Page 1

A

CD Stereo System

SA-PM71SDE

SA-PM71SDEB

SA-PM71SDEG

Colour

(S)... Silver Type

ORDER NO. MD0504157C2

Specification

n Amplifier Section

RMS output power, both channels driven

10%, Total harmonic distortion

1 kHz (Low channel) 40 W per channel

(6 Ω)

8 kHz (High channel) 40 W per channel

(6 Ω)

Total Bi-Amp power 80 W per channel

Output Impedance

Headphone 16Ω -32Ω

n FM Tuner Section

Frequency range 87.50 MHz to 108.00 MHz

(50 kHz steps)

Sensitivity 1.50 µV (IHF)

S/N 26dB 1.70 µV

ntenna terminals 75 Ω (unbalanced)

Preset stations 15

n AM Tuner Section

Frequency range 522 kHz to 1629 kHz (Default)

(9 kHz steps)

520 kHz to 1630 kHz

(10 kHz steps)

Sensitivity S/N 20 dB at 999 kHz 560 µV/m

Preset stations 15

n Cassette Deck Section

Track system 4 track, 2 channel

Heads

Record/playback Solid permalloy head

Erasure Double gap ferrite head

Motor DC servo motor

Recording system AC bias 100 kHz

Erase system AC erase 100 kHz

Tape speed 4.8cm/s(1-7/8ips)

Overall frequency response (+3 dB, -6 dB) at DECK OUT

Normal 35 Hz to 14 kHz

Wow and flutter 0.10% (WRMS)

Fast forward and rewind time Approx. 120 seconds with C-60

cassette tape

n CD Section

Disc CD,MP3,WMA,CD-R/RW,

HighMat

8cm (3”) / 12 cm (5”)

Sampling frequency

CD 44.1 kHz

MP3/WMA 32 kHz, 44.1 kHz, 48 kHz

Bit rate

MP3 32 kbps to 320 kbps

WMA 40 kbps to 192 kbps

Decoding 16 bit linear

Pickup

Beam source Semiconductor laser

Wavelength 780 nm

Number of channels Stereo

Frequency response 20 Hz to 20 kHz (+1dB, -2 dB)

© 2005 Matsushita Electric Industrial Co. Ltd.. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

Wow and flutter Below measurable limit

Digital filter 8fs

D/A converter MASH (1 bit DAC)

n SD Section

Sampling frequency 32 kHz (LP), 44.1 kHz (SP,XP)

Coding system

SD Audio Playback AAC, MP3, W MA

SD Audio Record AAC

Number of channels 2 channel (stereo)

n Other

CD → SD Recording speed Maximum 4 times (LP)

n General

Power supply AC 230 V, 50 Hz (For E/EG)

AC 230 - 240 V, 50 Hz (For EB)

Power consumption 130 W

Dimensions (W x H x D) 175 mm x 249.5 mm x 379.6 mm

(6 29/32 x 9 27/32” x 14 31/32”)

Mass 5.8 kg (12.8 Ibs)

Power consumption in standby

mode

Notes :

1. Specifications are subject to change without notices. Mass and

dimensions are approximate.

2. Total harmonic distortion is measured by the digital spectrum

analyzer.

n System : SC-PM71SDE-S

n System : SC-PM71SDEBS

n System : SC-PM71SDEGS

Music center: SA-PM71SDE-S

Speaker: SB-PM71P-M

Music center: SA-PM71SDEBS

Speaker: SB-PM71P-M

Music center: SA-PM71SDEGS

Speaker: SB-PM71P-M

0.5 W

CONTENTS

Page Page

1 Safety Precautions

1.1. GENERAL GUIDELINES

2 Caution for AC Mains Lead

3 Before Repair and Adjustment

4 Protection Circuitry

5 Handling the Lead-free Solder

5.1. About lead free solder (PbF)

6 Precaution of Laser Diode

7 Handling Precautions For Traverse Deck

8 Accessories

9 Operation Procedures

9.1. Main Unit

9.2. Remote Control

10 Information on Disc & MP3

11 SD Card Information

12 About HighMAT

12.1. What 痴 HighMAT?

12.2. Why take advantage of HighMAT?

12.3. Benefits of HighMAT?

13 Assembling and Disassembling

13.1. Disassembly flow chart

13.2. Disassembly of Side Panel L & R

13.3. Disassembly of Top Cabinet

13.4. Disassembly of Deck Mechanism P.C.B. and Tape Eject

P.C.B.

13.5. Disassembly of Front Panel

13.6. Disassembly of SD Module P.C.B.

13.7. Disassembly of Panel P.C.B.

13.8. Disassembly of Rear Cabinet

4

4

5

6

6

6

6

7

8

9

10

10

11

12

14

16

16

16

17

20

20

21

21

21

22

23

23

24

13.9. Disassembly of Main P.C.B.

13.10. Disassembly of Transforme r P.C.B.

13.11. Disassembly of Tuner Pack

13.12. Disassembly of Power P.C.B.

13.13. Disassembly of CR16 Mechanism

13.14. Replacement of CD Lid and Inner CD Lid

13.15. Replacement of Cassette Lid

13.16. Replacement of the Power IC and Transistors

13.17. Procedure for Replacing Pinch Roller and Head Block

(Deck Mechanism Unit)

13.18. Procedure for Replacing Motor, Capstan Belt A, Capstan

Belt B, and Winding Belt (Deck Mechanism Unit)

13.19. Procedure for Replacing Parts on Deck Mechanism PCB

13.20. Disassembly of CR16 Mechanism

13.21. Replacement of optical pickup unit (CD mechanism)

13.22. Replacement of a traverse gear A and a traverse gear B

13.23. Procedure for removing CD loading mechanism

13.24. CR16 mechanism disassembly procedure

13.25. CR16 MECHANISM ASSEMBLY PROCEDURE

13.26. Disassembly of traverse mechanism

13.27. Handling of cassette tape jam

14 Service Positions

14.1. Checking procedure

14.2. Checking the major P.C.B

15 Self-Diagnostic Display Function

15.1. Entering into Self-Diagnostic Mode

15.2. Error Code Table

25

25

26

26

26

27

29

29

31

31

33

33

34

36

37

37

43

56

57

58

58

58

59

59

60

2

Page 3

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

15.3. Changer Reliability Test Mode 61

16 Procedure for Checking Operation of Individual Parts of Deck

Mechanism Unit

16.1. Operation Check with Cassette Tape

16.2. Operation Check without Cassette Tape

17 Measurement And Adjustments

17.1. Cassette Deck Section

18 Voltage Measurement and Waveform Chart

18.1. Voltage Measurement

18.2. Waveform Chart

19 Block Diagram

19.1. CD SERVO Block

19.2. MAIN Block

20 Notes of Schematic Diagram

21 Schematic Diagram

21.1. CD SERVO CIRCUIT

21.2. SD MODULE CIRCUIT

21.3. MAIN CIRCUIT

21.4. PANEL CIRCUIT and TRANSFORMER CIRCUIT

21.5. POWER CIRCUIT

62

62

62

64

64

66

66

72

74

74

76

83

84

84

86

91

96

98

21.6. DECK CIRCUIT, DECK MECHANISM CIRCUIT and TAPE

EJECT CIRCUIT

21.7. CD LOADING CIRCUIT

22 Printed Circuit Board

100

102

103

22.1. CD SERVO P.C.B

22.2. SD MODULE P.C.B

22.3. MAIN P.C.B

22.4. PANEL P.C.B

22.5. TRANSFORMER P.C.B

22.6. POWER P.C.B

22.7. DECK P.C.B and TAPE EJECT P.C.B

22.8. DECK MECHANISM P.C.B and CD LOADING P.C.B

23 Wiring Connection Diagram

24 Illustration of IC 痴, Transistors and Diodes

25 Terminal Function of ICエs

25.1. IC807 (MN103SF77RXW) IC SD Audio Drive Controller

25.2. IC703 (BA5948FPE2) IC 4CH Drive

26 Troubleshooting Flowchart (CD Section Circuit)

27 Troubleshooting Flowchart (SD Card Section Circuit)

28 Parts Location and Replacement Parts List

28.1. Deck Mechanism

28.2. CD LOading Mechanisms

28.3. Cabinet Part List

28.4. Electrical Part List

28.5. Packaging Materials & Accessories Parts List

28.6. Packaging

103

105

106

108

109

110

111

112

113

115

116

116

117

118

120

122

123

125

130

134

145

145

3

Page 4

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

1 Safety Precautions

1.1. GENERAL GUIDELINES

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, ensure that all the protective devices such as insulation barriers, insulation papers shields are properly installed.

3. After servicing, check for leakage current checks to prevent from being exposed to shock hazards.

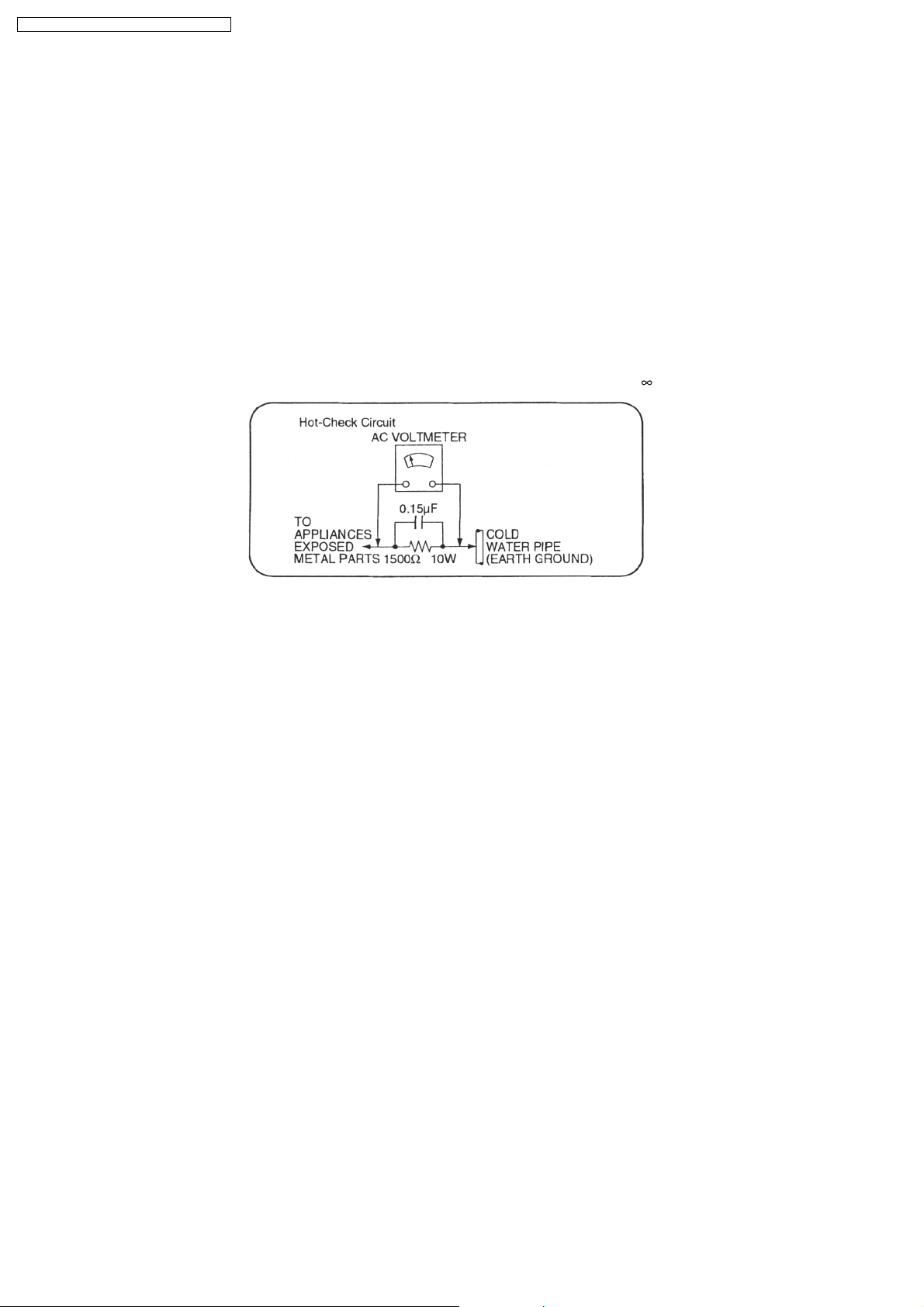

1.1.1. LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Using an ohmmeter measure the resistance value, between the jumpered AC plug and each expose d metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩand 5.2Ω.

When the exposed metal does not have a return path to the chassis, the reading must be

.

Fig. 1

1.1.2. LEAKAGE CURRENT HOT CHECK (See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use an isolatio n transfo rmer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent) may

be used to make the hot checks, leakage current must not exceed 1/2 milliamp. should the measurement is outside of the limits

specified, there is a possibility of a shock hazard, and the equipment should be repaired and re-checked before it is returned

to the customer.

4

Page 5

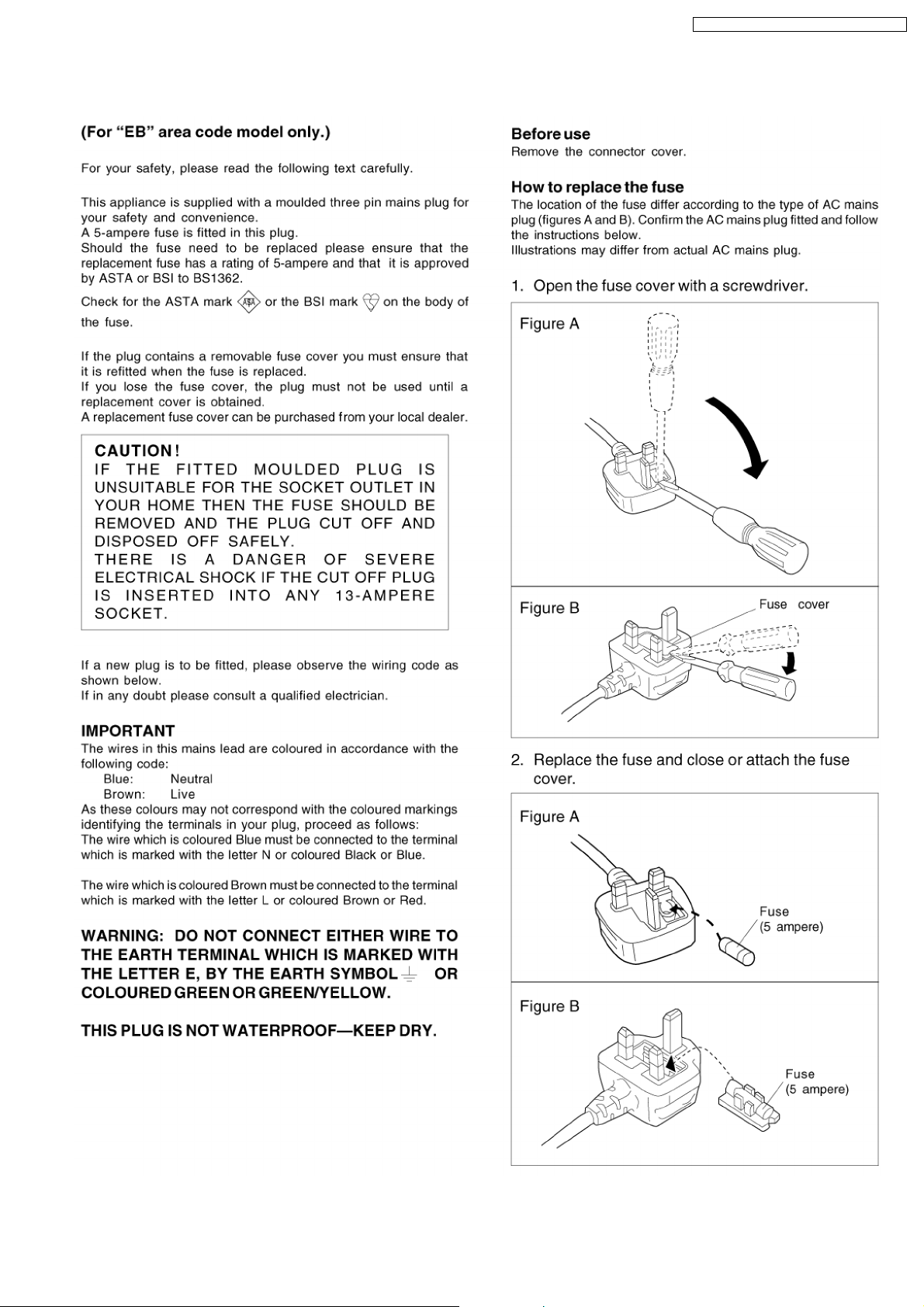

2 Caution for AC Mains Lead

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

5

Page 6

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

3 Before Repair and Adjustment

Disconnect AC power, discharge Power Supply Capacitors C448, C449, C452, C455, C456, C506, C507, C508 & C584 through

a10Ω, 1W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

· Current consumption at AC 230V, 50 Hz in NO SIGNAL mode should be ~300 mA. (For E/EG)

· Current consumption at AC 230V-2 40V, 50 Hz in NO SIGNAL mode should be ~300 mA. (For EB)

4 Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

· No sound is heard when the power is turned on.

· Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

"shorted", or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outline s below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

5 Handling the Lead-free Solder

5.1. About lead free solder (PbF)

Distinction of PbF P.C.B.:

P.C.B.s (manufactured) using lead free solder will have a PbF stamp on the P.C.B.

Caution:

· Pb free solder has a higher melting point than standard solder; Typically the melting point is 50 - 70°F (30 - 40°C) higher. Please

use a high temperature soldering iron. In case of soldering iron with temperature control, please set it to 700 ± 20°F (370 ±

10°C).

· Pb free solder will tend to splash when heated too high (about 1100°F/600°C).

· W hen soldering or unsoldering, please completely remove all of the solder on the pins or solder area, and be sure to heat the

soldering points with the Pb free solder until it melts enough.

6

Page 7

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

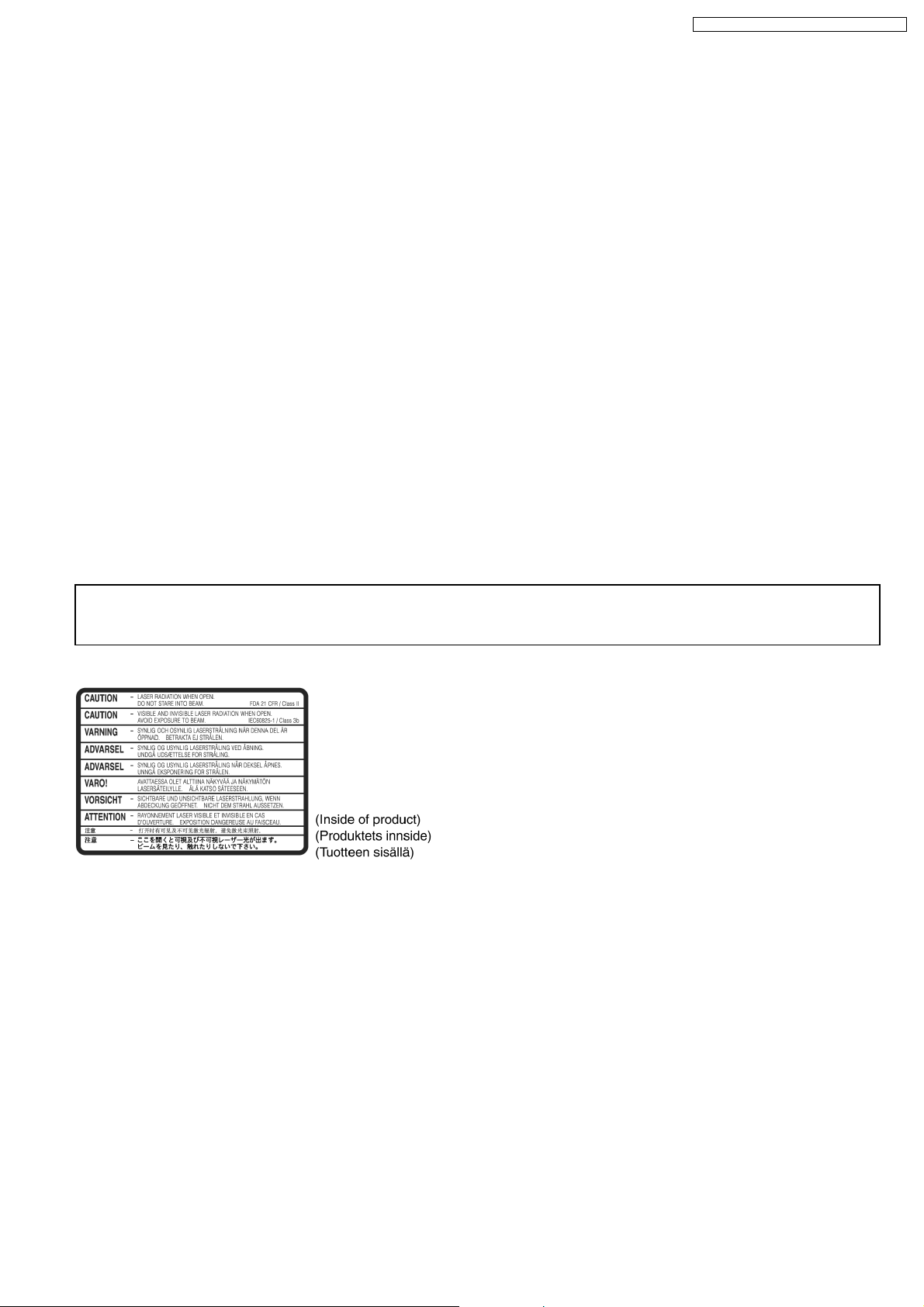

6 Precaution of Laser Diode

Caution :

This product utilizes a laser diode with the unit turned "ON", invisible laser radiation is emitted from the pick up lens.

Wavelength : 780 nm

Maximum output radiation power from pick up : 100 µW/VDE

Laser radiation from pick up unit is safety level, but be sure the followings:

1. Do not disassemble the optical pick up unit, since radiation from exposed laser diode is dangerous.

2. Do not adjust the variable resistor on the pick up unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at pick up lens for a long time.

ACHTUNG :

Dieses Produkt enthält eine Laserdiode. Im eingeschalteten Zustand wird unsichtbare Laserstrahlun g von der Lasereinheit

abgestrahlt.

Wellenlänge : 780nm

Maximale Strahlungsleistung der Lasereinheit :100µW/VDE

Die Strahlung an der Lasereinheit ist ungefährlich, wenn folgende Punkte beachtet werden:

1. Die Lasereinheit nicht zerlegen, da die Strahlung an der freigelegten Laserdiode gefährlich ist.

2. Den werkseitig justierten Einstellregler der Lasereinhit nicht verstellen.

3. Nicht mit optischen Instrumenten in die Fokussierlinse blicken.

4. Nicht über längere Zeit in die Fokussierlinse blicken.

ADVARSEL :

I dette a apparat anvendes laser.

CAUTION!

THIS PRODUCT UTILIZES A LASER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT

IN HAZARDOUS RADIATION EXPOSURE.

n Use of Caution Labels

7

Page 8

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

7 Handling Precautions For Traverse Deck

The laser diode in the traverse deck (optical pickup) may break down due to potential difference caused by static electricity of

clothes or human body. So, be careful of electrostatic breakdown during repair of the traverse deck (optical pickup).

· Handling of traverse deck (optical pickup)

1. Do not subject the traverse deck (optical pickup) to static electricity as it is extremely sensitive to electrical shock.

2. To prevent the breakdown of the laser diode, an antistatic shorting pin is inserted into the flexible board (FFC board).

3. Take care not to apply excessive stress to the flexible board (FFC board). When removing or connecting the short pin, finish

the job in as short time as possible. (Fig 7.1)

4. Do not turn the variable resistor (laser power adjustment). It has already been adjusted.

· Grounding for electrostatic breakdown prevention

1. Work table grounding. (Fig 7.2)

Use the anti-static wrist strap to discharge the static electricity from your body.

2. Work table grounding. (Fig 7.2)

Put a conductive material (sheet) or steel sheet on the area where the traverse deck (optical pickup) is place, and ground

the sheet.

Caution:

The static electricity of your clothes will not be grounded through the wrist strap. So, take care not to let your clothes touch the

traverse deck (optical pickup).

Caution when replacing the Traverse Deck

The traverse deck has a short point shorted with solder to protect the laser diode against electrostatics breakdown. Be sure to

remove the solder from the short point before making connections.

(Fig 7.1)

(Figs 7.2)

8

Page 9

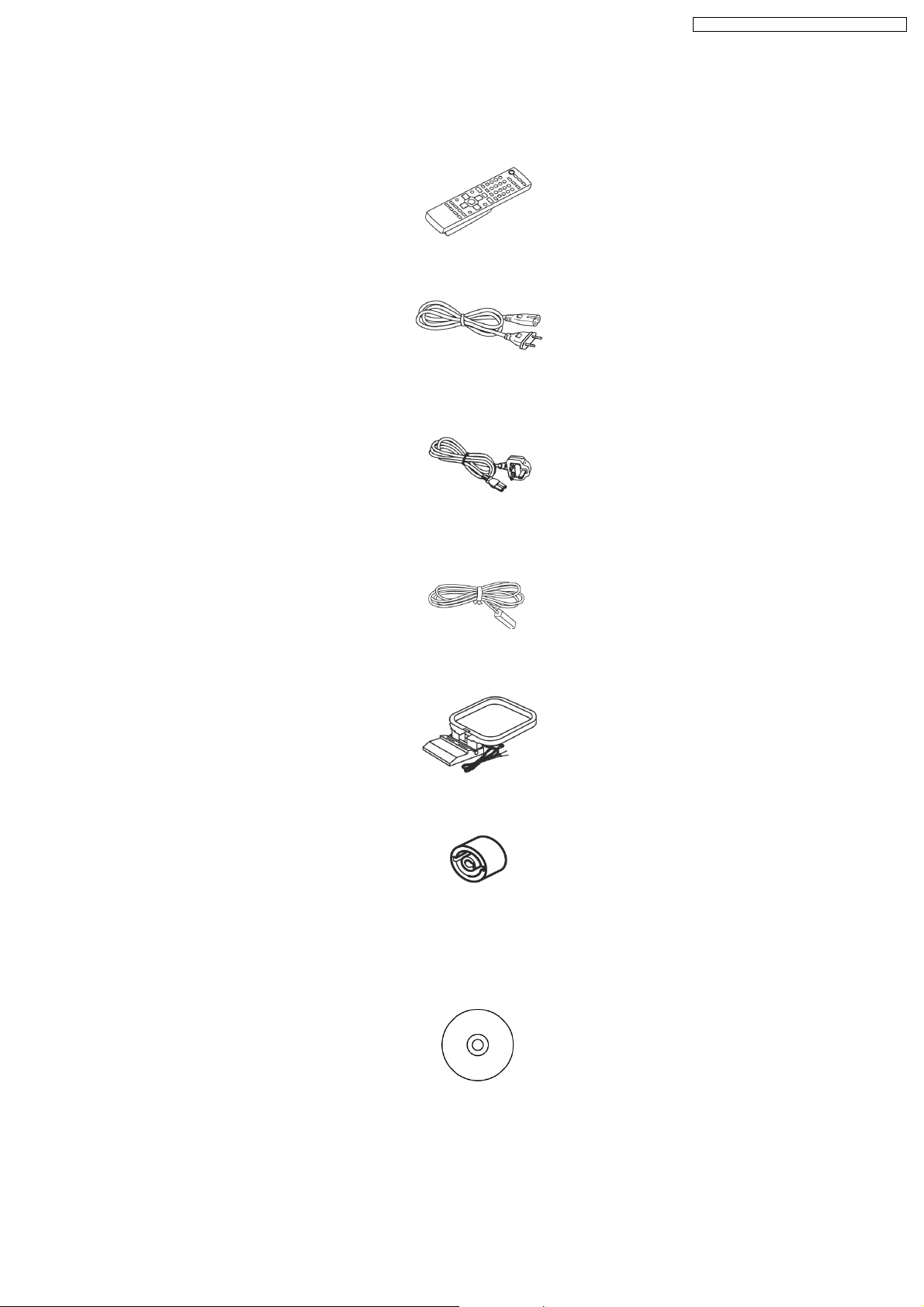

8 Accessories

Note : Refer to Packing Materials & Accessories Parts List (Section 28.5) for the part number.

Remote Control

AC cord (For E/EG

only)

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

AC cord (For EB

only)

FM indoor antenna

AM loop antenna

Antenna

plug

adaptor

(For EB

only)

CD ROM

9

Page 10

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

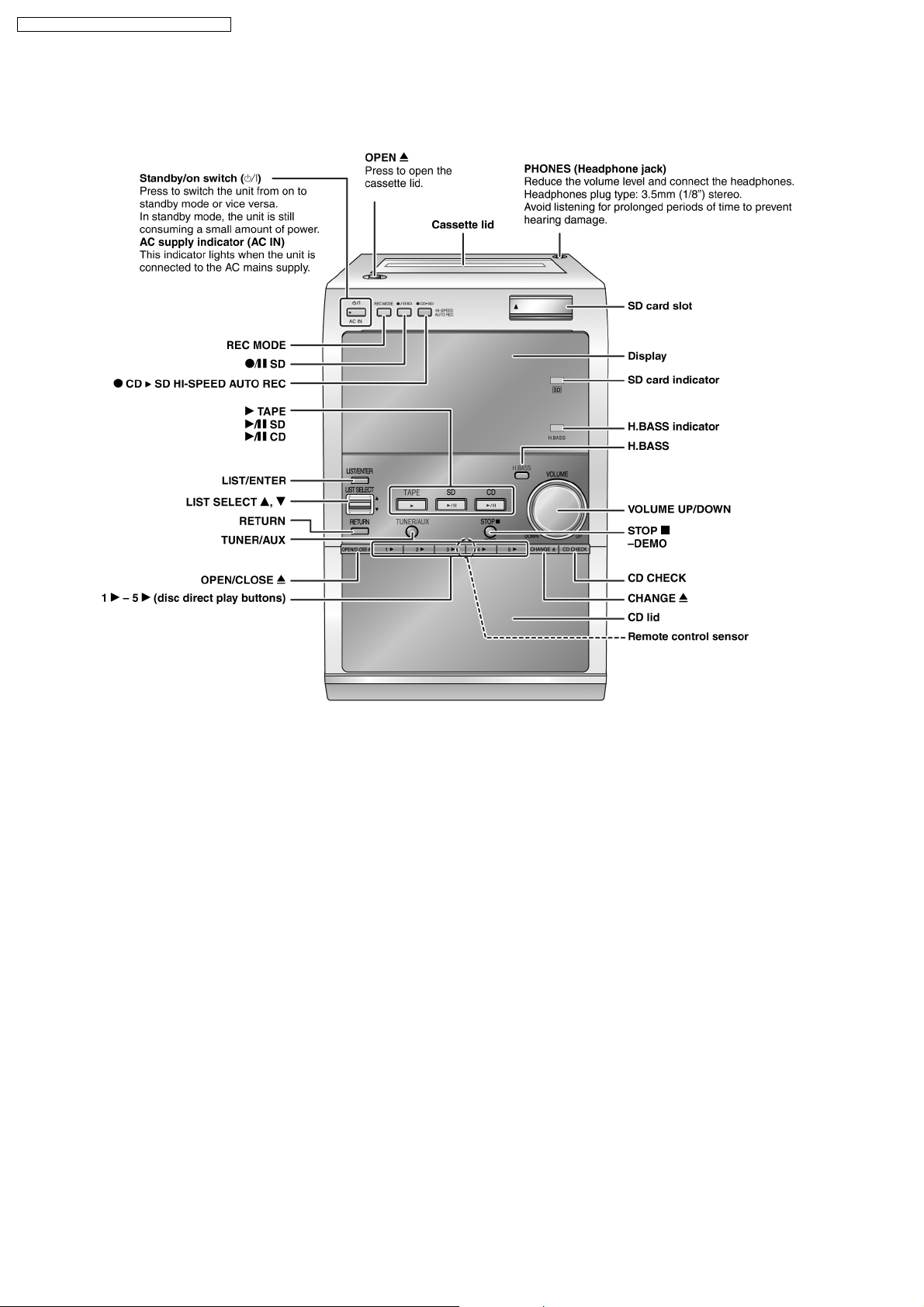

9 Operation Procedures

9.1. Main Unit

10

Page 11

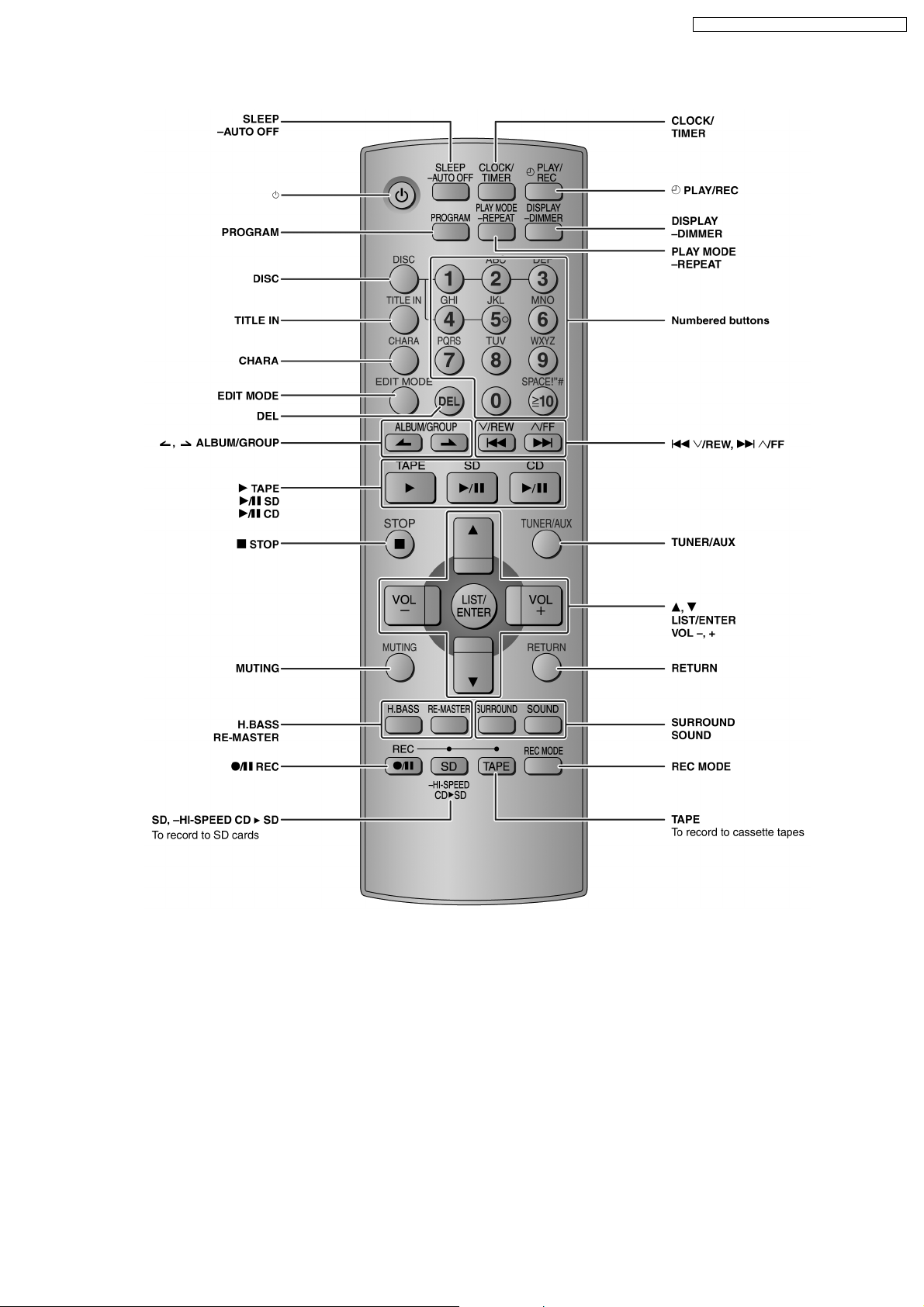

9.2. Remote Control

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

11

Page 12

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

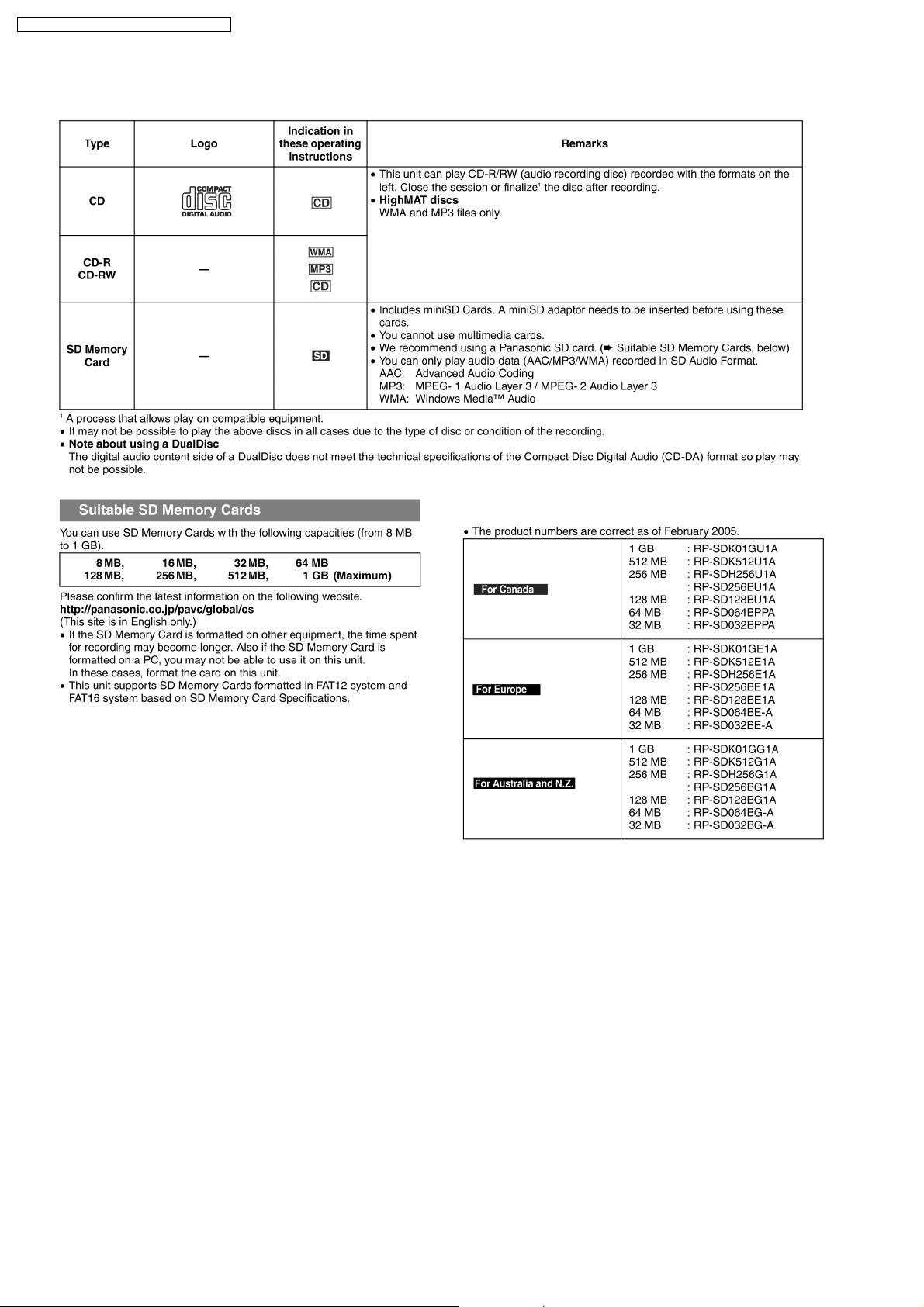

10 Information on Disc & MP3

12

Page 13

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

13

Page 14

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

11 SD Card Information

A New Lifestyle is Evolving with the SD Memory Card

The SD Memory Card is at the heart of many Panasonic products. It´s a high-capacity, high-speed storage medium for the digital

age. Incredibly small yet durable, the SD Memory Card is about the size of a postage stamp. It can store all kinds of digital content,

like video, still images, music and more! So you can transfer data easily between products with an SD Card slot.

The miniSD card

The miniSD card was developed to meet industry deman ds for a memory card small enough for today’s compact mobile phones.

It is about 40% smaller than a Panasonic SD Memory Card, but offers all the benefits-including copyright protection. Each miniSD

card comes with an adapter that makes the miniSD card compatible with standard SD-enabled products.

Ideal for MPEG2 Video Recording

The increasing data volume and expand ing range of digital contents require high data reading and writing speeds. Panasonic SD

Memory Cards, 256MB

1

and higher, achieve the data writing speed fast enough to record MPEG2 video in fine mode.

Compact & Slim

The SD Memory Card measures a mere 0.94" x 1.26" x .08" (24mm x 32mm x 2.1mm). Its slim, compact design promotes easy

handling-an important factor for moving between differe nt SD-compatible products. Our SD Memory Cards are small enough to be

used in select mobile phones and PDAs, as well as many other compact or multi-functional products.

Large Capacity

SD Memory Cards are currently available in several capacities up to 1GB

2

. Be on the lookout in the near future for 2GB2and 4GB

cards. This kind of large capacity is essential for use with various digital content types, especially high-quality MPEG2 video.

Fast Access

Providing quick response and effortless handling of digital content, SD Memory Cards 256MB

1

and higher can write data fast

enough to record high-quality MPEG2 video in fine mode.

Copyright Protection

The copyright protection technology used for the SD Memory Card, Content Protection for Recordable Media (CPRM), is the key

to enabling a new distribution system for music and other commercial media. CPRM assures a high level of protection against

illegal copying and was developed by 4C (The digital contents copyright protection technology licensing organization of IBM, Intel,

Matsushita, and Toshiba.).

2

This protection is enhanced in the SD Memory Card through the use of key revocation technology that is built into the card. The

14

Page 15

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

card´s control circuitry allows data to be read and written, in its protection area only when appropriate external devices are detected.

Copying data ("checking-out") from a PC to an SD Memory Card is restricted to three copies in compliance with the SDMI

specification.

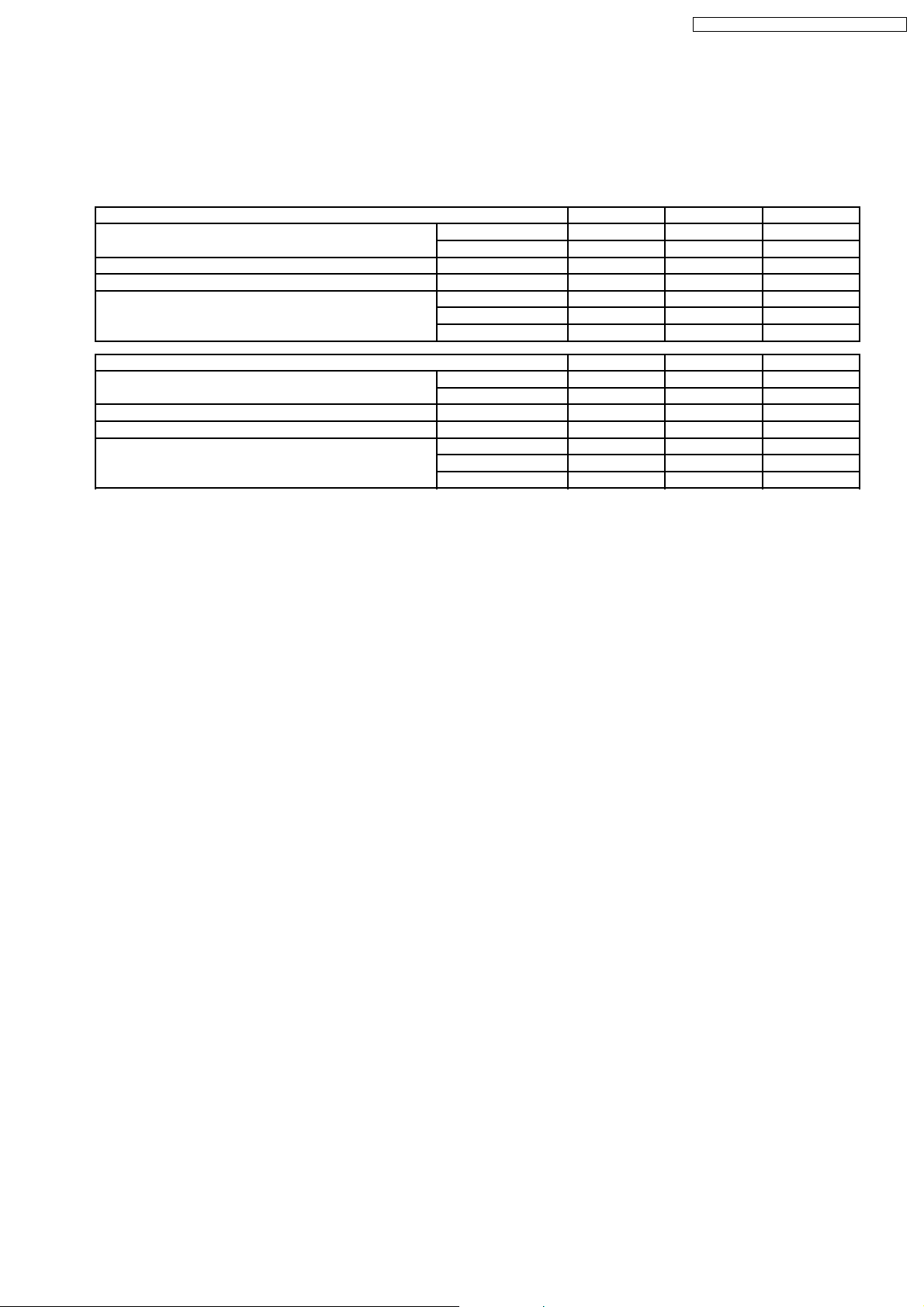

Comparison chart

File Type 1GB

2

Approx. Number of JPEG Photos3(1,600 x 1,200) Standard 2325 1209 600

Fine 1162 604 300

Approx. Time of MPEG4 Video (Using the D-snap SV-AV50) 384 Kbps, 12 fps 370 min. 180 min. 90 min.

Approx. Time of MPEG2 Video (Using the D-snap SV-AV100) 6 Mbps, 30 fp3 20 min. 10 min. 5 min.

Approx. Time of Recording Capacity for Music

(AAC/MP3/WMA)

4

High Quality (128kbps) 8h. 44 min. 4h. 20 min.

Normal (96kbps) 11h. 38 min. 5h. 46 min.

Long Play (64kbps) 17h. 28 min. 8h. 40 min.

File Type 128MB

1

Approx. Number of JPEG Photos3(1,600 x 1,200) Standard 301 149 72

Fine 150 74 36

Approx. Time of MPEG4 Video (Using the D-snap SV-AV50) 384 Kbps, 12 fps 40 min. 20 min. 10 min.

Approx. Time of MPEG2 Video (Using the D-snap SV-AV100) 6 Mbps, 30 fp3 N/A N/A N/A

Approx. Time of Recording Capacity for Music

(AAC/MP3/WMA)

4

High Quality (128kbps) 2h. 10 min. 1h. 4 min. 31 min.

Normal (96kbps) 2h. 54 min. 1h. 26 min. 42 min.

Long Play (64kbps) 4h. 21 min. 2h. 9 min. 1h. 3 min.

512MB

64MB

1

1

256MB

32MB

1

1

For Notes

1. MB = 1 million bytes. Usable capacity will be less.

2. GB = 1 billion bytes. Usable capacity will be less.

3. For normal shooting of 1,600 x 1,200 /static/Content. These figures vary depending on the subject being photographed and

on the particular model.

4. Approximate recording time in AAC format.

15

Page 16

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

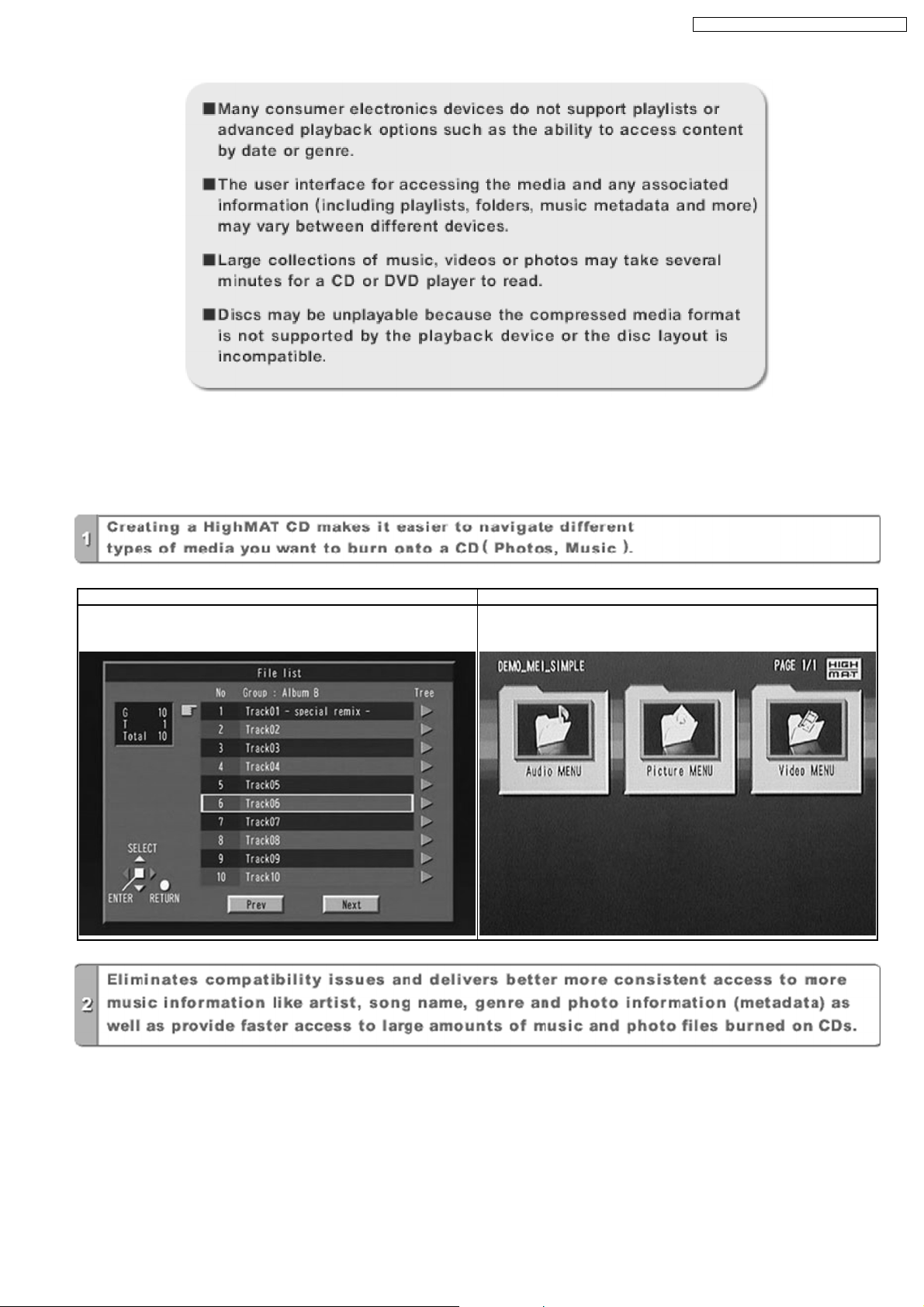

12 About HighMAT

12.1. What’s HighMAT?

Consumers worldwide are using PCs to create their own collections of music, photos and even video by burning them onto CDs.

But how these collections can be experie nced across different devices can be confusing to navigate, time consuming to access for

a DVD player, and be incomplete in terms of music information available to the customer.

HighMAT offers a solution to this growing consumer problem. HighMAT dramatically improves the digital media experience on

consumer electronic devices by delivering a simple, standardized approach that allows consumers who have created personal

collections of digital music, photography and video on their PC to:

· Create a HighMAT CD or DVD which can be easily played back on consum er electronics devices such as CD and DVD players,

and car stereos.

· Move digital media files (using recordable media such as CD-R and CD-RW) between the PC and various playback devices

such as CD and DVD players.

A new standard for creating personal media on consumer electronic devices, HighMAT enable easier and more seamless

interoperability between Windows PCs and devices designed for your living room, or the car.

12.2. Why take advantage of HighMAT?

A Problem Defined:Today, when consum ers create their own digital audio, video or photo collections on CD-R or other physical

formats, there are numerous, inconsistent ways that devices read the data. For the consumer, the playback experience can be

confusing:

16

Page 17

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

A Solution Created: HighMAT delivers a better digital media access experience by creating a standard approach for PCs to

structure digital media on various physical formats and for playba ck devices to read the data.

12.3. Benefits of HighMAT?

Conventional HighMAT

Even though DVD player is CD-R/RW compatible, the inconsistent ways

that various DVD players can read the music or photos files often leads

to a confusing and inconsistant playback experince.

HighMAT compatible products play content back with consistent

interface. This includes products which are JPEG compatible products

without HighMAT support.

17

Page 18

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

18

Page 19

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

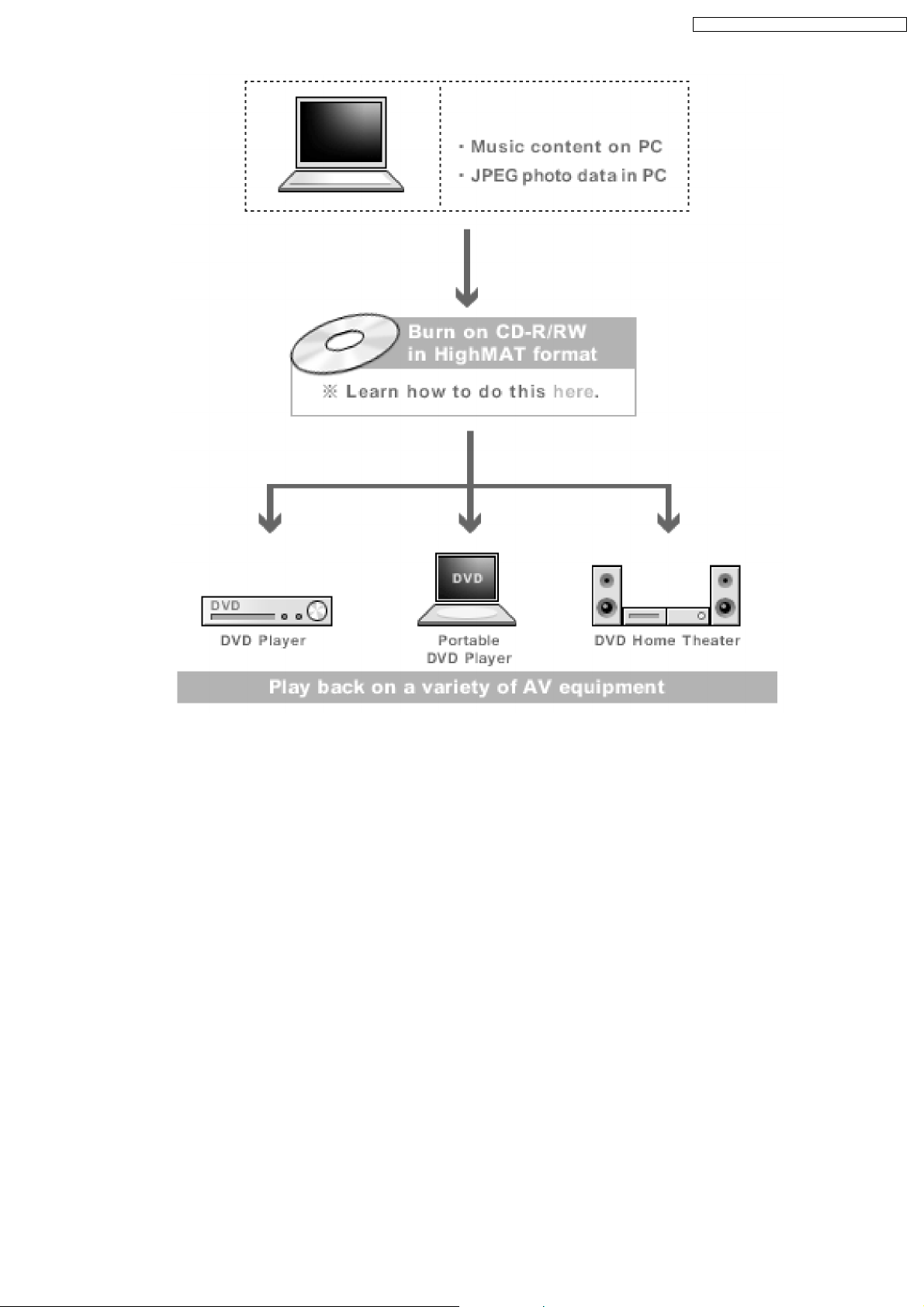

HighMAT is now available for CD Burning and in Leading DVD PlayersHighMAT is a new technology that is now available in leading

software and consumer electronic devices to dramatically improve the digital media experience when you create homemade

CDsHighMAT delivers a simple, standardized way for PC software and consum er electronics devices to talk to each other and work

better together.

When you create your homemade CDs with software that supports HighMAT CD burning, and then play them back on a DVD

player that supports HighMAT, you get better, easier navigation. You get folders you can access with a single click of your DVD

player´s remote control. You can view important information about your music like full song names, artist titles, album names and

genre. And you can get faster startup on your home entertainment device.

To enjoy the benefits of HighMAT, all you need is software that supports HighMAT for CD burning of music or photos, as well as

a home entertainment device like a DVD player that supports HighMAT for playback. Always look for the HighMAT logo on your

software or home entertainment device to ensure it supports the HighMAT experience.

19

Page 20

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

13 Assembling and Disassembling

“ATTENTION SERVICER”

Some chassis components may be have sharp edges. Be careful when disassembling and servicing.

1. This section describes procedures for checking the operation of the major printed circuit boards and replacing the main

components.

2. For reassembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

3. Select items from the following index when checks or replacement are required.

· Disassembly of Side Panel L & R

· Disassembly of Top Cabinet

· Disassembly of Deck Mechanism P.C.B. and Tape Eject P.C.B.

· Disassembly of Front Panel

· Disassembly of SD Module P.C.B.

· Disassembly of Panel P.C.B.

· Disassembly of Rear Cabinet

· Disassembly of Main P.C.B.

· Disassembly of Transformer P.C.B.

· Disassembly of Tuner Pack

· Disassembly of Power P.C.B.

· Disassembly of CR16 Mechanism

Warning:

This product uses a laser diode. Refer to “Precaution of Laser Diode”.

ACHTUNG:

Die Lasereinheit nicht zerlegen.

Die Lasereinheit darf nur gegen eine vom Hertsteller spezifizierte Einheit ausgetauscht werden.

13.1. Disassembly flow chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the

servicing.

To assemble the unit, reverse the steps shown in the chart below.

20

Page 21

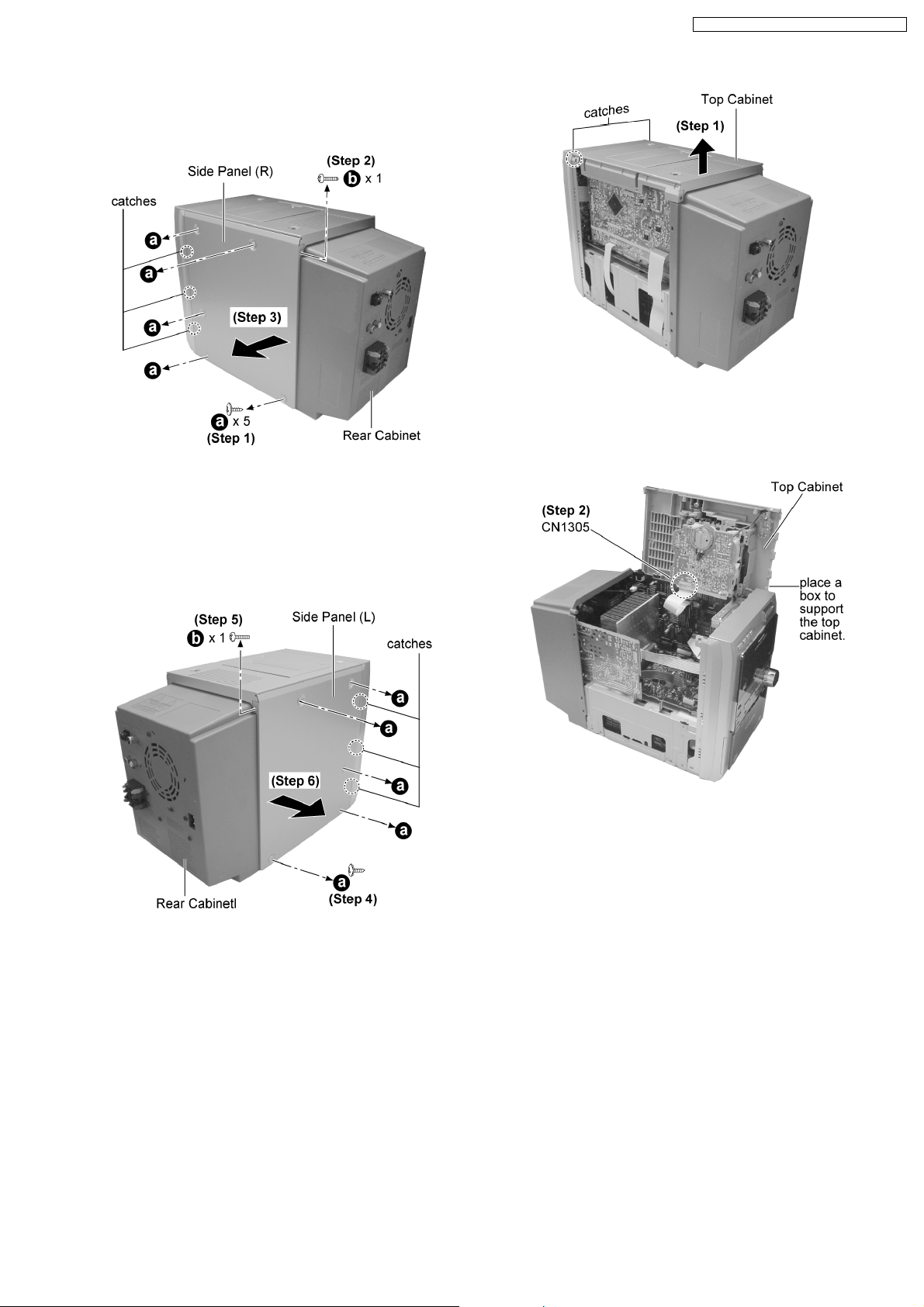

13.2. Disassembly of Side Panel L &

R

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

Step 1 : Lift up the top cabinet as arrow shown (Be careful of

the catches).

Step 1 : Remove 5 screws from the side panel (R).

Step 2 : Remove 1 screws from the corner of the side panel

(R).

Step 3 : Remove the side panel as arrow shown (Be careful of

the catches).

Step 4 : Remove 5 screws from the side panel (L).

Step 5 : Remove 1 screws from the corner of the side panel (L).

Step 6 : Remove the side panel as arrow shown (Be careful of

the catches).

Step 2 : Place the top cabinet as shown and detach the

connector CN1305.

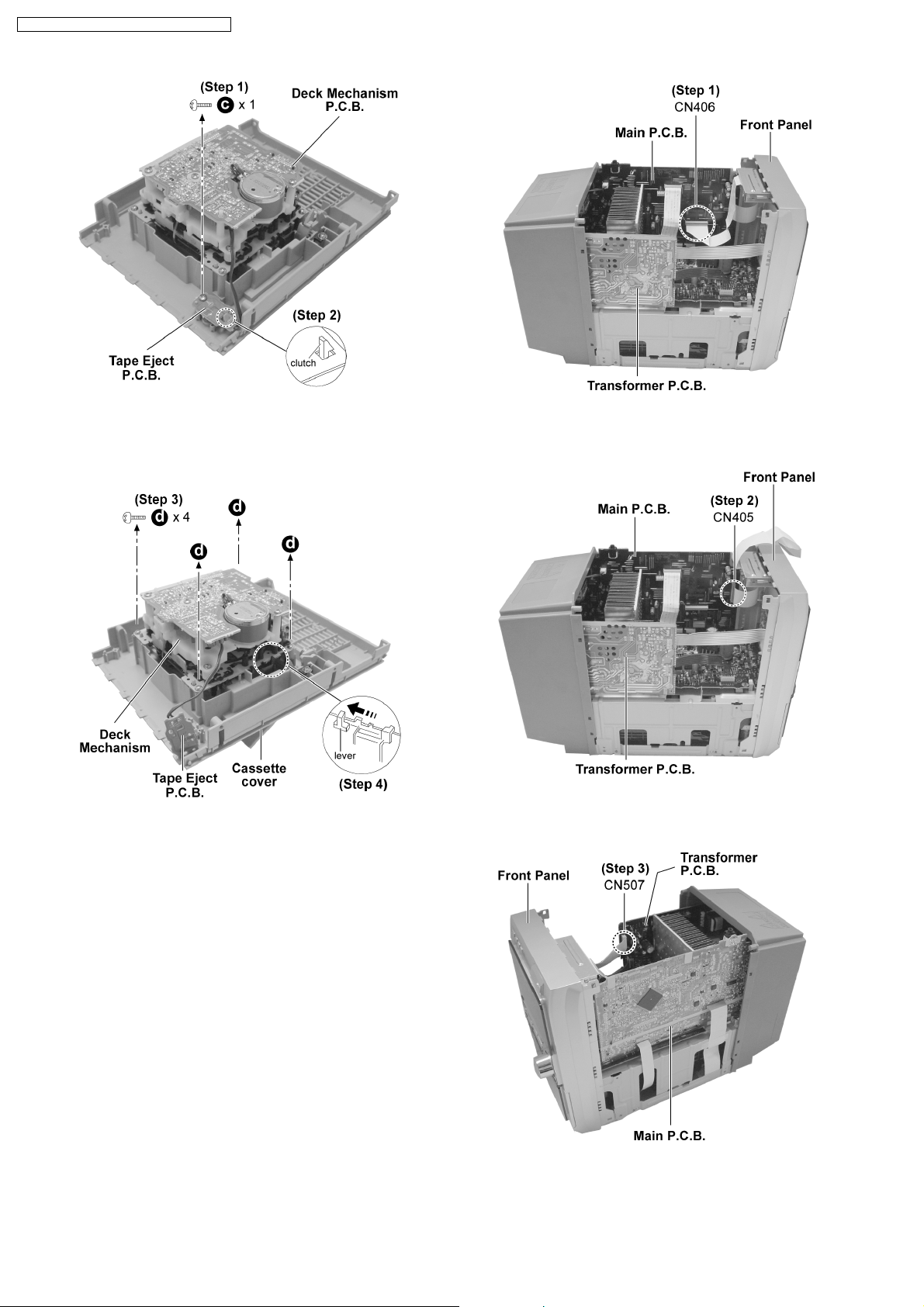

13.4. Disassembly of Deck

Mechanism P.C.B. and Tape

Eject P.C.B.

· Follow the (Step 1) - (Step 6) of item 13.2.

· Follow the (Step 1) - (Step 2) of item 13.3.

13.3. Disassembly of Top Cabinet

· Follow the (Step 1) - (Step 6) of item 13.2.

21

Page 22

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

Step 1 : Remove 1 screw.

Step 2 : Release the clutch and remove the Tape Eject P.C.B..

Step 3 : Remove 4 screws.

Step 4 : Push the lever as arrow shown to remove the Deck

Mechanism.

Step 1 : Detach the connector CN406.

Step 2 : Detach the connector CN405.

13.5. Disassembly of Front Panel

· Follow the (Step 1) - (Step 6) of item 13.2.

· Follow the (Step 1) - (Step 2) of item 13.3.

Step 2 : Detach the connector CN507.

22

Page 23

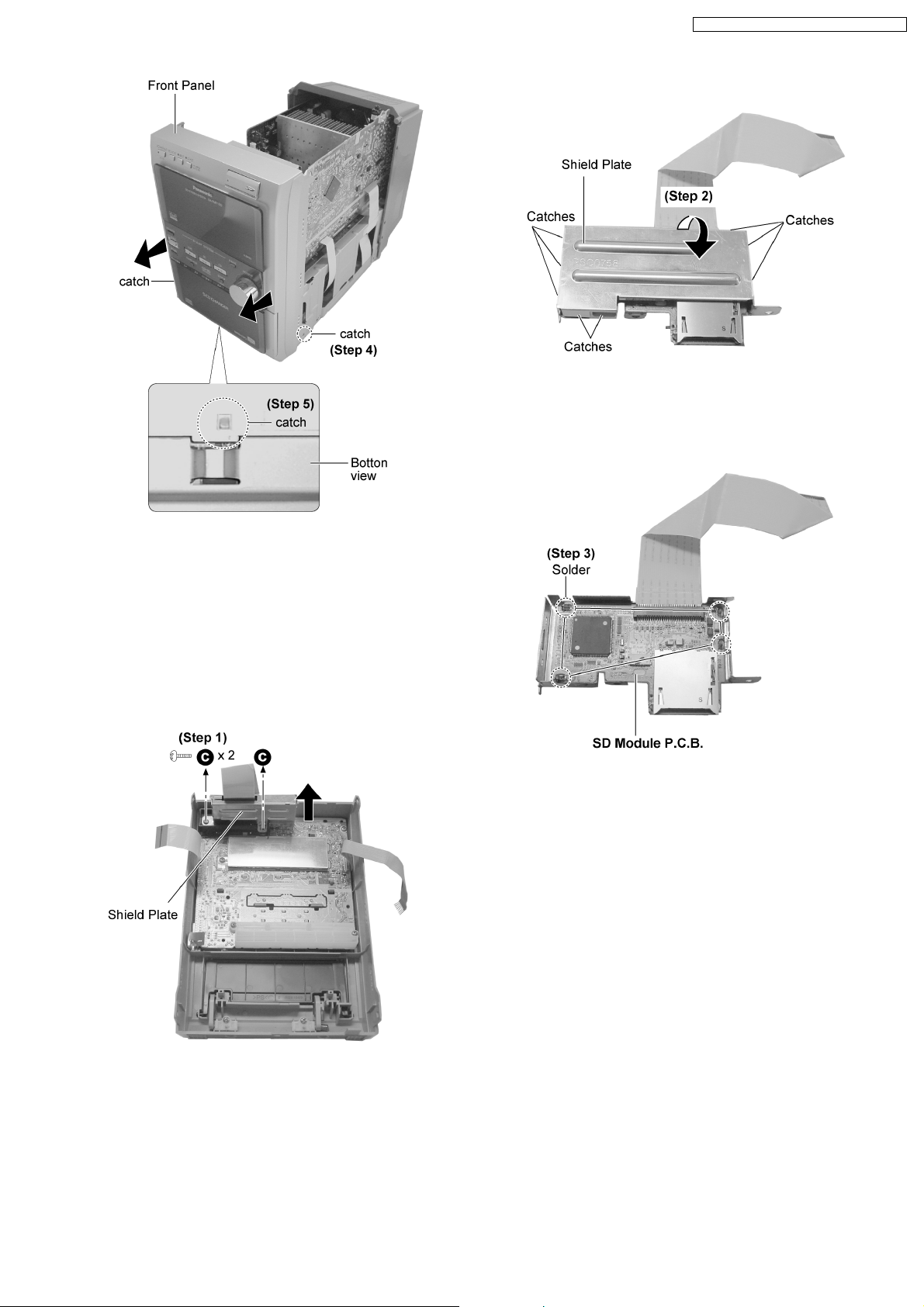

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

Step 2 : Remove shield plate. (Be careful of the catches)

Step 4 : Release 2 catches.

Step 5 : Release the catch at the bottom cabinet and remove

the front panel as arrow shown.

13.6. Disassembly of SD Module

P.C.B.

· Follow the (Step 1) - (Step 6) of item 13.2.

· Follow the (Step 1) - (Step 2) of item 13.3.

· Follow the (Step 1) - (Step 5) of item 13.5.

Step 3 : Unsolder 4 point to remove SD Module P.C.B..

13.7. Disassembly of Panel P.C.B.

· Follow the (Step 1) - (Step 6) of item 13.2.

· Follow the (Step 1) - (Step 2) of item 13.3.

· Follow the (Step 1) - (Step 5) of item 13.5.

· Follow the (Step 1) of item 13.6.

Step 1 : Remove 2 screws to remove the SD Module P.C.B.

with shield plate as arrow shown.

23

Page 24

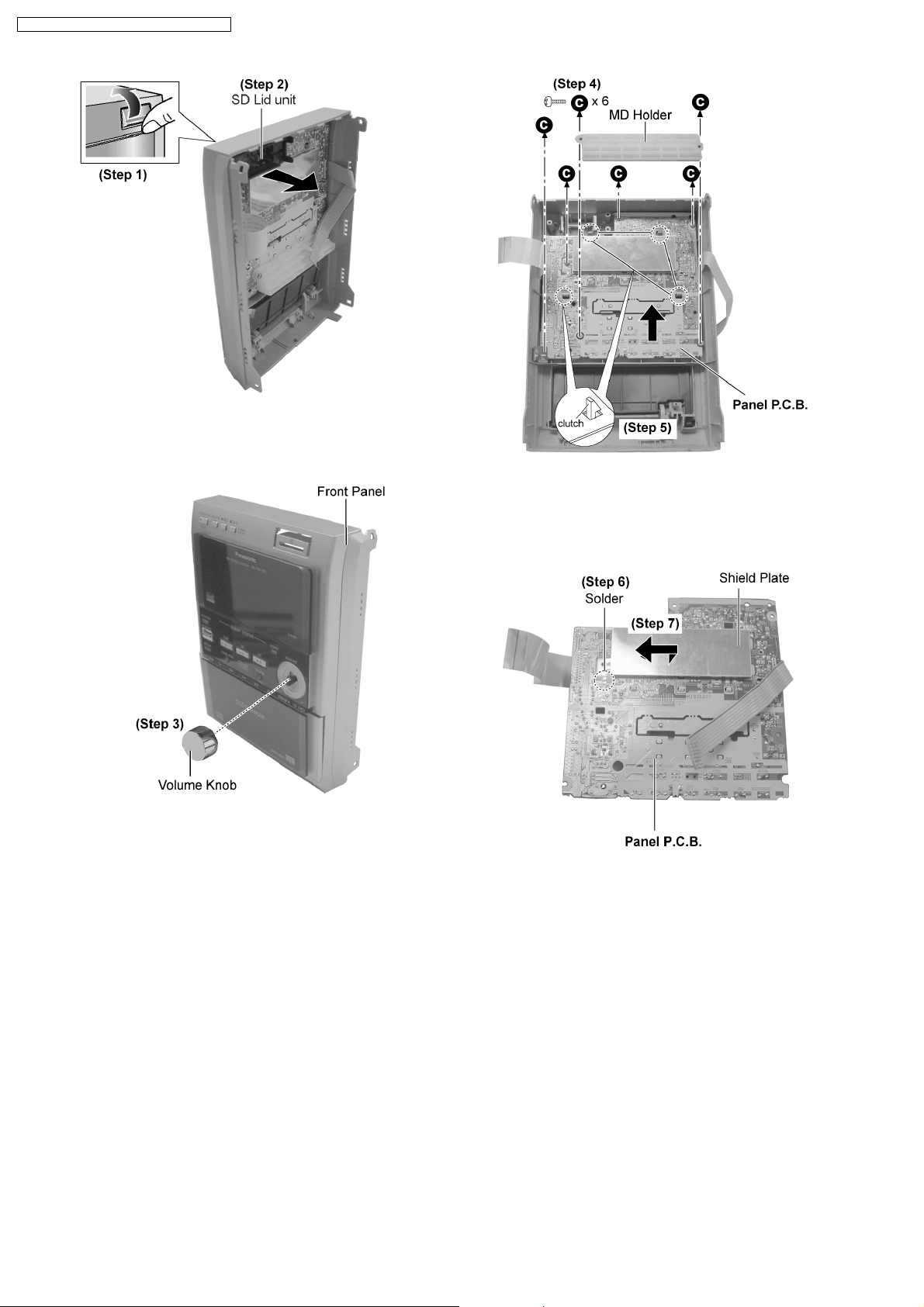

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

Step 1 : Flip open the SD cover as arrow shown.

Step 2 : Remove the SD Lid unit as arrow shown.

Step 3 : Remove the volume knob.

Step 4 : Remove 6 screws and MD Holder.

Step 5 : Release 4 clutches and remove the Panel P.C.B. as

arrow shown.

Step 6 : Unsolder the shield plate.

Step 7 : Remove the shield plate as arrow shown.

13.8. Disassembly of Rear Cabinet

· Follow the (Step 1) - (Step 6) of item 13.2.

· Follow the (Step 1) - (Step 2) of item 13.3.

24

Page 25

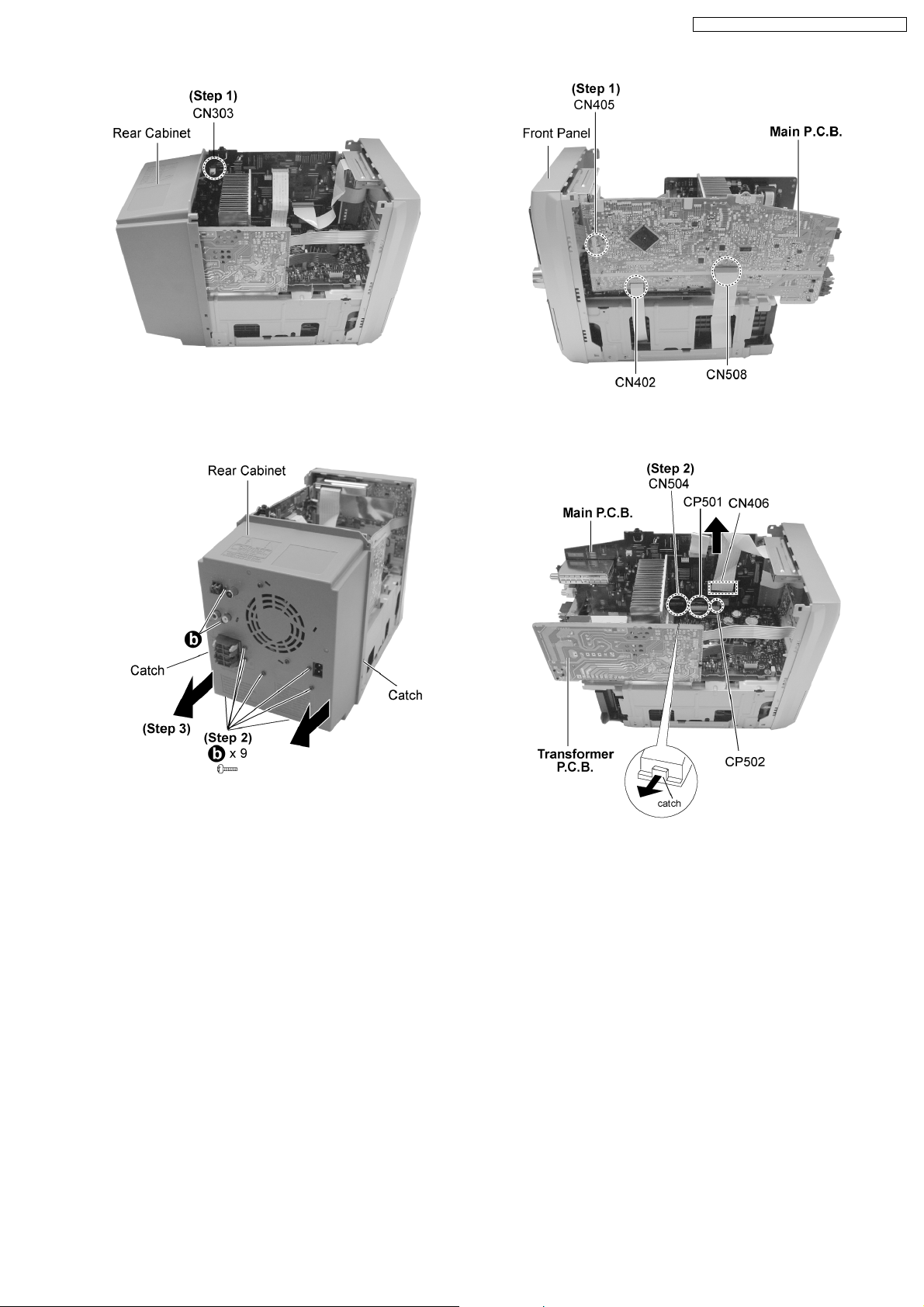

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

Step 1 : Detach the connector CN303.

Step 2 : Remove 9 screws altogether.

Step 3 : Remove the rear cabinet as arrows shown (Be careful

of the catches).

13.9. Disassembly of Main P.C.B.

· Follow the (Step 1) - (Step 6) of item 13.2.

· Follow the (Step 1) - (Step 2) of item 13.3.

· Follow the (Step 1) - (Step 3) of item 13.8.

Step 1 : Detach the connector CN405 , CN402 and CN508.

Step 2 : Detach the connectors CN406.

Step 3 : Releas e the catch as arrow shown and detach the

connector CN504, CP501 and CP502 and pull out the Main

P.C.B. as arrow shown.

13.10. Disassembly of Transformer

P.C.B.

· Follow the (Step 1) - (Step 6) of item 13.2.

· Follow the (Step 1) - (Step 2) of item 13.3.

· Follow the (Step 1) - (Step 3) of item 13.8.

25

Page 26

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

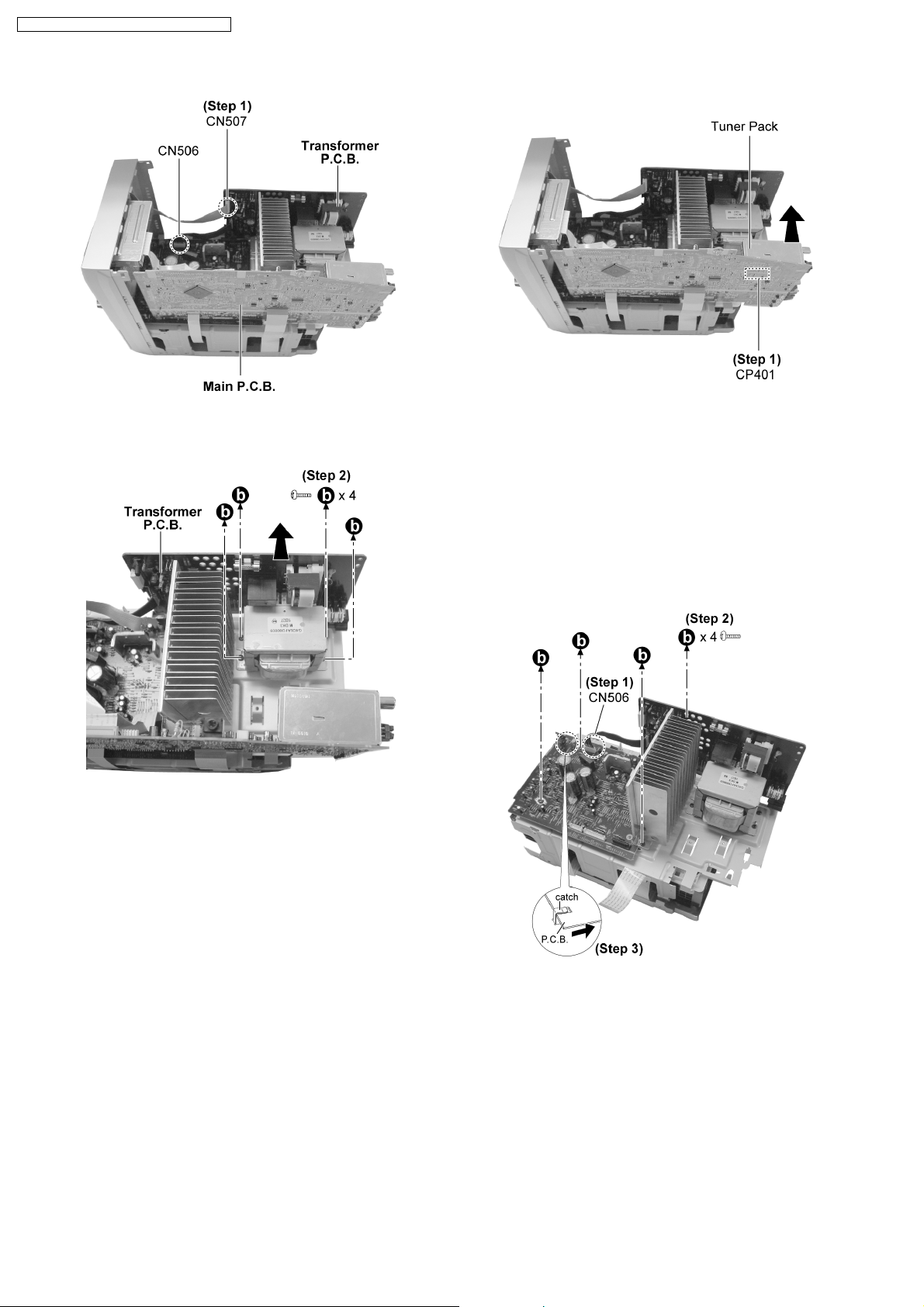

Step 1 : Detach the connectors CN506 and CN507.

Step 2 : Remove 4 screws and pull out the Transformer P.C.B.

as arrow shown.

13.11. Disassembly of Tuner Pack

Step 1 : Detach the connector CP401 and remove the tuner

pack as arrow shown.

13.12. Disassembly of Power P.C.B.

· Follow the (Step 1) - (Step 6) of item 13.2.

· Follow the (Step 1) - (Step 2) of item 13.3.

· Follow the (Step 1) - (Step 5) of item 13.5.

· Follow the (Step 1) - (Step 3) of item 13.8.

· Follow the (Step 1) - (Step 3) of item 13.9.

· Follow the (Step 1) - (Step 6) of item 13.2.

· Follow the (Step 1) - (Step 2) of item 13.3.

· Follow the (Step 1) - (Step 3) of item 13.8.

Step 1 : Detach the connector CN506.

Step 2 : Remove 4 screws.

Step 3 : Remove the Power P.C.B. (Be careful of the catch)

13.13. Disassembly of CR16

Mechanism

· Follow the (Step 1) - (Step 6) of item 13.2.

· Follow the (Step 1) - (Step 2) of item 13.3.

· Follow the (Step 1) - (Step 5) of item 13.5.

26

Page 27

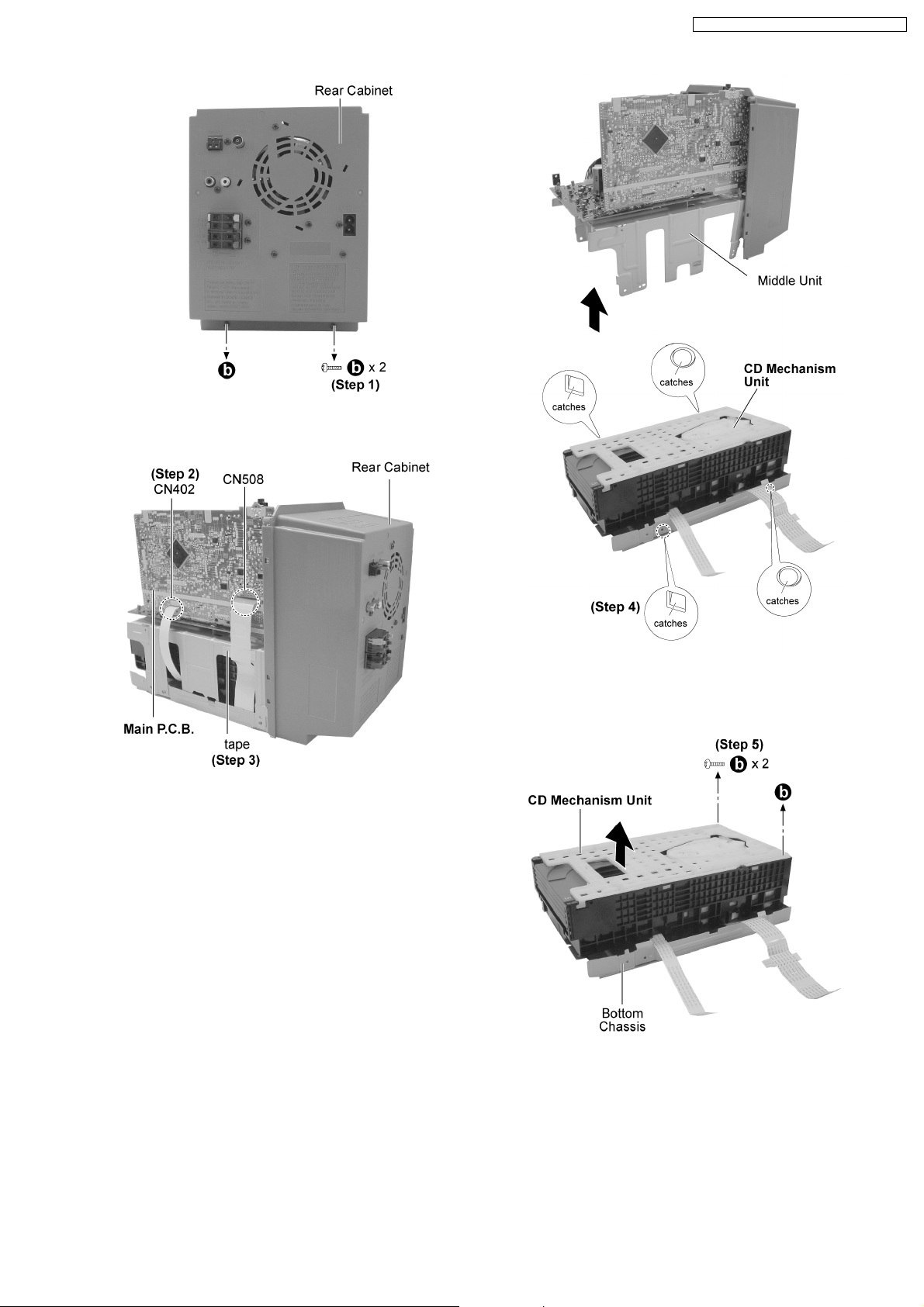

Step 1 : Remove 2 screws.

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

Step 2 : Detach the connectors CN402 and CN508.

Step 3 : Remove the tape which used to secure the FFC

connectors.

Step 4 : Release the catches and remove the middle unit as

arrow shown.

Step 5 : Remove 2 screws and remove the CD Mechanism Unit

from the bottom chassis as arrow shown.

13.14. Replacement of CD Lid and

Inner CD Lid

· Follow the (Step 1) - (Step 6) of item 13.2.

· Follow the (Step 1) - (Step 2) of item 13.3.

27

Page 28

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

· Follow the (Step 1) - (Step 5) of item 13.5.

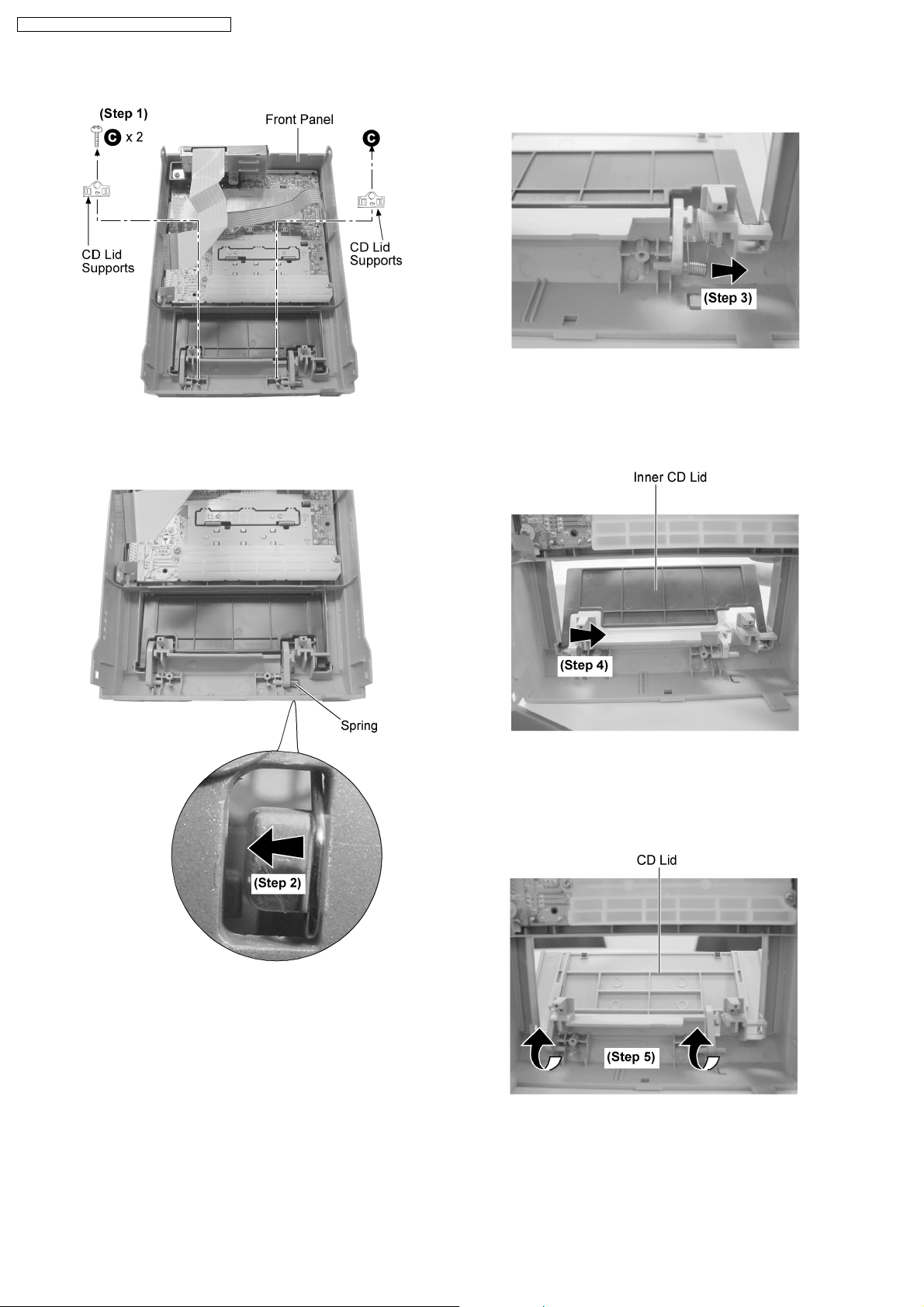

Step 1 : Remove 2 screws 2 CD Lid supports.

Step 3 : Remove the spring as arrow shown.

Step 2 : Release the spring hook as arrow shown.

Step 4 : Remove the Inner CD Lid as arrow shown.

Step 5 : Remove the CD lid as arrow shown.

28

Page 29

13.15. Replacement of Cassette Lid

· Follow the (Step 1) - (Step 6) of item 13.2.

· Follow the (Step 1) - (Step 2) of item 13.3.

· Follow the (Step 1) - (Step 4) of item 13.4.

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

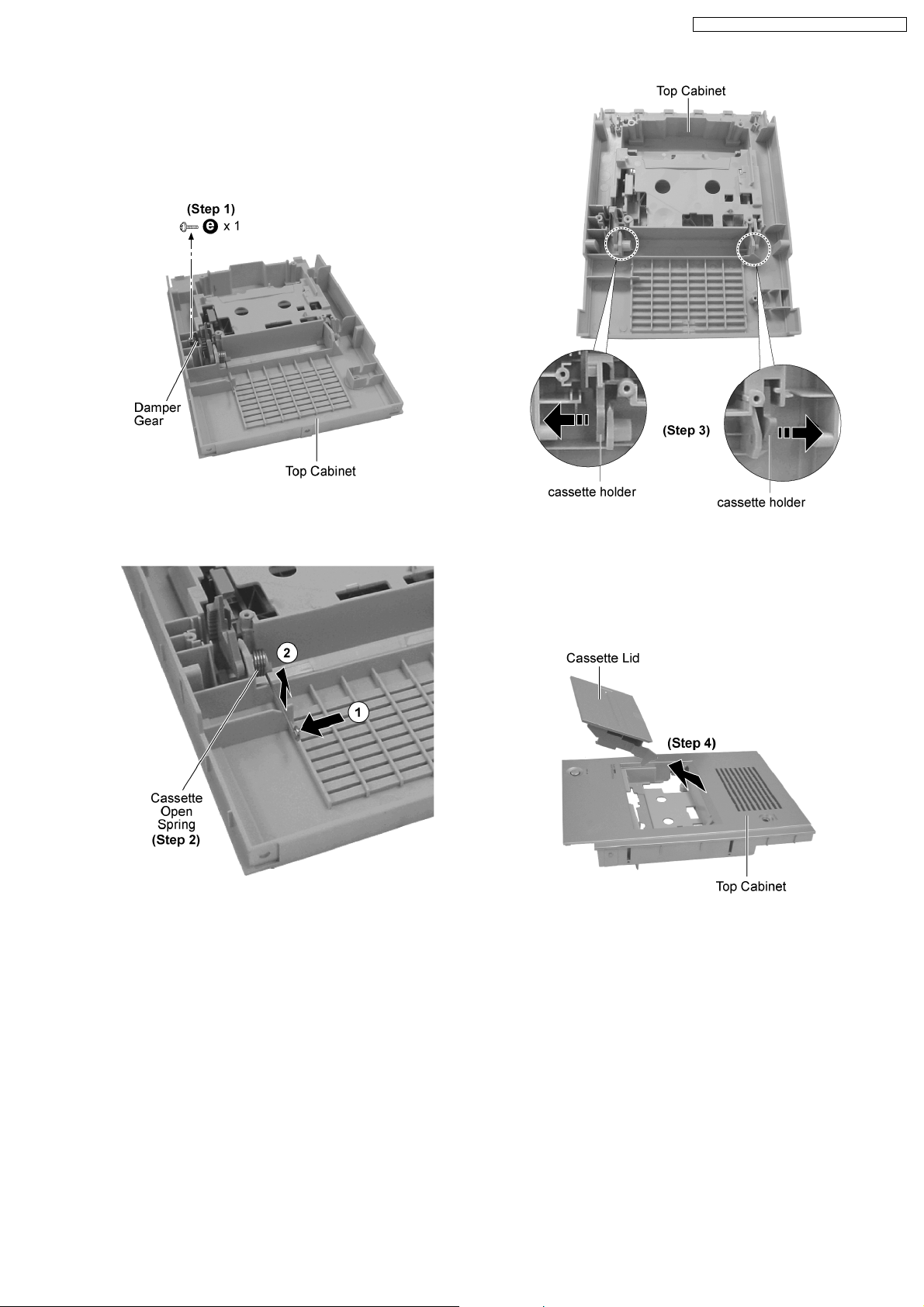

Step 1 : Remove 1 screw and the damper gear.

Step 2 : Remove the cassette open spring as arrows shown in

order.

Step 3 : Pull both sides cassette holders to the direction of the

arrows shown.

Step 4 : Remove the cassette lid as arrow shown.

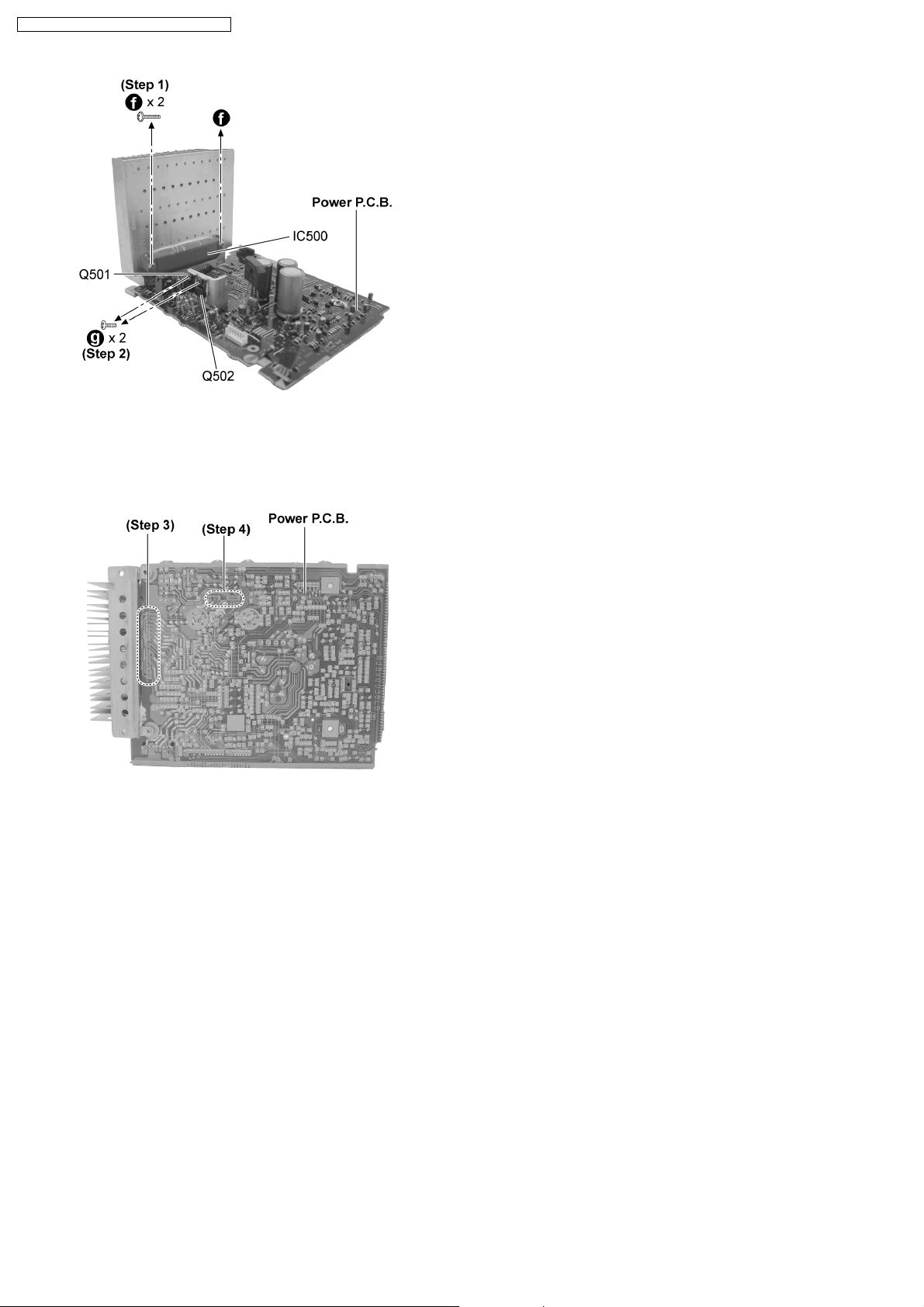

13.16. Replacement of the Power IC

and Transistors

· Follow the (Step 1) - (Step 6) of item 13.2.

· Follow the (Step 1) - (Step 2) of item 13.3.

· Follow the (Step 1) - (Step 5) of item 13.5.

· Follow the (Step 1) - (Step 3) of item 13.8.

· Follow the (Step 1) - (Step 3) of item 13.9.

· Follow the (Step 1) - (Step 3) of item 13.12.

29

Page 30

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

Step 1 : Remove 2 screws.

Step 2 : Remove 2 screws.

Step 3 : Unsolder the Power IC500.

Step 4 : Unsolder the Transistor Q501 and Q502.

30

Page 31

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

13.17. Procedure for Replacing Pinch Roller and Head Block (Deck

Mechanism Unit)

· Follow the (Step 1) - (Step 6) of Item 13.2.

· Follow the (Step 1) - (Step 2) of Item 13.3.

· Follow the (Step 1) - (Step 4) of Item 13.4.

13.18. Procedure for Replacing Motor, Capstan Belt A, Capstan Belt B, and

Winding Belt (Deck Mechanism Unit)

· Follow the (Step 1) - (Step 6) of Item 13.2.

· Follow the (Step 1) - (Step 2) of Item 13.3.

· Follow the (Step 1) - (Step 4) of Item 13.4.

· Follow the (Step 1) - (Step 4) of Item 13.17.

31

Page 32

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

32

Page 33

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

13.19. Procedure for Replacing Parts on Deck Mechanism PCB

· Follow the (Step 1) - (Step 6) of Item 13.2.

· Follow the (Step 1) - (Step 2) of Item 13.3.

· Follow the (Step 1) - (Step 4) of Item 13.4.

13.20. Disassembly of CR16 Mechanism

· Follow the (Step 1) - (Step 6) of Item 13.2.

· Follow the (Step 1) - (Step 2) of Item 13.3.

· Follow the (Step 1) - (Step 5) of Item 13.5.

· Follow the (Step 1) - (Step 5) of Item 13.13.

33

Page 34

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

13.21. Replacement of optical pickup unit (CD mechanism)

· Follow the (Step 1) - (Step 6) of Item 13.2.

· Follow the (Step 1) - (Step 2) of Item 13.3.

· Follow the (Step 1) - (Step 5) of Item 13.5.

· Follow the (Step 1) - (Step 5) of Item 13.13.

· Follow the (Step 1) - (Step 2) of Item 13.20.

34

Page 35

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

35

Page 36

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

13.22. Replacement of a traverse gear A and a traverse gear B

· Follow the (Step 1) - (Step 6) of Item 13.2.

· Follow the (Step 1) - (Step 2) of Item 13.3.

· Follow the (Step 1) - (Step 5) of Item 13.5.

· Follow the (Step 1) - (Step 5) of Item 13.13.

· Follow the (Step 1) - (Step 2) of Item 13.20.

· Follow the (Step 1) - (Step 4) of Item 13.21.

36

Page 37

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

13.23. Procedure for removing CD loading mechanism

1. Turn off by pressing power SW in the body.

2. Unplug AC power cord after the indication of [GOOD-BYE],

then disassemble the body.

3. Disassemble the body, and take out CD loading

mechanism.

4. Perform disassembly according to the following procedure

for disassembly.

13.24. CR16 mechanism disassembly procedure

13.24.1. Gear for servicing information

· This unit has a gear which used for checking items

(open/close of disc tray, up/down operation of traverse unit

by manually) when servicing. (For gear information, that is

described on the items for disassembly procedures.)

· For preparation of gear (for servicing), perform the

procedures as follows.

· In case of re-servicing the same set, the “ gear for servicing”

may be took off becaus e it had been used. So, the “gear for

servicing” must be stored.

1. Remove the gear attached to top cover of CD loading

mechanism.

2. Insert the hexagonal wrench (2.5mm) into the gear.

37

Page 38

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

13.24.2. Replacement for the disc tray

· Follow the (Step 1) - (Step 6) of Item 13.2.

· Follow the (Step 1) - (Step 2) of Item 13.3.

· Follow the (Step 1) - (Step 5) of Item 13.5.

· Follow the (Step 1) - (Step 5) of Item 13.13.

38

Page 39

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

39

Page 40

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

13.24.3. Replacement for the traverse deck

· Follow the (Step 1) - (Step 6) of Item 13.2.

· Follow the (Step 1) - (Step 2) of Item 13.3.

· Follow the (Step 1) - (Step 5) of Item 13.5.

· Follow the (Step 1) - (Step 5) of Item 13.13.

· Follow the (Step 1) - (Step 10) of Item 13.24.2

13.24.4. Disassembly for CD loading unit

· Follow the (Step 1) - (Step 6) of Item 13.2.

· Follow the (Step 1) - (Step 2) of Item 13.3.

· Follow the (Step 1) - (Step 5) of Item 13.5.

· Follow the (Step 1) - (Step 5) of Item 13.13.

· Follow the (Step 1) - (Step 10) of Item 13.24.2

· Follow the (Step 1) - (Step 4) of Item 13.24.3

40

Page 41

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

41

Page 42

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

42

Page 43

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

13.25. CR16 MECHANISM ASSEMBLY

PROCEDURE

The following specified greases and/or oil must be applied

when some specific parts are changed.

1. Floil grease (VFK1298) : The floil grease must be

applied to tray, tray (L) and tray (R).

2. Hanarl oil (VFK1700) : The hanarl oil must be applied to

any parts with grease other than the said parts.

· Follow the (Step 1) - (Step 6) of Item 13.2.

· Follow the (Step 1) - (Step 2) of Item 13.3.

· Follow the (Step 1) - (Step 5) of Item 13.5.

· Follow the (Step 1) - (Step 2) of Item 13.10.

· Follow the (Step 1) - (Step 5) of Item 13.13.

· Follow the (Step 1) - (Step 10) of Item 13.24.2

· Follow the (Step 1) - (Step 4) of Item 13.24.3

· Follow the (Step 1) - (Step 22) of Item 13.24.4

43

Page 44

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

44

Page 45

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

45

Page 46

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

46

Page 47

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

47

Page 48

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

48

Page 49

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

49

Page 50

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

50

Page 51

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

51

Page 52

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

52

Page 53

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

53

Page 54

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

54

Page 55

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

55

Page 56

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

13.26. Disassembly of traverse mechanism

· Follow the (Step 1) - (Step 6) of Item 13.2.

· Follow the (Step 1) - (Step 2) of Item 13.3.

· Follow the (Step 1) - (Step 5) of Item 13.5.

· Follow the (Step 1) - (Step 5) of Item 13.13.

· Follow the (Step 1) - (Step 2) of Item 13.20.

56

Page 57

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

13.27. Handling of cassette tape jam

· Follow the (Step 1) - (Step 6) of Item 13.2.

Step 1 : If the cassette tape cannot eject due to twinning

around capstan or pinch roller during play or record, rotate the

flywheel F as arrow shown to remove twined tape.

Step 2 : Push the lever as arrow shown to open the cassette lid

and remove the cassette tape.

57

Page 58

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

14 Service Positions

14.1. Checking procedure

Note : For the disassembling procedure, see the section 13.

14.2. Checking the major P.C.B

1. Disassembly of Side Panel L & R

2. Disassembly of Top Cabinet

3. Disassembly of Deck Mechanism P.C.B and Tape Eject P.C.B

4. Disassembly of Front Panel

5. Disassembly of SD Module P.C.B

6. Disassembly Panel P.C.B

7. Disassembly of Rear Cabinet

8. Disassembly of Main P.C.B

9. Disassembly of Transformer P.C.B

10. Disassembly of Power P.C.B

11. Disassembly of CR16 mechanism

58

Page 59

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

15 Self-Diagnostic Display Function

This unit is equipped with a self-diagnostic display function, which will be useful during servicing and maintenance.

· Refer to the next page for display symbols, symptoms, etc.

15.1. Entering into Self-Diagnostic Mode

15.1.1. Setting of Self-Diagnostic (Doctor Mode)

a) Turn on power for unit.

b) Select SD Stop Mode.

c) Press and hold [STOP n/-DEMO] button for at least 2 seconds, follow by [4] and [7] on remote control. In the case where there

is EEPRO M, then, the display should be as below:

15.1.2. Rom Correction Checksum and Micro-p version

a) Turn on power for unit.

b) Select CD Mode.

c) Press and hold [STOP n/-DEMO] button for at least 2 seconds, follow by [4] and [7] on remote control. In the case where there

is EEPRO M, then, the display should be as below:

59

Page 60

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

15.2. Error Code Table

15.2.1. Error codes for CR 16

Mode Present After modify Description

Initialize F17 F17

F17P Play

F22 F22

F22L Load

F22T Trouble

F22U Unload

F27 F27

F27T Trouble

F27P Play

F28 F22

F28P Play

Load/Unload F28 LOAD Load

F29 UNLOAD Unload

Disc Change F27 DCHU Disc change up

DCHD Disc change down

Single open / close F28 NSCL Normal single close

F29 NSOP Normal single open

Single open / close during play F27 PSOU Play single open up

PSOD Play single open down

PSCU Play single close up

PSCD Play single close down

F28 PSCL Play single close

F29 PSOP Play single open

All open / close H16 H16

F27 NAOU Normal all open up

NACD Normal all close down

F28 NACL Normal all close

F29 NAOP Normal all open

All open / close during play F27 PAOU Play all open up

PACD Play all close down

F28 PACL Play all close

F29 PAOP Play all open

Lock for shipment F27 LOCK Lock

Total of kind 5 33

Display of error code

1. Upon occurrence of error, a maximum of 5 will be displayed.

2. Upon occurrence of error, indication will be from number 1.

3. Upon occurrence of the same error time, the error will be displayed twice.

Example:

60

Page 61

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

1st occurrence ......... ERROR 1 DCHU

2nd occurrence ......... ERROR 2 NSOP

3rd occurrence ......... ERROR 3 PAOP

4th occurrence ......... ERROR 4 PAOP

5th occurrence ......... ERROR 5 NSOP

15.2.2. Error codes for Deck Mechanism

Error Code Abnormal Items Possible Cause

H01 MODE SW abnormal Normal operation during mecha transition, MODE SW abnormal is memorised. The content

H02 REC INH SW abnormal

H03 HALF SW abnormal

H06 Cr02 SW abnormal

F01 Reel pulse abnormal

F02 TPS abnormal

of abnormality can be confirmed in the abnormal detection mode explained in the later

section.

The content of abnormality can be confirmed in the abnormal detection mode explained in

the later section.

15.3. Changer Reliability Test Mode

1. After entering the inspection mode, push button [12] on the remote control for reliability testing mode.

2. Follow the flow process below

3. During the aging process, pressing the [PROGRAM] button will stop the process, and return it to NORMAL mode.

4. Enter the service mode.

5. Press,[

· DVD/CD function set to automatic mode.

· Input a Disc into each tray.

6. Set display uses 4-digit for counter display.

· [PLAYCHECK 0000] to max [PLAYCHECK 9999].

7. After 1 cycle process is completed, FL counter will display [1] count up from [0000] to max [9999]. From [9999] count up [1] will

display [0000].

8. During mechanism operation in test mode, if time over error occurs with arnormal operations, do not retry but stop the test

instead.

9. To exit from Test mode power off the set.

10. If during test mode, after TOC reading of disc and [NO DISC] [NO PLAY] is indicated, stop the test here. (Keep the counter

displayed in the same state as when it was stopped.) Do not reopen the reliability test mode after it stops,

11. Go back to [1] after 1 cycle finishe s.

· After 1 cycle process is completed, FL counter will display [1] count up from [0000] to max [9999]. From [9999] count up [1]

10], [2] with the settings below.

will display [0000] .

61

Page 62

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

16 Procedure for Checking Operation of Individual Parts of

Deck Mechanism Unit

16.1. Operation Check with Cassette Tape

1. Pull up the EJECT lever using a rubber band. (Fig. 6)

2. Supply DC5V to MOTOR. (→ MOTOR rotates.) (Fig. 5)

3. Insert a cassette tape to the unit.

4. Supply DC9V to the plunger, and turn the power ON and OFF. (→ Power +PL, -PL) (Fig. 5)

a. FWD PLAY: Supply the plunger power in a flash. (ON: approx. 5msec)

b. FWD FF: Supply the plunger power in a flash at PLAY mode. (ON: approx. 5msec)

c. STOP: Supply the plunger power in a flash at FWD FF mode. (ON: approx. 5msec)

d. REV PLAY: Supply the plunger power in a normal timing at STOP mode. (ON: approx. 200msec)

e. REV REW: Supply the plunger power in a flash at REV PLAY mode. (ON: approx. 50msec)

f. STOP: Supply the plunger power in a flash at FF mode. (ON: approx. 50msec)

Repeat the operation (→ FWD PLAY)

(Note) Other operation may start if a timing of supplying the plunger power is missed.

16.1.1. Connection Status between Mechanism and Power Supply (Motor, Plunger)

16.1.2. Operative Parts of Mechanism Unit (EJECT lever fitted with rubber band,

Plunger/Rib operation)

Fig. 6

16.2. Operation Check without Cassette Tape

1. Pull up the EJECT lever using a rubber band. (Fig. 6)

2. Supply DC5V to MOTOR. (→ MOTOR rotates.)

3. Lift up the mechanism unit’s plunger/rib with the tip of a negative screwdriver, and operate the unit in the same timing as

supplying the power. (Fig. 7)

62

Page 63

Fig. 7

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

63

Page 64

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

17 Measurement And Adjustments

17.1. Cassette Deck Section

17.1.1. Requirements

· Test tape (QZZCFM) (QZZCWAT)

· Normal blank cassette tape (QZZCRA)

· Digital frequency counter

· Oscilloscope

· Electrical voltmeter

· Headphone jack output jig (Fig. 8)

17.1.2. Setting of Unit

· VOLUME: MAX

17.1.3. Preparations

1. Apply under [13. Assembling and Disassembling].

2. Remove 4 screws from the mechanism unit to disassemble. under [13. Assembling and Disassembling].

3. Connect the headphone jack output jig (Fig. 8) to headphone jack.

Fig. 8

Fig. 9

17.1.4. Tape Speed Adjustment

· Normal speed adjustment (only during forward playback)

(Product reference value: 3,000±90Hz)

1. Connect a frequency indicator. (Fig. 12)

2. Playback the middle portion of the test tape (QZZCWAT).

3. Adjust the motor screw so that the following output level is produced. (Fig. 10)

Adjustment Range: 3,000 ± 90Hz (a constant speed)

64

Page 65

17.1.5. Bias Voltage Check

1. Connect an electrical voltmeter. (Fig. 9) (Fig. 12)

2. Set the function to “TAPE” position.

3. Insert a normal blank cassette tape (QZZCRA).

4. While pressing and holding down [REC (

pressing the buttons till the recording pause mode is activated.)

5. Check that the output level is within the standard range.

Standard Range: 14 ± 4mV

/ )] button, press [TAPE ( )] button to pause the recording mode. (Repeat

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

Fig. 10

Fig. 11

Fig. 12

17.1.6. Bias Frequency Check

1. Connect a digital frequency counter (Fig. 13).

2. Set the function to “TAPE” position.

3. Insert a normal blank cassette tape (QZZCRA) and press “REC” mode on main unit.

4. Check that the output frequency is within the standard range.

Standard Value: 98 ±8 kHz

Fig. 13

65

Page 66

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

18 Voltage Measurement and Waveform Chart

Note:

· Indicated voltage values are the standard values for the unit measured by the DC electronic circuit tester (high-impedance)

with the chassis taken as standard.

Therefore, there may exist some errors in the voltage values, depending on the internal impedance of the DC circuit tester.

· Circuit voltage and waveform described herein shall be regarded as reference information when probing defect point

because it may differ from actual measuring value due to difference of Measuring instrument and its measuring condition

and product itself.

18.1. Voltage Measurement

18.1.1. CD SERVO P.C.B.

CD SERVO P.C.B.

Ref No.

MODE 1234567891011121314151617181920

SD REC 0.2 2.5 3.3 0 2.2 2.1 1.7 1.5 1.6 1.6 2.1 1.2 0 0 0 3.3 0 1.6 1.7 1.6

SD PLAY 0 2.9 3.3 0 0 1.6 1.4 0.4 1.4 1.6 1.5 1.2 0 0.4 3.1 0 0 1.7 1.6 1.6

CD PLAY 0.2 2.5 3.3 0 2.2 2.1 1.7 1.5 1.6 1.6 2.1 1.2 0 0 0 3.3 0 1.6 1.7 1.6

STANDBY 0 -0.2 0.1 00000000000000000

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32

SD REC 1.7 1.7 1.7 0 1.7 1.7 2.0 2.0 1.8 1.8 1.8 1.8

SD PLAY 1.6 1.6 1.6 1.6 1.6 1.6 1.7 1.7 1.8 1.8 1.8 1.8

CD PLAY 1.7 1.7 1.7 0 1.7 1.7 2.0 2.0 1.8 1.8 1.8 1.8

STANDBY 000000000000

Ref No.

MODE 1234567891011121314151617181920

SD REC 3.3 1.5 1.5 0.3 3.1 1.6 1.5 3.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2 2.4 2.4 1.3 1.3 0

SD PLAY 3.3 0 0 0 3.3 0 0 3.3 3.3 3.3 00003.300000

CD PLAY 3.3 1.5 1.5 0.3 3.1 1.6 1.5 3.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2 2.4 2.4 1.3 1.3 0

STANDBY 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

SD REC 1.5 1.5 1.6 0 1.6 0 1.7 0 3.3 1.7 1.7 1.7 1.7 1.7 0 0 0 3.3 1.6 0.8

SD PLAY 1.5 1.5 1.6 3.3 1.6 0 1.7 0 3.3 1.7 1.7 1.7 1.7 1.7 0.4 3.1 0 0 0.1 0.8

CD PLAY 1.5 1.5 1.6 0 1.6 0 1.7 0 3.3 1.7 1.7 1.7 1.7 1.7 0 0 0 3.3 1.6 0.8

STANDBY 00000000000000000000

Ref No.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

SD REC 1.6 1.6 1.6 1.6 1.6 3.3 0 1.5 0 1.5 3.0 0 1.5 3.3 3.3 0 0 0 3.3 0

SD PLAY 1.5 0.1 0.3 0 0 3.3 0 1.5 0 1.5 3.0 0 1.5 3.3 00003.30

CD PLAY 1.6 1.6 1.6 1.6 1.6 3.3 0 1.5 0 1.5 3.0 0 1.5 3.3 3.3 0 0 0 3.3 0

STANDBY 00000000000000000000

Ref No.

MODE 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

SD REC 3.2 3.2 3.2 0.1 3.3 0.1 0.5 0.1 3.2 0 0.1 0.8 1.6 1.6 3.3 1.6 - 0 1.5 1.0

SD PLAY 00003.30003.203.3001.63.33.33.301.53.3

CD PLAY 3.2 3.2 3.2 0.1 3.3 0 0 0 3.2 0 0 0.8 1.6 1.6 3.3 - 1.6 0 1.5 1.6

STANDBY 00000000000000000000

Ref No.

MODE 1234567891011121314151617181920

SD REC1.601.60000007.74.53.43.63.63.53.73.63.57.70

SD PLAY 1.6 0 1.6 3.3 000007.74.04.03.63.63.63.63.63.67.70

CD PLAY 1.6 0 1.6 0000007.74.53.43.63.63.53.73.63.57.70

STANDBY 0000000000.20.10.10.100.10.10.10.10.20

Ref No.

MODE 21 22 23 24 25 26 27 28

SD REC 7.7 0 0 0 7.7 1.7 1.7 1.7

SD PLAY 7.7 0 0 0 7.7 1.7 1.7 1.7

CD PLAY 7.7 0 0 0 7.7 1.7 1.7 1.7

STANDBY 0.2 0 0 0 0.2 0 0 0

Ref No.

MODE E C B

SD REC 3.2 2.0 2.5

SD PLAY 3.3 0.8 2.9

CD PLAY 3.2 2.0 2.5

STANDBY 0.1 0.1 -0.3

Q701

IC701

IC701

IC702

IC702

IC702

IC702

IC 703

IC 703

66

Page 67

18.1.2. CD LOADING P.C.B

Ref No.

MODE 123456789

SD REC 7.7 0 0 0 7.7 7.7 3.1 0 3.1

SD PLAY 7.7 0 0 0 7.7 7.7 3.1 0 3.1

CD PLAY 7.7 0 0 0 7.7 7.7 3.1 0 3.1

STANDBY 0.1 0.1 0 0.1 0.1 0.1 0 0 0

Ref No.

MODE 123456789

SD REC 7.7 0 0 0 7.7 7.7 3.1 0 3.1

SD PLAY 7.7 0 0 0 7.7 7.7 3.1 0 3.1

CD PLAY 7.7 0 0 0 7.7 7.7 3.1 0 3.1

STANDBY 0.2 0 0 0.1 0.2 0.2 0 0 0

IC 11

CD LOADING P.C.B

IC 21

Ref No.

MODE 1234567891011121314151617181920

CD PLAY 3.8 3.8 3.8 3.8 0 3.8 3.8 3.8 3.8 3.8 3.8 3.8 3.8 3.8 3.8 3.8 3.8 0 0 0

STANDBY -0.1 -0.1 0.4 0.4 0 0.4 0.4 0.4 0.4 0.4 0.4 0.4 0.4 0.4 0.4 0.4 0.4 0 0 0

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY 7.6 0 3.8 3.8 3.8 3.8 3.8 3.8 3.8 3.8 3.8 3.8 3.8 3.8 3.8 3.8 3.8 3.8 3.8 3.8

STANDBY 0.2 0 0.3 0.2 0.2 0.1 0.2 0.2 0.1 0.1 0.2 0.2 0000000.10.1

Ref No.

MODE 12345678

SD REC 0 - - -8.6 0 0 0 8.9

SD PLAY 0 - - -8.6 0 0 0 8.9

CD PLAY 0 - - -8.6 0 0 0 8.9

STANDBY 0 0 0 0.2 0 0 0 0.2

Ref No.

MODE 12345678

SD REC 0 0 0 -8.6 0 - 0 8.9

SD PLAY 0 0 0 -8.6 0 - 0 8.9

CD PLAY 0 0 0 -8.6 0 0 0 8.9

STANDBY 0 0 0 0.2 0 0 0 0.2

Ref No.

MODE 12345678

SD REC 0 0 0 -8.6 - 0 0 8.9

SD PLAY 0 0 0 -8.6 - 0 0 8.9

CD PLAY 0 0 0 -8.6 - 0 0 8.9

STANDBY 0 0 0 0.2 0 0 0 0.2

Ref No.

MODE 12345678

SD REC 3.2 3.2 3.2 3.2 0 3.2 0 0

SD PLAY 3.2 3.2 3.2 3.2 0 3.2 0 0

CD PLAY 3.2 3.2 3.2 3.2 0 3.2 0 0

STANDBY 3.2 3.2 3.2 3.2 0 3.3 0 0

IC205

IC201

IC203

IC201

MAIN P.C.B.

IC206

IC403

18.1.3. MAIN P.C.B.

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

67

Page 68

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

Ref No.

MODE 1234567891011121314151617181920

SD REC 0 3.1 0 3.2 2.7 3.2 2.8 0 3.2 3.2 3.2 3.2 3.2 3.2 0 2.7 3.2 0 3.2 1.8

SD PLAY 0 3.1 0 3.2 2.7 3.2 2.8 0 3.2 3.2 3.2 3.2 3.2 3.2 0 2.7 3.2 0 3.2 1.8

CD PLAY 0 3.1 0 3.2 2.7 3.2 2.8 0 3.2 3.2 3.2 3.2 3.2 3.2 0 2.7 3.2 0 3.2 1.8

STANDBY 0 0 0 3.2 00003.23.23.23.23.23.202.83.200.51.8

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

SD REC3.23.23.23.2- -3.23.23.23.203.200000000

SD PLAY 3.2 3.2 3.2 3.2 - - 3.2 3.2 3.2 3.2 0 3.2 00000000

CD PLAY 3.2 3.2 3.2 3.2 3.2 3.2 3.2 3.2 3.2 3.2 0 3.2 00000000

STANDBY 3.3 3.3 3.3 2.6 00003.33.303.300000000

Ref No.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

SD REC3.23.23.23.201.201.23.200000003.23.200

SD PLAY 3.2 3.2 3.2 3.2 0 1.2 0 1.2 3.2 00000003.23.200

CD PLAY 3.2 3.2 3.2 3.2 0 0.7 0 0.7 3.2 00000003.23.200

STANDBY 000000003.3000000003.300

Ref No.

MODE 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

SD REC 0 3.2 0 1.8 3.2 0 3.2 0 0 0 1.4 1.6 0 3.2 1.8 3.2 1.5 1.6 0 0

SD PLAY 0 3.2 0 1.8 3.2 0 3.2 0 0 0 1.4 1.6 0 3.2 1.8 3.2 1.5 1.6 0 0

CD PLAY 0 3.2 0 1.8 3.2 0 3.2 0 0 0 1.4 1.6 0 3.2 1.8 3.2 1.5 1.6 0 0

STANDBY 0 0 3.3 1.8 3.3 0 3.3 0 0 0 1.4 1.6 0 3.2 1.8 3.2 1.5 1.6 0 0

Ref No.

MODE 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100

SD REC 1.8 3.2 0 0 3.2 0 3.2 0 3.2 0 0 0 3.2 3.2 3.2 3.2 0.2 3.2 3.2 3.2

SD PLAY 1.8 3.2 0 0 3.2 0 3.2 0 3.2 0 0 0 3.2 3.2 3.2 3.2 0.2 3.2 3.2 3.2

CD PLAY 1.8 3.2 0 3.2 0 0 3.2 0 3.2 0 0 0 3.2 3.2 3.2 3.2 0.2 3.2 3.2 3.2

STANDBY 1.8 3.2 0 3.2 000000003.30003.33.300

Ref No.

MODE 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120

SD REC0003.22.900000003.32.203.23.23.200

SD PLAY 0 0 0 3.2 2.9 00000003.32.203.23.23.200

CD PLAY 0 0 0 3.2 2.9 00000003.32.203.203.200

STANDBY 0 3.3 0 3.3 000000003.32.30003.300

Ref No.

MODE 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136

SD REC 0 0 0 3.2 3.2 0 0 0 0.1 3.2 3.2 0 1.8 3.2 3.2 0

SD PLAY 0 0 0 3.2 3.2 0 0 0 0.1 3.2 3.2 0 1.8 3.2 3.2 0

CD PLAY 0 0 0 3.2 3.2 0 0 0 0.1 3.2 3.2 0 1.8 3.2 3.2 0

STANDBY 0000000000001.83.33.30

IC405

IC405

IC405

IC405

IC405

IC405

IC405

68

Page 69

Ref No.

MODE 1 2 3

SD REC 5.0 0 3.3

SD PLAY 5.0 0 3.3

CD PLAY 5.0 0 3.3

STANDBY 0 0 0.1

Ref No.

MODE 12345

SD REC 6.7 6.7 0 3.3 3.3

SD PLAY 6.7 6.7 0 3.3 3.3

CD PLAY 6.7 6.7 0 3.3 3.3

STANDBY 0.9 0.9 0 0.1 0.1

Ref No.

MODE 12345

SD REC 7.4 7.4 0 5.0 5.0

SD PLAY 7.4 7.4 0 5.0 5.0

CD PLAY 7.4 7.4 0 5.0 5.0

STANDBY 0.3 0.3 0 0 0

Ref No.

MODE 12345

SD REC 3.2 3.2 0 0 1.6

SD PLAY 3.2 3.2 0 0 1.6

CD PLAY 3.2 3.2 0 0 1.6

STANDBY 3.2 3.2 0 0 1.6

Ref No.

MODE 1 2 3

SD REC 5.6 0 3.3

SD PLAY 5.6 0 3.3

CD PLAY 5.6 0 3.3

STANDBY 6.0 0 3.3

Ref No.

MODE 12345678910111213141516

SD REC 3.3 0 1.6 1.6 3.3 0 1.6 1.6 0 3.3 0 3.3 1.6 1.7 0 0

SD PLAY 3.3 0 1.6 1.6 3.3 0 1.6 1.6 0 3.3 0 3.3 1.6 1.7 0 0

CD PLAY 3.3 0 1.6 1.6 3.3 0 1.6 1.6 0 3.3 0 3.3 1.6 1.7 0 0

STANDBY 0 0 0.2 00000.200000000

Ref No.

MODE E C B E C B E C B E C B E C B

SD REC 0 0 0 0 0 0

0 0 -0.9

0 0 0.7 2.2 2.1 0

SD PLAY 0 0 0 0 0 0

0 0 -0.9

0 0 0.7 2.2 2.1 0

CD PLAY 0 0 0 0 0 0

0 0 -0.9

0 0 0.7 2.2 2.1 0

STANDBY 0 0 0 0 0 0

0 0 -1.9

0 0 -2.0 0 -2.0 0

Ref No.

MODE E C B E C B 1 2 3 E C B E C B

SD REC 0 -0.9 0 0 9.8 0 0 9.8 0 3.2 0 3.2 0 0 0

SD PLAY 0 -0.9 0 0 9.8 0 0 9.8 0 3.2 0 3.2 0 0 0

CD PLAY 0 -0.9 0 0 9.8 0 0 9.8 0 3.2 0 3.2 0 0 0

STANDBY 0 -1.9 0 0 0.2 0 0 0.2 0 3.3 0 3.3 0 0 0

Ref No.

MODE E C B E C B

SD REC 0 3.2 0 0 3.2 -1.4

SD PLAY 0 3.2 0 0 3.2 -1.4

CD PLAY 0 3.2 0 0 3.2 -1.4

STANDBY 0 0.5 0 0 0.5 0.2

IC608

Q205 Q209Q208

IC406

IC410

IC408

IC409

QR203

QR406

QR402

QR202

IC407

QR404 QR405QR403

Q204

QR703

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

69

Page 70

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

18.1.4. PANEL P.C.B.

PANEL P.C.B.

Ref No.

MODE 1234567891011121314151617181920

SD REC000000000003.21.601.53.33.3000

SD PLAY 000000000003.21.601.53.33.3000

CD PLAY 000000000003.21.601.53.33.3000

STANDBY 0000000000001.601.43.33.3000

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

SD REC000000-3.23.23.2000000003.23.2

SD PLAY 000000-3.23.23.2000000003.23.2

CD PLAY 000000-3.23.23.2000000003.23.2

STANDBY 0000000003.21.51.51.51.51.501.51.53.30

Ref No.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

SD REC00000003.200000003.20000

SD PLAY 00000003.200000003.20000

CD PLAY 00000003.200000003.20000

STANDBY 000001.51.51.51.51.51.51.51.51.51.51.51.51.51.51.5

Ref No.

MODE 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

SD REC 0 3.2 0 0 0 3.3 0 3.2 3.1 3.2 0 3.2 0 3.2 0 3.2 0 3.2 0 3.2

SD PLAY 0 3.2 0 0 0 3.3 0 3.2 3.1 3.2 0 3.2 0 3.2 0 3.2 0 3.2 0 3.2

CD PLAY 0 3.2 0 0 0 3.3 0 3.2 3.1 3.2 0 3.2 0 3.2 0 3.2 0 3.2 0 3.2

STANDBY 1.5 1.5 1.5 0 1.5 1.5 1.5 1.5 0 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5

Ref No.

MODE 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100

SD REC03.23.23.20000000000003.13.23.20

SD PLAY 0 3.2 3.2 3.2 0000000000003.13.23.20

CD PLAY 0 3.2 3.2 3.2 0000000000003.13.23.20

STANDBY 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 0 0 3.2 3.2 0

Ref No.

MODE E C B E C B E C B E C B E C B

SD REC 0 3.2 0 3.8 0 5.5 0 0.1 0.8 0 0 0.8 0 0 0.8

SD PLAY 0 3.2 0 3.8 0 5.5 0 0.1 0.8 0 0 0.8 0 0 0.8

CD PLAY 0 3.2 0 3.8 0 5.5 0 0.1 0.8 0 0 0.8 0 0 0.8

STANDBY 0 0.5 0 0.1 0 0 0 0.3 0 0 0.3 0 0 0.3 0

Ref No.

MODE E C B

SD REC 0 6.3 0

SD PLAY 0 6.3 0

CD PLAY 0 6.3 0

STANDBY 0 5.6 0

Q600 Q601

Q606

IC601

IC601

IC601

IC601

IC601

Q603 Q604 Q605

18.1.5. DECK P.C.B.

Ref No.

DECK P.C.B.

MODE 12345

SD REC6.00000

SD PLAY 6.0 0000

CD PLAY 6.0 0000

STANDBY 0.2 0000

Ref No.

MODE 1234567891011121314151617181920

SD REC 0 0.7 5.0 4.2 0 3.2 0 0.1 0 5.8 0 8.6 0 0 0.1 0 3.5 0.2 4.1 4.9

SD PLAY 0 0.7 5.0 4.2 0 3.2 0 0.1 0 5.8 0 8.6 0 0 0.1 0 3.5 0.2 4.1 4.9

CD PLAY 0 0.7 5.0 4.2 0 3.2 0 0.1 0 5.8 0 8.6 0 0 0.1 0 3.5 0.2 4.1 4.9

STANDBY 0 0.3 0.3 0.3 0 0.9 0 0 0 0.2 0 0.2 0000000.30.3

Ref No.

MODE 21 22

SD REC 0.7 0

SD PLAY 0.7 0

CD PLAY 0.7 0

STANDBY 0.3 0

Ref No.

MODE E C B E C B E C B E C B E C B

SD REC 0 0 0.7 0 0 0.7 2.0 1.9 0 0 6.0 0 6.0 0 6.0

SD PLAY 0 0 0.7 0 0 0.7 2.0 1.9 0 0 6.0 0 6.0 0 6.0

CD PLAY 0 0 0.7 0 0 0.7 2.0 1.9 0 0 6.0 0 6.0 0 6.0

STANDBY 0 0 0 0 0 0 0 0 0 0 0.2 0 0.2 0 0.2

Ref No.

MODE E C B E C B E C B E C B E C B

SD REC 0 8.6 0 0 8.6 0 0 0 0 9.8 -0.6 9.8 9.8 0 9.8

SD PLAY 0 8.6 0 0 8.6 0 0 0 0 9.8 -0.6 9.8 9.8 0 9.8

CD PLAY 0 8.6 0 0 8.6 0 0 0 0 9.8 -0.6 9.8 9.8 0 9.8

STANDBY 0 0.2 0 0 0.2 0 0 0 0 0.2 -1.4 0.2 0.2 0 0.2

Ref No.

MODE E C B E C B

SD REC 0 9.2 -0.6 0 0 0

SD PLAY 0 9.2 -0.6 0 0 0

CD PLAY 0 9.2 -0.6 0 0 0

STANDBY 0 0 -1.4 0 0 0

Q1101

Q1309 Q1310 Q1312

Q1316

Q1201 Q1302 Q1303

Q1317

IC 1000

IC 1001

IC 1001

Q1304

Q1314 Q1315

70

Page 71

18.1.6. POWER P.C.B.

Ref No.

MODE 123456789101112131415161718

SD REC -35.2 35.6 0 35.5 -35.2 0 0 0.2 0 -15.2 00000035.5 -35.2

SD PLAY -35.2 35.6 0 35.5 -35.2 0 0 0.2 0 -15.2 00000035.5 -35.2

CD PLAY -35.2 35.6 0 35.5 -35.2 0 0 0.2 0 -15.2 00000035.5 -35.2

STANDBY -0.2 35.8 0 35.8 -0.2 0000-0.2 00000035.8 -0.2

Ref No.

MODE 12345678

SD REC 0 0 0 -8.6 0 0 0 8.9

SD PLAY 0 0 0 -8.6 0 0 0 8.9

CD PLAY 0 0 0 -8.6 0 0 0 8.9

STANDBY 0 0 0 -0.3 0 0 0 0.2

Ref No.

MODE E C B E C B E C B E C B E C B

SD REC 9.0 13.6 9.6 13.7 9.9 13.1 0 -9.2 -0.6 -9.2 -34.1 -8.7 9.2 13.0 9.8

SD PLAY 9.0 13.6 9.6 13.7 9.9 13.1 0 -9.2 -0.6 -9.2 -34.1 -8.7 9.2 13.0 9.8

CD PLAY 9.0 13.6 9.6 13.7 9.9 13.1 0 -9.2 -0.6 -9.2 -34.1 -8.7 9.2 13.0 9.8

STANDBY 0.2 0.4 0.4 0.4 0.2 0.4 0 -0.1 0.2 -0.1 -0.1 0.2 0 0.4 0.4

Ref No.

MODE E C B E C B E C B E C B E C B

SD REC 13.1 14.0 13.7 0.1 3.2 0 0 3.2 0.1 0 1.1 -0.3 7.8 9.9 8.5

SD PLAY 13.1 14.0 13.7 0.1 3.2 0 0 3.2 0.1 0 1.1 -0.3 7.8 9.9 8.5

CD PLAY 13.1 14.0 13.7 0.1 3.2 0 0 3.2 0.1 0 1.1 -0.3 7.8 9.9 8.5

STANDBY 0.4 0 0.4 0.1 0.5 0 0 0.5 0.1 0 0 0.6 0.2 0.2 0.2

Ref No.

MODE E C B E C B E C B E C B E C B

SD REC 0 0 0.2 9.9 0 9.9 0 9.9 0 0 3.2 0 0 0 -5.9

SD PLAY 0 0 0.2 9.9 0 9.9 0 9.9 0 0 3.2 0 0 0 -5.9

CD PLAY 0 0 0.2 9.9 0 9.9 0 9.9 0 0 3.2 0 0 0 -5.9

STANDBY 0 0 0 0.2 0 0.2 0 0.2 0 0 0.5 0 0 0 0.1

Ref No.

MODE E C B E C B E C B E C B E C B

SD REC 0 0 -5.9 -1.6 9.0 -0.9 -1.5 9.0 -0.9 -0.7 9.0 -0.1 -0.7 9.0 -0.1

SD PLAY 0 0 -5.9 -1.6 9.0 -0.9 -1.5 9.0 -0.9 -0.7 9.0 -0.1 -0.7 9.0 -0.1

CD PLAY 0 0 -5.9 -1.6 9.0 -0.9 -1.5 9.0 -0.9 -0.7 9.0 -0.1 -0.7 9.0 -0.1

STANDBY 0 0 0.1 0.2 0.2 0 0.2 0.2 0 0.2 0.2 0 0.2 0.2 0

Ref No.

MODE E C B E C B E C B E C B E C B

SD REC 0 0 -5.9 0 0 -5.9 0 0 0 0 0 0 0 0 -5.9

SD PLAY 0 0 -5.9 0 0 -5.9 0 0 0 0 0 0 0 0 -5.9

CD PLAY 0 0 -5.9 0 0 -5.9 0 0 0 0 0 0 0 0 -5.9

STANDBY 0 0 0.1 0 0 0.1 0 0 0 0 0 0 0 0 0.1

Ref No.

MODE E C B E C B

SD REC 0 0 -5.9 0 -5.9 0

SD PLAY 0 0 -5.9 0 -5.9 0

CD PLAY 0 0 -5.9 0 -5.9 0

STANDBY 0 0 0.1 0 0 0

POWER P.C.B.

Q508

Q520

Q501 Q502 Q505 Q506

Q509 Q515 Q516 Q519

Q717

Q702 Q703 Q710

Q711

Q700 Q701

Q714 Q715 Q716

Q718 Q719 Q720 Q721 Q725

Q726 QR704

IC 501

IC 500

Ref No.

MODE E C B E C B E C B E C B

SD REC 0 0 0.7 5.8 8.0 6.5 0 2.2 -0.2 57.4 74.9 58.0

SD PLAY 0 0 0.7 5.8 8.0 6.5 0 2.2 -0.2 57.4 74.9 58.0

CD PLAY 0 0 0.7 5.8 8.0 6.5 0 2.2 -0.2 57.4 74.9 58.0

STANDBY 0 5.9 0 5.9 8.1 6.6 0 2.3 -0.1 0 0.3 0.3

Q577 Q578 Q579

TRANSFORMER P.C.B.

Q575

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

18.1.7. TRANSFORMER P.C.B.

71

Page 72

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

18.2. Waveform Chart

CN405 PIN 5

CD PLAY

3.44Vp-p (10msec.div)

CN406 PIN 1

CD PLAY

3.96Vp-p (25usec.div)

CN406 PIN 21

CD PLAY

3.40Vp-p (2.5msec.div)

CN405 PIN 18

CD PLAY

3.60Vp-p (50msec.div)

CN406 PIN 3

CD PLAY

4.16Vp-p (2.5usec.div)

CN506 PIN 1

CD PLAY

73.2Vp-p (25msec.div)

CN405 PIN 19

CD PLAY

3.48Vp-p (50msec.div)

CN406 PIN 5

CD PLAY

4.24Vp-p (2.5usec.div)

CN506 PIN 2

CD PLAY

73.2Vp-p (25msec.div)

CN405 PIN 20

CD PLAY

3.48Vp-p (50msec.div)

CN406 PIN 9

CD PLAY

3.44Vp-p (50usec.div)

CN507 PIN 3

CD PLAY

3.44Vp-p (25msec.div)

72

Page 73

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

CN507 PIN 6

CD PLAY

5.40Vp-p (25msec.div)

CN508 PIN 6

CD PLAY

3.36Vp-p (10msec.div)

CN508 PIN 10

CD PLAY

3.64Vp-p (10msec.div)

CN507 PIN 7

CD PLAY

5.52Vp-p (25msec.div)

CN508 PIN 7

CD PLAY

3.44Vp-p (10msec.div)

CN508 PIN 16

CD PLAY

4.40Vp-p (25usec.div)

CN508 PIN 4

CD PLAY

3.60Vp-p (10msec.div)

CN508 PIN 8

CD PLAY

3.44Vp-p (10msec.div)

CN508 PIN 17

CD PLAY

4.40Vp-p (25usec.div)

CN508 PIN 5

CD PLAY

3.32Vp-p (10msec.div)

CN508 PIN 9

CD PLAY

3.72Vp-p (10msec.div)

CN508 PIN 20

CD PLAY

43.48Vp-p (25usec.div)

73

Page 74

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

19 Block Diagram

19.1. CD SERVO Block

OPTICAL PICKUP

SEMICONDUCTOR

LASER

B

PHOTO DETECTOR

A

B

B

B

F

B

E

B

Q701

LASER

POWER DRIVE

B

IC701

AN22004A-NF

SERVO AMP

1

LPD

LD2

32

A

C

31

30

B

D

29

28

F

E

27

LDON

ARF

TRM

B

BDO

B

5

16

LDON

RFOUT

RFAMP

AMP

AMP

AMP

B

AMP

8

AGC

RFEQ

4

18

ARF

EQSW

EQBST

BCA

BCA

BCA

BCA

BandGap

SUB

SUB

13

BDO

BDO/OFTR

3TENV

B

NRFDET

11

HPFDET

(ENV) 3TOUT

OFTR

OFTCONT

/RFDET

FEOUT

TEOUT

CEA

FEN

OFTR

14

12

9

B

10

15

22

23

20

TEN

21

ENV

/RFDET

FE

TE

7

6

RFIN

AGC

GCA

GCA

GCA

GCA

B

VREF

19

GCTL

TBAL

24

FBAL

25

26

GND

17

B

GCTL

TBAL

FBAL

FOCUS COIL

TRACKING COIL

F-

F+

T-

T+

M701

TRAVERSE

MOTOR

M702

SPINDLE

MOTOR

M

_

M

_

IC703

BA5948FPE2

FOCUS COIL/TRACKING COIL/

TRAVERSE MOTOR/

SPINDLE MOTOR DRIVE

D3+

16

15

D3-

18

D4+

17

D4-

14

D2+

13

D2-

12

D1+

D1-11

FOCUS

COIL

DRIVE

TRACKING

COIL

DRIVE

TRAVERSE

MOTOR

DRIVE

SPINDLE

MOTOR

DRIVE

MUTE

[CH1]

28

IN3

27

IN4

1

IN2

3

IN1

4

PC1

FOP

TRP

TRVP

SPOUT

TRVM(PC)

74

Page 75

IC702

MN6627951GA1

SERVO PROCESSOR

DIGITAL SIGNAL

PROCESSOR/

DIGITAL FILTER/

D/A CONVERTER

BLKCK

FLAG

BCLK

SRDATA

LRCK

ARF

B

B

CD_RST

MDATA

MCLK

MLD

STAT

B

SBLKCK

SUBC

X701

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

TO MAIN BLOCK

A

B

72

67

74

73

BCLK

LRCK

SRDATA

SUBCODE

INTERFACE

39

ARF

RFSW

43

IREF

40

DSLF

42

PLLF

44

45

PLLF0

46

AVDD2

47

AVSS2

69

NRST

MDATA

62

MCLK

61

63

MLD

68

STAT

75

NTEST

SBLKCK

71

66

SUBC

OUTX2

76

77

INX1

64

55

FLAG

SBCK

DSL, PLL, VCO

INTERFACE

MICROCOMPUTER

TIMING

GENERATOR

BLKCK

CTRL

RAM

CTRCEOC

EFM DEMODULATION

SYNC INTERPOLATION

CONVERTER

1

DRVDD

CDROM EOC

MP3

DECODER

SERVO

SPINDLE

A/D

8

NCAS0

BUS

4

5

NWE

NRAS

DRAM

INTERFACE

UNIT

CONTROL

FS

CONVERTER

DSV

ADPCM

SERVO

CPU

INPUT

PORT

DIGITAL FILTER

SERIAL OUTPUT

D/A CONVERTER

(DAO)

INTERFACE

DIGITAL OUT

ANALOG

LOW PASS FILTER

4

A0~10

D0~3

IC704

C3ABMB000043

16M DRAM

CD SIGNAL

RCH

B

TRVM(PC)

/WE

/RAS

/CAS

RXIN

SPOUT

TRVP

FOP

TRM

TRP

GCTL

TBAL

FBAL

LDON

5

23

9~12,

9~19

A0~10

D0~3

EXT158EXT1

EXT2

EXT0

OUTL

OUTR

AVDD1

AVSS1

TRVM(PC)

SPOUT

TRVP

FOP

TRM

TRP

OUTPUT PORT

FOM

TBAL

FBAL

LDON

15~19,21

2,3,

24,25

2,3,6,7

56

57

48

50

51

49

60

TX

24

22

23

27

26

25

28

30

31

38

21,53,

79

DVDD1~3

20,52,

78

B

DVSS1~3

ADPVCC

41

TE

FE

RFENV

33

32

34

B

TE

FE

ENV

35

OFTR

NRFDET

OFT

BDO

36

37

65

PWMSEL

SPPOL

70

B

BDO

/RFDET

75

Page 76

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

19.2. MAIN Block

(DECK 2)

R/P HEAD

(DECK 2)

ERASE HEAD

LCH

IC1001

AN7326K

P/B REC AMP

LCH

22(1)

PB LIN(R)

IC1000

C1AA00000612

ANALOG SWITCH

2

FILTER

B

20(3)

PB L EQ(R)

Q1317

BEAT PROOF

LEVEL SWITCH

19(4)

MUTE

PB LOUT(R)

18

ALC LOW OUT

TPS

TPS OUT

6

21(2)

PB L NF(R)

3

5

4

17

TPS

GAIN ADJ

16(7)

REC

L1301

LIN(R)

15(8)

REC

L OUT(R)

REC AMP (L)

B

ALC

14

Q1309,

Q1310,

Q1312

ALC

SWITCH

BIAS

13

NOR/CRO SW

LOGIC

12

VCC

REJECTION

RIPPLE

SWITCH

10

PB/REC SW

9

RF

Q1101

(Q1201)

MUTING

SWITCH

Q1302

DECK

MUTING

CONT

IC971

CNB13030R2AU

PHOTO

INTERRUPTER

16

PHOTO

JOG_A

84

85

S651

VOLUME JOG

IC409

C0EBE0000338

RESET IC

JOG_B

D1301

S971

(MODE)

S972

(HALF)

IC410

C0CBABC00117

REGULATOR

65

CRTIMER

IC405

MNZSF77RSB1

MICROPROCESSOR

24

MK_IN2

23

MK_IN1

S975

(RECINH_F)

KEY3

17

S613~S619

KEY SW

KEY2

22

S608, S610~S612,

S621~S623

KEY SW

B

Q1304

Q1303

KEY1

21

S601~S606,

S609, S620

KEY SW

SWITCH

(REC:H)

SWITCH

107

TAPE_RECH

105

TAPE_DMT

76

Page 77

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

QR600

DETECT

SWITCH

QR601

D618,

D619

L601

FL601

CLK

LAT

31

32

37

38

LAT

CLK

62,99

B

VCC1,2

12

/RESET

27

/CS

SCK

SDATA

28

29

FL DISPLAY

IC601

C2CBKJ000142

FL DRIVER

Q603

SWITCH

D601,D604

D605,D606

BK

33

39

BK

XIN

15

X601

B

IC403

C3FBHA000004

FLASH MEMORY IC

SWITCH

36

VH

S1

34

35

S1

H.BASS LED

XOUT

13

SD_LED

SD_MD

B

B

69

55

97

FROM POWER

TRANSFORMER

UP/DOWN MOTOR

4

OUT1

IC11

C0GAG0000007

UP/DOWN

MOTOR DRIVER

F_IN

7

RM11

M

9

Q605

SWITCH

2

OUT2

R_IN

D609

Q606

SWITCH

LOADING MOTOR

4

OUT1

IC21

C0GAG0000007

LOADING

MOTOR DRIVER

F_IN

7

D610

RM21

Q604

SWITCH

M

B

B

D607

B

2

OUT2

R_IN

9

D971

4

2

1

10

26

25

FL_RST

TAPE_MOTH

FL_CS

27

FL_CLK

FL_DATA

28

TAPE_PL

108

QR402

PLUNGER

SWITCH

Q1315

SWITCH

PL

109

QR403

MOTOR

SWITCH

MOTOR

SUPPLY

SWITCH

M

Q1314,Q1316

2

DIMMER

9

DF_CLK

IC405

DF_DATAOUT

MNZSF77RSB1

MICROPROCESSOR

29

3

DF_RST

5

8

30

8

DF_CS

31

DF_WP

DF_DATAIN

94

S1

STOCK

UP/DOWN F

STOCK

101

95

S2

PLAY

UP/DOWN R

PLAY_SW

102

BOTTOM

CH_BOTTOM

96

S3

99

OPEN

OP/CL_F

S4

CH_OPEN

98

CHANGE

100

OP/CL_R

CH_CHANGE

93

S5

77

Page 78

SA-PM71SDE / SA-PM71SDEB / SA-PM71SDEG

IC803

C0JBAA000344

AND GATE

IC812

C0JBAE000302

AND GATE

S801

SD DETECTOR SW

1(2)

72,73,87,

88,112,113,

119,121,125,

131,133,134,

138,142,144

4,5,74,

103-109,117,

120,123,127,

140,141

129

10

2

66

70

92

83

85

95

96

68

3

94

ADIN

ACLKO

BLCK

LRCK2

NWT

NRAMLLB

NRAMLUB

A1

A15

D0

D15

NEXTDK

NRD

NRST

PRST

NPDOWNIO

MINTO

IC802

MN677382PA

SD AUDIO IC

IC804

C0CBCAD00065

REGULATOR

12

CKE

38

SCKE

75

111

CLK

60

SDCLKO

IRQ4

SDCLKI