Panasonic SAPM-71-SDGN Service manual

A

ORDER NO. MD0504156C3

CD Stereo System

SA-PM71SDGN

SA-PM71SDGT

Colour

(S)... Silver Type

Specification

n Amplifier Section

RMS output power, both channels driven

10%, Total harmonic distortion

1 kHz (Low channel) 40 W per channel

(6 Ω)

8 kHz (High channel) 40 W per channel

(6 Ω)

Total Bi-Amp power 80 W per channel

Output Impedance

Headphone 16Ω -32Ω

n FM Tuner Section

Frequency range 87.50 MHz to 108.00 MHz

(50 kHz steps)

Sensitivity 1.50 µV (IHF)

S/N 26dB 1.70 µV

ntenna terminals 75 Ω (unbalanced)

Preset stations 15

n AM Tuner Section

Frequency range 522 kHz to 1629 kHz (Default)

(9 kHz steps)

520 kHz to 1630 kHz

(10 kHz steps)

Sensitivity S/N 20 dB at 999 kHz 560 µV/m

Preset stations 15

n Cassette Deck Section

Track system 4 track, 2 channel

Heads

Record/playback Solid permalloy head

Erasure Double gap ferrite head

Motor DC servo motor

Recording system AC bias 100 kHz

Erase system AC erase 100 kHz

Tape speed 4.8cm/s(1-7/8ips)

Overall frequency response (+3 dB, -6 dB) at DECK OUT

Normal 35 Hz to 14 kHz

Wow and flutter 0.10% (WRMS)

Fast forward and rewind time Approx. 120 seconds with C-60

cassette tape

n CD Section

Disc CD,MP3,WMA,CD-R/RW,

HighMat

8cm (3”) / 12 cm (5”)

Sampling frequency

CD 44.1 kHz

MP3/WMA 32 kHz, 44.1 kHz, 48 kHz

Bit rate

MP3 32 kbps to 320 kbps

WMA 40 kbps to 192 kbps

Decoding 16 bit linear

Pickup

Beam source Semiconductor laser

Wavelength 780 nm

Number of channels Stereo

Frequency response 20 Hz to 20 kHz (+1dB, -2 dB)

© 2005 Matsushita Electric Industrial Co. Ltd.. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

SA-PM71SDGN / SA-PM71SDGT

Wow and flutter Below measurable limit

Digital filter 8fs

D/A converter MASH (1 bit DAC)

n SD Section

Sampling frequency 32 kHz (LP), 44.1 kHz (SP,XP)

Coding system

SD Audio Playback AAC, MP3, W MA

SD Audio Record AAC

Number of channels 2 channel (stereo)

n Other

CD → SD Recording speed Maximum 4 times (LP)

n General

Power supply AC 230 - 240 V, 50 Hz (For GN)

AC 110 V, 60 Hz (For GT)

Max. power consumption 248 W (1% total harmonic

distortion) (For GT)

Power consumption 130 W

Dimensions (W x H x D) 175 mm x 249.5 mm x 379.6 mm

(6 29/32 x 9 27/32” x 14 31/32”)

Mass 5.8 kg (12.8 Ibs)

Power consumption in standby

mode

Notes :

1. Specifications are subject to change without notices. Mass and

dimensions are approximate.

2. Total harmonic distortion is measured by the digital spectrum

analyzer.

n System : SC-PM71SDGN-S

n System : SC-PM71SDGTS

Music center: SA-PM71SDGN-S

Music center: SA-PM71SDGTS

0.5 W (For GN)

0.3 W (For GT)

Speaker: SB-PM71P-M

Speaker: SB-PM71P-M

CONTENTS

Page Page

1 Safety Precautions

1.1. GENERAL GUIDELINES

2 Before Repair and Adjustment

3 Protection Circuitry

4 Handling the Lead-free Solder

4.1. About lead free solder (PbF)

5 Precaution of Laser Diode

6 Handling Precautions For Traverse Deck

7 Accessories

8 Operation Procedures

8.1. Main Unit

8.2. Remote Control

9 Information on Disc & MP3

10 SD Card Information

11 About HighMAT

11.1. What 痴 HighMAT?

11.2. Why take advantage of HighMAT?

11.3. Benefits of HighMAT?

12 Assembling and Disassembling

12.1. Disassembly flow chart

12.2. Disassembly of Side Panel L & R

12.3. Disassembly of Top Cabinet

12.4. Disassembly of Deck Mechanism P.C.B. and Tape Eject

P.C.B.

12.5. Disassembly of Front Panel

12.6. Disassembly of SD Module P.C.B.

12.7. Disassembly of Panel P.C.B.

12.8. Disassembly of Rear Cabinet

12.9. Disassembly of Main P.C.B.

4

4

5

5

5

5

6

7

8

9

9

10

11

13

15

15

15

16

19

19

20

20

20

21

22

22

23

24

12.10. Disassembly of Transforme r P.C.B.

12.11. Disassembly of Tuner Pack

12.12. Disassembly of Power P.C.B.

12.13. Disassembly of CR16 Mechanism

12.14. Replacement of CD Lid and Inner CD Lid

12.15. Replacement of Cassette Lid

12.16. Replacement of the Power IC and Transistors

12.17. Procedure for Replacing Pinch Roller and Head Block

(Deck Mechanism Unit)

12.18. Procedure for Replacing Motor, Capstan Belt A, Capstan

Belt B, and Winding Belt (Deck Mechanism Unit)

12.19. Procedure for Replacing Parts on Deck Mechanism PCB

12.20. Disassembly of CR16 Mechanism

12.21. Replacement of optical pickup unit (CD mechanism)

12.22. Replacement of a traverse gear A and a traverse gear B

12.23. Procedure for removing CD loading mechanism

12.24. CR16 mechanism disassembly procedure

12.25. CR16 MECHANISM ASSEMBLY PROCEDURE

12.26. Disassembly of traverse mechanism

12.27. Handling of cassette tape jam

13 Service Positions

13.1. Checking procedure

13.2. Checking the major P.C.B

14 Self-Diagnostic Display Function

14.1. Entering into Self-Diagnostic Mode

14.2. Error Code Table

14.3. Changer Reliability Test Mode

24

25

25

25

26

28

28

30

30

32

32

33

35

36

36

42

55

56

57

57

57

58

58

59

60

2

SA-PM71SDGN / SA-PM71SDGT

15 Procedure for Checking Operation of Individual Parts of Deck

Mechanism Unit

15.1. Operation Check with Cassette Tape

15.2. Operation Check without Cassette Tape

16 Measurement And Adjustments

16.1. Cassette Deck Section

17 Voltage Measurement and Waveform Chart

17.1. Voltage Measurement

17.2. Waveform Chart

18 Block Diagram

18.1. CD SERVO Block

18.2. MAIN Block

19 Notes of Schematic Diagram

20 Schematic Diagram

20.1. CD SERVO CIRCUIT

20.2. SD MODULE CIRCUIT

20.3. MAIN CIRCUIT

20.4. PANEL CIRCUIT and TRANSFORMER CIRCUIT

20.5. POWER CIRCUIT

61

61

61

63

63

65

65

71

73

73

75

82

83

83

85

90

95

97

20.6. DECK CIRCUIT, DECK MECHANISM CIRCUIT and TAPE

EJECT CIRCUIT

20.7. CD LOADING CIRCUIT

21 Printed Circuit Board

99

101

102

21.1. CD SERVO P.C.B

21.2. SD MODULE P.C.B

21.3. MAIN P.C.B

21.4. PANEL P.C.B

21.5. TRANSFORMER P.C.B

21.6. POWER P.C.B

21.7. DECK P.C.B and TAPE EJECT P.C.B

21.8. DECK MECHANISM P.C.B and CD LOADING P.C.B

22 Wiring Connection Diagram

23 Illustration of IC 痴, Transistors and Diodes

24 Terminal Function of ICエs

24.1. IC807 (MN103SF77RXW) IC SD Audio Drive Controller

24.2. IC703 (BA5948FPE2) IC 4CH Drive

25 Troubleshooting Flowchart (CD Section Circuit)

26 Troubleshooting Flowchart (SD Card Section Circuit)

27 Parts Location and Replacement Parts List

27.1. Deck Mechanism

27.2. CD LOading Mechanisms

27.3. Cabinet Part List

27.4. Electrical Part List

27.5. Packaging Materials & Accessories Parts List

27.6. Packaging

102

104

105

107

108

109

110

111

112

114

115

115

116

117

119

121

122

124

129

133

144

144

3

SA-PM71SDGN / SA-PM71SDGT

1 Safety Precautions

1.1. GENERAL GUIDELINES

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, ensure that all the protective devices such as insulation barriers, insulation papers shields are properly installed.

3. After servicing, check for leakage current checks to prevent from being exposed to shock hazards.

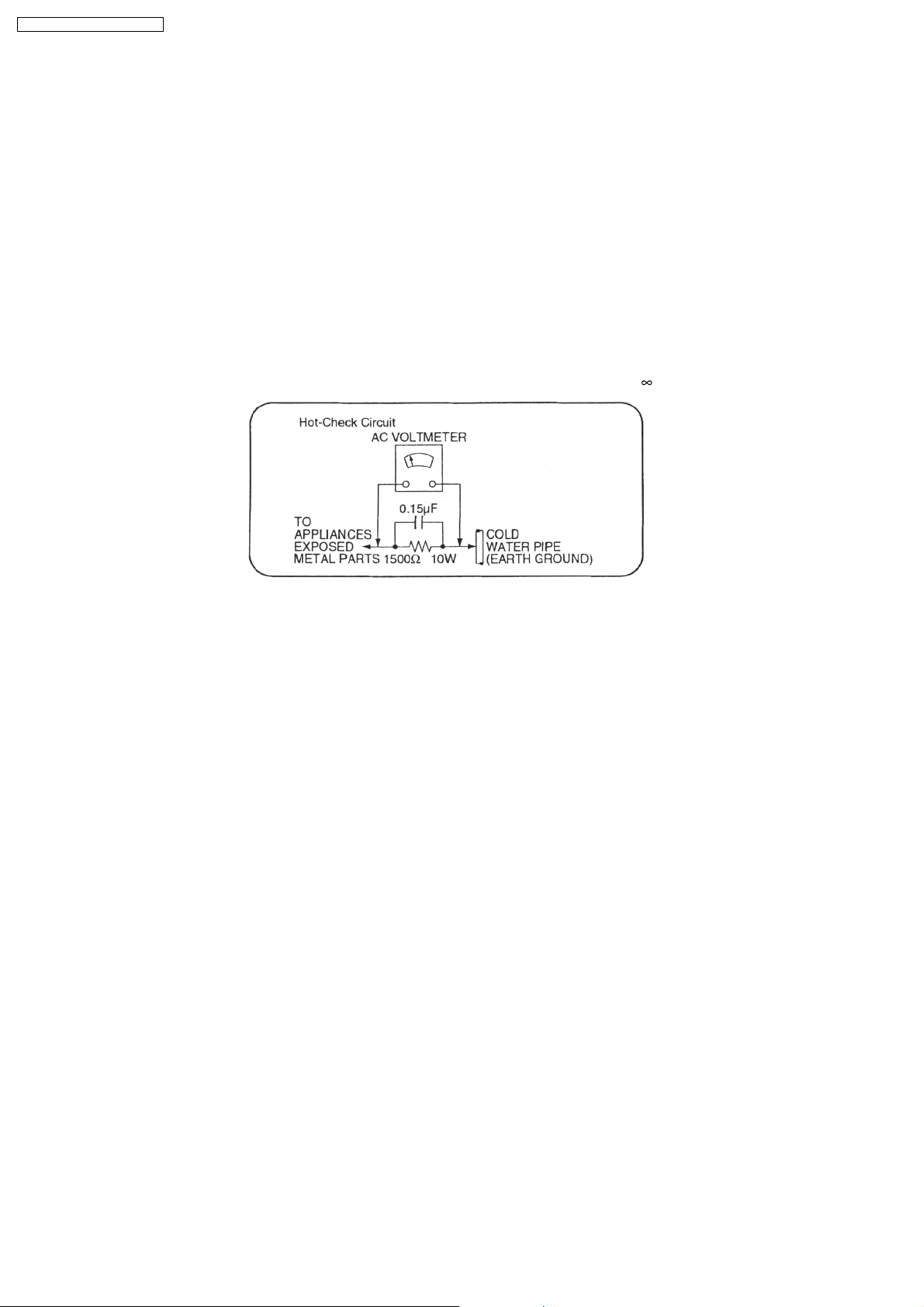

1.1.1. LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Using an ohmmeter measure the resistance value, between the jumpered AC plug and each expose d metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩand 5.2Ω.

When the exposed metal does not have a return path to the chassis, the reading must be

.

Fig. 1

1.1.2. LEAKAGE CURRENT HOT CHECK (See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use an isolatio n transfo rmer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent) may

be used to make the hot checks, leakage current must not exceed 1/2 milliamp. should the measurement is outside of the limits

specified, there is a possibility of a shock hazard, and the equipment should be repaired and re-checked before it is returned

to the customer.

4

SA-PM71SDGN / SA-PM71SDGT

2 Before Repair and Adjustment

Disconnect AC power, discharge Power Supply Capacitors C448, C449, C452, C455, C456, C506, C507, C508 & C584 through

a10Ω, 1W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

· Current consumption at AC 230V-2 40V, 50 Hz in NO SIGNAL mode should be ~300 mA. (For GN)

· Current consumption at AC 110V, 60 Hz in NO SIGNAL mode should be ~350 mA. (For GT)

3 Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

· No sound is heard when the power is turned on.

· Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

"shorted", or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outline s below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

4 Handling the Lead-free Solder

4.1. About lead free solder (PbF)

Distinction of PbF P.C.B.:

P.C.B.s (manufactured) using lead free solder will have a PbF stamp on the P.C.B.

Caution:

· Pb free solder has a higher melting point than standard solder; Typically the melting point is 50 - 70°F (30 - 40°C) higher. Please

use a high temperature soldering iron. In case of soldering iron with temperature control, please set it to 700 ± 20°F (370 ±

10°C).

· Pb free solder will tend to splash when heated too high (about 1100°F/600°C).

· W hen soldering or unsoldering, please completely remove all of the solder on the pins or solder area, and be sure to heat the

soldering points with the Pb free solder until it melts enough.

5

SA-PM71SDGN / SA-PM71SDGT

5 Precaution of Laser Diode

CAUTION:

This unit utilizes a class 1 laser.

Invisible laser radiation is emitted from the optical pickup lens.

When the unit is turned on:

1. Do not look directly into the pick up lens.

2. Do not use optical instruments to look at the pick up lens.

3. Do not adjust the preset variable resistor on the pickup lens.

4. Do not disassemble the optical pick up unit.

5. If the optical pick up is replaced, use the manufacturer’s specified replacement pick up only.

6. Use of control or adjustments or performance of procedures other than those specified herein may result in hazardous radiation

exposure.

CAUTION!

THIS PRODUCT UTILIZES A LASER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT

IN HAZARDOUS RADIATION EXPOSURE.

6

SA-PM71SDGN / SA-PM71SDGT

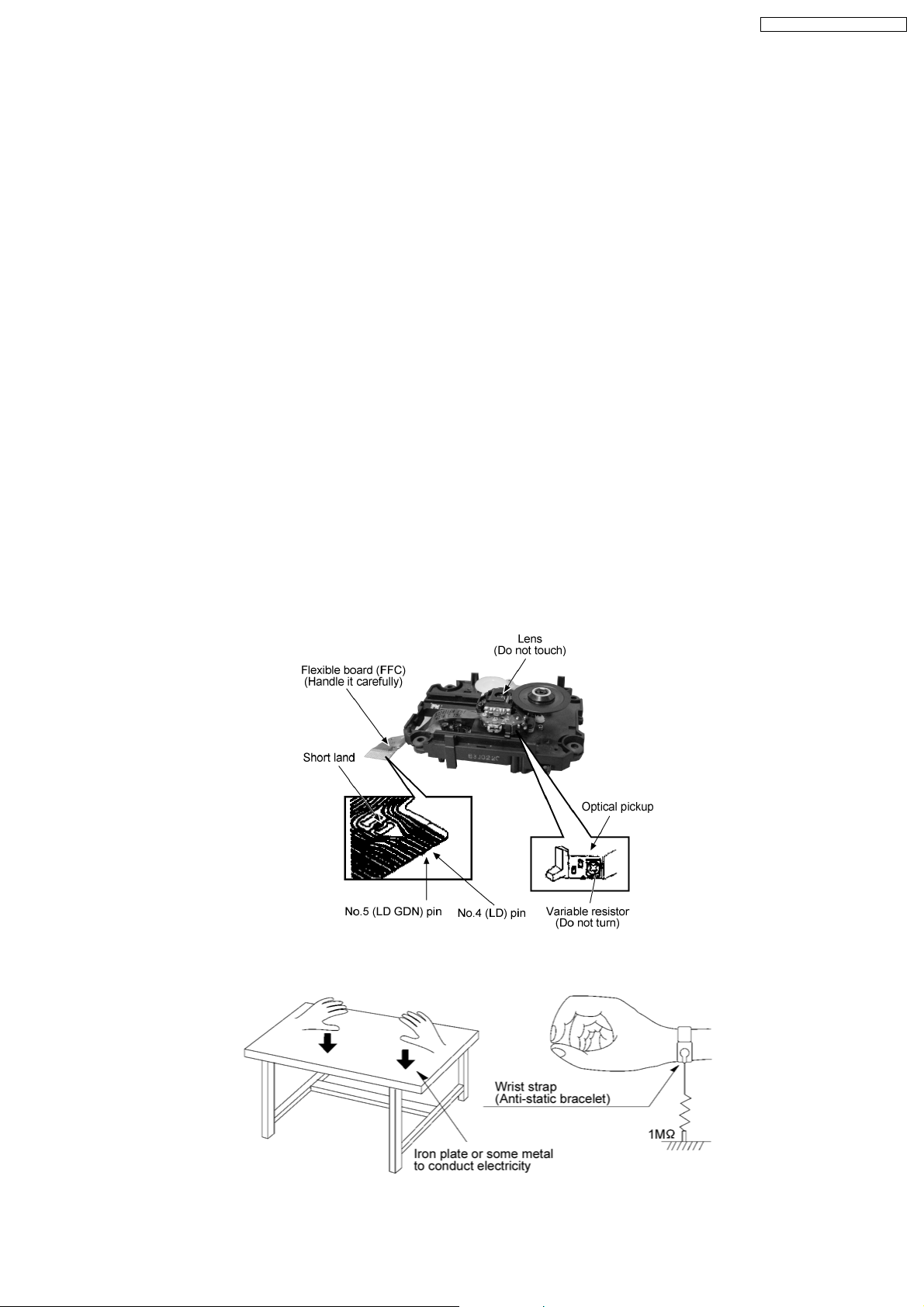

6 Handling Precautions For Traverse Deck

The laser diode in the traverse deck (optical pickup) may break down due to potential difference caused by static electricity of

clothes or human body. So, be careful of electrostatic breakdown during repair of the traverse deck (optical pickup).

· Handling of traverse deck (optical pickup)

1. Do not subject the traverse deck (optical pickup) to static electricity as it is extremely sensitive to electrical shock.

2. To prevent the breakdown of the laser diode, an antistatic shorting pin is inserted into the flexible board (FFC board).

3. Take care not to apply excessive stress to the flexible board (FFC board). When removing or connecting the short pin, finish

the job in as short time as possible. (Fig 6.1)

4. Do not turn the variable resistor (laser power adjustment). It has already been adjusted.

· Grounding for electrostatic breakdown prevention

1. Work table grounding. (Fig 6.2)

Use the anti-static wrist strap to discharge the static electricity from your body.

2. Work table grounding. (Fig 6.2)

Put a conductive material (sheet) or steel sheet on the area where the traverse deck (optical pickup) is place, and ground

the sheet.

Caution:

The static electricity of your clothes will not be grounded through the wrist strap. So, take care not to let your clothes touch the

traverse deck (optical pickup).

Caution when replacing the Traverse Deck

The traverse deck has a short point shorted with solder to protect the laser diode against electrostatics breakdown. Be sure to

remove the solder from the short point before making connections.

(Fig 6.1)

(Figs 6.2)

7

SA-PM71SDGN / SA-PM71SDGT

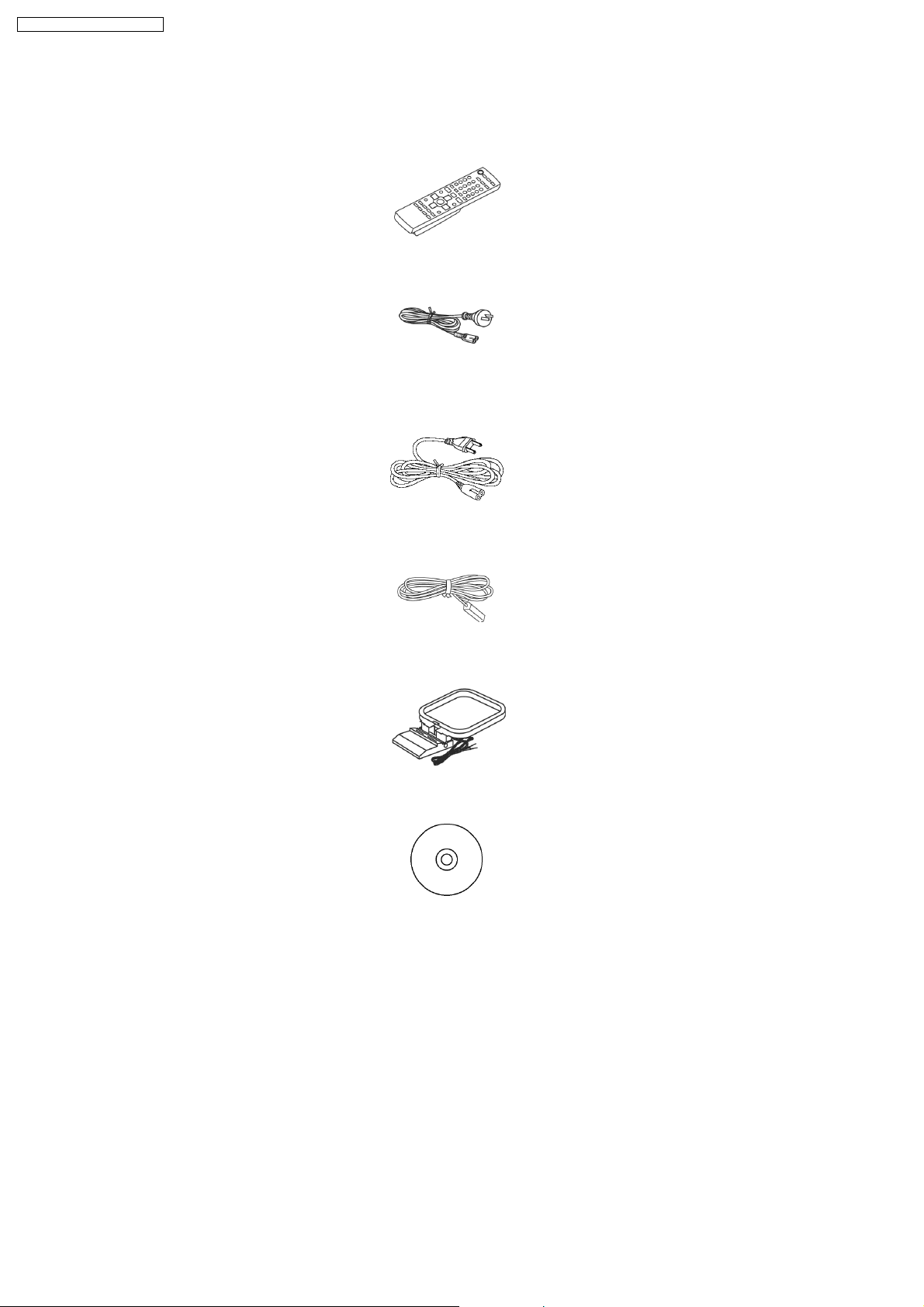

7 Accessories

Note : Refer to Packing Materials & Accessories Parts List (Section 27.5) for the part number.

Remote Control

AC cord (For GN

only)

AC cord (For GT only)

FM indoor antenna

AM loop antenna

CD ROM

(For GN

only)

8

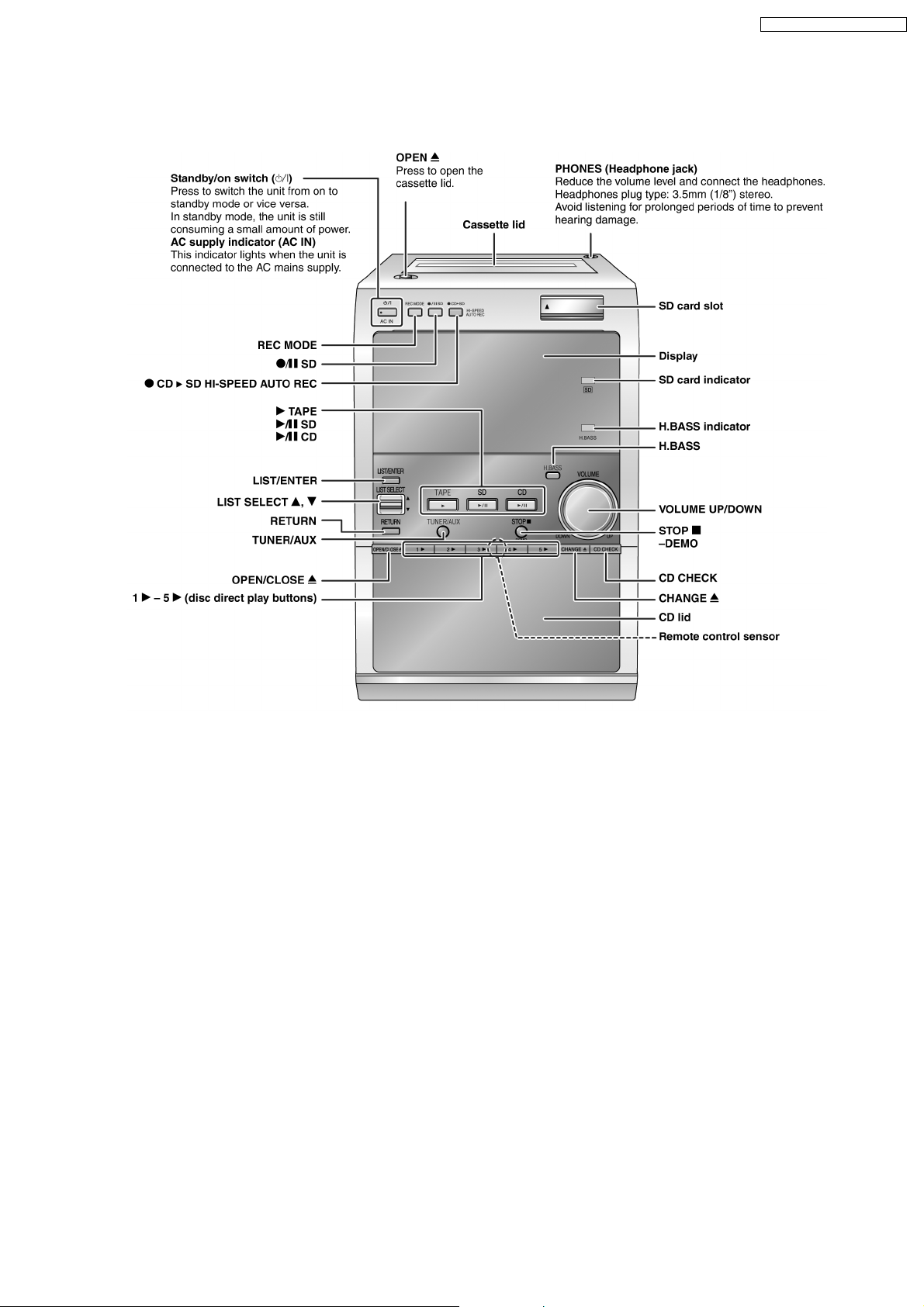

8 Operation Procedures

8.1. Main Unit

SA-PM71SDGN / SA-PM71SDGT

9

SA-PM71SDGN / SA-PM71SDGT

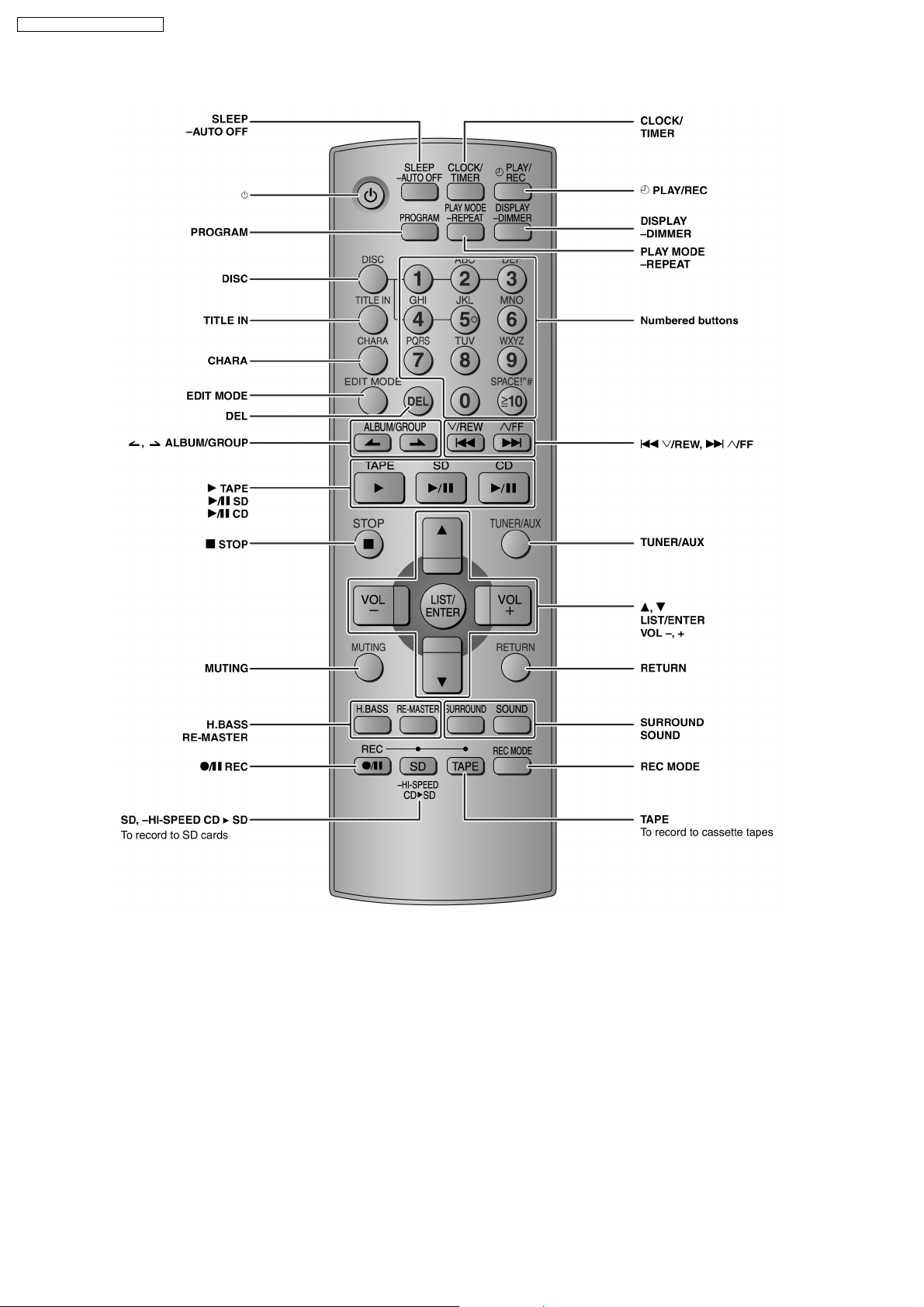

8.2. Remote Control

10

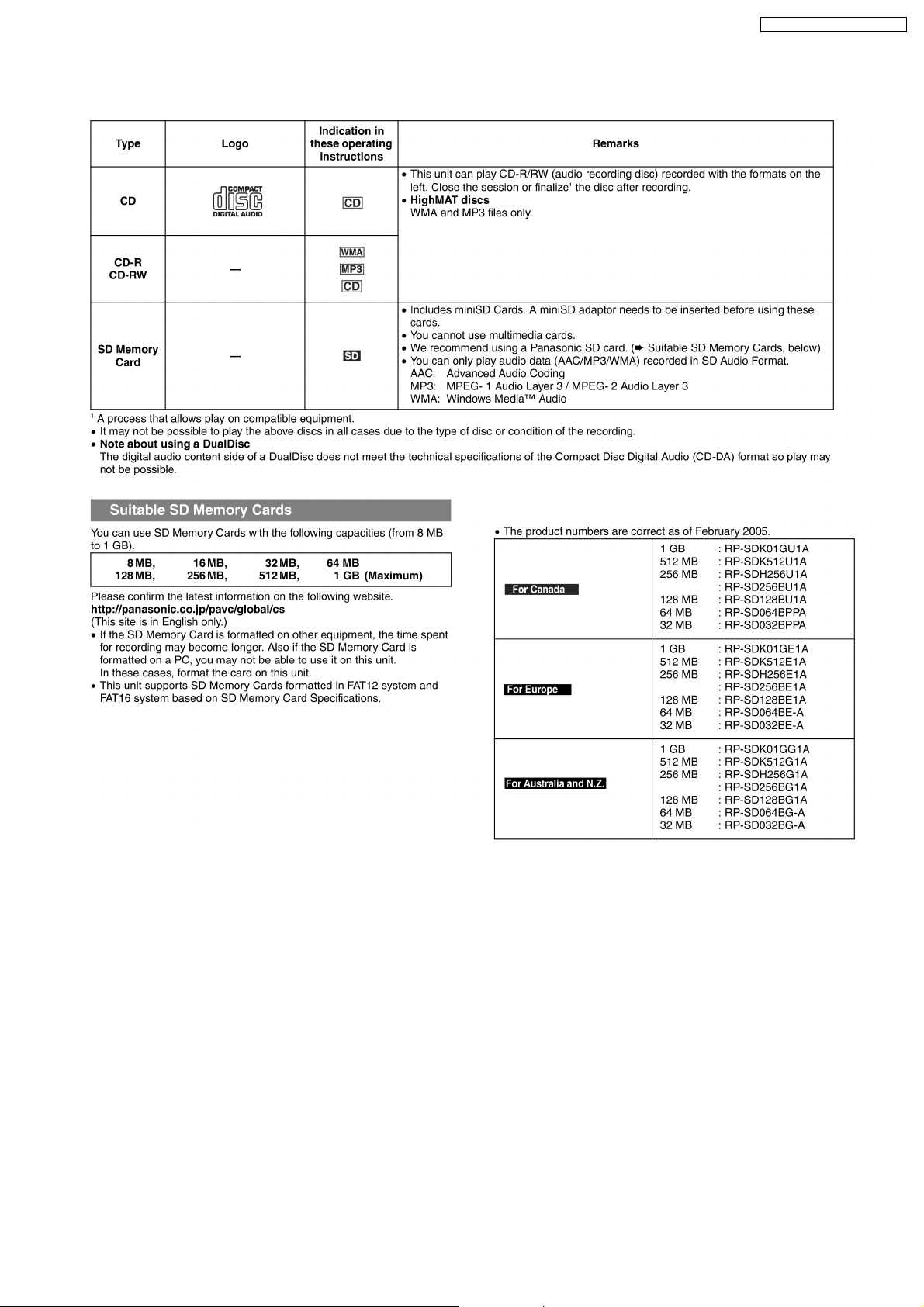

9 Information on Disc & MP3

SA-PM71SDGN / SA-PM71SDGT

11

SA-PM71SDGN / SA-PM71SDGT

12

SA-PM71SDGN / SA-PM71SDGT

10 SD Card Information

A New Lifestyle is Evolving with the SD Memory Card

The SD Memory Card is at the heart of many Panasonic products. It´s a high-capacity, high-speed storage medium for the digital

age. Incredibly small yet durable, the SD Memory Card is about the size of a postage stamp. It can store all kinds of digital content,

like video, still images, music and more! So you can transfer data easily between products with an SD Card slot.

The miniSD card

The miniSD card was developed to meet industry deman ds for a memory card small enough for today’s compact mobile phones.

It is about 40% smaller than a Panasonic SD Memory Card, but offers all the benefits-including copyright protection. Each miniSD

card comes with an adapter that makes the miniSD card compatible with standard SD-enabled products.

Ideal for MPEG2 Video Recording

The increasing data volume and expand ing range of digital contents require high data reading and writing speeds. Panasonic SD

Memory Cards, 256MB

1

and higher, achieve the data writing speed fast enough to record MPEG2 video in fine mode.

Compact & Slim

The SD Memory Card measures a mere 0.94" x 1.26" x .08" (24mm x 32mm x 2.1mm). Its slim, compact design promotes easy

handling-an important factor for moving between differe nt SD-compatible products. Our SD Memory Cards are small enough to be

used in select mobile phones and PDAs, as well as many other compact or multi-functional products.

Large Capacity

SD Memory Cards are currently available in several capacities up to 1GB

2

. Be on the lookout in the near future for 2GB2and 4GB

cards. This kind of large capacity is essential for use with various digital content types, especially high-quality MPEG2 video.

Fast Access

Providing quick response and effortless handling of digital content, SD Memory Cards 256MB

1

and higher can write data fast

enough to record high-quality MPEG2 video in fine mode.

Copyright Protection

The copyright protection technology used for the SD Memory Card, Content Protection for Recordable Media (CPRM), is the key

to enabling a new distribution system for music and other commercial media. CPRM assures a high level of protection against

illegal copying and was developed by 4C (The digital contents copyright protection technology licensing organization of IBM, Intel,

Matsushita, and Toshiba.).

2

This protection is enhanced in the SD Memory Card through the use of key revocation technology that is built into the card. The

13

SA-PM71SDGN / SA-PM71SDGT

card´s control circuitry allows data to be read and written, in its protection area only when appropriate external devices are detected.

Copying data ("checking-out") from a PC to an SD Memory Card is restricted to three copies in compliance with the SDMI

specification.

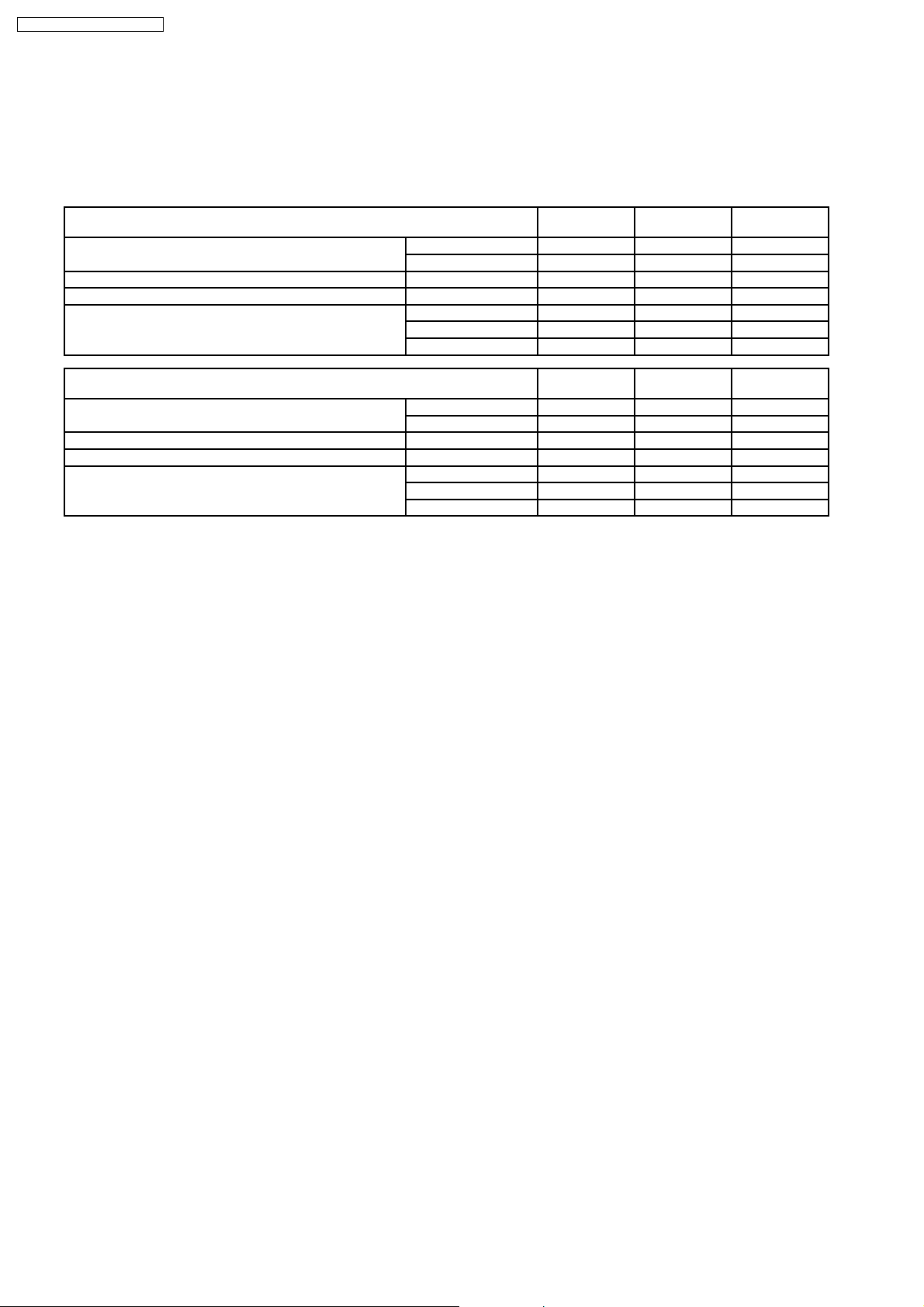

Comparison chart

File Type 1GB

2

Approx. Number of JPEG Photos3(1,600 x 1,200) Standard 2325 1209 600

Fine 1162 604 300

Approx. Time of MPEG4 Video (Using the D-snap SV-AV50) 384 Kbps, 12 fps 370 min. 180 min. 90 min.

Approx. Time of MPEG2 Video (Using the D-snap SV-AV100) 6 Mbps, 30 fp3 20 min. 10 min. 5 min.

Approx. Time of Recording Capacity for Music

(AAC/MP3/WMA)

4

High Quality (128kbps) 8h. 44 min. 4h. 20 min.

Normal (96kbps) 11h. 38 min. 5h. 46 min.

Long Play (64kbps) 17h. 28 min. 8h. 40 min.

File Type 128MB

1

Approx. Number of JPEG Photos3(1,600 x 1,200) Standard 301 149 72

Fine 150 74 36

Approx. Time of MPEG4 Video (Using the D-snap SV-AV50) 384 Kbps, 12 fps 40 min. 20 min. 10 min.

Approx. Time of MPEG2 Video (Using the D-snap SV-AV100) 6 Mbps, 30 fp3 N/A N/A N/A

Approx. Time of Recording Capacity for Music

(AAC/MP3/WMA)

4

High Quality (128kbps) 2h. 10 min. 1h. 4 min. 31 min.

Normal (96kbps) 2h. 54 min. 1h. 26 min. 42 min.

Long Play (64kbps) 4h. 21 min. 2h. 9 min. 1h. 3 min.

512MB

64MB

1

1

256MB

32MB

1

1

For Notes

1. MB = 1 million bytes. Usable capacity will be less.

2. GB = 1 billion bytes. Usable capacity will be less.

3. For normal shooting of 1,600 x 1,200 /static/Content. These figures vary depending on the subject being photographed and

on the particular model.

4. Approximate recording time in AAC format.

14

SA-PM71SDGN / SA-PM71SDGT

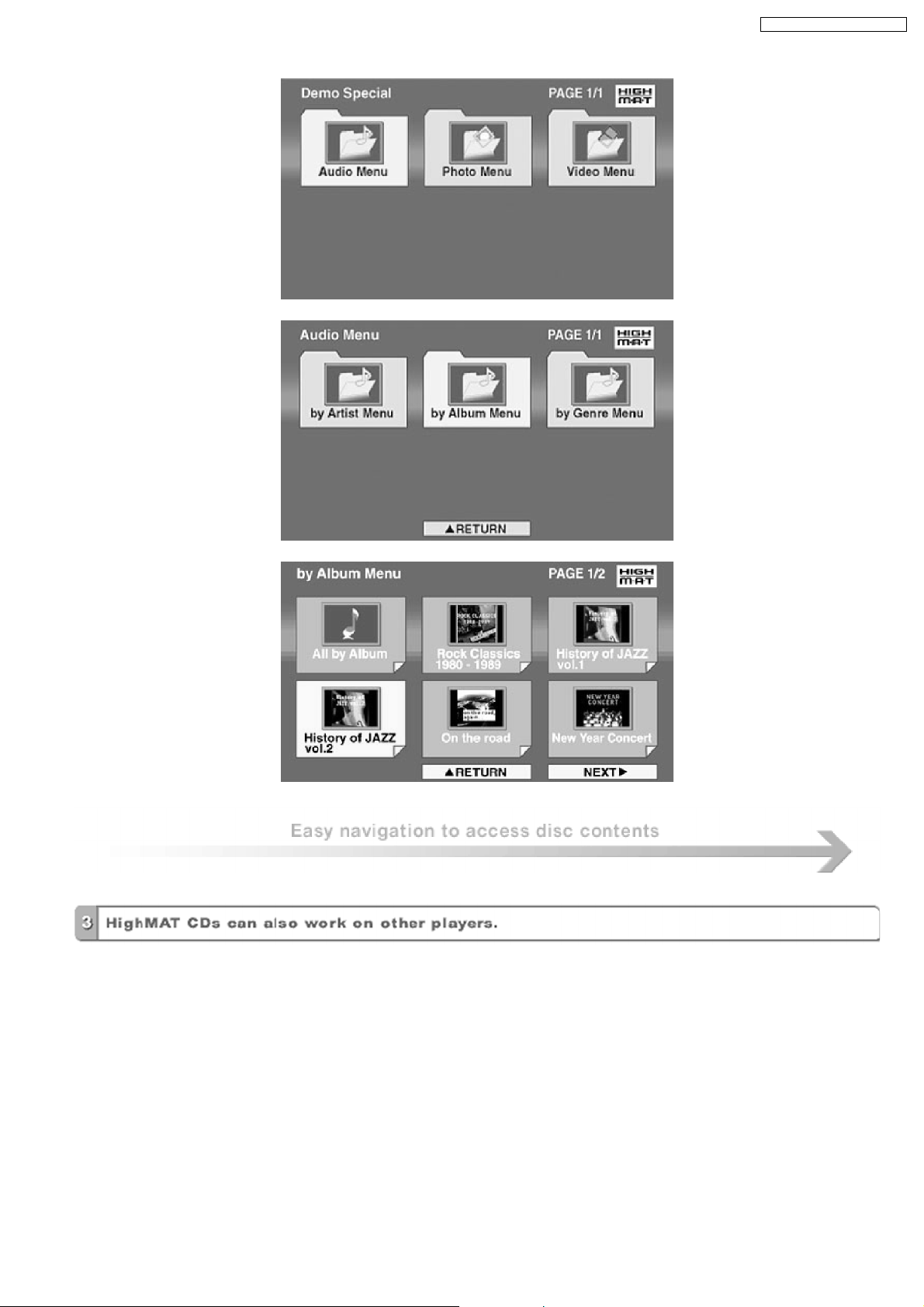

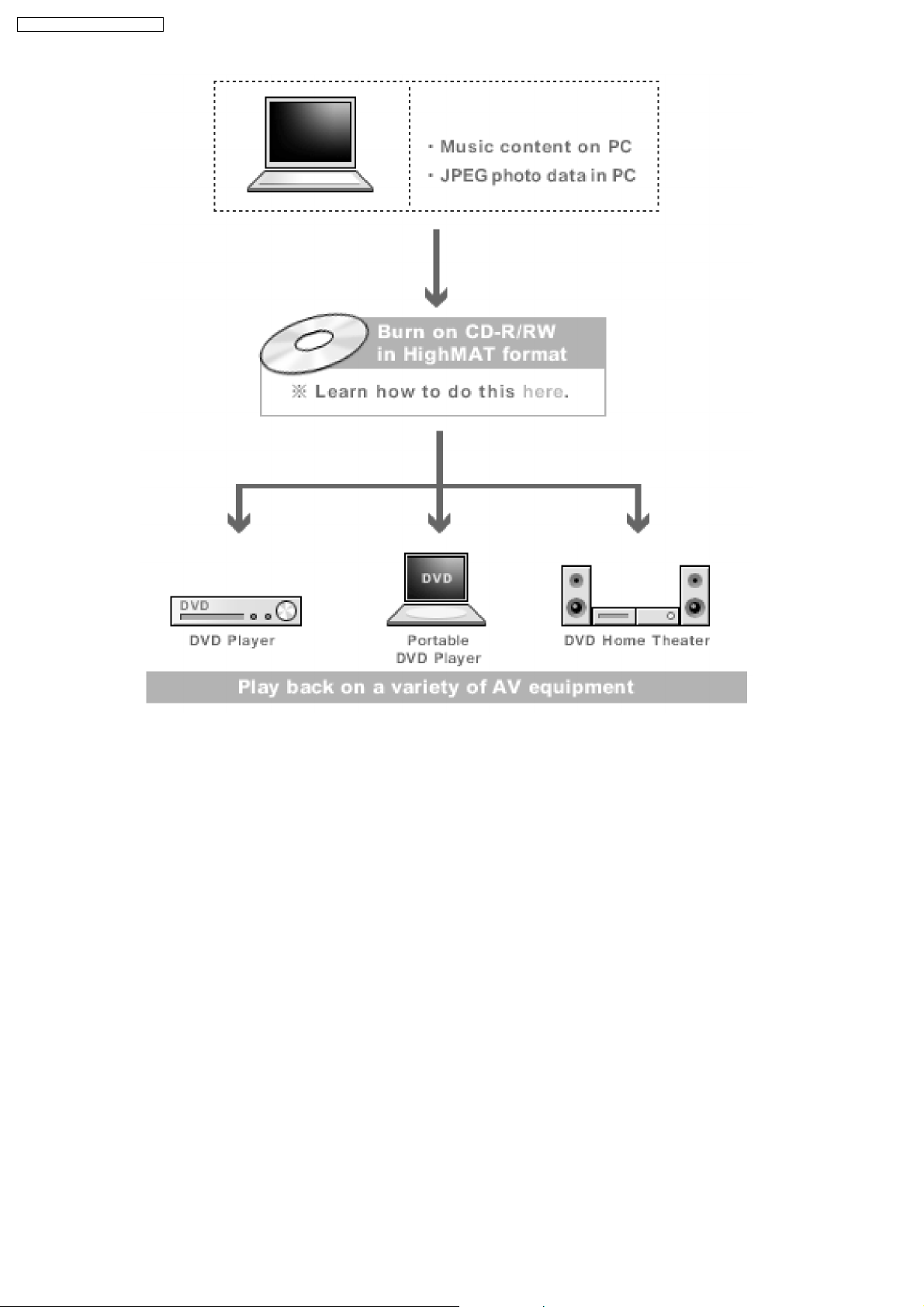

11 About HighMAT

11.1. What’s HighMAT?

Consumers worldwide are using PCs to create their own collections of music, photos and even video by burning them onto CDs.

But how these collections can be experie nced across different devices can be confusing to navigate, time consuming to access for

a DVD player, and be incomplete in terms of music information available to the customer.

HighMAT offers a solution to this growing consumer problem. HighMAT dramatically improves the digital media experience on

consumer electronic devices by delivering a simple, standardized approach that allows consumers who have created personal

collections of digital music, photography and video on their PC to:

· Create a HighMAT CD or DVD which can be easily played back on consum er electronics devices such as CD and DVD players,

and car stereos.

· Move digital media files (using recordable media such as CD-R and CD-RW) between the PC and various playback devices

such as CD and DVD players.

A new standard for creating personal media on consumer electronic devices, HighMAT enable easier and more seamless

interoperability between Windows PCs and devices designed for your living room, or the car.

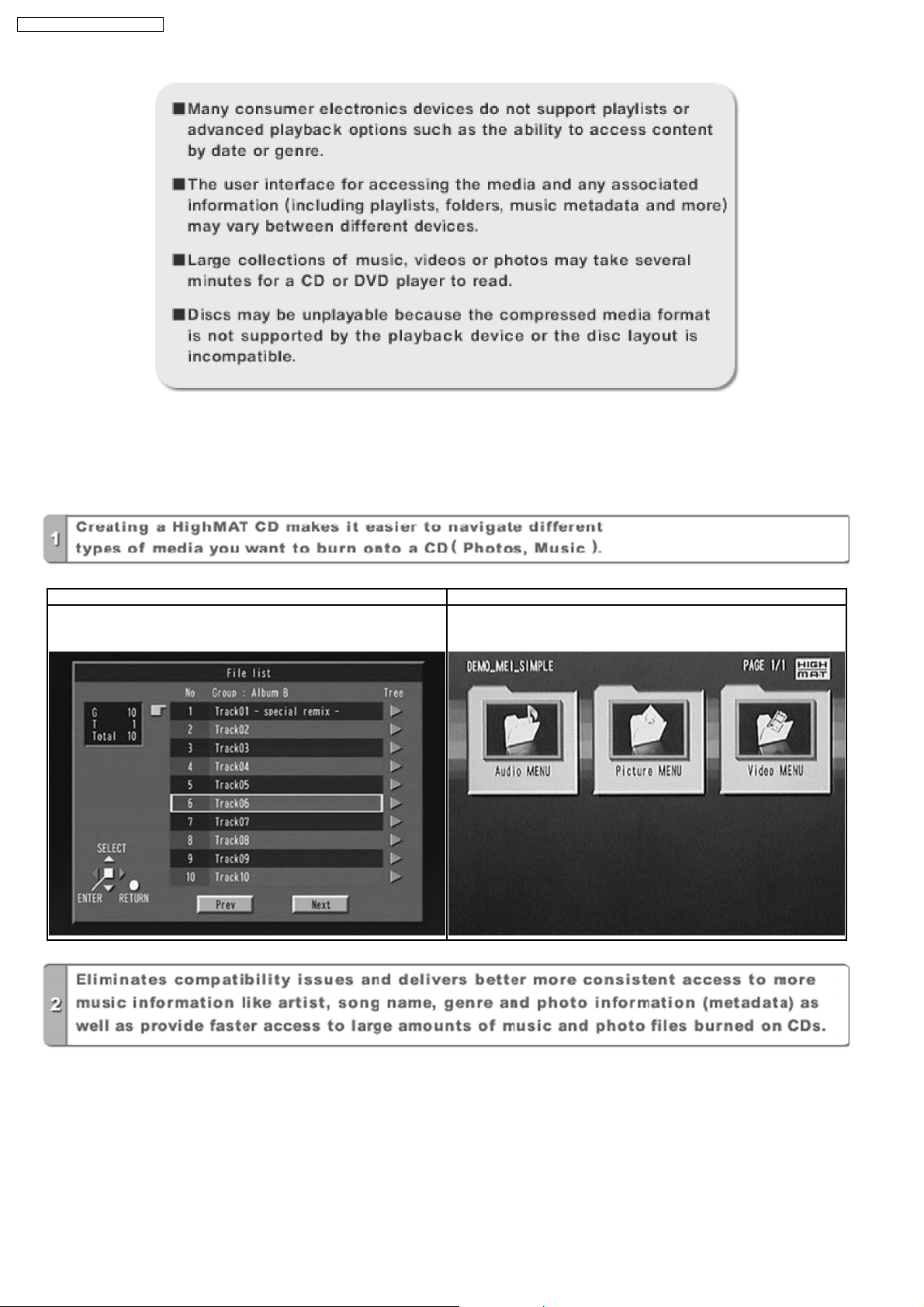

11.2. Why take advantage of HighMAT?

A Problem Defined:Today, when consum ers create their own digital audio, video or photo collections on CD-R or other physical

formats, there are numerous, inconsistent ways that devices read the data. For the consumer, the playback experience can be

confusing:

15

SA-PM71SDGN / SA-PM71SDGT

A Solution Created: HighMAT delivers a better digital media access experience by creating a standard approach for PCs to

structure digital media on various physical formats and for playba ck devices to read the data.

11.3. Benefits of HighMAT?

Conventional HighMAT

Even though DVD player is CD-R/RW compatible, the inconsistent ways

that various DVD players can read the music or photos files often leads

to a confusing and inconsistant playback experince.

HighMAT compatible products play content back with consistent

interface. This includes products which are JPEG compatible products

without HighMAT support.

16

SA-PM71SDGN / SA-PM71SDGT

17

SA-PM71SDGN / SA-PM71SDGT

HighMAT is now available for CD Burning and in Leading DVD PlayersHighMAT is a new technology that is now available in leading

software and consumer electronic devices to dramatically improve the digital media experience when you create homemade

CDsHighMAT delivers a simple, standardized way for PC software and consum er electronics devices to talk to each other and work

better together.

When you create your homemade CDs with software that supports HighMAT CD burning, and then play them back on a DVD

player that supports HighMAT, you get better, easier navigation. You get folders you can access with a single click of your DVD

player´s remote control. You can view important information about your music like full song names, artist titles, album names and

genre. And you can get faster startup on your home entertainment device.

To enjoy the benefits of HighMAT, all you need is software that supports HighMAT for CD burning of music or photos, as well as

a home entertainment device like a DVD player that supports HighMAT for playback. Always look for the HighMAT logo on your

software or home entertainment device to ensure it supports the HighMAT experience.

18

SA-PM71SDGN / SA-PM71SDGT

12 Assembling and Disassembling

“ATTENTION SERVICER”

Some chassis components may be have sharp edges. Be careful when disassembling and servicing.

1. This section describes procedures for checking the operation of the major printed circuit boards and replacing the main

components.

2. For reassembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

3. Select items from the following index when checks or replacement are required.

· Disassembly of Side Panel L & R

· Disassembly of Top Cabinet

· Disassembly of Deck Mechanism P.C.B. and Tape Eject P.C.B.

· Disassembly of Front Panel

· Disassembly of SD Module P.C.B.

· Disassembly of Panel P.C.B.

· Disassembly of Rear Cabinet

· Disassembly of Main P.C.B.

· Disassembly of Transformer P.C.B.

· Disassembly of Tuner Pack

· Disassembly of Power P.C.B.

· Disassembly of CR16 Mechanism

Warning:

This product uses a laser diode. Refer to “Precaution of Laser Diode”.

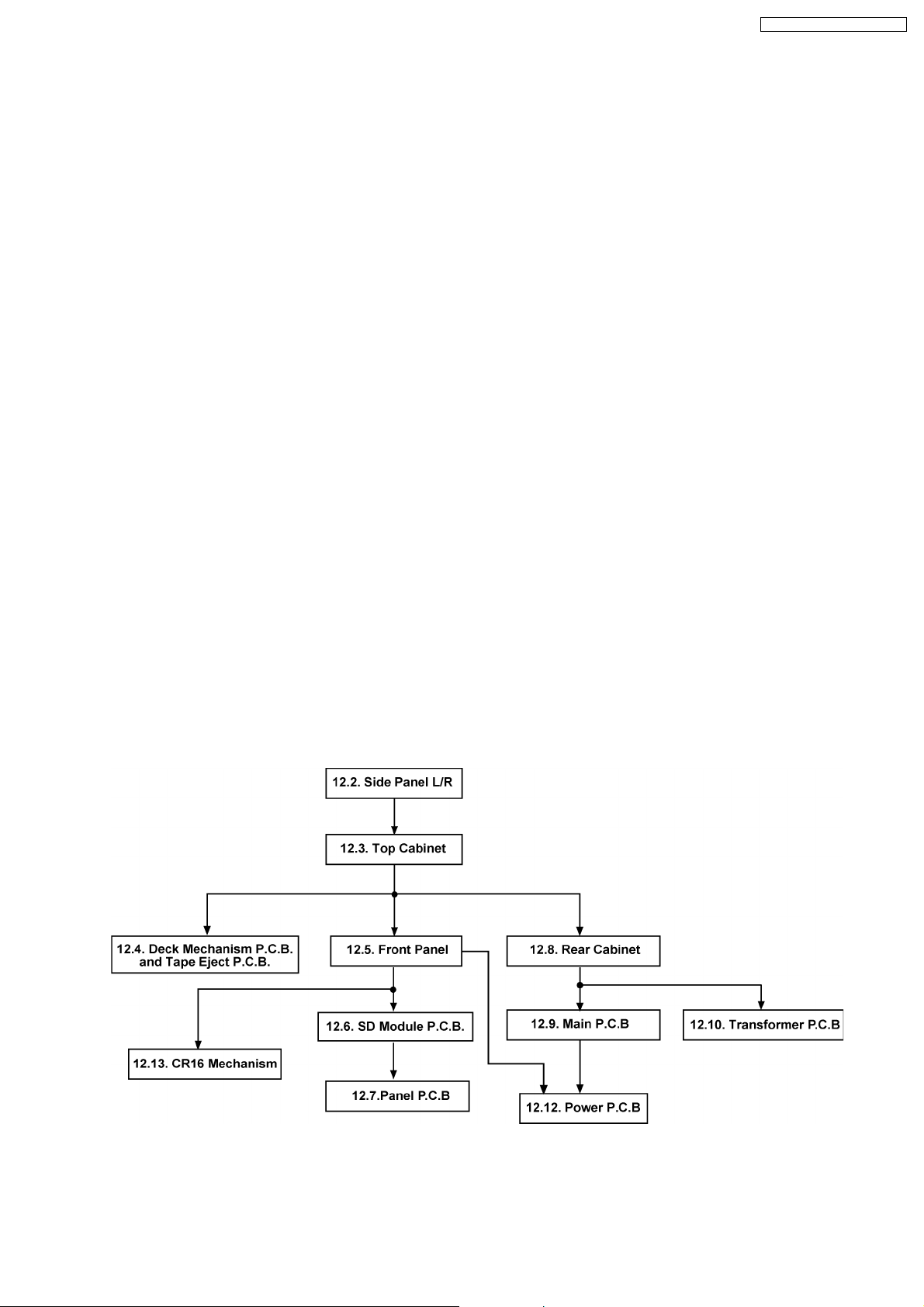

12.1. Disassembly flow chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the

servicing.

To assemble the unit, reverse the steps shown in the chart below.

19

SA-PM71SDGN / SA-PM71SDGT

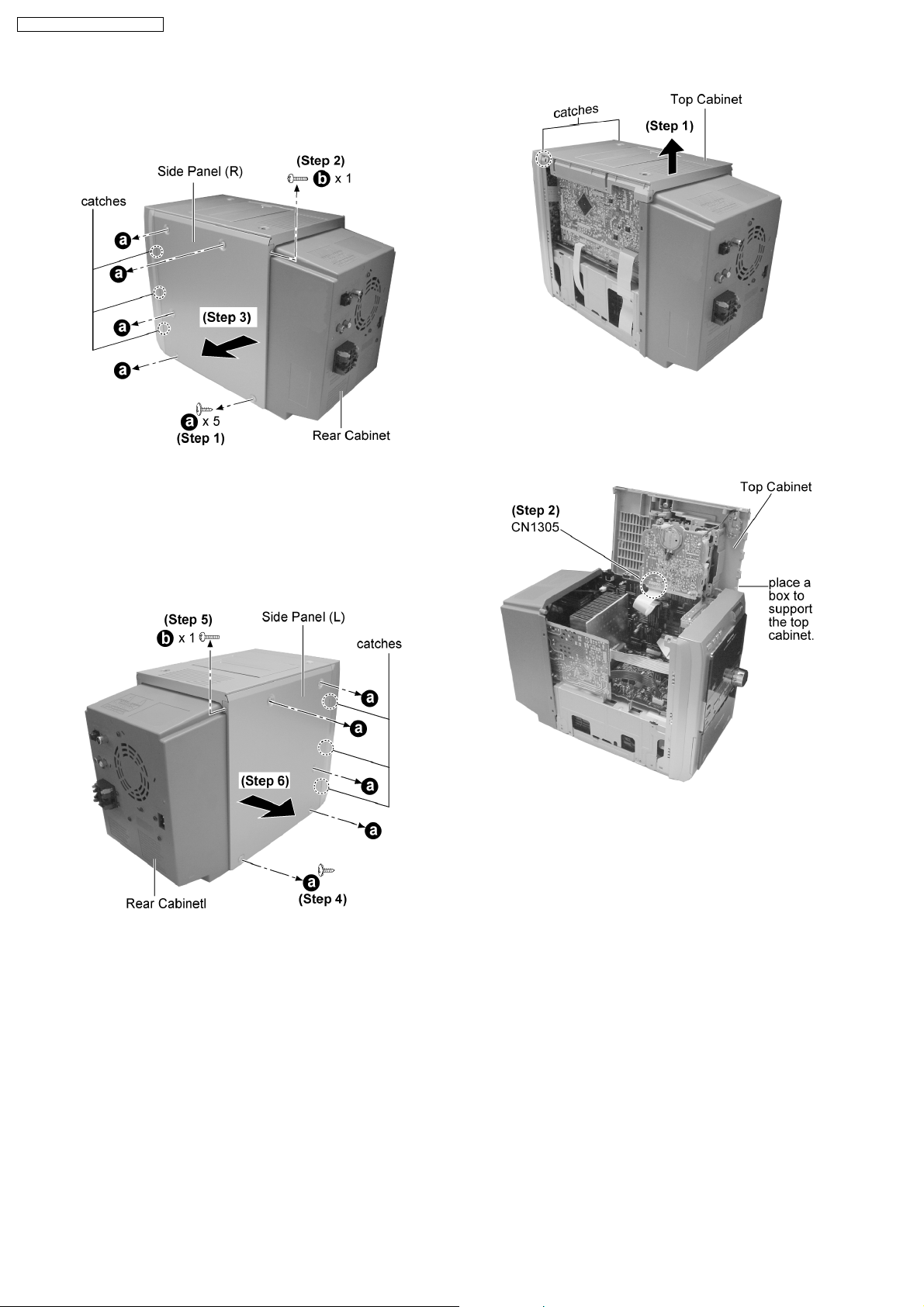

12.2. Disassembly of Side Panel L &

R

Step 1 : Lift up the top cabinet as arrow shown (Be careful of

the catches).

Step 1 : Remove 5 screws from the side panel (R).

Step 2 : Remove 1 screws from the corner of the side panel

(R).

Step 3 : Remove the side panel as arrow shown (Be careful of

the catches).

Step 4 : Remove 5 screws from the side panel (L).

Step 5 : Remove 1 screws from the corner of the side panel (L).

Step 6 : Remove the side panel as arrow shown (Be careful of

the catches).

Step 2 : Place the top cabinet as shown and detach the

connector CN1305.

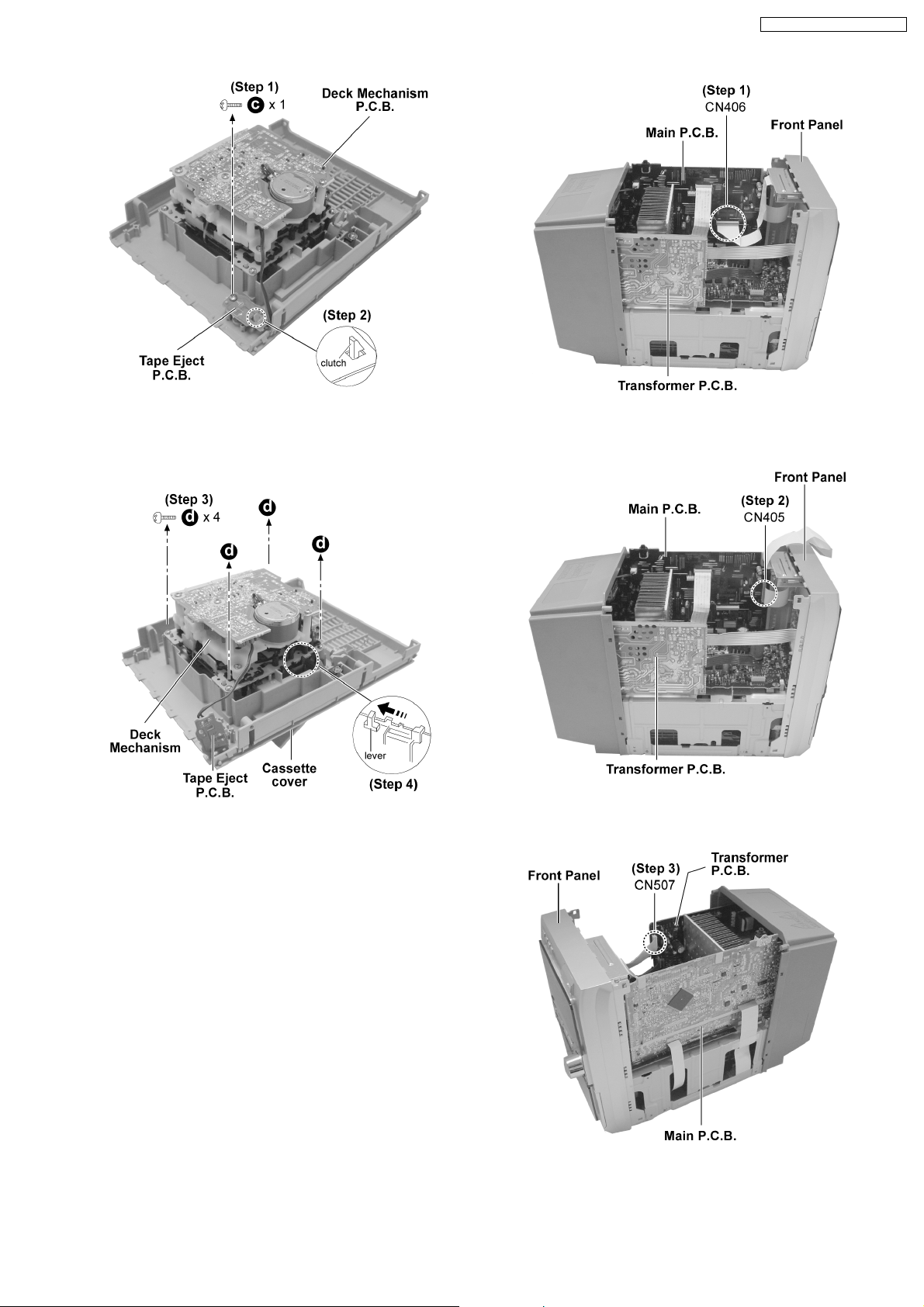

12.4. Disassembly of Deck

Mechanism P.C.B. and Tape

Eject P.C.B.

· Follow the (Step 1) - (Step 6) of item 12.2.

· Follow the (Step 1) - (Step 2) of item 12.3.

12.3. Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 6) of item 12.2.

20

SA-PM71SDGN / SA-PM71SDGT

Step 1 : Remove 1 screw.

Step 2 : Release the clutch and remove the Tape Eject P.C.B..

Step 3 : Remove 4 screws.

Step 4 : Push the lever as arrow shown to remove the Deck

Mechanism.

Step 1 : Detach the connector CN406.

Step 2 : Detach the connector CN405.

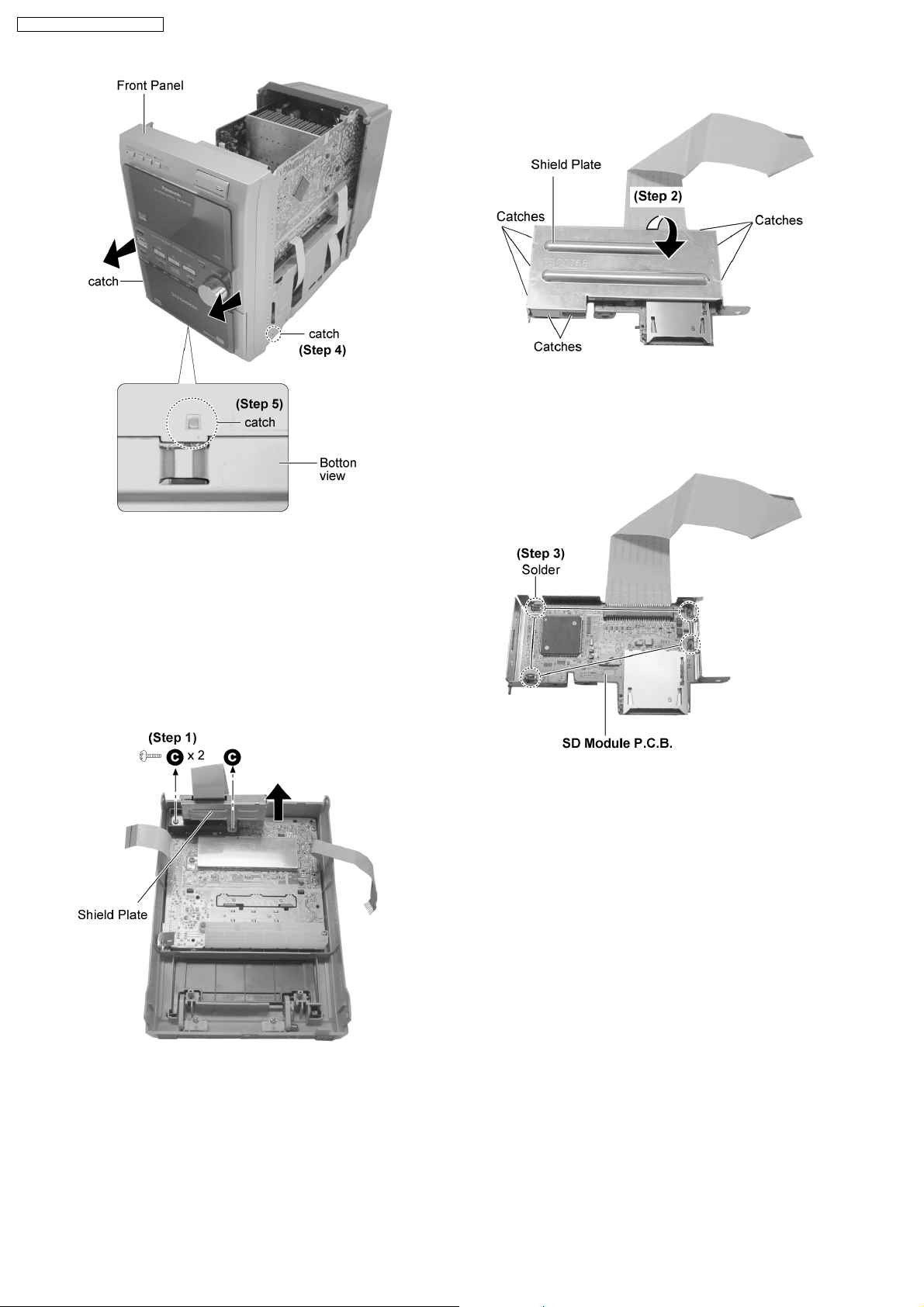

12.5. Disassembly of Front Panel

· Follow the (Step 1) - (Step 6) of item 12.2.

· Follow the (Step 1) - (Step 2) of item 12.3.

Step 2 : Detach the connector CN507.

21

SA-PM71SDGN / SA-PM71SDGT

Step 2 : Remove shield plate. (Be careful of the catches)

Step 4 : Release 2 catches.

Step 5 : Release the catch at the bottom cabinet and remove

the front panel as arrow shown.

12.6. Disassembly of SD Module

P.C.B.

· Follow the (Step 1) - (Step 6) of item 12.2.

· Follow the (Step 1) - (Step 2) of item 12.3.

· Follow the (Step 1) - (Step 5) of item 12.5.

Step 3 : Unsolder 4 point to remove SD Module P.C.B..

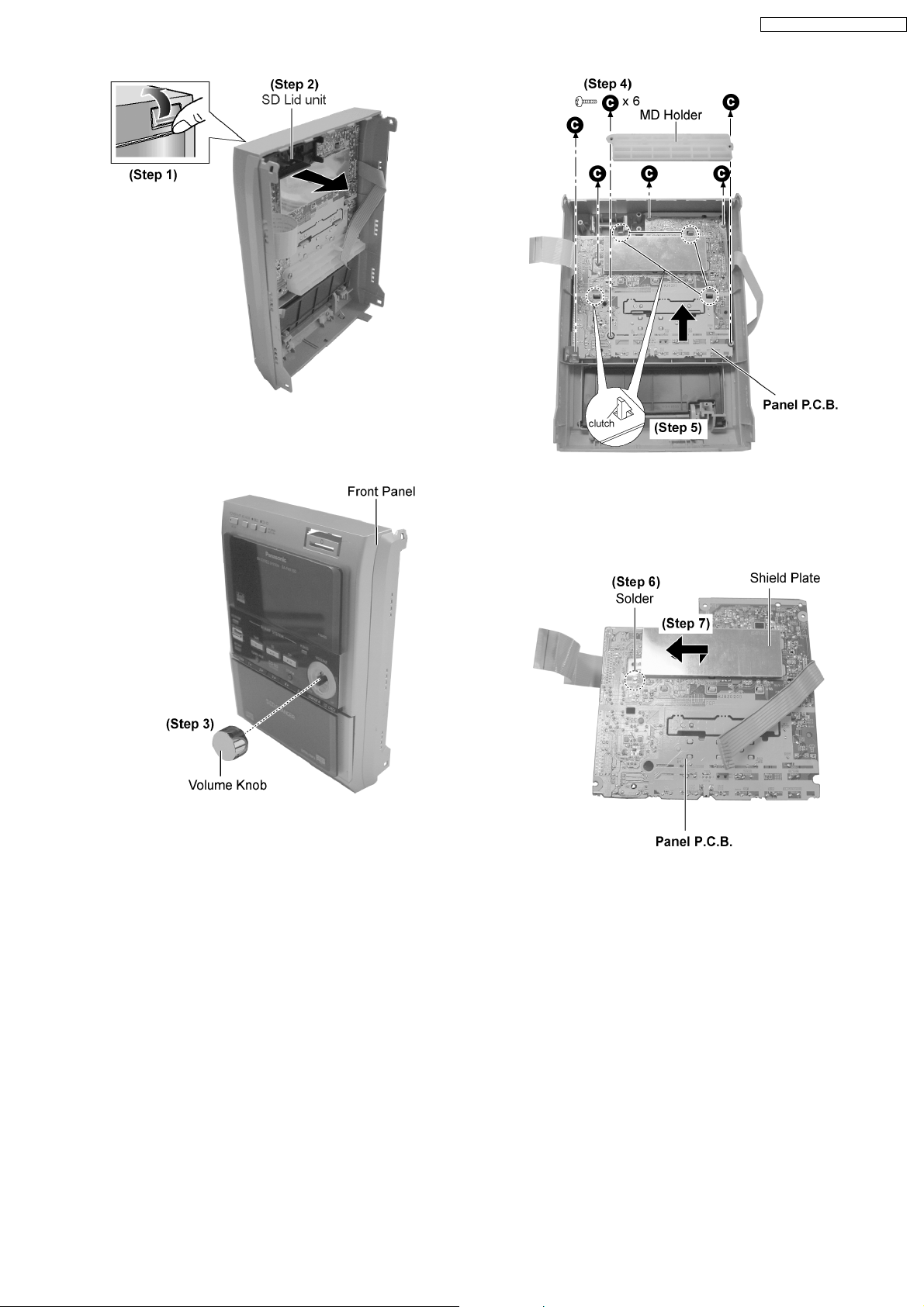

12.7. Disassembly of Panel P.C.B.

· Follow the (Step 1) - (Step 6) of item 12.2.

· Follow the (Step 1) - (Step 2) of item 12.3.

· Follow the (Step 1) - (Step 5) of item 12.5.

· Follow the (Step 1) of item 12.6.

Step 1 : Remove 2 screws to remove the SD Module P.C.B.

with shield plate as arrow shown.

22

Step 1 : Flip open the SD cover as arrow shown.

Step 2 : Remove the SD Lid unit as arrow shown.

SA-PM71SDGN / SA-PM71SDGT

Step 3 : Remove the volume knob.

Step 4 : Remove 6 screws and MD Holder.

Step 5 : Release 4 clutches and remove the Panel P.C.B. as

arrow shown.

Step 6 : Unsolder the shield plate.

Step 7 : Remove the shield plate as arrow shown.

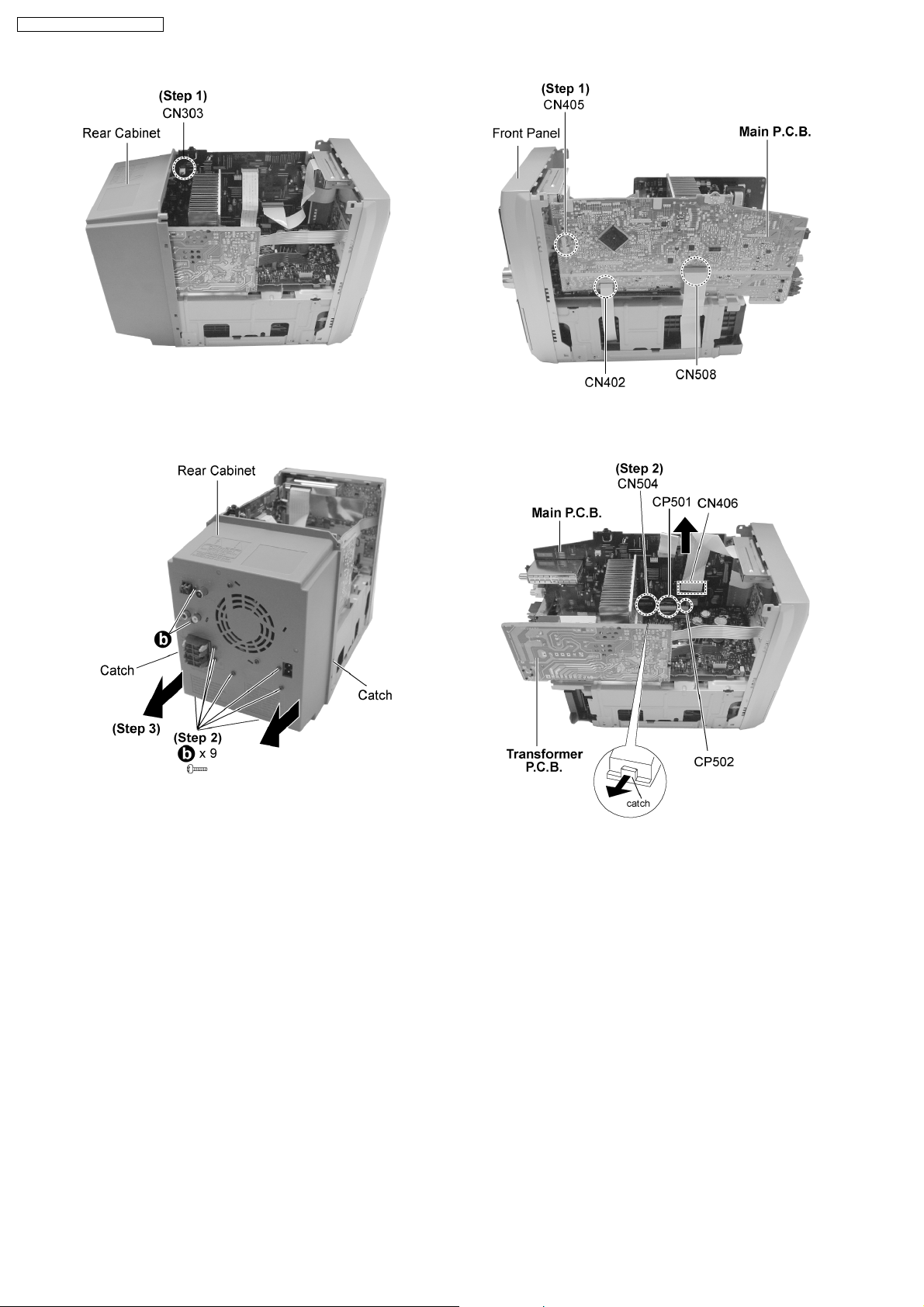

12.8. Disassembly of Rear Cabinet

· Follow the (Step 1) - (Step 6) of item 12.2.

· Follow the (Step 1) - (Step 2) of item 12.3.

23

SA-PM71SDGN / SA-PM71SDGT

Step 1 : Detach the connector CN303.

Step 2 : Remove 9 screws altogether.

Step 3 : Remove the rear cabinet as arrows shown (Be careful

of the catches).

12.9. Disassembly of Main P.C.B.

· Follow the (Step 1) - (Step 6) of item 12.2.

· Follow the (Step 1) - (Step 2) of item 12.3.

· Follow the (Step 1) - (Step 3) of item 12.8.

Step 1 : Detach the connector CN405 , CN402 and CN508.

Step 2 : Detach the connectors CN406.

Step 3 : Releas e the catch as arrow shown and detach the

connector CN504, CP501 and CP502 and pull out the Main

P.C.B. as arrow shown.

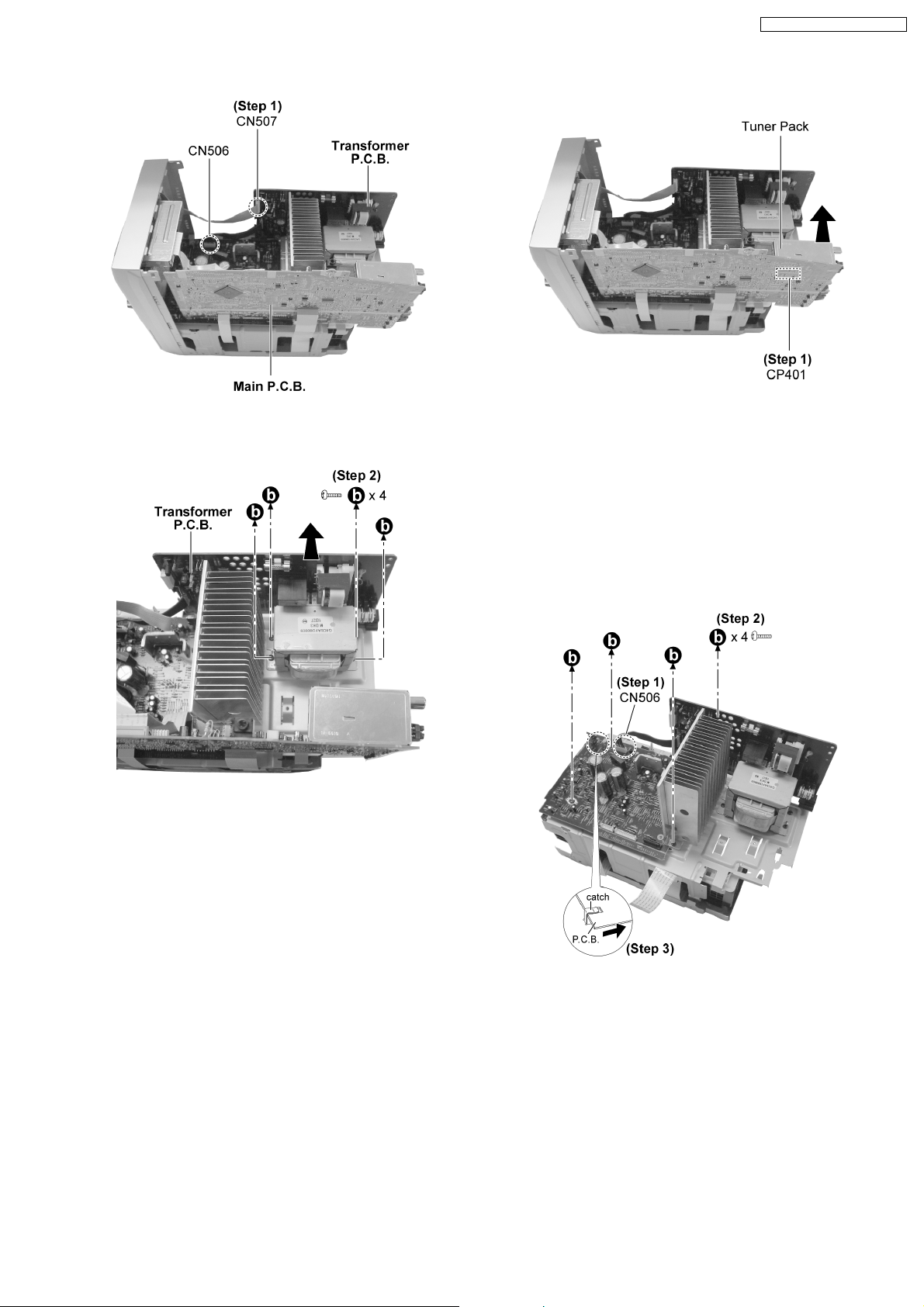

12.10. Disassembly of Transformer

P.C.B.

· Follow the (Step 1) - (Step 6) of item 12.2.

· Follow the (Step 1) - (Step 2) of item 12.3.

· Follow the (Step 1) - (Step 3) of item 12.8.

24

SA-PM71SDGN / SA-PM71SDGT

Step 1 : Detach the connectors CN506 and CN507.

Step 2 : Remove 4 screws and pull out the Transformer P.C.B.

as arrow shown.

12.11. Disassembly of Tuner Pack

Step 1 : Detach the connector CP401 and remove the tuner

pack as arrow shown.

12.12. Disassembly of Power P.C.B.

· Follow the (Step 1) - (Step 6) of item 12.2.

· Follow the (Step 1) - (Step 2) of item 12.3.

· Follow the (Step 1) - (Step 5) of item 12.5.

· Follow the (Step 1) - (Step 3) of item 12.8.

· Follow the (Step 1) - (Step 3) of item 12.9.

· Follow the (Step 1) - (Step 6) of item 12.2.

· Follow the (Step 1) - (Step 2) of item 12.3.

· Follow the (Step 1) - (Step 3) of item 12.8.

Step 1 : Detach the connector CN506.

Step 2 : Remove 4 screws.

Step 3 : Remove the Power P.C.B. (Be careful of the catch)

12.13. Disassembly of CR16

Mechanism

· Follow the (Step 1) - (Step 6) of item 12.2.

· Follow the (Step 1) - (Step 2) of item 12.3.

· Follow the (Step 1) - (Step 5) of item 12.5.

25

SA-PM71SDGN / SA-PM71SDGT

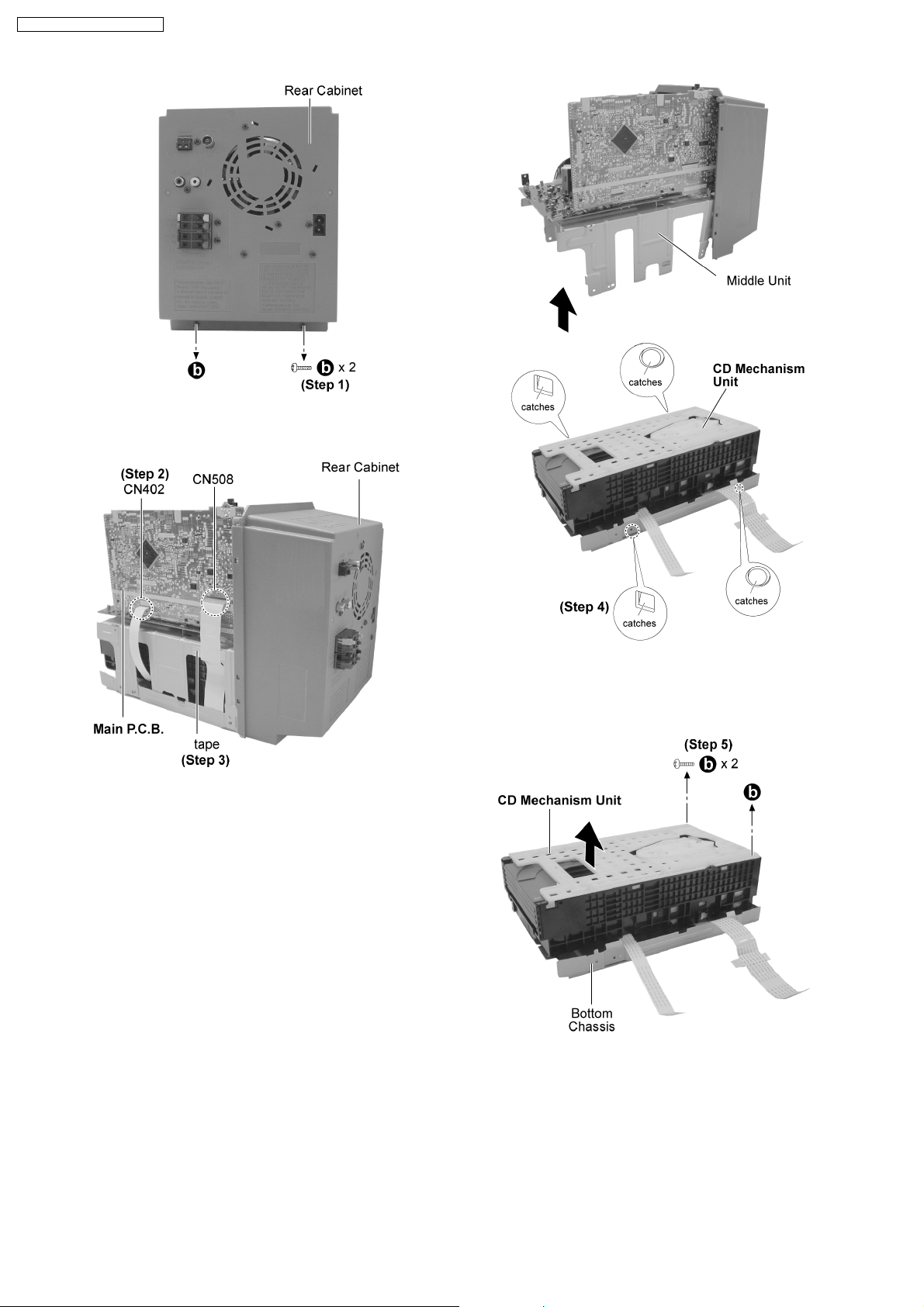

Step 1 : Remove 2 screws.

Step 2 : Detach the connectors CN402 and CN508.

Step 3 : Remove the tape which used to secure the FFC

connectors.

Step 4 : Release the catches and remove the middle unit as

arrow shown.

Step 5 : Remove 2 screws and remove the CD Mechanism Unit

from the bottom chassis as arrow shown.

12.14. Replacement of CD Lid and

Inner CD Lid

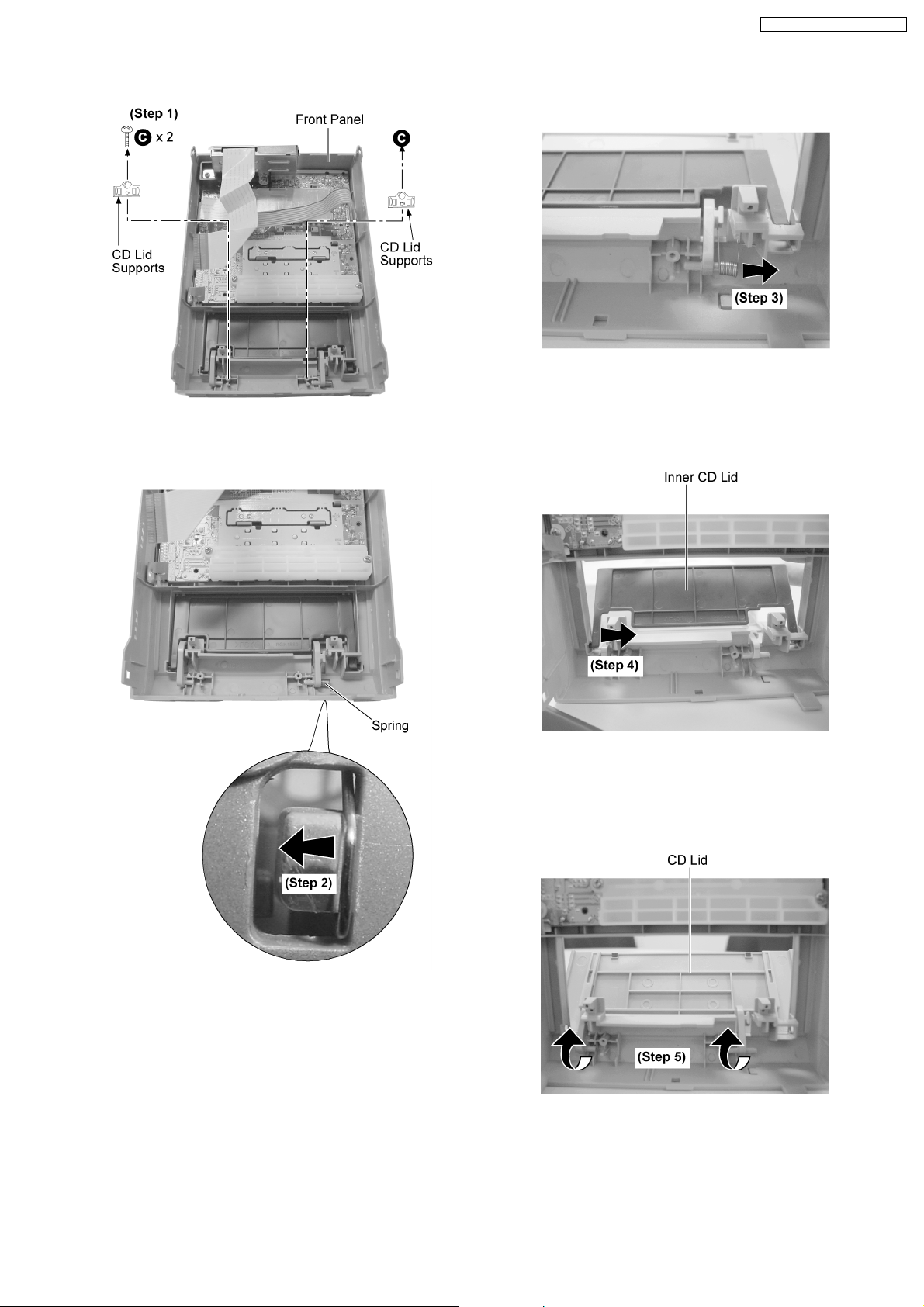

· Follow the (Step 1) - (Step 6) of item 12.2.

· Follow the (Step 1) - (Step 2) of item 12.3.

26

· Follow the (Step 1) - (Step 5) of item 12.5.

Step 1 : Remove 2 screws 2 CD Lid supports.

SA-PM71SDGN / SA-PM71SDGT

Step 3 : Remove the spring as arrow shown.

Step 2 : Release the spring hook as arrow shown.

Step 4 : Remove the Inner CD Lid as arrow shown.

Step 5 : Remove the CD lid as arrow shown.

27

SA-PM71SDGN / SA-PM71SDGT

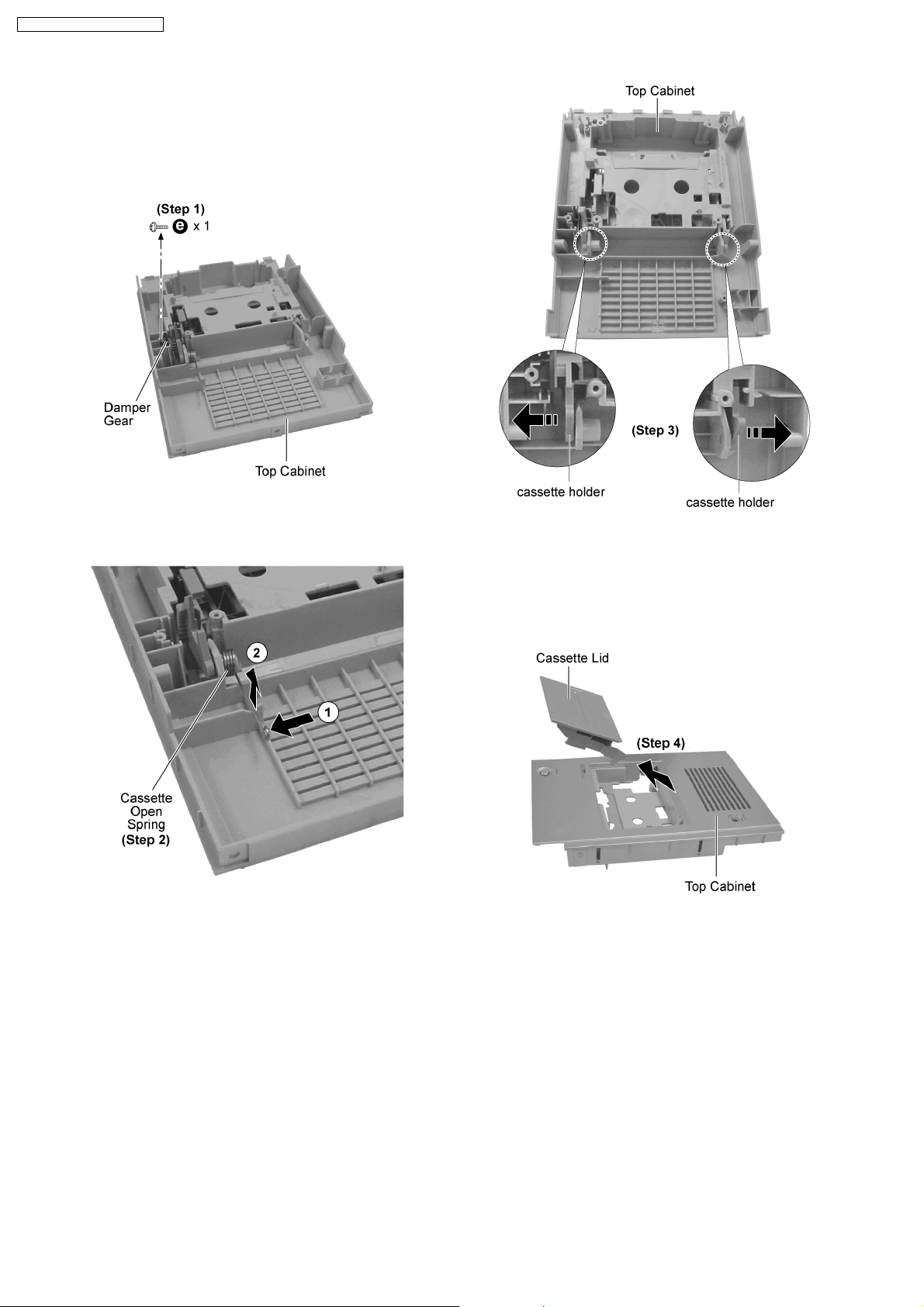

12.15. Replacement of Cassette Lid

· Follow the (Step 1) - (Step 6) of item 12.2.

· Follow the (Step 1) - (Step 2) of item 12.3.

· Follow the (Step 1) - (Step 4) of item 12.4.

Step 1 : Remove 1 screw and the damper gear.

Step 2 : Remove the cassette open spring as arrows shown in

order.

Step 3 : Pull both sides cassette holders to the direction of the

arrows shown.

Step 4 : Remove the cassette lid as arrow shown.

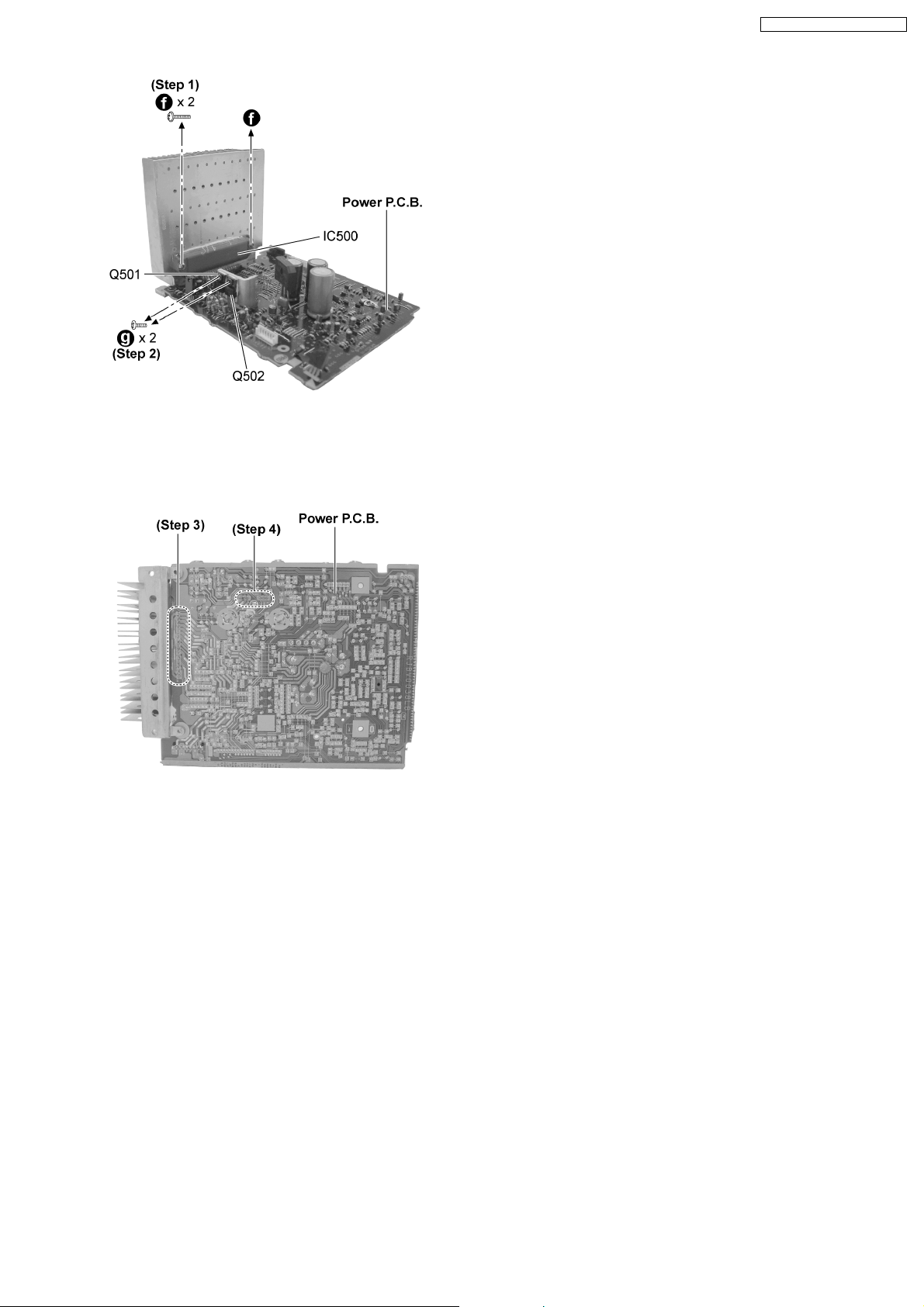

12.16. Replacement of the Power IC

and Transistors

· Follow the (Step 1) - (Step 6) of item 12.2.

· Follow the (Step 1) - (Step 2) of item 12.3.

· Follow the (Step 1) - (Step 5) of item 12.5.

· Follow the (Step 1) - (Step 3) of item 12.8.

· Follow the (Step 1) - (Step 3) of item 12.9.

· Follow the (Step 1) - (Step 3) of item 12.12.

28

Step 1 : Remove 2 screws.

Step 2 : Remove 2 screws.

SA-PM71SDGN / SA-PM71SDGT

Step 3 : Unsolder the Power IC500.

Step 4 : Unsolder the Transistor Q501 and Q502.

29

SA-PM71SDGN / SA-PM71SDGT

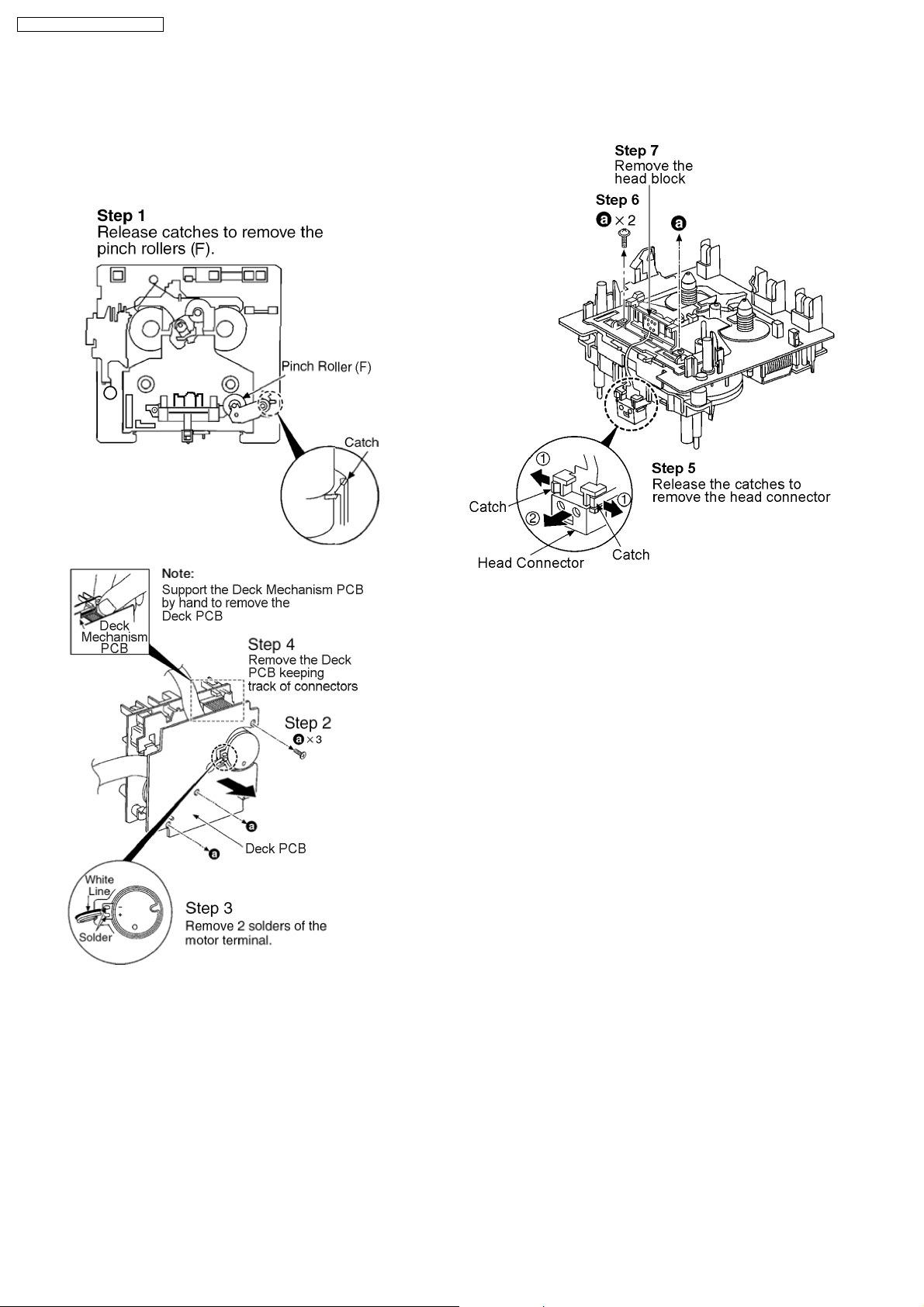

12.17. Procedure for Replacing Pinch Roller and Head Block (Deck

Mechanism Unit)

· Follow the (Step 1) - (Step 6) of Item 12.2.

· Follow the (Step 1) - (Step 2) of Item 12.3.

· Follow the (Step 1) - (Step 4) of Item 12.4.

12.18. Procedure for Replacing Motor, Capstan Belt A, Capstan Belt B, and

Winding Belt (Deck Mechanism Unit)

· Follow the (Step 1) - (Step 6) of Item 12.2.

· Follow the (Step 1) - (Step 2) of Item 12.3.

· Follow the (Step 1) - (Step 4) of Item 12.4.

· Follow the (Step 1) - (Step 4) of Item 12.17.

30

Loading...

Loading...