Page 1

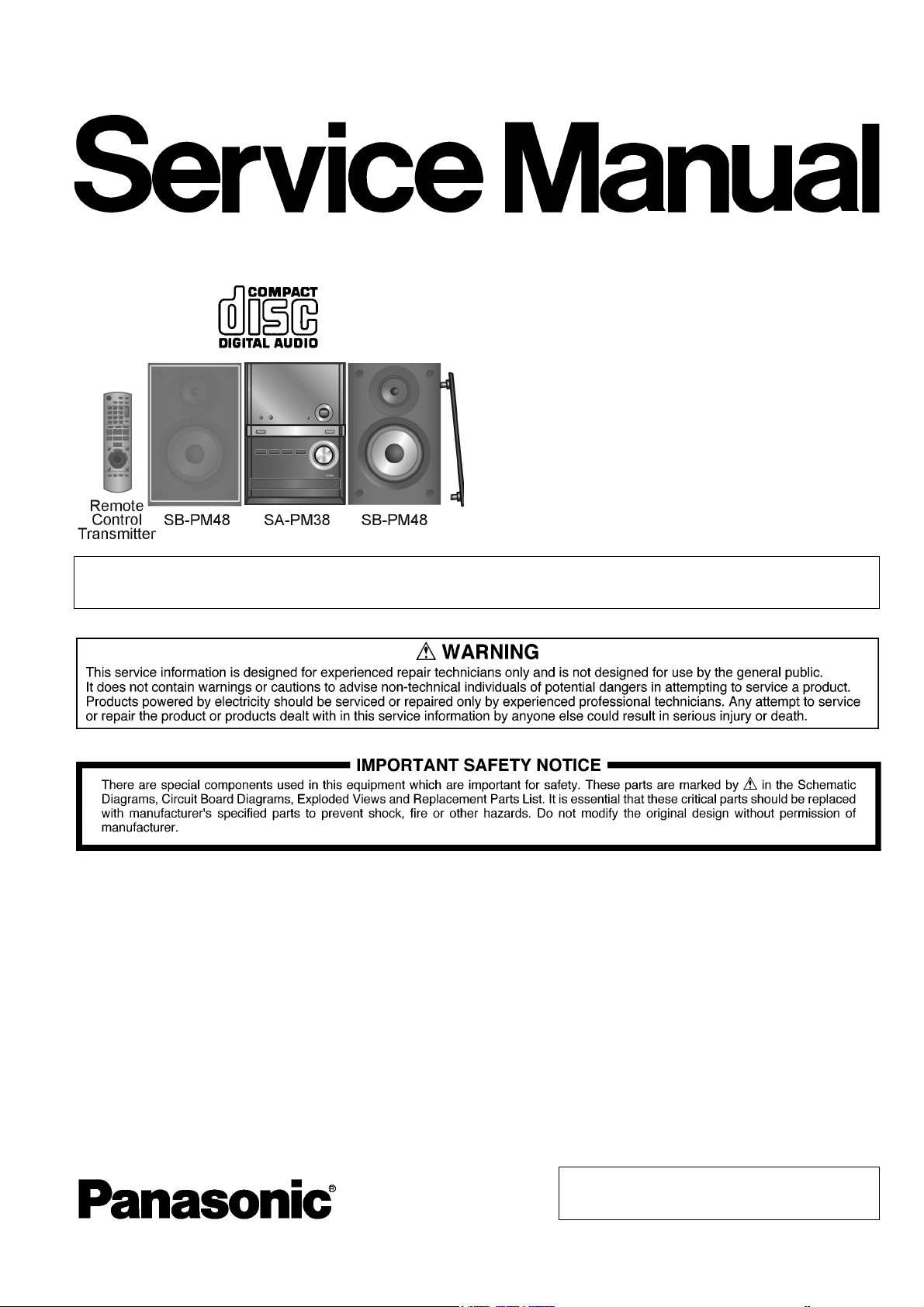

CD Stereo System

Model No. SA-PM38PP

Product Color: (K)...Black Type

PSG0903001CE

A6

Notes: This model’s CD mechanism unit is DLS6C. Please refer to the Original Service Manual (Order No.

MD0803034CE) for this mechanism.

TABLE OF CONTENTS

PAGE PAGE

1 Safety Precautions----------------------------------------------- 3

1.1. General Guidelines---------------------------------------- 3

1.2. Before Repair and Adjustment------------------------- 4

1.3. Protection Circuitry ---------------------------------------- 4

1.4. Safety Part Information----------------------------------- 4

2 Warning-------------------------------------------------------------- 5

2.1. Prevention of Electro Static Discharge (ESD)

to Electrostatically Sensitive (ES) Devices---------- 5

2.2. Precaution of Laser Diode------------------------------- 6

2.3. Service caution based on Legal restrictions-------- 7

2.4. Handling Precaution for Traverse Unit --------------- 8

3 Service Navigation----------------------------------------------10

3.1. Service Information-------------------------------------- 10

4 Specifications ---------------------------------------------------- 11

5 Location of Controls and Components------------------ 12

5.1. Main Unit Key Button Operations -------------------- 12

5.2. Remote Control Key Button Operations------------ 12

6 Operating Instructions ---------------------------------------- 13

6.1. Disc Information ------------------------------------------ 13

7 Self diagnosis and special mode setting --------------- 14

7.1. Service Mode Summary Table------------------------ 14

7.2. Service Mode Table ------------------------------------- 15

7.3. Error Code Table ----------------------------------------- 18

8 Troubleshooting Guide --------------------------------------- 19

© Panasonic Corporation 2009. All rights reserved.

Unauthorized copying and distribution is a violation of

law.

Page 2

9 Service Fixture & Tools --------------------------------------- 20

10 Disassembly and Assembly Instructions---------------21

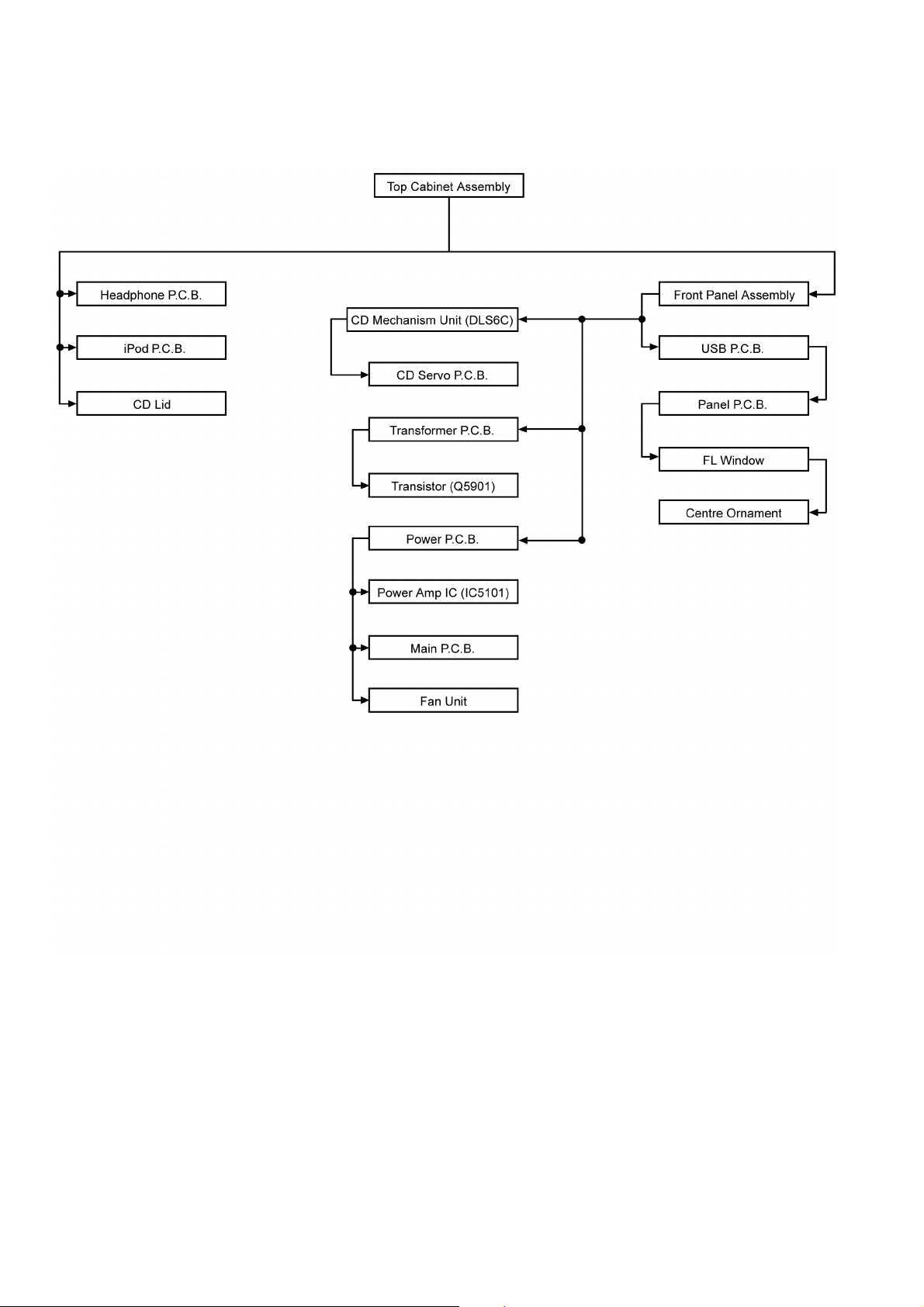

10.1. Disassembly flow chart --------------------------------- 22

10.2. Main Parts Location Diagram ------------------------- 23

10.3. Disassembly of Top Cabinet Assembly------------- 24

10.4. Disassembly of Headphone P.C.B. ------------------ 25

10.5. Disassembly of iPod P.C.B.---------------------------- 26

10.6. Disassembly of Front Panel Assembly -------------26

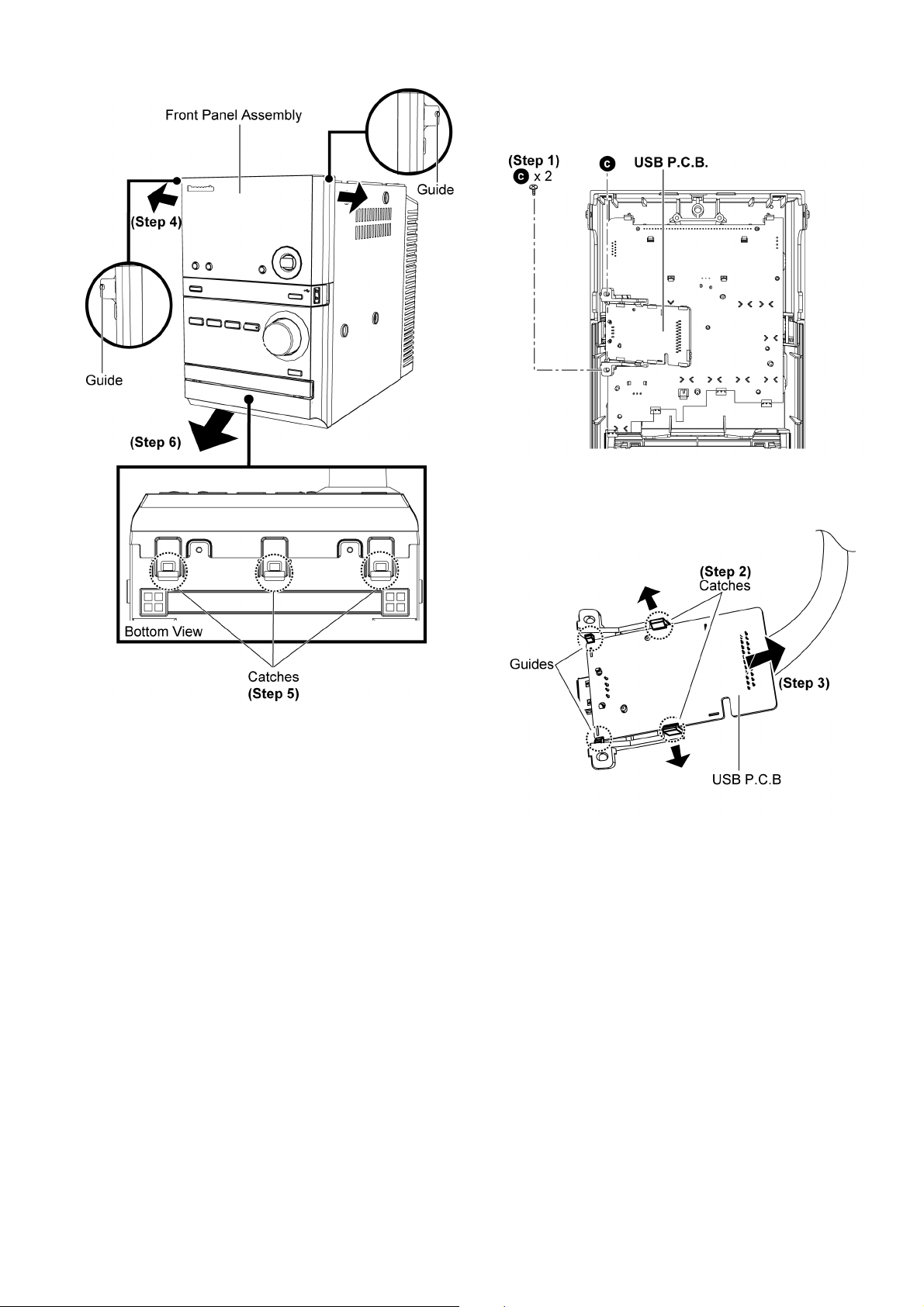

10.7. Disassembly of USB P.C.B. --------------------------- 27

10.8. Disassembly of Panel P.C.B.-------------------------- 28

10.9. Disassembly of FL Window---------------------------- 29

10.10. Disassembly of Centre Ornament ------------------- 30

10.11. Disassembly of CD Lid----------------------------------30

10.12. Disassembly of CD Mechanism Unit (DLS6C) --- 31

10.13. Disassembly of Power P.C.B. ------------------------- 32

10.14. Replacement of Power Amp IC (IC5101) ---------- 33

10.15. Disassembly of Main P.C.B. --------------------------- 34

10.16. Disassembly of Fan Unit -------------------------------36

10.17. Disassembly of Transformer P.C.B. ----------------- 37

10.18. Replacement of Transistor (Q5901)----------------- 39

10.19. Disassembly of CD Servo P.C.B.--------------------- 40

11 Disassembly and Assembly of Traverse Unit --------- 42

11.1. Disassembling Procedures ---------------------------- 42

11.2. Assembling Procedure---------------------------------- 43

12 Service Position ------------------------------------------------- 45

12.1. Checking & Repairing USB P.C.B.------------------- 45

12.2. Checking & Repairing Panel P.C.B. ----------------- 47

12.3. Checking & Repairing CD Servo P.C.B.------------ 48

12.4. Checking & Repairing Power P.C.B. ---------------- 49

12.5. Checking & Repairing Transformer P.C.B.--------- 50

12.6. Checking & Repairing Main P.C.B. ------------------ 51

13 Voltage Measurement & Waveform Chart--------------- 52

13.1. USB P.C.B.-------------------------------------------------52

13.2. CD SERVO P.C.B. ---------------------------------------53

13.3. MAIN P.C.B. (1/2) ---------------------------------------- 54

13.4. MAIN P.C.B. (2/2) ---------------------------------------- 55

13.5. PANEL P.C.B. ---------------------------------------------56

13.6. POWER P.C.B. ------------------------------------------- 56

13.7. TRANSFORMER P.C.B.--------------------------------56

13.8. Waveform Chart ------------------------------------------ 57

14 Illustration of IC’s, Transistors and Diodes ------------ 58

15 Overall Simplified Block for PM38------------------------- 59

16 Block Diagram --------------------------------------------------- 60

16.1. CD SERVO BLOCK DIAGRAM ---------------------- 60

16.2. MAIN(1/2)/ PANEL/TRANSFORMER BLOCK

DIAGRAM-------------------------------------------------- 61

16.3. MAIN(2/2)/ HEADPHONE/ iPod/ USB BLOCK

DIAGRAM-------------------------------------------------- 62

17 Wiring Connection Diagram --------------------------------- 63

18 Schematic Diagram Notes -----------------------------------64

19 Schematic Diagram---------------------------------------------65

19.1. CD SERVO CIRCUIT -----------------------------------65

19.2. MAIN CIRCUIT (1/4) ------------------------------------ 66

19.3. MAIN CIRCUIT (2/4) ------------------------------------ 67

19.4. MAIN CIRCUIT (3/4) ------------------------------------ 68

19.5. MAIN CIRCUIT (4/4) ------------------------------------ 69

19.6. PANEL CIRCUIT and HEADPHONE CIRCUIT---70

19.7. USB CIRCUIT--------------------------------------------- 71

19.8. iPod CIRCUIT and POWER CIRCUIT-------------- 72

19.9. TRANSFORMER CIRCUIT----------------------------73

20 Printed Circuit Board ------------------------------------------ 74

20.1. CD SERVO P.C.B. and TRANSFORMER

P.C.B. ------------------------------------------------------- 74

20.2. MAIN P.C.B.----------------------------------------------- 75

20.3. PANEL P.C.B., HEADPHONE P.C.B. and

POWER P.C.B. ------------------------------------------- 76

20.4. iPod P.C.B. and USB P.C.B. -------------------------- 77

21 Terminal Function of IC’s ------------------------------------ 78

21.1. IC7001 (MN6627954AMA) IC SERVO

PROCESSOR -------------------------------------------- 78

21.2. IC7002 (BA5948FPE2) IC 4CH Drive -------------- 79

21.3. IC800 (RFKWMPM38EG) IC MICROPROCESSOR -------------------------------------------- 79

22 Exploded View and Replacement Parts List----------- 81

22.1. Exploded View and Mechanical replacement

Parts List--------------------------------------------------- 81

22.2. Electrical Replacement Parts List ------------------- 85

2

Page 3

1 Safety Precautions

1.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, carry out the following leakage current checks to prevent the customer from being exposed to shock hazards.

(This “Safety Precaution” is applied only in U.S.A.)

1. Before servicing, unplug the power cord to prevent an electric shock.

2. When replacing parts, use only manufacturer’s recommended components for safety.

3. Check the condition of the power cord. Replace if wear or damage is evident.

4. After servicing, be sure to restore the lead dress, insulation barriers, insulation papers, shields, etc.

5. Before returning the serviced equipment to the customer, be sure to make the following insulation resistance test to prevent

the customer from being exposed to a shock hazard.

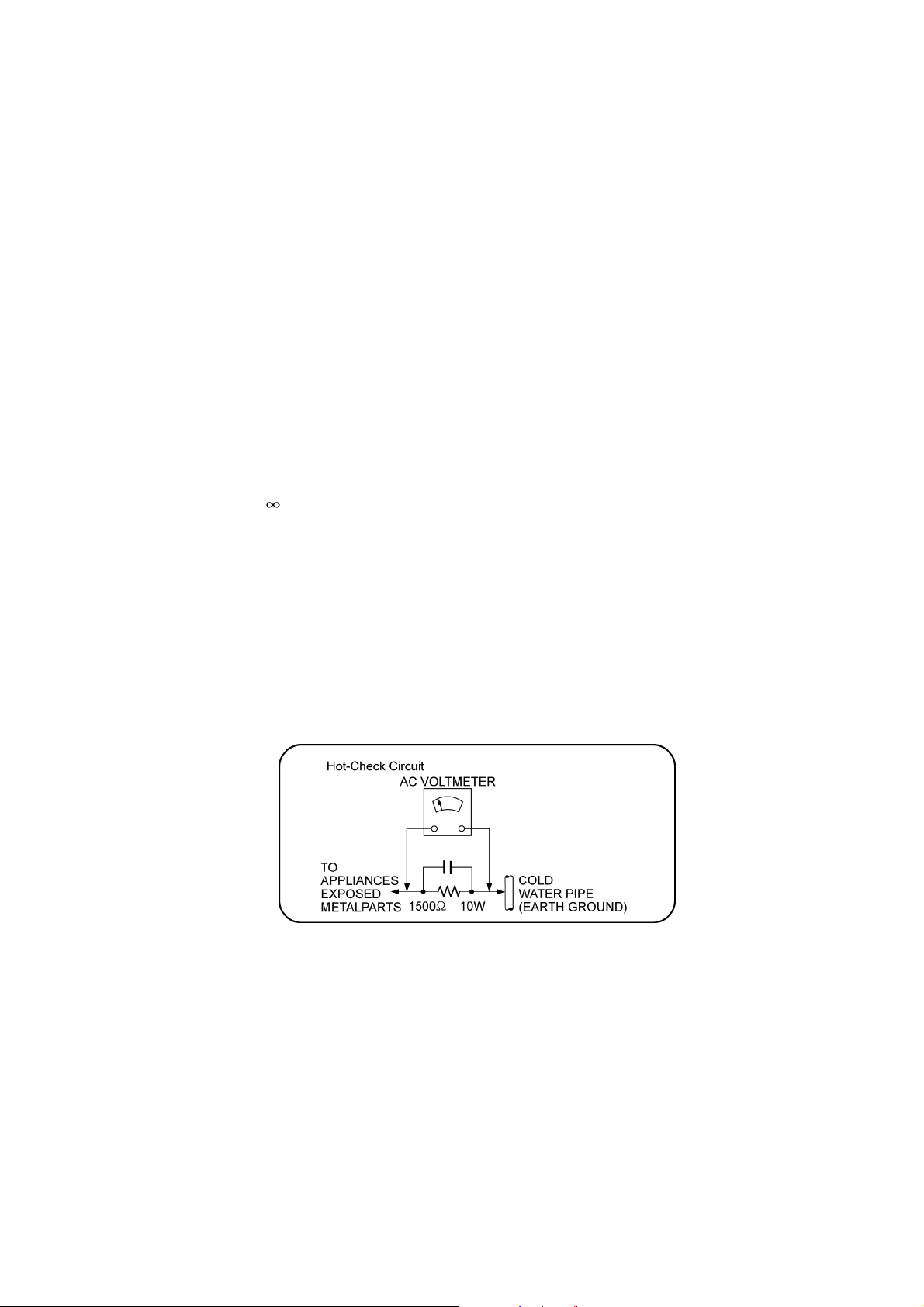

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. measure the resistance value, with an ohmmeter between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩ and 5.2MΩ. When the exposed metal does not have a return path to the chas-

sis, the reading must be

1.1.2. Leakage Current Hot Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15μF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent)

may be used to make the hot checks, leakage current must not exceed 1/2 milliamp. In case a measurement is outside of the

limits specified, there is a possibility of a shock hazard, and the equipment should be repaired and rechecked before it is

returned to the customer.

Figure. 1

3

Page 4

1.2. Before Repair and Adjustment

Caution : DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

• Current consumption at AC 120V, at 60Hz in NO SIGNAL mode (at volume min in FM Tuner mode) should be ~150 mA.

1.3. Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

• No sound is heard when the power is turned on.

• Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

"shorted", or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

1.4. Safety Part Information

Safety Parts List:

There are special components used in this equipment which are important for safety.

These parts are marked by in the Schematic Diagrams, Exploded View & Replacement Parts List. It is essential that these

critical parts should be replaced with manufacturer’s specified parts to prevent shock, fire or other hazards. Do not modify the

original design without permission of manufacturer.

Table 1

Safety Ref. No. Part No. Part Name & Description Remarks

301 RAEX0190Z-V TRV UNIT (W/O SERVO P.C.B.) (RTL)

A2 K2CB2CB00021 AC CORD

A3 RQTX0192-P O/I BOOK

A7 J0KG00000037 AC CLAMP FILTER

PCB7 REPX0708F TRANSFORMER P.C.B (RTL)

L5901 ELF15N035AN LINE FILTER

T5901 G4CYBYY00025 MAIN TRANSFORMER

T5902 G4C2AAD00004 SUB TRANSFORMER

Z5901 ERZVA5Z471 ZENER

F5901 K5D162APA008 FUSE

RL5901 K6B1AEA00003 RELAY

FP5901 K5G502AA0002 FUSE PROTECTOR

JK5901 K2AB2B000007 AC INLET

4

Page 5

2 Warning

2.1. Prevention of Electro Static Discharge (ESD) to Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor “chip” components. The following techniques should be used to help reduce the incidence of component damage

caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equiped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equiped with ES devices, place the assembly on a conductive surface such as aluminium foil, to prevent electrostatic charge build up or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder remover device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminium foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution :

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) suf-

ficient to damage an ES device).

5

Page 6

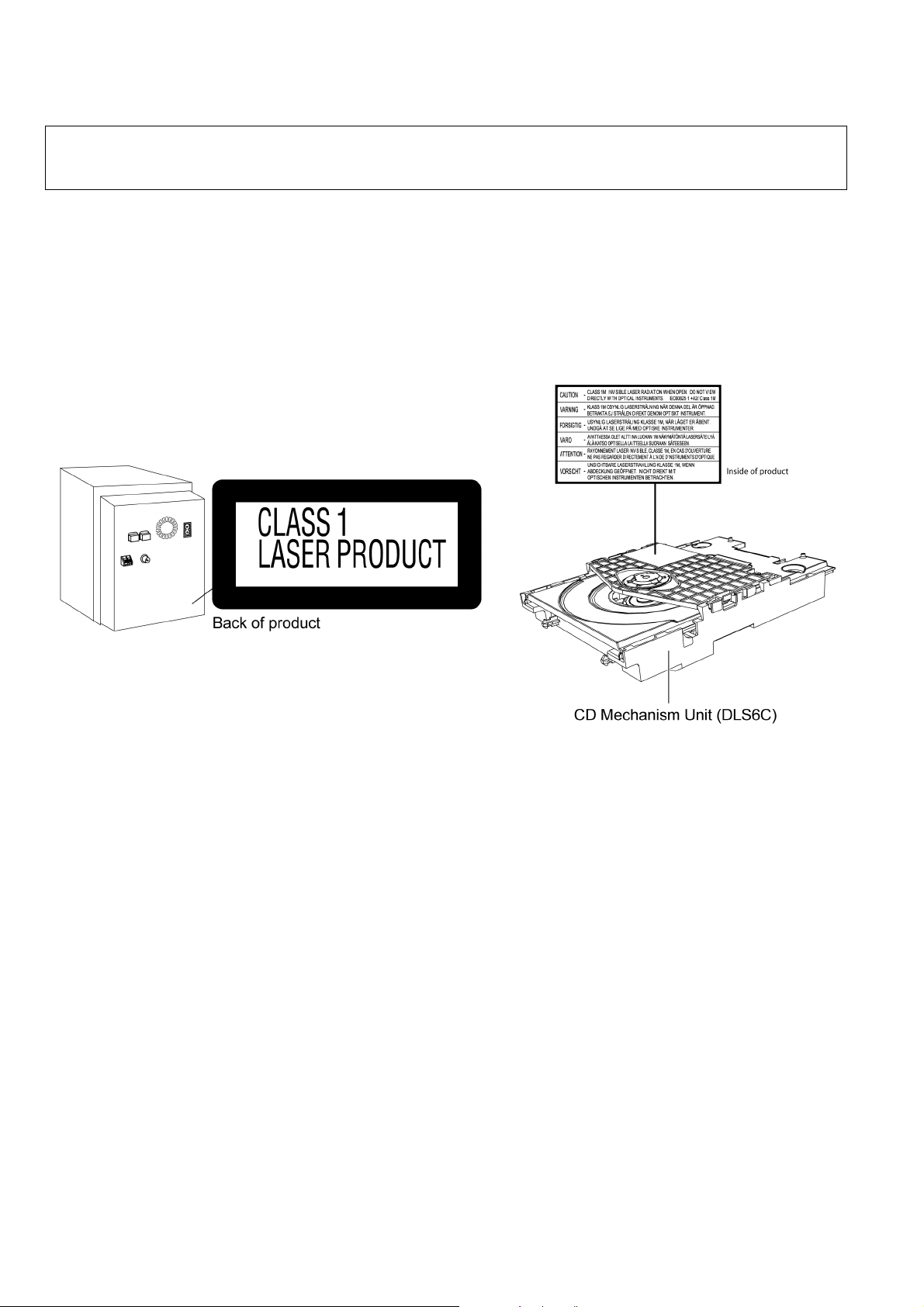

2.2. Precaution of Laser Diode

CAUTION!

THIS PRODUCT UTILIZES A LASER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT

IN HAZARDOUS RADIATION EXPOSURE.

Caution:

This product utilizes a laser diode with the unit turned "on", invisible laser radiation is emitted from the pickup lens.

Wavelength: 785 nm (CD)

Maximum output radiation power from pickup: 100 μW/VDE

Laser radiation from the pickup unit is safety level, but be sure the followings:

1. Do not disassemble the pickup unit, since radiation from exposed laser diode is dangerous.

2. Do not adjust the variable resistor on the pickup unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at pickup lens for a long time.

6

Page 7

2.3. Service caution based on Legal restrictions

2.3.1. General description about Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86°F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

The letter of “PbF” is printed either foil side or components side on the PCB using the lead free solder.

(See right figure)

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30 degrees

C (662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: Tin (Sn), 96.5%, Silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

7

Page 8

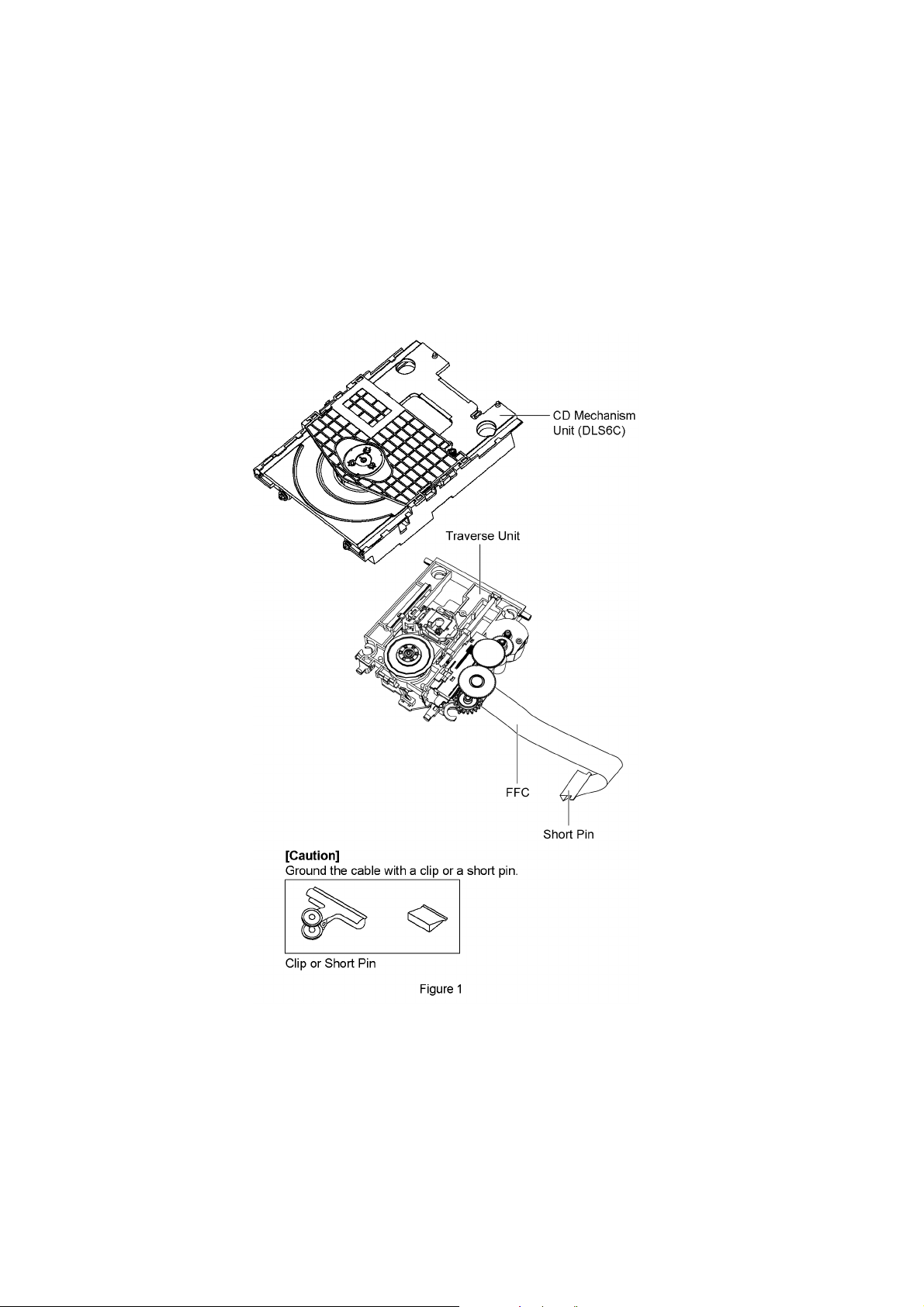

2.4. Handling Precaution for Traverse Unit

The laser diode in the optical pickup unit may break down due to static electricity of clothes or human body. Special care must be

taken avoid caution to electrostatic breakdown when servicing and handling the laser diode in the traverse unit.

2.4.1. Cautions to Be Taken in Handling the Optical Pickup Unit

The laser diode in the optical pickup unit may be damaged due to electrostatic discharge generating from clothes or human body.

Special care must be taken avoid caution to electrostatic discharge damage when servicing the laser diode.

1. Do not give a considerable shock to the optical pickup unit as it has an extremely high-precise structure.

2. To prevent the laser diode from the electrostatic discharge damage, the flexible cable of the optical pickup unit removed

should be short-circuited with a short pin or a clip.

3. The flexible cable may be cut off if an excessive force is applied to it. Use caution when handling the flexible cable.

4. The antistatic FPC is connected to the new optical pickup unit. After replacing the optical pickup unit and connecting the flexible cable, cut off the antistatic FPC.

2.4.2. Grounding for electrostatic breakdown prevention

Some devices such as the CD player use the optical pickup (laser diode) and the optical pickup will be damaged by static electricity

in the working environment. Proceed servicing works under the working environment where grounding works is completed.

2.4.2.1. Worktable grounding

1. Put a conductive material (sheet) or iron sheet on the area where the optical pickup is placed, and ground the sheet.

8

Page 9

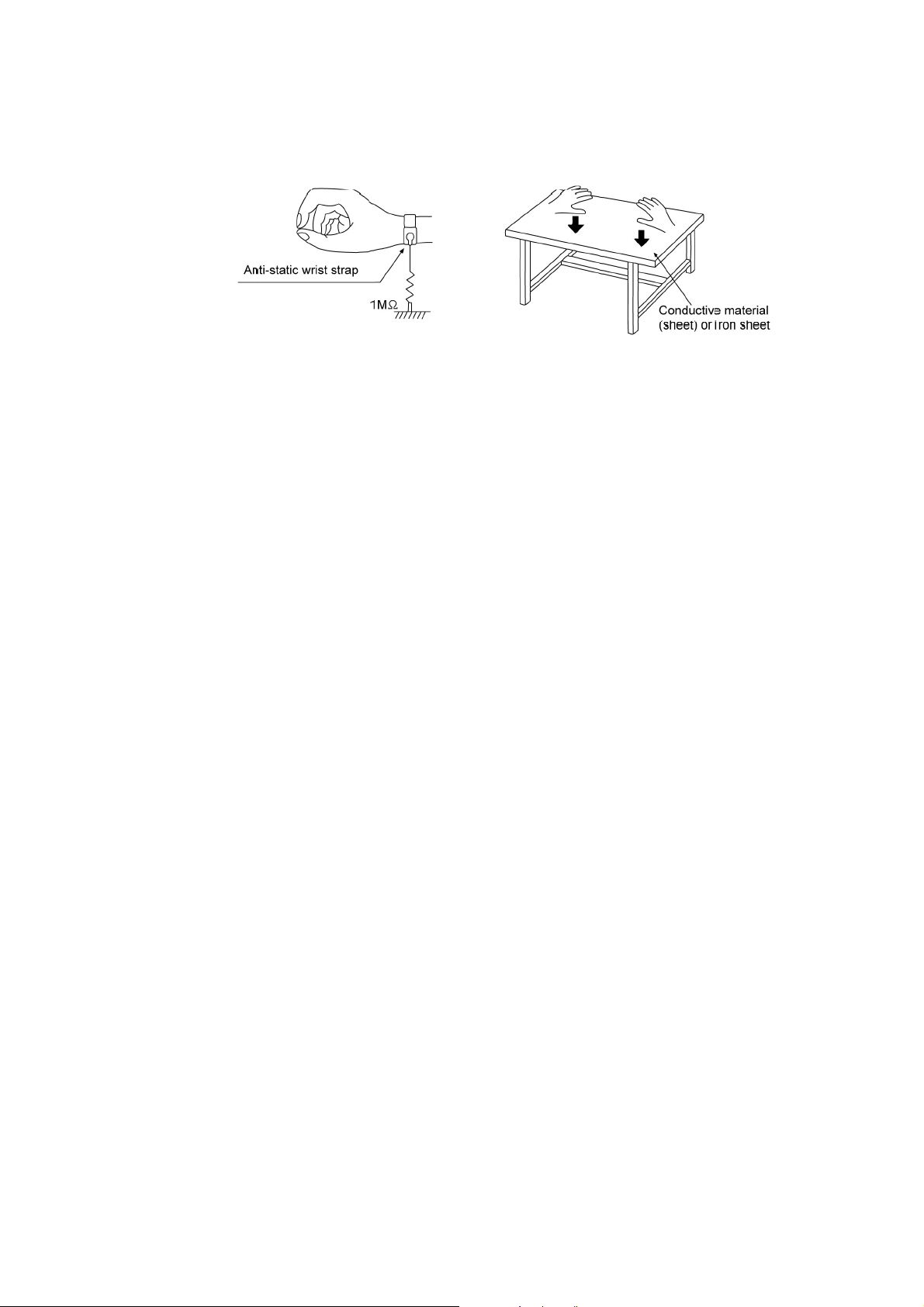

2.4.2.2. Human body grounding

1. Use the anti-static wrist strap to discharge the static electricity form your body (Figure 2).

Figure 2

9

Page 10

3 Service Navigation

3.1. Service Information

This service manual contains technical information which will allow service personnel’s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, this information will be followed by supplement service manual to be filed with original service

manual.

1. CD Mechanism Unit:

• This model uses CD Mechanism Unit (DLS6C).

• This service manual does not contain the following information on CD Mechanism Unit (DLS6C).

- CD Mechanism Unit P.C.B..

- Parts List for individual parts of CD Mechanism Unit (DLS6C).

- Exploded View and Part List for individual parts of CD Mechanism Unit (DLS6C).

Please refer to original service manual (Order No. MD0803034CE).

2. Micro-processor:

• Micro-processor IC, (IC800) is supplied as assembled part (RFKWMPM38EG).

10

Page 11

4 Specifications

Q Amplifier Section

RMS Output Power Stereo Mode

Front Ch (both ch driven) 20 W per channel (4 Ω),

FTC Output Power Stereo Mode

Front Ch (both ch driven) 15 W per channel (4 Ω),

60 Hz to 20 kHz, 10% THD

Phone jack

Terminal Stereo, 3.5 mm (1/8”)

Q Tuner Section

Preset station FM 30 stations

Frequency Modulation (FM)

Frequency range 87.9 MHz to 107.9 MHz

Antenna terminals 75 Ω (unbalanced)

Amplitude Modulation (AM)

Frequency range 520 kHz to 1710 kHz (10 kHz

Q USB Section

Supported audio file format MP3 (*.mp3)

Maximum port power 500 mA

Q CD Section

Disc played [8 cm (3”) or 12 cm (5”)]

(1) CD-Audio (CD-DA)

(2) CD-R/RW (CD-DA, MP3)

(3) MP3

Pickup

Wavelength 785 nm

Laser power CLASS I (CD)

Audio output (Disc)

Number of channels FL, FR, 2 channel

Q General

Power supply AC 120 V, 60 Hz

Power consumption 70 W

Dimensions (W x H x D) 153 mm x 226 mm x 292 mm

(6 1/32” x 8 29/32” x 11 1/2”)

Mass 2.5 kg (5.5 lbs.)

Operating temperature range 0°C to +40°C (+32°F to +104°F)

Operating humidity range 35% to 80 % RH (no condensa-

Power consumption in standby mode 0.35 W (approx)

Notes :

1. Specifications are subject to change without notices. Mass and

dimensions are approximate.

2. Total harmonic distortion is measured by the digital spectrum analyzer.

Q System : SC-PM38PP-K Music center: SA-PM38PP-K

Speaker: SB-PM48EG-KC

1 kHz, 10% THD

AM 15 stations

(200 kHz step)

87.5 MHz to 108.0 MHz

(100 kHz step)

step)

tion)

11

Page 12

5 Location of Controls and Components

5.1. Main Unit Key Button Operations

5.2. Remote Control Key Button Operations

12

Page 13

6 Operating Instructions

6.1. Disc Information

13

Page 14

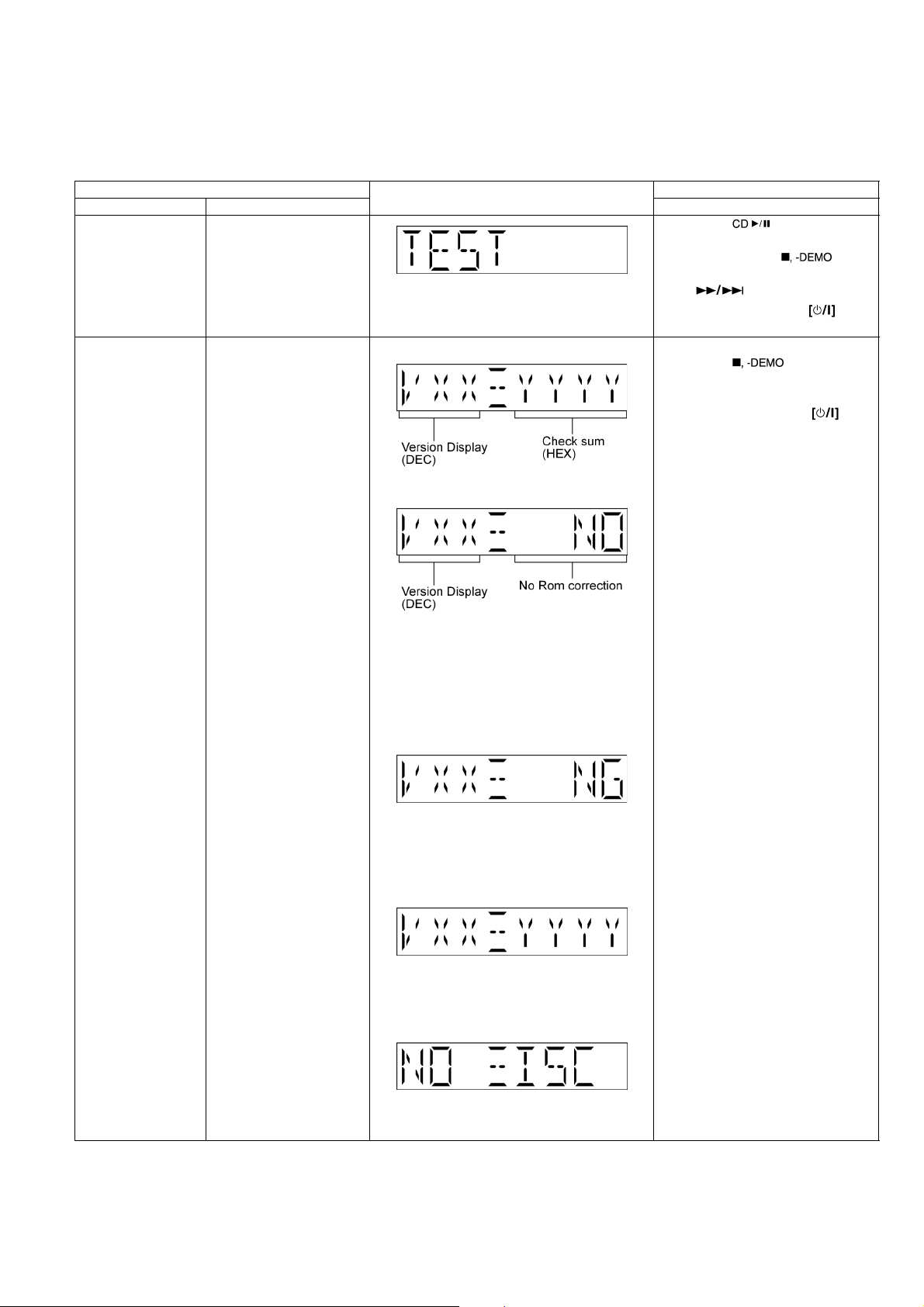

7 Self diagnosis and special mode setting

This unit is equipped with features of self-diagnostic & special mode setting for checking the functions & reliability.

7.1. Service Mode Summary Table

The service modes can be activated by pressing various button combination on the main unit and remote control unit.

Below is the summary for the various modes for checking:

Player buttons Remote control unit buttons Application Note

[4], [7] To Enter into Doctor Mode for vari-

ous checking

Player buttons Remote control unit buttons Mode Name Note

Note : Applicable in Doctor Mode [DIMMER] FL Display Test (Refer to the section “7.2.2 service

[7] VOLUME setting (50dB) (Refer to the section “7.2.2 service

[8] VOLUME setting (29dB) (Refer to the section “7.2.2 service

[9] VOLUME setting (0dB) (Refer to the section “7.2.2 service

[ ], [1], [1]

[ ], [1], [2]

[ ], [1], [3]

[SLEEP] Cold Start (Refer to the section “7.2.2 service

[2] USB Test Mode (Refer to the section “7.2.2 service

CD Loading Test Mode (DLS6C) (Refer to the section “7.2.2 service

CD Traverse Unit Test Mode

(DLS6C)

CD Combination Test Mode

(DLS6C)

(Refer to the section “7.2.1 Service

Mode Table 1.)

mode Table 2 for more information.)

mode Table 2 for more information.)

mode Table 2 for more information.)

mode Table 2 for more information.)

mode Table 2 for more information.)

(Refer to the section “7.2.2 service

mode Table 2 for more information.)

(Refer to the section “7.2.2 service

mode Table 2 for more information.)

mode Table 2 for more information.)

mode Table 2 for more information.)

14

Page 15

7.2. Service Mode Table

Below is the various special modes for checking:-

7.2.1. Service Mode Table 1

Item FL Display Key Operation

Mode Name Description Front Key

Self -Diagnostic Mode To enter into self diagnostic

checking for main unit.

Doctor Mode To enter into Doctor Mode

for checking of various

items and displaying

EEPROM and firmware version.

Note: The micro-processor

version as shown is an

example. It will be revise

when there is an updates.

FL Display sequence Display 1 → 2

(Display 1)

Checksum : (Condition 1)

1. Select [ ] for CD mode

(Ensure no CD inserted).

2. Press and hold [ ]button

for 2 seconds follow by

[].

To exit Doctor Mode, press button

on main unit or remote control.

In CD mode:

1. Press [ ] button on main

unit follow by [4] and [7] on

remote control.

To exit Doctor Mode, press button on main unit or remote control.

(a) If there is NO EEPROM header string

OR

(b) If there is no EEPROM ( no data is

received by micro-processor) [NO] is displayed.

Checksum : (Condition 2)

If the version of the EEPROM does not

match or not working properly [NG] is display.

Checksum : (Condition 3)

If the EEPROM version matches, checksum

[YYYY] is displayed.

(Display 2)

The Checksum of EEPROM and firmware

version will be display for 2 sec.

15

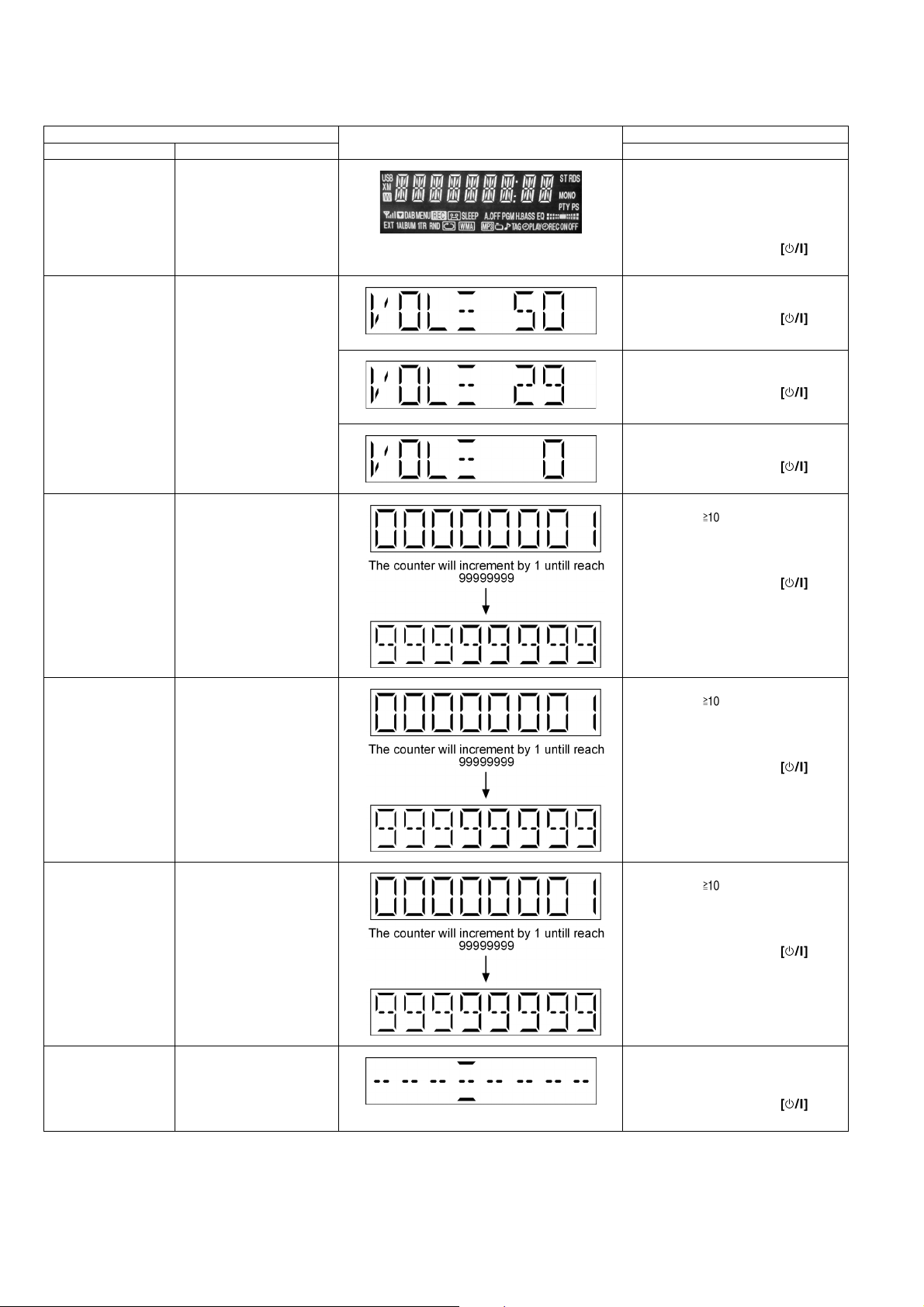

Page 16

7.2.2. Service Mode Table 2

Item FL Display Key Operation

Mode Name Description Front Key

FL Display Test To check the FL segments

display (All segments will

light up)

Volume Setting To check for volume setting

CD Loading Test Mode

(DLS6C)

during this mode, Bass &

treble is set to 0dB & EQ is

switch off.

To determine the reliability of

CD Loading unit.

To check for the Open/Close

operation for the CD loading

unit. It fails when there is

abnormality in opening or

closing.

In Doctor Mode:

1. Press [DIMMER] button on

remote control.

To cancel, press [0] button on remote

control.

To exit Doctor Mode, press button on main unit or remote control.

In Doctor Mode:

1. Press [7] button on remote control.

To exit Doctor Mode, press button on main unit or remote control.

In Doctor Mode:

2. Press [8] button on remote control.

To exit Doctor Mode, press button on main unit or remote control.

In Doctor Mode:

3. Press [9] button on remote control.

To exit Doctor Mode, press button on main unit or remote control.

In Doctor Mode:

1. Press [ ], [1], [1] button on

remote control.

To cancel, press [0] button on remote

control.

To exit Doctor Mode, press button on main unit or remote control.

CD Traverse Unit Test

Mode (DLS6C)

CD Combination Test

Mode (DLS6C)

Cold Start To activate cold start upon

To check for the traverse unit

operation. In this mode, the

first & last track is access &

read. (TOC). It fails when

TOC is not completed by IOS

or the traverse is out of

focus.

A combination of CD loading

& traverse unit test.

next AC power up.

In Doctor Mode:

1. Press [ ], [1], [2] button on

remote control.

To cancel, press [0] button on remote

control.

To exit Doctor Mode, press button on main unit or remote control.

In Doctor Mode:

1. Press [ ], [1], [3] button on

remote control.

To cancel, press [0] button on remote

control.

To exit Doctor Mode, press button on main unit or remote control.

In Doctor Mode:

1. Press [SLEEP] button on remote

control.

To exit Doctor Mode, press button on main unit or remote control.

16

Page 17

Item FL Display Key Operation

Mode Name Description Front Key

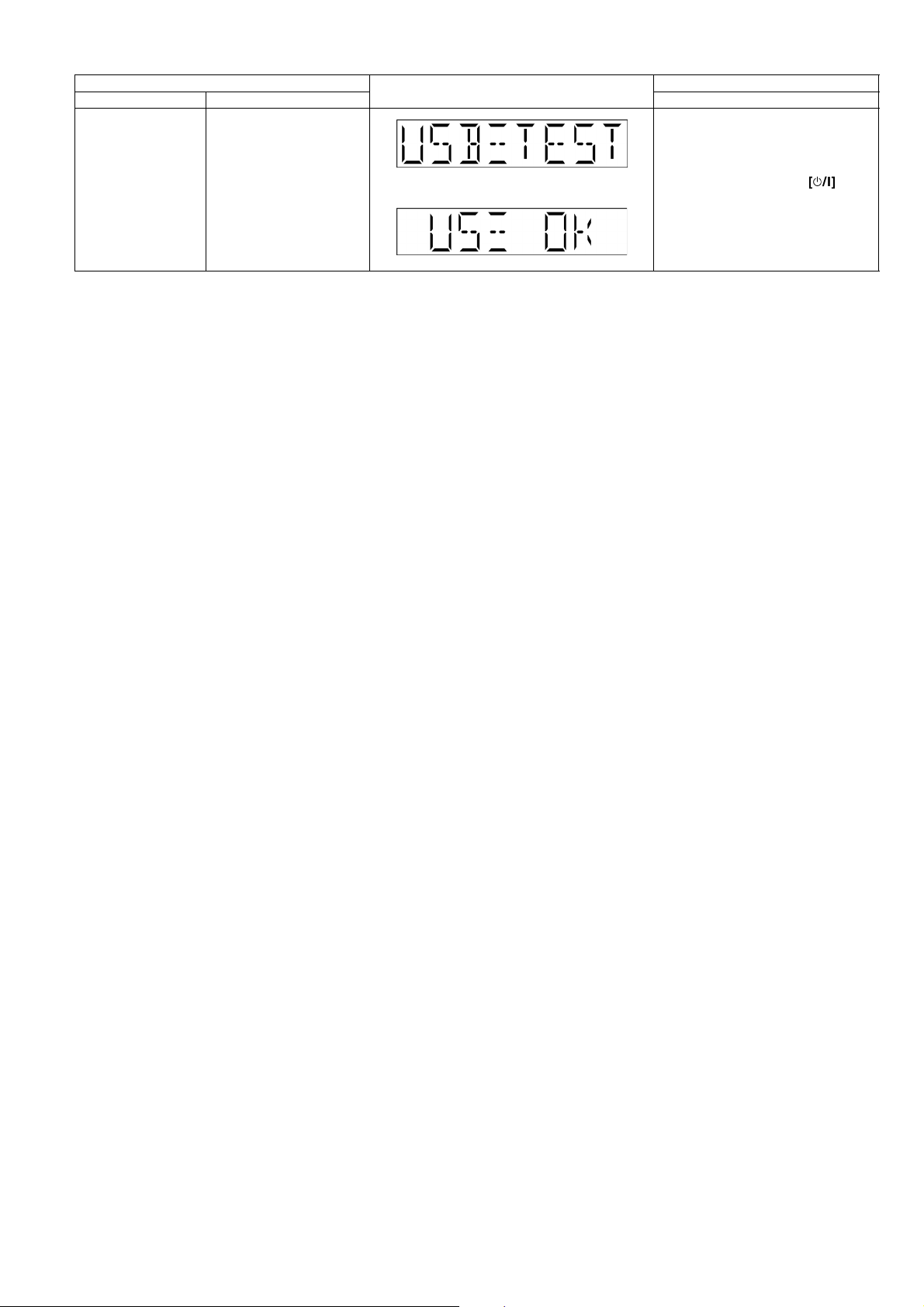

USB Test Mode To Inspect USB Testing.

The display will appear after 3s,

In Doctor Mode:

1. Select to USB mode.

2. Press [2] button on remote control.

To exit Doctor Mode, press button

on main unit or remote control.

17

Page 18

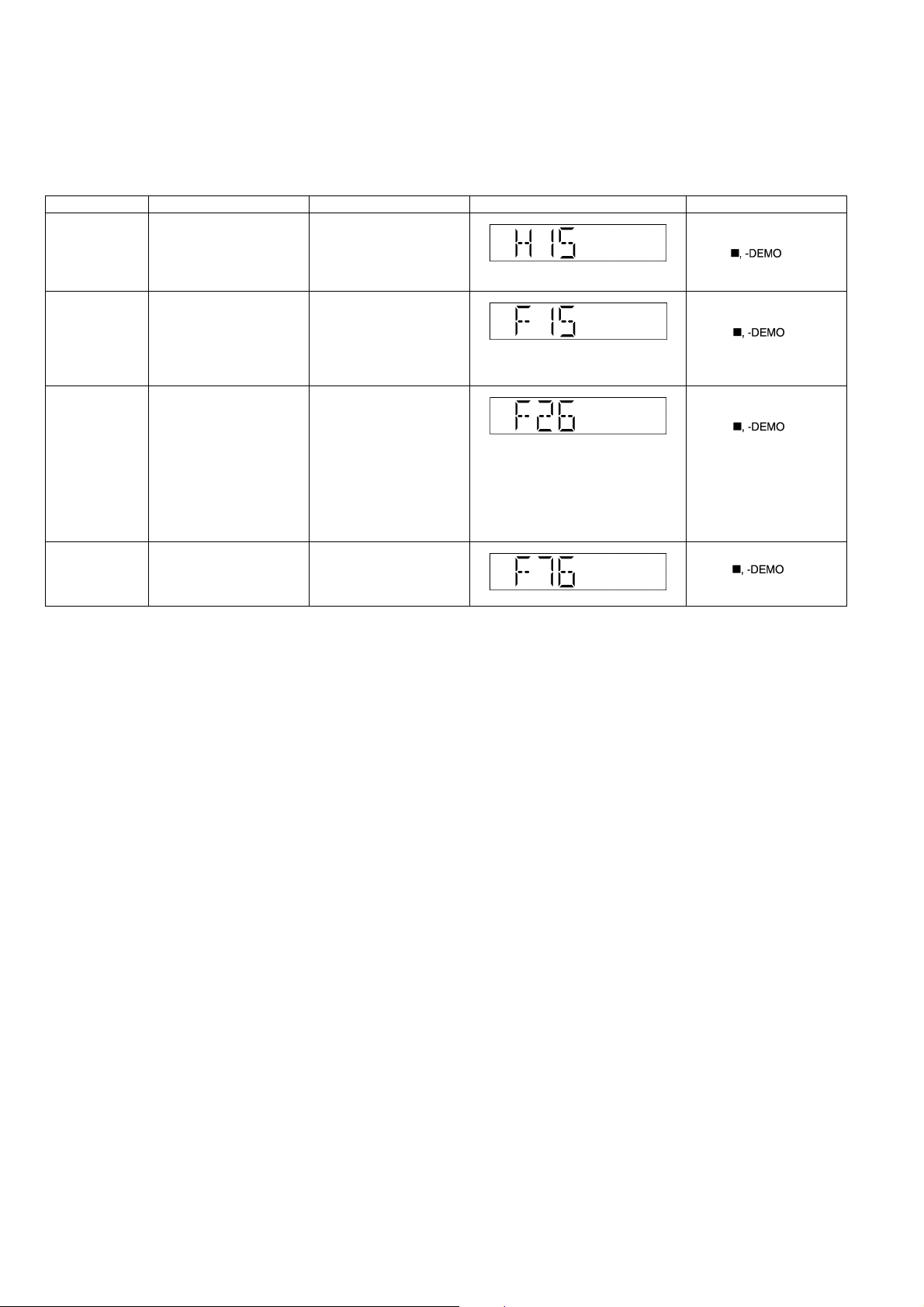

7.3. Error Code Table

Self-Diagnosis Function provides information on any problems occuring for the unit and its respective components by displaying

error codes. Thesed error code such as U**, H** and F** are stored in memory and held unless it is cleared.

The error code is automatically display after entering into self-diagnostic mode.

Error Code Diagnosis Contents Description of error Automatic FL Display Remarks

H15 CD Open SW Abnormal During normal operation

CD OPEN SW On fail to be

detected with 4 sec. Error

No. shall be clear by force

or during cold start.

F15 CD REST SW Abnormal CD traverse position intial

F26 Communication between

CD servo LSI and micro-p

abnormal.

F76 Power Amp IC output

abnormal

setting operation failsafe

counter (1000 ms) waiting

for REST SW to turn on.

Error No. shall be clear by

force or during cold start.

CD function DTMS command, after system setting, If SENSE = 'L' cannot

be detected. Memory shall

contain F26 code. After

Power on, CD function

shall continue, error disp l a y s h a l l b e " N O D I S C " .

Error No. shall be clear by

force or cold start.

DCDET1 = L (NG) For power.

For CD Mechanism Unit

(DLS6C).

Press [ ] on main

unit for next error.

For CD Mechanism Unit

(DLS6C).

Press [ ] on main

unit for next error.

For CD Mechanism Unit

(DLS6C).

Press [ ] on main

unit for next error.

Press [ ] on main

unit for next error.

18

Page 19

8 Troubleshooting Guide

19

Page 20

9 Service Fixture & Tools

Prepare service tools before process service position.

Service Tools Remarks

Main P.C.B. (CN901) - Panel P.C.B. (CN900) REEX1022 (11P FFC) (RTL)

20

Page 21

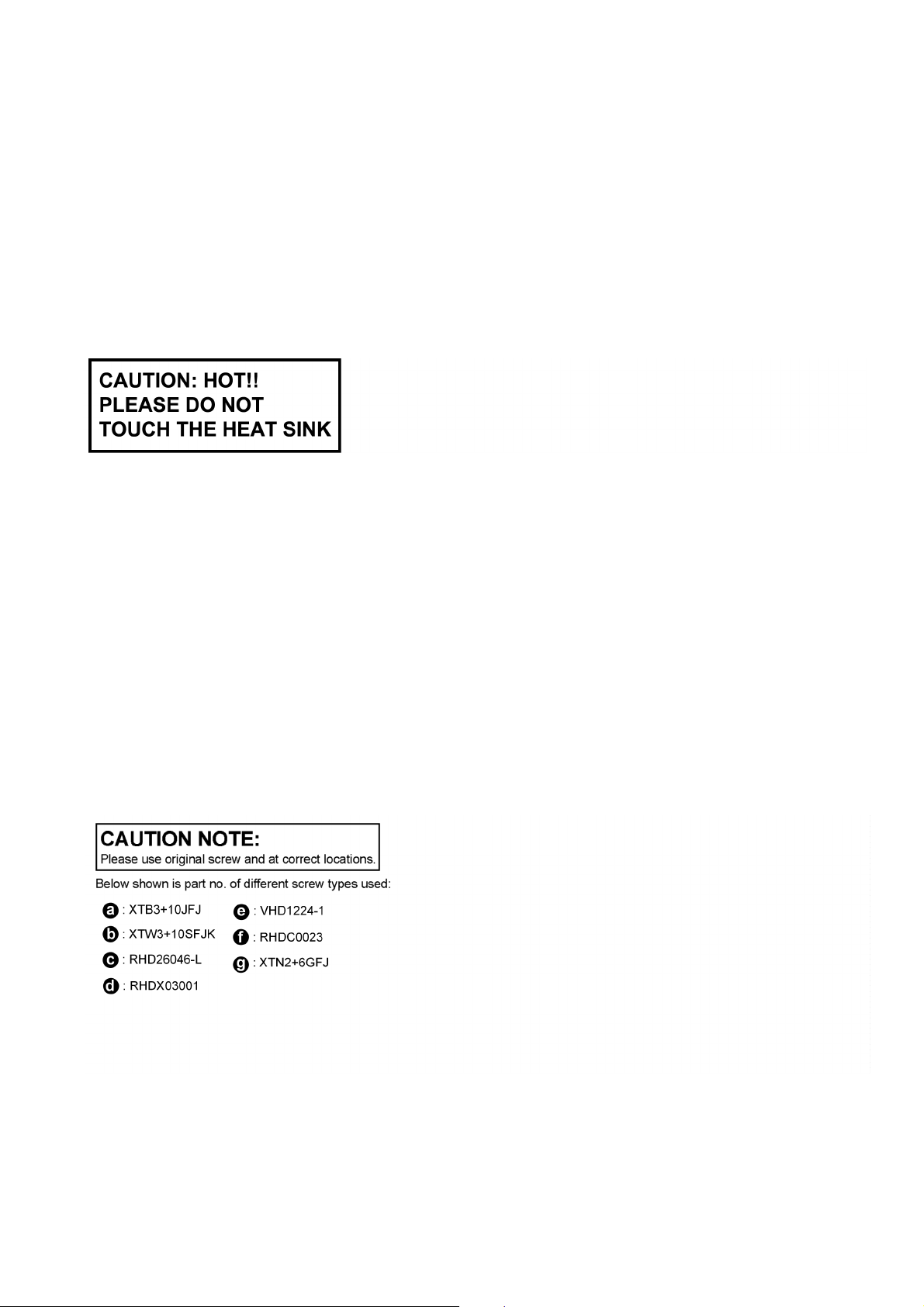

10 Disassembly and Assembly Instructions

“ATTENTION SERVICER”

Be careful when disassembling and servicing.

Some chassis components may have sharp edges

Special Note:

1. This section describes the disassembly procedures for all the major printed circuit boards and main components.

2. Before the disassembly process was carried out, do take special note that all safety precautions are to be carried out.

(Ensure that no AC power supply is connected during disassembling.)

3. For assembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

4. Do take note of the locators on each printed circuit board during reassembling procedures.

5. The Switch Regulator IC may have high temperature after prolonged use.

6. Use caution when removing the top cabinet and avoid touching heat sinks located in the unit.

7. Select items from the following index when checks or replacement are required.

• Disassembly of Top Cabinet Assembly

• Disassembly of Headphone P.C.B.

• Disassembly of iPod P.C.B.

• Disassembly of Front Panel Assembly

• Disassembly of USB P.C.B.

• Disassembly of Panel P.C.B.

• Disassembly of FL Window

• Disassembly of Centre Ornament

• Disassembly of CD Lid

• Disassembly of CD Mechanism Unit (DLS6C)

• Disassembly of Power P.C.B.

• Replacement of Power Amp IC (IC5101)

• Disassembly of Main P.C.B.

• Disassembly of Fan Unit

• Disassembly of Transformer P.C.B.

• Replacement of Transistor (Q5901)

• Disassembly of CD Servo P.C.B.

21

Page 22

10.1. Disassembly flow chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the servicing.

To assemble the unit, reverse the steps shown in the chart below.

22

Page 23

10.2. Main Parts Location Diagram

23

Page 24

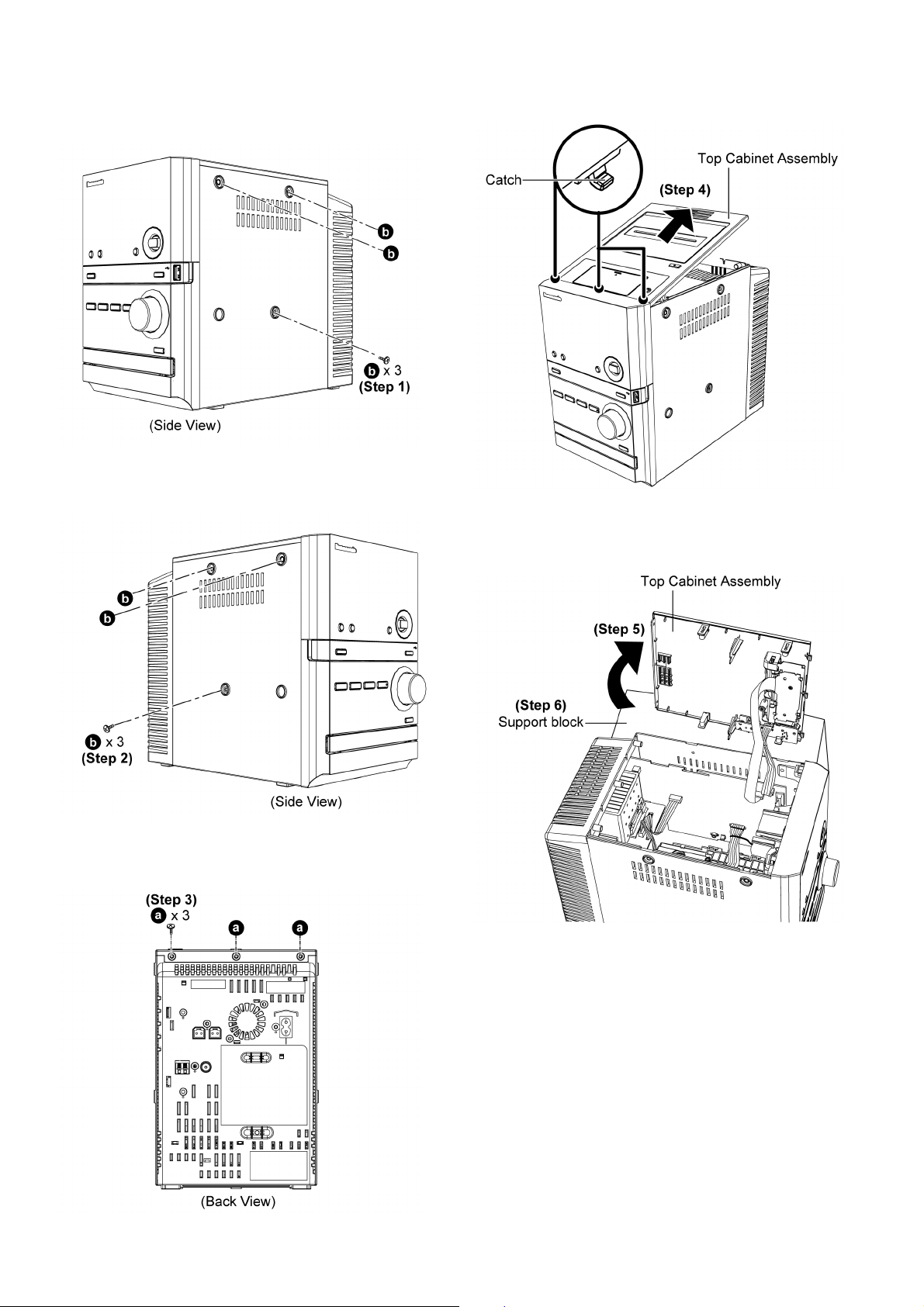

10.3. Disassembly of Top Cabinet

Assembly

Step 1 : Remove 3 screws.

Step 3 : Remove 3 screws.

Step 4 : Lift the Top Cabinet Assembly as arrow shown to

release 3 catches.

Step 2 : Remove 3 screws.

Step 5 : Upset the Top Cabinet Assembly as arrow shown.

Step 6 : Place a support block underneath the Top Cabinet

Assembly.

24

Page 25

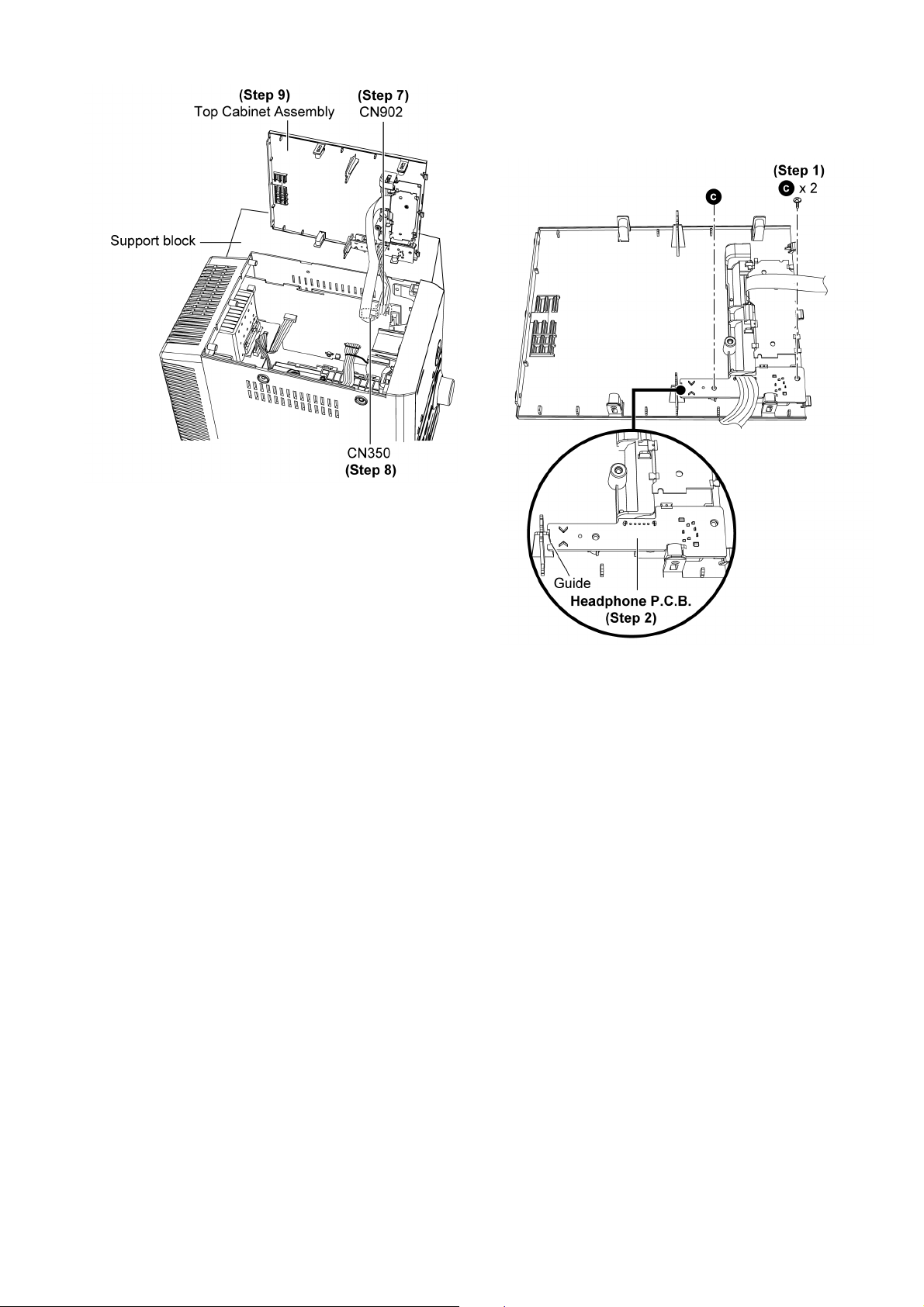

Step 7 : Detach 5P cable at connector (CN902) on Main P.C.B..

Step 8 : Detach 14P FFC at connector (CN350) on Main

P. C.B ..

Step 9 : Remove Top Cabinet Assembly.

10.4. Disassembly of Headphone

P.C.B.

• Follow the (Step 1) - (Step 9) of item 10.3.

Step 1 : Remove 2 screws.

Step 2 : Release guide and remove Headphone P.C.B..

25

Page 26

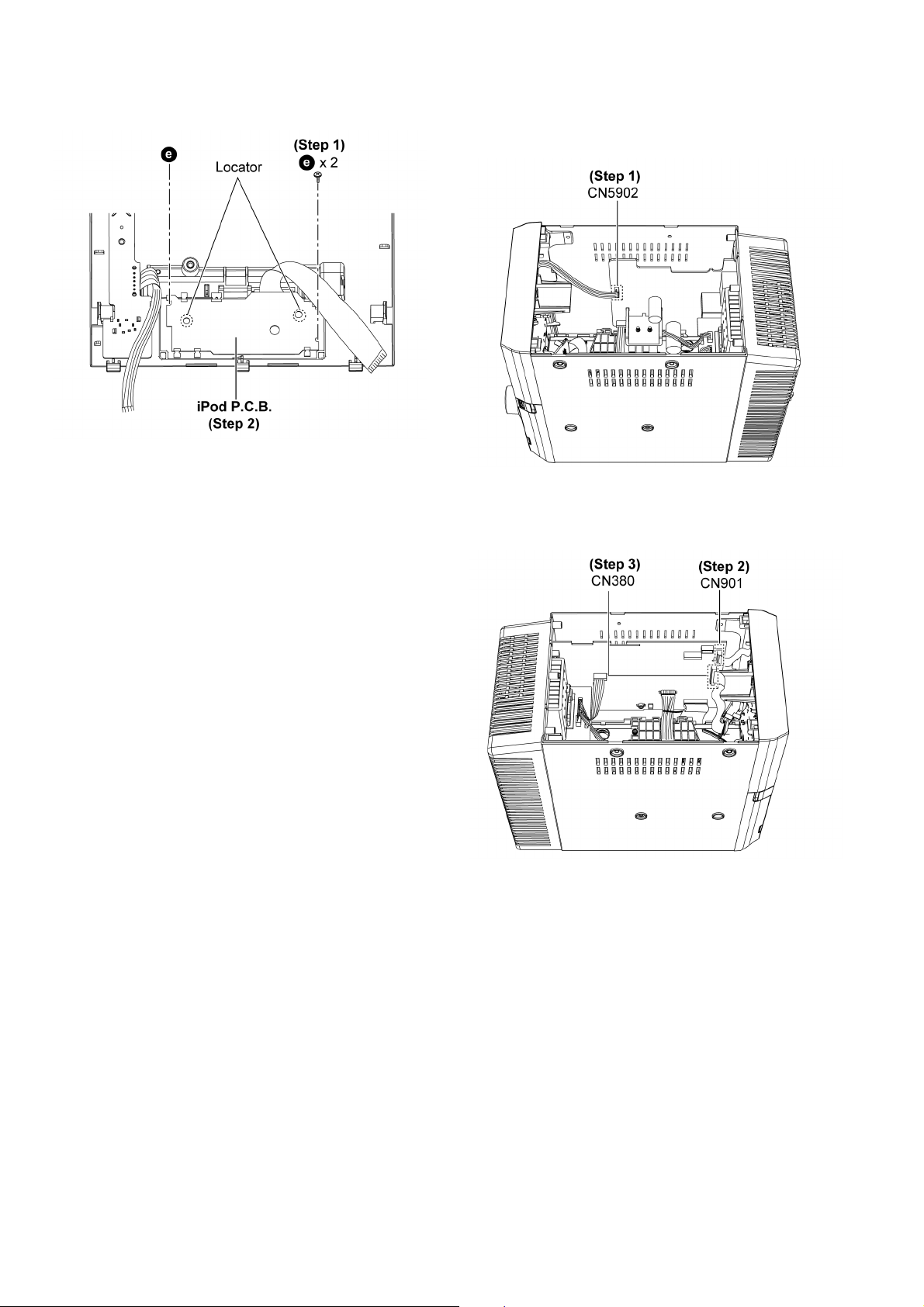

10.5. Disassembly of iPod P.C.B.

• Follow the (Step 1) - (Step 9) of item 10.3.

Step 1 : Remove 2 screws.

Step 2 : Remove iPod P.C.B..

Caution : Ensure the iPod P.C.B. is seated properly on the

locator after assembled.

10.6. Disassembly of Front Panel

Assembly

• Follow the (Step 1) - (Step 9) of item 10.3.

Step 1 : Detach 4P cable at connector (CN5902) on Transformer P.C.B..

Step 2 : Detach 11P FFC at connector (CN901) on Main

P. C.B ..

Step 3 : Detach 22P FFC at connector (CN380) on Main

P. C.B ..

26

Page 27

10.7. Disassembly of USB P.C.B.

• Follow the (Step 1) - (Step 9) of item 10.3.

• Follow the (Step 1) - (Step 6) of item 10.6.

Step 1 : Remove 2 screws.

Step 4 : Release both guides.

Step 5 : Release 3 Catches from the bottom.

Step 6 : Remove the Front Panel Assembly.

Caution : Do not attempt to exert strong force when

detaching the front panel assembly.

Step 2 : Release both catches as arrows shown.

Step 3 : Detach the USB P.C.B as arrow shown to release from

both guides.

27

Page 28

Caution : Ensure that the USB P.C.B. is firmly catched and

properly seated on the guides during assembly of the USB

P.C.B..

10.8. Disassembly of Panel P.C.B.

• Follow the (Step 1) - (Step 9) of item 10.3.

• Follow the (Step 1) - (Step 6) of item 10.6.

• Follow the (Step 1) - (Step 3) of item 10.7.

Step 1 : Remove Volume Knob.

Step 2 : Remove 4 screws.

28

Page 29

Step 3 : Release the catch

Step 4 : Remove the Panel P.C.B. as arrow shown.

Caution : During assembly ensure that Panel P.C.B. are

slot under the top guides. A ‘click’ sound will be heard

when fully catched.

10.9. Disassembly of FL Window

• Follow the (Step 1) - (Step 9) of item 10.3.

• Follow the (Step 1) - (Step 6) of item 10.6.

• Follow the (Step 1) - (Step 3) of item 10.7.

• Follow the (Step 1) - (Step 4) of item 10.8.

Step 1 : Release all catches by pushing the edge of the

catches as arrows shown.

Caution : Do not apply strong force in releasing the

catches to avoid damage to the Front Panel Assembly & FL

Window.

Step 2 : Remove FL Window.

29

Page 30

10.10. Disassembly of Centre Ornament

• Follow the (Step 1) - (Step 9) of item 10.3.

• Follow the (Step 1) - (Step 6) of item 10.6.

• Follow the (Step 1) - (Step 3) of item 10.7.

• Follow the (Step 1) - (Step 4) of item 10.8.

• Follow the (Step 1) - (Step 2) of item 10.9.

10.11. Disassembly of CD Lid

• Follow the (Step 1) - (Step 9) of item 10.3.

Step 1 : Release 4 catches as arrows shown.

Caution : During assembly ensure that centre ornament

are properly catched to the Front Panel Assembly.

Step 2 : Remove Centre Ornament.

Step 1 : Lift the spring out of the hook.

Caution : Keep the spring in a safe place and place it back

during assembling.

30

Page 31

Step 2 : Move the shaft (L) of the CD Lid in the direction of

arrow shown.

10.12. Disassembly of CD Mechanism Unit (DLS6C)

• Follow the (Step 1) - (Step 9) of item 10.3.

• Follow the (Step 1) - (Step 6) of item 10.6.

Step 1 : Detach 22P FFC at connector (CN370) on Main

P. C . B . .

Step 3 : Move the shaft (R) of the CD Lid in the direction of

arrow shown.

Step 4 : Remove the CD Lid in the direction of arrow shown.

Caution : Do not excert strong force to the shafts during

removal and assembly of the CD Lid.

Step 2 : Remove 2 screws.

Step 3 : Slightly tilt and remove the CD Mechanism Unit

(DLS6C) as arrow shown.

31

Page 32

10.13. Disassembly of Power P.C.B.

• Follow the (Step 1) - (Step 9) of item 10.3.

• Follow the (Step 1) - (Step 6) of item 10.6.

Step 1 : Remove 1 screw.

Step 4 : Remove 2 screws.

Step 5 : Remove Power P.C.B. as arrow shown.

Step 2 : Detach 4P cable at connector (CN5101) on Power

P. C . B . .

Step 3 : Detach 6P cable at connector (CN200) on Main P.C.B..

Caution 1 : Ensure the heatsink supports are seat properly.

Caution 2 : Ensure the 4P wire is properly dressed into the

hook of Power P.C.B. and prevent touching the heatsink

unit.

32

Page 33

10.14. Replacement of Power Amp IC

(IC5101)

• Follow the (Step 1) - (Step 9) of item 10.3.

• Follow the (Step 1) - (Step 6) of item 10.6.

• Follow the (Step 1) - (Step 5) of item 10.13.

Caution : Handle the heatsink uni P.C.B. with caution due

to its high temperature after prolonged use. Touching it

may lead to injuries.

Step 3 : Remove Power Amp IC (IC5101).

Step 1 : Desolder pins of Power Amp IC (IC5101).

Step 2 : Remove 2 screws.

33

Page 34

• Assembly of Power Amp IC (IC5101)

Step 1 : Apply grease to the heatsink unit.

Step 2 : Install Power Amp IC onto Power P.C.B..

Caution : Ensure the pins are inserted & seated properly

on the Power P.C.B..

Step 3 : Fix the Power Amp IC (IC5101) onto the heatsink unit

with 2 screws.

10.15. Disassembly of Main P.C.B.

• Follow the (Step 1) - (Step 9) of item 10.3.

• Follow the (Step 1) - (Step 6) of item 10.6.

• Follow the (Step 1) - (Step 5) of item 10.13.

Step 1 : Detach 2P cable at connector (CN100) on Main P.C.B..

Step 2 : Detach 22P FFC at connector (CN370) on Main

P. C.B ..

Step 4 : Solder pins of the Power Amp IC (IC5101) on the solder side of Power P.C.B..

Caution : Check for solderability of the Power Amp IC.

Caution : Ensure the 22P FFC properly dressed into the

hook of Main P.C.B. during assembling.

34

Page 35

Step 3 : Detach 7P cable at connector (CN5903) on Transformer P.C.B..

Step 4 : Remove 1 screw.

Step 5 : Use a paper clip to release the catch.

Step 6 : Remove Main P.C.B..

35

Page 36

10.16. Disassembly of Fan Unit

• Follow the (Step 1) - (Step 9) of item 10.3.

• Follow the (Step 1) - (Step 6) of item 10.6.

• Follow the (Step 1) - (Step 5) of item 10.13.

Step 1 : Remove 2 screws.

Caution : Ensure the Main P.C.B. fix onto the catches.

Step 2 : Detach 2P cable at connector (CN100) on Main P.C.B..

36

Page 37

Step 3 : Release 2 catches.

Step 4 : Remove 2P cable from the holder.

Step 5 : Remove Fan Unit.

Caution : Ensure the Fan Unit is seated properly onto the

rear panel assembly.

10.17. Disassembly of Transformer

P.C.B.

• Follow the (Step 1) - (Step 9) of item 10.3.

• Follow the (Step 1) - (Step 6) of item 10.6.

Step 1 : Detach 4P cable at connector (CN5101) on Power

P. C . B . .

Step 2 : Detach 7P cable at connector (CN5903) on Transformer P.C.B..

Caution : Ensure the 2P wire inserted into the Holder.

Step 3 : Remove 1 screw.

37

Page 38

Step 4 : Place a support block to tilt the unit as shown.

Step 5 : Remove 4 screws.

Step 7 : Remove Transformer cover P.C.B. and Trans spacer.

Caution : Keep them in safe place for assembling use.

Step 6 : Remove Transformer P.C.B..

Caution : Keep Transformer cover P.C.B. in safe place for

assembling use.

38

Page 39

10.18. Replacement of Transistor

(Q5901)

• Follow the (Step 1) - (Step 9) of item 10.3.

• Follow the (Step 1) - (Step 6) of item 10.6.

• Follow the (Step 1) - (Step 6) of item 10.17.

Caution : Handle the heatsink unit and P.C.B. with caution

due to its high temperature after prolonged use. Touching

it may lead to injuries .

Step 3 : Remove Transistor (Q5901).

Step 1 : Desolder pins of Transistor (Q5901).

Step 2 : Remove 1 screw.

39

Page 40

• Assembly of Transistor (Q5901)

Step 1 : Apply grease to the heatsink unit.

Step 2 : Install Transistor (Q5901) onto Transformer P.C.B..

Caution : Ensure the pins are inserted & seated properly

on Transformer P.C.B..

Step 3 : Fix the Transistor (Q5901) onto the heatsink unit with 1

screw.

10.19. Disassembly of CD Servo

P. C . B .

• Follow the (Step 1) - (Step 9) of item 10.3.

• Follow the (Step 1) - (Step 6) of item 10.6.

• Follow the (Step 1) - (Step 3) of item 10.12.

Step 4 : Solder pin of the Transistor (Q5901) on the solder side

of Main P.C.B..

Caution : Check for solderability of the Transistor (Q5901).

Step 1 : Remove 3 screws.

Step 2 : Unsolder 4 points.

Step 3 : Move up the CD Servo P.C.B.

Step 4 : Flip the CD Servo P.C.B.

40

Page 41

Step 5 : Detach 16P FPC at the connector (CN7001) on CD

Servo P.C.B.

41

Page 42

11 Disassembly and Assembly of Traverse Unit

11.1. Disassembling Procedures

Step 1 : Release the guide.

Step 2 : Push the traverse slide plate (rib), ensure both grooves

are opened.

Step 3 : Slide out the traverse unit as arrow shown.

Caution : Ensure the OPU is face upwards, avoid touching

the surface of the traverse unit.

42

Page 43

11.2. Assembling Procedure

Caution : Removal of the short pin is necessary for

replacement of new traverse unit.

Step 1 : Release the guide.

Step 2 : Push the traverse slide plate (rib), ensure both grooves

are opened.

43

Page 44

Step 3 : Slot the traverse unit at approximately 45° into the

mecha chassis as arrow shown.

Caution : Ensure the bosses fix exactly onto the guides.

Step 4 : Release the guide.

Step 5 : Push the traverse slide plate (rib) to lock the traverse

unit in.

44

Page 45

12 Service Position

Note: For description of the disassembly procedures, see the Section 10

12.1. Checking & Repairing USB

P. C . B .

Step 1 : Remove Top Cabinet Assembly.

Step 2 : Detach 11P FFC at connector (CN901) on Main

P. C.B ..

Step 3 : Release both guides.

Step 4 : Release 3 Catches.

Step 5 : Slightly remove Front Panel Assembly.

Step 6 : Remove 2 screws.

45

Page 46

Step 7 : Place a support block underneath the Top Cabinet

Assembly.

Step 8 : Connect 14P FFC at connector (CN350) on Main

P. C . B . .

Step 9 : Connect 5P cable at connector (CN902) on Main

P. C . B . .

Step 11 : Place a support block underneath the USB P.C.B..

Step 12 : Check & repair USB P.C.B. according to the diagram

shown.

Step 10 : Connect 11P FFC at connector (CN901) on Main

P. C . B . .

46

Page 47

12.2. Checking & Repairing Panel

P. C . B .

Step 1 : Remove Top Cabinet Assembly.

Step 2 : Remove Front Panel Assembly.

Step 3 : Remove USB P.C.B..

Step 4 : Remove Panel P.C.B..

Step 10 : Connect 4P cable at connector (CN5902) on Trans-

former P.C.B..

Step 11 : Connect 22P FFC at connector (CN380) on Main

P. C . B . .

Step 12 : Check & repair Panel P.C.B. according to the diagram

shown.

Step 5 : Place a support block underneath the Top Cabinet

Assembly.

Step 6 : Connect 14P FFC at connector (CN350) on Main

P. C.B ..

Step 7 : Connect 5P cable at connector (CN902) on Main

P. C.B ..

Step 8 : Lay an insulating material on Panel P.C.B..

Step 9 : Attach extension cable REEX1022 (11P FFC from

CN901 on Main P.C.B. to CN900 on Panel P.C.B.).

47

Page 48

12.3. Checking & Repairing CD

Servo P.C.B.

Note : Insert CD before Checking CD Servo P.C.B.

Step 1 : Remove Top Cabinet Assembly.

Step 2 : Remove Front Panel Assembly.

Step 3 : Remove CD Mechanism Unit (DLS6C).

Step 9 : Connect 22P FFC at connector (CN370) on Main

P. C.B ..

Step 4 : Place a support block underneath the Top Cabinet

Assembly.

Step 5 : Connect 14P FFC at connector (CN350) on Main

P. C . B . .

Step 6 : Connect 5P cable at connector (CN902) on Main

P. C . B . .

Step 10 : Upset CD Mechanism Unit (DLS6C).

Step 11 : Check & repair CD Servo P.C.B. according to the dia-

gram shown.

Step 7 : Connect 11P FFC at connector (CN901) on Main

P. C . B . .

Step 8 : Connect 22P FFC at connector (CN380) on Main

P. C . B . .

48

Page 49

12.4. Checking & Repairing Power

P. C . B .

Step 1 : Remove Top Cabinet Assembly.

Step 2 : Remove Front Panel Assembly.

Step 3 : Remove 1 screw.

Step 7 : Put insulating material under Power P.C.B..

Step 4 : Remove 2 screws.

Step 5 : Detach Power P.C.B..

Step 6 : Flip over Power P.C.B. as arrow shown.

Step 8 : Place a support block underneath the Top Cabinet

Assembly.

Step 9 : Connect 14P FFC at connector (CN350) on Main

P. C . B . .

Step 10 : Connect 5P cable at connector (CN902) on Main

P. C . B . .

49

Page 50

12.5. Checking & Repairing Transformer P.C.B.

Step 1 : Remove Top Cabinet Assembly.

Step 2 : Remove Front Panel Assembly.

Step 3 : Remove USB P.C.B..

Step 4 : Remove Panel P.C.B..

Step 5 : Remove Power P.C.B..

Step 6 : Remove Main P.C.B..

Step 7 : Remove Transformer P.C.B..

Step 8 : Remove CD Mechanism Unit (DLS6C).

Step 9 : Remove Fan Unit.

Step 11 : Connect 11P FFC at connector (CN901) on Main

P. C . B . .

Step 12 : Connect 22P FFC at connector (CN380) on USB

P. C . B . .

Step 13 : Connect 4P cable at connector (CN5902) on Transformer P.C.B..

Step 10 : Place a support block as diagram shown.

Step 11 : Connect 6P cable at connector (CN200) on Main

P. C.B ..

Step 12 : Connect 22P cable at connector (CN380) on Main

P. C.B ..

Step 13 : Connect 22P cable at connector (CN370) on Main

P. C.B ..

Step 14 : Check & repair Power P.C.B. according to the dia-

gram shown.

Step 14 : Connect 4P cable at connector (CN5101) on Power

P. C.B ..

50

Page 51

Step 15 : Connect 7P cable at connector (CN5903) on Transformer P.C.B..

12.6. Checking & Repairing Main

P.C.B.

• Follow (Step 1 - Step 19) of item 12.5

Step 16 : Place on insulating material under Panel P.C.B..

Step 17 : Connect 4P cable at connector (CN5902) on Trans-

former P.C.B..

Step 18 : Attach extension cable REEX1022 (11P FFC from

CN901 on Main P.C.B. to CN900 on Panel P.C.B.).

Step 1 : Flip over Fan Unit.

Step 2 : Check & repair Main P.C.B. according to the diagram

shown.

Step 19 : Connect 2P cable (Fan Unit) at connector (CN100)

on Main P.C.B..

Step 20 : Check & repair Transformer P.C.B. according to the

diagram shown.

51

Page 52

13 Voltage Measurement & Waveform Chart

Note:

• Indicated voltage values are the standard values for the unit measured by the DC electronic circuit tester (high-impedance) with

the chassis taken as standard.

Therefore, there may exist some errors in the voltage values, depending on the internal impedance of the DC circuit tester.

• Circuit voltage and waveform described herein shall be regarded as reference information when probing defect point because it

may differ from actual measuring value due to difference of Measuring instrument and its measuring condition and product itself.

13.1. USB P.C.B.

REF NO.

MODE 1234567891011121314151617181920

CD PLAY 0.7 0.7 0.7 0 0 0 3.3 3.3 3.3 1.8 1.6 1.6 00003.33.33.30.7

STANDBY 0.7 0.7 0.7 0 0 0 3.4 3.3 3.4 1.8 1.6 1.6 00003.43.43.40.7

REF NO.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 3.3 0.7 0

STANDBY 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 3.4 0.7 0

REF NO.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

CD PLAY 0.7 1.8 0.7 0 0.7 3.3 0.3 3.3 3.3 0 3.3 0.7 0 0 0.7 3.0 1.0 1.0 0 0.7

STANDBY 0.7 1.8 0.7 0 0.7 3.3 0.3 3.3 3.4 0 3.4 0.7 0 0 0.7 3.3 0 0 0 0.7

REF NO.

MODE 61 62 63 64

CD PLAY 0 1.8 0.7 3.3

STANDBY 0 1.8 0.7 3.3

IC900

IC900

IC900

IC900

SA-PM38PP USB P.C.B.

52

Page 53

13.2. CD SERVO P.C.B.

Ref No.

MODE 1 2 3 4 567891011121314151617181920

CD PLA

Y

000 0 0000000000000003.2

STANDB

Y

000 0 0000000000000000

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLA

Y

1.6 0 1.6 1.6 1.8 0 3.2 1.5 0 0 0 1.6 1.6 2 0 1.9 1.9 0 1.7 1.7

STANDB

Y

000 0 0000000000000000

Ref No.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

CD PLA

Y

0.2 2.4 1.7 1.9 0 0 3.2 1.2 0 1.2 1.6 1.6 0.9 1.4 1.5 1.5 0 3.2 0 0

STANDB

Y

000 0 0000000000000000

Ref No.

MODE 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

CD PLA

Y

000 0 003332.903.20001.63.203.21.6

STANDB

Y

000 0 0000000000000000

Ref No.

MODE 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100

CD PLA

Y

1.61.60 0 000000003.20000000

STANDB

Y

000 0 0000000000000000

Ref No.

MODE 1 2 3 4 567891011121314151617181920

CD PLA

Y

1.601.50000007.51.73.23.23.22.83.83.23.27.50

STANDB

Y

000 0 0000000000000000

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30

CD PLA

Y

0 0 0 0 7.1 1.6 1.6 1.6 0 0

STANDB

Y

000 0 000000

Ref No.

MODE E C B

CD PLAY 3.1 2 2.4

STANDBY 0 0.1 0

IC7001

IC7002

IC7002

Q7601

IC7001

IC7001

IC7001

IC7001

SA-PM38PP CD SERVO P.C.B.

53

Page 54

13.3. MAIN P.C.B. (1/2)

REF NO.

MODE 1234567891011121314151617181920

CD PLAY 0 0 4.5 0 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 0 3.3 3.3

STANDBY 0 0 0.5 0 0.5 0.5 0.5 0.5 0 0 0 0.5 0 0.5 0.5 0.5 0.5 0 0 0

REF NO.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY 9 4.5 4.5 4.5 0.9 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 0 4.5 0 0 4.5

STANDBY 0 0 0.5 0.5 0 0.5 0 0 0 0 0 0 0 0 0.5 0 0.5 0 0 0.5

REF NO.

MODE 41 42 43 44 45 46 47 48 49 50 51 52

CD PLAY 0 4.5 0 4.5 0 4.5 4.5 0 0 4.5 0 4.5

STANDBY 0 0.5 0 0.5 000000.500

REF NO.

MODE 12345

CD PLAY 7.5 7.5 0 5 1.25

STANDBY 0.5 0.5 0 0.7 1.25

REF NO.

MODE 12345

CD PLAY 5 0 1.2 3.3 5

STANDBY 0.7 0 0 0 0.7

REF NO.

MODE 12345678

CD PLAY 4.8 0 4.8 0 4.8 0 4.8 9

STANDBY 00000000

IC200

IC200

IC200

IC600

IC601

IC700

SA-PM38PP MAIN P.C.B.

54

Page 55

13.4. MAIN P.C.B. (2/2)

REF NO.

MODE 1234567891011121314151617181920

CD PLAY 3.3 3.3 1.2 0 3.3 0 3.3 0 3.3 0 0 1.5 1.5 0 1 1.6 3.3 1.8 3.3 3.3

STANDBY 0000003.300001.51.501.51.53.301.83.3

REF NO.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY 0 3.2 0 0 3.3 10001.13.32.83.303.33.31.8003.3

STANDBY 0 1.2 2 0 3.3 2 1.5 0 0 0 0 0 0 0 0 1.2 1.8 0 0 3.3

REF NO.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

CD PLAY 0 3.3 3.3 0 3.3 0 3.3 3.3 0 0 0 0 00000000

STANDBY 0 3.3 3.3 00003.3000000000000

REF NO.

MODE 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

CD PLAY 0 3.3 00000000001.60001000

STANDBY 0 3.3 00000000001.20001.2000

REF NO.

MODE 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100

REC 000000003.33.303.33.3002.22003.3

STANDBY 000000003.33.303.33.3001.223.303.3

REF NO.

MODE 123456

REC 0 -1.4 0 0 -1.4 0

STANDBY 0 0.7 0 0 0.7 0

IC800

IC800

IC800

IC800

IC800

Q760

REF NO.

MODE 123456

REC 0 -1.1 0 0 -1.1 0

STANDBY

REF NO.

MODE

CD PLAY

STANDBY

REF NO.

MODE

CD PLAY

STANDBY

REF NO.

MODE

CD PLAY

STANDBY

000000

Q100 Q101

ECB ECB ECB ECB ECB

0 2.3 0 0 0 0.5 0 3.3 0 5.4 5.4 4.6 0 1.3 0

0 0 0 0 0 0 0 3.3 0 0 1.3 1.3 0.5 0 0.5

Q600 Q603

ECB ECB ECB ECB ECB

13.6 9 13 8.8 13 9 5.3 5 0 3.3 -1 3.3 3.3 -1 3.3

0 0 0 0 0 0.5 0 0 0 3.3 3.3 0 3.3 3.3 0

ECB ECB ECB ECB ECB

0 3.3 0 0 0 3.2 3.3 3.3 0 0 1.3 0 0 0 5

0 3.3 0 0 1.3 0 0 1.7 1.3 0 0.5 0 0 0 0

Q761

Q350

Q604 Q761

Q375

Q382

Q762

QR600Q802 QR375 QR376 QR384

SA-PM38PP MAIN P.C.B.

55

Page 56

13.5. PANEL P.C.B.

REF NO.

MODE 1234567891011121314151617181920

CD PLAY 00001.801.20.81.20003.3-29-29-27-27-27-24.5 -24.5

STANDBY 00000.900000001.20.70.70.70.70.70.70.7

REF NO.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY -29 -24.5 -27 -29.5 -29.5 -29.5 -29.5 -24.5 -20 -24.5 -24.5 -27.5 -24.5 -27 -27 -27 -27 -27 -27 -27

STANDBY 0.7 0.7 0 0.7 0.7 0.7 0.7 0.7 0 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7

REF NO.

MODE 41 42 43 44

CD PLAY -27 -27 3.3 0

STANDBY 0.7 1.1 1.2 0

IC900

IC900

IC900

SA-PM38PP PANEL P.C.B.

13.6. POWER P.C.B.

REF NO.

MODE 123456789101112

CD PLAY 15.2 7.1 0 7 3.3 0 0 0 2.6 7.1 0 7.1

STANDBY 0.9 00000001.2000

IC5101

SA-PM38PP POWER P.C.B.

13.7. TRANSFORMER P.C.B.

REF NO.

MODE 12345

CD PLAY 6 0 1.5 3.3 6

STANDBY 6.5 0 1.2 0 6.5

REF NO.

MODE

CD PLAY

STANDBY

REF NO.

MODE

CD PLAY

STANDBY

Q5901 Q5902 Q5903 Q5904

ECB ECB ECB ECB ECB

14.5 7 12 6.8 6.8 7.2 0 0 0 0 1.8 1.8 0 0 0

0.5 0.2 0.2 0 0.2 0.5 0.6 0 0 0 1.8 2 0 6 0

Q5907

ECB

6 9.2 8

6 11 6.6

IC5901

Q5905

SA-PM38PP TRANSFORMER P.C.B.

56

Page 57

13.8. Waveform Chart

WF No. IC200 - 5,35

(PLAY)

2.28Vp-p (100usec.div)

WF No. IC200 - 42,50

(PLAY)

588mVp-p (50nsec.div)

WF No. IC800 - 13

(PLAY)

WF No. IC200 - 17,22

(PLAY)

668mVp-p (50nsec.div)

WF No. IC700 - 1,7

(PLAY)

1.48Vp-p (250usec.div)

WF No. IC800 - 15

(PLAY)

WF No. IC200 - 20

(PLAY)

2Vp-p (100nsec.div)

WF No. IC800 - 6

(PLAY)

3.44Vp-p (5usec.div)

WF No. IC800 - 16

(PLAY)

WF No. IC200 - 40,52

(PLAY)

2.24Vp-p (10msec.div)

WF No. IC800 - 12

(PLAY)

700mVp-p (50usec.div)

WF No. IC800 - 51

(PLAY)

2.48Vp-p (100nsec.div)

WF No. IC900 - 8

(PLAY)

1.2Vp-p (500usec.div)

WF No. IC7001 - 81

(PLAY)

1.2Vp-p (25nsec.div)

3.52Vp-p (50nsec.div)

WF No. IC5101 - 2,12

(PLAY)

172mVp-p (5nsec.div)

1.72Vp-p (50nsec.div)

WF No. IC5101 - 6,8

(PLAY)

112mVp-p (5nsec.div)

2.2Vp-p (50nsec.div)

WF No. IC7001 - 80

(PLAY)

3.56Vp-p (25nsec.div)

57

Page 58

14 Illustration of IC’s, Transistors and Diodes

BA5948FPE2 (28P)

C0AABB000125

5

8

4

1

B1ABDF000026

B1ADCF000001

B1ADCE000012

B1GBCFGN0016

B1GBCFJN0009

B0BC6R8A0266

AN17831A

B1GFGCAA0001

4

3

2

1

UNR211100L

UNR221100L

UNR521400L

C0HBB0000057 (44P)

C0DBGYY00089

C0DAEJG00001

C1AB00003013 (52P)

MN6627954AMA (100P)

MNZSFB5KJM2 (64P)

RFKWMPM38EG (100P)

1

1

B1BABG000007 B1BCCD000019 B1BCCG000023

5

6

E

C

B

B1ABCF000176

B1GBCFJJ0051

MA2J11100L

MAZ80560ML

B0EAKM000117

B0EAMM000038

5

4

2

3

1

3

5

2SB0621AHA

MAZ80680ML

B0ADFJ000004MAZ80910MLB0BC02900004

58

Page 59

15 Overall Simplified Block for PM38

NIL_BAD::63

NIR_BAD:4

TUOL_PSA:22

TUOR_PSA:71

NIL_NUT:73

NIR_NUT:3

L_BSU/DC:04

R_BSU/DC:25

NIL_EPAT:24

NIR_EPAT:05

NIL_DOPI:44

NIR_DOPI:74

LTUO_LES:53

RTUO_LES:5

CIENOHP/H

007CI

L+_TUO:01

L-_TUO:21

R+_TUO:2

R-_TUO:4

ASP Gain

CD/USB:

TAPE:

TUNER:

DAB:

IPOD:

ASP IC200

C1AB00003013

C273 / C473

5.6K

C270 / C470

6.8K

C242 / C442

0.1u

Gain = +18.0dB

Gain = -7.0dB

Gain = +40.0dB

POWER AMP IC

IC5101

AN17831A

Gain = -25.57dBC220 / C420

0.56u

R216 R416

18k

R215 / R415

1k

R2303 / R2403

4.7k

From Selector

Source

C0AABB000125

59

Page 60

16 Block Diagram

: USB SIGNAL LINE

REST SWITCH

S7201

[68]MDATA

[70]STAT

[67]MCLK

[71]BLKCK

[72]RST

[69]MLD

167

5

18

12,1310,11

122

320

9,12,13,14

9,12,13,14

3

CP701

CP1902

7

CP701

CP1902

9

CP701

CP1902

2

CP701

CP1902

11

CP701

CP1902

4

CP701

CP1902

16

CP701

CP1902

15

CP701

CP1902

14

13

CP701

CP1902

CP701

CP1902

TO MAIN(2/2)

BLOCK DIAGRAM

TO MAIN(1/2)

BLOCK DIAGRAM

MUTE

[CH1]

LEVEL

SHIFT

[CH3]

LEVEL

SHIFT

[CH4]

LEVEL

SHIFT

[CH2]

LEVEL

SHIFT

[CH1]

MUTE

[CH2]

[41]PD

[42]LD

[25]FOP

IC7002

BA5948FPE2

4CH DRIVER

IN4

27

[24]TRP

IN3

28

IN2

1

[23]TRVP

[21]SPOUT

[22]PC

IN1

3

PC2

2

VREF

PVCC1

PVCC2

VCC

26

10,19,25

D4-

17

D4+

18

D3-

15

D3+

16

D2+

14

D2-

13

M7301*

TRAVERSE

MOTOR

D1+

12

D1-

11

M7302*

SPINDLE

MOTOR

OPTICAL PICKUP P.C.B

B

FOCUS

COIL

TRACKING

COIL

T+

OPTICAL PICKUP

PHOTO DETECTOR

SEMICONDUCTOR

LASER

F+

F-

T-

<LD_SW>

PC1

4

B

B

M

M

[34]VREF

<+VREF>

<+VREF>

<+7.5V>

B

<3.3V>

B

IC7001

Q7601

LASER POWER

DRIVE

MN6627954AMA

SERVO PROCESSOR

[39]C

EEEE

EFEF

DC

AB

DC

[38]B

[35]E

[40]A

[37]D

[36]F

[56]OUTL

[47]AVDD2

[27]IODD2

[20]PRAMVDD15

[77]IODD1

[79]REGON

[82]NTEST

CD SIGNAL LCH

X7201

[81]X1

[80]X2

CN7002

CN7002

[59]OUTR

CD SIGNAL RCH

CN807

CN807

CN807

CN807

CN807

CN807

CN7002

CN7002

CN7002

CN7002

CD OPEN

SWITCH

S7202

203

CN807

CN7002

SA-PM38PP CD SERVO BLOCK DIAGRAM

CD SERVO P.C.B

[63]EXT1

[64]EXT2

CN7002

CN807

7,816,15

: CD AUDIO INPUT SIGNAL LINE

16.1. CD SERVO BLOCK DIAGRAM

60

Page 61

16.2. MAIN(1/2)/ PANEL/TRANSFORMER BLOCK DIAGRAM

: FM SIGNAL LINE

: USB SIGNAL LINE

RL5901

VOLUME JOG

KEY SW

-Vp

+3.3V

REMOTE SENSOR

S900-S904,

S906-S911

X802

32KHz

[16]XO

[9]FL_CS

[7]FL_DATA

[8]FL_CLK

FL900

FL DISPLAY

SEG1~SEG17

FROM

TRANSFORMER

MUTEA

GRID1~GRID11

14-29

32-42

31

[15]XI

5

<D3.3V>

<-Vp>

[13]VDD

[43]VDD

[30]-Vp

[19]NRST

[65]ASP_DATA

[64]ASP_CLK

ASP_DATA

TUNER_LEFT

TUNER_RIGHT

ASP_CLK

[90]AMP_MUTE

MUTE_HP

HP_SW

[5]MUTE_HP

[7]HP_SW

[98]VOL_JOG1

[93]KEY2

[92]KEY1

[25]RMT

[3]FL_CS

[4]FL_DATA

[6]FL_CLK

[1]PCONT_1

[96]DCDET

Q600

VOLTAGE

REGULATOR

Q603

POWER

CONTROL

Q604

QR600

Q100,Q101

POWER

CONTROL

VOLTAGE

REGULATOR

D603

X801

8MHz

[12]OSC2

[13]OSC1

INVERTER

SWITCH

Q350

Q382

LEVEL

SHIFTER

QR384

F5901

L5901

D5905,D5907

D5909,D5911

D5901~D5904

D5921-D5924

TO FL

DISPLAY

Q5903

<-VP>

VOLTAGE

REGULATOR

Q5901,Q5902

VOLTAGE

REGULATOR

Q5907

VOLTAGE

REGULATOR

Q5905

PCONT

SWITCH

Q5904

VOLTAGE

REGULATOR

<SYS3.3V>

3.3V

<+VREF>

T5901

T5902

VR900

Z900

IC900

C0HBB0000057

MICROPROCESSOR

IC800

RFKWMPM38EG

J3CCBB000011

Z300*

JK5901

AC INLET

MAIN

TRANSFORMER

SUB

TRANSFORMER

FL DRIVER

TUNER PACK

2

3

5

OUT

IN

GND

IC5901

C0DBGYY00089

VOLTAGE

REGULATOR

3

[4]OUT

[1]CTL

[2]VCC

GND

IC600

C0DAEJG00001

VOLTAGE

REGULATOR

TO MAIN(2/2)

BLOCK DIAGRAM

TO MAIN(2/2)

BLOCK DIAGRAM

<SYS3.3V>

11

B

B

6,7

CN900CN901

CN901

CN901

CN901

CN900

CN900

CN900

9,10

1,2,3

7

6

CN5903

CN5903

CN600 CN5903

2

CN600

CN600

CN600

CN5903

B

PANEL P.C.B

SA-PM38PP MAIN(1/2)/ PANEL/TRANSFORMER BLOCK DIAGRAM

TRANSFORMER P.C.B

MAIN P.C.B

<CD_STAT>

P901

P901

P901

P901

P901

CN380

CN380

CN380

CN380

CN380

CN380

P901

13,15 8,10

7

16

CN7002

CN7002

CN7002

CN7002

CN7002

CN7002

CN370

CN370

CN370

CN370

CN370

CN370

[40]CLOSE_L

[43]REST_SW

[41]OPEN_H

[24]USB_RST

[34]USB_SDA

[20]USB_IRQ

[36]USB_SCL

[22]TERR

[23]VERR

[21]MMOD

3,5,6,19

4,14,22

10 13

D804

D805

4

2

4

4

3

3

617

7,816,15

19

4

8,11,17,18

TO CD SERVO

BLOCK DIAGRAM

TO USB

BLOCK DIAGRAM

TO iPod

BLOCK DIAGRAM

123

CN350CN1002

CN1002

CN350

132

CN1002

CN350

411

[31]CD_MDATA

[33]CD_MCLK

[45]CD-RST

[35]CD_MLD

8,7,6,3

10,11,12,15

13,145,4

[32]STAT

[29]BLKCK

5

18

RESET

Q802

<SYS6V>

B

<M+9V>

<AMP_VCC>

B

<A9V>

B

<IPOD5V>

B

<USB5V>

B

5

3

CD3.3V

[1]Vin

GND

IC601

C0DBGYY00089

VOLTAGE

REGULATOR

<3.3V>

B

[26]HALT

4,17,18,20

5,6,12,15

1,9,19

[56]IPOD_PCONT

[50]TU_SDA

[52] TU_TUNED

[51] TU_CLK

[49]TU_STEREO

[77]

[76]

UART_IN

UART_OUT

<+VREF>

B

<DOCK5V>

B

SWITCH SWITCH

Q375

QR375,

QR376

<USB5V>

B

<D3.3V>

B

[59]

IPOD_DET

DC DETECT

61

Page 62

16.3. MAIN(2/2)/ HEADPHONE/ iPod/ USB BLOCK DIAGRAM

: FM SIGNAL LINE

: AUDIO OUTPUT SIGNAL LINE

: USB SIGNAL LINE

[3]TU-R

[52]CD-R

SPEAKERS

+9V

+VCC

[22]L_OUT[17]R_OUT

[19]SDA

[20]SCL

[21]VCC

Q762

Q761

MUTING

SWITCH

MUTING

CONTROL

AMP_MUTE

[37]TU-L

[9]MUTE

[2]OUT_R+

[12]OUT_L+

[8]IN_L

[6]IN_R

[4]OUT_R-

[10]OUT_L-

FILTER

FILTER

CN902

CN902

CN950

CN950

CN902CN950

CN902CN950

<A9V>

1

3

5,7

5,7

4

[1]VCC

FP5901

<AMP_VCC>

TO CD SERVO

BLOCK DIAGRAM

TO iPod

BLOCK DIAGRAM

TO DECK

BLOCK DIAGRAM

315

[40]CD-L

HP_SW

HP_MUTE

TAPE_EJECT

117

ASP_DATA

ASP_CLK

TUNER_LCH

TUNER_RICH

RCH

LCH

IC200

C1AB00003013

IC700

C0AABB000125

+

-

+

-

JK950

HEADPHONE

IC5101

AN17831A

JK501

LEFT CHANNEL

RIGHT CHANNEL

AUDIO SIGNAL PROCESSOR

OP-AMP(HEADPHONE)

POWER AMPLIFIER

TO MAIN(1/2)

BLOCK DIAGRAM

TO MAIN(1/2)

BLOCK DIAGRAM

TO MAIN(1/2)

BLOCK DIAGRAM

CN7002

CN7002

CN370

CN370

CD SIGNAL RCH

CD SIGNAL LCH

HEADPHONE P.C.B

POWER P.C.B

MAIN P.C.B

SA-PM38PP MAIN(2/2)/ HEADPHONE/ iPod/ USB BLOCK DIAGRAM

3

1

CN200

CN200

CN200

CN5102

CN5102

6

CN5102

USB P.C.B

TO MAIN 1/2

BLOCK DIAGRAM

TO MAIN 1/2

BLOCK DIAGRAM

P903

USB PORT

3,5,6,19 4,17,18,20

8,11,17,18 5,6,12,15

10

[58]CD_DATA

[61]STIN

[54]STREQ

[58]TCLK

[57]CD_STAT

[64]CD_MLD

[14]NRST

[48]I2C_DATA

[47]I2C_REQ

[46]I2C_CLK

[8]CD_NRST

[56]CD_CLK

4,14,22 1,9,19

3

4

4

3

P901

P901

P901

P901

7,8,10

CN380

CN380

CN380

CN380

CN380

[4]USBD[6]USBD+

[50]VERR

[51]TERR

[15]MMOD0

<3.3V>

B

<D1.8V>

B

IC900

MNZSFB5KJM2

USB CONTROLLER

[7]VDD

[9]VDD33

[17]VPP

[38]VDD33

[49]VDD5

[10]VDDI

[42]VDDI

[62]VDDI

12MHz

X900

[11]OSCI

[12]OSCO

P901

13,15,16

[2]D+

[3]D-

[1]USB_VBUS

VSS

S936

[35]REC_L

[5]REC_R

[50]TAPE P/BACK-R

[42]TAPE P/BACK-L

[47]IPOD_RCH

[44]IPOD_LCH

78

CN350CN1002

510

CN350CN1002

TAPE EJECT

SW

CN1303

CN1303

CN360

CN360

CN360

CN360

CN1303

49

CN1303

58

85

76

TO MAIN 1/2

BLOCK DIAGRAM

TO MAIN 2/2

BLOCK DIAGRAM

78

CN350CN1002

510

CN350CN1002

123

TX

OUT_L

OUT_R

RX

IPOD_DET

CN350CN1002

CN1002

CN350

132

CN1002

CN350

411

DOCK

FOR iPod

CN1001

iPod P.C.B

: CD AUDIO INPUT SIGNAL LINE

: iPod AUDIO INPUT SIGNAL LINE

62

Page 63

17 Wiring Connection Diagram

DOCK FOR iPod

16

2

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

16

15

1

1

21

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

22

2

CD SERVO P.C.B.

M7301*

(TRV MOTOR)

M7302*

(SPL MOTOR)

CN7001

CN7002

CN905

CN900

VR900

JK950

CN950

CN5101

CN5102

JK5101

CN5903

CN5901

JK5901

SOLDER SIDE

SOLDER SIDE

SOLDER SIDE

SOLDER SIDE

SOLDER SIDE

SOLDER SIDE

SOLDER SIDE

SOLDER SIDE

CN5902

T5902

(SUB-TRANSFORMER)

CAUTION

RISK OF ELECTRIC SHOCK

AC VOLTAGE LINE.

PLEASE DO NOT TOUCH THIS P.C.B.

120V 60Hz

AC IN ~

VOLUME

HEADPHONE

Z300*

(TUNER PACK)

CN200

CN600

CN370

CN380

CN901

CN902

CN350

CN100

P903

P901

USB PORT

CN1001

CN1002

(SIDE B)

PANEL P.C.B.

HEADPHONE P.C.B.

POWER P.C.B.

MAIN P.C.B.

F

USB P.C.B.

1

4

.

.

.

.

.

1

11

2

10

.

.

.

.

.

.

.

1

4

....

.............

...........

16

1

4

1

1

4

.

.

.

.

.

.

.

.

7

..........

1

5

12

........

...............

...............

...............

......

........

........

17

1

2

21

22

1

5

1

13

2 14

1

21

2

22

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1

11

2

10

1

1

30

.................

................

14

1

21

2

22

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

TRANSFORMER P.C.B.

H

G

SPEAKER

E

iPod P.C.B.

Z900

SENSOR

T5901

(MAIN TRANSFORMER)

63

Page 64

18 Schematic Diagram Notes

(All schematic diagrams may be modified at any time with

the development of new technology)

Notes:

S900:

S901:

S902:

S903: FM/AM switch.

S904:

S906:

S907:

S908:

S909:

S910: BASS/TREBLE switch.

S911: D.BASS switch.

S7201: REST switch.

S7202: CD OPEN switch.

VR900: Volume jog.

• “ * ” REF IS FOR INDICATION ONLY.

• Importance safety notice :

Components identified by ( ) mark have special characteristics important for safety.

Furthermore, special parts which have purposes of fire-retardant (resistors), high-quality sound (capacitors), low-noise

(resistors), etc. are used.

When replacing any of components, be sure to use only

manufacturer's specified parts shown in the parts list.

-DEMO switch ( / -DEMO).

CD PLAY/PAUSE switch (CD / ).

USB switch (USB / ).

iPod switch (iPod / ).

CD EJECT switch (OPEN/CLOSE ).

POWER switch ( ).

REW switch ( ).

FWD switch ( ).

• Voltage and Signal lines:

: +B Signal Line

: -B Signal Line

: CD Audio Input Signal Line

: iPod Audio Input Signal Line

: Audio Output Signal Line

: FM Signal Line

: USB Signal Line

• Capacitor values are in microfarad(μF) unless specified otherwise, F=Farad, pF=Pico-Farad

Resistance values are in ohm(Ω), unless specified otherwise, 1K=1,000Ω, 1M=1,000KΩ

64

Page 65

19 Schematic Diagram

A

A

CD SERVO CIRCUIT

SCHEMATIC DIAGRAM - 1

SA-PM38PP CD SERVO CIRCUIT

B

TO

MAIN CIRCUIT

(CN370)

IN SCHEMATIC

DIAGRAM - 4

: CD AUDIO INPUT SIGNAL LINE: +B SIGNAL LINE

A

B

C

D

E

F

G

H

1 2 3 4 5 6 7 8 9 10 11 12 13 14

1 2 3 4 5 6 7 8 9 10 11 12 13 14

A

B

D

E

F

H

G

C

C7223

50V4.7

50V1

C7227

MAZ80560ML

D7650

50V1

C7228

1K

R7217

C7218

0.082

820

R7212

C7217

0.1

C7225

1000P

R7218

1K

C7226

1000P

100

R7221

C7230

0.1

C7231

6.3V220

82K

R7211

0.1C7263

LB7262 0

0

0LB7264

LB7263

C7241

1000P

C7216

680P

C7244

0.015

C7102 0.47

0.1C7204

6.3V10

C7235

C7161

0.1

C7234

0.1

C7203

6.3V220

C7315

0.47

88

C7339

0.018

10K

R7328

3.3K

R7315

R7330

5.6K

10K

R7111

C7142 3300P

C7221 15P

C7222

15P

10

C7164

10C7165

C7232

6.3V220

1KR7254

470P

C7253

C7166

0.01

0.1

C7233

10R7253

R7214

470

1M

R7220

H0H169500013

X7201

S7202

CD OPEN

0.1

C7243

6

5

8

9

11

12

10

18

15

17

16

20

19

13

14

7

2

1

4

3

22

22

1

21

CN7002

S7201

REST

0.022C7107

C7155 0.1

0.1C7154

C7264 0.1

79

77

76

78

49

47

48

50

7471 7267 685655 58575251 5453 65 6661 6259 60 6463 7069 73 75

10

879

12 11

99

100

95

94

96

97

90

91

89

93

92

98

465 213

81

82

80

86

87

88

84

83

85

45

19 17 15 141618

43

23 21 20224124

39

37

33

35

34

29

30

27

26

28

32

31

36

38

25

40

42

44

13

46

MN6627954AMA

IC7001

C7601

6.3V33

4.7

R7601

C7614

6.3V100

C7670

0.1

C7626

0.1

B1ADCF000001

Q7601

5.6R7650

LASER POWER DRIVE

+

M7302*

SPINDLE MOTOR

4CH DRIVER

39

+

M7301*

TRAVERSE MOTOR

C7334

10V220

C7335

0.1

C7613 0.1

6

5

8

9

10

12

11

7

2

1

4

3

14

13

16

15

CN7001

TO

OPTICAL

PICKUP UNIT

28 (VREF)

100

R7335

10

R7336

1K

R7332

27K

R7331

6.8K

R7323

330

R7325

1K

R7327

18K

R7349

1K

R7329

C7352

0.018

C7338

0.027

1K

R7339

GND1

191817 2015 16

14 12 9 811 1013

22 233021 282724 25 26

2167

29

345

IC7002

BA5948FPE2

A. GND

LCH OUT

TX

MCLK

RST

3.3V

STAT

7.5V

MLD

LD SW

P. GND

D. GND

BLKCK

MDATA

3.3V

REST SW

LOADING

CD OPEN SW

RCH OUT

SRDATA (ST_IN)

BCLK (ST_CLK)

LRCK (ST_REQ)

[51] ARFIN

IREF

OUTR

OUTL

TX

MLD

MCLK

NRST

STAT

FLAG

PLLF

DVDD2

AVSS1

DVSS3

BLKCK

MDATA

AVDD1

PLLF0