Page 1

A

4

A

CD Stereo System

SA-PM32DBEB

Colour

(S)... Silver Type

ORDER NO. MD0603069C2

Specification

n Amplifier Section

RMS OUTPUT POWER both channel driven simultaneously

10% total harmonic distortion 5 W per channel (6 Ω)

Input impedance

MUSIC PORT 250 mV 12 kΩ

Output impedance

HEADPHONE 16 Ω to 32 Ω

Phone jack

Terminal Stereo, 3.5 mm

Music Port input jack

Terminal Stereo, 3.5 mm

DAB External antenna

Terminal F-Connector (75 Ω)

n FM Tuner Section

Frequency range 87.50 MHz to 108.00 MHz

(50 kHz step)

Sensitivity 3.2 µV (IHF)

S/N 26 dB 1.2 µV

ntenna terminals 75 Ω (unbalanced)

Preset station FM 15 stations

AM 15 stations

n AM Tuner Section

Frequency range 522 kHz to 1629 kHz

(9 kHz steps)

Sensitivity

S/N 20 dB (at 999 kHz) 1412 µV/m

n DAB Section

Frequency Band (Wavelength)

Band III (UK only) 11B ~ 12D (218.640 MHz ~

229.072 MHz)

Band III (Europe) 5A ~ 13F (174.928 MHz ~

239.200 MHz)

Intermediate frequency 1st : 38.912 MHz, 2nd : 2.048

MHz

Sensitivity *BER 4x10

MAX. Input Power 0dBm

Min Requirement -98 dBm

Selectivity

djacent Channel (Band III) 33 dB

Far-Off Channel (Band III) 45 dB

DAB memories 20 channels

n CD Section

Disc played [8 cm or 12 cm]

(1) CD-Audio (CD-DA)

(2) CD-R/RW (CD-DA, MP3 formatted disc)

(3) MP3

Sampling frequency

CD 44.1 kHz

-

© 2006 Matsushita Electric Industrial Co. Ltd.. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

A

SA-PM32DBEB

MP3 32 kHz, 44.1 kHz, 48 kHz

Bit rate

MP3 32 kbps to 384 kbps

Decoding 16/20/24 bit linear

Pickup

Beam source Semiconductor laser

Wavelength 785 nm

Laser power CLASS 1

udio output (Disc)

Number of channels 2 channel

Frequency response 20 Hz to 20 kHz (+1, -2dB)

Wow and flutter Below measurable limit

Digital filter 8fs

D/A converter MASH (1 bit DAC)

n General

Power supply AC 230 to 240 V, 50 Hz

Power consumption 25 W

Dimensions (W x H x D) 165 mm x 227 mm x 327 mm

Mass 2.8 kg

Operating temperature range +5°C to +35°C

Operation humidity range 5% to 90% RH (no condensation)

Power consumption in standby

mode

Notes :

1. Specifications are subject to change without notices. Mass and

dimensions are approximate.

2. Total harmonic distortion is measured by the digital spectrum

analyzer.

n System : SC-PM32DBEBS

Music center: SA-PM32DBEBS

Speaker: SB-PM3EG-M

0.8 W

CONTENTS

Page Page

1 Safety Precautions 4

1.1. General Guidelines

1.2. Caution for AC Cord

1.3. Before Repair and Adjustment

1.4. Protection Circuitry

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

3 Precaution of Laser Diode

4 Handling Precautions For Traverse Deck

5 Handling the Lead-free Solder

5.1. About lead free solder (PbF)

6 Accessories

7 Operating Instructions Procedures

7.1. Main Unit Operation

7.2. Remote Control Operation

7.3. Disc Information

8 Self diagnosis and special mode setting

8.1. Special Mode Table

8.2. Error Code Table

9 Assembling and Disassembling

9.1. Caution

9.2. Disassembly flow chart

9.3. Main Parts Location Diagram

9.4. Disassembly of Side Panel L & R

9.5. Disassembly of Top Cabinet Unit

9.6. Disassembly of Headphone P.C.B.

9.7. Disassembly of Front Panel

9.8. Disassembly of DAB Module unit

9.9. Disassembly of Panel P.C.B.

10

10

11

12

12

13

13

14

14

15

16

16

17

18

19

19

20

20

21

21

9.10. Disassembly of Rear Panel

4

5

6

6

7

8

9

9.11. Disassembly of Tuner Pack

9.12. Disassembly of Main P.C.B.

9.13. Disassembly of Power P.C.B.

9.14. Disassembly of Speaker Terminal P.C.B.

9.15. Disassembly of Transformer P.C.B.

9.16. Disassembly of CD Mechanism

9.17. Disassembly of Traverse Unit, Driving Gear, and Cam

Gear (CD Mechanism Unit)

9.18. Disassembly of Optical Pickup (CD Mechanism Unit)

9.19. Disassembly of Traverse Gear A and Traverse Gear B

(CD Mechanism Unit)

10 Service Fixture and Tools

11 Service Positions

11.1. Checking and Repairing Headphone P.C.B.

11.2. Checking and Repairing of DAB Module Unit and Panel

P.C.B.

11.3. Checking and Repairing of Transformer P.C.B.

11.4. Checking and Repairing of Main P.C.B.

11.5. Checking and Repairing of CD Servo P.C.B.

11.6. Checking and Repairing of Speaker Terminal P.C.B.

11.7. Checking and Repairing of Power P.C.B.

12 Voltage Measurement and Waveform Chart

12.1. Voltage Measurement

12.2. Waveform

13 Wiring Connection Diagram

14 Block Diagram

15 Notes of Schematic Diagram

16 Schematic Diagram

21

22

22

22

23

24

24

25

28

29

30

30

30

31

32

33

34

35

36

37

37

40

41

43

47

49

2

Page 3

SA-PM32DBEB

16.1. CD SERVO CIRCUIT 49

16.2. MAIN CIRCUIT and TUNER EXTENT CIRCUIT

16.3. PANEL CIRCUIT

16.4. POWER CIRCUIT

16.5. SPEAKER TERMINAL CIRCUIT, TRANSFORMER

CIRCUIT and HEADPHONE CIRCUIT

17 Printed Circuit Board

17.1. CD SERVO P.C.B

17.2. MAIN P.C.B and TUNER EXTENT P.C.B

17.3. PANEL P.C.B

17.4. POWER P.C.B and SPEAKER TERMINAL P.C.B

17.5. TRANSFORMER P.C.B and HEADPHONE P.C.B

18 Illustration of IC's, Transistors and Diodes

19 Terminal Function of IC's

50

52

53

19.1. IC7001 (MN6627954MA) IC SERVO

PROCESSOR/DIGITAL SIGNAL PROCESSOR/DIGITA L

FILTER D/A CONVERTER

19.2. IC7002 (BA5948FPE2) IC 4CH Drive

54

55

55

56

57

58

59

19.3. IC401 (C2CBYY000223) IC MICROPROCESSOR

20 Troubleshooting Flowchart (CD Section Circuit)

21 Exploded Views

21.1. Cabinet Parts Location

21.2. Traverse Deck Part Location

21.3. Packaging

22 Replacement Parts List

61

62

62

63

63

65

67

67

68

69

71

3

Page 4

SA-PM32DBEB

1 Safety Precautions

1.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, ensure that all the protective devices such as insulation barriers, insulation papers shields are properly installed.

3. After servicing, check for leakage current checks to prevent from being exposed to shock hazards.

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Using an ohmmeter measure the resistance value, between the jumpered AC plug and each expose d metallic cabine t part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩ and 5.2Ω.

When the exposed metal does not have a return path to the chassis, the reading must be

.

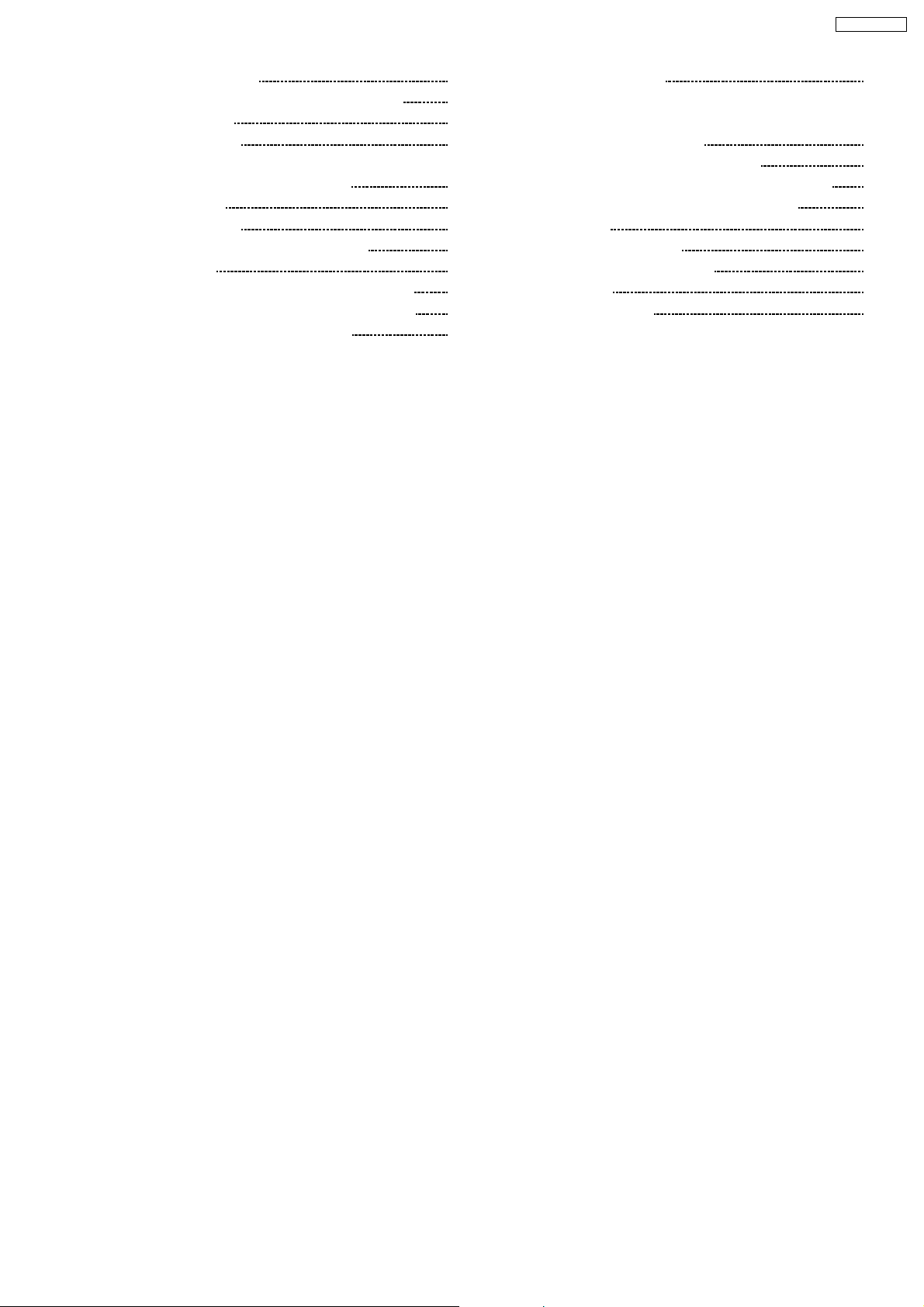

Figure 1

1.1.2. Leakage Current Hot Check (See Figure 1)

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent) may

be used to make the hot checks, leakage current must not exceed 1/2 milliamp. should the measurement is outside of the limits

specified, there is a possibility of a shock hazard, and the equipment should be repaired and re-checked before it is returned

to the customer.

4

Page 5

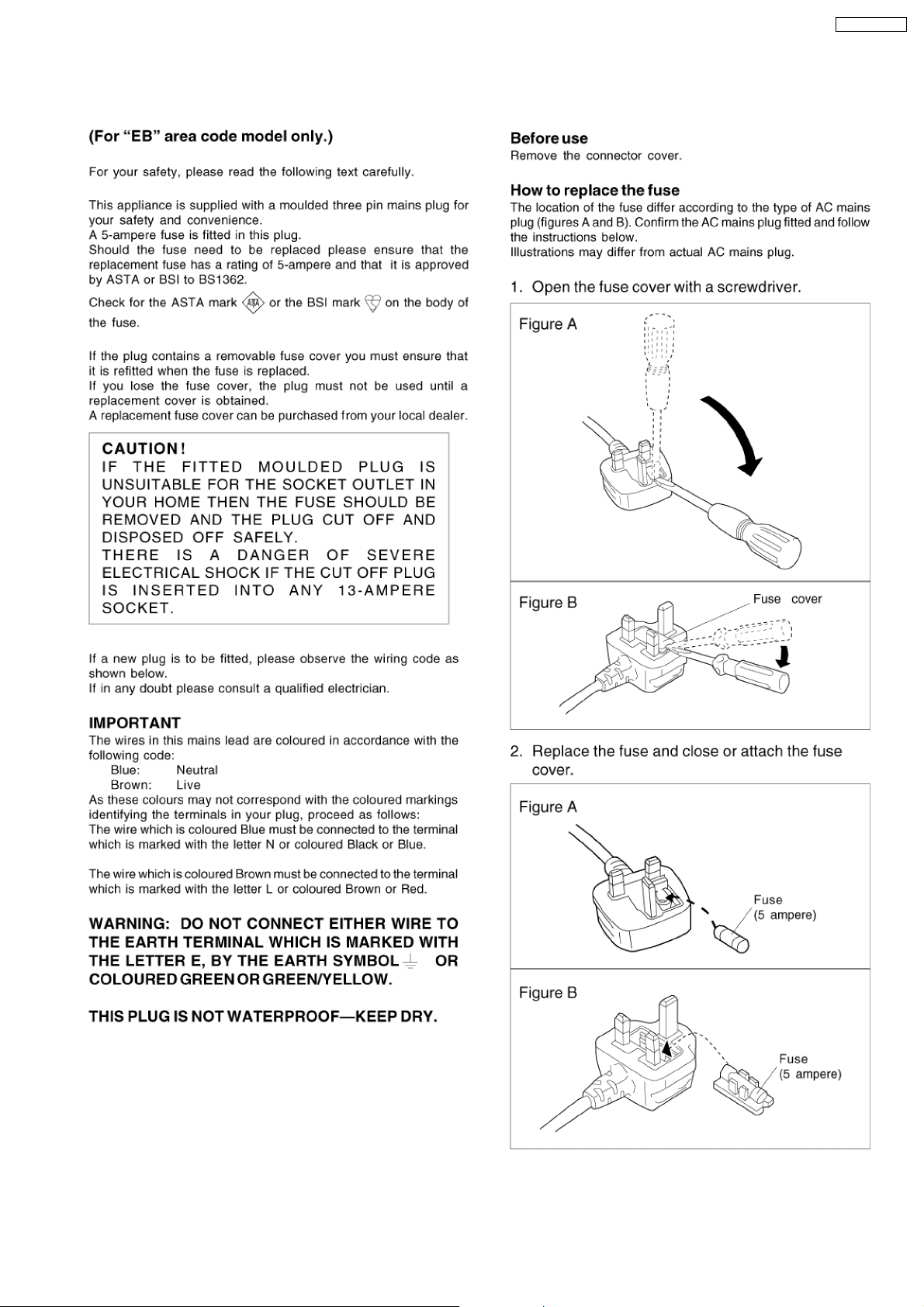

1.2. Caution for AC Cord

SA-PM32DBEB

5

Page 6

SA-PM32DBEB

1.3. Before Repair and Adjustment

Disconnect AC power, discharge Power Supply Capacitors C501, C601, C807, C813, C814, C831, C839, C840, C909, C910,

C911, C923 & C966 through a 10Ω, 1W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

· Current consumption at AC 230-240 V, 50 Hz in NO SIGNAL mode at (volume minimal) should be ~160 mA.

1.4. Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

· No sound is heard when the power is turned on.

· Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speake r connection wires are

"shorted", or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

6

Page 7

SA-PM32DBEB

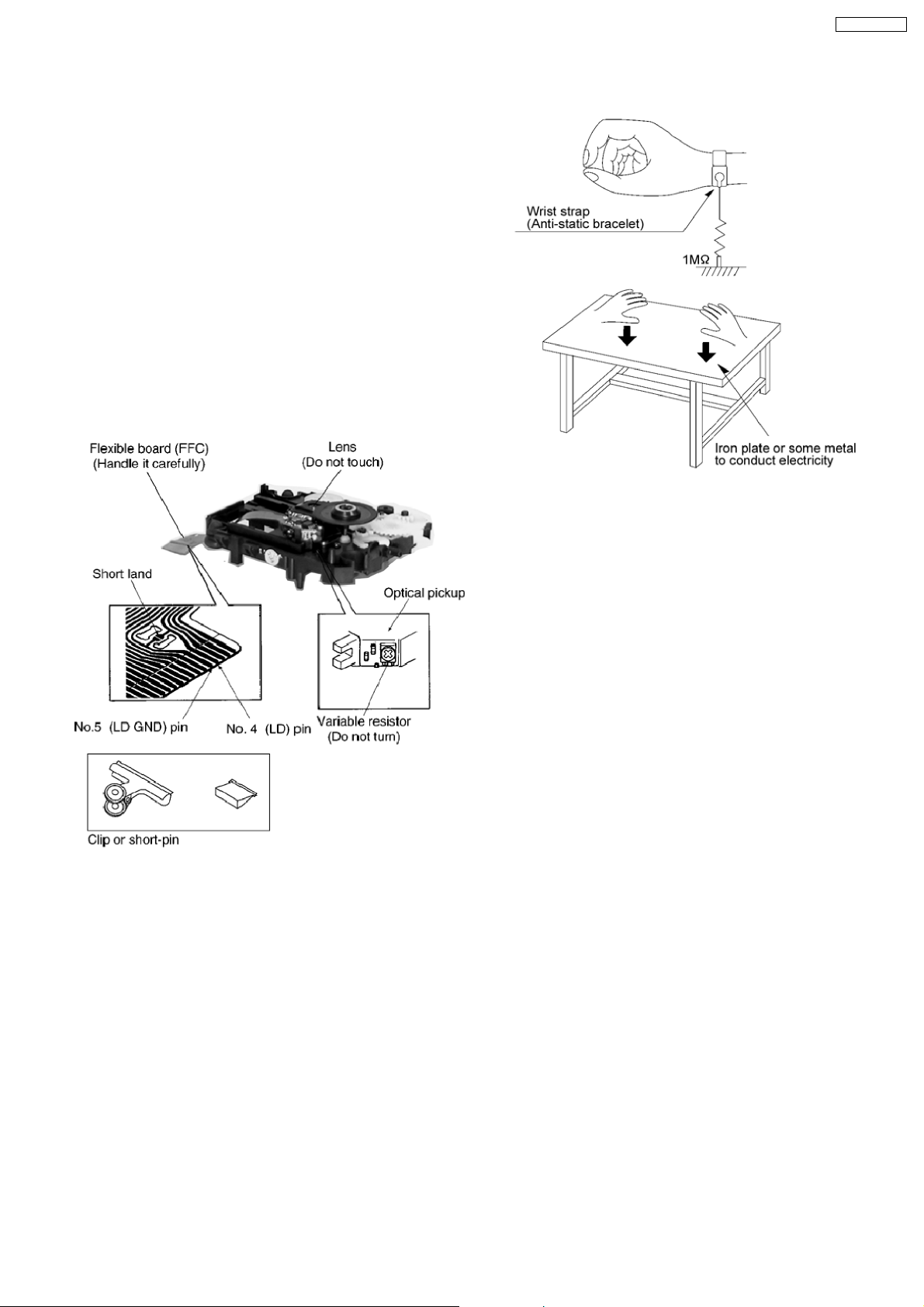

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor “chip” components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handlin g any semiconductor component or semiconductor-equiped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applyin g power to the unit under test.

2. After removing an electrical assembly equiped with ES devices, place the assembly on a conductive surface such as aluminium

foil, to prevent electrostatic charge build up or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder remover device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminium foil or

comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installe d.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize body motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to

damage an ES device).

7

Page 8

SA-PM32DBEB

3 Precaution of Laser Diode

CAUTION:

This unit utilizes a class 1 laser.

Invisible laser radiation is emitted from the optical pickup lens.

When the unit is turned on:

1. Do not look directly into the pick up lens.

2. Do not use optical instruments to look at the pick up lens.

3. Do not adjust the preset variable resistor on the pickup lens.

4. Do not disassemble the optical pick up unit.

5. If the optical pick up is replaced, use the manufacturer’s specified replacement pick up only.

6. Use of control or adjustments or performance of procedures other than those specified herein may result in hazardous radiation

exposure.

CAUTION!

THIS PRODUCT UTILIZES A LASER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT

IN HAZARDOUS RADIATION EXPOSURE.

8

Page 9

4 Handling Precautions For Traverse Deck

The laser diode in the traverse deck (optical pickup) may break

down due to potential difference caused by static electricity of

clothes or human body.

So, be careful of electrostatic breakdown during repair of the

traverse deck (optical pickup).

l Handling of CD traverse deck (optical pickup)

1. Do not subject the traverse deck (optical pickup) to

static electricity as it is extremely sensitive to electrical

shock.

2. The short land between the No.4 (LD) and No.5 (GND)

pins on the flexible board (FFC) is shorted with a solder

build-up to prevent damage to the laser diode.

3. Take care not to apply excessive stress to the flexible

board (FFC board) (Fig 4.1).

4. Do not turn the variable resistor (laser power

adjustment). It has already been adjusted.

SA-PM32DBEB

Fig 4.1

l Grounding for electrostatic breakdown prevention

1. Human body grounding (Fig 4.2)

Use the anti-static wrist strap to discharge the static

electricity from your body.

2. Work table grounding (Fig 4.2)

Put a conductive material (sheet) or steel sheet on the

area where the traverse deck (optical pickup) is placed,

and ground the sheet.

Caution :

The static electricity of your clothes will not be grounded

through the wrist strap. So, take care not to let your

clothes touch the traverse deck (optical pickup).

Fig 4.2

Caution when Replacing the Optical Pickup :

The traverse has a short point shorted with solder to protect

the laser diode against electrostatics breakdown. Be sure to

remove the solder from the short point before making

connections.

9

Page 10

SA-PM32DBEB

5 Handling the Lead-free Solder

5.1. About lead free solder (PbF)

Distinction of PbF P.C.B.:

P.C.B.s (manufactured) using lead free solder will have a PbF stamp on the P.C.B.

Caution:

· Pb free solder has a higher melting point than standard solder; Typically the melting point is 50 - 70°F (30 - 40°C) higher. Please

use a high temperature soldering iron. In case of soldering iron with temperature control, please set it to 700 ± 20°F (370 ±

10°C).

· Pb free solder will tend to splash when heated too high (about 1100°F/600°C).

· W hen soldering or unsoldering, please completely remove all of the solder on the pins or solder area, and be sure to heat the

soldering points with the Pb free solder until it melts enough.

10

Page 11

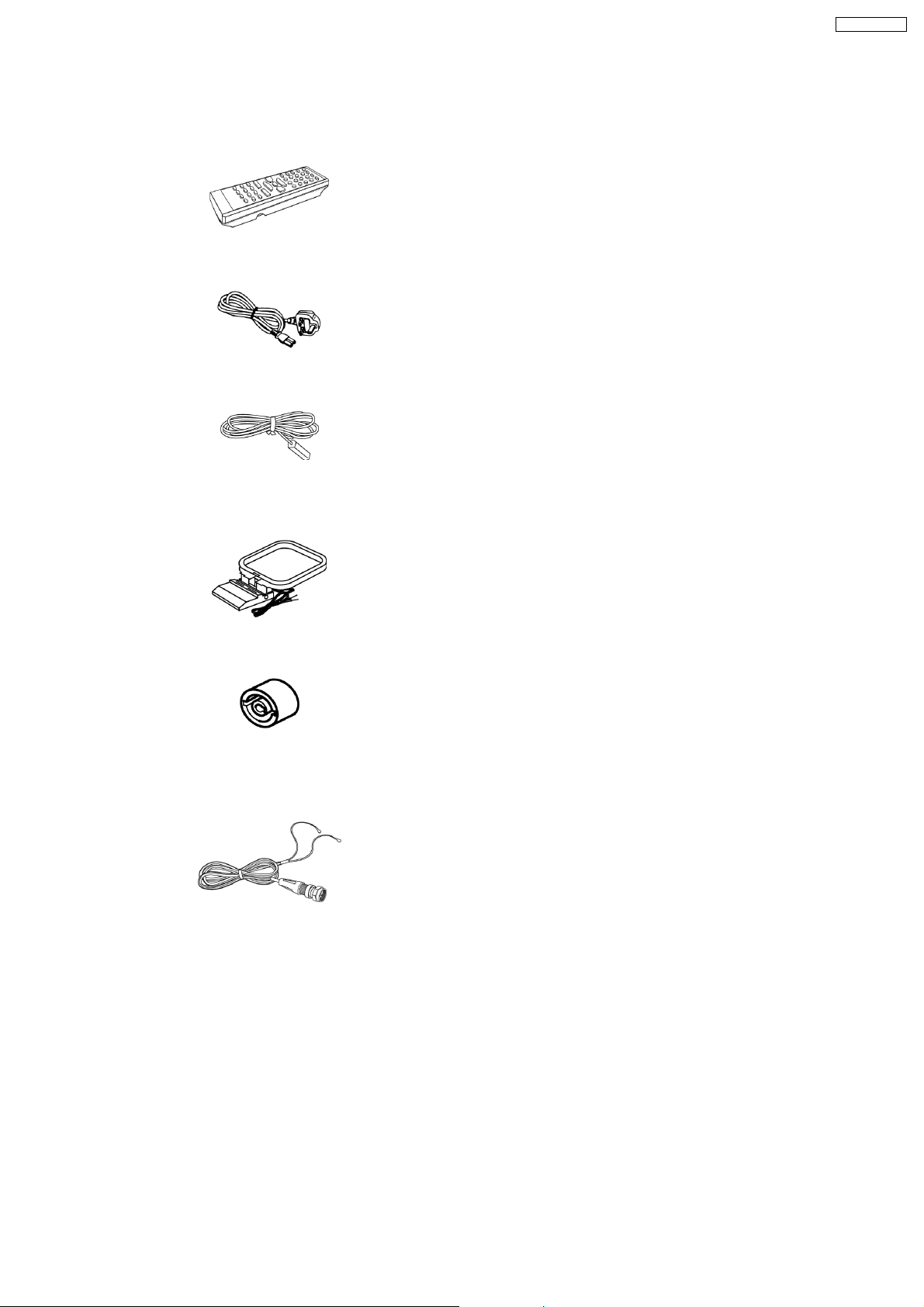

6 Accessories

Note : Refer to Packing Materials & Accessories (Section 22) for part number.

Remote control

AC cord

SA-PM32DBEB

FM indoor

antenna

AM loop antenna

Antenna

plug

adaptor

DAB antenna

11

Page 12

SA-PM32DBEB

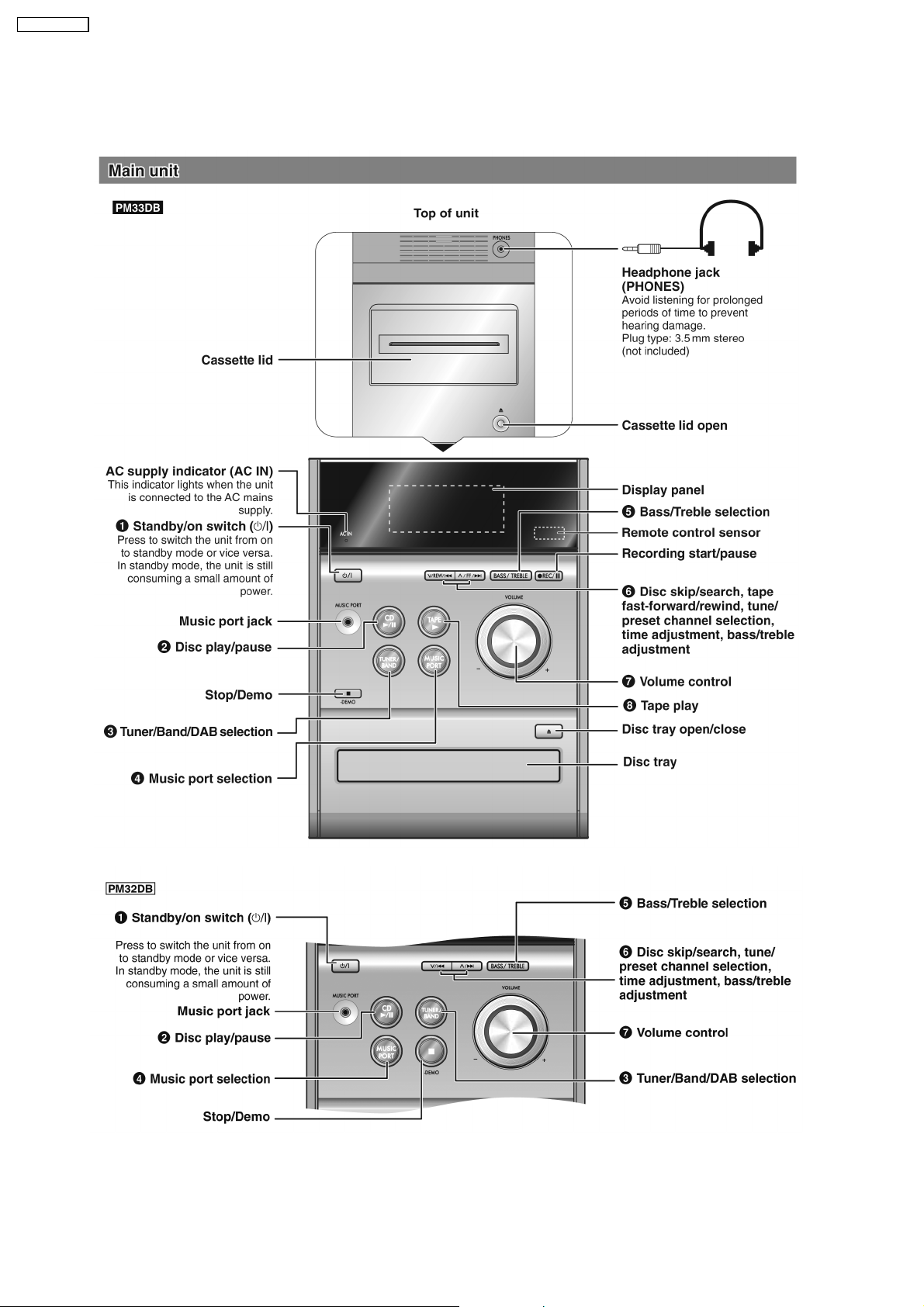

7 Operating Instructions Procedures

7.1. Main Unit Operation

12

Page 13

7.2. Remote Control Operation

SA-PM32DBEB

7.3. Disc Information

13

Page 14

SA-PM32DBEB

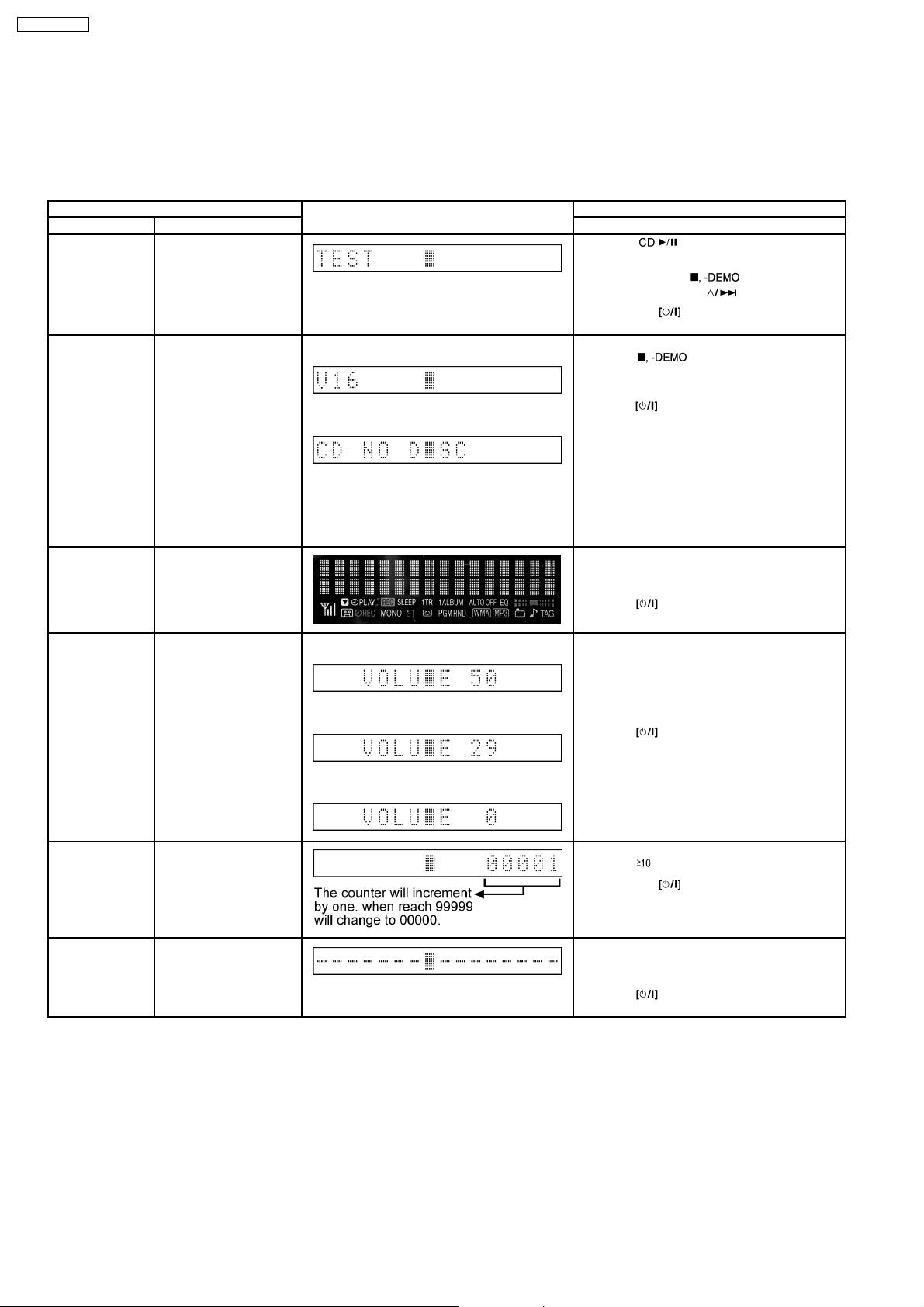

8 Self diagnosis and special mode setting

This unit is equipped with features of self-diagnostic & special mode setting for checking the functions & reliability.

8.1. Special Mode Table

Below is the various special modes for checking:-

Item FL Display Key Operation

Mode Name Description Front Key

Self -Diagnostic

Mode

Doctor Mode To enter into Doctor

FL Display Test To check the FL

Volume Setting To Forced Volume

To enter into self

diagnostic checking for

main unit.

Mode for checking of

various items and

displaying EEPROM and

firmware version.

(For more information,

refer to section 8.1.1)

Note: The microprocessor version as

shown is an example. It

will be revise when there

is an updates.

segments display (All

segments will light up)

Setting.

1.

2.

The Check Sum of EEPROM and firmware

version will be display for 1 sec.

* ROM correction

** Firmware version No:

1.

2.

1. Select [ ] for CD mode (Ensure no

tape or CD inserted).

2. Press and hold [

seconds follow by [

To exit, press

remote control.

In any mode:

1. Press [

by [4] and [7] on remote control.

To exit, press [ENTER] button on remote

control or

control.

In doctor mode:

1. Press [DIMMER] button on remote control.

To exit, press [ENTER] button on remote

control or

control.

In doctor mode:

1. Press [7] button on remote control.

2. Press [8] button on remote control.

3. Press [9] button on remote control.

To exit, press [ENTER] button on remote

control or

control.

button on main unit or

] button on main unit follow

button on main unit or remote

button on main unit or remote

button on main unit or remote

]button for 2

].

3.

Traverse Test To determine the

reliability of CD unit.

Cold Start To activate cold start ipon

next AC power up.

In doctor Mode:

1. Press [

To exit, press

remote control.

In doctor mode:

1. Press [SLEEP] button on remote control.

To exit, press [ENTER] button on remote

control or

control.

], [1], [2] button on remote control.

button on main unit or

button on main unit or remote

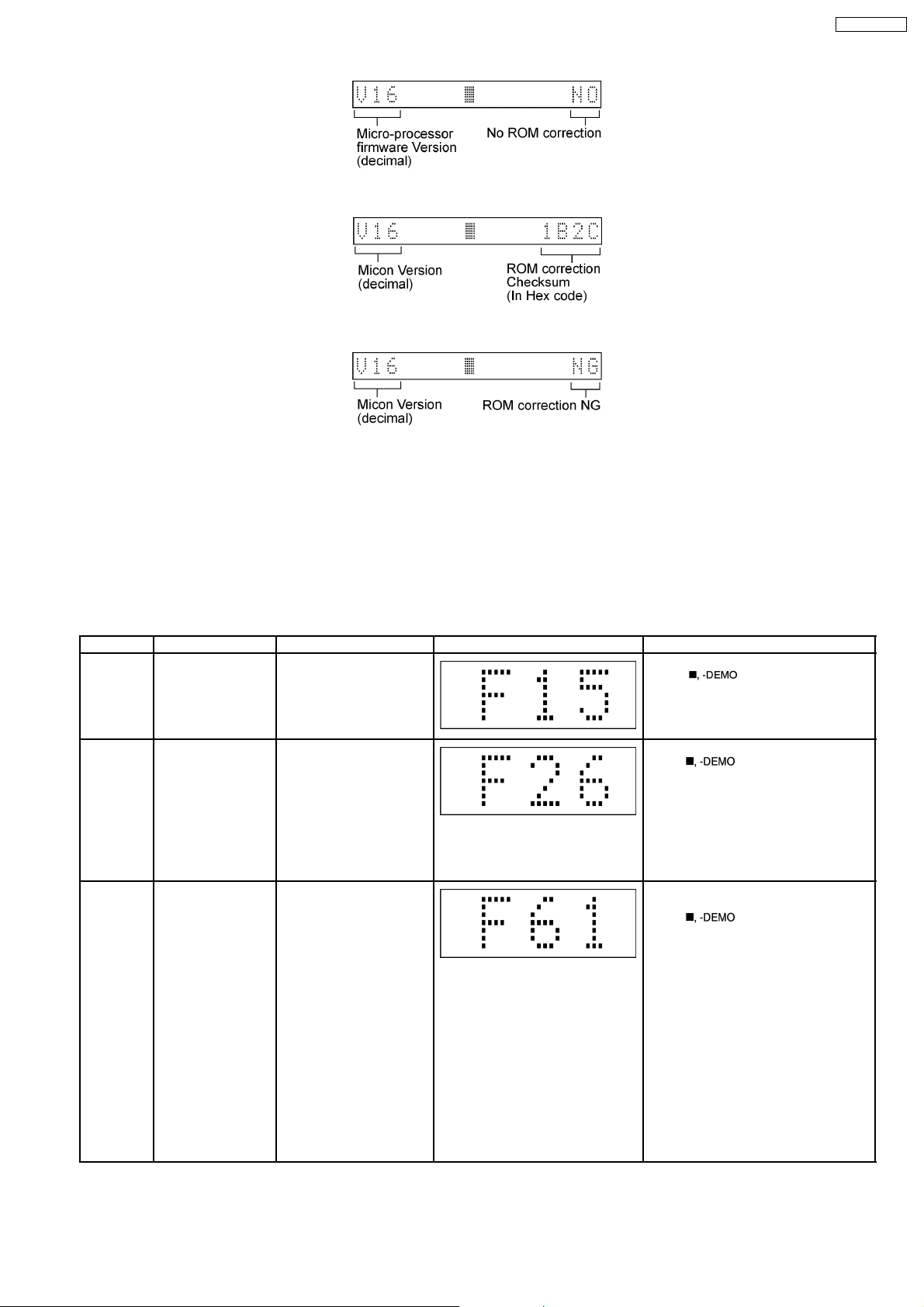

8.1.1. EEPROM Checksum (ROM correction)

Purpose : To check for micro-processor firmware version & EEPRO M check (ROM correction).

Below is the procedures for this mode.

Step 1: Enter into Doctor mode (For more information refer to section 8.1 on key operation to enter into this mode.

Step 2: Check for firmware version & EEPRO M checksum.

· W hen entering into DOCTOR MODE the firmware version & checksum of EEPROM (if applicable) will appear on FL display .

Below is information on the EEPROM IC (Rom correction) under 3 examples:

1. When EEPROM IC is detected and there is no ROM correction:

14

Page 15

SA-PM32DBEB

2. When EEPROM IC is detected and has ROM correction:

3. When EEPROM IC is detected and has ROM correction but NG:

Note: Micro-processor firmware version refers to version No. (Eg.MS079_12) for micro-processor IC.

It is subject to change which would update accordingly.

· Rom correction checksum refers to the hex code that is display upon key buttons pressed if an EEPROM is loaded in the unit.

(Main P.C.B)

8.2. Error Code Table

Self-Diagnosis Function provides information on any problems occuring for the unit and its respective components by display ing

error codes. Thesed error code such as U**, H** and F** are stored in memory and held unless it is cleared.

The error code is automatically display after entering into self-diagnostic mode.

Error Code Diagnosis Contents Description of error Automatic FL Display Remarks

F15 CD REST SW

Abnormal

F26 Communication

between CD servo

LSI and micro-p

abnormal.

POWER

AMP output

abnormal

CD traverse position intial

setting operation failsafe

counter (1000 ms) waiting

for REST SW toturn on.

Error No. shall be clear by

force or during cold start.

CD function DTMS

command, after system

setting, If SENSE = ´L´

cannot be detected.

Memory shall contain F26

code. After Power on, CD

function shall continue,

error display shall be "NO

DISC". Error No. shall be

clear by force or cold start.

During normal operation, if

DCDET becomes "L",

normal POWER OFF

process shall not be

executed, PCONT shall be

switched to "L"

immediately. "GOODBYE"

shall not be display but the

error display F61 is

displayed instead. 2

seconds after the F61

displayed, ECONO shall be

set to "L" and FL display

shall be turned off. The

error content shall be

memorized when the

abnormality occurs and can

be display in the C-mecha

self-diagnostic mode

described later.

For CD unit (For Traverse).

Press [

error.

For CD unit (For Traverse).

Press [

error.

For Power Supply Related Error

Detection.

Press [

error.

] on main unit for next

] on main unit for next

] on main unit for next

15

Page 16

SA-PM32DBEB

9 Assembling and Disassembling

9.1. Caution

“ATTENTION SERVICER”

Some chassis components may be have sharp edges. Be careful when disassembling and servicing.

1. This section describes procedures for checking the operation of the major printed circuit boards and replacing the main

components.

2. For reassembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

3. Select items from the following index when checks or replacement are required.

Warning:

This product uses a laser diode. Refer to “Precaution of Laser Diode”.

Below is the list of disassembly sections

· Disasse mbly of Side Panel L & R

· Disasse mbly of Top Cabinet Unit

· Disasse mbly of Headphone P.C.B.

· Disasse mbly of Front Panel

· Disasse mbly of DAB Module Unit

· Disasse mbly of Panel P.C.B.

· Disasse mbly of Rear Panel

· Disasse mbly of Tuner Pack

· Disasse mbly of Main P.C.B.

· Disasse mbly of Power P.C.B.

· Disasse mbly of Speaker Terminal P.C.B.

· Disasse mbly of Transformer P.C.B.

· Disasse mbly of CD Mechanism

· Disasse mbly of Traverse Unit, Driving Gear, and Cam Gear (CD Mechanism Unit)

· Disasse mbly of Optical Pickup (CD Mechanism Unit)

· Disasse mbly of Traverse Gear A and Traverse Gear B (CD Mechanism Unit)

16

Page 17

SA-PM32DBEB

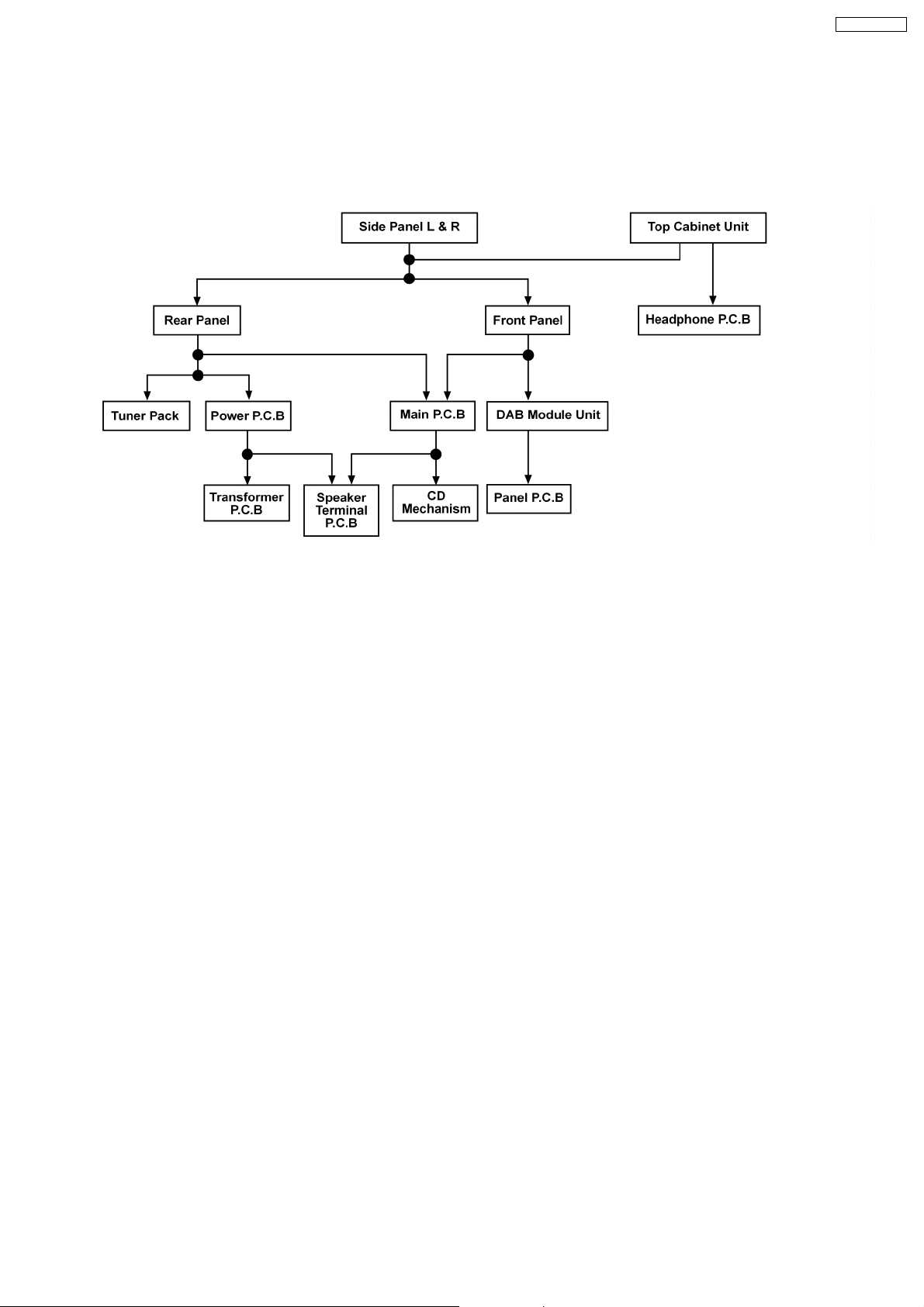

9.2. Disassembly flow chart

The following chart is the procedure for disassembling the casing and inside parts for internal inspection when carrying out the

servicing.

To assemble the unit, reverse the steps shown in the chart below.

17

Page 18

SA-PM32DBEB

9.3. Main Parts Location Diagram

18

Page 19

SA-PM32DBEB

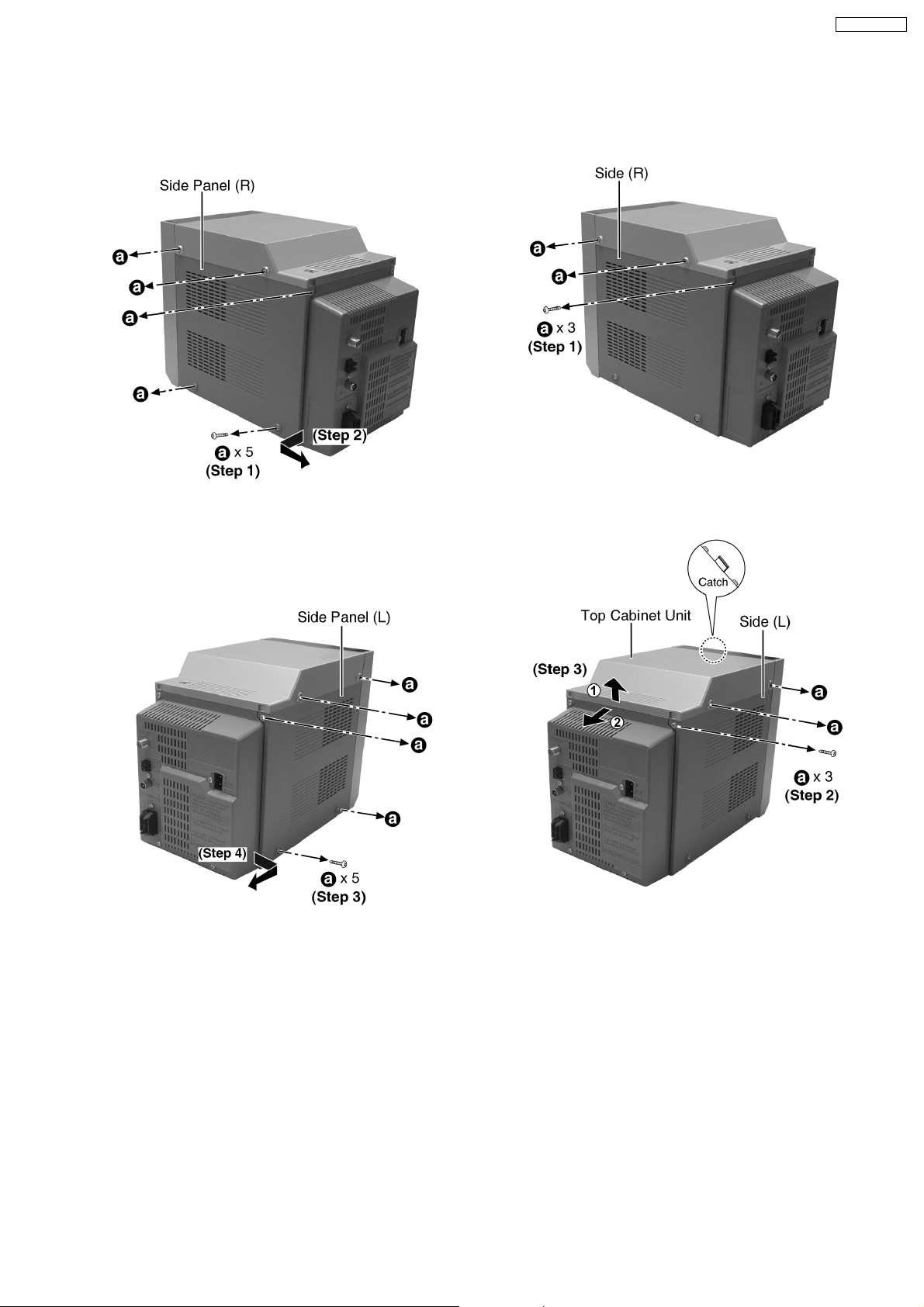

9.4. Disassembly of Side Panel L &

R

· Disasse mbly of Side Panel (R)

Step 1: Remove 5 screws.

Step 2: Remove the side panel (R) as arrow shown.

9.5. Disassembly of Top Cabinet

Unit

Step 1: Remove 3 screws.

· Disasse mbly of Side Panel (L)

Step 3: Remove 5 screws.

Step 4: Remove the side panel (L) as arrow shown.

Step 2: Remove 3 screws.

Step 3: Lift up the top cabinet unit, push backward

as arrow shown and flip top cabinet unit sideway.

(Be careful of the catch)

19

Page 20

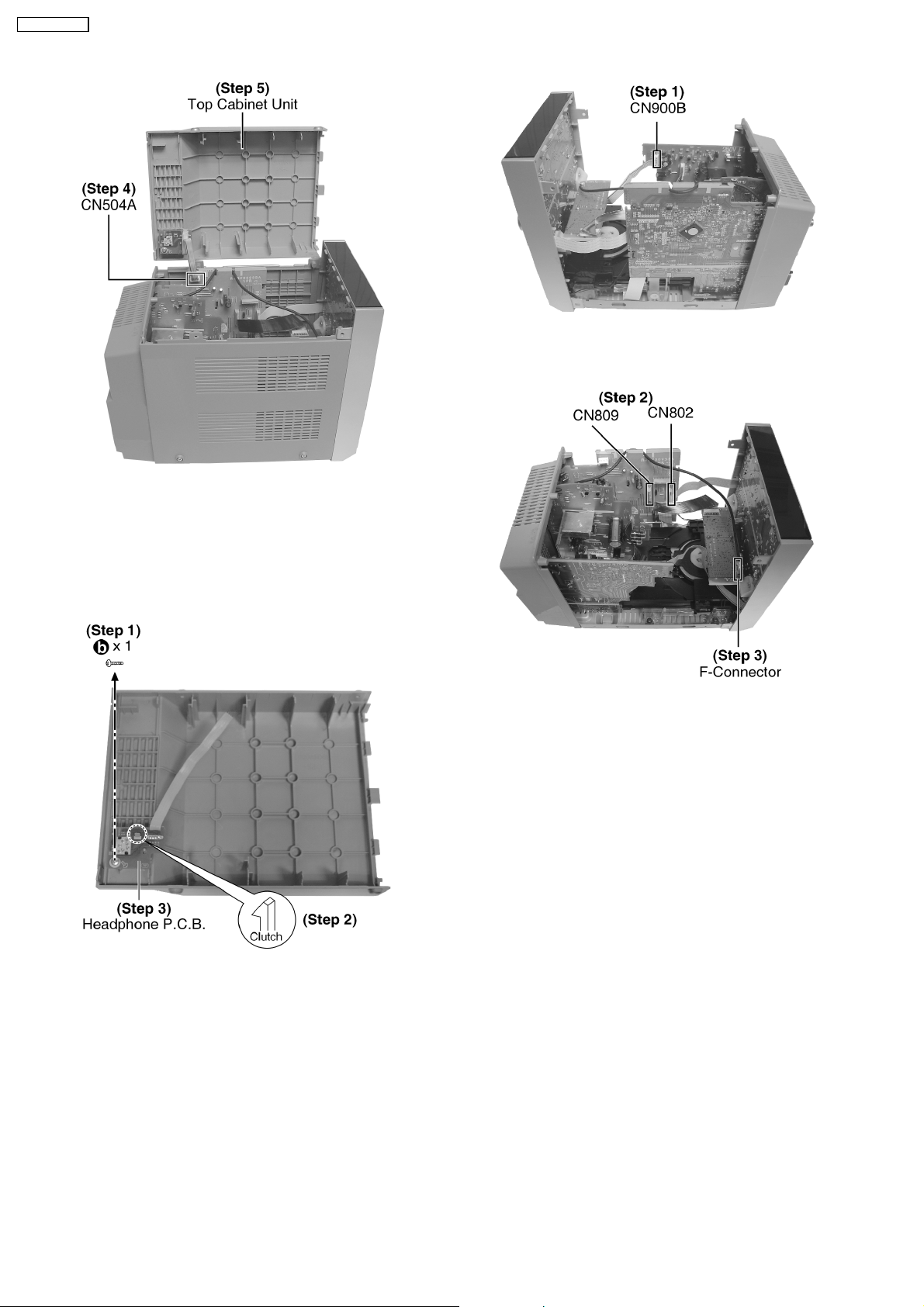

SA-PM32DBEB

Step 1: Detach connector (CN900B).

Step 4: Detach connector (CN504A).

Step 5: Remove top cabinet unit.

9.6. Disassembly of Headphone

P.C.B.

· Follow the (Step 1) - (Step 5) of Item 9.5.

Step 2: Disconnect FFC cable (CN802 and CN809).

Step 3: Disconnect F-Connector.

Step 1: Remove 1 screw.

Step 2: Release the clutch.

Step 3: Remove the Headphone P.C.B.

9.7. Disassembly of Front Panel

· Follow the (Step 1) - (Step 4) of Item 9.4.

· Follow the (Step 3) - (Step 5) of Item 9.5.

20

Page 21

Step 1: Remove 2 screws.

Step 2: Remove the DAB Module Unit

SA-PM32DBEB

Step 4: Release 3 claws.

Step 5: Remove the Front Panel as arrow shown.

9.8. Disassembly of DAB Module

unit

· Follow the (Step 1) - (Step 4) of Item 9.4.

· Follow the (Step 3) - (Step 5) of Item 9.5.

· Follow the (Step 1) - (Step 5) of Item 9.7.

9.9. Disassembly of Panel P.C.B.

· Follow the (Step 1) - (Step 4) of Item 9.4.

· Follow the (Step 3) - (Step 5) of Item 9.5.

· Follow the (Step 1) - (Step 5) of Item 9.7.

· Follow the (Step 1) - (Step 2) of Item 9.8.

Step 1: Remove 8 screws.

Step 2: Remove the Volume Knob.

Step 3: Release 2 catches.

Step 4: Remove the Panel P.C.B.

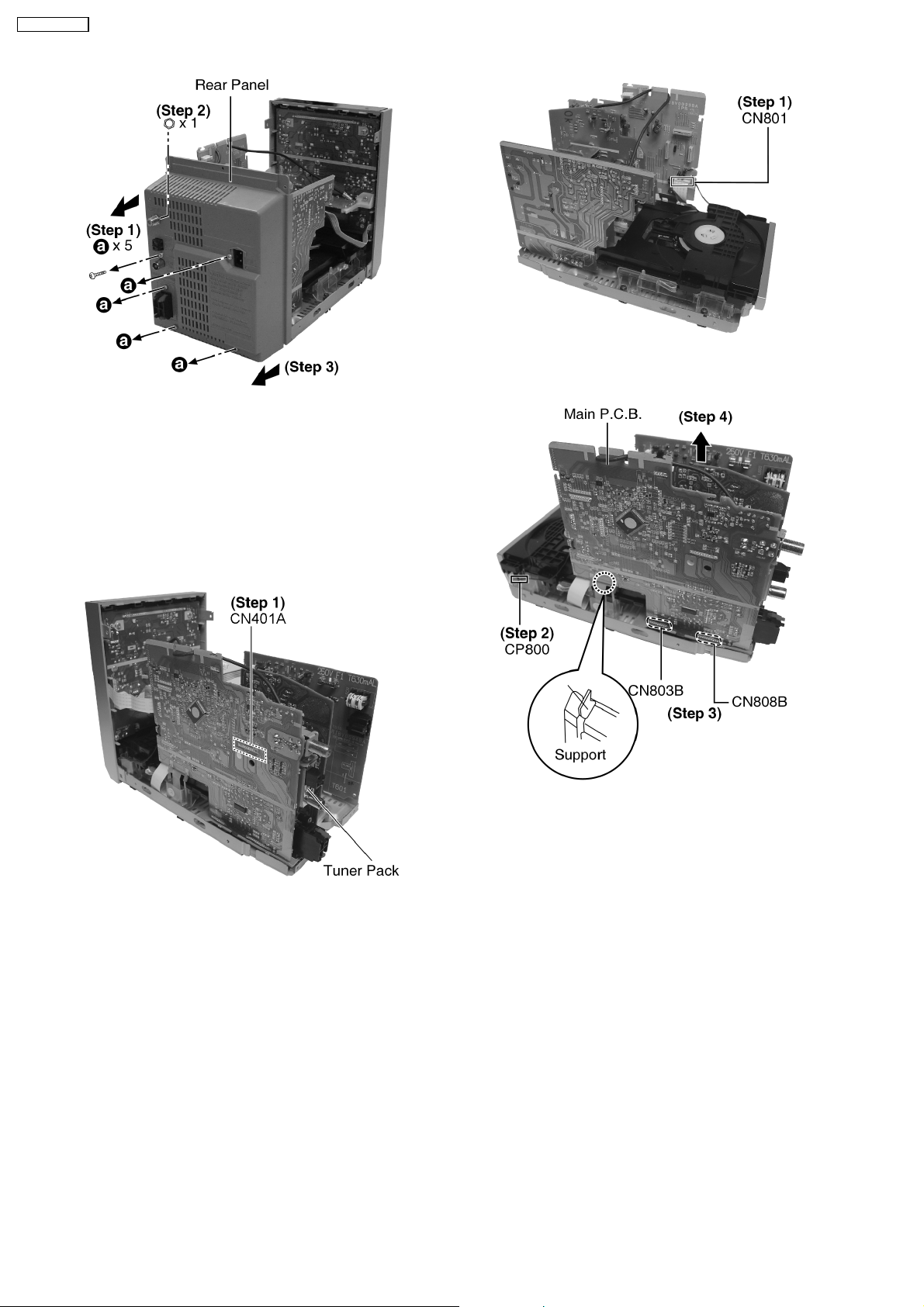

9.10. Disassembly of Rear Panel

· Follow the (Step 1) - (Step 4) of Item 9.4.

· Follow the (Step 3) - (Step 5) of Item 9.5.

21

Page 22

SA-PM32DBEB

Step 1: Detach the FFC CN801.

Step 1: Remove 5 screws.

Step 2: Remove 1 nut.

Step 3: Remove the Rear Panel as arrow shown.

9.11. Disassembly of Tuner Pack

· Follow the (Step 1) - (Step 4) of Item 9.4.

· Follow the (Step 3) - (Step 5) of Item 9.5.

· Follow the (Step 1) - (Step 3) of Item 9.10.

Step 1: Detach the connec tor CN401A and remove

the tuner pack as arrow shown.

9.12. Disassembly of Main P.C.B.

· Follow the (Step 1) - (Step 4) of Item 9.4.

· Follow the (Step 3) - (Step 5) of Item 9.5.

· Follow the (Step 1) - (step 5) of Item 9.7.

· Follow the (Step 1) - (step 3) of Item 9.10.

Step 2: Detach connector CP800.

Step 3: Detach connector CN803B and CN808B.

Step 4: Remove the Main P.C.B. as arrow shown.

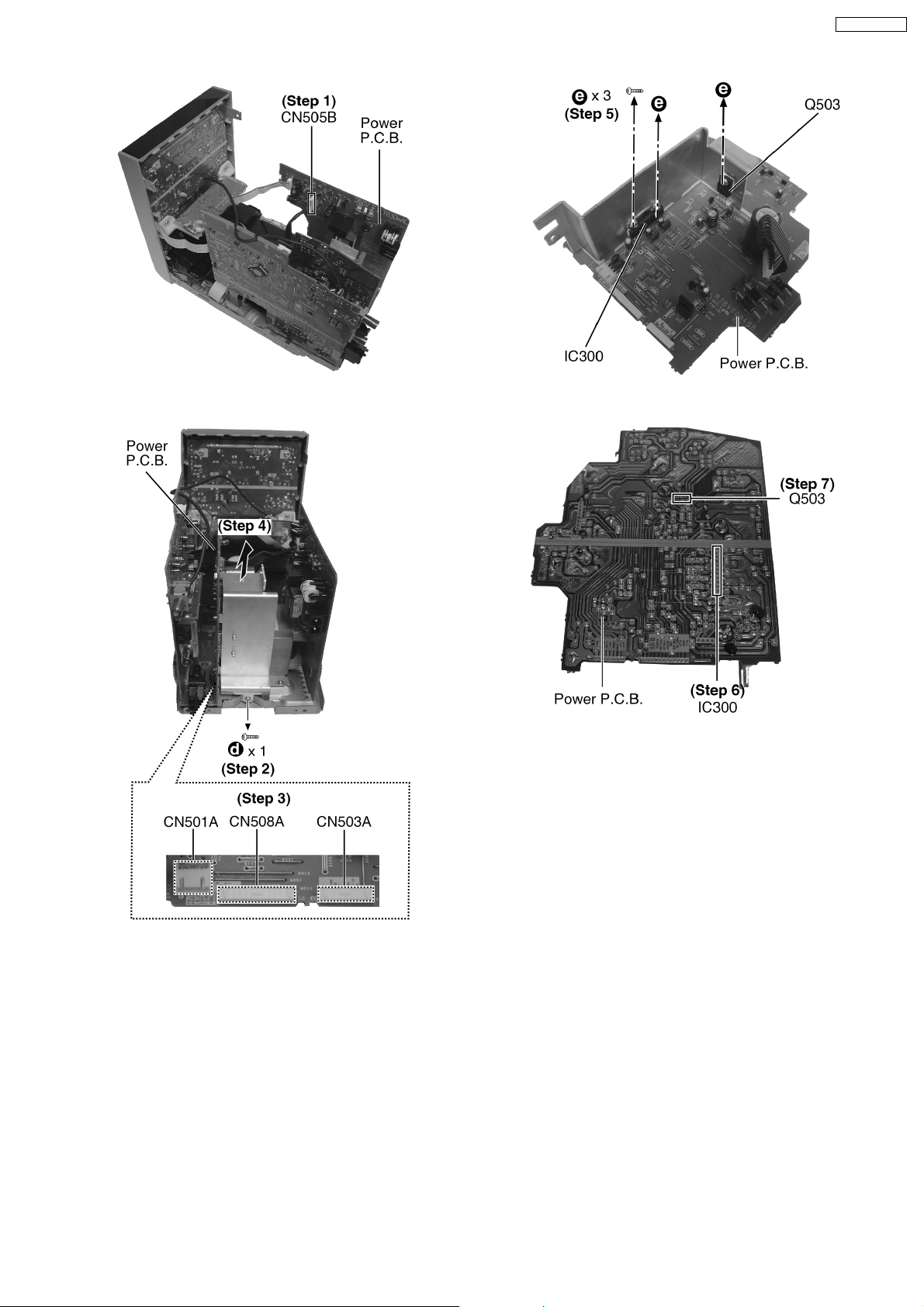

9.13. Disassembly of Power P.C.B.

· Follow the (Step 1) - (Step 4) of Item 9.4.

· Follow the (Step 3) - (Step 5) of Item 9.5.

· Follow the (Step 1) - (Step 3) of Item 9.10.

22

Page 23

SA-PM32DBEB

Step 1: Detach the connector CN505B.

Step 5: Remove 3 screws.

Step 6: Unsolder the terminal of Power Amp IC

(IC300) and replace the component.

Step 7: Unsolder the terminal of Transistor (Q503)

and replace the component.

9.14. Disassembly of Speaker

Terminal P.C.B.

Step 2: Remove 1 screw.

Step 3: Detach the connector CN501A, CN508A

and CN503A.

Step 4: Remove the Power P.C.B. as arrow shown.

· Replacement of Power Amplifier IC

· Follow the (Step 1) - (Step 4) of Item 9.4.

· Follow the (Step 3) - (Step 5) of Item 9.5.

· Follow the (Step 1) - (step 3) of Item 9.10.

· Follow the (Step 3) of Item 9.12.

· Follow the (Step 1) - (step 4) of Item 9.13.

23

Page 24

SA-PM32DBEB

Step 1: Remove 1 screw.

Step 2: Release the clutch.

Step 3: Remove the Speaker Terminal P.C.B. as

arrow shown.

9.15. Disassembly of Transformer

P.C.B.

· Follow the (Step 1) - (Step 4) of Item 9.4.

· Follow the (Step 3) - (Step 5) of Item 9.5.

· Follow the (Step 1) - (Step 3) of Item 9.10.

· Follow the (Step 1) - (Step 4) of Item 9.13.

Step 1: Detach the connector CN900B.

Step 2: Remove 4 screws.

Step 3: Remove the Transformer P.C.B. as arrow

shown.

9.16. Disassembly of CD

Mechanism

· Follow the (Step 1) - (Step 4) of Item 9.4.

· Follow the (Step 3) - (step 5) of Item 9.5.

· Follow the (Step 1) - (step 5) of Item 9.7.

· Follow the (Step 1) - (step 3) of Item 9.10.

· Follow the (Step 1) - (step 4) of Item 9.12.

24

Page 25

Step 1: Remove 4 screws.

Step 2: Remove the Main P.C.B. support.

Step 3: Remove CD Mechanism as arrow shown.

SA-PM32DBEB

9.17. Disassembly of Traverse Unit,

Driving Gear, and Cam Gear

(CD Mechanism Unit)

9.17.1. Disassembly of the Traverse Unit

· Follow the (Step 1) - (Step 4) of Item 9.4.

· Follow the (Step 3) - (Step 5) of Item 9.5.

· Follow the (Step 1) - (Step 5) of Item 9.7.

· Follow the (Step 1) - (Step 3) of Item 9.10 .

· Follow the (Step 1) - (Step 4) of Item 9.12.

· Follow the (Step 1) - (Step 3) of Item 9.16.

· Disasse mbly of gears drive

25

Page 26

SA-PM32DBEB

26

Page 27

SA-PM32DBEB

27

Page 28

SA-PM32DBEB

9.18. Disassembly of Optical Pickup

(CD Mechanism Unit)

· Follow the (Step 1) - (Step 4) of Item 9.4.

· Follow the (Step 3) - (Step 5) of Item 9.5.

· Follow the (Step 1) - (Step 5) of Item 9.7.

· Follow the (Step 1) - (Step 3) of Item 9.10 .

· Follow the (Step 1) - (Step 4) of Item 9.12.

· Follow the (Step 1) - (Step 3) of Item 9.16.

· Follow the (Step 1) - (Step 4) of Item 9.19.1.

28

Page 29

· Follow the (Step 1) - (Step 3) of Item 9.10 .

· Follow the (Step 1) - (Step 4) of Item 9.12.

· Follow the (Step 1) - (Step 3) of Item 9.16.

· Follow the (Step 1) - (Step 2) of Item 9.19.1.

SA-PM32DBEB

9.19. Disassembly of Traverse Gear

A and Traverse Gear B (CD

Mechanism Unit)

· Follow the (Step 1) - (Step 4) of Item 9.4.

· Follow the (Step 3) - (Step 5) of Item 9.5.

· Follow the (Step 1) - (Step 5) of Item 9.7.

29

Page 30

SA-PM32DBEB

10 Service Fixture and Tools

Service Tools

Extension P.C.B.

(A) Main P.C.B. - Speaker Terminal P.C.B. RFKZPM33E

11 Service Positions

Note: For description of the disassembly procedures, see the Section 9

11.1. Checking and Repairing Headphone P.C.B.

30

Page 31

11.2. Checking and Repairing of DAB Module Unit and Panel P.C.B.

SA-PM32DBEB

31

Page 32

SA-PM32DBEB

11.3. Checking and Repairing of Transformer P.C.B.

32

Page 33

11.4. Checking and Repairing of Main P.C.B.

SA-PM32DBEB

33

Page 34

SA-PM32DBEB

11.5. Checking and Repairing of CD Servo P.C.B.

34

Page 35

11.6. Checking and Repairing of Speaker Terminal P.C.B.

SA-PM32DBEB

35

Page 36

SA-PM32DBEB

11.7. Checking and Repairing of Power P.C.B.

36

Page 37

12 Voltage Measurement and Waveform Chart

Note:

· Indicated voltage values are the standard values for the unit measured by the DC electronic circuit tester (high-impedance)

with the chassis taken as standard.

Therefore, there may exist some errors in the voltage values, depending on the internal impedance of the DC circuit tester.

· Circuit voltage and waveform described herein shall be regarded as reference information when probing defect point

because it may differ from actual measuring value due to difference of Measuring instrument and its measuring condition

and product itself.

12.1. Voltage Measurement

12.1.1. CD SERVO P.C.B

SA-PM32DBEB

Ref No.

MODE 1 234567891011121314151617181920

CD PLAY 0 00 0000000000000001.33.3

STANDBY 00 0 0000000000000.20.2000.3

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY 1.6 0 1.6 0 1.8 0 3.3 1.5 3.3 3.3 0 0 1.6 1.6 1.6 2 2 1.4 1.8 1.8

STANDBY 0 0 0 0 0 0 0.4 0 0.2 0.2 0 0 0.2 0 0 0 0.2 0.2 0.2 0.2

Ref No.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

CD PLAY 0.2 2.4 0 1.8 1.2 1.8 3.3 1.2 1.2 1.2 1.7 1.9 0.8 1.5 1.4 0 0 3 1.5 0

STANDBY 0 0.3 0 0 0.2 0.1 0.3 0.4 0.2 0.2 0.1 0.1 0.3 0 0 0 0 0.4 0 0

Ref No.

MODE 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

CD PLAY 3.3 0 0 0 0 0 3.1 3.1 3.1 2.5 0 3.1 0 1.6 0 1.5 3.3 0 3.3 1.6

STANDBY 0.2 0.2 0.2 0.2 0.2 0.2 0 0 0 0 0 0 0.2 0.3 0.3 0 0.2 0 0.2 0.1

Ref No.

MODE 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100

CD PLAY 1.62.300000000 0 03.30000000

STANDBY 0.10.200000000 0 00.3000000 0

Ref No.

MODE 1 234567891011121314151617181920

CD PLAY 1.601.60000007.54.23.53.53.503.303.87.50

STANDBY 00 0 00000000000000000

Ref No.

MODE 21 22 23 24 25 26 27 28

CD PLAY 0 7.5 0 0 7.5 0 1.6 0

STANDBY 00 0 00000

Ref No.

MODE E C B

CD PLAY 3.3 2.4 2.4

STANDBY 0.3 0 0.3

Q7601

IC7001

IC7001

IC7001

IC7001

IC7001

IC7002

IC7002

CD SERVO P.C.B

37

Page 38

SA-PM32DBEB

12.1.2. MAIN P.C.B

Ref No.

MODE 1 234567891011121314151617181920

CD PLAY 0 0 0 0 0 0 3.1 0 0 1.3 0.7 3.1 1.5 0 1.4 3.1 3.1 3.1 0 1.8

STANDBY 0 0 0 0 0 0 3.1 0 0 0.4 0.7 3.1 1.5 0 1.4 0 3.1 3.1 0 1.8

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

CD PLAY 3.100000.83.12.200.5000000002.92

STANDBY 0 0 0 00000000000000000

Ref No.

MODE 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

CD PLAY 0 0 3.1 0 0 0 0 1.8 3.1 0 0.1 1.3 0 0 0 1.4 3.1 0 0 0

STANDBY 0 0 0 0000000 02.10 000.10000

Ref No.

MODE 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

CD PLAY 1.43.10000003.13.103.100000003.1

STANDBY 0.13.10000000000000000.100

Ref No.

MODE 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100

CD PLAY 0 0 0 0 1.4 0 0 0 3.1 0 0 3.1 3.1 3.1 0 0 3.1 3.1 3.1 1.5

STANDBY 00.10.100000003.13.13.13.12.503.13.13.11.6

Ref No.

MODE 1 2345678

CD PLAY 4.8 4.8 4.6 0 4.5 4.8 4.8 9

STANDBY 0 0 0 00000

Ref No.

MODE 1 234567891011121314151617181920

CD PLAY 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 0 0 0 8.8 8.8

STANDBY 0.4 0.4 0.3 0 0.3 0.3 0.3 0.3 0.3 0.3 0.3 0.3 0.3 0.3 0 0 0 0 0.3 0.3

Ref No.

MODE 21 22 23 24 25 26 27 28 29 30 31 32

CD PLAY 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5 4.5

STANDBY 0.3 0.3 0.3 0.3 0.3 0.3 0.3 0.3 0.3 0.3 0.3 0.3

Ref No.

MODE 1 2 3

CD PLAY 5.7 0 3.9

STANDBY 5.8 0 3.9

Ref No.

MODE 1 2345

CD PLAY 0 0 4.8 0 3.3

STANDBY 0 0 0 0 0.2

Ref No.

MODE 1 2345678

CD PLAY 03.10 00000

STANDBY 03.10 00000

Ref No.

MODE E C B E C B E C B E C B E C B

CD PLAY 0 0 0.3 0 0 0.3 0 0 0.3 0 0 0.3 9.6 0.3 9.7

STANDBY 0 0 0 000 00 0 000 000

Ref No.

MODE E C B E C B E C B E C B E C B

CD PLAY 0 9.7 0 0 3.1 0 0 4.8 0 4.8 0 4.8 0 0 3.1

STANDBY 0 00 03.10 000 000 000

Ref No.

MODE E C B E C B

CD PLAY 0 2.1 0 0 2.1 0

STANDBY 0 0 0 0 0 0

MAIN P.C.B

IC401

IC401

IC401

IC401

IC401

IC700

IC800

IC800

IC801

IC802

IC804

Q221 Q222 Q421 Q422 Q750

Q751 Q800 Q801 Q802

Q807 Q808

Q803

38

Page 39

12.1.3. PANEL P.C.B

Ref No.

MODE 1 2345

CD PLAY 4.8 0 4.8 0 3.3

STANDBY 0.1 0 0.1 0 0.2

12.1.4. POWER P.C.B

Ref No.

MODE 1 23456789101112

CD PLAY 12.45.703.830004.25.705.7

STANDBY 00.200.2000000.200.2

Ref No.

MODE E C B E C B E C B E C B E C B

CD PLAY 12.4 11.4 12.4 4.6 11.6 5.6 12.3 9.7 11.6 5 9.1 5.6 4.8 7.5 5.5

STANDBY 2.8 2.4 2.8 2.4 2.5 3.2 2.9 0.2 2.5 2.4 0 0 0 0 0

Ref No.

MODE E C B E C B

CD PLAY 7.5 9.7 8.2 8.8 9.1 9.5

STANDBY 0 0.1 0.1 0 0 0

Q500 Q501 Q503 Q504

Q507 Q530

SA-PM32DBEB

PANEL P.C.B

IC900

POWER P.C.B

IC300

Q505

12.1.5. TRANSFORMER P.C.B

Ref No.

MODE E C B E C B E C B E C B

CD PLAY 0 0.2 0.8 5.7 13.8 6.4 0 1.7 2.8 31.2 32.2 31.8

STANDBY 0 5.7 0 5.7 13.8 6.4 0 1.7 2.6 0 0.4 0.4

Q600 Q601 Q602 Q603

TRANSFORMER P.C.B

39

Page 40

SA-PM32DBEB

12.2. Waveform

CN801 PIN 7

CD PLAY

3.52Vp-p (25msec.div)

CN802 PIN 15

CD PLAY

3.28Vp-p (10msec.div)

IC401 PIN 19

CD PLAY

3.36Vp-p (10msec.div)

CN801 PIN 8

CD PLAY

3.4Vp-p (10msec.div)

CN803B PIN 5

CD PLAY

3.2Vp-p (10msec.div)

IC401 PIN 26

CD PLAY

3.24Vp-p (10msec.div)

CN801 PIN 15

CD PLAY

448mVp-p (1msec.div)

IC401 PIN 13

CD PLAY

3.52Vp-p (50nsec.div)

IC401 PIN 28

CD PLAY

3.44Vp-p (5usec.div)

CN801 PIN 17

CD PLAY

364mVp-p (1msec.div)

IC401 PIN 15

CD PLAY

2.28Vp-p (100nsec.div)

IC401 PIN 30

CD PLAY

3.48Vp-p (10msec.div)

IC401 PIN 39

CD PLAY

3.84Vp-p (10msec.div)

IC401 PIN 42

CD PLAY

3.4Vp-p (25msec.div)

IC401 PIN 43

CD PLAY

3.52Vp-p (10msec.div)

40

IC401 PIN 48

CD PLAY

3.6Vp-p (25msec.div)

Page 41

13 Wiring Connection Diagram

SA-PM32DBEB

H

HEADPHONE P.C.B.

SOLDER SIDE

AC IN

230V-240V

50Hz

JK600

SOLDER SIDE

CAUTION

RISK OF ELECTRIC SHOCK

AC VOLTAGE LINE.

PLEASE DO NOT TOUCH THIS P.C.B

G

TRANSFORMER P.C.B.

T600

(Back Up Transformer)

T601

(Power Transformer)

PbF

CN505B

SOLDER SIDE

CN900B

5

.

.

.

1

.

.

.

.

.

.

.

.

8

1

CN802

15

.

14

.

.

.

.

.

.

.

.

.

.

.

.

.

2

1

2 1

CN801

2 . . . . . . . . 16

1 . . . . . . . . . . 17

CP800

CN809

18

.

17

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1

DAB MODULE UNIT

.

.

.

2

CD OPEN SW

1..4

CN504A

B

MAIN P.C.B.

To DAB Module unit

CN401A

1 . . . . . . . . . . 10

CN505B

1

.

.

.

.

3

JK809

DAB ANT

JK900

PbF

HEADPHONE

4 . . 1

WH504

Tuner Pack

1 . . . . . . . . . . 10

CN10

Z401

1 . . . . . . . . . . 10

CN803B

9 . . . . . . . . . . . 1

CN808B

13 . . . . . . . . . . . . . . . . 1

PbF

SOLDER SIDE

PbF

C

TUNER EXTENT P.C.B.

SENSOR

VOLUME

Z901

CN901A

15

.

14

.

.

.

.

.

.

.

.

.

.

.

.

2

1

SOLDER SIDE

VR900

FL900

D

PANEL P.C.B.

PbF

JK303

SOLDER SIDE

WH505A

1

.

.

.

.

.

.

.

.

MUSIC

PORT

8

E

POWER P.C.B.

CN501B

4 . . 1

CN503B

9 . . . . . . . . . 1

W

H

9

0

0

5

.

.

.

1

CN508B

13 . . . . . . . . . . . . . . 1

PbF

CN7002

17

.

16

.

.

.

.

.

.

.

.

.

.

.

2

1

A

CD SERVO P.C.B.

SOLDER SIDE

CN

.

.

.

.

.

.

.

15

16

OPTICAL PICKUP

7001

1

.

2

.

.

.

.

.

.

.

.

.

.

.

.

.

.

PbF

9 . . . . . . . . . 1

CN803A

F

SPEAKER TERMINAL P.C.B.

CN503A

9 . . . . . . . . . 1

CN508A

13 . . . . . . . . . . . . . . 1

13 . . . . . . . . . . . . . . 1

CN808A

CN501A

4 . . 1

0

K

5

J

SOLDER SIDE

PbF

1

SPEAKERS

41

Page 42

SA-PM32DBEB

42

Page 43

14 Block Diagram

OPTICAL PICKUP

SA-PM32DBEB

PHOTO DETECTOR

EE EE

D C

A B

D C

EFEF

SEMICONDUCTOR

LASER

B

FOCUS

COIL

TRACKING

COIL

35

E

40

A

39

C

38

B

37

D

36

Q7601

SWITCH

LD_SW

F

41

PD

42

LD

OUTL

OUTR

56

59

CD SIGNAL

RCH

TO MAIN BLOCK

A

IC7002

BA5948FPE2

4CH DRIVE

26

VREF

F+

F-

T+

T-

D3-

15

[CH3]

D3+

16

D4-

17

[CH4]

18

D4+

LEVEL

SHIFT

LEVEL

SHIFT

IN3

28

27

IN4

B

FOP

TRP

BLKCK

TX

NRST

MLD

MCLK

MDATA

STAT

71

BLKCK

66

TX

72

NRST

69

MLD

67

MCLK

68

MDATA

70

STAT

IC7001

MN6627954MA

LSI IC

SPOUT

TRVP

TRP

FOP

21

22

PC

23

24

25

SPOUT

PC

TRVP

TRP

FOP

M7301

TRAVERSE

MOTOR

M7302

SPINDLE

MOTOR

D2+14

M

M

[CH2]

13

D2-

D1+

12

[CH1]

D1-

11

LEVEL

SHIFT

LEVEL

SHIFT

MUTE

[CH1]

MUTE

[CH2]

IN2

1

3

IN1

PC1

4

PC2

2

TRVP

LOADING

SPOUT

X1

X2

81 80

X7201

PC

S7201

RESET SWITCH

RESTSW

43

Page 44

SA-PM32DBEB

JK303

AUX INPUT JACK

IC800

A1(A2)

5(6)

LEFT(RIGHT)18S1

C1(C2)

22(21)

9(10)

C1BB00000732

ASP

SC

17

IC700

C0ABBB000297

FILTER

FILTER

OP AMP

Q221,Q222

(Q421,Q422)

MUTING

SWITCH

D1(D2)

B1(B2)

11(12)

7(8)

CD SIGNAL

DAB SIGNAL

HEADPHONE

RCH

JK900

TO

DAB MODULE

DAB SIGNAL

DAB_LCH

(DAB_RCH)

D

VOL_JOG

95

VR900

VOLUME JOG

E_DATA

24

5

6

D0

D1

IC804

EEPROM

( NOT SUPPLIED )

D_NRST

Z401

TUNER PACK

71ST71

IC401

C2CBYY000223

MICROPROCESSOR

E_CLK

E_CS

23

22

4

E_CLK

3

E_CS

S900~S910

KEY194KEY2

93

KEY SW

TUNED

70CL69

SDA

27

FL DISPLAY

26

/FL_RESET

B

FL900

FL_CS

30

FL_DATA

D906

STANDBY LED

FROM

TRANSFORMER

28

FL_CLK

67

68

ASP_DATA

ASP_CLK

XCIN10XCOUT

11

X801

32.678KHz

1,3,5

IC900

C0DBZGC00067

3.3V REGULATOR

2

XOUT

XIN

15

13

X800

10MHz

IC401

C2CBYY000223

MICROPROCESSOR

B

D_DOWFIC

D_MPUMOD

52

53

54

D_DOWFIC

D_MPUMOD

RMT

18

Z901

REMOTE SENSOR

51

D_NRST

D_LOCKDET

D_NRFRESET

50

D_LOCKDET

B

D_PLLSDA

45

D_PLLSDA

D_NRFRESET

/RESET

12

Q800

RESET

SWITCH

D_PLLSCL

44

DMPU_CLK

37

D_PLLSCL

DMPU_TX

36

DMPU_CLK

35

DMPU_TX

55

Q801

SWITCH

DMPU_RX

DMPU_RX

D_PON

Q802

SWITCH

B

44

Page 45

SIGNAL LINES

: MAIN SIGNAL LINE

: FM/AM SIGNAL LINE

( ) Indicates Pin No. of Right Channel

: CD SIGNAL LINE

: DAB SIGNAL LINE

Note : Signal Lines are applicable to the Left Channel only.

IC300

AN17831A

POWER AMP IC

SA-PM32DBEB

IC401

C2CBYY000223

MICROPROCESSOR

TO CD

BLOCK

A

VCC

1

B

FP352

Q803

MUTING

SWITCH

IN_L(IN_R)

8(6)

Q751

SWITCH

STBY

5

OUT_L-(OUT_R-)

10(4)

Q750

SWITCH

OUT_L+(OUT_R+)

12(2)

D751

D750

B

1,3

B

IC801

C0CAABC00007

REGULATOR

2

STAT

MDATA

MCLK

REST_SW

D804 D805

REST_SW

BLKCK

S730

NRST

MLD

LD_SW/CLDCK

B

5

IC802

C0DBZGC00067

3.3V REGULATOR

2

B

B

Q507

REGULATOR

Q505

REGULATOR

B

Q530

REGULATOR

MUTE

9

JK501

SPEAKER L(R)

D382

(D383)

Q600

PCONT

SWITCH

TO FL

DISPLAY

Q603

SWITCH

B

Q503

STABALIZER

Q501

SWITCH

B

Q500

CURRENT

LIMITTING

D609

D504,D505

D521,D522

T601

POWER

TRANSFORMER

RY600

B

CD OPEN SW

42

48

39

78

STATUS

CD_MDATA

CD_MCLK

CD_OPEN_SW

91

92

CD_CLOSE

CD_OPEN

82

REST_SW

19

80

BLKCK

CD-RST

43

CD_MLD

IC401

C2CBYY000223

MICROPROCESSOR

86(85)

VOL_DETL

(VOL_DETR)

57

MUTEA

HALT

20

21

PCONT_2

49

PCONT_1

Q602

SWITCH

Q504

SWITCH

B

T600

B

Q601

REGULATOR

SYS6V

D603~D606

Z600

SUB

ZJ01

JK600

L600

F1

AC INLET

TRANSFORMER

D608

45

Page 46

SA-PM32DBEB

46

Page 47

15 Notes of Schematic Diagram

(All schematic diagrams may be modified at any time with

the development of new technology)

Note :

S780 CD Open switch

S900 Stop/-Demo switch

S901 CD_Play switch

S903 Tuner/Band switch

S904 UP/FF switch

S905 DOWN/REW switch

S906 Power switch

S907 CD Open/Close switch

S908 Bass/Treble switch

S910 Music Port switch

S7201 Reset switch

VR900 VR Volume Jog

· The voltage value and waveforms are the reference voltage

of this unit measured by DC electronic voltmeter (high

impedance) and oscilloscope on the basis of chassis.

Accordingly, there may arise some error in voltage values

and waveforms depending upon the internal impedance of

the tester or the measuring unit.

· Importance safety notice :

Components identified by

characteristics important for safety. Furthermore, special

parts which have purposes of fire-retardant (resistors), highquality sound (capacitors), low-noise (resistors), etc. are

used. When replacing any of components, be sure to use

only manufacturer´s specified parts shown in the parts list.

Caution !

IC, LSI and VLSI are sensitive to static electricity.

Secondary trouble can be prevented by taking care during

repair.

· Cover the parts boxes made of plastics with aluminium foil.

· Put a conductive mat on the work table.

· Ground the soldering iron.

· Do not touch the pins of IC, LSI or VLSI with fingers directly.

mark have special

SA-PM32DBEB

47

Page 48

SA-PM32DBEB

48

Page 49

16 Schematic Diagram

16.1. CD SERVO CIRCUIT

OPTICAL

PICKUP CIRCUIT

LASER DIODE

6

8

11

12

4

9

10

5

2

3

C

C

GND

1

NBOUT

8

2

VCC

C

3

BIN

4

AIN

GND

NAOUT

VREF

7

6

5

C

C

CP701

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

CN7001

SCHEMATIC DIAGRAM - 1

CD SERVO CIRCUIT

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

VCC

F

E

LD

LD GND

GND

A

GND

B

VREF

LPD

GND

T-

T+

F-

F+

C7335

0.1

C7334

10V220

W7023 0

W7027

0

39

37

14

D3-

D2+

W7026 0

W7024 0

1615

17

D3+

D2-

1

13

M

M

C7613 0.1

D4-

D1+

2

C7614

6.3V100

18

D4+

D1-

11

W7025

20

19

PVCC2

PVCC1

10

9

38

M7301

TRV

MOTOR

36

M7302

SRL MOTOR

0

PGND2

PGND1

21

GND

NC

IC7002

BA5948FPE2

4 CH DRIVE

GND

NC

8

: +B SIGNAL LINE : CD SIGNAL LINE

R7601

C7601

4.7

6.3V33

R7650

5.6

Q7601

Q7601

B1ADCF000001

LASER POWER DRIVE

22

NCNCNC

NC

7

23

NC

R7335

25 26 27 28

24

VCC

NC

PC1

100

3456

VREF

IN1

: CD-DA SIGNAL LINE

C7670

0.1

R7329 1K

IN3

IN4

PC2

IN2

12

C7338

0.056

R7323

3.3K

R7325 330

C7626

0.1

R7327

1K

R7336

10

C7352

0.018

C7315

0.47

R7331

22K

W7020 0W7022 0

W7017 0

W7021 0

R7328 10K

R7349

18K

C7339

0.018

R7339

1K

R7315

3.3K

W7016

0

R7330

16

6.3V220

C7223 50V4.7

C7204 0.1

5.6K

C7203

50

W7012 0

W7019

0

W7018

0

C7218

0.082

C7241

1000P

R7211

C7244 0.015

C7217 0.1

51(RF)

C7216

680P

W7014

0

C7161

W7015 0

C7102

C7142

C7107

R7111 10K

W7013 0

C7154

C7155

82K

SA-PM32DBEB

14

0

0

0

W7010

1

W7007

0

C7232

6.3V220

0

C7263

S7201

RESET SW

11

8

0.1

13

LCH OUT

RCH OUT

REST SW

LOADING

W7004

0

W7002

0

W7003

0

W7001

0

18

7

9

31

A.GND

+3.3V

D.GND

LD SW

TX

+7.5V

PGND

MCLK

MDATA

MLD

BLKCK

STAT

/RST

3

4

210

17

16

15

14

13

12

11

10

TO

9

MAIN CIRCUIT

(CN801) ON SCHEMATIC

8

DIAGRAM-2

7

6

5

4

3

2

1

CN7002

470

C7253

470P

1917

W7011

0

R7028

0

10

1K

0.01

C7233

W7006

0.1

W7008

W7009

C7243

0.1

C7225

1000P

C7226

1000P

75

SMCK

DQSYTXT

A11

1

234

PMCK

IOVDD1

NTEST2

DVDD2

DVSS2

NTEST

D15

D14

DRVDD

D13

D12

D11

D10

SDRCK

C7227

50V1

C7228

50V1

X2

X1

D2

D1

D0

D3

D4

D5

D6

D7

D9

D8

D7650

MAZ80560ML

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

X7201

H2B169500005

C7264

0.1

C7234 0.1

C7235

16V10

R7332

1K

R7253

R7254

C7166

R7220

1M

R7214

R7217

1K

R7218

1K

R7212

820

R7221 100

54

53

51

IREF

DSLF

ARFFB

ARFOUT

ARFDC

AVD D2

RFIN

RFOUT

RFENV

CENV

LD

PD

A

C

B

D

F

E

VREF

CTRCRS

OSCIN

AVSS2

SRVMON1

SRVMON0

DVDD1

IOVDD2

DVSS1

ARFIN

FOP

TRVP

TRP

245225

23

0.1

50

49

48

47

0.47

46

45

3300P

44

0.022

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

0.1

28

0.1

27

26

58

57

55

56

PLLF

OUTL

PLLF0

AVS S1

AVD D1

DIGITAL SIGNAL PROCESSOR/

DIGITAL FILTER D/A CONVERTER

PRAMVDD15

PRAMVDD33

PC

SPOUT

21

20

19

10

C716510C7164

PRAMVSS33

18

22

59

17

OUTR

BA1

C7230 0.1

C7231 6.3V220

W7005

0

24

60

61

62

63

65

EXT2

EXT1

EXT0

DVSS3

NSRVMONON

IC7001

MN6627954MA

SERVO PROCESSOR/

BA0

A10

A3

A1A0A2

15

14

126413

16

11

66

FLAG

10

676869

TX

NRAS

NCAS

MCLK

70

MLD

MDATA

NWEA8A7A9A5

A4

789

STAT

71

56

BLKCK

A6

727374

NRST

49

SA-PM32DBEB CD SERVO CIRCUIT

Page 50

SA-PM32DBEB

16.2. MAIN CIRCUIT and TUNER EXTENT CIRCUIT

SCHEMATIC DIAGRAM - 2

: AUX SIGNAL LINE

TUNER EXTENT CIRCUIT

MAIN CIRCUIT

: +B SIGNAL LINE : TAPE PLAYBACK SIGNAL LINE

: CD SIGNAL LINE

: TUNER SIGNAL LINE

: TAPE RECORDING SIGNAL LINE

: DAB SIGNAL LINE

: MAIN SIGNAL LINE

TO TUNER PACK

Z401

(ENG07811QF)

TO DAB MODULE

Z402

RAL0044

TO

CD SERVO

CIRCUIT

(CN7002) ON

SCHEMATIC

DIAGRAM-1

DAB

ANT

JK809

CN801

PORTSEL

1

CL

2

SDA

3

TUNED

4

TUNER_LCH

5

STEREO

6

TUNER_RCH

7

DET

8

TUNER_9V

9

TNR_GND

10

1

2

3

1

2

3

4

5

C101

1000P

CD_L

17

A_GND

16

CD_R

15

CD_3.3V

14

CD_DGND

13

LD_SW/CLOCK

12

TX

11

CD_7.5V

10

PWR_GND

9

MCLK

8

MDATA

7

MLD

6

BLKCK

5

STATUS

4

RST

3

REST_SW

2

LOADING

1

TUNER_LCH

TUNER_RCH

TUNER_9V

L204

G1C2R2MA0060

WA5

0

L812 J0JKB0000020

S780

CD OPEN

PORTSEL

SDA

TUNED

STEREO

DET

TNR_GND

C825

1

CL

2

3

4

5

6

7

8

9

10

C824

1000P

R875 100

R876 100

R877 100

R878 100

R879 100

R891 100

CP800

CN401ACN10

C216

1000P

L801 J0JKB0000020

C416

1000P

L803 J0JKB0000020

L802 J0JKB0000020

1000P

GND

1

CD_OPEN_SW

2

PORTSEL

1

CL

2

SDA

3

TUNED

4

TUNER_LCH

5

STEREO

6

TUNER_RCH

7

DET

8

TUNER_9V

9

TNR_GND

10

L903 G0A200D00002

IC802

C0DBZGC00067

3.3V REGULATOR IC

VIN

GND

STBYNCVOUT

2345

1

C830

16V22

R881 10K

R880 10K

C829

0.1

PORTSEL

SDA

TUNED

TUNER_LCH

STEREO

TUNER_RCH

DET

TUNER_9V

TNR_GND

D5V

CD_LCH

CD_RCH

CD_7.5V

CD_DGND

PGND

CD_MCLK

CD_MDATA

CD_MLD

BLKCK

STAT

CD_RST

REST_SW

LOADING

CD_OPEN_SW

CL

A9V

REST_SW

VOL_DET1

VOL_DET2

LOADING

KEY2

KEY1

VOL_JOG

R870

10K

R853

12K

R854

10K

R871

D804, D805

B0ACCK000005

10K

10K

R869

R872

10K

C832

0.1

R868

10K

C818

560P

D804

D805

C819

R857

2.2K

560P

STYBY_3.3V

C815

220P

R855

1.5K

R856

3.3K

R858 100

R859 1K

R860 1K

R863 100

R864 100

R865 100

R866 100

R867 100

560P

C820

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

C821 0.01C823 1000P

C822 10V22

H0A327200111

PWRDET

/RESTSW

DAB_PDET

NC

VOL_DETR

VOL_DETL

MOTOR_H

PLUNGER

DECK_AD1

DECK_AD2

CD_CLOSE

CD_OPEN

KEY2

KEY1

VOL_JOG1

AVSS

REG

VREF

AVD D

DEMO SELECTOR

X801

X801

C801 22P

WA9

0

CD_RST

CD_OPEN_SW

R851 100K

R852 1K

77

787980

CD_RST

CD_OPEN_SW

TAPE_SELECT

NCNCNCNCNC

2

3

1

R805

390K

C802 18P

C800

100P

R803 15K

R802 15K

R801 15K

R800 15K

R892 10K

75

74

76

NCNCNCNCNC

MBP1

4

67

5

R806

73

MBP2

4.7K

8

72

BYTE

TUNED

STEREO

R804 1K

71

ST

TUNED

CNVSS

XCIN

9

10

H2B100500004

CL

70

CL

XCOUT

11

1

SDA

DMT

ASP_CLK

ASP_DAT

TAPE_EJECT

R848 1K

R849 1K

R893 1K

68

64

65

69

66

67

SDA

DMT

ASP_CLK

ASP_DAT

TAPE_EJECT

IC401

C2CBYY000223

MICROPROCESSOR

/RESET

XOUT(10MHZ)

VSS

XIN(10MHZ)

14

13

R807 0

R808

10M

2

3

15

VDD

16

17

R809 10K

C804

100P

C805

1000P

C806

0.1

C807

50V100

R812

22K

12

X800

62

63

NC

VSS

VDD

/NM1

RMT

BLKCK

19

18

R810 100

RMT

BLKCK

MUTEA

59

61

60

NC

PHOTO

HALT

PCONT2

21

22

20

R811 1K

R815 1K

R814 1K

R813 1K

HALT

PCONT2

E_CS

DAB_5V

Q802

R845

470

57

58

NC

REC

MUTEA

EE_CS

EE_CLK

EE_DATNCFL_CS

24

23

R817 1K

R816 1K

E_CLK

E_DATA

D5V

Q801

56

55

NC

26

25

R818 470

FL_CS

D_NRST

D_DOWFIC

D_MPUMIOD

R844 47K

R840 1K

R841 1K

54

53

52

D_PON

D_DOWFIC

D_MPUMIOD

/FL_RESET

FL_CLKNCFL_DATA

27

28

29

R820 470

R819 220

FL_RESET

FL_CLK

DAB_DGND

D_LOCKDET

B1ACND000003

B1GBCFJN0009

51

D_NRST

D_NRFRESET

D_LOCKDET

PCONT

STATUS

D_PLLSDA

D_PLLSCL

CD_MLD

CD_MDATA

CD_MCLK

D_MPUCLK

D_MPUTX

D_MPURX

30

R821 470

R894 4.7K

C808 220P

C809 220P

C810 220P

C811 220P

FL_DATA

Q802

SWITCH

Q801

SWITCH

R839 1K

50

R838 1K

49

R837 100

48

NC

47

CE

46

R836 1K

45

R835 220

44

R834 1K

43

R833 1K

42

EPM

41

NC

40

R832 1K

39

NC

38

R831 220

37

R830 220

36

R829 220

35

BUSY

34

SCLK

33

TXD

32

RXD

31

B1GBCFNN0009

R828 47K

R826

47K

C831

50V1

Q800

SWITCH

Q800

D_NRFRESET

PCONT1

STAT

D_PLLSDA

D_PLLSCL

CD_MLD

CD_MDATA

CD_MCLK

D_MPUCLK

D_MPUTX

D_MPURX

D802

C812

50V2.2

D803

D802, D803

B0ACCK000005

E_CS

E_CLK

E_DATA

WA8

0

D800, D801

B0ACCK000005

L804, L805

G0C3R3JA0027

L804

L805

R827

120

C813

6.3V0.22

SYS6V

C1002

D800

D801

0.01

C833

6V100

87216

NC

(NOT SUPPLIED)

NC

R1000 22K

2

GND

VOUT VIN

13

C834

0.001

D0

GND

IC804

EEPROM

VCCCSCLK

354

R1001 22K

R1002 100K

IC801

C0CAABC00007

REGULATOR IC

C814

16V470

WA15

0

R1003

4.7K

D1

C1000 100P

50

1

/

SA-PM32DBEB MAIN/TUNER EXTENT CIRCUIT

2

Page 51

SCHEMATIC DIAGRAM - 3

MAIN CIRCUIT

TUNER_LCH

TUNER_RCH

DAB_LCH

DAB_RCH

AUX_LCH

AUX_RCH

CD_LCH

CD_RCH

R201

5.6K

R401

5.6K

R209

2.7K

R409

2.7K

R207

4.7K

R407

4.7K

R203

2.7K

R403

2.7K

R202

5.6K

R402

5.6K

R210

3.9K

R410

3.9K

R208

8.2K

R408

8.2K

R204

6.8K

R404

6.8K

C201

680P

C401

680P

C209

220P

C409

220P

C207

220P

C407

220P

C203

220P

C403

220P

: AUX SIGNAL LINE

: +B SIGNAL LINE : TAPE PLAYBACK SIGNAL LINE

WA3

0

WA1

0

: CD SIGNAL LINE

C461

0.039

: TUNER SIGNAL LINE

: TAPE RECORDING SIGNAL LINE

C1BB00000732

C455

0.056

1

VIN1

SEL1OUT

C456

0.056

AGND

DAB_D5V

DAB_LCH

2

VIN2

3

4

SEL2OUT

A1

5

6

A2

B1

7

B2

8

C1

9

C2

10

D1

11

12

D2

13

E1

14

E2

FILTER

15

16

GND

D_DOWFIC

DAB_DGND

C462

0.039

C206 50V2.2

C406 50V2.2

C210 50V2.2

C410 50V2.2

C202 50V2.2

C402 50V2.2

C208 50V2.2

C408 50V2.2

C447

25V47

AGND

DAB_RCH

R446

27K

R447

27K

IC800

ASP IC

IC800

D_MPUTX

REC1

REC2

MNF1

MOUT1

MNF2

MOUT2

BNF1

BOUT1

BNF2

BOUT2

LEFT

RIGHT

D_MPURX

D_MPUCLK

32

31

30

29

28

27

26

25

24

23

22

21

20

CAP

VCC

19

18

S1

17

SC

D_NRST

D_PLLSDA

D_MPUMOD

C440 0.015

C449 0.015

C441 0.015

C442 0.015

C443 50V0.1

C444 0.068

C445 50V0.1

C446 0.068

C233 50V1

C433 50V1

C448 16V0.33

C463

C465

47P

C464

47P

D_PLLSCL

D_LOCKDET

D_NRFRESET

: DAB SIGNAL LINE

: MAIN SIGNAL LINE

B1GDCFGG0026

R443

3.3K

R444

3.3K

R442

6.8K

R445

6.8K

AGND

R441

33

16V100

AGND

ASP_CLK

ASP_DATA

MUTEA

Q750

SWITCH

B1GBCFJJ0044

A9V

FL_CS

FL_CLK

FL_RESET

Q750

R750

4.7K

Q751

Q803

Q803

MUTING SWITCH

C466

680P

AGND

RIGHT

RMT

VREF-

FL_DATA

VOL_JOG

D750

B1GBCFJJ0044

SWITCH

C266

680P

LEFT

D5V

KEY1

KEY2

TNR_GND

R7511KR752

B0ACCK000005

50V1

C750

Q751

WA4

0

WA2

0

AUX_LCH

AUX_RCH

2.2K

D751

B0ACCK000005

MUTEB

R753

10

R756 4.7K R755 4.7K

AGND

C220

50V1

C752 0.01

C751 6.3V47

C420

50V1

C221 330P

R220 100K

C421 330P

R420 100K

R221

12K

GND

AGND

5

C222

100P

R222

C223

100P

IC700

364

R421

12K

68K

C422

100P

WA14

78

+B

12

C423

100P

R422

68K

0

C224

6.3V47

R224 1K

C754 16V220

C753 0.01

AGND

R424 1K

C424

6.3V47

IC700

C0ABBB000297

OP-AMP

R223

C225

C425

R423

47

0.01

0.01

47

R225

39

Q221 Q222

R226

3.9K

Q421 Q422

R426

3.9K

R425

39

Q221, Q222

B1ABGC000005

SWITCH

Q421, Q422

B1ABGC000005

SWITCH

LEFT

RIGHT

TUNER_9V

TNR_GND

A9V

MUTEB

PCONT2

VOL_DET1

VOL_DET2

D5V

CD_DGND

DAB_DGND

HALT

PCONT1

SYS6V

CD_7.5V

PGND

WA13

0

R227

3.9K

R427

3.9K

AGND

C1

1000P

HP_GND

HP_SW

AGND

AGND

TUNER_9V

TUNER_GND

MUTEB

MOTOR_GND

MOTOR_9V

PCONT2

VOL_DET1

VOL_DET2

9V_GND

VREF-

CD_DGND

DAB_GND

PCONT1

SYS6V

CD_7.5V

PGND

HP_R

HP_L

IN_L

IN_R

A9V

D5V

HALT

SA-PM32DBEB

CN504A

TO

1

HEADPHONE

2

CIRCUIT (WH504)

3

ON SCHEMATIC

4

DIAGRAM-6

CN808B

1

2

3

4

5

TO

6

SPEAKER TERMINAL

CIRCUIT (CN808A)

7

ON SCHEMATIC

8

DIAGRAM-6

9

10

11

12

13

CN803B

1

2

3

TO

4

SPEAKER TERMINAL

CIRCUIT (CN803A)

5

ON SCHEMATIC

6

DIAGRAM-6

7

8

9

DAB_RCH

AGND

18

17

C826

1000P

DAB_LCH

D5V

16

15

D5V

DGND

14

13

R882 100

R884 100

DGND

DDOWFIC

NIRQ

MPUTX

MPURX

11

12

10

9

TO DAB MODULE

Z402

RAL0044

R885 100

R886 100

R887 100

MPUCLK

MPUMOD

NRST

8

6

5

7

R889 100

R888 100

PLL_SDA

PLL_SCL

RF_RST

4

3

2

R890 100

LOCK_DET

1

FL_CS

FL_RESET

FL_CLK

FL_DATA

RMT

STDBY_3.3V

VREF-

VOL_JOG

KEY1

KEY2

D5V

TNR_GND

AUX_LCH

AGND

AUX_RCH

14

15

CN802CN809

TO

PANEL CIRCUIT (CN901A)

ON SCHEMATIC DIAGRAM-4

9

13

12

11

10

4

8

6

7

1

5

2

3

2

/

SA-PM32DBEB MAIN CIRCUIT

2

51

Page 52

SA-PM32DBEB

16.3. PANEL CIRCUIT

SCHEMATIC DIAGRAM - 4

PANEL CIRCUIT

FL_DATA

FL_CLK

FL_CS

FL_RESET

D5V

: +B SIGNAL LINE : AUXILLARY SIGNAL LINE

F1

56

1

C911

50V22

C0DBZGC00067

VIN

1

2

IC900

3.3V REGULATOR IC

GND

2345

89101112 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 43 44

7

STBYNCVOUT

C925

C926

0.1

10V22

C952 220P

C953 220P

C954 220P

FL900

A2BC00000071

FL DISPLAY

C913

0.01

C955 220P

R928 100

R929 100

R930 100

R931 100

10V22

C924

C914

0.1

FL_DATA

FL_CLK

FL_CS

FL_RESET

OSD

R920 47K

WA25

0

VDDVHPGND

R91810R919

C915

0.1

C912

0.1

LGND

C910

50V22

R932 12K

R933 12K

R934 12K

10

C923

50V22

C966

50V22

F2

R917

68

D900

B0BC6R700006

L902

ERJ3GEY0R00V

R916

68

C909

50V22

R924

SYS6V

22

SYS6V

FL1

FL2

GND2

WH900

1

2

3

VP

4

5

TO

TRANSFORMER

CIRCUIT

(CN900B) ON

SCHEMATIC

DIAGRAM-6

CN901A

TO

MAIN CIRCUIT

(CN802) ON

SCHEMATIC

DIAGRAM-3

FL_CS

15

FL_RESET

14

FL_CLK

13

FL_DATA

12

RMT

11

STDBY_3.3V

10

VREF-

9

VOL_JOG

8

KEY1

7

KEY2

6

D5V

5

TNR_GND

4

AUX_LCH

3

AGND

2

AUX_RCH

1

FL_CS

FL_RESET

FL_CLK

FL_DATA

RMT

STDBY_3.3V

VOL_JOG

KEY1

KEY2

D5V

TNR_GND

AUX_LCH

AGND

AUX_RCH

KEY1

KEY2

O

RMT

VOL_JOG

STDBY_3.3V

SYS6V

VDD

G

321

Z901

B3RAD0000128

REMOTE SENSOR

C922

6.3V47

WA22

0

WA23

R911

R912

R913

R910

1.5K

1.2K

VR900

EVEJ1CF3024B

VOLUME JOG

ACOMB

1

23

R926

12K

R925

0

R915

1K

22K

C921

100P

D906

B3AAA0000489

STANDBY LED

C920

100P

WA24

0

S906

POWER

S900

STOP/-DEMO

R901

1.2K

S908

BASS/TREBLE

R902

S901

CD_PLAY

2.2K

1.5K

3.3K

R903

2.2K

S910

MUSIC PORT

S903

TUNER/BAND

R914

4.7K

S907

CD_OPEN/CLOSE

R904

3.3K

S904

UP/FF

R905

4.7K

S905

DOWN/REW

R921

1.8K

C959

470P

C958

1000P

AUX_RCH

TNR_GND

L203

J0JBC0000019

C962

0.01

L900

G0C3R3JA0027

AGND

C961

470P

C960

1000P

R922

1.8K

AUX_LCH

3

2

1

MUSIC PORT

JK303

SA-PM32DBEB PANEL CIRCUIT

52

Page 53

16.4. POWER CIRCUIT

SCHEMATIC DIAGRAM - 5

SA-PM32DBEB

TO

SPEAKER TERMINAL

CIRCUIT(CN501A)

ON SCHEMATIC

DIAGRAM-6

TO

SPEAKER TERMINAL

CIRCUIT(CN508A)

ON SCHEMATIC

DIAGRAM-6

TO

SPEAKER TERMINAL

CIRCUIT(CN503A)

ON SCHEMATIC

DIAGRAM-6

CN501B

CN508B

CN503B

POWER CIRCUIT

R+

1

R-

2

L-

3

L+

4

IN_L

1

AGND

2

IN_R

3

TUNER_9V

4

TUNER_GND

5

A9V

6

MUTEB

7

MOTOR_GND

8

MOTOR_9V

9

PCONT2

10

11

12

9V_GND

13

VREF-

1

D5V

2

CD_GND

3

DAB_GND

4

HALT

5

PCONT_1

6

SYS6V

7

CD_7.5V

8

PGND

9

IN_L

IN_R

MUTEB

: +B SIGNAL LINE

R495

R485

10K

8.2K

C497

1200P

R491

R492

6.8K

6.8K

C493

R295

10K

C297

1200P

R291

6.8K

C293

0.0270.027

R251

820

R451

820

R285

R292

: MAIN SIGNAL LINE

8.2K

C254

50V1

C454

50V1

6.8K

R380

2.2K

FP352

5A

IC300

AN17831A

POWER AMP IC

IC300

VCC

OUT_R+

OUT_GND

OUT_R-

STBY

IN_R

IN_GND

IN_L

MUTE

OUT_L-

OUT_GND

2

45

3

1

C374

50V10

6 7 8 9 10 11 12

C373

C351

470P

470P

C372

C352

1000P

1000P

R456

R256

56K

56K

C586

50V10

R586

47K

R381

10K

C368

16V22

OUT_L+

C365

470P

R616

C370

470P

R614

2.2

C376

470P

R615

2.2

C364

470P

R617

2.2

2.2

D5V

Q505

B1BACG000048

REGULATOR

L+

L-

R-

R+

C512

0.1

C542

25V10

C521

0.01

C522

0.01

C515

0.01

CD_7.5V

D501, D502, D504, D505

D0EAMM000038

D502

D501

B1AAJC000019

REGULATOR

R518

1K

D508

B0BA5R600016

D504

D505

Q507

C540

16V22

B1AACF000063

C502

25V10

C523

0.01

C524

0.01

C514

0.01

D506

Q501, Q504

SWITCH

R520

470

B0BA8R200005

R514

2.2K

R511

220

R506

2.7K

R504

220

TUNER_9V

Q530

2SD0592ARA

REGULATOR

C541

16V22

D512

B0BA9R600002

Q504

Q503

B1BCCG000002

STABILIZER

Q501

Q500

Q500

B1GCCFGA0006

CURRENT LIMITING

R517

470

MOTOR_9V

C516

0.01

R515

1.5K

C510

25V10

C507

0.01

R505

100K

R501 1.2

C501

35V6800

Q503

R502 1.2

R503 1.2

VCC

SYS6V

VCC

PCONT2

53

AMP_VCC1

AMP_VCC2

AMP_VCC2

AMP_VCC1

MOTOR_9V

PCONT_1

8

5

6

WH505A

7

TO

TRANSFORMER CIRCUIT

(CN505B) ON SCHEMATIC

DIAGRAM-6

SYS6V

GND1

4

GND2

HALT

1

2

3

SA-PM32DBEB POWER CIRCUIT

Page 54

SA-PM32DBEB