

with the initial value stored in the

EEPROM IC.

After the measurement, CD laser

emission is kept on. It is turned off

when POWER key is switched off.

FL Display sequence:

Display 1 2.

FL Display

(Display 1)

DVD laser current

measurement mode

The value denotes the current in decimal

notation.

(Display 2)

DVD

Laser

Initial Value

The above example shows the initial current

is XXXmA and the measured value is

YYYmA.

(Display 1)

The value denotes the current in decimal

notation.

(Display 2)

DVD

Laser

Value

CD laser current

measurement mode

Key Operation

Front Key

In STOP (no disc) mode,

press [STOP] button on the

main unit, and

[FUNCTIONS] button on

the remote control unit.

Cancelled automatically

5 seconds later.

Press [FL Display] on

remote control unit for next

page (FL Display) on values

of dvd drive current.

In STOP (no disc) mode,

press [STOP] button on

the main unit, and [3]

button on the remote

control unit.

Cancelled automatically

5 seconds later.

Press [FL Display] on

remote control unit for next

page. (FL Display)

Region display

CPPM/CRM

Keys Check

Region code display, TV broadcasting

system & the model no. information.

Note: Refer to Figure 7.1 for "Video

Design Information".

CPPM/CRM refers to the Content

Protection for Recordable Media and

Pre-Recorded Media. It displays the

existence of the keys as "1" or "0".

OK: Existing of keys.

NG: Non existing of keys.

CD

laser initial

value

The above example shows the initial current is

XXXmA and the measured value is YYYmA.

N: no PAL / P: PAL

Region No.: 0-8

0: NG

0: NG

1: OK

1: OK

CD laser

value

Model

No.

Information

N: NTSC / 6: PAL60

In STOP (no disc)

mode, press [STOP]

button on the main unit,

and [6] button on the

remote control unit.

Cancelled automatically

5 seconds later.

In STOP (no disc)

mode, press [STOP]

button on the main unit,

and [SOUND] button on

the remote control unit.

Cancelled automatically

5 seconds later.

18

Page 19

SA-PM86DGCS / SA-PM86DEE

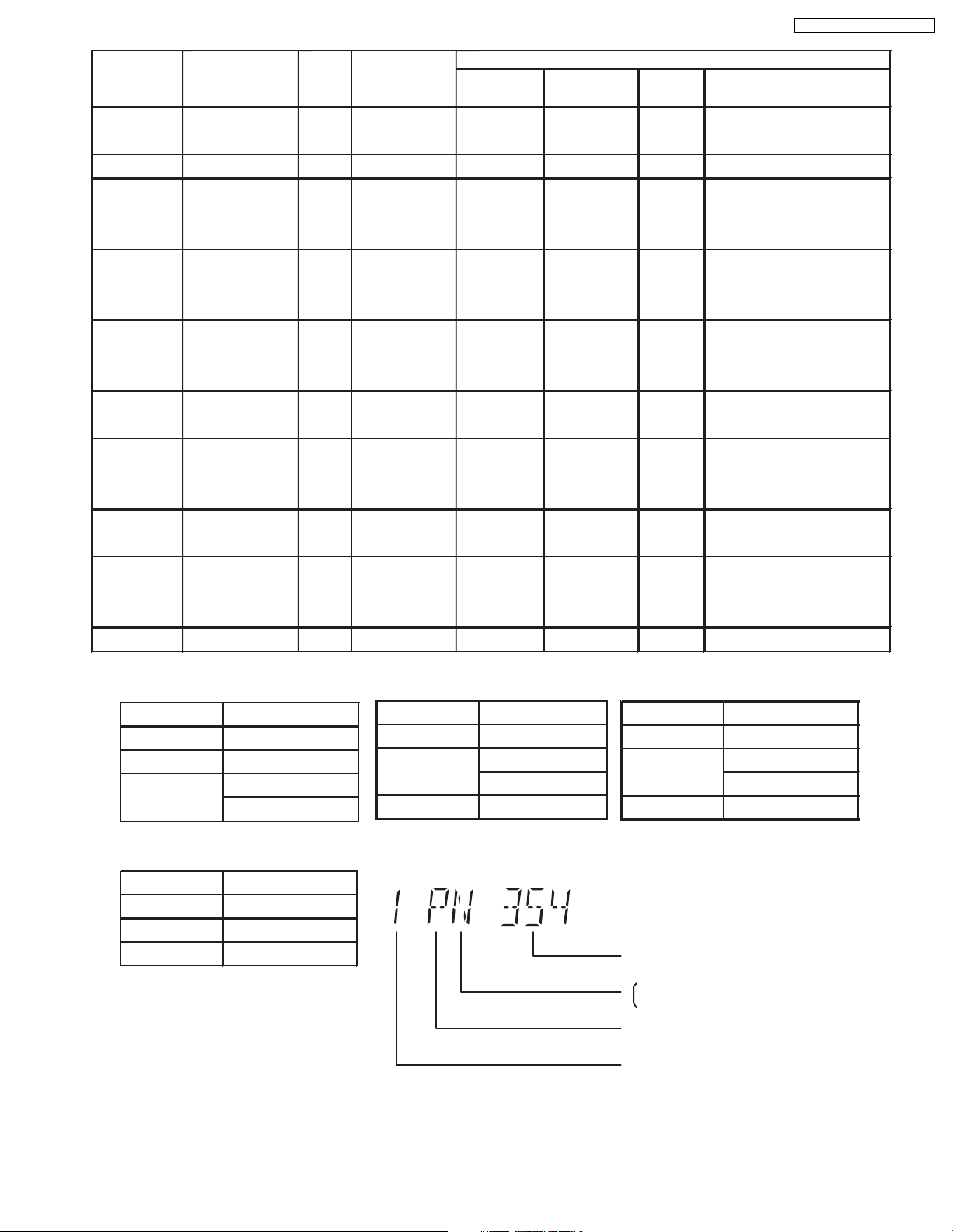

Product

OSD

Default

English

OSD Menu Language

English, Spanish,

Model Series

P, PC, PX

Country Region

USA, Canada, PX

Region

Code

1

TV Broadcasting

System

NTSC

Signal System

(Default)

NTSC (*A)

Region Display

(Default)

1PN

Canadian, French

(S) Japanese, English

Japan

2

NTSC

NTSC (*A)

2PN

Japanese

English, French, German,

E

Europe

2

PAL

PAL (*C)

2P6

English

Spanish, Polish, Russian,

Czech, Hungarian

English, French, German,

EB, EG

Europe

2

PAL

PAL (*C)

2P6

English

Italian, Spanish, Polish,

Swedish, Dutch

English, French, German,

GC, GS

Middle East

2

PAL

PAL (*C)

2P6

English

Spanish, Polish, Russian,

Czech, Hungarian

GCS, GD, English, Traditional Chinese

GT, GCT

GN

South East Asia,

Korea, Taiwan

New Zealand,

3

4

Australia

PL, GCP, LB

Central/South/

4

Latin America

PAL

NTSC

PAL

NTSC

NTSC (*B)

PAL (*C)

NTSC (*D)

3PN

4P6

4PN

English

English

English

English, French, German,

Italian, Spanish, Polish,

Swedish, Dutch

English, Spanish, French,

Brazilian Portuguese

English, French, German,

EE

CIS

5

SECAM

PAL (*C)

5P6

English

Spanish, Polish, Russian,

Czech, Hungarian

GK English, Simplified Chinese

China

6

PAL

NTSC (*B)

6PN

English

NTSC (*A)

Source Output

Screen Saver NTSC

NTSC disc NTSC

PAL disc

PAL (DVD-V)

NTSC (DVD-A/VCD)

NTSC (*D)

Source Output

Screen Saver NTSC

NTSC disc NTSC

PAL disc NTSC

NTSC (*B)

Source Output

Screen Saver NTSC

NTSC disc

NTSC (default)

PAL60

PAL disc PAL

Explanation of Display

Figure 7.1 Video Design Information

PAL (*C)

Source Output

Screen Saver PAL

NTSC disc

PAL60 (default)

NTSC

PAL disc PAL

Individual Model Code

N: If NTSC disc is played, NTSC output.

6: If NTSC disc is played, PAL60 output.

Can play PAL disc

Region code

19

Page 20

SA-PM86DGCS / SA-PM86DEE

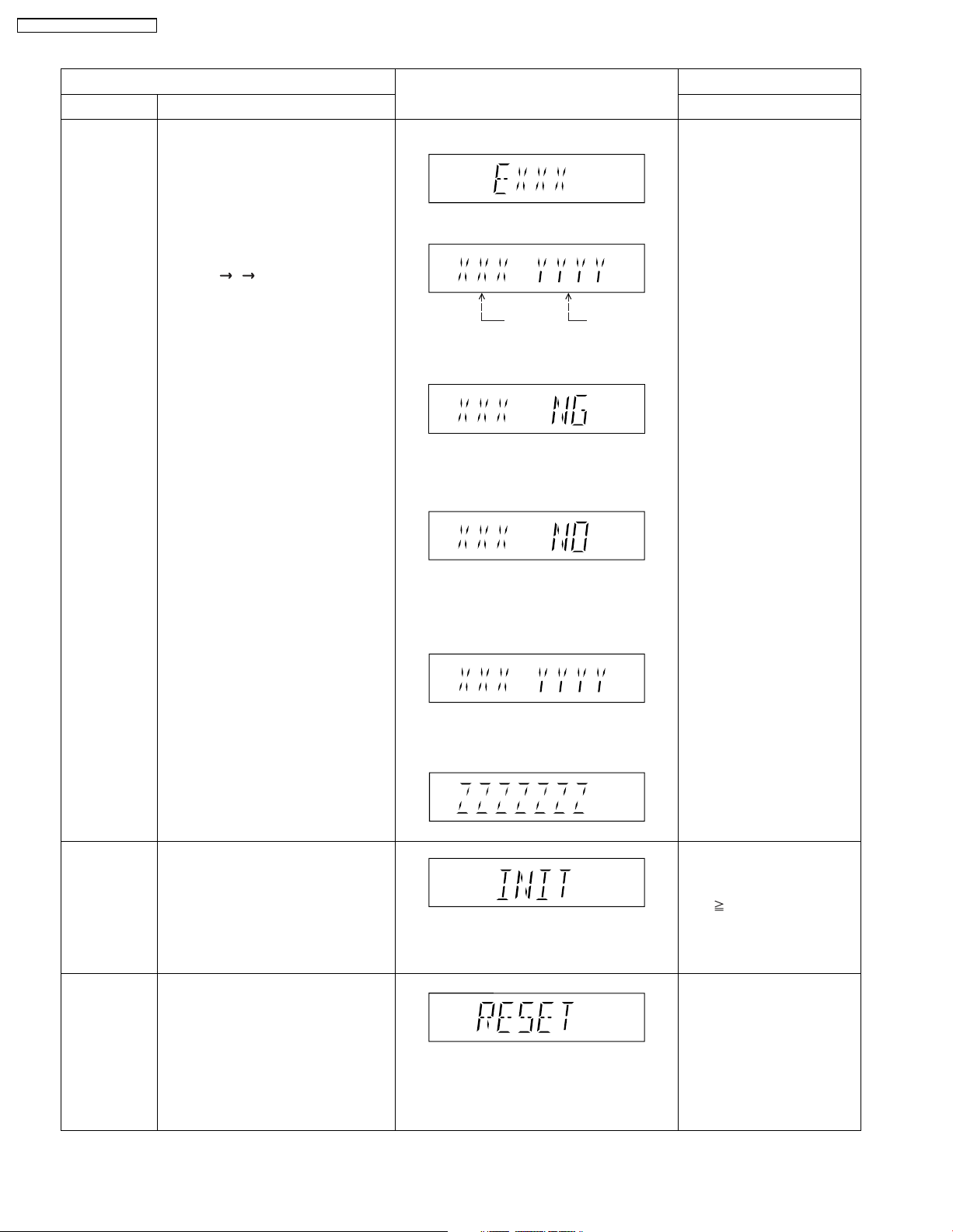

7.2.3. Service Mode Table 3

Micro-processor

firmware version

display &

EEPROM

checksum

display.

Item

DescriptionModel Name

Micro-processor firmware version

display & EEPROM checksum display.

EEPROM checksum is only available

due to existence of EEPROM IC.

Note: Condition 1/2/3 shows the state

of EEPROM IC.

FL Display sequence:

Display 1 2 3.

FL Display

(Display 1)

(Display 2)

Opecon

Version

(Condition 1)

If the version of the EEPROM does not match,

[NG] is displayed.

(Condition 2)

EEPROM

Checksum

(If applicable,

refer below.)

Key Operation

Front Key

In STOP (no disc)

mode, press [STOP]

button on the main unit,

and [7] button on the

remote control unit.

Cancelled automatically

5 seconds later.

Initialization

DVD

Module P.C.B.

Reset

Initialization.

User settings are cancelled and player

is initialized to factory setting.

It is necessary when after replacement

of Micro-processor (DV5 LSI) IC,

FLASH ROM IC (IC8651), EEPROM

IC (IC8611) & DVD Module P.C.B.

To reset DVD Module P.C.B.

This process is used when the DVD

Module P.C.B. or FLASH ROM

IC is replaced with a new one.

(a) If there is NO EEPROM header string

OR

(b) If there is no EEPROM (no data is received

by Micro-processor), [NO] is displayed.

(Condition 3)

If the EEPROM version matches, checksum

[YYYY] is displayed.

(Display 3)

Press [FL Display] button on

remote control unit for next

page. (FL Display)

In STOP (no disc)

mode, press [STOP]

button on the main unit,

and [ 10] button on the

remote control unit.

Cancelled automatically

5 seconds later.

While in initialization

mode, press & hold

[STOP] button on the main

unit for 3 seconds, follow

by [OK] button on the

remote control unit.

Cancelled automatically

5 seconds later.

20

Page 21

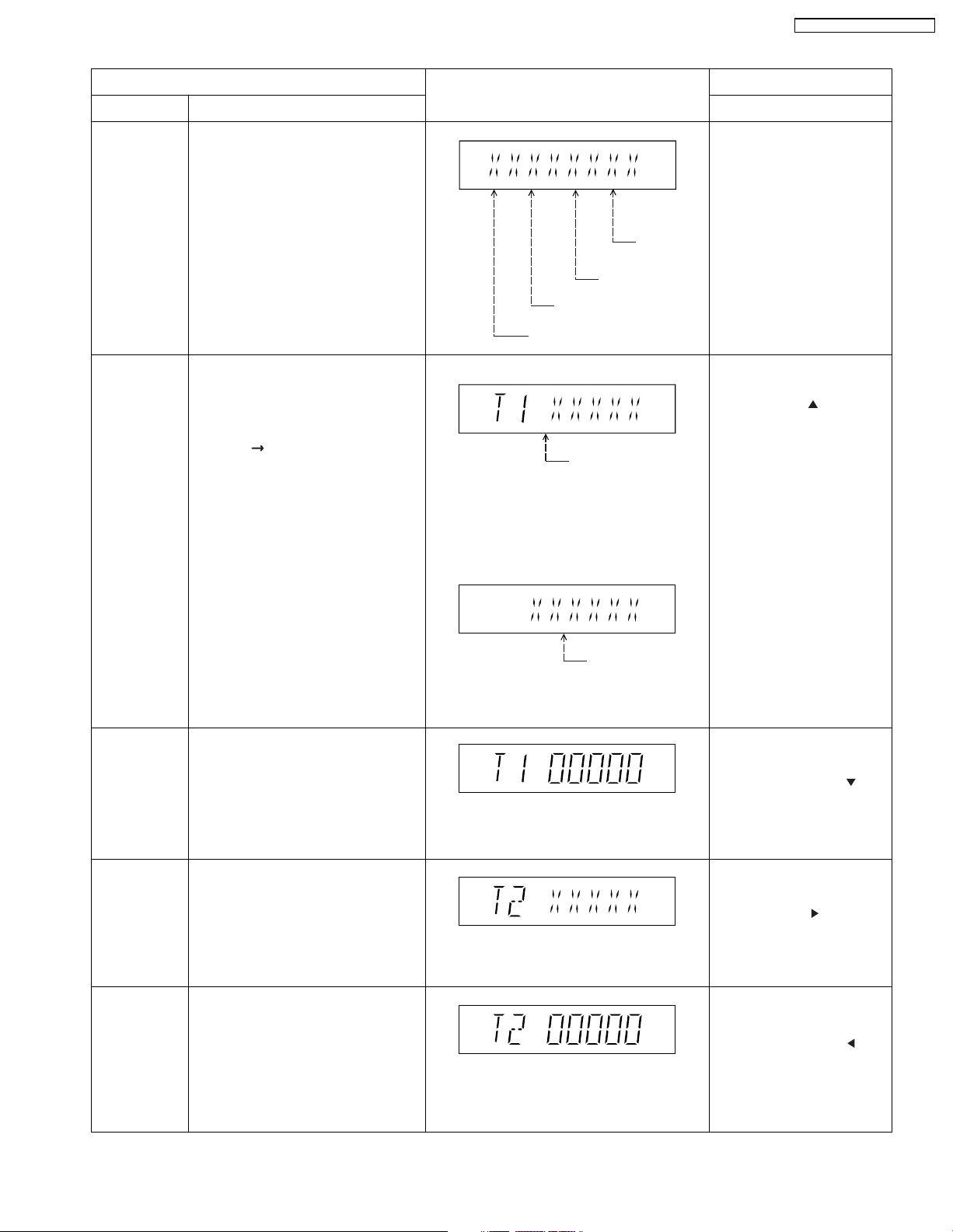

7.2.4. Service Mode Table 4

SA-PM86DGCS / SA-PM86DEE

DVD

Module P.C.B.

firmware

version display

Timer 1 check

Item

DescriptionMode Name

DVD Module P.C.B. firmware version is

displayed on the FL Display.

The firmware version can be updated

using recovery disc.

Note: It is necessary to check for

firmware version before carrying out

the version up using the disc.

Timer 1 check

Laser operation timer is measured

separately for DVD laser and CD laser.

FL Display sequence:

Display 1 2.

FL Display

System

controller

version

Destination

System controller

generation

Region No.: 0-8

(Display 1)

DVD laser usage time

Shown to the above is DVD laser usage

time, and to the below is CD laser usage

time.

Time is shown in 5 digits of decimal notation

in a unit of 10 hours.

"00000" will follow "99999". (DVD laser)

(Display 2)

Key Operation

Front Key

In STOP (no disc)

mode, press [STOP]

button on the main unit,

and [8] button on the

remote control unit.

Cancelled automatically

5 seconds later.

In STOP (no disc) mode,

press [STOP] button on the

main unit, and [ ] button

on the remote control unit.

Cancelled automatically

5 seconds later.

Press [FL Display] button for

next page of FL Display.

Timer 1 reset

Timer 2 check

Timer 2 reset

Timer 1 reset

Laser operation timer of both DVD

laser and CD laser is reset all at once.

Timer 2 check

Spindle motor operation timer

Timer 2 reset

Spindle motor operation timer

CD laser usage time

Time is shown in 6 digits of decimal notation

in a unit of 10 hours.

"000000" will follow "999999". (CD laser)

Time is shown in 5 digits of decimal notation

in a unit of 10 hours.

It will clear to "00000" upon reset.

Time is shown in 5 digits of decimal notation in

a unit of 1 hour.

"00000" will follow "99999".

Time is shown in 5 digits of decimal notation in

a unit of 1 hour.

It will be cleared to "00000" upon activating

this.

While displaying Timer 1

data, press [STOP] button

on the main unit, and [ ]

button on the remote control

unit.

Cancelled automatically

5 seconds later

In STOP (no disc) mode,

press [STOP] button on the

main unit, and [ ] button

on the remote control unit.

Cancelled automatically

5 seconds later.

While displaying Timer 2

data, press [STOP] button

on the main unit, and [ ]

button on the remote

control unit.

Cancelled automatically

5 seconds later.

21

Page 22

SA-PM86DGCS / SA-PM86DEE

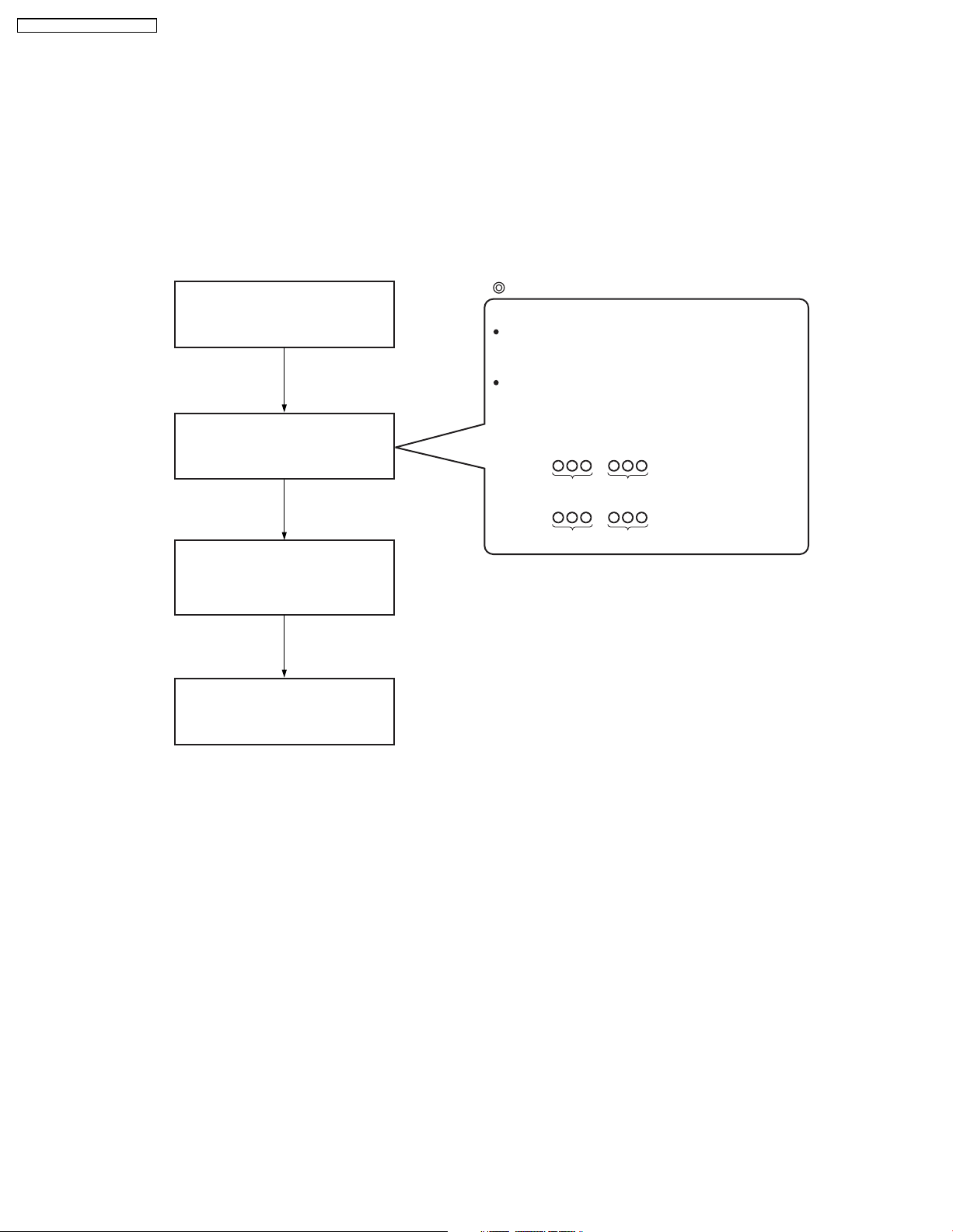

7.2.5. Optical Pick-up Self-Diagnosis

The optical pickup self-diagnosis function and tilt adjustment check function have been included in this unit. When repairing, use

the following procedure for effective self-diagnosis and tilt adjustment. Be sure to use the self-diagnosis function before replacing

the optical pickup when "NO DISC" is display ed. As a guideline, you should replace the optical pickup when the value of the laser

drive current is more than the specified value.

Note:

Press the power button to turn on the power, and check the value within three minutes before the unit warms up. (Otherwise,

the result will be incorrect.)

"NO DISC" is displayed, unit

does not play smoothly, etc.

Check the laser drive current.

Value is more than

37 (DVD), 41 (CD).

Replace the traverse unit.

(Refer to the section "OPTICAL

PICKUP REPLACEMENT

PROCEDURE" in this Guide.)

Initialize the main unit.

Use the optical pickup self-diagnosis function.

Method: With no disc in the main unit:

• Press the "FUNCTIONS" button on the remote

control unit while pressing the "STOP"

button on the main unit. (DVD)

•Press the "3" button on the remote

control unit while pressing the "STOP"

button on the main unit. (CD)

[Display content (display1/display2)]

/

LDD (DVD)

Factory setting Present value

LDC (CD)

/

Factory setting Present value

Replace with a new optical pickup if the present

value is more than 37 (DVD), 41 (CD).

Cause: Damage due to static electricity

during replacement.

22

Page 23

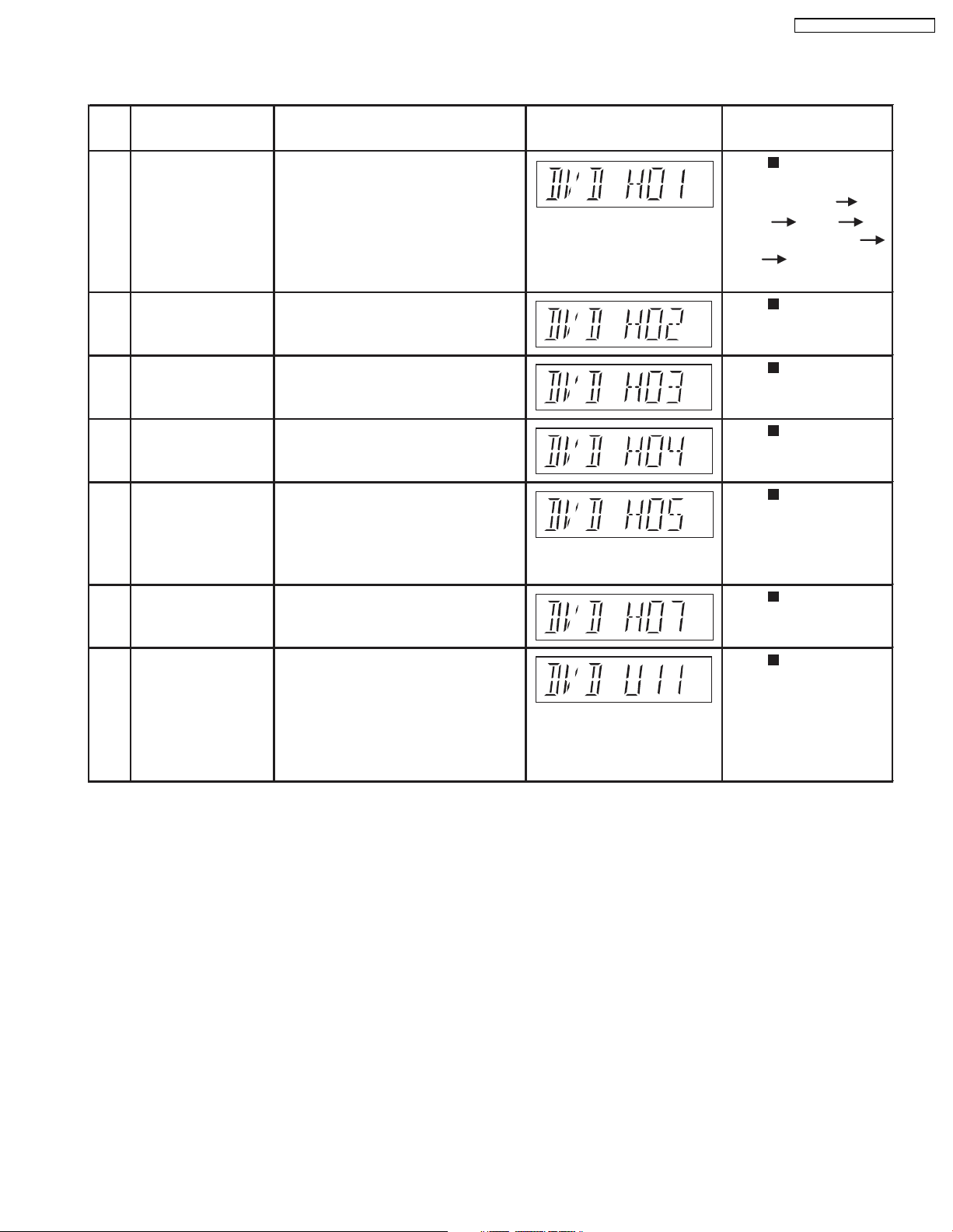

7.3. DVD Self Diagnostic Function-Error Code

Diagnosis Contents

7.3.1. Mechanism Error Code Table

SA-PM86DGCS / SA-PM86DEE

Error

Code

H01 Tray loading error The tray opening and closing is abnormal. Press [ STOP] on main

CLOSE and OPEN of the tray cannot be unit for next error.

carried out properly. Loading motor error, (OPEN time: OPEN

DV5 LSI IC (IC8001) error. CLOSE OPEN

H02 Spindle servo error The spindle servo/motor is abnormal. The Press [ STOP] on main

FG pulse is abnormal. CLV servo error. unit for next error.

H03 Traverse servo error The traverse is abnormal. (Traverse servo, Press [ STOP] on main

DV5 LSI IC (IC8001), TRV motor error.) unit for next error.

H04 Tracking servo error Tracking coil NG (OPU unit abnormal), Press [ STOP] on main

DV5 LSI IC (IC8001) error. unit for next error.

H05 Seek time out error It is not possible to access the disc. TOC Press [ STOP] on main

cannot read. Abnormal disc etc. Pickup unit for next error.

abnormal or disk is dirty. (TRV motor

error, DV5 LSI IC (IC8001) error.)

Description of error Automatic FL Display Remarks

H01 at CLOSE: CLOSE

OPEN CLOSE H01)

H07 Driver IC thermal shut The spindle motor is abnormal. Press [ STOP] on main

down (short between brushes) unit for next error.

U11 Focus servo error Focus coil, FE signal error. Disc may be Press [ STOP] on main

dirty. unit for next error.

(Unfinalized DVD-R

is likely to become

U11.)

23

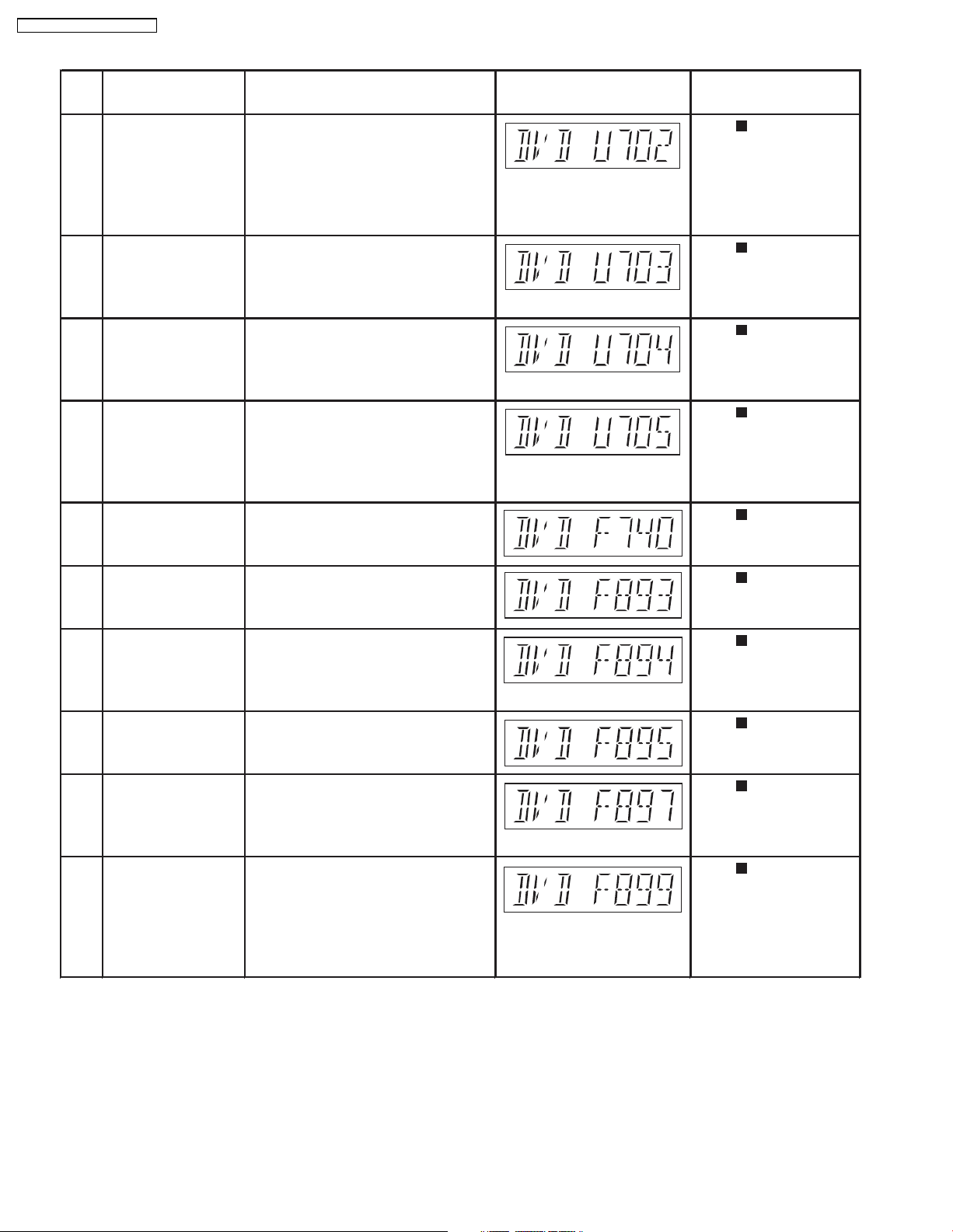

Page 24

SA-PM86DGCS / SA-PM86DEE

7.3.2. DVD Module Error Code Table

Error

Code

U702 HDMI/DVI I2C The communication error of I2C when Press [ STOP] on main

U703 HDMI/DVI attestation When attestation (HDCP) with the TV Press [ STOP] on main

U704 HDMI/DVI SRM It is generated at the equipment to which Press [ STOP] on main

U705 HDMI/DVI SRM disk It is generated at the time of it is time Press [ STOP] on main

F740 HDMI device key I2C error when writing HDMI Key device Press [ STOP] on main

Diagnosis Contents Description of error Automatic FL Display Remarks

communication error connecting it with HDMI/DVI. For unit for next error.

instance, when EDID information to which

information on the TV set side has been

described cannot be read, it is generated.

error side fails when connecting it with unit for next error.

HDMI/DVI, it is generated.

Riborcerar the TV set is Riborced when connecting it unit for next error.

with HDMI/DVI.

falsification check when illegal the SRM data of the unit for next error.

error reproducing disk (verify error), when

connecting it with HDMI/DVI.

into transmitter. unit for next error.

F893 FLASH ROM IC data Firmware error, DV5.0 LSI IC (IC8651) Press [ STOP] on main

falsification error error. unit for next error.

F894 EEPROM IC When failing in the access to EEPROM Press [ STOP] on main

abnormality error IC located in the DVD Module P.C.B. unit for next error.

(IC8611).

F895 Language area Firmware version agreement check for Press [ STOP] on main

abnormal factory preset setting failure prevention. unit for next error.

F897 Initialization Incomplete initialization after writing of Press [ STOP] on main

error new firmware (Factory preset setting unit for next error.

failure prevention)

F899 The communication Unsuitable combination of number of Press [ STOP] on main

specification system com and panel com used. unit for next error.

disagreement (Frimware)

between

micro-processor

24

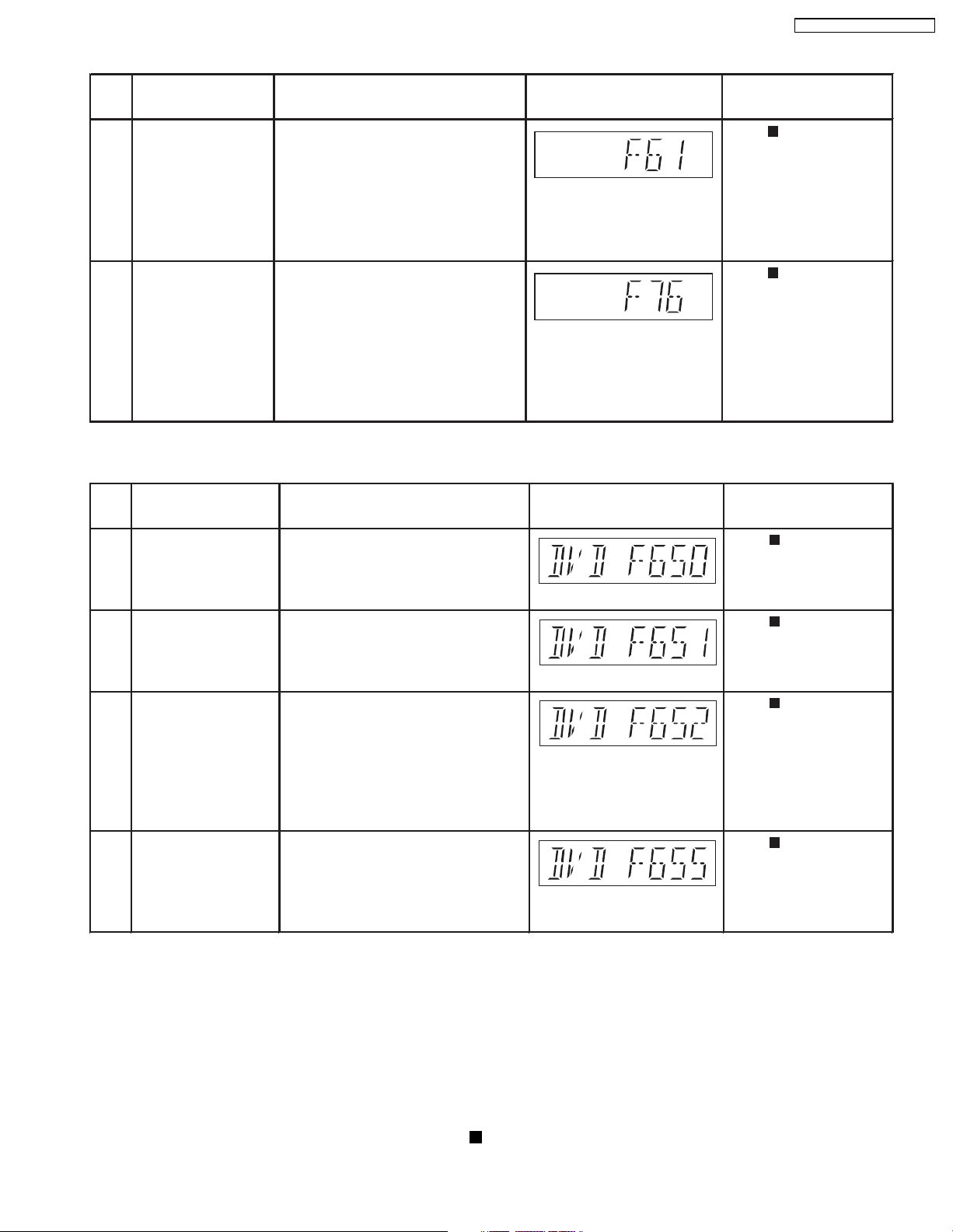

Page 25

7.3.3. Power Supply & Digital Amplifier Error Code Table

SA-PM86DGCS / SA-PM86DEE

Error

Code

F61 The abnormalities In normal operation, when DCDET2 goes Press [ STOP] on main

F76 Abnormality in the In normal operation when DCDET1 is Press [ STOP] on main

Diagnosis Contents Description of error Automatic FL Display Remarks

in an output or power to "L" (Low) (Not during POWER OFF unit for next error.

supply circuit of condition), F61 appears on FLDisplay

POWER AMP for 1 second and PCONT goes to

"L" (Low).This is due to speaker output

has DC voltage or fan is not working.

output voltage of detected "L" (Low) for two consecutive unit for next error.

stabilized power times, F76 is displayed on FL for

supply 1 second and after that PCONT will be

turned to "L" (Low). This is due to any of

the DC voltages (+9V, +7V, -7V, +5V,

+5.3V etc.) C22 not available.

7.3.4. USB Error Code Table

Error

Code

F650 USB device: Devices Devices other than the mass storage Press [ STOP] on main

Diagnosis Contents Description of error Automatic FL Display Remarks

other than mass class are connected. unit for next error.

storage

F651 USB device: Non-Full The device that the transfer rate did not Press [ STOP] on main

Speed Device correspond to Full Speed was unit for next error.

connected.

F652 USB device: The device in the interface (subclass) Press [ STOP] on main

Interface NG outside correspondence was connected. unit for next error.

(correspondence interface)

001b: Reduced Block Commands (RBC)

010b: SFF-8020i. MMC-2 (ATAPI)

110b: SCSI transparent command set.

F655 USB device: The overcurrent of 500mA or more was Press [ STOP] on main

Overcurrent detection detected in VDD USB, and the USB unit for next error.

device driver function was intercepted.

(To intercept the current.)

7.4. Sales Demonstration Lock Function

This function prevents discs from being lost when the unit is used for sales demonstrations by disabling the disc eject function.

"LOCKED" is displayed on the unit, and ordinary operation is disable d.

7.4.1. Setting

• Prohibiting removal of disc

1. Select the DVD/CD function.

2. At POWER ON condition, press and hold down the

button and the power button on the main unit for at least three

seconds. (The message, “LOCKED” appears when the function is activated.)

25

Page 26

SA-PM86DGCS / SA-PM86DEE

Note:

OPEN/CLOSE

• Prohibiting operation of selector and disc

1. Select the DVD/CD function.

2. At POWER ON condition, press and hold down the

seconds. (The message, “LOCKED” appears when the function is activated.)

Note:

The following buttons are invalid and the main unit displays “LOCKED” while the lock function mode is entered.

Main unit , /—DEMO, / , /

Remote

controller unit

button is invalid and the main unit displays “LOCKED” while the lock function mode is entered.

button and the power button on the main unit for at least three

USB, FM/AM, EXT-IN, NUMERIC KEYS 0~9, , , , , , , , RETURN, FUNCTIONS, FL

DISPLAY/—SLEEP/—T IMER PLAY, MUTING

7.4.2. Cancellation

The lock can be cancelled by the same procedure as used in setting. ("UNLOCKED" is displayed on cancellation. Disconnecting

the power cable from power outlet does not cancel the lock.)

7.5. Service Precautions

7.5.1. Recovery after the DVD player is repaired

• When the FLASH ROM IC or DVD Module P.C.B. is replaced, carry out the recovery processing to optimize the drive.

Playback the recovery disk to process the recovery automatically.

• Recovery disc (Product number: RFKZD03R005) [SPG]

• Performing recovery process

1. Load the recovery disc RFKZD03R005 on to the player and run it.

2. Recovery is performed automatically. When it is finished, a message appears on the screen.

3. Remove the recovery disc.

4. Turn off the power.

5. Initialize the player.

7.5.2. Firmware version-up of the DVD player

• The firmware of the DVD player may be renewed to improve the quality including operability and playab ility to the substandard

discs.processing to optimize the drive.

The recovery disc has also firmware version-up.

• After version-up, recovery processing is executed automatically.

• Part number of the recovery disc for version-up will be noticed when it is supplied.

• Updating firmware

1. Load the recovery disc on to the player and run it.

2. Firmware version of the player is automatically checked. Appropriate message appears whenever necessary.

3. Using remote controller´s cursor key, select whether version updating is to be done or not. (Selection of Yes/No)

4. a. If Yes is selected, version updating is performed.

b. If No is selected, only recovery is performed.

5. a. When updating is finished, remove the disc according to the message appearing on the screen.

b. Remove the disc according to the message appearing on the screen.

6. Turn off the power.

Note:

If the AC power supply is shut out during version-up due to a power failure, the version-up is improperly carried out.

In such a case, replace the FLASH ROM IC and carry out the version-up again.

7.5.3. DVD Module P.C.B. Reset

• When after replacing FLASH ROM IC or DVD Module P.C.B., FL displays error code “ DVD F897”. This means the unit is not

initialized properly and the following process needs to be carry out.

• Procedures:

1. Press

on remote control while pressing “STOP” button on main unit. (To enter into initializ ation)

26

Page 27

SA-PM86DGCS / SA-PM86DEE

2. FL display show “INIT”

3. While still pressing “STOP” button on main unit, press “OK” on remote control. (To reset the unit)

4. FL will display “RESET” before FL display will change to TOC reading again.

5. Power off unit. Unplug the AC cord.

6. Power on the unit. It should be no problem. If problem persist check on the DVD Module P.C.B. or FLASH ROM IC.

27

Page 28

SA-PM86DGCS / SA-PM86DEE

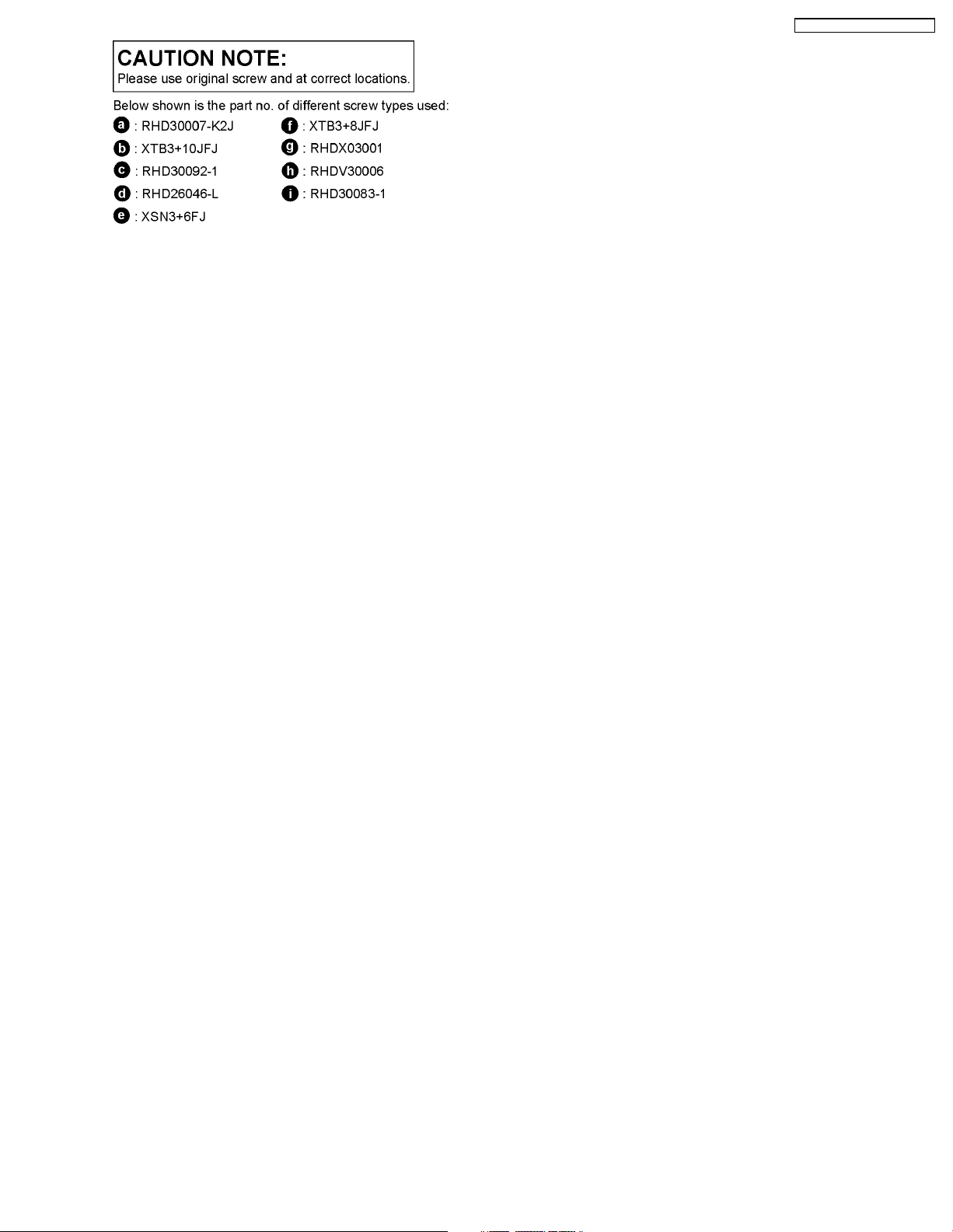

8 Assembling and Disassembling

“ATTENTION SERVICER”

Be careful when disassembling and servicing.

Some chassis components may have sharp edges.

Special Note:

1. This model uses a mechanism unit (DLS6). In this following section does not contain the necessary assembly and

disassembly information except the assembly and disassembly of the traverse unit. Kindly refer to the original service

manual for the mechanism unit. (Order No. MD0801003CE).

2. This section describes the disassembly procedures for all the major printed circuit boards and main components.

3. Before the disassembly process was carried out, do take special note that all safety precautions are to be carried out.

(Ensure that no AC power supply is connected during disassembling.)

4. For assembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

5. Do take note of the locators on each printed circuit board during reassembling procedures.

6. The Switch Regulator IC may have high temperature after prolonged use.

7. Use caution when removing the top cabinet and avoid touching heat sinks located in the unit.

8. Select items from the following index when checks or replacement are required.

• Disassembly of Top Panel

• Disassembly of Front Panel

• Disassembly of Panel P.C.B.

• Disassembly of USB P.C.B.

• Disassembly of Rear Panel

• Disassembly of Main P.C.B.

• Disassembly of Transformer P.C.B.

• Replacement of Transistor (Q5927)

• Replacement of Transistor (Q5921)

• Disassembly of Power P.C.B.

• Replacement of Digital Amp IC (IC5000)

• Replacement of Transistor (Q5105)

• Replacement of Transistor (Q5103)

• Replacement of Transistor (Q5100)

• Disassembly of Inner Chassis

• Disassembly of Video P.C.B.

• Replacement of DC-DC Conve rter IC (IC2741)

• Disassembly of DVD Module P.C.B.

• Disassembly of Mechanism Unit

• Disassembly of USB Lid

• Disassembly of DVD Lid

28

Page 29

SA-PM86DGCS / SA-PM86DEE

29

Page 30

SA-PM86DGCS / SA-PM86DEE

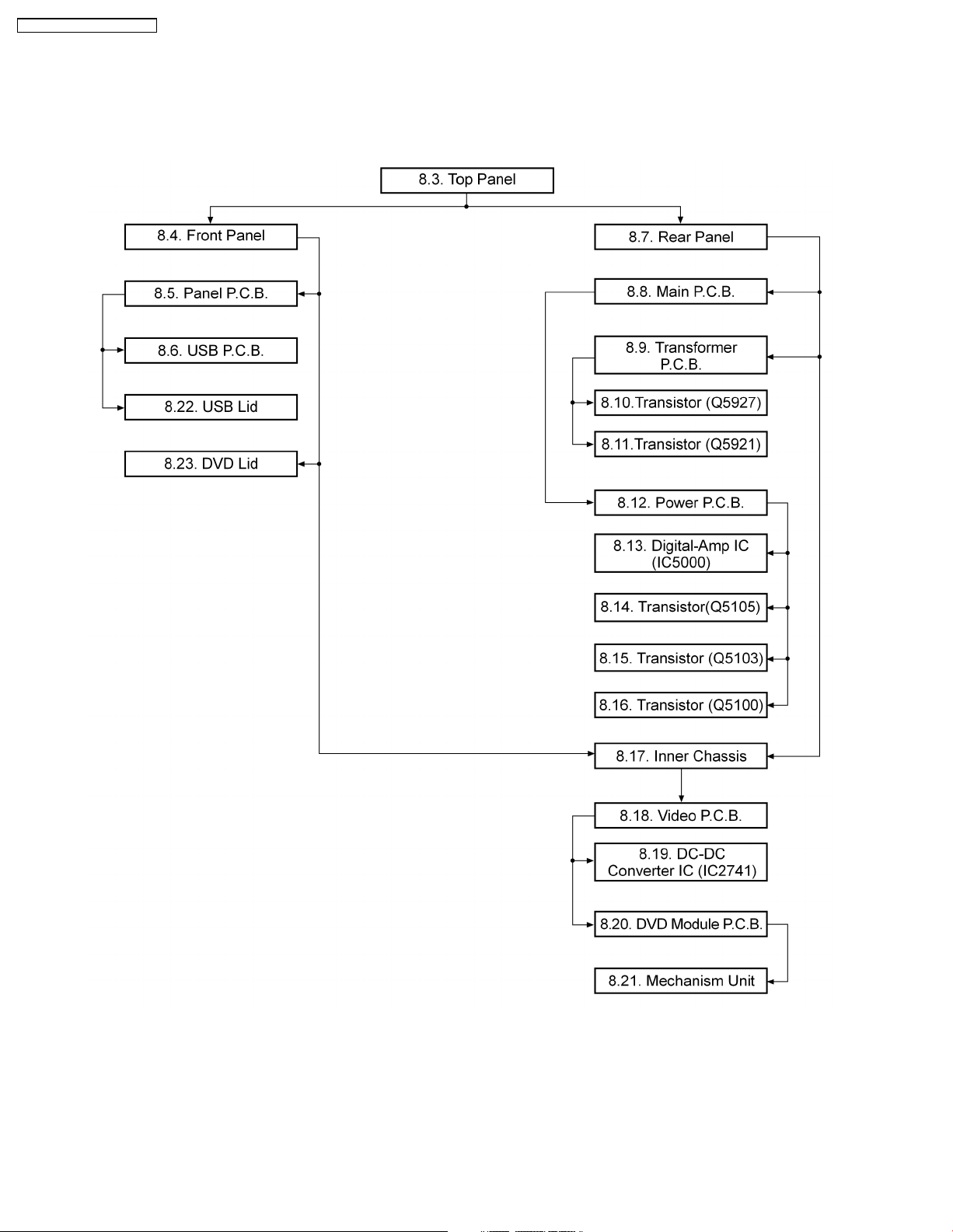

8.1. Disassembly flow chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the

servicing.

To assemble the unit, reverse the steps shown in the chart below.

30

Page 31

8.2. Main Parts Location Diagram

SA-PM86DGCS / SA-PM86DEE

31

Page 32

SA-PM86DGCS / SA-PM86DEE

8.3. Disassembly of Top Panel

Step 1 : Remove 2 screws at the side of Top Panel (L).

of arrow.

Step 2 : Remove 2 screws at the side of Top Panel (R).

Step 5 : Lift up the back part of the Top Panel and remove it in

the direction of arrow.

Step 3 : Remove 4 screws at the rear of Top Panel.

Step 4 : Lift both sides of Top Panel outwards in the direction

32

Page 33

8.4. Disassembly of Front Panel

• Follow the (Step 1) - (Step 5) of Item 8.3

SA-PM86DGCS / SA-PM86DEE

Step 1 : Detach 7P cable at the connector (CN5905) on

Transformer P.C.B.

Step 2 : Remove 1 screw from Main P.C.B..

Caution : Do not exert strong force when releasing the

catches.

Step 6 : Release the catch at each side of the Front Panel in

the direction of arrow.

Step 7 : Release the catches at the bottom of the Front Panel.

Step 8 : Remove Front Panal.

Note: During reassembling procedures, ensure the USB

cable is properly dresse d into the Front Pane’s Hook.

Step 3 : Detach 24P FFC cable at the connector (CN3720) on

Main P.C.B.

Step 4 : Detach USB cable at the connector (CN4200) on USB

P.C.B..

Step 5 : Remove USB cable from Front Panel’s Hook shown.

33

Page 34

SA-PM86DGCS / SA-PM86DEE

8.5. Disassembly of Panel P.C.B.

• Follow the (Step 1) - (Step 5) of Item 8.3

• Follow the (Step 1) - (Step 8) of Item 8.4

Step 1 : Remove the Volume Knob.

• Disassembly of Shield Plate

Step 2 : Remove 3 screws to remove the Shield Plate.

Step 3 : Remove 4 screws on the Panel P.C.B..

Caution : Keep the Ground Wire in safe place. Place it back

during assembling.

Step 4 : Release all the catches.

Step 5 : Remove Panel P.C.B..

Note: During reassembling procedures, ensure P.C.B. is

fully catched onto Front Panel.

8.6. Disassembly of USB P.C.B.

• Follow the (Step 1) - (Step 5) of Item 8.3

• Follow the (Step 1) - (Step 8) of Item 8.4

• Follow the (Step 1) - (Step 5) of Item 8.5

Step 1 : Remove USB P.C.B. from Panel P.C.B. in the direction

of arrow.

34

Page 35

8.7. Disassembly of Rear Panel

• Follow the (Step 1) - (Step 5) of Item 8.3

Step 1 : Detach Fan cable at the connector (CN3750) on Main

P.C.B..

SA-PM86DGCS / SA-PM86DEE

Step 3 : Releas e the catch at each side of the Rear Panel in

the direction of arrow.

Step 4 : Remove Rear Panel.

Step 2 : Remove 12 screws from the Rear Panel.

35

Page 36

SA-PM86DGCS / SA-PM86DEE

8.8. Disassembly of Main P.C.B

• Follow the (Step 1) - (Step 5) of Item 8.3

• Follow the (Step 1) - (Step 4) of Item 8.7

Step 5 : Detach connectors (CN3730, CN3740, CN3722) on

Main P.C.B. in the direction of arrow.

Step 1 : Detach 24P FFC cable at the connector (CN3720) on

Main P.C.B..

Note: During reassembling procedures, ensure that Main

P.C.B. is properly connected to Bridge P.C.B. and Power

P.C.B..

Step 2 : Detach 14P FFC cables at the connector (CN3660) on

Main P.C.B..

Step 3 : Detach 25P FFC cables at the connector (CN3661) on

Main P.C.B..

Step 4 : Remove 1 screw from Main P.C.B..

36

Page 37

8.9. Disassembly of Transformer

P.C.B.

• Follow the (Step 1) - (Step 5) of Item 8.3

• Follow the (Step 1) - (Step 4) of Item 8.7

SA-PM86DGCS / SA-PM86DEE

Step 5 : Detach connector (CN5900) on Transformer P.C.B..

Note: During reassembling procedures, ensure the 8P

cable is properly dresse d into the Support P.C.B..

Step 1 : Detach 8P cable at the connector (CN5104) on Power

P.C.B..

Step 2 : Remove 8P cable from Support P.C.B..

Step 3 : Remove 4 screws at Inner Chassis.

Step 4 : Detach 7P cable (CN5905) and 3P cable (H5902) at

the connector on Transformer P.C.B..

37

Page 38

SA-PM86DGCS / SA-PM86DEE

8.10. Replacement of Transistor

(Q5927)

• Follow the (Step 1) - (Step 5) of Item 8.3

• Follow the (Step 1) - (Step 4) of Item 8.7

• Follow the (Step 1) - (Step 5) of Item 8.9

8.10.1. Assembly of the Transistor

(Q5927)

Step 1 : Desolder pins of Transistor (Q5927) on reverse side of

Transformer P.C.B..

Step 2 : Remove 1 screw from the Transistor (Q5927) in the

direction of arrow.

Step 3 : Remove the Transistor (Q5927) from the Heat Sink.

Caution : Handle the Heat Sink unit with caution due to its high

temperature after prolonged use. Touching it may lead to

injuries.

Step 1 : Fix the Transistor (Q5927) to the Heat Sink.

Step 2 : Screw 1 screw at Transistor (Q5927) in the direction of

arrows.

Step 3 : Solder pins of the Transistor (Q5927) on the reverse

side of the transformer P.C.B..

Caution : Ensure pins of the Transistor (Q5927) are properly

seated and soldered on reverse side of Transformer P.C.B..

38

Page 39

8.11. Replacement of Transistor

(Q5921)

• Follow the (Step 1) - (Step 5) of Item 8.3

• Follow the (Step 1) - (Step 4) of Item 8.7

• Follow the (Step 1) - (Step 5) of Item 8.9

SA-PM86DGCS / SA-PM86DEE

8.11.1. Assembly of the Transistor

(Q5921)

Step 1 : Desolder pins of Transistor (Q5921) on reverse side of

Transformer P.C.B..

Step 2 : Remove 1 screw from the Transistor (Q5921) in the

direction of arrow.

Step 3 : Remove the Transistor (Q5921) from the Heat Sink.

Caution : Handle the Heat Sink unit with caution due to its high

temperature after prolonged use. Touching it may lead to

injuries.

Step 1 : Fix the Transistor (Q5921) to the Heat Sink.

Step 2 : Screw 1 screw at Transistor (Q5921) in the direction of

arrow.

Step 3 : Solder pins of the Transistor (Q5921) on the reverse

side of the Transformer P.C.B..

Caution : Ensure pins of the Transistor (Q5921) are properly

seated and soldered on reverse side of Transformer P.C.B..

39

Page 40

SA-PM86DGCS / SA-PM86DEE

8.12. Disassembly of Power P.C.B.

• Follow the (Step 1) - (Step 5) of Item 8.3

• Follow the (Step 1) - (Step 4) of Item 8.7

• Follow the (Step 1) - (Step 5) of Item 8.8

• Follow the (Step 1) - (Step 2) of Item 8.9

8.13. Replacement of Digital Amp IC

(IC5000)

• Follow the (Step 1) - (Step 5) of Item 8.3

• Follow the (Step 1) - (Step 4) of Item 8.7

• Follow the (Step 1) - (Step 5) of Item 8.8

• Follow the (Step 1) - (Step 2) of Item 8.9

• Follow the (Step 1) - (Step 2) of Item 8.12

Step 1 : Remove 3 screws on Power P.C.B..

Step 2 : Remove Power P.C.B..

Step 1 : Desolder pins of Digital Amp IC (IC5000) on reverse

side of Power P.C.B..

Step 2 : Release the IC Clip in the direction of arrow.

Step 3 : Remove IC Clip from the Digital Amp IC (IC5000).

Step 4 : Remove the Digital Amp IC (IC5000) from the Heat

Sink.

Caution : Handle the Heat Sink unit with caution due to its high

temperature after prolonged use. Touching it may lead to

injuries.

40

Page 41

8.13.1. Assembly of the Digital Amp IC

(IC5000)

Step 1 : Fix the Digital Amp IC (IC5000) to the Heat Sink.

Step 2 : Attach the IC clip to Digital Amp IC (IC5000).

SA-PM86DGCS / SA-PM86DEE

8.14. Replacement of Transistor

(Q5105)

• Follow the (Step 1) - (Step 5) of Item 8.3

• Follow the (Step 1) - (Step 4) of Item 8.7

• Follow the (Step 1) - (Step 5) of Item 8.8

• Follow the (Step 1) - (Step 2) of Item 8.9

• Follow the (Step 1) - (Step 2) of Item 8.12

Step 3 : Solder pins of the Digital Amp IC (IC5000) on the

reverse side of the Power P.C.B..

Caution : Ensure pins of the Digital Amp IC (IC5000) are

properly seated and soldered on reverse side of power P.C.B.

Step 1 : Desolder pins of Transistor (Q5105) on reverse side of

Power P.C.B..

Step 2 : Remove 1 screw from the Transistor (Q5105) in the

direction of arrows.

Step 3 : Remove the Transistor (Q5105) from the Heat Sink.

Caution : Handle the Heat Sink unit with caution due to its high

temperature after prolonged use. Touching it may lead to

injuries.

41

Page 42

SA-PM86DGCS / SA-PM86DEE

8.14.1. Assembly of the Transistor

(Q5105)

Step 1 : Fix the Transistor (Q5105) to the Heat Sink.

Step 2 : Screw 1 screw at Transistor (Q5105) in the direction of

arrows.

8.15. Replacement of Transistor

(Q5103)

• Follow the (Step 1) - (Step 5) of Item 8.3

• Follow the (Step 1) - (Step 4) of Item 8.7

• Follow the (Step 1) - (Step 5) of Item 8.8

• Follow the (Step 1) - (Step 2) of Item 8.9

• Follow the (Step 1) - (Step 2) of Item 8.12

Step 3 : Solder pins of the Transistor (Q5105) on the reverse

side of the Power P.C.B..

Caution : Ensure pins of the Transistor (Q5105) are properly

seated and soldered on reverse side of Power P.C.B..

Step 1 : Desolder pins of Transistor (Q5103) on reverse side of

Power P.C.B..

Step 2 : Remove 1 screw from the Transistor (Q5103) in the

direction of arrows.

Step 3 : Remove the Transistor (Q5103) from the Heat Sink.

Caution : Handle the Heat Sink unit with caution due to its high

temperature after prolonged use. Touching it may lead to

injuries.

42

Page 43

8.15.1. Assembly of the Transistor

(Q5103)

Step 1 : Fix the Transistor (Q5103) to the Heat Sink.

Step 2 : Screw 1 screw at Transistor (Q5103) in the direction of

arrows.

SA-PM86DGCS / SA-PM86DEE

8.16. Replacement of Transistor

(Q5100)

• Follow the (Step 1) - (Step 5) of Item 8.3

• Follow the (Step 1) - (Step 4) of Item 8.7

• Follow the (Step 1) - (Step 5) of Item 8.8

• Follow the (Step 1) - (Step 2) of Item 8.9

• Follow the (Step 1) - (Step 2) of Item 8.12

Step 3 : Solder pins of the Transistor (Q5103) on the reverse

side of the Power P.C.B..

Caution : Ensure pins of the Transistor (Q5103) are properly

seated and soldered on reverse side of Power P.C.B..

Step 1 : Desolder pins of Transistor (Q5100) on reverse side of

Power P.C.B..

Step 2 : Remove 1 screw from the Transistor (Q5100) in the

direction of arrows.

Step 3 : Remove the Transistor (Q5100) from the Heat Sink.

Caution : Handle the Heat Sink unit with caution due to its high

temperature after prolonged use. Touching it may lead to

injuries.

43

Page 44

SA-PM86DGCS / SA-PM86DEE

8.16.1. Assembly of the Transistor

(Q5100)

Step 1 : Fix the Transistor (Q5100) to the Heat Sink.

Step 2 : Screw 1 screw at Transistor (Q5100) in the direction of

arrows.

8.17. Disassembly of Inner Chassis

• Follow the (Step 1) - (Step 5) of Item 8.3

• Follow the (Step 1) - (Step 8) of Item 8.4

• Follow the (Step 1) - (Step 4) of Item 8.7

Step 3 : Solder pins of the Transistor (Q5100) on the reverse

side of the Power P.C.B..

Caution : Ensure pins of the Transistor (Q5100) are properly

seated and soldered on reverse side of Power P.C.B..

Step 1 : Detach 25P FFC cable (CN3661) at the connectors on

Main P.C.B..

Step 2 : Detach 14P FFC cable (CN3660) at the connectors on

Main P.C.B..

Step 3 : Detach 3P cable (H5902) at the connector on

Transformer P.C.B..

Step 4 : Remove 3P cable from Support P.C.B..

Step 5 : Release the Catch at each side of the Inner Chassis.

Step 6 : Remove Inner Chassis as arrows shown.

44

Page 45

Note: During reassembling procedures, ensure Inner

Chassis are properly catched onto Bottom Chassis.

SA-PM86DGCS / SA-PM86DEE

8.18. Disassembly of Video P.C.B.

• Follow the (Step 1) - (Step 5) of Item 8.3

• Follow the (Step 1) - (Step 8) of Item 8.4

• Follow the (Step 1) - (Step 4) of Item 8.7

• Follow the (Step 1) - (Step 6) of Item 8.17

Step 1 : Detach 50P FFC cable at the connector (CN2036) on

Video P.C.B..

Step 2 : Remove 2 screws on Video P.C.B..

Step 3 : Remove Video P.C.B. as the direction of the arrows.

Note: During reassembly procedures, ensure the Video

P.C.B. seated properly at locators.

45

Page 46

SA-PM86DGCS / SA-PM86DEE

8.19. Replacement of DC-DC

Converter IC (IC2741)

• Follow the (Step 1) - (Step 5) of Item 8.3

• Follow the (Step 1) - (Step 8) of Item 8.4

• Follow the (Step 1) - (Step 4) of Item 8.7

• Follow the (Step 1) - (Step 6) of Item 8.17

• Follow the (Step 1) - (Step 3) of Item 8.18

8.19.1. Assembly of DC-DC Converter IC

(IC2741)

Step 1 : Apply Grease to the Heat Sink Extrussion.

Step 2 : Fix and screw the DC-DC Converter IC (IC2741) to the

Heat Sink Extrussion.

Special Note : Ensure the DC-DC Converter IC (IC2741) is

tighly screwed to the Heat Sink Extrussion.

Step 1 : Desolder pins of DC-DC Converter IC (IC2741) on

reverse side of Video P.C.B..

Step 2 : Desolder pins of the Heat Sink Extrussion.

Step 3 : Remove the Heat Sink Extrussion in the direction of

arrow.

Step 4 : Remove 1 screw from the DC-DC Converter IC

(IC2741).

Step 5 : Remove the DC-DC Converter IC (IC2741) from the

Heat Sink Extrussion.

Caution : Handle the Heat Sink Extrussion with caution due to

its high temperature after prolonged use. Touching it may lead

to injuries.

Step 3 : Solder pins of the DC-DC Converter IC (IC2741) on

the reverse side of the Video P.C.B..

Step 4 : Solder pins of the Heat Sink Extrussion on the reverse

side of the Video P.C.B..

Caution : Ensure pins of the DC-DC Converter IC (IC2741) are

properly seated and soldered on reverse side of Video P.C.B..

46

Page 47

8.20. Disassembly of DVD Module

P.C.B.

• Follow the (Step 1) - (Step 5) of Item 8.3

• Follow the (Step 1) - (Step 8) of Item 8.4

• Follow the (Step 1) - (Step 4) of Item 8.7

• Follow the (Step 1) - (Step 6) of Item 8.17

• Follow the (Step 1) - (Step 3) of Item 8.18

• Disassembly of DVD Module Shield

Step 1 : Remove 3 screws on the DVD Module Shield.

SA-PM86DGCS / SA-PM86DEE

Step 3 : Detach 26P FFC cable (FP8531) and 7P FFC cable

(FP8251) at the connectors on DVD Module P.C.B..

Step 4 : Remove USB cable from P.C.B. Brackets Hook as

shown.

Step 5 : Remove DVD Module P.C.B. as the direction of the

arrows.

Note: During reassembling procedures, ensure the DVD

Module P.C.B. is seated properly at the locators and P.C.B.

Bracket’s Hook.

Step 2 : Remove DVD Module Shield.

47

Page 48

SA-PM86DGCS / SA-PM86DEE

8.21. Disassembly of Mechanism

Unit

• Follow the (Step 1) - (Step 5) of Item 8.3

• Follow the (Step 1) - (Step 8) of Item 8.4

• Follow the (Step 1) - (Step 4) of Item 8.7

• Follow the (Step 1) - (Step 6) of Item 8.17

• Follow the (Step 1) - (Step 3) of Item 8.18

• Follow the (Step 1) - (Step 5) of Item 8.20

• Disassembly of P.C.B. Bracket

Step 3 : Remove 2 screws from the Mechanism Unit.

Step 4 : Remove Mechanism Unit.

Note 1: During reassembling procedures, ensure the FFC cable

are underneath the P.C.B. bracket.

Note 2: For Disassembly and assembly of traverse unit, Please

refer to original service manual DLS6 Order No.

MD0801003CE.

Step 1 : Remove 2 screws at the P.C.B. Bracket.

Step 2 : Remove P.C.B. Bracket.

Note: During reassembling procedures, ensure P.C.B.

Bracket is properly catched under the Bottom Chassis’s

Hooks.

48

Page 49

8.22. Disassembly of USB Lid

• Follow the (Step 1) - (Step 5) of Item 8.3

• Follow the (Step 1) - (Step 8) of Item 8.4

• Follow the (Step 1) - (Step 5) of Item 8.5

SA-PM86DGCS / SA-PM86DEE

Step 4 : Press USB Lid at the right side as arrow shown.

• Disassembly of USB Lid Spring

Step 1 : Remove Power Button and Skip Button from Front

Panel.

Step 2 : Remove Mic Vol Button from Front Panel.

Step 3 : Lift up USB Lid as arrow shown.

Step 1 : Remove the USB Lid Spring.

Caution : Keep the USB Lid Spring unit in safe place.

49

Page 50

SA-PM86DGCS / SA-PM86DEE

8.23. Disaasembly of DVD Lid

• Follow the (Step 1) - (Step 5) of Item 8.3

• Follow the (Step 1) - (Step 8) of Item 8.4

Step 1 : Release the Spring.

Step 3: Remove DVD Lid as arrow shown.

Step 2 : Push the Shaft of the DVD Lid in the direction of arrow.

50

Page 51

SA-PM86DGCS / SA-PM86DEE

9 Assembling and Disassembling of Mechanism Unit

9.1. Disassembling Procedures

9.1.1. Disassembly of traverse unit

Step 3: Release the FFC as arrows shown.

Step 4: Lift the traverse unit up by approximately 45° as shown.

Step 1: Release the guide.

Step 2: Push the traverse slide plate (rib), ensure both grooves

are opene d.

Step 5: Slide out the traverse unit as arrow shown.

Caution:

Ensure the OPU is face upwards, avoid touching the

surface of the traverse unit.

51

Page 52

SA-PM86DGCS / SA-PM86DEE

9.2. Assembling Procedure

9.2.1. Assembly of traverse unit

Caution:

• Removal of the short pin is necessary for replacement

of new traverse unit.

52

Page 53

SA-PM86DGCS / SA-PM86DEE

Step 1: Release the guide.

Step 2: Push the traverse slide plate (rib), ensure both grooves

are opene d.

Step 3: Slot the traverse unit at approximately 45° into the

mecha chassis as arrow shown.

Note: Ensure the bosses fix exactly onto the guides.

Step 4: Place down the traverse unit.

Step 5: Place the FFC as arrows shown.

53

Page 54

SA-PM86DGCS / SA-PM86DEE

Step 6: Release the guide.

Step 7: Push the traverse slide plate (rib) to lock the traverse

unit in.

54

Page 55

SA-PM86DGCS / SA-PM86DEE

10 Service Fixture and Tools

Prepare service tools before proccess service position.

Service Tools Remarks

Panel P.C.B. (CN6001) - Main P.C.B. (CN3720) REEX0919 (24 pin FFC cable) [M](RTL)

Video P.C.B. (CN2035) - Main P.C.B. (CN3661) REEX0920 (25 pin FFC cable) [M](RTL)

Video P.C.B. (CN2034) - Main P.C.B. (CN3660) REEX0921 (14 pin FFC cable) [M](RTL)

Bride P.C.B. (CN4801) - Main P.C.B. (CN3722) REXX0695 (13 pin cable) [M](RTL)

55

Page 56

SA-PM86DGCS / SA-PM86DEE

11 Service Position

Note: For description of the disassembly procedures, see

the Section 8

11.1. Checking & Repairing Main

P.C.B

Step 1 : Remove Top Panel.

Step 2 : Remove Rear Panel and position it according to the

diagram show.

11.2. Checking & Repairing

Transformer P.C.B

Step 1 : Remove Top Panel.

Step 2 : Remove Rear Panel and position it according to the

diagram show.

Step 3 : Transformer P.C.B. can be checked at its original

postion.

Step 3 : Main P.C.B. can be checked at its original position.

56

Page 57

11.3. Checking & Repairing Panel

P.C.B

SA-PM86DGCS / SA-PM86DEE

11.4. Checking & Repairing Power

P.C.B

Step 1 : Remove Top Panel.

Step 2 : Remove Front Panel and position it according to the

diagram show.

Step 3 : Remove 3 screws to remove Shield Plate.

Step 4 : Attach original cable with Ground Cable.

Step 5 : Attach extension cable REEX0919 (24P FFC cable

from CN600 1 to CN3720).

Step 1 : Remove Top Panel.

Step 2 : Remove Rear Panel.

Step 3 : Remove 3 screws from Power P.C.B..

Step 4 : Attach original cable with Ground cable.

Step 5 : Attach extension cable REEX0919 (24P FFC cable

from CN600 1 to CN3720).

Step 6 : Attach original cable with extension cable REXX0658

(8P cable from CN5903 to CN5104).

Step 7 : Attach extension cable REEX0920 (25P FFC cable

from CN203 5 to CN3661).

Step 8 : Attach extension cable REEX0921 (14P FFC cable

from CN203 4 to CN3660).

Step 9 : Attach extension cable REEX0695 (13P FFC cable

from CN480 1 to CN3722).

57

Page 58

SA-PM86DGCS / SA-PM86DEE

11.5. Checking & Repairing Video

P.C.B

Step 1 : Remove Top Panel.

Step 2 : Remove Front Panel.

Step 3 : Remove Rear Panel.

Step 4 : Remove Inner Chassis.

Step 8 : Connect 24P FFC cable at the connec tor (CN3720) on

Main P.C.B..

Step 5 : Connect 2P cable at the connec tor (CN3750) on Main

P.C.B..

Step 6 :Connect 7P cable at the connector (CN5905) on

Transformer P.C.B..

Step 7 : Fit Ground Cable with 1 screw to Main P.C.B..

Step 9 : Remove 2 screws on the Video P.C.B..

58

Page 59

SA-PM86DGCS / SA-PM86DEE

11.6. Checking & Repairing DVD

Module P.C.B

• Servicing Side A of DVD Module P.C.B.

Step 1 : Follow step 1 - 15 of item 11.5.

Step 10 : Connect 5P cable at the connector (CN4200) on USB

P.C.B..

Step 11: Connect 3P cable at the connector (H5902) on

Transformer P.C.B..

Step 2 : Position Video P.C.B. according to the diagram shown.

Step 3 : Remove 3 screws from the DVD Module Shield.

Step 4 : Remove DVD Module Shield.

Step 12 : Place a box underneath the Video P.C.B..

Step 13 : Flip over Reverse side of Video P.C.B..

Step 14 : Attach extension cable REEX0920 (25P FFC cable

from CN203 5 to CN3661).

Step 15 : Attach extension cable REEX0921 (14P cable from

CN2034 to CN3660).

Step 5 : Check and Repair side A according to the diagram

shown..

• Servicing Side B of DVD Module P.C.B.

59

Page 60

SA-PM86DGCS / SA-PM86DEE

Step 6 : Check and Repair side B according to the diagram

shown.

60

Page 61

SA-PM86DGCS / SA-PM86DEE

12 Voltage Measurement & Waveform Chart

Note:

• Indicated voltage values are the standard values for the unit measured by the DC electronic circuit tester (high-impedance)

with the chassis taken as standard.

Therefore, there may exist some errors in the voltage values, depen ding on the internal impedance of the DC circuit tester.

• Circuit voltage and waveform described herein shall be regarded as reference information when probing defect point

because it may differ from actual measuring value due to difference of Measuring instrument and its measuring condition

and product itself.

12.1. Voltage Measurement

12.1.1. DVD MODULE P.C.B.

!"#$%&'

(&)" *+,-./012*3***+*,*-*.*/*0*1*2+3

4)$5678 9999*',*'-3+'2,'-33'*3'*,',33'*3'*,'-333

!"#$%&'

(&)" +* ++ +, +- +. +/ +0 +1 +2 ,3 ,* ,+ ,, ,- ,. ,/ ,0 ,1 ,2 -3

4)$5678 ,', 3'* 3 3 ,'- 3 3 ,', 3333*'/,'-3'23'*3'*3'23'*,'!"#$%&'

(&)" -* -+ -, -- -. -/ -0 -1 -2 .3 .* .+ ., .- .. ./ .0 .1 .2 /3

4)$5678 *'0 *', *'0 3'* *'0 3'* *', 3'* 3'* 3'* 3'* ,'- 3'* 3'* *', 3'* 3'* 3'* 3'* 3

!"#$%&'

(&)" /* /+ /, /- /. // /0 /1 /2 03 0* 0+ 0, 0- 0. 0/ 00 01 02 13

4)$5678 3 3 3 9 9 3'* 3'* 3'* 3'* ,'- 3'* 3'* 3'* 3'* *', 3'* 3'* 3 3 3'*

!"#$%&'

(&)" 1* 1+ 1, 1- 1. 1/ 10 11 12 23 2* 2+ 2, 2- 2. 2/ 20 21 22 *33

4)$5678 3'* 3'* 3'* ,'- *', 3'* *'3 3'2 *'1 *', 3'* +'+ 3'2 3'/ +'* 3'* 3'* 3'* 3'* ,'!"#$%&'

(&)" *3* *3+ *3, *3- *3. *3/ *30 *31 *32 **3 *** **+ **, **- **. **/ **0 **1 **2 *+3

4)$5678 3'* *', 3'* 3'* 3 ,'- ,'- ,'- *', 3 *'1 3'* ,', ,', ,'- *', *'0 3 3 ,'!"#$%&'

(&)" *+* *++ *+, *+- *+. *+/ *+0 *+1

4)$5678 ,'- 3 *', ,'- 3 *'- 9 9

K4,23*

K4,23*

K4,23*

K4,23*

K4,23*

K4,23*

K4,23*

61

Page 62

SA-PM86DGCS / SA-PM86DEE

!"#$%&'

(&)" *+,-.

4)$5678 1'. 3 *'- .'* 1'1

!"#$%&'

(&)" *+,-./012*3***+*,*-*.*/*0*1*2+3

4)$5678 3 3 3'* ,', 3'* ,', 3'* 3'* *'3 3'2 *'0 *'+ +'+ 3'2 3'* ,', 3'/ +'3 3'* *'+

!"#$%&'

(&)" +* ++ +, +- +. +/ +0 +1 +2 ,3 ,* ,+ ,, ,- ,. ,/ ,0 ,1 ,2 -3

4)$5678 +'. 3 3 +'+ 3 +'- 3 3'2 *'3 *'2 ,', 3 3 +'3 3'1 +'* +'3 *'3 3'2 +'!"#$%&'

(&)" -* -+ -, -- -. -/ -0 -1 -2 .3 .* .+ ., .- .. ./ .0 .1 .2 /3

4)$5678 +'- +'/ 3'* *'+ 3'* ,'+ ,'+ ,', ,', *'0 3'* ,', *'1 +'1 ,'3 ,', ,', ,', 3'/ ,'3

!"#$%&'

(&)" /* /+ /, /- /. // /0 /1 /2 03 0* 0+ 0, 0- 0. 0/ 00 01 02 13

4)$5678 *'/ 3'* 3'* 3'2 ,', *'2 *'0 3 ,', ,', 3 ,', ,', 3 3', *'+ ,', ,', ,', ,',

!"#$%&'

(&)" 1* 1+ 1, 1- 1. 1/ 10 11 12 23 2* 2+ 2, 2- 2. 2/ 20 21 22 *33

4)$5678 3'* 3'* *'+ ,', 3'2 +'- 3'* *'2 3'* 3'. *'1 ,', *'. *'. *'2 *'2 *'0 *'0 *'0 *'0

!"#$%&'

(&)" *3* *3+ *3, *3- *3. *3/ *30 *31 *32 **3 *** **+ **, **- **. **/ **0 **1 **2 *+3

4)$5678 3 3 3'+ 3'* 3'+ +'* ,', 3 +', *'0 +'. +'. +'. +'. +'. +'. +'- +'- +'- +'.

!"#$%&'

(&)" *+* *++ *+, *+- *+. *+/ *+0 *+1 *+2 *,3 *,* *,+ *,, *,- *,. *,/ *,0 *,1 *,2 *-3

4)$5678 *'2 +'3 *'0 *'0 3'* *'0 *'0 ,', 3'2 3'2 3'. ,', +'- *'3 *'3 +'- 3'* 3'. 3'2 3'*

!"#$%&'

(&)" *-* *-+ *-, *-- *-. *-/ *-0 *-1 *-2 *.3 *.* *.+ *., *.- *.. *./ *.0 *.1 *.2 */3

4)$5678 ,', ,', 3333,',*'.*'0*'03'2*'03,',*'.*'/3*'+,'39

!"#$%&'

(&)" */* */+ */, */- */. *// */0 */1 */2 *03 *0* *0+ *0, *0- *0. *0/ *00 *01 *02 *13

4)$5678 ,'3 ,'3 ,'* ,'3 3 ,', ,'3 ,'+ ,'+ ,'3 ,'3 ,'+ 3 ,', ,'3 ,'* ,'+ +'2 +'2 +'2

!"#$%&'

(&)" *1* *1+ *1, *1- *1. *1/ *10 *11 *12 *23 *2* *2+ *2, *2- *2. *2/ *20 *21 *22 +33

4)$5678 ,', *'/ *'/ ,', *'/ 3 *'+ ,', ,', ,'+ ,'/ 3 +'3 3 3 ,', *'/ 3'* 3 *'/

!"#$%&'

(&)" +3* +3+ +3, +3- +3. +3/ +30 +31 +32 +*3 +** +*+ +*, +*- +*. +*/

4)$5678 3'* *'/ 3'- 3 ,', *'0 *'1 3'- *'/ 3 *'+ +', +'0 +'0 ,', 3

!"#$%&'

(&)" *+,-./012*3***+*,*-*.*/*0*1*2+3

4)$5678 ,', ,'+ ,', +'2 +'2 3 ,'+ ,'3 ,', ,'+ ,'3 3 +'1 ,', +'1 ,', ,', ,'+ ,'+ +'3

!"#$%&'

(&)" +* ++ +, +- +. +/ +0 +1 +2 ,3 ,* ,+ ,, ,- ,. ,/ ,0 ,1 ,2 -3

4)$5678 *'/ 3 3'* 3'- 3'- *'/ ,', 3 *'. *'0 *'0 *'/ 3 3 3 9 ,', *'/ +'2 9

!"#$%&'

(&)" -* -+ -, -- -. -/ -0 -1 -2 .3 .* .+ ., .-

4)$5678 3 ,'+ ,', ,'3 3 3 ,'+ +'2 ,', ,'* +'2 3 ,'3 3

!"#$%&'

(&)" *+,-./01

4)$5678 ,', 9 3 *'2 -'1 9 9 .'*

K4,2.+

K4133*

K4133*

K4133*

K4133*

K4133*

K4133*

K4133*

K4133*

K4133*

K4133*

K4133*

K413.*

K413.*

K413.*

K41***

62

Page 63

SA-PM86DGCS / SA-PM86DEE

!"#$%&'

K41*.*

(&)" *+,-.

4)$5678 +', +', 3 *', 3'1

!"#$%&'

K41+.*

(&)" *+,-./012*3***+*,*-*.*/*0*1*2+3

4)$5678 *'0 *'0 *'0 +'+ +'+ +'3 3'* .'* ,', 3 +'. +'0 +'. +'0 -'* -'+ .'3 ,', 3 ,',

!"#$%&'

K41+.*

(&)" +* ++ +, +- +. +/ +0 +1 +2 ,3

4)$5678 1'2 1'0 *'1 *'0 *'0 *'0 ,', ,', 3 3

!"#$%&'

K41-+3

(&)" *+,-./012*3***+*,*-*.*/

4)$5678 *'0 *'0 3'2 *'0 ,', ,', ,', 3 3 +'/ +'/ +'/ 3 .'* .'* .'*

!"#$%&'

K41-+*

(&)" *+,-./012*3***+*,*-*.*/*0*1*2+3

4)$5678 *'0 *'0 3'2 *'0 ,', ,', ,', 3 3'2 3'* 3'* .'* .'* .'* 3 3 +'/ +'/ +'/ +'/

!"#$%&'

K41-+*

(&)" +* ++ +, +- +. +/ +0 +1 +2 ,3

4)$5678 +'/ +'/ 3 3'+ +'/ +'/ 3 .'* .'* .'*

!"#$%&'

K41-++

(&)" *+,-./012*3***+*,*-*.*/

4)$5678 +'/ +'/ 3 +'/ 3 .'* .'* 3 *'- *'0 *'/ *'0 ,', 3 .'* 3

!"#$%&'

K41/3*

(&)" *+,-

4)$5678 ,', *'+ 3 3

!"#$%&'

K41/3/

(&)" *+,-.

4)$5678 ,', ,', 3 3 9

!"#$%&'

K41/**

(&)" *+,-./01

4)$5678 3333,'+,'+3,',

!"#$%&'

K41/.*

(&)" *+,-./012*3***+*,*-*.*/*0*1*2+3

4)$5678 +'/ +'- +'+ 3'/ +'. *'+ 3'2 *'* *'2 3 ,', ,', ,', ,', *'* +'* 3'1 +'+ +'* *'3

!"#$%&'

K41/.*

(&)" +* ++ +, +- +. +/ +0 +1 +2 ,3 ,* ,+ ,, ,- ,. ,/ ,0 ,1 ,2 -3

4)$5678 3'2 +'. +'- +'/ +', +'0 3 +'0 +'+ +'. +', +'+ 3'. +'- *'* *'3 ,', *'3 +'+ +'*

!"#$%&'

K41/.*

(&)" -* -+ -, -- -. -/ -0 -1

4)$5678 *'3 3 +'- +'- +'. 3 ,', +'.

!"#$%&'

K41/2*

(&)" *+,-.

4)$5678 ,'3 ,'3 3 -'. .'*

!"#$%&'

K41/2.

(&)" *+,-.

4)$5678 +'0 +'0 3 -'+ .'*

!"#$%&'

K4103*

(&)" *+,-.

4)$5678 9 *'. 3 *'1 ,',

!"#$%&'

K4123*

(&)" *+,-.

4)$5678 ,', ,', 3 ,', ,',

!"#$%&'

K4233*

(&)" *+,-./012*3***+*,*-*.*/*0*1*2+3

4)$5678 3 +'+ +'/ +'- +'- 3'2 3'2 +'3 +'+ 3 +'0 +'+ +'* *'3 3'2 +'. +'- +'/ +', ,',

!"#$%&'

K4233+

(&)" *+,-./012*3***+*,*-*.*/*0*1*2+3

4)$5678 3 * * *'* +'- 3'/ +'* +', +'. 3 +'0 +'/ +', +', 3'/ +'. *'+ *'3 *'3 ,',

!"#$%&'

K4233,

(&)" *+,-./

4)$5678 *'/ 3'* *'/ *'0 ,', *'/

!"#$%&'

K4233.

(&)" *+,-./01

4)$5678 3'* .'* .'* 3'* ,', *'* *'* *'*

!"#$%&'

L,23* L,23+ L,23, L,2-*

L,2-+

(&)" " 4 D " 4 D " 4 D " 4 D " 4 D

4)$5678 3 3 3'0 ,', 3 ,'- ,', .'* 3 ,'0 ,'0 ,'0 3 3 3

!"#$%&'

L,2-, L1,+* L1,+. L1,,* L1,,.

(&)" " 4 D " 4 D " 4 D " 4 D " 4 D

4)$5678 -'* .'2 -'0 *'+ 3 3'. *'. 3 3'2 *'+ 3 3'. *'. 3 3'2

!"#$%&'

L1./+L1,-* L1..* L1..+ L1./*

(&)" " 4 D " 4 D " 4 D " 4 D " 4 D

4)$5678 *'. 3 3'2 3 .'* 3'* .'* 3'* .'* *'. ,'0 +'* -', *'2 ,'0

63

Page 64

SA-PM86DGCS / SA-PM86DEE

!"#$%&'

(&)" A ) B A ) B A ) B *+,-./

4)$5678 3 3'+ 3'* 3 3 ,', 3 3'* 3'0 3 3 *'+ 3 3 -'1

!"#$%&'

(&)" " 4 D " 4 D

4)$5678 3 -', 3 ,', 3 ,',

L1./, L1./- L1./. L!1***

L!1-+3 L!23,3

12.1.2. MAIN P.C.B.

!<N$%:'

(&)" * + , - ./01

4)$5678 0'- 0'- 0'- 3 0'- 0'- 0'- *-'1

AO7%)D8 *'3 *'3 3'+ 3 3 3'. 3'. 3'*

!<N$%:'

(&)" * + , - ./012*3***+*,*-*.*/*0*1*2+3

4)$5678 3 -'/ -'/ -'/ -'/ -'/ -'/ -'/ -'/ -'/ -'/ -'/ -'/ -'/ -'/ -'/ -'/ 3 -'2 -'2

AO7%)D8 3 3'- 3'- 3'- 3'- 3', 3', 333333'*3',3',3',3',333'*

!<N$%:'

(&)" +* ++ +, +- +. +/ +0 +1 +2 ,3 ,* ,+ ,, ,- ,. ,/ ,0 ,1 ,2 -3

4)$5678 2'+ -'/ -'/ -'/ 3'2 *'/ -'/ -'/ -'/ -'/ -'/ -'/ -'/ -'/ -'/ -'/ -'/ -'/ 3 -'/

AO7%)D8 3 3 3', 3', 3', 3 3', 3'+ 3 3 3 3'* 3'+ 3', 3'+ 3', 3', 3', 3 3',

!<N$%:'

(&)" -* -+ -, -- -. -/ -0 -1 -2 .3 .* .+

4)$5678 3 -'/ 3 -'/ -'/ -'/ -'/ 3 3 -'/ 3 -'/

AO7%)D8 3 3', 3 3', 3'. 3'+ 3'+ 3 3 3'+ 3 3'+

!<N$%:'

(&)" * + , - ./01

4)$5678 0'- 0'- 0'- 3 0'- 0'- 0'- *-'1

AO7%)D8 3'- 3'- 3 3 3 3'- 3'- 3'*

!<N$%:'

(&)" * + , - ./012*3***+*,*-*.*/

4)$5678 3 +'. +'. +'. +'. 3'/ 3'/ 3 +'. +'. +'. +'. +'. 3'2 . 3

AO7%)D8 3 3'* 3'* 3 3 3'* 3'* 3 3'* 3'* 3'* 33333

!<N$%:'

(&)" * + , - ./01

4)$5678 -'/ -'/ -'/ 3 -'/ -'/ -'/ 2'+

AO7%)D8 3'+ 3', 3 3 3 3'* 3'* 3

!<N$%:'

(&)" * + , - ./012*3***+*,*-*.*/*0*1*2+3

4)$5678 3 3 -'2 -'2 333333'03'0-'2+'-3+'--'2-'2-'2,'/3

AO7%)D8 3 3 -'2 -'2 333333'03'0-'1+'-3+',-'2-'2-'1,'.3

!<N$%:'

(&)" +* ++ +, +- +. +/ +0 +1 +2 ,3 ,* ,+ ,, ,- ,. ,/ ,0 ,1 ,2 -3

4)$5678 3 -'2 3 3 3 -', 3 -'. -'+ *'0 3333-'2-'2-'2-'2-'2-'2

AO7%)D8 3 -'2 3 3 3+33333333333-'233

!<N$%:'

(&)" -* -+ -, -- -. -/ -0 -1 -2 .3 .* .+ ., .- .. ./ .0 .1 .2 /3

4)$5678 3 -'2 -'2 3 33333333333333'+3-'2